Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

252results about How to "Small aspect ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

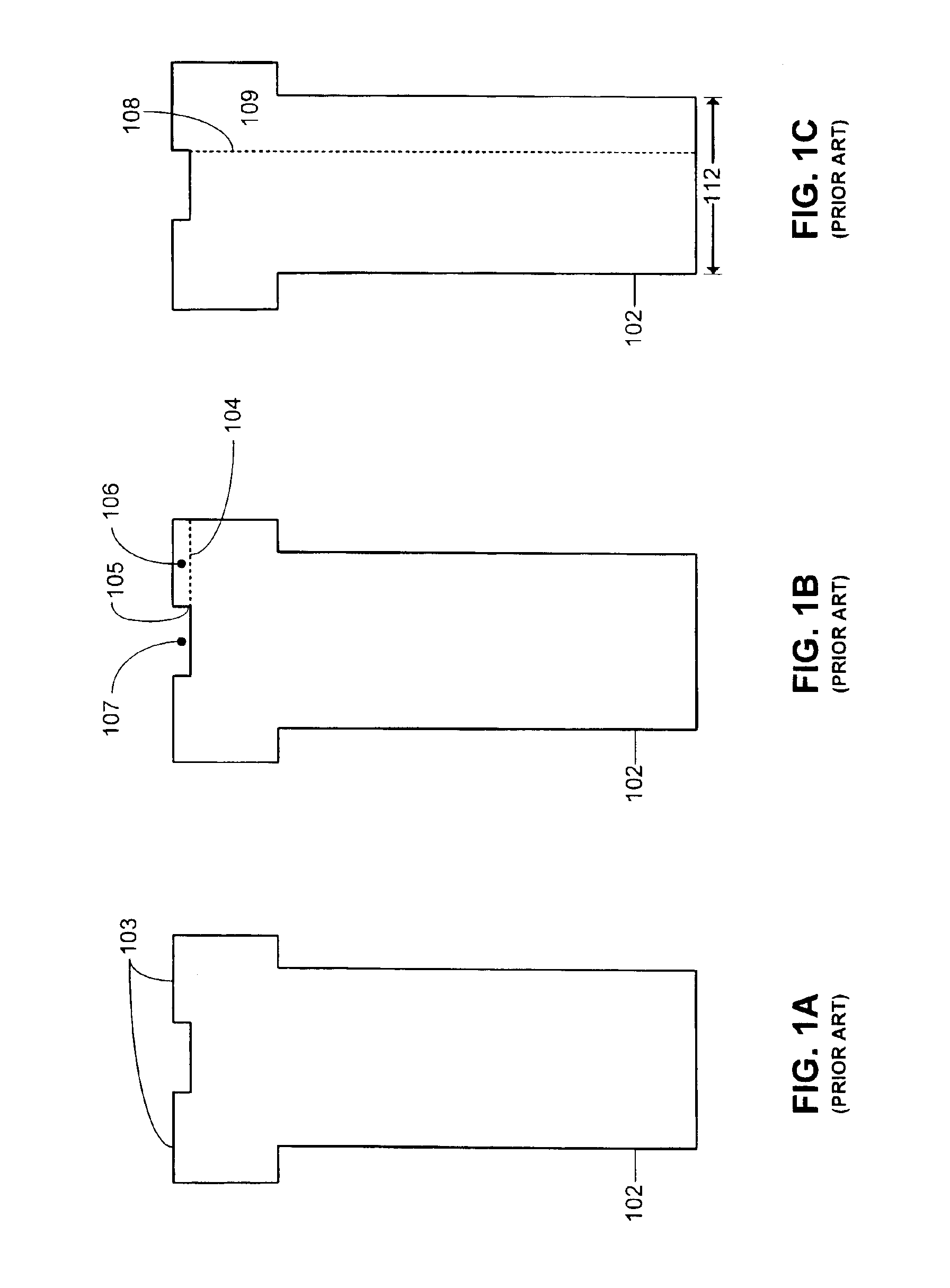

Multiple material golf club head

InactiveUS6491592B2Large coefficientImprove complianceMetal-working apparatusGolf clubsCoefficient of restitutionMetallic materials

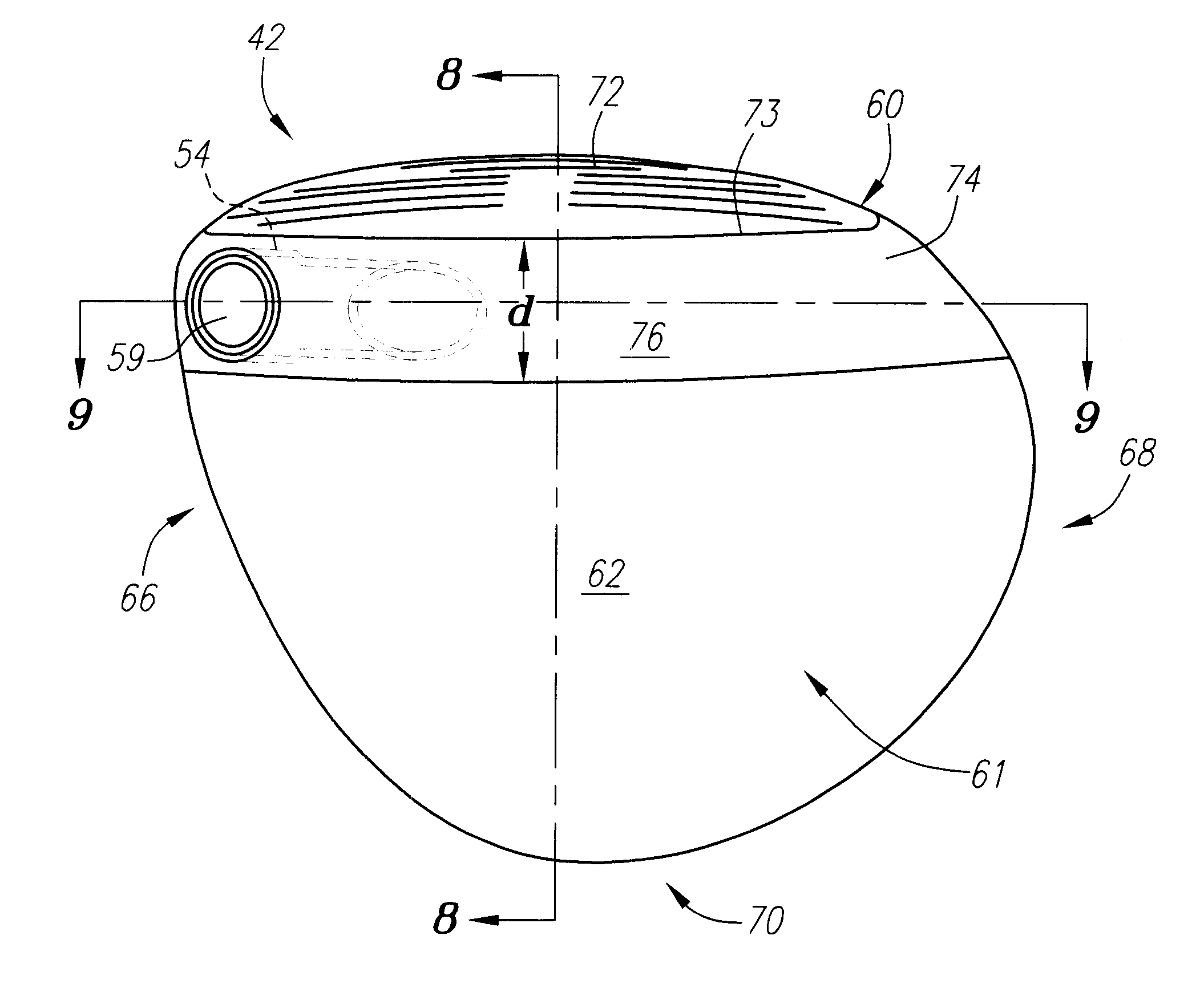

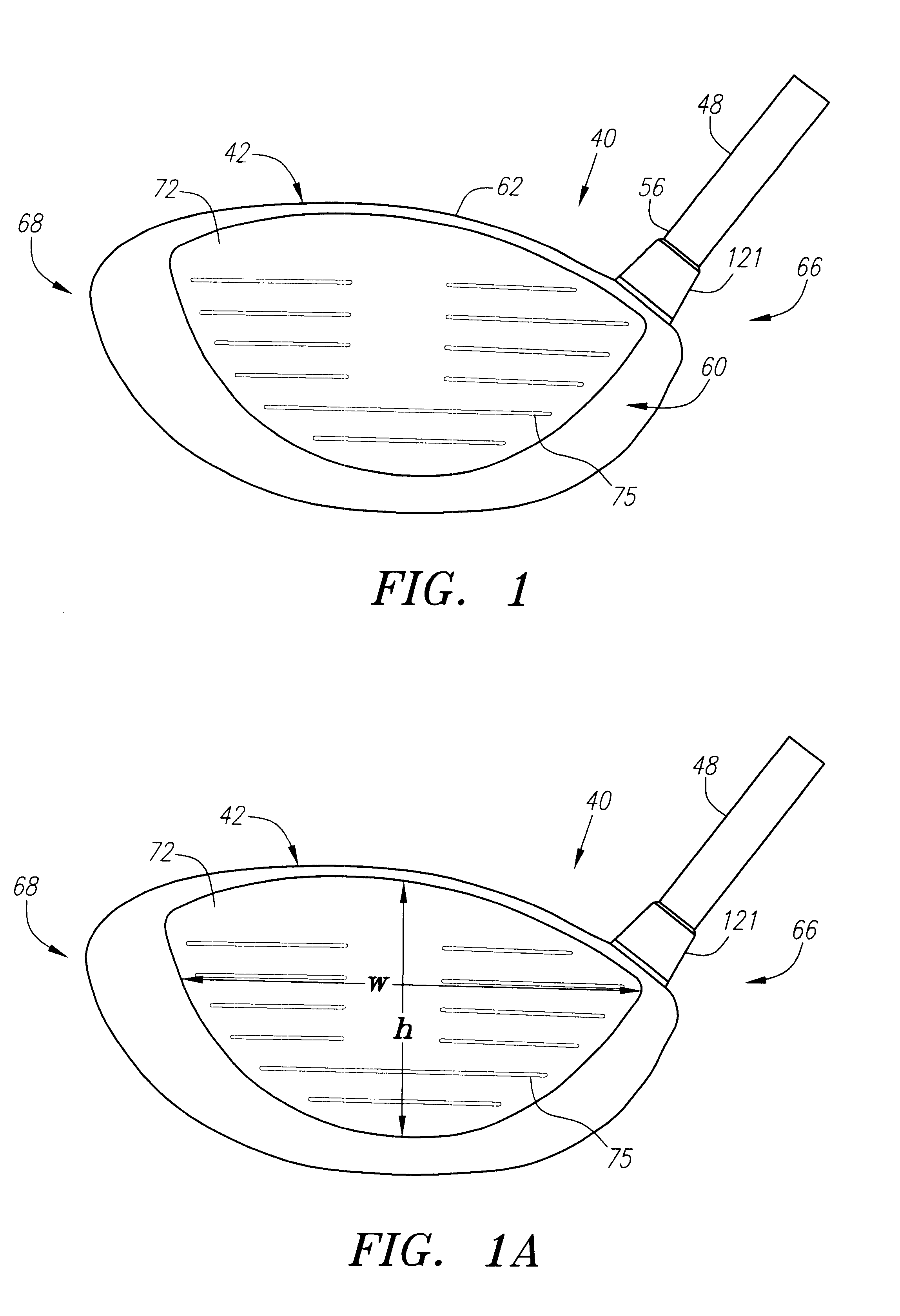

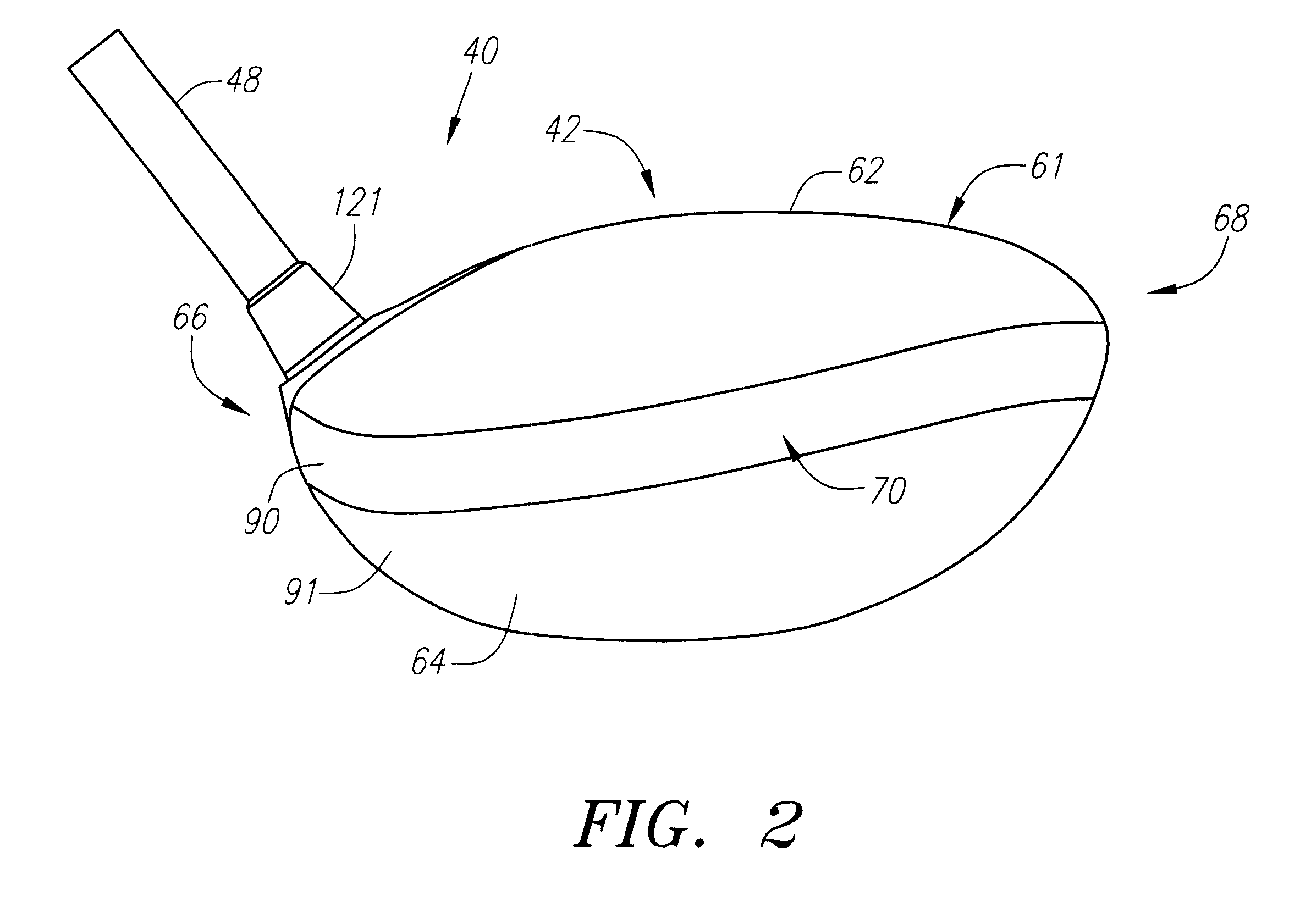

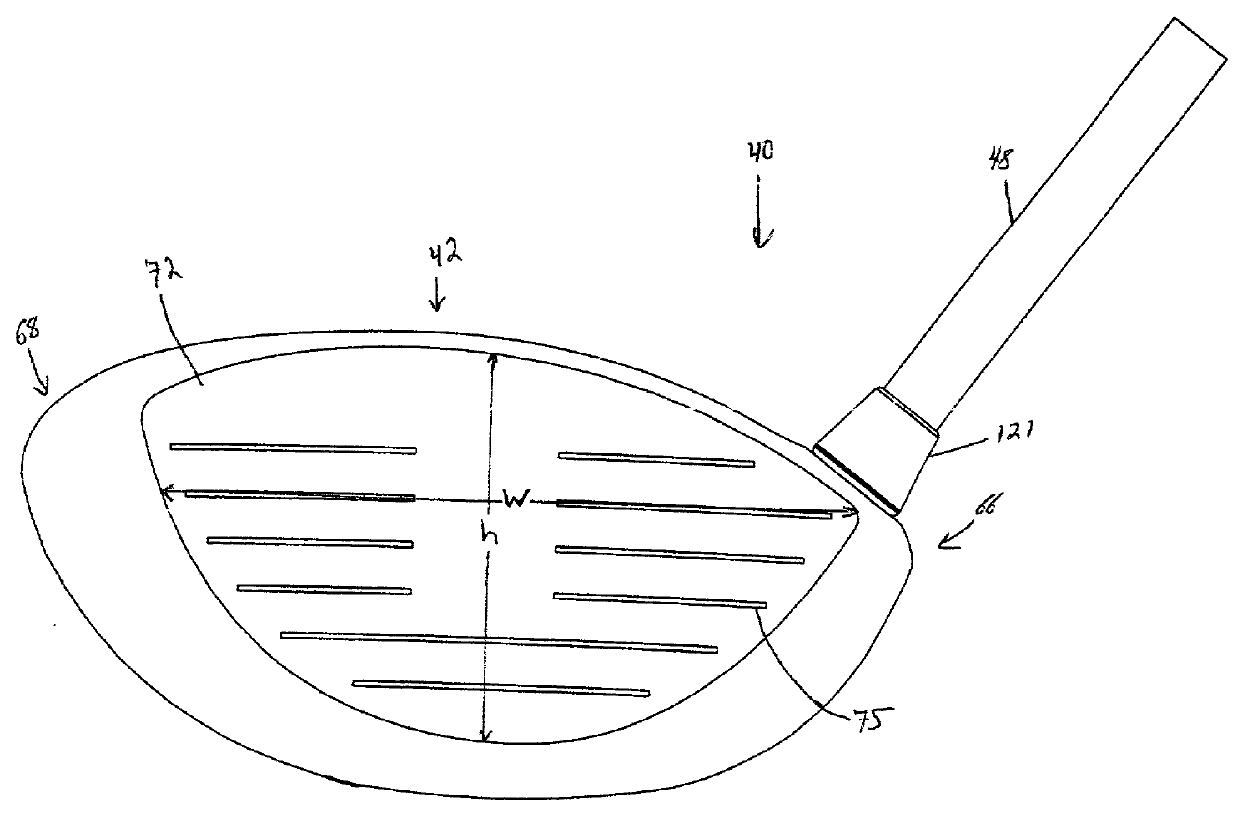

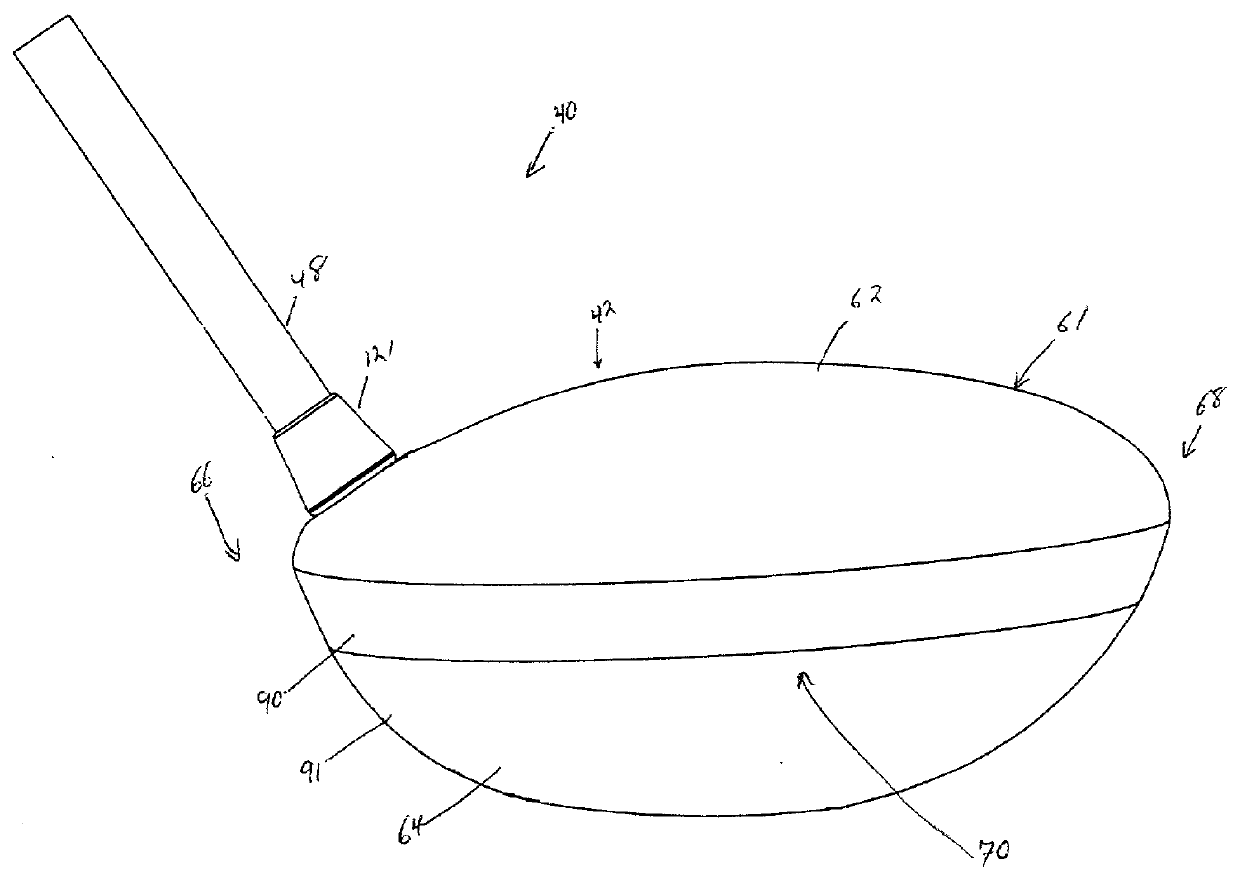

A golf club (40) having a club head (42) with a face component (60) and an aft-body (61) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61) is composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The face component (60) is composed of a metal material, and the aft-body (61) is composed of a non-metal material such as a composite material or a thermoplastic material. The striking plate portion (72) preferably has an aspect ratio less than 1.7. The striking plate portion (72) preferably has concentric regions of thickness with the thickness portion in the center (102). The club head (42) has a volume in the range of 300 cubic centimeters to 600 cubic centimeters, a weight in the range of 165 grams to 300 grams, and a striking plate portion (72) surface area in the range of 4.00 square inches to 7.50 square inches. The golf club head (42) has a coefficient of restitution greater than 0.81 under test such as the USGA test conditions specified pursuant to Rule 4-1e, Appendix II, of the Rules of Golf for 1998-1999.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Damascene process for carbon memory element with MIIM diode

InactiveUS7615439B1Small aspect ratioSolid-state devicesSemiconductor/solid-state device manufacturingMetal insulatorEngineering

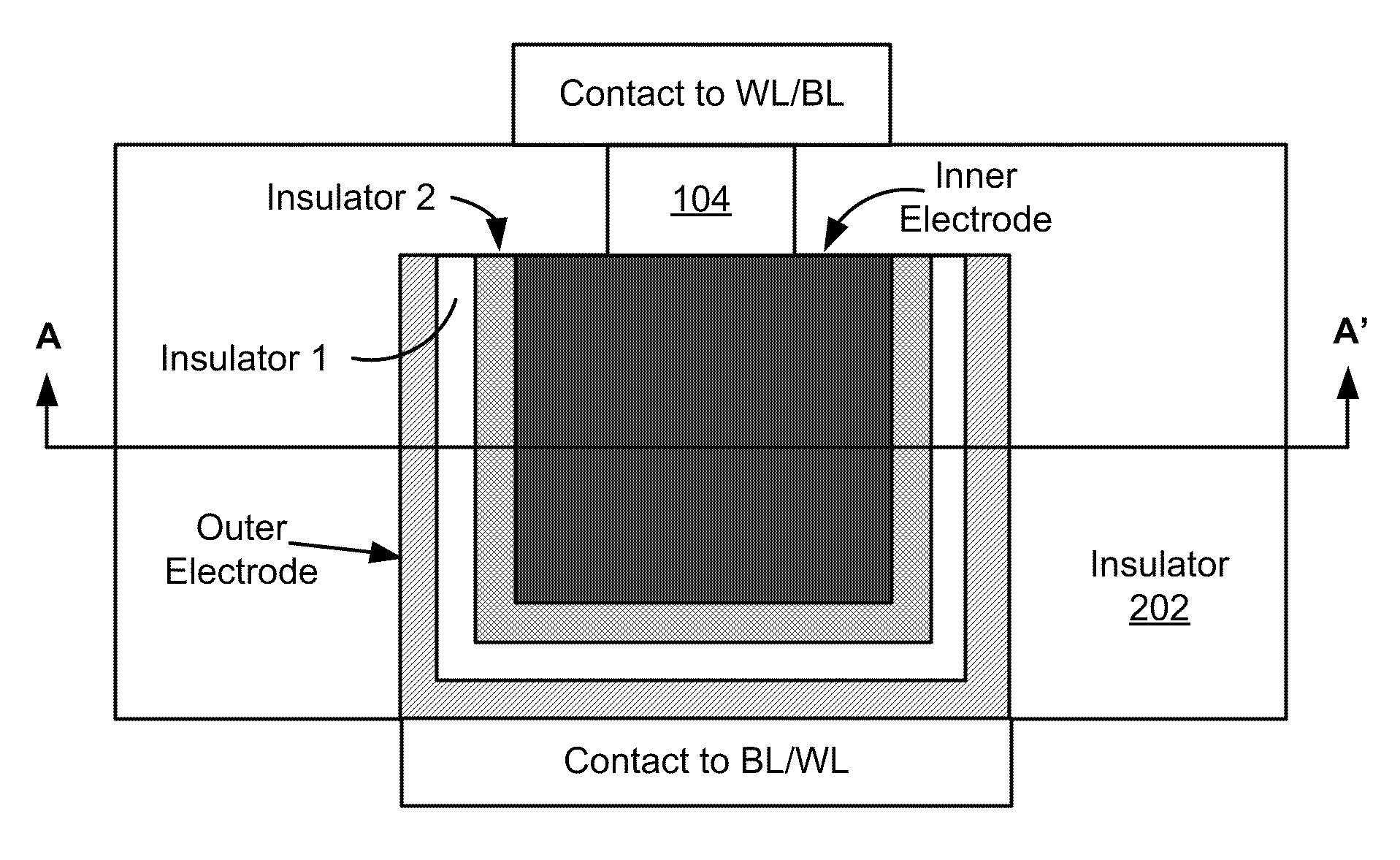

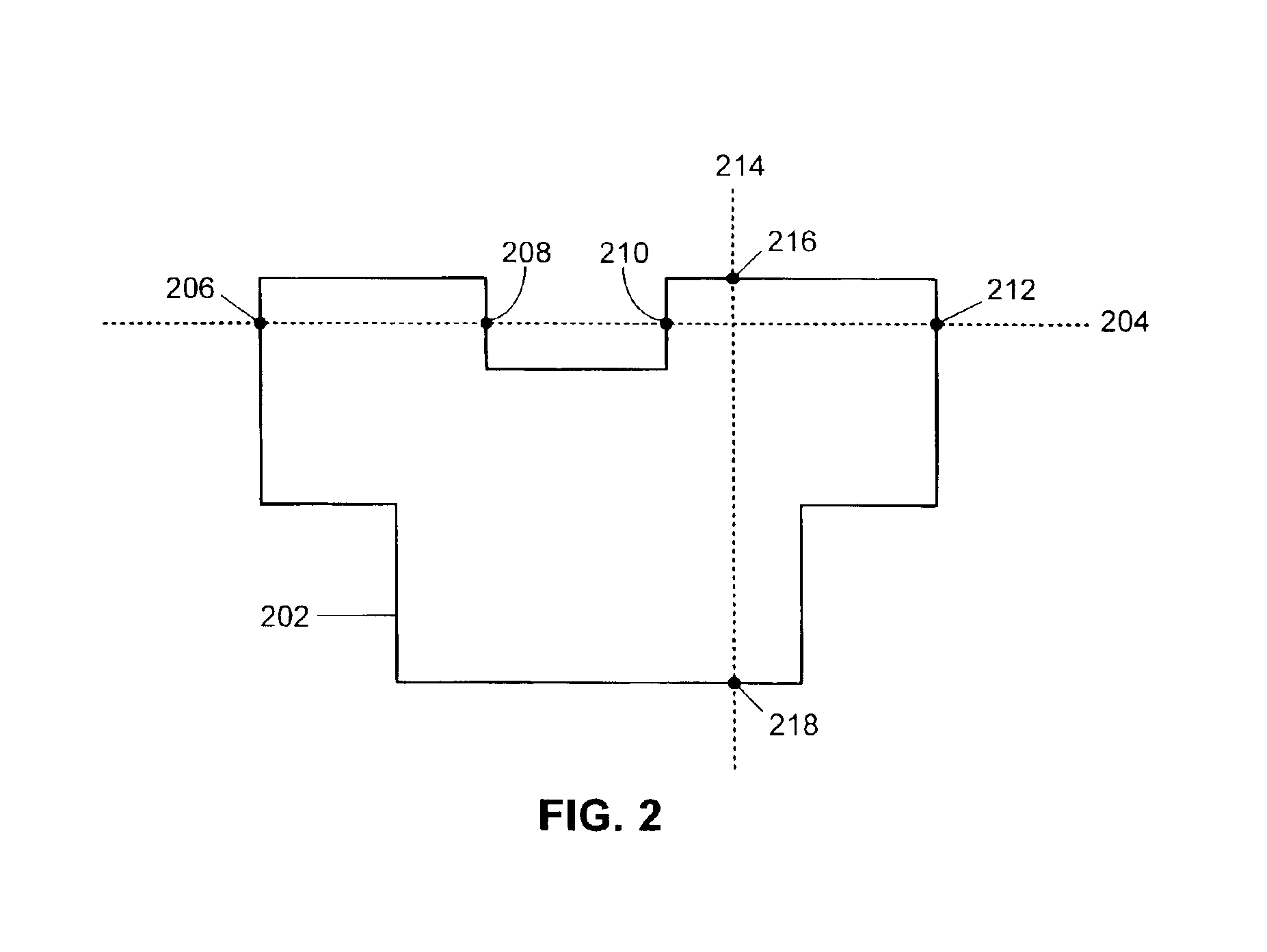

Forming a metal-insulator diode and carbon memory element in a single damascene process is disclosed. A trench having a bottom and a sidewall is formed in an insulator. A first diode electrode is formed in the trench during a single damascene process. A first insulating region comprising a first insulating material is formed in the trench during the single damascene process. A second insulating region comprising a second insulating material is formed in the trench during the single damascene process. A second diode electrode is formed in the trench during the single damascene process. The first insulating region and the second insulating region reside between the first diode electrode and the second diode electrode to form a metal-insulator-insulator-metal (MIIM) diode. A region of carbon is formed in the trench during the single damascene process. At least a portion of the carbon is electrically in series with the MIIM diode.

Owner:SANDISK TECH LLC

Multiple material golf club head

InactiveUS20010055995A1Large coefficientImprove complianceMetal-working apparatusGolf clubsGramCoefficient of restitution

A golf club (40) having a club head (42) with a face component (60) and an aft body (61) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61) is composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The face component (60) is composed of a metal material, and the aft-body (61) is composed of a non-metal material such as a composite material or a thermoplastic material. The striking plate portion (72) preferably has an aspect ratio less than 1.7. The striking plate portion (72) preferably has concentric regions of thickness with the thickness portion in the center (102). The club head (42) has a volume in the range of 300 cubic centimeters to 600 cubic centimeters, a weight in the range of 165 grams to 300 grams, and a striking plate portion (72) surface area in the range of 4.00 square inches to 7.50 square inches. The golf club head (42) has a coefficient of restitution greater than 0.81 under test conditions such as the USGA test conditions specified pursuant to Rule 4-1e, Appendix II, of the Rules of Golf for 1998-1999.

Owner:TOPGOLF CALLAWAY BRANDS CORP

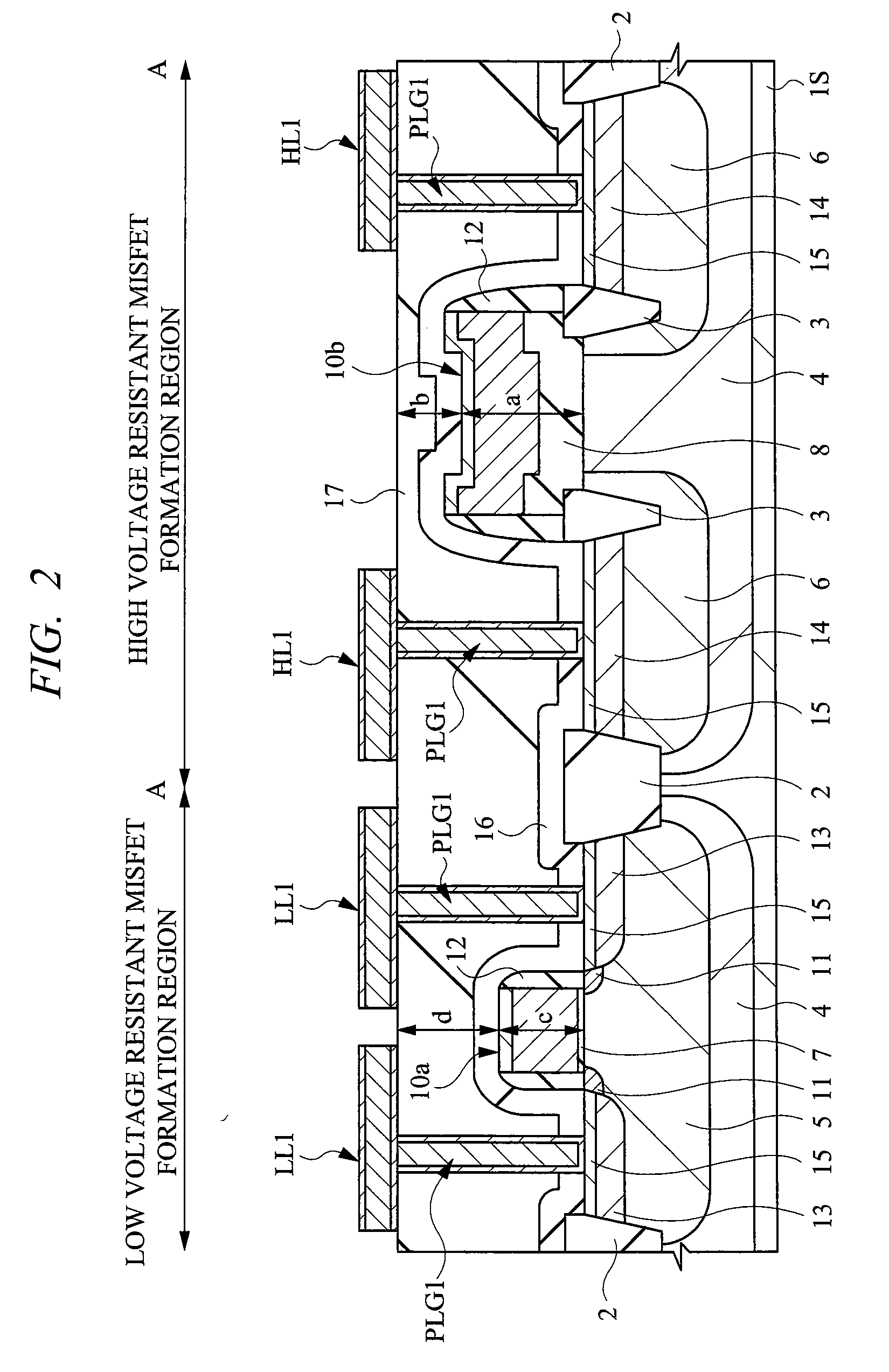

Semiconductor device and method of manufacturing the same

ActiveUS20080303968A1Lower resistanceReduce the overall diameterTransistorSemiconductor/solid-state device detailsDevice materialEngineering

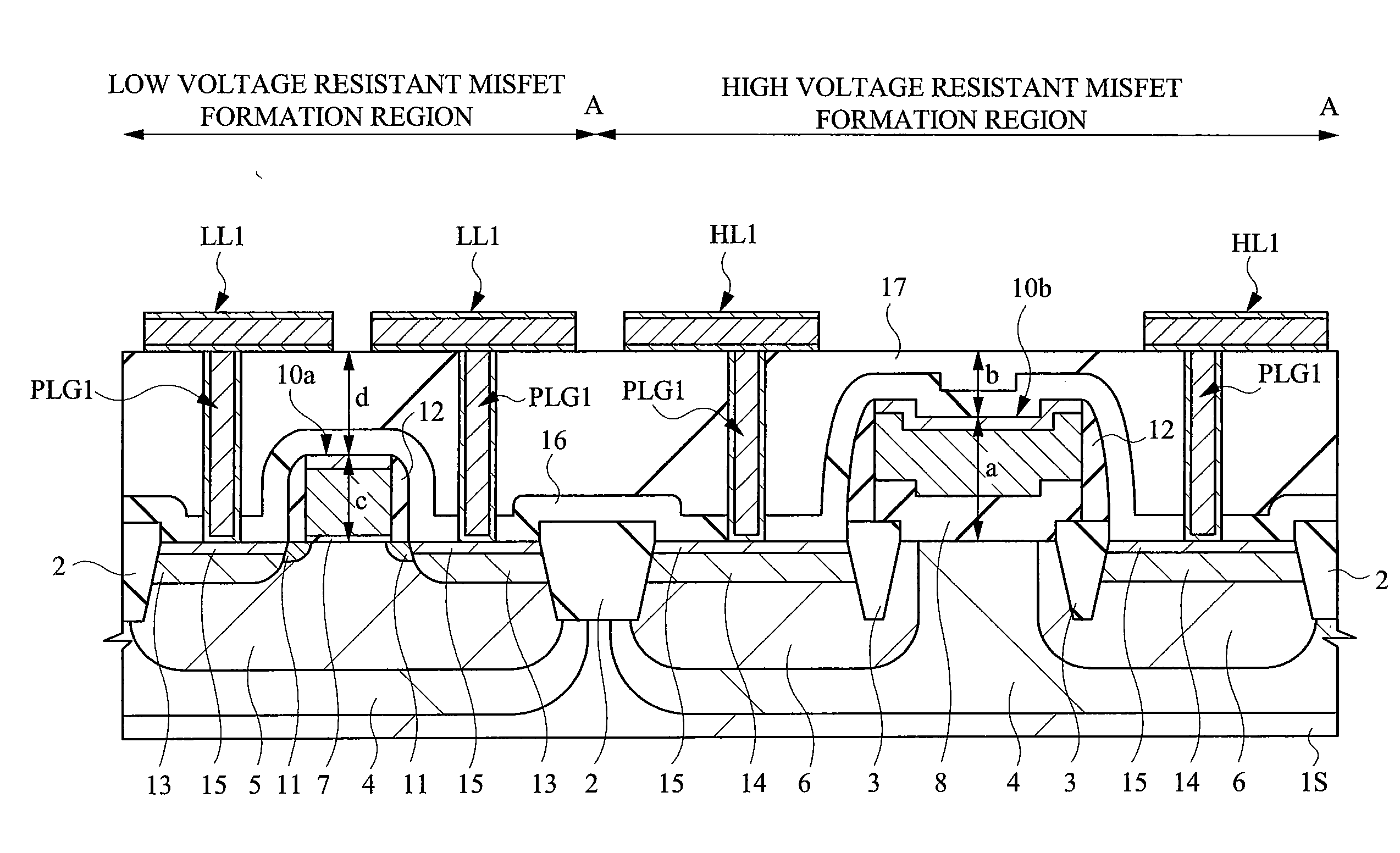

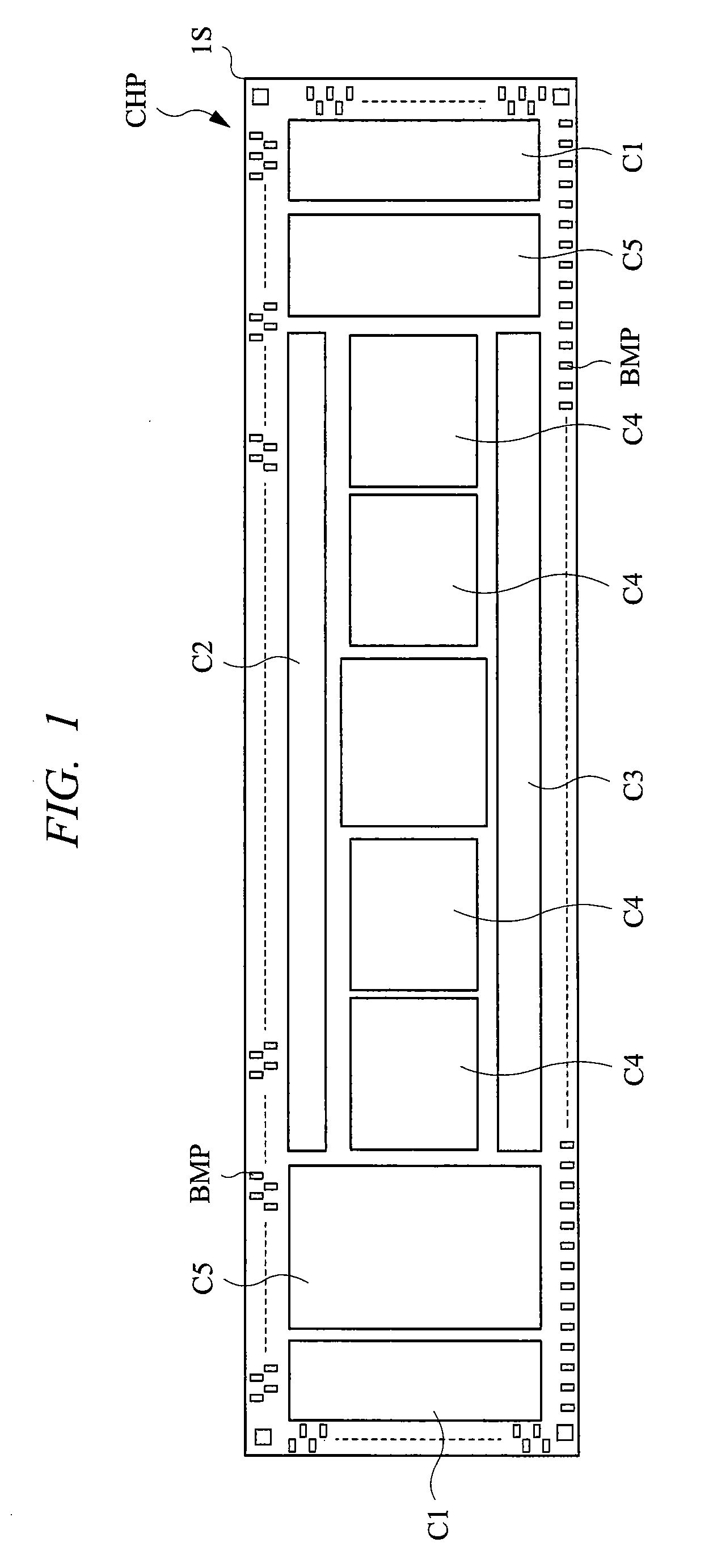

In an LCD driver, in a high voltage resistant MISFET, end portions of a gate electrode run onto electric field relaxing insulation regions. Wires to become source wires or drain wires are formed on an interlayer insulation film of the first layer over the high voltage resistant MISFET. At this moment, when a distance from an interface between a semiconductor substrate and a gate insulation film to an upper portion of the gate electrode is defined as “a”, and a distance from the upper portion of the gate electrode to an upper portion of the interlayer insulation film on which the wires are formed is defined as “b”, a relation of a>b is established. In such a high voltage resistant MISFET structured in this manner, the wires are arranged so as not to be overlapped planarly with the gate electrode of the high voltage resistant MISFET.

Owner:RENESAS ELECTRONICS CORP

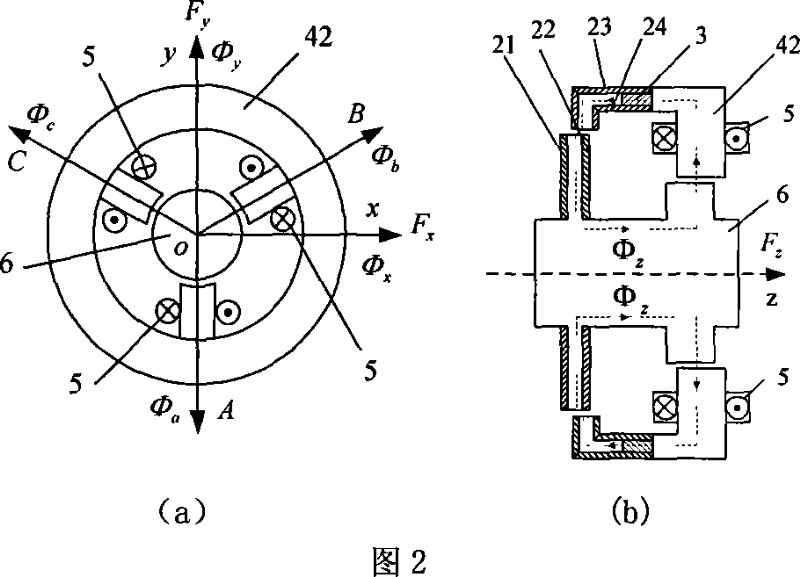

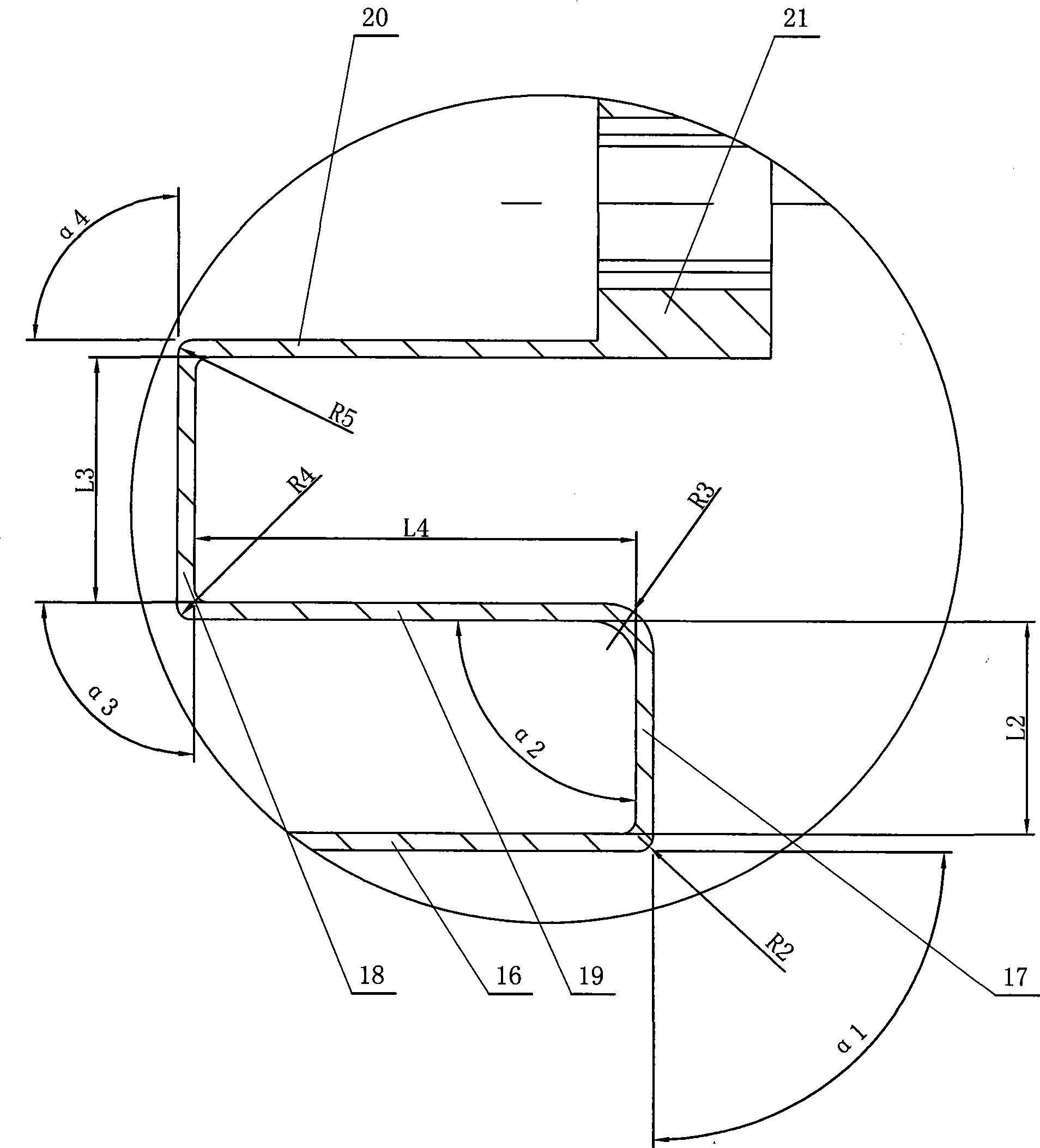

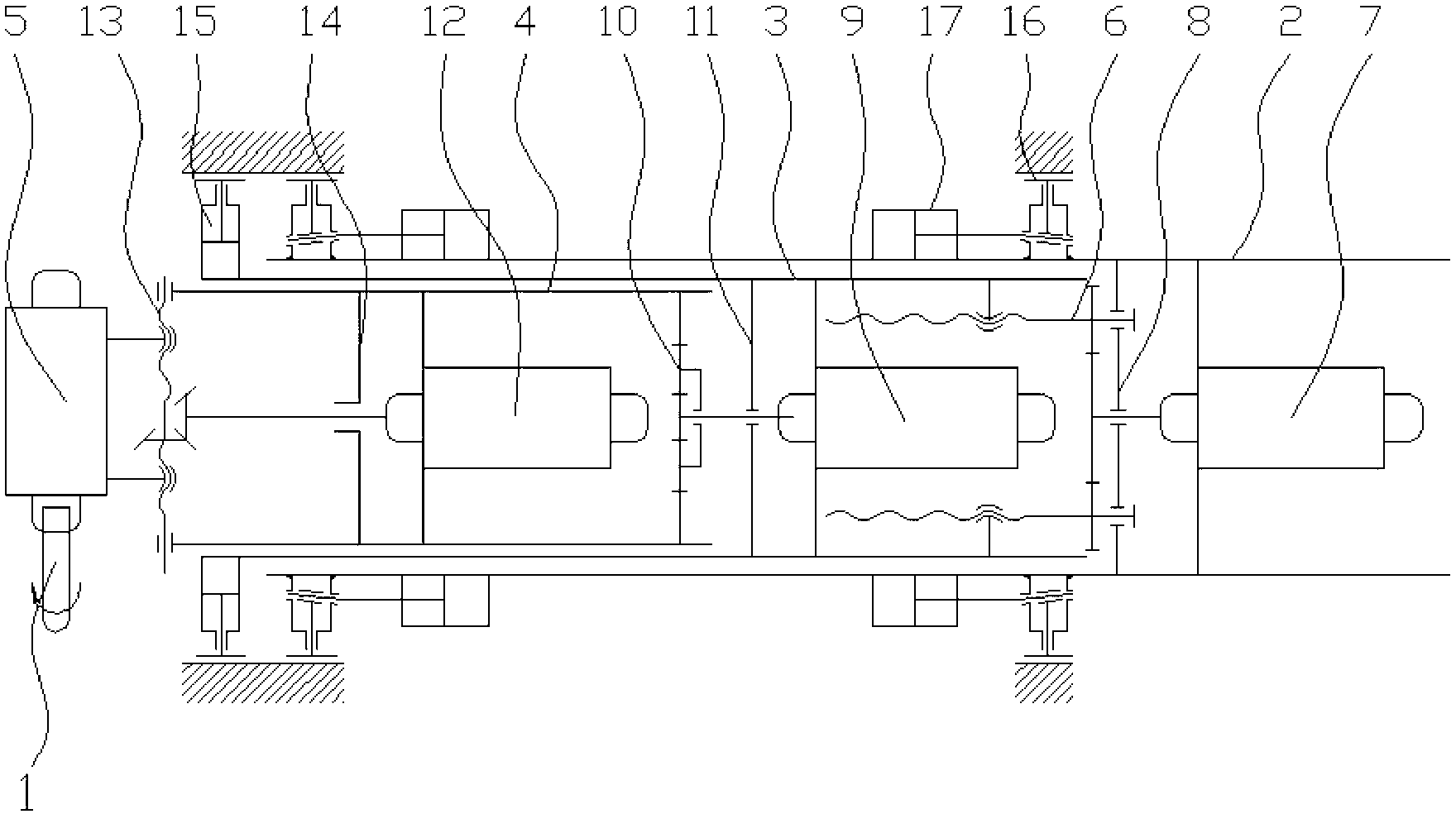

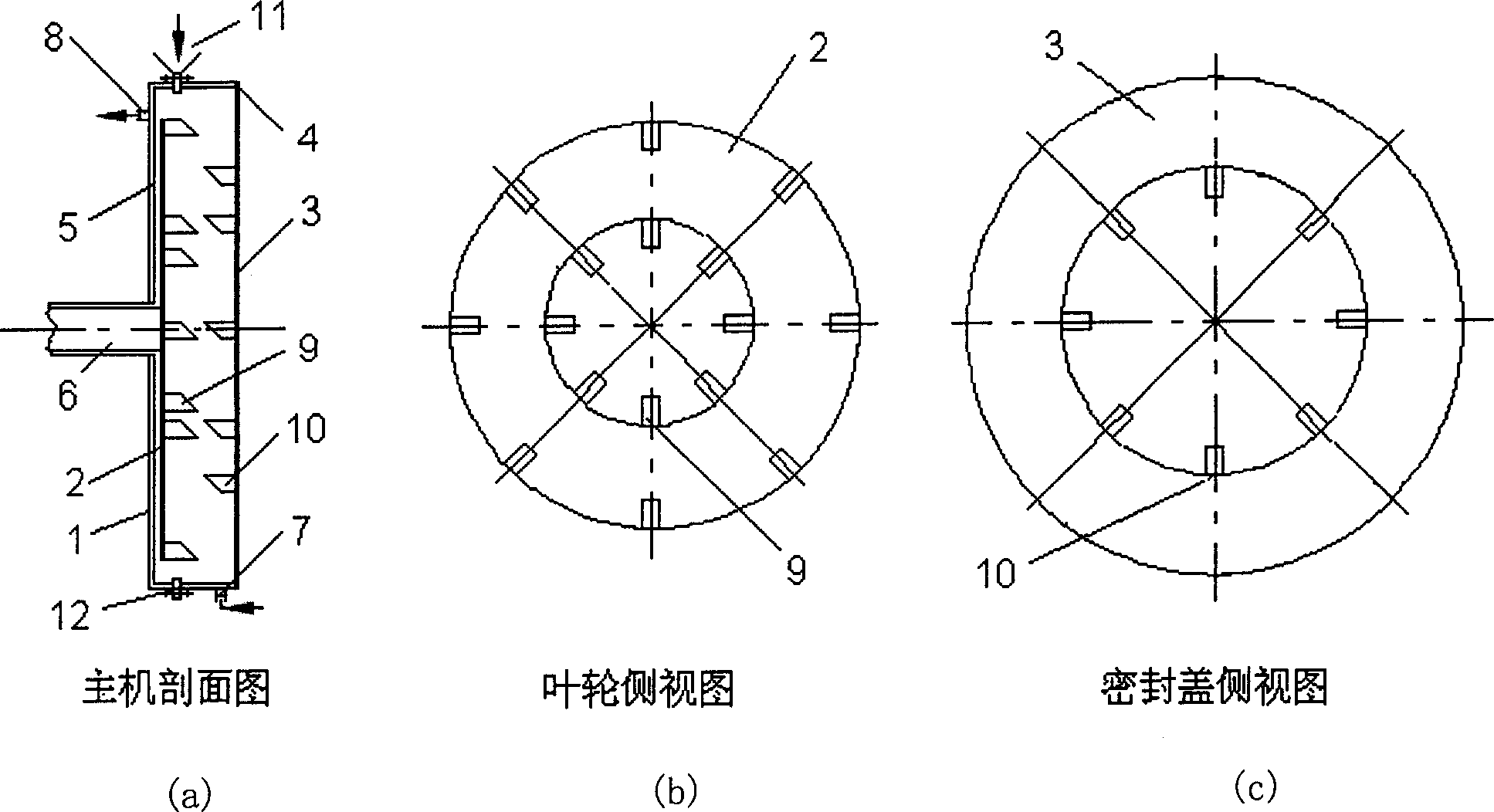

Three degrees of freedom AC mixing magnetic bearing

The invention belongs to electrical transmission equipment field, particularly a new type three degrees of freedom alternating current hybrid magnetic bearing. An annular permanent magnet is employed to provide axial and radial static offset magnetic flux simultaneously. The three degrees of freedom alternating current hybrid magnetic bearing is consisted of a rotation shaft, rotor outboard aluminum sheet, rotor inboard aluminum sheet, axial stator outboard aluminum sheet, axial stator inboard aluminum sheet, annular permanent magnet, thin-sheet shaped axial stator, radial stator, radial winding and a rotor with a thin-sheet shaped end. One end of the rotor is a thin-sheet shaped structure used as an axial bearing, the rotor outboard aluminum sheet and the rotor inboard aluminum sheet are used to increase strength and fatherly reduce length-diameter ratio. Tripolar structure AC excitation is employed in radial direction, which provides control current by employing a triphase inverter. Aluminum sheets are used to increase strength and reduce length-diameter ratio in the invention, passive suspension is realized based on lamellate electric motor principle, which improves passive suspension ability. Axial spacing dimension occupied by the magnetic bearing is greatly reduced for that no excitation winding is needed.

Owner:JIANGSU UNIV

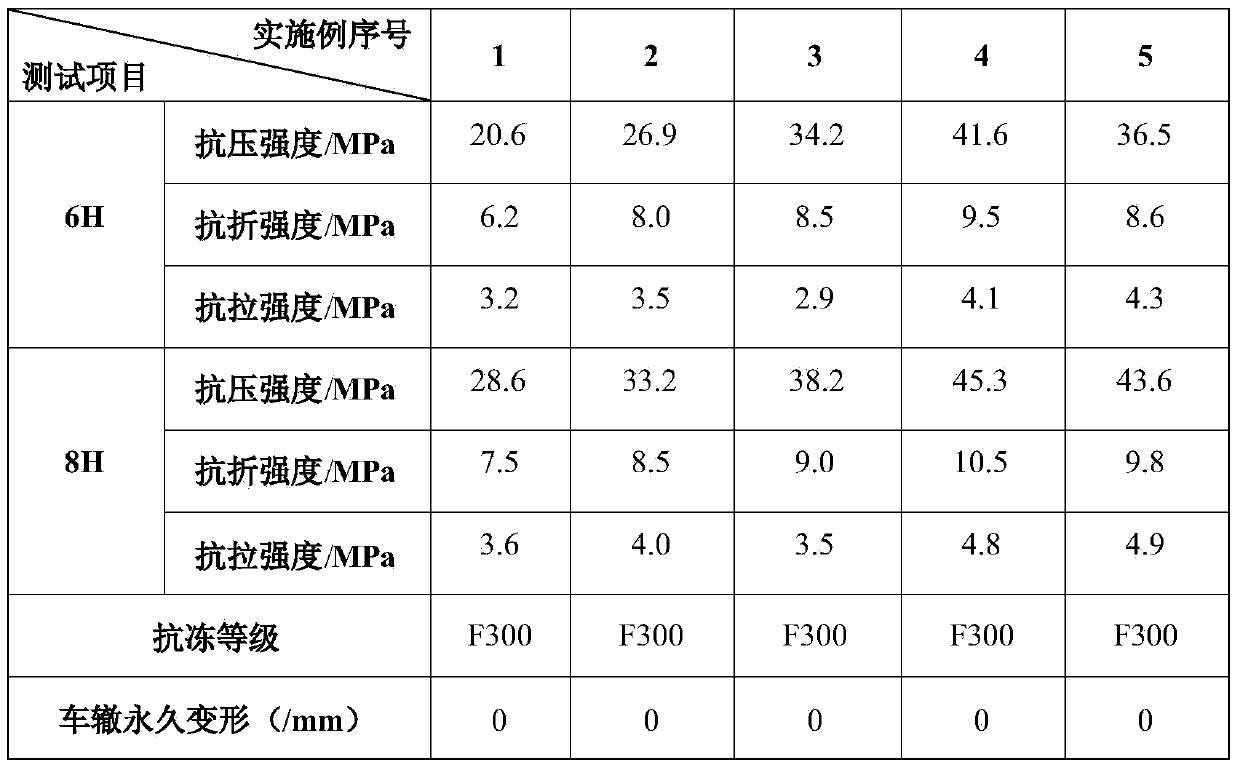

Concrete pavement material for heavy traffic roads and preparation method thereof

ActiveCN104193221AElastic modulus controllableHigh modulus of elasticitySolid waste managementMass ratioWaste rubber

The invention relates to a concrete pavement material for heavy traffic roads and a preparation method thereof. The material is composed of a component A, a component B and a component C in a mass ratio of 1:(0.2-0.6):(4-8). The component A comprises the following components in parts by mass: 40-80 parts of epoxy resin, 0-20 parts of epoxy reactive diluent, 10-50 parts of elastic modifier, 0.2 part of defoaming agent and 0.2 part of dispersing agent. The component B comprises the following components in parts by mass: 100 parts of curing agent, 0-10 parts of curing accelerator and 1 part of coupling agent. The component C comprises the following components in parts by volume: 100 parts of fine stone, 30-300 parts of fine sand, 130-800 parts of waste rubber particle, 50-100 parts of waste rubber powder and 10-20 parts of crystal whisker. Compared with the prior art, the concrete pavement material for heavy traffic roads has the advantages of high strength, favorable durability, favorable roadability, energy saving, environment friendliness and the like, and is convenient for construction.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

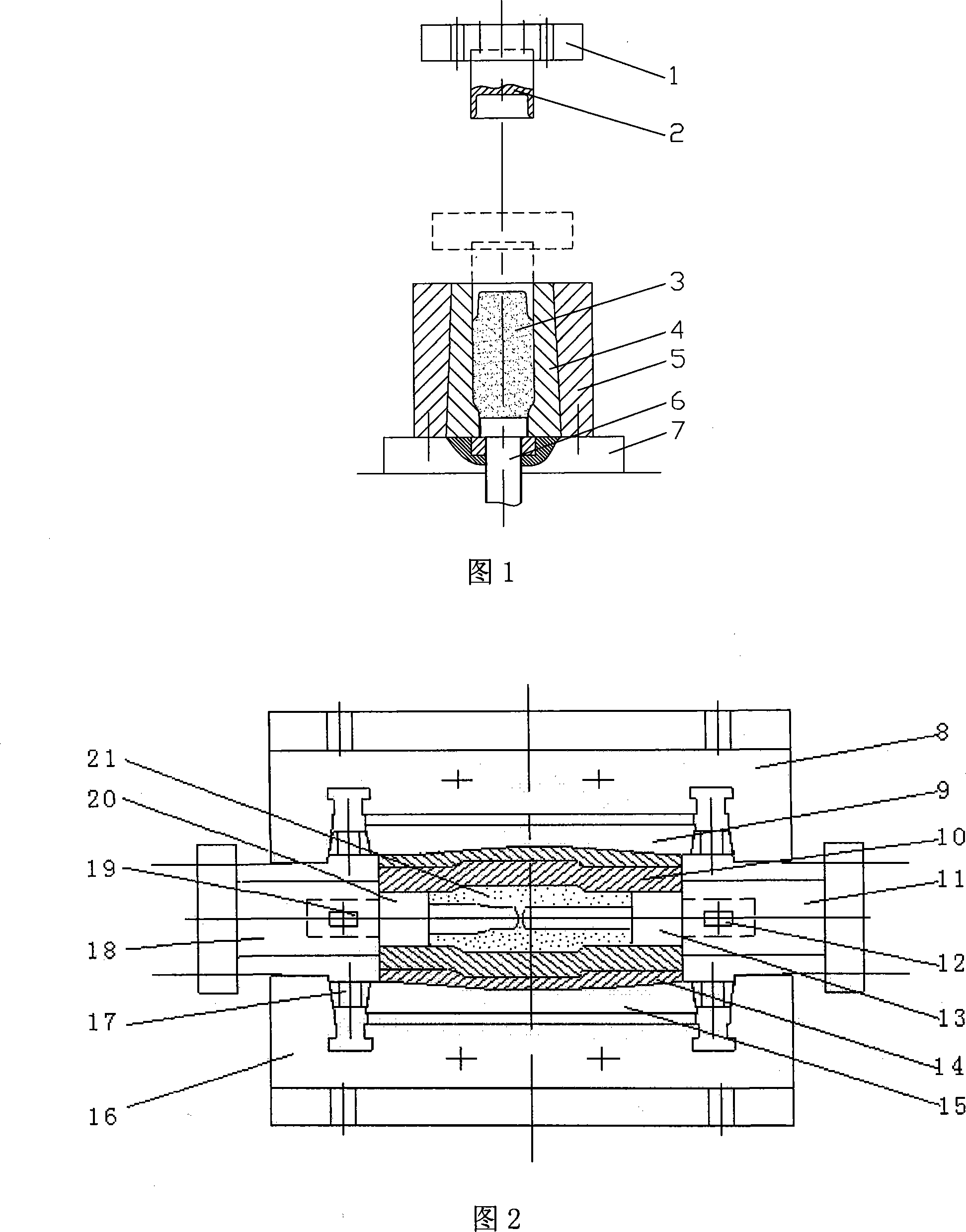

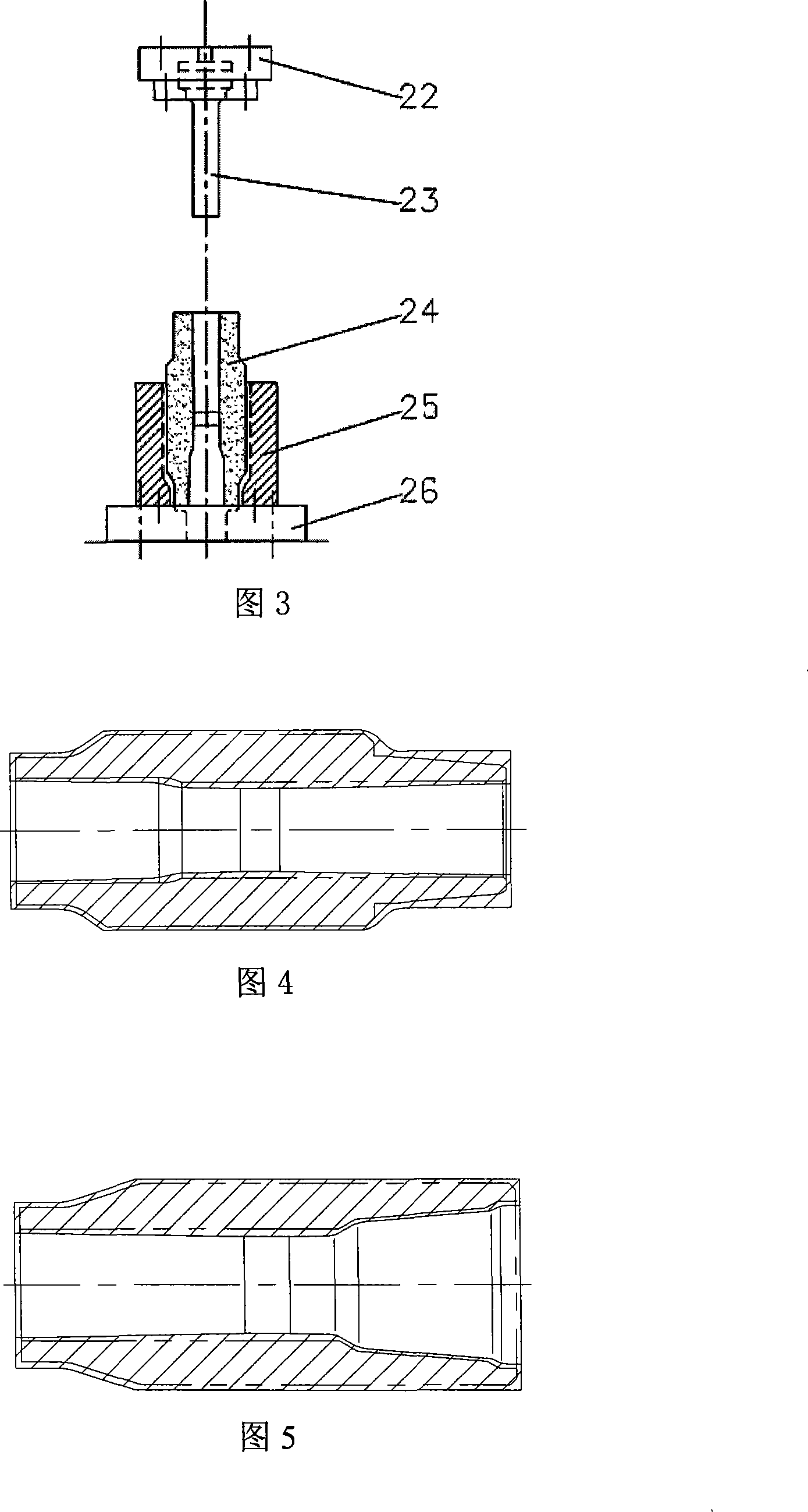

Drill pipe joint precision die forging process

InactiveCN101181730AEasy to moldSmall machining allowanceForging/hammering/pressing machinesMedium frequencyMaterial consumption

The invention discloses a precise die forging technique of a petroleum drill rod connector and is characterized in that: 1) flan material is prepared with a band saw; 2) the flan material is heated quickly at a temperature that is suitable for forging by a medium frequency electric induction furnace; 3) then the flan material is extruded in a close type into a prefabricated flan and a flan makes concave die on a quick flan-making oil hydraulic machine; 4) a molding concave by die level method extrudes and presses the prefabricate flan into a connector die forging piece on the quick flan-making oil hydraulic machine which can implement combination of the upper molding concave die and the lower molding concave die and relative extrusion and pressing from right and left and inner holes of the connector die forging piece is provided with wad; 5) finally a hole punching die punches away the recess inside the inner hole of the forging piece on a special hole punching oil hydraulic machine to obtain the connector forging piece with accurate specifications, excellent structure performance and central through holes. The invention has the advantages of good streamline distribution, material conservation, environmental protection and high production efficiency.

Owner:JIANGYIN LONGCHENG DRILLING & PRODN MACHINERY MFG

Flexible display device and manufacturing method thereof

ActiveCN102983155ARealize flexible and bendable displayHigh electron mobilitySolid-state devicesSemiconductor/solid-state device manufacturingElectricityImage resolution

The invention discloses a flexible display device and a manufacturing method thereof and relates to the field of display. The manufacturing method is simple and can realize flexible display. In addition, the high-quality display picture can be obtained without a threshold voltage compensation circuit and an external driving integrated circuit. The method comprises the following steps: bonding a monocrystalline silicon diaphragm on a substrate, forming a driving circuit and an electroluminescence device on the substrate bonded with the monocrystalline silicon diaphragm, and packaging on the electroluminescence device with a transparent flexible cover plate, wherein the monocrystalline silicon diaphragm forms an active layer of a thin film transistor in the driving circuit; the thin film transistor comprises a first thin film transistor arranged in the display area of the flexible display device; the monocrystalline silicon outside the thin film transistor is removed from the monocrystalline silicon diaphragm; and the monocrystalline silicon diaphragm is sealed with the flexible diaphragm. The invention further provides a flexible display device manufactured by the method. Compared with the existing device, the flexible display device has the advantages of uniform brightness, simple structure and higher resolution.

Owner:BOE TECH GRP CO LTD +1

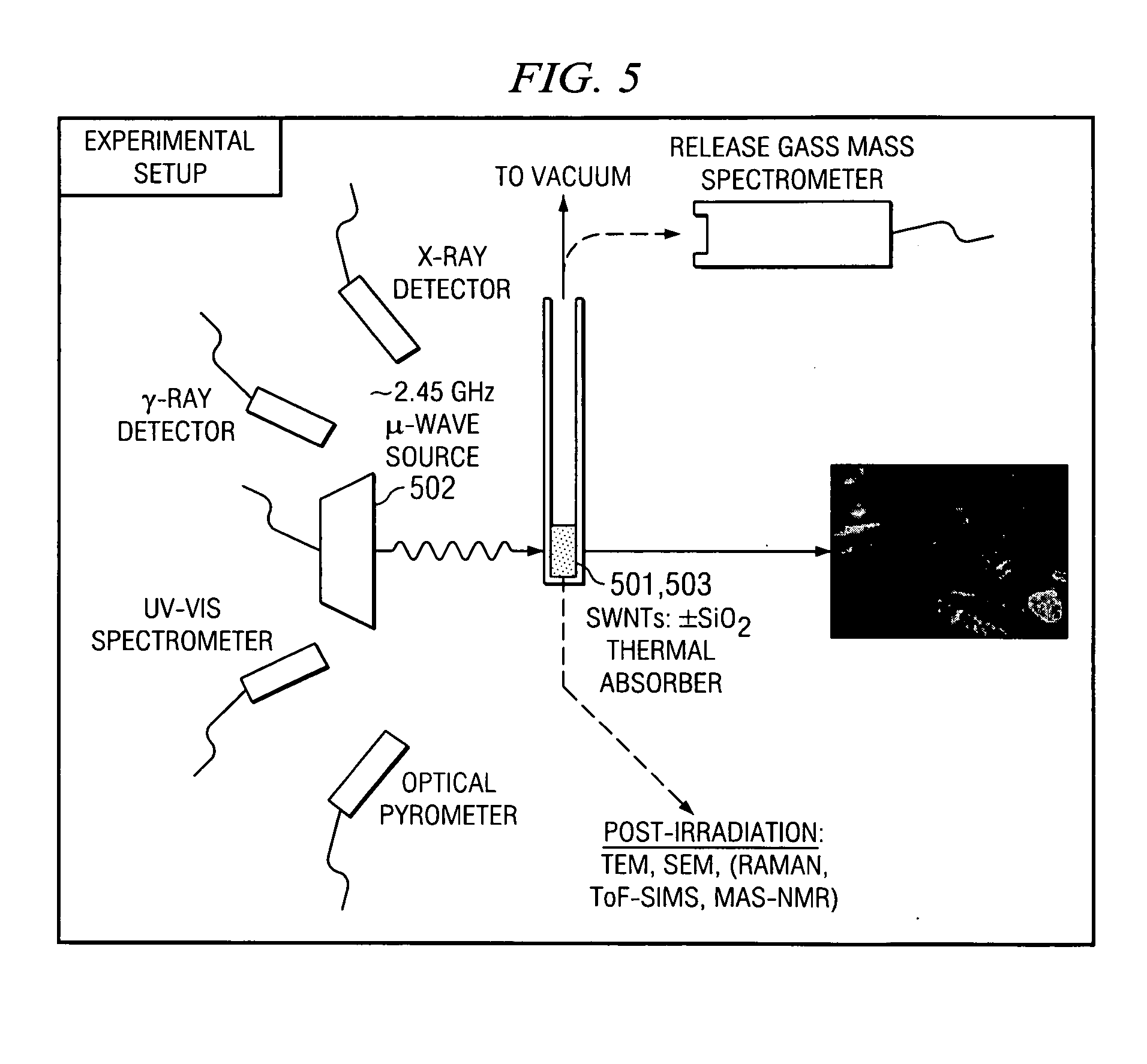

Process and apparatus for energy storage and release

UndeterminedUS20050007001A1Increasing purity of carbonReduce the overall diameterMaterial nanotechnologyReactant parameters controlMicrowaveLight energy

The present invention provides a process and apparatus to store and deliver controlled amounts of heat and light energy, from low levels to very intense levels, to microscopic locations in a object remotely, not necessarily involving direct contact with the object, where the energy delivered remotely is less than the energy released by the object. More specifically, the present invention comprises a novel and previously unanticipated source of local energy production by the exposure of carbon nanotubes by EM radiation in the radio and microwave spectral regions. The present invention comprising a process and apparatus to remotely delivering highly controlled amounts of EM to the carbon nanotubes.

Owner:PENN STATE RES FOUND +1

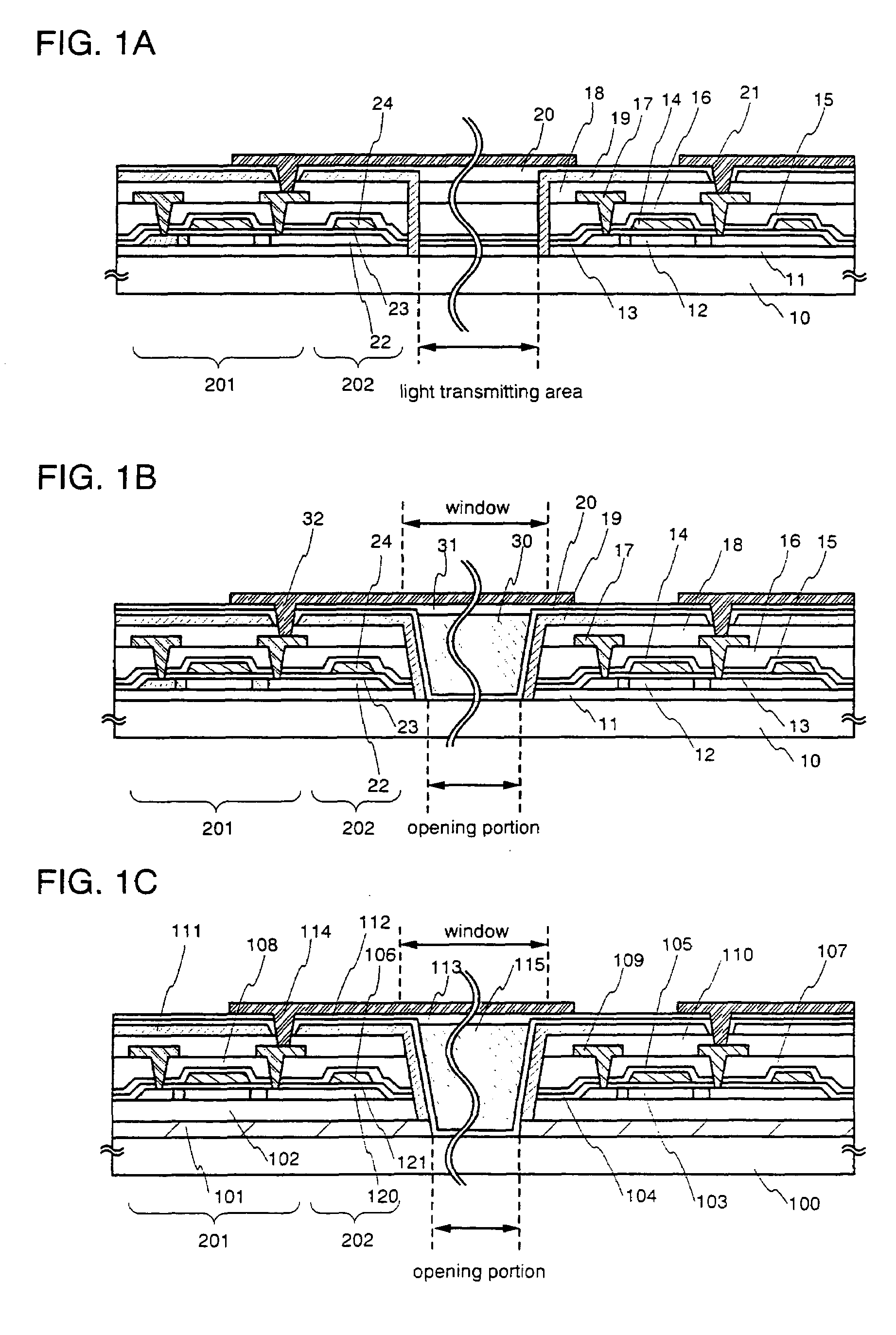

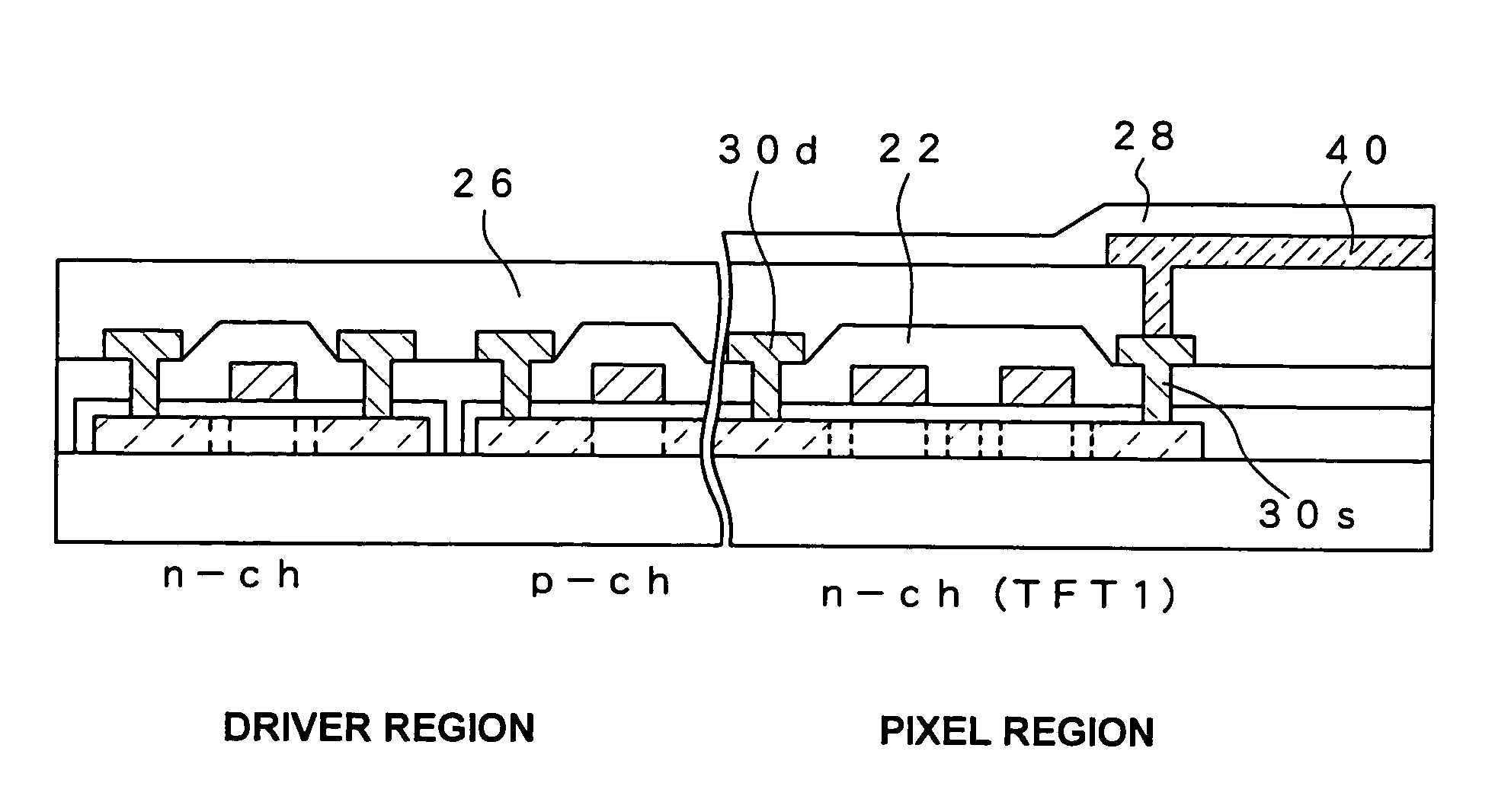

Semiconductor device

InactiveUS7095046B2Avoid it happening againReduce the ratioTransistorSolid-state devicesCapacitanceAperture ratio

Provided is a method of realizing a semiconductor device having a structure in which a sufficient light shielding property is compatible with a sufficient storage capacitance without reducing an aperture ratio. A lower light shielding film is formed on a substrate, a TFT is formed on the lower light shielding film, and an upper light shielding film is formed on the TFT via an interlayer insulating film to cover and fit the TFT. Thus, the TFT can be completely light-shielded by the lower light shielding film and the upper light shielding film and an occurrence of a photo leak current can be prevented.

Owner:SEMICON ENERGY LAB CO LTD

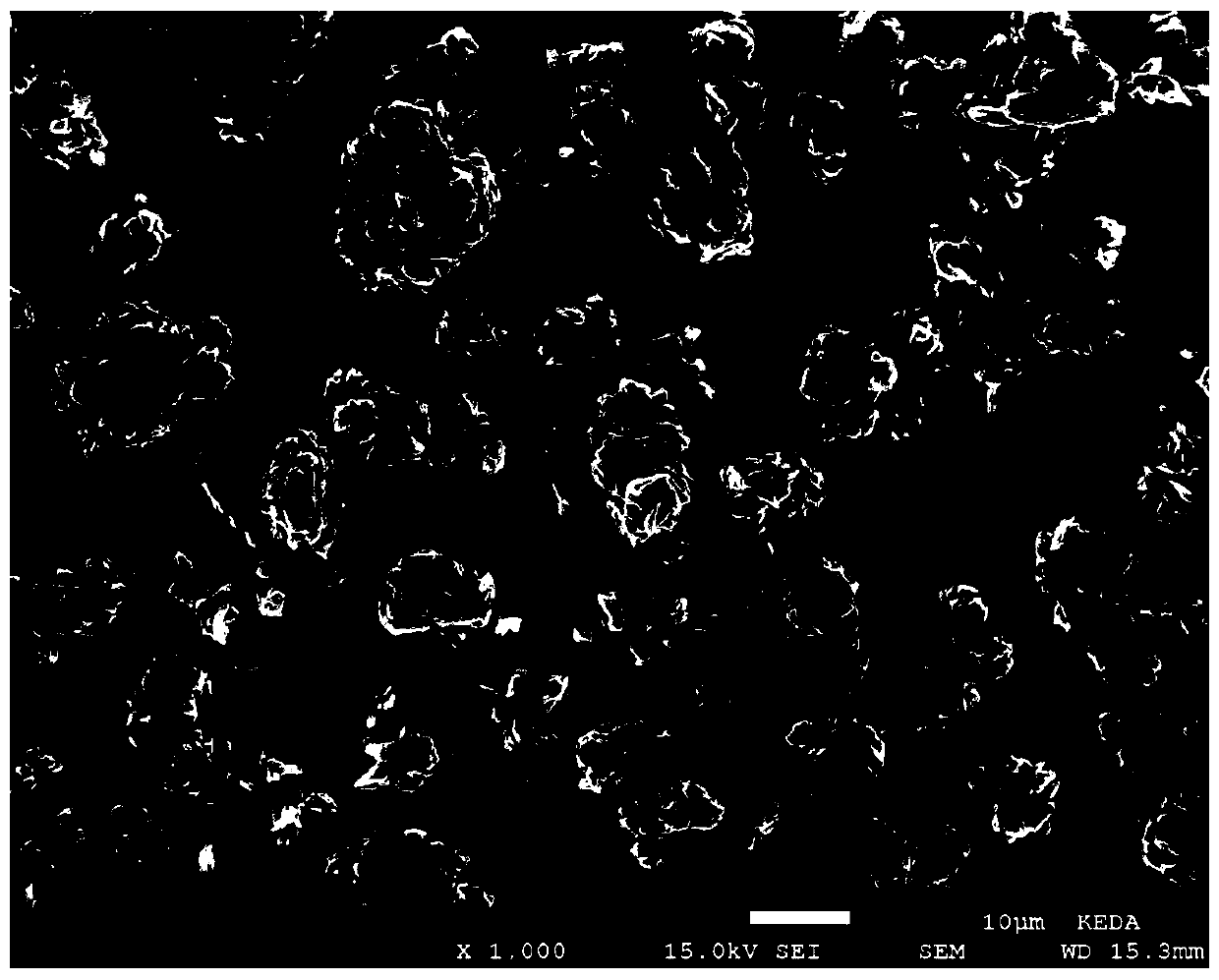

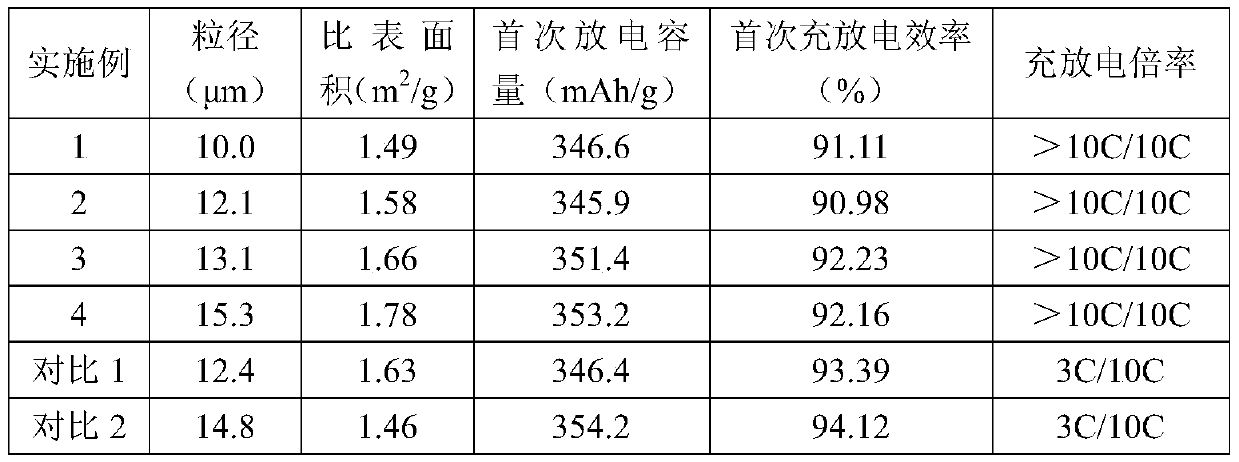

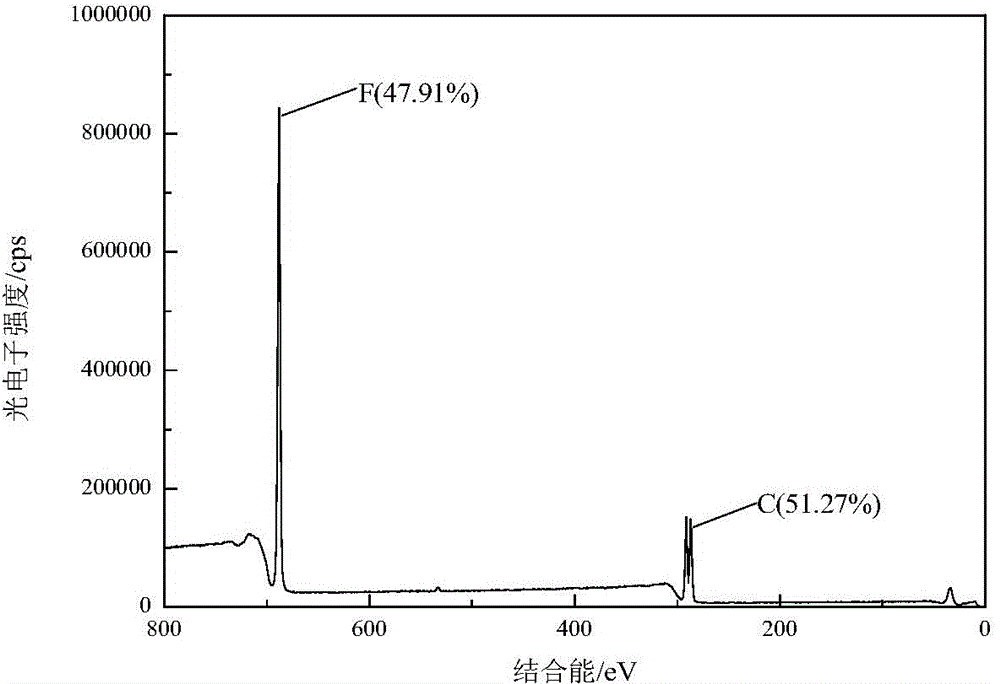

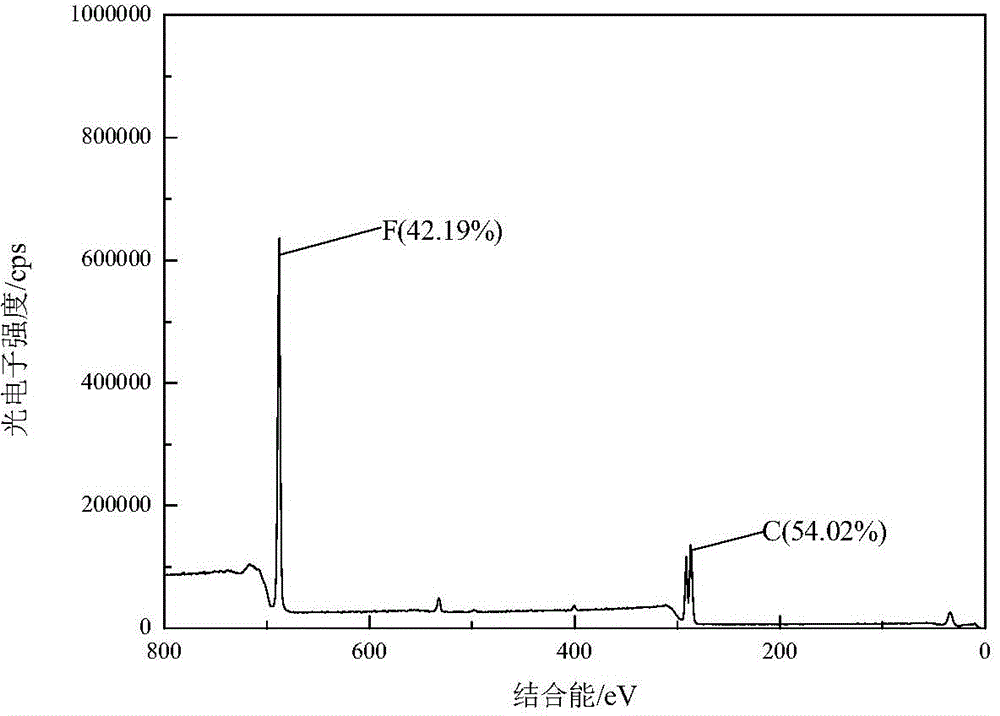

Method for preparing high-rate artificial graphite anode material

ActiveCN109830669AReduce processing costsReduce electrostatic attractionCell electrodesSecondary cells servicing/maintenanceHigh rateEconomic benefits

The invention belongs to the field of lithium ion batteries and relates to a method for preparing a high-rate artificial graphite anode material, comprising the following steps: (1) preferential selection of pulverized and shaped tailings; (2) mixing; (3) static coating and granulation; (4) breaking and spheroidization; (5) secondary mixing; (6) high-temperature graphitization; and (7) mixing andsieving. The anode material prepared by the method has excellent high rate charge / discharge performance, and has good cycle performance and low-temperature temperature. The method also fully processesand recycles the by-products produced in the processing of coke raw materials / asphalt raw materials in a high value-added manner, has broad market prospects, reduces the disposal cost of solid waste,and brings practical economic benefits.

Owner:KEDA (ANHUI) NEW MATERIAL CO LTD

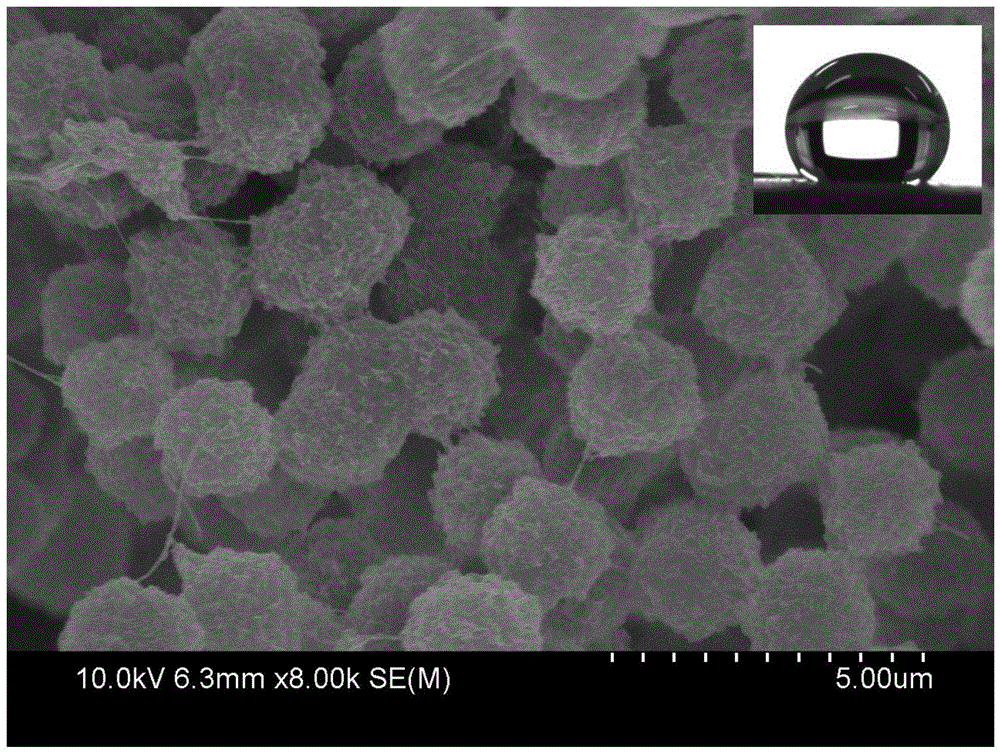

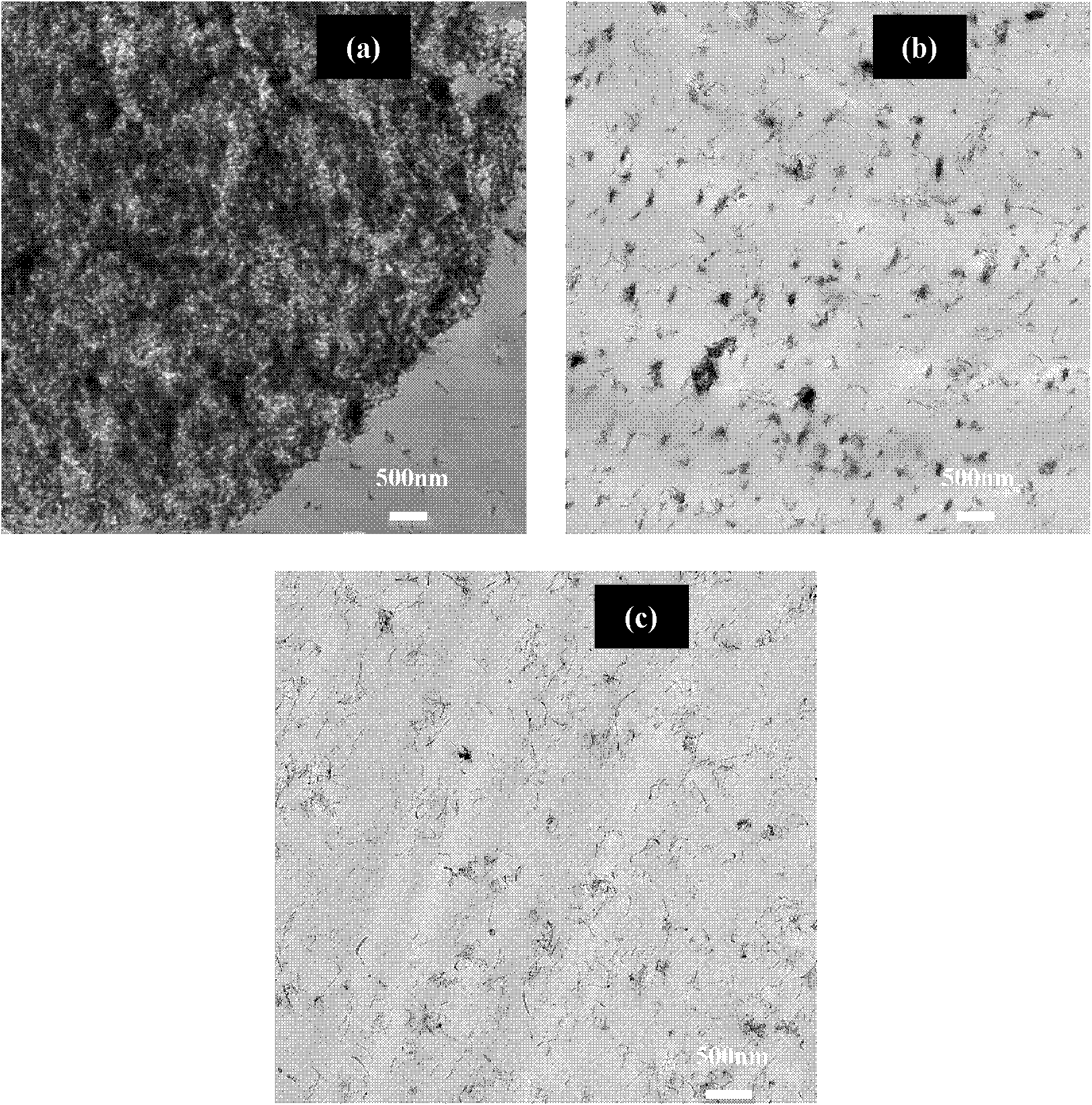

Production formula and method of PVDF (polyvinylidene fluoride)/carbon nano-tube super-hydrophobic film

InactiveCN104826503AImprove and modify pore structureImprove and modify distributionSemi-permeable membranesFiberHollow fibre

The invention discloses a production formula and method of a PVDF (polyvinylidene fluoride) / carbon nano-tube super-hydrophobic membrane. The formula includes, by weight, 5% to 30% of PVDF, 0.005% to 5% of carbon nano-tubes, and 67% to 91% of solvent. The production method includes: evenly dispersing the carbon nano-tubes in the solvent, adding the PVDF, and performing high-speed stirring at 50 DEG C to 100 DEG C to obtain casting solution; producing a flat membrane by scraping, or producing hollow fibers to obtain a primary membrane via a hollow spinneret; solidifying the primary membrane in the non-polar steam environment, and removing solvent residue by deionizing soaking so as to obtain the PVDF / carbon nano-tube super-hydrophobic membrane. The membrane produced by the formula and the method is rich in CNTs on surface and has super-hydrophobic surface and excellent permeability; the method is simple, and operability is high.

Owner:TIANJIN POLYTECHNIC UNIV

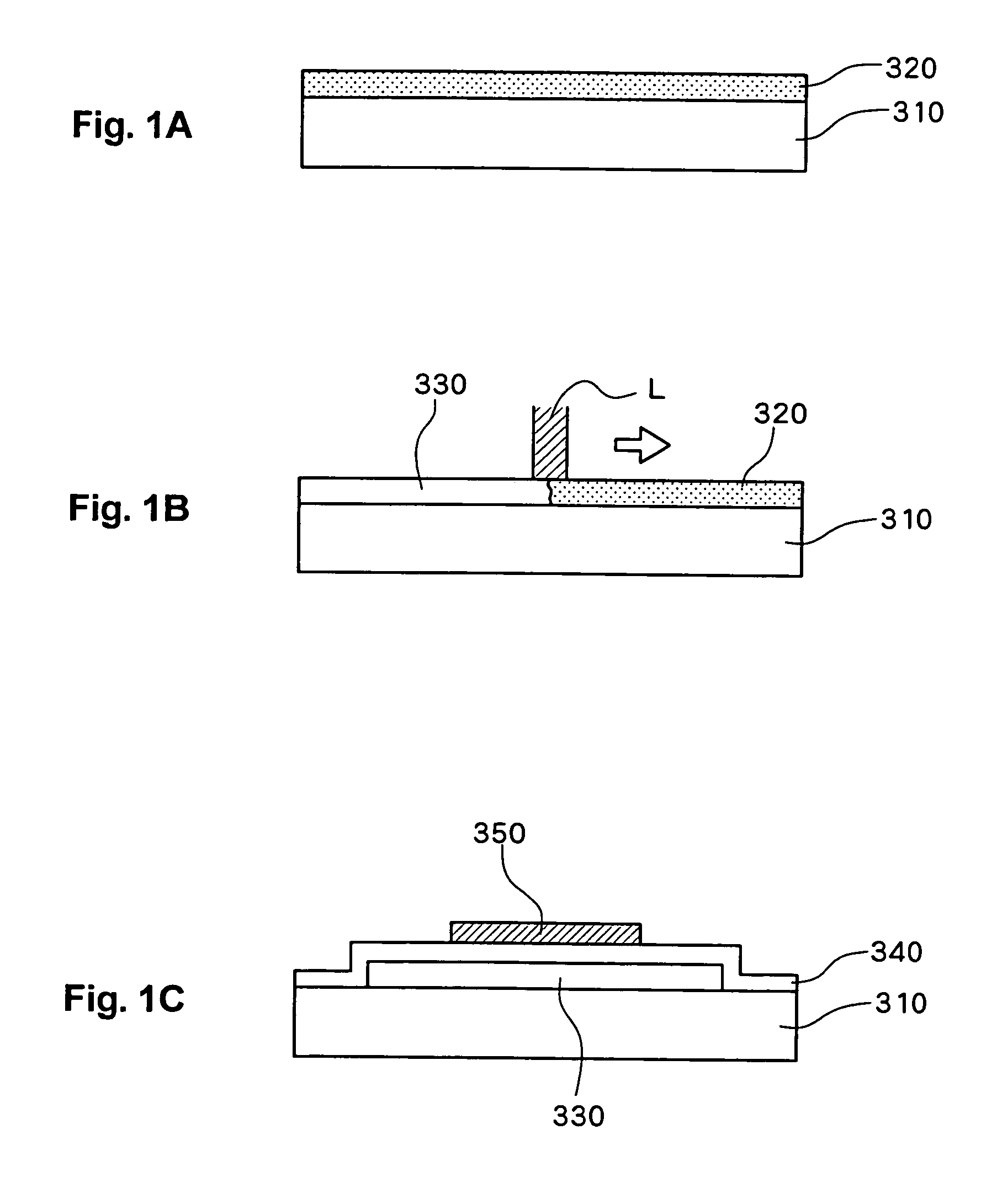

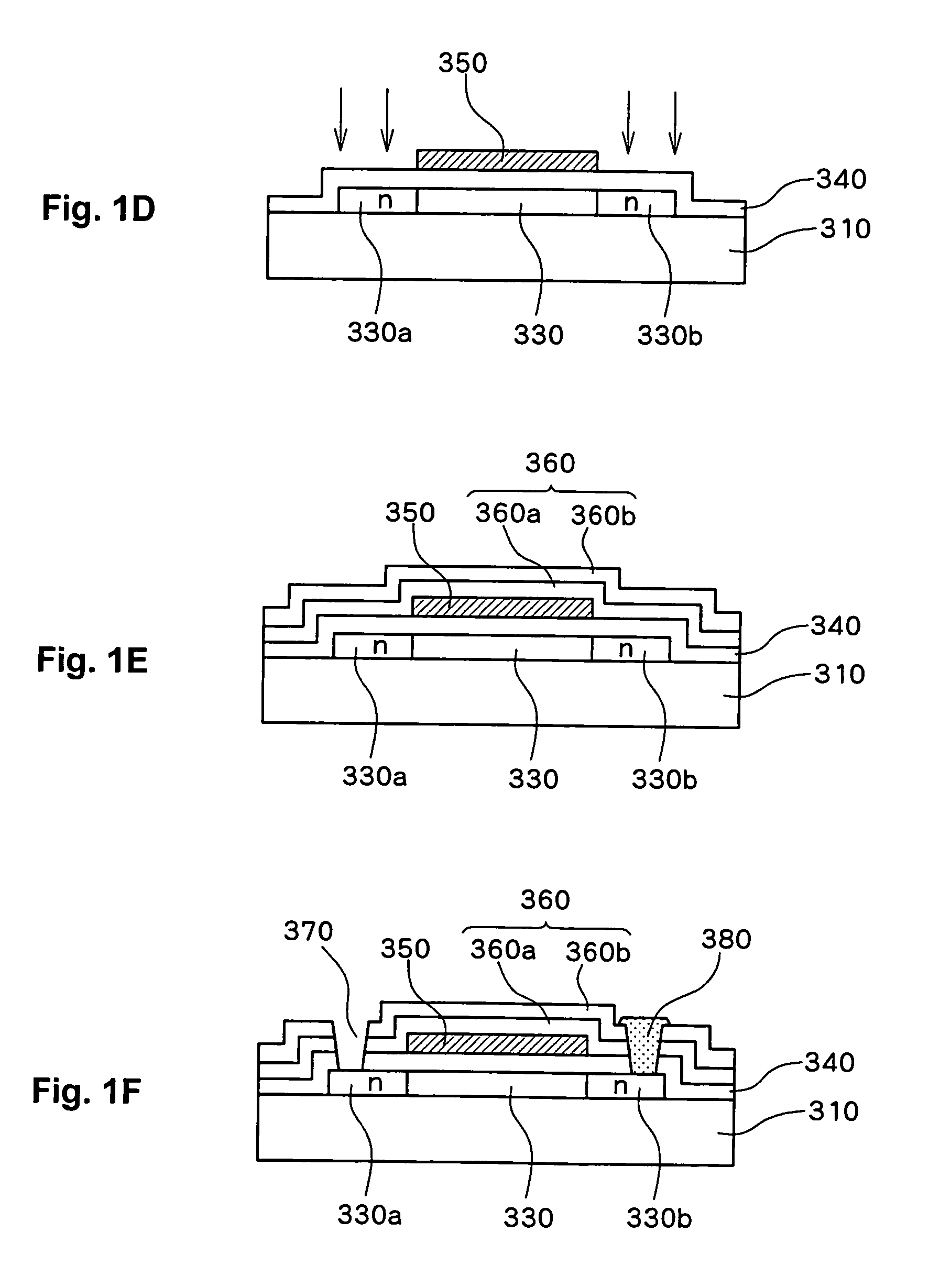

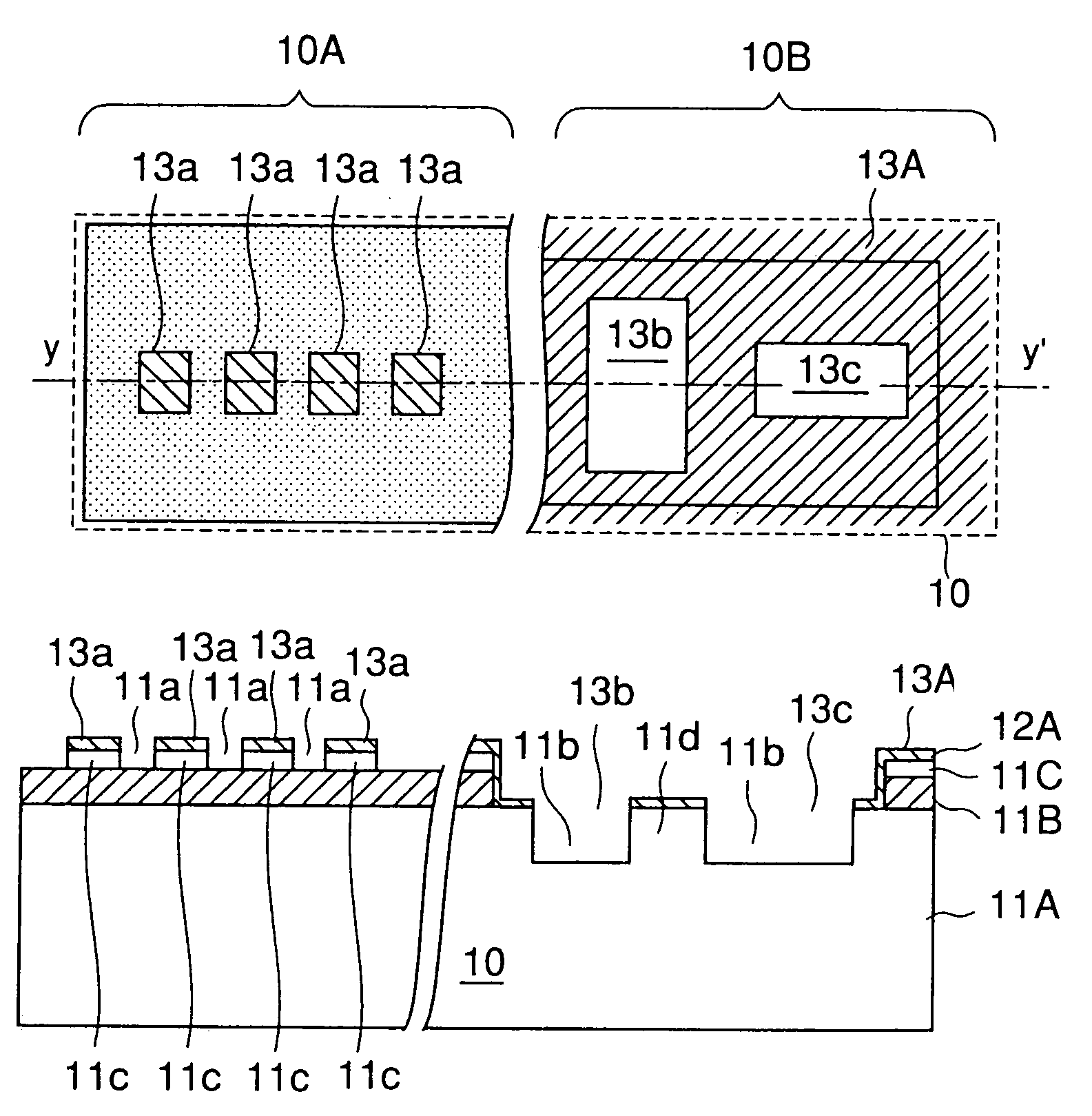

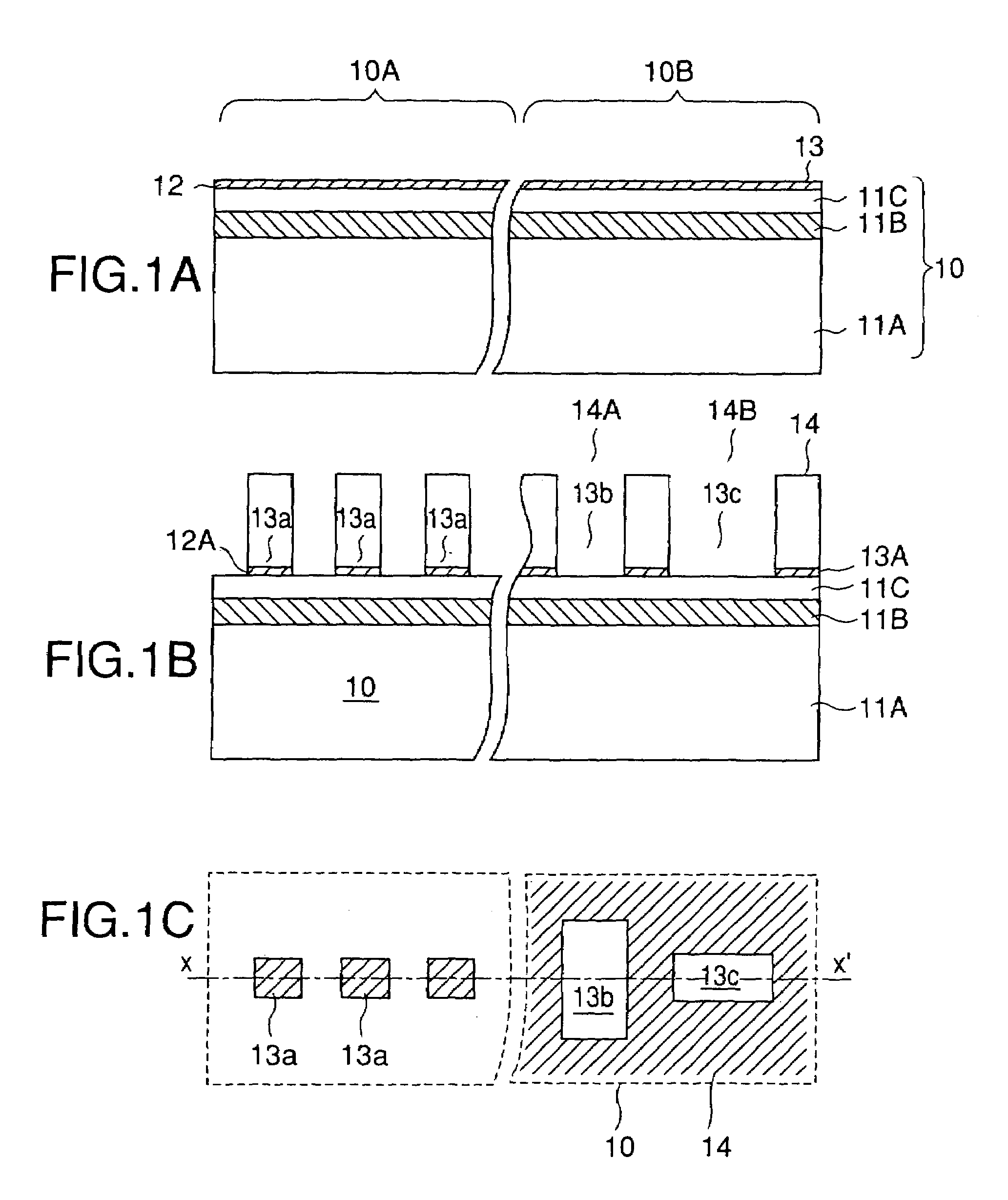

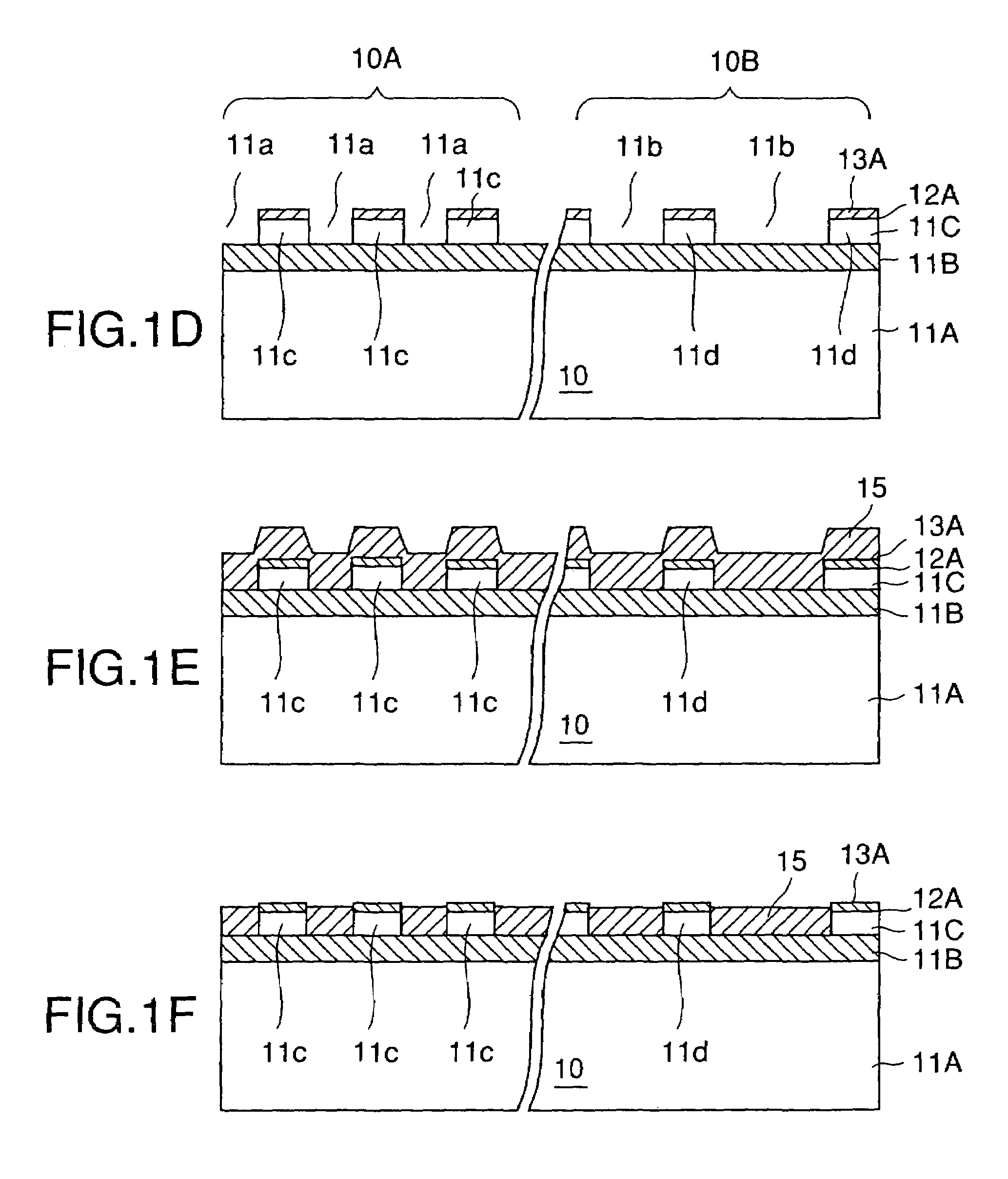

Thin film transistor and active matrix type display unit production methods therefor

A first contact hole is formed penetrating a gate insulating film, on which a gate electrode is formed and simultaneously a first contact is formed in the first contact hole. A second contact hole penetrating an interlayer insulating film is formed, and a second contact is formed in the second contact hole. A third contact hole is formed penetrating a planarization film, and an electrode is formed in the third contact hole. By using a plurality of contact holes for electrically connecting the electrode and a semiconductor film, the aspect ratio of each contact hole can be reduced, thereby achieving improvement in yield, high-level integration due to a reduction in difference in area between upper and bottom surfaces of the contact, and other advantageous improvements.

Owner:SANYO ELECTRIC CO LTD

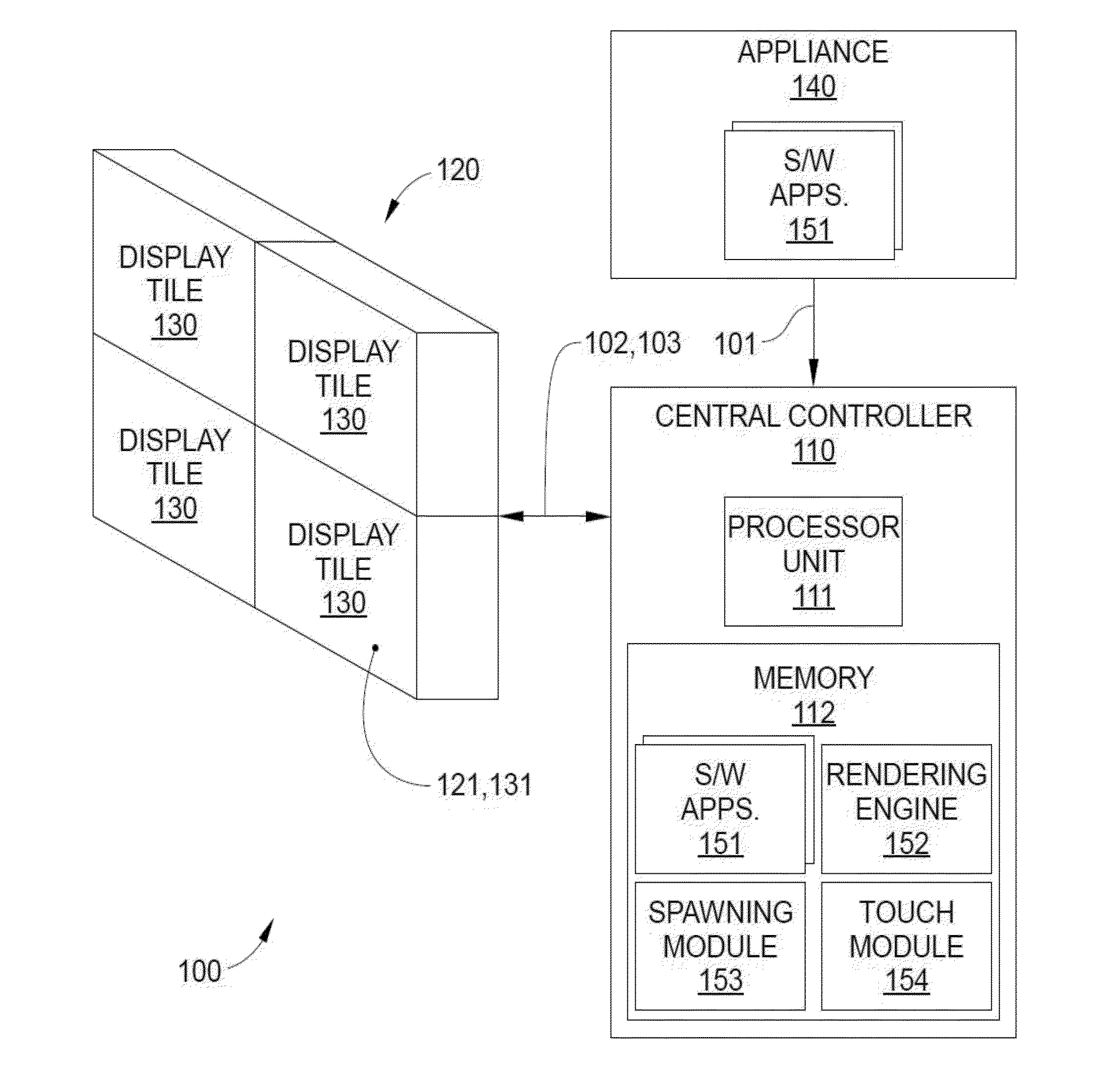

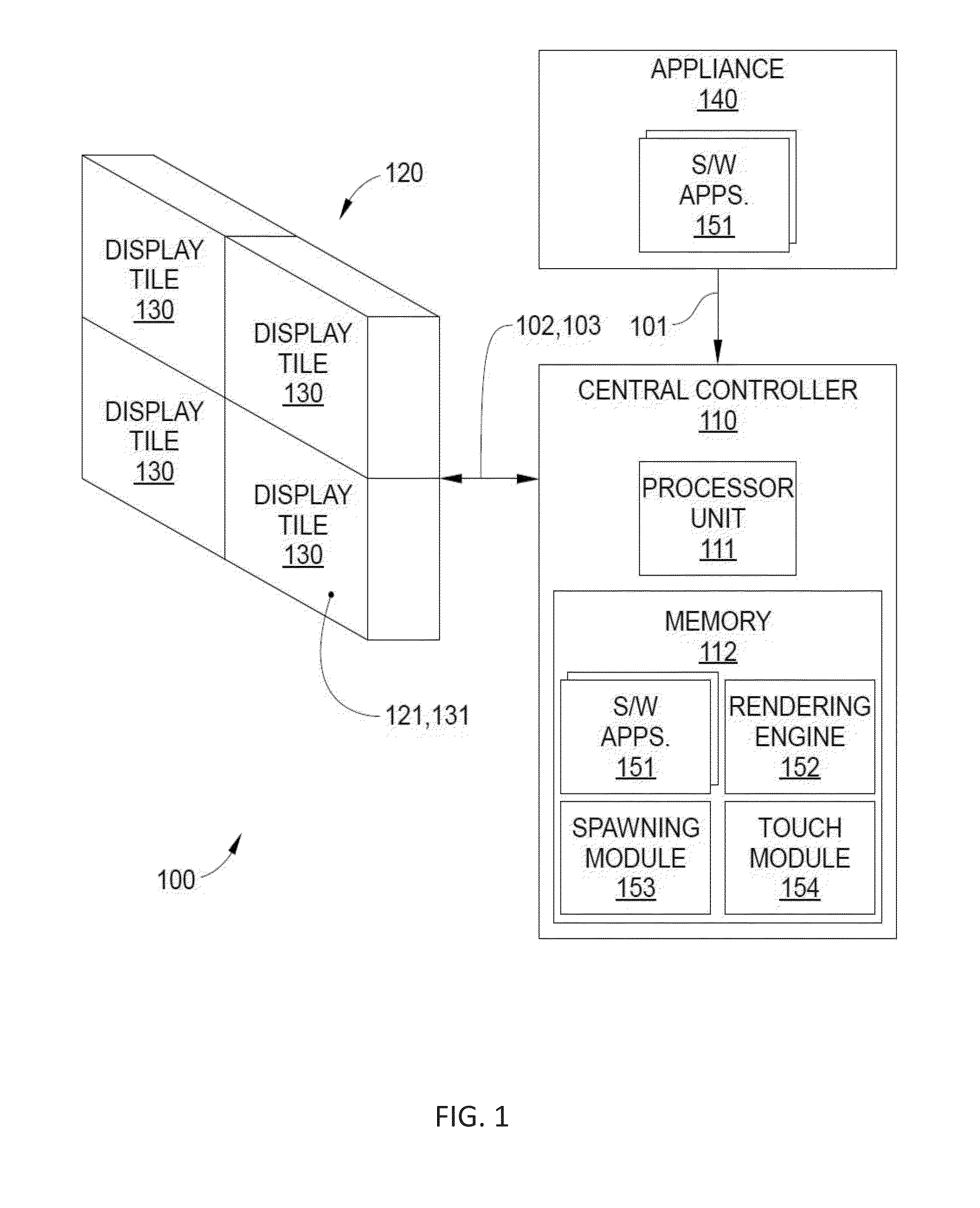

Content sharing with consistent aspect ratios

ActiveUS20160232647A1Small aspect ratioLess is lostGeometric image transformationDigital output to display deviceDisplay deviceWorkspace

An appliance device to display a workspace with an aspect ratio assigned to the workspace, regardless of the aspect ratio of a local display. The appliance device displays only a portion of the workspace in a viewport window at one time. The appliance device also displays a preview version of the entire workspace. The preview version comprises a user-interface tool which enables panning of the workspace in the viewport window. A presenter device makes a presentation while interacting with a workspace while viewer devices watch the presentation. A viewer device displays the workspace with the assigned aspect ratio and displays only portion of the workspace at one time. When the presenter device interacts with a location of the workspace, the presenter device operates in conjunction with a messaging infrastructure and the viewer devices to automatically cause each of the viewer devices to display the location of interaction in the workspace.

Owner:SOCOCO LLC

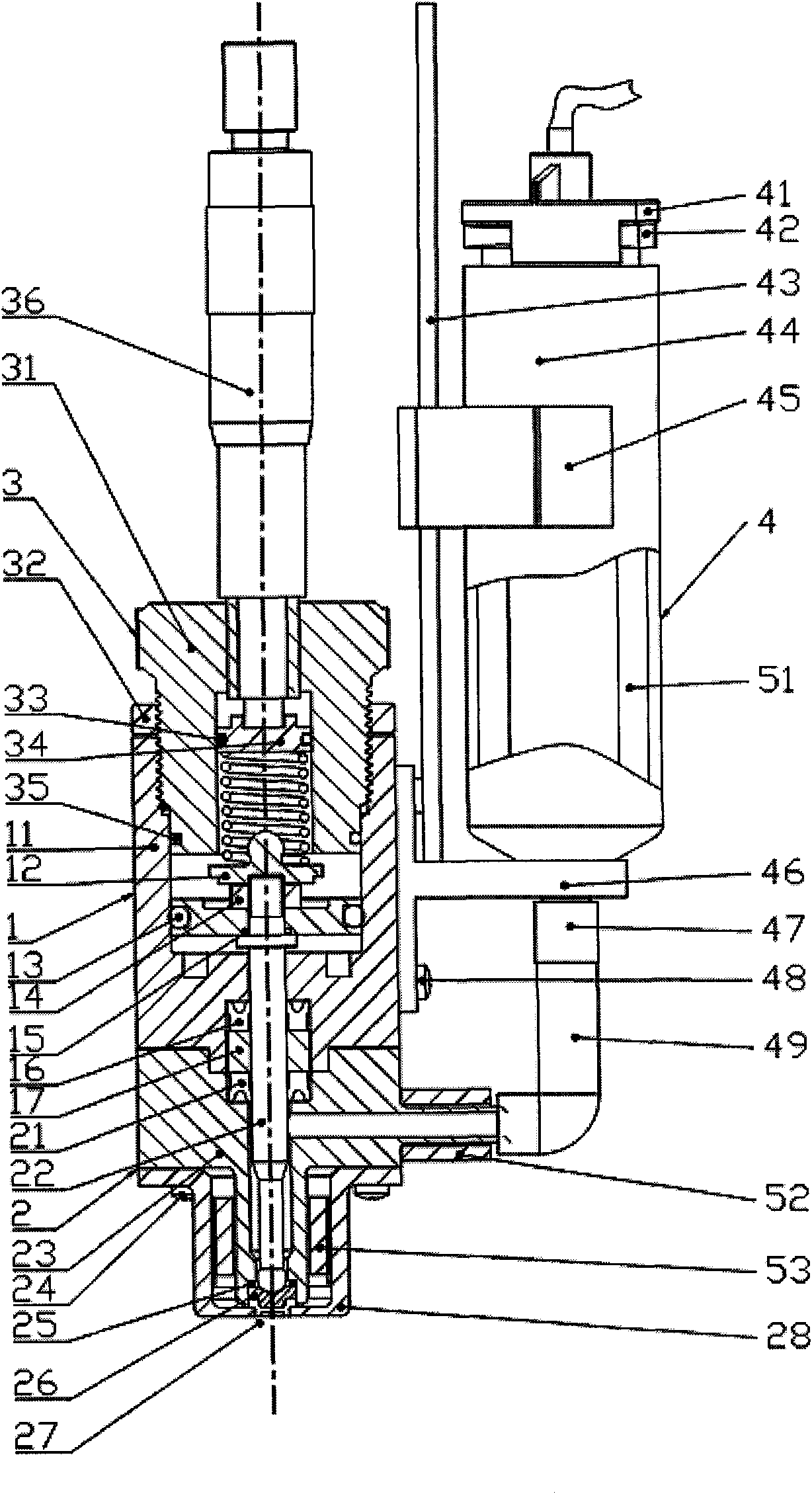

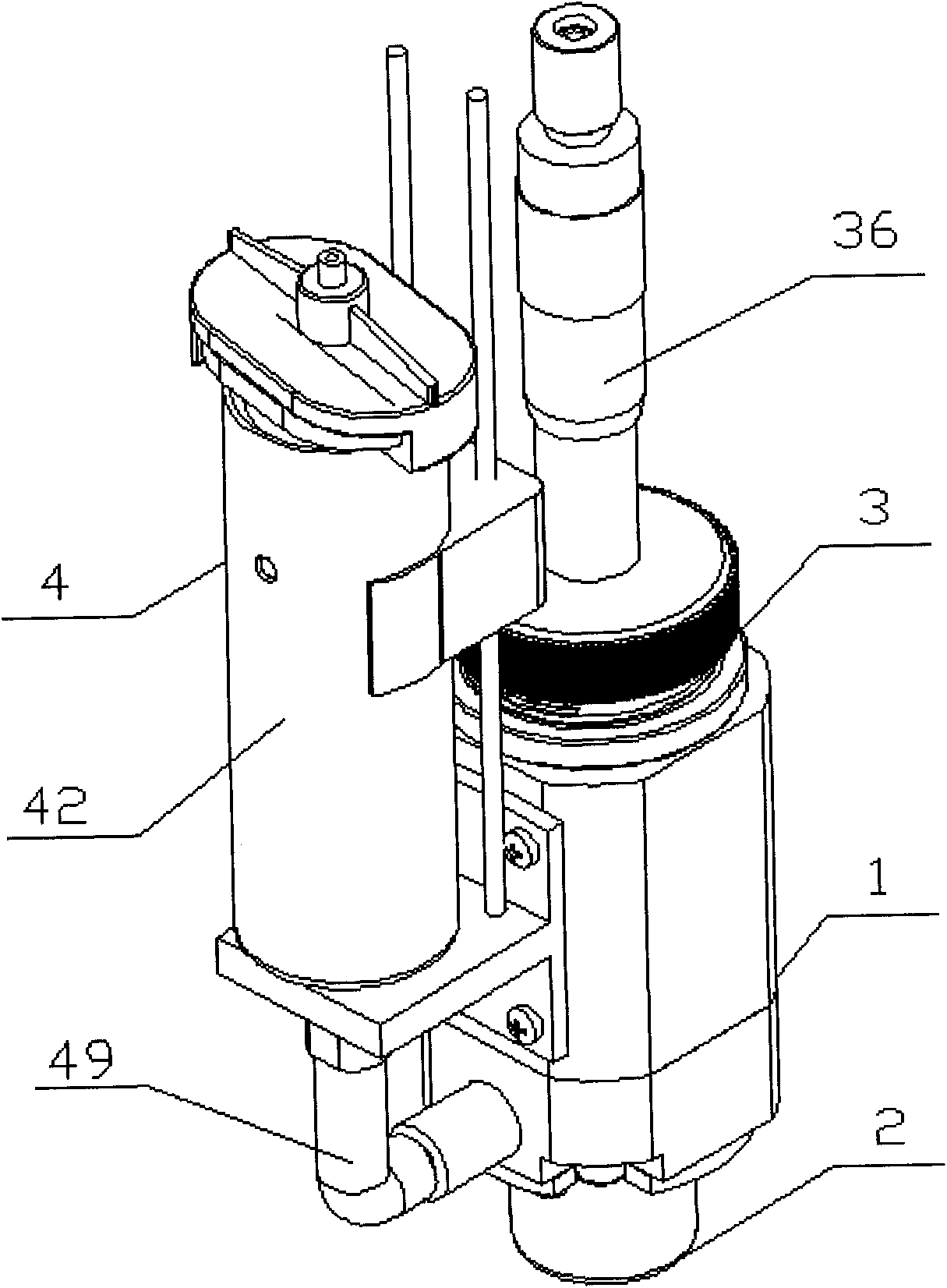

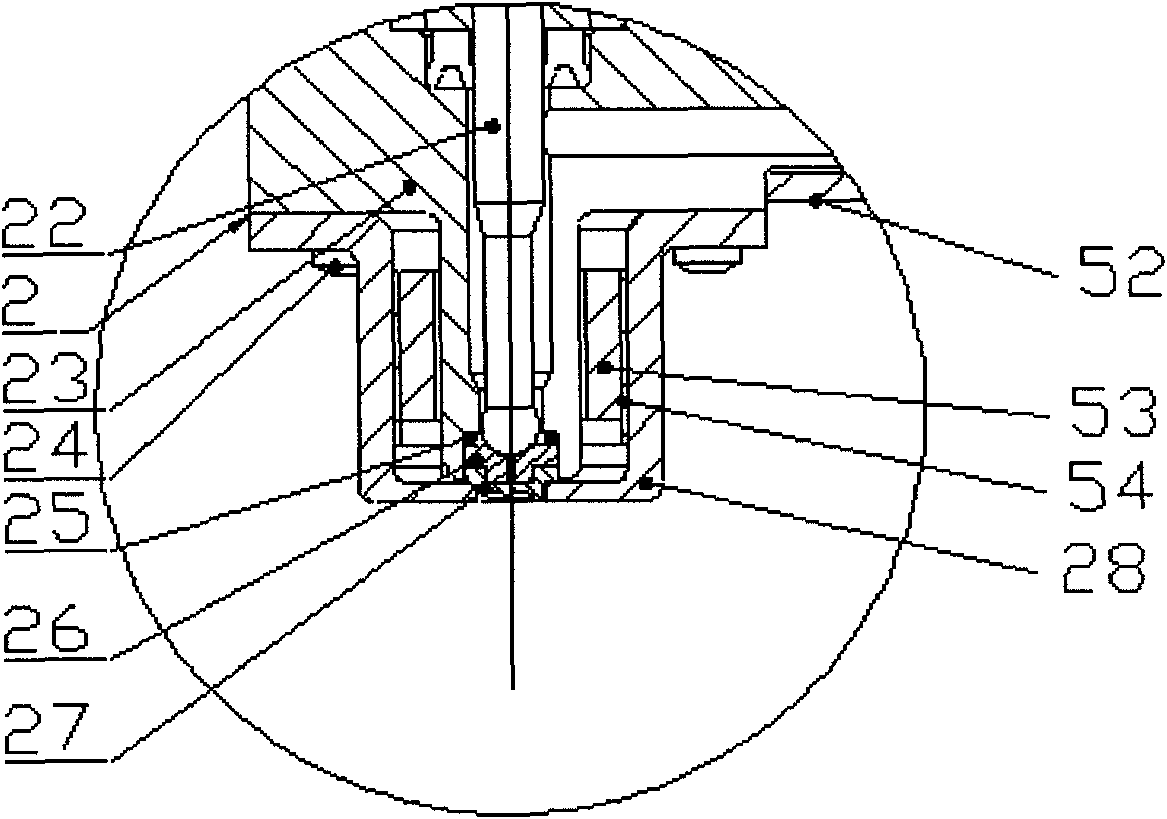

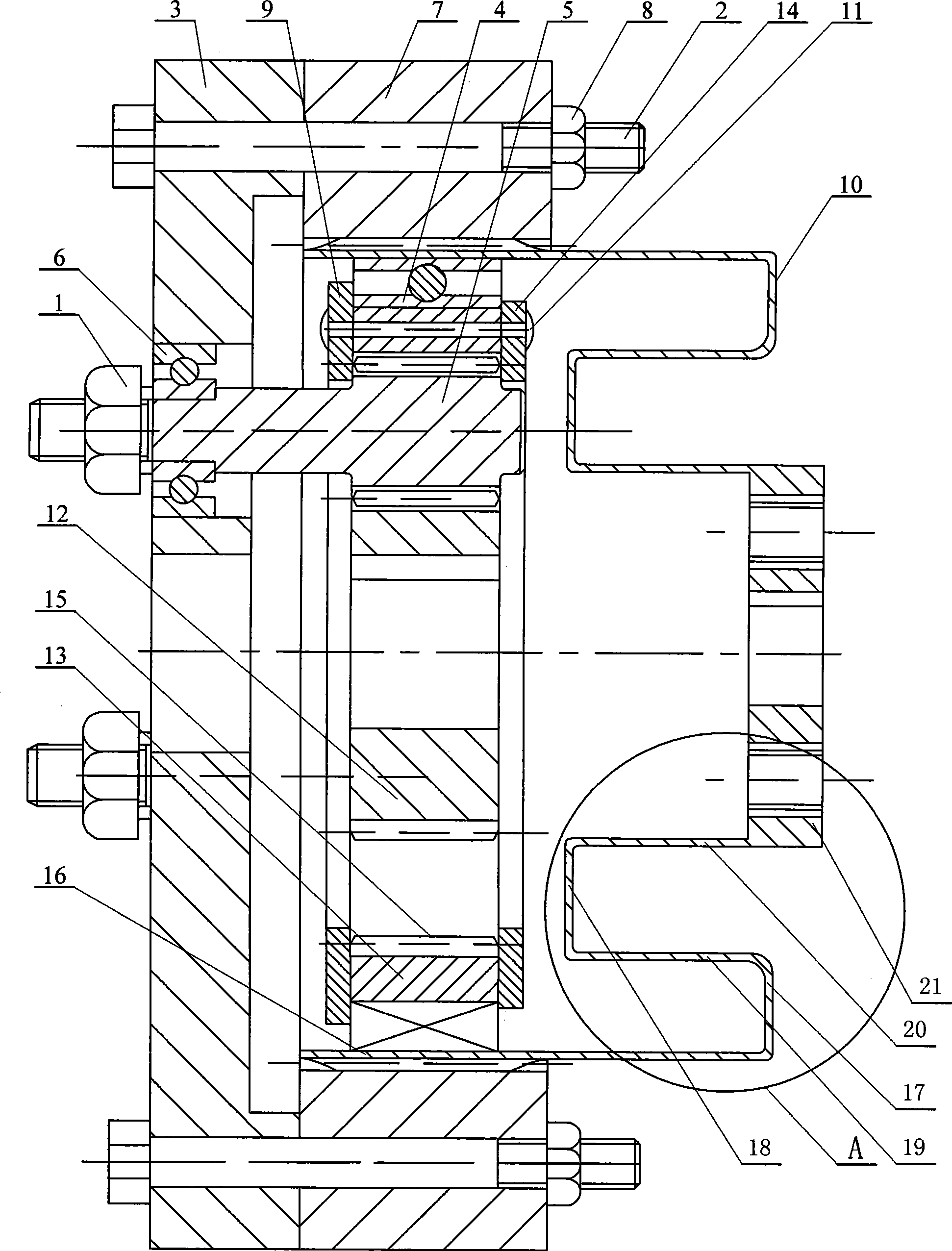

Ejecting adhesive dispenser based on dual-function cylinder

InactiveCN101844124AExtrude quicklyIncrease supplementLiquid surface applicatorsCoatingsThree stageDual function

The present invention provides an ejecting adhesive dispenser based on a dual-function cylinder, which comprises a driving mechanism, an ejecting mechanism, an adhesive supplying mechanism and a heating device. A device for a fine route tuning and a pre-pressure adjustment is arranged on the upper portion of the driving mechanism; the lower end of the driving mechanism is connected with the ejecting mechanism; the adhesive supplying mechanism is arranged on the side wall of the driving mechanism and connected with the ejecting mechanism via a feeding pipeline; and a three-stage heating device is provided around the head of the ejecting mechanism, the feeding pipeline and a feeding container. The driving mechanism comprises a dual-function cylinder and a returning spring; the ejecting mechanism comprises an ejecting needle integrated with the piston rod of the cylinder, a lower valve body and an ejecting head; and the ejecting head comprises an ejecting nozzle base, an ejecting nozzle and a clamping sleeve cup. The invention realizes the dispensing of high-viscosity fluid and has the advantages of micro amount, high speed, high frequency, no contact, high precision, high reliability, low cost and low requirements on processing precision.

Owner:SHANGHAI UNIV

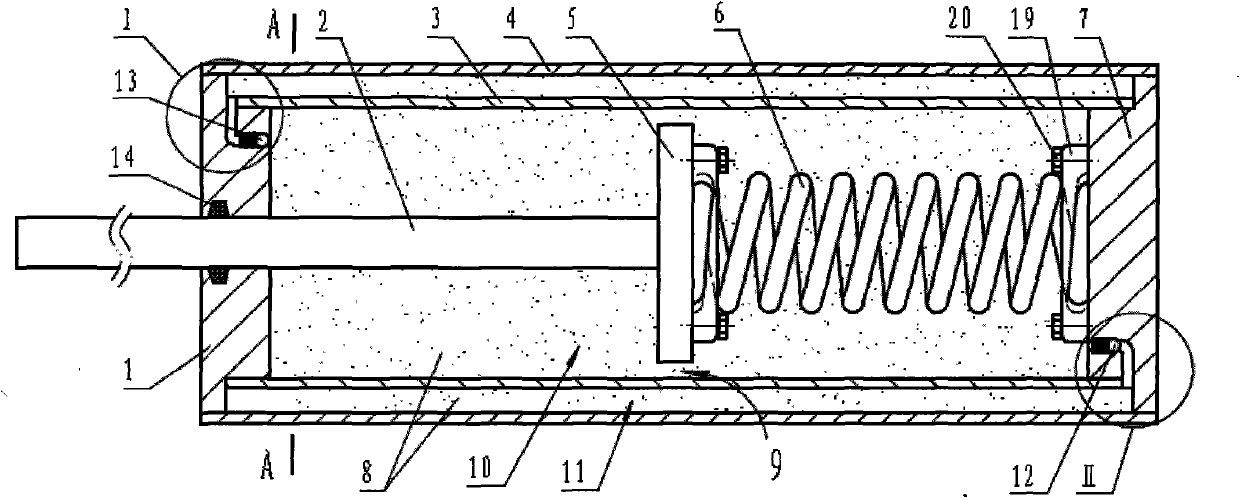

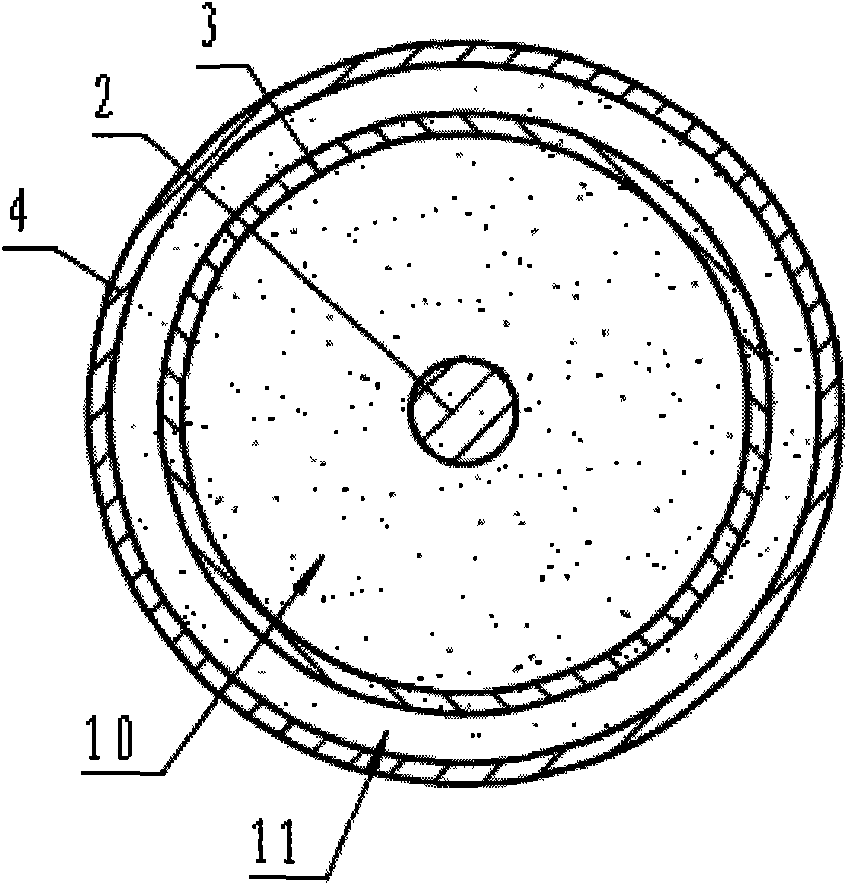

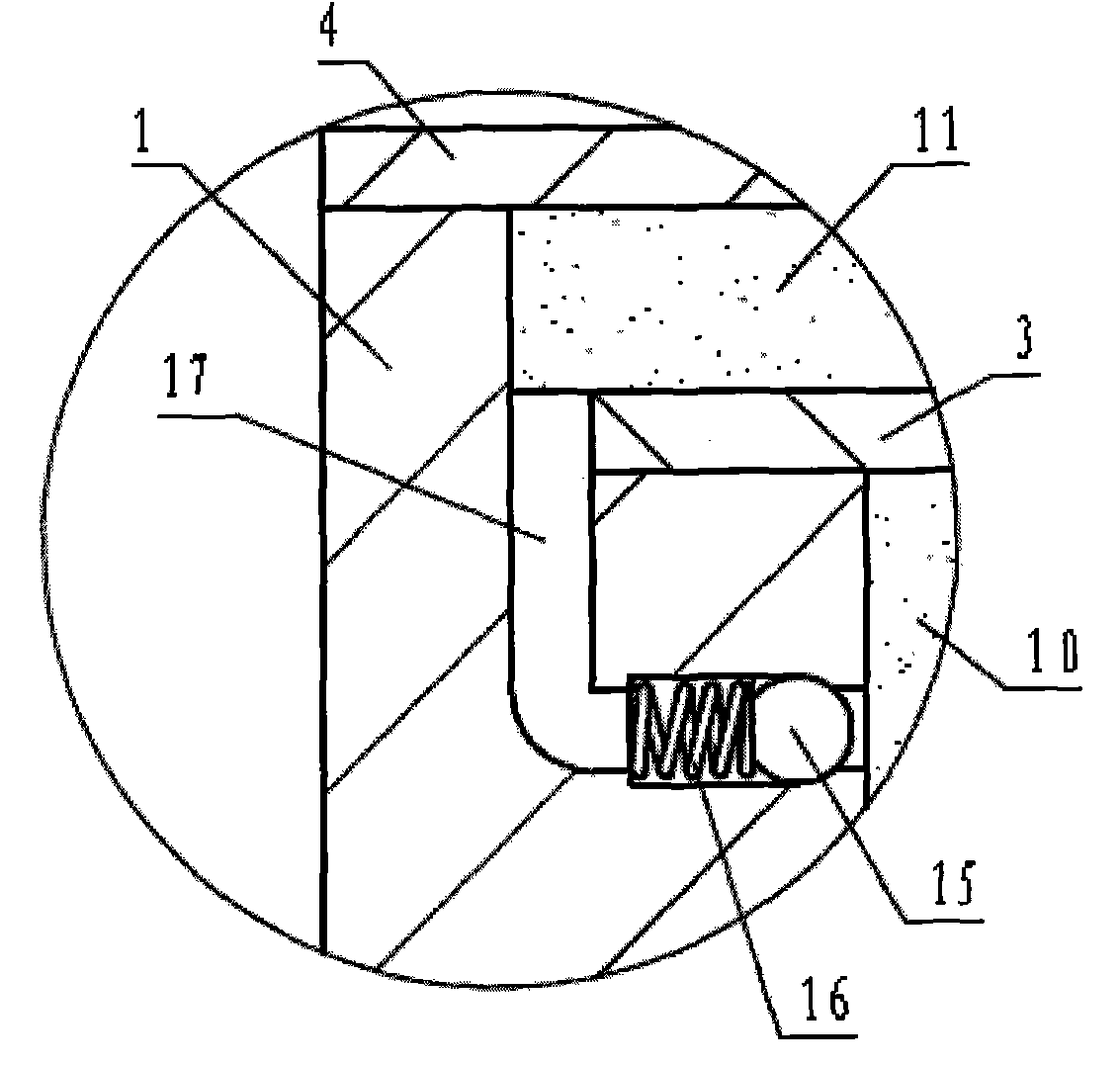

Composite damping single-piston rod viscous damper

InactiveCN101994775AShorten design lengthSmall aspect ratioSpringsShock absorbersViscous dampingBuilding unit

The invention relates to a vibration-proof building unit, in particular to a composite damping single-piston rod viscous damper. The damper is a single-piston rod viscous damper and is characterized in that: a piston rod (2) of the single-piston rod viscous damper passes through a left end cover (1) through a working cylinder (10) on the left of a piston (5); a cylindrical spiral spring (60 is arranged in the working cylinder (10) on the right of the piston (5); one end of the spring is fixed on a right end cover (7), while the other end is fixed to the end face of the piston (5); an outer cylinder barrel (4) is sleeved outside an inner cylinder barrel (3) of the working cylinder (10); the left end cover (1) and the right end cover (7) are respectively arranged at two ends of the outer cylinder barrel (4), so that a gap between the inner cylinder barrel (3) and the outer cylinder barrel (4) forms a compensation cylinder (11); one one-way valve (13) is arranged in the body of the left end cover (1); and another one one-way valve (12) is arranged in the body of the right end cover (7). The viscous damper can simultaneously provide viscous damping and elastic damping in the whole moving process of the piston.

Owner:GUANGZHOU UNIVERSITY

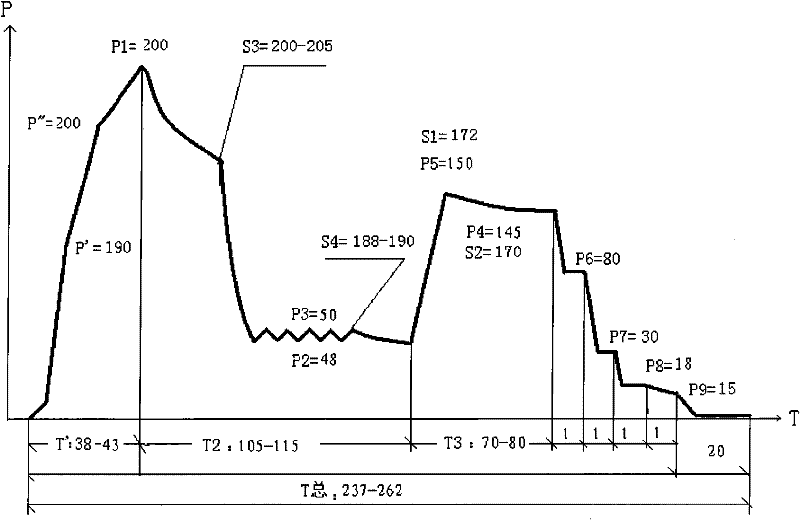

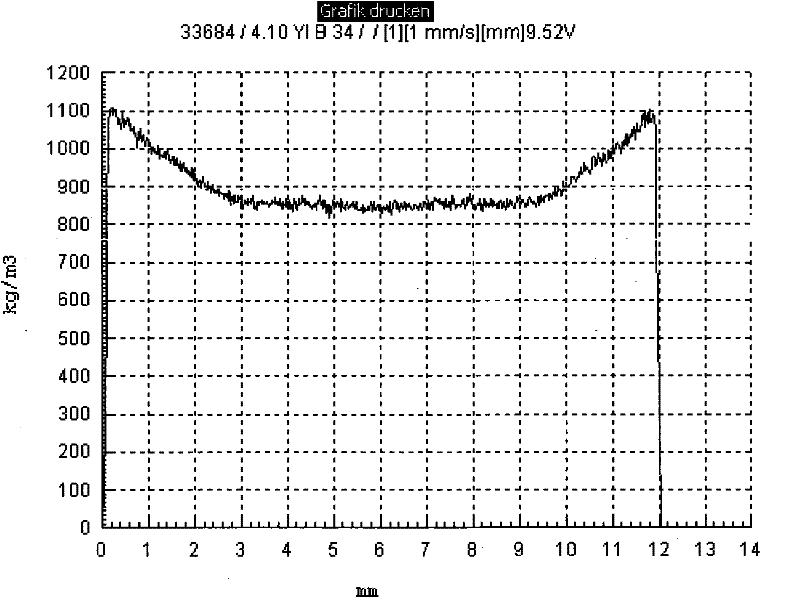

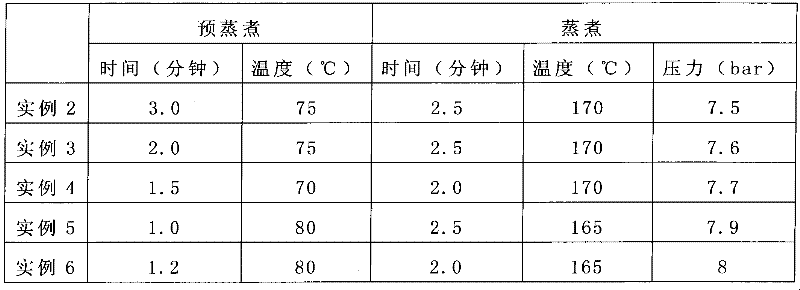

Manufacturing method of high density fiberboard for whitened type E1 grade floor substrate

InactiveCN102407553ASmall aspect ratioReduce cellulose contentWood working apparatusFlat articlesHexamethylenetetraminePhosphoric acid

The invention relates to a manufacturing method of a high density fiberboard for a whitened type E1 grade floor substrate, which comprises the steps of wood chipping and screening, pre-stewing and stewing, defibrator process for causing fiber separation, concoction of E1 grade urea formaldehyde resin glue, curing agent preparation, the application of urea-formaldehyde glue, curing agents and paraffins, drying, paving, hot pressing, cooling and tempering, and sanding and saw cutting, and is characterized in that woods are selected from major diameter cottonwoods with diameters larger than 8cm, are evenly chipped and are then placed in an outdoor storage yard to be fermented for 5 to 15 days; in the concoction process of the E1 grade urea formaldehyde resin glue, urea is added at 5 times; and the curing agents are formed by preparing phosphoric acid accounting for 3 to 5 percent of the total content, urotropin accounting for 1 to 3 percent of the total content, triethanolamine accounting for 1 to 3 percent of the total content, and ammonium sulfate accounting for 19 to 21 percent of the total content. The obtained whitened type E1 grade floor substrate has the advantages of little surface impurity, fine and smooth fiber, white color, good visual effect, reasonable density distribution and moderate intensity, and is frequently used for producing top grade indoor laminate flooring and composite floors.

Owner:DARE TECH

Specific crystallizer casting powder for sulphur free-cutting steel and production method thereof

The invention discloses a specific crystallizer casting powder for sulphur free-cutting steel and production method thereof, mass percents of chemical components thereof are as follows: 29-35% of CaO, 25-30% of Sio2, 2-5% of MgO, 3-5% of Al2O3, 2-6% of Fe2O3, 5-11% of NaO?, 0-2% of Li2O, 5-9% of CaF2?, 0-5% of MnO, 0.5-2.0% of Al grey, 0-2% of B2O3, 5-11% of solid carbon, and allowance is building material adhesive and water. The sulphur free-cutting steel has low high-temperature strength and high crack sensitivity, and the casting powder should have properly high basicity. Basicity of a slag is improved, so that diffusion velocity is accelerated, and absorption of impurities in molten steel is benefited. So, improvement of basicity is an effective means for improving absorption of the impurities and control of surface longitudinal crack.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

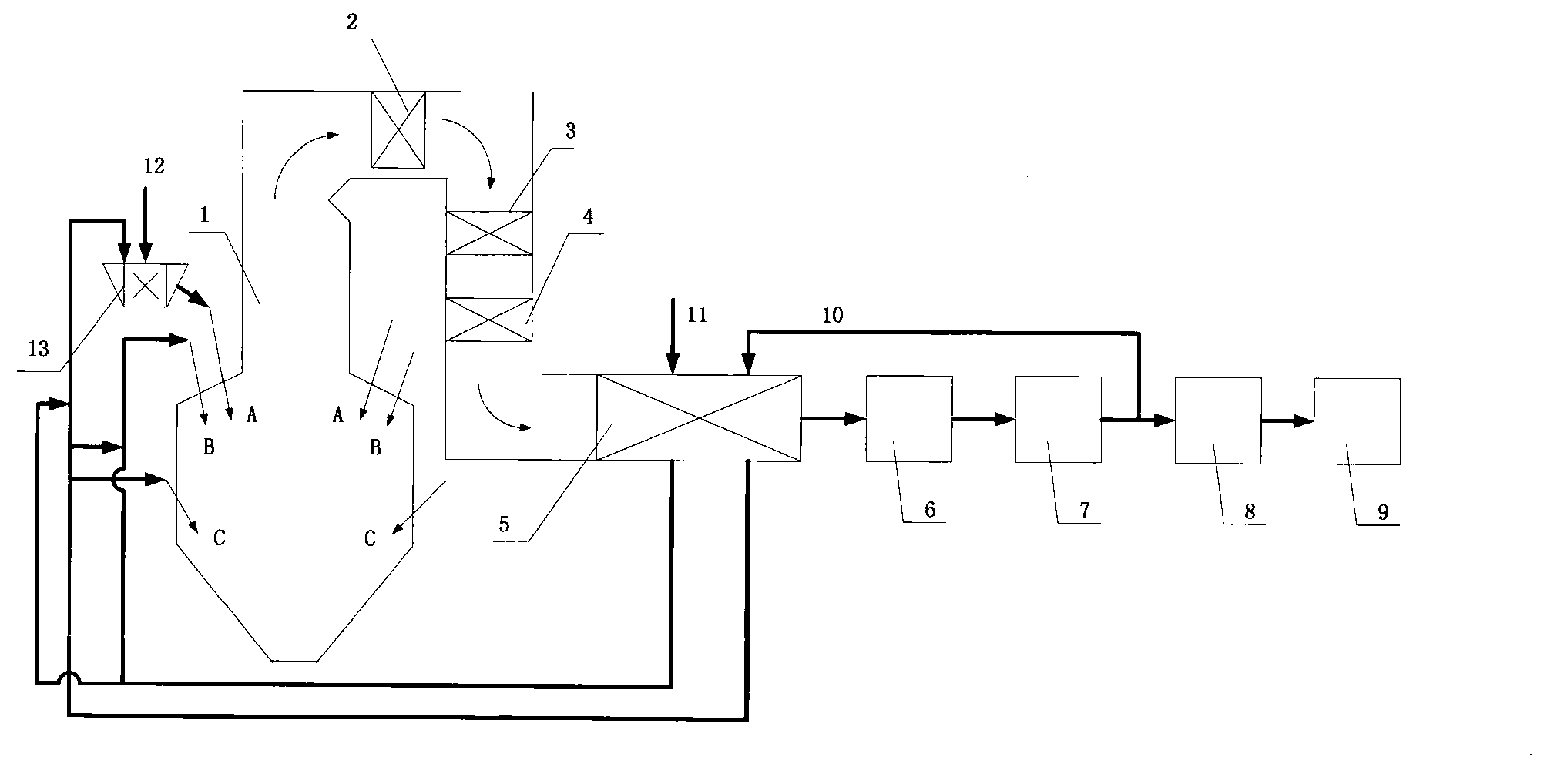

Oxygen-enriched combustion W-shaped flame boiler system and combustion process thereof

ActiveCN103017151AImprove fire conditionsIncreased radiant heat absorption areaIndirect carbon-dioxide mitigationCombustion apparatusSlagFlue

The invention provides an oxygen-enriched combustion W-shaped flame boiler system and a combustion process thereof. Flue gas discharged from a dewaterer is divided into two strands, wherein one strand of flue gas sequentially enters a desulfurization device and a CO2 recovery device and the other strand of flue gas enters a gas-gas heat exchanger and is heated by flue gas in a main flue; the flue gas in the main flue also heats O2 separated in the air when heating the recycled flue gas; the heated recycled flue gas is divided into three strands; O2 is divided into two strands; after the first strand of O2 is mixed with the first strand of recycled flue gas, the mixed gas enters a coal mill and enters a primary air pipeline; after the second strand of O2 is mixed with the second strand of recycled flue gas, the mixed gas enters a furnace arch secondary air pipeline; and the third strand of recycled flue gas enters a front and rear wall secondary air pipeline The system provided by the invention overcomes the defects in the prior art and greatly improves ignition conditions of a hearth; when the radiation and heat adsorption area of a lower hearth is effectively increased, slag-bonding possibility is greatly reduced; efficiency of the integral system is improved; steel consumption and manufacturing cost of a boiler are reduced; and zero emission of CO2 can also be realized.

Owner:SHANGHAI BOILER WORKS

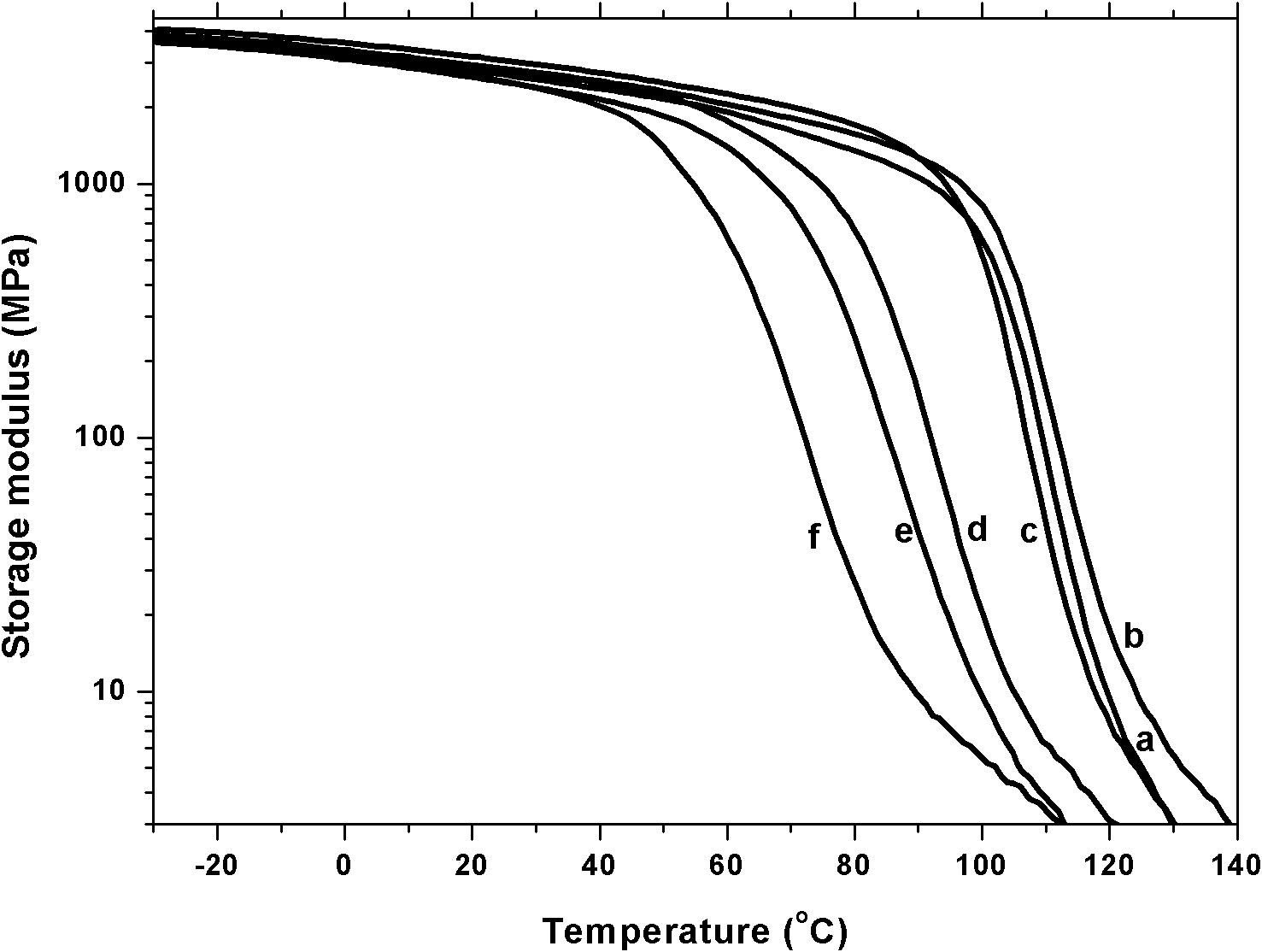

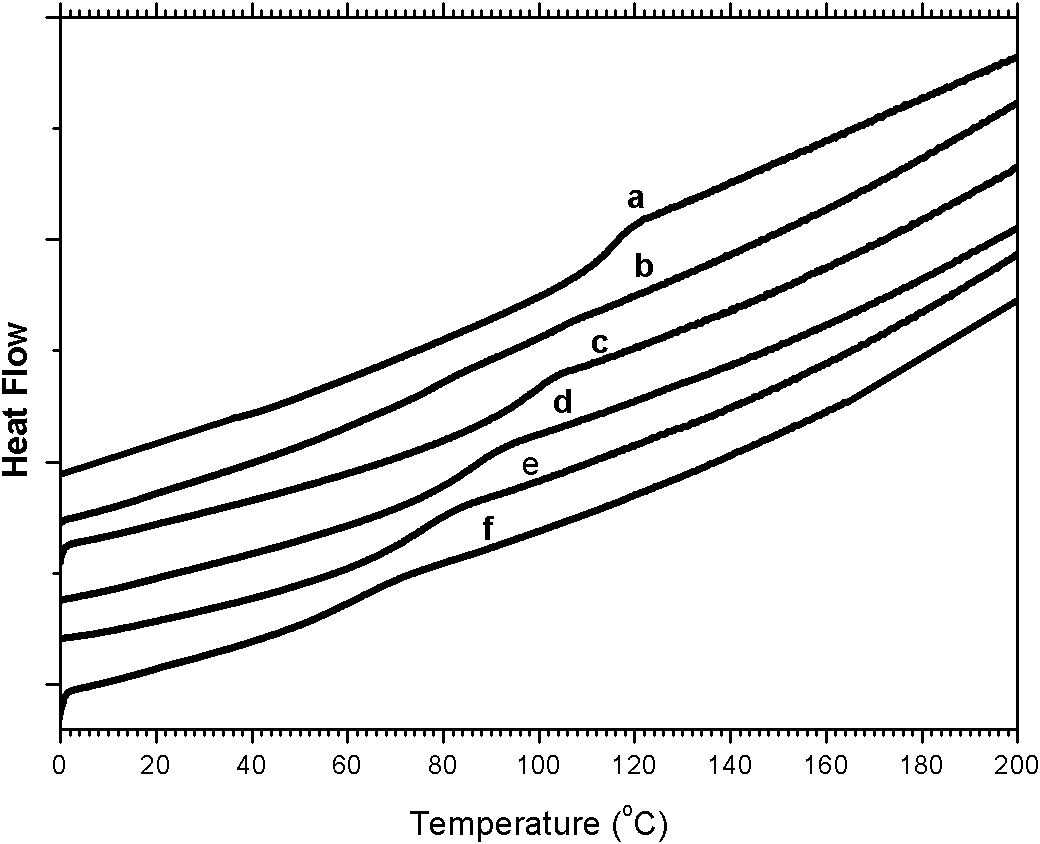

Carbon-nanotube-containing polymer nanocomposite and preparation method thereof

The invention discloses a carbon-nanotube-containing polymer nanocomposite, which comprises the following components in parts by mass: 1 part of carbon nanotube, 0.5-10 parts of ionic liquid and 5-2,000 parts of polymer. The invention further discloses a preparation method of the nanomaterial. The invention has the advantages that: (1) the carbon nanotube is coated with the ionic liquid, so that the conjugated structure of the carbon nanotube is not broken and superior physical property of the carbon nanotube per se is kept; (2) strong mechanical action is not used, so that fracture of the carbon nanotube is not caused and the length-diameter ratio of the carbon nanotube is lowered; and (3) the method for preparing the carbon-nanotube-containing nanocomposite has a small number of steps and high efficiency, is implemented without any other chemical reagents, and is simple, practicable and environment-friendly.

Owner:江苏清材智能制造有限公司

Hemi-membrane substrate integrated waveguide

Owner:SOUTHEAST UNIV

Through silicon via (TSV) structure and manufacturing method thereof

ActiveCN102623437AAvoid damageStrong blocking abilitySemiconductor/solid-state device detailsSolid-state devicesConductive materialsEngineering

The invention relates to a TSV structure and a manufacturing method thereof, which include forming a window in a former medium layer and a semiconductor substrate, and forming a second blocking layer in the window before forming a plurality of interlayer medium layers; forming a through hole after forming the plurality of the interlayer medium layers, wherein the hole diameter of the through hole is smaller than that of the window after the second blocking layer is formed, accordingly, surplus initial filling medium layer forms a filling medium layer between the through hole and the window after the second blocking layer is formed; forming a first blocking layer and through hole metal in the through hole afterwards, so that a three layer isolating structure comprising the first blocking layer, the filling medium layer and the second blocking layer is formed between the through hole and the semiconductor substrate. The continuity of the isolating structure is improved, the problem of the degradation of semiconductor devices caused by the fact that conductive materials of the through hole metal diffuse into the semiconductor substrate is further effectively solved, and the reliability of semiconductor devices is improved.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

Planetary-harmonic composite gear reducer

ActiveCN101545524ASmall aspect ratioIncrease the reduction ratioToothed gearingsAviationBall bearing

The invention relates to a planetary-harmonic composite gear reducer, which relates to a reducer, and aims at the problems that the prior cup-shaped harmonic reducer has small reduction ratio, large axial size, large volume, large mass and the like. A sun gear is engaged with at least two planetary gear shafts and is arranged in an elliptical internal gear ring of an elliptical cam, the at least two planetary gear shafts are engaged with the elliptical internal gear ring of the elliptical cam to form a primary planetary reduction gear train, the elliptical cam is arranged in a flexible ball bearing, the primary planetary reduction gear train and the flexible ball bearing form a wave generator, the flexible ball bearing is arranged in a flexible gear, the flexible gear is arranged in a rigid internal gear ring and is engaged with the rigid internal gear ring under the action of the wave generator, and a planetary gear shaft arranged in a shaft hole of a tie bar is provided with a rolling bearing. The reducer has the advantages of large reduction ratio, small axial size, small volume, light mass and the like, and is particularly suitable to be applied in the fields such as aviation and space detectors, various instruments and meters, and driving units of precision robots and the like.

Owner:成都川哈工机器人及智能装备产业技术研究院有限公司

Manufacture method of vermicular cast iron steam cylinder cover

InactiveCN102605134AAdjust mechanical propertiesMeet performance requirementsProcess efficiency improvementSulfurManganese

The invention relates to a manufacture method of a vermicular cast iron steam cylinder cover. The vermicular cast iron steam cylinder cover is manufactured by the following ingredients according to the following mixture ratio: 75 percent to 85 percent of foundry returns and 15 percent to 25 percent of waste steel. External desulfurization is carried out after the melting, the melting temperature is controlled to be higher than 1500 DEG C, the weight percent of sulphur in desulfurized molten iron is 0.008 percent to 0.2 percent, and ingredients after the refining comprise 3.70 percent to 3.80 percent of carbon, 1.50 percent to 1.60 percent of silicon, at most 0.30 percent of manganese, at most 0.50 percent of phosphorus and 0.008 percent to 0.012 percent of sulphur. The molten iron can be perfectly subjected to vermicularizing treatment, the vermicularity is controlled to be in a proper range, the influence on the vermicularity caused by sulphur content fluctuation is avoided, the casting rejection caused by unqualified vermicularity is reduced, and the cost is reduced. In addition, the vermicular shape can be perfectly controlled, further, the mechanical performance of the vermicular cast iron can be regulated, and the performance requirement of the steam cylinder cover is met.

Owner:RIYUE HEAVY IND

Semiconductor device and fabrication process thereof

InactiveUS7005755B2Eliminate the problemSmall aspect ratioSemiconductor/solid-state device detailsSolid-state devicesInsulation layerSoi substrate

A semiconductor device formed on a SOI substrate includes isolation trenches formed in a first region and reaching an insulation layer buried in the SOI substrate, and alignment marks formed in a second region and consisting of grooves extending into a support substrate.

Owner:FUJITSU SEMICON LTD

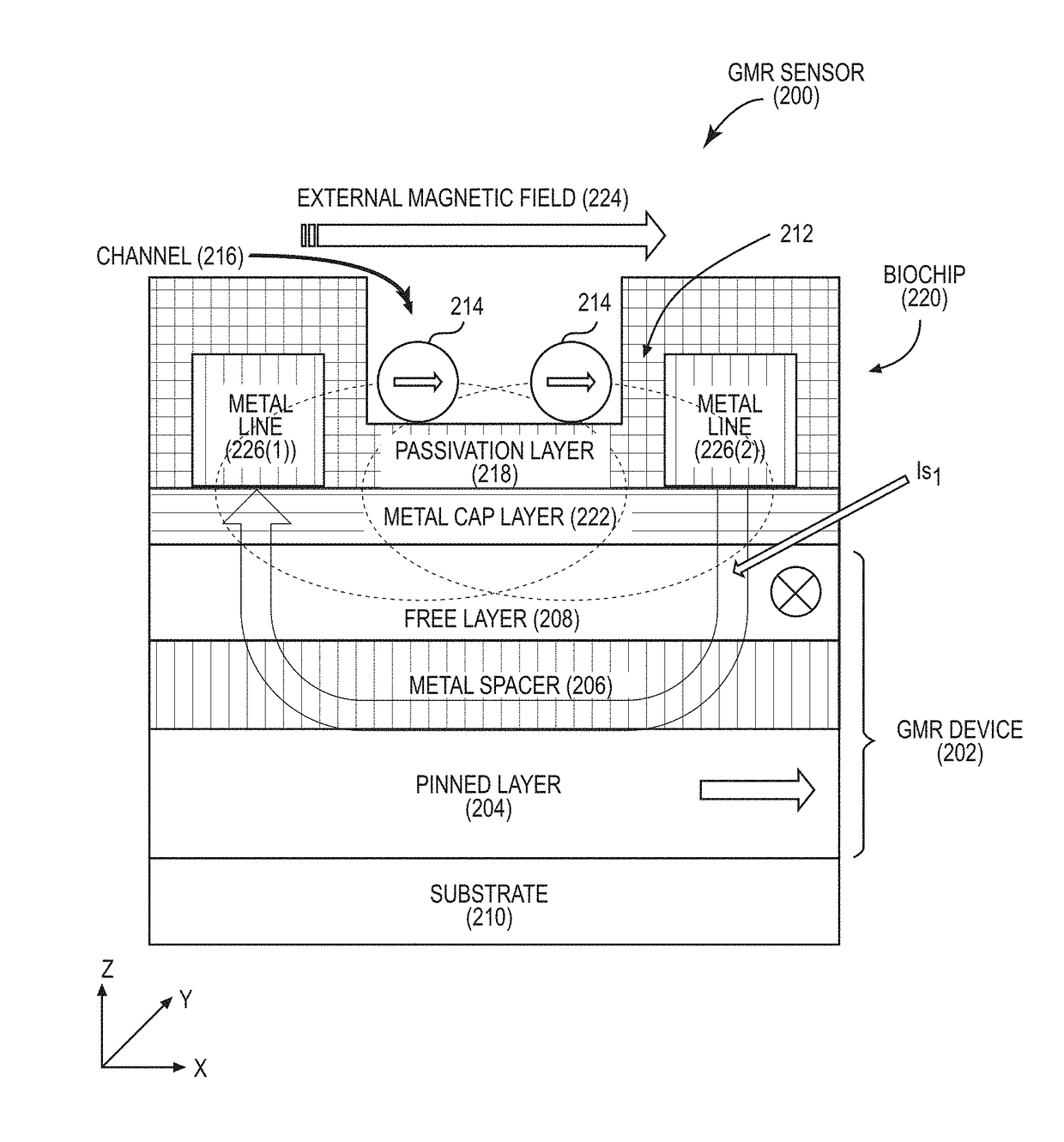

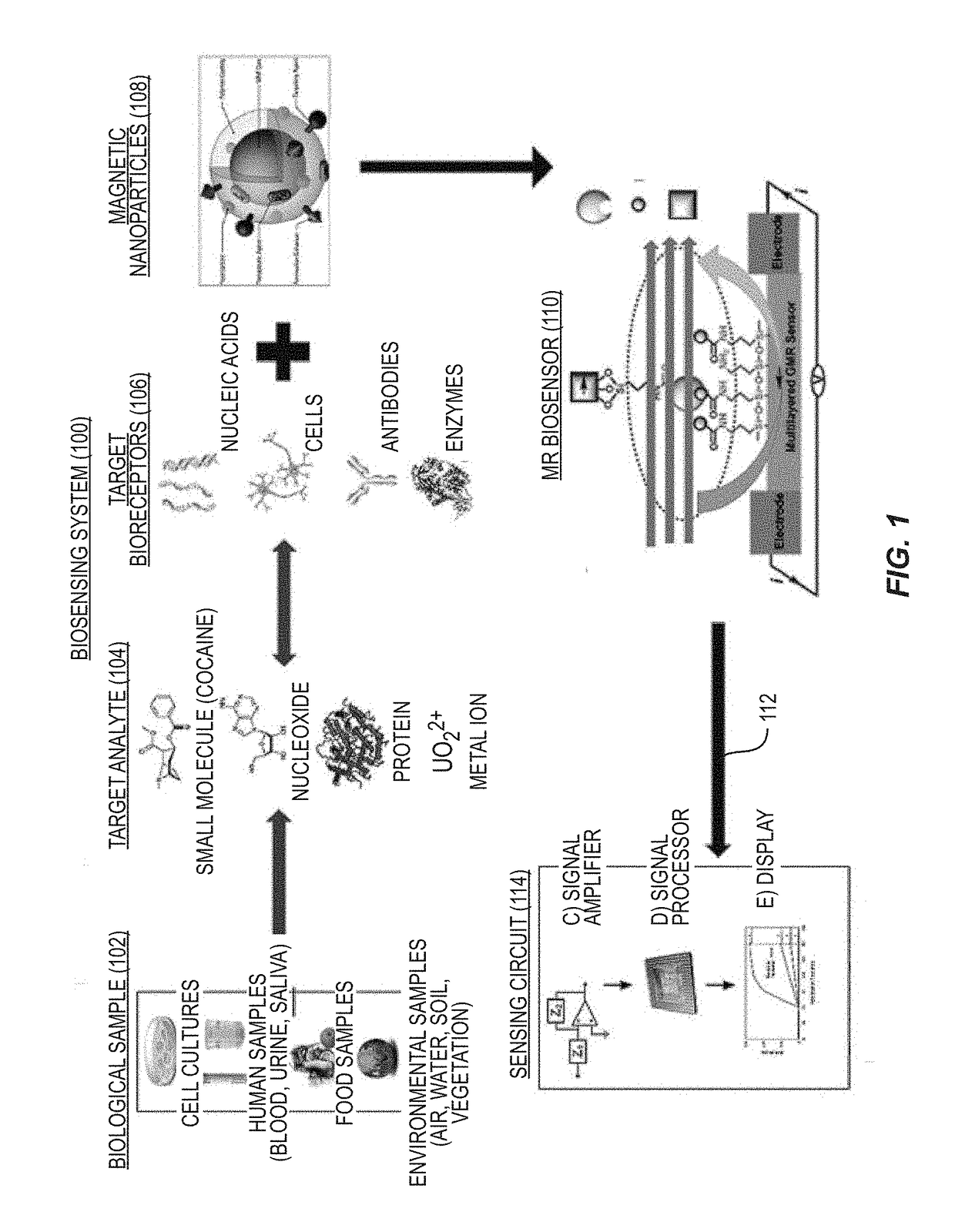

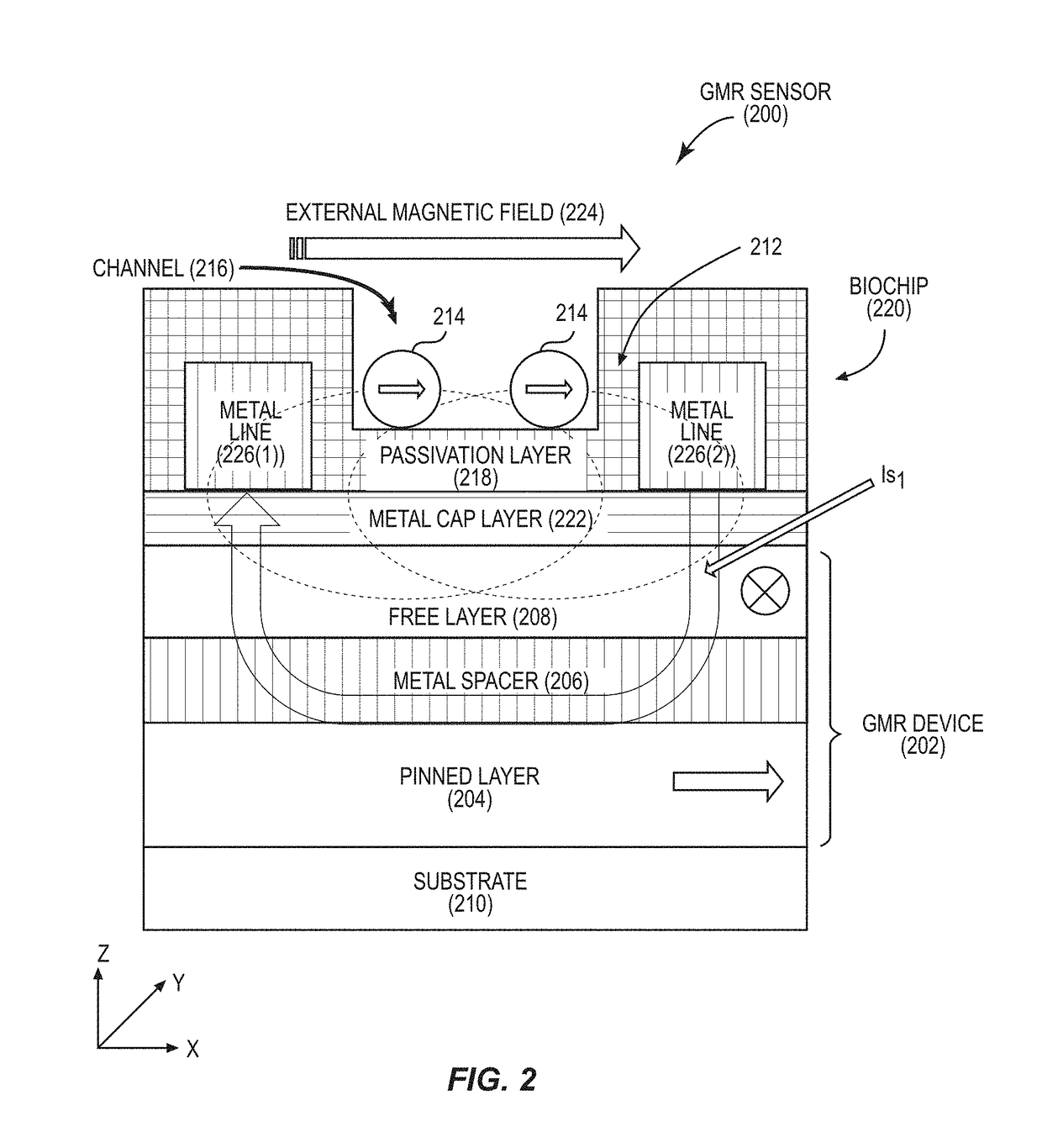

Tunnel magneto-resistive (TMR) sensors employing tmr devices with different magnetic field sensitivities for increased detection sensitivity

ActiveUS20180284200A1Easy to changeReduce magnetization angleMagnetic-field-controlled resistorsSolid-state devicesElectrical resistance and conductanceMagnetic anisotropy

Tunnel magneto-resistive (TMR) sensors employing TMR devices with different magnetic field sensitivities for increased detection sensitivity are disclosed. For example, a TMR sensor may be used as a biosensor to detect the presence of biological materials. In aspects disclosed herein, free layers of at least two TMR devices in a TMR sensor are fabricated to exhibit different magnetic properties from each other (e.g., MR ratio, magnetic anisotropy, coercivity) so that each TMR device will exhibit a different change in resistance to a given magnetic stray field for increased magnetic field detection sensitivity. For example, the TMR devices may be fabricated to exhibit different magnetic properties such that one TMR device exhibits a greater change in resistance in the presence of a smaller magnetic stray field, and another TMR device exhibits a greater change in resistance in the presence of a larger magnetic stray field.

Owner:QUALCOMM INC

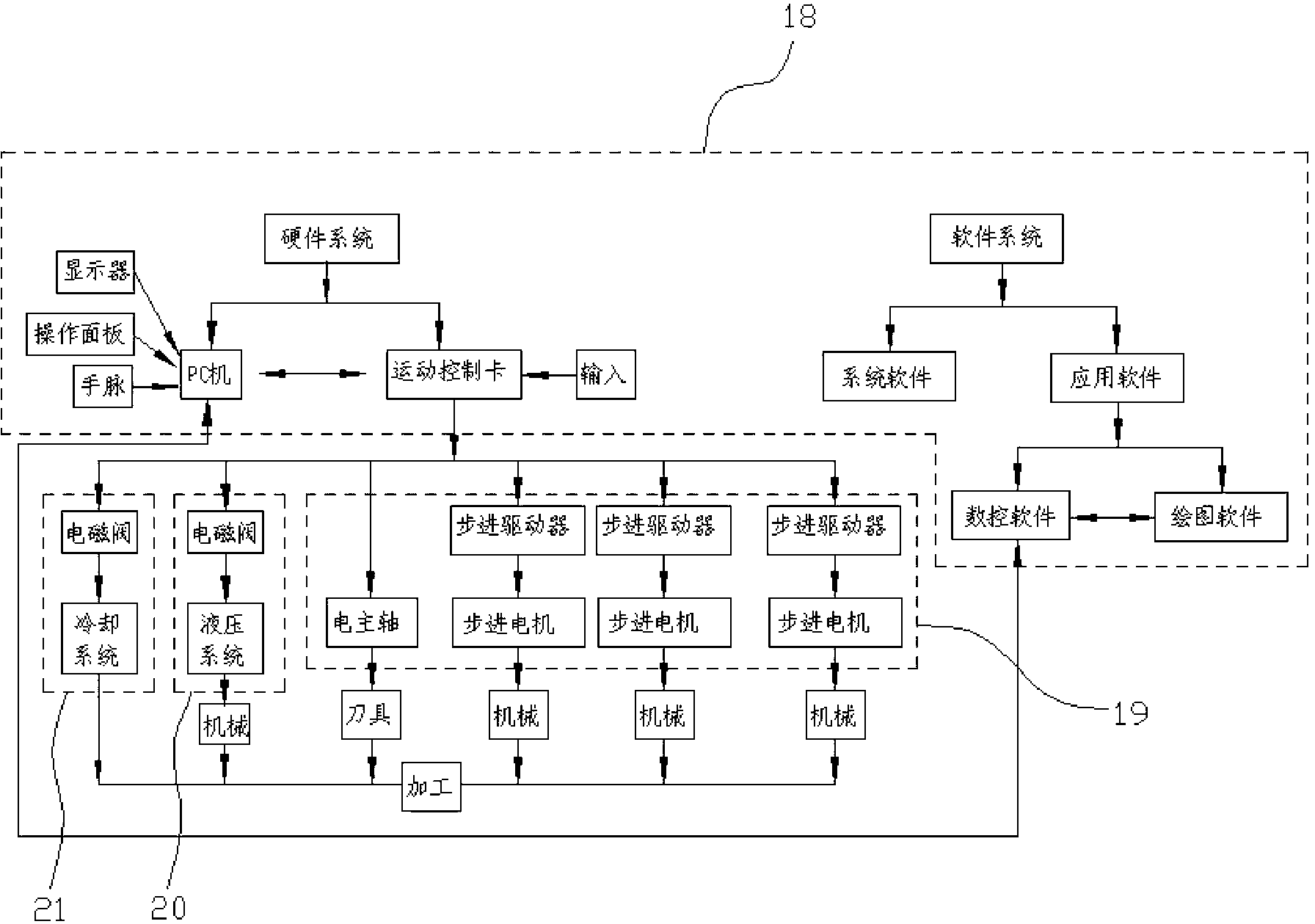

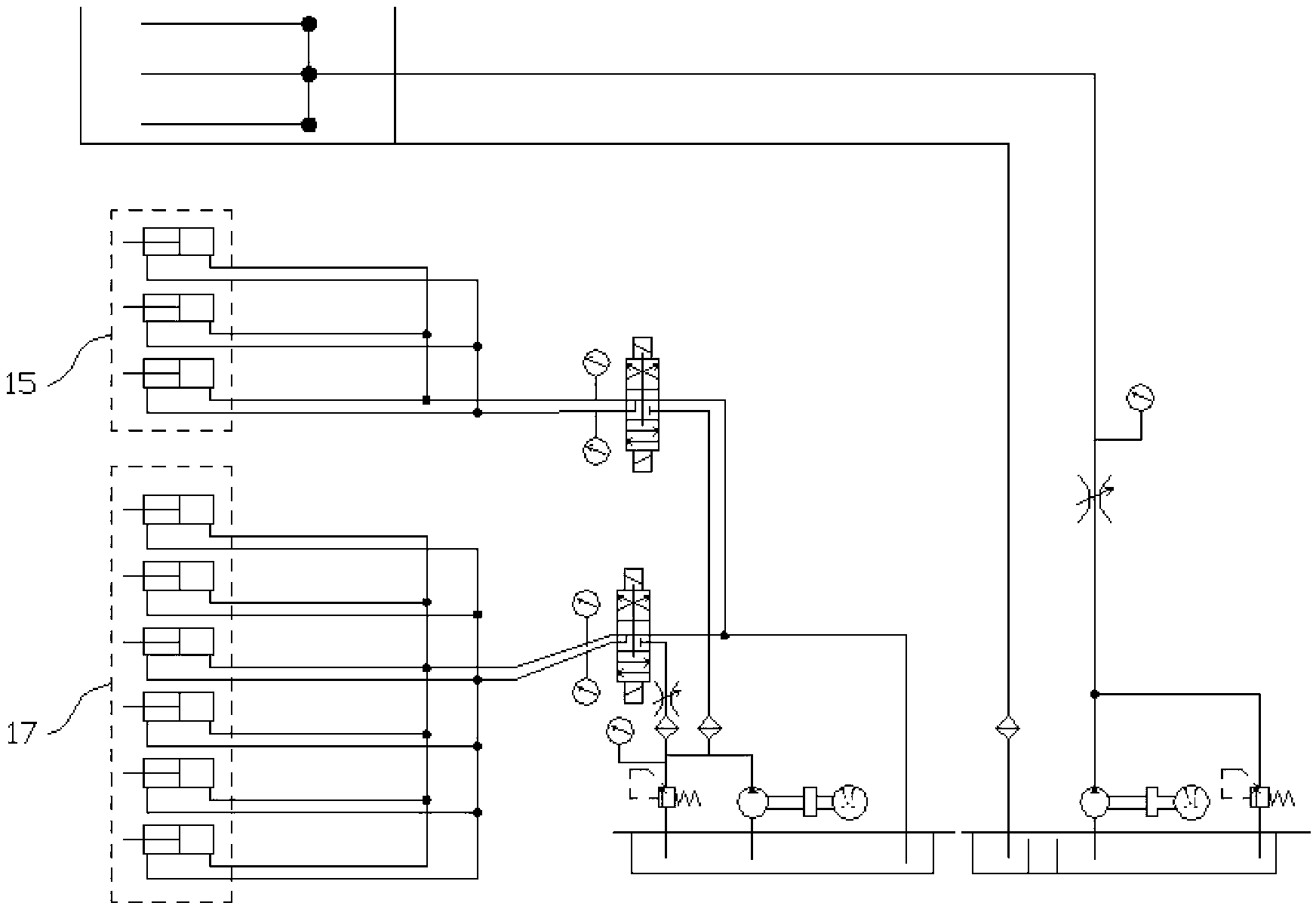

Deep hole machining manipulator

InactiveCN103072131ASmall aspect ratioHigh strengthProgramme-controlled manipulatorSingle degree of freedomControl system

The invention discloses a deep hole machining manipulator, which comprises an arm assembly, a working device and a control system, wherein the arm assembly can be used for at least providing axial feed and peripheral feed; the working device is fixed at the output end of the arm assembly, and is used for machining or detecting; the control system is used for controlling the feeding direction of the arm assembly and the working state of the working device; and the arm assembly comprises a fixed arm, a telescopic arm which is axially connected to the fixed arm at a single degree of freedom in a sliding way, and a rotating arm which is circumferentially connected to the telescopic arm at a single degree of freedom. Due to the adoption of the deep hole machining manipulator disclosed by the invention, deep hole machining and detecting can be performed by breaking through the limit of a deep hole aperture, the length-diameter ratio of a tool can be reduced greatly, the tool has high strength and high rigidity, the deep hole machining accuracy and surface quality can be ensured, the machining requirements of special structures such as inner splines machined in deep holes, in-hole curve structures, inner spiral grooves, and curved teeth are met, and integral machining and forming of deep hole parts having the special structures are realized.

Owner:CHONGQING TECH & BUSINESS INST

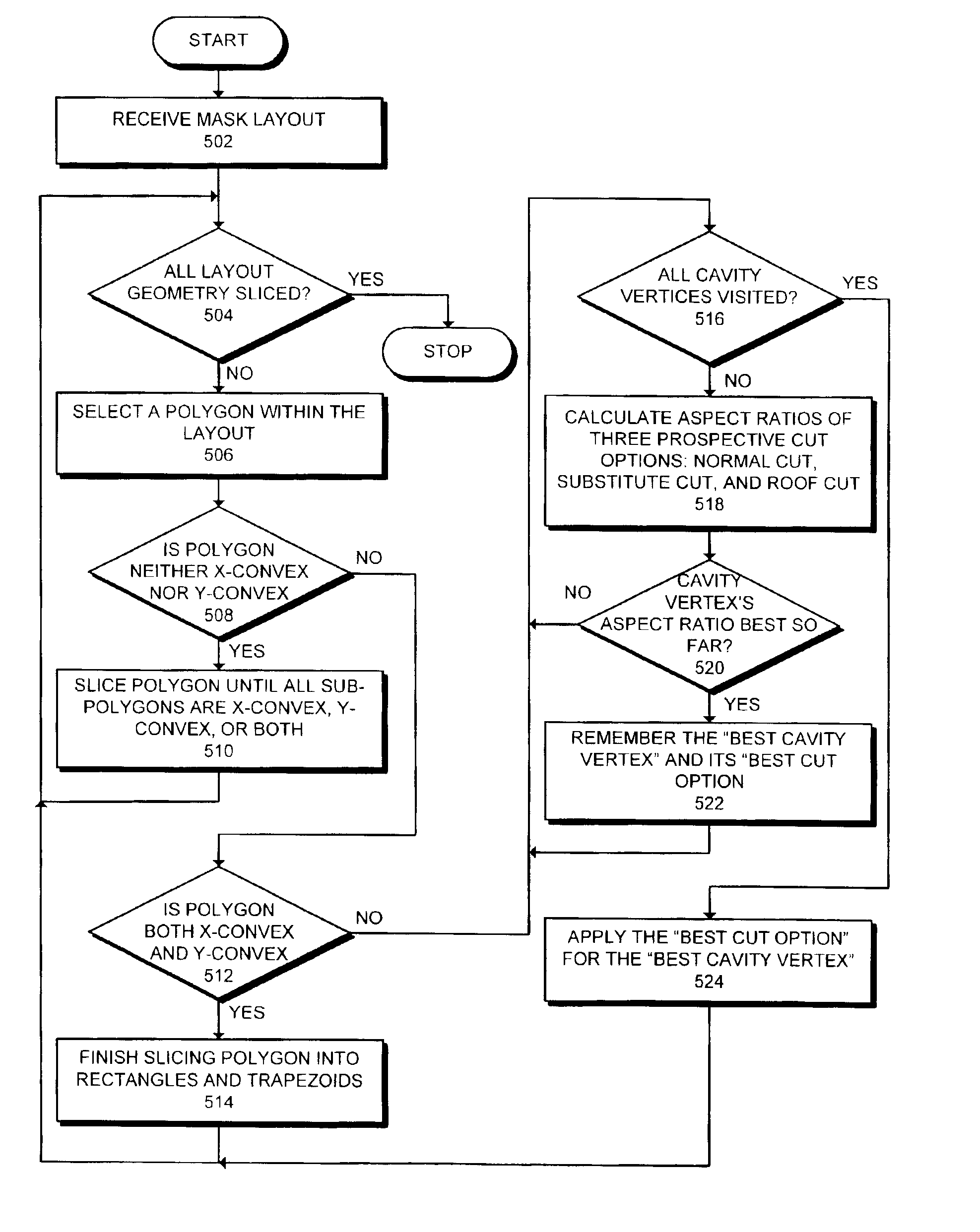

Method and apparatus for fracturing polygons on masks used in an optical lithography process

InactiveUS6887630B2Small aspect ratioOriginals for photomechanical treatmentSpecial data processing applicationsLithography processLithographic artist

A system for fracturing polygons on masks used in lithography processes for manufacturing an integrated circuit is described. The system fractures polygons that include cavities in either the horizontal edges or the vertical edges by examining the aspect ratio (length / width) of prospective slices made at each vertex of the polygon. After determining the aspect ratio of each prospective slice, the system selects the slice with the lowest aspect ratio and slices the polygon into two sub-polygons. Slicing the polygon in this manner effectively eliminates “slivers” or slices with extreme aspect ratios. This process is continued until each sub-polygon is either a rectangle or a trapezoid that can be printed by electron beam photolithography.

Owner:SYNOPSYS INC

Particle shaping method and device thereof

InactiveCN1827301ASmall aspect ratioRealize high value-added applicationsEdge grinding machinesPolishing machinesDiameter ratioAirflow

The invention relates to a particle shaping method and relative device, belonging to the powder further processing technique of material engineering. The invention is characterized in that: via the fine particle shaping system, using mechanical impact to mill and shape the powder particle, while the processed powder material carried by high-speed airflow is fed into the shaping processor; inside the main machine, by the quick impact of high-speed rotational rotor and blades, the material is separated with impacted by rotor and high-speed airflow, and rubbed and sheared between themselves, to be shaped while the edge and angle are finished; the material can be processed into ball shape with smaller length-diameter ratio and high vibrated density. The invention can grade the processed material to attain the products in different graininess and realize the high additive valves of different powder materials.

Owner:TSINGHUA UNIV

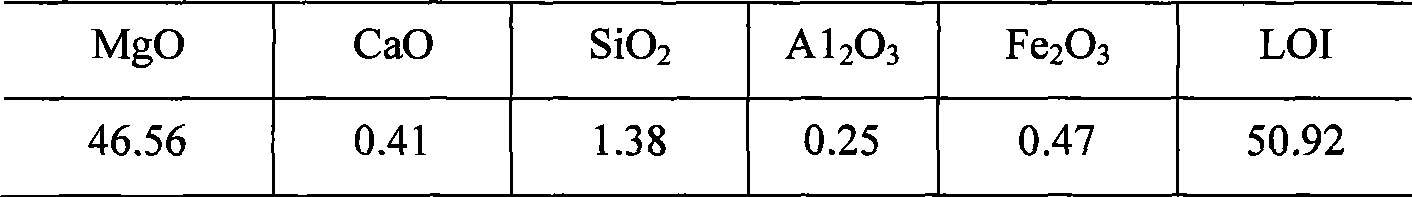

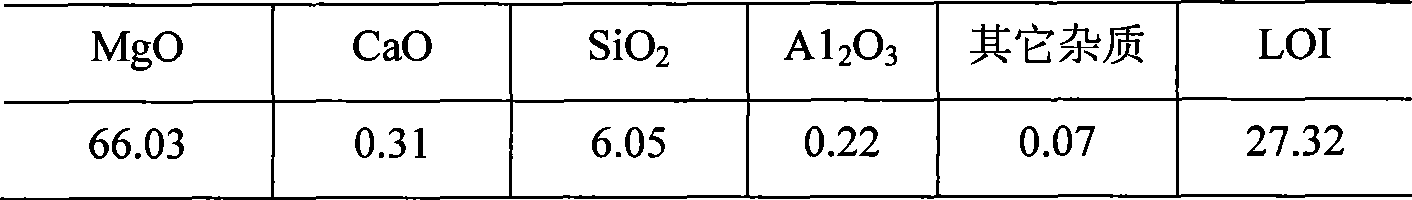

Preparation of magnesia crystal whisker

InactiveCN101498041ASimple production processUniform sizePolycrystalline material growthHeavy waterJacobsitePyrolysis

The invention relates to the field of inorganic and non-metal material preparation, in particular discloses a method of using magnesite or brucite as raw material to prepare magnesia whiskers by technologies of calcinations, fine grinding, hydration, carbonization, solid-liquid separation, dilution, pyrolysis, filtration, drying and calcination. The method comprises the following steps: adding 0.1 percent to 2.0 percent of soluble magnesium salt to high-magnesian water with the concentration of 3-100kg / 1000L to be pyrolyzed at a temperature of 40 DEG C to 80 DEG C under the stirring intensity of 50-500 round / min; firstly, preparing precursor magnesium carbonate whiskers; further calcining the whiskers at a temperature of 500 DEG C to 800 DEG C to obtain magnesia whisker products which have favorable crystallization growth, high purity and slenderness ratio and good dispersion and can be applied to the fields of material, chemical engineering, machinery, and the like, and the precursor magnesium carbonate whiskers can be also applied to the fields of material, chemical engineering, and the like and the preparation of magnesium hydrate, bitter salt, magnesium chloride, magnesium nitrate and other magnesium salt products. The method has simple technology, little investment and low production cost, has no pollution in a production process and can utilize various grades of magnesite and brucite lump ores and powder (tailing) to prepare the magnesia whiskers.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com