Composite magnesium plate ribbon of magnesium clad aluminum product and composition method

A technology of aluminum alloy strips and clad aluminum, which is applied in the field of aluminum clad magnesium strips, magnesium-based clad aluminum composite magnesium strips, and can solve the problems of high processing costs of magnesium and magnesium alloys, poor corrosion performance of magnesium alloys, Reduce pressure leakage and other problems, achieve the effect of reducing surface anti-corrosion coating treatment process, improving cold deformation ability, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

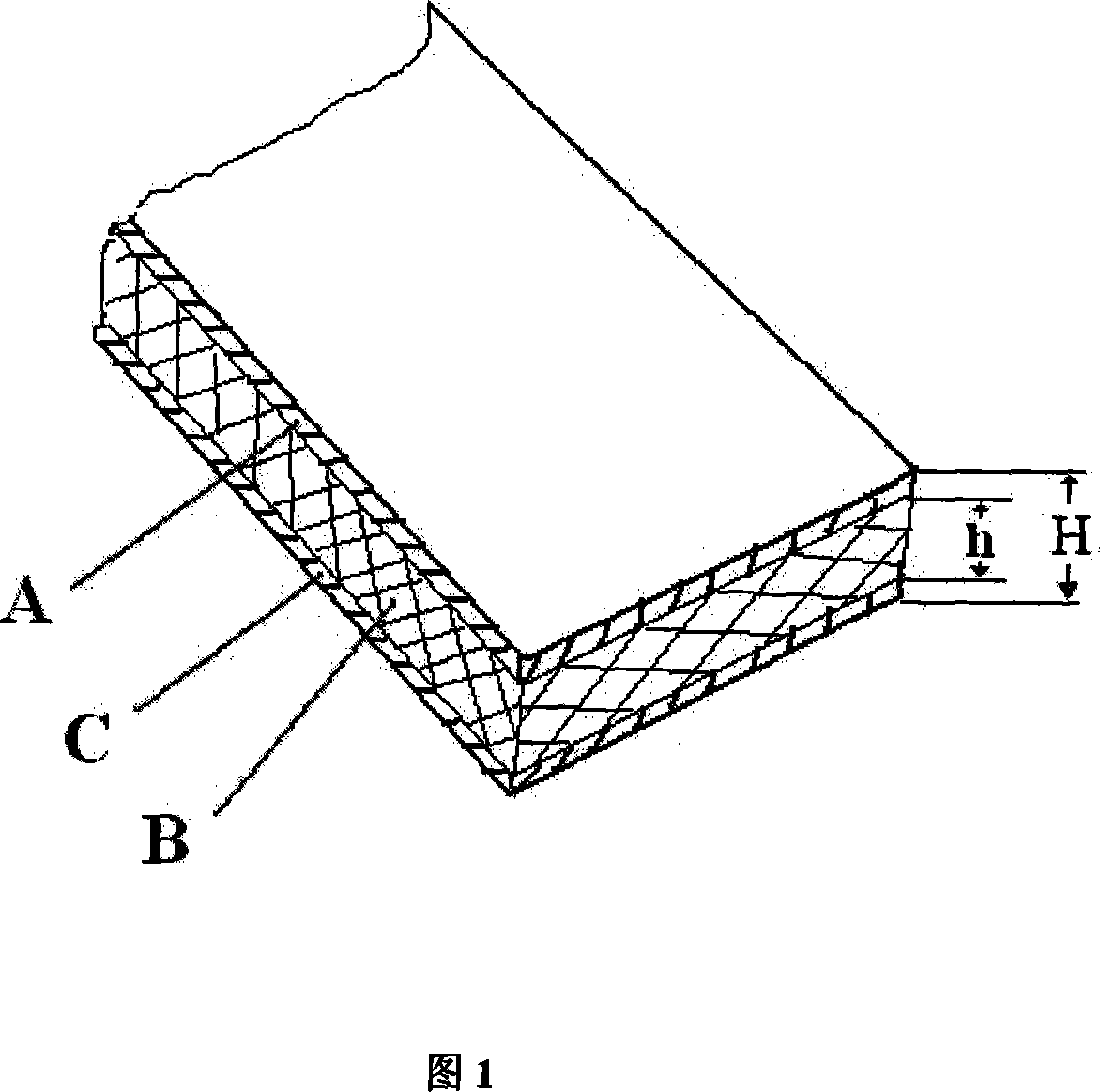

[0020] Example 1: AZ31 (American ASTM standard association grade) magnesium alloy-based aluminum clad plate coating method: AZ31 magnesium alloy is cast into a slab ingot, the size of the slab ingot is 30×150×300mm; 1060 aluminum alloy (state is not limited) is used as the package Cladding, cladding aluminum alloy specifications are 1×155×310mm, the upper and lower surfaces have the same alloy and the same specifications, the above magnesium ingot and the edge of the aluminum plate are spot welded together by ultrasonic welding, and heated in a heating furnace to 400°C- 510°C, keep warm for 1-24 hours, then go out of the furnace and then welded by hot rolling and plastic deformation. Note that the rolling speed of the first pass is 20 m / min, and the lubricating liquid cannot be sprayed during the rolling process. After the magnesium alloy and the clad aluminum plate are completely welded, they are rolled to the target thickness according to the normal hot rolling process of the...

example 2

[0021] Example 2: Roll the AZ31 magnesium alloy into a 2.5mm thick plate coil, prepare two rolls of 0.1mm thick pure aluminum foil coil with the same width as the AZ31 coil, and prepare two rolls of 0.1mm pure aluminum foil for one coil of 2.5mm thick AZ31 magnesium alloy The strip is covered in the middle and stacked into one coil, and the middle temperature stacking is welded on the double uncoiling cold rolling with a heating furnace. The temperature of the heating furnace is controlled from 100°C to 620°C. During the first rolling pass, no lubricating liquid or spraying is allowed. Cooling liquid, the rolling speed is 40 m / min, after the magnesium plate and the aluminum plate are welded together, they are rolled to the target thickness according to the general magnesium plate cold rolling process. Subsequent other processes are the same as the general magnesium alloy plate production process according to user requirements.

example 3

[0022]Example 3: MB5 (China's wrought magnesium alloy grade is equivalent to the American ASTM standard association AZ61A grade) base magnesium alloy clad aluminum plate coating method: MB5 is cast into an ingot, and the size of the ingot is 340×1260×2400mm; 1060 aluminum alloy ( The state is not limited) as the cladding, the specification of the cladding aluminum alloy is 20×1300×2450mm, the upper and lower surfaces are the same alloy and the same specification, and the edges of the above ingot and aluminum plate are spot welded together by sonic welding, or mechanically Pressure pre-welded together, heated to 400°C-510°C in a heating furnace, kept warm for 1-24 hours, and then hot-rolled and plastically deformed and welded. Note that the rolling speed of the first pass is 30 m / min, and the lubricating liquid cannot be sprayed during the rolling process. After the magnesium alloy and the clad aluminum plate are completely welded, they are rolled to the target thickness accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com