Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

210 results about "Plasma heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma heating performed by the plasma current and the injection of fast atoms and use of high-frequency and ultrahigh-frequency (UHF) power (in the case of a hot plasma also by charged products of the fusion reaction).

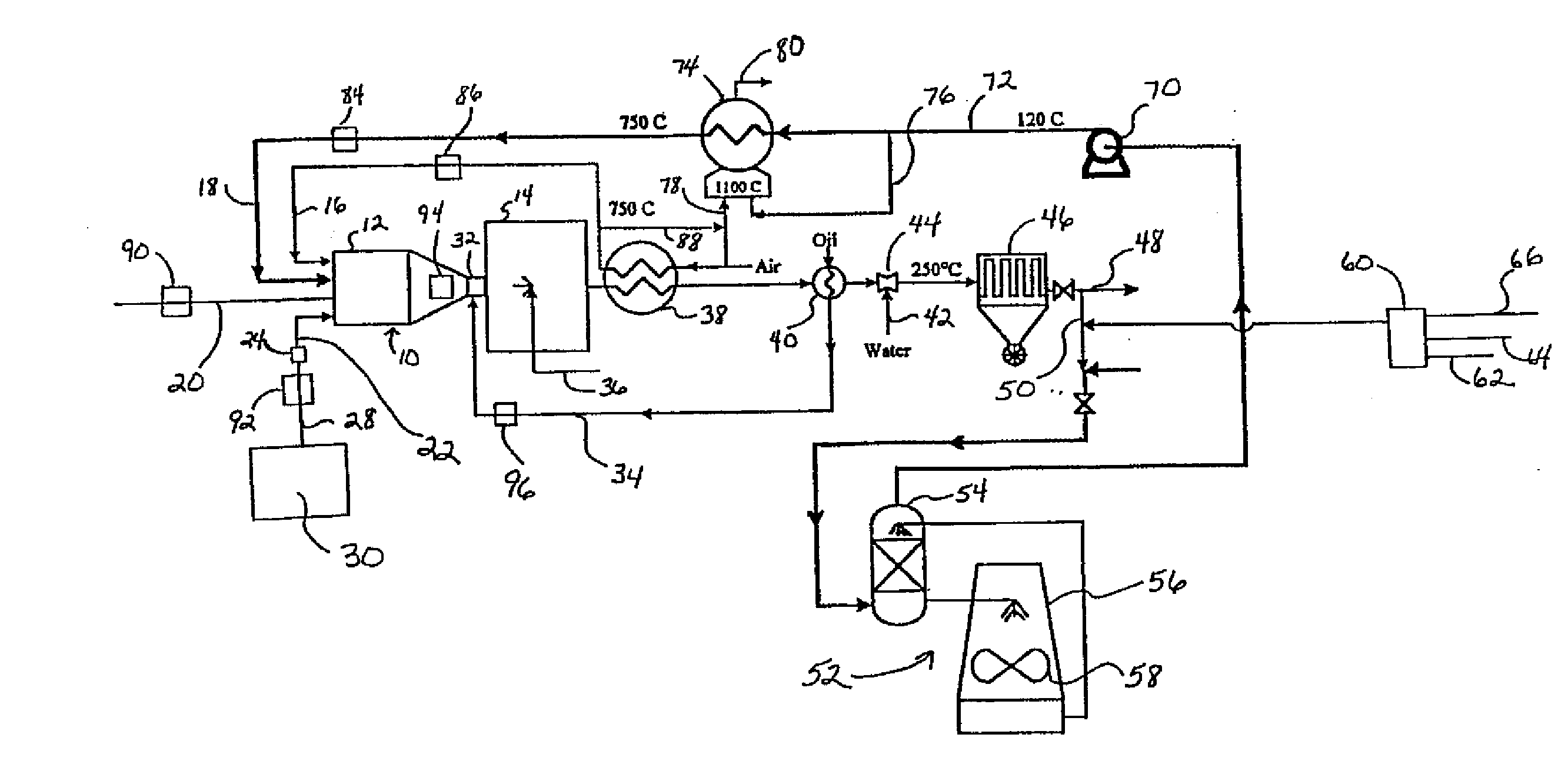

Process for production of carbon black

InactiveUS7655209B2Increase flexibilityLow costProcess control/regulationPigmenting treatmentCombustorProcess engineering

Off-gas from a carbon black furnace is employed as a combustion gas feed stream to the burner or combustion zone of the same or a different carbon black furnace in accordance with certain embodiments, suitable conduit and valving is provided to pass off-gas, from which carbon black has been substantially removed, from any and all of multiple different carbon black furnaces to the burner. The off-gas is heated, preferably by plasma heating, and dewatered. Carbon dioxide stripping or rather stripping of gas components from the dewatered heated off-gas is found to be unnecessary to achieve economically favorable use of off-gas recirculation.

Owner:CABOT CORP

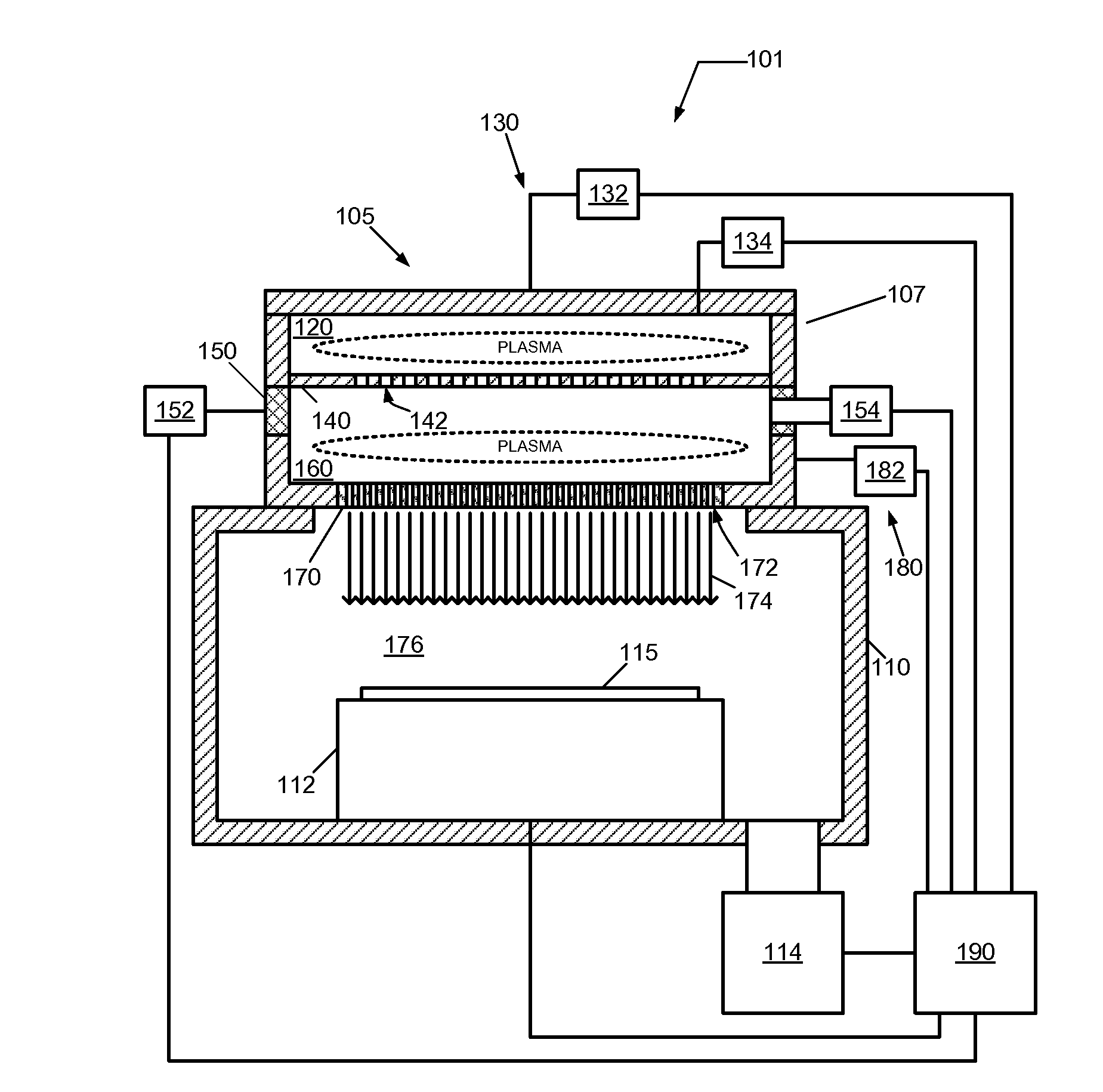

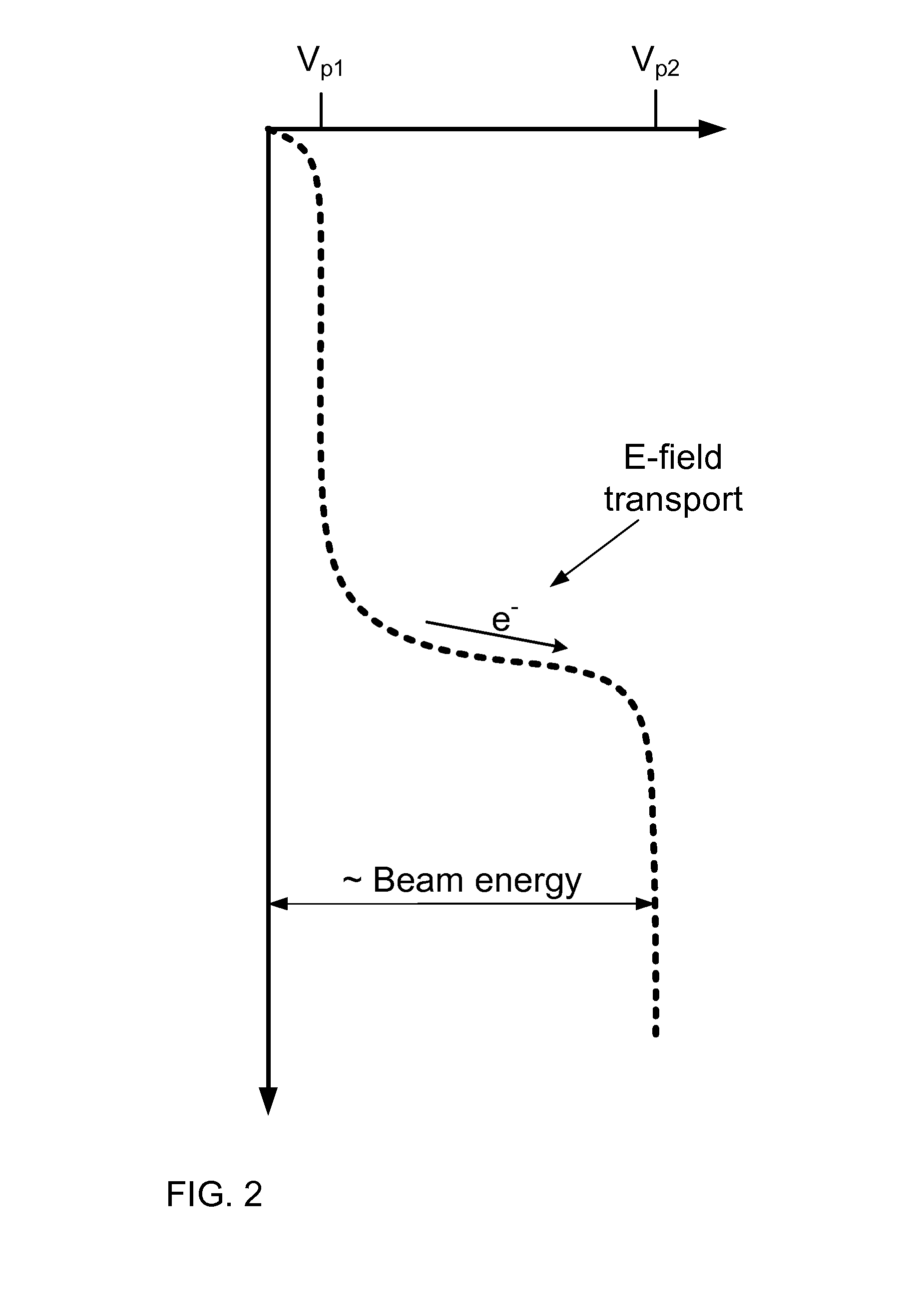

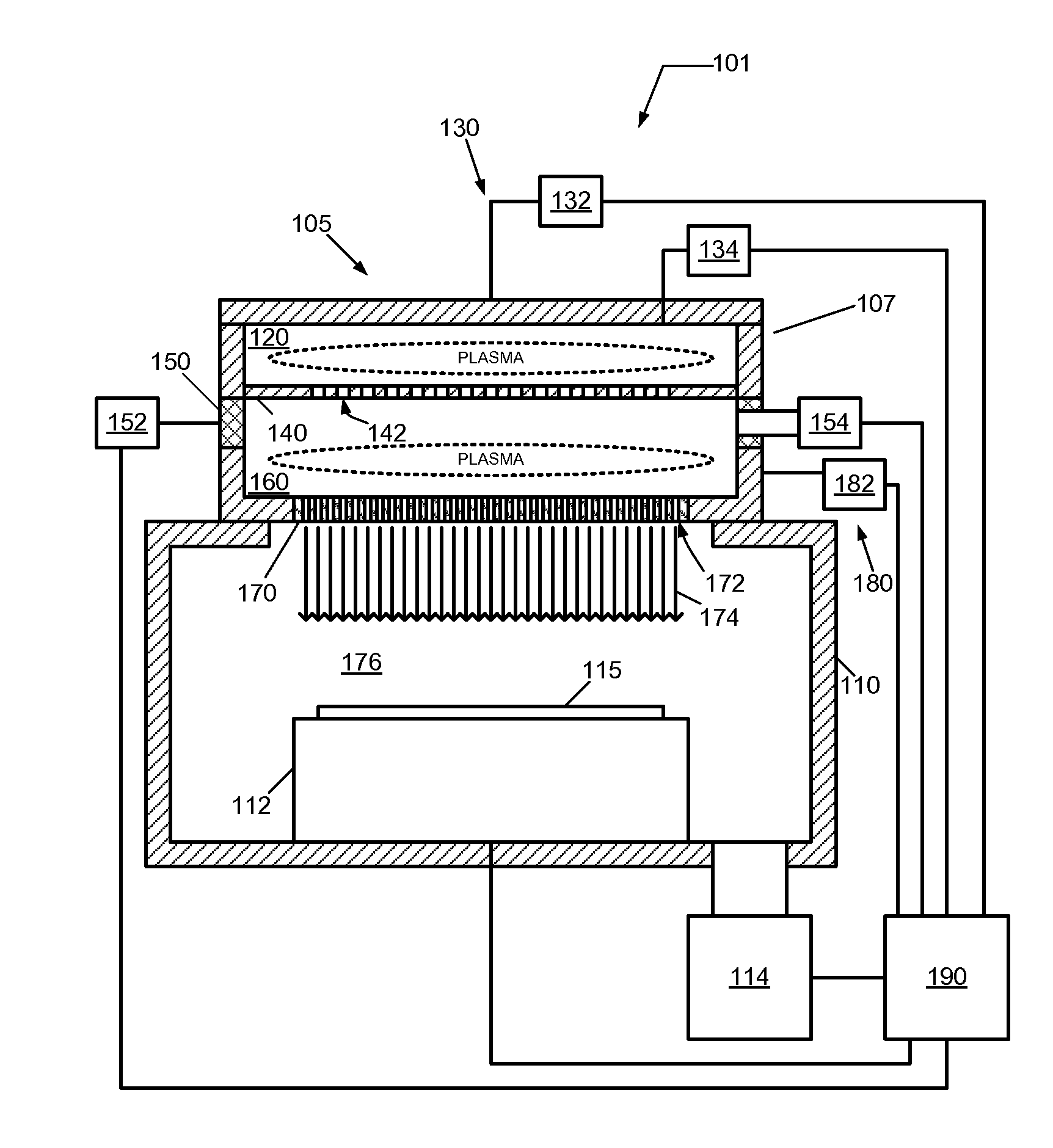

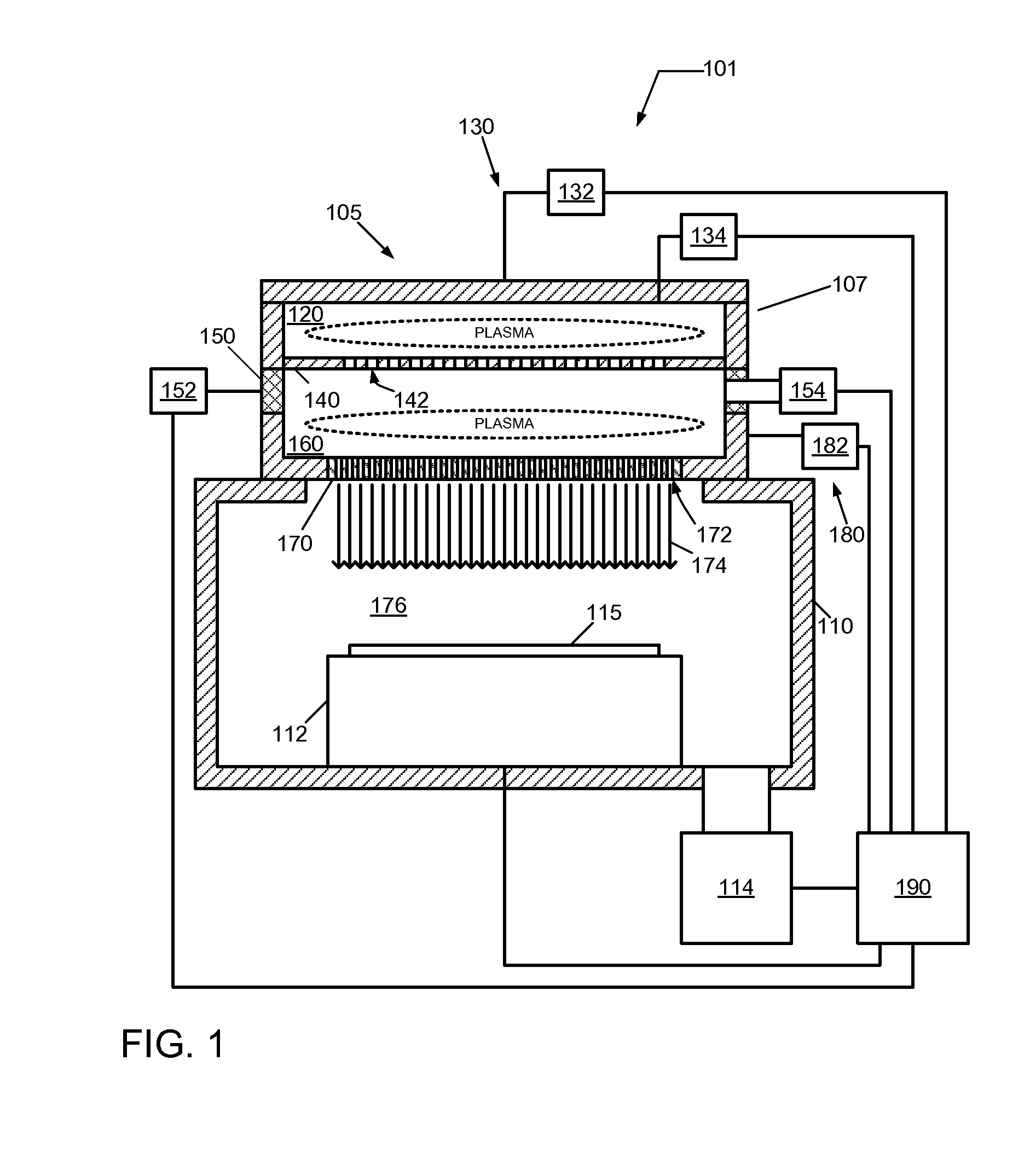

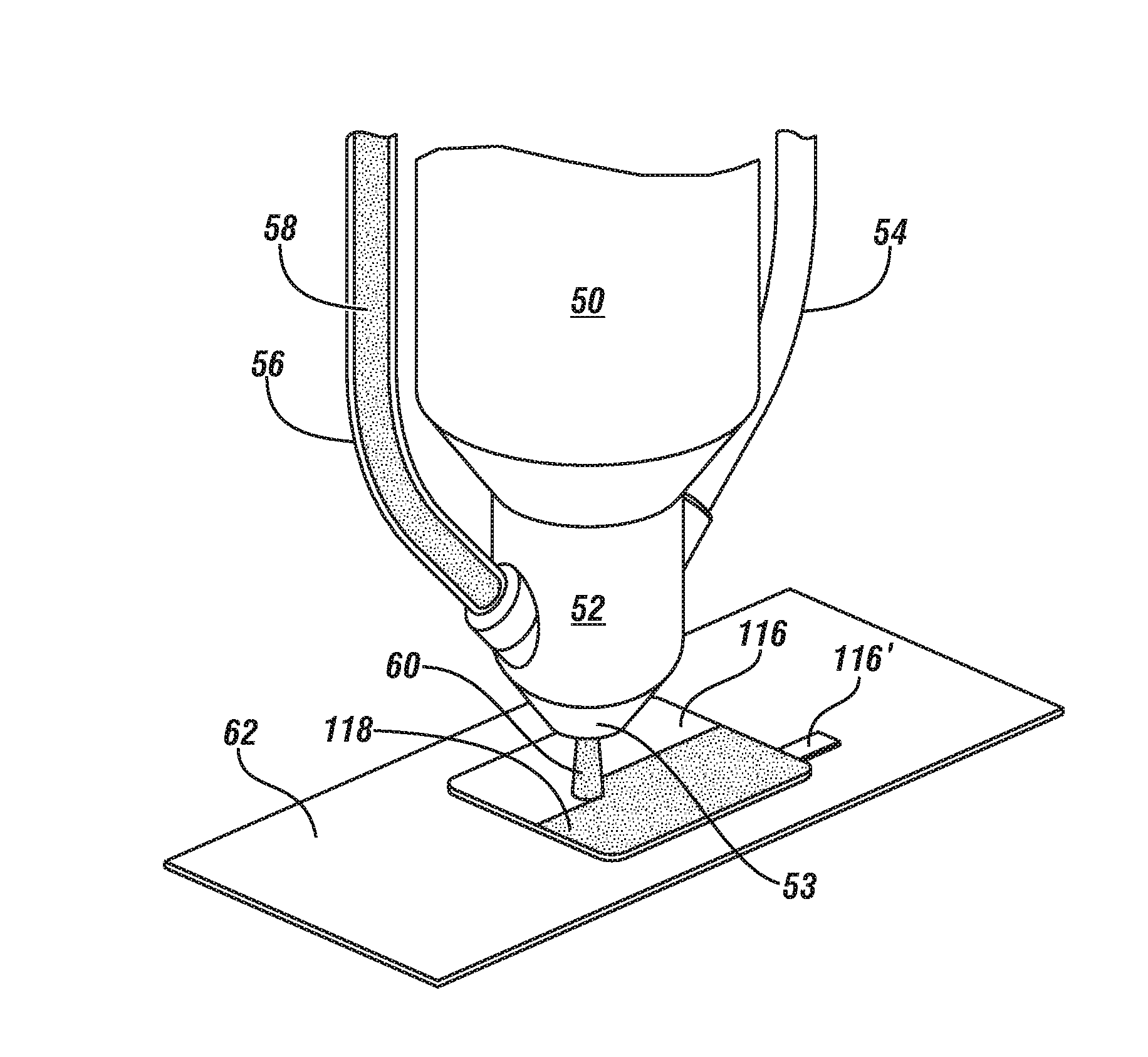

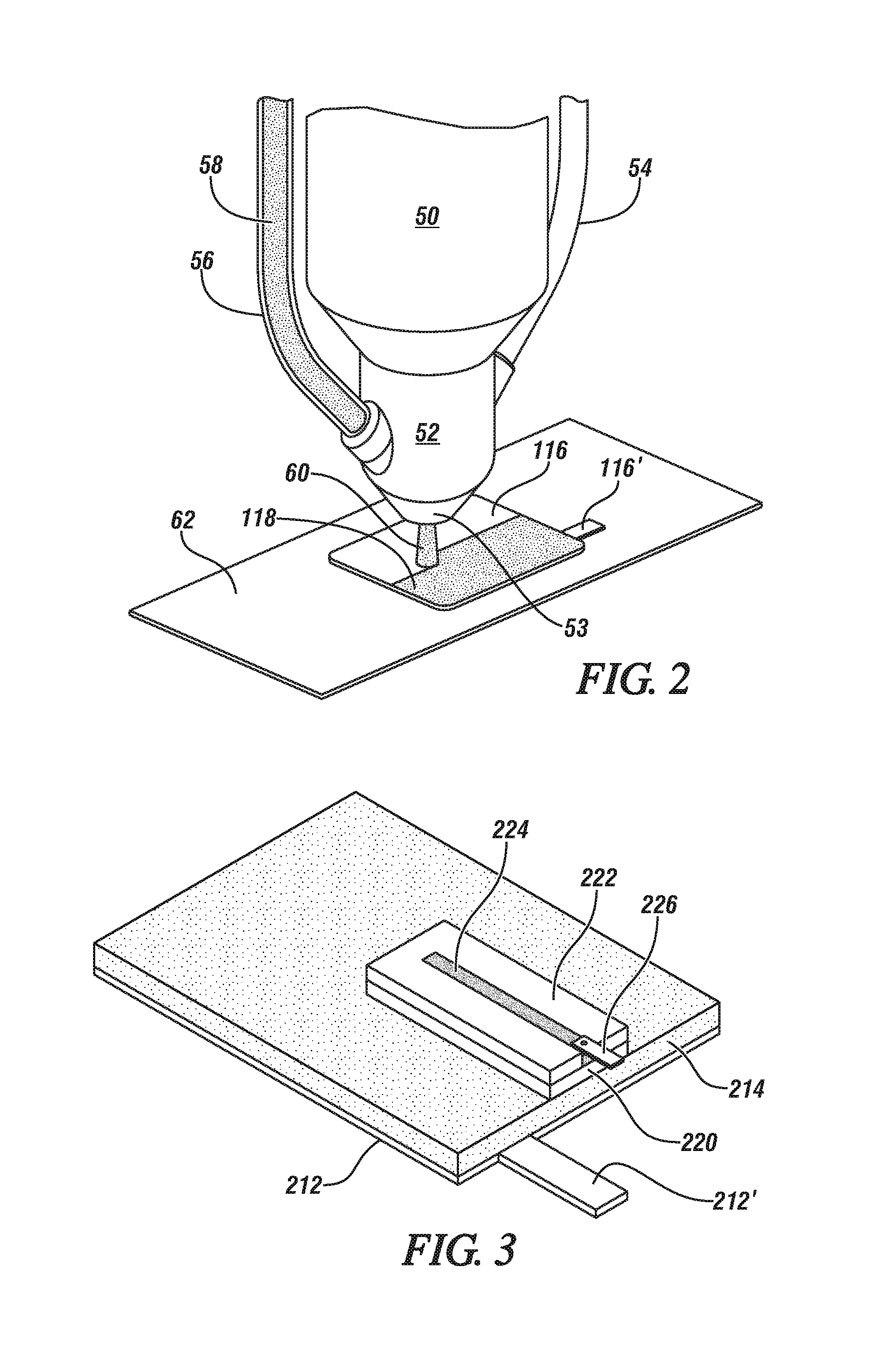

Method and system for low pressure plasma processing

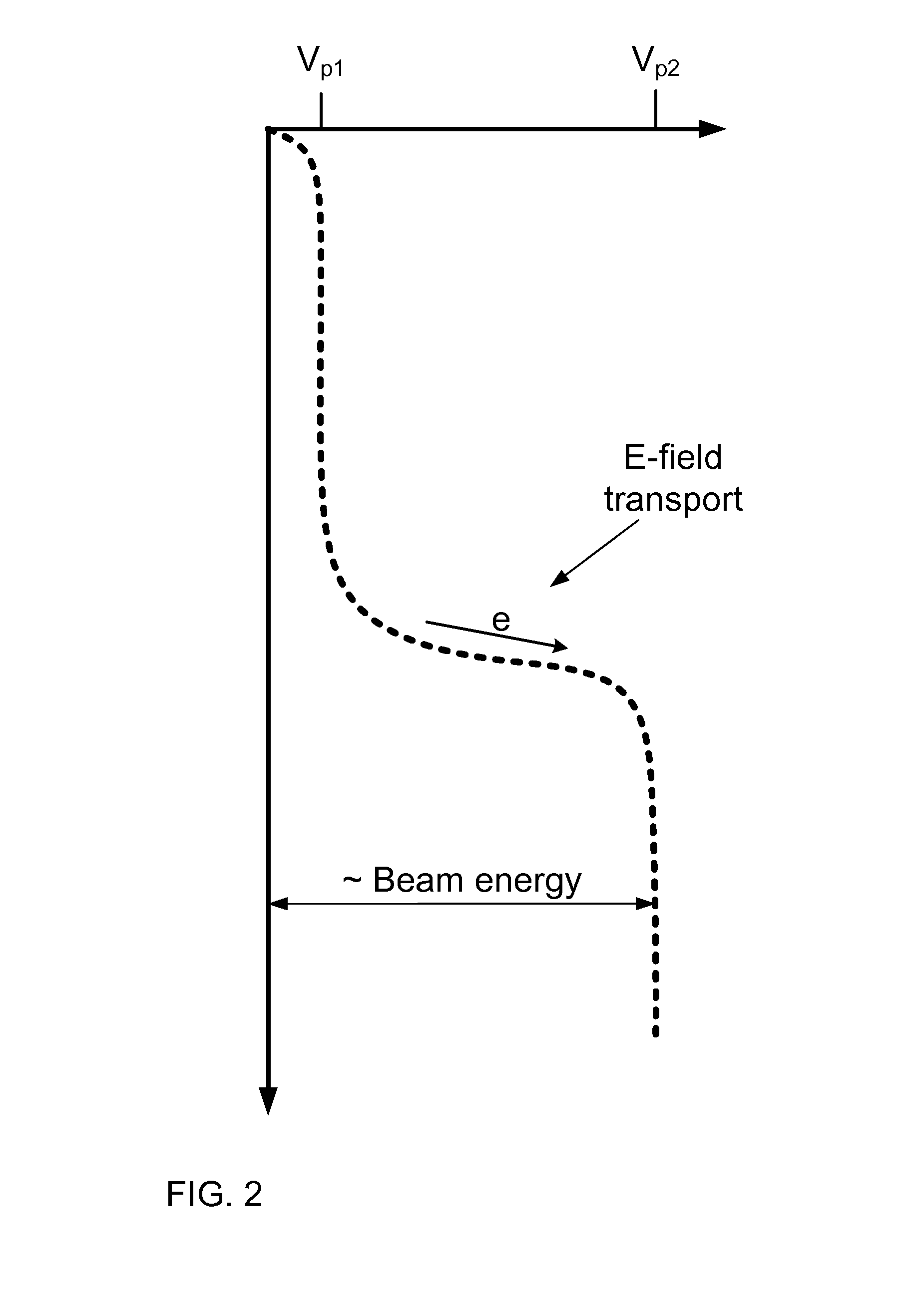

Method and system for treating a substrate with plasma under low pressure conditions is described. A plasma processing system comprises a plasma generation chamber having a first plasma region and a process chamber having a second plasma region disposed downstream of the first plasma region. A plasma generation system is coupled to the plasma generation chamber and configured to create a first plasma in the first plasma region, while a plasma heating system is coupled to the process chamber and configured to heat electrons supplied to the second plasma region from the first plasma region to form a second plasma. A substrate holder coupled to the process chamber is configured to support a substrate and expose the substrate to the second plasma.

Owner:TOKYO ELECTRON LTD

Multi-plasma neutral beam source and method of operating

Method and system for producing a neutral beam source is described. The neutral beam source comprises a plasma generation system for forming a first plasma in a first plasma region, a plasma heating system for heating electrons from the first plasma region in a second plasma region to form a second plasma, and a neutralizer grid for neutralizing ion species from the second plasma in the second plasma region. Furthermore, the neutral beam source comprises an electron acceleration member configured to accelerate the electrons from the first plasma region into the second plasma region. Further yet, the neutral beam source comprises a pumping system that enables use of the neutral beam source for semiconductor processing applications, such as etching processes.

Owner:TOKYO ELECTRON LTD

Process For Production of Carbon Black

InactiveUS20080226538A1Increase flexibilityLow costProcess control/regulationPigmenting treatmentCombustorProcess engineering

Off-gas from a carbon black furnace is employed as a combustion gas feed stream to the burner or combustion zone of the same or a different carbon black furnace in accordance with certain embodiments, suitable conduit and valving is provided to pass off-gas, from which carbon black has been substantially removed, from any and all of multiple different carbon black furnaces to the burner. The off-gas is heated, preferably by plasma heating, and dewatered. Carbon dioxide stripping or rather stripping of gas components from the dewatered heated off-gas is found to be unnecessary to achieve economically favorable use of off-gas recirculation.

Owner:CABOT CORP

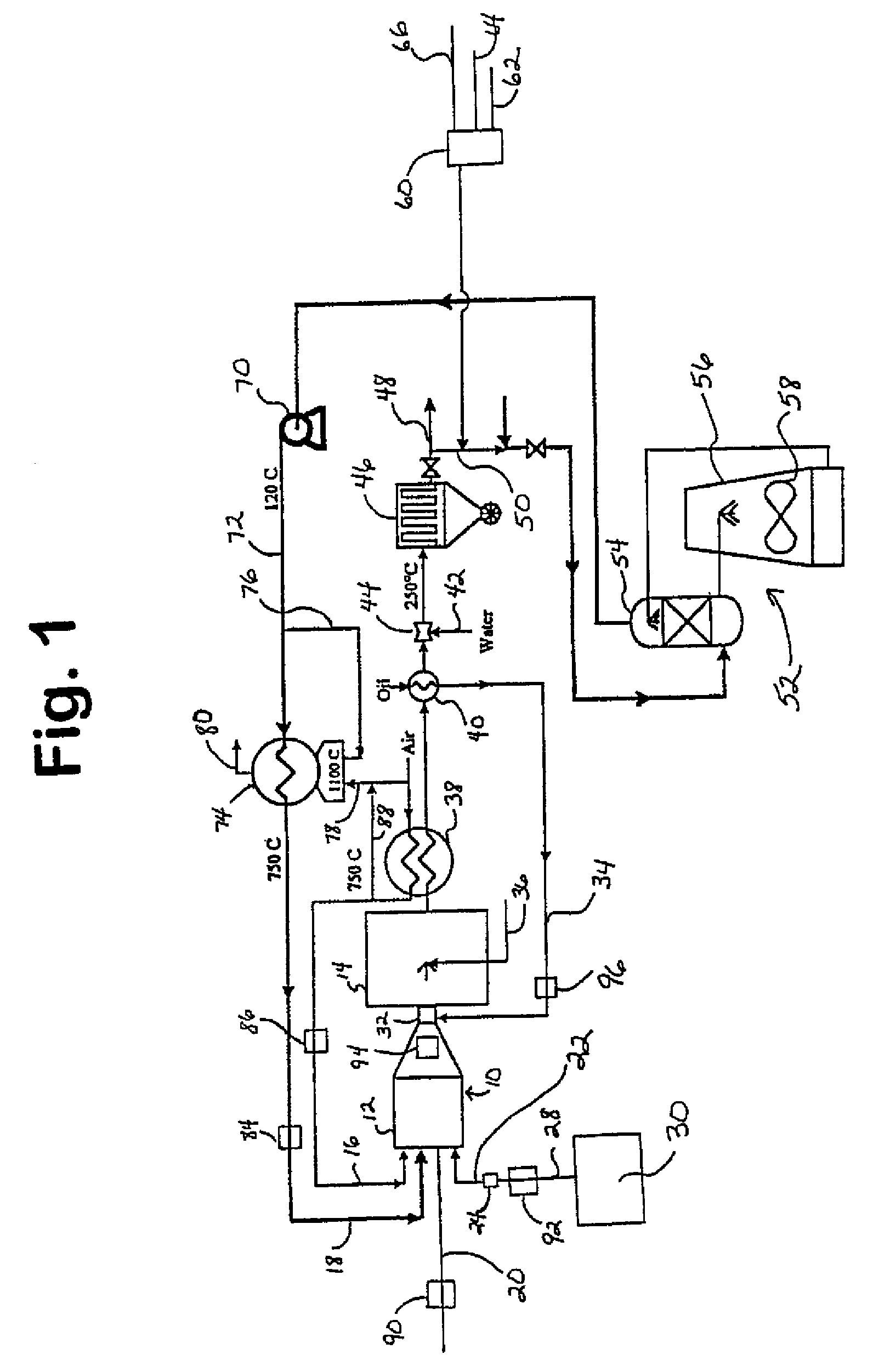

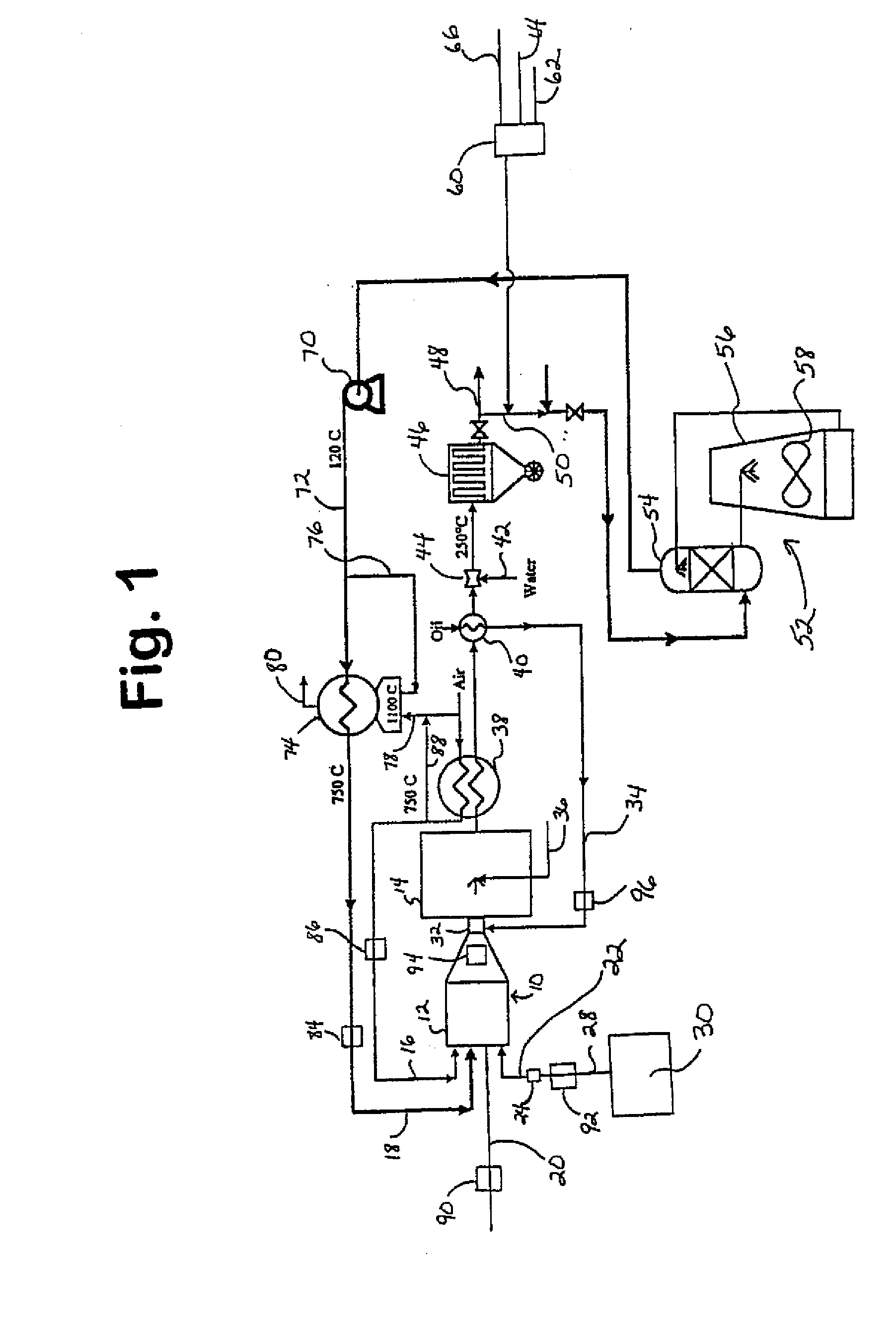

Residue conditioning system

The present invention provides a system for converting the residue of a carbonaceous feedstock gasification or incineration process into an inert slag and a gas having a heating value. The residue is converted by plasma heating in a refractory-lined residue conditioning chamber. The gas produced is optionally passed through a gas conditioning system for cooling and cleaning to provide a product gas that is suitable for use in downstream applications. The system also comprises a control subsystem for optimizing the conversion reaction

Owner:PLASCO ENERGY GROUP INC

Residue Conditioning System

The present invention provides a system for converting the residue of a carbonaceous feedstock gasification or incineration process into an inert slag and a gas having a heating value. The residue is converted by plasma heating in a refractory-lined residue conditioning chamber. The gas produced is optionally passed through a gas conditioning system for cooling and cleaning to provide a product gas that is suitable for use in downstream applications. The system also comprises a control subsystem for optimizing the conversion reaction

Owner:PLASCO ENERGY GROUP INC

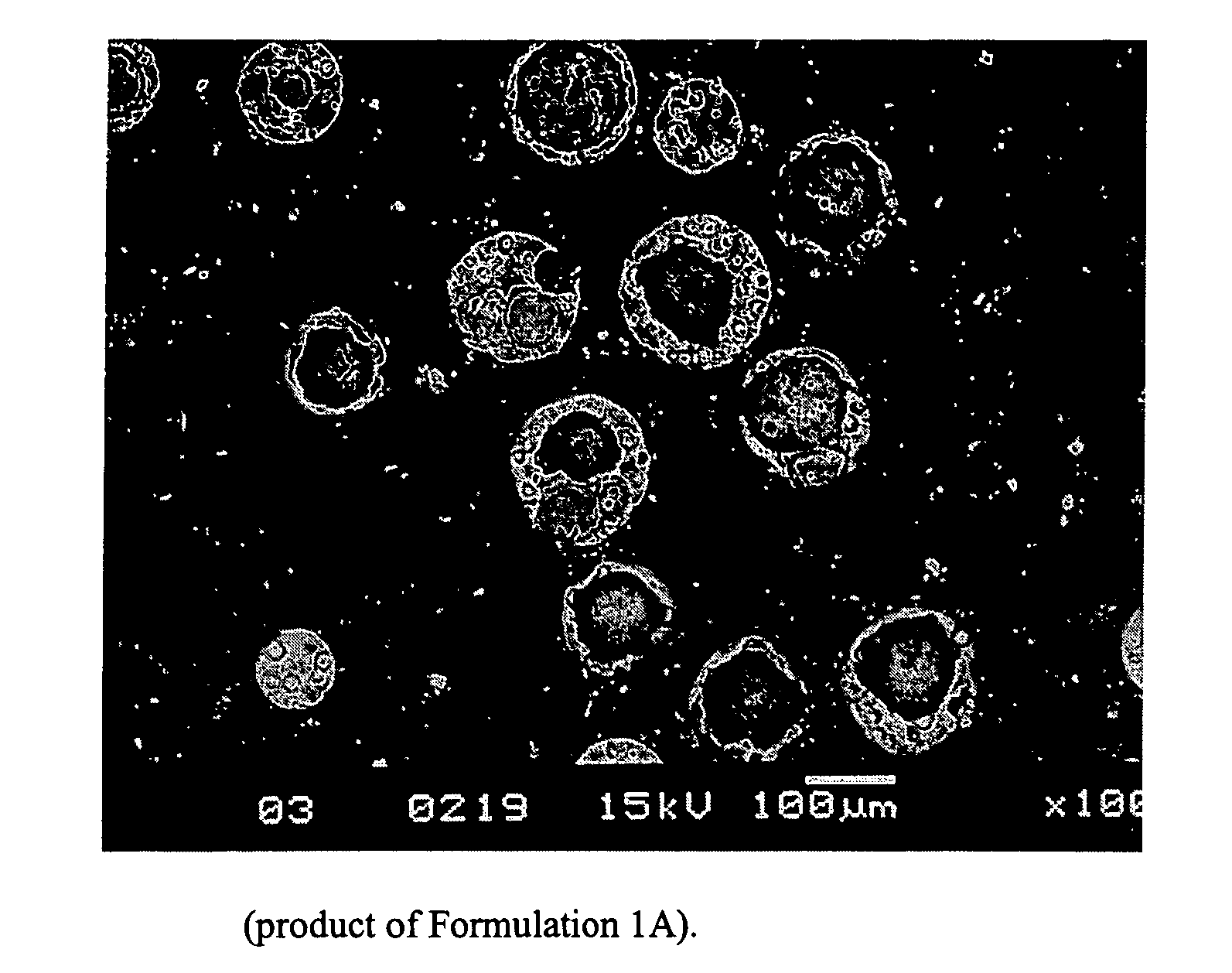

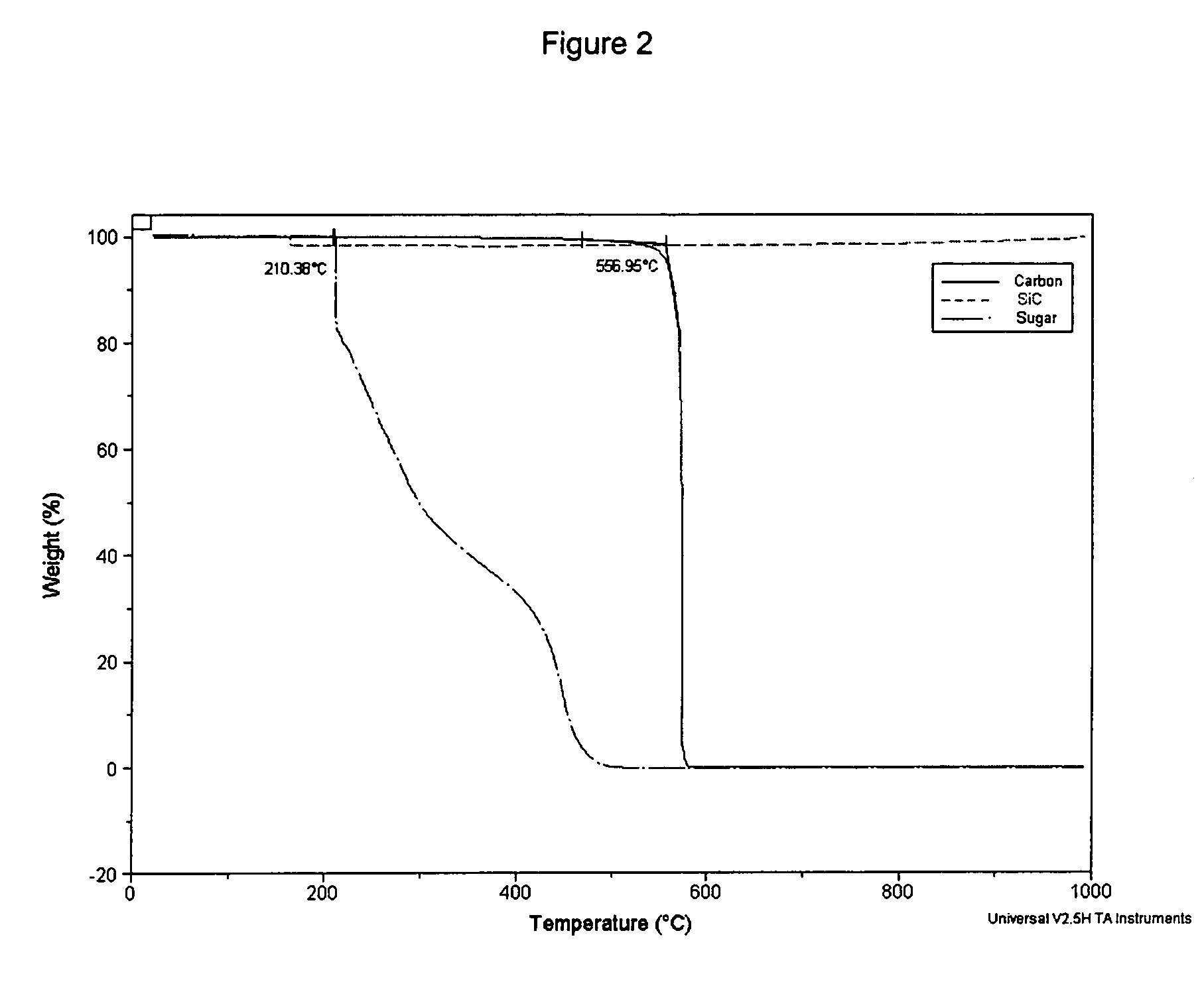

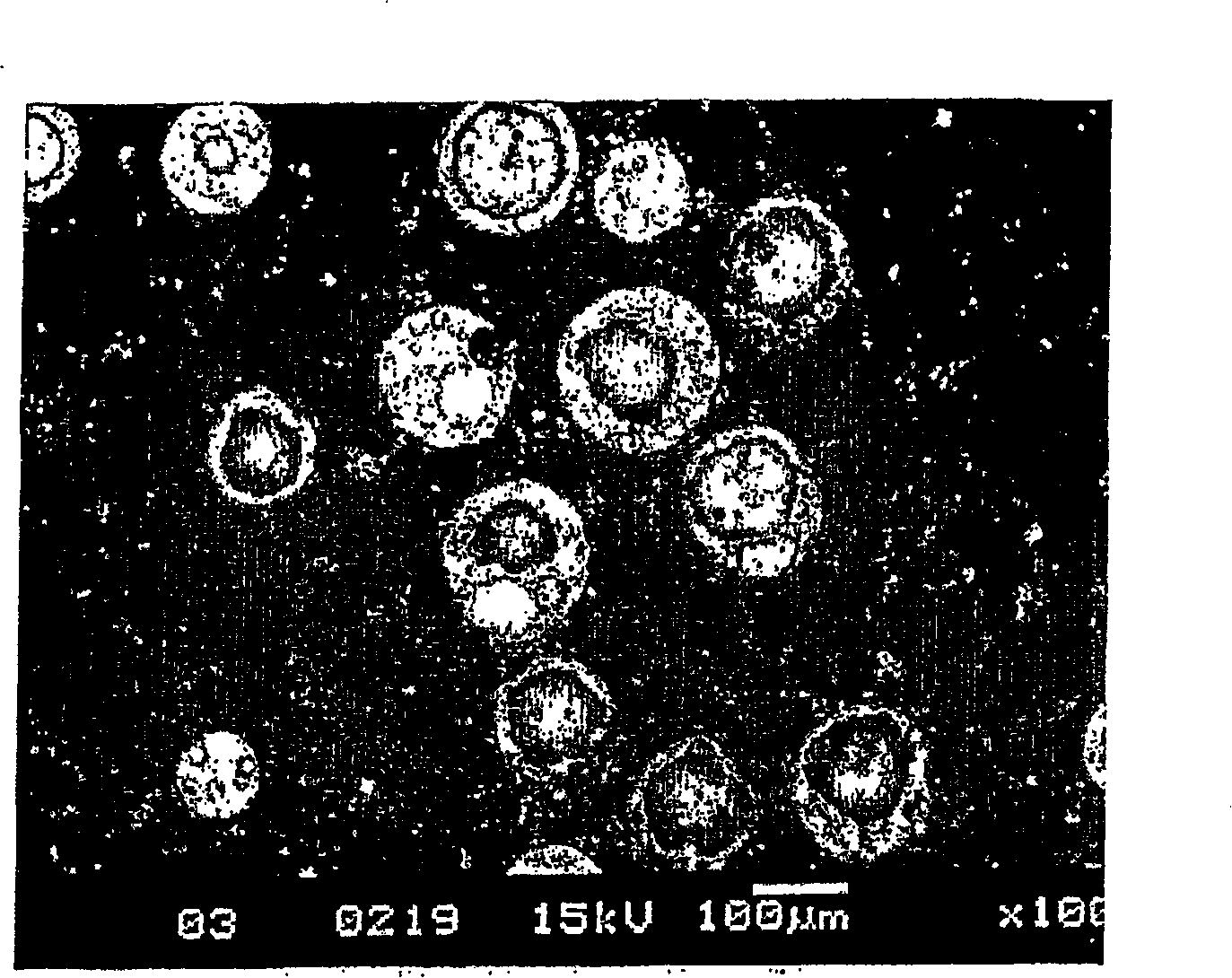

Methods for producing low density products

ActiveUS7455798B2High yieldHigh viscositySolid waste managementGlass shaping apparatusLow densityBiological activation

A method of preparing a low-density material and precursor for forming a low-density material is provided. An aqueous mixture of inorganic primary component and a blowing agent is formed, the mixture is dried and optionally ground to form an expandable precursor. Such a precursor is then fired with activation of the blowing agent being controlled such that it is activated within a predetermined optimal temperature range. Control of the blowing agent can be accomplished via a variety of means including appropriate distribution throughout the precursor, addition of a control agent into the precursor, or modification of the firing conditions such as oxygen deficient or fuel rich environment, plasma heating etc.

Owner:JAMES HARDIE TECH LTD

Multi-plasma neutral beam source and method of operating

Method and system for producing a neutral beam source is described. The neutral beam source comprises a plasma generation system for forming a first plasma in a first plasma region, a plasma heating system for heating electrons from the first plasma region in a second plasma region to form a second plasma, and a neutralizer grid for neutralizing ion species from the second plasma in the second plasma region. Furthermore, the neutral beam source comprises an electron acceleration member configured to accelerate the electrons from the first plasma region into the second plasma region. Further yet, the neutral beam source comprises a pumping system that enables use of the neutral beam source for semiconductor processing applications, such as etching processes.

Owner:TOKYO ELECTRON LTD

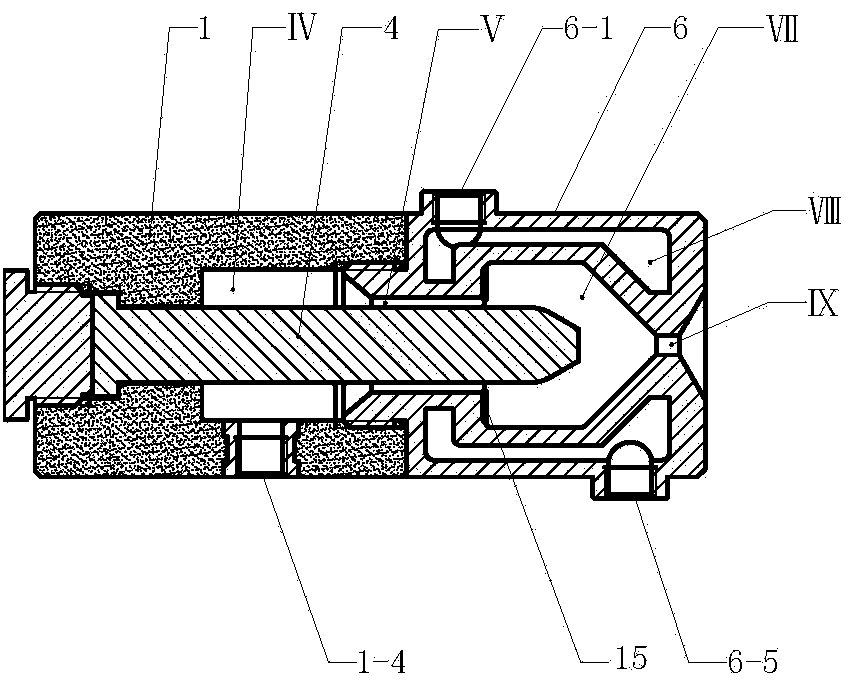

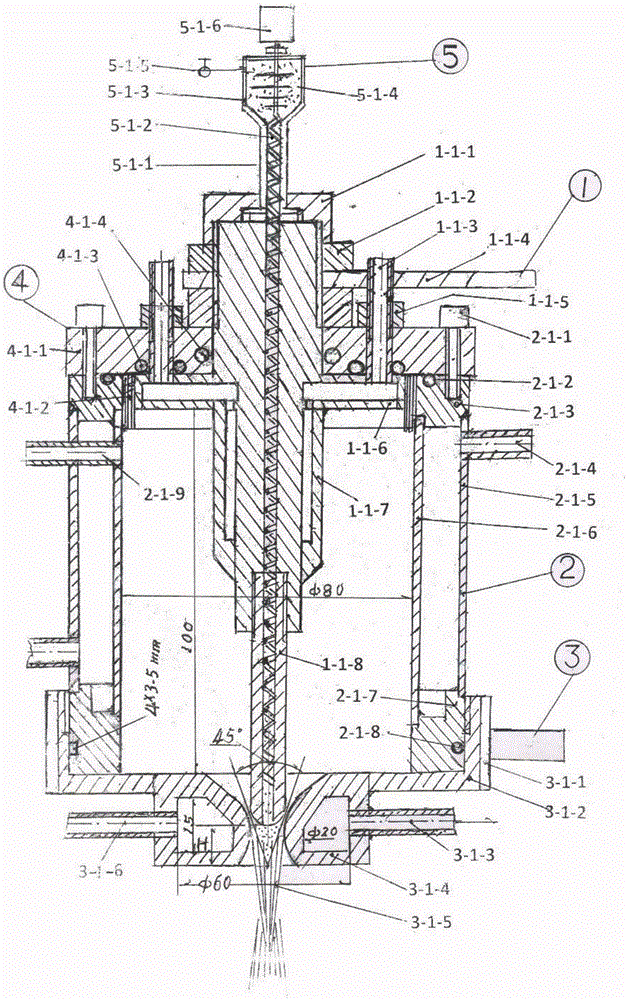

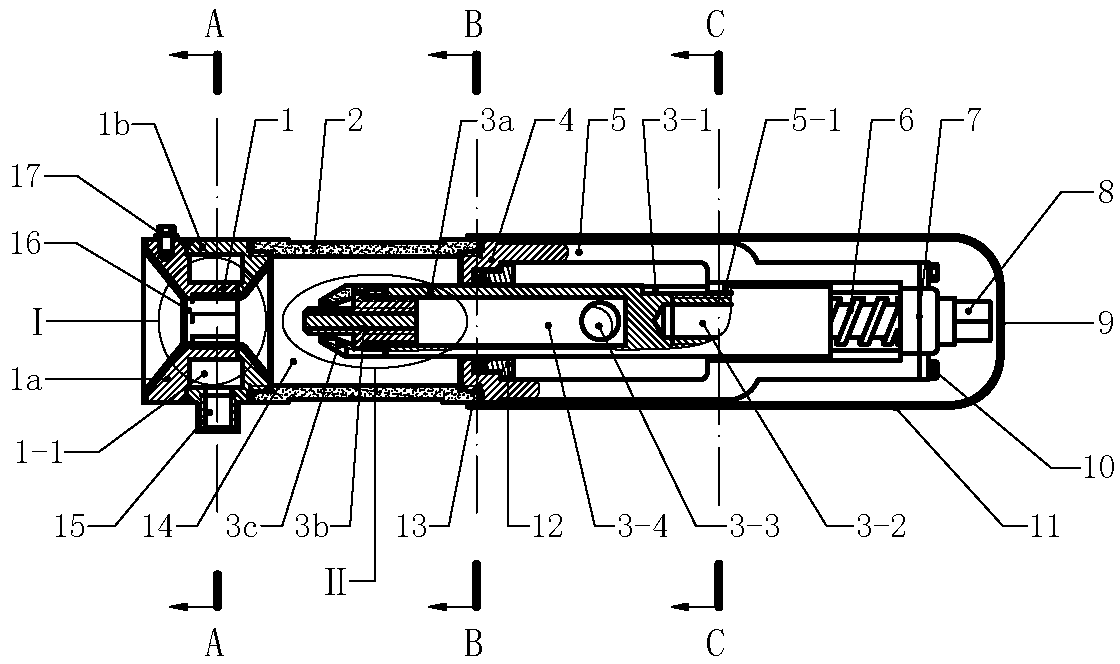

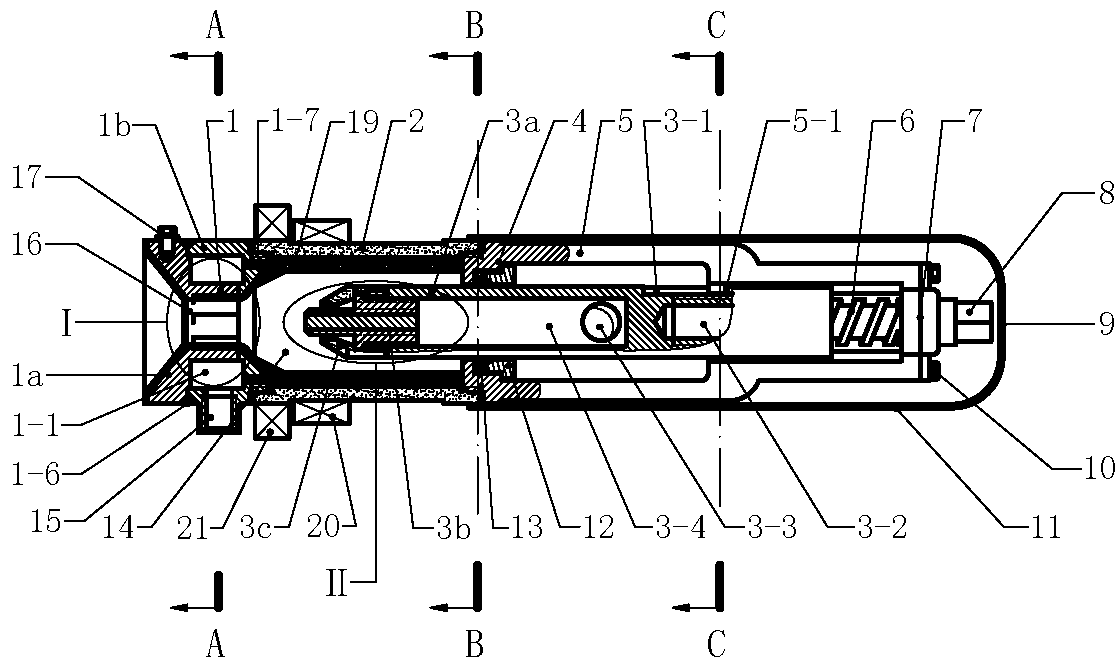

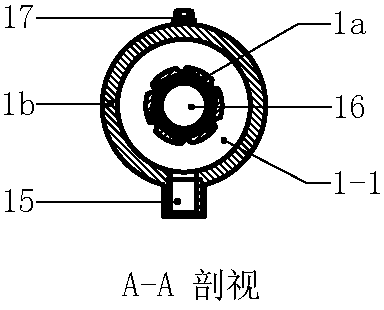

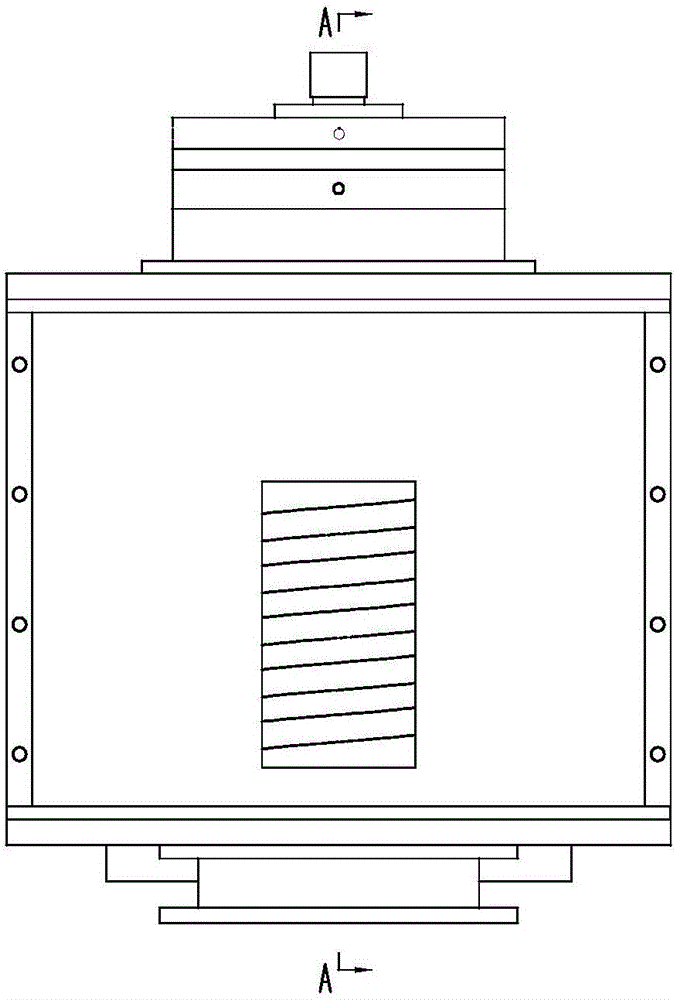

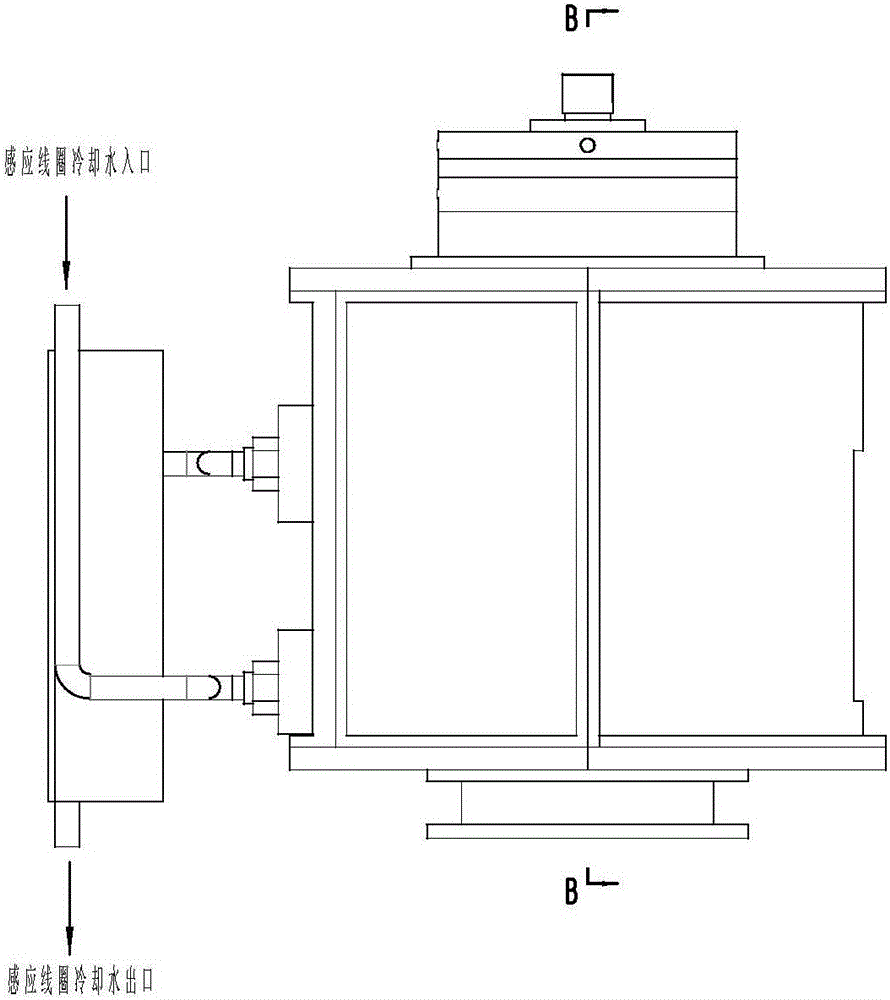

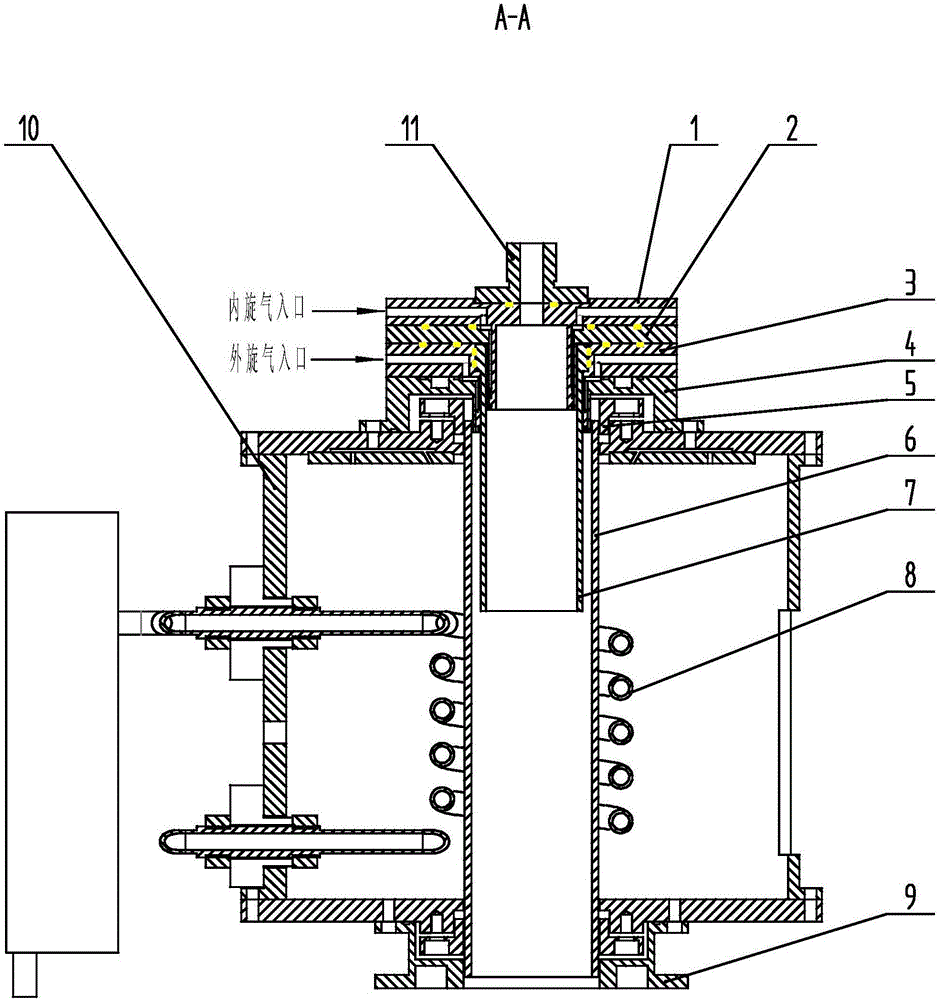

Inner-electric-arc plasma torch for gasifiers

The invention discloses an inner-electric-arc plasma torch for gasifiers and relates to plasma heating equipment. The inner-electric-arc plasma torch is mainly composed of a front torch body, a rear seat, a first electrode and a fourth electrode, an arc cavity and a cooling water jacket are structured in the front torch body, an inlet and a compression nozzle are respectively arranged in two ends of the arc cavity, the cooling water jacket is arranged on the outer side of the arc cavity, and the head of the first electrode is arranged out of the arc cavity of the front torch body and is close to the inlet; the head of the fourth electrode (8) extends to the compression nozzle side in the arc cavity through the compression nozzle, a metal component at the position of the compression nozzle forms a third electrode, a second annular discharging surface is arranged on the third electrode, a metal component at the position of the inlet forms a second electrode, and a first annular discharging surface is arranged on the second electrode; or the head of the fourth electrode further extends to the arc cavity from the compression nozzle and is close to the inlet, and the metal component at the position of the inlet forms an auxiliary electrode. By the inner-electric-arc plasma torch, water vapor can be heated and decomposed in the arc cavity, energy is concentrated on water molecules, and the water molecules are easier to decompose.

Novel technology for continuously producing nano powder by using ultra-high temperature plasma and preparation process thereof

InactiveCN101927352AAvoid wastingReduce the amount of investmentEnergy based chemical/physical/physico-chemical processesPlasma techniqueAir volumeCollection system

The invention discloses novel technology for continuously producing nano powder by using ultra-high temperature plasma and a preparation process thereof. The technology is implemented by a device consisting of an electrical control system, a vacuum pumping and measuring system, an gas charging system, an ultra-high temperature plasma heating, evaporating and pulverizing system, a high air-flow cooling and circulating system, a water cooling and circulating system, a nano powder supplementing and collecting system, a powder cleaning system and a vacuum packaging and storing system. High vacuum is adopted in the embodiment of the invention and the method comprises the following steps of: directly heating metal powder by using the ultra-high temperature plasma to form metal vapor quickly; and colliding the metal vapor quickly with high air-flow gas molecules to make the metal vapor loose energy and form clusters by using the high air-flow cooling and circulating system and water cooling circulation, and condensing the clusters into the nano metal powder. Metal hydride nano powder, metal nitride nano powder, metal oxide nano powder and pure metal nano powder can be produced by using different protective gases. Compared with the prior art, the nano metal powder produced by the method has the advantages of difficult agglomeration, simple process, high purity, convenient operation and maintenance, low production cost, easy realization of large-scale industrial production and wide popularization.

Owner:李立明

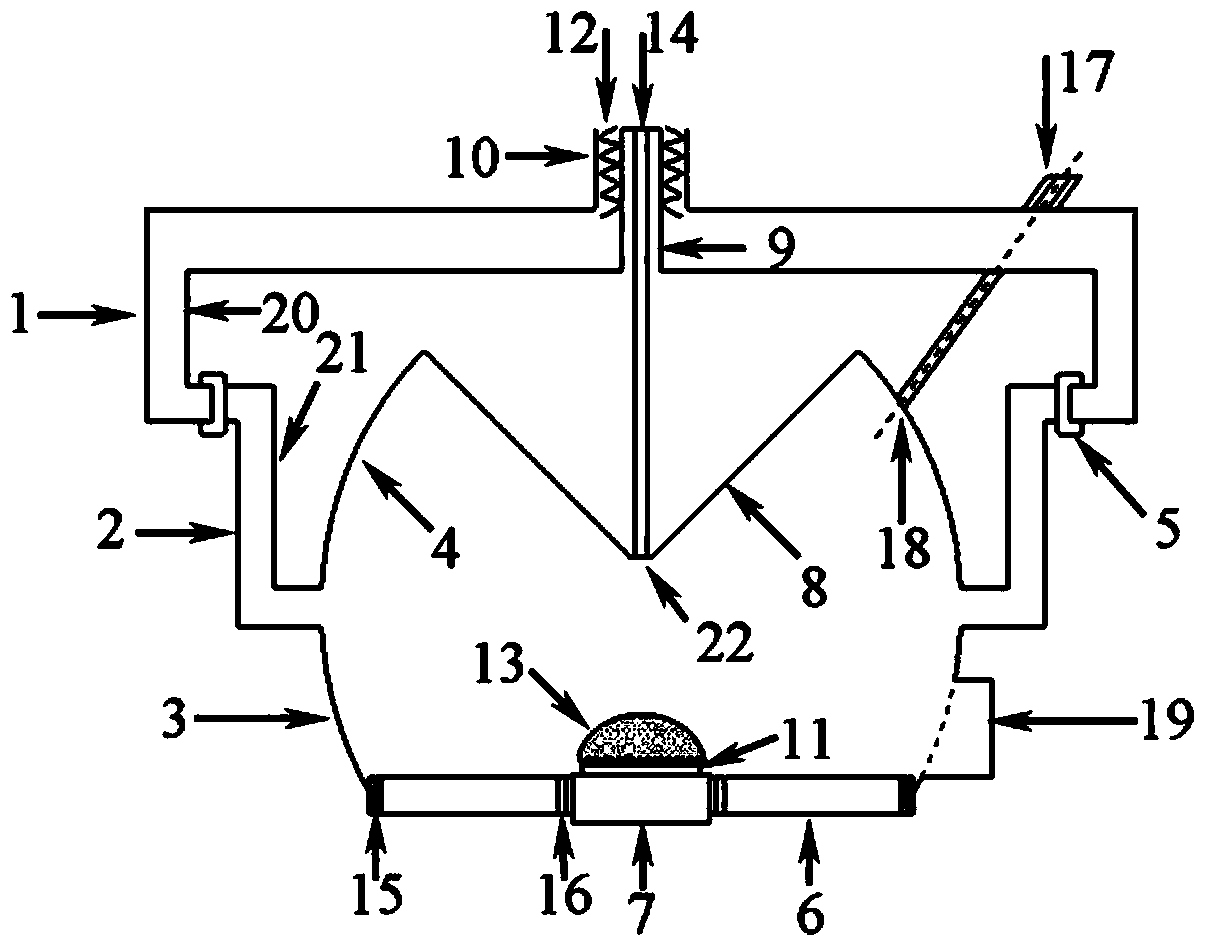

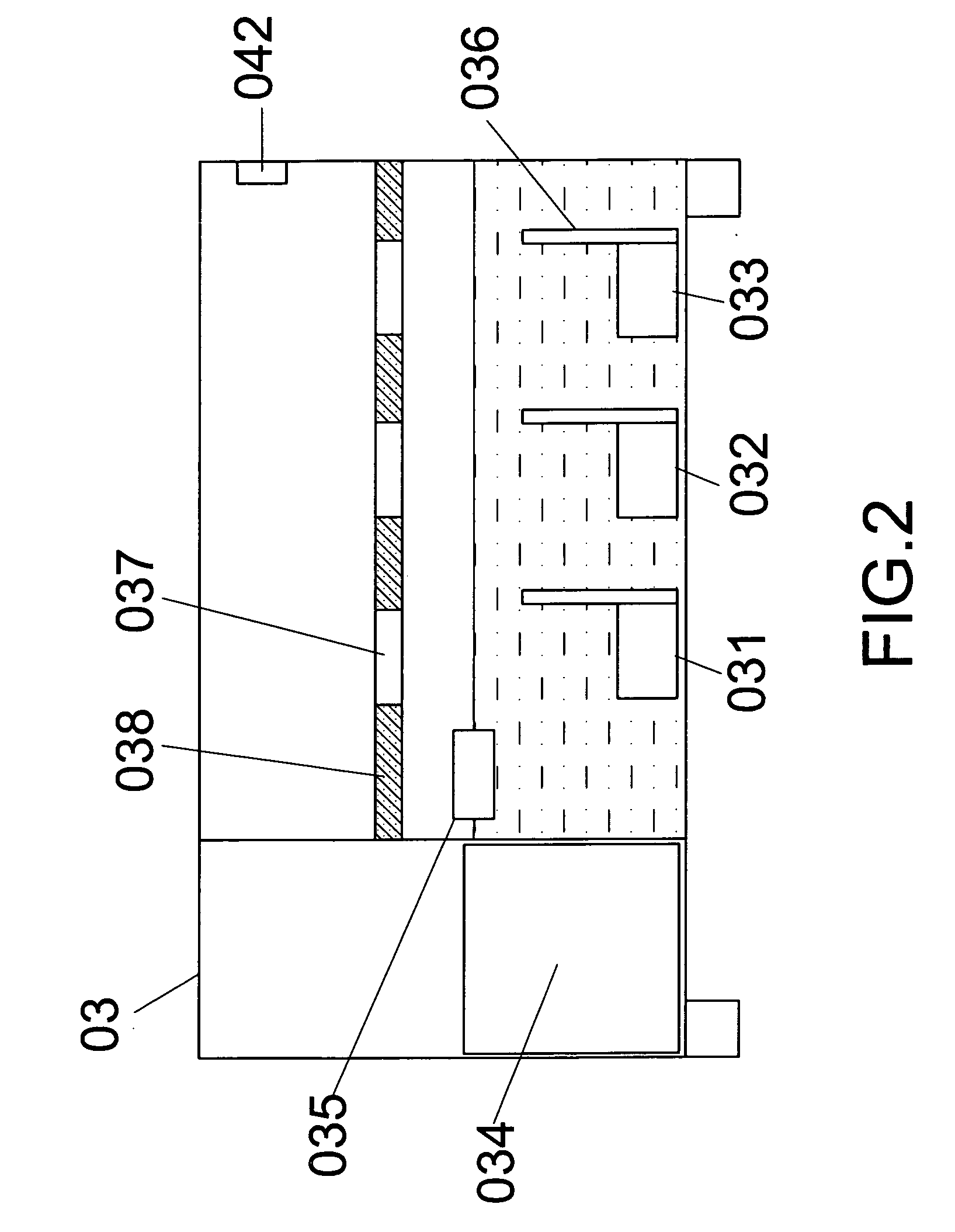

Ellipsoidal high-power microwave plasma diamond film deposition device

ActiveCN104164658AEfficient depositionStable positionElectric discharge tubesChemical vapor deposition coatingForeign matterEtching

The invention relates to an ellipsoidal high-power microwave plasma diamond film deposition device which is composed of a staisecase annular microwave coupled system, an annular quartz microwave window arranged at the staircase of an annular antenna, an ellipsoidal microwave resonant cavity, an adjustable deposition table, a conical upper reflecting body, an adjustable cylindrical lower reflecting body, an inlet and outlet, a temperature measurement hole, a view window and the like. By utilizing the design of the ellipsoidal upper and lower focal points, the conical upper microwave reflecting body is positioned on the upper focal point, the deposition table is positioned on the lower focal point, and the electric field is distributed centrally, so the excited plasma has high position stability and high density; the hidden microwave window can be protected from plasma heating, pollution and etching; the adjustable microwave lower reflecting body and the deposition table optimize the plasma distribution in real time; the inner wall of the ellipsoidal resonant cavity is far from the high-temperature plasma region, so that the heat radiation of the plasma to the inner wall of the cavity is reduced, thereby avoiding depositing foreign matters; and all the components of the device are cooled with water. The device can implement high-efficiency deposition of a large-area high-quality diamond film under the condition of high power.

Owner:HEBEI PLASMA DIAMOND TECH

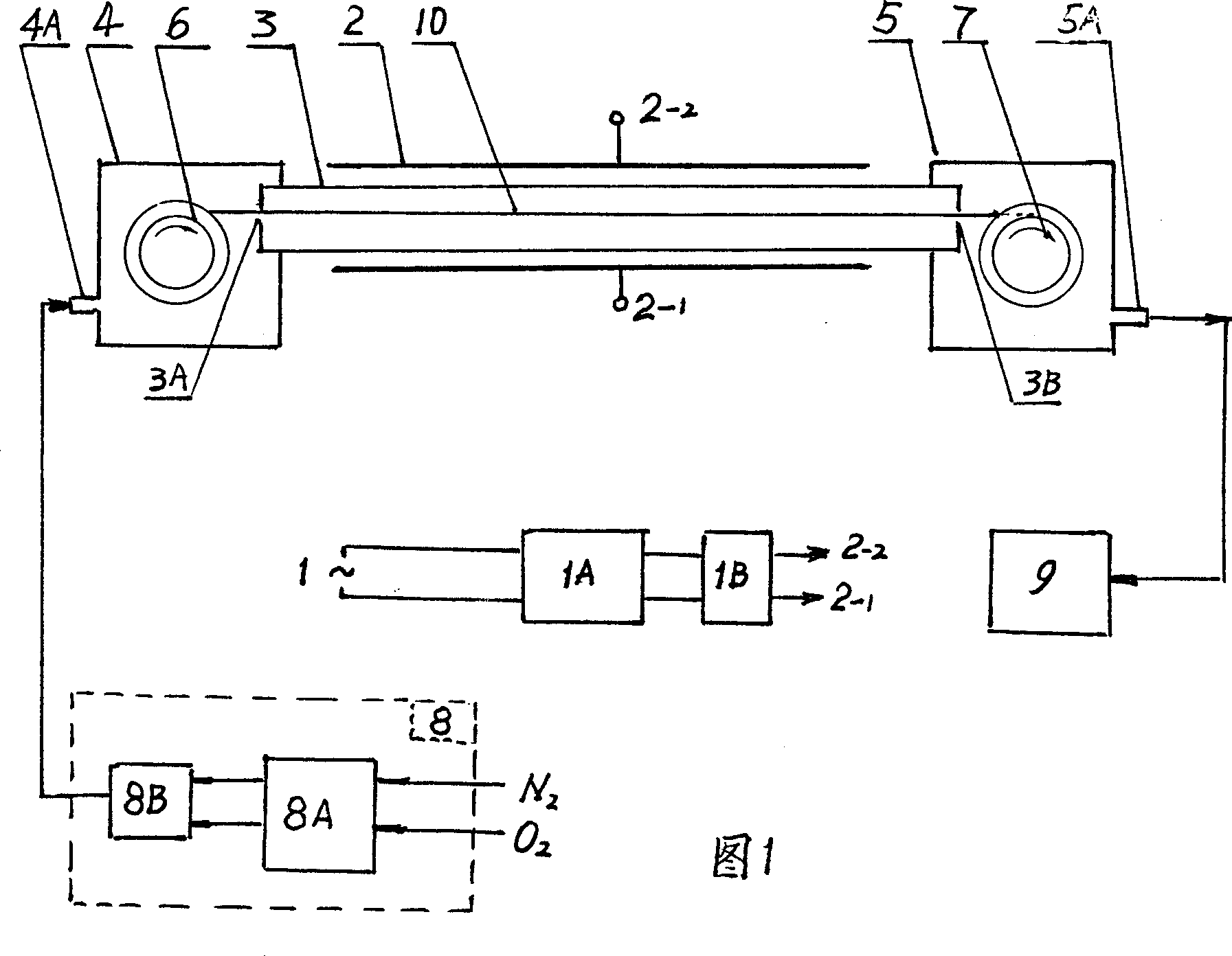

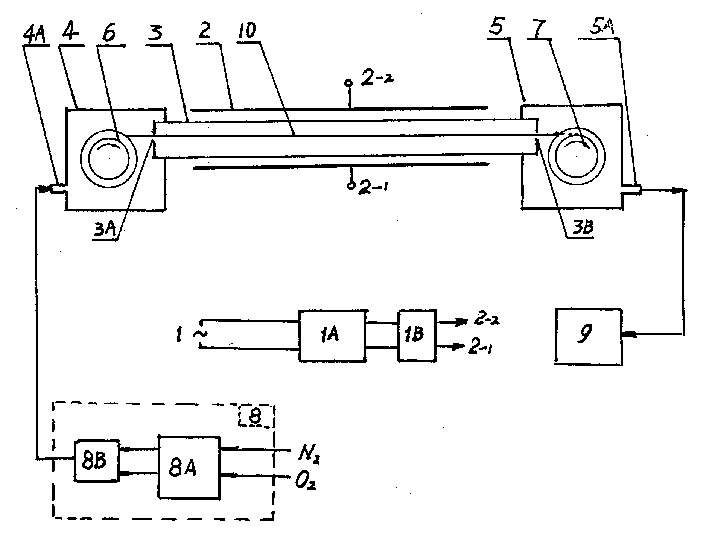

New technology and device for pdyacrylonitril fiber preoxidation and carbonation

A process for preoxidizing and carbonizing polyacrylonitrile fibres to obtain carbon fibres features the use of a HF negative-pressure plasma heater which is composed of HF power supply, parallel plate electrodes, flat reaction cavity made of quartz glass, and the accessory for generating negative pressure in reacion cavity and proportioning N2 and O2. The plasma generated in the reaction cavity can greatly lower the temp. of preoxidizing and carbonizing, so both steps can be performed in a single heater, resulting in low energy consumption and low cost.

Owner:陈新谋

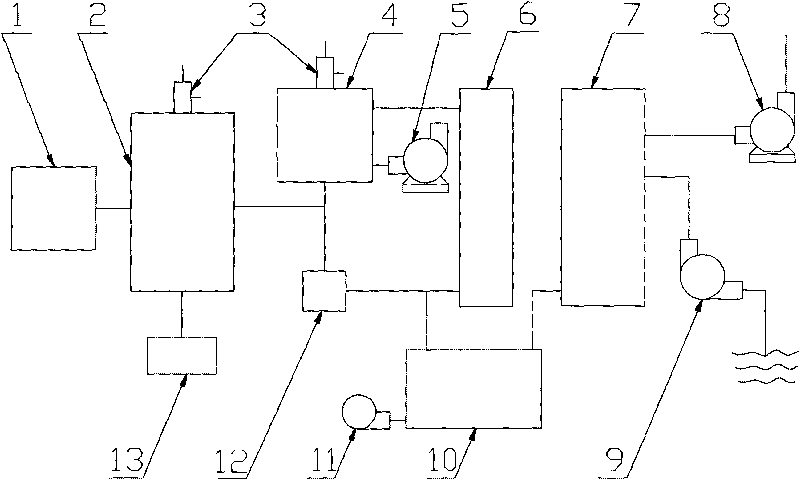

Thermal plasma device for incinerating marine garbage

ActiveCN101737785AGood heat transfer performanceImprove incineration efficiencyCombustion technology mitigationIncinerator apparatusLoss rateMelting tank

The invention relates to a thermal plasma device for incinerating marine garbage, which comprises a feed system, an incinerator, a plasma system, a secondary combustion chamber, a blast blower, a heat exchanger, a desulfurization and dust removal tower, a draught fan, a first water pump, a quench cooler, a second water pump, a tapping device and an automatic control system. The invention adopts a transferred-arc and non-transferred arc dual-purpose direct-current plasma generator as an incineration heat source, which not only can make full use of a shipborne dynamic power supply (or an accumulator battery) but also can use a non-transferred arc in the initial stage of incineration and adopt the working mode of a transferred arc after a molten pool is molten. Compared with a single non-transferred arc operation mode, the heat transmission property is better, the incineration efficiency is higher, and more energy is saved; in the invention, the secondary combustion chamber adopts plasma heating in a similar way, and the condition that new pollution is generated in the treatment process of secondary combustion is avoided; and by high temperature generated by the plasma generator adopted by the invention, the temperature of the molten pool exceeds 1500 DEG C and is sufficient to enable inorganic substances, slag and heavy metal to be fused together, the inorganic substances, the slag and the heavy metal are solidified in a neutral vitreous body and are not easy to precipitate, the treatment of the garbage is finished by one step, and the thermal ignition loss rate is less than 3%.

Owner:AEROSPACE ENVIRONMENTAL ENG

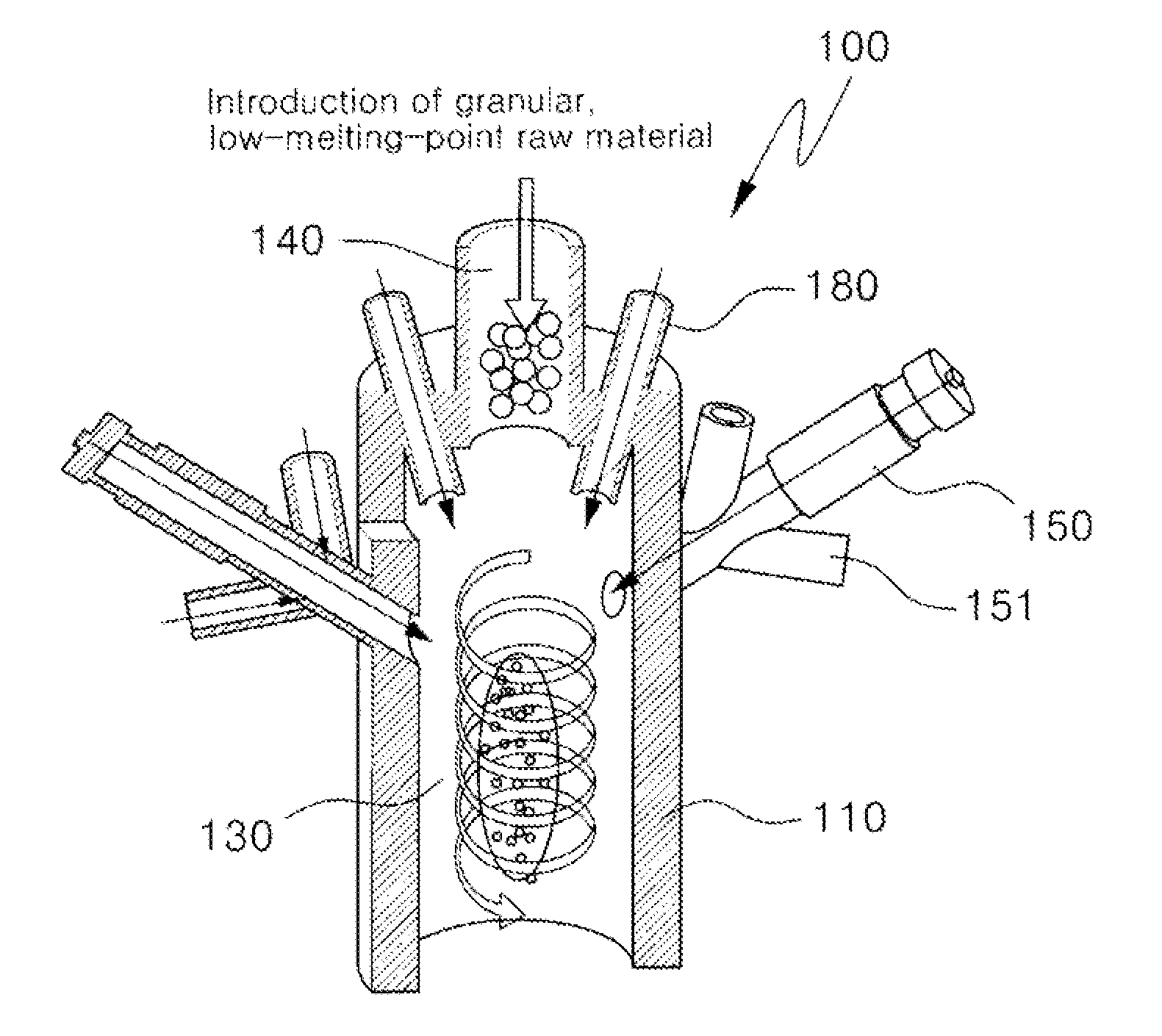

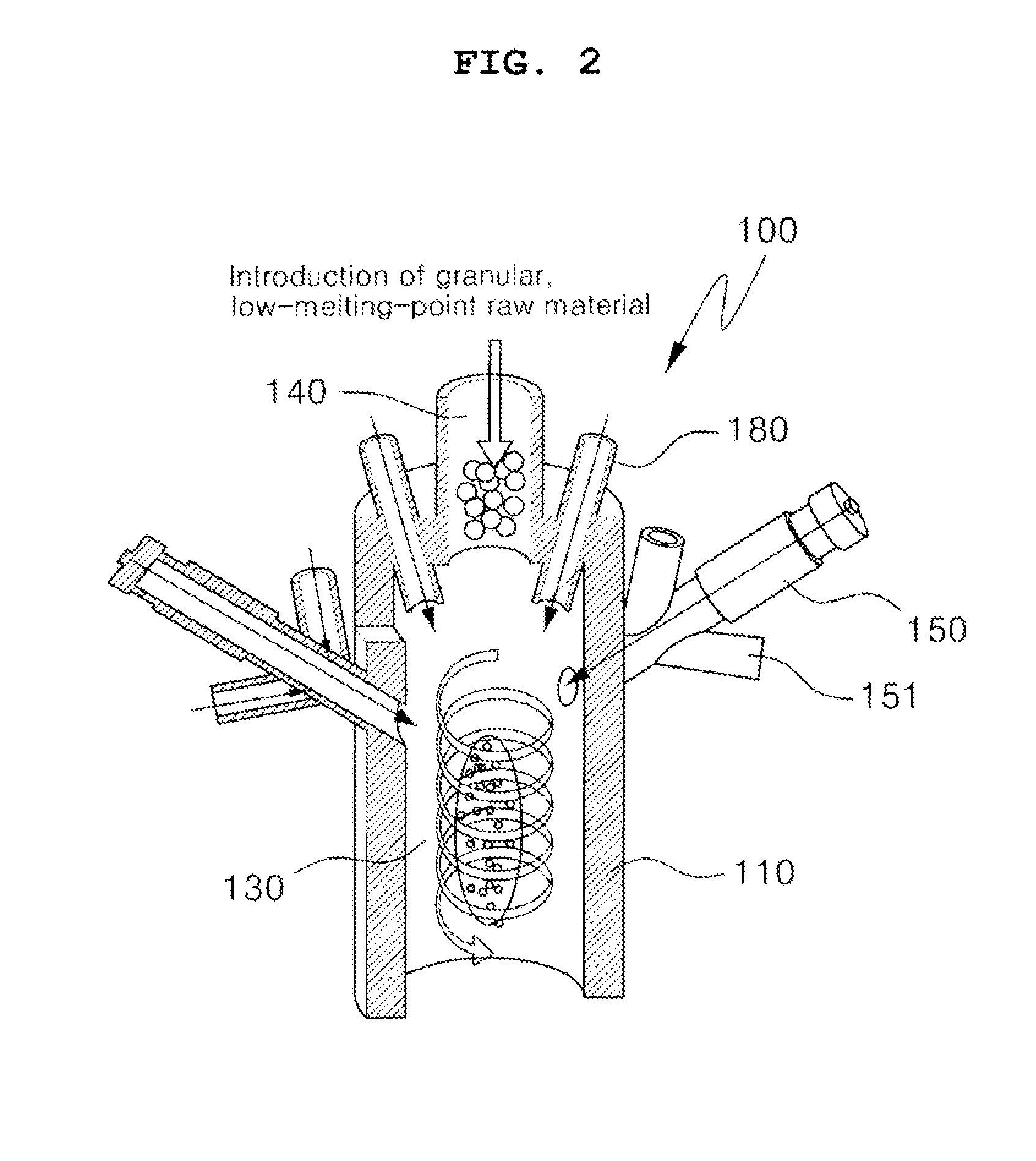

Low-carbon-type in-flight melting furnace utilizing combination of plasma heating and gas combustion, melting method utilizing the same and melting system utilizing the same

InactiveUS20120125052A1Maximizing residence timeCharging furnaceGlass furnace apparatusMelting tankCombustion

A low-carbon-type in-flight melting furnace for melting granular raw material for glass production in in-flight state using plasma heating and gas combustion, a melting method using the same and a melting system utilizing the same are provided. The low-carbon-type in-flight melting furnace includes a melting furnace body unit; a melting tank in the melting furnace body unit; a melting unit provided above the melting tank and serving to melt raw material; a raw material feeding unit provided outside the melting unit; a plasma / gas melting device provided around the melting unit and serving to spray high-temperature flames produced by plasma and gas; an exhaust tube provided at one side of the melting tank and serving to discharge exhaust gas; and a tap hole for tapping the melt, formed in the melting unit, through the melting tank, in the form of a slag.

Owner:KOREA INST OF ENERGY RES

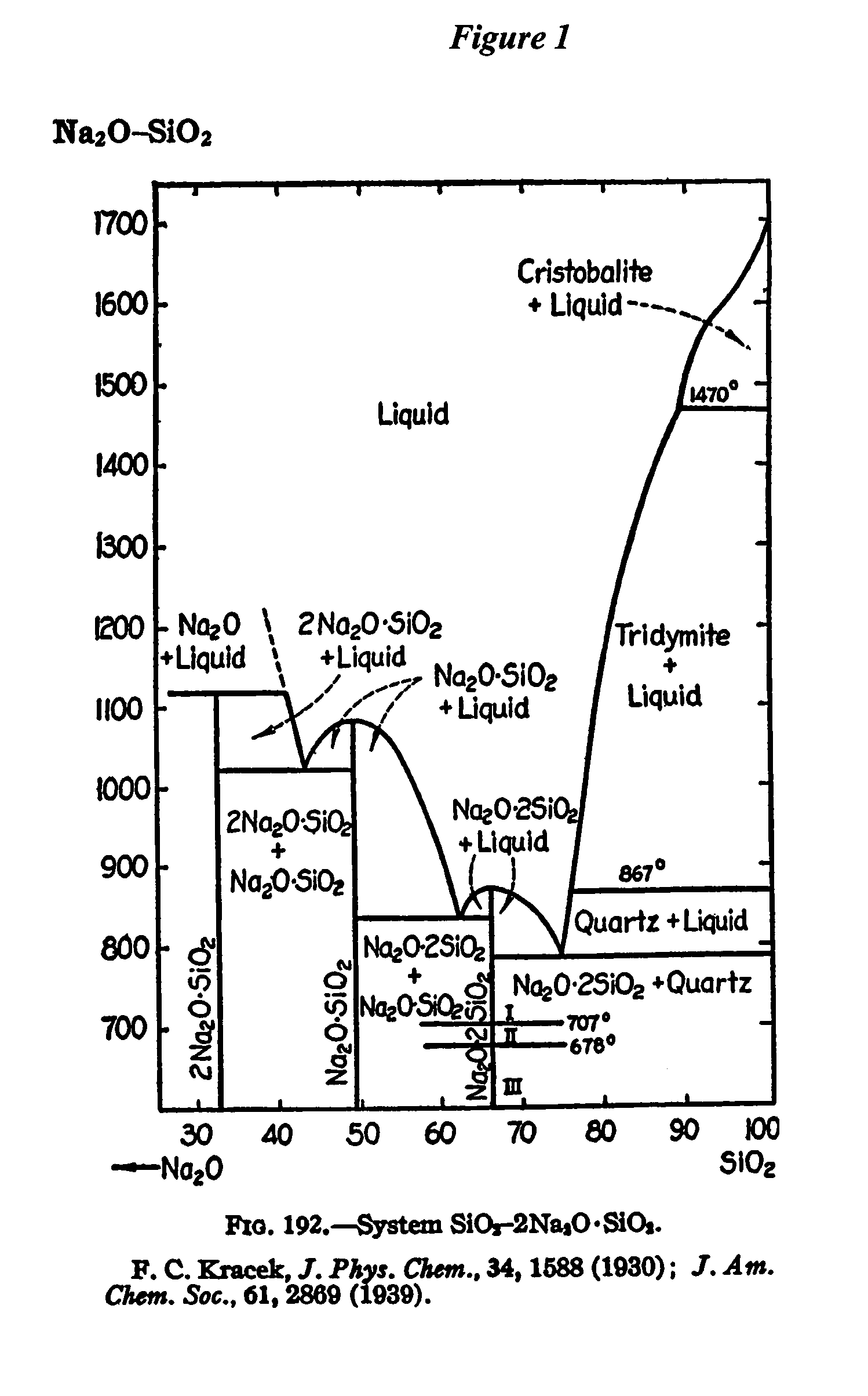

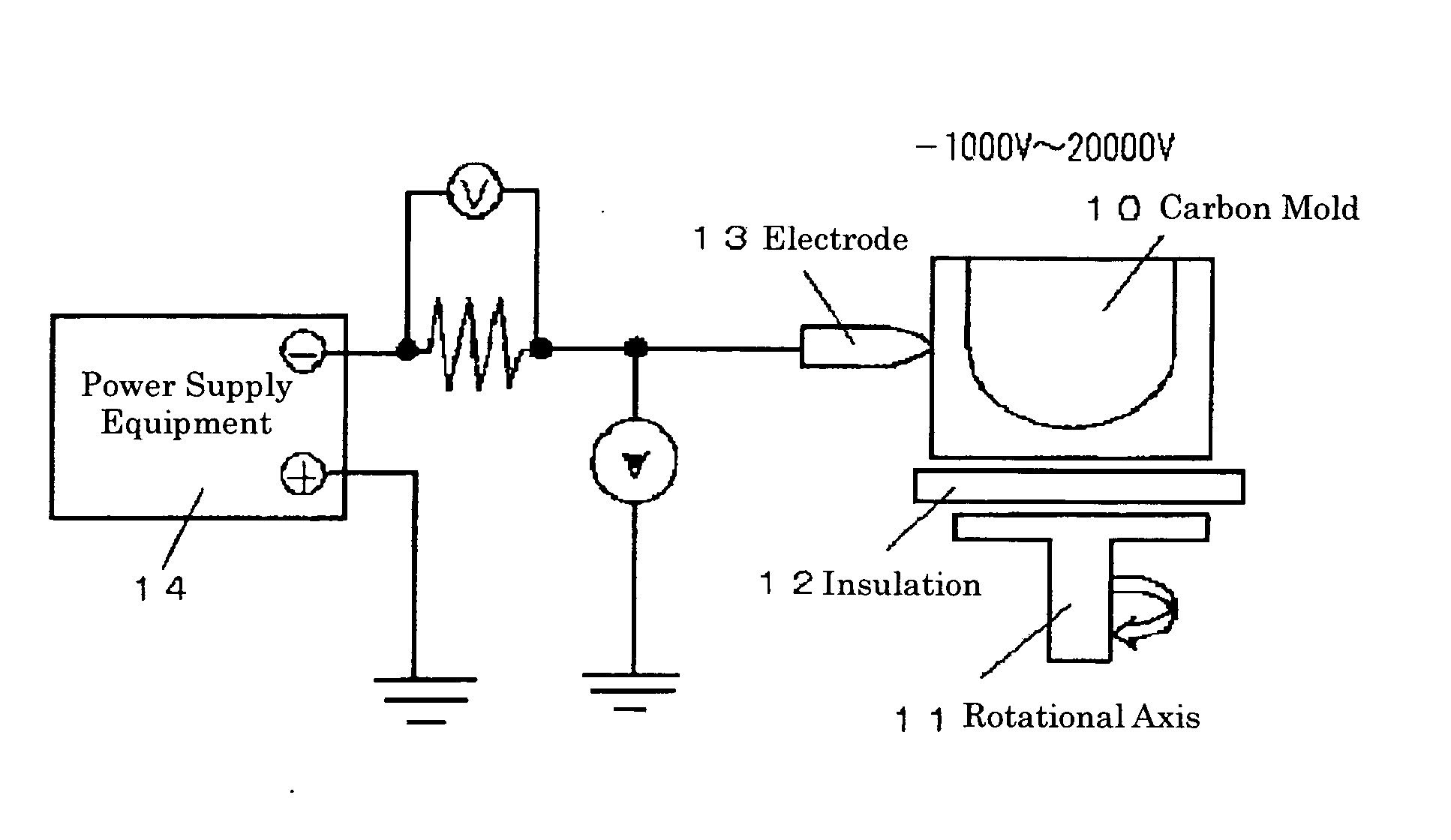

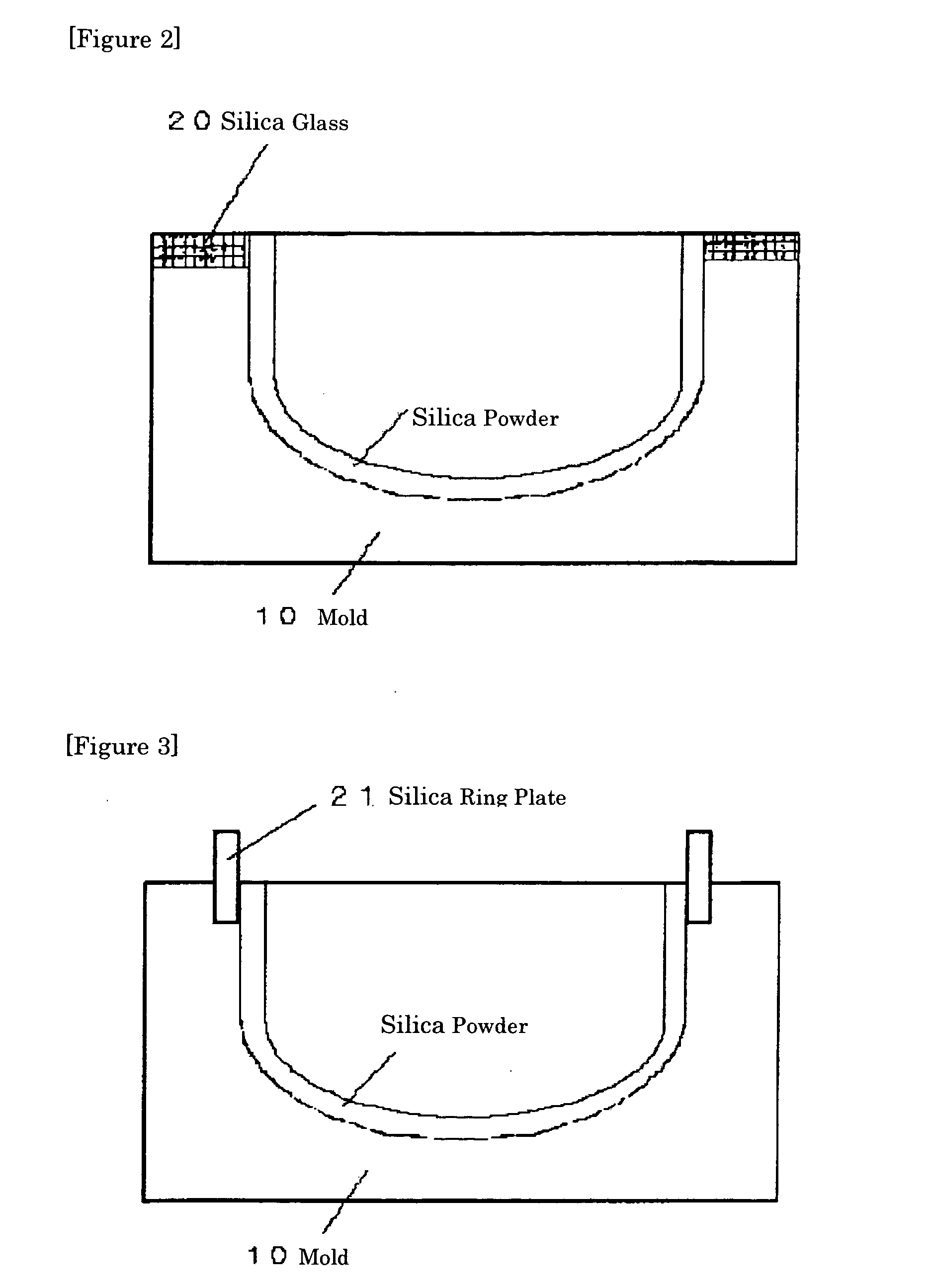

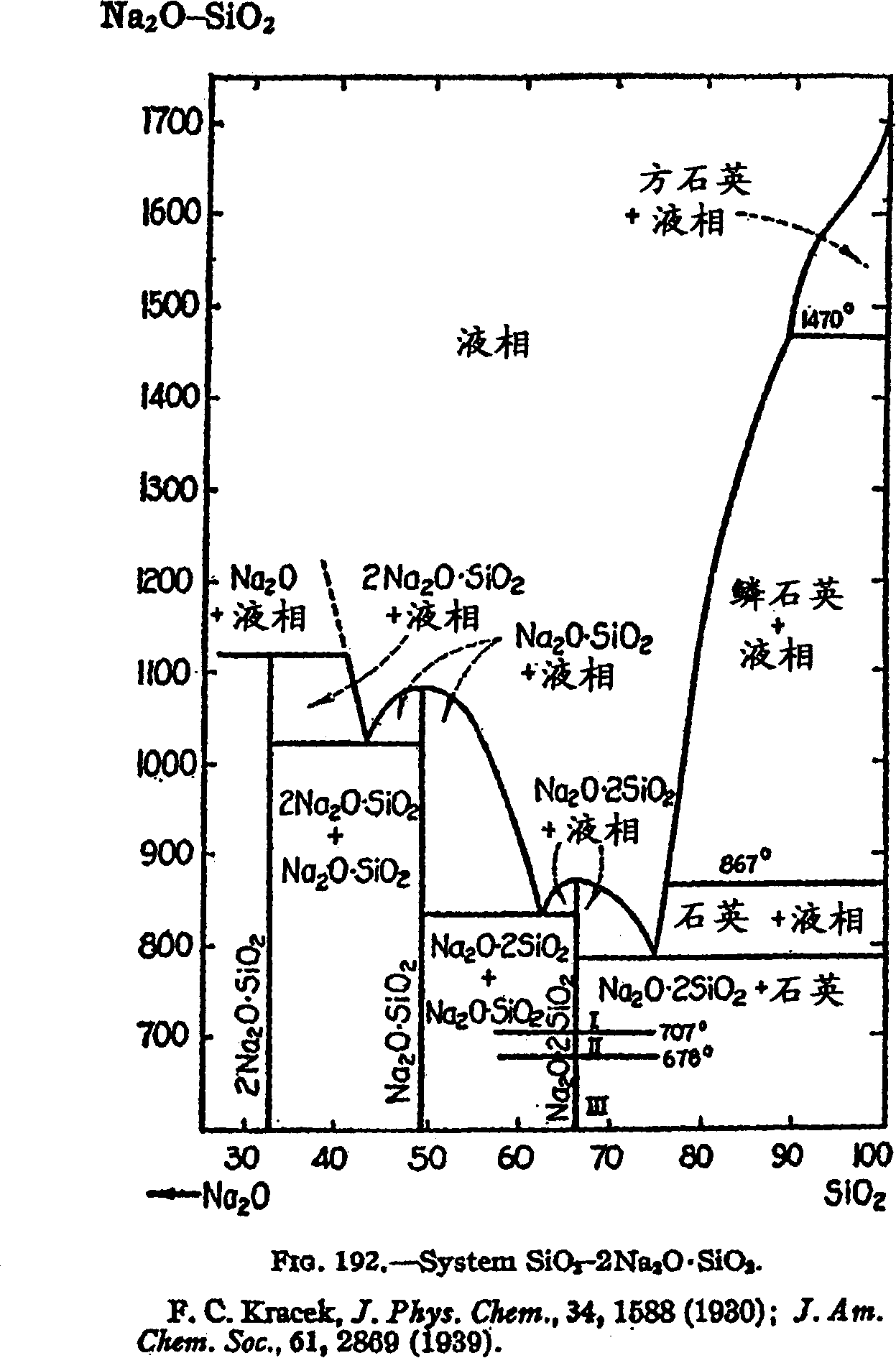

High purity silica crucible by electrolytic refining, and its production method and pulling method

This invention provides a high purity silica crucible having low impurity concentration in its inner portion, and its production method. The crucible, in which at least each content of Na and Li being contained in the depth of 1 mm from the inside surface is less than 0.05 ppm, is given by a production method of a high purity silica glass crucible, wherein a purity of the melted silica powder layer is increased by applying a voltage between a mold and an arc electrode to move impurity metals being contained in the melted silica glass layer to the outside, when the silica crucible is produced by arc plasma heating a raw material powder of silica in an inside surface of a hollow rotary mold. The method comprises, keeping an arc electrode potential of within ±500 V during an arc melting, applying a voltage of from −1000 V to −20000 V to a mold being insulated to the ground, and applying a high voltage to the un-melted silica powder layer of the outside.

Owner:JAPAN SUPER QUARTZ CORP

Hydrogen fuel supply system

Owner:WANG HSU YANG

Direct-current argon arc plasma powder spray gun and manufacturing method

ActiveCN105755421AExpand the field of technology applicationImprove stabilityMolten spray coatingMetallurgyPlasma heating

The invention discloses a direct-current argon arc plasma powder spray gun and a manufacturing method and belongs to the field of flame spraying equipment and technology of metal powder and metal ceramic powder.Two novel technologies including a hollow tungsten cathode outer surface annular arcing direct-current plasma heating method and an axial powder feeding mechanism penetrating the core of an argon arc are adopted, and position matching of a negative voltage pressure of the electric arc and the powder feeding mechanism is utilized, so that stability of the spray gun during long-time working is improved, and uniformity in heating temperature of metal powder particles, uniformity in spray speed and stability of spray layer quality are guaranteed.In addition, due to structural changing of a gun body, technology application field of the gun is expanded obviously, and the gun is expected to make a beneficial contribution to development of high technology in the future.

Owner:UNIV OF SCI & TECH BEIJING

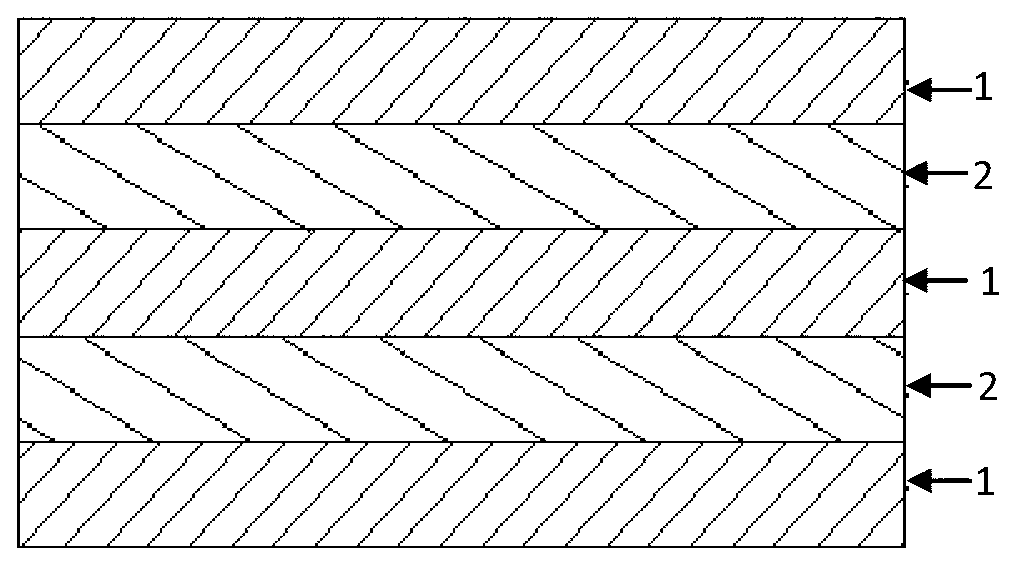

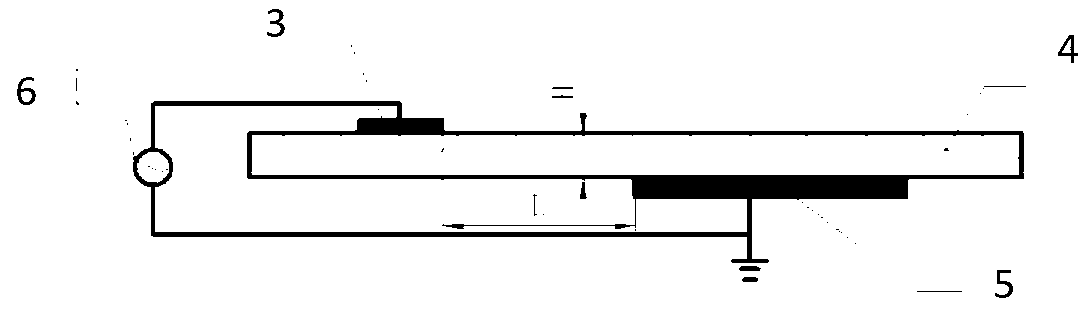

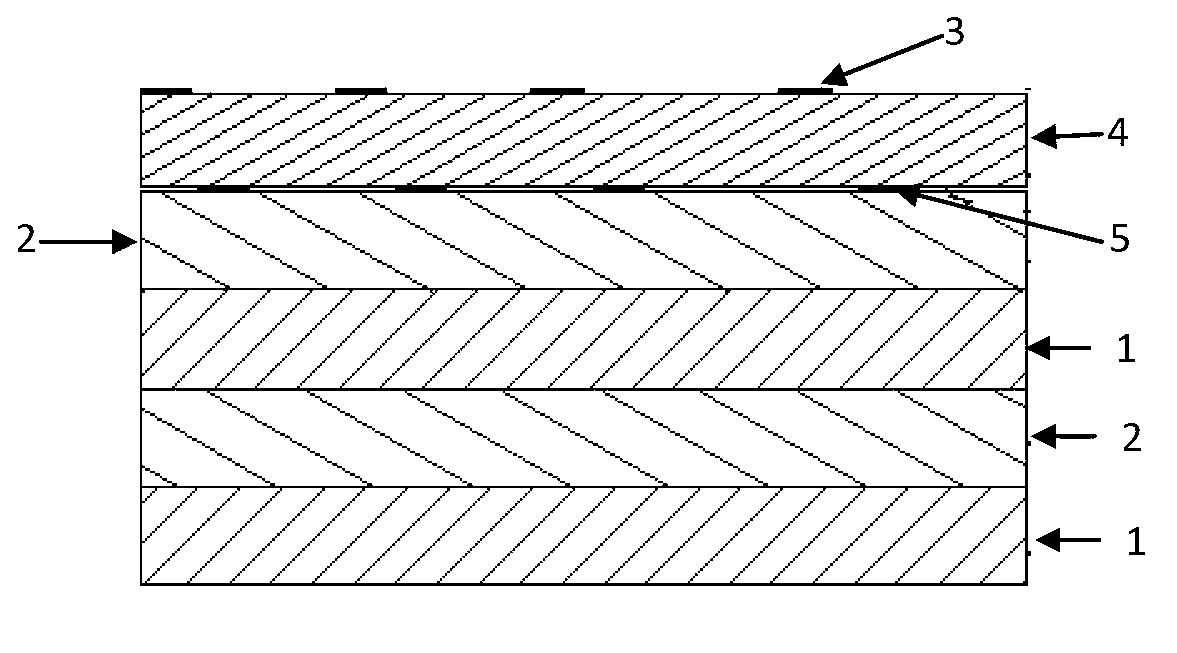

Laminated plate aircraft skin with flow control and deicing prevention functions

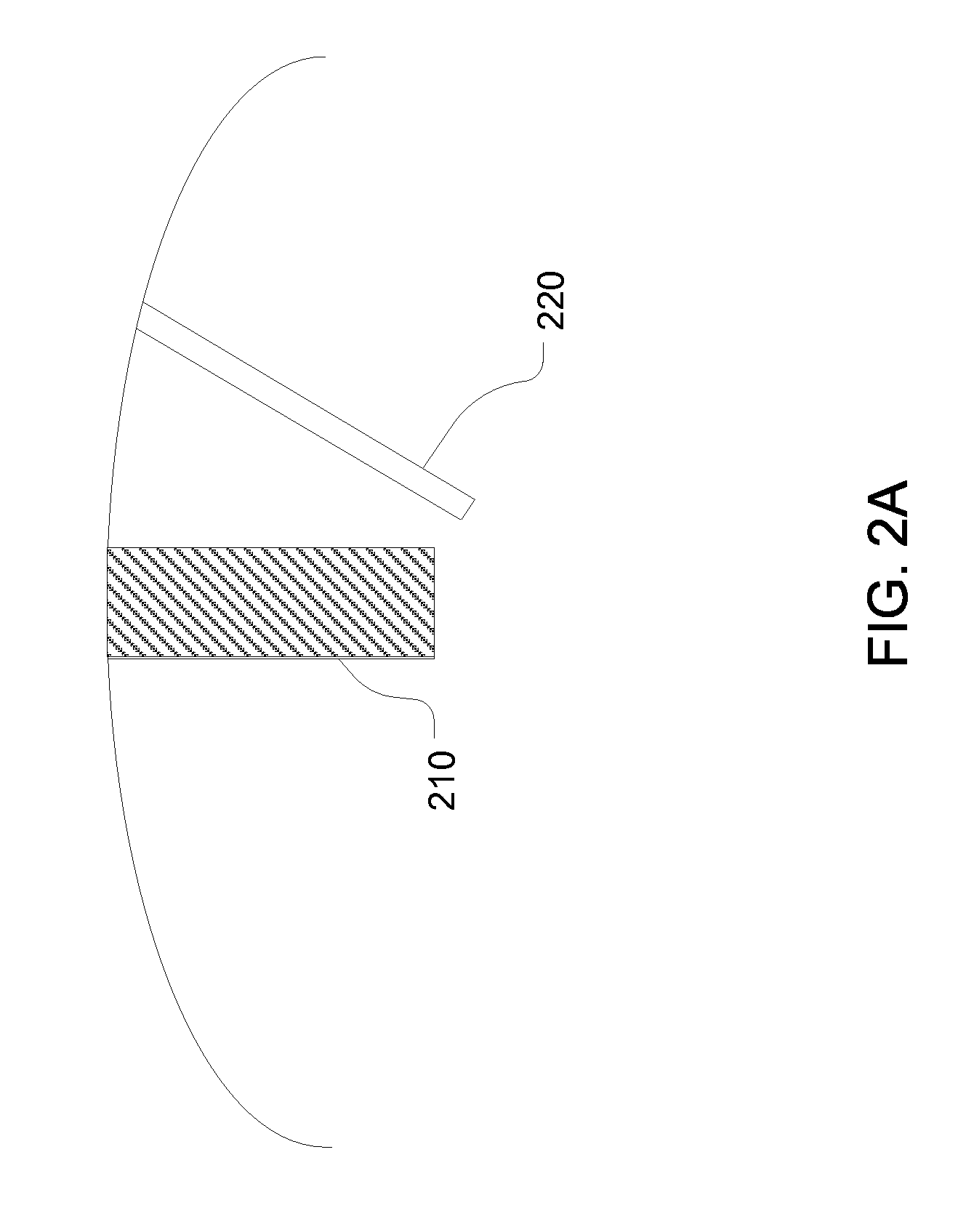

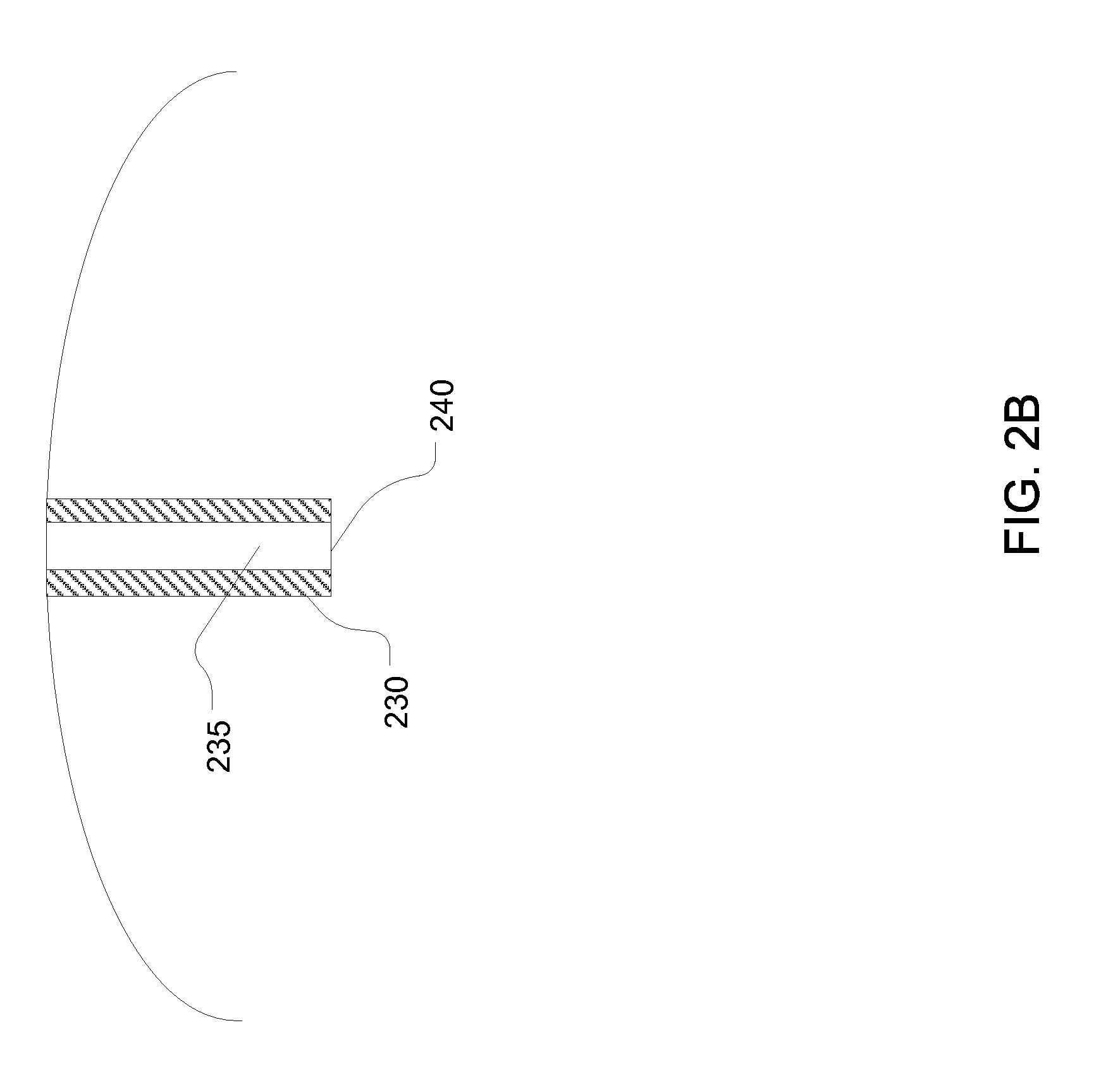

InactiveCN102991666AEffective controlDelayed stallSynthetic resin layered productsDe-icing equipmentsGlass fiberAlloy

The invention discloses a laminated plate aircraft skin with lift augmentation, resistance reduction, flow control and deicing prevention functions. The laminated plate aircraft skin comprises a glass fiber layer (2) and an aluminum alloy (1), wherein the glass fiber layer (2) and the aluminum alloy (1) are alternative; the surface of the skin is provided with an insulating material layer (4) and an electrode layer; the electrode layer is divided into an upper layer and a lower layer; the upper layer and the lower layer are respectively positioned on two sides of the insulating material layer (4) and are asymmetrically distributed; the upper electrode layer (3) is exposed in air and is connected with an alternating current power supply; and the lower electrode layer (5) is positioned below the insulating material layer (4) and is grounded. The laminated plate aircraft skin can be directly applied to aircraft manufacturing engineering, cannot be damaged by high-speed airflow and cannot bring parasite drag due to the damage of the original pneumatic shape. The deicing prevention function is realized by utilizing plasma heating on air and the pulse expansion wave function, the flow separation can be effectively controlled, the stall is delayed, the highest lift coefficient is increased, and the pressure difference resistance is reduced.

Owner:COMAC +1

Plasma heating decomposer

ActiveCN103987183AAchieve clean combustionProtect environmentPlasma techniqueEcological environmentHazardous substance

The invention relates to a plasma heating device, in particular to a plasma heating decomposer. The plasma heating decomposer is composed of an anode sleeve, an anode, a cathode substrate, a cathode and an insulating frame, wherein the anode is of a horn-shaped revolution solid structure, a diffusion cavity is formed in a horn-shaped inner space, a compression pore channel is formed by a throat at the rear end of the diffusion cavity, the anode is embedded into the anode sleeve, and a water jacket b is formed by the space between the outer wall of the anode and the anode sleeve; the cathode substrate is of a revolution solid structure with the center shaft protruding forwards, the cathode is embedded into the inner space of the center shaft of the cathode substrate, and a water jacket a is formed by space between the outer wall of a rod body of the cathode and the inner wall of the center shaft of the cathode substrate; the insulating frame is a connecting component between the anode sleeve and the cathode substrate, the anode sleeve is installed at the front end of the insulating frame, the cathode substrate is installed at the rear end of the insulating frame, a shrinking cavity is formed by the space between the front end of the center shaft of the cathode substrate and the compression pore channel at the rear end of the anode, and the head end of the cathode is arranged in the shrinking cavity. The plasma heating decomposer is suitable for production lines for hydrogen production through water pyrolysis or for treatment of hazardous substance and protects the ecological environment.

Owner:付顺坤

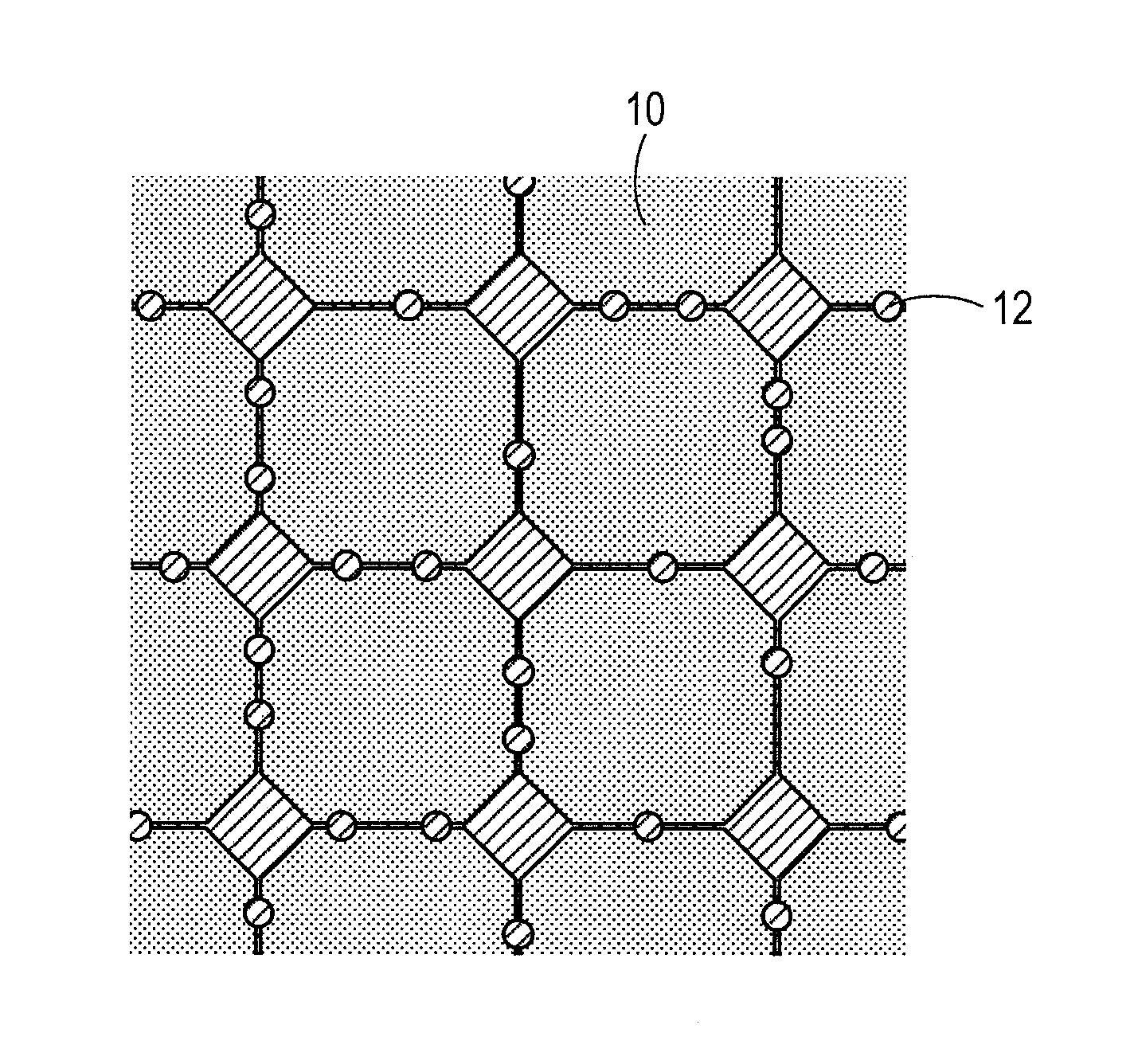

Nanoparticles and systems and methods for synthesizing nanoparticles through thermal shock

ActiveUS20180369771A1Increase temperatureHeat treatmentsMaterial nanotechnologyThermal energyThermal shock

Systems and methods of synthesizing nanoparticles on substrates using rapid, high temperature thermal shock. A method involves depositing micro-sized particles or salt precursors on a substrate, and applying a rapid, high temperature thermal pulse or shock to the micro-sized particles or the salt precursors and the substrate to cause the micro-sized particles or the salt precursors to become nanoparticles on the substrate. A system may include a rotatable member that receives a roll of a substrate sheet having micro-sized particles or salt precursors; a motor that rotates the rotatable member so as to unroll consecutive portions of the substrate sheet from the roll; and a thermal energy source that applies a short, high temperature thermal shock to consecutive portions of the substrate sheet that are unrolled from the roll by rotating the first rotatable member. Some systems and methods produce nanoparticles on existing substrate. The nanoparticles may be metallic, ceramic, inorganic, semiconductor, or compound nanoparticles. The substrate may be a carbon-based substrate, a conducting substrate, or a non-conducting substrate. The high temperature thermal shock process may be enabled by electrical Joule heating, microwave heating, thermal radiative heating, plasma heating, or laser heating.

Owner:UNIV OF MARYLAND

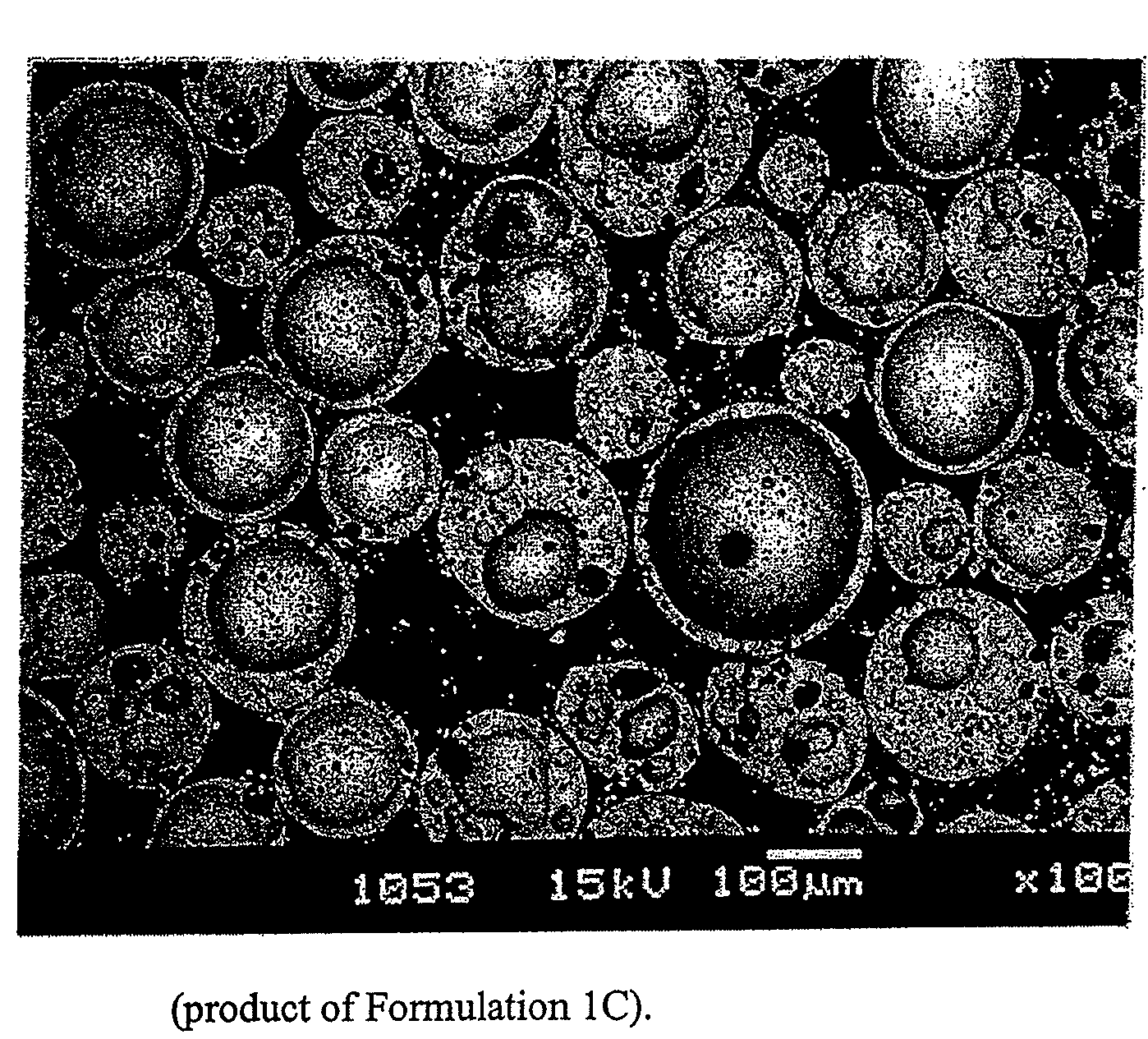

Methods for producing low density products

InactiveCN1805783AControl activationLow costGranulation by liquid drop formationMicroballoon preparationOxygen deficientBiological activation

The method of preparing a low-density material and precursor for forming a low-density material. An aqueous mixture of inorganic primary component and a blowing agent is formed, the mixture is dried and optionally ground to form an expandable precursor. Such a precursor is then fired with activation of the blowing agent being controlled such that it is activated within a predetermined optimal temperature range. Control of the blowing agent can be accomplished via a variety of means including appropriate distribution throughout the precursor, addition of a control agent into the precursor, or modification of the firing conditions i.e. oxygen deficient or fuel rich environment, plasma heating etc.

Owner:JAMES HARDIE INT FINANCE BV

Production technology for polycrystalline silicon

The invention discloses a production technology for polycrystalline silicon. The production technology includes the following steps: 1, a first coating, a second coating and a third coating are sequentially arranged on the surface of a crucible from inside to outside, and a crystalline silicone leftover material layer is laid; 2, a small quantity of raw polycrystalline silicon materials in the melted state is contained in the crucible, and the temperature of the crucible is controlled to be lower than the melting point of the crystalline silicone leftover material layer to enable the small quantity of melted raw polycrystalline silicon materials to form a crystallization protection layer; 3, in the vacuum environment, to-be-processed raw polycrystalline silicon materials are contained in the crucible, placed in a melting furnace with an electron beam generating device and processed through laser irradiation; 4, high-frequency induction heating is carried out in the vacuum environment, a slag forming constituent is added, plasma heating is carried out, steam-and-hydrogen-mixed argon is introduced, and directional solidification is carried out to obtain the polycrystalline silicon serving as the target product. By means of the production technology, the boron content, the phosphorous content and the metal impurity content can be effectively reduced, the complete polycrystalline silicon is prepared, long crystal dislocation is less, grain boundaries are proper, and the conversion rate of a polycrystalline silicon battery is increased.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

Arc plasma torch

The invention provides an arc plasma torch and relates to a plasma heating device. The arc plasma torch is characterized in that the torch is composed of a positive pole, a combined negative pole, a torch barrel and a back seat, wherein the positive pole, the torch barrel and the back seat are arranged in a coaxial mode, the back end of the torch barrel is connected on the back seat to form a torch body, the positive pole is connected at the front end of the torch barrel, a loop core space of the positive pole forms a nozzle, an inner space of the torch barrel forms an air chamber, and the back seat forms a back closed end of the torch barrel; the positive pole is of a hollow ring form structure, a ring-form cooling groove is arranged in the ring form, and the ring-form cooling groove is connected with a cooling water port; and the combined negative pole is composed of a negative pole rod, a negative pole head and a negative pole cap, the portion from the middle to the front end of the negative pole rod is of a tubular structure, a cooling cavity is formed in the space in a tube, the front end of the negative pole head is a reduced circular conical surface, and a back portion solid of the negative pole head is provided with a driving water gasification hole or a vaporization fin. The arc plasma torch is used in a gasification device, the efficiency of the torch reaches nearly 100%, and the arc plasma torch can effectively protect the negative pole and the negative pole from being ablated.

Owner:南通东湖国际商务服务有限公司

Making lithium secondary battery electrodes using an atmospheric plasma

InactiveUS20160254533A1Secure bondingMolten spray coatingFinal product manufactureElectrical batteryBattery capacity

The manufacture of electrode members for lithium-ion electrochemical cells and batteries is more efficient using an atmospheric plasma stream in carrying, heating, and directing current collector and electrode materials for deposition on thin sheet substrates. Particles of conductive metals are heated and partially melted in the plasma and deposited as current collector films for active electrodes (and reference electrodes) at relatively low temperatures (<100° C.) on separator sheets. Particles of lithium-ion accepting and releasing electrode materials are combined with smaller portions of conductive metals for plasma heating and deposition on current collector layers in forming positive and negative electrodes for lithium-ion cells. Such use of the atmospheric plasma avoids the need for the use of organic binders and wet deposition practices in electrode layer manufacture, and enables the deposition of thicker, lower stress layers of active electrode materials for higher cell capacity and power.

Owner:GM GLOBAL TECH OPERATIONS LLC

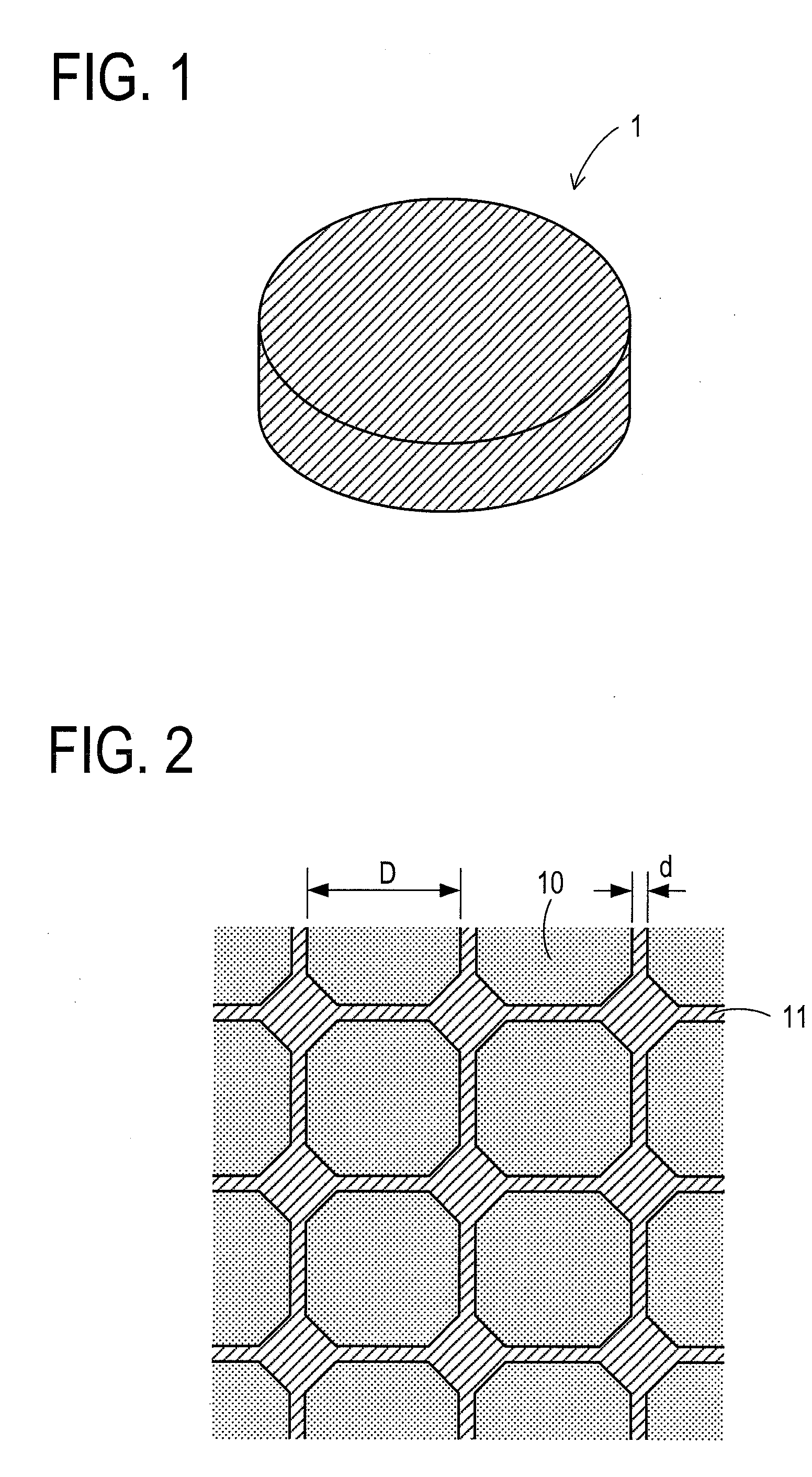

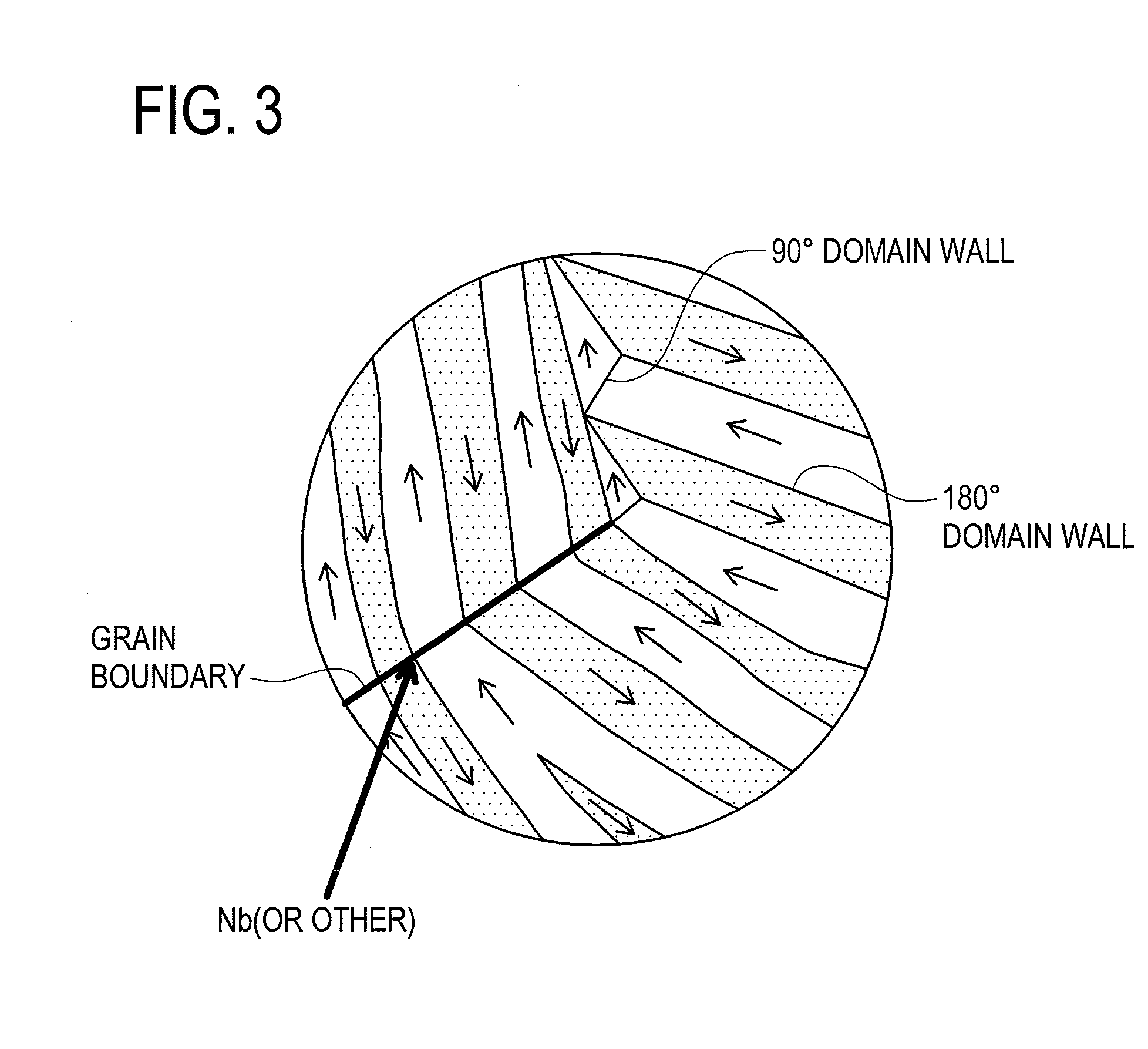

Permanent magnet and manufacturing method thereof

InactiveUS20120182109A1Residual magnetic flux density decreaseImprove magnetic propertiesTransportation and packagingMetal-working apparatusNeodymium magnetStructural formula

There are provided a permanent magnet and a manufacturing method thereof capable of inhibiting grain growth of magnet grains having single domain particle size during sintering so as to improve magnetic properties. To fine powder of milled neodymium magnet is added an organometallic compound solution containing an organometallic compound expressed with a structural formula of M-(OR)x (M represents V, Mo, Zr, Ta, Ti, W or Nb, R represents a substituent group consisting of a straight-chain or branched-chain hydrocarbon, x represents an arbitrary integer) so as to uniformly adhere the organometallic compound to particle surfaces of the neodymium magnet powder. Thereafter, the desiccated magnet powder is calcined by utilizing plasma heating and the powdery calcined body is sintered so as to form a permanent magnet 1.

Owner:NITTO DENKO CORP

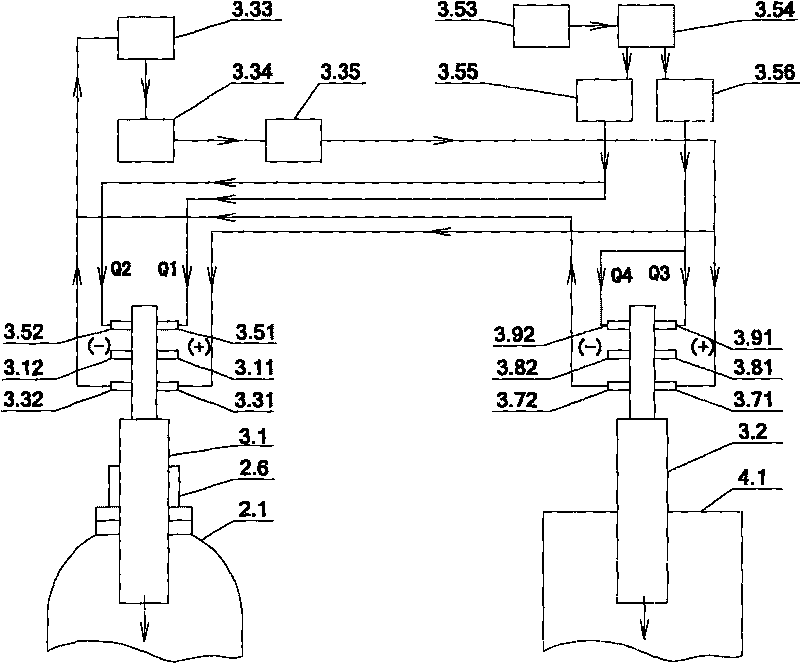

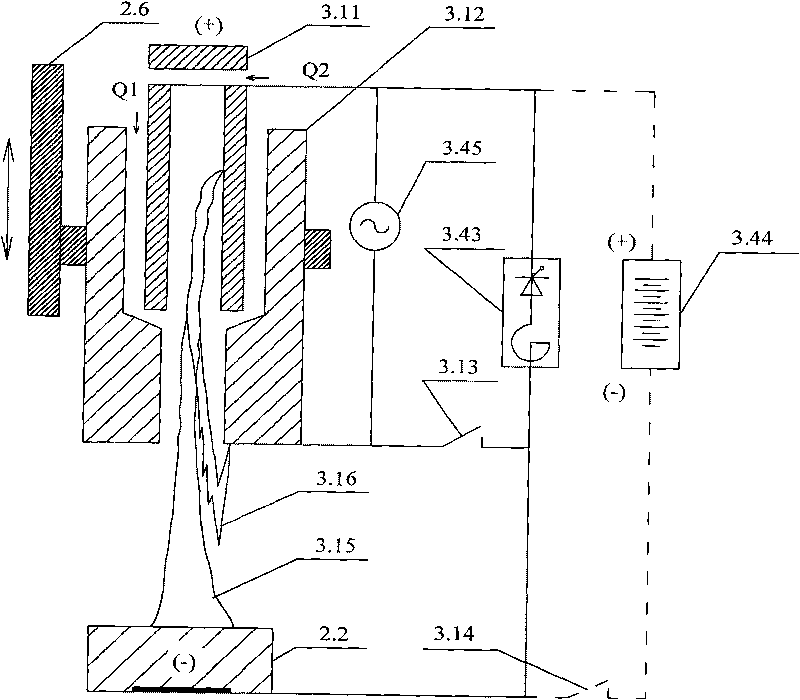

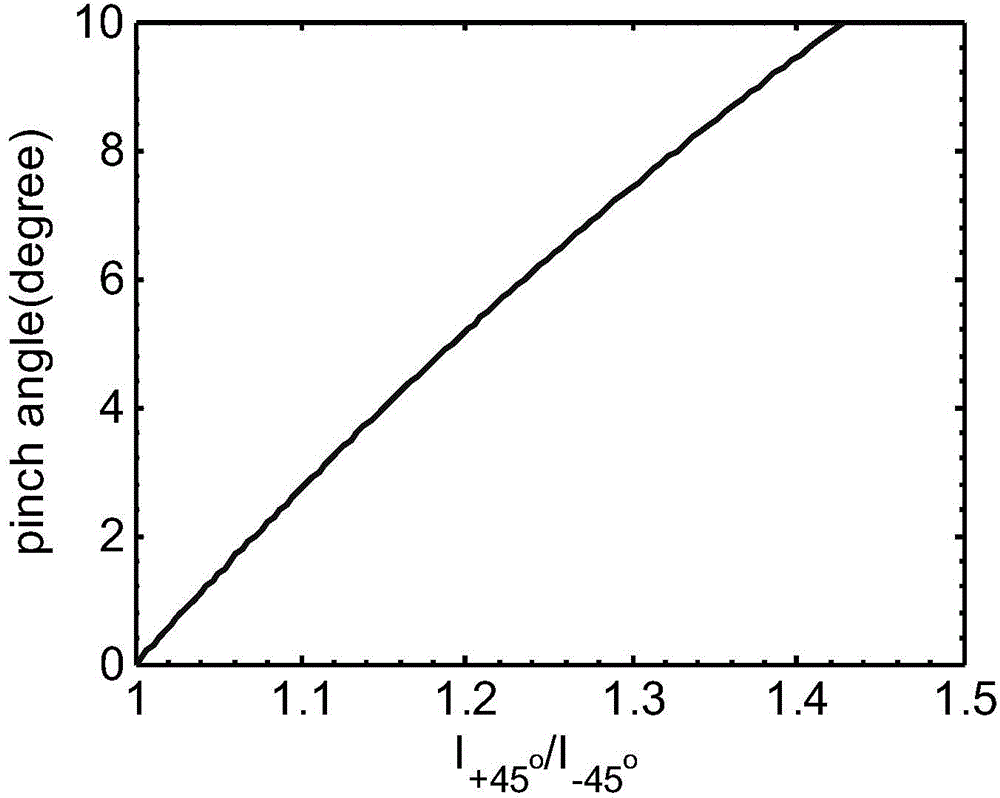

Polarized electron cyclotron emission (ECE) diagnosis system for measuring plasma current distribution

The present invention belongs to the nuclear fusion plasma diagnosis field, in particular relates to a polarized ECE diagnosis system for measuring the plasma current distribution and the safety factor distribution. The system is composed of a frequency sweep source, a signal generator, a frequency multiplier, a mixer, an isolator, a polarized antenna system, an intermediate frequency system, a demodulation system, a video amplification system, a data acquisition and analysis system and the like. By measuring a polarized distribution ratio of the ECE, a pitch angle of the magnetic field distribution, the plasma current distribution and the safety factor q distribution are obtained. According to the present invention, by utilizing the basic properties of an X mold and an O mold of an ECE wave and by two antenna channels, the intensity ratio of the ECE waves of different angles is measured, and the pitch angle of the magnetic field distribution is obtained, and further the current distribution and the safety factor distribution are obtained. The measurement of the system is not influenced by the external conditions, such as the plasma heating, etc., to be the passive measurement, so that the data of the current distribution and the safety factor distribution can be obtained at any time.

Owner:SOUTHWESTERN INST OF PHYSICS

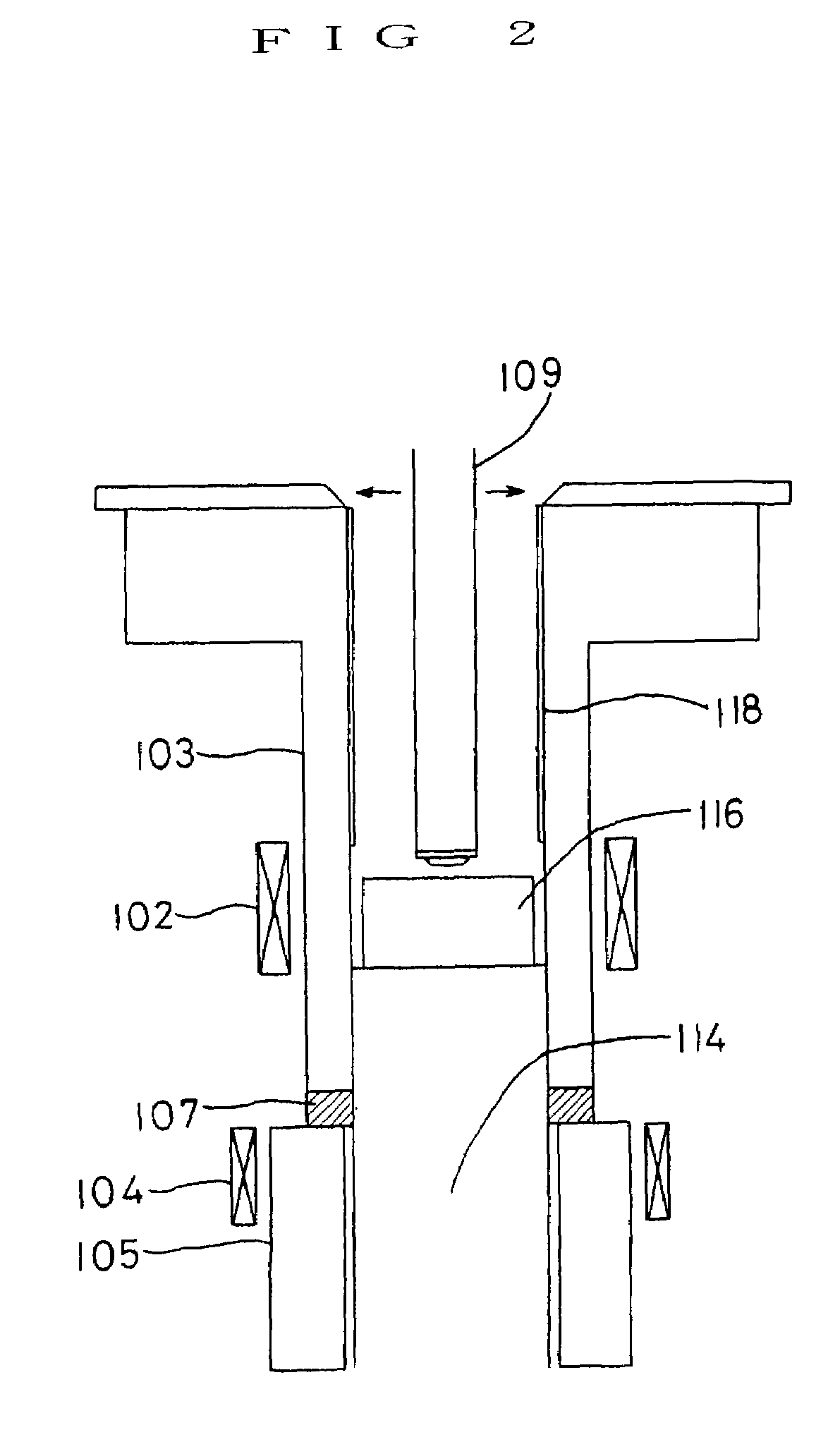

Silicon continuous casting method

InactiveUS6994835B2Inhibit outputDifficult to extractMelt-holding vesselsPolycrystalline material growthTorchSolar cell

The present invention reduces temperature gradient in the direction of the radius of solidified ingots of silicon immediately after solidification, which has serious influences on the quality as a solar cell and improves the quality. Silicon raw materials are melted inside a bottomless crucible combined with an induction coil by electromagnetic induction heating. The silicon melt formed inside the bottomless crucible is allowed to descend and solidified ingots of silicon are manufactured continuously. Plasma heating by a transferred plasma arc torch is also used for melting the silicon raw materials. The plasma arc torch is moved for scanning along the inner surface of the bottomless crucible in the horizontal direction. A plasma electrode on the solidified ingot side to generate transferred plasma arc is allowed to contact the surface of the solidified ingot at positions where the temperature of the solidified ingot becomes 500 to 900° C.

Owner:SUMITOMO MITSUBISHI SILICON CORP

Methods and Formulations for Producing Low Density Products

InactiveUS20090146108A1High yieldHigh viscositySolid waste managementCeramicwareOxygen deficientLow density

A method of preparing a low-density material and precursor for forming a low-density material is provided. An aqueous mixture of inorganic primary component and a blowing agent is formed, the mixture is dried and optionally ground to form an expandable precursor. Such a precursor is then fired with activation of the blowing agent being controlled such that it is activated within a predetermined optimal temperature range. Control of the blowing agent can be accomplished via a variety of means including appropriate distribution throughout the precursor, addition of a control agent into the precursor, or modification of the firing conditions such as oxygen deficient or fuel rich environment, plasma heating etc.

Owner:JAMES HARDIE TECH LTD

High frequency induction plasma heating wind tunnel

ActiveCN106679924AFulfil requirementsGuaranteed rotational strengthAerodynamic testingPlasma techniqueDeep space explorationPlasma generator

A high frequency induction plasma heating wind tunnel is used for a nonequilibrium thermal environment and deep space exploration research. The heating wind tunnel comprises a plasma generator, a jet pipe, a test segment, a diffusion segment, a cooler, a vacuum set and an assisting system. Working gas is heated by the plasma generator, acts on a model of the test segment under the effect of the jet pipe, and is discharged outside via the vacuum set by being pressurized by the diffusion segment and cooled by the cooling segment. The high frequency induction plasma heating wind tunnel is a ground simulation apparatus that can provide a chemically pure, high temperature and high speed air flow environment, and can meet requirements of gas components for deep space exploration research.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

High pressure gasifier system using electrically assisted heating

ActiveUS20110126461A1Good and more complete processingIncrease temperatureGasifier electrodesEngine sealsElectricityMicrowave

The problems of the prior art are overcome by the apparatus and method disclosed herein. The reactor vessel of a plasma gasifier is operated at high pressure. To compensate for the negative effects of high pressure, various modifications to the plasma gasifier are disclosed. For example, by moving the slag, more material is exposed to the plasma, allowing better and more complete processing thereof. In some embodiments, magnetic fields are used to cause movement of the slag and molten metal within the vessel. An additional embodiment is to add microwave heating of the slag and / or the incoming material. Microwave heating can also be used as an alternative to plasma heating in a high pressure gasification system.

Owner:INENTEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com