Method and device for cultivating anaerobic granular sludge

An anaerobic granular sludge and cultivation device technology, which is applied in the field of anaerobic granular sludge cultivation method and its device, can solve the problems of high technical requirements, limitation of anaerobic granular sludge biological strain types, inconvenient operation, etc. Achieve the effect of high culture efficiency, short culture period and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

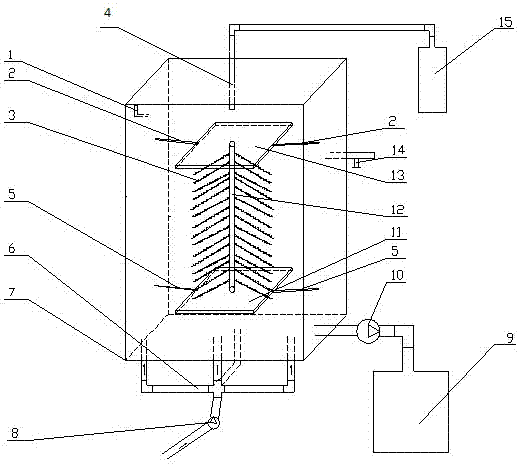

[0025] Such as figure 1 As shown, the internal volume of the body 7 of the anaerobic granular sludge cultivation device of the present invention is 200 L, and the volume of inoculated sludge added to the body 7 is 10 L, and high-concentration pig-raising wastewater is transported at the bottom of the body 7, and the initial volume of the pig-raising wastewater is measured. The COD value is 3000mg / L, the temperature inside the body 7 is 35°C, the pH value is 7.0, and the alkalinity of the influent water is 1000mg / L. In the initial stage of anaerobic granular sludge cultivation, the inoculated sludge was statically domesticated. During the domestication process, the hydraulic retention time was set to 20h. On the 11th day of domestication, the COD value of the effluent at the sampling port of the body 7 was measured. When the COD removal rate of the effluent of the body 7 reached 80% , the sludge domestication stage ends; the anaerobic granular sludge formation stage increases t...

Embodiment 2

[0028] Such as figure 1 As shown, the internal volume of the body 7 of the anaerobic granular sludge cultivation device of the present invention is 200 L, and the volume of inoculated sludge added to the body 7 is 10 L, and high-concentration pig-raising wastewater is transported at the bottom of the body 7, and the initial volume of the pig-raising wastewater is measured. The COD value is 4000mg / L, the temperature inside the main body 7 is 35°C, the pH value is 7.0, and the alkalinity of the influent water is 1000mg / L. In the initial stage of anaerobic granular sludge cultivation, the inoculated sludge was statically domesticated. During the domestication process, the hydraulic retention time was set to 24h. On the 12th day of domestication, the COD value of the effluent at the sampling port of the body 7 was measured. When the COD removal rate of the effluent of the body 7 reached 85% , the sludge acclimatization stage ended; the anaerobic granular sludge formation stage inc...

Embodiment 3

[0031] Such as figure 1 As shown, the volume of the body 7 of the anaerobic granular sludge cultivation device of the present invention is 200L, and the volume of inoculated sludge added to the body 7 is 10L, and the high-concentration pig-raising wastewater is transported at the bottom of the body 7, and the initial pig-raising wastewater is measured. The COD value is 5000mg / L, the temperature inside the main body 7 is 35°C, the pH value is 7.0, and the alkalinity of the influent water is 1000mg / L. In the initial stage of anaerobic granular sludge cultivation, the inoculated sludge was statically domesticated. During the domestication process, the hydraulic retention time was set to 25h. On the 15th day of domestication, the COD value of the effluent of the anaerobic body 7 sampling port was measured. When the COD removal rate of the effluent of the body 7 reached 90 %, the sludge domestication stage ends; the anaerobic granular sludge formation stage increases the hydraulic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com