Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

170results about How to "High expansion coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead- and zinc-free transparent fritted glaze

A fritted glaze without Pb and Zn for ceramics contains SiO2, Al2O3, CaO, MgO, K2O, Na2O, SrO, Li2O, B2O3, Fe2O3, Bi2O3 and Y2O3 proportionally. Its advantages are high adhesion, smooth and bright surface, and gay color.

Owner:JIANGSU BAIFU TECH CO LTD

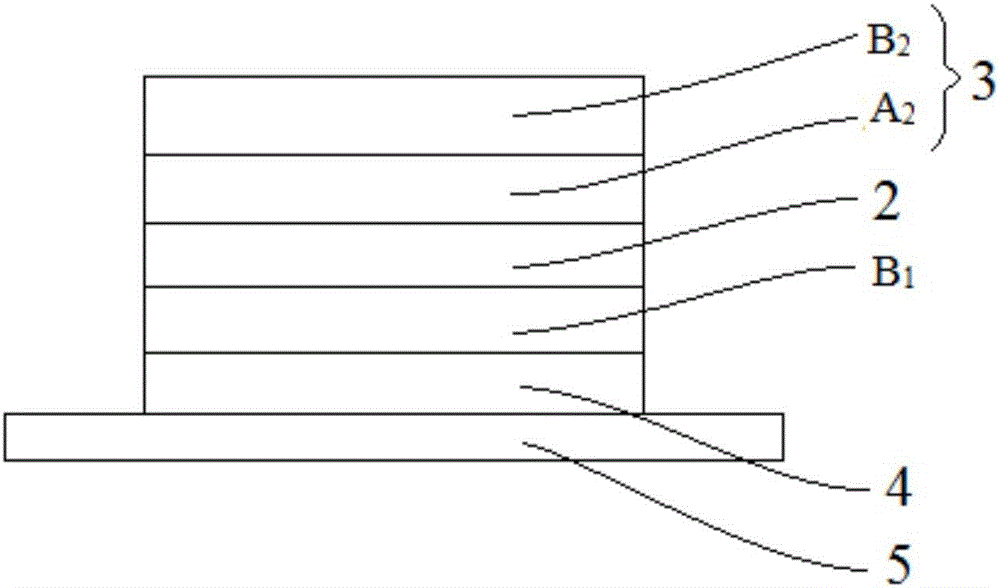

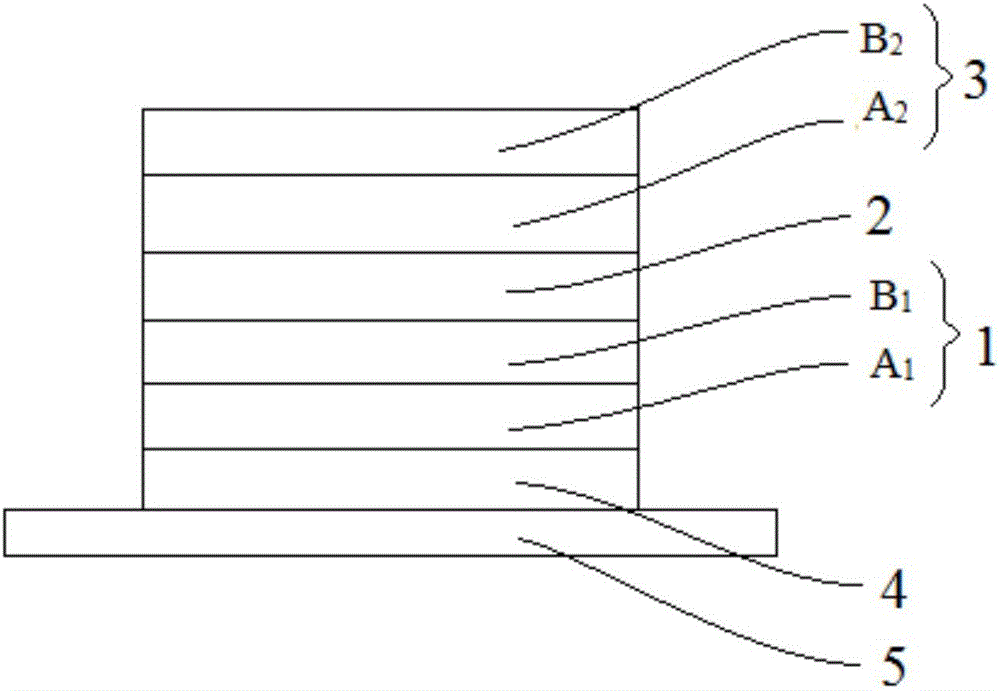

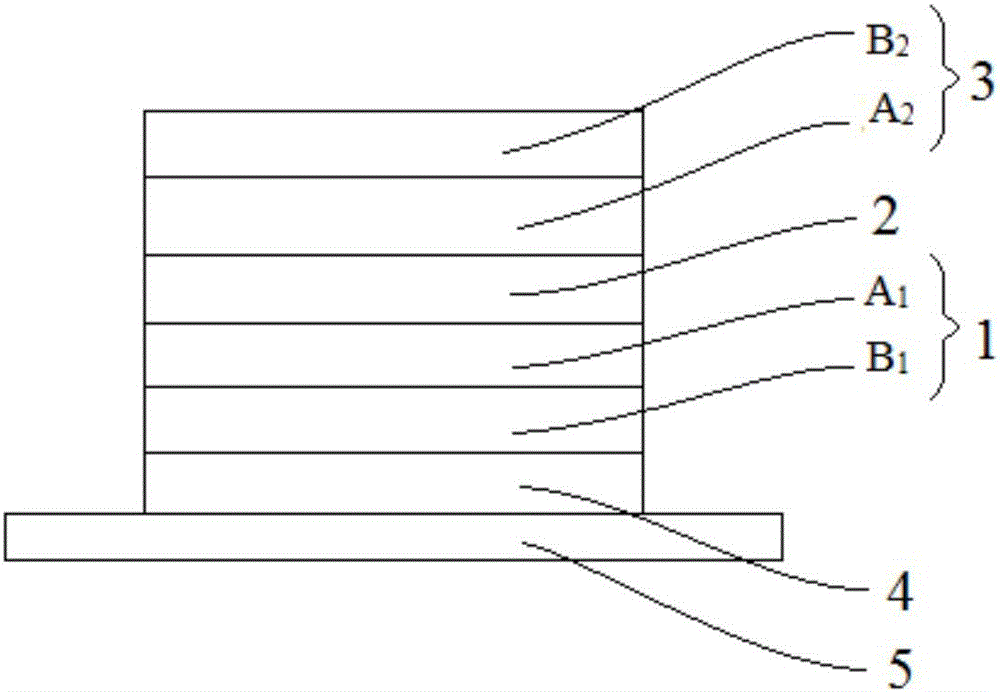

Thin film packaging method and structure

InactiveCN106299153ASmall expansion coefficientHigh expansion coefficientSolid-state devicesSemiconductor/solid-state device manufacturingPhysical vapor depositionInorganic materials

The application relates to the technical field of display, and particularly relates to a thin film packaging method and structure. The thin film packaging method disclosed by the application at least comprises the following steps of: sequentially preparing a first inorganic material layer, an organic material layer and a second inorganic material layer on the surface of a device to be packaged, and when the first inorganic material layer and / or the second inorganic material layer is prepared, firstly, preparing an inorganic layer A by adopting a physical vapor deposition method or a chemical vapor deposition method, and then preparing an inorganic layer B on the surface of the inorganic layer A by adopting an atomic layer deposition method; or, preparing the inorganic layer B by adopting the atomic layer deposition method, and then preparing the inorganic layer A on the surface of the inorganic layer B by adopting the physical vapor deposition method or the chemical vapor deposition method. According to the thin film packaging method and structure disclosed by the application, a composite inorganic layer prepared by utilizing the physical vapor deposition method or the chemical vapor deposition method and the atomic layer deposition method is gradually varied in density, so that a deviation of coefficients of thermal expansion of the prepared inorganic layer and organic material layer is reduced, and bending resistance of a display screen is improved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

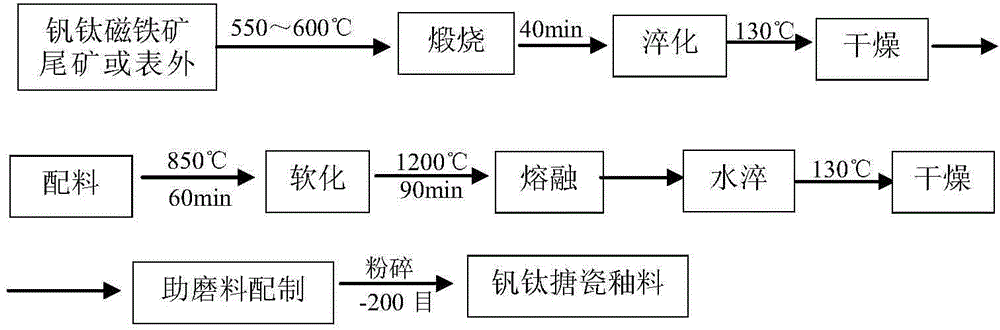

Vanadium-titanium enamel glaze material, and preparation method thereof

The invention belongs to the technical field of enamel material, and specifically relates to a vanadium-titanium enamel glaze material, and a preparation method thereof. The preparation method is used for solving technical problems that cost of a conventional vanadium-titanium enamel glaze material is high, glossiness of enamel glaze obtained via sintering is not high enough, fishscaling is observed, and acid and alkali resistance is not high enough. The vanadium-titanium enamel glaze material is prepared from, by mass, 22 to 28 parts of pretreated vanadium-titanium magnetite titanium separation tailing or vanadium-titanium boundary ore, 20 to 22 parts of feldspar powder, 5 to 8 parts of quartz sand, 24 to 26 parts of borax, 1.5 to 2 parts of sodium nitrate, 3.5 to 5.5 parts of lithium carbonate, 5 to 7 parts of fluorite powder, 0.1 to 0.3 part of sodium fluosilicate, 3 to 5 parts of cryolite, 2 to 4 parts of limestone, 3 to 4 parts of cobalt nitrate, 1 to 2 parts of nickel nitrate, 2 to 3 parts of sodium vanadate, and 1 to 2 parts of antimony oxide. Firm combination of the vanadium-titanium enamel glaze material with carbon steel billet can be realized; acid and alkali resistance is higher than that stipulated by national standard; and the vanadium-titanium enamel glaze material can be used for a plurality of matrixes such as hot-rolled carbon steel and cast iron.

Owner:PANZHIHUA UNIV

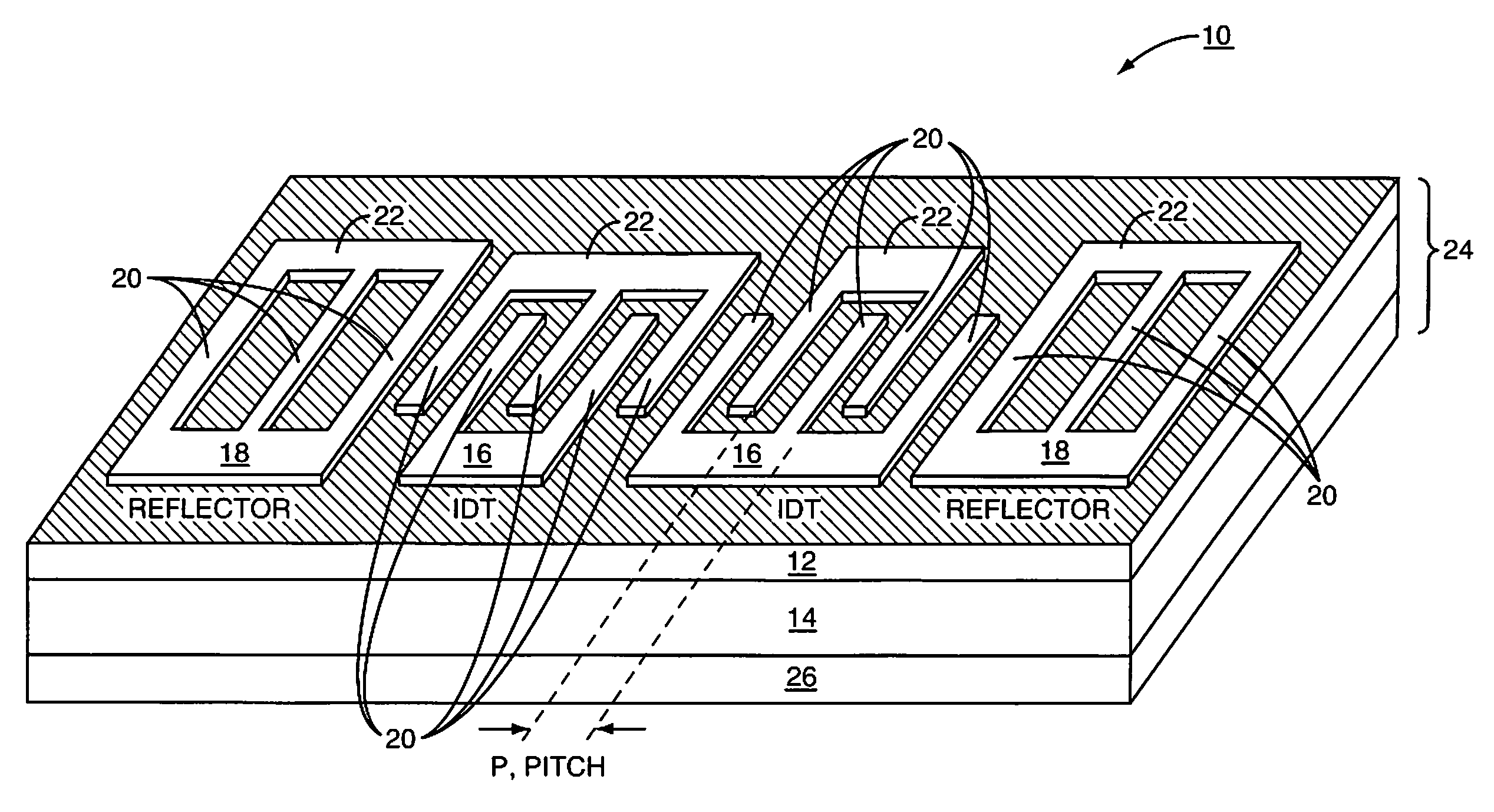

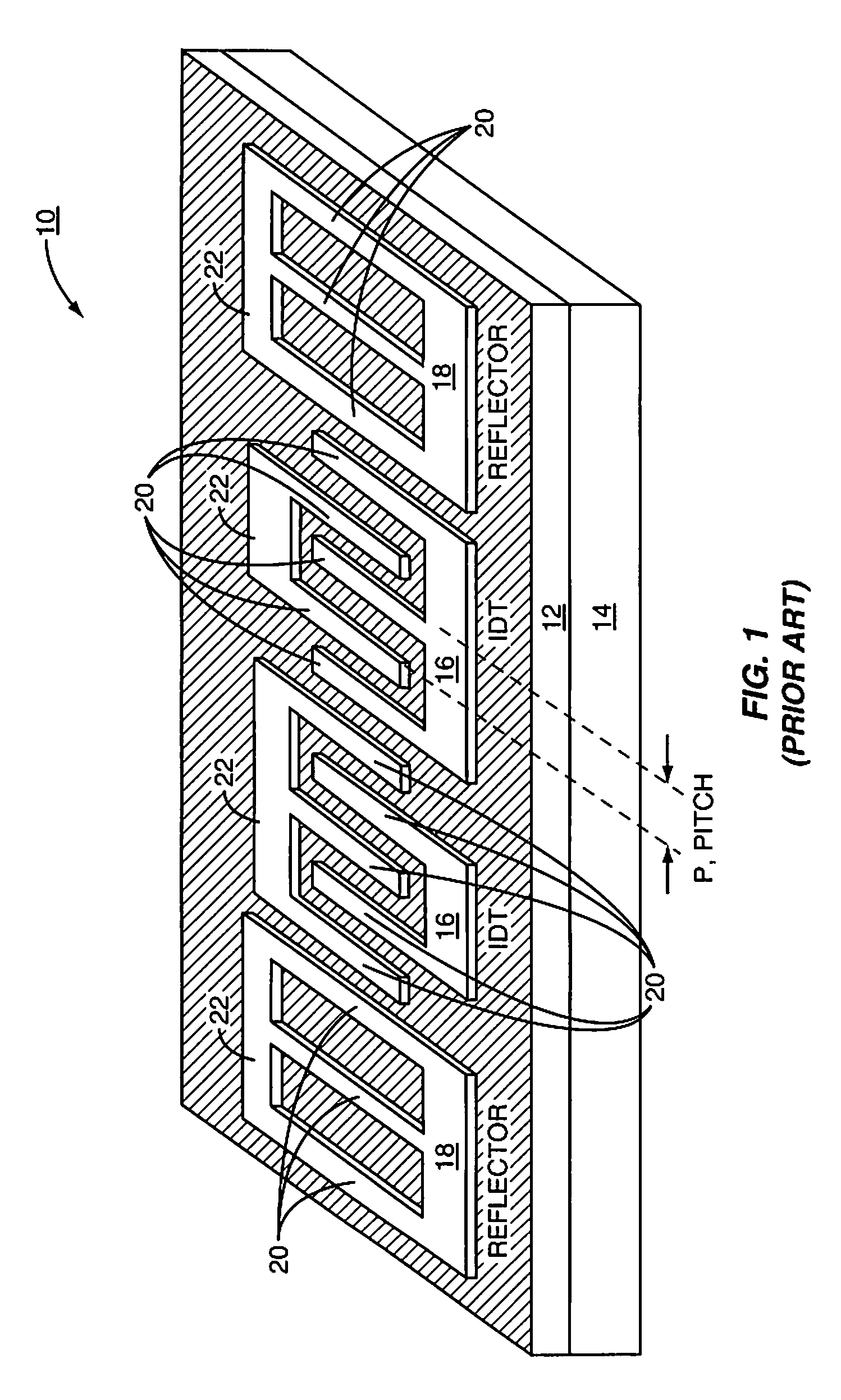

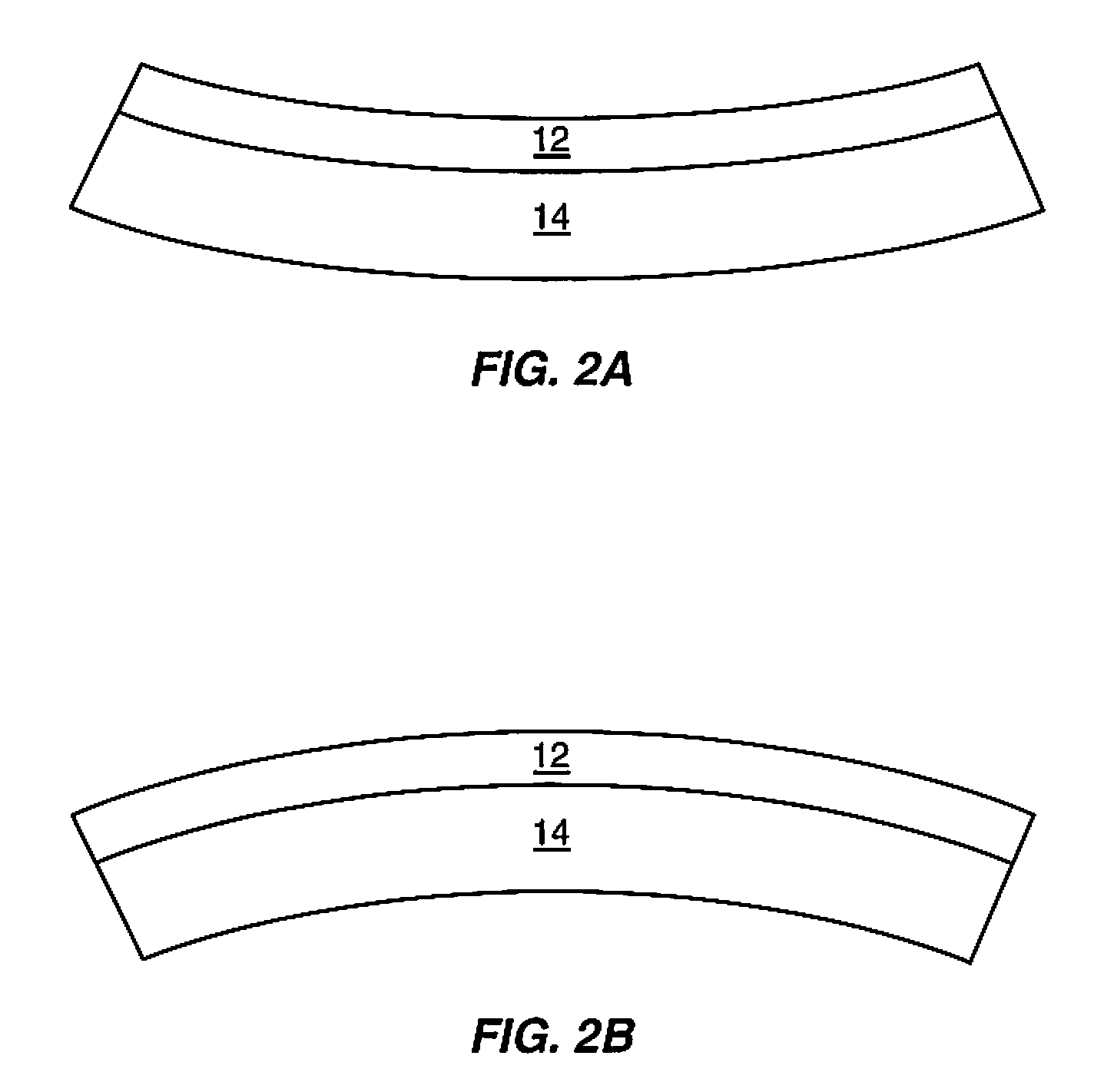

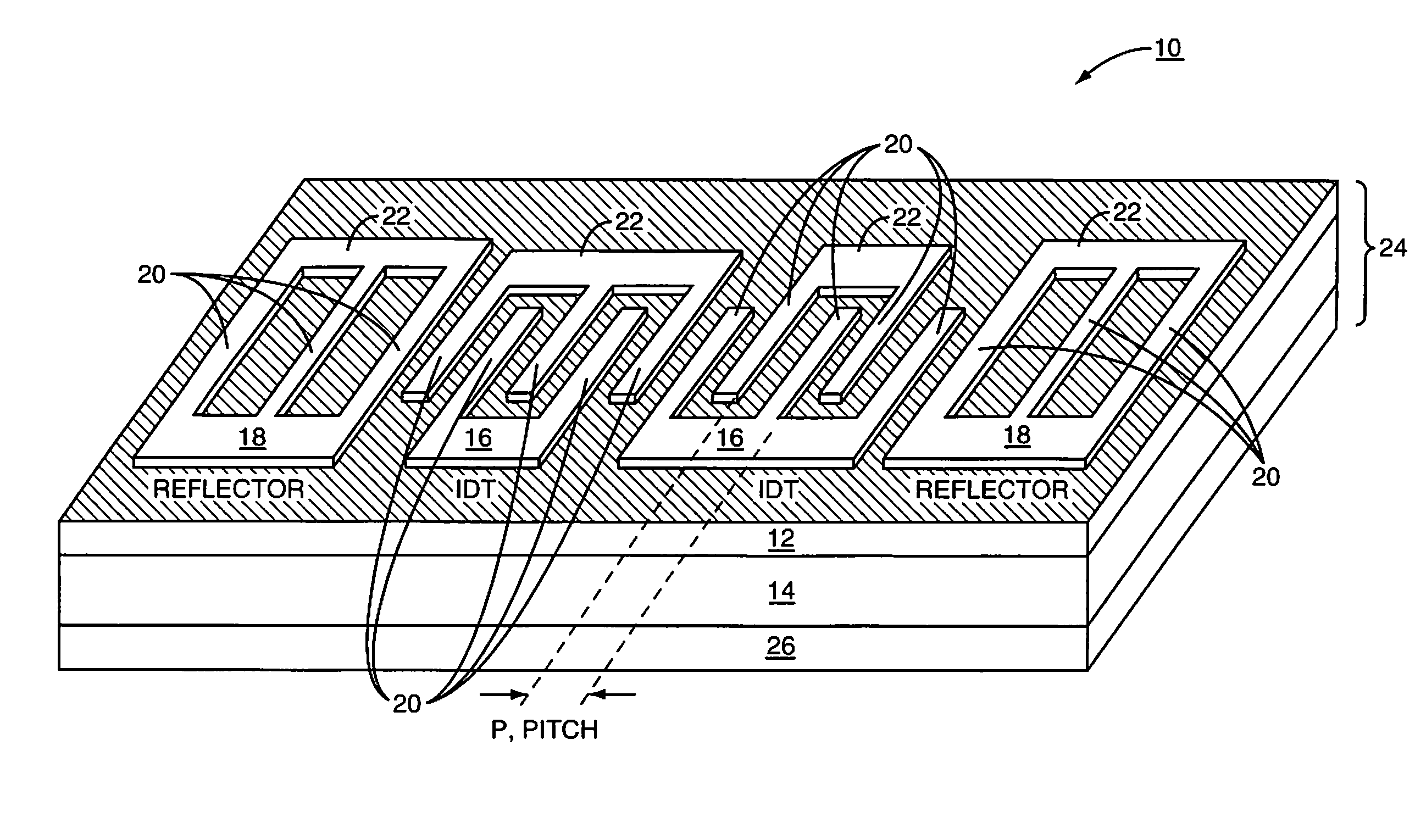

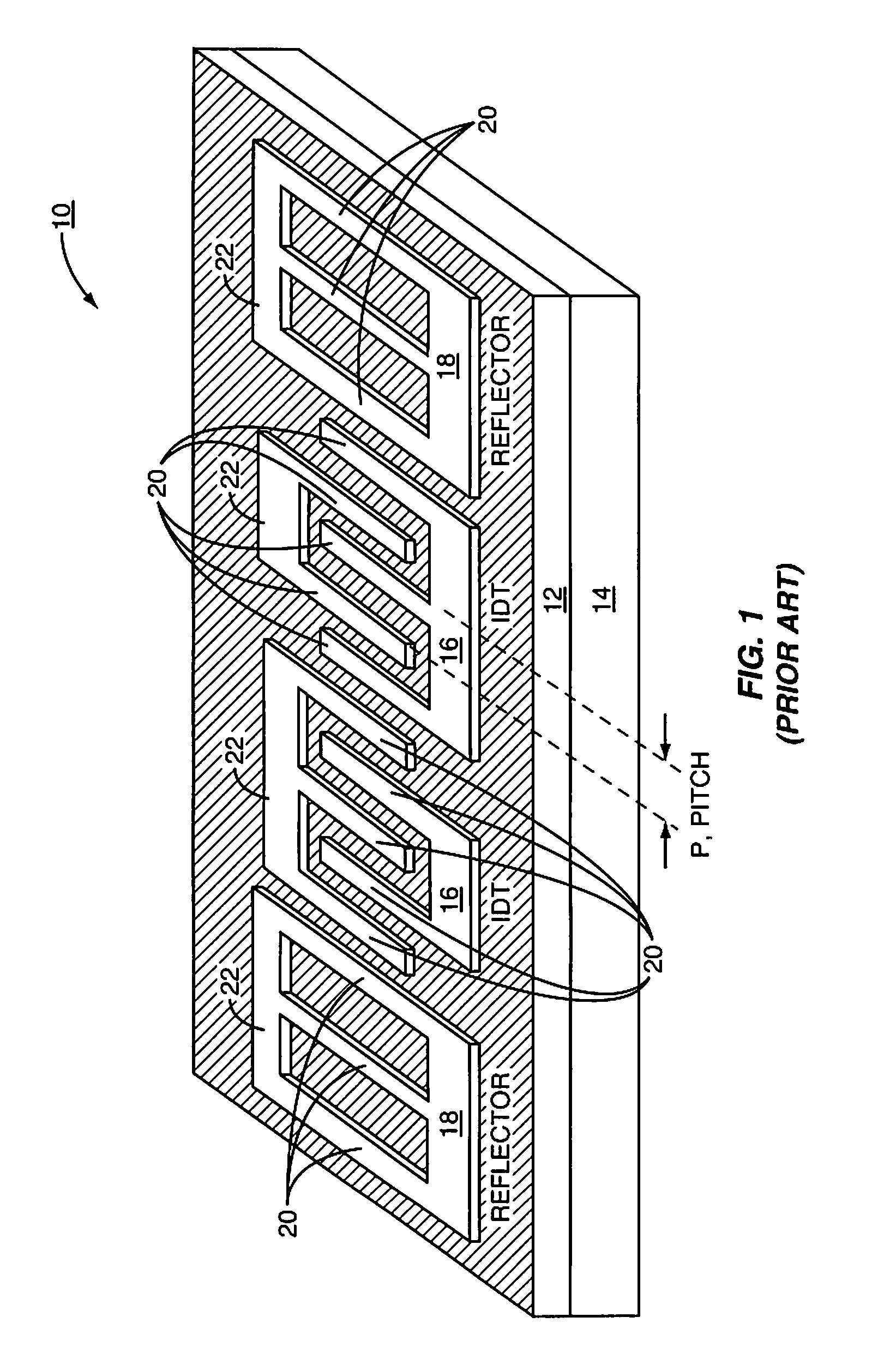

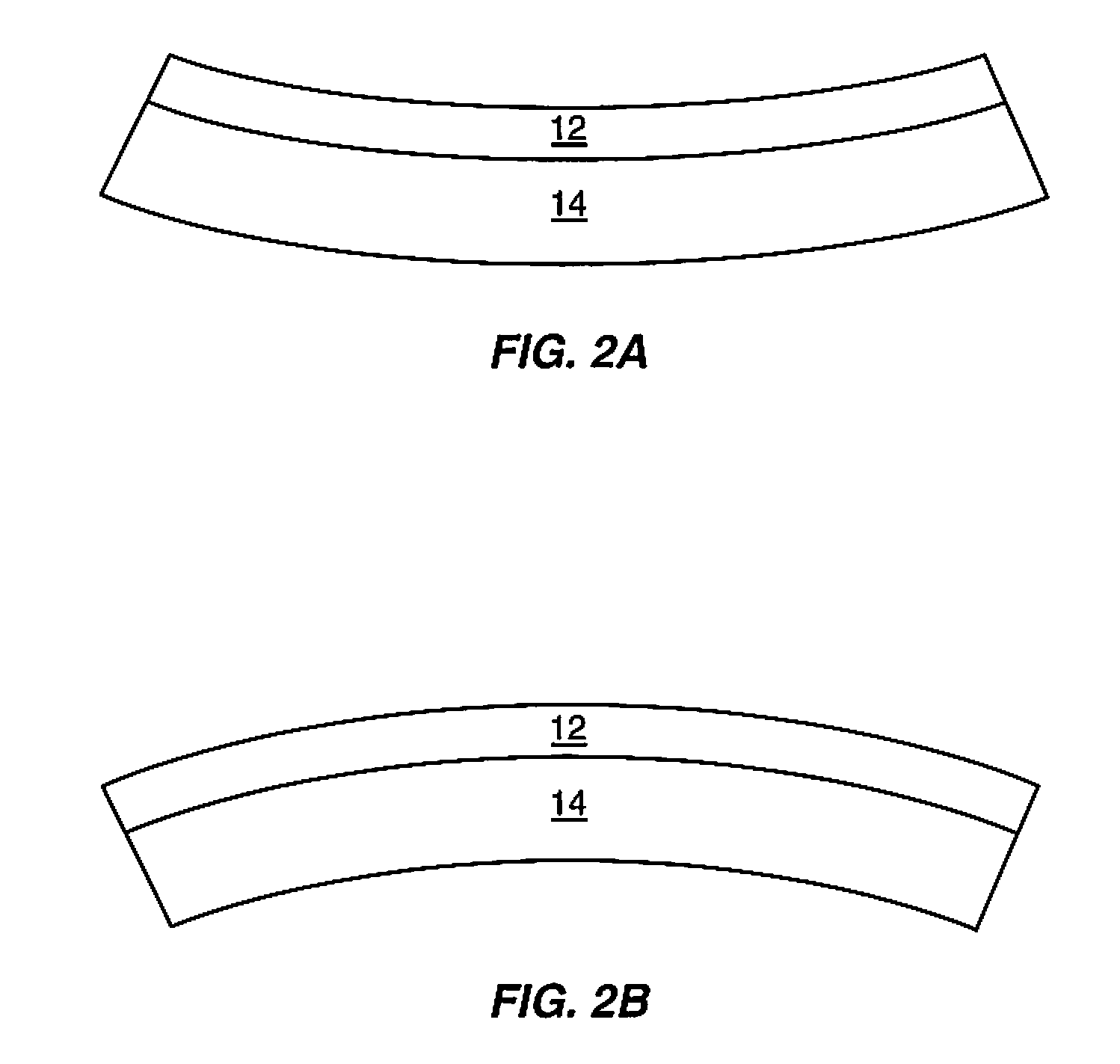

Piezoelectric substrate for a saw device

ActiveUS20080169724A1High expansion coefficientReduce contractionImpedence networksPiezoelectric/electrostriction/magnetostriction machinesThermal coefficientNanotechnology

The present invention provides a composite structure having a supporting substrate between a piezoelectric substrate and a compensation layer. The materials used to form the piezoelectric substrate and the compensation layer in isolation, have higher thermal coefficients of expansion (TCE) relative to the TCE of the materials forming the supporting substrate. Once the composite structure is created, the piezoelectric substrate and compensation layer tend to expand and contract in a similar manner as temperature changes. The expansion and contraction forces applied to the supporting substrate by the piezoelectric substrate due to temperature changes are substantially countered by similar opposing forces applied by the compensation layer, resulting in the opposing forces substantially counteracting one another. Due to the counteraction, the composite structure resists bending or warping, reducing expansion and contraction and increasing stress of the piezoelectric substrate, and thus reducing the effective TCE and TCF of the piezoelectric substrate.

Owner:QORVO US INC

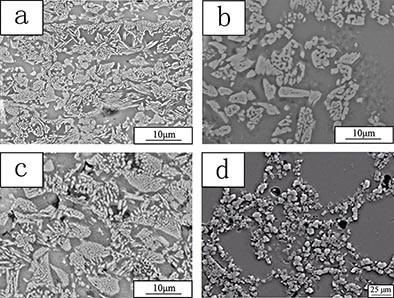

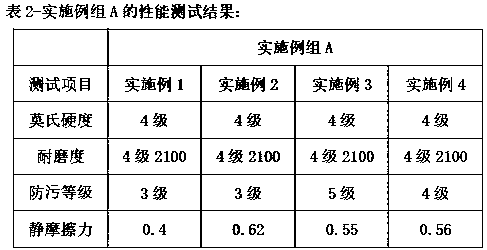

Wear-resistant antifouling glazed brick glaze and preparation method thereof

The invention discloses a wear-resistant antifouling glazed brick glaze and a preparation method thereof. The wear-resistant antifouling glazed brick glaze comprises raw glaze powder, No.1 frit powderand No.2 frit powder, wherein the raw glaze powder comprises the following raw materials in percentage by weight: 8-12% of kaolin, 10-18% of calcined kaolin, 12-20% of quartz, 12-20% of dolomite, 8-15% of calcined talc, 1-5% of wollastonite, 8-15% of nepheline, 5-10% of zinc oxide, 0-5% of calcite and 6-12% of strontium carbonate, wherein the No.1 frit powder is prepared from kaolin, calcined talc and fluorite, and the No.2 frit powder is prepared from zinc oxide, strontium carbonate and borax. The wear-resistant antifouling glazed brick glaze contains a large number of cordierite microcrystals, and the cordierite microcrystals have the characteristics of transparency, high hardness and the like, so that the wear resistance and the antiskid effect of a glaze layer can be enhanced, and thecontradiction between the transparency and the wear resistance of the glaze layer can be solved.

Owner:佛山市东鹏陶瓷发展有限公司

Piezoelectric substrate for a saw device

ActiveUS7408286B1High expansion coefficientReduce expansionPiezoelectric/electrostriction/magnetostriction machinesImpedence networksThermal coefficientNanotechnology

Owner:QORVO US INC

Method for planting konjak by corner land

The invention provides a method for planting konjak by corner land. According to the method, the konjak planting is carried out in corner land around houses, besides the forest, the land and the channel, at two sides of the road and in other places, so the konjak grows in the original ecology imitated environment, and the goals of reducing the disease occurrence and improving the konjak yield and the benefits are reached. The method comprises the following planting steps that (1) seeds are selected; (2) the seed konjak and the soil of the corner land are sterilized, and five-ingredient sterilization powder is adopted for the oil of the corner land; (3) ridges are formed on the corner land; (4) seeding and fertilization are carried out: a fertilization method with seeds at the lower side and fertilizers at the upper side is adopted; (5) weeding is carried out: after the konjak seeding, straws or corn stalks or chaffs or leaves are used for carrying out compartment surface coverage, or chemical weeding is adopted; (6) harvesting is carried out; and (7) the seeds are stored. The method has the advantages that the soil utilization of the existing corner land is improved, the konjak planting method and the konjak planting mode are innovated, the expansion space is widened, and the area of the planting base is increased.

Owner:湖北顺溪生物食品股份有限公司

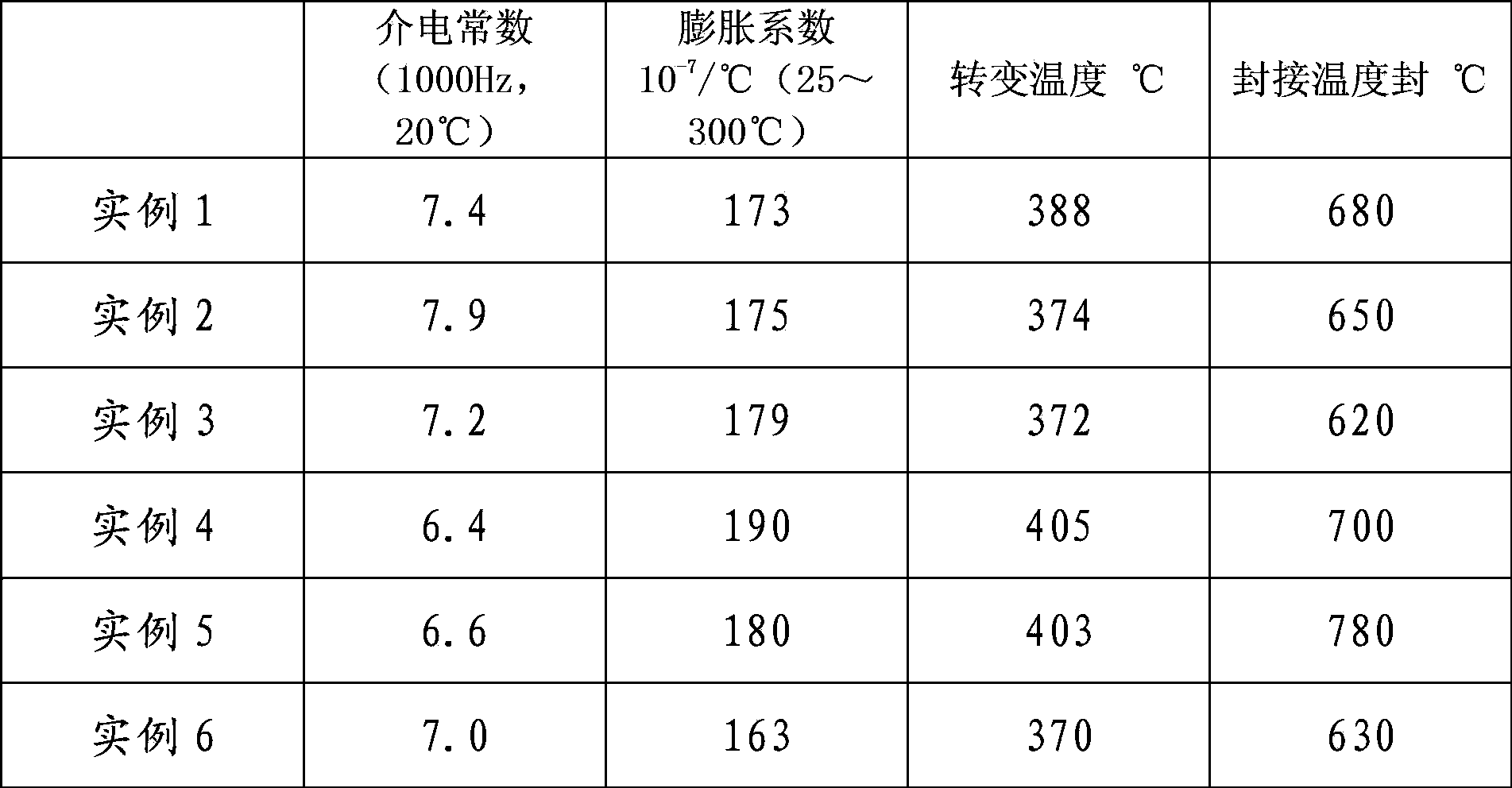

Sealing glass material and preparation method thereof

The invention discloses a sealing glass material and a preparation method thereof; silicon dioxide and boron trioxide are used as a skeleton structure and a network forming body for glass, wetting property and interface stability of the glass and titanium and a titanium alloy can be increased by adding of the boron trioxide, phase separation and crystallization problems are not easy to cause afterannealing and other heat treatment steps; alkali metal elements are used to lower melting temperature and increase expansion coefficient, and positive ions Mg<2+>, Ca<2+>, Sr<2+>, and Ba<2+> are filled into network spaces to produce mixed alkali effect and pressing effect to hinder the activity of alkali metal ions and improve the insulation performance of the glass; Al2O3 is added to form AlPO4units in the glass, and a linear structure is changed into a network structure, so that the structure of the glass tends to be stable, and the chemical stability is improved; ZnO and TiO2 oxides are added to improve the chemical stability and electrical insulation of the glass. The expansion coefficients of the sealing glass are matched, and the mechanical strength and chemical stability of the sealing glass are enhanced.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

Sealing glass powder for electric connectors, preparation method for sealing glass powder and sealing process of sealing glass powder

ActiveCN105859144ALower melting temperatureHigh expansion coefficientContact member assembly/disassemblyMixed alkali effectOxide

The invention discloses sealing glass powder for electric connectors. According to the sealing glass powder, silicon dioxide serves as a skeleton structure and serves as a network forming body of glass, and an extremely small amount of alkali metal element is used, so that the melting temperature is lowered, the coefficient of expansion is increased, and the influence on high-temperature insulating properties of the glass is relatively low; alkaline-earth metal oxides such as MgO, CaO, SrO and BaO are added, and network gaps are filled with cations, i.e., Mg<2+>, Ca<2+>, Sr<2+> and Ba<2+> of MgO, CaO, SrO and BaO and a mixed base effect and a depressing effect are generated, so that the movement of alkali metal ions is hindered, and thus the insulating properties of the glass is improved; due to relatively high content of BaO, the material properties of the glass can be improved, and the high-temperature insulating properties of the glass is greatly improved; due to the addition of Al2O3, an AlPO4 unit can be formed in the glass, and a straight chain is changed into a network structure, so that the structure of the glass is stabilized, and the chemical stability is improved; in addition, by adding oxides such as ZnO, TiO2, ZrO2 and V2O5, the improvement on the chemical stability and electrical insulating performance of the glass is facilitated.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

High-strength ice crack type ceramic product and preparation technology thereof

The invention relates to the technical field of preparation of ceramics, in particular to a high-strength ice crack type ceramic product and a preparation technology thereof. The high-strength ice crack type ceramic product comprises a blank and a glaze, wherein the blank comprises 58 parts of kaolin, 24 parts of potassium feldspar, 13 parts of quartz, 17 parts of clay, 2 parts of talcum, 15 partsof melting additive, 20 parts of wollastonite, 14 parts of brucite, 10 parts of sodium feldspar, 8 parts of calcium silicate, 8 parts of barium sulfate, and 6 parts of sepiolite; the glaze comprises45 parts of potassium feldspar, 16 parts of montmorillonite, 26 parts of quartz, 39 parts of sodium feldspar, 3 parts of color oxide, 2 parts of sodium hexametaphosphate, 5 parts of talcum, and 20 parts of calcium carbonate. The preparation technology comprises the following steps of S1, preparing of the materials; S2, drawing of the blank; S3, plain firing; S4, glaze applying; S5, firing. The high-strength ice crack type ceramic product prepared by the preparation technology has the advantages that the mechanical strength is high, the color is transparent and clear, and the cracks are fine and regular.

Owner:福建省泉州市契合工贸有限公司

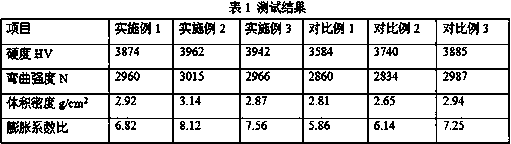

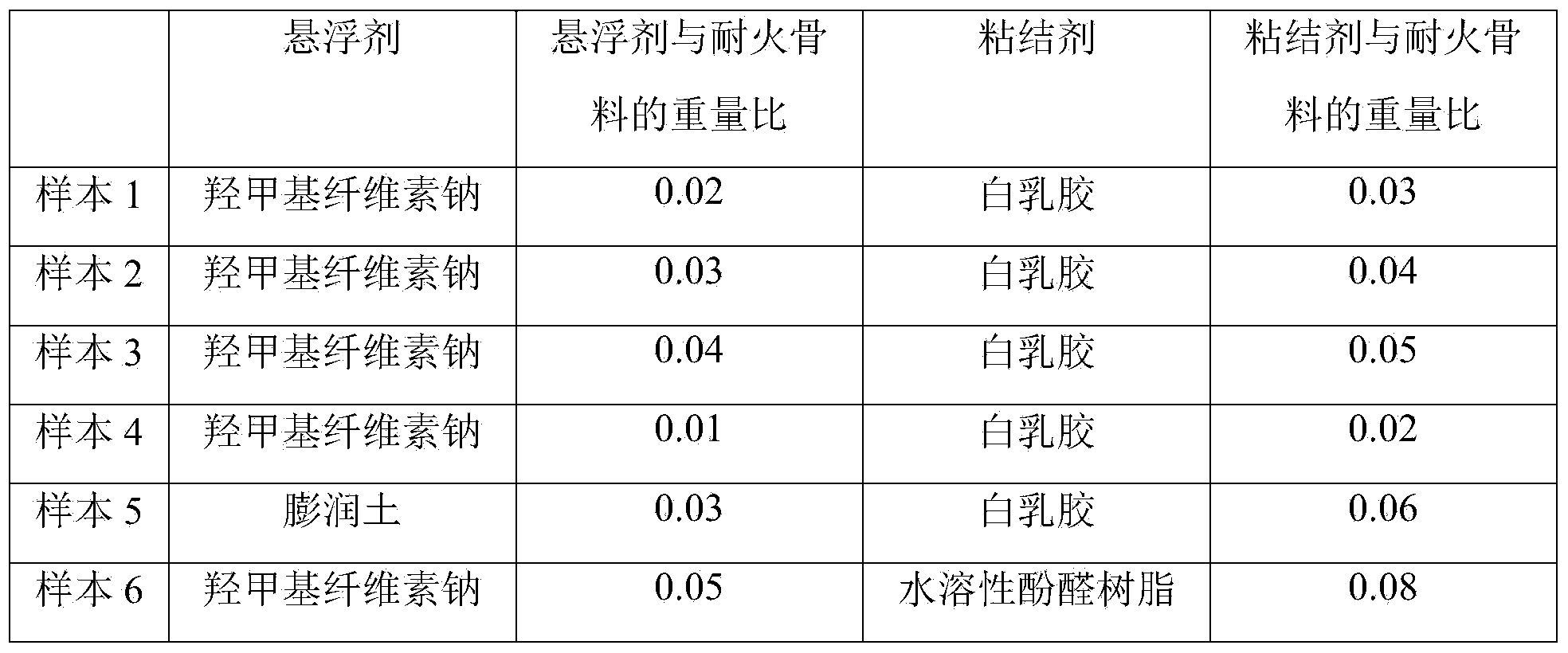

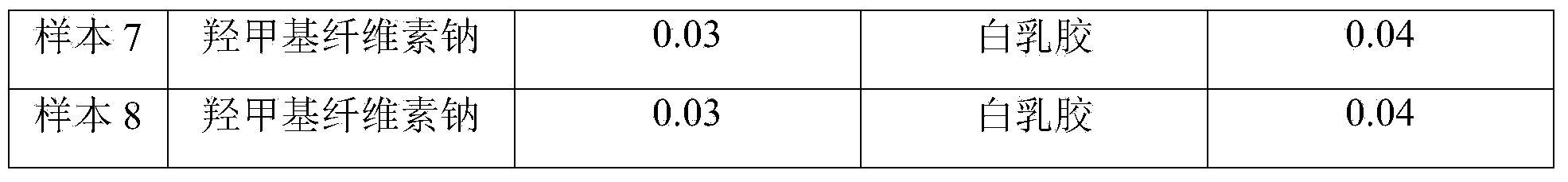

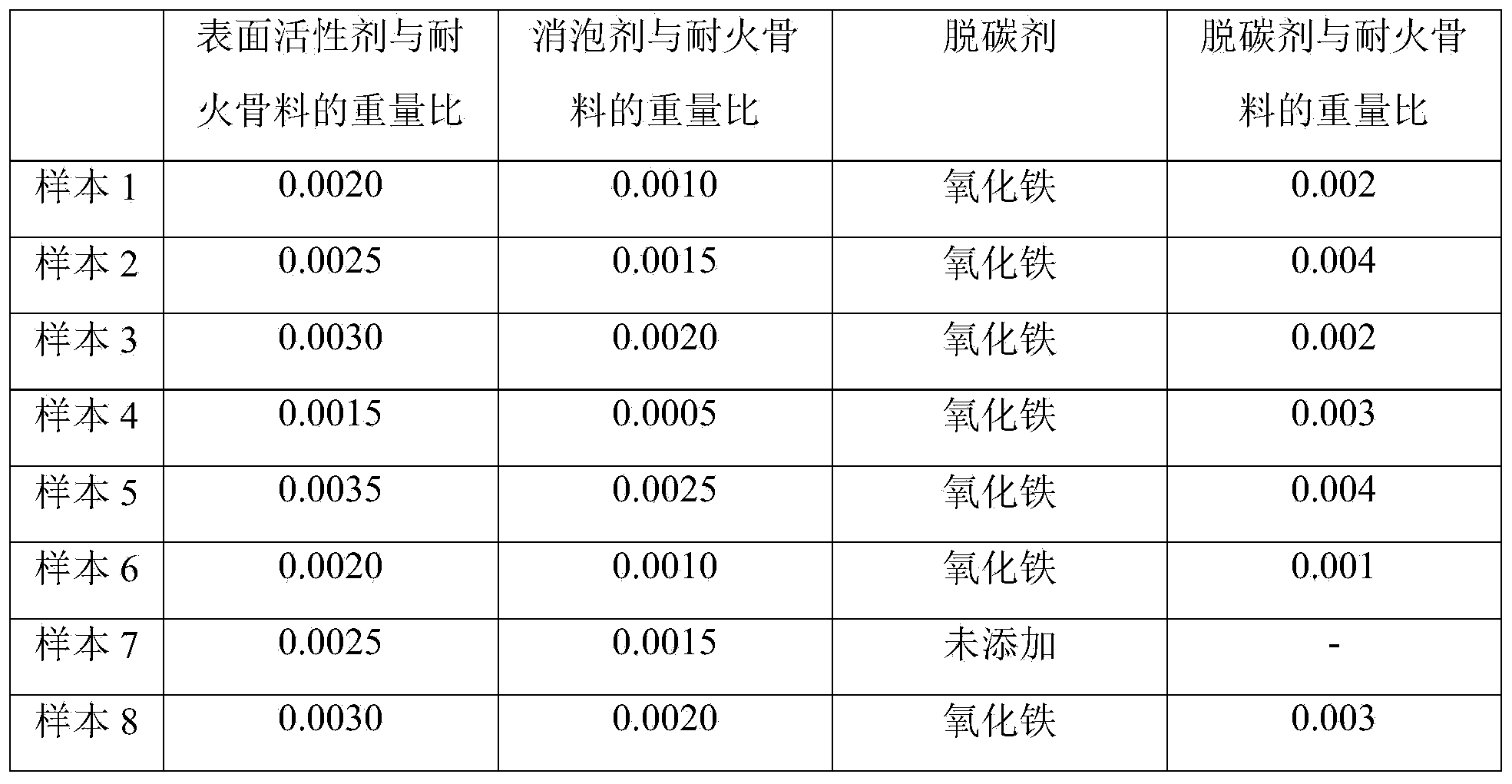

Coating for lost foam casting, and preparation method thereof

ActiveCN103506566AImprove fire resistanceImprove breathabilityFoundry mouldsFoundry coresSuspending AgentsLost-foam casting

The invention discloses a coating for lost foam casting and a preparation method of the coating. The coating comprises the following components: a refractory aggregate, a binder, a suspending agent and water, wherein the refractory aggregate comprises quartz sand and bauxite, and the weight ratio of quartz sand to bauxite is 3:7 to 4:6. The preparation method comprises the following steps: step 1, stirring and mixing the quartz sand and the bauxite to obtain the refractory aggregate, wherein the weight ratio of the quartz sand to the bauxite is 3:7 to 4:6; step 2, adding water into the refractory aggregate and stirring, wherein the weight ratio of the water to the refractory aggregate is 0.7 to 0.9; step 3, adding the binder into the mixture of the refractory aggregate and water and stirring. According to the invention, the coating has better performance and lower cost and is particularly suitable for lost foam casting of cast iron workpieces.

Owner:ZOOMLION HEAVY IND CO LTD

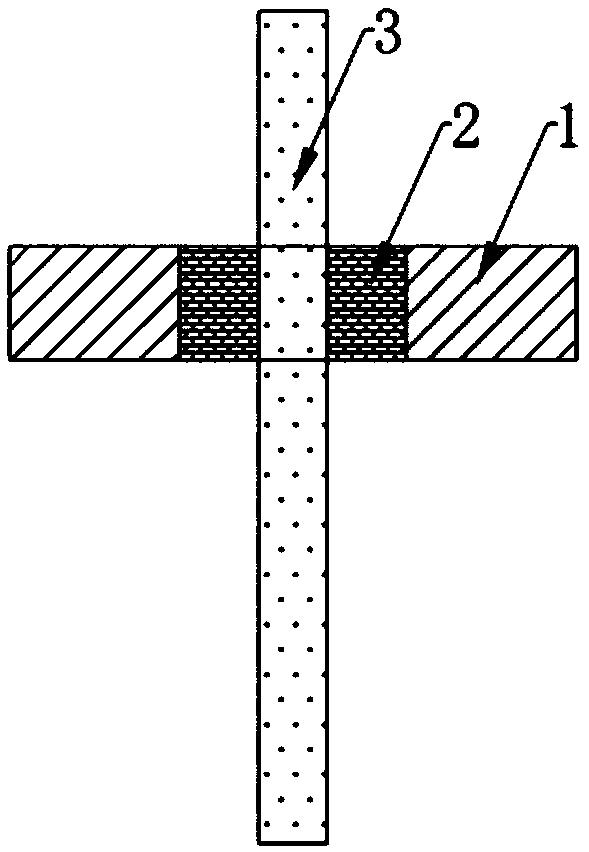

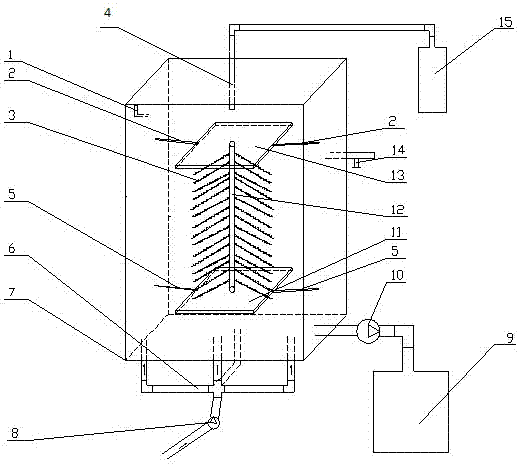

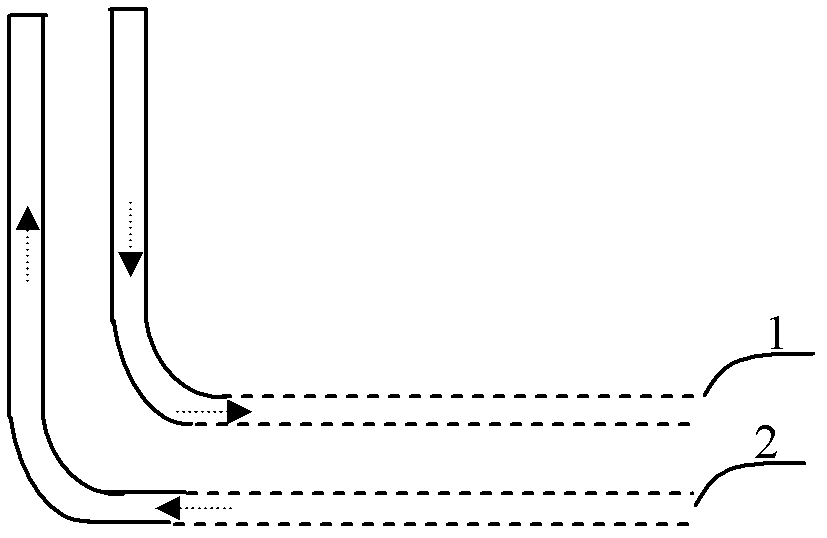

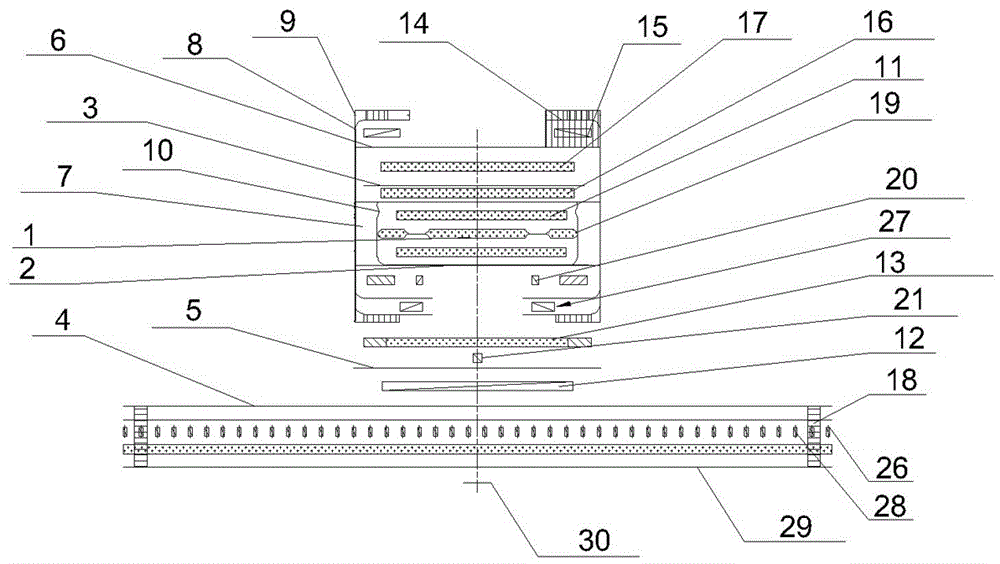

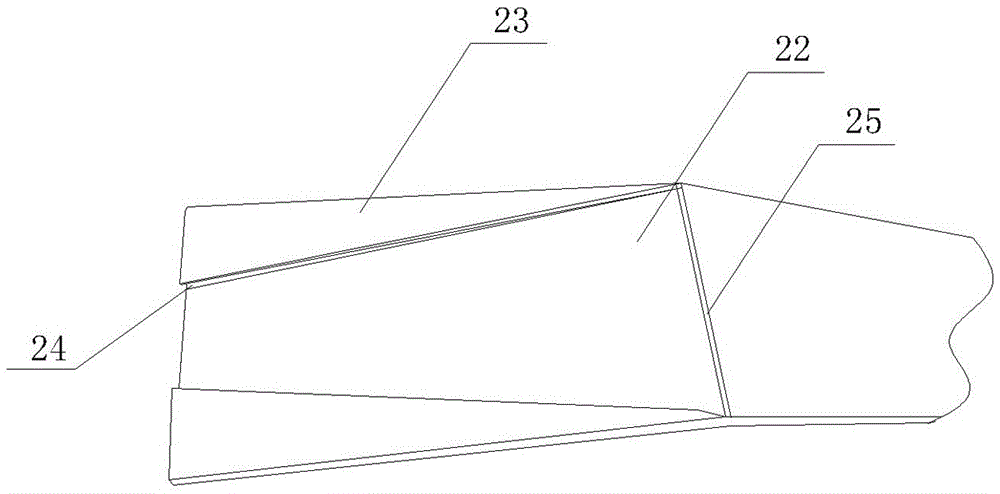

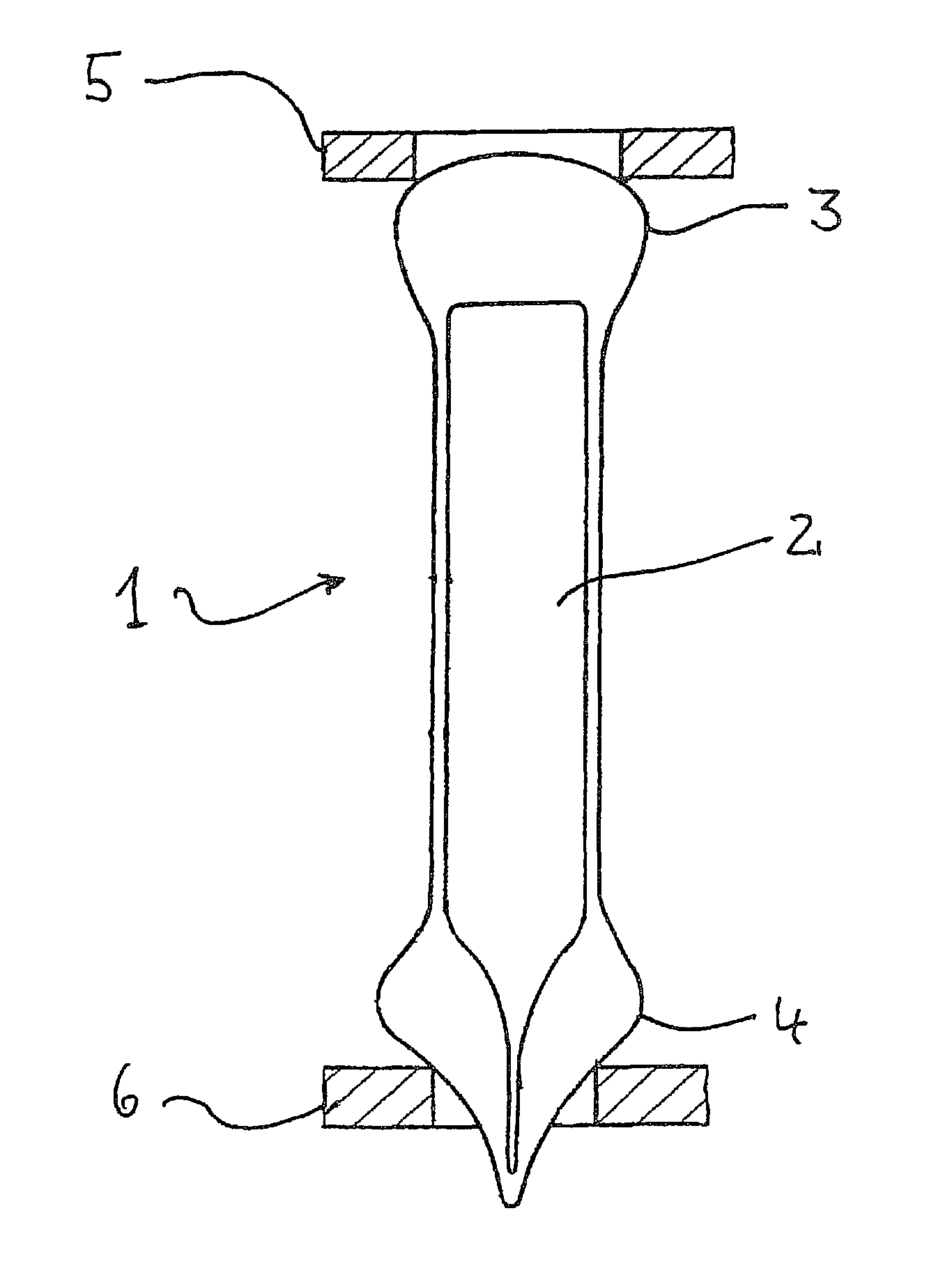

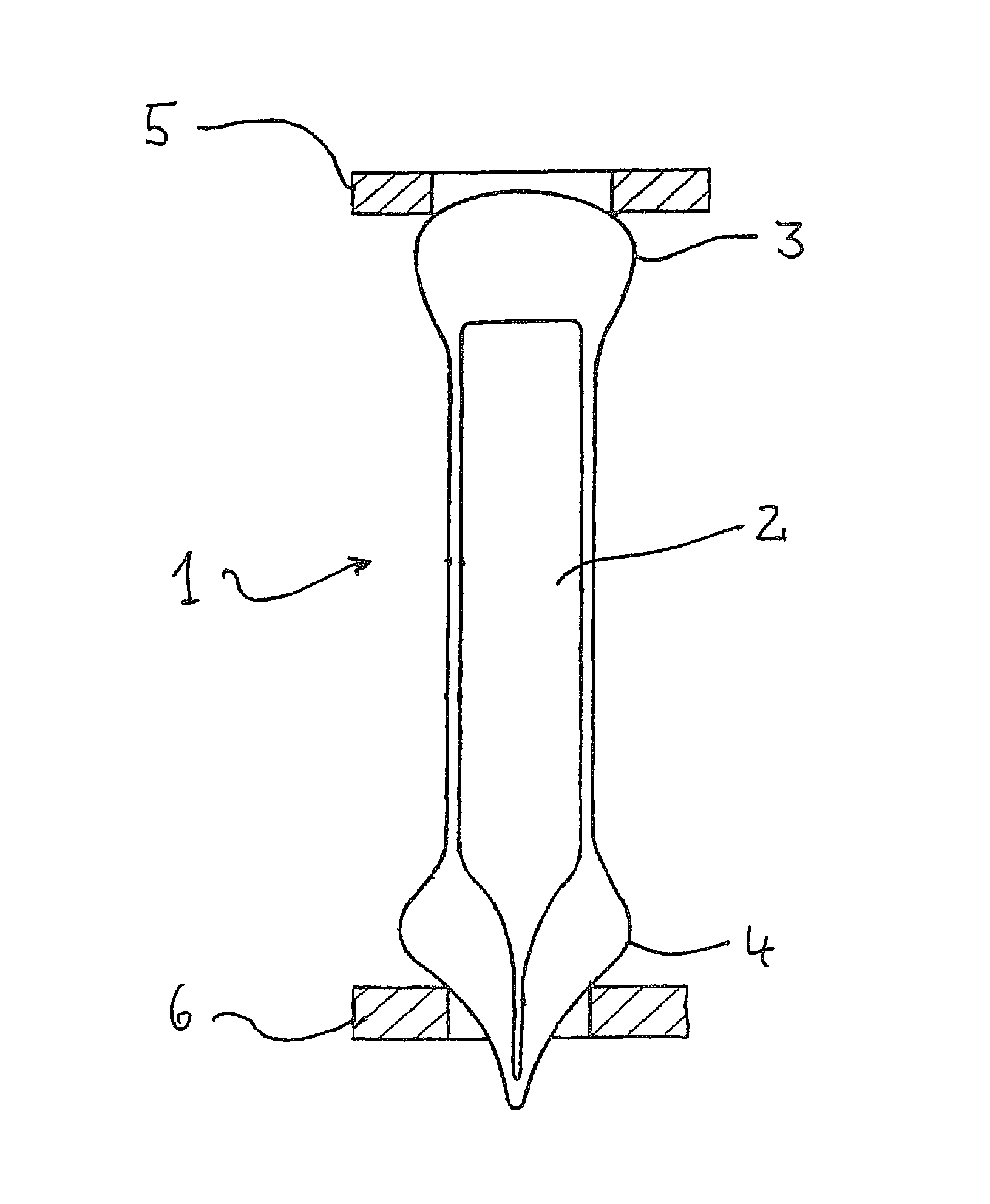

Method and device for cultivating anaerobic granular sludge

InactiveCN103043792AEasy to transportGuaranteed uptimeTreatment with anaerobic digestion processesSludgeEngineering

The invention discloses a device for cultivating anaerobic granular sludge. The device is characterized in that an artificial sludge bed is arranged inside a body and is formed in a manner that a packing support pipe is fixed between an upper support plate and a lower support plate in a penetrating manner; the upper support plate and the lower support plate are fixed together with the body through a lower fixing frame; radial packings are evenly distributed on the pipe wall of the packing support pipe; a plurality of paths of inlet water distributors are arranged at the bottom part of the body and are connected with a water inlet pump; a water outlet pipe is arranged at the upper part of the body; an overflow weir is arranged on the body above the water outlet pipe; an exhaust pipe is arranged on the body above the overflow weir and is connected with an air collector; and a sludge pump connected to the lateral wall of the bottom part of the body is connected with a sludge collecting tank. The invention also provides a method for cultivating the anaerobic granular sludge. A strain cultivated by the device and the device is stable in performance and has a strong capacity of adapting to changes of an external environment, an expansion coefficient of the anaerobic granular sludge bed is high, a cultivation period of the anaerobic granular sludge is short, the cultivation efficiency is high, and the performance of the anaerobic granular sludge is stable.

Owner:NORTHEAST DIANLI UNIVERSITY

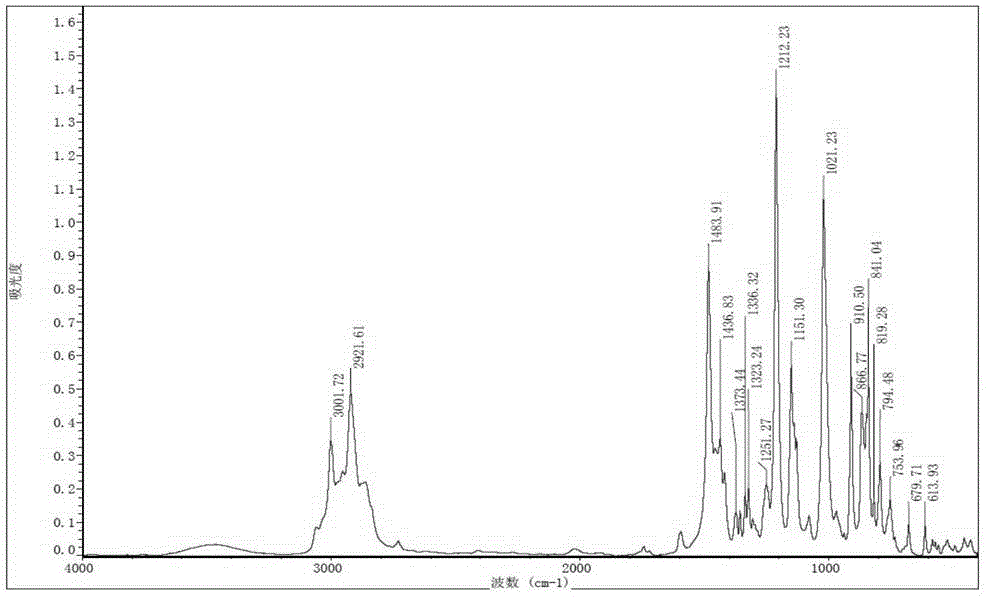

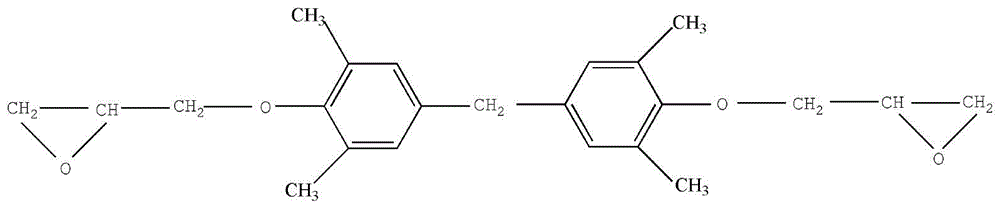

Preparation method of tetramethyl bisphenol F epoxy resin

The invention discloses a preparation method of a tetramethyl bisphenol F epoxy resin, belonging to the technical field of epoxy resins. The tetramethyl bisphenol F epoxy resin is prepared from 4,4'-methylene-bis(2,6-dimethyl)phenol and epoxy chloropropane in a mass ratio of 1:3-1:10. The preparation method comprises the following steps: (1) adding the 4,4'-methylene-bis(2,6-dimethyl)phenol and epoxy chloropropane, adding a cosolvent, adding an alkaline catalyst at 40-70 DEG C in a nitrogen protective atmosphere, reacting for 1-4 hours, adding an alkaline catalyst, reacting in a vacuum for 2-7 hours, and recovering the epoxy chloropropane under reduced pressure; and (2) adding a solvent and an alkaline catalyst, after the reaction finishes, washing with water to a neutral state, and removing the solvent to obtain the product. The tetramethyl bisphenol F epoxy resin obtained by the preparation method has lower melting point and viscosity, can implement high filling content in the semiconductor packaging material, and especially has favorable application prospects in the field of high-performance electronic packaging.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

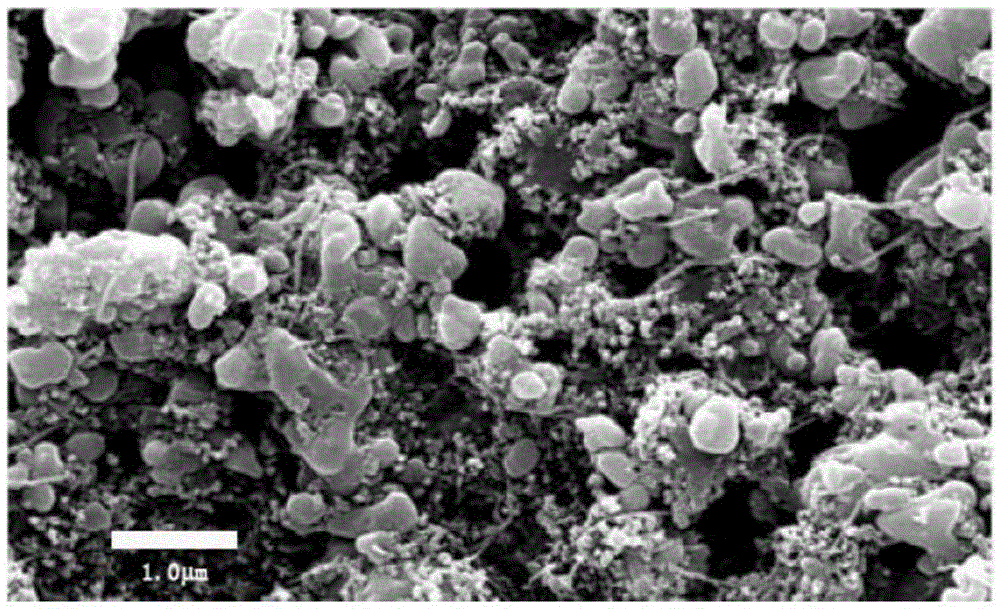

Lithium battery cathode additive, lithium ion battery, preparation method and uses thereof

ActiveCN105355849AStrong metal activityHigh specific capacityNon-aqueous electrolyte accumulator electrodesSecondary cells servicing/maintenanceActive agentCarbon nanotube

The invention discloses a lithium battery cathode additive, a lithium ion battery, a preparation method and uses thereof, and belongs to the technical field of lithium secondary battery. The cathode additive is a core-shell structure, wherein the core is composed of nanometer silicon powder, lithium powder compound and hollow carbon spheres, and the shell is composed of carbon nanotubes, surfactants and doping agents; the mass proportion of the nanometer silicon powder, the lithium powder compound and the hollow carbon spheres is 10-70:0.1-10:20-80; the mass proportion of the carbon nanotubes, surfactants, doping agents and nanometer silicon powder is 5-20:2.5-10:0.5-7:10-70; the lithium powder compound is a core-shell capsule constituted by lithium powder and polymer wrapping the lithium powder; the doping agents are sodium chloride and / or sodium fluoride; the surfactants is sodium dodecyl benzene sulfonate. The cathode additive is added to the graphite cathode, thereby obviously promotes gram volume, initial efficiency and circulation performance of the cathode materials and absorbing ability of the cathode plate.

Owner:CALB CO LTD

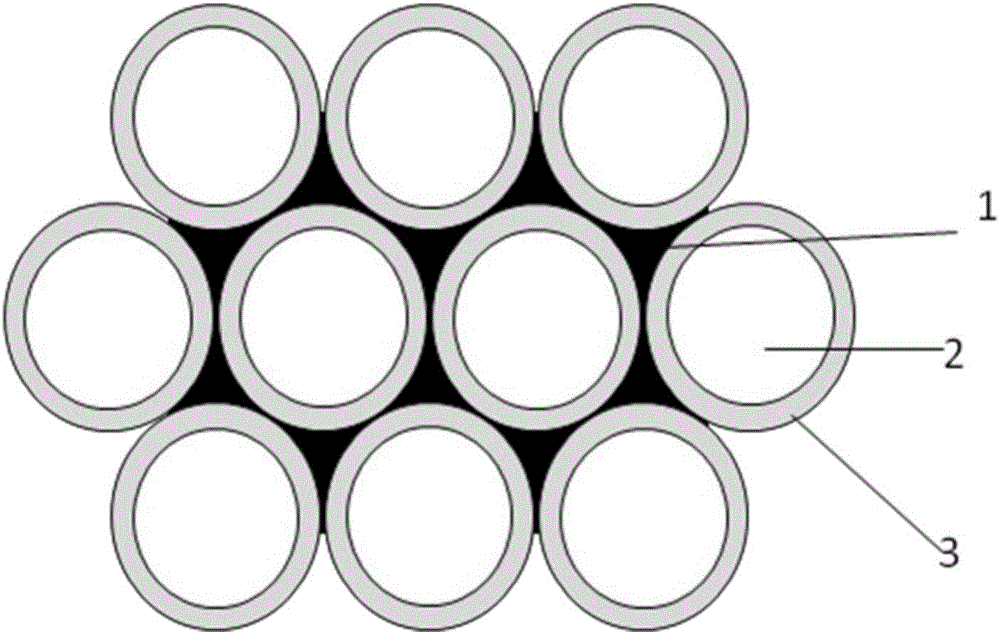

Low stray light crosstalk type optical fiber image transmission component and manufacturing method thereof

ActiveCN106772791AStray light crosstalk reductionImprove imaging clarityBundled fibre light guideRefractive indexStray light

The invention relates to a low stray light crosstalk type optical fiber image transmission component and a manufacturing method thereof. The optical fiber image transmission component comprises at least three cylindrical single optical fibers which are tightly stacked in parallel, wherein a space encircled by position at which any two of the three single optical fibers are tangent forms a light absorption glass jack; each light absorption glass jack is filled with light absorption glass; and the single optical fibers are composed of cylindrical fiber core glass rods with high refractive index and channel glass pipes with low refractive index coated outside the cylindrical fiber core glass with high refractive index. According to the low stray light crosstalk type optical fiber image transmission component disclosed by the invention, the stacking space is completely filled with the absorption glass, the stray light crosstalk of the optical fiber image transmission component is reduced, and the imaging definition is improved.

Owner:CHINA BUILDING MATERIALS ACAD

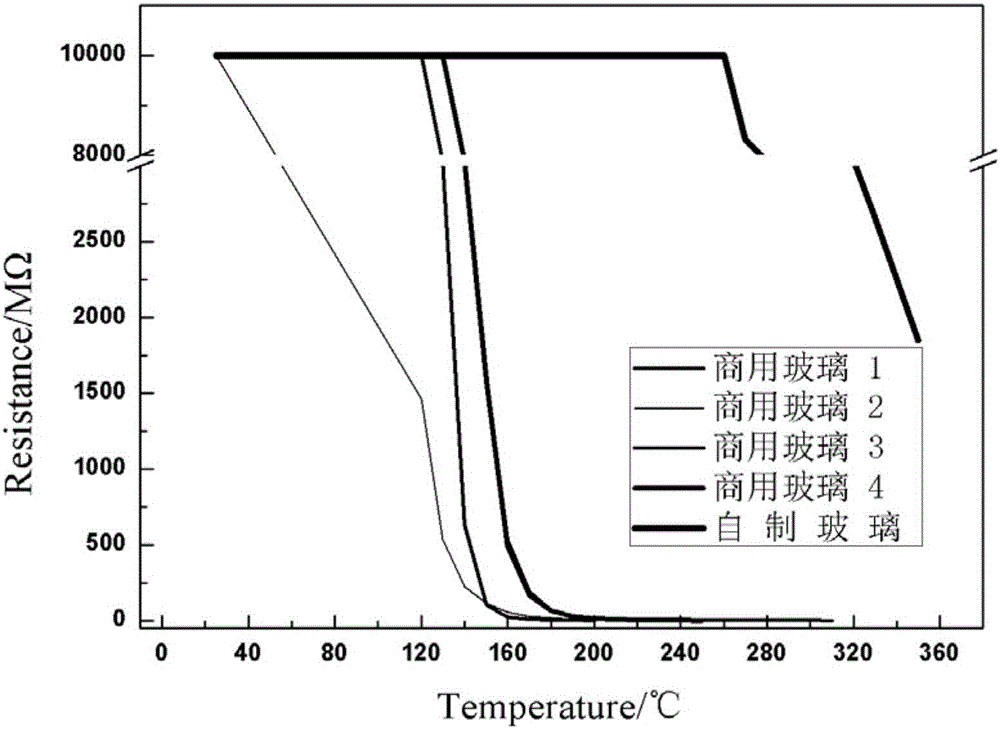

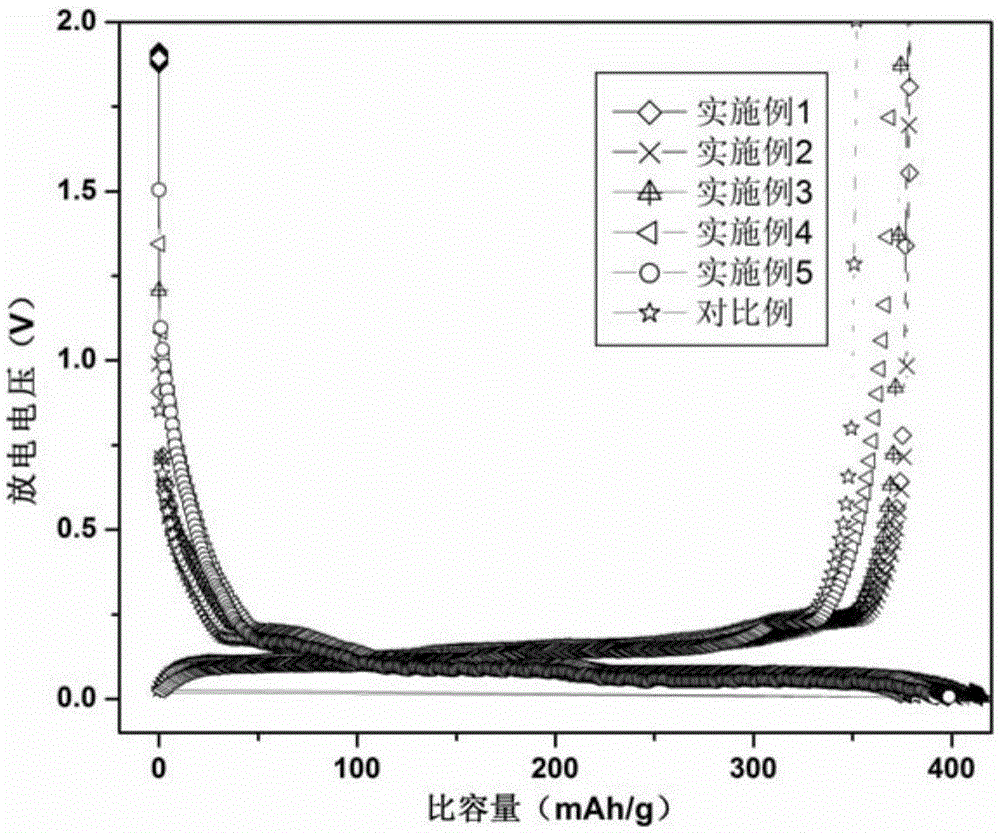

Preparation method and application of high expansion coefficient copper sealing glass powder

ActiveCN103880290AHigh expansion coefficientImprove mechanical propertiesCouplings bases/casesThermal insulationHigh resistivity

The invention relates to a preparation method and an application of high expansion coefficient copper sealing glass powder, wherein the technical difficult problems of high cost, long production period, high use environment requirements and the like of the existing copper seal electrical connector are solved. The high expansion coefficient copper sealing glass powder adopts a phosphate glass system and comprises the following components by mole: 45-65% of P205, 10-15% of B203, 4-15% of Al2O3, 5-20% of Na2O, 8-22% of K2O, and 0-12% of PbO+BaO+CaO+MgO. The application comprises: carrying out mixing, heating, stirring, molding, drying and other steps on the glass powder and a paraffin thin sheet, assembling a sealing copper shell and a glass billet, placing on a graphite mold, placing into a nitrogen atmosphere furnace or vacuum furnace, carrying out thermal insulation for 30 min at a temperature of 600-780 DEG C, and cooling to a room temperature to obtain the electrical connector with characteristics of high temperature resistance, high resistivity and high air-tightness. According to the present invention, the glass powder can match to the copper alloy shell expansion coefficient, the produced copper alloy electrical connector can achieve good electrical property, the preparation method is suitable for industrial production, and the economic benefits can be increased.

Owner:LIAONING SILICATE RES INST

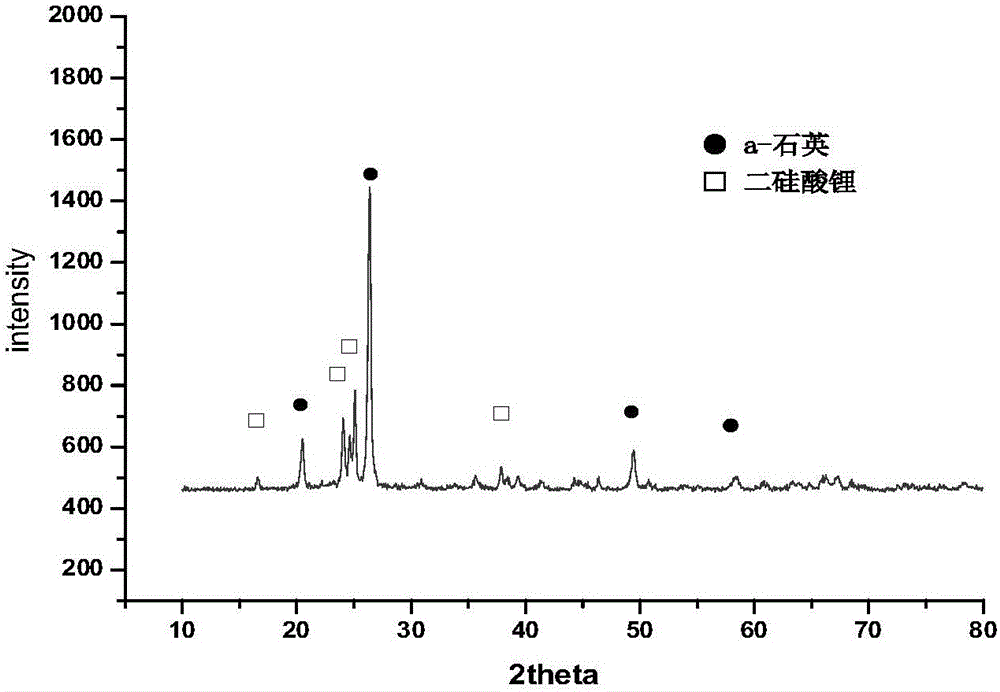

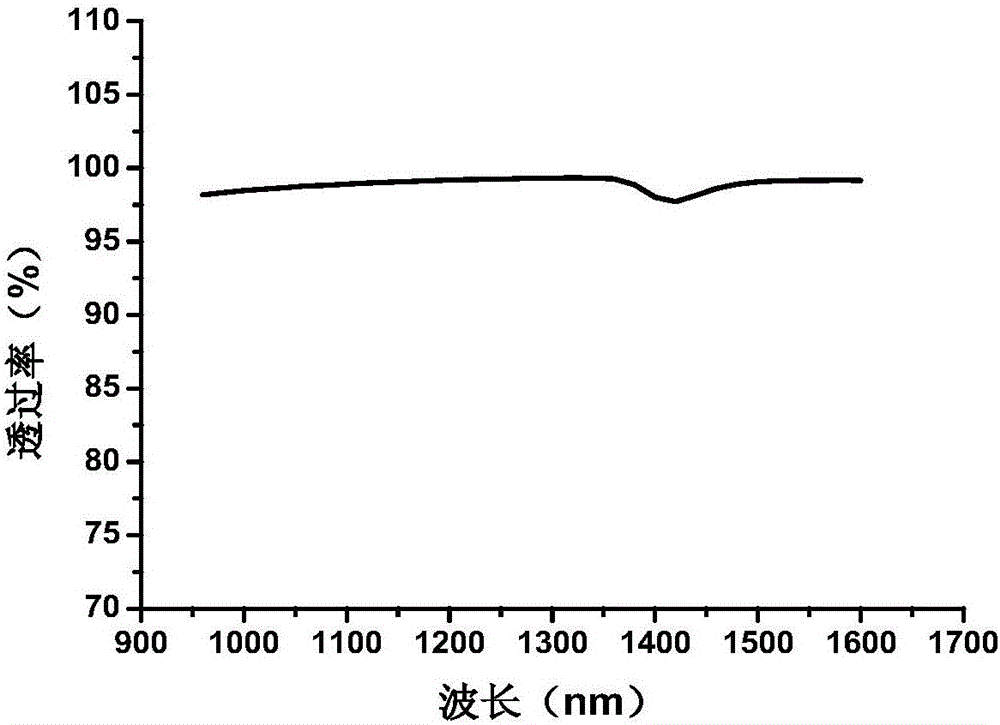

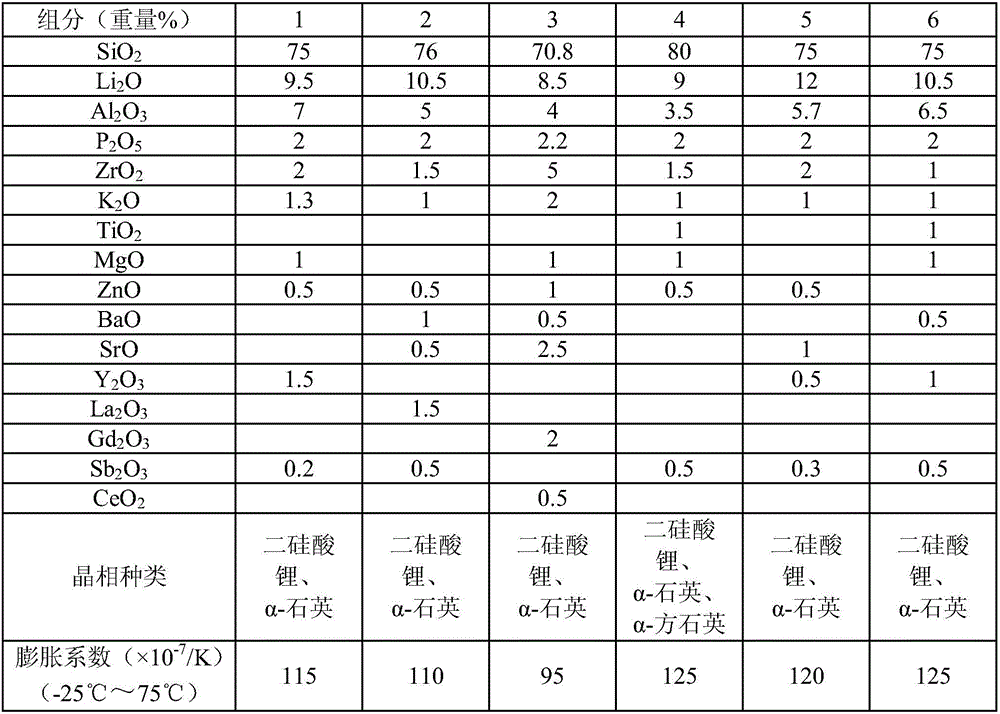

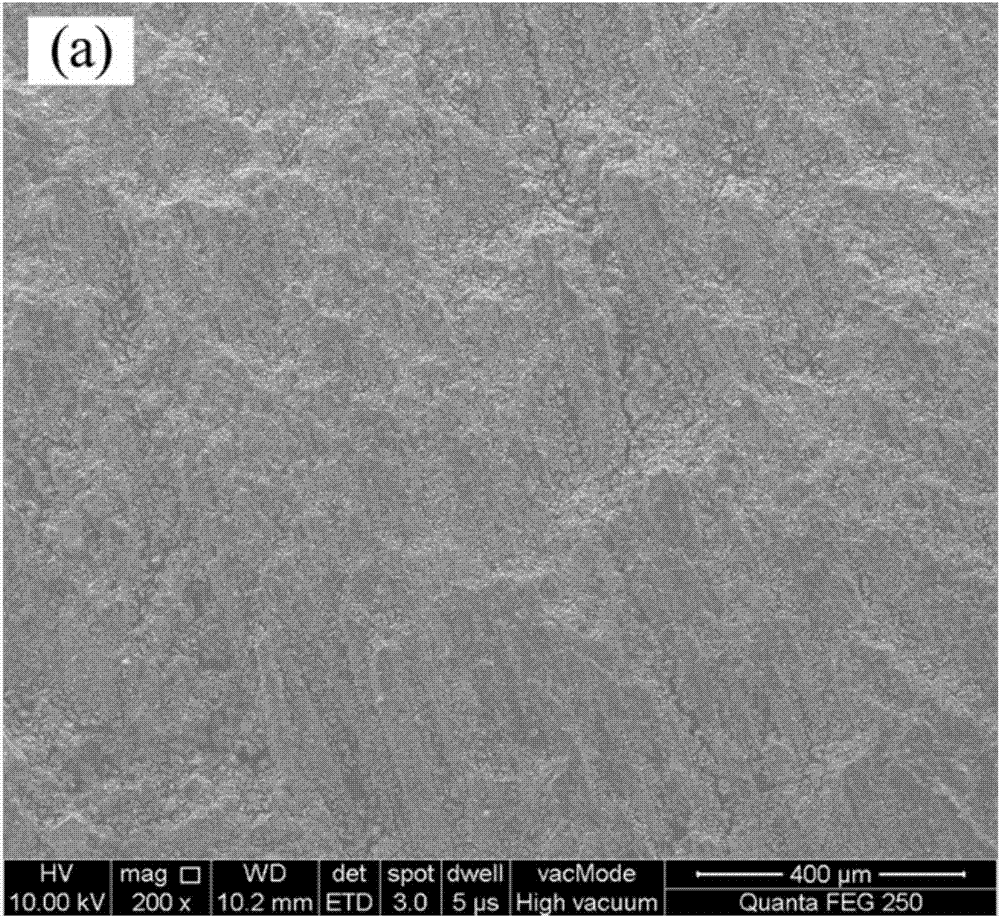

Glass ceramic and multilayer inorganic membrane filter

InactiveCN106045324AAvoid refractive index changesGuaranteed persistenceWaveguide type devicesRefractive indexGlass-ceramic

The invention provides high-mechanical-property glass ceramic for a multilayer inorganic membrane filter. The glass ceramic comprises, by weight, 69-80% of SiO2, 8-12.5% of Li2O, 4-10% of Al2O3, 1.5-3% of P2O, 1-8% of ZrO2, 0.5-3.0% of K2O and 0.5-5% of MgO+ZnO+BaO+SrO. The glass ceramic is free of harmful components such as PbO or As2O3 and high in expansion factor, refractive index variation of an inorganic membrane can be avoided at an application temperature of the multilayer inorganic membrane filter, and accordingly product temperature stability can be improved. In addition, the glass ceramic is high in mechanical property and chemical stability, durability of the filter is guaranteed, and high transmittance in a certain waveband (960-1600nm) is realized.

Owner:CDGM GLASS LLC

Ceramic modification C/C composite material with ceramic coating layer and preparation method thereof

ActiveCN106977223AImprove erosion and ablation resistanceImprove linear expansion coefficientFiberMetallurgy

The invention relates to a ceramic modification C / C composite material with a ceramic coating layer and a preparation method thereof. The preparation method of the ceramic modification C / C composite material comprises the following steps of performing density increase on a carbon fiber prefabricated body by a chemical vapor deposition process to obtain C / C porous bodies; performing more than once soaking-cracking process on the C / C porous body until the density of the ceramic modification C / C composite material reaches 1.8g / cm<3> or higher; obtaining the ceramic modification C / C composite material. According to the preparation method of the C / C composite material with the ceramic coating, a ceramic outer coating layer is mainly prepared on the surface of the ceramic modification C / C composite material. The method solves the problem of heat expansion coefficient unbalance of the base body and the coating, and has the advantages that the equipment and the process are simple; the operation is easy; the coating structure content is controllable; large-dimension and complicated-shape special-shaped workpieces can be prepared, and the like; great engineering application potential is realized.

Owner:湖南金钺新材料有限责任公司

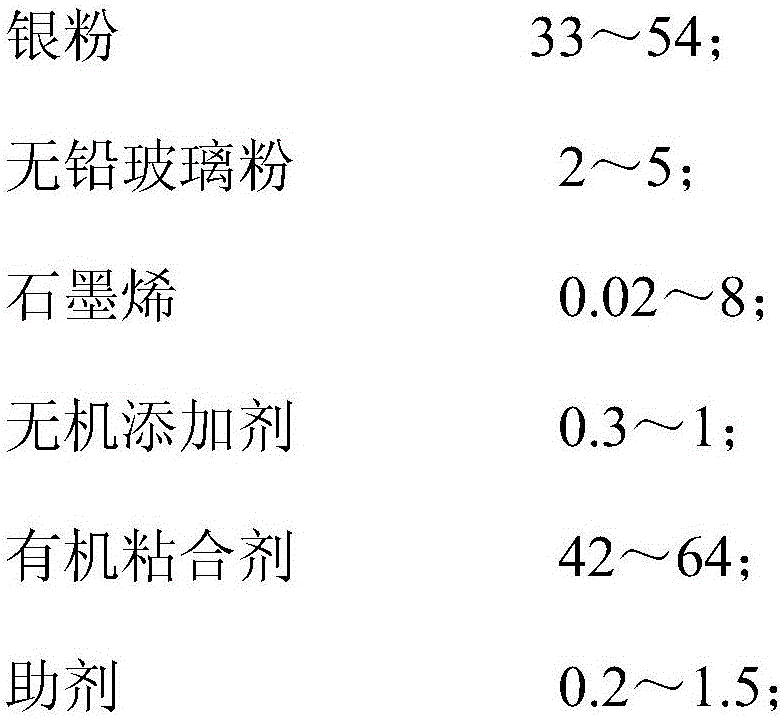

Silver paste of high-performance lead-free crystalline silicon solar battery back electrode and preparation method thereof

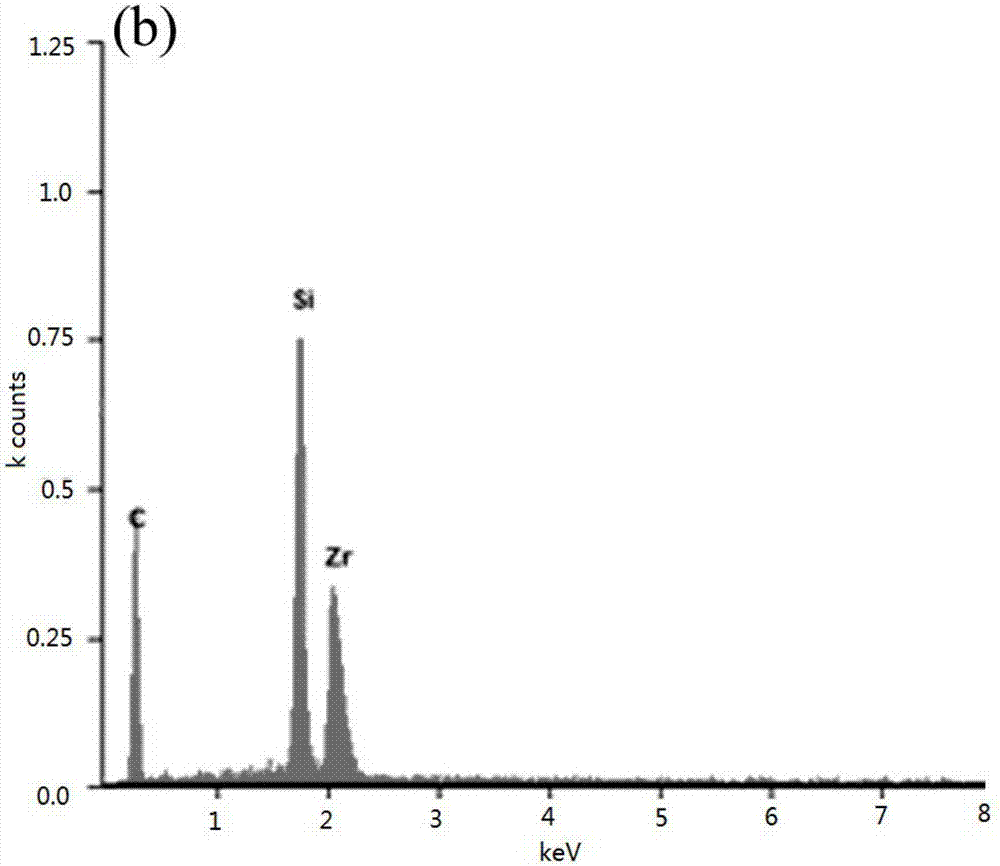

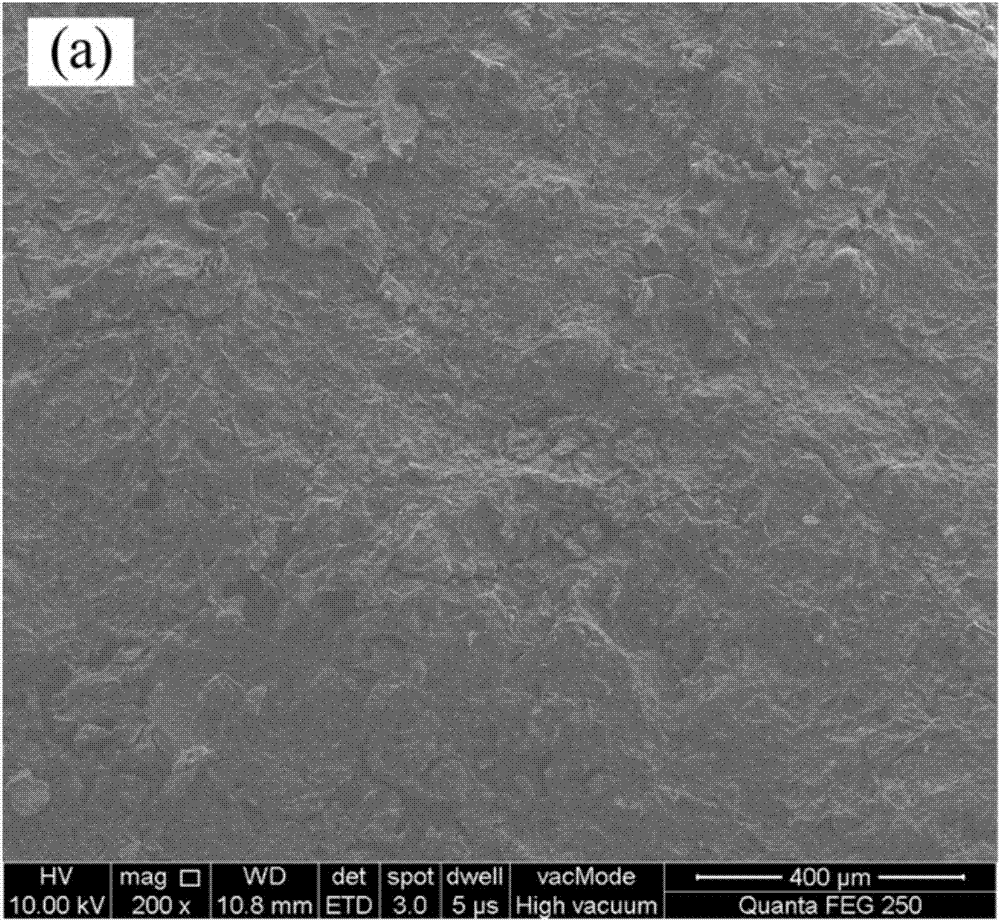

InactiveCN106128553AImprove compactnessHigh expansion coefficientNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a silver paste of a high-performance lead-free crystalline silicon solar battery back electrode. The silver paste comprises, by weight, 30 to 58% of silver powder, 1 to 5% of lead-free glass powder, 0.01 to 10% of graphene, 0 to 1% of inorganic additive, 40 to 68% of an organic adhesive, and 0. 1 to 2% of an auxiliary agent. The mixed silver powder is a mixture including irregularly-shaped silver powder and silver powder with a high specific surface area. In addition, the invention also discloses a preparation method for the silver paste of the high-performance lead-free crystalline silicon solar battery back electrode. Graphene, an auxiliary agent, and a part of organic adhesive are mixed and then the mixture is rolled to form a slurry, so that a graphene slurry is obtained; silver powder, lead-free glass powder, an inorganic additive, and the rest of organic adhesive are mixed and stirred uniformly and then the graphene slurry is added; and stirring and mixing are carried out continuously and uniformly, so that a needed silver paste is obtained. According to the invention, the fusion and contact with an aluminum back field are improved; the contact resistance between the silver electrode and the aluminum back field is reduced; the conversion efficiency of the battery piece is improved; and the electrode weldability and soldering resistance performance are enhanced.

Owner:苏州柏特瑞新材料有限公司

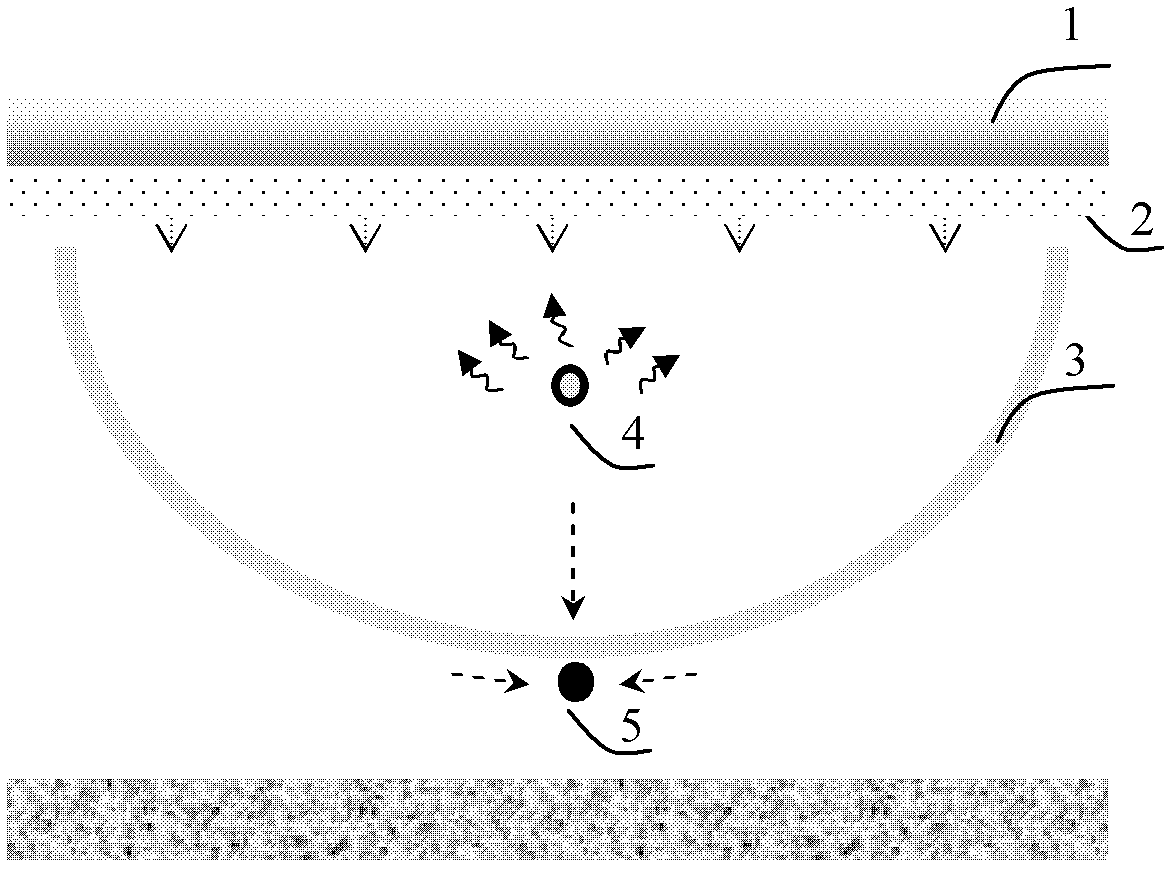

Multi-element thermal fluid auxiliary gravitational displacement process

The invention provides multi-element thermal fluid auxiliary gravitational displacement process for extracting ultra-thick or super-thick oil reservoirs. The multi-element thermal fluid auxiliary gravitational displacement process includes arranging a horizontal injection well on the upper portion of a thick oil reservoir and arranging a horizontal production well on the lower portion of the thick oil reservoir; and injecting multi-element thermal fluid from the injection well after circularly preheating the injection well and the production well, and then extracting thick oil from the production well. Crude oil viscosity break mechanism and oil extracting power of the multi-element thermal fluid auxiliary gravitational displacement process are rich, accordingly the use level of steam and steam and oil ratio in an extraction process are reduced, and thermal efficiency and economic benefit are improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Low temperature high silicon stoneware and its making process

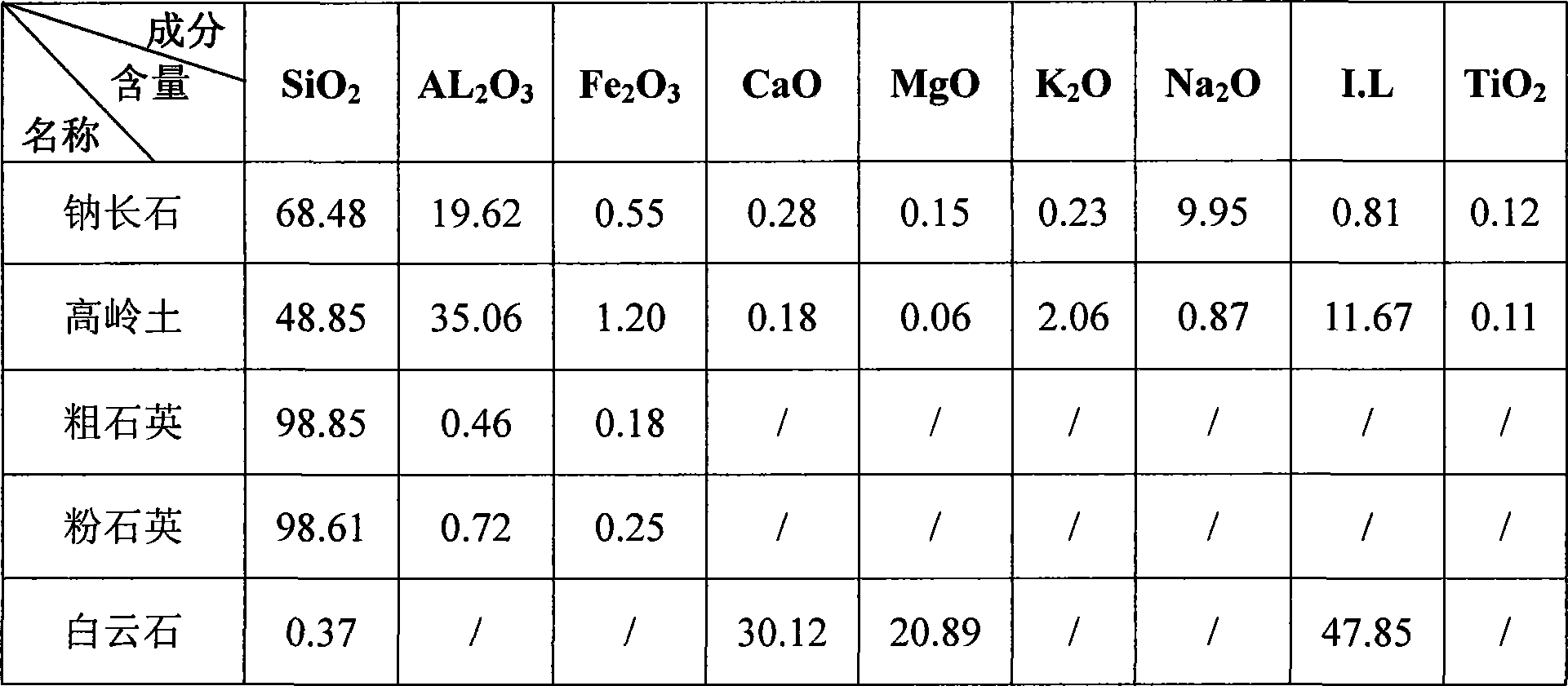

The present invention is low temperature high silicon stone ware and its making process. The low temperature high silicon stone ware has great amount of quartz in different granularities introduced to increase the expansion coefficient of the biscuit. It is prepared with the materials including albite 15-35 wt%, kaolin 25-40 wt%, quartz 35-50 wt% and dolomite 1-5 wt%, and through a common stone ware baking process. The low temperature high silicon stone ware features the firing range of 1,175-1,225 deg.c and water absorption of 1-4 %.

Owner:HUNAN HUALIAN YIBAILI CERAMIC IND

Unfired pyrophyllite hot metal ladle lining material and preparation method thereof

The invention relates to an unfired pyrophyllite hot metal ladle lining material and a preparation method thereof. The invention is characterized in that the unfired pyrophyllite hot metal ladle lining material is prepared from the following components in parts by weight: 50-70 parts of SiO2, 25-35 parts of Al2O3, 315 parts of bonding agent, 0.1-1 part of explosion-proof fiber and 1-5 parts of steel fiber. The SiO2 is one or a mixture of pyrophyllite, bauxite and silicon micropowder; and the Al2O3 is one or a mixture of pyrophyllite, bauxite and corundum. The preparation method comprises the following steps: putting the raw materials into a mixing machine in proportion to be evenly mixed, molding in a brick press or die, drying and packaging. From the appearance, the product can be a molded part, prefabricated part or amorphous powder, and the color is greyish white. Compared with the prior art, the hot metal ladle lining material has the advantages of high high-temperature strength, long service life which is prolonged to more than 500 times, smooth surface and favorable integrity, and is free of firing and simple for construction.

Owner:鞍山盛晨耐火材料有限公司

Alumina fiber reinforced boron nitride ceramic matrix composite and preparation method thereof

The present invention discloses an alumina fiber reinforced boron nitride ceramic matrix composite and a preparation method thereof, the alumina fiber reinforced boron nitride ceramic matrix composite is characterized by comprising the following raw materials by weight: 20-25 parts of aluminum nitride, 60-80 parts of boron nitride, 10-13 parts of modified alumina fiber, 2-4 parts of nitrile rubber powder, 0.02-0.03 part of cumene hydroperoxide, 5-6 parts of acrylonitrile, 0.3-0.5 part of hydroxypropyl acrylate, 5-8 parts of calcium carbonate, 1-3 parts of Arabic gum, 1-2 parts of sodium tripolyphosphate, 25-30 parts of ethanol, and 30-40 parts of deionized water; the antioxidant treated alumina fiber added in the alumina fiber reinforced boron nitride ceramic matrix composite is used as ceramic reinforcing phase, and has ceramic toughness reinforcing properties, mechanical properties, abrasion resistance, hardness and high temperature resistance, the added calcium carbonate in the molten state at a high temperature can improve the smoothness, expansion coefficient and viscosity of the ceramic surface, and the added nitrile rubber powder has a relatively strong high temperature viscosity, can bond solid particles together, and increase the viscosity of the ceramic.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

High-absorptivity baby training pants and a manufacture process therefor

InactiveCN106109101AIncreased flanging stabilityHigh expansion coefficientAbsorbent padsBaby linensSurface layerMechanical engineering

The invention discloses a high-absorbency baby pull-up pants, which comprises a surface layer structure, an absorbent core structure, a bottom layer structure, a closed structure and a viscose structure, the surface layer structure includes a surface layer non-woven fabric, and the absorbent core body structure includes Composite core, core-spun non-woven fabric and flow-guiding layer, the underlying structure includes the underlying non-woven fabric and a water-proof membrane bonded to the inner side of the underlying non-woven fabric, the closed structure includes elastic waist, elastic waist elastic, three-dimensional Guard, three-dimensional guard elastic and plane elastic, the absorbent core structure is fixed on the underlying structure, the surface non-woven fabric is covered on the absorbent core structure, and the flow guide layer is arranged on the surface non-woven fabric Between the core-wrapped non-woven fabric, both sides of the surface layer non-woven fabric are fixed on the underlying structure, and there is an expansion space between the two sides of the absorbent core structure and the surface layer non-woven fabric. The invention can improve the expansion coefficient of the pull-up pants, thereby prolonging the use time of the pull-up pants and improving the wearing comfort of babies.

Owner:杭州嘉杰实业有限公司 +1

Thermal triggering element for sprinklers, valves or the like

ActiveUS8714180B2Highly precise and sensitive in terms of temperatureHigh expansion coefficientEqualizing valvesFire rescueCelsius DegreePhosphate

A thermal triggering element for sprinklers, valves or the like including an enclosed compartment with a container filled with a highly temperature-sensitive shattering fluid for precise and reproducible adjustment of a triggering temperature within the range of a few degrees Celsius. The invention increases the accuracy of the triggering temperature and identifies shattering liquids that allow precise sensitive triggering action in terms of temperature of the triggering element and open up further triggering temperatures ranges. The triggering fluid contains or consists of a hydrocarbon compound selected among one of the following substance groups or a mixture thereof:d) a heterocyclic hydrocarbon having a OH, NH or NH2 group bonded to a carbon atom;e) a hydrocarbon having at least one benzene ring with an OH group bonded to one of the carbon atoms of the benzene ring;f) a phosphate with at least one hydrocarbon moiety.

Owner:JOB LIZENZ GMBH & CO KG +1

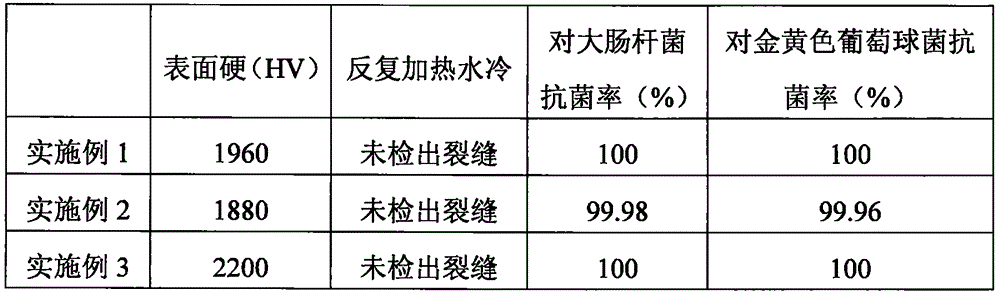

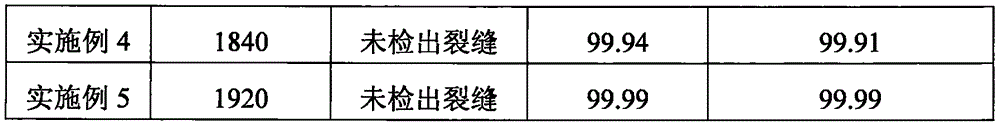

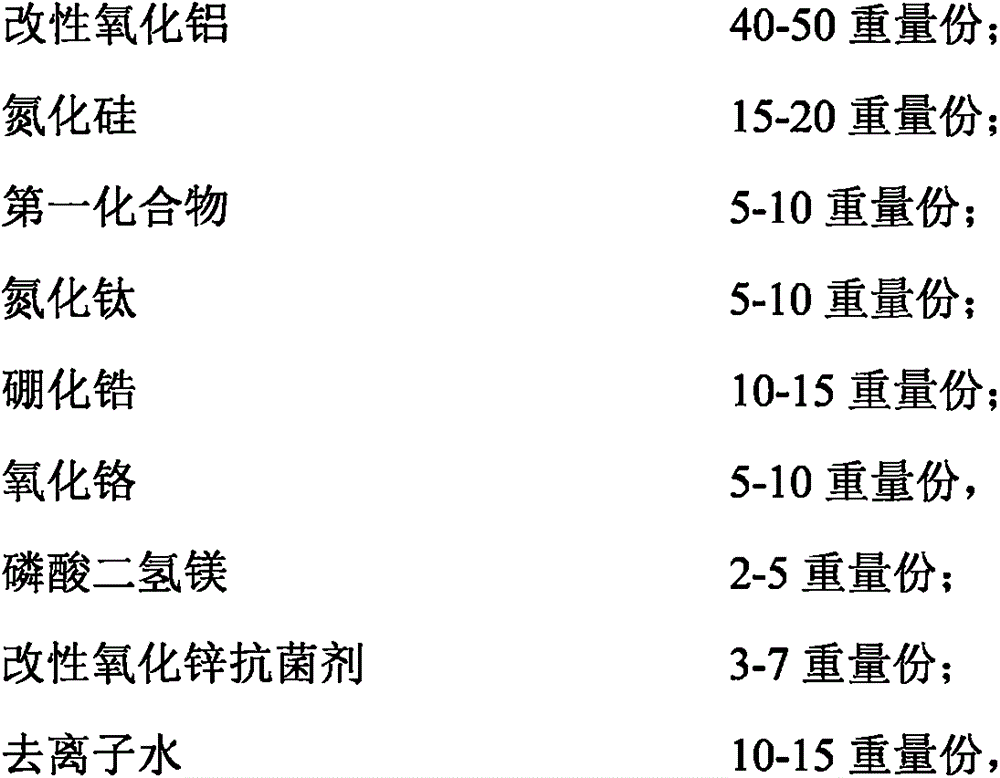

Antibacterial ceramic coating layer for non-stick pan and preparation method thereof, and non-stick pan

InactiveCN105967661AImprove toughnessHigh hardnessCooking-vessel materialsMonomagnesium phosphateBoride

The invention provides an antibacterial ceramic coating layer for a non-stick pan and a preparation method thereof, and the non-stick pan. The antibacterial ceramic coating layer adopts the following raw materials: modified alumina, silicon nitride, silicon dioxide and / or titanium dioxide, titanium nitride, zirconium boride, chromium oxide, a modified zinc oxide antibacterial agent and magnesium dihydrogen phosphate. Compared with the prior art, the modified alumina is adopted, on one hand, the toughness of the coating layer is enhanced, on the other hand, the expansion coefficient of a ceramic film is improved and is closer to a metal substrate expansion coefficient, and a chipping phenomenon is improved to a certain extent. Secondly, the modified zinc oxide antibacterial agent has synergistic effect with zinc oxide, silicon dioxide and titanium dioxide, so that the coating layer has relatively high antibacterial properties; thirdly, chromium oxide, titanium nitride, zirconium boride and other components can increase the hardness and wear resistance of the coating layer through a dispersion strengthening mechanism. Therefore, the prepared coating layer has the advantages of high-temperature resistance, wear resistance, bacteria resistance, and excellent non-stick performance and adhesion power.

Owner:NINGBO XIAYUAN TECH

EVA (Ethylene Viny Acetate) hot melt adhesive packaging material and preparation method thereof

InactiveCN102994010AHigh expansion coefficientSmall expansion coefficientMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPhysical chemistryCross linker

The invention discloses an EVA (Ethylene Viny Acetate) hot melt adhesive packaging material, which is prepared from ethylene-vinyl acetate copolymer, inorganic heat conductive material treated by coupling reagent, cross-linking agent and antioxygen, the sum of the quality of ethylene-vinyl acetate copolymer and inorganic heat conductive material treated by coupling reagent is 100%, wherein the mass percent of the ethylene-vinyl acetate copolymer is 40-80%, and the mass percent of the inorganic heat conductive material treated by coupling reagent is 20-60%; the quality of the cross-linking agent is 0.1-1.5% that of the ethylene-vinyl acetate copolymer, and the quality of the antioxygen is 0.1-1% that of the ethylene-vinyl acetate copolymer. The invention also discloses a preparation method for the EVA hot melt adhesive packaging material. When the EVA hot melt adhesive packaging material is adopted as a solar energy battery packaging material, the subfissure probability of a battery piece is lowered, and the photoelectric converting efficiency of the solar energy battery can be improved.

Owner:TIANWEI NEW ENERGY HLDG

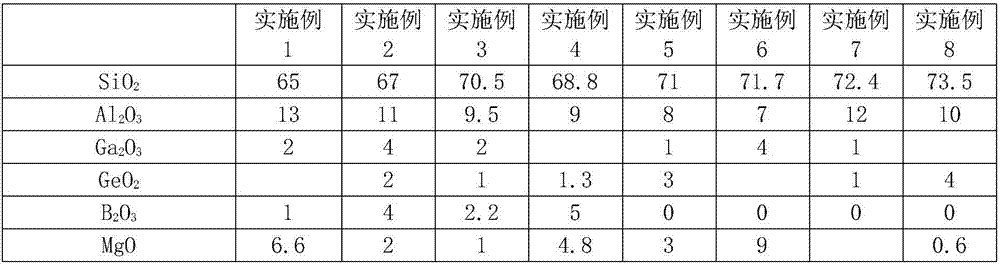

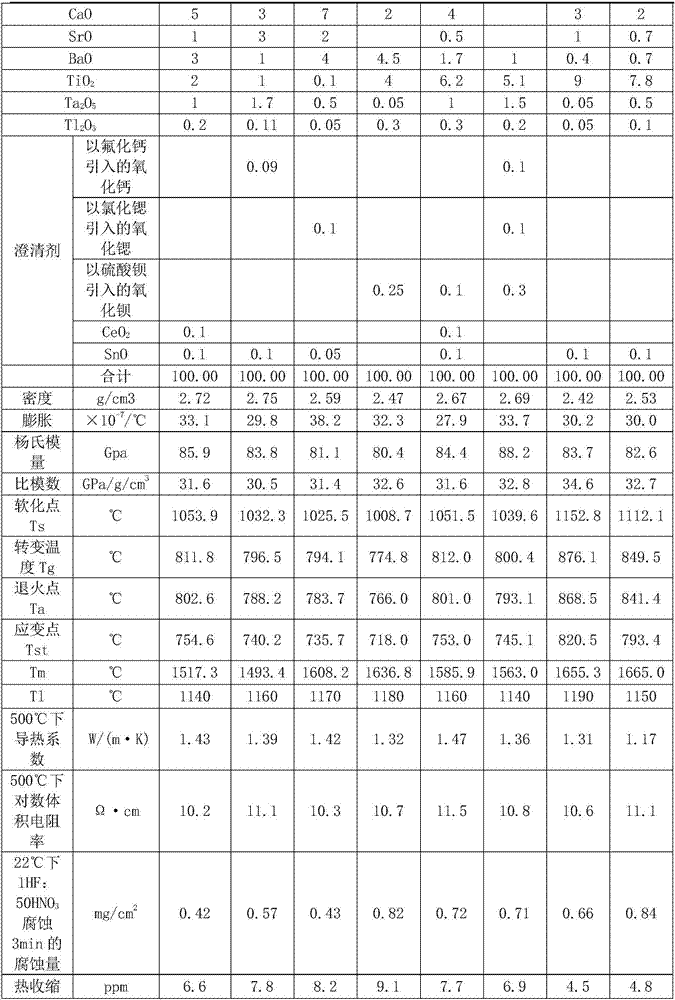

Alkali-free silicate glass and preparation method and application thereof

ActiveCN107382052AHelps to reduce weightHigh expansion coefficientGlass shaping apparatusGlass productionAlkali freeSilicate glass

The invention relates to the field of glass and particularly relates to alkali-free silicate glass and a preparation method and application thereof. The alkali-free silicate glass comprises, by mole, 65-75 mol% of SiO2, 11-17 mol% of Al2O3, Ga2O3 and GeO2, 0-8 mol% of B2O3, 0-15 mol% of MgO, 2-10 mol% of CaO, 0.5-14 mol% of SrO and BaO, 0-10 mol% of TiO2, 0.01-2 mol% of Ta2O5 and 0.01-0.5 mol% of Tl2O3. The alkali-free silicate glass has high thermal stability and dimensional stability, a high strain point, a high specific modulus, a low melting temperature, a low liquidus temperature and low density and is suitable for large-scale industrial production.

Owner:ZHENGZHOU UNIV

High resistivity and high expansion coefficient glass powder for aluminum and aluminum alloy sealing and preparation method thereof

The invention relates to a high resistivity and high expansion coefficient glass powder for aluminum and aluminum alloy sealing and a preparation method thereof, and solves the problems of high technical cost, long production cycle, high use environment requirement and the like in the prior art. The glass powder adopts a phosphate glass system, and comprises 45-72% of P2O5, 6-15% of B2O3, 4-12% of Al2O3, 5-15% of Na2O, 8-17% of K2O, and 0-15% of PbO+BaO+CaO+MgO. The preparation method includes: according to the proportion, weighing and mixing the components, conducting heat preservation at 200-250DEG C for 10h in a 800ml alumina dry pot, then conducting heat preservation at 950-1150DEG C for 2h, performing water quenching with cold water, then placing the water quenched glass in a 150-170DEG C oven to conduct drying for 2-4h, after drying, adding alcohol into the ceramic pot to carry out ball milling, drying and sieving, thus obtaining the required product. The product is mixed with paraffin slices, compression moulding and drying are carried out, and then an aluminum and aluminum alloy shell and a green glass body are assembled and placed in a graphite mold, the mold is placed into a vacuum furnace, heat preservation is performed and then the temperature is lowered to room temperature, thus obtaining an electric connector. The glass powder provided by the invention can effectively improve the signal transmission ability and anti-interference ability of electronic components.

Owner:辽宁法库陶瓷工程技术研究中心

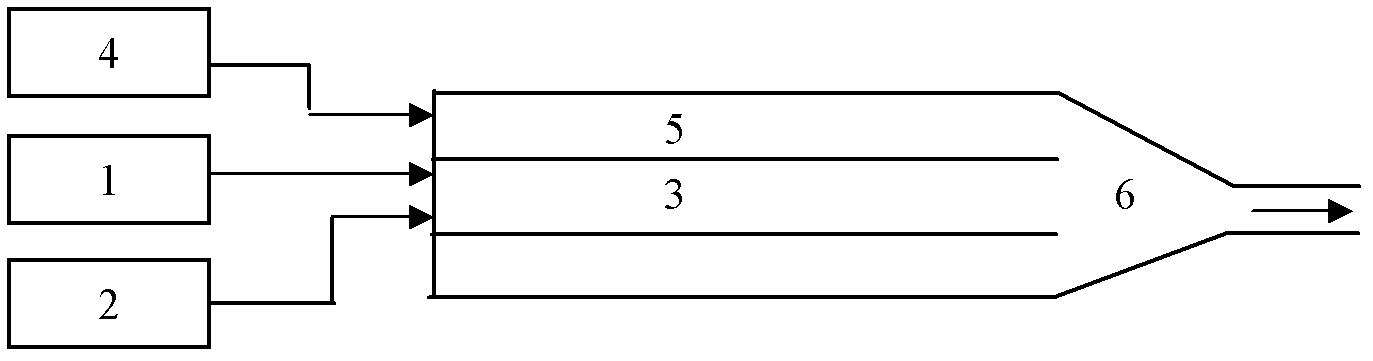

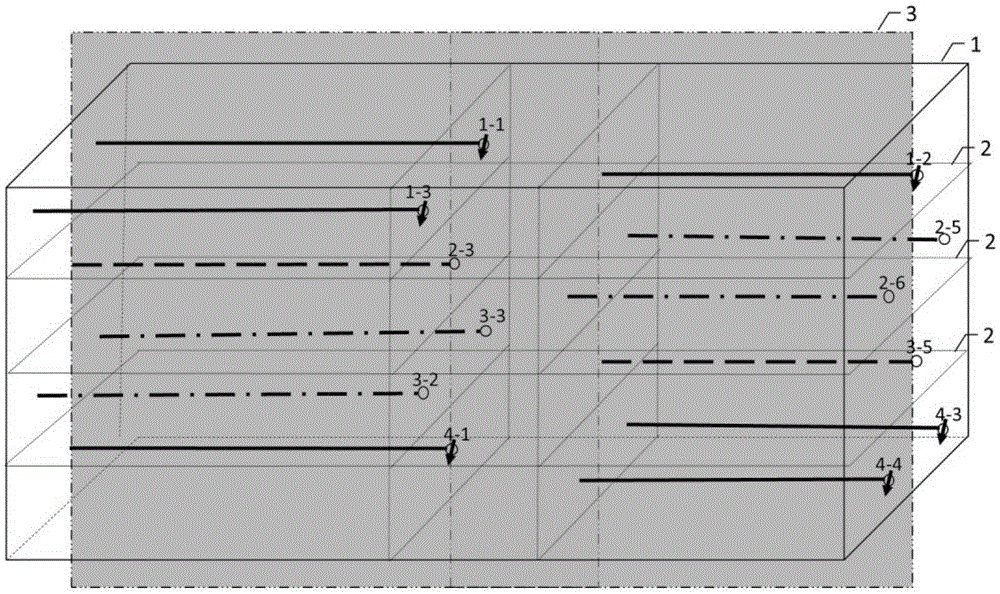

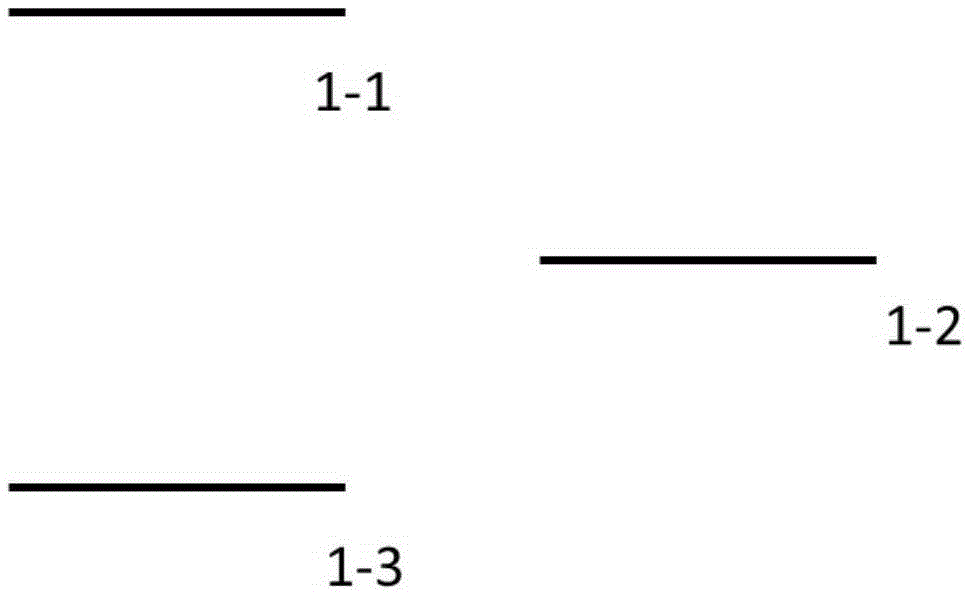

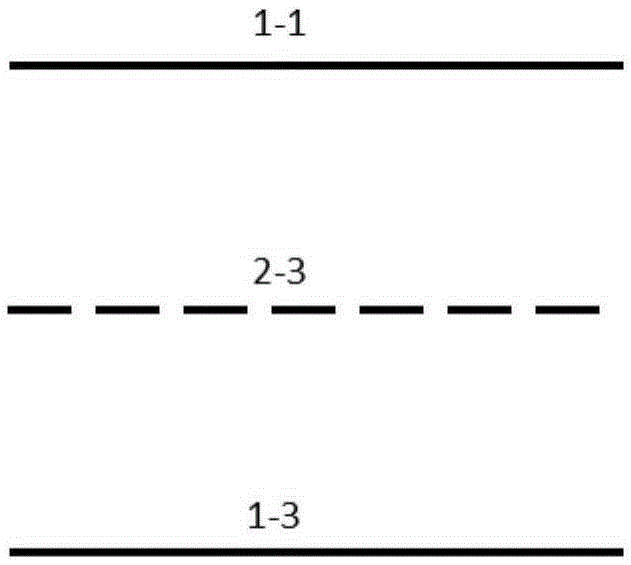

Oil reservoir three-dimensional gas injection method and well pattern structure

ActiveCN105298452AGood physical propertiesIncrease in sizeFluid removalInjection wellInjections methods

The invention provides an oil reservoir three-dimensional gas injection method and a well pattern structure. The oil reservoir three-dimensional gas injection method comprises steps of simultaneously injecting gas to the top portion and the lower portion of an oil reservoir, wherein gas-injection wells for the lower portion of the oil reservoir are a part of watered-out wells which are arranged at the lower portion of the oil reservoir 1-2 years ago before gas injection. The invention also provides the oil reservoir three-dimensional gas injection well pattern structure comprising multiple horizontal production wells and multiple horizontal gas injection wells. The horizontal wells in adjacent rows in the same plane are arranged in a staggered manner, and the horizontal wells in the adjacent layers in the vertical view are also arranged in a staggered manner, so that the three-dimensional gas injection well pattern structure in which the horizontal wells are arranged in a staggered manner in the plane and vertical views is formed. The oil reservoir three-dimensional gas injection method and the well pattern structure can effectively improve the oil extraction efficiency.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com