New forging process for yoke shaft of transmission shaft

A technology of transmission shaft and new process, applied in the direction of manufacturing tools, engine components, metal processing equipment, etc., can solve the problems of large machining allowance, low production efficiency and high heating energy consumption of forgings, and achieve small machining allowance and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The new forging process of transmission shaft joint yoke shaft of the present invention comprises the following steps:

[0026] (1) Blanking: use a fully automatic CNC sawing machine or CNC shearing machine to blank the round steel into blanks of specified size;

[0027] (2) Local medium-frequency induction heating: Medium-frequency induction heating is performed on one-third of the length of each billet, and the heating temperature is controlled between 1100° and 1150°C, and the temperature measurement and control adopts an infrared thermometer;

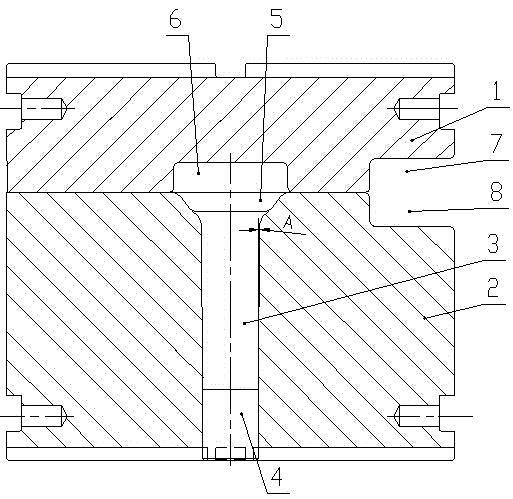

[0028] (3) Billet making: put the heated billet into the billet making mold on the billet making press, operate the billet press to forge the heated end of the billet, take out the head after forging and forming, and operate the billet press to The head is flattened into the shape of an athletics track;

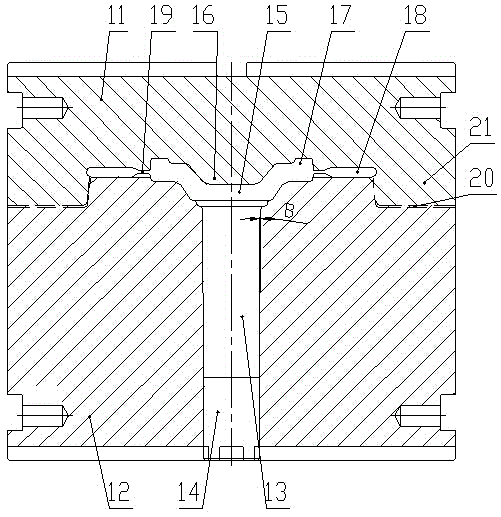

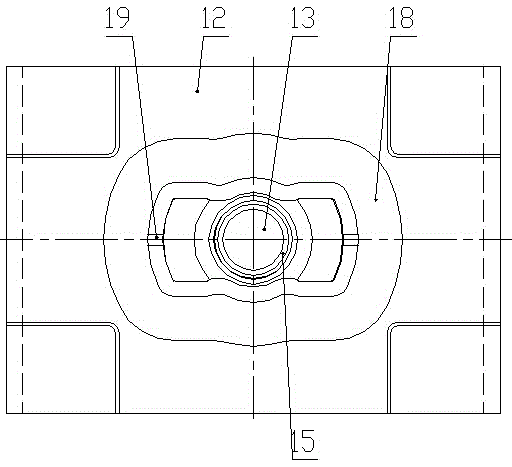

[0029] (4) Final forging: place the billet in the final forging die on the final forging press for forging, and after for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com