Titanium alloy spherical shell superplastic shaping method

A superplastic forming and titanium alloy technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as coarsening of internal and external structures, large machining allowance, difficult forming, etc., and achieve great social significance and machining surplus Small amount of effect

Inactive Publication Date: 2006-08-09

725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

View PDF0 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The pressure shell of deep submersibles with a large depth (above 6000 meters) is usually made of titanium alloy, but because titanium alloy has the characteristics of high strength, low plasticity, and difficulty in forming, the conventional forming method is hot stamping, and hot stamping has the following Disadvantages: ①The effective temperature zone for plastic deformation of titanium alloy is narrow, coupled with the chilling effect of the mold, resulting in a rapid drop in the temperature of the slab, a large increase in deformation resistance, and a sharp decrease in plasticity. Inconvenient, ②The deformation of each part of the sphere is uneven, some areas are thinned, some are locally thickened, the machining allowance is large, the thermal effect of local deformation is serious, and the temperature rises, resulting in coarsening of the internal and external tissues, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0043] The molding method and process are the same as in Example 1. In this example, after the one-time molding process is completed, the temperature is lowered to 50°C, that is, 750°C, which is the lower limit temperature of the molding, and the temperature rises, and in Example 1, the temperature is 720°C. The molding speed is 1.0mm / min.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

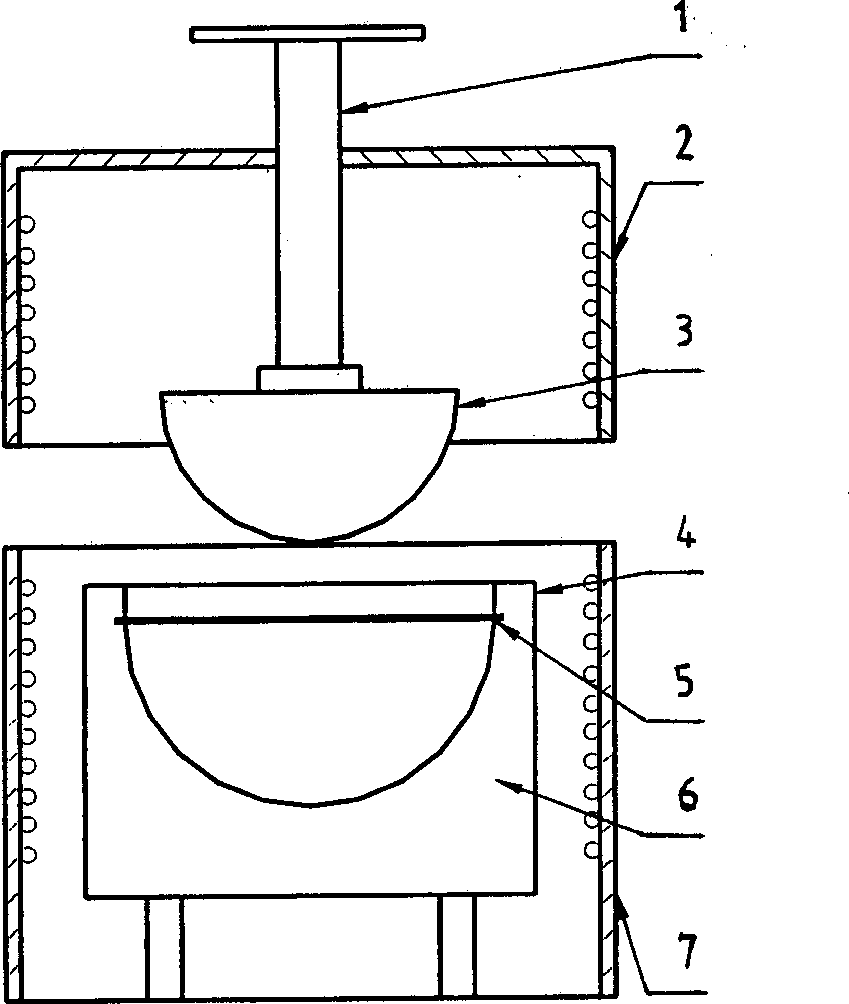

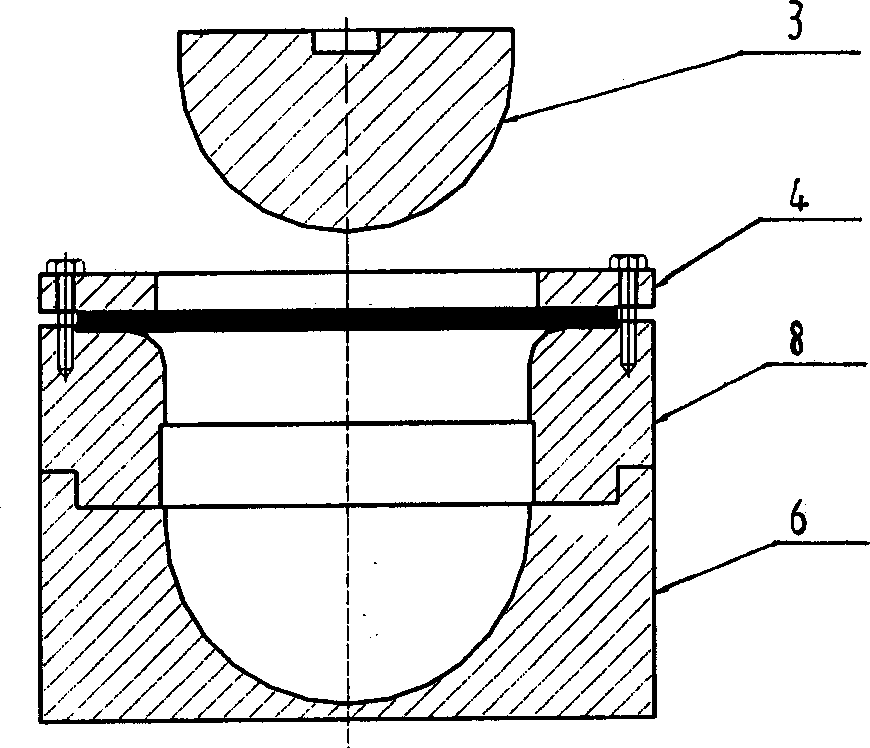

This invention provides titanium alloy ball shell plastic forming method. Titanium alloy embryo material is filled into down film, heat preservation is done when it is heated by electric furnace to get the floor temperature, then fluid pressure machine press to form and temperature boost at the same time, the temperature stop when the highest temperature is reached, once cycle over. When temperature is down to 50-80 degree centigrade below floor temperature, the temperature begin to lift, forming begins when temperature reach floor temperature, and stop forming when temperature reaches the highest temperature, the second cycle over. The forming accomplished after several cycles. The forming temperature range is 800-900 degree centigrade, and only forming in processing of temperature boosting. The amplitude of fluctuation is 100 degree centigrade, forming velocity is 0.6mm / min-1.0mm / min. This invention can be used to the diameter less than 800 mm and different wall thickness titanium alloy ball shell forming. Pressure proof ball need by deep diving submersible is this technique method. The inner surface of the ball shell doesn't need process, and processing margin of outer surface and roof is very little.

Description

Technical field [0001] The invention belongs to the forming technology of titanium alloy products, and mainly proposes a superplastic forming method of a titanium alloy spherical shell. Background technique [0002] The pressure-resistant shell of deep submersibles (more than 6000 meters) is usually made of titanium alloy, but because titanium alloy has the characteristics of high strength, low plasticity, and difficult to form, the conventional forming method is hot stamping, and hot stamping has the following Disadvantages: ①The effective temperature zone for plastic deformation of titanium alloy is relatively narrow, coupled with the chilling effect of the mold, resulting in a rapid drop in the temperature of the slab, a large increase in deformation resistance, and a sharp drop in plasticity. It requires multiple heating and stamping to complete, which brings production Inconvenience: ②The deformation of each part of the sphere is uneven, some areas are thinned, and some are ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D22/20B21D22/22B21D37/16B21D37/12

Inventor 孟祥军刘茵琪冯岩赵国超陈卫

Owner 725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com