Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

168results about How to "Formaldehyde free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester fiber coconut fiber plate and preparation method thereof

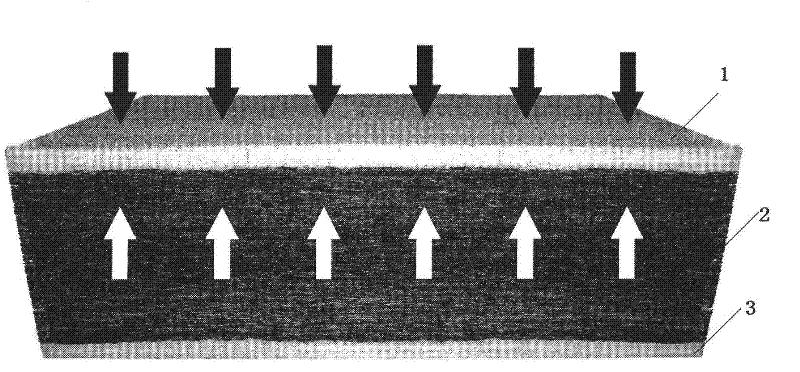

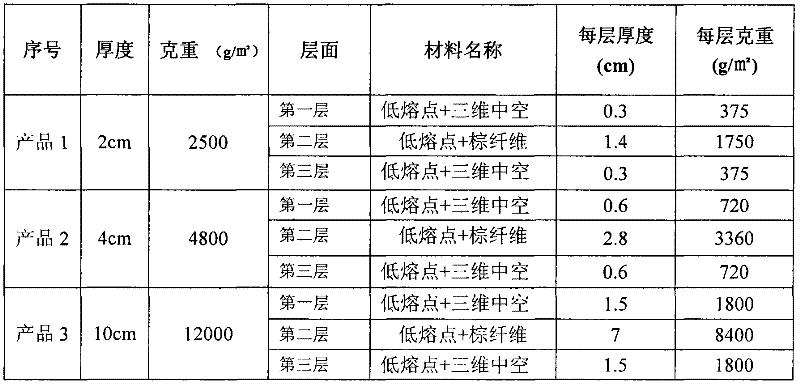

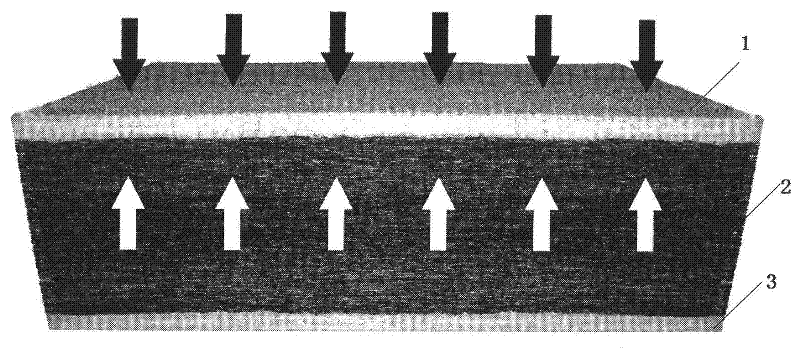

The invention discloses a polyester fiber coconut fiber plate and a preparation method thereof. The polyester fiber coconut fiber plate is characterized by including three layers, wherein the upper and lower layers are made from same materials which are low melting point double-component sheath core fiber and three-dimensionally coiled round hollow fiber, the middle layer is made from low melting point double-component sheath core fiber and coconut fiber, and the three layers are molded integrally through a process. The coconut fiber plate is formed by heat-melting hot-air penetration, melting, bonding and cooling technologies. The polyester fiber coconut fiber plate is environmental-friendly, formaldehyde-free, odorless, temperature-difference-resistant, deformation-free, elastic, strong in tension, impact-resistant, uniform in thickness, and good in sound insulation effect; three layers are molded integrally through the process, the upper and lower layers made from polyester fiber cotton have strong tension, the lining is formed by combining the low melting point polyester fiber with the coconut fiber; and under stress, each layer orderly buffers pressure so as to avoid deformation.

Owner:昆山吉美川纤维科技有限公司

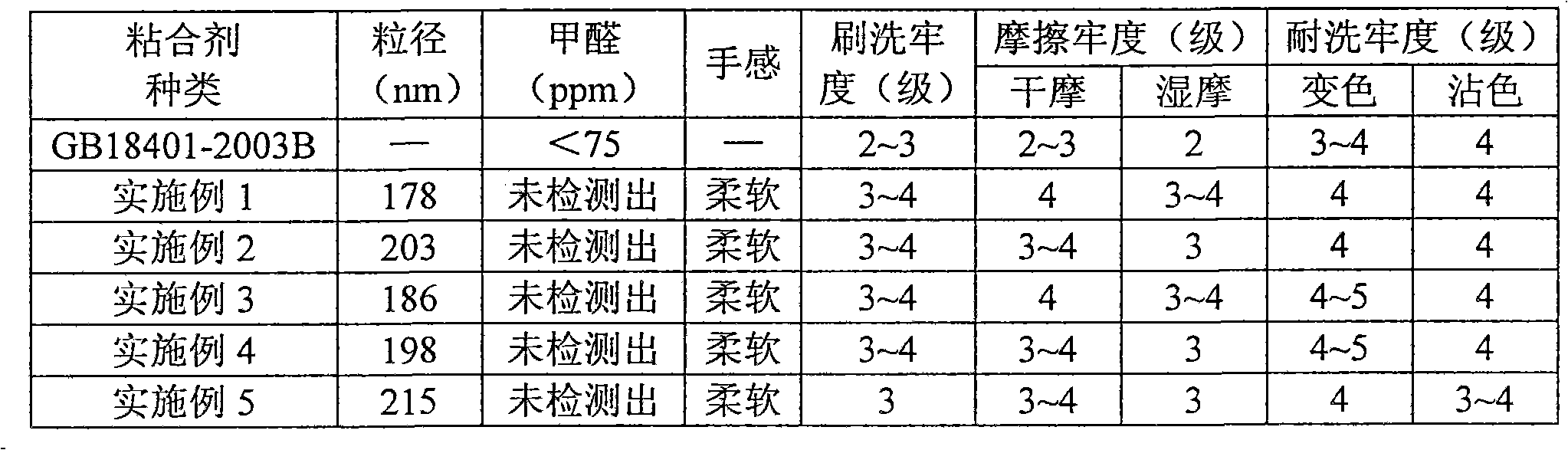

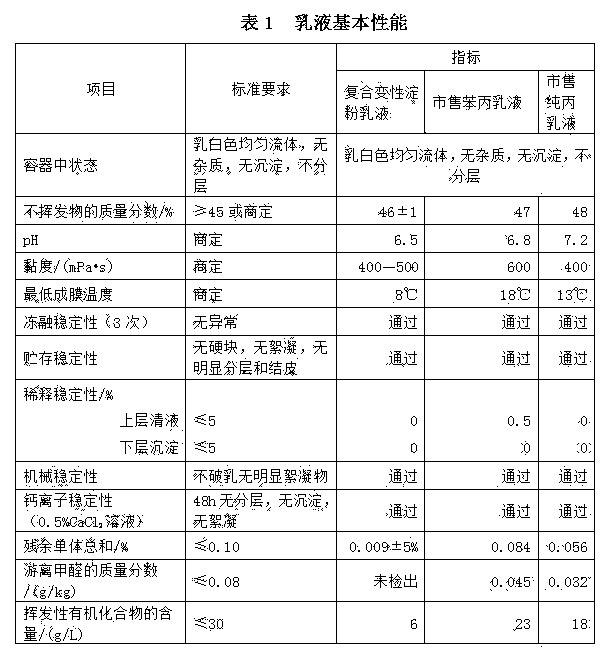

Environmentally-friendly acrylic ester coating printing adhesive emulsion and preparation method

InactiveCN101928367AThe polymerization process is stableEvenly distributedEster polymer adhesivesDyeing processEpoxyFunctional monomer

The invention discloses environmentally-friendly acrylic ester coating printing adhesive emulsion and a preparation method. An emulsion polymerization process is adopted. The emulsion comprises the following raw materials in part by weight: 50 to 90 parts of soft monomer, 10 to 20 parts of hard monomer, 2 to 10 parts of functional monomer, 2 to 5 parts of emulsifying agent, 0.2 to 0.5 part of initiator, 0.2 to 0.5 part of pH buffer, 80 to 120 parts of deionized water and a proper amount of pH adjustor, wherein the total amount of the soft monomer, the hard monomer and the functional monomer is 100 parts by weight. The three monomers are cooperatively used as functional monomers for generating carboxyl crosslinking, hydroxy crosslinking, epoxy crosslinking and the like so that the obtained printing adhesive emulsion has excellent water tolerance and mechanical property. The crosslinking monomers and the emulsifying agent do not contain the components such as N-methylol acrylamide, APEO and the like, so the emulsion does not release formaldehyde during baking and using and is suitable for high-grade environmentally-friendly printing adhesive.

Owner:SOUTH CHINA UNIV OF TECH

Wet-mixed mortar admixture as well as preparation method and application thereof

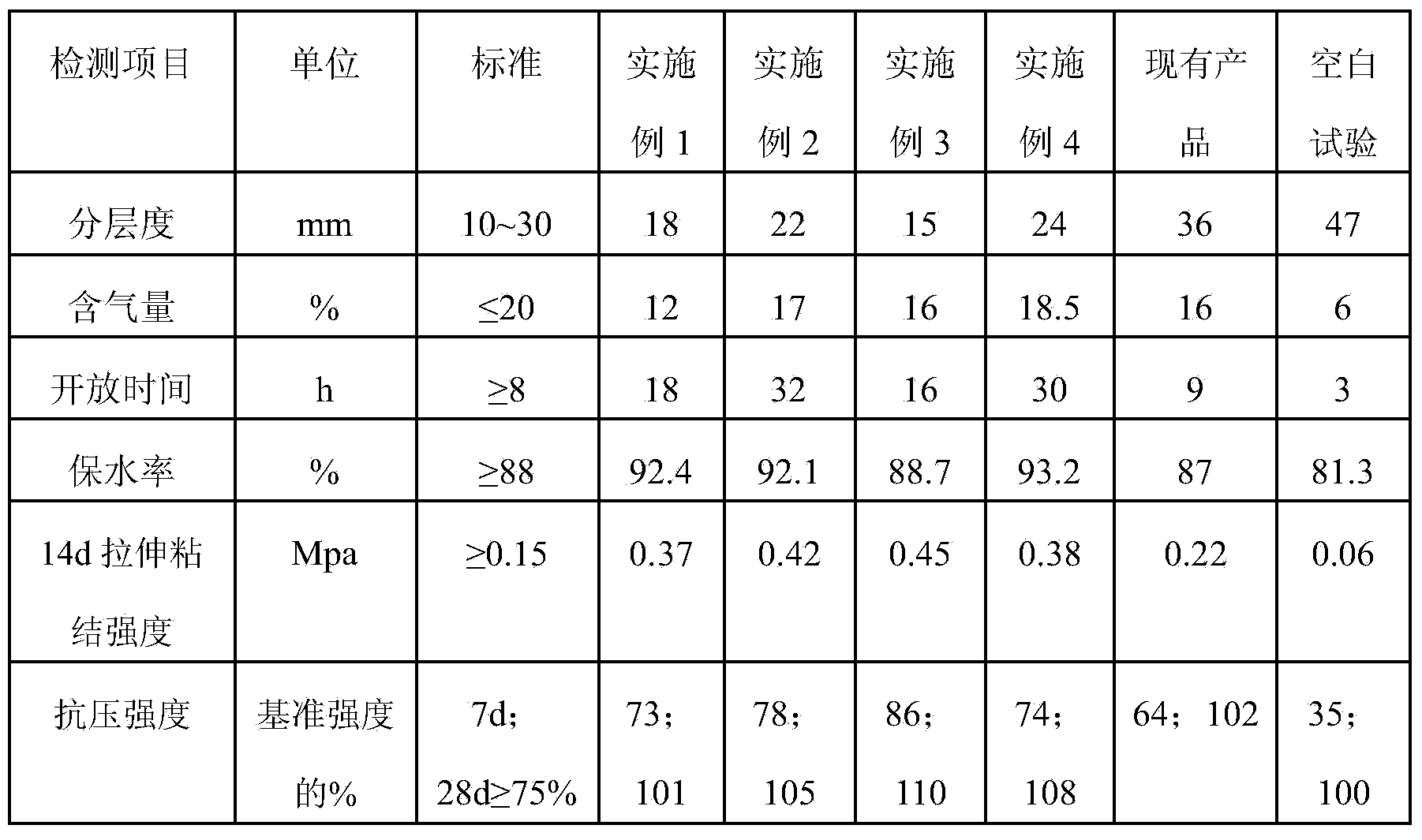

ActiveCN104129943AHigh water reduction rateGood material adaptabilityMaterials scienceCompressive strength

The invention relates to a wet-mixed mortar admixture as well as a preparation method and application thereof, and belongs to the technical field of building mortar. For solving technical problems, the invention provides the wet-mixed mortar admixture consisting of a material A and a material B, wherein the material A consists of the following components in percentage by weight: 0.8-2% of air entraining agent, 2-4% of retarder, 0.06-0.15% of anti-cracking agent, 0.6-1.2% of reinforcing agent, 0.3-0.7% of water retaining agent and the balance of water; the material B consists of the following components in percentage by weight: 3-12% of water reducing agent, 0.2-0.5% of shrinkage reducing agent and the balance of water. The wet-mixed mortar admixture disclosed by the invention is high in water reducing rate, environment-friendly, and can be used for improving the open time, workability and water retaining rate of mortar and improving the compressive strength and the bonding strength; by adopting a double-mixing manner of the materials A and B, the consumption of the material A or B can be effectively adjusted according to the performance of the mortar, and the performance of the mortar can be easily controlled.

Owner:四川恒泽建材有限公司

Compositions suitable for use as joint compounds and related methods

ActiveUS20080305252A1Formaldehyde freeAntifouling/underwater paintsLayered product treatmentJoint compoundCalcium Sulfate Dihydrate

The invention provides a composition useful as a joint compound comprising water, a filler comprising one or more of calcium carbonate, calcium sulfate dihydrate or calcium sulfate hemihydrate, a binder and / or a biocide, wherein the composition after curing is formaldehyde-free.

Owner:UNITED STATES GYPSUM CO

Producing method of water-base polyurethane

InactiveCN103073692AImprove performanceControl distributionPolyureas/polyurethane adhesivesPolymer scienceSpinning

The invention discloses a producing method of water-base polyurethane, which comprises the steps of preparing a polyurethane prepolymer, preparing polyurethane prepolymer salt and finally obtaining water-base polyurethane. Water-base polyurethane prepared by the method has the characteristics of good strength, moderate crosslinking degree, uniform particle size, good water resistance, high binding power and the like, can be applied to spinning adhesive, and can serve as the spinning adhesive.

Owner:烟台宜彬新材料科技有限公司

Composite hydrosol color fixing finishing agent, synthesizing method and use thereof

InactiveCN1546781AReduce pollutionReduce washing waste waterFibre treatmentDyeing processFiberPolymer science

The invention refers to a kind of compound lyosol fixing arrangement agent, a synthesizing method and the usage. The arrangement agent is made up of following products: (1) the silicon sol is made up of gamma-glycidol ether oxygen propyl trimethoxy-silane, water and hydrochloric acid, whose mol proportion is: 1:5-100:1í‡10 -5-1í‡10 -1; (2) the titanium sol is made up of titanic acid butyl ester, water and hydrochloric acid whose proportion is 1:0.1-10:10-200: 1í‡10 -4-1í‡10 -1; (3) the product is produced by mixing above mentioned silicon sol and titanium sol, the mol proportion of silicon and titanium is 1:0.05-1.0. The arrangement agent may form a mesh particle film on the surface of the fiber, realizes the color fixing aim.

Owner:DONGHUA UNIV

Heat unbinding polyurethane finishing agent resistant to crushing, and production method

InactiveCN101003945AOvercome the disadvantages of reducing fabric strengthImprove wrinkle resistanceNatural fibresAlcoholHydrogen

The present invention relates to a thermal deblocking polyurethane crease-resisting finishing agent. Its composition includes (by wt%) 20-60% of hydroxyl terminated polymer whose average mole mass is 400-6000; 0.1-10% of tribasic alcohol compound; 6-20% of dimethylol carboxylic acid compound; 20-50% of polyisocyanate compound; 6-30% of isocyanate blocking agent and 0.6-6% of ammonia water. Said invention also provides its preparation method and concrete steps.

Owner:LIAONING FIXED STAR FINE CHEM

Flame-retardant roll type curtain and production process thereof

InactiveCN102078132AGood flame retardant performanceSimple processFibre treatmentCurtainsSolventAlkylphenol

The invention relates to a flame-retardant material and a production process thereof, in particular to a flame-retardant roll type curtain and a production process thereof. Both the front and the back of the curtain fabric of the flame-retardant roll type curtain have a colorless and transparent flame-retardant coating. Slurry for the flame-retardant coating comprises the following components in percentage by mass: 10 to 40 percent of environmentally-friendly flame-retardant agent, 10 to 45 percent of environmentally-friendly nanometer adhesive, 2 to 5 percent of thickener and 45 to 78 percent of water. The roll type curtain has an excellent flame-retardant property, and a GB5455 vertical burning method is adopted for an flame-retardant test, and the flame-retardant property of the roll type curtain reaches above B2 level when assessed according to 6817591; the curtain is free of solvent volatilization pollution, formaldehyde, alkylphenol ethoxylates (APEO), or toxic gas released in the process of burning; the production process is simple, can realize continuous production without any special equipment, and also can be combined with other processes for one-step implementation.

Owner:CHANGZHOU UNIV +1

Quick-hardened early-strengthened non-cracking surface layer self-leveling mortar and preparing method thereof

The invention discloses quick-hardened early-strengthened non-cracking surface layer self-leveling mortar. The mortar is prepared from, by mass, 30-60% of semi-hydrated gypsum, 5-20% of cement, 5-15%of coarse whiting, 10-30% of quartz sand, 10-20% of quartz powder, 0.05-0.25% of retarder, 0.2-0.5% of water reducing agent, 0.1-1.0% of redispersible powder, 0.03-0.1% of thickening stabilizer, 0.1-0.5% of defoaming agent, 0.1-0.5% of pigment, 0.4-1.0% of silicon dioxide fiber, 0.2-0.5% of water-proofing agent and 0.3-1.0% of coalescing agent. The invention further discloses a preparing method ofthe quick-hardened early-strengthened non-cracking surface layer self-leveling mortar. The self-leveling mortar has the advantages of being quick in hardening, early in strengthening, free of cracking and curing, resistant to wear and water, free of formaldehyde, easy to construct, high in adaptability and the like. The self-leveling mortar is mainly used for houses, schools, cinemas, shopping malls, workshops and other ground high-end leveled places.

Owner:浙江恒起新材料科技有限公司

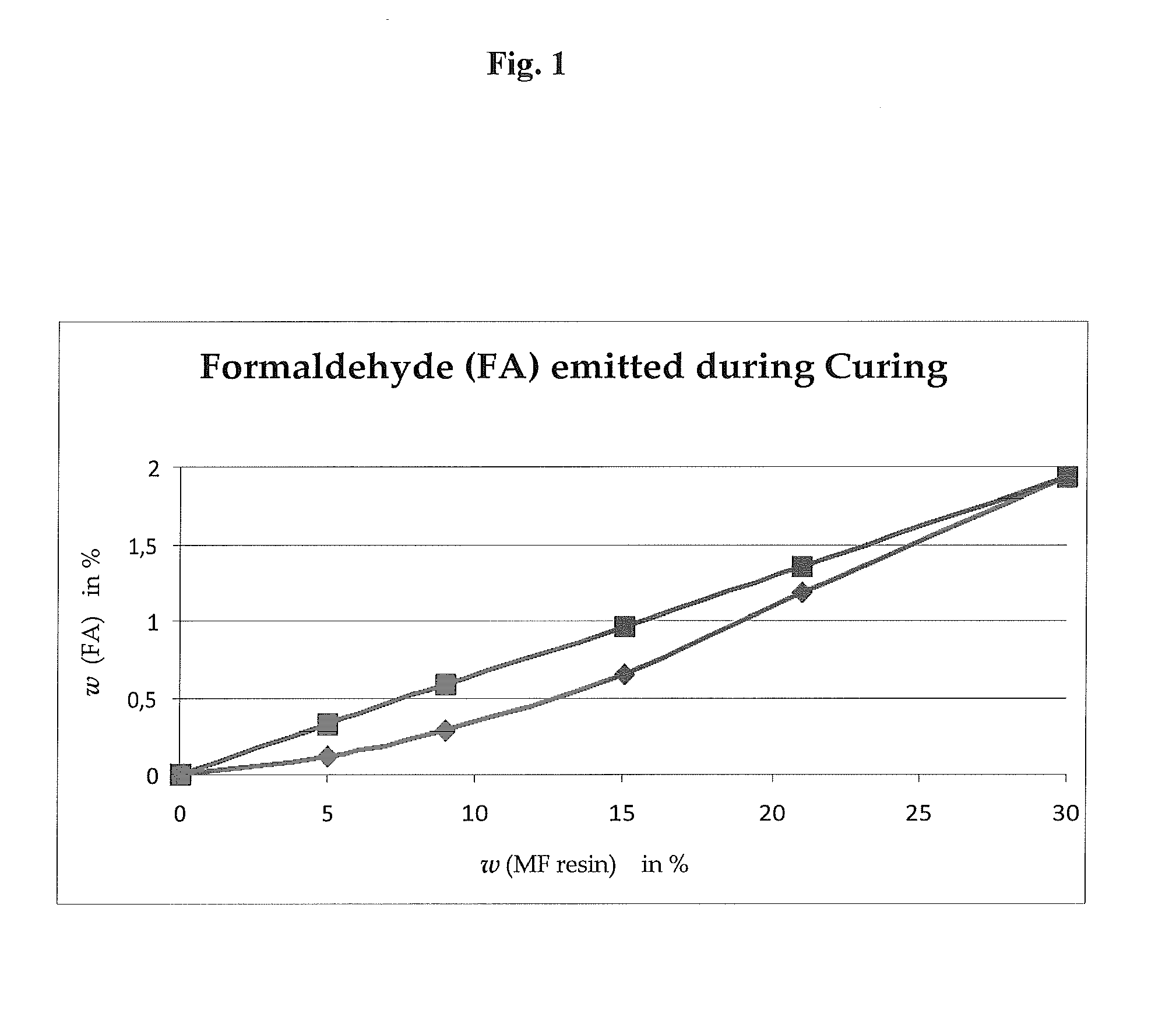

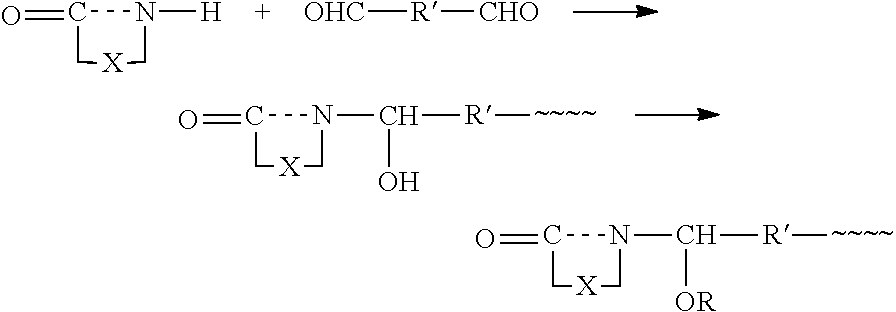

Mixtures of crosslinking agents

The invention relates to a crosslinker composition comprising a reaction product of a cyclic urea U and a multi-functional aliphatic aldehyde A, and at least one crosslinker selected from the group consisting of reaction products of an amino-triazine and at least one aldehyde selected from the group consisting of aliphatic monoaldehydes and multifunctional aliphatic aldehydes having the structure Y(CHO)n, where Y is an n-functional aliphatic residue, and n is greater than 1; reaction products of urea and / or cyclic ureas and formaldehyde; alkoxycarbonyl-aminotriazines; multifunctional isocyanates which may be partially or completely blocked; reaction products of phenols and aliphatic monoaldehydes; multifunctional epoxides; multifunctional aziridines; and multifunctional carbodiimides, wherein any of the crosslinkers which have hydroxyl groups may be etherified with one or more linear, branched, or cyclic aliphatic alcohols.

Owner:ALLNEX NETHERLANDS BV

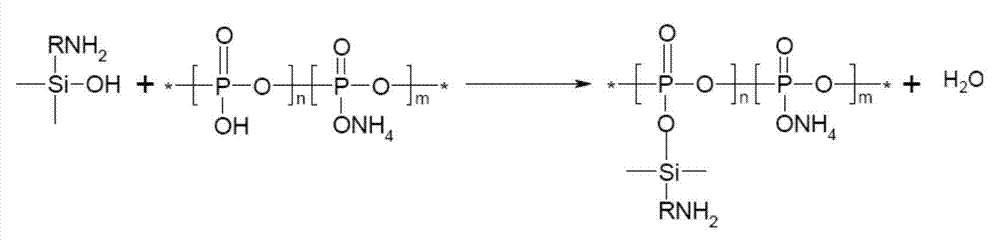

Non-formaldehyde and low-water solubility ammonium polyphosphate product and preparation method thereof

The invention relates to a non-formaldehyde and low-water solubility ammonium polyphosphate product and a preparation method thereof. The product needs to solve the problems of no formaldehyde and low water solubility; and the method needs to solve the problem of causing after-treatment troubles due to use of a reaction medium. According to the product, the phosphorus content ranges from 29.0% to 31.0%, and the water solubility at the temperature of 25 DEG C is smaller than or equal to 0.15 g / 100 ml water. The method comprises the following steps: (1) reacting amino siloxane on the surfaces of ammonium-lacking crystal II type ammonium polyphosphate particles; and (2) coating process: mixing the ammonium polyphosphate, whose surface reacts with the amino siloxane, with organic silicon epoxy resin for 5-60 minutes, mixing for 5-60 minutes after the temperature is heated up to 50-90 DEG C, reacting for 0.5-3 hours when the temperature is continuously heated up to 100-220 DEG C, cooling and screening to obtain the product.

Owner:HANGZHOU JLS FLAME RETARDANTS CHEM

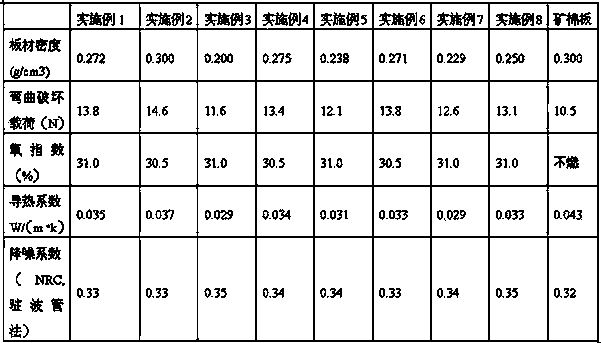

Preparation method of environment-friendly PU (polyurethane) ceiling with flame retardant and sound absorption functions

The invention discloses a preparation method of an environment-friendly PU (polyurethane) ceiling with flame retardant and sound absorption functions. The preparation method comprises the following steps: adopting polyester isocyanate prepolymer as an adhesive; uniformly mixing the polyester isocyanate prepolymer with crushed waste PU rigid foam granules; carrying out mould pressing to manufacture the environment-friendly PU ceiling with the flame retardant and sound absorption functions. The ceiling comprises 5-10 parts of the polyester isocyanate prepolymer and 90-95 parts of the crushed waste PU rigid foam granules by weight; the polyester isocyanate prepolymer is isocyanate prepolymer which is prepared through reaction between diisocyanate and polyester polyatomic alcohol in 60-80 DEG C and contains 10-30% of NCO. The preparation method adopts the polyester isocyanate prepolymer as the adhesive; a product prepared according the method is excellent in performance, out of solvent and formaldehyde, safe, and environment-friendly; a large quantity of waste polyurethane rigid foam can be treated by adding a small quantity of the polyester isocyanate prepolymer; meanwhile, a pressed plate is low in density, material consumption and comprehensive cost.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD +1

Sol-gel color fixing method

The present invention belongs to the field of chemical technology and is a kind of sol-gel color fixing method. Reagent capable of producing chemical combination with fabric fiber is selected as material for sol finishing liquid to finish fabric at 100-180 deg.C. Thn and transparent complicated network film is formed on the inner and outer surface of fiber to fix the dye on the fabric and to raise the color fastness of fabric.

Owner:DONGHUA UNIV

Flame retardant sound absorbing board based on polyester fiber material and production process thereof

ActiveCN106968049AImprove flame retardant performanceImprove mechanical propertiesHeat resistant fibresNon-woven fabricsPolyesterCold air

The invention discloses a flame retardant sound absorbing board based on polyester fiber material and a production process thereof. Waste plastics are used as raw materials; the regenerated polyester staple fiber and regenerated low melting skin core type polyester staple fiber are prepared by melt spinning; the flame retardant is sprayed on the upper surface of the board uniformly, and the partial thickness of the lower surface of the board is dipped into the flame retardant; the flame retardant sound absorbing board is obtained by predrying, cooling down with cold air after calendering and cutting. The production process comprises the following steps: (1), preparing the raw materials; (2), mixing a formation mesh of the regenerated staple fiber; (3), reinforcing the fiber mesh; (4), spraying the flame retardant, and being dipped into the lame retardant; (5), predrying, calendering, and cooling; (6), cutting and arranging. According to the method of spraying and immersion which work at the same time and by spraying the flame retardant on the upper surface and dipping the lower surface into the flame retardant, the good flame retardant effect of the sound absorbing board is effectively guaranteed; a good formability of the sound absorbing board after drying is ensured, and the hardness is up to standard.

Owner:青岛博时阻燃织物有限公司

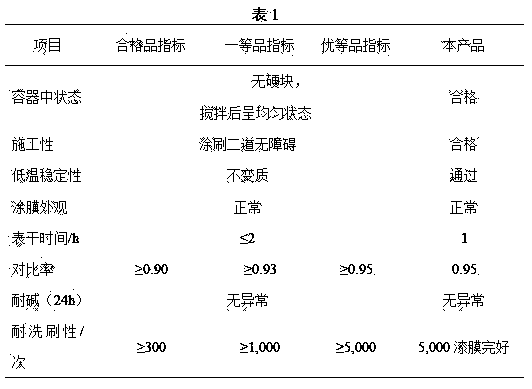

Biomass internal wall paint and preparation method thereof

ActiveCN104109444AGood film formingGood scrub resistanceStarch coatingsHazardous substanceSoftened water

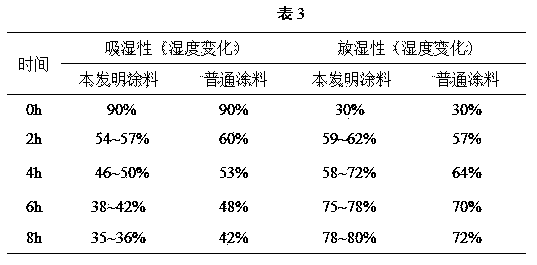

The invention discloses a biomass internal wall paint and a preparation method thereof, and aims to solve the problems of high harmful substance content and especially high formaldehyde content in the existing internal wall paint. The preparation method comprises the following steps: taking softened water, dodecenyl starch aluminum succinate, dispersing agent, wetting agent, titanium white, calcined kaolin, highly-crosslinked porous starch, ground calcium carbonate and light calcium carbonate, adding into a dispersion machine, dispersing at the high speed of 1500 r / min for 20-40 minutes, lowering the speed to 500 r / min, sequentially adding the composite modified starch emulsion, propanediol and defoaming agent, and uniformly dispersing to obtain the composite modified starch-base biomass paint. The obtained biomass internal wall paint has the advantages of delicate paint film, scrub resistance, low VOC (volatile organic compound) content and no formaldehyde, has favorable humidity regulation function, and is green and environment-friendly.

Owner:GANSU GLDARK NEW MATERIAL

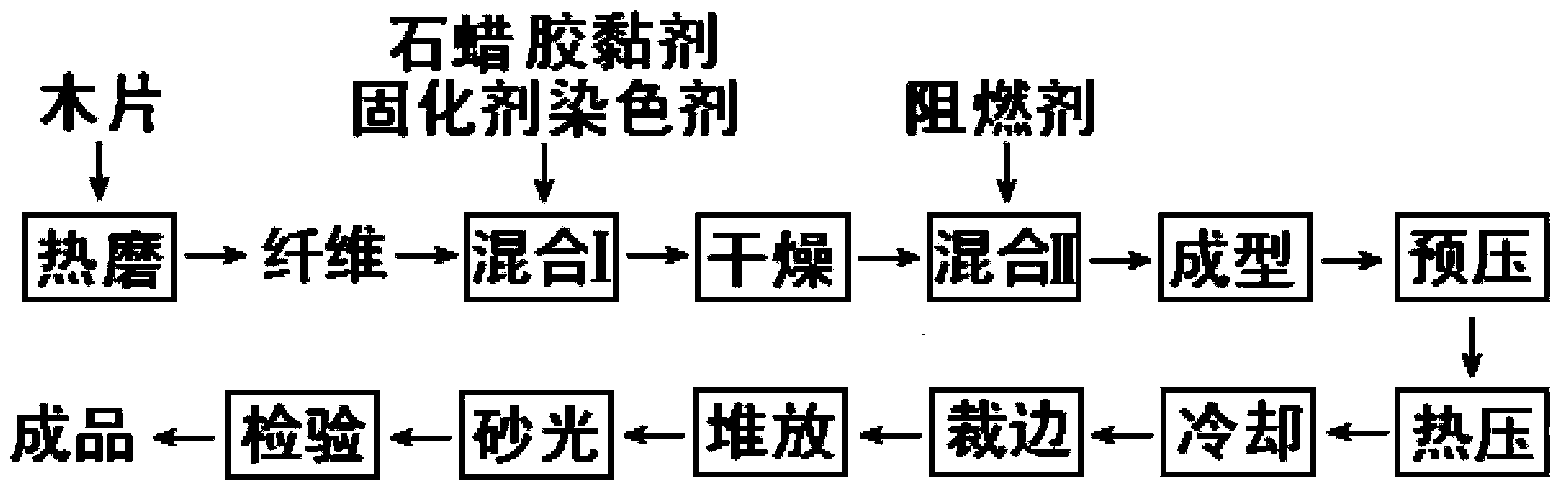

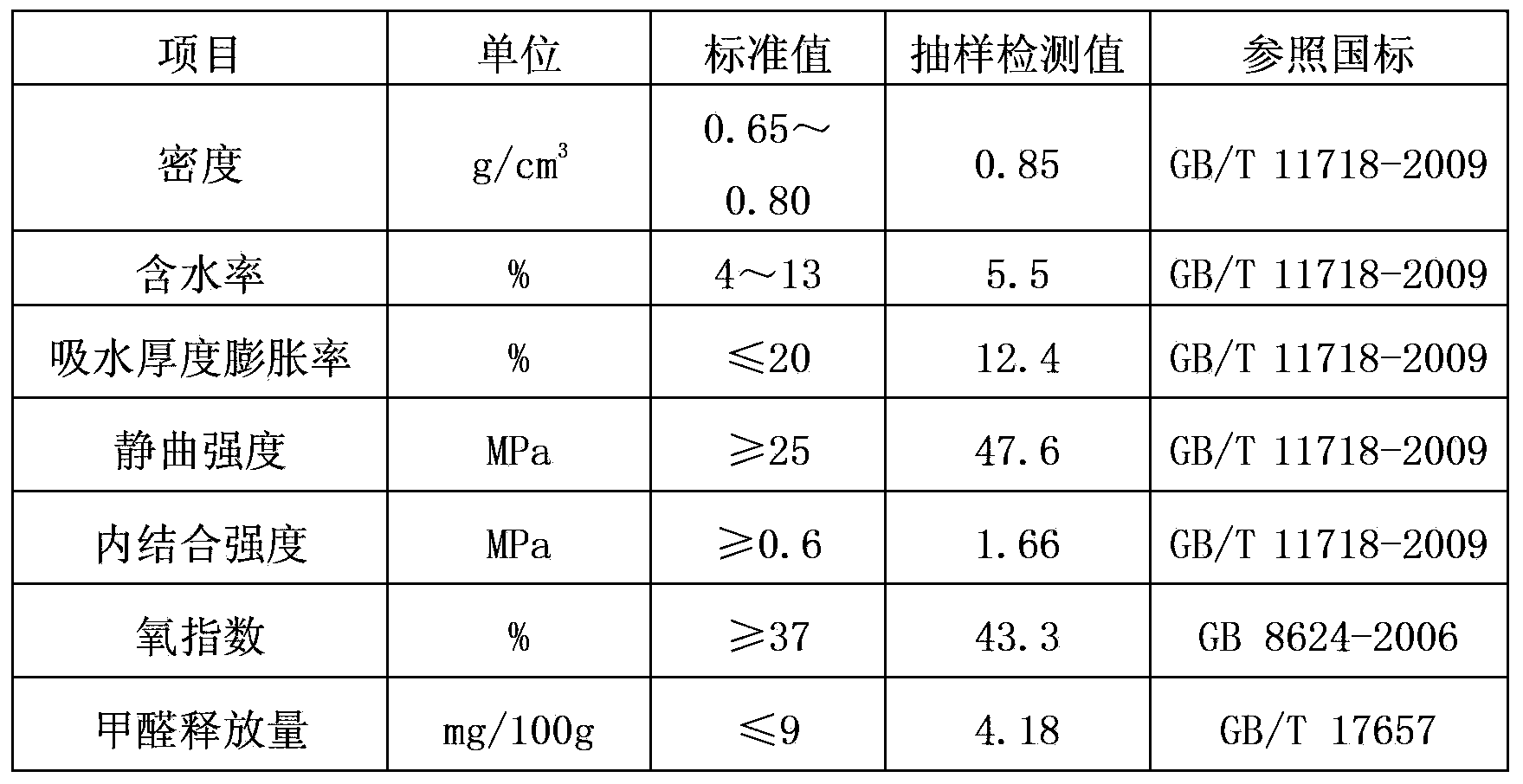

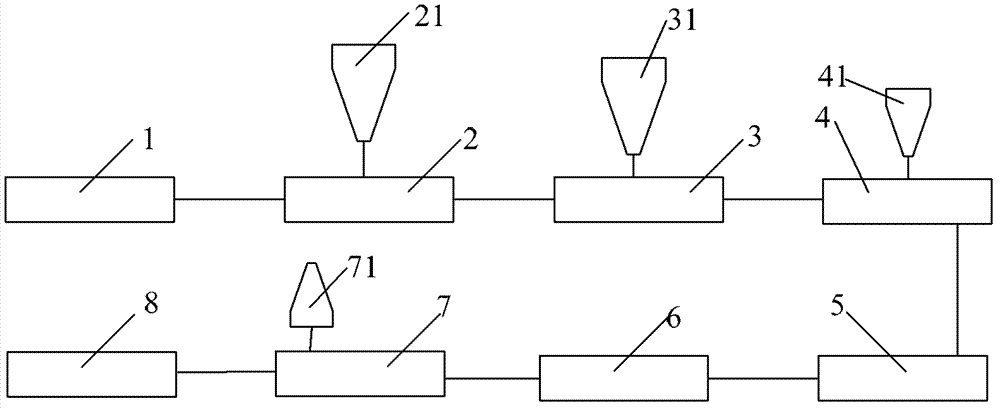

High-grade environment-friendly flame-retardant fiberboard and manufacturing method thereof

ActiveCN103406968AEasy to implementSimple production processFlat articlesDomestic articlesParaffin oilsFire retardant

The invention discloses a high-grade environment-friendly flame-retardant fiberboard and a manufacturing method thereof. Wood chips are used as raw materials and hot-ground to obtain fibers, auxiliary raw materials are added to the fibers, and the high-grade environment-friendly flame-retardant fiberboard is manufactured. Each cubic meter of the high-grade environment-friendly flame-retardant fiberboard is composed of, by weight, 580-630kg of fibers, 7-9kg of paraffin, 200-230kg of adhesive (the solid content ranges from 40% to 50%), 0.2-0.3kg of curing agent, 1.0-2.0kg of coloring agent, 38-50kg of fire retardant and appropriate water. The manufacturing method of the high-grade environment-friendly flame-retardant fiberboard comprises the working procedures of hot-grinding, mixing, drying, shaping, hot-pressing, edge cutting and sanding. Production processes are simple, technical parameters are accurate, process reliability is strong, production efficiency is high, and the high-grade environment-friendly flame-retardant fiberboard produced in the manufacturing method is good in flame retardant property, low in formaldehyde emission and excellent in physical and mechanical performance.

Owner:GUANGXI UNIV

Method for preparing decorative material by utilizing modified plant straws

InactiveCN104530735AImproves strength and hardnessImprove stabilityReed/straw treatmentCorn starchMagnesium

The invention relates to a method for preparing a decorative material by utilizing modified plant straws. The preparation method comprises the following steps: with 100 parts of plant straws by weight as a cardinal number, weighing 20 parts of waste plastic particles, 3 parts of bamboo powder, 0.5 part of curcumin, 2 parts of calcined shell, 1 part of metal magnesium powder, 5 parts of calcined kaolin, 1 part of a fire retardant, 2 parts of linear polyethylene, 0.8 part of a silane coupling agent, 1 part of hydroxypropyl methylcellulose, 0.8 part of modified corn starch, 1 part of soybean oil, 0.5 part of cyclohexanone and 2 parts of nanometer silicon dioxide; airing the plant straws, smashing, drying straw powder, sending the straw powder to a reaction kettle to react, taking out the straw powder, cooling, and sending the straw powder to a refrigerating device to obtain modified straw powder; mixing the modified straw powder and other materials, pouring the mixture to a grinding machine and grinding for 2 hours; and carrying out hot melting extrusion to mold. The decorative material has high fire resistance, corrosion resistance, moisture resistance, steeping resistance, worm-eaten resistance, dimensional stability and the like.

Owner:王旭

Environment-friendly wall fireproof heat-preserving board and preparation method thereof

The invention discloses an environment-friendly wall fireproof heat-preserving board and a preparation method thereof. The environment-friendly wall fireproof heat-preserving board is prepared from the following raw materials in parts by weight: 26-60 parts of straw powder, 0.2-3 parts of guanylurea phosphate, 0.1-1.2 parts of boric acid, 15-45 parts of magnesium oxide, 5-15 parts of magnesium chloride or magnesium sulfate, 1-30 parts of coal ash or diatomite in powder, 0-30 parts of crushed crude pearlite or leech powder, 0.1-0.5 part of a styrene-acrylic emulsion, 0.1-0.5 part of calcium lignosulphonate and 5-25 parts of tap water. The preparation method comprises the following steps: first, mixing straw powder, guanylurea phosphate, boric acid, magnesium oxide, coal ash or the diatomite in powder, crushed crude pearlite or leech powder and calcium lignosulphonate; then, adding magnesium chloride or magnesium sulfate, the styrene-acrylic emulsion and tap water; and after fully and uniformly stirring at normal temperature, putting in a template, rolling, maintaining and demoulding to prepare the wall fireproof heat-preserving board. The environment-friendly wall fireproof heat-preserving board has the characteristics of high compression and breaking strength, good moisture absorption, water adsorption, flame retardant and anti-freezing performances, small heat conductivity coefficient, no formaldehyde, environmental friendliness, fireproofness and heat preservation.

Owner:ANHUI ZHONGYI NEW MATERIAL TECH CO LTD +1

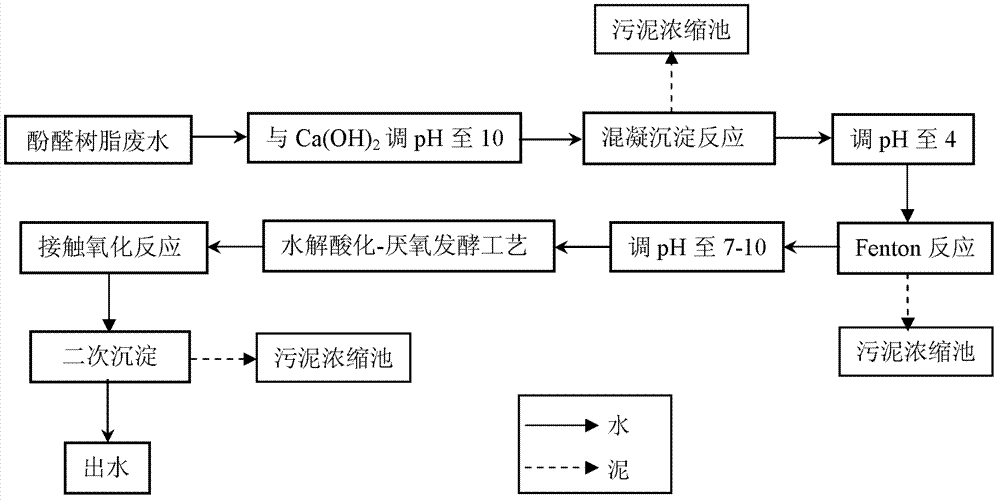

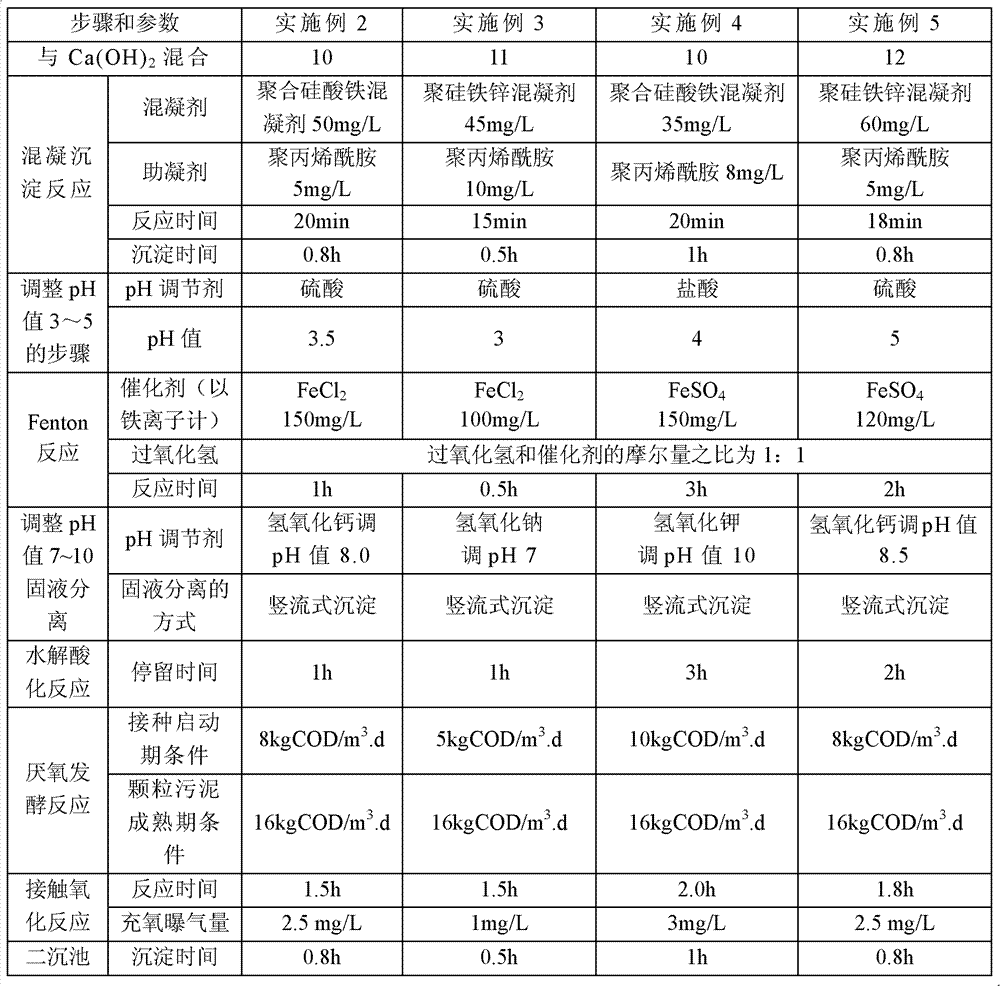

Phenolic resin wastewater processing method and special-purposed device

InactiveCN103086562ASimple and fast operationFew control conditionsMultistage water/sewage treatmentNature of treatment waterFenton reactionWastewater

The invention discloses a phenolic resin wastewater processing method and a special-purposed device. The phenolic resin wastewater processing method comprises the following steps: phenolic resin wastewater is mixed with Ca(OH)2, and a pH value is regulated to 10-12; a coagulation and sedimentation reaction is carried out; a pH value is regulated to 3-5; a Fenton reaction is carried out; a pH value is regulated to 7-10, and solid-liquid separation is carried out; a hydrolytic acidification-anaerobic fermentation process is carried out; a contact oxidation reaction is carried out; and secondary sedimentation is carried out. The special purposed device comprises the sequentially connected components of: a wastewater feeding tank, a coagulation and sedimentation reaction rank with a first feeder, a Fenton reaction device with a second feeder, a solid-liquid separation device with a third feeder, a hydrolytic acidification tank, an anaerobic fermentation tank, a contact oxidation reaction rank with an aeration device, and a secondary sedimentation tank. With the processing method, pollutant content in the processed wastewater reaches a discharge standard. The operation is simple, control conditions are less, and cost is low.

Owner:SHANGHAI BODAN ENVIRONMENTAL ENG TECH

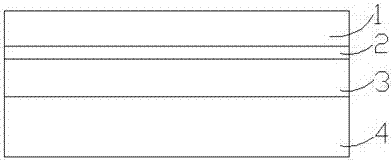

Elastic sound-absorbing PVC (Polyvinyl Chloride) floor and preparation method thereof

PendingCN107471803AElasticComfortable feetSynthetic resin layered productsLaminationNoise generationSound generation

The invention belongs to the field of PVC (Polyvinyl Chloride) floors and relates to an elastic sound-absorbing floor. The elastic sound-absorbing PVC floor comprises an elastic PVC transparent layer, a printing fabric layer, a base material layer and an elastic sound-absorbing layer which are arranged in sequence from top to bottom. The elastic sound-absorbing PVC floor has the advantages that due to use of highly-polymerized PVC, the transparent layer has elasticity and is comfortable in foot feel and low in noise; the base material layer has an effect of stabilizing the physical properties of the floor; the elastic sound-absorbing layer has a structure with convex and concave patterns, the part with the convex patterns has high elasticity and can generate elastic deformation when the floor is stepped, and the part with the concave patterns and the ground form a cavity so as to realize the effects of reducing sound generation and absorbing sound; and the elastic sound-absorbing layer and the other layers are laminated together by one time of heat lamination, so that the elastic sound-absorbing floor does not contain glue, VOC (Volatile Organic Compound) and formaldehyde, and is more environment-friendly.

Owner:HUIZHOU WEIKANG NEW BUILDING MATERIALS CO LTD

Novel environment-friendly energy-saving wood-plastic composite board for truck carriages and preparation method of novel environment-friendly energy-saving wood-plastic composite board

The invention discloses a novel environment-friendly energy-saving wood-plastic composite board for truck carriages and a preparation method of the novel environment-friendly energy-saving wood-plastic composite board. The composite board is obtained by mixing wooden powder and HDPE (high-density polyethylene) resin with surface treating agent, processing auxiliaries, intensifier and compatilizer according to a certain proportion in a high-speed mixer by means of characteristics of high-polymer interface chemical principles and plastic filling modification, pelleting to obtain the composite board material through an extruder after mixing. The processed wood-plastic composite board material has the advantages of simple-substance materials including plastic, wood and metal and the like, can be used as bottom boards and retaining board of carriages of light trucks and van trucks and substitute for conventional wooden boards, bamboo plywood boards and steel boards, waterproof, mildew-proof and formaldehyde-free effect, improving grade of the trucks, environment friendliness and recycling of resources are realized.

Owner:ANHUI RED FOREST NEW MATERIAL TECH

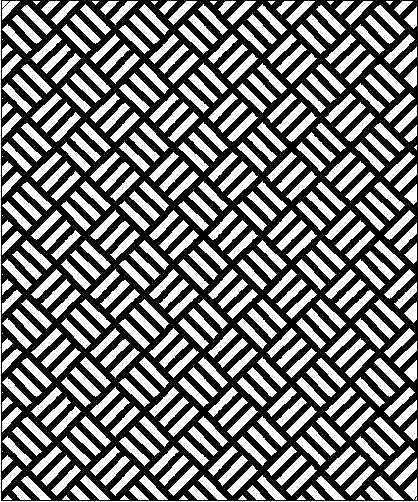

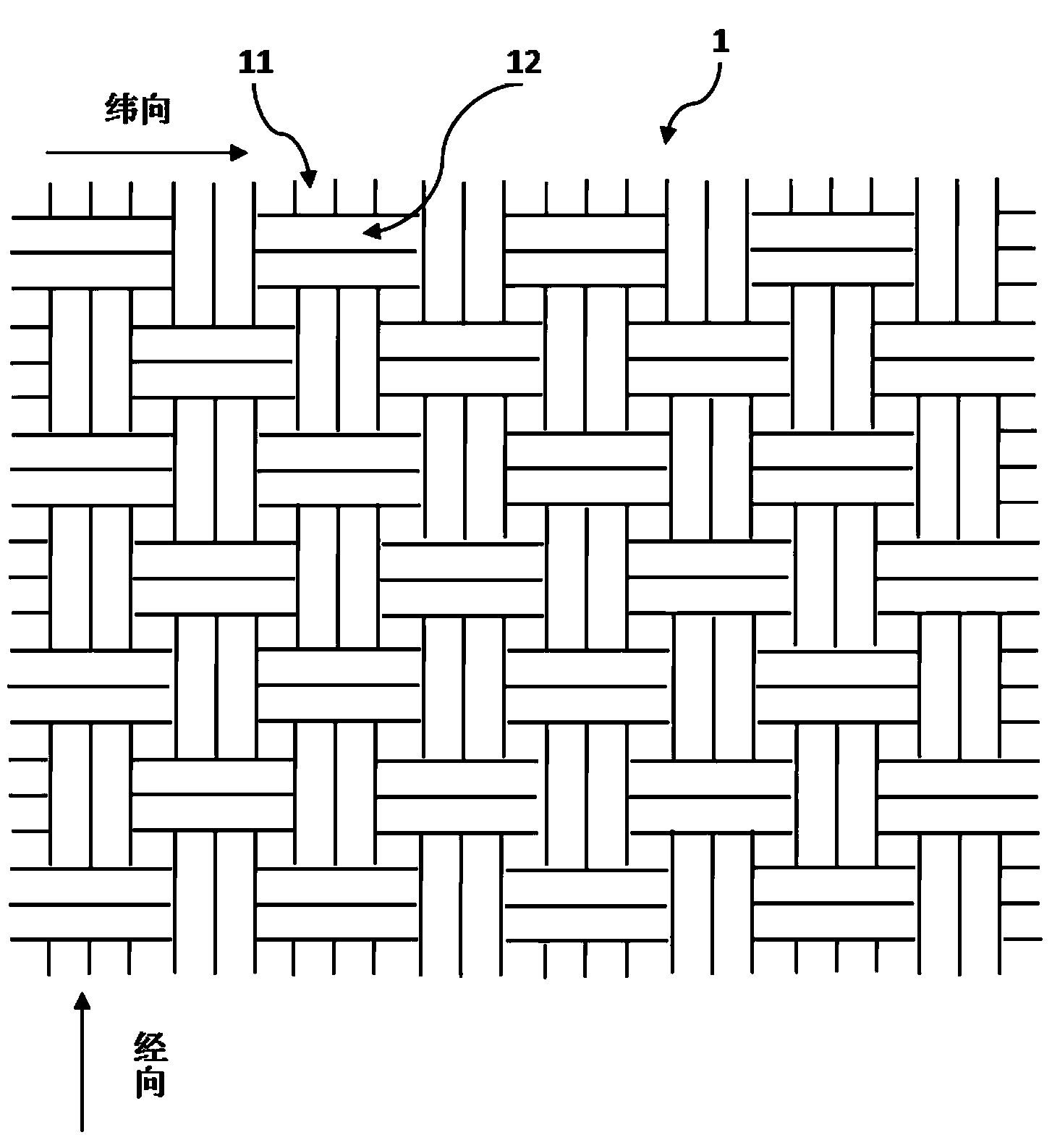

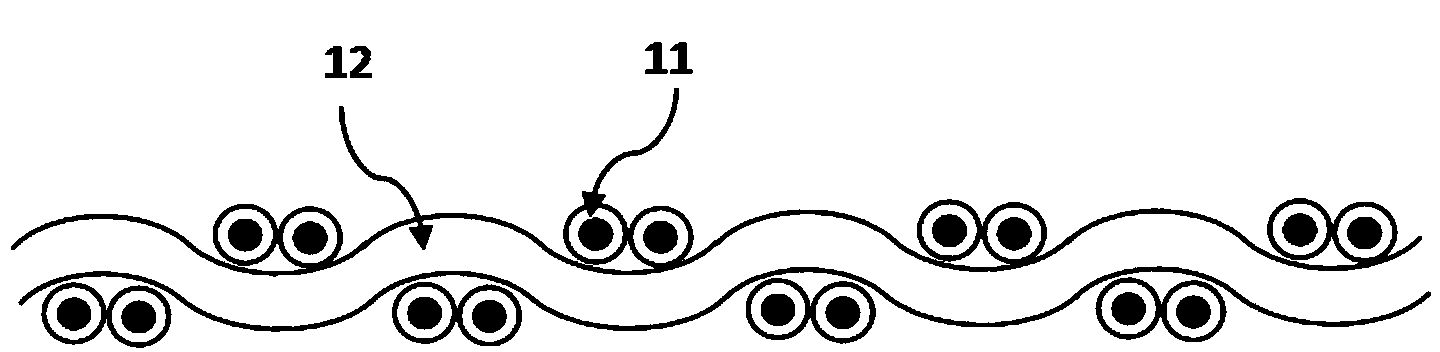

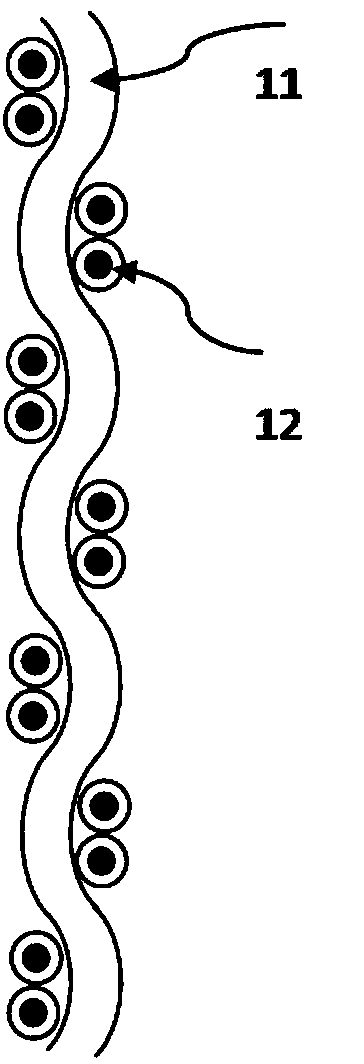

Halogen-free flame-retardant environment-friendly covered polyolefin yarn fabric and preparation method thereof

InactiveCN104233569AImprove breathabilityTranslucentHeating/cooling textile fabricsWoven fabricsPolyesterYarn

The invention relates to a halogen-free flame-retardant environment-friendly covered polyolefin yarn fabric and a preparation method thereof. The fabric is formed by weaving covered threads and has warp and weft structures; the covered threads comprise polyester fibers and halogen-free flame-retardant environment-friendly polyolefin composite materials covering the surfaces of the polyester fibers; the covered threads are 0.3-0.4 millimeter in diameter, rectangular or square gaps are reserved between the warp structures and the weft structures, and the aperture ratio is 2 to 10 percent; the halogen-free flame-retardant environment-friendly covered polyolefin yarn fabric is 0.55-0.75mm in total thickness and 350-420g / m<2>. The invention also provides a preparation method for the fabric. The fabric has the characteristics of sunshading, ultraviolet resistance, flame retardancy, high color fastness and the like of similar PVC (polyvinyl chloride) substrate fabrics, and also has the advantages of no halogen, environment friendliness, low smoke density during combustion, high self-cleaning property, high chemical stability, light weight, high air permeability and the like.

Owner:NINGBO XIANFENG NEW MATERIAL

Environment-friendly humidifying wallpaper and preparation method thereof

InactiveCN103911914ARegulate indoor humiditySimple preparation processDefoamers additionCovering/liningsAbsorption capacitySuper absorbent

The invention relates to environment-friendly humidifying wallpaper and a preparation method thereof. The wallpaper comprises a wallpaper base layer, wherein a waterborne printing coating with a humidifying function is printed on the wallpaper base layer; the wallpaper base layer is environment-friendly rich mineral paper or non-woven paper; the waterborne printing coating consists of an adhesive, a porous inorganic mineral material, super absorbent resin, water, a thickening agent, an antifoaming agent and a wetting agent, and the absorbent resin has an effect of increasing the water absorption capacity of the wallpaper. The waterborne printing coating is printed to the wallpaper base layer by adopting a round screen or plain net or gravure process. The thickness of the wallpaper base layer is 100-1,000microns, and the thickness of the waterborne printing coating is 5-50 microns. When the wallpaper achieves a decorative effect, high-efficiency indoor humidity regulation can be performed, and the environment-friendly humidifying wallpaper is pollution-free and formaldehyde-free and has no indoor volatile organic pollutant.

Owner:宋旭

Method for improving color fastness of photochromic fabric

InactiveCN103572621AFormaldehyde freeColor becomes smallerDyeing processColour fastnessTextile fiber

The invention relates to a method for improving the color fastness of a photochromic fabric. The method comprises the following steps: (1), at the room temperature, mixing tetraethoxysilane and glutamic-pyruvic transamine with ethyl alcohol, stirring until uniform mixing, then dripping hydrochloric acid drop by drop under stirring, and stirring unceasingly for 5 hours so as to obtain a finishing liquor; (2), at the room temperature, carrying out two times of soaking and two times of rolling to the photochromic fabric in the finishing liquor, then drying, and finally baking the photochromic fabric. The method provided by the invention has the advantages that the color fixing is convenient, the consumed time is short, the cost is low, pollutions to the environment are small, and the effect in improving the color fastness of the photochromic fabric is obvious; an agent capable of being in reaction with and combined with textile fiber is selected as a raw material to prepare a colloidal sol finishing liquor, when finishing is performed on the photochromic fabric, overhigh temperature is not required, not only can the effect of improving the color fastness of the photochromic fabric be improved, but also damage to fabrics can be prevented.

Owner:DONGHUA UNIV

Compound material used for stone-moulding and composite board made up thereof

InactiveCN1830876AFormaldehyde freeNo pollution in the processSolid waste managementMetallurgyPlastic materials

A composite stone-plastic material used to prepare composite plate with high strength and anticorrosion nature and no pollution of formaldehyde and radioactive material is proportionally prepared from stone powder chosen from light calcium carbonate stone powder and heavy one, PVC resin, and the powder of plant chosen from wheat straw, cotton stalk and wood.

Owner:陈锡宝

Composite modified starch emulsion for coating and preparation method of emulsion

The invention discloses composite modified starch emulsion for a coating and a preparation method of the emulsion. The emulsion adopts modified starch obtained by cross-linking oxidized starch with acidified etherified starch as a framework and adopts hard monomer, soft monomer and functional monomer as mixed monomer. The preparation method comprises the following steps: mixing the oxidized starch with the acidified etherified starch to prepare starch milk, performing alkalization and cross-linking reaction, heating for pasting, and adding an emulsifier, an initiator solution and the mixed monomer for grafting reaction; adjusting the pH value by NaOH to obtain the emulsion for the coating. The emulsion has the advantages of acrylate and starch emulsion, and is excellent in film-forming performance, good in washability and breathability, formaldehyde-free and high in solid content. Compared with the existing common pure acrylic emulsion for the coating, the emulsion disclosed by the invention has the characteristics that the problems of poor film-forming performance, small adhesive force and high hardness of the emulsion are improved and the cost is effectively reduced.

Owner:GANSU GLDARK NEW MATERIAL

Novel environment-friendly dyeing method for jeans apparel

InactiveCN105926316AGood effectExcellent moisture resistance color fastDry-cleaning apparatus for textilesDyeing processPigmentChemistry

The invention provides a novel environment-friendly dyeing method for jeans apparel. The novel environment-friendly dyeing method specifically comprises the following steps: (1) pretreatment: desizing; (2) preparation of a modified solution; (3) pad drying; (4) preparation of dye liquor; (5) dyeing and padding of jeans apparel; (6) finishing of the jeans apparel. According to the novel environment-friendly dyeing method for the jeans apparel, a sizing agent on the apparel is removed by desizing; by the adoption of cationic modification treatment, natural medicinal plant extract pigment dye for dyeing and jeans apparel finishing, satisfactory environment-friendly jeans cloth can be prepared, and the effect is obvious; the jeans apparel has excellent advantages of resistance to wet color, resistance to wash color, sun durability, long service life and the like, and is higher in practical value; the process is energy-saving and environment-friendly, and the jeans apparel does not contain formaldehyde.

Owner:太仓红桥服饰有限公司

One-step molding mattress

InactiveCN102660843ASimple manufacturing processFormaldehyde freeUpholstery manufactureNon-woven fabricsHazardous substanceEthylene

The invention provides a preparation method for a one-step molding mattress. The preparation method is characterized by comprising the following steps of: separately and respectively mixing different fiber materials with ES (Ethylene-Propylene Side By Side) fiber to form different mixtures, respectively carding and lapping the different mixtures obtained by the previous step by the corresponding carding machine to form different fiber layers, putting the different fiber layers into the same drying oven and stacking together for heat treatment, wherein the temperature of the heat treatment is between 200 DEG C and 220 DEG C, and the processing time is 5-6 minutes; in the process of heat treatment, the ES fiber is melted by heating, the molten ES fiber can form heat bonding points among different fiber layers, the heat bonding points can be firmly bound with each other, finally pressed and shaped by air cooling treatment and cropped to obtain the finished product. The preparation method provided by the invention is simple and practical; by utilizing the one-step molding treatment, the labor force is saved, glue bonding is also saved, and the bonding treatment can be realized by the heat bonding points formed among different fiber layers by heating to melt the ES fiber, thus avoiding methanal and harmful substances.

Owner:韩国明

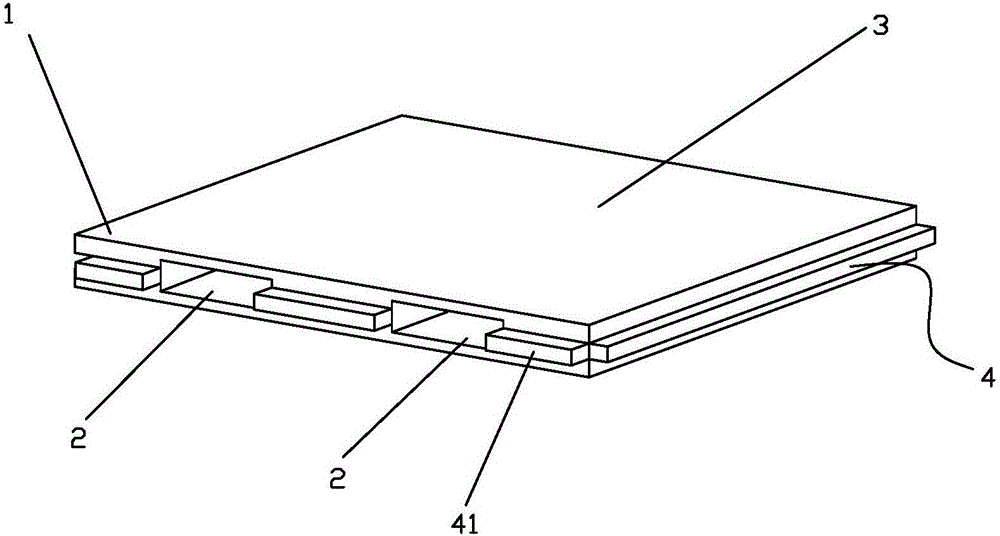

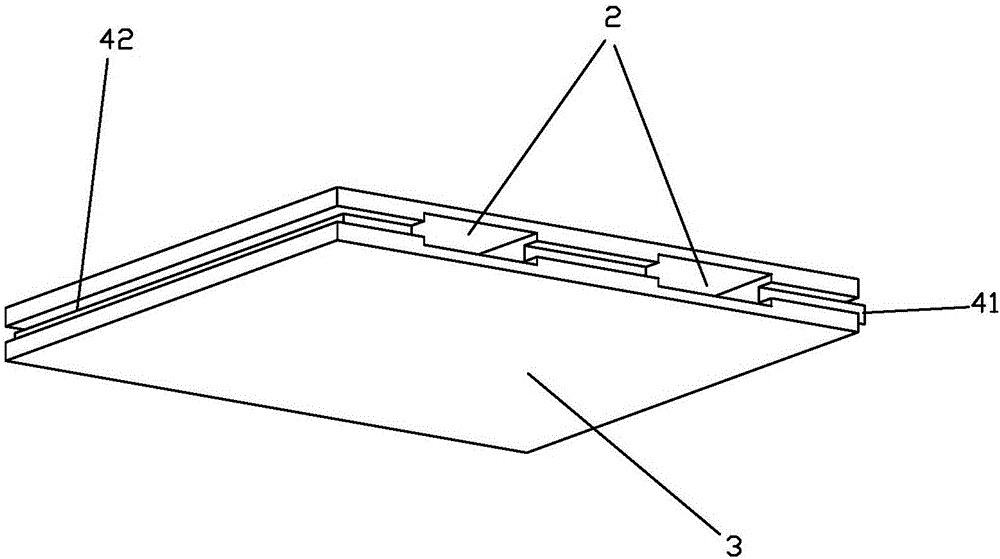

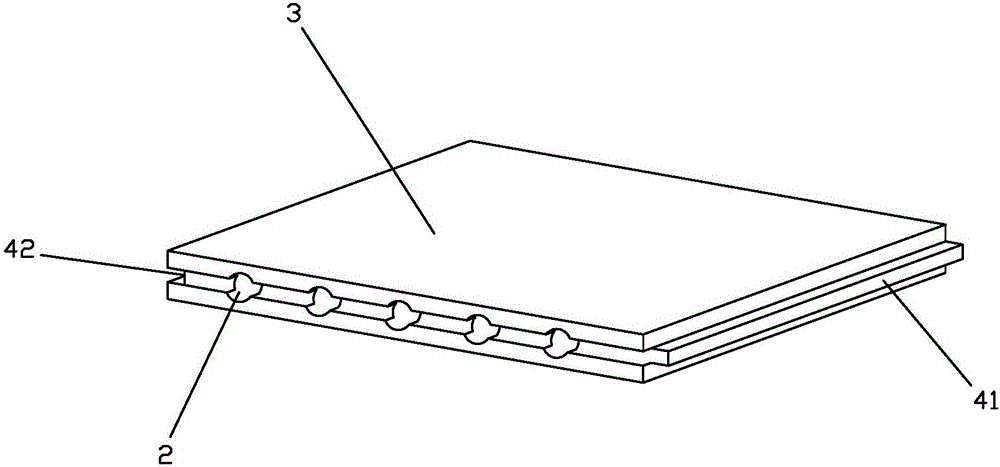

Building assembly type ceramic tile and building technology using ceramic tile

The invention discloses a building assembly type ceramic tile and a building technology using the ceramic tile. According to the technical scheme, the building assembly type ceramic tile comprises a tile body which is internally provided with functional grooves penetrating through the two opposite side faces of the tile body. The outer side of the tile body is provided with a ceramic decorative layer, the tile body and the ceramic decorative layer are integrally subjected to sintering forming, and the ceramic decorative layer is integrally formed on the outer surface of the tile body. The outer side of the tile body is further provided with a connecting mechanism used for being connected with and fixed to an adjacent tile body. The building assembly type ceramic tile is integrally formed and produced by combining the characteristics of a ceramic brick, a clay brick, a lime sand brick and ceramic, construction is more convenient, time and labor are saved, the cost is greatly lowered, and the brand new construction technology is brought in. The invention further provides a house built through the assembly type ceramic tile. The invention further provides the building technology using the building assembly type ceramic tile.

Owner:郑招伟

Method for preparing white latex by utilizing polystyrene waste

InactiveCN101787102AMake up for the shortcomings of high rigidity and brittlenessHigh bonding strengthPolymer sciencePolyvinyl acetate

The invention relates to the field of recycling of polystyrene waste, in particular to a method for preparing white latex by utilizing the polystyrene waste. In order to overcome the defects in the prior art for preparing polystyrene / polyvinyl acetate core-shell emulsion, the invention provides the method for preparing the white latex from the polystyrene waste, which can overcome the defects of rigidity and easy oxidability of polystyrene chains and ensure that the polyvinyl acetate emulsion prepared after the polystyrene waste is added has stability. The compositions for preparing the white latex by utilizing the polystyrene waste comprise deionized water, the polystyrene waste, polyvinyl alcohol, vinylacetate, acrylic ester, an initiator, an emulsifier, a plasticizer and an antioxygen. The method for preparing the white latex by utilizing the polystyrene waste comprises the following steps: (1) preparing solution of vinylacetate; (2) preparing solution of polyvinyl alcohol; (3) preparing solution of initiator; and (4) performing emulsion polymerization.

Owner:ZHEJIANG NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com