Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Good cold deformation ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

10.9-grade boron-containing spheroidizing-free cold heading steel wire rod and manufacturing method thereof

ActiveCN102321851AImprove hardenabilityGood cold deformation abilityTemperature control deviceWire rodBoron containing

The invention discloses a 10.9-grade boron-containing spheroidizing-free cold heading steel wire rod and a manufacturing method thereof. The wire rod comprises the following components in percentage by weight: 0.23 to 0.33 percent of C, 0.02 to 0.20 percent of Si, 0.50 to 0.90 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.025 percent of S, 0.005 to 0.040 percent of Al, 0.005 to 0.050 percent of Ti, 0.0005 to 0.0035 percent of B, 0.58 to 1.50 percent of Cr, 0.01 to 0.05 percent of Ni and the balance of iron and impurities, and also comprises 0.01 to 0.05 weight percent of V preferably. The manufacturing method sequentially comprises the following steps of: smelting; refining outside a furnace; continuously casting; performing high-speed wire controlled rolling; and cooling. The wire rod has the advantages of low hardness, good plasticity, high cold deformability, high hardenability and the like; and the preparation process is simple, and low in cost. In the process of preparing a fastener from the wire rod, a spheroidizing process before drawing can be saved, and the effects of saving energy, reducing pollution, improving yield and reducing use cost are achieved. The product completely meets the production and use requirements of 10.9-grade fasteners.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

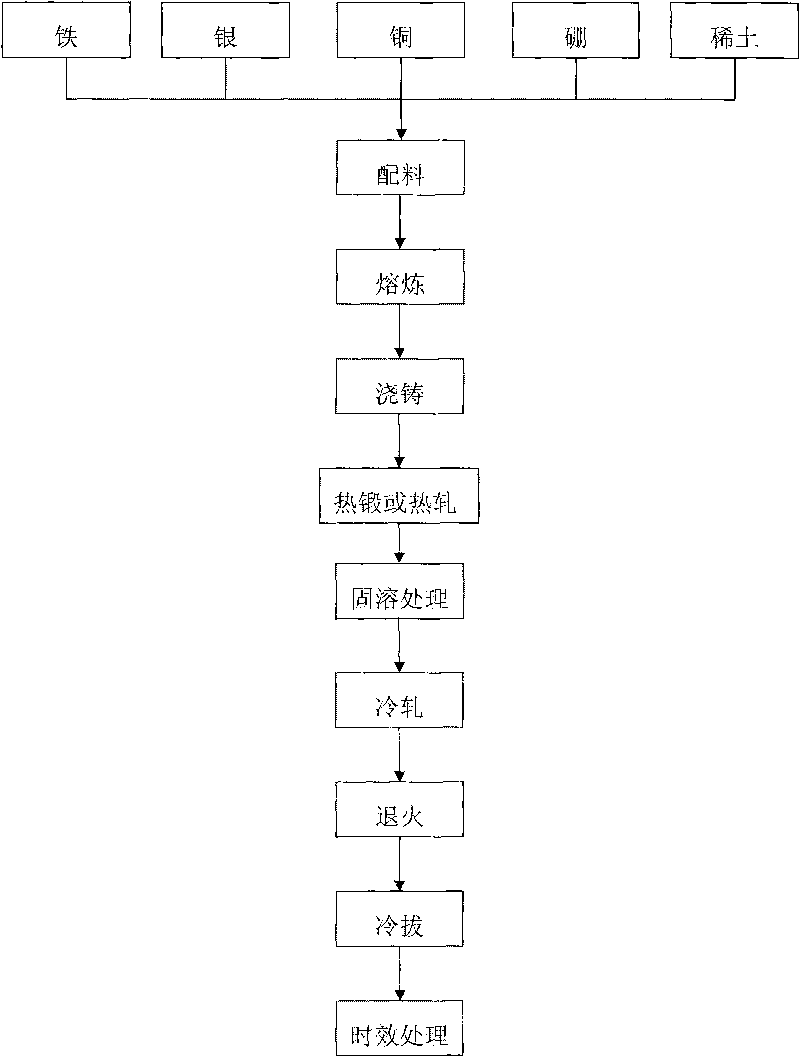

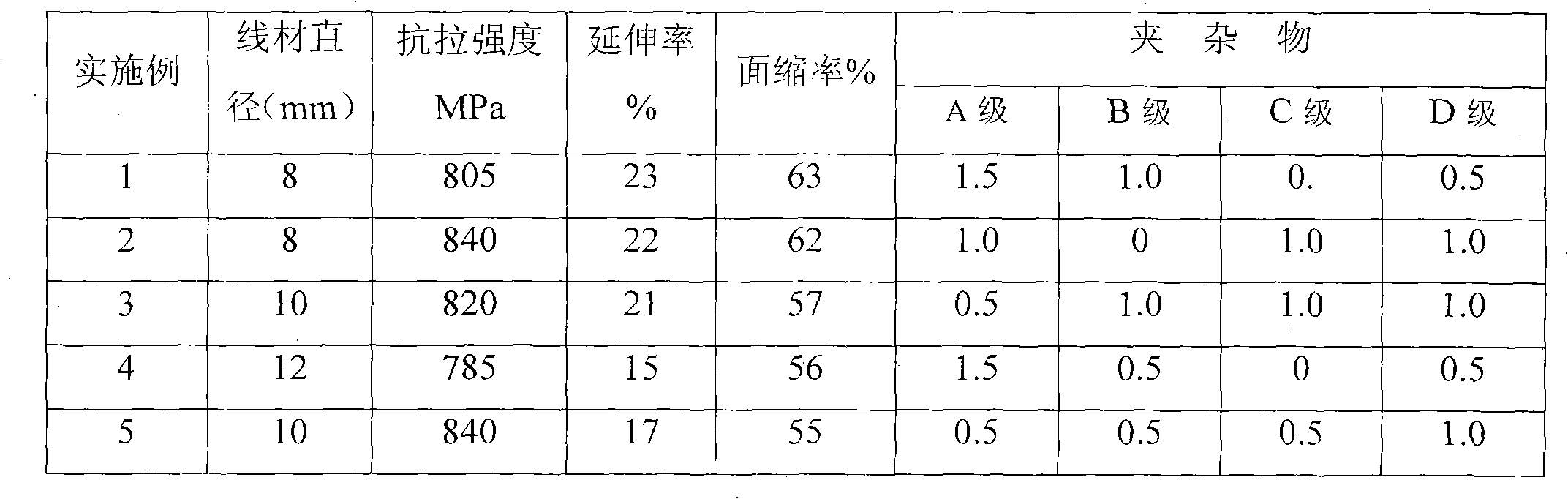

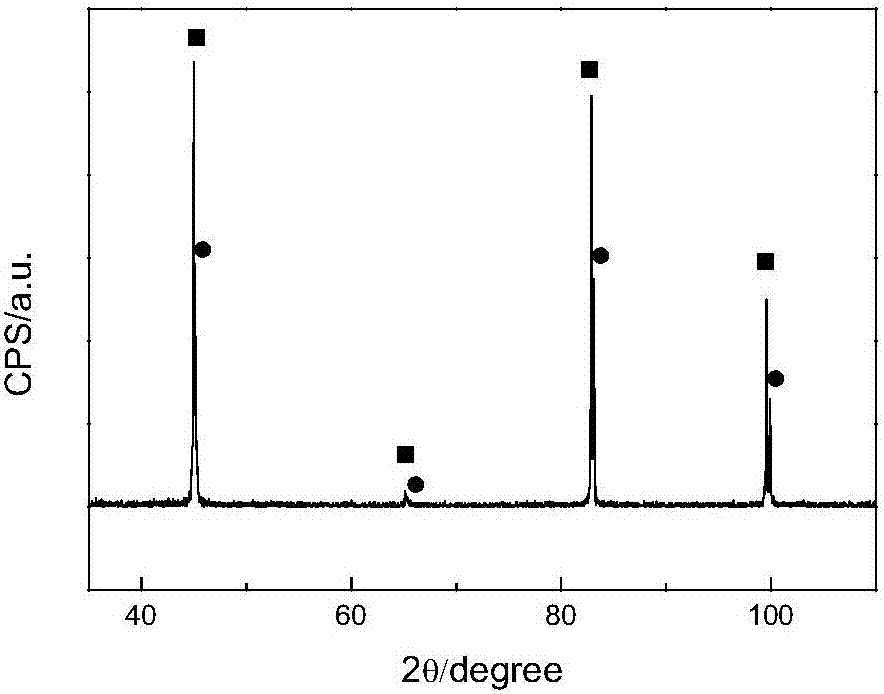

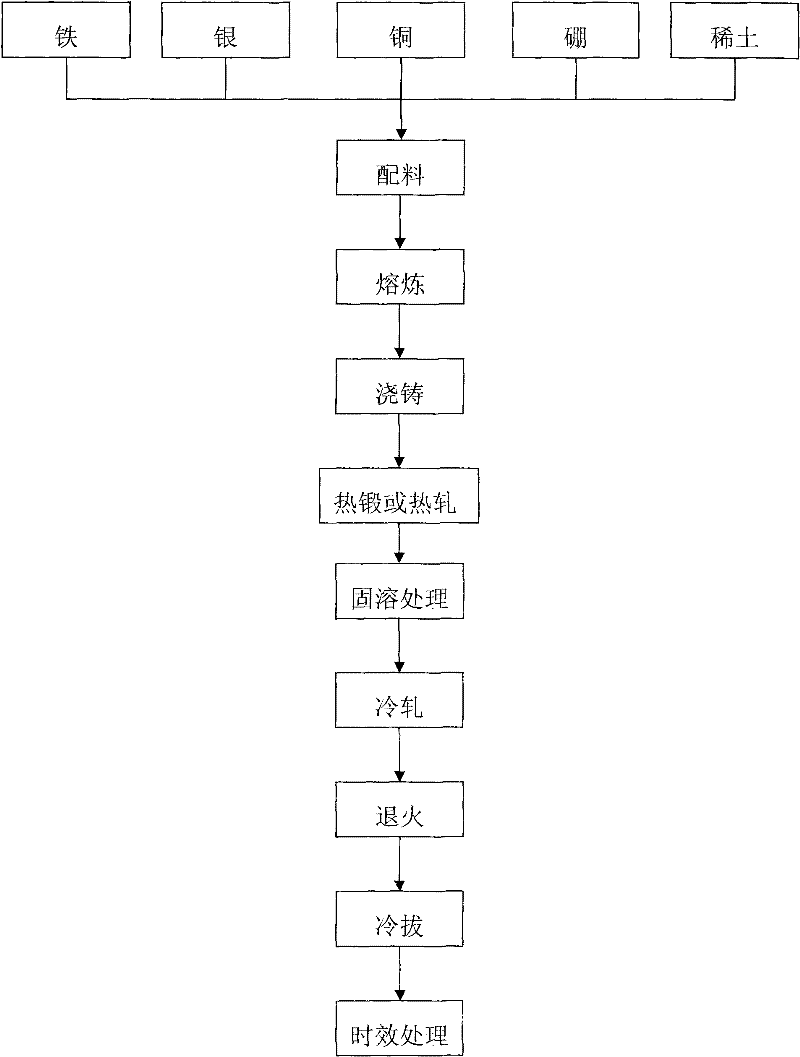

Cu-Fe in-situ composite with boron, silver and rare earth elements added and preparation method thereof

The invention discloses a Cu-Fe in-situ composite with boron, silver and rare earth elements added and a preparation method thereof. The invention is characterized by adopting multimode comprehensive strengthening technology such as multi-micro alloying, solid solution strengthening, aging strengthening, fine grain strengthening, distortion strengthening, fiber strengthening and the like, using Cu as the base and adding a little Fe and trace Ag and B, rare earth or rare earth compounds to prepare the high strength and high conductivity copper alloy material through smelting, casting, hot forging or hot rolling, solid solution treatment, cold rolling or cold drawing, aging and the like. The prepared material has the advantages of high strength, good electric and thermal conductivity, simple preparation process and low cost, thus realizing wide application in the fields such as electronics, information, transportation, energy, metallurgy, electromechanics and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

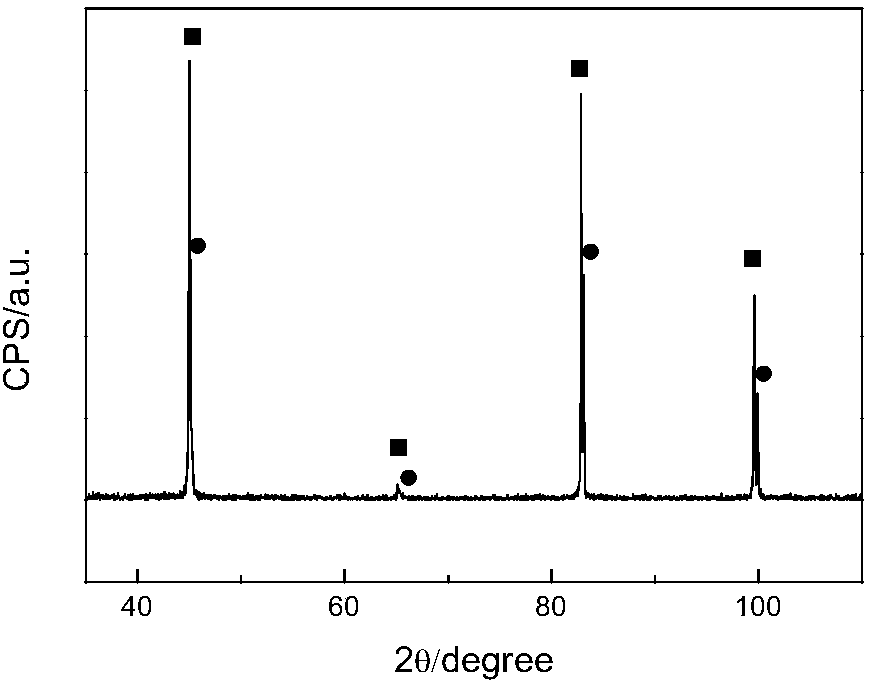

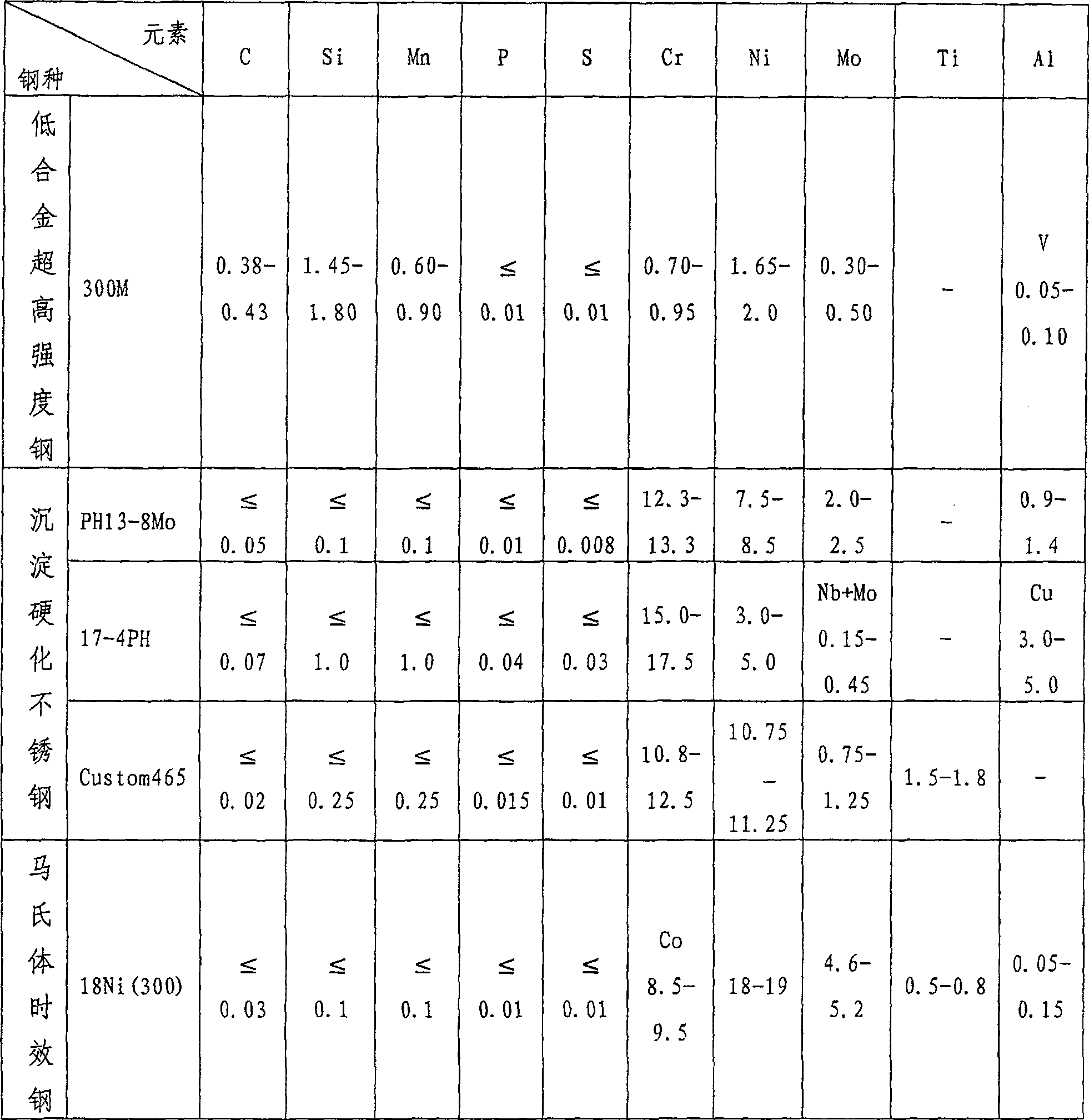

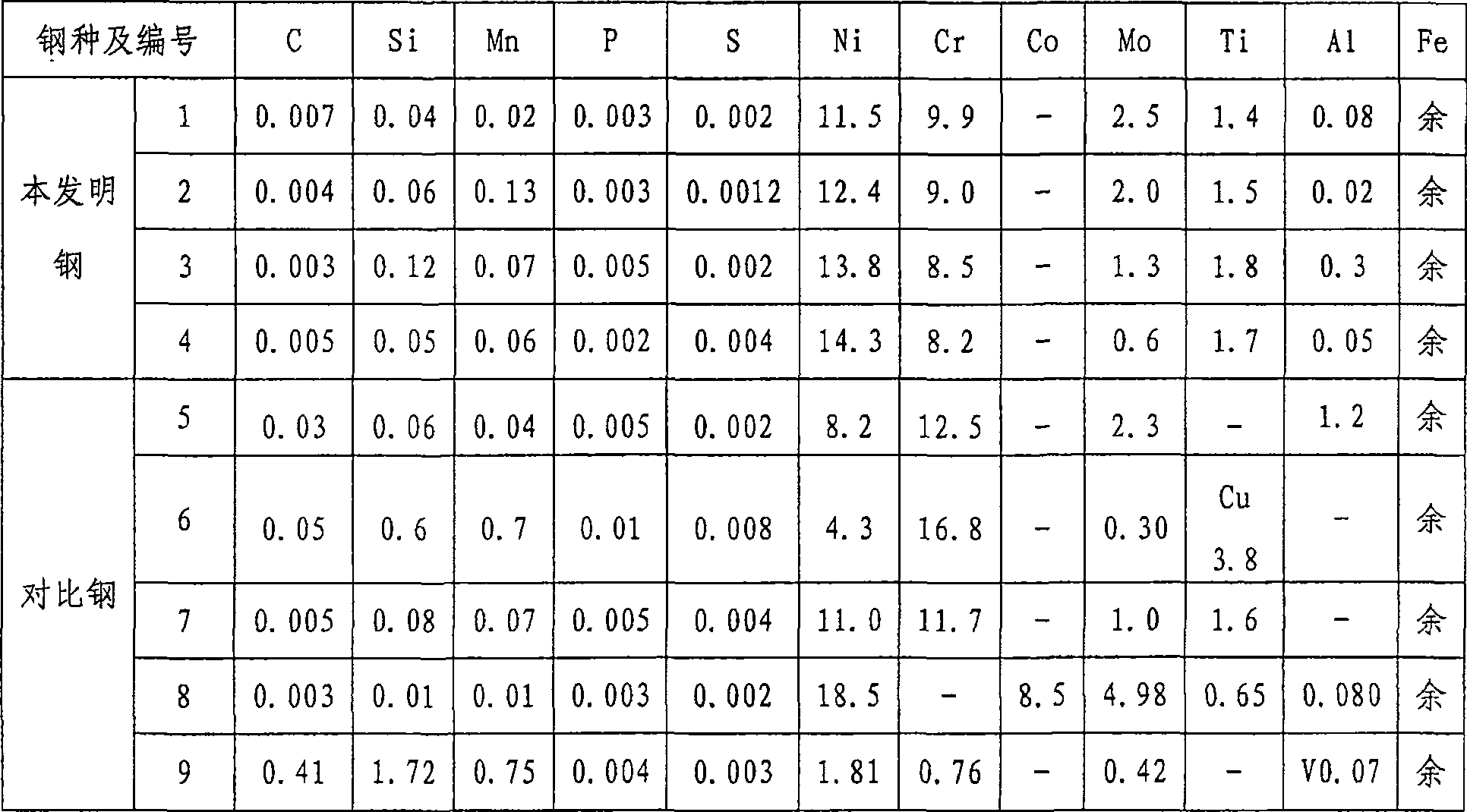

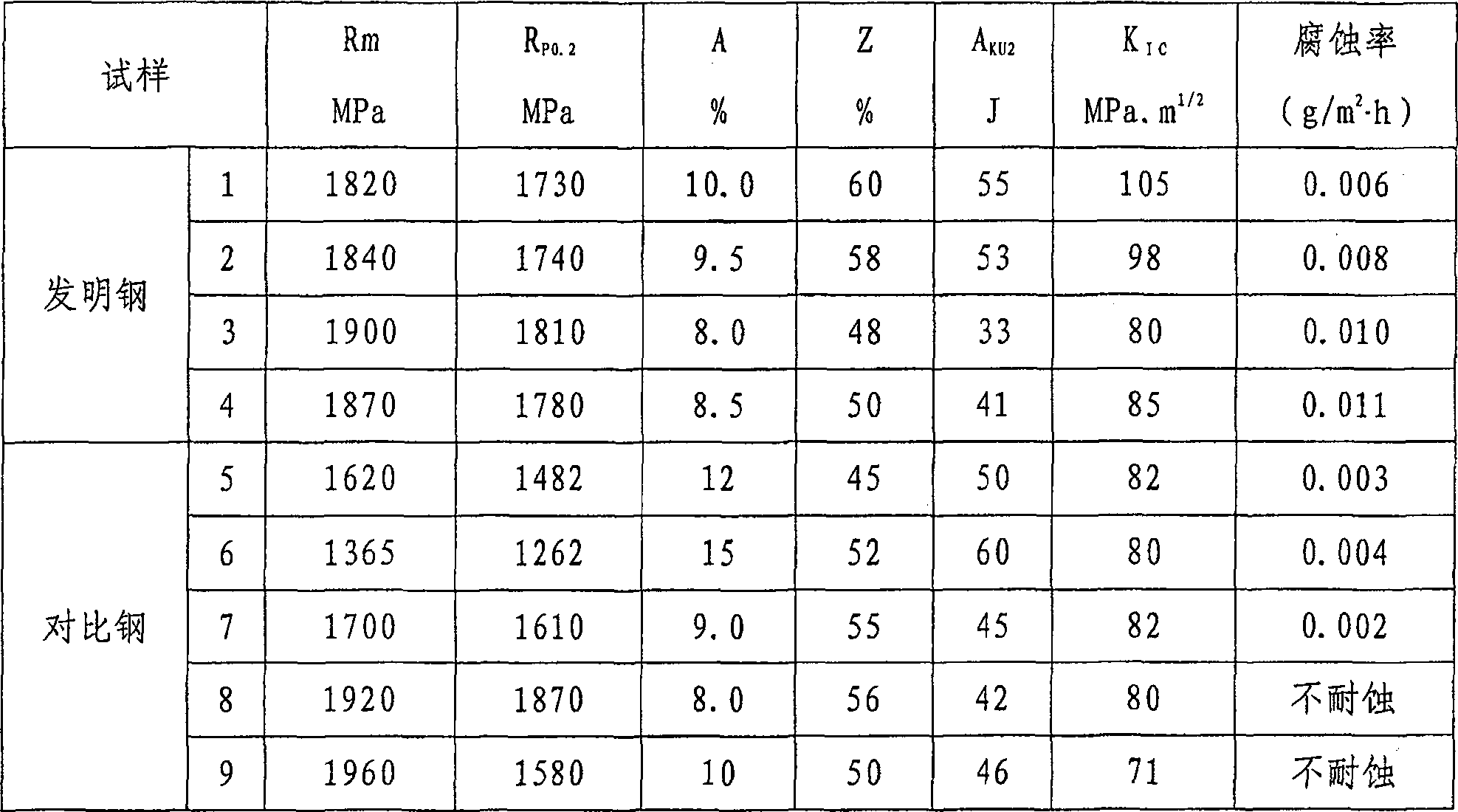

Martensite ageing stainless steel with high strength and high toughness

This invention relates to a high-strength and high-toughness maraging stainless steel, whose chemical composition is: C less than or equal to 0.02 wt.%, Si less than or equal to 0.1 wt.%, Mn less than or equal to 0.1 wt.%, S less than or equal to 0.01 wt.%, P less than or equal to 0.01 wt.%, Cr 10.0-11.5 wt.%, Ni 11.7-12.5 wt.%, Mo 0.5-2.0 wt.%, Ti 1.2-1.7 wt.%, Al 0.02-0.5 wt.%, and Fe as balance. The strength of the maraging stainless steel is 1700-1800 MPa. The maraging stainless steel has such advantages as low cost, high strength, high fracture toughness, and high corrosion resistance.

Owner:CENT IRON & STEEL RES INST

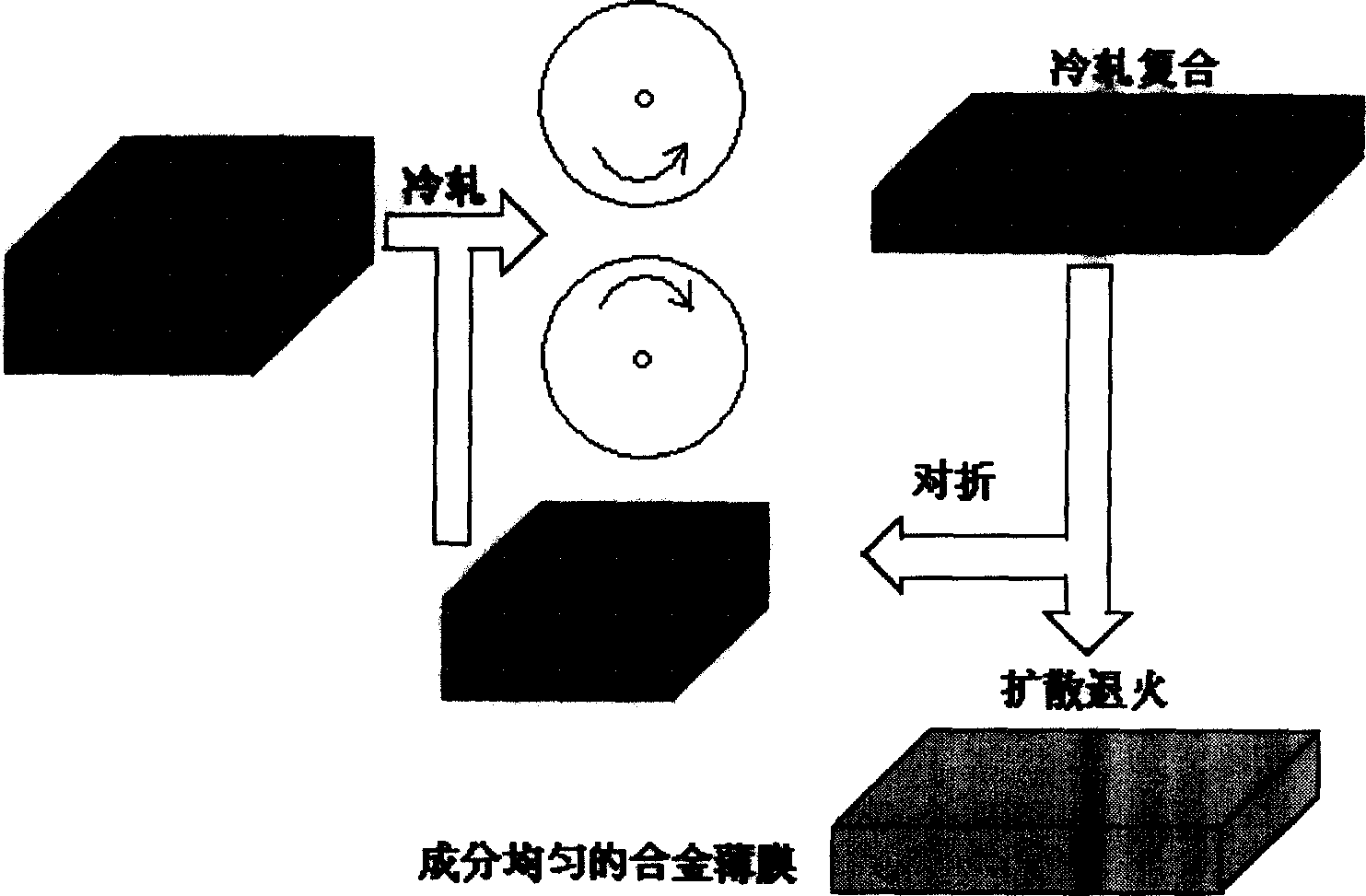

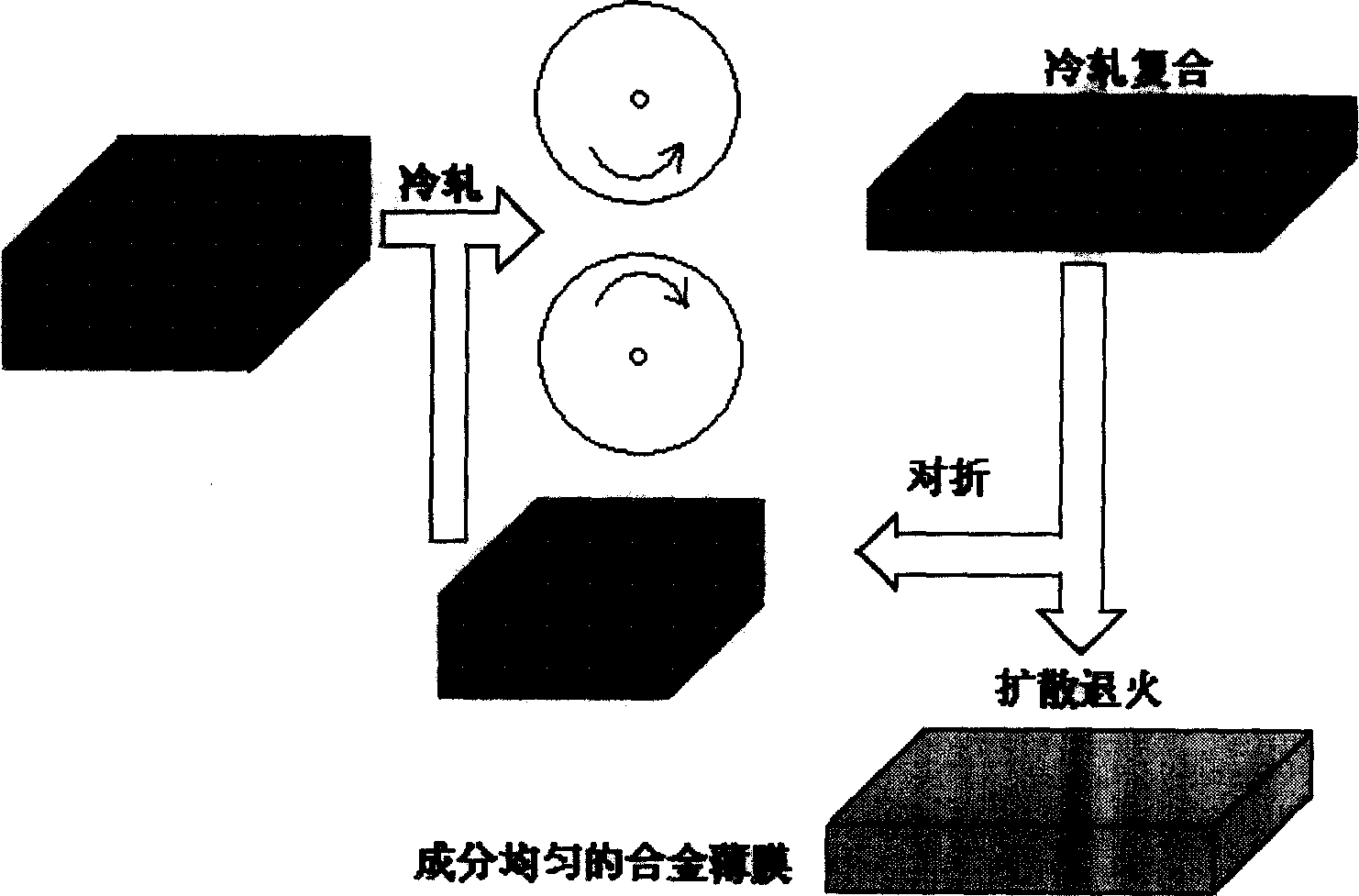

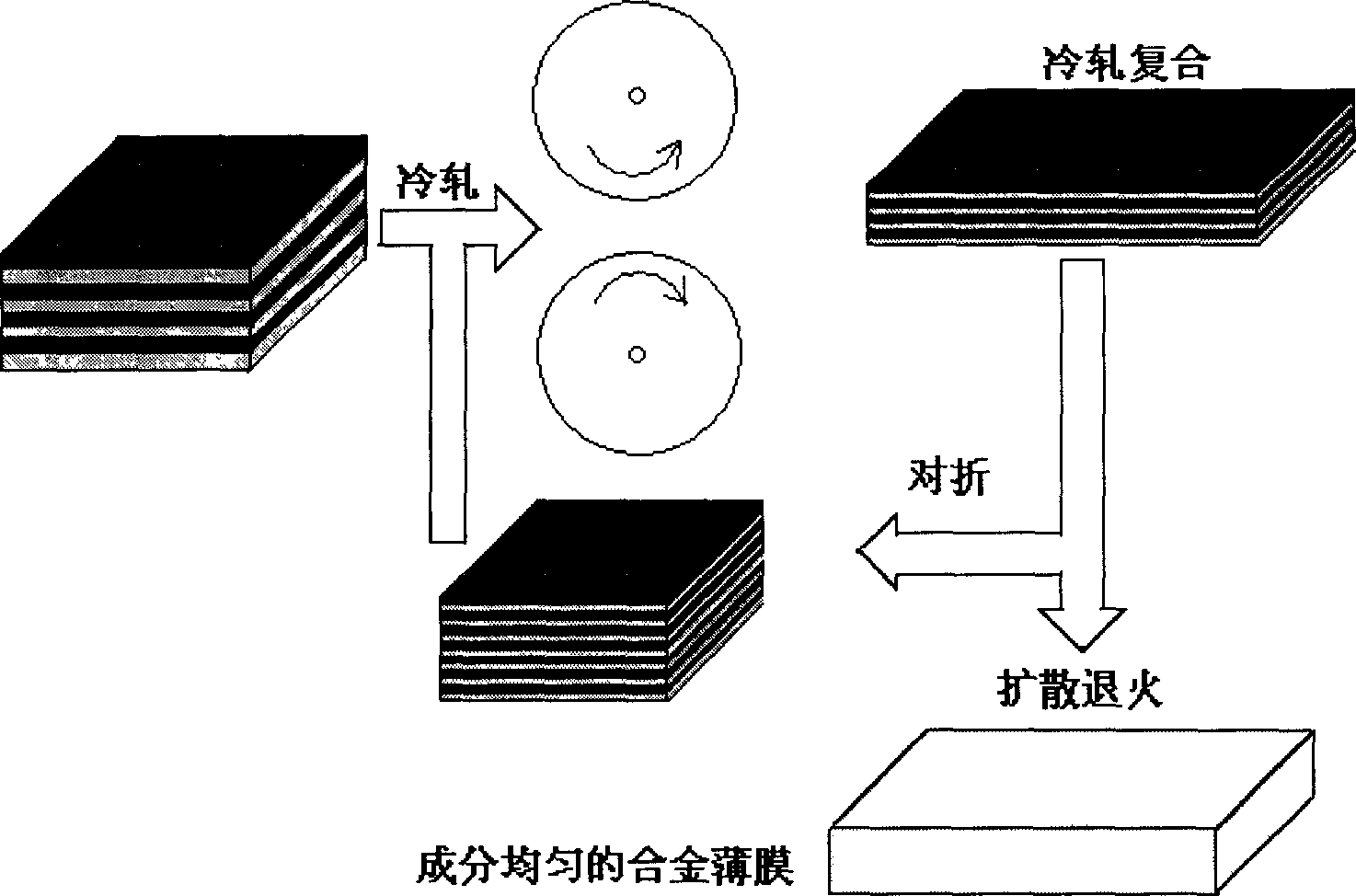

Method for preparing NiAl shape memory alloy film by cold rolling ultra-thin laminated alloy foil

InactiveCN1667144AGood shape memory effectImprove plasticityMetal rolling arrangementsMetal foilAlloy thin film

This invention discloses a method of preparing NiAl shape memory alloy thin film through cold rolling ultrathin lamination alloying. Good plasticity, easy deformed Al foil, Ni foils are materials, and foil thickness is defined according to atom constitution formula Ni1-XAlX. Metal foils are alternating laid, sandwich structure is got after big deformation cold rolling, it is repeated again and again, and finally components uniform alloy film is got after diffusion annealing alloying. The reactant ratio is 0.30íœxíœ0.40. The film components made by this method is easy control, crystal grain is small, fatigue life is high, area is large and cost is low.

Owner:SICHUAN UNIV

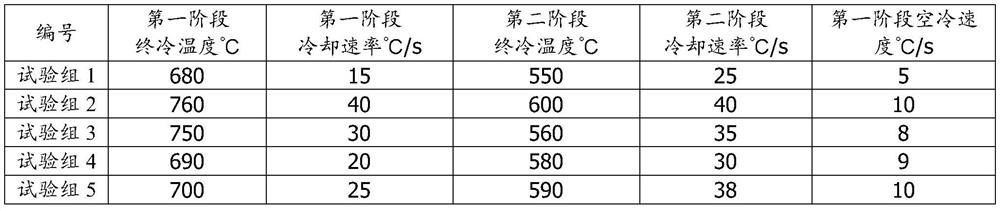

Drahtstahl for high strength fastening piece and production method thereof

InactiveCN101787491AWith energy savingReduce manufacturing costMetal rolling arrangementsWire rodHigh intensity

The invention relates to a drahtstahl for a fastening piece and a production method thereof, and the drahtstahl comprises the following components by weight percent: 0.39-0.48 % of C, 0.15-0.35% of Si, 0.30-0.90% of Mn, 0.60-1.20% of Cr, 0.010-0.07% of Als, less than or equal to 0.035% of P, less than or equal to 0.035% of S and the balance Fe and unavoidable impurity; and the production method comprises the following steps: smelting with a clean steel process and casting into a blank, and adding Si-Ca line in the refining; heating the continuous casting to 980-1,080 DEG C; rough rolling: controlling the deflection to be 70-80%; intermediate rolling: controlling the deflection to be 80-90%; pre-precision rolling: controlling the deflection to be 65-75%; water-cooling until the temperature is cooled to be 1,000-1,020 DEG C; precision rolling: controlling the deflection to be 60-90%; water-cooling for the second time until the temperature is cooled to be 800-900 DEG C; spinning; cooling to phase change initial temperature, namely the range from Ar3 to 50 DEG C higher than Ar3 by adopting an aerial fog mixed method; and continually cooling until the temperature is cooled to be 400-500 DEG C and naturally cooling to environment temperature. The invention can be drawn directly, has good cold deformation and is not easy to crack.

Owner:武钢集团有限公司

Production of TiNiCu shape memory alloy thin membrane by cold rolling superthin laminated alloy

InactiveCN1644740ASolve brittle, difficult-to-process problemsGood shape memory effectMetal rolling arrangementsAlloy thin filmShape-memory alloy

The invention was involved in the method to preparation of TiNiCu shaped memory alloy firm by cold roll ultrathin lamination alloying. Using Ti foil, Ni foil, Cu foil and NiCu foil as the rough material which has good plastic nature that easy to distortion. The thickness of foil determined according to Tix(Nil-yCuy)1-x. The foils were placed by mutual overlap, and the ultrathin sandwich structure formed by cool roll. The ultrathin structure was repeated cool rulled. The foil that has a homogeneous ingredient was gained after diffusion annealing. The ingredient has the quality of 0.45<=x<=0.55, 0<=y<=0.6. Its advantages: ingredients easy to be controlled and has a small crystal grain; has a long endurance life, a large area and a low cost.

Owner:SICHUAN UNIV

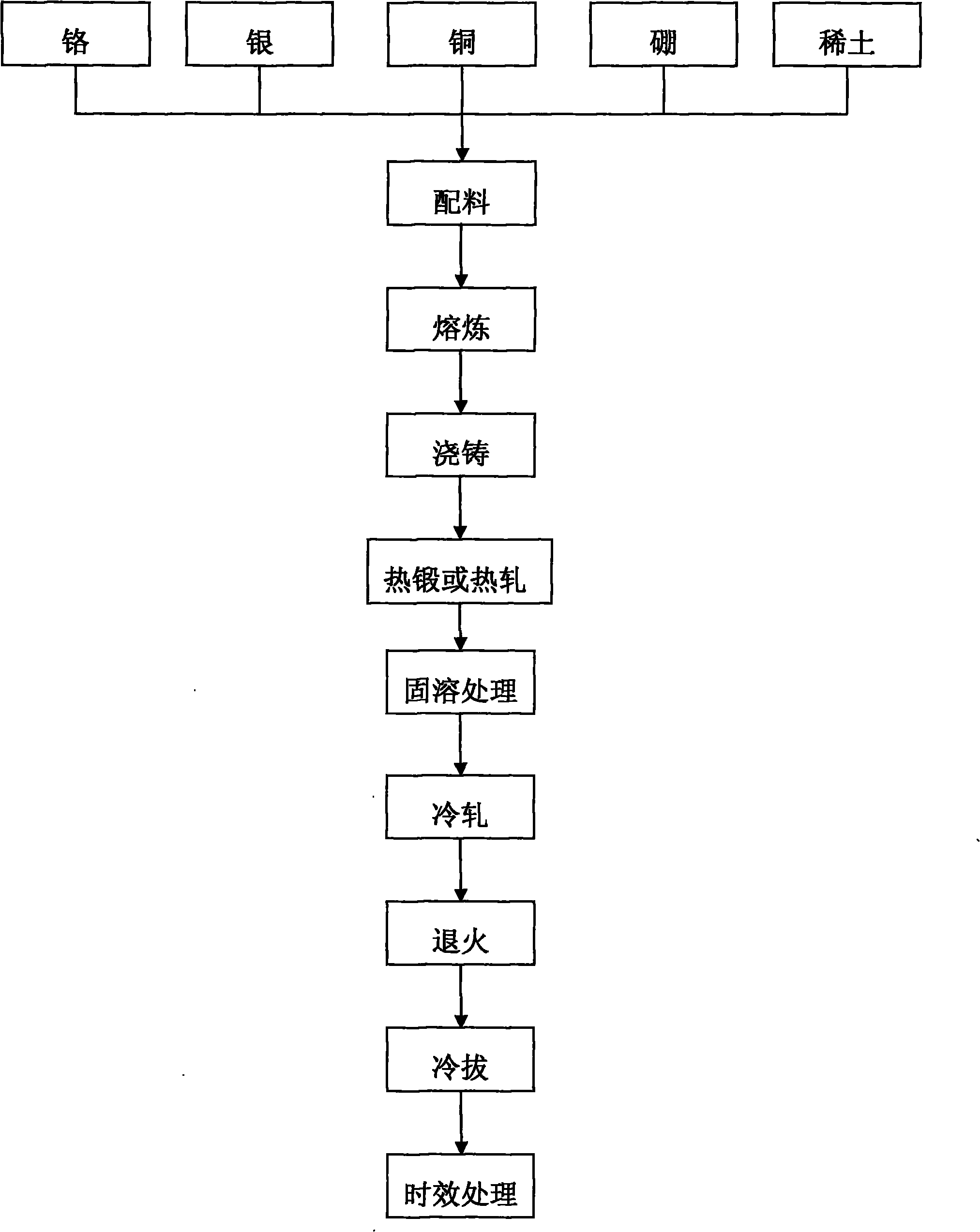

Cu-Cr in-situ composite with boron, silver and rare earth elements added and preparation method thereof

The invention discloses a Cu-Cr in-situ composite with boron, silver and rare earth elements added and a preparation method thereof. The invention is characterized by adopting multimode comprehensive strengthening technology such as multi-micro alloying, solid solution strengthening, aging strengthening, fine grain strengthening, distortion strengthening, fiber strengthening and the like, using Cu as the base and adding a little Cr and trace Ag and B, rare earth or rare earth compounds to prepare the high performance copper alloy in-situ composite through smelting, casting, hot forging or hot rolling, solid solution treatment, cold rolling or cold drawing, aging and the like. The prepared material has the advantages of high strength, good electric and thermal conductivity, simple preparation process and low cost, thus realizing industrial application in the aspects such as electrician switches, contact materials, resistance electrodes, rotor conductors of large electrical high speed turbine generators, overhead conductors of electric cars and electric trains, lead frames of very large scale integrated circuits and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

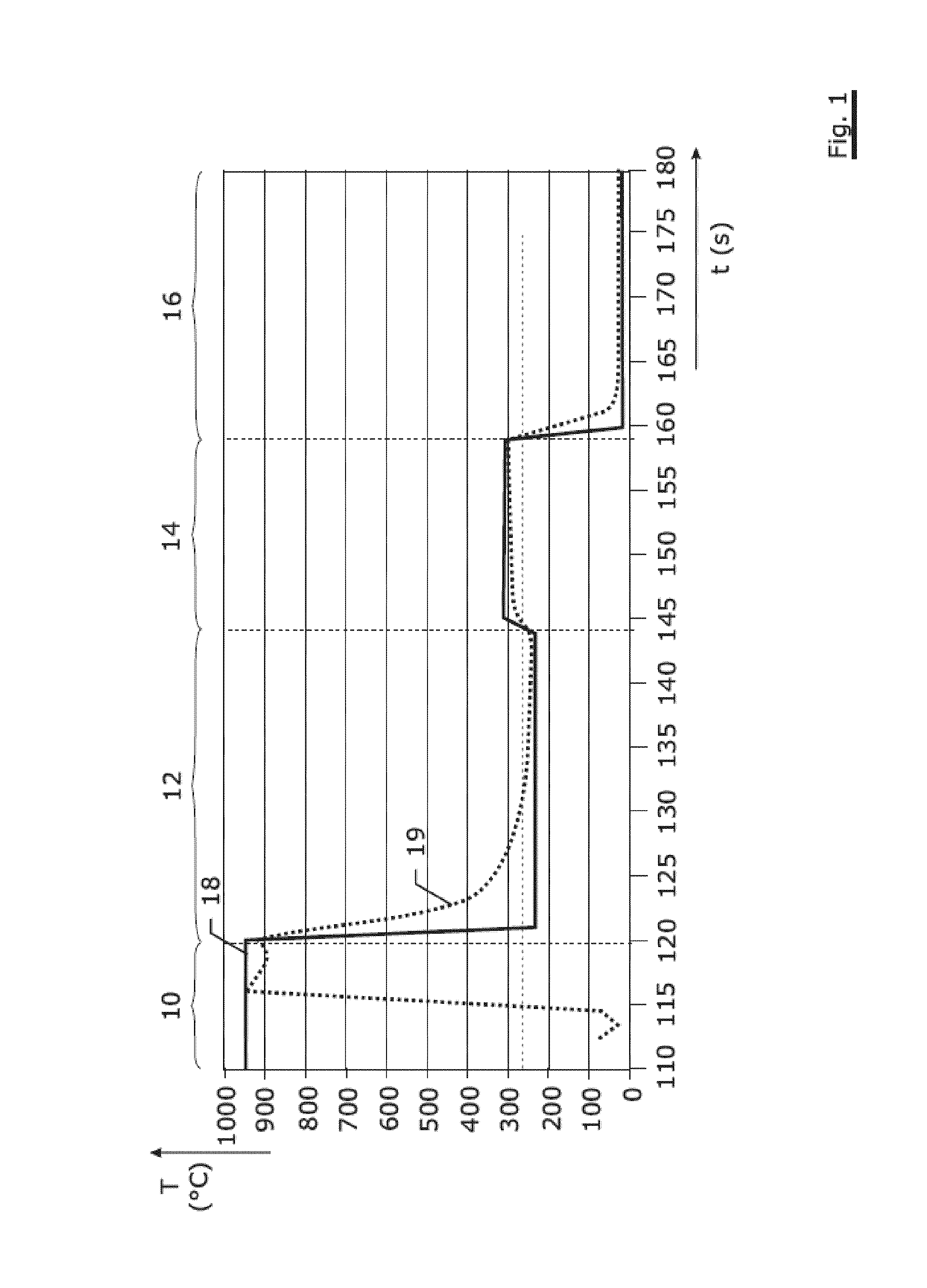

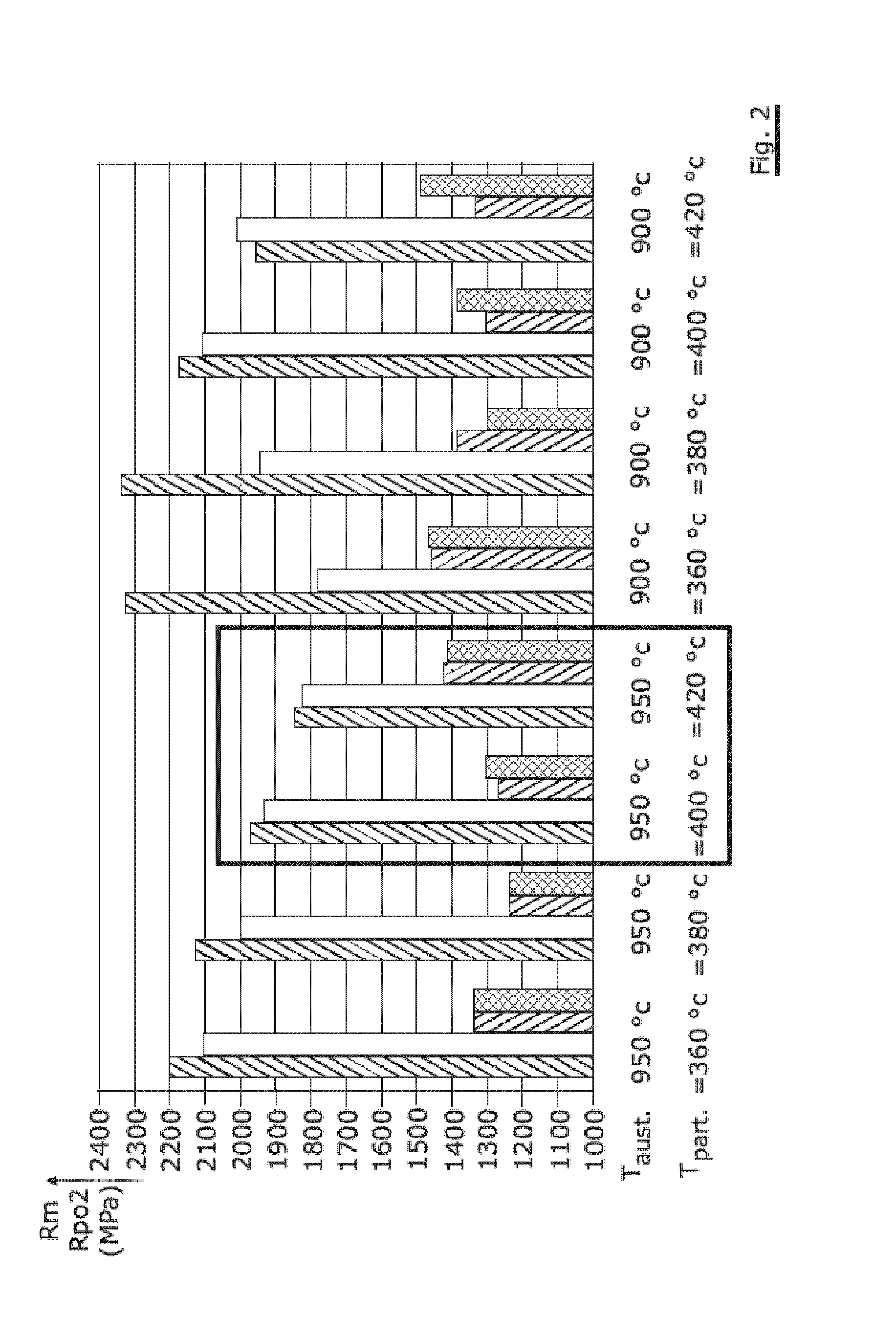

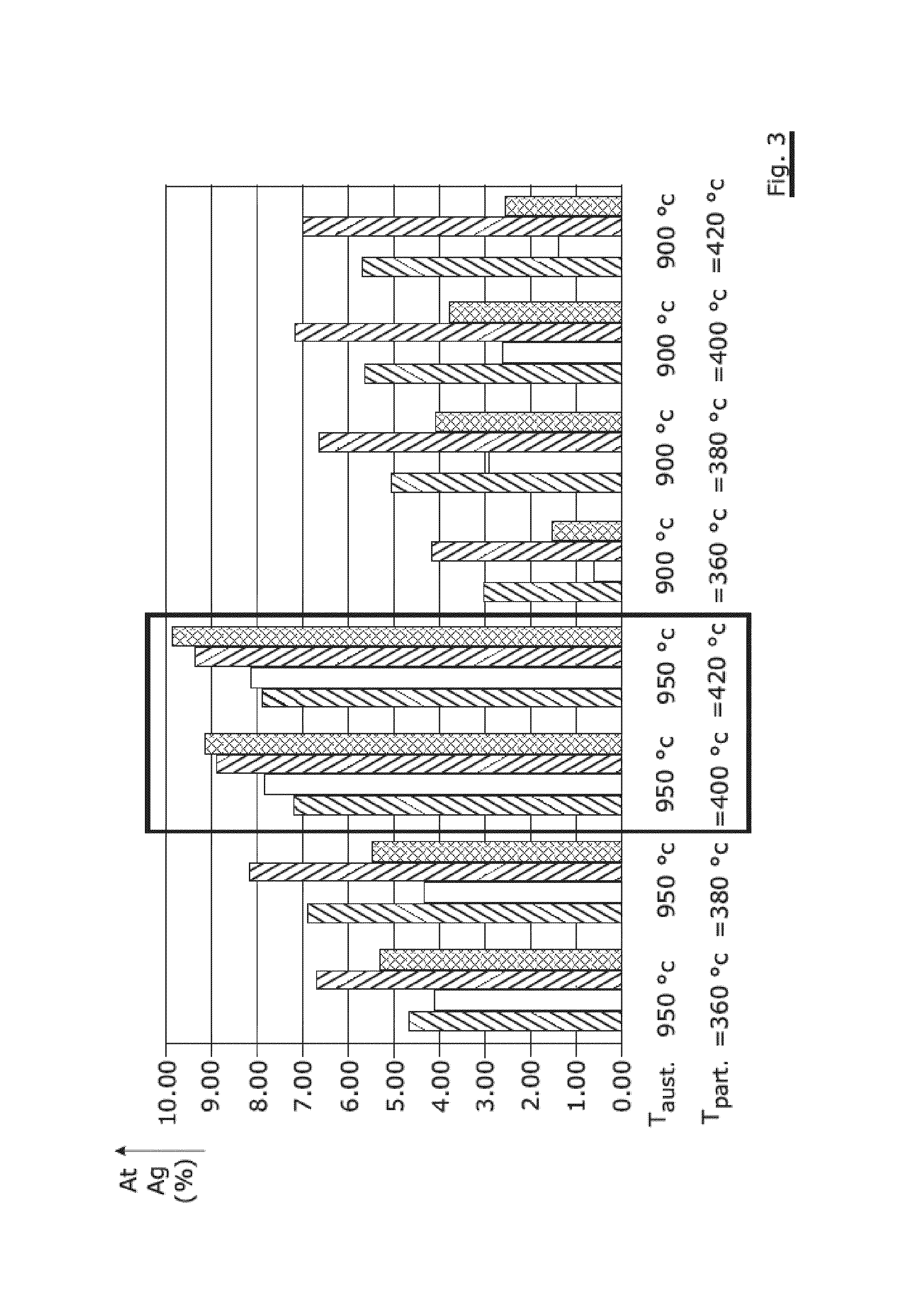

Quenched and partitioned high-carbon steel wire

InactiveUS20140227546A1Improve resistance to damageIncrease damage tolerancePortable framesPig casting plantsManganeseMartensite

A high-carbon steel wire has as steel composition: a carbon content ranging from 0.40 weight percent to 0.85 weight percent, a silicon content ranging from 1.0 weight percent to 2.0 weight percent, a manganese content ranging from 0.40 weight percent to 1.0 weight percent, and a chromium content ranging from 0.0 weight percent to 1.0 weight percent. The remainder is iron. This steel wire has as metallurgical structure a volume percentage of retained austenite ranging from 4 percent to 20 percent, while the remainder is tempered primary martensite and untempered secondary martensite. The steel wire is obtained by partitioning after quenching.

Owner:NV BEKAERT SA

Production of CuALNiMn shape memory alloy thin membrane by cold rolling superthin laminated alloy

InactiveCN1644728AGood shape memory effectImprove plasticityMetal rolling arrangementsThin membraneAlloy thin film

The invention opened a method to make CuAlNiMn shape-memory alloy firm by the cold-roll ultrathin laminated alloy. The process use the Al foil, CuNiMn alloy foil as the material and decide the thickness according to the the composition. The foil is interactively overlapped and cold-rooled to form the ultrathin laminated alloy. The CuAlNiMn alloy firm is consists of Al11.5-14.5%, Ni 0-5%, Mn 0-3%, the remain is Cu. The alloy firm has the good features of fine crystal, long life, big area and low cost.

Owner:SICHUAN UNIV

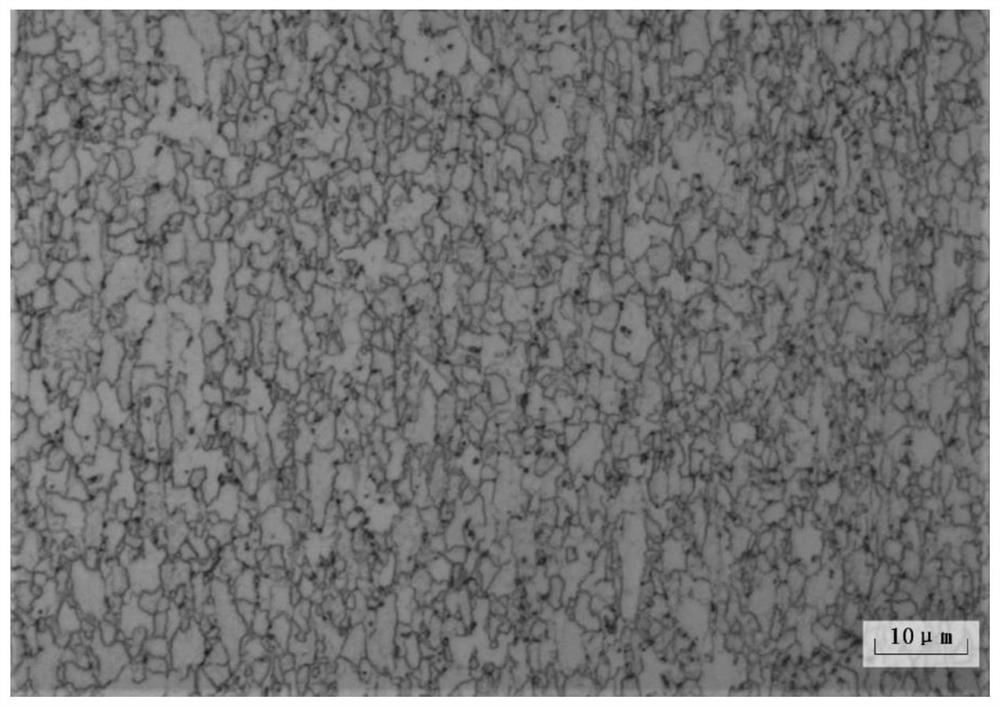

Full-ferrite high-strength steel and preparation method thereof

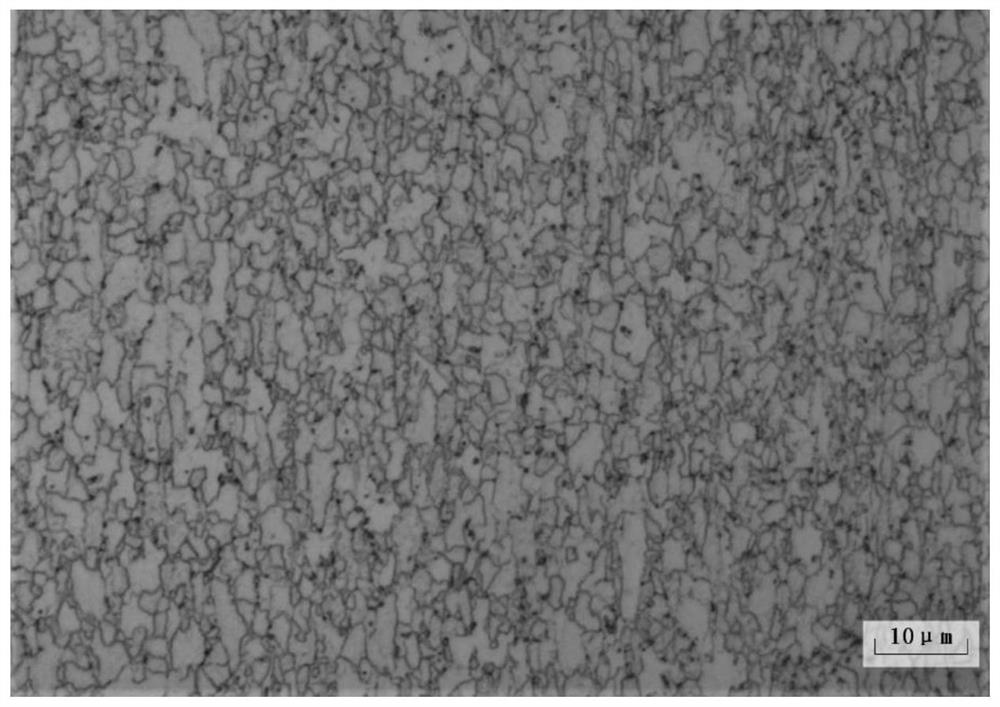

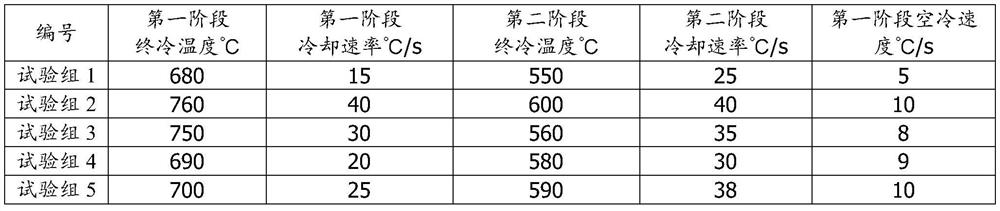

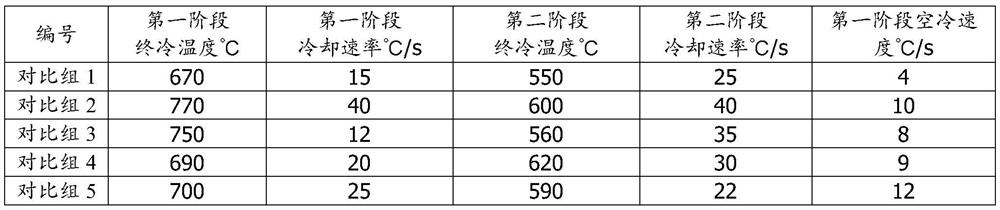

The invention belongs to the technical field of iron and steel smelting, and particularly relates to full-ferrite high-strength steel and a preparation method thereof. The full-ferrite high-strength steel comprises the following components in percentage by mass: 0.03-0.10 % of C, 0-0.05 % of Si, 0.8-1.30 % of Mn, less than or equal to 0.015 % of P, less than or equal to 0.005 % of S, 0.02-0.04 % of Al, 0.03-0.070 % of Nb, 0.05-0.10 % of Ti and 0.10-0.50 % of Mo, optionally, 0.02%-0.07% of V and / or 0.1%-0.5% of Cr, and the balance of iron and inevitable impurities. According to the full-ferritehigh-strength steel and the preparation method thereof, the technical problems that in the prior art, after the strength of a steel plate is improved through ultrafine grains, the work hardening rateof the steel plate is low, the secondary cold bending performance is poor, and the cold deformation capacity is remarkably reduced are solved.

Owner:SHOUGANG CORPORATION

Non-oriented electrical steel for hub motor of portable electric bicycle and manufacturing method of non-oriented electrical steel

ActiveCN113215473ALow iron loss performanceImprove motor efficiencyFurnace typesHeat treatment furnacesElectrical steelElectric machine

The invention discloses non-oriented electrical steel for a hub motor of a portable electric bicycle and a manufacturing method of the non-oriented electrical steel, and belongs to the field of non-oriented steel. In order to solve the problems of high processing difficulty and low efficiency of existing non-oriented steel for a small motor, the invention provides the non-oriented electrical steel for the hub motor of the portable electric bicycle. The non-oriented electrical steel for the hub motor of the portable electric bicycle is prepared from the following components in percentage by weight: 1.50-3.00% of Si, 0.50% to 2.00% of Als;, 0.20% to 1.00% of Mn, 0.01% to 0.20% of P, less than or equal to 0.005% of C, less than or equal to 0.03% of S, less than or equal to 0.03% of N, less than or equal to 0.005% of Ti, and the balance of iron and inevitable impurities, wherein the weight percentage of C, S, N and Ti meets the following formula: C% + S% + N% + Ti% is less than or equal to 0.01%. According to non-oriented electrical steel for the hub motor of the portable electric bicycle, the ductility of silicon steel is improved by reasonably controlling the element content, and machining is convenient. According to the manufacturing method of the non-oriented electrical steel, eddy current and magnetic hysteresis loss in a wound iron core is reduced, meanwhile, surface oxidation and surface nitride precipitation of a steel coil can be avoided, and the iron core loss is reduced; compared with existing non-oriented silicon steel with the same iron loss level, the elongation is higher, the subsequent cold machining performance is more excellent, and the machining is convenient while the excellent performance is ensured.

Owner:MAANSHAN IRON & STEEL CO LTD

Production of TiNiPd shape memory alloy thin membrane by cold rolling superthin laminated alloy

InactiveCN1644730AGood shape memory effectImprove plasticityMetal rolling arrangementsThin membraneShape-memory alloy

The invention opened thea. method to make TiNiPd shape-memory alloy firm by the cold-roll ultrathin laminated alloy. The method is to use the Ti foil, Ni foil or NiPd as the material, and decidethe thickness according to the Tix(Ni1-yPdy)1-x. The foil is interactively overlapped and cold-rooled to form the ultrathin laminated alloy. The content satisfies 0.48<=x<=0.5; 0.4<=y<=0.8 respectively. The alloy firm has the good features of fine crystal, long life, big area and low cost.

Owner:SICHUAN UNIV

Powder extrusion manufacturing method of high-silicon steel strip

The invention discloses a powder extrusion manufacturing method of a high-silicon steel strip. Reduction Fe powder with irregular morphology and fine high-purity ferrosilicon powder with a Si contentof 70-80% are adopted to form Fe-4.5-6.7% Si mixed powder. A square blank is formed through mold pressing; Fe phase austenitizing is realized by heating to 950-1050 DEG C; a plate blank is formed through hot extrusion by deformation with an extrusion ratio of 8-16; then, vacuum or reduction atmosphere protective sintering is performed on the powder extrusion plate blank in a temperature range of 1070-1170 DEG C; then, multiple times of cold rolling and low-temperature dispersion sintering are performed; finally, vacuum or reduction atmosphere protective sintering is performed in a temperaturerange of 1275-1335 DEG C to realize uniform alloying of high-silicon steel; and the high-silicon steel strip with Si of 4.5-6.7%, a thickness of 0.1-0.5 mm and a density of not less than 7.38 g / cm3 isobtained.

Owner:CENT SOUTH UNIV

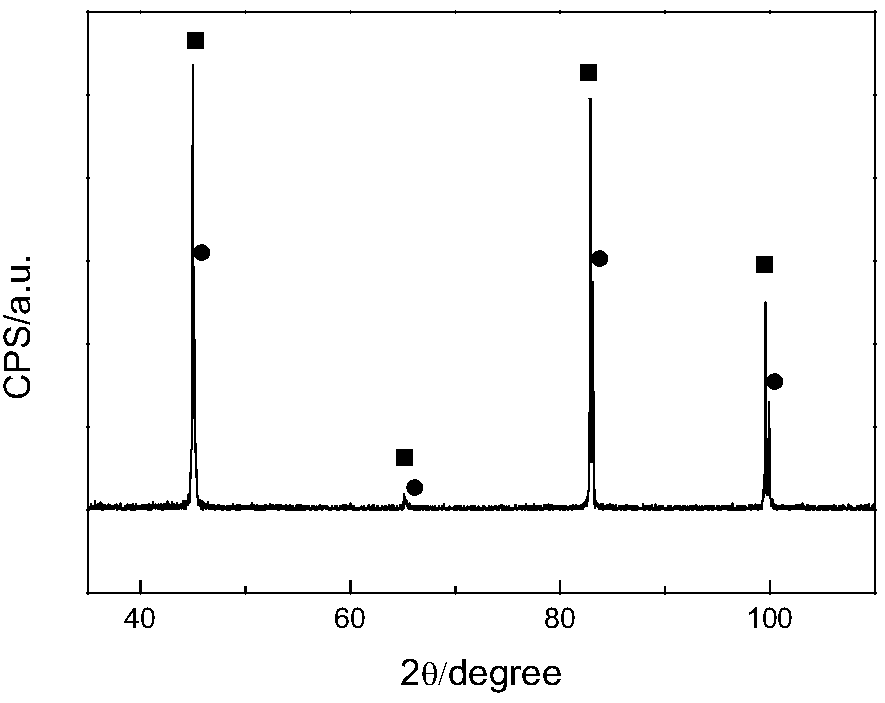

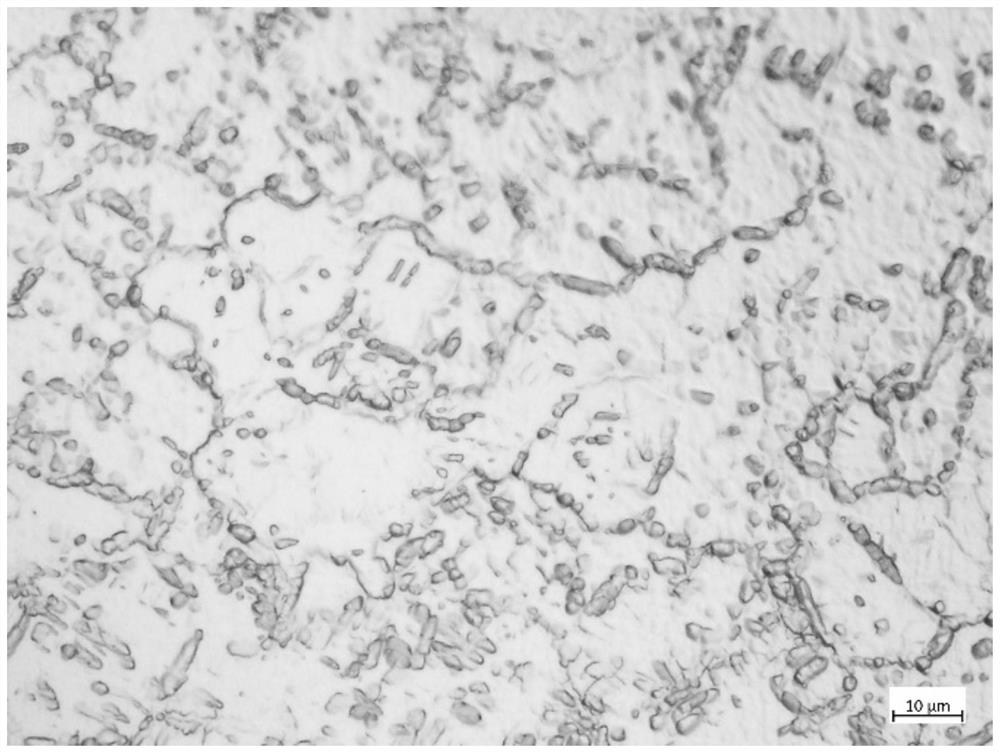

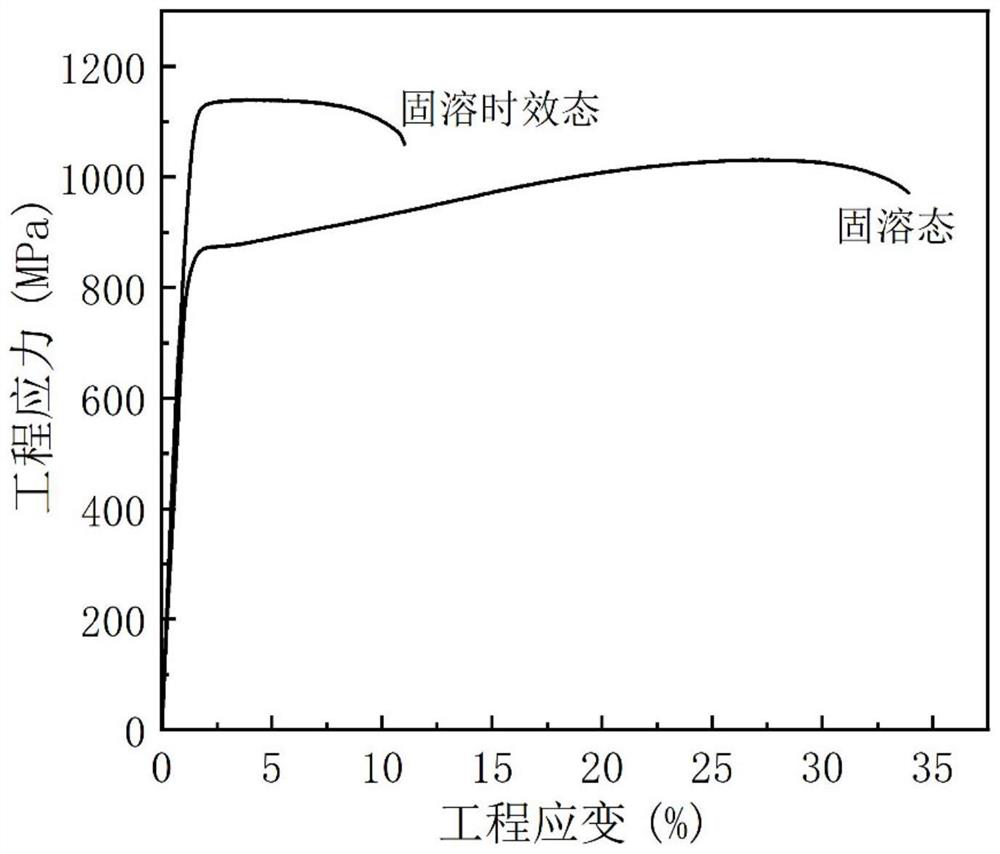

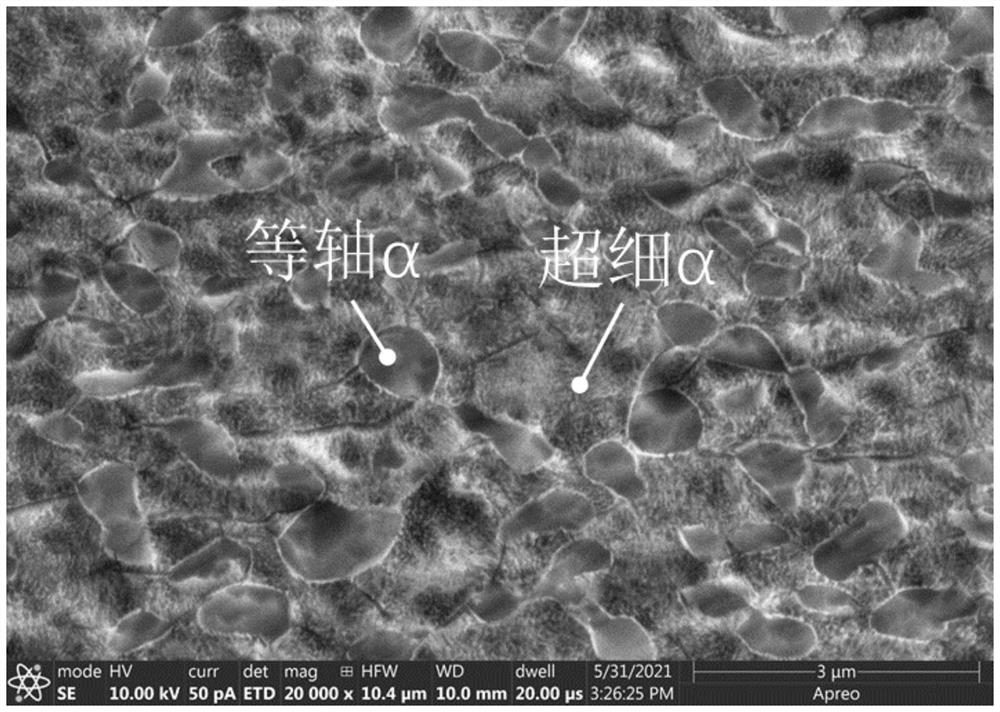

High-strength plastic titanium alloy suitable for cold deformation processing and preparation method thereof

ActiveCN114657417AImprove plastic processing performanceGood strength and plasticity matchingMetal-working apparatusSolution treatmentIngot

The invention discloses a high-strength and high-plasticity titanium alloy suitable for cold deformation processing and a preparation method thereof, and the high-strength and high-plasticity titanium alloy comprises the following components in percentage by mass: 3.5-4.5% of Mo, 2.5-3.5% of Cr, 0.7-1.5% of Fe, and Olt. 0.35%, and the balance being Ti; the preparation method comprises the following steps: preparing a titanium alloy ingot through raw material proportioning and vacuum melting; carrying out hot processing at the temperature of 1150-720 DEG C; and carrying out solution treatment at 790-730 DEG C to obtain a finished product of the high-strength plastic titanium alloy, or further carrying out aging treatment at 430-530 DEG C to obtain the finished product of the high-strength plastic titanium alloy, or carrying out cold rolling and aging heat treatment after heat treatment to obtain the finished product of the high-strength plastic titanium alloy. Strong beta stable elements of Mo, Cr and Fe are added, no alpha stable element is added to improve the plastic deformation capacity of an alpha phase at the room temperature and the high temperature, the content and element distribution of the alpha phase and the beta phase are regulated and controlled through thermomechanical treatment, the cold deformation machining performance and strength and plasticity matching of the titanium alloy are improved, and the mechanical property of the titanium alloy is improved. The alloy has the characteristics of low cost, easiness in cold processing and excellent strength and plasticity matching.

Owner:BEIHANG UNIV

Heat treatment method for improving the bearing capacity of thin wall steel pieces

InactiveCN1621564AGood cold deformation abilityCold deformation ability does not affectChemical compositionNitrogen

The heat treatment method of raising bearing capacity of thin-wall steel part includes first heating the cold deformation formed workpiece to the temperature range of Fe-N system austenite arean and nitriding to form nitrogen containing austenite layer, and then cooling the workpiece fast to below 300 deg.c to inhibit the euterctoid conversion of the nitrogen containing austenite and to decompose the austenite layer into dispersed two-phase structure or to convert into martensite. The said method makes the nitrogen containing austenite layer reinforced and the raises the overall structural strength of the thin-wall steel part greatly. The said method of raising the bearing capacity features no special requirement in the chemical components of the material and is suitable for ultralow carbon steel, low carbon steel, low alloy steel, etc.

Owner:SHANGHAI JIAO TONG UNIV

Production process of aluminum alloy gutter profile

InactiveCN113388793AImprove thermal deformationGood cold deformation abilityIngot castingThermal deformation

The invention provides a production process of an aluminum alloy gutter profile, and belongs to the technical field of aluminum alloy profile production. The production process comprises an ingot casting procedure, an extrusion forming procedure, a quenching treatment procedure, a stretching and straightening procedure and an aging treatment procedure which are sequentially carried out, wherein a preliminary heat treatment procedure is added between the ingot casting procedure and the extrusion forming procedure, and the preliminary heat treatment procedure comprises the following steps that a blank formed after the ingot casting procedure is heated to 610-630 DEG C, then the temperature is reduced to 585 + / - 5 DEG C, the heat preservation is carried out for 2.5-3.5 hours, and finally, the blank is rapidly cooled to the room temperature. According to the production process, after a bar material is formed in the ingot casting procedure, the bar material is subjected to the preliminary heat treatment procedure, so that the intracrystalline segregation can be eliminated or reduced, the thermal deformation and cold deformation capacity of the material is improved, the mechanical property of a product is improved, and the internal stress generated during solidification is eliminated.

Owner:LEAR ALUMINUM

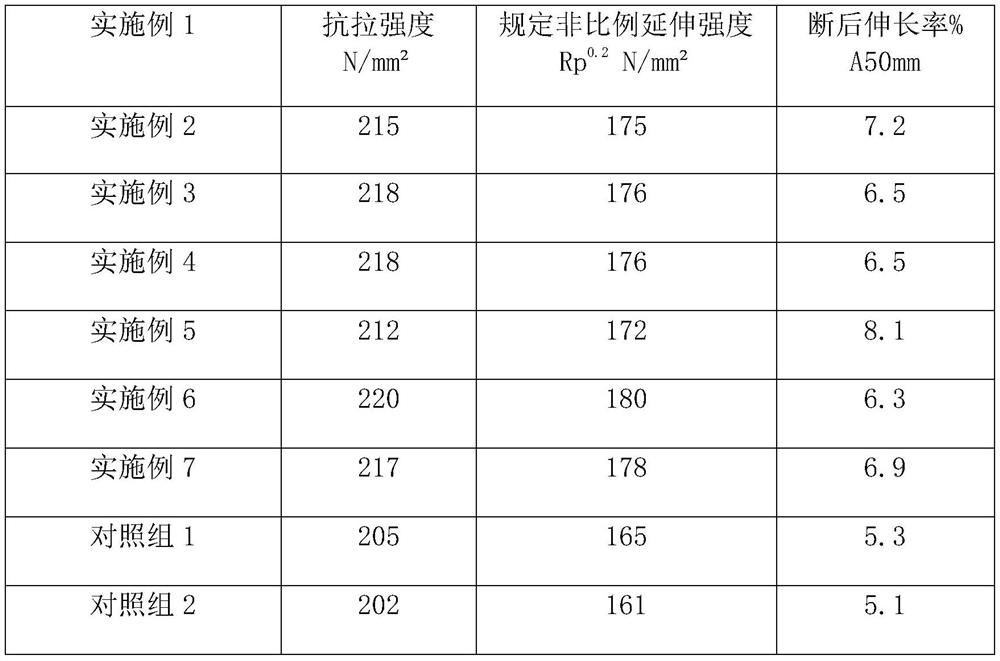

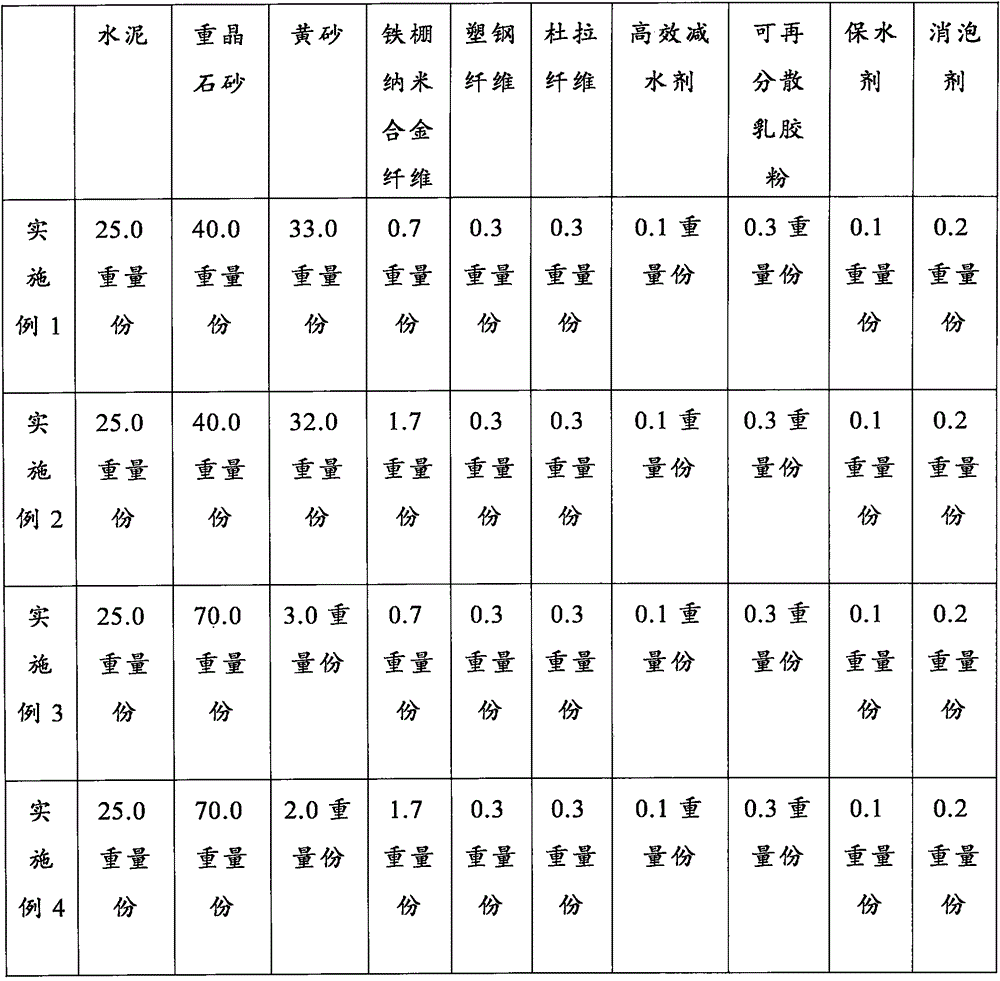

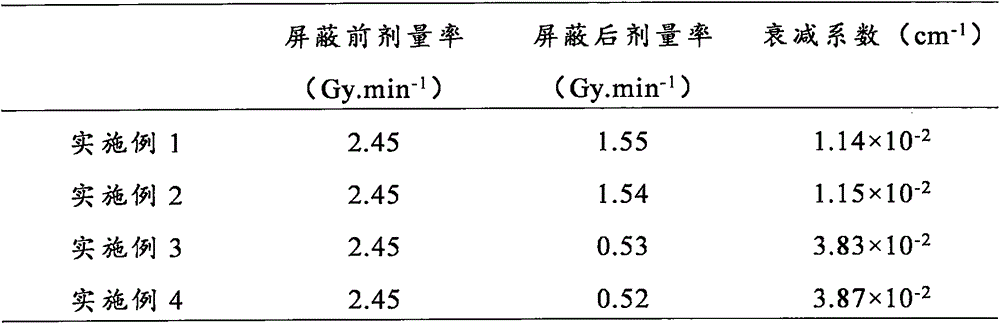

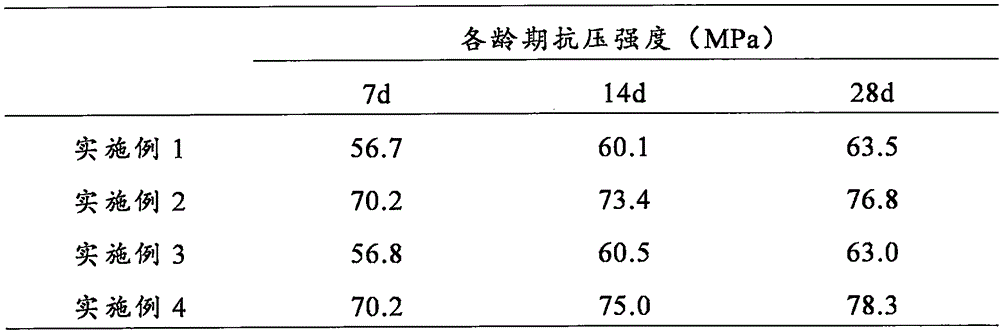

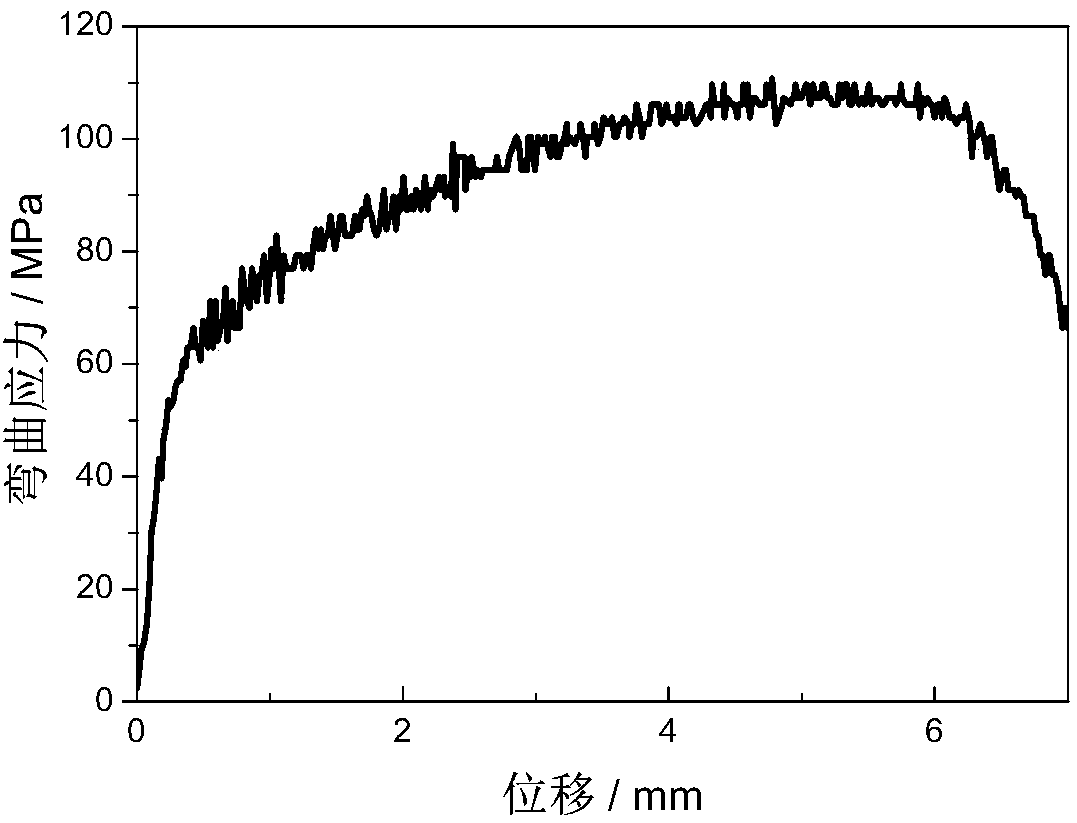

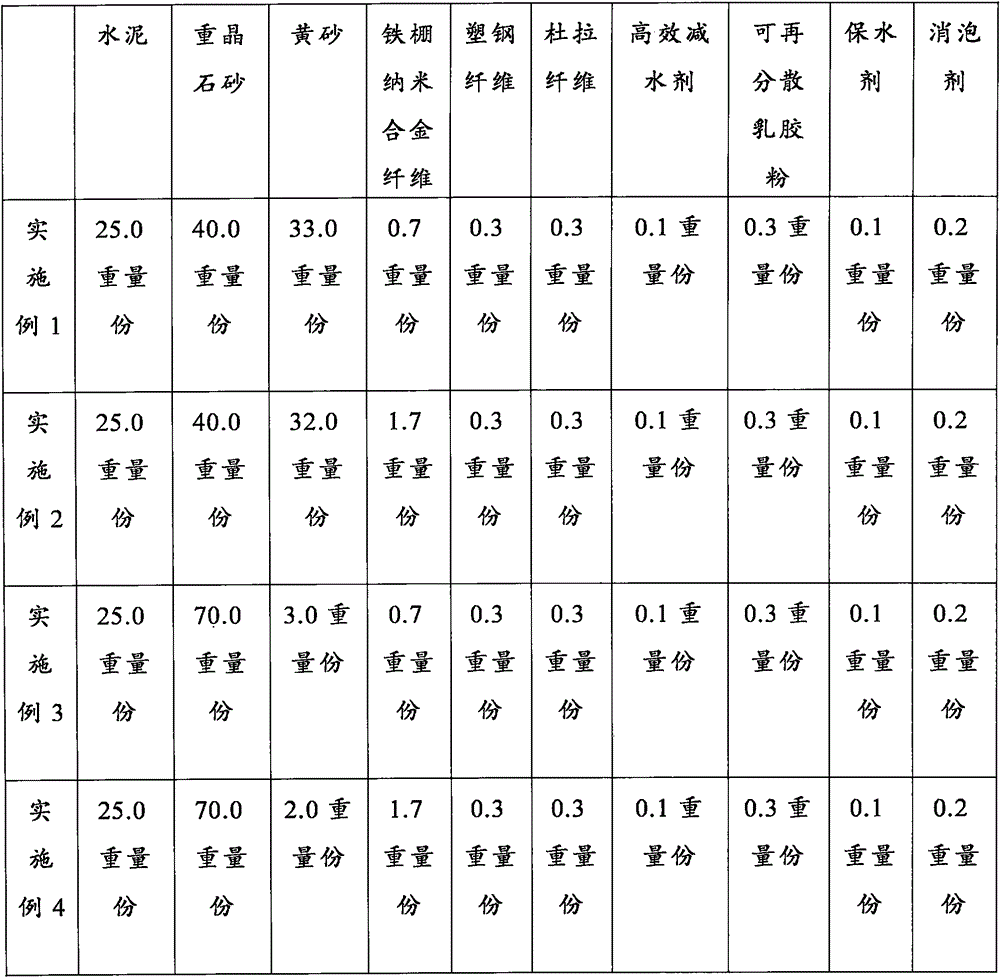

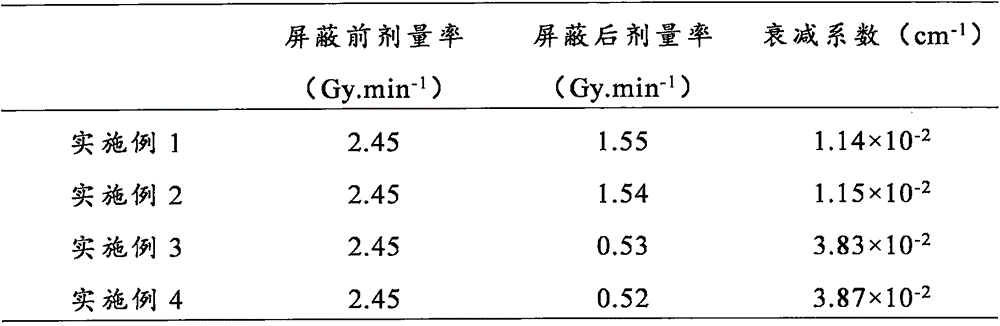

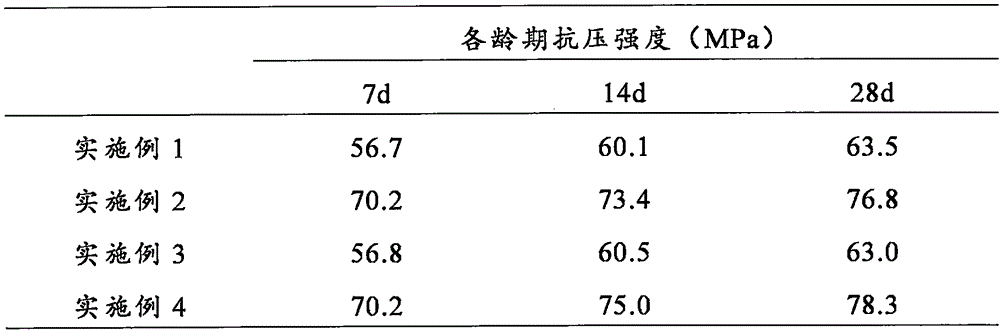

A kind of anti-radiation dry powder mortar and preparation method thereof

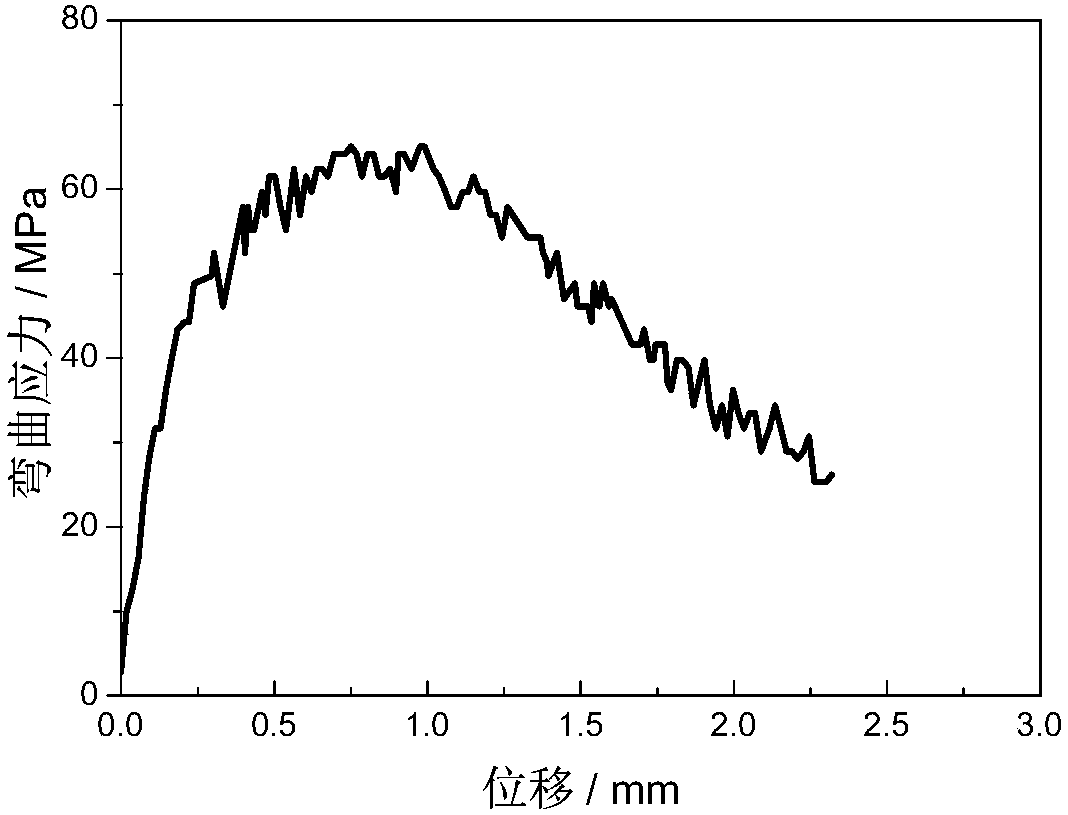

The invention provides an anti-radiation dry-mixed mortar and a preparation method thereof. The anti-radiation dry-mixed mortar comprises, by weight, 25 to 32 parts of cement, 40 to 70 parts of barite sand, 2 to 33 parts of yellow sand, 1.3 to 2.3 parts of ternary hybrid fiber of iron-boron nanometer alloy fiber, glass-reinforced plastic fiber and Durafiber, and 0.5 to 2 parts of an additive. According to the invention, the ternary hybrid fiber of iron-boron nanometer alloy fiber, glass-reinforced plastic fiber and Durafiber used in the invention can effectively restrict generation and development of primary fractures formed in early-stage concrete due to factors like separation, bleeding and contraction, so generation of the primary fractures and the quantity and size of the primary fractures are reduced from a source, compactness of concrete is greatly improved, effective filling of different levels of fractures in a concrete matrix are realized, and the performance of an interface transition layer is further improved. Experiment results show that the anti-radiation dry-mixed mortar prepared in the invention has good radiation protection performance and mechanical properties.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Method for preparing high silicon steel thin strip by powder extrusion

InactiveCN107900354AAchieve uniformityHigh densityTransportation and packagingMetal-working apparatusSilicon ironMulti phase

The invention discloses a method for preparing a high silicon steel thin strip by powder extrusion. Reduced Fe powder and 50-70% of high-purity silicon iron powder are used as raw materials to form Fe-Si mixed powder with the Si content being 4.5-6.7%. The mixed powder is subjected to mold-pressing to form a square billet which is then heated to 950-1050 DEG C to achieve Fe phase austenitizing, and the square billet is hot-extruded into a slab with the deformation amount under the extrusion ratio of 8-16. The extruded slab is then subjected to vacuum or reducing atmosphere protective sinteringin a temperature range of 1060-1160 DEG C, so that Fe powder particles are metallurgically bonded, Si and Fe are partially alloyed, and dense poor-Si alpha-Fe crystal grains with plastic deformationcapacity and a brittle multi-phase structure high silicon steel billet with the high-Si phase are formed; and several times of cold rolling and low-temperature diffusion sintering are performed, thenvacuum or reducing atmosphere protective sintering is performed at the temperature of 1270-1320 DEG C, and the high silicon steel strip with 4.5-6.7% Si is obtained, and the thickness is 0.1-0.5mm andthe density is more than or equal to 7.39g / cm3.

Owner:CENT SOUTH UNIV

Corrosion resistant structural steel with ultra high strength

This invention relates to an ultrahigh-strength and corrosion-resistant structural steel, whose chemical composition is: C less than or equal to 0.02 wt.%, Si less than or equal to 0.15 wt.%, Mn less than or equal to 0.15 wt.%, S less than or equal to 0.01 wt.%, P less than or equal to 0.01 wt.%, Cr 8.0-10.0 wt.%, Ni 11.5-14.5 wt.%, Mo 0.5-2.5 wt.%, Ti 1.0-2.0 wt.%, Al 0.02-0.5 wt.%, and Fe as balance. The strength of the structural steel is 1800-1900 MPa. The structural steel has such advantages as low cost, high strength, high fracture toughness, and high corrosion resistance.

Owner:CENT IRON & STEEL RES INST

A kind of low-carbon equivalent high-strength wear-resistant steel plate and its production method

InactiveCN101748333BHigh strengthHigh hardnessTemperature control deviceElectric furnaceBrinellingHardness

The invention discloses a low-carbon-equivalent high-strength wear-resistant steel plate, which is prepared from the following components in percentage by weight: 0.15 to 0.18 percent of C, 0.20 to 0.40 percent of Si, 1.30 to 1.40 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.040 to 0.050 percent of V, 0.017 to 0.030 percent of Nb, 0.020 to 0.040 percent of Al, 0.15 to 0.25 percent of Cr, 0.18 to 0.28 percent of Mo, 0.017 to 0.026 percent of Ti, 0.0015 to 0.0030 percent of B, and the balance of Fe and inevitable impurities. The thickness of the steel plate is 8 to 60mm. The high-strength wear-resistant steel plate has the yield strength over 1,000MPa, the Brinell hardness between 380 and 430HBW, the carbon equivalent between 0.41 and 0.49 percent, the maximum tensile strength of 1,280MPa, good low temperature toughness, and the maximum thickness of 60mm.

Owner:WUYANG IRON & STEEL +1

Anti-radiation dry-mixed mortar and preparation method thereof

ActiveCN105254251AReduce quantity and sizeImprove compactnessRadiation protectionMechanical properties of carbon nanotubes

The invention provides an anti-radiation dry-mixed mortar and a preparation method thereof. The anti-radiation dry-mixed mortar comprises, by weight, 25 to 32 parts of cement, 40 to 70 parts of barite sand, 2 to 33 parts of yellow sand, 1.3 to 2.3 parts of ternary hybrid fiber of iron-boron nanometer alloy fiber, glass-reinforced plastic fiber and Durafiber, and 0.5 to 2 parts of an additive. According to the invention, the ternary hybrid fiber of iron-boron nanometer alloy fiber, glass-reinforced plastic fiber and Durafiber used in the invention can effectively restrict generation and development of primary fractures formed in early-stage concrete due to factors like separation, bleeding and contraction, so generation of the primary fractures and the quantity and size of the primary fractures are reduced from a source, compactness of concrete is greatly improved, effective filling of different levels of fractures in a concrete matrix are realized, and the performance of an interface transition layer is further improved. Experiment results show that the anti-radiation dry-mixed mortar prepared in the invention has good radiation protection performance and mechanical properties.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Method for preparing NiTiHf shape memory alloy film by cold rolling ultra-thin laminated alloy foil

InactiveCN1667143ASolve brittle, difficult-to-process problemsGood shape memory effectMetal rolling arrangementsAlloy thin filmShape-memory alloy

This invention discloses a method of preparing NiTiHf shape memory alloy thin film through cold rolling ultrathin lamination alloying. Good plasticity, easy deformed Ni foil, Ti foil, Hf foil or TiHf alloy foil are materials, foil thickness is defined according to atom constitution formula NiX (Ti1-yHf1-y)1-X. metal foils are alternating laid, sandwich structure is got after big deformation cold rolling, it is repeated again and again, finally components uniform alloy film is got after diffusion annealing alloying. The reactant ratio is 0.04íœxíœ0.55, 0íœyíœ0.8. The film components made by this method is easy control, crystal grain is small, fatigue life is high, area is large and cost is low.

Owner:SICHUAN UNIV

A kind of all-ferritic high-strength steel and its preparation method

Owner:SHOUGANG CORPORATION

Method for preparing high-silicon steel strip through high-temperature diffusion sintering and powder extrusion

InactiveCN107900353AImprove uniformityLow degree of alloyingTransportation and packagingMetal-working apparatusIron powderReducing atmosphere

Disclosed is a method for preparing a high-silicon steel strip through high-temperature diffusion sintering and powder extrusion. The method comprises the steps that two kinds of industrial Fe powderof reduced Fe powder and water atomized Fe powder are selected and mixed according to the proportion of 4:6-6:4, then fine Si powder is added as raw powder, and thus Fe-Si mixed powder is formed withthe Si content being 4.5%-6.7%; a square blank is formed through die pressing, heating is conducted till the temperature reaches 950-1050 DEG C, thus a Fe phase is austenitized, and the square blank is subjected to hot extrusion into a slab through deformation with the extrusion ratio being 8-16; then the powder extruded slab is sintered under vacuum protection or reducing atmosphere protection atthe temperature of 1080-1180 DEG C for metallurgical bonding of Fe powder particles; and after the multiple times of cold rolling and low-temperature diffusion sintering, sintering is conducted undervacuum protection or reducing atmosphere protection at the temperature of 1280-1350 DEG C finally, homogeneous alloying of high-silicon steel is achieved, and thus the high-silicon steel strip with the Si content being 4.5%-6.7%, the thickness being 0.1-0.5 mm and the density being larger than or equal to 7.39 g / cm<3> is obtained.

Owner:CENT SOUTH UNIV

Method for preparing Fe-6.5% Si strip by powder extrusion and diffusion sintering processes

InactiveCN107999767AAchieve uniformityHigh densityTransportation and packagingMetal-working apparatusFerrosiliconReducing atmosphere

The invention discloses a method for preparing a Fe-6.5% Si strip by powder extrusion and diffusion sintering processes. The method comprises the steps that reduced Fe powder and water atomized Fe powder are selected and mixed according to the ratio of 4:6-6:4, then high-purity ferrosilicon powder with the Si content of 70-80% is added to form Fe-4.5-6.7% Si mixed powder; and mold pressing is carried out to form a square blank, then the square blank is heated to 950-1050 DEG C to realize Fe-phase austenitizing, hot extrusion is carried out by using the deformation amount with the extrusion ratio being 8-16 to form a slab, then vacuum or reducing atmosphere protection sintering is carried out at the temperature of 1070-1170 DEG C to make Fe powder particles realize metallurgical bonding, cold rolling and low-temperature diffusion sintering are carried out for multiple times, finally vacuum or reducing atmosphere protection sintering is carried out at the temperature of 1275-1335 DEG C to realize homogenization alloying of the high silicon steel, and the high silicon steel strip with 4.5-6.7% of Si, the thickness of 0.1-0.5 mm and the density larger than or equal to 7.40g / cm<3> is obtained.

Owner:CENT SOUTH UNIV

Cu-Fe in-situ composite with added boron, silver and rare earth elements and preparation method thereof

The invention discloses a Cu-Fe in-situ composite with boron, silver and rare earth elements added and a preparation method thereof. The invention is characterized by adopting multimode comprehensive strengthening technology such as multi-micro alloying, solid solution strengthening, aging strengthening, fine grain strengthening, distortion strengthening, fiber strengthening and the like, using Cu as the base and adding a little Fe and trace Ag and B, rare earth or rare earth compounds to prepare the high strength and high conductivity copper alloy material through smelting, casting, hot forging or hot rolling, solid solution treatment, cold rolling or cold drawing, aging and the like. The prepared material has the advantages of high strength, good electric and thermal conductivity, simple preparation process and low cost, thus realizing wide application in the fields such as electronics, information, transportation, energy, metallurgy, electromechanics and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

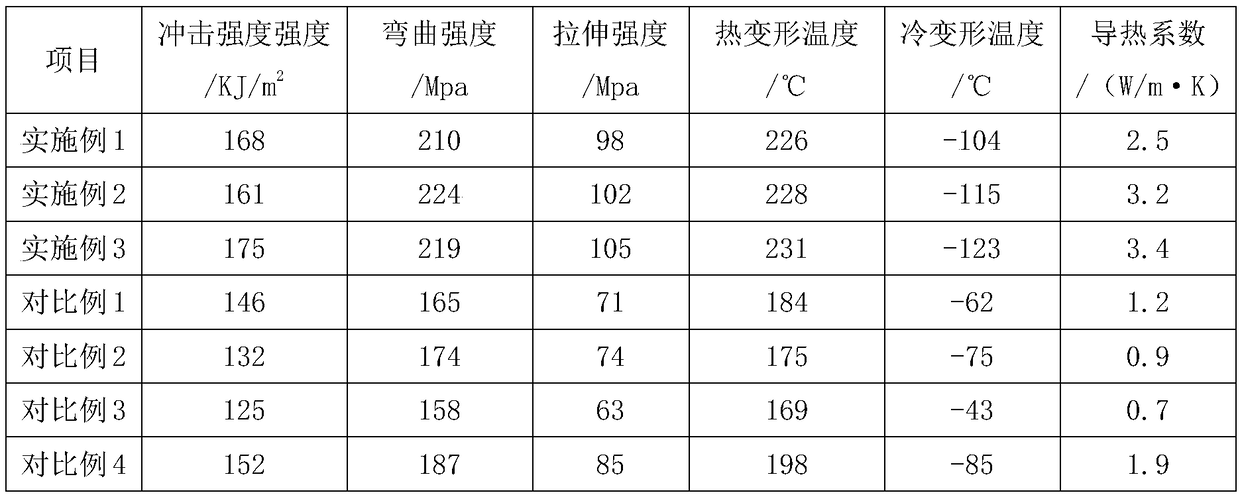

High-strength heat-conductive plastic and preparation method thereof

InactiveCN108997722AHigh mechanical strengthImprove thermal deformationHeat-exchange elementsDiphenylmethaneHigh intensity

The invention discloses high-strength heat-conductive plastic and a preparation method thereof. The high-strength heat-conductive plastic comprises the following raw materials in parts by weight: 65-80 parts of unsaturated polyester, 11-15 parts of 2,3,6,7-tetracarboxylic acid dianhydride triptycene, 10-15 parts of 2,4-diamino-diphenylmethane, 3-7 parts of 4,4-dichlorodiphenyl sulfone, 4-8 parts of zinc dioxide, 5-10 parts of citric acid and 6-10 parts of green algae. The high-strength heat-conductive plastic provided by the invention has high mechanical strength and good heat deformation andcold deformation performance, can be used in a high temperature or low temperature environment, has wide application prospects, is simple in preparation method, and facilitates the realization of industrial production.

Owner:姜纲法

Cu-Cr in-situ composite with boron, silver and rare earth elements added and preparation method thereof

InactiveCN101709401BPromote precipitationImprove conductivityMetal/alloy conductorsRare-earth elementFiber

The invention discloses a Cu-Cr in-situ composite with boron, silver and rare earth elements added and a preparation method thereof. The invention is characterized by adopting multimode comprehensive strengthening technology such as multi-micro alloying, solid solution strengthening, aging strengthening, fine grain strengthening, distortion strengthening, fiber strengthening and the like, using Cu as the base and adding a little Cr and trace Ag and B, rare earth or rare earth compounds to prepare the high performance copper alloy in-situ composite through smelting, casting, hot forging or hotrolling, solid solution treatment, cold rolling or cold drawing, aging and the like. The prepared material has the advantages of high strength, good electric and thermal conductivity, simple preparation process and low cost, thus realizing industrial application in the aspects such as electrician switches, contact materials, resistance electrodes, rotor conductors of large electrical high speed turbine generators, overhead conductors of electric cars and electric trains, lead frames of very large scale integrated circuits and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

A method of preparing fe-6.5%si strip by diffusion sintering and powder extrusion

The invention provides a method for preparing a Fe-6.5%Si strip material by diffusion sintering and powder extrusion. The method for preparing the Fe-6.5%Si strip material by the diffusion sintering and the powder extrusion comprises the steps of selecting reduction Fe powders and water-atomized Fe powders, then mixing the reduction Fe powders and the water-atomized Fe powders in the ratio of 4:6- 6:4, and adding high-purity ferrosilicon powder with the Si content of 50-70% to form Fe-4.5-6.7%Si mixed powders; then die pressing the Fe-4.5-6.7%Si mixed powders into a square blank, then heatingthe blank to 950-1050 DEG C to realize the austenization of Fe phase, and hot extruding the blank into a plate blank by the deformation quantity with the extrusion ratio of 8-16; and conducting vacuum or reducing atmosphere protection sintering at the temperature of 1060-1160 DEG C and conducting cold rolling and low temperature diffusion sintering for many times; finally conducting vacuum or reducing atmosphere protection sintering at the temperature of 1260-1320 DEG C to realize the homogeneity alloying of high silicon steel and obtaining a high silicon steel strip material with the thickness of 4.5-6.7%Si being 0.1-0.5 mm and the density being equal to or greater than 7.41g / cm3.

Owner:CENT SOUTH UNIV

Method for preparing Fe-6.5%Si strip material by diffusion sintering and powder extrusion

The invention provides a method for preparing a Fe-6.5%Si strip material by diffusion sintering and powder extrusion. The method for preparing the Fe-6.5%Si strip material by the diffusion sintering and the powder extrusion comprises the steps of selecting reduction Fe powders and water-atomized Fe powders, then mixing the reduction Fe powders and the water-atomized Fe powders in the ratio of 4:6- 6:4, and adding high-purity ferrosilicon powder with the Si content of 50-70% to form Fe-4.5-6.7%Si mixed powders; then die pressing the Fe-4.5-6.7%Si mixed powders into a square blank, then heatingthe blank to 950-1050 DEG C to realize the austenization of Fe phase, and hot extruding the blank into a plate blank by the deformation quantity with the extrusion ratio of 8-16; and conducting vacuum or reducing atmosphere protection sintering at the temperature of 1060-1160 DEG C and conducting cold rolling and low temperature diffusion sintering for many times; finally conducting vacuum or reducing atmosphere protection sintering at the temperature of 1260-1320 DEG C to realize the homogeneity alloying of high silicon steel and obtaining a high silicon steel strip material with the thickness of 4.5-6.7%Si being 0.1-0.5 mm and the density being equal to or greater than 7.41g / cm3.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com