Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134 results about "Ore sorting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ore sorting refers to the process of separating an ore into separate constituent parts. Today, ore sorters are widely used in industrial mineral mines, diamond mines and base and precious metal mines. Ores are typically sorted to increase the efficiency of other refining processes, by reducing the amount of material to be processed while simultaneously increasing its purity.

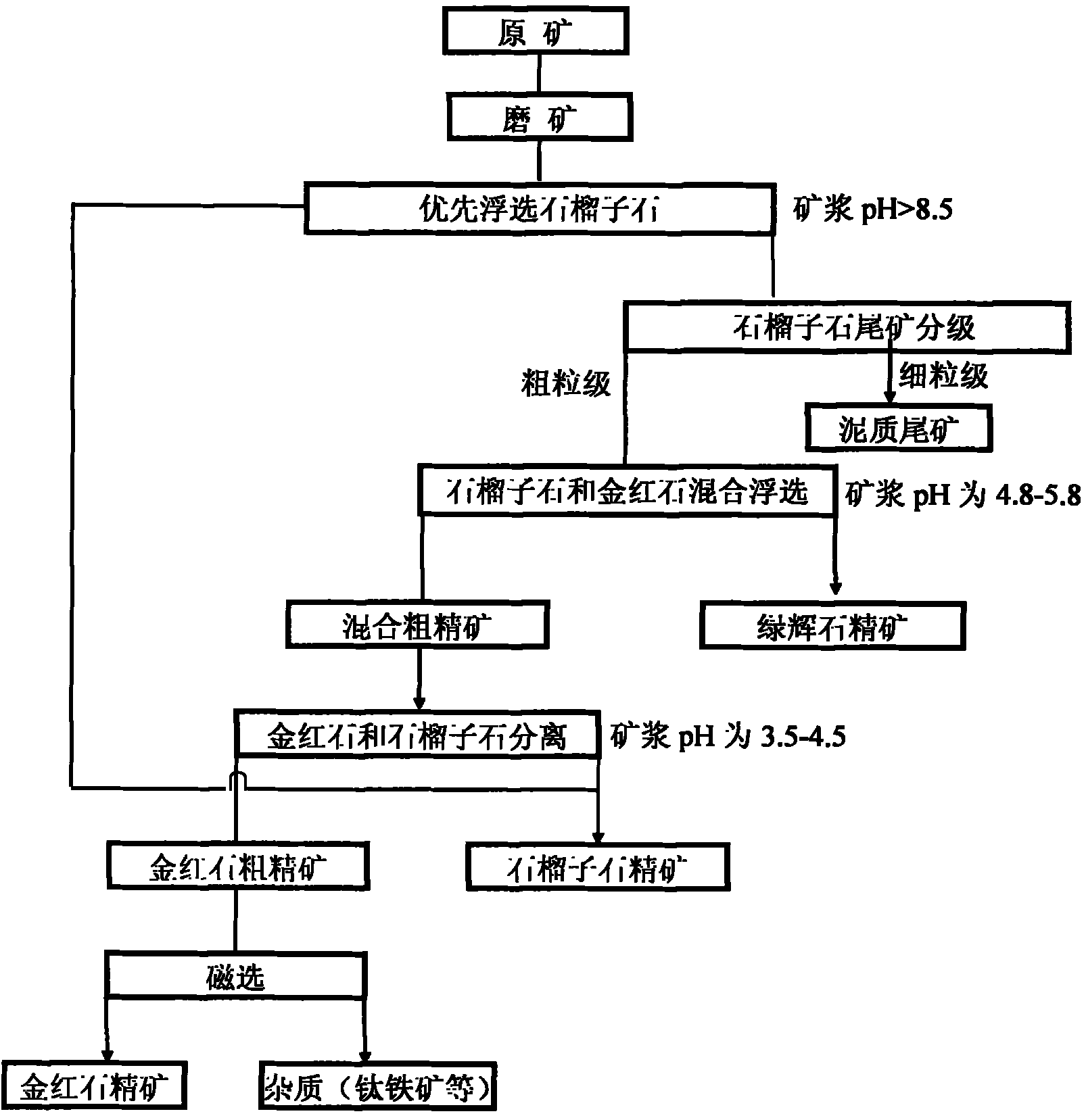

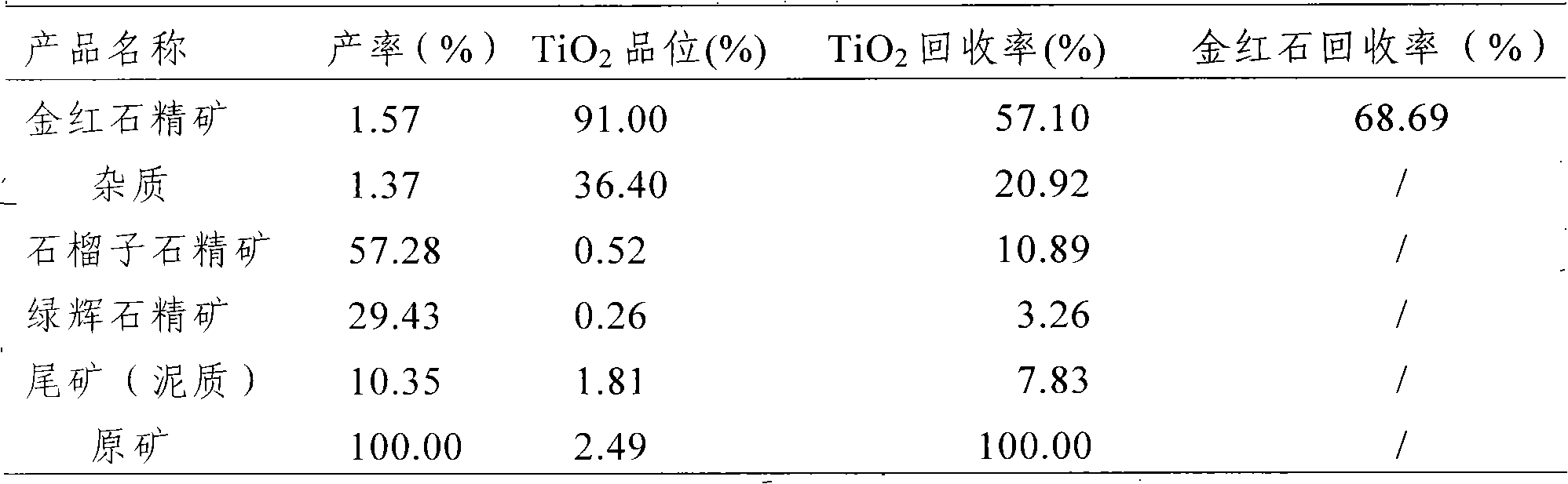

Eclogitic rutile ore sorting method

The invention provides an eclogitic rutile ore sorting method. The method comprises the following steps of: floating garnet after the eclogitic rutile ore is grinded so as to obtain garnet concentrate; grading the garnet tailing; performing collective floatation on garnet and rutile mixed rough concentrate to separate omphacite so as to obtain omphacite concentrate; separating the mixed rough concentrate to obtain garnet concentrate and rutile concentrate; and magnetically separating the rutile rough concentrate to obtain rutile concentrate. Most garnet is preferentially floated, so the method ensures great reduction of the using amount of reagents for the subsequent rutile sorting operation and reduction of rutile sorting cost, realizes the separation of the rutile, the garnet and the omphacite by adopting floatation and magnetic separation by controlling the pH value of the ore pulp, basically realizes no tailing emission, reduces environmental pollution, has the advantages of low cost and easy implementation, and can remarkably improve the comprehensive reclaiming level of the eclogitic rutile ore.

Owner:西安西北有色地质研究院有限公司

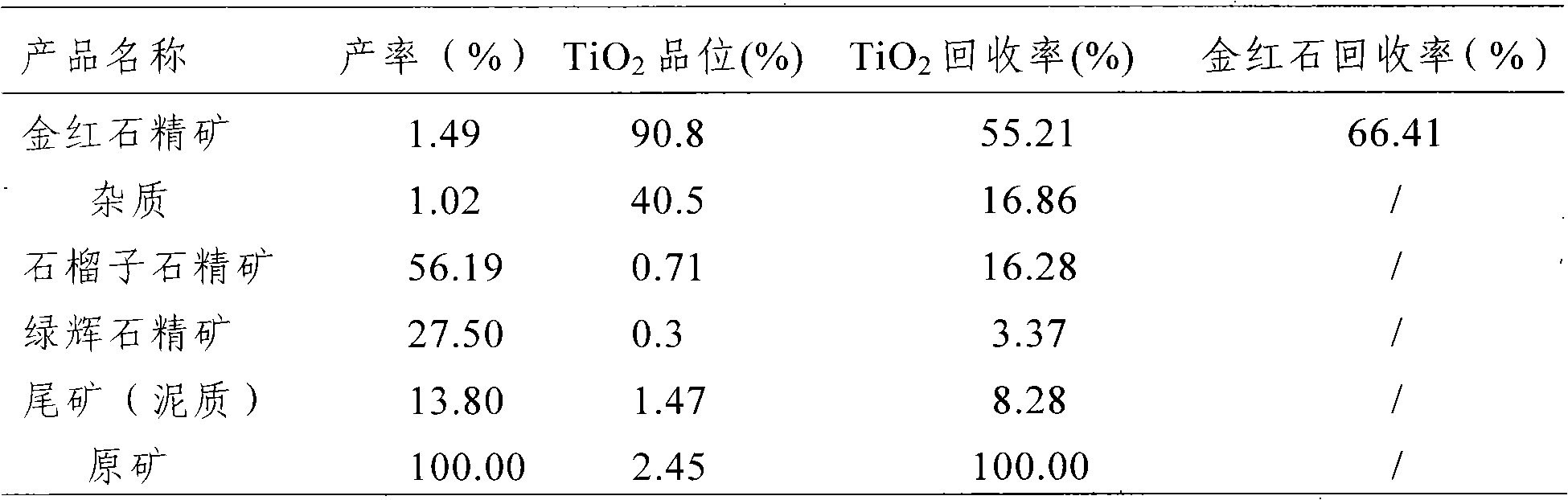

Ore dressing method for lead-zinc-silver poly-metallic ores

The invention provides an ore dressing method for lead-zinc-silver poly-metallic ores. Lead-silver concentrates and zinc concentrates are finally obtained through the steps of raw ore grinding, lead fast roughing, lead slow roughing, lead scavenging, lead fast concentration, lead slow concentration, zinc fast roughing, zinc slow roughing, zinc scavenging, zinc fast concentration and zinc slow concentration. The lead-zinc-silver poly-metallic ores sorted by the ore dressing method provided by the invention are good in sorting index and high in separation efficiency; the ore dressing method is a lead-zinc-silver ore dressing method which is stable, efficient, strong in adaptive capacity, good in sorting effect, high in comprehensive recovery index and low in production cost and is suitable for popularization and application.

Owner:DONGSHENGMIAO MINING LLC +2

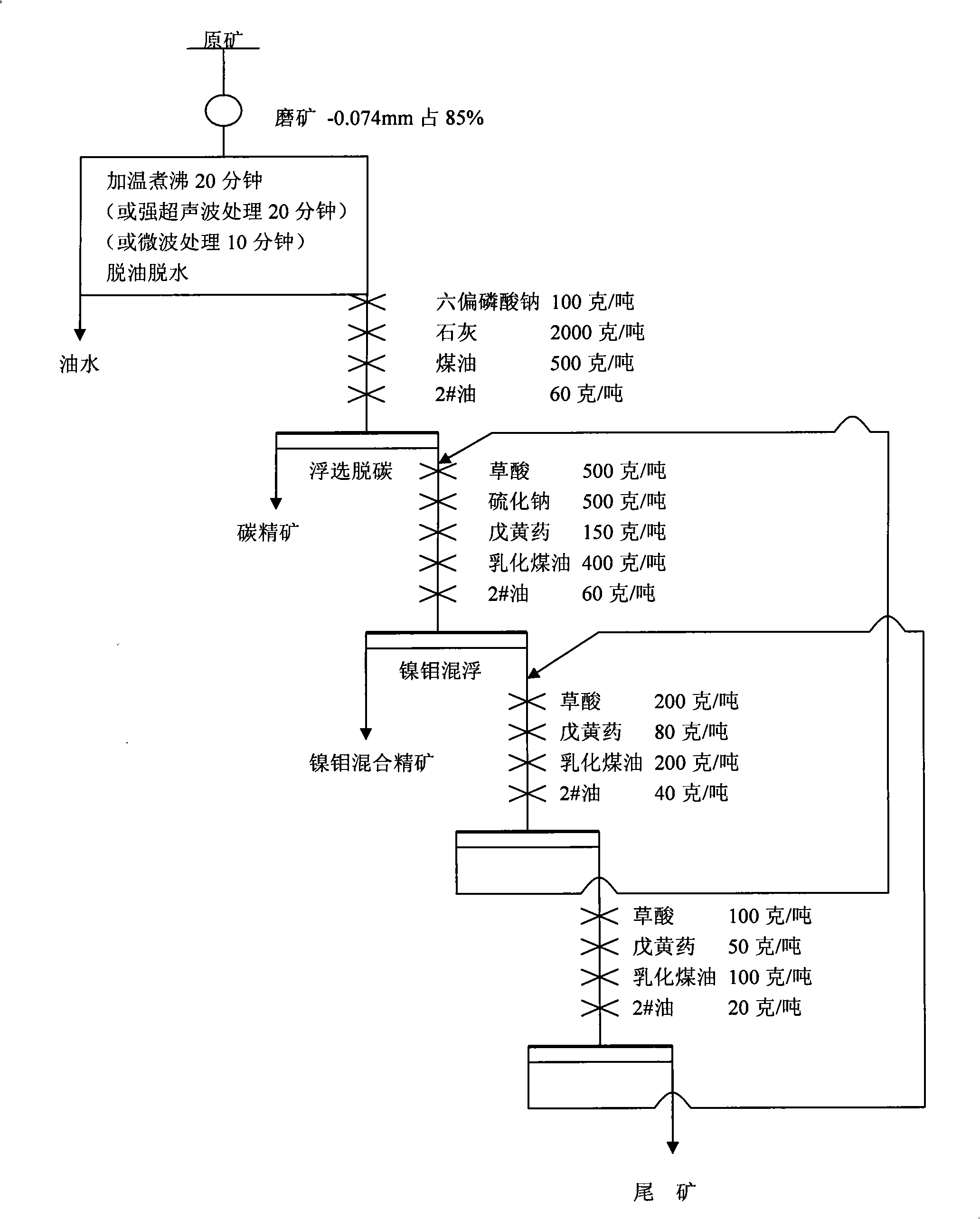

High-efficiency ore sorting technique for nickel-molybdenum mineral

The invention provides a high-efficiency beneficiation technology of NiMo minerals. The technical proposal of the invention is that: a strong physical field is introduced to preprocess and decarbonize minerals, such as a thermodynamic field, an intense ultrasonic wave field or a microwave field, etc., and after adding high-efficiency activating agents to activating Ni and Mo, kerosene or xanthate is used for collection. 0.5 to 2 percent of low grade NiMo minerals are processed by the technology of the invention to obtain NiMo mixed concentrate with the NiMo grade of 5 to 8 percent and a recovery rate of more than 75 percent, which fully satisfies the requirement of metallurgical materials in a united flow of the beneficiation and metallurgy, thus providing a new way for NiMo mineral resources in China refractory black rock series.

Owner:CENT SOUTH UNIV

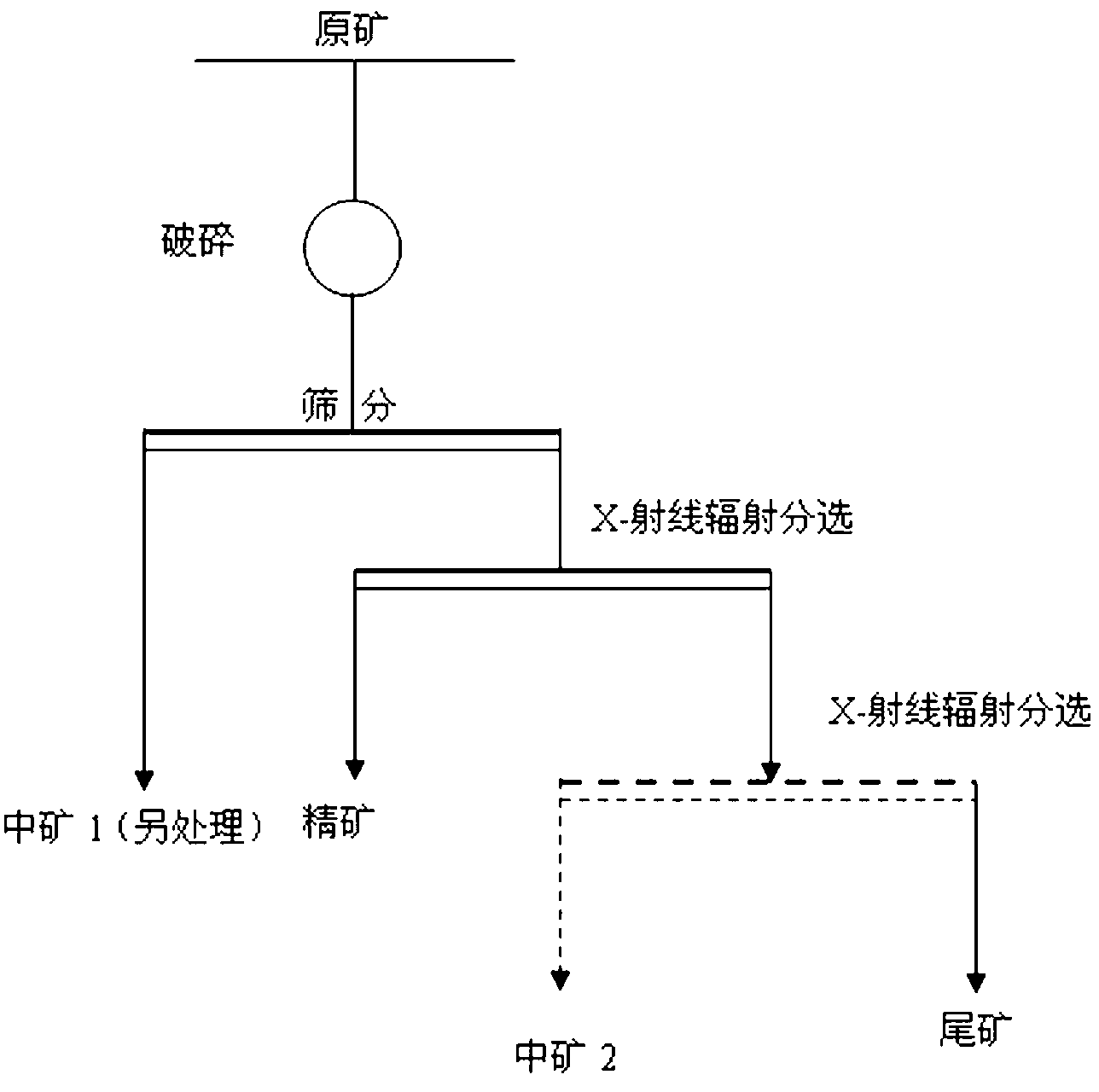

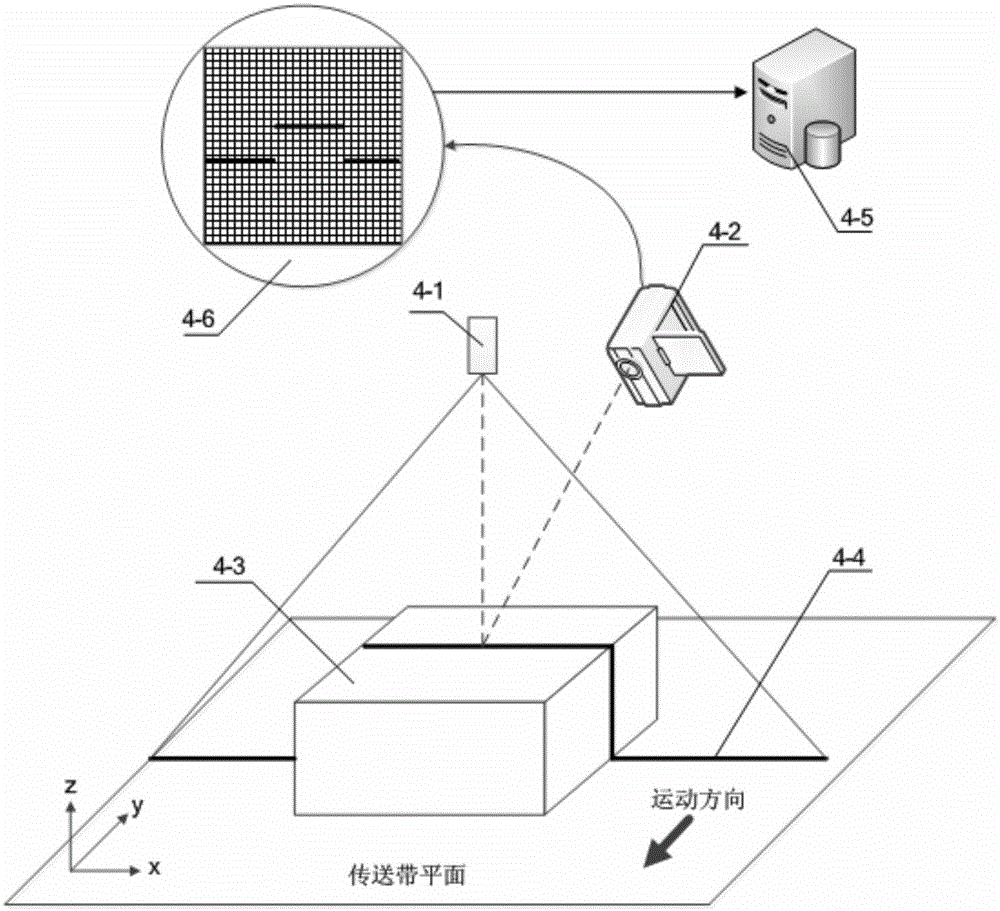

Method for sorting and pre-enriching lean hematite by using X-ray radiation

The invention relates to a method for sorting and pre-enriching lean hematite by using X-ray radiation. The invention belongs to the technical field of mineral processing. The method comprises the steps that: copper-containing ores are crushed to a size below 150mm by using a crusher; the crushed material is sieved by using a sieving machine with a mesh size greater than or equal to 20mm; on-sieve material is delivered to an X-ray radiation sorting machine through a feeder; a sorting threshold is set in the control system of the X-ray radiation sorting machine according to the iron content in crude ore; and after the sorting of the X-ray radiation sorting machine, concentrate and tailings are obtained. The method provided by the invention is domestically initiative. Target component grade of processed ore is low, mechanical and automation degrees are high, ore-sorting cost is saved, the grade of selected material iron of a concentrator is greatly improved, and equipment utilization rate is substantially improved. Also, the process provided by the invention has the advantages of reasonable technology and stable running. With the method, industrialization of lean hematite pre-sorting can be easily realized, and concentrator economic and technical indicators and comprehensive benefits can be greatly improved.

Owner:NORTHEASTERN UNIV

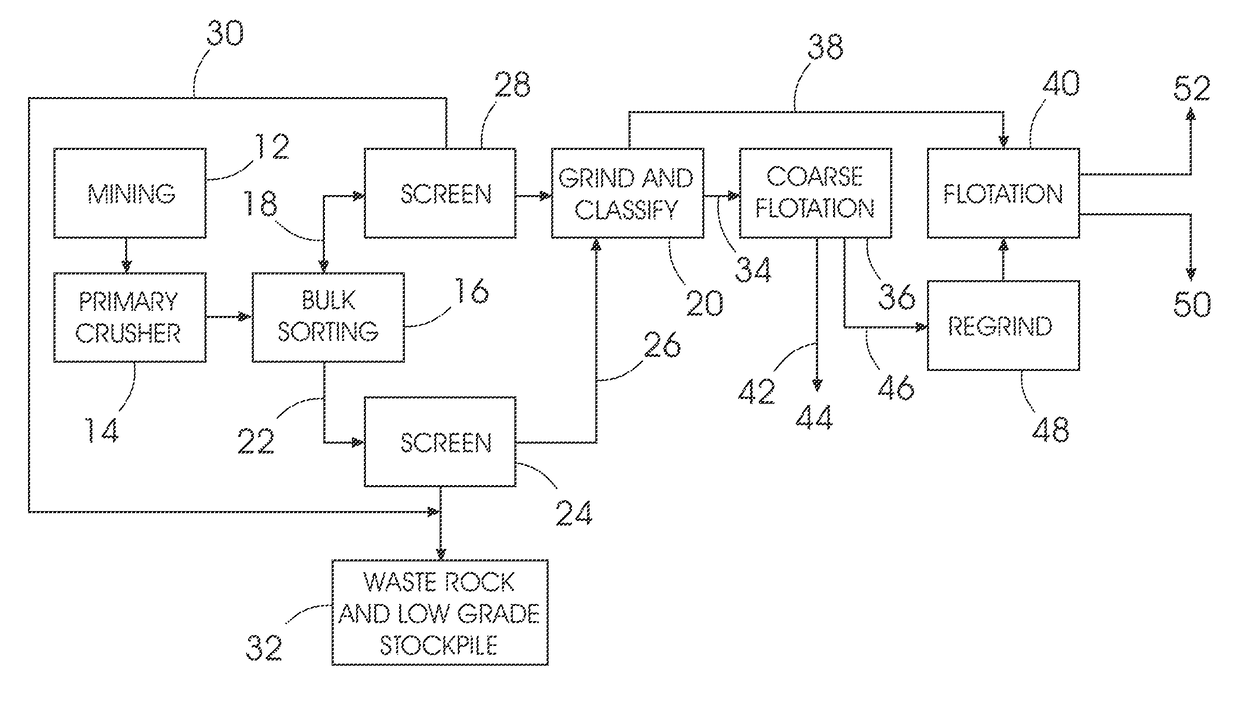

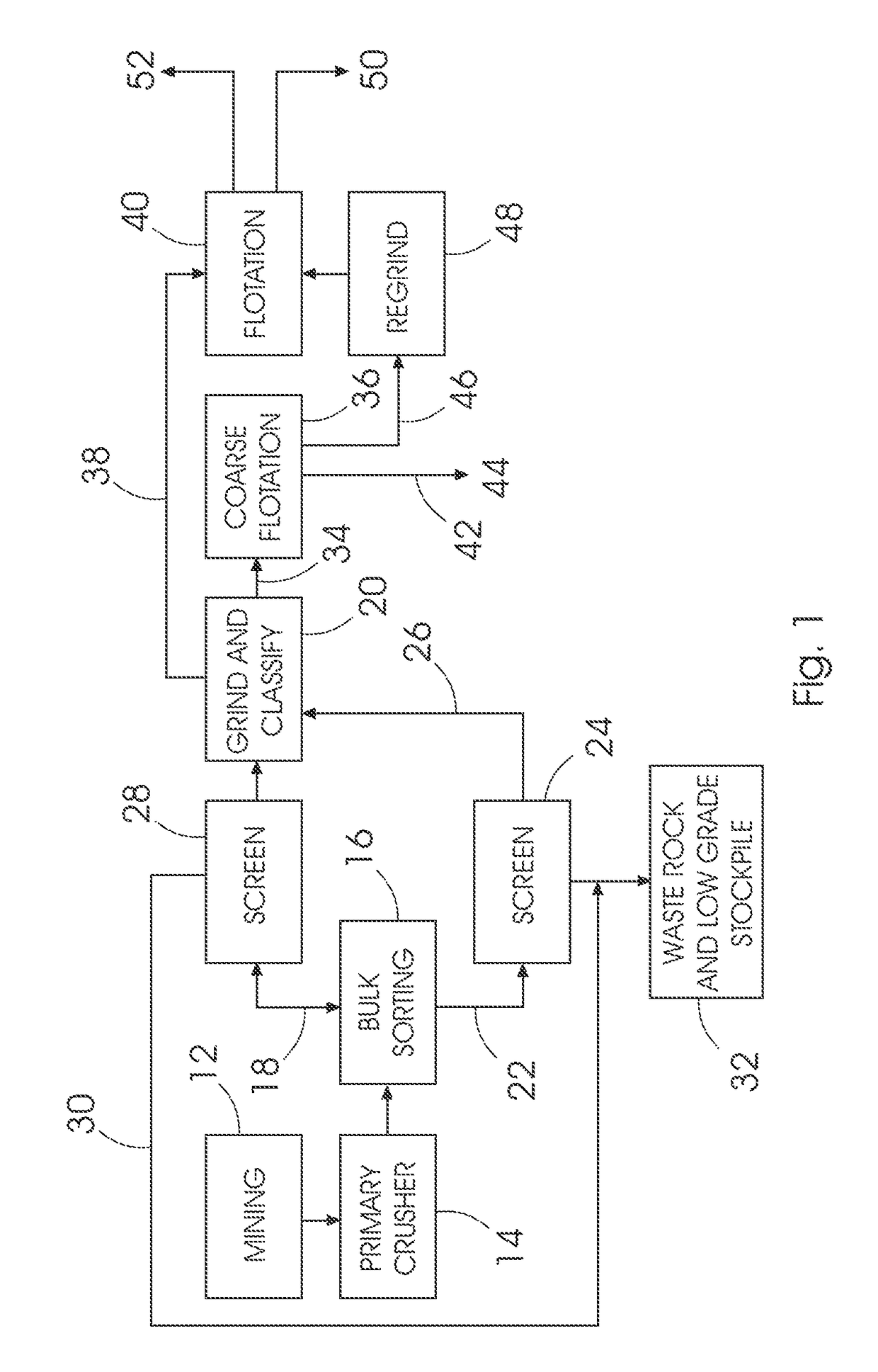

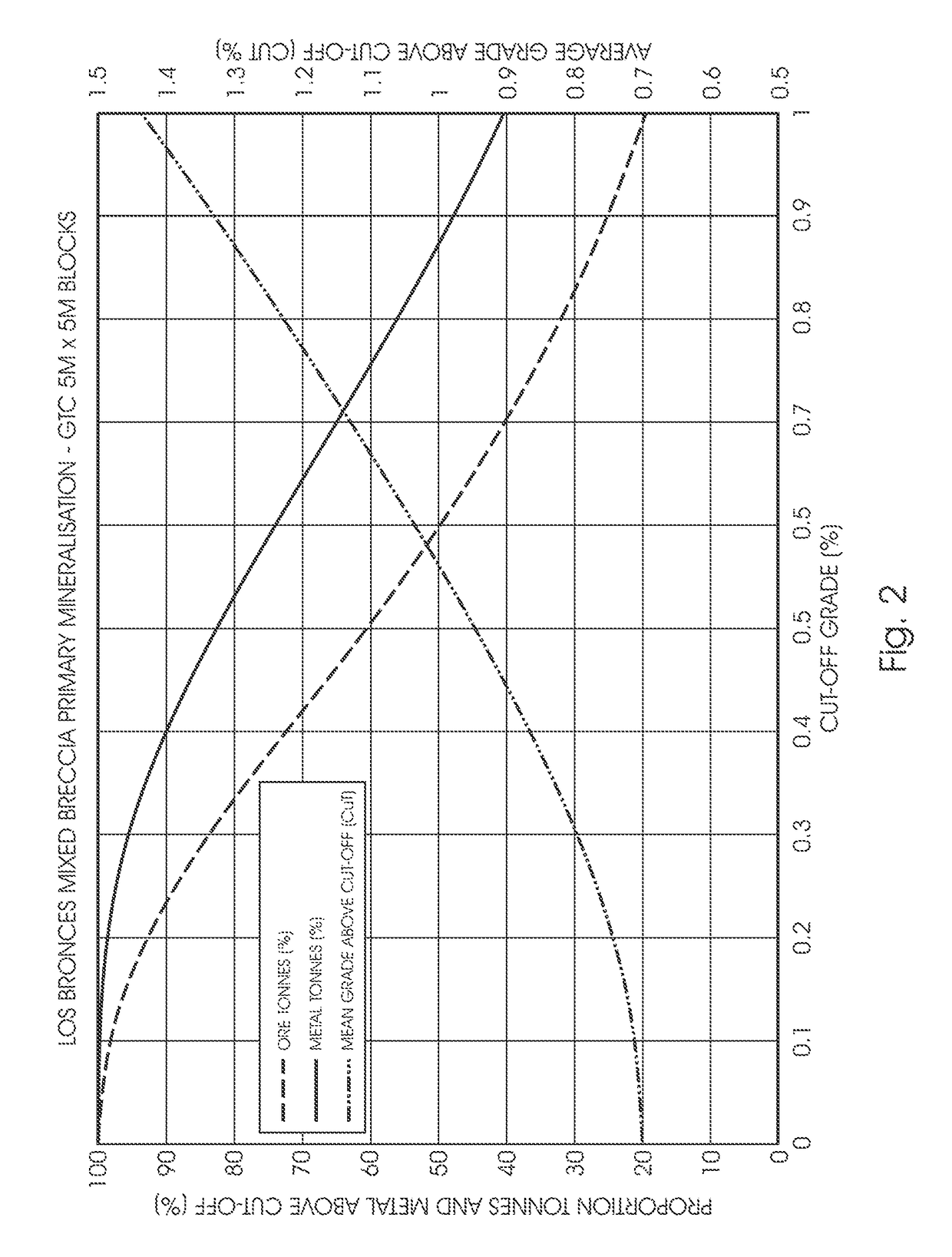

Maximise the value of a sulphide ore resource through sequential waste rejection

This invention relates to an integrated process for recovering value metals from sulphide ore which includes the steps of bulk sorting 16 and screening 24 / 28 crushed ore. The sorted / screened coarse ore stream is ground and classified 20 to provide a coarse fraction 34 suitable for coarse flotation and a first fine fraction 38 suitable for flotation. The coarse fraction suitable for coarse flotation is subjected to coarse flotation 36 thereby to obtain a gangue 42 and an intermediate concentrate 46. The intermediate concentrate is subjected to grinding 48 to provide a second fine fraction suitable for conventional flotation. The first fine fraction and the second fine fraction are subjected to conventional flotation 40 to provide a concentrate and tailings. This process that capitalizes on the natural heterogeneity of sulphide orebodies, and utilizes bulk sorting, screening and coarse flotation beneficiation technologies in a novel multistage configuration to reject the maximum quantity of waste gangue prior to fine comminution.

Owner:ANGLO AMERICAN TECH & SUSTAINABILITY SERVICES LTD

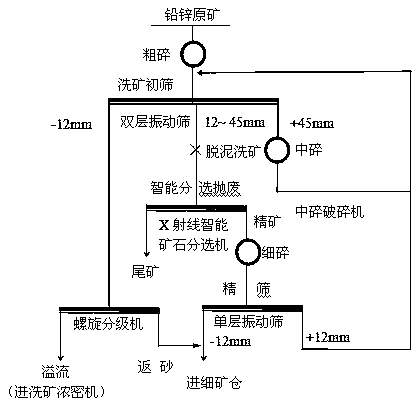

Intelligent sorting method for lead-zinc massive ore

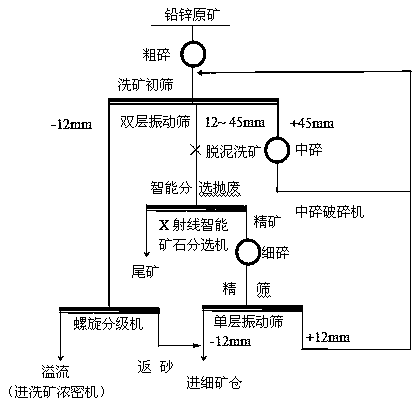

The invention discloses an intelligent sorting method for lead-zinc massive ore. The method comprises the following steps: (1) coarse crushing and primary screening, specifically, crushing the lead-zinc raw ore by a coarse crushing crusher, and then washing, screening and grading the crushed lead-zinc raw ore by a double-layer vibrating screen; (2) medium crushing, specifically, conveying the primarily screened large-particle-size ore to a medium crushing crusher, and washing and screening the crushed ore through the double-layer vibrating screen in the step (1); (3) intelligent sorting and waste throwing, specifically, conveying the primarily screened medium-particle-size ore to an X-ray intelligent ore sorting machine for intelligently sorting and waste throwing to obtain tailings and waste rocks; and (4) fine crushing and fine screening, specifically, conveying the intelligently sorted fine ore to a fine crushing crusher, and feeding the crushed fine ore into a single-layer vibrating screen for fine screening. According to the intelligent sorting method for the lead-zinc massive ore, the lead-zinc massive ore is coarsely crushed at first, and then the gangue mineral dissociatedin the lead-zinc massive ore is directly thrown out by the X-ray intelligent ore sorting machine, so that the ore dressing cost is reduced, the ore dressing grade and the processing capacity of a dressing plant are improved, the tailing yield is reduced, and the pressure of insufficient storage capacity of a tailing pond is relieved.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

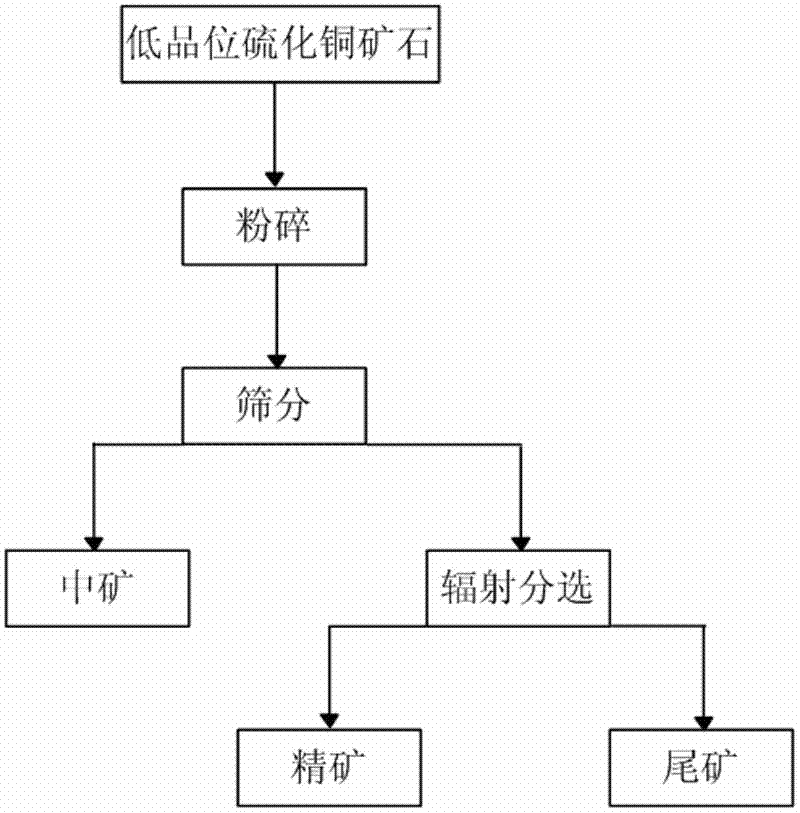

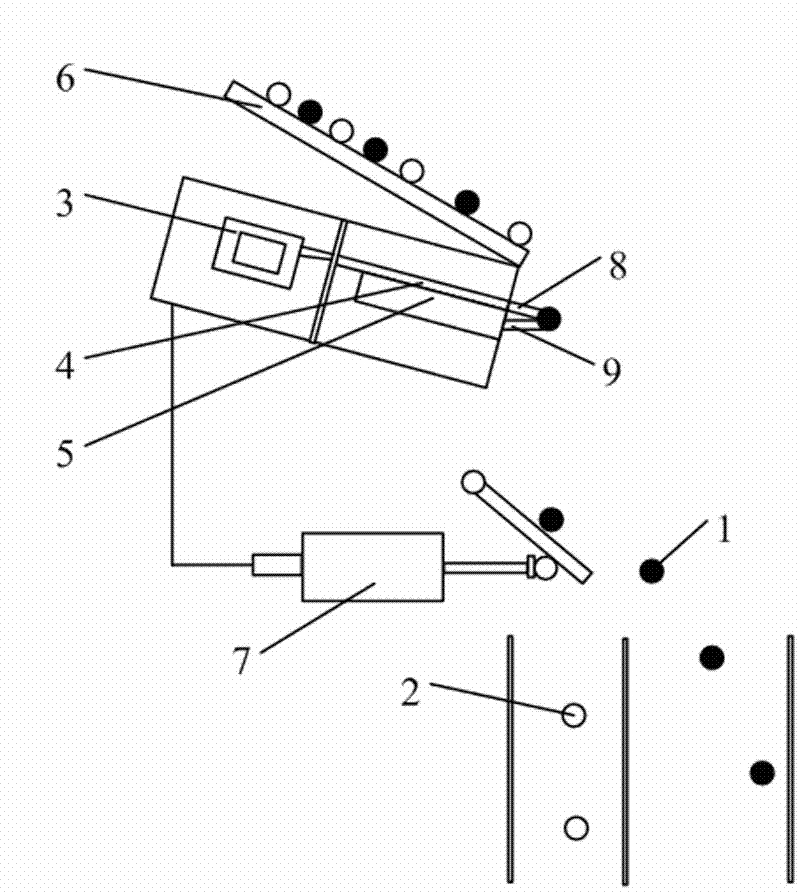

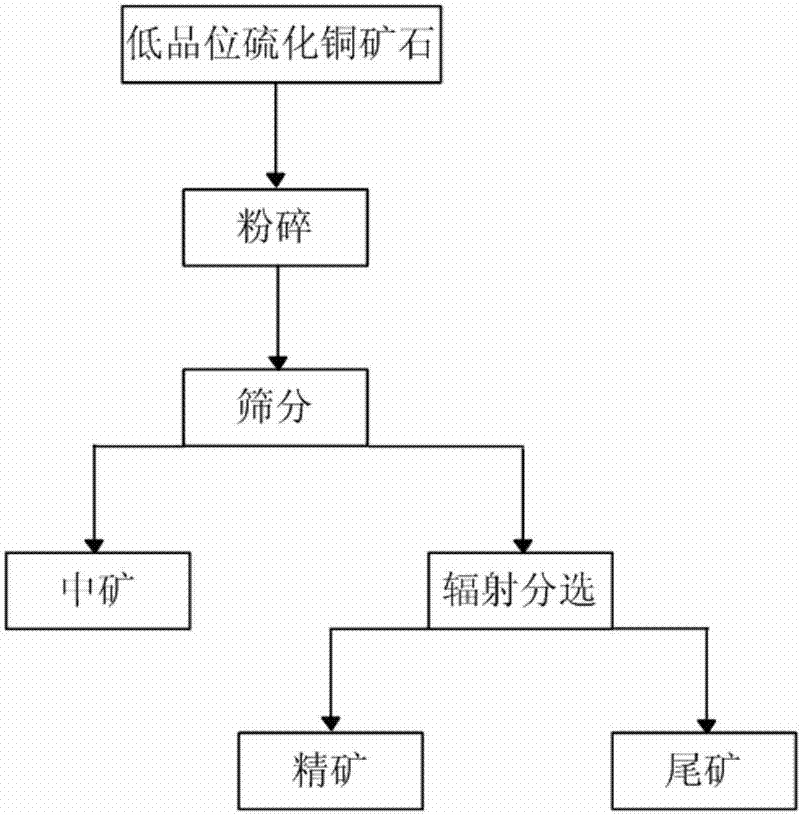

X-ray radiation pre-selecting enrichment method for copper sulfide ore with low grade

The present invention provides an X-ray radiation pre-selecting enrichment method for copper sulfide ores with a low grade, which belongs to the technical field of ore processing. The method includes steps as follows: 1) crushing original ores of the copper sulfide ores with a low grade into particles with a size of no more than 200 mm; 2) sieving the crushed materials to obtain the copper sulfide feeding through a sieving machine with 20-50 mm sieve mesh; 3) setting a grade threshold within 0.15-0.30 for sorting ore concentrates and tailings in a control system of an X-ray sorting machine, putting the copper sulfide ore feeding into the X-ray sorting machine, and sorting the copper sulfide ore feeding to obtain the ore concentrates and the tailings of the copper sulfide ore. The method has high mechanization degree and automation degree, reasonable technique, stable operation, and low ore sorting cost, which is easy to realize the industrialization of copper ores with a low grade.

Owner:NORTHEASTERN UNIV +1

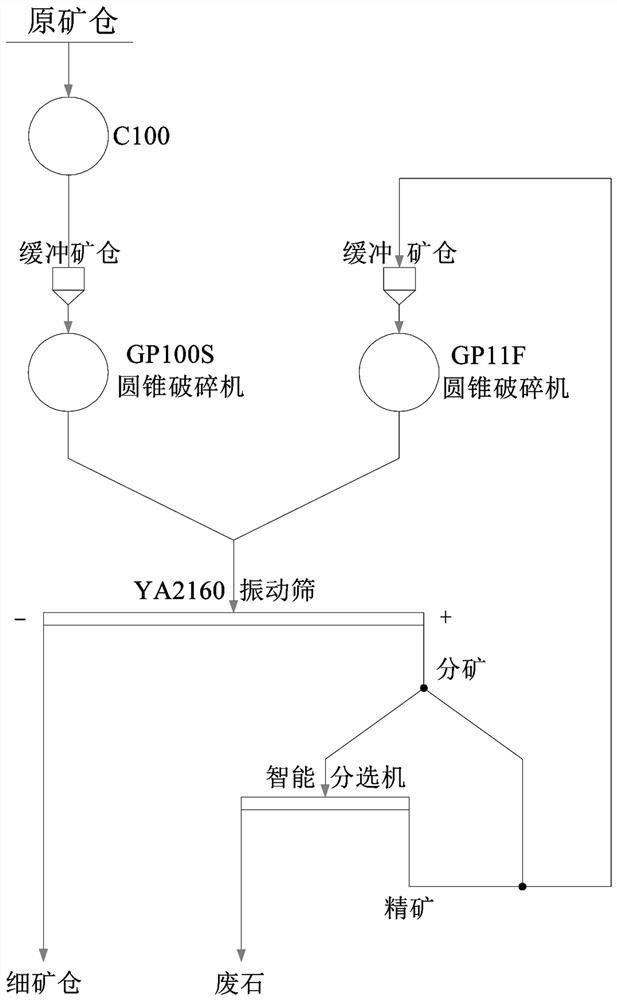

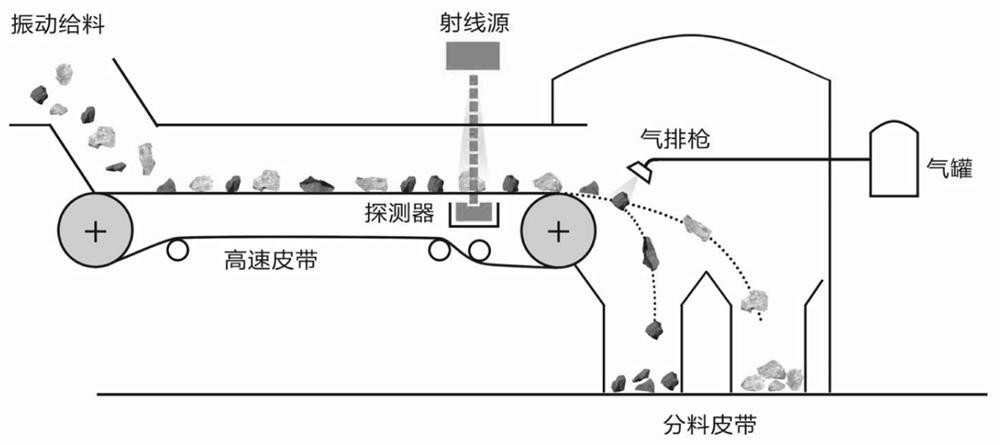

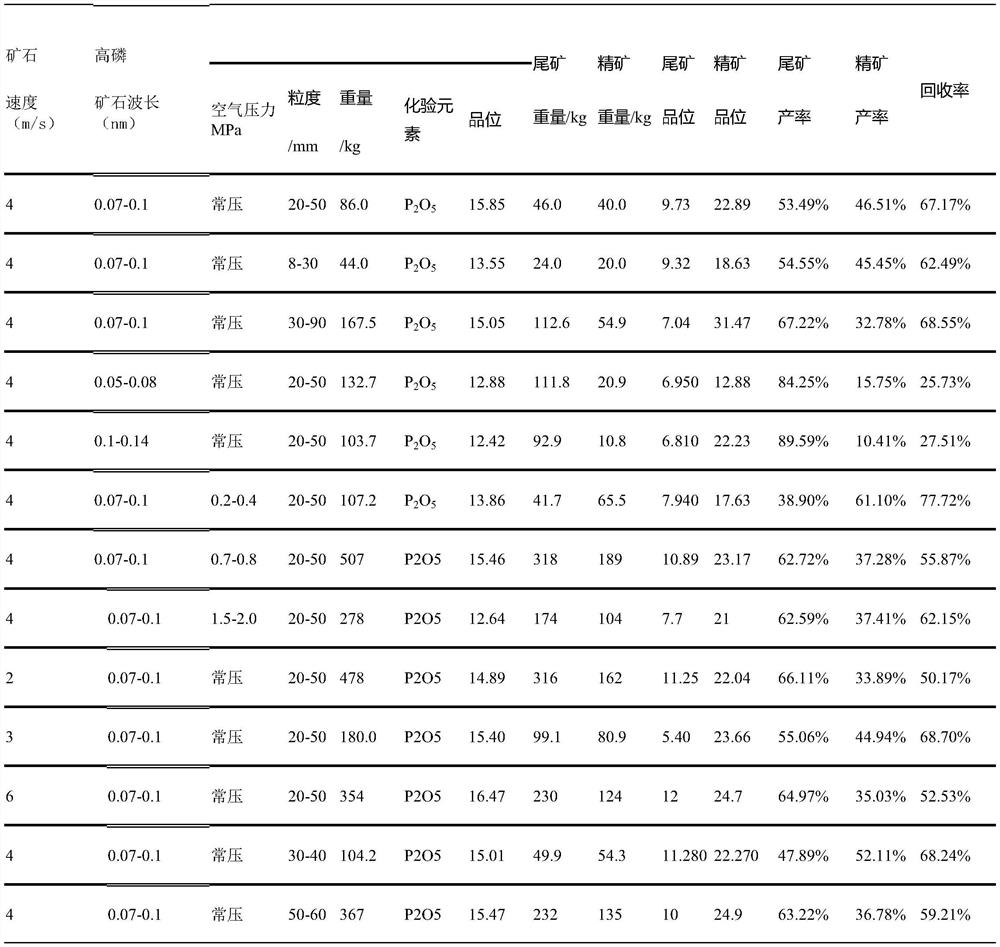

Photoelectric beneficiation sorting process for phosphorite

ActiveCN112221657AFew supporting facilitiesReduce pressure on environmental protectionGrain treatmentsSortingMining engineeringPhosphorite

The invention provides a photoelectric beneficiation sorting process for phosphorite. The process comprises the following steps of screening phosphorite raw ore; conveying the ore obtained through screening into a photoelectric sorting machine through a belt conveyor, conducting X-ray ore radioscopy and substance recognition , recognizing each piece of ore through X-rays, collecting data through adetector, and recognizing and distinguishing the ore and waste rock through an intelligent algorithm; and after recognition by the photoelectric sorting machine is completed, a high-speed gas exhaustgun is used for accurate striking to separate concentrate from tailings , and then photoelectric beneficiation of the phosphorite can be completed. In the process of screening the phosphorite raw ore, the raw ore is crushed and vibrated to obtain ore with the particle size larger than 50 mm, then the ore is crushed again, and obtained ore with the particle size being 20-50 mm is conveyed into thephotoelectric sorting machine to be subjected to photoelectric sorting. At present, the process is only targeted at medium-phosphorus-layer high-magnesium phosphorite, the sorting effect is remarkable, and when the grade of sorted raw ore is 17.5%, the yield can reach 40% or above, and the recovery rate is high.

Owner:HUBEI SHANSHUYA MINING SCI & TECH DEV +1

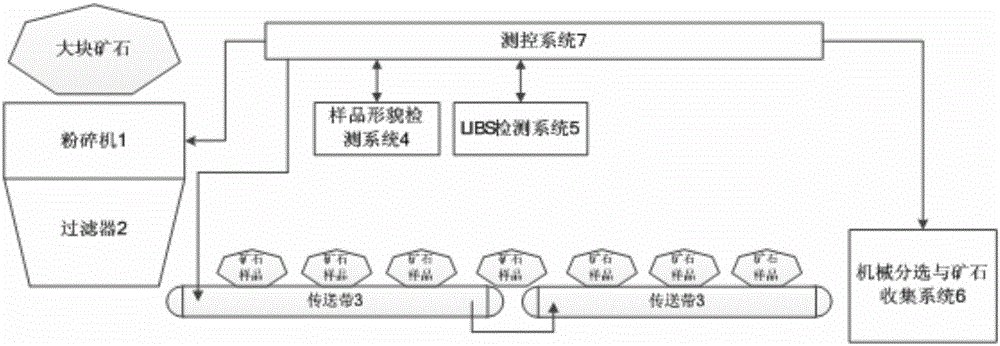

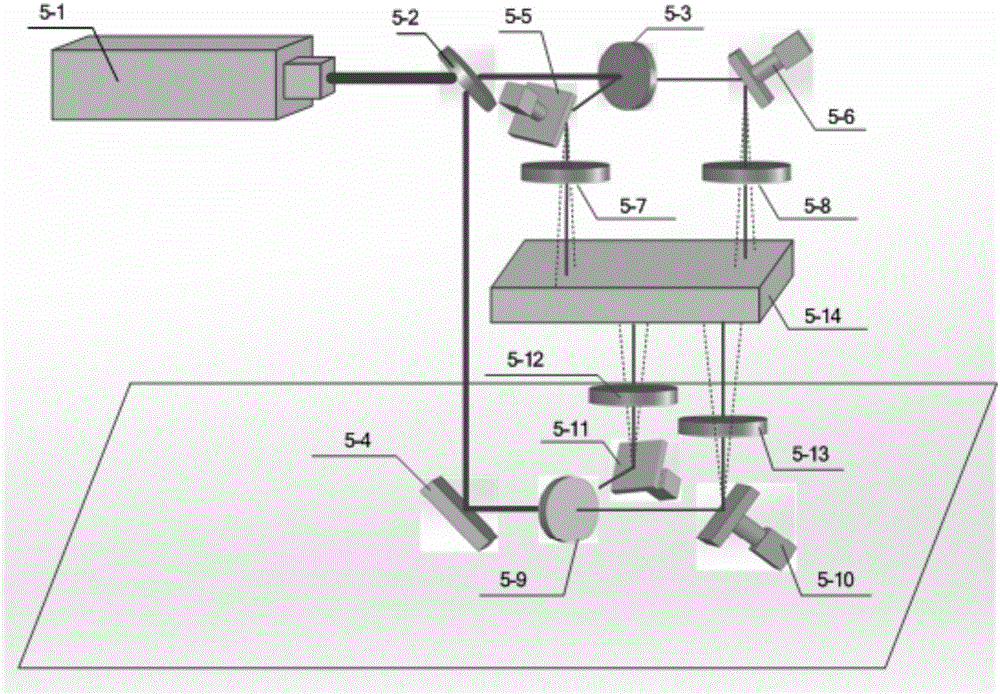

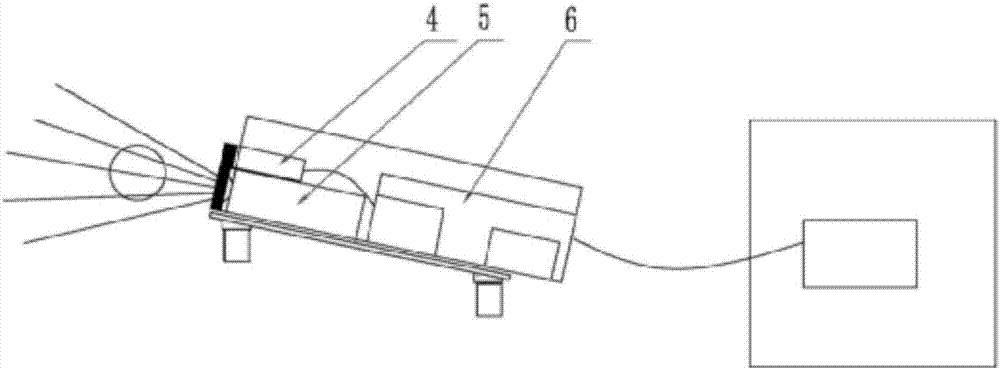

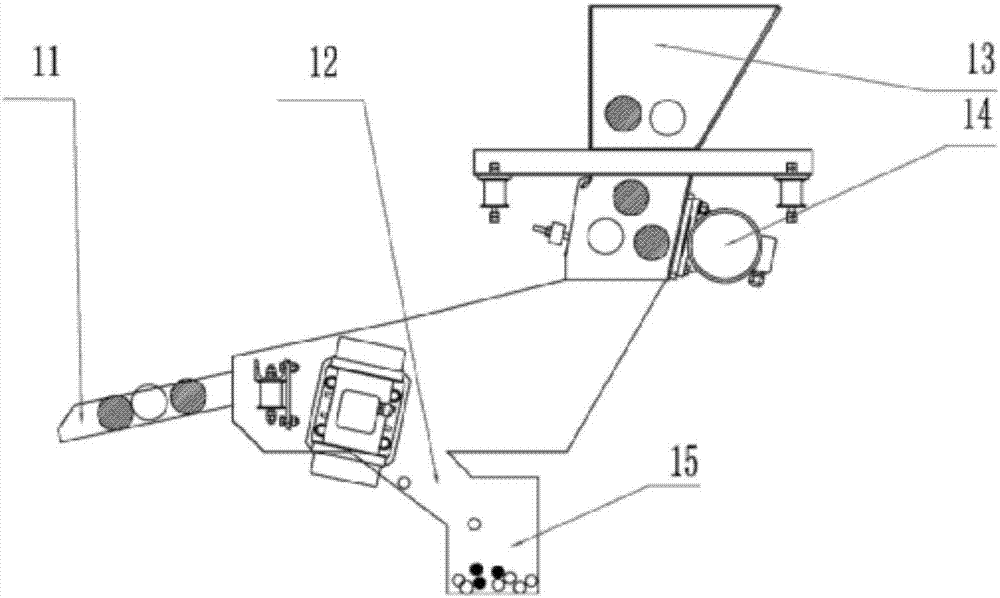

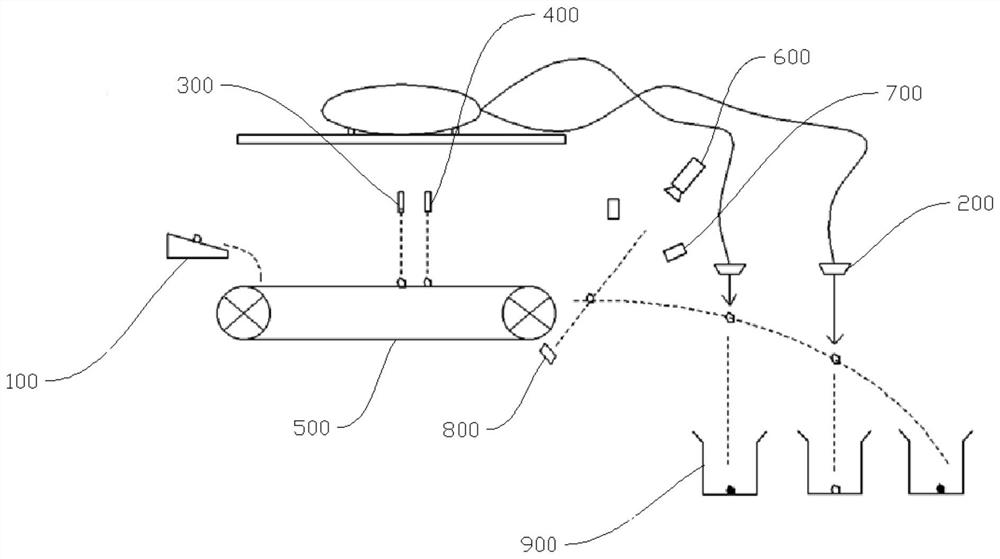

Waste ore sorting method and device based on laser induced breakdown spectroscopy (LIBS)

ActiveCN106824825AAccurately reconstruct geometryAnalysis by thermal excitationSortingControl systemCollection system

The invention belongs to the field of laser spectroscopy detection and ore sorting, and discloses a waste ore sorting method and device based on the laser induced breakdown spectroscopy (LIBS). The device comprises an ore pulverizer, a filter, a conveying device, a sample shape inspection system, an LIBS detection system, a mechanical sorting and ore collecting system and a measurement and control system. The pulverizer and the filter are used for smashing massive waste ore into small ore blocks of the similar sizes and shapes. The sample shape inspection system is used for obtaining the average heights and boundary dimensions of samples, and further controlling the focusing distance and scanning range of the LIBS detection system. The LIBS detection system is used for detecting material compositions of the ore and determining the ore grade. The mechanical sorting system conveys the ore and the waste ore to different ore collecting tanks separately according to detection results. The measurement and control system is used for performing unified coordination control over all functional units of the device.

Owner:JILIN UNIV

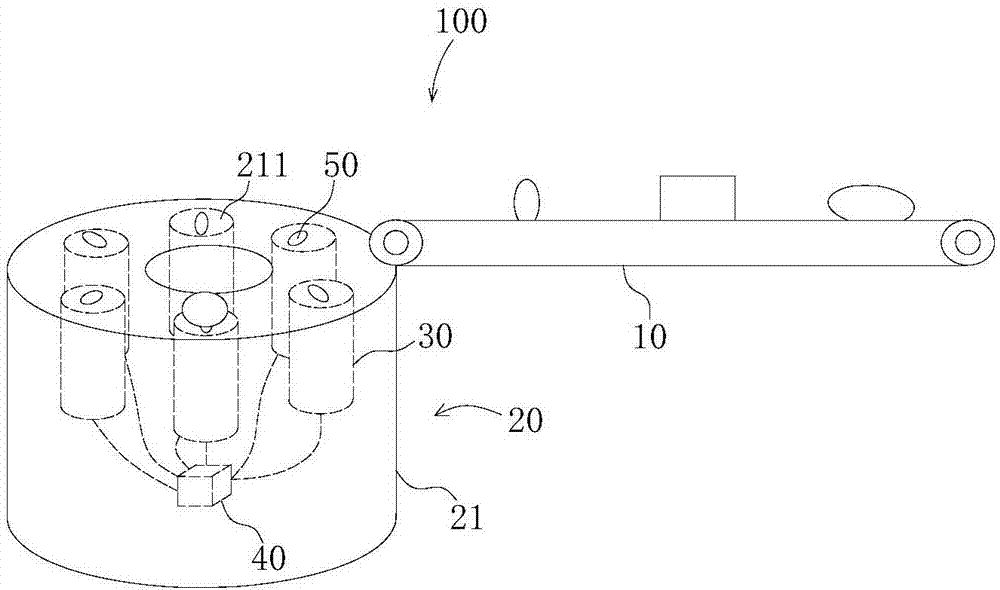

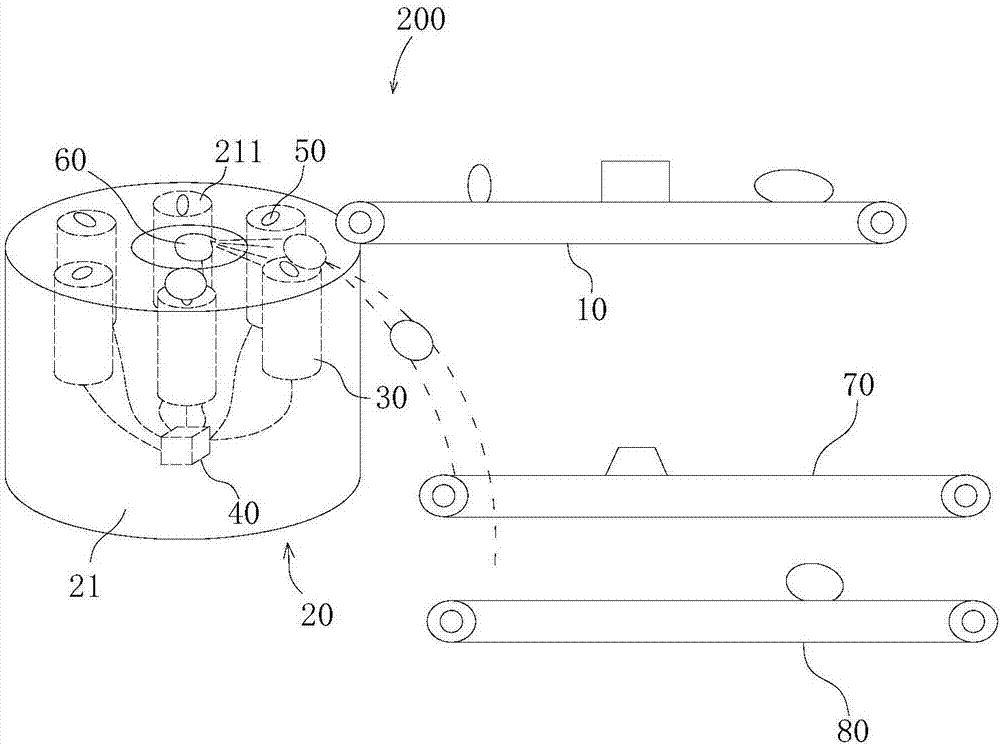

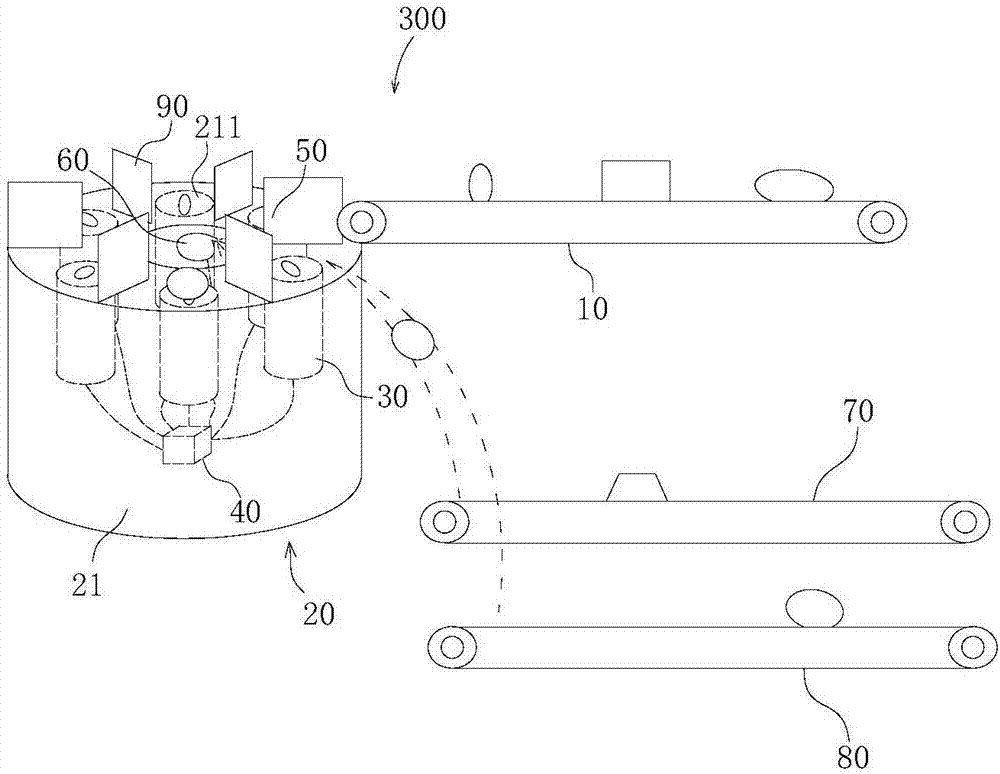

Atomic ore sorting system

The invention provides an atomic ore sorting system. The atomic ore sorting system comprises a conveying belt, an annular rotary measuring table, nuclear radiation detectors, a processor and pressure sensors. The annular rotary measuring table comprises a hollow turntable; and the turntable can rotate around the center of the turntable. The nuclear radiation detectors and the processor are put in the turntable; the surface of the turntable is divided into multiple measurement areas; the nuclear radiation detectors are correspondingly arranged at the bottoms of all the measurement areas; and the pressure sensors are arranged on the surfaces of the measurement areas. Ores to be sorted can rotate on the turntable; and in the rotating process, the nuclear radiation detectors performs radioactive intensity measurement on the ores to be sorted, so that the time of the nuclear radiation detectors measuring radioactive intensity is prolonged, and the measurement accuracy of radioactive intensity is improved to prevent wrong judgment. Meanwhile, the masses of the ores to be sorted can be measured in the measurement areas on the turntable; radioactive intensity reference values of the ores are calculated through the masses; and for the ores with different densities, calculated results are more accurate.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

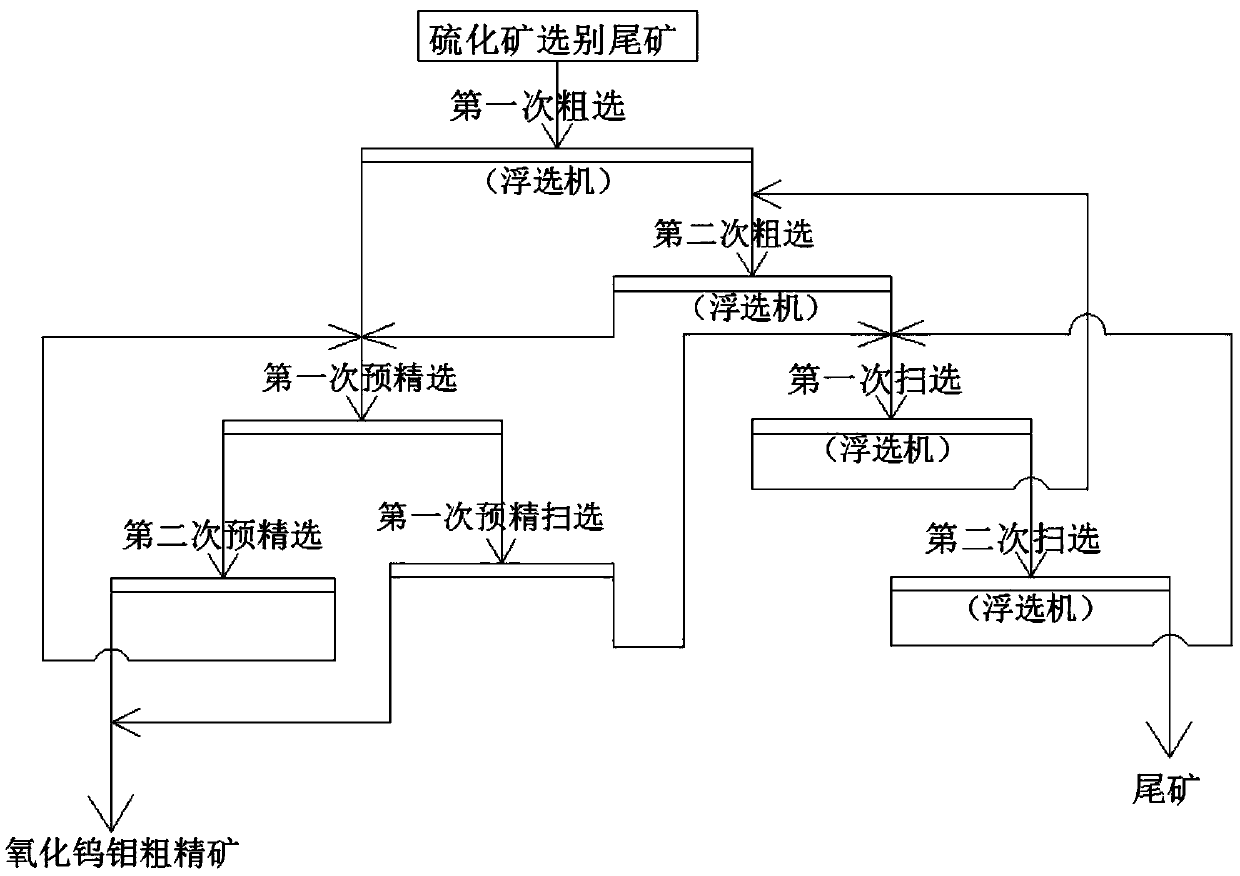

Molybdenum-tungsten oxide pre-finishing scavenging technology

The invention discloses a molybdenum-tungsten oxide pre-finishing scavenging technology. The technology comprises the steps that firstly, breaking, grinding, grading and desliming are conducted on rawore; then sulfide ore sorting is conducted, and primary roughing and secondary roughing are conducted on tailings obtained after sorting is completed through a flotation machine; primary preconcentration is conducted on roughing concentrate obtained through roughing; secondary preconcentration is conducted on concentrate obtained through primary preconcentration; concentrate obtained through secondary preconcentration is sent into a concentrator for concentration treatment; and the treatment process of molybdenum-tungsten oxide pre-finishing scavenging is completed. By means of the molybdenum-tungsten oxide pre-finishing scavenging technology, the grade and recovery rate of the concentrate can be obviously improved, so that the recovery rate of the molybdenum-tungsten oxide rough concentrate is high; and the outstanding effect is achieved especially for molybdenum-tungsten oxide with the high mud content and the low disseminated grain size, the grade and recovery rate of the concentrate are very high, and the high economic value is achieved.

Owner:中国黄金集团中原矿业有限公司

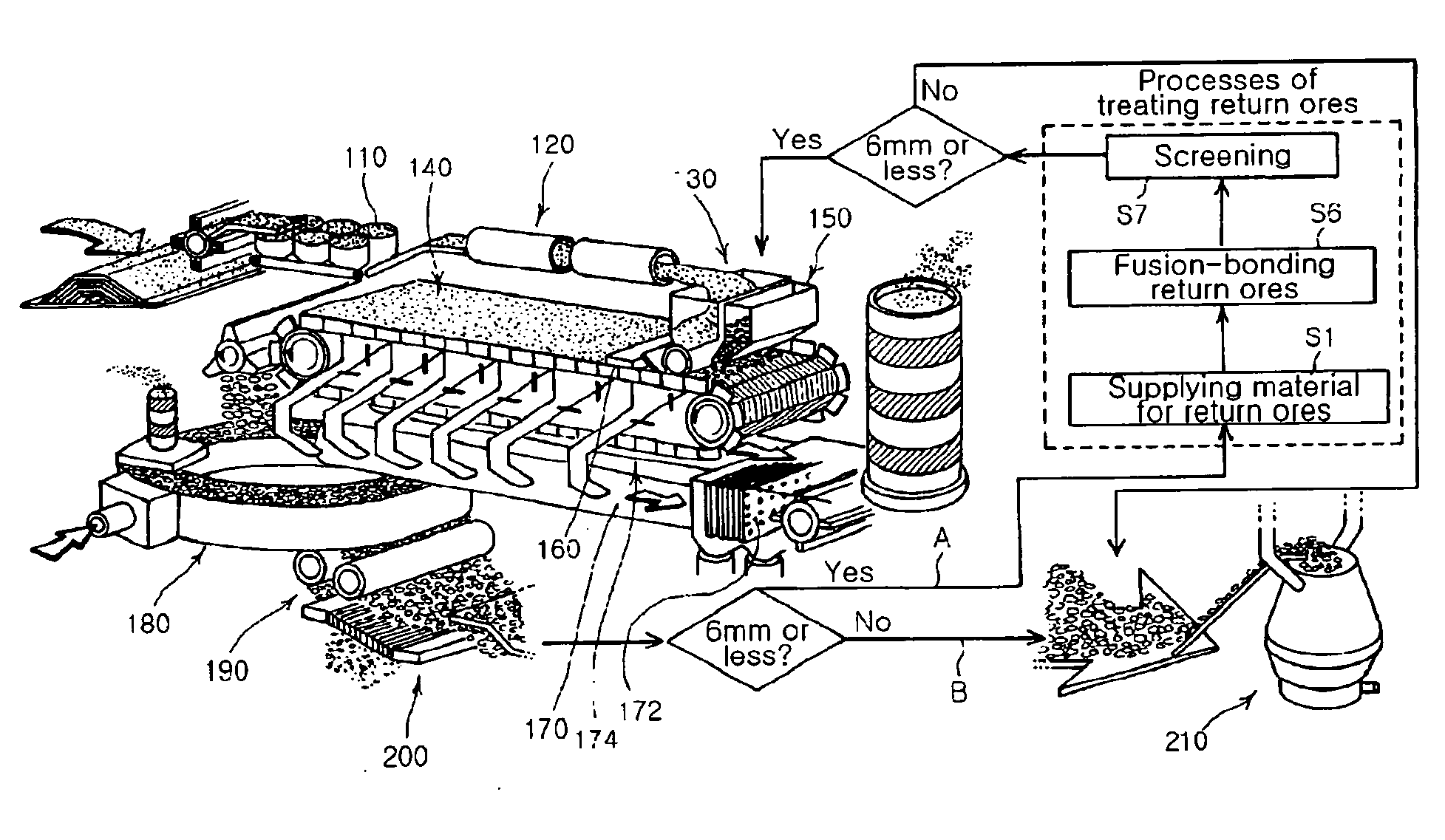

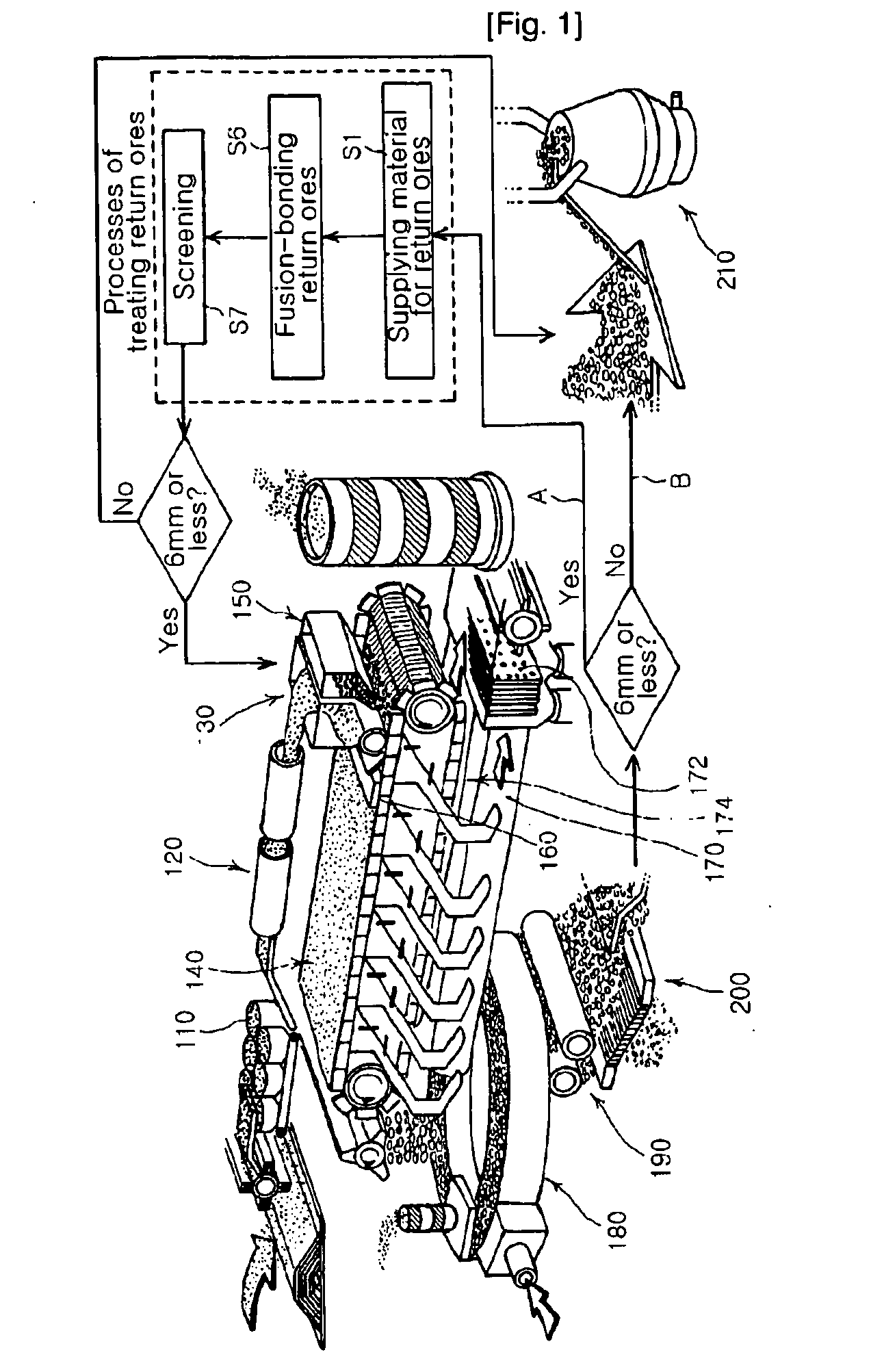

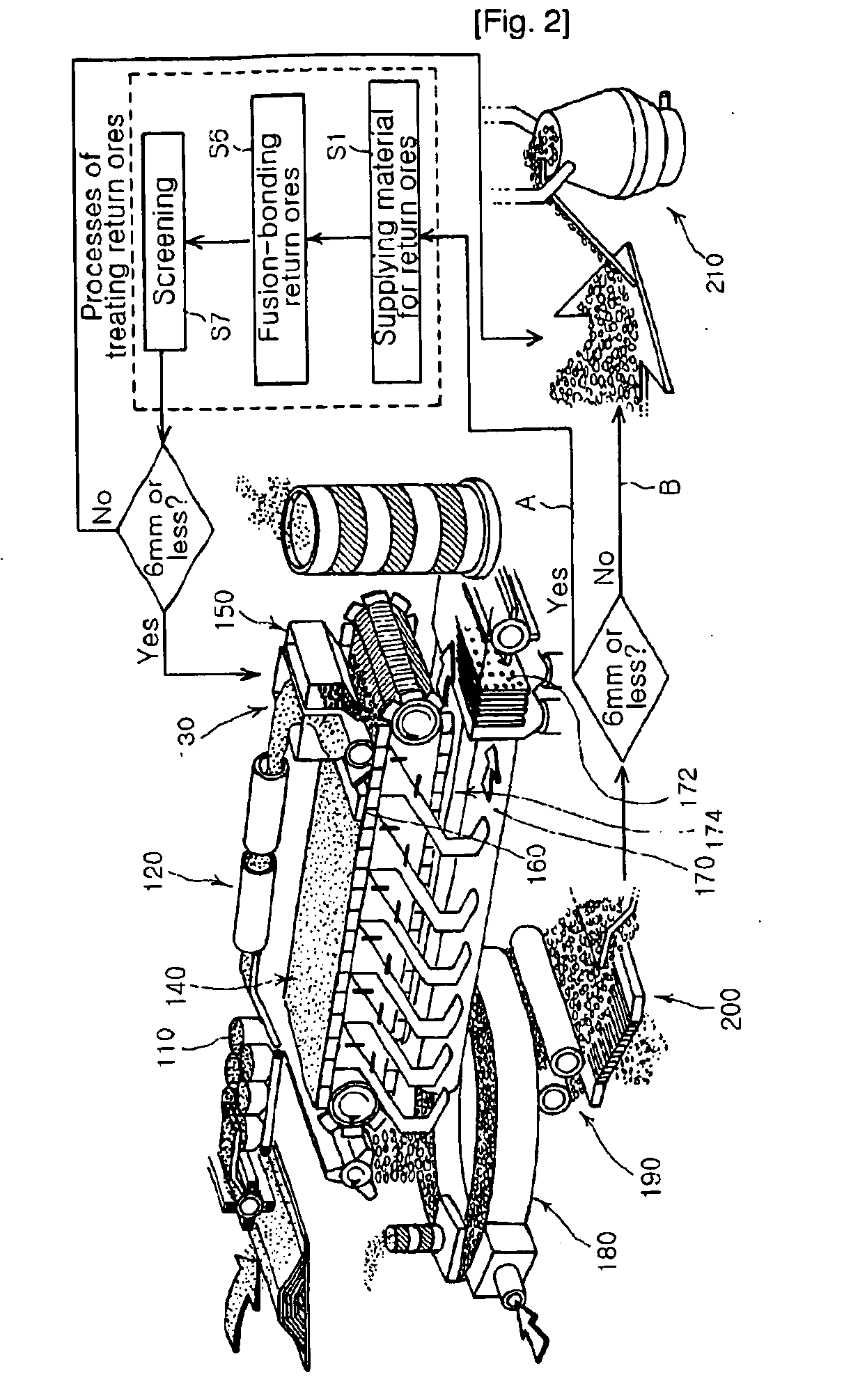

Method and Apparatus for Treating Return Ores Using Plasma

InactiveUS20100024595A1Improve productivityEasy to solveTuyeresBell-and-hopper arrangementBonding processPlasma heating

There is provided a method and an apparatus for treating return ores using plasma, capable of treating sintered return ores generated in a sintering process in a steel maker or return ores (iron ores) employed in other ironmaking process such as FINEX. The method of treating return ores using plasma includes: providing return ores sorted out by a sorting process; and bonding the return ores by fusing and agglomerating the return ores using plasma. Also, an apparatus for treating return ores using plasma includes a plasma heating device used to fuse and agglomerate sorted return ores. The return ores of a predetermined grain size are fusion-bonded and agglomerated using a flame of a plasma heating device. Particularly, the return ores can be treated in a massive amount to enhance productivity of a fusion-bonding process of the return ores. Furthermore, a great amount of sintered return ores generated in the sintering process can be subjected to a fewer number of re-treatment processes.

Owner:POHANG IRON & STEEL CO LTD

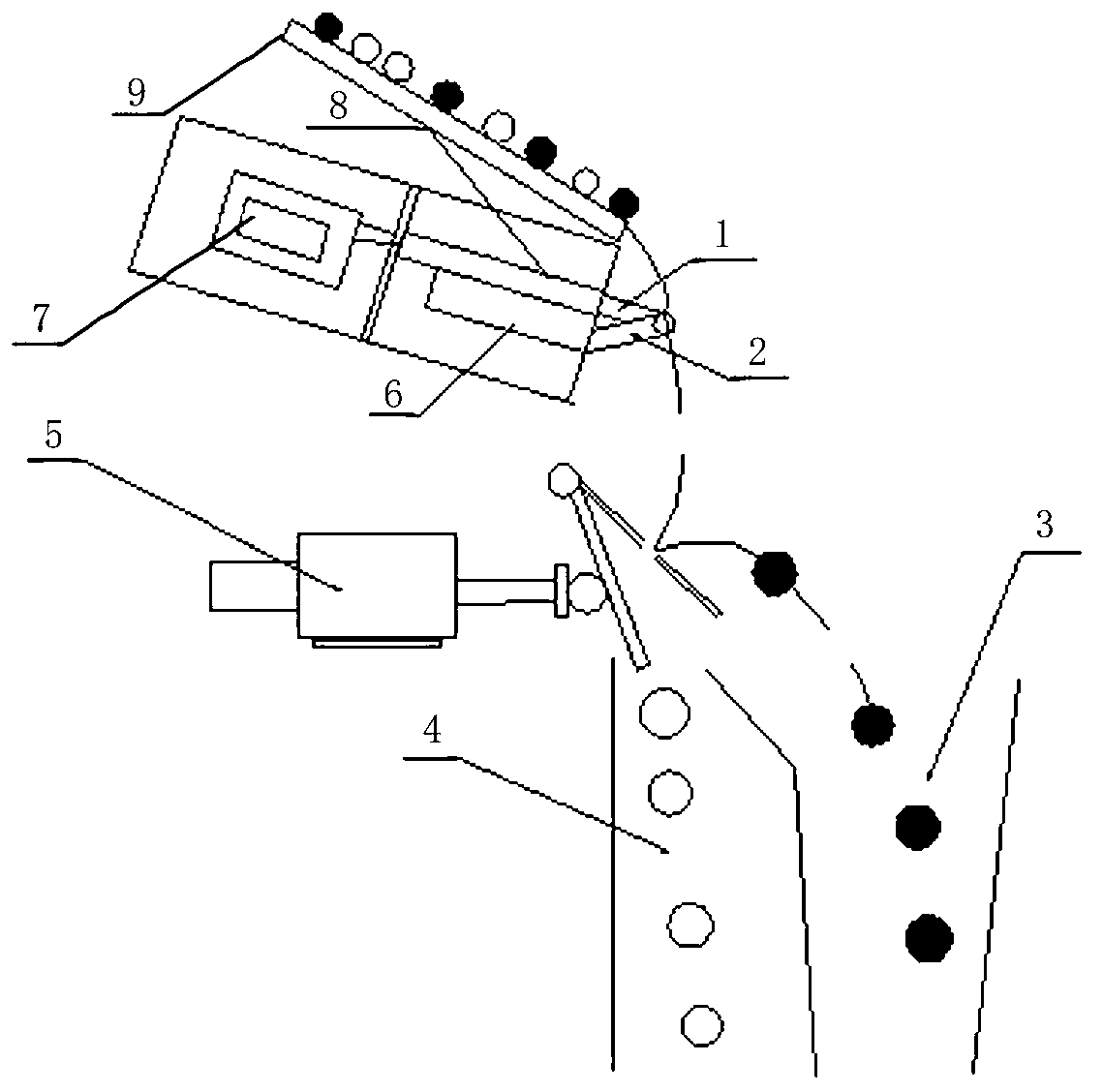

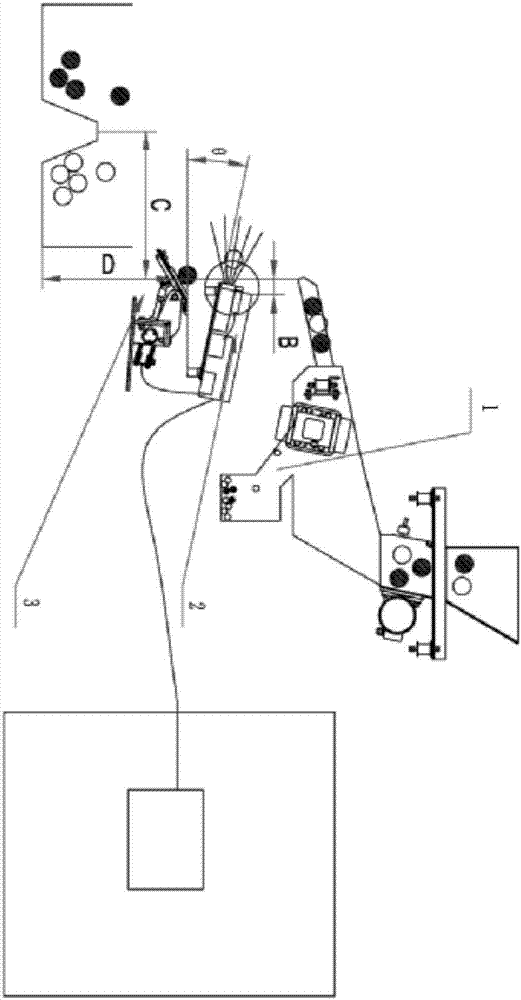

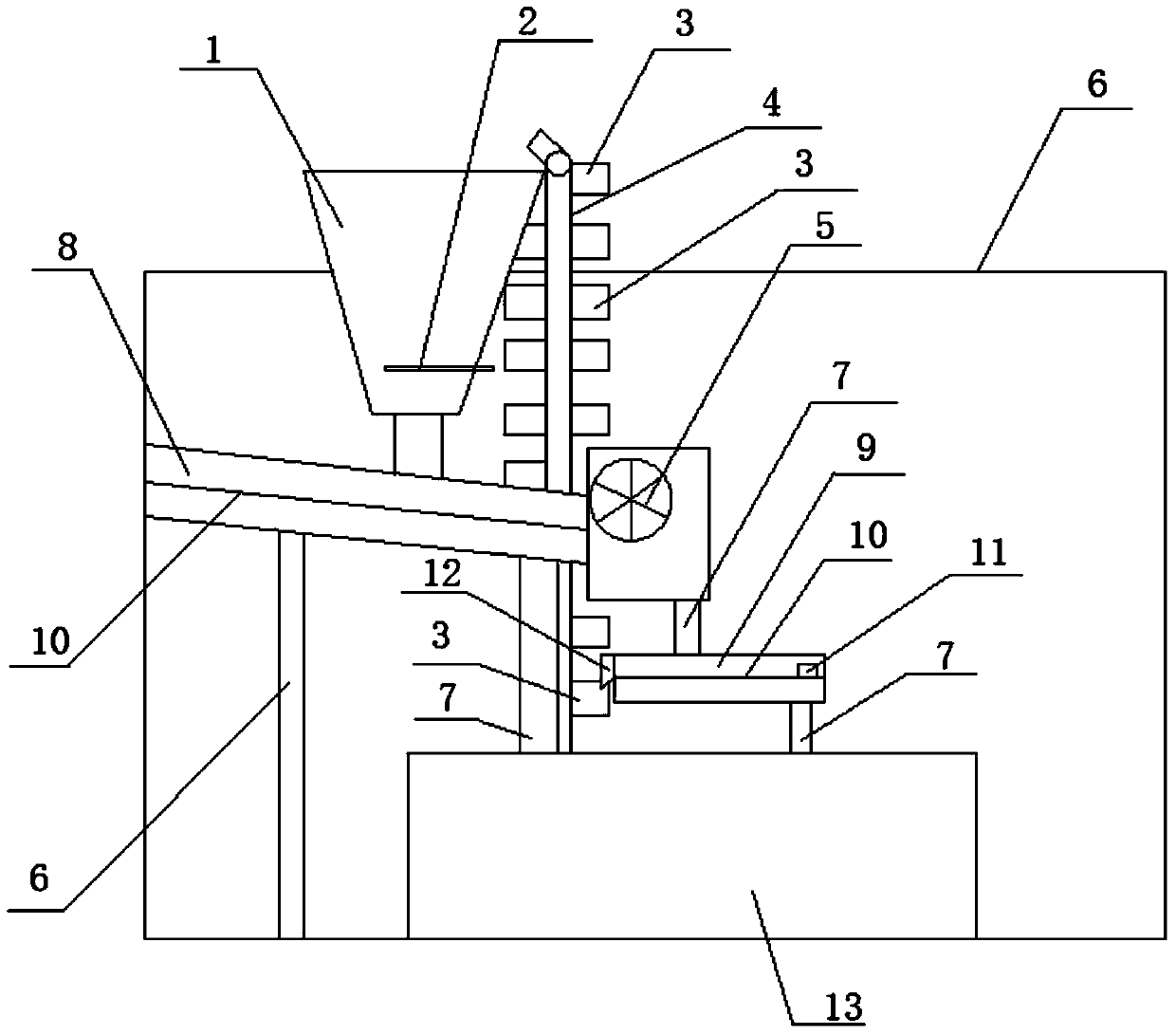

Intelligent ore sorting equipment and method based on X-ray recognition

Provided are intelligent ore sorting equipment and method based on X-ray recognition. The equipment comprises a feeding unit with a toothed grader, an X-ray motivating unit with an optical filter, a characteristic spectrum receiving unit with an optical filter, a computer analysis control unit and a sorting unit, wherein the computer analysis control unit is provided with a central controller, a spectrum collection system, an industrial personal computer and a command output system; and the sorting unit is provided with an air cylinder and an abrasion-resistant kickplate. The feeding unit is used for feeding materials through a vibration feeder, the materials are graded through the toothed grader, the X-ray motivating unit is used for motivating ore to be detected to generate a characteristic X-ray spectrum, the characteristic spectrum receiving unit is used for receiving the characteristic X-ray spectrum, then the computer analysis control unit is used for analyzing the spectrum and sending a sorting command according to the analysis result, and a dressing plant can perform sorting on magnetic ore or non-magnetic ore according to the sorting command. The intelligent ore sorting equipment and method based on X-ray recognition have the advantages that the quality is improved to a great extent, the recycling rate and the handling capacity are high, water consumption is low, the automation degree is high, and the like.

Owner:LONGI MAGNET CO LTD

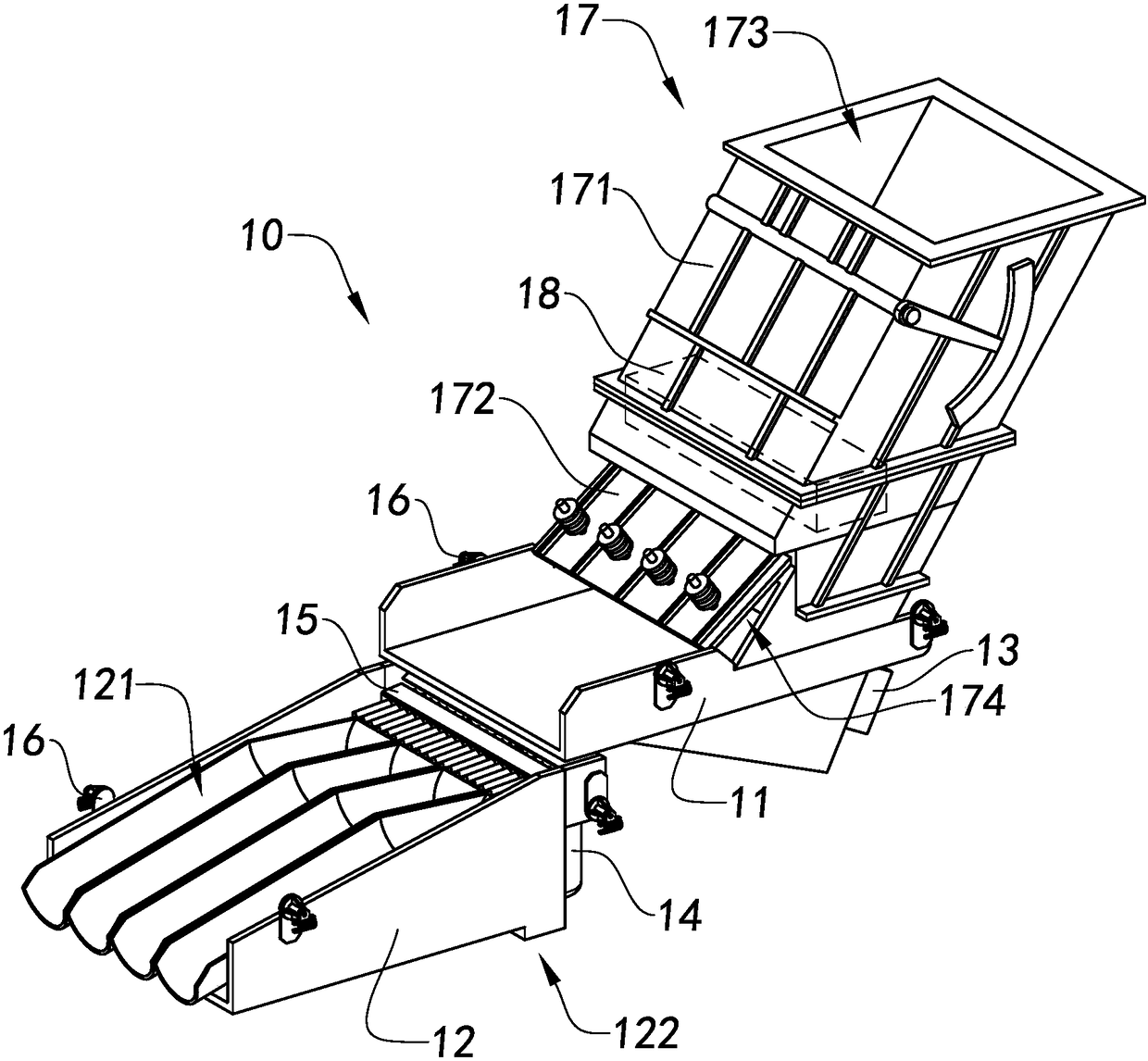

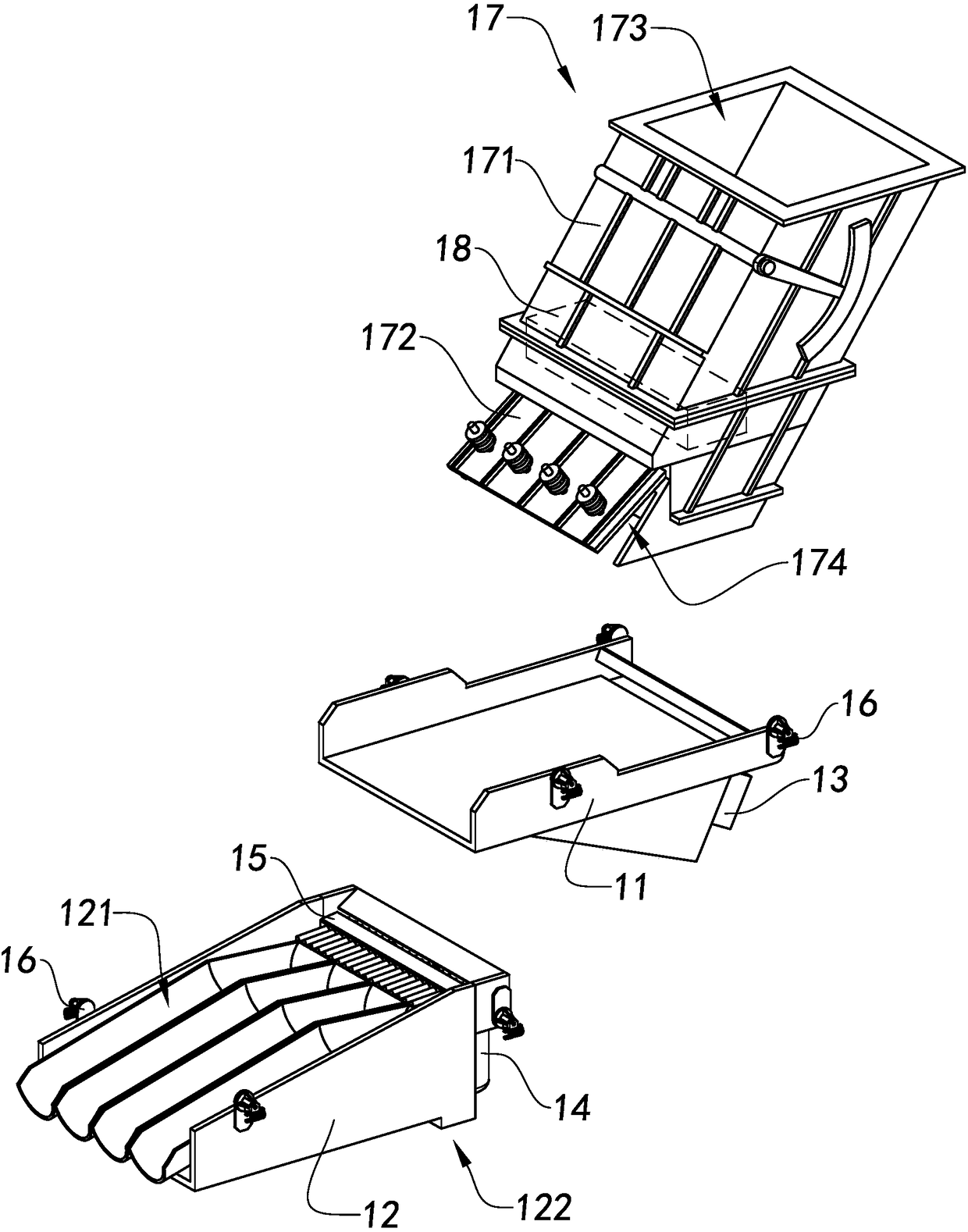

An ore sorting device

InactiveCN104084288ARealize sortingRealize secondary crushingSievingScreeningEngineeringConveyor belt

The invention relates to the field of ore separation production equipment, and particularly relates to an ore sorting device. The ore sorting device comprises a hopper, a first sorting mechanism, a smasher, a second sorting mechanism, a storing box, a rack and a conveyor belt. The hopper is fixedly installed on the rack. The bottom of the hopper is connected to the first sorting mechanism. The first sorting mechanism is connected to the storing box through a conveying pipeline. The first sorting mechanism is also connected to the smasher. The smasher is connected to the second sorting mechanism through a conveying pipeline. The second sorting mechanism is connected to the storing box through a conveying pipeline. The second sorting mechanism is also provided with a material outlet. The material outlet leads to the conveyor belt. The conveyor belt is communicated with the top of the hopper. The beneficial effects of the ore sorting device are that: the structure of the device is simple, operation is convenient, ore sorting is achieved by utilization of the simple device and secondary smashing processing of the ore is achieved at the same time.

Owner:GUANYANG CHENGONG ORE DRESSING MACHINERY MFG

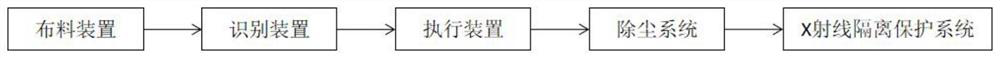

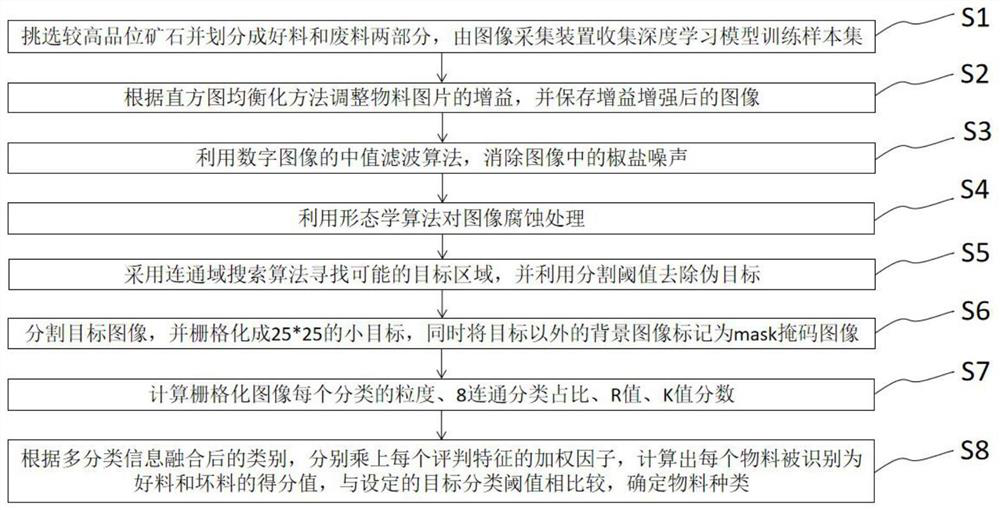

Intelligent ore sorting equipment and method based on dual-energy X rays

InactiveCN113019955AImprove sorting efficiencySortingCleaning processes and apparatusDust controlX-ray

The invention discloses intelligent ore sorting equipment and method based on dual-energy X rays. The equipment comprises a material distribution device, an identification device, an execution device, a dust removal system, a heat dissipation system and an X-ray isolation protection system. The identification device comprises a dual-energy X-ray generating device arranged above a transmission belt and a dual-energy X-ray detector arranged below a direct radiation point of the dual-energy X-ray generating device; and the execution device is composed of an electromagnetic valve, a sorting air cylinder and a nozzle and used for controlling high-pressure air to blow and strike the ore in the throwing process of the target ore. According to the equipment, good material and waste material pictures are acquired through image acquisition to serve as a deep learning model training sample set, acquired ore sample images are processed, a target area is found and segmented, then small target images are sent into a trained classification model, confidence coefficients of good materials and waste materials are compared and recognized, according to the category after multi-classification information fusion, the material category is determined, the ore separation efficiency is improved, and meanwhile energy conservation and environmental protection are achieved.

Owner:HEFEI MINGDE PHOTOELECTRIC TECH LTD

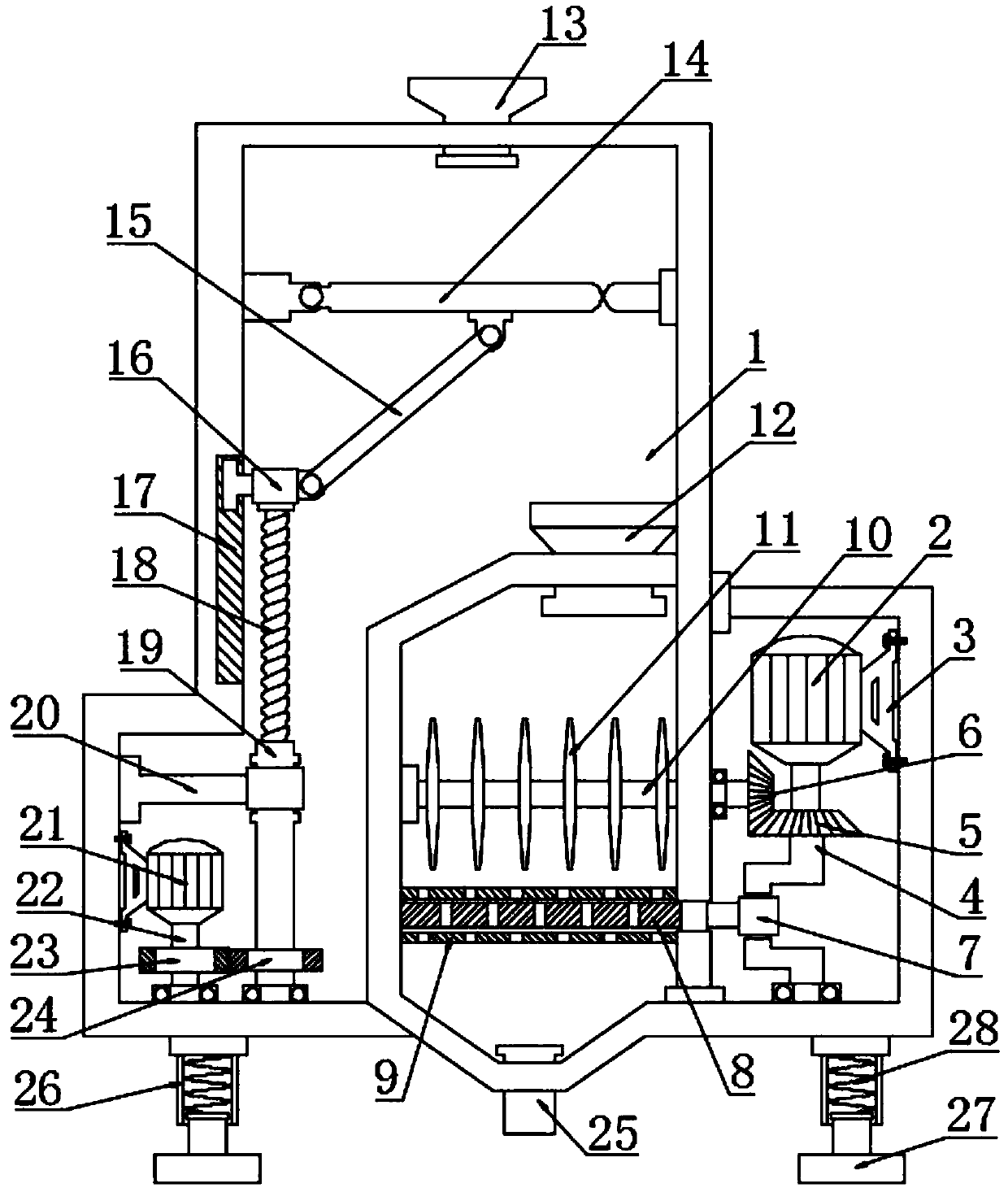

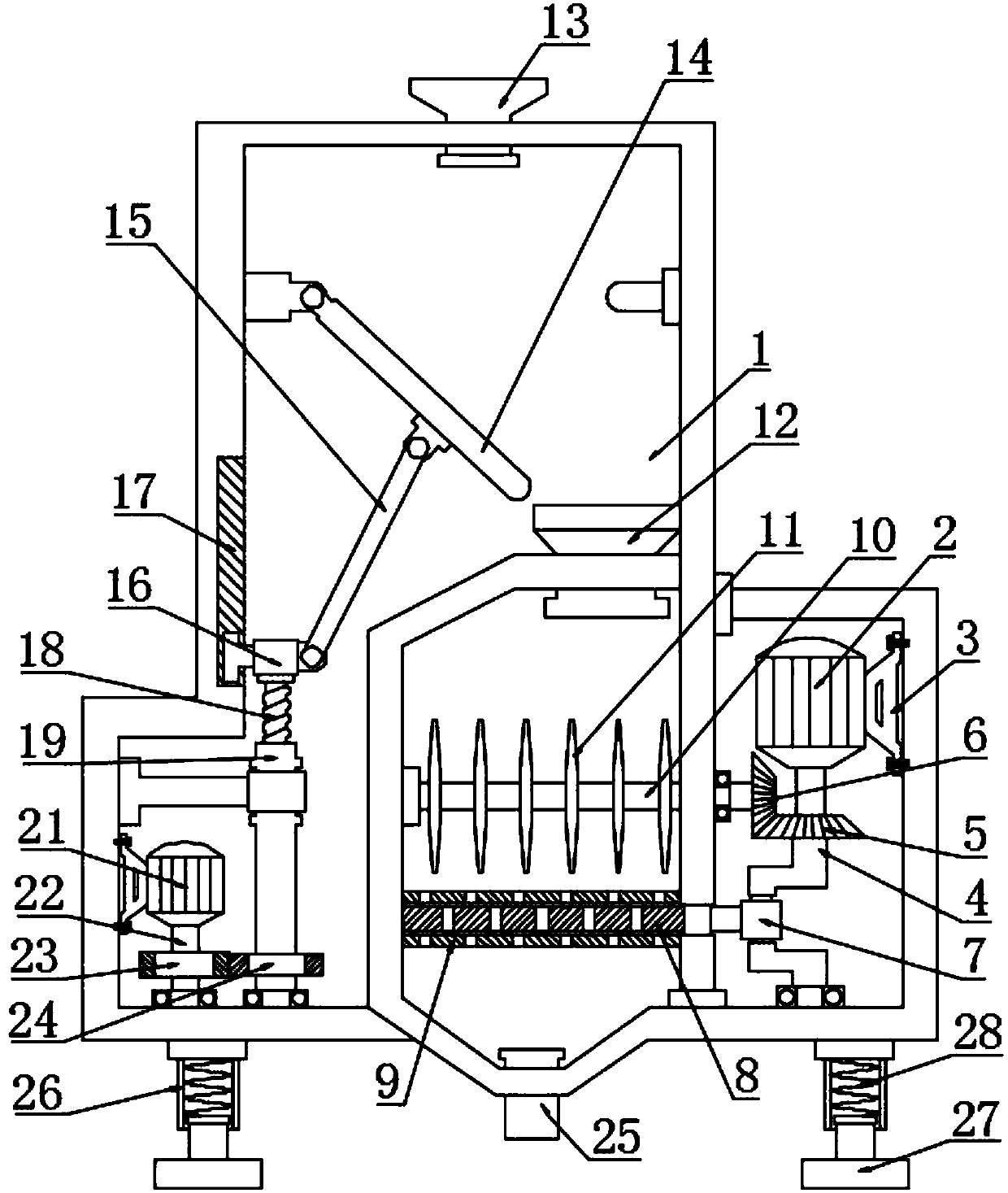

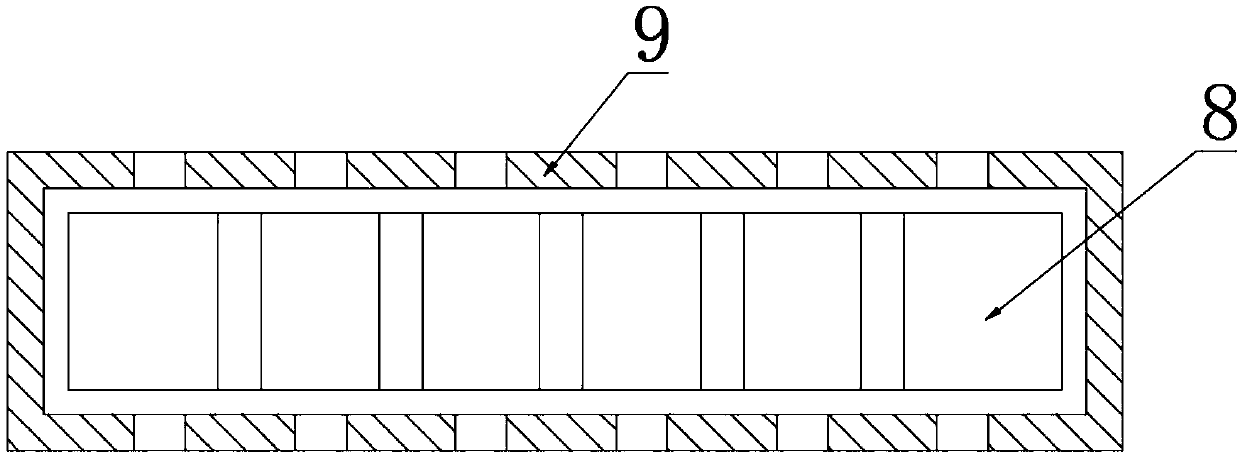

Ore separating and crushing device

ActiveCN107855176AImprove the quality of sorting and crushingReasonable structural designGrain treatmentsEngineeringThreaded rod

The invention discloses an ore separating and crushing device. A separating plate is arranged at the lower end of an ore inlet; the left end of the separating plate is rotationally connected with theside wall of a device body; the lower end of the separating plate is hinged to the upper end of a connecting rod; the lower end of the connecting rod is hinged to the right end of a sliding block; theleft end of the sliding block is glidingly connected with a guide groove; the lower end of the sliding block is fixedly connected with the upper end of a threaded rod; the lower end of the threaded rod is in threaded connection with a threaded sleeve; the upper end of the threaded sleeve is sleeved with the right end of a transverse support rod; the left end of the transverse support rod is fixedly connected with the side wall of the device body; a bearing at the bottom of the threaded sleeve is rotationally connected with the device body; and the lower end of the threaded sleeve is fixedly connected with a large gear. According to the device, the bottoming function is used through cooperation of the threaded rod and the threaded sleeve, the separating plate swings up and down in a reciprocating manner to realize intermittent feeding, a No.1 motor drives a rotating roller through a bevel gear group to rotate to crush ore, and then the crushed ore is separated by the aid of a sieve plate and a fixed filter plate. The device is reasonable and applicable in structural design and high in connection rigidity, the ore separating and crushing quality is greatly improved, and the production efficiency is accelerated.

Owner:远安县明宇矿业有限公司

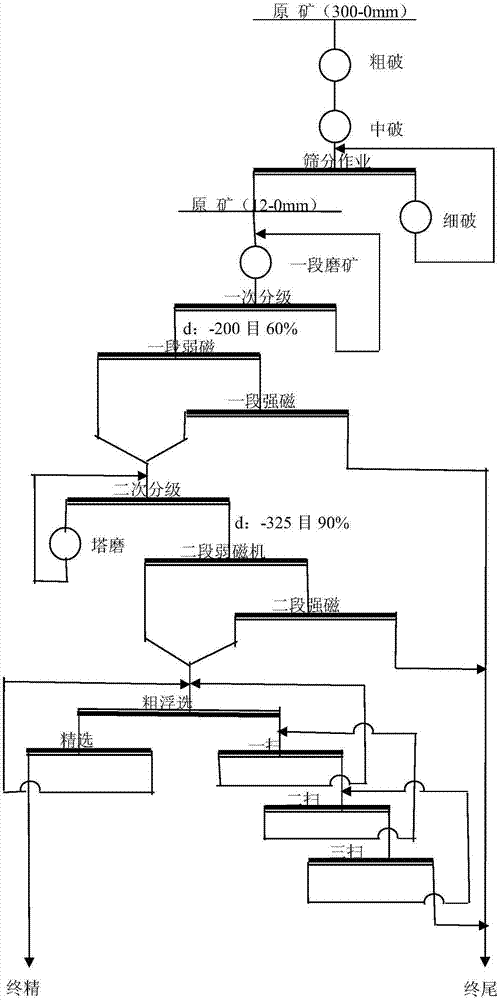

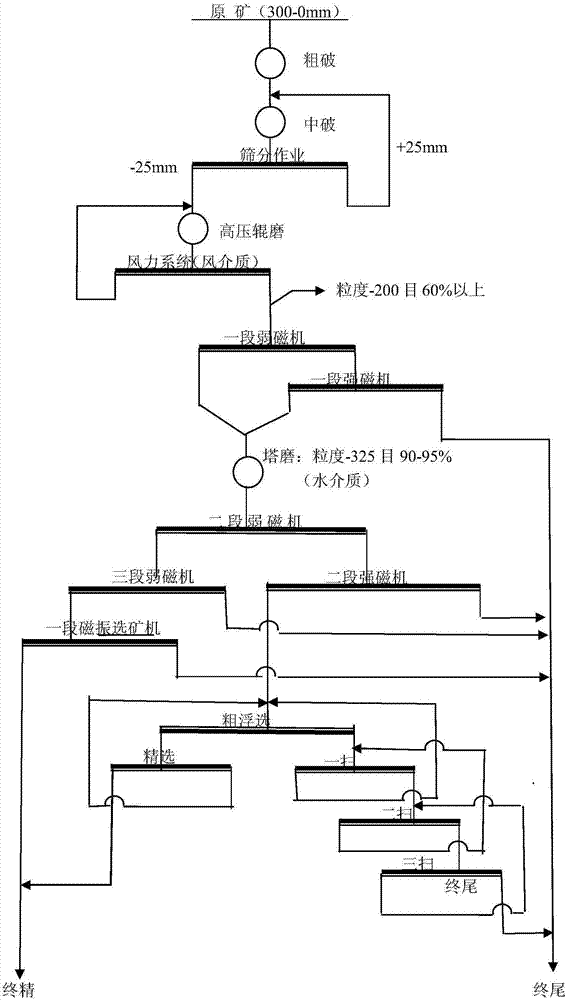

Mixed ore high pressure roll milling dual-media magnetic separation-hematite ore sorting process

InactiveCN107029868AReduce the amount of oreReduce consumptionWet separationHigh pressureMaterials science

The invention relates to a mixed ore high pressure roll milling dual-media magnetic separation-hematite ore sorting process. The process is characterized by comprising the following steps that raw ore is subject to coarse breaking and medium breaking two-section breaking and screening until the content of products with the granularity reaching -25 mm being 90% or above, then the material is fed into a high pressure roll milling-wind hierarchy system, and the content of products with the granularity being -200 meshes is 60%-65%; and the material is fed into a first-section low-intensity magnetic separator and a first-section high intensity magnetic separator for sorting, first-section low intensity magnetic separation concentrate and first-section high intensity magnetic ore are fed into a tower mill to be milled until the content of products with the granularity being -325 meshes is 90% or above, the products are fed into a second-section low-intensity magnetic separator, a third-section low-intensity magnetic separator, a first-section magnetic vibrating concentrator and an anion reverse flotation operation, concentrate with the grade being 67%-67.5% is obtained, and first-section high intensity magnetic separation tailing, second-section low intensity magnetic separation tailing, third-section low intensity magnetic separation tailing, second-section high intensity magnetic separation tailing and first-section magnetic vibrating concentrator tailing are combined into final tailing. According to the mixed ore high pressure roll milling dual-media magnetic-hematite ore grading process, fine breaking operation and two-section ore grinding operation are reduced, the fine screening operation is eliminated, the flow structure is simplified, and dual-media and short-flow grading is achieved, and the mineral separation cost is reduced.

Owner:ANSTEEL GRP MINING CO LTD

Pre-separation and waste-discarding beneficiation method for low-grade copper sulphide ores

InactiveCN112264181AAchieve pre-separationSave capacityWet separationCopper sulfideMaterials science

The invention relates to the technical field of beneficiation, and provides a pre-separation and waste-discarding beneficiation method for low-grade copper sulphide ores. According to the method, low-grade copper sulfide ores are screened into -60+10 mm, -10+6 mm, -6+2 mm, -2+0.15 mm and -0.15 mm ores through crushing and repeated screening, the -0.15 mm ores are regarded as primary slime and aredirectly used as qualified ores, the -2+0.15 mm, -6+2 mm and -10+6 mm ores are subjected to pre-separation and waste discarding through jigging, and the -60+10 mm ores are subjected to pre-separationand waste discarding through intelligent ray ore separation, and the copper grade of the finally obtained qualified ores is 0.27% or above. According to the provided method, pre-separation of the copper sulphide ore and a large amount of barren rock is realized, the copper grade of the selected ores is improved, the amount of ores entering a concentrating mill for grinding and separation is reduced, operation is stable, the cost is low and industrial production is realized easy.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

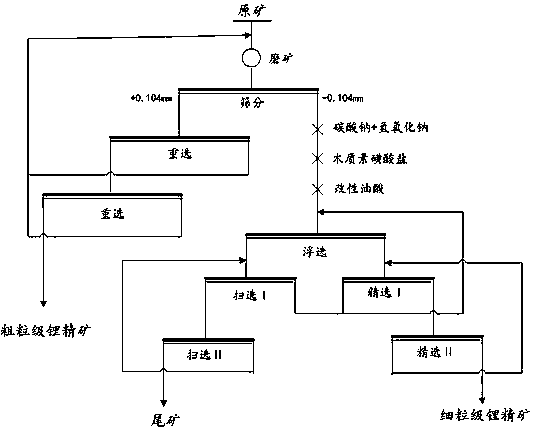

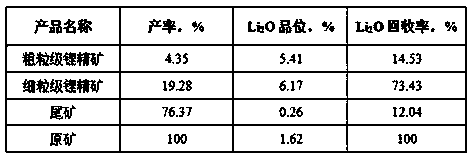

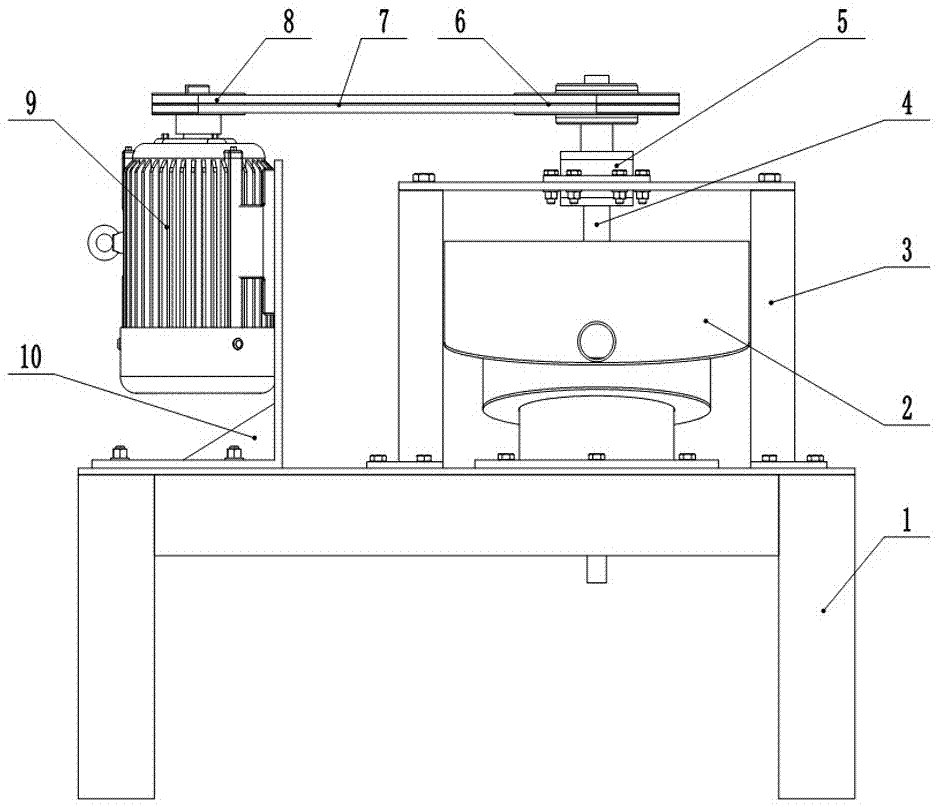

High-efficiency spodumene beneficiation method

ActiveCN109290051AImprove sorting effectReduce grinding costsSolid separationDensity differenceOleic Acid Triglyceride

The invention discloses a high-efficiency spodumene beneficiation method which comprises the steps of screening and grading a finely ground spodumene ore pulp, feeding spodumene ores with +0.104 mm particle size into a centrifugal separator for reselecting, and separating large-particle monomer separated spodumene mineral from gangue mineral according to the density difference; and adding sodium carbonate and sodium hydroxide into the -0.104mmparticlesize spodumene ore pulp, stirring for a long time, adding lignosulfonate as a dispersing agent and a gangue inhibitor, adopting modified oleic acid as a collecting agent for flotation, so that high-efficiency sorting of the spodumene mineral can be realized. The high-efficiency spodumene beneficiation method provided by the invention adopts the combined process comprising thick-thin ore separation, and reselection-flotation, the characteristic that the requirements of different beneficiation methods for the optimal particle size of the processed ore are different is fully utilized, so that the ore grinding cost is reduced, and the defect that the spodumene thick particles are difficult to float is overcome; and the method has the advantages of the simple process, low production cost, the good spodumene sorting effect and the like.

Owner:SHANDONG UNIV OF TECH

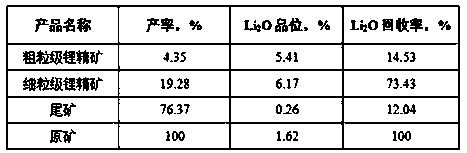

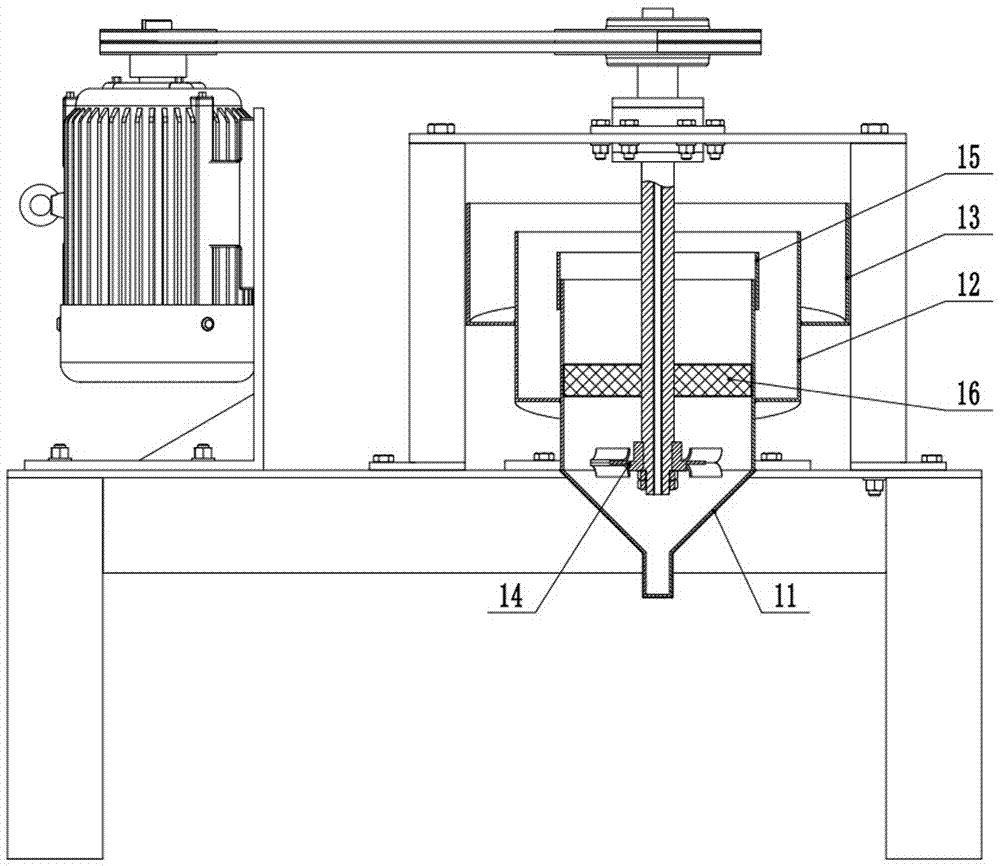

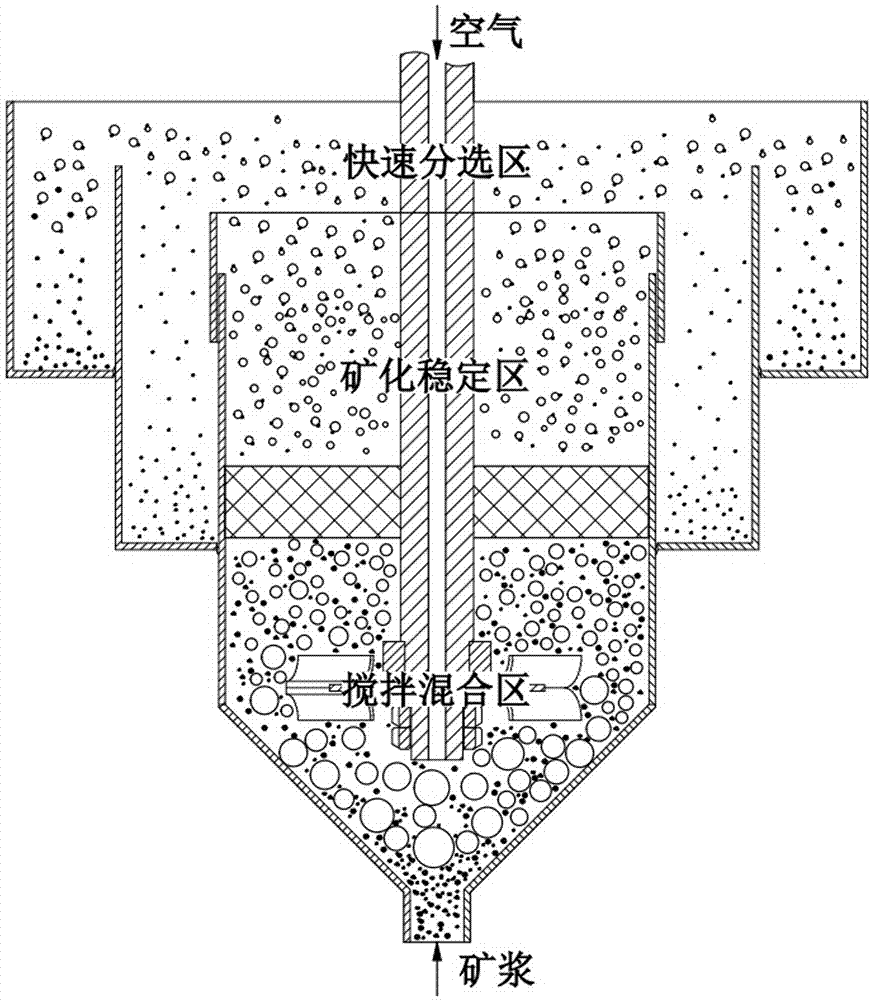

Coarse grain flotation machine

The invention discloses a coarse grain flotation machine which comprises a rack. A sorting barrel, a bearing pedestal support and a motor seat are arranged on the rack. A large belt wheel is arranged at the top end of a stirring shaft. The bottom end of the stirring shaft stretches into the sorting barrel and is provided with a stirrer. The sorting barrel is composed of an inner barrel, a middle barrel and an outer barrel. The middle barrel is fixed to the outer wall of the inner barrel. The outer barrel is fixed to the outer wall of the middle barrel. The upper edge of the outer barrel is higher than the upper edge of the middle barrel. The upper edge of the middle barrel is higher than the upper edge of the inner barrel. An ore feed opening is formed in the bottom of the inner barrel. A filling medium is arranged on the upper middle portion of the inner barrel. A tailing outlet is formed in the bottom of the middle barrel. A concentrate outlet is formed in the bottom of the outer barrel. The coarse grain flotation machine is suitable for separation and purification of minerals which are coarse in flotation target mineral grain size and meanwhile are influenced by fine silt in the flotation process; and the coarse grain flotation machine is mainly applied to aluminosilicate non-metal ore sorting and flotation and separation of oxidized ore and other minerals, such as flotation of multiple minerals of andalusite, kyanite, phosphorite, rare earth ore, oxidized ore, other aluminosilicate and the like.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

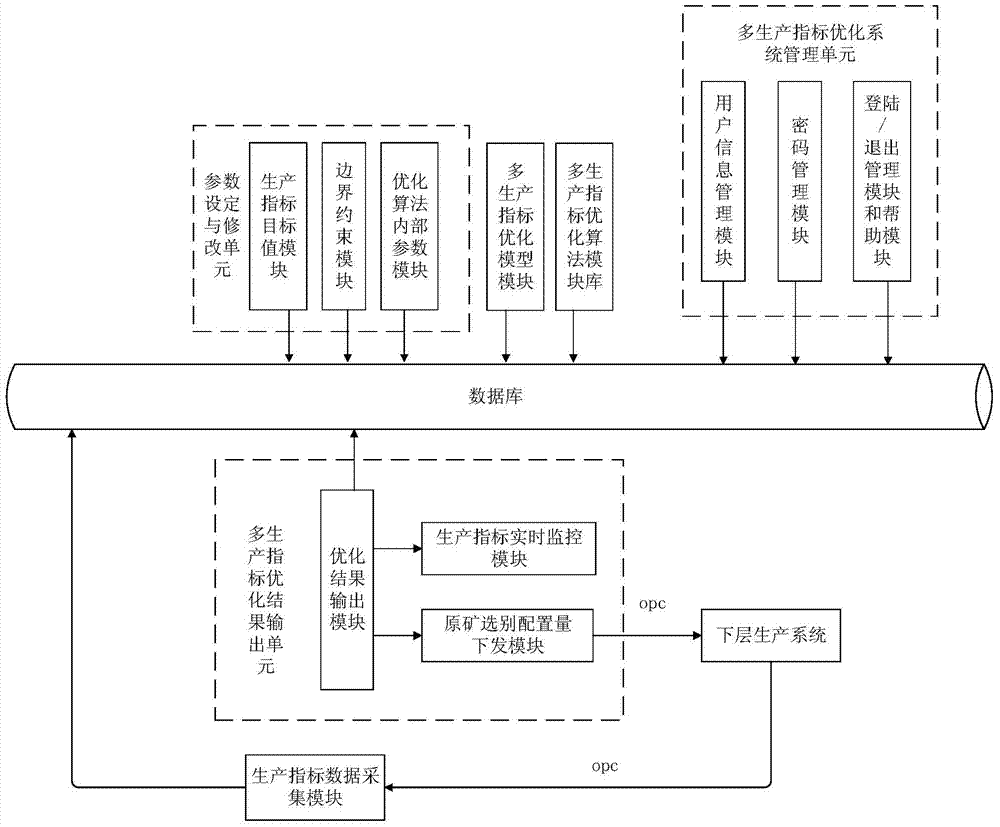

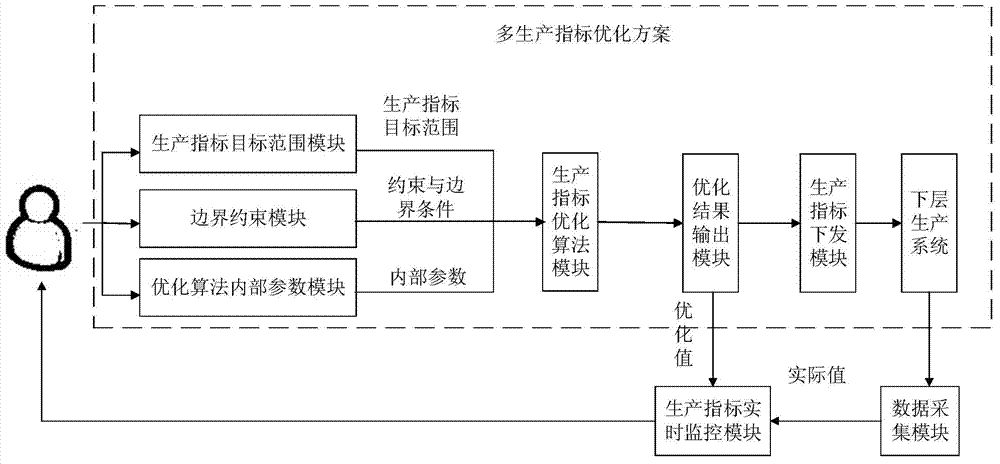

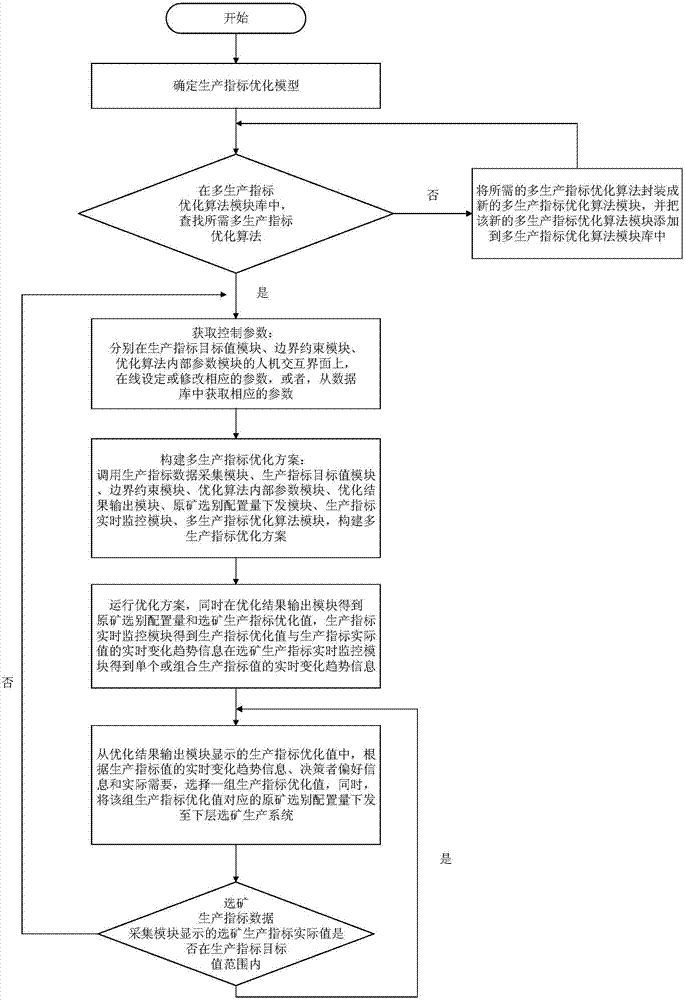

System and method for optimizing multiple production indexes in sorting process of raw ore based on man-machine interaction

ActiveCN104281134AReduce manufacturing costConvenient package functionTotal factory controlProgramme total factory controlManagement unitComputer module

The invention discloses a system and method for optimizing multiple production indexes in the sorting process of raw ore based on man-machine interaction, and belongs to the technical field of ore-dressing production processes. The system comprises a data acquisition module, a parameter setting and modifying unit, an optimization algorithm module library, an optimization model module, an optimization result output unit and a multi-production index optimization system management unit. The method includes the steps that the optimization algorithm module library is searched for a needed optimization algorithm first according to an optimization model; if the algorithm is not found out, the needed optimization algorithm is packaged into a new optimization algorithm module, and if the algorithm is found out, a needed parameter is acquired; an optimization scheme is established; the optimization scheme is operated; a set of production index optimization values are acquired, and meanwhile corresponding raw ore sorting configuration quantity optimal values are issued to an under layer ore dressing production system; if a production index actual value is placed within the production index target value range, the optimization scheme is operated continuously, and if not, the parameter acquiring step is executed again. By the adoption of the system and method, the purposes for saving energy, reducing consumption, lowering production cost and improving economic benefits can be achieved.

Owner:NORTHEASTERN UNIV

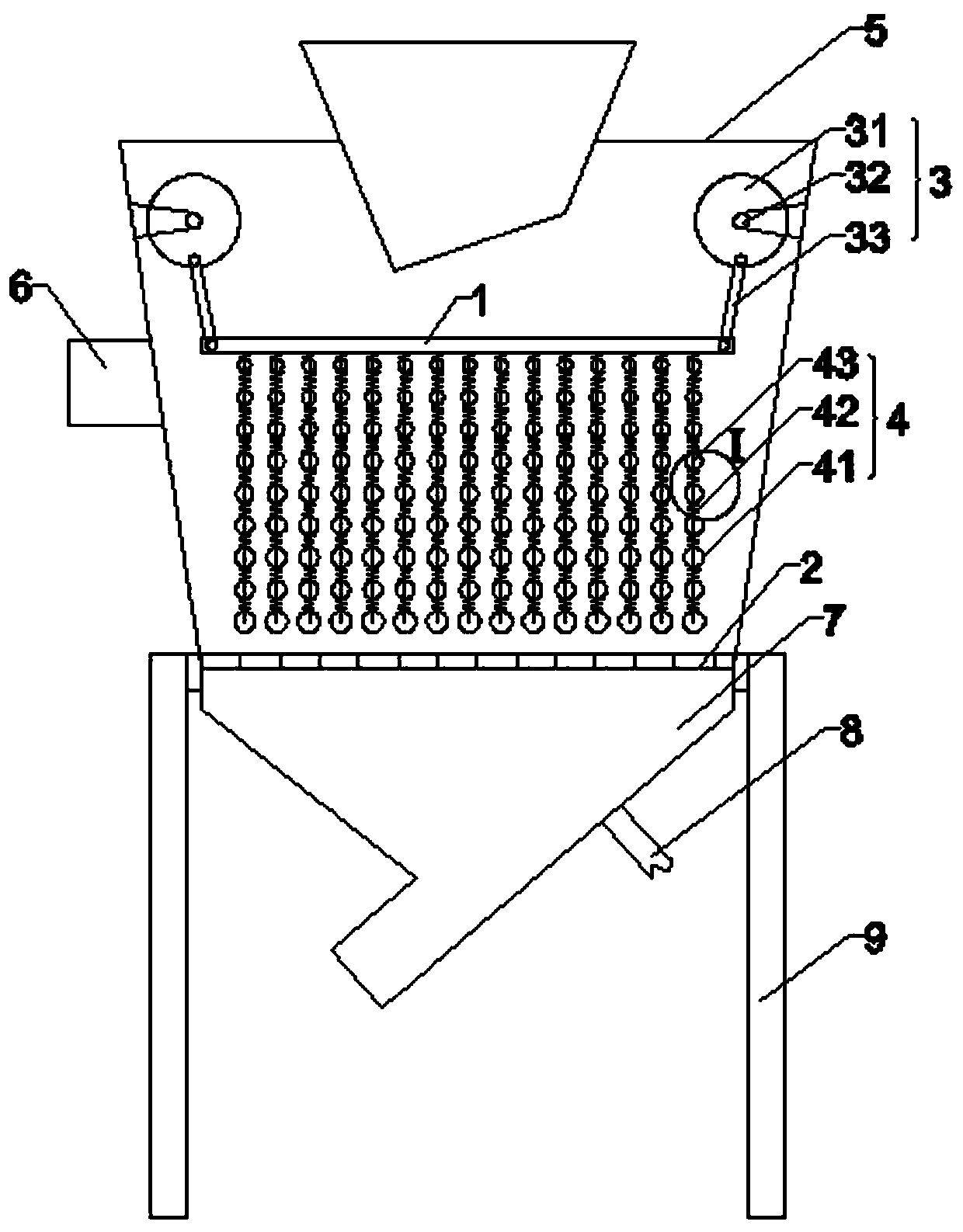

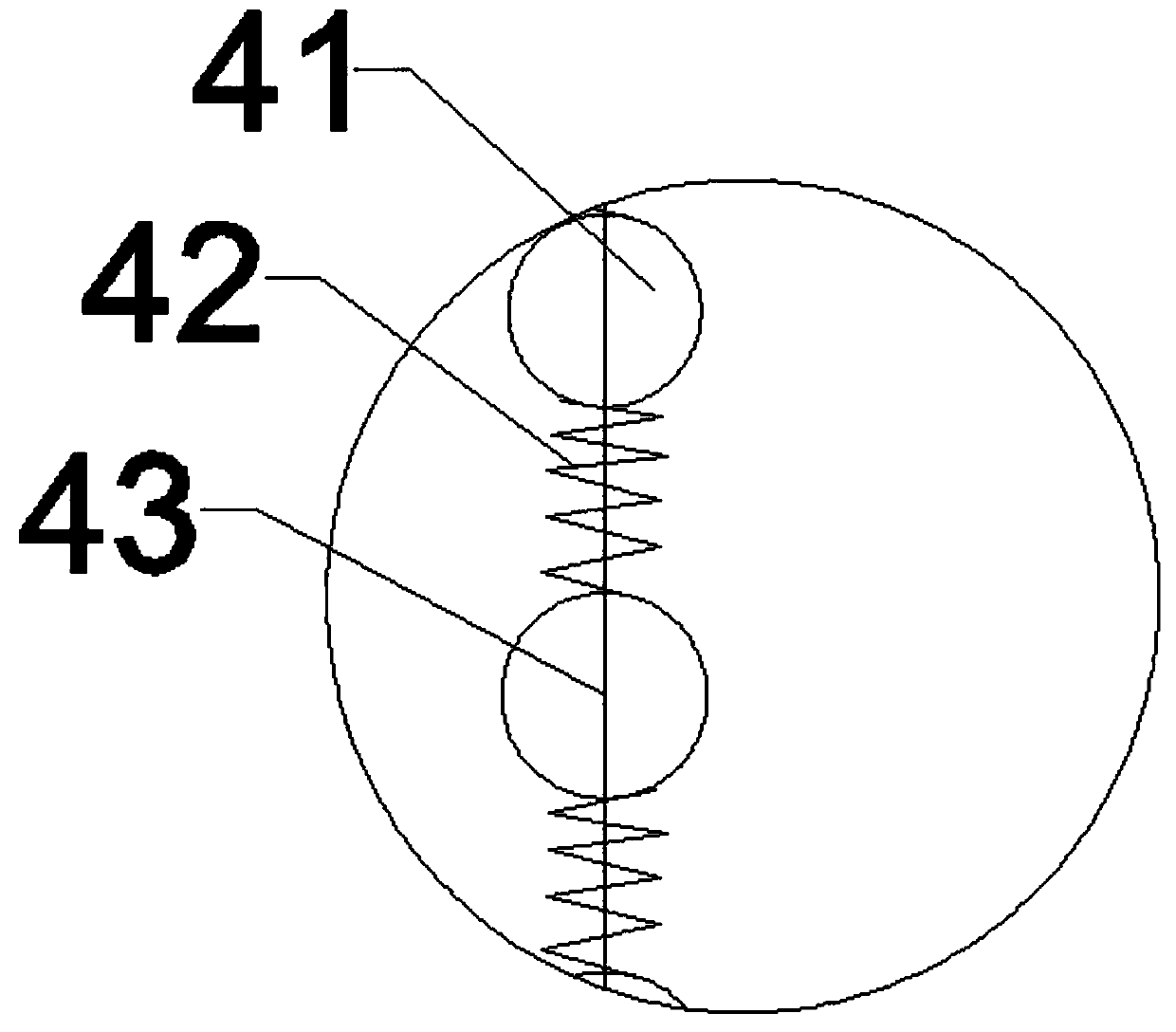

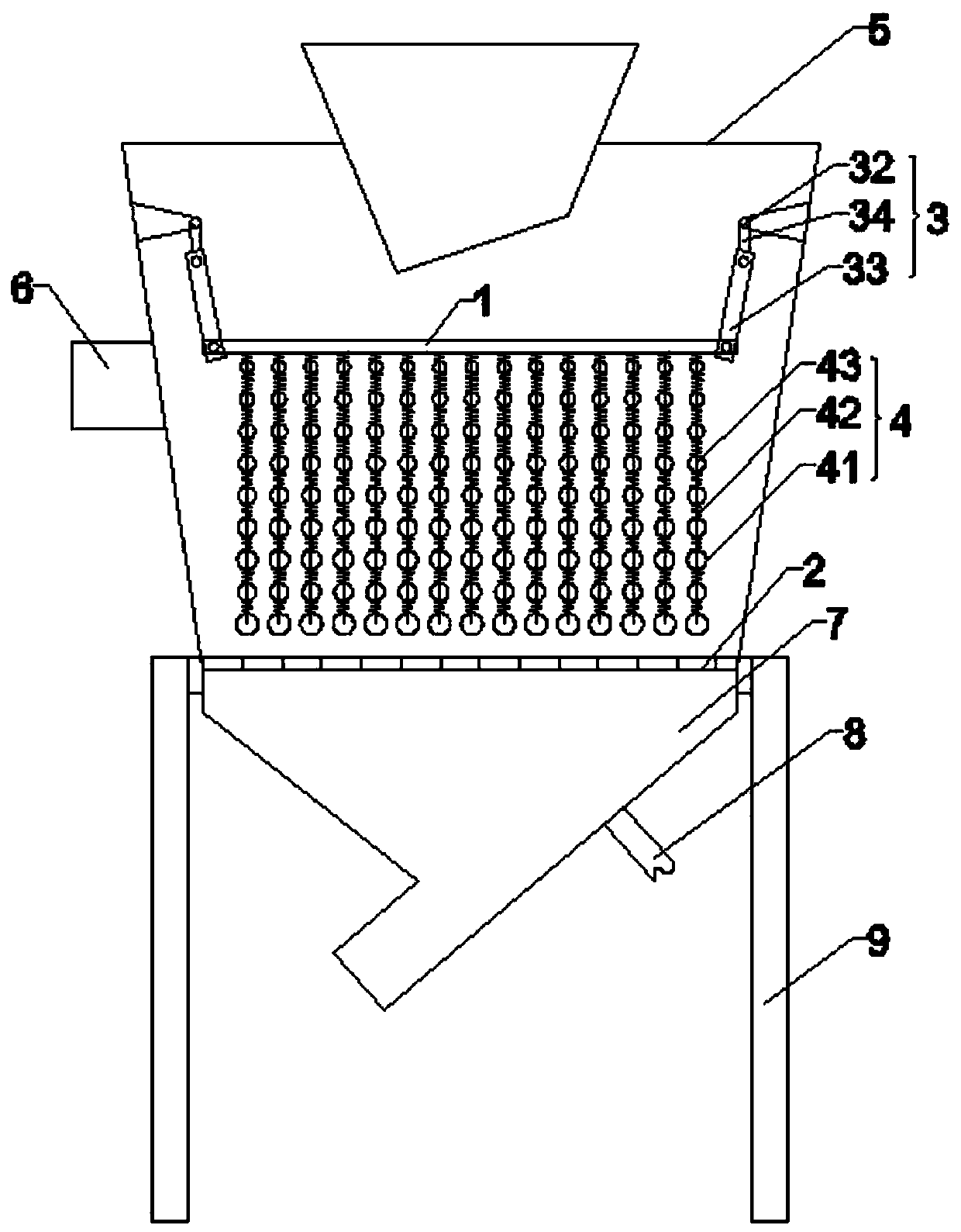

Dense medium ore sorting equipment

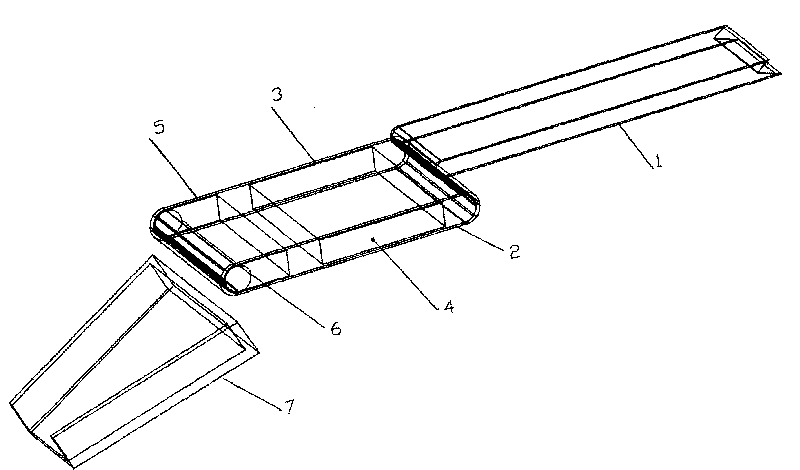

PendingCN110302889AAchieve horizontal uniform distributionWon't settleWet separationEngineeringMaceral

The invention discloses dense medium ore sorting equipment, and belongs to the field of beneficiation equipment. The dense medium ore sorting equipment comprises a sorting cylinder body (5), a movablescreen plate (1), a fixed screen plate (2) and a lifting device (3), the fixed screen plate (2) is arranged at a discharging port of the sorting cylinder body (5), the movable screen plate (1) is arranged in the sorting cylinder body (5), moreover, the lifting device (3) can drive the movable screen plate (1) to move up and down, dense medium chain strings (4) are arranged at the lower end of themovable screen plate (1) at intervals, one ends of steel ropes (43) of the dense medium chain strings (4) are connected with the end surface of the movable screen plate (1), and dense medium balls (41) are arranged on the steel ropes (43) in a penetrating and sleeving mode. According to the dense medium ore sorting equipment, the principle that light minerals and heavy minerals generate floatingand sinking and jigging ore dressing phenomena in a heavy suspension liquid is adopted, the lifting device (3) drives the dense medium chain strings (4) to do vertical movement so as to realize transverse uniform distribution of dense media at the sorting cylinder body (5) or in the cylinder body, then the dense media can not precipitate in the up-and-down movement, and the purpose of screening ores is realized.

Owner:PANZHIHUA UNIV

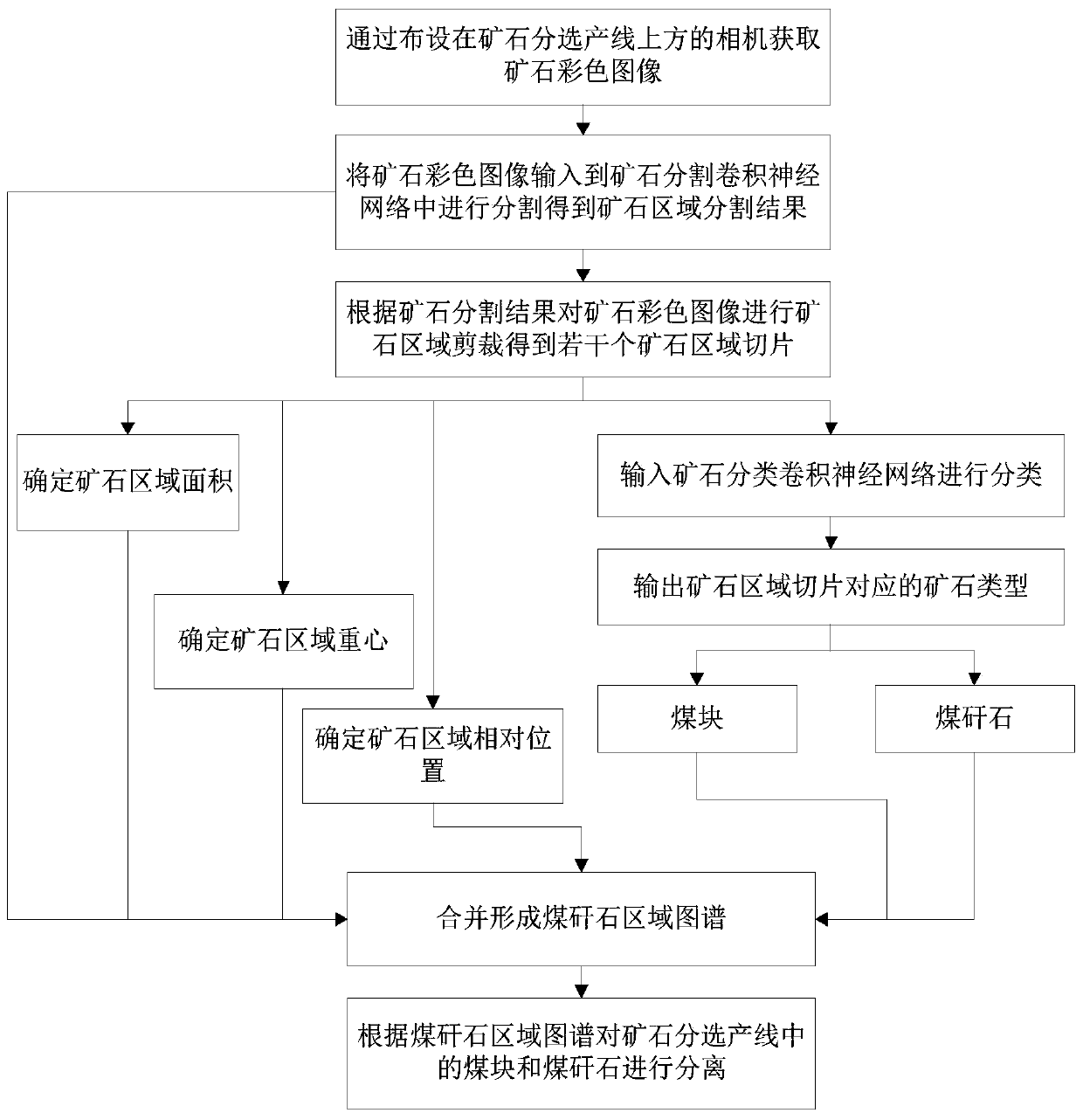

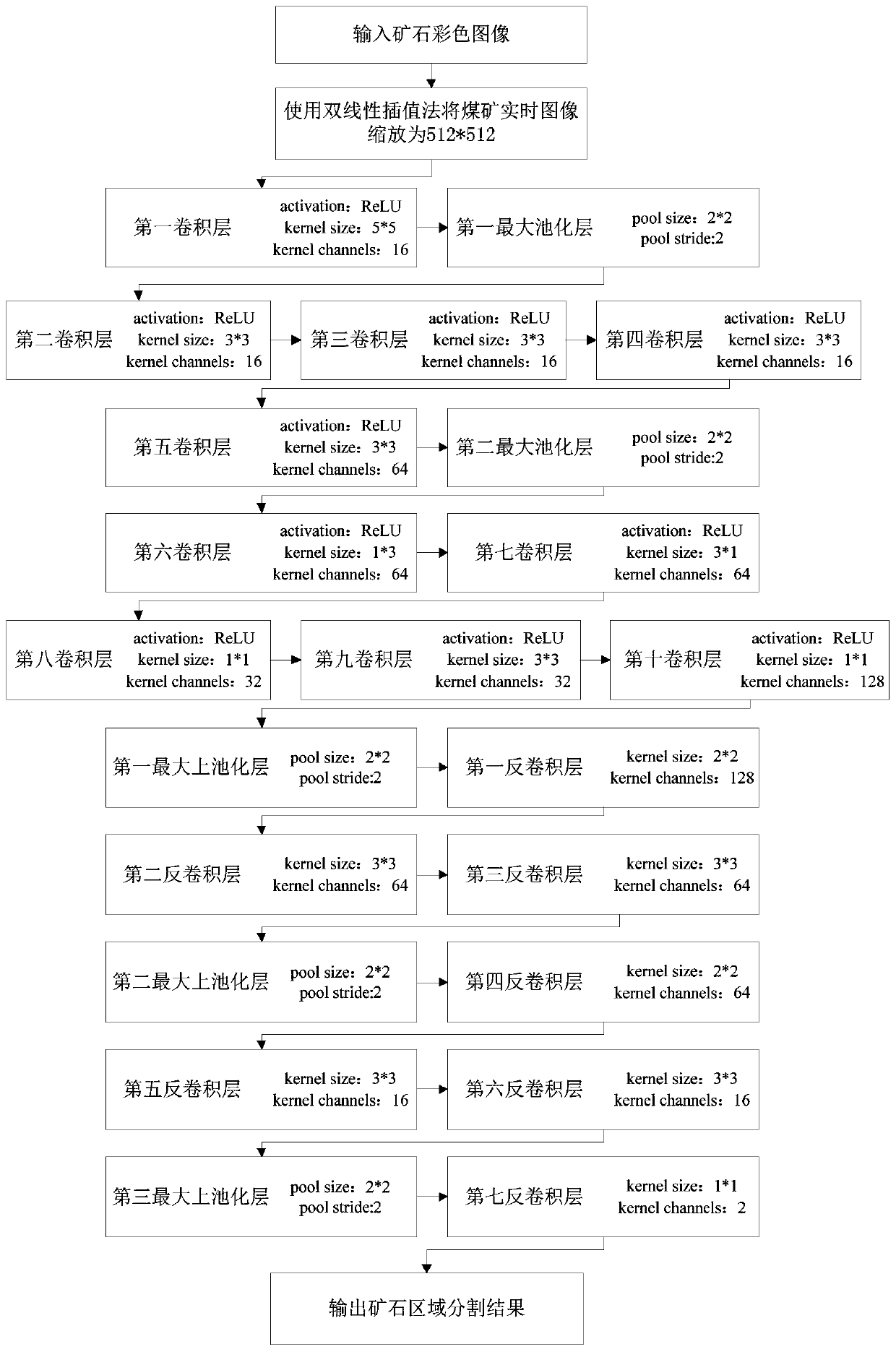

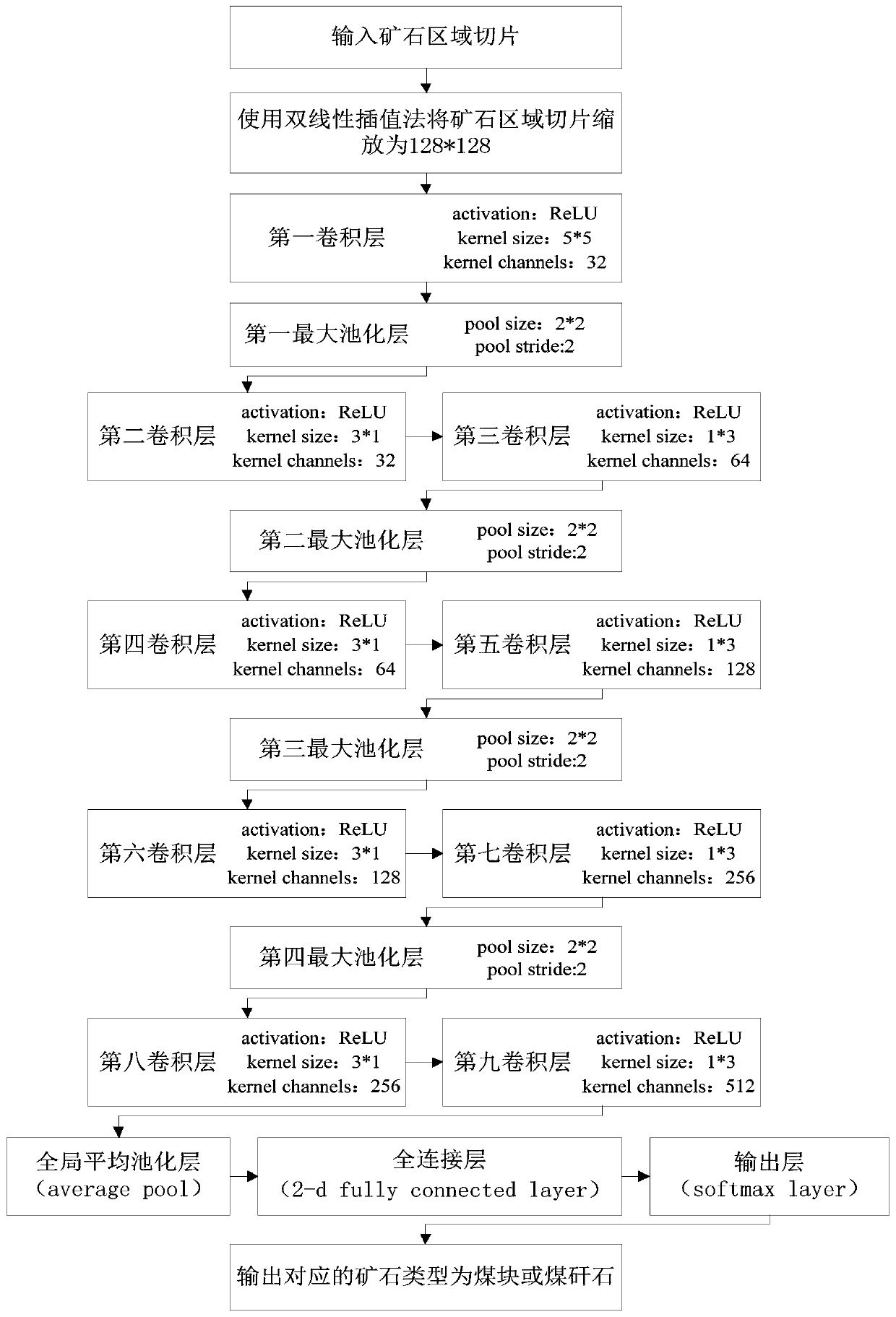

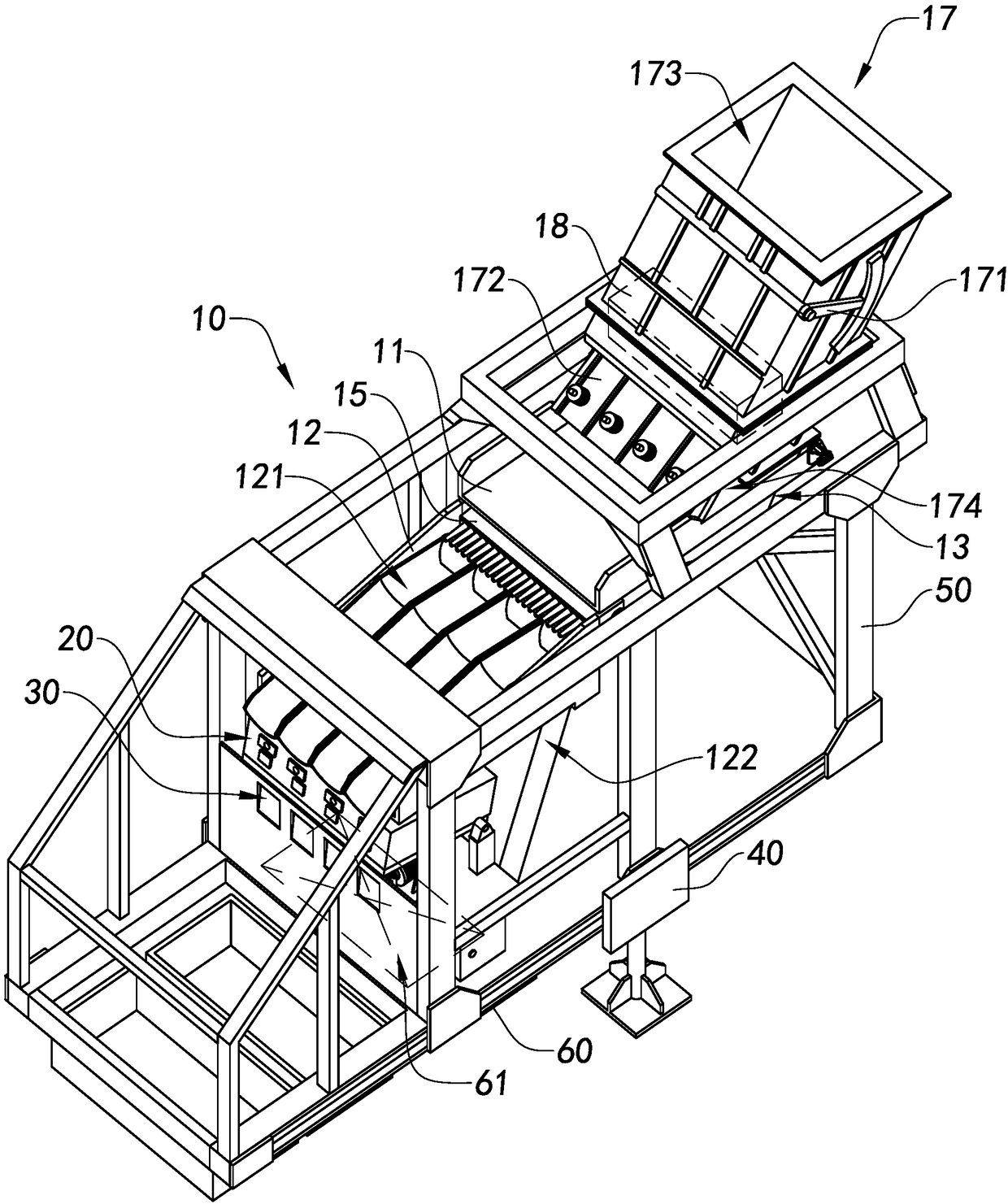

Coal gangue separation method based on deep vision

ActiveCN111468430AAccurate guide informationImprove separation efficiencyNeural architecturesSortingCoal briquetteColor image

The invention discloses a coal gangue separation method based on deep vision, and relates to the technical field of robot vision. The method comprises the steps of taking ore color images of an ore separation production line as input, utilizing an ore segmentation convolutional neural network for conducting segmentation to obtain an ore area segmentation result, conducting ore area cutting on theore color images according to the ore segmentation result to obtain a plurality of ore area slices, then utilizing an ore classification convolutional neural network to output coal briquettes or coalgangue, conducting image analysis on the ore area slices to determine ore information, and finally automatically separating the coal briquettes and the coal gangue. By means of the method, rapid detection and precise recognition can be achieved, by estimating the volume class and relative position of ore, accurate guide information is provided for automatic separation of the coal gangue, and the separation efficiency is high. The two convolutional neural networks are customized special for an ore separation scene, and the coal gangue separation method has the advantages of being small in mass,high in real-time performance, high in detection precision and the like.

Owner:WUXI XUELANG DIGITAL TECH CO LTD

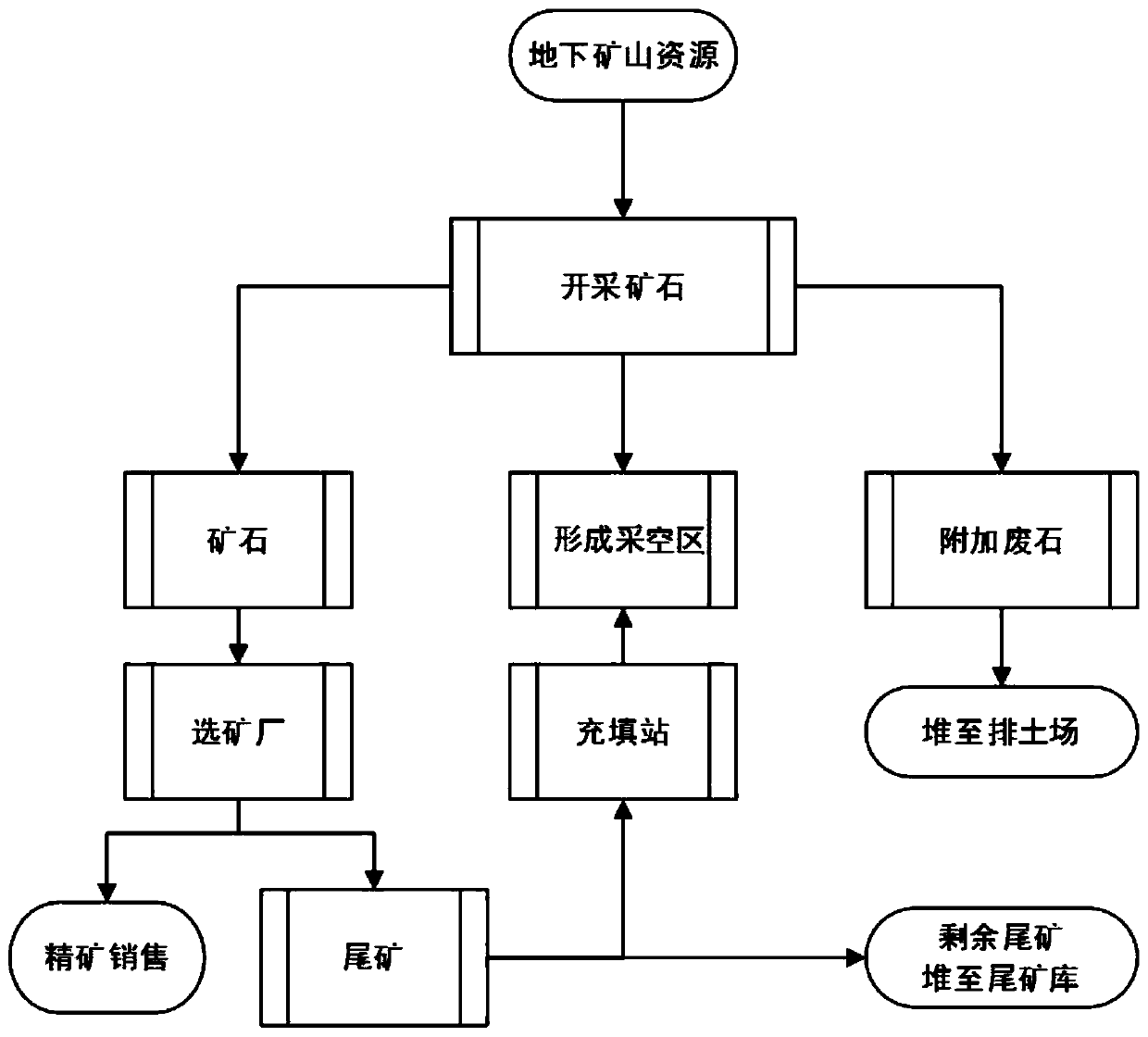

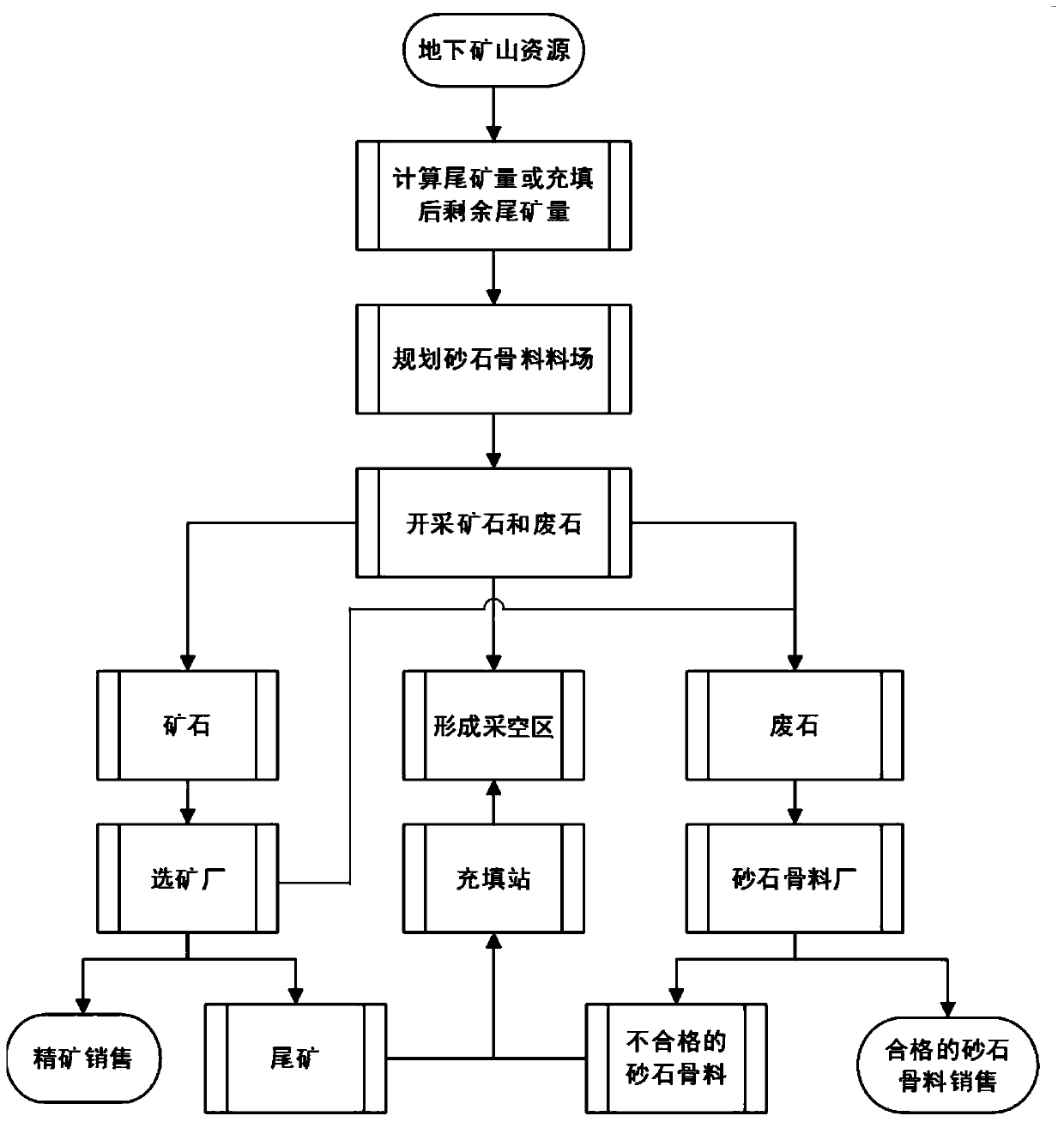

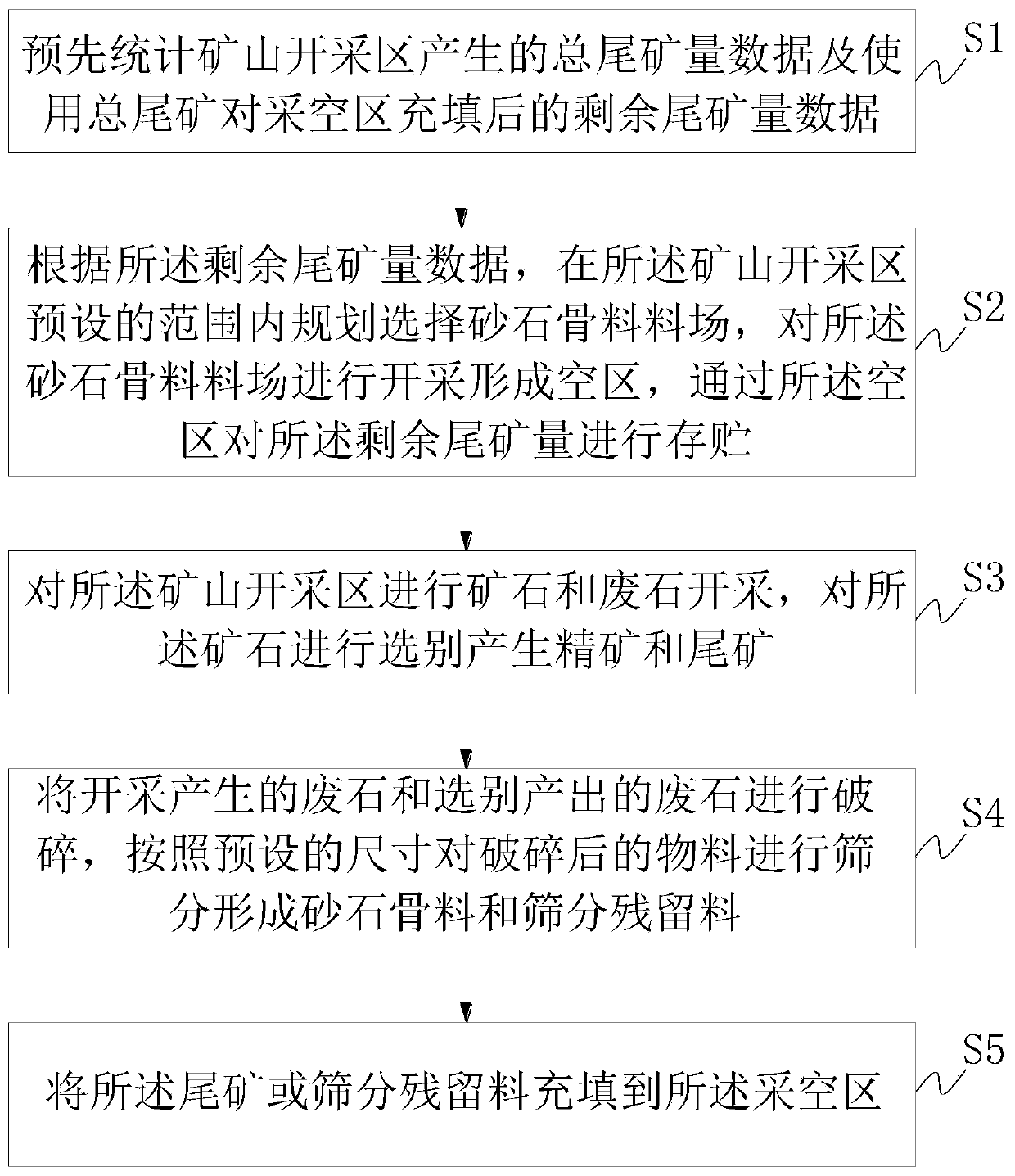

Underground mining process without building tailings pond

ActiveCN109736808ARealize fillingSmall footprintUnderground miningSurface miningMineralogyConstruction aggregate

The invention relates to an underground mining process without building a tailing pond. The underground mining process comprises the following steps: counting total tailing quantity data generated ina mining area and residual tailing quantity data after a goaf is filled; planning and selecting a gravel aggregate material field within a preset range of the mining area, and the formed empty area meeting the storage requirement for the remaining tailing amount; mining ores and waste rocks in the mining area, and sorting the ores to generate concentrates and tailings; crushing waste rocks produced by mining and waste rocks produced by sorting, and screening the crushed materials according to a preset size to form gravel aggregates and screening residues; and filling the tailings or the screened residues into the goaf. After the ores and waste rocks are mined, the goaf for containing tailings is formed, and the size of the goaf meets the storage requirements of tailings generated by ore sorting and needed cementing materials. An enough empty area is formed to fill tailings generated after mineral separation into a well, the tailing pond is not arranged on the ground surface, tailing-free mines are truly achieved, sand aggregate can be sold, and environmental protection and national economy construction are facilitated.

Owner:金建工程设计有限公司

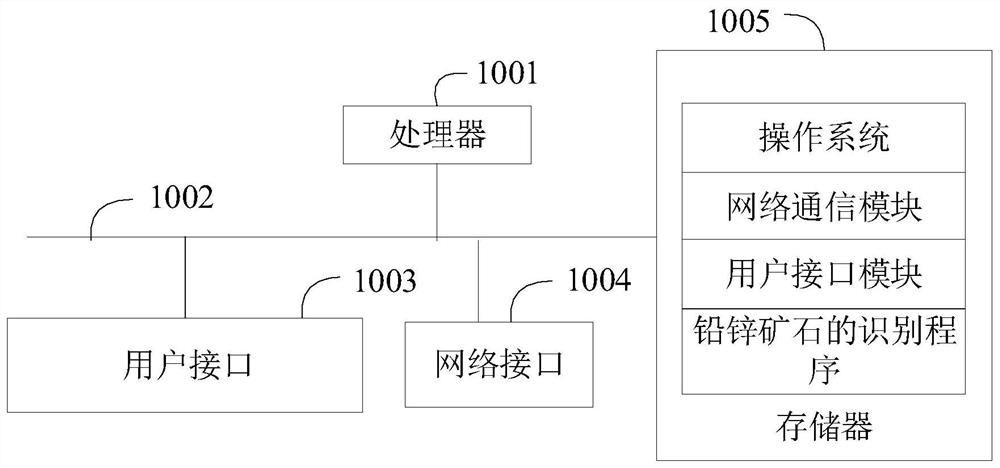

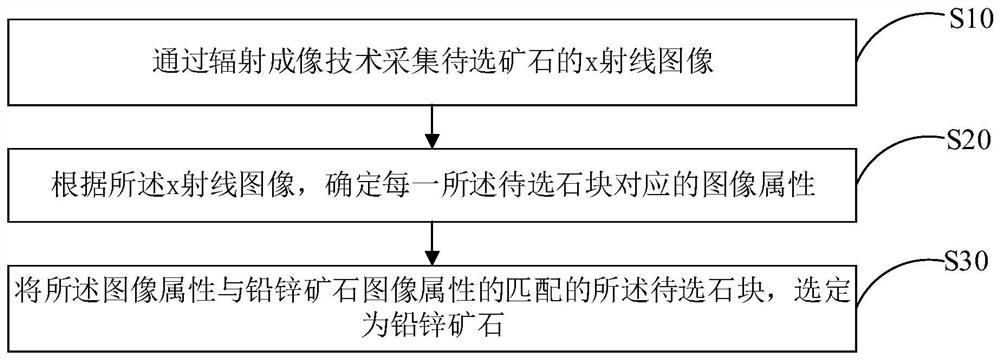

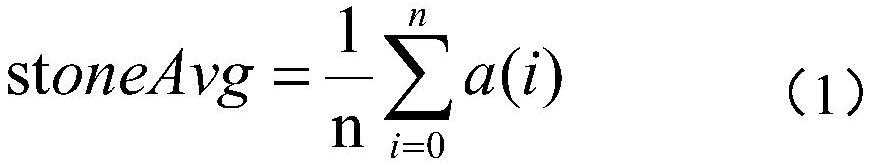

Lead zinc ore identification method, terminal equipment and storage medium

PendingCN112785558AImprove sorting efficiencyImprove recognition accuracyImage enhancementImage analysisRadiation imagingTerminal equipment

The invention discloses a lead zinc ore identification method. The identification method comprises the following steps: acquiring an x-ray image of to-be-selected ore through a radiation imaging technology; according to the x-ray image, determining an image attribute corresponding to each stone to be selected; and selecting the to-be-selected stones with the image attribute matched with the image attribute of lead zinc ore as the lead zinc ore. The invention further discloses terminal equipment and a computer readable storage medium, and the effect of improving the lead zinc ore sorting efficiency is achieved.

Owner:GANZHOU BROTHERS TECH CO LTD

Method for continuously and dynamically removing iron from minerals

The invention provides a method for continuously and dynamically removing iron from magnetic mineral ores. The invention belongs to a method for ore sorting, in particular to a method for continuously and dynamically removing iron from the magnetic mineral ore. The method comprises the following steps that: the lower part of a discharge end of an ore main conveying belt is provided with a segment of auxiliary conveying belt, and ore block on the front segment of the auxiliary conveying belt is paved by vibration, so that both of the ore block and the iron which is possibly mixed in the ore block can be directly contacted with the surface of the auxiliary conveying belt; and the lower part of the back segment of the discharge end of the auxiliary conveying belt is provided with a magnet, so that the ores can be discharged from the end part, and the iron can be conveyed to a position away from the magnet along with the auxiliary conveying belt, and then discharged. The equipment has a simple structure, and the dynamical and continuous removal of the iron from the ores containing the magnetic minerals can be easily achieved in lower cost under a condition of no ores mixed in the sorted iron.

Owner:KUNMING UNIV OF SCI & TECH

Efficient ore sorting machine

An efficient ore sorting machine comprises a bottom plate, a frame device, a first support device, a first air cylinder device, a second air cylinder device, a first filtering device, a first recycling device, a second recycling device and a second filtering device; a first supporting block and a first roller are arranged on the bottom plate; the frame device comprises a first frame, a first triangular block, a first limiting block, a second roller and a first convex block; the support device comprises a first supporting rod, a first inclined rod, a first transverse rod, a first cam, a second inclined rod and a first spring; the first air cylinder device comprises a first air cylinder, a first push frame, a first filter screen, a first vibrator, a first inclined plate, a second spring, a second supporting rod and a third spring; the second air cylinder device comprises a second air cylinder, a first push rod, a first support, a first push plate and a second triangular block; the first filter device comprises a second support, a third support, a second frame and a second cam; through the machine, ores can be screened and separated, and the screening and separating efficiency is higher.

Owner:重庆龙蒲工贸有限公司

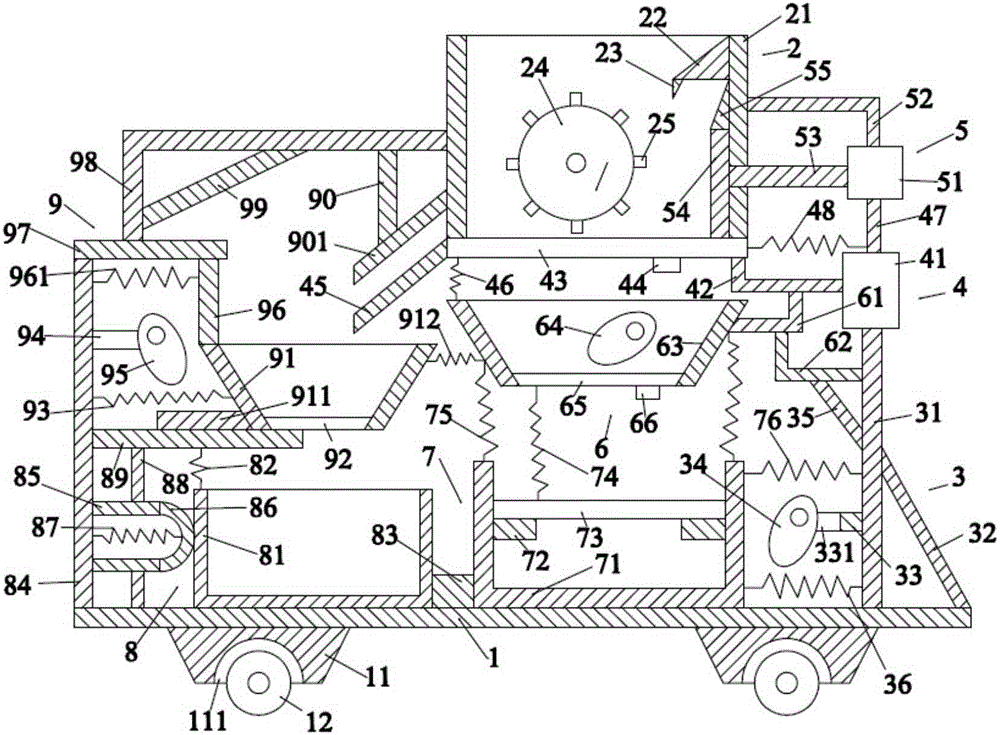

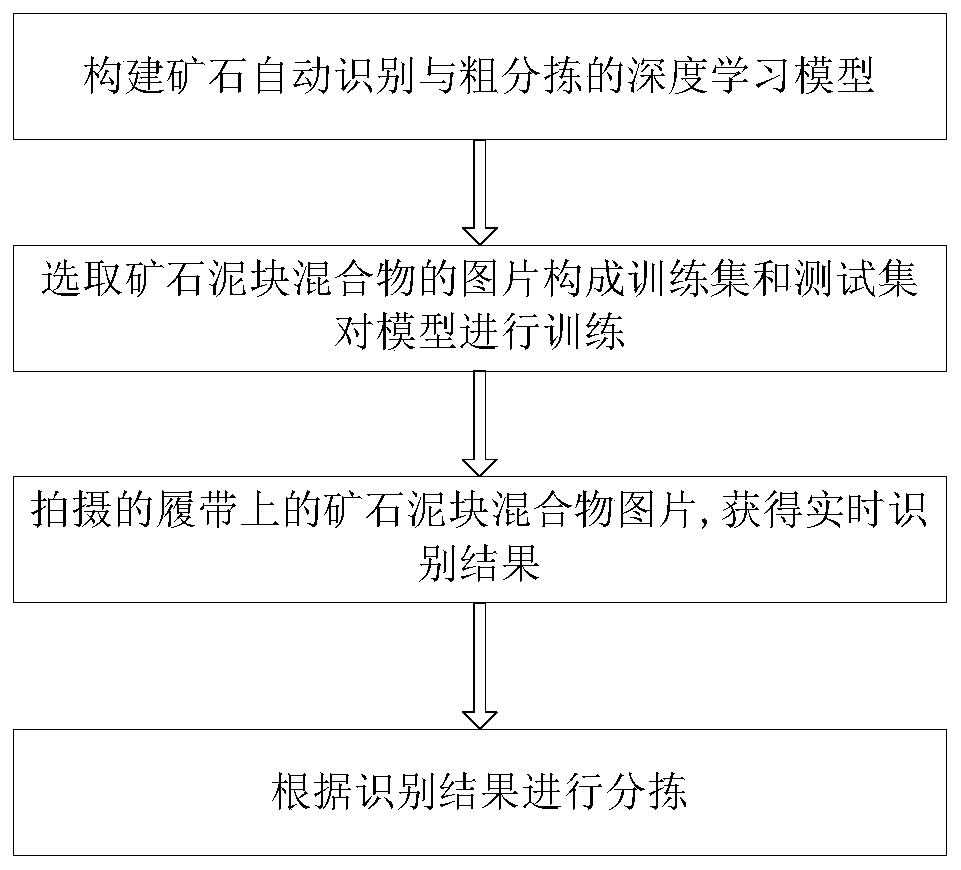

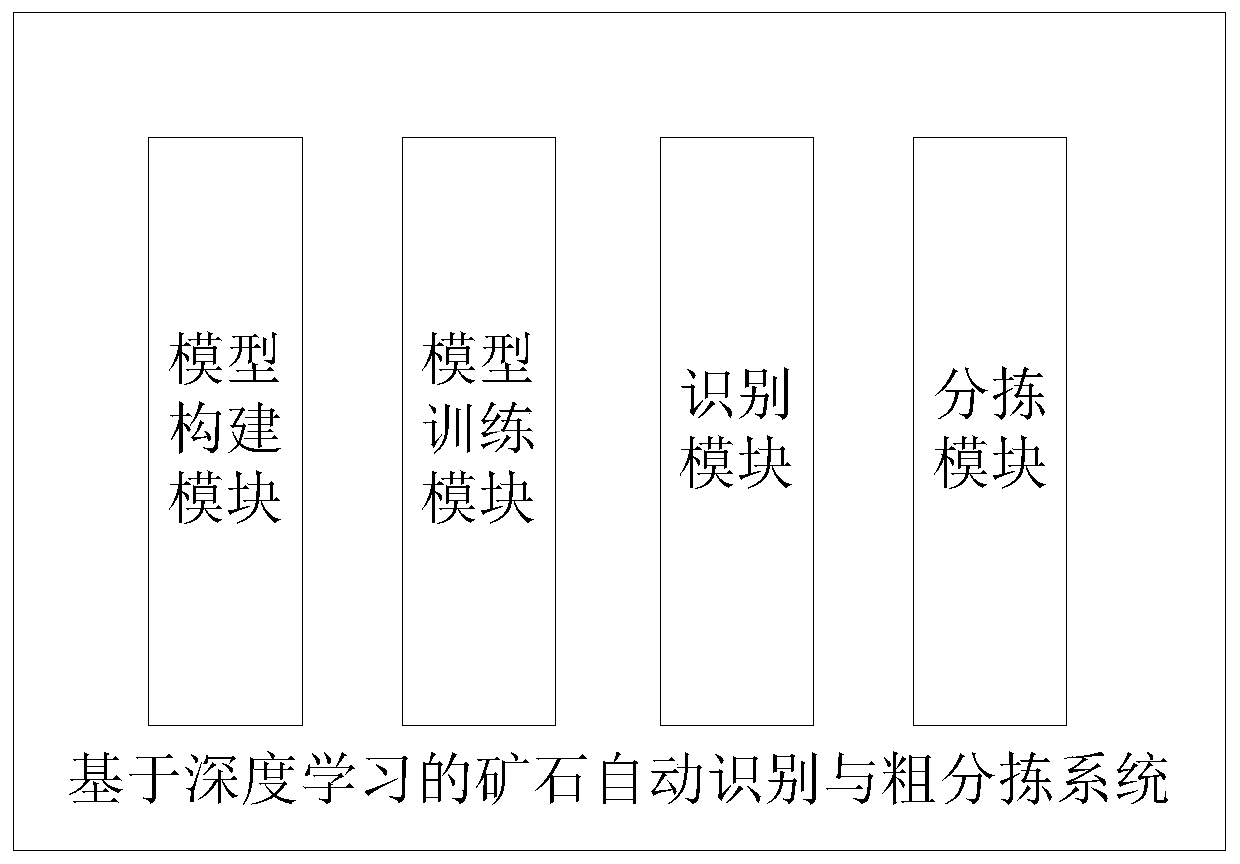

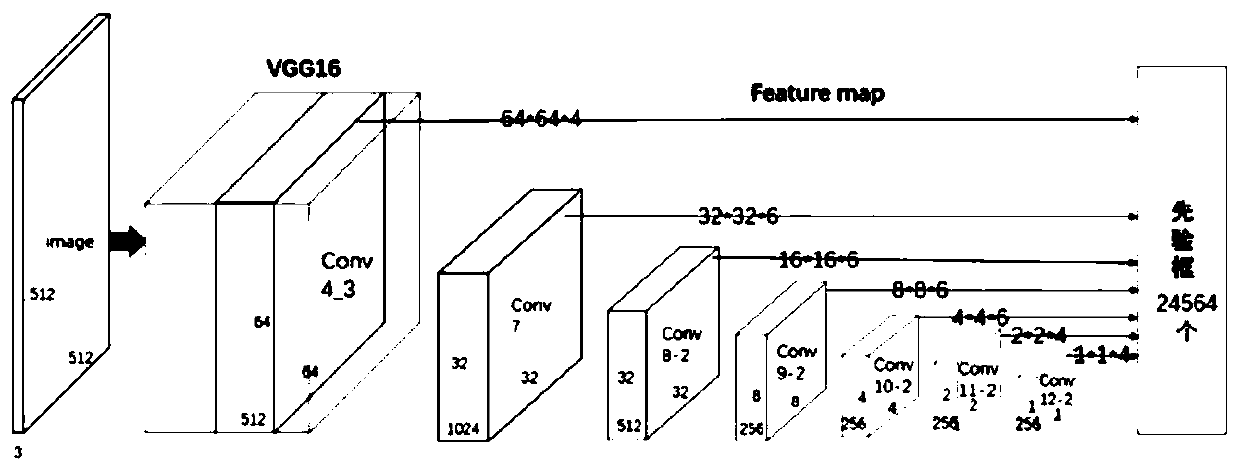

Ore automatic identification and coarse sorting system based on deep learning

PendingCN111507379AReduce human involvementFully automatedCharacter and pattern recognitionNeural architecturesEngineeringHigh pressure water

The invention discloses an ore automatic identification and coarse sorting system based on deep learning, and the system comprises: a model construction module which is used for constructing a deep learning model of ore automatic identification and coarse sorting; a model training module which is used for forming a training set and a test set according to the pictures of the selected ore mud blockmixture to train a deep learning model for automatic ore identification and coarse sorting; a recognition module which is used for inputting the shot ore and mud block mixture pictures on the crawlerbelt into a trained ore automatic recognition and rough sorting deep learning model to obtain a real-time recognition result; and a sorting module which is used for controlling the crawler belt to feed the batch of ores into the next procedure according to the recognition result of the recognition module if the mud content after recognition is smaller than a set threshold value, otherwise, controlling the high-pressure water gun to perform fixed-point flushing on the recognized mud blocks, and then feeding the mud blocks into the next procedure. According to the invention, deep learning is creatively introduced into the ore sorting process, and full automation of ore coarse sorting is achieved.

Owner:WUHAN UNIV OF TECH

Intelligent ore sorting machine

The invention relates to the technical field of sorting mechanical equipment, in particular to an intelligent ore sorting machine. The machine adopts a three-dimensional laser imaging system to reconstruct a three-dimensional structure of an ore, shape information of the ore can be obtained, a first detection mechanism can be combined with the shape of the ore to accurately identify the ore, the ore containing thin mineral substances cannot be missed, the detection precision of the ore is improved, the yield of the qualified ore is increased, quartz with wide commercial values in a waste rockcan be further recognized and separated from a metamorphic rock in combination with a second detection mechanism, the utilization rate of the waste rock is increased, the overall resource utilizationrate of a raw ore is increased, the complexity of waste rock treatment in the later period is reduced, and benefits are increased for enterprises.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com