High-strength white porcelain glaze ceramic product and preparation method thereof

A ceramic product, high-strength technology, applied in the field of ceramics, can solve the problems of single gloss, can not meet consumer aesthetic standards, low surface gloss, etc., achieve high whiteness, shorten drying time, and large glaze fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

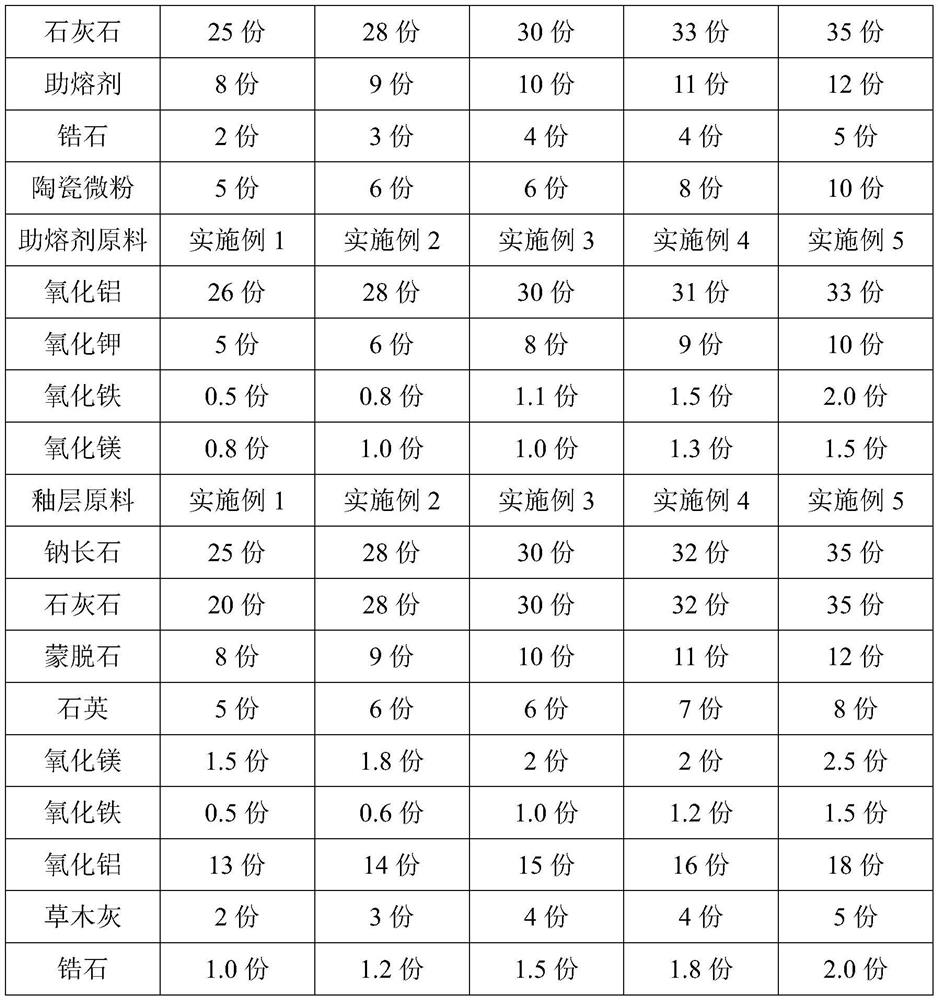

Embodiment 1

[0029] This embodiment provides a high-strength white enamel ceramic product, including a base material and a glaze material. The base material includes the following raw materials in parts by weight: 25 parts of kaolin, 45 parts of potassium feldspar, 25 parts of limestone, 8 parts of flux, zirconium 2 parts of stone, 5 parts of ceramic powder; the glaze includes the following raw materials: 25 parts of albite, 20 parts of limestone, 8 parts of montmorillonite, 5 parts of quartz, 1.5 parts of magnesium oxide, 0.5 part of iron oxide, 13 parts of aluminum oxide 1 part, 2 parts of plant ash, 1 part of zircon.

[0030] Specifically, the flux includes the following raw materials in parts by weight: 26 parts of aluminum oxide, 5 parts of potassium oxide, 0.5 part of iron oxide, and 0.8 part of magnesium oxide.

[0031] This embodiment also provides a preparation method of a high-strength white enamel ceramic product, comprising the following steps:

[0032] Step 1, raw material pr...

Embodiment 2

[0037] This embodiment provides a high-strength white enamel ceramic product, including a base material and a glaze material. The base material includes the following raw materials in parts by weight: 28 parts of kaolin, 50 parts of potassium feldspar, 28 parts of limestone, 9 parts of flux, zirconium 3 parts of stone, 6 parts of ceramic powder; the glaze includes the following raw materials: 28 parts of albite, 23 parts of limestone, 9 parts of montmorillonite, 6 parts of quartz, 1.8 parts of magnesium oxide, 0.6 part of iron oxide, 14 parts of aluminum oxide parts, plant ash 3 parts, zircon 1.2 parts.

[0038] Specifically, the flux includes the following raw materials in parts by weight: 28 parts of aluminum oxide, 6 parts of potassium oxide, 0.8 part of iron oxide, and 1.0 part of magnesium oxide.

[0039] This embodiment also provides a preparation method of a high-strength white enamel ceramic product, comprising the following steps:

[0040]Step 1, raw material prepara...

Embodiment 3

[0045] This embodiment provides a high-strength white enamel ceramic product, including a base material and a glaze material. The base material includes the following raw materials in parts by weight: 30 parts of kaolin, 50 parts of potassium feldspar, 30 parts of limestone, 10 parts of flux, zirconium 4 parts of stone, 6 parts of ceramic powder; the glaze includes the following raw materials: 30 parts of albite, 25 parts of limestone, 10 parts of montmorillonite, 6 parts of quartz, 2 parts of magnesium oxide, 1 part of iron oxide, 15 parts of aluminum oxide parts, plant ash 4 parts, zircon 1.5 parts.

[0046] Specifically, the flux includes the following raw materials in parts by weight: 30 parts of aluminum oxide, 8 parts of potassium oxide, 1.1 parts of iron oxide, and 1.0 part of magnesium oxide.

[0047] This embodiment also provides a preparation method of a high-strength white enamel ceramic product, comprising the following steps:

[0048] Step 1, raw material prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com