Camshaft sand mold manufactured with tectorial membrane sand with reclaimed sand as roughing sand and manufacturing method thereof

A technology of coated sand and camshaft, applied in manufacturing tools, casting equipment, molds, etc., can solve the environmental hazards of phenolic resin and other problems, and achieve the effect of improving surface quality, facilitating stacking and transporting, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: a kind of camshaft sand mold (seeing Fig. 1) that is the coated sand manufacture of former sand with regenerated sand, it is characterized in that it is a middle that is formed by the sand mold on the coated sand and the sand mold under the coated sand opposite to it. Through shaft with boss.

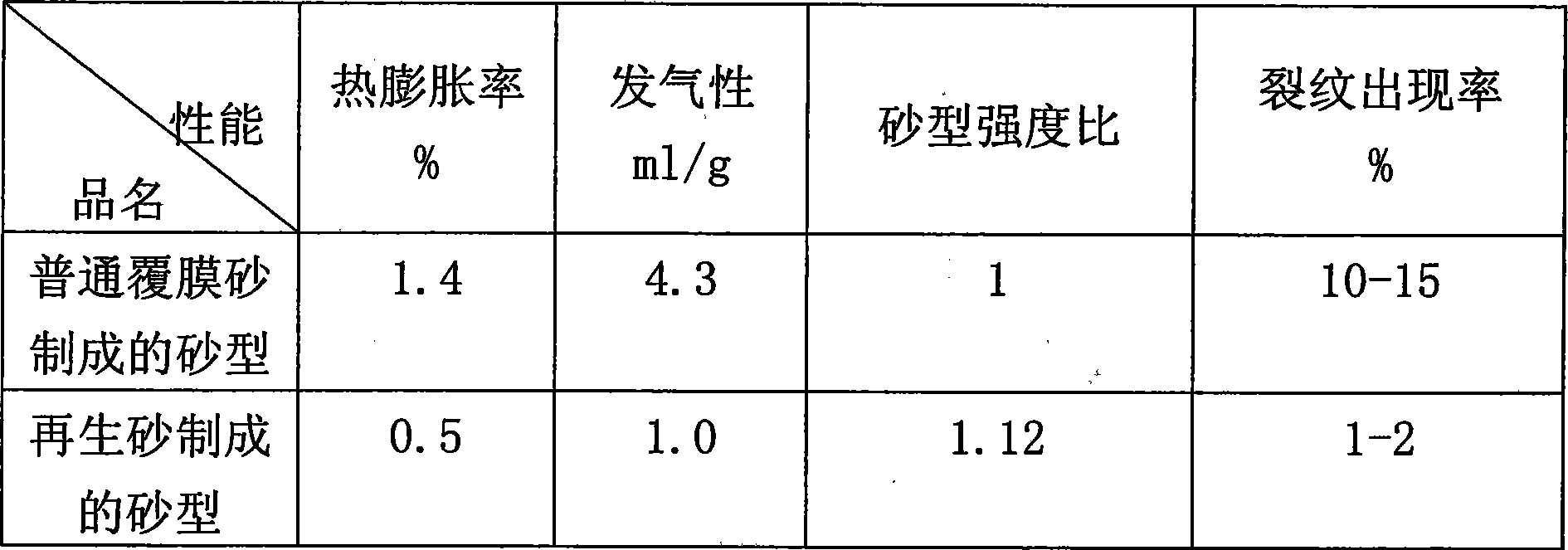

[0020] The above-mentioned coated sand is composed of raw sand, binder, curing agent and lubricant, and the weight ratio is 100:2:0.3:0.1.

[0021] The above-mentioned raw sand is regenerated sand.

[0022] The above-mentioned binding agent is phenolic resin.

[0023] Additives can be added to the above-mentioned coated sand, and the additives are dibutyl phthalate or iron oxide powder.

[0024] A method for making camshaft sand molds (seeing Fig. 1) with regenerated sand as the coated sand of former sand, is characterized in that it comprises the following steps:

[0025] (1) The waste sand is regenerated at high temperature, and the oxide quartz of crystalline si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com