Manufacturing method of high density fiberboard for whitened type E1 grade floor substrate

A technology of high-density fiberboard and manufacturing method, which is applied in the direction of applications, household components, flat products, etc., can solve the problems of physical and mechanical properties, durability and water resistance, resin water solubility, and curing time prolongation, etc., to achieve good visual effects , small drying load, clear color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The manufacturing process of high-density fiberboard for whitening type E1 floor base material, the manufacturing steps are:

[0028] 1. Chipping and screening of wood (ashing): the fresh poplar trees that have been placed for 8 days are chipped into wood chips of uniform size. After the chips are uniform, they are placed in the outdoor storage yard to ferment for 10 days. , bark and other debris, and then through two high-power fans, the wind blows the wood chips to the waterfall, and removes dust, leaves, plastic paper and silt and other sundries and garbage;

[0029] 2. Pre-cooking and cooking: pre-cook the chipped and screened wood chips with saturated steam and hot water for 3.5 minutes, the pre-cooking temperature is 80°C, and extrude a large amount of wood extracts after being extruded by a cork screw Squeeze the water out of dark yellow color, then cook for 3 minutes, the cooking temperature is 180°C, and the cooking pressure is 7.8bar;

[0030] 3. Fiber separa...

Embodiment 2-6

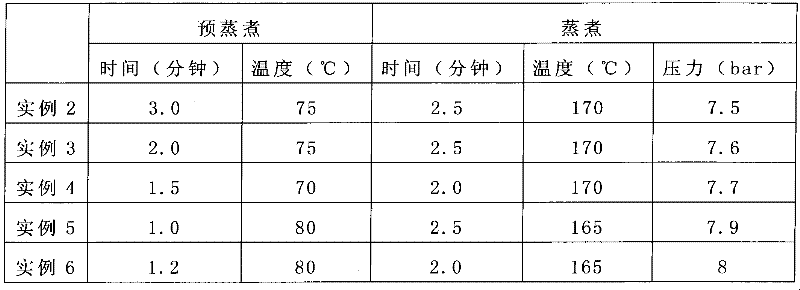

[0047] The steps of Embodiment 2-6 are the same as that of Embodiment 1, except that the addition ratio of each composition is shown in the following list:

[0048] Table 1 is the parameters of the precooking and cooking steps in Examples 2 to 6.

[0049]

[0050] Table 2 is the parameter of each component percentage in the preparation step of curing agent in embodiment 2 to embodiment 6.

[0051]

[0052] The timber situation list that table 3 embodiment 2-6 adopts:

[0053] Example 2

Embodiment 7

[0055] Take the product obtained in Example 1, and adopt the national standard coating 4-cup detection process: first adjust the horizontal position of the coating 4 cup, press the lower outlet with the left index finger, and then inject urea-formaldehyde glue with a temperature of 25°C into the cup, Scrape off the urea-formaldehyde glue that is higher than the mouth of the cup with a glass rod. While releasing the left index finger, press the stopwatch on the right hand for timing. When the urea-formaldehyde glue flows from the 4 cups, press the stopwatch at the same time to record the stopwatch The reading is repeated twice, and the average value is taken, and this value is the viscosity of the urea-formaldehyde glue.

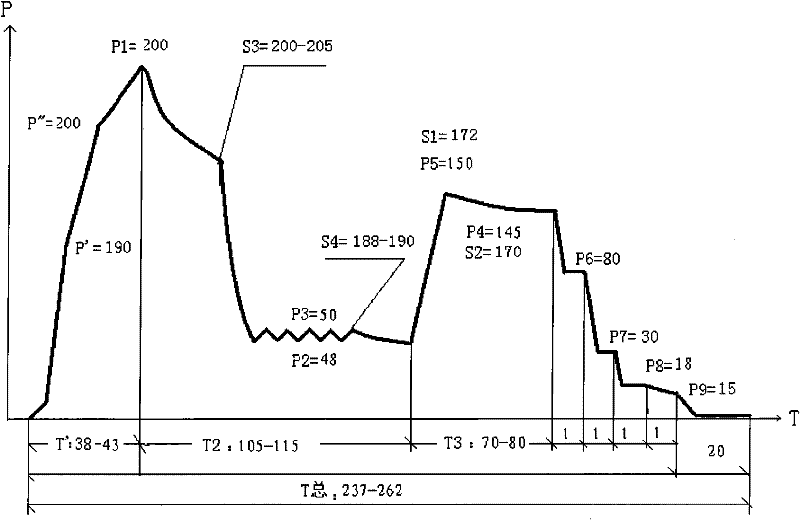

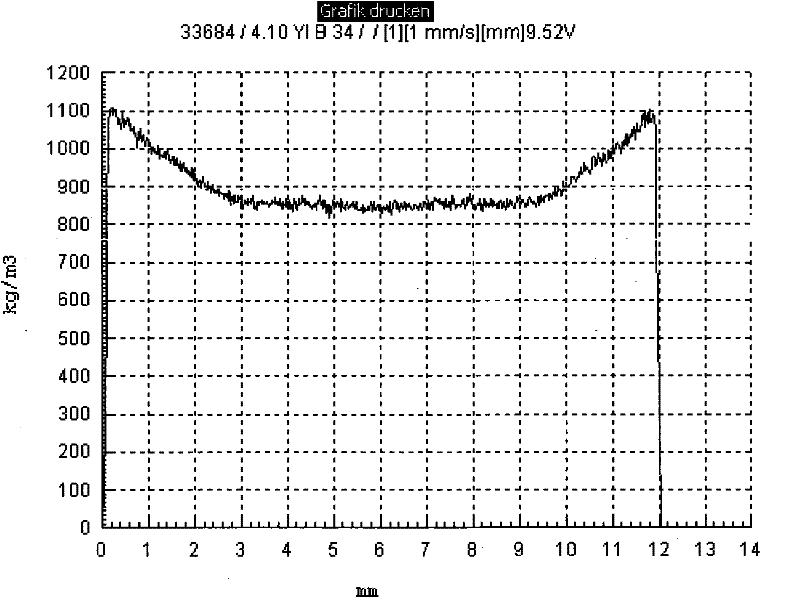

[0056] figure 1 is the thermocompression curve, figure 2 A screenshot of the experimental results of the cross-sectional density distribution. according to figure 1 , figure 2 The display mutual combination comparative analysis shows:

[0057] attached...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com