Environment-friendly humidifying wallpaper and preparation method thereof

An environmentally friendly stone paper and wallpaper technology, applied in the field of decorative materials, can solve the problems that PVC wallpaper is not environmentally friendly and flame-retardant, cannot meet the needs of fast and efficient adjustment of indoor humidity, and the ability of inorganic fillers to absorb and release water is limited, so as to achieve easy control, The effect of strong water absorption and discharge capacity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

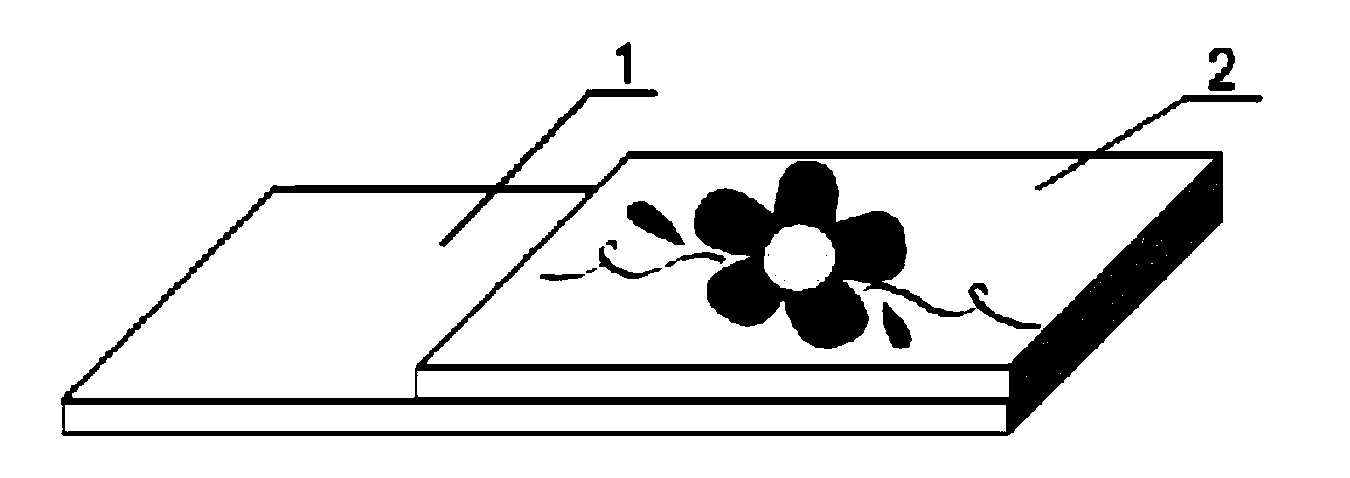

Image

Examples

Embodiment 1

[0031] First prepare 15 parts of carboxymethyl cellulose aqueous solution (solid content is 1%), and grind it into 200 mesh particles, then use mechanical stirring to disperse 20 parts of sepiolite and 1.5 parts of hyperbranched polycarboxylic acid dispersant in 30 After stirring for 12 minutes, add 15 parts of an aqueous solution of carboxymethylcellulose and continue stirring for 7 minutes. Then add 30 parts of water-based polyurethane, 1.5 parts of mercaptans and 0.5 part of higher alcohol, and continue to stir for 18 minutes; then add 1.5 parts of polyurethane thickener to adjust the viscosity of the slurry.

[0032] The moisture-adjustable functional paste was printed on a non-woven paper substrate with a thickness of 300 μm by a gravure printing process, with a drying temperature of 120 °C and a drying time of 11 minutes.

Embodiment 2

[0034] First prepare 22 parts of polyacrylate aqueous solution (solid content is 1%), and grind into 150 mesh particles, then use mechanical stirring to disperse 25 parts of montmorillonite, 20 parts of zeolite and 0.8 part of polyacid copolymer dispersant in 20 parts of water, after stirring for 8 minutes, add 10 parts of polyacrylate aqueous solution, and continue stirring for 5 minutes. Then add 22 parts of polyacrylate copolymer emulsion, 1.2 parts of soybean lecithin and 0.5 parts of polysiloxane, and continue to stir for 10 minutes; then add 0.5 parts of polyurethane thickener to adjust the viscosity of the slurry.

[0035] The moisture-adjustable functional paste was printed on a 500-micron thick stone paper substrate by a rotary screen printing process, with a drying temperature of 90 °C and a drying time of 10 minutes.

Embodiment 3

[0037] First prepare 30 parts of hydroxyethyl cellulose aqueous solution (1% solid content), and grind it into 120 mesh particles, then disperse 5 parts of zeolite and 0.5 parts of polyacid copolymer dispersant in 20 parts of water by mechanical stirring After stirring for 19 minutes, add 30 parts of an aqueous solution of hydroxyethyl cellulose, and continue stirring for 12 minutes. Then add 42 parts of polyacrylate copolymer emulsion, 1.2 parts of soybean lecithin and 0.5 parts of polysiloxane, and continue to stir for 10 minutes; then add 0.5 parts of polyurethane thickener to adjust the viscosity of the slurry.

[0038] The moisture-adjustable functional paste was printed on a 100 μm thick stone paper substrate by a flat screen printing process, with a drying temperature of 90 °C and a drying time of 15 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com