Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Achieve lead-free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment protection type silicon solar cell back electric field aluminum pulp and producing method thereof

InactiveCN101425545AImproved chemical stability and electrical performanceImprove uniformityFinal product manufactureNon-conductive material with dispersed conductive materialSolventElectric field

The invention relates to a manufacturing method of environment-friendly aluminum paste for a silicon solar battery back electric field. The aluminum paste comprises the following components and contents (weight percentage): 50 to 80 percent of aluminum conducting powder, 1 to 10 percent of crown glass binding agent, 0.05 to 5 percent of trivalent metal organic compound, 2 to 15 percent of organic resin, 10 to 25 percent of solvent and 2 to 10 percent of additive. The manufacturing method of the environment-friendly aluminum paste comprises the preparation of a glass binding agent, the preparation of an organic carrier, the formulation of aluminum paste stock and the processing technique of paste stock. The paste stock researched by the invention can not increase or generate substances which are harmful to human bodies and pollute the environment during the production and processing; the lead content of the paste stock is less than 100 ppm; and the contents of other hazardous substances such as Hg, Cd and the like can satisfy the environmental protection requirements. The aluminum past is applied to electrodes in the silicon solar battery back electric field; and the aluminum past has strong adhesion, good ohmic contact, and high conversion efficiency of a battery through the quick heat treatment in a continuous tunnel furnace.

Owner:WUHAN SUPERNANO OPTOELEC TECH CO LTD

Lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics and preparation method thereof

ActiveCN102751000AAchieve lead-freeImprove adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesion forceSlurry

The invention discloses a lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics. The lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics is prepared from the following raw materials in percentage by weight: 50 to 75 percent of conducting silver micro powder, 0.5 to 5 percent of inorganic additive, 1 to 15 percent of lead-free glass powder and 15 to 45 percent of organic carrier. The lead-free and cadmium-free electrode silver slurry is technologically advantaged in that a boron-bismuth-silicon-zinc-titanium glass system is designed, the traditional lead-containing glass can be completely substituted, a lead-free product is realized, the system glass can react with a piezoelectric ceramic substrate to form a firm interface between an electrode and the substrate, and the adhesion force of the interface is more than 15N / mm<2>.

Owner:HEFEI SHENGDA ELECTRONIC TECH IND CO LTD

Leadless platinum electrode slurry and manufacturing method thereof

InactiveCN101168472AImprove liquidityPromote wettingMaterial analysis by electric/magnetic meansElectrically-conductive paintsPlatinumAdhesive

The invention relates to a leadless platinum electrode slurry and process for preparation, wherein the platinum electrode slurry is prepared from 2-10mass% leadless glass adhesive, 2-10mass% metal oxide, 10-20mass% organic adhesive, and ultra-fine platinum powder at left amount. The production comprises leadless glass adhesive preparation, organic adhesive preparation, leadless platinum electrode slurry formulation, and slurry treatment. The invention can produce leadless platinum electrode slurry which lead content is lower than 100ppm, while the slurry applied in the electrode of zirconium oxide oxygen sensor can sinter at 1200DEG C, and via the formula adjustment of the leadless glass adhesive, the invention can produce platinum electrode slurry which can sinter at 800-1500DEG C. The electrode has the advantages of strong zirconium oxide substrate adhesive force, high conductivity, and stable electrical property.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

Preparation method for smoky yellow crystal bead blanks

InactiveCN102503126AAchieve lead-freeHigh refractive indexGlass pressing apparatusPotassium carbonatePotassium permanganate

The invention discloses a preparation method for smoky yellow crystal bead blanks. The preparation method for smoky yellow crystal bead blanks aims to overcome shortcomings that existing preparation process for smoky yellow crystal bead blanks needs lead oxide as a raw material, coloring and optical properties of iron ions are poor, coloring property of manganese is unstable, and rhinestone bead blanks are poor in physical and chemical properties. Raw materials of the preparation method do not contain lead oxide, and the crystal bead blanks are good in physical and chemical properties, are proper in hardness and high in corrosion resistance. In the preparation method for the smoky yellow crystal bead blanks, raw materials of the smoky yellow crystal bead blanks include, by weight ratio, from 50 to 65 parts of quartz sand, from 2 to 20 parts of titanium dioxide, from 2 to 10 parts of sodium carbonate, from 7 to 20 parts of potassium carbonate, from 0.3 to 5 parts of potassium nitride, from 0.1 to 5 parts of cerium oxide, equal to or lower than 6 parts of boric acid, equal to or lower than 2 parts of aluminum hydroxide, equal to or lower than 8 parts of zinc oxide, equal to or lower than 10 parts of magnesium carbonate, equal to or lower than 15 parts of barium carbonate, equal to or lower than 2 parts of lithium carbonate, equal to or lower than 2 parts of potassium permanganate, equal to or lower than 4 parts of sodium nitrate and equal to or lower than 3 parts of iron oxide red.

Owner:ZHEJIANG WEIXING CRYSTAL

Heat sensitive resistor for high Curie temperature BaTiO3 base positive temperature coefficient and its making method

InactiveCN101188156AAchieve lead-freeReduce synthesisPositive temperature coefficient thermistorsElectrical resistance and conductanceMixed materials

The invention relates to a BaTiO3 group positive temperature coefficient thermistance and a preparation method thereof, wherein, the BaTiO3 group positive temperature coefficient thermistance has high Curie temperature. The invention belongs to the electronic ceramics technique. The recombination positive temperature coefficient thermistance is composed of main materials and assistant materials. The mol ratio of TiO2 and (BaCO3+SrCO3+Bi2O3+Na2CO3) of the main materials is 1:1. The mol components of the assistant materials are that Nb2O5 is 0.0011; TiO2 is 0.01; Sb2O3 is 0.0006; MnO2 is 0.0004; SiO2is 0.005; Al2O3 is 0.0017. The preparation process comprises that materials are weighed and mixed according to the mol prescription; the mixed materials are processed with ball milling after being added with water, and preparative complex materials are made through drying and heat preservation. The preparative complex materials are again added with raw materials, and then the preparative complex materials are processed with ball milling after being added with the water, thus the positive temperature coefficient thermistance is made through drying, granulation, foliation and baking. The invention has the advantages that the process of the composite (Na0.5Bi0.5)TiO3 is simple; the made positive temperature coefficient thermistance is unleaded and environment-friendly.

Owner:TIANJIN UNIV

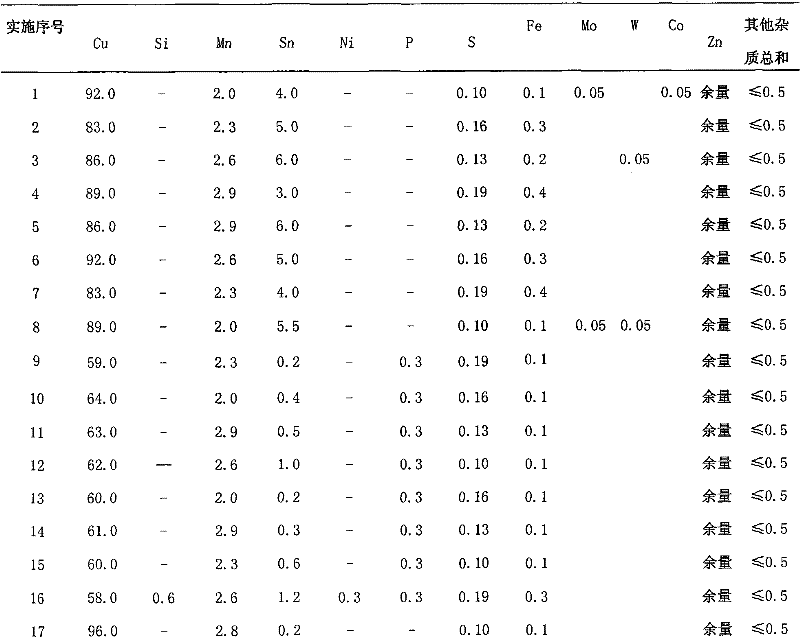

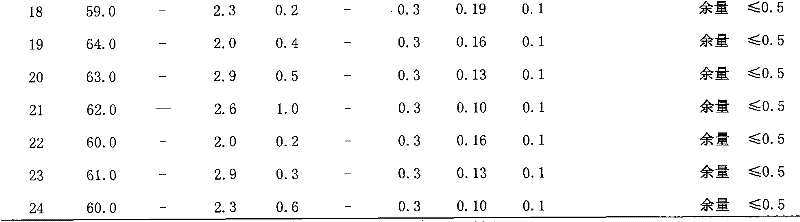

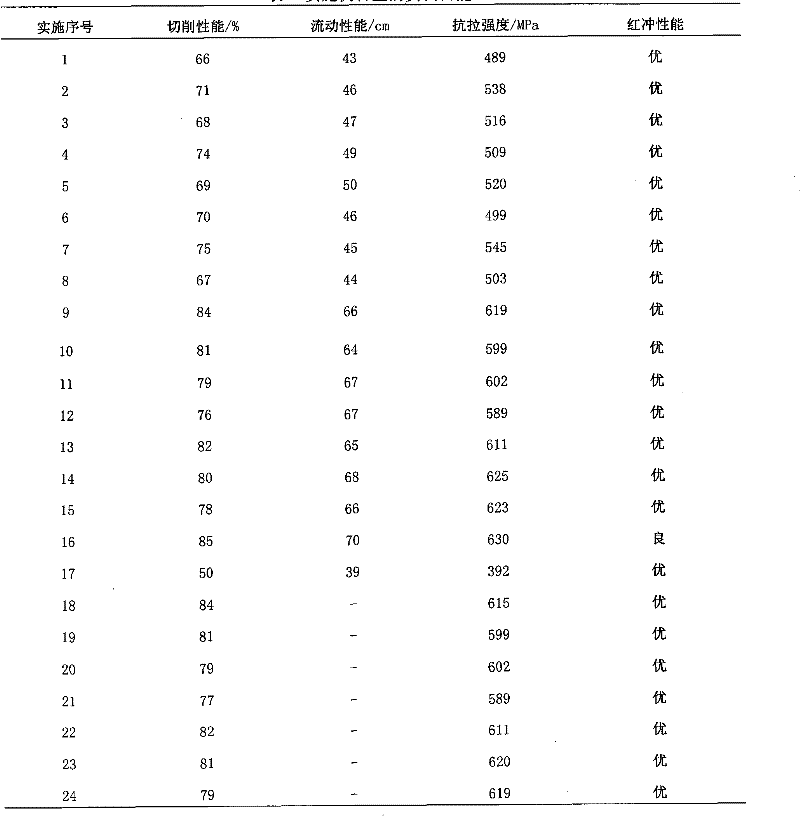

Leadless free-cutting copper alloy and preparation method

A leadless free-cutting copper alloy and a preparation method. The copper alloy comprises the following elements by mass: 58.0%-96.0% of copper, 2.0%-2.9% of manganese, 0.2%-6.0% of tin, not more than 0.3% of phosphor, not more than 0.3% of nickel, 0.10%-0.19% of sulfur, 0.1%-0.9% of the sum of 1-3 elements selected from silicon, iron, molybdenum, tungsten, and cobalt, and the balance of zinc. In the alloy, the mass ratio of manganese and sulfur is more than 10 and less than 30; the other elements are impurities, and the mass fraction of any one of the impurities is not more than 0.03%; the sum of the mass fractions of all the impurities is not more than 0.5%. The preparation method comprises the following steps: melting and alloying the base metal element of copper and the important metal element of manganese, adding other alloy elements and performing homogenization, performing refining, adding sulfide or sulfur, performing homogenization and adding zinc rapidly, immediately casting into a ingot casting or performing atomization to obtain powder. The leadless free-cutting copper alloy and the preparation method of the invention are applicable to cutting processing, hot forging processing, and polishing processing of copper alloy.

Owner:HUNAN TERRY NEW MATERIALS COMPANY

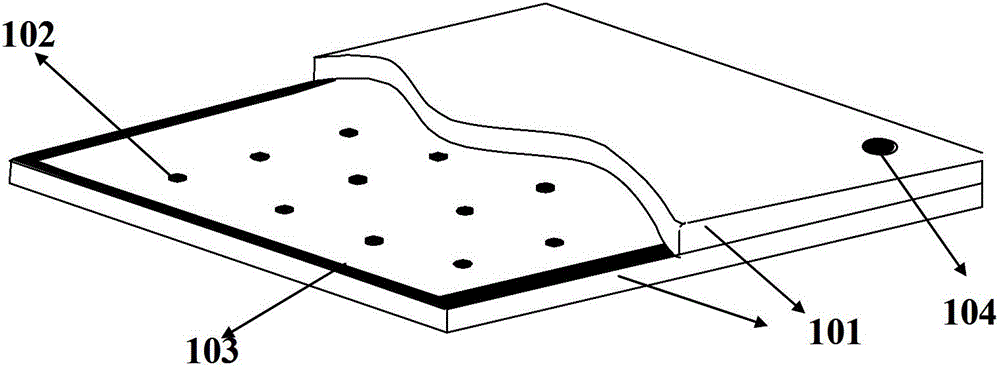

Vacuum glass with metal edge-sealing structure and making method thereof

Belonging to the field of vacuum glass and its edge-sealing technologies, the invention relates to a vacuum glass with a metal edge-sealing structure and a making method thereof. The vacuum glass comprises two flat glass sheets, a plurality of supports and a sealing layer. A metal transition layer is respectively cured on a sealing surface of the two flat glass sheets, and the two metal transition layers are fused and sealed by a metal layer formed by a low-melting-point metal welding material, and the fused and sealed metal transition layers and the metal layer form the low-melting-point metal sealing layer. The technical scheme involved in the invention not only can realize convenient and low-cost metal edge-sealing of vacuum glass, is easy to realize large-scale production, but at the same time also can realize low temperature (130DEG C-400DEG C) sealing of vacuum glass and lead-free manufacturing. Therefore, the vacuum glass and the method provided by the invention have great significance in reducing the production cost of vacuum glass and broadening the application scope of vacuum glass.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

Method for preparing high Curie point leadless PTC ceramic resistance material

InactiveCN101224979ASolve the technical problems of semiconductorizationAvoid pollutionCeramicsPositive temperature coefficient thermistorsElectrical resistance and conductanceCompound a

A preparation method of a lead-free high-Curie temperature PTC varistor ceramic material, the Na2Co3, Bi2O3 and TiO2 are mixed into a compound A while the TiO2 and BaCO3 are mixed into a compound B, the Na0.5Bi0.5TiO3 powder and the BaTiO3 powder are synthesized respectively through ball milling of the compound A and B; the synthesis Na0.5Bi0.5TiO3 powder and BaTiO3 powder, the semi-derived element and the TiO2 are ball milled, dried, granulated, and molded; the body molded is sintered to obtain a semi-derived ceramic sample which is oxidized for the lead-free high-curie temperature PTC varistor ceramic material. The invention fulfills unleaded requirements, avoids environmental pollution and human harm caused by lead application in manufacturing of resistance material, and solves the technical difficulties for the semi-derived lead-free high-curie temperature PTC varistor ceramic material.

Owner:SHAANXI UNIV OF SCI & TECH

Lead-free silver electrode size and preparation method thereof

InactiveCN101609724AUniform adhesionImprove conductivityConductive materialCable/conductor manufactureSilver electrodeMaterials science

The invention relates to a lead-free silver electrode size and a preparation method thereof. The invention is characterized in that the size comprises the following compositions in portion by weight: 60 to 75 weight portions of ultrafine silver powder, 2 to 10 weight portions of lead-free glass binder, 2 to 5 weight portions of oxide and 10 to 30 weight portions of organic binder. The lead-free silver electrode size can completely replace a conventional leaded glass size; and the lead-free silver electrode size can be fused through sintering at a temperature of 600 DEG C and has good fluidity, can be wetted with a ceramic substrate and shows stable performance and good electric performance.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

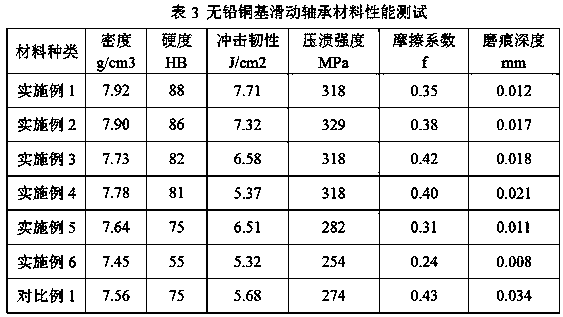

Unleaded Cu-based sliding bearing material and preparation method thereof

InactiveCN101576118AAchieve lead-freeImprove mechanical propertiesLiquid/solution decomposition chemical coatingSliding contact bearingsGraphiteHigh intensity

The invention relates to an unleaded Cu-based sliding bearing material and a preparation method thereof and the invention has the characteristics that: the material is composed of nickel, tin, zinc, iron, graphite, bismuth, copper and assistants, the substrate of the material is unleaded copper alloy, and the antifriction and antisticking constituent element is bismuth and graphite. The Cu-based bearing material features high intensity, and good antifriction and antisticking, thus realizing an unleaded Cu-based bearing material. The lead is cancelled in an original bearing material with lead and copper, and a synergistic effect of bismuth and graphite can replace the use of lead, thus completely overcoming the defect of lead pollution; moreover, the service performance of the bearing remains nearly the same, therefore the unleaded Cu-based sliding bearing material can completely replace the bearing material with lead and copper. The material of the invention can be applied in food machinery, drugs machinery, construction machinery, automobile and other products, and has advantages of good antifriction and antisticking, good heat dissipation effect, oxidation resistance and corrosive resistance.

Owner:HEFEI UNIV OF TECH

Lead-free electrocondution slurry used for crystalline silicon solar cell back electrode and preparation method thereof

ActiveCN103400633AImprove solder resistanceImprove adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureSlurrySolvent

The invention relates to lead-free electrocondution slurry used for a crystalline silicon solar cell back electrode. The lead-free electrocondution slurry used for the crystalline silicon solar cell back electrode consists of the following components in percentage by weight: 40-70wt% of silver plating copper powder, 2-10wt% of inorganic lead-free glass powder and 25-50wt% of organic carrier, wherein the organic carrier is the mixture of solvent, thickening agent and additive, and the prepared electrocondution slurry printing back electrode has the advantages of big thickness, small bulk resistance, excellent soldering resistance, strong welding adhesive force and silver ion migration resistance. Meanwhile, after cell pieces are subjected to series welding, an assembly has the advantages of higher stability and stronger anti-aging capability.

Owner:SHANGHAI BONA ELECTRONICS TECH

Thyristor core manufacturing process

InactiveCN101752248AImprove welding characteristicsImproved high temperature characteristicsSemiconductor/solid-state device manufacturingEvaporationAlloy

The invention discloses a thyristor core manufacturing process. The manufacturing process is characterized in that the manufacturing process includes the following steps: 1) boron diffusion; 2) oxidization; 3) primary photoetching; 4) phosphorus diffusion; 5) sintering; 6) evaporation; 7) alloying; 8) secondary photoetching; 9) surface treatment-nickeling; 10) surface treatment-silvering; 11) tertiary photoetching; 12) angle grinding; 13) surface corrosion. Primary diffusion-oxidization-photoetching-secondary diffusion are carried out on an original N-type silicon slice so as to form a four-layer (P-N-P-N) structure; sintering and bonding are carried out under the vacuum condition and high temperature; high-purity aluminum is gasified on the surface of a mono-crystalline silicon slice by an electron beam under high temperature so as to form an effective protective film; finally, nickeling and silvering treatments are respectively carried out on a surface layer of a sintered and film-coated thyristor core, and an anode and a cathode which can be welded are led out at the two ends of the thyristor core, so as to prepare the entire thyristor core suitable for both welding encapsulation and pressure-welding encapsulation at the same time as removing a traditional lead evading technology.

Owner:ZHEJIANG SIFANG ELECTRONICS

Lead-free copper-based alloy powder material and preparation method thereof

The invention relates to copper-based alloy powder, in particular to lead-free copper-based alloy powder used for manufacturing mechanical parts, automobile bearings and the like, and a preparation method thereof. A lead-free copper-based alloy powder material consists of the following components in percentage by weight: 87 to 89 percent of Cu, 5 to 7 percent of Sn, and 5 to 7 percent of Zn; and the total weight of the Cu, the Sn and the Zn is 100 percent. The preparation method realizes no lead by blending the content of copper, tin and zinc, and saves cost; and the wear resistance and bonding strength of a bearing material produced by sintering the alloy powder can be equal to or even superior to those of a sintered copper-lead bimetallic material. The lead-free copper-based alloy powder material is a novel material capable of replacing the copper-lead bimetallic material, is mainly used in aspects such as the mechanical parts, automobile bearings and the like, improves the influence of a lead-containing metal material on the environment in the sintering process, and avoids lead-containing rejected materials causing negative effect on the environment.

Owner:浙江旭德新材料有限公司

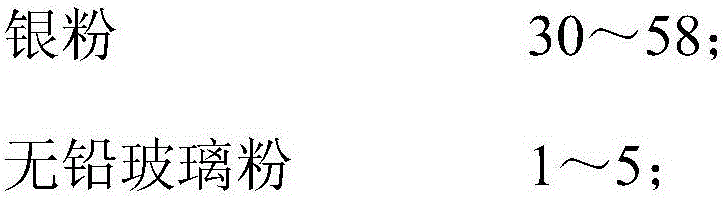

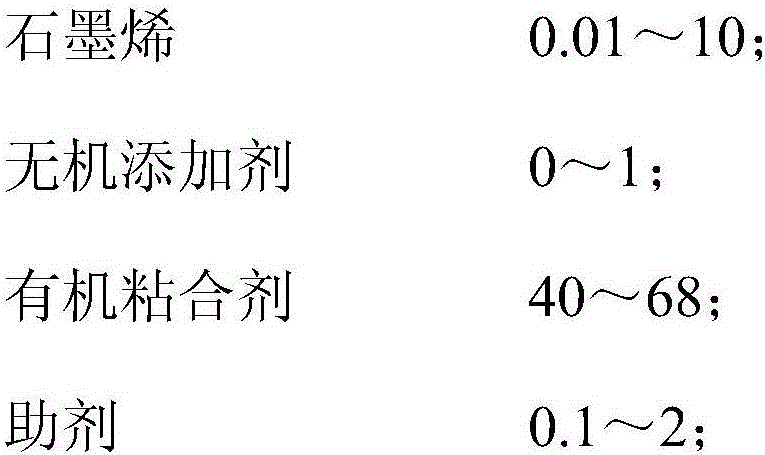

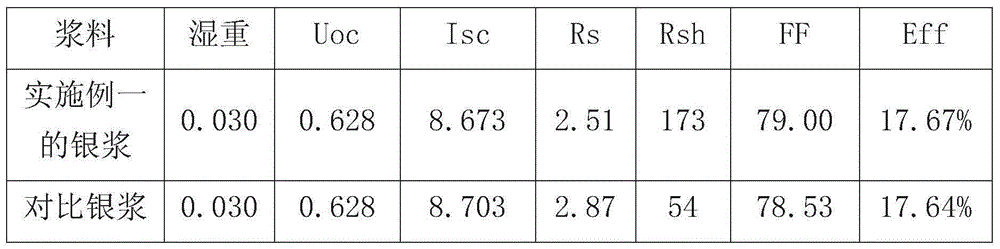

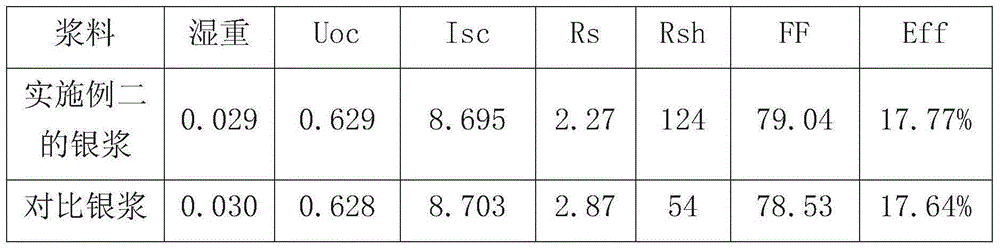

Silver paste of high-performance lead-free crystalline silicon solar battery back electrode and preparation method thereof

InactiveCN106128553AImprove compactnessHigh expansion coefficientNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a silver paste of a high-performance lead-free crystalline silicon solar battery back electrode. The silver paste comprises, by weight, 30 to 58% of silver powder, 1 to 5% of lead-free glass powder, 0.01 to 10% of graphene, 0 to 1% of inorganic additive, 40 to 68% of an organic adhesive, and 0. 1 to 2% of an auxiliary agent. The mixed silver powder is a mixture including irregularly-shaped silver powder and silver powder with a high specific surface area. In addition, the invention also discloses a preparation method for the silver paste of the high-performance lead-free crystalline silicon solar battery back electrode. Graphene, an auxiliary agent, and a part of organic adhesive are mixed and then the mixture is rolled to form a slurry, so that a graphene slurry is obtained; silver powder, lead-free glass powder, an inorganic additive, and the rest of organic adhesive are mixed and stirred uniformly and then the graphene slurry is added; and stirring and mixing are carried out continuously and uniformly, so that a needed silver paste is obtained. According to the invention, the fusion and contact with an aluminum back field are improved; the contact resistance between the silver electrode and the aluminum back field is reduced; the conversion efficiency of the battery piece is improved; and the electrode weldability and soldering resistance performance are enhanced.

Owner:苏州柏特瑞新材料有限公司

Preparation method of lead-free high-Curie-point BaTiO3-based positive-temperature-coefficient thermal sensitive ceramic

The invention relates to a lead-free high-Curie-point BaTiO3-based positive-temperature-coefficient thermal sensitive ceramic, and a preparation method thereof, and belongs to the field of ceramic with high technological functions, and applications of the ceramic with high technological functions. According to the preparation method, tetragonal perovskite BaTiO3 phase is taken as a matrix, (Bi0.5Na0.5)TiO3 is taken as a peak moving reagent of Curie point, rare earth oxide Ta2O5 or Sm2O3 is used for reducing room temperature electrical resistivity, and transition metal oxide MnO2 is added to increase resistance increasing ratio; one pot reaction is adopted to prepare the lead-free BaTiO3-based thermal sensitive ceramic; reduction-reoxidation sintering is adopted to obtain the BaTiO3-based positive-temperature-coefficient thermal sensitive ceramic with excellent heat sensitive properties. The preparation method comprises following steps: weighing, material mixing, ball milling, drying, sintering, grinding and sieving, pelletizing, tabletting, hydrocarbon removing, sintering, and coating with electrode. The lead-free high-Curie-point BaTiO3-based positive-temperature-coefficient thermal sensitive ceramic is high in Curie point and resistance increasing ratio, low in room temperature electrical resistivity, contains no lead, and is especially suitable to be used for preparing parts used for heating protection, overtemperature protection, overcurrent protection, and temperature monitoring and sensing.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Leadless free-cutting slicon graphite brass

The invention relates to lead-free free-cutting silicon graphite brass, which belongs to the technical field of metal material manufacturing. The mass fractions of each alloying element of the brass are respectively copper 58.0-62.0 %, silicon 0.1-3.5% and graphite 0.1-3.5%, the summation of the mass fraction of the silicon and the mass fraction of the graphite is 1.0-4.0%, allowance is zinc, and the total amount of impurity is no more than 0.05%. The graphite brass of the invention adopts the silicon and the graphite elements to replace lead element which pollutes environment and is very harmful to human health on the basis of existing free-cutting lead brass and aiming at the concrete requimrents of the material under using environment and using conditions, which realizes the lead-free soldering of the free-cutting lead brass. The brass has excellent cutting performance and thermoplasticity, the hot extrusion ratio reaches more than 80, cryogenic brittleness phenomenon does not appear, and the brass is applied in the fields of electronic devices, water heating bathroom facilities, constructional elements and the like and replaces the existing free-cutting lead brass.

Owner:XIAMEN LAVIDA HI TECH MATERIAL CO LTD

Method for preparing aluminum bronze powder by water atomization

An embodiment of the invention discloses a method for preparing aluminum bronze powder by water atomization. The method includes the steps: smelting 90.5-93.5% of Cu and 6.5-9.5% of Al to form alloy liquid under normal pressure at the temperature of 1250 DEG C; performing chemical refining deoxidation and slag raking; measuring and controlling components, adding covering agents into the alloy liquid and keeping the temperature at 1220-1250 DEG C in a standing manner; pouring the alloy liquid into a leakage ladle, atomizing the alloy liquid under the water pressure of 3-5MPa and at the water temperature of 45-50 DEG C by a free-fall nozzle under protection of inert gas to form alloy powder; dewatering and drying the alloy powder; and screening the alloy powder to obtain the aluminum bronze alloy powder with -150-+350 meshes. The aluminum bronze powder prepared by the method can serve as an anti-friction coating material in an engine sliding bearing, and environmental pollution caused by leaded anti-friction coating material is avoided.

Owner:PUJIANG HUIKAI POWDER TECH

High-curie point lead-free PTC thermal sensitive ceramic resistor material

InactiveCN101412625AAchieve lead-freeSolve the technical problems of semiconductorizationInorganic saltsElectrical resistance and conductance

The invention relates to a high Curie point leadless PTC thermal sensitive ceramic resistor material, which comprises the main component of (Bi1 / 2K1 / 2)Ti1-x-wCexDyO3, wherein x is equal to between 0.2 and 0.5, y is equal to between 0.001 and 0.004, and w is equal to between -0.02 and 0.02; D is a semiconductive element consisting of at least one of the elements of Sb, Nb, Ta, and V; and a few additive components can be added to the formulation in addition, such as a compound of oxide, inorganic salt or organic salt and the like which contains at least one metallic element from elements of B, Si, Al, Mn and the like. The high Curie point PTC thermal sensitive ceramic material does not contain lead to avoid the harm to the environment and human bodies in the manufacturing process and the using process of resistor components. The method solves the technical problem of semiconducting of the high Curie point leadless PTC thermal sensitive ceramic resistor material, and can achieve PTC thermal sensitive ceramic resistor materials with different Curie points through adjusting the main component.

Owner:CENT SOUTH UNIV

Lead-free solder capable of achieving evenly organized soldering spots and soldering method thereof

ActiveCN104043911AAchieve low temperature solderingSolve the problem of high melting pointWelding/cutting media/materialsMetal working apparatusElectronic componentSoldering

The invention discloses a lead-free solder capable of achieving evenly organized soldering spots and a soldering method of the lead-free solder. The lead-free solder is formed by mixing low-temperature solder powder and high-temperature solder powder according to the mass ratio ranging from 3:1 to 1:3 and adding soldering flux or soldering paste into the mixture, wherein the melting temperature of the low-temperature solder powder ranges from 110 DEG C to 150 DEG C, and the melting temperature of the high-temperature solder powder ranges from 210 DEG C to 230 DEG C. The lead-free solder is free of lead and solves the problem that traditional lead-free solder is over high in melting temperature currently, low-temperature soldering of the lead-free solder is achieved, and therefore the lead-free solder can be applied to soldering of materials of electronic components developed on the basis of Sn-Pb eutectic solder and can effectively replace the Sn-Pb eutectic solder, and the lead-free solder has good application prospects in the field of electronic packaging.

Owner:HOERSON ELECTRONICS TECH +1

Lead-free copper-based bimetallic wear-resistant material and preparation method thereof

The invention discloses a lead-free copper-based bimetallic wear-resistant material and a preparation method thereof. According to the lead-free copper-based bimetallic wear-resistant material and thepreparation method thereof, copper-plated molybdenum disulfide, copper-plated graphite and copper-plated hexagonal boron nitride are added into lead-free bronze powder, alloy powder is laid on a steel plate, the copper-steel bimetallic lead-free wear-resistant composite material is prepared through a powder metallurgy re-sintering and re-rolling technology, and the effects of antifriction and wear resistance of the molybdenum disulfide, the graphite and the hexagonal boron nitride are exerted in a synergistic mode. The obtained composite material has the advantages of being good in antifriction and wear resistance performance, excellent in mechanical property, free of toxic element of lead, pollution-free to the environment and suitable for industries of medicine, food, machinery and thelike.

Owner:无锡神意模具新材料有限公司

Sintered leadless free-cutting brass and preparation method thereof

The invention relates a sintered leadless free-cutting brass and a preparation method thereof and the brass comprises the following elements by weight percent: 48.0%-70.0% of copper, 0.3%-0.4% of aluminum, 4.0%-4.3% of magnesium, 0.1%-0.2% of manganese, 0.08%-0.11% of cerium, 0.01%-0.03% of lanthanum, 0.4-2.4% of BN powder and the balance zinc and not more than 0.05% of impurities; various powders and binding agent are prepared according to the following proportioning by weight percent: 0.4-2.4% of BN powder, 2-4% of zinc powder used as sintering activator, 1% of zinc stearate used as binding agent and the balance brass powder. The preparation method comprises the following steps: using a planetary ball mill to mix powder, the weight ratio of ball to powder is 10:1, the mixing time is 6h, after mixing powders pressing is performed; then sintering is performed, the sintering technology is as follows: the temperature is heated from the room temperature to a sintering temperature, the heating time is 5h, the sintering temperature is 840 DEG C, the sintering time is 2h, the sintering atmosphere is hydrogen atmosphere and after sintering, the temperature is fast cooled to the room temperature. The alloy of the invention contains no lead in composition, is environmentally friendly and has simple production process and the powder metallurgy method is applicable to large-scale batch production and has low processing cost.

Owner:XIAMEN LAVIDA HI TECH MATERIAL CO LTD

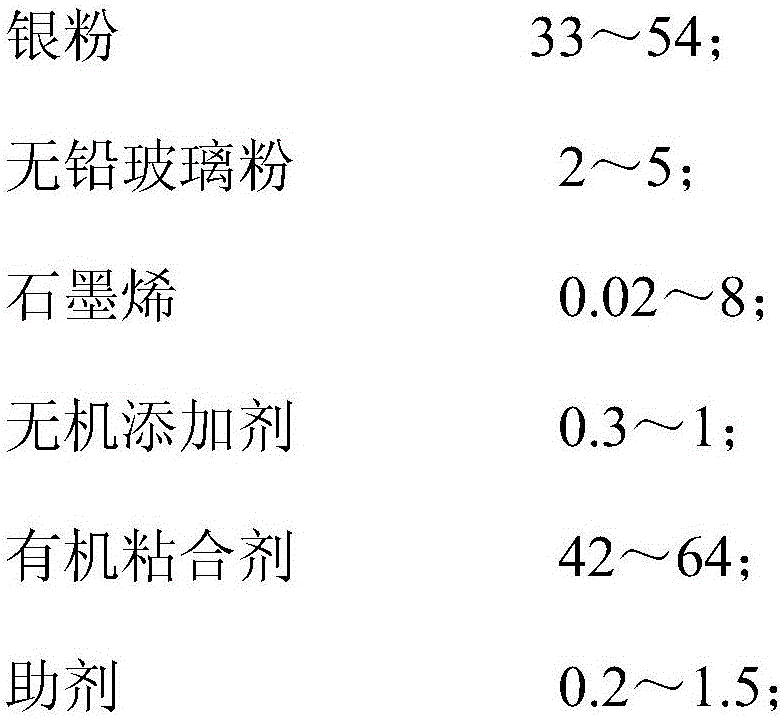

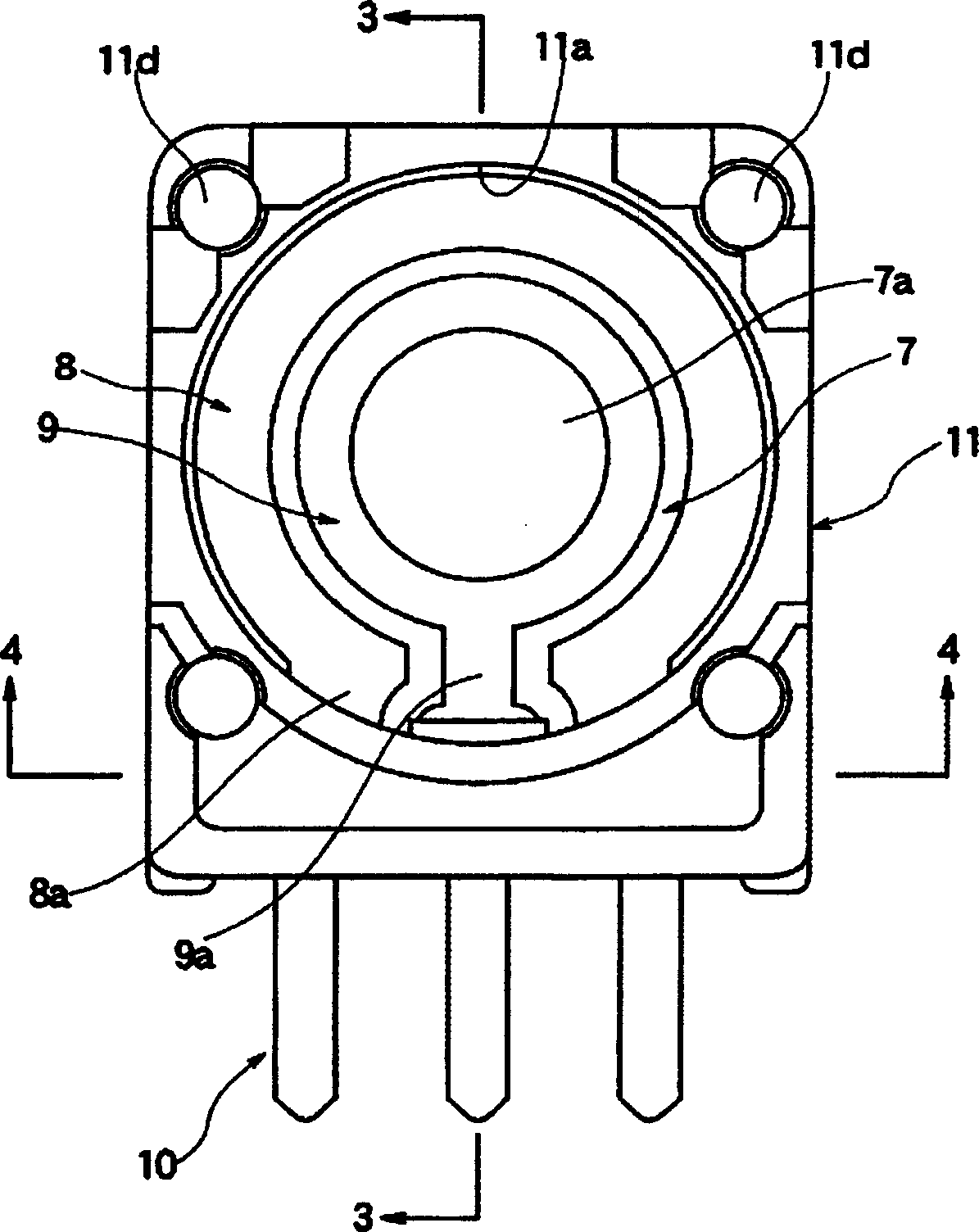

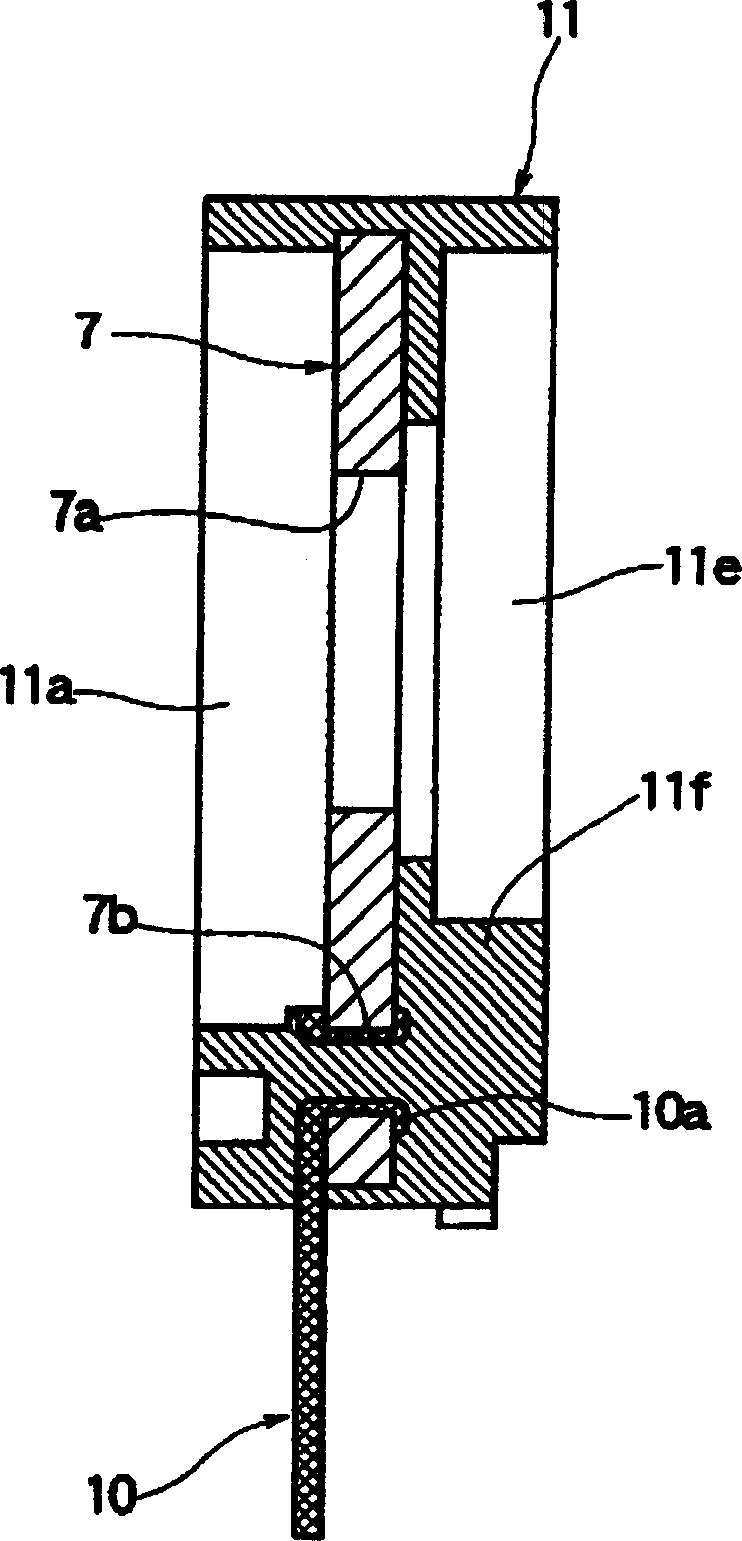

Variable resistance

ActiveCN1855320AIncrease production capacityImprove migrationResisitors with sliding contactSurface mountable resistorsSynthetic resinResistor

To provide a highly reliable variable resistor for hardly generating a short-circuit failure between terminals even if insert-molding an insulating substrate in a housing made of synthetic resin. This variable resistor is provided with a plate-shaped insulating substrate 7 formed with a resistor 8 and a collector 9, a plurality of mounting holes 7b formed at one edge side of the insulating substrate 7, a plurality of terminals 10 fixed to the plurality of mounting holes 7b so as to be conducted to the resistor 8 and the collector 9, and extended from one edge side of the insulating substrate 7 to the outside, a holding member 11 made of synthetic resin in which the fixed sections of the plurality of terminals 10 and the insulating substrate 7 are embedded in such a status that the resistor 8 and the collector 9 are exposed and a slider 6 sliding on the resistor 8 and the collector 9 and an insulating protrusions 11b and 11c extended to a direction crossing the plane face of the insulating substrate 7 between fixed sections of the plurality of terminals 10 fixed to the insulating substrate 7.

Owner:ALPS ALPINE CO LTD

Environmentally-friendly low-series resistance crystalline silicon solar cell back electrode silver paste

InactiveCN104992747AEnhanced Fusion ContactIncrease contact resistanceNon-conductive material with dispersed conductive materialSemiconductor devicesAdhesiveBack surface field

The invention relates to a silicon solar cell back electrode raw material, in particular, an environmentally-friendly low-series resistance crystalline silicon solar cell back electrode silver paste. With the environmentally-friendly low-series resistance crystalline silicon solar cell back electrode silver paste of the invention adopted, the problems of poor printing performance, large series resistance and low photoelectric conversion efficiency of the components of a silicon solar cell back electrode can be solved. The environmentally-friendly low-series resistance crystalline silicon solar cell back electrode silver paste is composed of the following components in part by weight: 50 to 58 parts of silver aluminum mixed powder, 1 to 3 parts of lead-free glass powder, 0.1 to 1 part of inorganic additive, and 39 to 48 parts of organic adhesive; the fine degree of the silver paste is smaller than 15 micron; and the viscosity of the silver paste ranges from30 to 60Pa.s. According to the environmentally-friendly low-series resistance crystalline silicon solar cell back electrode silver paste of the invention, irregularly-shaped silver powder and spherical aluminum powder are adopted as the base materials of the silver paste; a uniform and compact silver conductive layer is formed on the back surface of a silicon wafer in a high-temperature sintering treatment process, and excellent ohmic contact can be realized between the silver conductive layer and an aluminum back surface field as well as between the silver conductive layer and the silicon wafer; and therefore, lower series resistance and higher photoelectric conversion efficiency can be realized, and the weldability and adhesion of a back electrode can be improved, and the series resistance of a cell sheet can be small, and conversion efficiency is high.

Owner:苏州柏特瑞新材料有限公司

Environment protection type silicon solar cell back electric field aluminum pulp and producing method thereof

InactiveCN101425545BControl melting pointGood chemical stabilityFinal product manufactureNon-conductive material with dispersed conductive materialHazardous substanceOhmic contact

The invention relates to a manufacturing method of environment-friendly aluminum paste for a silicon solar battery back electric field. The aluminum paste comprises the following components and contents (weight percentage): 50 to 80 percent of aluminum conducting powder, 1 to 10 percent of crown glass binding agent, 0.05 to 5 percent of trivalent metal organic compound, 2 to 15 percent of organicresin, 10 to 25 percent of solvent and 2 to 10 percent of additive. The manufacturing method of the environment-friendly aluminum paste comprises the preparation of a glass binding agent, the preparation of an organic carrier, the formulation of aluminum paste stock and the processing technique of paste stock. The paste stock researched by the invention can not increase or generate substances which are harmful to human bodies and pollute the environment during the production and processing; the lead content of the paste stock is less than 100 ppm; and the contents of other hazardous substances such as Hg, Cd and the like can satisfy the environmental protection requirements. The aluminum past is applied to electrodes in the silicon solar battery back electric field; and the aluminum past has strong adhesion, good ohmic contact, and high conversion efficiency of a battery through the quick heat treatment in a continuous tunnel furnace.

Owner:WUHAN SUPERNANO OPTOELEC TECH CO LTD

High-strength lead-free copper-base sliding material and preparing method thereof

The invention discloses a high-strength lead-free copper-base sliding bearing material and a preparing method thereof. FeS powder and bronze powder are mechanically alloyed through the ball milling technology, the interface bonding capability between FeS and copper is improved, FeS particles are evenly distributed in a copper base body, the defect that aggregating is likely to happen when the content of the FeS is high is overcome, the dispersion strengthening function of FeS can be brought into play, and the material mechanical performance is improved. According to the high-strength lead-free copper-base sliding bearing material and the preparing method thereof, the good solid self-lubricating capability of FeS is mainly utilized, the friction and abrasion performance of the lead-free copper-base sliding bearing material is improved, effective unification between the high strength and the good lubricating character of the copper-base sliding bearing material is achieved, and application of the lead-free copper-base bearing material under complex work conditions is widened.

Owner:HEFEI UNIV OF TECH

Lead-free copper-based sliding bearing material and preparation method thereof

The invention discloses a lead-free copper-based sliding bearing material and a preparation method thereof. The raw materials comprises nickel, tin, iron, bismuth, molybdenum disulfide, phosphorus and cooper, the cooper serves as base materials, cooper-plated molybdenum disulfide and the bismuth serve as lubricating components, and lead in a bearing is replaced by a synergistic effect of the molybdenum disulfide and the bismuth; a cooper plating layer is formed on the surface of the molybdenum disulfide through a chemical plating effect, so that a combining effect of the molybdenum disulfide and the cooper base is improved, and decomposing does not happen in sintering; and the bismuth has antifriction and antiadhesion effects, the cooper-tin-bismuth powder is subjected to atomization treatment, and the situation that the brittle phase bismuth falls off from the base body is effectively avoided. According to the lead-free copper-based sliding bearing material, antifriction and antiadhesion performance is good, mechanical performance is excellent, the lead-free copper-based sliding bearing material can be used in the fields of food machinery, medicine machinery, engineering machinery and the like, and broaden application prospects are achieved.

Owner:HEFEI UNIV OF TECH

Preparation method of shallow crystal and yellow crystal bead blank

ActiveCN102320747AHigh refractive indexAchieve lead-freeGlass pressing apparatusManganesePotassium carbonate

The invention discloses a preparation method of a shallow crystal and yellow crystal bead blank. For overcoming the defects that lead oxide is needed in the raw materials, iron ions have poor coloring and optical properties, the coloring of manganese is instable and the crystal bead blank is poor on the aspects of physical and chemical properties and the like in the conventional process for preparing the shallow crystal and yellow crystal bead blank, the invention provides the preparation method of the shallow crystal and yellow crystal bead blank, wherein in the method, the lead oxide is notneeded in the raw materials, and the crystal bead blank has good physical and chemical properties, proper hardness and strong corrosion resistance. The method is technically characterized in that: the shallow crystal and yellow crystal bead blank comprises the following raw materials in part by weight: 50 to 65 parts of quartz sand, 2 to 20 parts of titanium white powder, 2 to 10 parts of sodium carbonate, 1.6 to 13 parts of potassium carbonate, 0.3 to 3 parts of potassium nitrate, 0.1 to 5 parts of cerium oxide, less than or equal to 6 parts of boric acid, less than or equal to 2 parts of aluminum hydroxide, less than or equal to 8 parts of zinc oxide, less than or equal to 10 parts of strontium carbonate, less than or equal to 15 parts of barium carbonate, less than or equal to 2 parts of lithium carbonate, and less than or equal to 2 parts of potassium permanganate.

Owner:浙江鑫伟兴水晶有限公司

Antifriction lead-free copper-based sliding bearing material and preparation method thereof

InactiveCN108486404AImprove friction and wear propertiesAchieve lead-freeShaftsBearing componentsWear resistantBronze

The invention discloses an antifriction lead-free copper-based sliding bearing material and a preparation method thereof. The ferrous sulfide powder, the bismuth powder and the bronze powder are subjected to mechanical alloying by adopting a ball milling technology to improve the interface adhesive strength of the ferrous sulfide, the bismuth and the bronze, and the phenomenon that the ferrous sulfide is easy to agglomerate when the content of copper matrix is relatively high is improved, the structure of FeS is good in oil storage capacity, the stability of the liquid-solid lubricating film is enabled to be good, so that the process of Bi spalling, the fusion of the low-melting-point component Bi and separating out of the low-melting-point component Bi are relieved, and the liquid-solid lubricating film can also be repaired and completed, so that the antifriction performance of the material is improved; in conclusion, the antifriction and wear-resistant properties of the copper-basedsliding bearing material are improved, the lead which is used as a lubricant in the copper-based bearing material is replaced by the good synergistic effect of the ferrous sulfide and the bismuth, sothat the pollution of lead is avoided; and the antifriction lead-free copper-based sliding bearing material and the preparation method thereof have the advantages of being low in cost and suitable forindustrial production.

Owner:HEFEI UNIV OF TECH

Antioxidative leadless copper alloy powder prepared by water mist method

InactiveCN106041049AUniform and round particlesHigh strengthTransportation and packagingMetal-working apparatusAdditive ingredientBenzotriazole

Antioxidative leadless copper alloy powder prepared by a water mist method is characterized in that the powder is prepared from the following ingredients: 500 parts of raw copper powder, 25-30 parts of tin powder, 8-10 parts of zinc powder, 3-7 parts of benzotriazole, 3-7 parts of ammonium molybdate, 3-7 parts of lauryl sodium sulfate and 6-8 parts of OP surfactant. The raw copper powder is subjected to oxidation resistance treatment; then, the contents of copper, tin and zinc are allocated to achieve lead freeness of the product; and the antioxidative leadless copper alloy powder is prepared; and the prepared antioxidative leadless copper alloy powder is uniform and round in particle, and has low oxygen content, and good strength, thermal conductivity, abrasive resistance and color.

Owner:安徽旭晶粉体新材料科技有限公司

Silver-aluminum paste easy to sinter for solar cell

InactiveCN105810288AAchieve complete melting and sinteringPrecise heatingNon-conductive material with dispersed conductive materialSemiconductor devicesSilver pasteMetallurgy

The invention discloses a conductive silver paste, which comprises the following components in weight percentage: 60-70% of silver powder, 1-2% of graphite powder, 2-5% of ceramic micropowder, 11-17% of glass powder, and 9% of organic binder ‑18%, auxiliary agent 1‑2%, total 100%; the silver powder is 61‑90nm silver powder; the graphite powder is 200‑400 mesh graphite powder; the glass powder contains the following components: SiO 2 3‑17%, TiO 2 1‑2%, Bi 2 o 3 35‑55%, Al 2 o 3 4-8%, SrCl 2 1‑7%, B 2 o 3 15‑38%, SnO 2 2-5%, CaO 0.1-2%, 100% in total.

Owner:江阴市天邦涂料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com