Fiber decorative film and preparation method and product thereof

A decorative film and fiber technology, applied in the field of decorative materials, can solve the problems of expensive printing equipment and ink, comparable three-dimensional texture of carbon fiber, and incomparable strength, and achieve high yield and good surface quality, simple and convenient molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

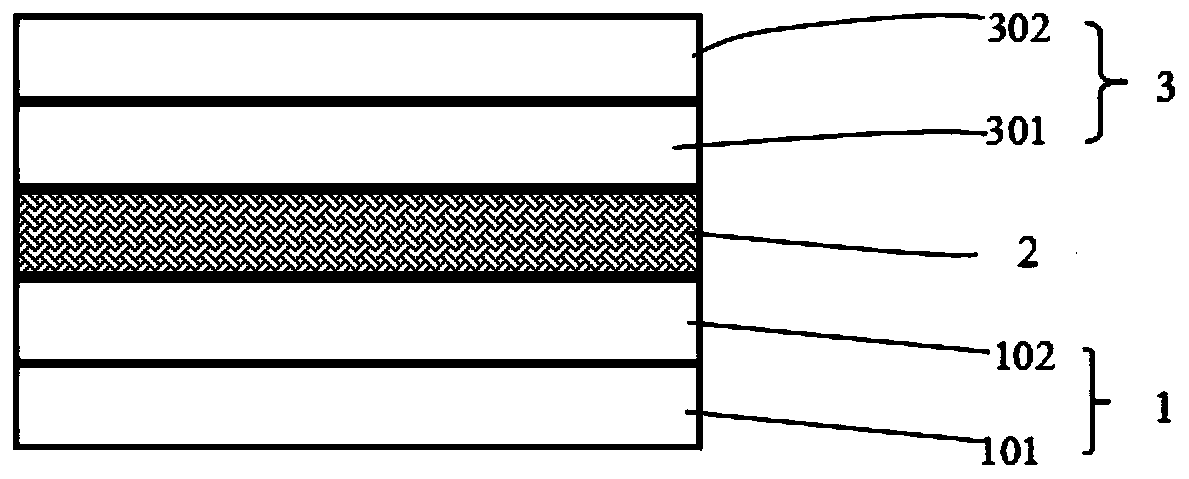

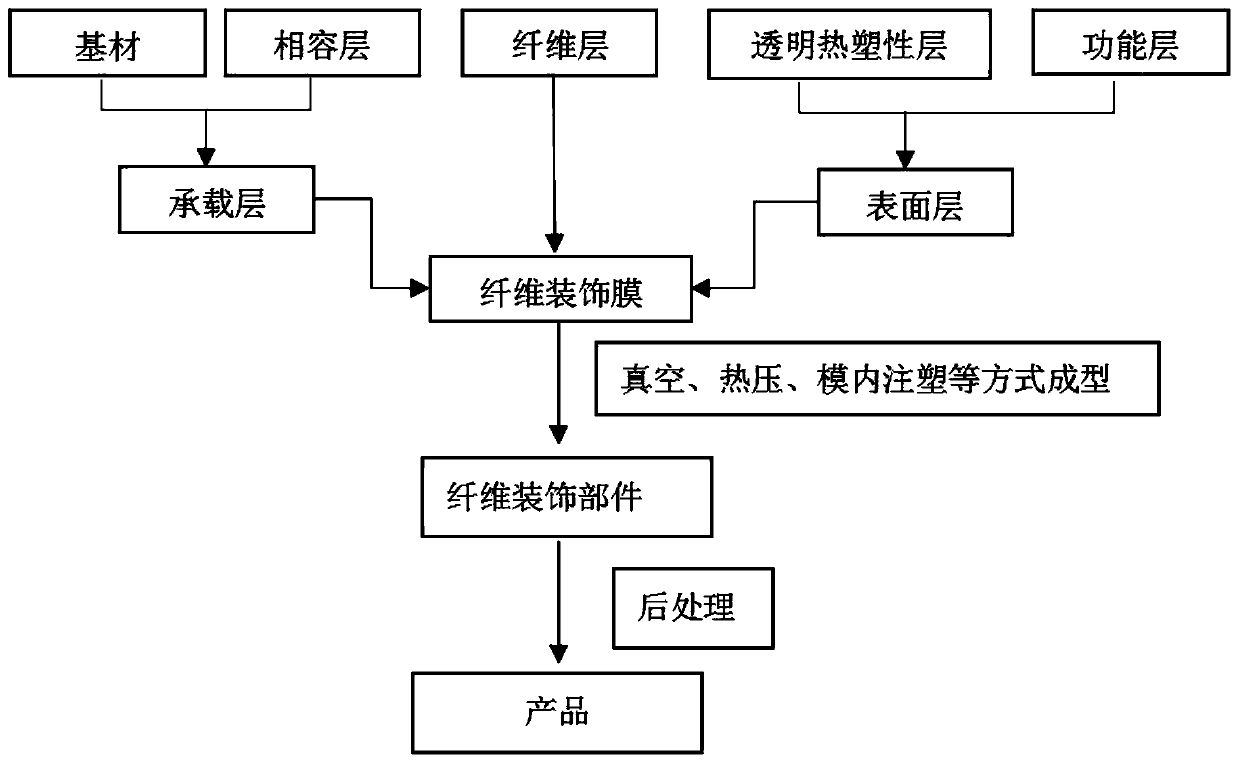

[0033] The present invention provides a method for preparing a fiber decorative film described in the above technical solution, comprising the following steps:

[0034] The substrate layer and the compatible layer are made into the bearing layer, and the transparent thermoplastic layer and the functional layer are made into the surface layer, which are stacked in sequence according to the order of the bearing layer, fiber layer and surface layer, and are carried out in a roll-to-roll continuous compounding manner Laminated to obtain a fiber decorative film.

[0035]In the present invention, the substrate layer and the compatibilizing layer are made into a bearing layer. In the present invention, the compatibility layer is preferably spread on the surface of the substrate layer by methods such as coating, bonding, spraying, etc., and dried to obtain a bearing layer; the drying temperature is preferably 60-150°C.

[0036] The present invention will preferably include but not li...

Embodiment 1

[0045] Spray a silicone coating solution compatibilizer (thickness 50 μm) on the surface of ABS film (thickness 200 μm), and after drying at 90 ° C, a bearing layer is obtained; coat a wear-resistant coating (thickness 25 μm) on the surface of PMMA (thickness 50 μm) to obtain a layer; carbon fiber and aramid fiber are laid and woven to obtain a carbon fiber and aramid twill mixed fiber layer (thickness 220 μm);

[0046] From bottom to top, roll-to-roll continuous lamination is carried out in the order of bearing layer, fiber layer, and surface layer under heating and pressure conditions. After winding, the fiber decorative film is obtained;

[0047] Open the lower cavity of the vacuum blister forming machine, put in the injection molded parts and the fiber decorative film, preheat the fiber decorative film (preheating temperature 120°C), when the fiber decorative film reaches the preheating temperature , close the lower chamber of the molding machine, open the valve of the va...

Embodiment 2

[0049] Spray silicone coating liquid compatibilizer (thickness 75μm) on the surface of PP film (thickness 300μm), dry at 110°C to get bearing layer; coat UV resin (thickness 25μm) on PC surface (thickness 350μm), emboss with pattern roller Finally, the surface layer is obtained by 365nm UV light curing; the carbon fiber is woven according to the 3K twill weave, and the 3K twill carbon fiber layer is obtained;

[0050] From bottom to top, roll-to-roll continuous lamination is performed under heat and pressure in the order of bearing layer, carbon fiber layer, and surface layer. After pressing and rolling, a carbon fiber decorative film is obtained;

[0051] Open the upper and lower chambers of the thermocompression molding machine with the desired shape and preheat to 200°C, put in the carbon fiber decorative film, pressurize and close the upper and lower chambers at a pressure of 16 MPa, hold the pressure for 3 minutes, take it out, and trim the edges to obtain A carbon fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com