Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

897 results about "K feldspar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Orthoclase, or orthoclase feldspar (endmember formula KAlSi 3O 8), is an important tectosilicate mineral which forms igneous rock. The name is from the Ancient Greek for "straight fracture," because its two cleavage planes are at right angles to each other. It is a type of potassium feldspar, also known as K-feldspar.

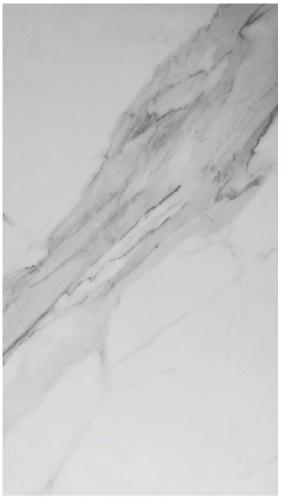

Production method of once-fired super-spar ceramic tile and ceramic tile

The invention relates to a production method of once-fired super-spar ceramic tile and the ceramic tile. The production method of the once-fired super-spar ceramic tile comprises the following steps: preparing green body powder; pressing a tile body; cleaning the green body; pouring ground glaze; printing; pouring overglaze; firing a glaze body at a high temperature; polishing; performing surface treatment; performing edge polishing; and packaging to obtain a finished product, wherein the overglaze comprises the following components in parts by weight: 5 to 13 parts of quartz powder, 3 to 20 parts of potassium feldspar, 20 to 28 parts of soda feldspar, 12 to 18 parts of dolomite, 3 to 6 parts of fired talc, 3 to 8 parts of kaolin, 14 to 22 parts of calcined kaolin, 3 to 8 parts of zinc oxide, 7 to 14 parts of barium carbonate and 3 to 6 parts of grammite. According to the invention, the problems that microlite has low wear resistance and is difficult to process in the prior art are solved, and the defect of water ripples caused by the situations that fully-polished glaze absorbs dirt, bottom is easy to expose and the tile surface is uneven is also solved. The super-spar product produced with the method has the advantages that the microlite is transparent, bright and smooth like a mirror and does not absorb dirt completely; and the fully-polished glaze is light, thin and wear-resistant.

Owner:周予

Household strengthen porcelain containing bone substances and production technology thereof

The invention relates to ceramics and a production technology thereof, in particular to a household strengthen porcelain containing bone substances and the production technology thereof. The strengthen porcelain body comprises petalite, powdered alumina, bone powder, quartz, Longyan braying, Guizhou soil, Zimo saved soil and humic acid sodium; the glaze comprises spodumene, fritted glaze 317, bone powder, kaolin, zirconia, potassium feldspar and aedelforsite; the production technology of the strengthen porcelain comprises the steps of batching, water adding and ball milling, sifting out, iron removing, filter pressing, primary smelting, ageing, refining, molding, drying, glazing and kiln firing. The product of the invention has the advantages of high mechanical strength, good thermal stability, fine and glossy glaze, high whiteness, good transmittance and the like.

Owner:CHAOZHOU LIANYUAN CERAMICS MFG

Daily-used fine porcelain with high property and preparation method thereof

The invention belongs to the technical field of daily-used ceramics, relating to daily-used fine porcelain with high property and a preparation method thereof. The chemical constituents of the daily-used fine porcelain are 52-60% of SiO2, 32-40% of Al2O3, 1-3% of K2O, 1-3% OF Na2O, 1.5-3.5% of CaO, 0.5-1.5% of MgO and 1-2% of P2O5. The adopted raw material formulation is as follows: 40-45% of kaoline, 15-25% of quartz, 10-15% of potassium feldspar, 10-20% of alumina and 8-15% of antireflective agent. The daily-used fine porcelain of the invention integrates three characteristics of high strength, high white and high transparence, and has the characteristics of good molding property, wide sintering arrange and high thermal stability and the like, thereby overcoming the defect of bad light transmittance of normal strengthened porcelain, and solving the problems of uneasy molding and narrow sintering arrange of high-grade porcelain such as steatite porcelain and bone porcelain. The porcelain is sintered at the temperature of 1270-1320 DEG C, is easy to be produced and promoted, and is hopeful to become novel high-grade daily-used fine porcelain after bone porcelain and steatite porcelain.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Production raw material of foamed glass and process for producing foamed glass

The invention relates to raw materials for producing foam glass and a method for applying the same to produce the foam glass. The compositions by weight portion of the raw materials are: 380 to 580 portions of quartz sand, 105 to 250 portions of potassium feldspar, 130 to 270 portions of albite, 115 to 200 portions of dolomite, 5 to 25 portions of calcite, 150 to 250 portions of calcined soda, 0.5 to 30 portions of glauber salt, 1.0 to 12 portions of magnesium carbonate and 1.0 to 8.5 percent of potassium carbonate. The method comprises the following steps that: firstly, various raw material compositions are mixed into uniform glass mixture; secondly, the glass mixture is melted and cooled into cullet; thirdly, ball milling, foaming and annealing of the cullet are performed, and then foam glass is obtained. The method can automatically control and adjust the chemical compositions of the glass and add various functional compositions as required to meet the demand of producing the foam glass with different performances by adoption of common mineral and chemical raw materials of the natural world.

Owner:ZHEJIANG ZHENSHEN INSULATION TECH CORP

Capacitor film with biaxially oriented polypropylene as base body and preparation method thereof

InactiveCN103102588AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethyleneEpoxy

The invention discloses a capacitor film with biaxially oriented polypropylene as a base body and a preparation method thereof. The capacitor film comprises the raw materials in parts by weight: 68-72 parts of biaxially oriented polypropylene, 23-28 parts of LDPE (low-density polyethylene), 10-15 parts of homo-polypropylene, 3-5 parts of epoxy linseed oil, 2-3 parts of polyving akohol, 1-2 parts of aluminium hydroxide, 1-2 parts of polyisobutene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 0.7-0.9 part of poly-4-methyl-1-amylene, 10-12 parts of K-feldspar powder, 1-3 parts of nanosilicon dioxide, 0.9-1.1 parts of 2,6-di tert butyl phenol-alpha-dimethylamino phenol, 1-3 parts of calcium stearate, 1.4-1.6 parts of phenyltriethoxysilane, and 1.7-2.3 parts of modified tree ash. The biaxially oriented polypropylene serving as a primary material, low-density polyethylene serving as an auxiliary material and a plurality of auxiliary materials are mixed, extruded and subjected to film blowing, shaping and cutting to prepare the capacitor film. The capacitor film is simple in preparation method; and the diatomite, the K-feldspar powder, the nanosilicon dioxide and the modified tree ash are added to the materials at the same time. Therefore, the barrier property and the gas tightness of the film are increased; and the capacitor film has good resistance to pressure and shock resistance, and has the characteristics of high heat sealing strength and good heat sealing property at the same time.

Owner:TONGLING YIHENGDA ELECTRONICS

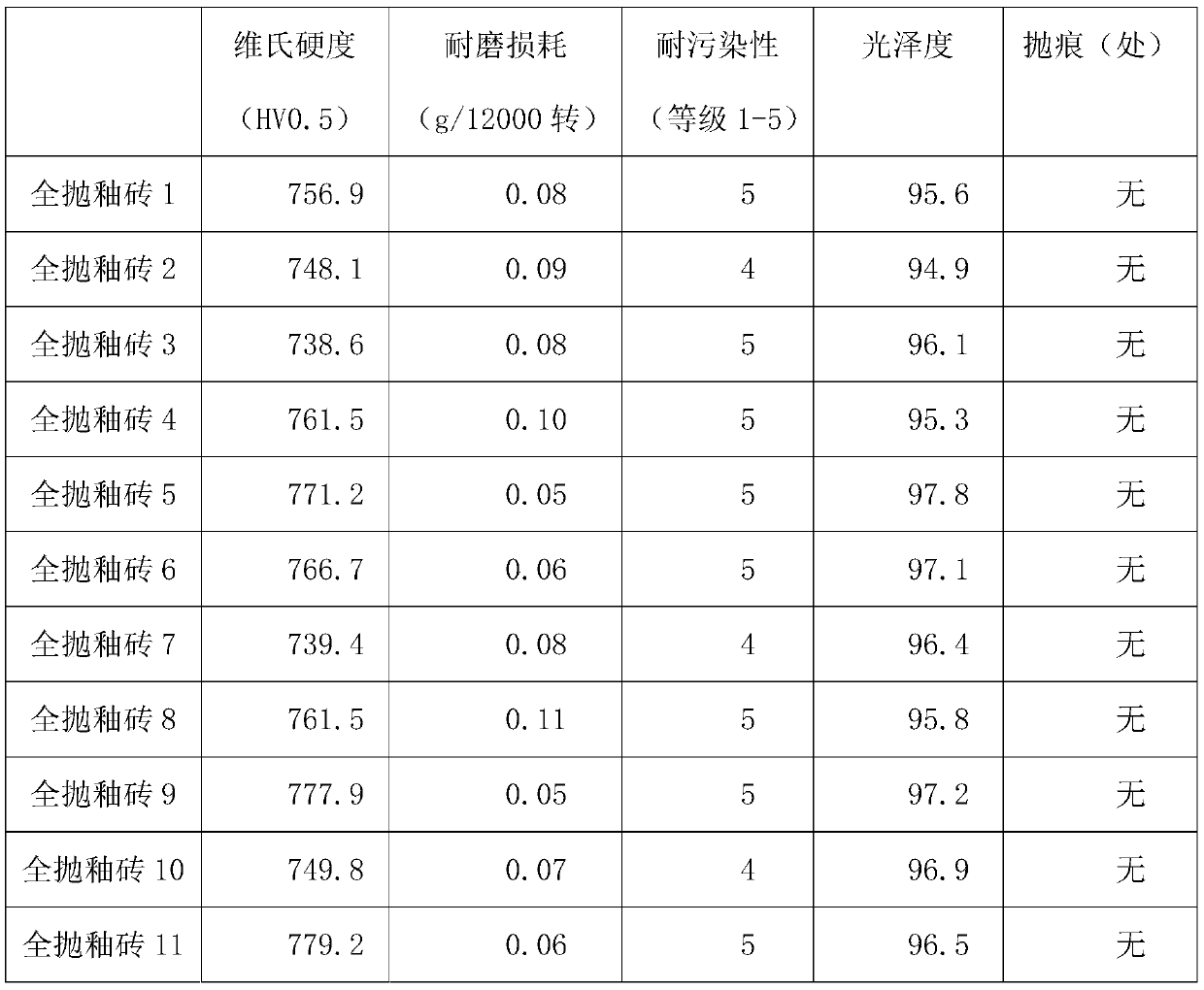

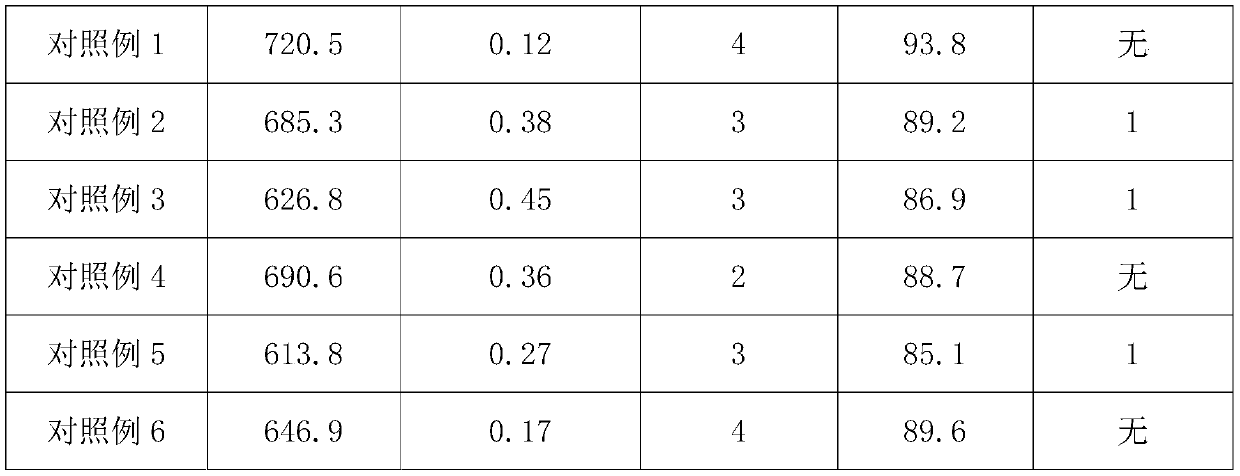

Wearing-resistant high-hardness ceramic glaze and preparation method thereof

The invention discloses a wearing-resistant high-hardness ceramic glaze and a preparation method thereof and relates to the technical field of ceramic glazes. The wearing-resistant high-hardness ceramic glaze comprises the following raw materials: albite, potassium feldspar, kaolin, quartz sand, zinc white, high-aluminum clay, calcite, talc, lithium porcelain, cordierite, zirconium sand, mullite powder, wollastonite, boron carbide, niobium pentoxide, zinc oxide and frit. Both the Vickers hardness and the wearing resistance of a full polish glaze brick made of the glaze disclosed by the invention can be improved, and market requirements on full polish glaze bricks with high hardness and wearing resistance can be met; when a glaze surface is sintered, a great number of bubbles are not generated, and the product is good in antifouling performance and high in glossiness after polishing; expansion coefficients of the full polish brick and a glaze layer are approximate to those of a porcelain blank, the glaze layer is subjected to small inner stress, polishing omission or partial exposure phenomena can be avoided in polishing, and thus product quality can be ensured.

Owner:黄奕雯

Superabsorbent composite and preparation method thereof

InactiveCN102321486AImprove water absorptionImprove water retentionOrganic fertilisersSoil conditioning compositionsSludgePolyacrylamide

The invention discloses a superabsorbent composite and a preparation method thereof. The superabsorbent composite disclosed by the invention comprises a conventional polyacrylamide or polyacrylate water-retaining agent or a mixture of a water absorbent (SAP) and an auxiliary material; the auxiliary material is an organic and / or inorganic auxiliary material; the organic auxiliary material is one or the mixture of restaurant sludge, municipal sludge, beer filtered mud, sugar mill mud, paper mud and plant residues; and preferably, the inorganic auxiliary material is one or the mixture of bentonite, zeolite, potassium feldspar, kieselguhr, magnesite and carbamide. In the invention, the superabsorbent composite is prepared by using a simple mixing and synthesis processing method through adding the cheap auxiliary material with a better cooperation effect with the SAP; the superabsorbent composite has the advantages of good water absorption and water retaining effects and low cost; and the method disclosed by the invention is simple and practical and has significant meanings in actual promotion and application.

Owner:SOUTH CHINA AGRI UNIV

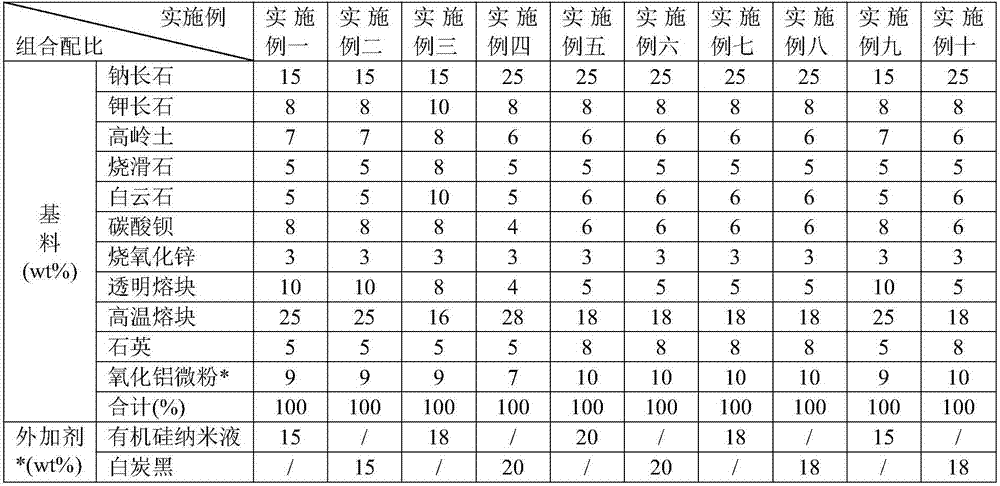

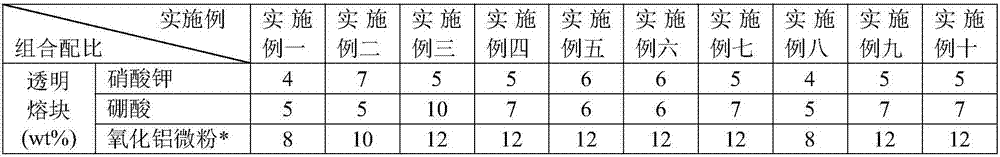

Low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and preparation method thereof

The invention discloses a low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze which contains a base material and an admixture. The base material is prepared from, by weight, 15-25% of albite, 8-16% of potassium feldspar, 6-10% of kaolin, 5-8% of calcined talc, 5-10% of dolomite, 4-12% of barium carbonate, 3-5% of calcined zinc oxide, 4-20% of transparent frit, 16-28% of high-temperature frit, 5%-18% of quartz and 7-15% of alumina micro-powder, wherein the admixture is an organic silicon nano-solution or white carbon black, and the usage amount of the admixture is 15-2% by weight. In addition, the invention further discloses a preparation method of the low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and a product prepared by the same. The melting temperature is reduced through a reasonable formula system, the melting temperature range of the glaze is enlarged while energy saving and emission reduction are promoted, the hardness and abrasion resistance of the glaze surface are remarkably improved, the higher usage requirements can be very well met, and technical progress and application development of the industry of architectural ceramics are promoted.

Owner:JINGDEZHEN CERAMIC INSTITUTE

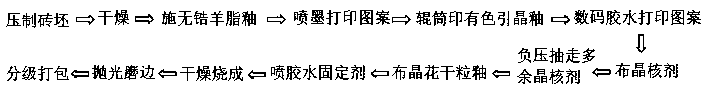

Colored seeding glaze, and positioning crystal pattern ceramic tile prepared using same

The invention discloses a colored seeding glaze, and a positioning crystal pattern ceramic tile prepared using. The colored seeding glaze comprises a base glaze and a coating pigment, and raw materials of the base glaze comprises, by mass, 24-30% of potassium feldspar, 6-10% of albite, 10-14% of calcined kaolin, 3-5% of calcite, 1-3% of dolomite, 7-9% of barium carbonate, 3-5% of strontium carbonate, 5-7% of wollastonite, 1-3% of calcined talc, 2-4% of zinc oxide, 14-20% of seeding agent frit, 1-3% of tungsten oxide, 2-4% of calcium phosphate and 1-3% of tin oxide.

Owner:MONALISA GRP CO LTD

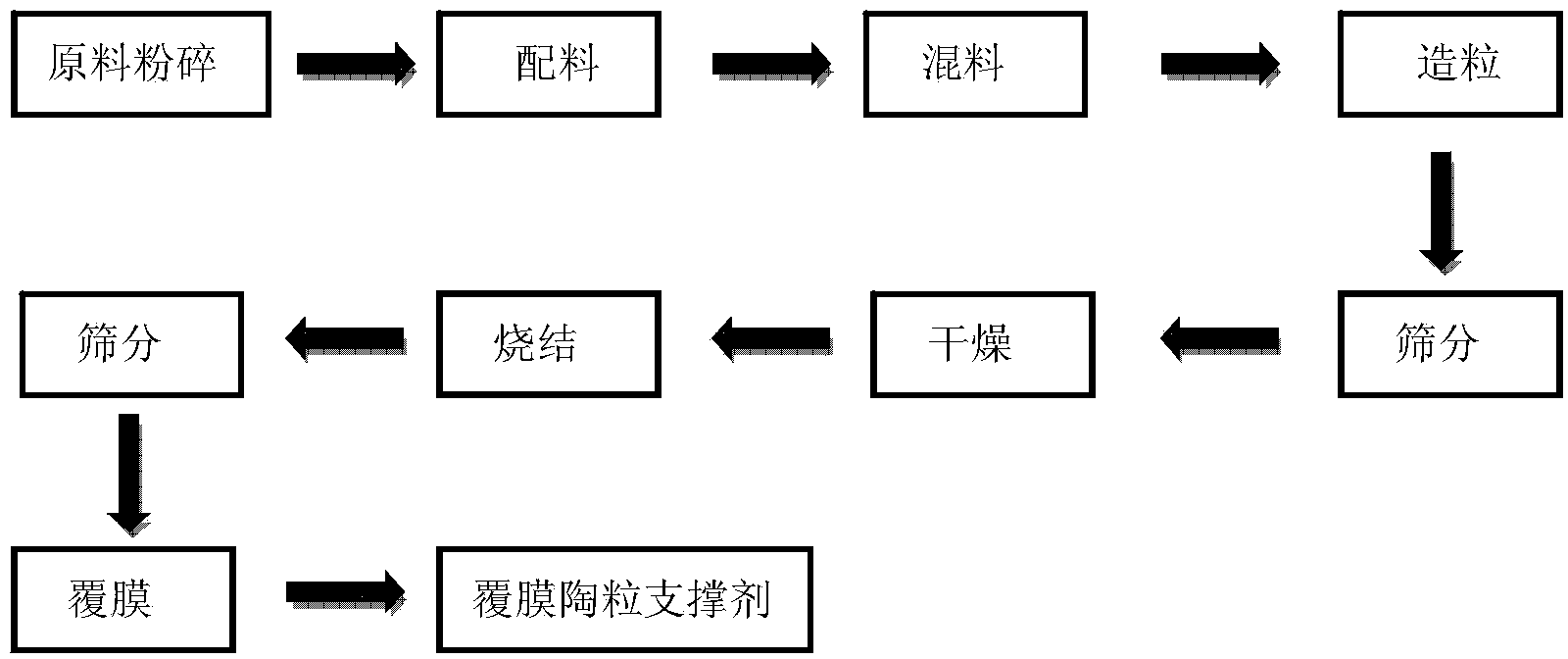

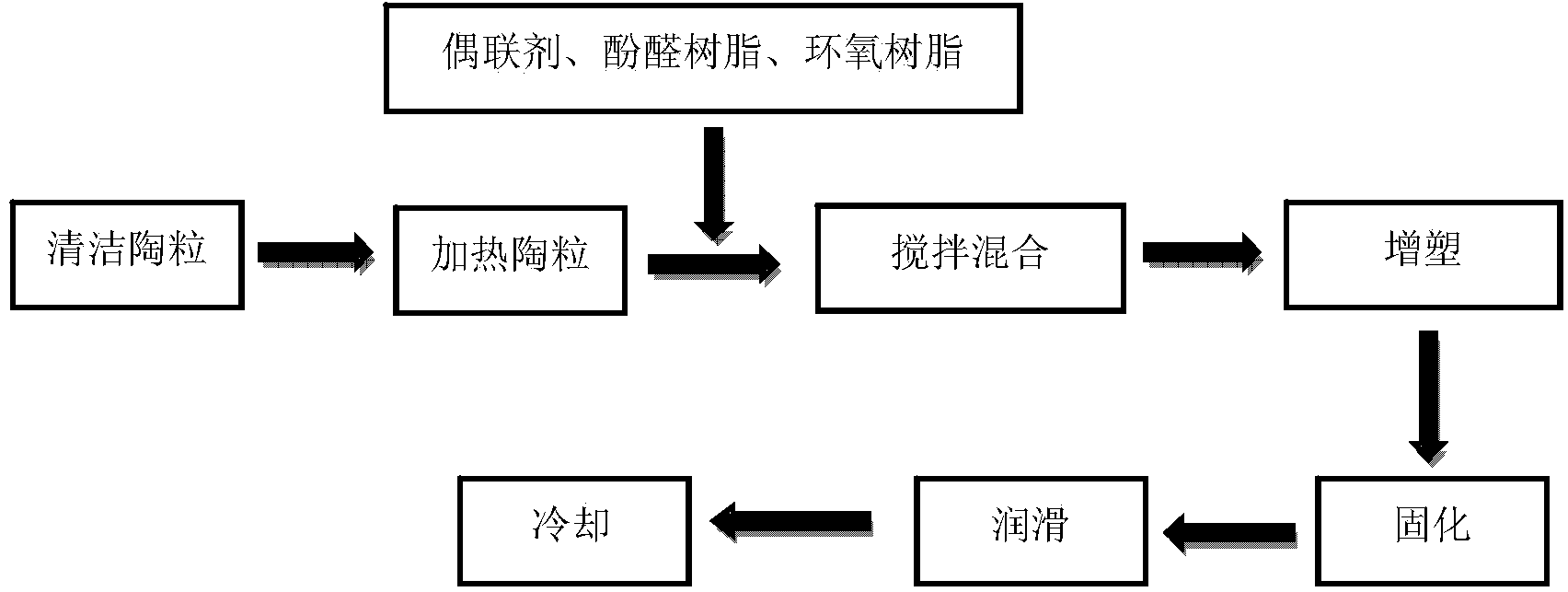

Low-density coated ceramic proppant prepared through fly ash and preparation method of low-density coated ceramic proppant

InactiveCN104263347ALower firing temperatureHigh strengthFluid removalDrilling compositionPotassiumExpanded clay aggregate

The invention discloses a low-density coated ceramic proppant prepared through fly ash and a preparation method of the low-density coated ceramic proppant. The low-density coated ceramic proppant is prepared from the following raw materials in percentage by weight: 85-98 wt% of fly ash, 1-5 wt% of MnO2 powder and 0-10 wt% of potassium feldspar powder through the steps of granulation, calcination and coating. In the preparation method, the fly ash is taken as a main raw material, a small amount of additive is used as a fluxing agent, high-aluminum-content materials such as bauxite and the like are not introduced, and the coated ceramic proppant is prepared by a coating process. The prepared coated ceramic proppant has the characteristics that the particle size is 20-40 meshes, the bulk density is smaller than or equal to 1.55 g / cm<3>, the apparent density is smaller than or equal to 2.70 g / cm<3>, the breakage rate is smaller than or equal to 5% at 52 MPa and the breakage rate is smaller than or equal to 9% at 69MPa.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

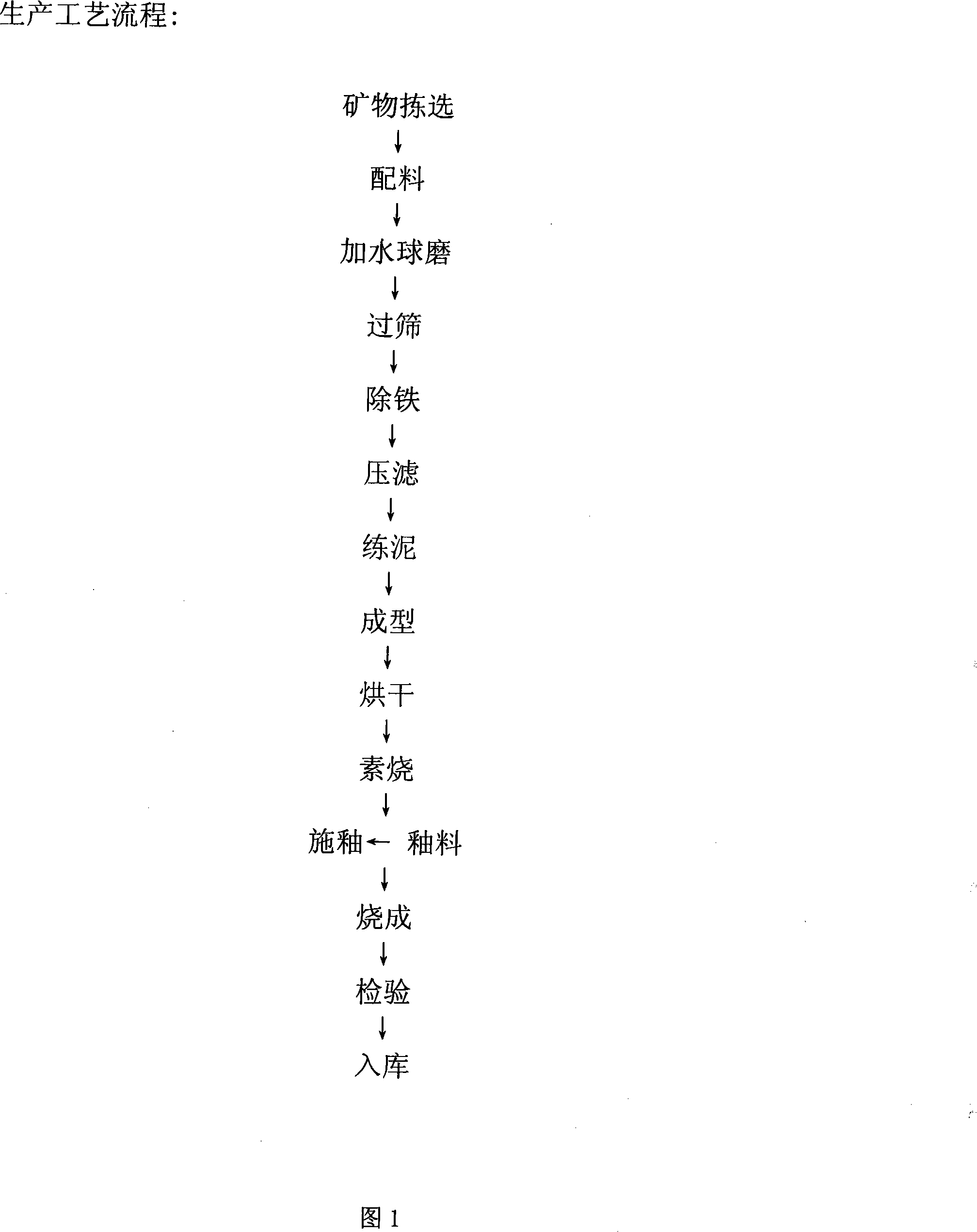

Thin-walled body strengthen porcelain and production technique thereof

The invention relates to a strengthen porcelain and a production process thereof, which more particularly relates to an eggshell strengthen porcelain and the corresponding production process. A body of the eggshell strengthen porcelain comprises kaolin, weathered potash feldspar, quartz, Alpha oxidized aluminum single crystal, zirconia single crystal, bentonite and talc. The production process of the eggshell strengthen porcelain comprises steps of ore sorting, batching, ball milling by adding water, sieving, removing iron, pressure filtering, clay preparation, forming, baking, biscuit firing, glazing, sintering to finish. The product of the invention has good whiteness, transmittance and thermo stability, high mechanical strength, smooth glaze, light instrument; the thickness of the product is approximately one half of the traditional strengthen porcelain only.

Owner:林伟河

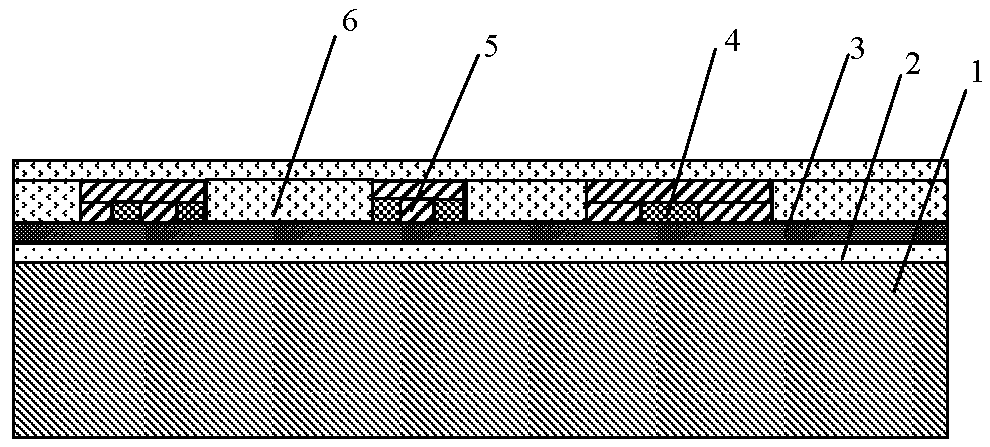

Diamond dry particles, glazed brick with positioning diamond flashing effect and preparation method of glazed brick

The invention provides diamond dry particles, a glazed brick with a positioning diamond flashing effect and a preparation method of the glazed brick. The diamond dry particles are composed of the rawmaterials by mass: 8 to 13 percent of kaolin, 23 to 30 percent of albite, 10 to 20 percent of potassium feldspar, 20 to 25 percent of calcite, 5 to 10 percent of aluminum oxide, 3 to 6 percent of calcined talc, 3 to 5 percent of zinc oxide and 15 to 25 percent of zircon sand with the particle size of 150 mesh-250 mesh. Zircon sand with the particle size of 150-250 mesh is subjected to iron removalscreening, so that a dirt falling problem of a white brick surface can be effectively solved, and the dry diamond particles with the particle size of 40-150 mesh can be prepared without destroying the crystal structure of the zircon sand, and dry particles can be conveniently spread by a dry glue particle machine.

Owner:MONALISA GRP CO LTD

Middle-temperature high-grade daily tableware porcelain and preparation method thereof

ActiveCN105967643ALower firing temperatureFine and transparent porcelainClaywaresPotassiumBarium carbonate

The invention relates to the technical field of porcelain manufacture and concretely relates to a middle-temperature high-grade daily tableware porcelain and a preparation method thereof. Blank materials of the middle-temperature high-grade daily tableware porcelain comprise kaolin, potassium feldspar, wollastonite, quartz, lithionite, dolomite and calcinedtalc. Glaze materials of the middle-temperature high-grade daily tableware porcelain comprise low temperature transparent frit, feldspar, kaolin, waste glass, fluorite, quartz, zinc oxide, barium carbonate and lithionite. Through adjustment of the blank materials and glaze materials and use of a reasonable formula and specially-produced frit, a sintering temperature is reduced to 1050-1150 DEG C so that a sintering temperature is low, fuel is saved, product stability is high and a production cost is reduced. The glaze materials improve blank whiteness. The middle-temperature high-grade daily tableware porcelain has fine and transparent texture, good light transmittance and a gentle color, has qualitative sense close to that of bone-china, does not release lead and cadmium in a test, is safe for use and has good social and economic benefits.

Owner:德化县如瓷生活文化有限公司

Antibacterial sanitary ceramic and preparation method thereof

The invention relates to antibacterial sanitary ceramic and a preparation method thereof and belongs to the technical field of ceramic production. The ceramic comprises components in parts by weight as follows: 70-90 parts of ceramic clay, 5-10 parts of quartz, 5-10 parts of potassium feldspar, 0.001-0.003 parts of nano-silver, 0.001-0.003 parts of nano silicon oxide, 0.001-0.003 parts of nano aluminium oxide, 0.001-0.003 parts of nano titanium, 1-5 parts of frit, 0.5-1 part of kaolin, 0.01-0.03 parts of zinc oxide, 0.01-0.05 parts of zircon powder, 0.01-0.05 parts of silver nitrate and 0.01-0.05 parts of calcium fluoride. The preparation method of the antibacterial sanitary ceramic specifically comprises the steps as follows: molding bodies, preparing glazes, glazing and calcining. The antibacterial sanitary ceramic has the good antibacterial performance and is low in manufacturing cost, smooth, glossy and, attractive and elegant in appearance.

Owner:GUANGDONG TREND GROUP

High-strength electroceramics ash glaze formulation and preparation method thereof

The invention relates to a high-strength electrotechnical porcelain ash glaze formulation which comprises white glaze base materials and coloring materials with mass of 15 to 35% of that of the white glaze base materials, wherein the white glaze base material comprises the following components in parts by weight: 23 to 27 parts of potassium feldspar, 25 to 29 parts of quartz, 8 to 15 parts of Xinhui powder, 4 to 9 parts of washed kaolin, 5 to 8 parts of Xingzi kaolin, 8 to 15 parts of talc, 4 to 7 parts of limestone, 3 to 8 parts of Zuoyun earth, 2 to 6 parts of zirconium silicate, and 5 to 15 parts of alumina. The preparation method comprises the following steps of: roasting three colorant raw materials at a high temperature firstly; grinding finely; and then milling in a wet way along with white glaze based on the ratio until the size fineness reaches to 325 meshes; and finally sieving to residue of 4 to 6%. The electrotechnical porcelain ash glaze prepared based on the formulation is suitable for various porcelain blank bodies, and can be coated to form a good intermediate layer which can be combined with the porcelain body well, thus, the mechanical performance of the porcelain can be greatly improved, and the bending strength of the porcelain can be increased by more than 30%; and meanwhile, the glazed surface of a porcelain component is smooth, the color is white gray and clear, and the surface has no defect, and the market demand can be met.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

Chromium-containing diversion sands for steel ladle and preparation method thereof

The invention relates to chromium-containing diversion sands for a steel ladle and a preparation method thereof. The preparation method adopts the technical scheme that chromium ore of 50 to 70 percent (by weight percent) and quartz sands of 20 to 40 percent are added to a stirrer at first, and the stirring is carried out for 2 to 3 minutes; then potash feldspar of 5 to 10 percent is added to thestirrer, and the stirring is carried out for 5 to 10 minutes; flake graphite of 1 to 2 percent is added to the stirrer, and the stirring is carried out for 10 to 15 minutes; and finally, the four types of materials that are stirred uniformly are poured out from the stirrer, and are baked for 30 to 40 minutes under the temperature ranging from 180 to 220 DEG C, so as to obtain the chromium-containing diversion sands for the steel ladle. The prepared chromium-containing diversion sands for the steel ladle are characterized in that the refractoriness is high, the high-temperature sintering property is good, molten steel erosion resistance and molten slag erosion resistance are good, the particle size distribution of granules is uniform, the flowability is good, the heat expansion rate is lower, the cost is appropriate, and the automatic-opening ratio is high.

Owner:WUHAN UNIV OF SCI & TECH

Low-hydrogen super diphasic stainless steel electrode

InactiveCN101367161AArc stabilizationWell formed weldWelding/cutting media/materialsSoldering mediaPotassium feldsparFerrosilicon

The invention discloses a low-hydrogen type super duplex stainless steel welding rod. The prior duplex stainless steel wire is adopted as a welding core. The coating of the welding rod comprises the compositions in percentage by weight: 35 to 45 percent of marble, 20 to 33 percent of fluorite, 0 to 5 percent of titanium pigment, 2 to 5 percent of potassium feldspar, 0 to 2 percent of sodium carbonate, 5 to 15 percent of iron alloy, 10 to 20 percent of metal powder, and 0 to 2 percent of CrN iron, wherein the iron alloy consists of ferrosilicon and ferromolybdenum under the condition of constant total content, and the metal powder consists of manganese metal, chromium metal, and nickel powder under the condition of the constant total content. After raw materials of the compositions of the coating are mixed evenly, pure sodium water glass with certain Baume concentration is added, and the pressing of the welding rod is performed on welding rod production equipment. The use of the welding rod can satisfy the welding need of super duplex stainless steel in the national engineering construction, the welded welding seam has excellent mechanical property and good corrosion resistance, the tensile strength can reach 800MPa, and the welding rod has good low-temperature toughness.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Raw material matte glaze, and preparation method and application thereof

The invention discloses raw material matte glaze, and a preparation method and application thereof, wherein the raw material matte glaze is prepared from the following ingredients in parts by weight: 1 to 5 parts of zinc oxide, 15 to 35 parts of barium carbonate, 15 to 30 parts of potassium feldspar, 10 to 15 parts of soda feldspar, 0 to 10 parts of dolomite, 3 to 10 parts of kaolin, 4 to 15 parts of quartz and 4 to 15 parts of calcium phosphate. The raw material matte glaze provided by the invention is formed by combining all raw materials; the materials do not need to be made into fused blocks; energy sources are saved; the cost is low; the raw material matte glaze is suitable for being used for one-step fast firing products; in addition, the phosphate ingredient is introduced for matte glaze proportioning; the introduction of infusible compounds is not needed. When the raw material matte glaze is applied to ceramic product production, the glaze surface texture of a final product of the matte glaze is fine; the glossiness is low; the anti-corrosion performance and the wear-resistant performance are good; the coloring of ink-jet printing ink can be facilitated; the problems of rough hand feeling, unstable anti-corrosion performance, poor coloring effect of the ink-jet printing ink and the like of matte glaze series products in the market at present can be solved.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK

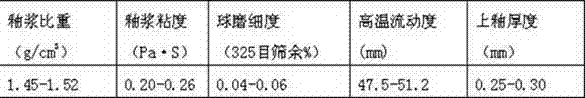

Preparation method of matte glaze sanitary ceramic

The invention discloses a preparation method of matte glaze sanitary ceramic. The preparation method comprises the steps of carrying out ball milling on 27.8%-29% of quartz, 25.5%-26.9% of Changding potassium feldspar, 13.55%-15.5% of calcite, 3.83%-4.3% of dolomite, 3%-3.3% of Zhangzhou kaolin, 9%-10.1% of zirconium silicate, 9.83%-10.1% of aluminum oxide, 3.2%-3.4% of zinc oxide, 0.03%-0.04% of sodium carboxymethylcellulose and 1.06%-1.95% of sodium carbonate until the particle size of slurry is smaller than 10 microns and the ratio is 60%-65%, adding ceramic pigments, continuing to carry out ball milling until the particle size of slurry is smaller than 10 microns and the ratio is 69%-71%, sieving by virtue of a 180-mesh sieve so as to obtain uniform sanitary ceramic matte glaze slurry, spraying the sanitary ceramic matte glaze slurry to the surface of a sanitary ceramic blank, adequately drying, firing in a tunnel kiln at 1200-1250 DEG C for 15-18 hours, and cooling, so as to obtain the matte glaze sanitary ceramic product. The prepared matte glaze sanitary ceramic has a special matte effect and pure colors and is rich in aesthetic perception, and the problem of poor sewage resistance of traditional matte glaze is further overcome.

Owner:JOMOO KITCHEN & BATHROOM

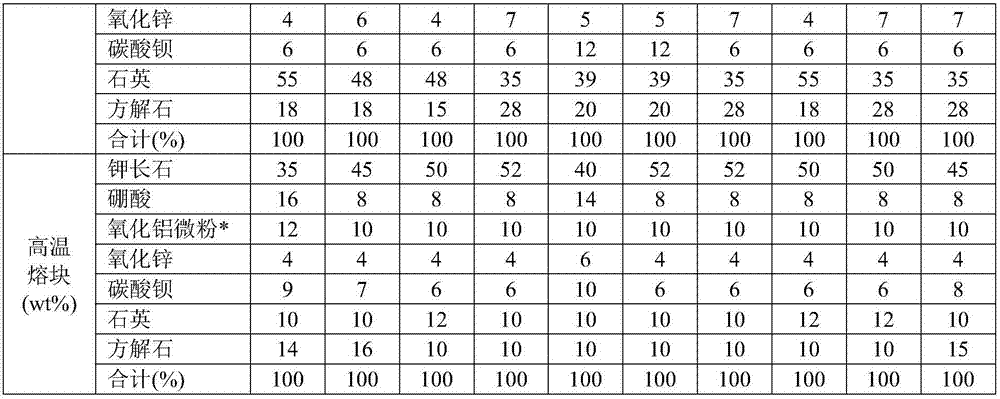

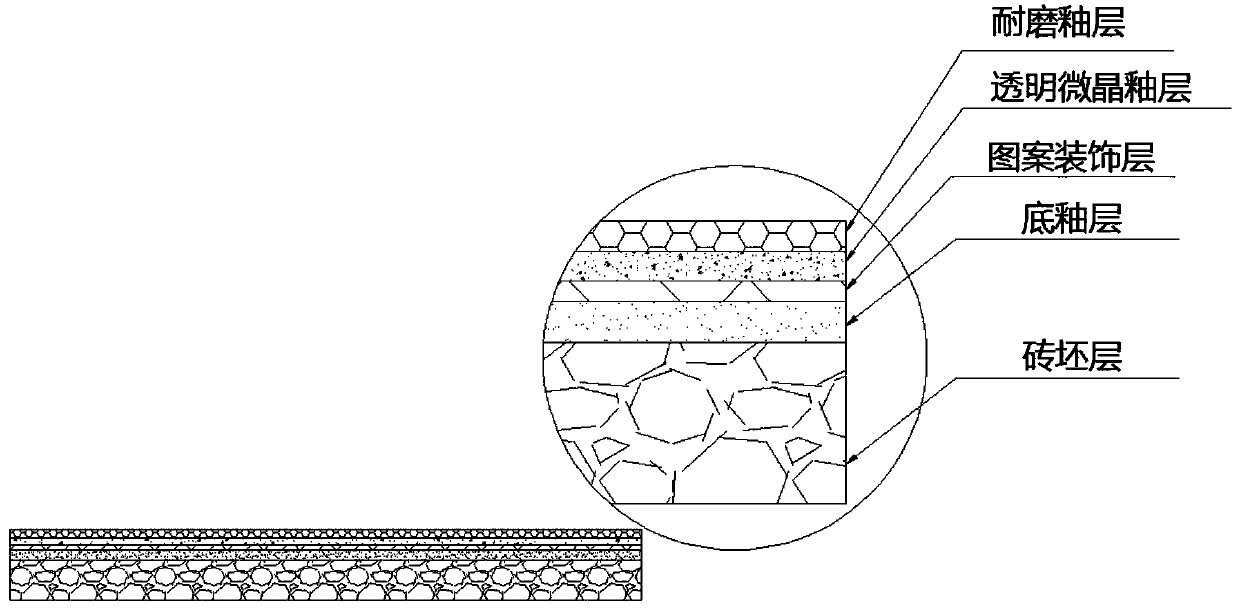

Microcrystalline glaze, wear-resistant glaze, transparent microcrystalline wear-resistant full-polished glaze ceramic tile and preparation method

The invention relates to transparent microcrystalline glaze, a wear-resistant transparent glaze, a transparent microcrystalline wear-resistant full-polished glaze ceramic tile and a preparation method. The transparent microcrystalline glaze comprises the following components in parts by weight: 5 parts of barium carbonate; 18 parts of potassium feldspar; 9 parts of albite; 8 parts of aluminum oxide; 16 parts of calcite; 4 parts of quartz powder; 6 parts of dolomite; 10 parts of kaolin; 12 parts of calcined kaolin; 5 parts of wollastonite; 1 part of calcium fluoride; 1 part of titanium dioxide.The preparation method of the transparent microcrystalline wear-resistant full-polished glazed ceramic tile comprises the following steps: (1) pressing a green body; (2) applying / not applying groundcoat; (3) drying or not drying a glaze line; (4) carrying out comprehensive combined decoration including planographic printing, rubber roller printing, ink jet printing and the like; (5) drying or not drying a glaze line; (6) applying transparent microcrystalline glaze; (7) pouring / spraying wear-resistant transparent glaze; (8) performing firing in a kiln; and (9) conducting glaze polishing.

Owner:GUANGDONG JIA MEI CERAMIC +3

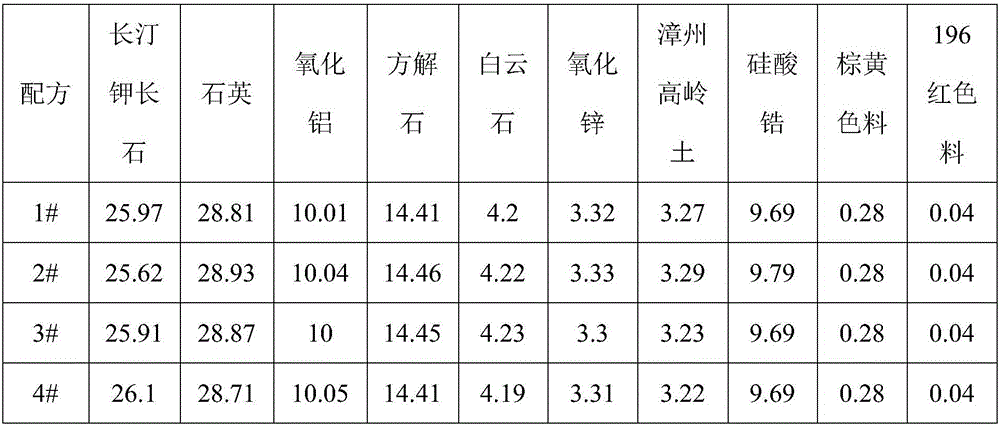

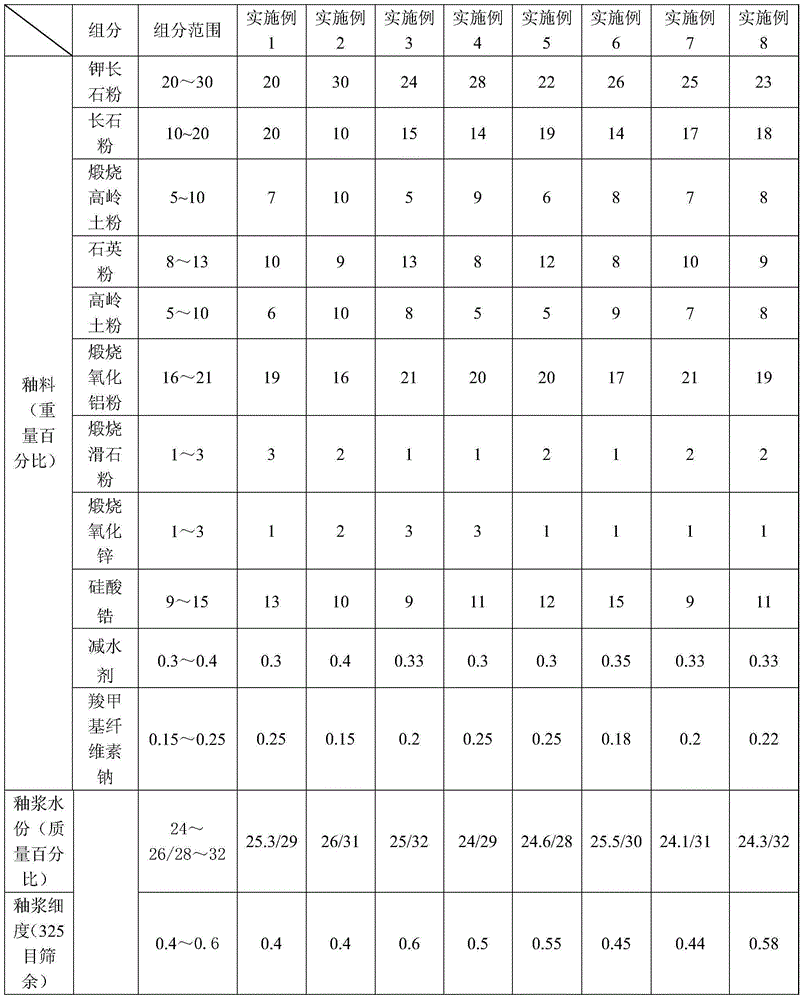

Ground coat used for producing fully-glazed ceramic tile and beneficial to color development of ceramic ink

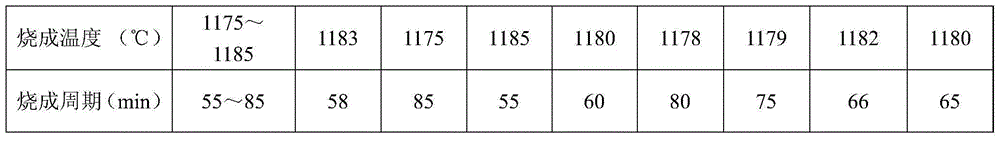

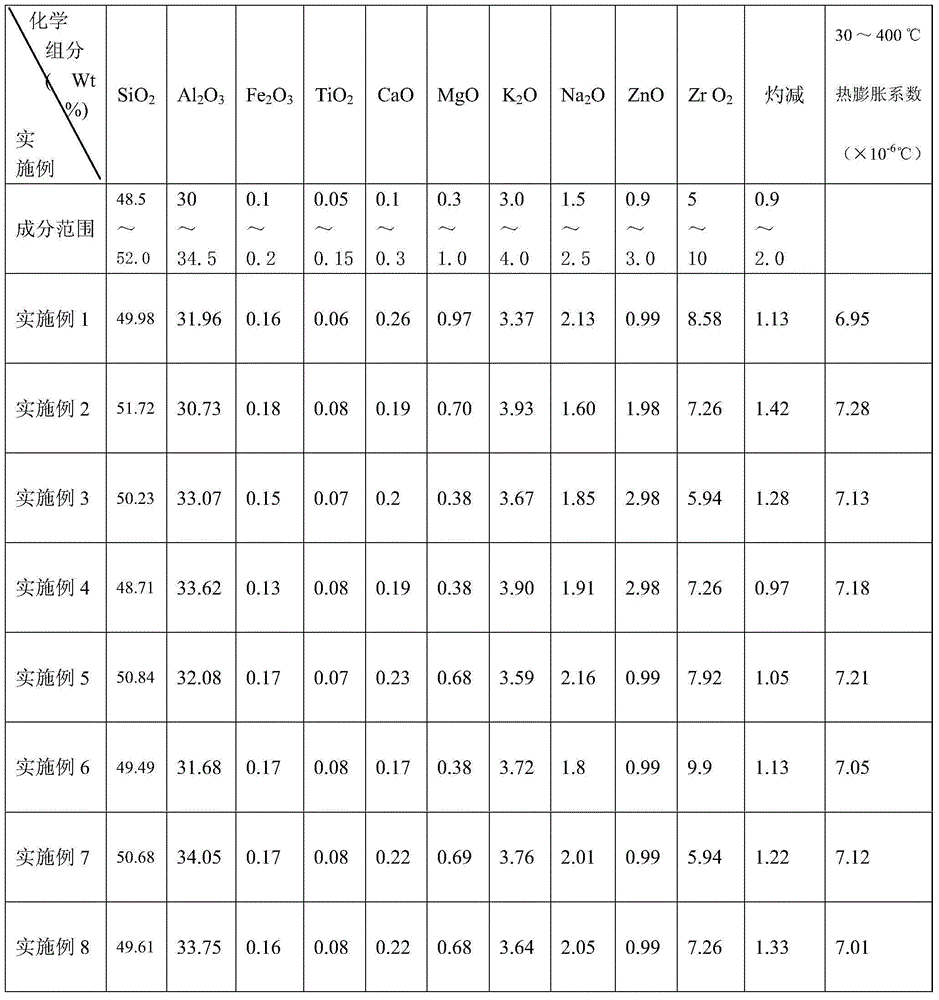

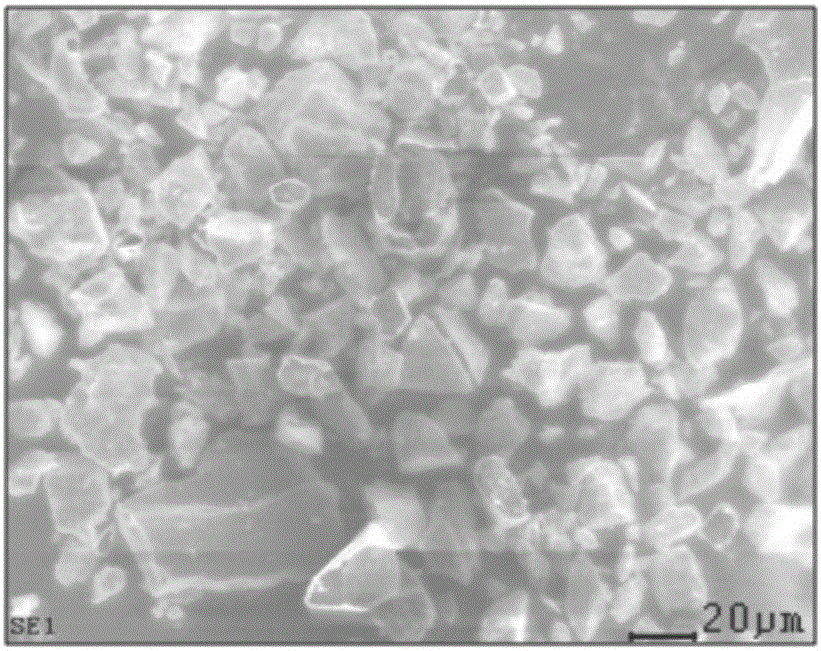

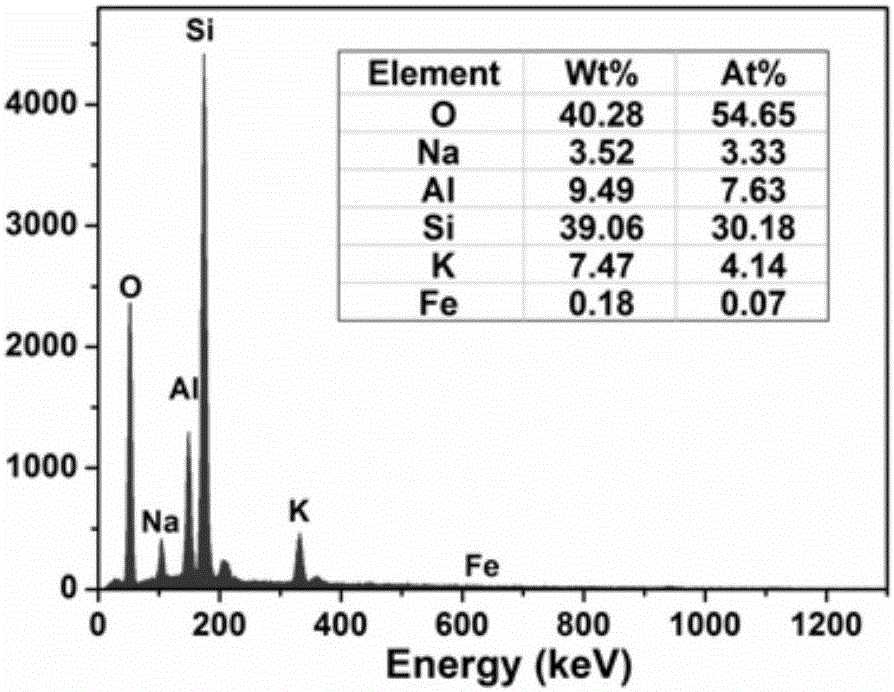

The invention discloses a ground coat used for producing a fully-glazed ceramic tile and beneficial to color development of ceramic ink. The ground coat is mainly prepared from, by weight, 20%-30% of potassium feldspar powder, 10%-20% of feldspar powder, 5%-10% of calcined kaolin powder, 8%-13% of quartz powder, 5%-10% of kaolin powder, 16%-21% of calcined alumina powder, 1%-3% of calcined talcum powder, 1%-3% of calcined zinc oxide, 9%-15% of zirconium silicate, 0.3%-0.4% of water reducing agent and 0.15%-0.25% of methyl. The content of single raw material chemical component CaO is smaller than 3%. The raw material chemical components of the ground coat comprise 48.5%-52.0% of SiO2, 30%-34.5% of Al2O3, 0.1%-0.2% of Fe2O3, 0.05%-0.15% of TiO2, 0.1%-0.3% of the CaO, 0.3%-1.0% of MgO, 3.0%-4.0% of K2O, 1.5%-2.5% of Na2O, 0.9%-3.0% of ZnO, 5%-10% of ZrO2 and 0.9%-2.0% of igloss. The technological process of the ground coat includes the steps of blending, ball milling, sieving, deironing and glaze slip staling. The using method of the ground coat includes the step of glazing through a bell jar glaze pouring technology or a linear glaze pouring technology. By the adoption of the ground coat, the colors of the product are enriched, color development of the ceramic ink is facilitated, color development of each color is deeper, the hue is pure, and the rate of qualified products is high.

Owner:GUANGDONG XINRUNCHENG CERAMICS

3D dazzling ceramic tile and preparation method thereof

The invention discloses a 3D dazzling ceramic tile which sequentially comprises a green body layer, a dazzling surface glaze layer, an ink-jet pattern texture layer, a functional ink layer and a transparent protective glaze layer from bottom to top, the dazzling surface glaze layer comprises 35-40 parts of albite, 12-15 parts of kaolin, 11-15 parts of barium carbonate, 1-2 parts of zinc oxide, 16-20 parts of quartz, 2-4 parts of aluminum oxide, 5-6% of calcined kaolin and 0.5-12 parts of ink-jet frit; the transparent protective glaze layer comprises 12-15 parts of potassium feldspar, 18-24 parts of albite, 12-13 parts of kaolin, 8-12 parts of calcined talc, 3-5 parts of wollastonite, 22-26 parts of barium carbonate, 10-14 parts of dolomite, 4-6 parts of zinc oxide, 1-2 parts of aluminum oxide and 2-6 parts of transparent high-brightness frit. The ceramic tile product has a remarkable 3D effect and can adapt to different water absorption rates so that the application range of the 3D dazzling ceramic tile is greatly widened.

Owner:FOSHAN TAOYING NEW MATERIAL CO LTD

Method for impurity removal and whitening of potassium feldspar

The invention discloses a method for impurity removal and whitening of potassium feldspar. Firstly, the potassium feldspar is crushed to particles; then, a ball mill is adopted to grind the potassium feldspar particles to sand powder; the sand powder is magnetically separated by a multi-stage strong magnetic separator after screening; and finally, the hydrothermal acid washing is performed for the magnetically separated potassium feldspar sand powder by sulfuric acid to obtain high-grade and high-whiteness potassium feldspar sand powder. An acid washing purification process is in a closed environment without generating a dust flying problem; the purified potassium feldspar sand powder not only can satisfy the requirements on high-whiteness potassium feldspar sand powder in such industries as glass and ceramics, but also can improve the utilization efficiency of sulfuric acid to a greater extent so as to reduce generation of waste acid; and the method is a green and environment-friendly purifying and whitening production process.

Owner:洛南县大秦钾矿有限公司

Antibacterial ceramic tile and preparation method thereof

The invention relates to an antibacterial ceramic tile and a preparation method thereof, belonging to the technical field of ceramic production. The antibacterial ceramic tile comprises the following components in parts by weight: 60-90 parts of kaolin, 30-40 parts of ceramic clay, 1-10 parts of quartz, 1-10 parts of potassium feldspar, 0.1-0.5 part of silver phosphate and 1-5 parts of copper oxide. The preparation method comprises the following steps: mixing the substances uniformly in proportion, controlling the pressure to be 30-40MPa, carrying out compression moulding on powder, then drying the powder at 50-60 DEG C for 4-6 hours, putting a product obtained after drying into a firing furnace, controlling the temperature to be 1200-1300 DEG C, firing for 1-2 hours, reversing a mould and cooling the product, thus obtaining the antibacterial ceramic product. The ceramic tile has stable antibacterial property and wide application range.

Owner:DOSHAN NEW STRATEGY INTPROP CULTURECO

Refractory heat insulation material and preparation method thereof

The invention relates to a refractory heat insulation material and a preparation method thereof. According to raw materials of the refractory heat insulation material, hole-closed perlite floating beads serve as heat insulation aggregate, bauxite, kaolin and pyrophyllite serve as refractory aggregate, potassium feldspar serves as a sintering agent and sodium-based bentonite serves as a forming agent. The preparation method includes the steps of stirring the raw materials, forming a blank through a mould, air-drying the blank, performing demoulding after low-temperature drying, and performing high-temperature ceramization and sintering forming on the blank. By fully utilizing the physicochemical characteristics of all the components, the overall performance of the refractory heat insulation material is optimized, and the prepared refractory heat insulation material has the advantages of being high in refractoriness and strength, small in bulk density, low in heat conductivity coefficient, good in heat insulation effect, environmentally friendly and the like and can be applied to heat insulation of heating furnaces or heat equipment in the machinery industry, the metallurgy industry, the chemical industry and the like and slow down heat energy diffusion to save energy.

Owner:HUBEI UNIV OF TECH

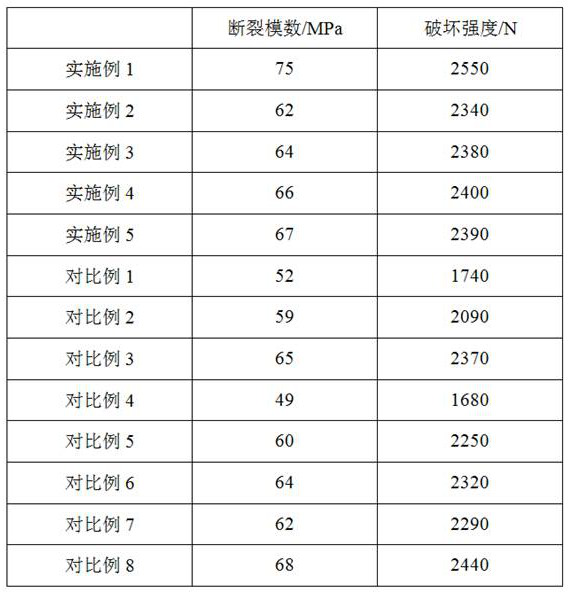

Non-crackable rock slab and preparation method thereof

The invention discloses a non-crackable rock slab and a preparation method thereof. The non-crackable rock slab is prepared from the following raw materials; 40-55 parts of wollastonite, 25-40 parts of mullite, 15-20 parts of potassium feldspar, 10-20 parts of flint clay, 6-12 parts of calcined hydrotalcite, 5-10 parts of high-alumina bauxite, 4-8 parts of modified silicon carbide, 2-6 parts of dolomite, 2-5 parts of magnesium oxide, 2-5 parts of strontium carbonate, 0.8-1.8 parts of far-infrared ceramic powder and 10-25 parts of reinforcing agent. The rock slab of the present invention has anexcellent modulus of rupture and extremely high breaking strength, so that the rock slab is not easy to be broken. The modulus of rupture and the breaking strength of the rock slab are significantlyimproved by adding modified silicon carbide and reinforcing agent to the formula of the rock slab.

Owner:GUANGDONG OVERLAND CERAMICS CO LTD

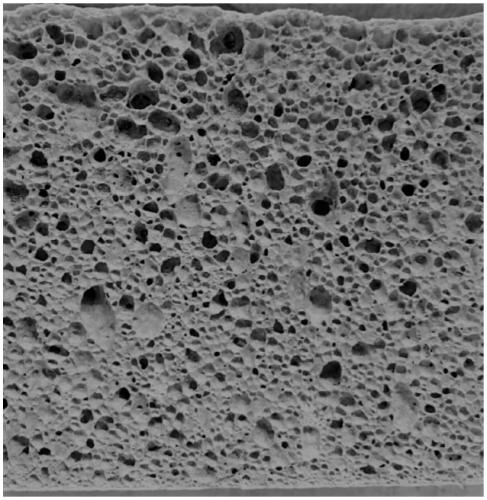

Ultra-thick foamed ceramic plate and production process

The invention provides an ultra-thick foamed ceramic plate and a production process thereof, and belongs to the technical field of foamed ceramics. The components of the ultra-thick foamed ceramic plate comprise a raw material, a foaming agent, a foam stabilizer and a thermal inert modifier, wherein the components of the raw material include 40-60 parts of fluorite tailings, 5-15 parts of potassium feldspar, 10-20 parts of bluestone powder, and 15-30 parts of waste porcelain powder; the foaming agent is at least one of silicon carbide, carbon powder, calcium carbonate, manganese dioxide, sodium nitrate and potassium nitrate; the foam stabilizer is at least one of borax, boric acid, zinc oxide and barium carbonate; the thermal inert modifier is at least one of high borosilicate glass, potash-lime glass, silica, alumina and glass fiber powder; and the mass percentage ratio of the raw material to the foaming agent to the foam stabilizer to the thermal inert modifier is 100:(0.5-2):(1-3):(2-10). The ultra-thick foamed ceramic plate of the invention can be directly used as a wall material of a building partition wall, is less in leftovers of a unit finished material, and is used for processing large-sized special-shaped parts.

Owner:江西璞晶新材料股份有限公司

Microcrystalline glass with strong breaking resistance and preparation method thereof

The invention discloses microcrystalline glass with strong breaking resistance, which is formed by the following raw materials in parts by weight: 25-30 parts of coal gangue, 20-30 parts of quartz sand, 15-20 parts of fly ash, 10-15 parts of silicon dioxide, 10-15 parts of calcium carbonate, 10-15 parts of alabaster, 6-8 parts of zinc oxide, 5-7 parts of aluminum oxide, 5-7 parts of barium oxide, 3-4 parts of potassium oxide, 3-4 parts of table salt, 2-4 parts of magnesium fluoride, 2-3 parts of calcium fluoride, 2.5-3 parts of wood charcoal, 3-4 parts of clay, 2-3 parts of boron oxide, 2-3 parts of lithium oxide, 2.5-3 parts of tree ash, 2-3 parts of plant ash, 2-3 parts of sodium oxide, 0.25-0.4 part of potassium feldspar, 0.15-0.3 part of sodium tetraborate, 0.15-0.3 part of vanadium pentoxide and 0.15-0.2 part of zirconium dioxide. The microcrystalline glass disclosed by the invention has the advantages of good flatness, high mechanical strength, great hardness, and good heat resistance, bending strength, corrosion resistance and wear resistance; and the product can be made into various types of pipes and sheet materials and can be widely applied to wear-resisting and corrosion-resisting materials and building decoration materials of buildings.

Owner:中山市新感觉玻璃有限公司

Method for preparing lightweight high-strength ceramsite by aid of coal gangue

PendingCN106966707AMeet the requirements of ceramsite proppant materials for developmentHigh strengthFluid removalDrilling compositionMolding machinePotassium feldspar

The invention discloses a method for preparing lightweight high-strength ceramsite by the aid of coal gangue. The method includes steps of crushing and grinding the coal gangue with the carbon content of 5-15% to obtain coal gangue powder which can completely pass 325-mesh sieves; uniformly mixing, by weight, 40%-80% of coal gangue powder, 0%-45% of bauxite powder, 1%-9% of calcium oxide and 5%-15% of potassium feldspar with one another to obtain raw materials; carrying out ball-milling on the raw materials, then granulating the raw materials in a granulator, mixing the raw materials which are subjected to ball-milling with one another and molding, drying and screening the raw materials on a ceramsite molding machine to obtain ceramsite green bodies; heating and calcining the ceramsite green bodies thrice and cooling the ceramsite green bodies with furnaces to obtain the lightweight high-strength ceramsite. The method has the advantages that the coal gangue content can reach 40%-80%, the bulk density of the lightweight high-strength ceramsite prepared by the aid of the method ranges from 0.6 g / cm<3> to 1.55 g / cm<3>, and the strength of the lightweight high-strength ceramsite is improved by 10%-15% as compared with the prior art under the condition of identical density; requirements on ceramsite propping agent materials for building light aggregate and oil and gas exploitation can be met.

Owner:TIANJIN CHENGJIAN UNIV

Silk- and satin-texture ceramic glaze, preparation method and ceramic rock plate using silk- and satin-texture ceramic glaze

ActiveCN111943723AExcellent overall performance of the glazeReduce manufacturing costFritPotassium feldspar

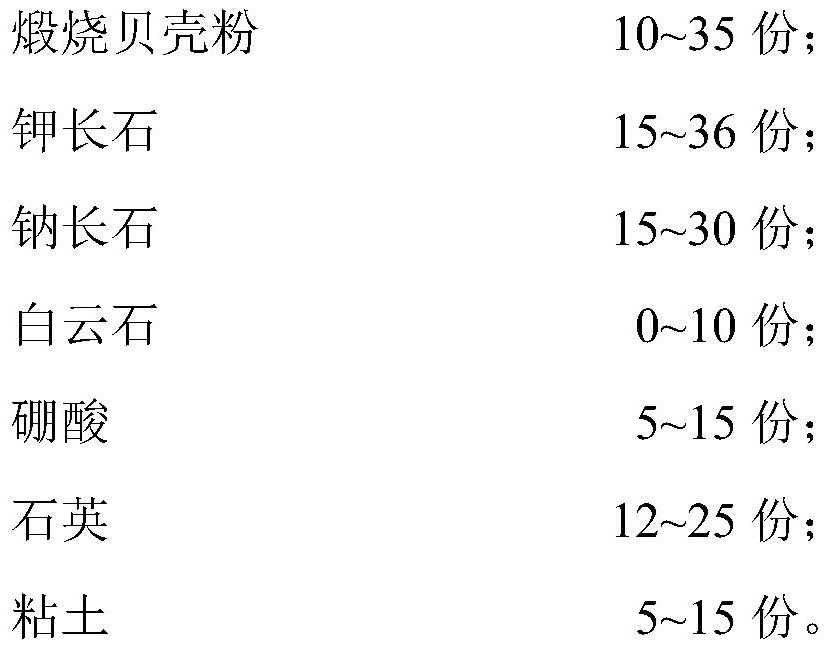

The invention discloses a silk- and satin-texture ceramic glaze which comprises the following components in parts by weight: 10-35 parts of calcined shell powder, 15-36 parts of potassium feldspar, 15-30 parts of albite, 0-10 parts of dolomite, 5-15 parts of boric acid, 12-25 parts of quartz and 5-15 parts of clay. According to the ceramic glaze disclosed by the invention, CaO is introduced by taking the calcined shell powder containing a large amount of nepheline crystal forms as a raw material, so that the ceramic glaze has the decorative effects of silk-like luster and texture and the advantage of excellent comprehensive performance of a glaze surface after sintering molding on the premise that a frit glaze raw material with a narrow sintering range is not required to be added; meanwhile, the production cost is low, the firing range is wide, and the glaze is particularly suitable for surface decoration of ceramic rock plates. The invention further discloses a ceramic rock plate withthe silk and satin texture on the surface, and the problems that an existing ceramic rock plate product is poor in surface decoration effect, and an existing ceramic brick with the silk glaze effectis narrow in firing range and high in production cost are solved.

Owner:FOSHAN OCEANO CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com