Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Low forming temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of titanium alloy hollow component

ActiveCN101786223AIncrease productivityImprove efficiencyNon-electric welding apparatusTitanium alloyStressed skin

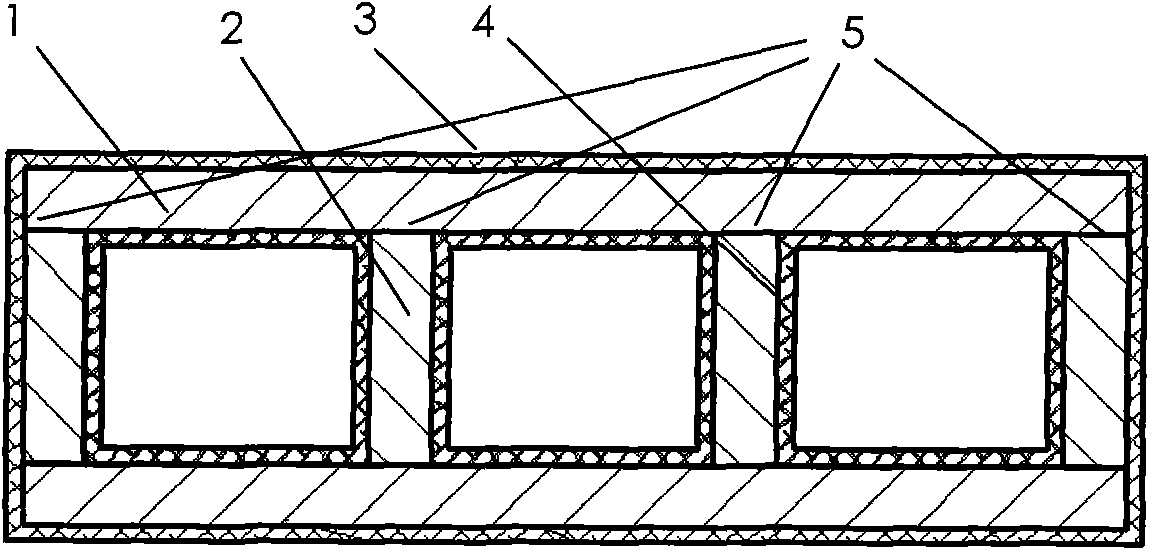

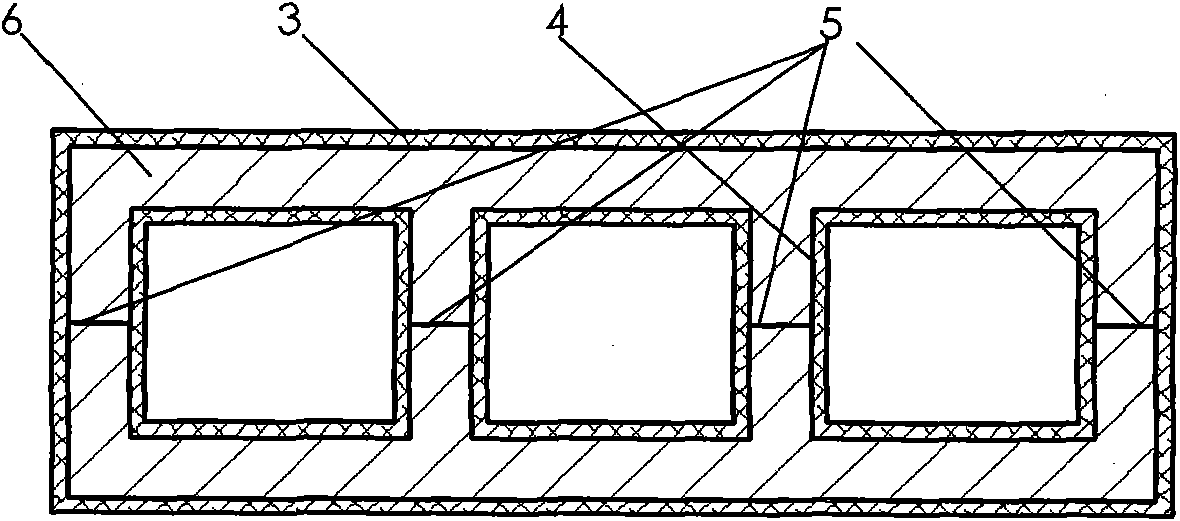

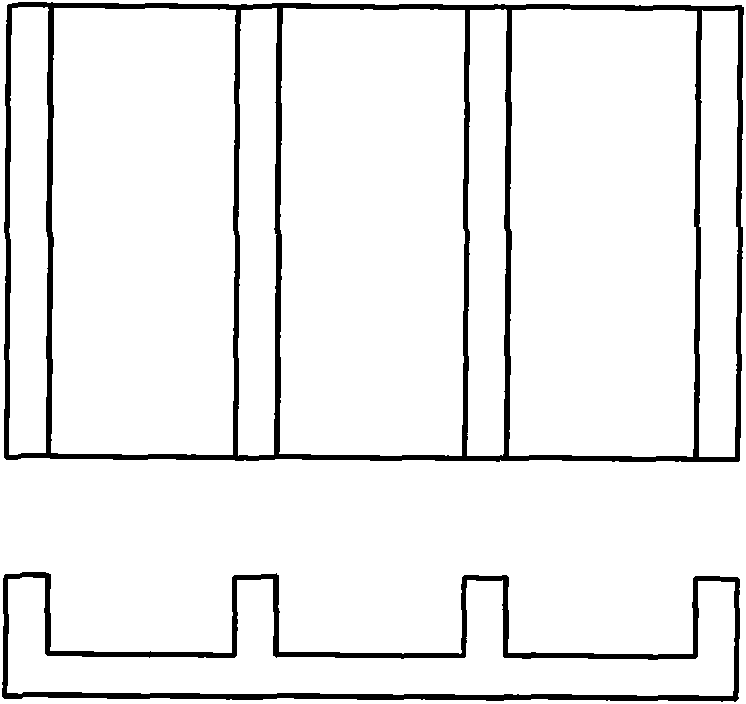

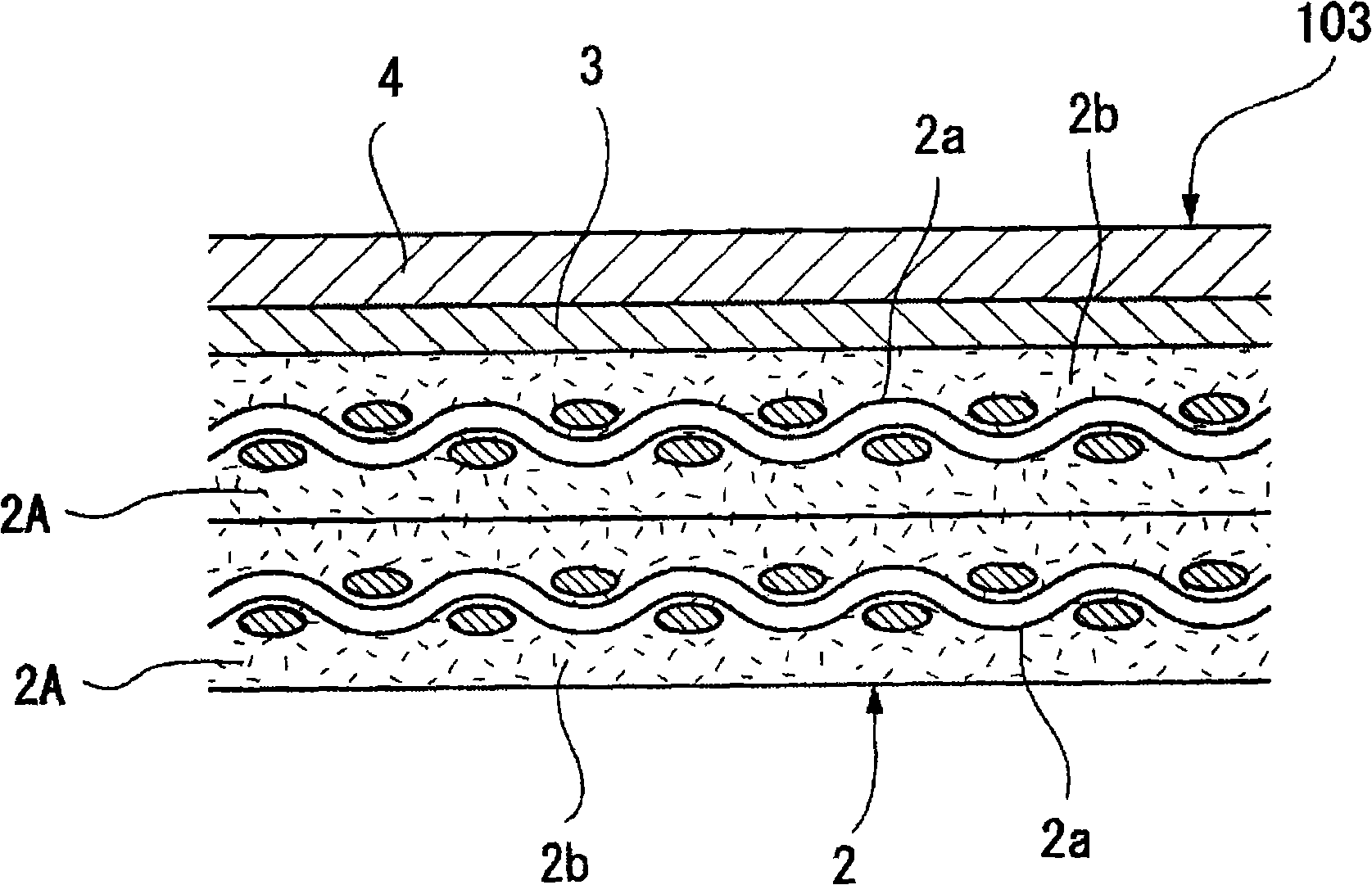

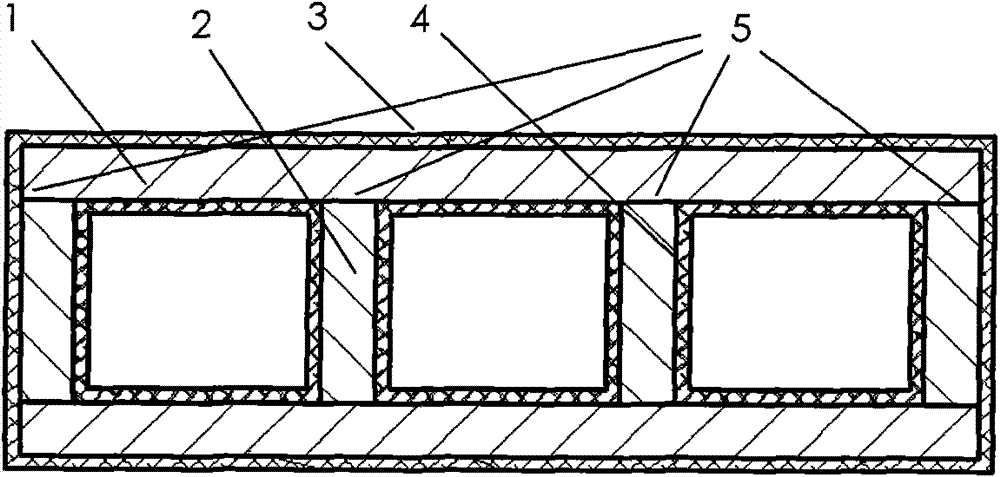

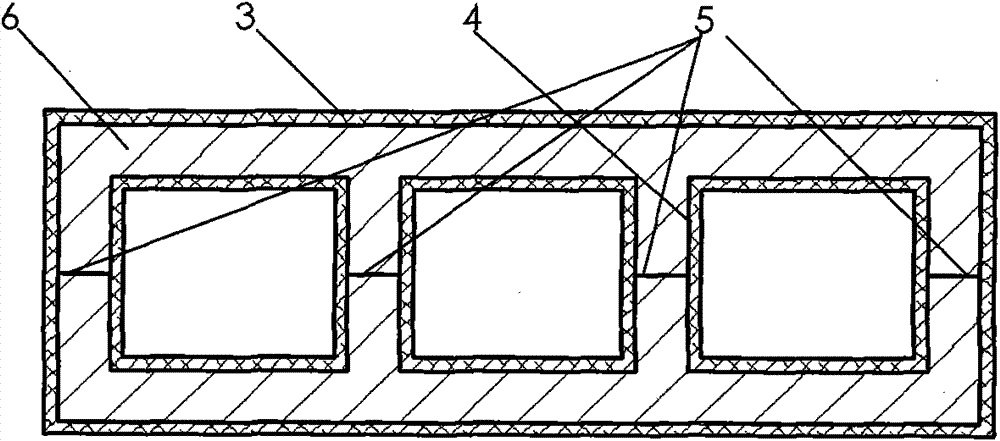

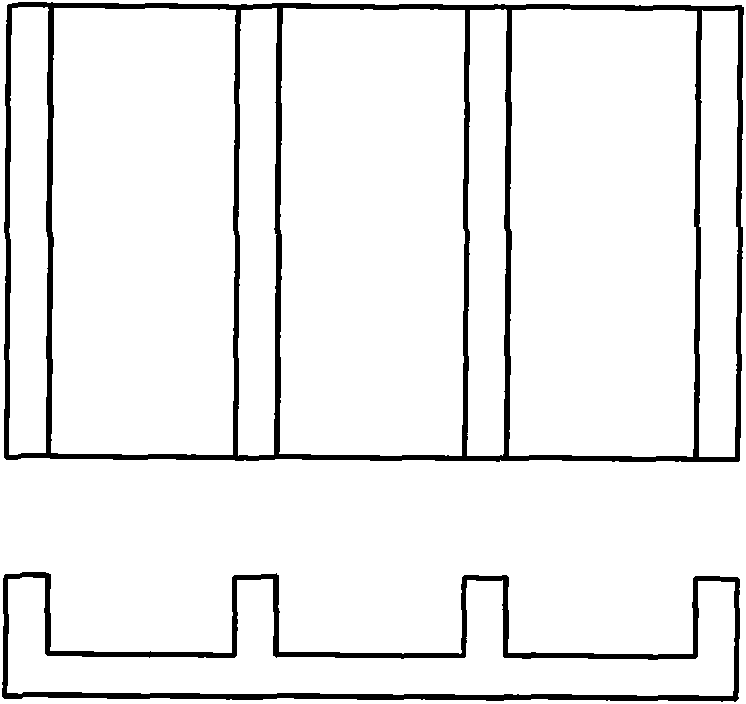

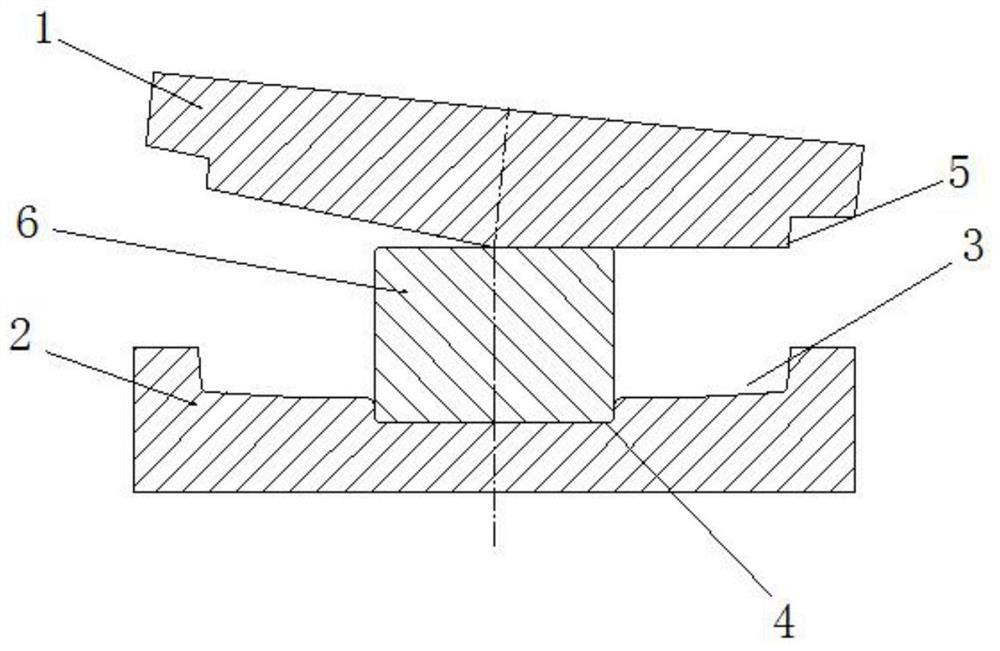

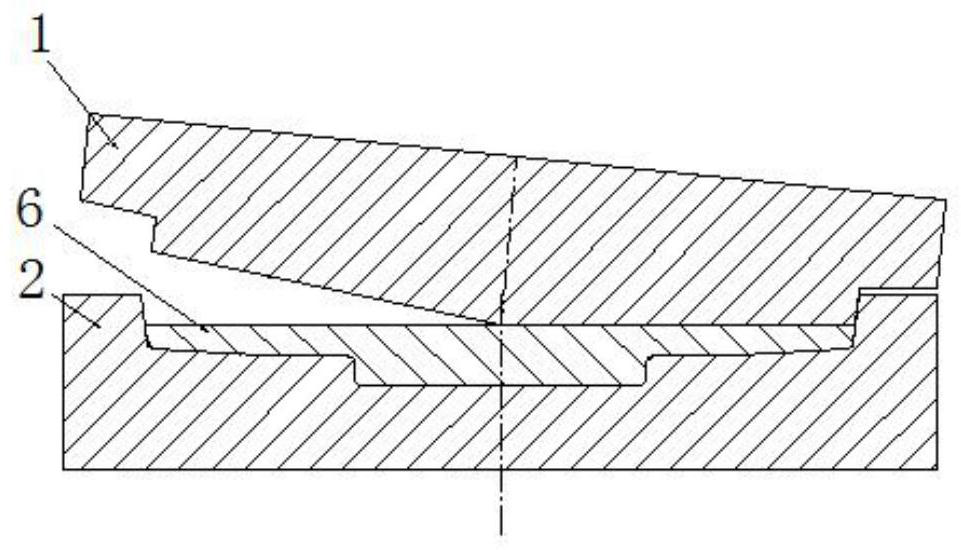

The invention relates to a manufacturing method of a titanium alloy thin-wall ribbed hollow component. The method comprises the following steps that: a. the titanium alloy hollow component is decomposed into a stressed-skin and ribbed structure form or a stressed-skin ribbed structure form according to the structure features of a hollow component, and an inner sheath and an outer sheath structure forms are determined according to a hollow part of the hollow component; b. the stressed-skin and ribbed or the stressed-skin ribbed structural part is processed or formed according to the decomposed structure forms; c. the inner and the outer sheaths are processed or formed; d. the stressed-skin and ribbed or the stressed-skin ribbed structural part being well processed is assembled with the inner and the outer sheaths, the inner and the outer sheaths are sealed in a welding way and are vacuum encapsulated, and the vacuum degree is 1.0 *10-3Pa; e. the dispersion connection of each structural part is realized through a hot isostatic pressing method; f. surface treatment on each prefabricated structural part is undertaken so as to prepare the hollow structural component. The manufacturing method has high production efficiency; a plurality of components can be prepared through one technical circulation; and the welding rate is more than 95 percent.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Cast Al-Si alloy

The cast Al-Si alloy consists of Si 11.0-13.5 wt%, Mg 0.15-0.55 wt%, Sr 0.015-0.080 wt%, B 0.010-0.050 wt%, Cu <0.20 wt%, Fe <0.20 wt%, Zn <0.10 wt%, Mn <0.10 wt%, Ti <0.10 wt%, each of other impurity<0.05 wt%, total impurity content<0.15 wt%, and Al the rest. The cast Al-Si alloy has Si content near the eutectic point of the alloy, and its alloy liquid has excellent flowability, powerful shrink feeding capacity, low gas absorption and less casting defaults. The cast Al-Si alloy has high toughness and lowered casting mold cost.

Owner:SOUTHEAST UNIV

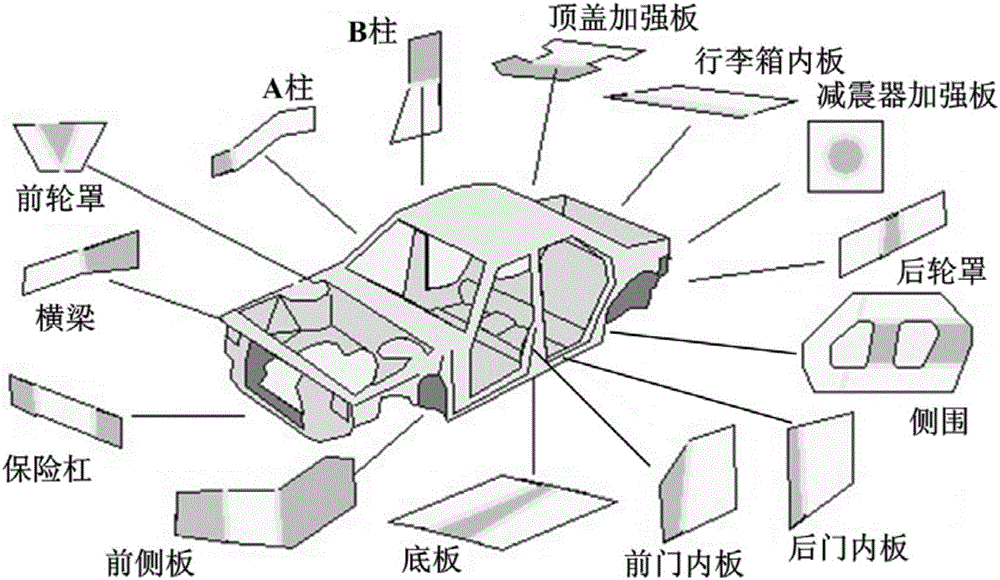

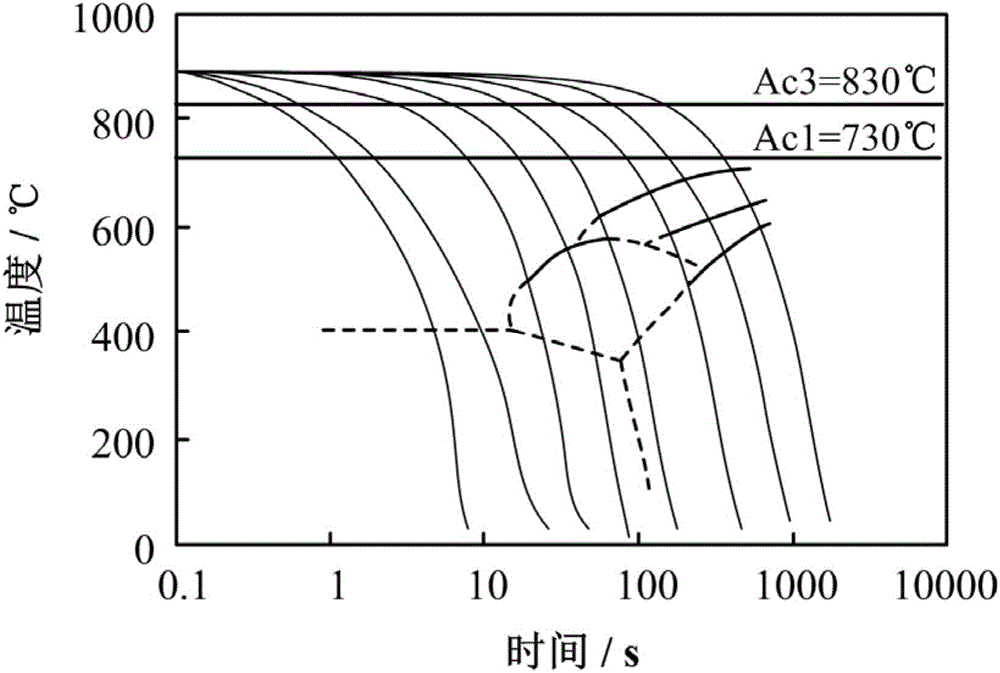

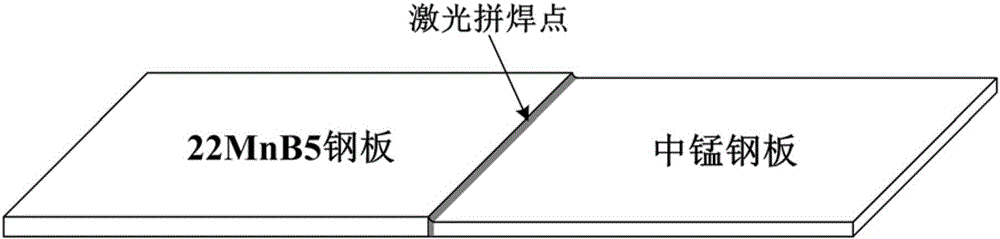

Laser tailor-welded high-strength steel warm forming preparation method

InactiveCN106350741AReduce manufacturing costLow quenching rateLaser beam welding apparatusThree-phaseQuenching

The invention discloses a laser tailor-welded high-strength steel warm forming preparation method. The laser tailor-welded high-strength steel warm forming preparation method is characterized by comprising the following steps: manufacturing a 22MnB5 steel plate and a medium manganese steel plate into a steel part for later use; carrying out laser tailor-welded connection treatment; carrying out heating treatment on the steel part for later use, which is subjected to laser tailor-welding; transferring the steel part onto a stamping mold to carry out stamping forming and quenching; finally obtaining a two-phase or three-phase microstructure formed by lots of ferrite, martensite or bainite in the 22MnB5 steel area of the tailor-welded steel part; and obtaining a martensite organization structure in the medium manganese steel area, thereby forming a warm forming technology of the laser tailor-welded high-strength steel, which has no need for coating treatment in advance and has gradient distributed mechanical property. The laser tailor-welded high-strength steel warm forming preparation method has the beneficial effects that the process combination of laser tailor-welding and the warm forming technology is realized; the warming forming technology is used for enabling 22MnB5 steel to form the two-phase or three-phase microstructure; the two-phase or three-phase microstructure is matched with medium manganese steel having martensitic structure in the end to obtain a custom-made warm forming part with gradient distributed performances; the technological process is simplified; and the production efficiency is improved.

Owner:DALIAN UNIV OF TECH

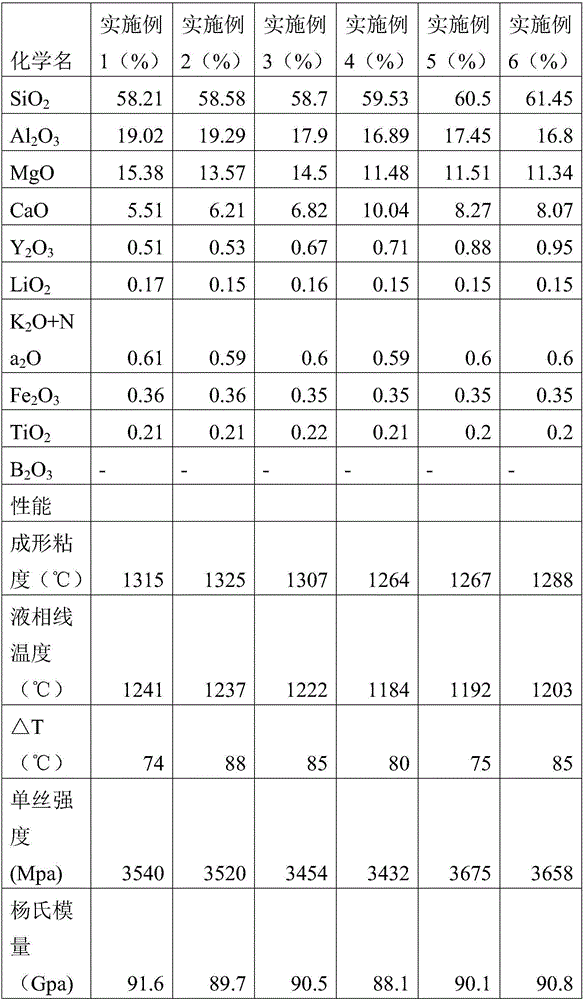

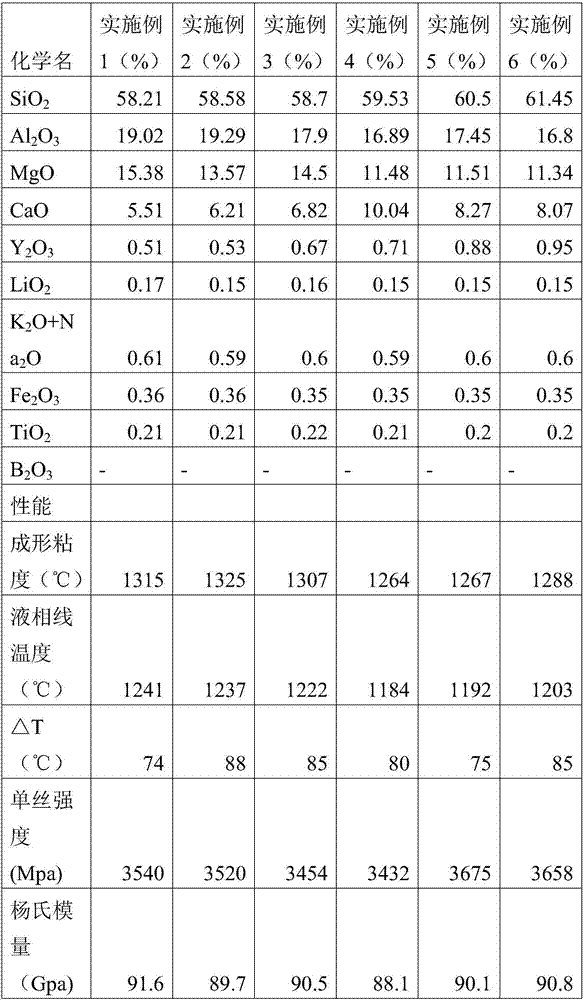

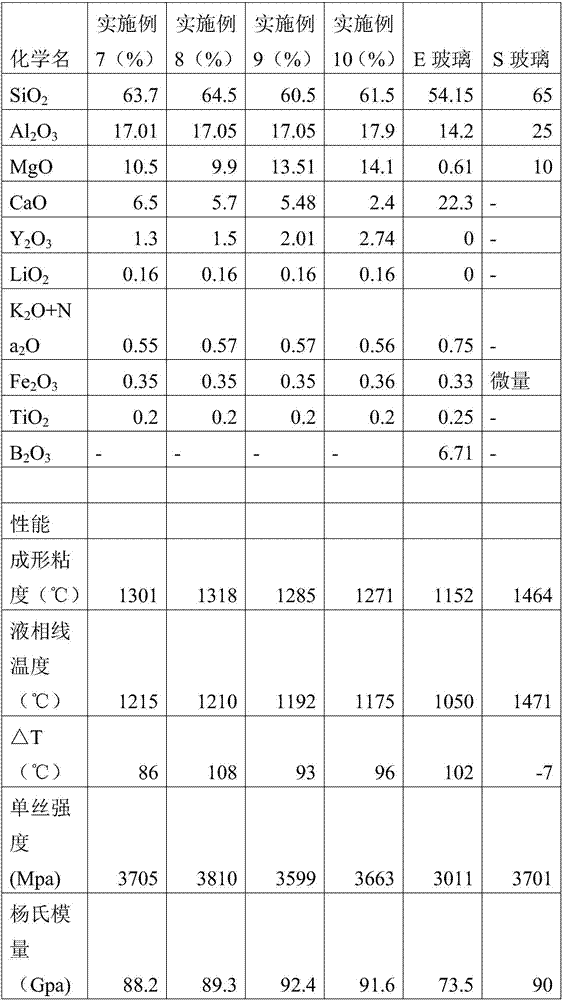

Enhancement type glass fiber composition

The invention belongs to the technical field of glass fiber and relates to an enhancement type spinning high-strength and high-modulus glass fiber composition applied to the fields of electromechanics, chemical engineering, aircrafts and the like. The enhancement type spinning glass fiber composition is prepared from, by weight, 56-65% of SiO2, 15-21% of Al2O3, 9-18% of MgO, 5-13% of CaO, 0.1-4% of Y2O3, 0-0.8% of Li2O, 0.1-1% of K2O+Na2O, and 3% or less of other impurities. The enhancement type glass fiber composition is prepared through a tank furnace technological process, by means of optimization and combination of the oxide components and particularly the introduction of Y2O3, the melting temperature, the clarification temperature and the shaping temperature of the enhancement type glass fiber composition are reduced under the situation that high strength and high modulus are guaranteed, the temperature difference between the shaping temperature and the liquidus temperature is increased, the wiredrawing situation is improved, and the enhancement type glass fiber composition is beneficial to the industrial production of high-strength and high-modulus fibers.

Owner:SHANDONG FIBERGLASS GRP

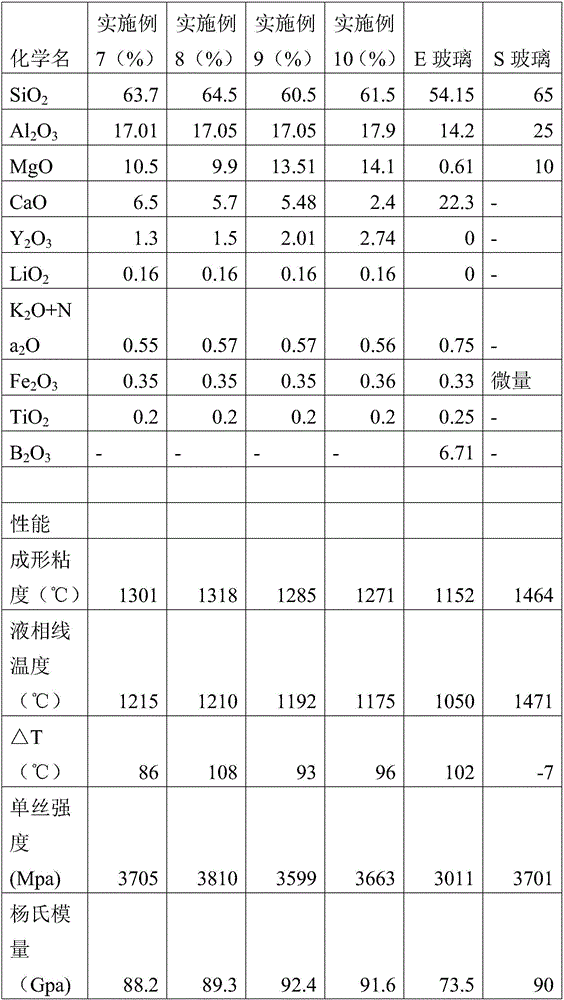

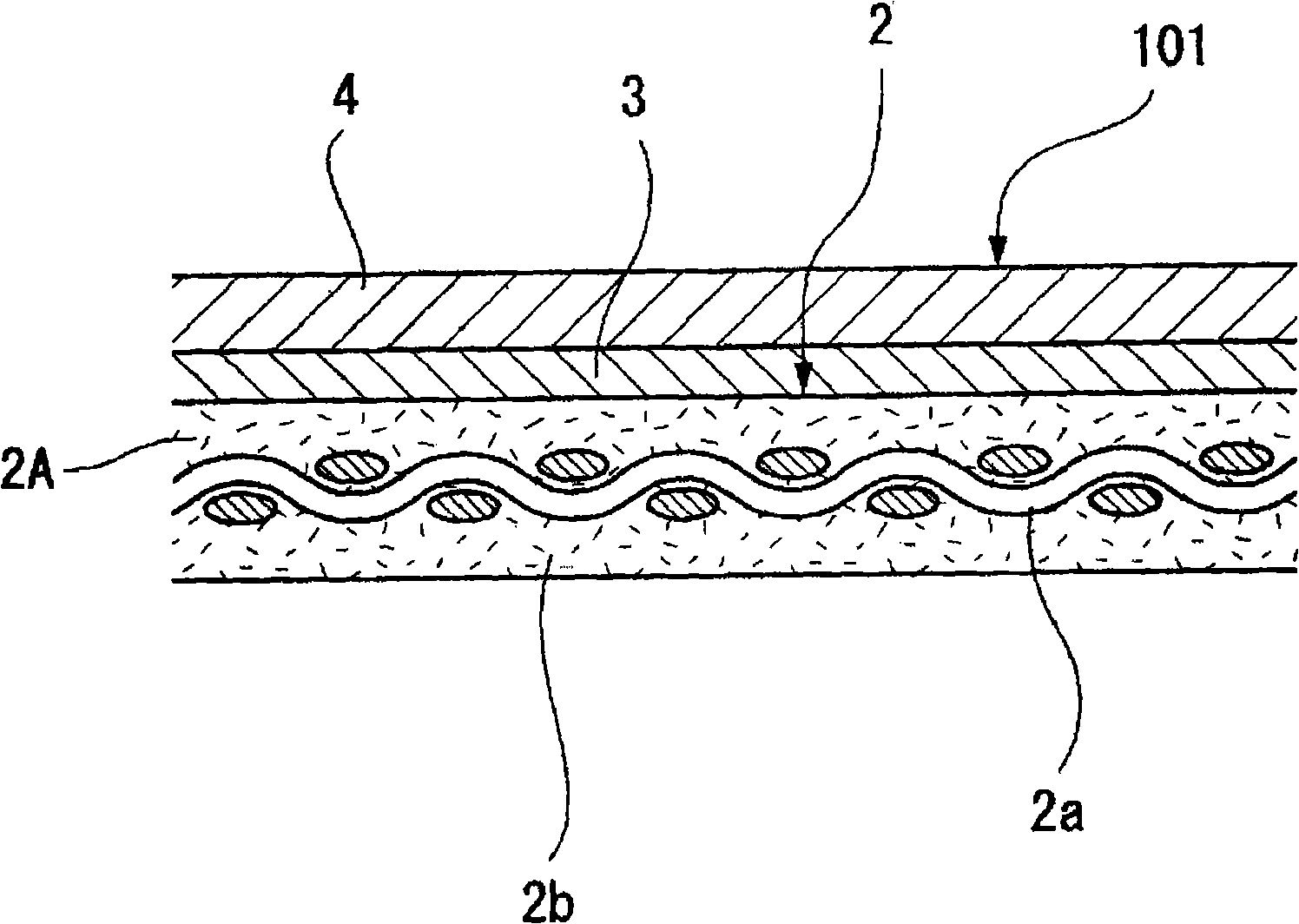

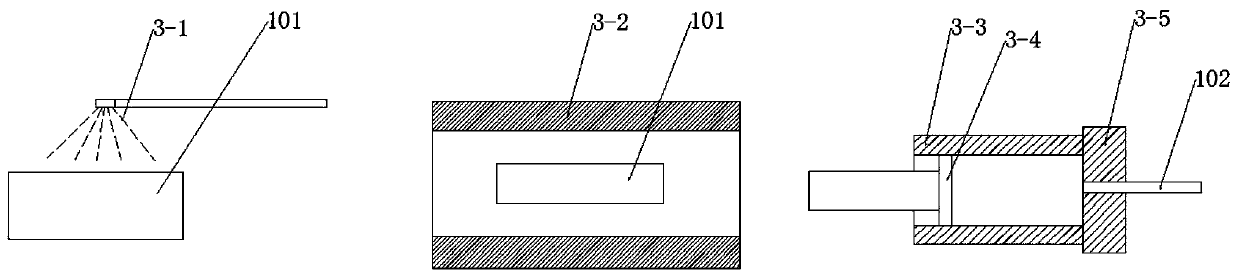

Copper-clad laminate, printed wiring board, multilayer printed wiring board, and methods for producing those

ActiveCN101277816AHigh bonding strengthReduce lossesDielectric materialsWoven fabricsCopper foilUltimate tensile strength

Disclosed is a copper-clad laminate wherein the copper foil adhesion strength (copper foil peeling strength) is greatly improved without subjecting the copper foil surface to a roughening treatment or a blackening treatment, a printed-wiring board, a multi-layer printed-wiring board and manufacturing method thereof. This copper-clad laminate can be adequately used in a high frequency region. Specifically disclosed is a copper-clad laminate (101) for single-sided printed wiring boards, which is obtained by bonding a copper foil (4) onto one surface of an insulating substrate (2), which is composed of a fluoroplastic prepreg (2A), via a composite film (3) of LCP and PFA. The copper foil (4) is a rolled copper foil having a smooth surface without being subjected to a roughening treatment or a blackening treatment on both sides. The insulating substrate (2) and the copper foil (4) are bonded with each other via the composite film (3) by being fired and pressed at a temperature higher than the melting point of PFA by 5-40 DEG C and lower than the melting point of LCP.

Owner:NIPPON PILLAR PACKING CO LTD +1

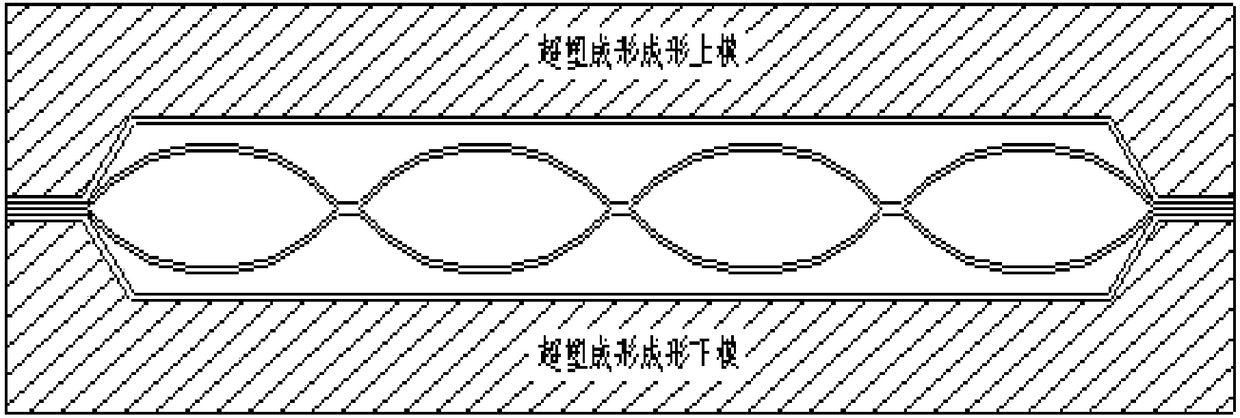

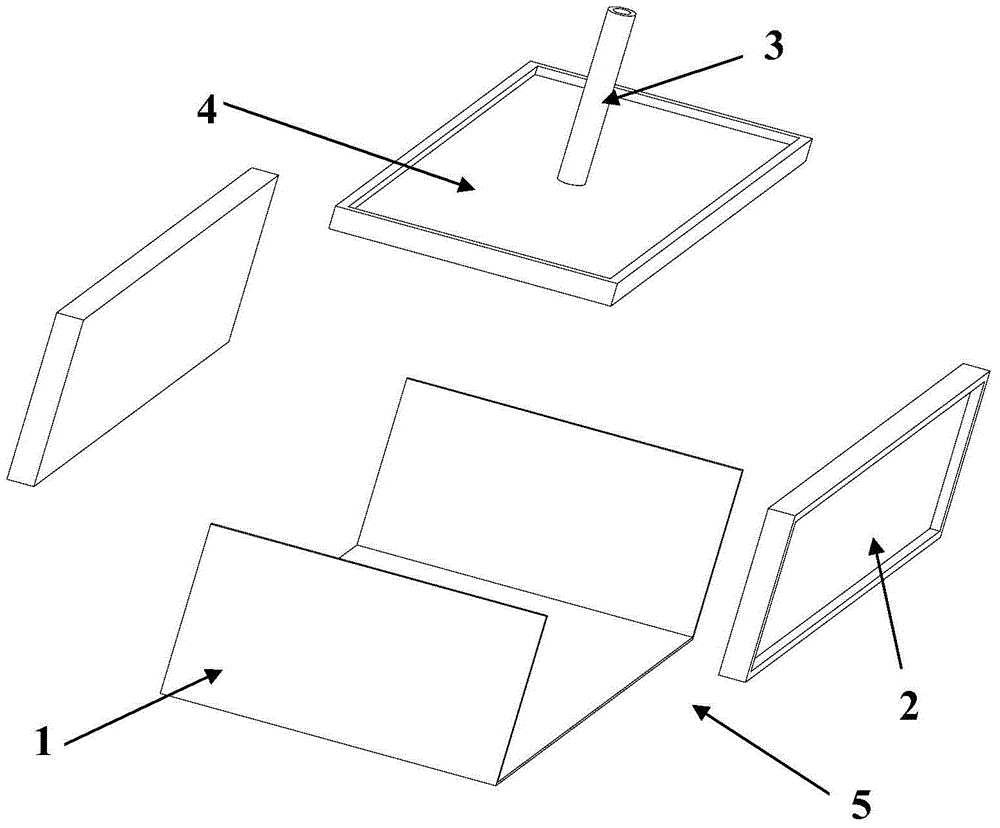

Preparation method of Ti2AlNb/TA15 bi-metal titanium alloy composite hollow structure

The invention provides a preparation process of a Ti2AlNb / TA15 bi-metal titanium alloy composite hollow structure part. The Ti2AlNb / TA15 bi-metal titanium alloy composite hollow structure wing type component is prepared through the steps of blank preparation, surface treatment, welding stop agent coating, superplastic forming / diffusion bonding, cooling, out of a furnace and the like. The superplastic forming / diffusion bonding process method of the dissimilar material hollow structure part breaks through the key technology of the multi-layer hollow structure prepared by combining a Ti2AlNb intermetallic compound and an ordinary titanium alloy, the high-temperature resisting characteristic of the Ti2AlNb intermetallic compound and the good superplasticity of the TA15 titanium alloy are givento full play, structure weight losing is achieved, the guided missile thrust-weight ratio is increased, the application of the Ti2AlNb intermetallic compound to types is promoted, the material application range is expanded, the material utilization rate is increased, and the cost is reduced.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

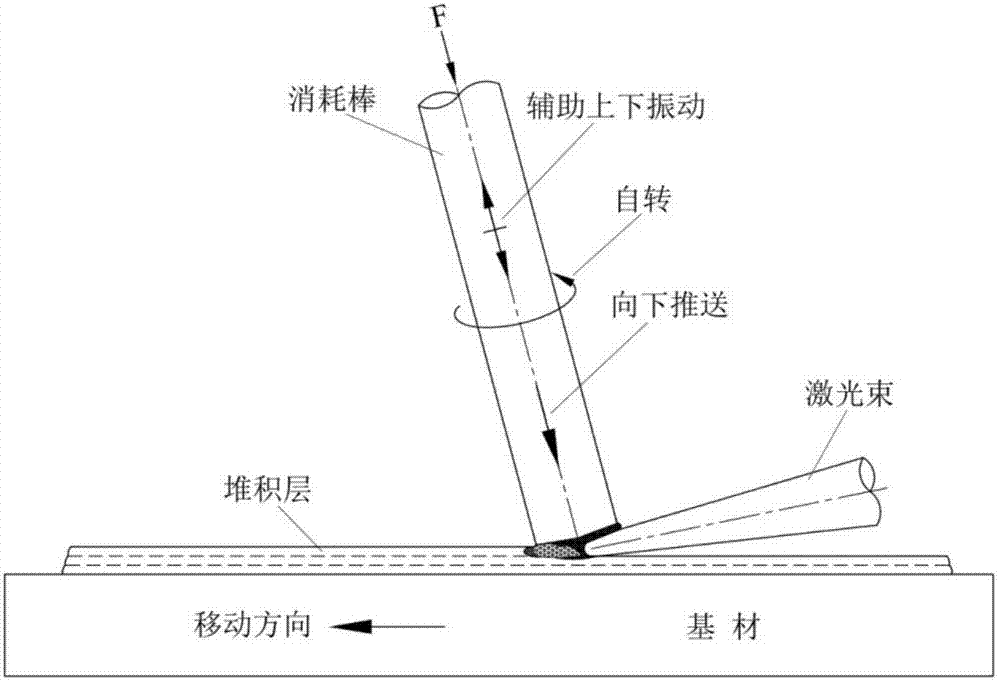

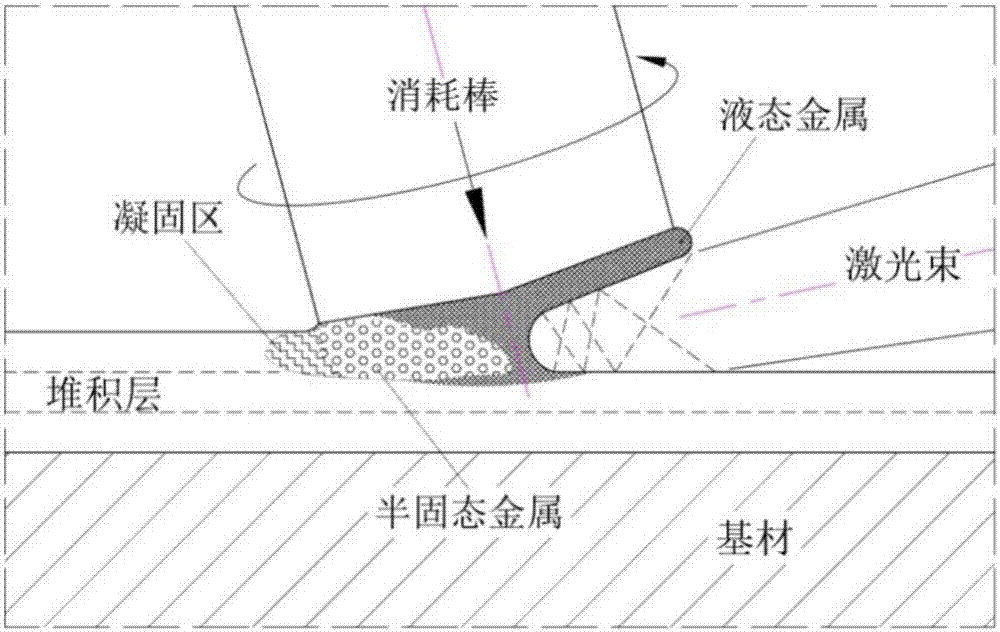

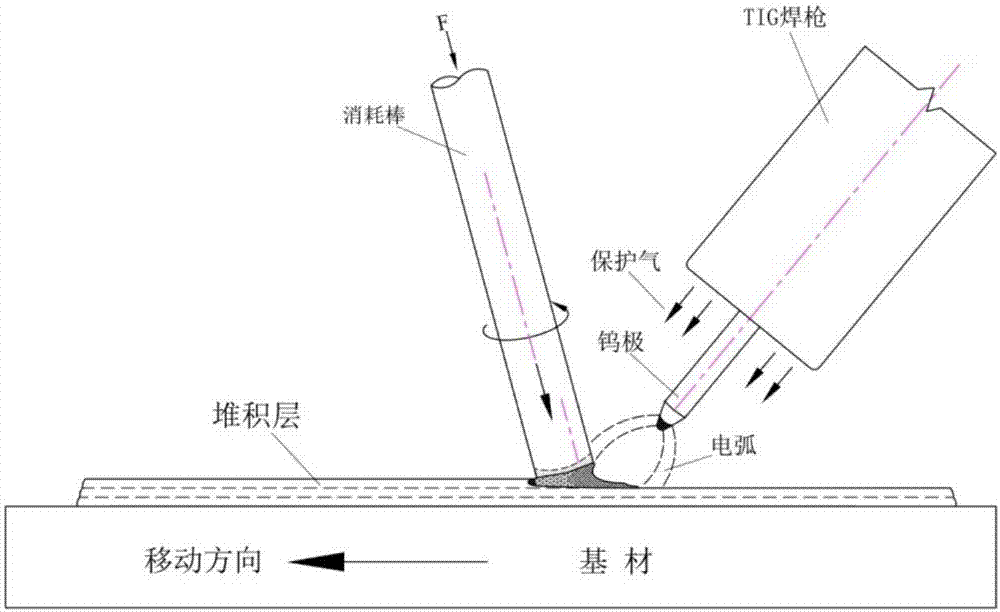

Micro-domain semi-solid state additive manufacturing method

ActiveCN107414325AReduce distortionReduced tendency to crackAdditive manufacturing apparatusArc welding apparatusMaterials preparationHigh energy

The invention provides a micro-domain semi-solid state additive manufacturing method. The problems about structure homogeneity, performance reliability, stress and deformation, air holes and cracks and the like of a molding piece are mainly solved. A stick-shaped material serves as a consumable item, and heating manners such as high energy beams, electric arcs and resistance heat are adopted for acting on the front end of the consumable item to enable the front end to be in a solid-liquid two-phase coexistence semi-solid state; and meanwhile, rotating twisting force and axial thrust are applied to the consumable item to conduct powerful effects such as shearing, stirring and extruding on semi-solid state metal, and in other words, mold-free semi-solid state flowing deformation molding is carried out. The consumable item is transited to bottom layer metal continuously in the manner to form metallurgical bonding, the stacking process is repeated according to a planned route obtained after discretization slicing treatment, and then a solid piece or a stacking layer in a special shape can be formed. The micro-domain semi-solid state additive manufacturing method is simple in operation process, the part performance is excellent, many defects in traditional additive manufacturing are overcome, and the prospects in the aspects of large structure shaping, damaged part repairing and composite material preparation are wide.

Owner:BEIJING UNIV OF TECH

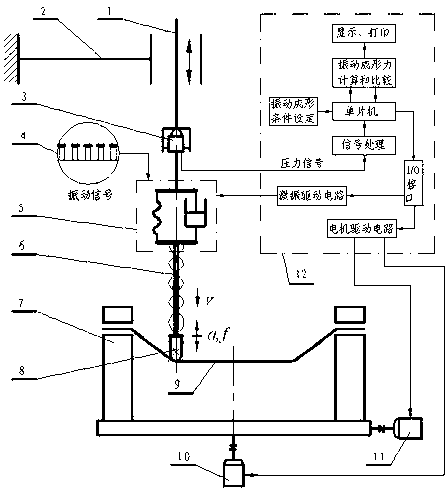

Single-point longitudinal vibration controllable progressive forming system for metal plate

InactiveCN103071726AImprove forming conditionsLighten or wrinkleLongitudinal vibrationParameter control

The invention discloses a single-point longitudinal vibration controllable progressive forming system for a metal plate. The main shaft of the single-point longitudinal vibration controllable progressive forming system for the metal plate is installed on a rack; a force sensor is installed on the shaft end of the main shaft; a vibration signal generator is connected with a vibration exciter; the vibration exciter is installed below the force sensor; a tool head is connected with the vibration exciter via a connecting rod; a workbench is installed just below the main shaft; the input end of a parameter controller is connected with the force sensor; and the output end of the parameter controller is respectively connected with the vibration frequency and amplitude control port of the vibration exciter as well as the X-shaft driving motor control port and the Y-shaft driving motor control port of the workbench. A single-point longitudinal vibration plasticity forming condition of the plate material is established by combining a forming technology parameter, a vibration mode parameter and a forming force parameter, and the parameter controller is used for monitoring and regulating the forming technology parameter and the vibration mode parameter in real time according to the plate material forming technology state and the vibration plasticity forming condition. The single-point longitudinal vibration controllable progressive forming system for the metal plate, which is disclosed by the invention, has the beneficial effects that the technical defects of single-point progressive forming can be overcome, the technology parameter and the vibration mode parameter can be monitored and regulated in real time according to the plate material vibration plasticity forming condition in the forming process, and efficient and precise progressive forming of the metal plate material can be realized.

Owner:JIANGXI UNIV OF SCI & TECH

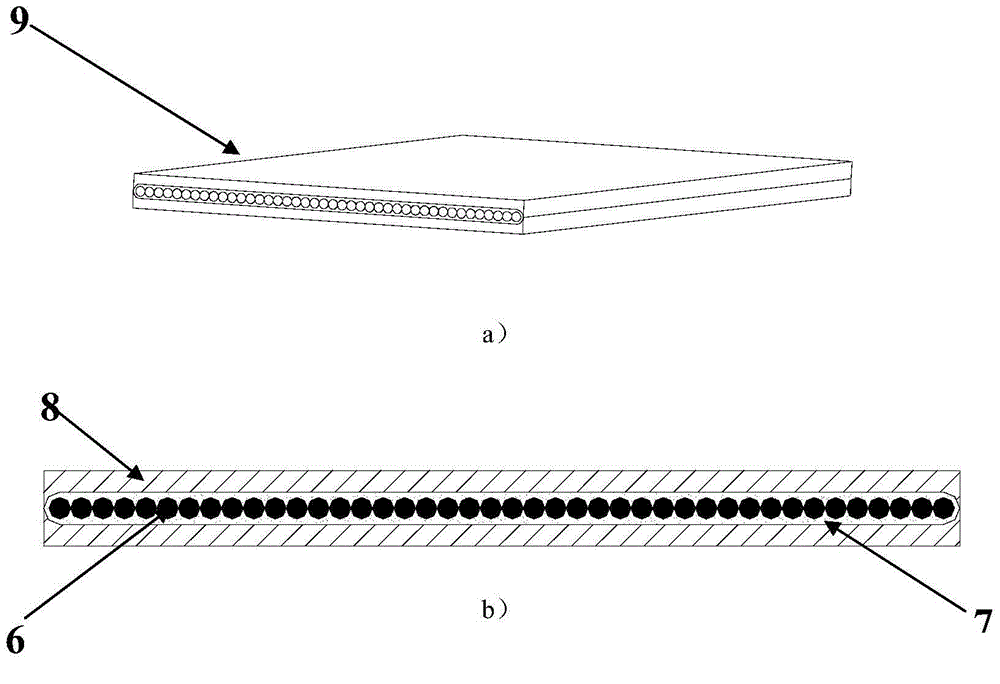

High-temperature and high-pressure preparation method of continuous carbon fiber reinforced aluminum base composite material powder

The invention provides a high-temperature and high-pressure preparation method of continuous carbon fiber reinforced aluminum base composite material powder, which comprises the following steps: preparing a can, a carbon fiber preform and spherical aluminum alloy powder; putting the carbon fiber preform into the can; vacuumizing the can; performing hot isostatic pressing treatment on the vacuumized can; mechanically removing the can; and mechanically cutting to obtain the carbon fiber reinforced aluminum base composite material having an appropriate thickness, etc. According to the high-temperature and high-pressure preparation method of continuous carbon fiber reinforced aluminum base composite material powder, the aluminum alloy powder is consolidated and densified through hot isostatic pressing technology and is closely combined with the carbon fiber material, thus overcoming the defects of the traditional preparation method, such as strict requirements for molds and equipment, high formation temperature, high pressure and the like; the compounding and formation of a metal matrix and a reinforcement can be completed simultaneously; and the prepared composite material is uniform and compact in structure, has no shrinkage cavities, gas pockets or other defects, and has uniform performance.

Owner:BEIHANG UNIV

Forming method of block-shaped amorphous composite material

The invention relates to a forming method of a block-shaped amorphous composite material, which is characterized by comprising the following steps: (1) selecting a block-shaped amorphous composite material which has the component purity greater than 99.3% and substrate components with strong glass forming capacity, preparing a high-purity block-shaped amorphous composite material, and cutting the block-shaped amorphous composite material into an ingot blank according to a forming part; (2) heating the ingot blank under gas protection at the speed of 0.5-50 DEG C / s to the liquidus temperature and the solidus temperature range of the block-shaped amorphous composite material, and insulating for 3-30 minutes; and (3) under pressure, filling a liquid-solid coexistent metal slurryinto a mold cavity at a deformation rate of 102-106s<-1>, and forcibly cooling for solidifying at the cooling speed of 1-200 DEG C / s while maintaining the pressure. The invention can obtain the metal slurry the second phase of which is uniformly distributed in the liquid phase, has low forming temperature, long service life of the mold and high production efficiency, improves the product performance, can be used for forming parts with complex forming shapes and thin walls, and can be widely applied to amorphous composite materials of Zr-series, Cu-series, Ti-series, La-series, Co-series and the like.

Owner:NANCHANG UNIV

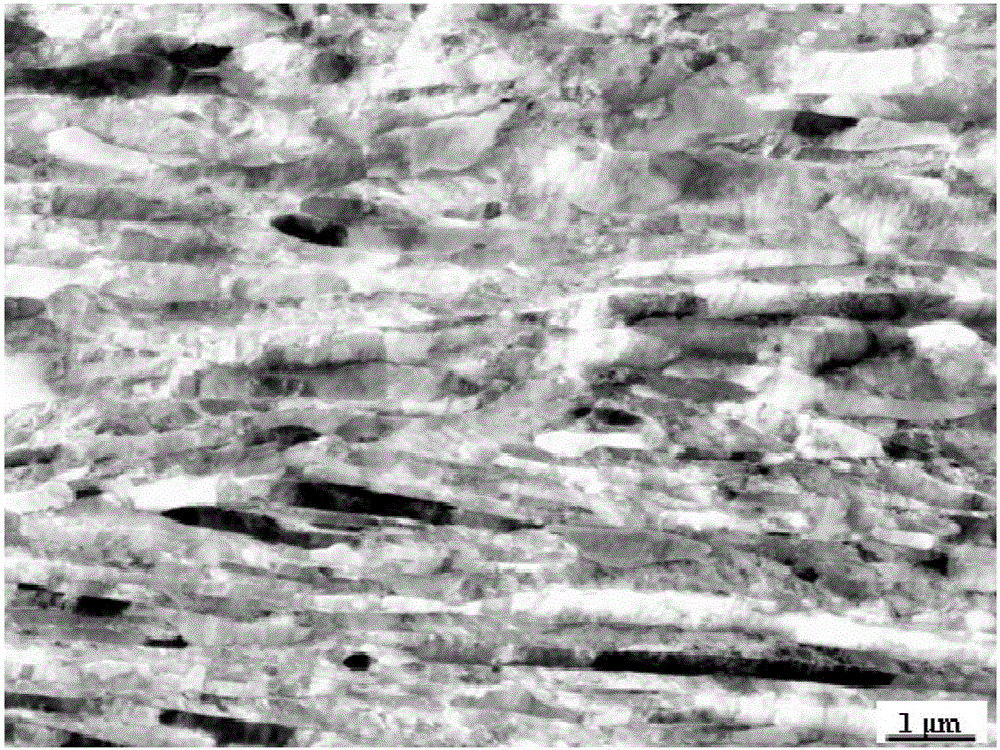

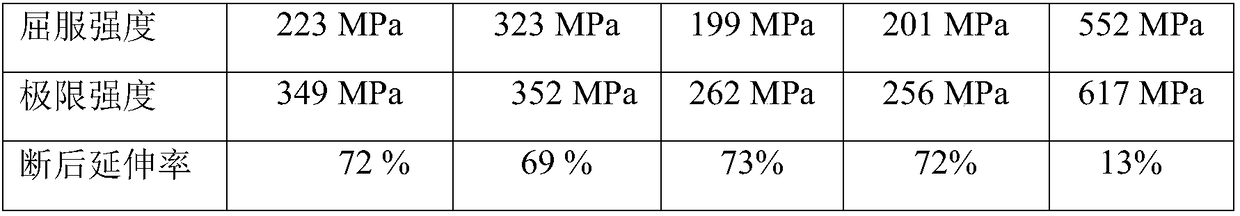

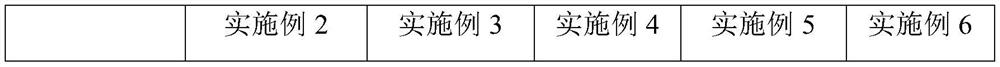

Nano/superfine medium-manganese TRIP (transformation induced plasticity) steel plate and warm-rolling preparation method thereof

The invention relates to a nano / superfine medium-manganese TRIP (transformation induced plasticity) steel plate and a warm-rolling preparation method thereof, belonging to the technical field of ultrahigh-strength steel. The nano / superfine medium-manganese TRIP steel plate comprises the following chemical components in percentage by weight: 0.17-0.25wt.% of C, 0.00-0.50wt.% of Si, 5.00-7.00wt.% of Mn, 1.00-1.50wt.% of Al, 0.014-0.03wt.% of N, 0.00-0.06wt.% of Nb, 0.00-0.25wt.% of Mo, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: smelting, forging, carrying out hot rolling, and carrying out warm rolling to obtain the nano / superfine medium-manganese TRIP steel plate; and carrying out heat treatment on the steel plate to obtain the nano / superfine medium-manganese TRIP heat-treated steel plate. By using the warm-rolling technique instead of the typical technique for producing manganese steel, the method provided by the invention has the advantages of simple technique, short production cycle and controllable plate shape. The prepared steel plate has a nano / superfine structure, has the advantages of high strength and favorable properties, and satisfies the target requirements of resource saving, energy consumption reduction, light weight and crash safety enhancement for automobile industry.

Owner:NORTHEASTERN UNIV

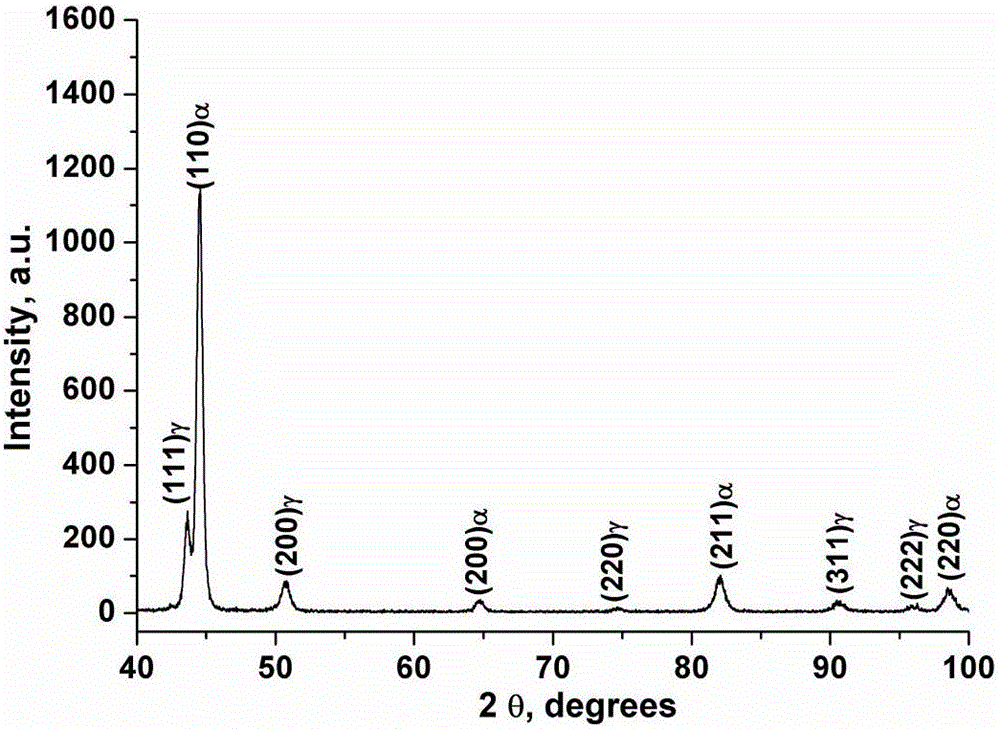

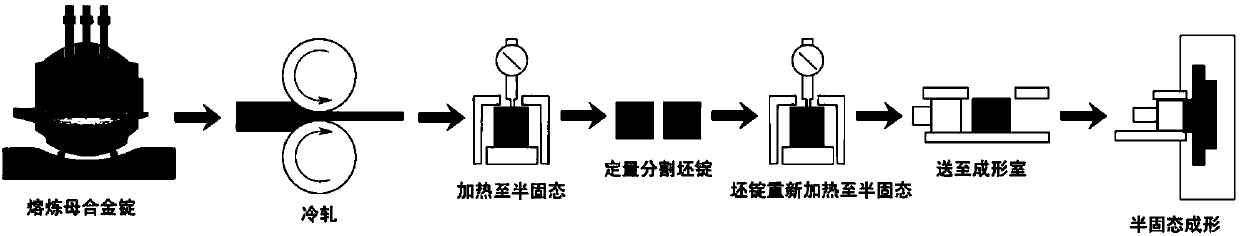

Semi-solid forming method of high-melting-point equal-component high-entropy alloy

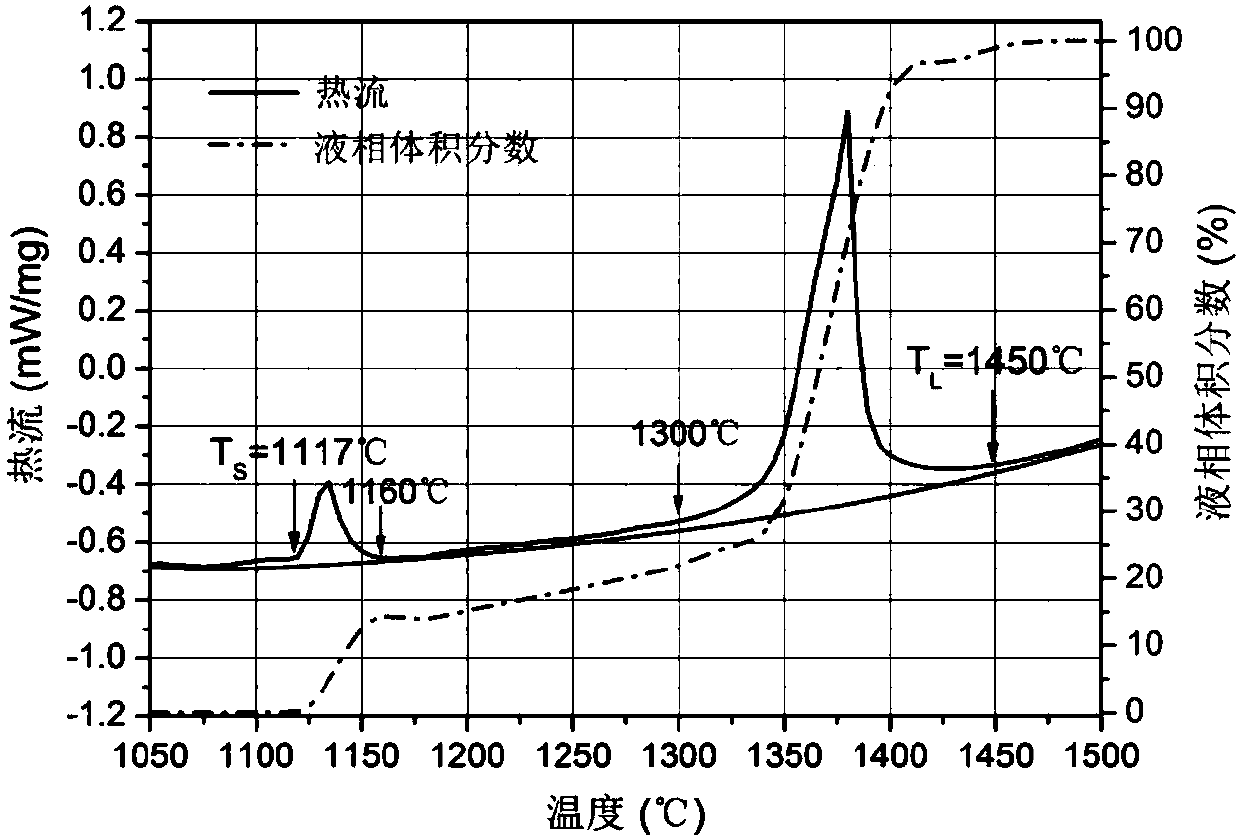

The invention discloses a semi-solid forming method o a high-melting-point equal-component CoCrCuFeNi high-entropy alloy. The method is mainly characterized in that an electric arc smelting technologyis adopted to repeatedly smelt a high-entropy alloy raw material for seven times, and a uniform-component as-cast high-entropy alloy ingot of a dendrite structure is obtained; the as-cast high-entropy alloy ingot is subject to room-temperature cold-rolling pre-deformation treatment, the alloy ingot subject to cold-rolling deformation is heated to 1160 to 1300 DEG C, heat preservation is carried out for 5 to 80 minutes, and water quenching rapid cooling is carried out, and a semi-solid blank with spherical grains is obtained; the semi-solid blank is subject to quantitative cutting and block cutting according to needs, and reheated to 1160 to 1300 DEG C, heat preservation is carried out for 5 minutes, the blank is rapidly fed into a forming room, through an extrusion method, the semi-solidblank is pressed into a grinding tool prepared in advance, and the formed high-entropy alloy part is obtained. The cost for manufacturing the high-entropy alloy part can be reduced, production efficiency and the product quality are greatly improved, and industrial production of the high-entropy alloy part can be achieved.

Owner:YANSHAN UNIV

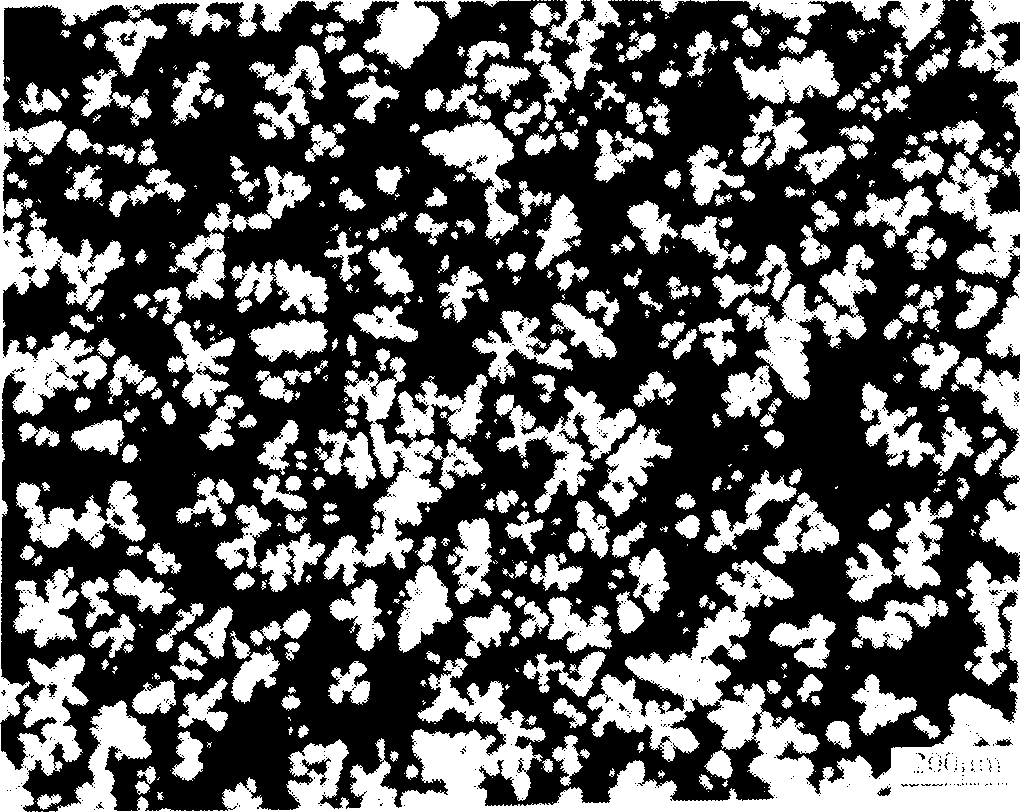

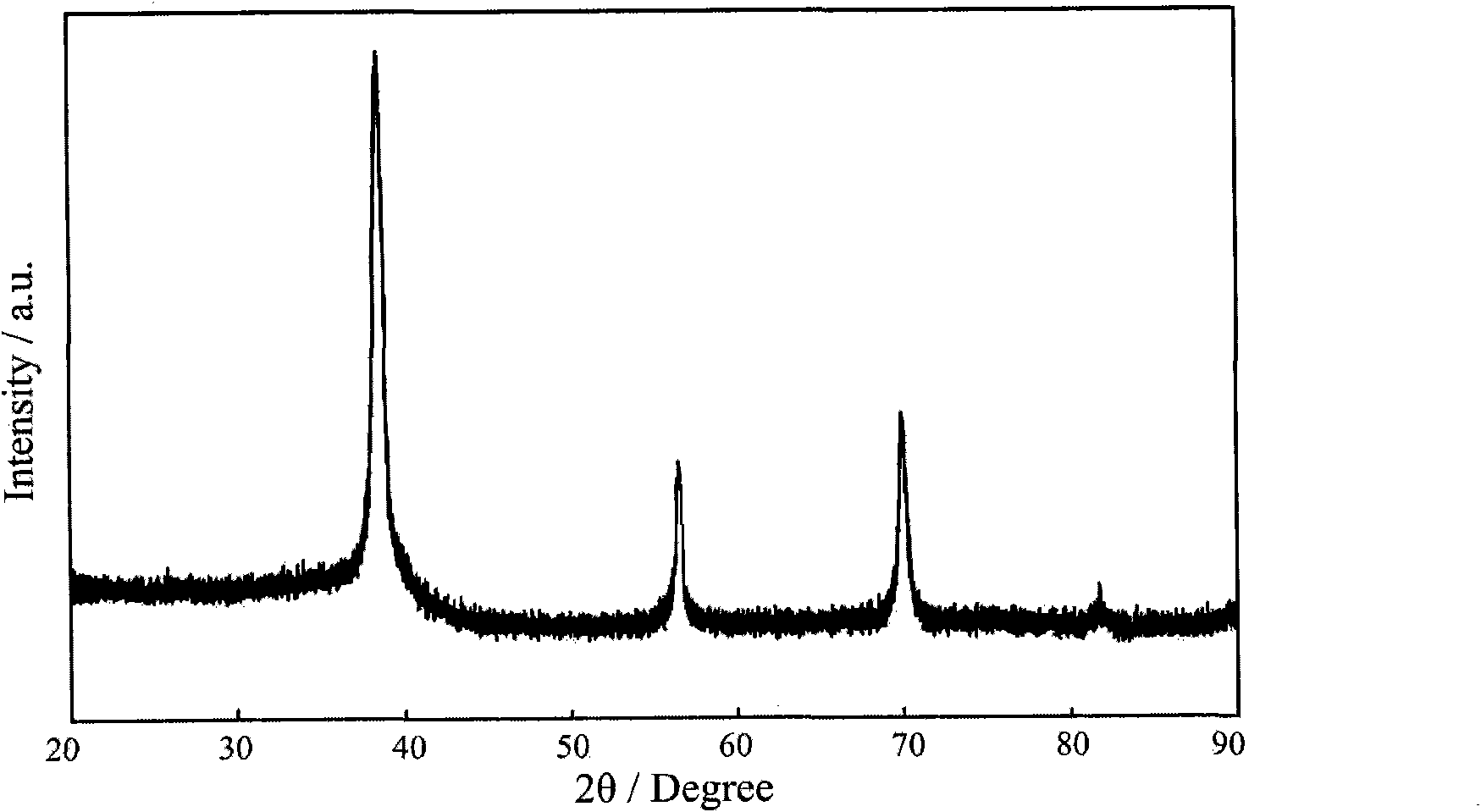

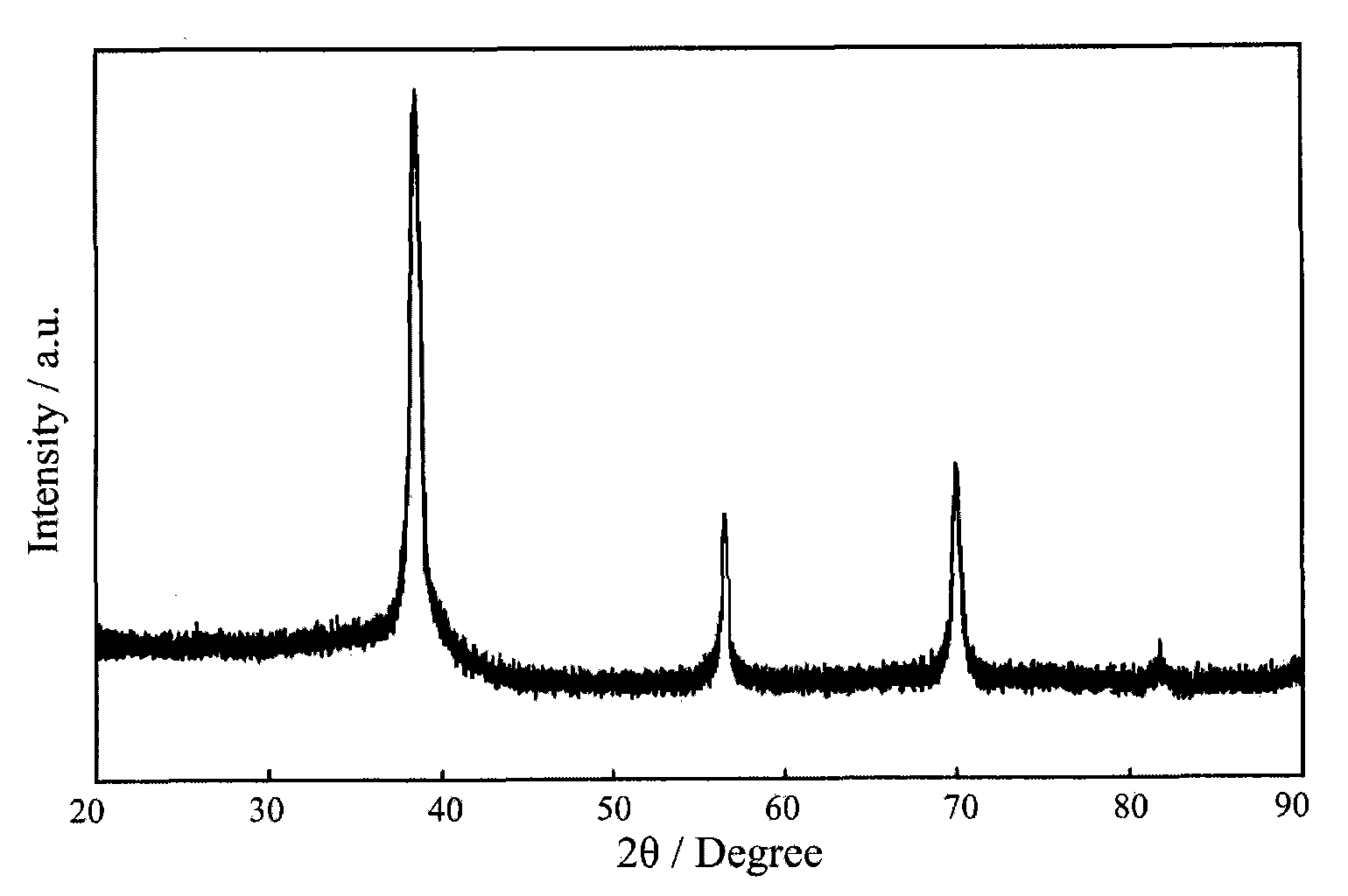

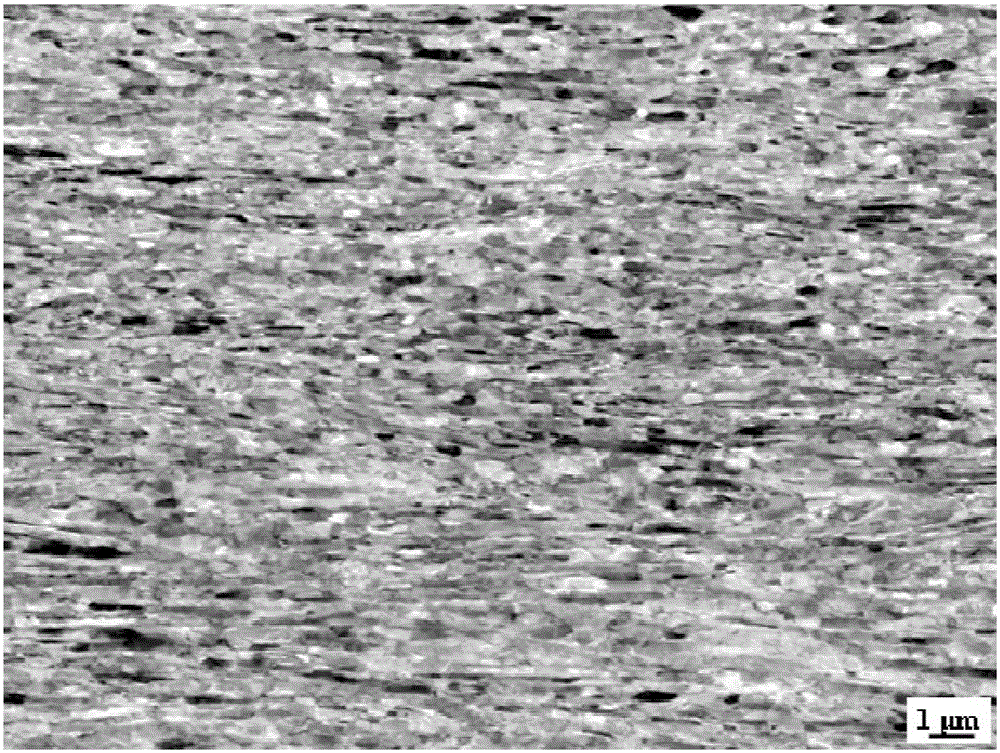

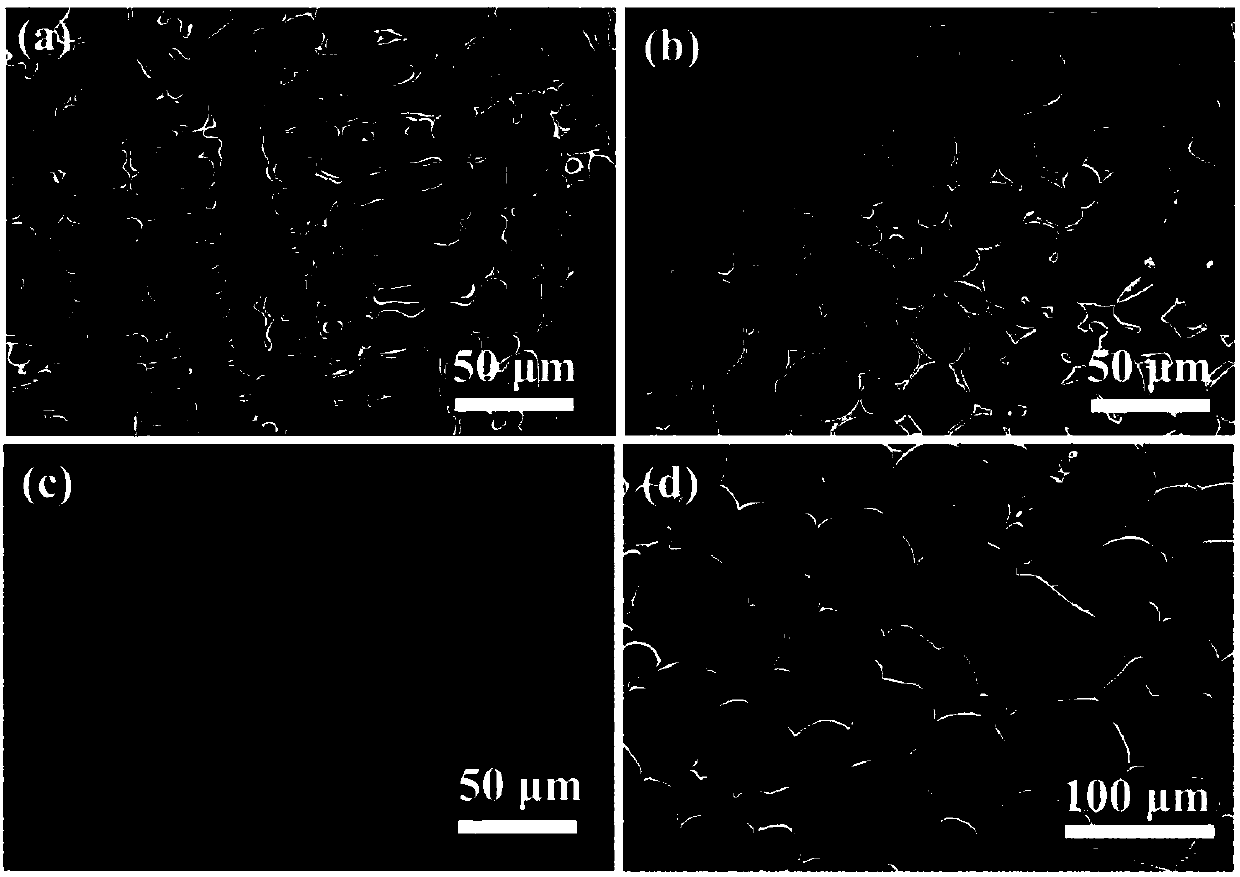

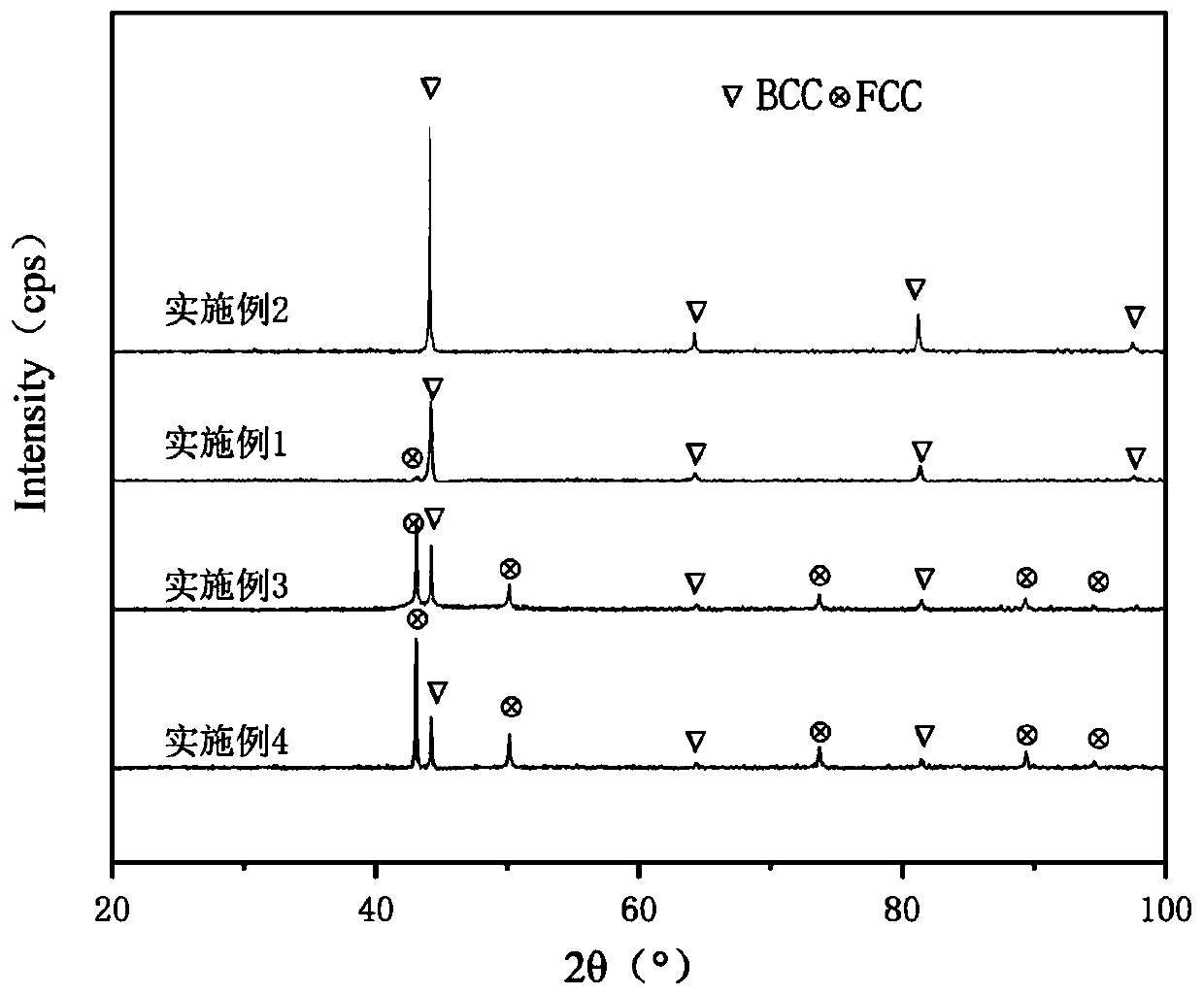

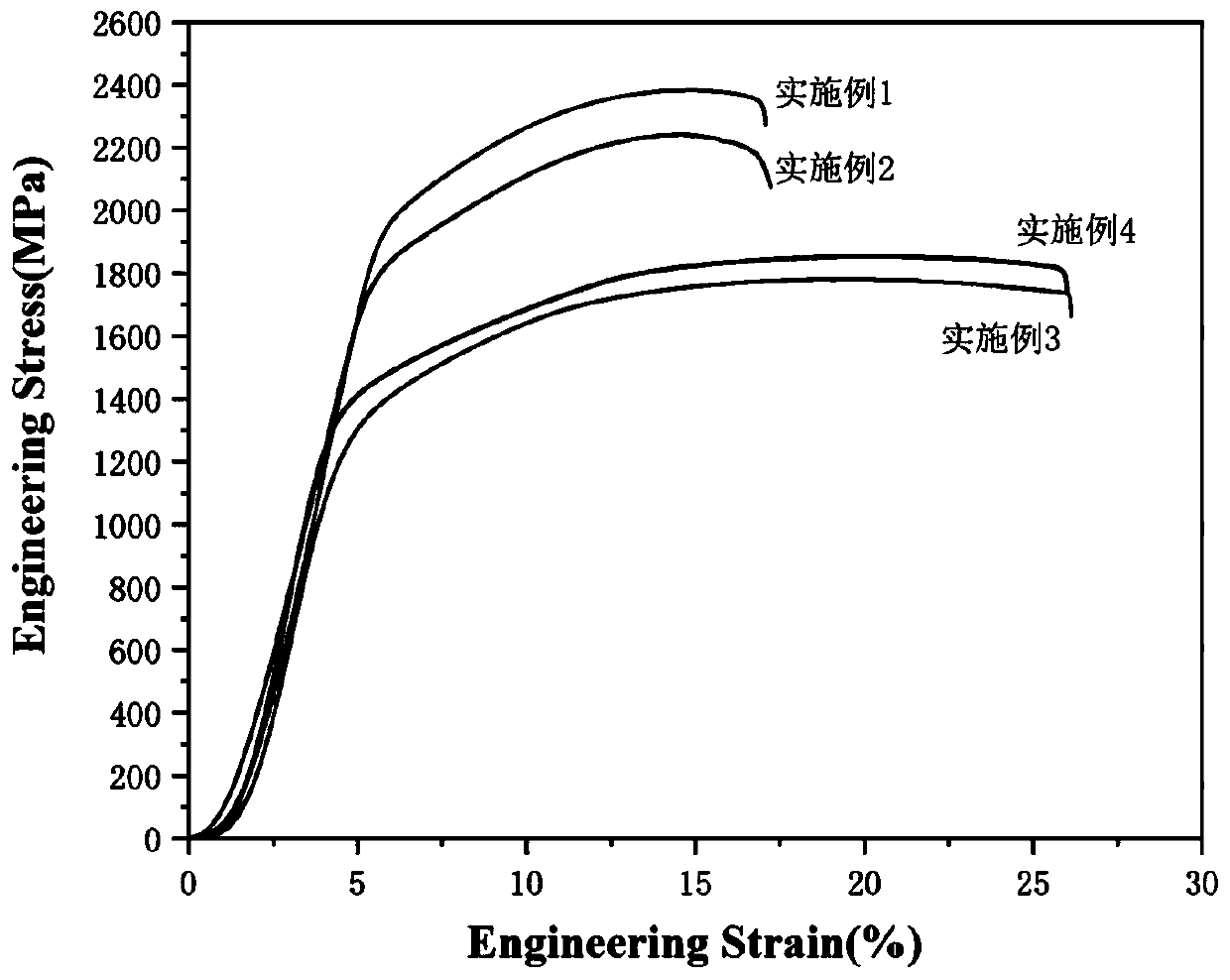

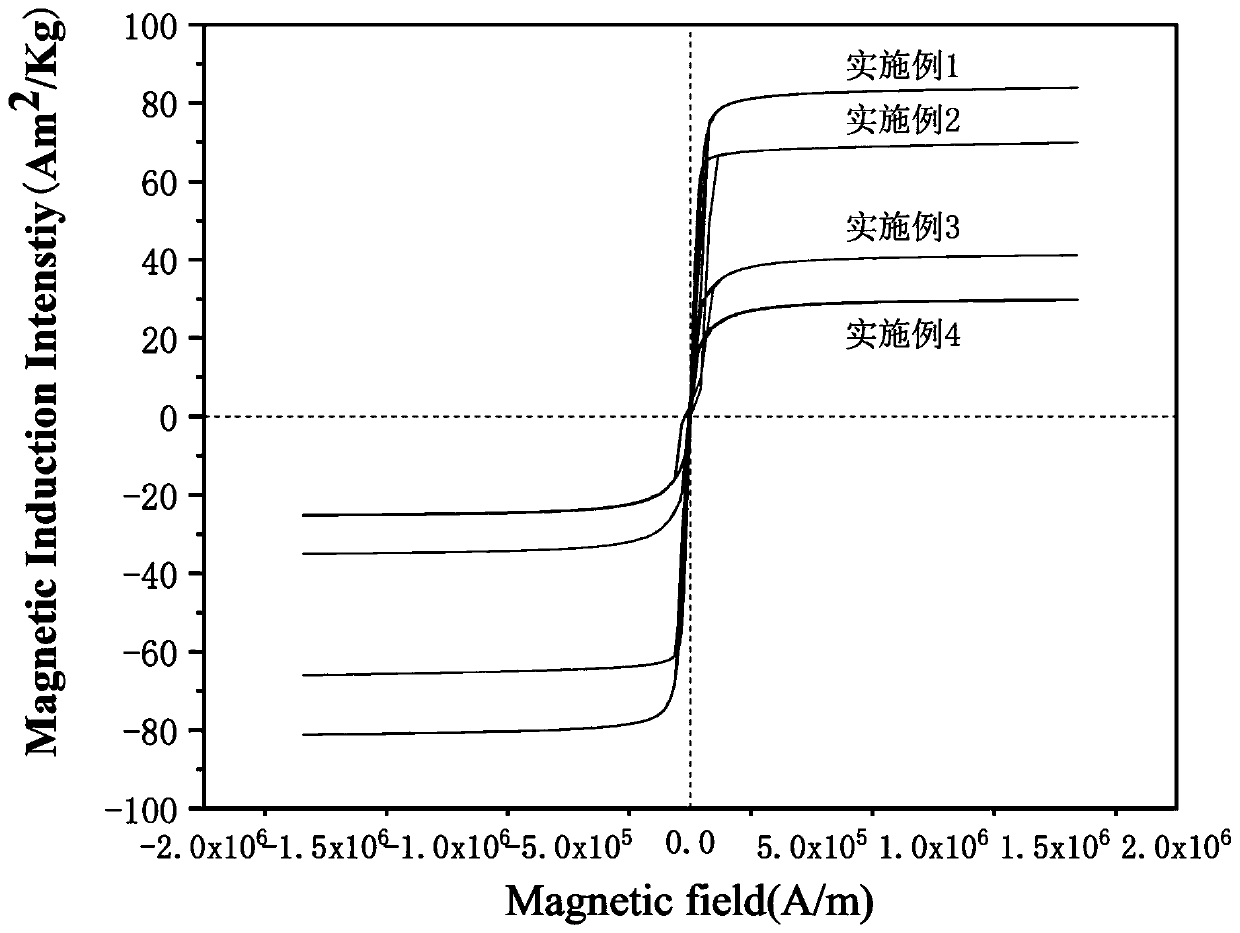

Ultra-fine grain high-strength high-entropy alloy with magnetism and preparing method of ultra-fine grain high-strength high-entropy alloy

InactiveCN111206174ALow costLow forming temperatureTransportation and packagingMetal-working apparatusHigh entropy alloysPlasticity

The invention belongs to the technical field of high-entropy alloys, and discloses an ultra-fine grain high-strength high-entropy alloy with magnetism and a preparing method of the ultra-fine grain high-strength high-entropy alloy. The preparing method of the high-entropy alloy is further provided, and in other words, a mechanical alloying and spark plasma sintering combined method is provided. The structure of the high-entropy alloy is a BCC+FCC double-phase structure or BCC single-phase structure, wherein the average grain size of the BCC phase is about 200-500 nm, the average grain size ofthe FCC phase is about 400-600 nm, and good comprehensive mechanical performance and magnetic performance are achieved. When the content of Al is 16%, the room-temperature compression yield strength of the Al is 1916 MPa, the plasticity strain capacity during fracture is 11.48%, the maximum compressive strength is 2379 MPa, hardness is 614 Hv, the saturation magnetization strength is 83.07 Am<2> / Kg, and the coercive force is 1238.39 A / m.

Owner:SOUTH CHINA UNIV OF TECH

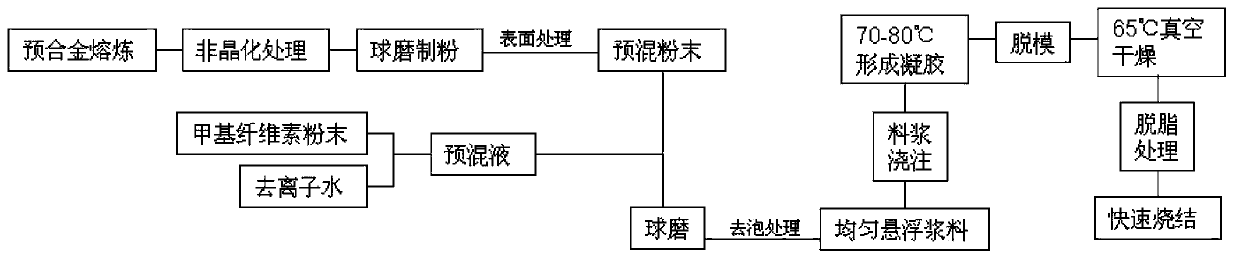

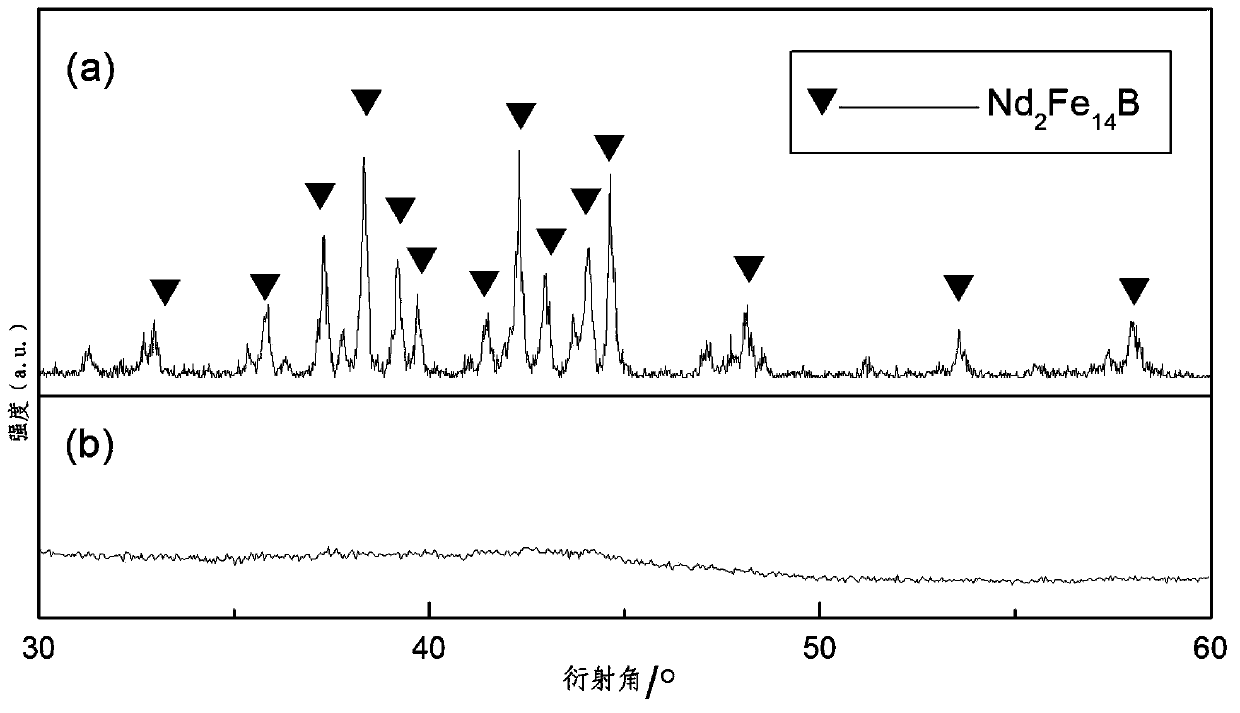

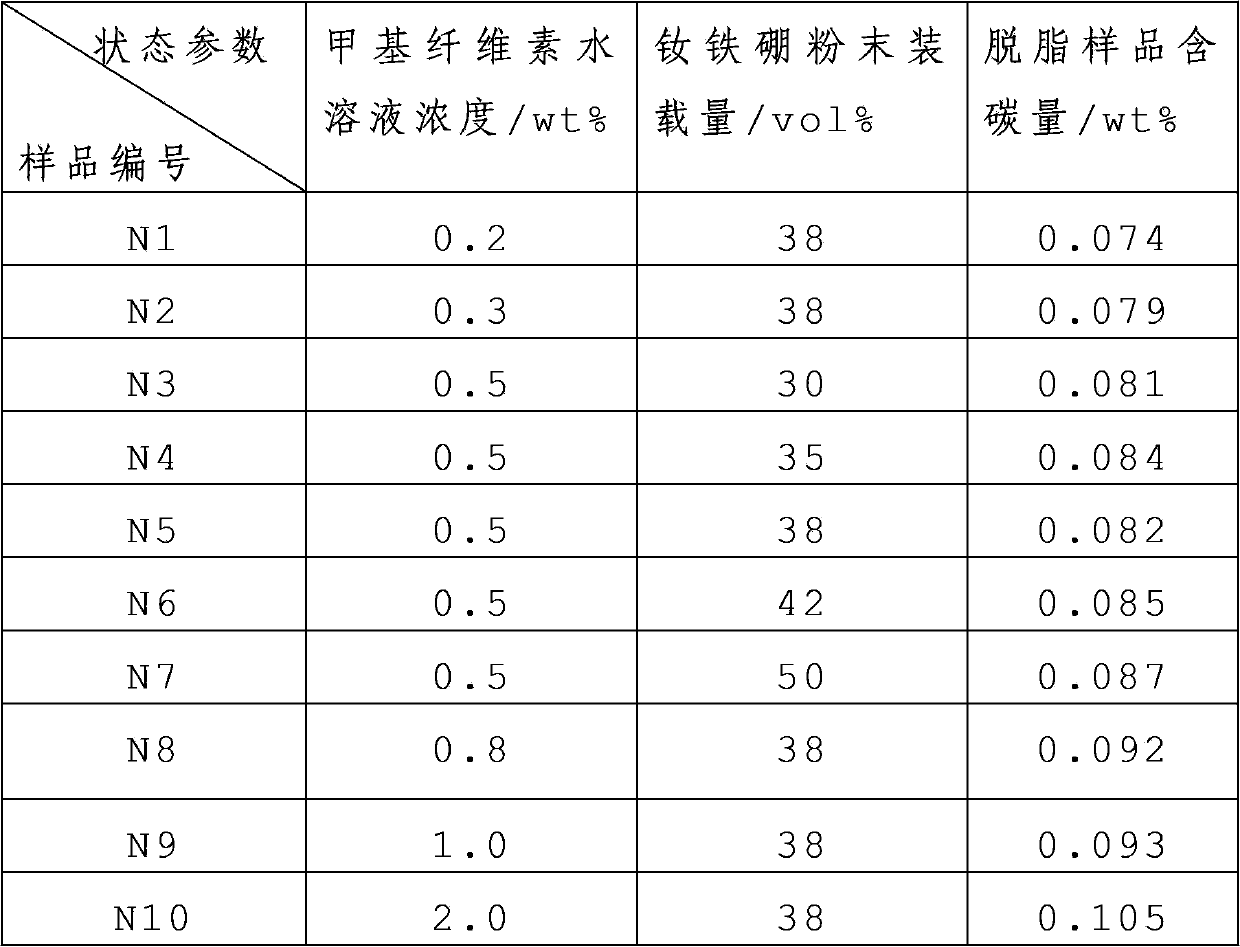

Method for forming isotropic neodymium-iron-boron magnet

The invention provides a method for forming an isotropic neodymium-iron-boron magnet. The method comprises the step of smelting an alloy raw material into a prealloyed cast ingot, the step of performing non-crystallizing treatment on the prealloyed cast ingot to obtain a fast-quenched alloy, the step of performing ball milling on the fast-quenched alloy to obtain a powder, the step of mixing the powder with a binder to obtain a slurry, and the step of forming the slurry into the magnet. The binder is a water-based binder, preferably a methylcellulose aqueous solution, and the solid content in the slurry ranges from 30vol% to 60vol%. The method is capable of realizing the formation of the isotropic neodymium-iron-boron magnet large in dimension and complex in shape, and therefore, the purpose of reducing the oxygen content is achieved, and simultaneously, the carbon residue in a degreasing process can be greatly reduced.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

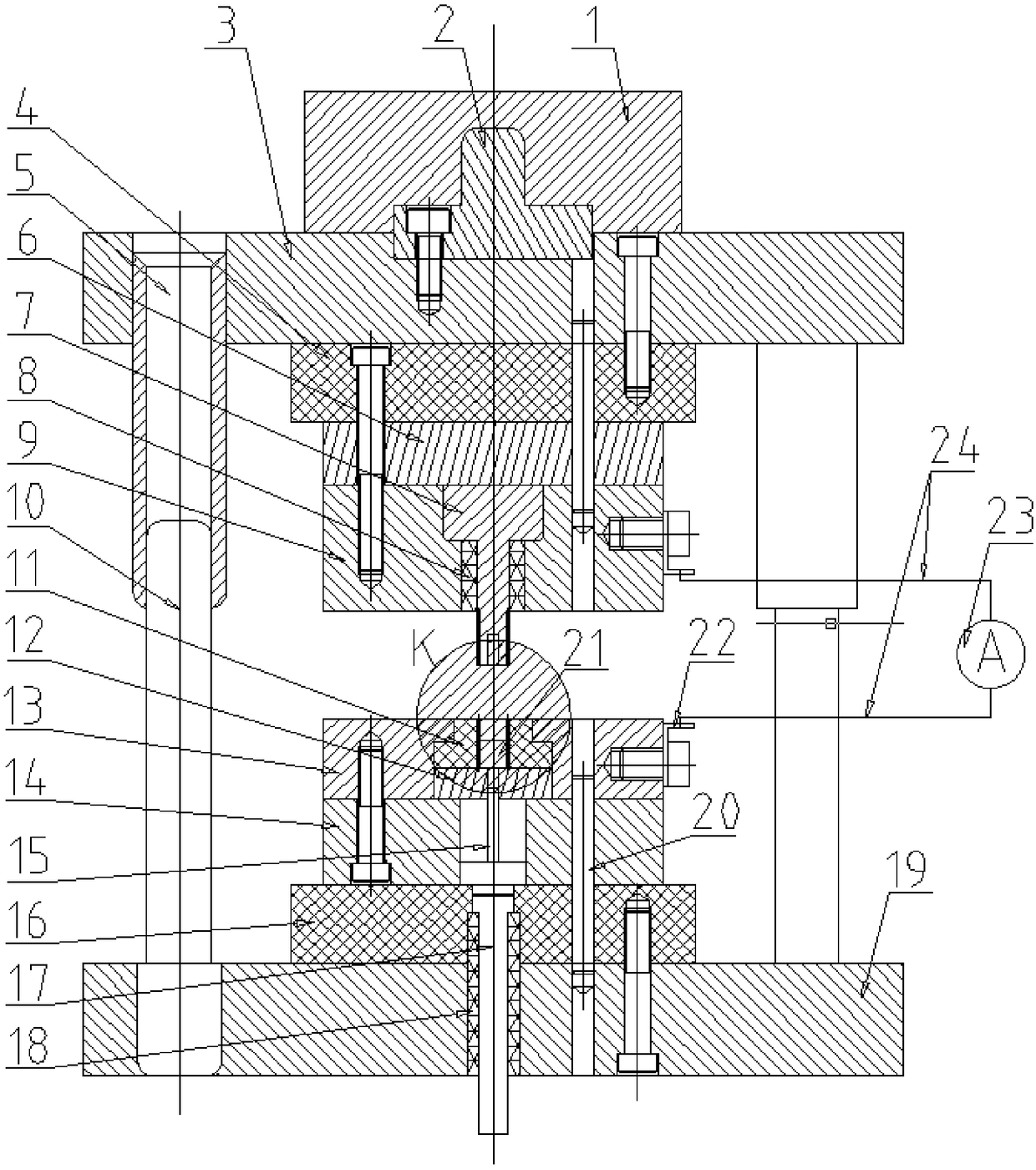

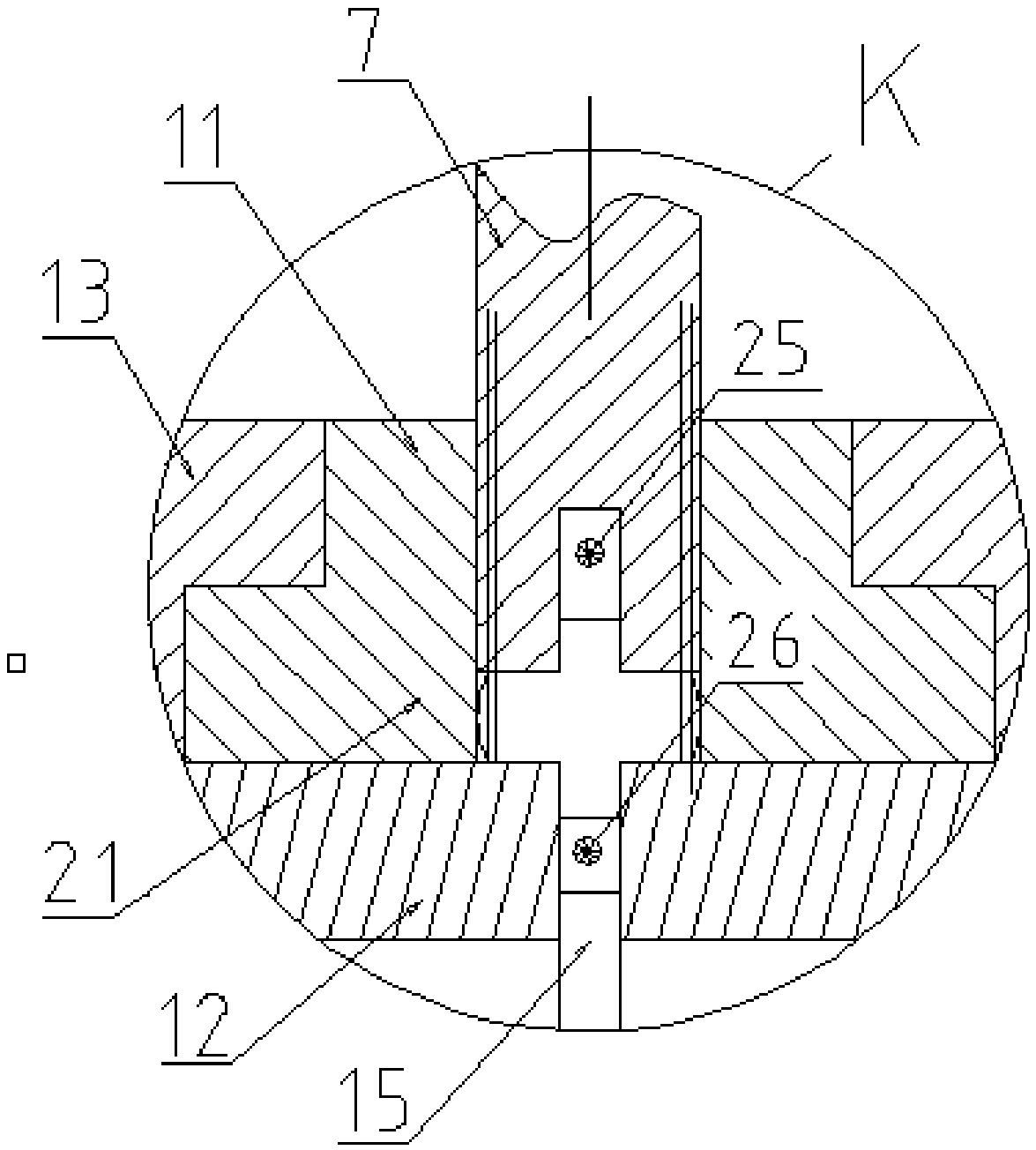

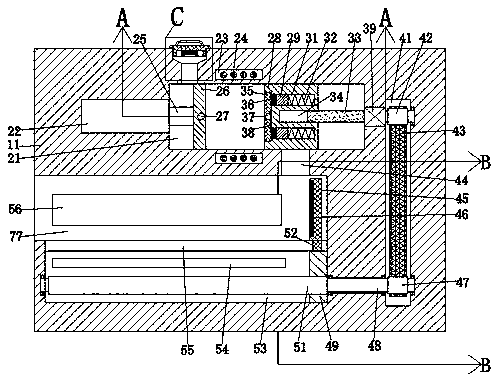

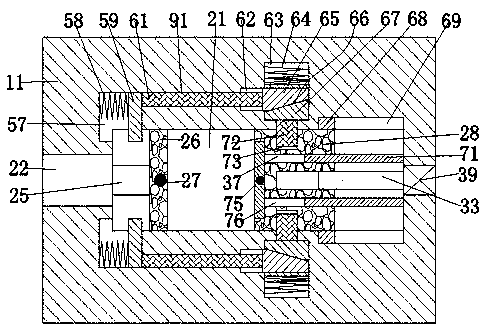

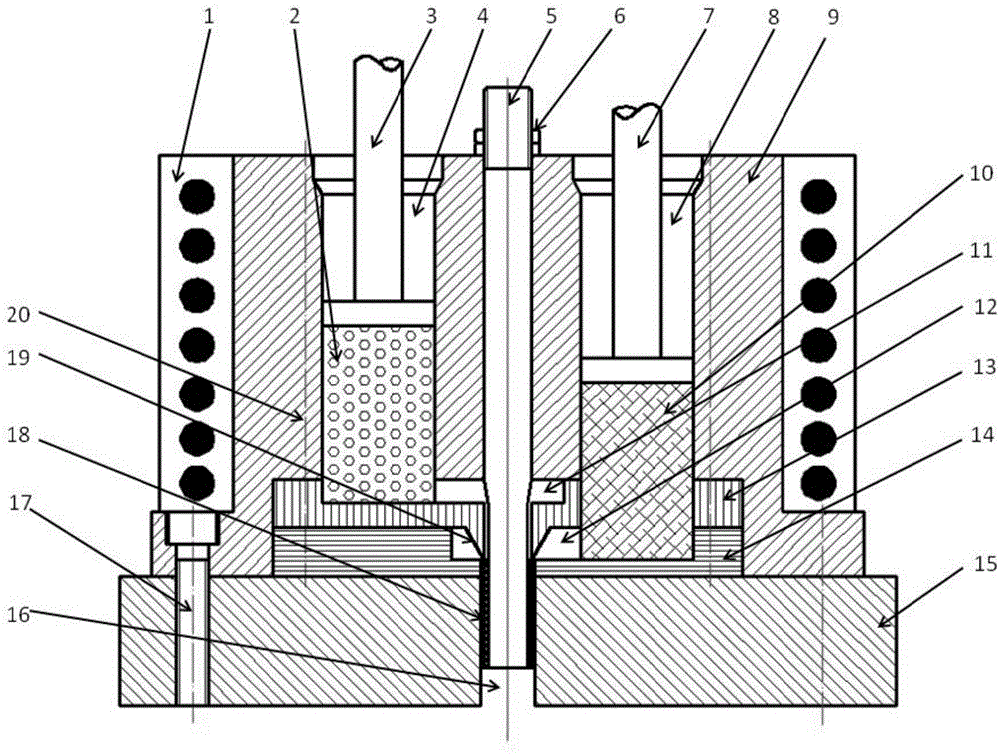

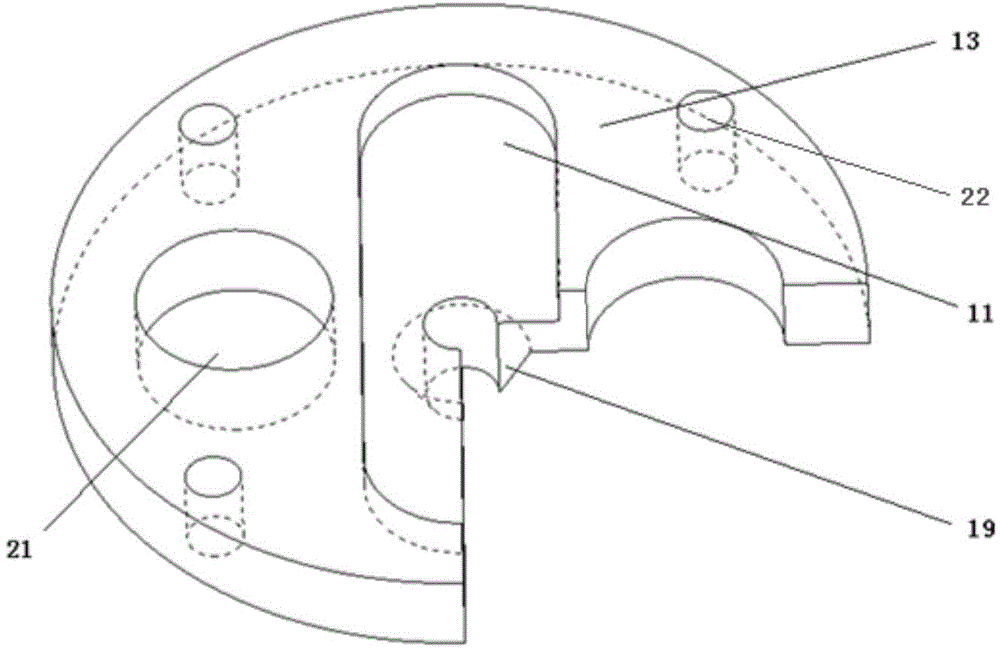

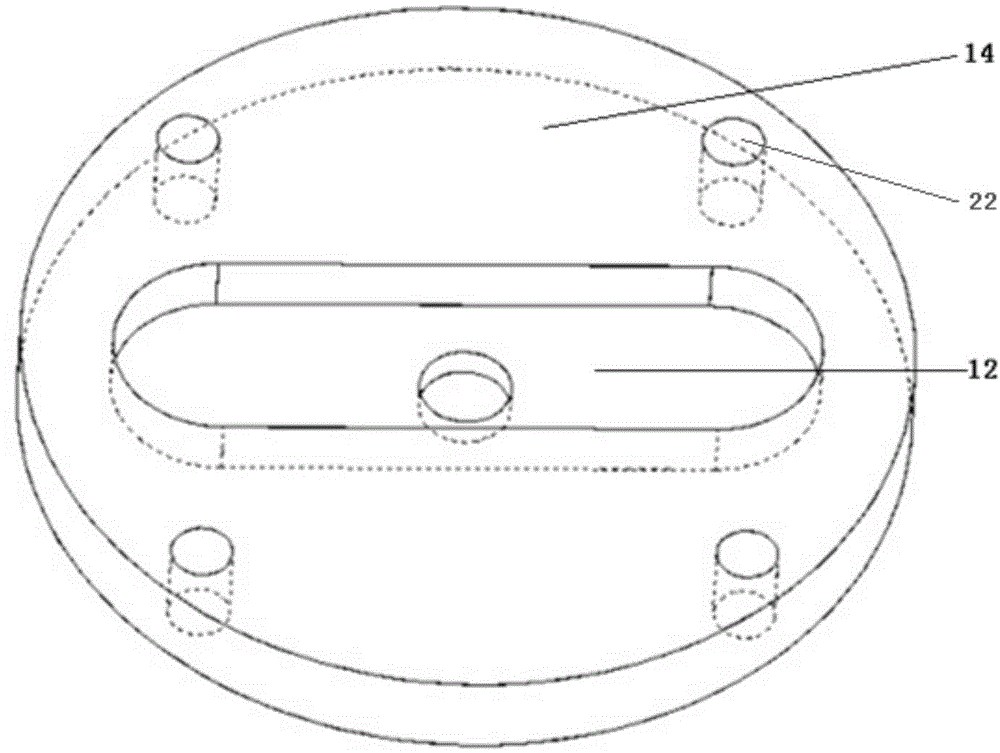

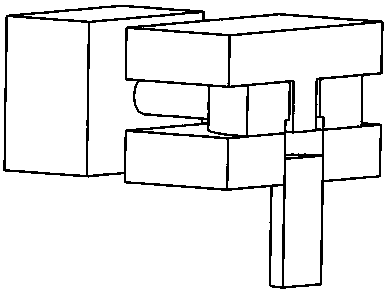

Pulse current assisted hollow splitting micro-forming die and method for titanium alloy micro-gear

The invention discloses a pulse current assisted hollow splitting micro-forming die and method for a titanium alloy micro-gear, relates to the pulse current assisted micro-forming die for the micro-gear and the hollow splitting micro-forming method, and solves the problems of high forming difficulty of the titanium alloy micro-gear or a gear shaft structure and short service life of the die. The die comprises a die part and a power part, the die part comprises a die handle, a male die seat, an upper insulating plate, a guide component, a male die baseplate, a male die, a male die protection sleeve, a male die clamping body, a female die, a female die baseplate, a female die fixing plate, a female die gasket, an ejector, a lower insulating plate, a lower ejection rod, a lower ejection rod sleeve and a female die seat, the method is implemented according to the following steps: step 1, installing the die; step 2, compressing a titanium alloy blank; step 3, heating and forming; and step 4, demolding. The pulse current assisted micro-forming die for the micro-gear and the hollow splitting micro-forming method belong to the technical field of machine manufacturing and plastic micro-forming.

Owner:HARBIN INST OF TECH

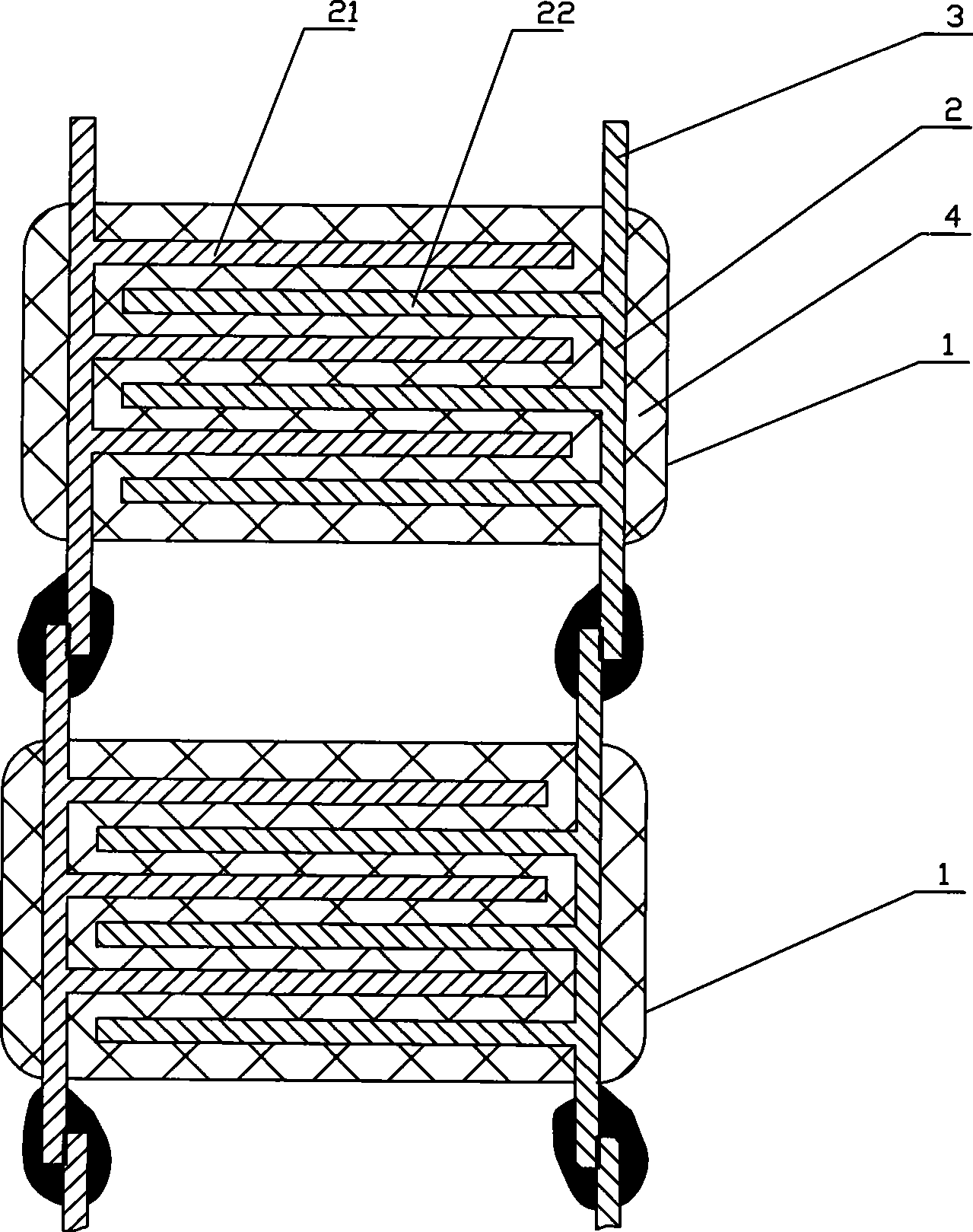

Preparation method of ultrahigh power multilayer composite membrane capacitor

InactiveCN101533710AHigh energy storage densityIncrease powerFixed capacitor dielectricStacked capacitorsBarium titanateCeramic capacitor

The invention relates to a preparation method of a multilayer composite membrane capacitor, comprising the following steps of: firstly preparing ceramic powder doped with barium titanate, then preparing alkali metal low-temperature electrocondutive slurry, preparing a multilayer membrane, carrying out pretreatment and isostatic pressing, finally connecting a plurality of multilayer membrane blocks and forming an ultrahigh power multilayer composite membrane capacitor. The multilayer composite membrane capacitor adopts isostatic pressing technique, solves the technical problems of high cost and low qualification rate of the existing sheet-type multilayer ceramic capacitor when adopting sintering technique for preparation, has the advantages of high voltage, high power, low cost and the like, greatly improves the energy storage density of the ceramic capacitor and reduces the technique cost of the capacitor. The capacitor can be used in various fields which have high requirements for discharging power and voltage of the capacitor.

Owner:柯昌凤

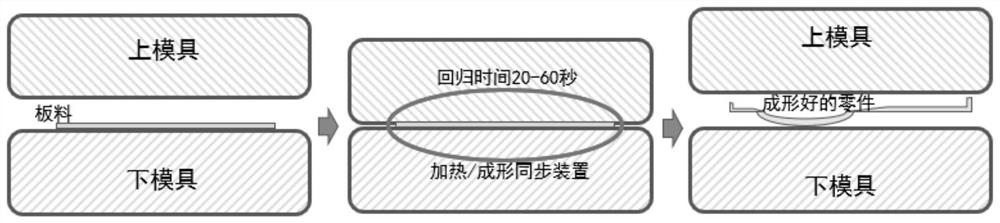

Artificial aging-state high-strength aluminum alloy retrogression forming synchronous process

ActiveCN109487184AImprove forming efficiencyReduce energy consumptionElectromagnetic inductionHolding time

The invention provides an artificial aging-state high-strength aluminum alloy retrogression forming synchronous process. Firstly, a stamping forming die is cleaned, and an artificial aging-state aluminum alloy is placed on the die; a sheet is rapidly heated to a temperature higher than an artificial aging temperature by 120-160 DEG C by means of electromagnetic induction or electric conduction heating; the heat preservation is carried out for a certain time period, wherein the heat preservation time is controlled to be 20-60 seconds or within; the stamping and the forming are carried out in the process, and a formed component is air-cooled to the room temperature; and the artificial aging strengthening treatment can be continuously carried out at a later stage according to the requirements. According to the process, the alloy stamping formability can be remarkably improved at a lower temperature, and specifically, the formability efficiency of the high-strength aluminum alloy is improved while the material performance of the high-strength aluminum alloy is ensured; and the synchronous process is beneficial to the cooperative control of the shape and performance of the high-strengthalloy, and can be used for manufacturing parts of automobiles, aerospace, ships and the like.

Owner:CENT SOUTH UNIV

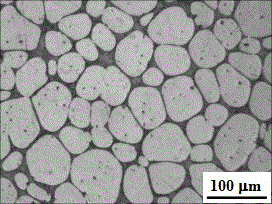

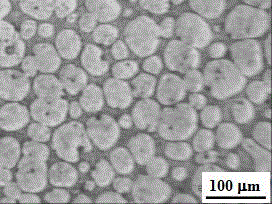

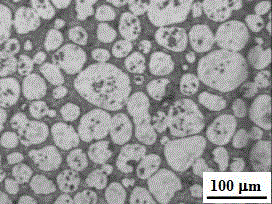

Mg-Gd-Zn-Ni-Zr rare-earth magnesium alloy for semisolid forming and preparation method for semisolid blank of semisolid Mg-Gd-Zn-Ni-Zr rare-earth magnesium alloy

The invention discloses an Mg-Gd-Zn-Ni-Zr rare-earth magnesium alloy for semisolid forming and a preparation method for a semisolid blank of the semisolid Mg-Gd-Zn-Ni-Zr rare-earth magnesium alloy. The alloy comprises the following components in percentage by weight: 15-21% of Gd, 2.0-3.6% of Zn, 0-0.5% of Ni, 0.3-0.7% of Zr and Mg in balancing amount. The preparation method for the semisolid blank comprises the following steps: taking pure Mg, pure Gd, pure Zn, pure Ni and an Mg-30wt.%Zr intermediate alloy as raw materials, first smelting the raw materials to prepare a master alloy ingot, then performing low-temperature semisolid isothermal heat treatment of the master alloy ingot, and finally performing water quenching to obtain the semisolid blank. The magnesium alloy for semisolid forming, provided by the invention, belongs to an Mg-RE series high-strength magnesium alloy, the semisolid forming temperature of the magnesium alloy is low, the solid-phase content of the magnesium alloy has low susceptibility to temperature variation, and the roundness of obtained solid-phase particles is high. According to the preparation method for the semisolid blank, provided by the invention, the preparation temperature is low, less oxidation and combustion are caused, the process is easy to control, and a semisolid forming technology is appropriate for preparing high-strength and complex-shaped magnesium alloy parts.

Owner:NANCHANG HANGKONG UNIVERSITY

Degradable antibacterial magnesium alloy and preparation method thereof

ActiveCN110373588AEnhance biological antibacterial effectImprove antibacterial propertiesTissue regenerationProsthesisOsteoblastDie casting

The invention provides a degradable antibacterial magnesium alloy and a preparation method of the degradable antibacterial magnesium alloy, and relates to the field of metal biomedical materials. Thedegradable antibacterial magnesium alloy comprises main active elements of Ag, Cu, Zn and Sr, and by means of composition optimization design of the magnesium alloy, the components comprise, by mass,1.35-1.65% of Ag, 0.9-1.1% of Cu, 3.6-4.4% of Zn, 0.9-1.1% of Sr, 0.36-0.44% of Ca and the balance Mg and other inevitable impurities. After the magnesium alloy material implant finishes the action, the magnesium alloy material implant can be completely degraded to avoid secondary operation removal, the medical cost and the pain of patients are reduced, the antibacterial property of the implant isimproved, and the magnesium alloy material implant has the functions of promoting osteoblast formation and inhibiting osteoclast bone absorption; the degradable antibacterial magnesium alloy adopts asemi-solid rheological die casting process, the microstructure of the product is uniformly distributed, the internal structure is compact, the defects of pores, segregation and the like are few, andthe requirements for high quality and high precision of implant products can be met.

Owner:NORTHEASTERN UNIV

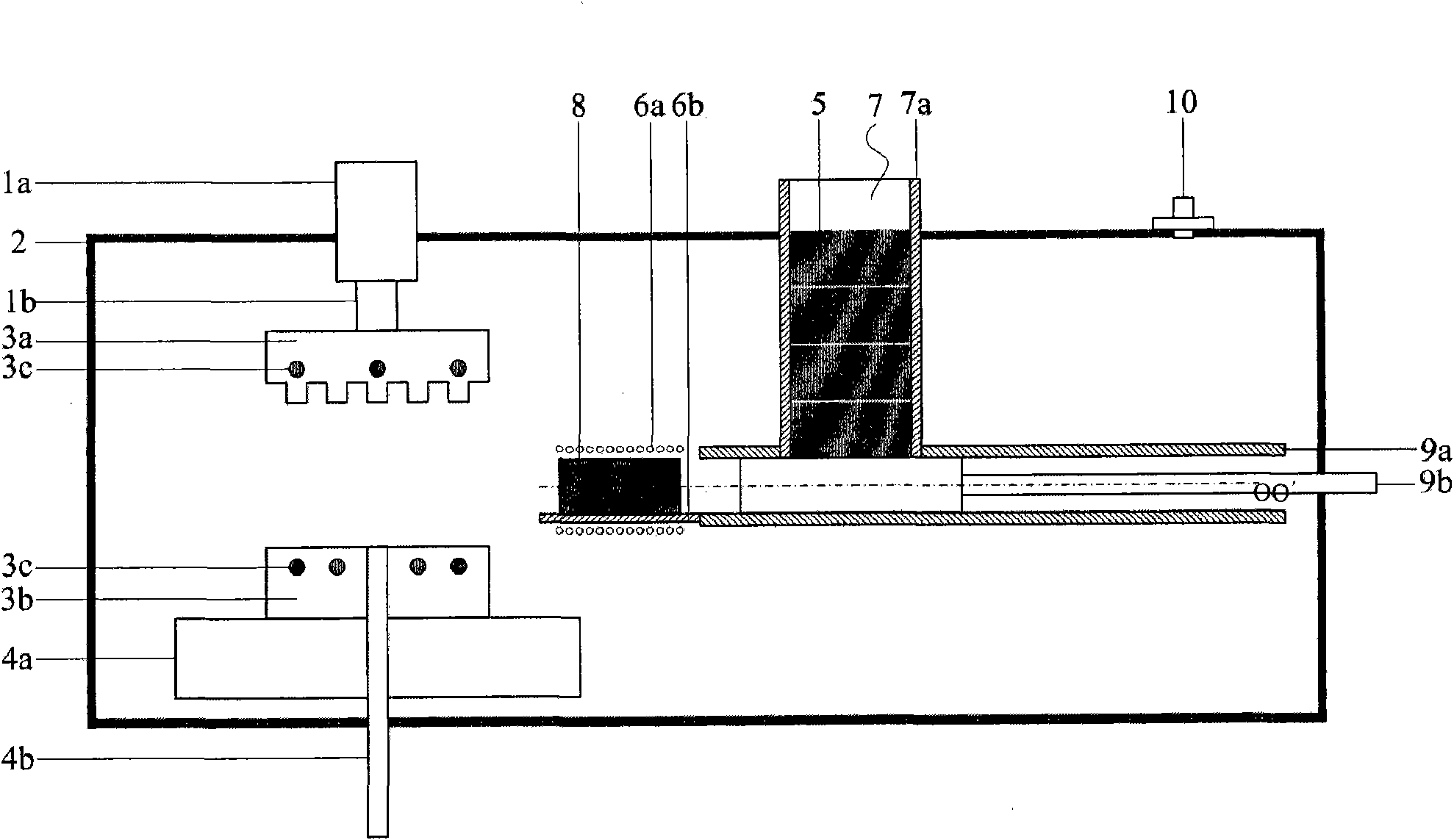

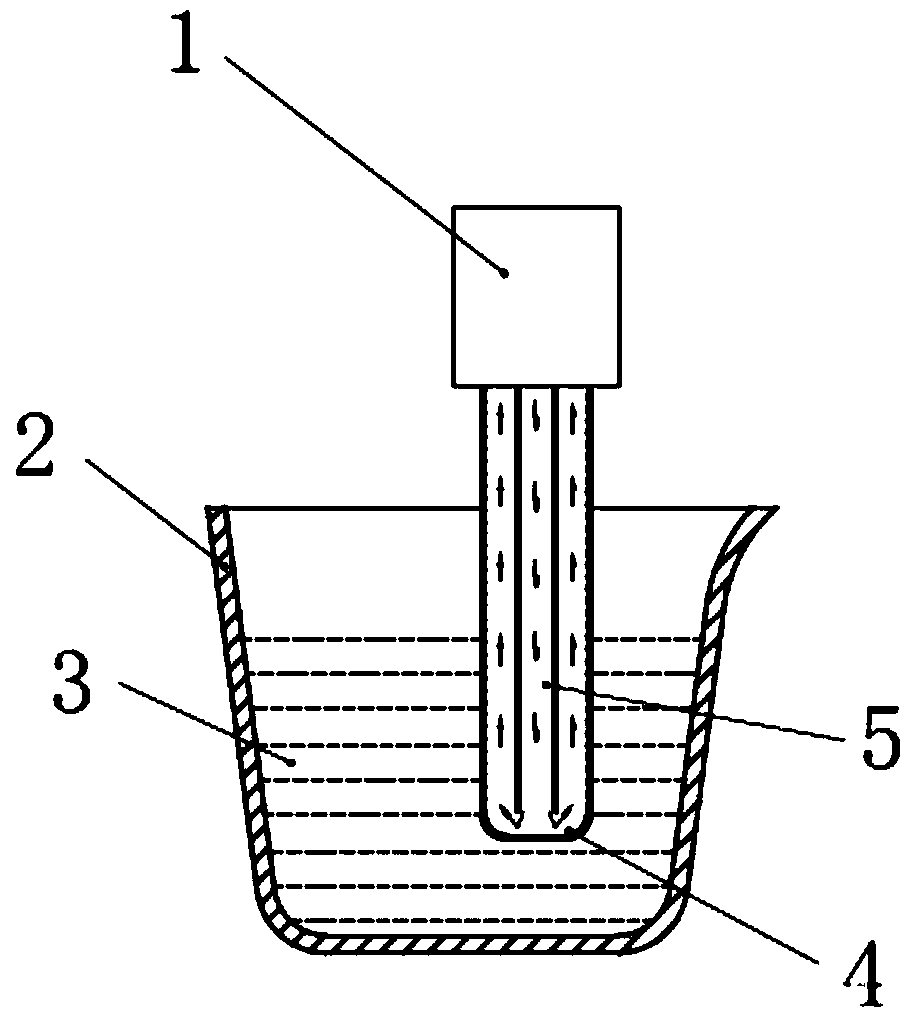

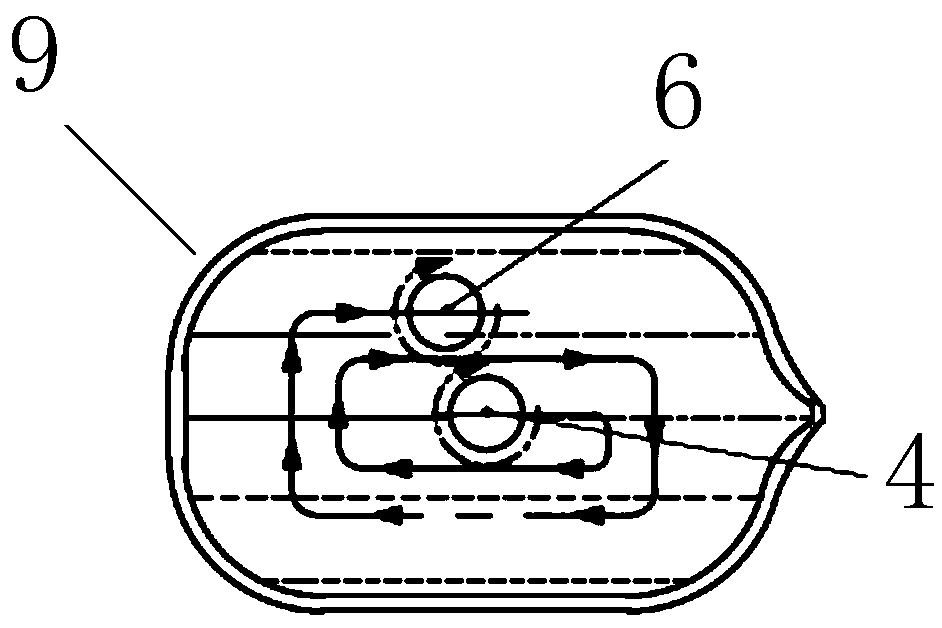

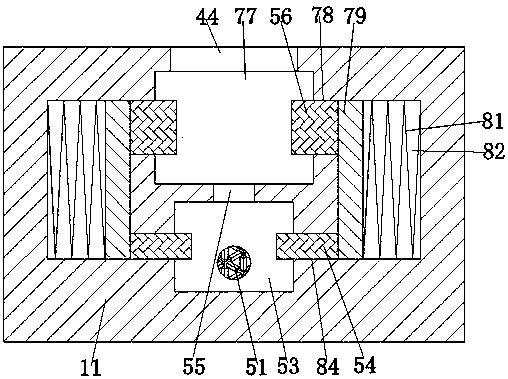

Semi-solid slurry pulping device

PendingCN109513886APromote growthUniform nucleationRotary stirring mixersTransportation and packagingSemi solidSlurry

The invention provides a semi-solid slurry pulping device comprising a rotor mixer (1) and a pulping tank (2). The rotor mixer (1) comprises a mixing drum (9) and a rotor mixing rod (4) extending fromthe mixing drum (9) to the interior of the pulping tank (2), and the mixing drum (9) is internally provided with a driving device used for driving the rotor mixing rod (4) to rotate by itself. The end face, facing the pulping tank (2), of the mixing drum (9) is provided with a transmission gear (6), the rotor mixing rod (4) is connected with the transmission gear (6) in an engaged manner, the transmission gear (6) is provided with n teeth, the spacing between the adjacent front and rear teeth is a, and the tooth width of each tooth is b; and the end, connected with the transmission gear (6),of at least one rotor mixing rod (4) is provided with engaged teeth matched with the transmission gear (6), each rotor mixing rod (4) comprises m engaged teeth, the spacing between the adjacent frontand rear engaged teeth is b, and the tooth width of each engaged tooth is a.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

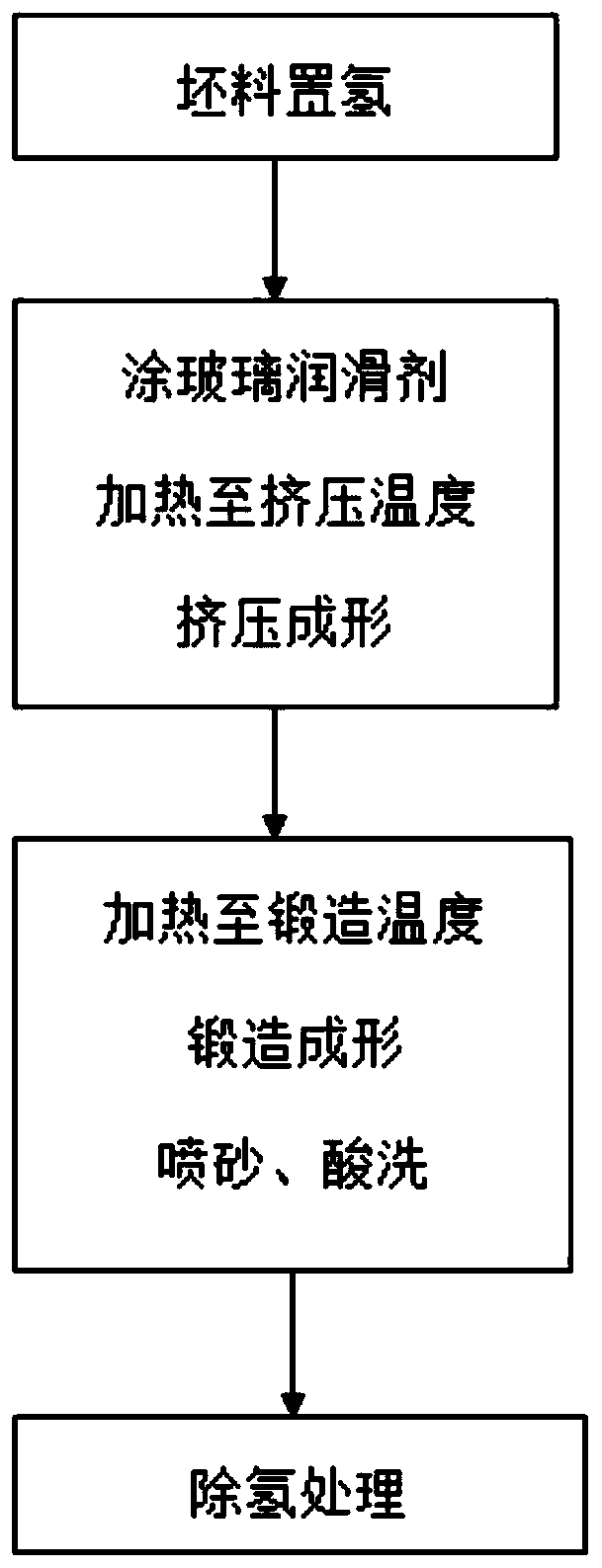

Method for extrusion forging composite near-net forming of titanium alloy thin-wall profile

ActiveCN110340166ALow forming temperatureImprove plasticityForging/hammering/pressing machinesLarge deformationHydrogen treatment

The invention belongs to the technical field of material forming, and particularly relates to a method for extrusion forging composite near-net forming of a titanium alloy thin-wall profile. The method comprises the following steps that S1, a titanium alloy blank is subjected to hydrogen treatment; S2, the titanium alloy blank subjected to hydrogen treatment is extruded and formed; S3, an extrusion profile is subjected to high-frequency forging and shaping into a forged profile; and S4, the forged profile is subjected to annealing and hydrogen removal treatment. The forming temperature of a titanium alloy is reduced through a thermohydrogen treatment process, plasticity of the titanium alloy is improved, large deformation is completed through extrusion forming, and thickness thinning and surface finishing are completed through forging and shaping. According to the method, near-net forming of the titanium alloy thin-wall profile can be achieved, and the problems that in the prior art, the material utilization rate is low and the production cost is high are solved. The method is used for extrusion forging composite near-net forming of the titanium alloy thin-wall profile.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

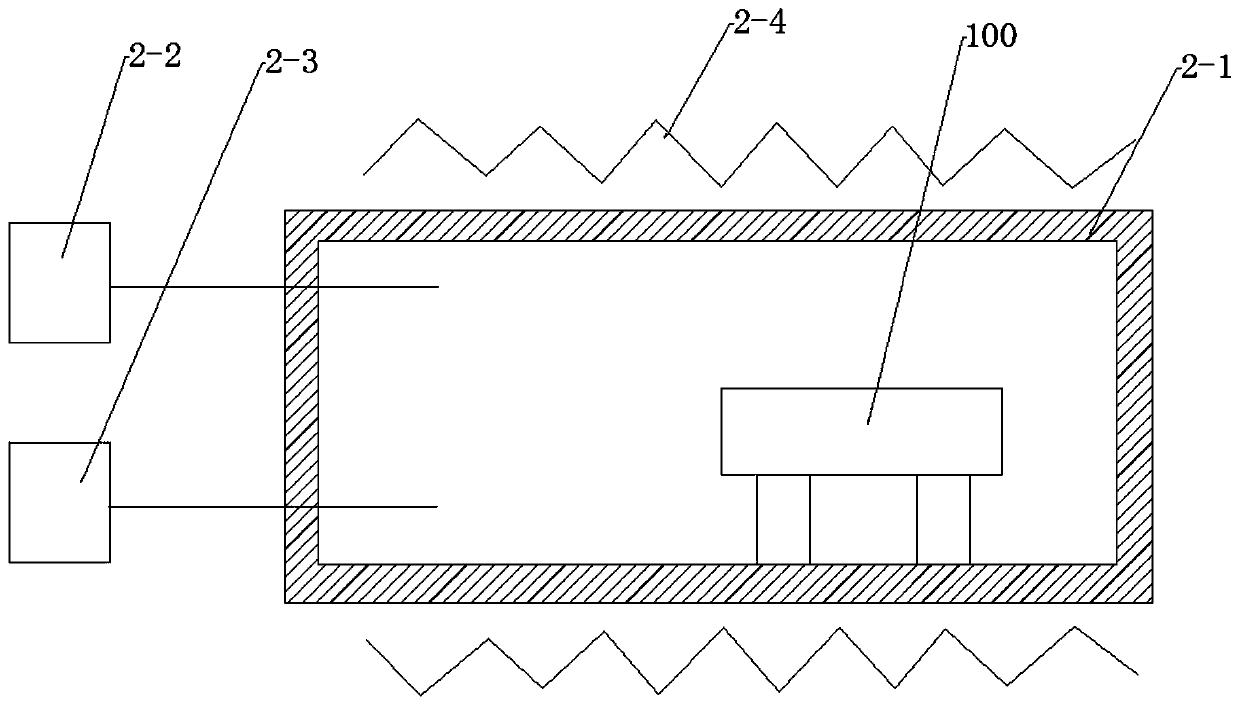

Hot isostatic pressing forming equipment

The invention discloses hot isostatic pressing forming equipment. The hot isostatic pressing forming equipment comprises a device body, a device main body and a forming device arranged in the device main body. The forming device comprises a first cavity formed in the device main body. Locking devices are symmetrically arranged on the front and back side inner walls of the first cavity, a hydrauliccylinder is fixedly arranged in the left side inner wall of the first cavity, a first slide block capable of sliding left and right is arranged in the first cavity, and a hydraulic inner column is infit connection between the left side end surface of the first slide block and the hydraulic cylinder. The hot isostatic pressing technology has the advantages of integrating advantages of hot pressing and isostatic pressing and being low in forming temperature, compact in product and excellent in performance, so that the hot isostatic pressing technology is a necessary means of preparing a high performance material. At present, the hot isostatic pressing technology is extremely low in popularizing rate in China. As the hot isostatic pressing technology is not applied in a large scale industrially, the production cost is relatively high. The invention aims to provide the device which can lower the preparation cost and improve the forming efficiency while achieving hot isostatic pressing work.

Owner:YIWU ZHIXIN TECH CO LTD

A Simultaneous Regression Forming Process of Artificially Aged High-Strength Aluminum Alloy

ActiveCN109487184BTo achieve the effect of precipitation strengtheningInhibition of the effect of aging treatment enhancementAerospaceAluminium alloy

The invention provides an artificial aging-state high-strength aluminum alloy retrogression forming synchronous process. Firstly, a stamping forming die is cleaned, and an artificial aging-state aluminum alloy is placed on the die; a sheet is rapidly heated to a temperature higher than an artificial aging temperature by 120-160 DEG C by means of electromagnetic induction or electric conduction heating; the heat preservation is carried out for a certain time period, wherein the heat preservation time is controlled to be 20-60 seconds or within; the stamping and the forming are carried out in the process, and a formed component is air-cooled to the room temperature; and the artificial aging strengthening treatment can be continuously carried out at a later stage according to the requirements. According to the process, the alloy stamping formability can be remarkably improved at a lower temperature, and specifically, the formability efficiency of the high-strength aluminum alloy is improved while the material performance of the high-strength aluminum alloy is ensured; and the synchronous process is beneficial to the cooperative control of the shape and performance of the high-strengthalloy, and can be used for manufacturing parts of automobiles, aerospace, ships and the like.

Owner:CENT SOUTH UNIV

Method for recycling steel scraps

The invention relates to steel and iron materials, in particular to a method for recycling steel scraps. The principle of the method is characterized in that the characteristic that the viscosity of aluminum scraps is large at the temperature close to the liquidus temperature of the aluminum scraps, the steel scraps and the aluminum scraps are pressed together at the temperature, reactive sintering is implemented under the pressure effect, steel and aluminum are interacted in the sintering process to form an iron-aluminum intermetallic compound, oxide on the surfaces of the steel scraps and the aluminum are reacted to generate aluminum oxide, and compact composite materials composed of steel particles, the iron-aluminum intermetallic compound and the aluminum oxide are finally formed.

Owner:JIANGSU UNIV

Extrusion molding die and method in semi-solid preparation method of aluminum-clad magnesium composite pipe

The invention relates to an extrusion moulding mold and method in a semi-solid state preparation method of an aluminium-coating magnesium composite pipe. The inner layer of the composite pipe is made from AZ91S magnesium alloy, and the outer layer of the composite pipe is made from 7075 aluminium alloy. The extrusion moulding method comprises preparation of blank, secondary heating and semi-solid state extrusion moulding, and specifically comprises the following steps: placing prepared aluminium alloy semi-solid state blank and magnesium alloy semi-solid state blank with solid fraction being 70%-90% into an extrusion cavity of an extrusion barrel through a hot charging process, and performing extrusion moulding to obtain the aluminium-coating magnesium composite pipe with the wall thickness of 4-8mm and the length of 1,200-3,000mm, wherein the preheating temperature of the mold is 250-300 DEG C, and the extrusion speed is 60-150mm / s. According to the invention, the bonding interface of the aluminium-coating magnesium composite pipe completely reaches the metallurgical bonding, and compared with other moulding methods, the extrusion moulding method has the advantages of high efficiency, short flow, good pipe quality, simple structure, and simplicity in implementation; the prepared aluminium-coating magnesium composite pipe is small in density, and high in specific strength and specific stiffness, the outer layer is corrosion-resistant, the inner layer is good in shock absorption and shock resistance, and the prepared aluminium-coating magnesium composite pipe is particularly suitable for the fields of manufacturing of baggage holders of high speed trains, seats, portable bicycle frames, high-grade lamps and lanterns, and the like, and has very wide application prospect.

Owner:UNIV OF SCI & TECH BEIJING

Manufacturing method of titanium alloy hollow component

ActiveCN101786223BIncrease productivityImprove efficiencyNon-electric welding apparatusTitanium alloyStressed skin

The invention relates to a manufacturing method of a titanium alloy thin-wall ribbed hollow component. The method comprises the following steps that: a. the titanium alloy hollow component is decomposed into a stressed-skin and ribbed structure form or a stressed-skin ribbed structure form according to the structure features of a hollow component, and an inner sheath and an outer sheath structureforms are determined according to a hollow part of the hollow component; b. the stressed-skin and ribbed or the stressed-skin ribbed structural part is processed or formed according to the decomposedstructure forms; c. the inner and the outer sheaths are processed or formed; d. the stressed-skin and ribbed or the stressed-skin ribbed structural part being well processed is assembled with the inner and the outer sheaths, the inner and the outer sheaths are sealed in a welding way and are vacuum encapsulated, and the vacuum degree is 1.0 *10-3Pa; e. the dispersion connection of each structuralpart is realized through a hot isostatic pressing method; f. surface treatment on each prefabricated structural part is undertaken so as to prepare the hollow structural component. The manufacturing method has high production efficiency; a plurality of components can be prepared through one technical circulation; and the welding rate is more than 95 percent.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Axial closed rolling forming device and method for metallic thin circular plate with large radius-thickness ratio

InactiveCN113714446AAvoid crackingImprove surface qualityFurnace typesForging press detailsCircular discEngineering

The invention discloses an axial closed rolling forming device and method for a metallic thin circular plate with a large radius-thickness ratio. The device comprises an upper die and a lower die, wherein a cavity is formed in the lower die, a boss matched with the cavity is arranged on the upper die, the bottom end surface of the boss is a conical surface, and the included angle between the conical surface and the horizontal plane is 4-12 degrees. The method comprises the following steps: heating a blank, and preheating an upper die and a lower die; putting the blank in a groove part of the lower die to be positioned; making the lower die rotate and the upper die apply pressure, wherein when the pressure reaches a specified stroke, the upper die stops pressing downwards, and the lower die continues to rotate to shape disk forgings; and after forging is finished, carrying out air cooling and heat treatment. A closed rotary forging technology is adopted, and the axial direction is adopted, so that on one hand, the problem of overlarge load can be solved, the requirements for equipment and cost are reduced, the forming temperature is reduced, the forming precision is improved, and grains are refined, and on the other hand, due to the stress and the needed positioning table arranged in the groove part, the center cracking condition can be avoided, and the structure consistency can be improved to a certain extent, and the performance isotropy is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

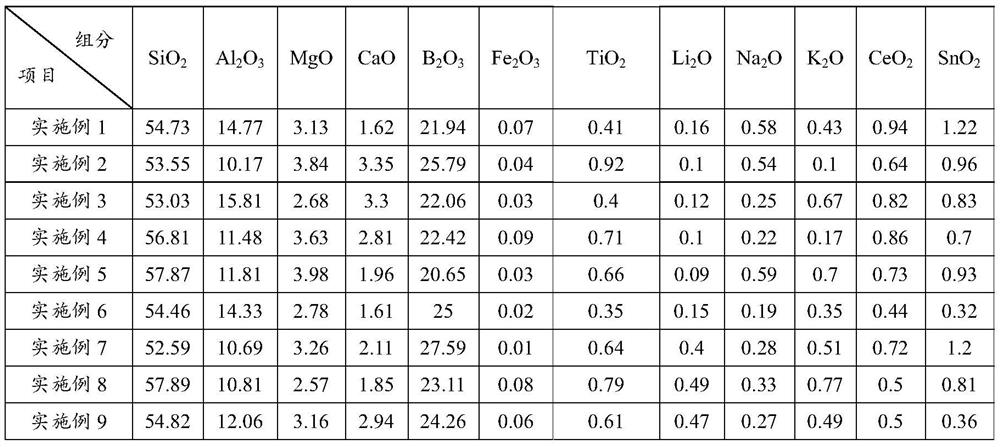

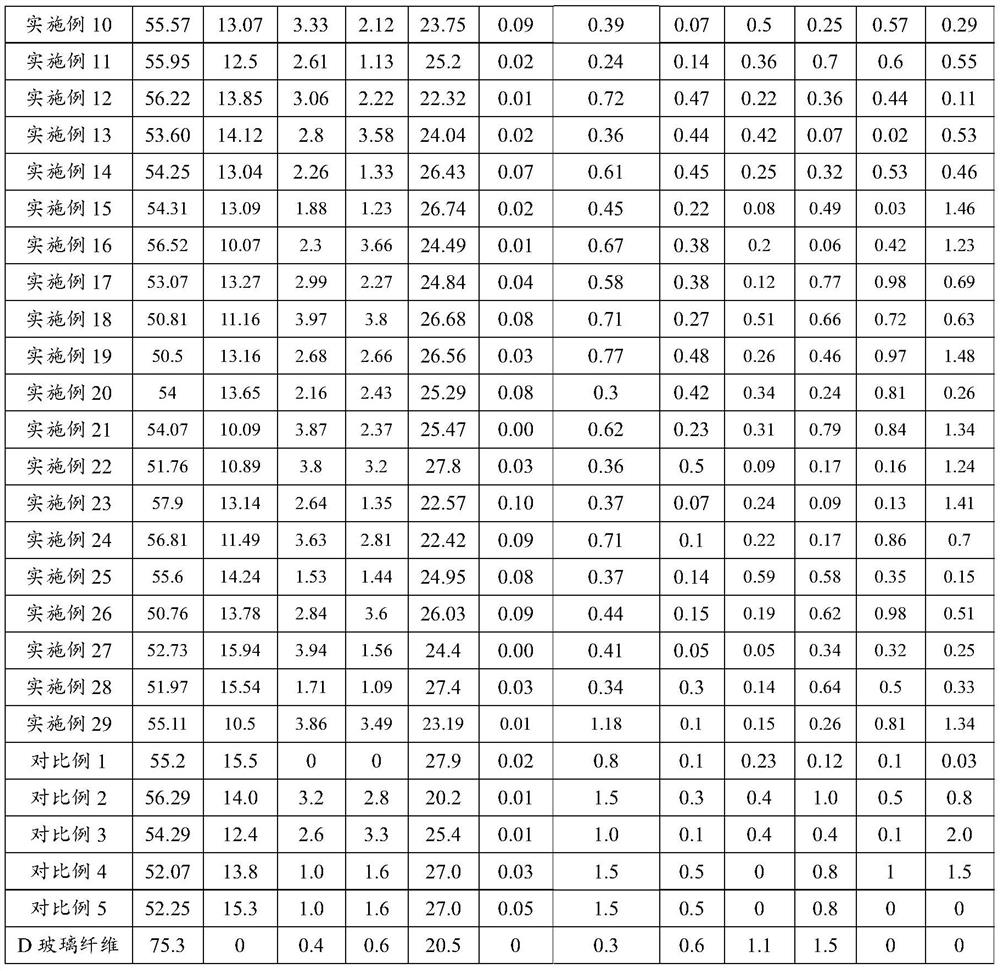

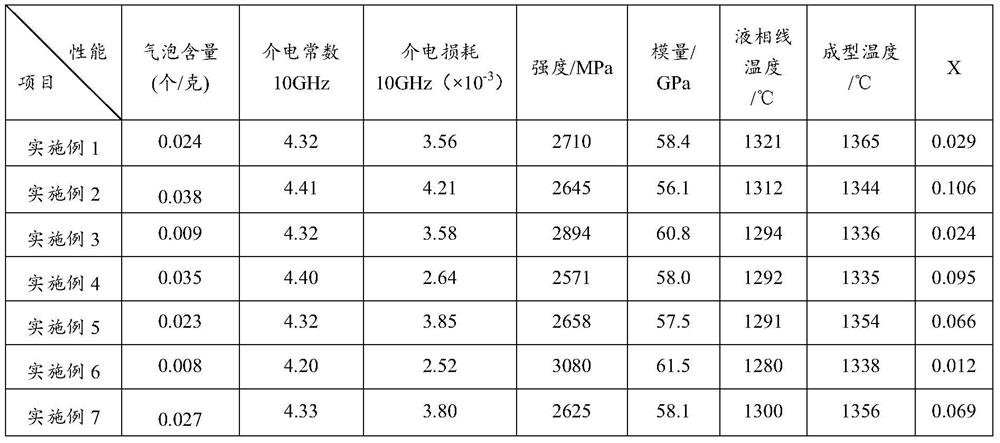

Low dielectric glass fiber and preparation method, glass fiber product, composite material and application

ActiveCN113135666BLow dielectric constantImprove performanceCasings/cabinets/drawers detailsQuartz/glass/vitreous enamelsGlass fiberAlkali metal oxide

The invention provides a low-dielectric glass fiber and its preparation method, glass fiber product, composite material and application. The invention reasonably adjusts the ratio of each oxide in the glass component to obtain high mechanical strength, good dielectric performance and melting Low-dielectric glass with excellent comprehensive performance such as simpler process. Specifically, by reasonably setting the ratio of silicon oxide, aluminum oxide and boron oxide, the glass fiber has a lower dielectric constant and dielectric loss, and the viscosity of the glass is properly adjusted. At the same time, considering the dielectric properties and mechanical strength Under the premise, through reasonable setting of alkaline earth metal oxides, alkali metal oxides, TiO 2 , CeO 2 and SnO 2 The dosage of the glass further improves the melting and clarifying performance of the glass, the temperature of the wire drawing is lower, the stability and yield are higher, the density is lower, and it has excellent workability.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

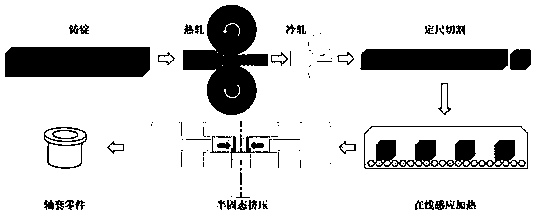

Preparation method for semisolid squeeze cast shaft sleeve part

The invention discloses a preparation method for a semisolid squeeze cast shaft sleeve part and belongs to the field of semisolid forming. The method comprises the steps that a rectangular cast ingotis heated to the temperature 50-100 DEG C higher than the recrystallization temperature through an induction heating furnace at first, then subjected to multidirectional multi-pass hot rolling, cooledto the room temperature, then subjected to multidirectional multi-pass cold rolling, and put into the induction heating furnace to be heated to the temperature 10-20 DEG C higher than the Tm after being cut, heat preservation is conducted for 10-15 min, then the rectangular cast ingot is conveyed into a die for semisolid bottom filling squeeze casting, a left concave die body and a right concavedie body are controlled to apply lateral pressure to a shaft sleeve after squeezing is completed, pressure is maintained, finally, the die is dismounted, the shaft sleeve part is taken out, and forming of the next part is conducted. The method adopts bottom filling squeezing, a squeezed part is stressed in three directions, the mechanical performance of the formed part is good, and the method is easy to operate, convenient to control, short in technological process and capable of achieving mechanical control.

Owner:KUNMING UNIV OF SCI & TECH

A reinforced glass fiber composition

Owner:SHANDONG FIBERGLASS GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com