Planetary-harmonic composite gear reducer

A gear reducer, planetary harmonic technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of large axial size, small reduction ratio, large volume, etc., and achieve small axial size , The effect of large reduction ratio and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

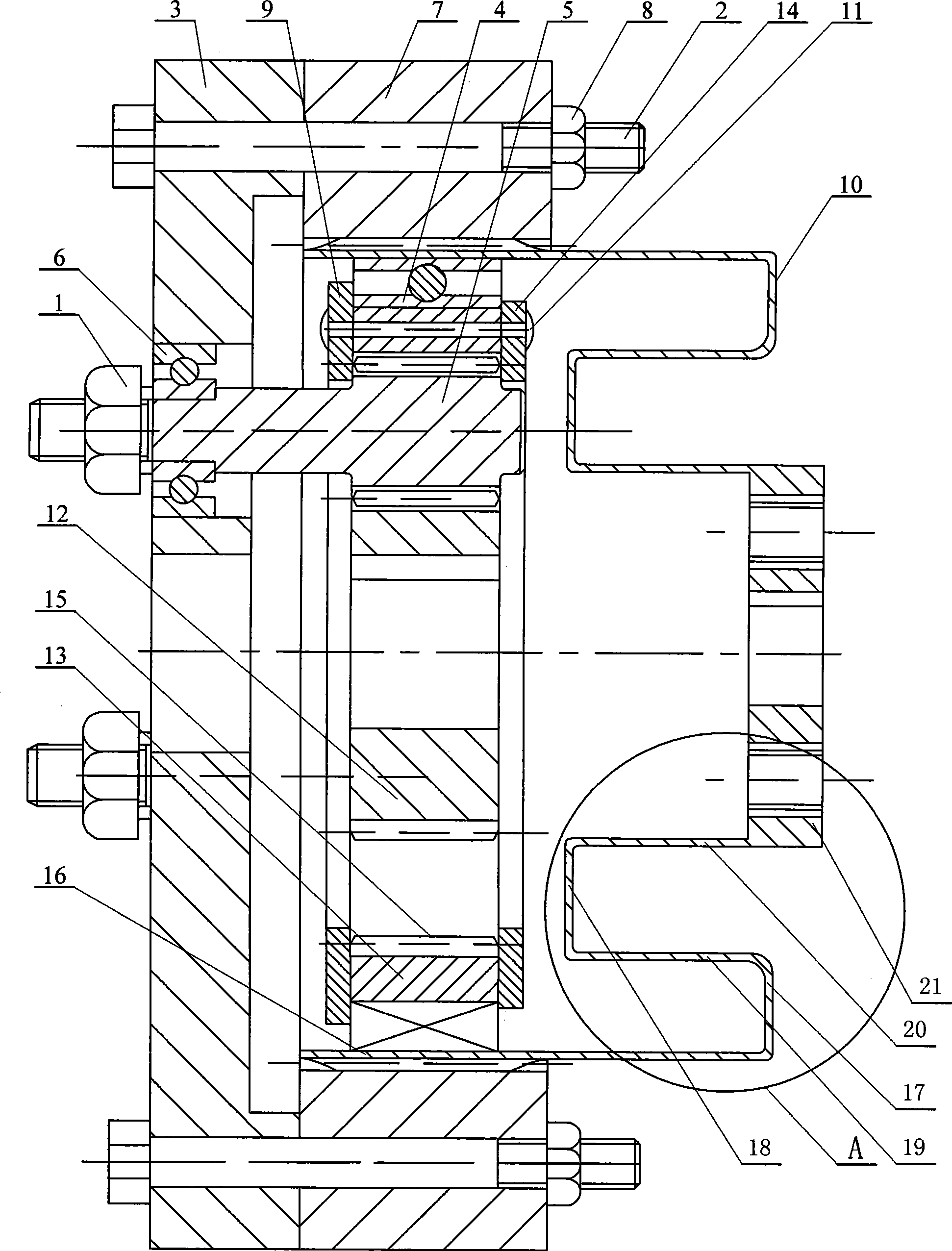

[0007] Specific implementation mode 1: Combination figure 1 with figure 2 To illustrate this embodiment, the reducer of this embodiment includes an elliptical cam 13 and a flexible ball bearing 4; the reducer of this embodiment also includes a planetary gear shaft nut 1, two tie rod fixing bolts 2, a tie rod 3, at least two A planetary gear shaft 5, at least two rolling bearings 6, a rigid inner ring gear 7, two tie rod fixing nuts 8, a large annular stopper 9, a small annular stopper 14, a flexible gear 10 and a sun gear 12; the ellipse The center of the cam 13 is provided with an elliptical hole, the inner wall of the elliptical hole is machined with teeth to form an elliptical inner ring gear 15, the sun gear 12 and at least two planets evenly arranged along the circumference of the sun gear 12 The gears on the gear shaft 5 mesh with each other, the sun gear 12 and at least two planetary gear shafts 5 are placed in the elliptical ring gear 15 of the elliptical cam 13, and the ...

specific Embodiment approach 2

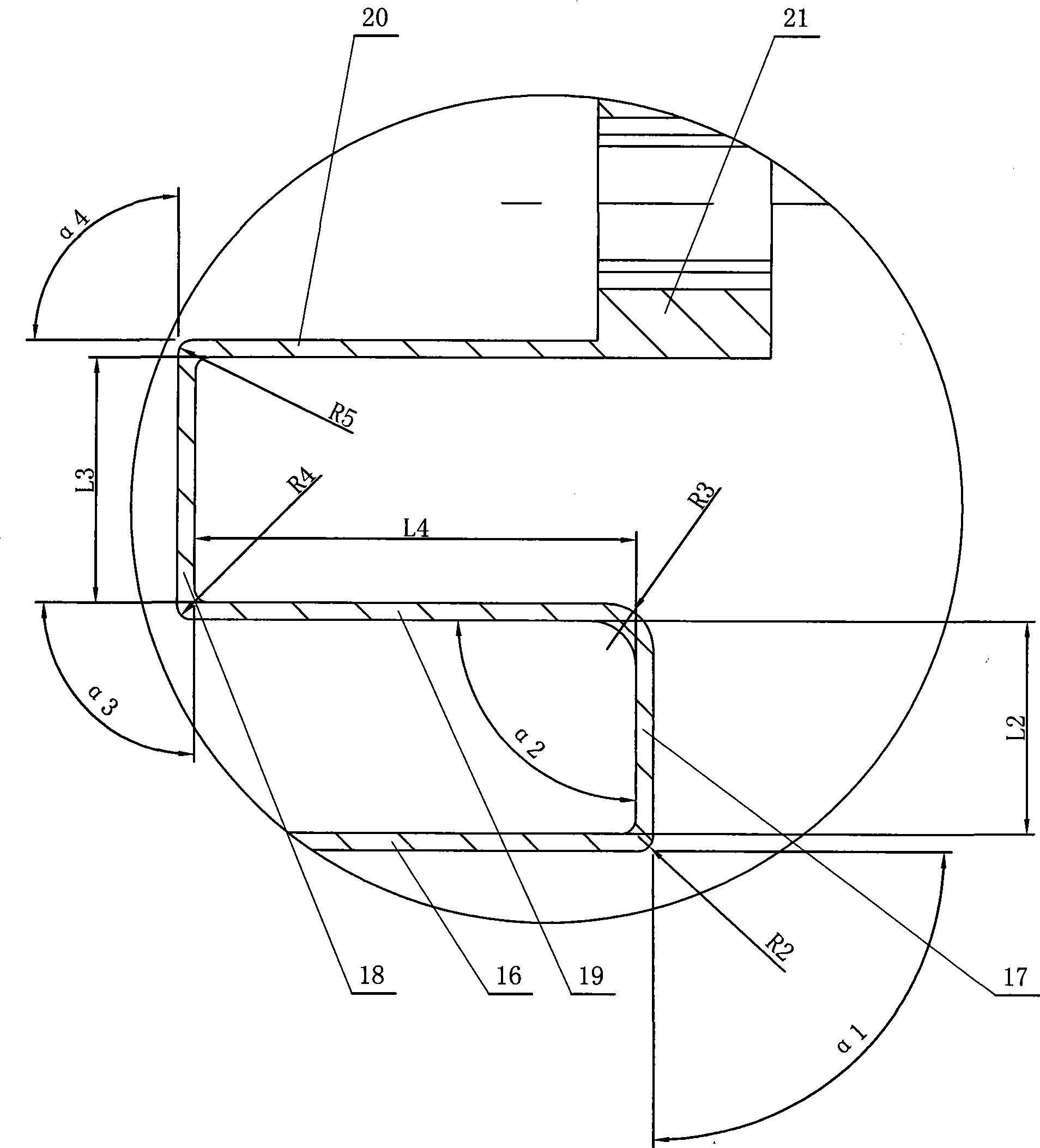

[0008] Specific implementation manner two: combination figure 1 with figure 2 To illustrate this embodiment, the flexible gear 10 of this embodiment is composed of an integrated outer gear sleeve 16, a large annular plate 17, a small annular plate 18, an intermediate thin-walled sleeve 19, an inner thin-walled sleeve 20, and an end cover 21. The large annular plate 17 is installed in the outer tooth sleeve 16, the outer circumferential end surface of the large annular plate 17 is fixed to the inner wall of one end of the outer tooth sleeve 16, and the middle thin-walled sleeve 19 is installed in the outer tooth sleeve 16, and the middle is thin One end of the wall sleeve 19 is installed in the central hole of the large annular plate 17, the outer wall of the middle thin-wall sleeve 19 is fixedly connected to the inner wall of the central hole of the large annular plate 17, and the small annular plate 18 is installed in the middle thin-wall sleeve 19, the outer circumferential end...

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 The present embodiment will be described. The number of teeth of the flexible gear 10 of the present embodiment is two less than the number of teeth of the rigid ring gear 7. With this arrangement, when the wave generator rotates once, the flexible gear 10 drives the rigid ring gear 7 to rotate through the angle of two teeth in the opposite direction, thereby realizing a large transmission ratio. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com