Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

671results about How to "Improve thermoplasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

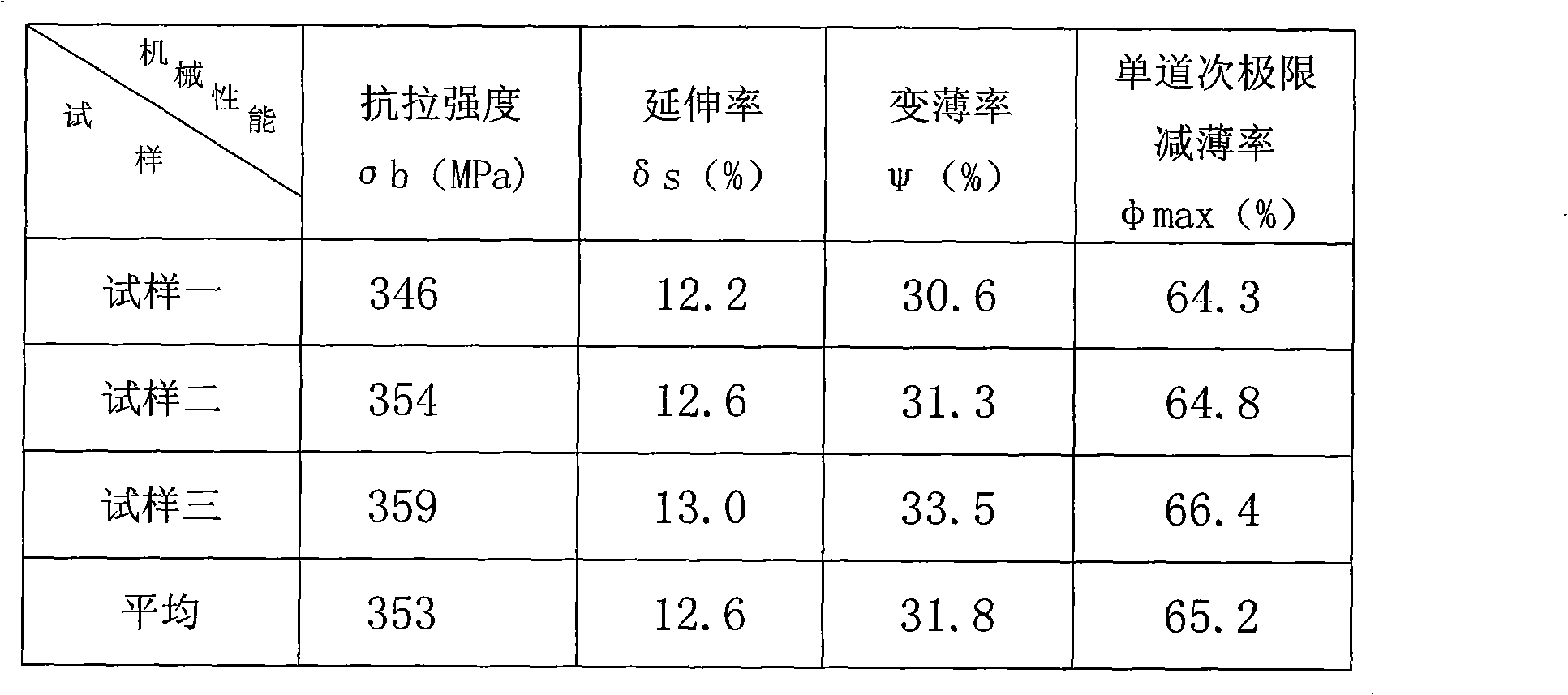

Manufacturing method of high-strength automobile aluminum-alloy rim material

The invention relates to a manufacturing method of a high-strength automobile aluminum-alloy rim material, which relates to a manufacturing method of automobile fitting materials. The manufacturing method comprises the following steps of: preparing materials; smelting; adding a refiner; adjusting components; refining; casting; quenching; carrying out aging treatment; and packaging to prepare the high-strength automobile aluminum-alloy rim material which comprises 0.4-0.8 percent of Si, 0.8-1.2 percent of Mg, 0.16-0.22 percent of Ti, 0.2-0.3 percent of Zn, 0.6-0.8 percent of Fe, 0.15-0.4 percent of Cu, 0.08-0.32 percent of Cr, 0.1-0.2 percent of Mn, 0.02-0.06 percent of RE rare earth, 0.02-0.06 percent of Zr, 0.02-0.06 percent of Sr and the balance of Al. The invention has reasonable process parameter and simple manufacturing method, and the manufactured aluminum-alloy rim material has the advantages of high strength, good mechanical performance and the like and is suitable for being popularized and used in small, medium and large automobiles.

Owner:卢森锴

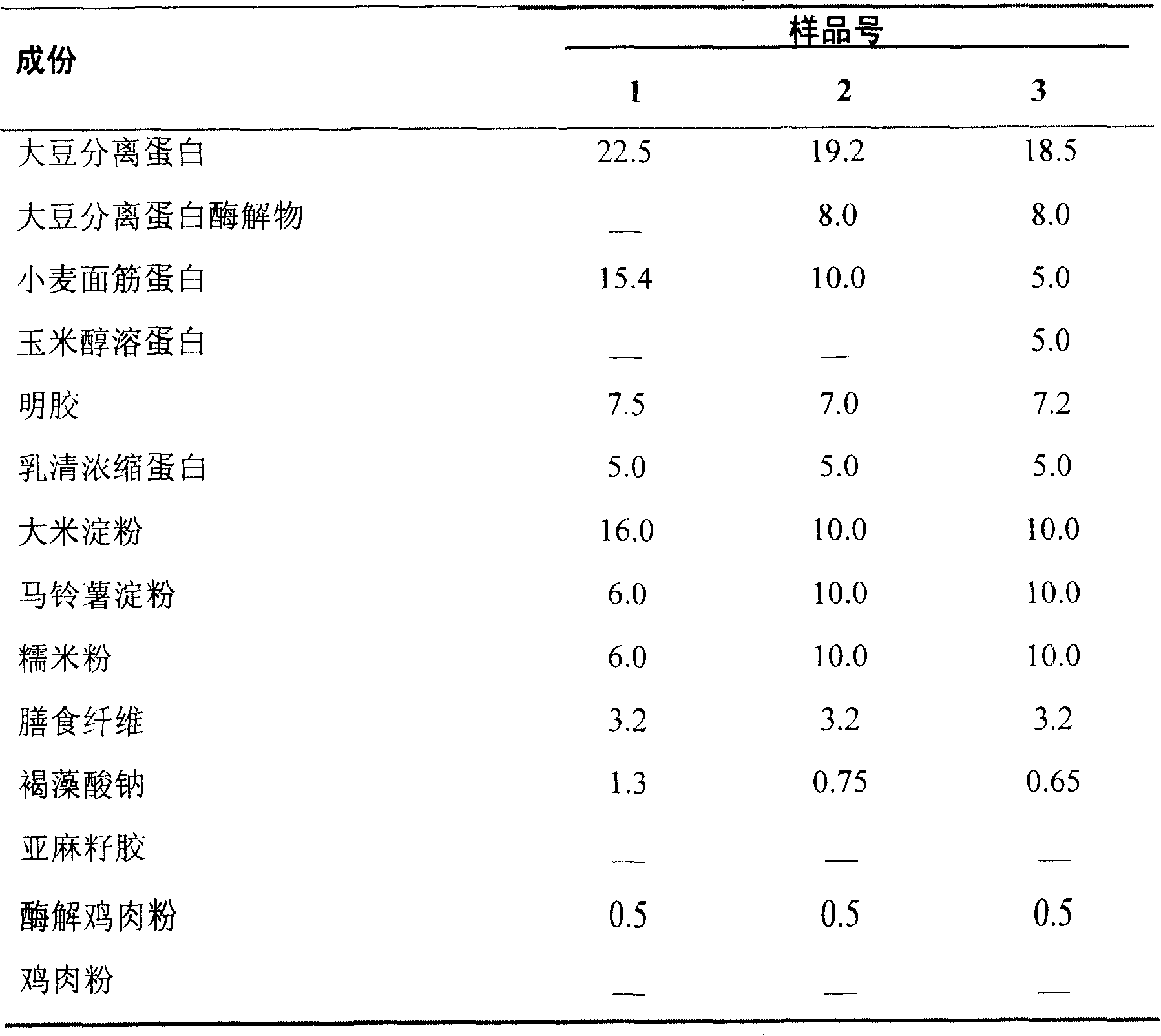

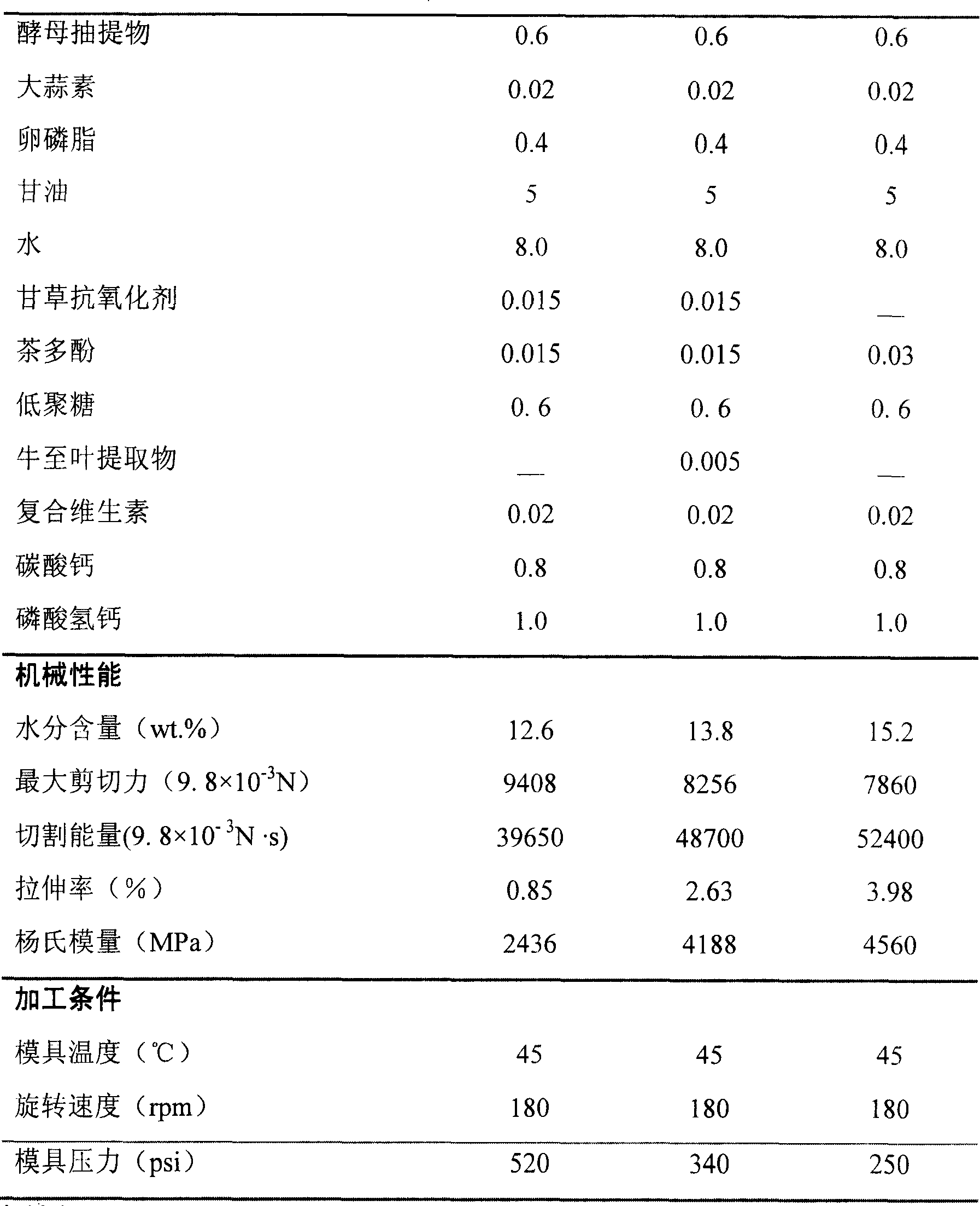

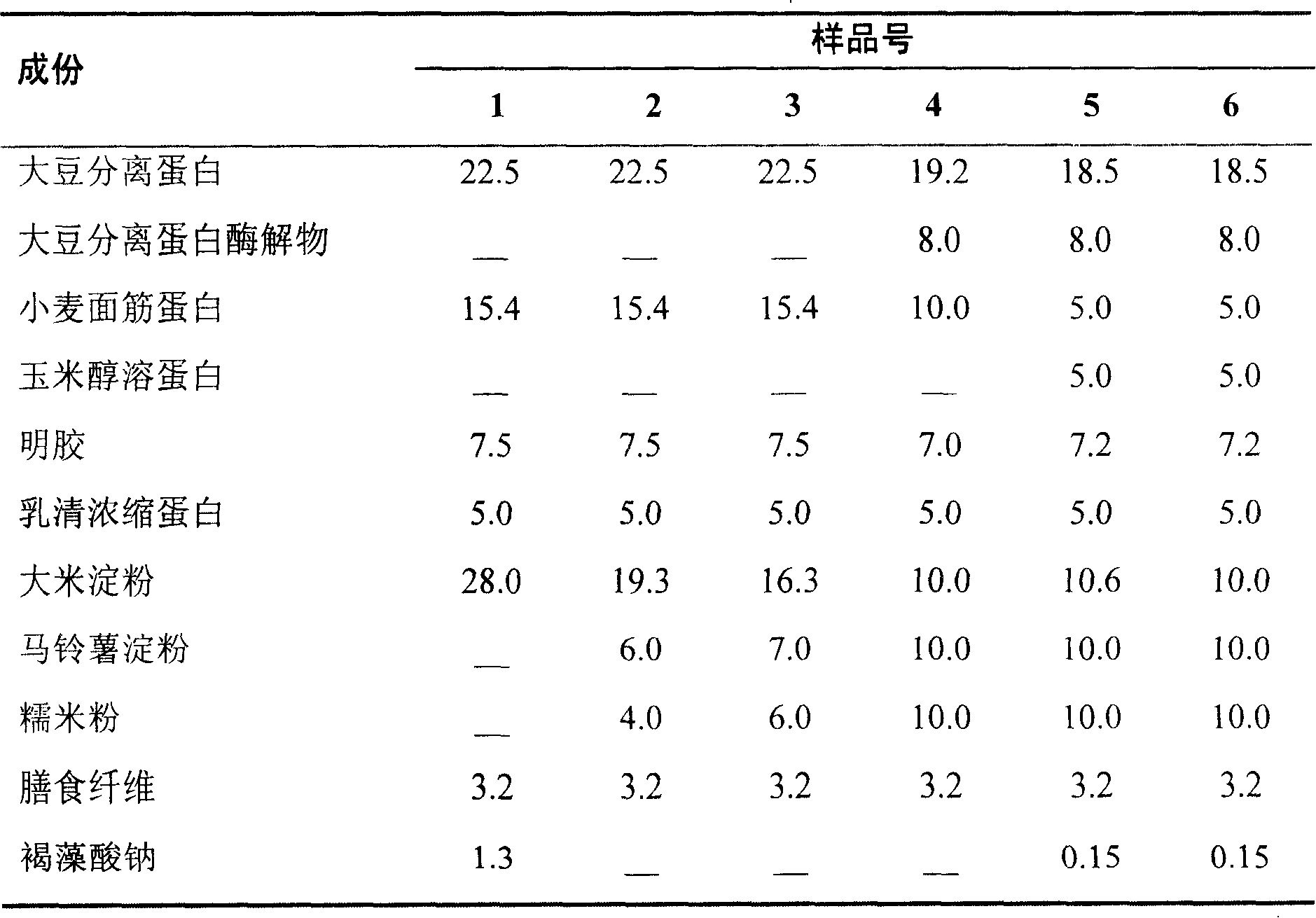

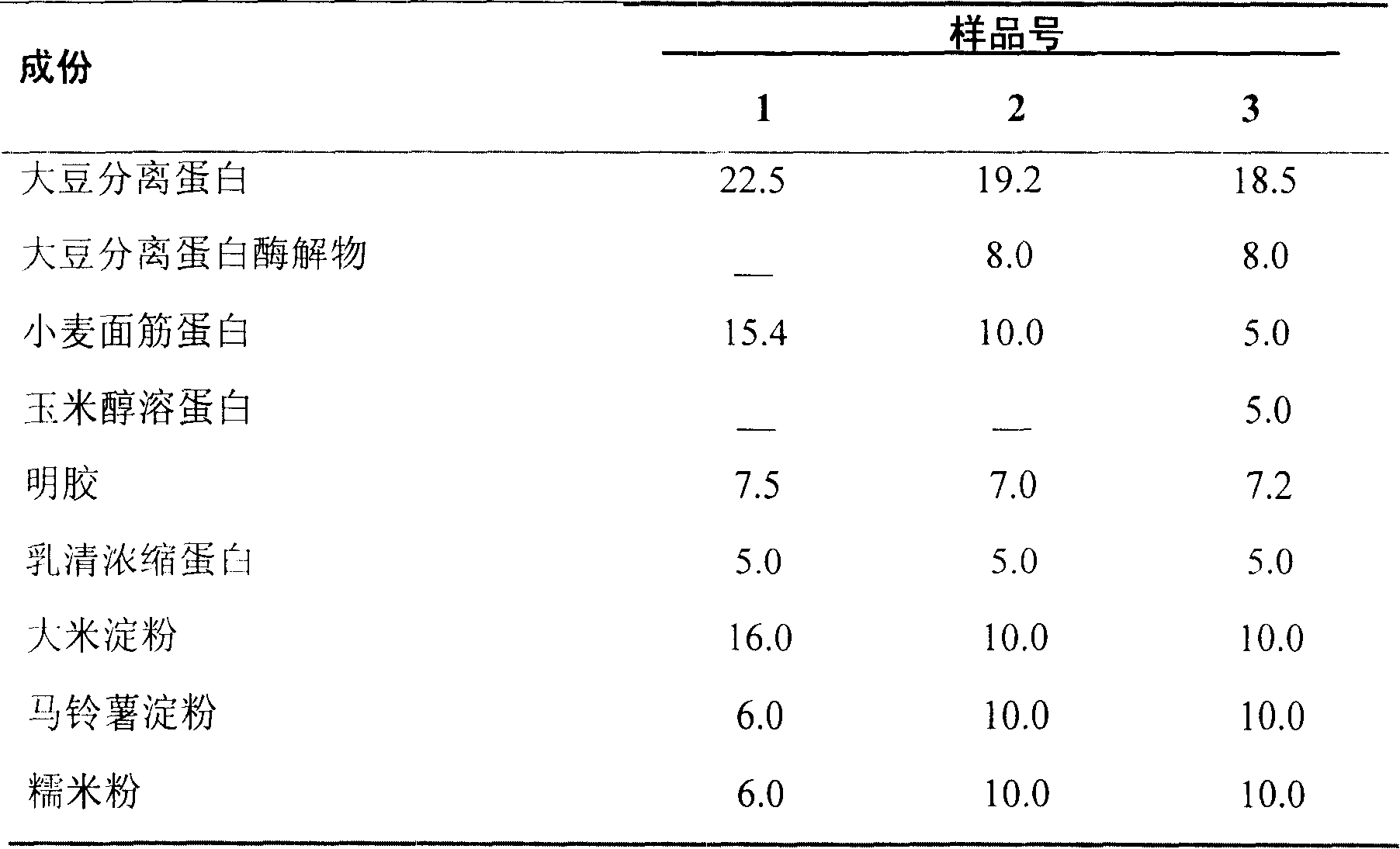

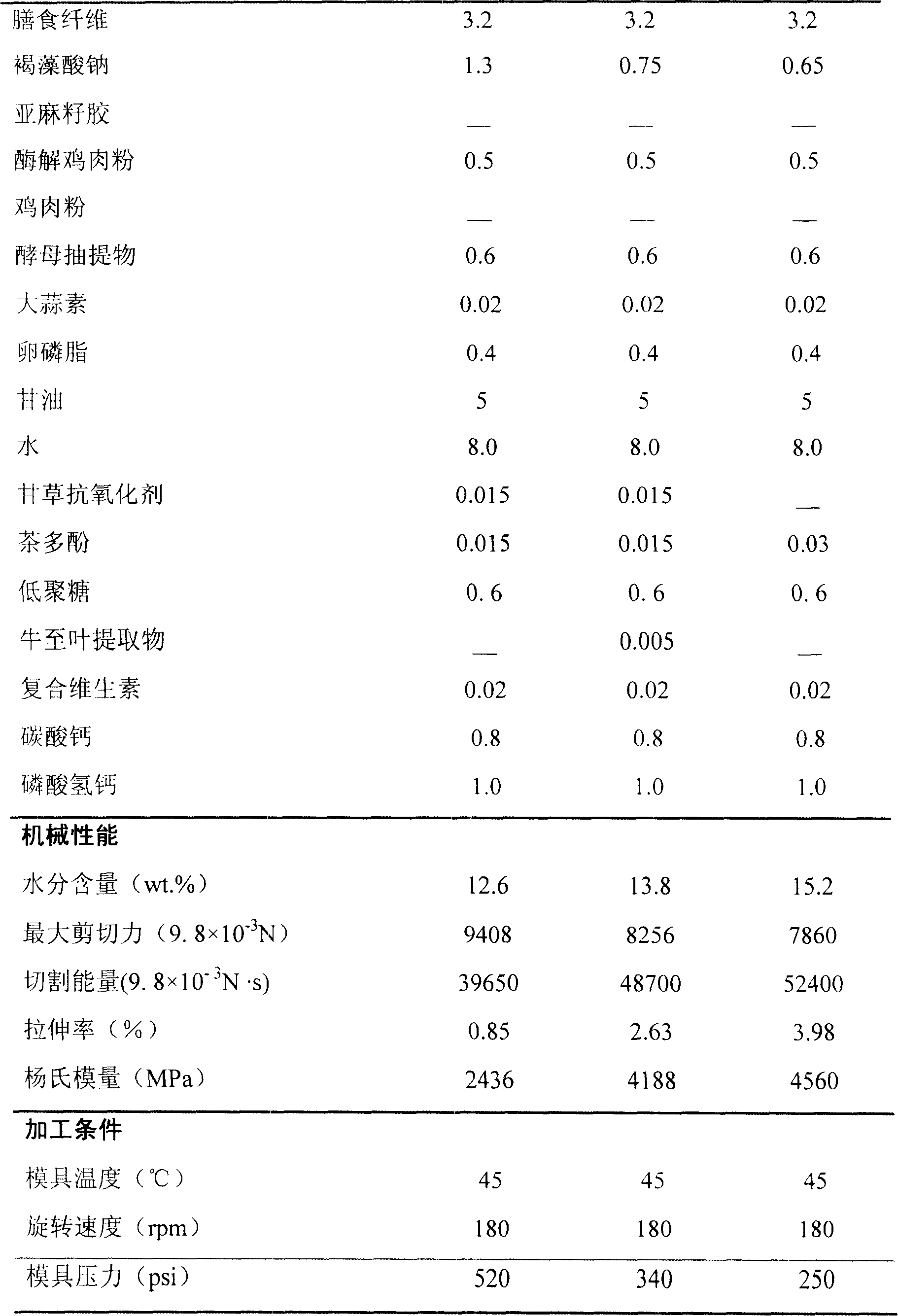

High protein functional pet chaw and preparation method thereof

ActiveCN101209030AHigh strengthHigh hardnessAnimal feeding stuffTaming and training devicesBiotechnologyNutrition

The invention discloses a pet chaw with high protein. The chaw comprises 40 to 60 wt. percent of protein compound which consists of plant protein and animal protein, 15 to 40 wt. percent of faecula, 6 to 12 wt. percent of oil, 1 to 8wt. percent of prandial fibre, 1 to 4wt.percent of quality modifying agent and flavouring agent, 0.1 to 3wt. percent of antioxidant, 0.1 to 3wt. percent of nutrition or health additive, and the rest is water. The weight percentage is counted by the total weight of the pet chaw. Simultaneously, the invention also discloses a preparing method for the pet chaw with high protein and a pet toy or artificial dog bone manufactured by the method.

Owner:JIANGXI HUAHENG PET FOODS CO LTD

Novel fire resistant polyimide foam and method of producing the same

The invention relates a novel high temperature resistant polyimide foam and the preparation process thereof is as follows: (1) firstly, 2, 3, 3', 4'-biphenyl tetracarboxylic dianhydride or 2, 3, 3', 4'-biphenyl tetracarboxylic dianhydride and another type of aromatic dianhydride are heated and refluxed in a fatty alcohol solution so as to change the tetracarboxylic dianhydride into diacid diester; (2) in accordance with a certain proportion, the obtained diacid diester is synthesized into a precursor solution with one type or more of aromatic diamine and a blocking agent of acetylenyl benzene and a certain quantity of foam stabilizer is added into the solution; (3) the solution is heated to remove tiny molecule volatile matter and obtain a polymide precursor powder; and (4) the precursor powder is filled into a mould to be frothed at high temperature and carries out imidization so as to obtain the polyimide foam. The density of the novel high temperature resistant polyimide foam is 10 kg / m<3> to 500 kg / m<3> and the vitrified transformation temperature is over 350 DEG C; and the foam is characterized by excellent high temperature resistance, low temperature resistance, mechanical properties and functions of anti flaming, heat insulation or noise reduction.

Owner:SHENZHEN HIFUTURE ELECTRIC

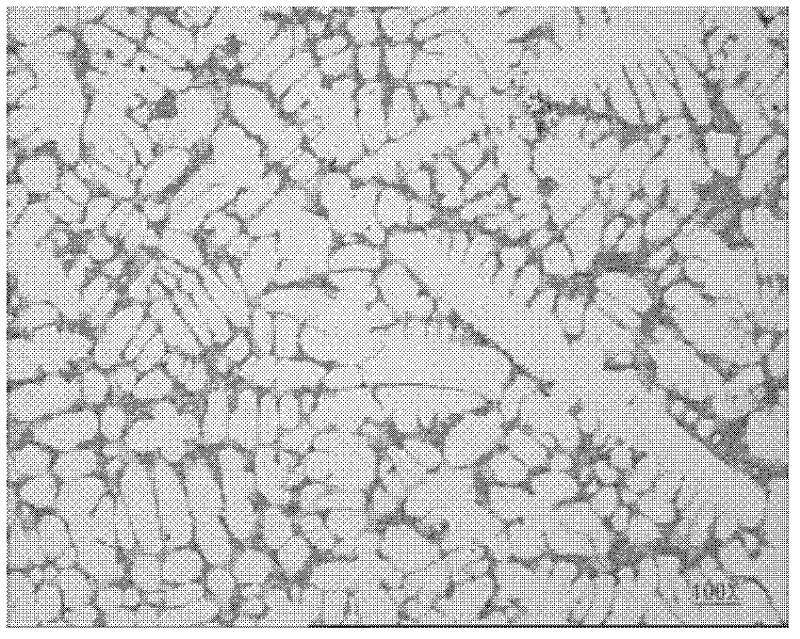

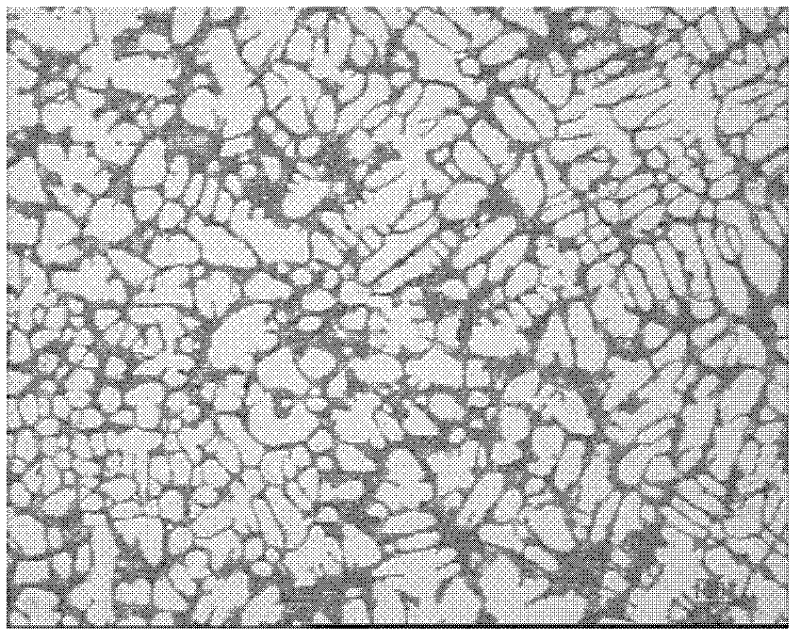

Novel manufacturing process of phi 300 mm-phi 700 mm high-carbon high-chromium cold-working die steel forged round steel

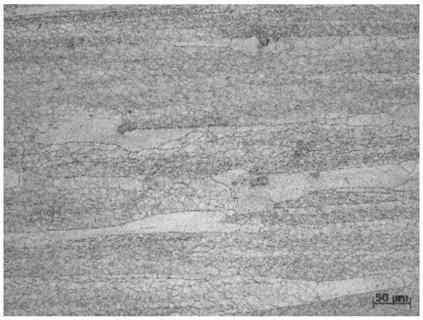

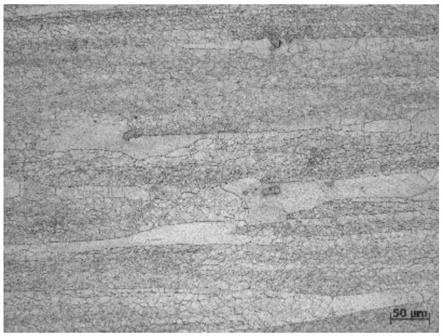

ActiveCN102418042AImprove cleanlinessImprove segregationMetal-working apparatusProcess efficiency improvementCarbideHot working

The invention discloses a manufacturing process of phi 300 mm-phi 700 mm high-carbon high-chromium cold-working die steel forged round steel, and the purpose is to solve the problems of quite severe ununiformity of large-section forging material eutectic carbides and the increase of defects of internal cracks and surface cracks during the forging process caused by segregation deterioration of cast structure carbides of large steel ingots. By using steel-making technical measures such as LF refining, VD degassing, aluminium wire feeding, and the like, the invention improves the molten steel cleanliness, the control of electroslag remelting output power, and the homogenization treatment before forging, and improves the segregation of eutectic carbides and the hot-working plasticity of steel; by controlling the forging heating numbers and various deformation amounts of large high-carbon high-chromium steel ingots, large granular carbides are crushed; the ununiformity of eutectic carbides is improved; crack defects during the forging process are prevented; and the produced high-carbon high-chromium steel large-section forging materials has ununiformity of eutectic carbides of up to grade 4-grade 6; the results of ultrasonic inspection are at good levels of E / e grade, D / d grade.

Owner:FUSHUN SPECIAL STEEL SHARES

Duplex stainless steel and manufacturing method thereof

The invention relates to duplex stainless steel. The duplex stainless steel comprises the following chemical components in percent by weight: 0.01-0.08% of C, 0.2-1.0% of Si, 1.5-3.5% of Mn, 19.0-21.0% of Cr, 1.2-2.8% of Ni, 0.08-0.18% of N, less than or equal to 0.5% of Mo, less than or equal to 1.0% of W, less than or equal to 1.0% of Cu and the balance of Fe and inevitable impurities; PREN (Pitting Resistance Equivalent Number) is 20-24, the martensitic temperature Md formed by strain induction is 60-130 DEG C. A manufacturing method comprises the following steps of: selecting vacuum induction smelting in an electric furnace, argon oxygen decarburization (AOD) or electric furnace, argon oxygen decarburization (AOD), external refining and LF (Ladle Furnace) smelting; carrying out die casting or continuous casting on molten steel, controlling the superheat degree to be 20-50 DEG C in die casting, matching with fast cooling, preventing nitrogen from escaping, and controlling the overheat degree to be 20-50 DEG C and the plate blank casting speed to be 0.8-2m / min; and putting a die-casting blank or a continuous casting blank into a heating furnace for heating to 1100-1250 DEG C, preserving the heat for 0.5-1.5 hours, processing the die-casting blank or the continuous casting blank on a forging production line or a hot-rolling mill group to the needed thickness, then carrying out annealing at the speed of 0.5-2.5min / mm and the temperature of 1030-1150 DEG C. The obtained duplex stainless steel has excellent corrosion resistance and TRIP effect.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

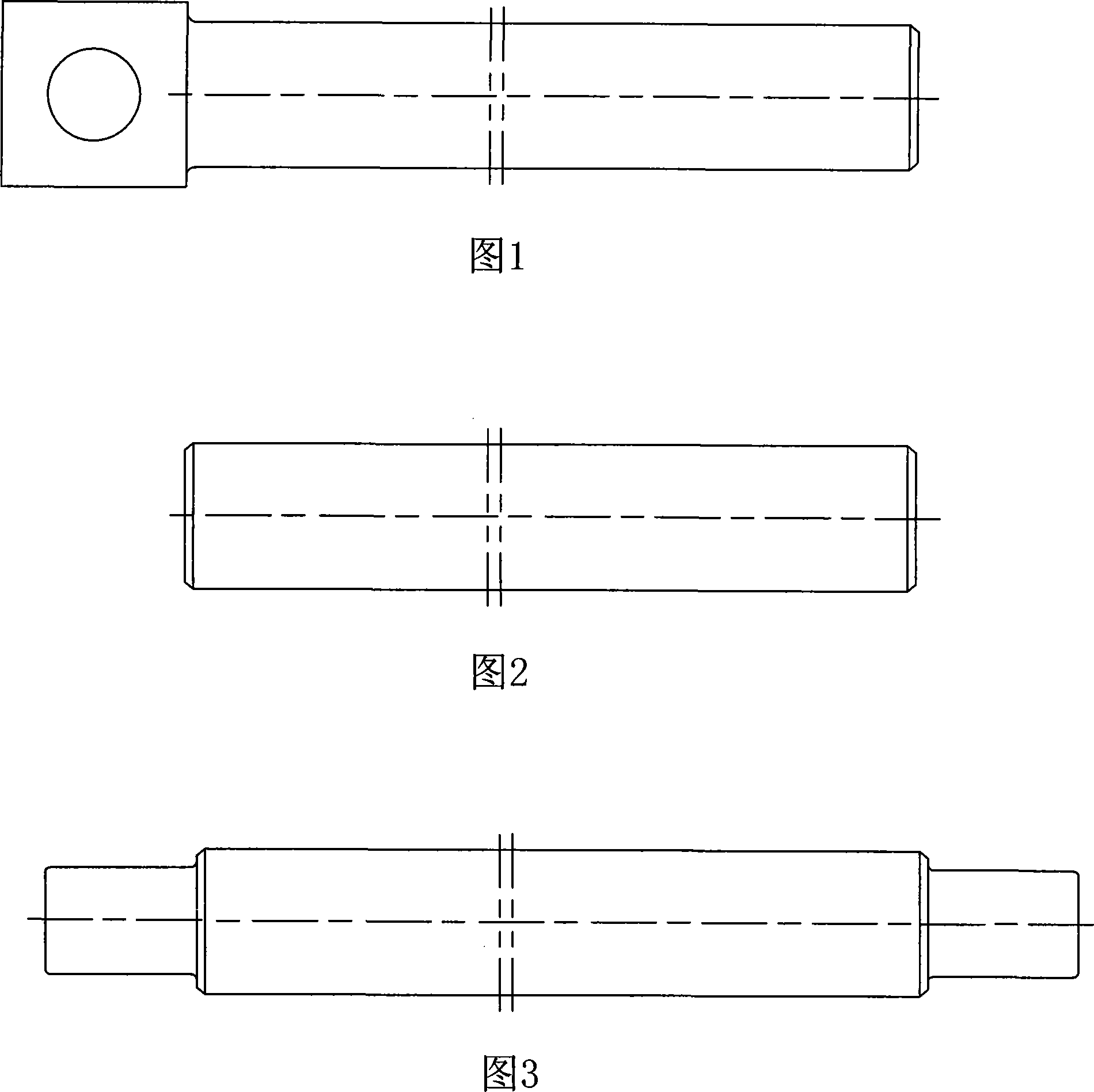

Roller and producing technique

The invention relates to the field of steel rolling machinery, in particular to a roller and a production process for the roller which is made of W6Mo5Cr4V2 high speed steel; the production process comprises the following steps: a. material preparation; b. the processing of two end faces of blanks; c. the processing of central holes of two ends; d. the processing of rough turn; e. the drilling of hoisting holes outside the length of finished products; f. carrying out quenching and tempering treatment to cause the roller hardness to reach 40 to 50 HSD; g. the modification of the central holes of the two ends; h. the processing of half finish turning; i. coarse grinding of the roller body; j. carrying out quenching and tempering treatment to lead the surface of the roller body to reach the quenching hardness of 88 to 93 HSD; k. the processing of the lengths of the two ends to required sizes; l. the processing of finish turning; m. the coarse grinding of the roller body and a roller neck; n. stress relief treatment; o. the repairing of the central holes of the two ends; p. fine grinding of the roller body and the roller neck; q. super grinding of the roller body and the roller neck to finished products. The roller and the production process thereof solves the problem of big size, high production cost, tedious process and great production difficulty of rollers which are produced with conventional materials.

Owner:CHANGZHOU ECCO ROLLER

Method for vacuum scattering intermetallic compound for coupling TiAL

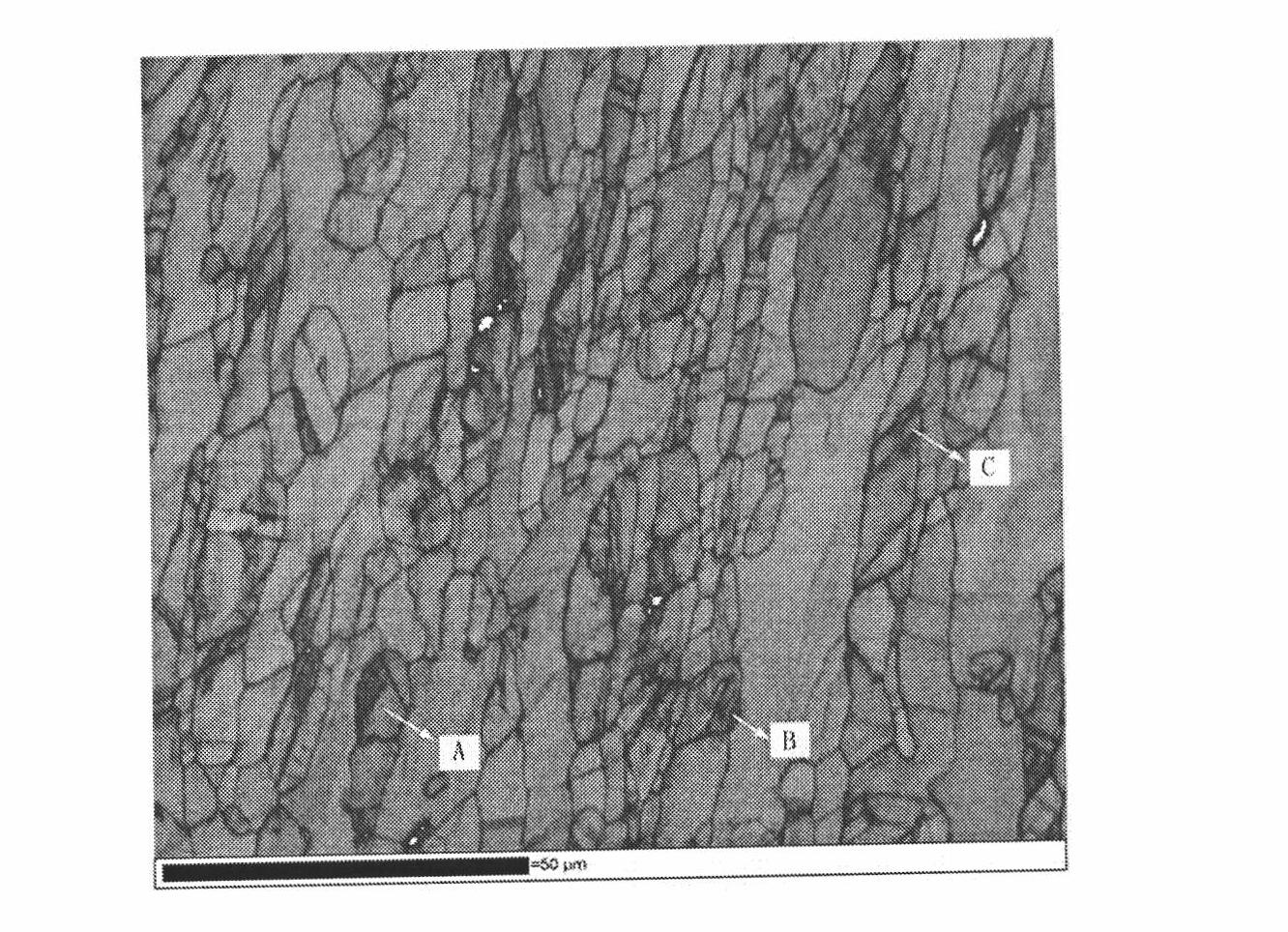

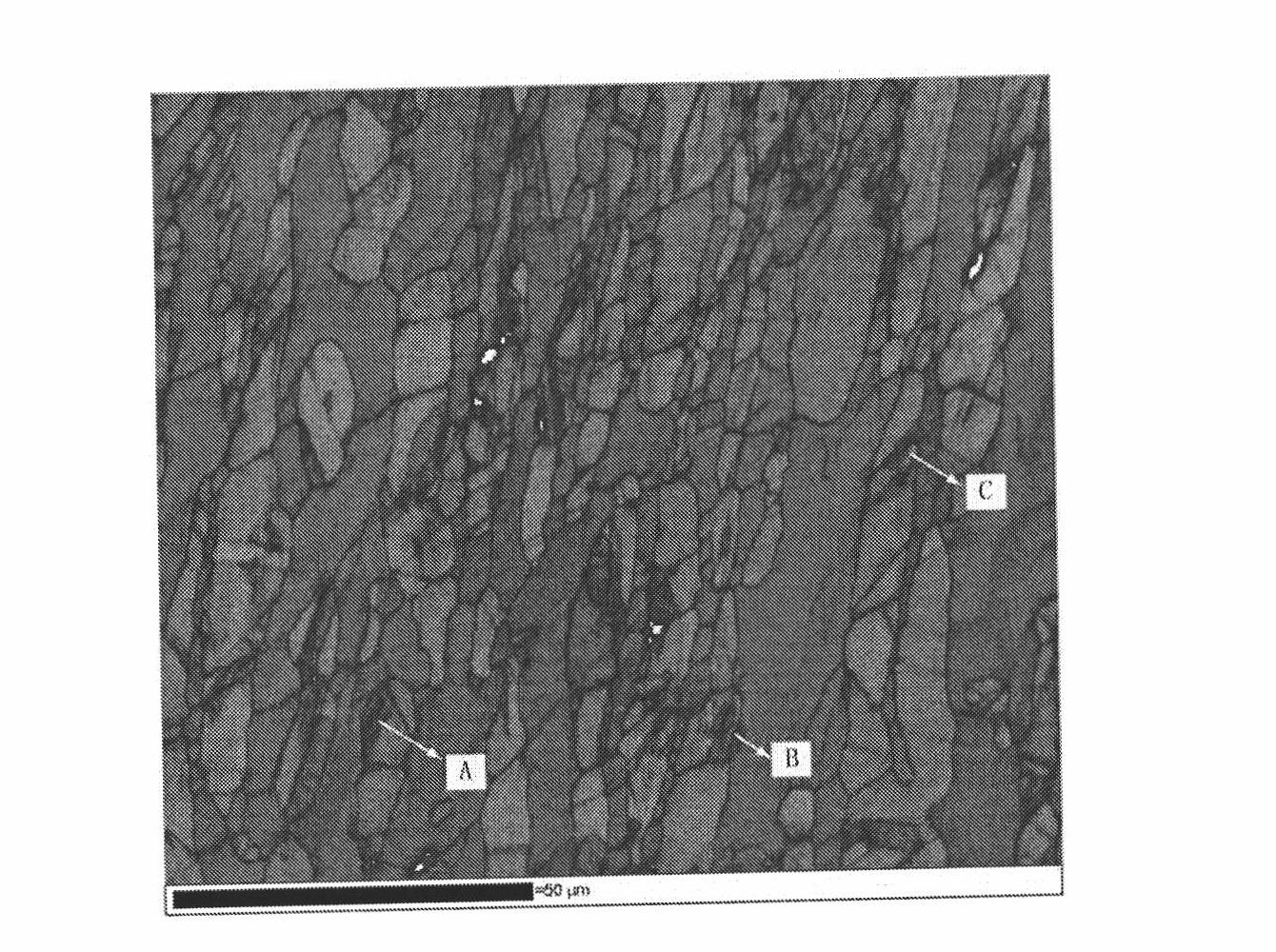

InactiveCN101176946AImprove diffusion abilityGood removal effectNon-electric welding apparatusBeta phaseThermal deformation

The invention relates to a TiAl-intermetallic-compound vacuum diffusing connection method, belonging to the TiAl-intermetallic-compound welding field, which overcomes the technical drawbacks of high temperature of diffusing connection and high pressure of diffusing connection in the prior TiAl-intermetallic-compound diffusing connection technology. The invention adopts hydrogenated titanium or titanium alloy chaff as the interface layer of diffusing connection. Ti3Al+TiAl dual phase (Alpha2+Gamma) organ can be formed under the temperature of diffusing connection titanium, which facilitates the formation of high-intensity connector lug of TiAl-intermetallic-compound diffusing connection. And hydrogen makes the flow stress of thermal deformation of titanium or titanium alloy decrease and the thermal plasticity increase, so that hydrogenated titanium or titanium alloy is prone to deform under high temperature. Meanwhile,, the self-diffusing capacity of hydrogen in titanium or titanium alloy and the diffusing capacity of solute are enhanced, more particularly, in Beta phase the capacities are more enhanced, so that hydrogen can accelerate the diffusing of the alloy elements, reduce the atomic combination energy and the diffusing activation energy, promote the diffusing coordinated deformation capacity, and the reliable diffusing connection of connector lug of TiAl-intermetallic-compound can be realized under comparatively low temperature.

Owner:HARBIN INST OF TECH

Transparent laminate, plastic lens for eyeglass and primer composition

InactiveUS20020159160A1Good weather resistanceImprove impact resistancePolyurea/polyurethane coatingsMountingsAnti-reflective coatingPolymer science

A novel primer composition which does not need to be thermally cured at a high temperature after it is applied to a plastic substrate and a transparent laminate, for example, a plastic lens for spectacles, which comprises the above primer composition and has high impact resistance and high heat resistance even when a transparent anti-reflection coat is formed. This transparent laminate comprises a transparent plastic substrate and a coating film formed on at least one side of the plastic substrate by applying and curing a liquid primer composition which comprises (A) a self-emulsifiable emulsion of a linear polyurethane having a pendant carboxylic acid group and no crosslinked structure between polymer chains, (B) a sol of an inorganic oxide having a hydrophobic group on the surface, and (C) a compound having 5 to 9 carbon atoms and at least one hydroxyl group and at least one oxygen atom other than an oxygen atom constituting a hydroxyl group in the molecule.

Owner:SDC TECHNOLOGIES INC

Vinyl for manufacturing toy and preparation method of vinyl

The invention relates to vinyl for manufacturing a toy. The vinyl for manufacturing a toy is prepared from the following raw materials in percentage by weight: phthalate, dioctyl phthalate, dibasic lead stearate, PVC (polyvinyl chloride) paste resin, PVC coarse powder, PVC medium powder, talcum powder, PVC hard oil, plasticizer TXIB, acetyl-tri-n-butyl citrate, vanillin, amyl acetate, geranyl butyrate and maltol. The vinyl has good hardness, smooth handfeel, strong plasticity, high re-shaping ability and high stability, and does not deform easily after multiple extrusions; and meanwhile, the vinyl is non-toxic and harmless and has fresh fruit aroma.

Owner:浙江银太郎动漫文化股份有限公司

High-plasticity economical duplex stainless steel and manufacturing method thereof

The invention relates to a high-plasticity economical duplex stainless steel and a manufacturing method thereof. The high-plasticity economical duplex stainless steel comprises the following chemical components by weight part: 0.01-0.06% of C, 0.1-1.0% of Si, 0.5-4.0% of Mn, 19.5-22.0% of Cr, 1.8-3.5% of Ni, 0.1-0.18% of N, 0.5-1.3% of Mo, 0.1-1.0% of Cu and the balance of Fe and inevitable impurities. According to the invention, Ni is replaced by Mn and N, so that the cost is lowered; the contents of Cr and Mo are adjusted, so that the steel has excellent corrosion resistance, higher plasticity, excellent low-temperature toughness, and excellent welding property; the Md 30 / 50 is controlled at 50-100 DEG C; and PREN value is 23-29. Thus, the high-plasticity economical duplex stainless steel can be widely applied to an environment with higher demand on corrosion resistance and plasticity, such as heat exchanger, water tank, and the like, so that the 304 austenitic stainless steel containing 8% of nickel and the 316 stainless steel containing of 10% Ni and 2% of Mo are replaced under the conditions of room temperature and low temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

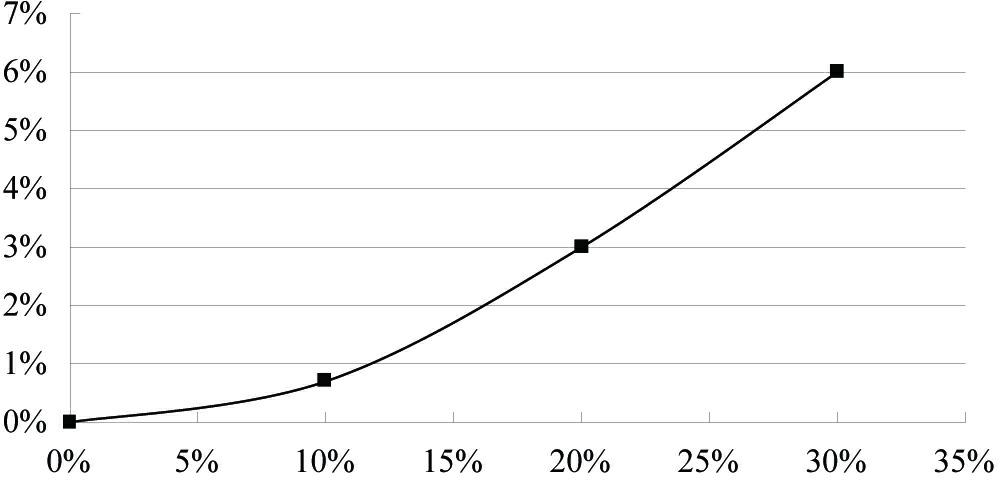

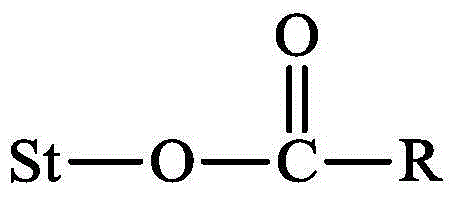

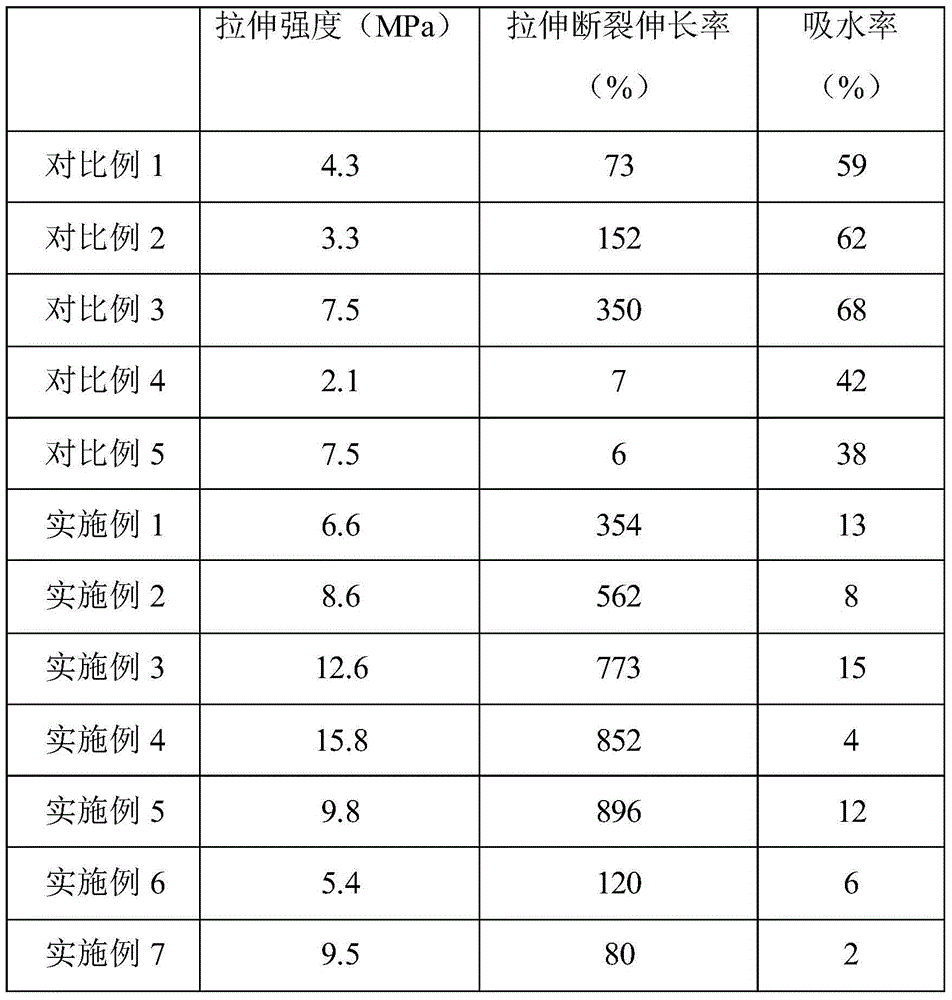

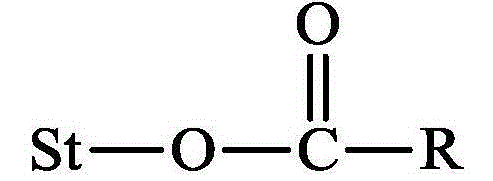

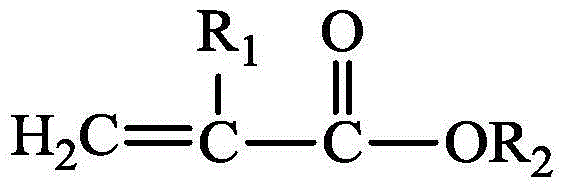

Starch-based composite and preparation method thereof

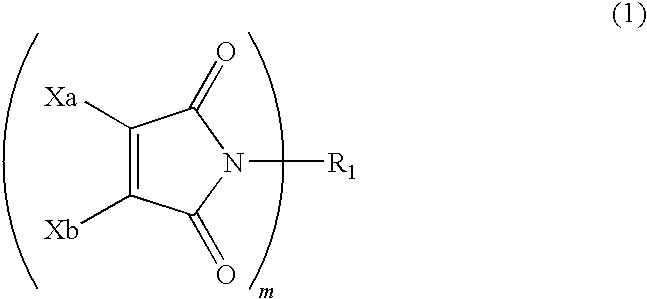

The invention discloses starch-based composite and a preparation method thereof. The composite is formed by, by weight, 100 parts of modified starch and 10-100 parts of polyester through melt blending. The structural formula of the modified starch is showed in the description and claims, wherein St refers to starch molecules and R group is alkyl group (CnH2n+1). Esterified starch comprises, by weight, 100 parts of natural starch, 0-200 parts of solvent, 10-50 parts of catalyst and 1-50 parts of modifier. The preparation method includes melt blending the components according to the weight to obtain the starch-based composite. The preparation method is high in efficiency, low in cost, simple in process, controllable in performance, and suitable for preparing thermoplastic materials with various performance requirements.

Owner:JIANGNAN UNIV

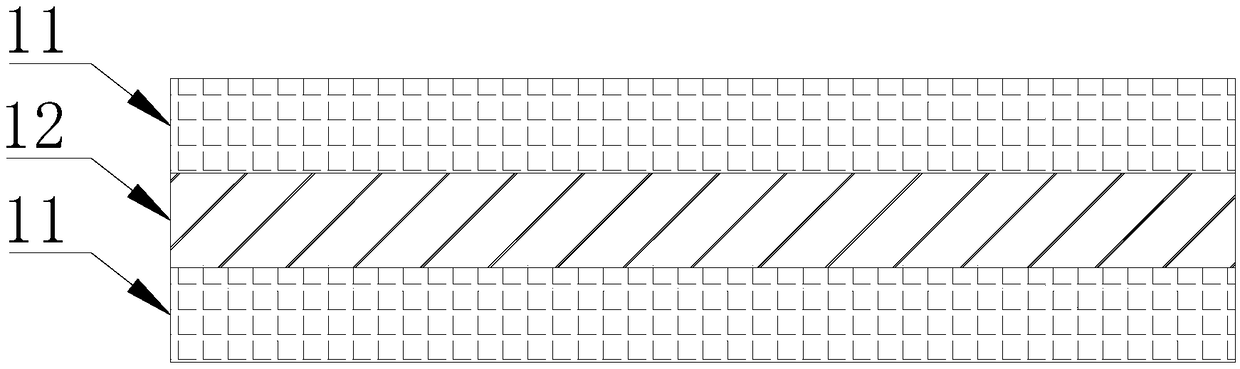

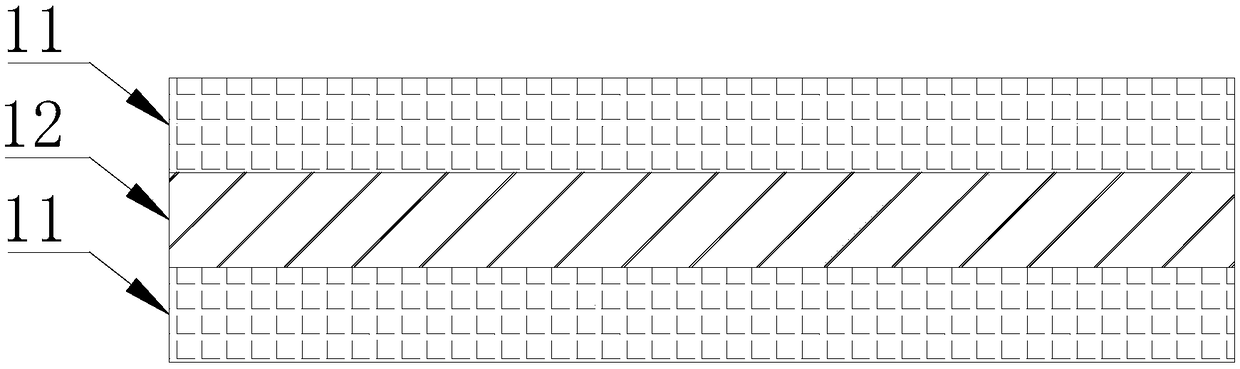

A loudspeaker diaphragm and a loudspeaker

ActiveCN109005487AIncrease stiffnessIncrease dampingPolymeric diaphragmsSynthetic resin layered productsElastomerPolyester

The invention discloses a loudspeaker diaphragm and a loudspeaker. The loudspeaker diaphragm comprises two composited surface layers and at least one intermediate layer located between the two surfacelayers, at least one of the surface layer is a thermoplastic polyester elastomer film layer and at least one of the intermediate layers is an adhesive layer, wherein the plastic polyester elastomer is a copolymer composed of a polyester hard segment A and a polyether or aliphatic polyester soft segment B, and the mass percentage of the polyester hard segment A is 10-95%. The loudspeaker diaphragmhas excellent stiffness, good damping performance, resilience and so on.

Owner:GOERTEK INC

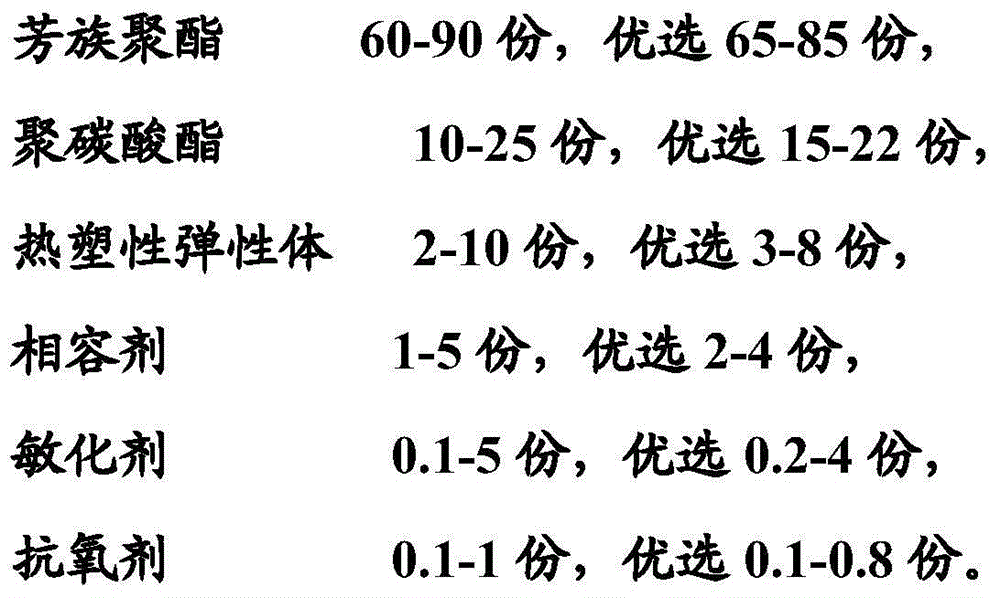

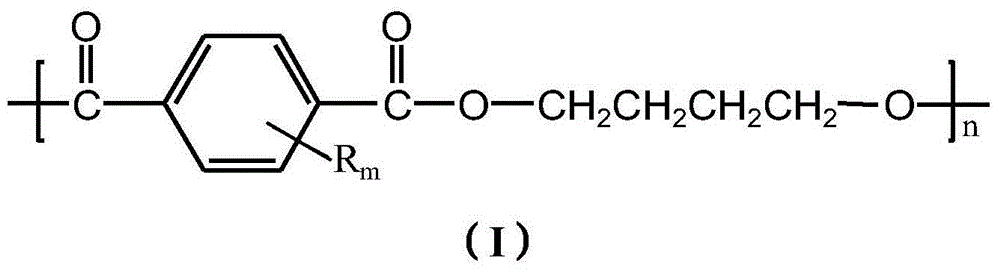

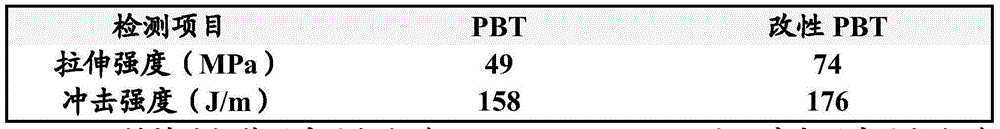

3D printing aromatic polyester material and preparation method thereof

The invention relates to a 3D printing aromatic polyester material comprising the following components in parts by weight: 60-90 parts of aromatic polyester, 10-25 parts of polycarbonate, 2-10 parts of a thermoplastic elastomer, 1-5 parts of a compatibilizer, 0.1-5 parts of a sensitizing agent, and 0.1-1 part of an antioxidant. The aromatic polycarbonate and the aromatic polyester are utilized for co-mixing modification so as to improve the shock resistance, and after the co-mixed material is drawn into thin strips, the thin strips are subjected to a certain extent of crosslinking by irradiation with a certain dose of electron beams, so that a purpose of noumenon enhancement is achieved, at the same time, good fusion processability is maintained, and the aromatic polyester is allowed to have a wider application prospect in 3D printing materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Starch based thermoplastic material and preparation method thereof

The invention discloses a starch based thermoplastic material and a preparation method thereof. The thermoplastic material is prepared from polymerization of components comprising, by weight, 100 parts of modified starch, 100-300 parts of monomers, 0.5-10 parts of initiators and 200-1000 parts of water. The modified starch is prepared from components comprising, by weight, 100 parts of natural starch, 0-200 parts of solvent, 10-50 parts of catalysts and 1-50 parts of modifiers. The preparation method includes that that the starch based thermoplastic material is prepared from the components according to the stated amounts after polymerization reaction. Plasticizing processing of starch can be realized without adding of plasticizers and blending with other materials, production efficiency is high, the thermoplastic material is low in cost, simple in process, controllable in performance, and applicable to preparation of thermoplastic materials with various performance requirements.

Owner:JIANGNAN UNIV

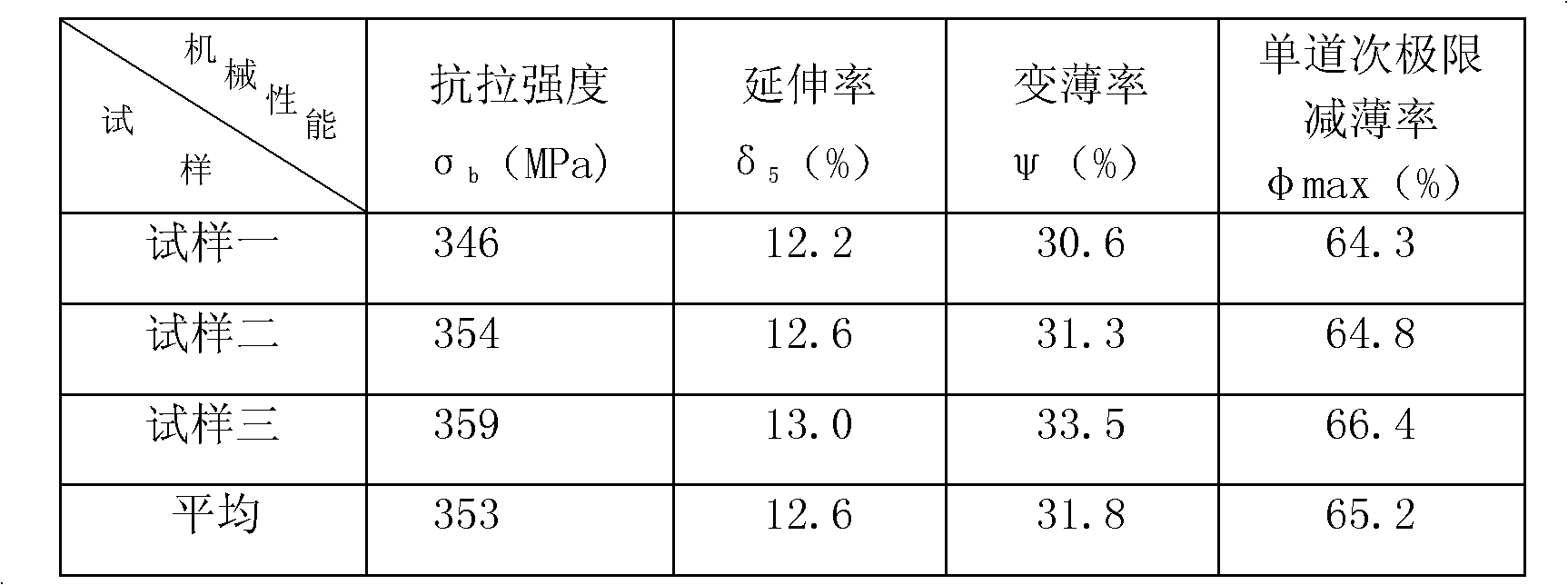

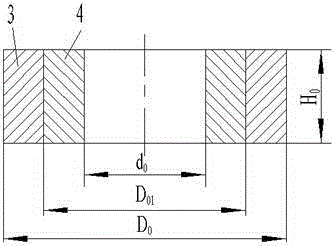

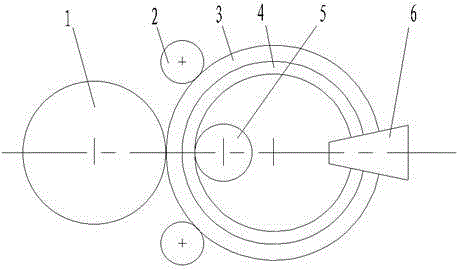

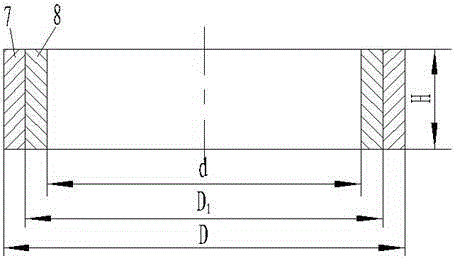

Centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology

InactiveCN105170850AImprove surface qualityPrecise DimensionsMetal rollingUltimate tensile strengthMechanical property

The invention relates to a centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology, and belongs to the technical field of ring part rolling expansion machining. The centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology is characterized by comprising the following steps: (1) isothermal heating is carried out; (2) a heated duplex-metal composite ring blank is placed on a radial and axial direction ring rolling machine; (3) the contact relation between a forming roller and the ring blank is determined; (4) a driving roller drives the duplex-metal composite ring blank and a core roller to perform rotation motion, meanwhile, the core roller does straight line feeding motion in the radial direction of the ring blank, an end face taper roller only keeps the rotary motion rather than conducting axial feeding, and continuous local plastic deformation of wall thickness reduction, diameter enlarging and cross section layout shaping is continuously carried out on the duplex-metal composite ring blank; and (5) when a preset value of the outer diameter of a duplex-metal composite ring part is obtained, a guide roller gives out a signal, the core roller stops feeding, and extend-rolling is finished. The centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology has the beneficial effects that the process procedure is shortened, the device investment is reduced, and energy and materials are saved; and meanwhile, the composite ring part interface plastic deformation is sufficient, the bonding strength is high, the mechanical property is good, and the service life is long.

Owner:定州市金华蓝天汽车零部件有限公司 +1

Loudspeaker diaphragm and loudspeaker

ActiveCN108551642AIncrease stiffnessIncrease dampingPolymeric diaphragmsLoudspeakersPolyesterElastomer

The invention discloses a loudspeaker diaphragm and a loudspeaker. The diaphragm includes two surface layers that are compounded together and at least one intermediate layer located between the two surface layers, wherein at least one of the surface layers is a thermoplastic polyester elastomer film layer, at least one of the intermediate layers is an adhesive layer, a thermoplastic polyester elastomer is a copolymer composed of a polyester hard segment A and a polyether or aliphatic polyester soft segment B, the thickness of the thermoplastic polyester elastomer film layer is 5-70 microns, and the thickness of the adhesive layer is 1-40 microns.

Owner:GOERTEK INC

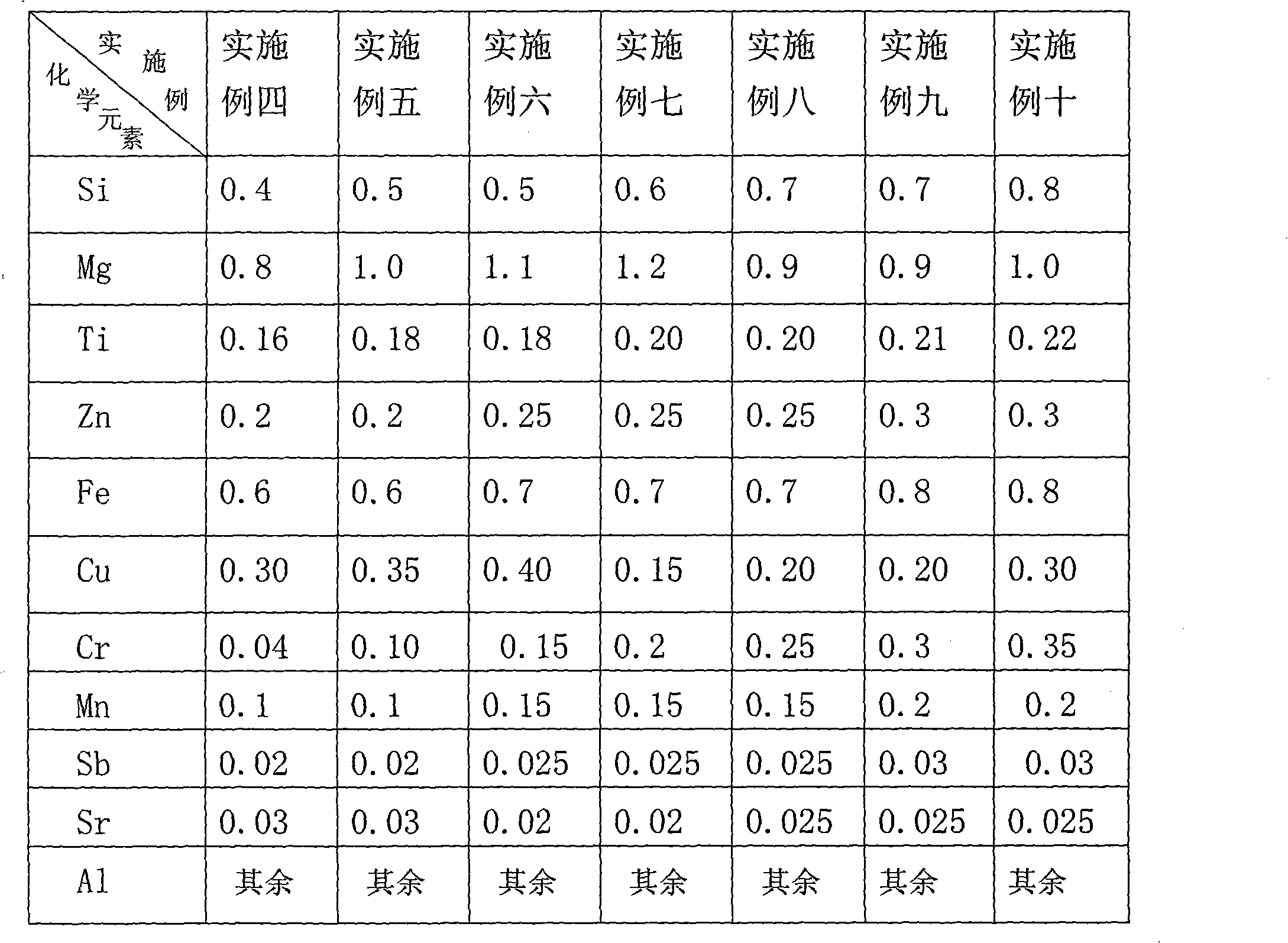

High strength automobile aluminium alloy wheel rim

The invention relates to a high strength automobile aluminium alloy wheel rim, in particular to an automobile wheel rim matched with oversize vehicles. The high strength automobile aluminium alloy wheel rim is made of high strength aluminium alloy material which comprises main chemical elements with the mass percent: 0.4-0.8% of Si, 0.8-1.2% of Mg, 0.16-0.22% of Ti, 0.2-0.3% of Zn, 0.6-0.8% of Fe,0.15-0.4% of Cu, 0.04-0.35% of Cr, 0.1-0.2% of Mn, 0.02-0.03% of Sb, 0.02-0.03% of Sr and the rest of Al. The automobile aluminium alloy wheel rim has high tensile strength which is 10% higher than that of the existing aluminium alloy wheel rim produced by 6061-T6, is good in mechanical property, enhances the rotatable performance of alloy when the structure is refined, and has the advantages ofwide application scope, low production cost and easy popularization and use.

Owner:HECHI UNIV

Two-component PU (polyurethane) coating and preparation method thereof

InactiveCN104893558AIncrease the degree of cross-linkingLow water absorptionPolyurea/polyurethane coatingsPrepolymerInteraction forces

The invention discloses a two-component PU (polyurethane) coating. Firstly, castor oil is used for cross-linking prepolymers: a multifunctional group structure in the castor oil can cross-link the polymers to a certain extent, the cross-linking degree of the polymers is increased, so that the interaction force among molecular chains is increased, motion of the molecular chains is hindered, water molecules can hardly enter the molecular chains to enable the polymers to swell, and the water absorption of a film is reduced; meanwhile, the castor oil is a triglyceride of fatty acid, the film has the good hydrophobicity due to long nonpolar fatty acid chains in molecules of the castor oil, and the water absorption is further reduced; besides, ester groups in the castor oil have higher cohesive energy, so that the tensile strength of the film can be enhanced; ethyl cellulose has better heat resistance and thermoplasticity, has good compatibility with PU and can improve the comprehensive performance of the prepolymers; then blending modification is performed on the PU prepolymers and polysilsesquioxane.

Owner:HEFEI JIKE NEW MATERIALS

Gluing-free middle and high-density fiber board preparation method

InactiveCN101086150AAvoid dependencyTake advantage ofPulping with acid salts/anhydridesRaw material divisionCelluloseHigh density

The invention discloses a no glue bonding middle or high-density fiberboard preparation method, its process steps are: (1) preparing dissolvant; (2)collecting and processing plant fiber materials; (3) feeding materials; (4) reaction; (5) solvent recovery; (6) beating and separating hemi-cellulose; (7) activating lignin; (8) render hydrophobic; (9) blank plate pavement; (10) hot (or cold) pressure molding. The advantages are: (1) the problem of free formaldehyde releasing in middle fiber plate is completely resolved; (2) so the herbaceous plant fiber has same economic value with woody plant and is used in the production of middle or high-density fiberboard fully; (3) the plant fiber materials are used fully, it basically has not the waste emissions problems.

Owner:NANCHANG UNIV

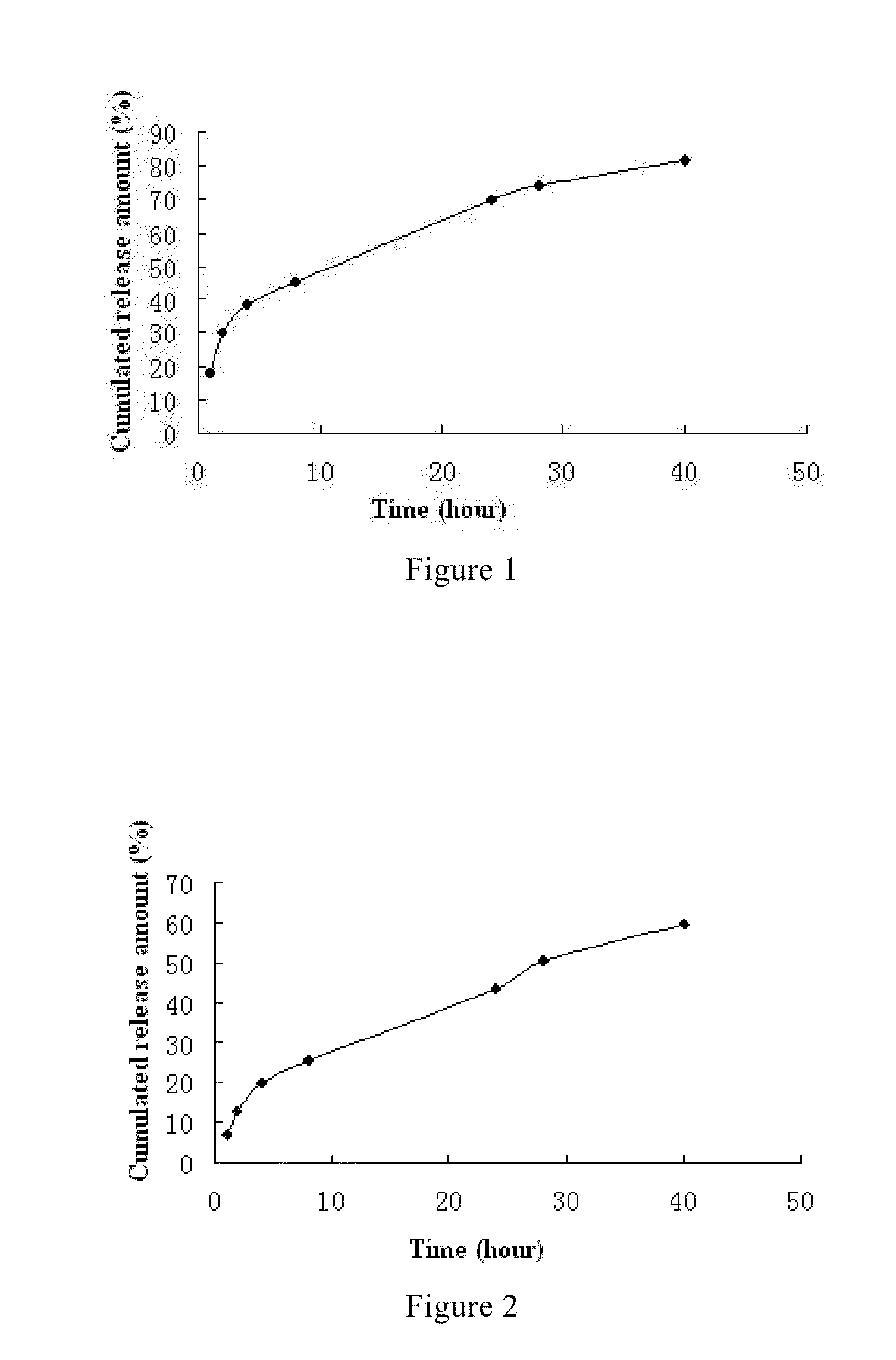

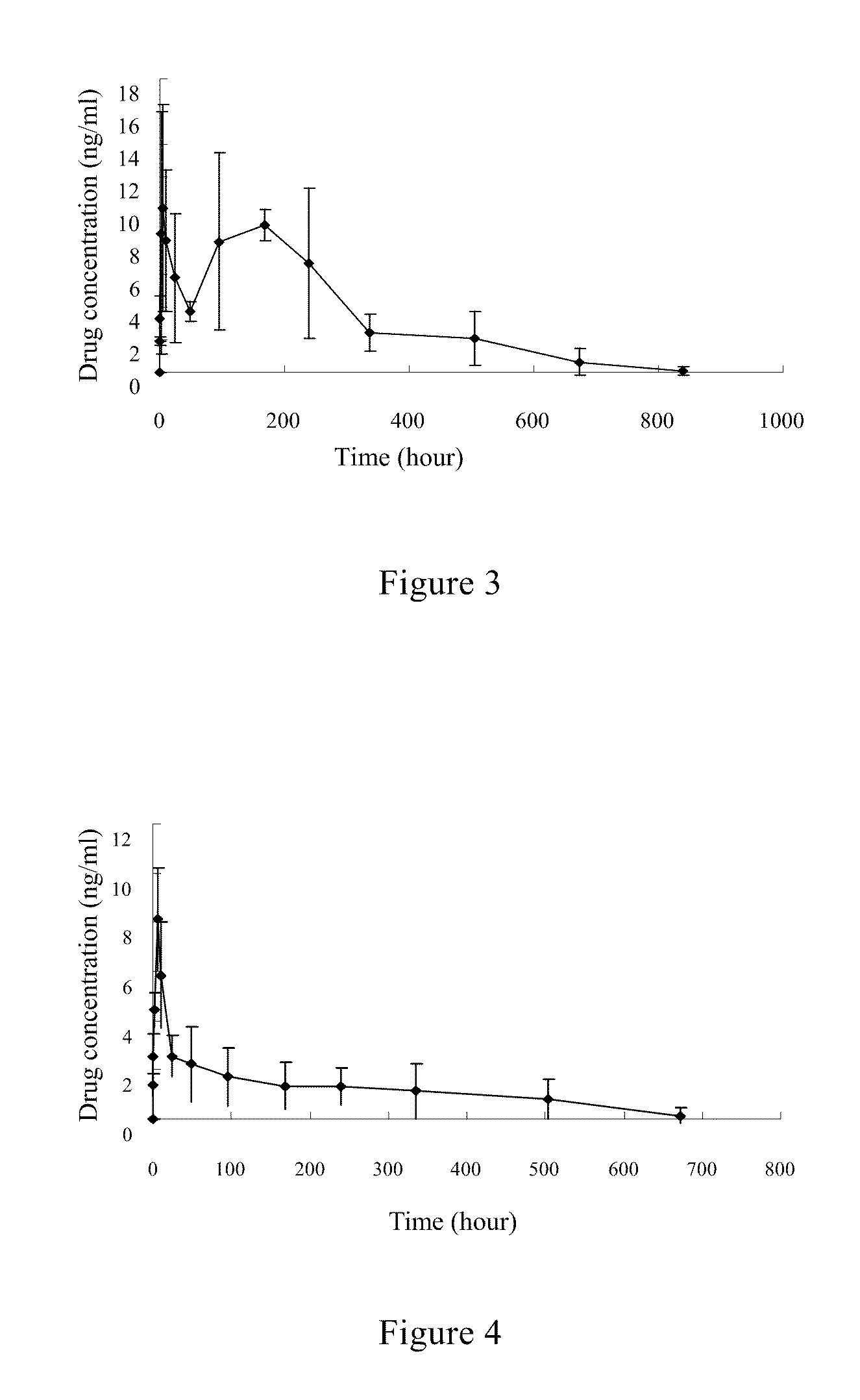

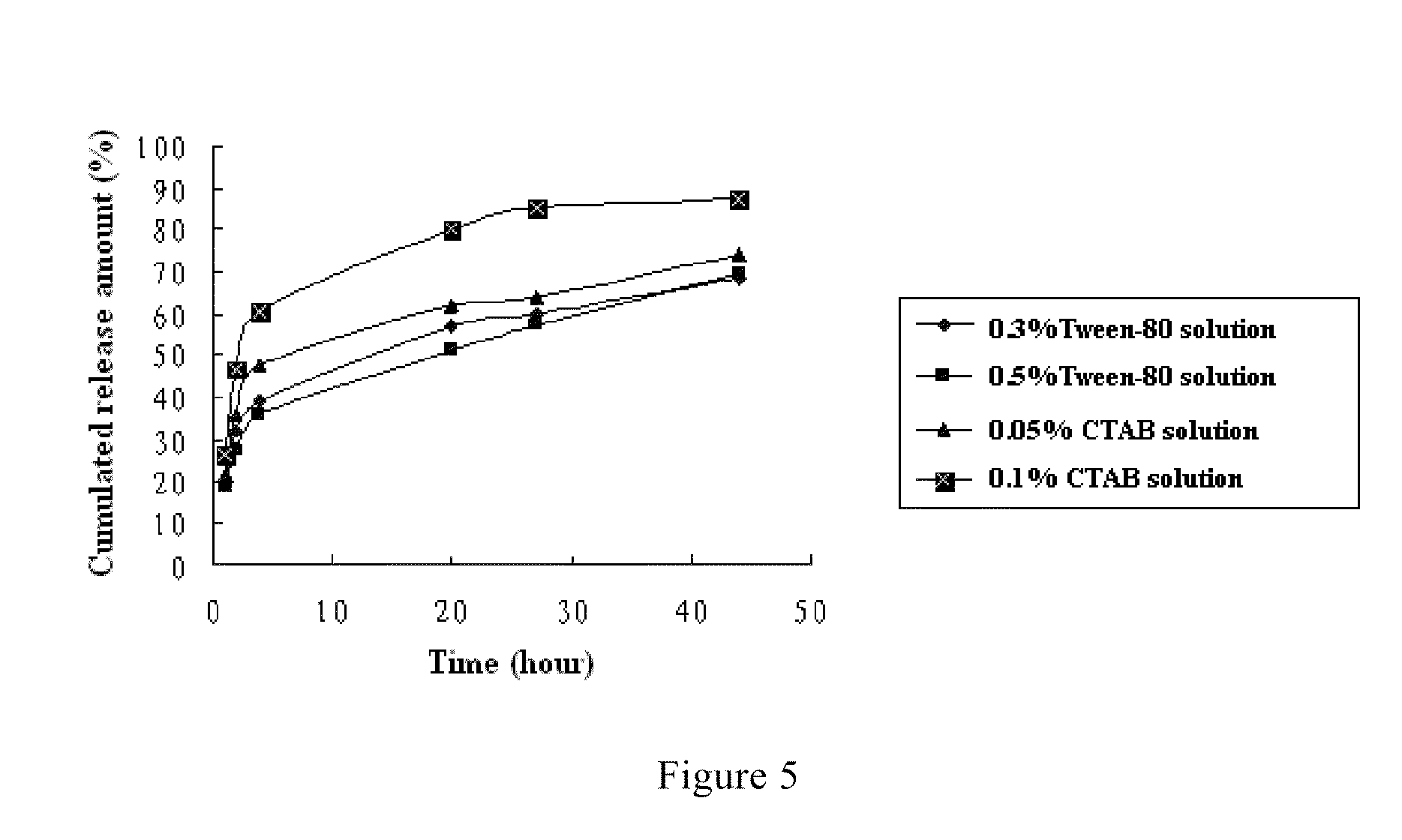

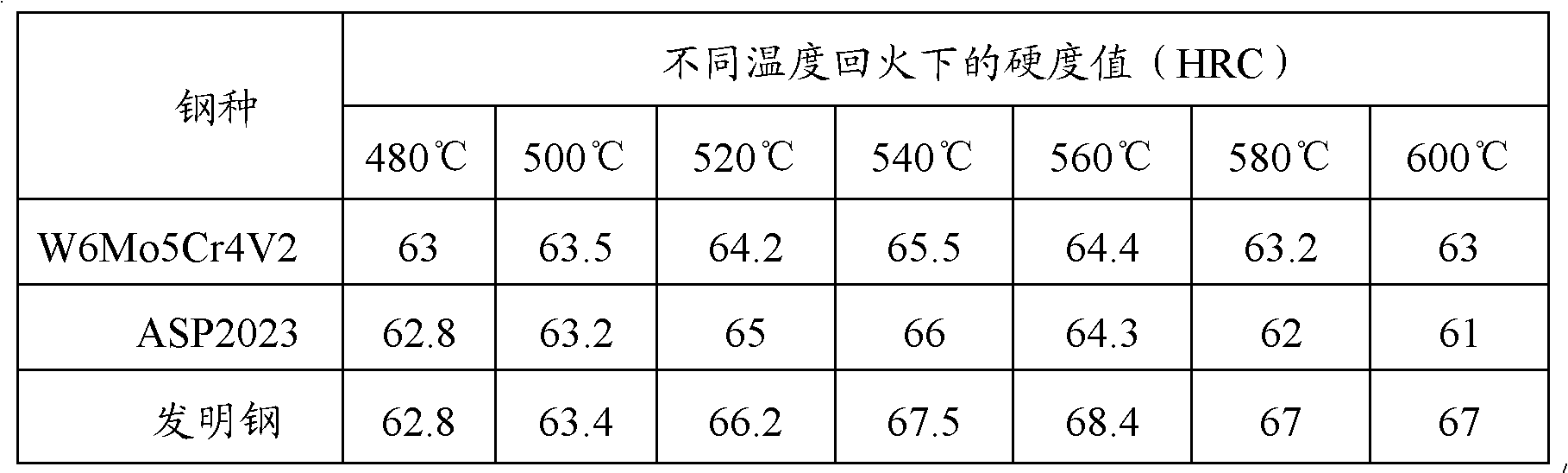

Fulvestrant nanosphere/microsphere and preparative method and use thereof

ActiveUS20110318420A1Avoid damageGood biocompatibilityPowder deliveryOrganic active ingredientsMicrospherePolyethylene glycol

Fulvestrant nanosphere / microsphere and preparation method and use thereof are provided in the present invention. The carrier material of the fulvestrant nanosphere / microsphere is methoxy ended polyethylene glycol-polylactic acid block copolymer. The nanosphere / microsphere is prepared by solvent-nonsolvent method, in-liquid drying method and / or spray drying method, and has the features of high drug loading and high encapsulation efficiency, controllable release of medicine and no irritant to application site or blood vessel. The fulvestrant nanosphere / microsphere can be used to treat metastatic advanced breast cancer in post-menopausal woman.

Owner:XIAN LIBANG PHARMA TECH

Leadless free-cutting magnesium silicon brass

InactiveCN101487091AAchieve lead-freeReduce manufacturing costManufacturing technologyMetallic materials

The invention discloses a lead-free easy-cutting magnesium silicon brass, belonging to the manufacturing technology field of metal materials. The components of the brass comprise alloying elements, such as copper, zinc, silicon, magnesium, aluminum and the like, and the mass fractions of the elements are as follows: 58.0 percent to 80.0 percent of copper, 0.2 percent to 3.5 percent of magnesium, 0.2 percent to 3.5 percent of silicon and 0 to 0.6 percent of aluminum. The sum of the mass fractions of silicon and magnesium is 1.2 percent to 4.0 percent, the impurity amount is not more than 0.05 percent and the balance is zinc. The lead-free easy-cutting magnesium silicon brass is developed on the basis of the existing easy-cutting lead brass and Bi brass and aiming at the demand of brass parts for cutting process and the application environment of finished products. According to the demand for products containing lead at home and abroad, the lead brass is forced to be replaced by lead-free products. The magnesium silicon brass uses silicon and magnesium to replace lead, realizing the purpose of lead-free easy-cutting lead brass. The brass has good cutting and processing properties, has no cold shortness and hot shortness phenomena, can be used in fields, such as electrics and electronics, bathroom wares, toy devices and the like and can replace the existing easy-cutting lead brass and lead-free easy-cutting Bi brass.

Owner:CENT SOUTH UNIV

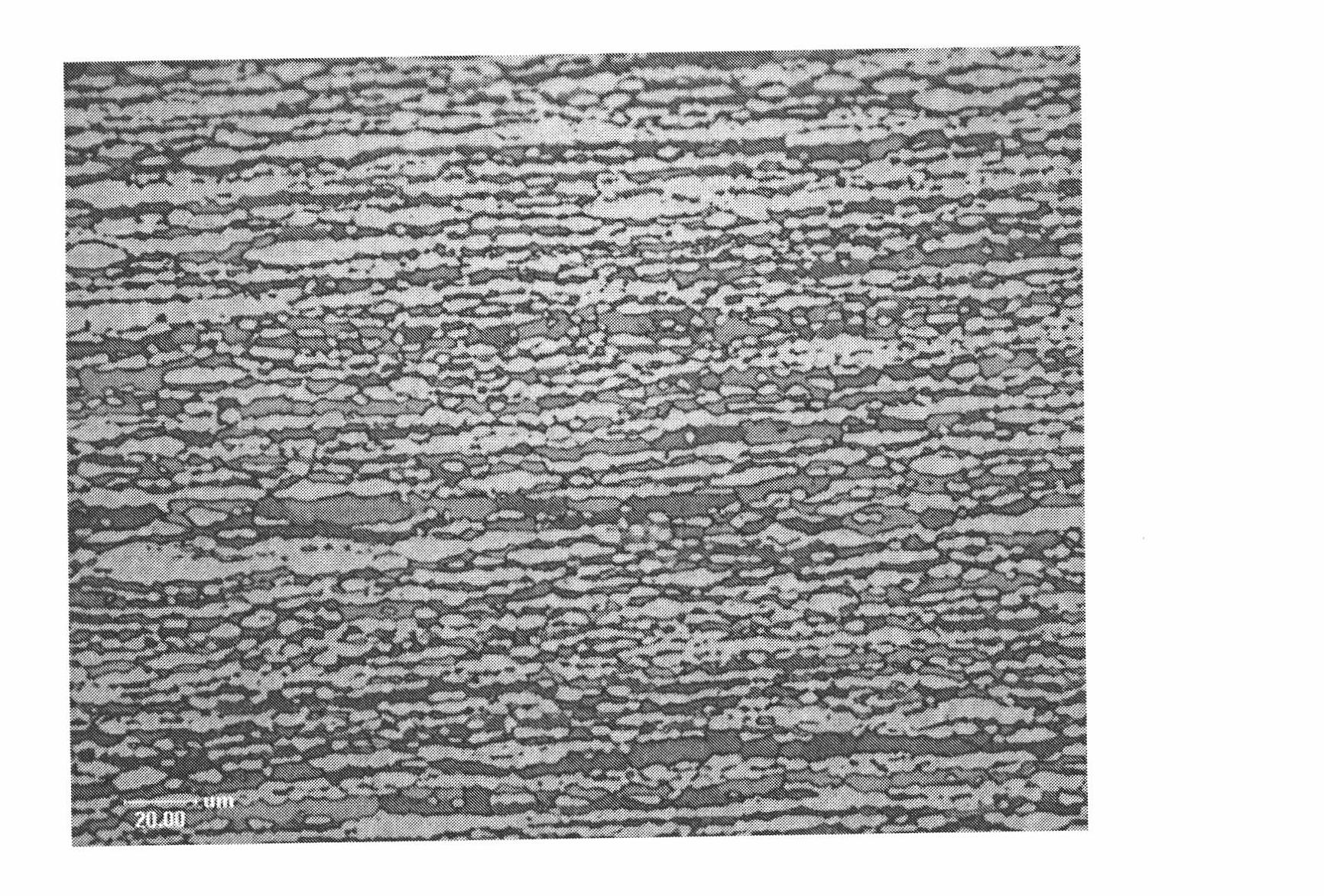

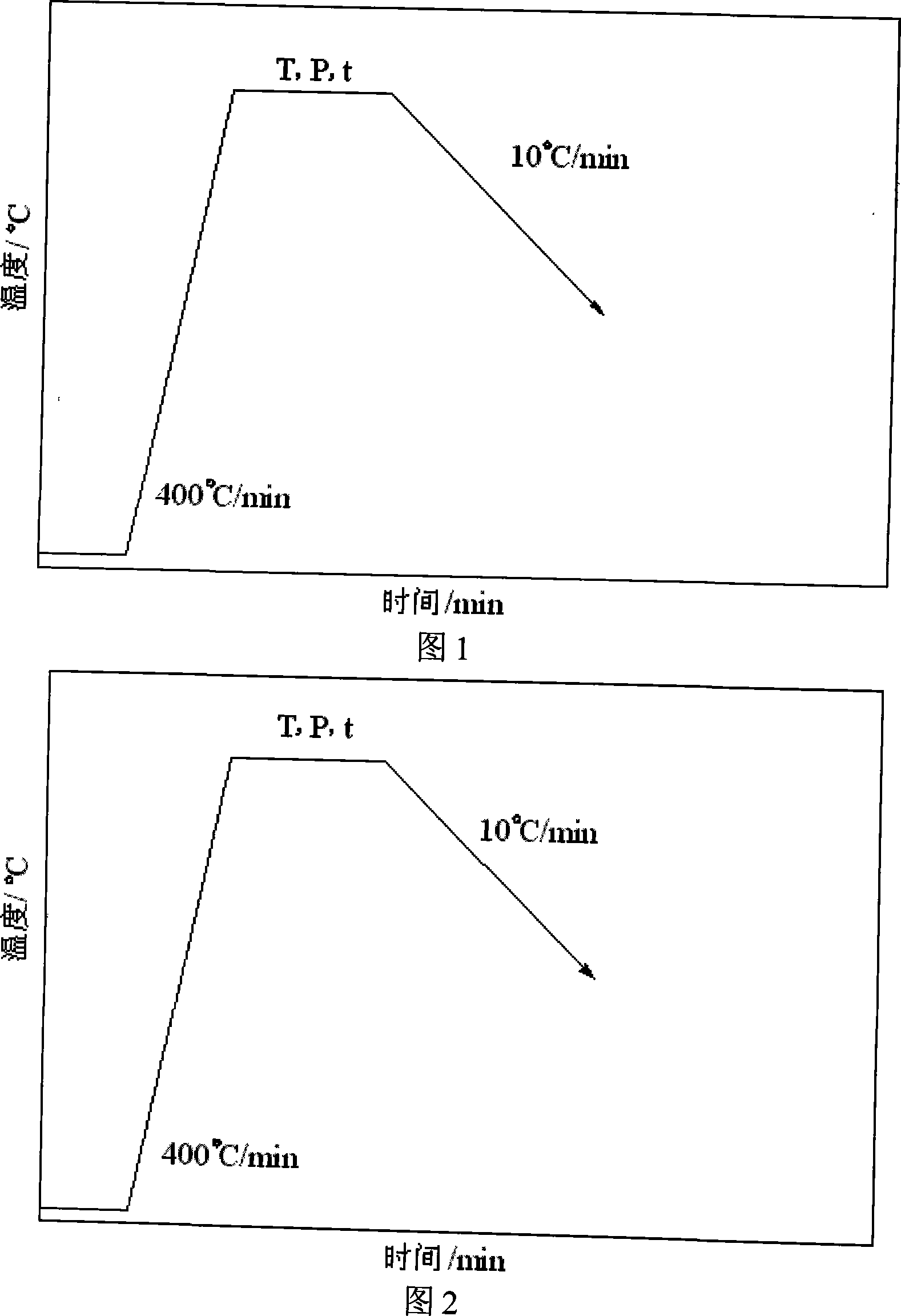

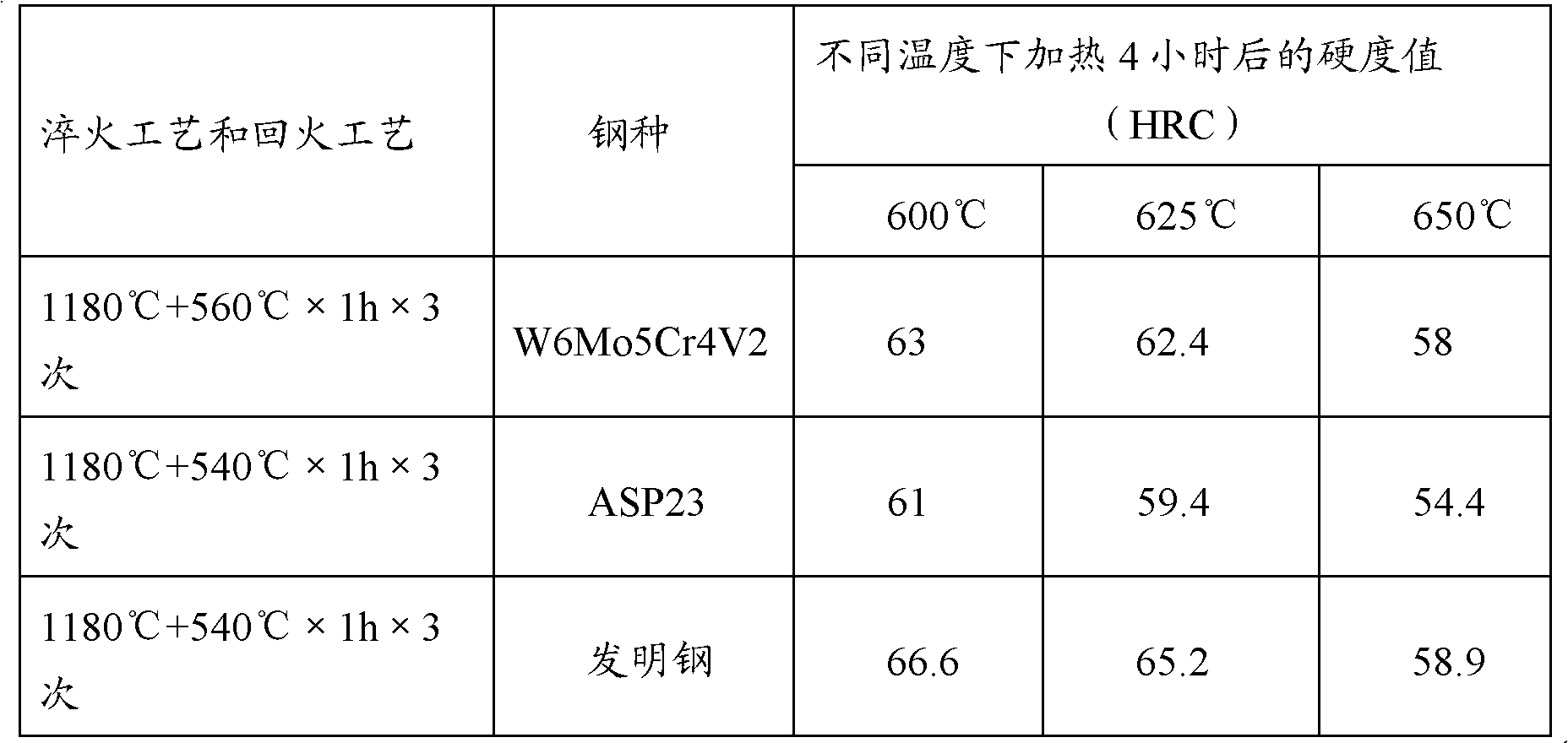

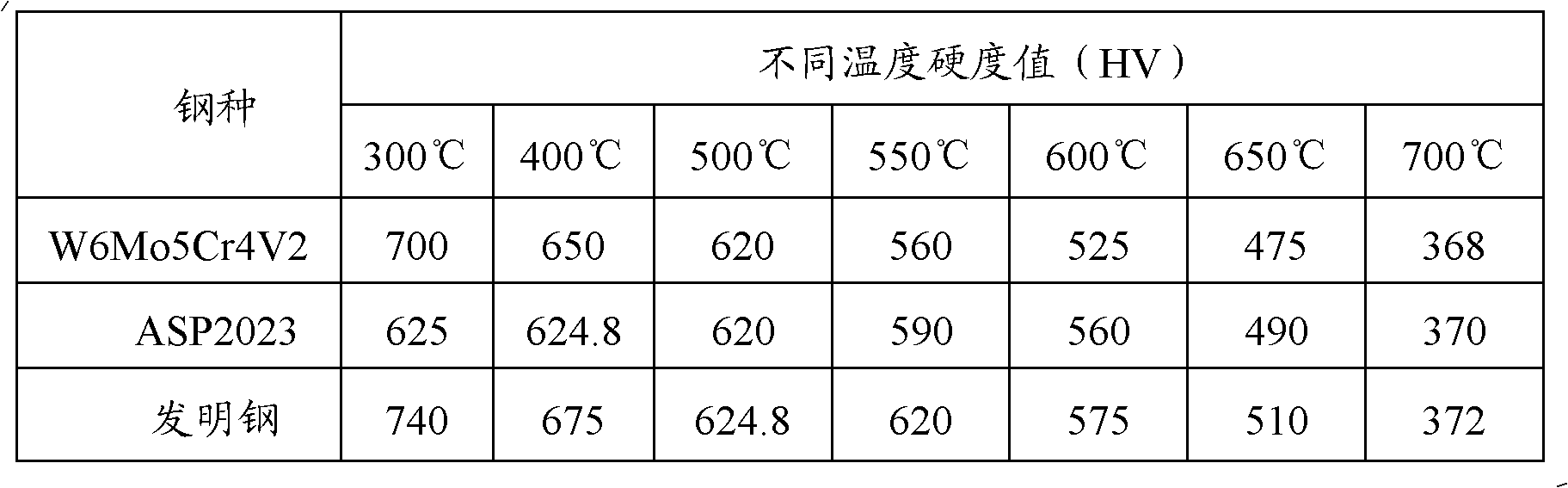

Ultrahigh-hardness high-toughness malleable spray-formed high-speed steel and preparation method thereof

The invention provides ultrahigh-hardness high-toughness malleable spray-formed high-speed steel and a preparation method of the steel, belonging to the field of material and preparation. The steel comprises the following chemical compositions: 1.3-1.8% of C, 6-8% of W, 5-7% of Mo, 4-6% of Cr, 3-5% of V and 1-3% of Nb, wherein Si is less than or equal to 0.4, Mn is less than or equal to 0.4, S is less than or equal to 0.03, P is less than or equal to 0.03, and the balance of Fe. Technologically, the method comprises the following steps of: obtaining a columnar deposition billet with the tissue size being 15-30mum and the carbide size being 3-8mum on a base plate by adjusting the angle of an atomizing nozzle, controlling the speed of a pull base plate, heating a deposition plate, slowing down the temperature reduction of deposited steel liquid, and atomizing the solution into solution drops; annealing under the temperature of 1100-1180 DEG C before the deposition billet is forged, and gradually forging according to the technology when the deposition billet is forged, wherein the forging ratio of each fire is not more than 35%, the forging heating temperature is 1130-1180 DEG C, and the final forging temperature is not less than 900 DEG C; and further refining the sizes of the forged crystalline grain and the carbide into 10-15mum and 2-5mun. The ultrahigh-hardness high-toughness malleable spray-formed high-speed steel and the preparation method of the steel have the advantages of low cost, and short technological process, the cost of the spray-formed high-speed steel is only 1 / 5-1 / 10 of that of the power high-speed steel, and the technological process is reduced by 2 / 3; and the spray-formed high-speed steel has the high hardness and the red hardness, which are close to those of the similar powder high-speed steel, and the toughness of the spray-formed high-speed steel is higher than that of the powder high-speed steel.

Owner:UNIV OF SCI & TECH BEIJING

Production technology of high-strength 7-series aluminum alloy pipe

ActiveCN109355538AHigh strengthIncreased resistance to stress corrosion susceptibilityFurnace typesHeat treatment furnacesIngot castingMechanical property

The invention belongs to the technical field of heat treatment of aluminum alloy, and relates to a production technology of a high-strength 7-series aluminum alloy pipe. An aluminum alloy ingot casting is prepared from the following raw materials according to the mass percentage: 7.5-8.5% of Zn, 1.0-3.5% of Mg, 0.10-0.20% of Cu, 0.05-0.3% of Zr, 0.1-1.5% of Mn, 0.05-0.3% of Cr, 0 .05% of Ti, 0.05%of B, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of impurities in total and the balance Al. The two-stage homogenizing treatment and the two-stage aging heat treatment are adopted in the production technology of the aluminum alloy pipe, wherein according to the two-stage homogenizing system, the heat preservation is carried out for 24 hours at the temperature of 470 DEG C, and the heat preservation is carried out for 10 hours at the temperature of 480 DEG C; and according to the two-stage aging system, the heat preservation is carried out for 7 hours at the temperature of 110 DEG C to 130 DEG C, and the heat preservation is carried out for 10 hours at the temperature of 165 DEG C to 170 DEG C. The overall mechanical property of the high-strength 7-series aluminum alloy pipe is effectively improved.

Owner:CHINA ZHONGWANG

Machining method for 7-series aluminum alloy thick plates

The invention belongs to the technical field of aluminum alloy production, and relates to a machining method for 7-series aluminum alloy thick plates. Aluminum alloy ingots comprise the following components in percentage by mass: Si not more than 0.20%, Fe not more than 0.25%, 1.2-2.1% of Cu, 1.2-2.2% of Mg, 5.0-7.0% of Zn, 0.02-0.15% of Ti, 0.02-0.15% of Zr, Ti+Zr not more than 0.15%, single impurity not more than 0.05%, total impurity not more than 0.15%, and the balance of Al. The machining method for the aluminum alloy thick plates adopts a mode of multi-pass hot rolling, and adopts double-stage solid solution and double-stage aging to enable the finally prepared 7-series aluminum alloy thick plates to achieve excellent strength and rupture toughness.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Loudspeaker diaphragm and loudspeaker

ActiveCN108551643AImprove structural strengthAvoid breakingPolymeric diaphragmsLoudspeakersElastomerPolyester

The invention discloses a loudspeaker diaphragm and a loudspeaker. The diaphragm comprises a thermoplastic polyester elastomer film layer, wherein the thermoplastic polyester elastomer is a copolymerformed by a polyester hard segment A and a polyether or aliphatic polyester soft segment B, wherein the mass percent of the polyester hard segment A is 10%-95%. The loudspeaker diaphragm is high in structural strength, difficult to damage, good in toughness resilience performance and good in sound production effect.

Owner:GOERTEK INC

Loudspeaker diaphragm and loudspeaker

ActiveCN108966088AIncrease stiffnessIncrease dampingPolymeric diaphragmsPolyureas/polyurethane adhesivesPolyesterLoudspeaker

The invention discloses a loudspeaker diaphragm and a loudspeaker. The loudspeaker diaphragm comprises two surface layers compounded together and at least one intermediate layer located between the two surface layers. At least one surface layer is a thermoplastic polyester elastomer film layer; and the at least one intermediate layer is an adhesive layer. The Young's modulus of the thermoplastic polyester elastomer film layer is 1-1000MPa; the loss factor thereof is larger than or equal to 0.015; and the elastic recovery rate thereof is greater than or equal to 80% after 10% of strain.

Owner:GOERTEK INC

Biodegradable plastic with high starch content and preparation method of biodegradable plastic

The invention discloses a biodegradable plastic with high starch content and a preparation method of the biodegradable plastic. The preparation method comprises the steps: with corn starch, potato starch and other natural plant starches as main raw materials, completely biodegradable polyvinyl alcohol as a main toughening agent and polyethylene glycol as an auxiliary toughening agent, adding an environment-friendly composite plasticizer and a processing acid, and mixing all the components to obtain the biodegradable plastic with high starch content. The biodegradable plastic with high starch content, prepared by the invention, contains at most 90wt% of starch, has favorable plasticity and machinability, and can be prepared into products such as pipes, sheets, profiles, films, vessels, foamed base materials and the like with various shapes by using the traditional polymer forming and machining method.

Owner:宋旭

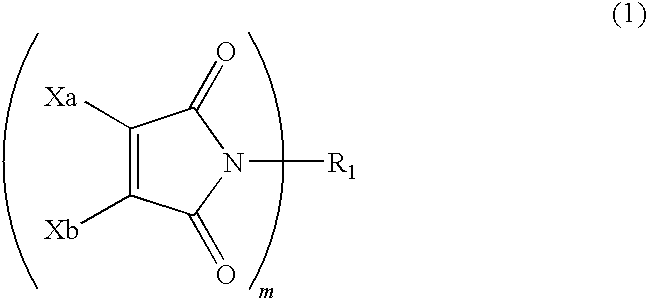

Thermosetting Resin Composition of Semi-IPN Composite, and Varnish, Prepreg and Metal Clad Laminated Board Using the Same

ActiveUS20100233495A1Good high-frequency propertyGood heat resistanceSynthetic resin layered productsPrinted circuit aspectsPrepolymerMetal foil

Provided is a thermosetting resin composition which can be used for the production of printed circuit boards, having good dielectric properties in high frequency bands so that transmission loss can be significantly lowered, having excellent heat resistance after moisture absorption and thermal expansion properties, and satisfying peeling strength between the resin composition and metal foil.The present invention relates to a thermosetting resin composition of a semi-IPN composite, comprising (A) a polyphenylene ether, and a prepolymer formed from (B) a chemically unmodified butadiene polymer containing 40% or more of a 1,2-butadiene unit having a 1 2,-vinyl group in a side chain of a molecule and (C) a crosslinking agent, in a compatibilized and uncured state; and a resin varnish, a prepreg and a metal clad laminated board using the same.

Owner:RESONAC CORP

Edible pet quid containing nutrition rod and preparing method thereof

ActiveCN101223937AEasy to digest and absorbBoost immunityMetabolism disorderAnimal feeding stuffProtein nutrientsChemistry

The invention discloses a pet masticatory containing a nutrition bar and consists of a nutrition bar and a livestock skin which enwinds the nutrition bar. The pet masticatory comprises by weight percentage: 20-80 percent of livestock skin selected from pigskin, cowskin or sheepskin, 10-60 percent of protein nutrition bar which is the mixture of animal protein and vegetable protein, 5-50 percent of starch, 1-10 percent of grease, 1-8 percent of dietary fiber, 1-4 percent of quality modifying agent and flavoring agent, 0.1-5 percent of antioxidant, 0.1-3 percent of nutrient or healthy additive and the rest of water. At the same time, the invention also discloses a preparation method for the product.

Owner:JIANGXI HUAHENG PET FOODS CO LTD

Preparation method for graphene rare earth aluminum alloy high-conductive material

ActiveCN107099708AReduce the degree of reunionLow densityConductive materialMetal/alloy conductorsRare earthConductive materials

The invention discloses a preparation method for a graphene rare earth aluminum alloy high-conductive material. The method comprises the following steps: adding aluminum scrap, silicon calcium alloy, copper aluminum alloy, zinc aluminum alloy, magnesium ingot, rare earth aluminum alloy and graphene into a smelting furnace for smelting; performing ladle analysis, thereby acquiring an aluminum alloy solution; casting and rolling the aluminum alloy solution, thereby acquiring aluminum alloy; performing homogenization treatment on the aluminum alloy; performing ageing treatment, thereby acquiring the graphene rare earth aluminum alloy high-conductive material. According to the preparation method for the graphene rare earth aluminum alloy high-conductive material, provided by the invention, the technical parameters are reasonably set, the graphene structure is optimized and the overall performance of the aluminum alloy is effectively improved, so that the acquired graphene rare earth aluminum alloy high-conductive material has excellent electric conductivity, heat resistance, arc altitude resistance and mechanical properties.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com