Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1169 results about "Plastic foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

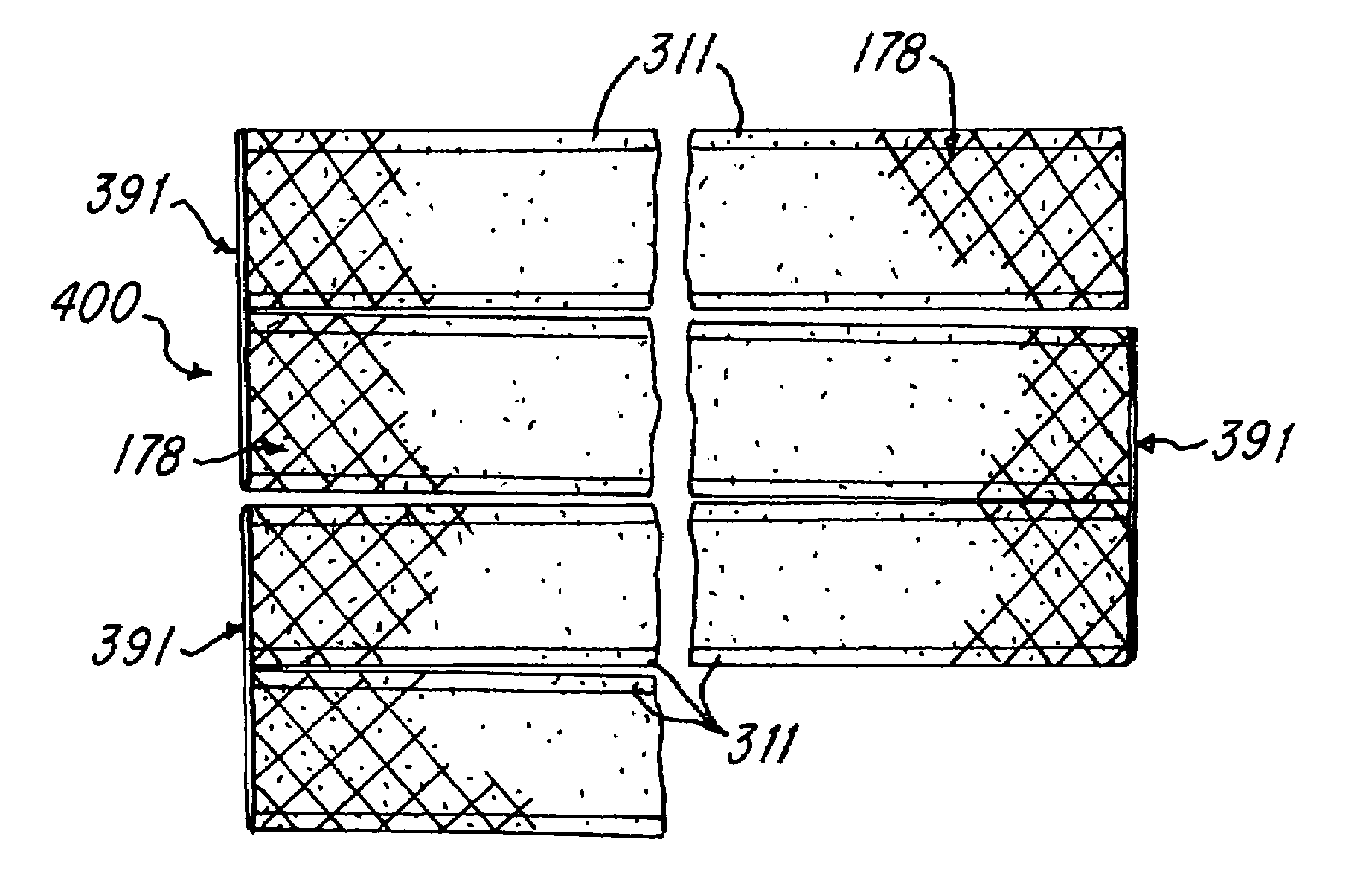

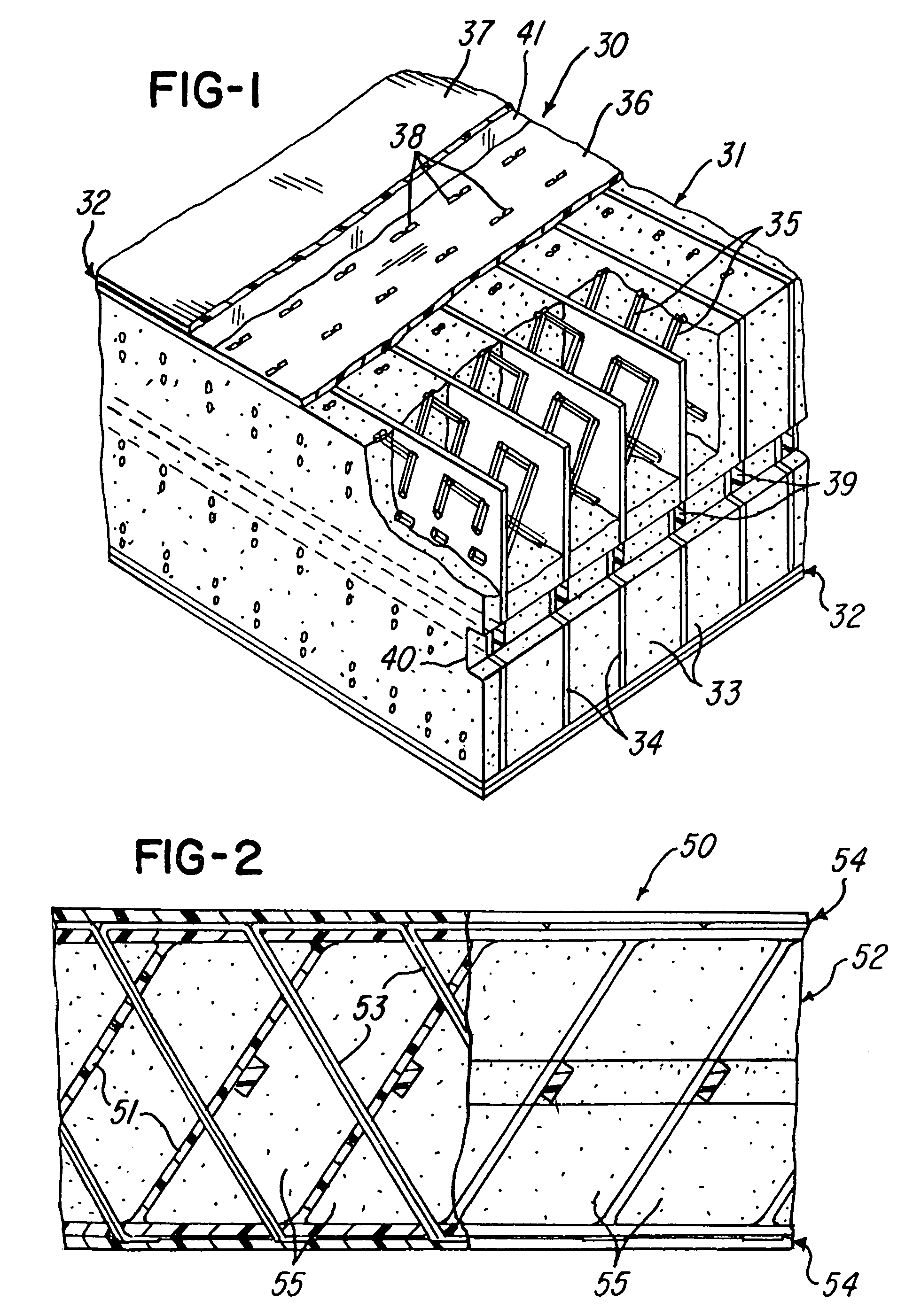

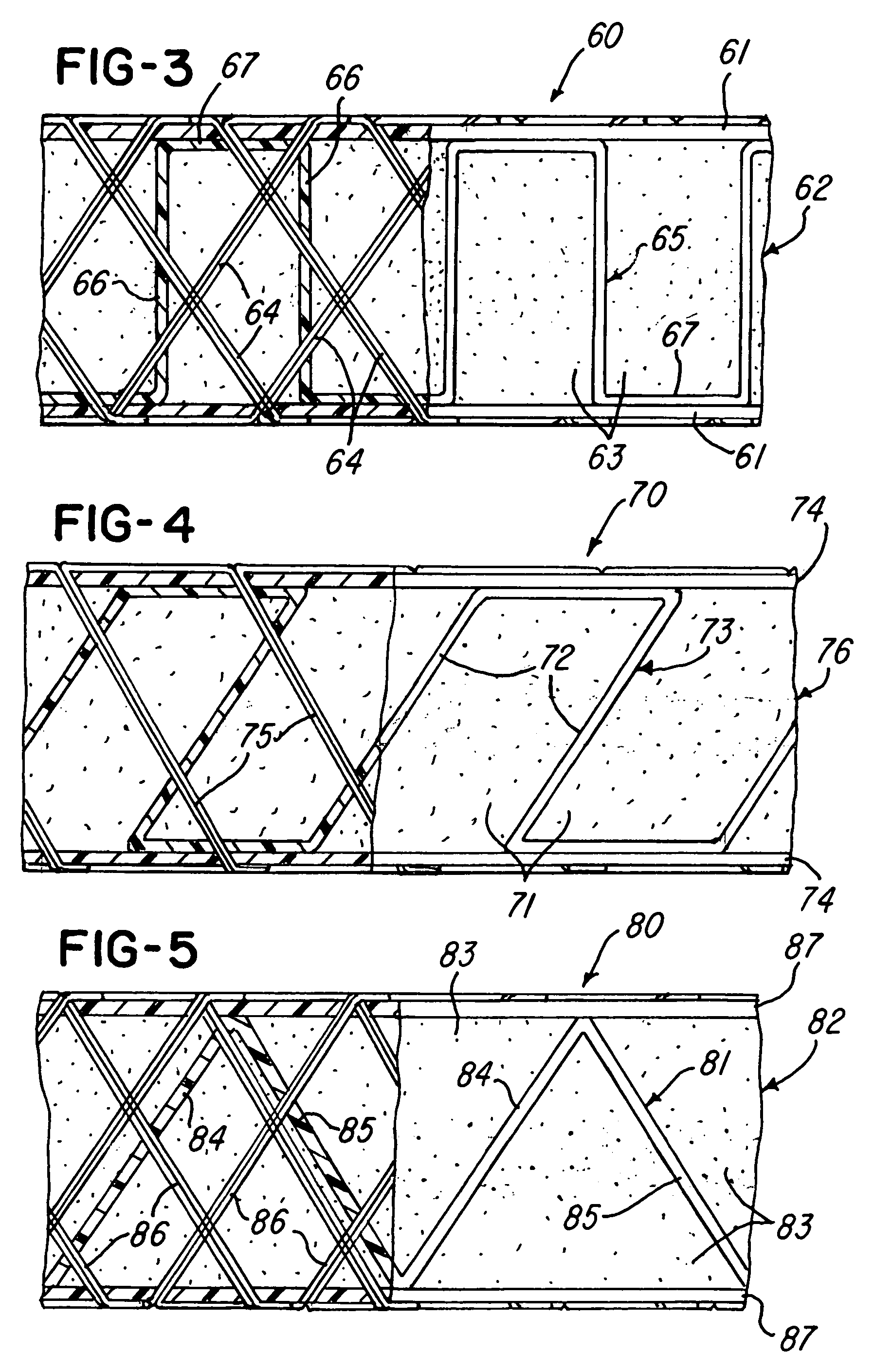

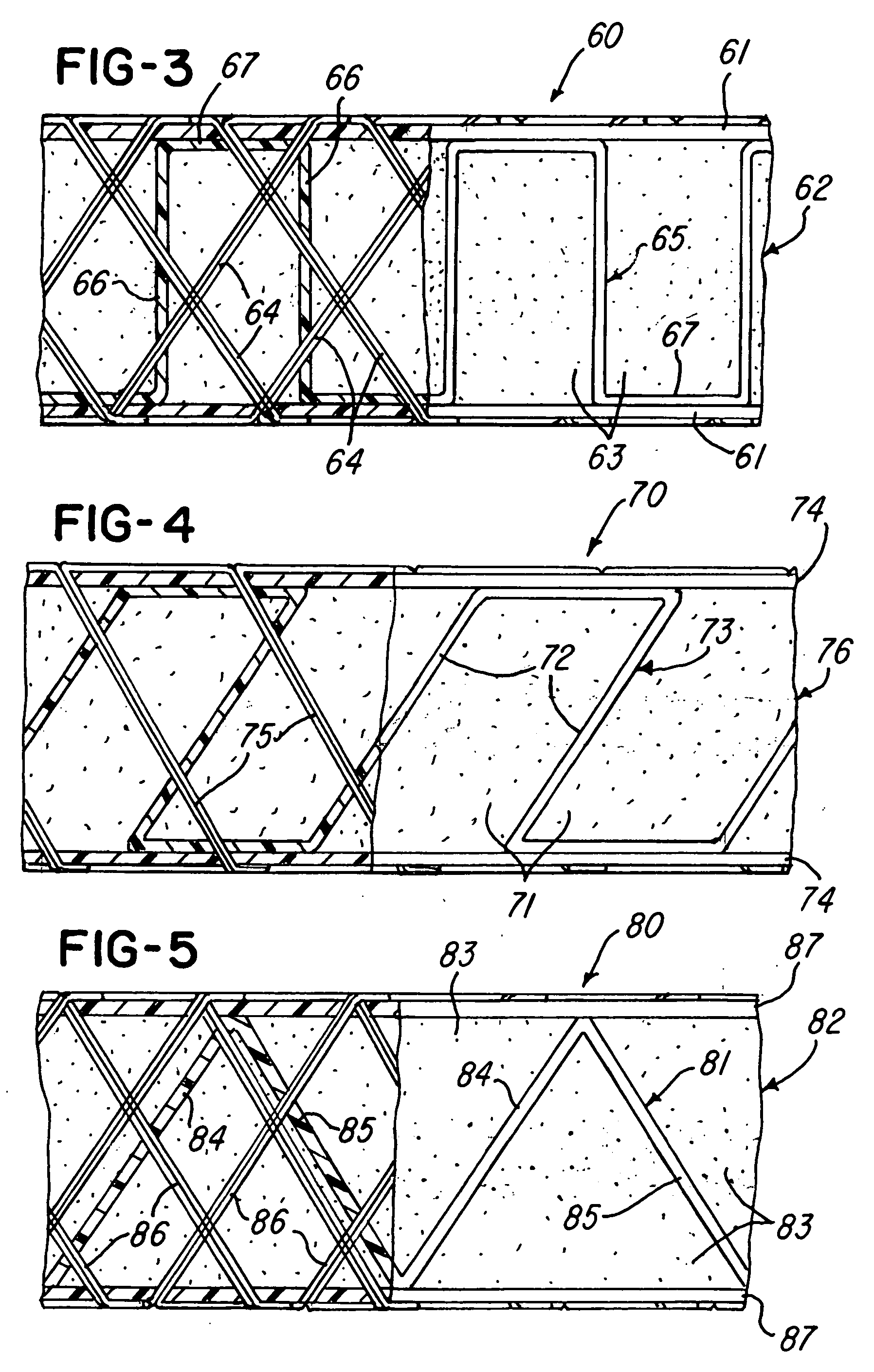

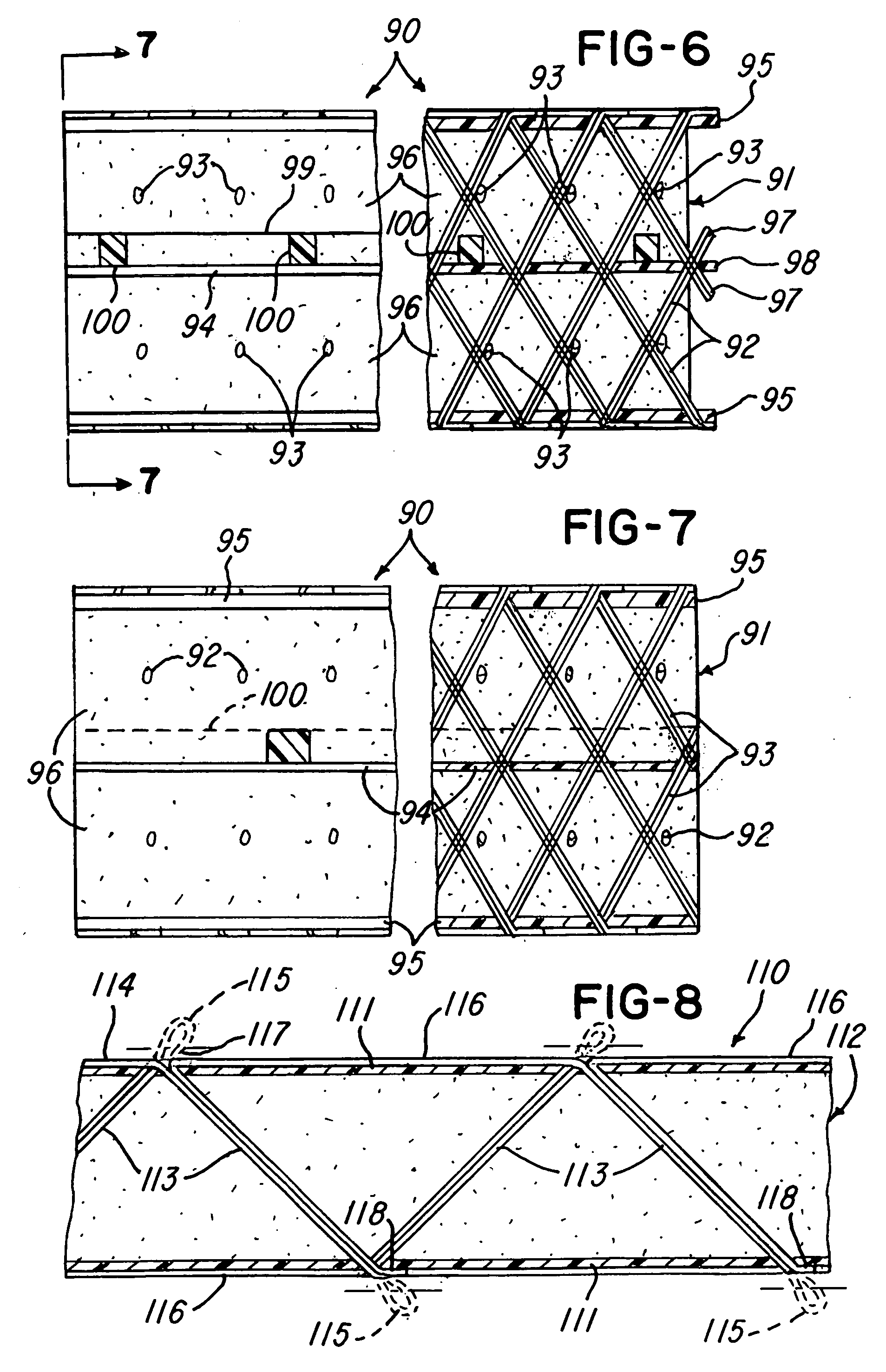

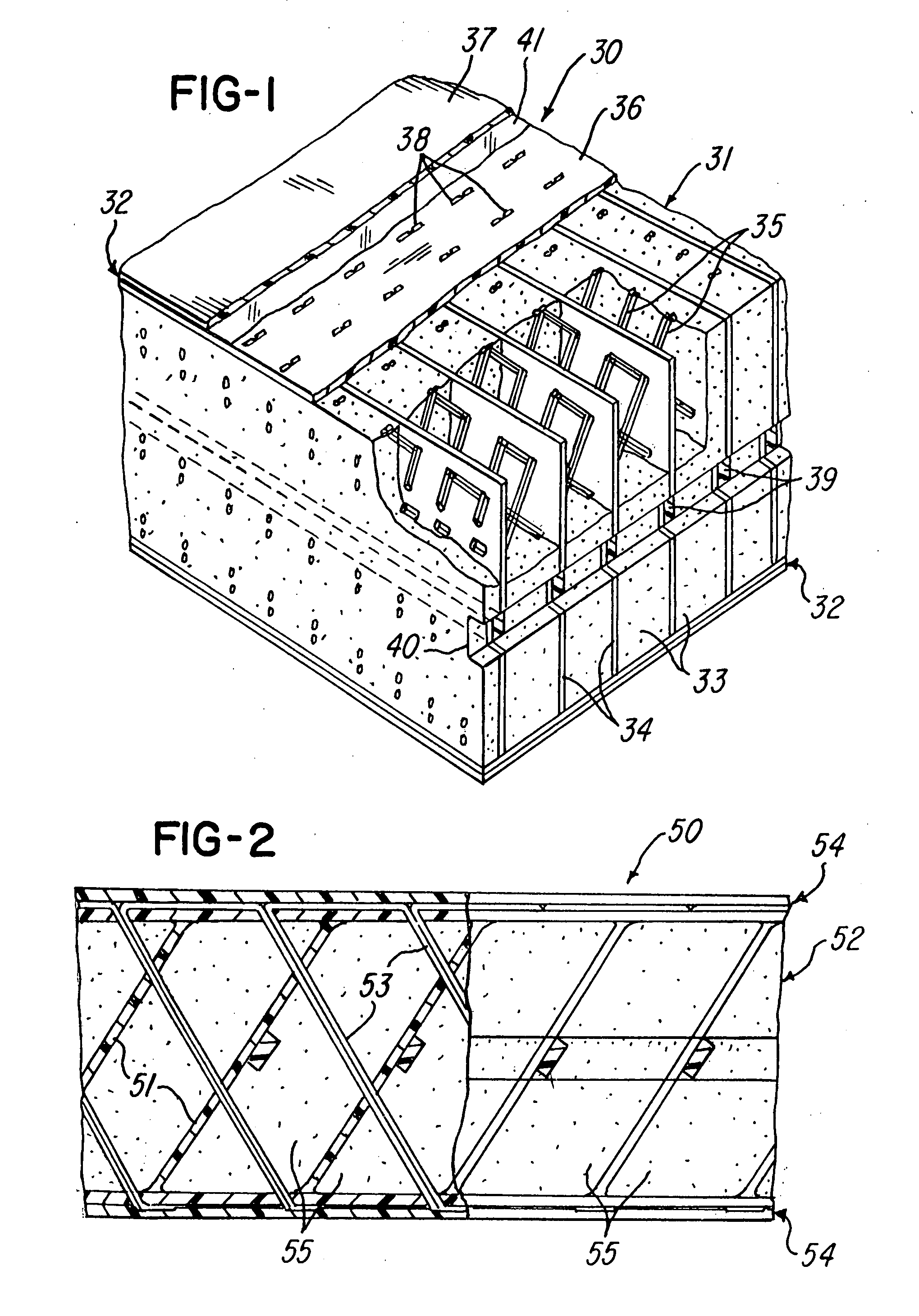

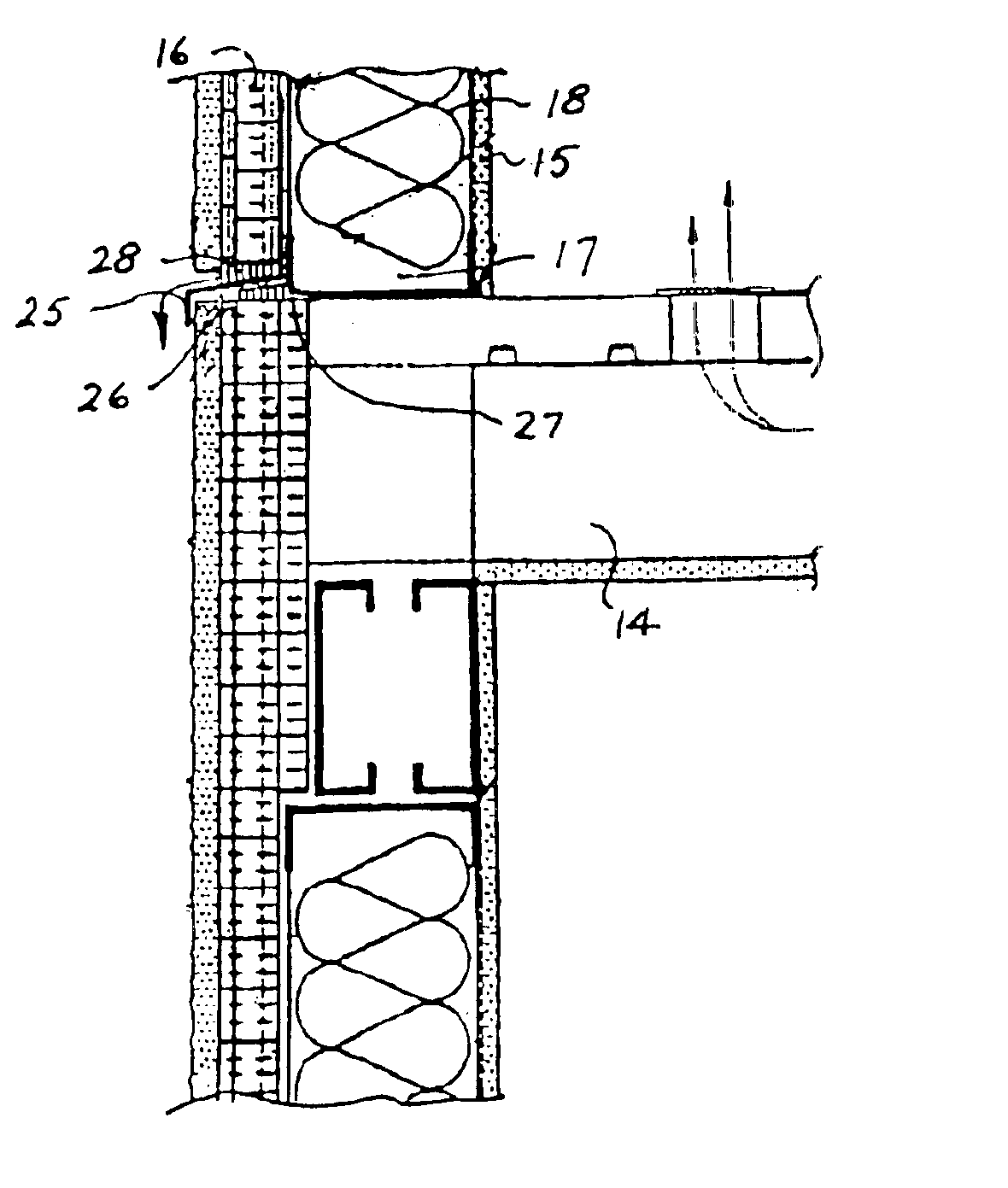

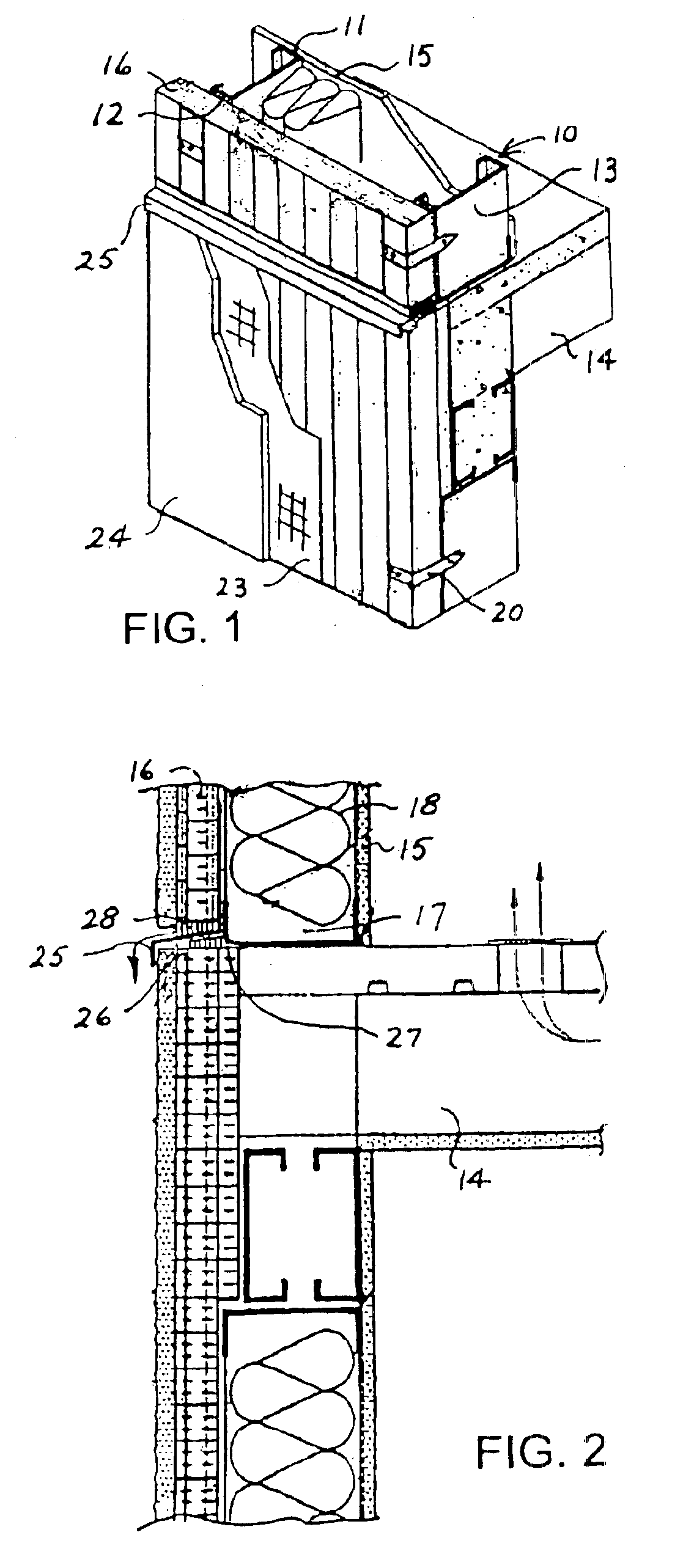

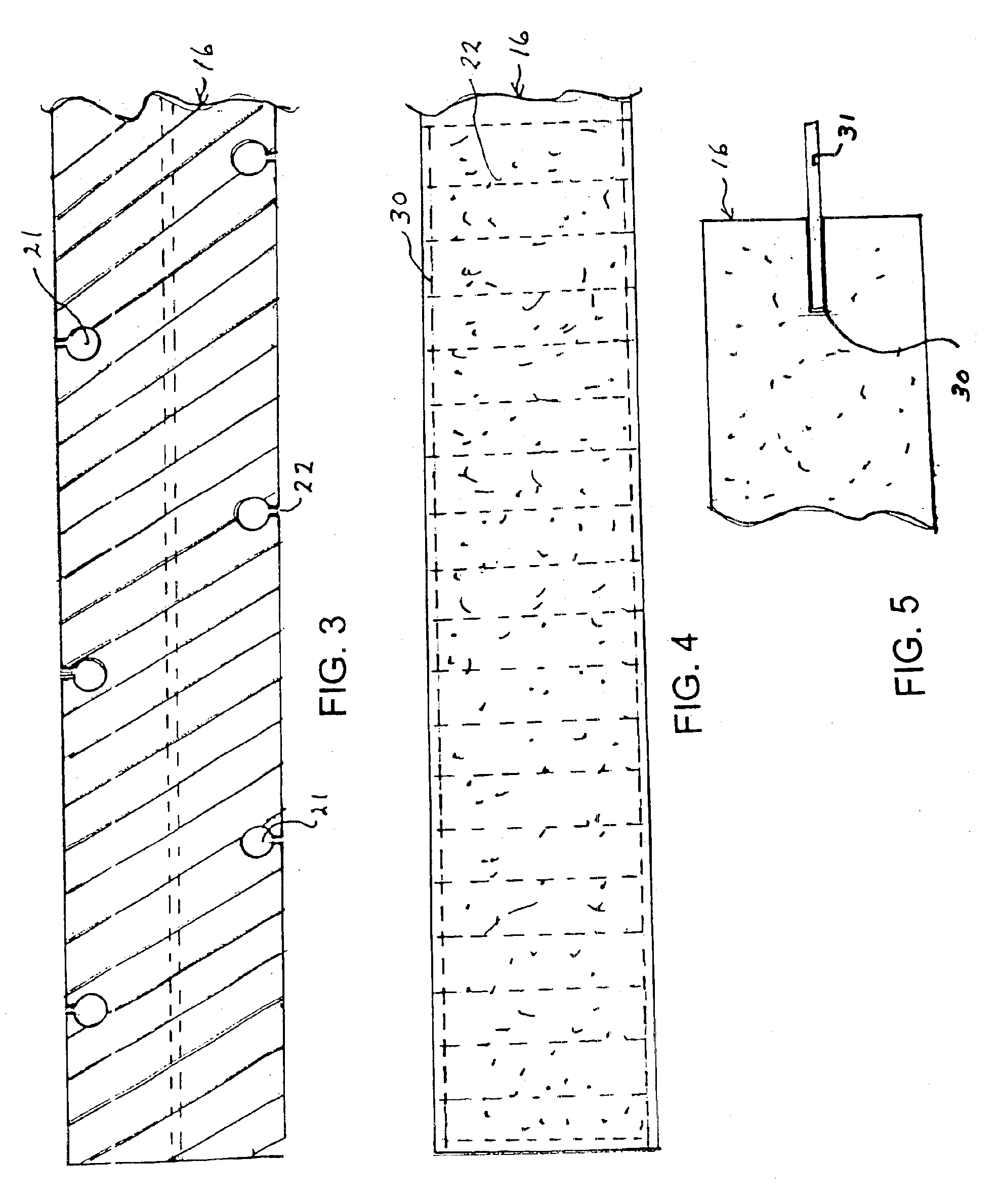

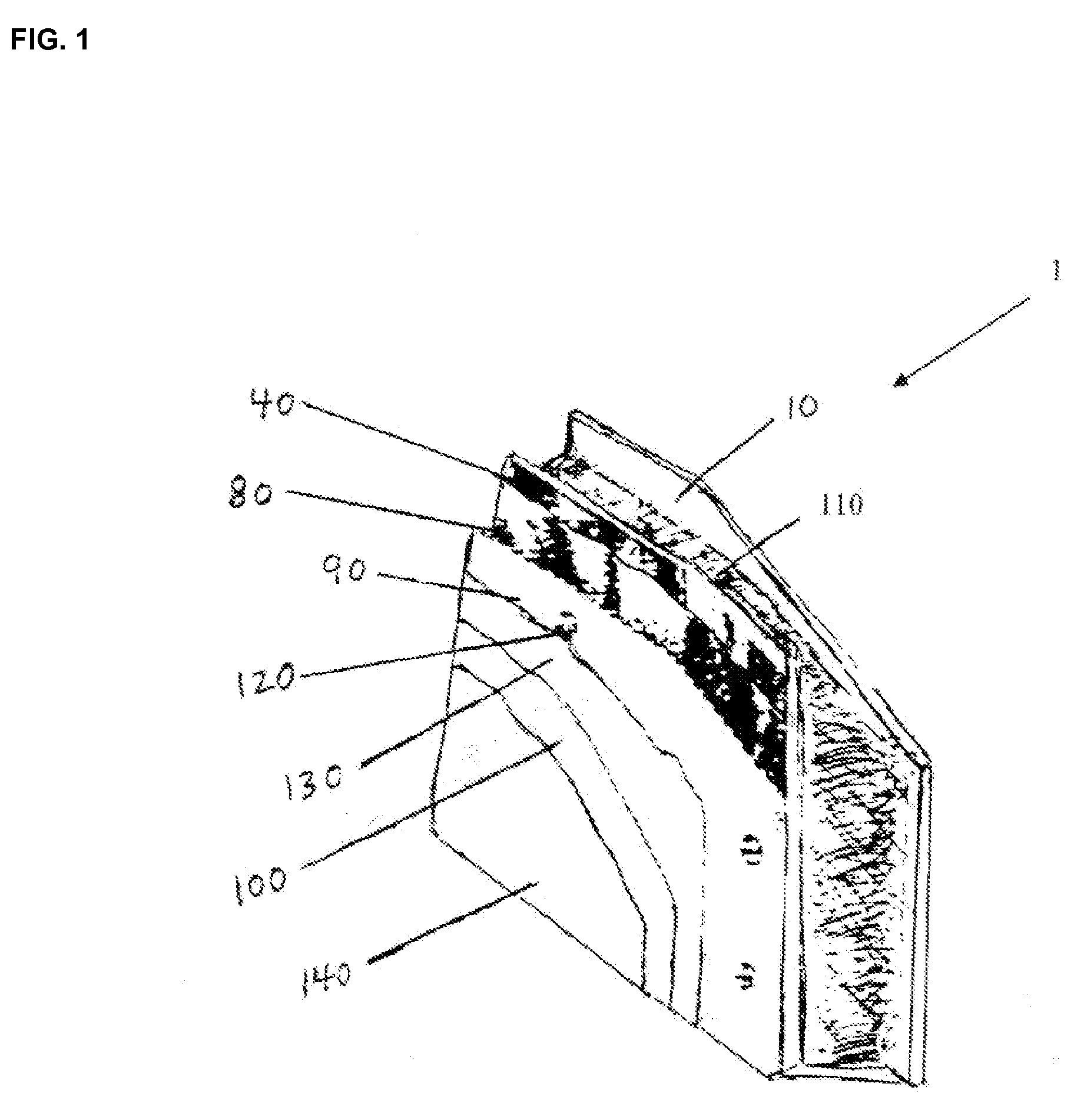

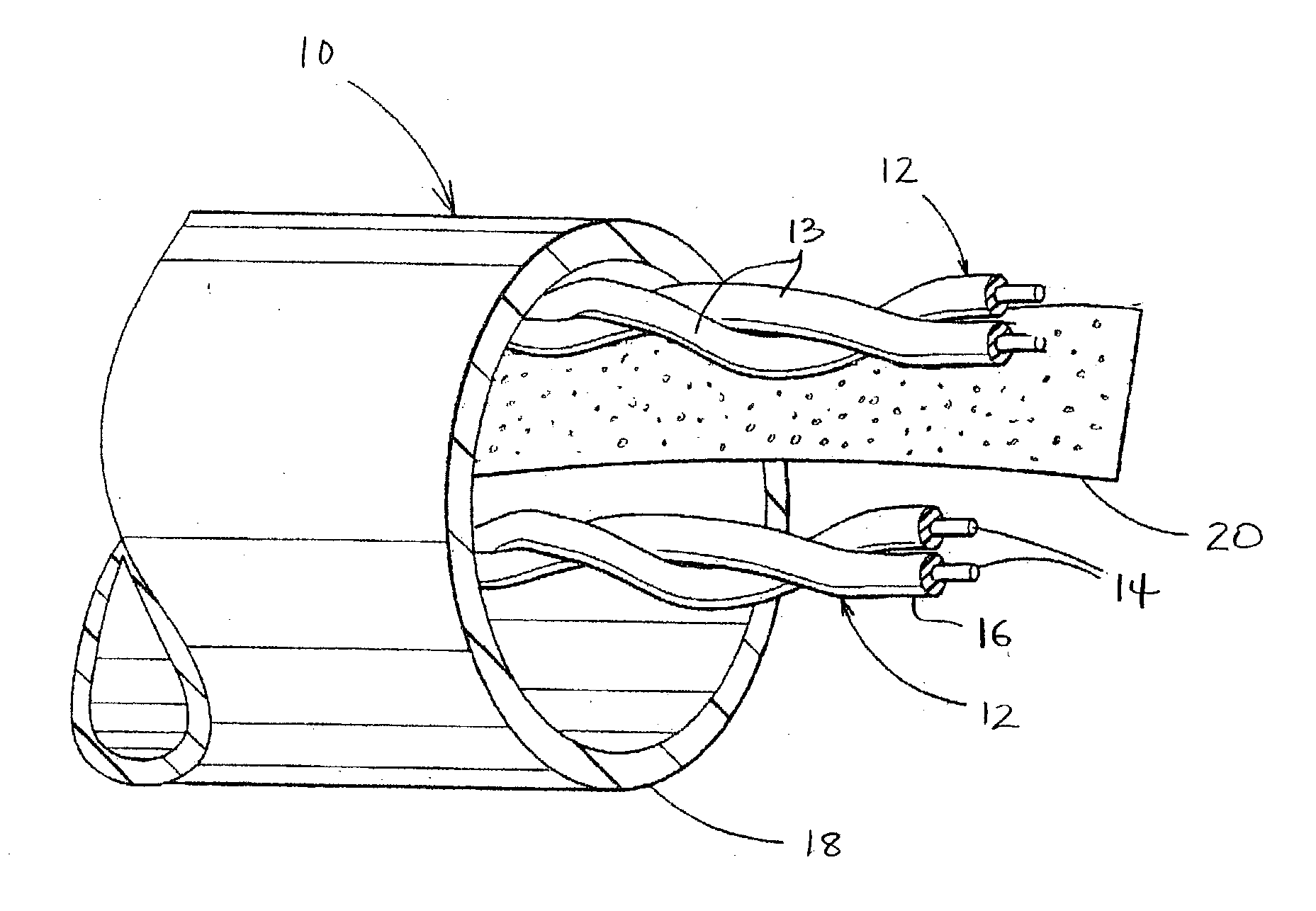

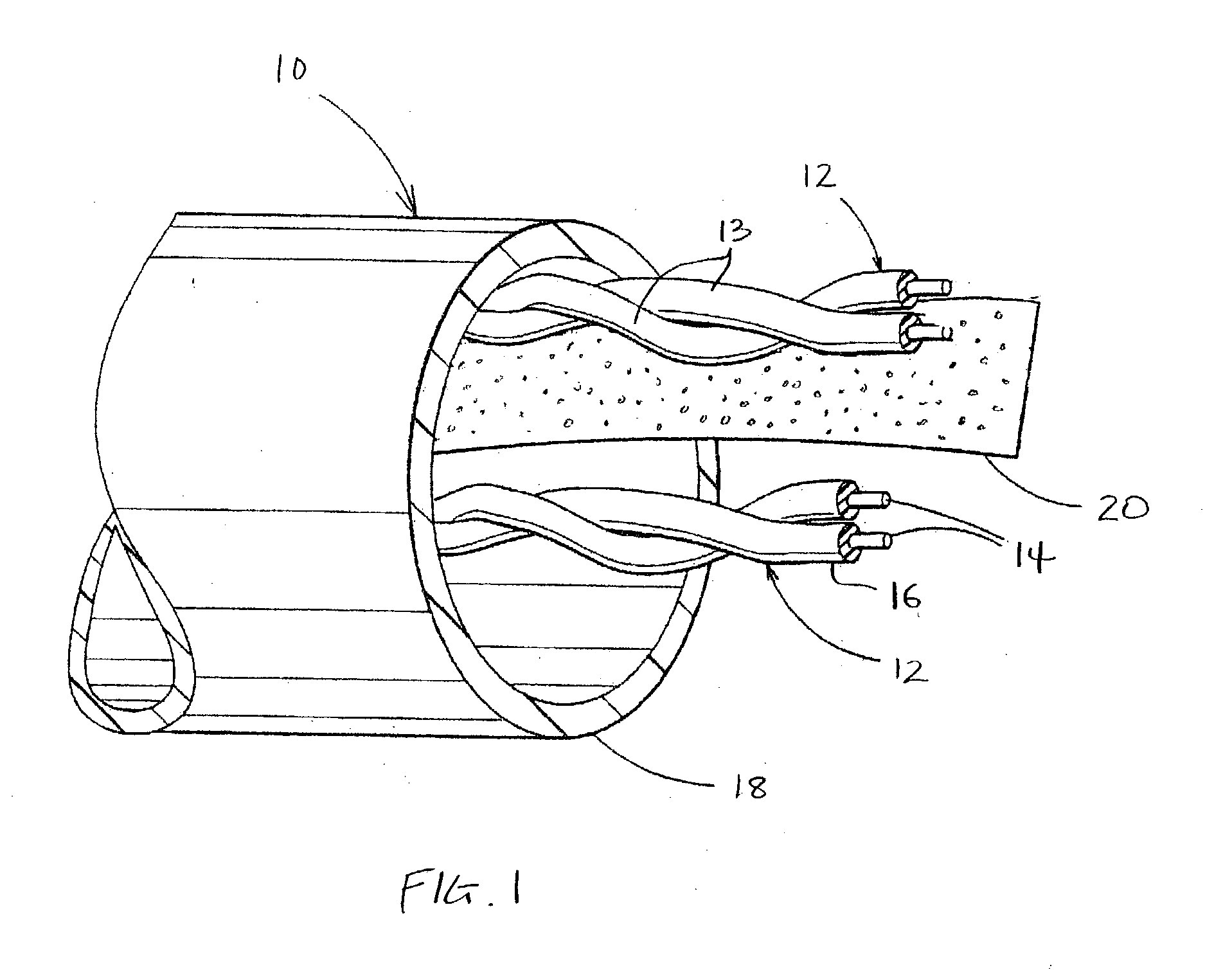

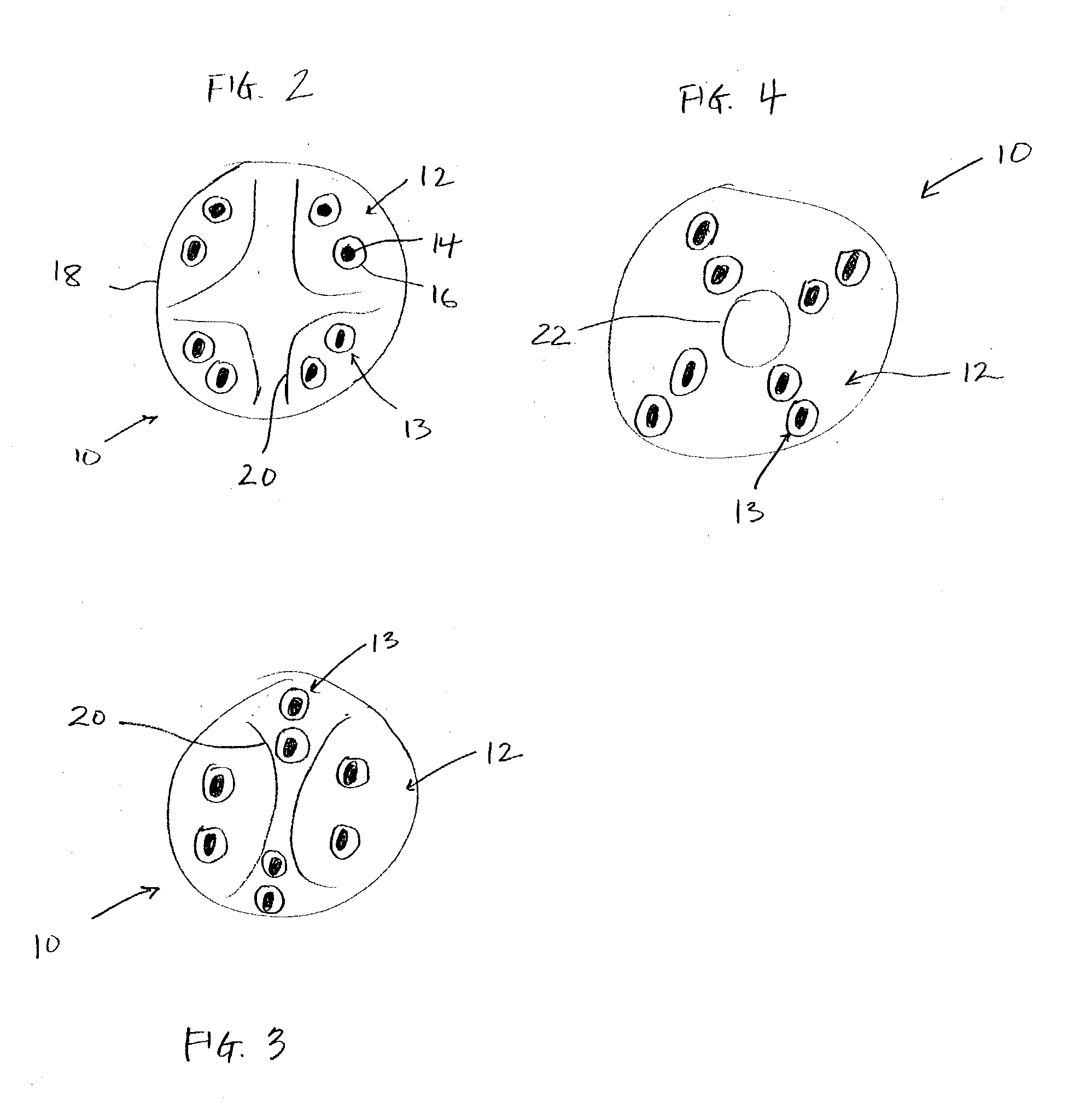

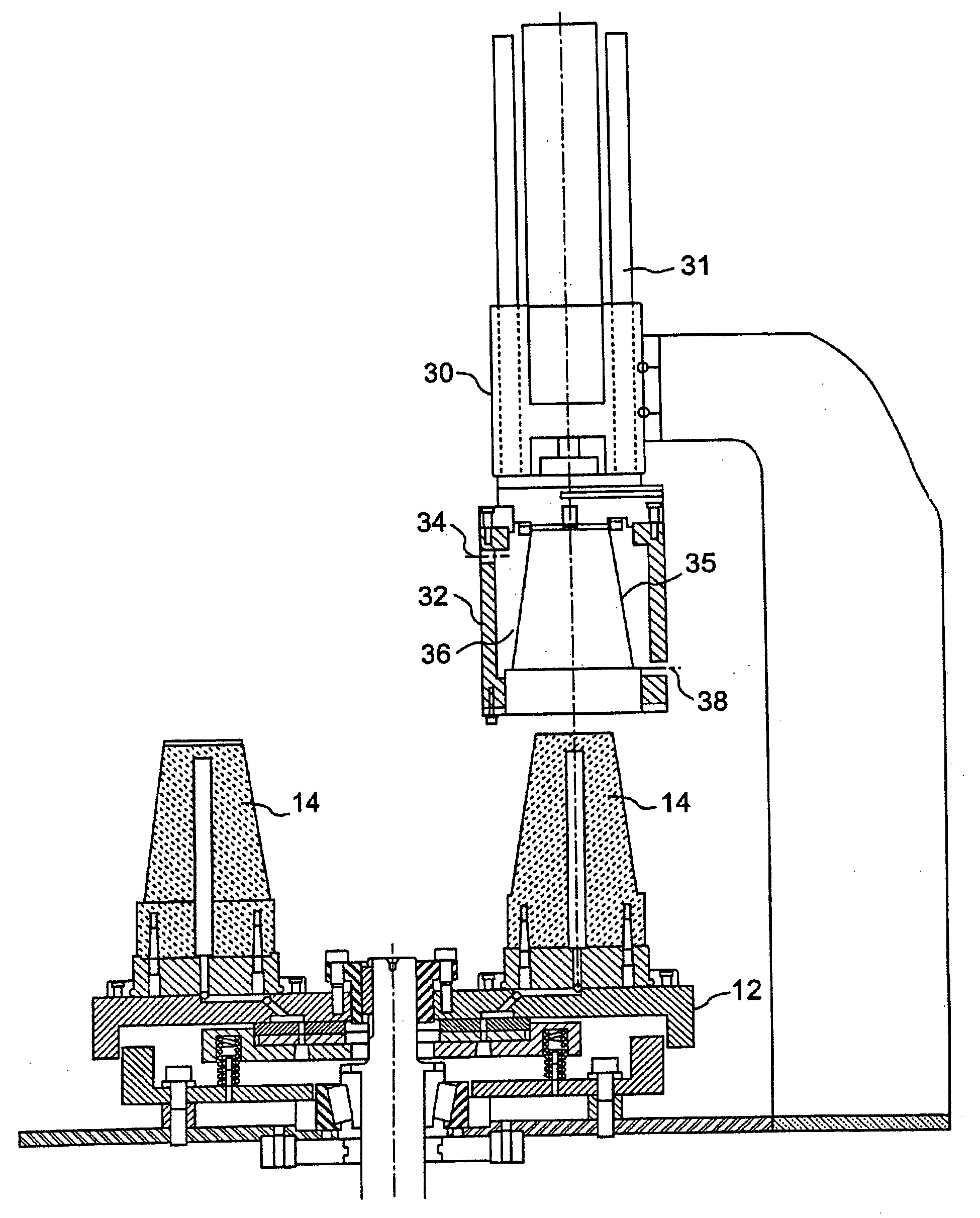

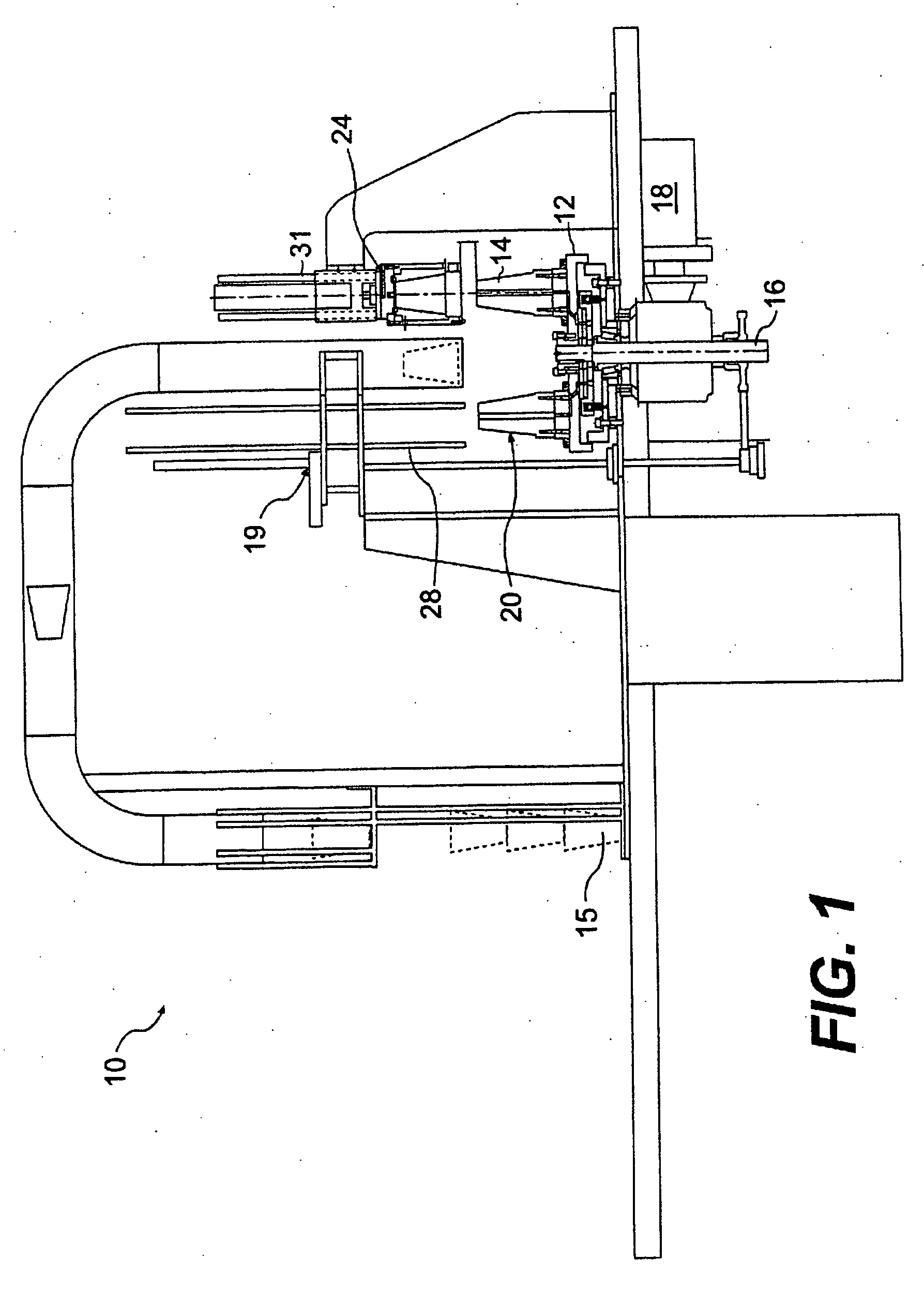

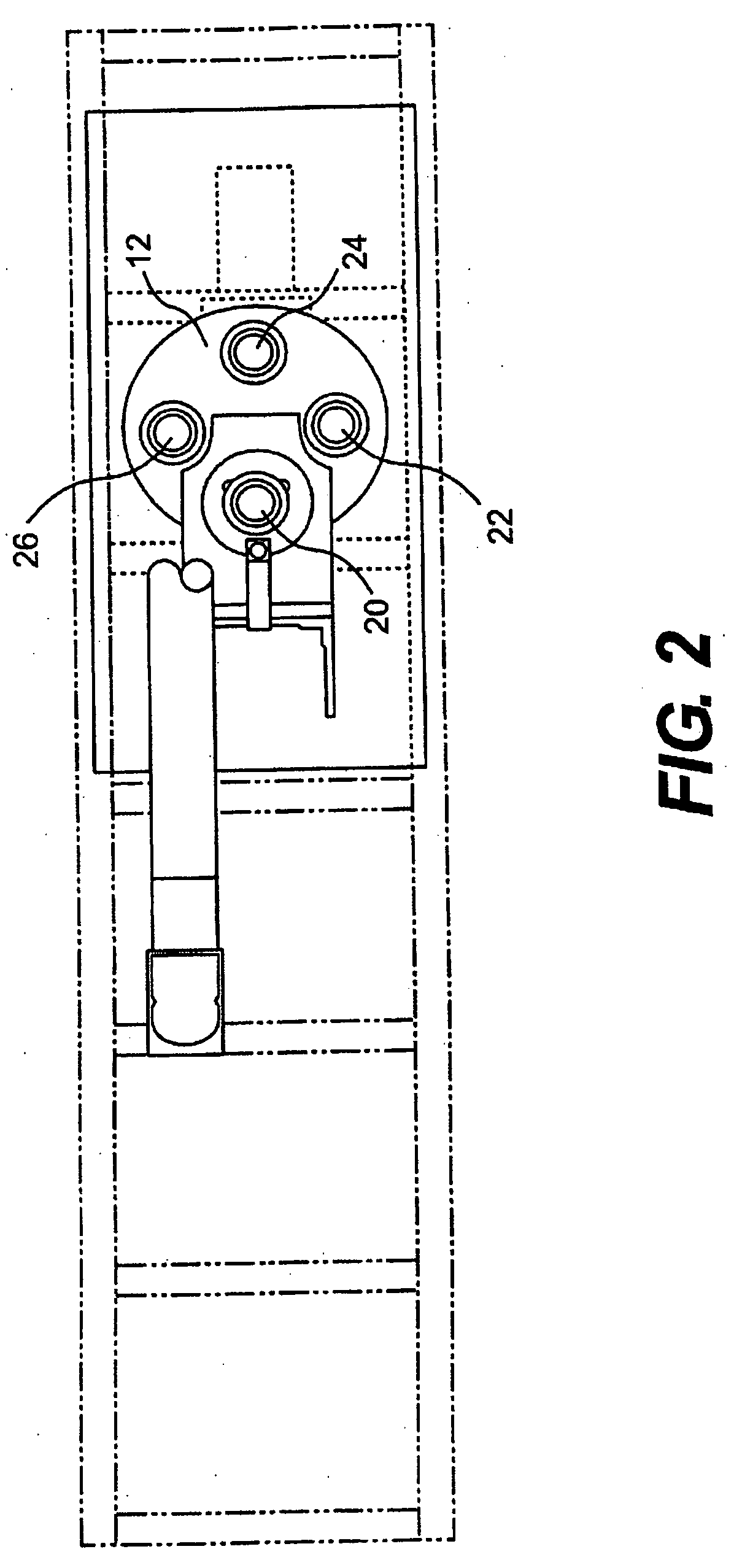

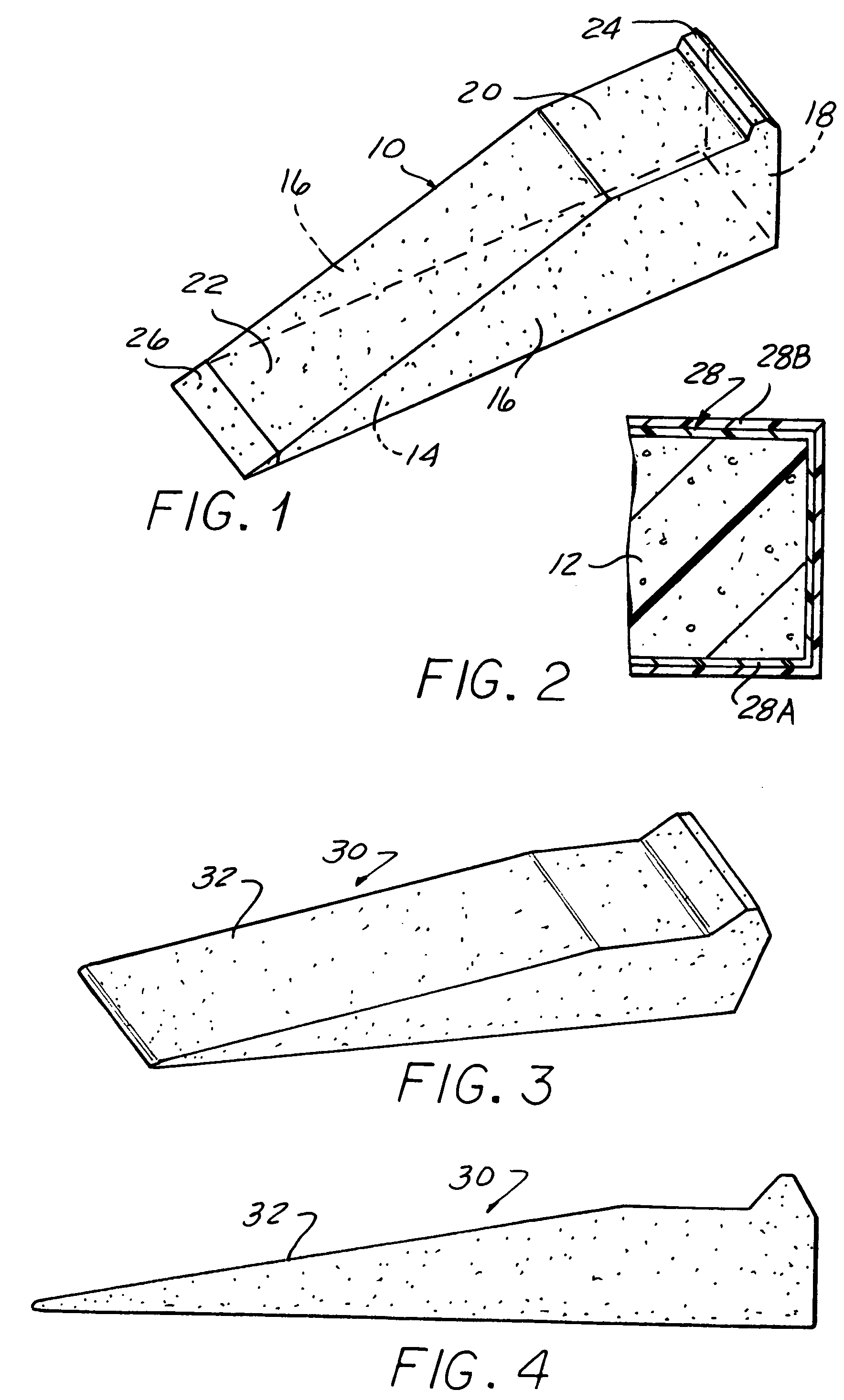

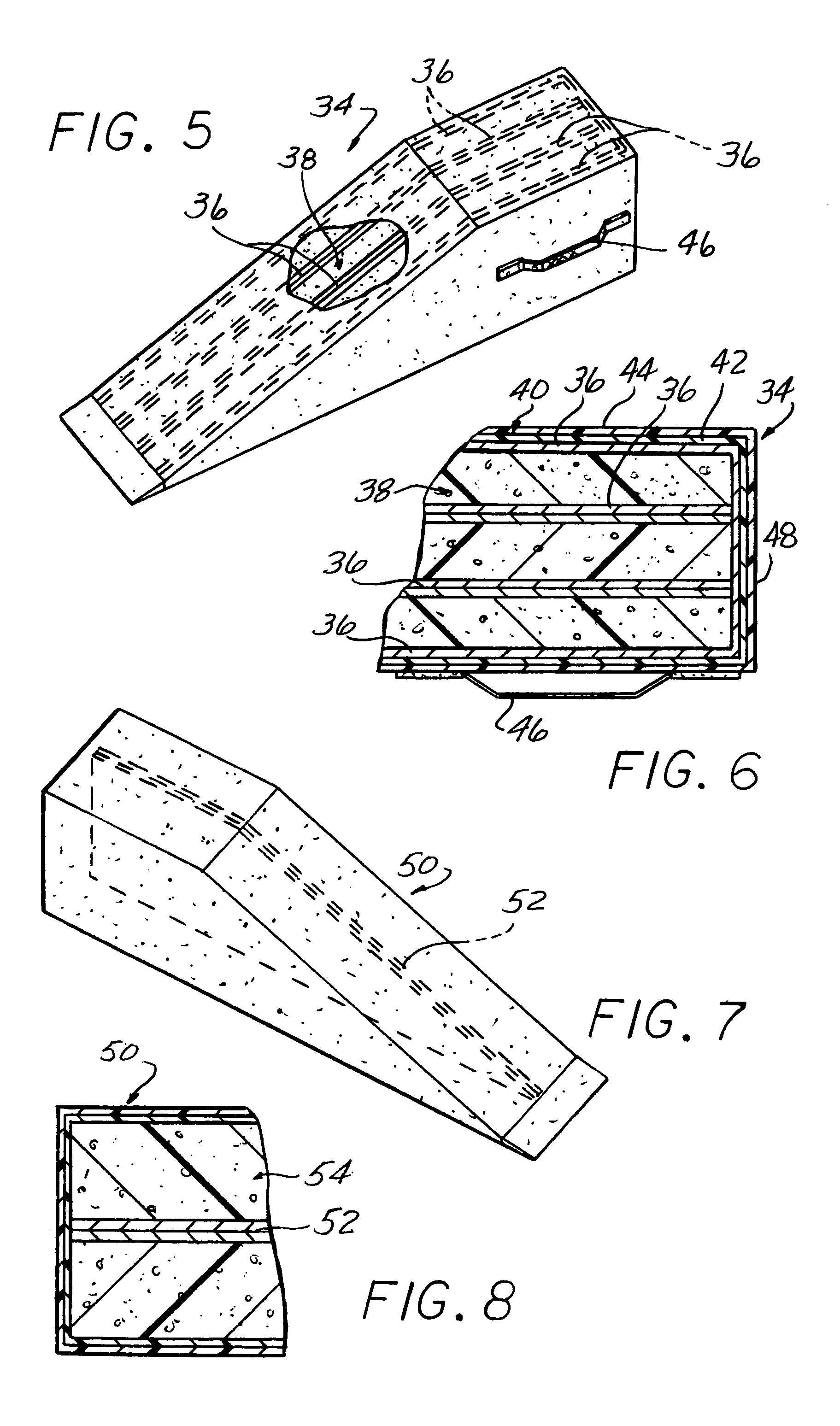

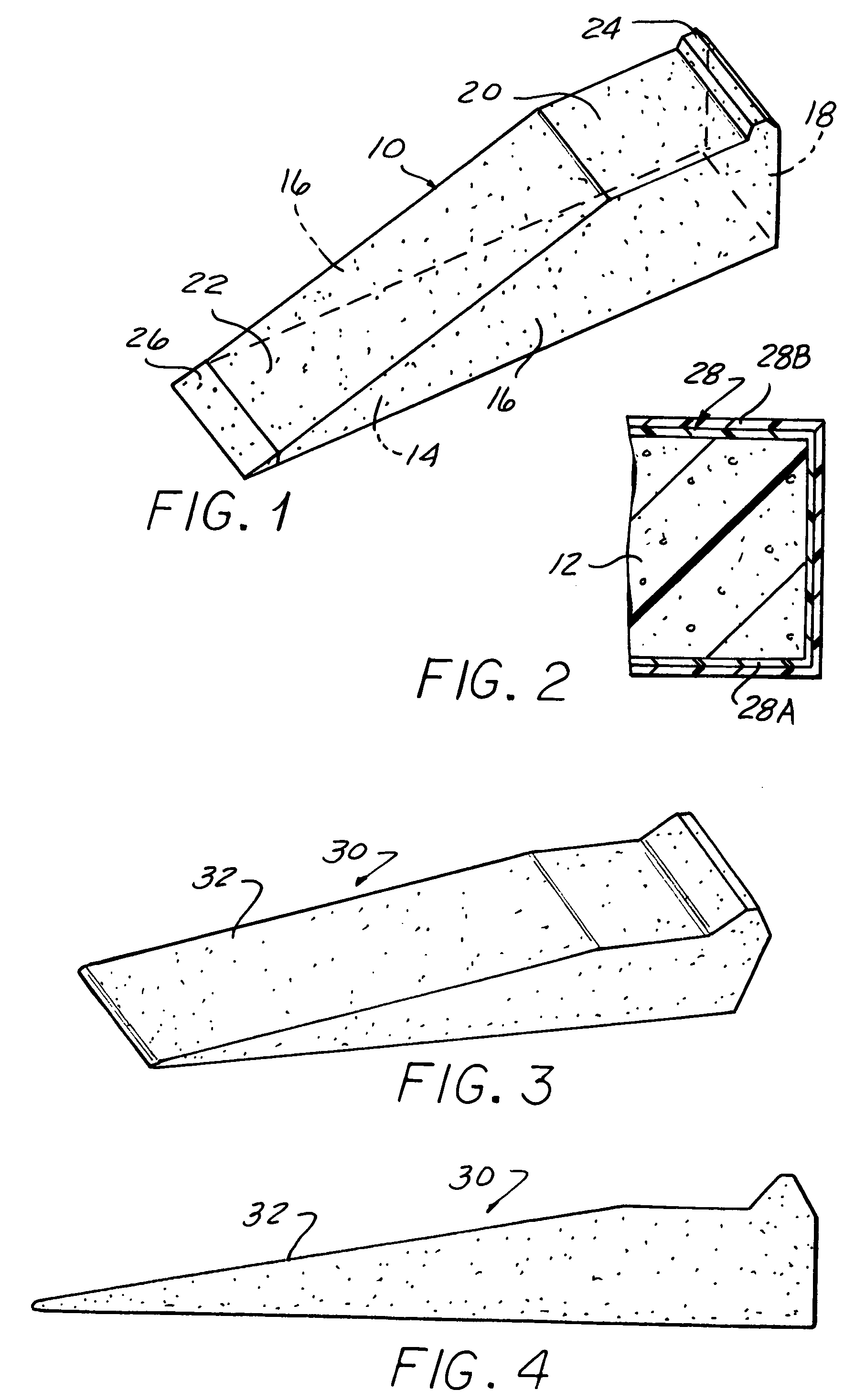

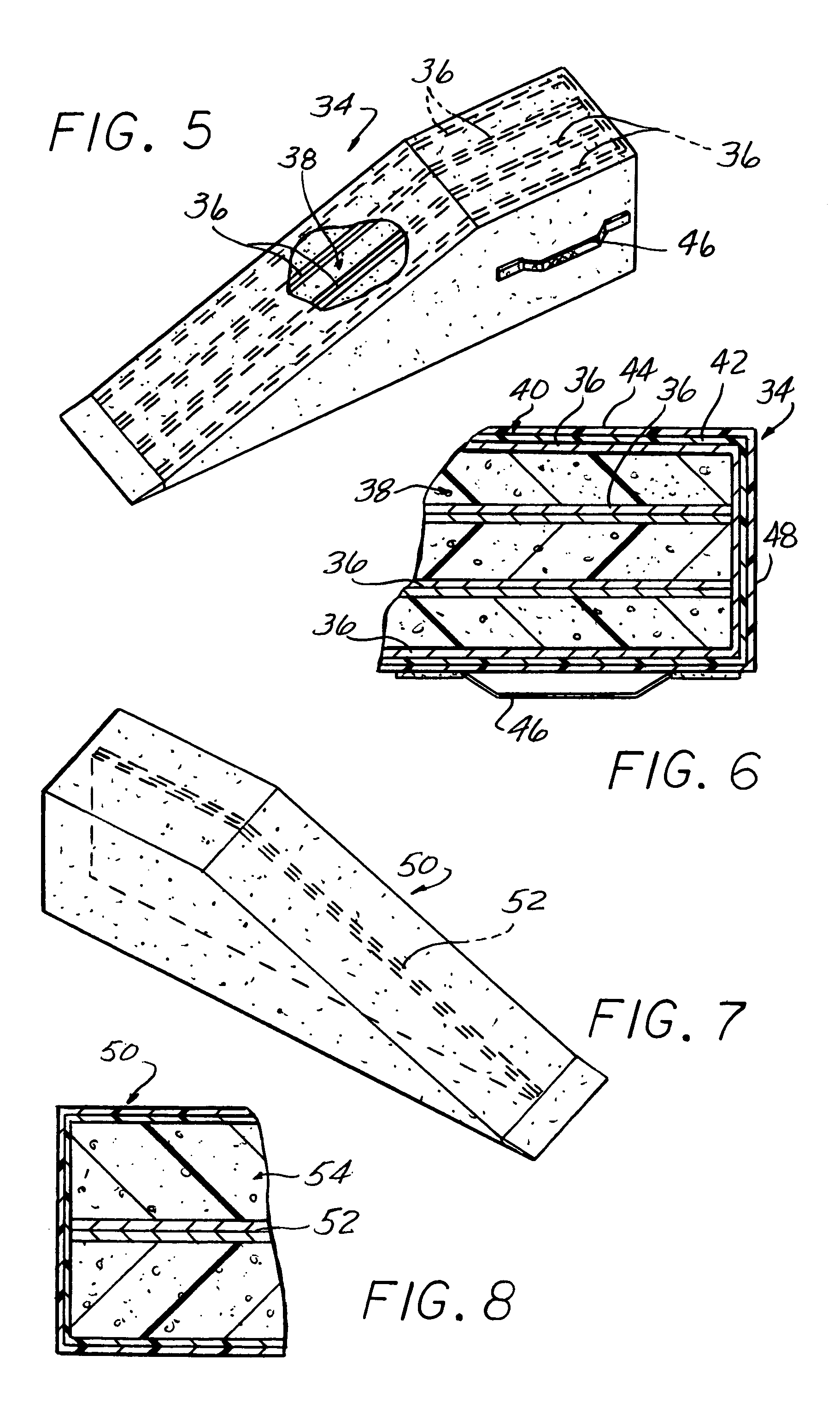

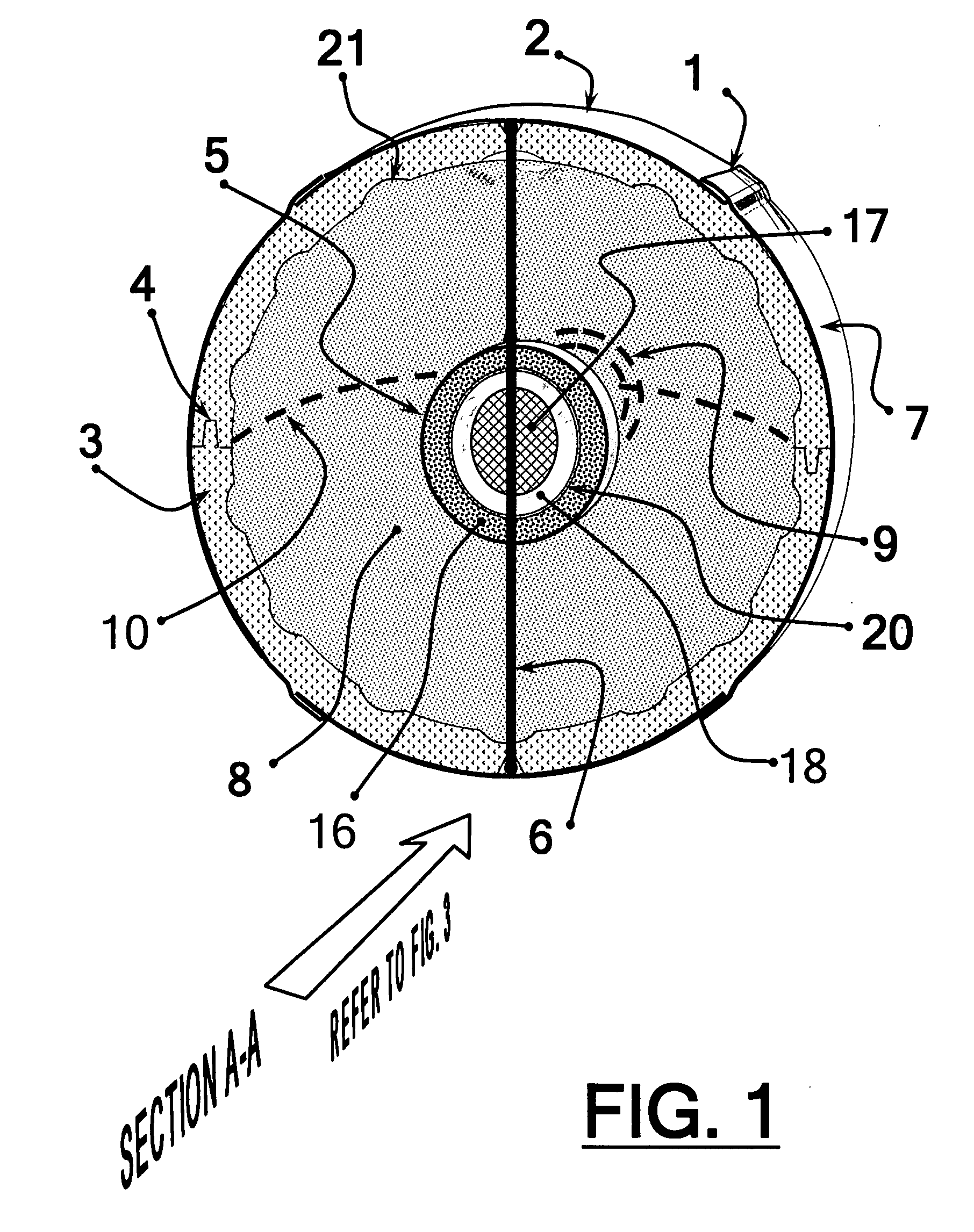

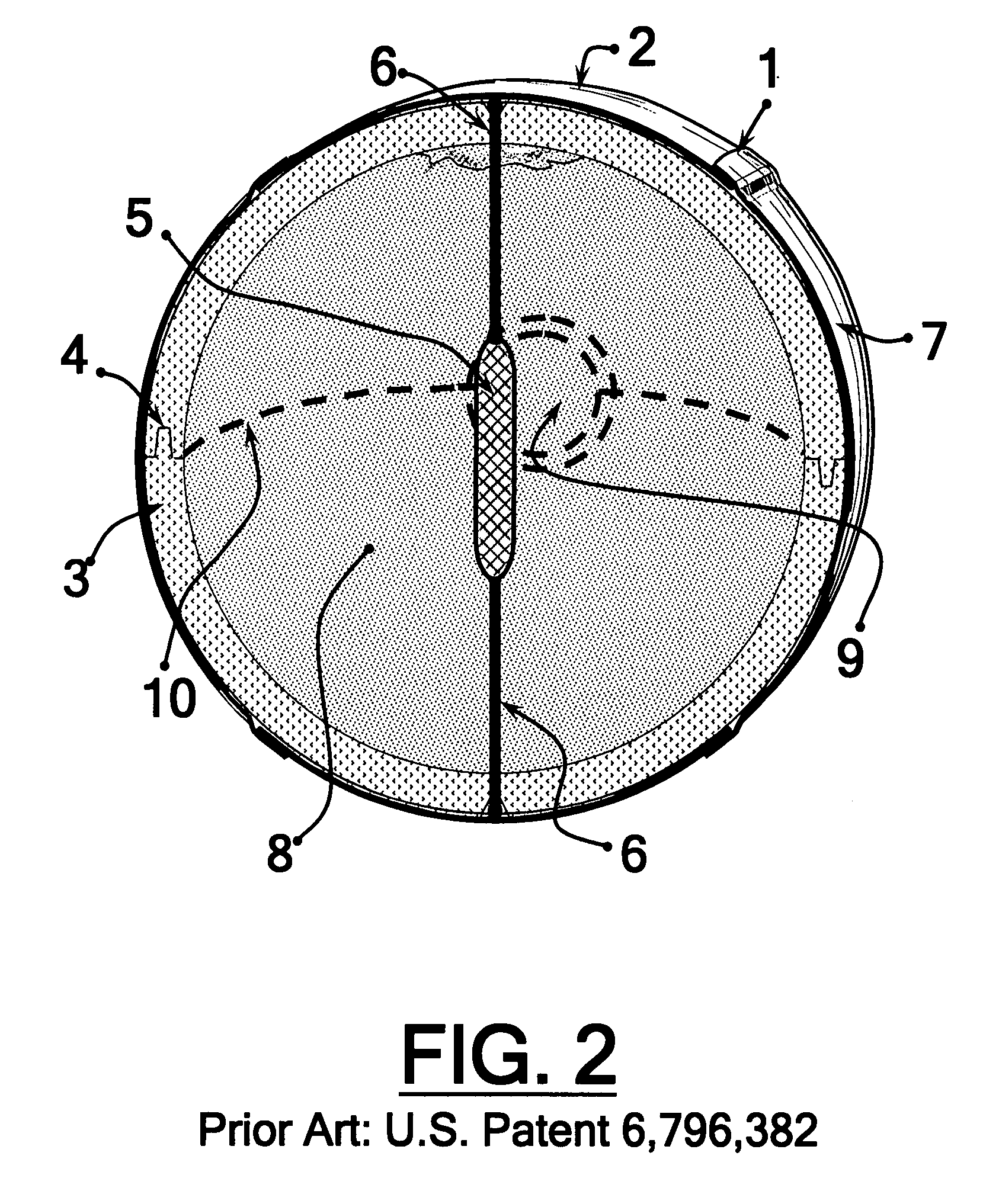

Fiber reinforced composite cores and panels

InactiveUS7393577B2Effective structureImprove impact resistanceSynthetic resin layered productsBuilding componentsEngineeringFiber-reinforced composite

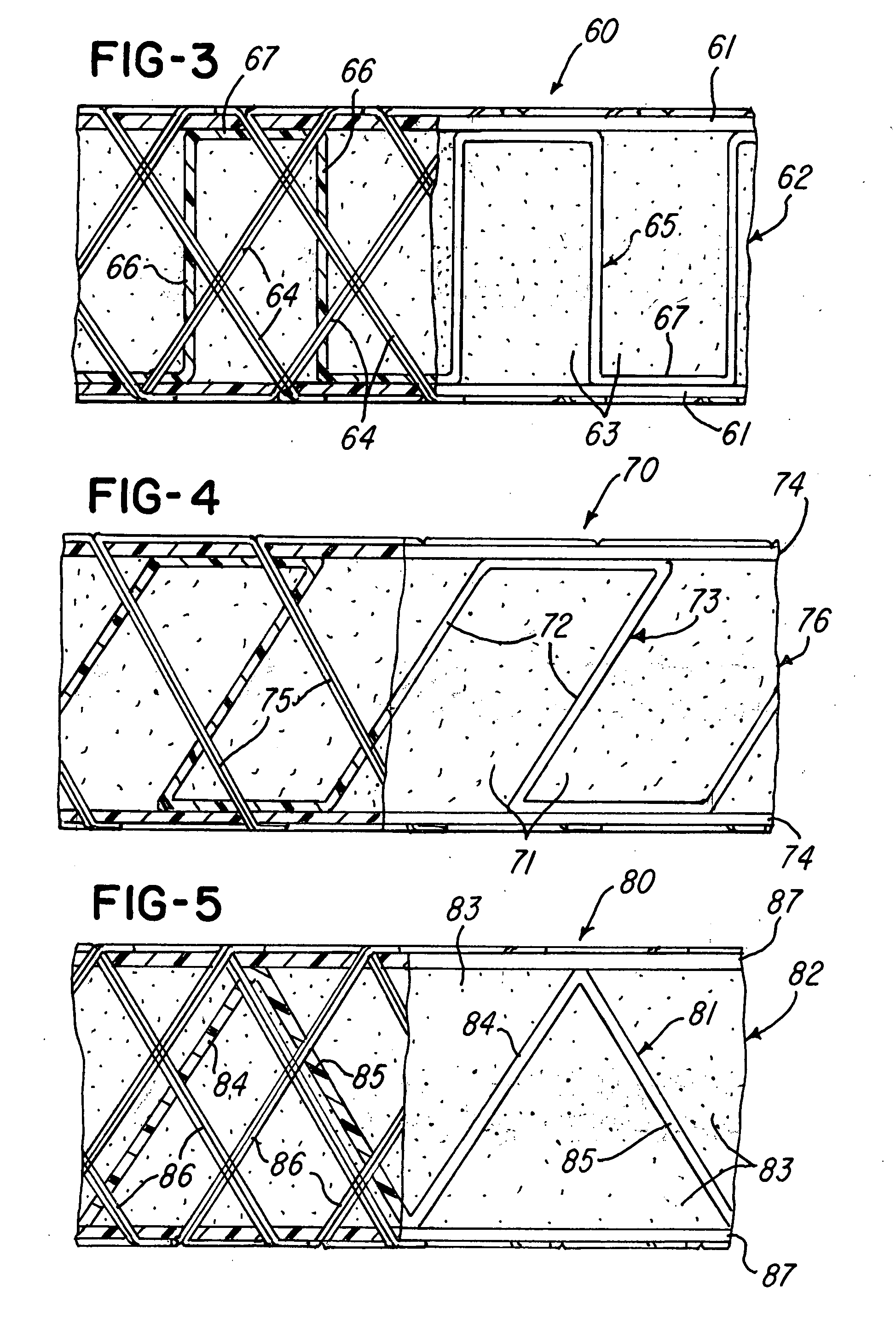

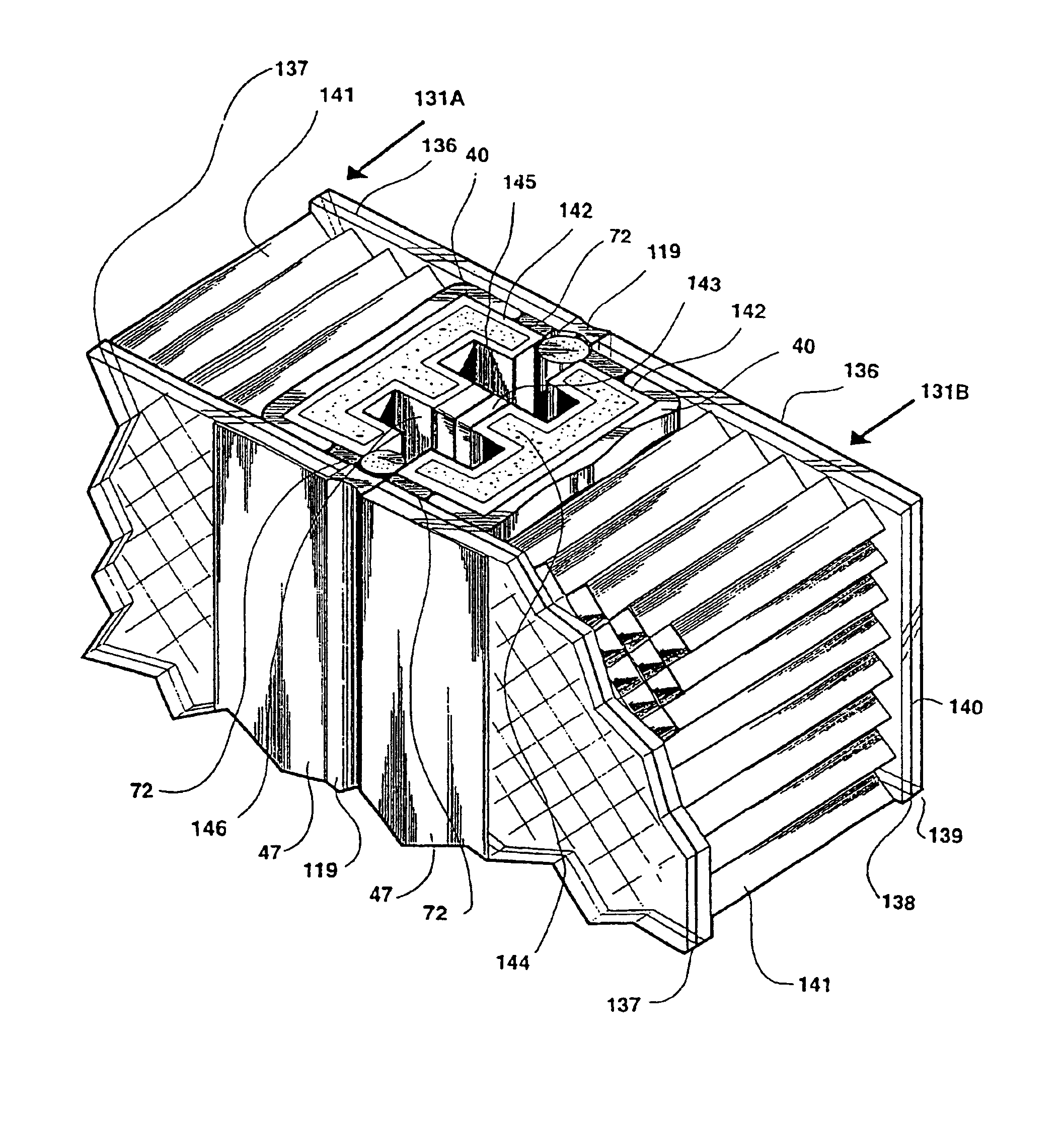

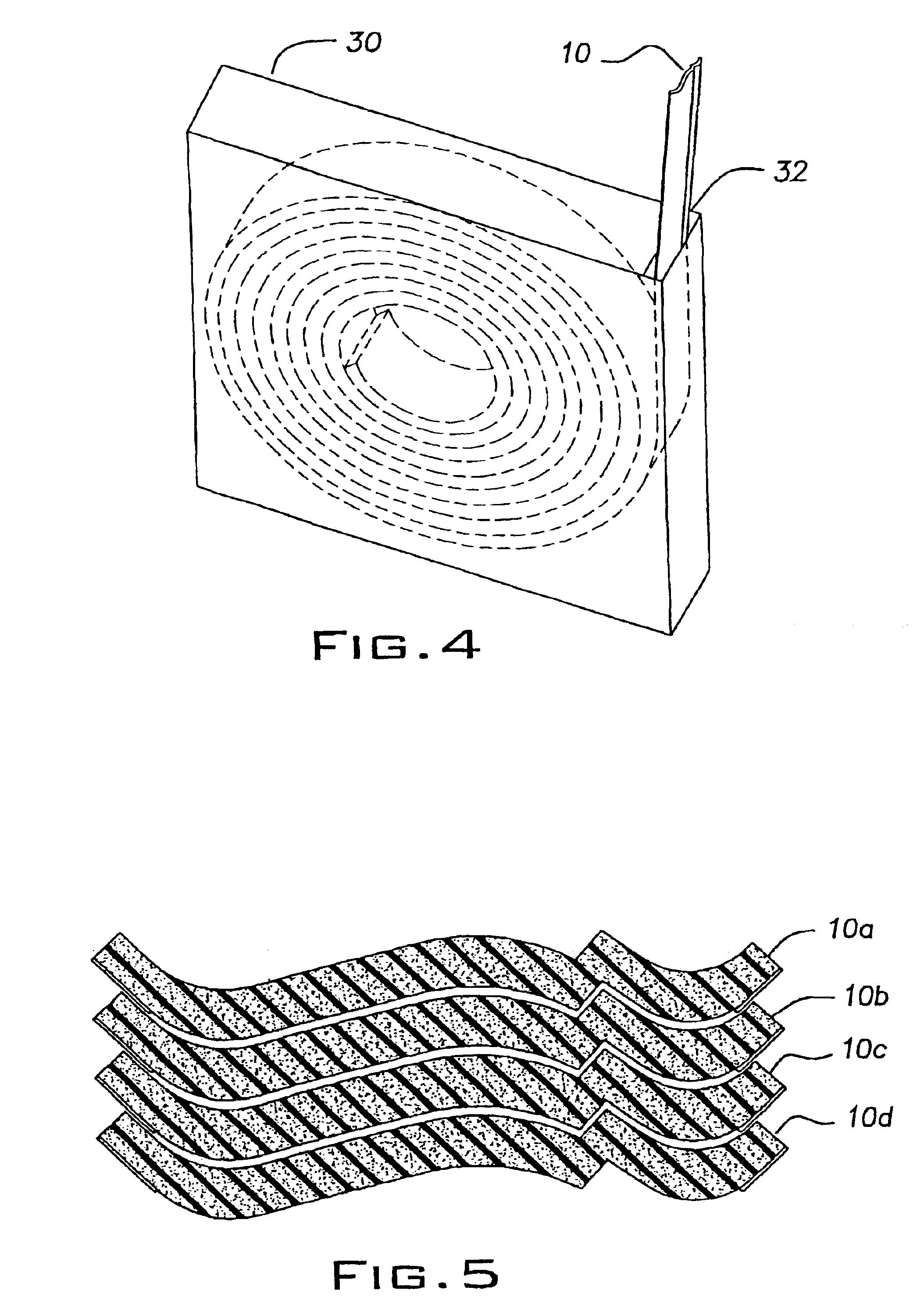

A fiber reinforced core panel is formed from strips of plastics foam helically wound with layers of rovings to form webs which may extend in a wave pattern or may intersect transverse webs. Hollow tubes may replace foam strips. Axial rovings cooperate with overlying helically wound rovings to form a beam or a column. Wound roving patterns may vary along strips for structural efficiency. Wound strips may alternate with spaced strips and spacers between the strips enhance web buckling strength. Continuously wound rovings between spaced strips permit folding to form panels with reinforced edges. Continuously wound strips are helically wrapped to form annular structures, and composite panels may combine both thermoset and thermoplastic resins.

Owner:METYX USA INC

Fiber reinforced composite cores and panels

InactiveUS20050074593A1Effective structureImprove impact resistanceSynthetic resin layered productsBuilding componentsEngineeringFiber-reinforced composite

A fiber reinforced core panel is formed from strips of plastics foam helically wound with layers of rovings to form webs which may extend in a wave pattern or may intersect transverse webs. Hollow tubes may replace foam strips. Axial rovings cooperate with overlying helically wound rovings to form a beam or a column. Wound roving patterns may vary along strips for structural efficiency. Wound strips may alternate with spaced strips and spacers between the strips enhance web buckling strength. Continuously wound rovings between spaced strips permit folding to form panels with reinforced edges. Continuously wound strips are helically wrapped to form annular structures, and composite panels may combine both thermoset and thermoplastic resins.

Owner:METYX USA INC

Insulating sleeve for grasping container and manufacturing method

InactiveUS6814253B2Easy to masterEasy to useSynthetic resin layered productsRefuse receptaclesPlastic materialsVolumetric Mass Density

Owner:DOUBLE TEAM

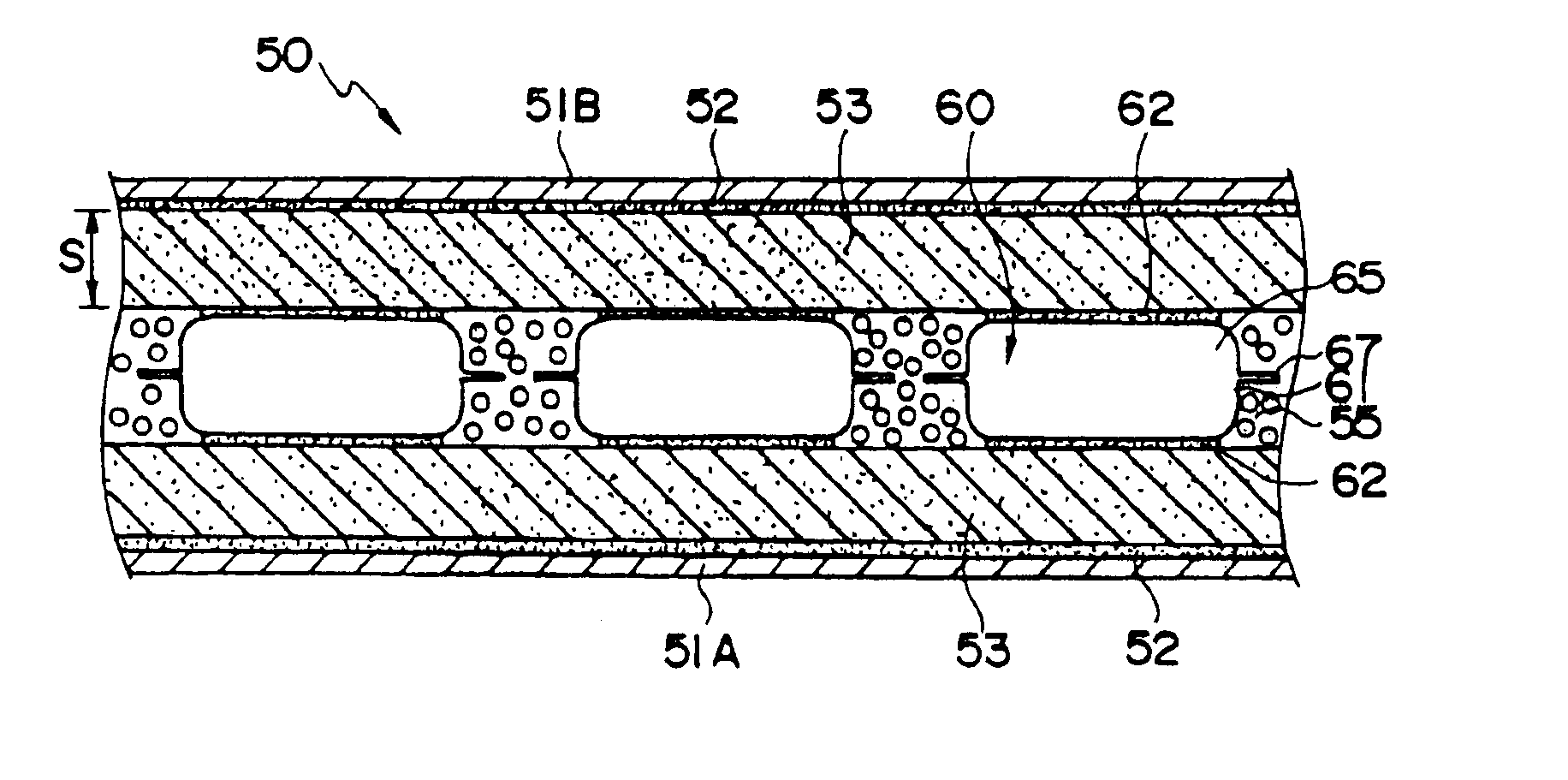

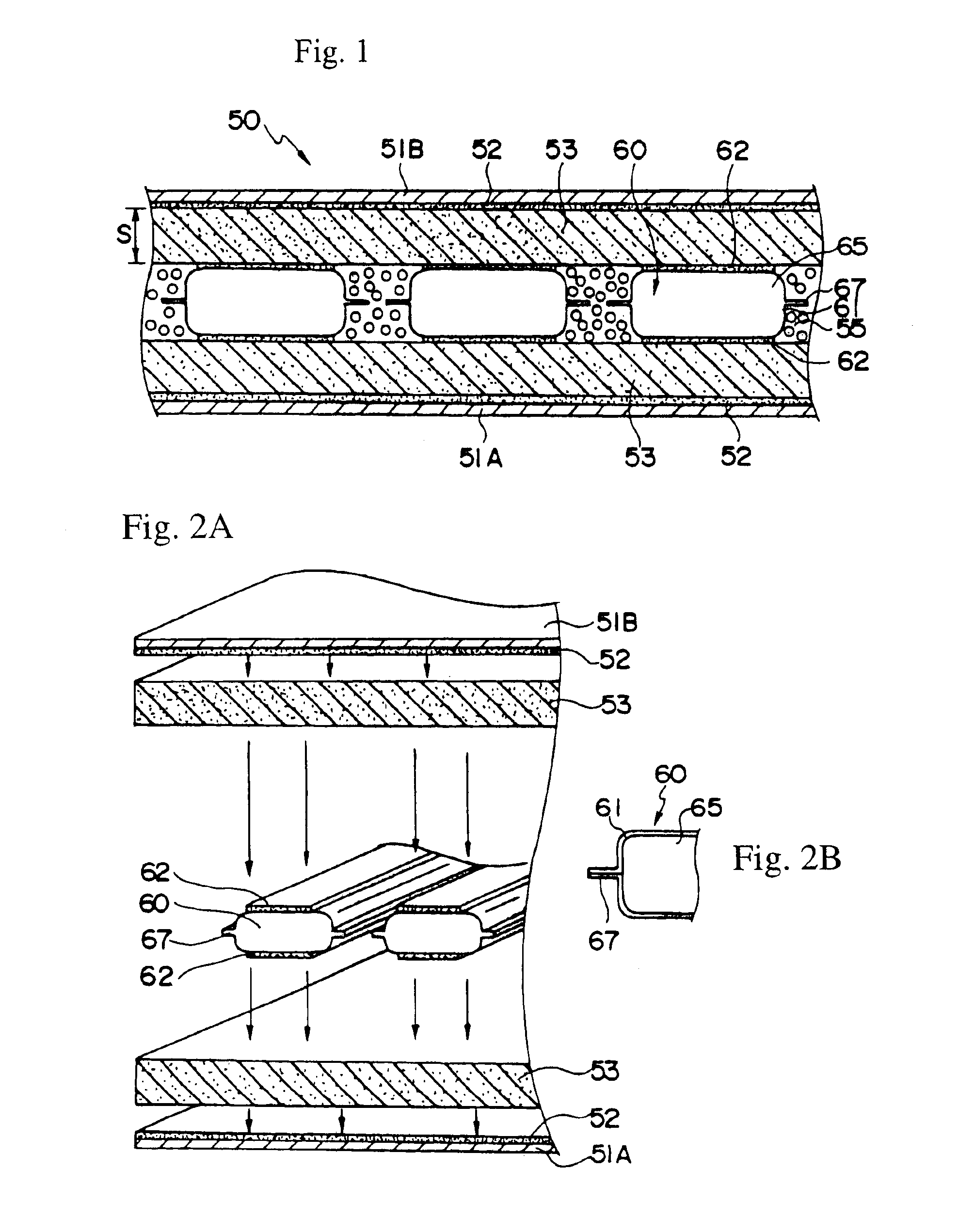

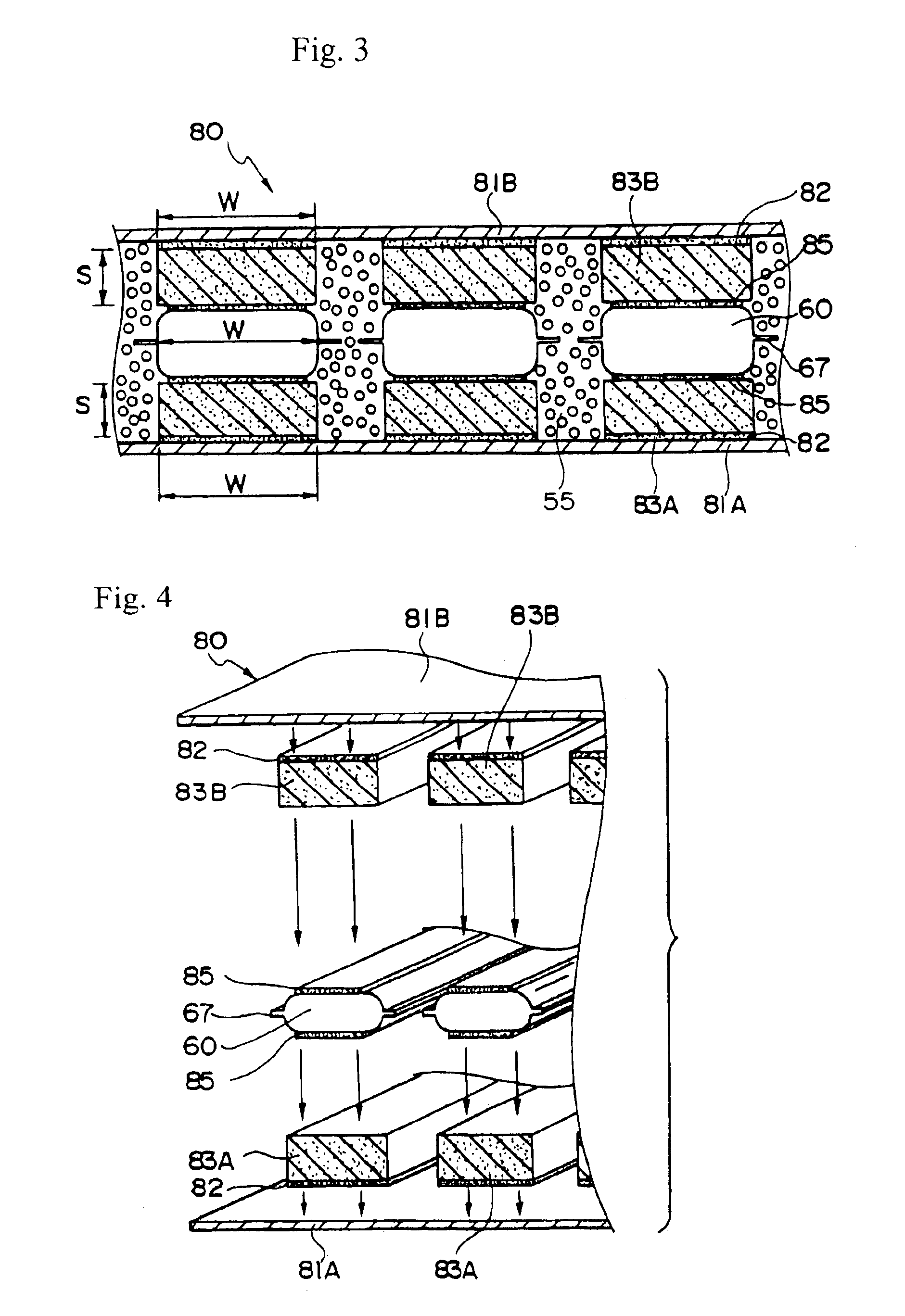

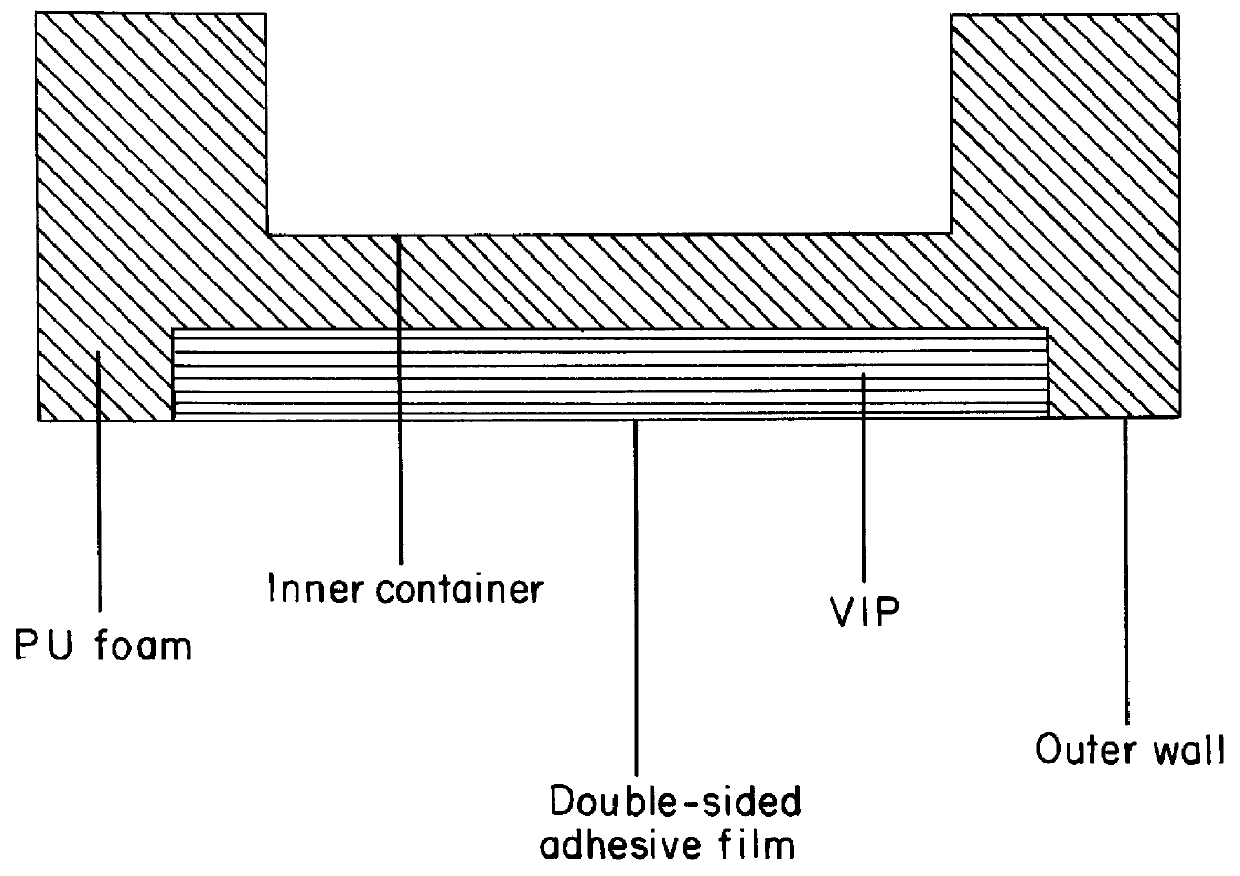

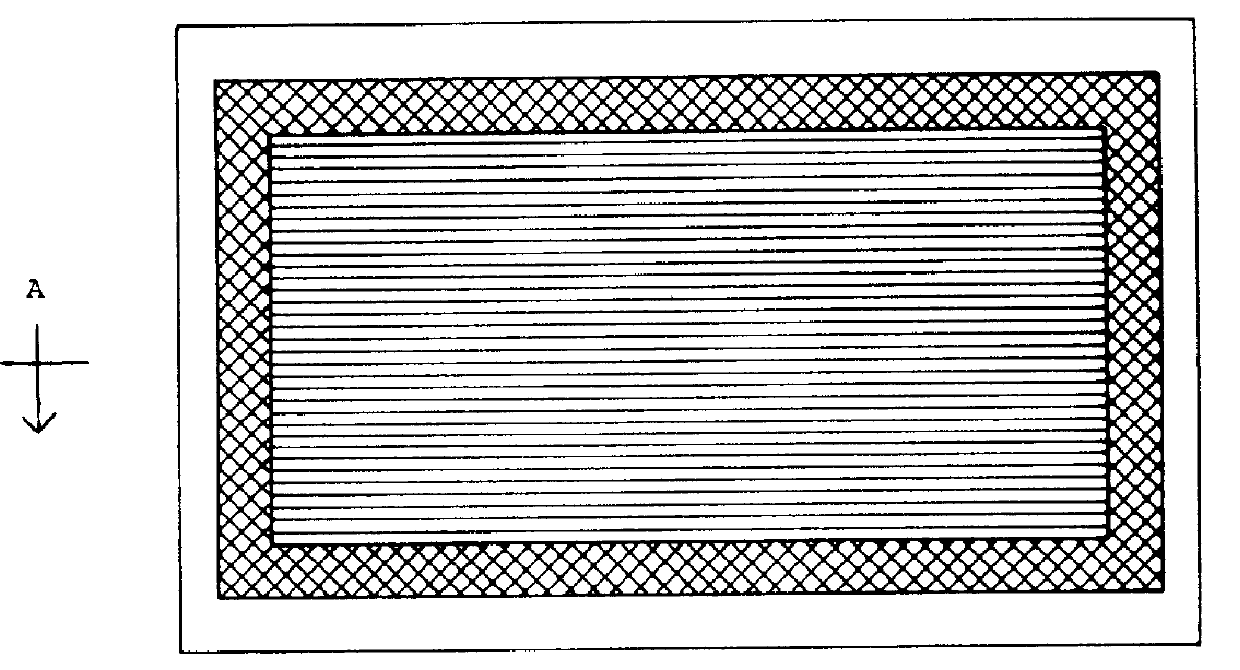

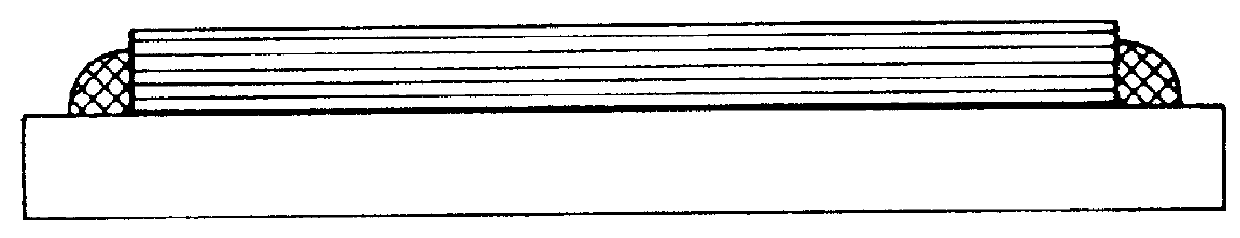

Heat insulating wall member, and method of manufacturing the same

InactiveUS6860082B1Improve insulation performanceLighting and heating apparatusRefrigerated goods vehicleEngineeringPlastic foam

A heat insulating wall, and a method of manufacturing the same. A laminated body includes a first panel, a first plate-shaped insulating member made of plastic foam and having a predetermined thickness, a vacuum insulation member mounted on the insulating member, a second plate-shaped insulating member made of plastic foam, and a second panel. The area between the first and second panels surrounded by the first plate-shaped insulating member, the vacuum insulation member, and the second plate-shaped insulating member is filled with expanded plastic foam. The thickness of the first and second plate-shaped insulating members is set to a predetermined thickness S.

Owner:ISUZU MOTORS LTD

Wood plastic foamed material and machine-shaping process thereof

The foamed wood-plastic material is produced with plastic, wood dust, mineral stuffing, assistant, modifier, foaming agent, etc. in certain proportion and through mixing, heating to fusion, foaming and forming in a heat forming apparatus. It has continuous homogeneous pores, and is light, high in specific strength, waterproof, anticorrosive and heat insulating, and may be nailed, sawn and planed, so that it may be used widely in building, transportation, packing, household decoration and daily use articles.

Owner:北京欧尼克新型材料有限公司

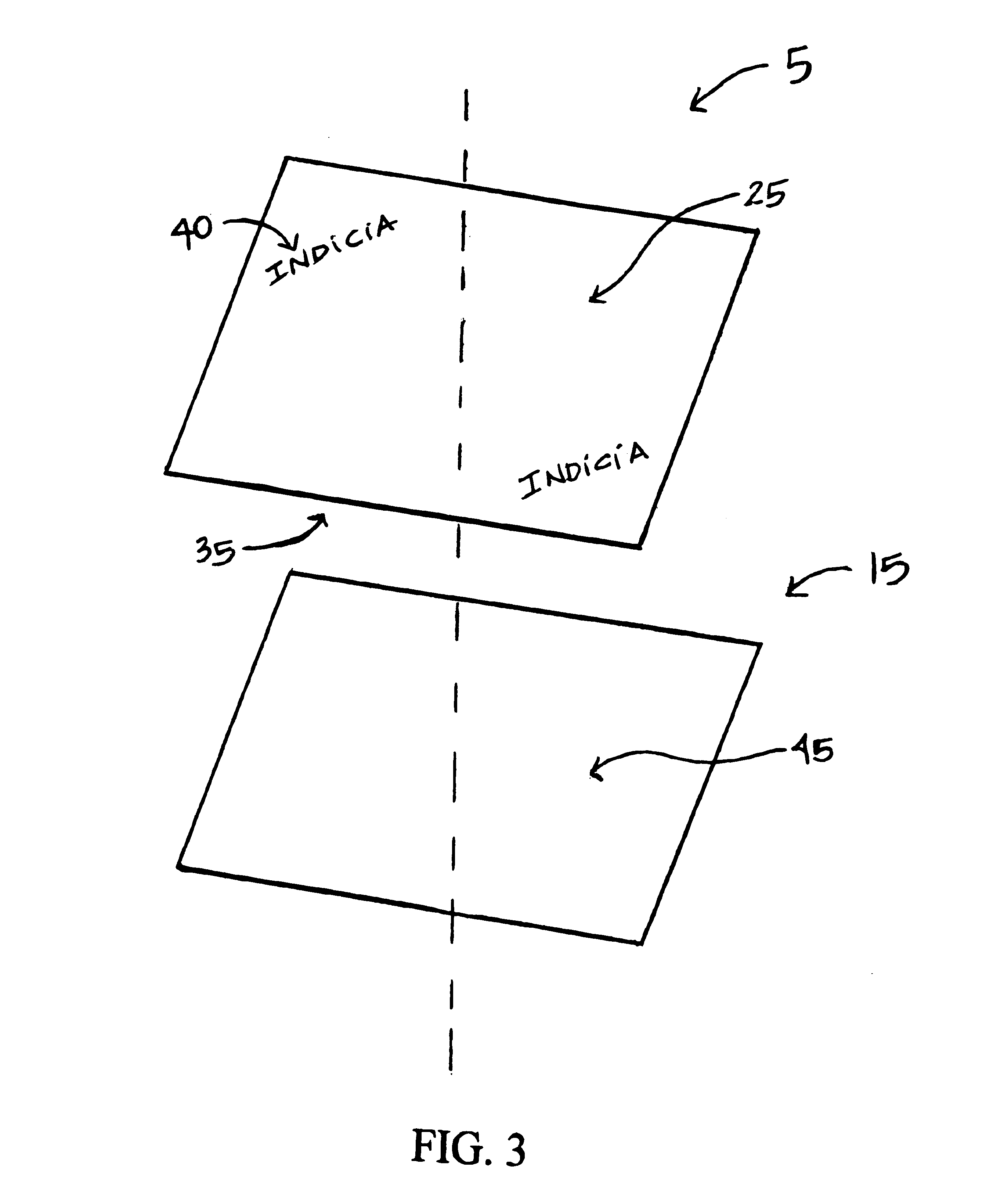

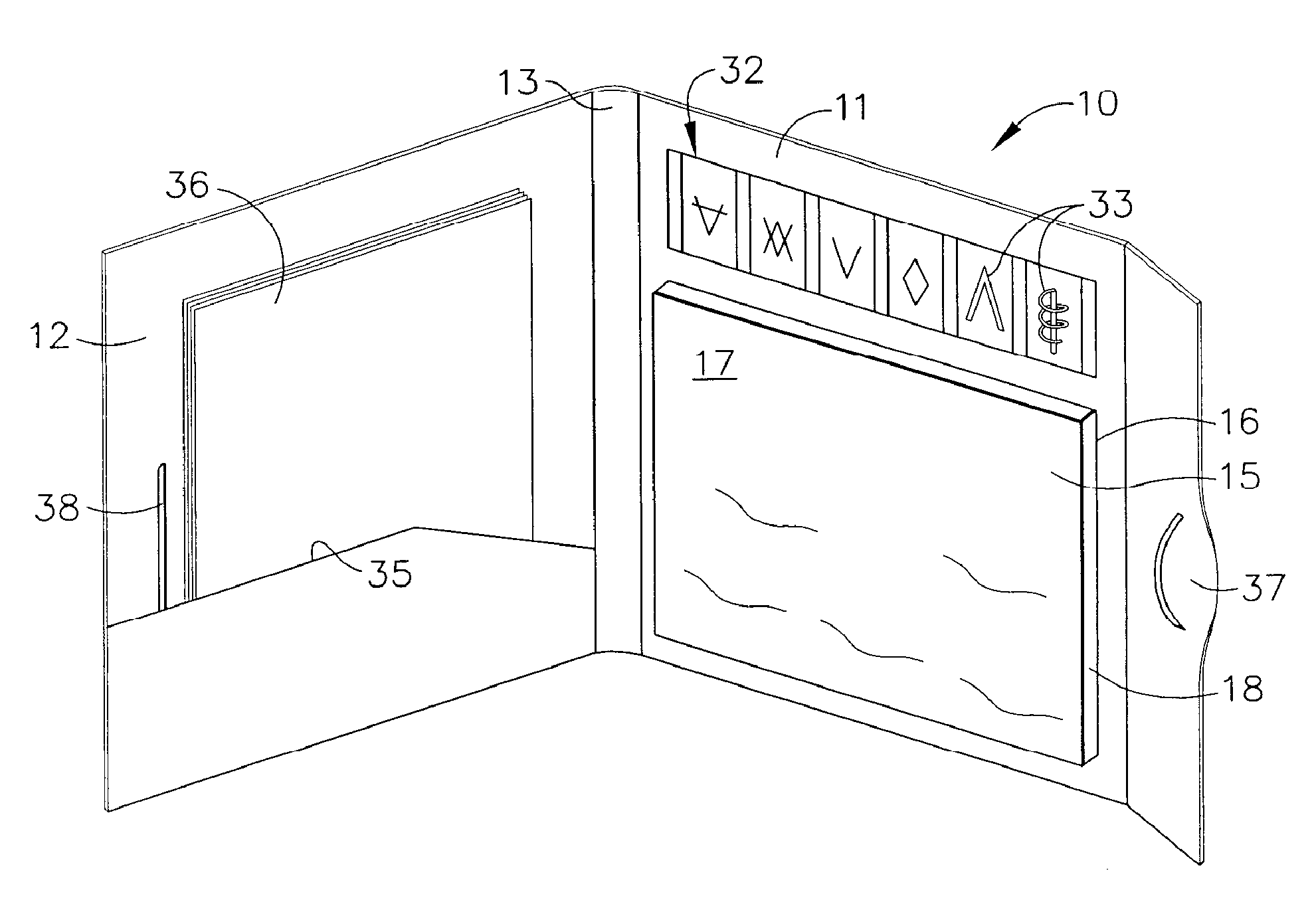

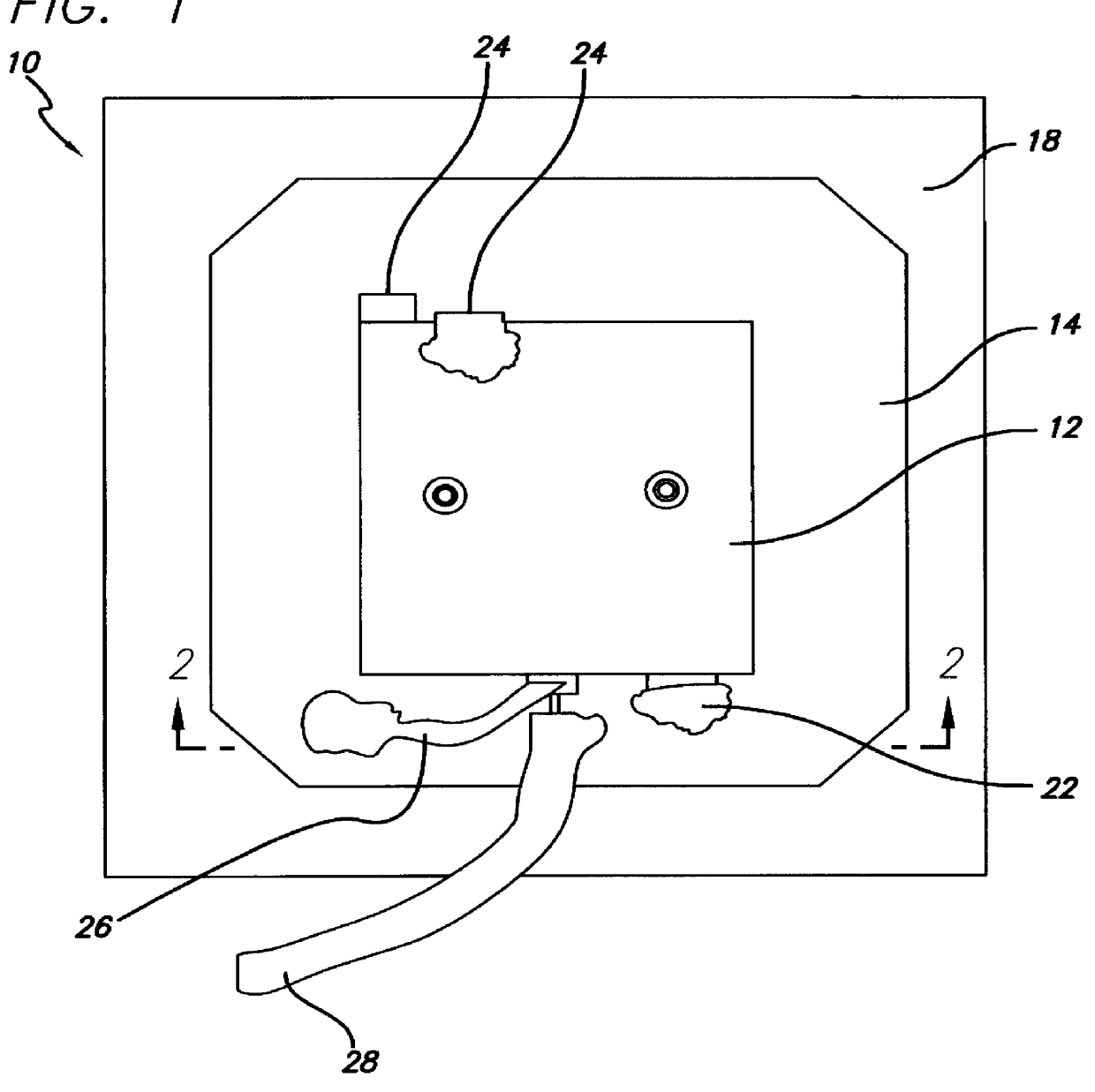

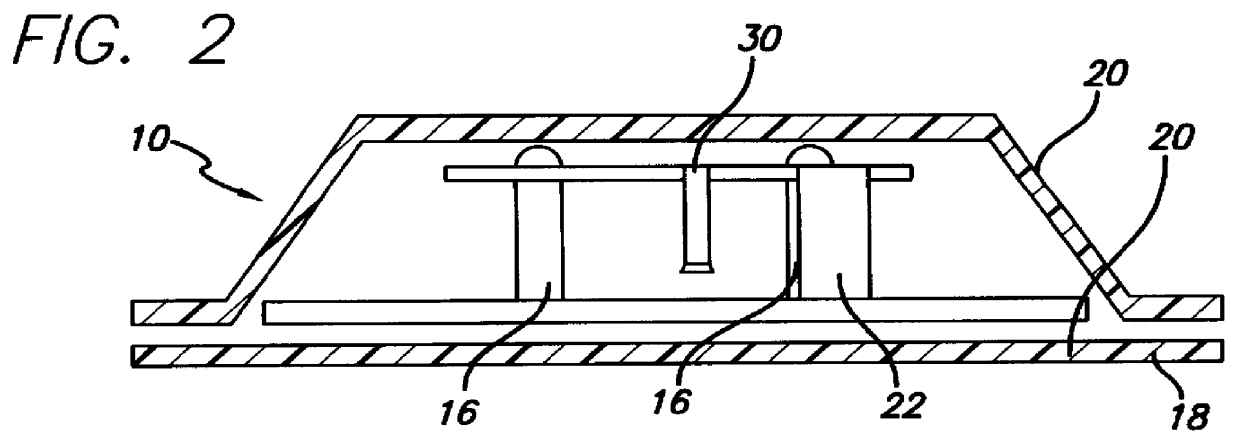

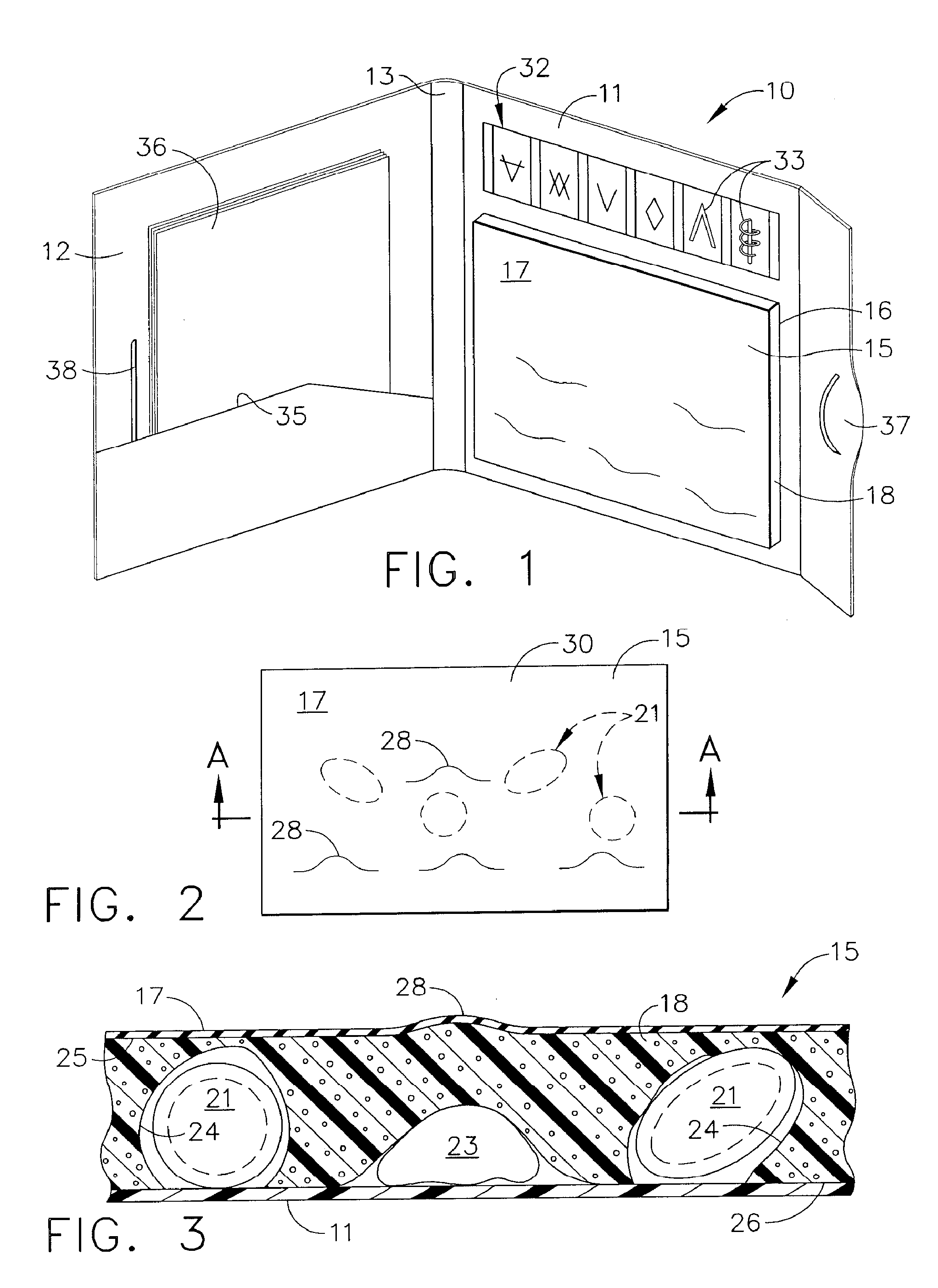

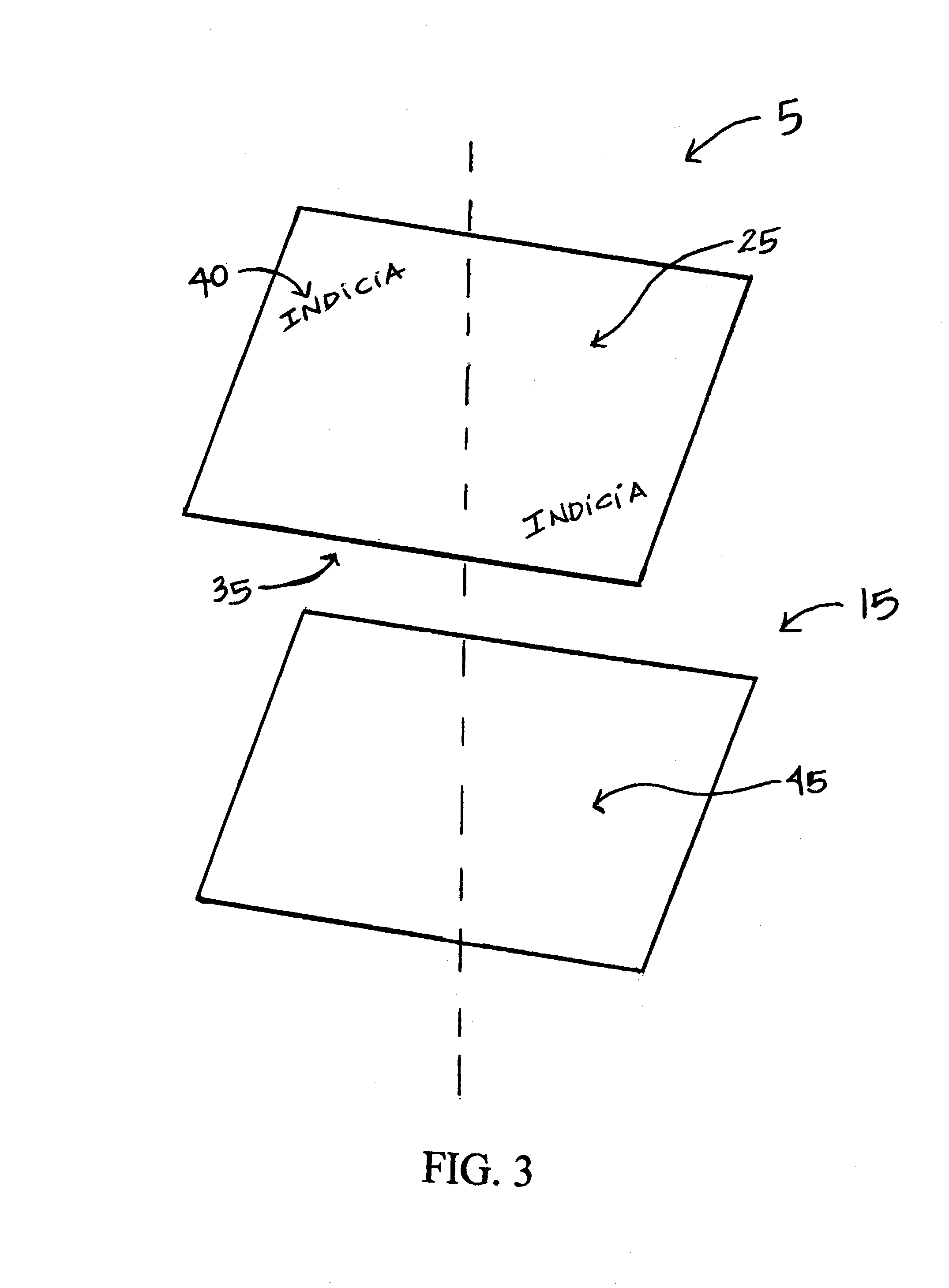

Surgery practice kit

A simple to use, inexpensive and readily portable surgical practice and teaching kit is described that includes in portfolio form a two layer practice suturing pad including a latex rubber layer simulating human skin attached to a plastic foam layer that simulates underlying human tissue, the foam layer having incorporated therein simulated subcutaneous growths or lesions such as simulated lipomas or sebaceous cysts. The practice pad is mounted on a folder or portfolio for convenient access and use by the student or practitioner, the portfolio also including pictorial illustrations showing various proper suturing techniques as a visual guide to the user in practicing suturing procedures.

Owner:PALAKODETI RATNA K

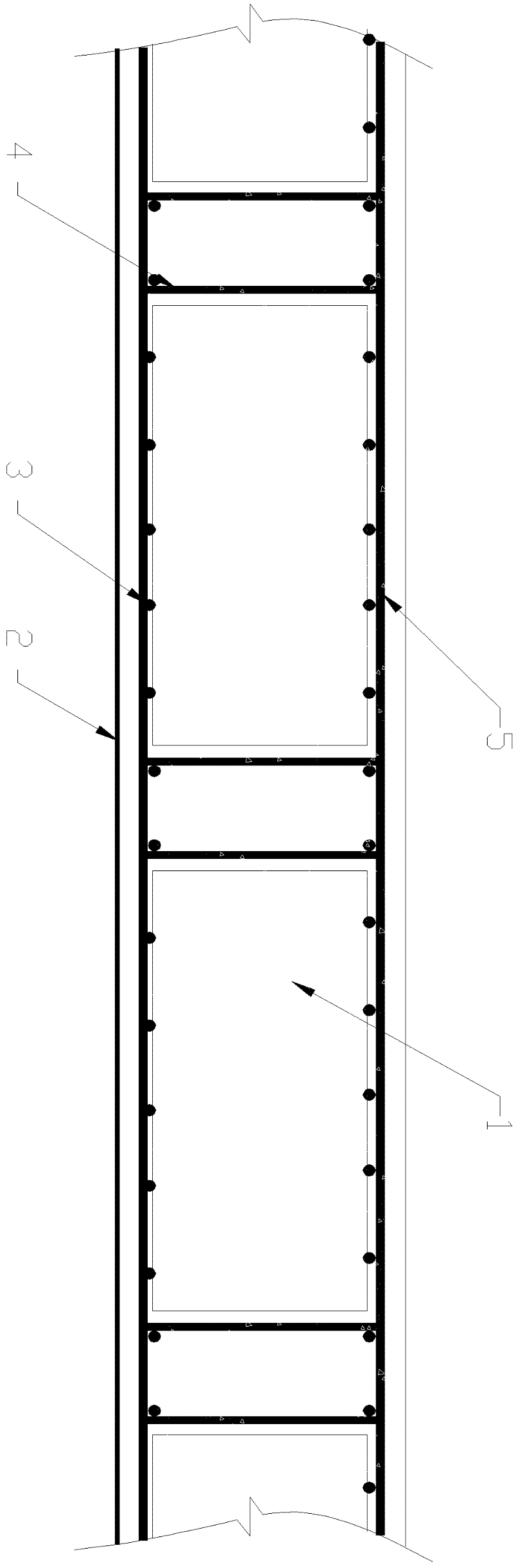

Hollow floor system made of steel bar and foam combined filled member

Owner:HUNAN BDF ENERGY SAVING TECH

Fixed vacuum insulation panel

InactiveUS6164030ASimple wayReliable anchoringThermal insulationInsulation for cooling apparatusEngineeringOpen cell

An apparatus is described which consists of a rigid plate and a vacuum insulation panel, in which the vacuum insulation panel is fixed to the rigid plate by a polyurethane foam applied as a liquid reaction mixture, wherein the vacuum insulation panel contains open-cell rigid plastics foam and / or open-cell rigid plastics foam recyclate. A refrigerated cabinet element containing said apparatus is additionally described.

Owner:KARL WERNER DIETRICH

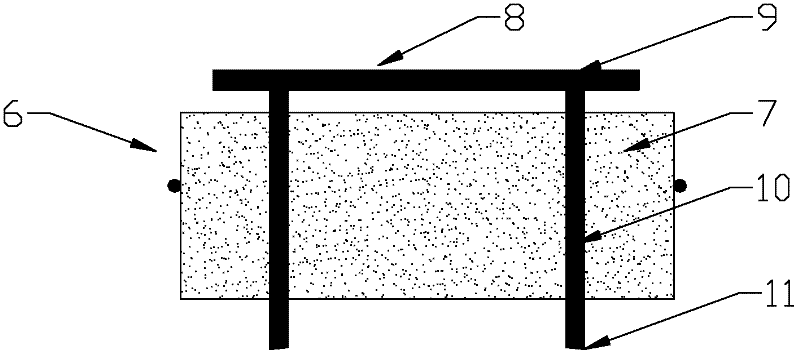

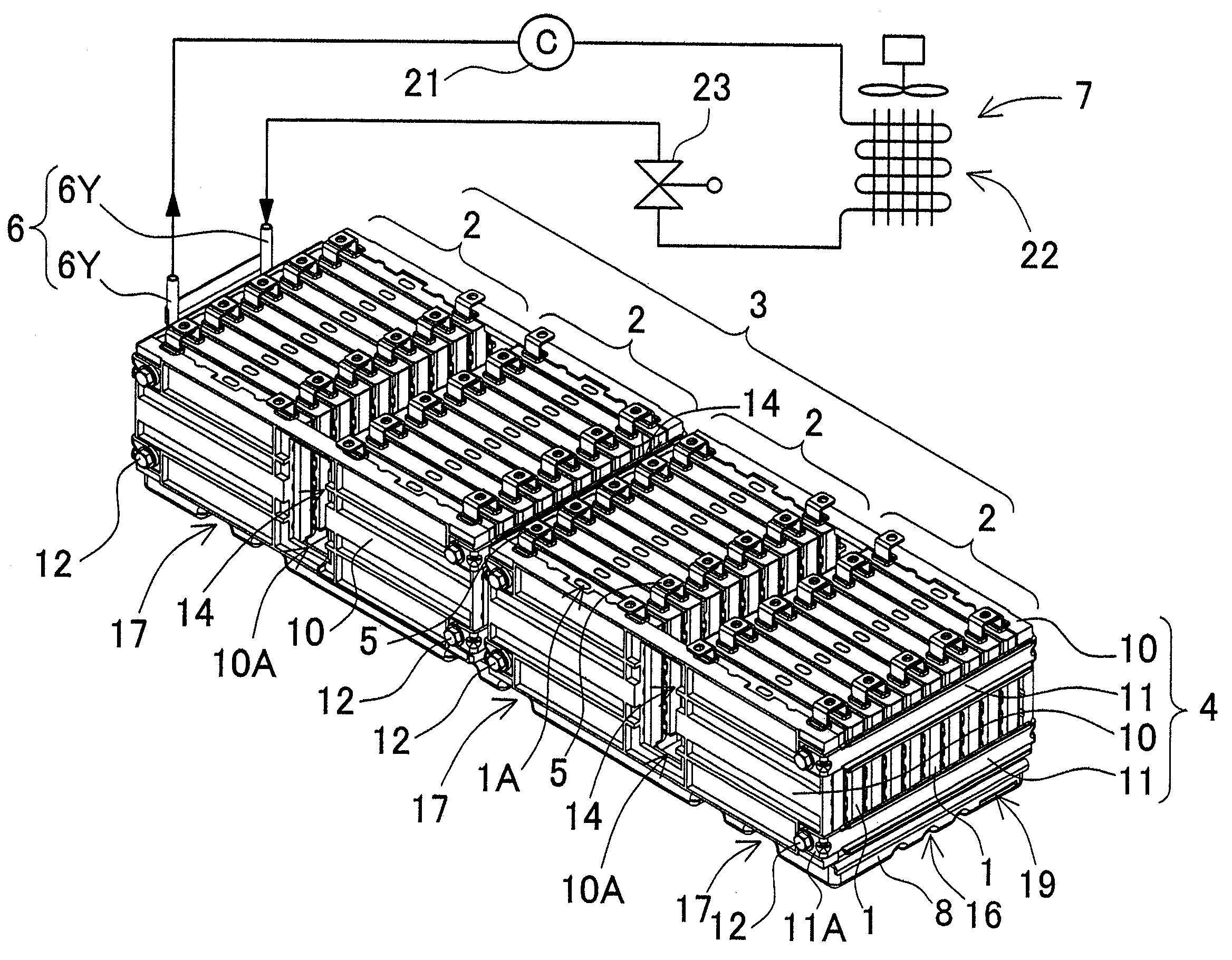

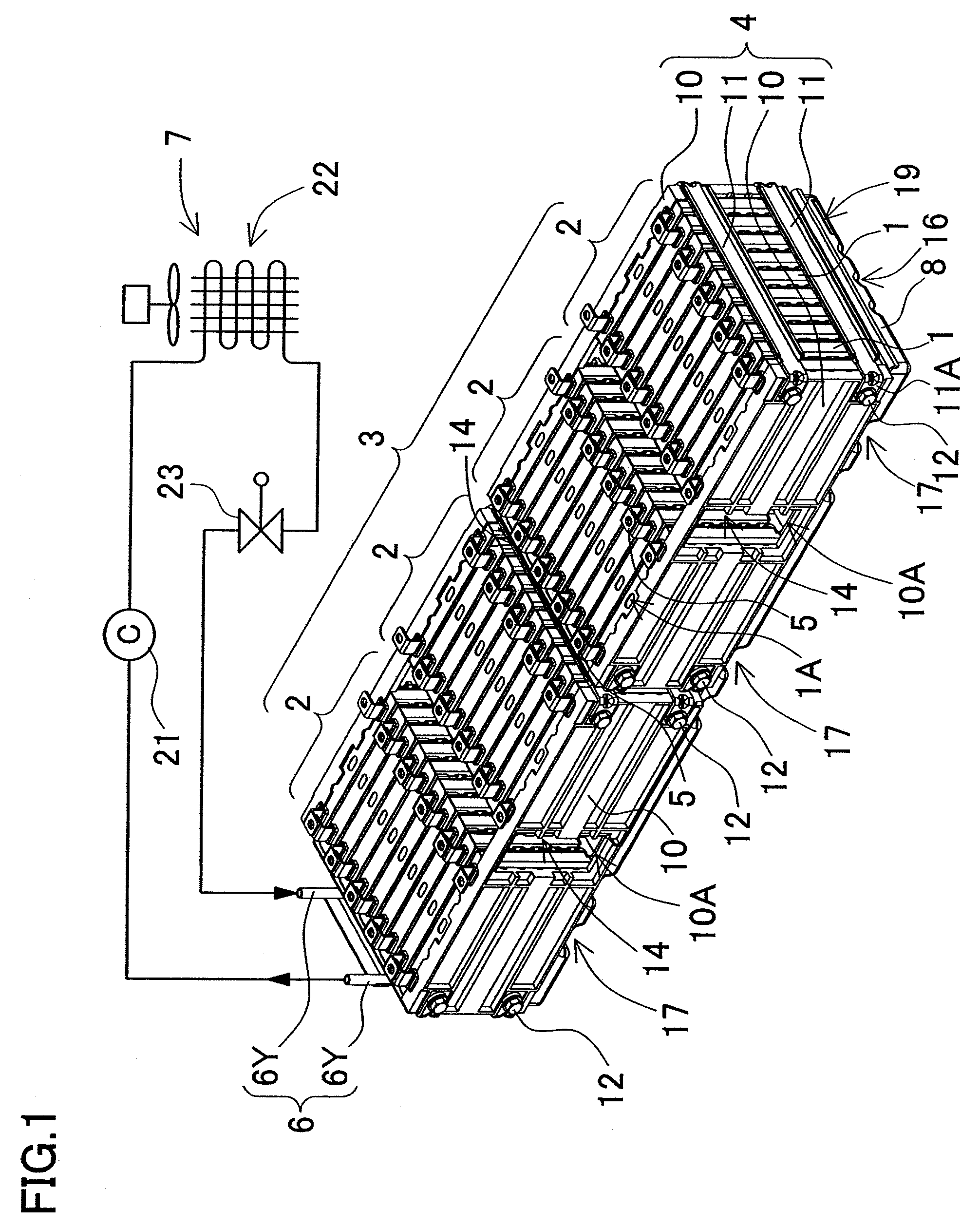

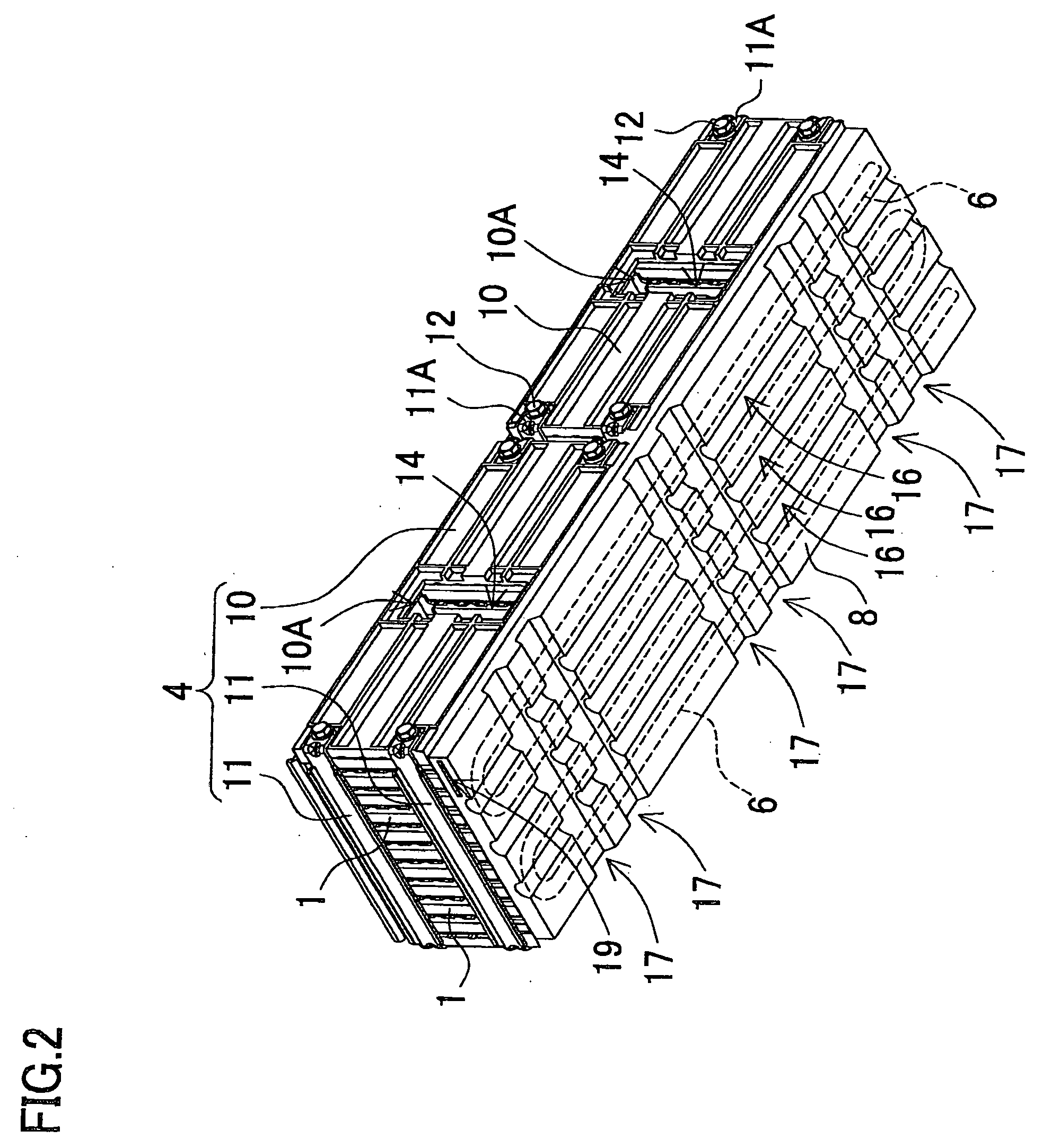

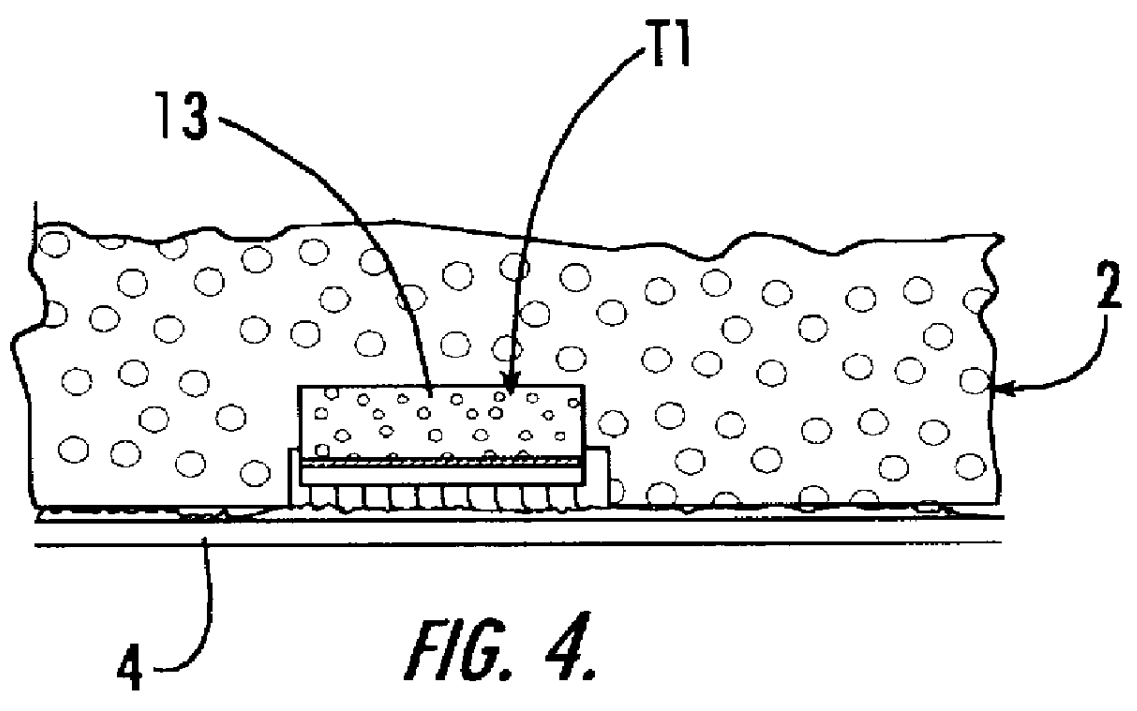

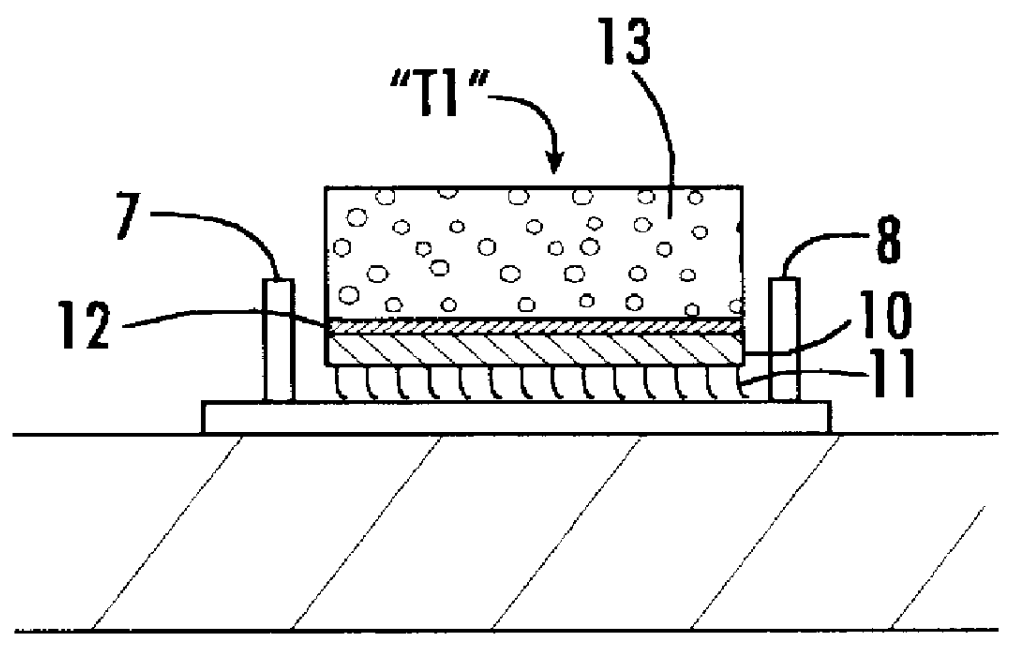

Battery system cooled via coolant

InactiveUS20090142628A1Increase contact areaImprove cooling effectSmall-sized cells cases/jacketsCell temperature controlThermal contactCooling pipe

The battery system cooled via coolant has a battery block 3 with a plurality of rectangular batteries 1 retained in a stacked configuration by a battery holder 4; a cooling plate 8 disposed in thermal contact with the bottom surface of the battery block 3 and having a hollow region 18 inside; cooling pipe 6 disposed inside the hollow region 18 of the cooling plate 8; and a coolant supply device 7 to supply coolant to the cooling pipe 6. The hollow cooling plate 8 has a surface plate 8A that makes thermal contact with the bottom surface of the battery block 3, and cooling pipe 6 is disposed within the hollow region 18 in contact with the inside of the surface plate 8A. Further, the cooling plate 8 hollow region 18 is filled with plastic foam 9.

Owner:SANYO ELECTRIC CO LTD

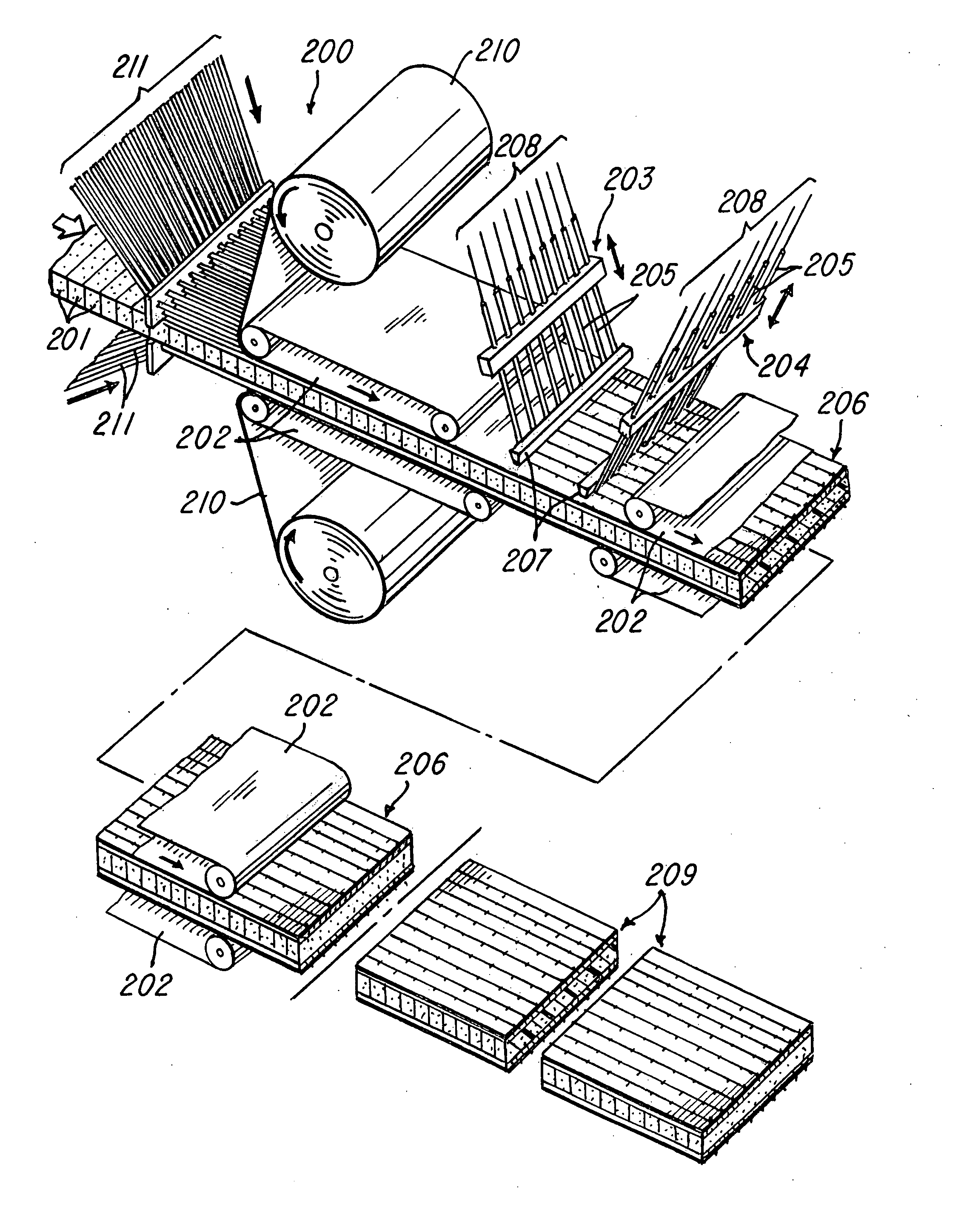

Fiber reinforced composite cores and panels

InactiveUS20100266833A1Produced economicallyReduce intensityLamination ancillary operationsLaminationEngineeringFiber-reinforced composite

A fiber reinforced core panel is formed from strips of plastics foam helically wound with layers of rovings to form webs which may extend in a wave pattern or may intersect transverse webs. Hollow tubes may replace foam strips. Axial rovings cooperate with overlying helically wound rovings to form a beam or a column. Wound roving patterns may vary along strips for structural efficiency. Wound strips may alternate with spaced strips, and spacers between the strips enhance web buckling strength. Continuously wound rovings between spaced strips permit folding to form panels with reinforced edges. Continuously wound strips are helically wrapped to form annular structures, and composite panels may combine both thermoset and thermoplastic resins. Continuously wound strips or strip sections may be continuously fed either longitudinally or laterally into molding apparatus which may receive skin materials to form reinforced composite panels.

Owner:METYX USA INC

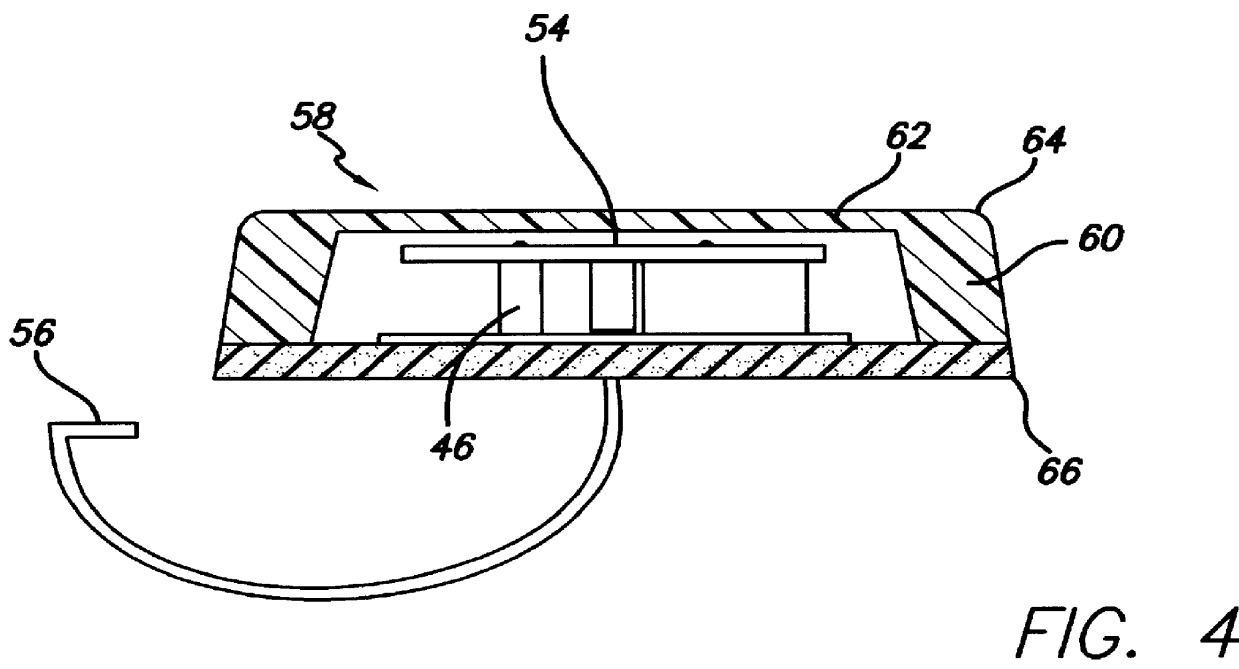

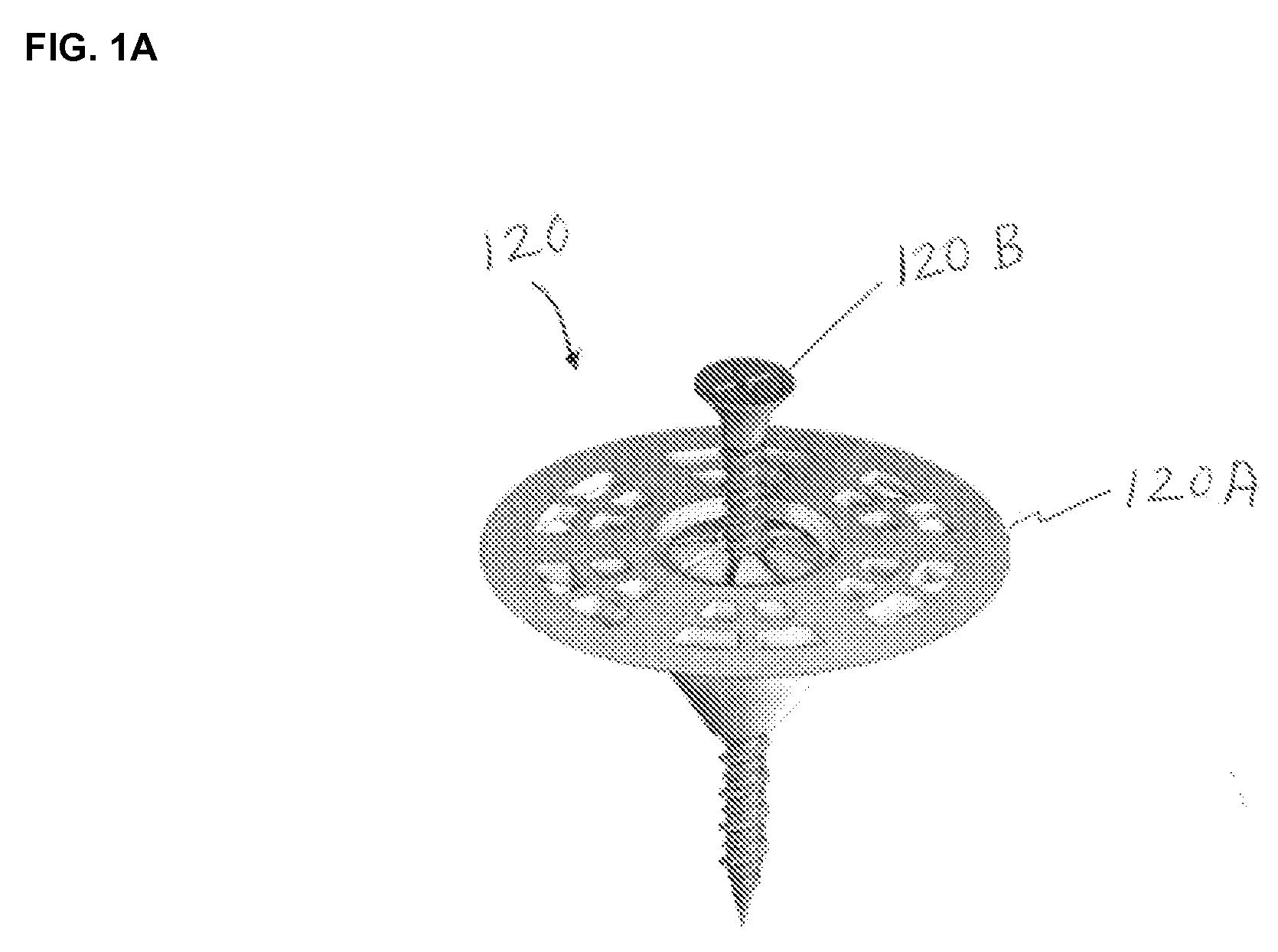

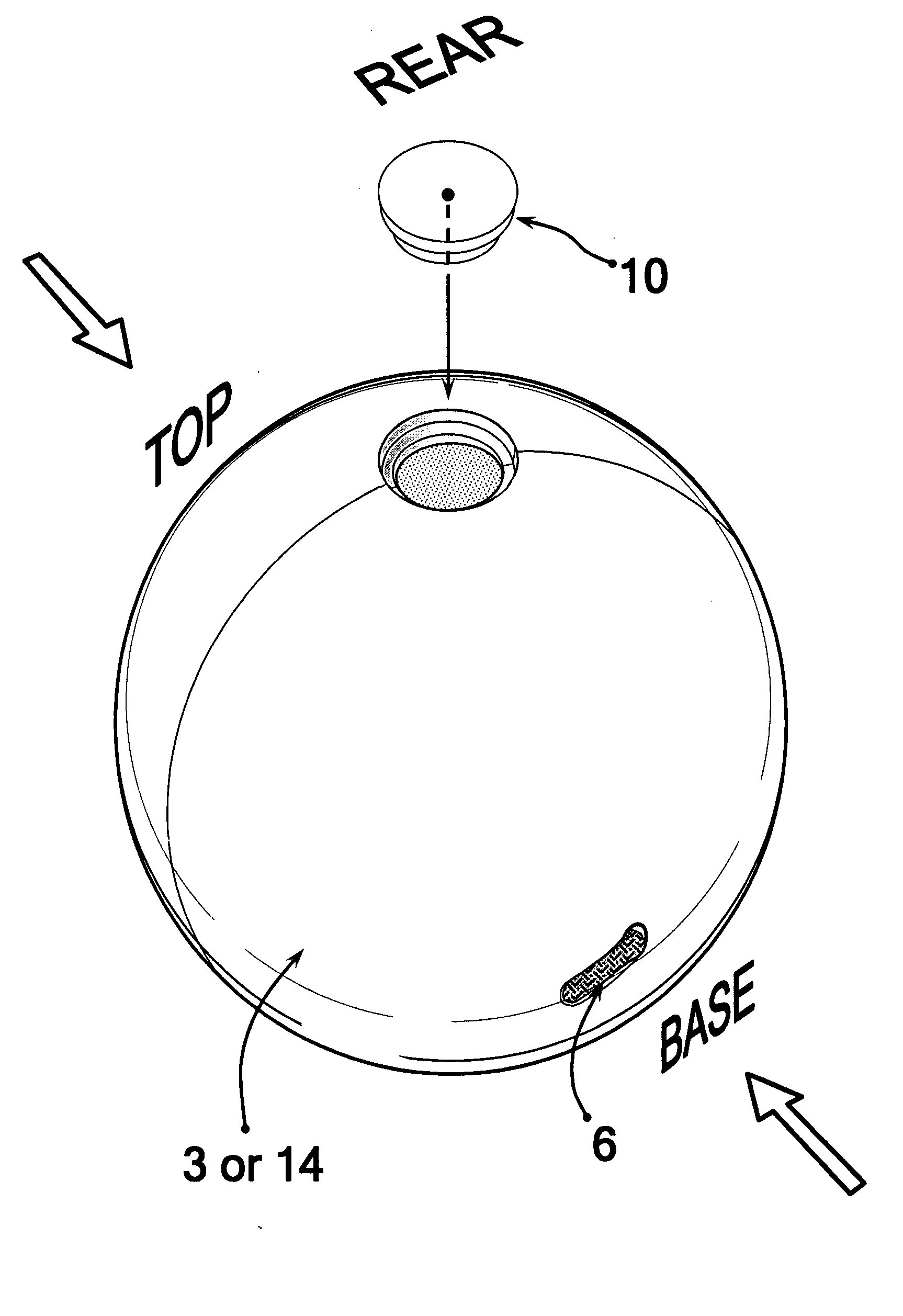

Low profile antenna

InactiveUS6157348AGood radiation characteristicsEasy to adjustSimultaneous aerial operationsRadiating elements structural formsWireless transmissionGround plane

A low-profile antenna has increased broad-banding capacities as well as a lower radiation angle for enhanced cellular or mobile telephone wireless transmissions. Enhancing a basic PIFA antenna, a top metal radiator is notched so as to provide additional corners and greater perimeter length thereby enhancing the bandwidth capabilities of the antenna. Both ground and tuning tabs serve to enhance operational characteristics and a dielectric cover incorporating prismatic qualities serves to lower the radiation angle of transmission from approximately forty degrees (40 DEG ) to twenty degrees (20 DEG ). The prisms provide an operating radiation angle in the range of approximately seventy degrees (70 DEG ) to twenty degrees (20 DEG ). In one embodiment, a sheet of plastic foam slightly thicker than the depth of an associated connector is secured to the underside of the bottom plate to act as a friction seal when the antenna is screwed onto a mating connector, allowing for slight variations in the curvature of the mounting surface. By making the bottom conductive plate only slightly larger than the top radiator, the antenna's resonant frequency becomes independent of ground plane mounting and may not require such a ground plane. Under such circumstances, some adjustment of the tuning parameters may be required in order to provide optimum response.

Owner:LAIRD CONNECTIVITY INC

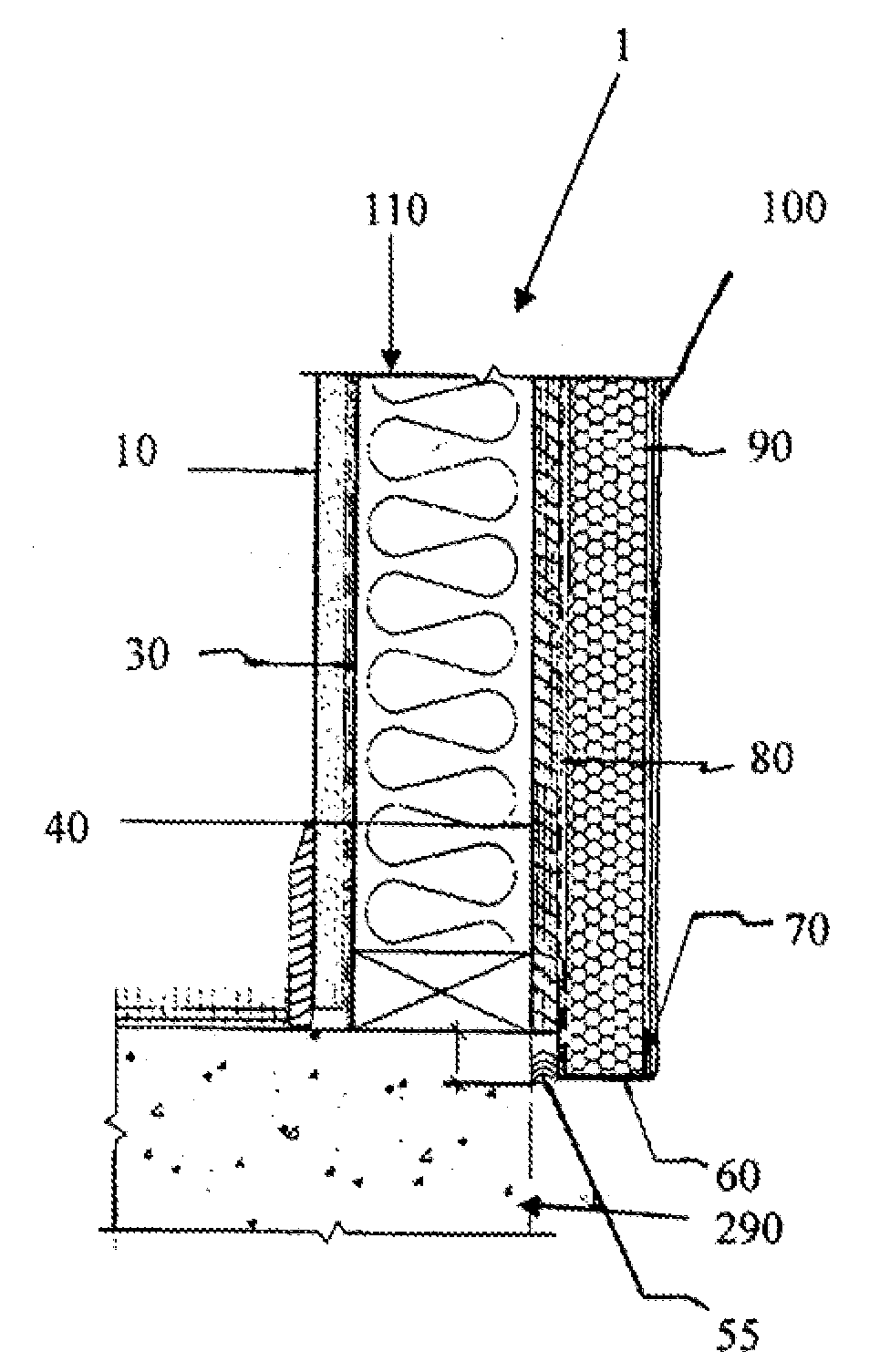

Exterior building cladding having rigid foam layer with drain channels

InactiveUS6886301B2Reduce conductivityStructural failureCeilingsConstruction materialInsulation layerSteel frame

A novel building construction is described for exterior building walls. The construction comprises an interior frame formed of a plurality of laterally spaced studs or beams, a layer of rigid insulation adjacent to the exterior side of this steel frame, exterior building cladding adjacent the exterior side of the rigid insulation and a plurality of low conductivity connectors, e.g. insulating plastic connectors or thin metal strips having an insulating plastic foam coating, extending through the layer of rigid insulation and connecting together the exterior cladding and the interior steel studs or beams. Vertical channels are formed adjacent both the inside and outside faces of the insulation layer to remove moisture. This provides the required structural strength with a minimum of thermal conductivity from the warm side to the cold side of the building envelope, while providing exterior drain channels and interior moisture removing channels.

Owner:SCHILGER HERBERT K

Gypsum wood fiber structural insulated panel arrangement

InactiveUS20080245007A1Low costHigh tensile strengthBuilding componentsMesh reinforcementCellulose fiber

A generally planar, structural insulated panel for building construction includes a pair of outer facings disposed on opposed surfaces of a plastic foam core. Both of the outer facings are gypsum cellulose fiber board such as gypsum wood fiber board. Disposed on the exterior surface of the gypsum wood fiber board on the exterior surface and between another expanded polystyrene insulation panel is a weather resistant barrier that is fastened to the gypsum wood fiber board. The exterior surface of the second insulation panel is fastened to the gypsum wood fiber board by mechanical fasteners. The insulation panels are then coated with a basecoat which has an embedded mesh reinforcement and then a finishing coat is applied to the base coating. Vinyl or aluminum metal siding can be fastened to the structural assembly by G screw fasteners or other mechanical fasteners.

Owner:UNITED STATES GYPSUM CO

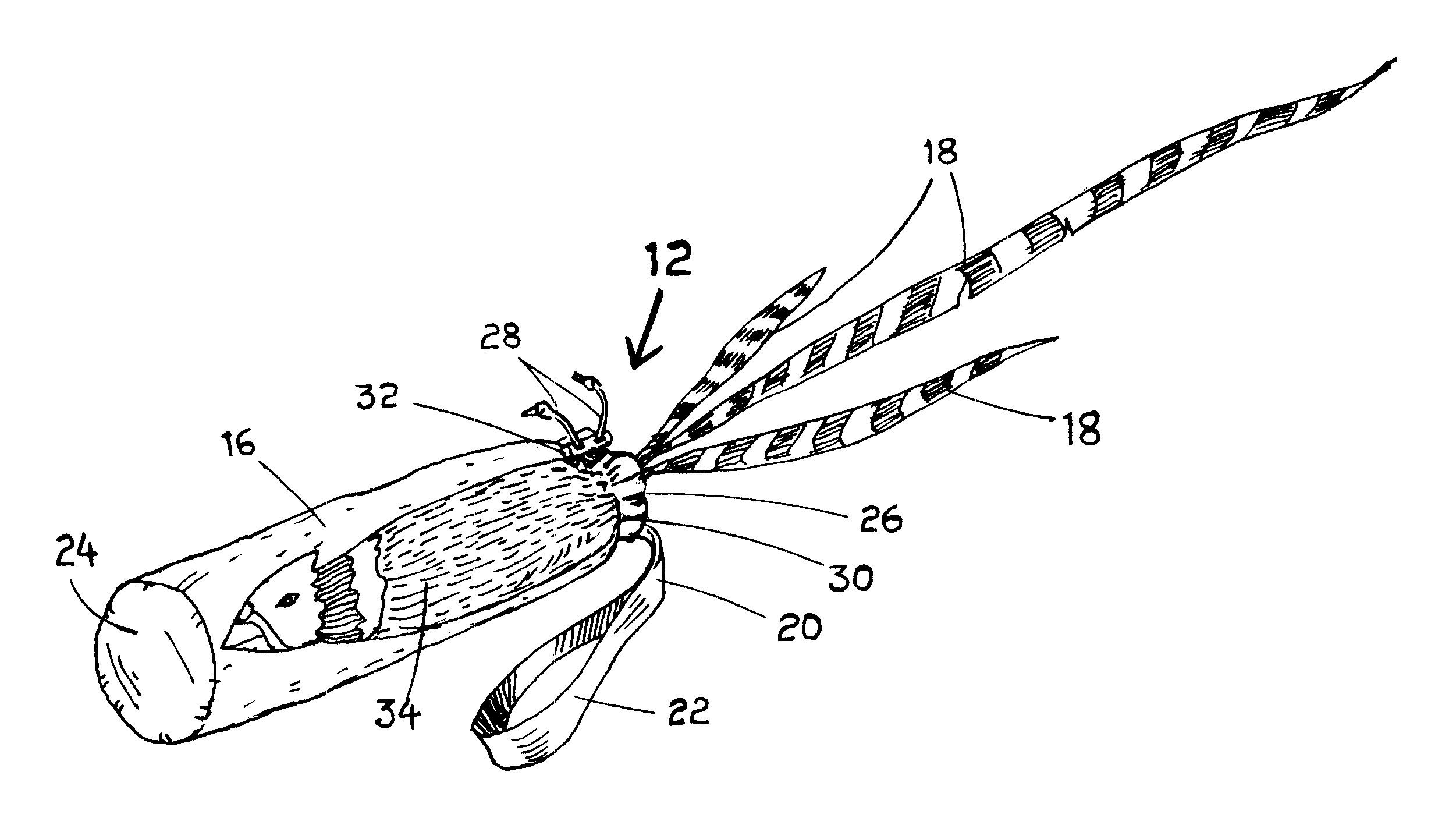

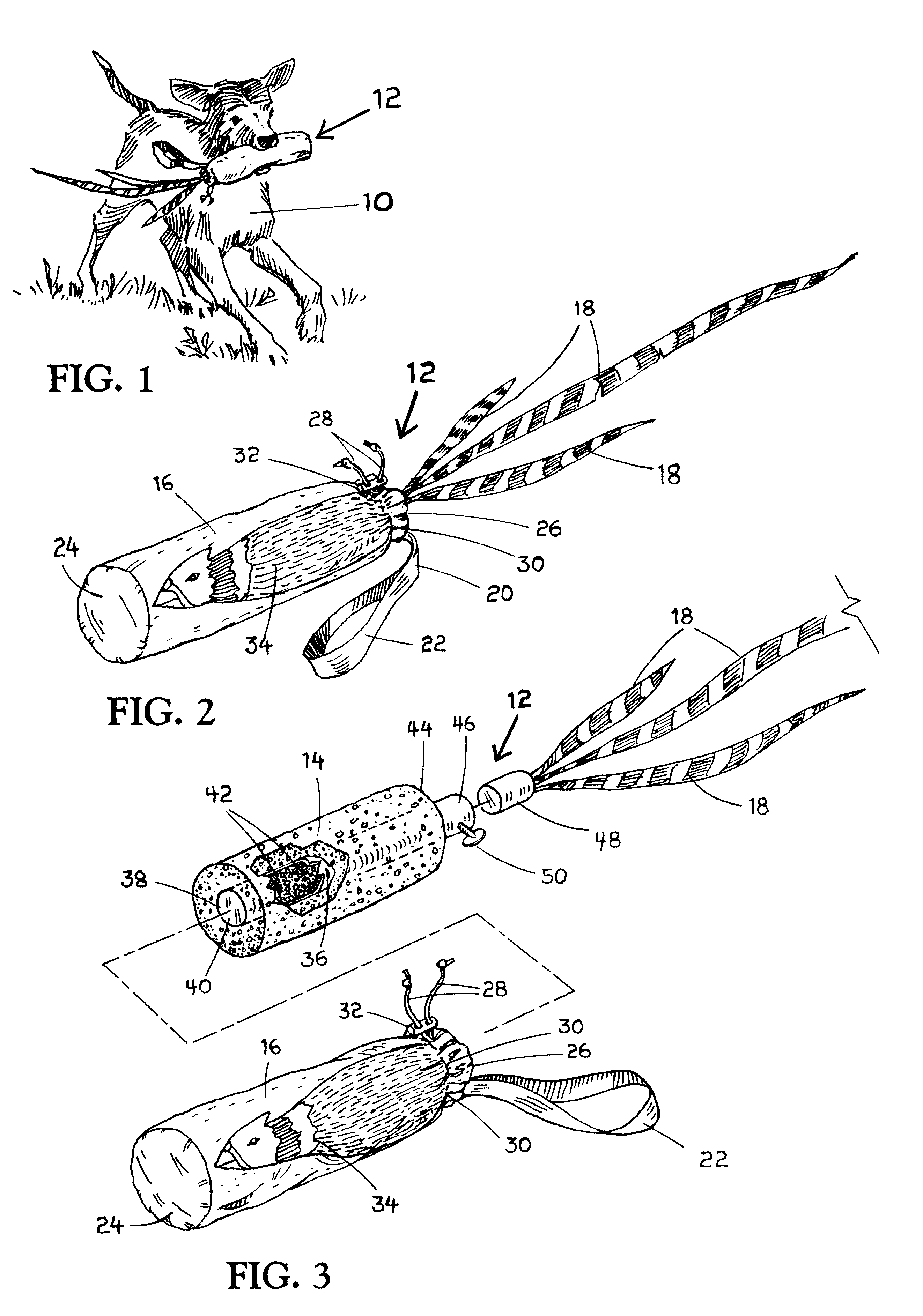

Simulated bird hunting dog-training device for teaching a dog to retrieve

InactiveUS6681721B1Easy to adjustAdd realism and bird scentOther apparatusTaming and training devicesEngineeringCanis lupus familiaris

A simulated bird hunting dog-training device used for teaching a dog to run and retrieve. The dog-training device includes a soft, flexible, lightweight, plastic foam cylindrical body. The cylindrical body is dimensioned in length and diameter to be similar in size to the body of a bird being hunted. The body includes a bore therethrough for receiving weighted material therein. Using the weighted material, the weight of the device can be easily adjusted to be similar in weight to a game bird to be hunted. One end of the cylindrical body is attached to a female tube connector. The female tube connecter is used for receiving potting material, such as heated glue, formed into a cylindrical shape. The potting material is used to hold together quill ends of a plurality of bird feathers, which extend outwardly therefrom. The bird feathers add realizium and bird scent to the training device, when teaching the dog. The training device also includes a removable cover, which is received over the cylindrical body. The cover includes a throwing strap used for tossing the training device in the air and for retrieval by the dog.

Owner:BUSCHY CHRISTOPHER L

Flat tape cable separator

InactiveUS20040118593A1Reduce the amount of crosstalkLow fuel valueCables with twisted pairs/quadsElectrical conductorEngineering

The present invention is directed to a high speed electrical data cable having a plurality of twisted pair conductors lying adjacent to one another and separated by at least two flat tape separators. In the preferred embodiment, the electrical cable has four twisted pairs wrapped in an insulation jacket and separated with four flat tape separators. The tape separators are made of a plastic foam material having a low dielectric constant to reduce the crosstalk between adjacent twisted pairs and consequently, improve the cable's electrical performance. The plastic foam material is also highly flexible, providing the data cable with a high degree of flexibility and workability.

Owner:GENERAL CABLE TECH CORP

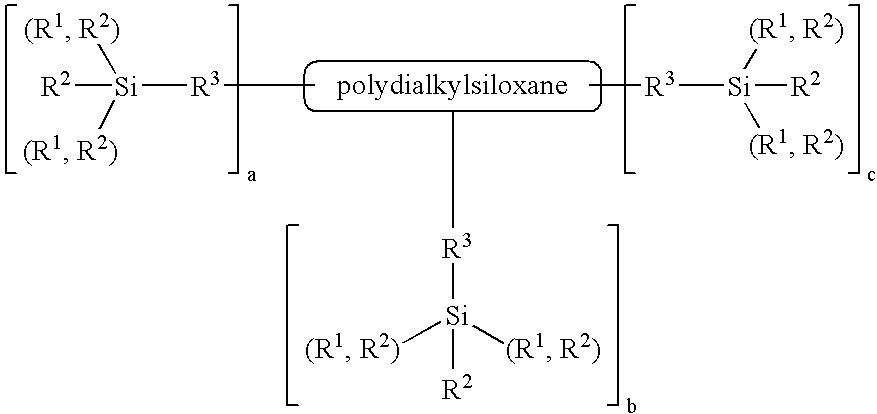

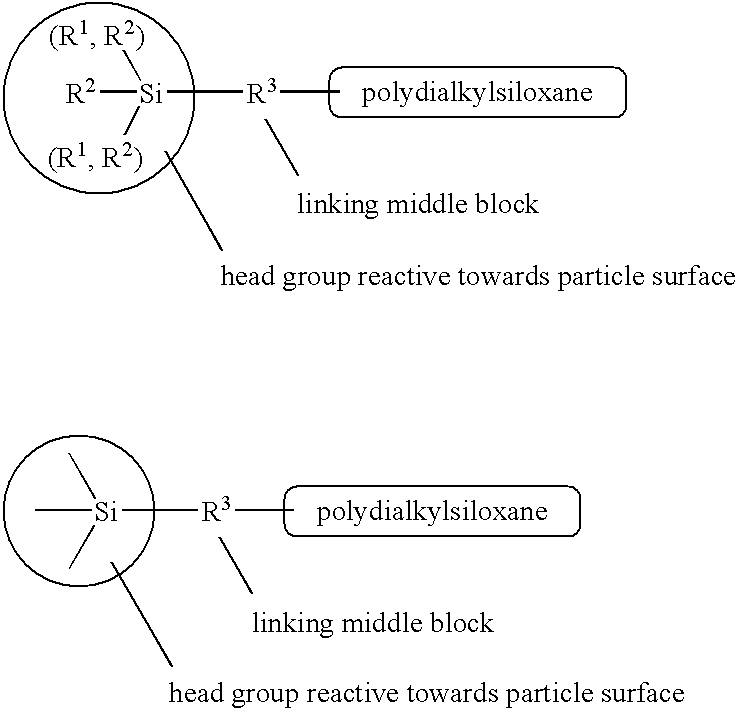

Surface-modified nanoparticles, their preparation and use

ActiveUS20060204528A1Suitable for preparationEasy to measureCosmetic preparationsMaterial nanotechnologyNanoparticleVarnish

Owner:BYK CHEM GMBH

Process for producing polyurethane foam, polyurethane foam, and abrasive sheet

InactiveUS20020183409A1Get stableFine and uniform cellsAbrasion apparatusLapping toolsChemical reactionAdditive ingredient

A process for producing a finely cellular polyurethane foam by mixing a first ingredient comprisi an isocyanate compound and a second ingredient comprising a compound containing an active hydrogen group, characterized by comprising adding a nonionic silicone surfactant containing no hydroxyl group to at least one of the first ingredient and the second ingredient in an amount of 0.1 to 5 wt %, excluding 5 wt %, based on the total amount of the first ingredient and the second ingredient, subsequently agitating the surfactant containing ingredient together with an unreactive gas to disperse the unreactive gas as fine bubbles to prepare a bubble dispersion and then mixing the bubble dispersion with the remaining ingredient to cure the resultant mixture. Thus, a polyurethane foam having uniform fine cells and a higher hardness than ones having the same density can be produced without using a chemically reactive blowing agent such as water, vaporizable expandable blowing agent such as fluorocarbon, or other substance such as a finely particulate hollow foam or solvent soluble substance.

Owner:TOYOBO CO LTD +1

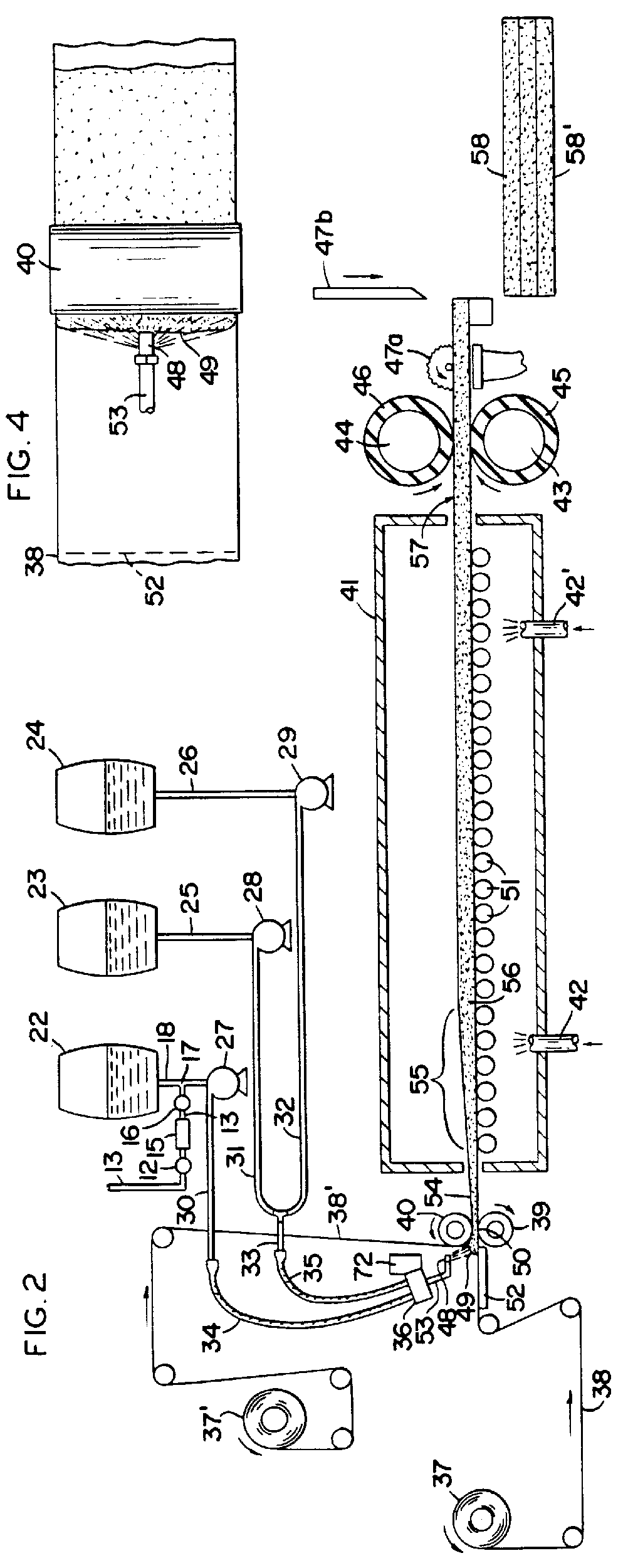

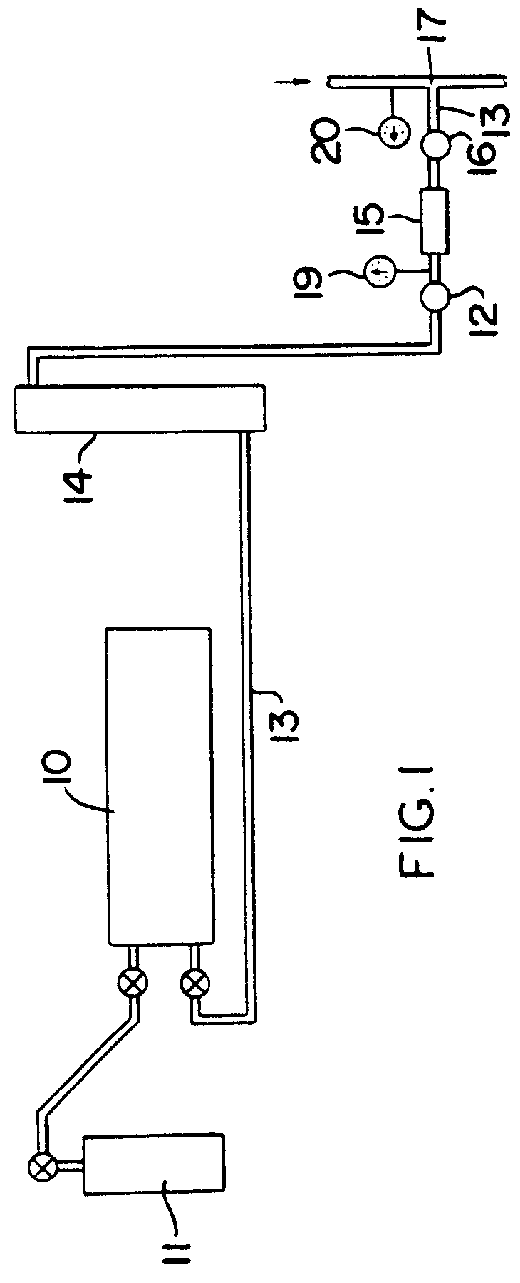

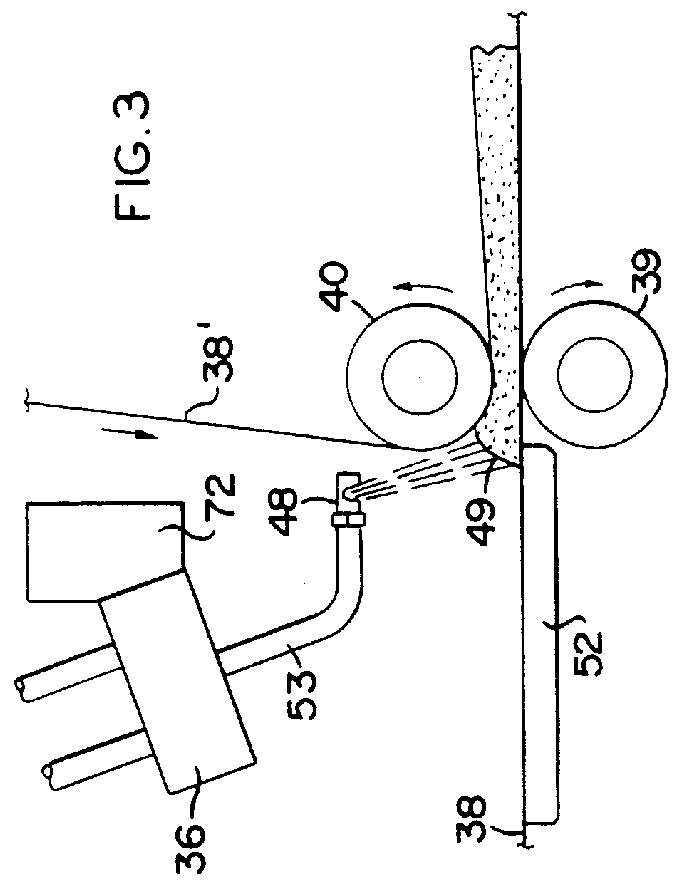

Faced foam insulation board and froth-foaming method for making same

InactiveUSRE36674E1Big lossSimple and economical mannerConfectionerySweetmeatsProduction lineEngineering

A method for continuously producing an insulation board comprising a rigid plastic foam core having two major surfaces and a facing material on one or both of the major surfaces, the method including conveying a facing material along a production line, depositing a partially expanded froth foam of a plastic mixture, which contains at least one frothing agent, on the facing material, and further expanding and curing the froth foam in contact wiht the facing material to form the insulation board. The board is particularly useful as roof insulation.

Owner:THE DOW CHEM CO

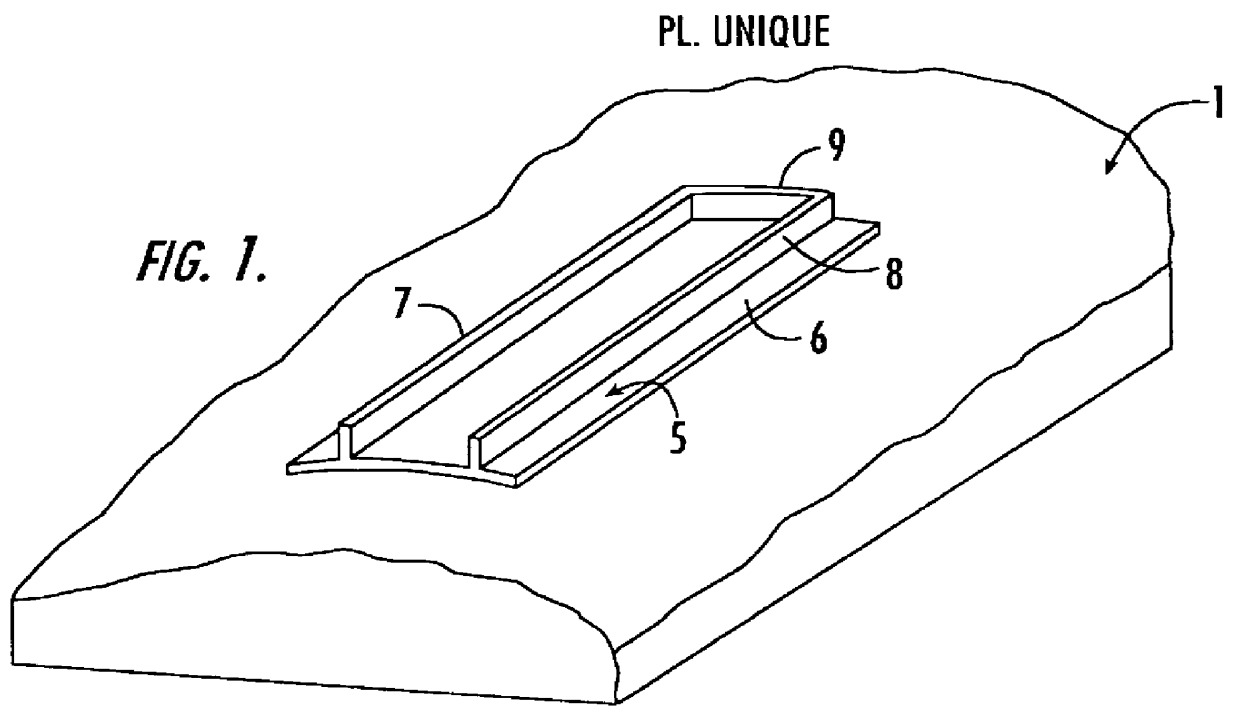

Laminated self-gripping tape, molded product, and method of manufacturing a molded article including a self-gripping tape

A laminated tape including a self-gripping sheet with hook-fastening elements, characterized by a layer of plastic foam and a layer of metal which can be attracted by a magnet and which is inserted between the layer of plastic and the self-gripping sheet.

Owner:APLIX INC

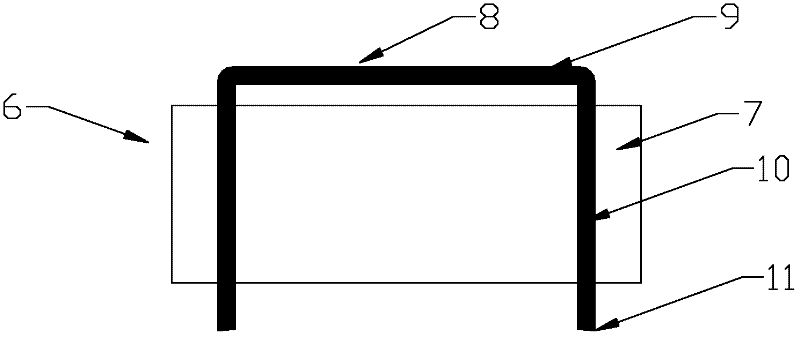

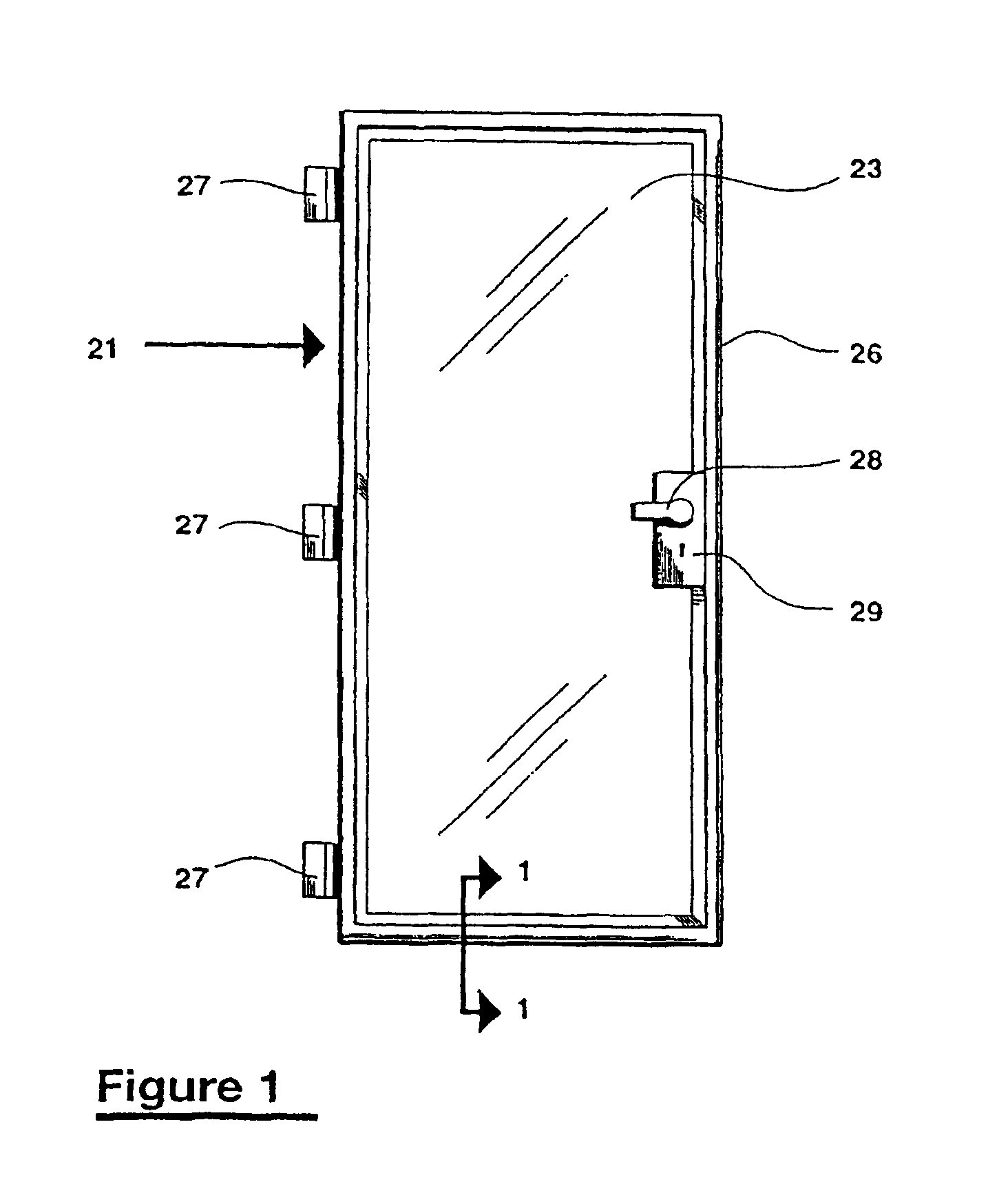

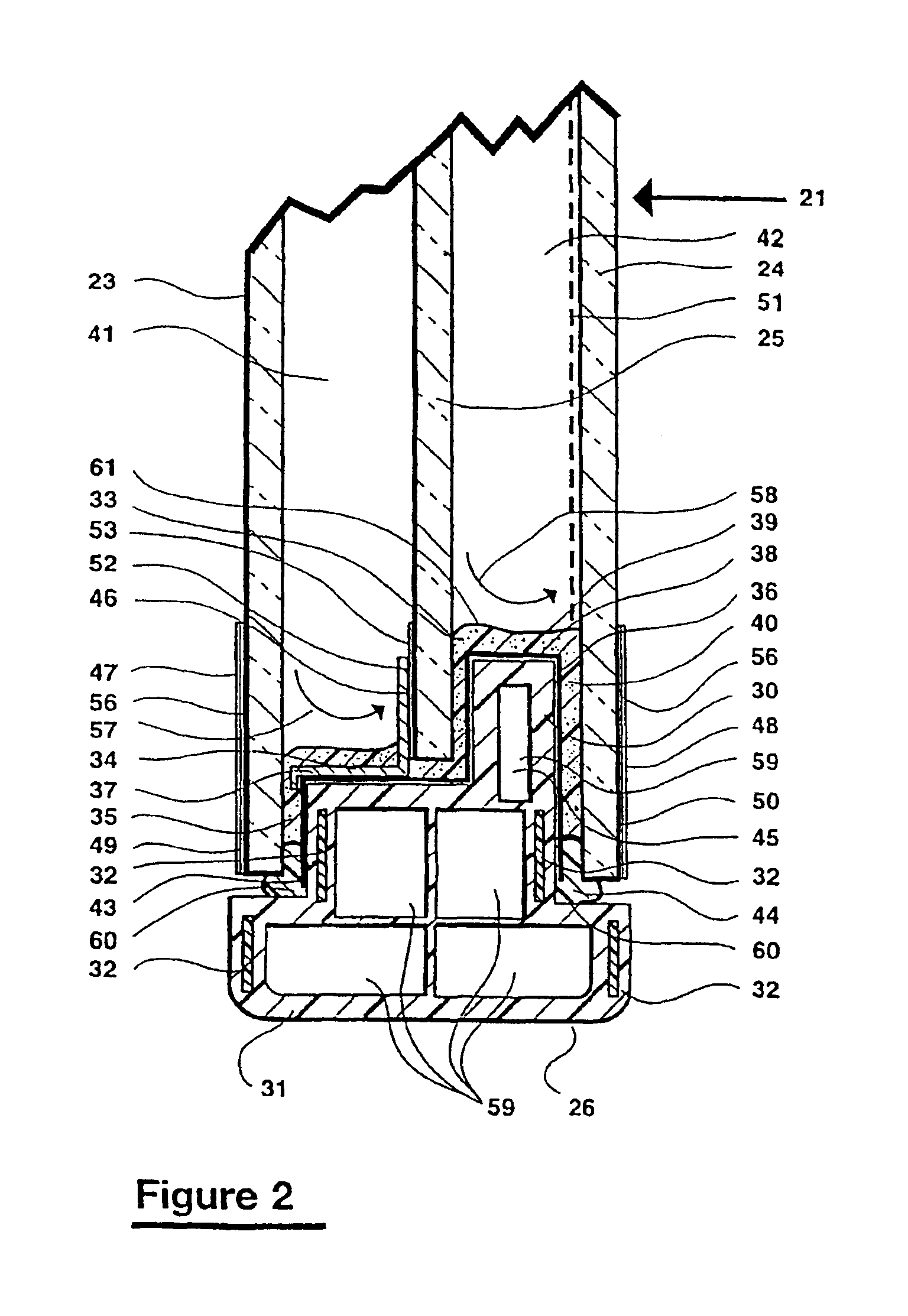

Fenestration sealed frame, insulating glazing panels

A fenestration sealed frame insulating glazing panel has an integral planar frame formed by four rigid plastic profiles interconnected end-to-end to define corners, the profiles having a low heat conductivity. Two glazing sheets are arranged in a spaced parallel relationship attached on opposite sides of the frame in a rigid manner by thermosetting adhesive to form an integral structure having an insulating cavity enclosed by the frame. The front face of each frame profile facing towards the cavity is covered by a low permeability sealant. The sealed frame glazing panel can include a third glazing sheet positioned in parallel between the first two glazing sheets and likewise interconnected at its perimeter to the frame to divide the insulating cavity into two parallel coextensive sub-cavities. The profiles of the frame can be made from structural plastic foam material, glass fiber, oriented thermoplastic, or various other materials of low thermal conductivity.

Owner:BYSTRONIC MASCH

Surgery Practice Kit

InactiveUS20080032272A1Practical materialSmall sizeEducational modelsSebaceous CystSurgical department

A simple to use, inexpensive and readily portable surgical practice and teaching kit is described that includes in portfolio form a two layer practice suturing pad including a latex rubber layer simulating human skin attached to a plastic foam layer that simulates underlying human tissue, the foam layer having incorporated therein simulated subcutaneous growths or lesions such as simulated lipomas or sebaceous cysts. The practice pad is mounted on a folder or portfolio for convenient access and use by the student or practitioner, the portfolio also including pictorial illustrations showing various proper suturing techniques as a visual guide to the user in practicing suturing procedures.

Owner:PALAKODETI RATNA K

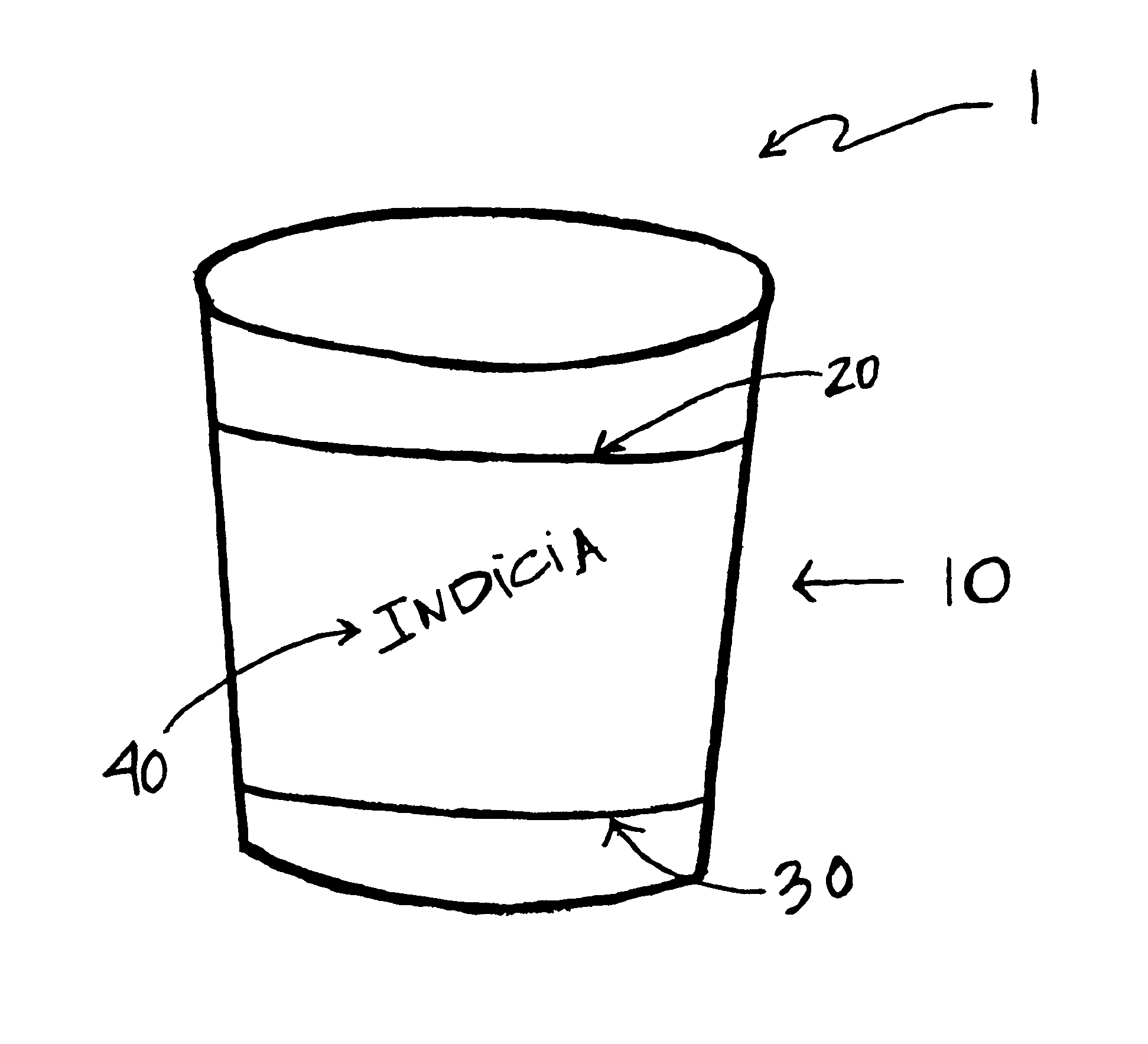

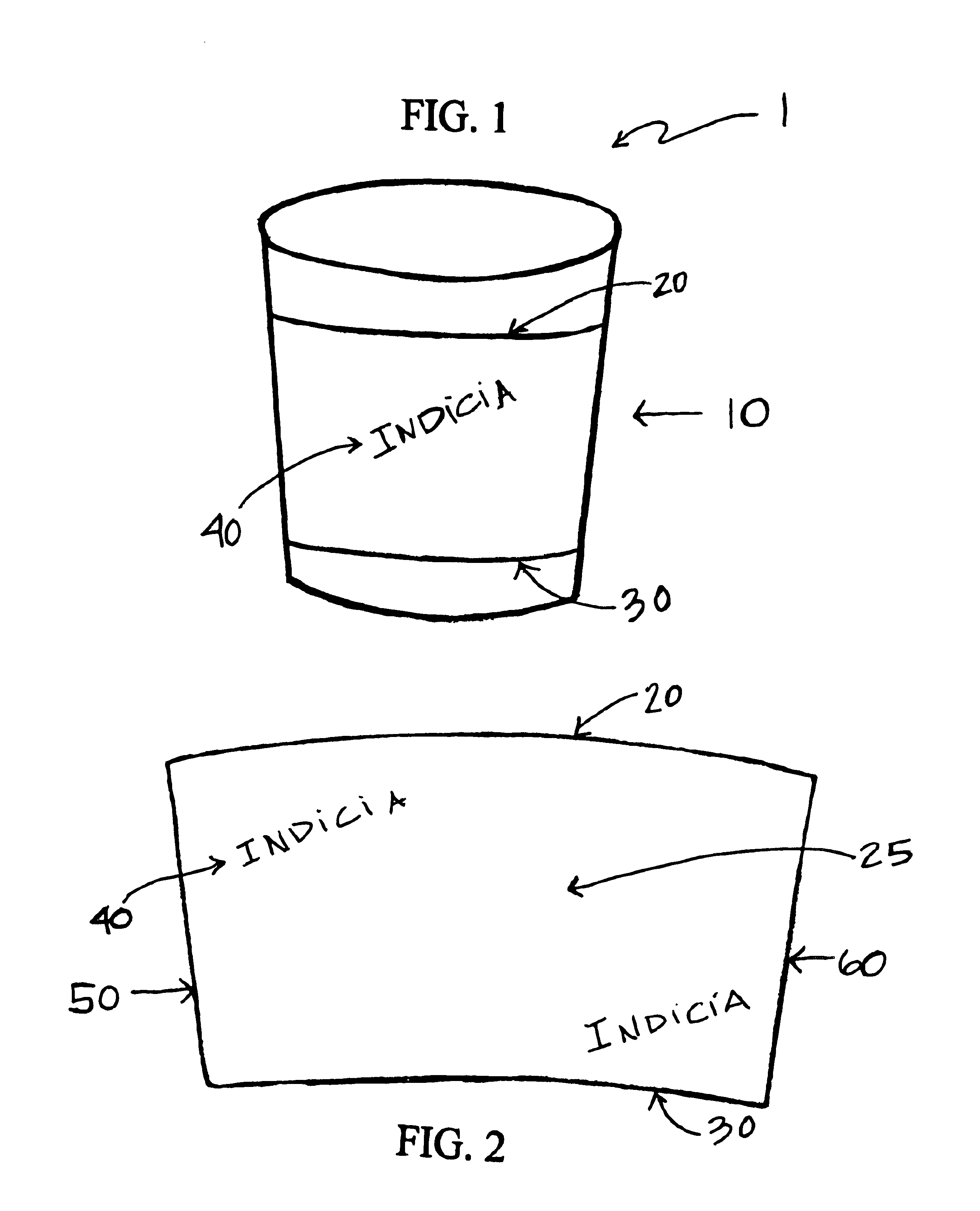

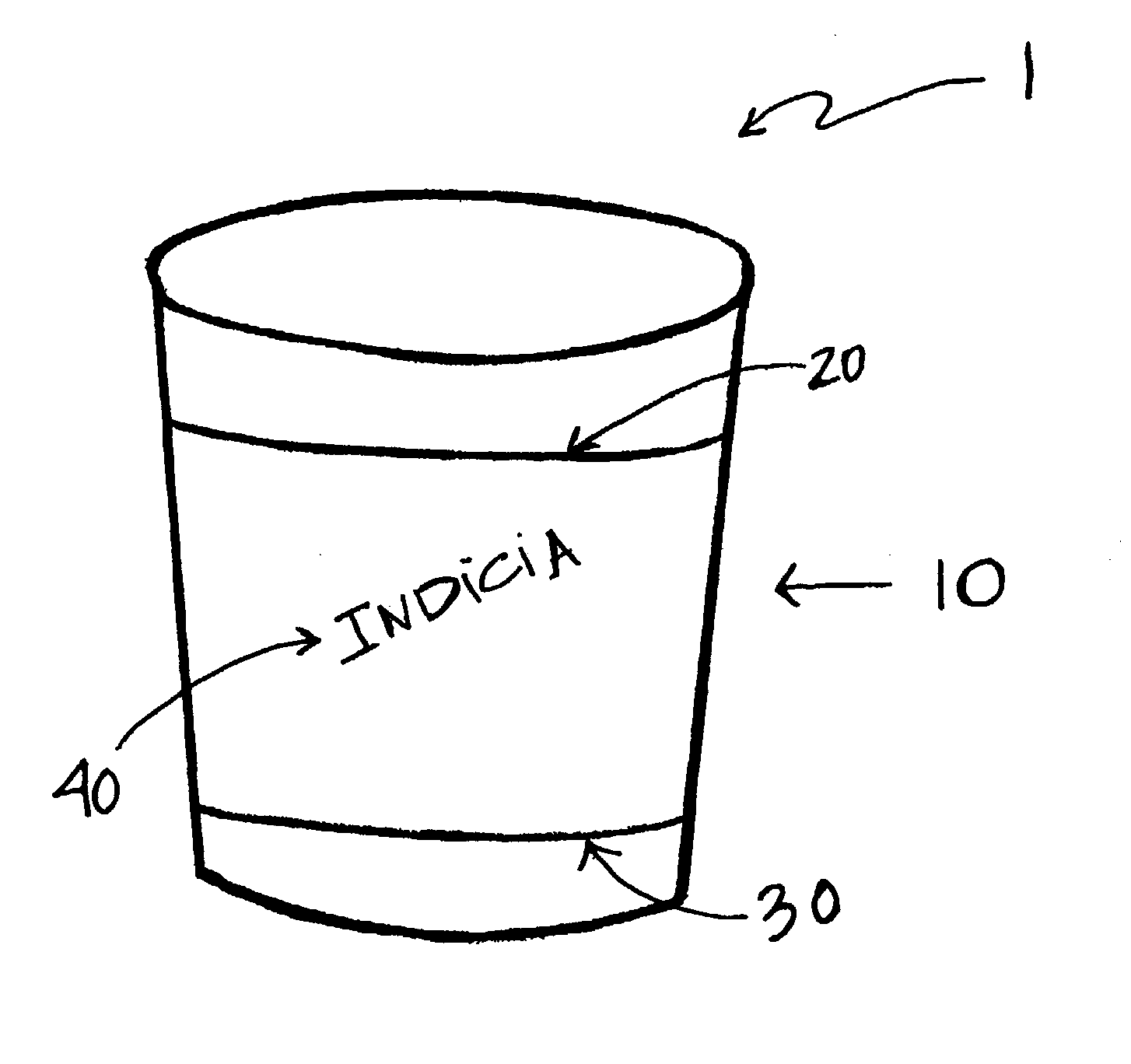

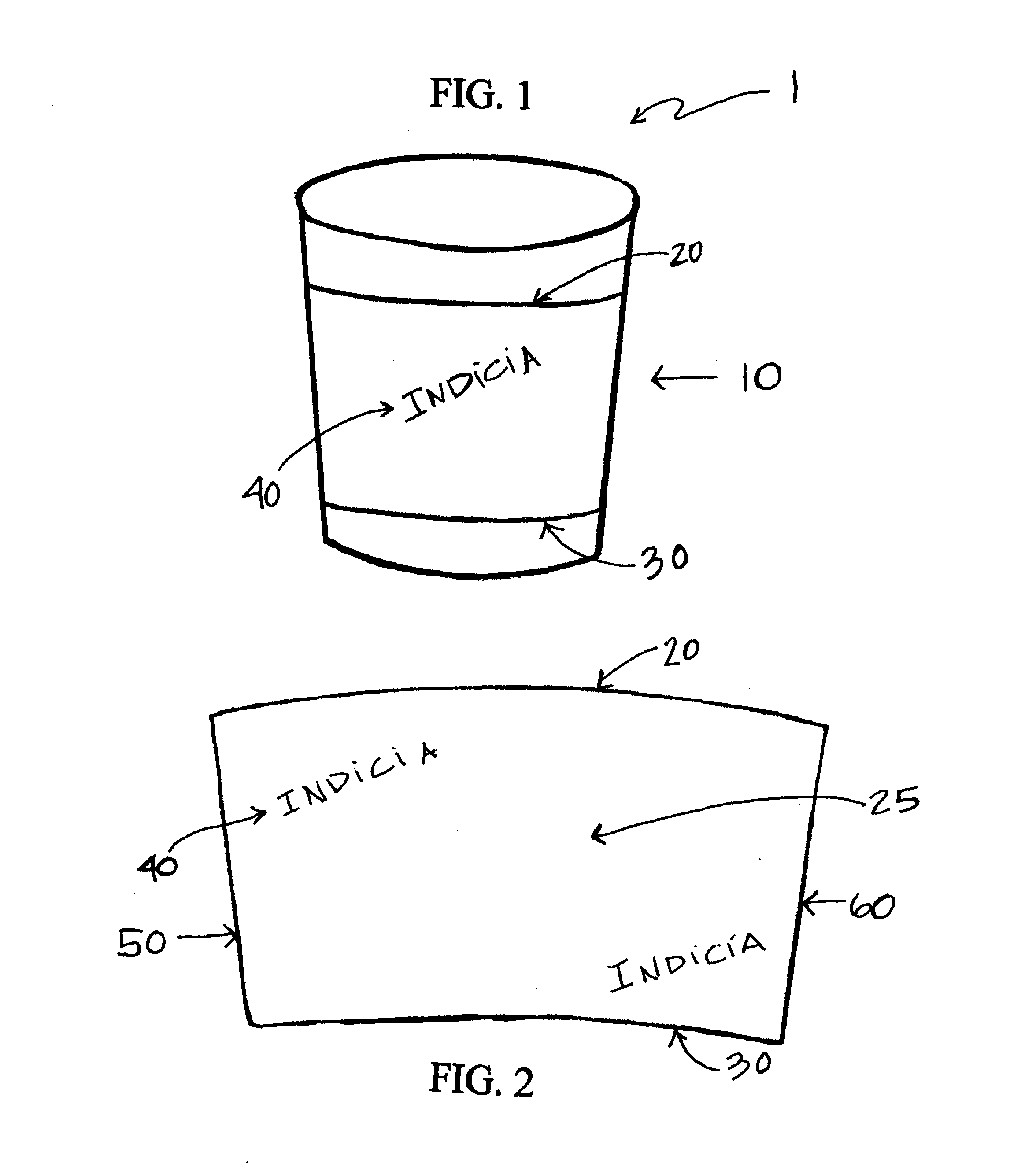

Method and apparatus for producing labeled, plastic foam containers, and product of same

InactiveUS20060005917A1Low densityLow stiffnessMechanical working/deformationAdhesivesMechanical engineeringPlastic foam

A method and apparatus for producing labeled, plastic foam containers, such as a labeled EPS cup uses a heated pocket to thermally bond a label to a plastic cup. Also described is a labeled plastic foam container, such as a labeled EPS cup, having high quality printing capabilities, sufficient stiffness, acceptable insulation and barrier properties and reduced production cost.

Owner:GRUPO CONVERMEX DE C V

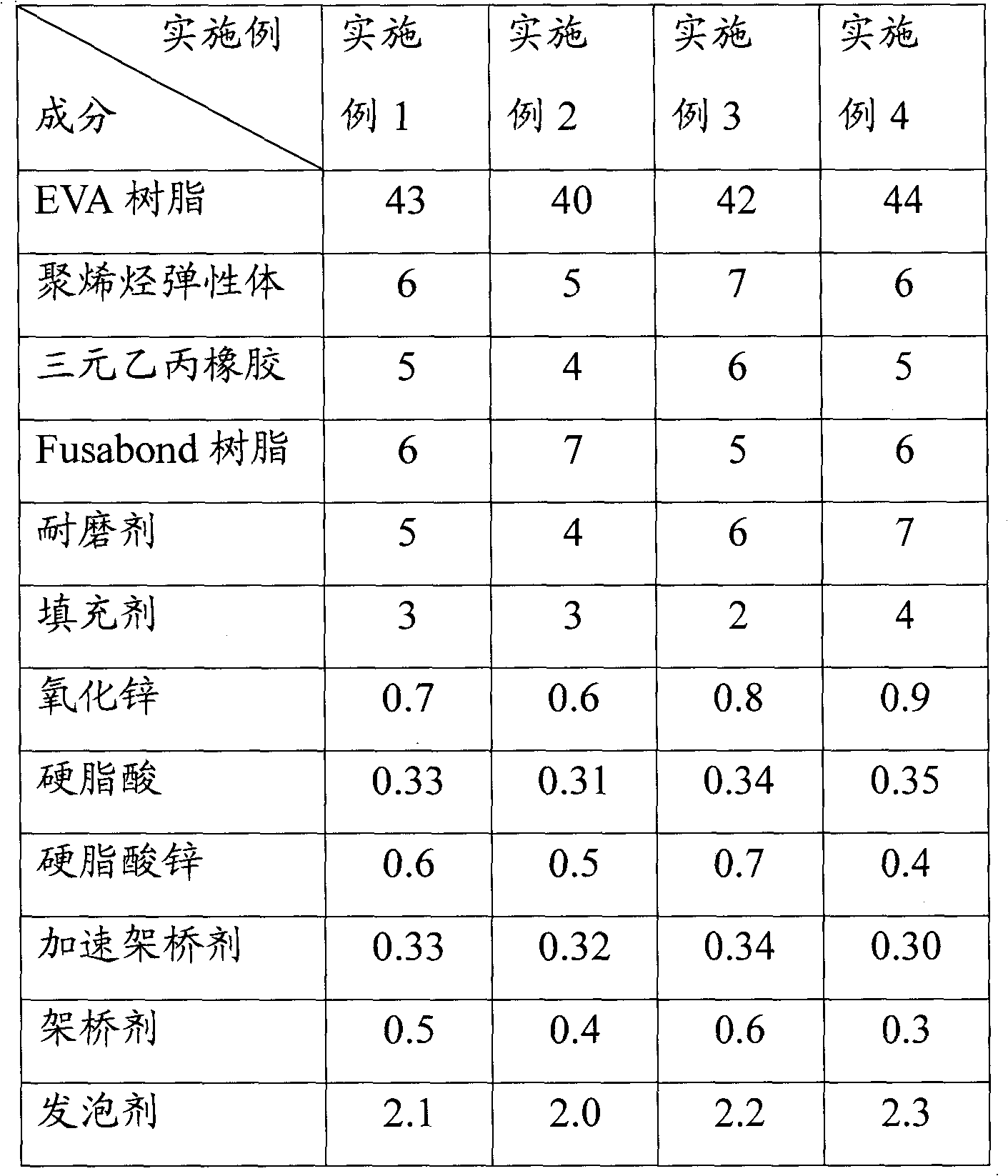

Plastic foam for sport shoe sole

The invention discloses a plastic foam for a sport shoe sole, which comprises the following components in part by weight: 70-74 parts of ethylene-vinyl acetate copolymer, 8-12 parts of ethylene-octylene copolymer, 6-10 parts of ethylene propylene ethylene-propylene-diene monomer, 8-12 parts of ethylene-acrylic acid copolymer, 8-9 parts of wear-resisting agent, 4-6 parts of filler, 1.0 -1.2 parts of zinc oxide, 0.5-0.6 part of stearic acid, 0.8-1.0 part of zinc stearate, 0.5-0.7 part of accelerate bridging agent, 0.8-0.9 part of bridging agent and 3.2-3.8 parts of foaming agent, wherein the ethylene propylene ethylene-propylene-diene monomeris a terpolymer of ethylene-propylene and non-conjugate diolefin. The plastic shoe sole of the sport shoe has the light weight performance, wear resistant performance and comfortable performance which are superior to those of a foam plastic formula injected by common IP, greatly reduces the physical consumption of athletes and has a plurality of performances such as durable comfort, durable buffer resistant performance and the like.

Owner:ANTA CHINA

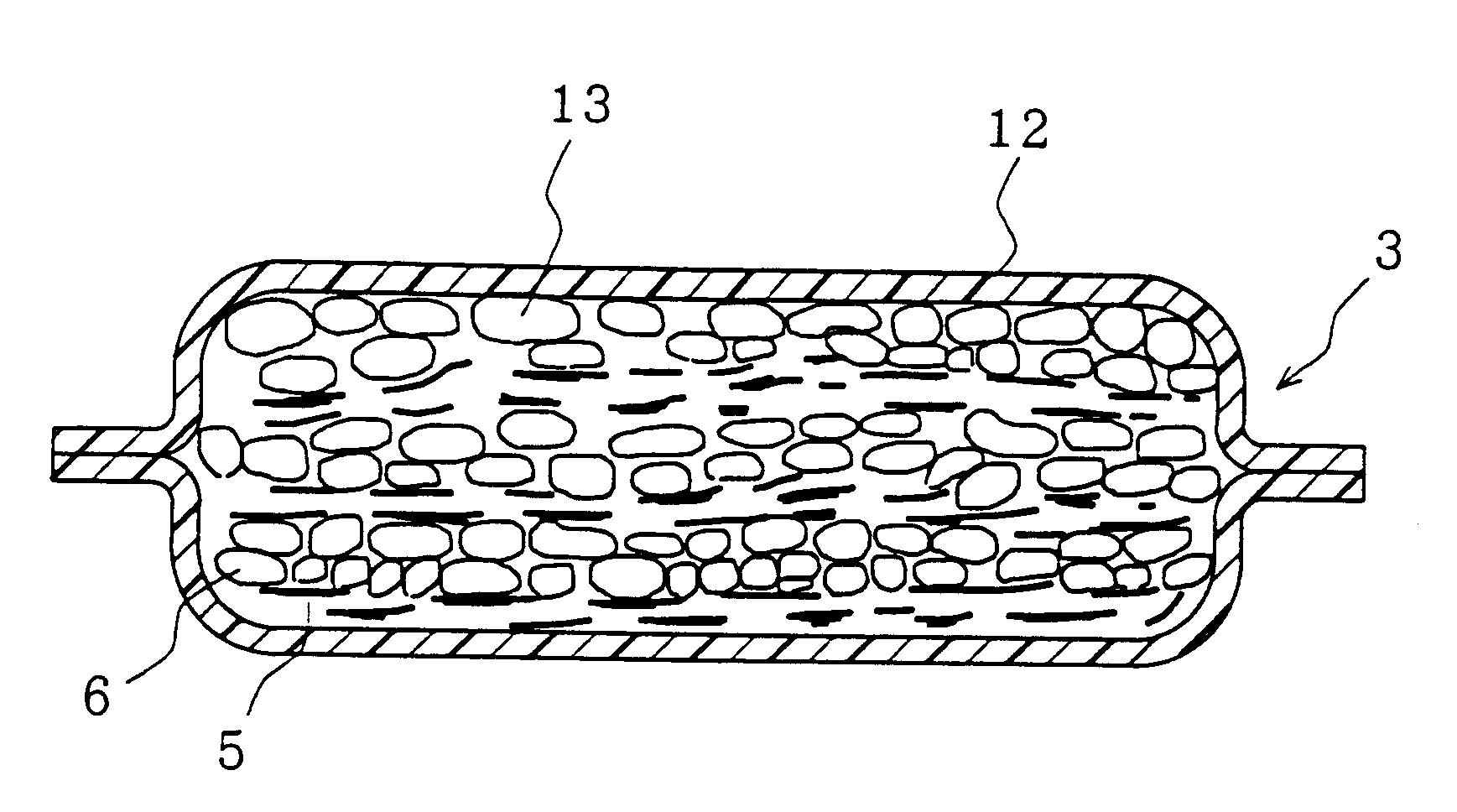

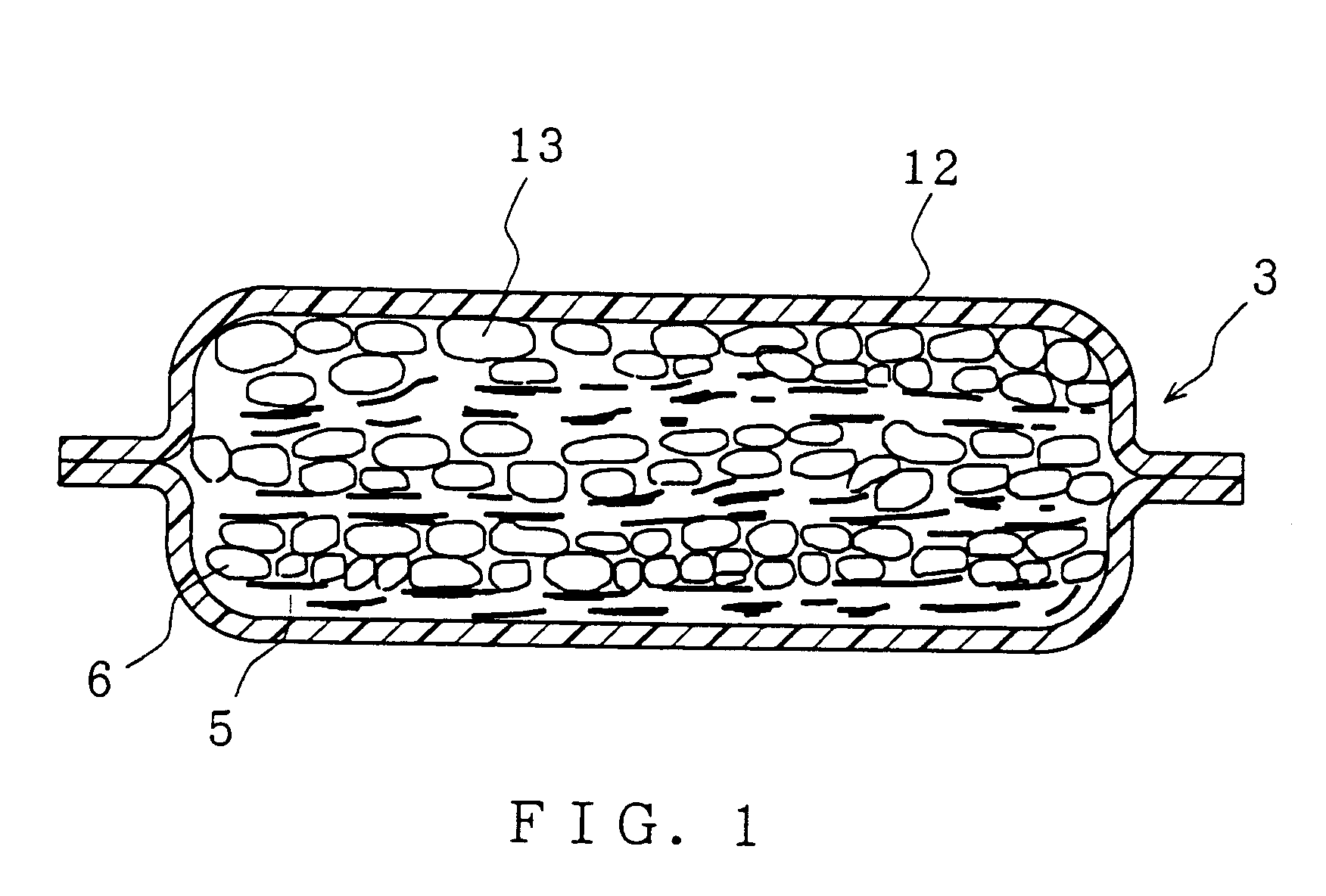

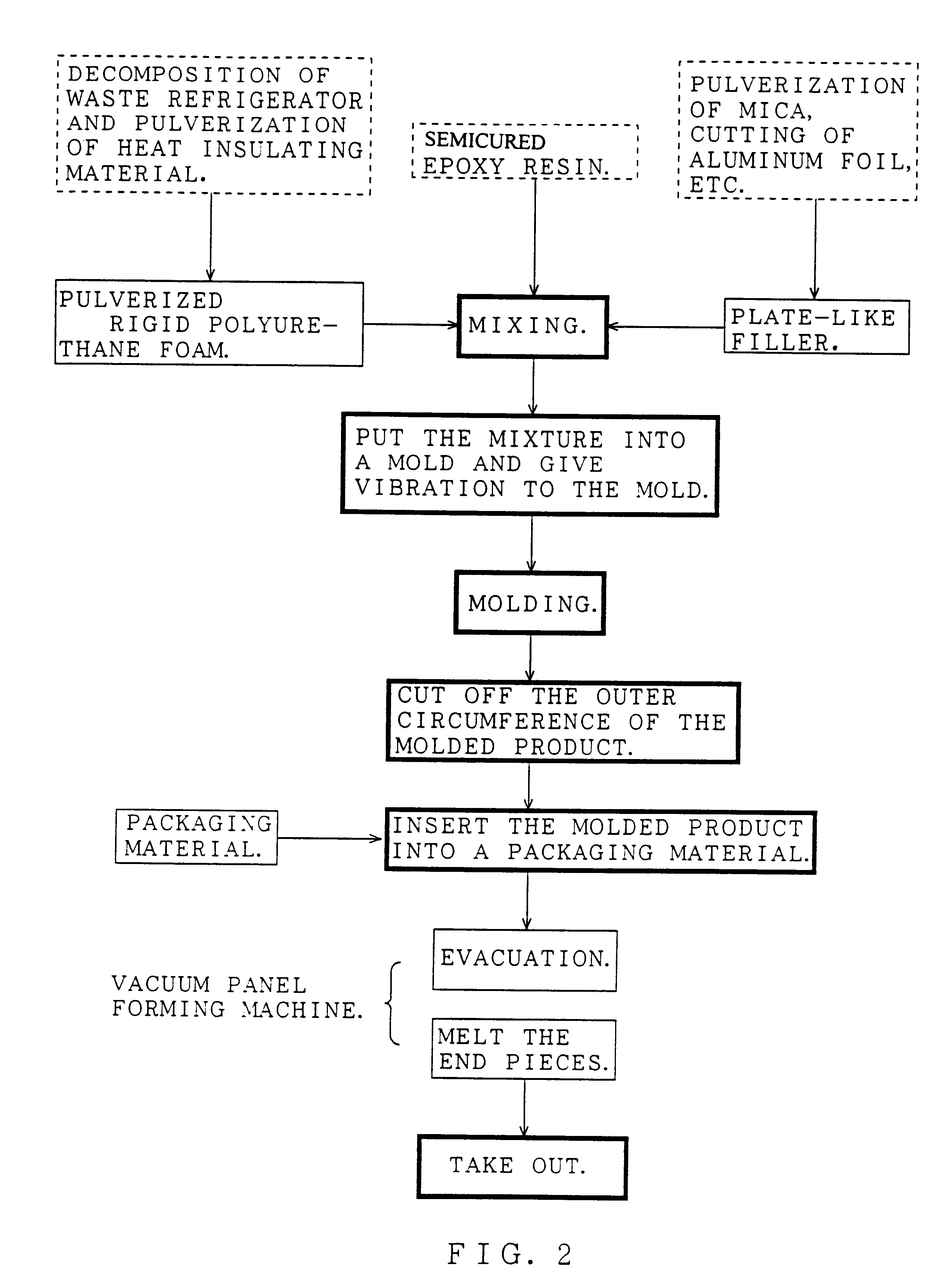

Vacuum heat-insulating panel and method for producing the same

A vacuum heat-insulating panel includes a porous core material formed from a mixture containing plastic foam powder and a filler in the form of flakes or a porous core material formed from a mixture containing plastic foam powder and thermoplastic resin powder; and a packaging material for packaging the core material, the inside of the package material being kept in a vacuum, the core material holding its shape. Rigid polyurethane foam may be used as the plastic foam. Mica flakes, plastic films each coated with thin metal film, metal foil or the like may be used as the filler. Styrene resin may be used as the thermoplastic resin.

Owner:MITSUBISHI ELECTRIC CORP

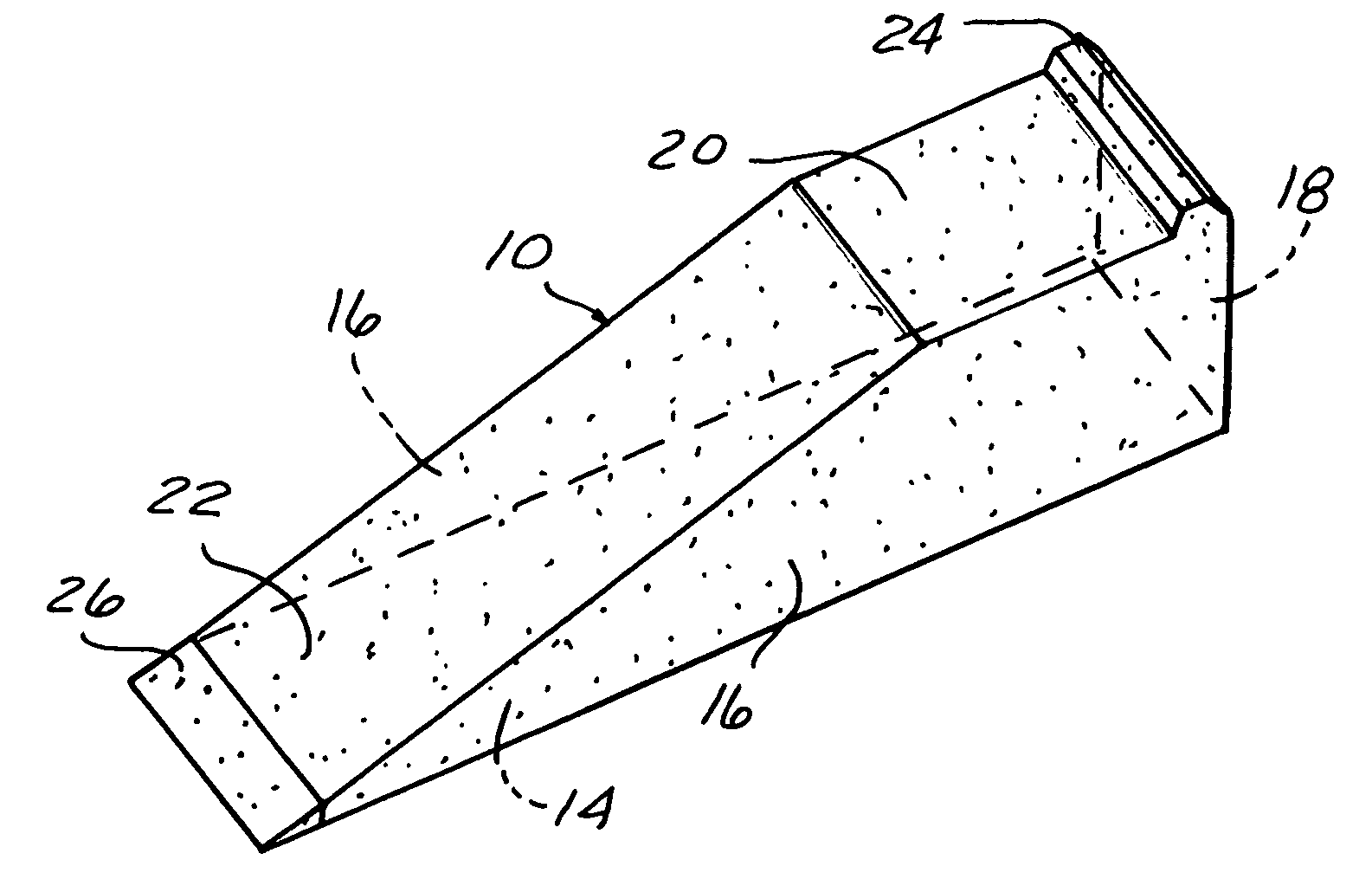

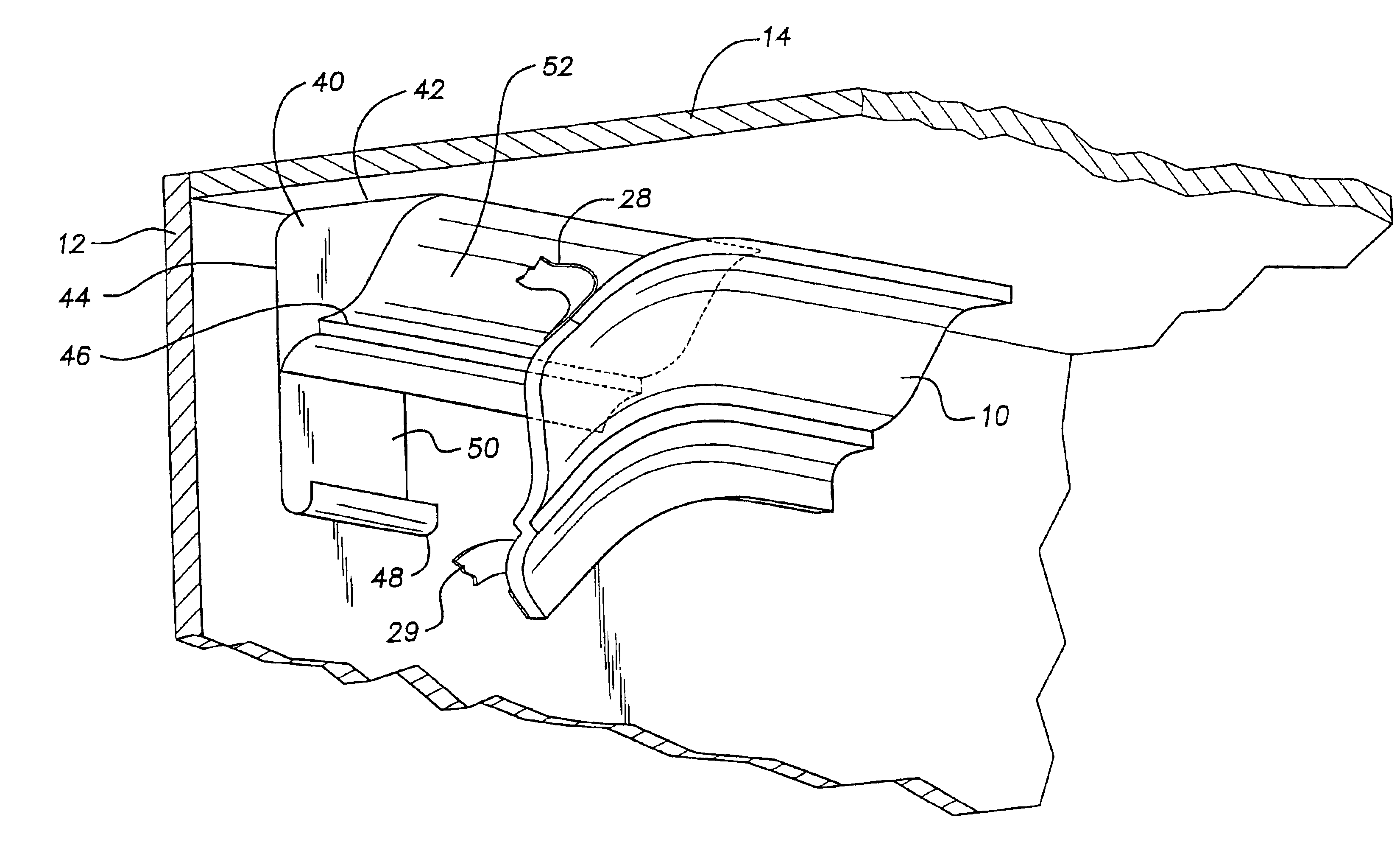

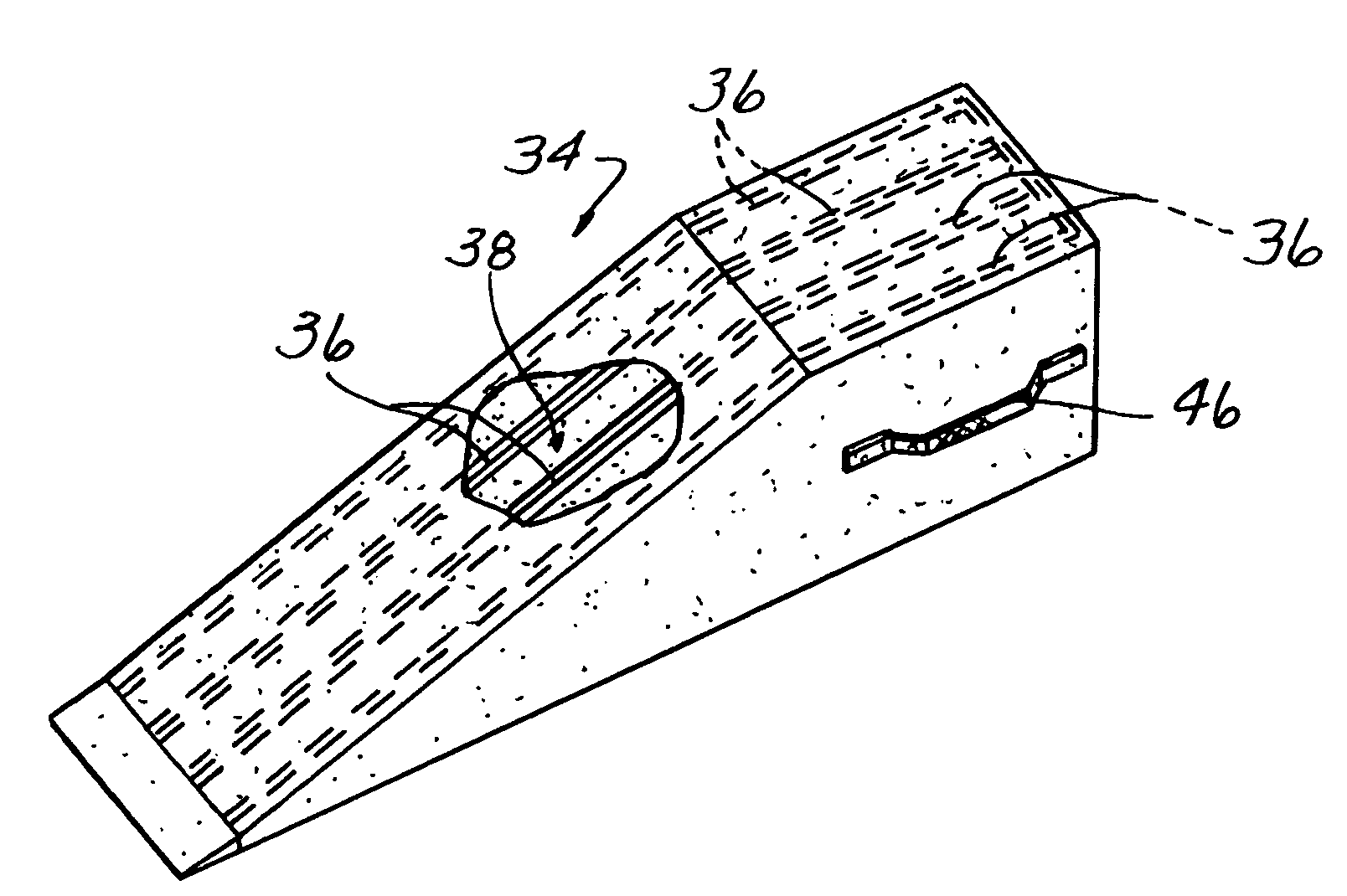

Ramp and method of construction

ActiveUS20060027794A1Easily and economically cut outTrend downInclined ship-liftingSynthetic resin layered productsEngineeringHeavy duty

A ramp constructed of an expanded plastic foam parallelepiped core encased in a thick coating of polyurea provides a lightweight, stable ramp suitable for vehicle servicing. A low angle, long length ramp of a low weight is provided. Heavy duty versions have on edge panels embedded in the core.

Owner:BRUTE IND INC

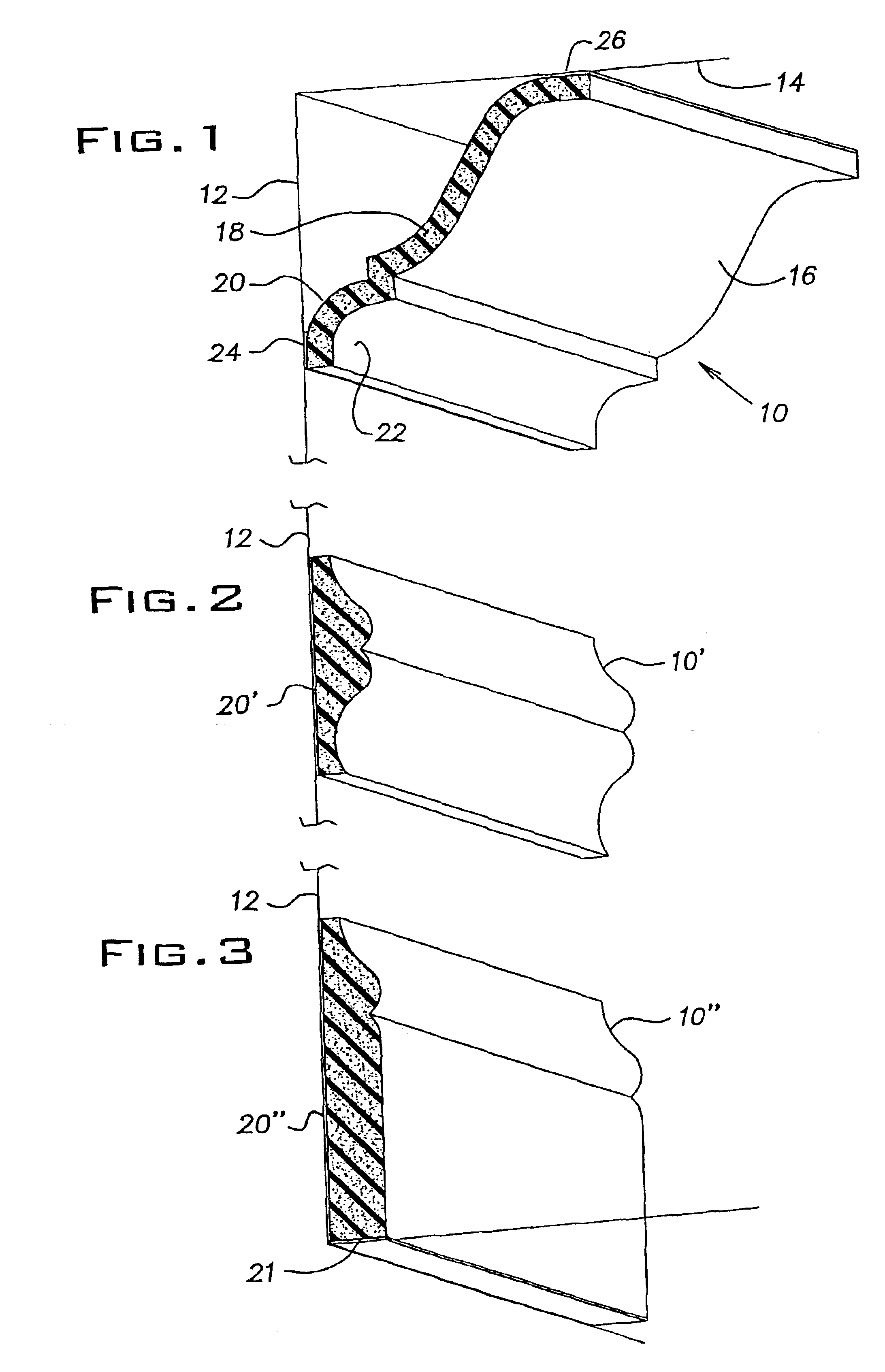

Architectural molding

InactiveUS6918977B1Building roofsLamination ancillary operationsMechanical engineeringPressure sensitive

An architectural molding (10) includes an extruded flexible plastic foam member (16) having a front side (22), a rear side (20) and a cross sectional profile (18). Also included is a layer of pressure sensitive adhesive (24, 26) affixed to at least a portion of the rear side and a release strip (28, 29) releasibly adhered to the layer of pressure sensitive adhesive.

Owner:NOMACO

Insulating sleeve for grasping container and manufacturing method

InactiveUS20040070222A1Easy to masterEasy to useSynthetic resin layered productsRefuse receptaclesPlastic materialsVolumetric Mass Density

An embodiment of the present invention is a sleeve, which facilitates the gripping of, and insulates the hand from, a hot or cold container. The sleeve comprises of sheet foam of a thick, opaque, plastic material that is suitable for snuggly fitting over the exterior surface of a container while permitting any pre-printed indicia on the sheet foam to be visible there through. The sleeve is opaque enough to cover any printing on the container itself. The foam is also available in a variety of forms such as anti-static, laminated, expanded and high or low density which provide different degrees of protection. Different density plastic foam and film material is used to achieve the opaque, thick, gripping and insulating effect for use with a variety of containers.

Owner:DOUBLE TEAM

Ramp and method of construction

ActiveUS7114210B2Easily and economically cut outTrend downInclined ship-liftingSynthetic resin layered productsEngineeringHeavy duty

A ramp constructed of an expanded plastic foam parallelepiped core encased in a thick coating of polyurea provides a lightweight, stable ramp suitable for vehicle servicing. A low angle, long length ramp of a low weight is provided. Heavy duty versions have on edge panels embedded in the core.

Owner:BRUTE IND INC

Plastic foam sheet material of poly lactic acid as suction plastic, and preparation method

Owner:TONGJI UNIV

Fire extinguishing device

An explosive fire extinguishing device is used in interior or localized exterior environments. The force of detonation is minimalized through the use of low-density, low-mass components. A container is composed of a lightweight casing of rigid plastic foam or other suitably frangible material, with an abrasion-resistant, thin plastic, protective, exterior sheathing. Within an internal cavity of the device, the above-mentioned low-yield pyrotechnic detonator is located at or near the center of mass, and is actuated by fuse cords secured at or near the exterior surface. An interior volume of a hollow casing is charged with fire-retardant chemical agents, including dry powders, two-part reactants, liquid components or others, singly or in combination.

Owner:SIAM SAFETY PREMIER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com