A reinforced glass fiber composition

A glass fiber and composition technology, applied in the field of glass fiber preparation, can solve problems such as unfavorable fiber drawing, unfavorable glass fiber drawing, glass strength reduction, etc., and achieves the benefits of industrialized production, improvement of wire drawing operation, and reduction of clarification temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

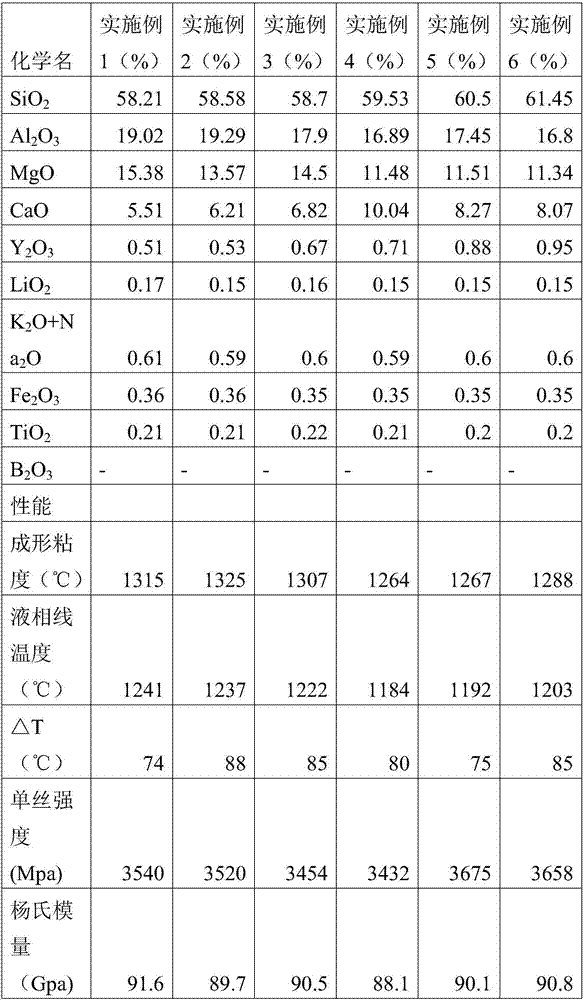

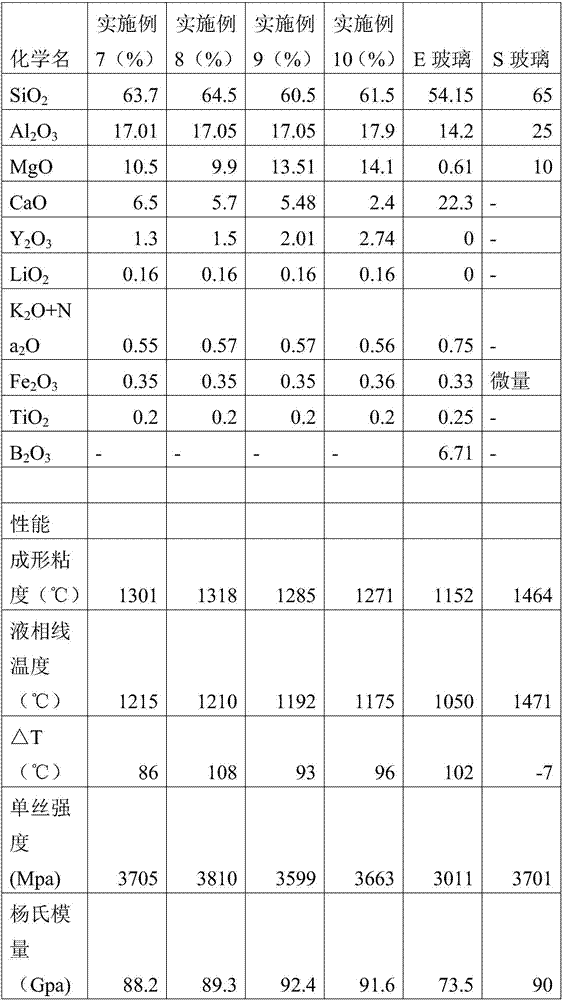

Embodiment 1

[0011] The total content of each component in this example is slightly less than 100%. It is understood that the residual amount is trace impurities or components that cannot be analyzed; the specific preparation process is as follows: each raw material is proportioned according to the components in Table 1, and after mixing evenly, put platinum Crucible, melting and heat preservation at 1550-1600°C for 3 hours, pour the prepared glass into water to make broken glass, put it into the crucible furnace after drying, and flow out through the porous platinum leak plate for wetting agent coating Draw again with a wire drawing machine to obtain the original silk cake or yarn ball of the glass fiber composition, and then use conventional methods to carry out deep processing to meet the expected requirements; use a high-temperature glass viscometer to measure the forming viscosity (log3 temperature); in a platinum-alloy ship, by exposing the glass to an isothermal gradient for 8 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com