Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1172results about How to "High specific strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of silicon-carbide-fibrofelt-enhanced silica aerogel composite material

The invention relates to a preparation method of a silicon-carbide-fibrofelt-enhanced silica aerogel composite material, and relates to an aerogel composite material. According to the invention, a carbon-rich silicon carbide micro-nano ceramic fibrofelt with small fiber diameter, high porosity, communicating pores, fast impregnation speed, and good compatibility with a substrate is prepared with a static electro-spinning technology combined with a precursor conversion method; a silica sol is prepared with an acid-alkali two-step method; with an infiltration technology, the electro-spun silicon carbide ceramic fibrofelt or precast is soaked into the sol; and through processes such as gel process, aging, curing, solvent exchange, supercritical drying, and the like, the silicon-carbide-fibrofelt-enhanced silica aerogel composite material is obtained. The prepared composite material has the characteristics of low density, large specific surface area, super-hydrophobicity, low thermal conductivity, and the like. The strength and toughness of the material are also greatly improved. The carbon-rich silicon carbide fiber has an infrared shielding effect, such that composite material thermal insulation effect and ultra-high-temperature stability can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

Expandable particles for producing polymethacrylimide foamed material and application thereof

The invention discloses expandable particles for producing a polymethacrylimide foamed material and application thereof. The expandable particles are prepared by the following steps of: putting acrylic acid or methacrylic acid, acrylonitrile or methacrylonitrile, an initiator, a molecular weight regulator, a foaming agent, a foam stabilizer, a cross-linking agent and an additive into a mold; performing a primary bulk polymerization reaction at the temperature of between 30 and 50 DEG C for 10 to 72 hours; performing a further bulk polymerization reaction at the temperature of between 50 and 100 DEG C for 1 to 30 hours to obtain a copolymer plate; smashing and screening the copolymer plate to obtain the expandable particles for producing the polymethacrylimide foamed material. Pre-foamed particles can be prepared by pre-foaming the expandable particles at the temperature of between 150 and 230 DEG C for 0.1 to 2 hours, and polymethacrylimide foam particles can be prepared by foaming the pre-foamed particles at the temperature of between 190 and 260 DEG C and curing the foamed particles at the temperature of between 150 and 230 DEG C. The expandable particles expand the use range of the polymethacrylimide foamed material.

Owner:SICHUAN UNIV

Method for manufacturing high-strength 7055 aluminum alloy forge piece formed by spraying

The invention belongs to a manufacturing technology of aluminum alloy and relates to a method for manufacturing a high-strength 7055 aluminum alloy forge piece formed by spraying. The method sequentially comprises the following steps: (a) melting components of 7055 alloy in an intermediate frequency furnace; (b) degassing, deslagging, refining and filtering an aluminum alloy fusant; (c) forming the filtered fusant by spraying to obtain a columnar aluminum alloy ingot blank; (e) carrying out hot extrusion on the aluminum alloy ingot blank formed by spraying; (f) constantly cutting the extrusion ingot as required and then carrying out free forging; (g) carrying out blocker-type forging and / or stamp forging on the blank after the free forging to obtain a stamp forging piece; and (h) carrying out T6 heat treatment on the stamp forging piece. A large-specification and high-property 7055 product can be obtained by using the method which is suitable for industrial production.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

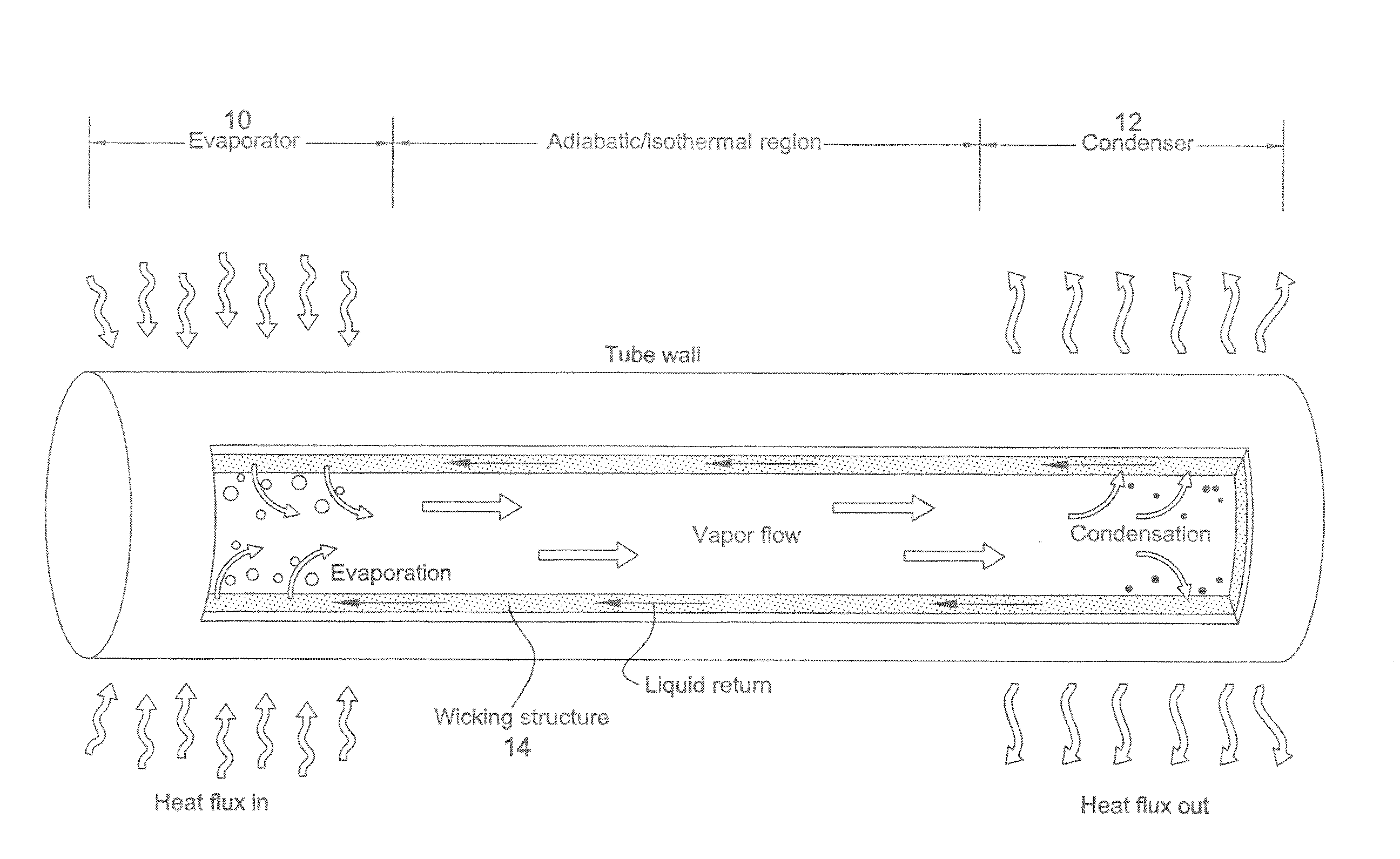

Heat-Managing Composite Structures

ActiveUS20100236759A1Improve spraying effectHigh dynamic strengthCorrosion preventionBuilding componentsHigh stressRocket

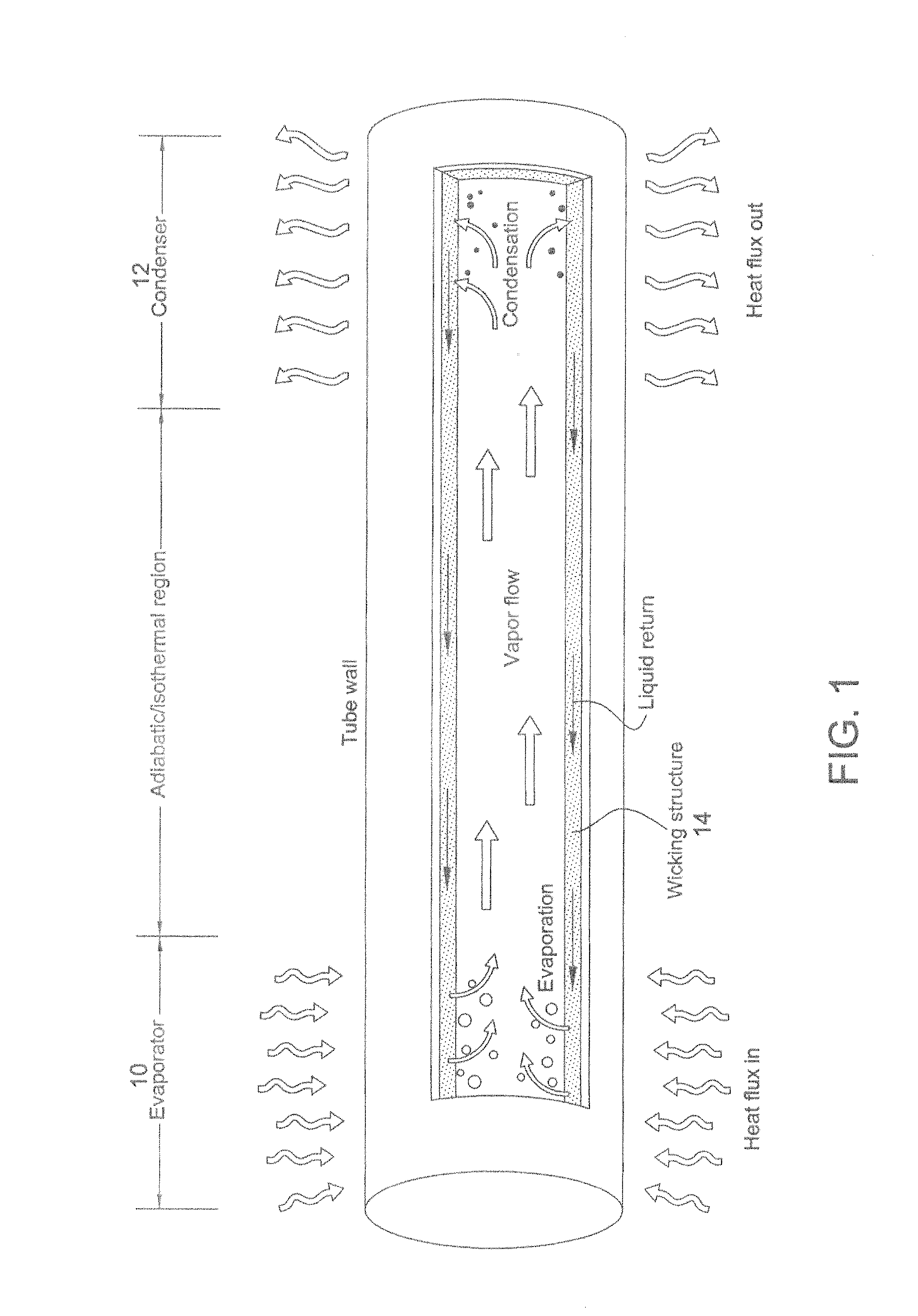

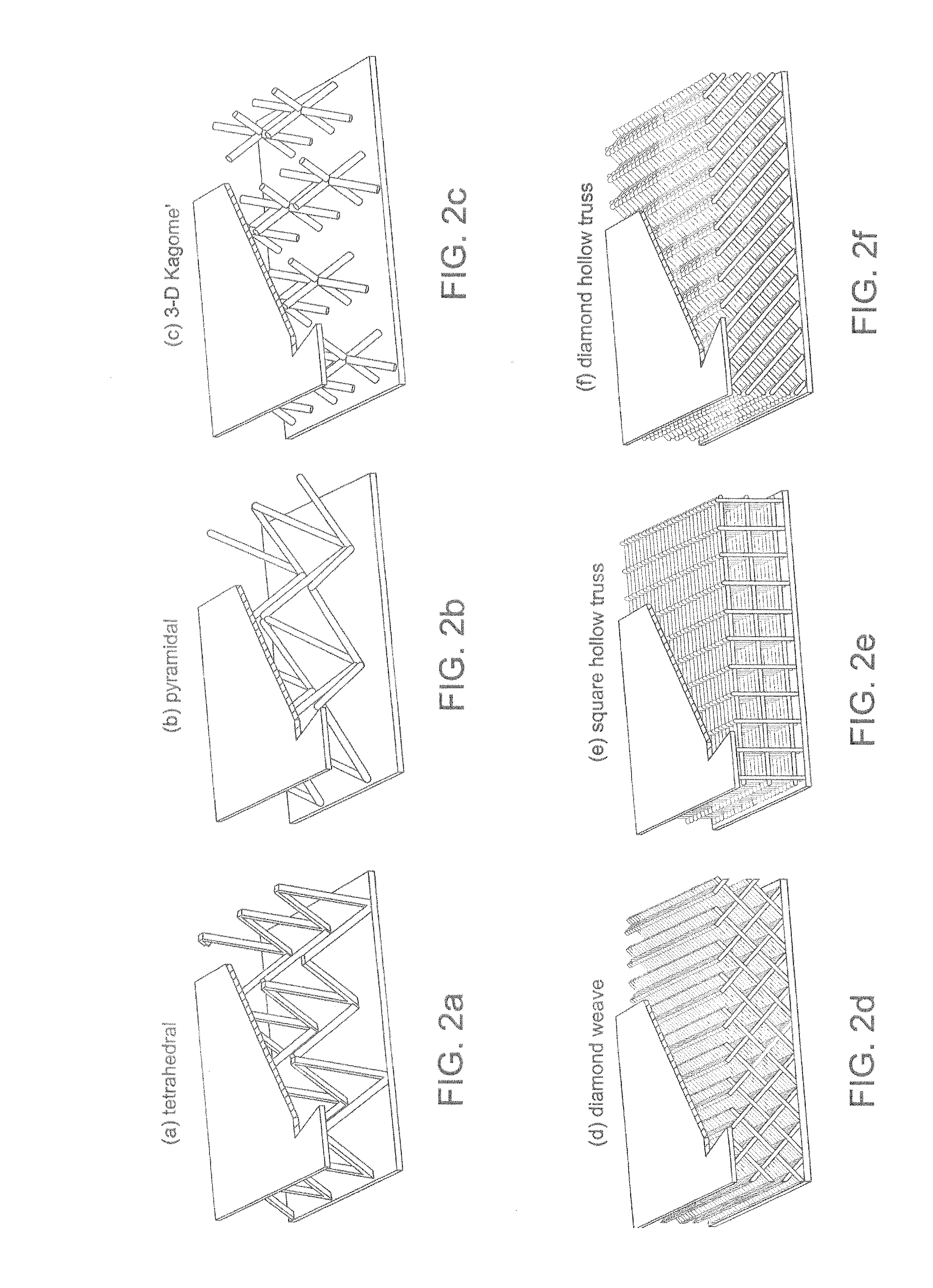

Light-weight, heat-managing structures feature open-cell lattice, honeycomb, and / or corrugated (prismatic) arrangements in their substructures, combined with heat pipe / heat plate arrangements for managing heat to which the structures are subjected. The structures are well suited to aerospace applications and may be employed in the leading edge of wings or other airfoil-shaped components; gas turbine engine components; rocket nozzles; and other high-heat, high-stress environments.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

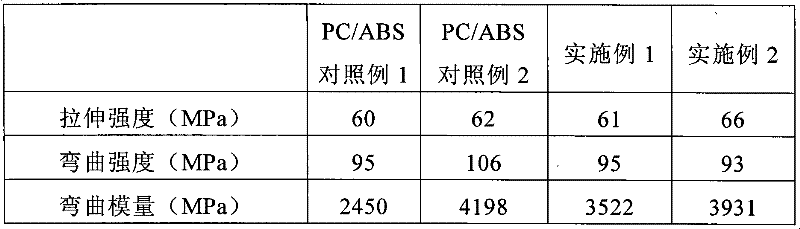

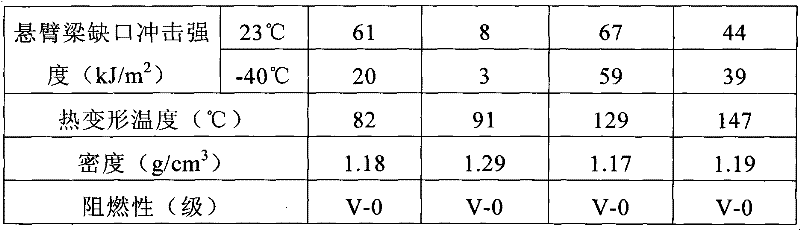

Low coefficient of thermal expansion thermoplastic resin composition, preparation method and application thereof

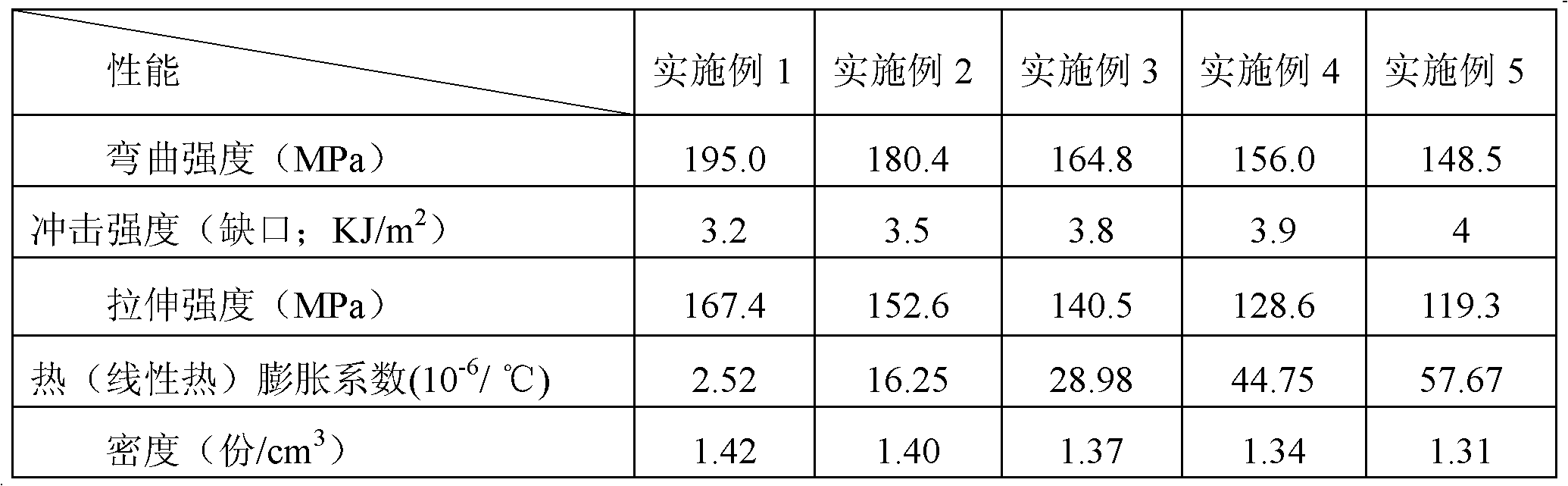

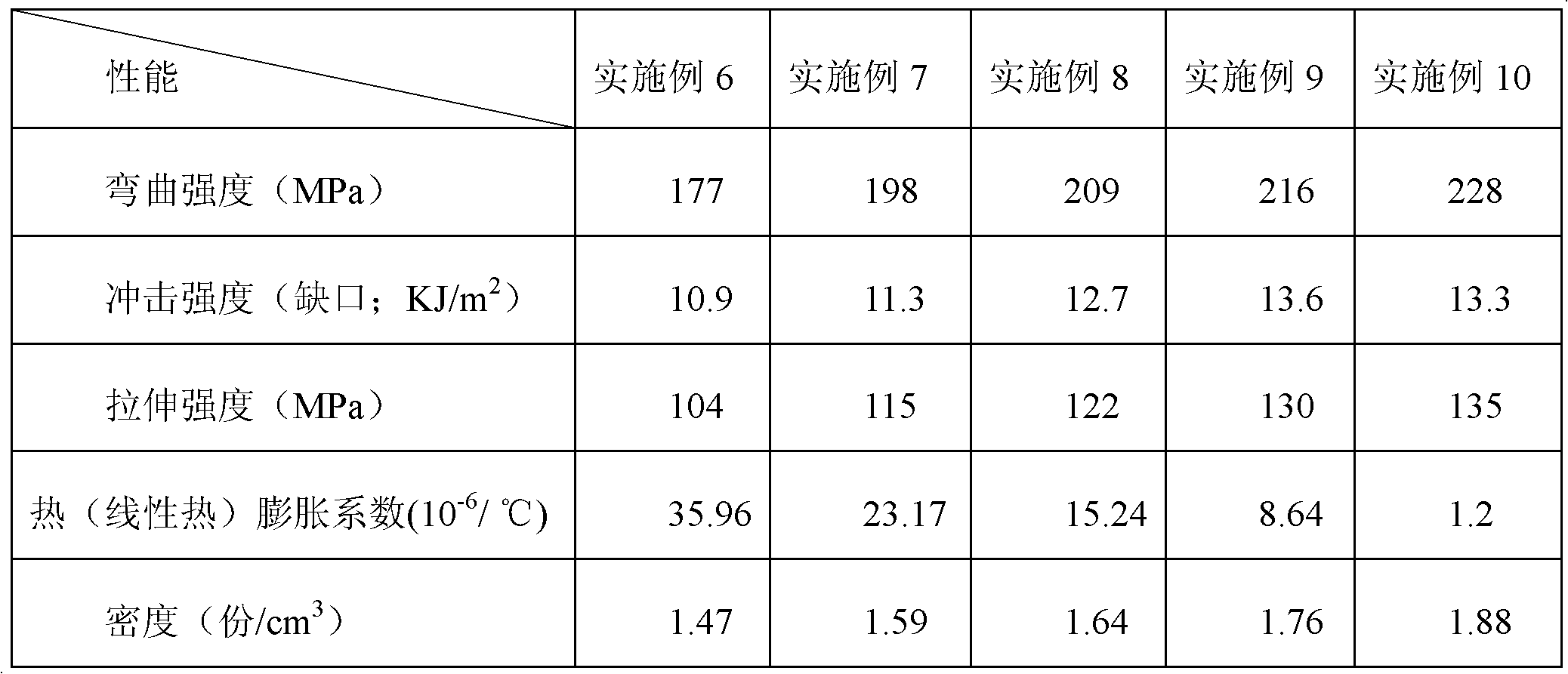

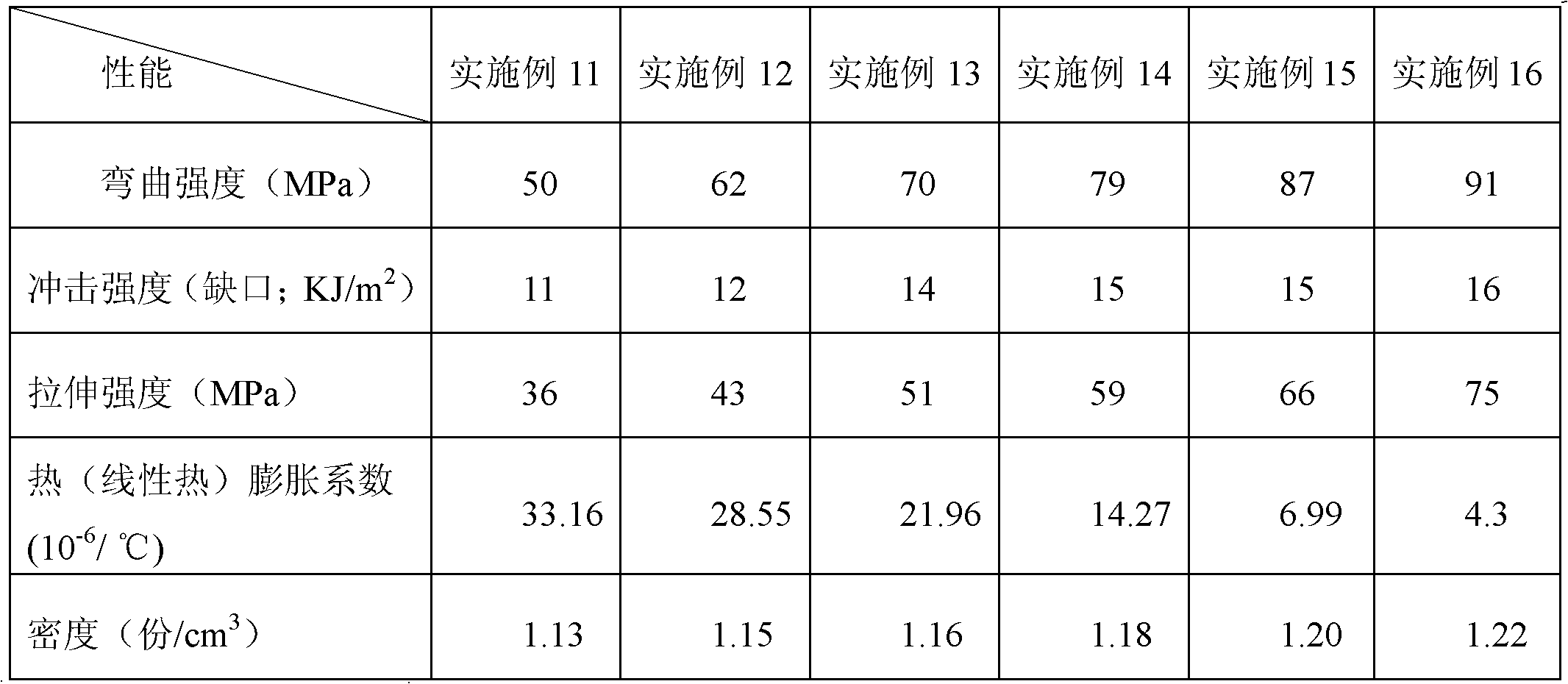

The invention belongs to the technical field of high polymer materials, and discloses low coefficient of thermal expansion thermoplastic resin composition, a preparation method and application of the low coefficient of thermal expansion thermoplastic resin composition. The resin composition is composed of, by weight, 340 to 900 parts of thermoplastic resin, 100 to 500 parts of carbon fibers, 0 to 5 parts of antioxygen, 0 to 5 parts of lubricating agent and 0 to 150 parts of flexibilizer. The preparation method comprises adding the 340 to 900 parts of the thermoplastic resin, the 0 to 5 parts of the antioxygen, 0 to 5 parts of the lubricating agent and the 0 to 150 parts of the flexibilizer to a high mixing machine to mix for 1 to 30 min, adding the mixture to a double-screw extruder, adding the 100 to 500 parts of the carbon fibers from the glass fiber feeding port or the side feeding port of the double-screw extruder to mix evenly, and carrying out extruding, dragging and prilling on mixed materials in the double-screw extruder to obtain the low coefficient of thermal expansion thermoplastic resin composition. The use of the low coefficient of thermal expansion thermoplastic resin composition applied to the fittings of a metal piece is provided. The thermoplastic resin is high in flexural modulus, tensile strength and impact strength, and low in linear expansion coefficient.

Owner:HEFEI GENIUS NEW MATERIALS

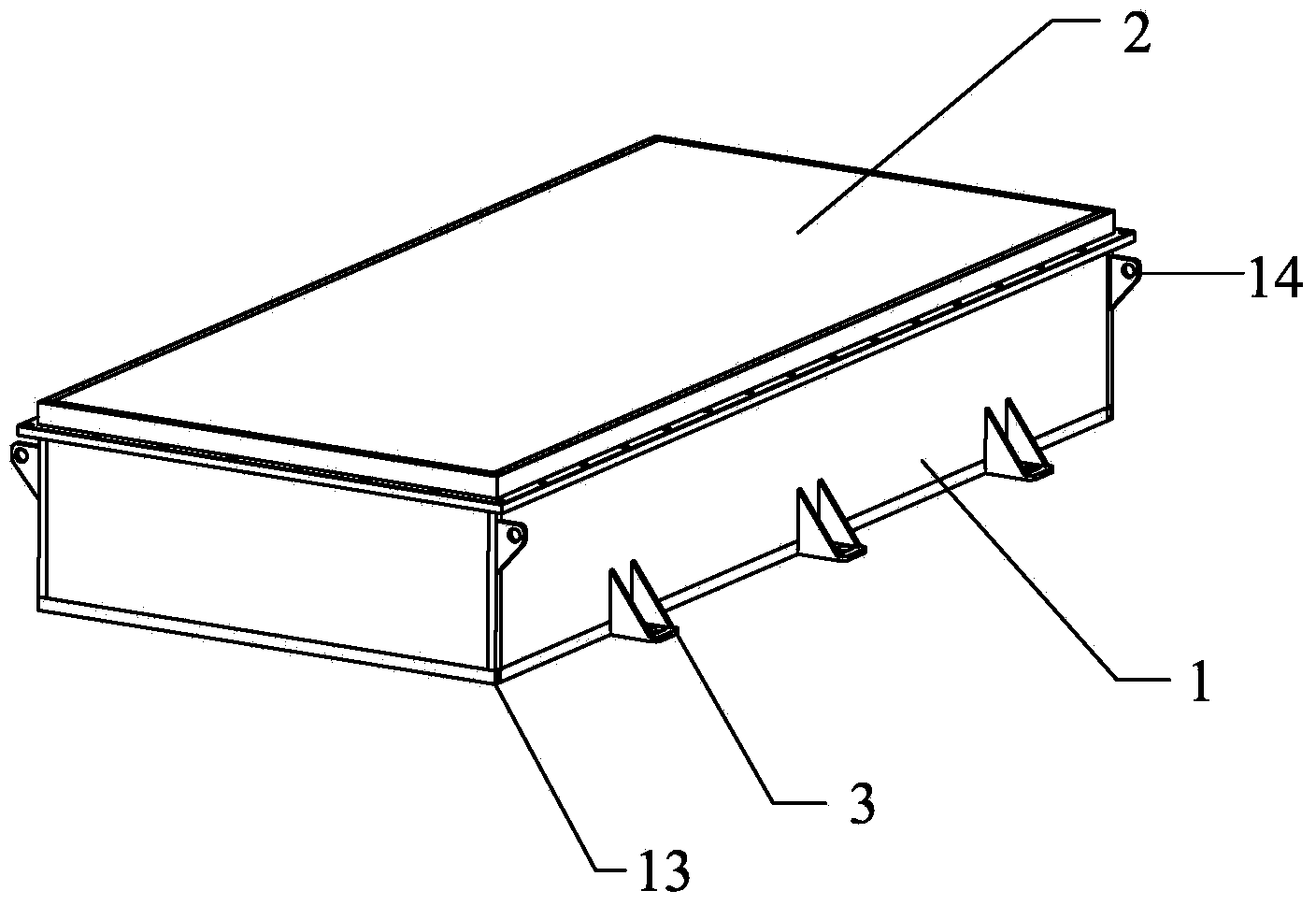

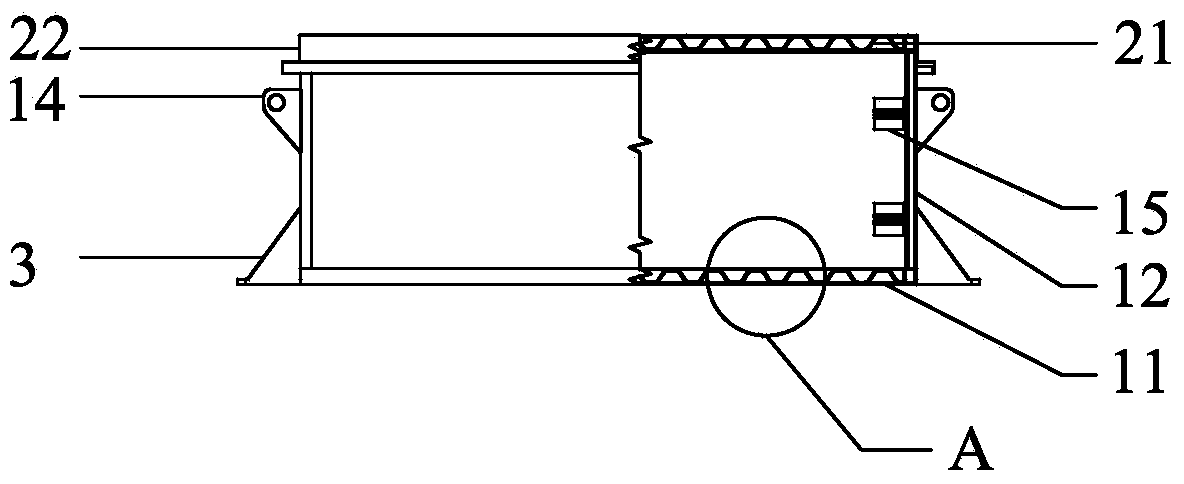

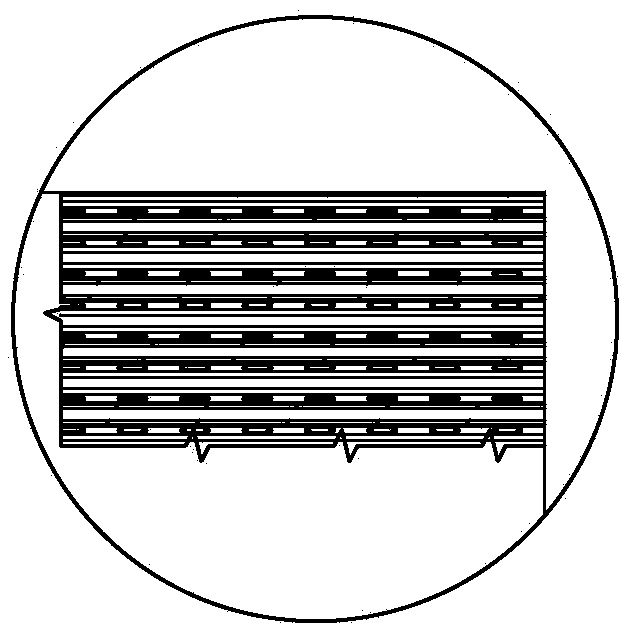

Corrugated sandwich protective structure of battery box of electric vehicle

InactiveCN103730616AUndamagedFree from destructionElectric propulsion mountingVehicle sub-unit featuresAutomotive batteryEngineering

The invention discloses a corrugated sandwich protective structure of a battery box of an electric vehicle. The protective structure comprises a box body and a box cover, wherein the box body is not closed at top, is composed of a baseplate and a baseplate wallboard fixed around the baseplate and is used for accommodating batteries; the box cover comprises a top plate and a top-plate wallboard fixed around the top plate, and the box cover and the box body are buckled so as to form a closed space. The protective structure is characterized in that the baseplate and the baseplate wallboard are respectively made of a corrugated sandwich protective plate. According to the invention, the box body and the box cover are made of the corrugated sandwich protective plates, so that the batteries can be prevented from being damaged; the corrugated sandwich protective structure has the advantages of high specific stiffness, high specific strength, high fatigue life, strong impact resistance and shock resistance, good impacting energy absorption property, light weight, and the like, thereby facilitating the promotion and application of electric vehicles and passenger cars.

Owner:DALIAN UNIV OF TECH

Hollowed-out lattice sandwich layer with gradient functionality and manufacturing method of hollowed-out lattice sandwich layer

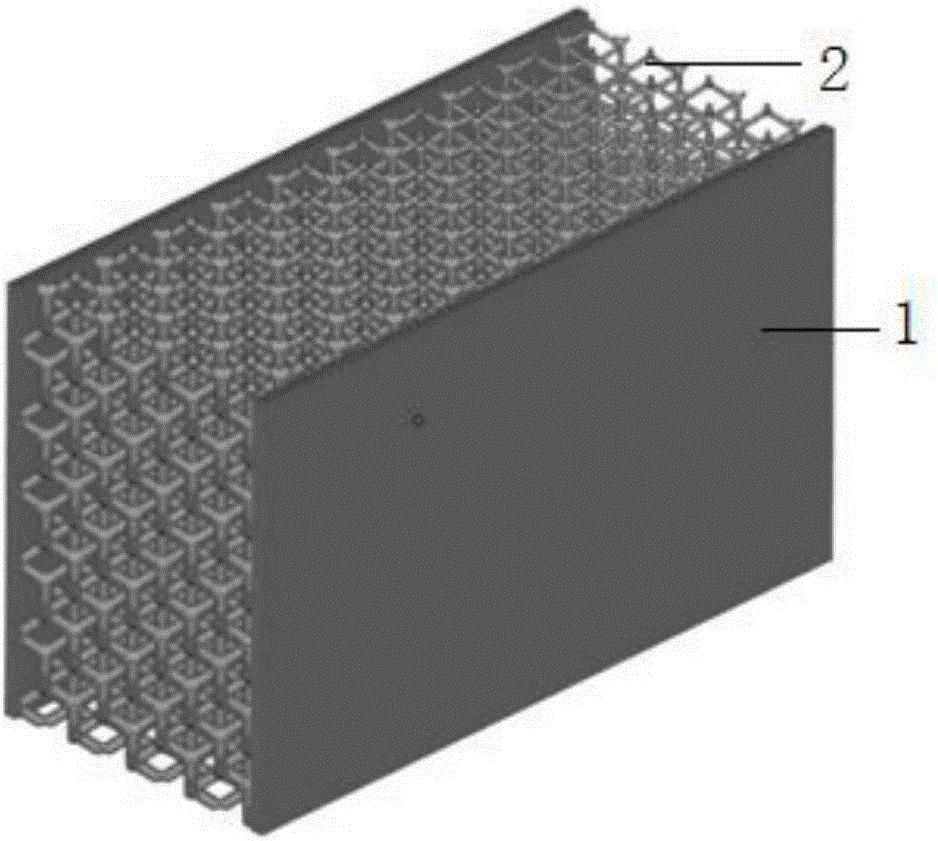

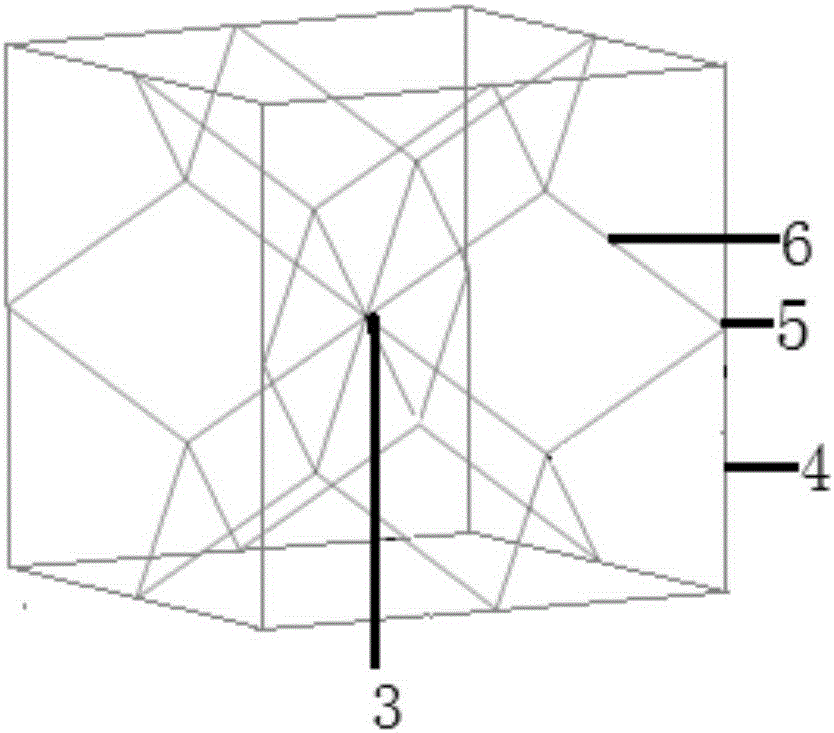

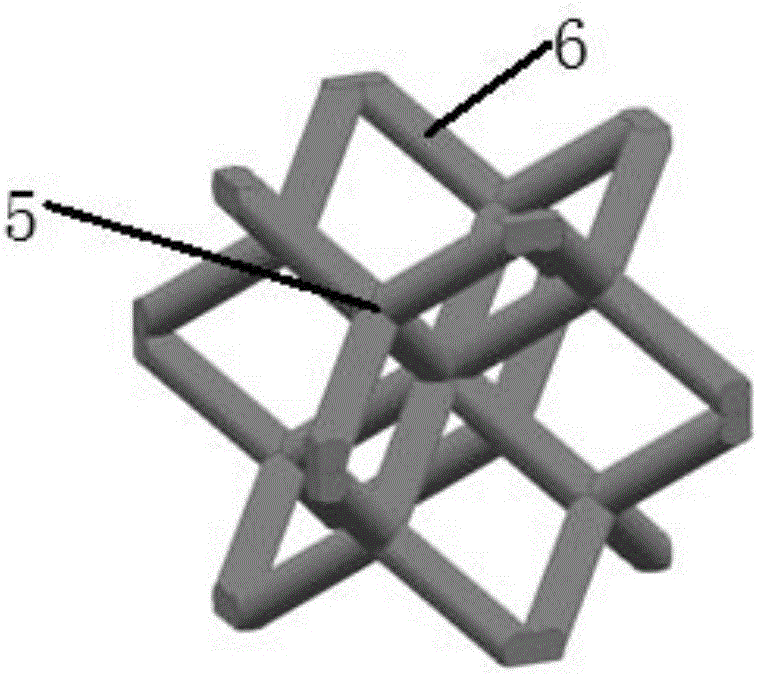

ActiveCN106694884ALightweight structureHigh specific strengthAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSandwich board

The invention discloses a hollowed-out lattice sandwich layer with gradient functionality. The hollowed-out lattice sandwich layer with gradient functionality comprises two cladding plates, wherein a core sandwich layer is arranged between the cladding plates and comprises a plurality of hollowed-out lattice filling units which are connected with one another; and each hollowed-out lattice filling unit consists of a plurality of tiny dense hollowed-out base cells. The hollowed-out sandwich layer is formed by the hollowed-out lattice filling units, and is light in structure weight and high in specific strength, the maximum weight reduction benefit can reach 85% or above, and meanwhile, the hollowed-out lattice sandwich layer has functional benefits such as heat insulation and sound insulation; comprehensive benefits of structure light weight and functionalization are improved, property mismatching of a sandwich board with the single structure in the application field under various working conditions is avoided, and finally, the gradient function is fulfilled; and meanwhile, a selective laser melting technology is adopted, the risk of reduction of strength of a connecting region between a traditional sandwich layer and an outer cladding plate and complicated multi-process flow can be avoided, and therefore, the use value is quite high.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

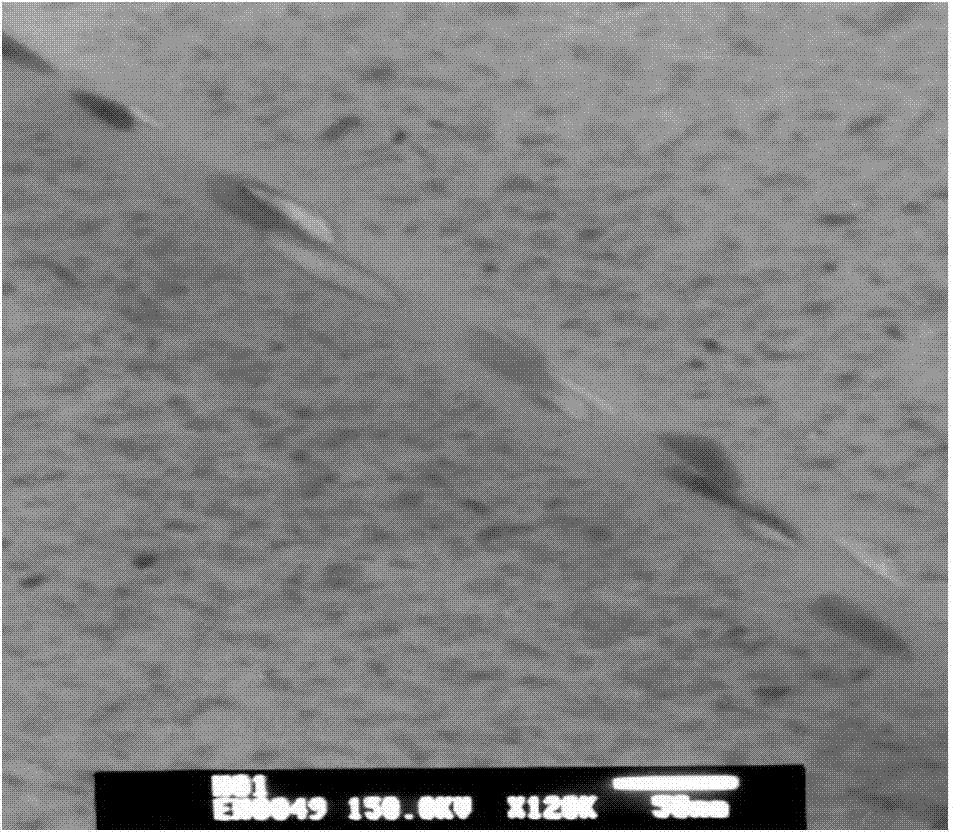

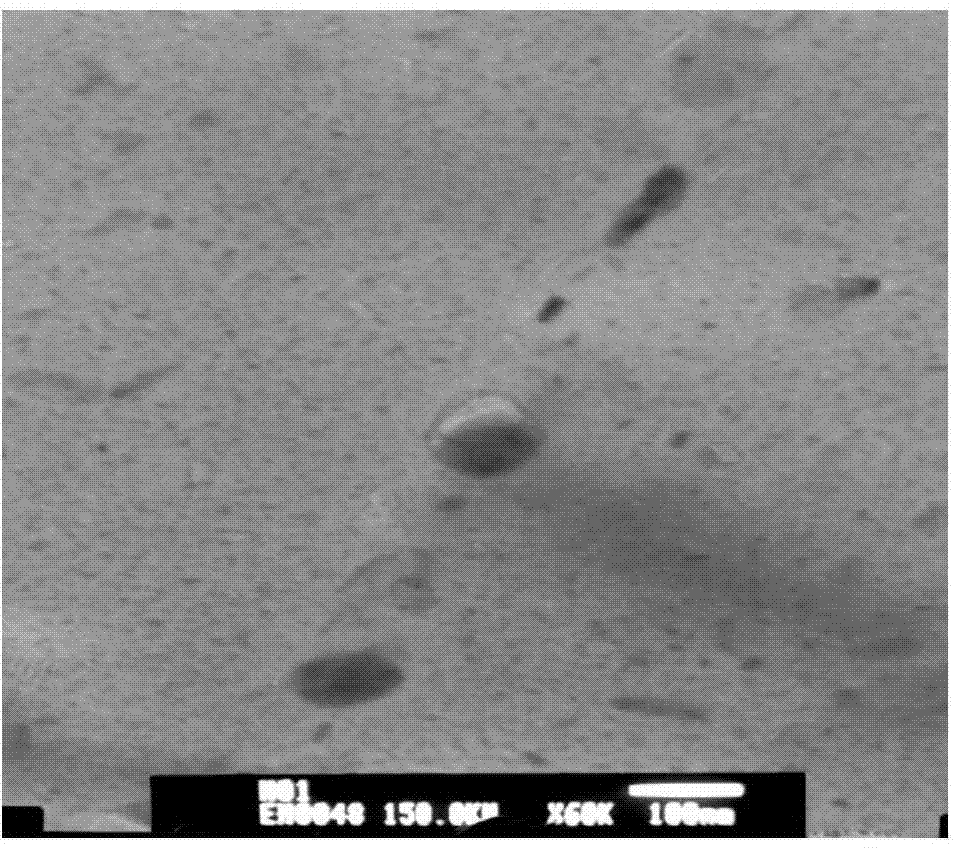

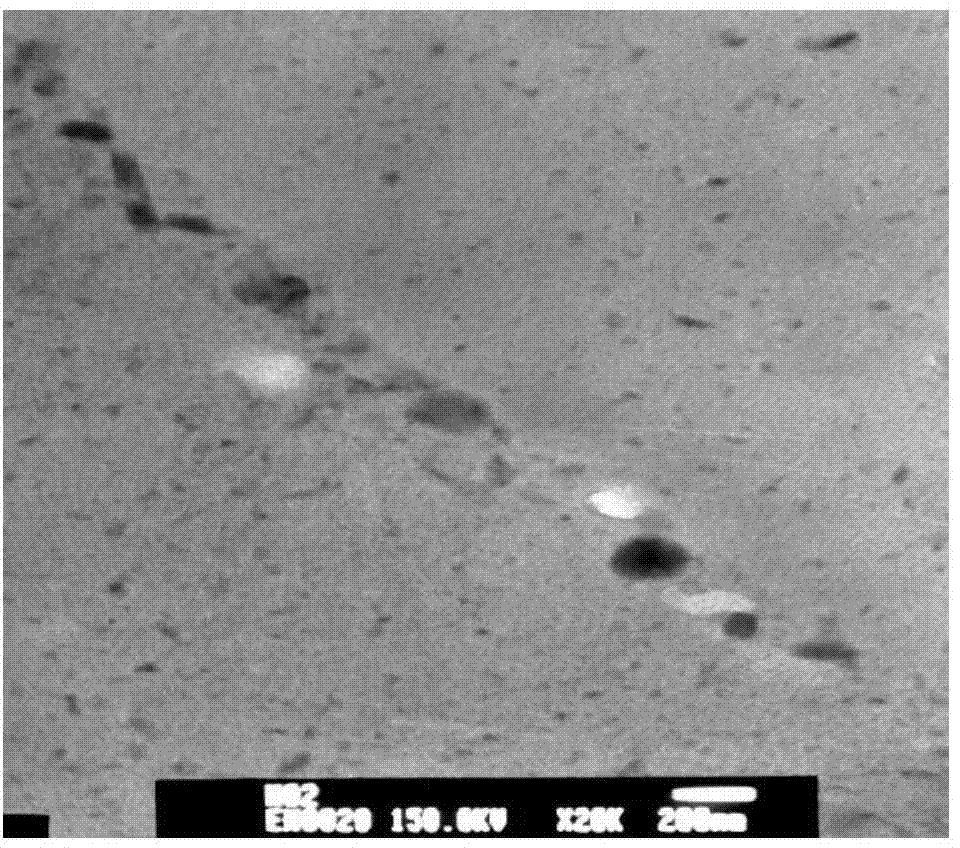

Graphene-reinforced titanium-based composite and preparation method thereof

The invention discloses a graphene-reinforced titanium-based composite and a preparation method thereof. The preparation method comprises the following steps: S1, weighing titanium powder and graphene nanoflake and carrying out ultrasonic dispersion; S2, subjecting the titanium powder and graphene nanoflake having undergone mixing and dispersion to ball milling; S3, drying and grinding mixed powder formed after ball milling; S4, putting the mixed powder obtained in the step S3 into a graphite die and placing the graphite die in a spark plasma sintering system; S5, carrying out spark plasma sintering on a compacted powder material in the graphite die; and S6, after completion of sintering, cooling a sintered sample to room temperature in a furnace and taking out the sample. The preparation method prepares the graphene-reinforced titanium-based composite with lightweight and high strength and toughness; and according to the method, ultrasonic dispersion and ball milling technologies are employed for powder mixing, then the composite is prepared from the uniformly mixed powder through spark plasma sintering technology, so the advanced composite with lightweight and high specific strength is obtained.

Owner:SUZHOU UNIV

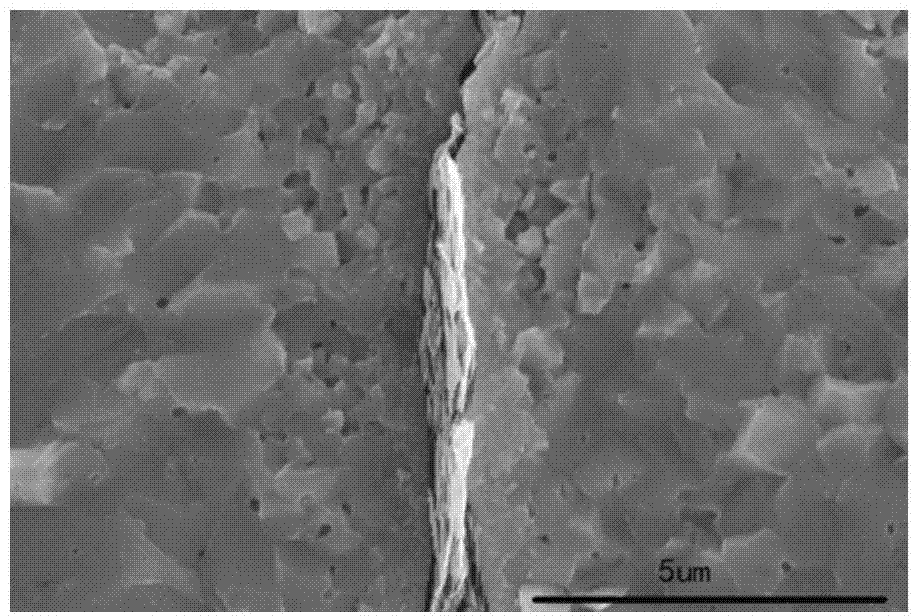

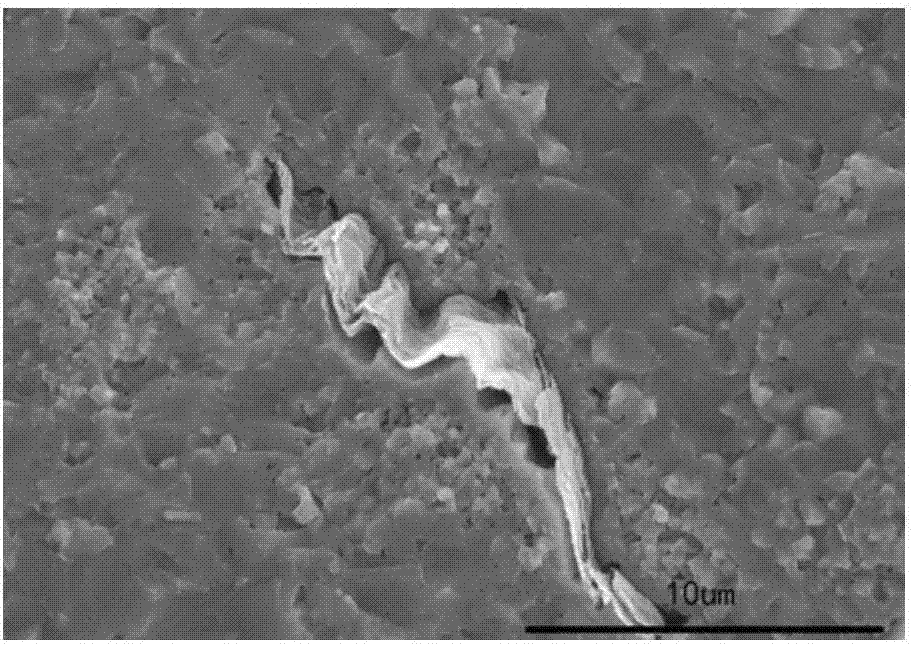

Thermoplastic resin composite material for laptop shells and manufacturing method thereof

The invention relates to a thermoplastic resin composite material for laptop shells and a manufacturing method thereof. The composite material comprises the following components in percentage by weight: 40 to 60 parts of thermoplastic resin, 10 to 20 parts of organic fibers, 0 to 20 parts of inorganic fibers, 0 to 10 parts of other aids, and 20 to 40 parts of halogen-free flame-retarding master batch. The manufacturing method comprises: melting thermoplastic resin to obtain melt, immersing fibers into the melt of the thermoplastic resin, adding other aids into the melt, cooling the melt, and making fiber reinforced thermoplastic resin granules; and mixing the granules and the halogen-free flame-retarding master batch in batch to obtain the composite material. Compared with the prior art, the composite material manufactured by the method has high toughness, high strength and high rigidity, and has the characteristics of environment-friendliness, flame retardance, high thermostability, and low-temperature toughness. The thermoplastic resin composite material is an ideal novel laptop shell material.

Owner:HEFEI GENIUS NEW MATERIALS

Automobile steel plate spring assembly with auxiliary spring made of composite material and assembly method thereof

InactiveCN104972859AReduce manufacturing costHigh specific strengthLeaf springsResilient suspensionsSteel platesSheet steel

The invention discloses an automobile steel plate spring assembly with an auxiliary spring made of a composite material. The automobile steel plate spring assembly comprises a U-shaped bolt metal clamping plate, a main spring, the auxiliary spring and a lower gasket. The lower gasket, the auxiliary spring, the main spring and the U-shaped bolt metal clamping plate are sequentially stacked from bottom to top and then are fixedly connected for limiting through a center bolt, and clamping and fixing are assisted through a U-shaped bolt. The main spring is a steel plate spring, and the auxiliary spring is a composite material plate spring. The auxiliary spring is made of the E glass fibers / polyurethane composite material and is integrally formed through a high-pressure RTM technique. The fiber laying layers of the composite material are all 0 degree, and the volume content of the fibers of the composite material is 58%. According to the automobile steel plate spring assembly with the auxiliary spring made of the composite material, on the basis that the requirement for the performance of an automobile steel plate spring is met, design cost is reduced, the mass of the plate spring assembly is lowered, and the service life of the plate spring assembly is prolonged. The invention further discloses an assembly method of the automobile steel plate spring assembly with the auxiliary spring made of the composite material.

Owner:JILIN UNIV +2

Light-weight and high-strength plastic steel sandwich board and its making method

ActiveCN102991046ALight in massQuality improvementSynthetic resin layered productsLaminationThermoplasticAdhesive

The invention belongs to the technical field of building decoration and transportation, and discloses a light-weight and high-strength plastic steel sandwich board and its making method. The plastic steel sandwich board comprises two panels and a sandwich layer fixed between the two panels. The making method of the plastic steel sandwich board comprises the following steps: placing the sandwich layer between the two panels, and respectively bonding the two panels with the right and wrong surfaces of the sandwich layer through an adhesive to prepare the plastic steel sandwich board, wherein each of the panel is obtained through compounding one side of a continuous fiber reinforced thermoplastic plastic board with a non-woven fabric through hot-press molding. The plastic steel sandwich board has the advantages of light weight, high strength, heat insulation, fire resistance, moisture resistance, corrosion resistance and the like.

Owner:滁州格美特科技有限公司

Aluminum alloy for 480 MPa-class aluminum alloy oil pipe and pipe manufacturing method thereof

The invention discloses an aluminum alloy for a 480 MPa-class aluminum alloy oil pipe. The aluminum alloy comprises the following components by weight percent: 5.10-6.90% of Zn, 1.10-1.80% of Mg, 0.05-0.20% of Cu, 0.10-0.30% of Mn, 0.10-0.30% of Cr, 0.01-0.02% of Ti, 0.15-0.2% of Zr and the balance of Al and unavoidable impurities, wherein in the unavoidable impurities, the content of the Si is not greater than 0.15 of the total weight of the aluminum alloy and the content of Fe is not greater than 0.15 of the total weight of the aluminum alloy. The manufacture method of the aluminum alloy pipe comprises the following steps: (1) smelting the raw materials according to the weight percentage, performing external refining and casting to obtain a pipe blank; (2) performing three-stage homogenization treatment; (3) squeezing under high temperature; (4) performing twin-stage solid solution treatment, quenching and cooling; (5) prestretching and deforming; and (6) performing twin-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Polyvinyl chloride (PVC) wood-plastic foaming wood grain section and preparation method thereof

The invention discloses a polyvinyl chloride (PVC) wood-plastic foaming wood grain section and a preparation method thereof. The wood-plastic foaming wood grain section is prepared from the following raw materials: plastics, an organic filler, an aid, a modifier, a foaming agent, a wood grain masterbatch and the like. The preparation method comprises the following steps of: mixing a foaming mixed material and the wood grain masterbatch and co-extruding from an extruder in a conical twin screw extrusion production line according to a one-step process route; foaming and molding by using a foaming mold; and cooling and shaping by using a shaping mold to obtain the PVC wood-plastic foaming wood grain section. The PVC wood-plastic foaming wood grain section has the advantages of light weight, high specific strength, waterproofness, corrosion resistance and heat preservation, and has the processing characteristic that wood can be nailed, sawed and planed; in addition, the PVC wood-plastic foaming wood grain section has highly simulated solid wood appearance, natural and clear textures, and bright surface color, is an ideal wood-simulated wood-plastic product, and can be widely applied to building, transportation, packaging, home decoration and daily product markets.

Owner:北京欧尼克环保技术有限公司

Aluminum-base alloy self-lubricating material and preparation method thereof

A aluminum-based alloy self-lubricating materials and method for making same relates to the technology for preparing composite metal materials. Aimming at the evil of large gas cavity amount in aluminum-based alloy self-lubricating materials, there is disclosed a aluminum-based alloy self-lubricating materials and method for making same. Said scheme is as follows: selecing aluminium alloy as a basal body alloy, adding a slipping agent into the aluminium alloy fused mass, wherein said slipping agent is composed of one of copper facing mineral carbon or one mixture of copper facing mineral carbon and copper facing carbon fabric or one mixture of copper facing mineral carbon and nickel plating carbon fibre and is prepared through stirring-mixing, vacuum outgassing and casting, and the basal body aluminium alloy comprises (based on mass percent) Si of 6.5-9.0, Mg of 0.8-1.2, Mn of 0.1-0.5, Ti of 0.1-0.25, Zn of not more than 0.3, Fe of not more than 0.5, Cu of not more than 0.3, Ni of not more than 0.1, in which the allowance is Al. The weight of the added substance is 7-12%, 10-18% and 10-17 of the total weight of the aluminum-based alloy respectively when copper facing mineral carbon, the mixture of copper facing mineral carbon and copper facing carbon fabric and the mixture of copper facing mineral carbon and nickel plating carbon fibre are adopted. There is less gas cavities existing in said material.

Owner:NORTHEASTERN UNIV

PVC (Poly Vinyl Chloride) wood-plastic foaming composite and preparation method thereof

ActiveCN102501506AGood weather resistanceReduce formulation costsSynthetic resin layered productsASA-polymerWeather resistance

The invention discloses a PVC (Poly Vinyl Chloride) wood-plastic foaming composite and a preparation method of the wood-plastic foaming composite. The PVC wood-plastic foaming composite comprises a PVC wood-plastic foaming base material layer and an ASA (Acrylonitrile Styrene Acrylate) layer which is co-extruded and formed on at least one side of the PVC wood-plastic foaming base material layer, wherein the PVC wood-plastic foaming base material layer comprises the following components in parts by weight: 100 parts of PVC, 50-100 parts of paddings, 1-1.5 parts of coupling agents, 5-7 parts of compound stabilizers, 1.0-1.5 parts of compound foaming agents and 6-8 parts of blowing promoters. The PVC wood-plastic foaming composite disclosed by the invention has the characteristics of light weight, high specific strength, water prevention, corrosion prevention, heat preservation, good weather resistance, low formula cost and low material density, and can be widely used in outdoor product markets such as exterior decoration of buildings, garden landscapes, fences, plank ways and the like.

Owner:北京欧尼克新型材料有限公司

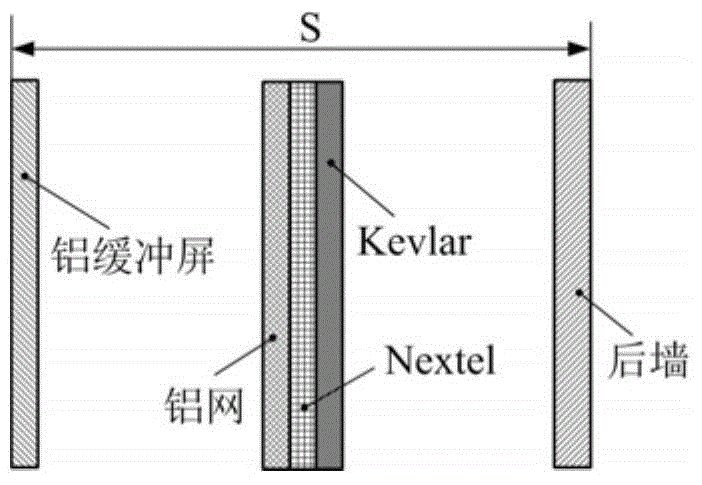

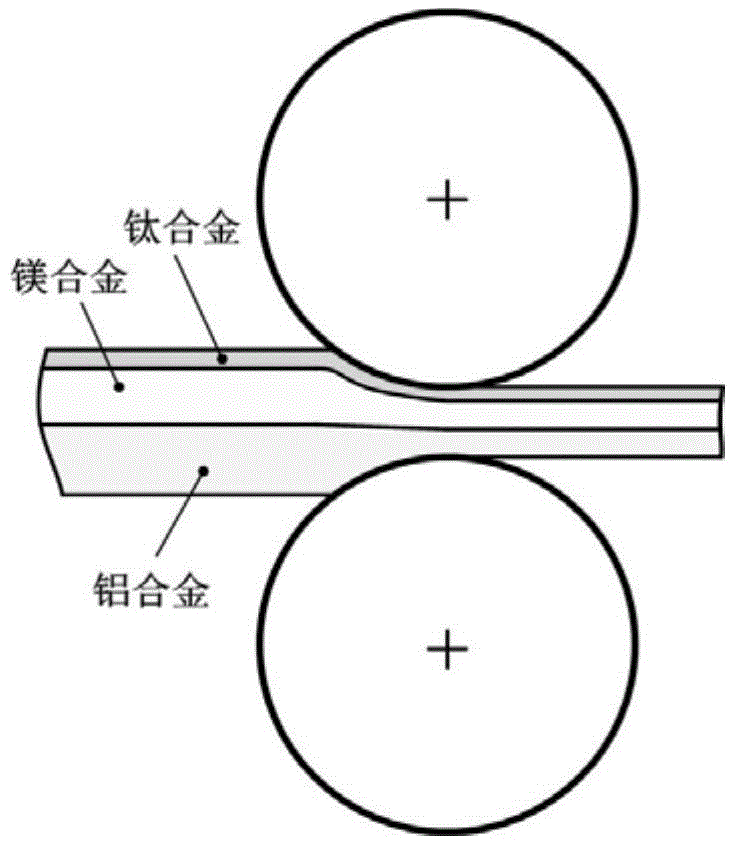

Rolling compounding method for aluminum/magnesium/titanium three-layer composite plate

ActiveCN104056859ALow densityHigh specific strengthAuxillary arrangementsMetal rolling arrangementsComposite plateTitanium alloy

The invention discloses a rolling compounding method for an aluminum / magnesium / titanium three-layer composite plate. The characteristics of high strength of titanium alloy, low melting point and good vibration reducing performance of magnesium alloy, good plasticity and space adaptation of the aluminum alloy, and the like, are utilized and the excellent characteristics of respective component metals are combined by the aluminum / magnesium / titanium three-layer composite plate provided by the invention, so that the high-speed impact damage resisting property which the component metals do not own is acquired. Through the control on the ratio and interface of the aluminum alloy, the magnesium alloy and titanium alloy, the degree of fragmentation, melting and atomizing of shred cloud after the buffer composite plate is subjected to high-speed impact is changed and adjusted, so that the form of the shred cloud is changed, the degree of impact damage to a backplate is reduced, and the high-speed impact damage resisting property is increased. The aluminum / magnesium / titanium three-layer composite plate is applied to an outer layer buffer plate in an outer layer protecting structure of an aerospace vehicle and can be used for replacing a traditional single aluminum alloy material. The space environmental effect and protecting level of the space vehicle are increased; the design level of the space vehicle are greatly promoted, and the service life of the space vehicle are greatly prolonged.

Owner:CHONGQING UNIV

Aramid fiber enhanced wood-plastic composite material and preparation method thereof

InactiveCN101629022AImprove mechanical propertiesImprove thermal stabilityFibre treatmentChemical LinkageThermoplastic

The invention relates to aramid fiber enhanced wood-plastic composite material and a preparation method thereof, relating to fiber enhanced wood-plastic composite material and the preparation method thereof. The invention solves the problem that the existing wood-plastic composite material has bad comprehensive mechanical property. The wood-plastic composite material comprises thermoplastic, wood fiber material, lubricant, bulking agent and graft modification aramid fiber. The preparation method of the invention is as follows: 1. weighing raw materials; 2. preparing premixing materials; 3. melting, extruding and molding the premixing materials to obtain the fiber enhanced wood-plastic composite material. The preparation method utilizes carbon-carbon double bond and silane alkyl on the surface of modified aramid fiber and polyolefin and wood flour to form chemical bonds so that aramid fiber and polyolefin has good compatibility, and effectively enhances the interface binding force of the composite materials; the aramid fiber enhanced wood-plastic composite material simultaneously has high strength, high tenacity, and good comprehensive mechanical property. The method can be used for producing the wood-plastic composite material with high performances such as structural engineering materials, etc.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

High-plasticity two-phase yttrium-containing magnesium-lithium-aluminum alloy and preparation method thereof

The invention discloses high-plasticity two-phase yttrium-containing magnesium-lithium-aluminum alloy and a preparation method thereof. The alloy comprises the following specific components in percentage by weight: 9.50-10.80% of Li, 3.00-5.00% of Al, 0.50-0.70% of Y, 0.10-0.30% of Zr and the balance of Mg; the alloy has the structural characteristics that an alpha phase, a beta phase and a precipitated phase exist at the same time, wherein the alpha phase is a Mg-based solid solution and is in a close-packed hexagonal structure, the beta phase is a Li-based solid solution and is in a body-centered cubic structure, and the precipitated phase is a rare earth compound Al2Y; and the alloy has the characteristics of low density, high plasticity and higher strength. The preparation method disclosed by the invention is a normal-temperature plastic deformation method which combines casting with equal channel angular extrusion or traditional extrusion deformation process; and compared with the traditional high-temperature deformation process, the preparation method has good practicality and is simpler and more convenient to operate, and can be used for effectively lowering the production cost, thus the preparation method has good industrial production prospects.

Owner:SOUTH CHINA UNIV OF TECH

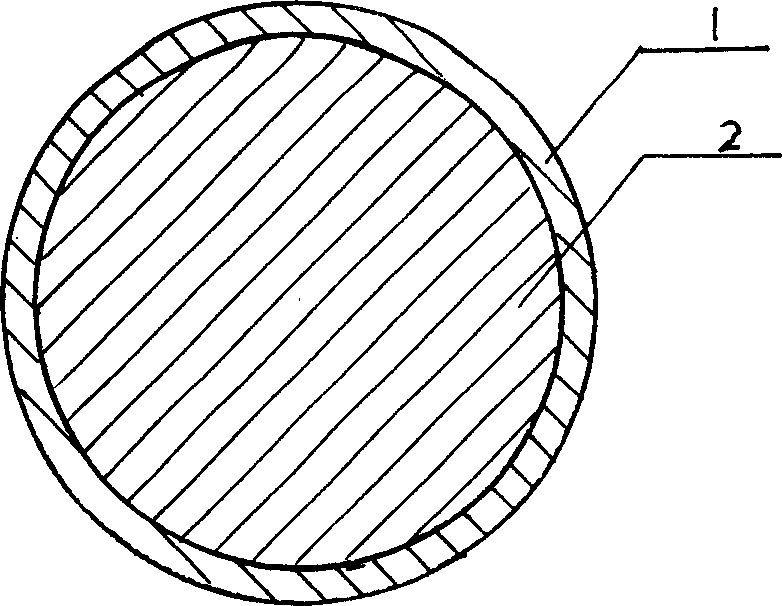

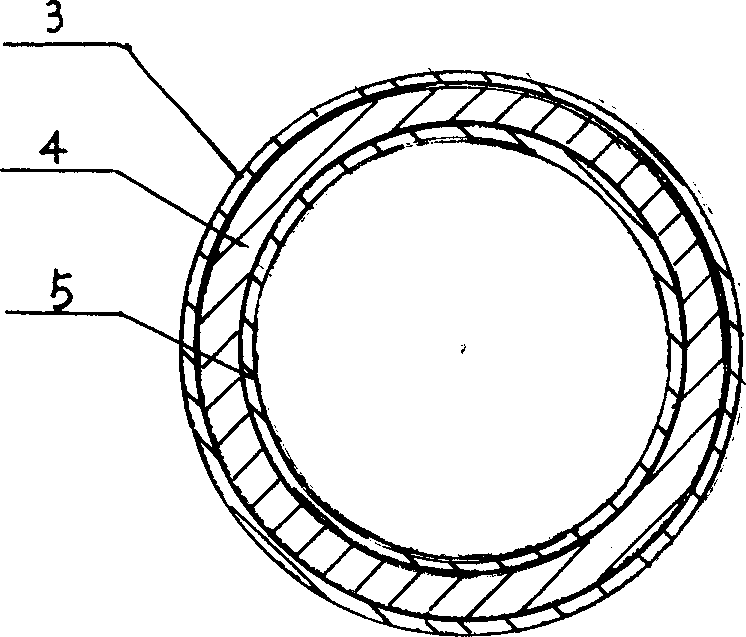

Magnesium-aluminium bimetal composite pipe/bar

InactiveCN1850383ALow densityHigh specific strengthExtrusion diesExtrusion control devicesIngotHeating temperature

The present invention relates to a kind of magnesium aluminium bimetal composite pipe / rod material. It is formed from interior magnesium alloy pipe / rod material and aluminium alloy layer covering surface of said interior magnesium alloy pipe / rod material. Its processing process includes the following steps: utilizing aluminium alloy and magnesium alloy to prepare combined ingot, heating said combined ingot and heat-insulating, extruding and straightening so as to obtain the invented product. Its extruding ratio is greater than 10, heating temperature is 300-400 deg.C, heat-insulating time is 1-5h and extruding speed is 0.5-3m / min.

Owner:CHONGQING UNIV

Light-weight and high-strength thermoplastic composite material sandwich board and production method thereof

InactiveCN103568396ALight in massLightweight and high-strength qualitySynthetic resin layered productsLaminationSandwich boardHoneycomb

The invention relates to a light-weight and high-strength thermoplastic composite material sandwich board and a production method thereof. The light-weight and high-strength thermoplastic composite material sandwich board comprises two panels and a sandwich layer, wherein the sandwich layer is fixedly arranged between the two panels. The preparation method comprises the following steps: putting the sandwich layer between the two panels; and sticking the two panels on the front and rear faces of the sandwich layer by a thermoplastic glue film through a hot pressing process and a cold pressing process to produce the thermoplastic composite material sandwich board. The panels are continuous fiber enhanced thermoplastic composite material boards and the sandwich layer is made of a honeycomb aluminum material. Compared with the prior art, the thermoplastic composite material sandwich board has the advantages of light weight, high strength, heat preservation, fireproof prevention, moisture prevention, corrosion prevention and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

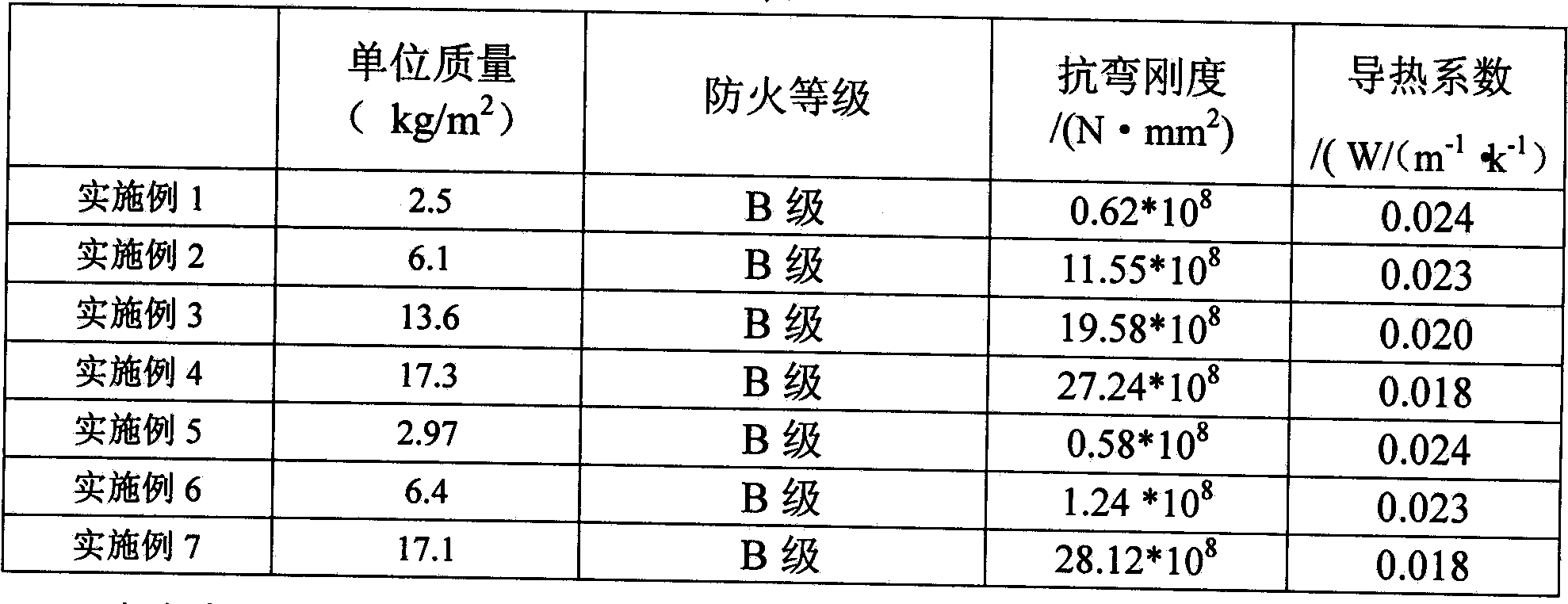

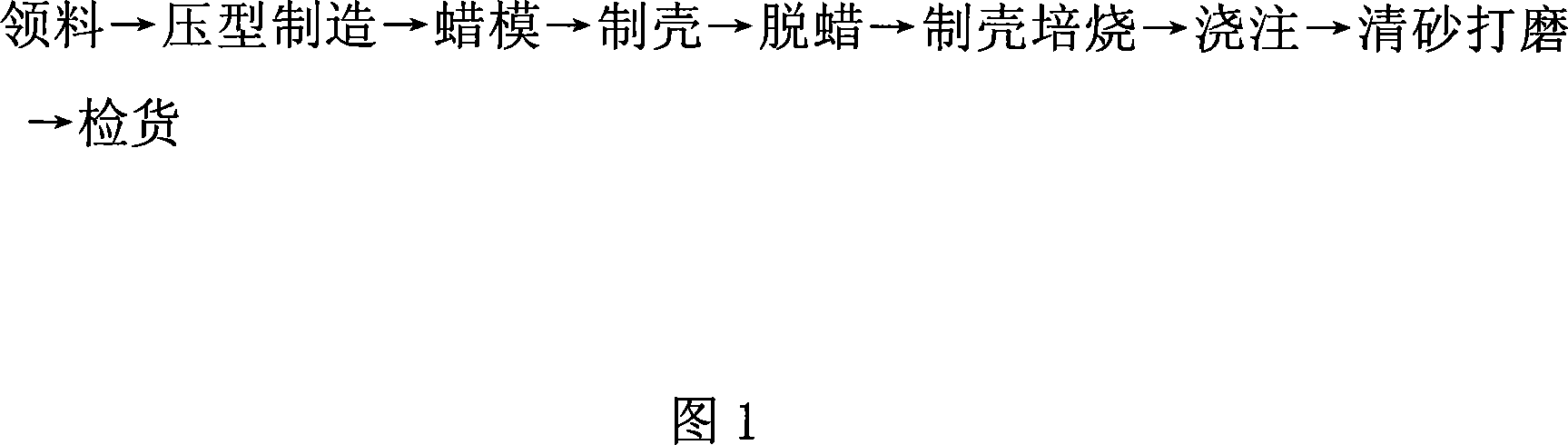

Titanium alloy fine casting melting method

InactiveCN101143381AWide operating temperature rangeSmall operating temperature rangeFoundry mouldsFoundry coresWaxInvestment casting

The invention relates to a method of processing titanium alloy. The method of casting and melting the titanium alloy is: after wax pattern is made, a shell is made; and then processes of de-waxing, roasting, pouring and post-processing are practiced. Wherein, the process of roasting adopts fireproof silica solution coating to make the shell. Refractory fillers are yttrium oxide of 95 per cent and zirconia mixture powder of 5 per cent. The shell is made up of 6 layers and a half to 8 layers and a half. The process of melting begins when vacuum of the melting and the pouring reach 6.65 to 0.665 Pa. When the temperature of titanium reaches the required temperature, a centrifugal rotary table is started and rotational speed is adjusted to reach all values. The whole pouring process is completed within 3 to 5 minutes. After a casting is cooled in a furnace until the temperature of the casting is below 400 DEG C, a precise casting of titanium alloy is manufactured. The titanium alloy manufactured by the invention has a wider operation temperature range, the low temperature of which is 253 DEG C below zero and the high temperature of which is 550 DEG C. The titanium ally manufactured by the invention has low density, light weight, high strength, good resistance to decay and stable property, which can be used in different medium such as nitric acid and manganic acid.

Owner:DALIAN JINMEI VALVE

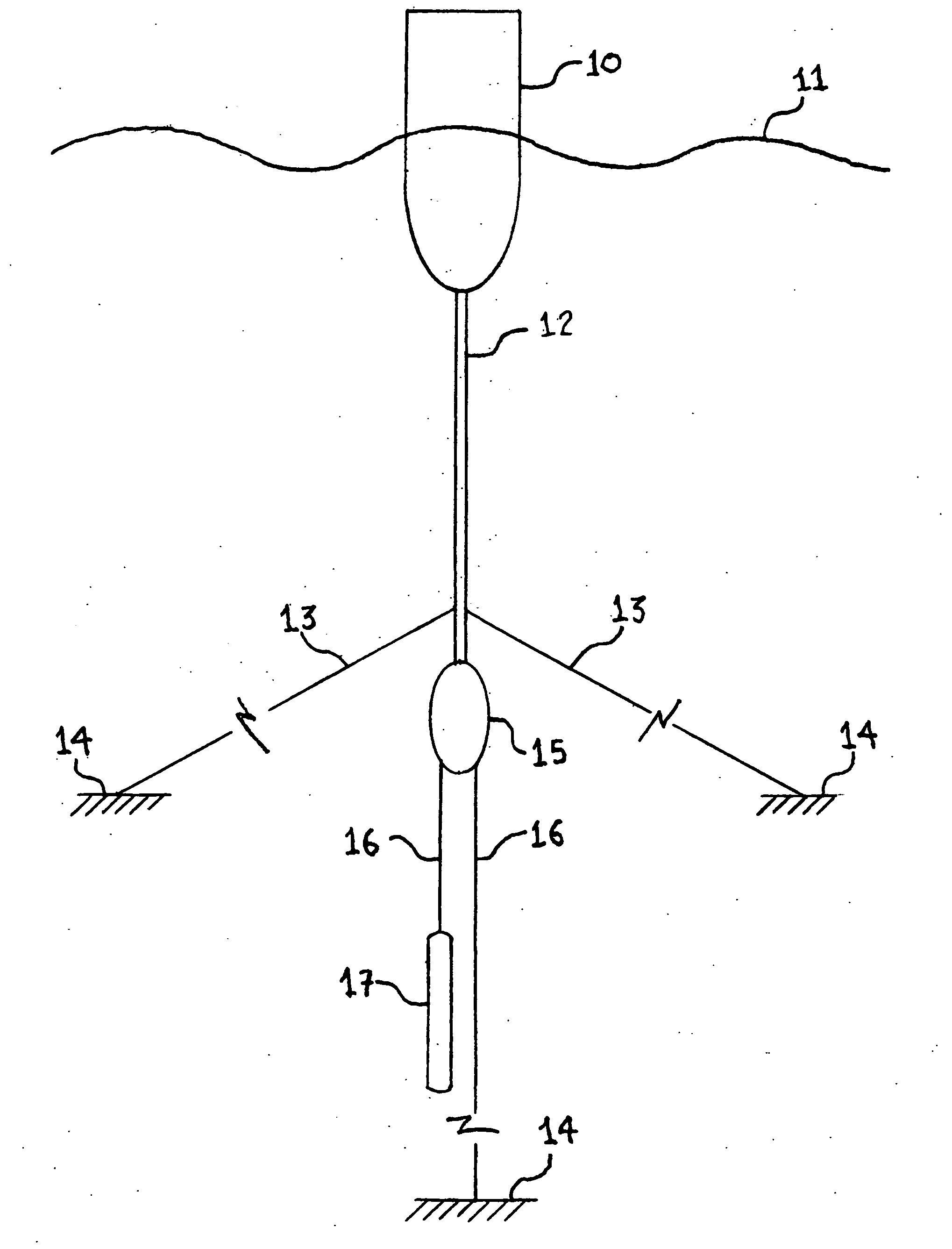

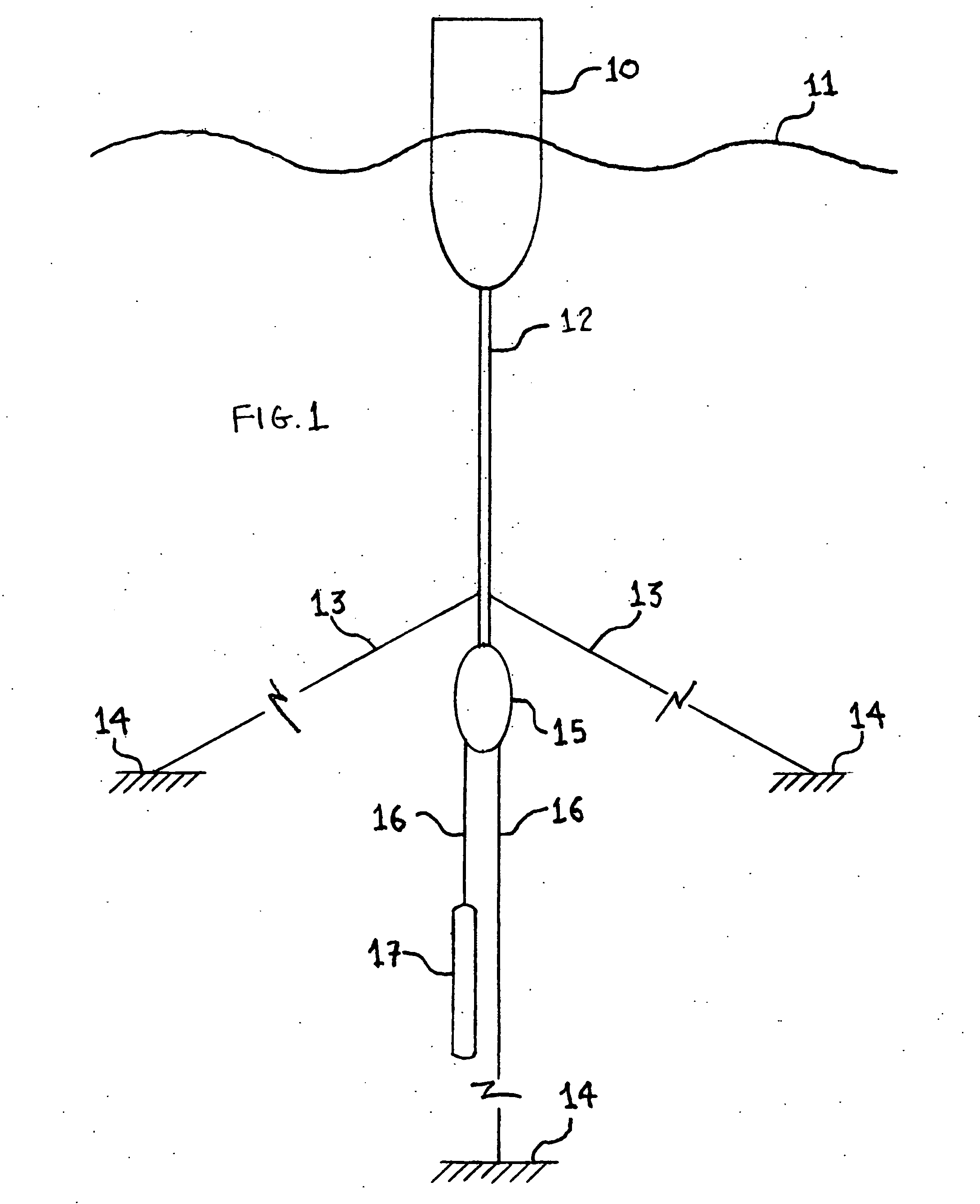

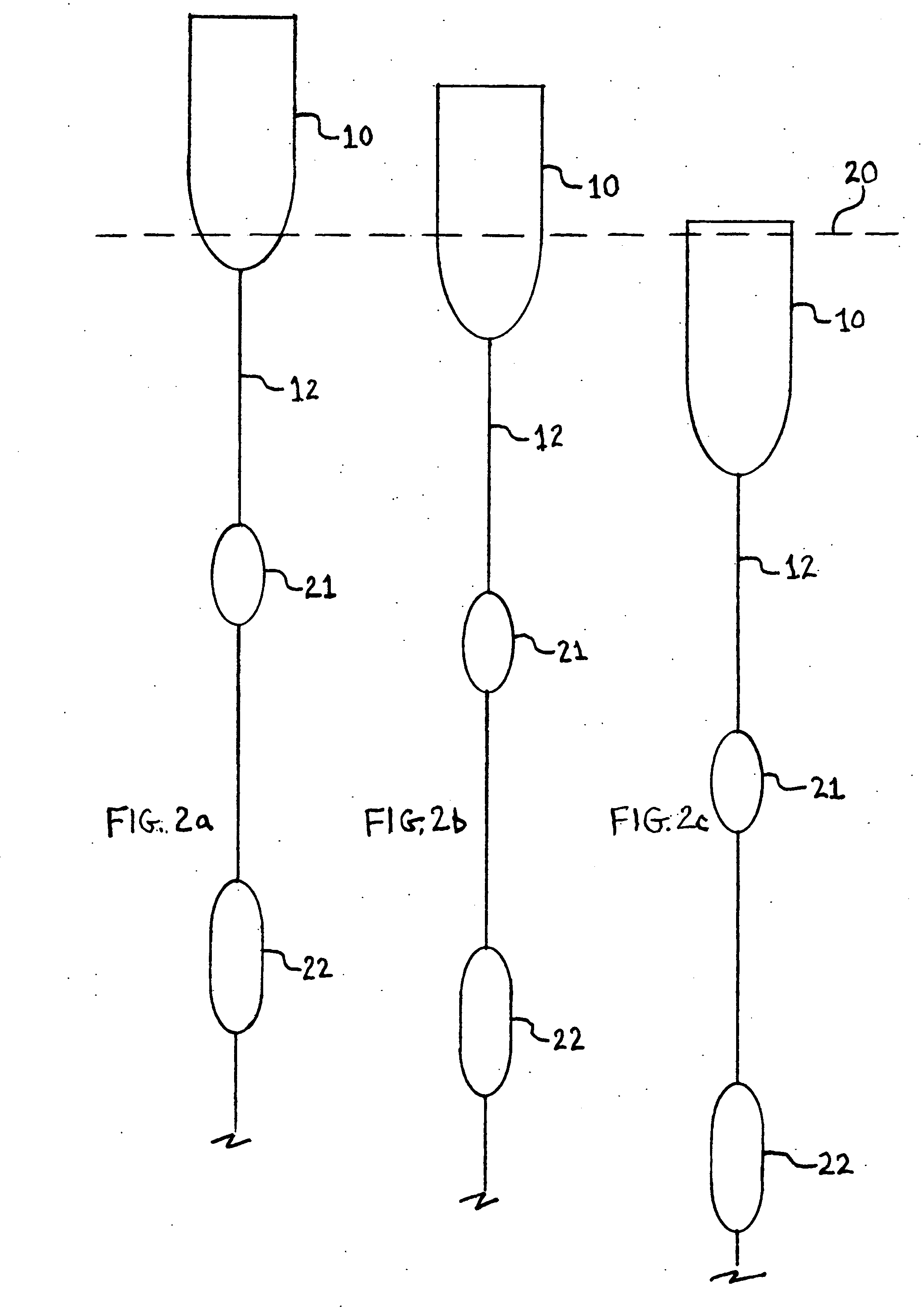

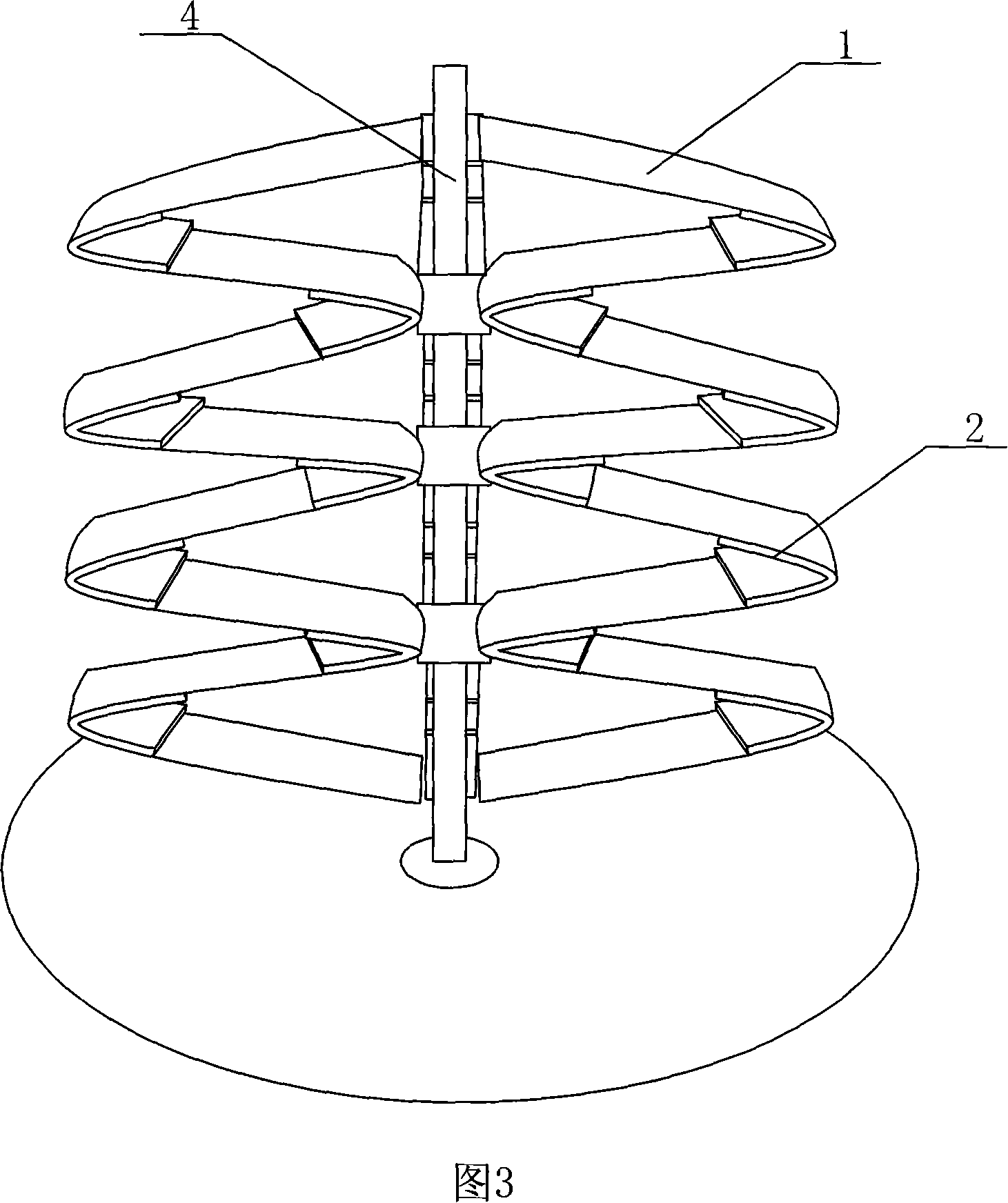

Dynamic Tuning for Wave Energy Conversion

ActiveUS20140117671A1High specific strengthIncrease stiffnessBuoyancy controlMachines/enginesRadius of gyrationEngineering

Wave energy converter efficiency is improved by dynamic tuning over periods from 5 to 15 seconds. Tuning methods are: for heaving, mass is varied by locking and unlocking neutrally buoyant masses or by trapping and releasing seawater; for surging, water-plane area is varied by force; for rotational variants of heaving and surging and for pitching, the radius of gyration is varied. Fixed mass is reduced by using materials and structures with high ratios of strength to weight. Fixed added mass is reduced by streamlining, by constant radius body profiles and by keeping moving structures out of the water. Added mass is varied continuously by using variable angle fins: effectiveness is enhanced by enclosure. In pitching, wave-bridging is addressed by limiting length, using locking and unlocking segments of the floating body or by using gravity as the restoring force. Solutions are described for heaving, surging, pitching and wave-following.

Owner:GREGORY BRUCE

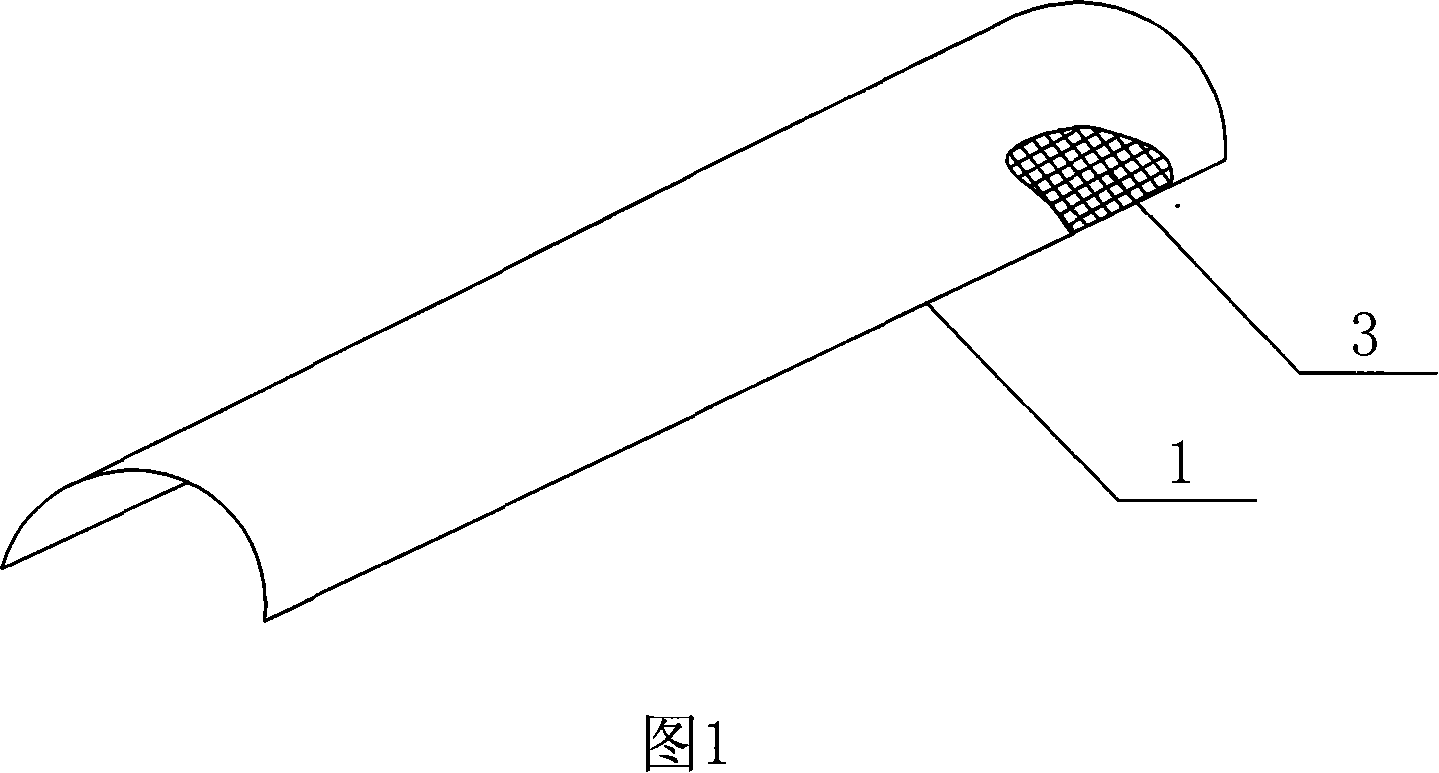

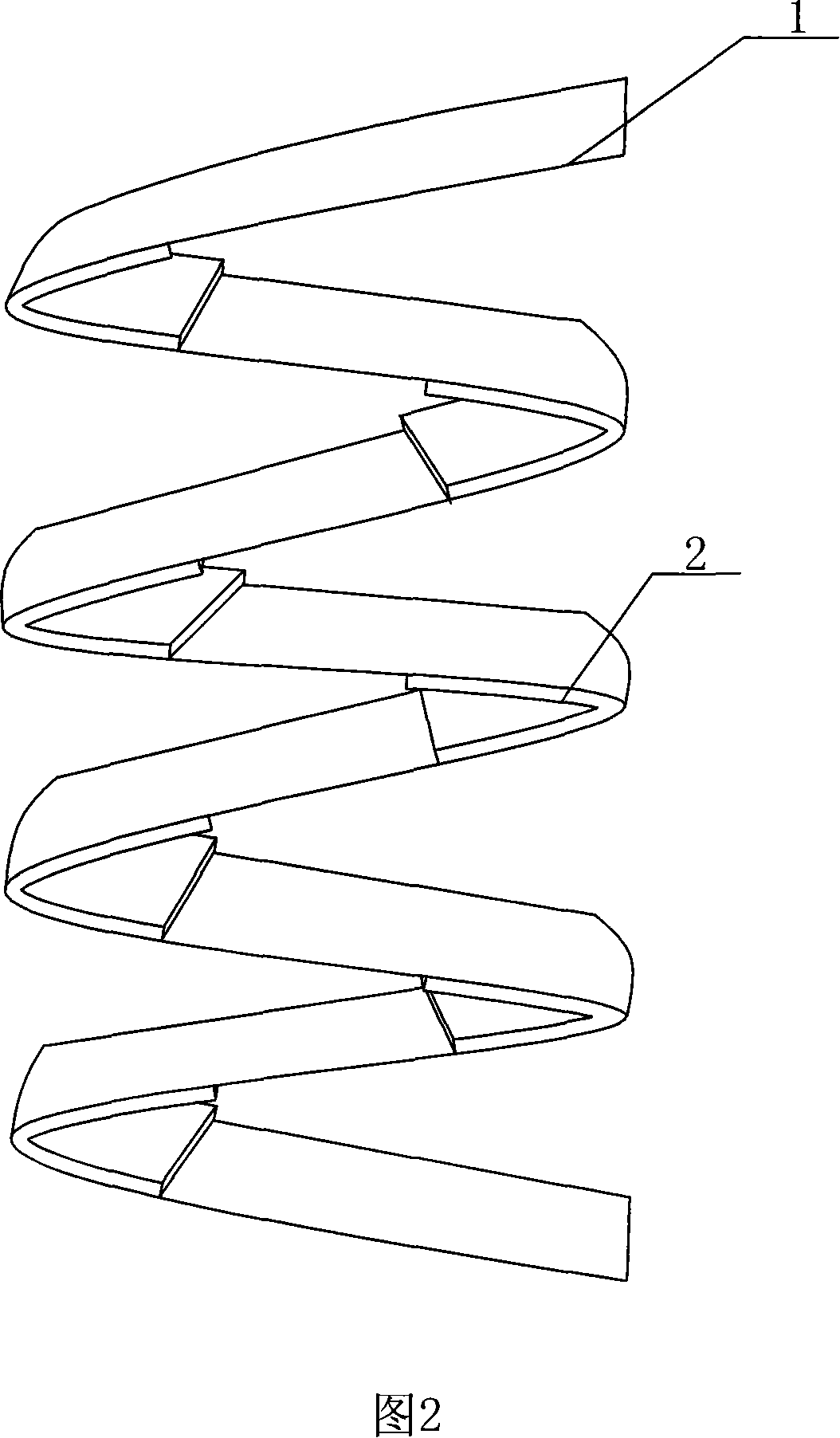

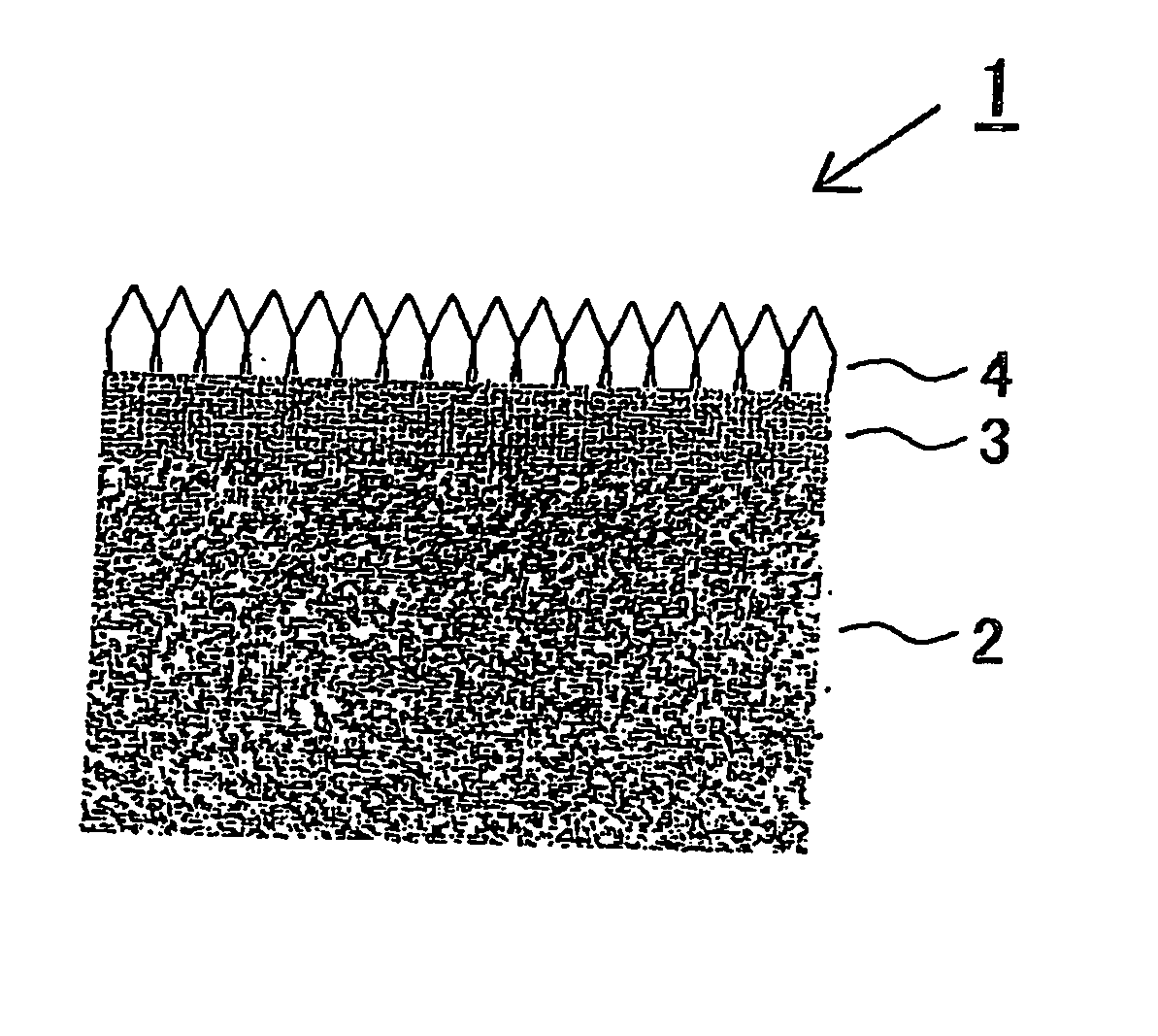

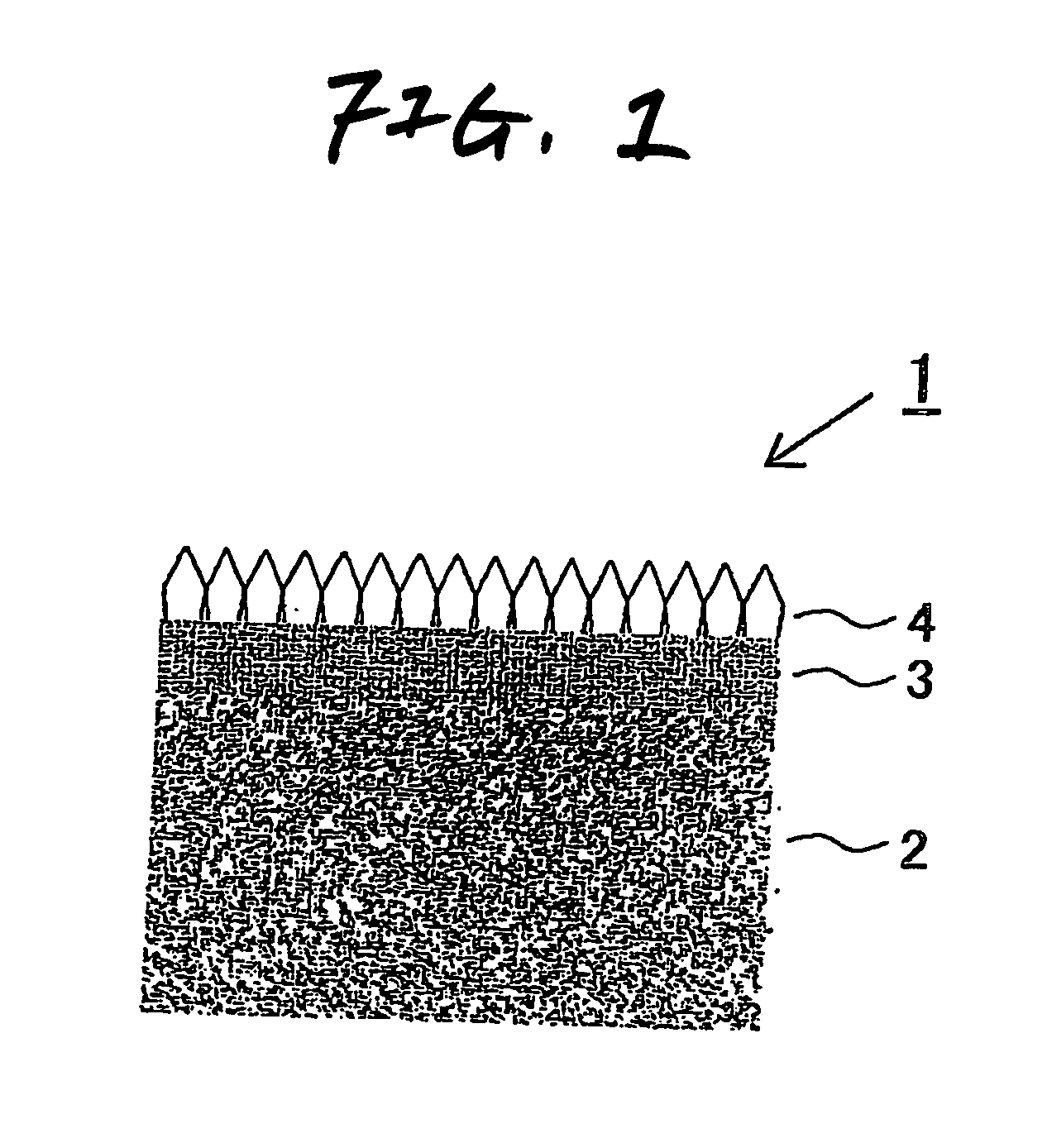

Shape memory polymer composite body with spatially-expanded three-wing beam and its preparation method

InactiveCN101055344AHigh specific strengthHigh specific modulusLamination ancillary operationsSynthetic resin layered productsElectrical resistance and conductancePolymer science

A space expanded three-wing-beam shaped remember polymer compound and the preparation thereof relates to a space expanded three-wing-beam shaped remember polymer and the preparation thereof, and to solve the problems of large material weight, complicated expanded mechanical performance, unsteady controlling of the expanding-telescoping procedure, and complicated fabrication technology in the existing space expanded beam structure design procedure. The compound material layer of the shaped remember polymer compound is shaped as superposition and the electric resistance silk screen is located therein. The inner of the compound material layer bending part of the shaped remember polymer compound is connected with a yalloy material layer, the preparation of which comprises the steps of: sorting, confect material, curing. The invention has the advantages of: high specific strength, small material weight, strong controlling ability for beam expanding, simple mechanical performance of the space beam expanding. Moreover, the invention has the characteristic of shaped remember and simple technological operation of the preparation.

Owner:HARBIN INST OF TECH

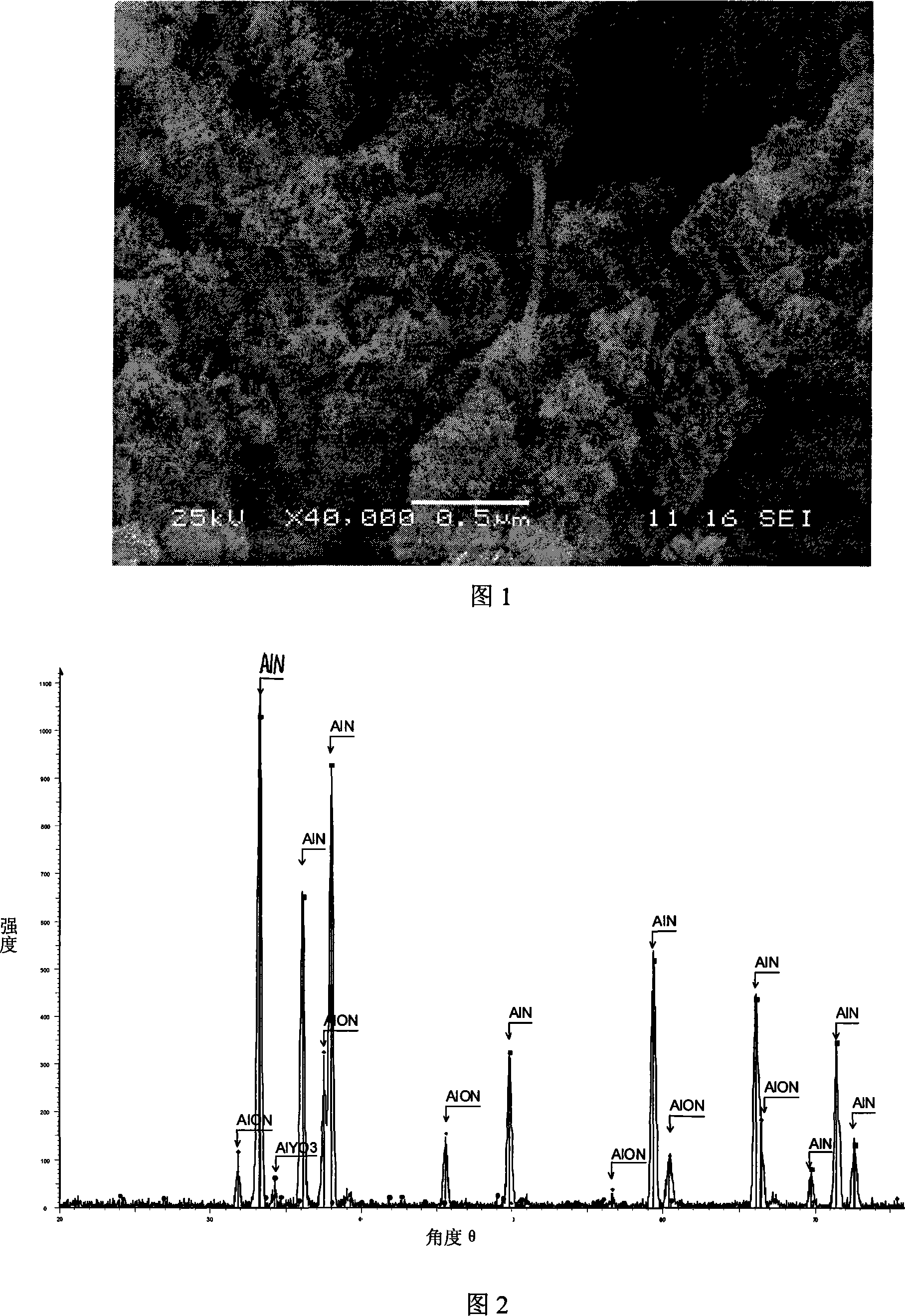

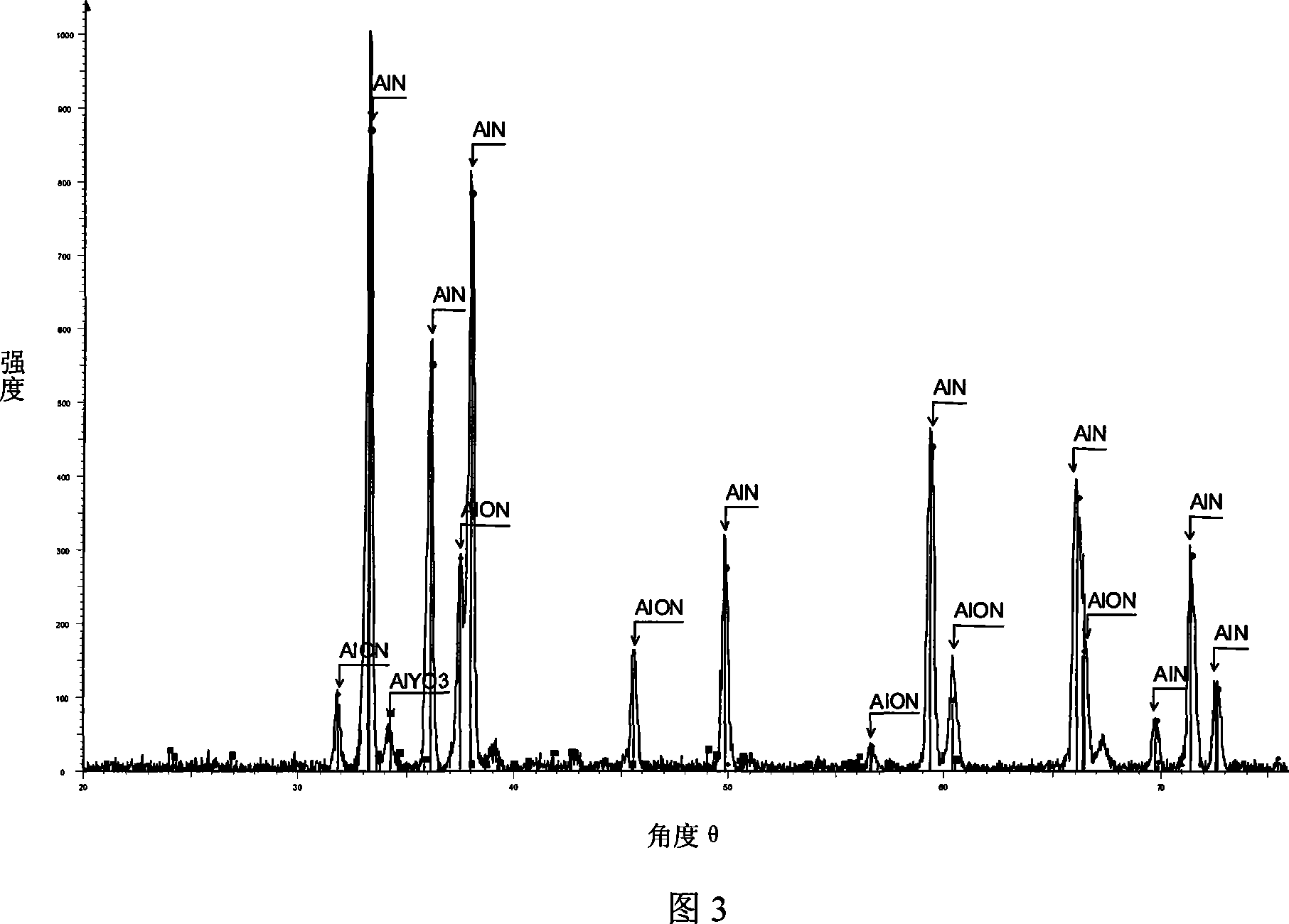

Carbon nano-tube enhanced aluminum nitride composite material and preparation method thereof

This invention relates to carbon nanometer tubes reinforced aluminium nitride composite material, and its preparation method. The preparation procedures are: the carbon nanometer tubes (1-3wt%) being chemically purified, ultrasonic dispersed, being mixed with aluminium nitride (89-95wt%) and agglutinants: yttrium oxide (2-4wt%) and calcium fluoride (2-4wt%); proceeding ball-milling dispersing to produce mixture slurry, drying, milling, sieving and finally pressure sintered to obtain this inventive product with excellent mechanical properties. This invention is of low temperature compacting agglutination with simple process and low cost.

Owner:NAT UNIV OF DEFENSE TECH

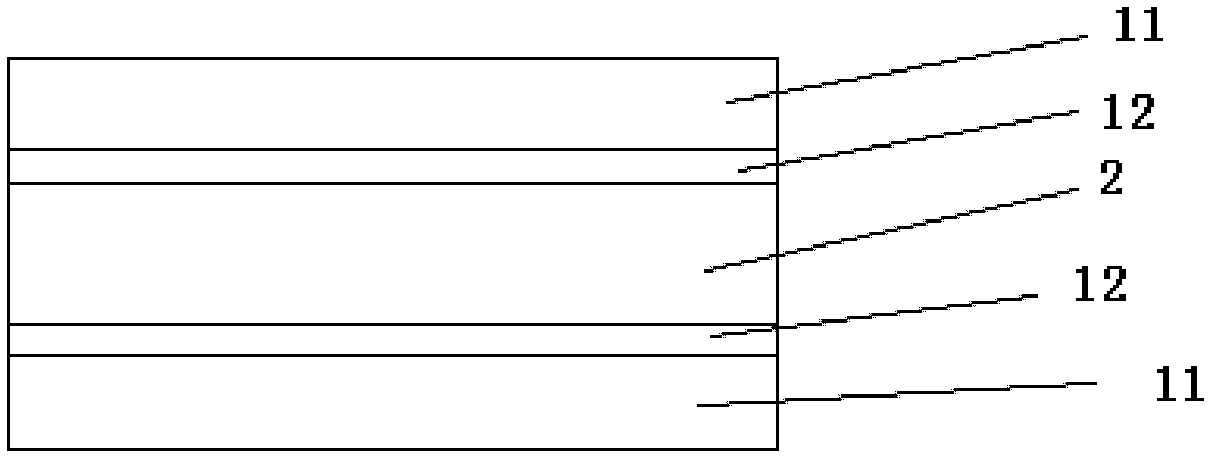

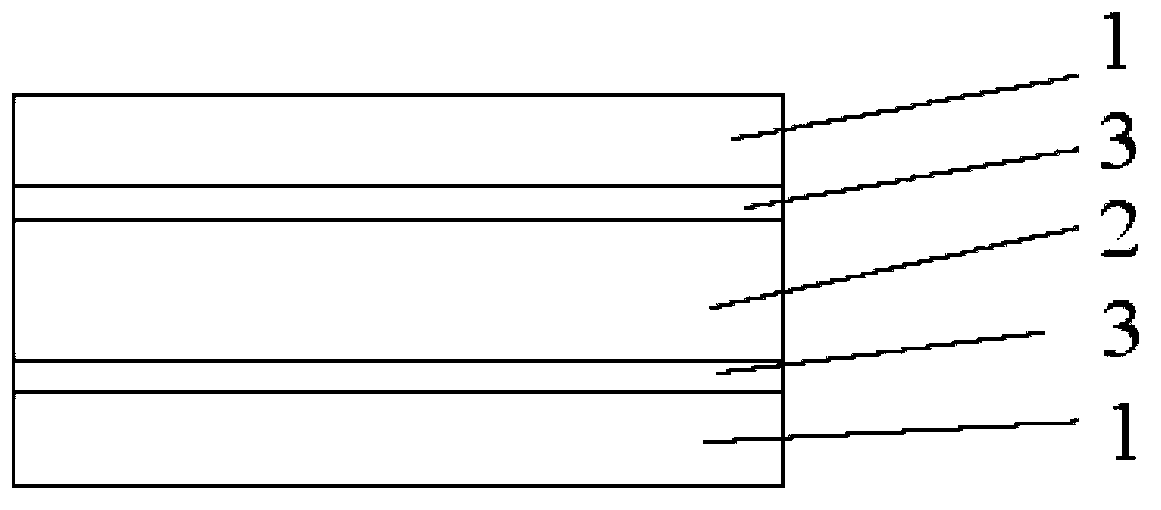

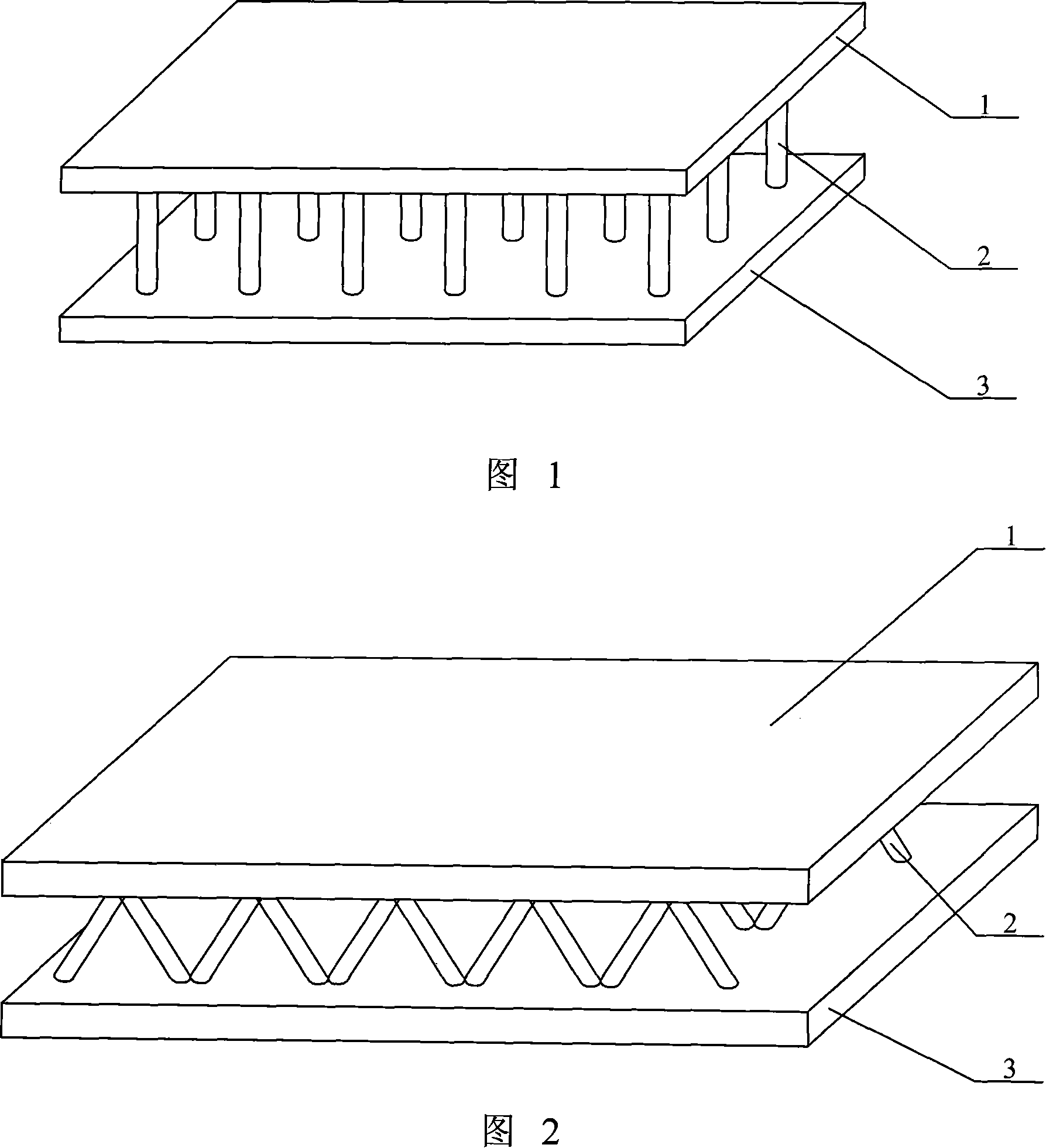

Fibre-reinforced composite lattice sandwich plate and its preparing process

The invention is a lattice sandwich plate made of reinforced composite fiber material and a manufacture method of the sandwich plate, and relates to a lattice sandwich plate and a manufacture method of the sandwich plate. The invention settles the problem that a prior lattice sandwich plate is difficult to be molded and materials used are limited to metal materials. A lattice of the invention is arranged between an upper fiber composite panel (1) and a lower fiber composite panel (3), and consists of a plurality of fiber composite columns (2). The upper ends of the fiber composite columns (2) are connected with the upper fiber composite panel (1) in a fixing way, while the lower ends of the fiber composite columns (2) is connected with the lower fiber composite panel (3) in a fixing way. The manufacture method is as follows: 1. a cleaning mould is designed and a demoulding agent is applied on the mould; 2. a pre-immersed material is cut into the designed size and filed into a pole, which is put into a mould hole; 3. the upper panel and the lower panel are laid; (4) solidification by heating and pressurizing is done, and the reinforced composite fiber material lattice sandwich plate is made. Compared with a traditional metal lattice sandwich plate, the reinforced composite fiber material lattice sandwich plate of the invention is provided with the higher intensity and rigidity, and can be designed easily.

Owner:HARBIN INST OF TECH

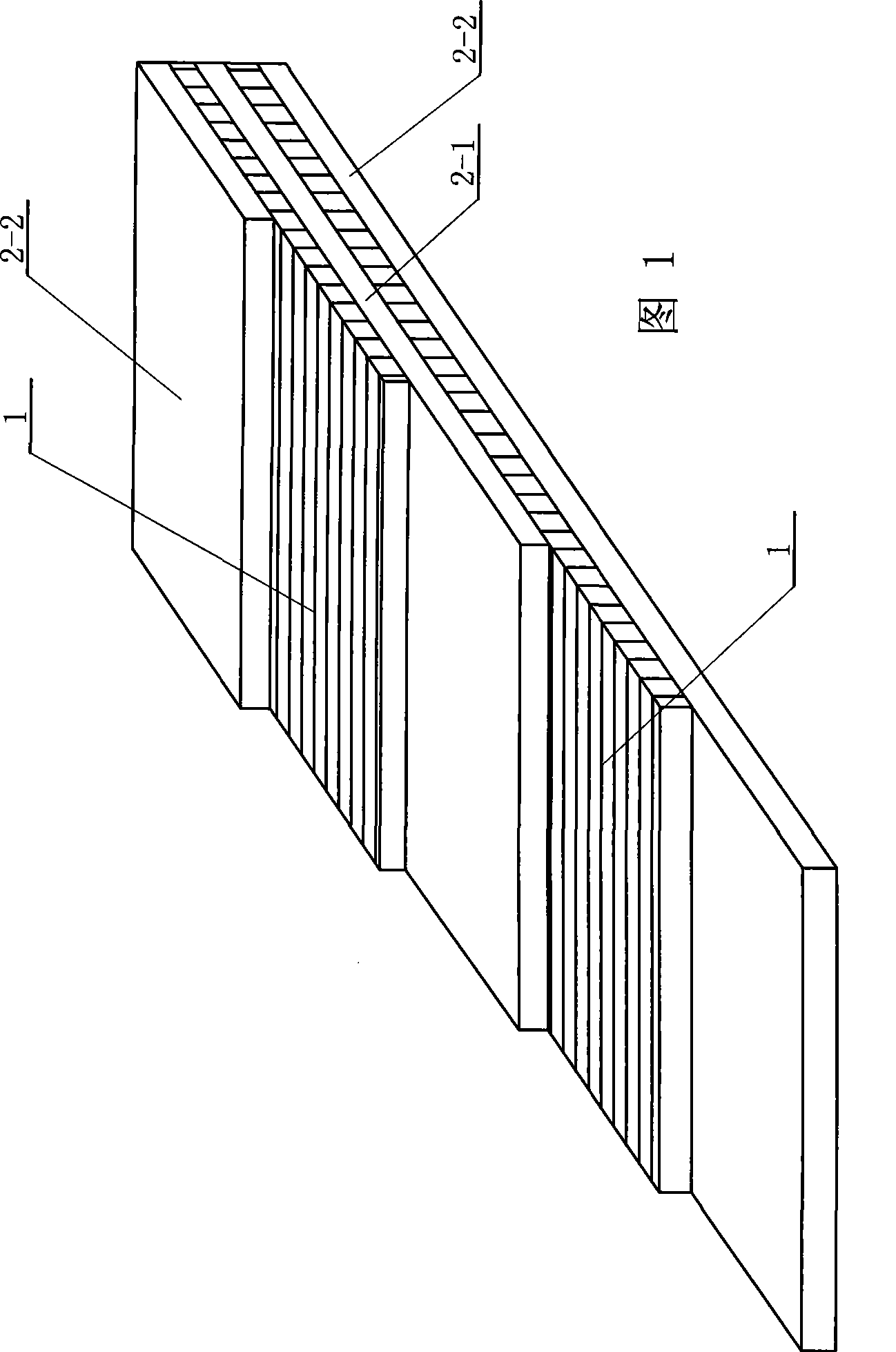

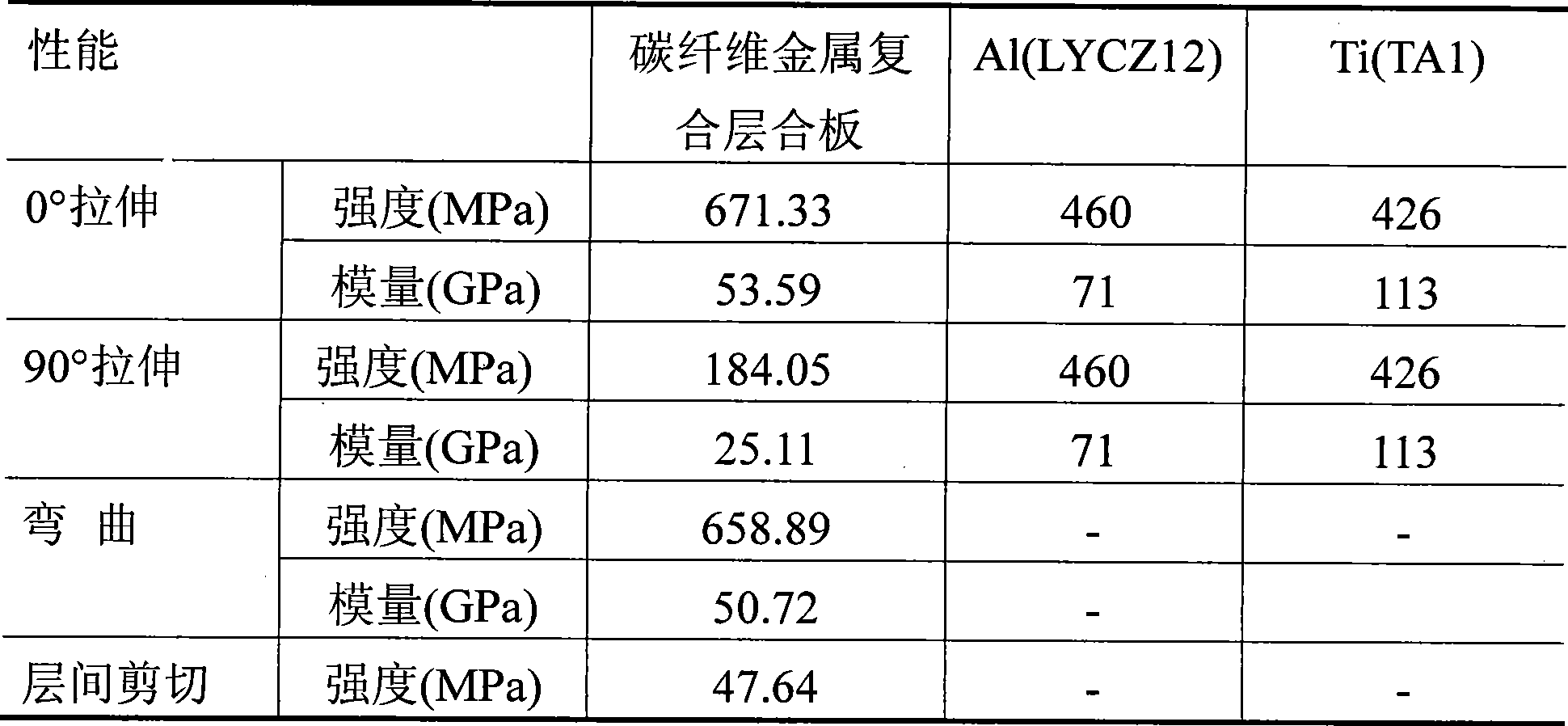

Manufacture method of carbon fiber metal composite laminated plate

InactiveCN101417524AFlame retardantImpact resistantLamination ancillary operationsLaminationFiberEpoxy

A manufacturing method of a carbon fiber metal composite laminated plate relates to a manufacturing method of a fiber metal composite laminated plate. The method aims at solving the problems that no manufacturing methods for manufacturing aircraft structural material with high specific stiffness, high specific strength, tenacity and workability exist in China. The method comprises the following steps of: carrying out surface treatment to three pieces of metal plates; winding a carbon fiber composite material layer which is soaked in liquid cement on one of the metal plates, wherein, the liquid cement is prepared by epoxy resin, a metaphenylene diamine curing agent and an anhydrous alcohol solvent according to the mass ratio of 1:0.1 to 0.18:0.15 to 0.2; fixedly arranging another two metal plates on the upper surface and the lower surface of the carbon fiber composite material layer so as to be integrally put into a mould, and then treated with mould assembling, drying, solidification by adopting the method of gradient temperature increasing, and demoulding. The manufacturing method of the invention is simple and is easy for operation. The carbon fiber metal composite laminated plate manufactured by the method of the invention has the advantages of high specific stiffness, high specific strength, also high tenacity and workability of metal material, good fatigue property, and good damage tolerance capability.

Owner:HARBIN INST OF TECH

Thermosetting plastic

The invention discloses a thermosetting plastic. The thermosetting plastic is characterized by comprising the following components in parts by weight: 60-95 parts of thermosetting resin, 5-40 parts of low-shrink additive, 150-300 parts of an inorganic mineral filler, 2-4 parts of an initiator, 0.6-1 part of calcium hydroxide micro powder, 2-6 parts of zinc stearate micro powder and 30-60 parts of glass fiber. In comparison with a conventional thermosetting plastic, the thermosetting plastic can be solidified more rapidly, high strength can be maintained within a wide temperature range, and the flame-retardant effect is good.

Owner:宁波华缘复合新材料有限公司

Conductive diamond electrode and process for producing the same

ActiveUS20070031694A1Improvement in substrate stabilityExcellent in economical efficiencyMachining electrodesWater/sewage treatmentDiamond electrodesNiobium

The present invention provides a conductive diamond electrode having: a conductive substrate; a coating layer formed on a surface of the conductive substrate, the coating layer containing one of a metal and an alloy each including at least one of niobium and tantalum; and a conductive diamond layer formed on a surface of the coating layer, and a process for producing the conductive diamond electrode.

Owner:DE NORA PERMELEC LTD

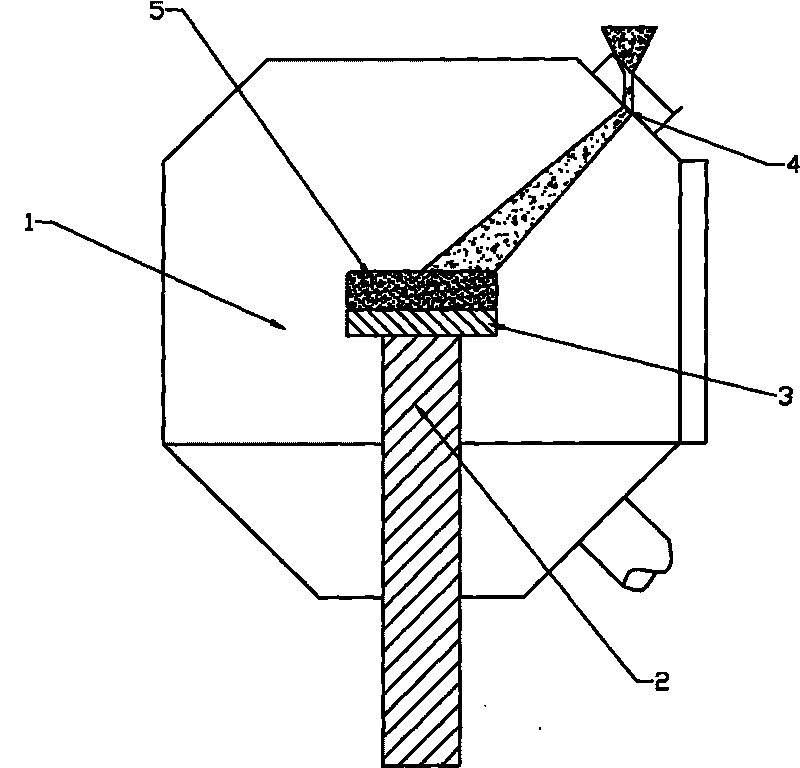

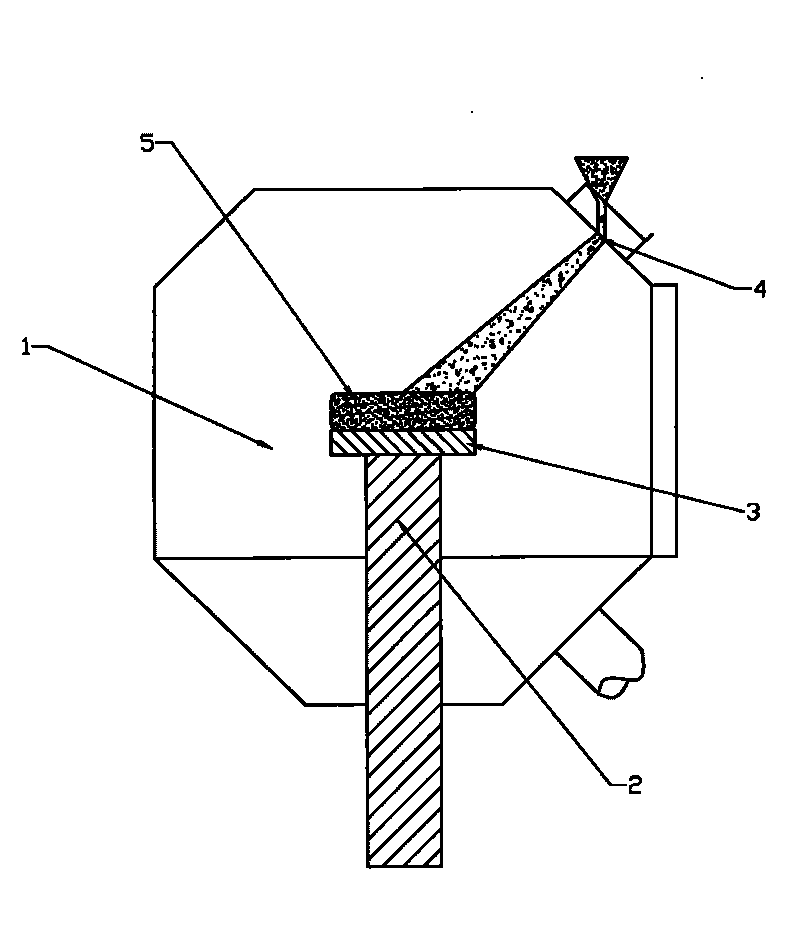

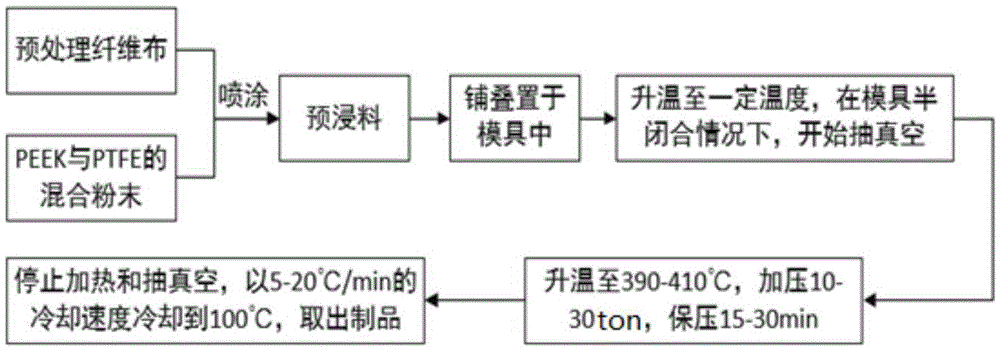

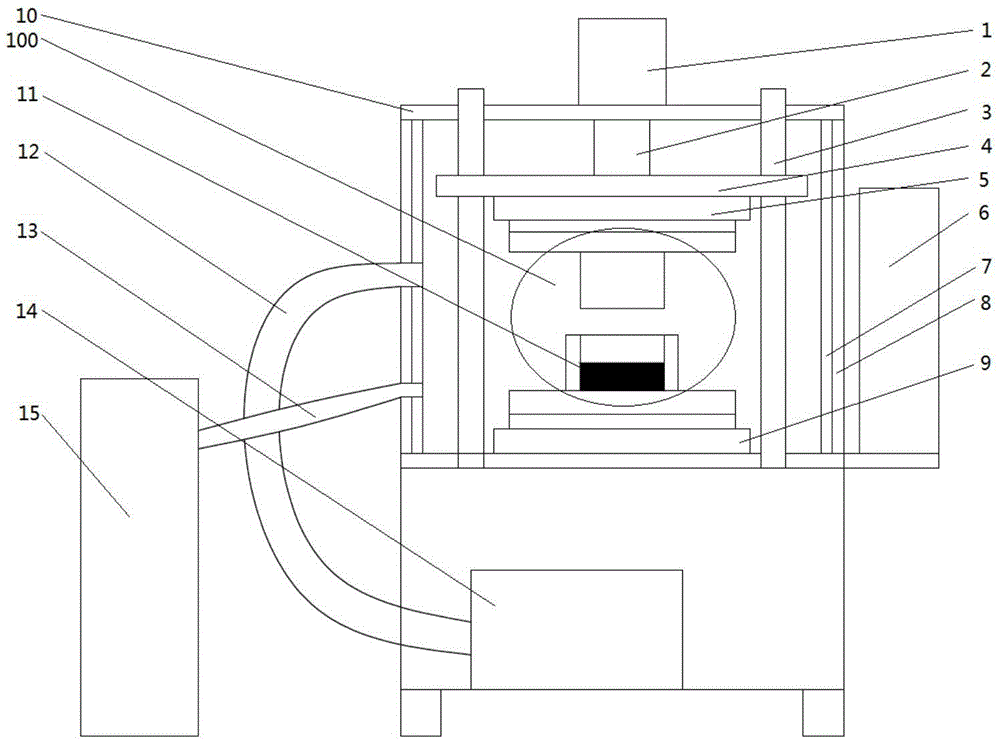

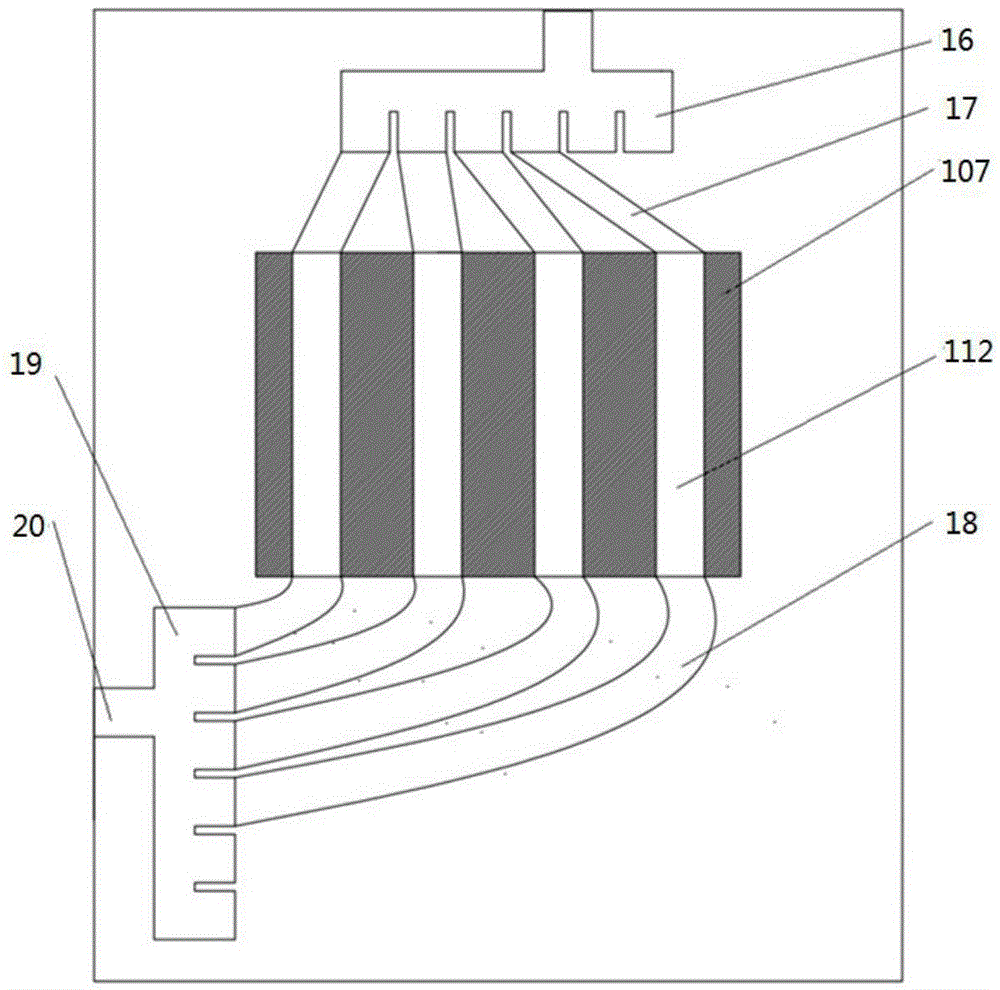

Hot press molding device for carbon fiber enhanced polyether-ether-ketone (PEEK) composite material and technological method thereof

The invention provides a hot press molding device for a carbon fiber enhanced polyether-ether-ketone (PEEK) composite board. The hot press molding device comprises a hydraulic machine, a molding die and a vacuum system. According to the device, a heating unit is separated from the hydraulic machine, and a heating pipe is used for heating the die to achieve a high temperature hot pressing function; by carrying out hot press molding in a vacuum environment, the content of bubbles in resin can be greatly reduced, and the test piece surface smoothness and workpiece performances are improved; a cooling unit is arranged in the die, and cooling speed is regulated by regulating the flow and temperature of high pressure cold air, so as to control the crystallinity of matrix resin and realize flexible selection between high strength and high toughness. Correspondingly, the invention also provides a hot press molding method for the carbon fiber enhanced polyether-ether-ketone (PEEK) composite board. A carbon fiber enhanced polyether-ether-ketone (PEEK) composite board produced by adopting the device and the method disclosed by the invention through hot press molding is simple in production equipment and solves the problems that material internal porosity is large, resin impregnation fiber is insufficient, test piece performance is insufficient, molding cycle is long and the like during production of polyether-ether-ketone resin with high melting point and high viscosity.

Owner:HUAZHONG UNIV OF SCI & TECH

Manufacturing method of 6063T6 aluminum alloy large-scale bar for power equipment

The invention belongs to the technical field of aluminum alloy materials for power equipment, and particularly relates to a manufacturing method of a high-strength high-conductivity aluminum alloy large-scale bar. A 6063 high-strength high-conductivity large-specification bar is used for processing a high-strength high-conductivity large electric element in power equipment, particularly a 6063T6 aluminum alloy bar with a diameter over 150-300mm. A sixth-system round aluminum alloy ingot is adopted and contains the following elements in percentage by mass: 0.40-0.44% of Si, less than or equal to 0.13% of Fe, less than or equal to 0.1% of Cu, less than or equal to 0.10% of Mn, 0.55-0.60% of Mg, less than or equal to 0.05% of Zn, less than or equal to 0.05% of Ti, less than or equal to 0.10% of Cr, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of all impurities and the balance of Al. The problems in production and delivery can be effectively solved, the strength and conductivity of the large-specification aluminum alloy bar are improved, and the processing and application are facilitated; by adopting the method, the mechanical properties and conductivity are stable; and through repeated reproduction operations, the national standard for a diameter below 150mm can be met, the national standard for bars with diameters over 150-300mm can be supplemented or completed, and all performance indexes are introduced into the national standard.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com