Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

950results about How to "Small machining allowance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fast laser depositing process of preparing antinwear heat resistant composite coating on surface of crystallizer

InactiveCN1932082ANo pollution in the processRadiation-freeMolten spray coatingArc welding apparatusAutomatic controlHigh power lasers

The fast laser depositing process of preparing antiwear heat resistant composite coating on the surface of crystallizer features that high power laser is first utilized in fast scanning to form transition layer in excellent metallurgical binding with the substrate of crystallizer copper plate on the surface of the plate and then utilized in wide band deposition to form Co base alloy with excellent heat resistance and high wear resistance on the surface of the transition layer. Compared with convenient technological process, the present invention has the advantages of precise control in laser power, position, shape and other parameters, easy automatic control of the whole process, no environmental pollution, high production efficiency, low power consumption, etc. and may be used widely.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Laser fusing and coating process of wear resistant and anticorrosion alloy coatings at surface of slide plate of railroad turnout

InactiveCN101338425ANo pollution in the processImprove productivityMetallic material coating processesNumerical controlWear resistant

A laser cladding process of an exterior wear-resisting anti-corrosive alloy coating of a slide chair of a railway switch comprises processes as follows: firstly, the surface of the slide chair is pre-heated, which means the surface of the slide chair is degreased and de-rusted under room temperature; and the surface is cleaned up by alcohol; then alloy powder is prefabricated, which means iron-base, nickel-base or cobalt base alloy powders that are ready for cladding are preplaced on the processed surface of the slide chair, and a scraping straightedge provided with a rail is used for adjusting the pretreated metal powder so that the alloy powder can be distributed on the surface of the slide chair evenly and has proper thickness to meet the thick requirement of the coating after cladding; and finally, the slide chair is hardened by the laser cladding; the laser of CO2 gas is adopted; a numerical control machine is used as a working table and the surface of the slide chair is hardened by the laser cladding. The laser cladding process has the characteristics of no pollution, high production rate, low energy consumption, the little finishing allowance of cladding coating and low combined cost.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Extrusion casting method for aluminum alloy automobile speed changing box shell

ActiveCN102363211AImprove blank precisionSmall machining allowanceGearboxesThermal treatmentHardness

The invention discloses an extrusion casting method for an aluminum alloy automobile speed changing box shell. The method comprises the following steps of: preparing materials, smelting, preparing a die, performing extrusion casting and performing heat treatment. In the extrusion casting process, the manufactured aluminum alloy automobile speed changing box shell has higher tensile strength and yield strength and hardness by optimizing the design of aluminum alloy ingredients, process parameters of smelting and extrusion casting and a heat treatment system. By the extrusion casting method, the accuracy of blanks can be improved, machining allowance can be reduced, low consumption of resources and energy is realized, and the economic benefit is improved.

Owner:JIANGSU HIDA MARINE VALVE

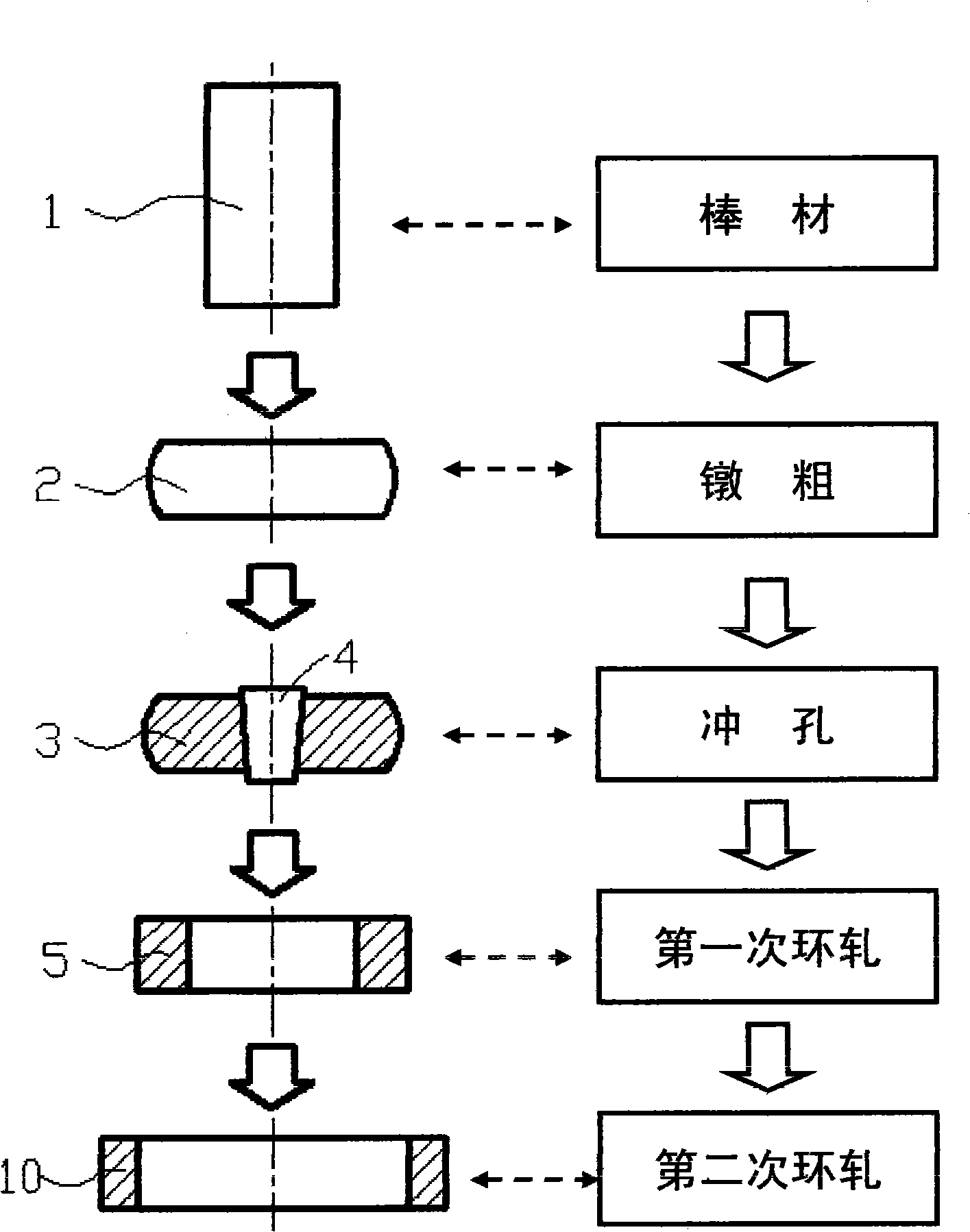

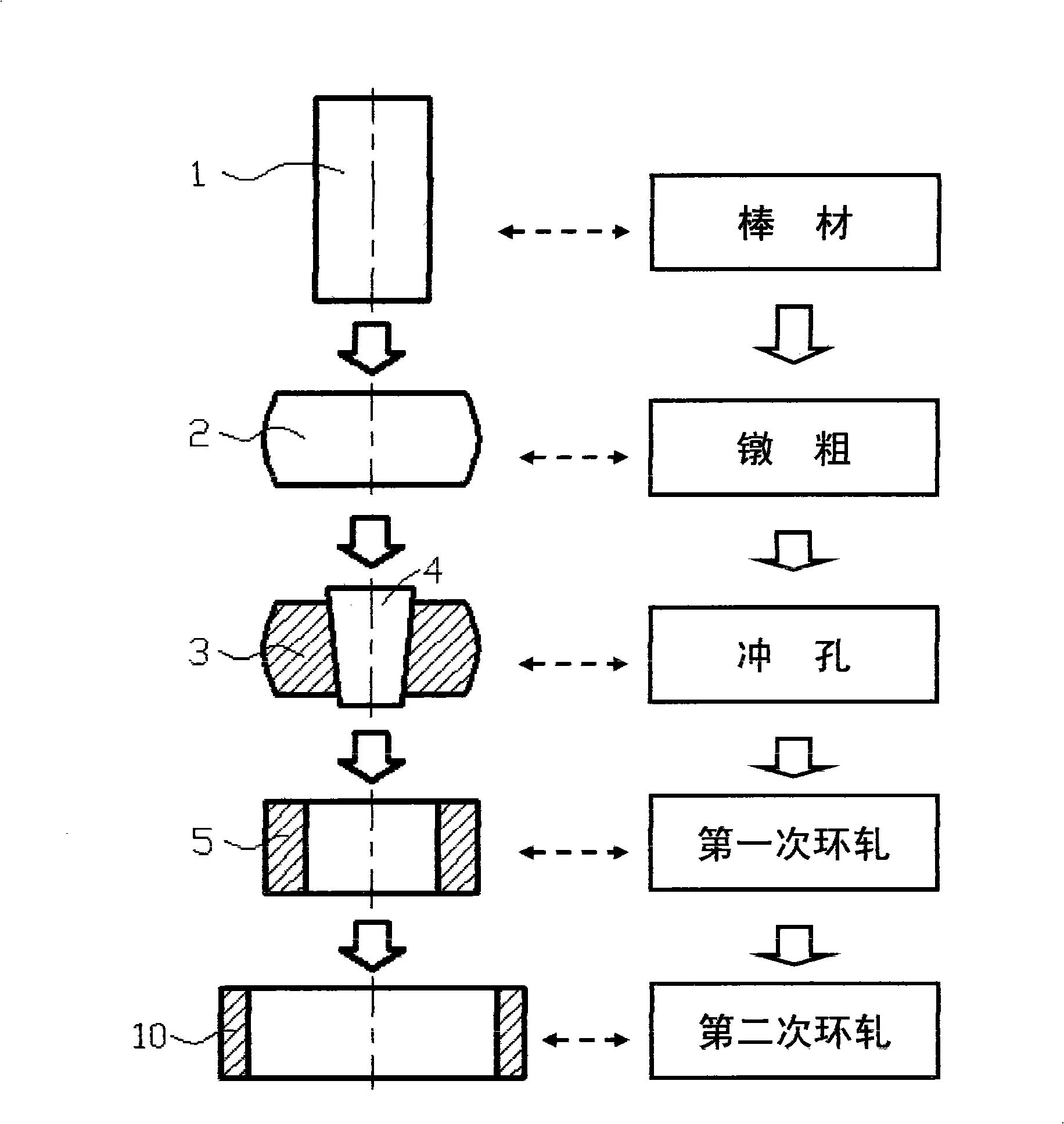

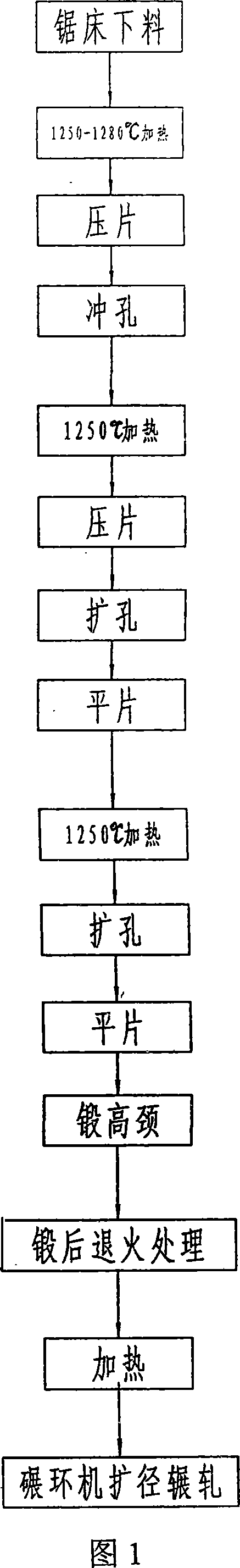

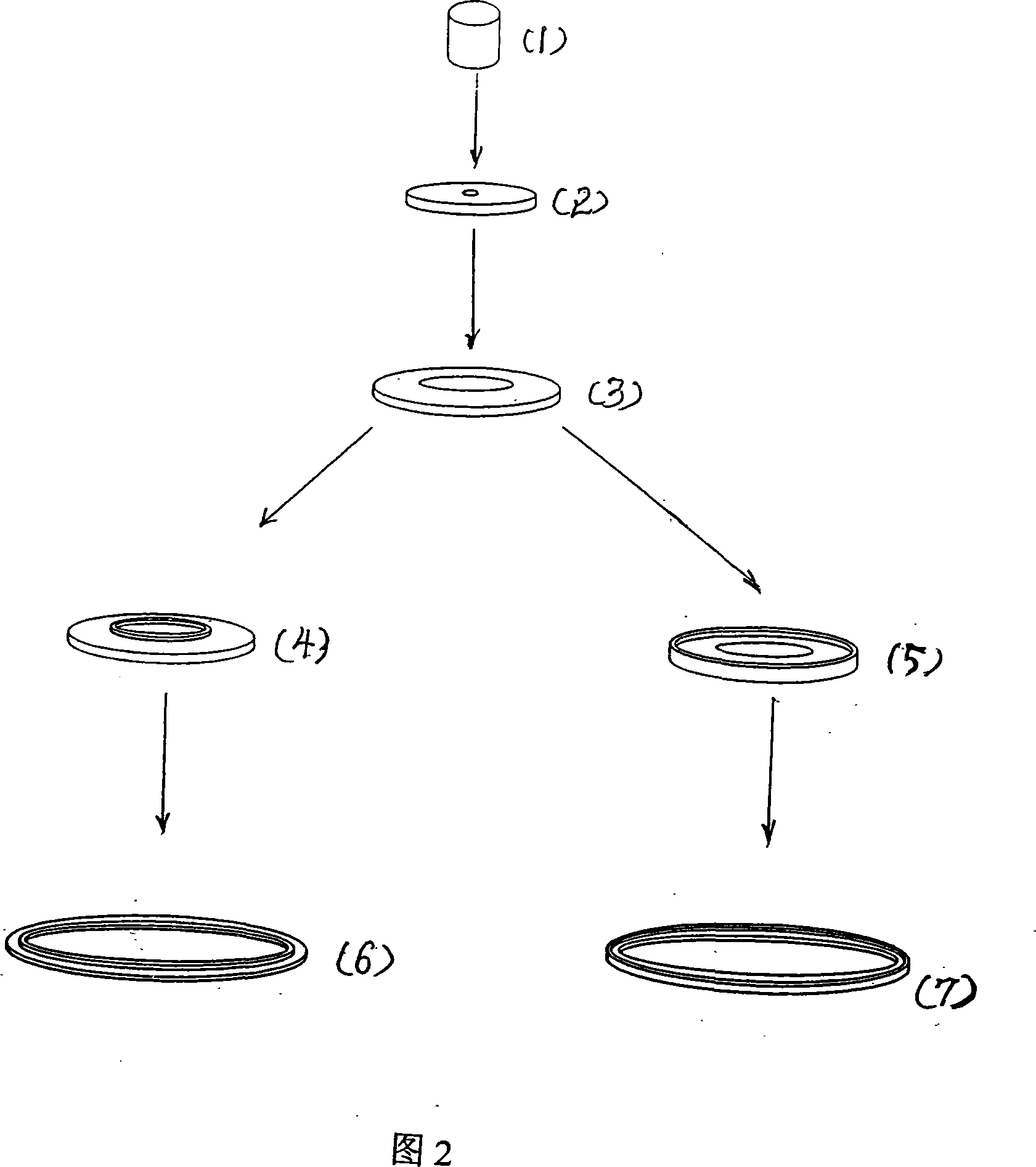

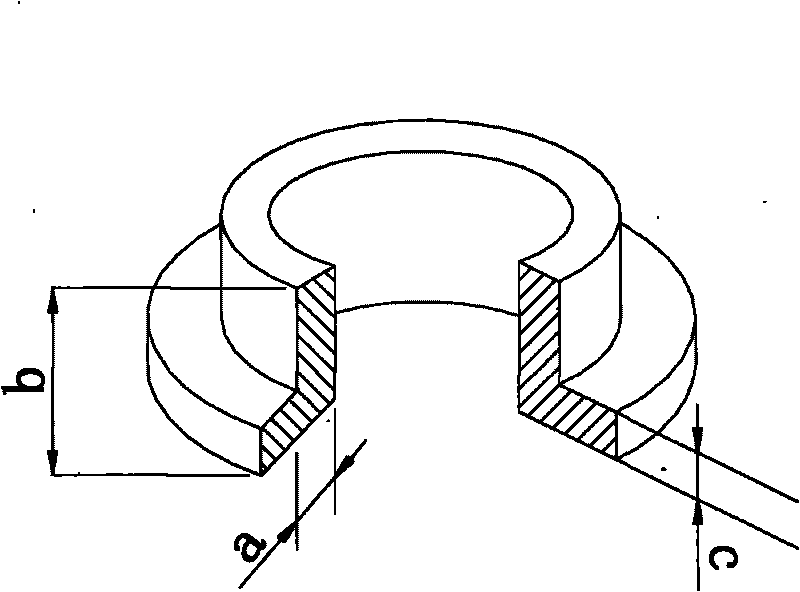

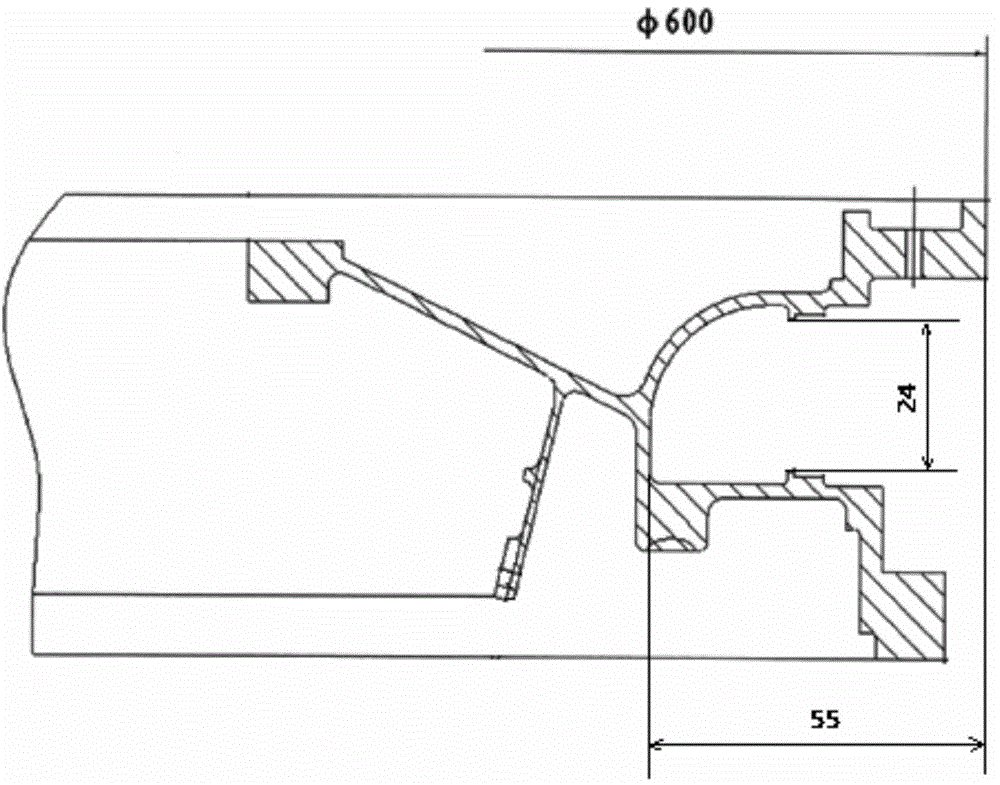

Method for rolling and shaping titanium alloy special-shaped ring forging

ActiveCN101279345AReduce manufacturing costHigh dimensional accuracyMetal rollingTitanium alloyAbnormal shaped

The invention discloses a rolling and shaping method for a titanium alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 65 to 70 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle ring blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 25 to 30 percent; a rectangle pre-rolling blank is obtained after the rectangle ring blank is heated, rolled circularly and deformed by 25 to 30 percent again; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and becomes a heterotypic ring forging after being rolled and deformed by 40 to 45 percent in a section groove of the die. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 40000kg to 220000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine or a gas turbine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

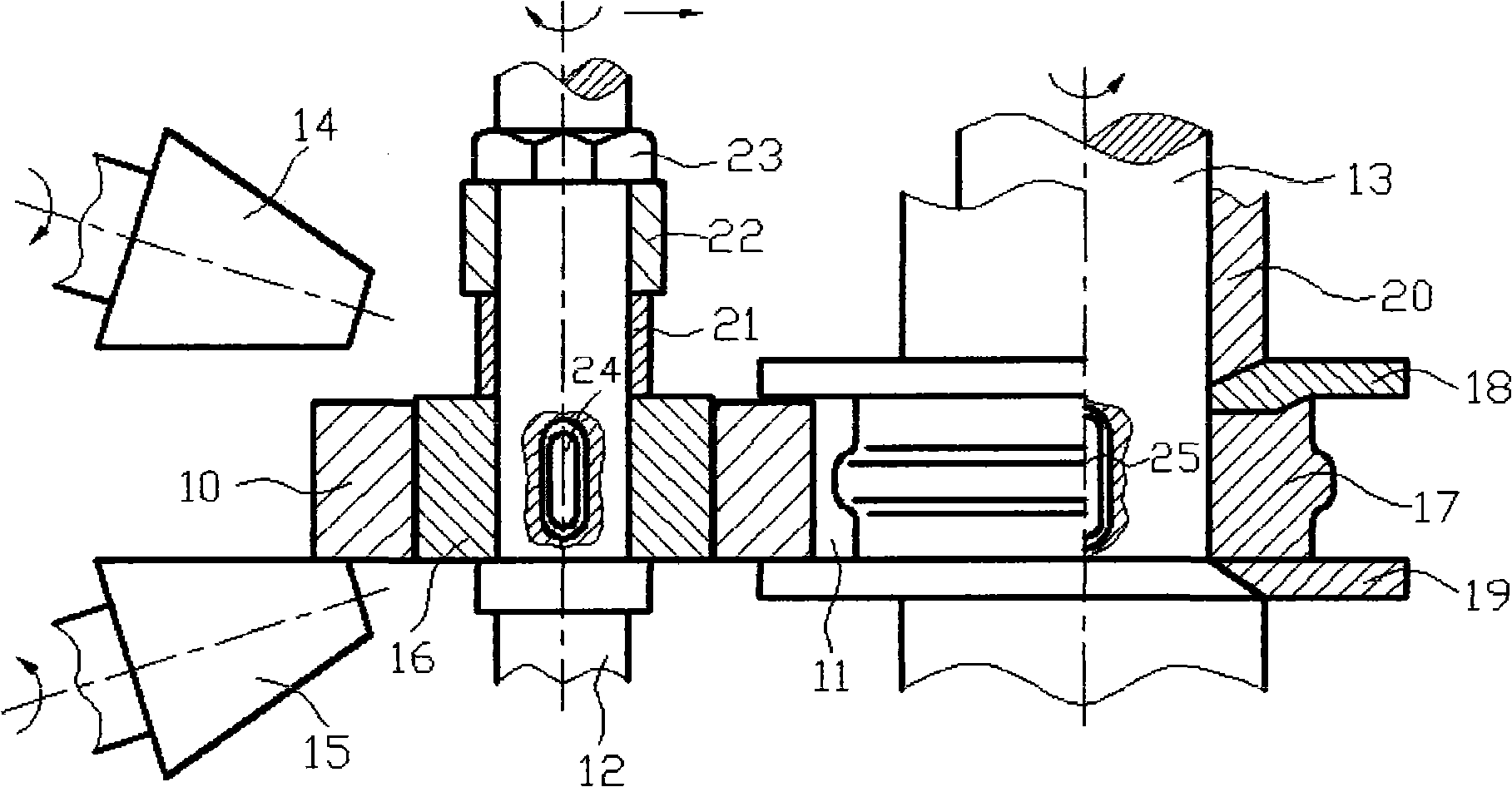

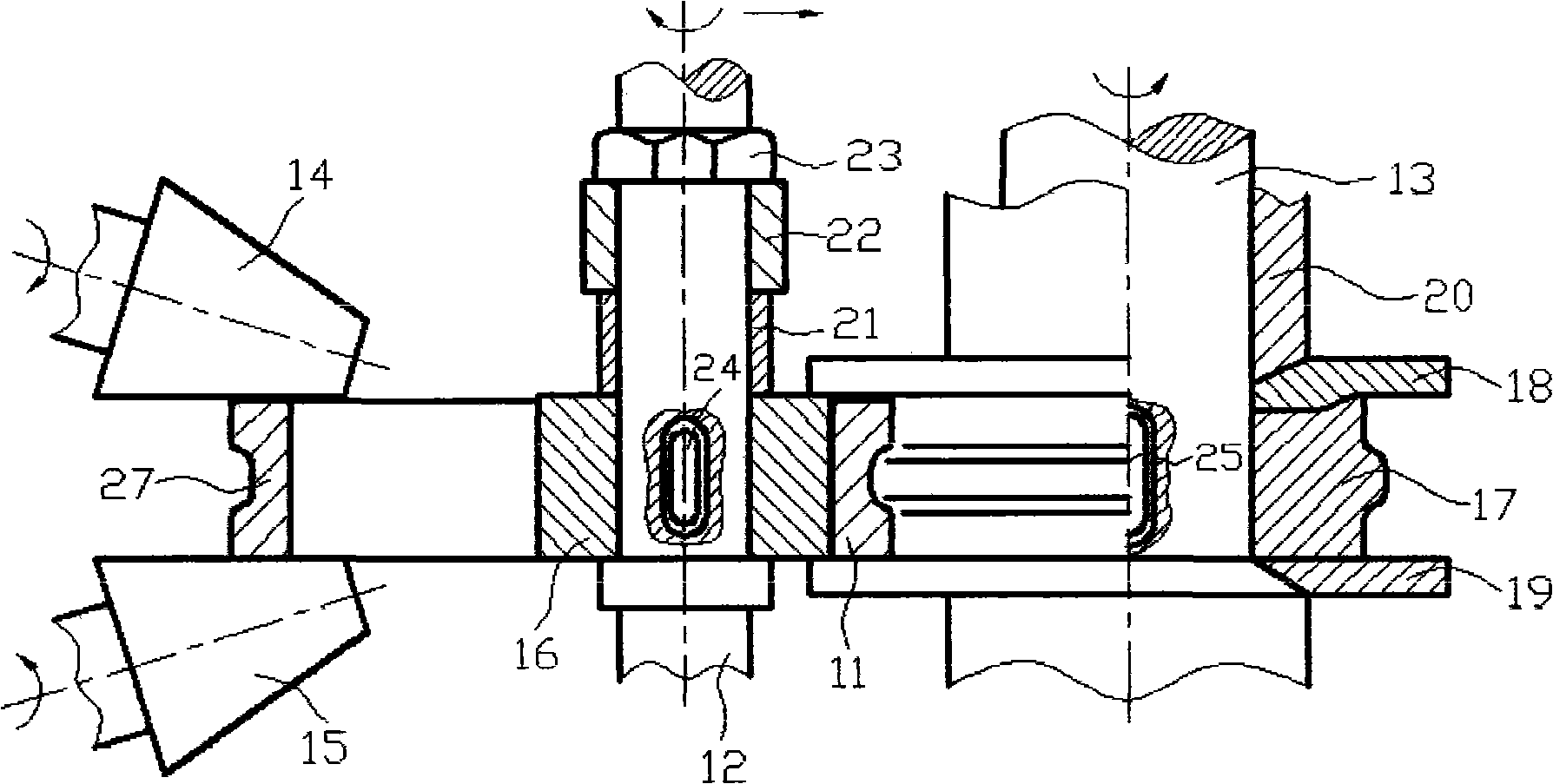

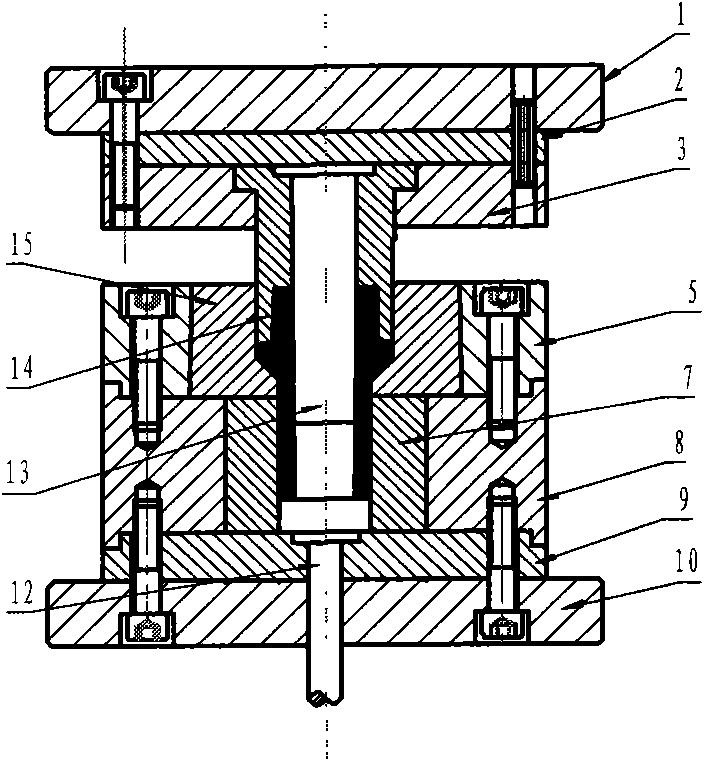

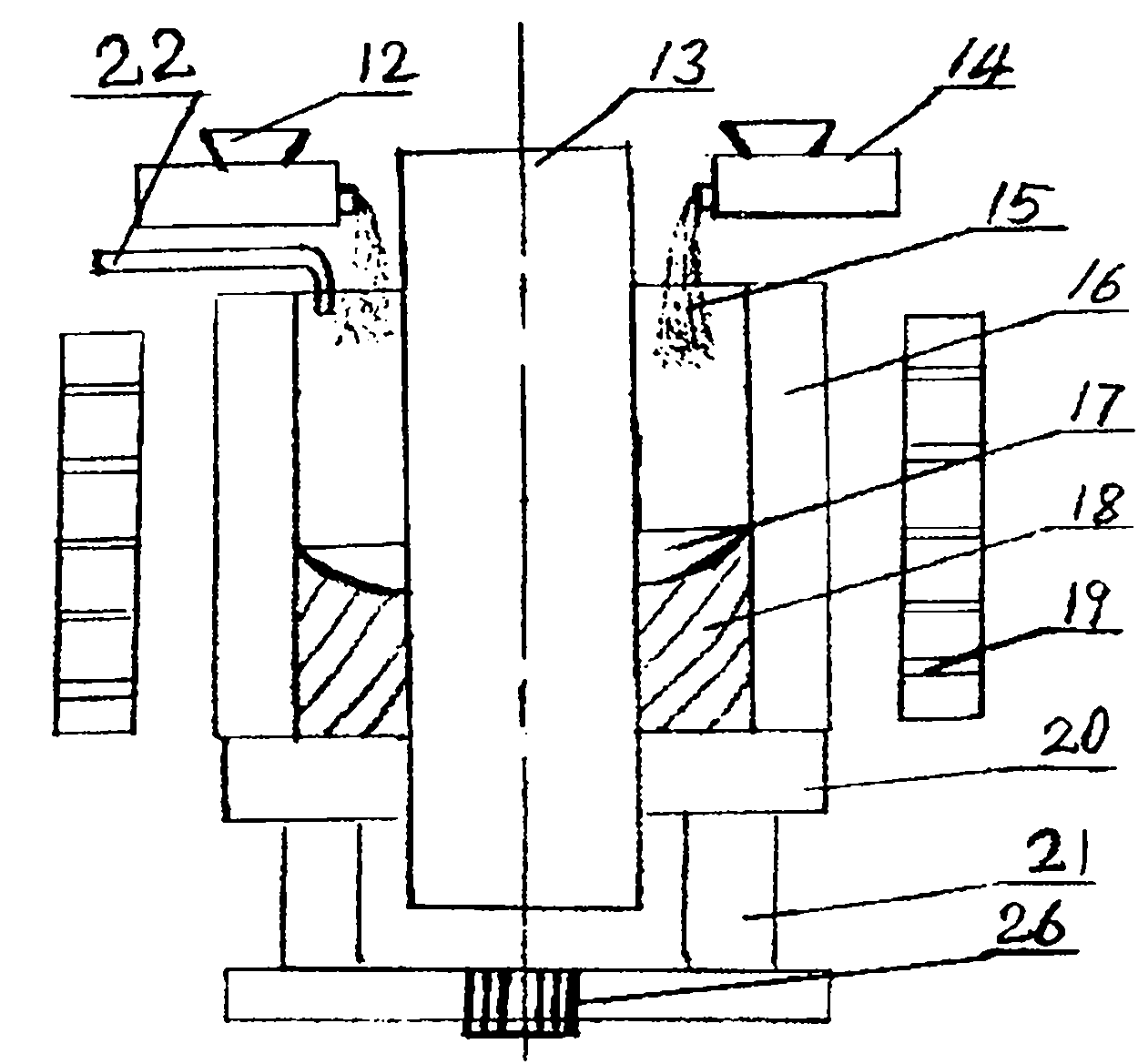

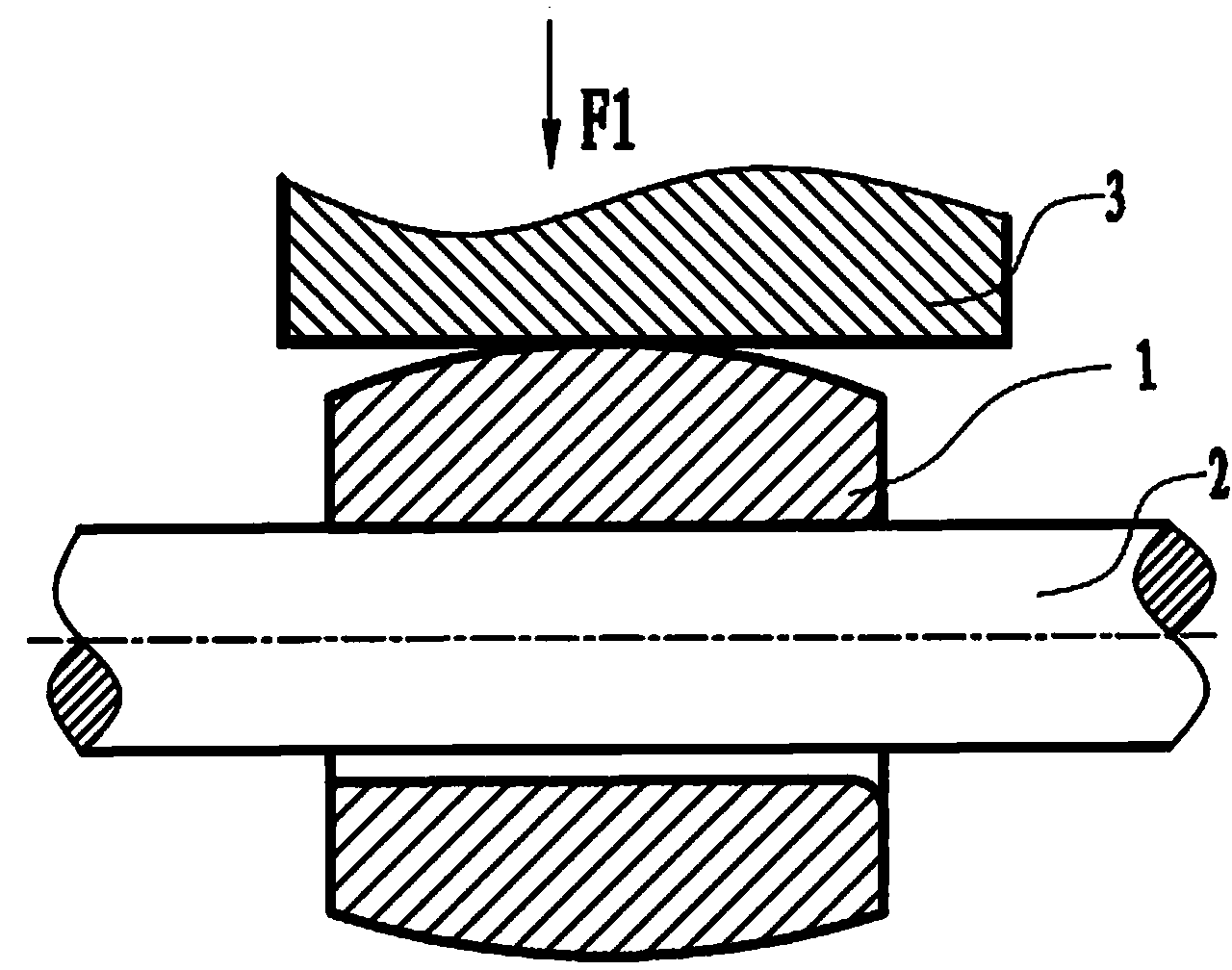

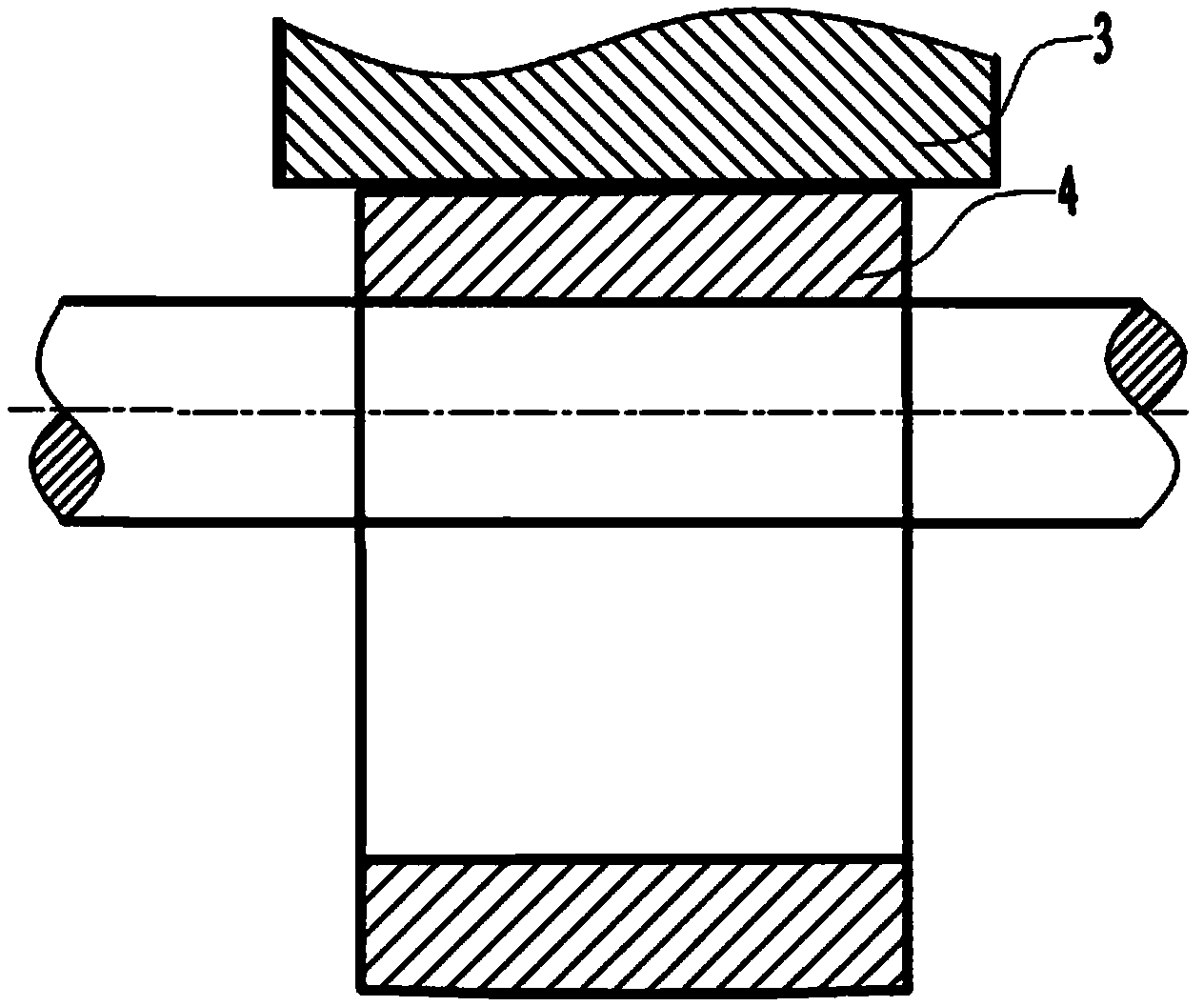

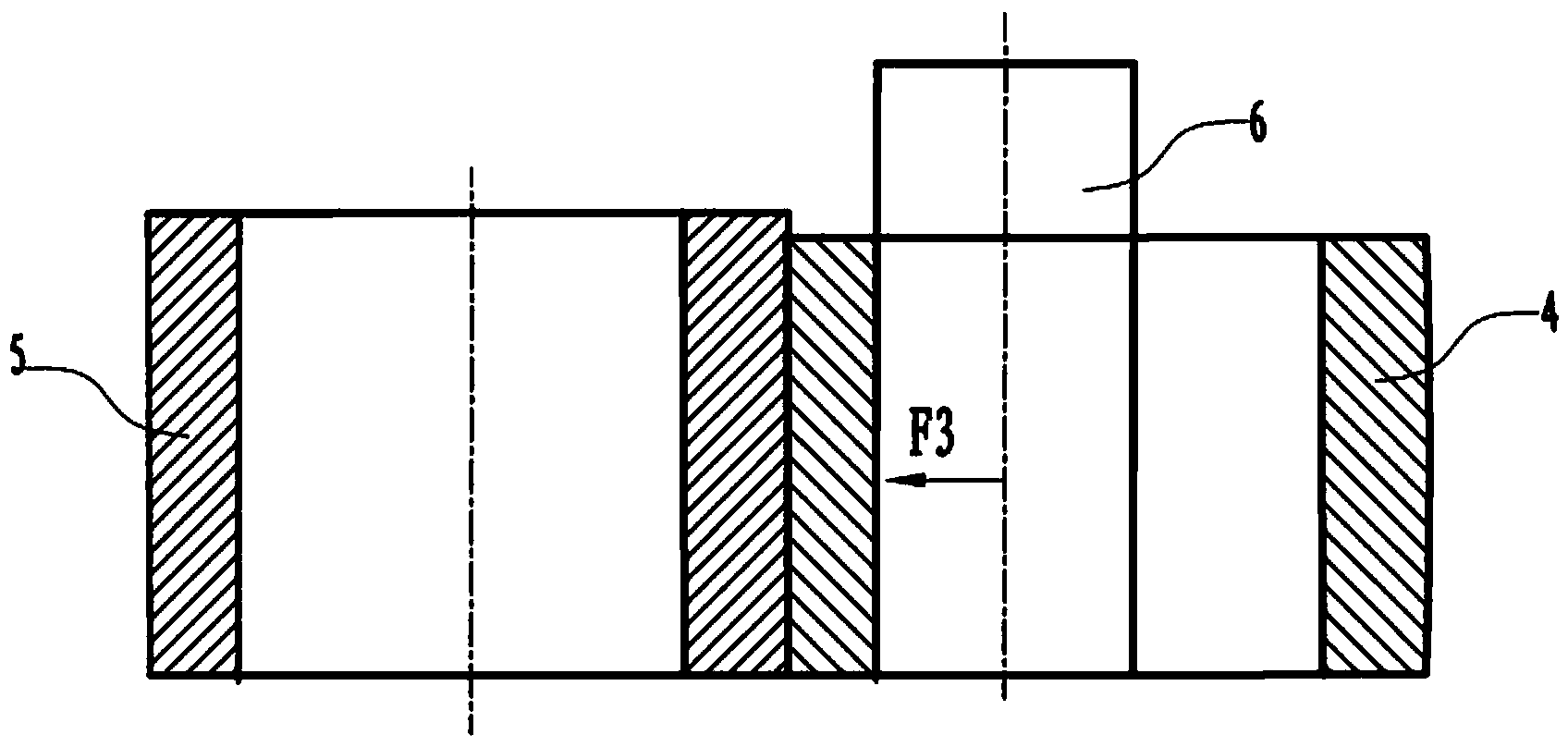

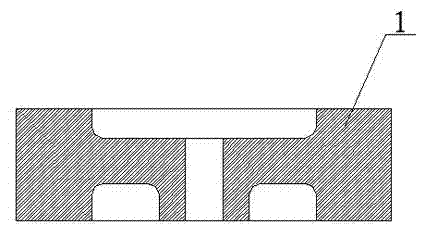

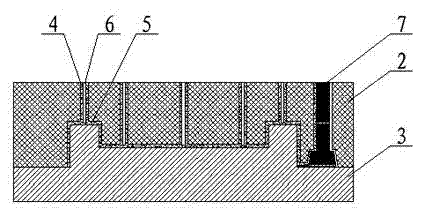

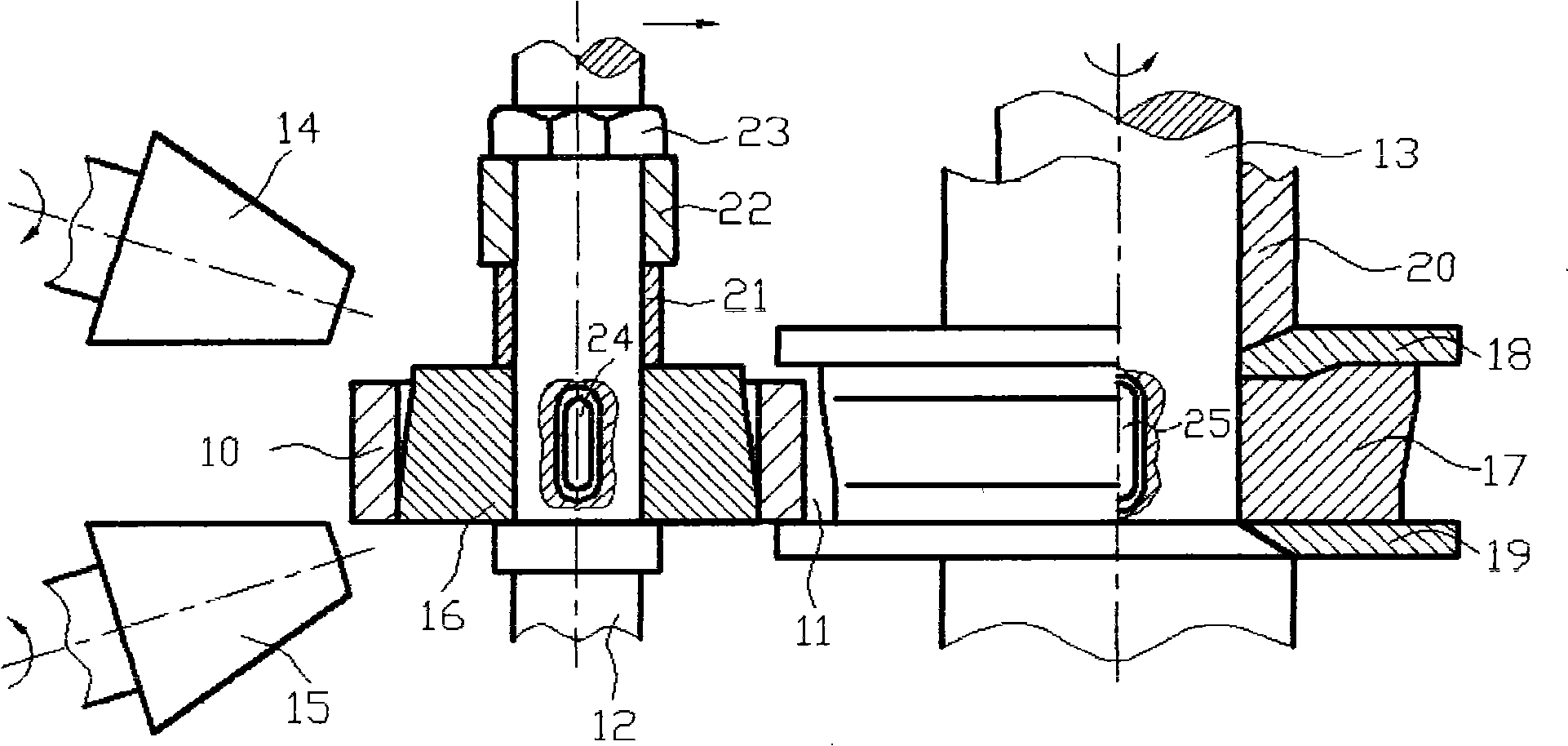

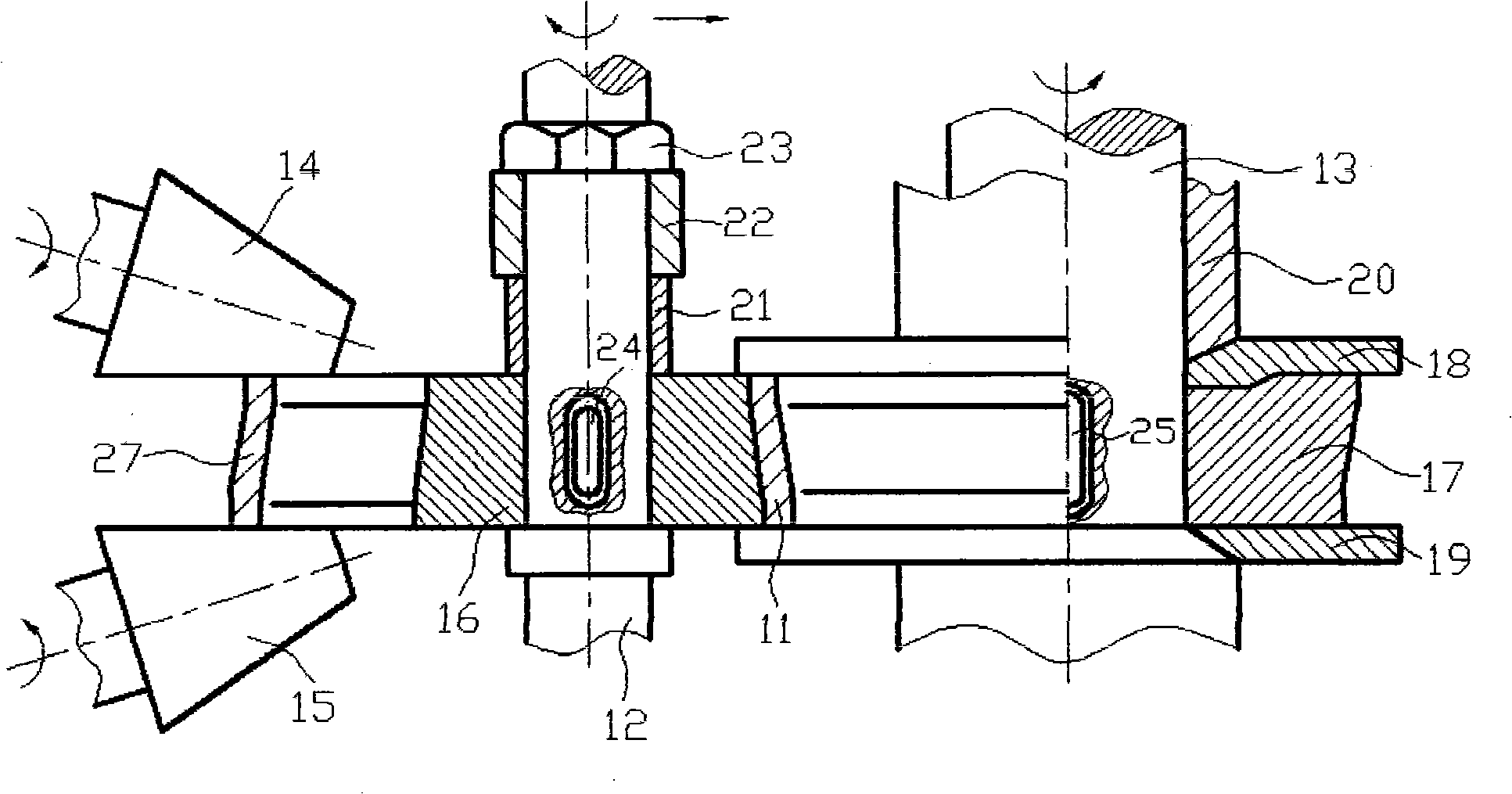

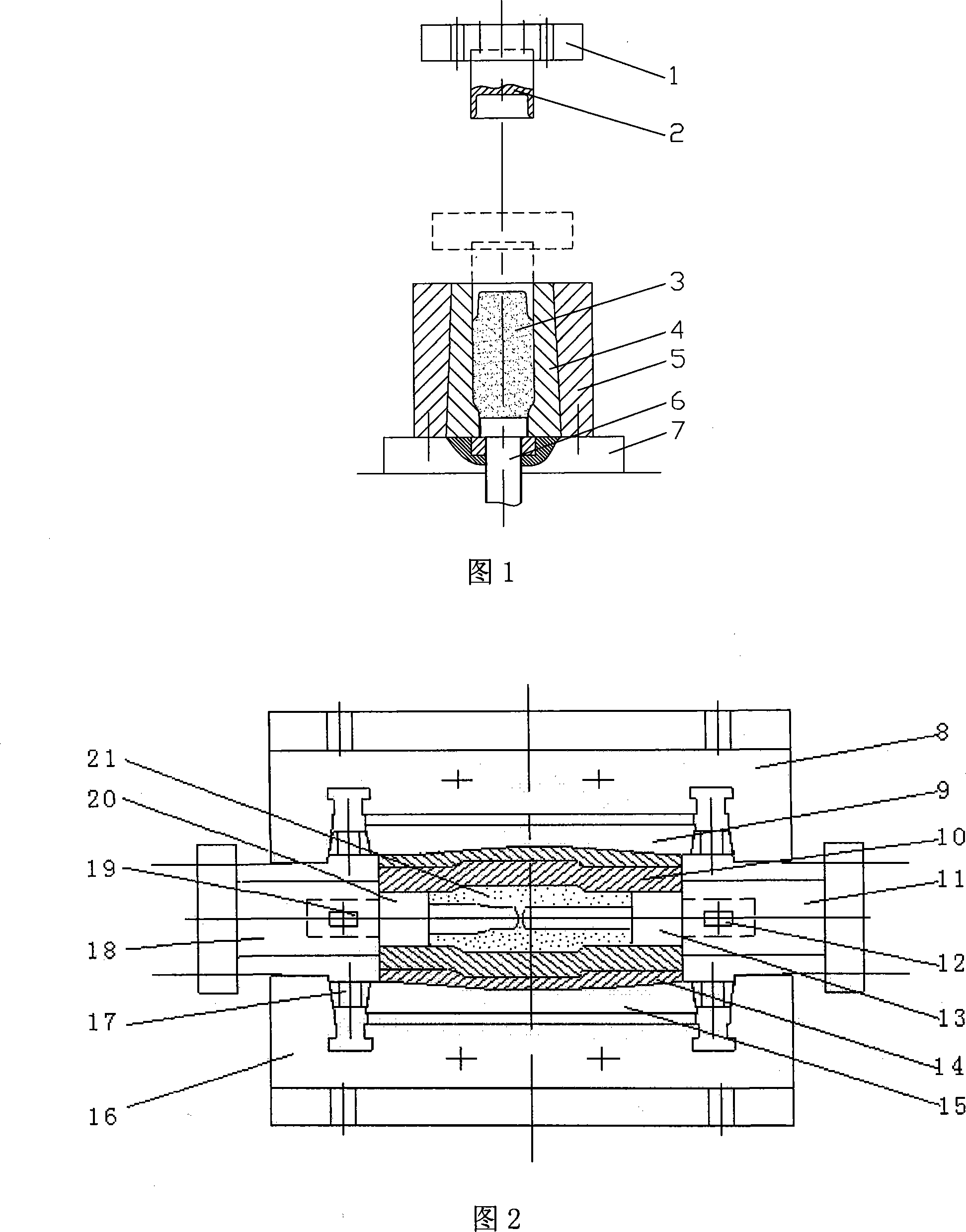

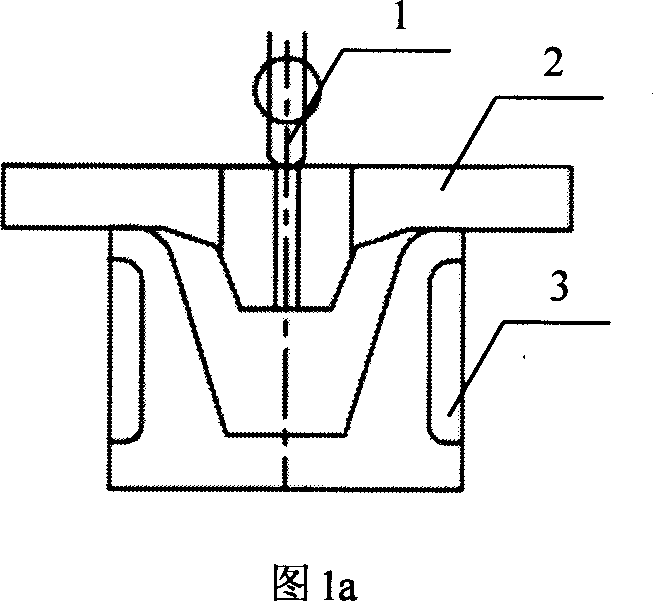

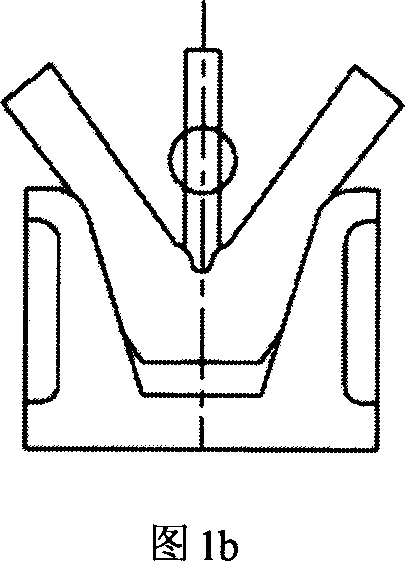

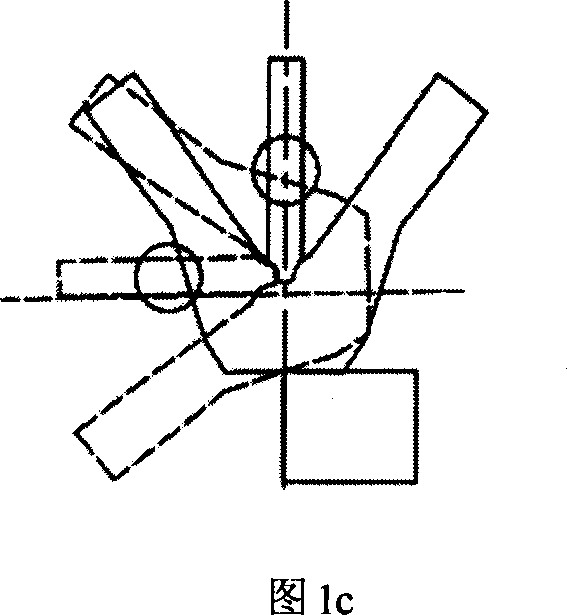

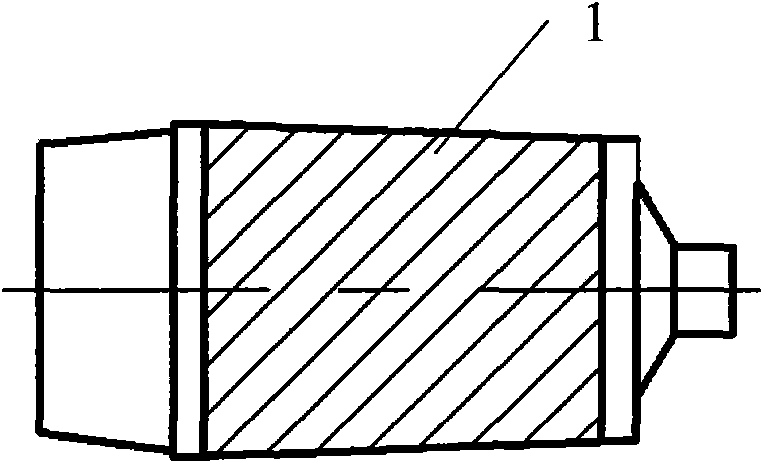

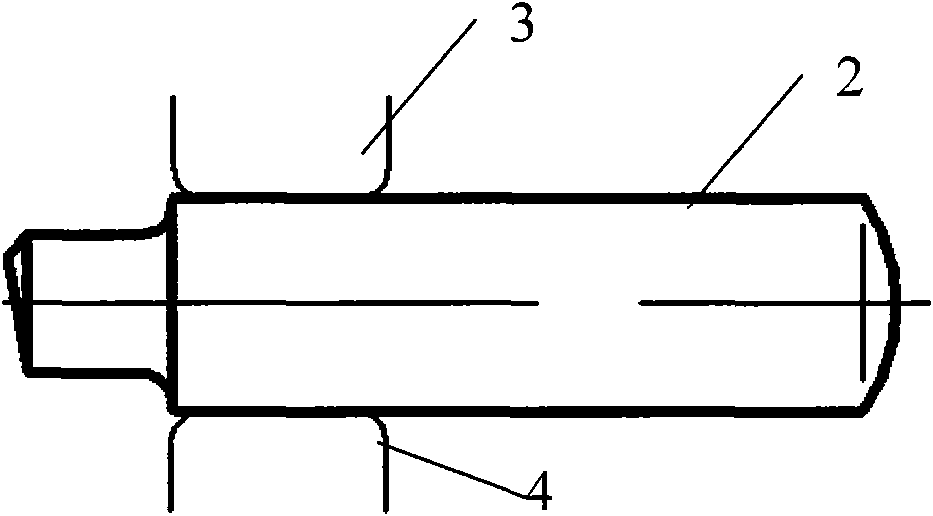

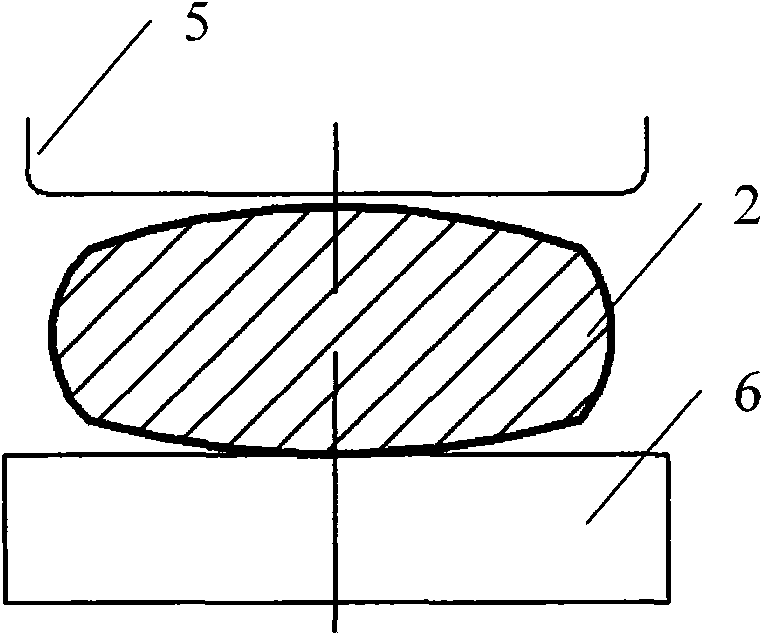

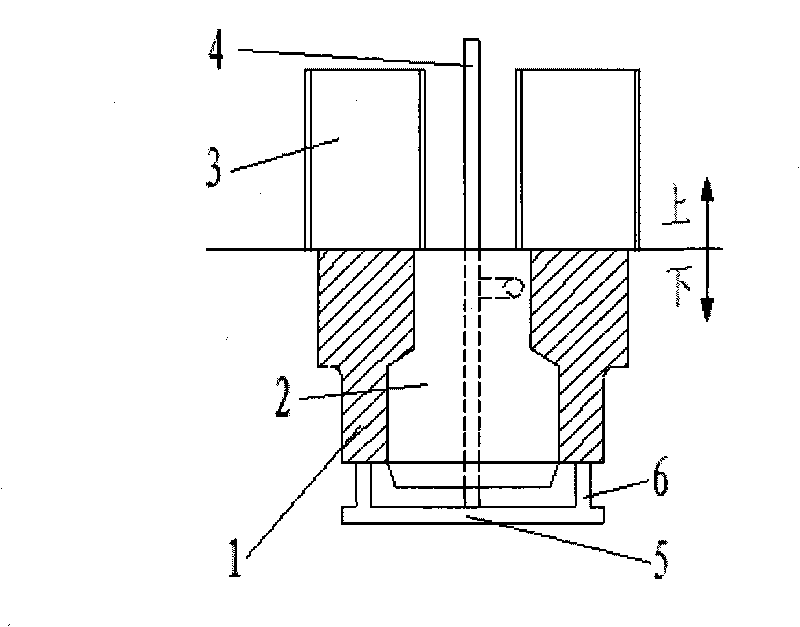

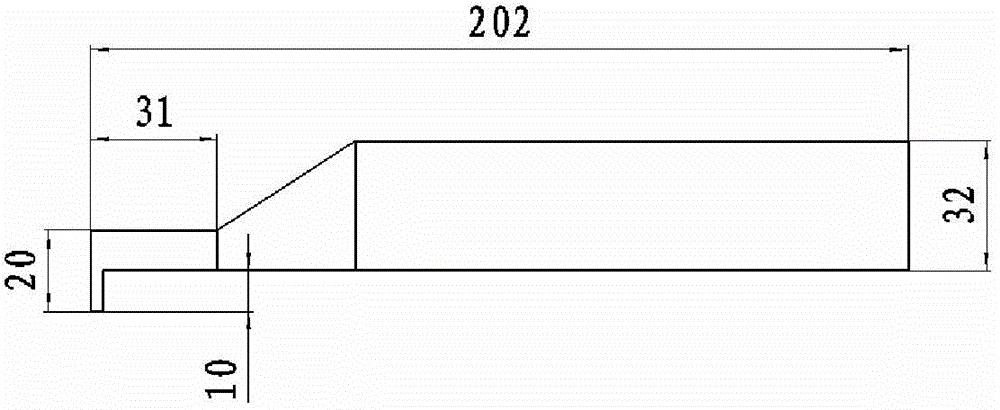

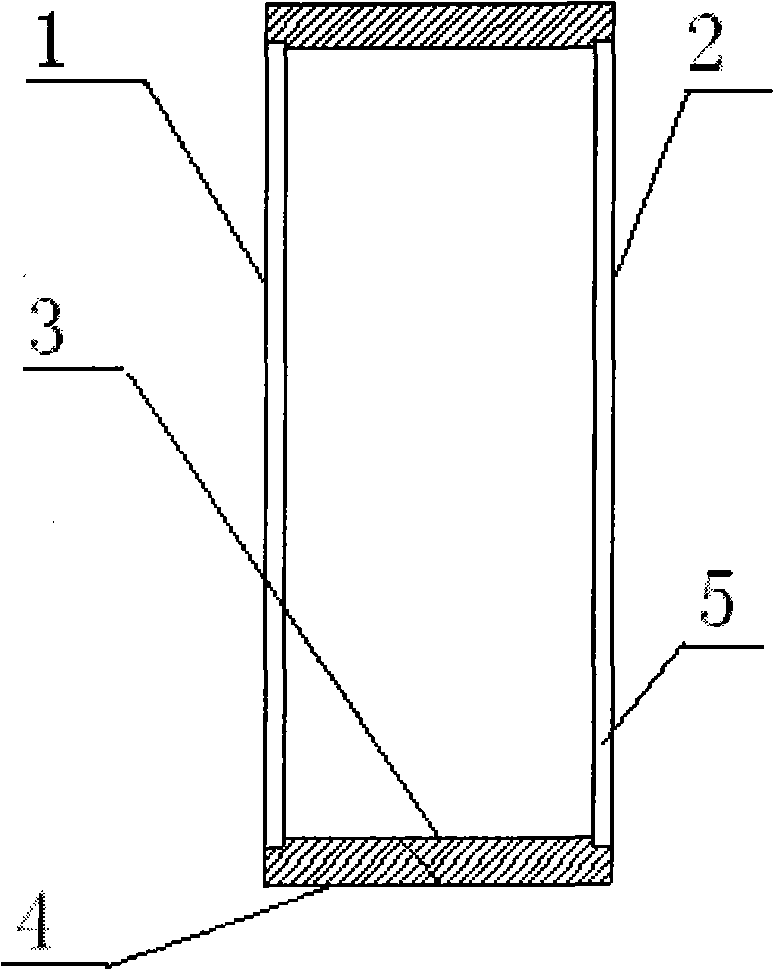

Extrusion forming process of thin-wall long pipe-shaped part blank with flange and mould

InactiveCN101829698AImprove internal qualityHigh dimensional accuracyExtrusion diesMaterials scienceForming processes

The invention belongs to extrusion forming technologies for non-ferrous metal materials and relates to a precise extrusion forming process of a thin-wall long pipe-shaped part blank with a flange. The forming process comprises two steps of primary backward extrusion and secondary forward extrusion, wherein in the step of primary backward extrusion, a primary backward extrusion convex mould (6) is utilized to match with a primary backward extrusion concave mould to together with a piece pusher (11) as an auxiliary for obtaining a primary backward extrusion pipe blank (17) with a web; a secondary forward extrusion convex mould consisting of a forward extrusion convex mould (14) and a mandrel (13) and a secondary forward extrusion concave mould (15) are utilized to carry out the secondary forward extrusion; and the secondary forward extrusion convex mould is placed into a primary backward extrusion pipe blank (18) and moves downwards to extrude the primary backward extrusion pipe blank (18) to obtain a secondary forward extrusion pipe blank (19) so as to finish a secondary forward extrusion process. The internal quality, the size precision and the material utilization rate of the produced thin-wall long pipe-shaped part blank with the flange are greatly improved; and meanwhile, the production efficiency is improved, and the production cost is reduced.

Owner:HENAN UNIV OF SCI & TECH

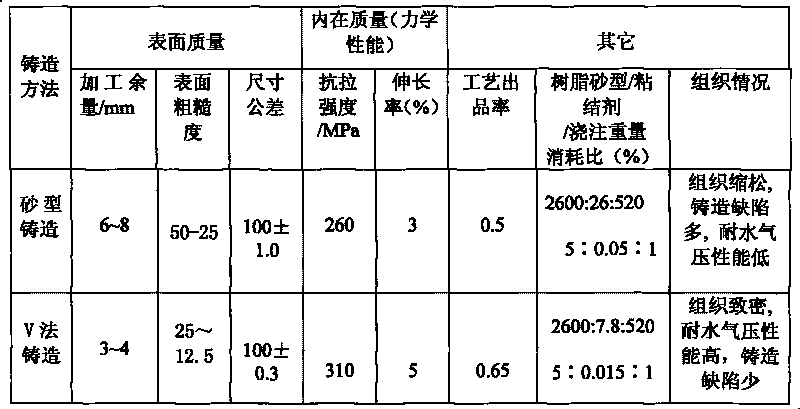

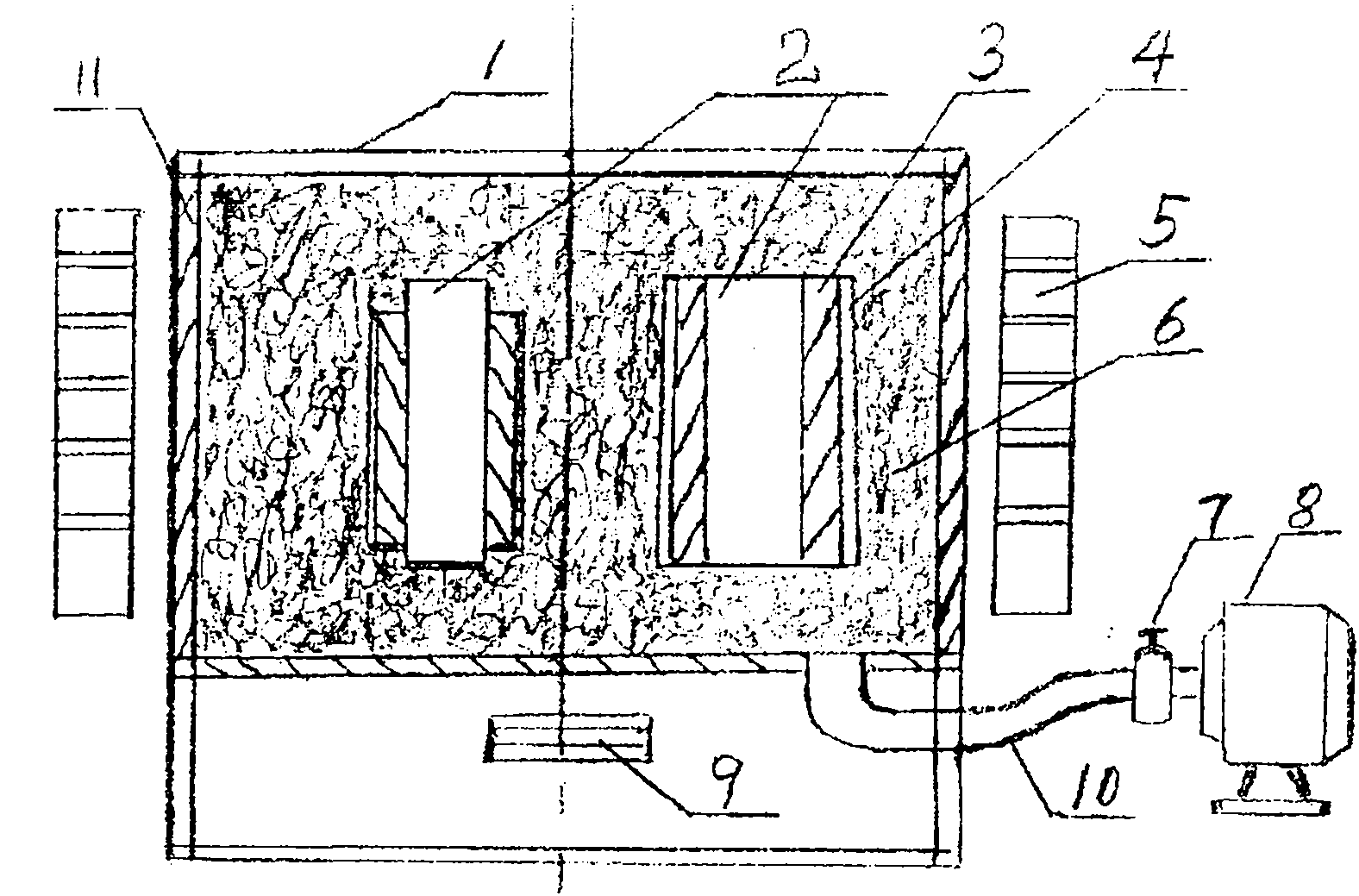

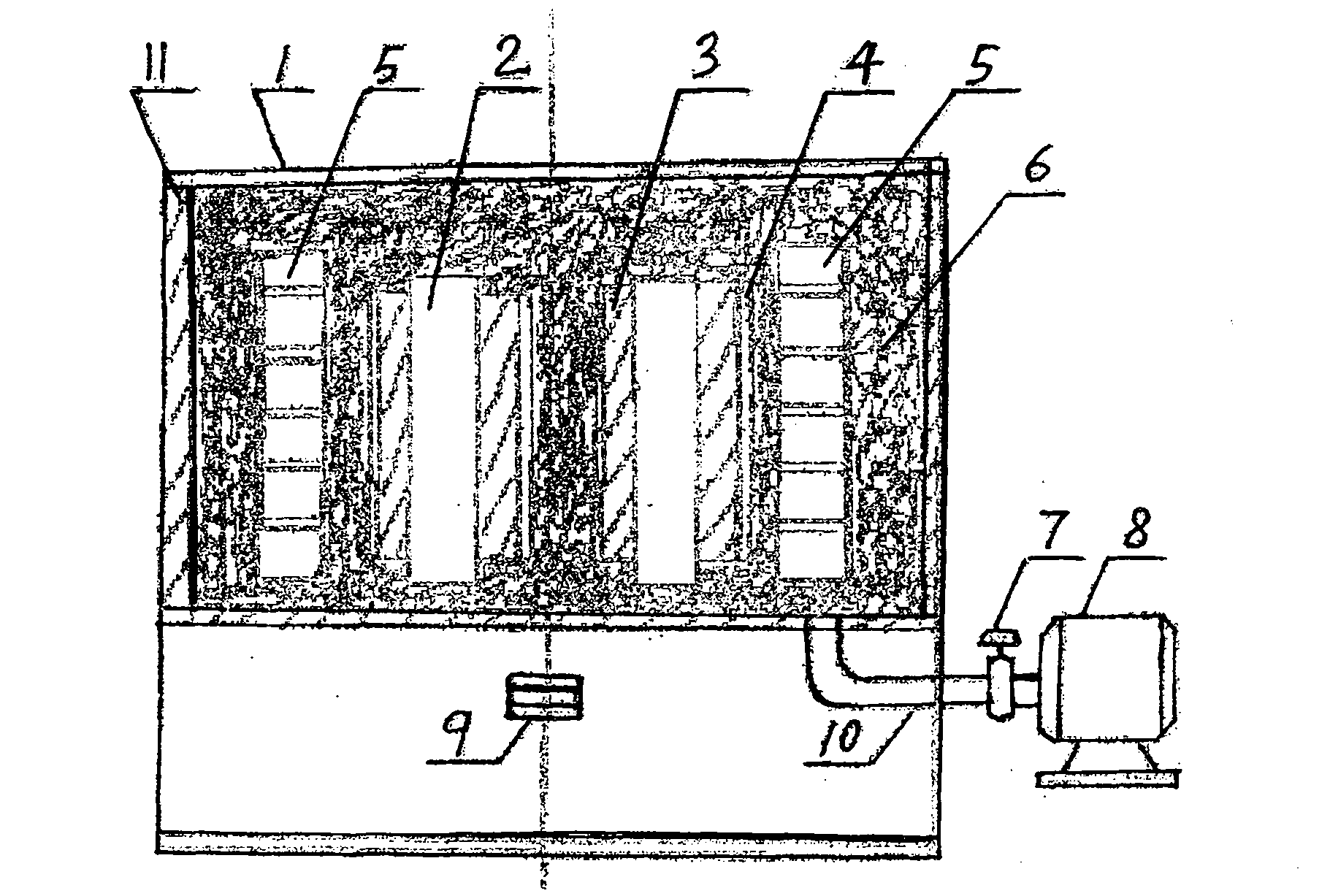

Method for producing voltage-bearing aluminum alloy tank body of ultra-high voltage switch by V-process

ActiveCN101693282AImprove mechanical propertiesImprove quality levelFoundry mouldsFoundry coresFoundryIntermediate frequency

The invention discloses a method for producing a voltage-bearing aluminum alloy tank body of an ultra-high voltage switch by a V-process, comprising the following steps: model making, thin film heating, thin film shaping (film absorbing), coating spraying, sandbox placing, ram-jolting by adding sand , back film covering, film loosening, core setting, box folding, pouring, removing box and shaking out. After the process is improved, an intermediate frequency furnace is utilized to melt and a crucible heat preserving furnace is utilized to modify and refine. When melting in the intermediate frequency furnace, microelements such as tombarthite and the like are replenished and a new non-stirring melting and refining technology is adopted so as to reduce oxide inclusion content in alloy liquid. Modification and refining treatment in the crucible heat preserving furnace ensures high purity degree and high component precision of aluminum liquid, and using pure aluminum alloy liquid can increase the ratio of acquiring qualified pressure-proof tank body foundry products.

Owner:NANYANG HUISEN PRECISION INSTR CASTING

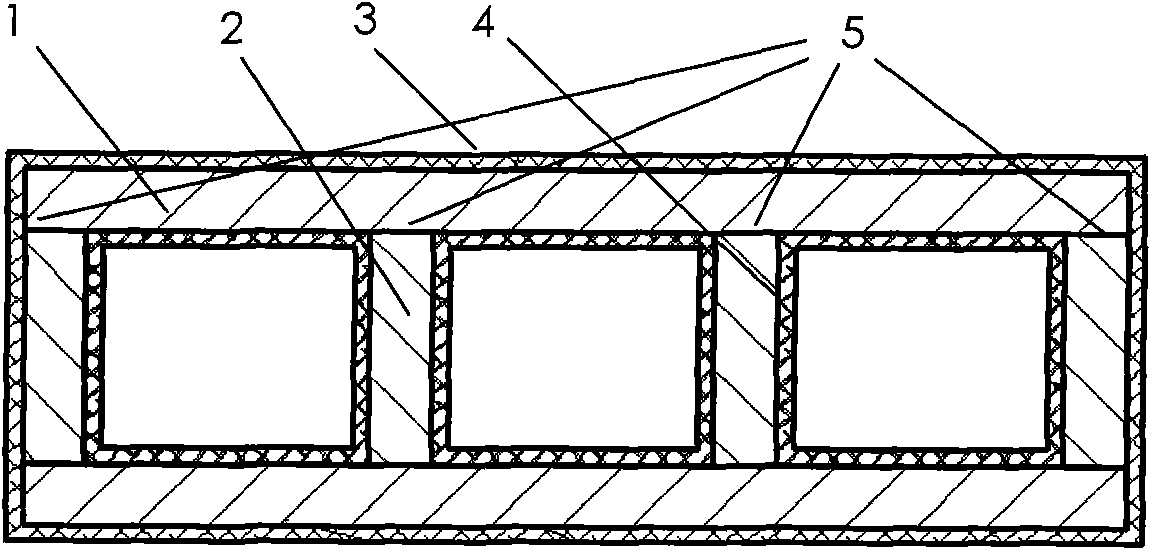

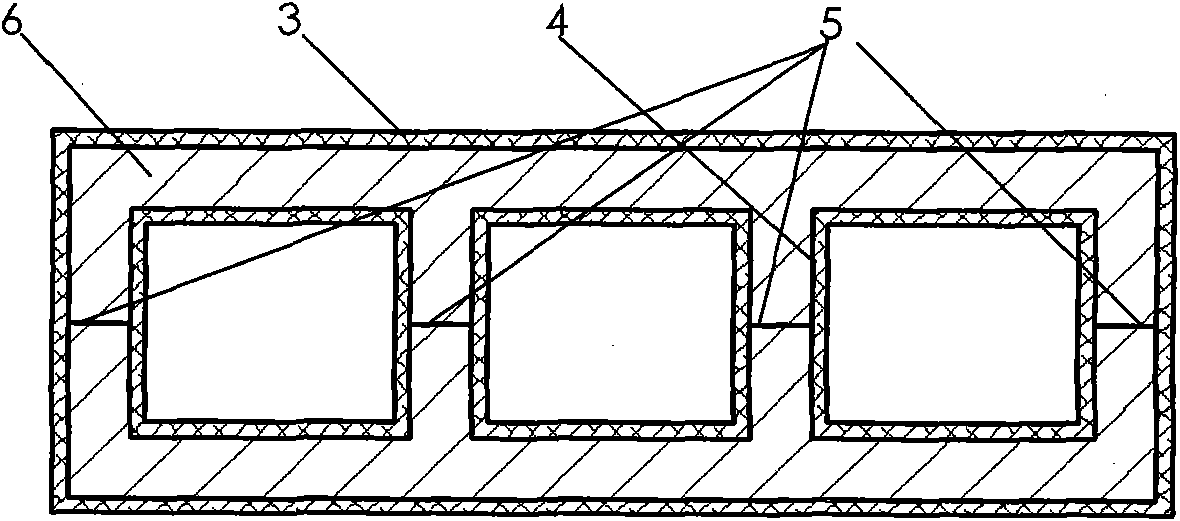

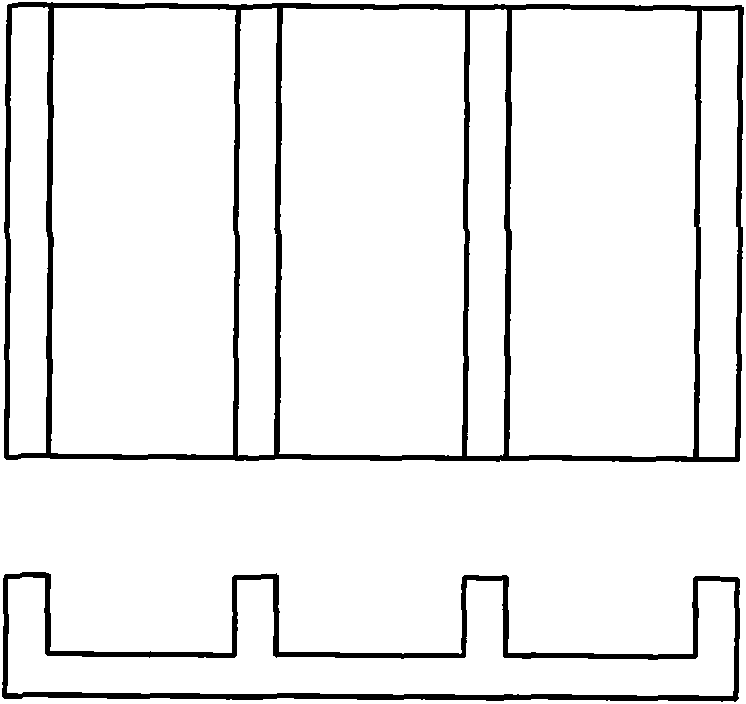

Preparation process and device of nano-particle reinforced bimetal composite

InactiveCN101914767ALow melting pointImprove toughnessMetallic material coating processesCorrosionBonding strength

The invention relates to a preparation process and a device of a nano-particle reinforced bimetal composite, the nano-particle reinforced bimetal composite comprises the following chemical components by weight percent: 6-25% of Cr, 4-18% of Ni, 1.0-4% of Mo, 1.0-1.8% of Si, 1.2-3% of Mn, 0.4-2.2% of B, 0.1-1.2% of MgO, 0.2-2% of CaF2, 0.2-0.7% of C, 0.2-0.8% of Nb, not more than 0.9% of one or the combination of CeO2, Y3O2 and La2O3, 0.0-0.8% of Co, and the balance of Fe, and mixed particles of nano-sized carbides, nitrides, borides or carbonitrides are added in alloy powder. The vacuum induction melting and the cladding processes and equipment are adopted for melting and cladding the mixture on a workpiece, the thickness of a cladding layer is 0.1-25mm, the cladding layer contains 1%-50% of nano-reinforcing particles of one or the combination of the carbides, the nitrides, the borides and silicides, and the cladding layer has special performances of wear resistance, corrosion resistance, electrical conductivity, self-lubrication performance and the like. A coating layer and a base material form the metallurgical bonding, thereby having high bonding strength, overcoming the drawbacks in various coating processes at home and abroad, leading the coating layer to avoid the defects of shrinkage cavities, inclusion, cracking, shedding and the like and having the advantages of high heating temperature, fast speed, high production efficiency, small energy consumption, simple preparation process and low cost.

Owner:丁家伟

Forging method of GH4169 alloy inner cartridge receiver special-shaped ring part

The invention discloses a forging method of a GH4169 alloy inner cartridge receiver special-shaped ring part. The forging method comprises the steps of sawing, upsetting, punching, chambering and rolling, wherein the forging method further comprises the step of mold formation after the rolling step. The forging method has the following beneficial effects: the forged ring part is finally formed by a mold; the subsequent machining margin of the obtained forged part is low; the material utilization rate is high; the production efficiency is high; and in addition, a mold forming process nearly damages the streamline of the forged part.

Owner:GUIZHOU AVIATION TECHN DEV

Sand-line iron mould casting process for grey cast iron flywheel housing of diesel engine

ActiveCN102728790AGood size consistencyPut an end to the phenomenon of sand swellingFoundry mouldsFoundry coresDieselingSurface roughness

The invention discloses a sand-line iron mould casting process for grey cast iron flywheel housings of diesel engines. In the invention, upper and lower sand-line iron mould processes are used, so that produced grey cast iron flywheel housing blanks have favorable geometric size precision which can be up to CT8 grade, favorable surface roughness which can be up to 12.5 microns and favorable mechanical properties, the blank processing has small allowance which can be controlled in 3mm, small flashing distortion which can be controlled in 0.5mm and small cleaning workload, so that the labor environment is improved, the environmental protection is improved, the yield is high and can be up to 95%, and the national policies of energy conservation, environmental protection and sustainable development are met.

Owner:JIANGSU SONGLIN AUTOMOBILE PARTS

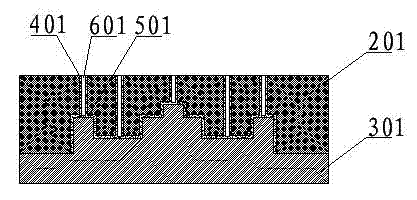

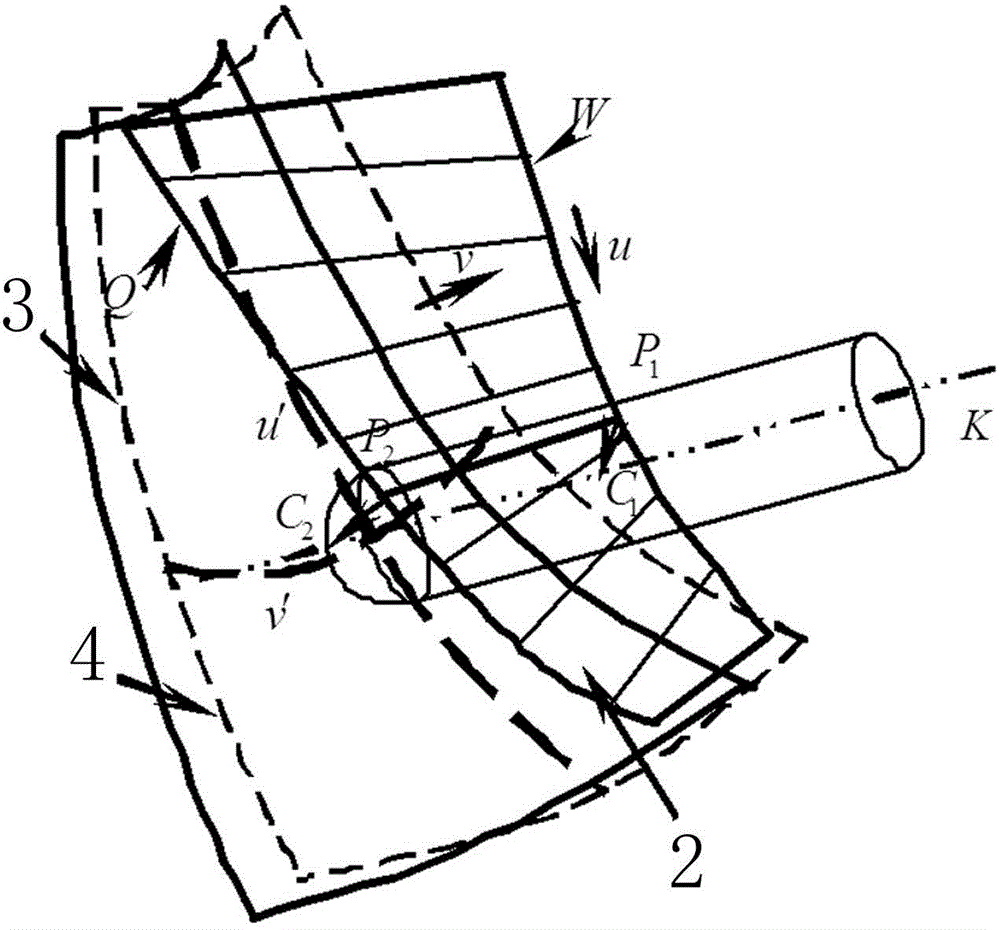

Five-axis plunge milling machining method for ruled surface impeller

InactiveCN102722137AImprove machining accuracySmall machining allowanceMilling equipment detailsNumerical controlImpellerMaterial removal

The invention discloses a five-axis plunge milling machining method for a ruled surface impeller. The method comprises the following steps of: generating a boundary vector, interpolating the boundary vector, calculating the row pitch and step pitch, calculating a cutter center point, and planning a cutter path until machining of a ruled surface impeller part is finished. By the method, the defect of low rough machining efficiency in the prior art is overcome, the material removal rate and machining efficiency of the plunge milling are guaranteed, and the method is applicable to popularization and application.

Owner:SHENYANG POLYTECHNIC UNIV

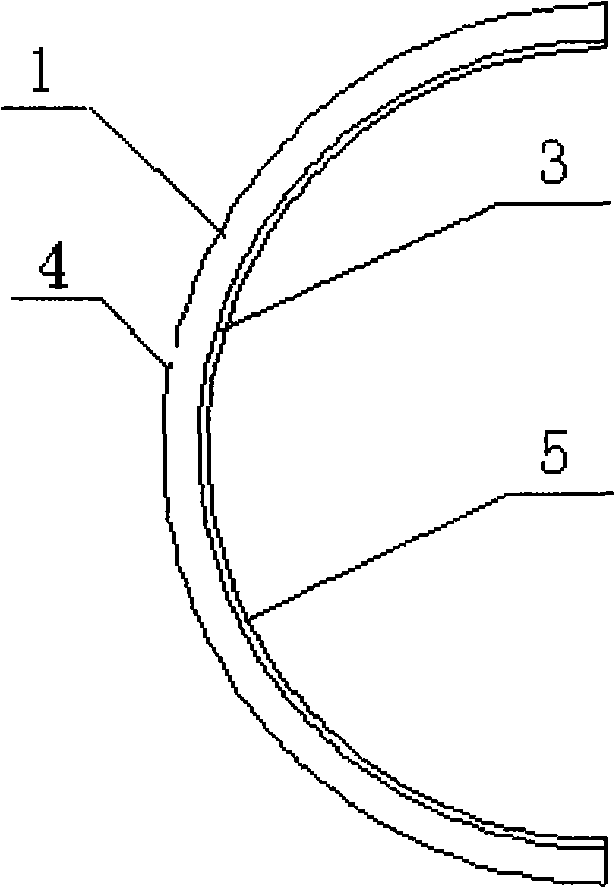

Rolling and shaping method of titanium alloy taper ring forged piece

The invention discloses a method for rolling and shaping titanium alloy tapered-ring forge pieces. In order to obtain the titanium alloy tapered-ring forge piece with good organization and performance, and realize precise rolling, the method comprises the following steps: an alloy bar is subjected to heating and continuous upsetting, deformed by 50%-55%, made into solid cake, and then subjected to punching to cause the hole diameter to be 30%-35% of the outer diameter thereof so as to obtain a hollow cake; the hollow cake is subjected to heating and rolling and deformed by 20%-25% to obtain a rectangular ring blank; the rectangular ring blank is subjected to heating and rolling and deformed by 30%-35% to obtain a rectangular pre-rolling blank; the pre-rolling blank is subjected to heating, loaded in the rolling mould of a ring rolling mill, rolled in the tapered hole of the rolling mould, and deformed by 25%-30% to obtain the tapered-ring forge piece. When being rolled, the widening speed of the pre-rolling blank along radial direction is 2mm / s-15mm / s, and the received radial roll force is 40000kg-220000kg. The method is mainly used for shaping the tapered-ring forge piece of an aeroengine. By the method, the tapered-ring forge piece, the ring surface of which is a complex curved surface and distributed in a streamline form along the shape of the piece, can be obtained.

Owner:GUIZHOU AVIATION TECHN DEV

Manufacturing method of titanium alloy hollow component

ActiveCN101786223AIncrease productivityImprove efficiencyNon-electric welding apparatusTitanium alloyStressed skin

The invention relates to a manufacturing method of a titanium alloy thin-wall ribbed hollow component. The method comprises the following steps that: a. the titanium alloy hollow component is decomposed into a stressed-skin and ribbed structure form or a stressed-skin ribbed structure form according to the structure features of a hollow component, and an inner sheath and an outer sheath structure forms are determined according to a hollow part of the hollow component; b. the stressed-skin and ribbed or the stressed-skin ribbed structural part is processed or formed according to the decomposed structure forms; c. the inner and the outer sheaths are processed or formed; d. the stressed-skin and ribbed or the stressed-skin ribbed structural part being well processed is assembled with the inner and the outer sheaths, the inner and the outer sheaths are sealed in a welding way and are vacuum encapsulated, and the vacuum degree is 1.0 *10-3Pa; e. the dispersion connection of each structural part is realized through a hot isostatic pressing method; f. surface treatment on each prefabricated structural part is undertaken so as to prepare the hollow structural component. The manufacturing method has high production efficiency; a plurality of components can be prepared through one technical circulation; and the welding rate is more than 95 percent.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

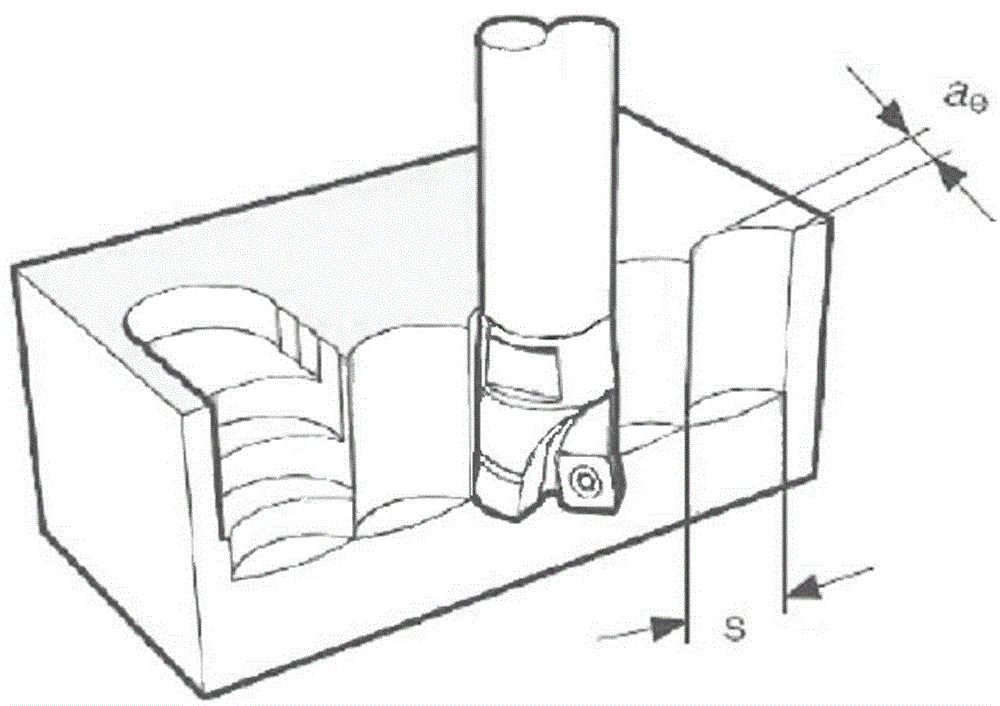

Blisk manufacturing method based on 3D (three-dimensional) printing and electric spark finishing

ActiveCN104690517AWide range of processingHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlEngineering

The invention discloses a blisk manufacturing method based on 3D (three-dimensional) printing and electric spark finishing. The blisk manufacturing method includes: 1) manufacturing a wheel hub of a blisk, washing the wheel hub of the blisk prior to positioning and fixing the wheel hub on a numerical control table; 2) generating a slicing file; 3) manufacturing a blisk blank on the numerical control table by 3D printing according to the slicing file; 4) subjecting the blisk blank to hot isostatic pressing; 5) measuring a practical three-dimensional model of the blisk blank; 6) acquiring the accuracy error and deformation amount between the practical three-dimensional model of the blisk blank and a target three-dimensional model of the blisk; 7) determining spark machining allowance according to the accuracy error and the deformation amount; 8) subjecting the blisk bland to spark machining according to the spark machining allowance so as to obtain a blisk sample; 9) removing a fused layer on the surface of the blisk sample and grinding the blisk sample to obtain the blisk. The blisk manufacturing method based on 3D printing and electric spark finishing has the advantages of capability of blisk manufacturing, material saving and high machining precision.

Owner:XI AN JIAOTONG UNIV

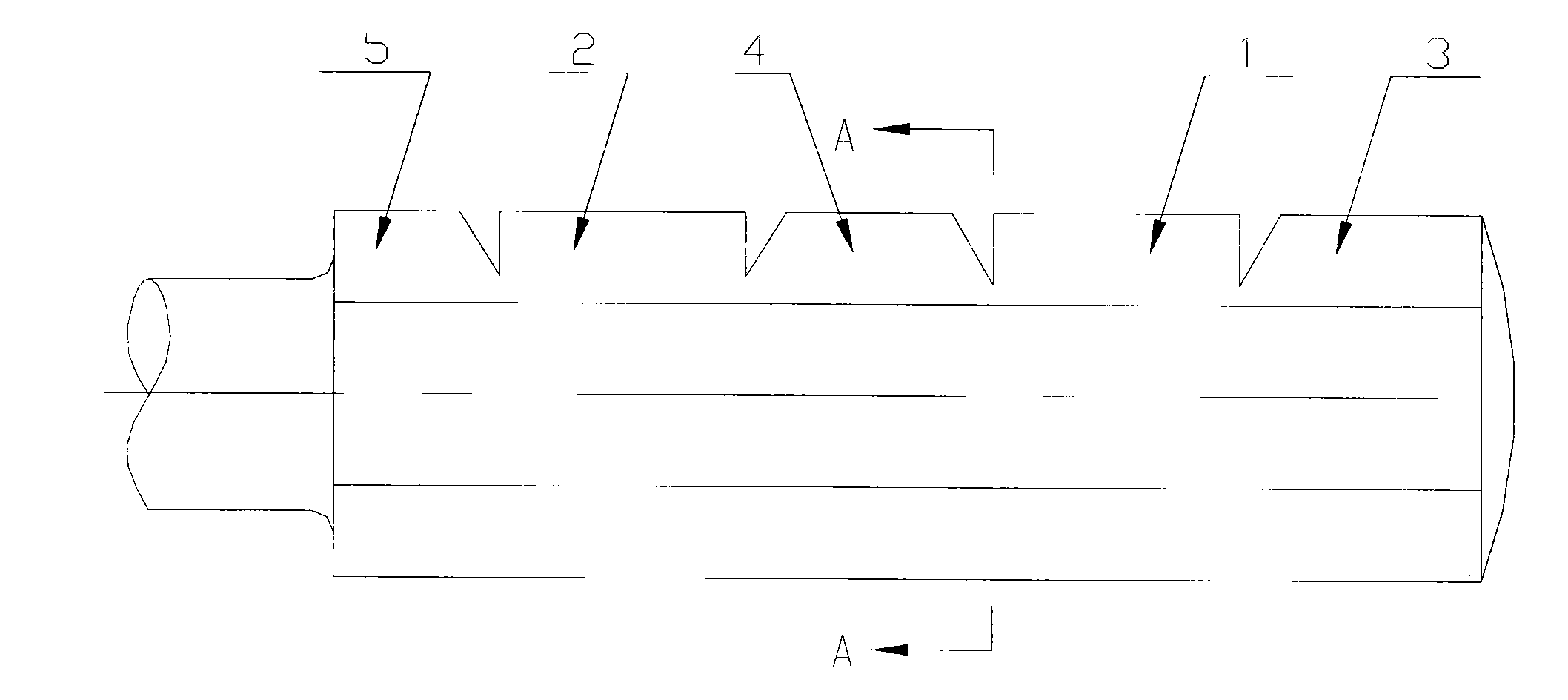

Drill pipe joint precision die forging process

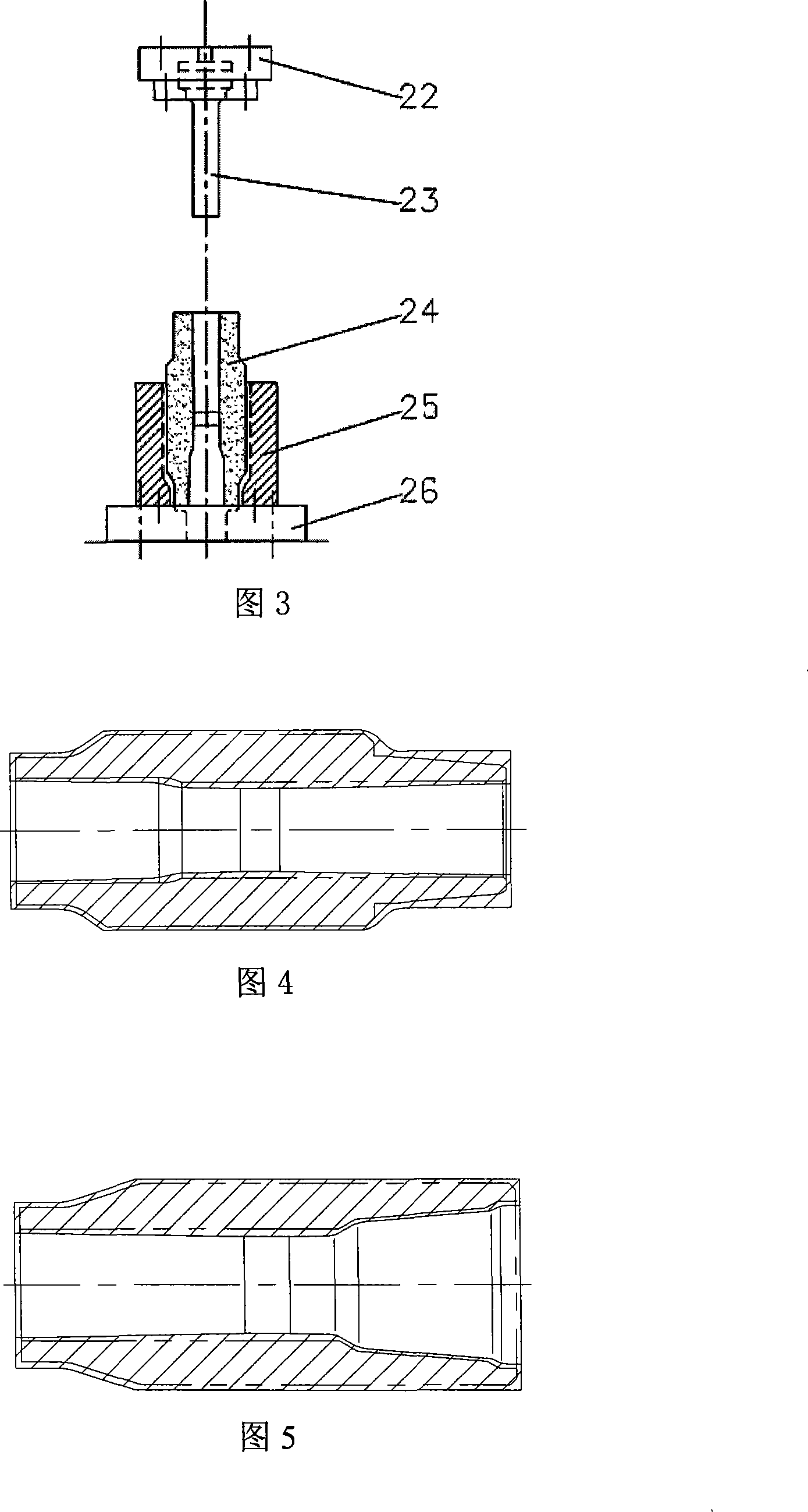

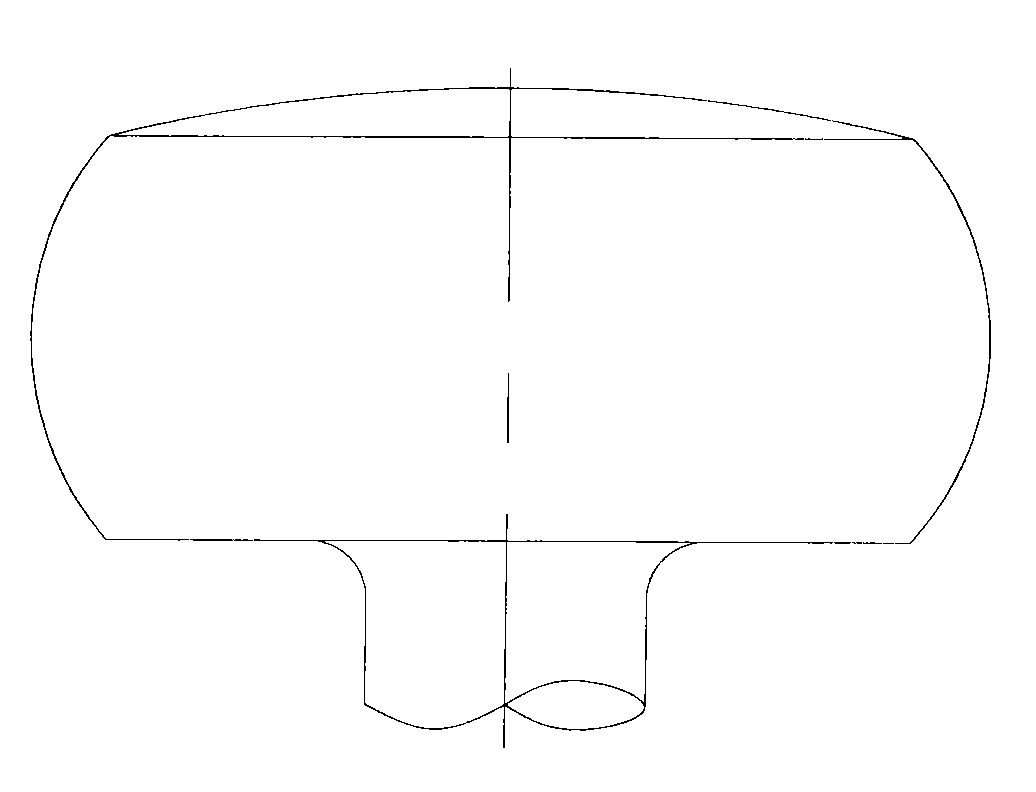

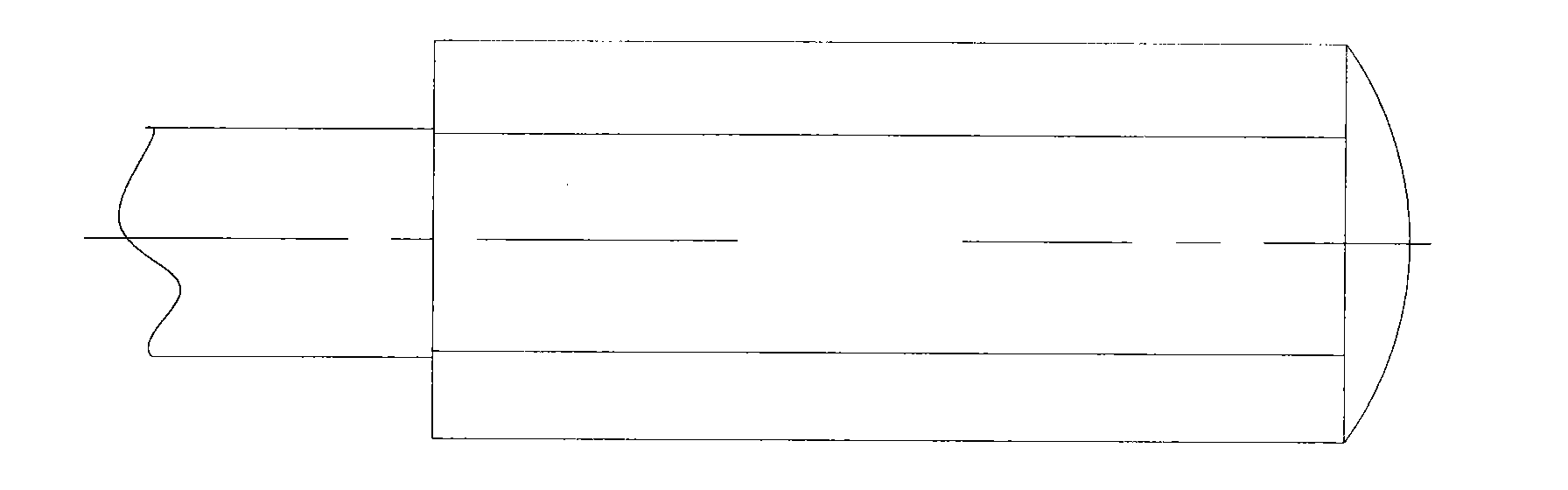

InactiveCN101181730AEasy to moldSmall machining allowanceForging/hammering/pressing machinesMedium frequencyMaterial consumption

The invention discloses a precise die forging technique of a petroleum drill rod connector and is characterized in that: 1) flan material is prepared with a band saw; 2) the flan material is heated quickly at a temperature that is suitable for forging by a medium frequency electric induction furnace; 3) then the flan material is extruded in a close type into a prefabricated flan and a flan makes concave die on a quick flan-making oil hydraulic machine; 4) a molding concave by die level method extrudes and presses the prefabricate flan into a connector die forging piece on the quick flan-making oil hydraulic machine which can implement combination of the upper molding concave die and the lower molding concave die and relative extrusion and pressing from right and left and inner holes of the connector die forging piece is provided with wad; 5) finally a hole punching die punches away the recess inside the inner hole of the forging piece on a special hole punching oil hydraulic machine to obtain the connector forging piece with accurate specifications, excellent structure performance and central through holes. The invention has the advantages of good streamline distribution, material conservation, environmental protection and high production efficiency.

Owner:JIANGYIN LONGCHENG DRILLING & PRODN MACHINERY MFG

Forging molding method for million kilowatt nuclear power main pipe

InactiveCN101670416AReduce weightGuaranteed Grain SizeEngine componentsOther workshop equipmentNuclear powerIngot

The invention discloses a forging molding method for a million kilowatt nuclear power main pipe. The forging process of the method comprises the following steps of a, upsetting; b, stretching; c, single-side marking; d, stretching at two ends and a middle part respectively; and e, final fire stretching. The method adopts the single-side marking technology in the forging process so that a forge piece has two-side asymmetrical deformation in the forging process and then a required eccentric shaft neck can be formed. The forge piece formed by the method can be forged on the main pipe in the forging process to form two joint pipes between which an angle of 45 degrees is arranged, so the processing quality of products can be ensured and the weight of the forge piece can be lightened. Because the size of the forge piece has deformation quantity in the final fire forging process, the grain size of austenitic stainless steel can be ensured. The forging molding method for manufacturing the million kilowatt nuclear power main pipe has the advantages of light required steel ingot weight, low cost and small processing allowance.

Owner:SHANGHAI HEAVY MACHINERY PLANT

Equipment for bend-forging crank axle toggle of large ship and method for forging the same

ActiveCN1947886AUnder-forecastSimulation is accurateForging/hammering/pressing machinesEngine componentsMarine engineeringIngot

A bending-forging machine for manufacturing the large crankshaft or bellcrank used by ship is composed of upper die with lower arc end, bending lower die, upper and lower flat stocks, and insertion plate with lower arc end. Its forging method includes such steps as upsetting a steel ingot to become a flat square billet, drawing it to become a blank with shoulder, pressing V-shaped die on the middle of blank to form symmetric two V-shaped slots, bending by upper and lower dies, removing the upper and lower dies, inserting the insertion plate for finishing, trimming, and removing insertion plate.

Owner:SHANGHAI HEAVY MACHINERY PLANT +1

Process and device for forming straight-edge conical cylinder forged piece of nuclear power evaporator

ActiveCN101564750ASmall machining allowanceControl taperMetal-working apparatusNuclear powerEngineering

The invention belongs to the field of forging, and particularly relates to a process and a device for forming a straight-edge conical cylinder forged piece of a nuclear power evaporator, which are applicable to the nuclear power and the process design and manufacturing process for the straight-edge conical cylinder forged piece of a hydrogenation reactor. The forming process comprises the following steps: (1) primary forming of a blank; (2) forming of a conical cylinder structure and a thin-wall conical cylinder structure with equal wall thickness; and (3) forming of the straight-edge conical cylinder forged piece of the nuclear power evaporator. The forming device is provided with a trestle, a saddle and a correcting twist block, wherein the saddle is placed on the trestle; the saddle is matched with an upper flat anvil outside the forged piece blank; and the correcting twist block is matched with the saddle. The operation of the process is simple and convenient, the structure of the device is simple, and the problem that the straight-edge conical cylinder forged piece is difficult to form and the like is solved. The straight-edge conical cylinder forged piece forged by the process has even processing allowance, and the size of each part can meet the requirement of components.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND +1

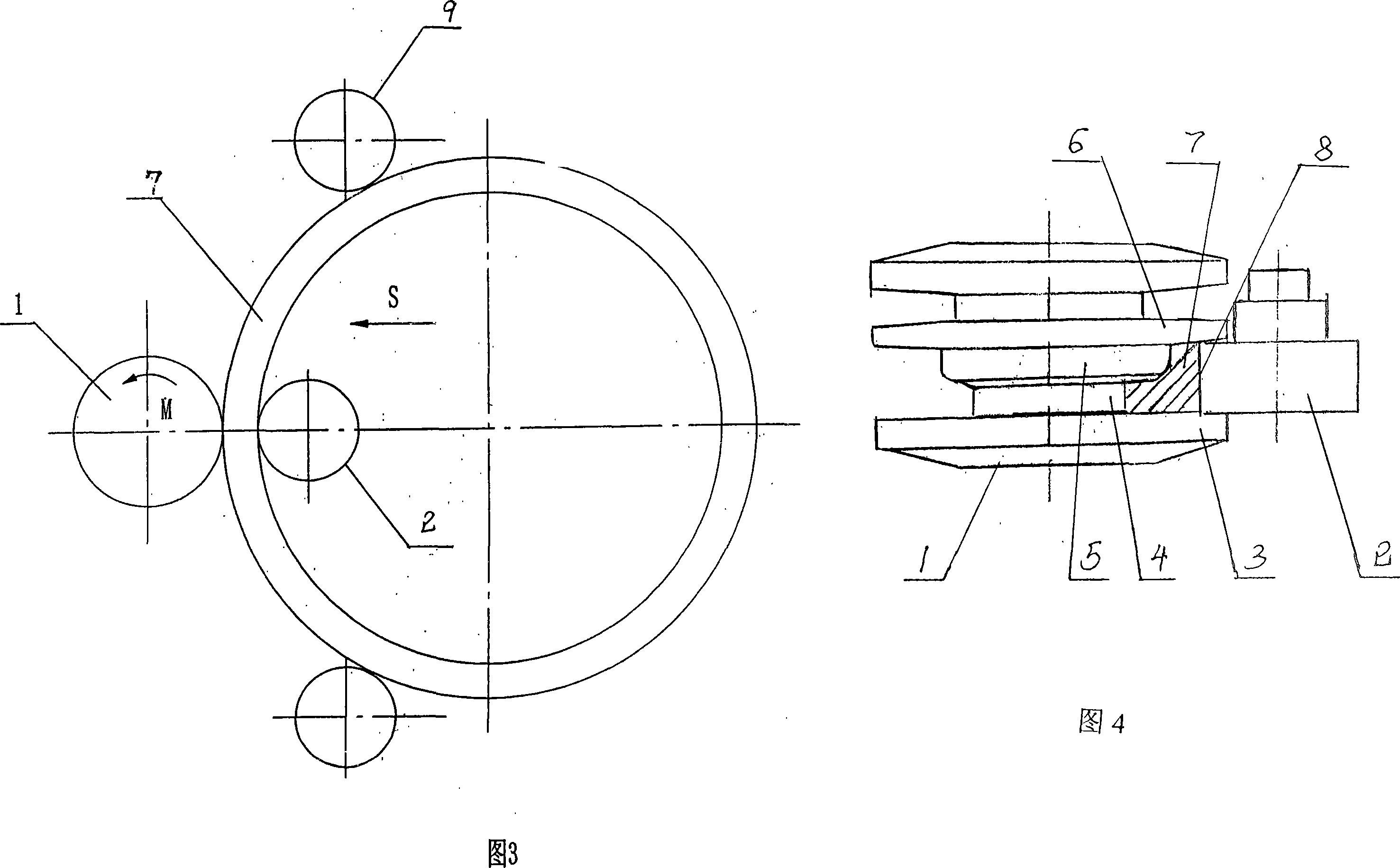

Flange of wind power generation tower barrel forging shaping process

ActiveCN101081426ASolving Forming DifficultiesSmall machining allowanceMetal rollingEngineeringTower

The present invention relates to ring part forging and rolling formation technology, and is especially forging and rolling process of forming flange for wind motor tower. The forging and rolling process includes the following steps: heating the forged flange blank with a disc and a neck in a heating furnace to 1200-1250 deg.c, maintaining for 40-50 min and discharging with one discharging machine; rolling in a ring rolling machine; and finish rolling in the ring rolling machine with double retaining rib molds. Compared with available technology, the present invention has the advantages of saving in material, low power consumption and low production cost.

Owner:兰鹏光

Method for casting cylinder cover of low-speed diesel for large-bore vessel

InactiveCN101722277AReduce manufacturing costShorten the production cycleFoundry mouldsFoundry coresLow speedSmelting process

The invention relates to a method for casting a cylinder cover of a low-speed diesel for a large-bore vessel, which mainly comprises the steps of planning a casting process, manufacturing a wood mould, manufacturing a sand mould, assembling the moulds, pouring, cooling and cleaning cast. The method comprises the following steps in details: (1) planning the casting process of the cylinder cover, and designing a parting surface and a casting system according to a flat parting method; (2) manufacturing the wood mould according to the technological requirement, and positioning the wood mould on a template; (3) manufacturing cast and placing risers; (4) assembling the moulds, and drying the sand mould; (5) smelting cast solution, blowing inert gas and feeding in the smelting process; (6) pouring the cast; and (7) preserving the heat and cooling the cast, and carrying out performance heat treatment on the cast. The method manufactures the cylinder cover of the low-speed large-bore diesel by a casting mode instead of forging, can greatly reduce production cost, and shorten production period.

Owner:HUDONG HEAVY MACHINERY +1

Processing method for controlling processing deformation of titanium-aluminum alloy thin-wall case

The invention relates to a processing method for controlling processing deformation of a titanium-aluminum alloy thin-wall case. The technical scheme of the processing method is as follows: the processing method comprises the steps as follows: a primary rough turning process, a primary heat treatment process, a secondary rough turning process, a secondary heat treatment process, a fine turning process, a third heat treatment process and a finish turning process. According to the processing method for controlling the processing deformation of the titanium-aluminum alloy thin-wall case, reasonable processing parameters are set, and an appropriate cutter is used, so that the processing deformation of the titanium-aluminum alloy thin-wall case is controlled, and the processing requirement is met.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

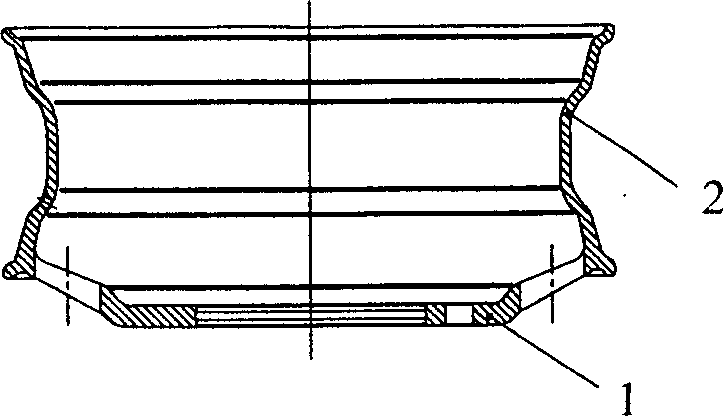

Forging and rotary extrusion forming process for aluminium alloy wheel

InactiveCN1827289AQuality improvementLight in massMetal-working apparatusMaterial consumptionRotational molding

The invention relates to a forging aluminum alloy wheel forging-rotational molding method, which combines the forging and rotational compressing techniques. In forging, molding part of spoke of wheel, and pre-molding the rim; then in rotational compressing, rotationally compressing the rim to complete the molding. Wherein, the rim is molded by forging, and the rim is mainly molded by rotational compression. The invention can combine the forging and rotational compression to express their advantages. And the inventive aluminum alloy wheel has better quality, high accuracy, less finish allowance, higher strength, and reduced material consumption.

Owner:JIAXING STONE WHEEL

Manufacturing process of high-power low-speed diesel shaft bushing

InactiveCN101275606AReduced edge defectsHigh bonding strengthBearing componentsManufacturing technologyLow speed

Owner:CHONGQING YUEJIN MACHINERY

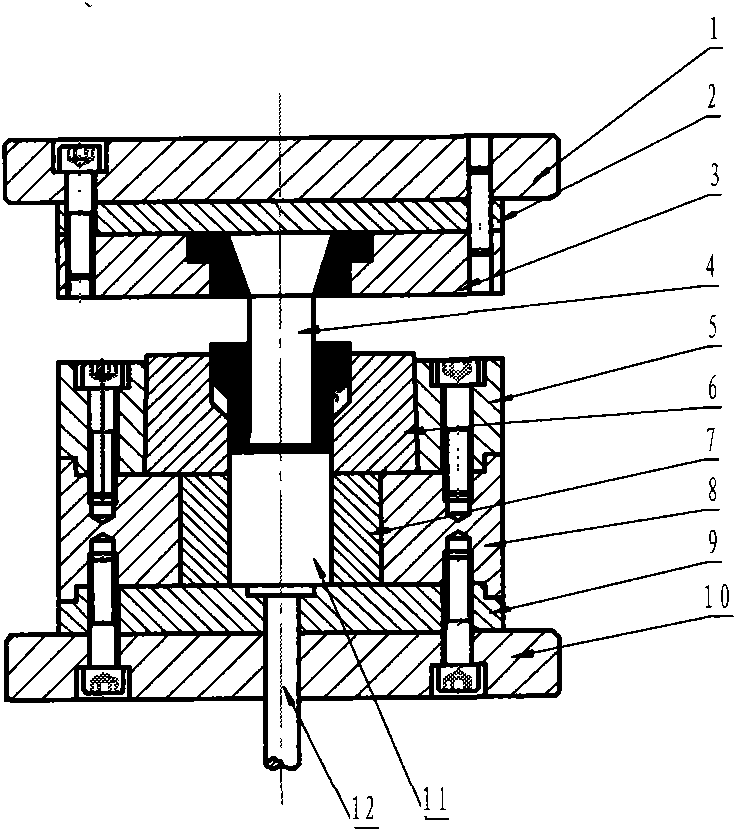

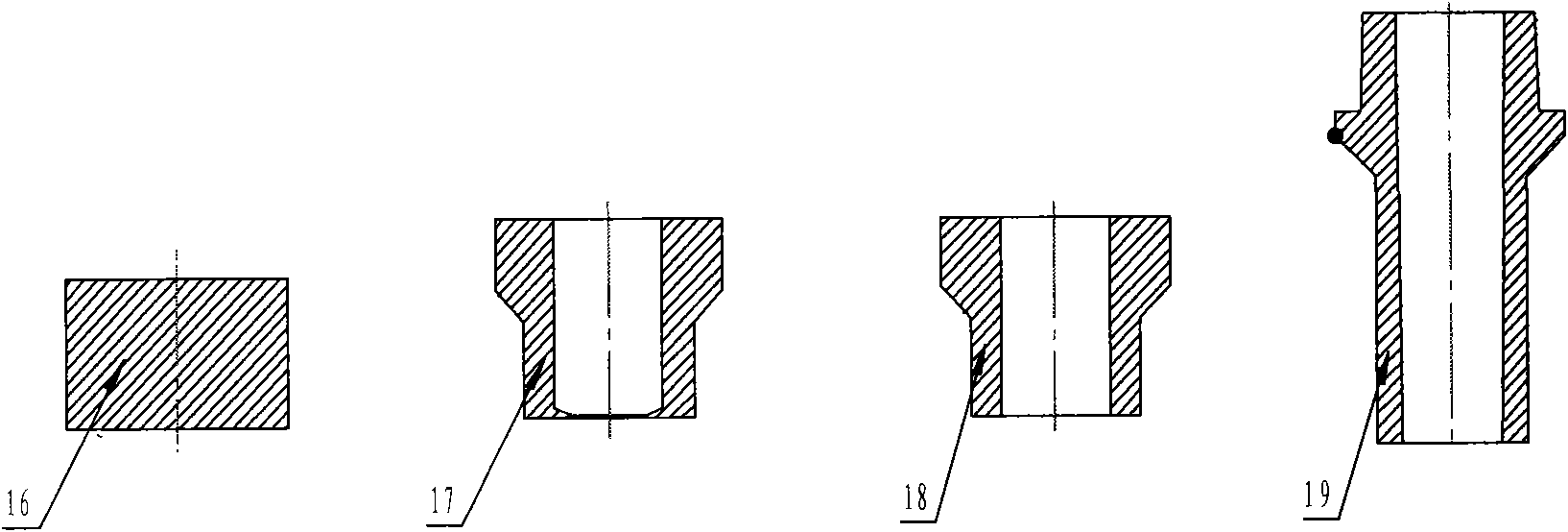

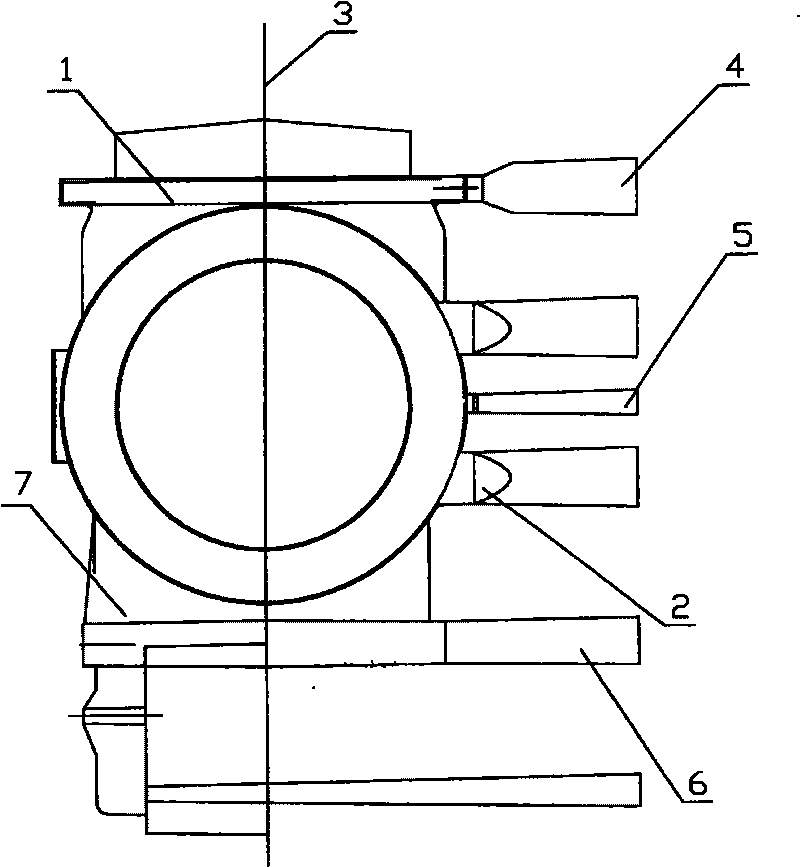

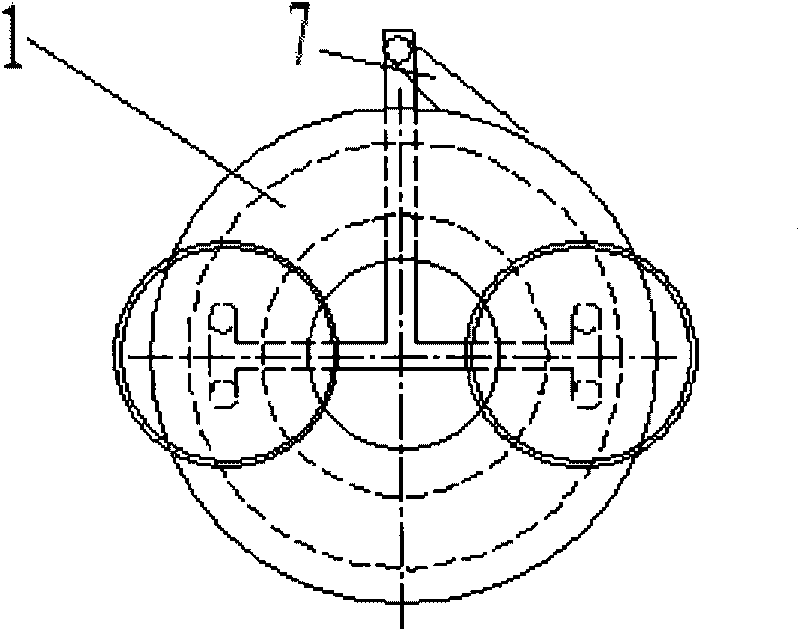

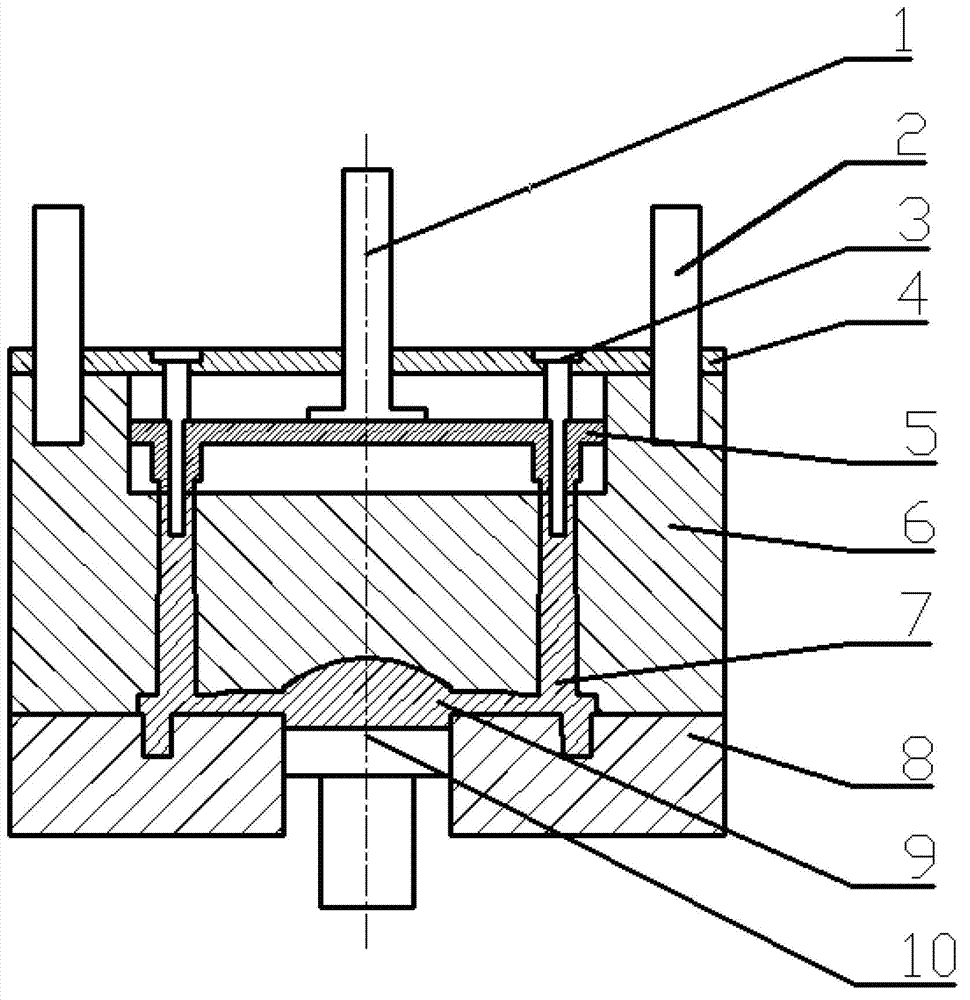

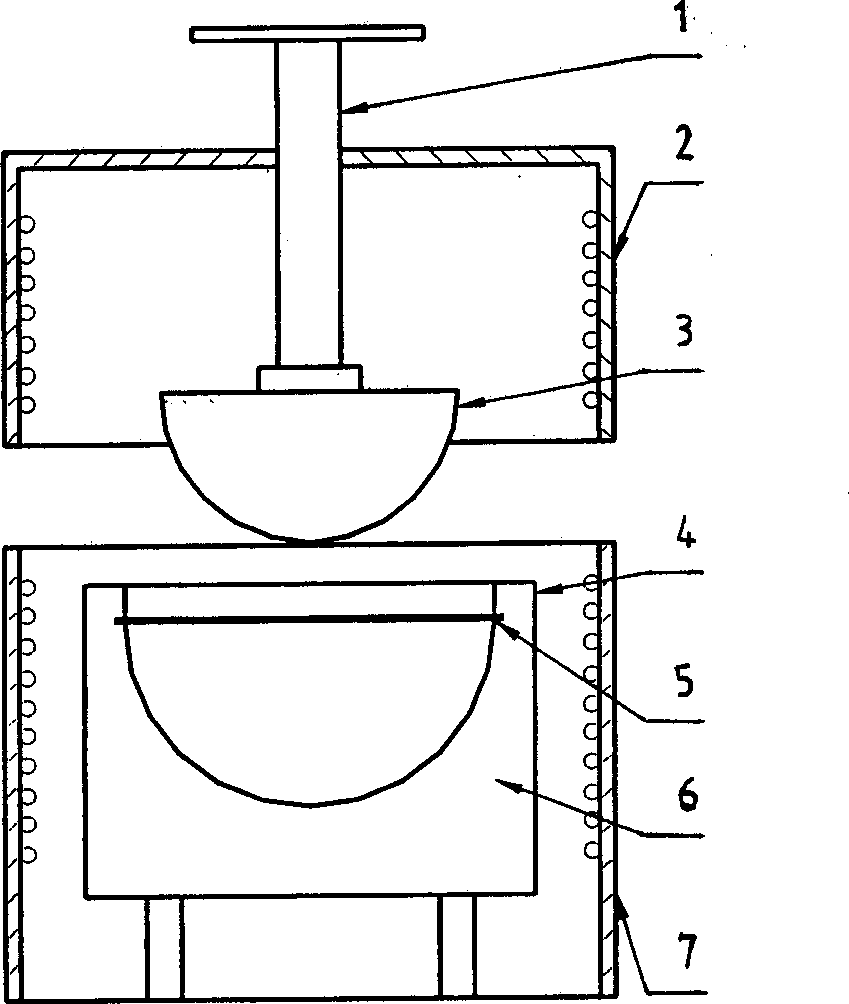

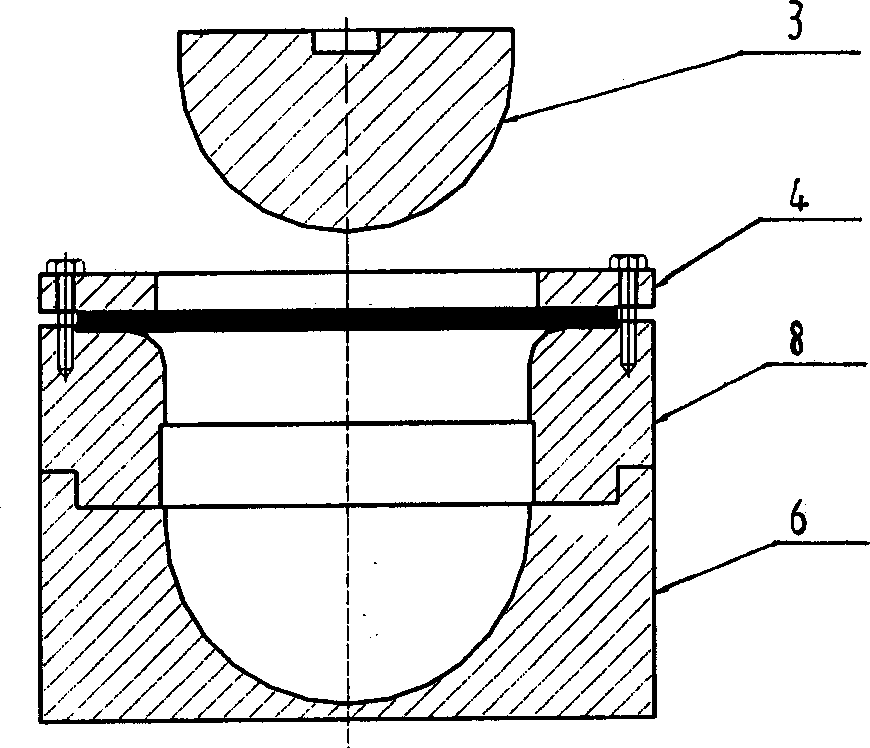

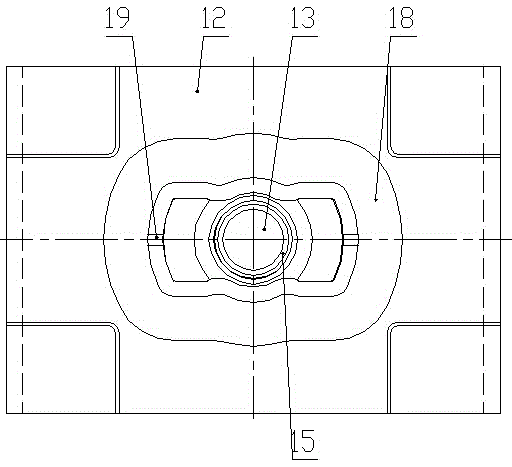

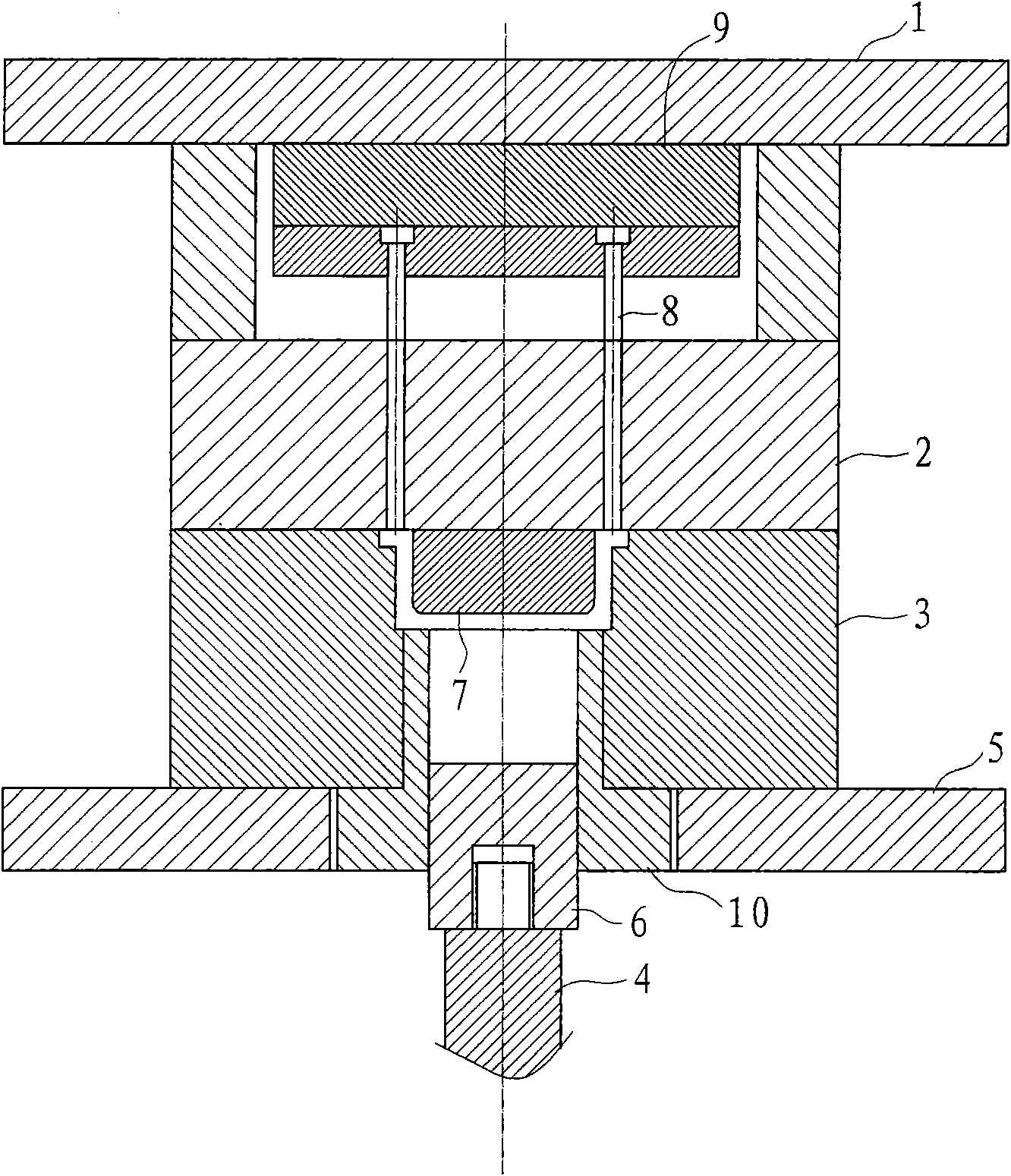

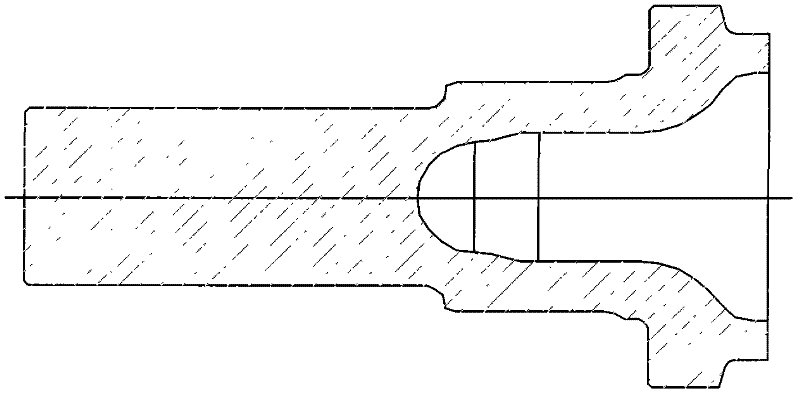

Semi-solid extruding and casting molding mould and molding process of compressor crankshaft and

The invention provides a semi-solid extruding and casting molding mould and molding process of a compressor crankshaft. The mould comprises an upper mould and a lower mould, wherein a closed space is formed by carrying out die assembly on the upper mould and the lower mould and serves as a cavity of a extruding and casting piece of the compressor crankshaft; a puncher pin passes through a hole at the center of the lower mould to enter the cavity; a template of the upper mould is fixedly connected with a lug boss part at the top of the upper mould through a pressing rod; the top of a mould core is fixedly connected to the template of the upper mould through a thread; a piston rod passes through the center of the template of the upper mould; the flange end at the lower part of the piston rod is in threaded connection with a pressurizing plate to drive the pressurizing plate to move in the space of a groove at the upper part of the upper mould; the bottom face of the pressurizing plate is connected with an annular lug boss; and the mould core passes through a middle hole of the annular lug boss and is inserted into the top of the mould cavity. In the molding process, semi-solid slurry is adopted to fill the mould, a casting temperature is low, and a mould filling process is gentle; and an extruding and casting method is adopted for molding. Therefore, the molding mould and the molding process have the advantages that the material utilization rate is high, the service life of the molding mould is long, tissues of a molded piece are dense, and the production efficiency is high.

Owner:XI AN JIAOTONG UNIV

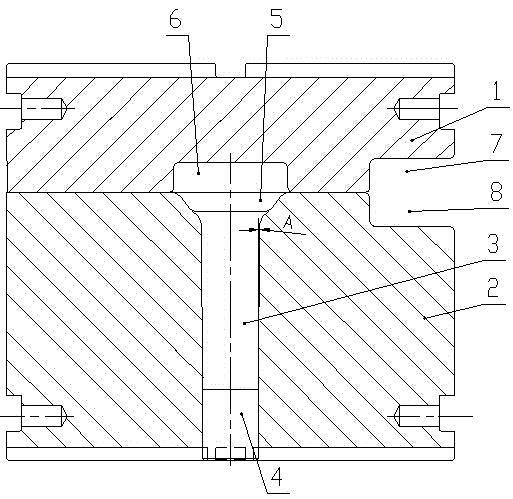

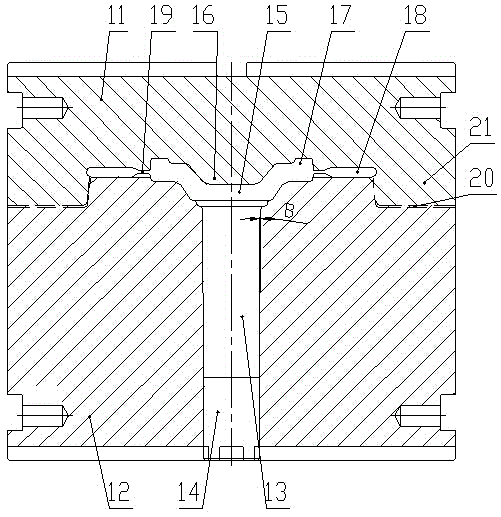

Semi-solid rheo-extrusion casting technology and equipment of hypereutectic Al-Si alloy casting

The invention provides a hypereutectic Al-Si alloy semi-solid rheological squeezing casting technique and a device, which pertains to a technical field of metal material semi-solid forming. The technique comprises the steps: alloy molten metal is smelted; hypereutectic Al-Si alloy semi-solid sizing agent is prepared by an electromagnetic stirring method; the sizing agent is cast into a holding furnace with a temperature of 610 DEG C-630 DEG C for storing; then a quantitative vacuum cup is utilized to cast the sizing agent into a mould which is preheated with a temperature of 150 DEG C-250 DEG C; the sizing agent is squeezing cast with a squeezing speed of 0.1mm / s-0.5mm / s, under moulding pressure of 50MPa-150MPa and with a pressure-keeping time of 10s-80s. The semi-solid continuous rheological squeezing casting of the hypereutectic Al-Si alloy products is realized, which improves the utilization ratio of the materials, reduces finishing allowance and reduces energy consumption but also refines granules of primary Si, refines and spheroidizes eutectic structure. The whole structure of a cast is compact with high-quality surface. The technique is simple and has short process, small investment of equipment, low cost and relatively strong practicability of the technique and the equipment.

Owner:KUNMING UNIV OF SCI & TECH

Titanium alloy spherical shell superplastic shaping method

This invention provides titanium alloy ball shell plastic forming method. Titanium alloy embryo material is filled into down film, heat preservation is done when it is heated by electric furnace to get the floor temperature, then fluid pressure machine press to form and temperature boost at the same time, the temperature stop when the highest temperature is reached, once cycle over. When temperature is down to 50-80 degree centigrade below floor temperature, the temperature begin to lift, forming begins when temperature reach floor temperature, and stop forming when temperature reaches the highest temperature, the second cycle over. The forming accomplished after several cycles. The forming temperature range is 800-900 degree centigrade, and only forming in processing of temperature boosting. The amplitude of fluctuation is 100 degree centigrade, forming velocity is 0.6mm / min-1.0mm / min. This invention can be used to the diameter less than 800 mm and different wall thickness titanium alloy ball shell forming. Pressure proof ball need by deep diving submersible is this technique method. The inner surface of the ball shell doesn't need process, and processing margin of outer surface and roof is very little.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

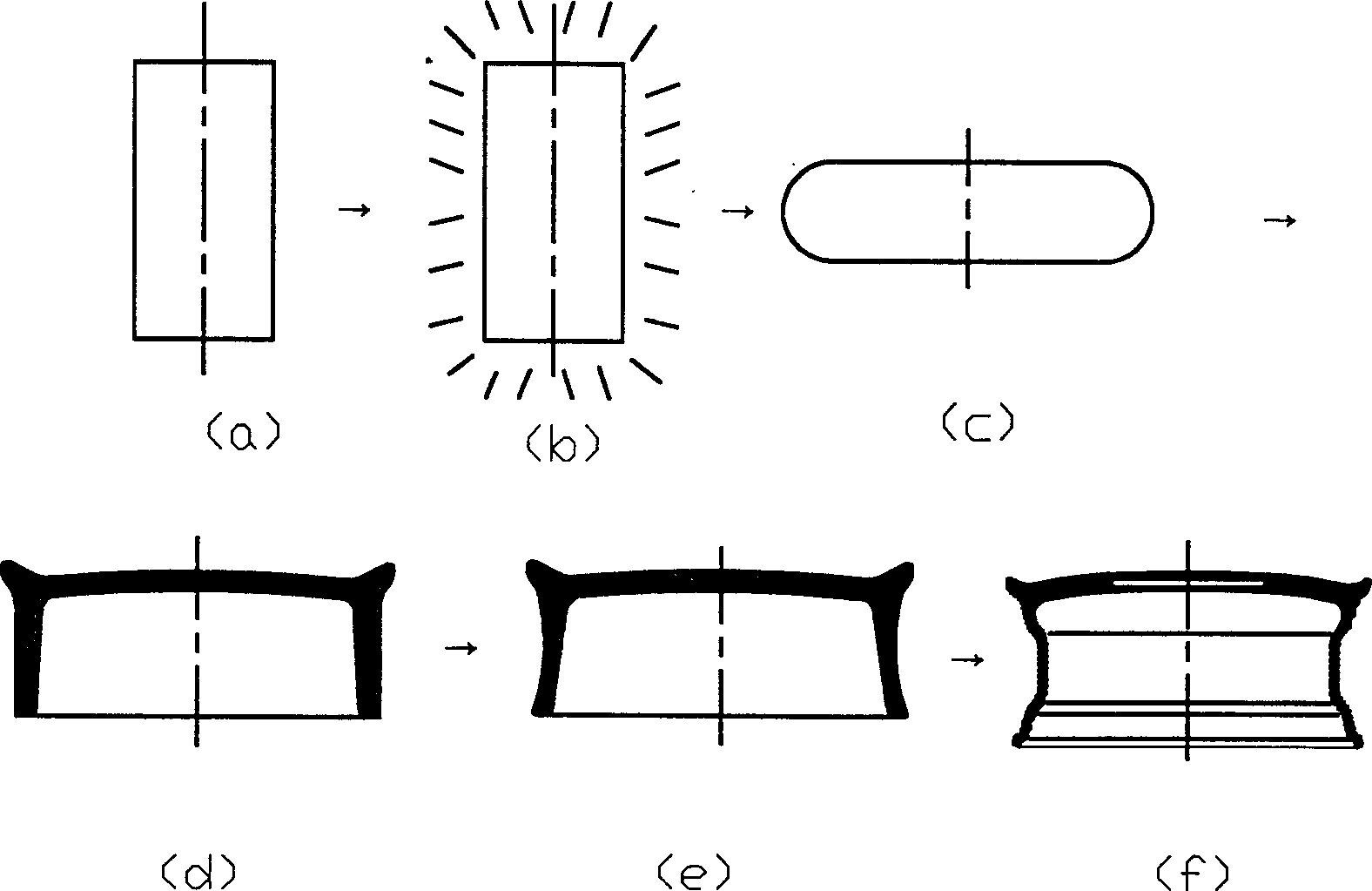

New forging process for yoke shaft of transmission shaft

ActiveCN104439027AReduce energy consumptionSmall machining allowanceForging/hammering/pressing machinesEngine componentsStress concentrationMedium frequency

A new forging process for a yoke shaft of a transmission shaft comprises the following steps that first, blanking is performed; second, local medium frequency induction heating is performed; third; blanks are formed, wherein heated blank materials are placed in a blank-forming mold on a blank-forming press machine, the blank-forming press machine is controlled to forge and press the heating ends of the blank materials, the blank materials are taken out after the heads are formed in a forged and pressed mode, and the blank-forming press machine is controlled to press the heads flat and enable the heads to be in the shape of a track for athletic running; fourth, final forging is performed, wherein the blank materials are placed in a final forging mold on a final forging press machine to be forged and pressed, and the blank materials become final forged pieces after being forged and pressed; fifth, edge cutting is performed, wherein middle recess parts or flash parts of the final forged pieces are cut off so that the final forged pieces can become forged piece products. Through the new forging process for the yoke shaft of the transmission shaft, stress concentration between blank material rods and the molds is avoided, the cost of pre-forging mold materials and the mold machining cost are saved, the mold production cycle is shortened, machining allowance is small, production efficiency is further improved, the labor intensity of workers is relieved, and production cost is reduced.

Owner:XUCHANG ZHONGXING FORGING +1

Preparation method of aluminum-alloy gas meter end cover

InactiveCN101598585AReduce weightImprove anti-corrosion performanceVolume meteringMechanical pressureAir tightness

The invention discloses a preparation method of an aluminum-alloy gas meter end cover, which is characterized by comprising the following steps: (1) respectively configurating aluminum alloy material and magnesium; (2) melting and refining; (3) pretreating and extruding cast mould; (4) extruding and moulding; (5) carrying out heat processing; and (6) carrying out post-processing. Compared with the prior art, the invention has the advantages that aluminum alloy material and advanced indirect extruding and casting process are adopted, so that the moulding material of the gas meter end cover is light in weight and good in corrosion resistance performance; the aluminum alloy melt solution is crystallized at a higher mechanical pressure, the crystal grain is refined, the organizational density is increased, and the defects of porosity, shrinkage, needle eye and the like inside the casting are eliminated, thereby significantly increasing the air tightness, hardness and tensile strength of the casting.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Manufacturing technology for half-axis sleeve tube

InactiveCN102476259ALow costSmall machining allowanceMetal-working apparatusManufacturing technologyMid-frequency

The invention relates to a manufacturing technology for a half-axis sleeve tube, and the manufacturing technology comprises the following steps: blanking; forging; performing normalizing treatment; performing mechanical fine machining; performing quenching and tempering treatment; and performing the mechanical fine machining. In the manufacturing technology, a heating and forging method comprises the following steps: 1) mid-frequency inductively heating a round steel material to be at a preset temperature of 1100 DEG C to 1200 DEG C; 2) using a rolling forging machine to pre-forge and form; and 3) using a special 800-ton frame type hydraulic press to perform once die-forging forming treatment and completely running through an inner hole. According to the manufacturing technology, a processing process and labor hours are reduced, a tool cost is saved, a forged piece is free from any burr, the use ratio of materials can reach 99%, and the production efficiency and product quality of the half-axis sleeve tube are increased.

Owner:GUIZHOU SHUNFENG AUTOMOBILE PARTS MFG

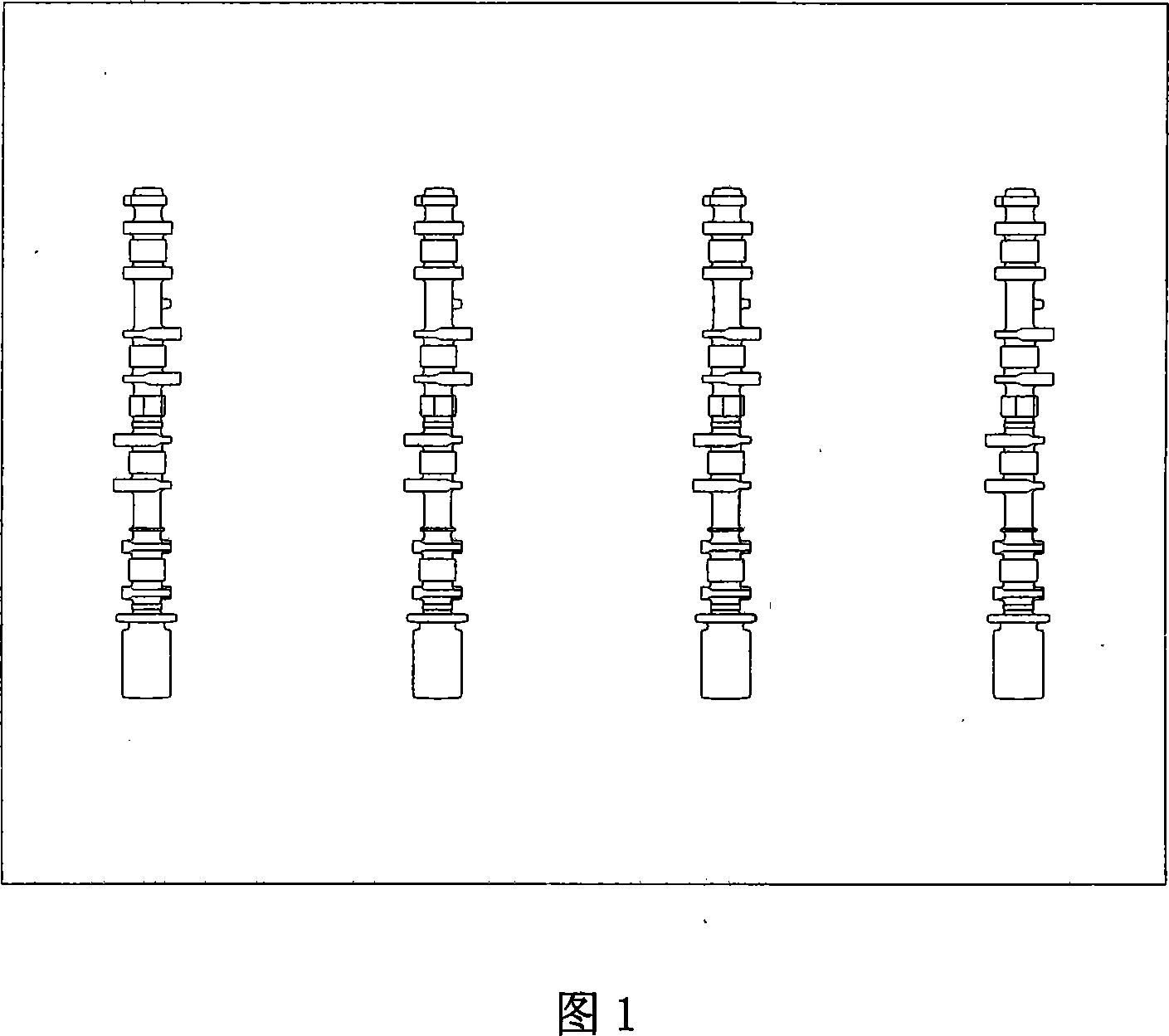

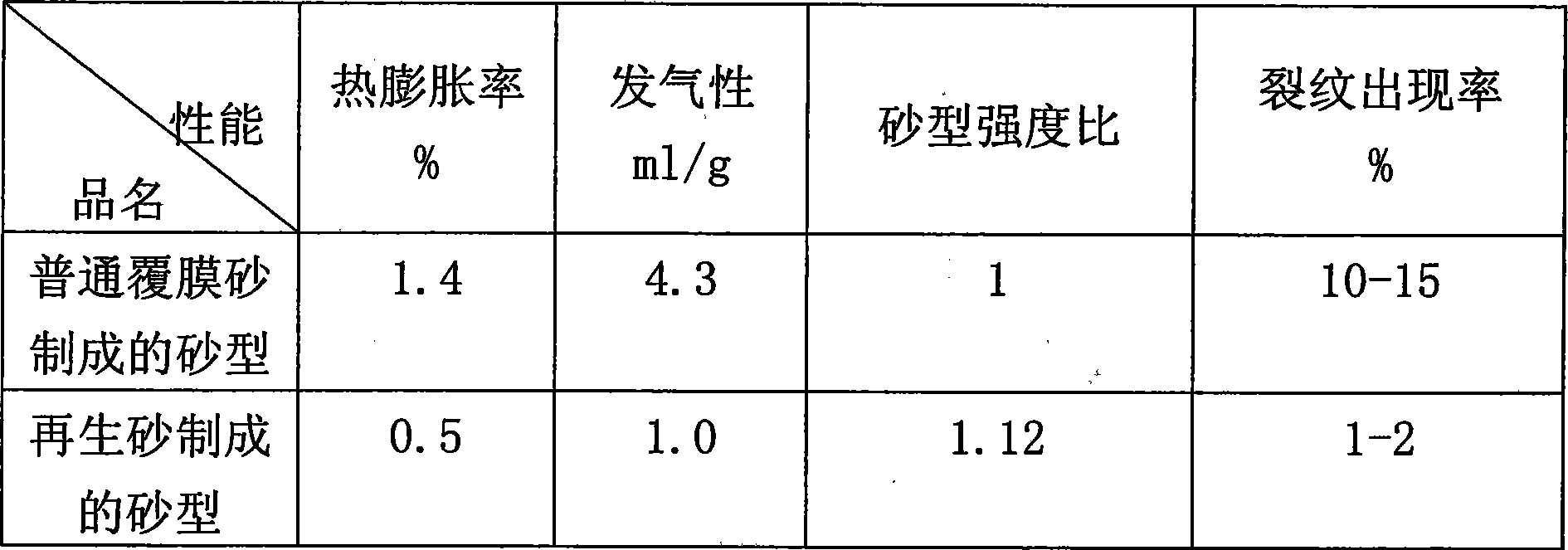

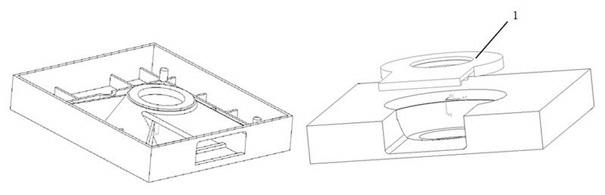

Camshaft sand mold manufactured with tectorial membrane sand with reclaimed sand as roughing sand and manufacturing method thereof

InactiveCN101195148AAvoid deformationAvoid breakingFoundry mouldsFoundry coresTectorial membraneThermal expansion

The invention discloses a camshaft sand mould for manufacturing coated sands, which takes regenerated sands as base sands. The invention is characterized in that the invention is a passing shaft which is composed of an upper sand mould of the coated sands and a lower sand mould of the coated and, and provided with a boss in the middle portion. A manufacturing method comprises firstly, enabling waste sands to regenerate under high temperature, secondly, producing the regenerated sand, thirdly, taking the regenerated sands as the base sands and producing the coated sands, fourthly, heating the mould to 290-310 DEG C, fifthly, inbreathing the coated sands into the camshaft sand mould through compressed air, heating for 110-130 seconds, and curing into the mold, sixthly, obtaining an intact camshaft sand mould after adhering the upper sand mould and the lower sand mould. The superiorities of the invention lie in that blank dimensions of camshaft casts can be more accurate and process redundancy can be minimized due to the low thermal expansion rate of the sands, and cost can be saved. Defects of casts as air holes can be lowered due to low air forming property, and simultaneously effects to environment can be minimized, deformation and cracks of sand moulds can be avoided due to high strength, which is beneficial to arrange and transport, and the quality of cast surfaces can be increased. Flow ability can be improved, and defective indexes of the casts can be lowered. The invention has high strength, smooth surface and good breathing property.

Owner:TIANJIN YABU NEW TECH

Precise casting technology for green sand vacuum sealing model

InactiveCN102218505ALow costReduce energy consumptionFoundry mouldsFoundry coresSmooth surfaceVacuum pumping

The present invention provides a precise casting technology for a green sand vacuum sealing model, which belongs the vacuum casting technical field. The invention is characterized in that the green sand is taken as a molding material, quantity of the sand core can be minimized through an effective usage of foamed materials, which is suitable for producing medium and small sized comparative precision castings. The problems of serious dust pollution, long vacuum-pumping time and production efficiency affected by using paint in a present V method can be solved. When a complex cavity is casted, the foamed material is provided at the position unsuitable for drafting to form a portion of the cavity, the foamed material is melted when casting, therefore the purposes of minimizing sand core quantity and weight can be reached, so that the production technology can be simplified as well as cost can be saved. The produced casting has the advantages of high dimensional precision, clear contour and smooth surface.

Owner:JIAHE ZHONGHE CASTING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com