Non-quenched cold heading steel for high-strength fasteners and manufacturing method thereof

A manufacturing method, non-quenching and tempering technology, applied in the direction of temperature control, etc., can solve the problems of large consumption, short life of cold heading mold, large deformation resistance of cold heading, etc., and achieve the effect of energy saving, low deformation resistance and moderate strength.

Inactive Publication Date: 2010-08-25

INST OF RES OF IRON & STEEL JIANGSU PROVINCE

View PDF5 Cites 52 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this type of steel has the disadvantages of high resistance to cold heading deformation, short life of cold heading dies, and large consumption, so it has not been popularized and applied.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

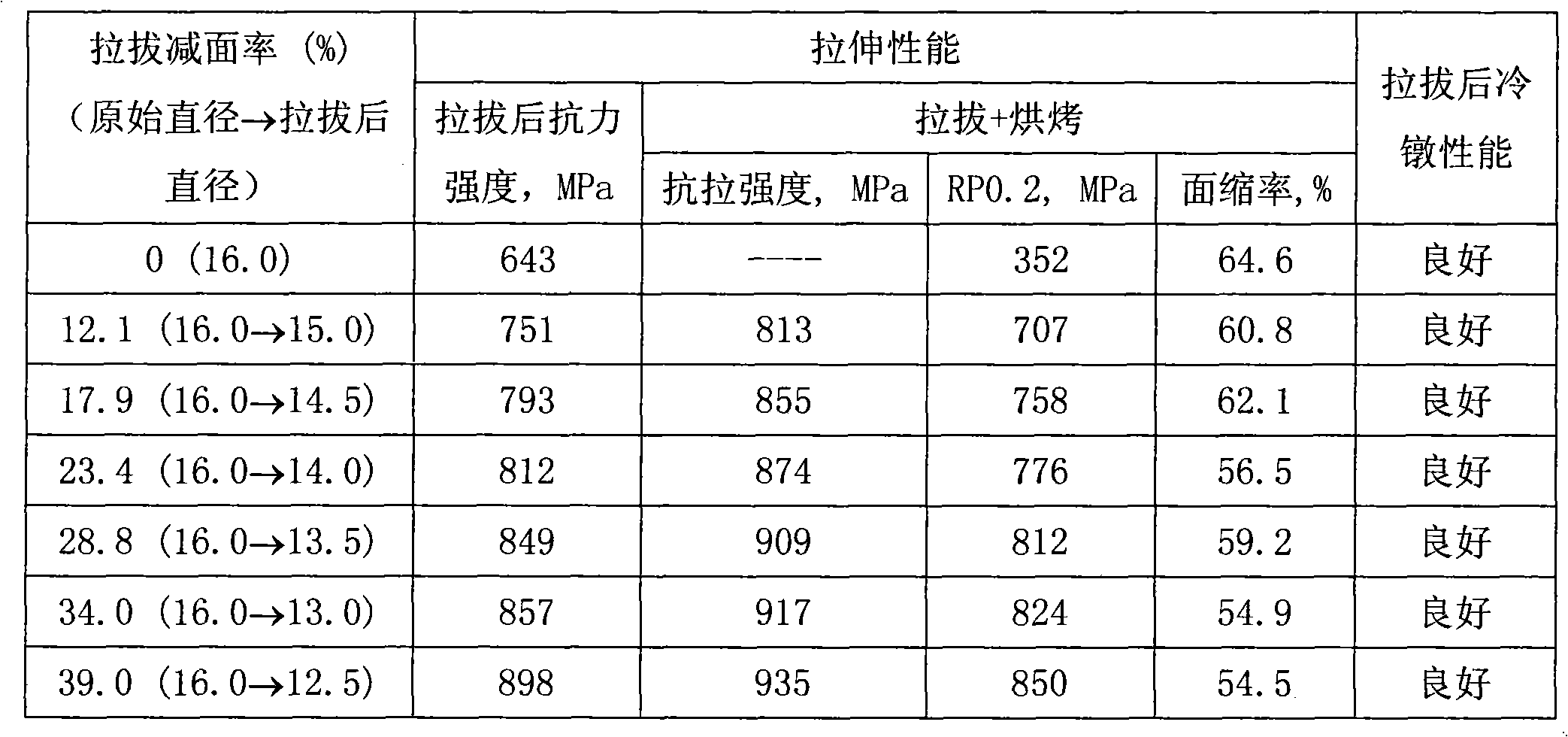

Embodiment 1

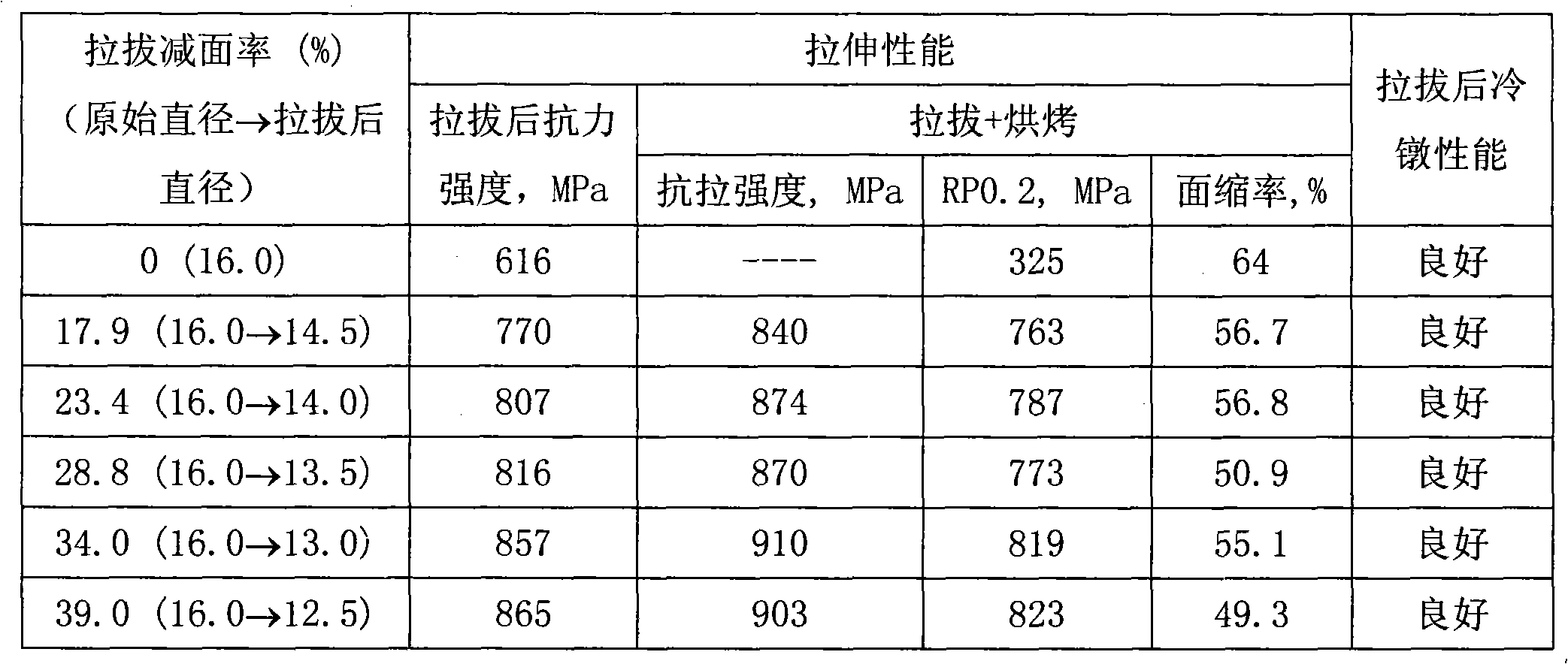

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to non-quenched cold heading steel for high-strength fasteners and a preparation process thereof. The non-quenched cold heading steel comprises the following components in percentage by weight: 0.15-0.35% of C, not more than 0.30% of Si, 0.8-1.80% of Mn, 0.20-0.80% of Cr, 0.01-0.10% of Al, not more than 0.035% of P, not more than 0.035% of S and the balance of iron and impurities. The process comprises the following steps of: preparing a casting blank having the same components with the non-quenched cold heading steel, heating the casting blank, and carrying out controlling rolling, coil collecting and controlling cooling treatment to form rod bundles as finished products. The non-quenched cold heading steel for high-strength fasteners has moderate strength, good plasticity, low deformation resistance in the cold heading and shaping of the fasteners, simple manufacturing process, effective saving of energy resources, environment pollution reduction and cost reduction, and is suitable for industrial production on a large scale.

Description

technical field The invention relates to a steel and its preparation process in the technical field of metal materials, in particular to a non-quenched and tempered cold heading steel for 8.8-grade high-strength fasteners and a manufacturing method thereof. Background technique Fasteners are one of the three basic components, and their applications are large and wide. In 2008, the output of fasteners in my country was as high as 5.6 million tons, and one of the most important products was 8.8-grade high-strength fasteners. The common 8.8-level fastener manufacturing process is generally "hot-rolled wire rod→spheroidizing annealing→drawing→cold heading→quenching and tempering treatment". Severe environmental pollution not only increases production costs, but also causes loss of metal materials. More importantly, these two processing links are prone to heat treatment deformation when manufacturing slender fasteners, which affects the quality of bolts. For this reason, how t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/38C22C38/18B21B37/74

Inventor 何毅周蕾陈树铭杨浩高利容齐振余甘望益峰公雄

Owner INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com