Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10461results about How to "Suitable for large-scale industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

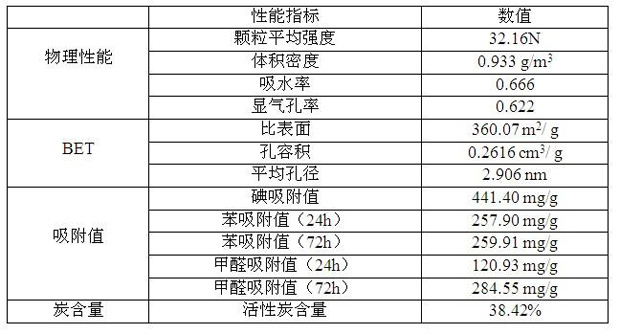

Activated alumina and activated carbon compounded material and preparation method thereof

InactiveCN101890336AAchieve the perfect combinationEasy to useCatalyst carriersOther chemical processesActivated carbonAir purification

The invention provides an activated alumina and activated carbon compounded material and a preparation method thereof. According to a formula, the material comprises the following raw materials in percentage by mass: 40 to 99 percent of aluminum hydroxide, 1 to 60 percent of activated carbon, and 15 to 35 percent of binder. The material is prepared by uniformly mixing, pelleting, ageing, molding, airing, sintering, rinsing, drying and the like. The invention aims to compound the activated carbon with the activated alumina; on the one hand, the material with a certain shape can be processed, the defects of loose shape, low strength, difficult recovery and the like of the activated carbon are overcome, and the material is easy to recycle; and on the other hand, the adsorption property of the activated alumina material is greatly improved. The method has the advantages of simpleness, practicality, readily available raw materials, low cost and suitability for industrial mass production, and can be widely applied to various fields such as industry, agriculture, environmental protection, air purification, water treatment and the like.

Owner:FUZHOU UNIV

Preparation method and applications of porous metal organic skeleton material

ActiveCN104370820AGood application effectEasy to operateOther chemical processesGroup 8/9/10/18 element organic compoundsMetal-organic frameworkSolvent

The invention relates to a preparation method of a porous metal organic skeleton material. The porous metal organic skeleton material comprises at least a metal ion and at least an organic compound that can be matched with the metal ion. The material can be prepared by dissolving metal compounds, organic ligand, and sustained-released alkali into a solvent and carrying out direct water (solvent) thermal synthesis at a certain temperature under a certain pressure so as to obtain the porous metal organic skeleton material. The operation of the provided preparation method is simple, the preparation method is suitable for massive industrial production and is suitable for the synthesis of porous metal organic skeleton membrane, and the provided porous metal organic skeleton material is used to absorb, separate, and store gas.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

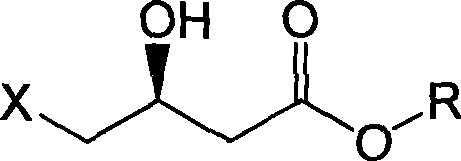

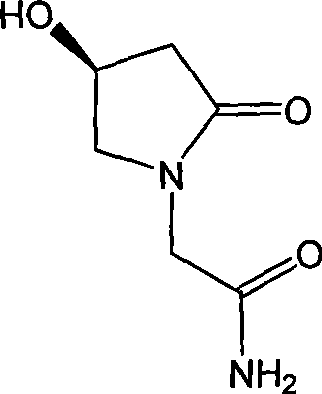

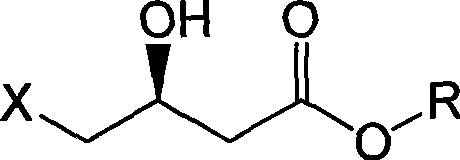

Preparation method for (S)-4-hydroxyl-2-oxo-1-pyrrolidine ethanamide

The present invention provides a preparation method of (S)-4-hydroxyl-2-oxo-1-pyrrolidine acetamide. The preparation method comprises: (S)-4-halogen-3-hydroxyl butyric ester as a raw material reacts under the conditions with polar solvent and alkalinity to prepare the crude product of (S)-4-hydroxyl-2-oxo-1-pyrrolidine acetamide; and the crude product is purified. The preparation method is characterized in that inorganic alkali is added for a plurality of times in the reaction process under the condition with alkalinity so as to control the pH value in the reaction to be less than or equal to 8.5. A large quantity of repeated tests are completed to determine that the optimum pH value of the reaction under the condition with alkalinity is less than or equal to 8.5, and the alkali is added in batches to strictly control the pH value of the whole reaction process, so that the alkali conditions required in the reaction can be satisfied and the reaction can be performed completely, and the target product (S)-oxiracetam is prevented from being damaged in the alkaline solution, thereby improving the yield rate of the target product (S)-oxiracetam and reducing the cost.

Owner:CHONGQING RUNZE PHARM CO LTD

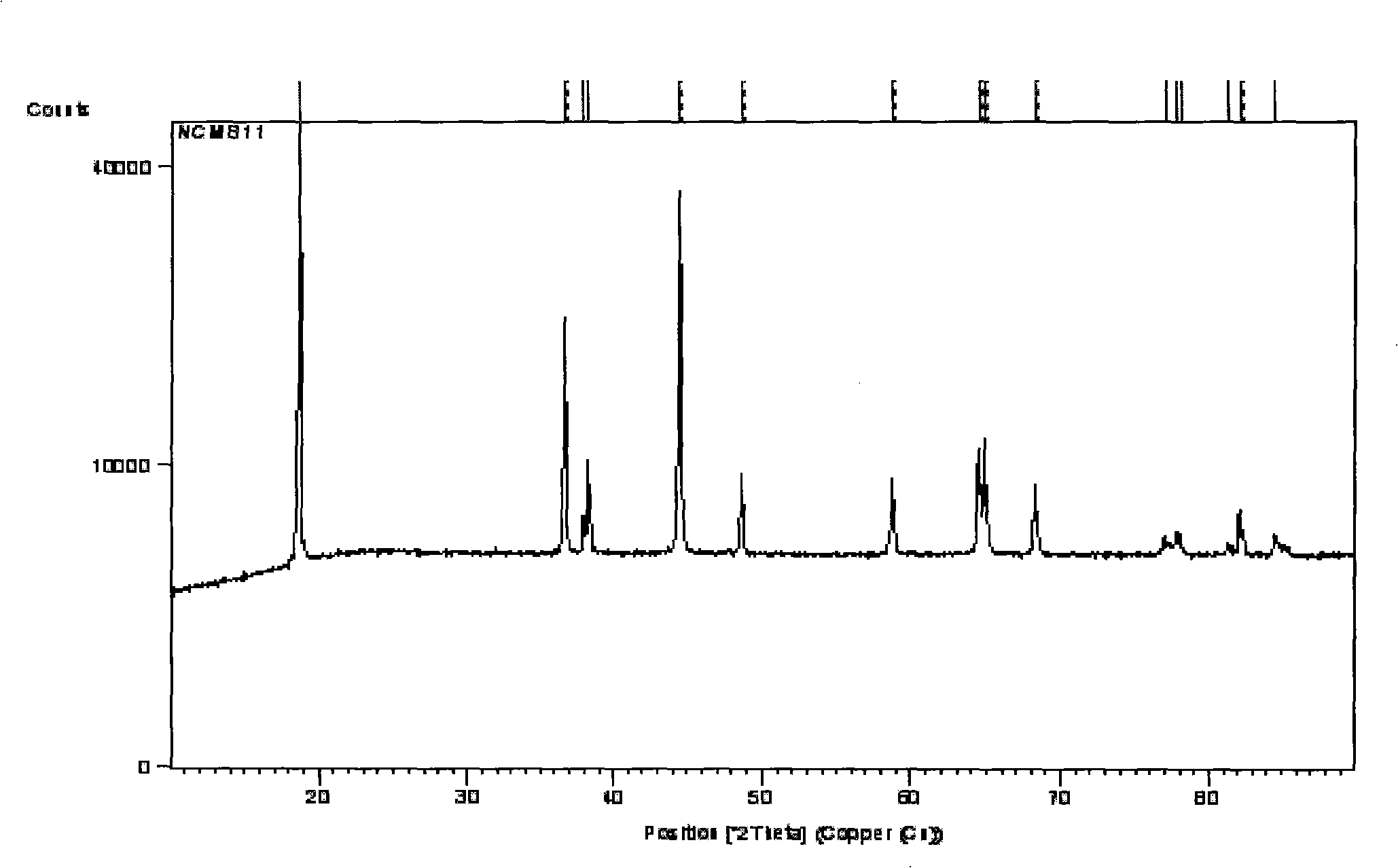

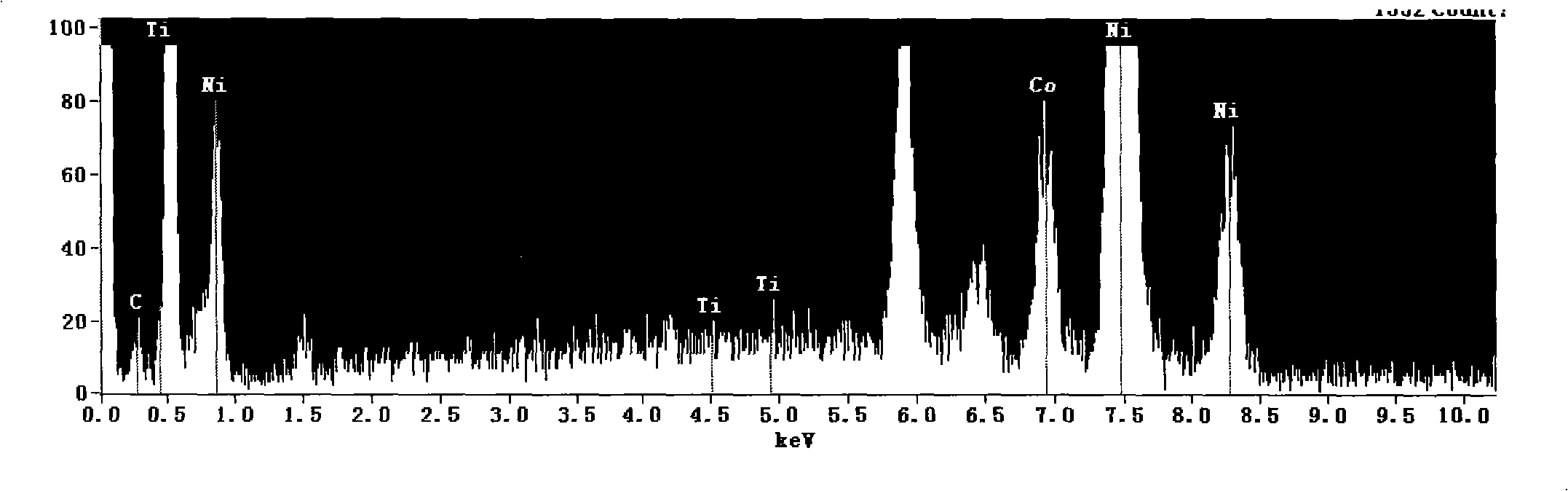

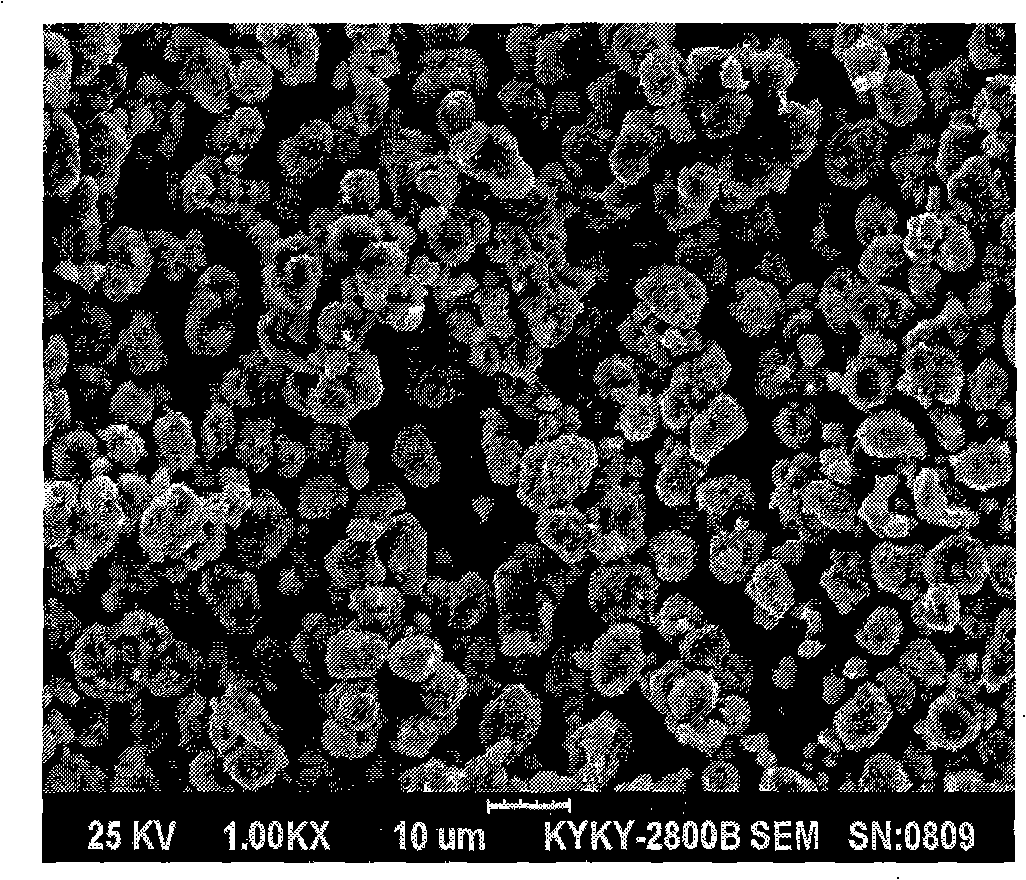

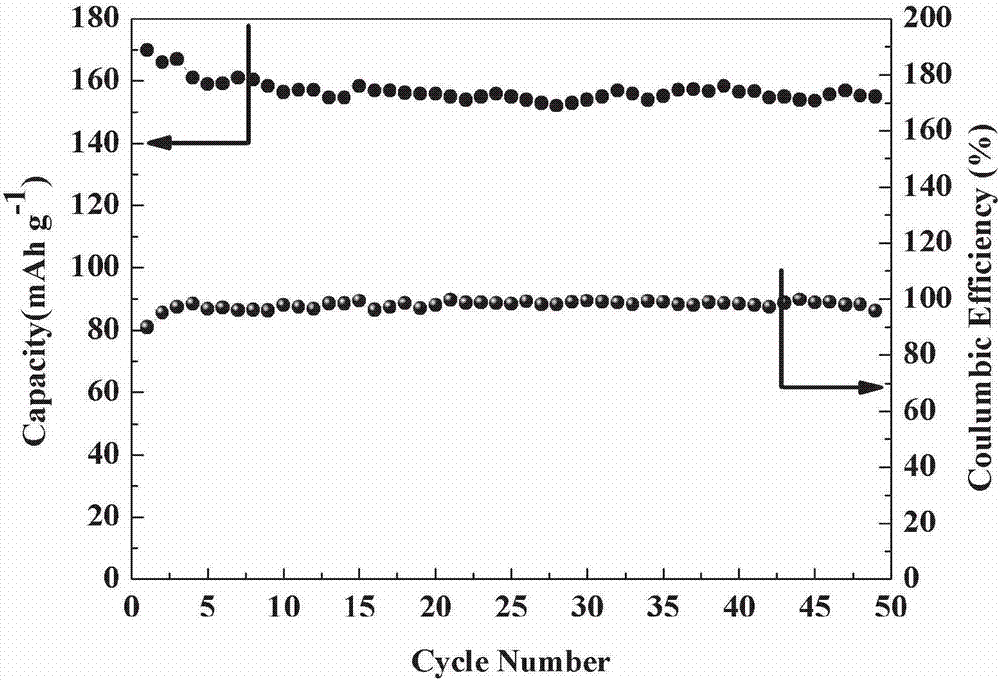

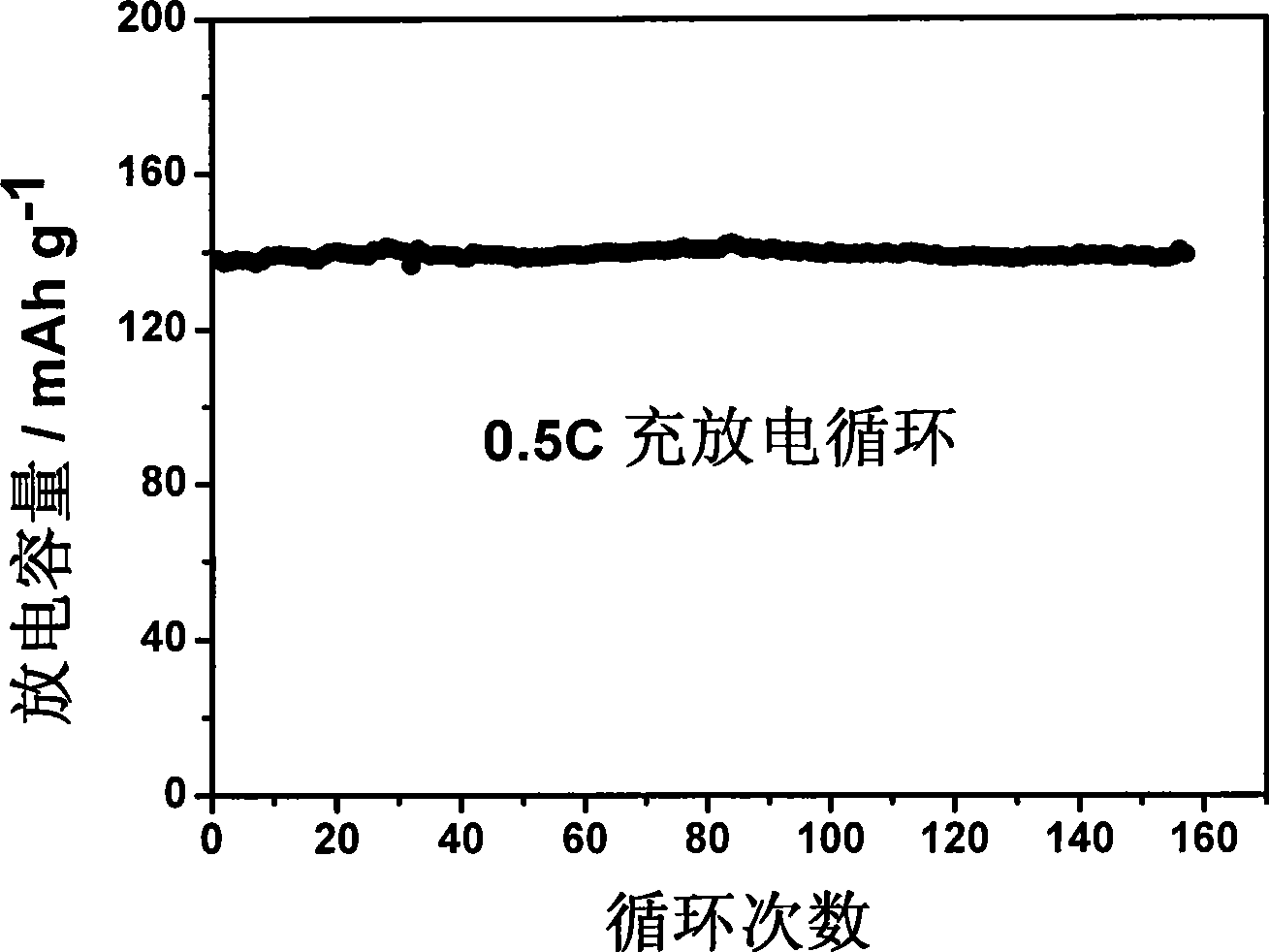

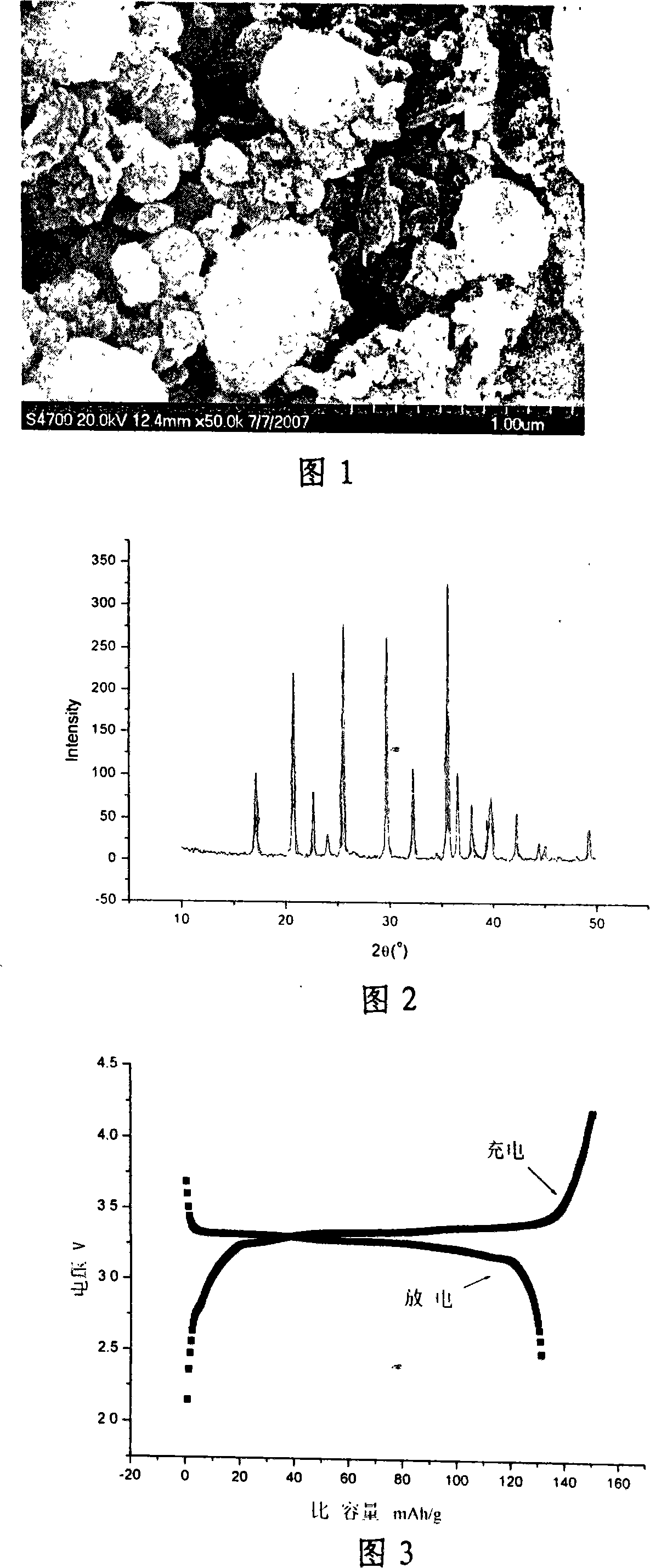

Composite coated positive pole material of lithium ionic cell and preparing method thereof

ActiveCN101308925ASimple processProgram controllableElectrode manufacturing processesChemical/physical/physico-chemical processesVoltageFunctionally gradient material

The invention discloses a coated composite lithium ion battery anode material and the preparation method thereof, aiming at improving the electrochemical property of the coated composite lithium ion battery anode material. The invention takes Li0.8-1.2Ni0.7Co0.2Mn0.1O2, and Li-0.8-1.2Ni0.8Co0.1Mn0.1O2, or Li0.8-1.2Ni0.9Co0.05Mn0.05O2 as the substrate, and adopts hexagonal crystal structure; the surface of the substrate is coated with a functionally gradient material layer which is 1-20%of the quality of the substrate. The preparation method includes the steps of preparing powder, mixing the materials, sintering, coating the surface, heating, and coating with organic material coating. Compared with prior art, the anode material can be combined with lithium metal and assembled to an analog battery; if the battery is charged or discharged at current density of 0.3C under 2.5-4.2V, the discharge capacity is more than 190mAh / g, the first coulomb efficiency will reach 90% and the capacity retention is more than 95% after 100 cycles. The coated composite lithium ion battery anode material is simple in technique and low in cost and is suitable for large-scale industrial production.

Owner:BTR NEW MATERIAL GRP CO LTD

Rare earth-containing high strength heat resisting magnesium alloy and preparation thereof

The invention relates to a high strength heat-resistant magnesium alloy containing rare earths of the technical field of metallic materials and a preparation method thereof. The magnesium alloy comprises the following components according to the mass percent: Y with more than or equal to 3% and less than or equal to 16%, Gd with more than or equal to 0% and less than or equal to 10%, Ca with more than or equal to 0.3% and less than or equal to 5%, Zr with more than or equal to 0.1% and less than or equal to 1.5%, and one or a plurality of Nd, Si, Sb, Ti, Sn, Sr, Bi, Cd, Nd with more than or equal to 0% and less than or equal to 5%, Si with more than or equal to 0% and less than or equal to 5%, Sb with more than or equal to 0% and less than or equal to 5%, Ti with more than or equal to 0% and less than or equal to 5%, Sn with more than or equal to 0% and less than or equal to 5%, Sr with more than or equal to 0% and less than or equal to 5%, Bi with more than or equal to 0% and less than or equal to 5%, Cd with with more than or equal to 0% and less than or equal to 5%, and the rest is Mg and impurities. The magnesium alloy is obtained by using melting and the subsequent heat treatment. The magnesium alloy not only can serve as casting magnesium alloy but also can serve as the deformation magnesium alloy and has better predominant mechanical property compared with the WE series commercial magnesium alloy.

Owner:SHANGHAI JIAO TONG UNIV

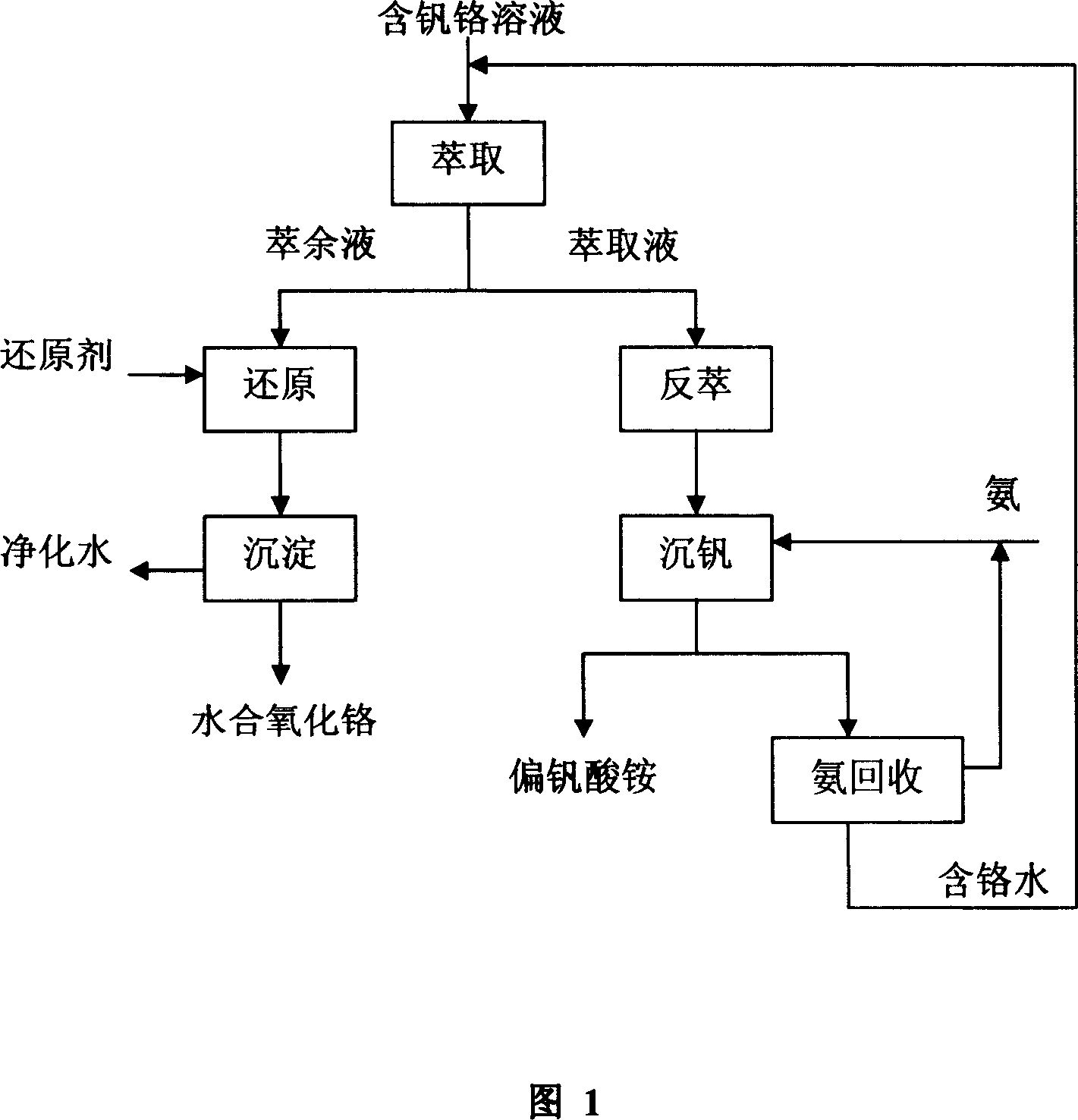

Method for separating and reclaiming vanadium and chromium from solution containing vanadium and chromium

ActiveCN101121962ALow costSimple processProcess efficiency improvementHydration reactionDistillation

This invention relates to an entirely new technology of completely recovering chromium and vanadium from vanadium-chromium miscible liquid. The main procedures include: first a primary-secondary compound amine extracting agent contacts the vanadium-chromium miscible liquid by means of countercurrent contact and extract, so as to extract most of vanadium and a small amount of chromium into a organic phase while most of chromium stays into a aqueous phase; and a reduction reaction is conducted with pH of acid adjustable faffinate (aqueous phase) and a certain amount of a reducing agent; the sodium hydroxide is used for adjusting pH value of the solution and filter, and finally the product is hydrous chromium oxide; at that time, the lye is used as a stripping agent; the vanadium is stripped from the vanadium-rich organic phase into water in the manner of countercurrent contact; and the vanadium is separated from the solution witthe method of ammonium precipitation and in the form of ammonium metavanadate; and finally the supernatant clear solution of the one is processed with deposited vanadium with a high-efficient distillation technology, and the strong aqua ammonia is left in the tower top and deamidization solution is left in the tower bottom until the extraction process is reached. The invention uses the primary-secondary compound amine as the extracting agent, extracts and separates vanadium and chromium selectively at a low temperature. The invention not only has a simple process flow, but also is low-cost, quite applicable in large-scale industrial production. In addition, the invention also provides high-purity ammonium metavanadate and 16 percentage strong aqua ammonia, and makes sure the vanadium and chromium can be completely recovered through re-use of the solution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

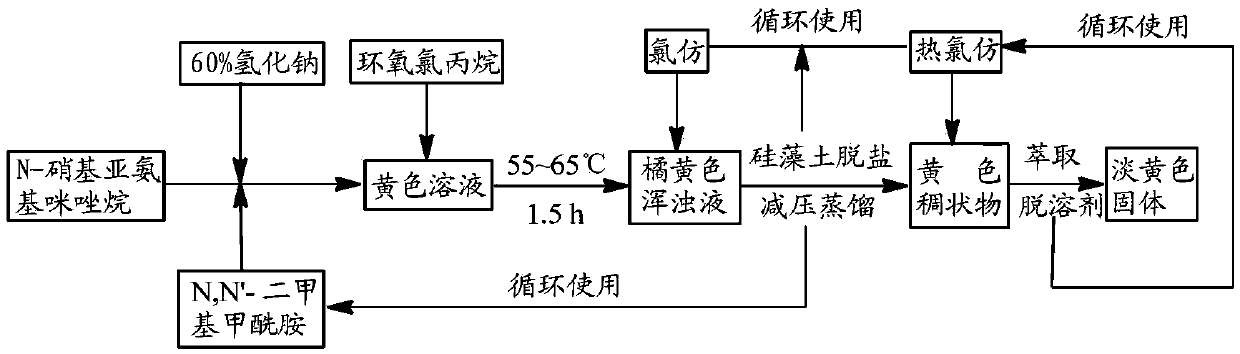

Method for preparing cycloxylidin

The invention discloses a method for preparing cycloxylidin, which belongs to the technical field of pesticides preparation. The method comprises the following steps: under nitrogen protection, N-nitroiminoimidazolidine and an organic solvent are added in a reactor, then sodium hydride is added in batches, and the material is heated to the temperature of 50-60 DEG C, chloropropylene oxide is added drop by drop in the reactor, after the reaction product is cooled, chloroform is added, and the product is filtered by diatomite, then evaporative crystallization is carried out, and the crystals can be precipitated, vacuum distillation is carried out on a processed filtrate to obtain a light yellow dense solid, then heat chloroform is used for extraction, and finally heat ethanol or acetone is used for recrystallization to obtain cycloxylidin: 1-(2,3-glycidyl)-N-nitroimidazoline-2-ylamine, wherein the yield is about 83%. The method has the advantages of short reaction time, high yield and green environmental protection, and is more suitable for large-scale industrial production.

Owner:山东聚强绿洲生物科技有限公司

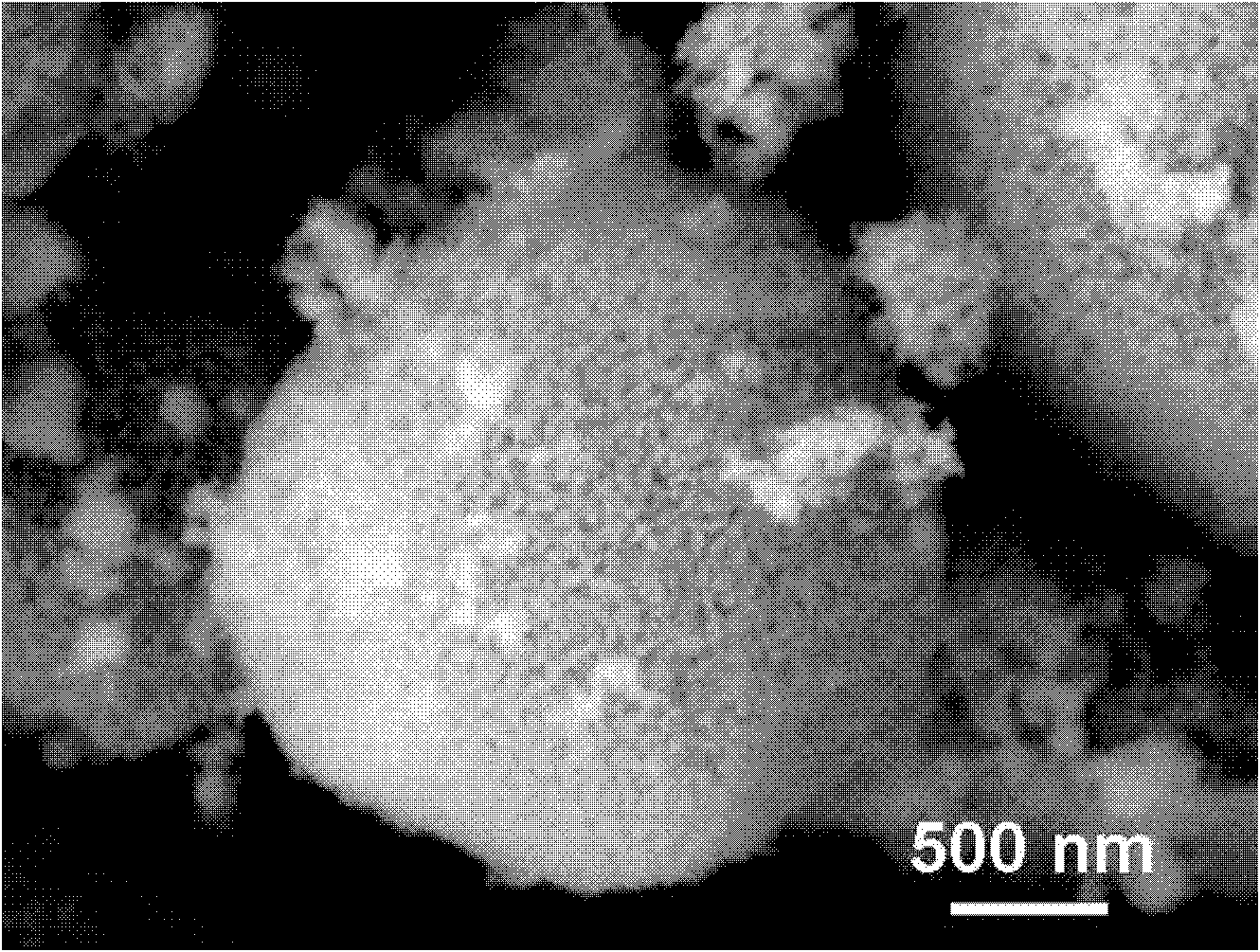

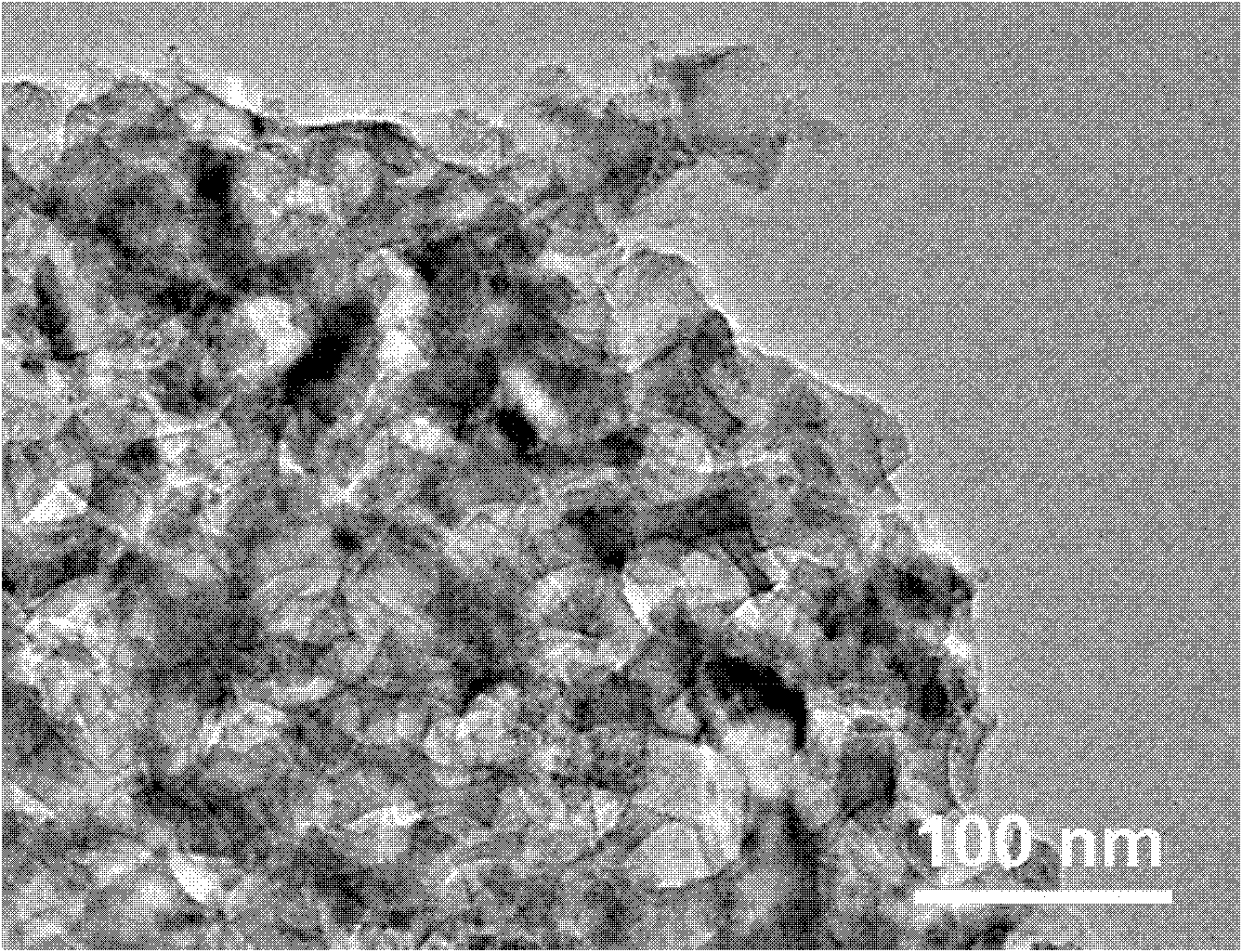

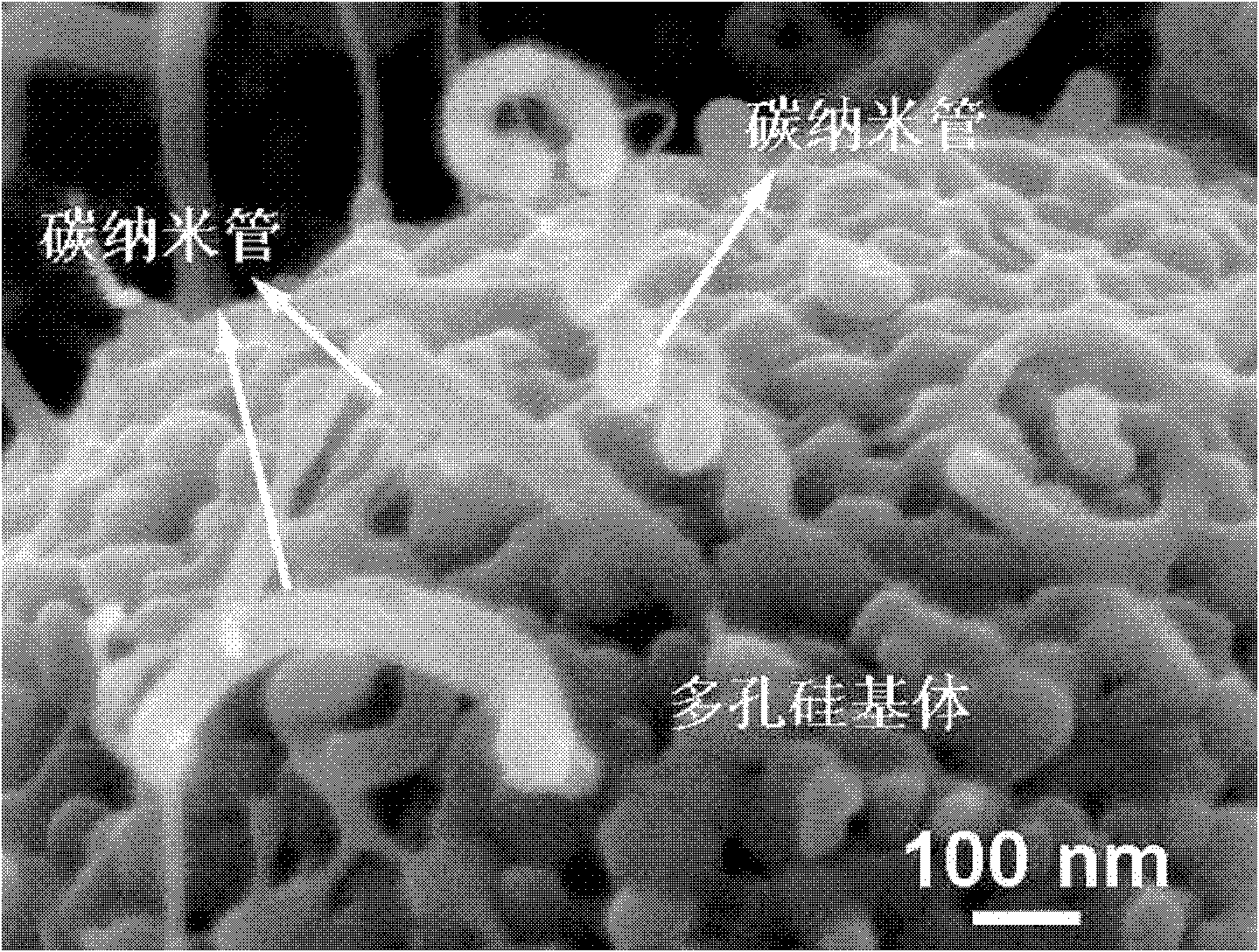

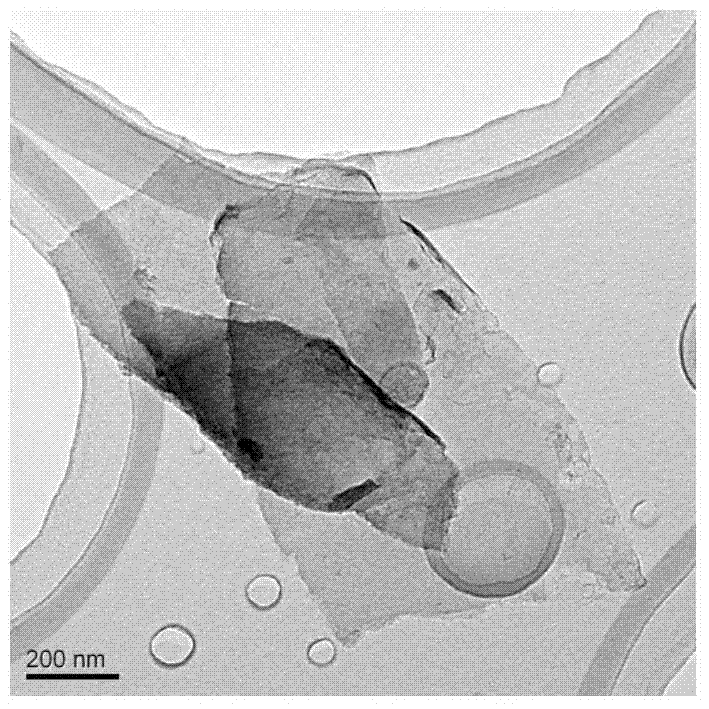

Silicon carbon composite material and preparation method thereof

ActiveCN102185128AIncrease productivityReduce manufacturing costCell electrodesFiberCarbon composites

The invention discloses a silicon carbon composite material and a preparation method thereof. The material disclosed by the invention comprises a porous silicon substrate, a one-dimensional carbon nano material and amorphous carbon, wherein the one-dimensional carbon nano material is a carbon nano tube or carbon nano fiber. The preparation method disclosed by the invention comprises the following steps: preparing the porous silicon substrate; loading a catalyst precursor; and carrying out the chemical vapor deposition. The one-dimensional carbon nano material directly grows on the porous silicon substrate, and the one-dimensional carbon nano material and the porous silicon substrate are coated with the amorphous carbon. The silicon carbon composite material provided by the invention is suitable for the cathode material of a lithium ion battery, and has the advantages of high capacity and stable circulation performance. A constant-current charge and discharge test is carried out under the 300mA / g current density, and the silicon carbon composite material disclosed by the invention has the characteristics that the first reversible capacity is 1149mAh / g; the reversible capacity is 1087mAh / g after the circulation is carried out for 100 times; and the capacity conservation rate is up to 95%.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

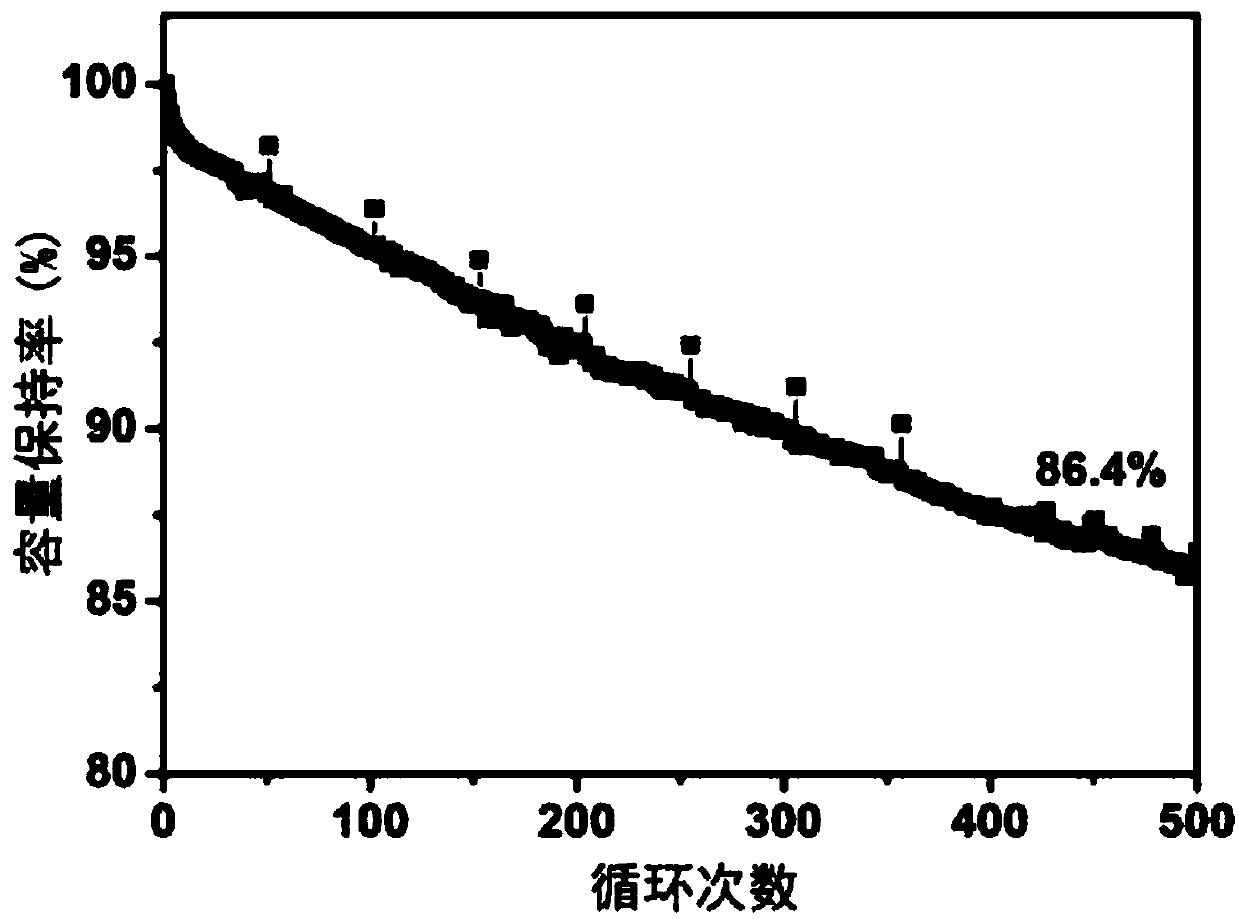

Doped multi-layer core-shell silicon-based composite material for lithium ion battery and preparation method thereof

ActiveCN109599551AInhibits and buffers swellingPrevent partial failureMaterial nanotechnologySecondary cellsCarbon filmComposite film

The present invention relates to a doped multi-layer core-shell silicon-based composite material for a lithium ion battery, and a preparation method thereof. Other than being doped with a necessary lithium element, the material is also doped with at least a non-metallic element and a metal element; the material has a structure in which a silicon oxide particle doped with elements is taken as a core, and a multilayer composite film which is tightly coated on the surface of the core particle is taken as a shell; the core particle contains uniformly dispersed monoplasmatic silicon nanoparticles,the content of doping elements gradually decreases from the outside to the inside without a clear interface, and a dense lithium silicate compound is formed on the surface of the core particle by embedding and doping the lithium element; and the multilayer composite film is a carbon film layer and a doped composite film layer composed of the carbon film layer and other elemental components. The doped multi-layer core-shell silicon-based composite material provided by the present invention has a high capacity, good rate performance, high coulombic efficiency, good cycle performance, a low expansion rate, and other electrochemical characteristics when the material is used for the negative electrode of lithium ion battery.

Owner:BERZELIUS (NANJING) CO LTD +1

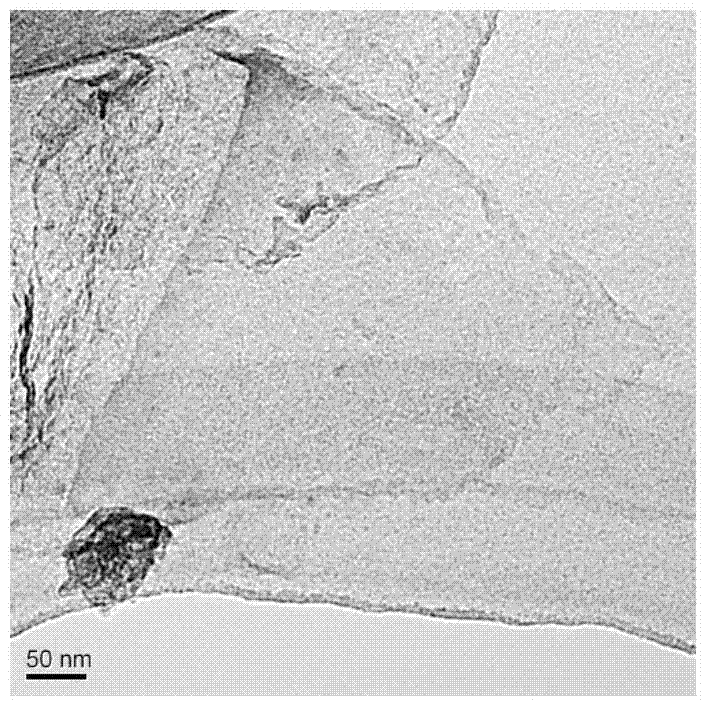

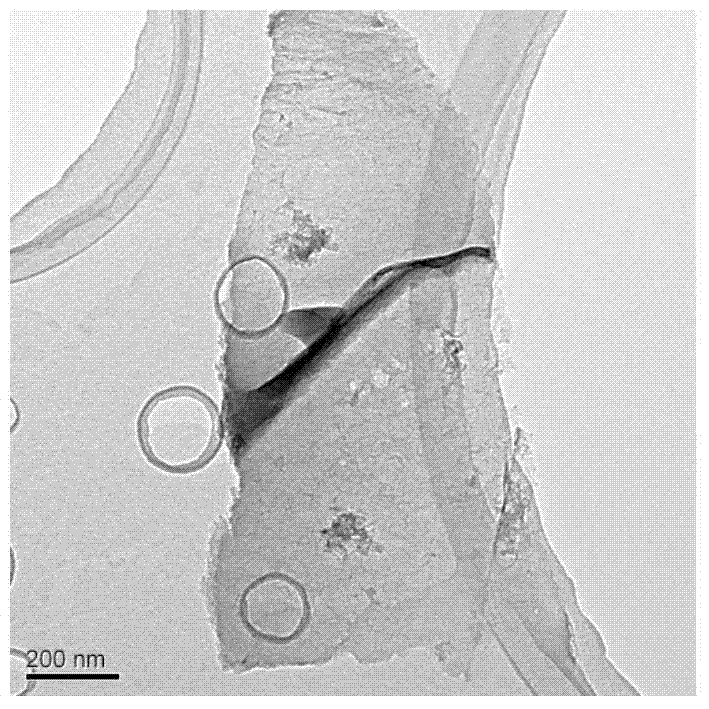

Method for preparing graphene by taking biomass as raw material

InactiveCN104724696AMitigate post-processing issuesEfficient strippingMaterial nanotechnologyOrganic solventCvd graphene

The invention discloses a method for preparing graphene by taking biomass as a raw material. The method comprises the following steps: dipping the biomass in an organic solvent for 1-5 hours, centrifuging, drying, calcining for 1-24 hours at the temperature of 600-1600 DEG C in the presence of inert gas, and cooling, thus obtaining graphene. The method for preparing the graphene by taking the biomass as the raw material has the advantages that cheap and easily available biomass is taken as the raw material, the problem of aftertreatment of dried-up herbaceous plants is effectively solved, and an effective path is provided for high value-added utilization of the herbaceous plants; a preparation technology in each step is controllable and is high in repeatability, the prepared graphene is obvious in exfoliation, and the minimum lamellar thickness is 3nm only; and the method is simple and environmentally friendly, low in capital investment and suitable for large-scale industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

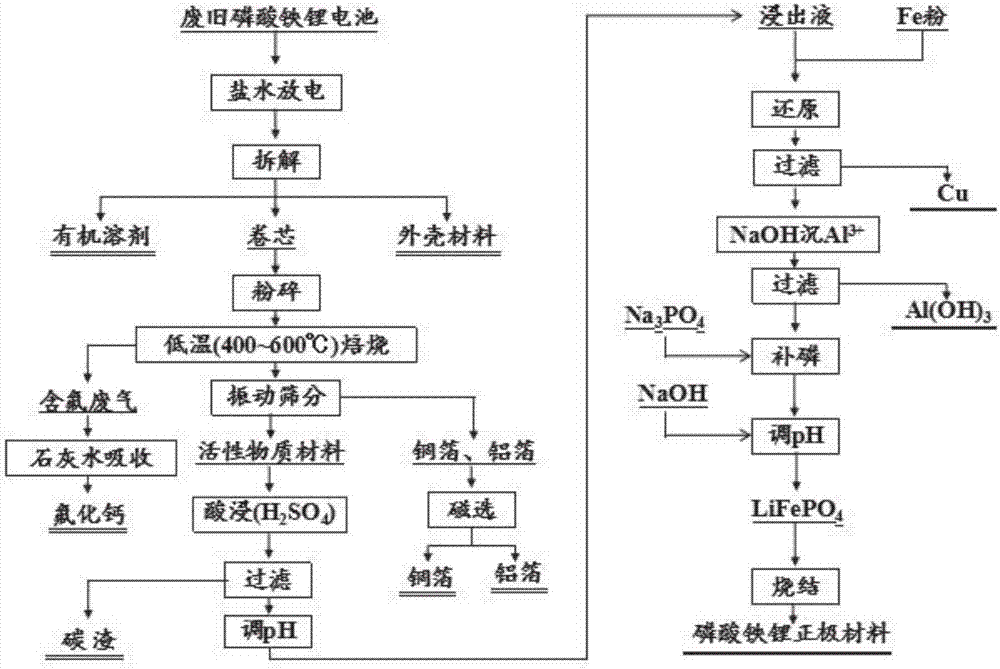

Method for regenerating positive active material from waste lithium iron phosphate batteries

ActiveCN106910889ARealize combination generationQuality assuranceCell electrodesWaste accumulators reclaimingFiltrationCopper foil

The invention discloses a method for regenerating a positive active material from waste lithium iron phosphate batteries. The method comprises the steps as follows: 1) waste lithium iron phosphate batteries are discharged in saline water, and organic solvents, roll cores and casing materials are disassembled; 2) the roll cores are subjected to crushing, calcination and other steps, and active materials, copper foil and aluminum foil are separated through vibrating screening. Fluorine-containing waste gas is absorbed with lime water, the copper foil and the aluminum foil are separated with a magnetic separation method, the active materials are leached out with sulfuric acid, and a leachate and carbon residues are obtained through separation; 3) Cu<2+> in the leachate is reduced to elementary copper by adding iron powder, meanwhile, Fe<3+> is reduced to Fe<2+>, copper and excessive iron residues are filtered out, aluminum is removed through precipitation with an alkaline liquid, the filtrate is supplemented with a phosphorus source after filtration, the pH value is adjusted by adding the alkaline liquid, coarse lithium iron phosphate precipitates are produced, and finally, battery-grade lithium iron phosphate is obtained through sintering. Comprehensive utilization of the waste lithium iron phosphate batteries and regeneration of the active materials are realized with a simple, practical, economical and feasible method, no secondary pollution is produced, and the method is suitable for industrial production.

Owner:CENT SOUTH UNIV

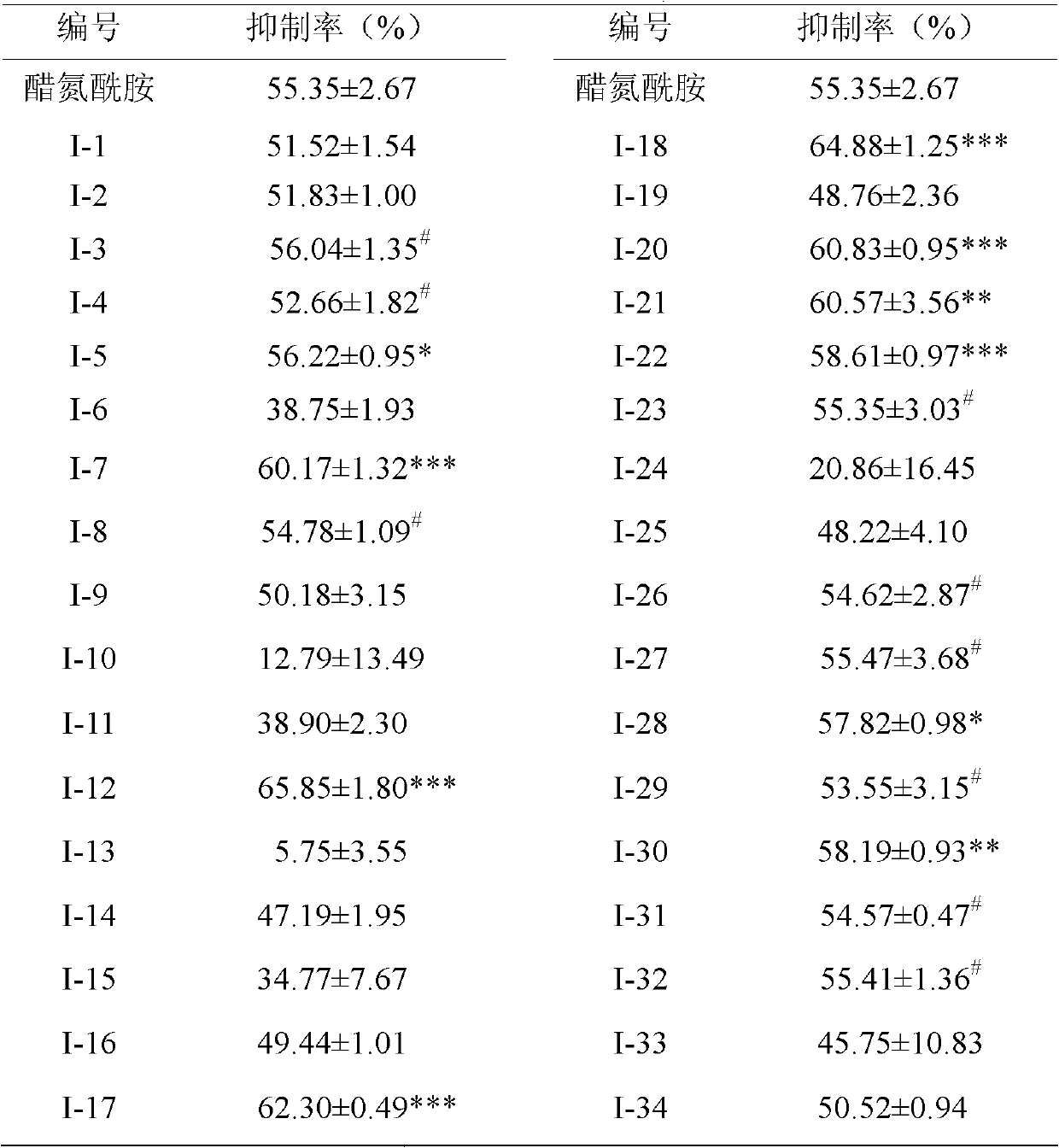

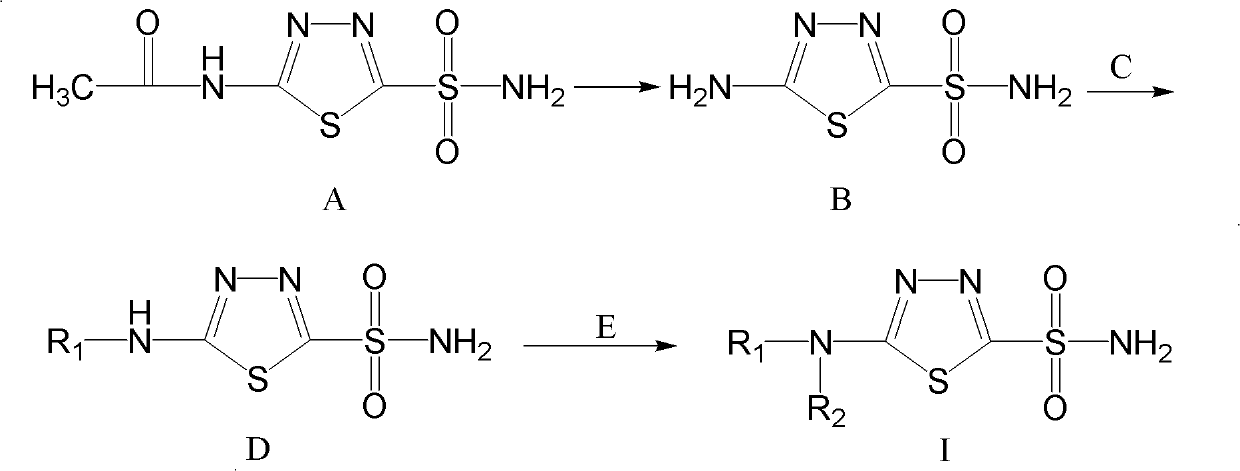

Sulfonamides compound for inhibiting carbonic anhydrase II and synthesis method and application thereof

InactiveCN101921245AHigh resource utilizationThe synthesis method is simpleOrganic active ingredientsOrganic chemistrySynthesis methodsCarbonic anhydrase II

The invention relates to a sulfonamides compound for inhibiting carbonic anhydrase II and a synthesis method and an application thereof. The compound has the structure as shown in the specification. The invention features economical and reasonable synthetic route and high utilization of resources. The synthesis method is simple and easy to carry out and is more suitable for large-scale industrialized production. With human carbonic anhydrase II (Human Carbonic Anhydrase II, hCA II) expressed by procaryotic cell as an enzyme source, the invention establishes an in-vitro carbonic anhydrase inhibitor screening model. In addition, the compound of the invention has inhibitive effect on activity of the human carbonic anhydrase II.

Owner:INST OF HYGIENE & ENVIRONMENTAL MEDICINE PLA ACAD OF MILITARY MEDICAL +1

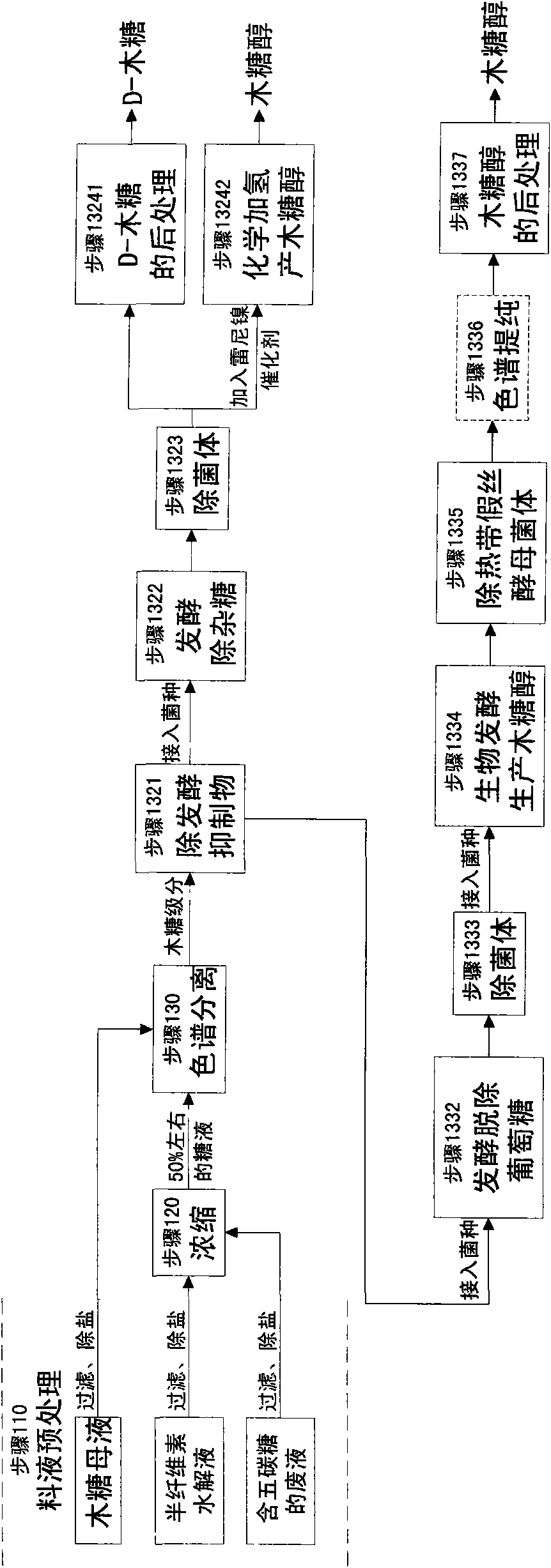

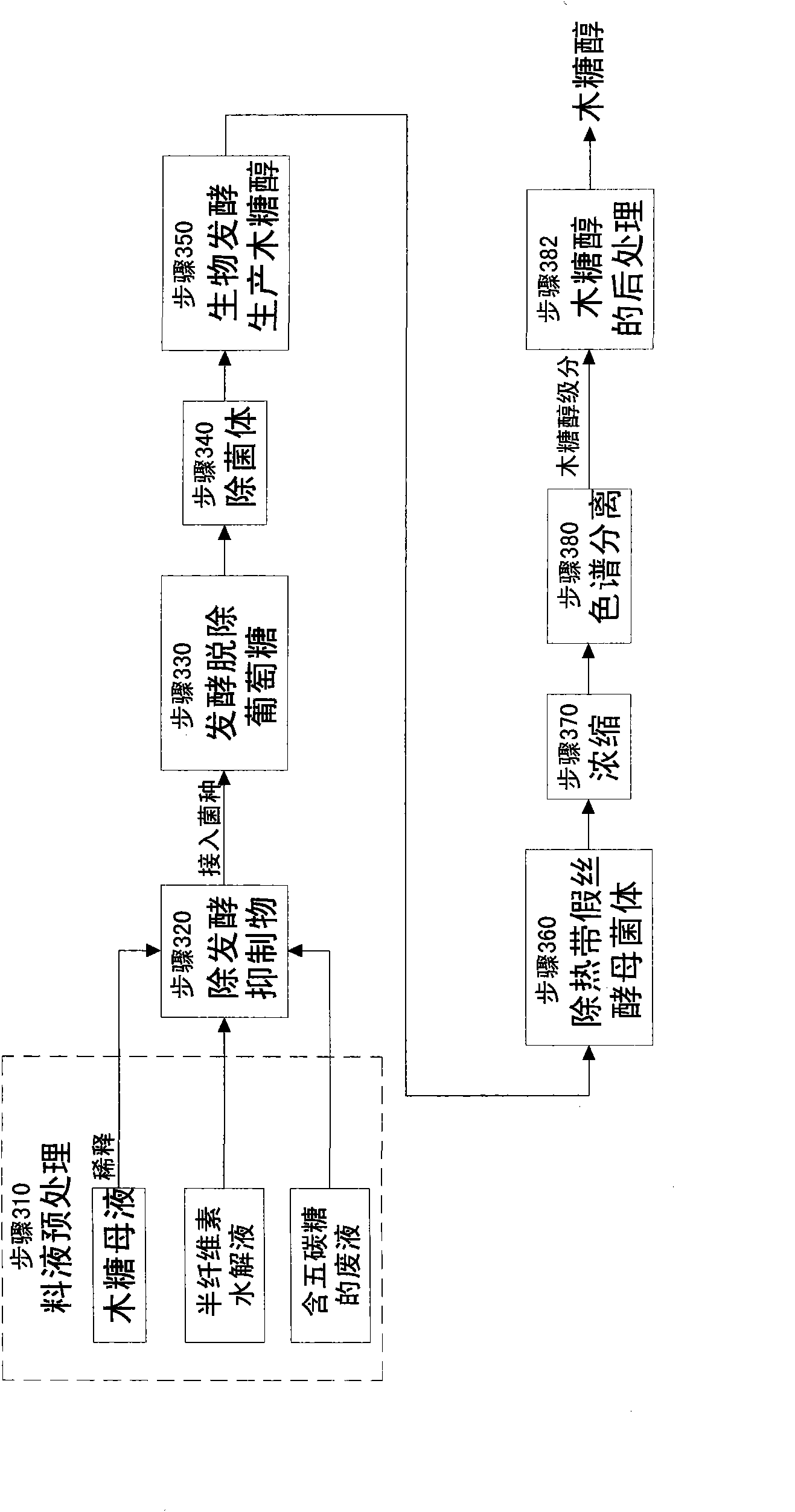

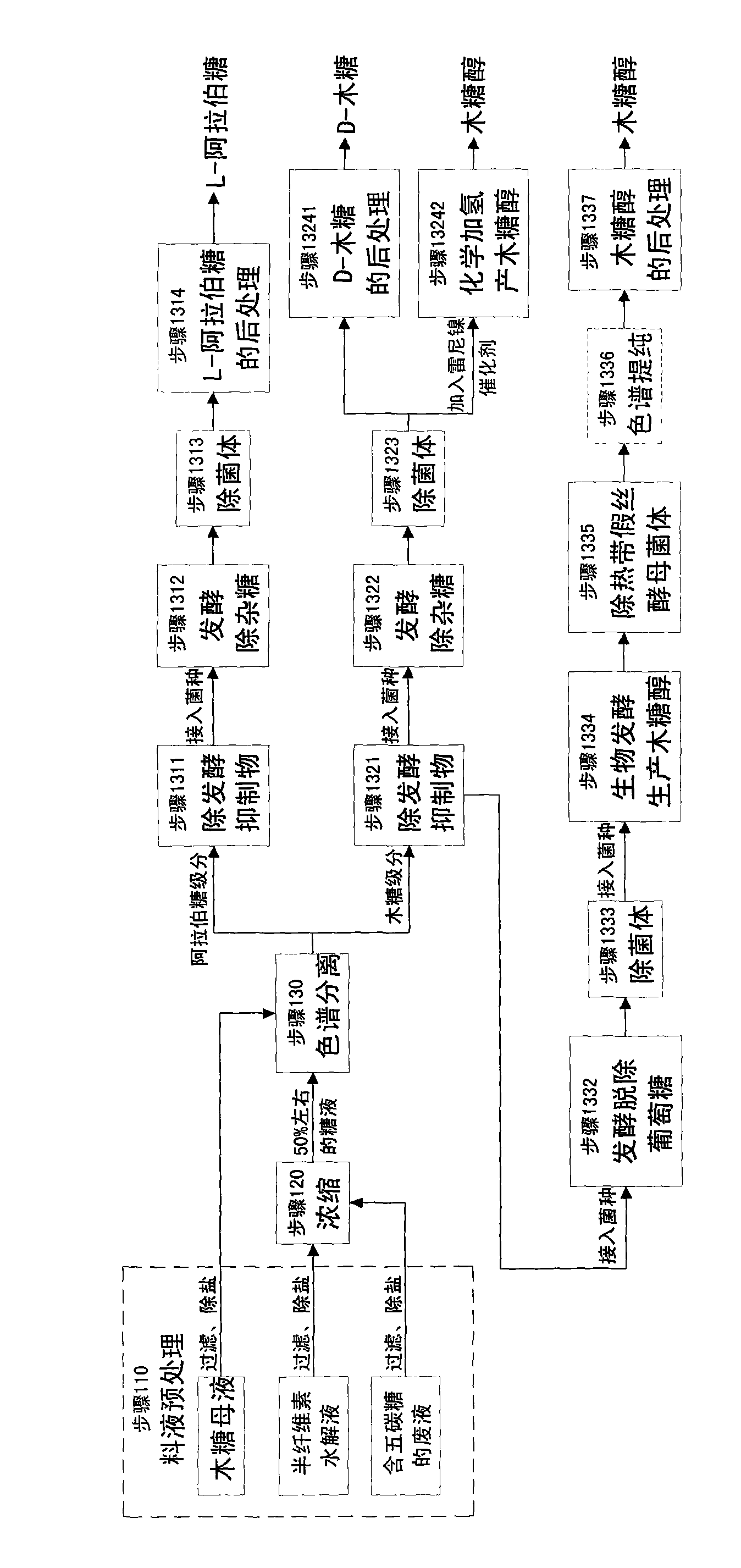

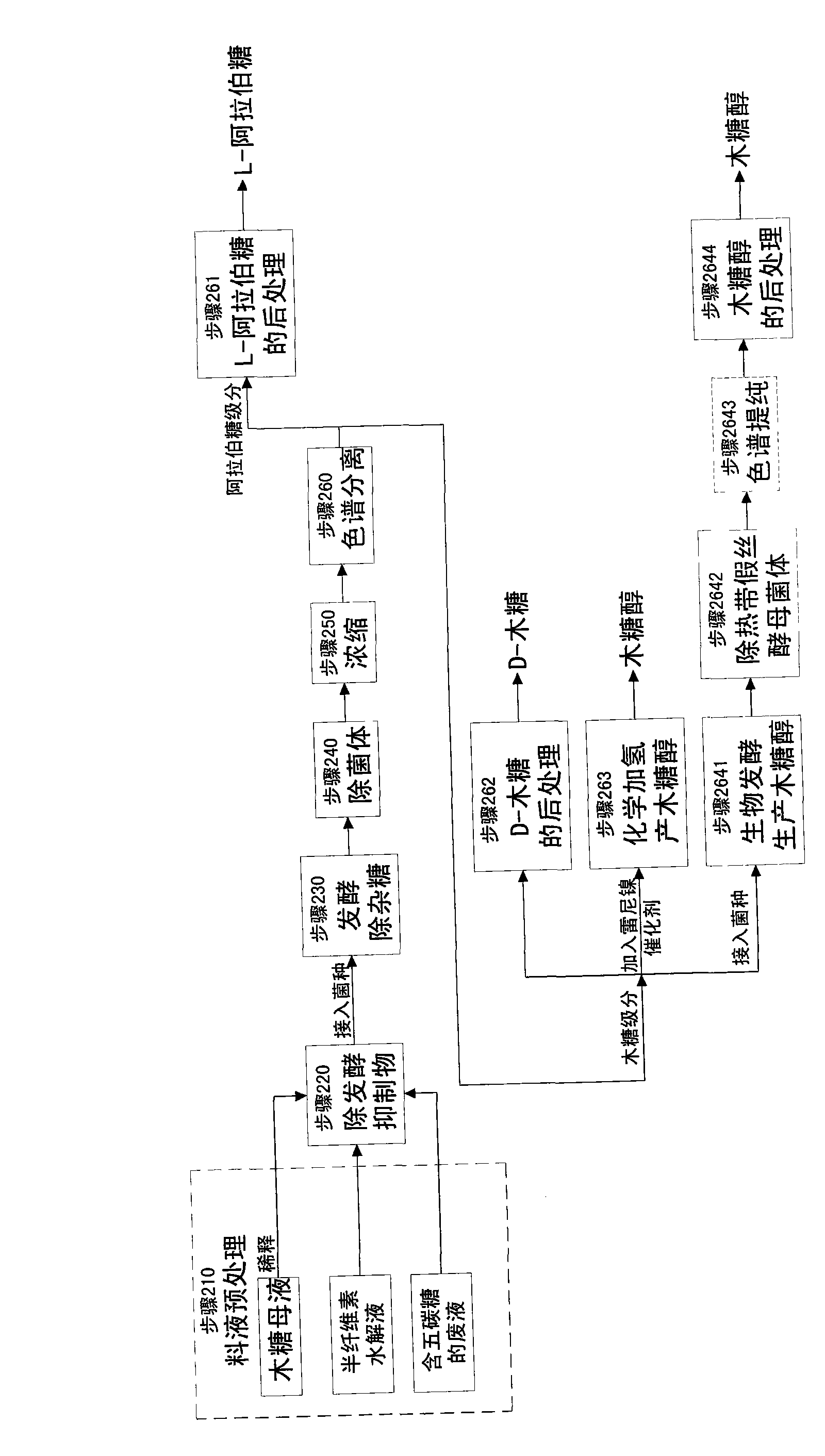

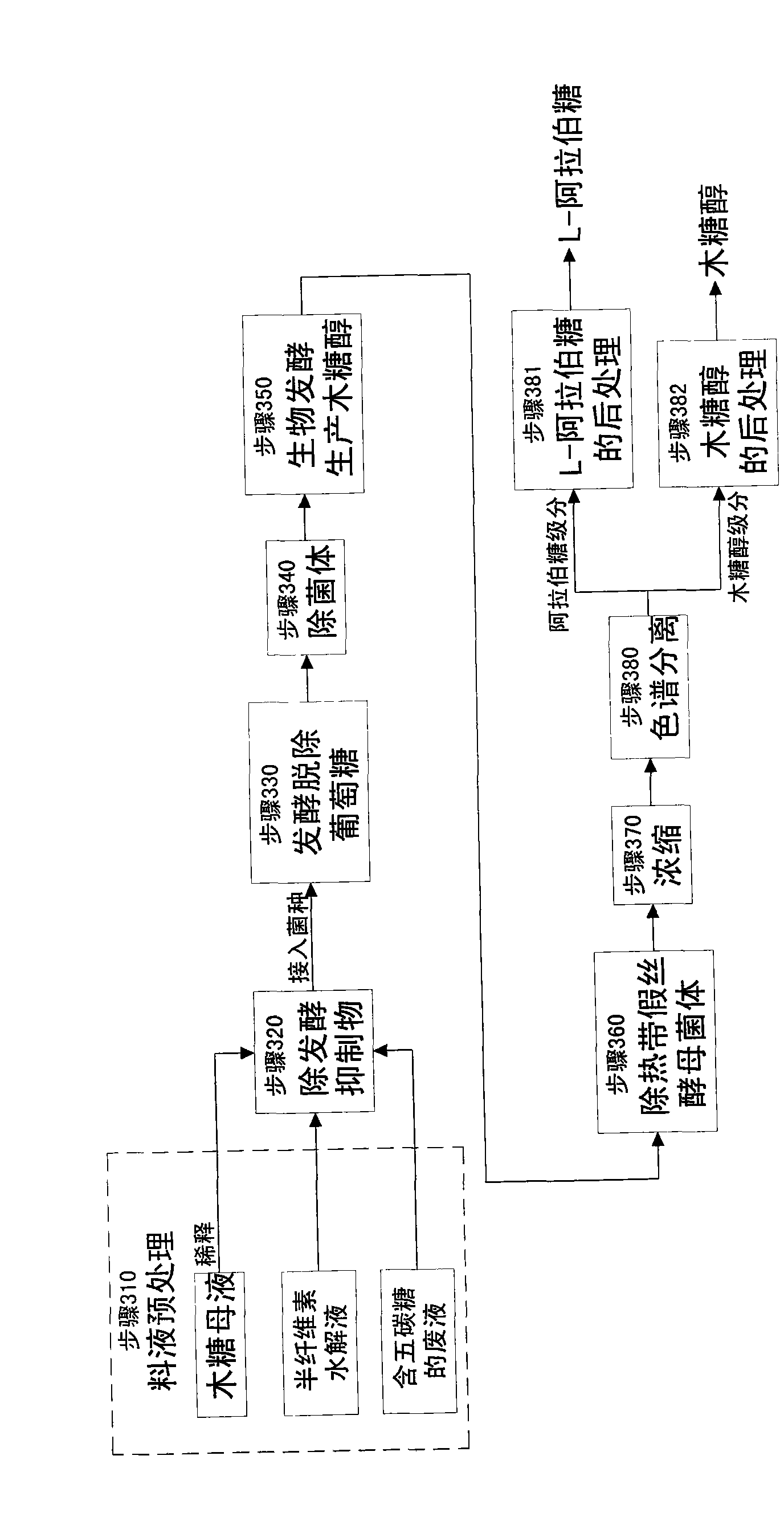

Method for producing wood sugar product

ActiveCN101659681AHigh purityFermentation went wellIon-exchange process apparatusSugar derivativesChromatographic separationHydrolysis

The invention relates to a method for producing a wood sugar product and a byproduct of ethanol or D-ribose or citric acid. The method takes hydrolysis liquid, wood sugar mother liquor and / or production waste liquid containing pentose of agricultural or forestry waste as the raw materials, comprising the following steps: (a) preprocessing feed liquid; (b) colour spectrum separation: separating thefeed liquid into arabinose fraction feed liquid and wood sugar fraction feed liquid; (c) removing mixed sugar at least containing glucose and galactolipin; and (d) carrying out aftertreatment on thewood sugar fraction feed liquid to obtain the wood sugar product. The wood sugar product comprises xylitol and D-wood sugar. The invention has low production cost and high efficiency and is suitable for large-scale industrial production.

Owner:SHENGQUAN HEALTANG

Li-ion secondary battery cathode material preparation method with nuclear shell structure

ActiveCN101752547AGuaranteed electrical conductivityImproving the performance of electrochemical lithium intercalation reactionElectrode manufacturing processesCarbon layerSolvent

The invention relates to a Li-ion secondary battery cathode material preparation method with a nuclear shell structure; the preparation method is characterized in that: SiO, asphalt and graphite are weighted and are added in solvent for carrying out stirring; drying is carried out; the solvent is extracted out to obtain precursors which are uniformly distributed; the precursors are arranged in a high-temperature furnace, high-temperature sintering is carried out at inert atmosphere, the temperature is reduced to room temperature, so as to obtain the Li-ion secondary battery cathode material preparation method with the nuclear shell structure; meanwhile, the SiO, the asphalt and the graphite are chosen as initial raw material, so as to prepare the Si-SiO2-C electrode material with the nuclear shell structure, when the volume of the buffering Si material is expanded, the electricity-conducting capacity of the electrode material is ensured and the electro-chemical Li-embedded reaction property of the electrode material is improved; the asphalt is used as a carbon source, while reducing the product cost, the material is coated; a regular carbon layer structure is set up in the material body and on the surface, so as to improve the electricity-conducting performance of the material; the method has simple process and is suitable for large-scale industrial production.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

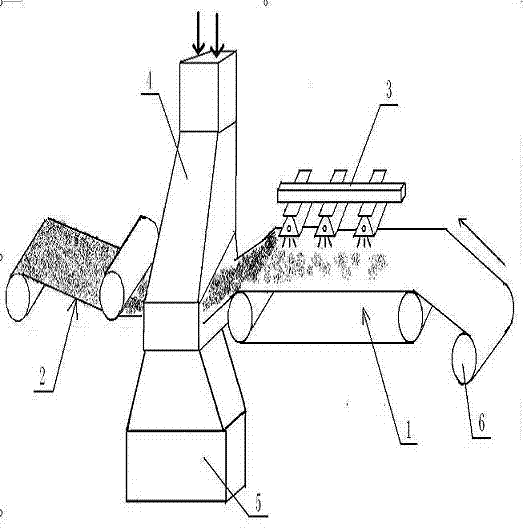

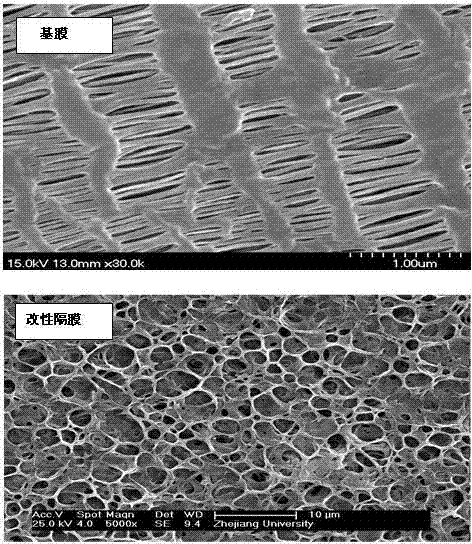

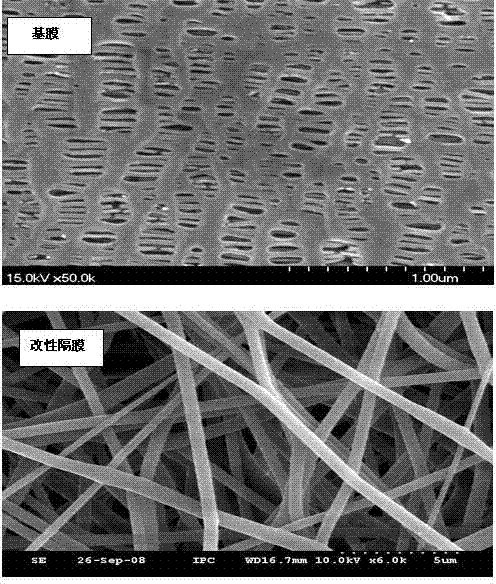

Preparation method of modified diaphragm for lithium-ion secondary battery as well as product and preparation device thereof

ActiveCN102218871AOvercome the disadvantages of poor mechanical propertiesHigh strengthSynthetic resin layered productsFilament/thread formingFiberPolyolefin

The invention discloses a preparation method of a modified diaphragm for a lithium-ion secondary battery as well as a prepared modified diaphragm and a preparation device and is aimed to solve the problem of lithium battery modified diaphragms in the prior art. The method concretely comprises the following steps of: (1), evenly dispersing special fiber or oxide and a binder into an organic solvent to prepare composite mixed liquid, and adding a cosolvent into the organic solvent; (2) evenly spraying the composite mixed liquid obtained in the step (1) on a polyolefin base membrane to form a primary composite membrane through an electrostatic spinning method; and (3), drying the primary composite membrane obtained in the step (2) and recycling the solvent, and then finally obtaining the finished product. The preparation method is convenient to operate and environmental friendly, can realize large-scale production and has strong feasibility.

Owner:WANXIANG 123 CO LTD

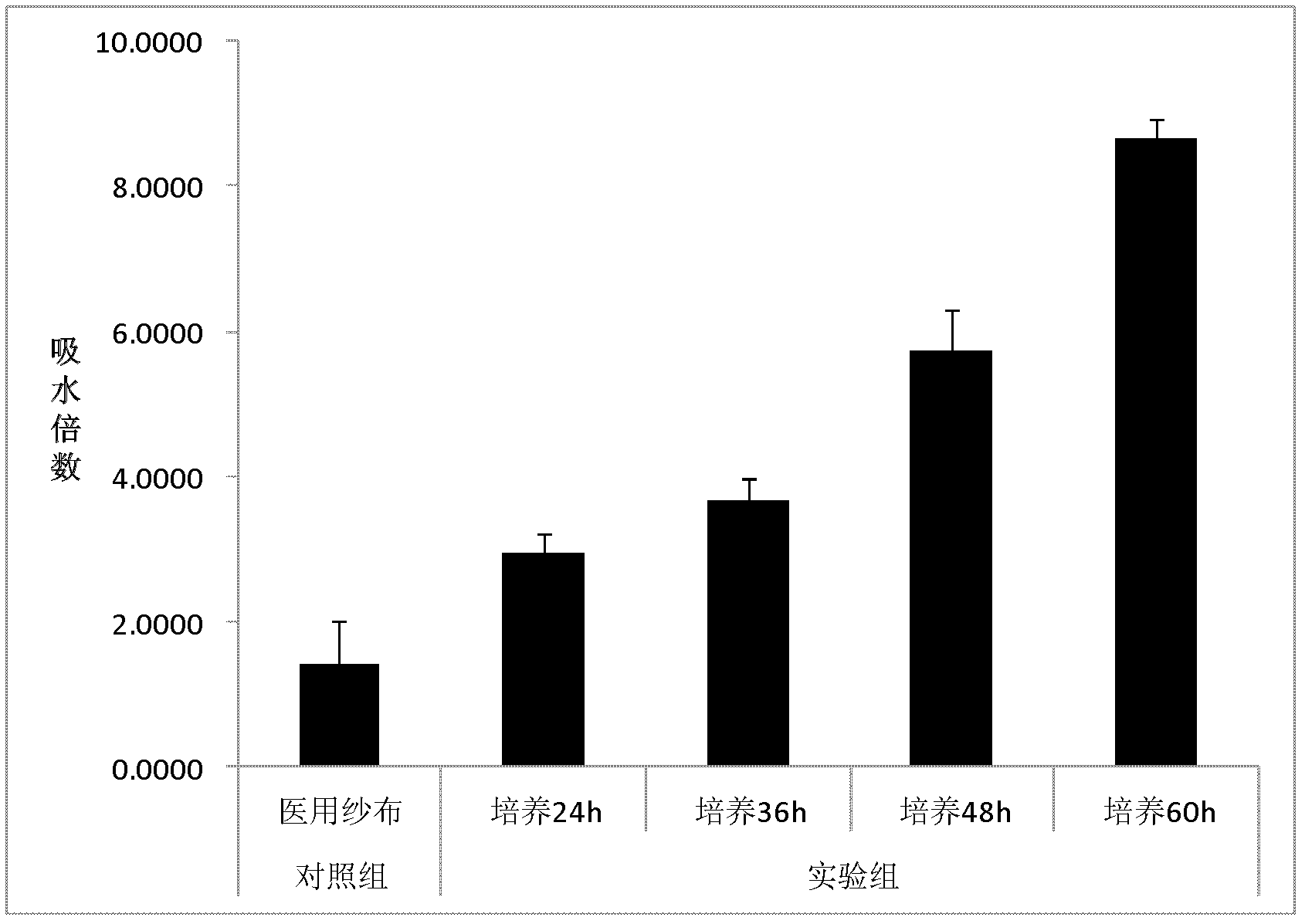

Method for preparing nano-cellulose antibacterial composite material through on-line culture

ActiveCN102552965ARealize fermentation productionImprove continuityCosmetic preparationsBacteriaWater bathsFiber

The invention relates to a method for preparing a nano-cellulose antibacterial composite material through on-line culture. The method comprises the following steps of: (1) inoculating an activated bacterial cellulose producing strain into a liquid culture medium, performing amplification culture, transferring the liquid culture medium into a bioreactor, culturing, adding an antibacterial material into the liquid culture medium, and continuing to culture to obtain an unpurified antibacterial bacterial cellulose composite material; and (2) peeling a bacterial cellulose membrane from a framework or directly soaking the composite material in a NaOH solution, treating in water bath, and washing until an obtained product is neutral to obtain the nano-cellulose antibacterial composite material. The preparation efficiency is high, and the method is simple, convenient, feasible and low in cost; and the surface of the bacterial cellulose composite material has a nanoscale three-dimensional fibrous mesh-shaped structure, the tensile strength of the material is greatly improved compared with that of a pure bacterial cellulose membrane, and the material can be widely applied to products such as facial masks, wound dressings, plasters, artificial skins and the like.

Owner:DONGHUA UNIV

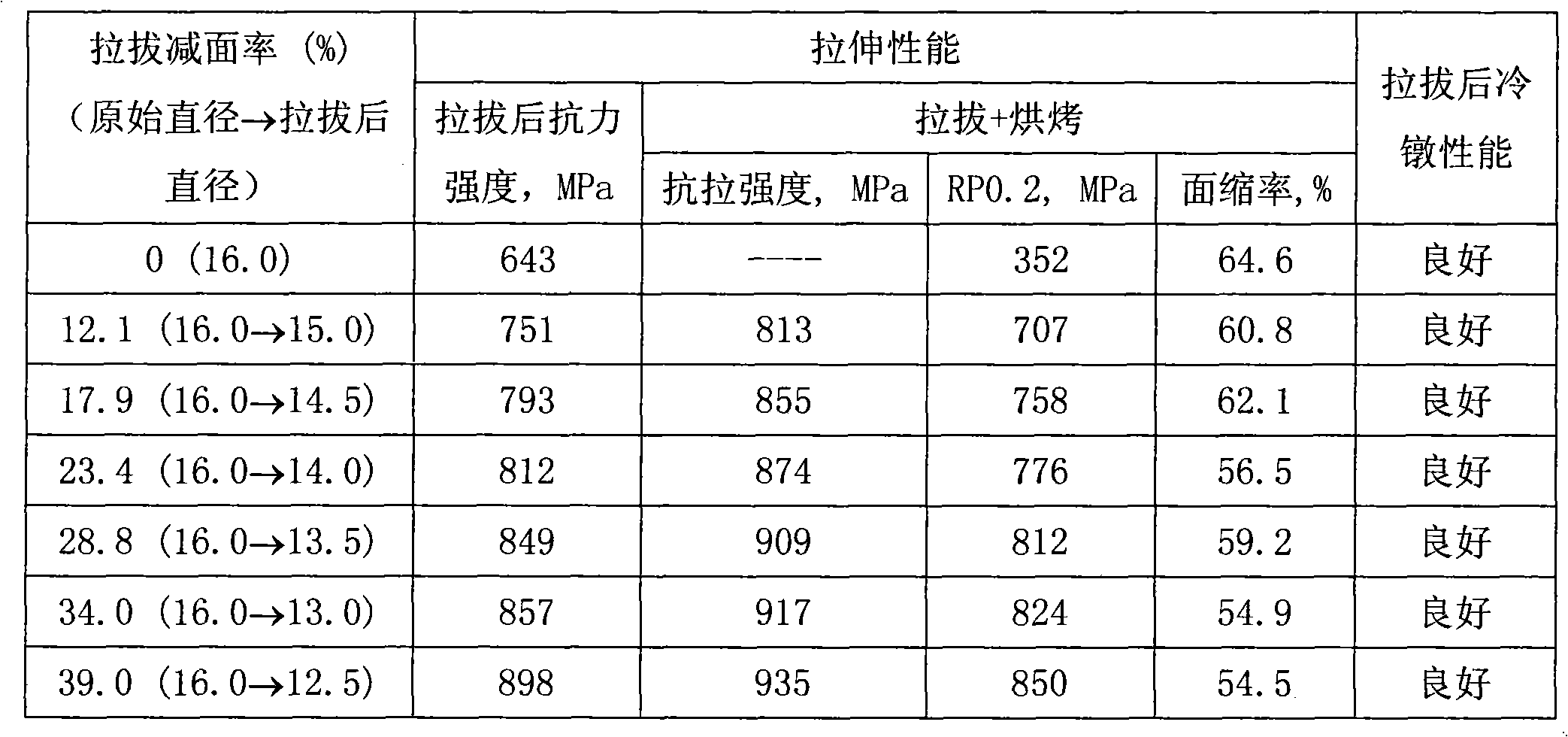

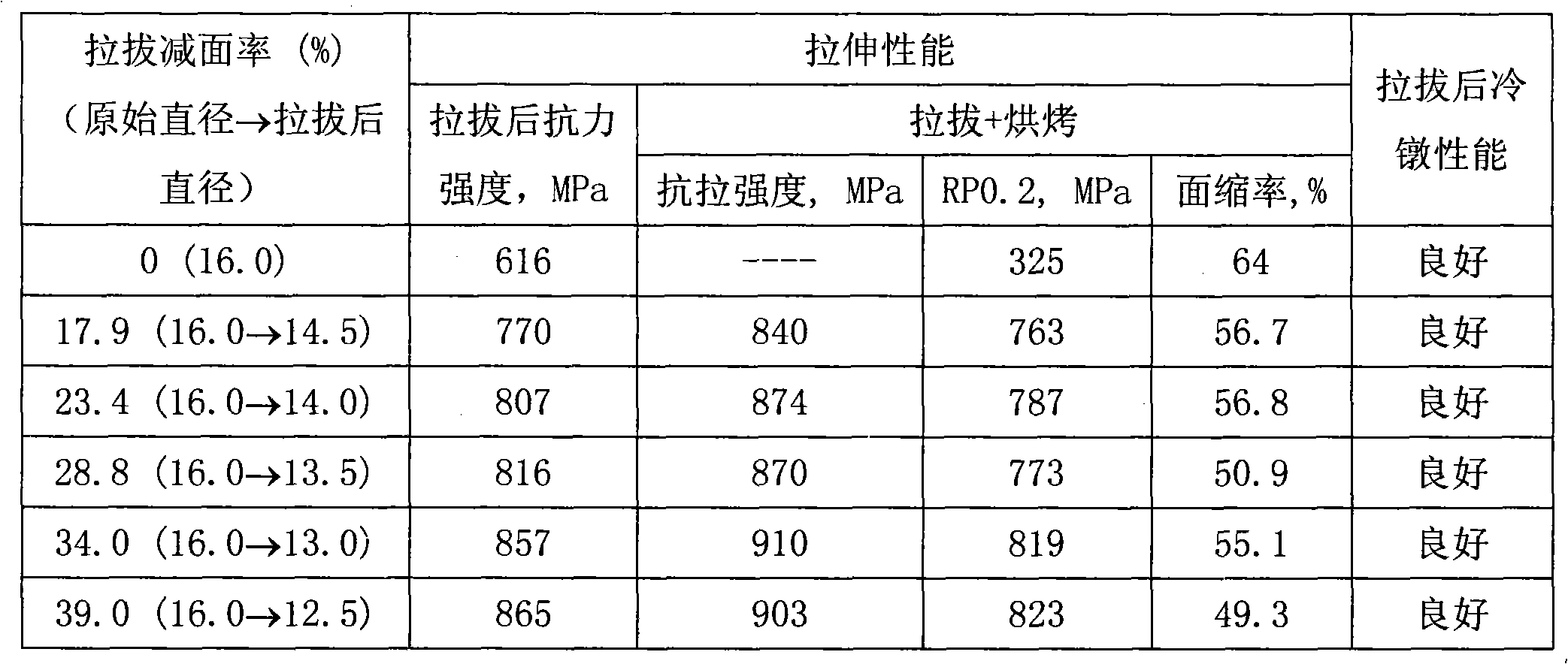

Non-quenched cold heading steel for high-strength fasteners and manufacturing method thereof

InactiveCN101812644AModerate intensityImprove plasticityTemperature control deviceHigh intensityUltimate tensile strength

The invention relates to non-quenched cold heading steel for high-strength fasteners and a preparation process thereof. The non-quenched cold heading steel comprises the following components in percentage by weight: 0.15-0.35% of C, not more than 0.30% of Si, 0.8-1.80% of Mn, 0.20-0.80% of Cr, 0.01-0.10% of Al, not more than 0.035% of P, not more than 0.035% of S and the balance of iron and impurities. The process comprises the following steps of: preparing a casting blank having the same components with the non-quenched cold heading steel, heating the casting blank, and carrying out controlling rolling, coil collecting and controlling cooling treatment to form rod bundles as finished products. The non-quenched cold heading steel for high-strength fasteners has moderate strength, good plasticity, low deformation resistance in the cold heading and shaping of the fasteners, simple manufacturing process, effective saving of energy resources, environment pollution reduction and cost reduction, and is suitable for industrial production on a large scale.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

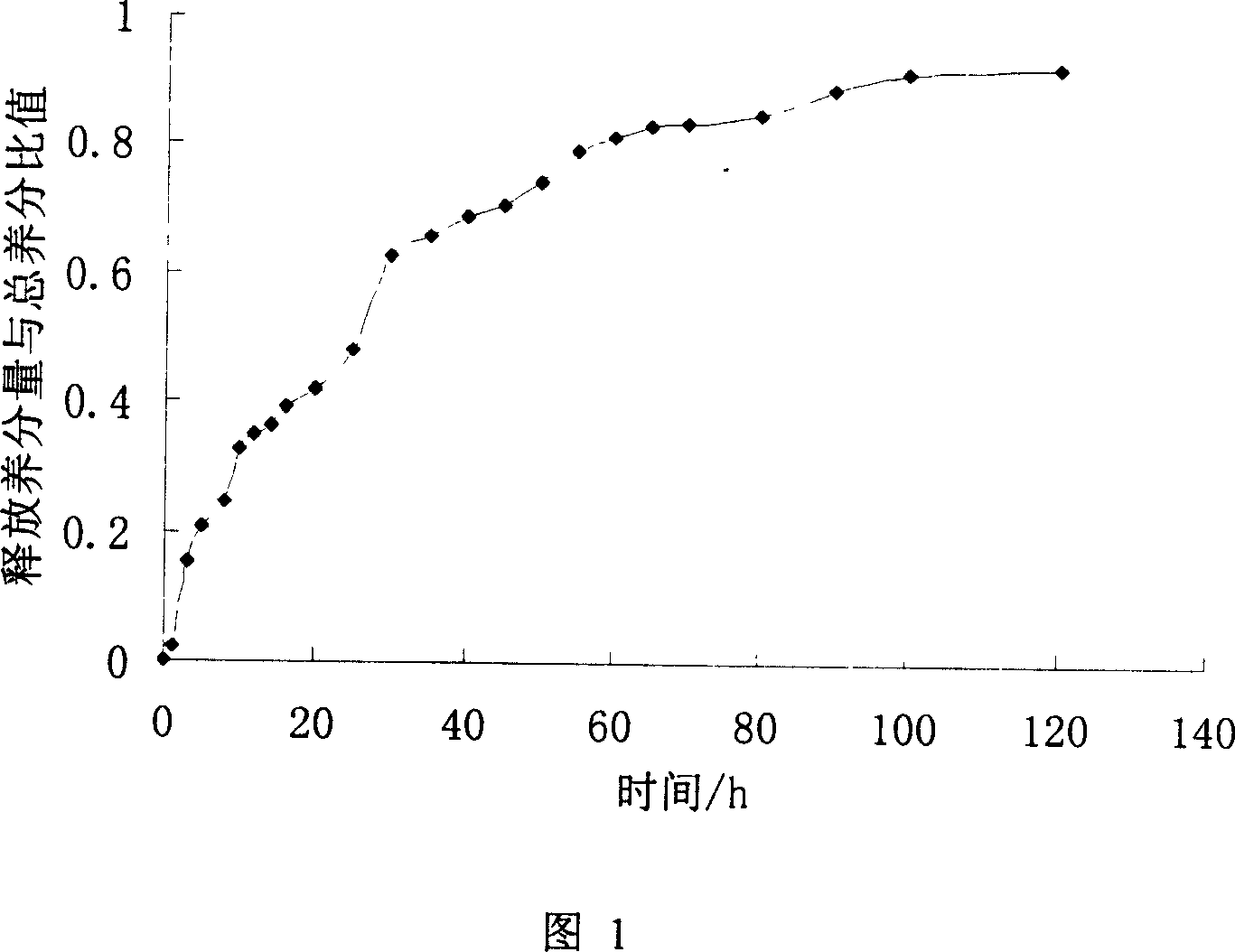

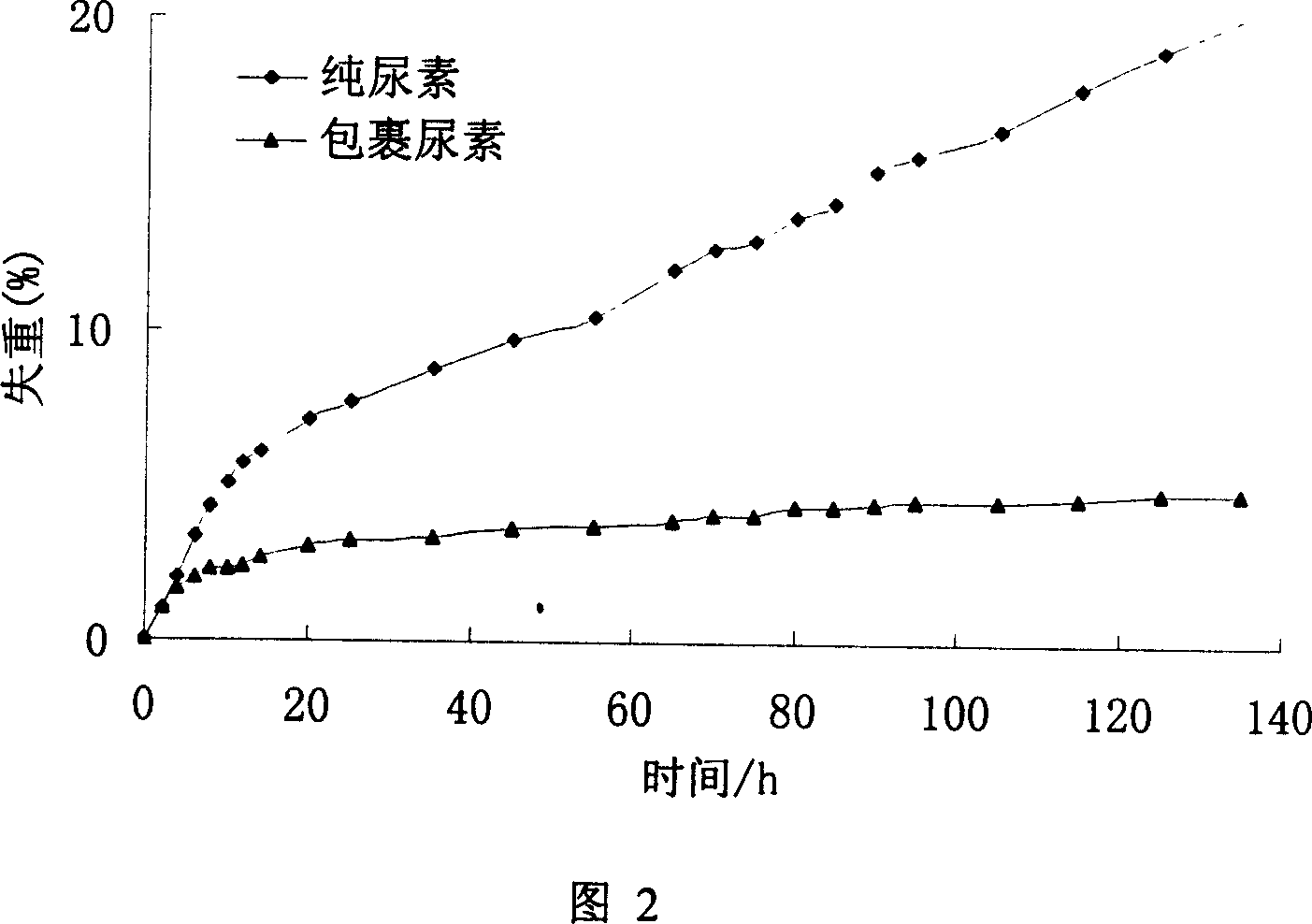

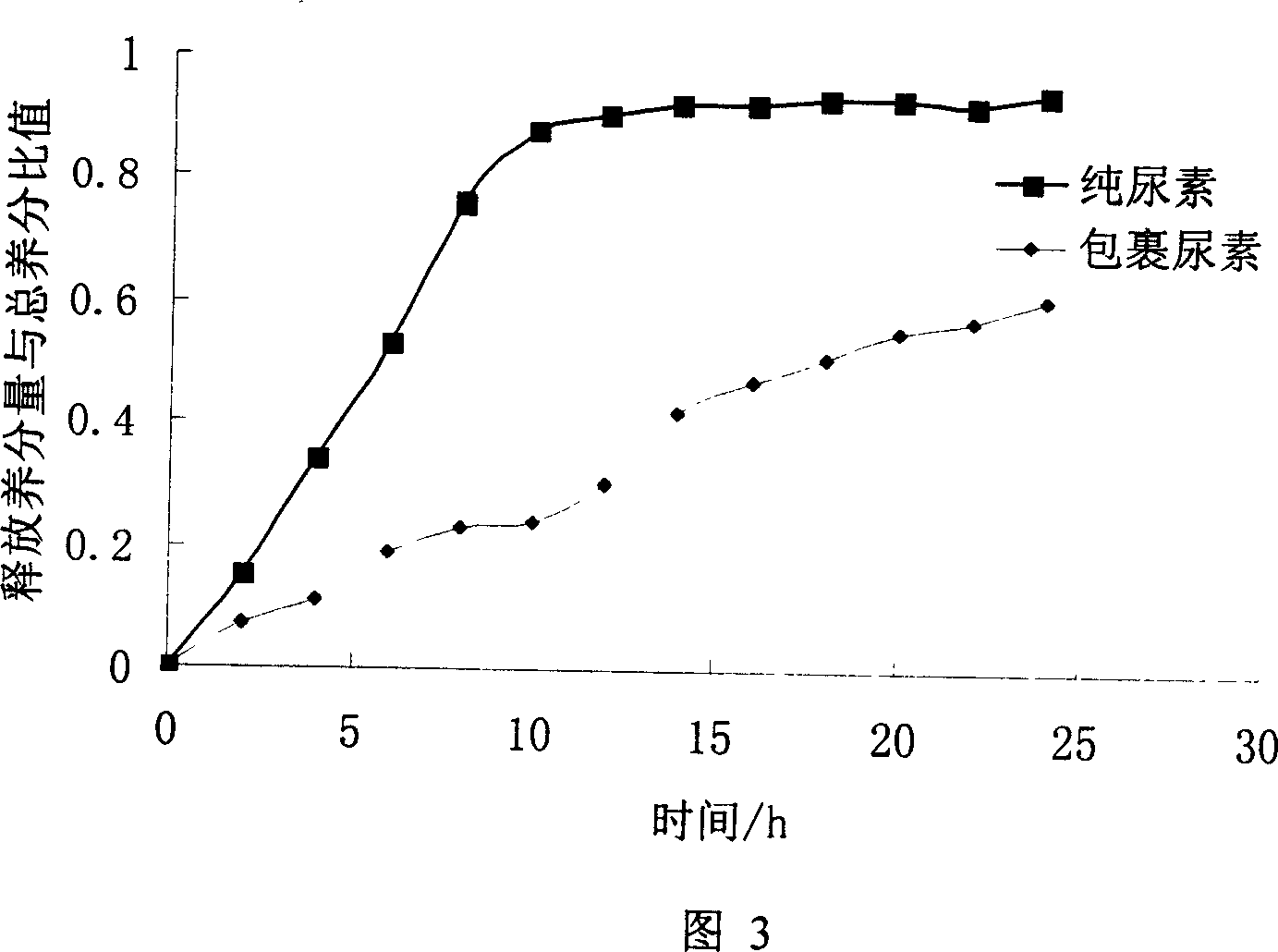

Degradable natural organic matter bundled slow-releasing fertilizer and preparation method and usage thereof

InactiveCN101062878AImprove fertilizer efficiencyLow costFertilizer mixturesCircular discOrganic film

The invention discloses a degraded natural organic bundle slow release fertilizer, which comprises the following steps: comprising easy soluble nitrogen particle fertilizer; coating natural organic bundle slow release with the main element as lignin; coating vegetable fat film layer out of nature organic film layer as sealer; bruising the nature organic matter with the main element below 60 order as coating material; adopting normal disc pelleting method; sticking the coating material to the surface of easy soluble nitrogen fertilizer particle; drying; spraying vegetable fat as sealer; getting the product. This fertilizer is very cheap, which can be used to cotton, corn, wheat, flower and lawn.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

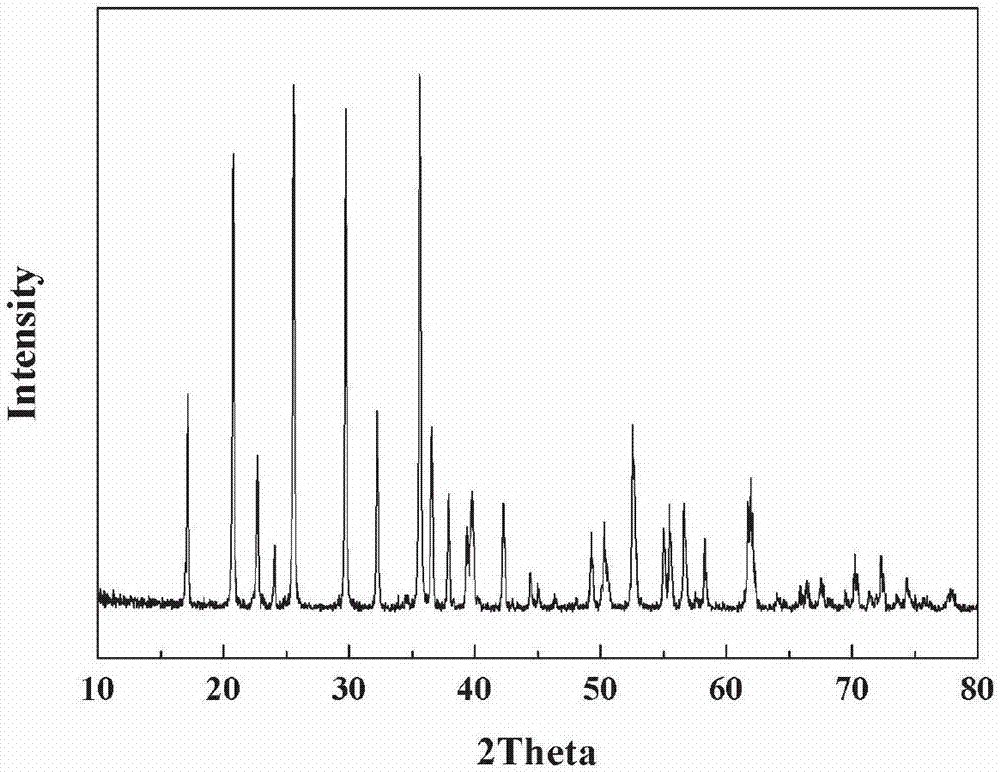

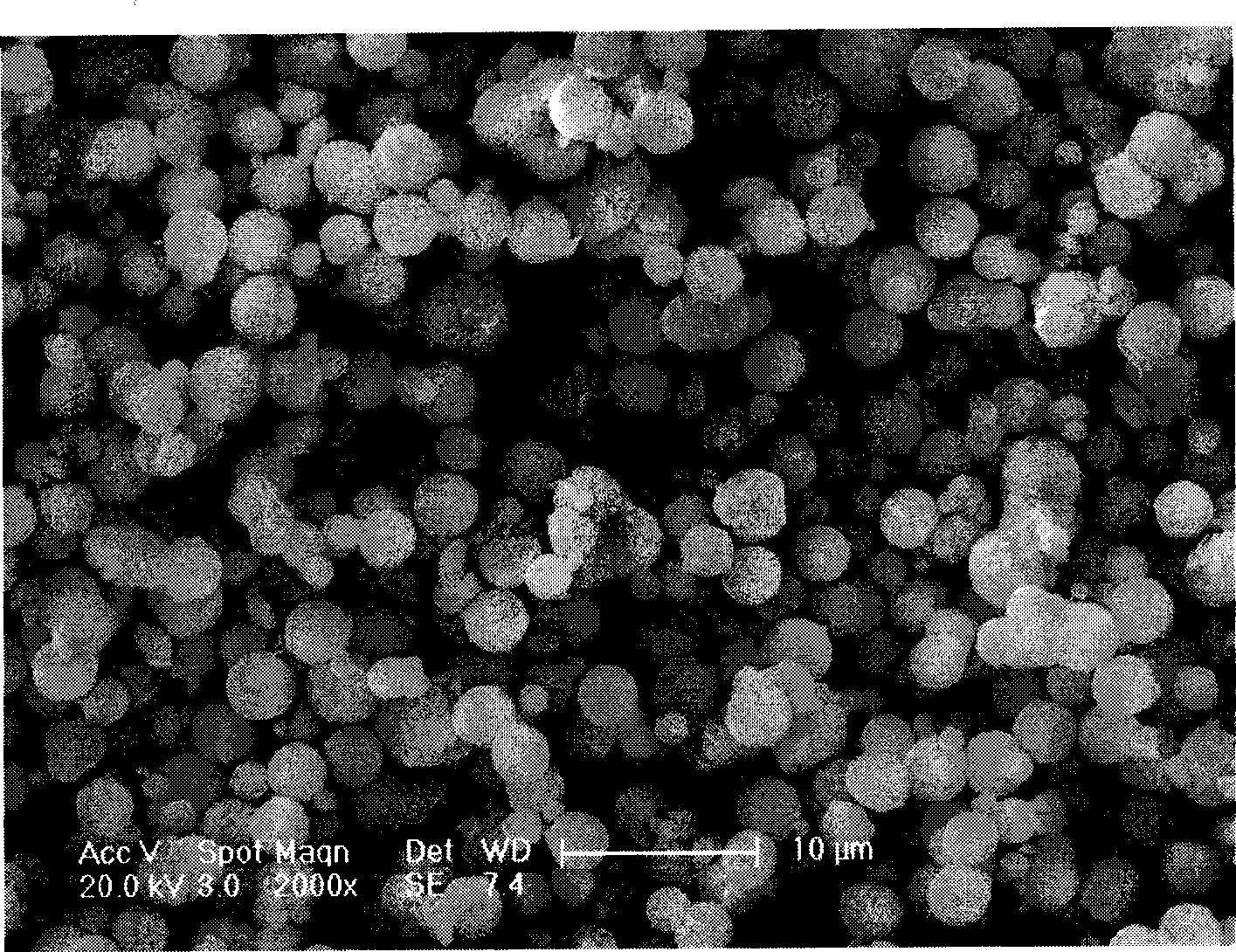

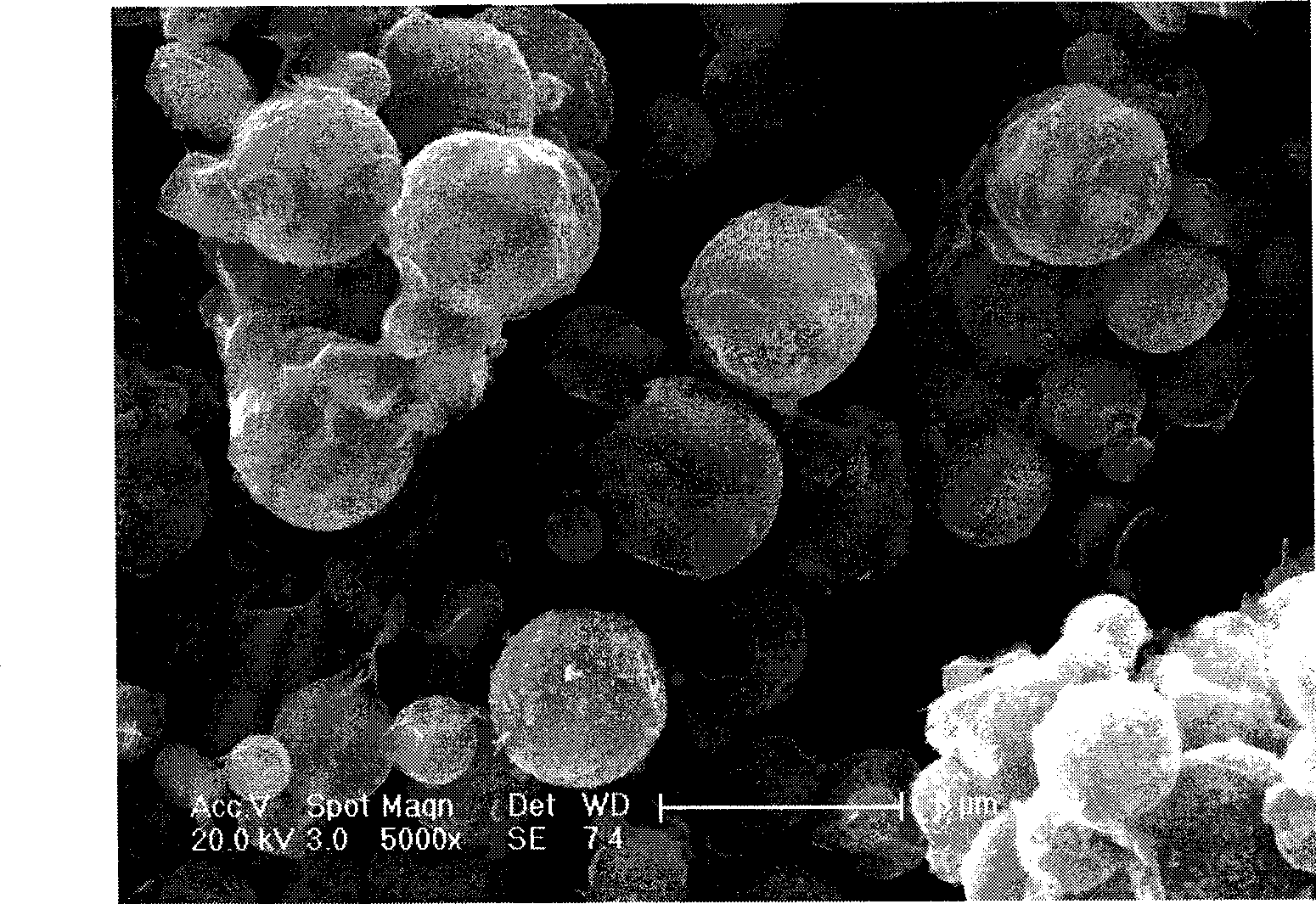

Preparation of lithium iron phosphate nano composite microsphere

ActiveCN101475157AImprove conductivityHigh tap densityElectrode manufacturing processesPhosphorus compoundsMicrospherePhosphoric acid

The invention discloses a method for preparing a lithium iron phosphate nano composite microsphere for a lithium-ion secondary battery anode material by a hydrothermal method, which comprises the following steps: evenly mixing a lithium source, an iron source and a phosphoric acid source according to the stoichiometric ratio of 1-1.05:1:1 to prepare an aqueous solution with certain concentration, adding proper amount of reducing agent, carbonizing agent, ion dopant and the like into the aqueous solution, growing and curing crystals under high-temperature hydrothermal condition, removing a solvent from a hydrothermal product, and burning the hydrothermal product in inert or reducing atmosphere to obtain a final product. The lithium iron phosphate anode material prepared by the method has a regular nano composite microsphere structure, has a particle diameter of between 2 and 4 mu m, even distribution, tap density up to 1.3 to 1.6 g / cm, and has excellent cycle performance and multiplying power performance. The method has simple and easily-controlled process, can use cheap trivalent iron as the iron source, can obtain rich raw materials, and is a practical technique for preparing lithium iron phosphate.

Owner:湖北金泉新材料有限公司

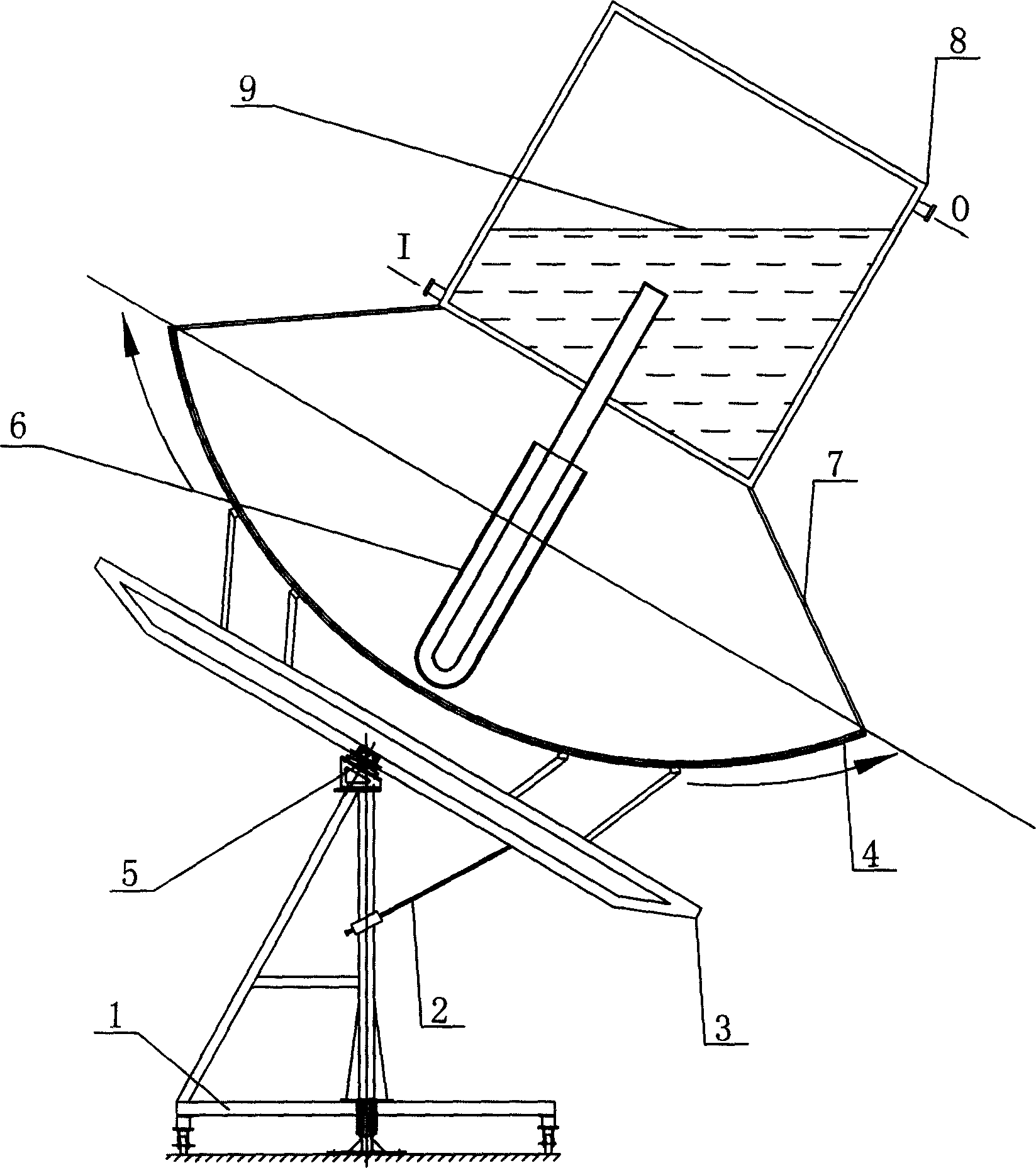

Heat pipe type spherical disc type solar energy light and heat collector

InactiveCN1908549ALow costPromote absorptionSolar heating energySolar heat devicesHeating effectEngineering

The present invention relates to a heat pipe type spherical disc type solar energy light and heat collector, belonging to the solar energy heat collection establishment technical field, which includesa spherical reflecting mirror disposed on the solar energy optical tracker system and a steam drum supported above the reflecting mirror. The steam drum is made up of an inlet and an outlet and stored up with working medium. A heat pipe type vacuum heat collecting pipe is arranged on the focusing part of the spherical reflecting mirror. The heating zone of the heat pipe type vacuum heat collecting pipe is positioned on the condensing wimble of the spherical reflecting mirror. The cooling zone of the heat pipe type vacuum heat collecting pipe is inserted into the working medium of the stream drug. The invention has simple technology, low cost, scientific design and easy to generalization and application. It has been found that the invention has fast tempera the rise, excellent heating effect, high efficiency, suitable for large scale industrialization production, secure and reliable performance.

Owner:HOHAI UNIV

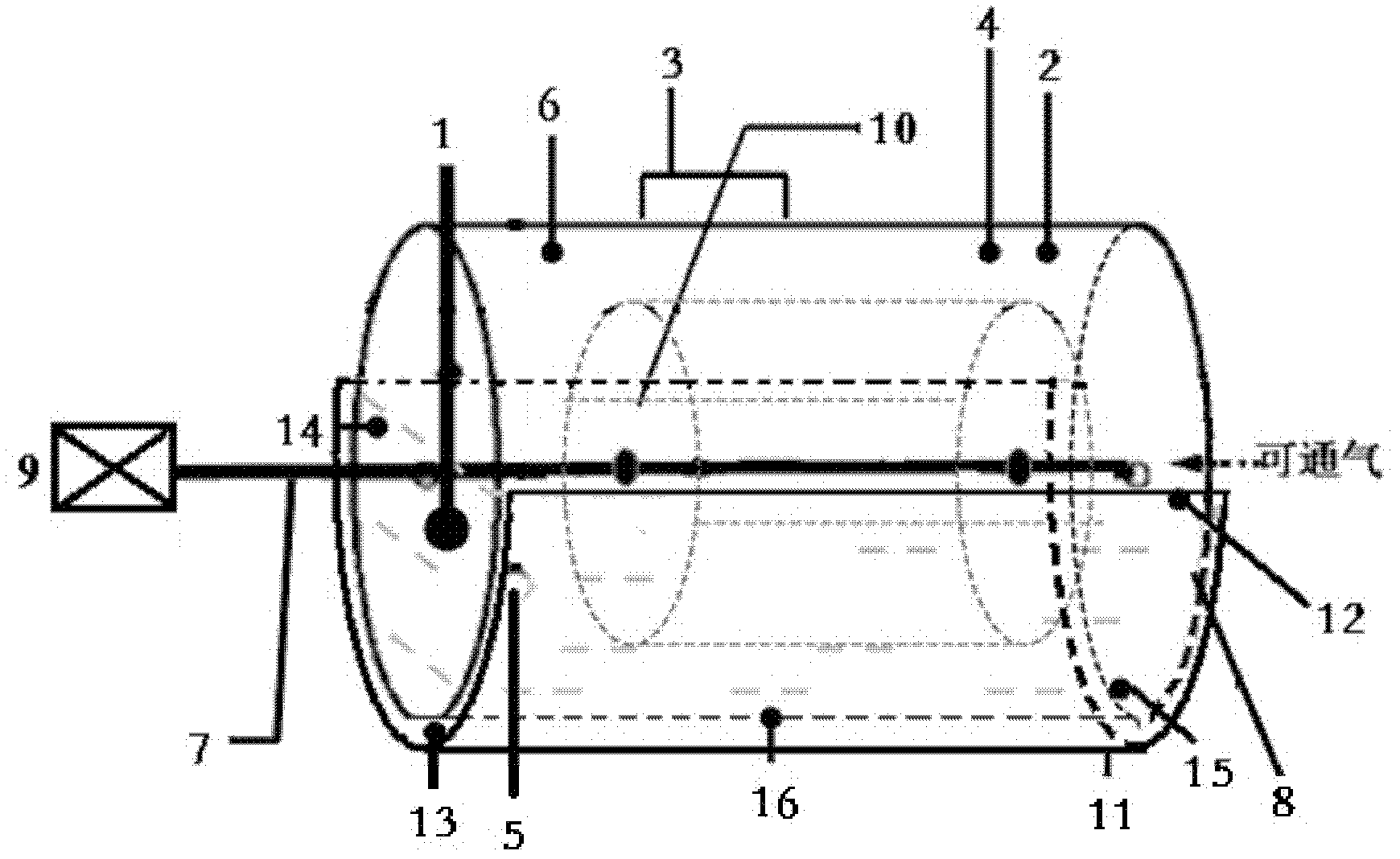

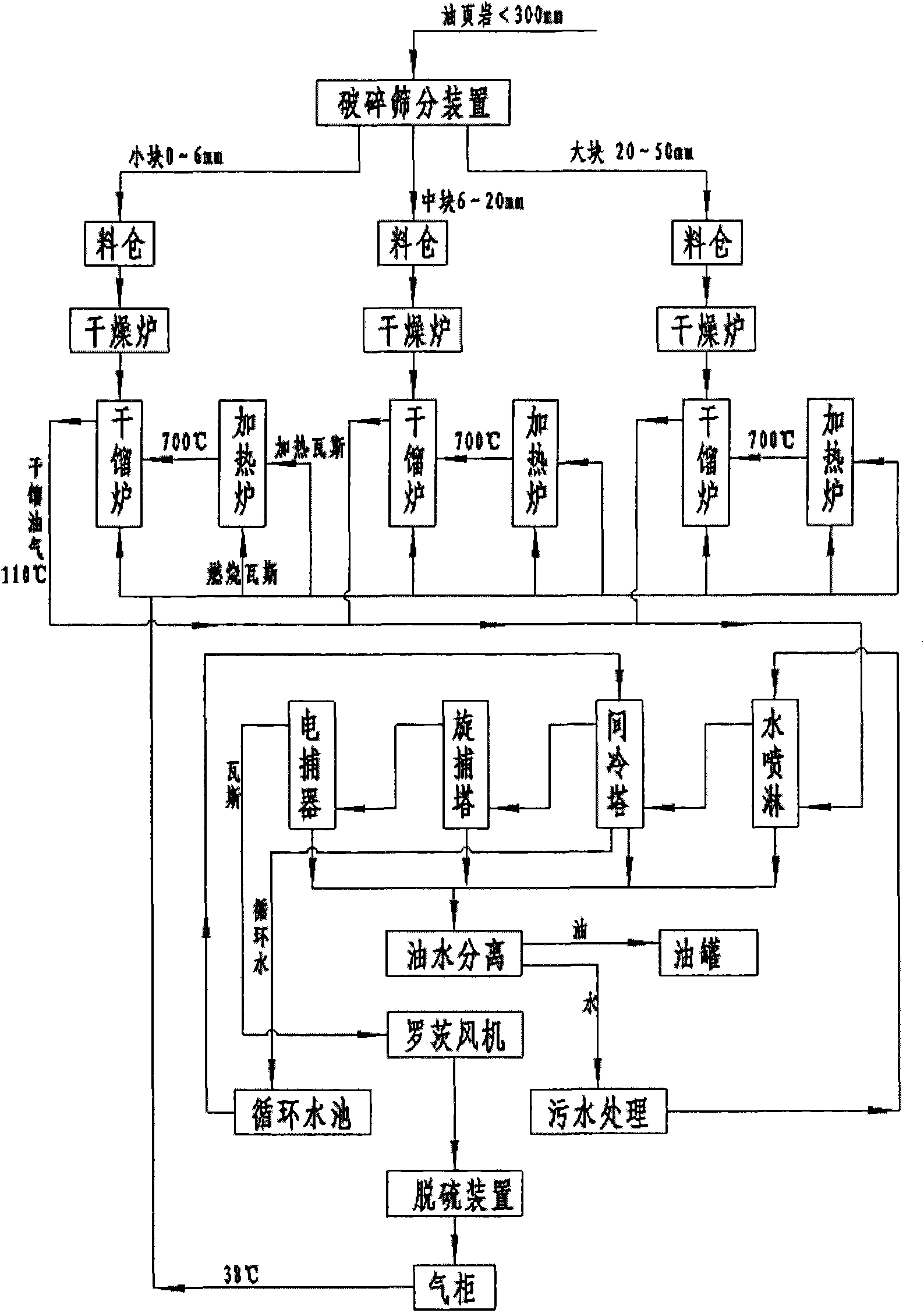

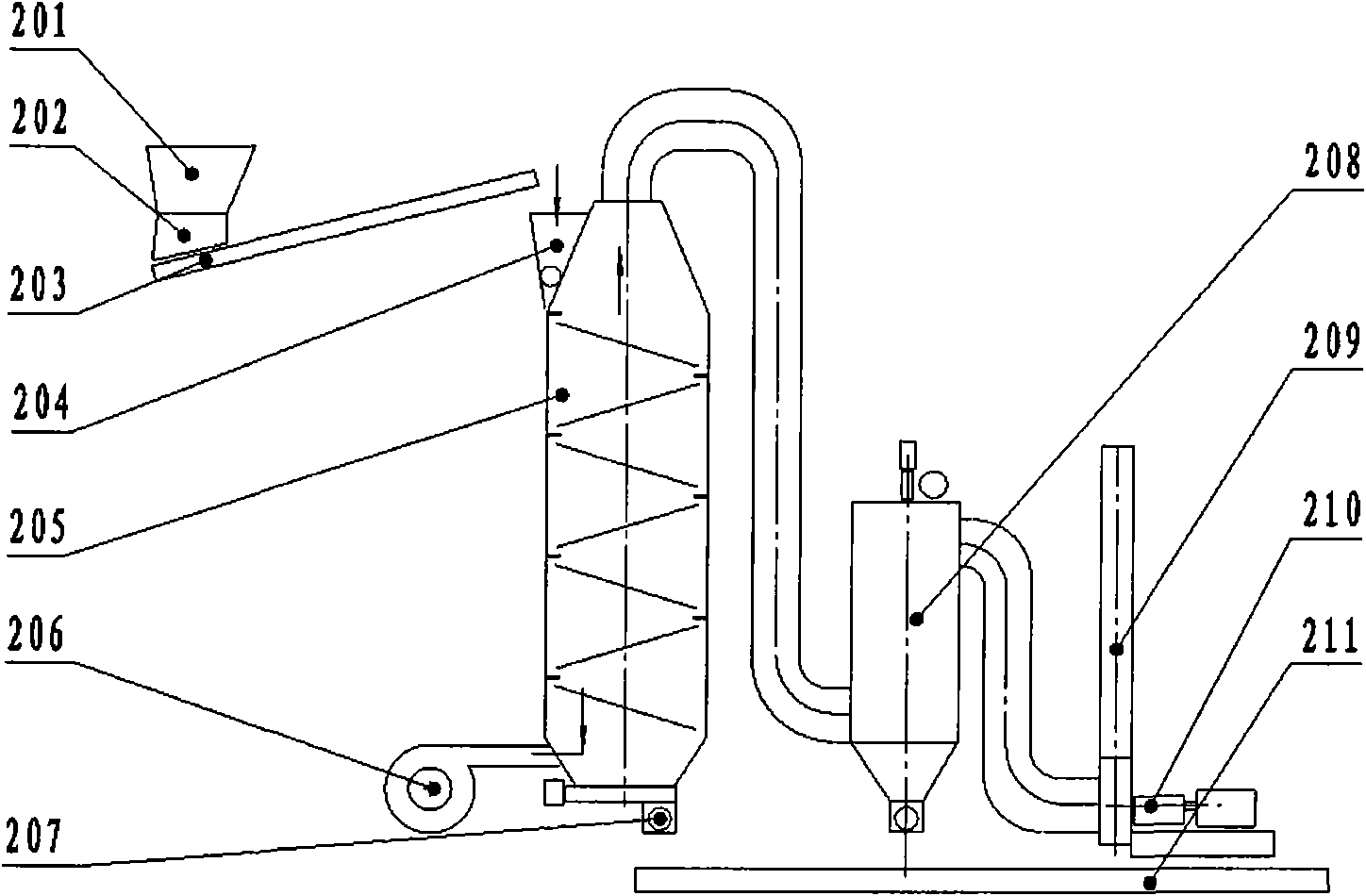

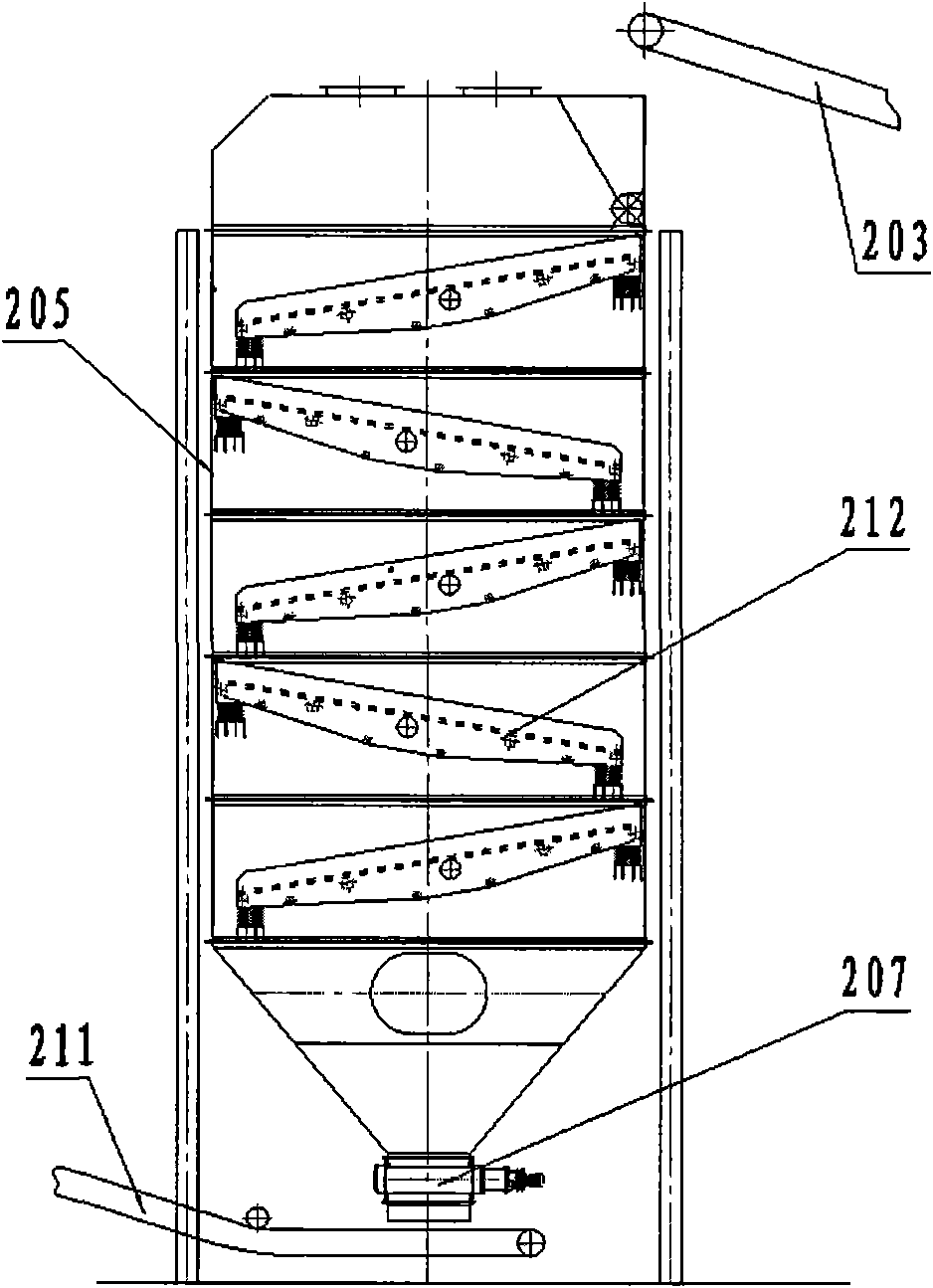

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

Pre-irradiation polypropylene graft copolymer and preparation method thereof

The application relates to a pre-irradiation polypropylene graft copolymer and a preparation method thereof. At present, the exploration of methods for improving surface property remains a research hotspot in the field of modification of polypropylene always. The method comprises the following steps: performing pre-irradiation on polypropylene resin after having constant weight at the temperature of 60 DEG C by using a 60 Co radiation source or a DD-1.2 / 1.0-800 type high-frequency high-pressure electron accelerator in air, keeping the dosage rate at 300Gy / min, keeping the dose at 3-50kGy, adding the pre-radiated polypropylene resin into solution containing N, N'-methylenebis acrylamide, auxiliary monomers and additives, keeping the using amount of the N, N'-methylenebis acrylamide to be 0.5-5% by weight of the weight of polypropylene, performing nitrogen filling and oxygen removal on mixed solution for 30 minutes, then heating to 50-75 DEG C for performing reaction for 6 hours under magnetic stirring, nitrogen production and reflux conditions, washing the polypropylene resin which is filtered out with ethanol-water twice, further extracting with ethanol-water solution for 24 hours, drying at the temperature of 60 DEG C and enabling the weight to be constant. The method is used for preparing the polypropylene graft copolymer.

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

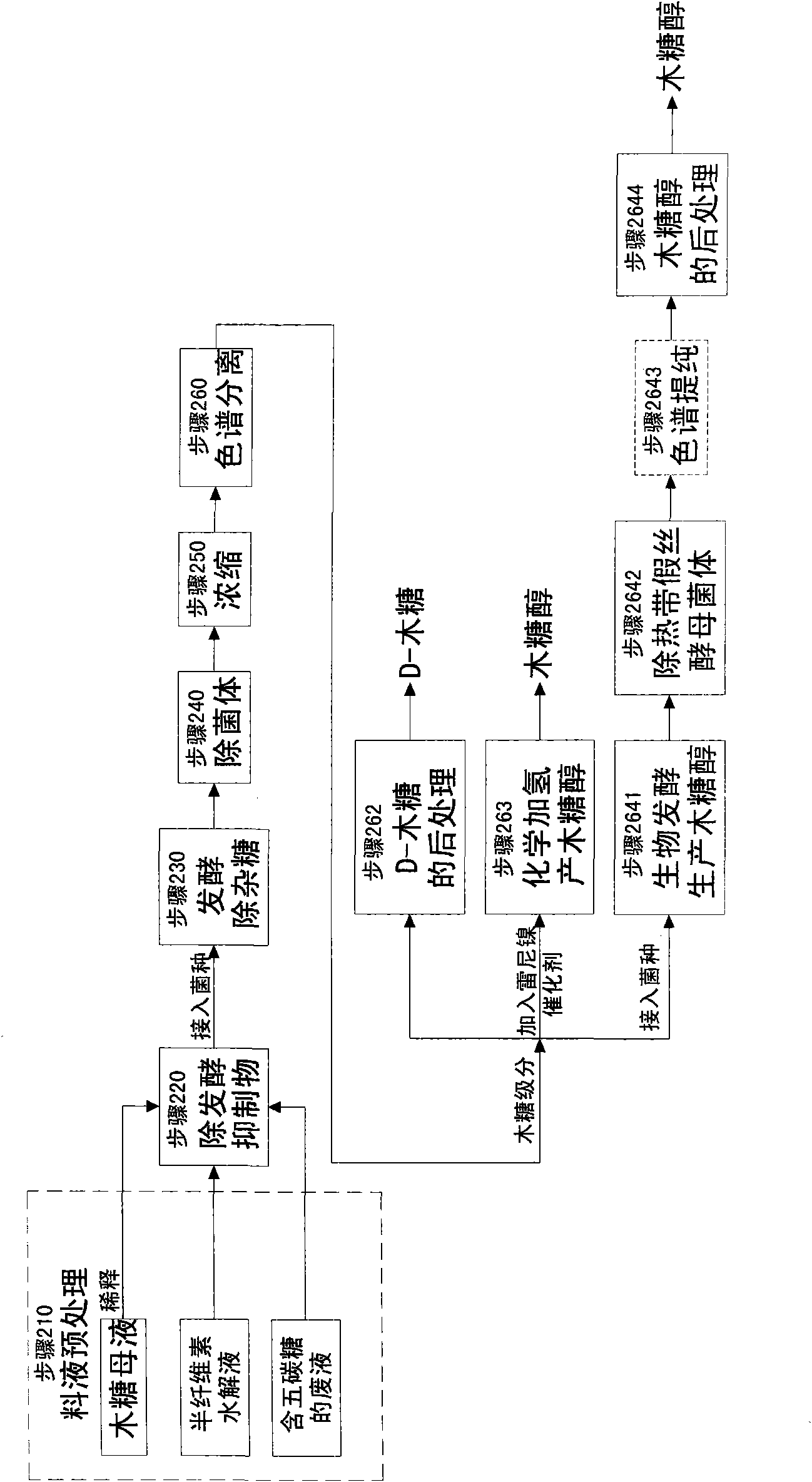

Method for producing L-arabinose and D-xylose

ActiveCN101665523AHigh purityFermentation went wellIon-exchange process apparatusSugar derivativesBiotechnologyChromatographic separation

The invention relates to a method for producing L-arabinose and D-xylose, which can simultaneously produce ethanol or D-ribose or citric acid as a byproduct. The method utilizes a hydrolyzate of agricultural waste, a xylose mother liquor and / or a production waste liquor containing pentose as the raw materials and comprises the following steps: (1) pretreating the raw materials; (b) carrying out the chromatographic resolution to separate the raw materials into an arabinose-stage liquor and a xylose-stage liquor; (c1) removing fermentation inhibitors which are impurities and unwanted bacteria, which have an inhibiting effect on the fermentation; (c2) fermenting to remove unwanted saccharides at least comprising glucose and galactose; (d) and finally, respectively carrying out the post treatment on the arabinose-stage liquor and the xylose-stage liquor to obtain the L-arabinose and the D-xylose. Steps (c1) and (c2) are arranged before the chromatographic resolution in step (b) or after step (b). The method has the advantages of low production cost and high efficiency, and is suitable for large-scale industrial production.

Owner:SHENGQUAN HEALTANG

Lithium sulfur battery anode composite material, anode and lithium sulfur battery

ActiveCN102208645AImprove conductivityHigh specific capacityCell electrodesLi-accumulatorsCarbon coatedAdhesive

The invention discloses a carbon coated sulfur-based anode composite material in the field of lithium sulfur batteries. The composite material comprises a sulfur-based anode material and amorphous carbon, wherein the amorphous carbon is uniformly and compactly coated on the surface of the sulfur-based anode material, the particle diameter of the sulfur-based anode material is 10 nanometers to 10 microns, and the thickness of the amorphous carbon layer is 1 to 5 nanometers. The invention also discloses an anode, which comprises a current corrector and an anode material supported on the current corrector, wherein the anode material comprises an anode active substance, anode adhesive and a conductive component; and the anode active substance is the carbon coated sulfur-based anode material. The anode is adopted for preparing a corresponding lithium sulfur battery; the amorphous carbon is coated on the surface of the sulfur-based anode active material so as to remarkably improve the electric conductivity of the anode material, and the lithium sulfur battery adopting the anode has high specific capacity and good cycle performance; and the preparation process is simple and suitable for large-scale industrialized production.

Owner:DONGFANG ELECTRIC CORP LTD

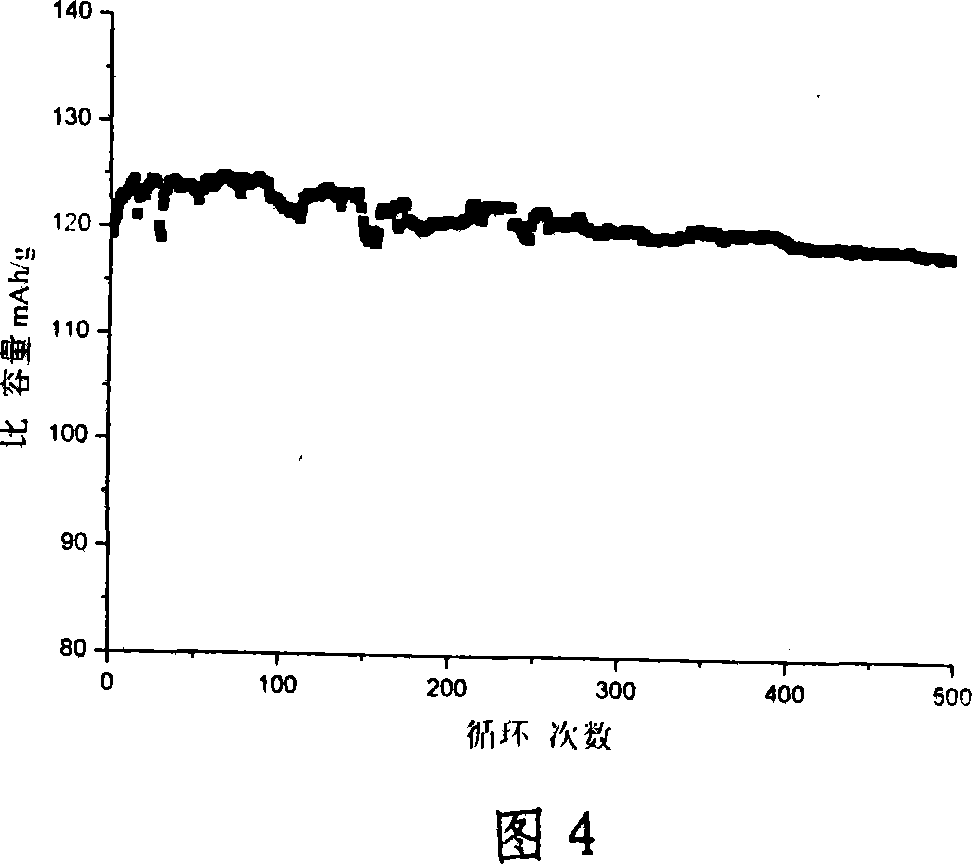

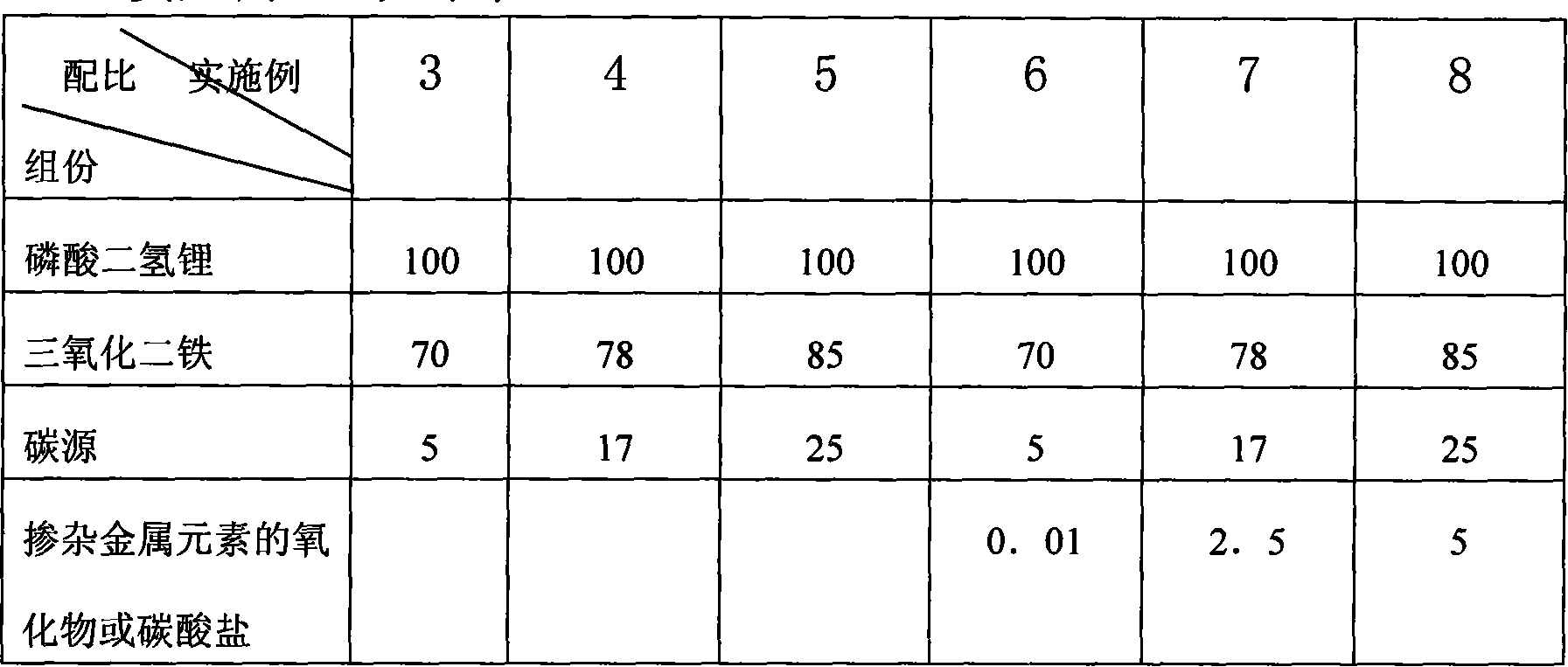

Method of producing lithium iron phosphate with high compacted density and excellent adhesive property

InactiveCN101152961AGood winding performanceGood bonding performanceCell electrodesPhosphorus compoundsNitrogen atmosphereOxide

The present invention relates to a method preparing phosphate iron lithium with high compacted density and good cohesiveness. The technical points are as follows: firstly, ferric oxide, phosphate dihydrogen lithium, oxide or carbonate doping metal elements and carbon source are ball-milled evenly in an aqueous solution and are then sprayed and dried so that a spherical powder is obtained; the spherical powder is secondly mixed with carbon source; after ball-milling and in nitrogen atmosphere protection, the mixture is presintered for 4 hours to 48 hours in 300 DEG C to 400 DEG C; after breaking, the mixture is heat treated for 4 hours to 48 hours in a high temperature of 600 DEG C to 800 DEG C so the phosphate iron lithium with high compacted density and good cohesiveness is obtained. The present invention has the advantages that the phosphate iron lithium prepared by the present invention is good in cohesiveness when used as lithium ion battery anode, an anode plate is high in compacted density, softness and winding performance. The preparing method generates no harmful gas, costs little, is simple in process and especially suitable for large-scale industrial production.

Owner:天津科斯特汽车技术有限责任公司

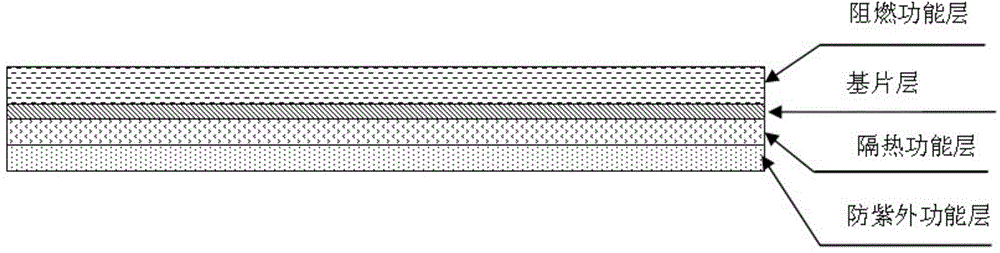

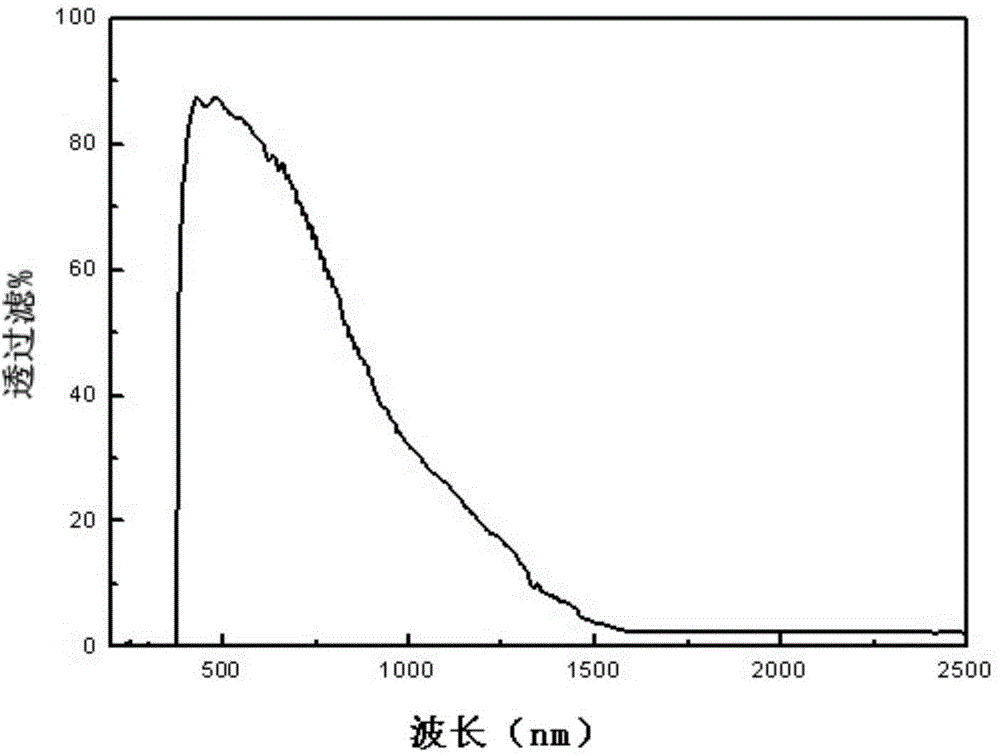

Transparent, flame-retardant, thermal-insulation and anti-ultraviolet polymer composite film as well as preparation method and application thereof

ActiveCN104553215AImprove energy savingImprove flame retardant performanceSynthetic resin layered productsElectrical equipmentPolymer scienceThermal insulation

Disclosed is a transparent, flame-retardant thermally-insulating, UV-blocking polymer composite film, comprising sequentially from the top: a flame retardant layer, a base layer, a thermal insulation layer, and a UV-blocking layer, having a total film thickness of 1um to 500um, visible light transmittance greater than 80%, UV light transmittance less than 1%, and near-infrared transmittance less than 10%. Also disclosed is a preparation method for the present transparent, flame retardant thermally-insulating, UV-blocking polymer composite film, the technical processes whereof are simple and easy to execute, involve low production costs, and are suitable for industrial mass production. The present transparent, flame retardant thermally-insulating, UV-blocking polymer composite film can be used on such transparent materials and items as glass, windows, protective films, containers and electronic components, and has applications in such fields as construction, transportation, electronics, aerospace and medicine.

Owner:BEIJING UNIV OF CHEM TECH +1

Method for extracting refined cordycepin and cordycepin polysaccharide from cordyceps mititaris

ActiveCN101124988ALow costReduce pollutionSugar derivativesSugar derivatives preparationAmylaseAdditive ingredient

The present invention relates to a method for extracting the purificatory cordycepin and the cordyceps amylase from the cordyceps militaris, belonging to the fields of medicines and health protection and chemical engineering. The cordyceps militaris powder is extracted and filtrated by a cooling seep method, the filter residue is mixed with ethanol, the supersonic wave assists to extract and offcenter, the supernatant has the processes of concentration and alcohol-precipitating, then the alcohol-precipitated supernatant has the processes of decompression, concentration and elution, the eluted liquid has the processes of concentration and crystallization and recrystallization using the n-butyl alcohol, at last the purificatory amylase is obtained after freezing and drying. The preparation progress of the present invention only uses water and ethanol as the solvent, thus reducing the pollution, the resin is capable of being reused a plurality of times with low cost. The present invention fully exploits the biological activity ingredients of the cordyceps militaris, realizes the coextraction of the cordycepin and the cordyceps amylase, guarantees the biological activities of the cordycepin and the cordyceps amylase, farthest increases the utilization rate of the raw material to the largest extent, reduces the manufacturing cost. The present invention is suitable for the large-scale industrialized manufacture.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Preparation method for vanadium dioxide and doped powder thereof

The invention discloses a preparation method for vanadium dioxide and doped powder thereof. The method comprises the following steps: 1, weighing vanadium pentoxide, hydrogen peroxide and distilled water, preparing the materials into a V<5+>-containing complex aqueous solution; 2, adding a reducing agent, a surfactant and a dopant to the complex aqueous solution, and stirring to form a clear solution; 3, transferring the resulting solution from the step 2 to a hydrothermal reaction kettle, and carrying out a reaction for 1-168 hours at a temperature of 140-220 DEG C to obtain the doped powderof the VO2(B); 4, placing the resulting doped powder of the VO2(B) from the step 3 in high pure argon atmosphere or nitrogen atmosphere, and annealing for 10-720 minutes at the temperature of 400-700DEG C to obtain the doped powder of the VO2(M). The method of the present invention has characteristics of low cost, simple process and easy control, and is suitable for the large-scale industrial production. With the method of the present invention, the doping of the VO2 powder material can be realized, and the doped atoms can be uniformly dispersed in the VO2.

Owner:张家港楚人新材料科技有限公司

Production method of whole-grain fast-food nutritional porridge

InactiveCN103815299AIncrease productionProduct quality is stableFood preparationPre treatmentBrewing

The invention discloses a production method of whole-grain fast-food nutritional porridge. Whole grains are taken as raw materials; the purpose of balanced nutrition is achieved through preprocessing and grinding the raw materials and proportioning nutritional ingredients well; the whole-grain fast-food nutritional porridge is prepared by the processes of extruding for curing by a double-screw extruder, accurately controlling the gelatinization degree of starch in the raw materials, granulating for forming, pre-drying, roasting, and cooling. High viscosity of a porridge body during brewing is ensured by accurately controlling the gelatinization degree of the starch in the raw materials in the preparation process, so that any thickener or auxiliary material does not need to be added, the manually cooked porridge can be brewed with hot water without adding cured powdery materials, good granule shape can be kept after the porridge is brewed for 20 minutes, and the appearance and the mouth feel of the fast-food nutritional porridge can be equivalent to those of porridge cooked at home.

Owner:谷伊家食品科技有限责任公司

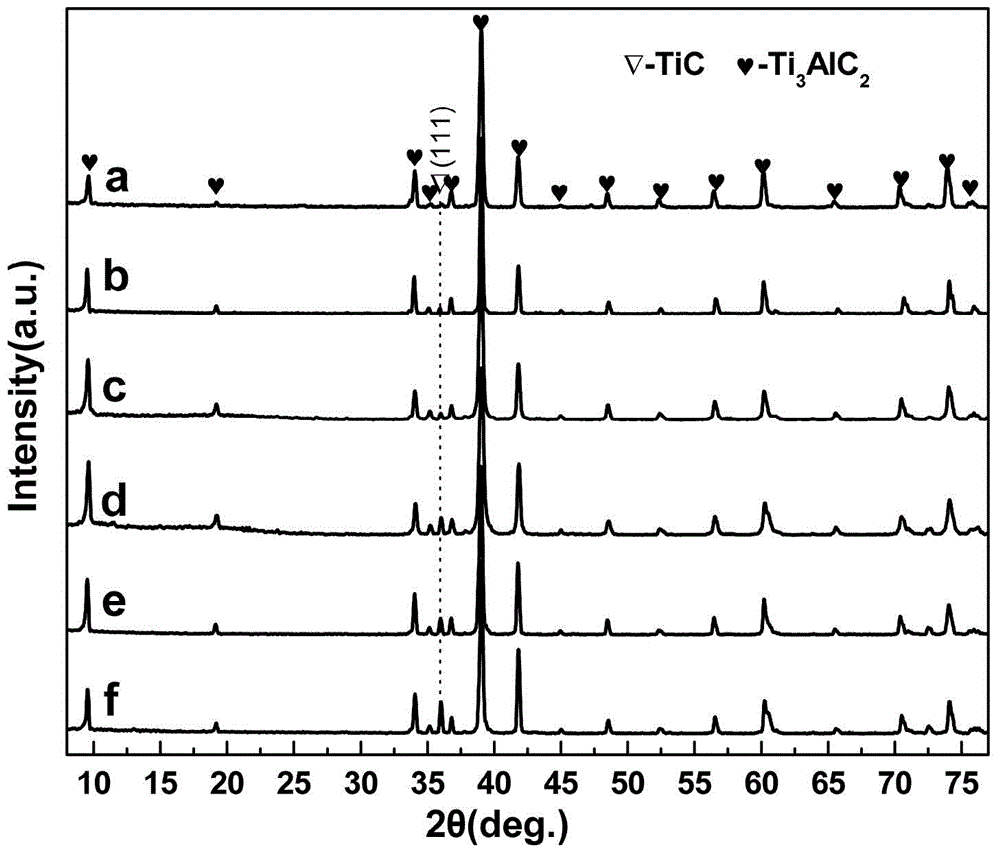

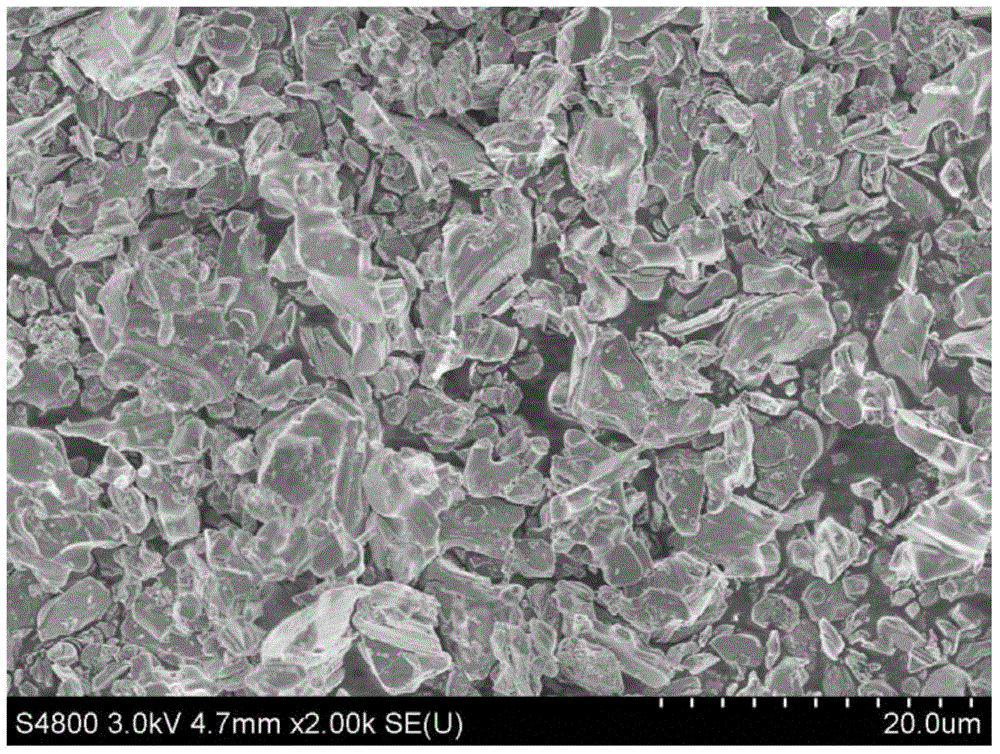

Preparation method of Ti3AlC2 ceramic powder

The invention discloses a preparation method of a Ti3AlC2 ceramic powder, and belongs to the technical field of material science. The preparation method includes the following steps: taking Ti, Al and TiC respectively according to a molar ratio of Ti:Al:TiC:Sn:Si equal to 1:(1-1.3): 2:(0.05-0.2):(0.05-0.15), then adding a Sn powder and a Si powder and mixing well to obtain a mixture; 2) adding ethanol, conducting fully ball milling to obtain a uniform powder and drying; and 3) sintering the dried mixture in vacuum and cooling to obtain the Ti3AlC2 ceramic powder. The simple process provided by the invention is simple; addition of a grinding aids improves mixing uniformity of the mixture; addition of synthetic additives improves the purity of the product and reduces the impurities; and using TiC powder as a C source not only reduces the synthesis temperature but also improves the purity of the product.

Owner:SHAANXI UNIV OF SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com