Full-ferrite high-strength steel and preparation method thereof

A ferritic and high-strength steel technology, applied in the field of all-ferritic high-strength steel and its preparation, can solve the problems of low work hardening rate of steel plate materials, decreased cold deformation ability, poor secondary cold bending performance, etc., and achieve high strength , High cold deformation ability, good secondary cold bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

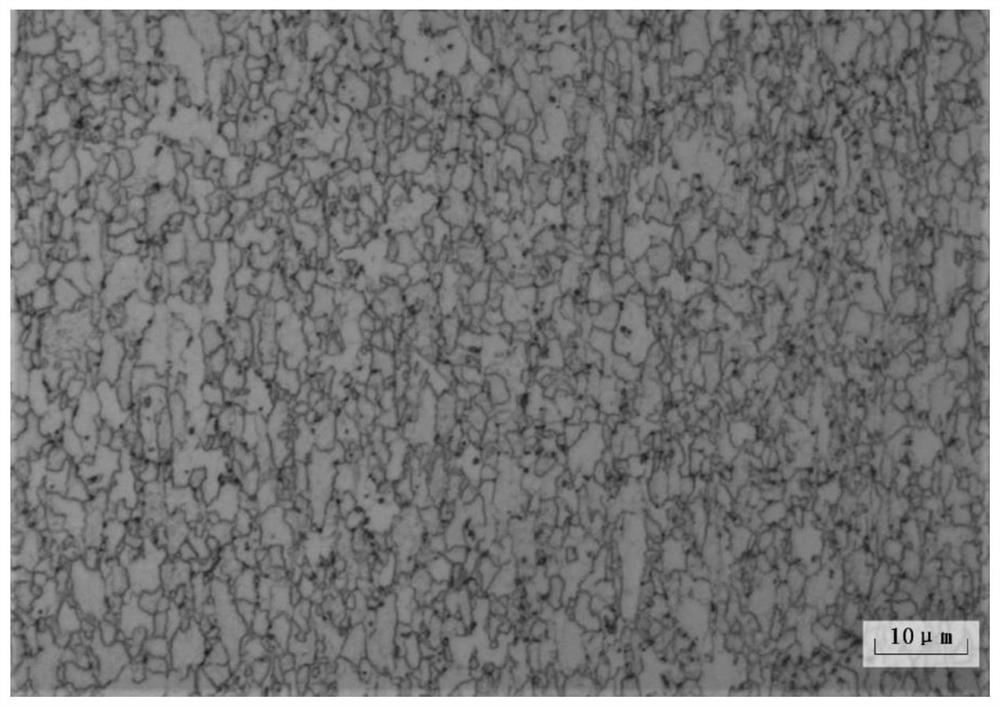

Image

Examples

preparation example Construction

[0068] The present invention also provides the preparation method of the all-ferritic high-strength steel described in the present invention, and the preparation method comprises the following steps:

[0069] Smelting and continuous casting to obtain a steel slab, and hot rolling the steel slab to obtain a hot-rolled plate;

[0070] laminar cooling and coiling of the hot-rolled sheet to obtain the all-ferritic high-strength steel;

[0071]Wherein, in terms of mass percentage, the steel slab includes: C 0.03-0.10%, Si 0-0.05%, Mn 0.8-1.30%, P≤0.015%, S≤0.005%, Al 0.02-0.04%, Nb 0.03- 0.070%, Ti 0.05-0.10%, Mo 0.10-0.50%; optionally contain V 0.02-0.07% and / or Cr 0.1-0.5%; the balance is iron and unavoidable impurities;

[0072] In some preferred embodiments, by mass percentage, the steel slab comprises: C 0.06%, Si 0.02%, Mn 1.1%, P 0.012%, S 0.0015%, Al 0.04%, Nb 0.05%, Ti 0.075% , Mo0.25%; optionally contain V 0.03% and / or Cr 0.4%; the balance is iron and unavoidable impuri...

Embodiment 1

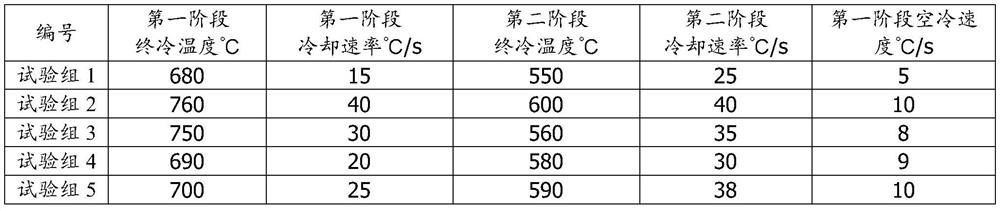

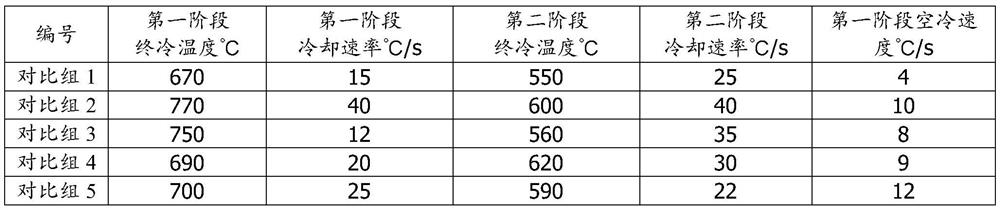

[0093] In this embodiment, 5 test groups are adopted, and in test groups 1-5, the all-ferritic high-strength steel is prepared by the method of the present invention;

[0094] One, adopt known smelting methods such as converter to smelt the molten steel that contains alloy composition of the present invention, and can obtain steel slab by known casting methods such as continuous casting method, by mass percentage, the chemical composition that steel slab comprises is as table 1 shown;

[0095] Table 1: Chemical composition contained in the steel slab of the present invention

[0096] serial number C(%) Si(%) Mn(%) P(%) S(%) Nb(%) Ti(%) Al(%) Mo(%) V(%) Cr(%) Test group 1 0.03 0.8 0.015 0.005 0.03 0.05 0.02 0.10 0.07 Test group 2 0.10 0.05 1.3 0.014 0.0035 0.07 0.10 0.04 0.50 0.1 Test group 3 0.06 0.02 1.1 0.012 0.0015 0.05 0.075 0.04 0.25 0.03 0.4 Test group 4 0.09 0.03 0.85 0.010 0.002 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com