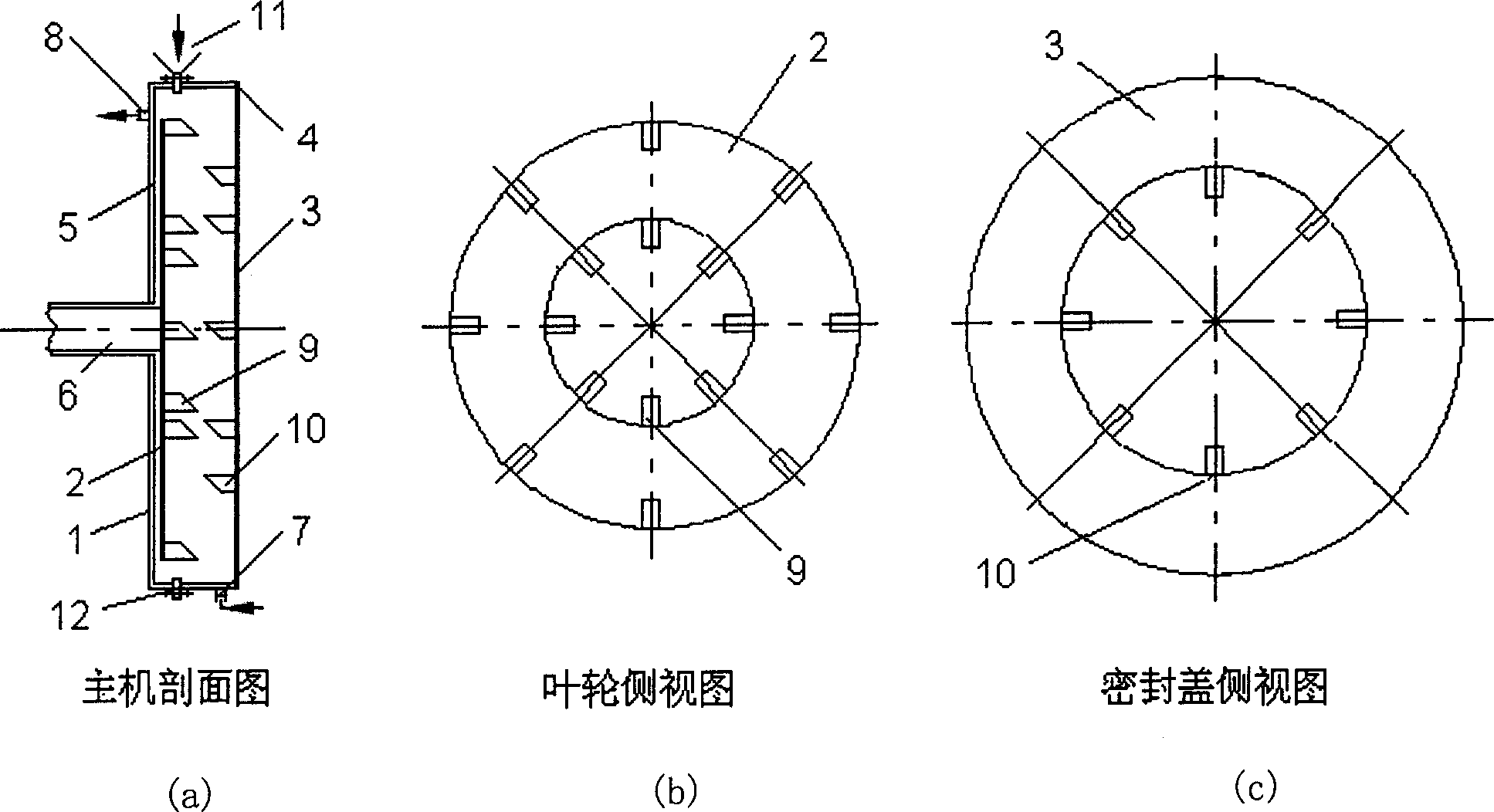

Particle shaping method and device thereof

A shaping device and particle technology, used in grinding machines, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of difficulty in combining strength and high temperature performance, low yield strength, etc., and achieve high value-added applications and small aspect ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The flake graphite provided by Inner Mongolia Baotou Jingyuan Graphite Co., Ltd. contains more than 98% carbon and is pulverized by an impact mechanical pulverizer. The D50 of the product is 40-50 μm. The operating conditions of the fine particle shaping machine are: the rotating speed is 4000rpm, and the processing time is 10min and 15min respectively. The aspect ratio before shaping is 2.84, and the tap density is 0.174g / cm 3 , after 10 minutes of plastic treatment, the length-to-diameter ratio is 1.91, a decrease of 32.75%, and the tap density is 0.275g / cm 3 ; After 15 minutes of surface modification, the aspect ratio is 1.45, which is 48.94% less natural, and the tap density is 0.301g / cm 3 .

Embodiment 2

[0048] The natural microcrystalline graphite provided by Jicai Graphite Mine in Chenzhou, Hunan has a purity of 99% and a particle size of less than 43μm (325 mesh). The operating conditions of the fine particle shaping machine are: the rotating speed is 3500rpm, and the processing time is 5min and 10min respectively. The aspect ratio before shaping is 2.53, and the tap density is 0.861g / cm 3 , after 5 minutes of shaping treatment, the aspect ratio is 1.85, which is reduced by 26.88%, and the tap density is 0.853g / cm 3 ; After 10 minutes of plastic treatment, the aspect ratio is 1.26, which is reduced by 50.20%, and the tap density is 0.846g / cm 3 . Because the unclassified sample of microcrystalline graphite after shaping still contains a part of the ultra-fine graphite powder that was ground off during the shaping process, resulting in a tap density that is lower than the density before shaping; after the ultra-fine graphite powder is removed by an air classifier, Although...

example 3

[0050] The -400 mesh hydrogenated dehydrogenation (HDH) titanium powder purchased on the market has a purity of more than 99%, the content of impurities such as Fe, Si, Cl, C, N, O, and H is 0.75wt%, and the median particle size of the powder is D 50 is 18.47 μm. The operating conditions of the fine particle shaping machine are: the rotating speed is 3000rpm and 5000rpm respectively, and the processing time is 15min.

[0051] parameter number

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com