Preparation method of environment-friendly PU (polyurethane) ceiling with flame retardant and sound absorption functions

A polyurethane and environmentally friendly technology, applied in the field of polymer chemical materials, to achieve the effects of low overall cost, low board density, and less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

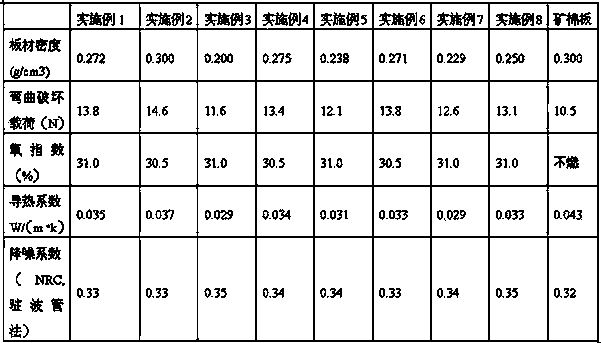

Examples

preparation example Construction

[0025]The invention provides a method for preparing an environment-friendly polyurethane flame-retardant sound-absorbing ceiling. Polyester-type isocyanate prepolymer is used as an adhesive, mixed evenly with pulverized waste polyurethane rigid foam particles, and then molded into an environment-friendly polyurethane insulation ceiling. Sound-absorbing ceiling, wherein, the polyester-type isocyanate prepolymer is 5-10 parts by weight, the crushed waste polyurethane rigid foam particles is 90-95 parts by weight, and the polyester-type isocyanate prepolymer is An isocyanate prepolymer with an NCO content of 10-30% is prepared by reacting diisocyanate and polyester polyol at 60-80°C.

[0026] Wherein, a better processing flow using the method of the present invention is:

[0027] (1) a. Prepare polyester type isocyanate prepolymer;

[0028] The isocyanate prepolymer with an NCO content of 10-30% is prepared by reacting diisocyanate and polyester polyol at 60-80°C; among them...

Embodiment 1

[0053] Put 5.0kg of PMDI and 3.9kg of PEDA1500 into the reaction kettle, control the temperature at 60~65°C for 3~4h, discharge, and detect that the NCO content is 15.1%, and obtain a qualified polyester isocyanate prepolymer;

[0054] Pulverize the waste polyurethane rigid foam into particles below 10 mesh through a pulverizer;

[0055] Put 12 kg of waste polyurethane rigid foam particles into the mixer, start stirring to make the above particles roll in the equipment, spray evenly into 1 kg of the above-mentioned prepared polyester isocyanate prepolymer, stir and mix evenly;

[0056] Spread the mixture obtained above evenly into a mold of 2.00×1.00×0.02m between the heating plates of the press, and perform a preheating treatment at 100°C for 5 minutes; then, start the pressure to 15MPa, and then hold Press for 15 minutes, demould, and get the environment-friendly polyurethane flame-retardant sound-absorbing ceiling.

[0057]

Embodiment 2

[0059] Put 5.0kg of PMDI and 0.158kg of PEDA2000 into the reaction kettle, control the temperature at 60~65°C for 3~4h, discharge the material, and detect that the NCO content is 30.0%, and obtain a qualified polyester isocyanate prepolymer;

[0060] Pulverize the waste polyurethane rigid foam into particles below 10 mesh through a pulverizer;

[0061] Put 13.68kg of waste polyurethane rigid foam particles into the mixer, start stirring to make the above particles roll in the equipment, spray evenly into 0.72kg of the above-mentioned polyester isocyanate prepolymer, stir and mix evenly;

[0062] Spread the mixture obtained above evenly into a mold of 2.00×1.00×0.02m between the heating plates of the press, and perform a preheating treatment at 120°C for 5 minutes. At the same time, place PVC leather veneer materials on both sides of the mold; then, start The pressure is increased to 20 MPa, and then the pressure is maintained at 120°C for 20 minutes, and the mold is demoulded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com