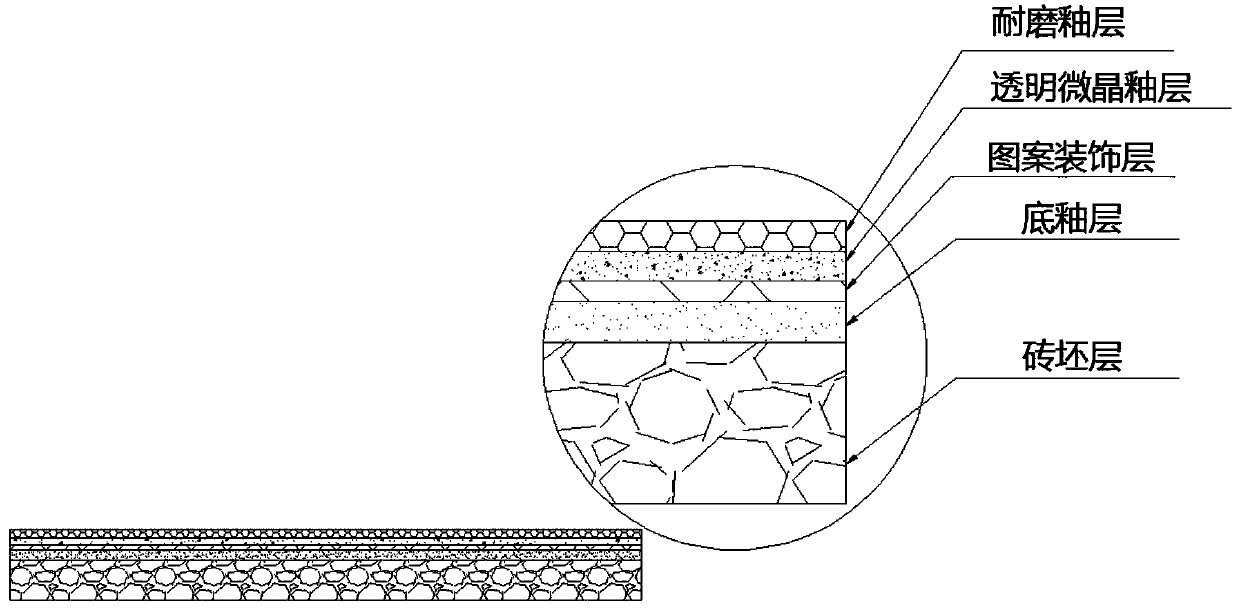

Microcrystalline glaze, wear-resistant glaze, transparent microcrystalline wear-resistant full-polished glaze ceramic tile and preparation method

A transparent glaze and microcrystalline technology, applied in the field of ceramic tiles, can solve the problems of unsuitable development of dark-colored products, low wear resistance of full-polished glazed tiles, and difficulty in production control, so that the preparation cost will not increase, and the production Reduced control difficulty and wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The process implementation plan for producing white products with a specification of 600*600mm and a thickness of 10mm is as follows:

[0066] Described transparent microcrystalline glaze comprises the following raw materials by weight:

[0067] 5 parts of calcined zinc oxide; 5 parts of barium carbonate; 18 parts of potassium feldspar; 9 parts of albite; 6 parts of alumina; 16 parts of calcite; 4 parts of quartz powder; 6 parts of dolomite; 10 parts of kaolin; 12 parts of calcined kaolin ; 5 parts of wollastonite; 1 part of calcium fluoride; 1 part of titanium dioxide; 1 part of corundum powder.

[0068] The preparation method of the transparent microcrystalline wear-resistant fully polished glazed ceramic tile comprises the following steps:

[0069] 1) Green body pressing;

[0070] 2) Pour the bottom glaze, the brick blank is drenched with a decorative bottom glaze through the disc bell jar, and the amount of the decorative bottom glaze is 610g / m2 2 , the specific ...

Embodiment approach

[0077] The production process of dark gray products with a specification of 600*1200mm and a thickness of 10mm is as follows:

[0078] Described transparent microcrystalline glaze comprises the following raw materials by weight:

[0079] 5 parts of calcined zinc oxide; 5 parts of barium carbonate; 18 parts of potassium feldspar; 9 parts of albite; 8 parts of alumina; 16 parts of calcite; 4 parts of quartz powder; 6 parts of dolomite; 10 parts of kaolin; 12 parts of calcined kaolin ; 5 parts of wollastonite; 1 part of calcium fluoride; 1 part of titanium dioxide.

[0080] The preparation method of the transparent microcrystalline wear-resistant fully polished glazed ceramic tile comprises the following steps:

[0081] 1) Green body pressing;

[0082] 2) Pour the bottom glaze, the brick blank is poured a decorative bottom glaze through the disc bell jar, and the amount of the decorative bottom glaze is 620g / m2 2 , the specific gravity is 1.79, and the glaze flow rate is 27s; ...

Embodiment 3

[0090] The implementation of the process for producing black products with a size of 1200*2600mm and a thickness of 6mm is as follows:

[0091] Described transparent microcrystalline glaze comprises the following raw materials by weight:

[0092] 5 parts of calcined zinc oxide; 5 parts of barium carbonate; 18 parts of potassium feldspar; 9 parts of albite; 8 parts of alumina; 16 parts of calcite; 4 parts of quartz powder; 6 parts of dolomite; 10 parts of kaolin; 12 parts of calcined kaolin ; 5 parts of wollastonite; 1 part of calcium fluoride; 1 part of titanium dioxide.

[0093] The preparation method of the transparent microcrystalline wear-resistant fully polished glazed ceramic tile comprises the following steps:

[0094] 1) Green body pressing;

[0095] 2) No primer is applied, and the combination of rubber roller and inkjet decoration is directly used to decorate the glaze pattern;

[0096] 3) Drying, using electric infrared drying method to dry the brick blank with p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com