Environmentally-friendly low-series resistance crystalline silicon solar cell back electrode silver paste

A solar cell and back electrode technology, applied to conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, can solve problems such as low photoelectric conversion efficiency, poor printability, and large series resistance, and achieve Improve photoelectric conversion efficiency, good contact, and improve conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The environment-friendly low series resistance crystalline silicon solar cell back electrode silver paste of the present embodiment is formulated by 55g of silver-aluminum mixed powder, 2.2g of lead-free glass powder, 0.4g of inorganic additives and 42.4g of organic binder; The aluminum powder in the silver-aluminum mixed powder is 2.2g; the nano silicon powder in the inorganic additive is 0.05g.

[0014] After the above-mentioned ingredients were stirred and mixed uniformly in a container, the silver paste was obtained after grinding and dispersing on a three-roll mill for 2 hours.

[0015] Fineness of the silver paste: no more than 10 μm; viscosity: (25°C, Brookfield HB II Pro+) 44.5Pa·s.

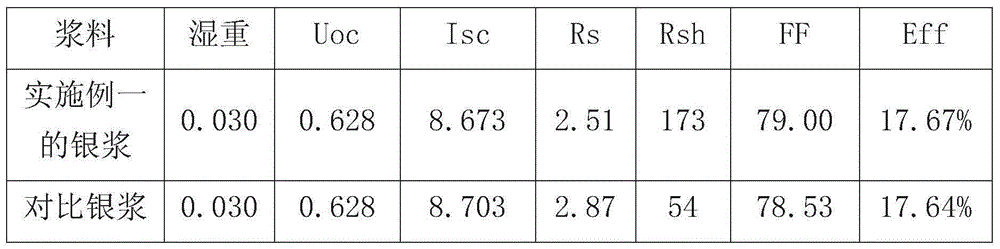

[0016] The environment-friendly low series resistance crystalline silicon solar cell back electrode silver paste and the comparative silver paste of this embodiment were printed and produced in a crystalline silicon solar cell for trial use, and their electrical performance results...

Embodiment 2

[0021] The silver paste for the back electrode of the environment-friendly low series resistance crystalline silicon solar cell of the present embodiment is formulated by 55g of silver-aluminum mixed powder, 2.2g of lead-free glass powder, 0.45g of inorganic additives and 42.35g of organic binder; The aluminum powder in the silver-aluminum mixed powder is 2.2g; the nano silicon powder in the inorganic additive is 0.07g.

[0022] After the above-mentioned ingredients were stirred and mixed uniformly in a container, the silver paste was obtained after grinding and dispersing on a three-roll mill for 2 hours.

[0023] Fineness of the silver paste: no more than 10 μm; viscosity: (25°C, Brookfield HB II Pro+) 44.5Pa·s.

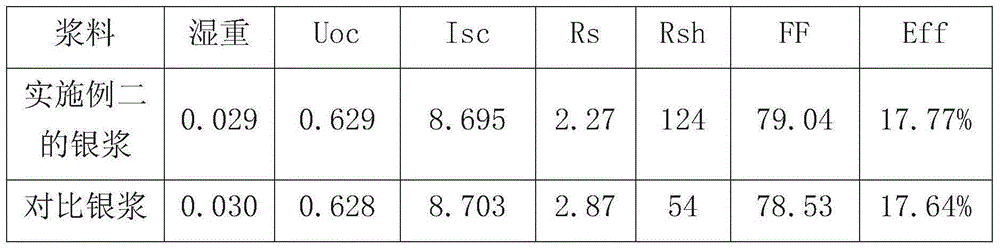

[0024] The environment-friendly low series resistance crystalline silicon solar cell back electrode silver paste and the comparative silver paste of this embodiment were printed and produced in a crystalline silicon solar cell for trial use, and their electrical pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com