Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "VOC-free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

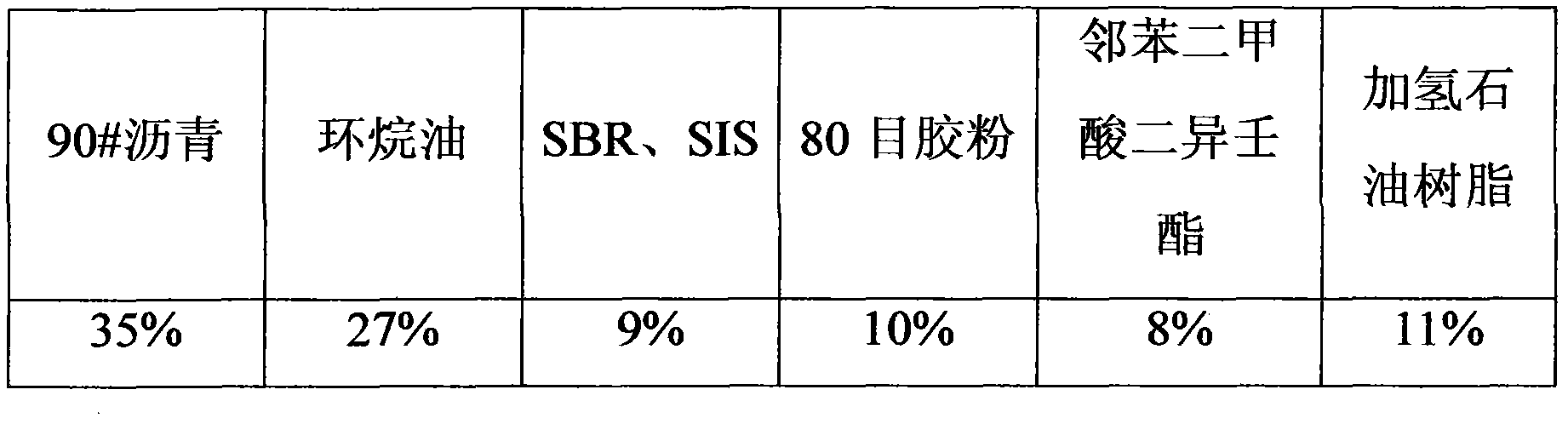

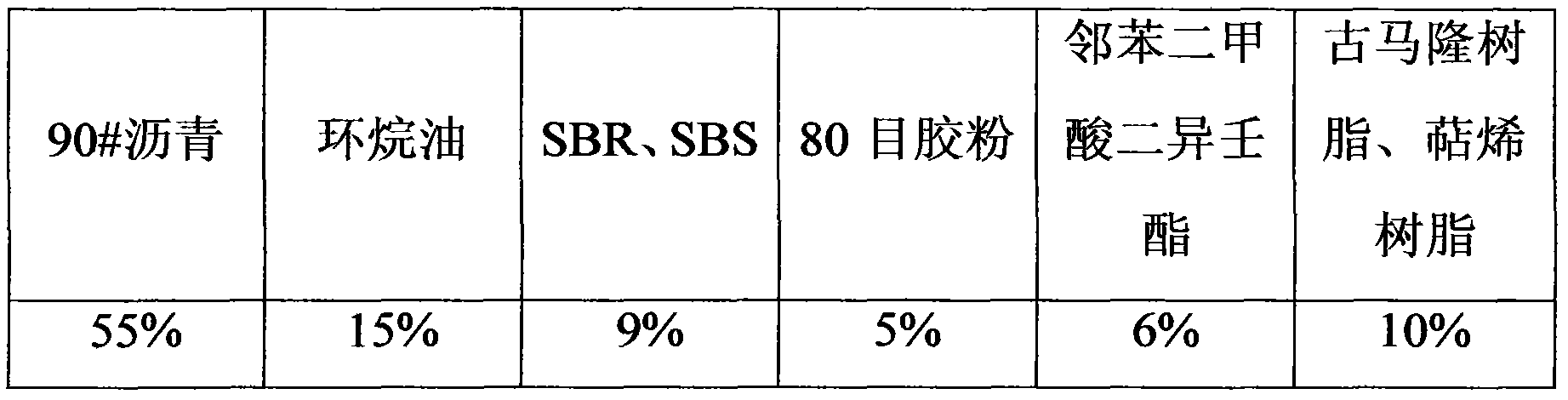

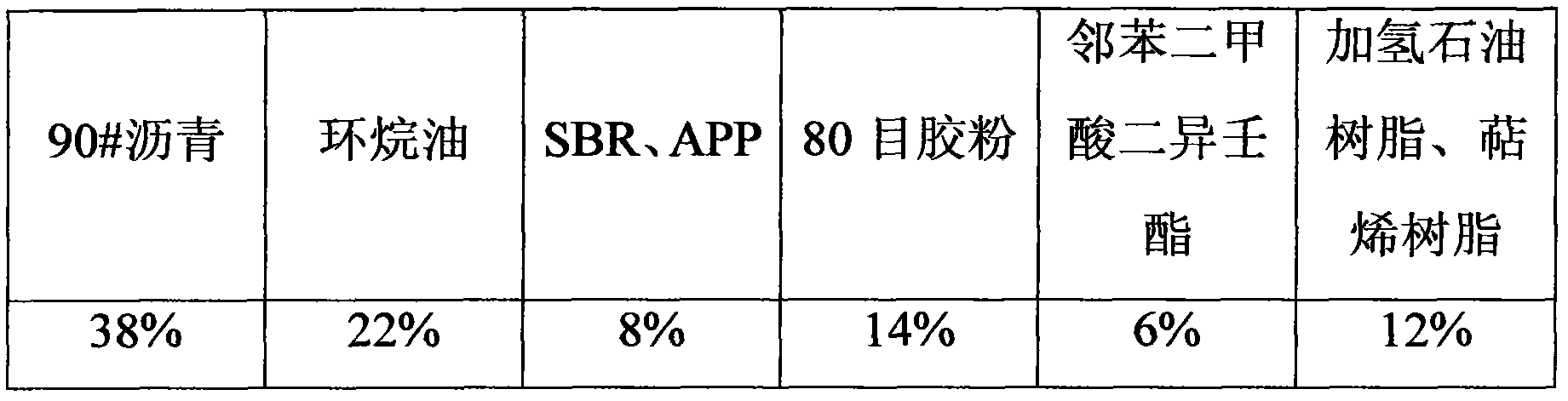

Non-cured asphalt mastic

The invention requests to protect non-cured asphalt mastic comprising the following components in percentage by weight: 35-55 asphalt, 15-30 naphthenic oil, 3-10 polymer modifying agent, 55-20 gelatin powder, 3-10 diisononyl phthalate and 10-20 tackifying resin. The non-cured asphalt mastic can be independently used or can be used with the matched coil to form a waterproof system and can effectively solve the problem of water leakage caused by the crack of a waterproof layer due to the deformation of a base layer.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

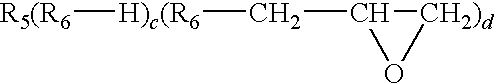

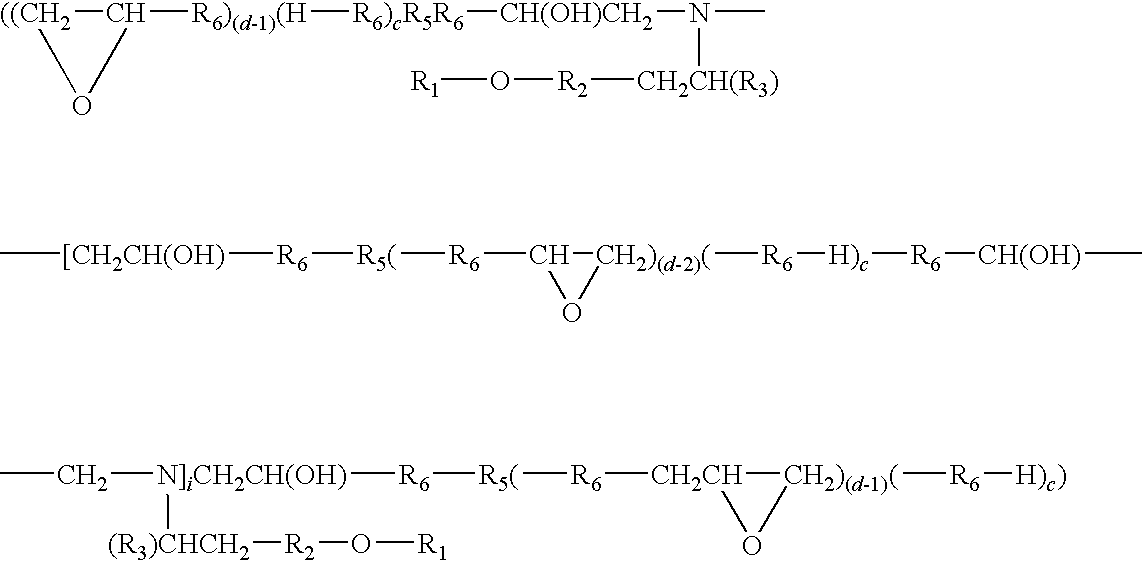

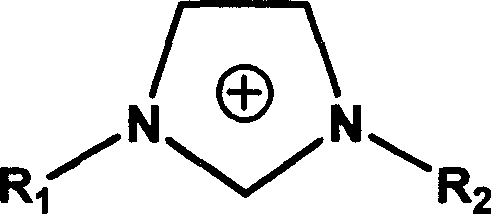

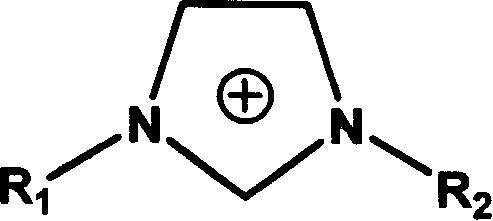

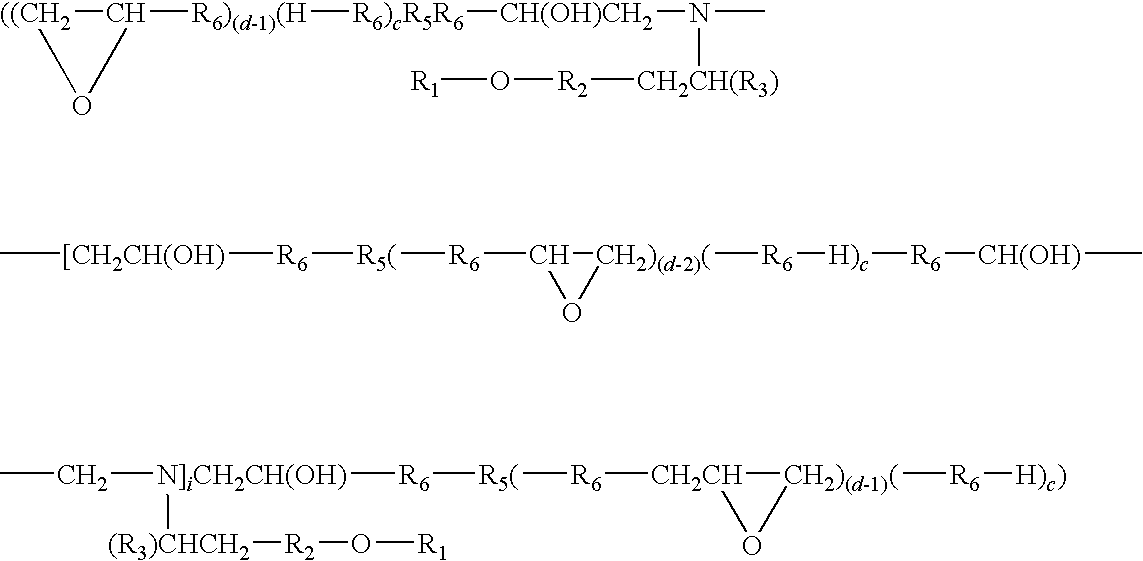

Primer compositions for adhesive bonding systems and coatings

ActiveUS20100285309A1Improve the immunityLong lasting resistanceSynthetic resin layered productsPretreated surfacesEpoxySelf emulsifying

The present invention relates to aqueous-based primer composition, comprising at least one thermosetting, self-emulsifying epoxy resin composition; at least one thermosetting, non-self-emulsifying resin composition; water; and at least one curative.

Owner:HENKEL KGAA

A compound electrolyte material and its making method

InactiveCN101241774ANo pollution in the processAvoid harmOrganic chemistryLight-sensitive devicesComposite electrolyteAlcohol

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Antiskid ventilating epoxide terrace paint

The invention relates to an antiskid and ventilating epoxy floor coating, which comprises base material and powder material with weight mixture ratio of 1 portion of base material and 1-2 portions of powder material. The base material mainly comprises epoxy resin, epoxy hardener and addition agent with weight mixture ratio of 60 portions of epoxy resin, 25 portions of epoxy hardener and 15 portions of addition agent. The invention has the advantages of: 1. no formaldehyde and no VOC after curing; 2. excellent binding capacity with the base material without peeling and hollowing; 3. certain air permeability, thus being capable of avoiding phenomena such as bubbling, cracking, etc., resulted from vapor pressure; 4. high strength and excellent antiskid, wear resistant and impact resistant performances; 5. excellent corrosion resistance and water resistance; 6. certain flexibility and cracking prevention, thereby being capable of avoiding cracking to certain degree.

Owner:ZHEJIANG ZHONGCHENG CONSTR GRP

Environment-friendly humidifying wallpaper and preparation method thereof

InactiveCN103911914ARegulate indoor humiditySimple preparation processDefoamers additionCovering/liningsAbsorption capacitySuper absorbent

The invention relates to environment-friendly humidifying wallpaper and a preparation method thereof. The wallpaper comprises a wallpaper base layer, wherein a waterborne printing coating with a humidifying function is printed on the wallpaper base layer; the wallpaper base layer is environment-friendly rich mineral paper or non-woven paper; the waterborne printing coating consists of an adhesive, a porous inorganic mineral material, super absorbent resin, water, a thickening agent, an antifoaming agent and a wetting agent, and the absorbent resin has an effect of increasing the water absorption capacity of the wallpaper. The waterborne printing coating is printed to the wallpaper base layer by adopting a round screen or plain net or gravure process. The thickness of the wallpaper base layer is 100-1,000microns, and the thickness of the waterborne printing coating is 5-50 microns. When the wallpaper achieves a decorative effect, high-efficiency indoor humidity regulation can be performed, and the environment-friendly humidifying wallpaper is pollution-free and formaldehyde-free and has no indoor volatile organic pollutant.

Owner:宋旭

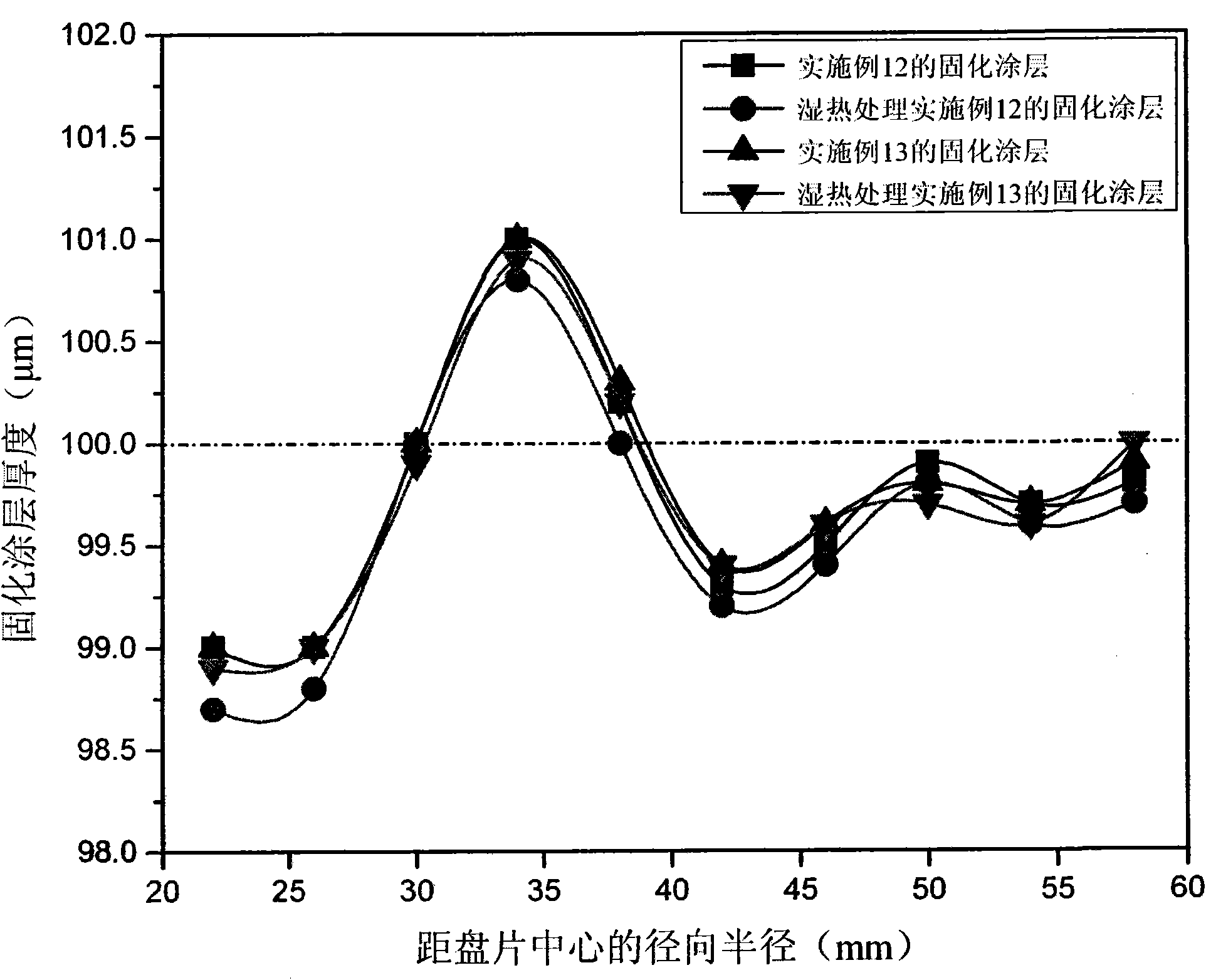

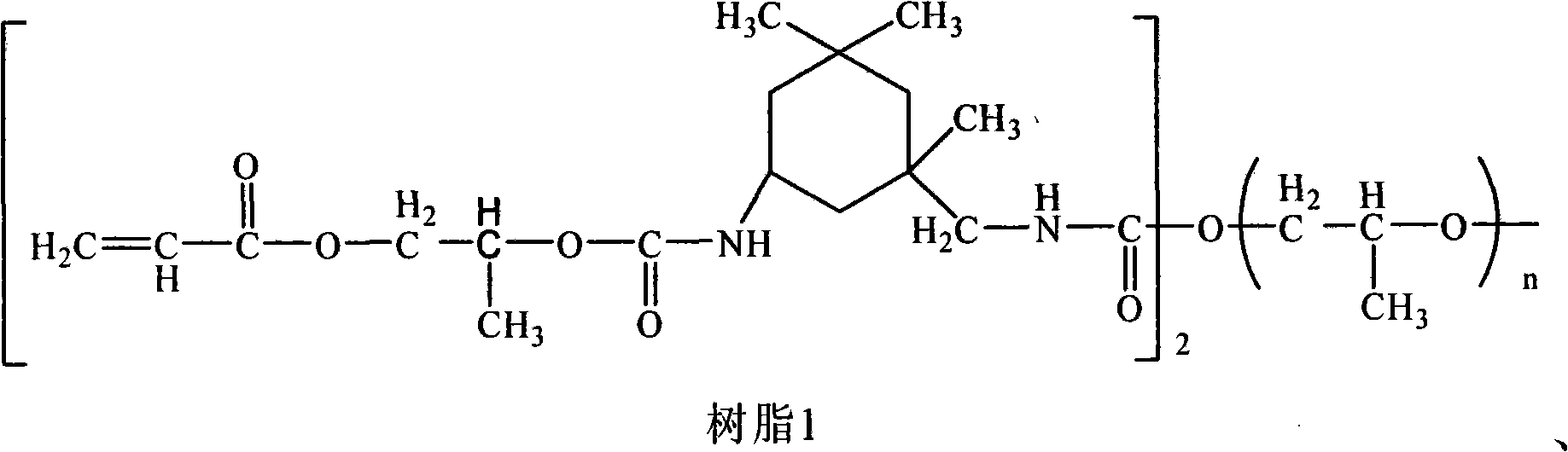

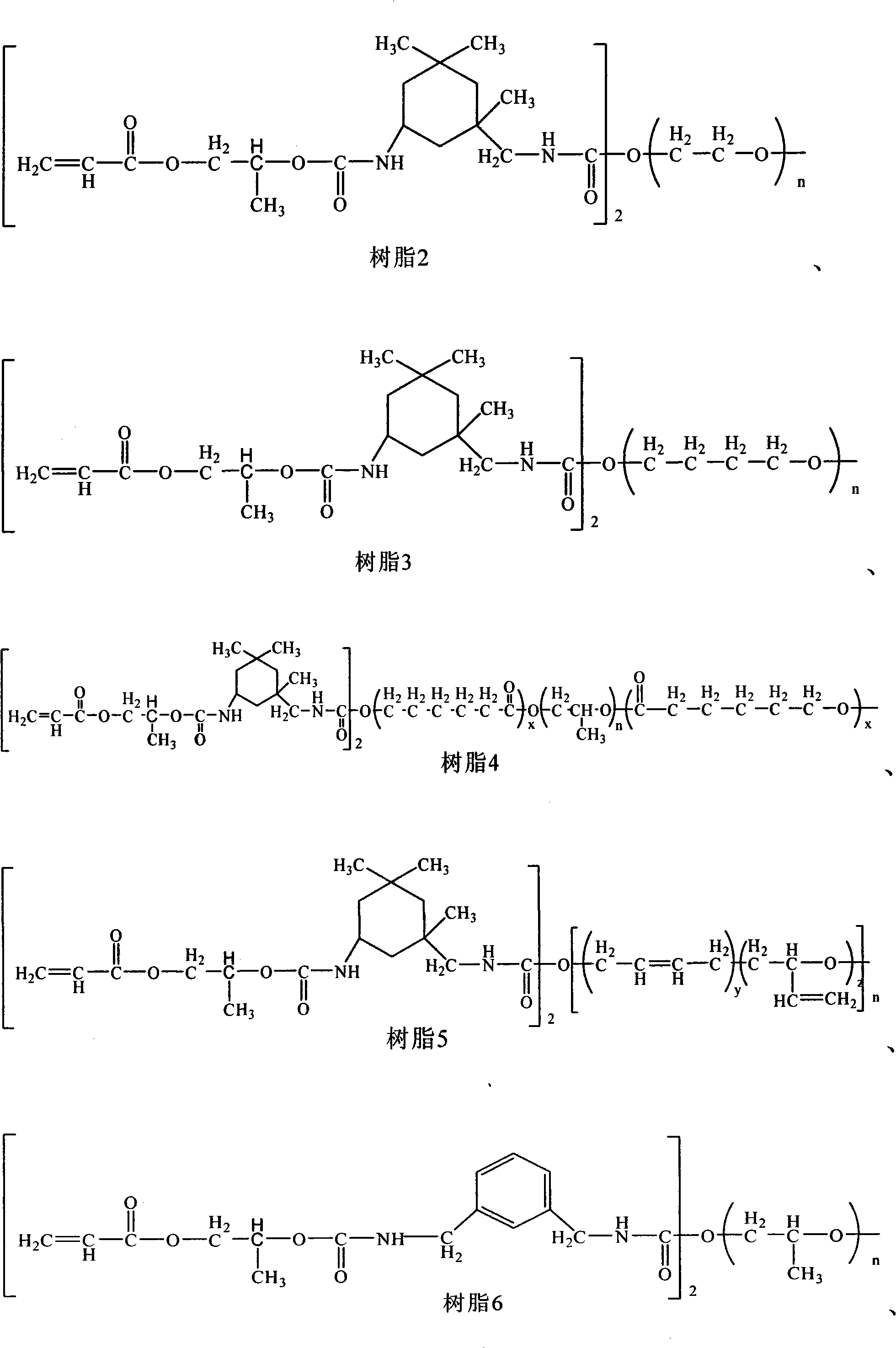

Ultraviolet light or electron beam-cured resin composition for blue-ray disc

ActiveCN102140155AAvoid warpingStress reliefRecord information storageOptical recording/reproducingUltraviolet lightsUrethane acrylate

The invention relates to an ultraviolet light or electron beam-cured resin composition for a blue-ray disc. The cured resin composition can be obtained by the following steps of: based on the parts by weight of a prepolymer, mixing 20-80 parts by weight of urethane acrylate resin prepolymer, 10-50 parts by weight of active monofunctional monomer, 0-10 parts by weight of bifunctional monomer or multifunctional monomer (preferably 1-10 parts by weight of bifunctional monomer or multifunctional monomer), 0-8 parts by weight of photo initiator and 0.2-5 parts by weight of aid; stirring uniformly;and filtering. Blue laser light with the wavelength of about 405 nanometers can pass through an euphotic layer obtained by curing the cured resin composition, so that information recording can be carried out on the blue-ray disc and the blue-ray disc can be recycled.

Owner:HUNAN SOKAN NEW MATERIAL

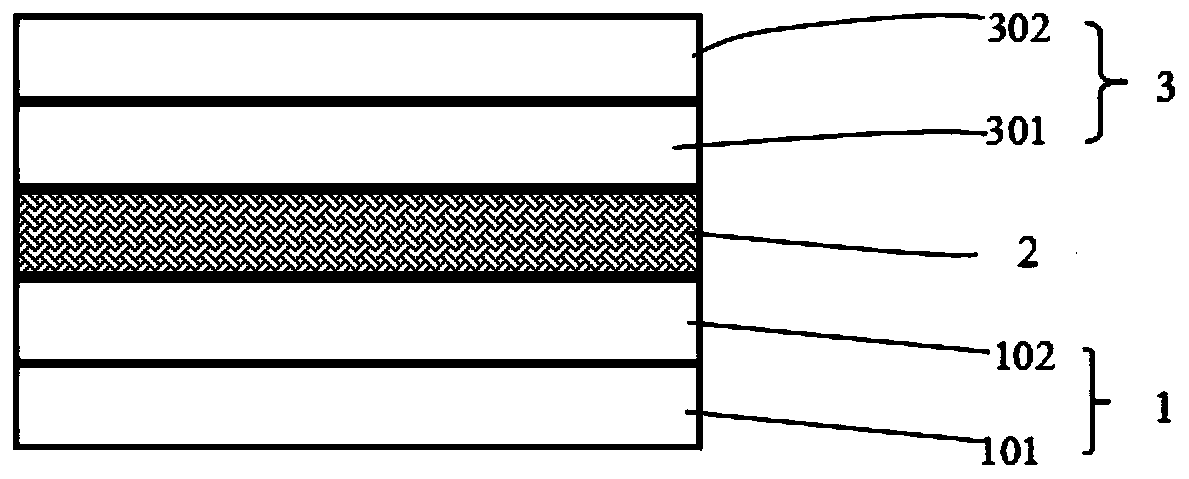

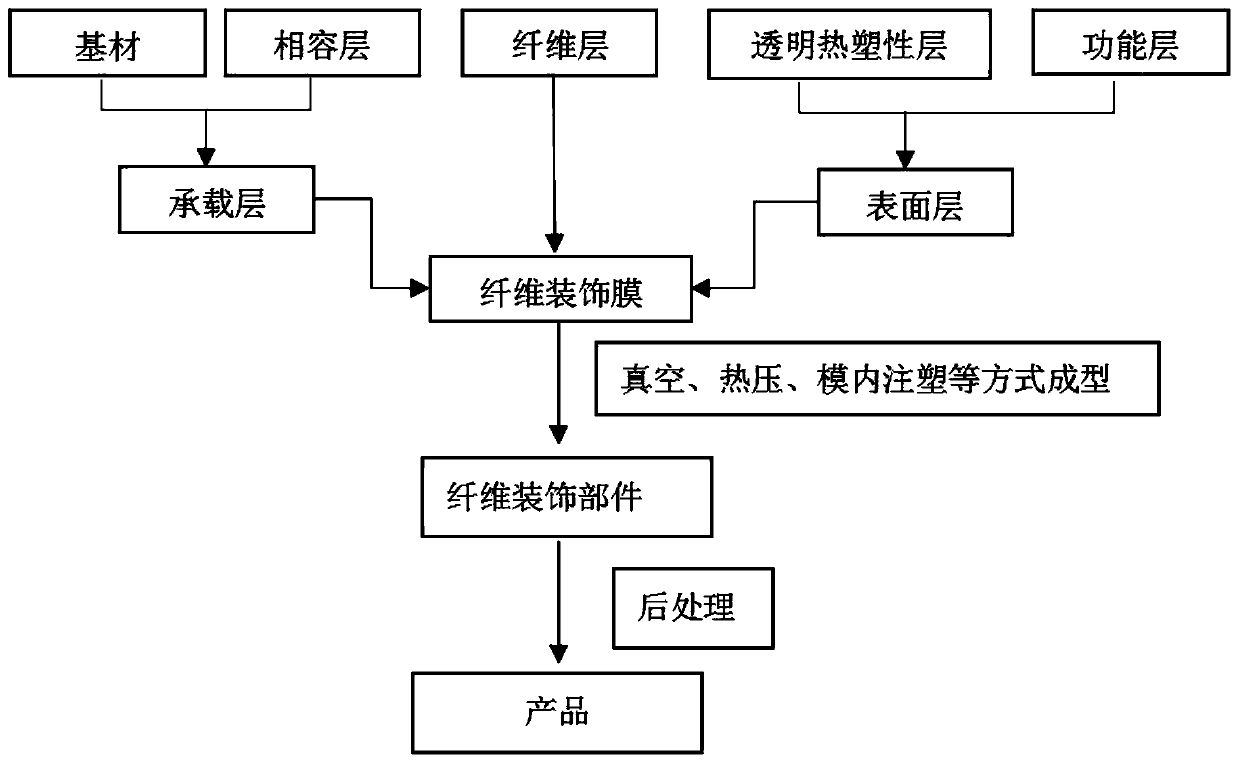

Fiber decorative film and preparation method and product thereof

PendingCN109878186AVOC-freeGood mechanical propertiesLayered productsFlat articlesFiberPolymer science

The invention belongs to the technical field of decorative materials, and particularly relates to a fiber decorative film and a preparation method and product thereof. The fiber decorative film is free of VOC, excellent in mechanical property, high in specific strength and specific rigidity, low in weight and good in surface quality; the fiber decorative film has good thermoplasticity, the productwith the complex geometrical shape can be prepared, no new mold needs to be developed, forming is easy and convenient, the speed is high, and the high yield and the short processing period can be achieved; the product prepared from the fiber decorative film is diversified in texture, has design flexibility and customization, has a beautiful appearance effect and is a feast for the eyes; and the product prepared from the fiber decorative film can be recycled, and thus waste and environment pollution are reduced to the utmost extent.

Owner:SHENZHEN MOMA CLEVER CHEM TECH CO LTD

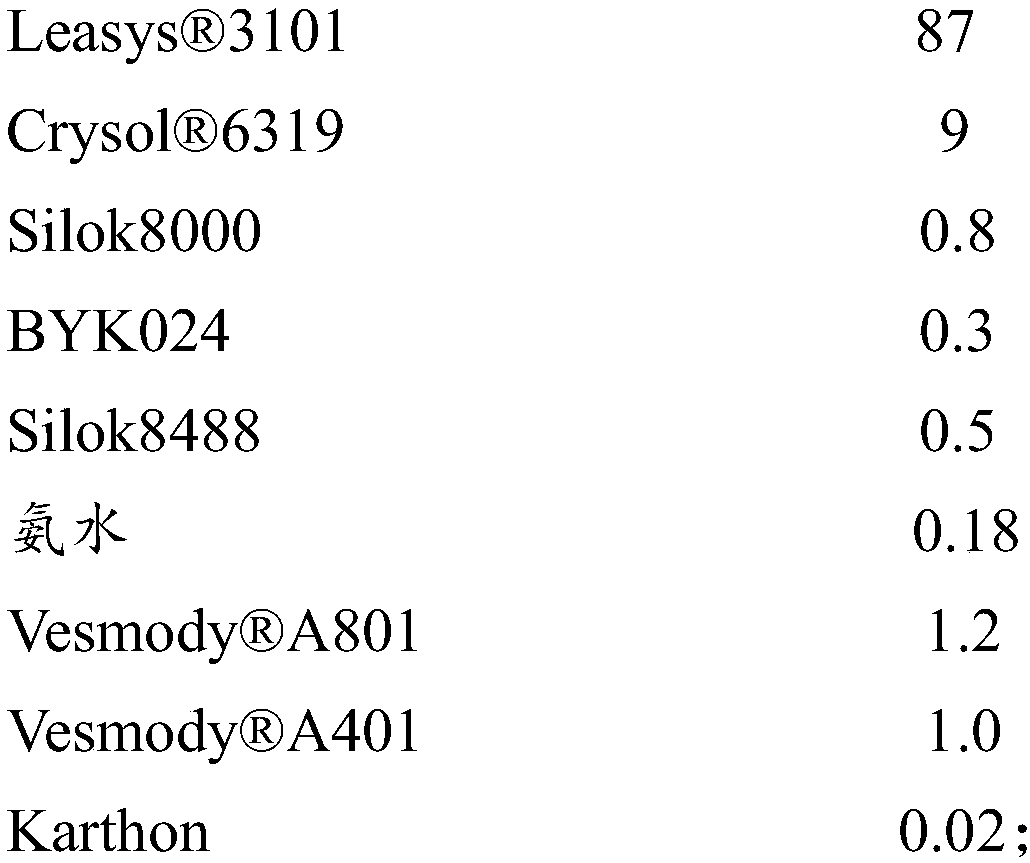

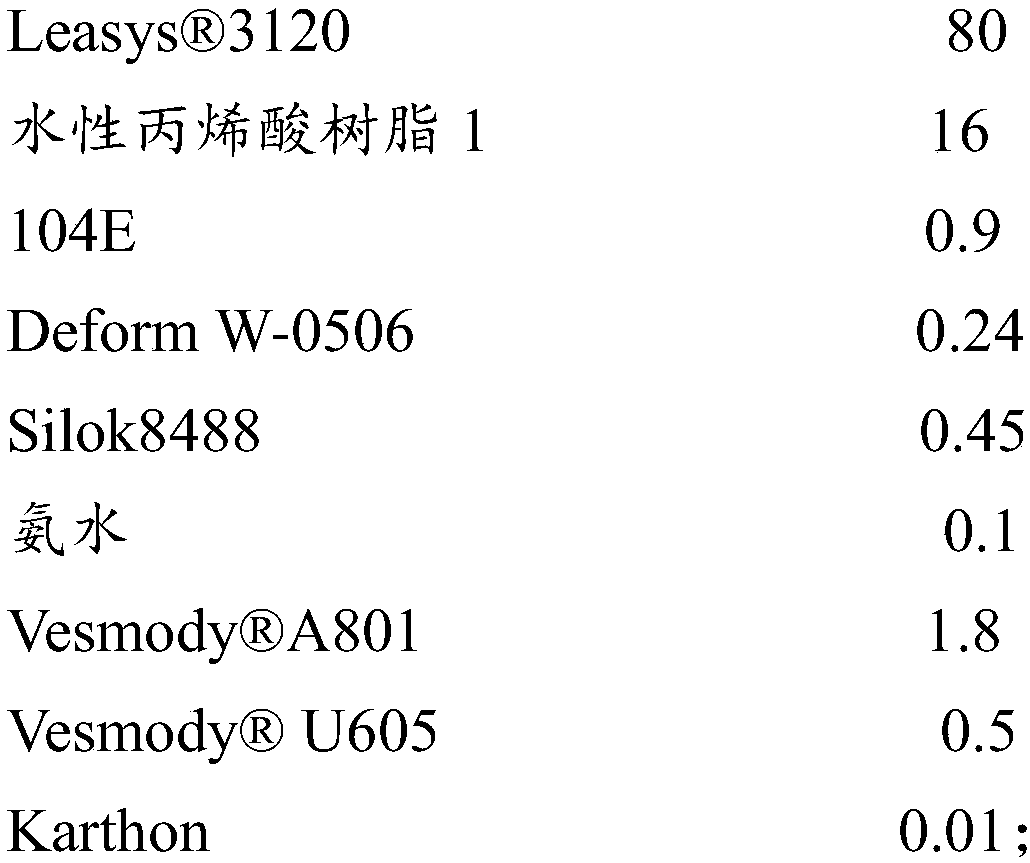

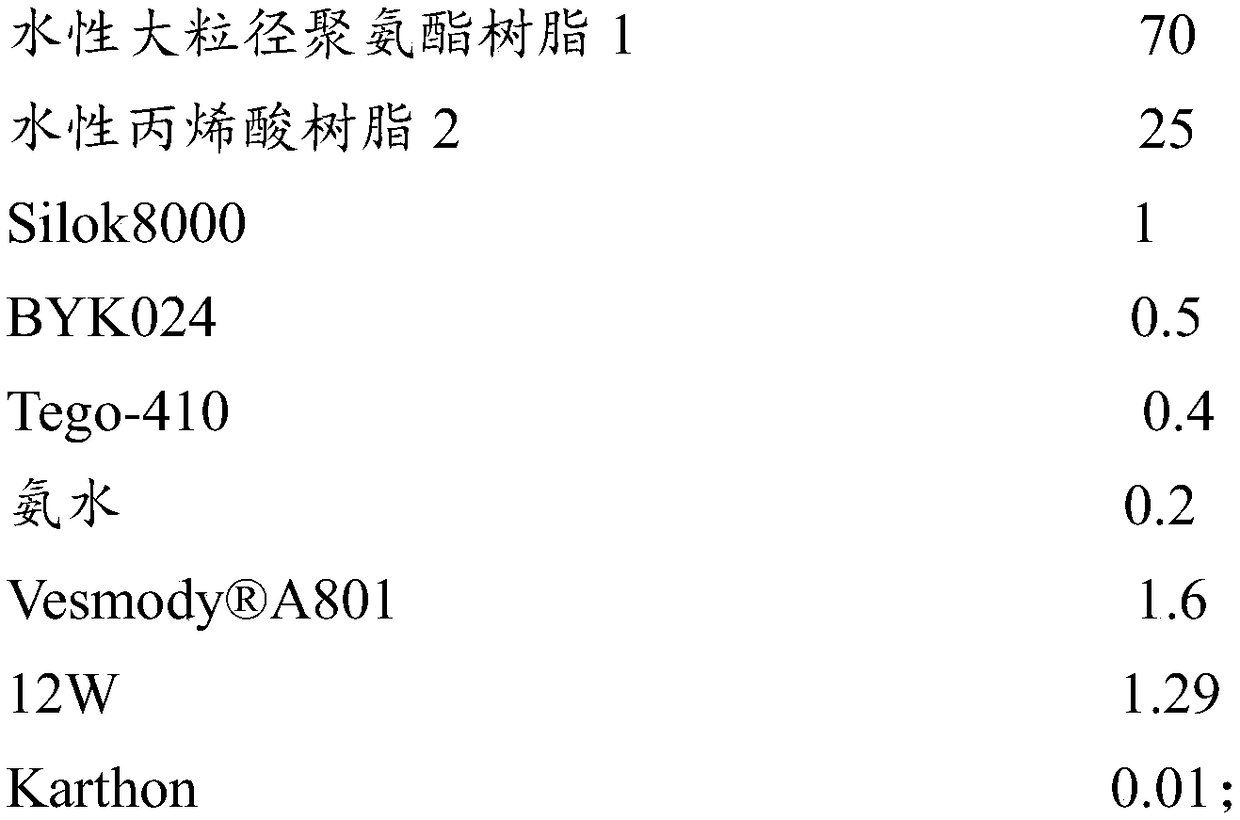

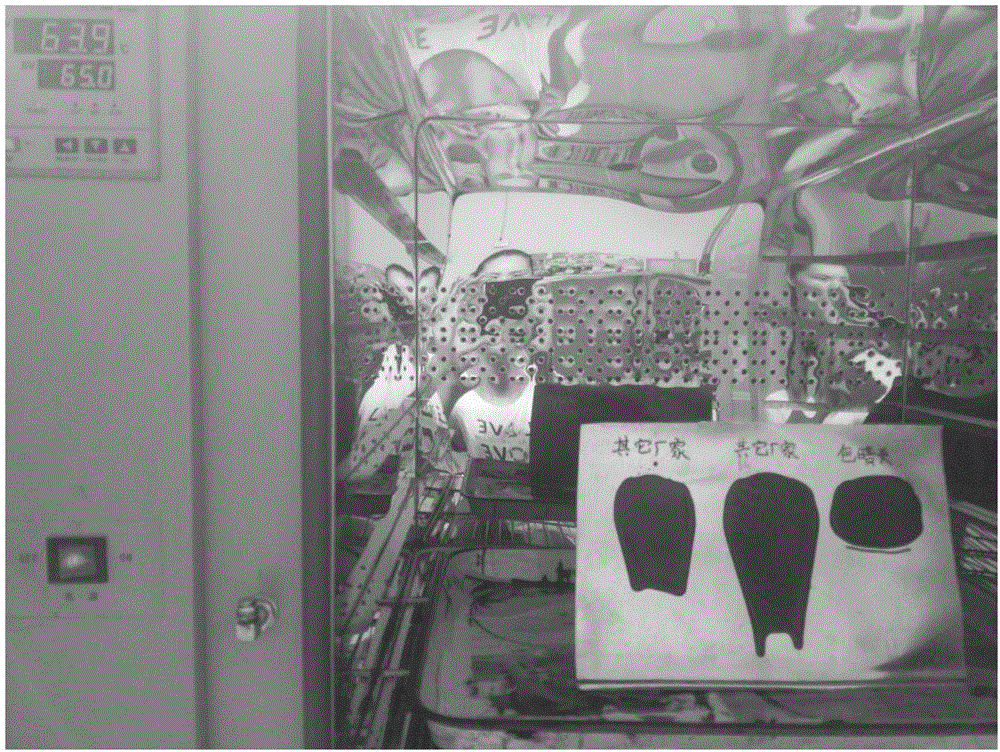

Water-based composite resin composition, water-based plastic paint and preparation method of water-based plastic paint

ActiveCN108192490ASimple recipeSimple and fast operationAnti-corrosive paintsPolyurea/polyurethane coatingsChemistryAcrylic resin

The invention belongs to the technical field of water-based plastic paints, and provides a water-based composite resin composition, a water-based plastic paint and a preparation method of the water-based plastic paint. The water-based composite resin composition is prepared by adopting the following components in percentages by weight: 70-90wt% of water-based large-particle-size polyurethane resinwith the particle size of 800-2000nm, 6-25wt% of water-based acrylic resin, and 2-8wt% of an auxiliary agent; and the water-based plastic paint is prepared by adopting the following raw materials inparts by weight: A, 100 parts of the above water-based composite resin composition, and B, 2-6 parts of a water-based isocyanate curing agent. According to the method provided by the invention, compounding of the water-based large-particle-size polyurethane resin and the water-based acrylic resin is adopted, so that the plastic paint has excellent adhesion, scratch resistance, abrasion resistance,chemical resistance and the like.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +2

Non-curable rubber modified asphalt waterproof coating material and fabrication process and construction method thereof

InactiveCN106318211AImprove stabilityReduce construction temperatureBuilding insulationsBituminous coatingsPolymer sciencePolymer modified

The invention relates to a non-curable rubber modified asphalt waterproof coating material and fabrication process and construction method thereof. The non-curable rubber modified asphalt waterproof coating material currently available on the market either has bad resistance to high temperature or can only be workable in a temperature above 150 DEG C with high pollution. The invention of non-curable rubber modified asphalt waterproof coating material comprises, by weight, 59-64.5 parts of asphalt, 17-20 parts of aromatic oil, 3-5 parts of polymer modifiers, 9-11 parts of rubber particles, 2.5 parts of tackifier. The invention also relates to the fabrication process and environment-friendly construction method of the non-curable rubber modified asphalt waterproof material. The invention of the non-curable rubber modified asphalt waterproof material achieves the energy-saving, environment-friendly features and the advantages of anti-sagging under 100 DEG C which makes it suitable to be used in various kinds of waterproof projects.

Owner:SHANDONG LECRON CONSTR ENERGY SAVING TECH CO LTD

Water-based insulating paint and preparation method thereof

ActiveCN105295658AImprove insulation performanceHigh normal electric strengthEpoxy resin coatingsWater basedSolvent

The invention discloses water-based insulating paint which comprises water-based epoxy resin, a polyol-modified waterborne epoxy curing agent and auxiliaries, wherein polyols comprise neopentyl glycol and 1,3,5-tris(2-hydroxyethyl)cyanuric acid; the weight ratio of the water-based epoxy resin to the polyol-modified waterborne epoxy curing agent is (2.5-3):1. The invention further discloses a preparation method for the water-based insulating paint. The preparation method comprises the following steps: enabling epoxy resin to react with polyols so as to obtain a prepolymer with epoxy-terminated functional groups; mixing polyamine with the prepolymer; dropwise adding epoxy resin, reacting completely, dropwise adding phenyl glycidyl ether and reacting to a final point; cooling, adding water and emulsifying so as to obtain the waterborne epoxy curing agent; weighing and uniformly mixing the waterborne epoxy curing agent, water-based epoxy resin, a defoaming agent, a levelling agent and a dispersing agent, baking and cooling. The water-based insulating paint is not added with a cosolvent, and free of VOCs and potential safety hazards, conforms to environmental protection requirements, and is high in electric strength and heat resistance.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Antifouling paint special for ships and preparation method thereof

PendingCN108707419AReduce adhesionGuaranteed antifouling performanceAntifouling/underwater paintsRosin coatingsEpoxyFluoropolymer

The invention provides an antifouling paint special for ships and a preparation method thereof. The method comprises the steps of mixing polysilane-modified epoxy resin, titanium dioxide and mica powder to obtain a resin mixture, and mixing the resin mixture, polytetrafluoroethylene, silicone oil, ferric oxide red and rosin to obtain the component A, and then mixing the component A with the curingagent to obtain the antifouling paint special for ships. The antifouling paint special for ships obtained by the above preparation method has the advantage of discarding the traditional organic tin antifouling agent, using the fluoropolymer and silicon polymer to form low-surface antifouling paint, and saving energy and protecting the environment under the premise of ensuring antifouling effect.

Owner:CHINA ACADEMY OF ENG PHYSICS FUNCTION MATERIAL RES INST

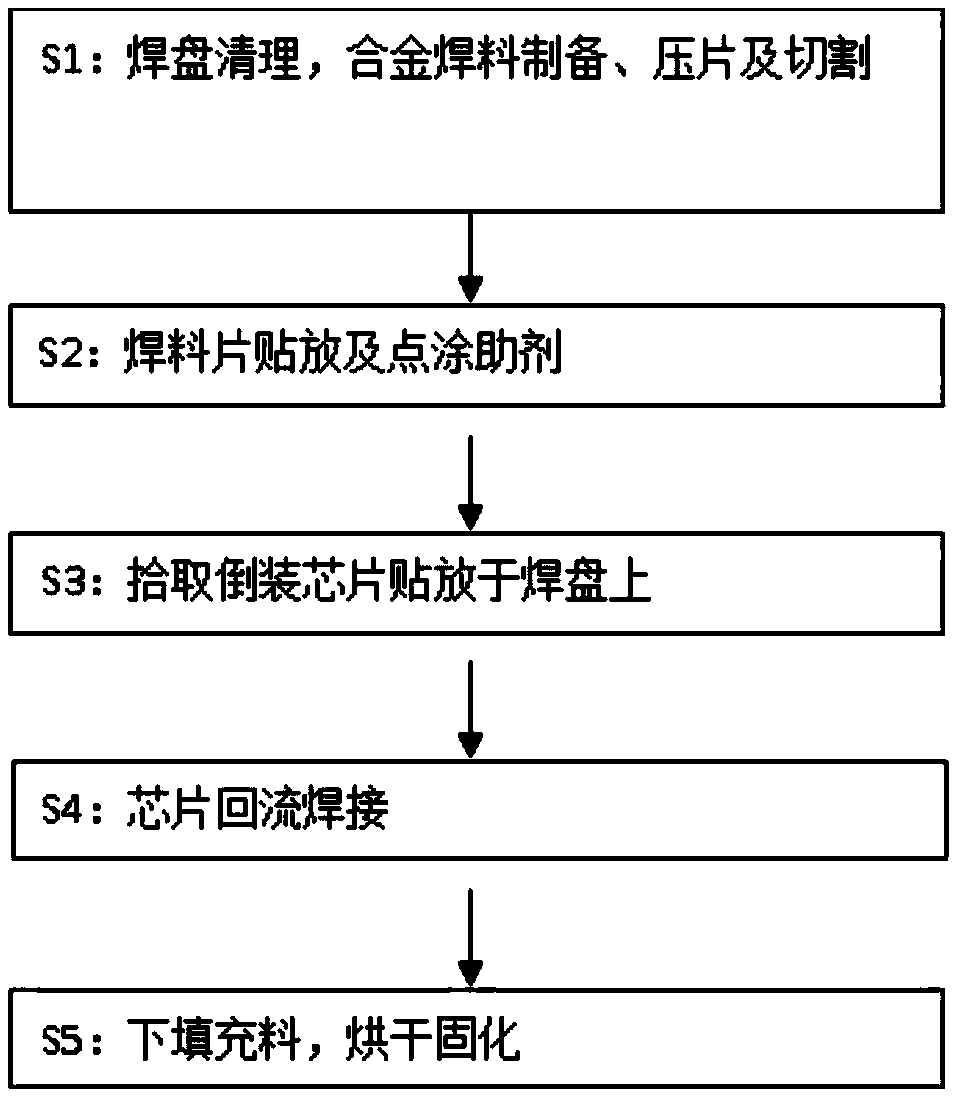

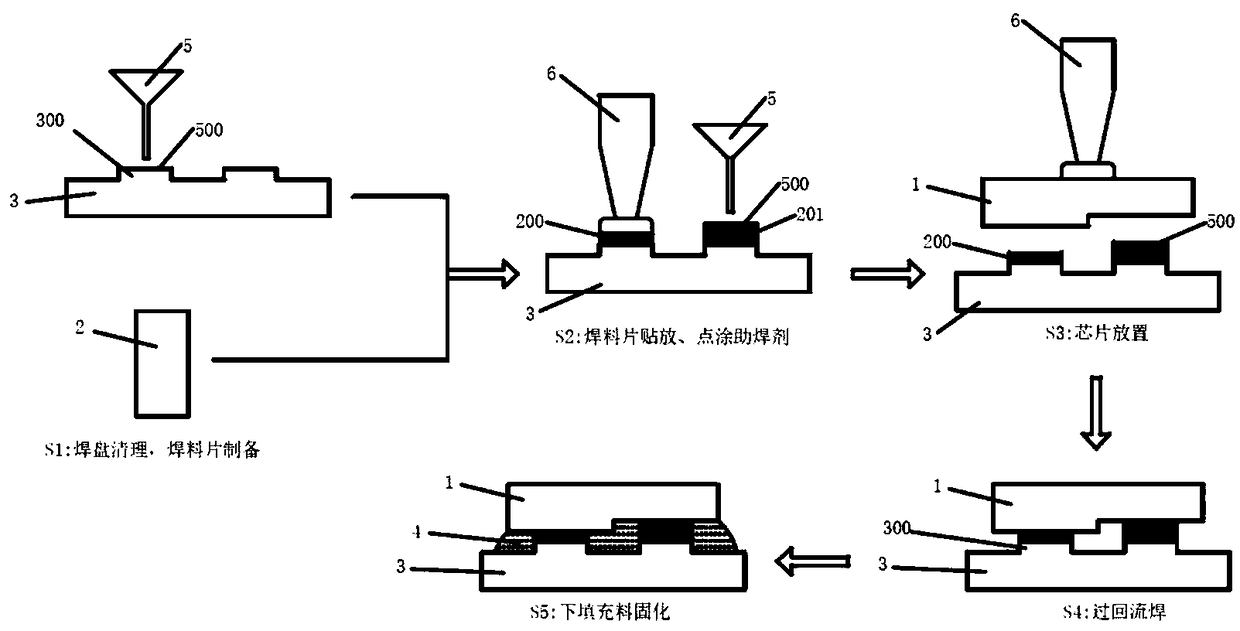

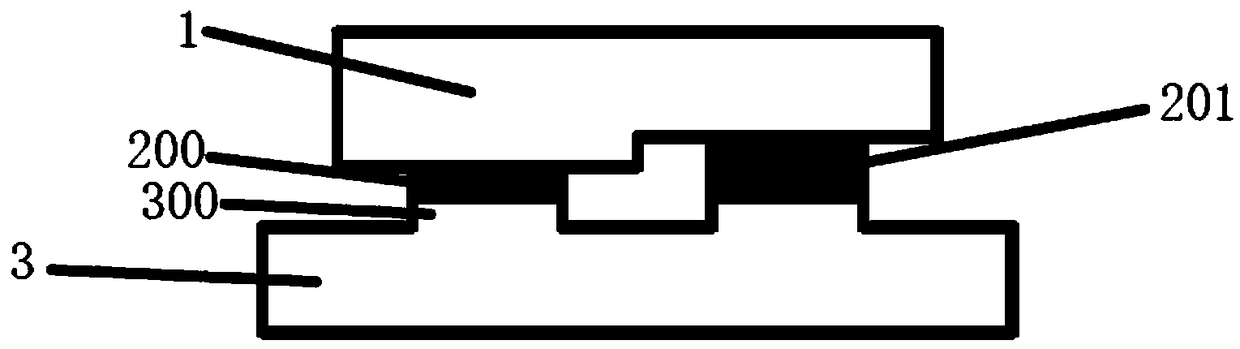

Solder for flip chip LED and application thereof

InactiveCN109175765AImprove thermal conductivityVOC-freeWelding/cutting media/materialsSoldering mediaJunction temperatureAlloy

The invention relates to solder for a flip chip LED and application thereof. The solder is an Sn-Zn-X multi-component alloy, wherein X is selected from one or more of Al, Ag, Cu and Bi. The solder isprepared from in percentage by mass: 40-95% (preferably 50-85%) of Sn, 5-60% (preferably 7-50%) of Zn, and 0.5-15% (preferably 0.5-10%) of X. The solder has the beneficial effects that a packaging technology is simplified, and the production efficiency of a flip chip is improved; the working junction temperature of the chip is lowered, the welding voidage of the chip is decreased, the heat-dissipating property of the chip can be improved, luminous decay is lowered, the luminous efficiency of the chip is improved greatly, and the service life of the chip is prolonged greatly; and meanwhile, thesolder can absorb heat stress generated during working of the chip, and thus stability and reliability of the chip are improved.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

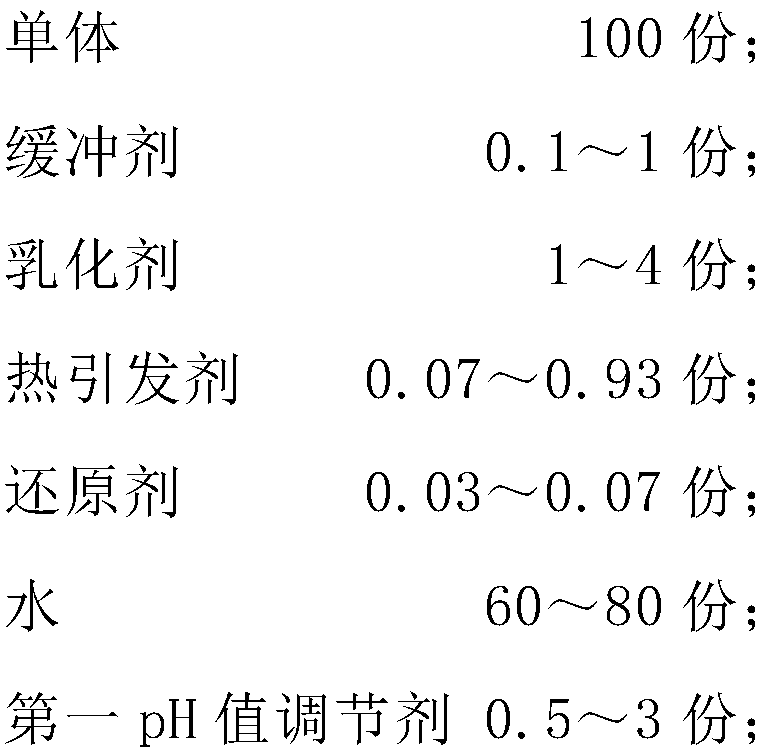

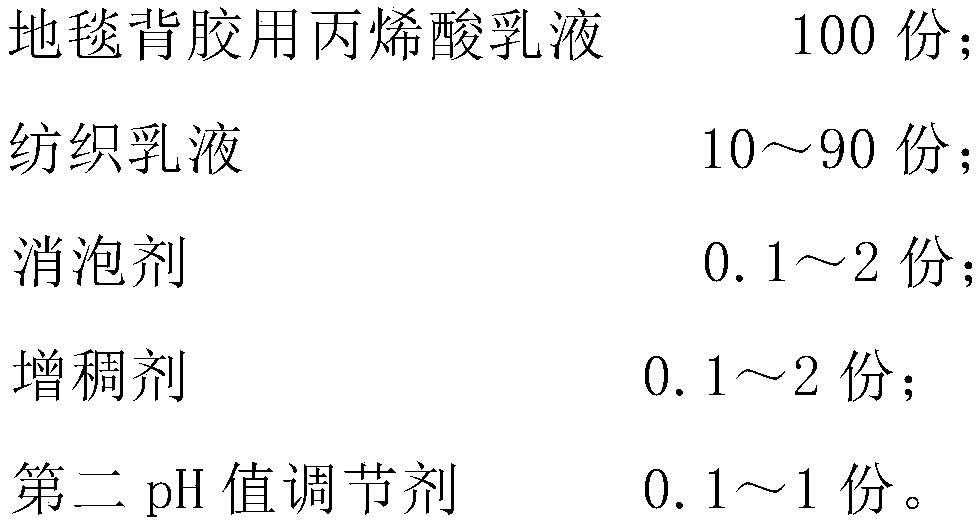

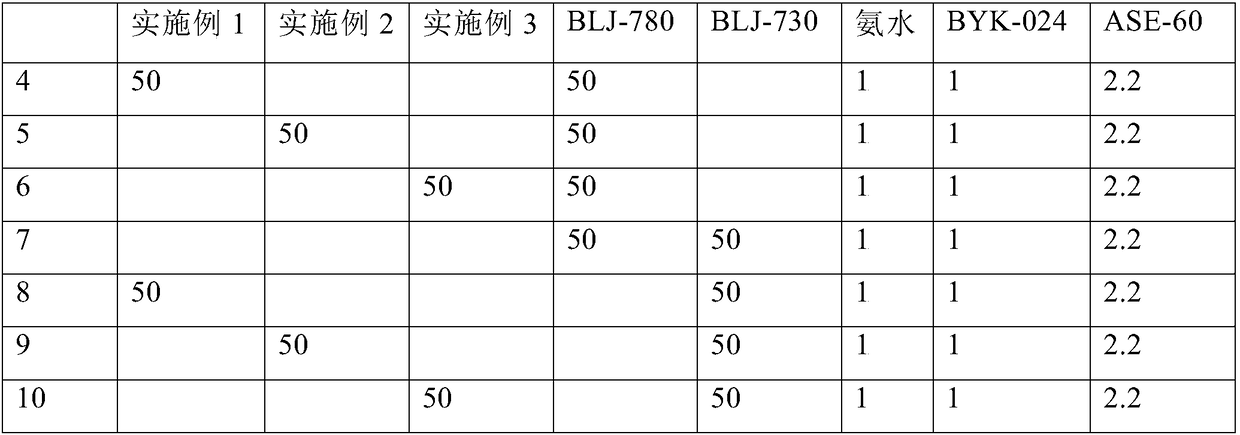

Acrylic emulsion for carpet gum, carpet gum and preparation method thereof

InactiveCN108794681ANo input requiredGood repeated peelingEster polymer adhesivesPressure sensitive film/foil adhesivesPolymer scienceEmulsion

The invention provides acrylic emulsion for a carpet gum, the carpet gum and a preparation method thereof. The acrylic emulsion for the carpet gum is prepared through a monomer, a buffering agent, anemulsifying agent, a thermal initiator, a reducing agent, water and a pH regulating agent, wherein the solid content of the acrylic emulsion for the carpet gum is 60%, and the viscosity is less than 300cps. The invention also discloses a preparation method of the acrylic emulsion for the carpet gum. The carpet gum is prepared by compositing the acrylic emulsion and Baolija emulsion adhesive for textile. The acrylic emulsion prepared through the abovementioned formula has the active effects of high solid content, high adhering intensity, high repeated separating performance, and water washing and dry cleaning resistance, and can be applicable to carpet gum of various materials.

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

High-temperature-resistant energy-saving nano coating

The invention discloses a high-temperature-resistant energy-saving nano coating. The high-temperature-resistant energy-saving nano coating is divided into a bottom coating and a surface coating in a weight ratio of 1:2, wherein the weight ratio of a component A to a component C in the surface coating is 1:(1.2-1.5), and the weight ratio of a component B to the component C in the bottom coating is 1:(1.0-1.5); the component A consists of feldspar, flint clay, kaolin, mullite, iolite, zirconium dioxide, zeolite, nano aluminum oxide, mica and zircon sand; the component B consists of nano titanium dioxide, conventional titanium dioxide, nano silicon dioxide, conventional silicon dioxide and nano aluminum oxide; and the component C consists of aluminum dihydrogen phosphate. The high-temperature-resistant energy-saving nano coating has long-term stable high emissivity, is compact in coating layer, has high high-temperature anti-powdering performance, and is long in service life, convenient to industrialize, and good in energy-saving effect.

Owner:中油新星纳米工程技术有限公司

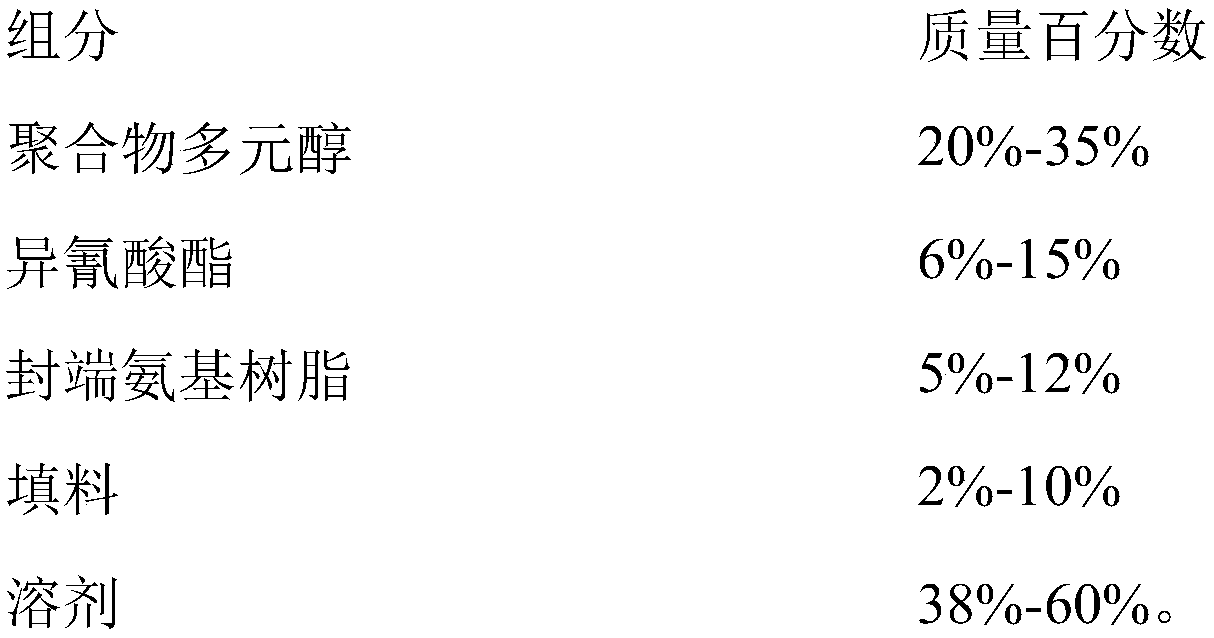

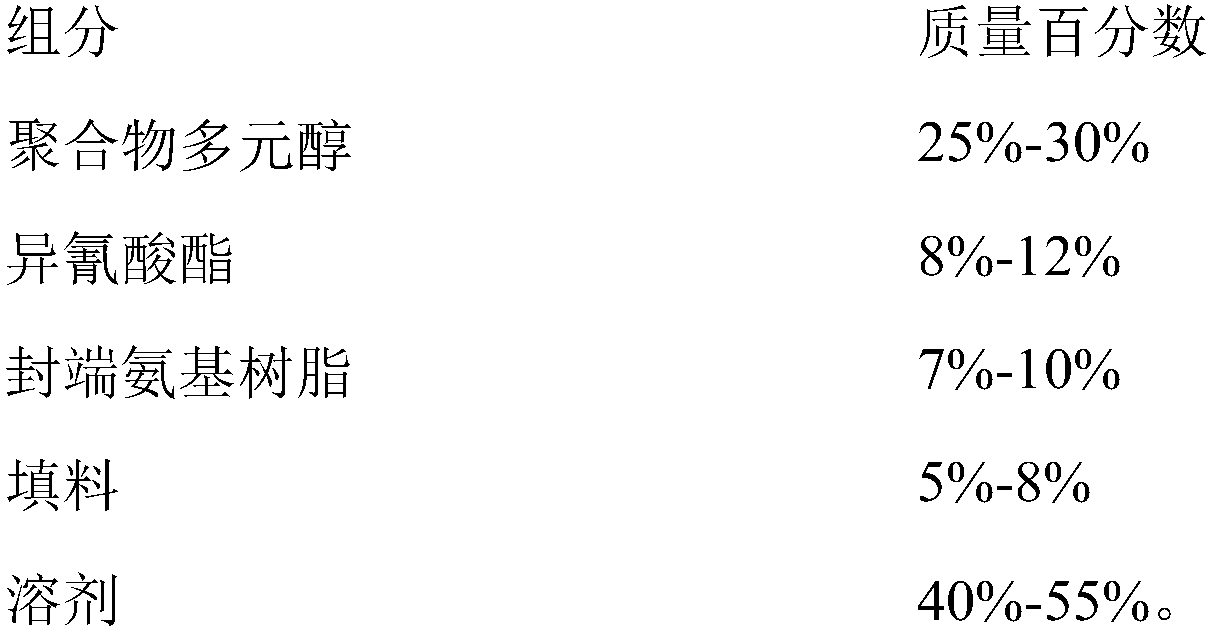

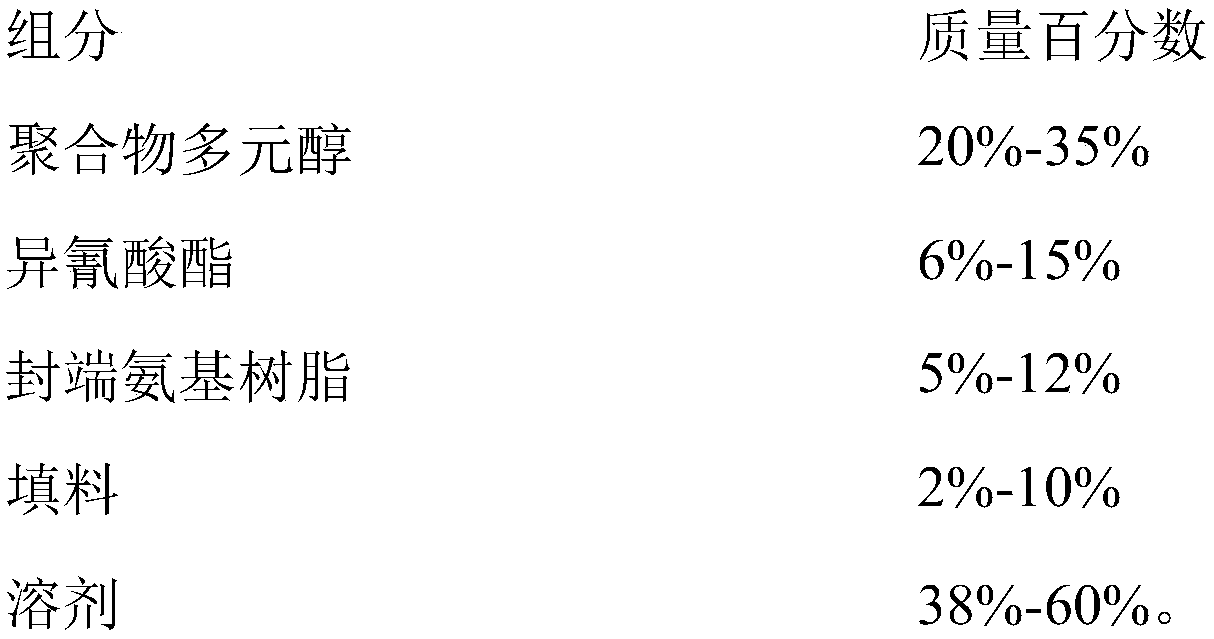

Abrasion-resistant single-component polyurethane coating and preparation method thereof

InactiveCN109593456AHigh hardnessLow temperature and quick dryingPolyurea/polyurethane coatingsPolyesterNoise reduction

The invention relates to the field of polyurethane coating, and discloses an abrasion-resistant single-component polyurethane coating and a preparation method thereof. The coating is prepared from thefollowing components in percentage by weight: 20-35 percent of polymer polyol, 6-15 percent of isocyanate, 5-12 percent of terminated amino resin, 2-10 percent of filler and 38-60 percent of solvent.The preparation method comprises the following steps: (1) adding the polyester polyol into a reaction kettle, heating to 100-120 DEG C, dehydrating for 1 hour in vacuum, cooling to room temperature,introducing nitrogen, and storing for later use; (2) adding the isocyanate into the reaction kettle, stirring, heating to 60-90 DEG C, and reacting for 2-5 hours; and (3) adding the terminated amino resin, stirring, insulating for 1-2 hours, adding the filler, additive and solvent under a stirring state, stirring and dispersing for 0.5 hour, discharging, and sealing for storage. The coating has the advantages of convenience in construction, small material usage, good preservation performance, quick curing, low volatile organic compounds, environmental friendliness, no toxicity, skid prevention, vehicle driving and ground friction noise reduction and durability.

Owner:长沙盾甲新材料科技有限公司

Polysilicon ceramic high-temperature-resistant and corrosion-resistant coating and preparation method thereof

InactiveCN108676461AAvoid it happening againPrevent intrusionFireproof paintsAnti-corrosive paintsEpoxyZinc

The invention provides a polysilicon ceramic high-temperature-resistant and corrosion-resistant coating and a preparation method thereof. The preparation method comprises the following steps: stirringmodified graphene with a polysilane modified epoxy resin to obtain a resin mixture; stirring the resin mixture, zirconium oxide and zinc oxide to obtain a component A; further mixing the component Awith a curing agent, thereby obtaining the polysilicon ceramic high-temperature-resistant and corrosion-resistant coating. According to the polysilicon ceramic high-temperature-resistant and corrosion-resistant coating prepared with the method, solutions and oxide packing crystal lattices in the coating heated at a high temperature are crosslinked, invasion of an oxidation medium can be effectively prevented by a stable Tg phase interface at the high temperature, and thus crystal lattice oxidation can be avoided; meanwhile, the coating comprises a great amount of corrosion-resistant factors and OH active groups, a polymer corrosion-resistant coating with a three-dimensional structure can be generated, and the coating has dual functions of electrochemical protection and physical shielding and is particularly applicable to long-acting high-temperature protection of substrates.

Owner:CHINA ACADEMY OF ENG PHYSICS FUNCTION MATERIAL RES INST

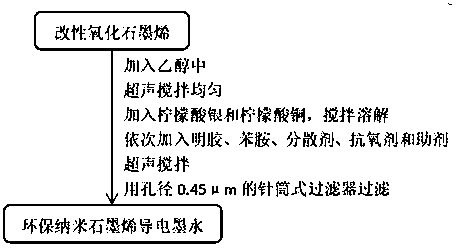

Environmentally friendly nano graphene conductive ink and preparation method and application thereof

The invention provides environmentally friendly nano graphene conductive ink. The environmentally friendly nano graphene conductive ink is prepared from the following raw materials in parts by weight:26 parts of modified graphene oxide, 20 parts of silver citrate, 17 parts of copper citrate, 6 parts of aniline, 4 parts of gelatin, 2.5 parts of a dispersing agent, 4 parts of an antioxidant, 3 parts of an auxiliary agent, 60 parts of ethanol and 30 parts of water. The preparation method of the modified graphene oxide comprises the following steps: S1, preparing graphene oxide by using a liquid-phase stripping method; S2, adding the prepared graphene oxide in deionized water, ultrasonically stirring uniformly, adding a silane coupling agent, carrying out stirring reaction at the temperatureof 60 DEG C, cooling to the room temperature, centrifuging, removing supernatant liquid, and drying solid to obtain silane coupling agent modified graphene oxide. The preparation method is simple, rawmaterial sources are wide, the electrical resistivity of the conductive ink is low, and the environmentally friendly nano graphene conductive ink adheres to a base material strongly, is unlikely to oxidize, is good in stability, can meet the requirement for printability, and is safe and environmentally friendly.

Owner:蓝宇涛

Low-hazard hot melting reflective coating

InactiveCN109401517AHigh whitenessImprove wear resistanceReflecting/signal paintsMoistureMaterials science

The invention discloses a low-hazard hot melting reflective coating. The reflective coating is prepared from the following raw materials in parts by weight: 500-650 parts of petroleum resin, 2-6 partsof polyethylene wax, 200-300 parts of titanium dioxide, 20-35 parts of a plasticizer, 80-120 parts of stone powder and 20-35 parts of glass beads, wherein the petroleum resin is used as a base material, the polyethylene wax is used as a compound dispersant, the titanium dioxide is used as a coloring agent, the stone powder is used as an auxiliary material, and the glass beads are used as a reflective material. The domestic commonly used cheap chemical building materials are used as main raw materials, so that the raw materials are easy to obtain, and the cost is low; furthermore, the manufacturing process is simple, and the manufacturing cost is low; the whiteness, wear resistance, compressive strength and rapid moisture-releasility of the reflective coating provided by the invention aresuperior to that of solvent based coatings; after the reflective coating is painted for 1-3 min, the coating is dry, and vehicles can pass through; construction can even be carried out without blocking traffic; the coating line is complete and clear, has distinctive edges and corners, is high in sharpness, is three-dimensional, and has a good reflection effect; the reflective coating is free fromvolatile components, and is safe and non-toxic.

Owner:南京鑫亮交通设施有限公司

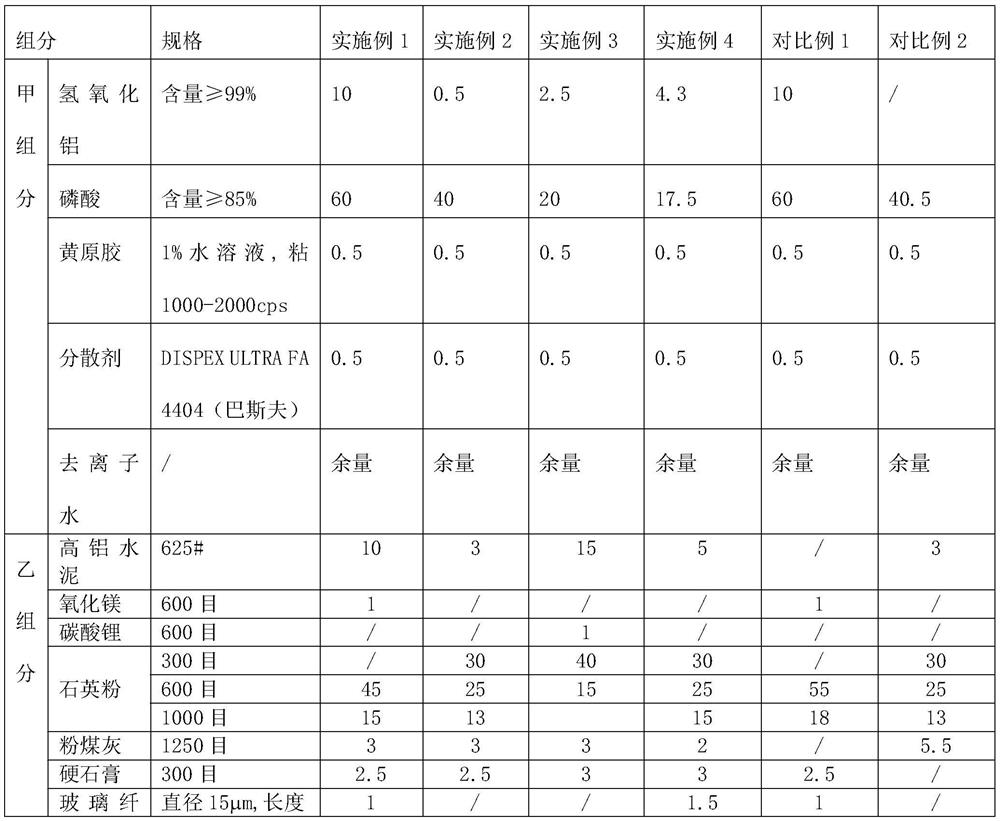

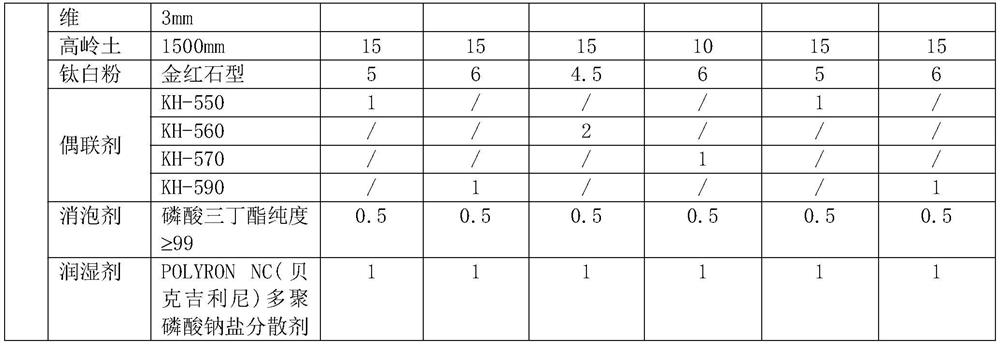

Coating composition for manufacturing ceramic-like coating as well as preparation method and application of coating composition

InactiveCN113248946AGood construction performanceReduce construction costsAnti-corrosive paintsO-Phosphoric AcidCeramic coating

The invention belongs to the technical field of coatings, and provides a coating composition for manufacturing ceramic-like coating, which comprises a component A and a component B, the component A comprises the following components in percentage by mass: 0.5-10% of aluminum hydroxide, 15-60% of phosphoric acid and the balance of water, and the sum of the components is 100%; the component B comprises the following components in percentage by mass: 3-30% of high-alumina cement, 50-80% of quartz powder, 2-10% of fly ash, 0.5-3% of anhydrite and 5-15% of kaolin, and the sum of the components is 100%. According to the coating composition, the phosphoric acid-aluminum hydrogen phosphate mixture serves as a main film forming substance, inorganic ceramic coatings can be formed on the surfaces of various base materials through normal-temperature or high-temperature baking, and the coatings have good scraping and abrasion resistance, chemical resistance, flame retardance, weather resistance and easy-to-clean performance and can protect the base materials in the high-temperature, high-humidity and high-corrosion environments.

Owner:恒昌涂料(惠阳)有限公司

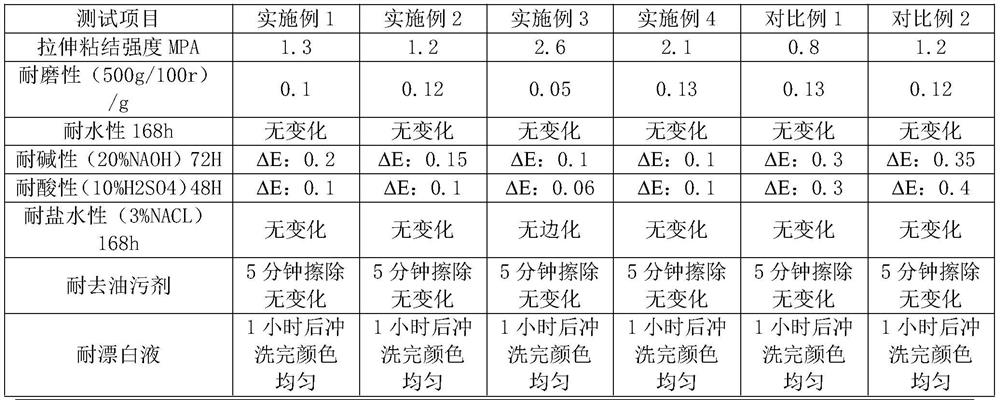

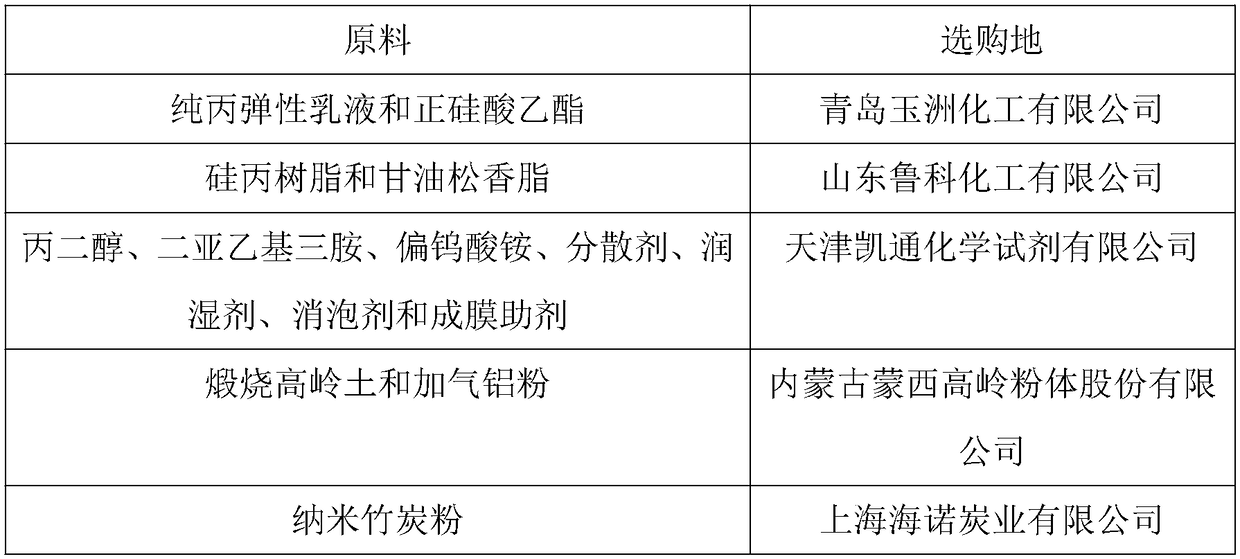

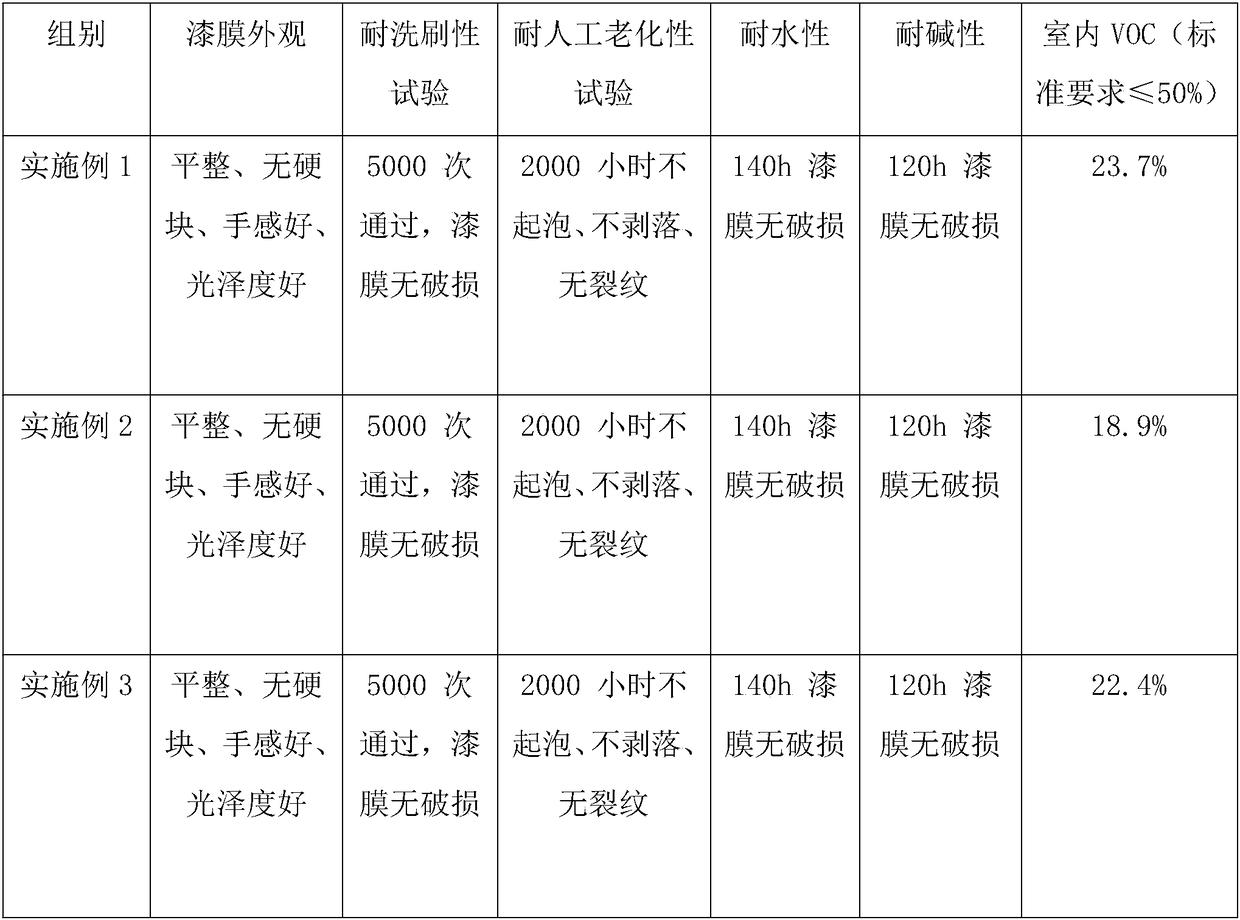

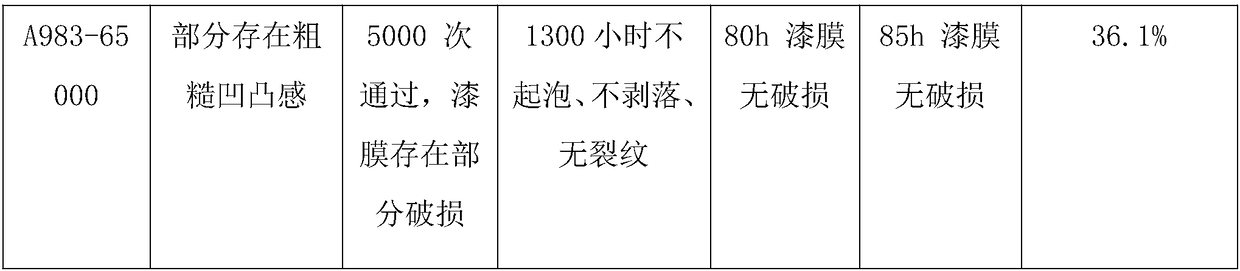

Environment-friendly latex paint and preparation method thereof

InactiveCN108285709ANo smellLow costAntifouling/underwater paintsPaints with biocidesAcrylic resinAmmonium metatungstate

The invention discloses an environment-friendly latex paint and a preparation method thereof, and relates to the technical field of environment-friendly latex paints. The latex paint comprises the rawmaterials of pure acrylic elastic emulsion, silicone acrylic resin, rosin glycerin ester, tetraethoxysilane, calcined kaolin, aerated aluminum powder, modified nano bamboo charcoal powder, propanediol, diethylenetriamine, ammonium metatungstate, dispersant, wetting agent, defoamer, coalescing agent and deionized water. The method comprises the steps of mixing, agitating and grinding of the raw materials, and then the latex paint is obtained. The latex paint has the advantages of being green and environmental friendly, free from odor, excellent in film forming performance and good in decorative effect; the paint film of the latex paint has excellent elasticity, strong covering power and a more durable humidifying function, and the latex paint has excellent durability, water resistance, scrub resistance and dirt resistance while certain refreshing and sterilizing effects on an indoor environment can be achieved, so that the indoor environment is effectively improved.

Owner:HEFEI DAHU ELECTRIC WIRE & CABLE TECH CO LTD

High-temperature-resistant plating-resisting coating and preparation method thereof

The invention discloses a high-temperature-resistant plating-resisting coating and a preparation method thereof. The plating-resisting coating comprises the raw materials in parts by weight as follows: 40-80 parts of high-temperature-resistant silicone resin, 5-10 parts of acrylic resin, 10-35 parts of mica powder, 10-15 parts of copper chromite black and 10-20 parts of silicon dioxide. The method comprises the steps as follows: the high-temperature-resistant silicone resin, the mica powder and the copper chromite black are uniformly mixed and dispersed under the condition of 200-1500 r / min, so that a mixture is obtained; the silicon dioxide is added to the mixture, and the mixture is fully dispersed for 2-5 h; and sedimentation is performed for about 1-3 h, so that the high-temperature-resistant plating-resisting coating is obtained. According to the high-temperature-resistant plating-resisting coating, the technical requirement indexes that a plating layer is perfectly protected and is not corroded by a high-temperature plating solution and the like in an environment of 300-1000 DEG C are met; and the adhesive force of the product is high, tedious processes such as primer coating and the like are not required, the paint coating process is simple, and the cost is greatly saved.

Owner:武汉市吉瑞化工科技有限公司

Low-carbon low-volatility water-based flux and preparation method thereof

PendingCN109530971ASolder joints are fullRound solder jointsWelding/cutting media/materialsSoldering mediaBenzoic acidWater based

The invention provides a low-carbon low-volatility water-based flux and a preparation method thereof. The low-carbon low-volatility water-based flux is prepared from the following components, by mass:2-4.5% of an active agent, 1.5-4% of a surface active agent, 0-0.4% of a film-forming agent, 0.01-0.3% of an antioxidant, 0.01-0.4% of a corrosion inhibitor and the balance a solvent, specifically, the active agent is prepared by mixing at least two of succinic acid, benzoic acid, DL-malic acid and adipic acid at the mass ratio of greater than 0% respectively at the temperature of 30-60 DEG C; and the surface active agent is any one of AEC-9NA or TX-10 phosphate, or the surface active agent is prepared by mixing both of the AEC-9NA and TX-10 phosphate at the mass ratio of greater than 0% respectively. The flux has low solid residue content, no halogen, no rosin, low carbon, no volatile organic compound, no irritating odor, little corrosion to a circuit board, and round and bright solder joints. Besides, the flux is easy to manufacture, quite low in cost, convenient to store and transport, free of solder explosion, stable in chemical property, free of influence on physical health of operators and environmentally friendly.

Owner:CHONGQING UNIV OF TECH

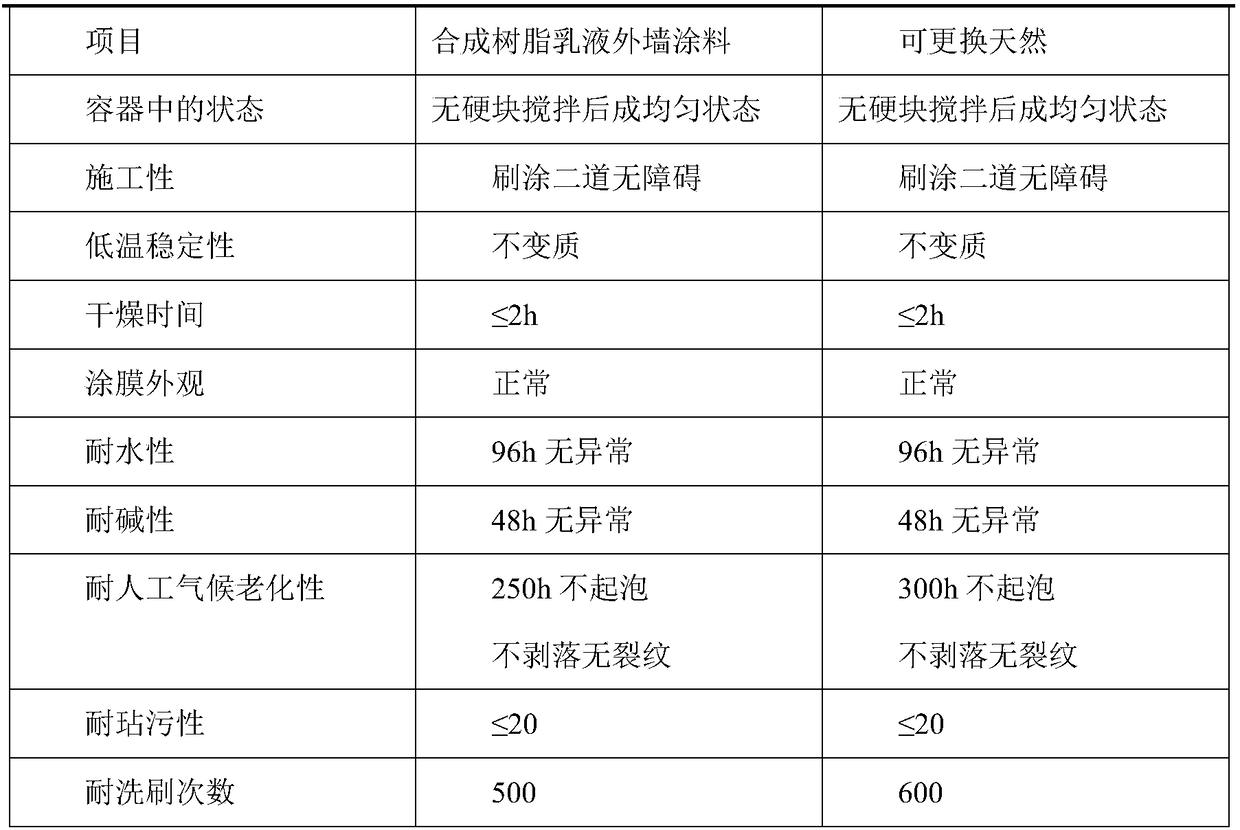

Replaceable natural polysaccharide coating for construction field and preparation method thereof

The invention discloses replaceable natural polysaccharide coating for a construction field. The environment-friendly type natural polysaccharide coating takes polysaccharide and a modified waterbornepolymer as a binding agent, and further comprises filler, an auxiliary agent and water; the replaceable natural polysaccharide coating is qualified coating for internal and external walls under conventional external conditions and under certain temperature and pressure. The natural polysaccharide coating disclosed by the invention takes a natural high molecular material polysaccharide and a modified waterborne polymer as the binding agent, does not contain any synthetic emulsion and can be completely degraded under certain conditions; in a film forming process, no organic solvents are volatilized and the requirements of no damages to human bodies are met, so that the replaceable natural polysaccharide coating is real environment-friendly coating. The natural polysaccharide coating is stable and beautiful at room temperature and is easy to crush and spray; a coating layer can be removed through pressure and warm water and rapid replacement of the coating layer is realized.

Owner:HUAZHONG NORMAL UNIV

Primer compositions for adhesive bonding systems and coatings

ActiveUS9522974B2Long lasting resistanceVOC freeSynthetic resin layered productsPretreated surfacesEpoxySelf emulsifying

The present invention relates to aqueous-based primer composition, comprising at least one thermosetting, self-emulsifying epoxy resin composition; at least one thermosetting, non-self-emulsifying resin composition; water; and at least one curative.

Owner:HENKEL KGAA

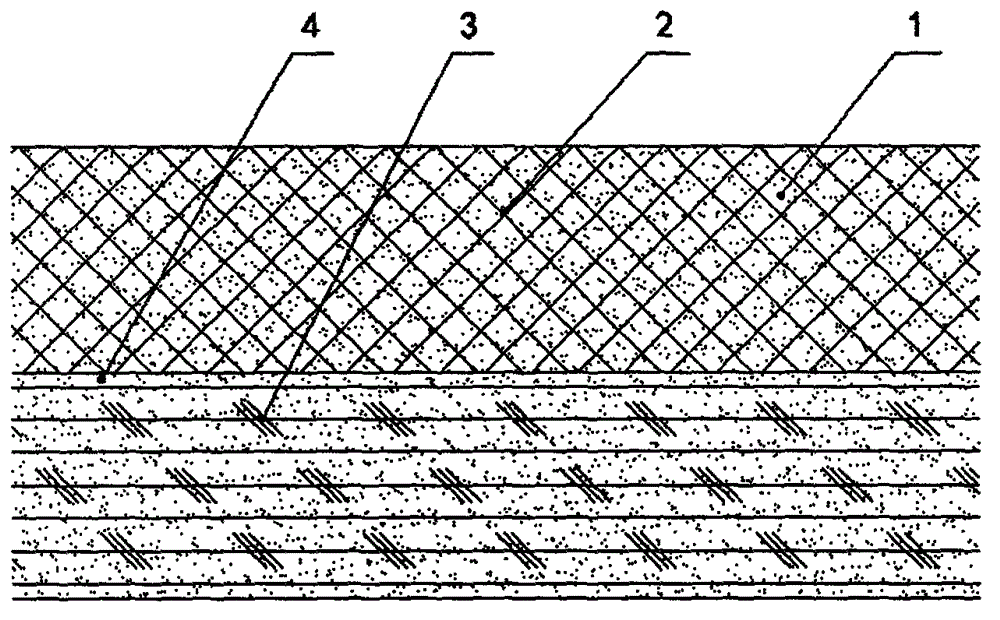

Plane single-sheet compound veneer with UV (Ultraviolet) primer

InactiveCN106142766AVOC-freeImprove plasticitySpecial ornamental structuresWood layered productsSurface layerAdhesive

The invention provides a plane single-sheet compound veneer with UV (Ultraviolet) primer. A multilayered structure is adopted; a surface layer is a veneer layer and a bottom surface is a nonwoven fabric or kraft paper; a compound adhesive is arranged between layers. UV paint is arranged into a microcosmic gap of a wood layer. The veneer has good flexible property, stability and good post process treatment property. The veneer can be laminated or coated on an abnormal-shape surface of any material. The secondary treatment or machining property is good and the veneer is stable and reliable. Compared with a traditional pasted veneer surface treatment process, a lot of process procedures are saved and the labor cost is saved, so that the production cost and technology cost of downstream products are reduced and the economic benefits of the downstream products are greatly improved.

Owner:应晨霞

40Cr steel surface antirust agent and preparation method thereof

InactiveCN106010242ASolve the problem of corrosionAvoid cavitationAnti-corrosive paintsCavitationCross-linked polyethylene

The invention discloses a 40Cr steel surface antirust agent. The 40Cr steel surface antirust agent consists of the following components in percentages by mass: 10-14% of barium petroleum sulfonate, 4-7% of 80# micro-crystalline wax, 59% of commercial castor oil, 11-14% of waterborne acrylic resin, 3-4% of naphthalene, 2-3% of 96% concentrated hydrochloric acid, 1-3% of crospovidone, 1-2% of a wetting agent, and 1-2% of a defoaming agent. Excellent materials are selected, a scientific processing method is adopted, the problem that the surface of existing steel can be corroded is solved, and antirust operation is facilitated; the commercial castor oil is used as a dispersion medium, and is environmentally friendly and pollution-free; the 40Cr steel surface antirust agent does not contain methylbenzene, ethylbenzene or dimethylbenzene, is low in VOC and does not contain formaldehyde, the heavy metal content is lower than the national compulsory standard, irritating odor does not exist, surface corrosion, cavitation and scaling of the steel can be prevented, a protecting layer is formed, time of rust generation of the surface of the steel is prolonged, chromic acid or dichromate in a formula is avoided, and the 40Cr steel surface antirust agent is low in cost, non-toxic, and excellent in construction performance, does not have adverse effects on skin, and has remarkable environmental benefit, economic benefit and social benefit.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

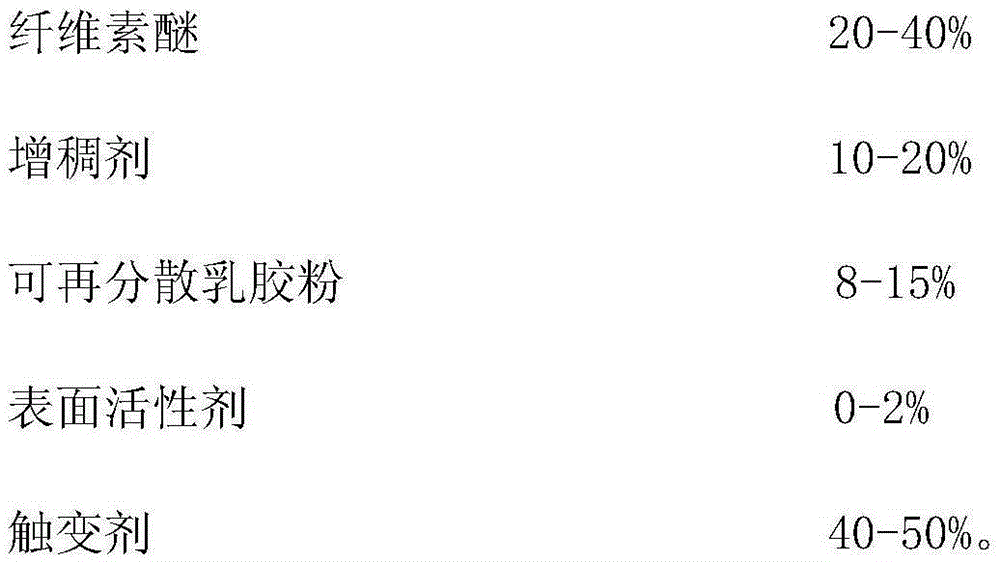

Water-retaining thixotropic agent for ready-mixed mortar and preparation method thereof

The invention discloses a ready-mixed mortar water-retention thixotropic agent and a preparation method thereof. The mortar comprises the components of, by mass: 20-40% of cellulose ether, 10-20% of a thickener, 8-15% of re-dispersible latex powder, 0-2% of a surfactant, and 40-50% of a thixotropic agent. The components with the specified mass percentages are uniformly mixed in a mixing machine, such that the ready-mixed mortar water-retention thixotropic agent is obtained. The ready-mixed mortar water-retention thixotropic agent has the characteristics of good water retention performance, cohesiveness, construction smoothness, and no VOC. When the agent is used in manual work mortar and machine-sprayed mortar, construction efficiency and project quality can be substantially improved.

Owner:江苏兆佳建材科技有限公司

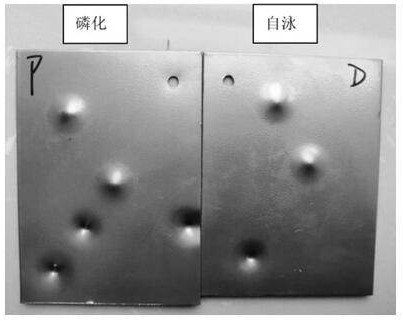

Autophoresis technology for surfaces of various metal furniture

InactiveCN111719174AThe test effect is goodStrong rust resistanceElectrophoretic coatingsSalt spray testPhysical chemistry

The invention discloses an autophoresis technology for surfaces of various metal furniture. The autophoresis technology comprises the following steps of workpiece washing, autophoresis in an autophoresis tank and baking curing. In the process of autophoresis in the autophoresis tank, the composition raw materials of autophoresis liquid in the autophoresis tank are water-based raw materials and comprise acrylic acid, solid powder, a stabilizer and a defoaming agent, during deposition, automatically deposited chemical reaction materials are added into the tank liquid, during autophoresis, workpieces are soaked in the autophoresis tank, the chemical reaction materials corrode the surfaces of the workpieces, wherein part of dissolved Fe ions react with the solid powder, so that the solid powder is separated out and deposits on the surfaces of the metal workpieces to form wet films, and finally, the wet films are fully dried through the baking curing process to form cured films. The surfaces of the various metal furniture treated through the autophoresis technology are good in salt spray test effect, high in rust resistance and good in impact resistance, the service life of the productis greatly prolonged, meanwhile, in the treatment process, the environment friendliness is good, the energy consumption is low, and thus the autophoresis technology is worthy of popularization.

Owner:JIANGYIN YOUBANG HOUSEWARES

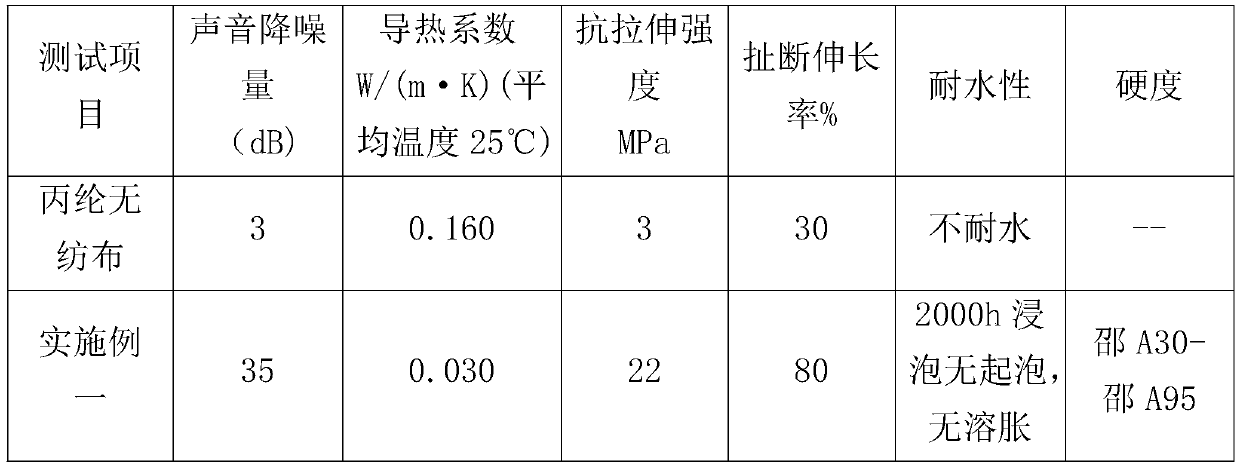

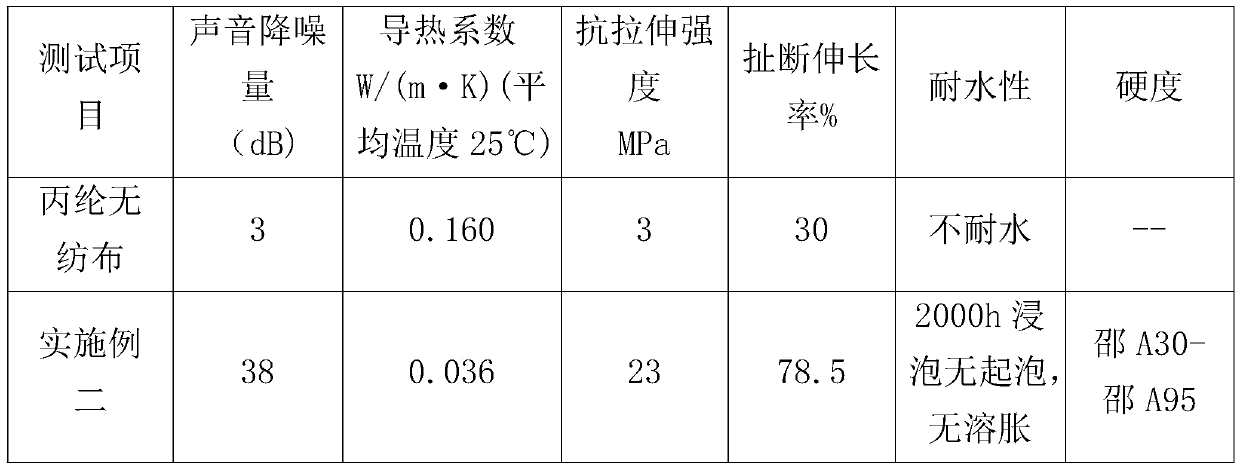

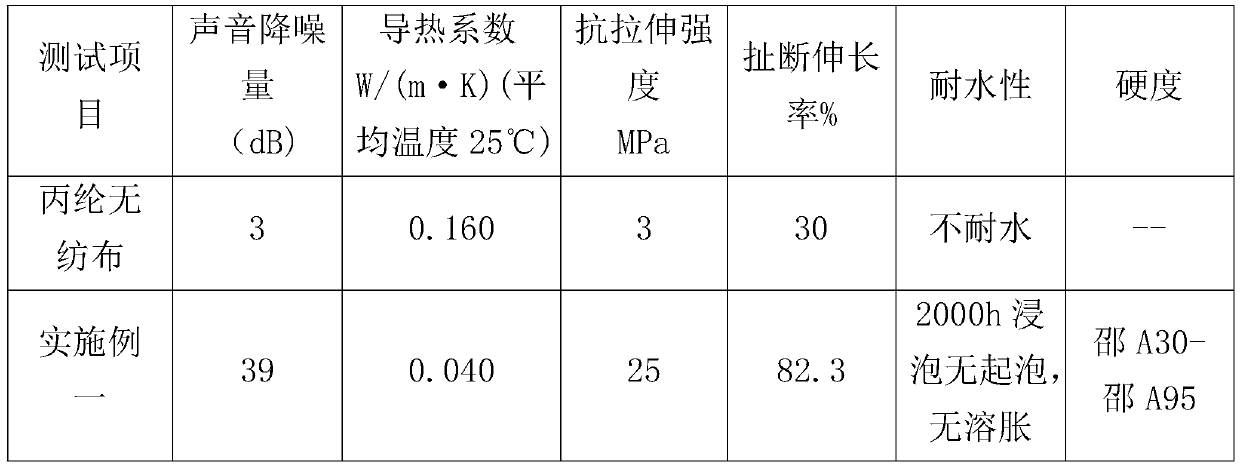

Environment-friendly heat-insulation and noise-reduction polyurea composite material and manufacturing method thereof

InactiveCN111535045AHigh solid contentEasy to makeChemical industryTextiles and paperFiberDimethyl methylphosphonate

The invention relates to the technical field of composite materials, and specifically discloses an environment-friendly heat-insulation and noise-reduction polyurea composite material. The environment-friendly heat-insulation and noise-reduction polyurea composite material comprises polyether polyol, tri(hydroxymethyl)propane, butyl acetate, isophorone diisocyanate, dimethyl methylphosphonate, a light stabilizer, polyaspartic acid resin, cellulose acetate butyrate, siloxane pigment, mica balls, silicate particles and a defoamer; a fiber texture is heated to 40 DEG C; the surface of the fiber texture is dried; the fiber texture is fixed on conveying rollers; one section of the fiber texture is placed on a fixing clamp; the fixing clamp draws the fiber texture to move forwards through a variable frequency motor under control of a PLC; relative positions of a rolling brush and a scraper to the fiber texture are controlled through sensors; a component A is mixed with a pre-mixed material to form slurry, and the slurry is pumped into a paint box by using a diaphragm pump; paint is extracted into a paint container, which is directly connected to the rolling brush, from the paint box according to a using amount; the slurry is painted on the fiber texture in a rolling manner by using the rolling brush; the slurry is slicked with the scraper and is dried; and then the environment-friendly heat-insulation and noise-reduction polyurea composite material is obtained.

Owner:青岛青材科技有限公司

A kind of water-based insulating paint and preparation method thereof

ActiveCN105295658BImprove insulation performanceHigh normal electric strengthEpoxy resin coatingsWater basedPolyol

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com