Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

794results about "Auxillary arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

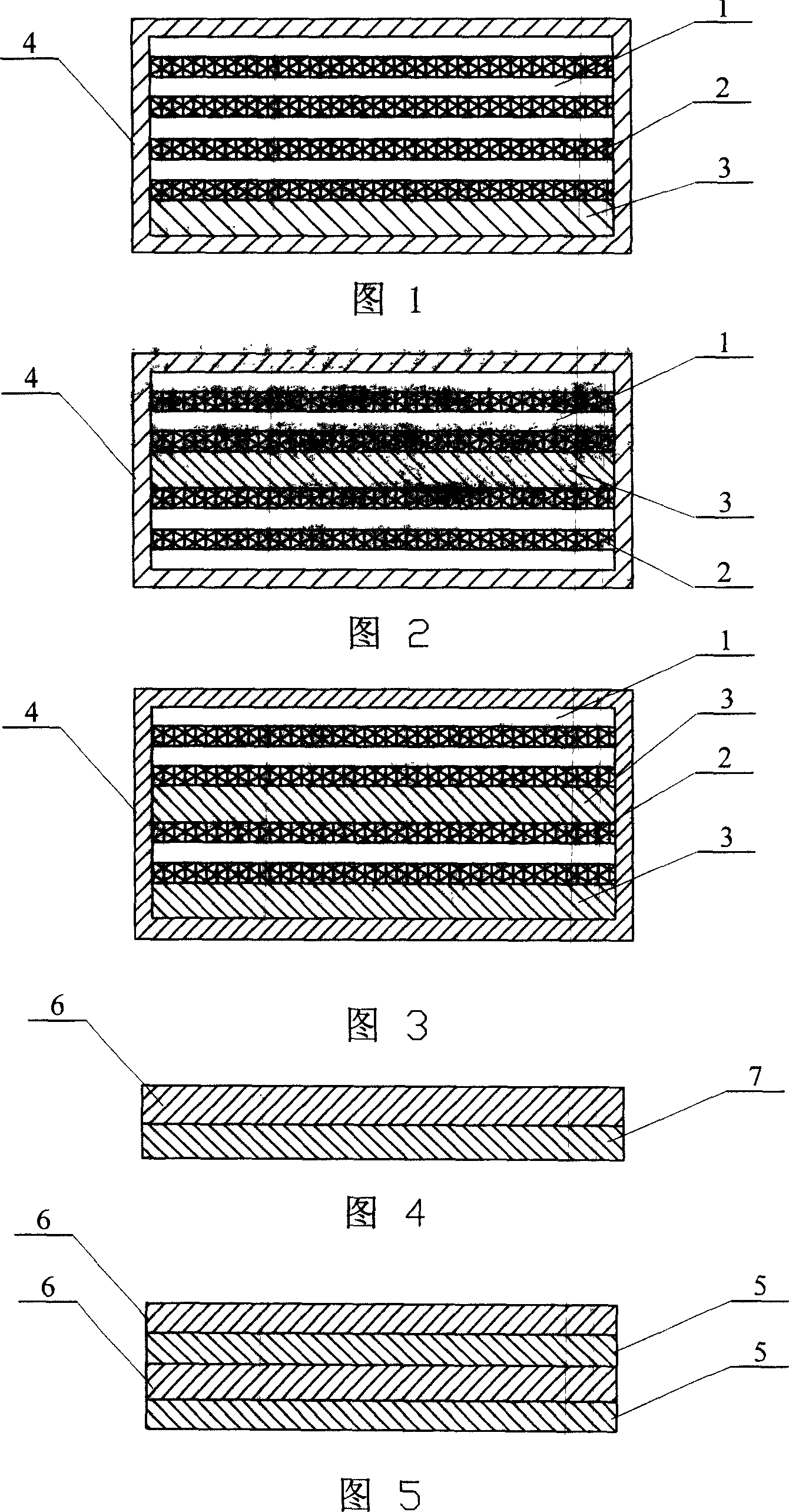

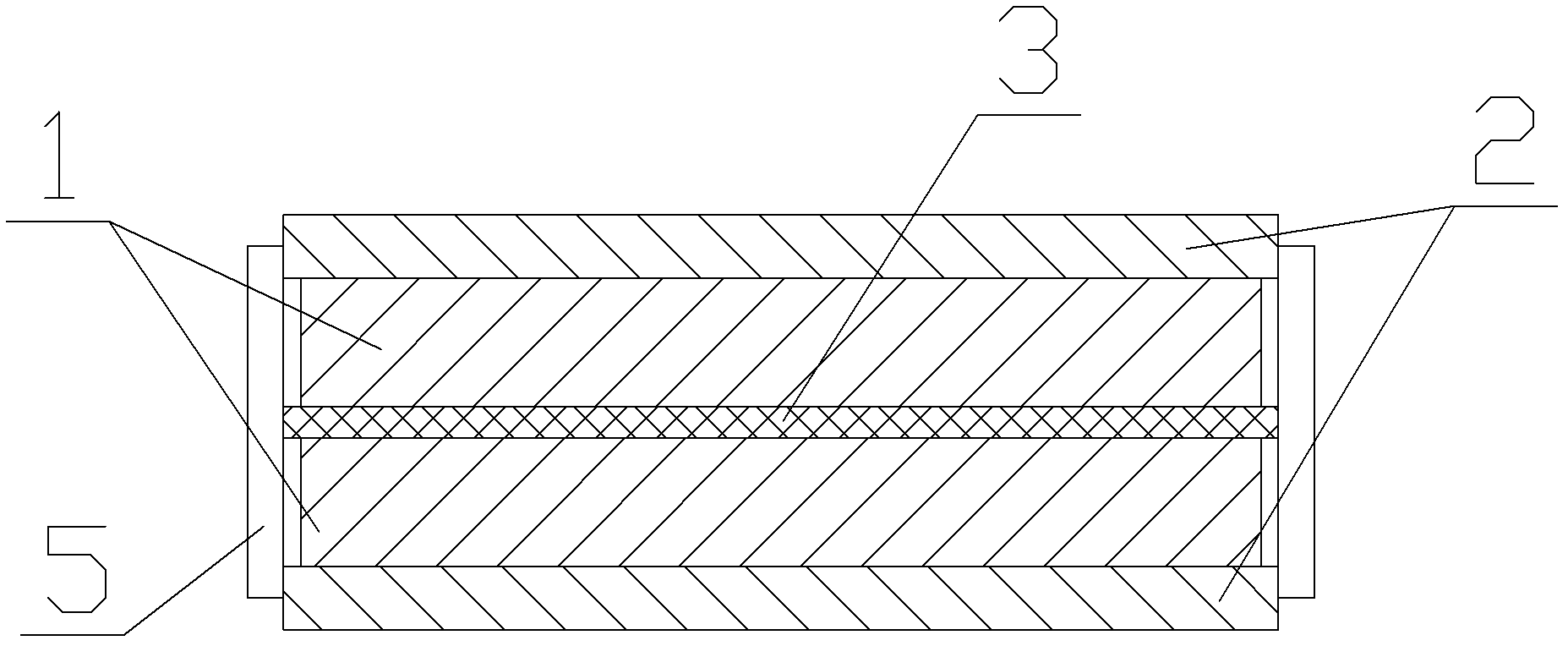

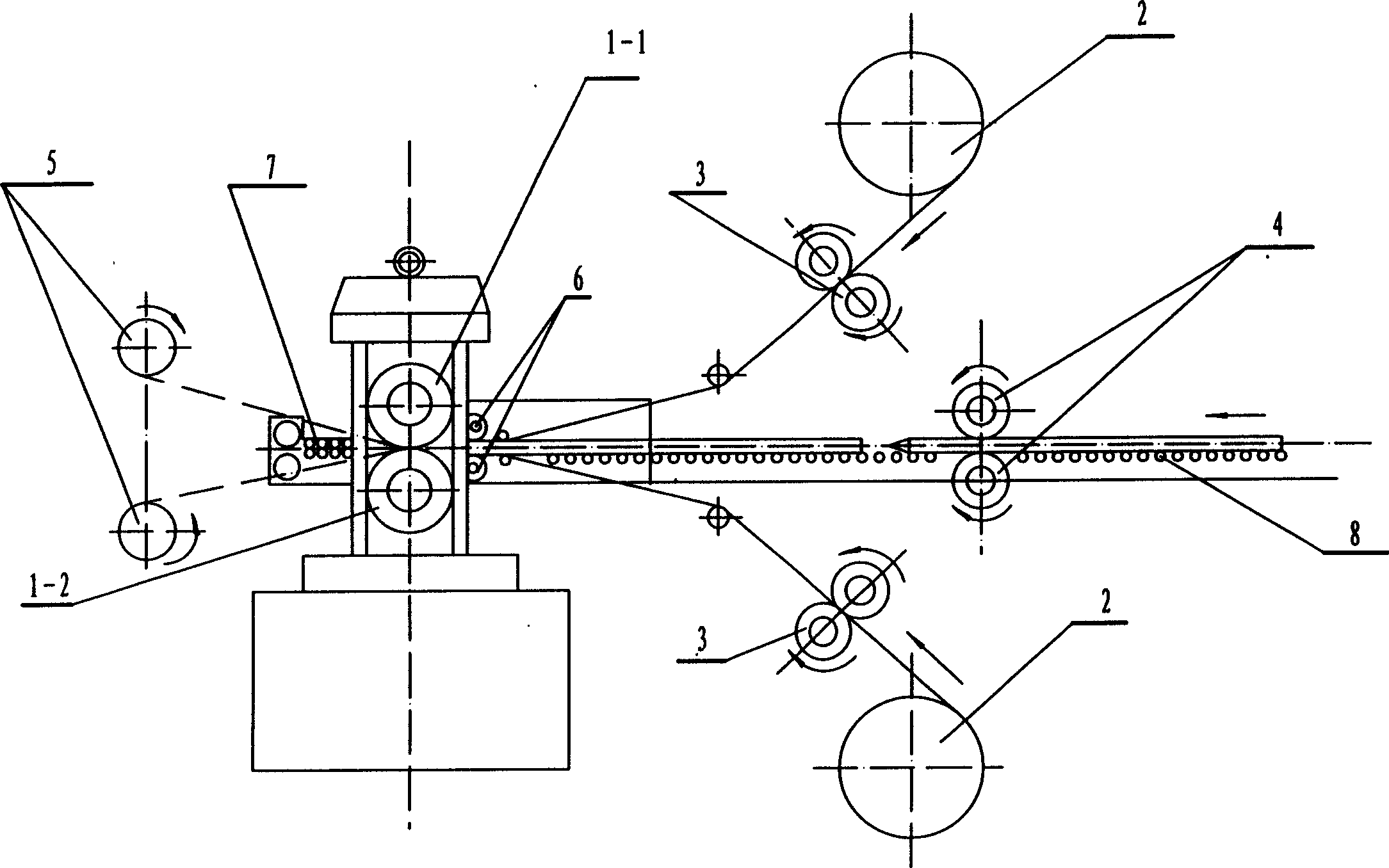

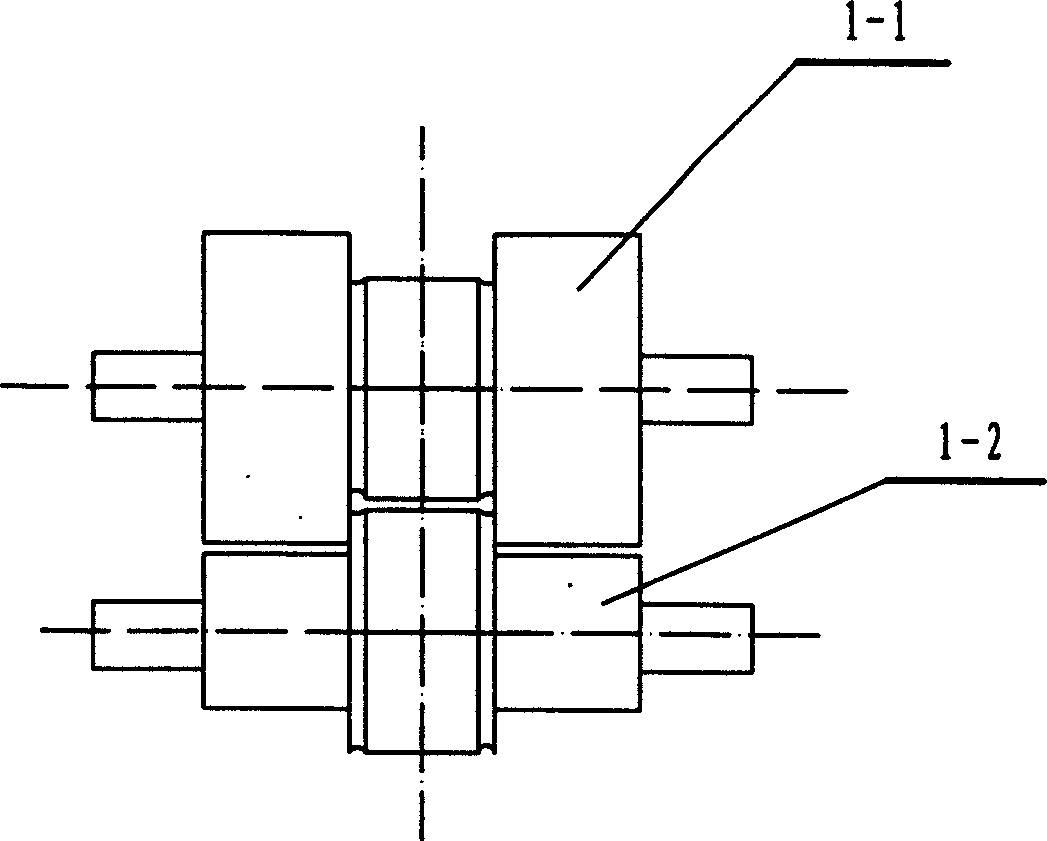

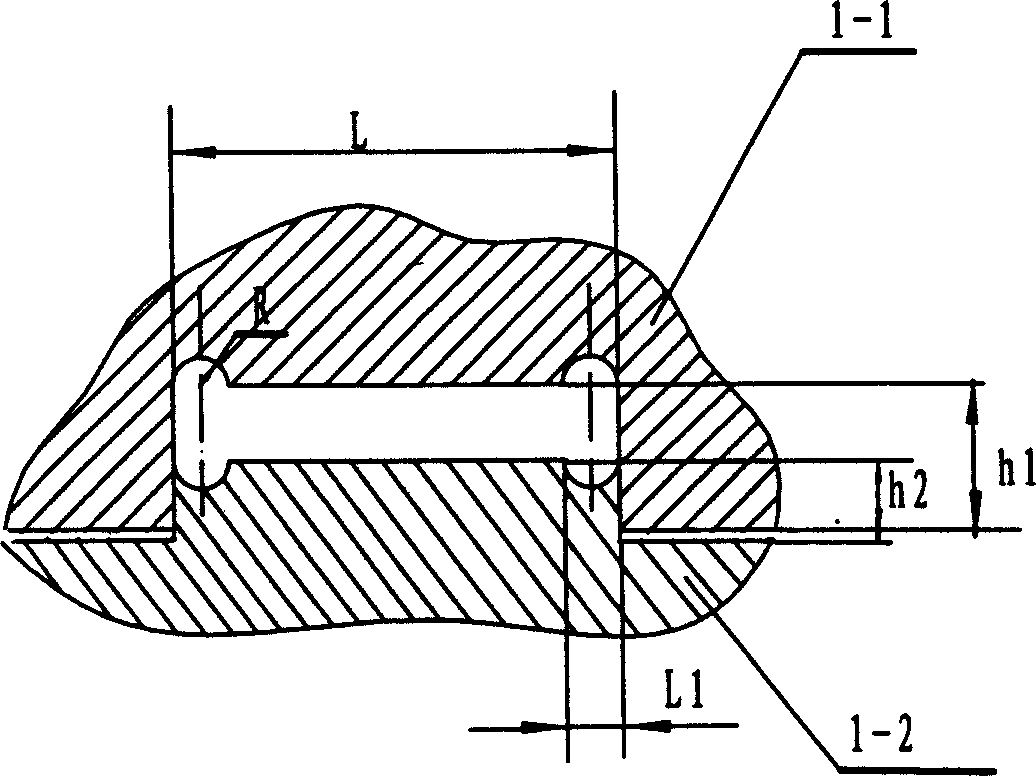

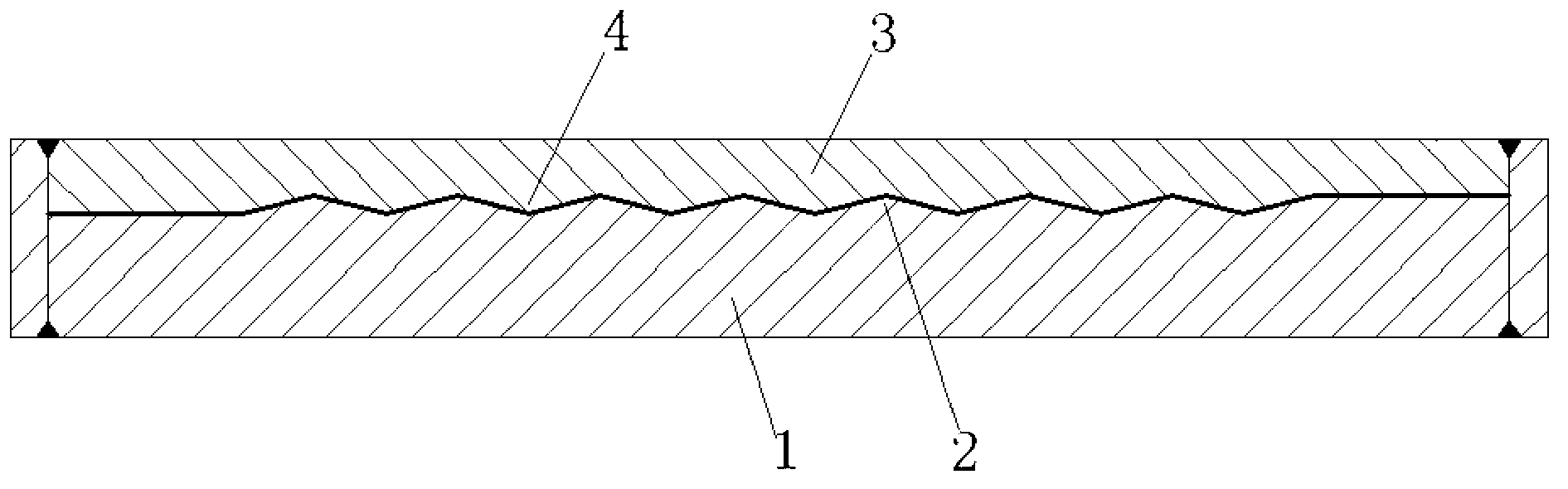

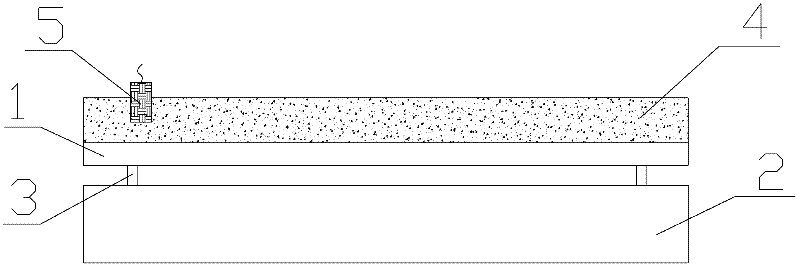

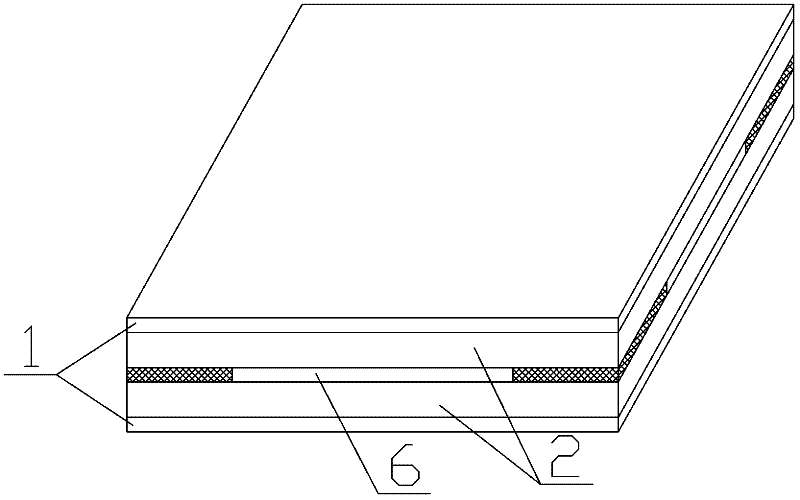

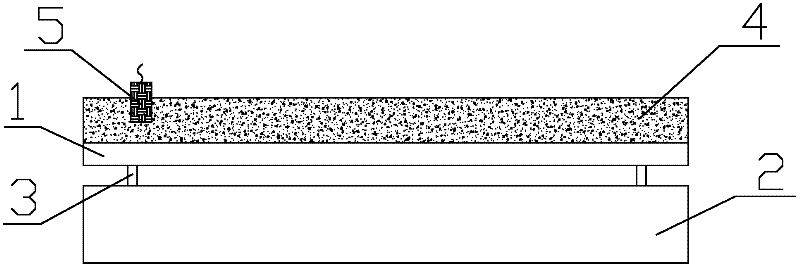

Technological process for producing super-thick plate

InactiveCN101439348AQuality improvementLow costTemperature control deviceElectron beam welding apparatusElectro-slag remeltingVacuum chamber

The invention relates to a process for producing an ultra-thick plate and belongs to the field of rolling and producing an ultra-thick steel plate in the metallurgical industry. The invention mainly overcome the defect of producing the ultra-thick steel plate by a traditional model casting manufacturing blank and an electro-slag remelting manufacturing blank. The method comprises the following steps: cutting and fixing lengths of the blanks, mechanically conditioning the blanks (eliminating, leveling and cleaning a single-surface oxide layer of a casting blank with a milling machine, a planer or a shot blast); clamping an assembly (relatively superposing the cleaning surfaces of the two blanks after processing, placing the two blanks oppositely and clamping the blanks); mounting the blanks in a vacuum chamber of an electronic beam welding machine for purpose of vacuuming; sewing the assembly on the electronic beam welding seal edge, heating the assembly in a furnace and rolling the assembly through temperature control; and then producing the ultra-thick steel plate. Compared with the traditional electro-slag remelting production process, the process has the advantages of high production efficiency, reduced electric power consumption, less investment of production devices and low production cost. Compared with the traditional die casting production process, the process solves the problem of segregation and looseness of a large-scale die casting ingot center part; the finished product ratio is high; and the finished product ratio of blank assembly is over 90 %.

Owner:SHANDONG IRON & STEEL CO LTD

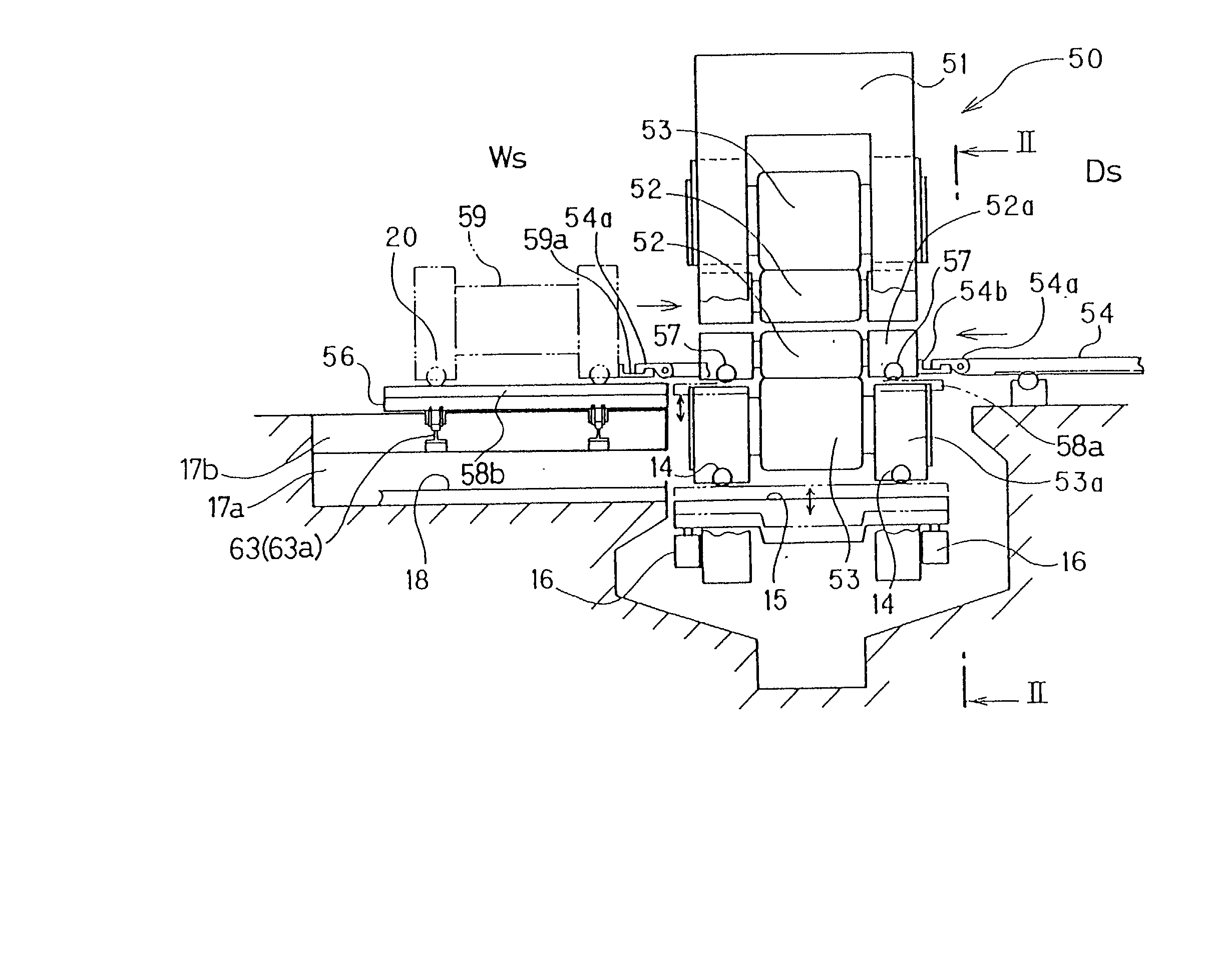

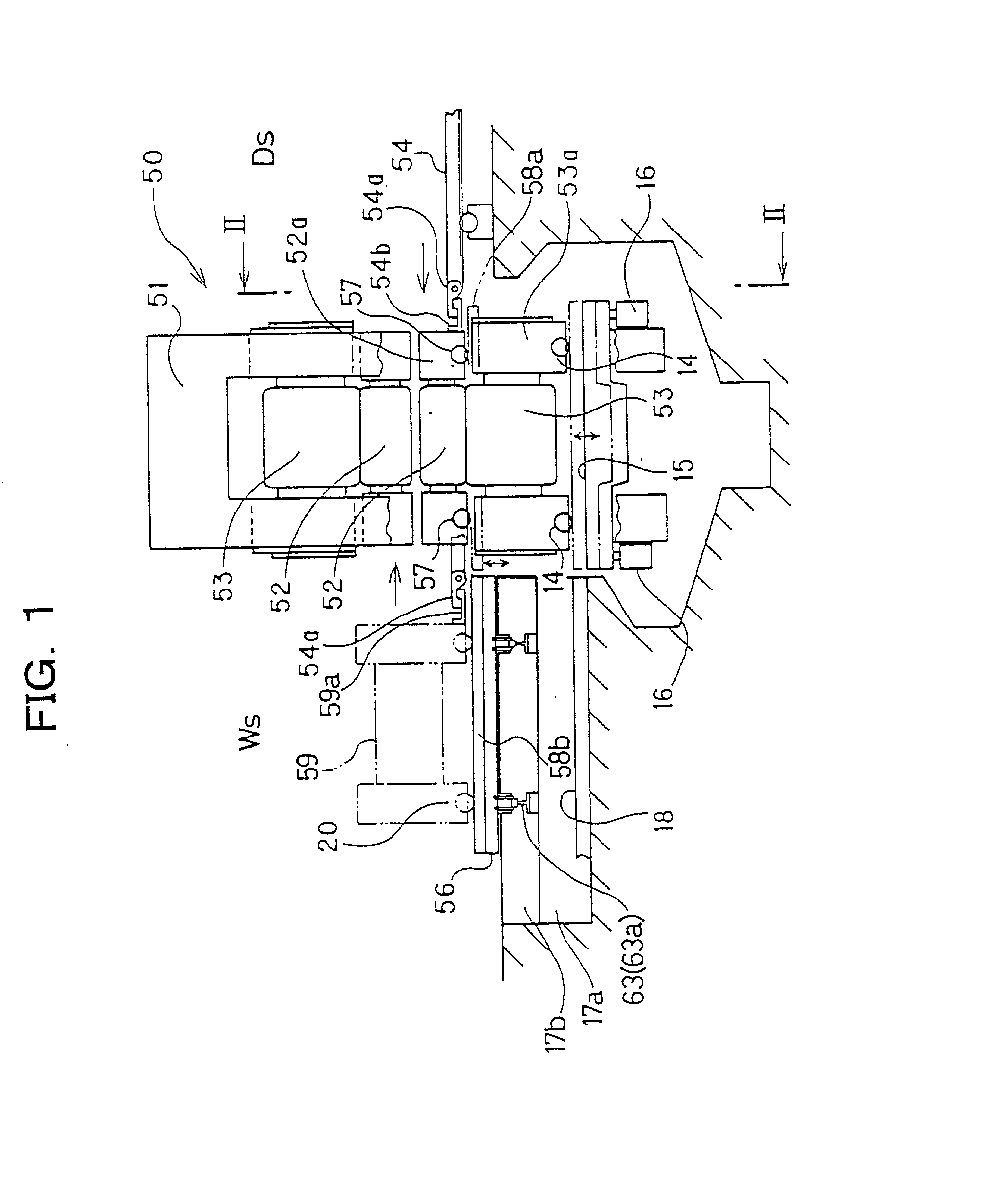

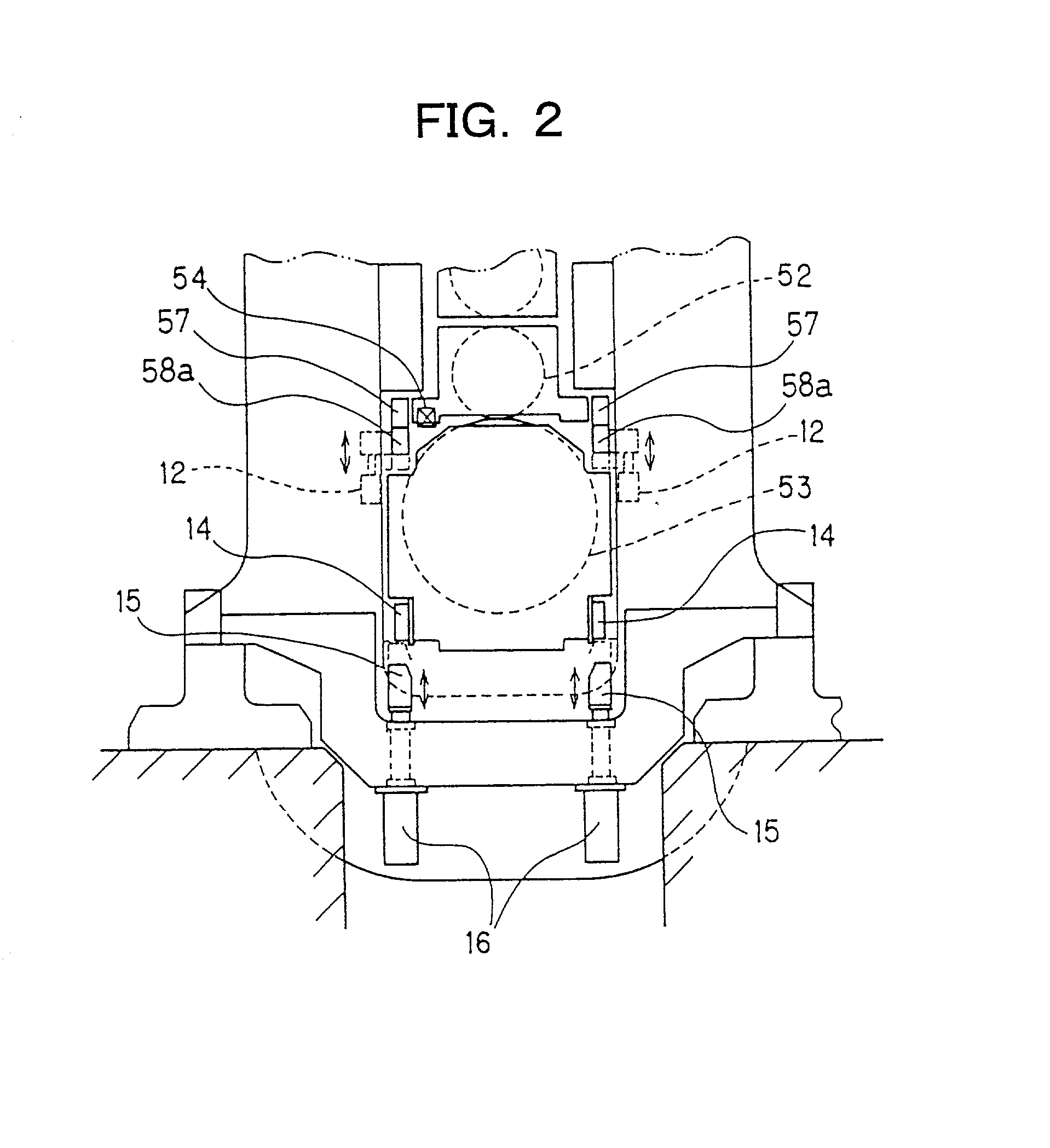

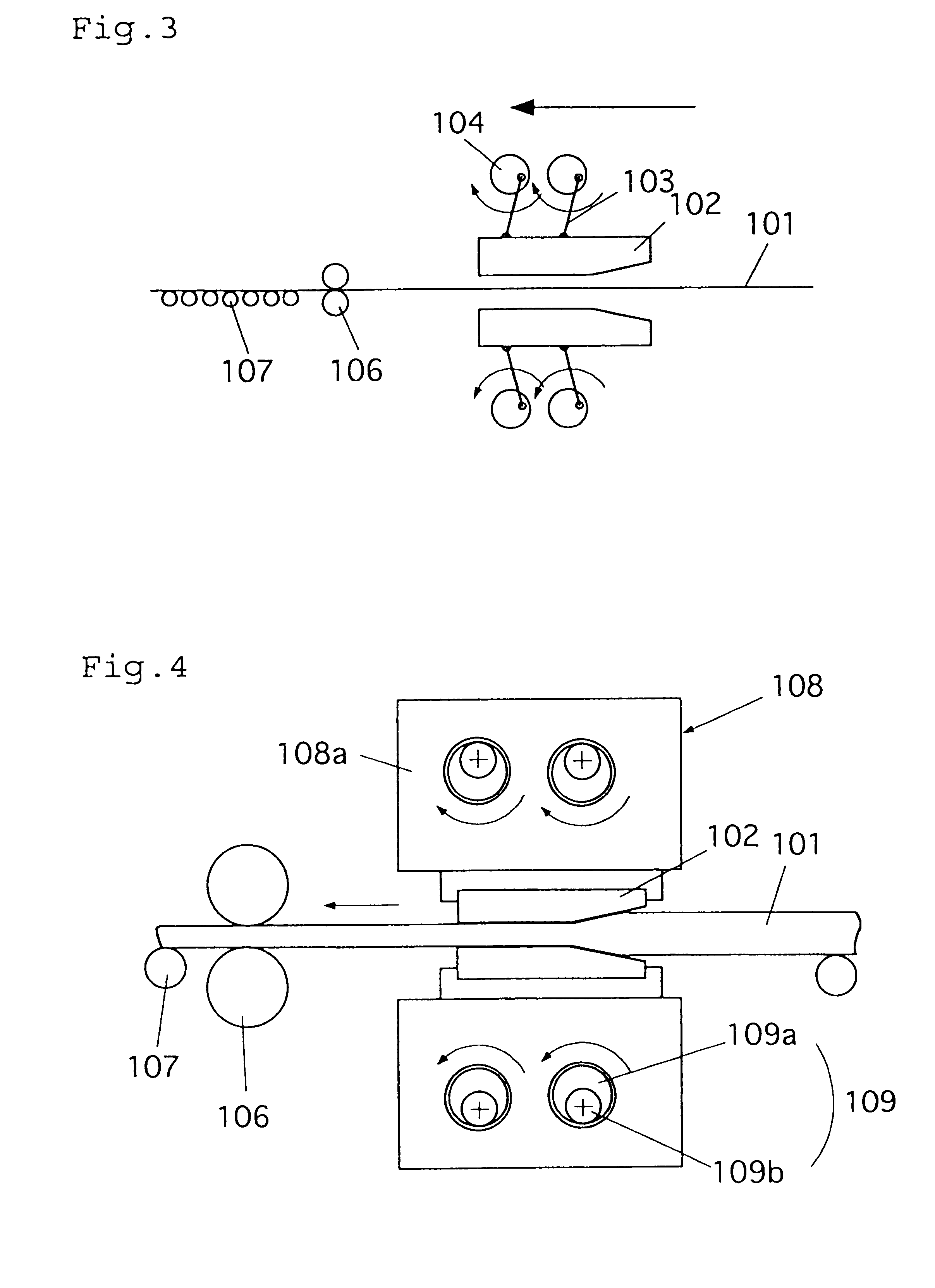

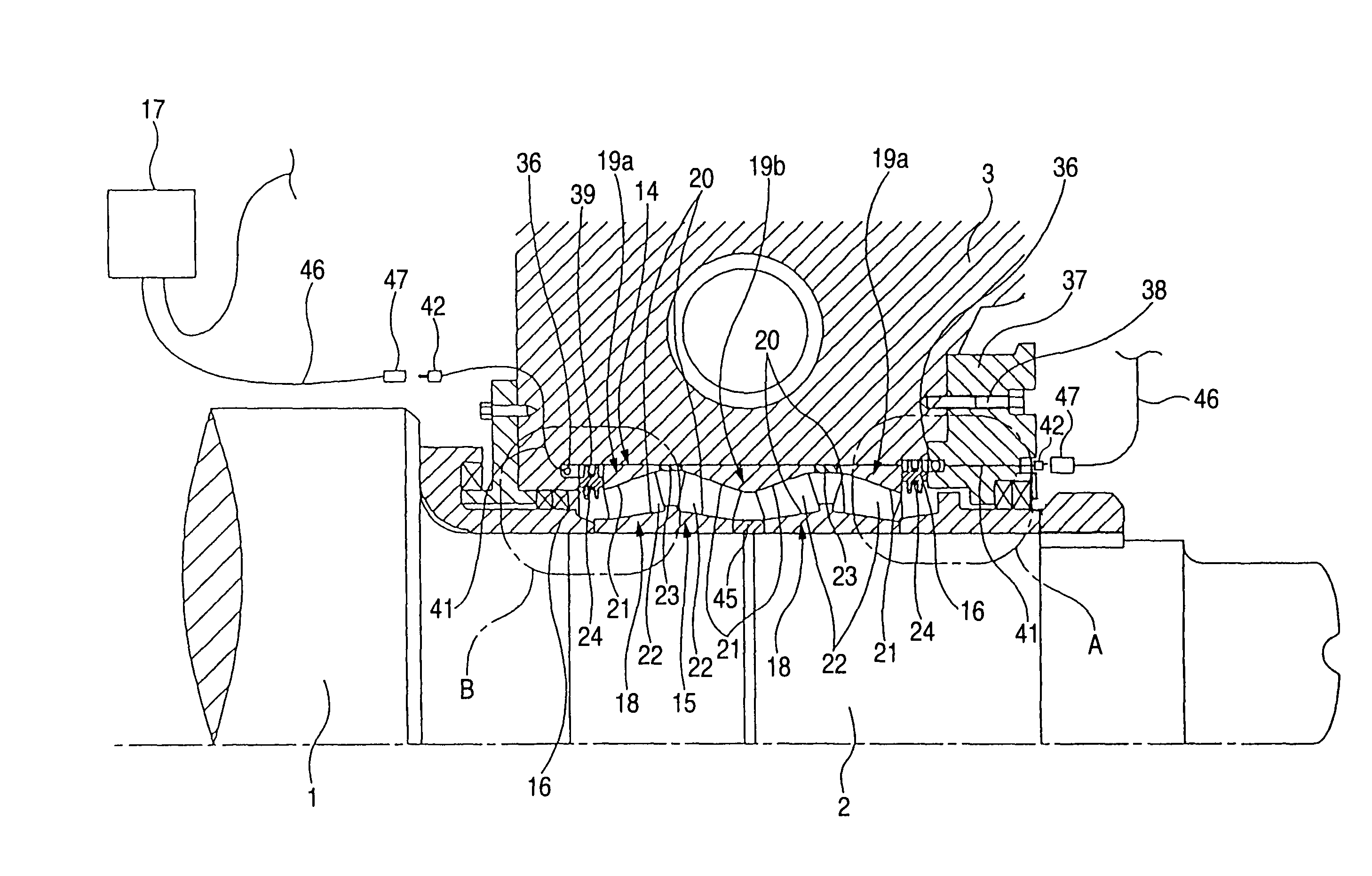

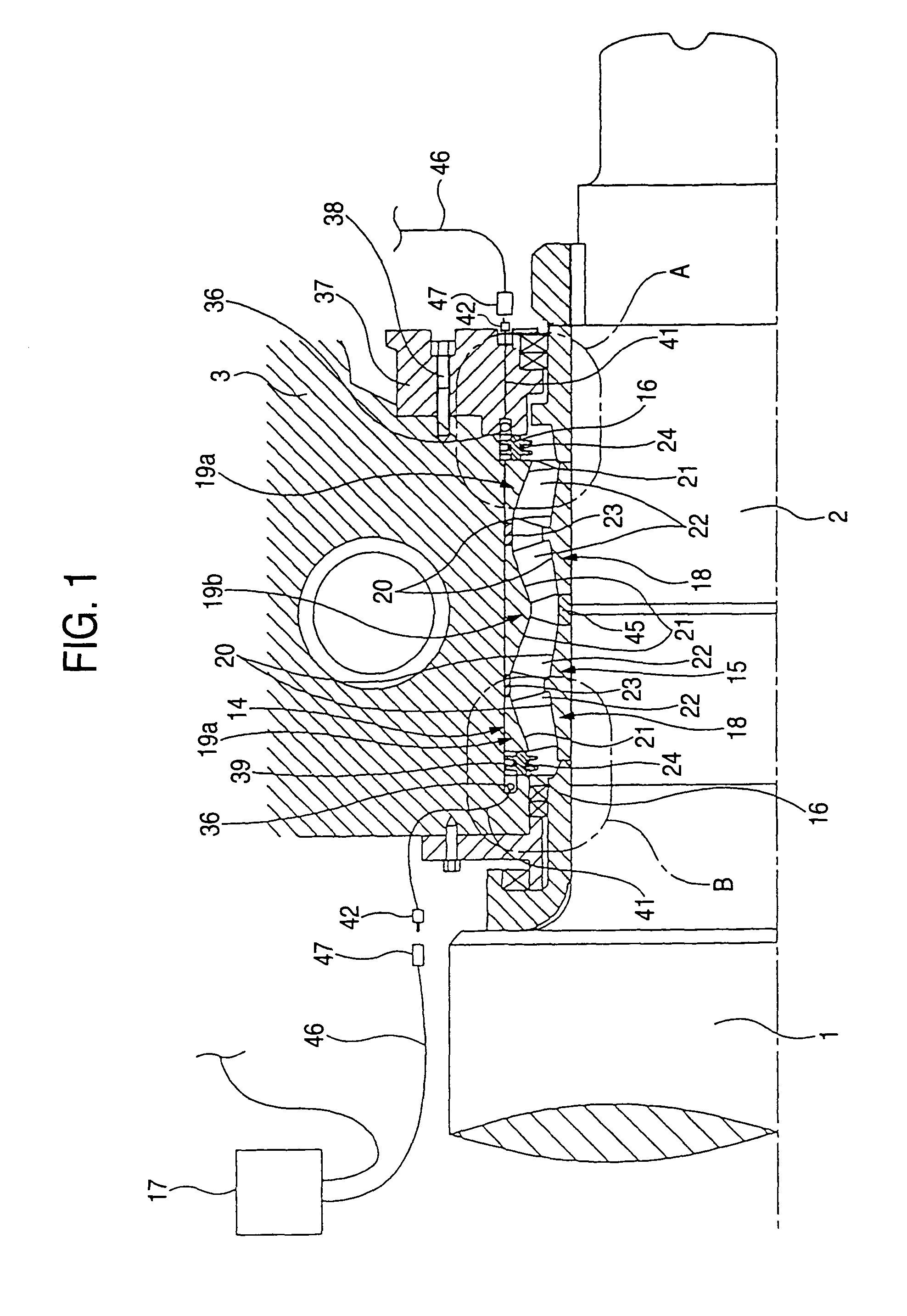

Roll changing apparatus and roll changing method for rolling mill

InactiveUS20020078728A1Low costReduce Fixture CostsMetal rolling stand detailsRollsWork rollEngineering

A roll changing apparatus for a four-high rolling mill comprises rails, provided in a rolling mill stand and on a work side of the rolling mill, for incoming and outgoing of a work roll assembly and a backup roll assembly, and a pusher, provided on a drive side or the work side of the rolling mill, for roll admission and withdrawal for both of work rolls and backup rolls. The roll changing apparatus can be modified into a side shift type roll changing apparatus with ease, at a low cost, and in a short time.

Owner:MITSUBISHI HEAVY IND LTD

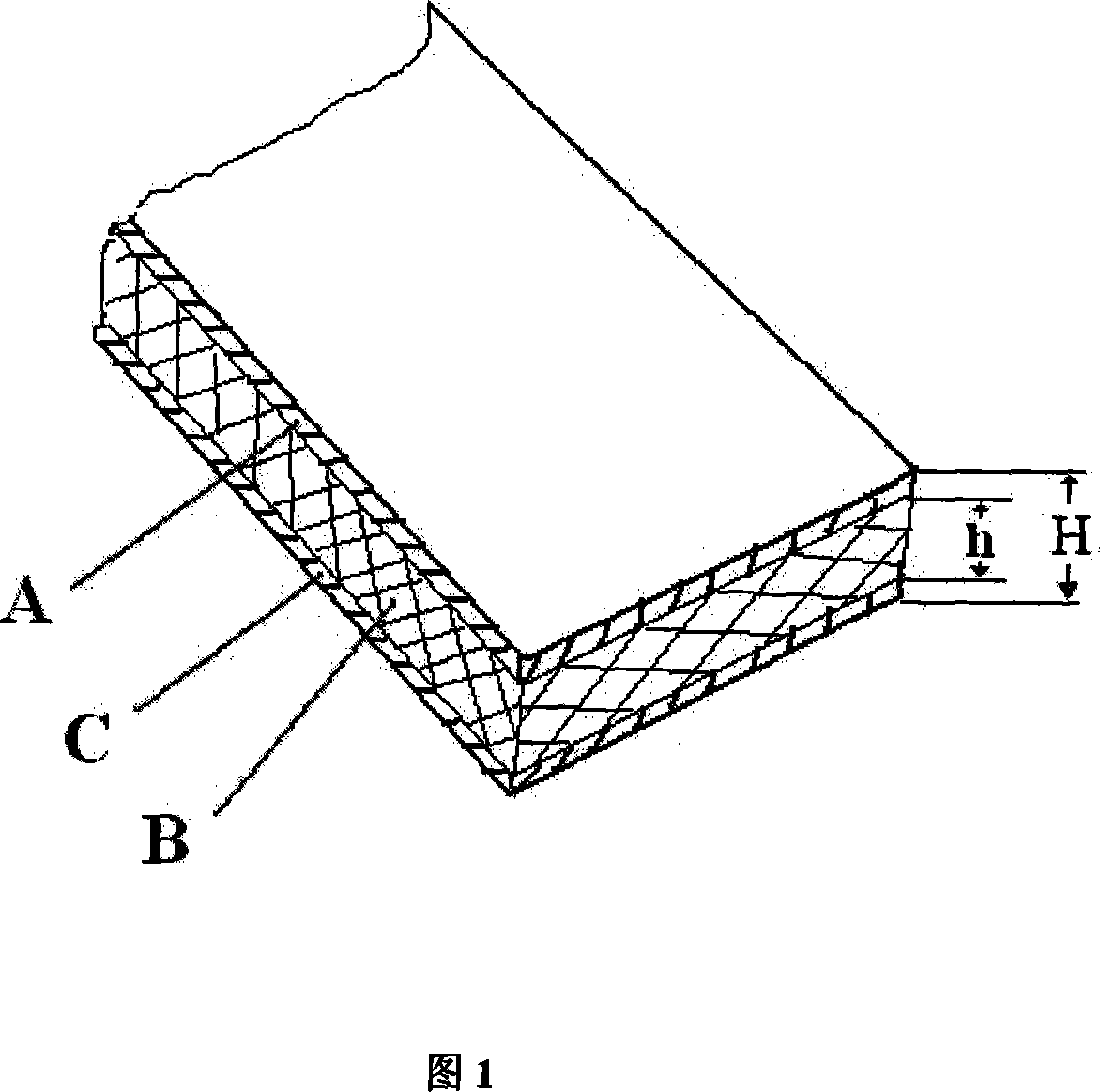

Method for composite preparation of Ti alloy/TiAl alloy composite plate material by using laminated rolling-diffusion method

InactiveCN101011706AReduce manufacturing costThe preparation method is simpleTemperature control deviceFurnace typesDiffusion methodsAlloy composite

The invention discloses a making method of titanium alloy / TiAl composite board, which is characterized by the following: overlapping A (titanium foil) and C (aluminium foil); placing at least one layer B (titanium or titanium alloy foil, titanium or titanium alloy board) on the upper and lower surfaces of overlapped layer or among overlapping layer; setting adjacent layer C to B; adopting three layers or more of A or B as the most outer layer; jacketing; rolling under 20-750 deg.c and 750-1300 deg.c.

Owner:HARBIN INST OF TECH

Cold rolling manufacture method of copper and aluminum composite plate strips

InactiveCN102615102ADiffuse fullyFull responseAuxillary arrangementsMetal rolling arrangementsChemical reactionCopper

The invention discloses a cold rolling manufacture method of copper and aluminum composite plate strips. The cold rolling manufacture method comprises the following steps that: 1, a copper plate and an aluminum plate are subjected to homogenization annealing treatment; 2, surface treatment is carried out: firstly, the copper plate and the aluminum plate subjected to the homogenization annealing treatment are subjected to soaking degreasing, then, the copper plate and the aluminum plate subjected to the soaking degreasing are taken out for drying, and next, the composite surfaces to be rolled of the copper plate and the aluminum plate are ground by a stainless steel wire brush; 3, the copper plate and the aluminum plate are subjected to cold rolling compounding by a cold rolling mill, so copper and aluminum composite plate blanks are obtained; and 4, the copper and aluminum composite plate blanks subjected to the cold rolling are subjected to the diffusion annealing treatment. The cold rolling manufacture method has the advantages that through improving the cold rolling process operation and the process parameters, the copper plate and the aluminum plate are subjected to full diffusion and chemical reaction on the composite surfaces in the manufacture process, so the transition structure with excellent performance is obtained at the composite surfaces, and the bonding intensity of finished products is effectively improved.

Owner:HONGGUANG ELECTRIC GROUP CO LTD

Stainless steel/aluminum composite material and preparation method thereof

ActiveCN101992567AImprove bindingHigh mechanical strengthTemperature control deviceCleaning using liquidsSurface layerAluminum composites

The invention relates to a metal composite material and a preparation method thereof, in particular to a stainless steel / aluminum composite material and a preparation method thereof. The material comprises a three-layer structure formed by hot rolling, wherein the bottom layer is a stainless steel layer, the middle layer is an aluminum alloy layer, and the surface layer is a pure aluminum layer; and the aluminum ally contains elements of Cu, Mg and Mn. The preparation method of the material comprises the following steps of: cleaning the surface of a raw material plate; performing lamination, hot rolling and heat treatment on a stainless steel plate and an aluminum alloy plate to form a once hot rolled plate; and laminating a pure aluminum plate on the aluminum alloy layer of the once hot rolled plate to perform hot rolling and heat treatment. The stainless steel / aluminum composite material has high bonding force, and cannot deform, crinkle and delaminate in the subsequent stamping process and the like.

Owner:BYD CO LTD

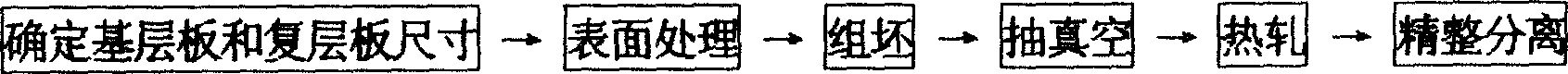

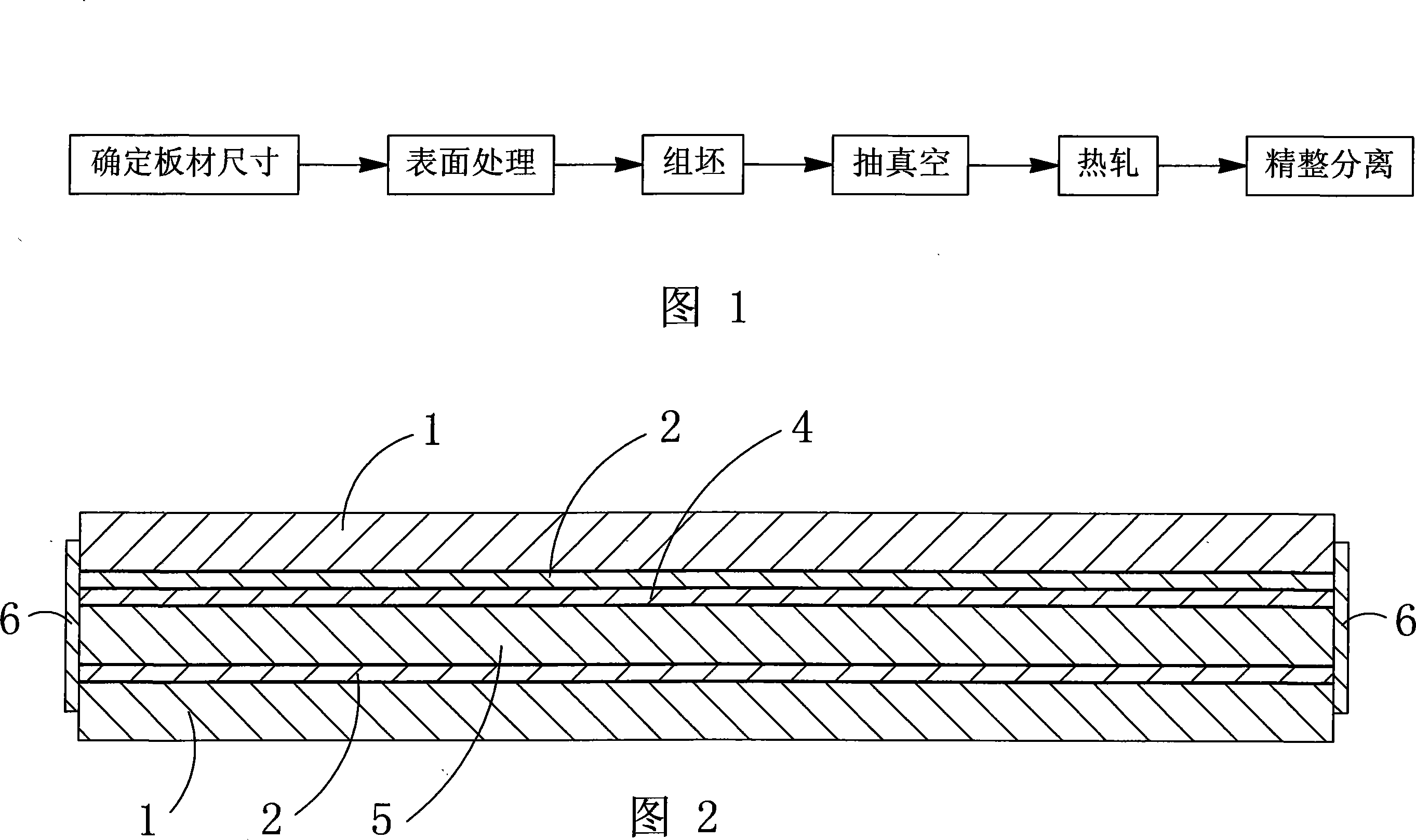

Process for producing brazing hot rolled metal composite plate adopting composite cog

InactiveCN1669687AImprove mechanical propertiesImprove corrosion resistanceSoldering apparatusAuxillary arrangementsVacuum pumpingComposite plate

The invention discloses a method for producing braze metal sandwich by compound compact, which comprises the following steps: ensuring the size of the basal layer and the composite layer, surface processing, making embryo, vacuum-pumping, hot-rolling, finishing and separating. The method can produce metal sandwich by present medium hot-rolling mill, and the sandwich has good mechanical property, non-corrodibility and reprocessing property, the bonding strength of two metal layers is high, and the shearing intensity can reach to 210MPa-350MPa, so the method can be used widely in producing the metal sandwich and roll bending.

Owner:吉欣(英德)热轧不锈复合钢有限公司 +2

Preparation method of high-performance thin clad titanium/steel compound plates

InactiveCN102489506AEasy to manufactureSimple methodWork treatment devicesAuxillary arrangementsOrganic solventTitanium

The invention discloses a preparation method of high-performance thin clad titanium / steel compound plates, and the method comprises the following steps: step 1) performing treatment on the surface to be compounded of a steel plate and the surface to the compounded of a titanium plate through a mechanical method, removing defects on the surfaces to be compounded and then washing the surfaces to be compounded of the steel plate and the titanium plate clean through an organic solvent; 2) assembling the steel plate and the titanium plate after cleaning into a rolled compact; 3) heating the rolled compact to 780 DEG C-880 DEG C and performing heat insulation for 20 min-180min; 4) sending the rolled compact after heat insulation into a rolling machine for rolling, and cooling to get the compound plate; 5) performing heat treatment on the compound plate; 6) leveling, and then cutting off the head, the tail and a weld joint part so as to get two titanium / steel compound plates, wherein the thickness of clad titanium of each titanium / steel compound plate is not more than 3.0mm, and the shear strength is not less than 180MPa. The method disclosed by the invention is simple and very easy to prepare thin clads, in particular to the titanium / steel compound plates with the clad thickness of less than 3.0mm.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Rolling method and apparatus for copper-aluminium double-face composite board

A technology for rolling the composite Cu-Al plate includes such steps as preheating the copper band and aluminium plate respectively at different temp for different time, acid washing of copper band, alkali washing of aluminium plate, brushing surface by steel wire brush, rolling by a pair of upper concave roller and lower convex roller, annealing in inertial gas, and straightening.

Owner:SHENYANG POLYTECHNIC UNIV

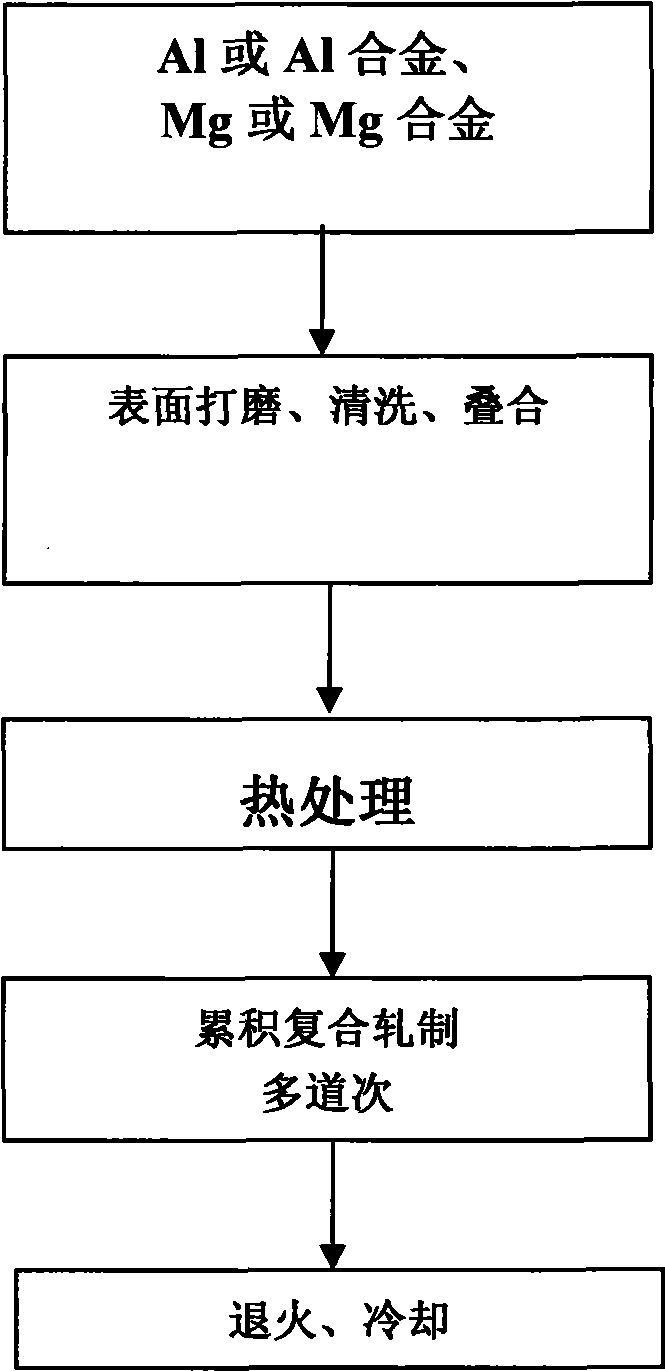

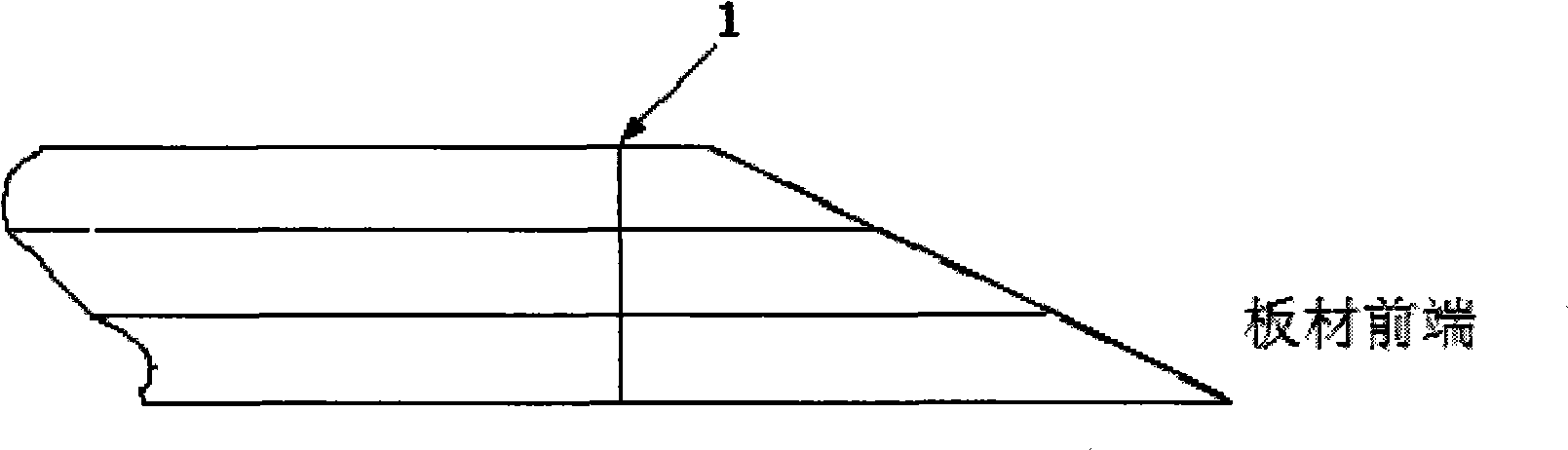

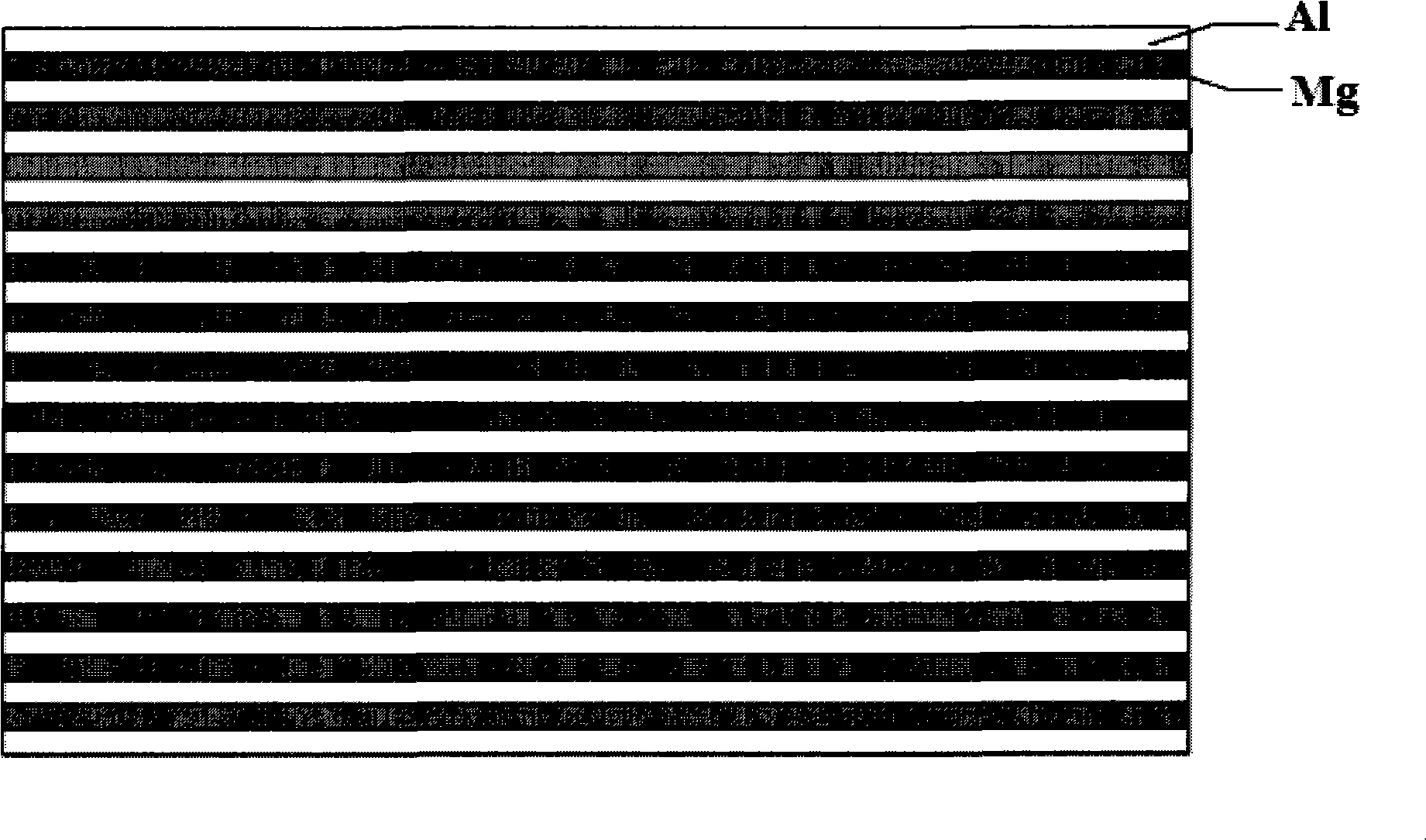

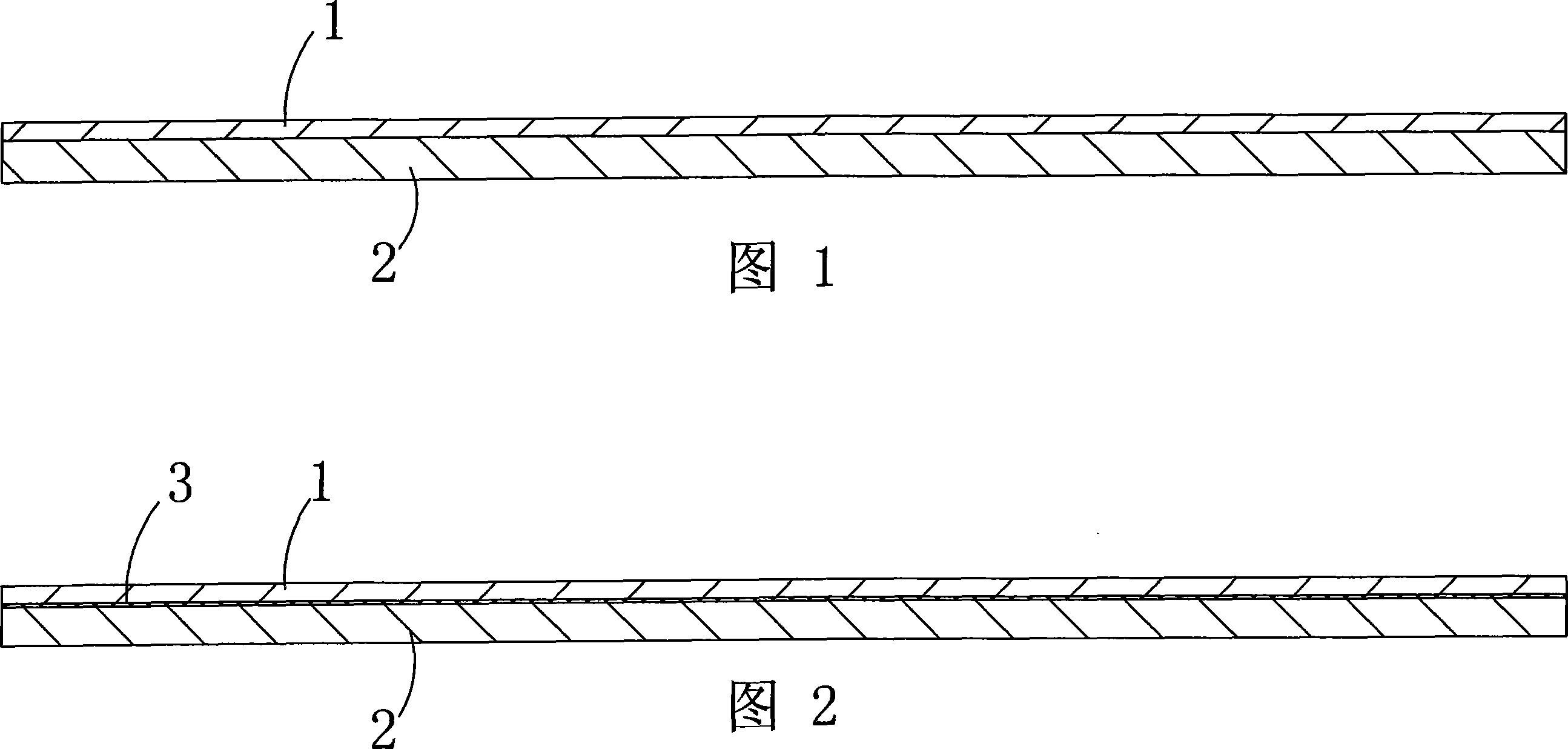

Method for preparing aluminum-magnesium ultrafine crystal composite plate with multilayer structure

InactiveCN101530860AImprove organizationHigh bonding strengthRoll force/gap control deviceHeat treatment process controlRoom temperatureAlloy

The invention relates to a method for preparing an aluminum-magnesium ultrafine crystal composite plate with a multilayer structure. The method selects a plate material Al or an Al alloy and Mg or a Mg alloy as raw materials; a structural layer of the prepared aluminum-magnesium ultrafine crystal composite plate with the multilayer structure is the Al / the Mg / the Al, or the Al alloy / the Mg alloy / the Al alloy or the Al / the Mg alloy / the Al in sequence; the preparation method adopts an accumulated composite rolling method which comprises the steps: polishing, cleaning, removing metal chips or impurities on the surface of the plate material, stacking in a hamburger mode, and positioning the stacked steel plate in a resistance furnace for heat treatment; taking out the plate material subjected to heat treatment, placing the plate material on a rolling machine, and rolling the plate material with 50 percent of rolling reduction in every pass; cutting cracked edges and burr in the edge part of the rolled plate material, cutting the plate material into two equivalent parts, and carrying out multipass accumulated composite rolling repeatedly; placing the plate material subjected to accumulated composite rolling in an air protection annealing furnace for heat treatment, cooling the plate material to the room temperature along the furnace and taking out the plate material; and the Al / Mg / Al composite steel plate with the multilevel structure can be obtained.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

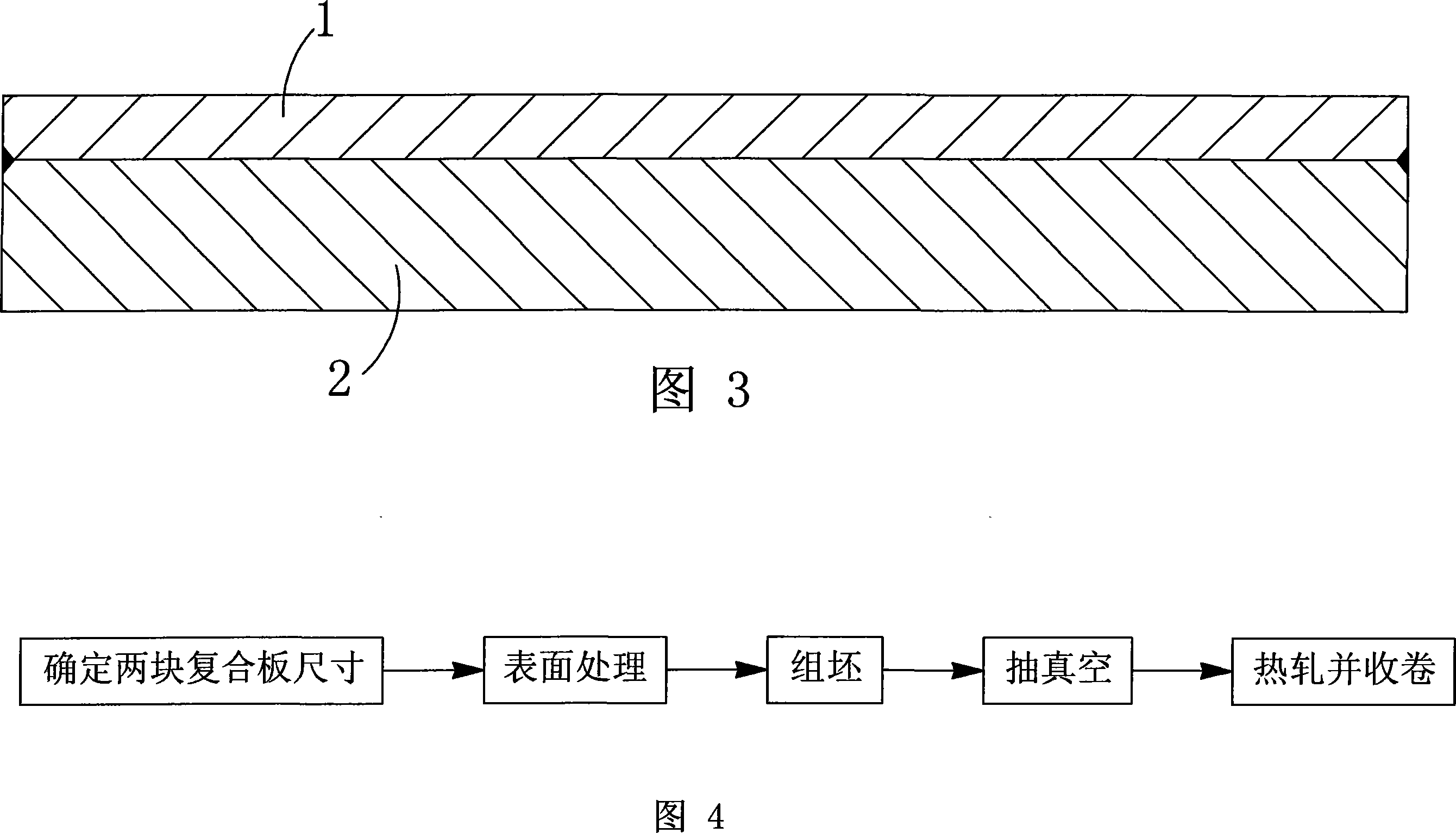

Double-layer stainless steel composite thin plate and its processing method

InactiveCN101214745ASolve the reprocessing problemEasy to useAuxillary arrangementsMetal rolling arrangementsComposite plateMetal

The invention discloses a double-layer stainless steel composite sheet and a processing method thereof, and belongs to the technical field of a metal composite sheet. The sheet is formed by compounding two corrosion resistant plates of different materials through hot rolling. The processing method comprises the following steps: firstly, the physical dimensions of the two corrosion resistant plates are determined according to the product requirement; secondly, the surfaces of the two corrosion resistant plates to be compounded are cleared up; thirdly, the surfaces of the two corrosion resistant plates to be compounded are arranged oppositely before the surfaces are superposed; the peripheral hems of the joint faces of the two corrosion resistant plates are welded and sealed under pressure; fourthly, the corrosion resistance plates are drilled and vacuumized; fifthly, the vacuumized compounded preform is hot rolled and moulded in the temperature of 900 DEG C to 1150 DEG C on a roll before the preform is coiled. The product disclosed by the invention has the advantages of excellent processability and low use cost.

Owner:吉欣(英德)热轧不锈复合钢有限公司 +2

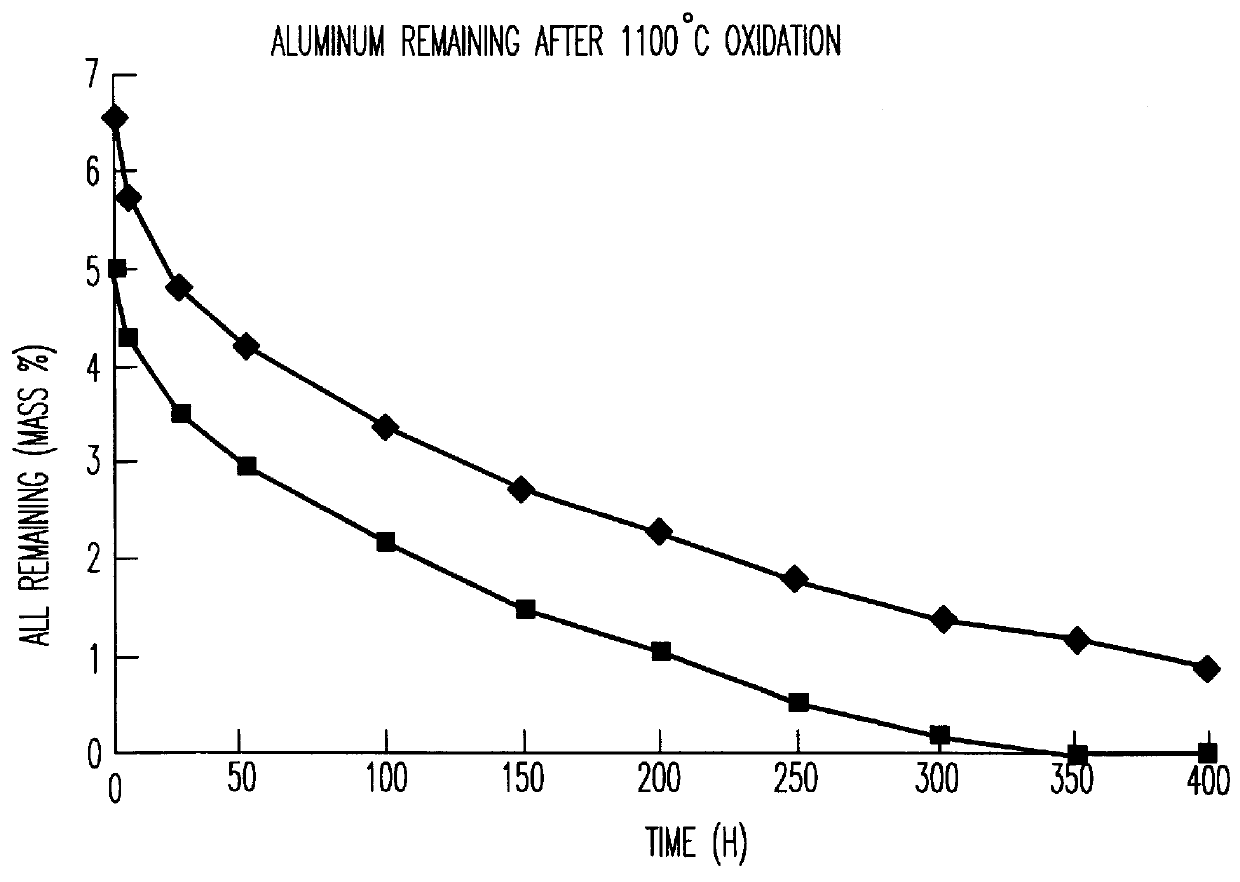

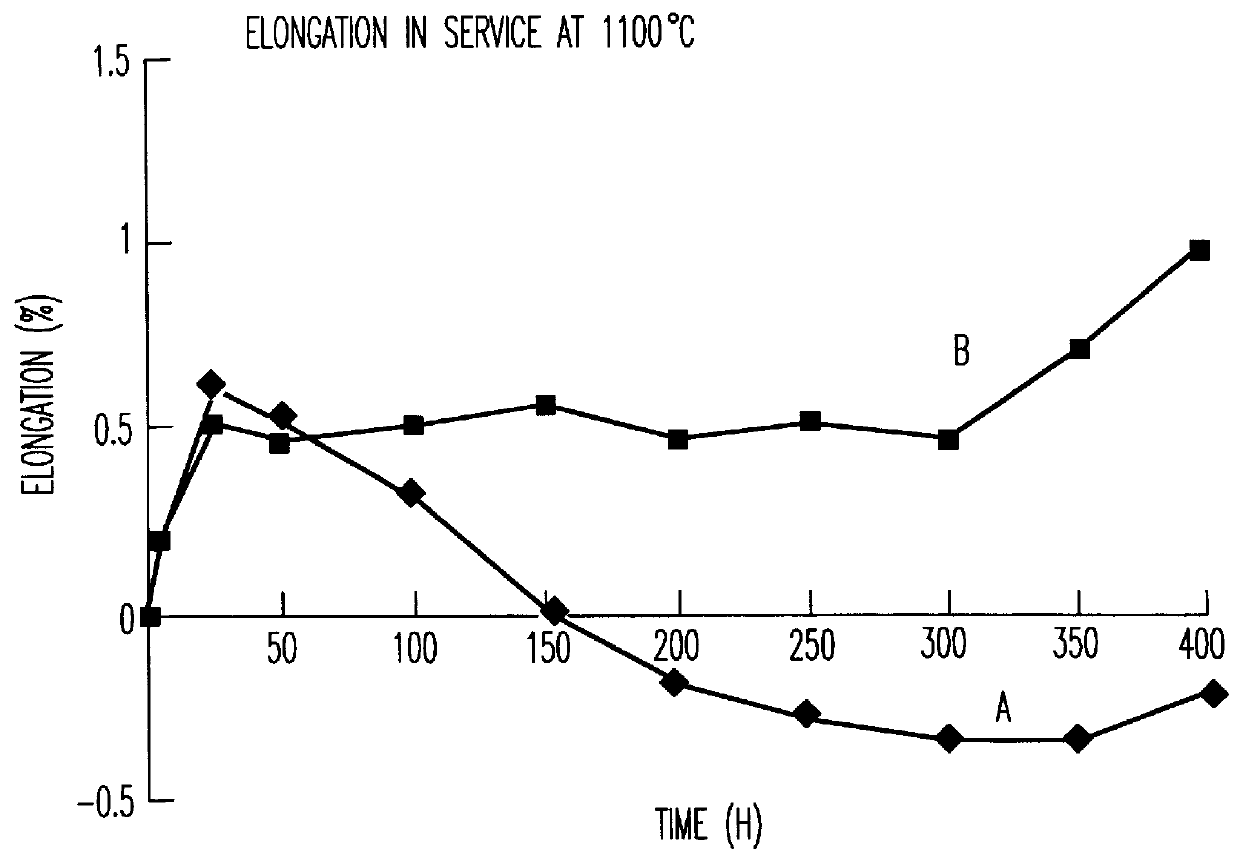

Process for manufacturing a foil of ferritic stainless steel having a high aluminum content, aluminum-containing ferritic stainless steel, and catalyst support useful for a motor-vehicle exhaust

InactiveUS6086689AHot-dipping/immersion processesDispersed particle separationRare-earth elementHydrogen atmosphere

Process for manufacturing a foil of ferritic stainless steel having a high aluminum content, which can be used in particular for a catalyst support in a motor-vehicle exhaust, wherein a ferritic stainless steel sheet of the following composition: 0.005%<carbon<0.060% 10%<chromium<23% 0.1%<aluminum<3% 0.003%<nitrogen<0.030% 0.1%<manganese<2% 0.1%<silicon<2% rare-earth elements in a proportion of between 0.03% and 0.15%, is subjected to: plating between two sheets of aluminum in order to obtain a laminate, rolling the laminate to a thickness of 0.03-0.25 mm to form a foil, static diffusion annealing the foil in a hydrogen atmosphere, and finish rolling greater than 20%.

Owner:UGINE SA

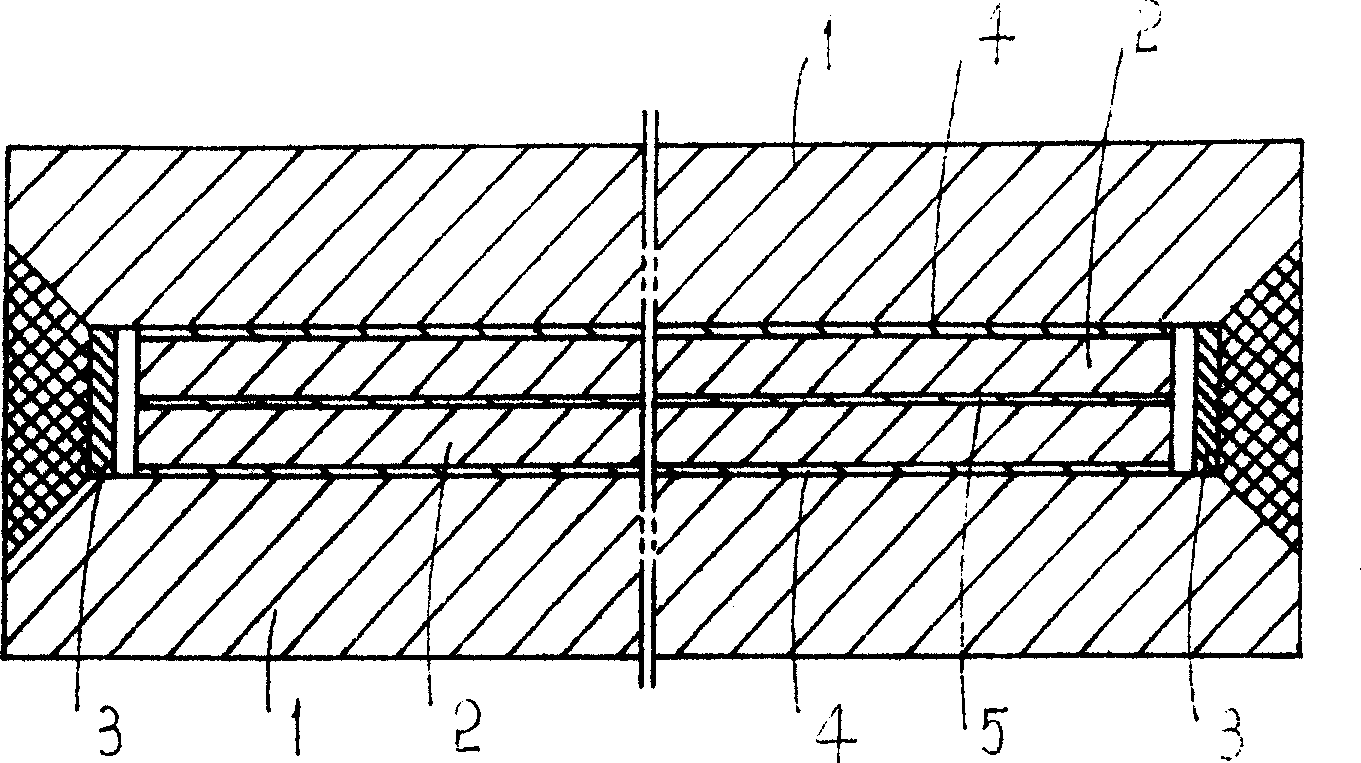

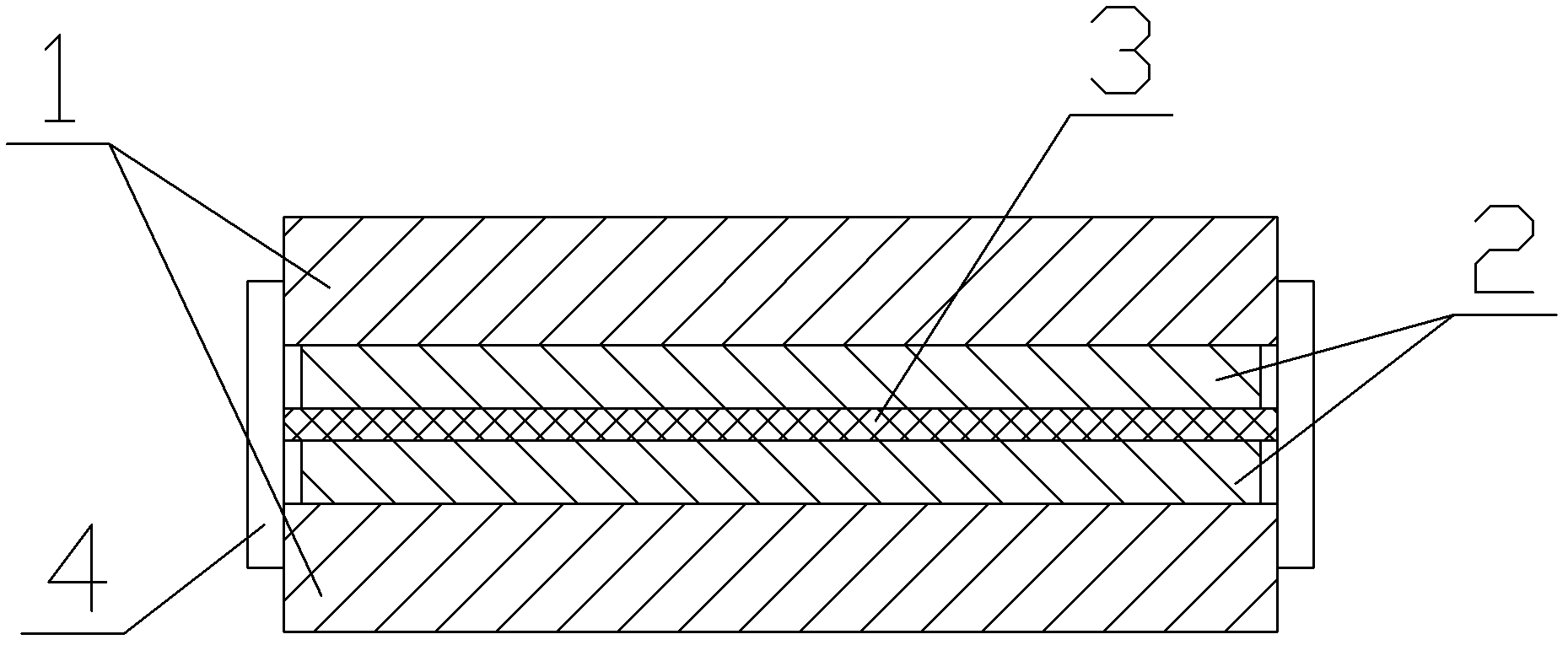

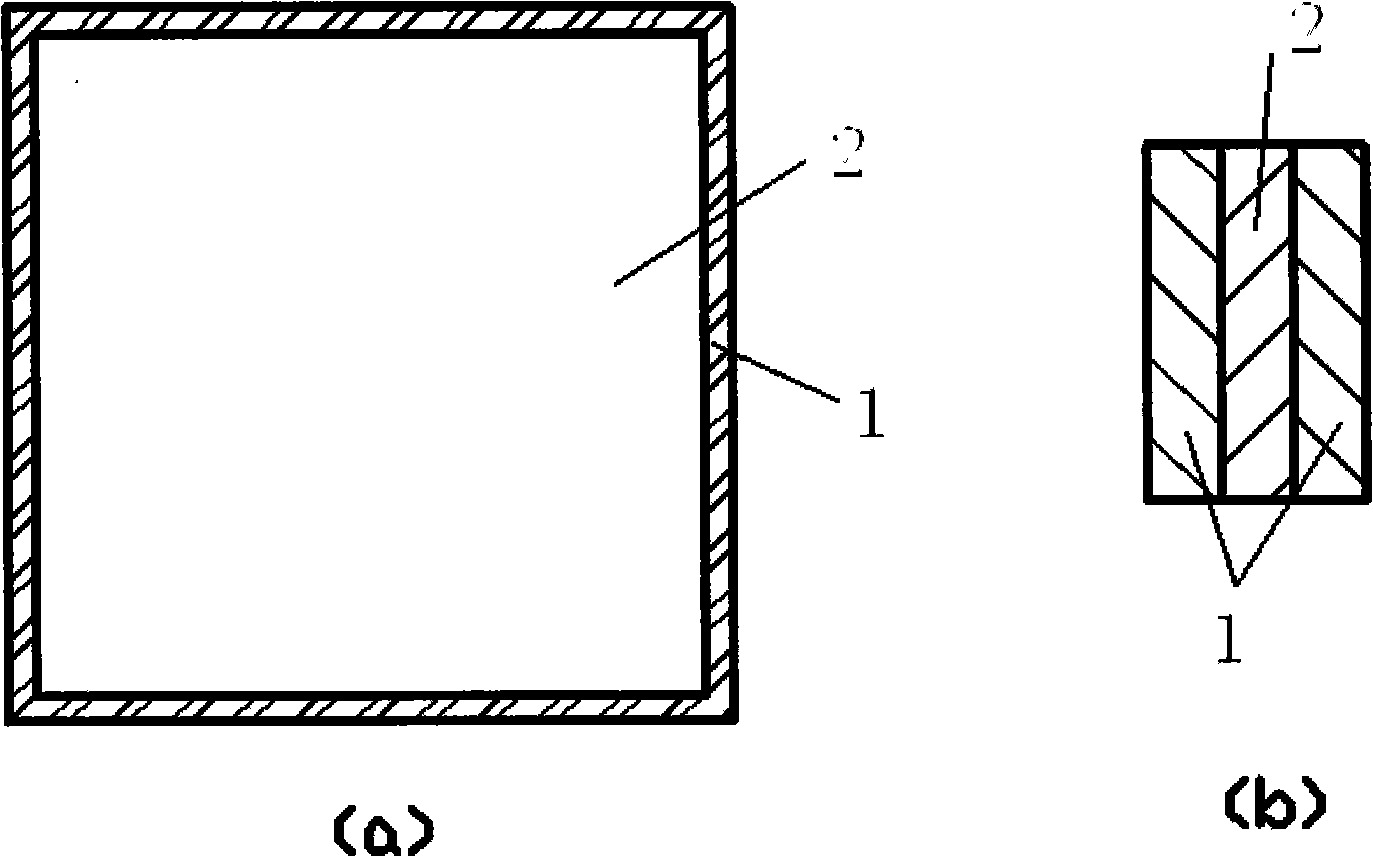

Method for simultaneously rolling three metal composite boards by composite blanks

InactiveCN101214497ASolve the reprocessing problemSimple processing methodSoldering apparatusAuxillary arrangementsVacuum pumpingComposite plate

The invention discloses a method that adopts a compound compact and rolls three metal composite boards at the same time. The method comprises the following procedures: (1) the shape and the size of each layer of the metal board are identified according product requirements; (2) each surface that is to be recombined is cleaned: (3) assembly; (4) drilling vacuum pumping; (5) hot rolling and (6) finishing separation. When in assembly, a base metal plate, a multi-layer metal plate, high temperature anti-adhesive agent, a stainless steel plate, the stainless steel plate, the high temperature anti-adhesive agent, the multi-layer metal plate and the base metal plate are arranged in order. Under pressure, the surrounding of two base metal plates are welded with a separator to make space between two base metal plates sealed. The invention has the advantages of little investment and high production efficiency and is used for processing the metal composite plate.

Owner:吉欣(英德)热轧不锈复合钢有限公司 +2

Apparatus and method for changing dies

The die changing apparatus for a plate reduction press machine, comprises an upper die support holder 28a and a lower die support holder 28b that are arranged vertically on opposite sides of a transfer line, and support holder guide rails 31 installed on the upper die support holder and extending substantially horizontally in the lateral direction of the transfer line, and an upper die 29a and a lower die 29b are mounted on the upper and lower die support holders, respectively using the rollers onto the dies, fixing devices 30 that fix the upper and lower dies on the upper and lower die support holders, respectively, die fastening members 38 which are placed on each side of the upper and lower dies, opposite each other in such a manner that they can be fastened to both dies, and a die changing mechanism that can move one of the die fastening members in a direction perpendicular to the transfer line.

Owner:JFE STEEL CORP +2

Production method of titanium steel composite board for calendering composite pot tool

ActiveCN101474632AHigh bonding strengthTightly wrappedAuxillary arrangementsMetal rolling arrangementsCarbon steelSteel plates

The invention discloses a manufacturing method of a calendered complex titanium clad steel plate used in a pan. The method comprises the following steps: taking two low carbon steel plates which have a carbon content lower than 0.15% and are 8-12mm thick and two titanium plates which are 2-3mm thick; polishing one surface of the steel plates and the titanium plates, and superposing the steel plates and the titanium plates by arranging the polished surfaces face to face in a four-layer order of steel-titanium-titanium-steel; sealing peripheral gaps between each two plates by fusing while pressfitting; heating clad billet plates to the temperature of 850-920 DEG C; calendering and cladding by a hot roll to cause a deformation rate not smaller than 65%, and then diffusion annealing at the temperature of 750 DEG C to remove oxide layers on the surfaces; cold rolling and calendering at the deformation rate not greater than 10%, and then relieving stress at the temperature of 650 DEG C; separating the four-layer superposed plates to obtain two calendered complex titanium clad steel plates used in the pan. The method helps manufacture the titanium clad steel plate by heating and calendaring the low carbon steel and the titanium which are produced at high temperature and have low brittleness; atoms on a titanium-steel interface are diffused with each other at the eutectic temperature to realize metallurgical bonding; the steel plates of the titanium clad steel plate are closely clad by the titanium plates of the titanium clad steel plate; the bonding strength of the titanium and the steel is high, thus the titanium clad steel plate is an ideal complex plate for the pan.

Owner:辽宁新华阳伟业装备制造有限公司

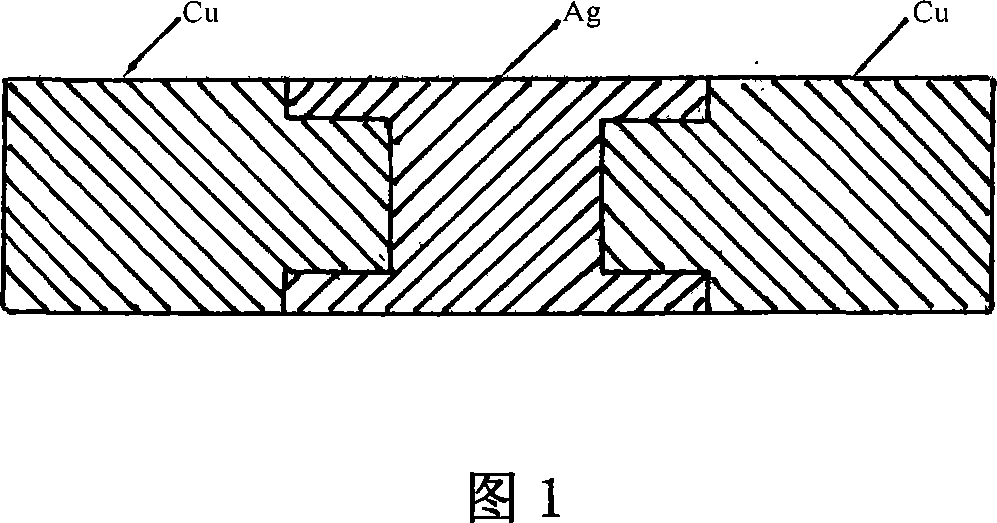

Method for preparing double side mosaic type hot-rolling composite silver copper strip

ActiveCN101053874AHigh bonding strengthMeet the use requirementsRoll mill control devicesHeat treatment process controlInterference fitUltimate tensile strength

A preparation method of bilateral surface mosaictype hot rolling compound silver copper strip material comprises: rolling silver ingot into a plate-shaped blank with a certain thickness, cutting the blank to form silver blank in sections, and processing the silver blank into bilateral groove-shape compound silver preform in machine tooling or deepdrawn manner; processing the copper blank into unilateral protruding shape compound copper preform in machine tooling or deepdrawn manner; hot rolling compositing the compound copper preform / compound silver preform / compound copper preform lateral under argon gas protection after interference fit, with heating temperature of 500-900DEG C., soaking time of 10 minutes-100 minutes, and deflection of 40%-90%, to change mechanical interference fit of the compound copper preform / compound silver preform / compound copper preform into crystal combination between mosaic atoms; and cold rolling, annealing and finishing rolling the strip material to obtain the product which has more strong compound layer with higher bonding strength compared with prior technology.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

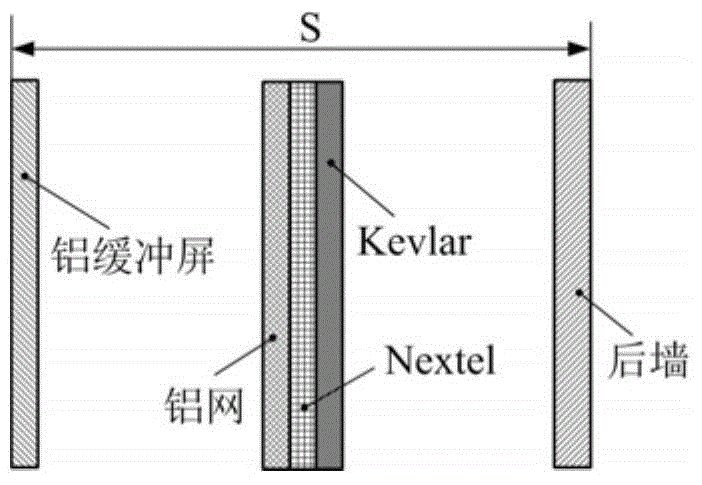

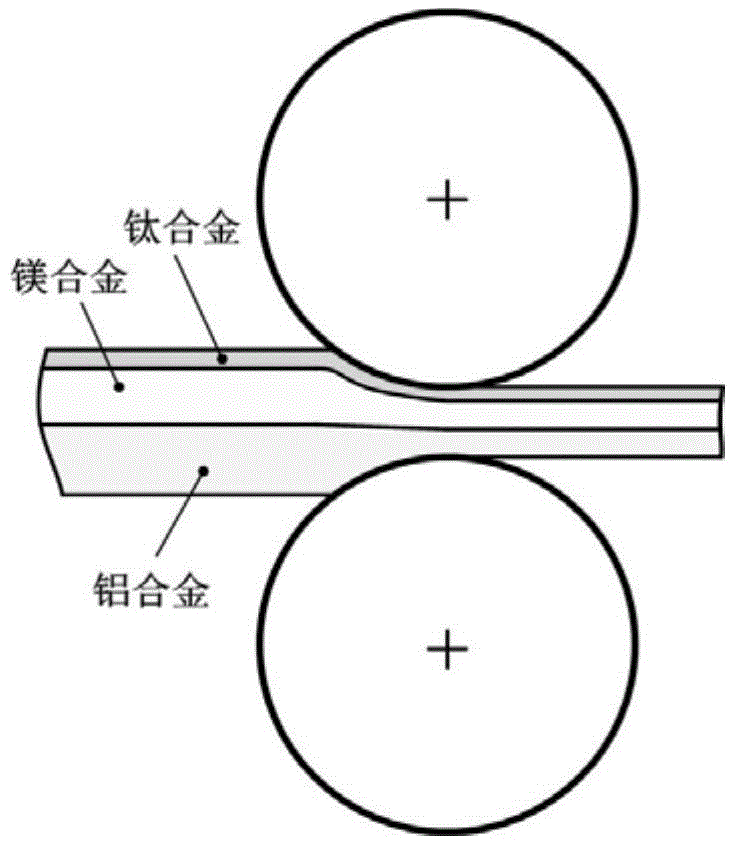

Rolling compounding method for aluminum/magnesium/titanium three-layer composite plate

ActiveCN104056859ALow densityHigh specific strengthAuxillary arrangementsMetal rolling arrangementsComposite plateTitanium alloy

The invention discloses a rolling compounding method for an aluminum / magnesium / titanium three-layer composite plate. The characteristics of high strength of titanium alloy, low melting point and good vibration reducing performance of magnesium alloy, good plasticity and space adaptation of the aluminum alloy, and the like, are utilized and the excellent characteristics of respective component metals are combined by the aluminum / magnesium / titanium three-layer composite plate provided by the invention, so that the high-speed impact damage resisting property which the component metals do not own is acquired. Through the control on the ratio and interface of the aluminum alloy, the magnesium alloy and titanium alloy, the degree of fragmentation, melting and atomizing of shred cloud after the buffer composite plate is subjected to high-speed impact is changed and adjusted, so that the form of the shred cloud is changed, the degree of impact damage to a backplate is reduced, and the high-speed impact damage resisting property is increased. The aluminum / magnesium / titanium three-layer composite plate is applied to an outer layer buffer plate in an outer layer protecting structure of an aerospace vehicle and can be used for replacing a traditional single aluminum alloy material. The space environmental effect and protecting level of the space vehicle are increased; the design level of the space vehicle are greatly promoted, and the service life of the space vehicle are greatly prolonged.

Owner:CHONGQING UNIV

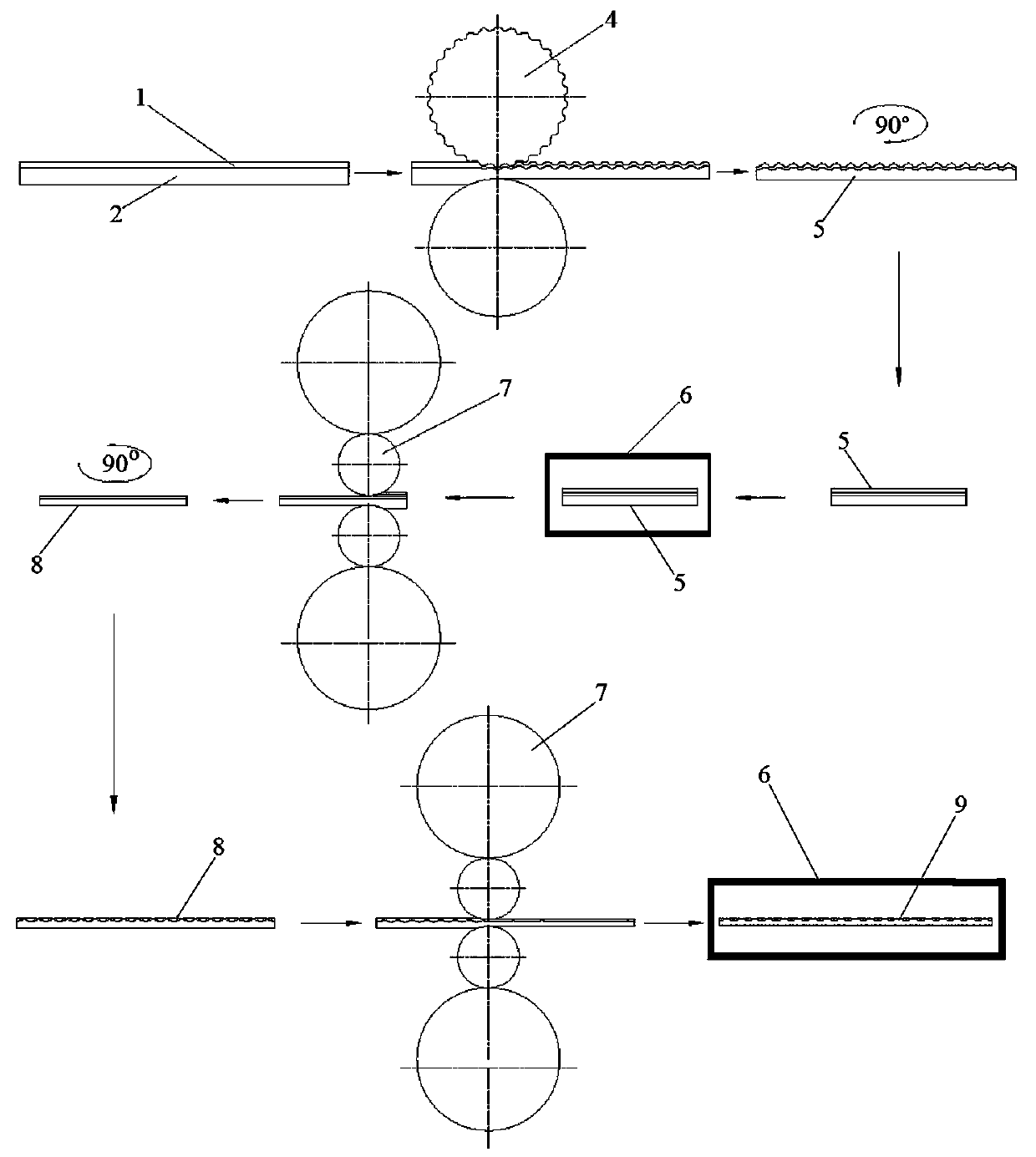

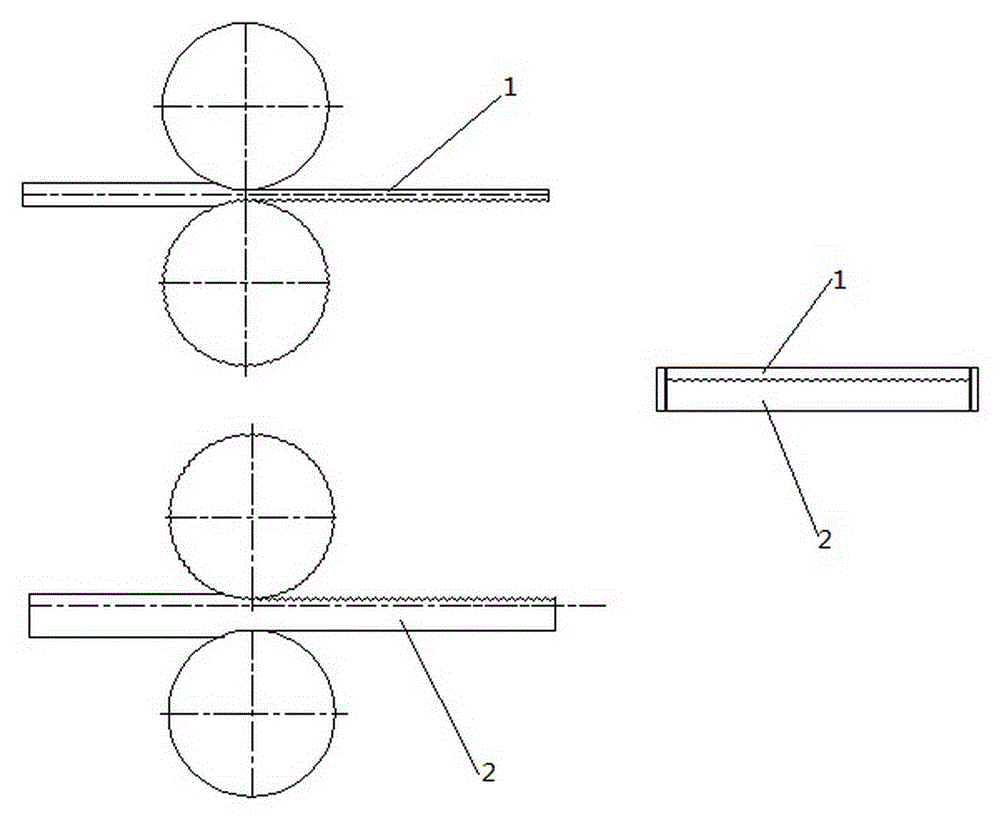

Method for continuously rolling metal composite substrate by corrugated roll and a flat roll

ActiveCN108672494AReduce warpageFacilitates continuous rollingAuxillary arrangementsMetal rolling arrangementsComposite substrateHigh intensity

The invention belongs to the technical field of material processing of metal composite plates, and particularly relates to a method for continuously rolling a metal composite substrate by a corrugatedroll and a flat roll. The method comprises the following steps: rolling a blank by using the corrugated roll to obtain a corrugated composite plate; and then flattening the corrugated-shaped composite plate by using a flat roll. In the process, high-strength combination of the composite plate from a local part to a whole surface can be realized by stress peaks at two different positions. Comparedwith a method for directly flattening in the original rolling direction, the method comprises the advantages that the elongation of metal in the plate width direction can be reduced by flattening after the corrugated composite plate rotates at an angle of 90 degrees, damage to positions which have been combined originally is reduced, extrusion at positions of wave peaks is obvious, the combination strength of portions which are originally combined weakly relatively is improved favorably, and thus, the combination quality of the whole surface is improved; and warping in a direction perpendicular to corrugations can also be prevented from being generated in a corrugated composite plate flattening process by flattening after the corrugated composite plate rotates at an angle of 90 degrees, and continuity of a follow-up thinning process is facilitated.

Owner:TAIYUAN UNIV OF TECH

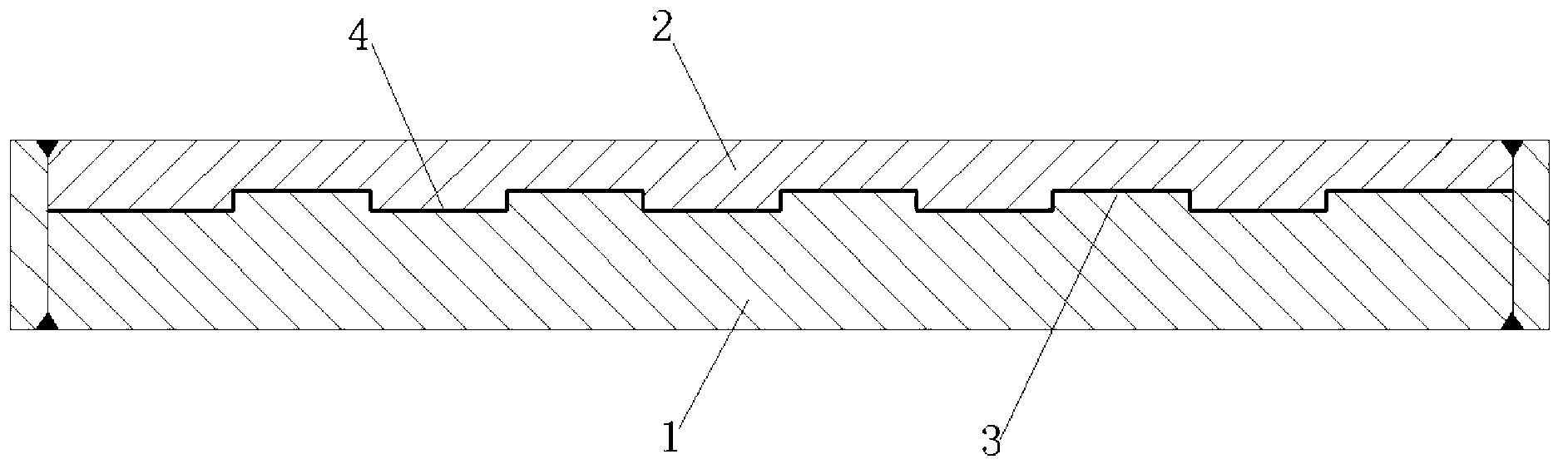

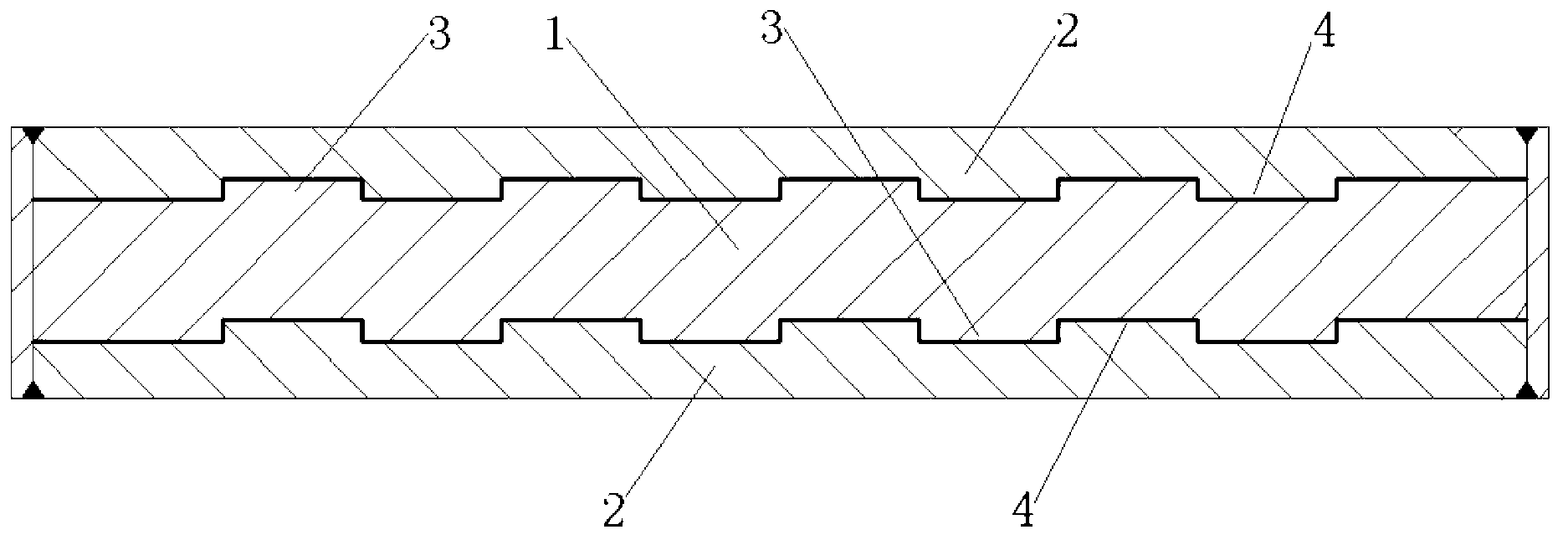

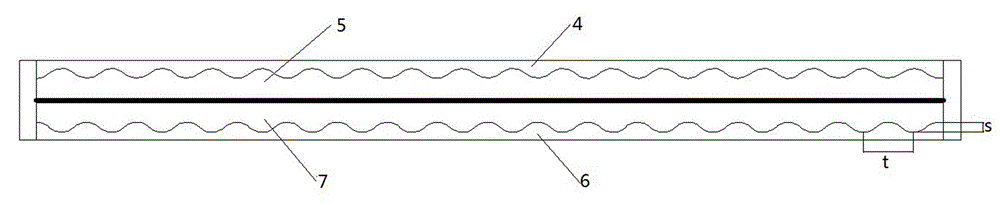

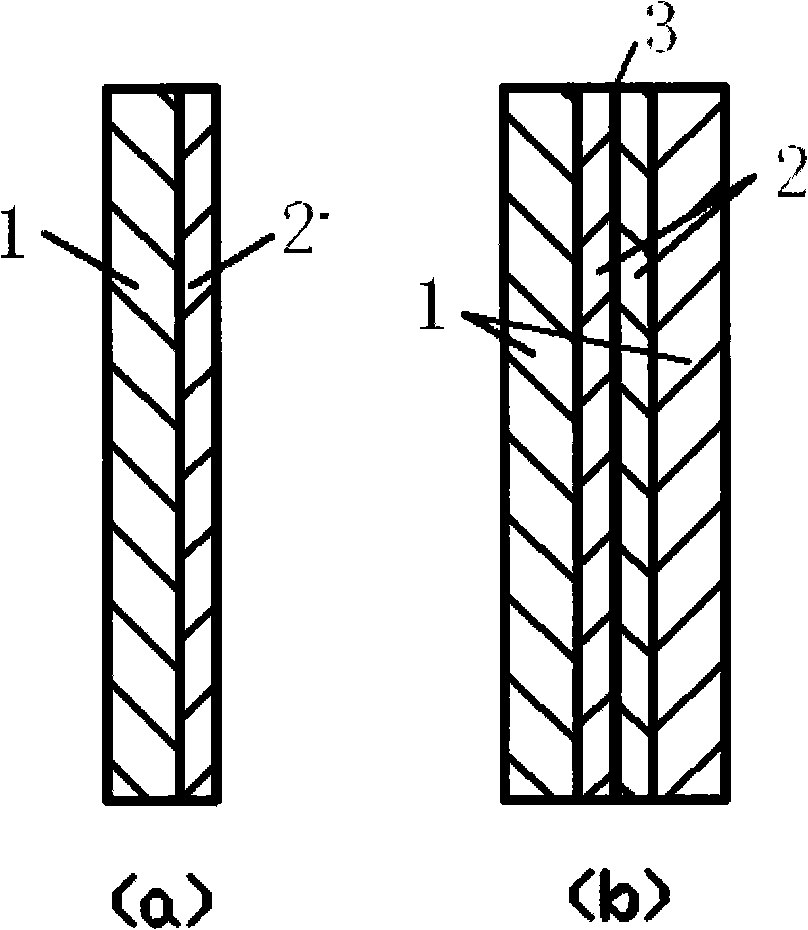

Meshing type composite plate vacuum rolling preparation method

InactiveCN103272842AImprove fitAvoid separationAuxillary arrangementsMetal rolling arrangementsComposite strengthComposite filter

The invention discloses a meshing type composite plate vacuum rolling preparation method. The meshing type composite plate vacuum rolling preparation method includes the steps: processing base plate protrusions and covering plate protrusions, which are matched mutually, on compositing surfaces of a base plate and a covering plate respectively; cleaning the compositing surfaces of the base plate and the covering plate; overlaying the base plate and the covering plate, and enabling the base plate protrusions on the base plate and the covering plate protrusions on the covering plate to be meshed mutually; obtaining a composite plate blank by means of blank assembly; and performing hot rolling so that a composite plate is obtained. The meshing type composite plate vacuum rolling preparation method has the advantages that the base plate protrusions and the covering plate protrusions which are matched mutually are processed on the compositing surfaces of the base plate and the covering plate respectively, so that fitting force between the base plate and the covering plate is increased by the aid of meshing force among the base plate protrusions and the covering plate protrusions, separation of the base plate from the covering plate during rolling is avoided, and rolling quality is improved while process is simple; meanwhile, contact area between the base plate and the covering plate is enlarged (namely, the area of a compositing interface is enlarged), so that compositing strength of the composite plate is enhanced; and the meshing type composite plate vacuum rolling preparation method is applicable to preparation of composite plates.

Owner:武钢集团有限公司

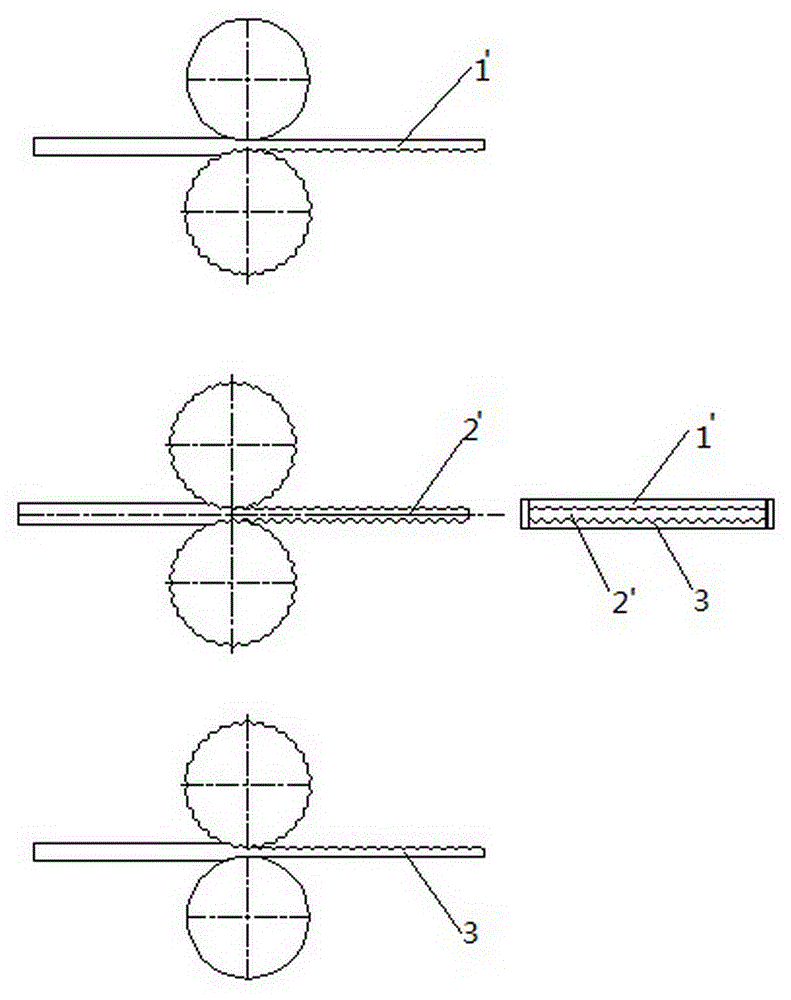

Metal composite plate rolling technique based on corrugated surface combining type blank forming

InactiveCN105127198AHigh bonding strengthSolve the problem of plate shape with large residual stress and serious driftAuxillary arrangementsMetal rolling arrangementsCrazingDissimilar metal

The invention discloses a metal composite plate rolling technique based on corrugated surface combining type blank forming and belongs to the technical field of machining of materials of metal composite plate strips. The metal composite plate rolling technique comprises the following steps that a metal base plate and a doubling plate are selected, arc-shaped base plate ripples and arc-shaped doubling plate ripples matched with the arc-shaped base plate ripples are rolled on the combined surfaces of the base plate and the doubling plate respectively, the section of each arc-shaped toothed ripple is in the shape of an arc or an elliptic arc or a sine wave, the height of each arc-shaped ripple is s, the width of each arc-shaped ripple is t, the thickness of the doubling plate is h, s / h=0.01-0.9, and t=(10-20)s; the base plate and the doubling plate are cleaned and stacked together, the base plate ripples and the doubling plate ripples are engaged, blank forming is conducted, and a composite plate blank comprises a double-layer metal composite plate blank or a three-layer metal composite plate blank or a four-layer metal composite plate blank; and a composite plate strip is obtained through rolling. By the adoption of the metal composite plate rolling technique, the technical problems that when a dissimilar metal composite plate is produced, the binding performance of a combined interface is poor, and bending, cracks and large residual stress occur are solved, the combining efficiency is high, and the binding strength is improved essentially.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Light metal-base laminar composite and preparation method thereof

InactiveCN107323030AHigh strengthImprove toughnessCoatingsRolling safety devicesOptoelectronicsMetal sheet

The invention relates to a light metal-based composite material and a preparation method thereof, comprising a layered light metal and graphene nanosheets distributed in the layered metal, the light metal-based composite material comprising at least two heterogeneous light metal substrate metal layers and At least one composite layer is alternately arranged, and the composite layer is located between two layers of heterogeneous light metal substrate metal layers; the light metal-based composite material is cold rolled, or warm rolled, or hot rolled, or electroplastically rolled, or It is prepared by the method of warm rolling + electroplastic rolling. The light metal base layer composite material prepared by the method of the invention has higher strength and toughness, and can realize large-scale production of layered composite boards, with simple process and relatively low cost.

Owner:CHANGZHOU UNIV

Hot roller rolling method for stainless steel/aluminium composite plate

InactiveCN1586751AImprove deep drawing performanceHigh yieldWork treatment devicesAuxillary arrangementsSolution treatmentHeating furnace

The hot roller rolling process of composite stainless steel / aluminum plate includes the main steps of: physical and chemical surface treatment of stainless steel plate and aluminum plate including alkali solution treatment, cold water and hot water flushing, soaking with nitric acid solution, cold water flushing, ultrasonic defatting of stainless steel plate in metal washing agent and cold water flushing and stoving; laminating stoved stainless steel plate and aluminum plate and heating at 250-500 deg.c; composite rolling in rolling mill with roller preheated to 100-400 deg.c; and final diffusion annealing of the composite plate. The present invention has the main advantages of less deformation in total reduction degree of 10-35 %, obviously raised interface combining strength, high qualified product rate and very high deep drawing performance.

Owner:NORTHEASTERN UNIV

Method for manufacturing ultra-fine crystal magnesium/titanium layered polystyrene-plywood laminate

InactiveCN101244429AImprove performanceHigh bonding strengthRoll force/gap control deviceTemperature control devicePolystyreneTitanium

The invention relates to a production method of ultra-fine crystal magnesium / titanium laminated composite panel, which comprises the following steps: firstly, cleaning the surfaces of the metal materials; secondly, stacking the metal materials; thirdly, annealing the stacked sheets; fourthly, rolling the sheets after annealing; fifthly, cutting the rolled sheets into two identical parts, trimming and deburring; repeating the first step to the fourth step for lamination and ply rolling; sixthly, annealing the composite panel obtained from lamination and ply rolling to obtain the ultra-fine crystal magnesium / titanium laminated composite panel. The production method solves the problems of complicated technology, high cost, poor corrosion resistant performance of material and poor interface binding performance of the magnesium / titanium laminated composite panel existing in the prior art. The production method has the advantages of simple technology, low cost as well as good corrosion resistant performance and good interface binding performance of the composite panel.

Owner:HARBIN INST OF TECH

Composite magnesium plate ribbon of magnesium clad aluminum product and composition method

InactiveCN101049745AReduce crackingReduce scratchesAuxillary arrangementsMetal rolling arrangementsIngotHeating furnace

An Al material clad Mg-base band is prepared from the Mg plate or Mg plate ingot as basic material and the cladding Al sheets through hot rolling or cold rolling to attach said Al sheets to both surfaces of basic material. It has high cold deformation power and anticorrosion ability.

Owner:SOUTHWEST UNIVERSITY

Titanium-coated aluminium laminated composite plate and preparation method thereof

InactiveCN101574861AGood surface bindingImprove conductivityHot-dipping/immersion processesMolten spray coatingInternal resistanceComposite plate

The invention discloses a titanium-coated aluminium laminated composite plate used for an insoluble anode in electrolysis process and a preparation method thereof, belonging to the technical field of wet-process metallurgy. The preparation method comprises the following steps of: adopting one or more of techniques of electric arc spraying, spray deposition, composite rolling, melt plating and thelike to coat an aluminium layer on the single surface of the surfaces of the titanium plate, obtaining two titanium / aluminium composite plates which are then prepared into the titanium-coated aluminium laminated composite electrode material which takes aluminium as an inner core (for improving the electric conductivity of the electrode) and is coated by titanium at the outer layer. The prepared titanium-coated aluminium laminated composite plate has the advantages of excellent interface coherency, good electric conductivity, good corrosion resistance, low cost and the like, a coating titaniumanode prepared by adopting the laminated composite plate as a substrate leads the internal resistance of inert electrode to be reduced, the current distribution to be even and the electrolytic productpurity to be improved, thus achieving the effects of saving energy and reducing consumption; and the bath voltage is reduced by 10 to 30 percent compared with that of the pure titanium coating anode.

Owner:KUNMING UNIV OF SCI & TECH

Brazing aluminium alloy multilayer composite board material and method for producing the same

InactiveCN101372161APrevent proliferationHigh strengthAuxillary arrangementsMetal rolling arrangementsHeat exchangerAluminium alloy

The invention relates to a braze-welding aluminum alloy multilayer composite material used in a heat exchanger main board of an automobile. The braze-welding aluminum alloy multilayer composite material is composed of AA4045 alloy, AA3003 alloy and Mod6060 alloy. A method provided by the invention is as follows: the three alloys are produced and are welded together by a sub-arc weld after the surfaces of the three alloys are cleaned in sequence that the AA4045 alloy is at the external layer, the AA3003 alloy is at the two middle layers and the Mod6060 alloy is at the internal layer. Then hot rolling and cold rolling are carried out. The alloys are processed to obtain the preset thickness which is 1.5mm to 2.5mm according to 20 percent to 30 percent of the cold processing rate, recrystallization and annealing are carried out at the thickness with the annealing temperature of 405 DEG C to 415 DEG C, heat preservation is carried out for 2 hours to 3 hours, and a finished product can be obtained by leveling and shearing after the alloys are sent out of a furnace. During the production process, each layer of the alloys plays the following functions respectively: the AA4045 alloy is mainly used for welding, the AA3003 alloy is used for isolating and the Mod6060 alloy is used for aging strengthening, strength reinforcing and collapse resisting.

Owner:南通华特铝热传输材料有限公司

Production method for ultralong thin titanium/steel compound plate

InactiveCN102441769AEasy to useGuaranteed lengthAuxillary arrangementsMetal rolling arrangementsSheet steelTitanium

The invention provides a production method for an ultralong thin titanium / steel compound plate, which comprises the following steps: firstly, correcting the shape of a multi-layer titanium plate and performing heat treatment; secondly, cleaning and polishing a basic-layer steel plate and the multi-layer titanium plate after the heat treatment; thirdly, explosively welding the basic-layer steel plate with the multi-layer titanium plate to prepare a compound plate; fourthly, leveling the compound plate and mechanically cutting to guarantee that the compound plate binding fraction gets to 100%; fifthly, relatively superposing and assembling the steel surfaces of two qualified compound plates with the same sizes, and welding to obtain a blank; sixthly, rolling the blank; and seventhly, leveling and machining to obtain the ultralong thin titanium / steel compound plate. The method provided by the invention is lower in production cost and high in production efficiency; and the method adopts a combination method of the explosive welding process and the superposing rolling process, so that the using performance of the compound plate can be guaranteed and the length and the thickness of the compound plate also can be guaranteed. Therefore, the qualified ultralong thin titanium / steel compound plate can be produced by using a general rolling process only.

Owner:XIAN TIANLI CLAD METAL MATERIALS

Rolling bearing unit

InactiveUS6971799B2Prolong lifeReduce signalingElectric signal transmission systemsRoller bearingsRolling-element bearingDistortion

A four-row tapered roller bearing is incorporated in the clearance between the inner surface of a housing and the outer surface of a rolling roller. A pair of supporting members supporting sensor devices are fitted in and supported by a part of the inner surface of the housing in such a manner that they are opposed to the ends of outer rings of the four-row tapered roller bearing disposed close to the both axial ends thereof. The sensor devices each comprise a distortion gauge as a detecting portion and a first coil for transmitting as a wireless signal a signal obtained by processing an output signal outputted from the distortion gauge. A second coil for receiving the wireless signal transmitted by the first coil is retained on a part of a member other than the supporting members.

Owner:NSK LTD

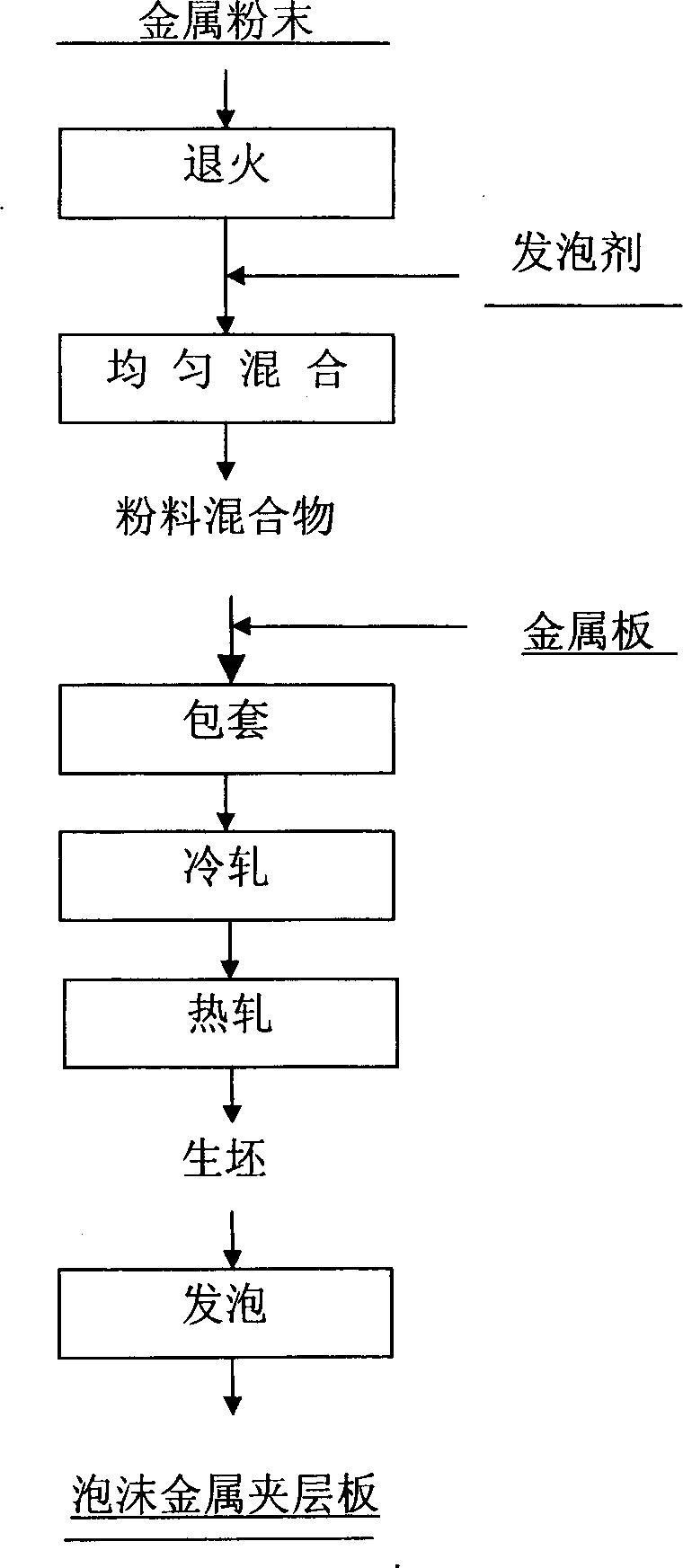

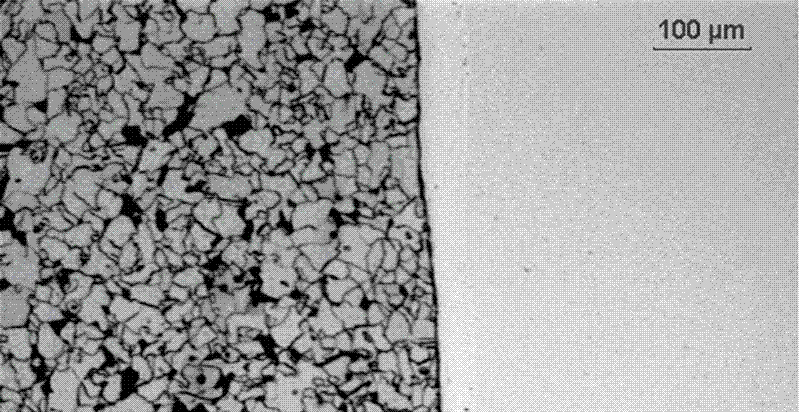

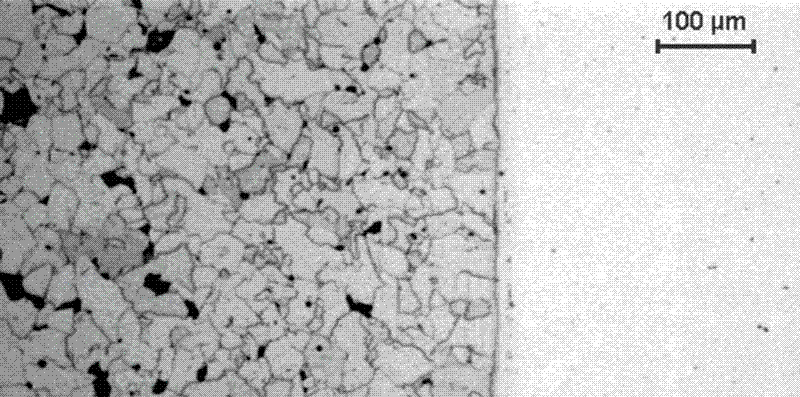

Preparation of foamed metal sandwich board using clad rolling method

InactiveCN1410200AHigh bonding strengthEquipment condition is simpleAuxillary arrangementsMetal rolling arrangementsFoaming agentSandwich board

A process for preparing sandwich plate of foam metal by wrapping-rolling method includes such steps as proportioning metal powder and foaming agent and controlling their granularity, mixing them, wrapping the mixture under stirring to uniformity, cold rolling, hot rolling for compactness, and foaming. Its advantages are simple apparatus and high binding strength between foamed core and metal plate and specific rigidity. It can be used to damp sound and vibration and insulate heat.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing non-brazing seam thin compound layer titanium/steel composite board

InactiveCN101406899AHigh bonding strengthGuaranteed Thickness RequirementsRoll mill control devicesFurnace typesSheet steelExplosive cladding

The invention discloses a method for preparing seamless thin multilayer titanium / steel composite plate and relates to a method for preparing the seamless titanium / steel composite plate with large specifications and a thin multilayer through a combined process of explosive welding plus hot rolling. The method is characterized in that after explosive cladding, a titanium plate and a steel plate form the composite plate through hot rolling. The method adopts a combined process of explosive welding plus hot rolling to prepare the seamless titanium / steel composite plate with the large specifications, an overall length over 10, 000mm and the thin multilayer, thereby not only ensuring the binding property and the specification requirements of the composite plate, but also meeting the demand on the seamless titanium / steel composite plate with the large specifications and the thin multilayer of large-scale pressure equipment.

Owner:XIAN TIANLI CLAD METAL MATERIALS

Method for preventing interface of stainless steel compound plate subjected to vacuum composite rolling from being oxidized

ActiveCN102179405ASolve the problem of elemental diffusionIncreased interfacial shear strengthAuxillary arrangementsMetal rolling arrangementsUltimate tensile strengthVacuum chamber

The invention discloses a method for preventing an interface of a stainless steel compound plate subjected to vacuum composite rolling from being oxidized, and belongs to the technical field of materials. The method comprises the following steps of: (1) performing surface treatment; (2) alternately overlapping a stainless steel plate material and a carbon steel plate material, and separating by using nickel foils to obtain a composite blank; (3) putting between two metal panels to form a clamped composite blank, or welding two composite blanks to form a composite blank-blocker-composite blankcombined structure, and putting between two metal panels to form the clamped composite blank; (4) putting in a vacuum chamber, vacuumizing and welding the peripheries of contact surfaces; (5) heatingand keeping temperature in a resistance furnace to obtain the composite blank subjected to heat treatment; and (6) removing the metal panels, and rolling the composition blank subjected to heat treatment. The method solves the problem of element diffusion of the interface in the process of preparing a stainless steel-carbon steel compound plate, so that the shear strength of the interface is improved by 10-40MPa, and the decarbonization and a chromium-rich layer of the interface are eliminated.

Owner:沈阳科安捷材料技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com