Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "The polymerization process is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

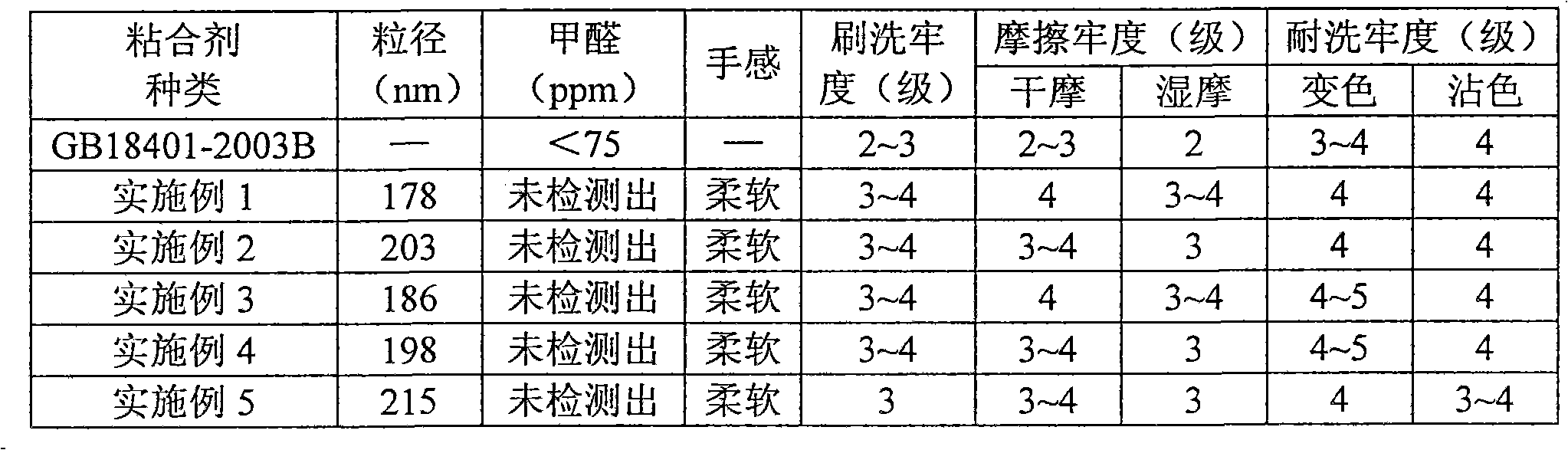

Environmentally-friendly acrylic ester coating printing adhesive emulsion and preparation method

InactiveCN101928367AThe polymerization process is stableEvenly distributedEster polymer adhesivesDyeing processEpoxyFunctional monomer

The invention discloses environmentally-friendly acrylic ester coating printing adhesive emulsion and a preparation method. An emulsion polymerization process is adopted. The emulsion comprises the following raw materials in part by weight: 50 to 90 parts of soft monomer, 10 to 20 parts of hard monomer, 2 to 10 parts of functional monomer, 2 to 5 parts of emulsifying agent, 0.2 to 0.5 part of initiator, 0.2 to 0.5 part of pH buffer, 80 to 120 parts of deionized water and a proper amount of pH adjustor, wherein the total amount of the soft monomer, the hard monomer and the functional monomer is 100 parts by weight. The three monomers are cooperatively used as functional monomers for generating carboxyl crosslinking, hydroxy crosslinking, epoxy crosslinking and the like so that the obtained printing adhesive emulsion has excellent water tolerance and mechanical property. The crosslinking monomers and the emulsifying agent do not contain the components such as N-methylol acrylamide, APEO and the like, so the emulsion does not release formaldehyde during baking and using and is suitable for high-grade environmentally-friendly printing adhesive.

Owner:SOUTH CHINA UNIV OF TECH

Neodymium (Nd)-based homogeneous rare earth catalyst as well as preparation method and application thereof

The invention relates to a novel neodymium (Nd)-based homogeneous rare earth catalyst as well as a preparation method and application thereof in conjugated diene polymerization. The synthesis method of the catalyst is simple and easy to control, and the homogeneous and stable catalyst with high activity can be obtained by utilizing the method. By utilizing the Nd-based homogeneous rare earth catalyst, a conjugated diene polymer can be synthesized, wherein, the cis-structure content of the polymer is more than 98%, the weight-average molecular weight of the polymer can be adjusted within the range of 1,000,000-2,500,000, and the molecular weight distribution (MWD) ranges from 3.0 to 4.0; and the polymerization process is stable and easy to control, thus being applicable to continuous technological operation.

Owner:CHINA PETROLEUM & CHEM CORP

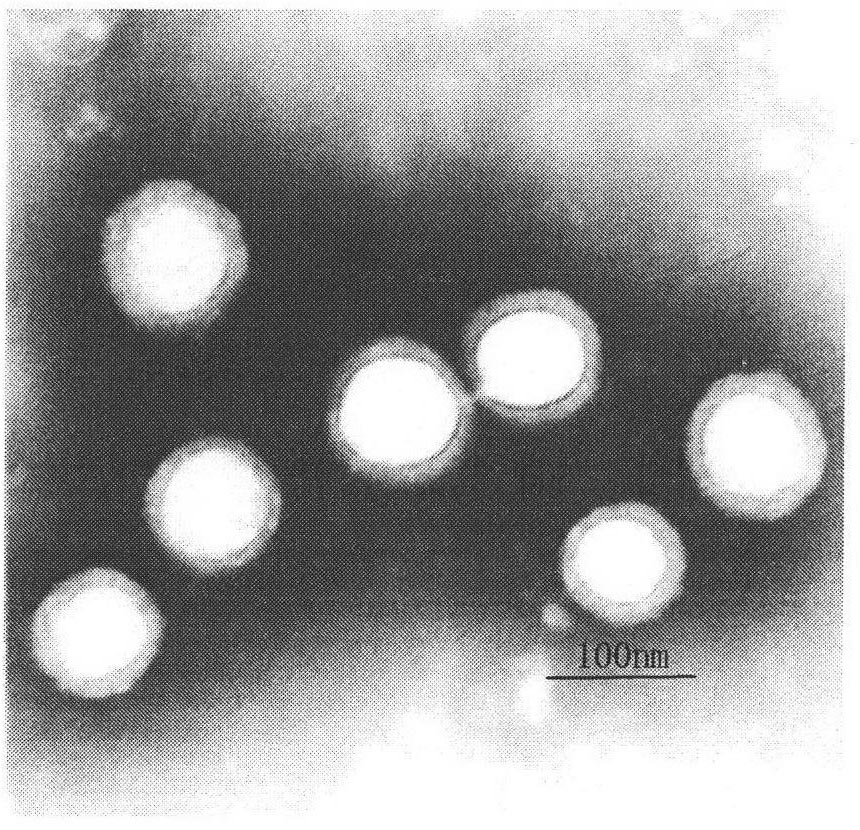

Preparation of nano silicone-acrylate core shell type composite latex for latex paints

InactiveCN101921360AThe polymerization process is stableGuaranteed yieldCoatingsChemistryWeather resistance

The invention relates to a preparation method of nano silicone-acrylate core shell type composite latex for latex paints. The preparation method solves the problem that latex paints prepared from the common latex is insufficient to meet the demands of people at the performance aspects of water resistance, weather resistance, pollution resistance and the like, and simultaneously reduces the restraint degrees of a region domain and a time and season domain for latex construction. In the preparation method, active organic silicon and acrylate monomers are mainly used as raw materials, and then the nano silicone-acrylate core shell type composite latex using polyacrylate as a core and using silicone-acrylate composite resin as a shell is synthesized by adopting a monomer pre-emulsifying process and a seed semi-continuous latex polymerization method, so that the preparation method has the advantages of stable polymerization process and convenient large-scale production. When used for preparing the latex paints of outer walls, the synthesized latex can greatly improve all performance of the latex paints, also solve the conflicts between the lowest film-forming temperature and film hardness and simultaneously realize the unification of the cost and the performance.

Owner:SHAANXI UNIV OF SCI & TECH

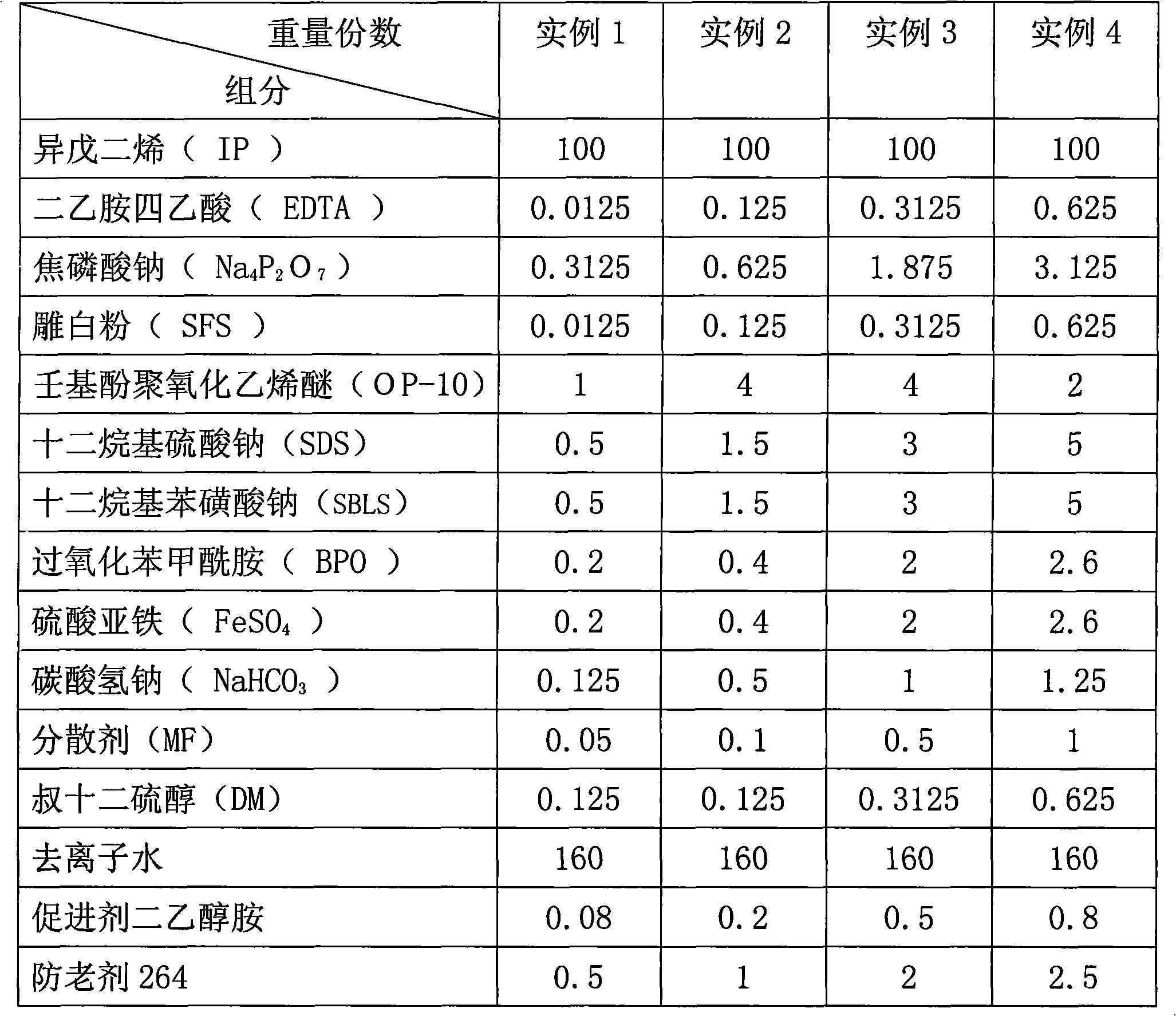

Production of high-performance polyisoprene water latex, its gloves and related products

ActiveCN101029163AEmulsion polymerization process is stableImprove conversion rateMale contraceptivesGlovesSynthetic polymerEmulsion

Production of polyisoprene water latex, its gloves and related products is carried out by polymerization reacting for isoprene monomer, emulsifying agent and evocating agent by emulsion free-radical at normal-temperature and pressure or mixing polyisoprene water latex with other synthetic polymer. It has excellent strength and extensibility.

Owner:SHANGHAI SHENGDA ENTERPRISE +1

Room temperature self-crosslinking polyacrylate pressure-sensitive adhesive and preparation method and application thereof

InactiveCN104004477AReduce surface tensionSolve the \"chicken paw print\"StampsNon-macromolecular adhesive additivesFunctional monomerKetone

The invention belongs to the field of room temperature self-crosslinking materials, and discloses a room temperature self-crosslinking polyacrylate pressure-sensitive adhesive and a preparation method and application thereof. The method comprises the steps of preparing a pre-emulsion from 85-95 parts of acrylate soft monomer, 5-15 parts of hard monomer, 2-5 parts of functional monomer, 1.3-4 parts of emulgator and 30-55 parts of deionized water by mass fraction; then heating up the pre-emulsion, the deionized water, an initiator, the emulgator and a PH buffer agent for reaction; dripping a chain transfer agent, the pre-emulsion and an initiator solution when the emulsion shows blue light; adding ketone-containing carbonyl monomer, heating up together and reacting; then cooling down and regulating pH value to be 6.5-7.0; and adding hydrazide monomer, stirring and mixing uniformly, so as to obtain the room temperature self-crosslinking polyacrylate pressure-sensitive adhesive. The room temperature self-crosslinking polyacrylate pressure-sensitive adhesive prepared by the method has excellent indexes like excellent initial adhesive force, excellent persistent viscosity force and excellent peel strength, and can be used for preparing labels with good bond performance.

Owner:SOUTH CHINA UNIV OF TECH

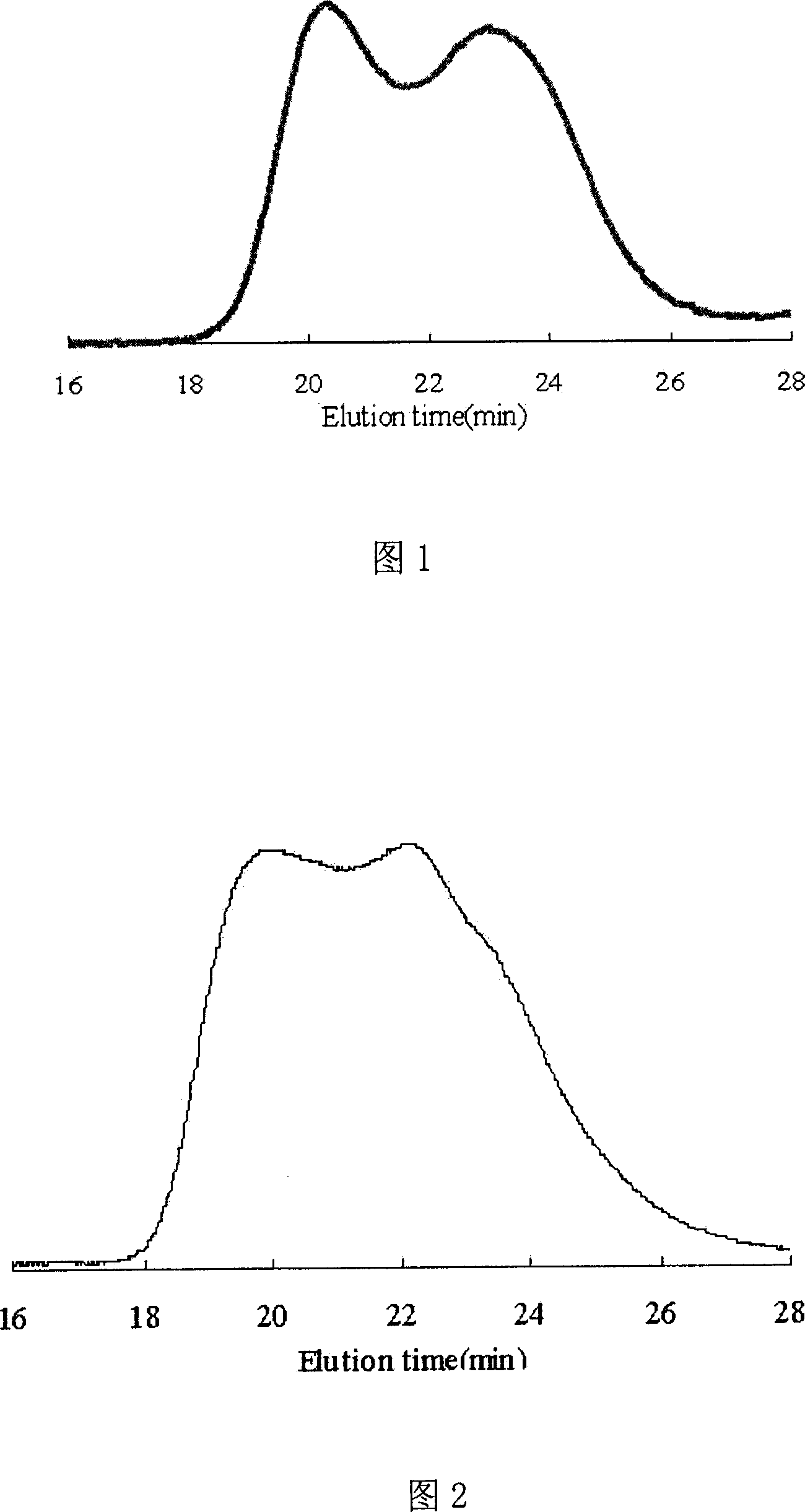

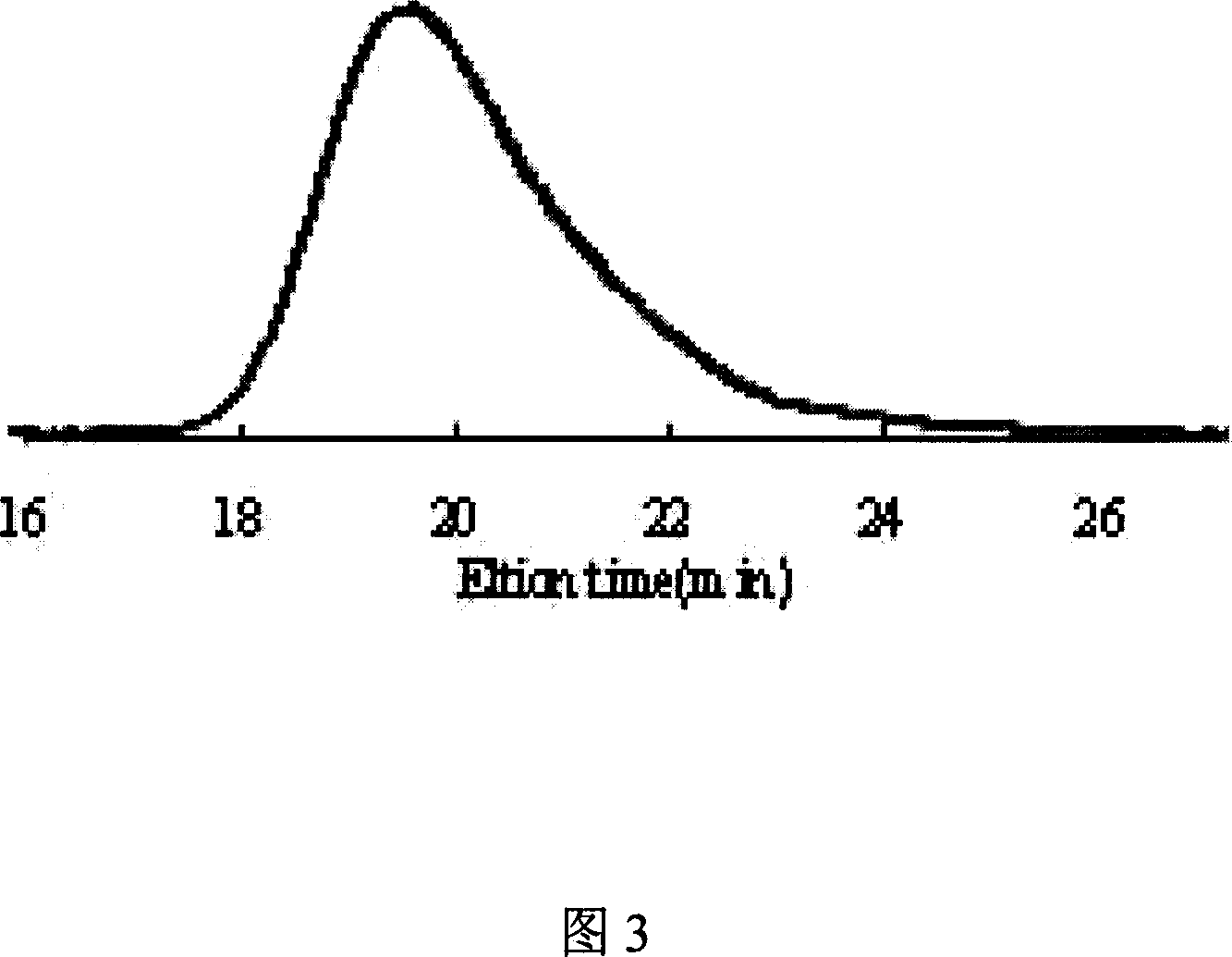

Splitblip molecular weight distribution high-cis-polydiene and preparation method thereof

InactiveCN101085818AHigh catalytic activityImprove catalytic performancePolymer scienceHigh molecular mass

The invention relates to a kind of sym-form polydiene rubber with bimodal molecular weight distribution and the preparation method. The conjugated polydiene with bimodal / acromion molecular weight distribution can be produced in one single reactor directly. The invention is characterized by high catalytic activity, stable catalytic property, easy controllable polymerization and conjugated polydiene with structure unit larger than 96%. The polymer produced in this invention can not only retain mechanical performance of high molecular part, but aslo retains the processing performance of low molecular weight part.

Owner:BEIJING UNIV OF CHEM TECH

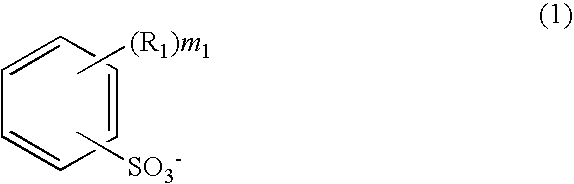

Dispersion stabilizer

ActiveUS20090111940A1Improve polymerization stabilityThe polymerization process is stableTransportation and packagingMixingPolymer scienceSide chain

The aforementioned problems can be solved by a dispersion stabilizer composed of a polyvinyl alcohol polymer (B) having a double bond in its side chain. The polyvinyl alcohol polymer (B) is obtained by esterifying a polyvinyl alcohol polymer (A) with a carboxylic acid having an unsaturated double bond or a salt thereof. Furthermore, the aforementioned problems can be solved with a dispersion stabilizer composed of a carboxylic acid-modified polyvinyl alcohol polymer (C) that is obtained by esterifying a polyvinyl alcohol polymer (A) with aliphatic carboxylic acid and / or aromatic carboxylic acid containing no olefinically unsaturated bond in the molecule or a salt thereof.

Owner:KURARAY CO LTD

Homogenous neodymium-based rare earth catalyst, and its preparation method and application

The invention relates to a novel homogenous neodymium-based rare earth catalyst, and a preparation method of the catalyst and application in polymerization of conjugated diene. The synthesis method of the catalyst is simple and easy to control, thus the obtained catalyst has high activity and good stability. By using the inventive homogenous neodymium-based rare earth catalyst for catalyzing polymerization of isoprene, the polymerization process is stable, easy to control, and suitable for continuous operation, and polyisoprene with a cis structure content higher than 98% and adjustable Mooney viscosity range within 60-100 can be synthesized.

Owner:CHINA PETROLEUM & CHEM CORP +1

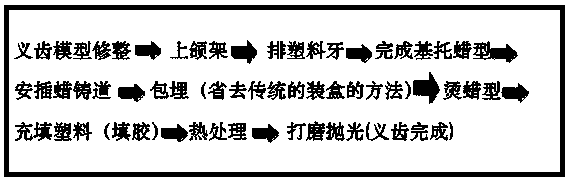

Manufacturing method of removable dentures

ActiveCN107854187AAvoid Coitus HeighteningAvoid Shrinkage Bubble PhenomenonArtificial teethWater bathsDental cast

The invention relates to a manufacturing method of removable dentures. Currently, the removable-denture manufacturing methods in all countries in the world are a thermos-coagulation packing method, need steps such as casing, filling, squeezer pressurizing and water bath polymerization (dental cast cooking pot), are complex in process, time-consuming and labor consuming, are non-uniform in moldingcase pressurizing and are difficult in precise mastering and control of heating speed and heating maintaining time during heat processing. The method has the advantages that the manufacturing flow oftraditional removable dentures is improved, joint height increasing and contraction bubbles of the removable dentures manufactured by the traditional manufacturing process are avoided, and the base-material filling of the partial removable dentures and attachment dentures can be performed; the models of the attachment dentures does not need to be pressurized on a squeezer, and the subfissure or deformation of the fixing-part porcelain teeth of the attachment dentures is avoided.

Owner:程昕

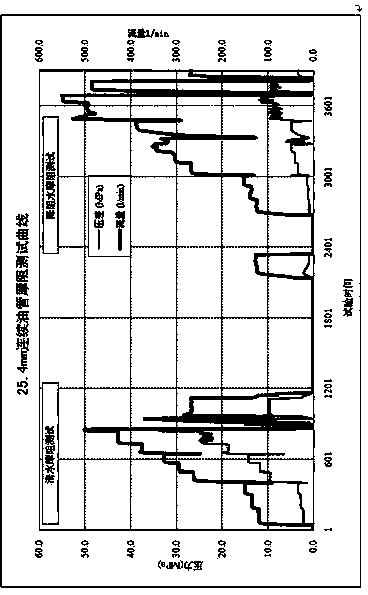

Inverse emulsion drag reduction agent for fracturing shale gas by using quick water and preparation method thereof

ActiveCN103881693AImprove structural stabilityGood drag reduction effectDrilling compositionFracturing fluidSodium hydrogen sulphite

The invention discloses an inverse emulsion drag reduction agent for fracturing a shale gas by using quick water and a preparation method thereof, and relates to the technical field of petroleum engineering. The inverse emulsion drag reduction agent is a macromolecular water soluble polymer which is prepared from acrylamide, sodium acrylate and dodecyl methacrylate copolymerized in an inverse emulsion, and azo diisobutyl hydrochloride and sodium hydrogen sulfite as complex initiation systems. A long-chain hydrophobic monomer is introduced into the drag reduction agent, so that the shear resistance of the drag reduction agent in a high displacement pump injection process is improved, meanwhile, the drag reduction agent is prepared from the inverse emulsion in a polymerization manner, the product is a liquor and instant, the liquor demands of a continuous mixed construction technology for fracturing the shale gas are met, the dosage for field use is 0.06-0.8% of mass of clean water, and the drag reduction rate can be up to 73%.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

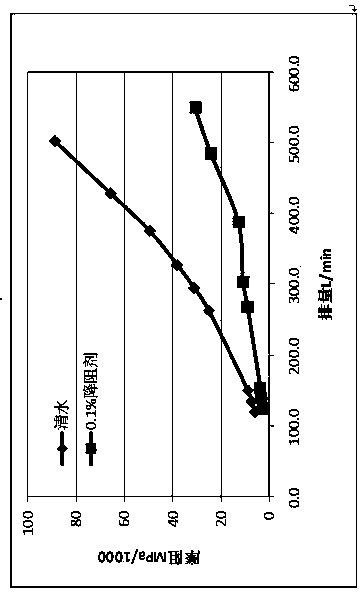

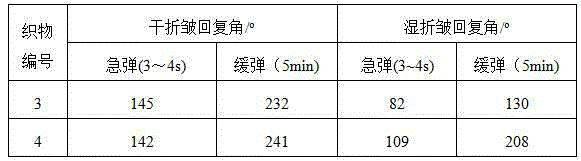

Silicone acrylic emulsion and application of silicone acrylic emulsion as textile finishing agent

The invention discloses silicone acrylic emulsion and the application of the silicone acrylic emulsion as a textile finishing agent. The silicone acrylic emulsion is manufactured by the following raw materials in parts by weight: 24-30 parts of butyl acrylate, 6-14 parts of methyl methacrylate, 0.15-1.0 part of initiator, 42.9-67.7 parts of deionized water, 1.2-6 parts of compound emulsifier, 0.3-0.6 part of pH buffer agent, 1-5 parts of vinyltriethoxysilane and 0.1-0.3 part of ammonium hydroxide. The silicone acrylic emulsion of the invention has the advantages that the composition is simple, the consumption of organosilicone monomer is low, the hydrolyzation of siloxane can be efficiently reduced through the matching of the silicone acrylic emulsion and seed emulsion, the polymerization process and the finally obtained emulsion are stable, and the emulsion is high in solid content, low in viscosity and convenient to use; the emulsion is used as the textile finishing agent so as to enable the textile to gain better weight increment and anti-wrinkle performance under the condition of keeping whiteness and intensity, no methyl aldehyde is realized during finishing, preservation and use, and the emulsion has the characteristics of remarkable effect, environmental protection and low cost.

Owner:SUZHOU UNIV

Artificial lawn adhesive composition with excellent performances

ActiveCN106085290ALow costUniform particle sizeNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross linkerOrganic chemistry

The invention discloses an artificial lawn adhesive composition with excellent performance. The adhesive composition comprises, by mass, 50-100 parts of aqueous latex, 20-30 parts of phenolic resin, 6-30 parts of a filler, 6-9 parts of aqueous PUR dispersion, 10-15 parts of a color paste, 1-3 parts of a cross-linking agent, 0.1-2 parts of a coupling agent, 0.1-0.5 parts of a mildew inhibitor, 0.1-0.3 parts of an antioxidant, 0.2-0.4 parts of an ultraviolet absorbent, 0.1-0.2 parts of an antifoaming agent, 0.5-1 part of a dispersant, 5-15 parts of a thickener and 2-5 parts of zinc oxide. The adhesive composition has the advantages of uniform particle size, stable properties, good weatherability, good waterproof property, strong ageing resistance, simple and easy preparation method, and low cost.

Owner:江蘇聯創人造草坪股ふん有限公司

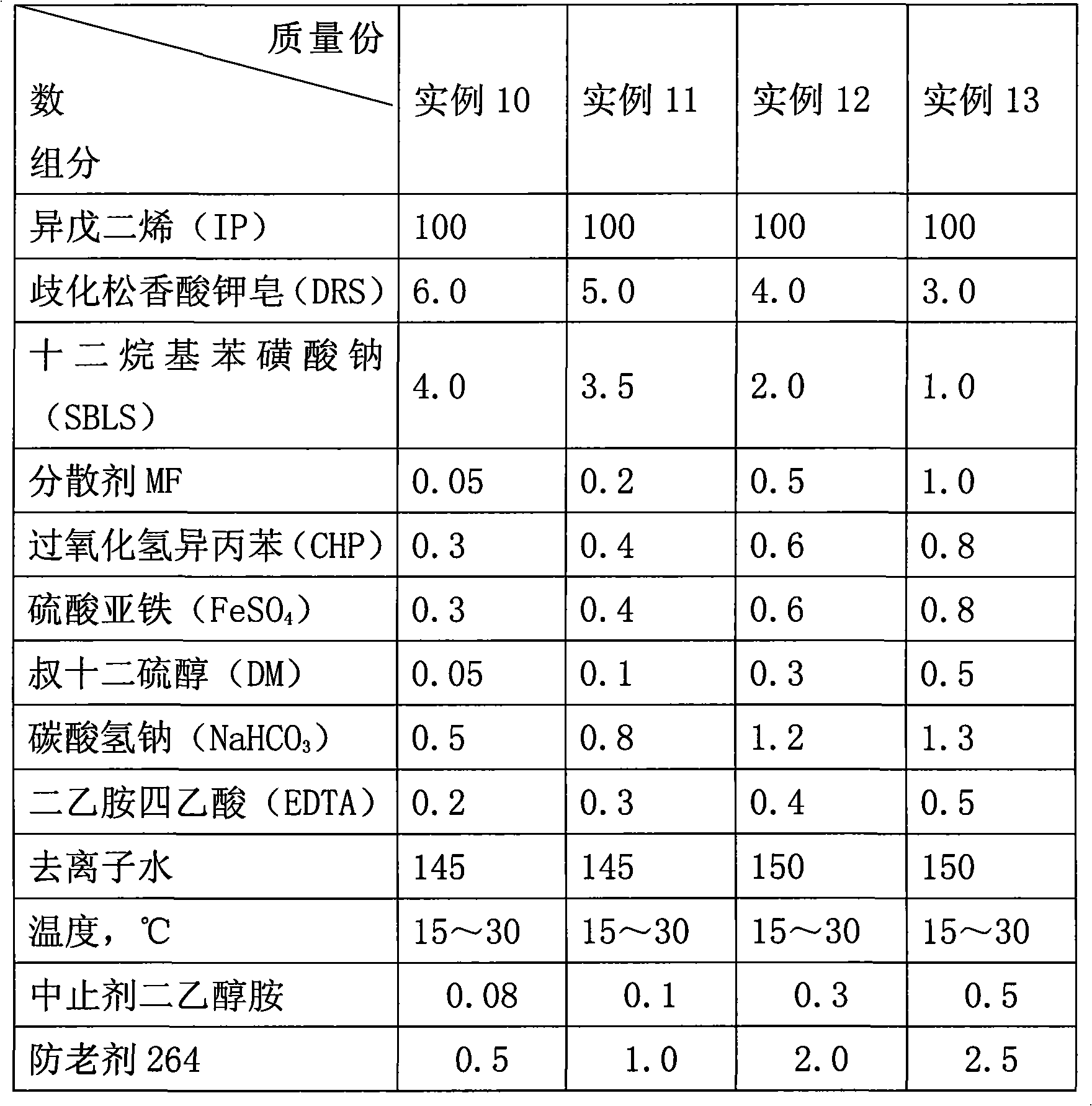

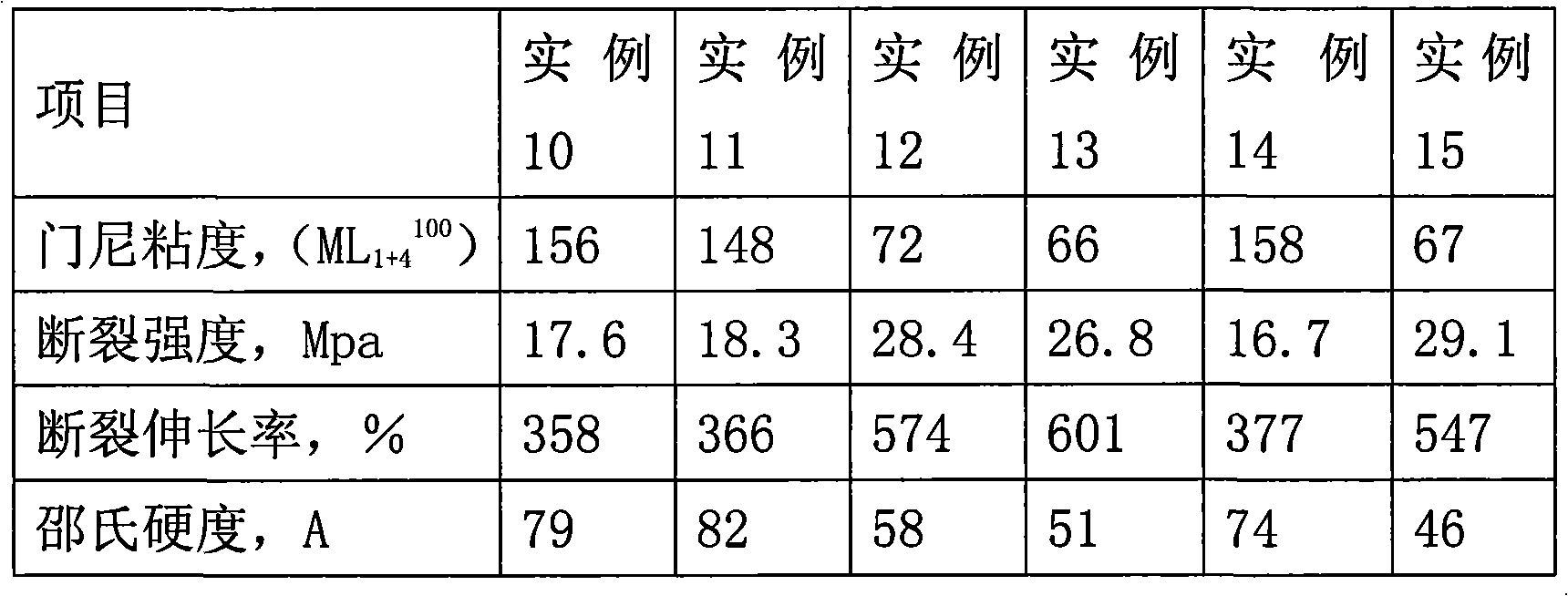

Polyisoprene aqueous emulsion and method for preparing glove and related products

InactiveCN101838360AThe polymerization process is stableEmulsion stabilizationGlovesCoatingsIsopreneRadical polymerization

The invention relates to a polyisoprene aqueous emulsion and a method for preparing a glove and related products thereof. The polyisoprene aqueous emulsion is a stable polyisoprene rubber emulsion which is obtained by performing radical emulsion polymerization under normal pressure and the initiation of an initiator by taking isoprene as a monomer, taking an emulsifying agent and a dispersant as an emulsification system and adopting a redox initiation system, wherein an oil phase obtained after the isoprene and the initiator are mixed and a reducing agent are added dropwise together in a sectional dropwise adding way. The polymerization conversion rate of the polyisoprene aqueous emulsion of the invention is increased to be over 97.5 percent from original 78 percent; and a prepared polyisoprene glove and related thin emulsion products have the characteristics of high strength, high extensibility, good handfeel and no anaphylaxis to human bodies, and can meet the requirements of different purposes.

Owner:SHANGHAI SHENGDA MEDICAL HEALTH STOCK

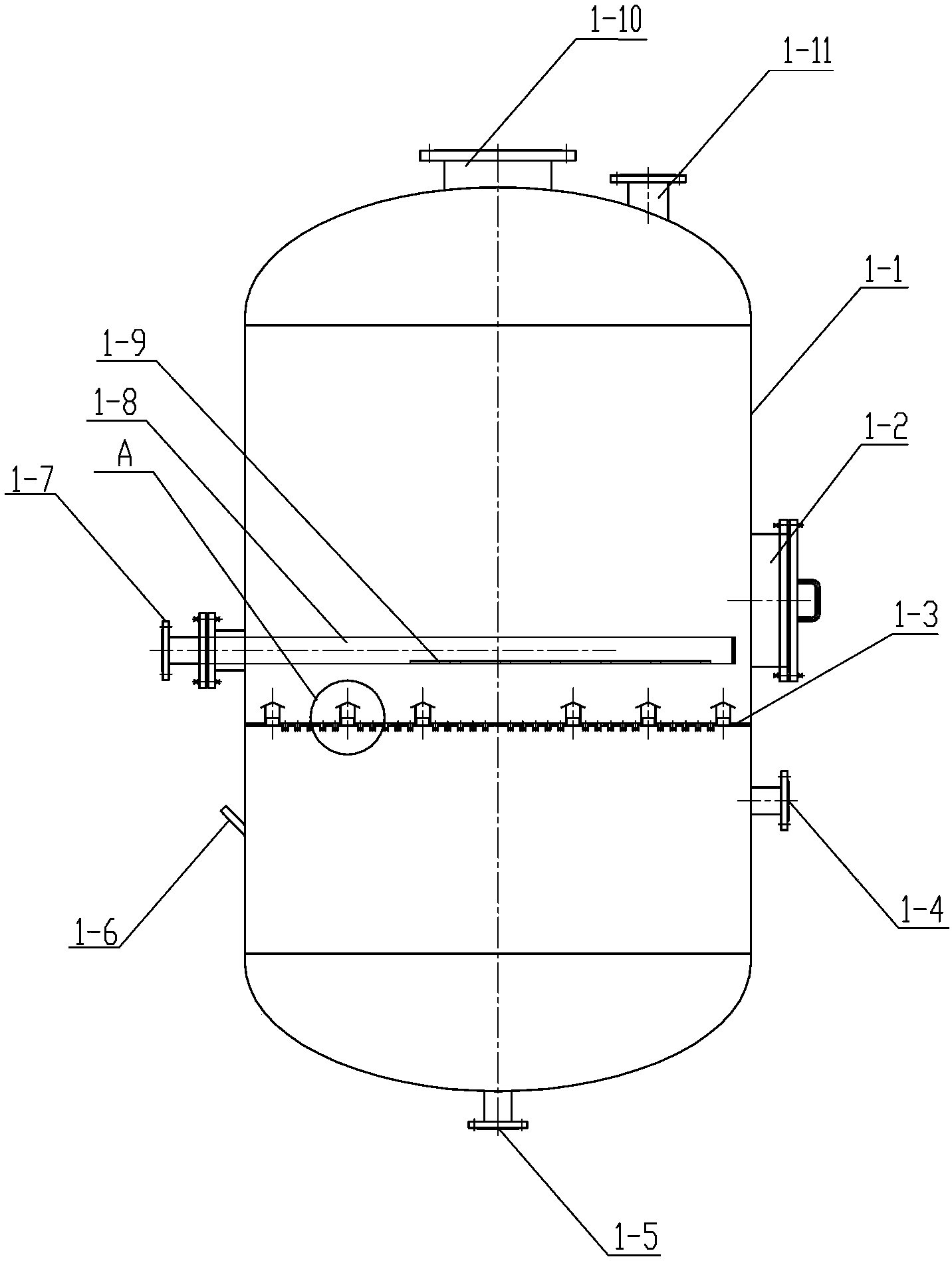

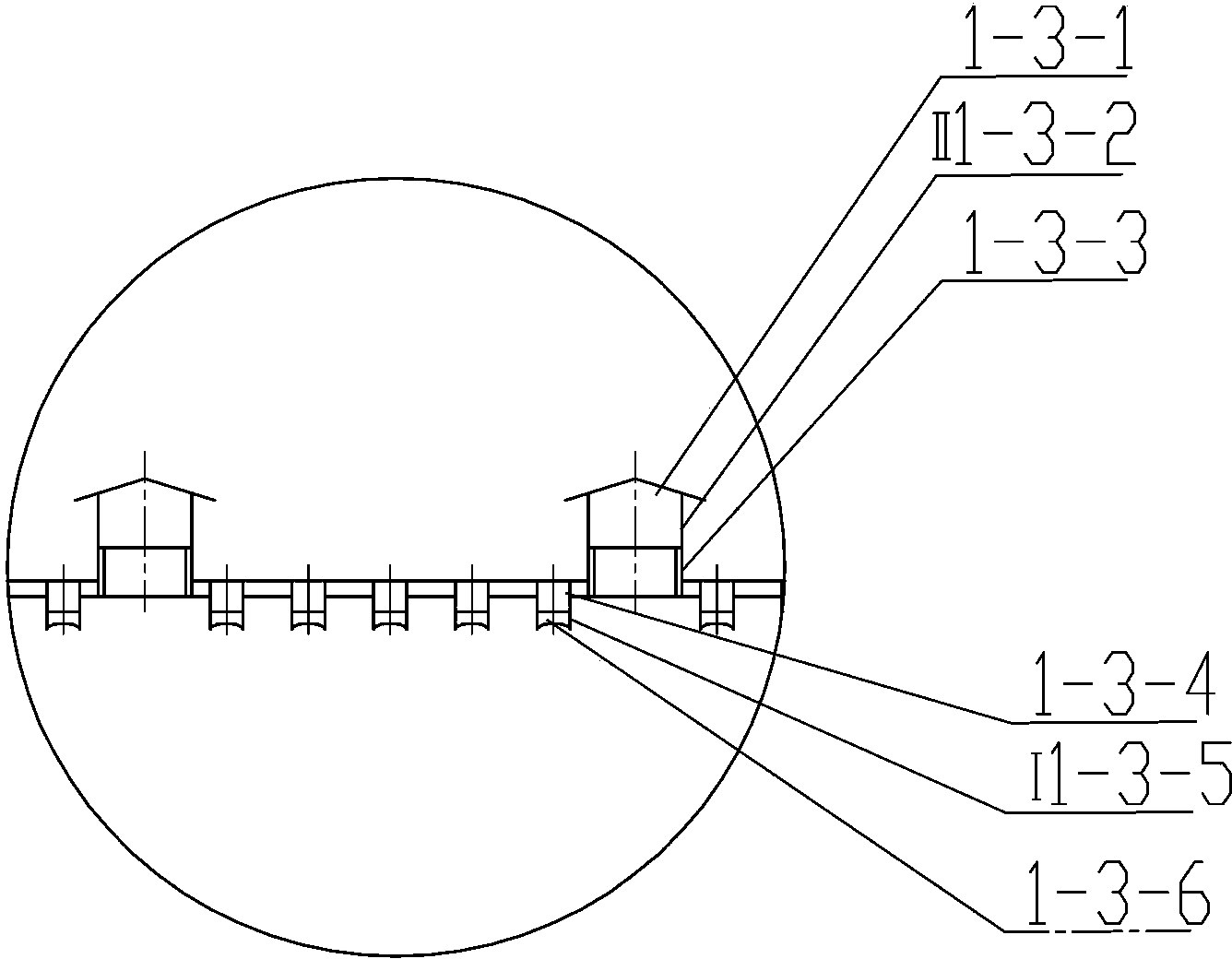

High-shear reaction kettle and application of kettle to production of suspension polymerization polyethylene

ActiveCN103894137APrevent the occurrenceSolve mass transferChemical/physical/physico-chemical stationary reactorsMotor driveParticle-size distribution

The invention relates to a high-shear reaction kettle which comprises a motor driving device, a stirring device, a kettle body, a clamping sleeve and a baffle plate, wherein the motor driving device is connected with the stirring device and is positioned on the top of the kettle body, and the stirring device is arranged in the kettle body; the clamping sleeve is arranged outside the kettle body, and the baffle plate is arranged in the kettle body; a material inlet, a material outlet and a kettle-inside temperature sensor inserting hole are formed in the kettle body, and a condensing medium inlet, a condensing medium outlet and a clamping sleeve temperature sensor inserting hole are formed in the clamping sleeve. The high-shear reaction kettle is applied to the production of the suspension polymerization polyethylene. Compared with the prior art, the reaction kettle can provide great radial shearing force, so that the generation of a dead angle in the reaction kettle is avoided. The polymerization reaction kettle is adopted to produce a polymerization product, namely the polyethylene, the molecular weight distribution and the particle size distribution of the polyethylene are narrow, the particle size of the polyethylene is uniform, the quality of finished products of the polymerization product is significantly improved and the rate of finished products of the polymerization product is significantly increased.

Owner:SHANGHAI RES INST OF CHEM IND +2

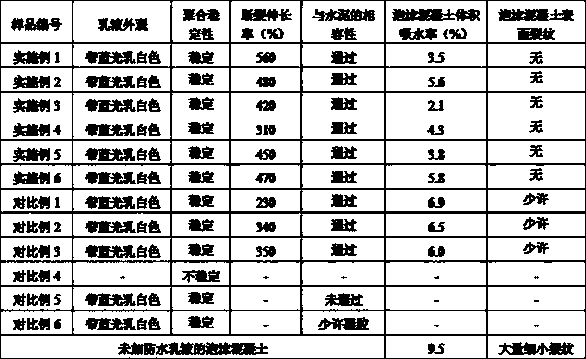

Elastic waterproof emulsion

ActiveCN105367698AImprove mechanical propertiesIncrease elasticityCeramicwareFoam concretePolymer science

The invention discloses an elastic waterproof emulsion, and is characterized in the emulsion is obtained by the steps of carrying out emulsion polymerization of an olefinic compound (a) at least having one unsaturated group in one molecule, an olefinic compound (b) at least having two unsaturated groups in one molecule, an unsaturated compound (c) having a group which can undergo a cross-linking reaction at room temperature in a molecule and an unsaturated compound (d) having a carboxyl or anhydride group under the action of an emulsifier (e), and then adding a compound (f) which is soluble in water and can undergo a chemical cross-linking reaction with the compound (c) at room temperature. The produced elastic emulsion has the characteristics of excellent calcium ion stability, good compatibility with cement, excellent waterproof performance, good anti-cracking performance, simple preparation, low cost and the like, is suitable for the fields of concrete waterproof and cement waterproof mortar, building exterior wall coatings, adhesives and other biological materials, and is especially suitable for the foam concrete waterproof and cement waterproof mortar, the building exterior wall coatings and the like.

Owner:湖南金利源新材料科技有限公司

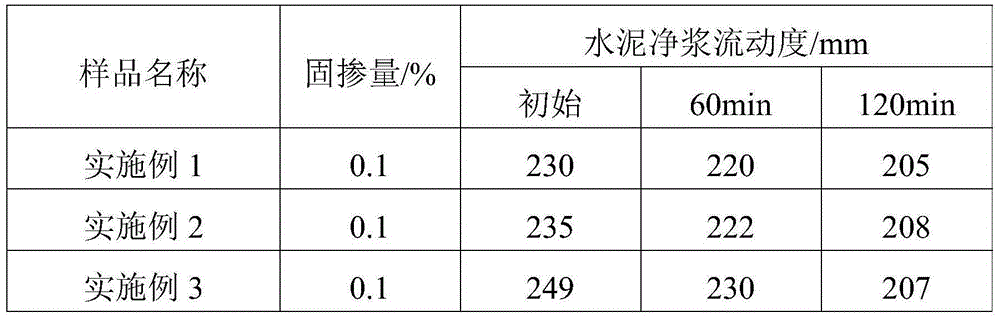

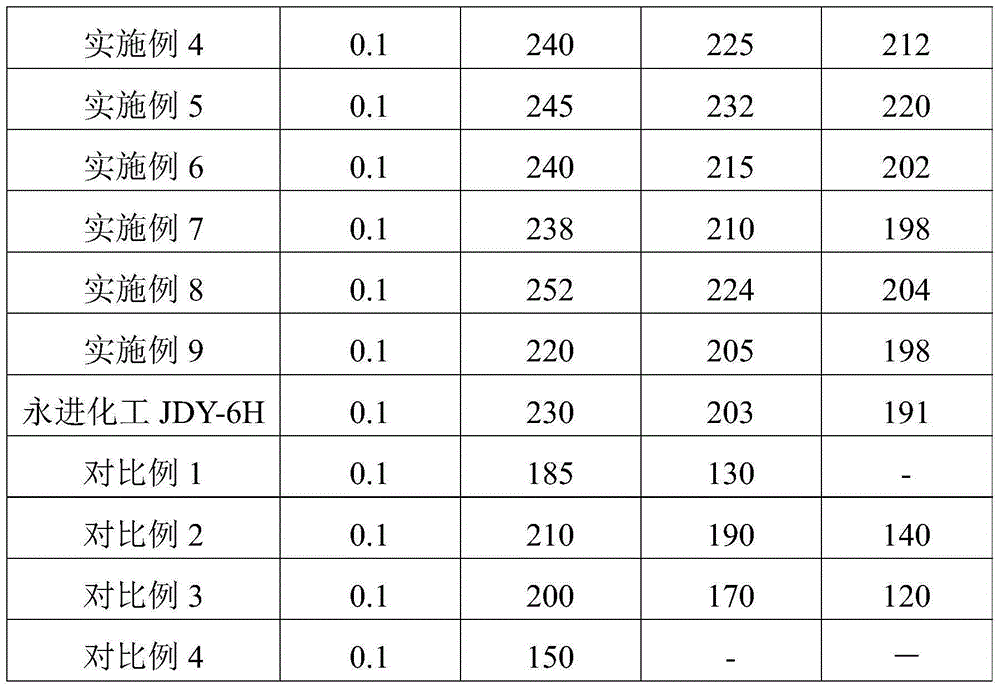

Powdery polycarboxylic acid water reducing agent, preparation method therefor and application of powdery polycarboxylic acid water reducing agent

The invention discloses a powdery polycarboxylic acid water reducing agent and a preparation method therefor. The water reducing agent contains the following ingredients: 100 parts of macromonomer A, 10-20 parts of monomer B, 0.6-2 parts of initiator and 0.6-2 parts of chain transfer agent, wherein the macromonomer A is R1-O-[CH2-CH2O]m-[CH2-CH(CH3)O]n-R2; and the monomer B is liquid-state unsaturated carboxylic acid. The method comprises the steps: mixing the macromonomer A with 5% to 20% of the monomer B, heating the mixture to 50 DEG C to 70 DEG C, and adding 60% to 80% of the initiator into the mixture; dropwise adding a mixed solution of the chain transfer agent and the rest of the monomer B, wherein the time for dropwise adding is 2 to 4 hours, 60% to 85% of the mixed solution is dropwise added uniformly in first 1 / 2 to 2 / 3 of the time, and the rest of the mixed solution is dropwise added uniformly in remaining time; and carrying out a heat-preservation reaction for 1 to 2 hours, and then, carrying out cooling and crushing. The powdery polycarboxylic acid water reducing agent disclosed by the invention is good in dispersity, high in water reducing rate, small in blended amount and good in slump loss resistant performance.

Owner:SHANGHAI DONGDA CHEM

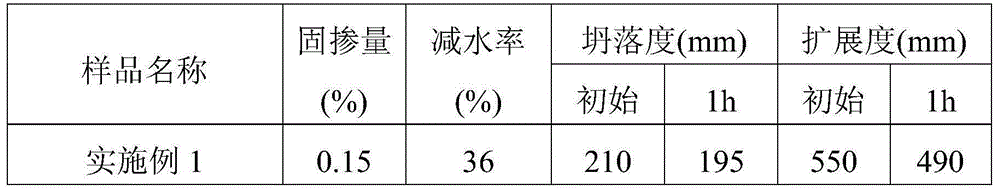

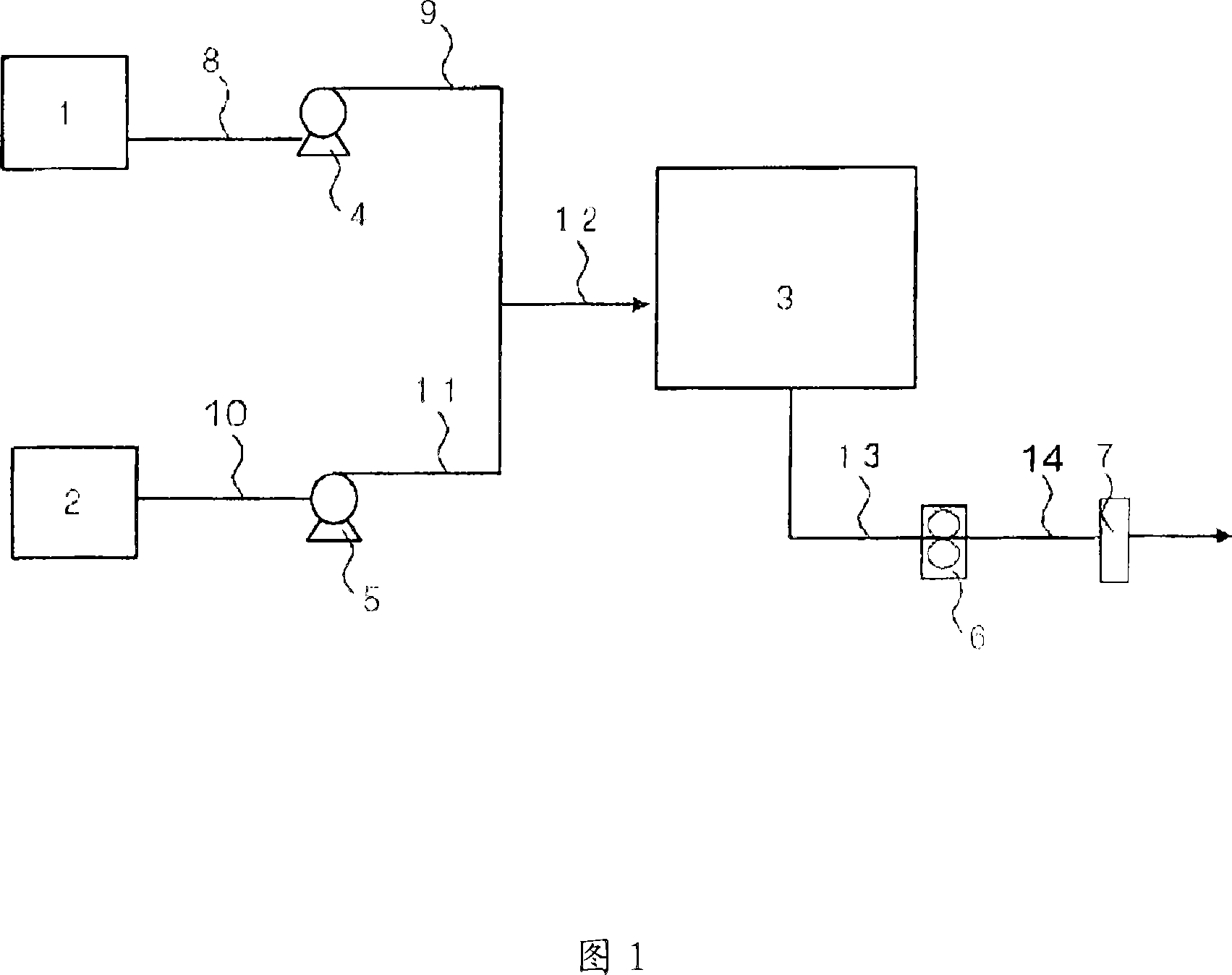

System for producing modified coal tar pitch and preparation method thereof

ActiveCN103756704AReduce consumptionReduce the power requiredWorking-up pitch/asphalt/bitumenTarProcess engineering

The invention relates to a system for producing modified coal tar pitch and a preparation method of the modified coal tar pitch. The method comprises the following steps: feeding mid-temperature pitch from a revaporizer of a tar processing device into modified intermediate pitch processing equipment with a flash oil-gas treatment device through a pipeline, allowing the flash oil and gas generated by flashing through a vacuum flasher to enter heavy oil treatment equipment for performing separation and condensation recycling on heavy wash oil fraction, and feeding the modified intermediate pitch generated by flashing into pitch modification reaction equipment for producing modified coal tar pitch. According to the system and the method, various indexes of the modified coal tar pitch are obviously improved, the energy and power consumption is greatly reduced, and pollutant escape in the whole reaction process is avoided.

Owner:ANSHAN XINGDE ENG TECH

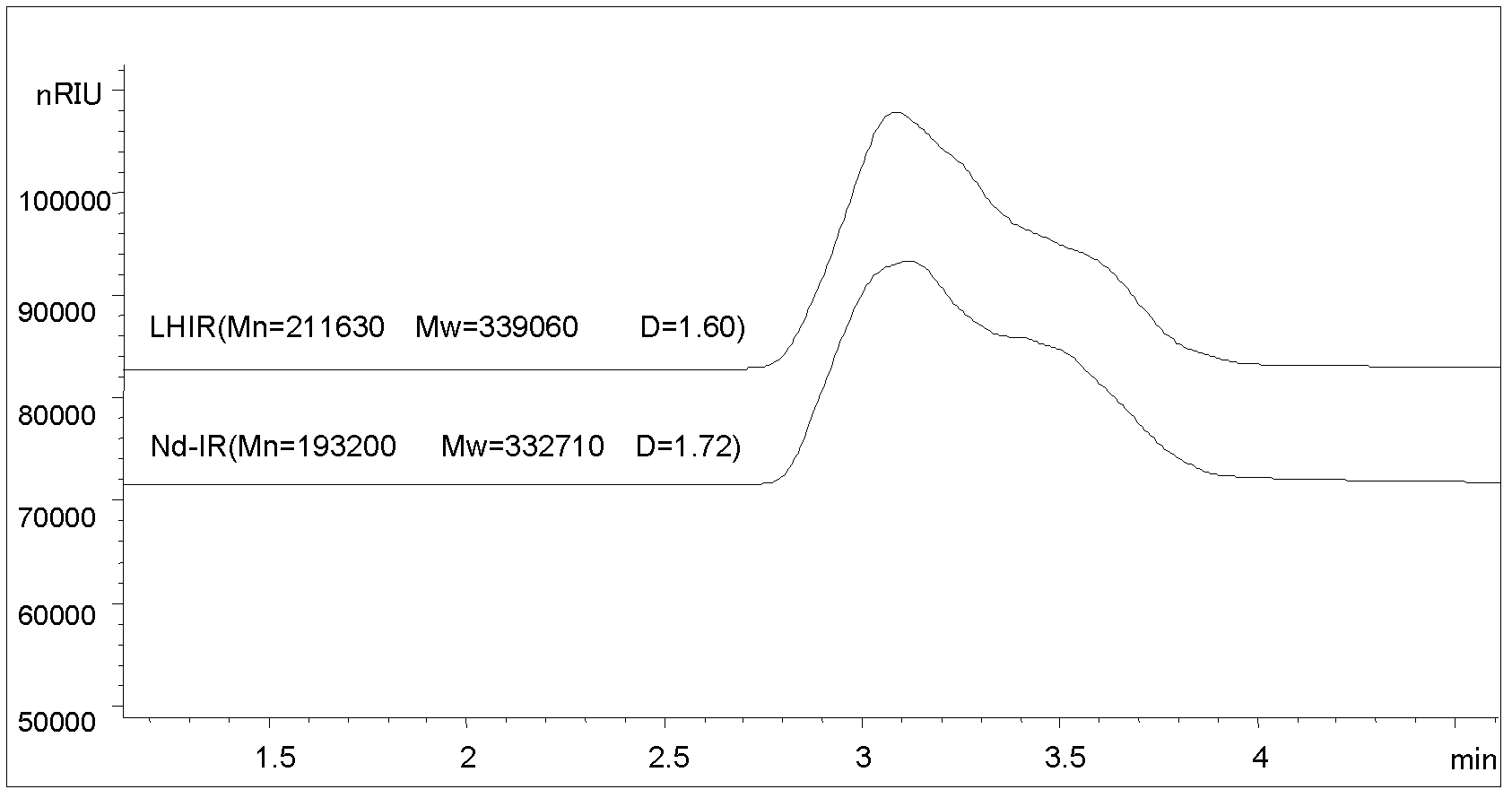

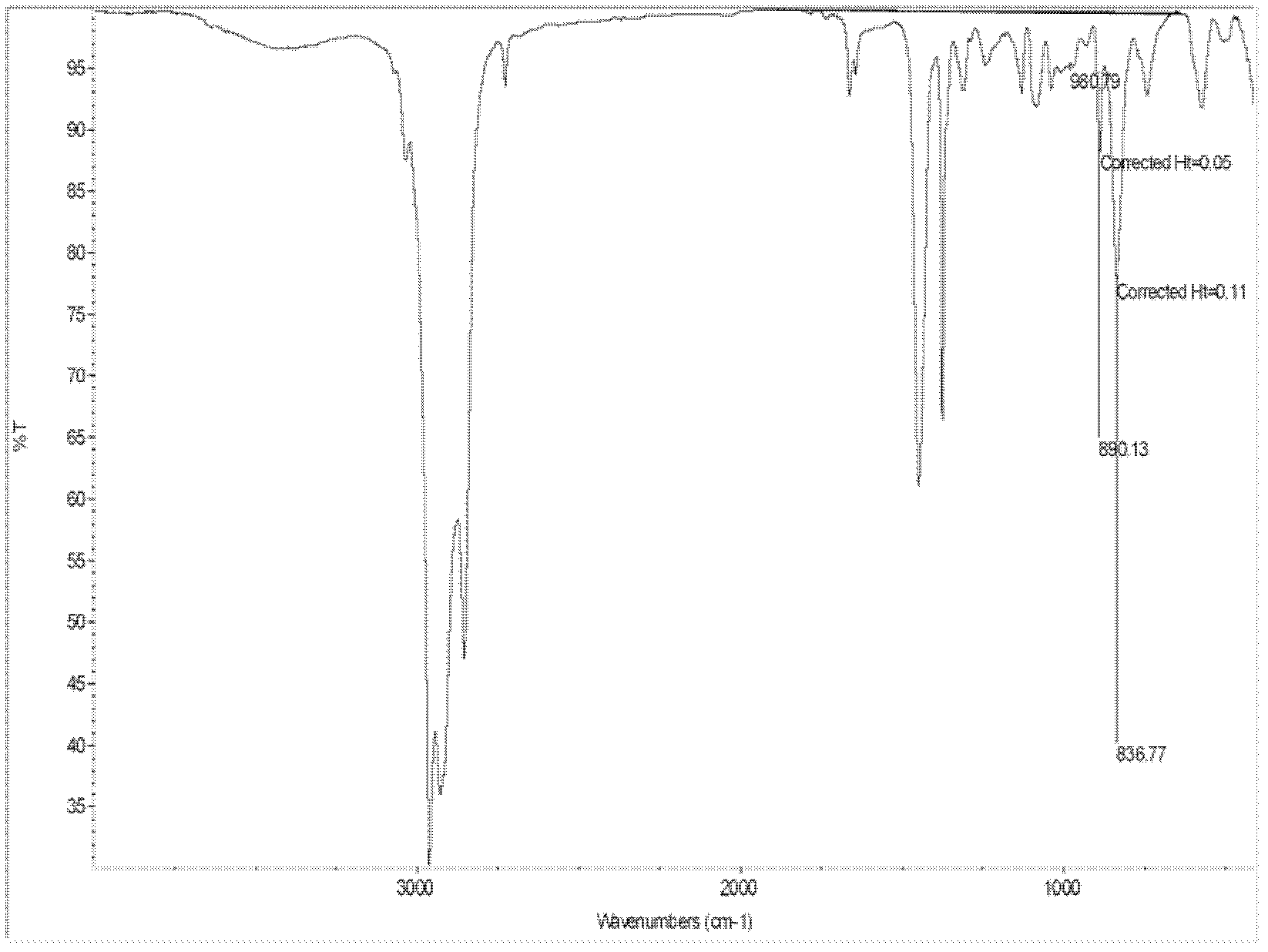

Catalyzing system for isoprene polymerization and preparation and application method of catalyzing system

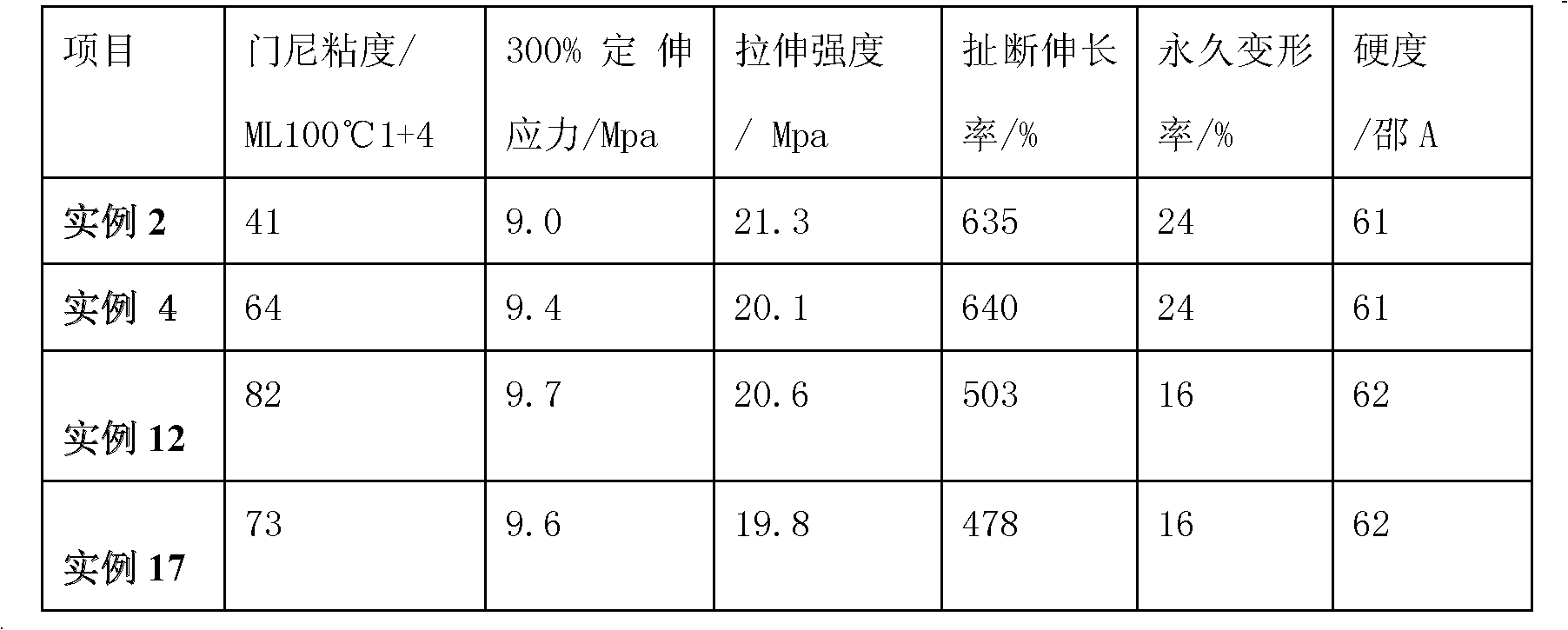

The invention belongs to a catalyzing system for isoprene polymerization and preparation and an application method of the catalyzing system. The catalyzing system is composed of A) rare earth organic carboxylate compound, B) organic aluminum compound, C) activating agent, D) acrylate compound and E) carboxylic aromatic cyclic ester compound containing total carbon number of C7-C9 according to molar ratios that A:B=1:1-30, A:C=1:1-3, A:D=1:1-60, and A:E=1:5-50. The prepared catalyzing system forms pre-polymerized catalyst activity central body during ageing at 0-80 DEG C. The catalyzing system can be maintained for 180 days at the room temperature, the monomer conversion rate is higher than 98% in polymerization, the molecular weight distribution index of the synthesized poly-isoprene rubber is 1.6-2.8, cis-form 1,4 structural unit content is higher than 96%, and the Mooney viscosity satisfies that ML1+4100 DEG C =40-80.

Owner:CHINA PETROCHEMICAL CORP

Epoxy modified acrylic emulsion and preparation method thereof

ActiveCN108752514AInconsistencyFast aggregationPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyMethacrylate

The invention discloses an epoxy modified acrylic emulsion and a preparation method thereof. The epoxy modified acrylic emulsion comprises three components A, B and C, wherein the component A comprises deionized water, an emulsifier, epoxy resin, an acylamino compound, styrene, acrylate, methacrylate and (meth)acrylic acid; the component B comprises deionized water, a buffer agent and an emulsifier; the component C comprises deionized water and an initiator; in the emulsion system, a reducing agent, protective glue, a functional monomer, a neutralizing agent and the like can also be included.The prepared emulsion has the characteristics of fine granules, good elasticity, light resistance, weather resistance, water resistance and the like, and can be applied to waterborne industrial coating, waterborne building coating and waterborne wood coating. The waterborne coating prepared from the emulsion provided by the invention has the characteristics of strong adhesion, high mechanical properties, low curing shrinkage, good water / oil resistance, good temperature change resistance, good heat resistance, excellent aging resistance, excellent electrical insulation, excellent chemical resistance and the like.

Owner:CHANGSHA YUANPENG CHEM TECH

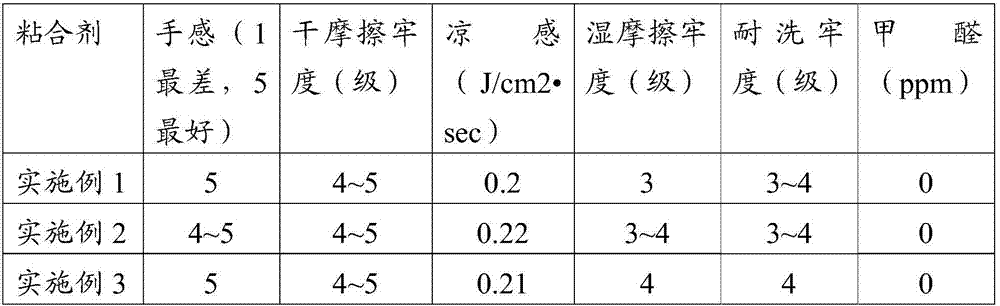

Printing adhesive and preparation method thereof, printing paste and clothing

The invention discloses a printing adhesive and a preparation method thereof, printing paste and clothing. The printing adhesive is prepared from the following components in parts by weight: 40-70 parts of a cool silicone emulsion, 0.6-1.0 part of an emulsifier, 36-59 parts of deionized water, 80-100 parts of soft monomer, 10-30 parts of a hard monomer, 0.6-3.0 parts of an emulsifier, 0.2-0.6 part of a pH buffer agent, 50-60 parts of deionized water, 0.2-0.6 part of an initiator and 1-4 parts of a cross-linking monomer. The printing adhesive has the advantages of low viscosity and good heat dispersion and has a relatively high polymerization reaction rate, and the obtained polymer is high in molecular weight.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

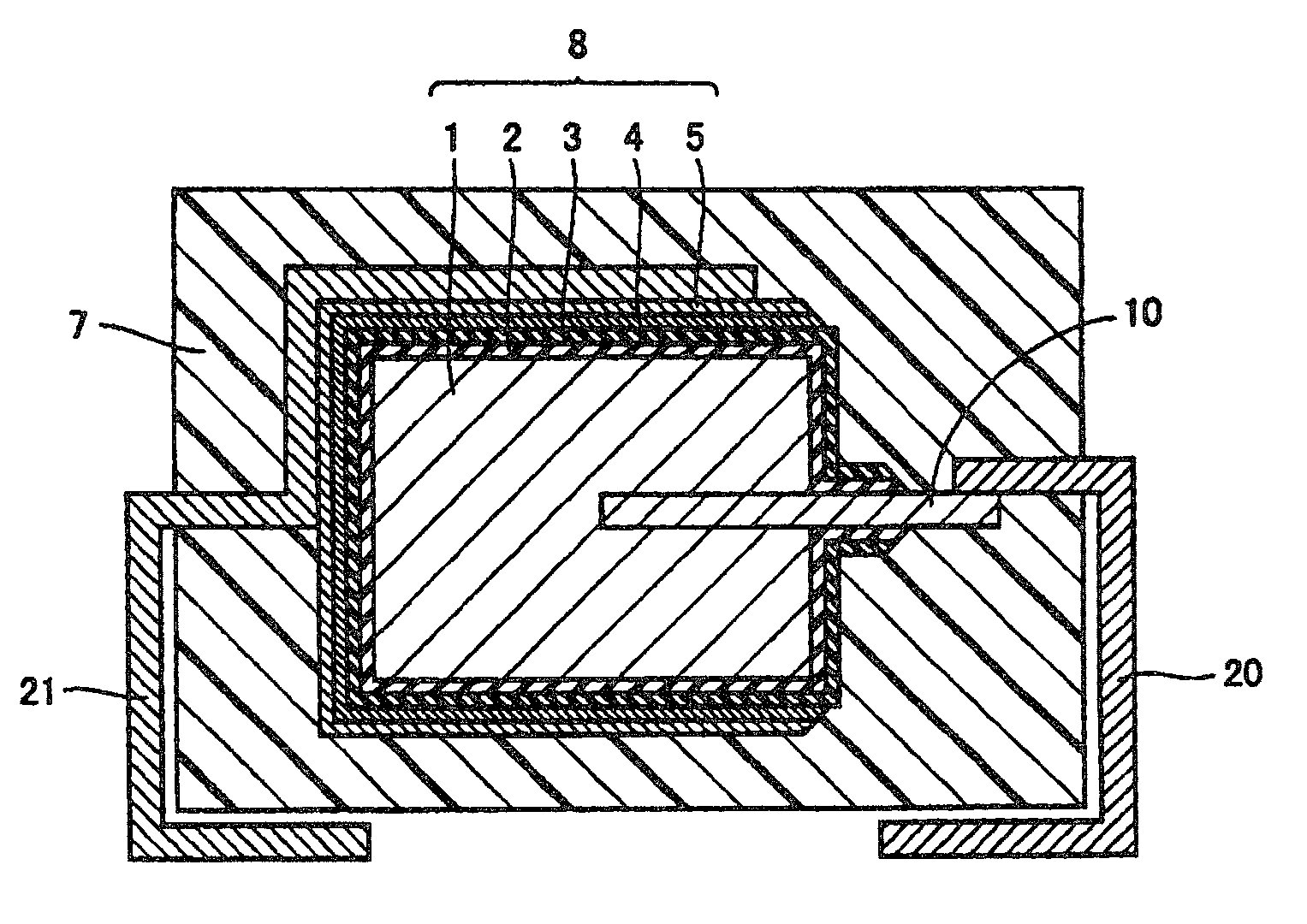

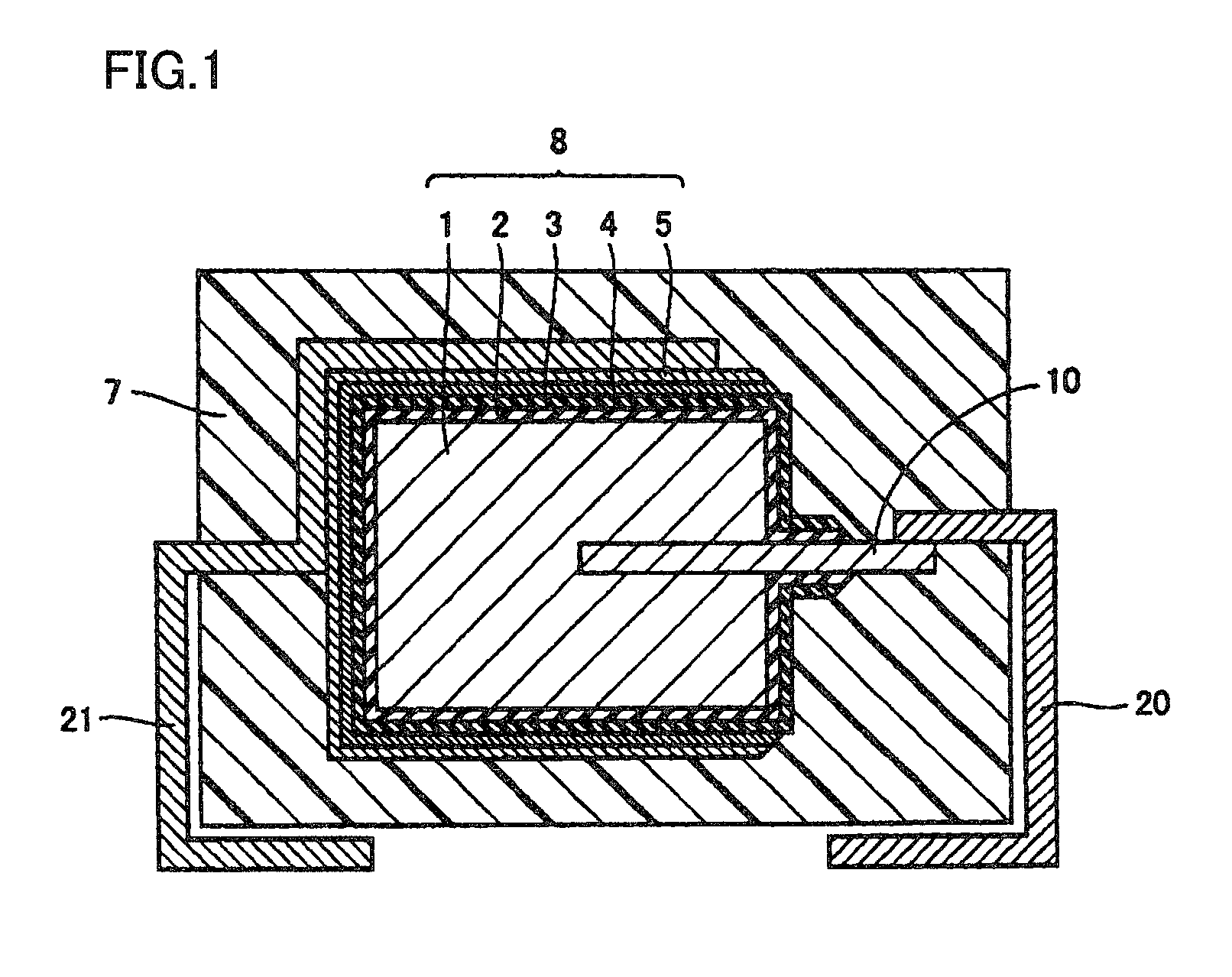

Solid electrolytic capacitor

ActiveUS7742281B2The polymerization process is stableOptimizationSolid electrolytic capacitorsCapacitor electrolytes/absorbentsDopantElectrolysis

Owner:SANYO ELECTRIC CO LTD

Method for preparing adhesive acrylic ester polymer syrup

InactiveCN101010344AThe polymerization reaction is stableHigh degree of polymerizationEster polymer adhesivesContinuous reactorPolymer science

Owner:LG CHEM LTD

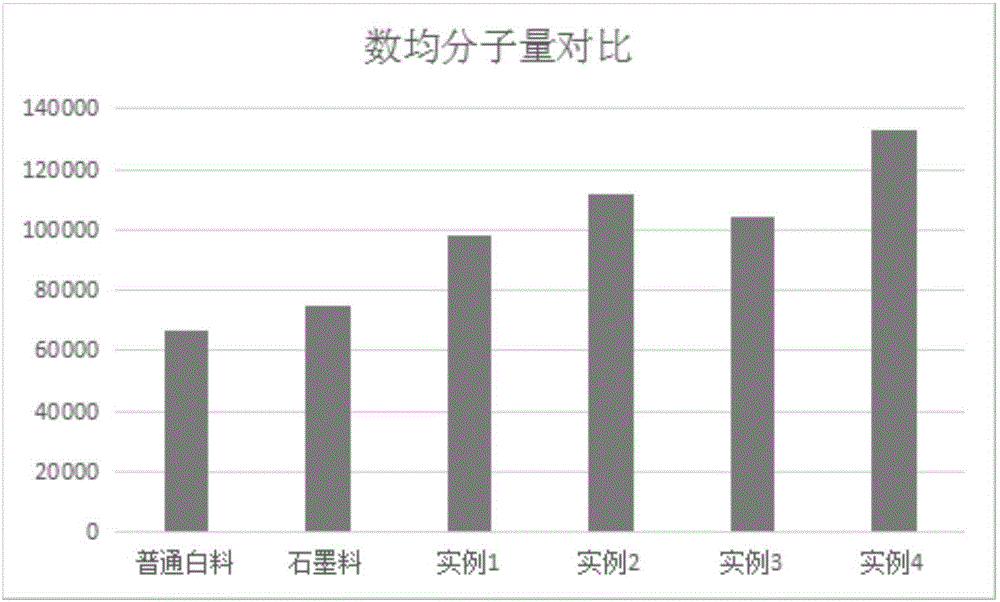

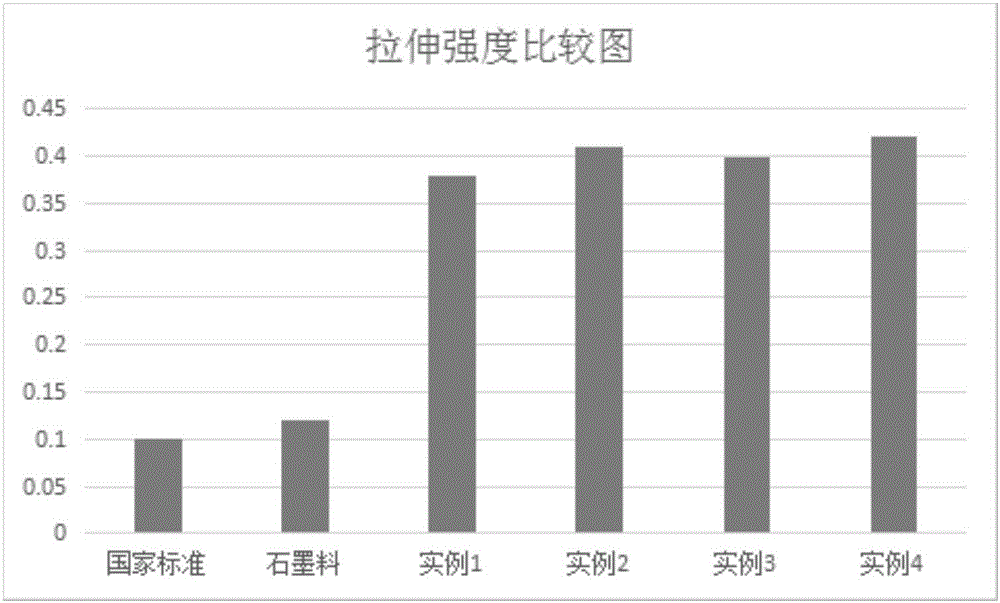

Preparation method of high-strength graphene expandable polystyrene board

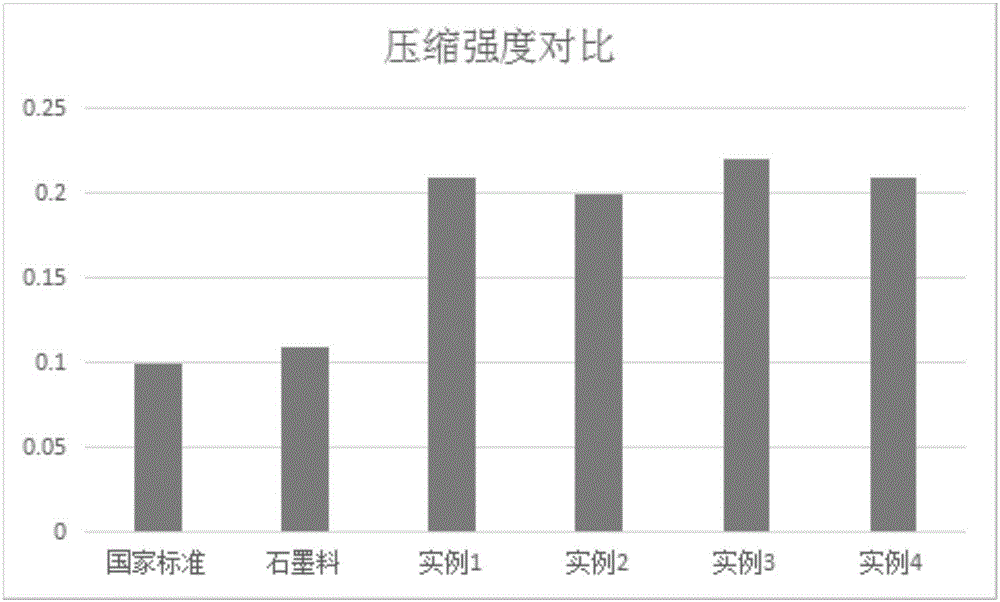

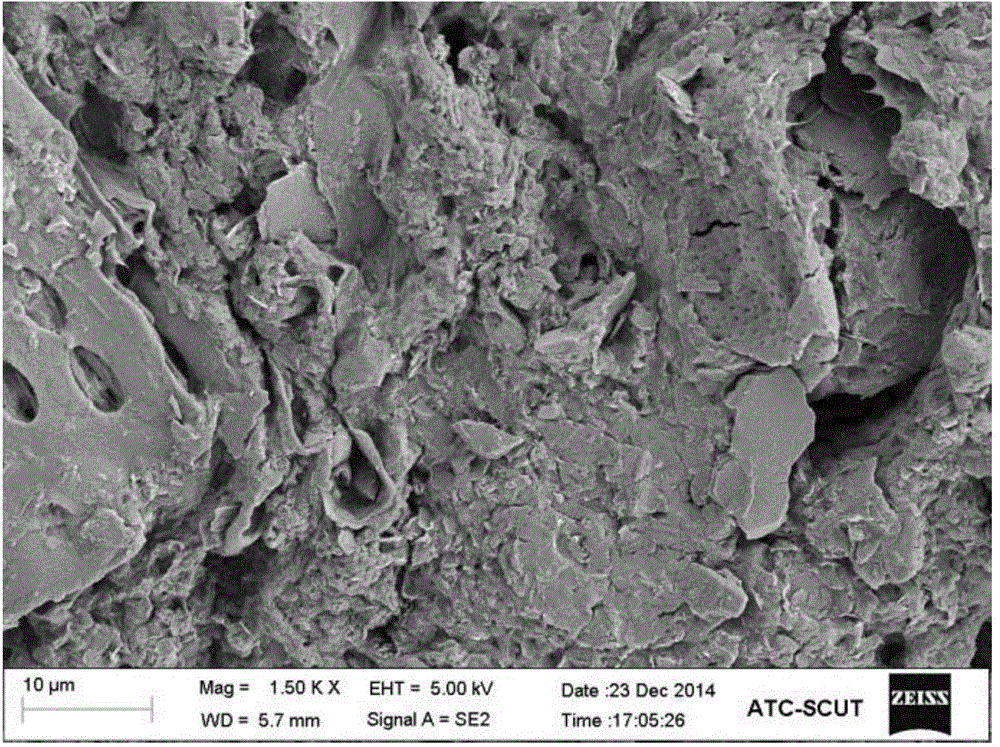

InactiveCN106674783AHigh strengthThe polymerization process is stablePre expansionPolystyrene particle

The invention relates to a preparation method of a high-strength graphene expandable polystyrene board. The prepared product has the mechanical strength higher than that of other existing expendable polystyrene boards. The method comprises the several steps as follows: preparing a modified graphene pre-dispersion liquid; adding an oily dispersant to prepare an oily mixed liquid; preparing graphene polystyrene particles through suspension polymerization in a reaction kettle; finally, measuring mechanical properties after molding with pre-expansion, curing and board making processes. The prepared graphene expandable polystyrene board has excellent mechanical properties, has the tensile strength 400% higher than the national standard and has the compressive strength 200% higher than the national standard. With the adoption of the method, the application of expandable polystyrene in the packaging industry is expanded, expandable polystyrene is suitable for packaging industries with higher mechanical properties, such as packaging of precise instruments, packaging of spaceflight navigation parts and the like, and the advantages of polystyrene as a packaging material are played.

Owner:JILIN YUNTING ENERGY SAVING TECH CO LTD

Process for the reduction of reactor fouling

A process for the reduction of reactor fouling at radical initiated high pressure polymerisation of ethylene (co)polymers is described. The process is characterised in that an adhesion reducing silicon containing compound is added to the polymerisation reactor, preferably in an amount of 0.001-3% by weight, based on the amount of polymer produced. Preferably the silicon containing compound is hexadecyl trimethoxy silane.

Owner:EI DU PONT DE NEMOURS & CO

Water-based acrylate adhesive for reflective coatings and preparation method thereof

ActiveCN104017146ALong-lasting and effective reflective effectPromote environmental protectionReflecting/signal paintsWater basedAdhesive

The invention discloses a water-based acrylate adhesive for reflective coatings and a preparation method thereof. The water-based acrylate adhesive comprises the raw materials in parts by weight: 8-10 parts of perfluoroalkyl phosphate amine salt, 0.5-1.5 parts of heterogeneous tridecyl alcohol polyoxyethylene (40) ether, 6-7 parts of diacetone acrylamide, 3-4 parts of adipic dihydrazide, 1-2 parts of vinyl-containing functional silicon oil, 145-155 parts of ethyl acrylate, 30-40 part of methyl methacrylate, 2-4 parts of acrylic acid, 1-1.4 parts of ammonium persulfate and 280 parts of deionized water. An emulsion is obtained through semicontinuous emulsion polymerization; the adhesive and the inorganic material are in high binding firmness, and the adhesive is abrasion-proof, weather-resistant, stain-proof and high in film-forming transparency.

Owner:LIAONING FIXED STAR FINE CHEM

Composite polymer sludge dewatering agent and preparation method thereof

ActiveCN104817251AImprove settleabilityThe polymerization process is stableSludge treatment by de-watering/drying/thickeningIonChemistry

The present invention discloses a composite polymer sludge dewatering agent and a preparation method thereof. The preparation method comprises: (1) respectively preparing a non-ionic monomer, an anionic monomer and a cationic monomer into aqueous solutions with deionized water, mixing, adjusting the pH value to 2-6, introducing nitrogen, and stirring; (2) adding a persulfate initiator, a sulfite reducing agent, an azo initiator and EDTA-2Na to the mixed solution prepared in the step (1), controlling the reaction temperature at 25-50 DEG C, and triggering a chain initiation and chain extending reaction; and (3) after the reaction in the step (2) is performed for 2-4 h, adding an inorganic salt, completely stirring, continuously introducing nitrogen to react for 1-3 h, discharging the material, and sequentially carrying out drying, crushing and granulation on the obtained colloid so as to obtain the sludge dewatering agent. The sludge dewatering agent of the present invention has advantages of complex water body conditioning, low consumption, low cost, thick floc, no residual toxic-harmful monomer, low moisture content of the treated sludge, inorganic suspended solids, good treatment effect, and the like.

Owner:浙江新海天生物科技有限公司

Polyisoprene aqueous emulsion and a method to fabricate gloves and related products

ActiveUS20100237541A1The polymerization process is stableIncrease conversion rateDischarging arrangementMouldsExtensibilityPolymer science

This invention relates to the method for fabrication of polyisoprene aqueous emulsion, gloves and related products thereof, wherein the aqueous emulsion is polyisoprene or polynitrile aqueous emulsion obtained through free-radical emulsion polymerization initiated by initiating agent under normal pressure with isoprene as the monomer, or isoprene monomer, acrylonitrile monomer, and (methyl)acrylic acid as the monomer mixture, and emulsifying agent and dispersing agent as the emulsification system. After the isoprene or the mixture of isoprene monomer, acrylonitrile monomer, and (methyl)acrylic acid is mixed with the initiating agent, the oil phase obtained together with reducing agent is added dropwise in different time quantums. The polymerization conversion rate of polyisoprene aqueous emulsion or polynitrile aqueous emulsion according to this invention is increased from the original 78% to over 97.5%. Fabricated polyisoprene or polynitrile gloves and thin latex products thereof have high strength and good extensibility, provide good hand touch, and do not cause allergies of the human body. They can be used for various purposes.

Owner:SHANGHAI SHENGDA MEDICAL APPL

Method for producing low-residue monoacrylamide polymer

The invention discloses a method for producing a low-residue monoacrylamide polymer. The method comprises the following steps: preparing a polymerization solution containing acrylamide, an ionic monomer, an auxiliary material, a solvent, a pH value regulator and an initiator; placing the polymerization solution on a polymerization belt which is protected by a gas and is continuously conveyed; carrying out low temperature-to-high temperature stepped initiation on the polymerization solution placed on the polymerization belt by using a composite initiator, wherein the composite initiator comprises a low-temperature photoinitiator and a medium-high-temperature polyazo initiator; and performing microwave radiation when the temperature in the reaction reaches the highest temperature or the temperature of a rubber block is reduced to achieve heat insulation of the rubber block. The photo-initiation and polyazo stepped initiation system and microwave radiation heat insulation are adopted, sothe synthesized product has the advantages of low residual monomer, low crosslinking degree, good solubility, simple process and easiness in industrial production.

Owner:JIANGSU FEYMER TECH

Preparation method of ternary polyacrylonitrile copolymer

InactiveCN104710565AImprove structural regularityImprove thermal stabilityMonocomponent synthetic polymer artificial filamentFiltrationAcrylonitrile

The invention relates to a preparation method of a ternary polyacrylonitrile copolymer, which comprises the steps of heating an aqueous solution of maleic anhydride, acrylamide and a dispersing agent to 55-75 DEG C under a nitrogen shielding condition, adding acrylonitrile to keep constant temperature for 20-30min, adding an initiator solution for reaction for 3-12h, and carrying out washing, demonomerisation, filtration and drying. The method employs a mixed solvent precipitation polymerization method for polymerization and has the advantages of high reaction yield, high viscosity average molecular weight, narrow distribution, easiness in temperature control, stable product quality and the like. The thermal property of the polyacrylonitrile copolymer prepared by the method can be effectively improved, and the copolymer has certain practical application prospects.

Owner:DONGHUA UNIV

Copolymerized functional nylon 6 polymer and preparation method thereof

ActiveCN109734899AThe polymerization process is simpleGood compatibilityMonocomponent synthetic polymer artificial filamentEndcappingAlcohol

The invention relates to a copolymerized functional nylon 6 polymer and a preparation method thereof. The preparation method includes the steps: mixing a nylon 6 prepolymer ester and a functional dibasic acid ester and then performing ester exchange reaction to prepare the copolymerized functional nylon 6 polymer; preparing a diacid terminated nylon 6 prepolymer from caprolactam and B, adding dihydric alcohol E1 and performing reaction on the dihydric alcohol E1 and end group carboxyl to prepare the nylon 6 prepolymer ester. B is functional diacid A1 and / or functional diacid derivative D1, dihydric alcohol E2 reacts with C to prepare a functional diacid ester, and C is functional diacid A2 and / or functional diacid derivative D2. The hot water extractable matter content of the prepared copolymerized functional nylon 6 polymer is 0.5-2wt%. The copolymerized functional nylon 6 polymer is simple in process, excellent in performance and good in application prospect, and spinning can be performed without hot water extraction.

Owner:JIANGSU NEW HORIZON ADVANCED FUNCTIONAL FIBER INNOVATION CENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com