Heat-type wind-speed and wind-direction sensor with heat insulation structure and preparation method thereof

A technology of wind speed, wind direction, and thermal isolation, which is applied in semiconductor/solid-state device manufacturing, using thermal variables to measure fluid velocity, instruments, etc. It can solve the problems of reducing the output sensitive signal amplitude, increasing the sensor, and unstable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

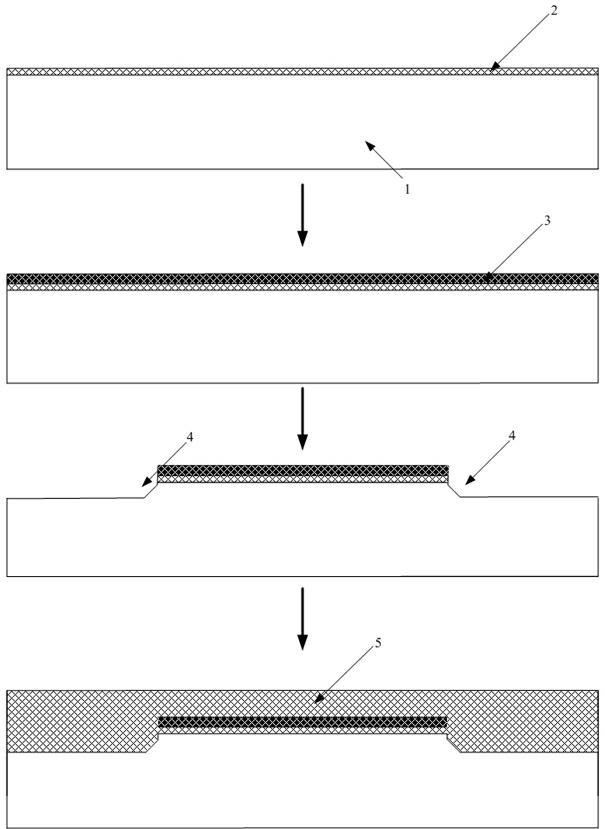

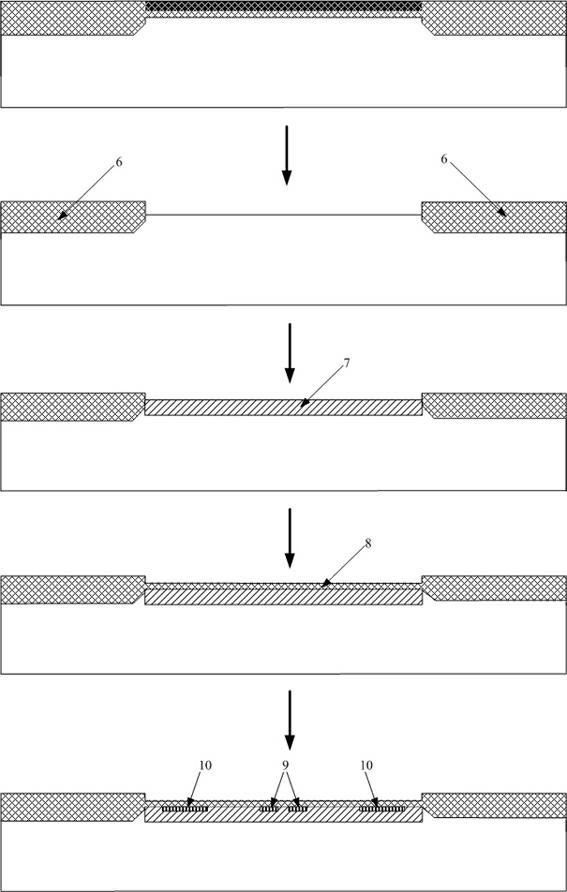

[0045] The manufacturing process of a thermal wind speed and direction sensor with thermal isolation structure is as follows:

[0046] The first step, the preparation of the silicon chip, see Figure 1 to Figure 3

[0047] Step 1, thermally growing a first thermal oxide layer 2 on the surface of the silicon chip 1;

[0048] Step 2, chemical vapor deposition of a silicon nitride layer 3 on the first thermal oxide layer 1;

[0049] Step 3, using RIE technology to etch the silicon chip 1 to define the active region 4;

[0050] Step 4, chemical vapor deposition of the second oxide layer 5;

[0051] Step 5, using CMP technology to polish the silicon chip 1;

[0052] Step 6, removing the silicon nitride layer 3 by wet etching, and preparing the field oxide layer 6;

[0053] Step 7, P ion implantation to prepare N well 7;

[0054] Step 8, thermally growing the gate oxide layer 8;

[0055] Step 9, B ion implantation, preparing the heating resistor 9 and one end 10 of the temperat...

Embodiment 2

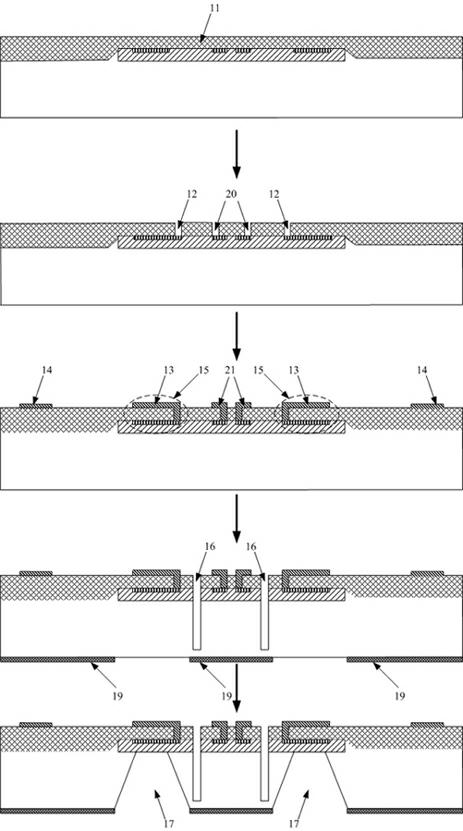

[0069] A thermal wind speed and direction sensor with a thermal isolation structure, comprising a silicon chip 1 and a ceramic substrate 20, the silicon chip 1 is located above the ceramic substrate 20, four heating elements 9 and 4 heat-sensing temperature-measuring elements 15, characterized in that a heat-insulating groove 16 is arranged between the heating element 9 and the heat-sensing temperature-measuring element 15, below the heat-sensing temperature-measuring element 15 on the back side of the silicon chip 1 A heat insulation cavity 17 is provided, and a gold layer 18 on ceramics and a gold layer 19 on silicon are provided between the silicon chip 1 and the ceramic substrate 20, and the gold layer 18 on ceramics and the gold layer 19 on silicon are connected through a gold-gold bonding process, It is used for thermal connection between the silicon chip 1 and the ceramic substrate 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com