Manufacturing method of titanium alloy hollow component

A technology of hollow components and manufacturing methods, which is applied in the field of manufacturing titanium alloy thin-walled ribbed hollow parts, can solve the problems of rectifier blade diffusion connection front edge defects, titanium alloy structure changes, and low production efficiency, so as to save raw materials, The effect of high production efficiency and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

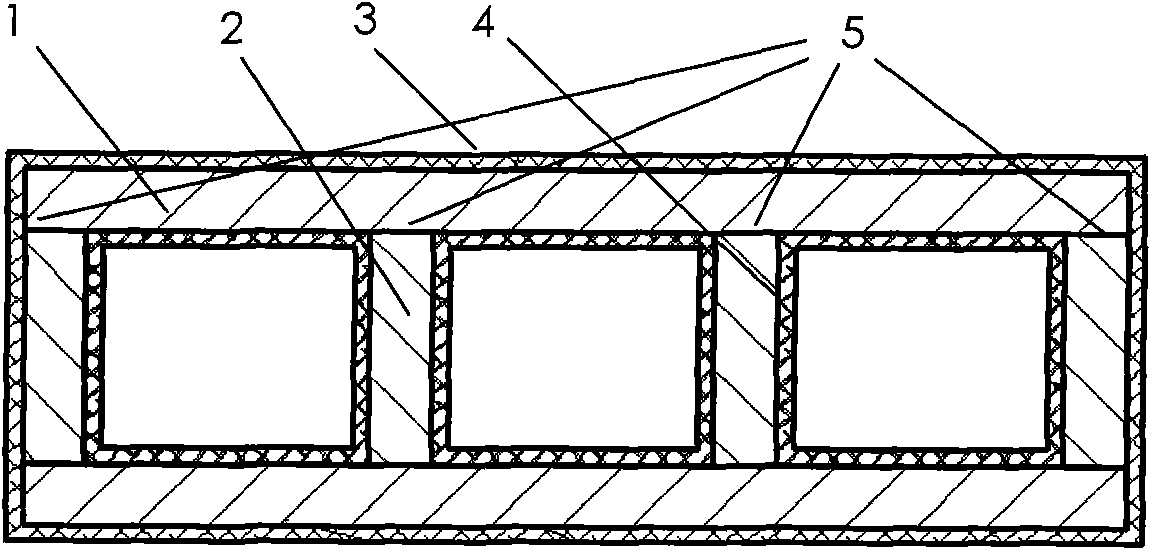

[0038] (1) According to the structural characteristics of the hollow member, it is decomposed into the structural form of the skin 1 and the rib 2, and the structural form of the inner sheath 3 and the outer sheath 4 is determined according to the hollow part of the hollow member, such as figure 1 shown;

[0039] (2) Process or form the structural parts of the skin 1 and the ribs 2 according to the decomposed structural form, and manufacture the skin 1 and the ribs 2 by machining, thermoforming, superplastic forming, and forging;

[0040] (3) Processing or forming the inner sheath 3 and the outer sheath 4. Process the inner sheath 3 and outer sheath 4 of titanium alloy by machining, precision casting, welding, etc., or process the inner sheath 3 and outer sheath 4 of A3 steel by machining, precision casting, welding, etc.;

[0041] (4) According to the structural form of the component, the structural components of the processed skin 1 and the rib 2 are combined with the inner...

Embodiment 2

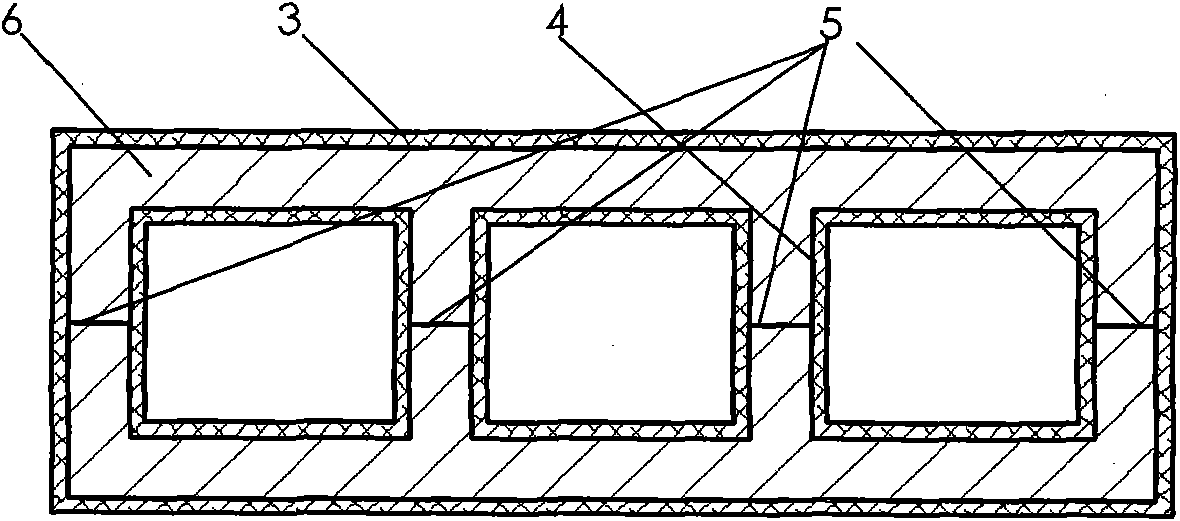

[0045] 1. According to the structural characteristics of the hollow member, it is decomposed into the structural form of the belt rib 6, and the structural form of the inner sheath 3 and the outer sheath 4 is determined according to the hollow part of the hollow member, such as figure 2 shown;

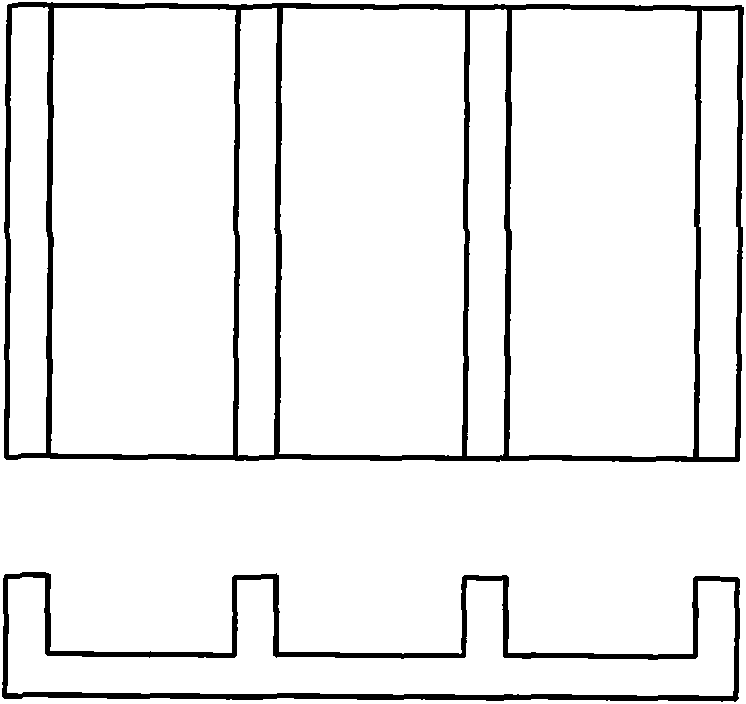

[0046] 2. Process or form the structural components of the pellicle belt ribs 6 according to the decomposed structural form, and adopt the method of mechanical processing and forging to manufacture the pellicle belt rib structure 6, such as image 3 shown;

[0047] 3. Process or form the inner sheath 3 and the outer sheath 4. Process the inner sheath 3 and outer sheath 4 of titanium alloy by machining, precision casting, welding, etc., or process the inner sheath 3 and outer sheath 4 of A3 steel by machining, precision casting, welding, etc.;

[0048] 4. According to the structural form of the components, combine the structural parts of the processed sling belt ribs 6 with the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com