High-strength ice crack type ceramic product and preparation technology thereof

A technology for ceramic products and ice cracks, applied in the field of high-strength ice crack ceramic products and their preparation, can solve problems such as difficulty in control, and achieve the effects of reducing expansion coefficient, increasing density, and difficult drying strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

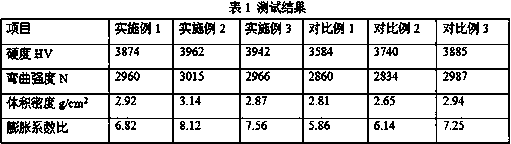

Examples

Embodiment 1

[0022] A high-strength ice crack ceramic product, comprising a blank and a glaze, the blank is composed of the following raw materials in parts by weight: 55 parts of kaolin, 23 parts of potassium feldspar, 12 parts of quartz, 16 parts of clay, 2 parts of talc, fluxing 14 parts of materials, 18 parts of wollastonite, 10 parts of brucite, 9 parts of albite, 8 parts of calcium silicate, 6 parts of barium sulfate, and 4 parts of sepiolite, wherein the fluxing material is composed of calcium borate and boron oxide according to Mixed with a weight ratio of 3:7; the glaze is composed of the following raw materials in parts by weight: 42 parts of potassium feldspar, 13 parts of montmorillonite, 23 parts of quartz, 36 parts of albite, and 2 parts of colored oxide , 1 part of sodium hexametaphosphate, 3 parts of talc, and 16 parts of calcium carbonate, wherein the colored oxide is formed by mixing chromium oxide and cobalt oxide in a ratio of 5:3 by weight.

[0023] This embodiment als...

Embodiment 2

[0030]A high-strength ice crack ceramic product, including a blank and a glaze, the blank is composed of the following raw materials in parts by weight: 58 parts of kaolin, 24 parts of potassium feldspar, 13 parts of quartz, 17 parts of clay, 2 parts of talc, fluxing 15 parts of materials, 20 parts of wollastonite, 14 parts of brucite, 10 parts of albite, 8 parts of calcium silicate, 8 parts of barium sulfate, and 6 parts of sepiolite, wherein the fluxing material is composed of calcium borate and boron oxide according to Mixed with a weight ratio of 3:7; the glaze is composed of the following raw materials in parts by weight: 45 parts of potassium feldspar, 16 parts of montmorillonite, 26 parts of quartz, 39 parts of albite, and 3 parts of colored oxide , 2 parts of sodium hexametaphosphate, 5 parts of talc, and 20 parts of calcium carbonate, wherein the colored oxide is formed by mixing chromium oxide and cobalt oxide in a ratio of 5:3 by weight.

[0031] This embodiment als...

Embodiment 3

[0038] A high-strength ice crack ceramic product, comprising a blank and a glaze, the blank is composed of the following raw materials in parts by weight: 65 parts of kaolin, 25 parts of potassium feldspar, 14 parts of quartz, 19 parts of clay, 4 parts of talc, fluxing 18 parts of materials, 22 parts of wollastonite, 15 parts of brucite, 12 parts of albite, 10 parts of calcium silicate, 11 parts of barium sulfate, and 7 parts of sepiolite, wherein the fluxing material is composed of calcium borate and boron oxide according to Mixed with a weight ratio of 3:7; the glaze is composed of the following raw materials in parts by weight: 50 parts of potassium feldspar, 18 parts of montmorillonite, 28 parts of quartz, 42 parts of albite, and 4 parts of colored oxide , 2 parts of sodium hexametaphosphate, 6 parts of talc, and 22 parts of calcium carbonate, wherein the colored oxide is formed by mixing chromium oxide and cobalt oxide in a ratio of 5:3 by weight.

[0039] This embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com