Five-axis plunge milling machining method for ruled surface impeller

A processing method and ruled surface technology, applied in the direction of metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problem of not considering the calculation criteria, the inability to guarantee the material removal rate and processing efficiency of plunge milling, and the unfavorable research of plunge milling, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Below in conjunction with accompanying drawing, the present invention will be further described:

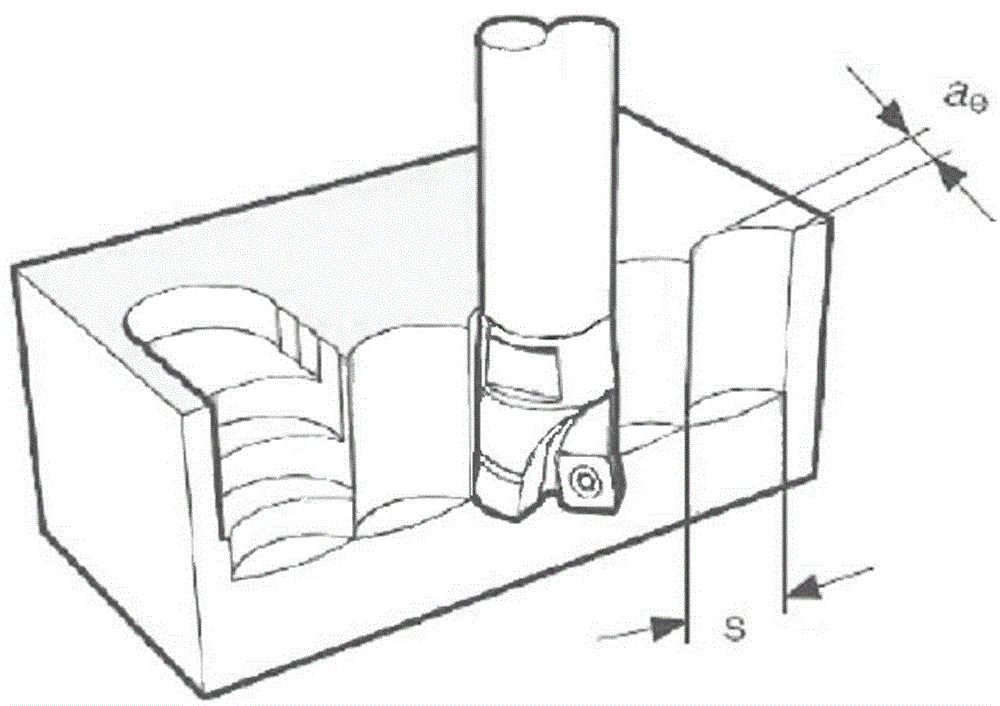

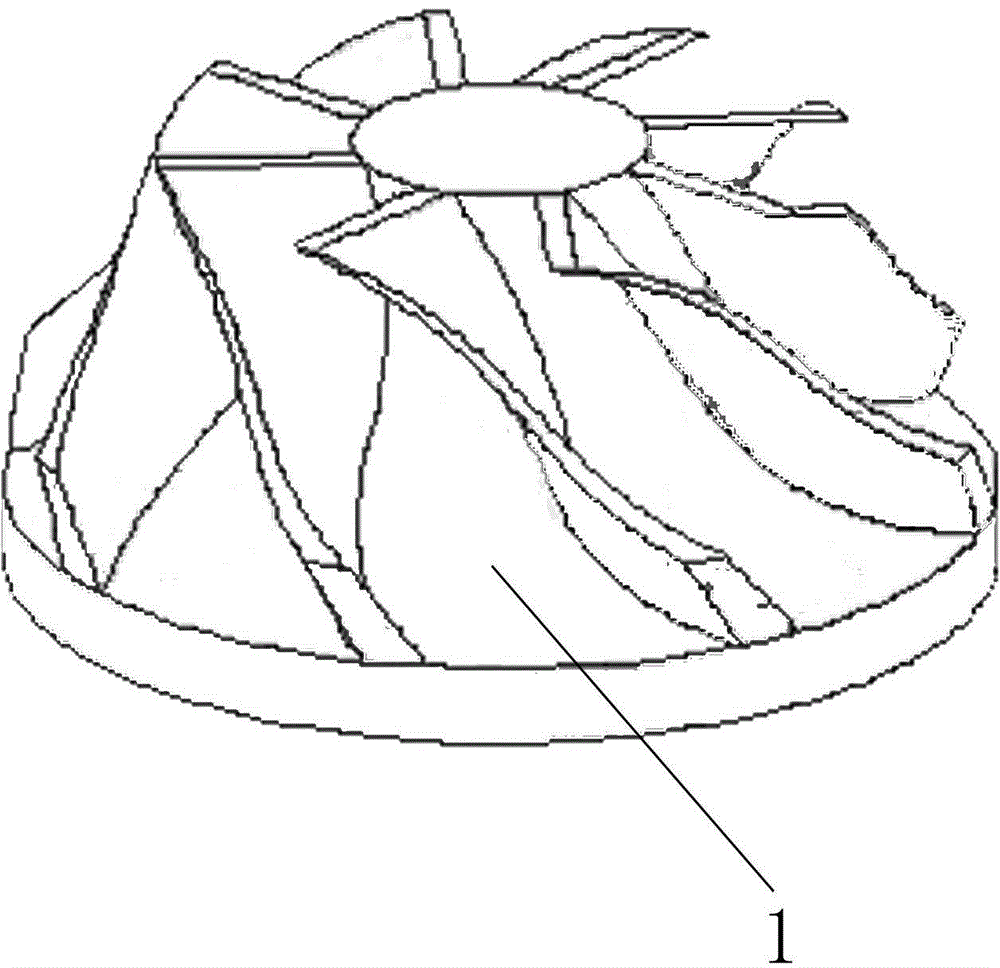

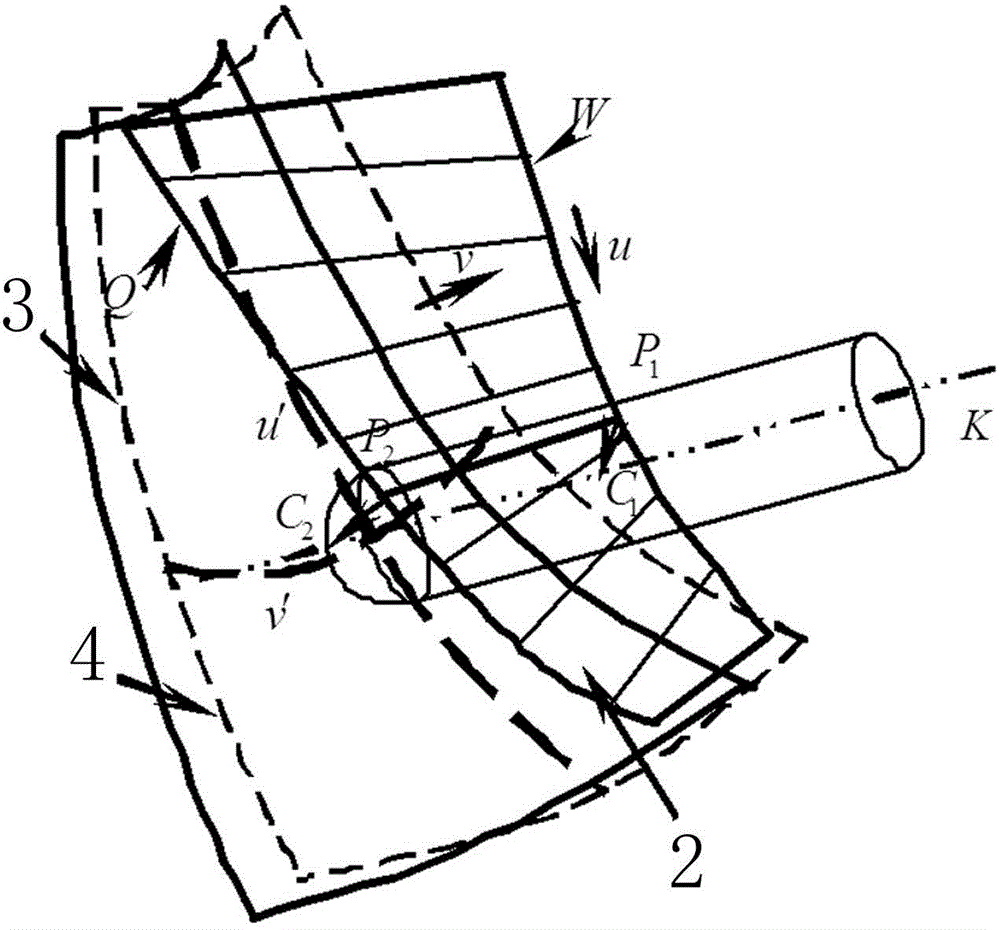

[0076] The invention is a five-coordinate plunge-milling processing method for a ruled surface impeller, which is characterized in that: according to the offset boundary vector of the ruled surface blade, the tool axis vector of the plunge-milling process is calculated by using the quaternion interpolation method, and the method is proposed and determined The line distance and step distance of the five-coordinate plunge milling process plan the tool machining trajectory, so as to process the workpiece. The specific steps of this method are as follows:

[0077] a. Generation of boundary vectors:

[0078] For the impeller whose blade shape is a free-form surface, the free-form surface can be fitted into a ruled surface by using the method proposed in "Research on Plunging and Milling Rough Machining Technology of Open Integral Blisk Channel" published by Hu Chuangguo et al. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com