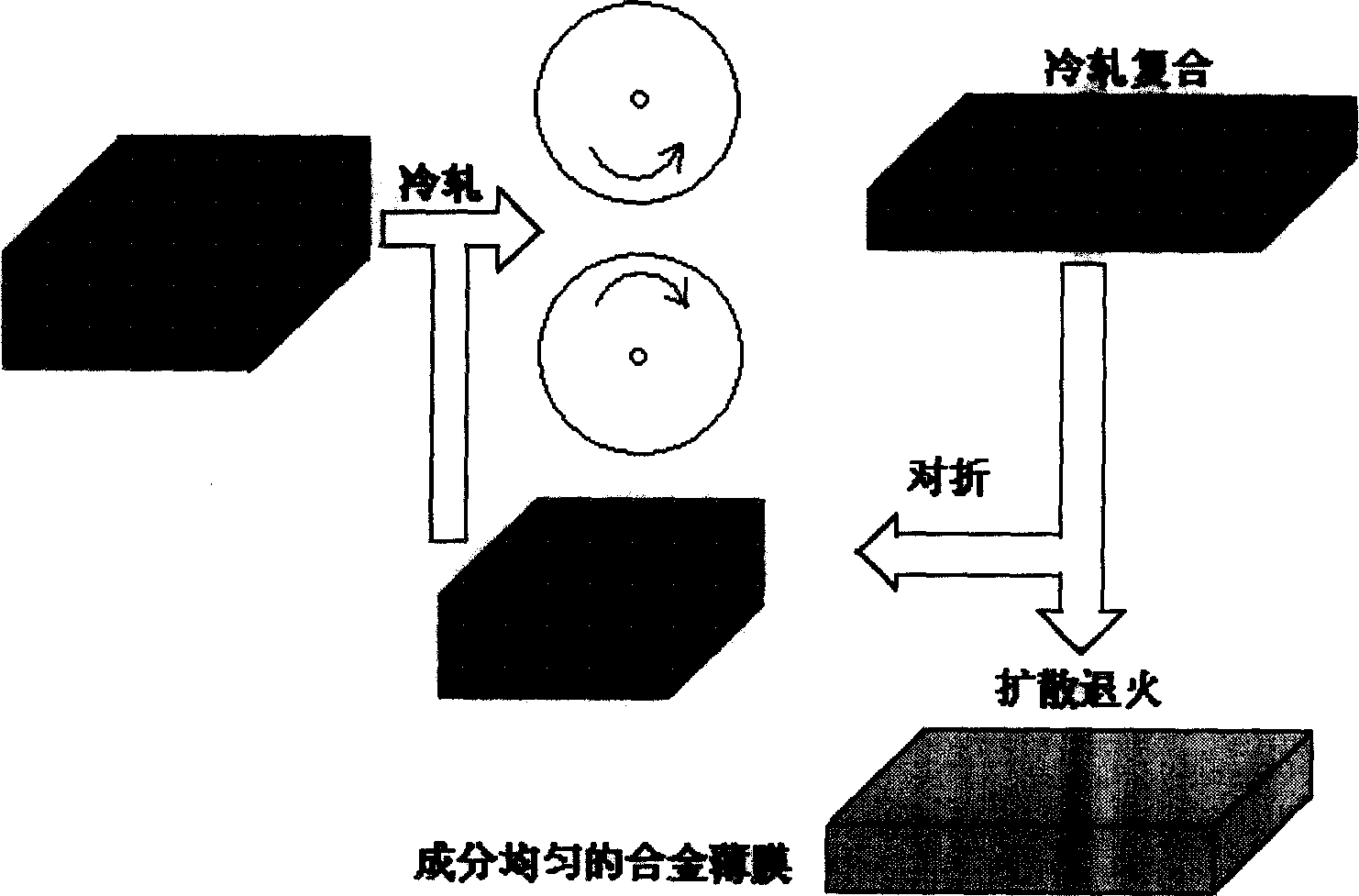

Production of TiNiPd shape memory alloy thin membrane by cold rolling superthin laminated alloy

A memory alloy and alloying technology, applied in the field of shape memory alloys, can solve the problems of difficulty in preparing thick thin films, unsuitability, etc., and achieve the effects of good cold deformation ability, good shape memory effect, plasticity and high performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] According to the designed composition formula Ti 0.5 (Ni 0.6 PD 0.4 ) 0.5 , Ti foil with a thickness of 0.140mm and Ni-40Pd (atomic percentage) alloy foil with a thickness of 0.100mm are used as raw materials, and 10 layers are stacked according to the stacking method of {Ti / NiPd}. First cold rolling to 1.200mm with a deformation of 50%, and then cold rolling to 0.080mm, the cold rolled film is folded and overlapped, and then cold rolled to 0.080mm, and so on for 10 passes. Finally, the cold-rolled 10-pass film was kept at 973K for 50 hours for alloying. The Ms point of the alloy was determined to be 366K by electrical resistance method, and the shape was completely recovered after heating at room temperature with a tensile deformation of 6%.

Embodiment 2

[0022] According to the designed composition formula Ti 0.5 (Ni 0.5 PD 0.5 ) 0.5 , Ti foil with a thickness of 0.110mm and Ni-50Pd (atomic percentage) alloy foil with a thickness of 0.080mm are used as raw materials, and 10 layers are stacked according to the stacking method of {Ti / NiPd}. First cold rolling to 0.950mm with a deformation of 50%, and then cold rolling to 0.060mm, the cold rolled film is folded and overlapped, and then cold rolled to 0.060mm, repeating 10 passes. Finally, the cold-rolled 10-pass film was kept at 1073K for 30 hours for alloying. The Ms point of the alloy was determined to be 476K by electrical resistance method, and the shape was completely recovered after being heated with 4% tensile deformation at room temperature.

Embodiment 3

[0024] According to the designed composition formula Ti 0.5 (Ni 0.4 PD 0.6 ) 0.5 , Ti foil with a thickness of 0.160mm and Pd-40Ni (atomic percentage) alloy foil with a thickness of 0.120mm are used as raw materials, and 10 layers are stacked according to the stacking method of {Ti / NiPd}. First cold rolling to 1.400mm with a deformation of 50%, and then cold rolling to 0.080mm, the cold rolled film is folded and overlapped, and then cold rolled to 0.080mm, and so on for 10 passes. Finally, the cold-rolled 10-pass film was kept at 1173K for 20 hours for alloying. The Ms point of the alloy was determined to be 511K by electrical resistance method, and the shape was completely recovered after being heated with 4% tensile deformation at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com