Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65 results about "Stressed skin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mechanical engineering, stressed skin is a type of rigid construction, intermediate between monocoque and a rigid frame with a non-loaded covering. A stressed skin structure has its compression-taking elements localized and its tension-taking elements distributed. Typically, the main frame has rectangular structure and is triangulated by the covering.

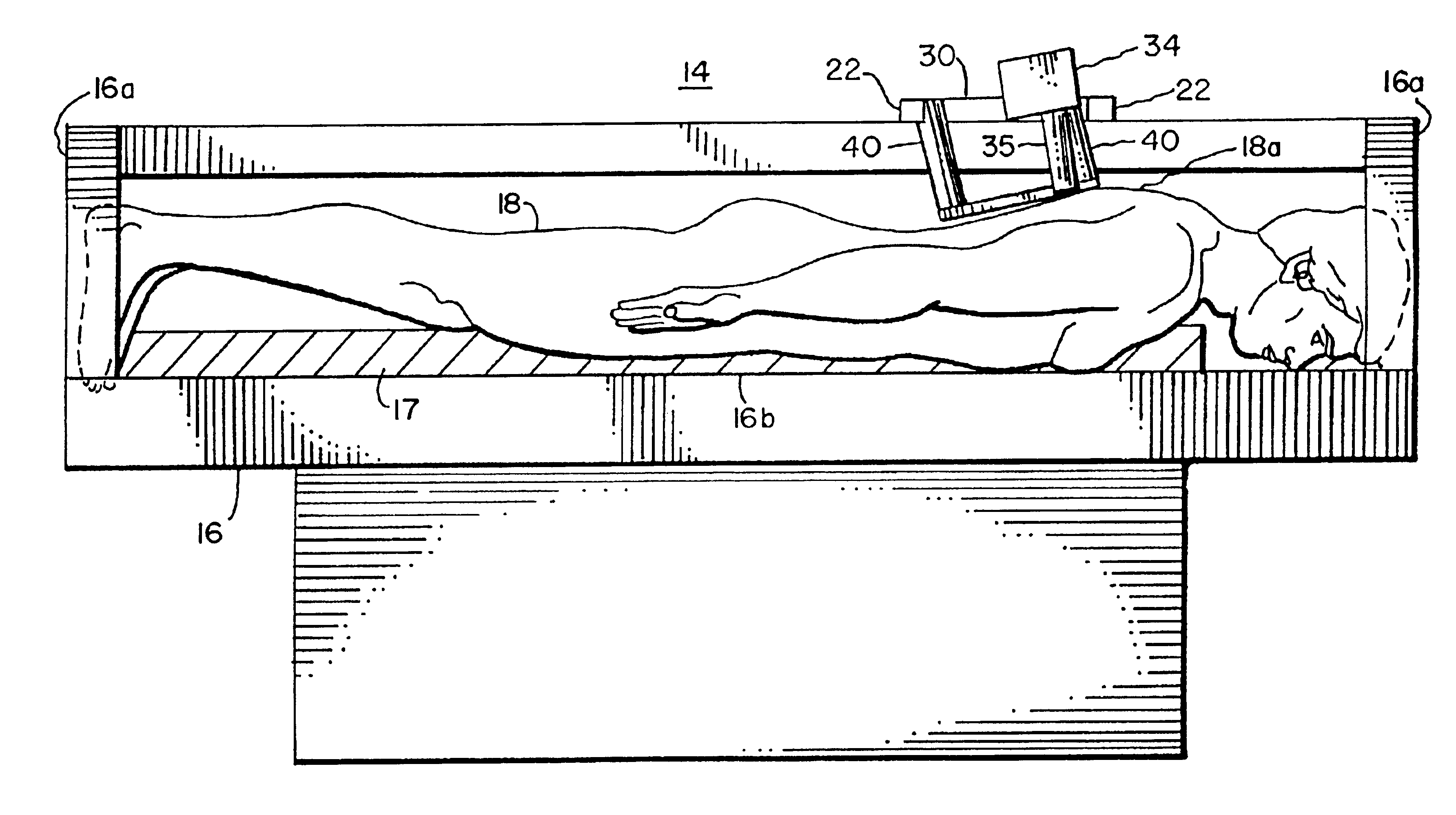

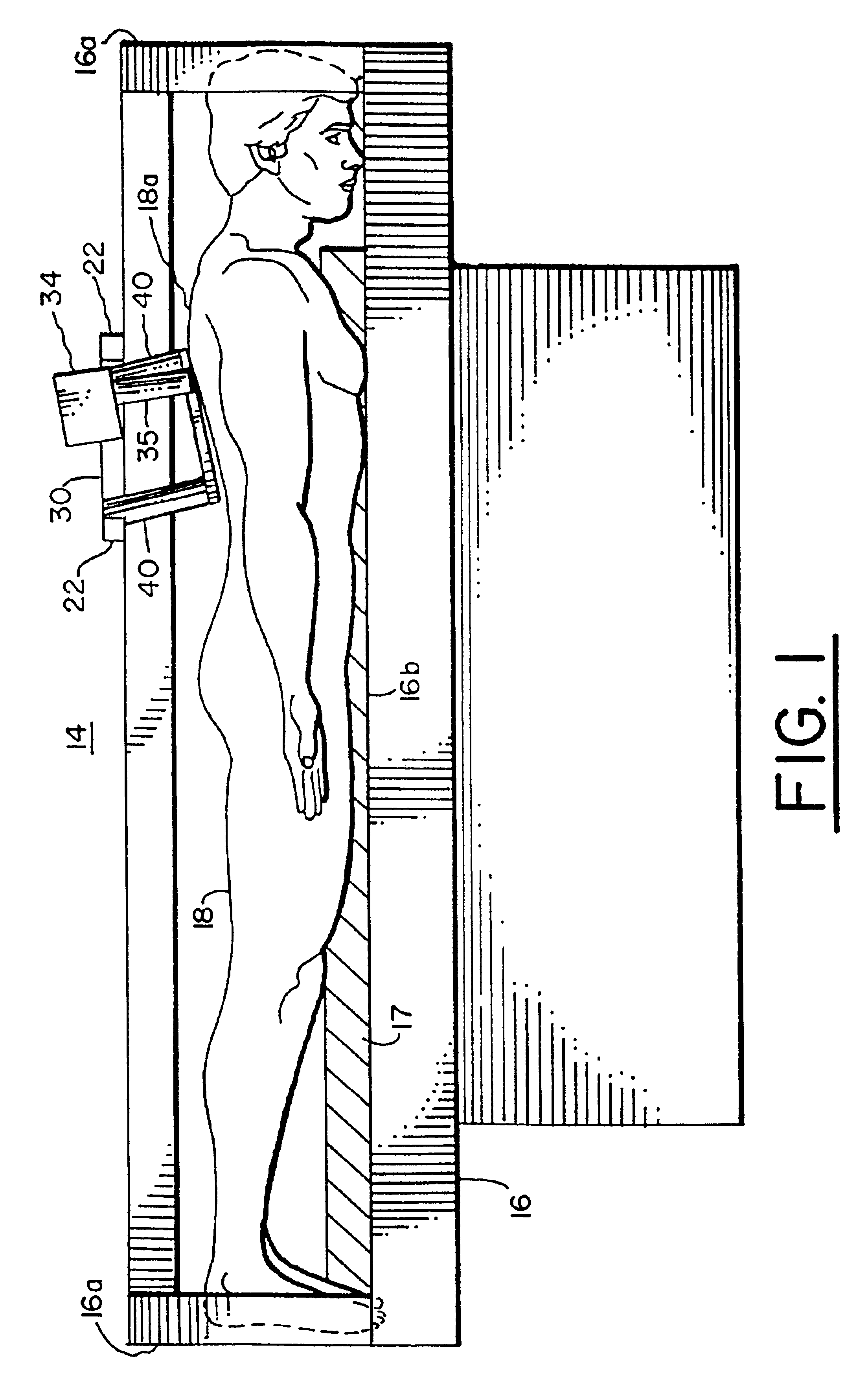

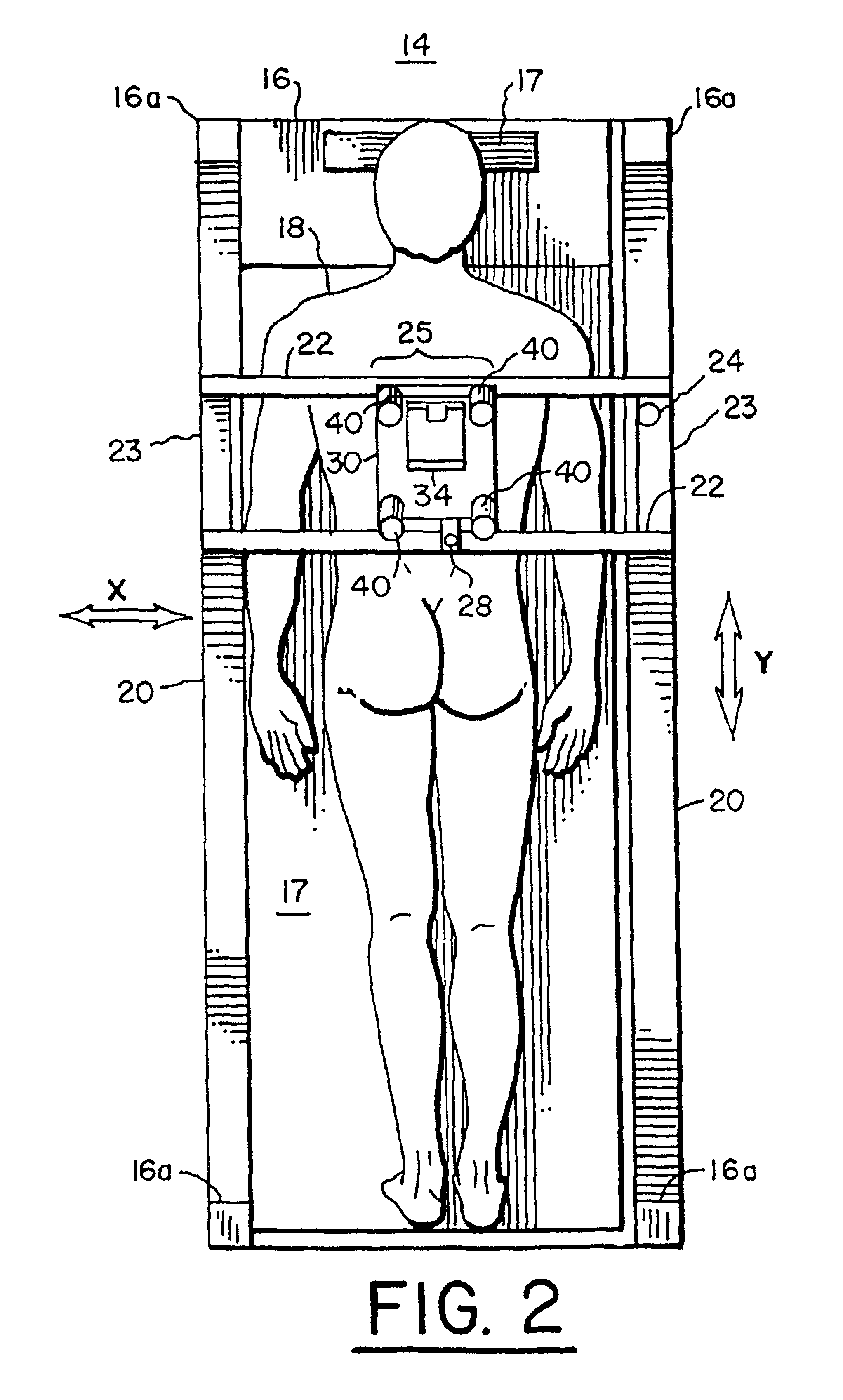

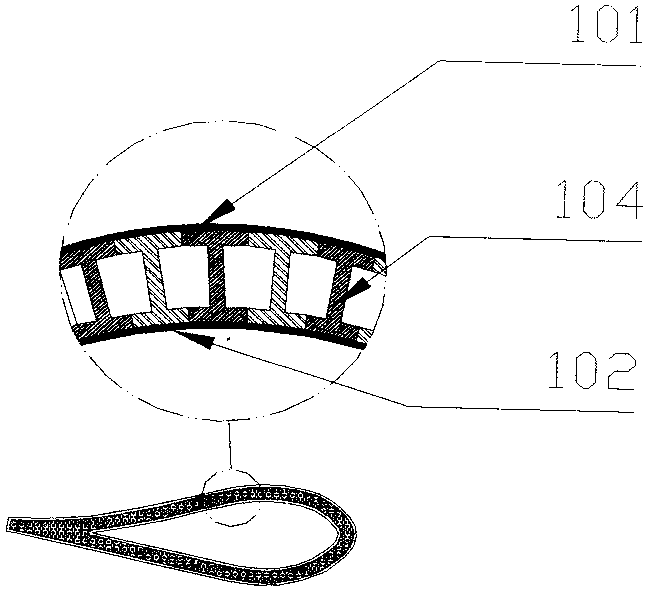

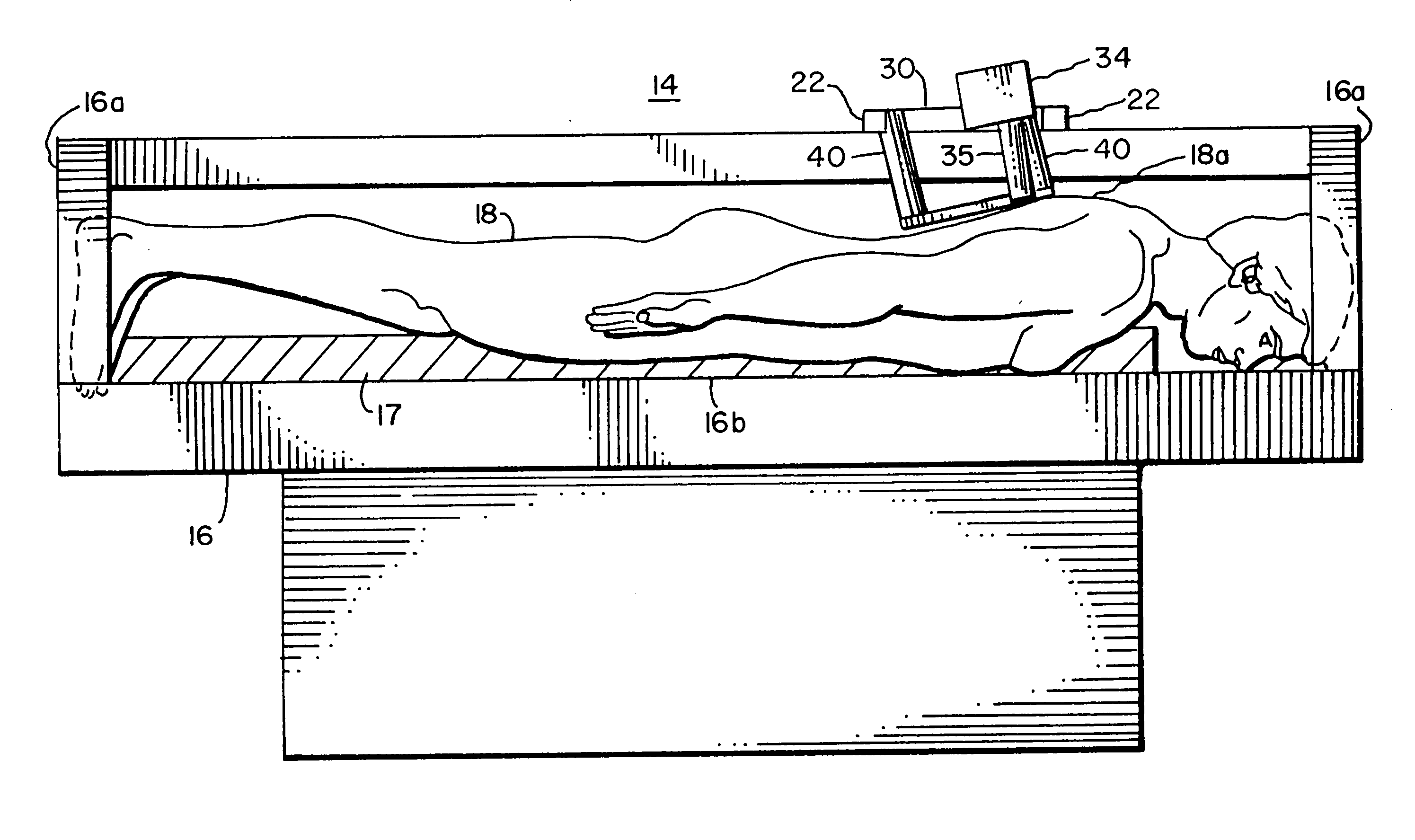

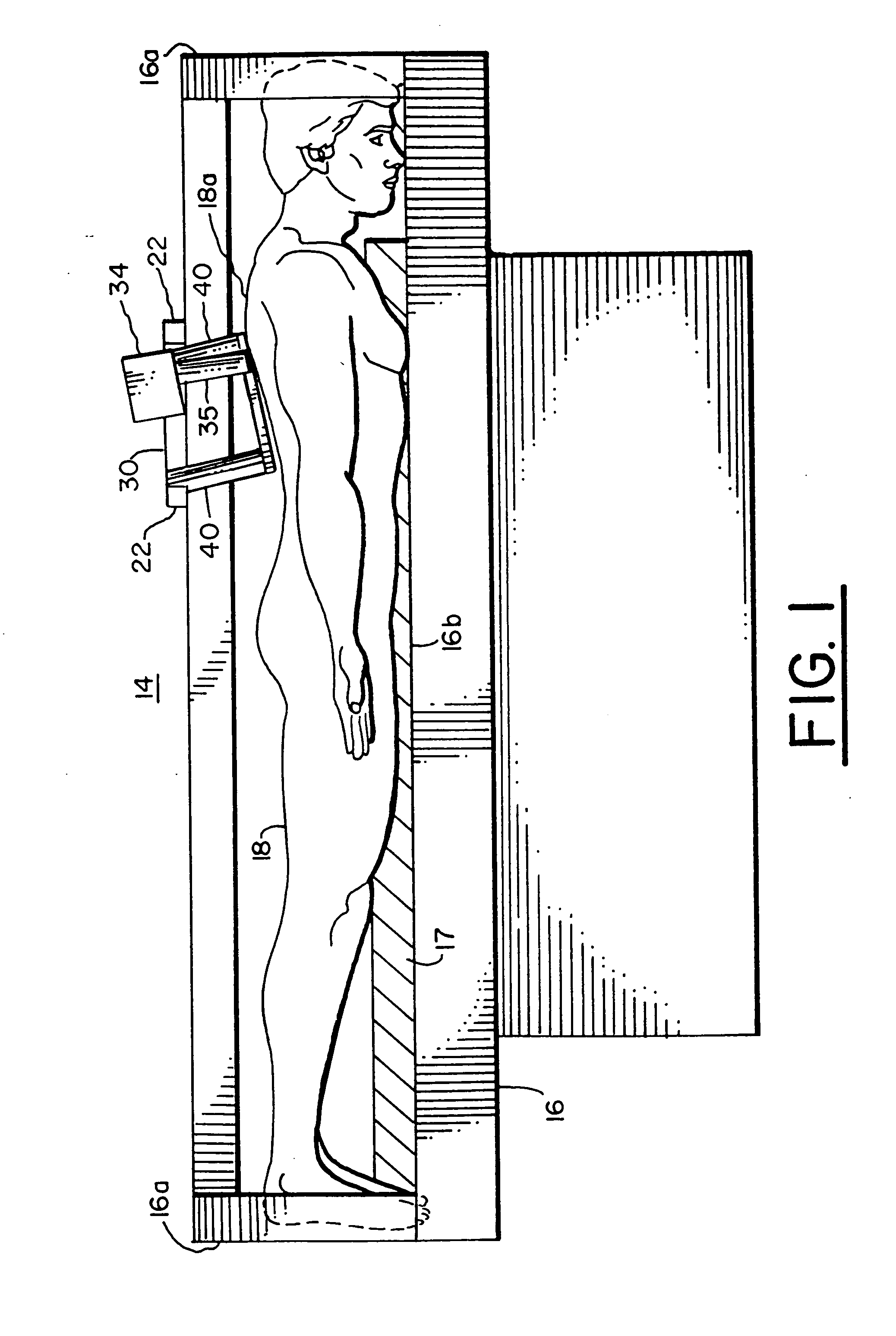

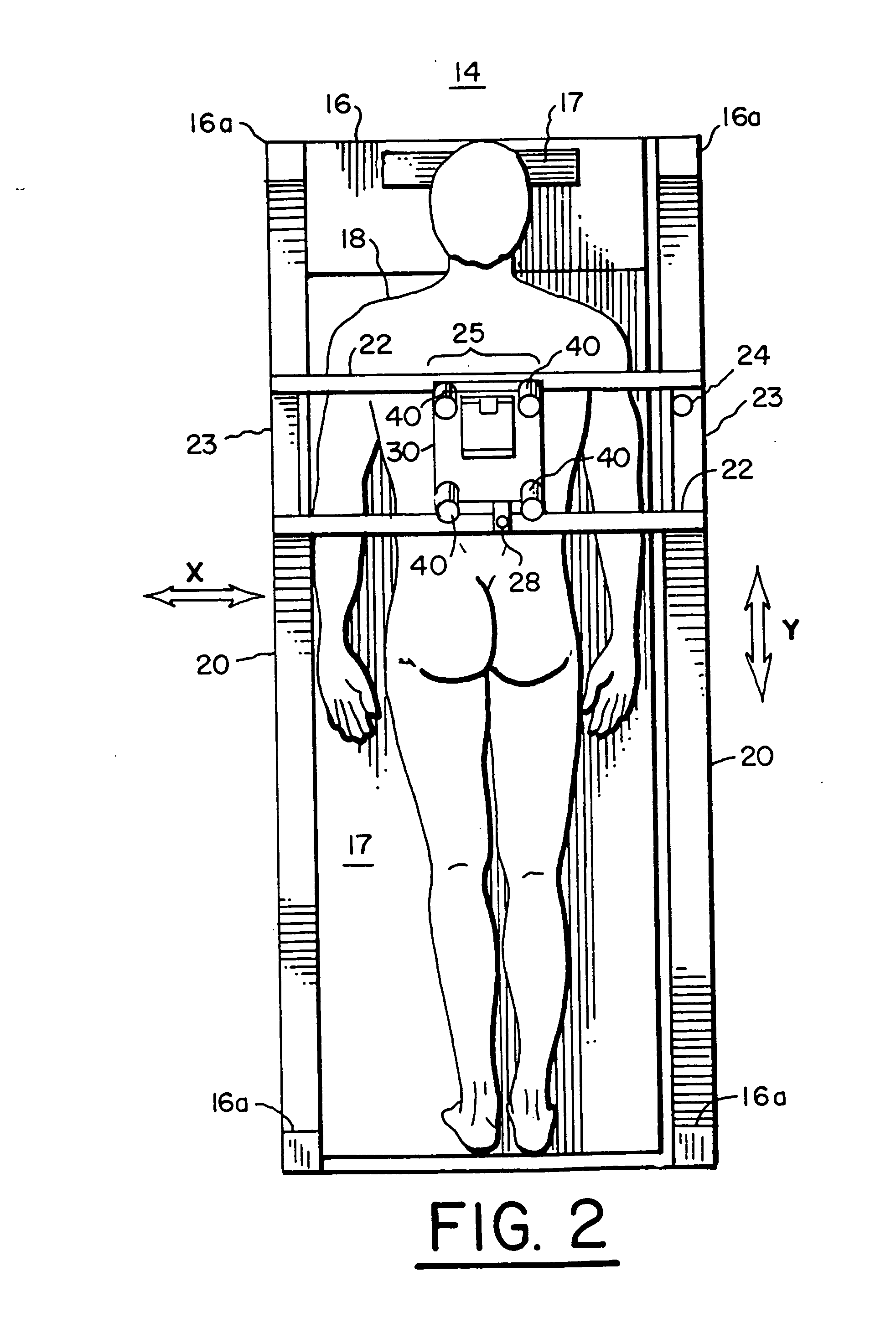

System for confocal imaging within dermal tissue

InactiveUS6937886B2Minimizes instabilityReduce relative motionDiagnostic recording/measuringSensorsInstabilityRelative motion

An improved system for confocal imaging within dermal tissue of a patient is provided which minimizes instability in confocal images by reducing the relative motion of the tissue with respect to the confocal imaging optics of the system. The system includes a mechanism for maintaining an area of skin tissue under stress by application of force at the edges of the area, and an imaging head coupled to this mechanism for imaging the stressed skin. The mechanism includes a mechanical structure, such as a platen, brace, or attachment, which both supports the imaging head of the system and applies stress to a limited surface area of the tissue to minimize skin motion during confocal imaging.

Owner:CALIBER IMAGING & DIAGNOSTICS

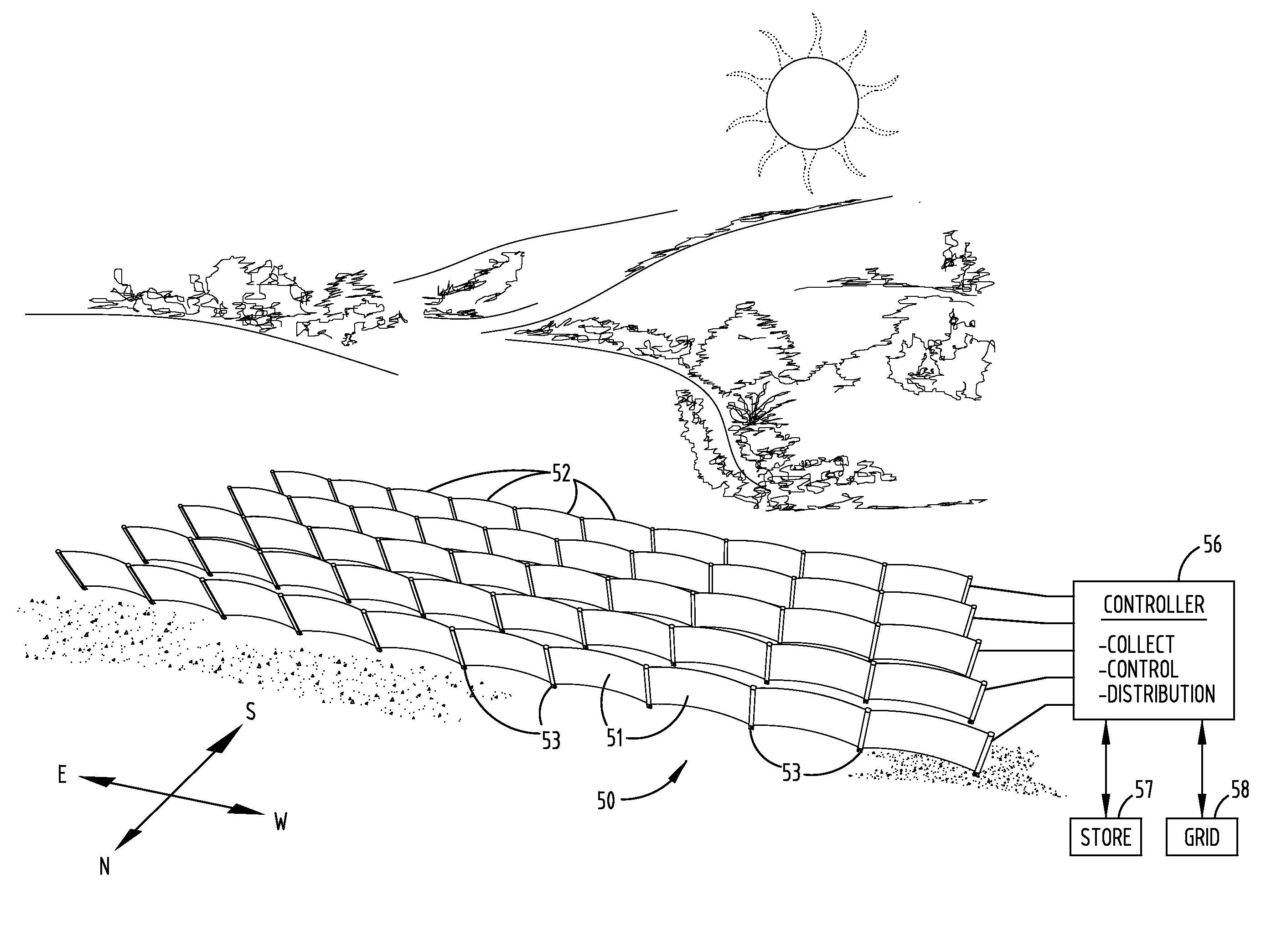

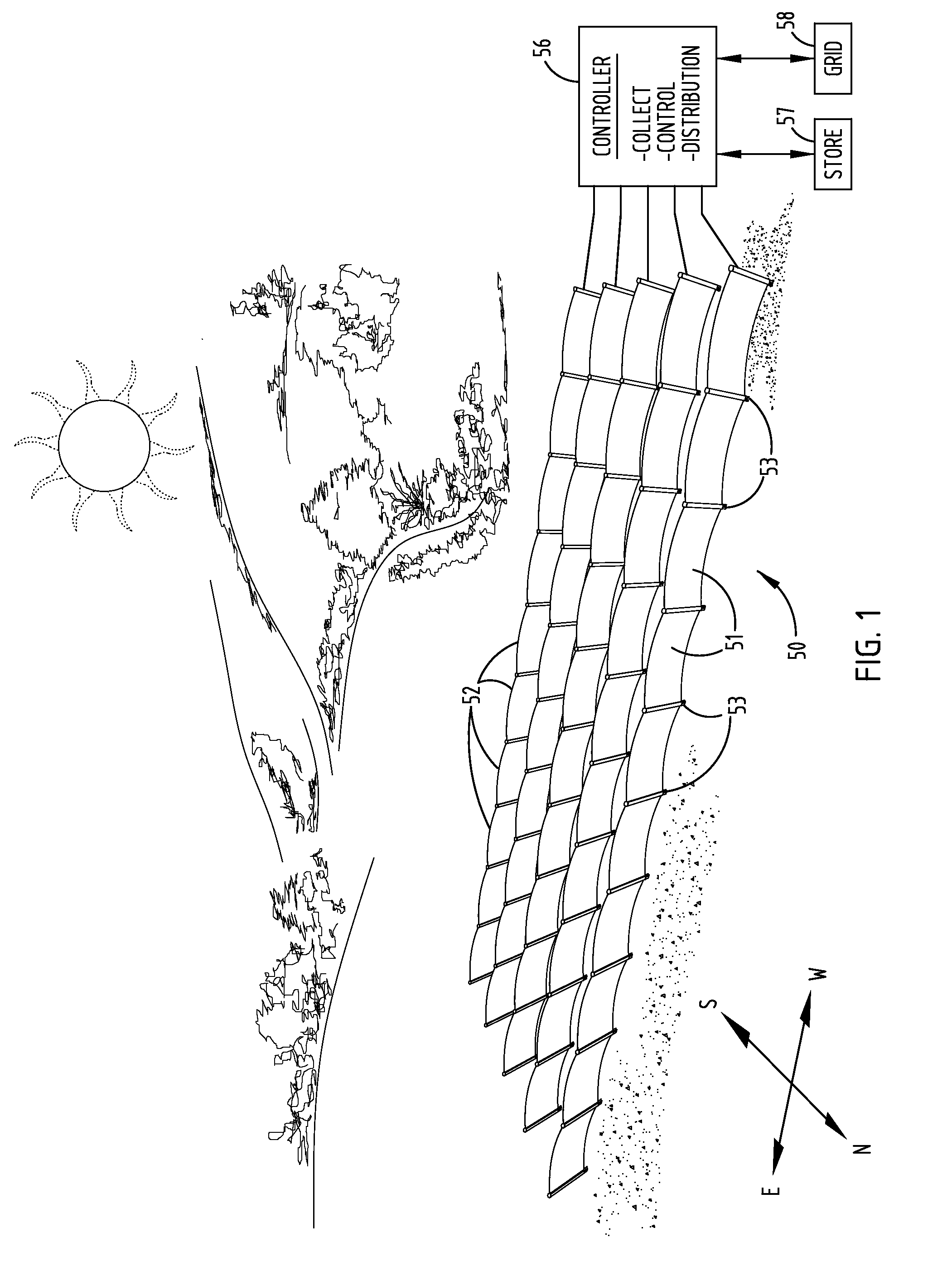

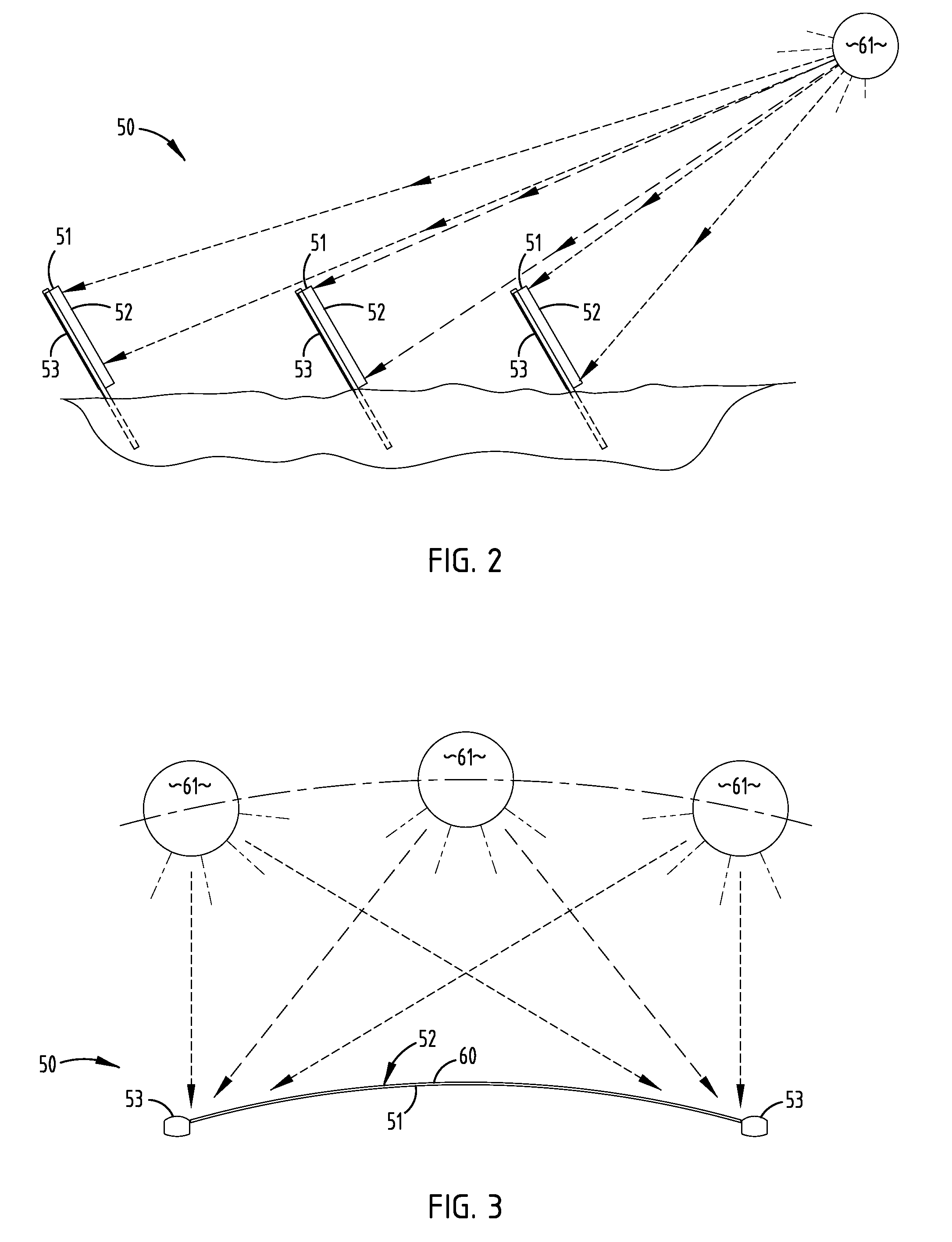

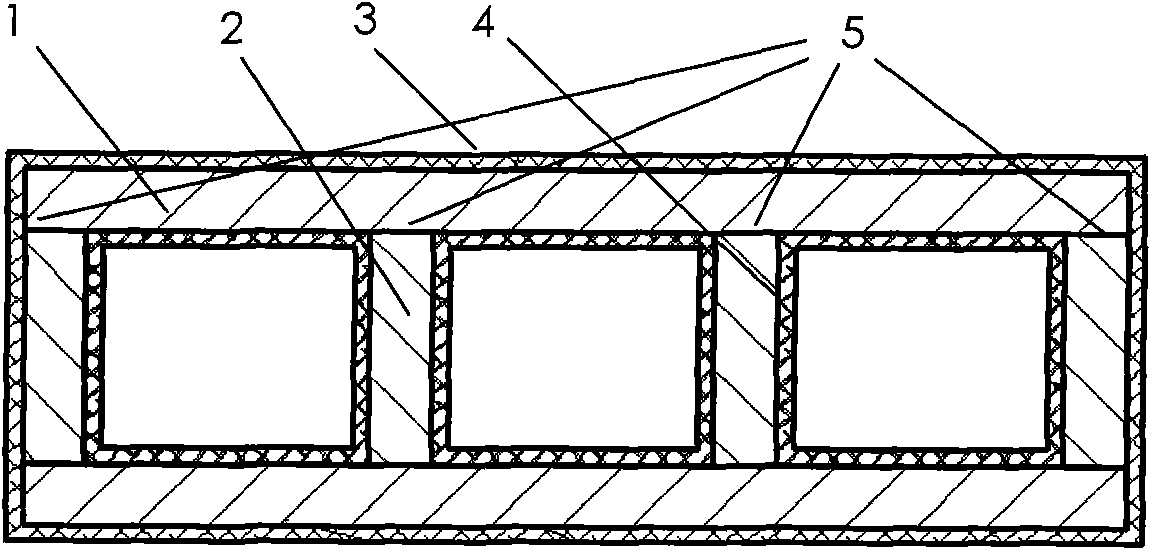

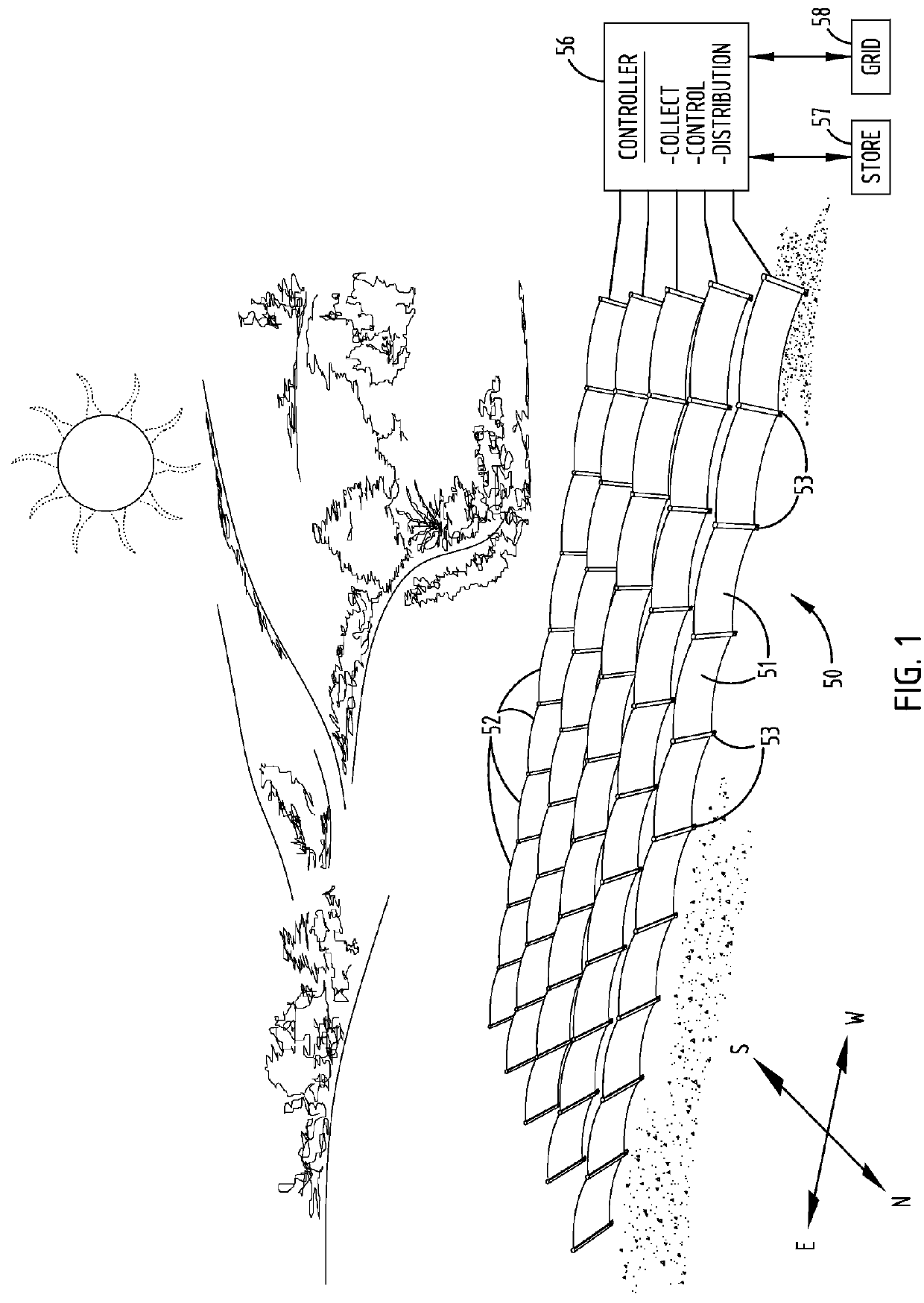

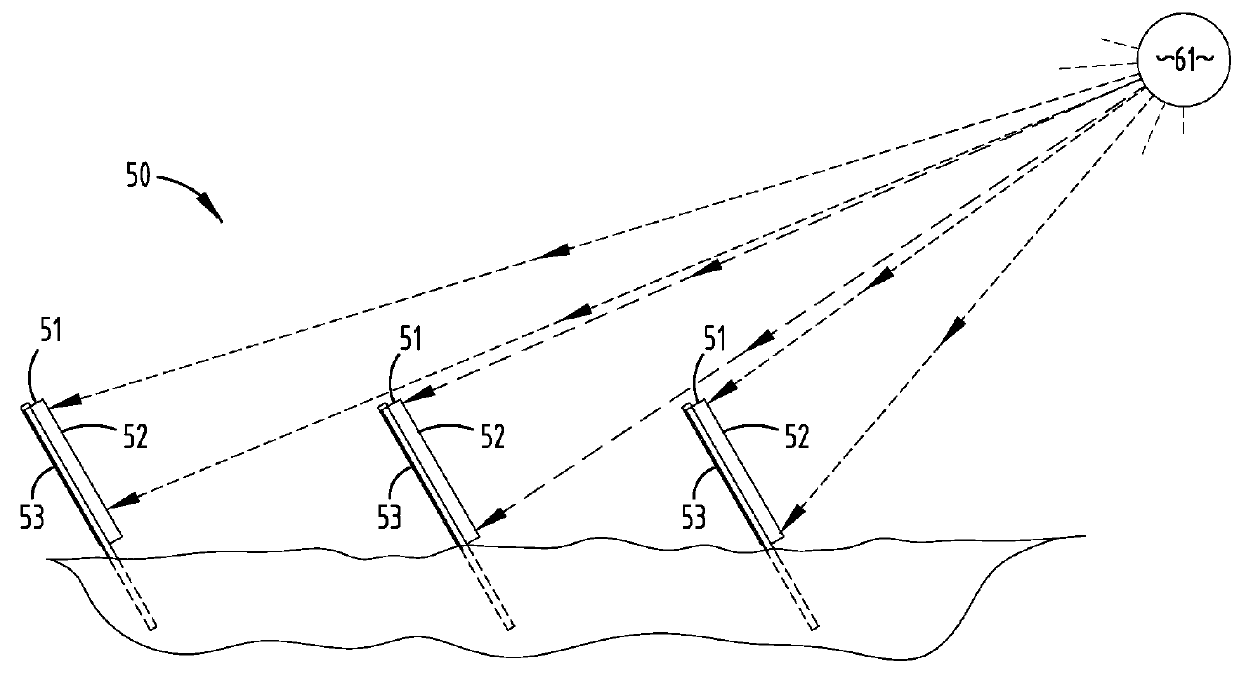

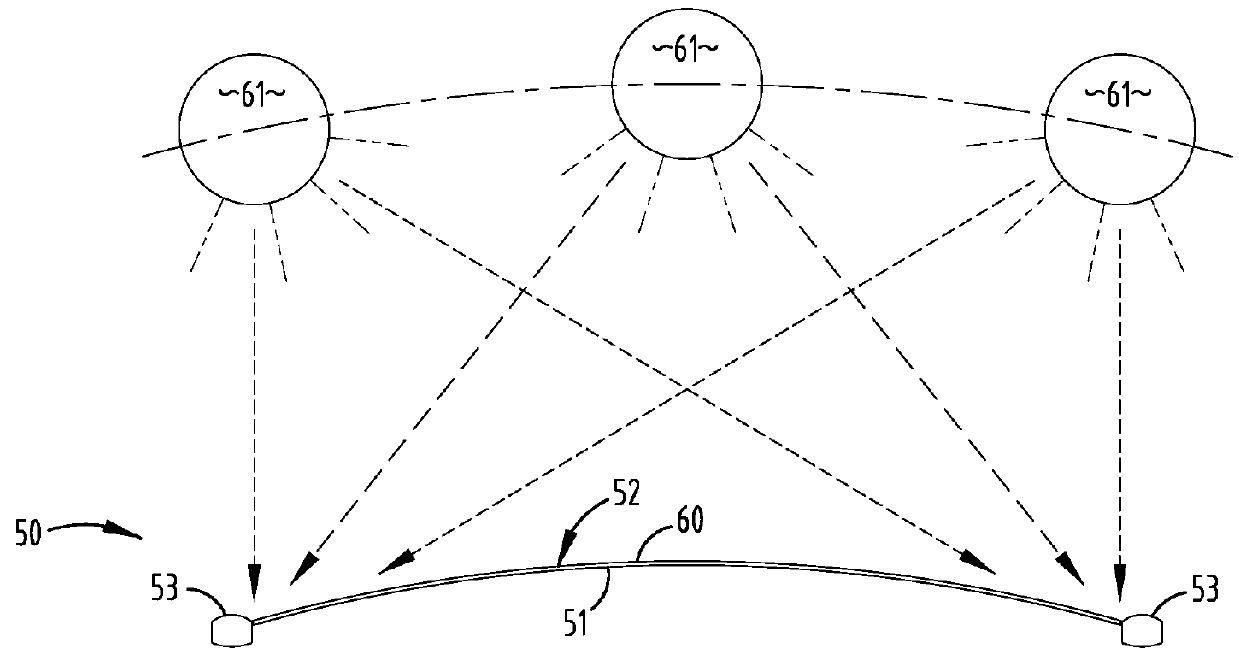

Solar panel system with monocoque supporting structure

ActiveUS20110303262A1Rapidly deployableSignificant and reliablePhotovoltaic supportsSolar heating energyControl powerElectrical battery

A solar panel system comprises a monocoque forming an enlarged solar-facing generally-convex outer support surface when in an installed position and that supports solar cells at optimal angles for capturing solar energy. The monocoque provides a stressed-skin support reducing weight while maintaining strength, optimal support surface, and minimizing cost. A post engages and supports adjacent edges of a pair of adjacent monocoques. An electrical circuit connects the solar cells for electrical flow and power management, and preferably includes a controller for controlling power from the solar cells, including combining them in series or parallel as optimal for a given systems configuration. The illustrated monocoque includes a roll formed sheet or a number of sheets, stacked vertically together and anchored to spaced posts using connectors in a “fence-like” pattern.

Owner:WOLTER JAMES F

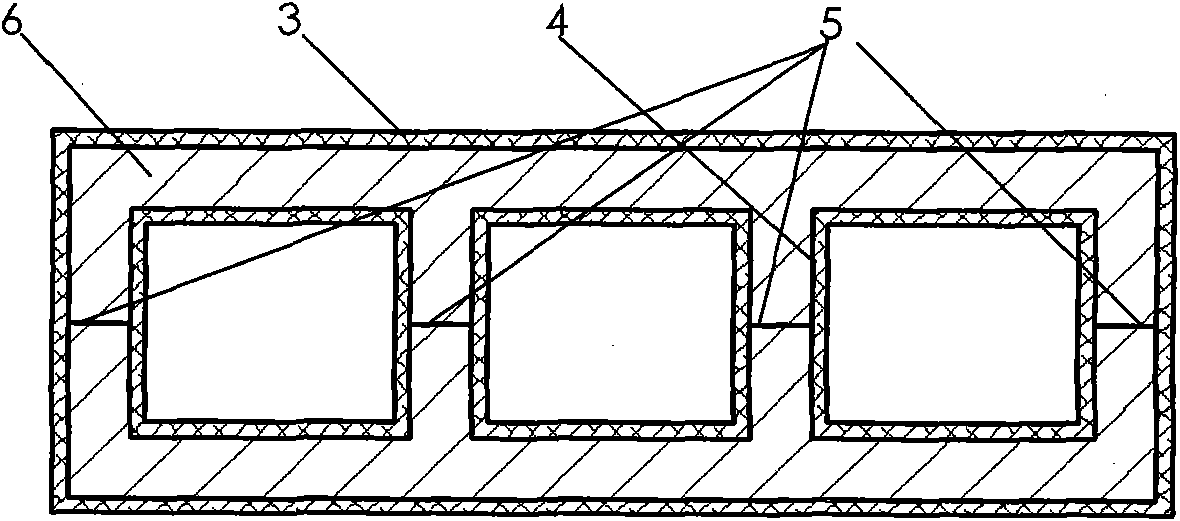

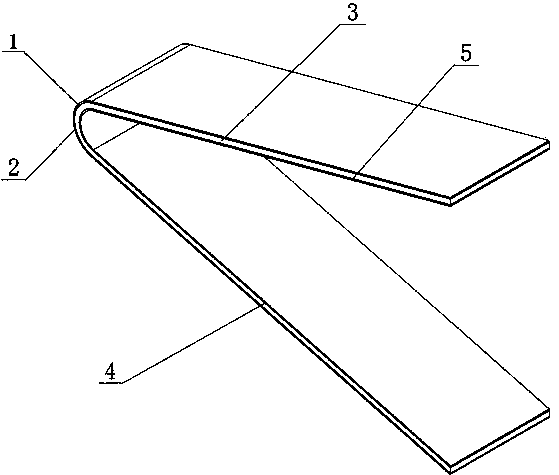

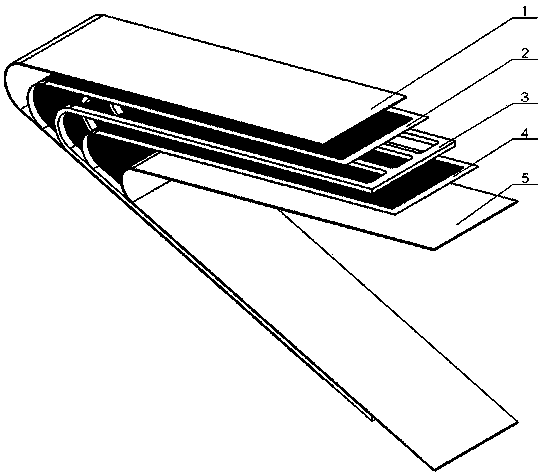

Manufacturing method of titanium alloy hollow component

ActiveCN101786223AIncrease productivityImprove efficiencyNon-electric welding apparatusTitanium alloyStressed skin

The invention relates to a manufacturing method of a titanium alloy thin-wall ribbed hollow component. The method comprises the following steps that: a. the titanium alloy hollow component is decomposed into a stressed-skin and ribbed structure form or a stressed-skin ribbed structure form according to the structure features of a hollow component, and an inner sheath and an outer sheath structure forms are determined according to a hollow part of the hollow component; b. the stressed-skin and ribbed or the stressed-skin ribbed structural part is processed or formed according to the decomposed structure forms; c. the inner and the outer sheaths are processed or formed; d. the stressed-skin and ribbed or the stressed-skin ribbed structural part being well processed is assembled with the inner and the outer sheaths, the inner and the outer sheaths are sealed in a welding way and are vacuum encapsulated, and the vacuum degree is 1.0 *10-3Pa; e. the dispersion connection of each structural part is realized through a hot isostatic pressing method; f. surface treatment on each prefabricated structural part is undertaken so as to prepare the hollow structural component. The manufacturing method has high production efficiency; a plurality of components can be prepared through one technical circulation; and the welding rate is more than 95 percent.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

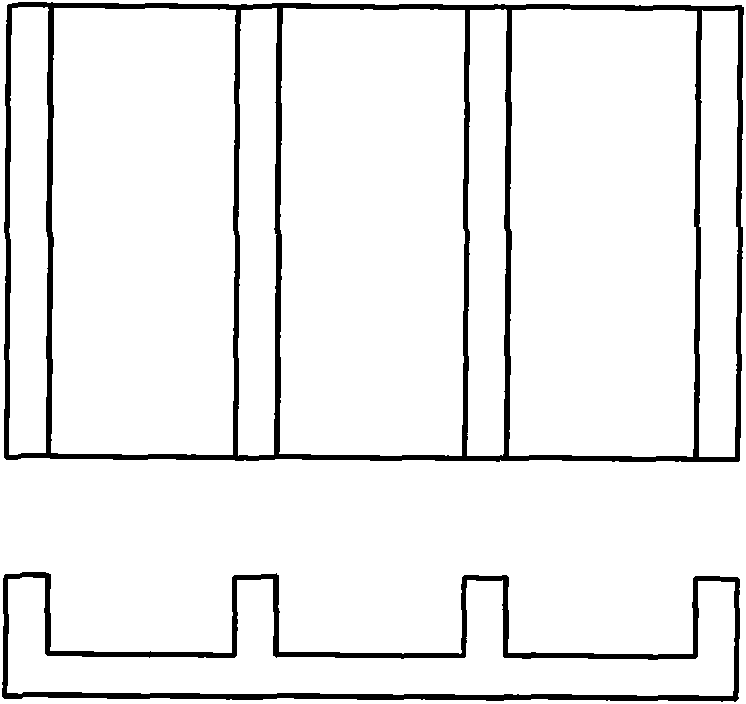

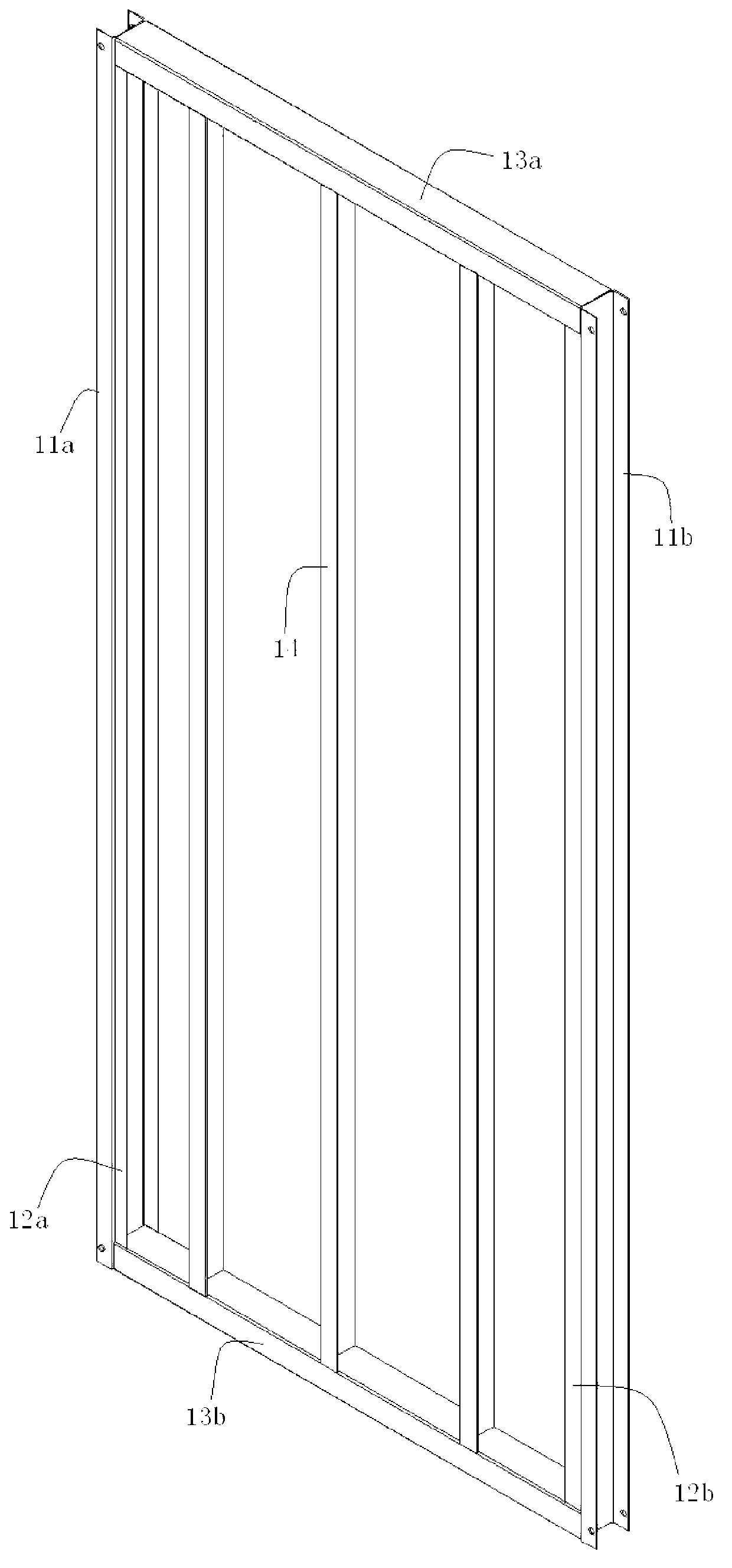

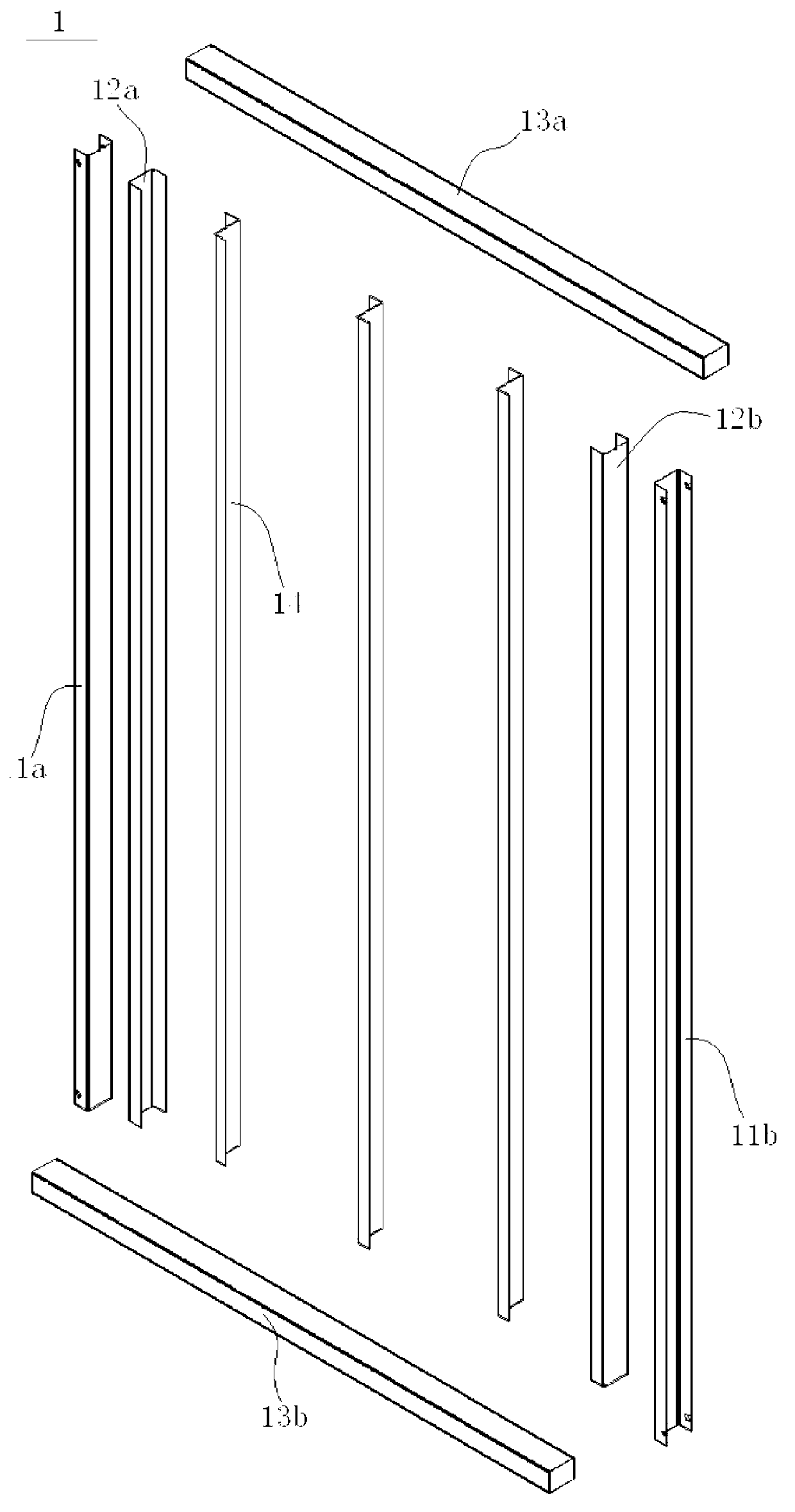

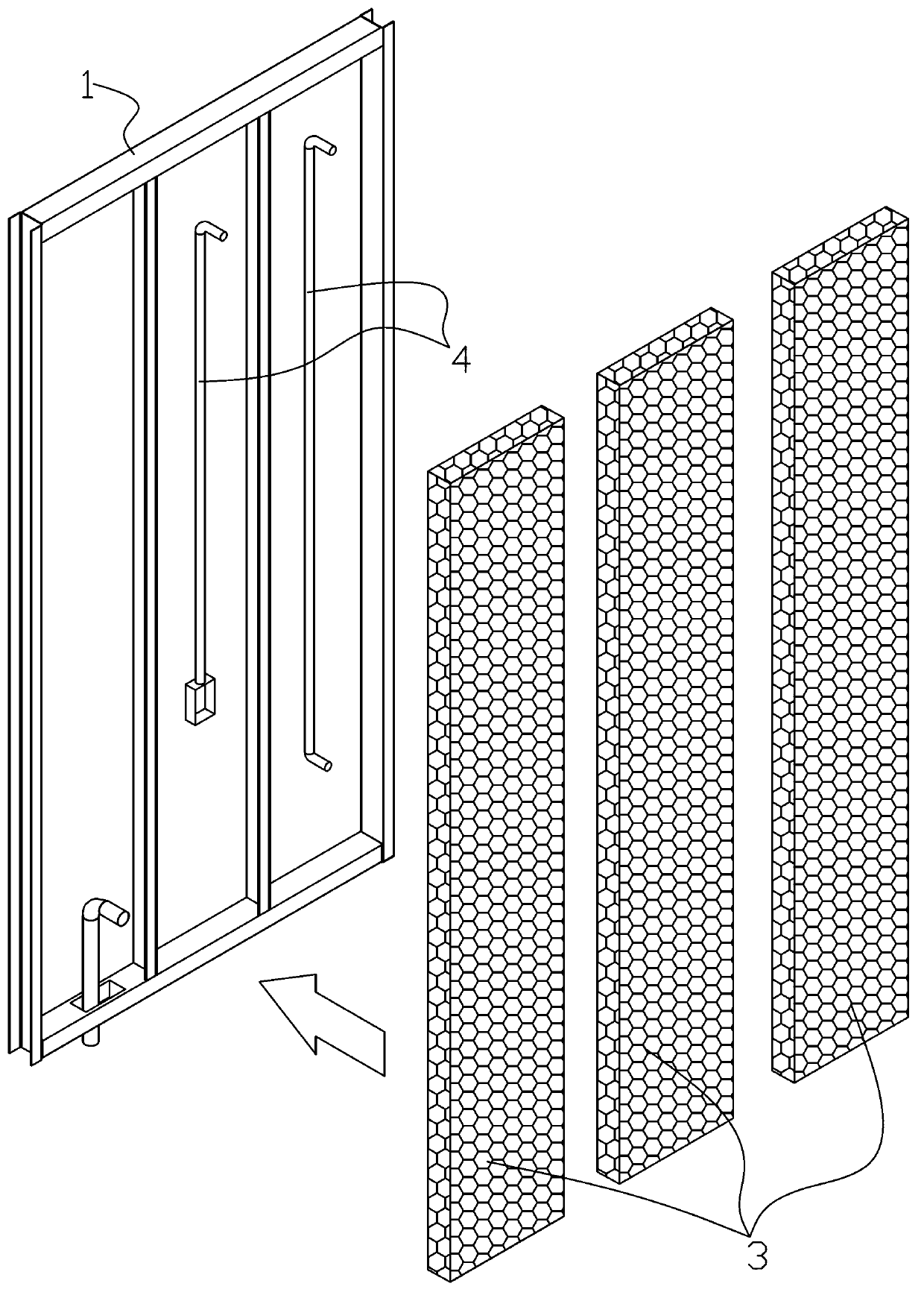

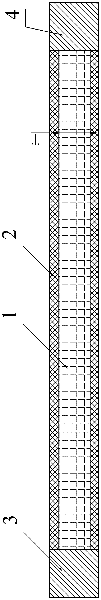

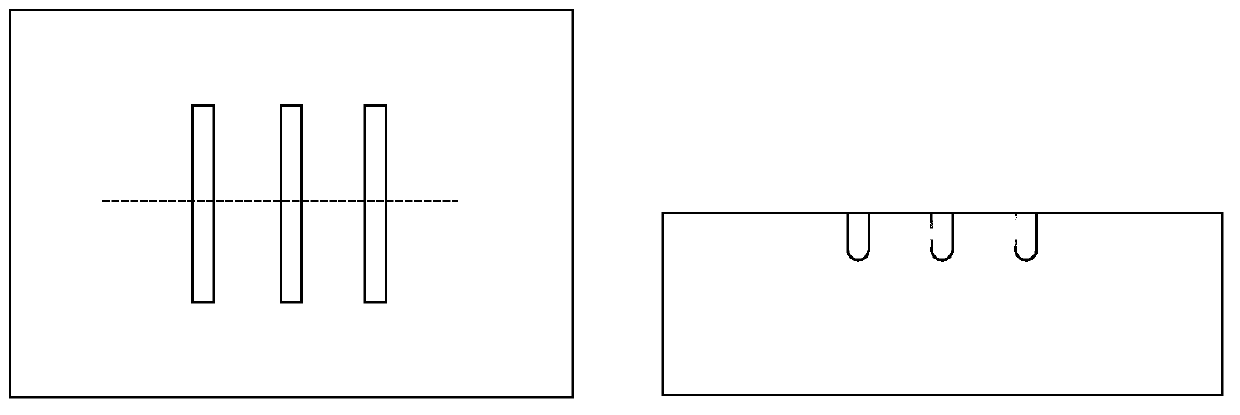

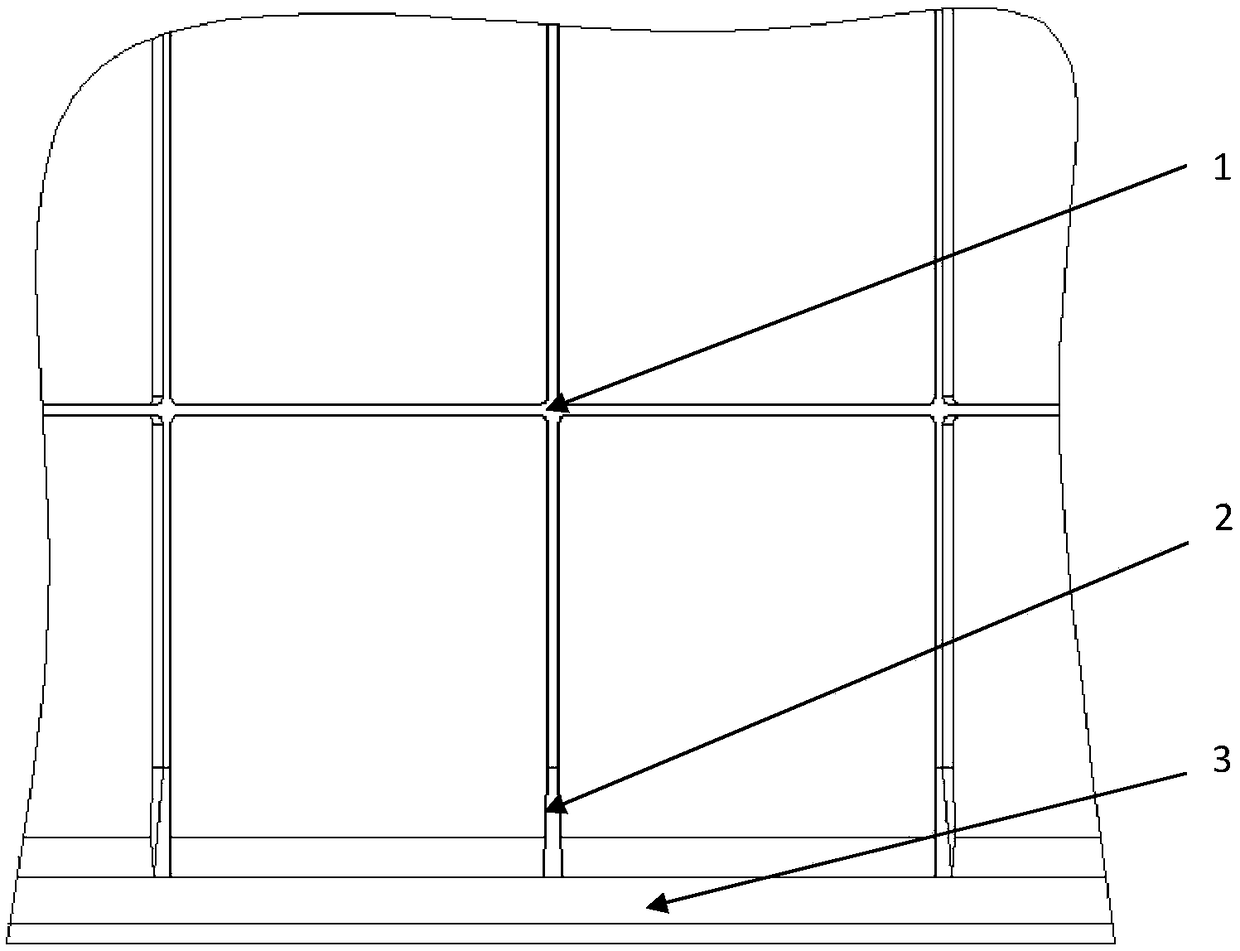

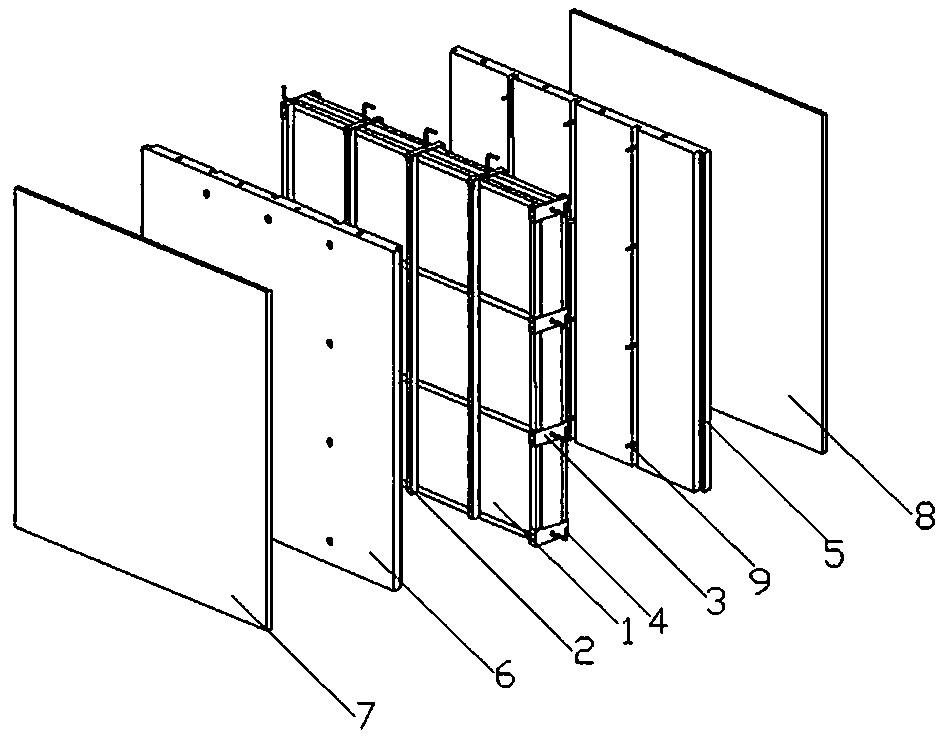

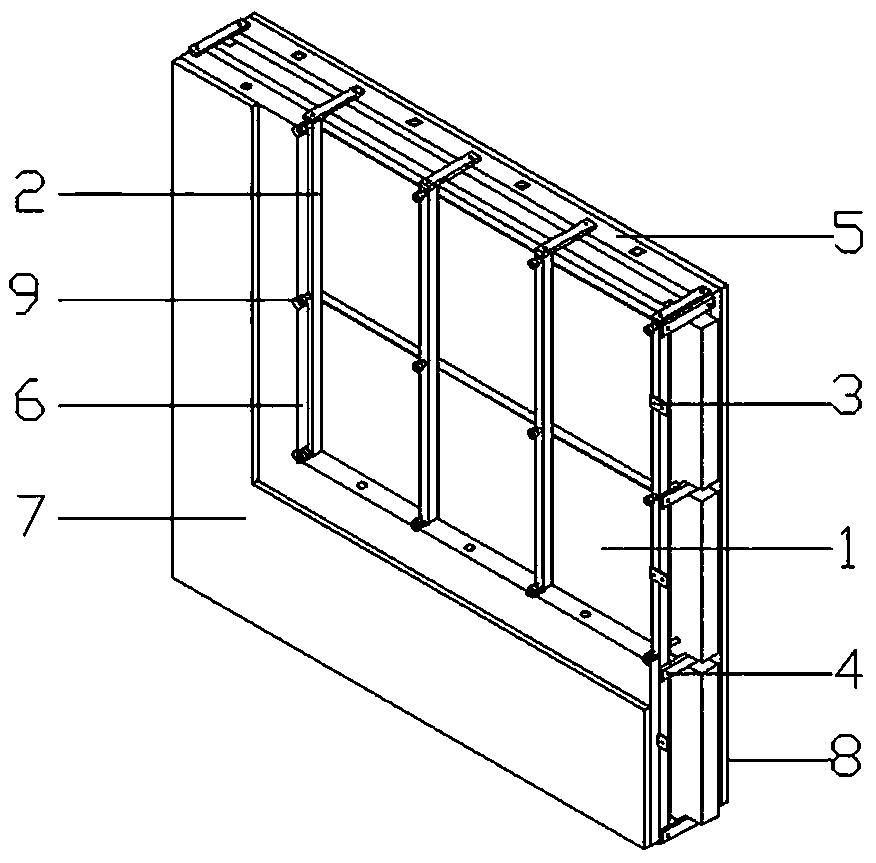

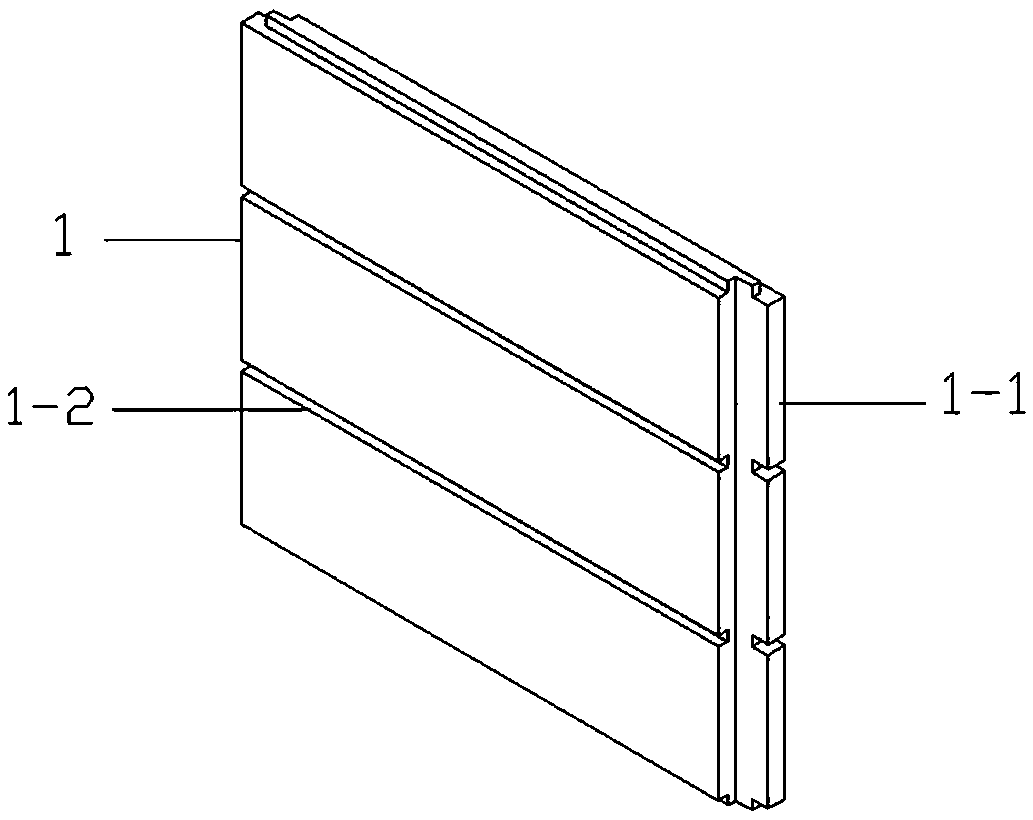

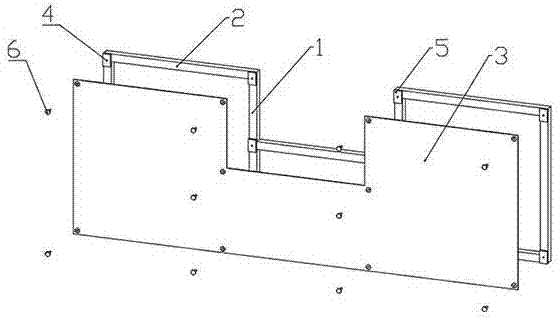

Prefabricated slab and fixed mounting structure thereof

The invention discloses a prefabricated slab and a fixed mounting structure thereof. The prefabricated slab comprises a light steel frame, a front board and a rear board, wherein the light steel frame comprises a left border, a right border, an upper border, and a lower border, which are enclosed together to form a square frame; U-shaped notches of the left border and the right border are respectively arranged towards the left and the right, so that the prefabricated slab can be inserted together with a structure member through the U-shaped notches; mounting holes through which bolts penetrate to fix the prefabricated slab on the structure member are arranged on front and rear connecting arms of the left and right borders; the front board and the rear board are respectively paved on the light steel frame as front and rear panels of the light steel frame; and the top surfaces and the bottom surfaces of the upper and lower borders are exposed outside. The light steel frame is internally built into the prefabricated slab; the light board is paved outside a skeleton by a 'stressed-skin effect' technology; the performance stronger than that of a single material is developed; and the light steel skeleton internally arranged inside the prefabricated slab is exposed at the periphery of the prefabricated slab, so that the prefabricated slab can be conveniently and effectively connected with a steel structure by the existing steel structure connecting technology.

Owner:广州市澳居科技有限公司

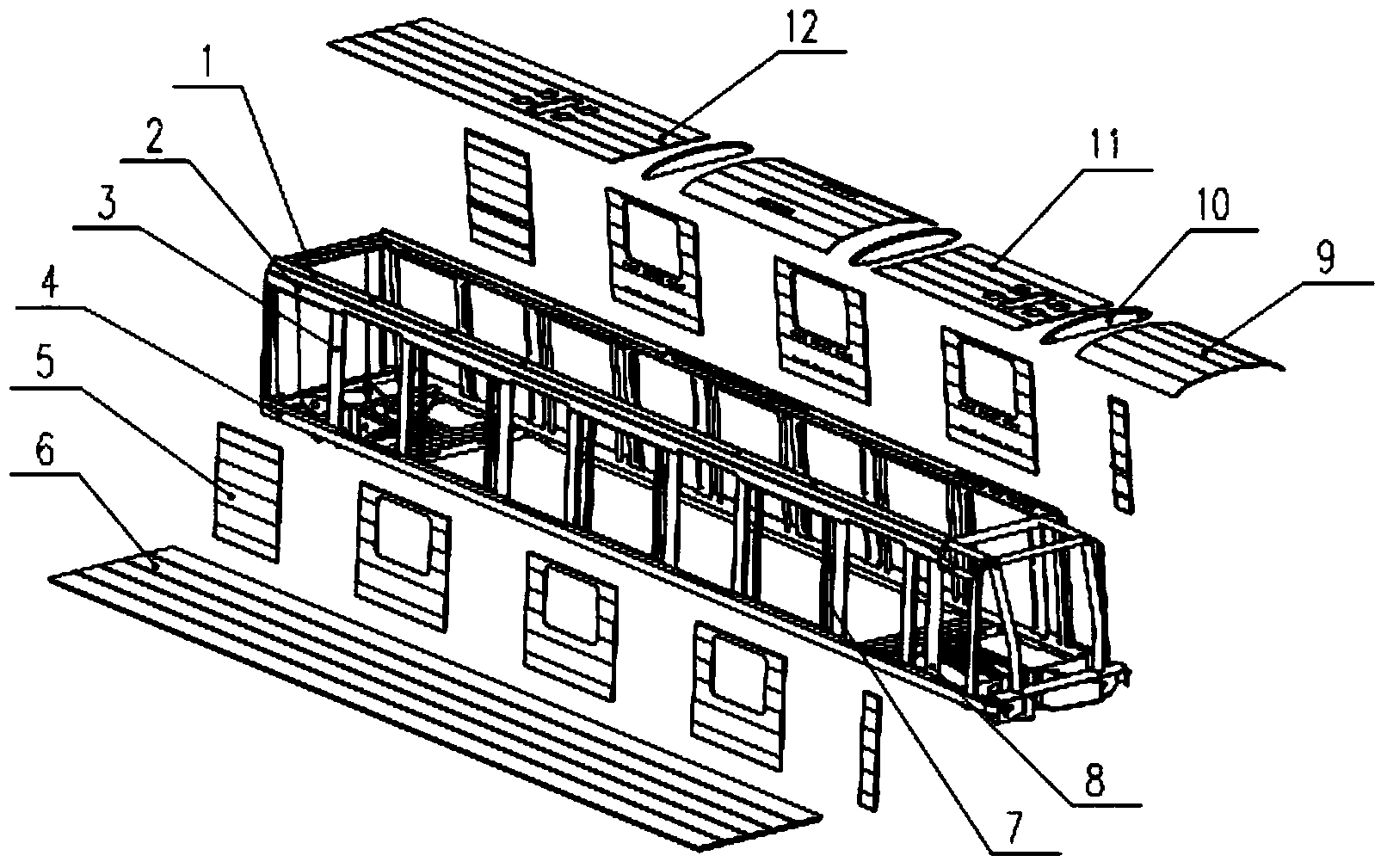

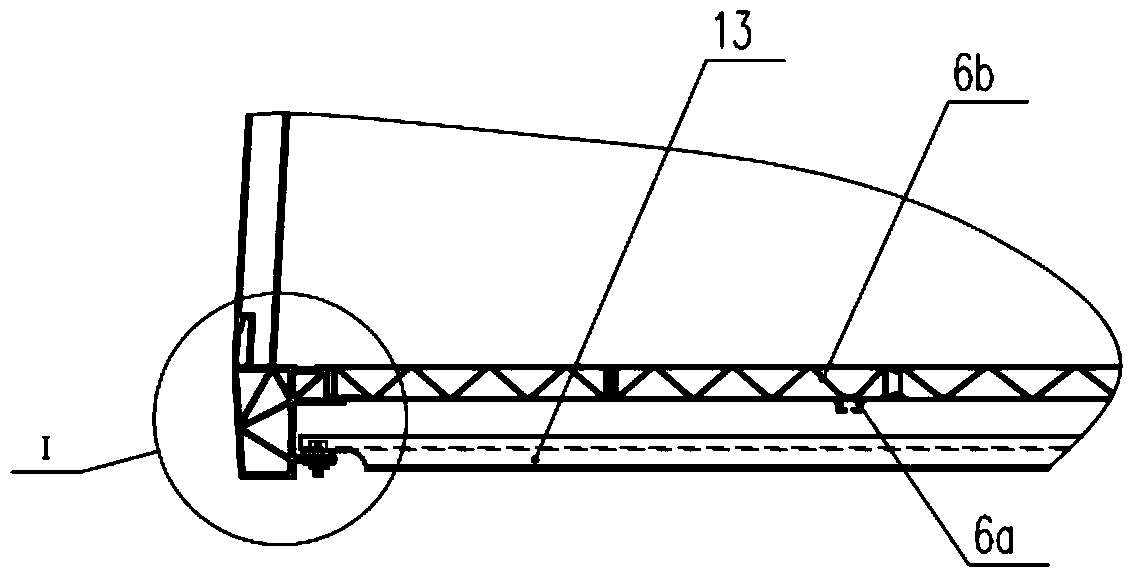

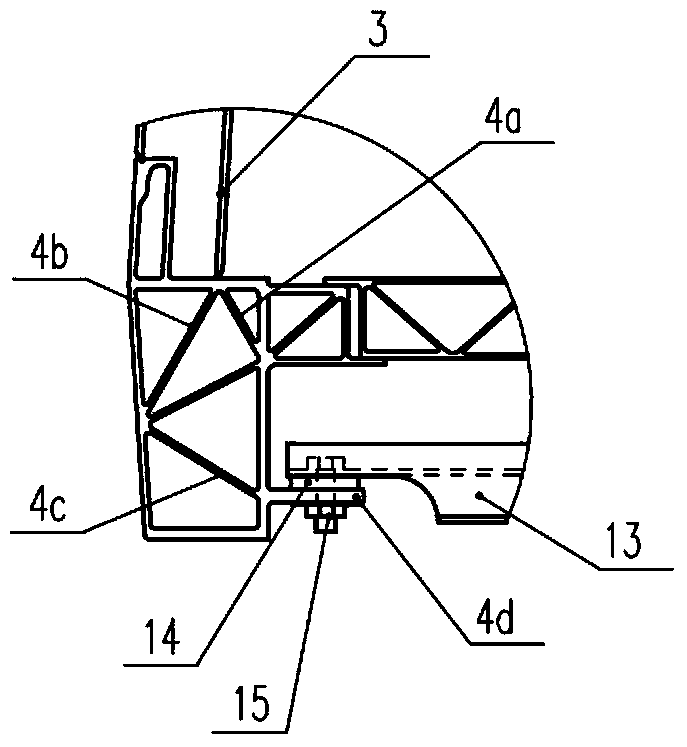

Car body structure of light weight railway vehicle

ActiveCN104309618AHigh strengthIncrease lateral stiffnessRailway transportAxle-box lubricationBaseboardEngineering

The invention discloses a car body structure of light weight railway vehicle. The car body structure of light weight railway vehicle comprises a car body upper part bearing girder composed of two top cover long girders and two top cover side girders, two bottom shelf side girders as car body lower part bearing girder, framework structure composed by connecting the guest room door stand column, side wall support girder and cab door stand column to the car body upper part bearing girder and the car body lower part bearing girder; the framework structure is fixedly connected to the bottom shelf end structure, cab framework, end wall framework for forming the framework structure; the stressed-skin structure is composed of the arc top cover, top cover isolated wall, air conditioning baseboard, pantograph baseboard, bottom shelf baseboard and side wall plate between two top cover long girders; the top cover side girder and the bottom shelf side girder are fixedly connected through the integrated side wall support girder; the air conditioning baseboard and the pantograph baseboard are formed on the same platform at the same height; the bottom shelf side girder has the structure for hooking under the car. The weight of the vehicle body can be reduced for 1 / 10 while the structure strength is guaranteed.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

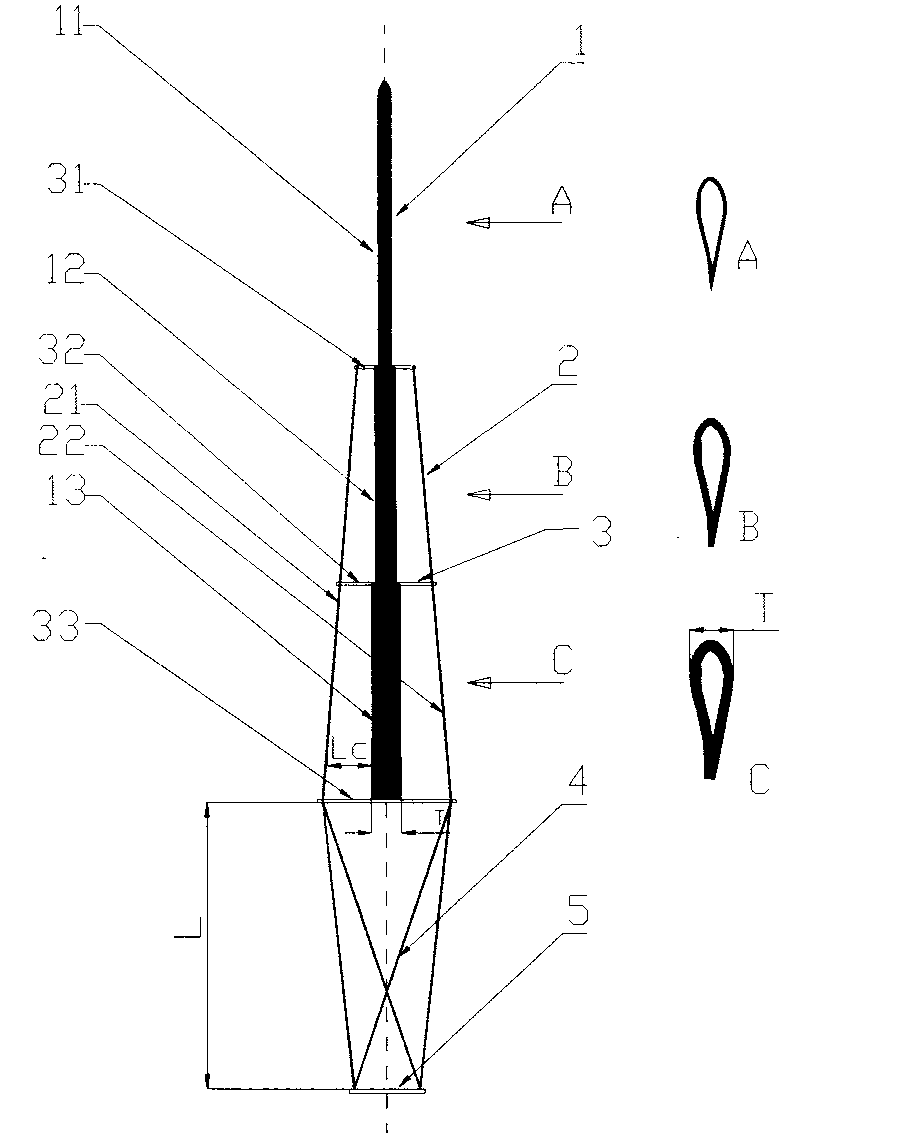

Actively deformed stressed-skin structure based on pneumatic muscles

The invention relates to an actively deformed stressed-skin structure, in particular to an actively deformed stressed-skin structure based on pneumatic muscles, which solves the problems that the existing stressed-skin material or structure deformation is passive and a complex mechanical transmission mechanism or drive mechanism is collocated in a deformed aerofoil to cause complex structure, heavy weight, large cost and the like. A plurality of pneumatic muscle fibers are arranged in parallel and plugged in a flexible basal body; the front ends of a plurality of pneumatic muscle fibers and the front end of the flexible basal body are connected with a first connection portion; the rear end of the pneumatic muscle fibers and the rear end of the flexible basal body are connected with a second connection portion; each pneumatic muscle fiber comprises a rubber capsule and a woven mesh cylinder for shape preservation; and the woven mesh cylinder for shape preservation is sleeved on the rubber capsule. Compared with the scale lamination or flexible stressed-skin materials, which are widely used today, the structure provided by the invention has the advantages of simple drive structure, light weight, integrated drive / deformation / load bearing and the like.

Owner:哈尔滨烯创新材料有限公司

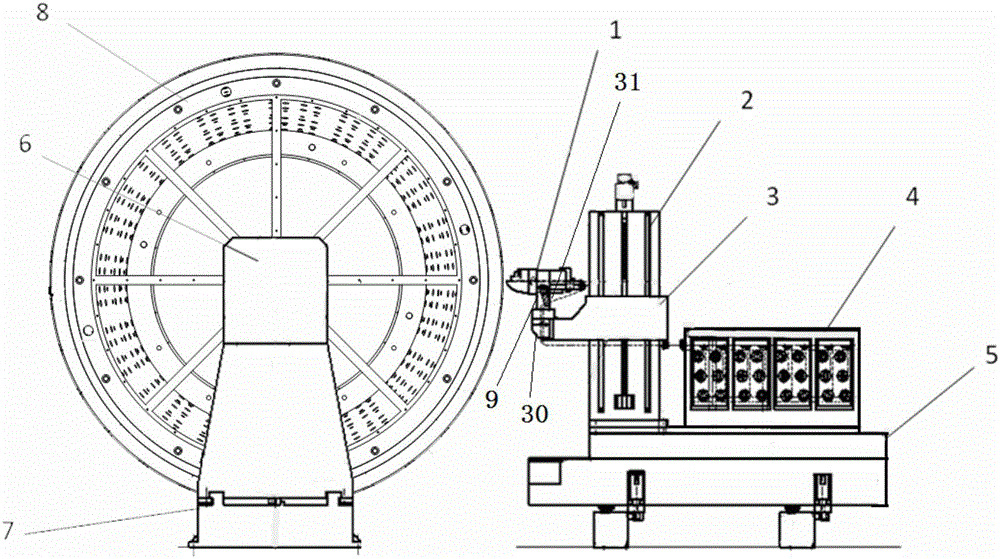

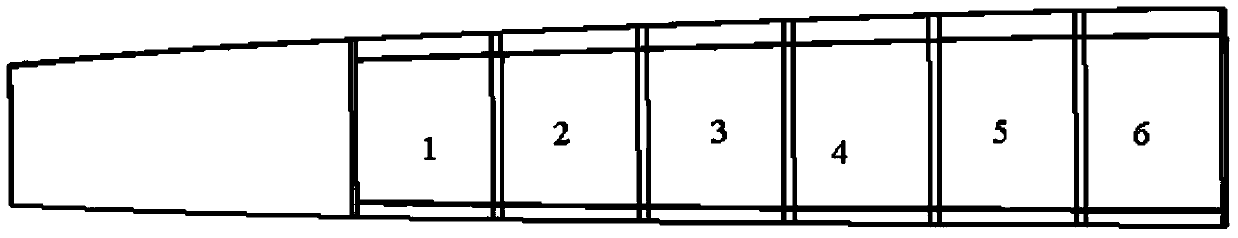

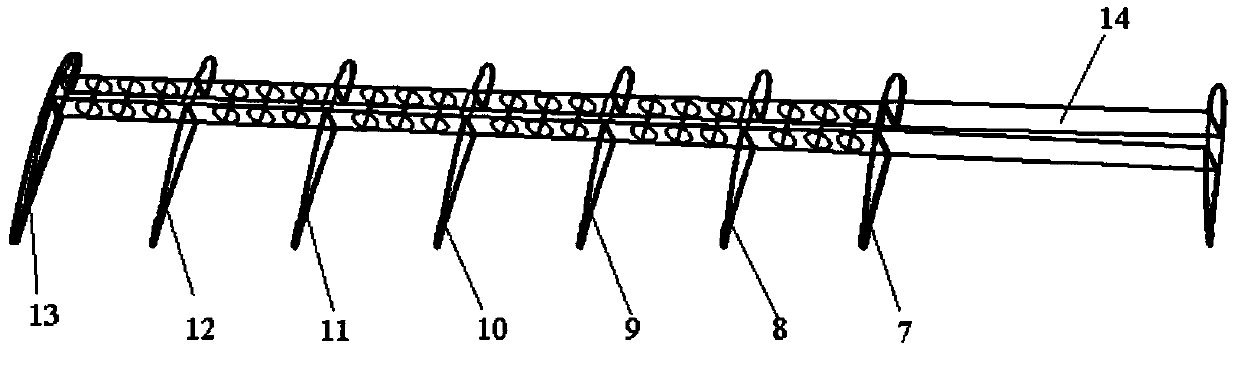

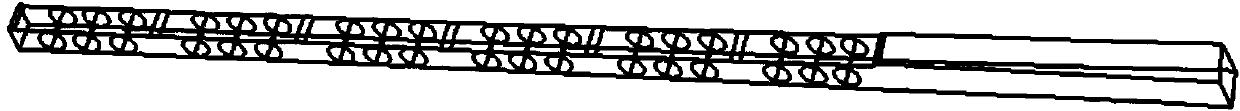

Blade of horizontal axis WTGS and forming method and equipment thereof

The invention discloses a composite blade of a horizontal axis WTGS (wind turbine generator system). A pneumatic functional part and a bearing structure part of the blade are separated from each other according to the design, particularly, external longitudinal beams are distributed on a front side surface and a rear side surface of the section surface of a pneumatic wing section and keep enough pneumatic clearance distances from the pneumatic wing section, and a section of truss structure is introduced at a blade stalk part of the blade, therefore, on the premise of guaranteeing the pneumatic power, the blade manufacture cost and transportation cost can be greatly lowered in comparison with the prior art. A horizontal axis fan formed on the basis of the pultrusion technology enhances the resin composite blade through using uniform-section fibers, a casing of the blade is divided into a stressed-skin construction layer and a core material construction layer which bear blade horizontal and longitudinal loads respectively, the core material part is made of preformed continuous-pultrusion sectional material, and the stressed-skin part is finished in the second pultrusion process. The method for manufacturing the full fiber composite blade by adopting the second pultrusion technology gives full play to the blade structure, material performance and technology advantages reasonably.

Owner:张向增

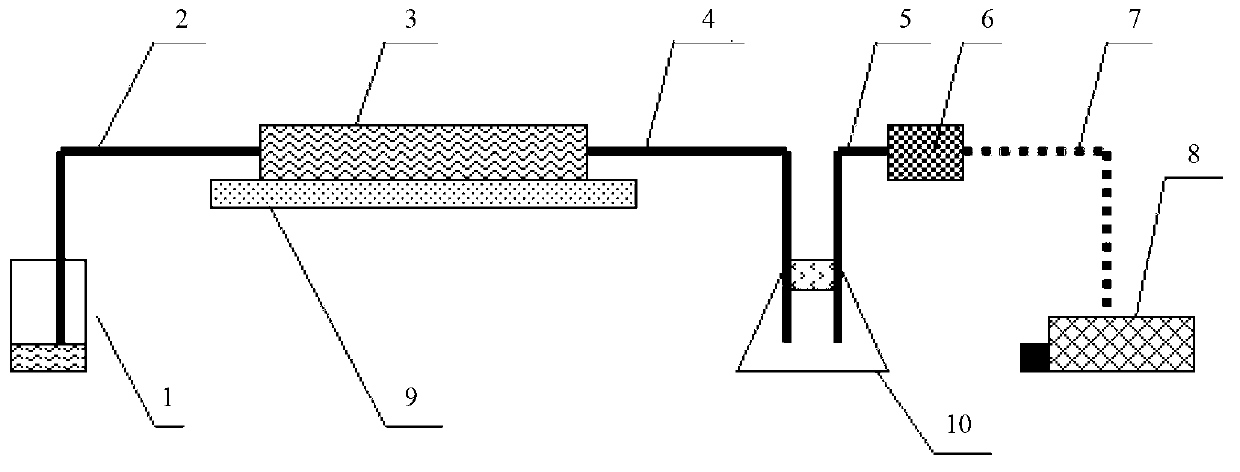

Liquid forming device and liquid forming method for composite material stiffened plate

The invention belongs to the forming technology of composite materials and relates to a liquid forming device and a liquid forming method for a composite material stiffened plate. The liquid forming device for the composite material stiffened plate comprises a glue solution cylinder, a packaging prefabricated member, a forming mould, a guide bottle, a connecting device and a vacuum pump, wherein the packaging prefabricated member is arranged on the forming mould with a groove to form a forming assembly; one end of the forming assembly is connected with the glue solution cylinder by a glue inlet tube to form an injection line; the other end of the forming assembly is connected to the guide bottle by a glue outlet tube to form a suction line, wherein the guide bottle is connected to the connecting device by the guide tube; and the connecting device is connected with the vacuum pump by a vacuum tube. According to the liquid forming device and the liquid forming method for the composite material stiffened plate provided by the invention, a rib structure stiffening fiber material is firstly placed in the groove of the forming mould for forming, a stressed-skin structure stiffening fiber material is spread and formed secondarily, and finally liquid resin is poured for integrally forming, so that precision of relative positions of the rib and the stressed-skin can be sufficiently ensured, the integrally formed appearance quality of the components is ensured, and a good practical application value is achieved.

Owner:COMAC +1

Finite element modeling simplification method of honeycomb sandwich structure

ActiveCN103984802ASimplified finite element modelingHigh precisionSpecial data processing applicationsIn planeElement model

The invention belongs to the field of finite element modeling and relates to a finite element modeling simplification method of a honeycomb sandwich structure. The method comprises the following steps: partitioning the honeycomb sandwich structure according to the regionality of rigidity changes; performing mechanics equivalency according to the structural rigidity of different regions; partitioning a finite element grid according to the regions of the honeycomb sandwich structure; establishing spatial topological relation of a unit by use of finite element modeling software by a unit selection plate unit; filling honeycomb structure material property data; filling unit attributes of different regions according to the result of rigidity equivalency of the step 2, and finishing finite element modeling of the honeycomb sandwich structure. The method has the advantages that rigidity equivalency is performed on honeycomb stressed-skin structures of different regions, one honeycomb sandwich structure is simplified into multiple plate units with different rigidity, and simplification is performed respectively on in-plane rigidity and flexural rigidity according to rigidity equivalency, so that finite element modeling simplification of a honeycomb structure under a full-aircraft finite element model of an aircraft is realized, and the airplane structure strength design and calculation accuracy can be improved.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

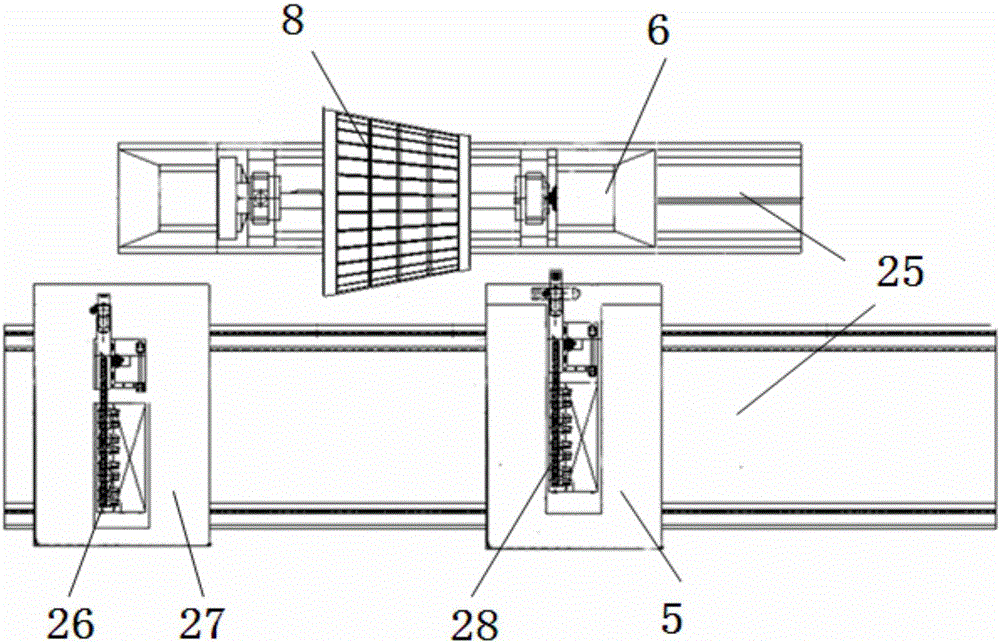

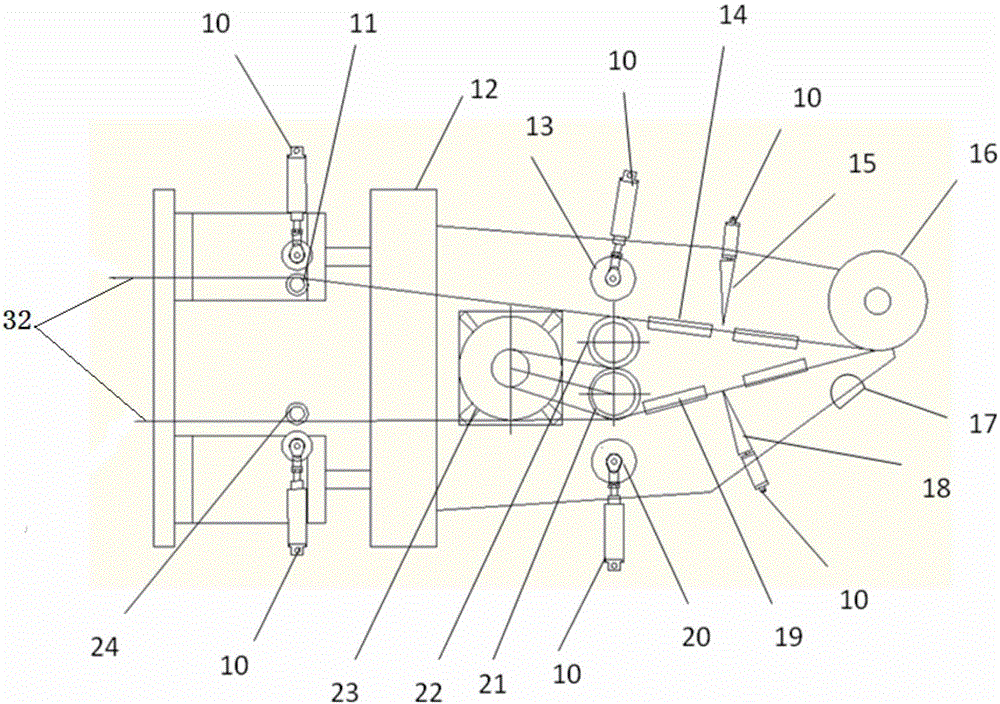

Composite material grid conical shell fiber placing and winding integrated molding device

ActiveCN105799187AImprove molding qualityImprove product qualityTemperature controlMaterials preparation

The invention discloses a composite material grid conical shell fiber placing and winding integrated molding device, and relates to the technical field of composite material preparation. The device comprises a grid conical shell component mold, a winding device, a winding trolley, a fiber placing device and a fiber placing trolley. The integrated molding device not only can be used for finishing the winding of grid ribs, but also can be used for finishing the fiber placement molding of stressed-skin constructions, and has a tow resin temperature control ability to realize control over the prepreg tow viscosity in the transmission process; a heating system is configured in a placing head to enable prepreg tows to be heated, so that the prepreg tows have a certain viscosity and then the process requirements are satisfied. The device disclosed in the invention can be applied to composite material grid conical shell components, and is good in molding quality, high in placing precision, good in product quality and high in manufacture efficiency; an automatic fiber placing system and a grid rib winding system are integrated in a set of equipment, so that the high-efficiency and high-quality composite integrated molding of the composite material grid conical shell components is realized.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

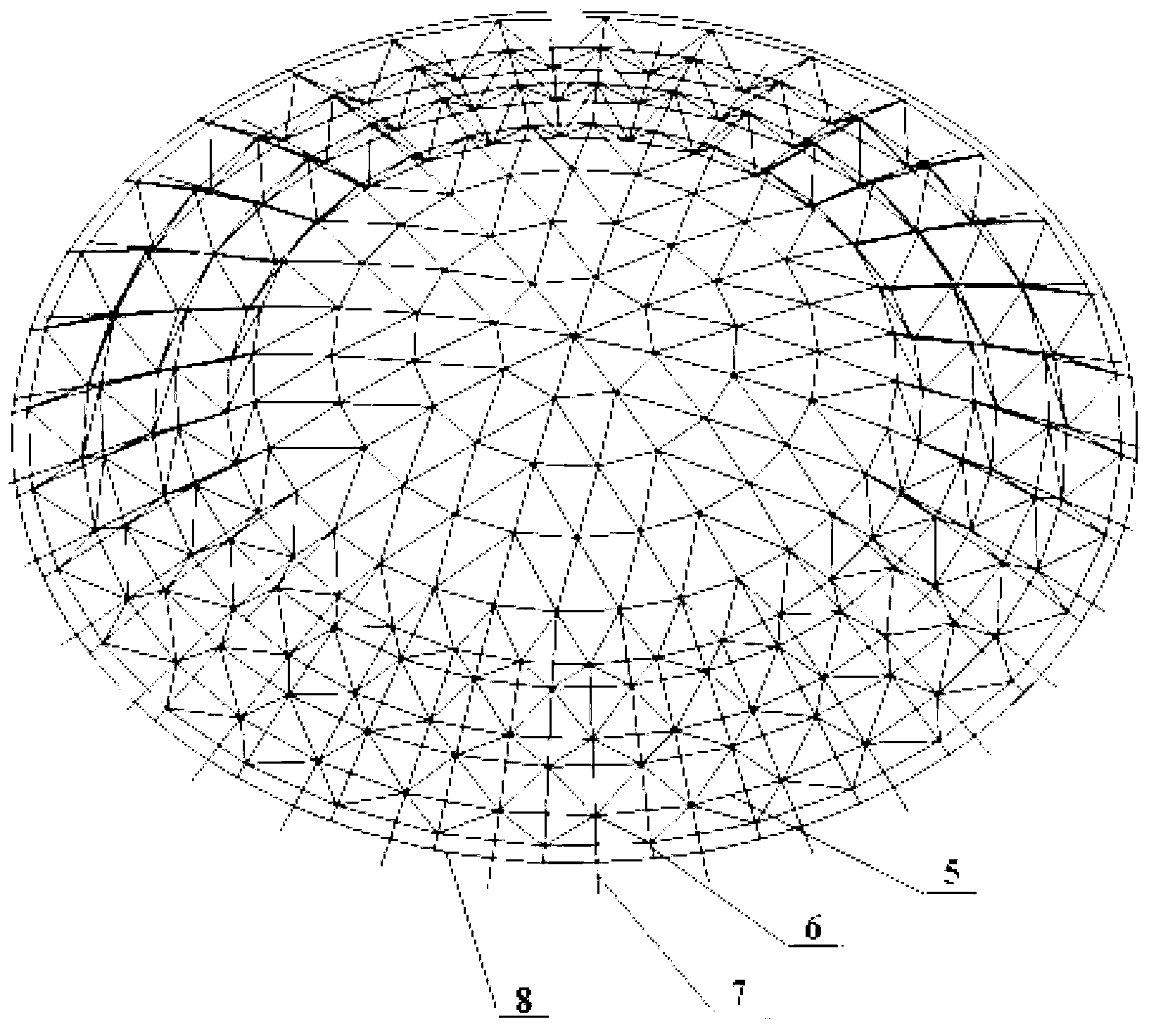

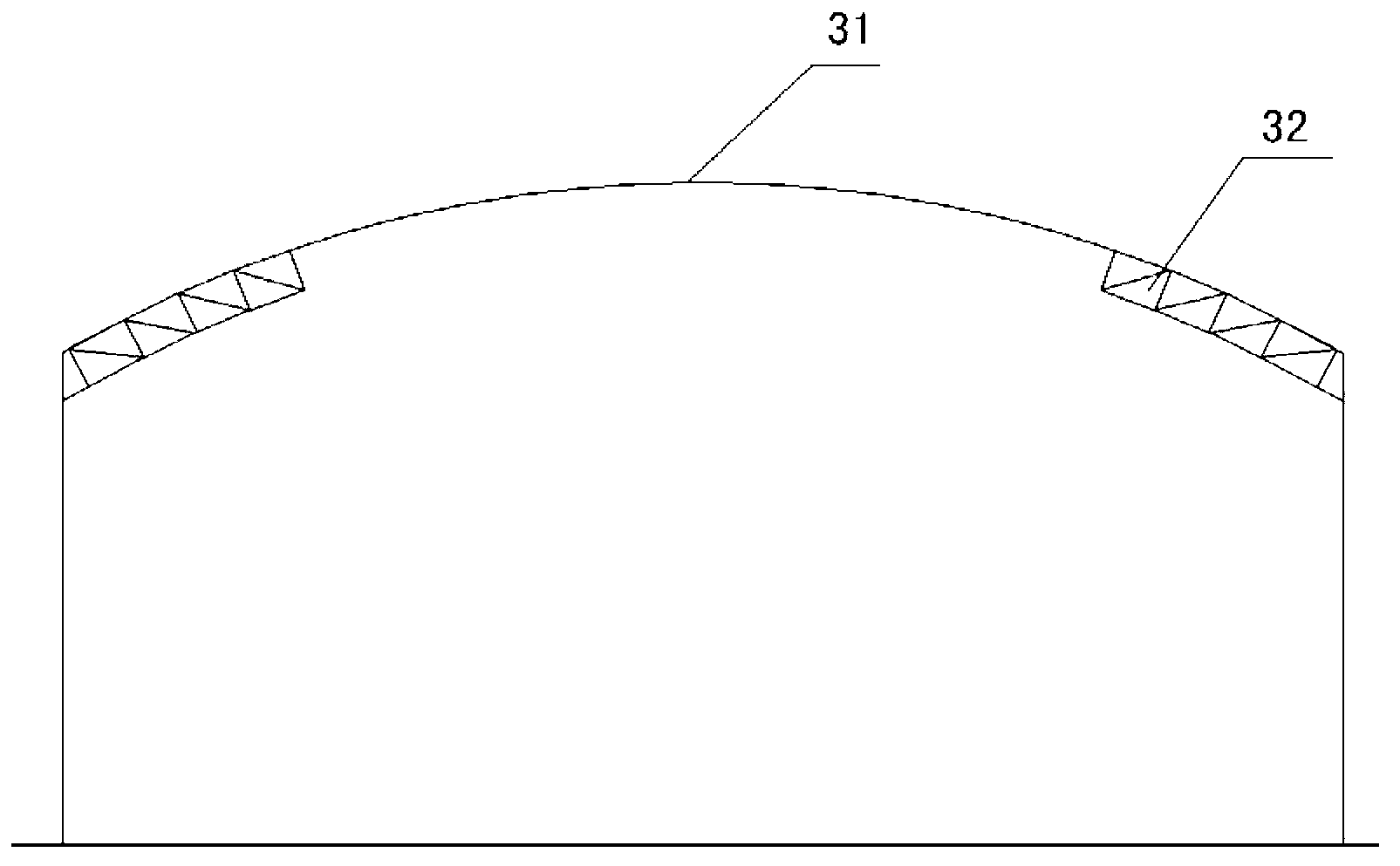

Partial double-layer spherical reticulated shell storage tank vault structure

The invention discloses a partial double-layer spherical reticulated shell storage tank vault structure. The partial double-layer spherical reticulated shell storage tank vault structure is characterized in that part of the periphery is a double-layer reticulated shell, the middle is a single-layer reticulated shell, and stressed-skin diaphragms are laid on the top of the double-layer reticulated shell and the top of the single-layer reticulated shell to be used as a storage tank vault. The single-layer reticulated shell in the middle of the reticulated shell is a Kiewitt reticulated shell, the outer layer of the double-layer reticulated shell in the part of the periphery is rib ring reticulated shell, and the rib ring reticulated shell and the inner layer are connected to form a quadrangular pyramid system. The reticulated shell is composed of chord members, web members and panel joints. Member pieces are steel tubes or profile steel, the panel joints are board panel joints or ball panel joints, and the member pieces are connected through the panel joints in a welding mode or through bolts in an assembling mode to form the reticulated shell. The inner layer and the outer layer of the whole reticulated shell are supported on supports of a tank wall or a ring beam to support the storage tank vault. The partial double-layer spherical reticulated shell storage tank vault structure has the advantages of being concise in structure, easy to construct, capable of being superior to the single-layer reticulated shell in carrying capacity, and applied to occasions with storage tanks of larger diameters and long-span vaults.

Owner:HEFEI GENERAL MACHINERY RES INST

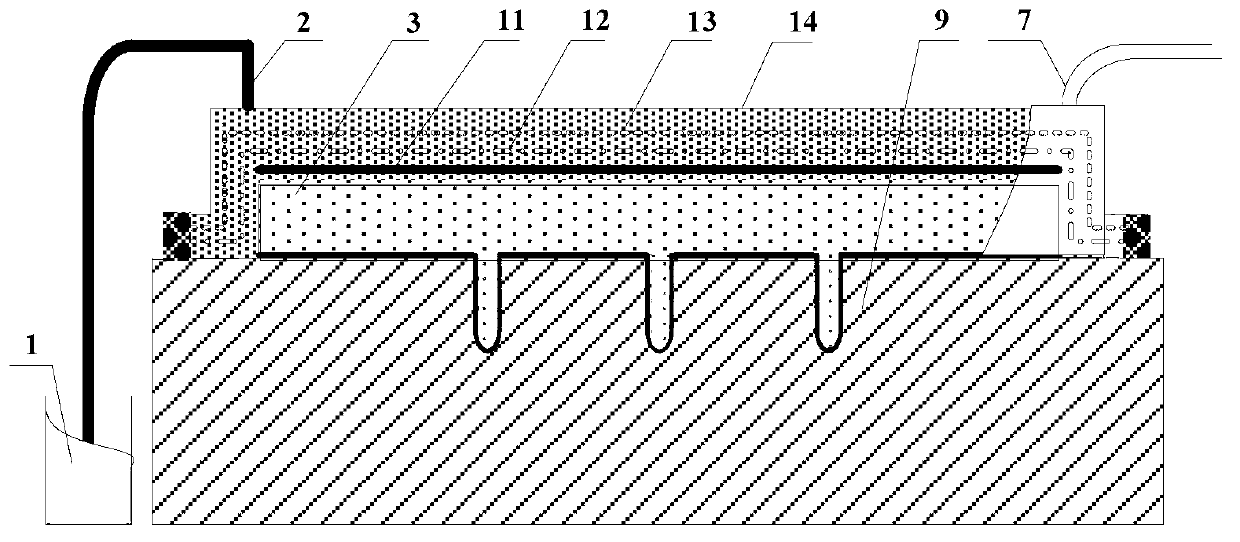

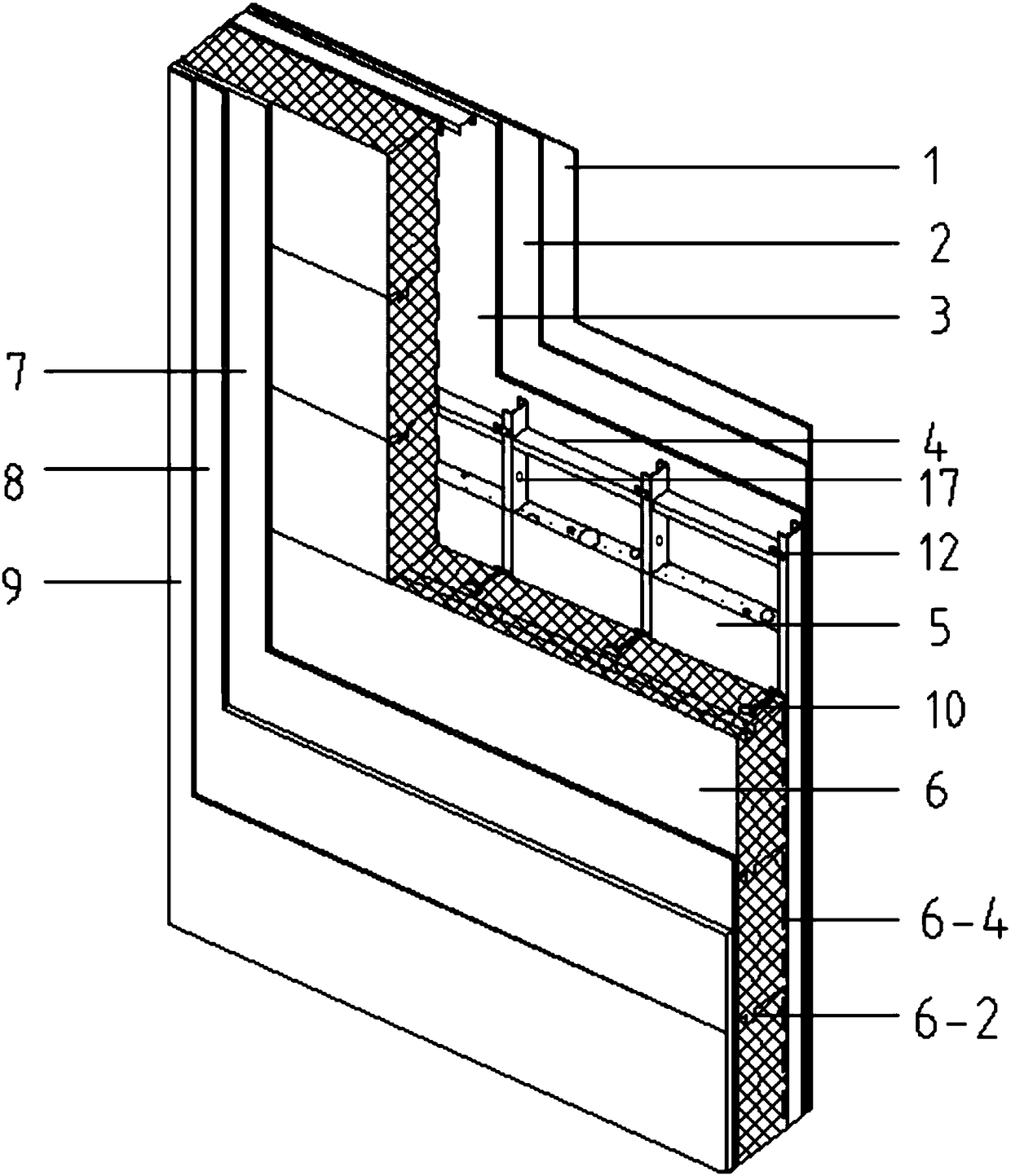

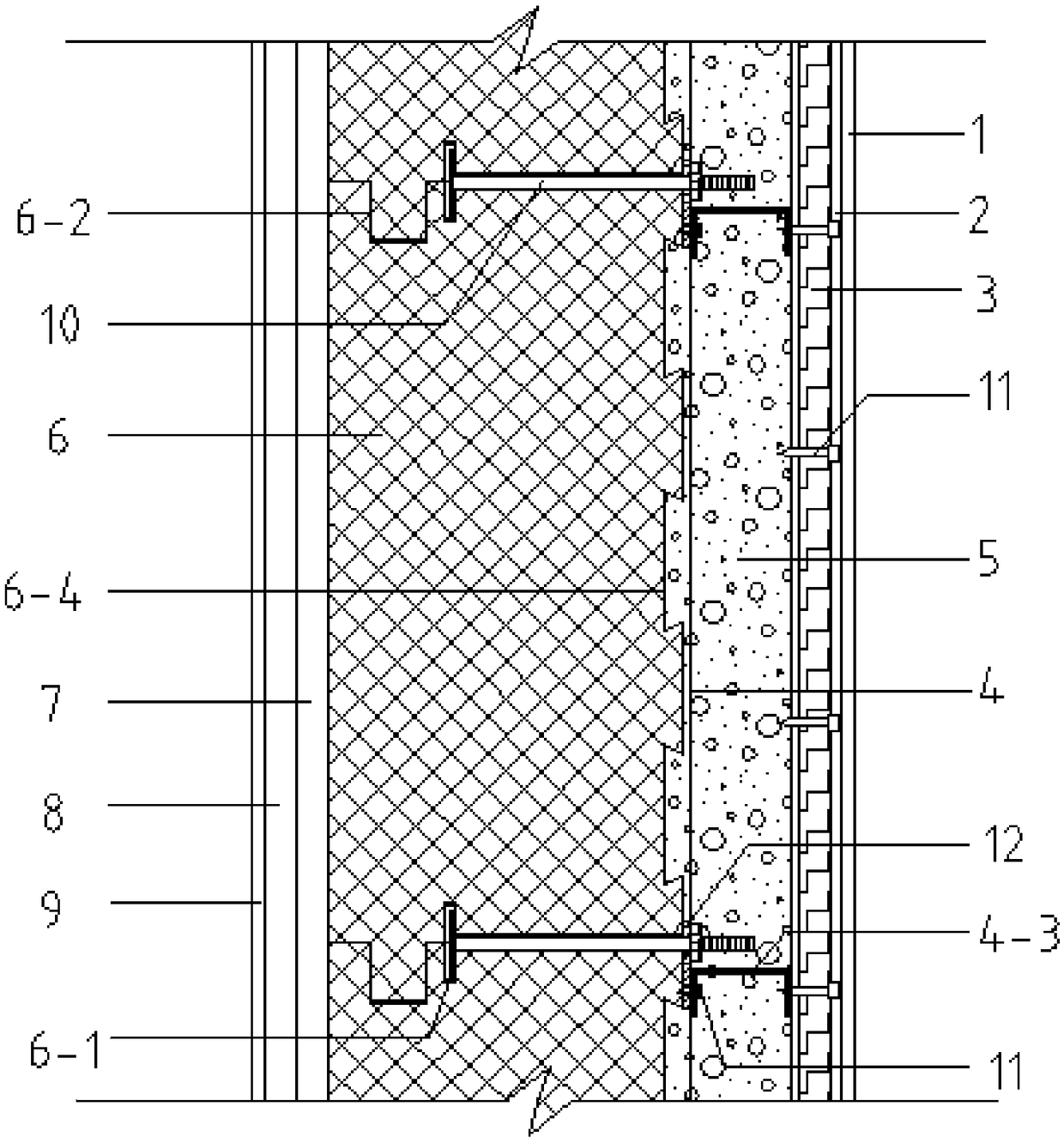

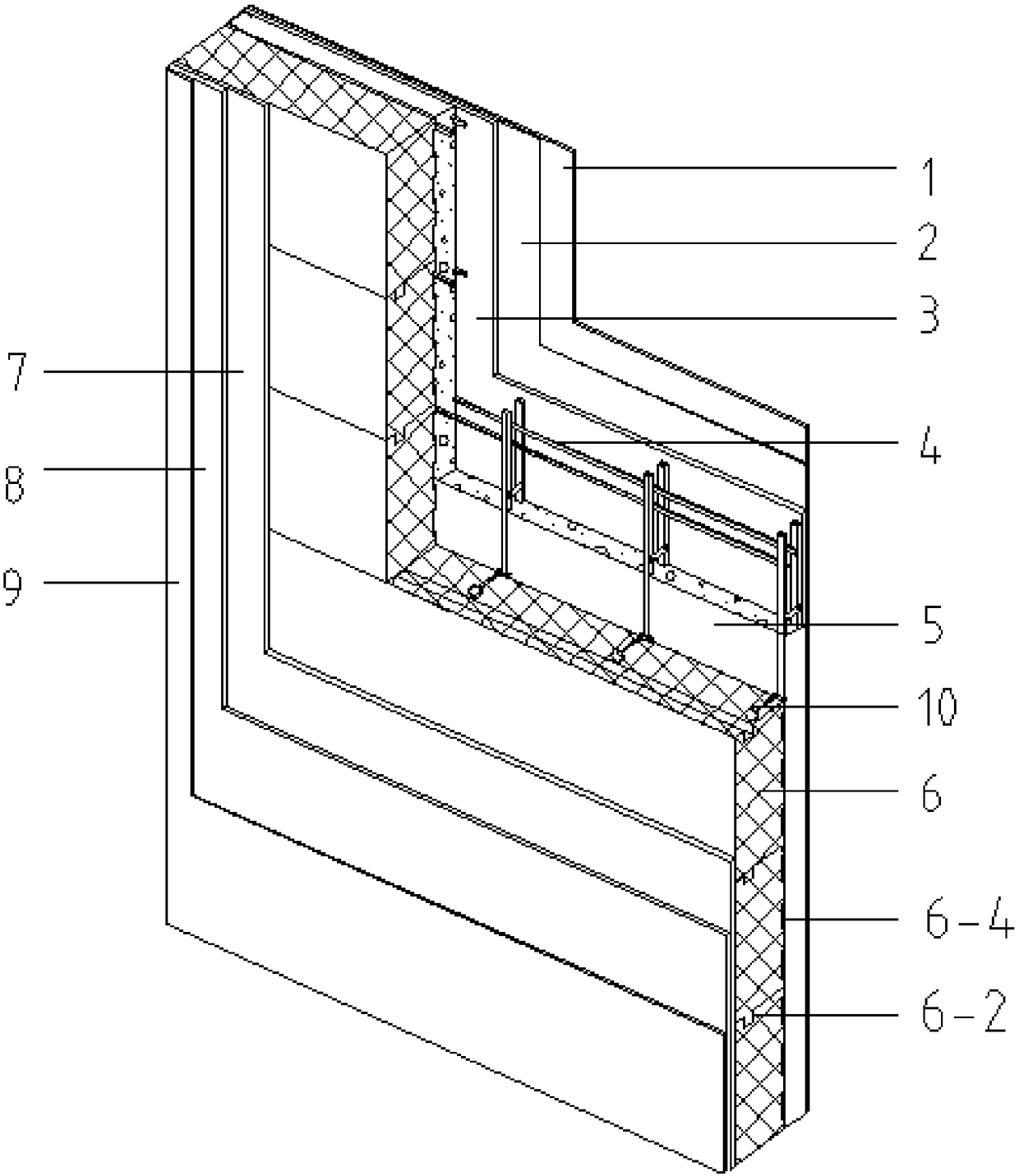

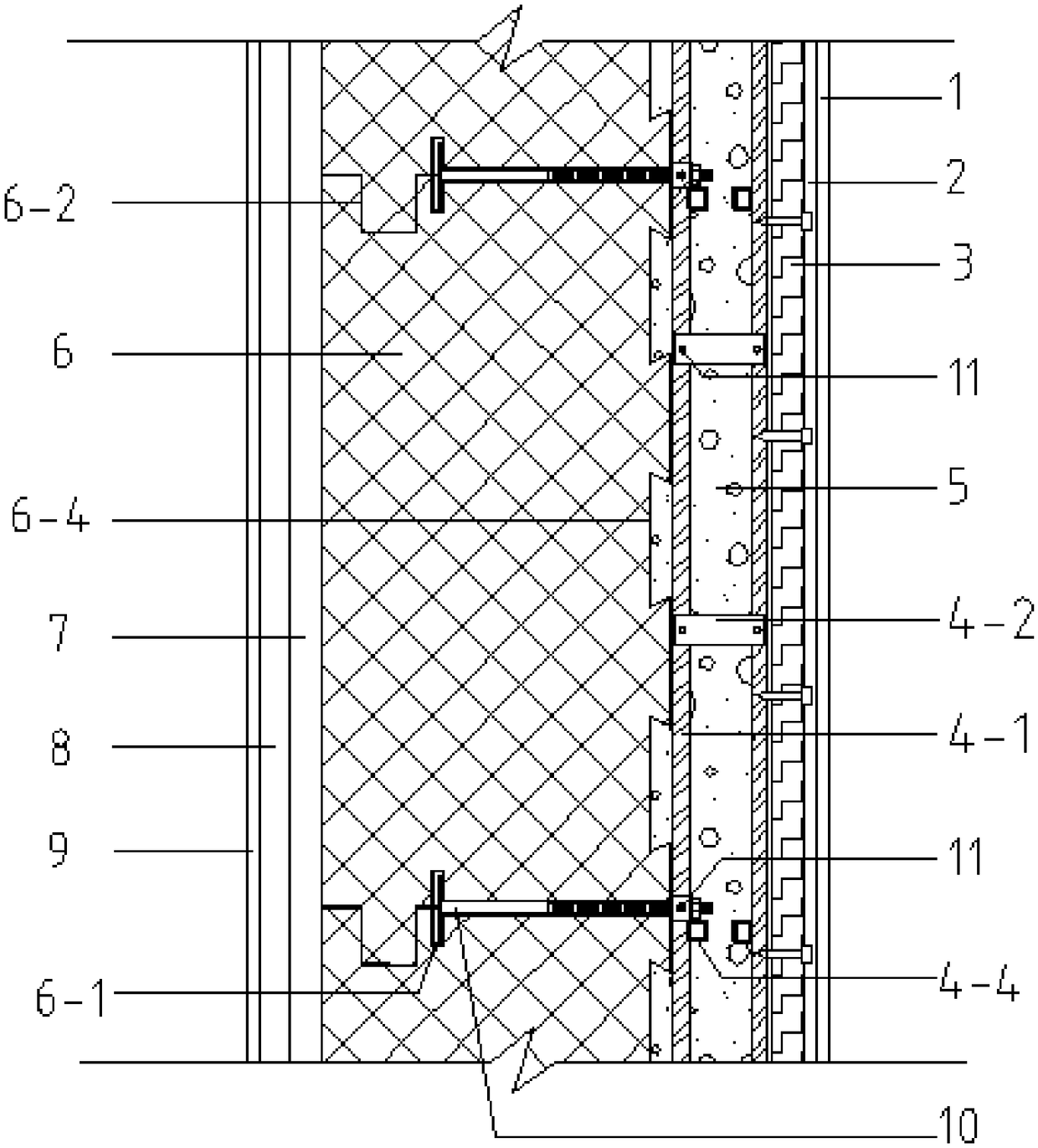

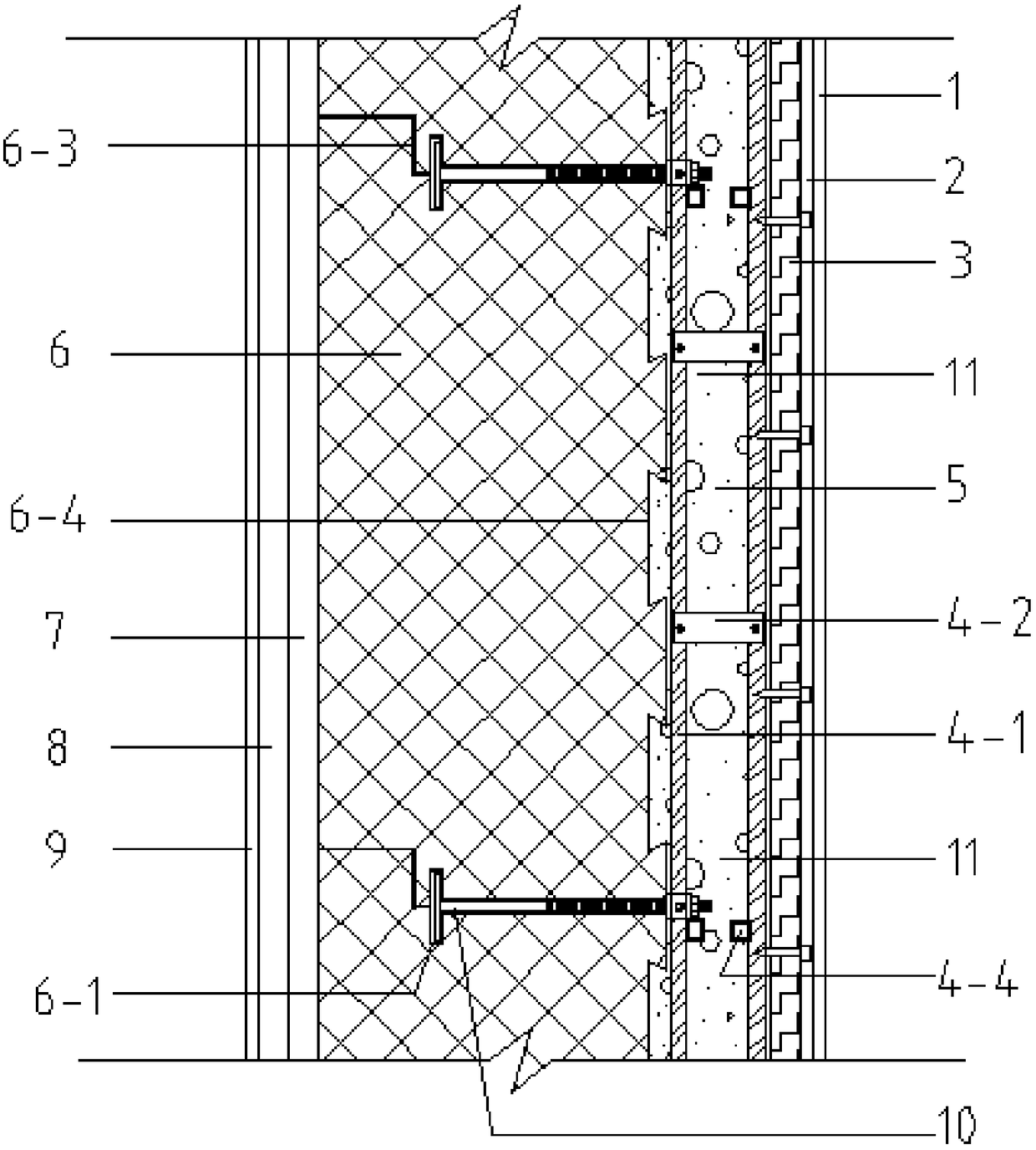

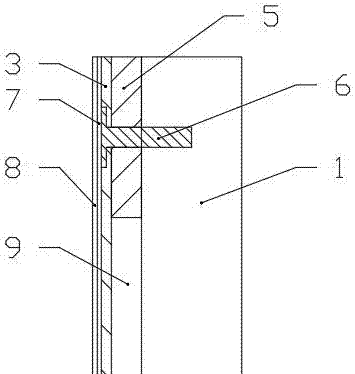

Prefabricated non-thermal bridge external thermal insulation wallboard with C-shaped steel light steel keel and manufacturing method thereof

The invention relates to a prefabricated non-thermal bridge external thermal insulation wallboard with a C-shaped steel light steel keel and a manufacturing method thereof. The wallboard comprises a base wall body, a break thermal bridge anchoring bolt, a connecting piece, a thermal insulation board and a stressed-skin diaphragm. The thermal insulation board and the base wall body are fixedly connected into a whole through the break thermal bridge anchoring bolt and the connecting piece, and the stressed-skin diaphragm is fixedly arranged on the other side, relative to the thermal insulation board, of the base wall body. The prefabricated non-thermal bridge external thermal insulation wallboard is convenient to construct and simple in structure, breaks the inherent concept of ''thermal insulation after wall body'' and proposes the integrated production of a thermal insulation wall body. Factory prefabrication and site assembly can be carried out, batch production and on-site installation are convenient, the construction efficiency is improved, the characteristics of low energy consumption, flexible arrangement and fast construction are achieved, and the requirements of green construction are met. The arrangement of the non-cut-through type break thermal bridge anchoring bolt and dovetail grooves avoids the phenomenon of a thermal bridge caused by joints and the like, the thermal insulation performance of the wall body is improved, and the structural integrity is increased; and the weight of the wall body is greatly reduced due to using of a light steel keel frame and lightweight concrete, and the cost of construction, transportation and seismic design of later structure is reduced.

Owner:沈阳领创建筑科技有限公司

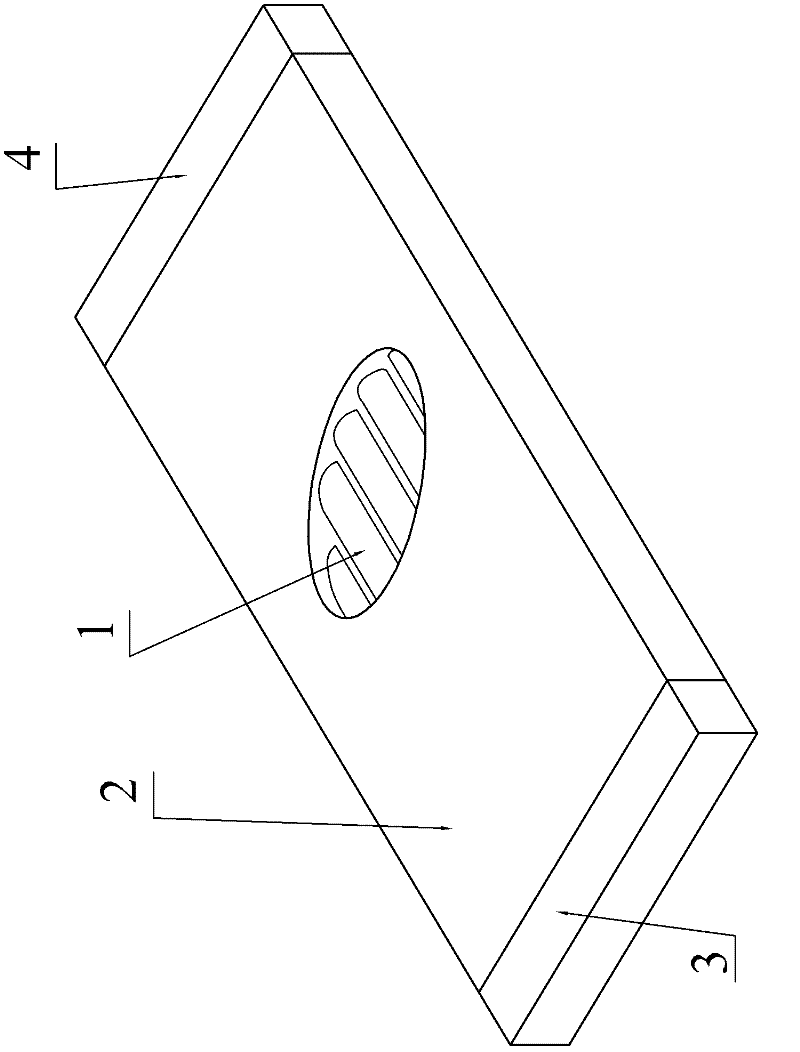

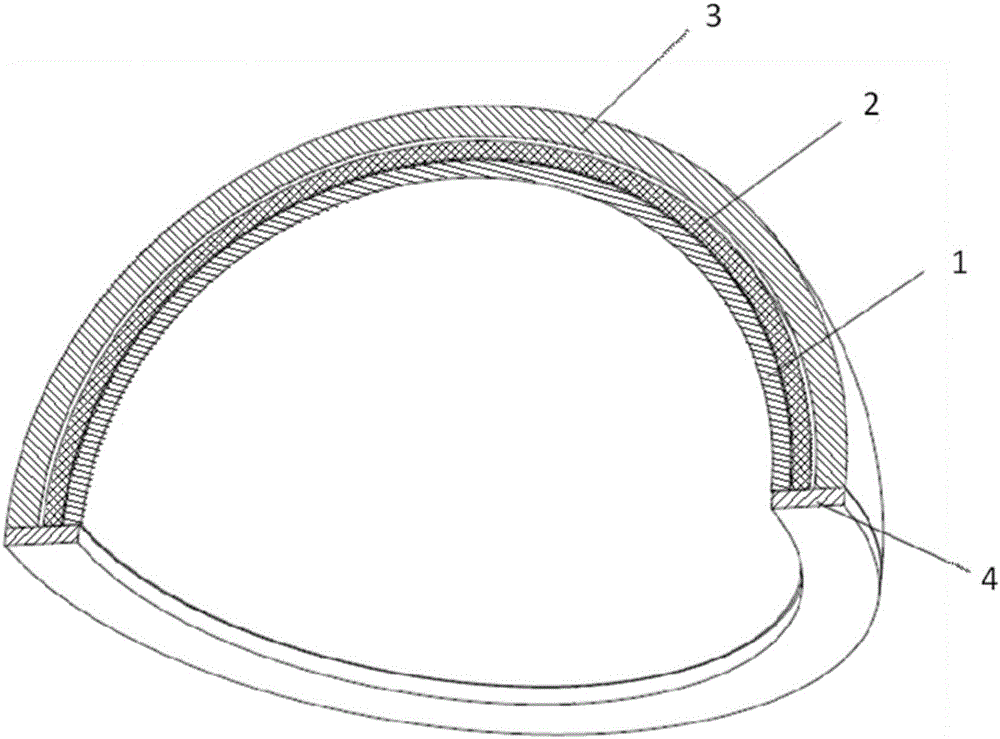

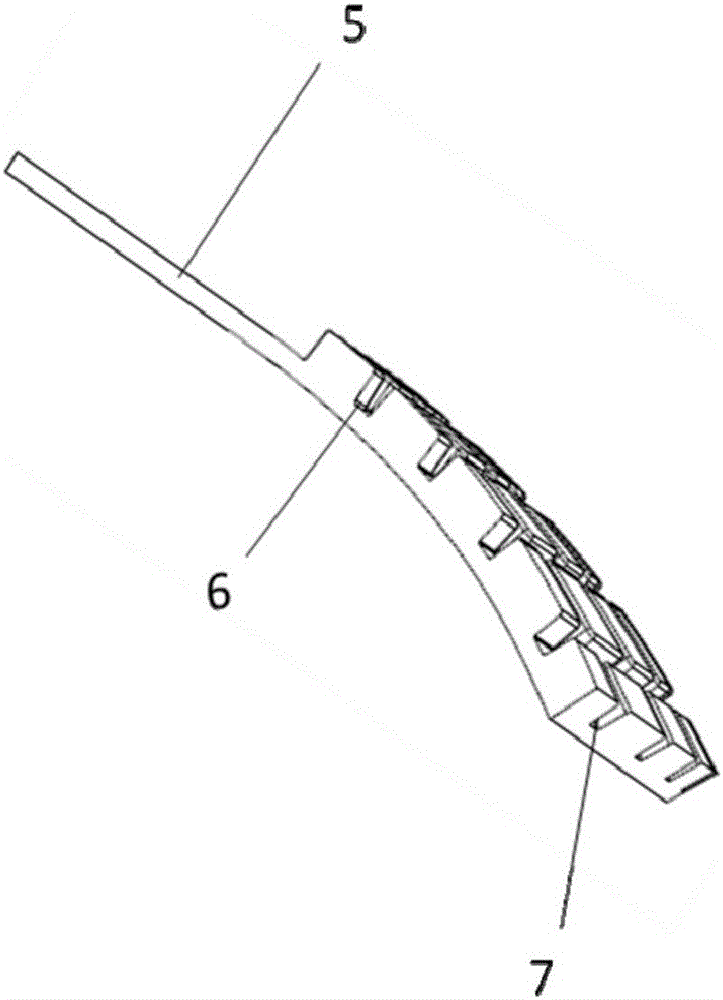

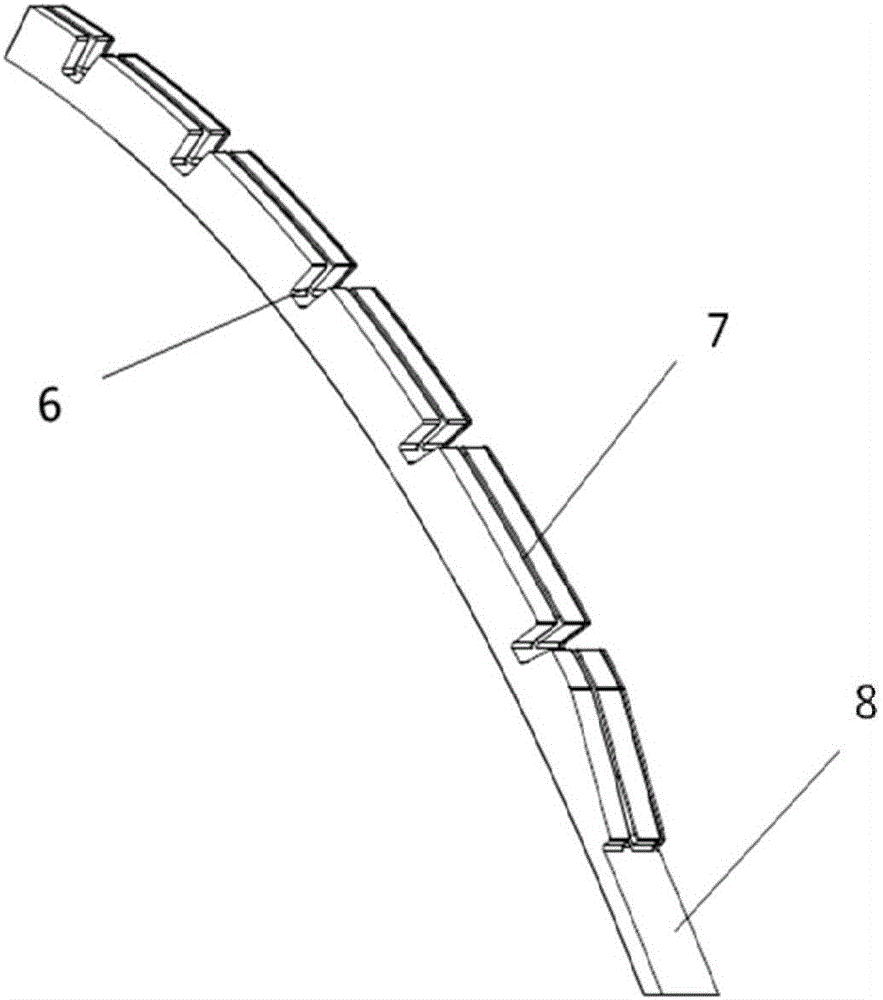

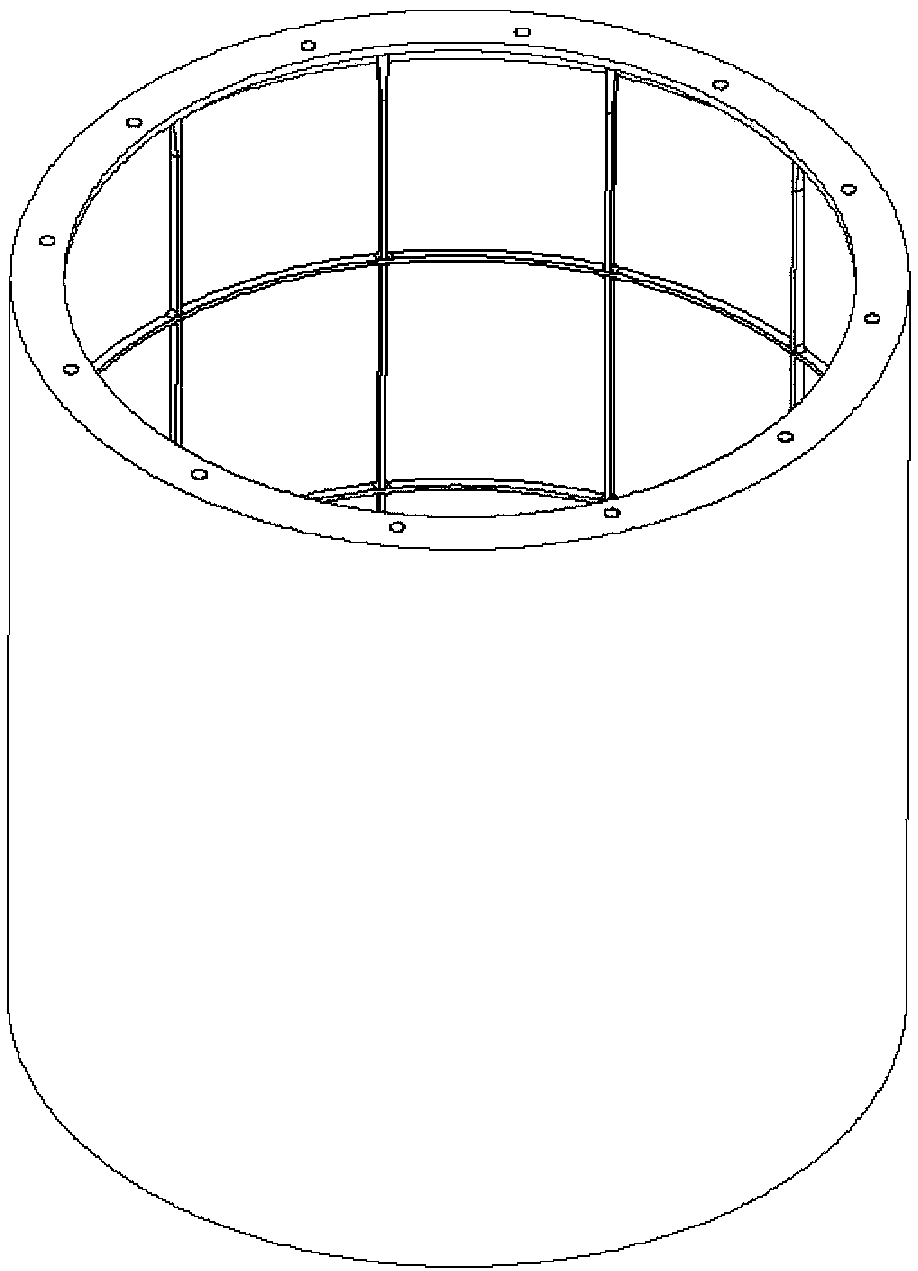

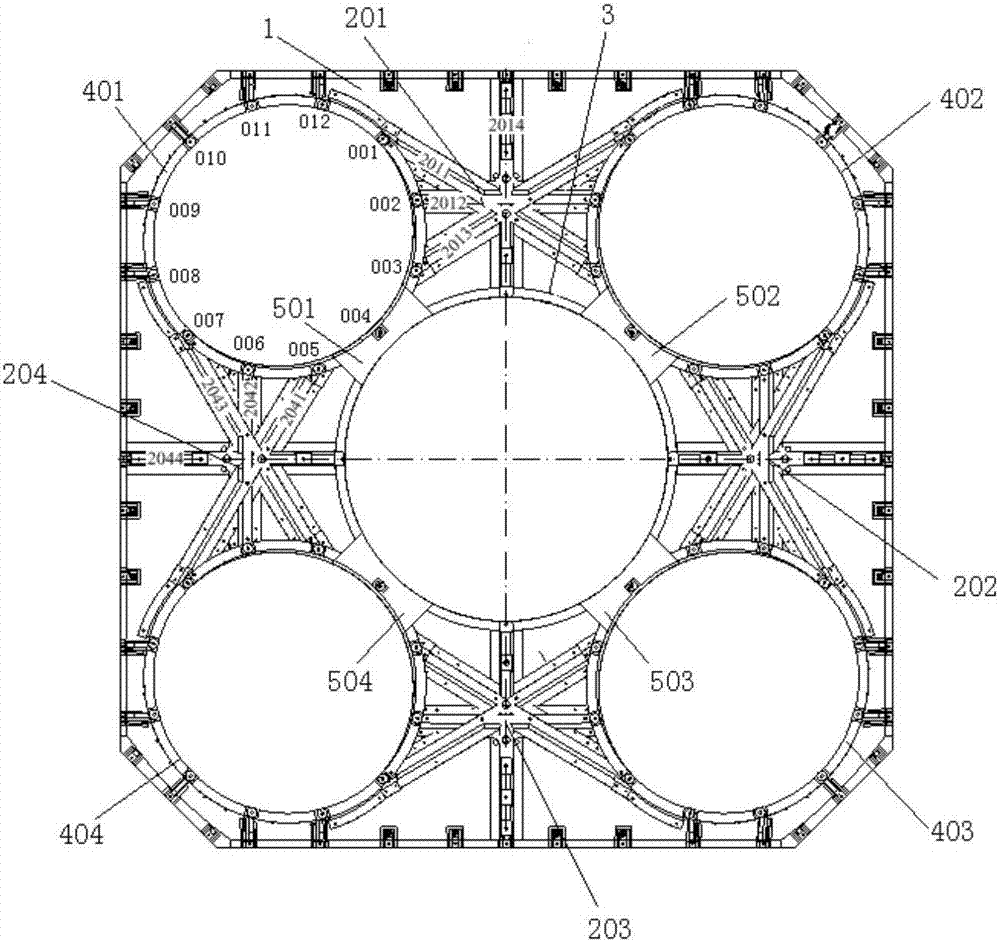

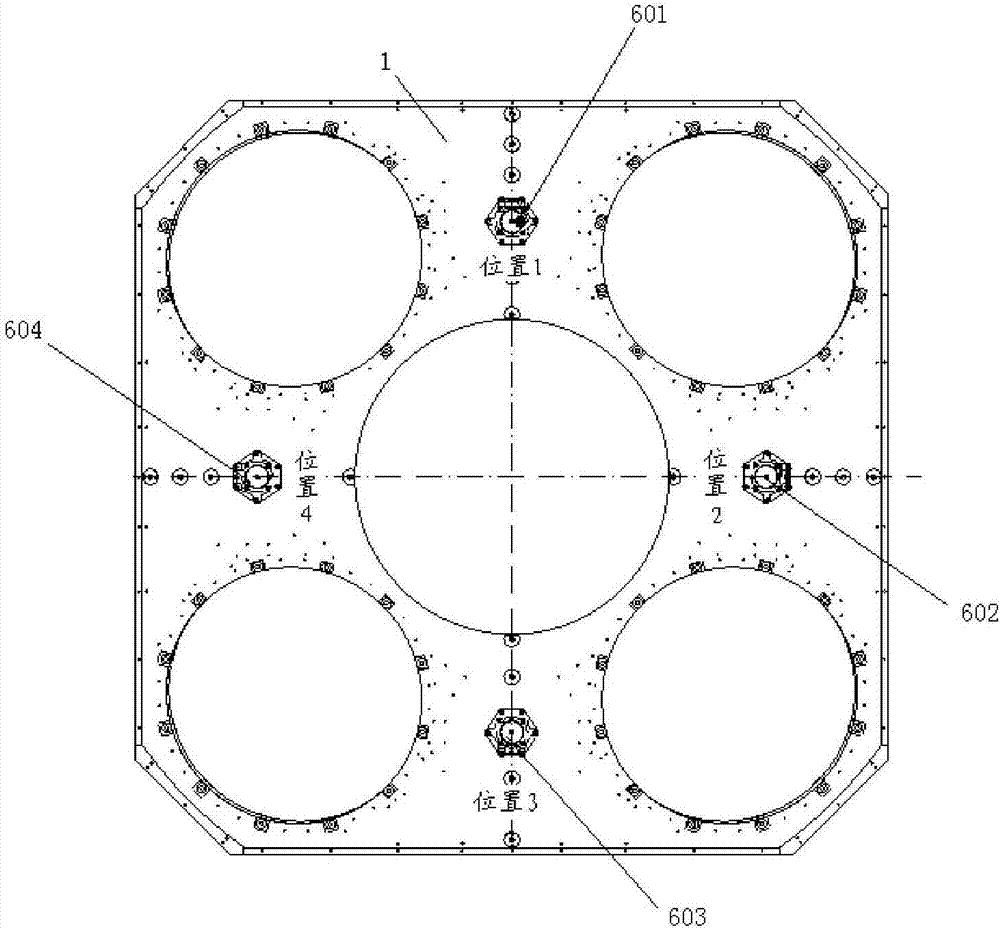

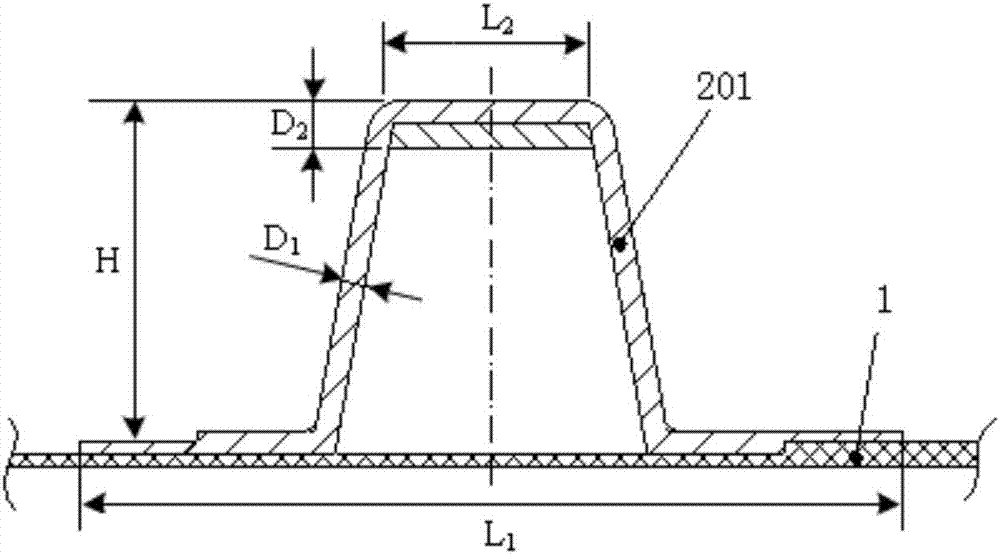

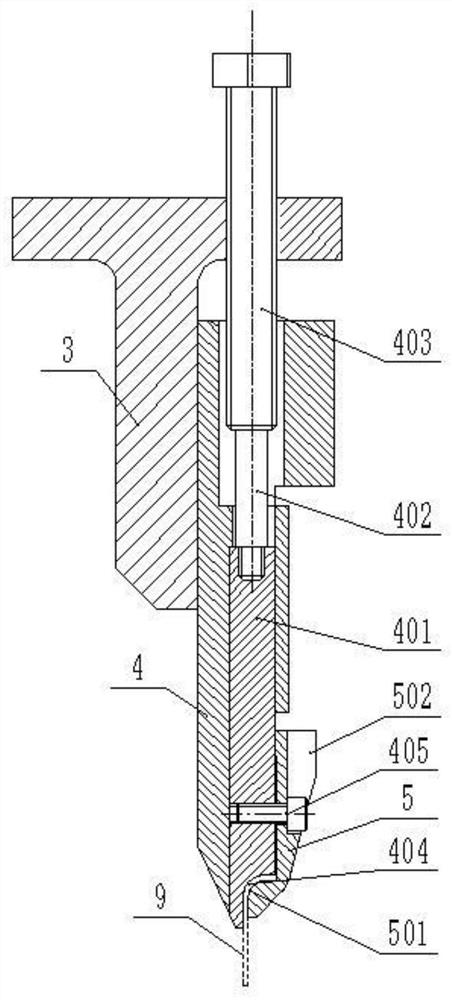

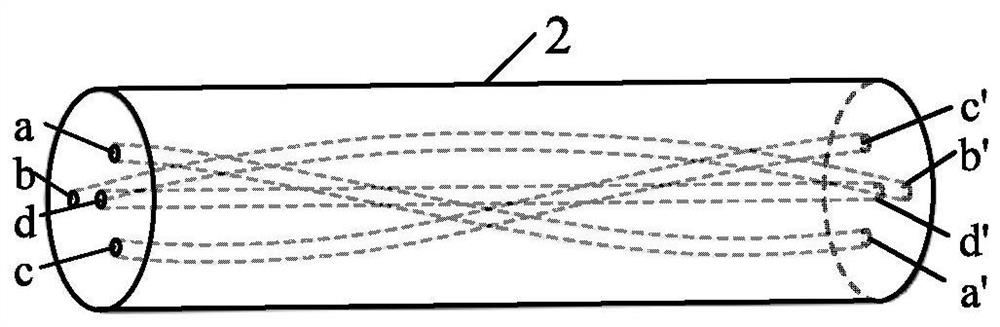

Die and method for molding composite material of semi-closed cavity gridding stressed-skin structure

ActiveCN105690795AHas ductile characteristicsStrong damage resistanceUltimate tensile strengthStressed skin

The invention relates to a die and method for molding a composite material of a semi-closed cavity gridding stressed-skin structure. The die comprises a core die bush (1), a male die body (2), an external female die body (3) and a lower-end pressing ring (4) having a supporting effect on the core die bush (1) and the external female die body (3); the male die body (2) is formed by splicing sectioning die sheets and is wrapped outside the core die bush (1), protrusions are arranged in the middle portion of the outer surface of the male die body (2), and rib grooves are formed between the protrusions; the external female die body (3) is wrapped outside the male die body (2), the distance between the external female die body (3) and the outer surface of the protrusions ranges from 1 mm to 5 mm, the external female die body (3) forms an upper-end thickening area (5) in an area without the protrusions, and the male die body (2) forms a lower-end thickening area (8) in the area without the protrusions; and the molding method includes the step that a semi-closed composite material component is manufactured through the die, wherein the upper-end thickening area (5) and the lower-end thickening area (8) are used for paving of prepreg so as to form end frames, and the rib grooves are used for wining of presoaking wires so as to form strengthening ribs. The composite material component is high in strength, and the gridding compactness is high.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Plywood type front edge structure of flying machine

The invention relates to a plywood type front edge structure of a flying machine, which can be particularly applied to the front edge of a nose cone or an aerofoil of a flying machine performing high-Mach flight, and comprises an outer layer stressed-skin diaphragm, an inner layer cladding plate and a flow pass combined plate arranged between the outer layer stressed-skin diaphragm and the inner layer cladding plate and used for circular flow of heat conduction working medium. According to the plywood type front edge structure, the structure similar to a heat pipe is formed by utilizing etching of layer plates and overlying, and the layer plates are connected through diffusion welding as per the shape of the front edge so as to form the integrated front edge structure of the flying machine, and the front edge structure has the advantages of simple structure, low investment, small size and high stability.

Owner:NAT UNIV OF DEFENSE TECH

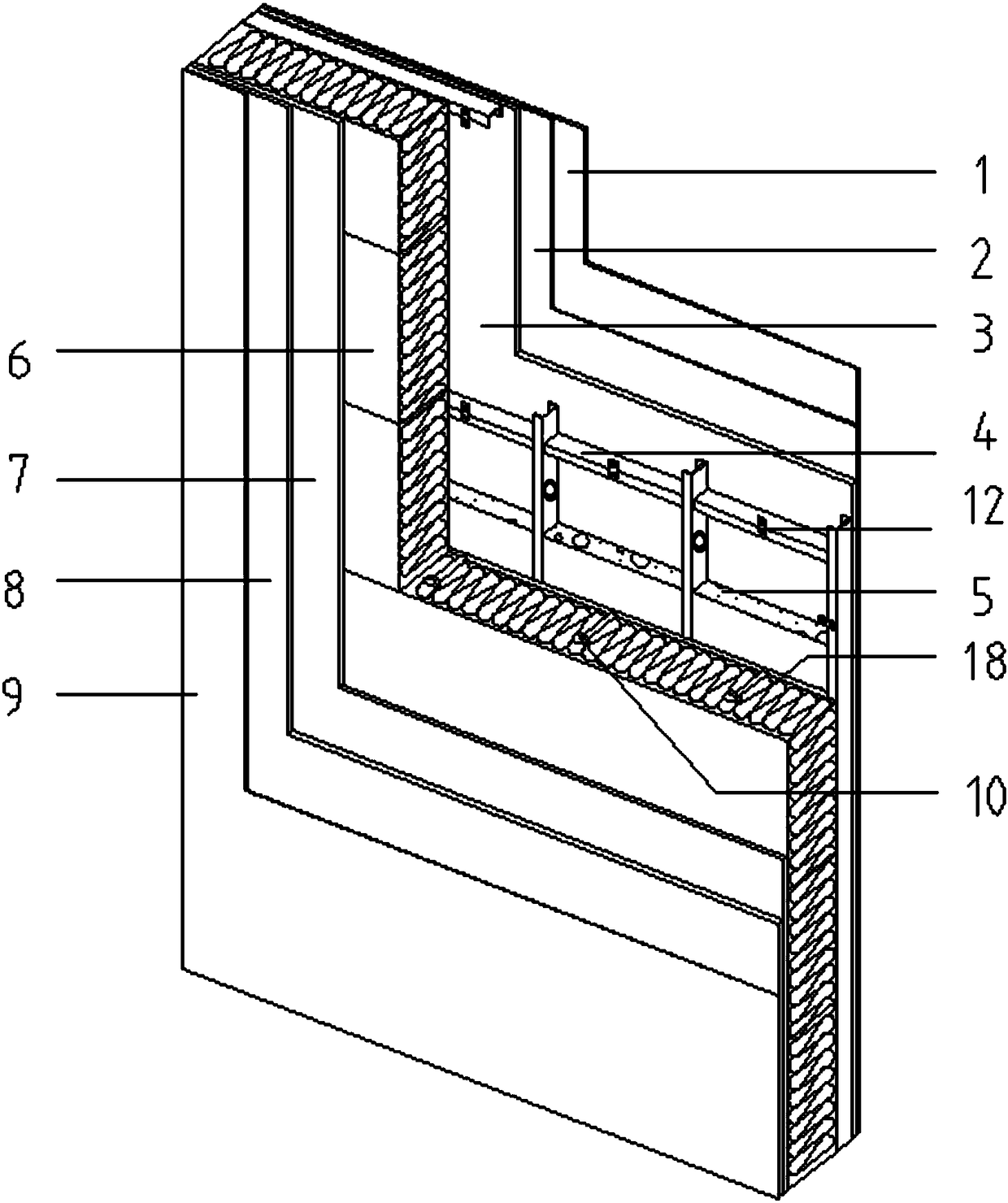

Prefabricated non-thermal bridge thermal insulation external wall of rectangular steel pipe keel and manufacturing method thereof

The invention relates to a prefabricated non-thermal bridge thermal insulation external wall of a rectangular steel pipe keel and a manufacturing method thereof. The prefabricated non-thermal bridge thermal insulation external wall comprises a base wall body, a break thermal bridge anchoring clamping piece, a thermal insulation board and a stressed-skin diaphragm. The thermal insulation board andthe base wall body are fixedly connected into a whole through the break thermal bridge anchoring clamping piece, and the stressed-skin diaphragm is fixedly arranged on the other side of the base wallbody relative to the thermal insulation board. The prefabricated non-thermal bridge thermal insulation external wall is convenient to construct and simple in structure, and breaks the inherent conceptof 'thermal insulation after wall body' and proposes the concept of integrated production of thermal insulation and wall body; batch production and on-site installation are convenient, the construction efficiency is improved, the characteristics of low energy consumption, flexible arrangement and fast construction are achieved, and the requirement of green construction is met; the use of the break thermal bridge anchoring clamping piece simplifies the construction process, an U-shaped connecting piece is connected with the rectangular steel pipe keel conveniently, and the construction speed is improved; and the setting of the rectangular steel pipe keel improves the integrity of concrete pouring in the later stage, and is beneficial to the overall stress of the structure. Dovetail groovesare arranged to solve the problem of thermal bridges caused by joints and the like, the thermal insulation performance of the wall body is improved and the structural integrity is increased.

Owner:SHENYANG JIANZHU UNIVERSITY

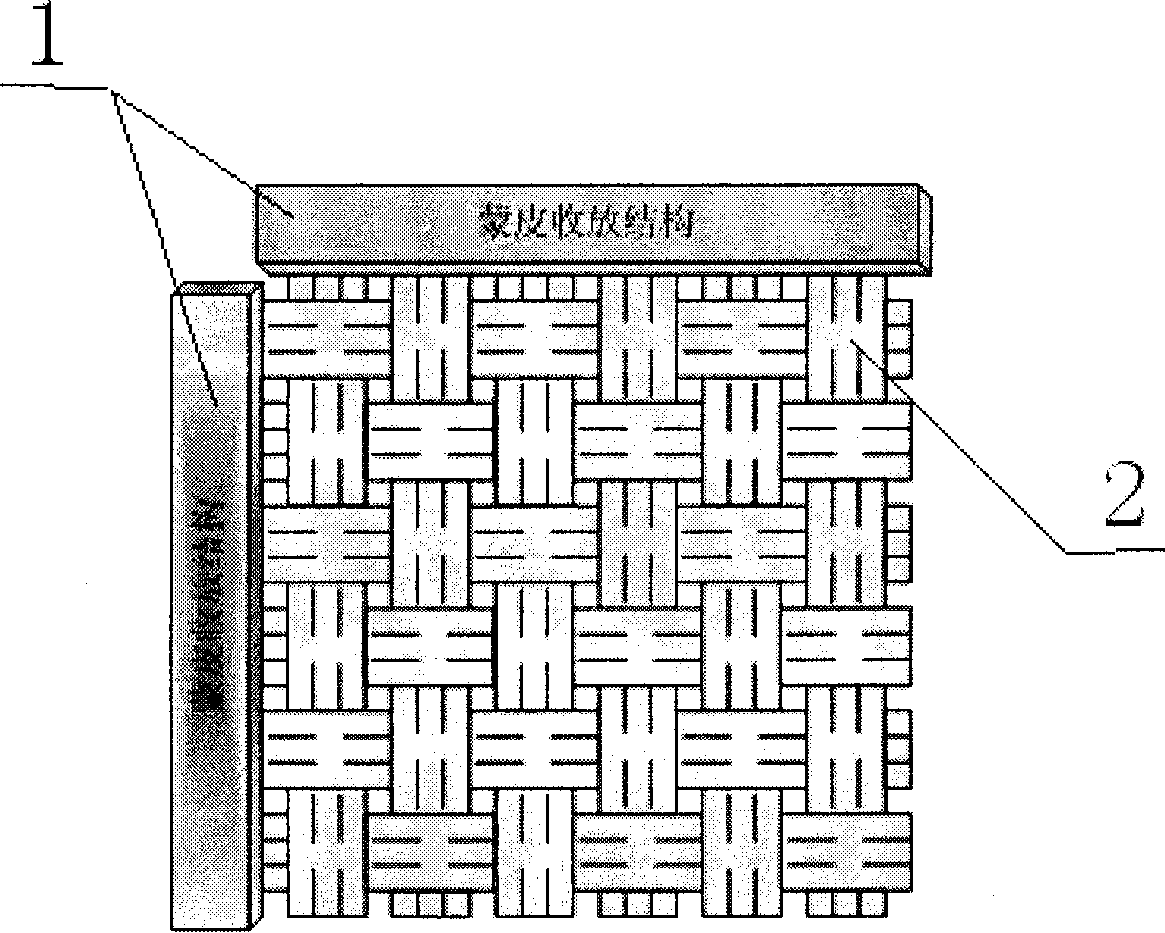

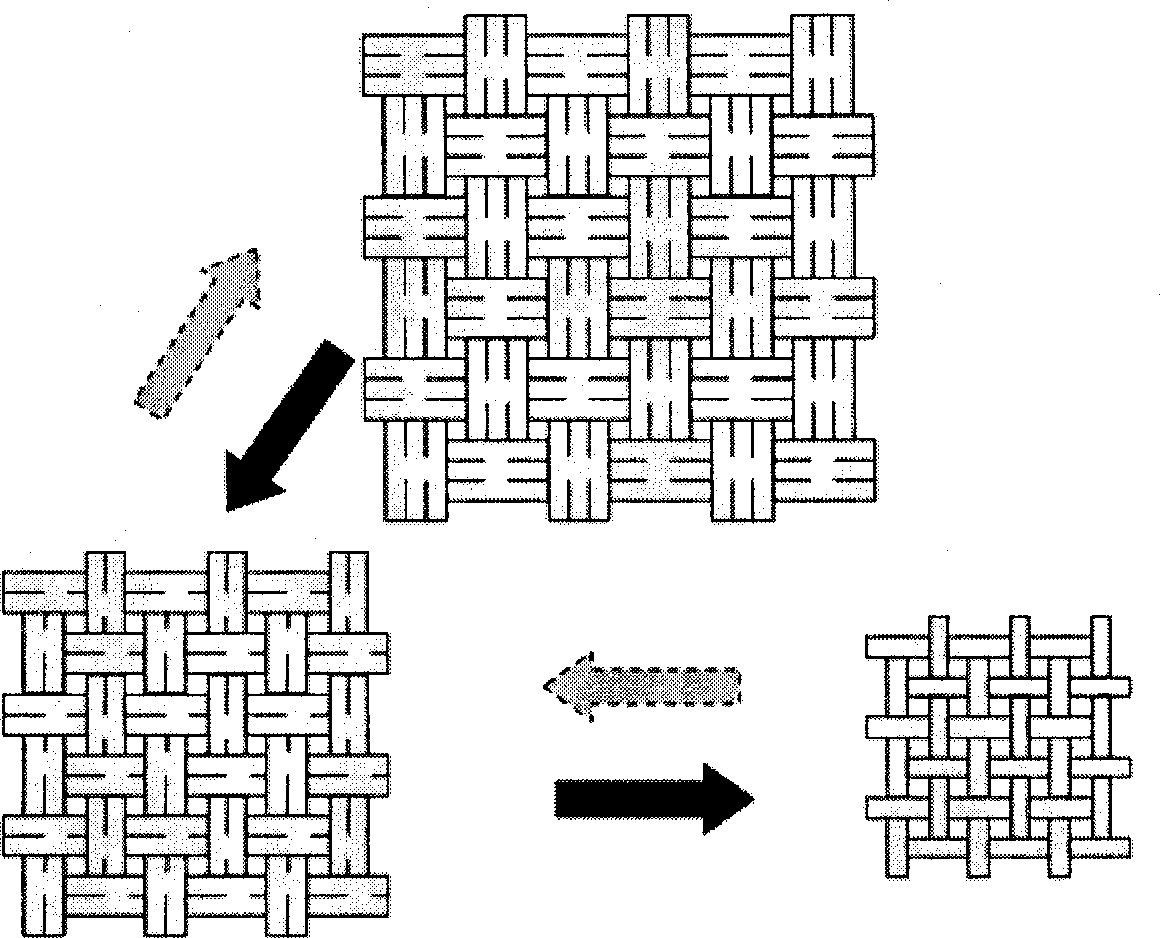

Stressed-skin construction capable of implementing large area deformation

The invention provides a skin structure which can realize large-area deformation. The skin structure is formed by grid-knitted skin overlapped structures. Skin overlapped structures clings to each other tightly without any clearance; the side of the skin overlapped structure is provided with a skin take up-pay off structure. The skin structure uses a knitting structure to realize the extensive deformation. In the skin take up-pay off structure, a roller and a skin storage room are used to make the flexible skin roll into or out of the skin take up-pay off structure; in the skin overlapped structure, a multi-slideway structure is adopted to make more layers of flexible skin overlapped into one layer entirely; a skin unit is flexible membrane material and the overlapped skins are in same size; when geometry shape complicated changes happen on the surface of the skin, the skin can be stretched or compressed at large scale without folds or damage simultaneously.

Owner:HARBIN INST OF TECH

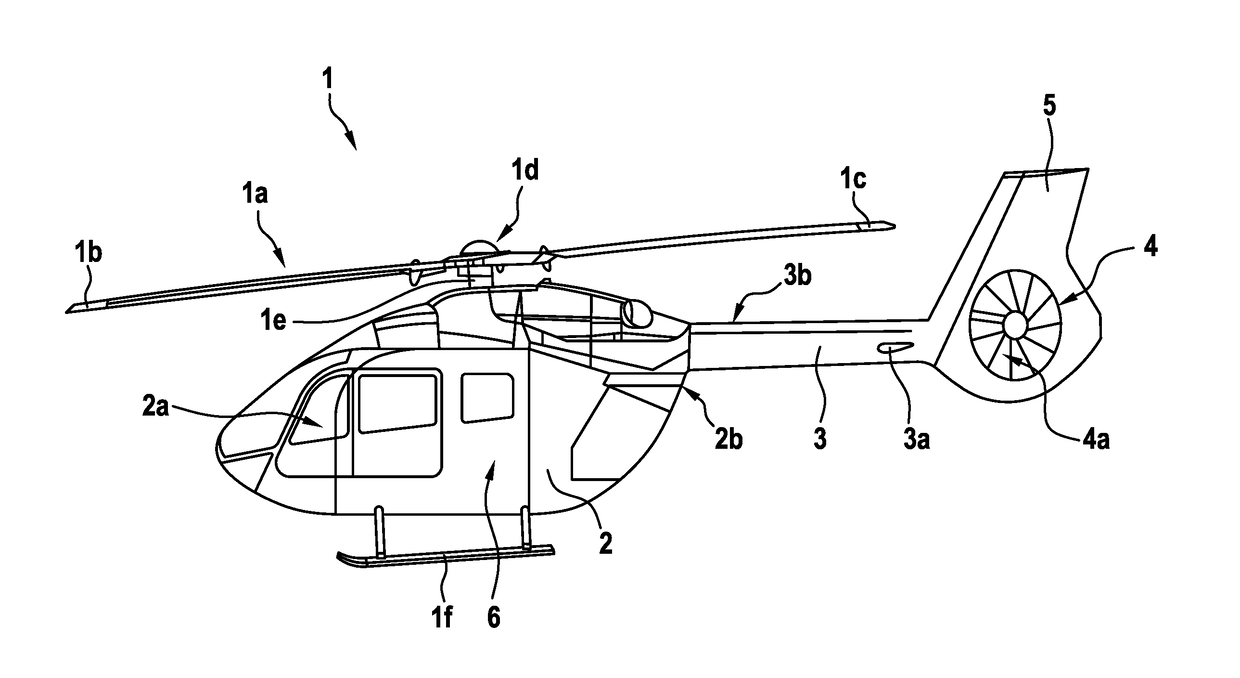

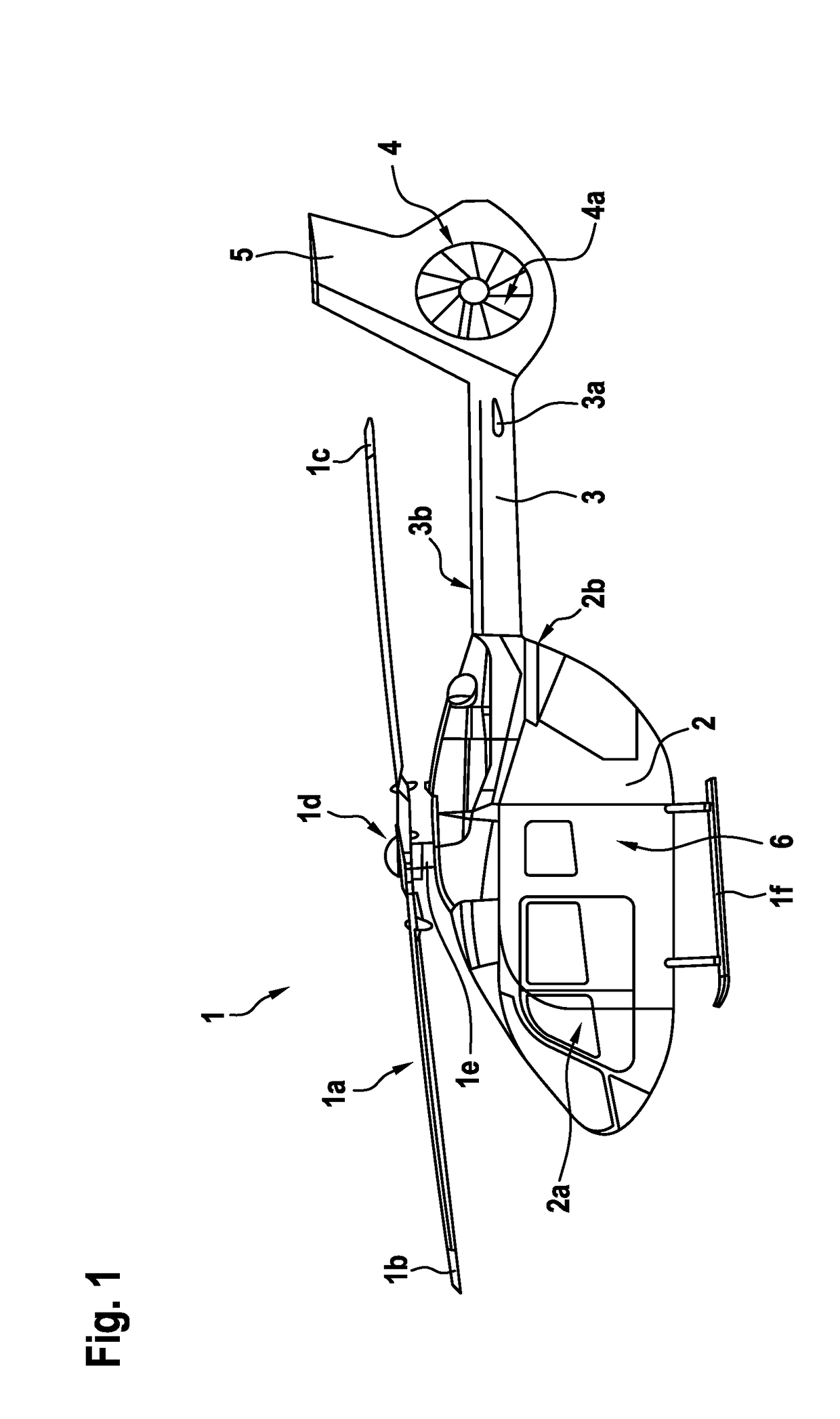

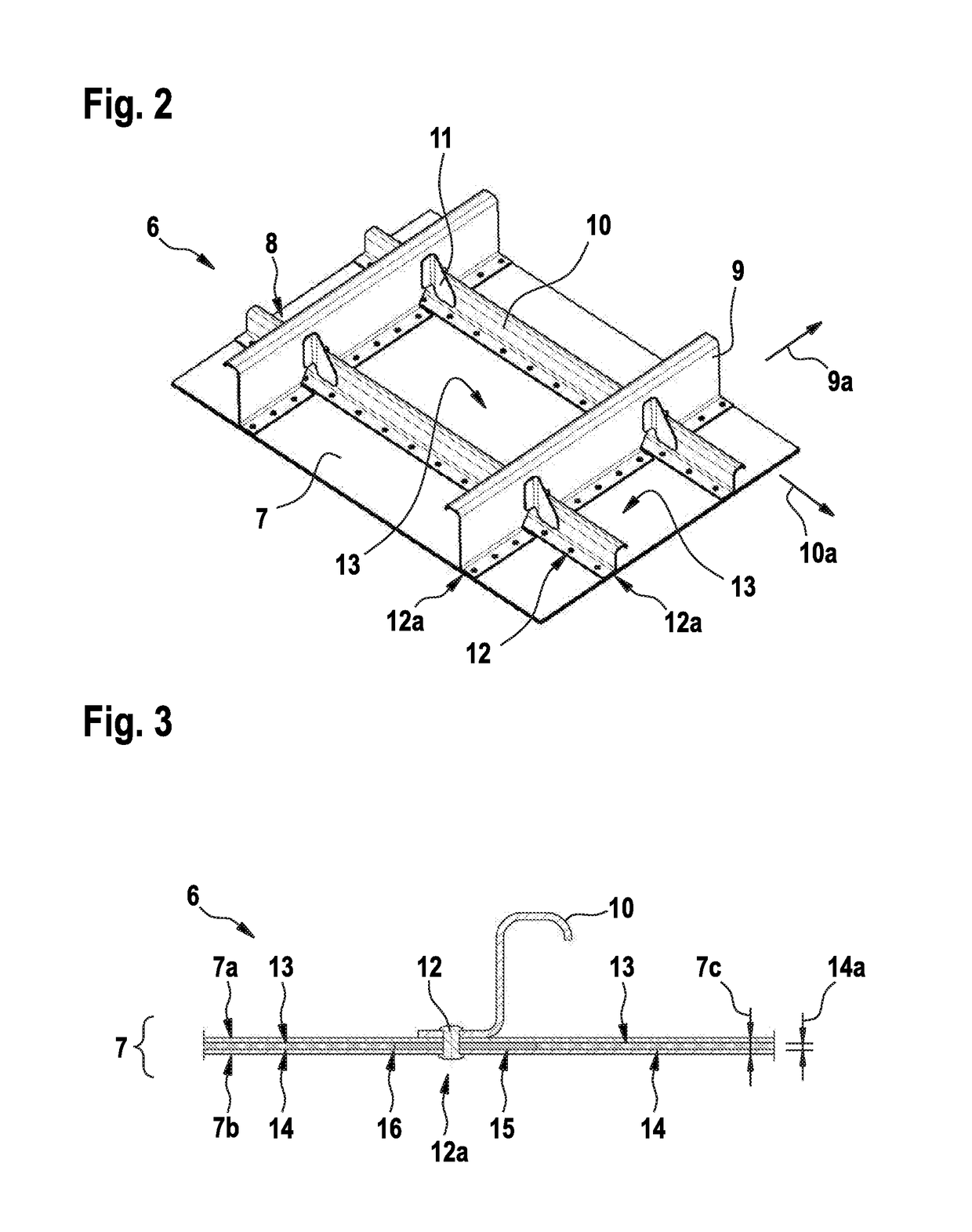

Rotary wing aircraft with a fuselage that comprises at least one structural stiffened panel

ActiveUS20180043982A1Increased structural weight efficiencyImprove noiseFuselage framesFuselage bulkheadsRotary wingStressed skin

A rotary wing aircraft with a fuselage that comprises at least one structural stiffened panel, the structural stiffened panel comprising a stressed skin and a stiffening framework that is rigidly attached to the stressed skin, wherein the stressed skin comprises an inner skin, an outer skin and a core element assembly that is arranged between the inner skin and the outer skin, the core element assembly comprising at least one viscoelastic core element and at least one intermediate core element that are tessellated, wherein the at least one viscoelastic core element is provided for noise and vibration damping.

Owner:AIRBUS HELICOPTERS DEUT GMBH

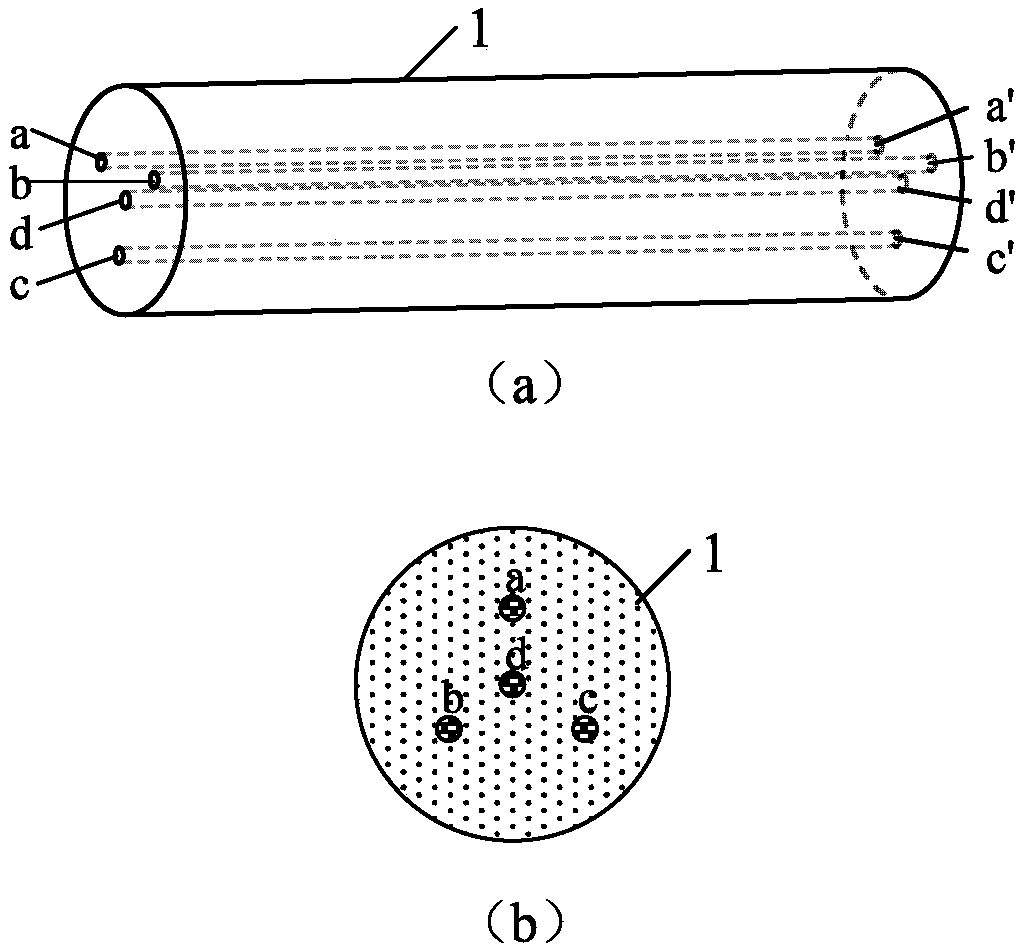

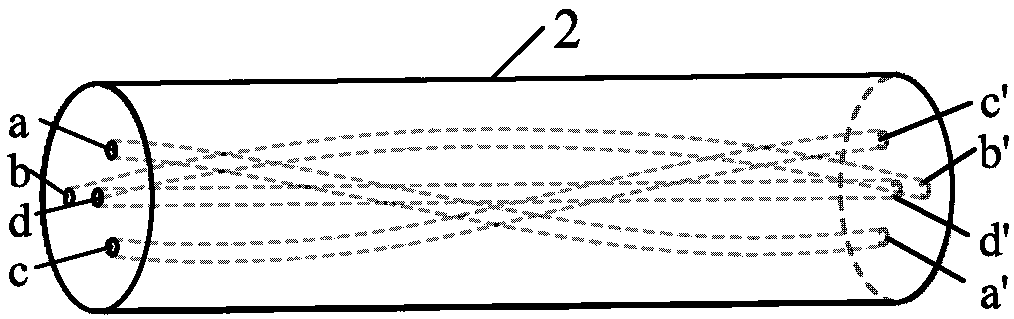

Carbon fiber reinforced cylinder structure

InactiveCN108061238AHigh specific strengthHigh specific modulusConstructions elementsSpecific modulusStressed skin

The invention relates to a carbon fiber reinforced cylinder structure, and belongs to the field of composite materials. The carbon fiber reinforced cylinder structure adopts a mesh structure formed bycrisscrossed ribs, and a preimpregnated cloth tape is enwound at the surface to form a stressed skin structure. The longitudinal and transverse tendons are continuous fibers in the direction of 0 degree, a flat slope is formed form the longitudinal tendons to the root portion and the flat slope intersperses into the stressed skin structure. The stressed skin structure is laid by adopting quasi-isotropic, and layer ratio of 0 degree, + / - 45 degrees, 90 degrees is 25:50:25. The stressed skin is flanged to form a flange, and the stressed skin is partly thickened at the root portions of the longitudinal tendons. The carbon fiber reinforced cylinder structure has the beneficially effect that the carbon fiber composite material has the advantages of high specific strength, high specific modulus, fatigue resistance and corrosion resistance, and then the carbon fiber reinforced cylinder structure with superior performance is obtained, and the ability of reinforced cylinder structure to bear axle load, bending and other external loads is greatly improved by an exquisite structural design.

Owner:HENGSHEN

Integrated straw sandwich filling wall preparation method and integrated straw sandwich filling wall

ActiveCN106592856AEliminate engineering quality effectsImprove construction efficiencyCeramic shaping apparatusBuilding componentsCompression moldingSlurry

The invention discloses an integrated straw sandwich filling wall preparation method and an integrated straw sandwich filling wall. The preparation method comprises the steps that a straw sandwich layer is prepared, through holes which are arranged according to rules are formed in a straw block subjected to compression molding, and transition conical surfaces are machined on the upper surface and the lower surface of the straw block respectively; the straw sandwich layer is placed in a mold frame, and the height is set for the straw sandwich layer through the distance of a cushion block and the inner bottom face of the mold frame; uniformly stirred self-compacting concrete and chopped basalt fiber mixed slurry is injected into the mold frame, primary whole casting molding is conducted according to preparation processes from bottom to top, the mixed slurry forms a lower stressed skin on the bottom surface of the straw sandwich layer, the mixed slurry forms an upper stressed skin on the upper surface of the straw sandwich layer, and the mixed slurry forms small columns which are connected with the upper stressed skin and the lower stressed skin in the through holes of the straw sandwich layer. The filling wall has the distinct characteristics and advantages in the aspects of heat preservation, structural integrity, system integration, construction efficiency, environmental friendliness and the like.

Owner:SOUTHEAST UNIV

Propeller arrangement structure capable of achieving internally cooperative jet flow and controlling method

The invention provides a propeller arrangement structure capable of achieving an internally cooperative jet flow and a controlling method. The arrangement structure is characterized in that blades are divided into a plurality of insulated single chambers which are arranged in a sectional-type continuous manner through a shell plate structure in the extension direction of the blades of a propeller. An individually cooperative jet flow apparatus is disposed in each insulated single chamber. Each cooperative jet flow apparatus comprises: a gas inlet, a gas outlet and at least one jet flow power apparatus, wherein the gas inlet is arranged on a back edge position of an upper stressed skin of the insulated single chamber in which the cooperative jet flow apparatus is arranged, and the gas outlet is arranged on a front edge position of an upper stressed skin of the insulated single chamber in which the cooperative jet flow apparatus is arranged. The jet flow apparatus is installed in an internal space of the insulated single chamber in which the cooperative jet flow apparatus is arranged.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

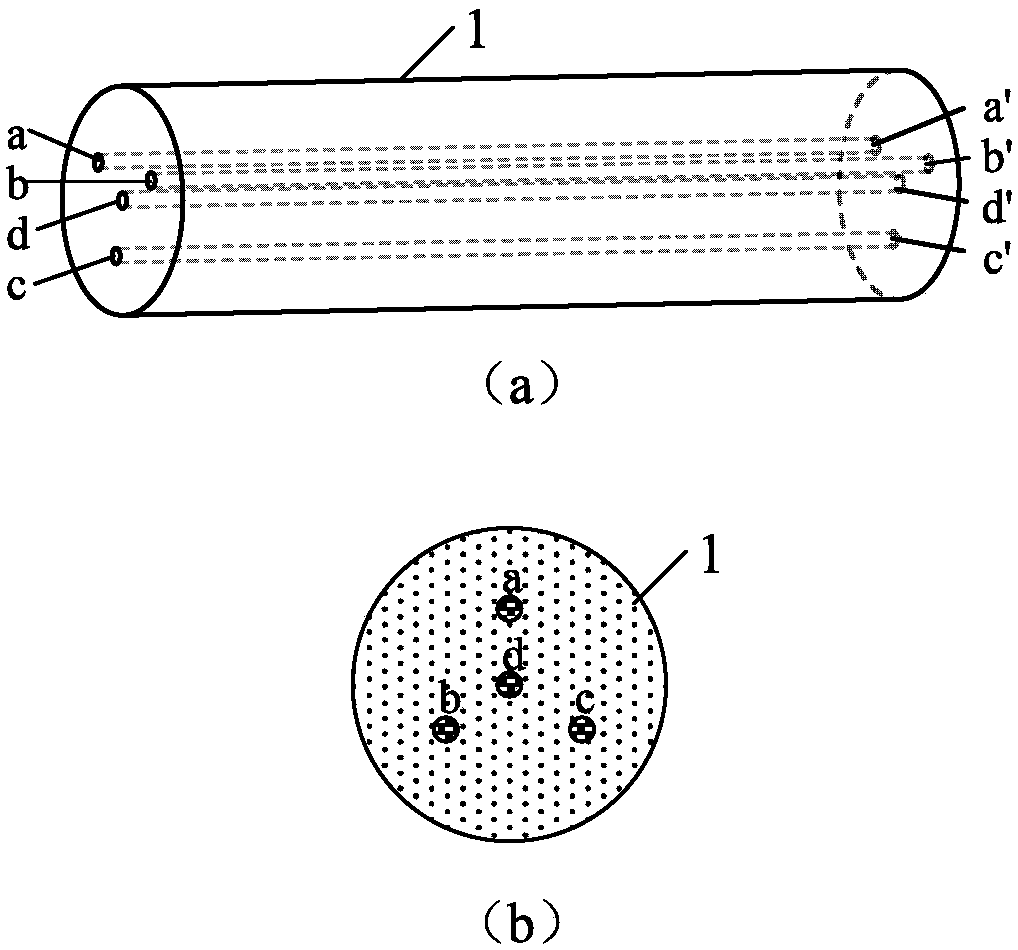

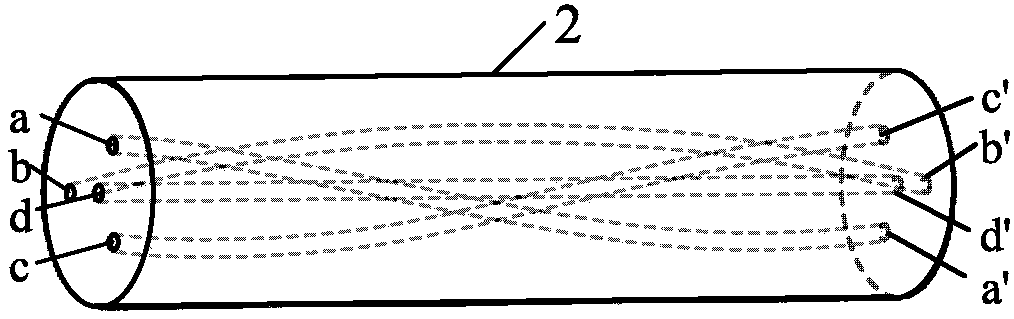

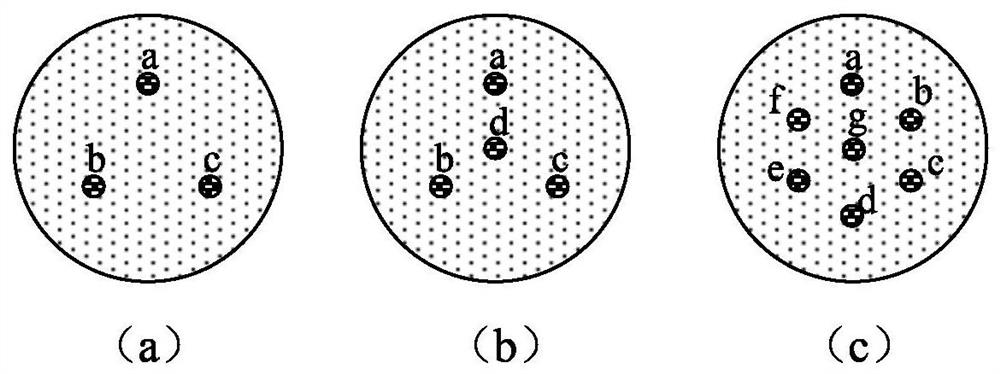

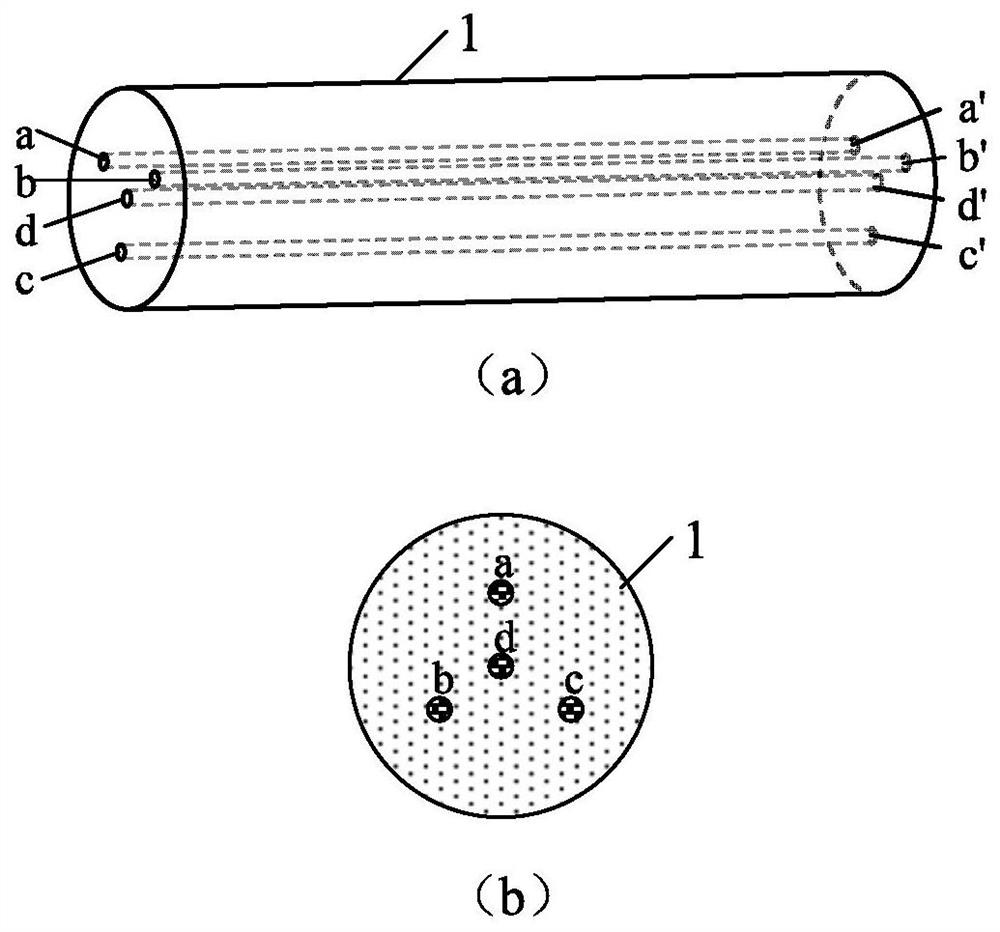

Dynamic BOTDA-based multi-core cycle series-connection fiber-shaped sensor

ActiveCN110243305AObviously highly integratedImprove stabilityUsing optical meansShape changeEngineering

The invention provides a dynamic BOTDA-based multi-core cycle series-connection fiber-shaped sensor. The fiber-shaped sensor comprises a multi-core fiber, a single-mode fiber and multi-core fiber Fan-in device, a single-mode fiber and multi-core fiber Fan-out device and a plurality of single-mode fibers, wherein the plurality of single-mode fibers are connected between the Fan-in device and the Fan-out device. By a mode of sequentially and circularly connecting a plurality of fiber cores of a multi-core fiber in series, the function of expanding the plurality of fiber cores to form a one-dimensional topological optical path is achieved. The fiber-shaped sensor can used for a shape sensing device of a dynamic BOTDA sensing system, can be widely used for monitoring health of an intelligent structure and also can be used for a stressed skin structure of a robot or an airplane wing, and the shape change thereof is detected in real time.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Core-by-core scanning type multi-core optical fiber shape sensor based on dynamic BOTDA (Brilouin Optical Timedomain Analysis)

InactiveCN110243301ARealize measurementObviously highly integratedUsing optical meansShape changeSkin structure

The invention provides a core-by-core scanning type multi-core optical fiber shape sensor based on dynamic BOTDA (Brilouin Optical Timedomain Analysis). The core-by-core scanning type multi-core optical fiber shape sensor consists of a multi-core optical fiber, a multi-core optical fiber Fan-in device, a multi-core optical fiber Fan-out device, two optical switches and single-mode optical fibers for connecting each part. Both ends of the multi-core optical fiber are sequentially connected with the multi-core optical fiber Fan-in / out devices and the optical switches; and by control of two optical switches, an optical wave can scan core by core in each fiber core of the multi-core optical fiber so as to acquire respective deformation information of each fiber core. The core-by-core scanning type multi-core optical fiber shape sensor can be used for a shape sensing device of a dynamic BOTDA sensing system, can be widely used for health monitoring of an intelligent structure, and also can be used for a stressed-skin structure of a robot or a aircraft wing to detect shape changes of the stressed-skin structure in real time.

Owner:GUILIN UNIV OF ELECTRONIC TECH

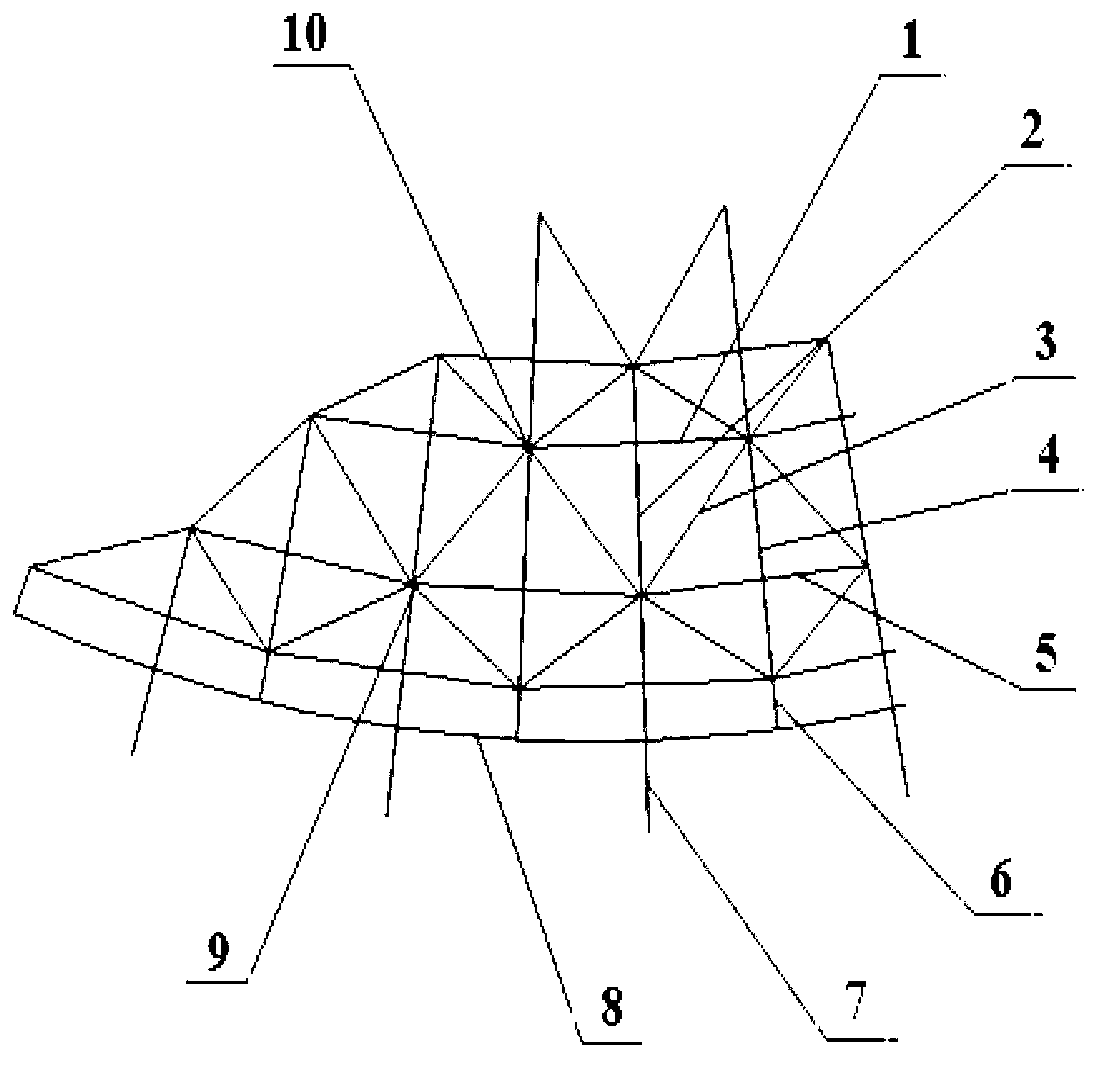

Main force-bearing structure for lightweight carbon fiber reinforced resin composite stiffened plate shell

ActiveCN106915474AReduce structural weightIncrease temperatureCosmonautic vehiclesCosmonautic partsFiberCarbon fibers

The invention discloses a main force-bearing structure for a lightweight carbon fiber reinforced resin composite stiffened plate shell. The main force-bearing structure comprises a stressed skin, a plurality of star-shaped cap beams, a center opening C-shaped beam, a plurality of equipment mounting C-shaped beams, a plurality of reinforcing pieces and a plurality of metal reinforcing blocks, wherein the star-shaped cap beams, the center opening C-shaped beam, the equipment mounting C-shaped beams and the reinforcing pieces are arranged on one face of the stressed skin, and the metal reinforcing blocks are arranged on the other face of the stressed skin. The multiple equipment mounting C-shaped beams are evenly distributed around the center opening C-shaped beam; the center opening C-shaped beam is connected with the equipment mounting C-shaped beams through the reinforcing pieces; every two equipment mounting C-shaped beams are connected through the corresponding star-shaped cap beam; the center opening C-shaped beam and the stressed skin are connected through the star-shaped cap beams; and the star-shaped cap beams and the stressed skin form a closed cross section. According to the main force-bearing structure for the lightweight carbon fiber reinforced resin composite stiffened plate shell, the weight of the structure is reduced, and the bearing capacity and the using temperature of the structure are improved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

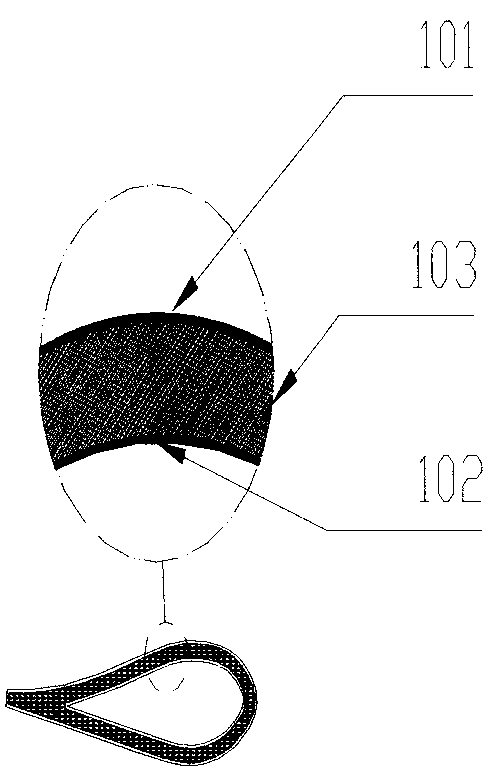

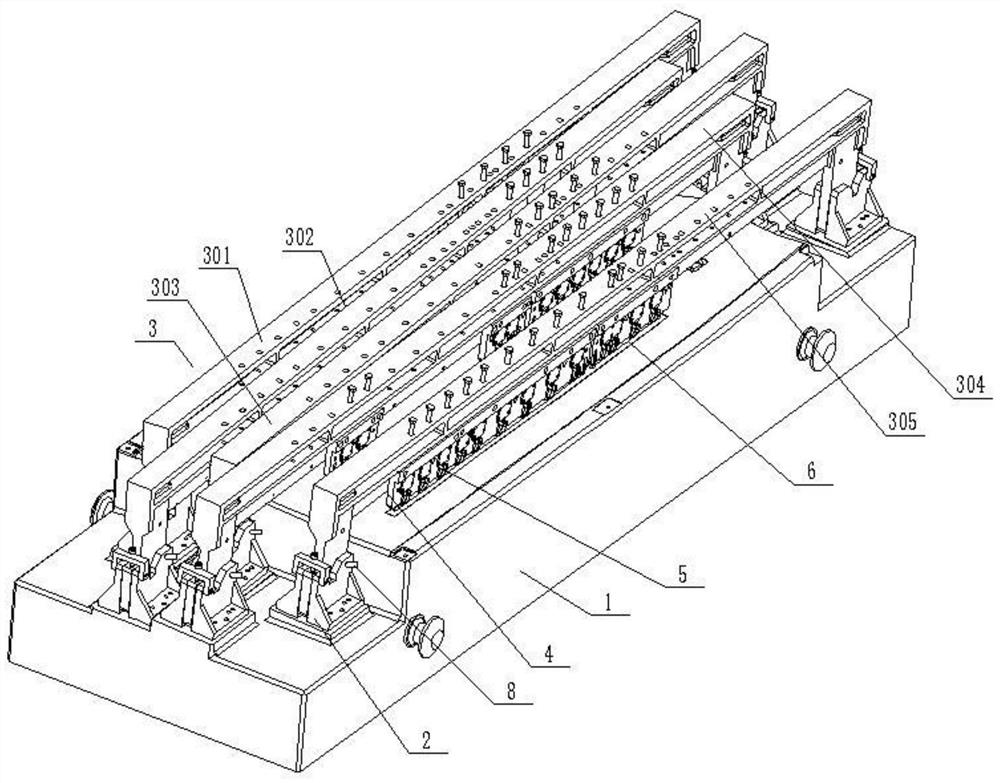

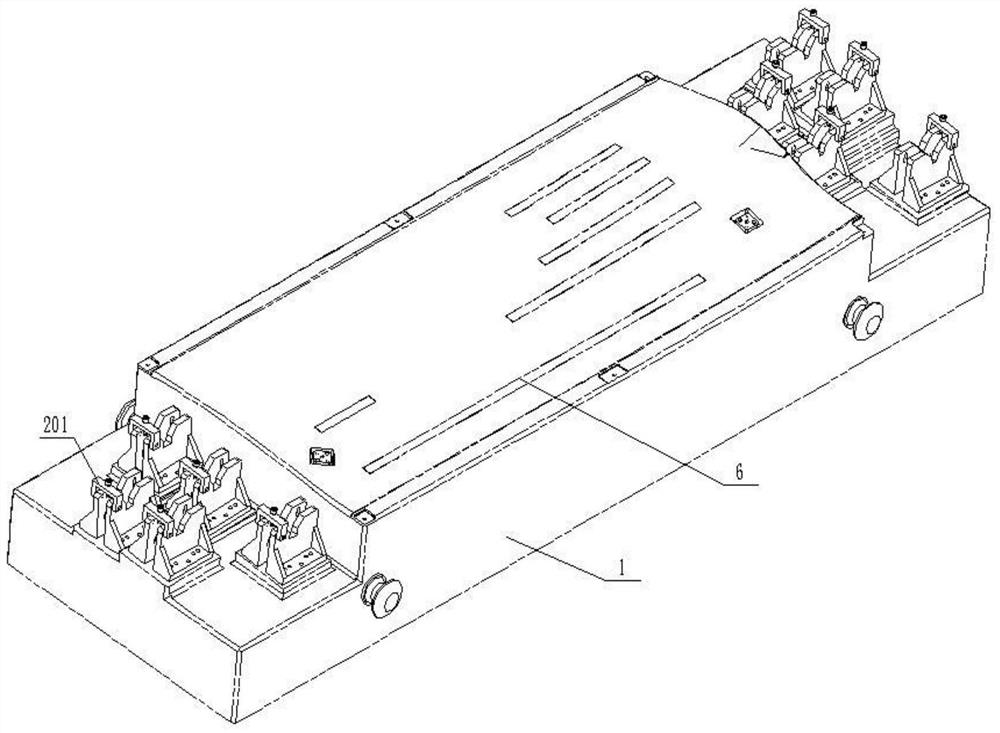

Laser double-beam welding tool for outer side of aircraft panel

PendingCN113084378AImprove welding efficiencyAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesDual beamStringer

The invention discloses a laser double-beam welding tool for the outer side of an aircraft panel, and belongs to the laser welding technology. The welding tool comprises a base and a support, cross beams are fixed to the support, each cross beam is provided with a clamping plate, and a plurality of pressing plates which are evenly arranged are fixed to each set of the clamping plates. The base is provided with at least one group of copper sheets for bearing stressed skin, and the bottom of each copper sheet is provided with a pressure sensor. Position sensors are arranged on the cross beams and the support, the position sensors on the support are used for detecting the position relation between the cross beams and the support, and the position sensors on the cross beams are used for detecting the position relation between the cross beams and the clamping plates. The position corresponding relation of the cross beams and the support and the clamping plates can be determined through position induction, the welding efficiency of a stringer and the stressed skin is improved, the pressure sensors are arranged below the copper sheets, the pressure applied to the stressed skin by pressing tongues on the clamping plates can be detected, damage to the stressed skin due to the fact that the applied pressure is too large is effectively prevented, and the product percent of pass is improved.

Owner:CHENGDU HONGXIA TECH CO LTD

Solar panel system with monocoque supporting structure

ActiveUS9252311B2Low costReduce manufacturing costPhotovoltaic supportsSolar heating energyControl powerElectrical battery

A solar panel system comprises a monocoque forming an enlarged solar-facing generally-convex outer support surface when in an installed position and that supports solar cells at optimal angles for capturing solar energy. The monocoque provides a stressed-skin support reducing weight while maintaining strength, optimal support surface, and minimizing cost. A post engages and supports adjacent edges of a pair of adjacent monocoques. An electrical circuit connects the solar cells for electrical flow and power management, and preferably includes a controller for controlling power from the solar cells, including combining them in series or parallel as optimal for a given systems configuration. The illustrated monocoque includes a roll formed sheet or a number of sheets, stacked vertically together and anchored to spaced posts using connectors in a “fence-like” pattern.

Owner:WOLTER JAMES F

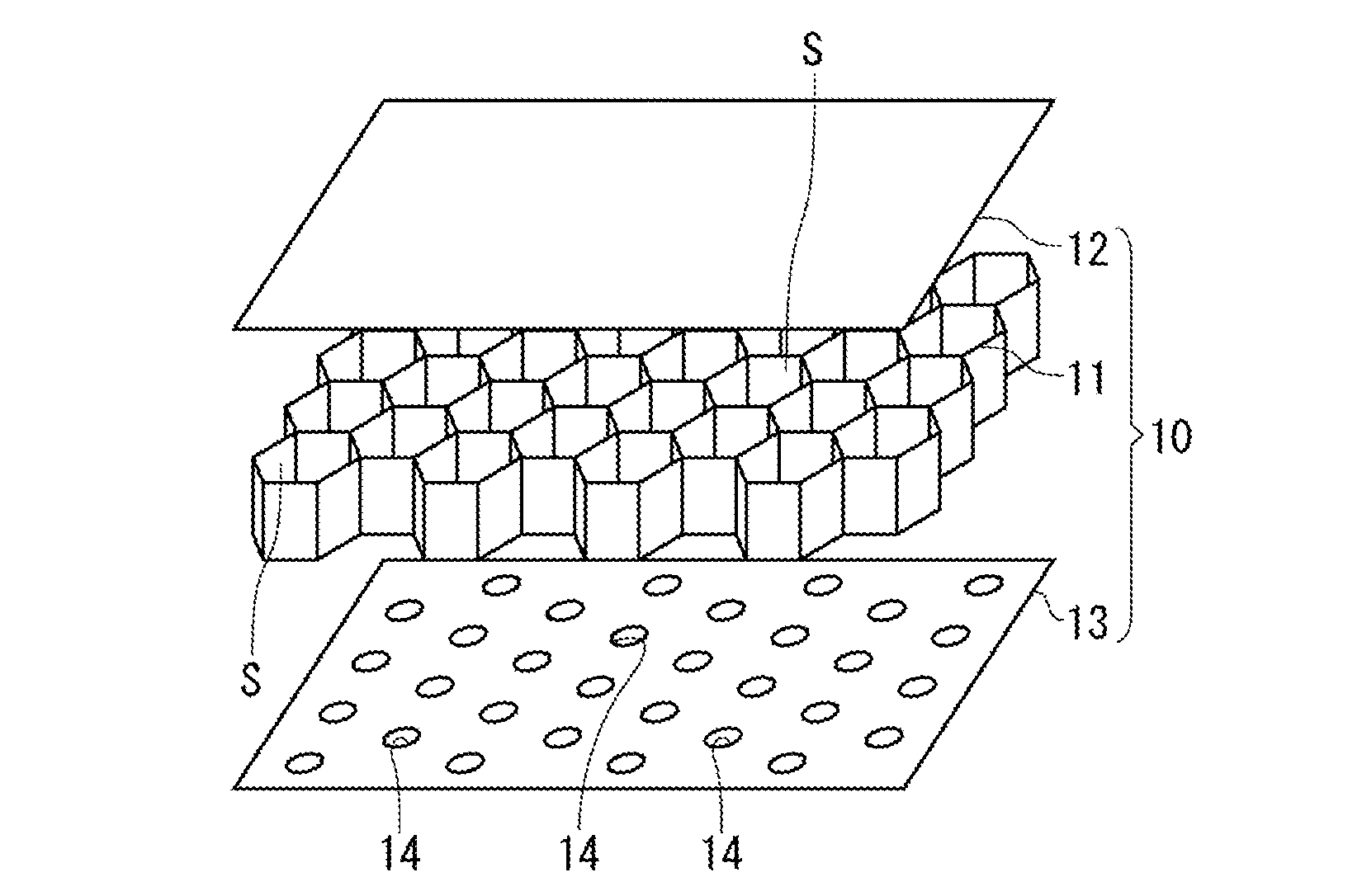

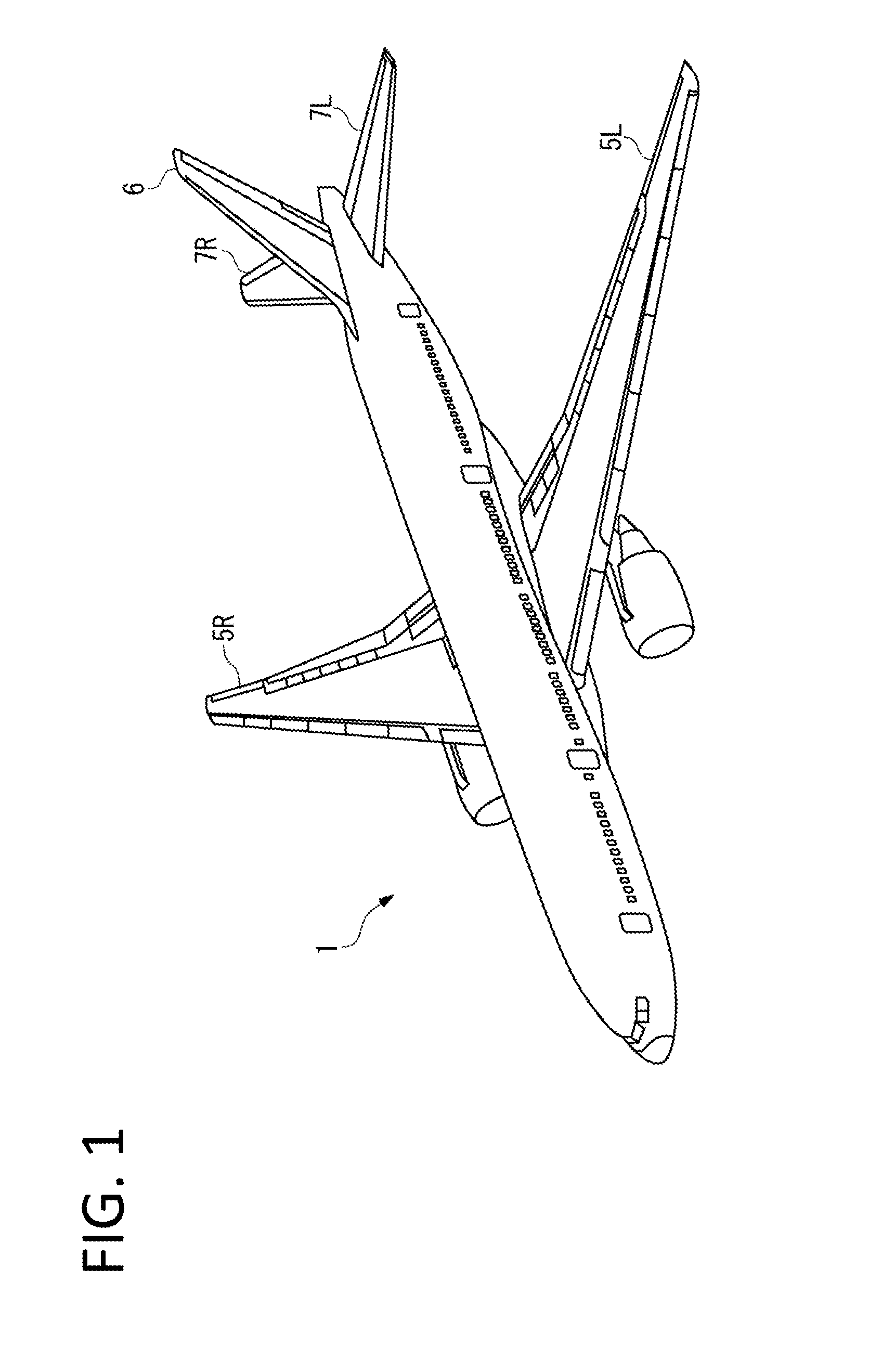

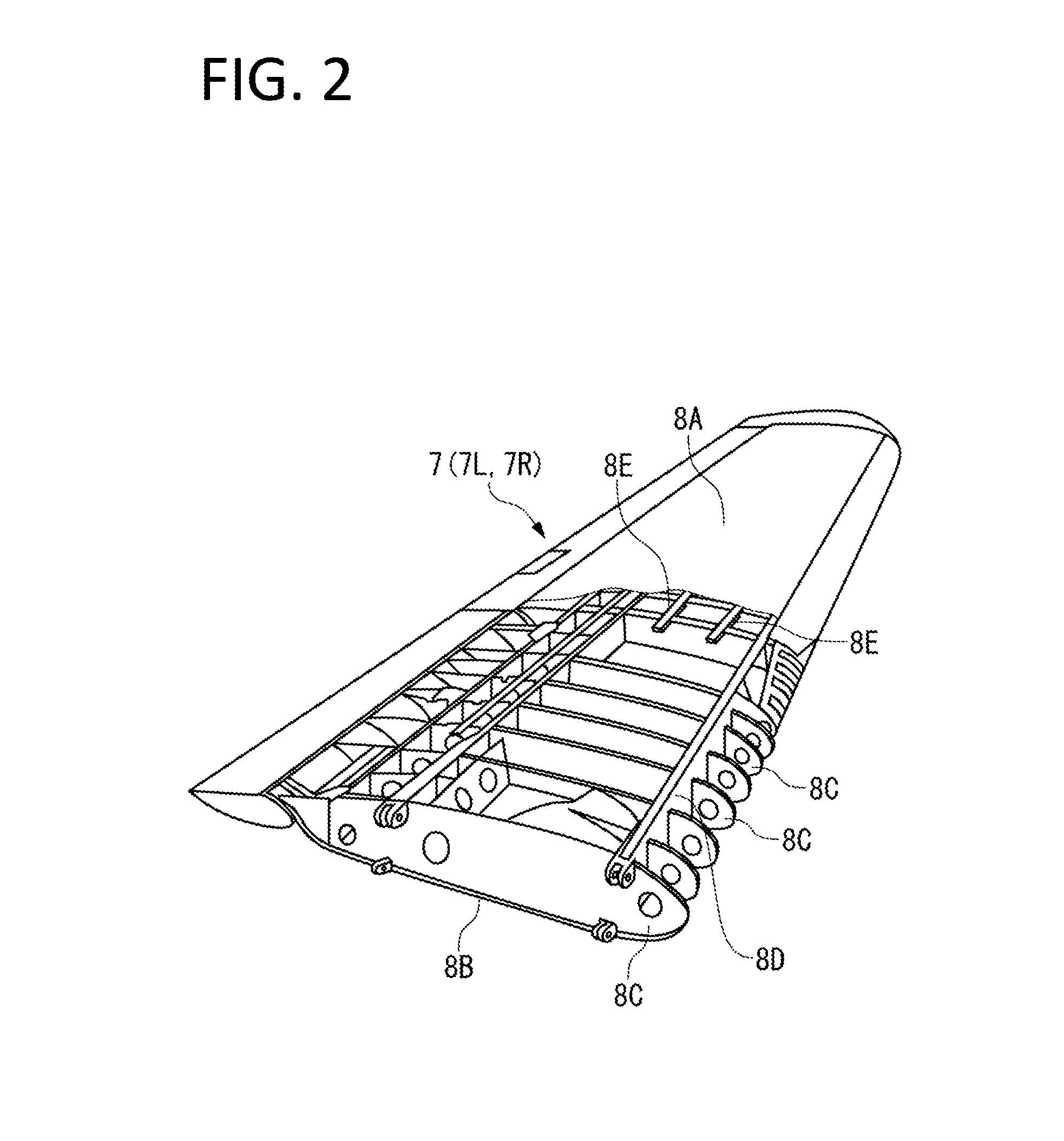

Aircraft reinforcing structure

An object of the present invention is to prevent accumulation of moisture which has entered inside a honeycomb sandwich panel used for a stressed-skin structure of an aircraft. A reinforcing structure includes an outer panel constituting an outer shell of a tailplane and a honeycomb sandwich panel reinforcing the outer panel. The honeycomb sandwich panel includes a honeycomb core having a plurality of cells, an outer skin joined on the front side of the honeycomb core and disposed on the side of the outer panel, and an inner skin joined on the back side of the honeycomb core and disposed on the inner side of the tailplane. The inner skin has drainage channels formed therein through which each of the plurality of cells communicates with the outside of the honeycomb sandwich panel.

Owner:MITSUBISHI AIRCRAFT

Light-weight heat preservation sound insulation wall

InactiveCN108331245AAct as a barrierImprove insulation effectBuilding componentsHigh densityPulp and paper industry

The invention relates to the technical field of building heat preservation, in particular to a light-weight heat preservation sound insulation wall. The light-weight heat preservation sound insulationwall is structurally provided with an inner decorative surface, a stressed-skin diaphragm, a wood frame, a heat preservation inner core, the wood frame, a sound insulation plate and an outer decorative surface from indoor side to outdoor side respectively. The connection surface of the heat preservation inner core is provided with a staggered section, the interior of the wood frame is filled withthe flame-retardant heat preservation inner core, and vertical grooves are formed in the sides, close to the wood frame, of the heat preservation inner core, the sound insulation plate and the stressed-skin diaphragm. The size of each vertical groove is consistent with the size of each vertical wood strip, and the wood frame can be completely wrapped. Replaceable embedded wire pipes are arrangedinside the sound insulation plate and the stressed-skin diaphragm. According to the light-weight heat preservation sound insulation wall, the wood frame is structurally filled with heat insulation materials, flame retardants are painted all around the wood frame, the effect of an isolation belt is achieved in case of a fire, the high-density sound insulation plate completely insulates the wood frame and a heat insulation plate from the outside air, the best effects of heat preservation, sound insulation and fire prevention are achieved, and the light-weight heat preservation sound insulation wall is suitable for using in high-rise buildings.

Owner:SHENYANG JIANZHU UNIVERSITY

Aluminum stressed skin structure of passenger car body side walls and processing method thereof

PendingCN107416032AGood adhesionReduced risk of bond crackingSuperstructure subunitsClassical mechanicsCar passenger

The invention relates to an aluminum stressed skin structure of passenger car body side walls. The passenger car body side walls comprise a side wall framework welded by vertically arranged column frameworks and horizontally arranged beam frameworks and aluminum stressed skin covering the side wall framework, wherein the aluminum stressed skin is bonded and fixed to the side wall framework by bonding glue; the column frameworks are provided with liner plates with framework riveting points; and the aluminum stressed skin is also riveted and fixed on the framework riveting points of the liner plates by rivets. The technical solution of the invention optimizes the bonding structure and processing of the aluminum stressed skin. By using the structure and the processing method combining bonding with riveting, the aluminum stressed skin structure of the passenger car body side walls ensures the reliable bonding of the stressed skin and no displacement, reduces the risk of cracking of the bonding of the aluminum stressed skin, and overcomes the shortcomings in the traditional processing of heating-tension stressed skins and bonding stressed skins in the prior art.

Owner:SHIJIAZHUANG ZHONGBO AUTOMOBILE CO LTD

System for confocal imaging within dermal tissue

InactiveUS20050171441A1Minimizes instabilityReduce relative motionDiagnostic recording/measuringSensorsInstabilityRelative motion

An improved system for confocal imaging within dermal tissue of a patient is provided which minimizes instability in confocal images by reducing the relative motion of the tissue with respect to the confocal imaging optics of the system. The system includes a mechanism for maintaining an area of skin tissue under stress by application of force at the edges of the area, and an imaging head coupled to this mechanism for imaging the stressed skin. The mechanism includes a mechanical structure, such as a platen, brace, or attachment, which both supports the imaging head of the system and applies stress to a limited surface area of the tissue to minimize skin motion during confocal imaging.

Owner:CALIBER IMAGING & DIAGNOSTICS

Dynamic botda-based multi-core circular fiber optic shape sensor

ActiveCN110243305BObviously highly integratedImprove stabilityUsing optical meansMechanical engineeringStressed skin

The invention provides a dynamic BOTDA-based multi-core cycle series-connection fiber-shaped sensor. The fiber-shaped sensor comprises a multi-core fiber, a single-mode fiber and multi-core fiber Fan-in device, a single-mode fiber and multi-core fiber Fan-out device and a plurality of single-mode fibers, wherein the plurality of single-mode fibers are connected between the Fan-in device and the Fan-out device. By a mode of sequentially and circularly connecting a plurality of fiber cores of a multi-core fiber in series, the function of expanding the plurality of fiber cores to form a one-dimensional topological optical path is achieved. The fiber-shaped sensor can used for a shape sensing device of a dynamic BOTDA sensing system, can be widely used for monitoring health of an intelligent structure and also can be used for a stressed skin structure of a robot or an airplane wing, and the shape change thereof is detected in real time.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com