Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

407results about How to "Improve incineration efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

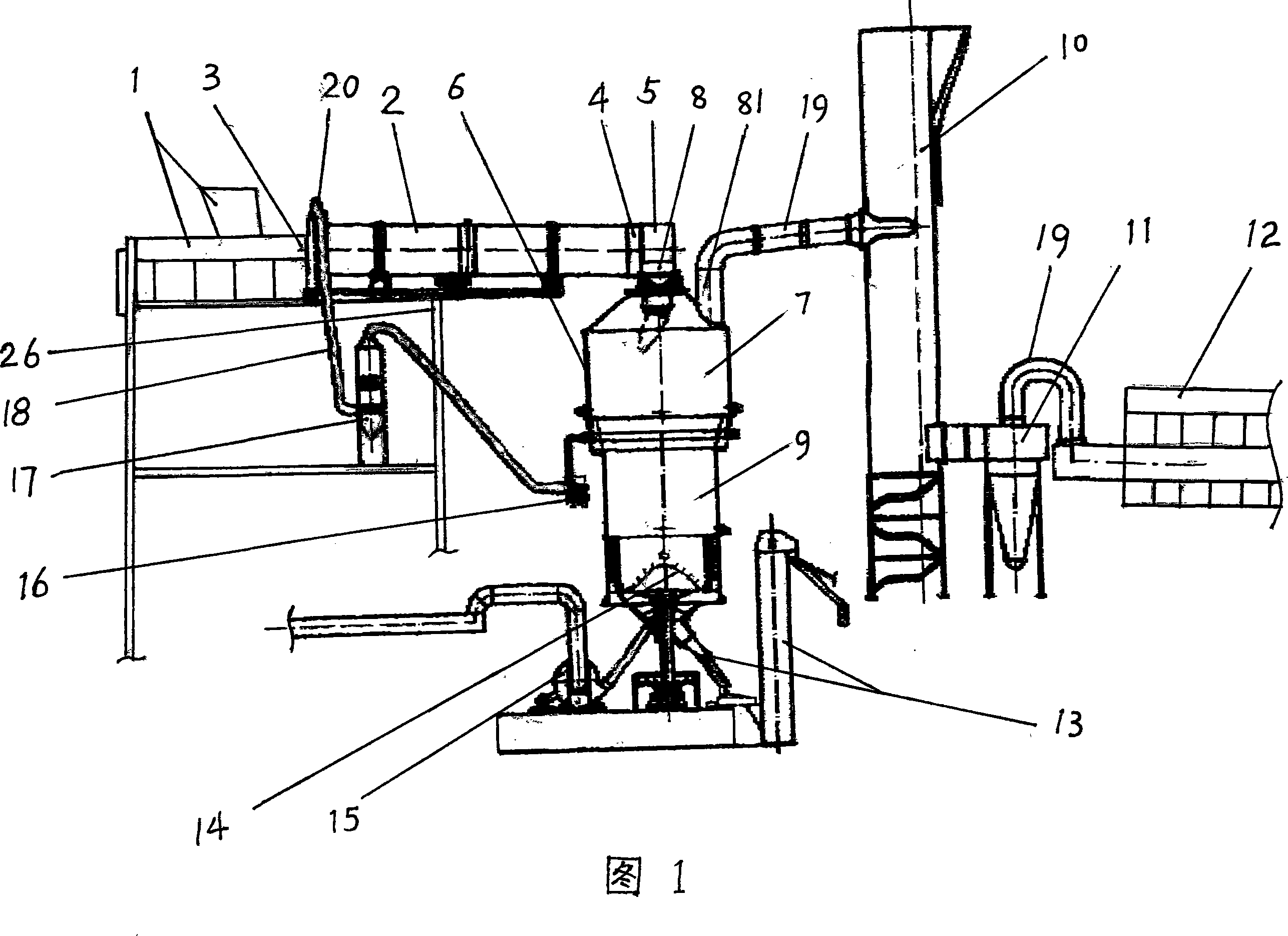

Double-loop double-pyrogenation incinerator for garbage harmless treatment and its usage method

InactiveCN101101120APrevent external consumptionPlay the role of thermal insulationIncinerator apparatusRefluxCombustion chamber

The invention relates to double loop double pyrolysis incinerator and its using method. Its features are that drying apparatus is formed by horizontal rotary kiln drying device, steam separator, and fume reflux line; the feed port of the horizontal rotary kiln is connected with discharge port of the feeding device; its discharge port is connected with the feed port above secondary burning chamber. While running, part of high temperature fume of secondary burning chamber can enter the rotary kiln to process reverse drying preheat and pyrolysis for the garbage; cooled fume is inducted into the secondary burning chamber by secondary fan after dehydrating by steam separator. Compared with exiting technique, the invention has the advantages of continual heat transfer, fast gasification rate, full burning, processing domestic garbage without auxiliary fuel etc.

Owner:福建省丰泉环保控股有限公司

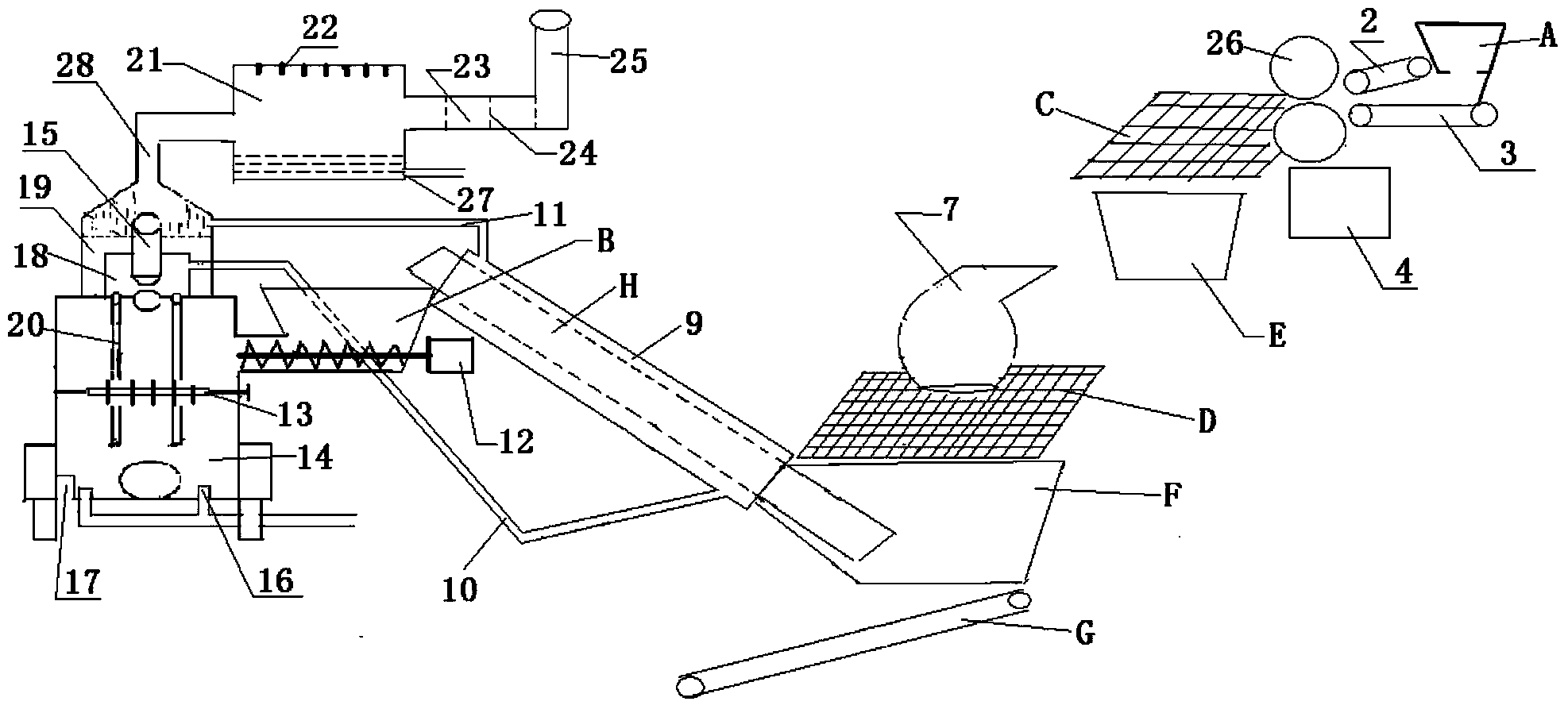

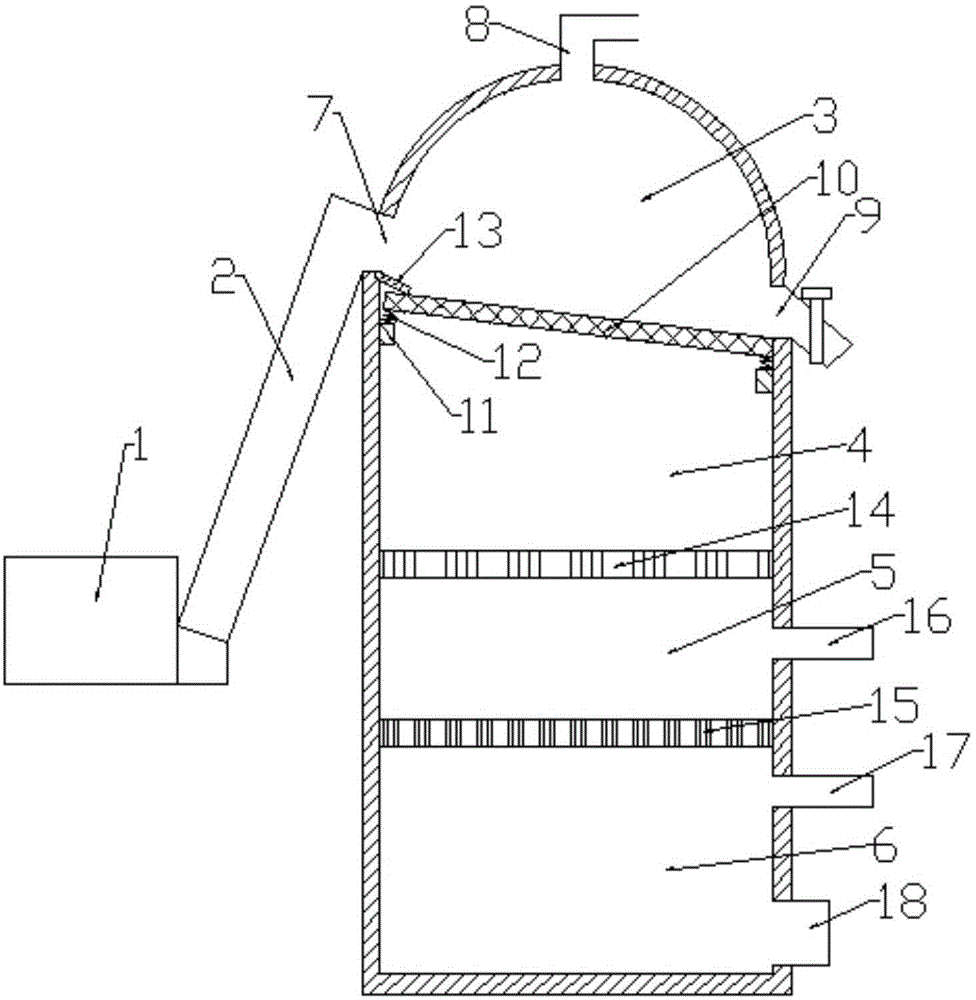

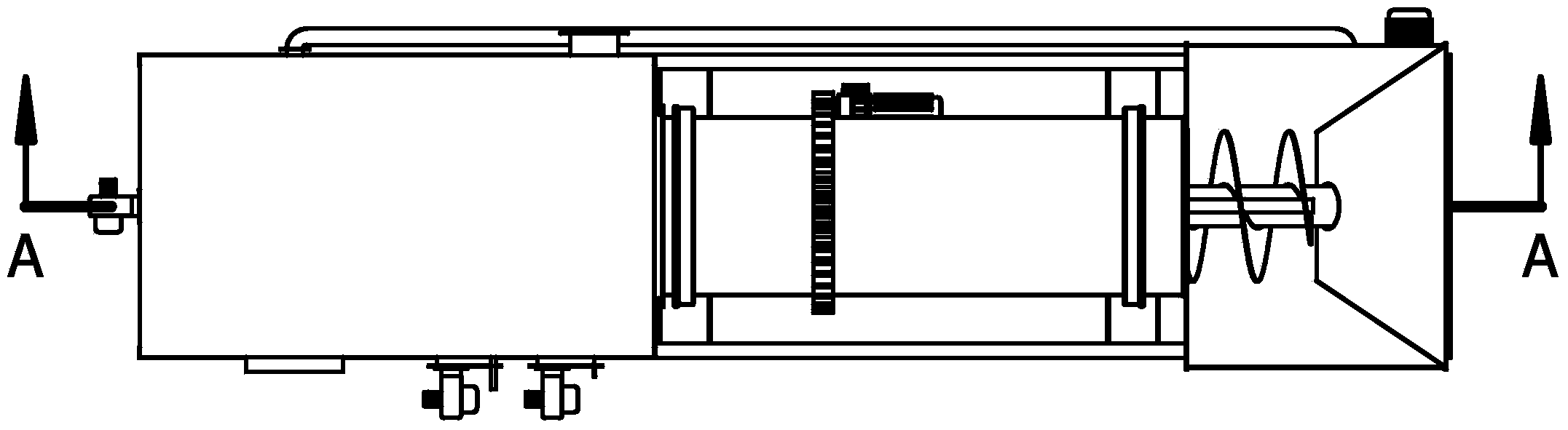

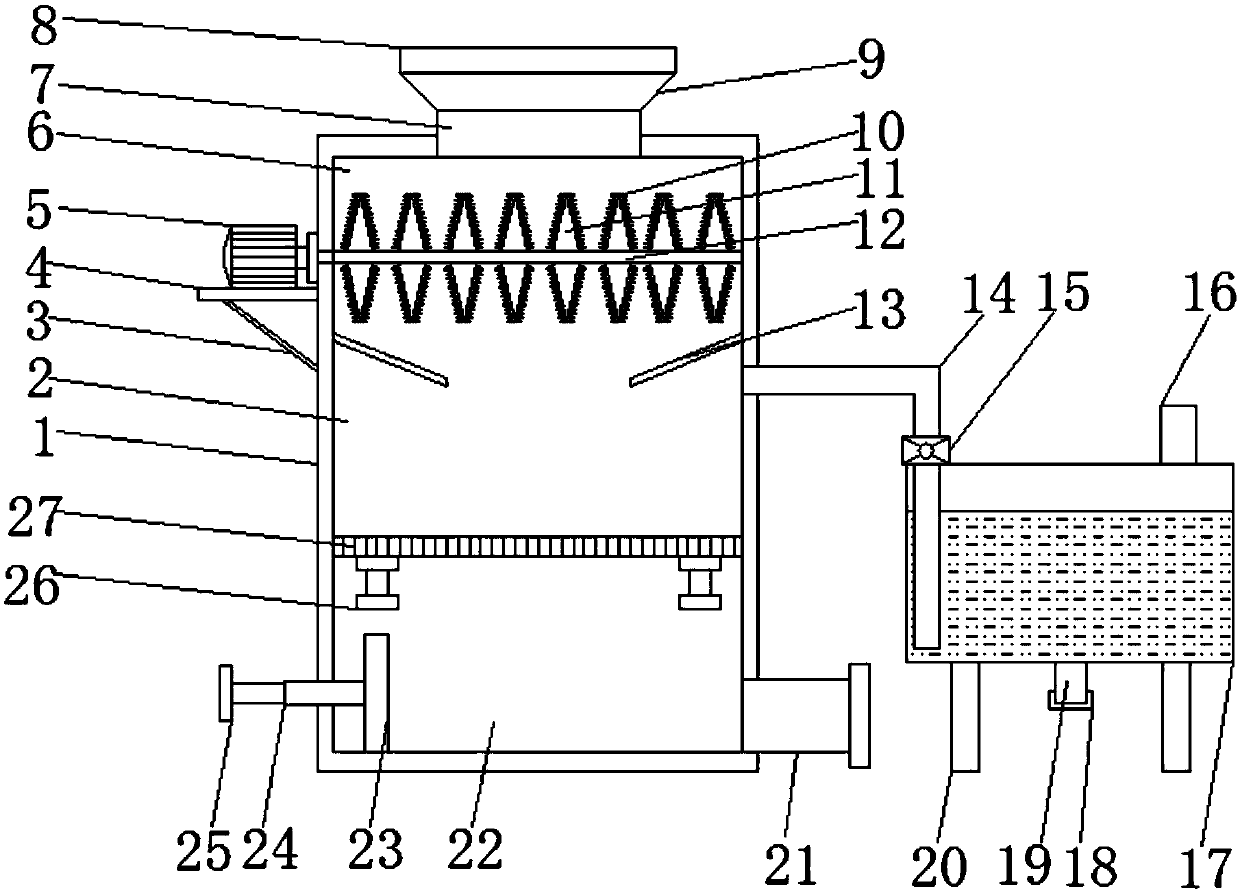

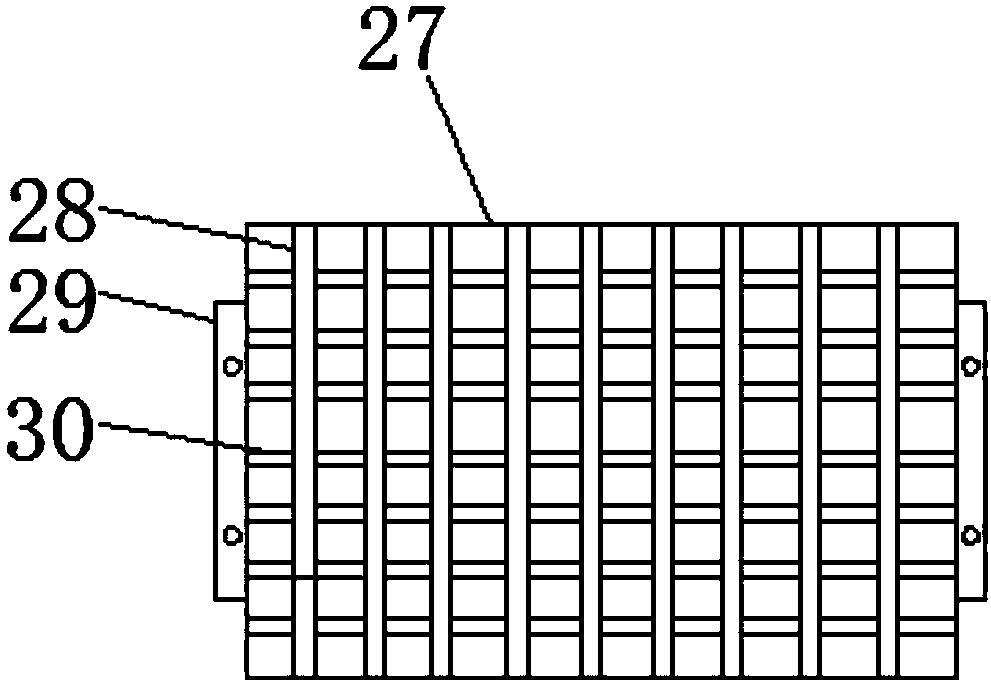

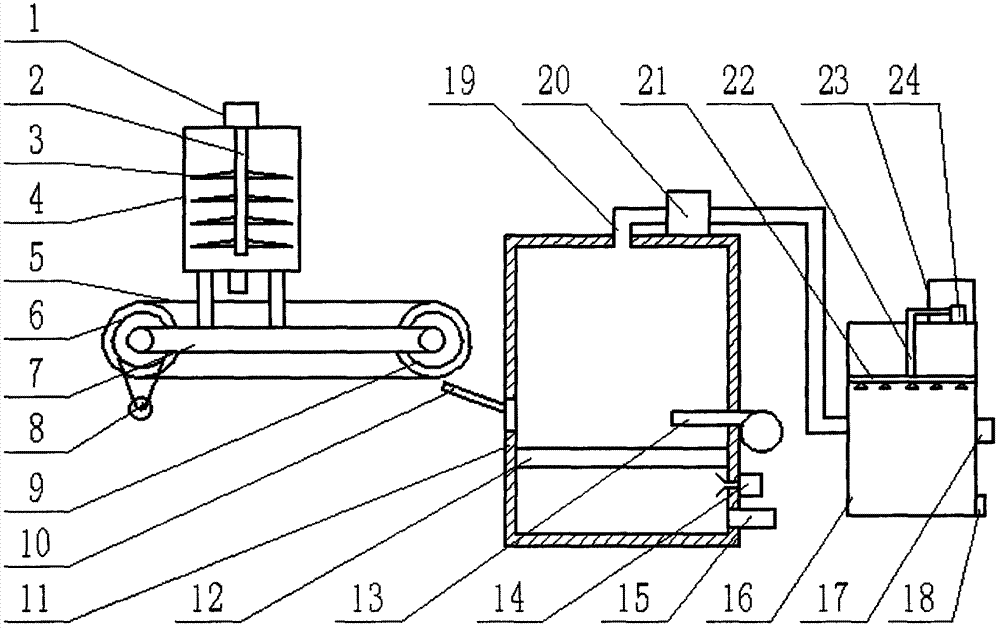

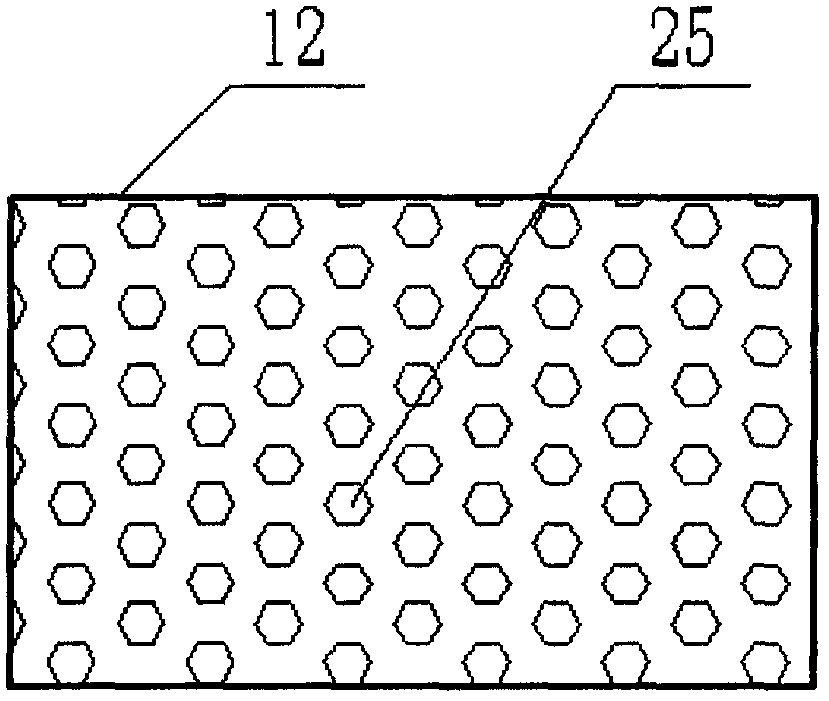

Solid waste combustion system

InactiveCN103398383AIncrease profitTake advantage ofIncinerator apparatusImpellerResource utilization

The invention provides a solid waste combustion system. The solid waste combustion system comprises a squeezing and water removing device, a screening device, a crushing device, a drying device, a combustion device and a smoke treating device, wherein the squeezing and water removing device comprises a waste feeding hopper; the feeding hopper is connected with a roller by a pressure conveying belt; the crushing device comprises a crusher and a shaking type screening net located on the bottom of the crusher; the combustion device comprises a hearth; the outer part of the hearth is connected with the feeding hopper and dried wastes are conveyed to the feeding hopper by a drying device conveying belt; a spiral conveying impeller is mounted on the connection part of the feeding hopper and the hearth; the hearth is internally provided with an agitation device; the smoke treating device is connected with the hearth; an opening is formed in the connection part of the hearth and the smoke treating device; the smoke treating device comprises a dust removing device and a desulfuration and deodorization device. The solid waste combustion system provided by the invention is high in combustion efficiency; the treated wastes can be utilized sufficiently so that the resource utilization rate is improved and a working process is environment-friendly and pollution-free.

Owner:黎汉东

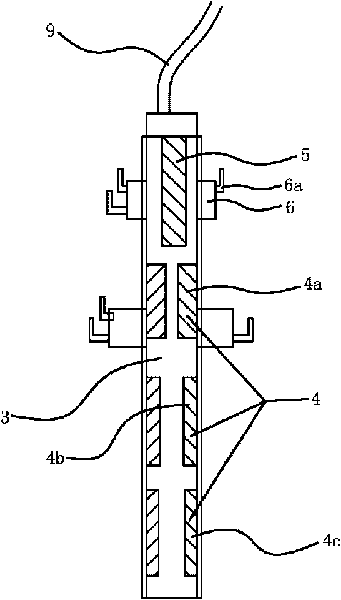

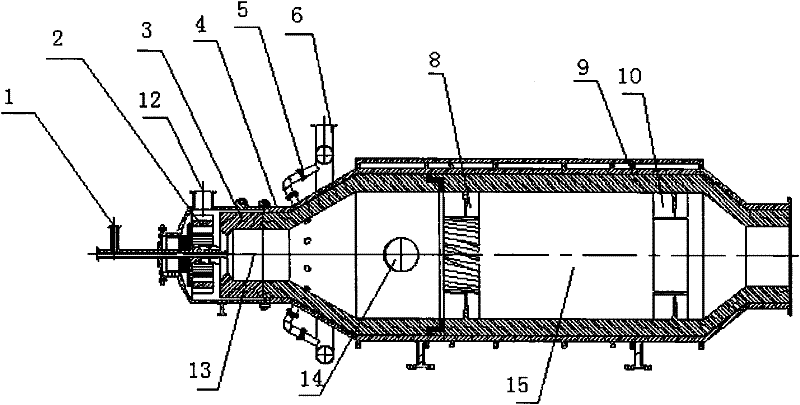

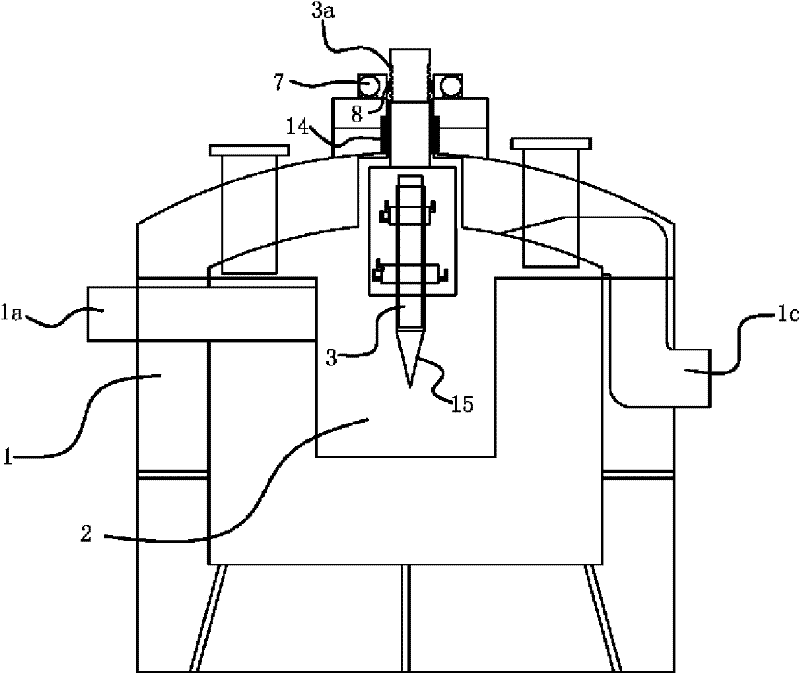

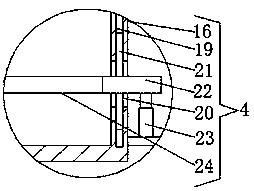

Plasma melting cracking treating equipment

ActiveCN101737786ABurn completelyImprove incineration effectIncinerator apparatusPlasma flameIncineration

The invention provides plasma melting cracking treating equipment belonging to the technical field of machines and solving the technical problems of low incineration temperature, poor incineration effect, insufficient incineration and the like of a traditional incineration furnace. The plasma melting cracking treating equipment comprises a furnace body with a charging port and a discharging port, wherein the furnace body is internally provided with an incineration cavity communicated with the charging port and the discharging port; the furnace body is also provided with a gas outlet communicated with the incineration cavity; the top of the furnace body is also provided with a plasma torch generator capable of generating plasma flames; one end of the plasma torch generator penetrates into the incineration cavity; and the other end penetrates out of the furnace body and is connected with a lifting mechanism capable of driving the plasma torch generator to lift upwards and downwards. The treating equipment has the advantages of higher flame temperature, more sufficient incineration, higher incineration efficiency and the like.

Owner:TAIZHOU WEIBO ENVIRONMENTAL PROTECTION EQUIP TECH

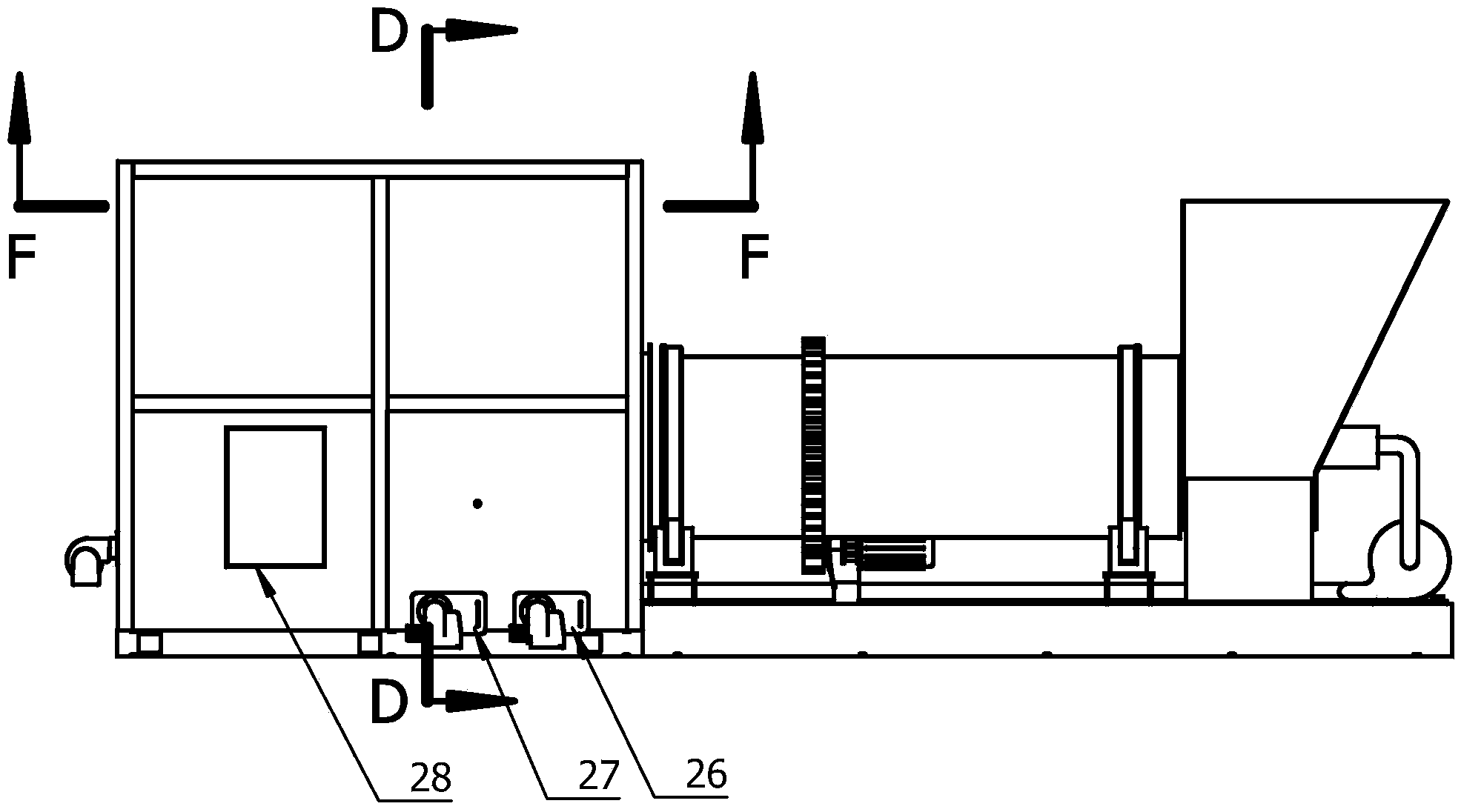

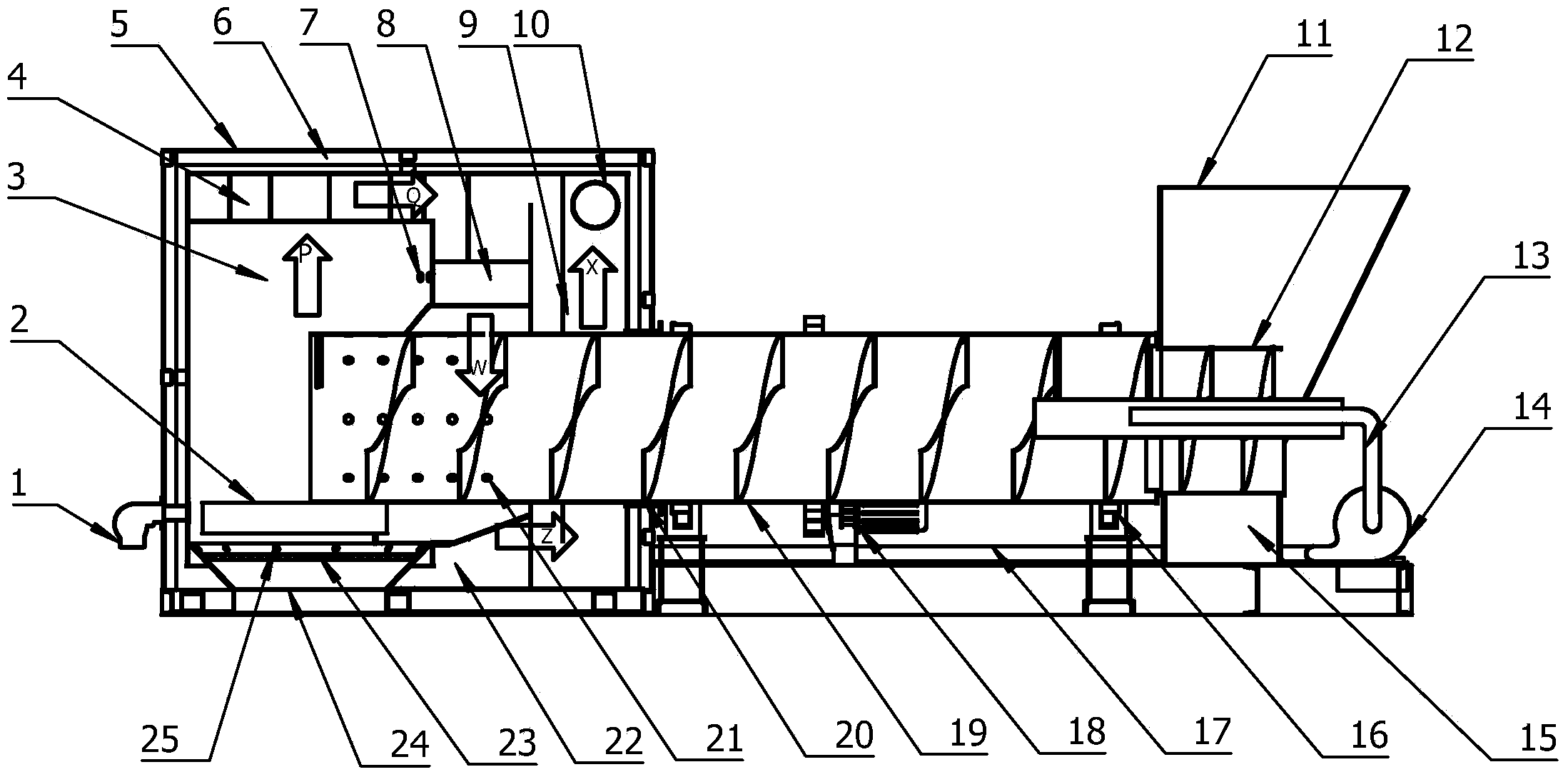

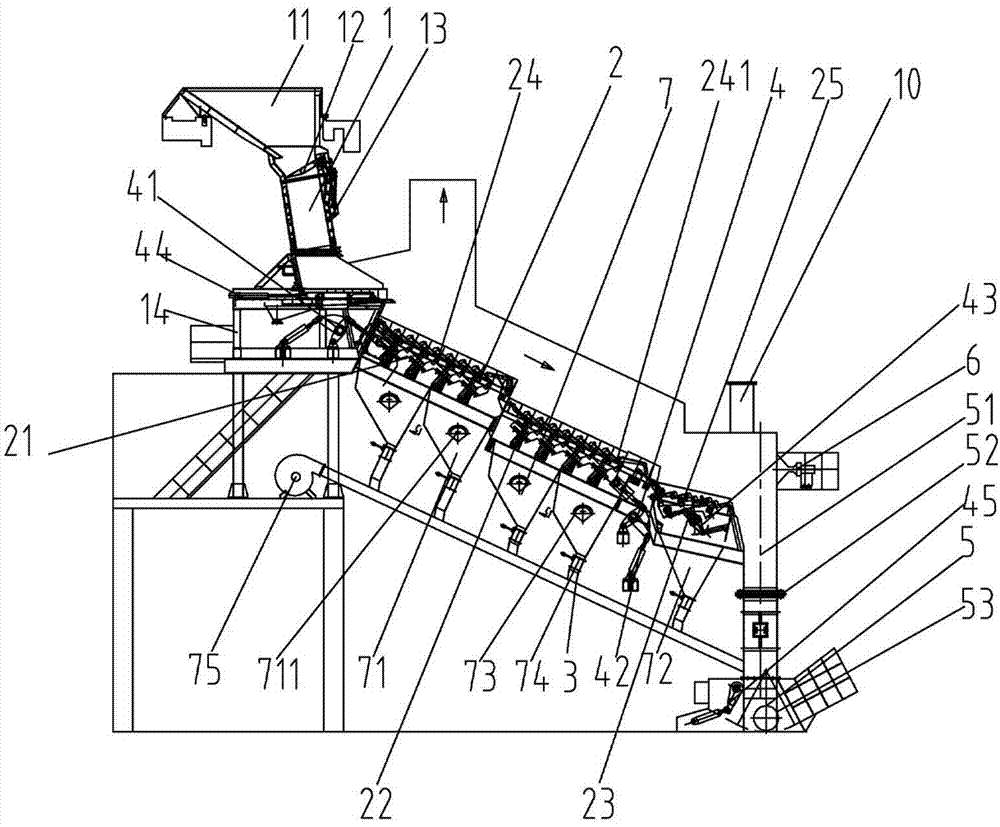

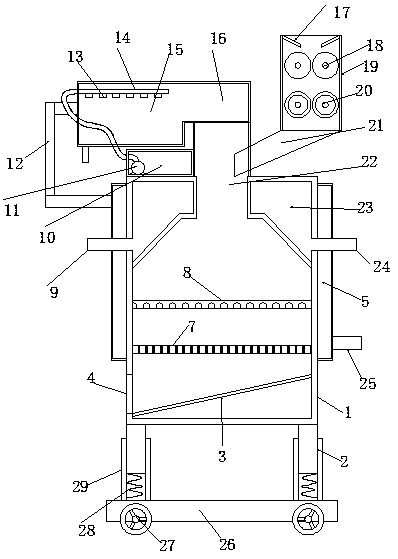

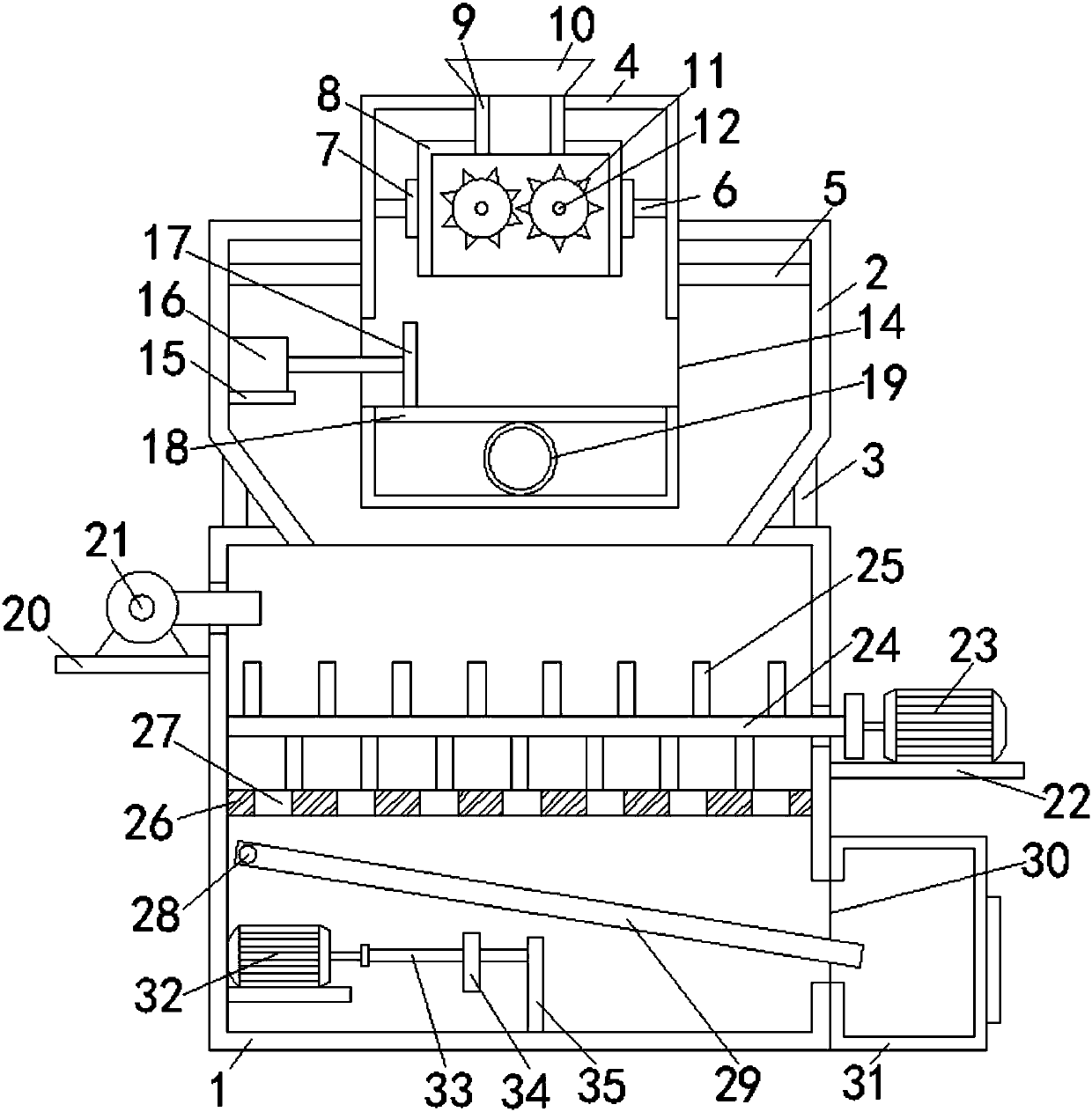

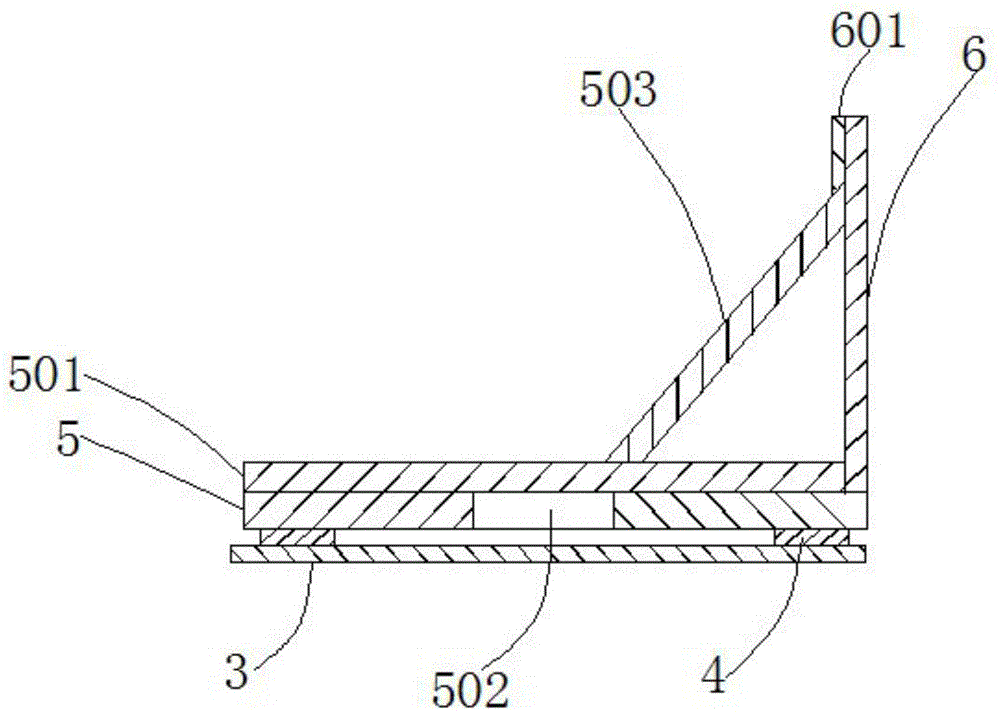

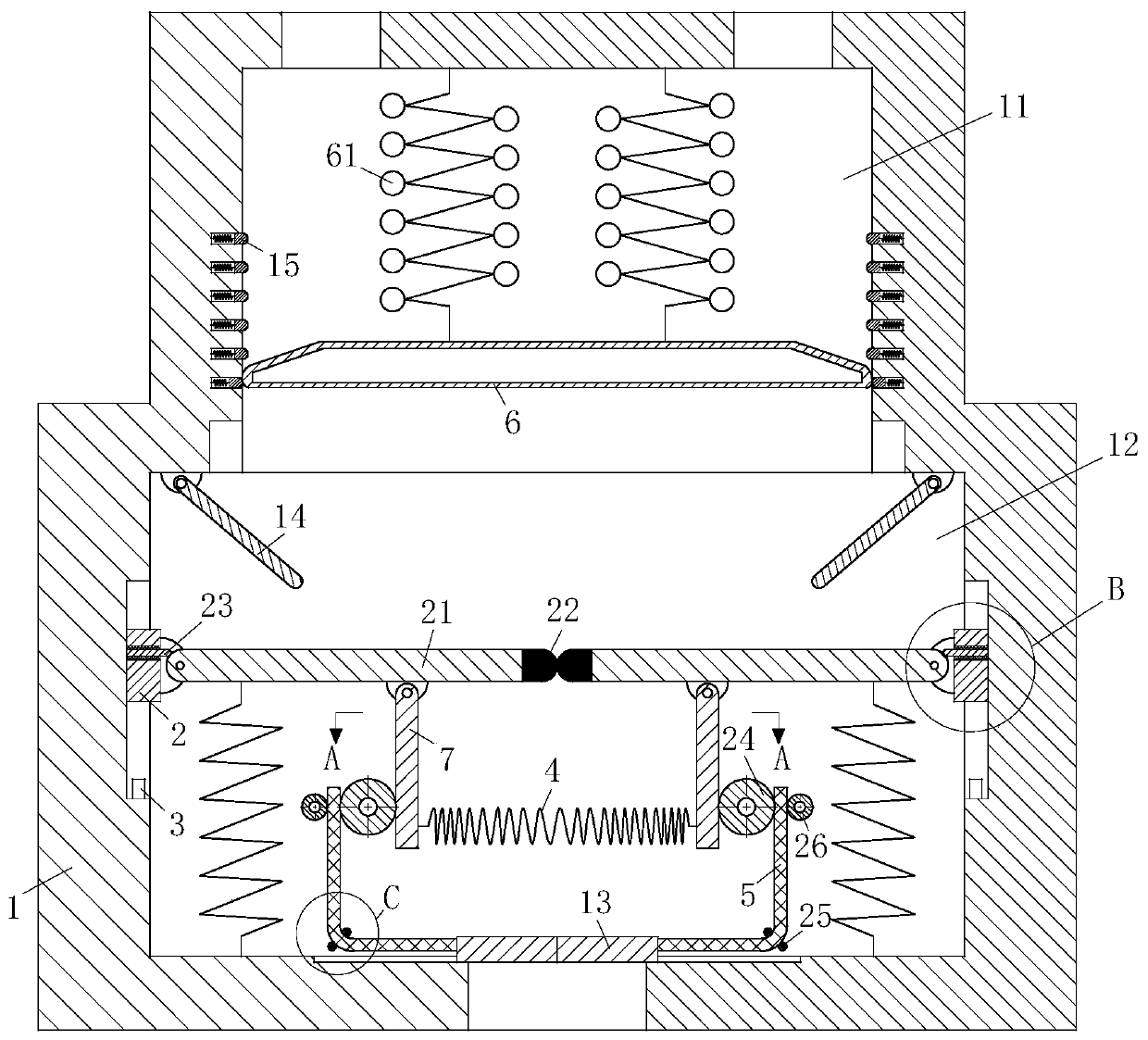

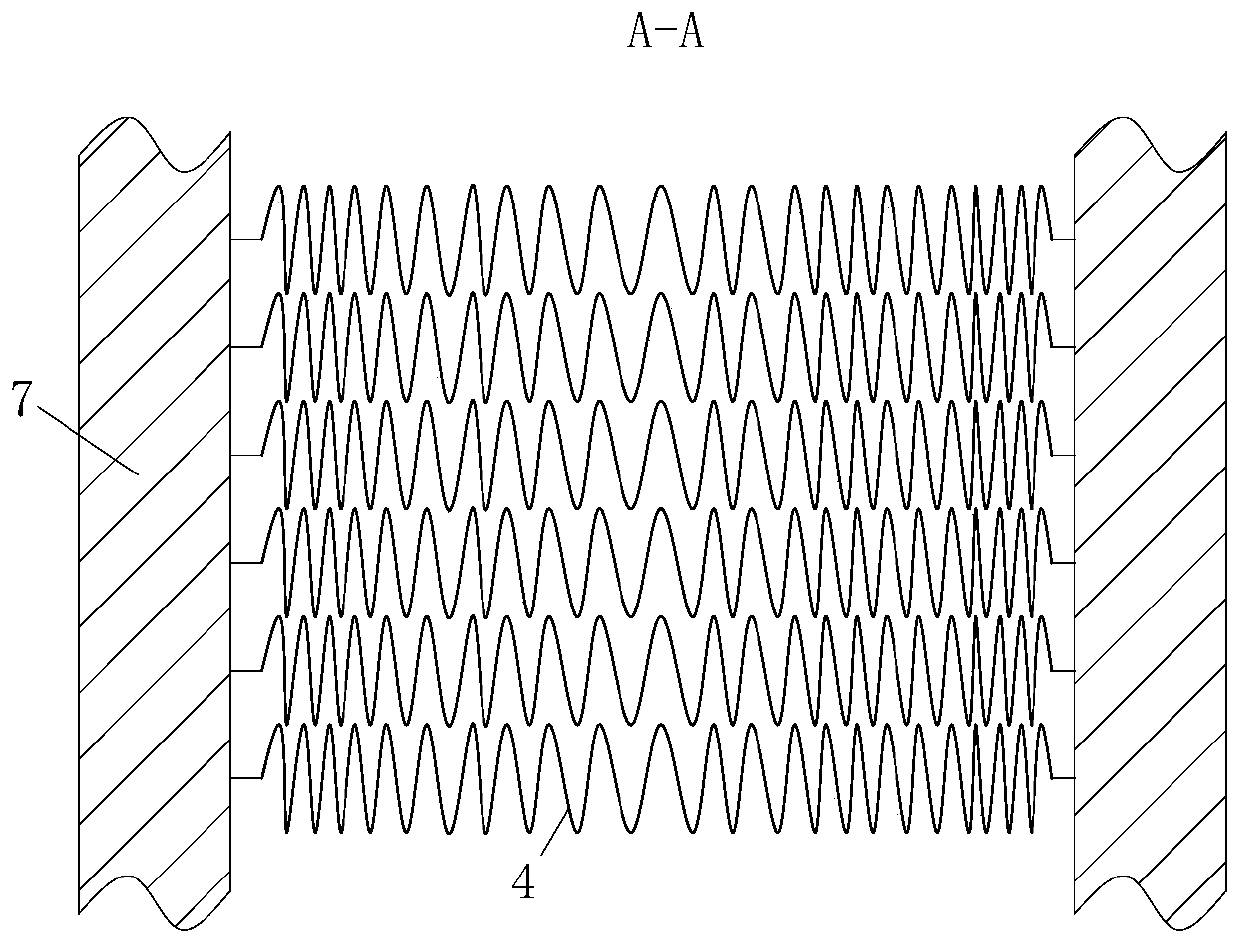

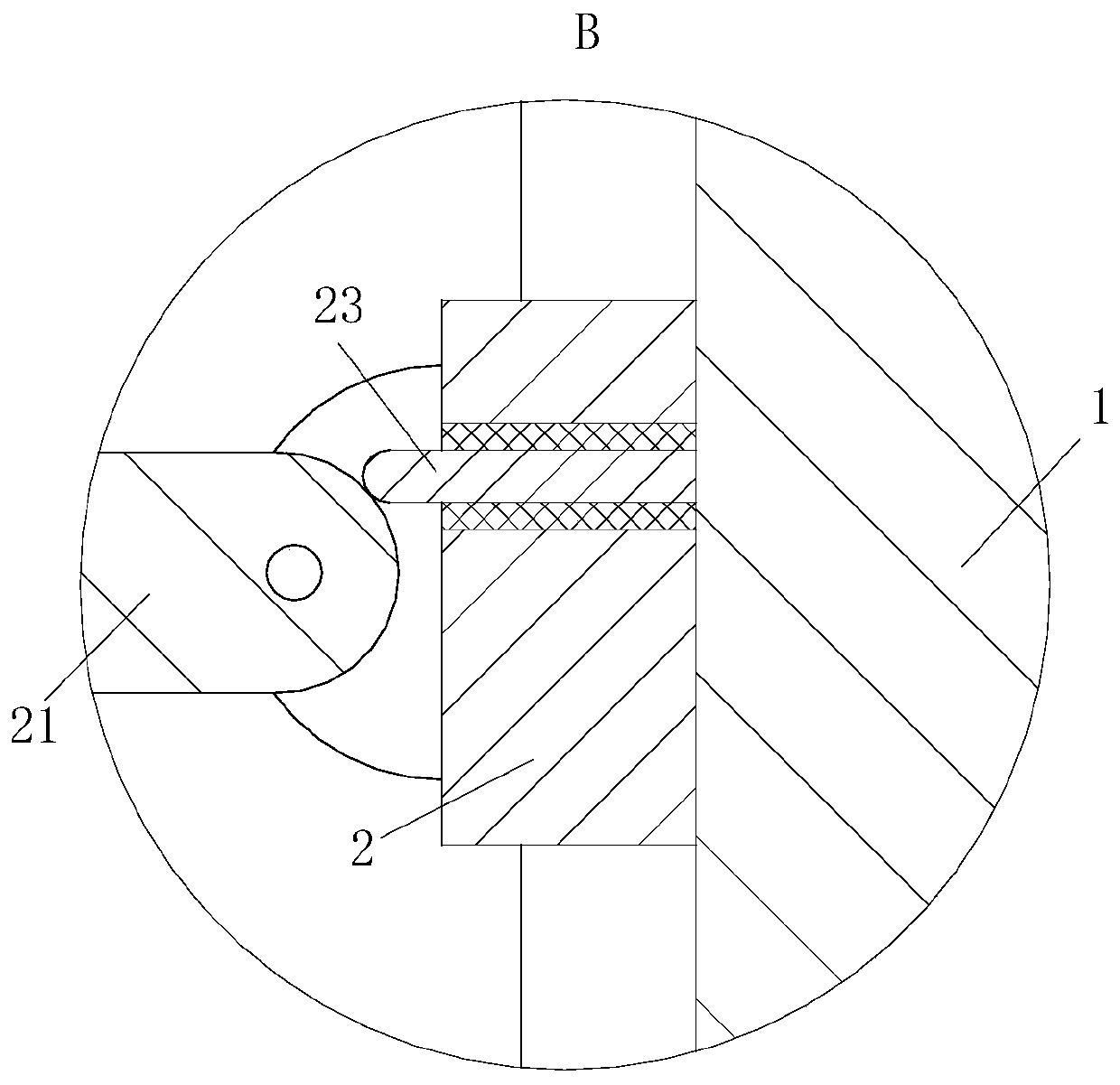

Coal mine waste moving processing device

InactiveCN104832926AReduce volumeReduce processing costsIncinerator apparatusWaste processingEnvironmental resistance

The invention relates to environmental protection equipment, in particular to a coal mine waste moving processing device. A smashing device is connected to a feeding opening of an incinerator through a delivery mechanism. The incinerator comprises a screening chamber, a first combustion chamber, a second combustion chamber and an ash chamber from top to bottom in sequence, the feeding opening is formed in one side of the screening chamber, a discharging opening is formed in the other side of the screening chamber, the top of the screening chamber is provided with a chimney, a screen is installed between the screening chamber and the first combustion chamber in an inclined mode, the higher end of the screen is located at the feeding opening, and the lower end of the screen is located at the discharging opening; a coarse grate is arranged between the first combustion chamber and the second combustion chamber, a fine grate is arranged between the second combustion chamber and the ash chamber, an upwind opening is formed in the second combustion chamber, and a downwind opening is formed in the ash chamber. By means of the coal mine waste moving processing device, the burning efficiency is improved, abundant burning is guaranteed, the device can move along with the change of working areas, the waste can be processed nearby, and the waste processing cost is saved.

Owner:HEBEI UNIV OF ENG

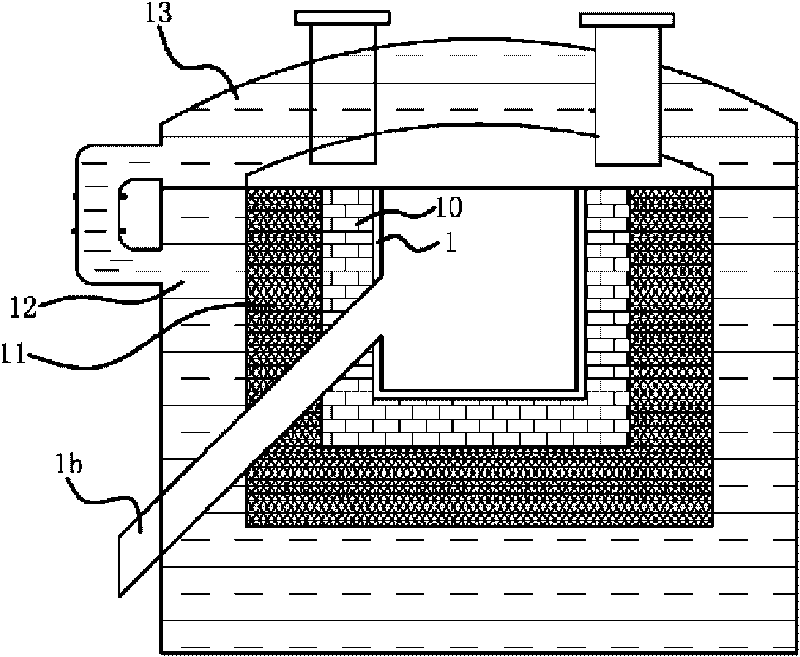

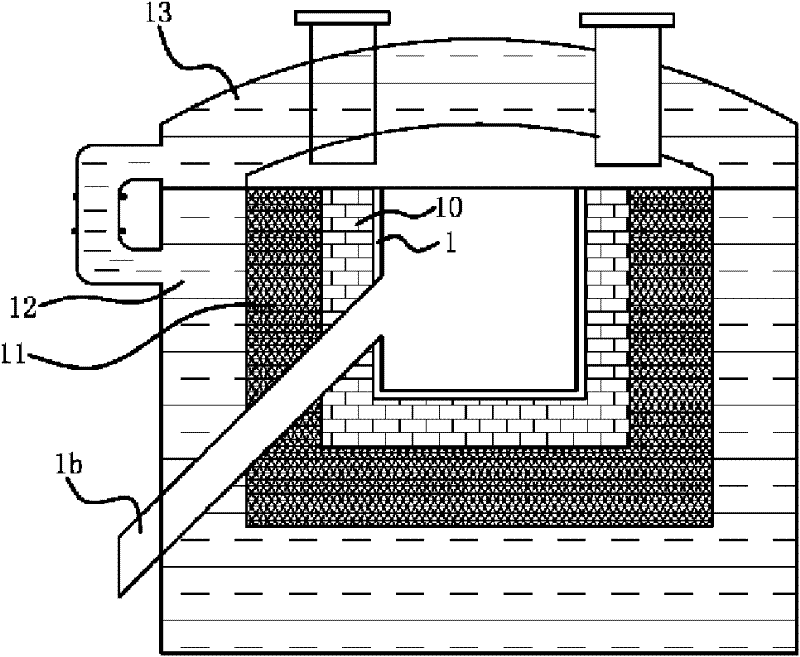

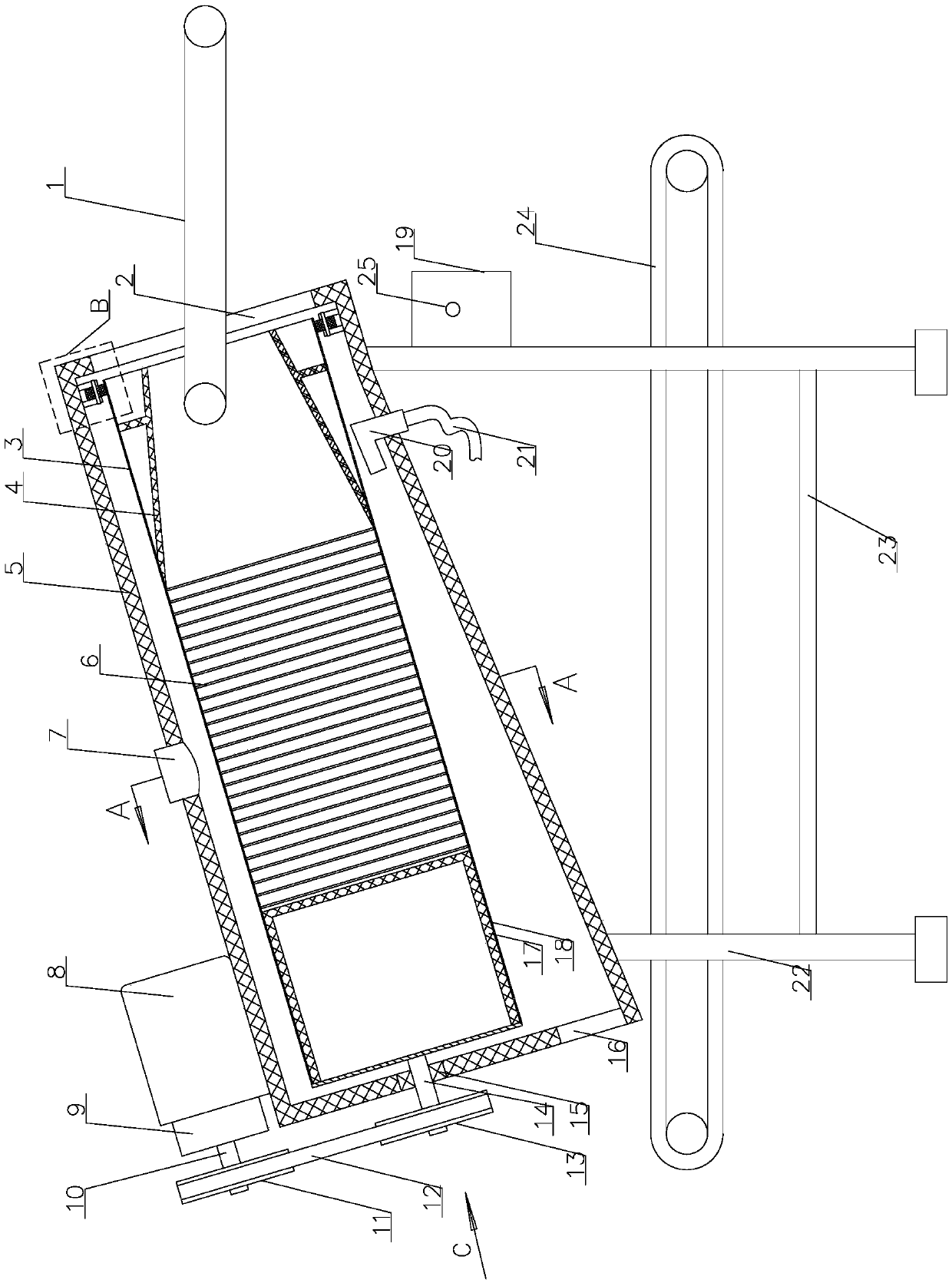

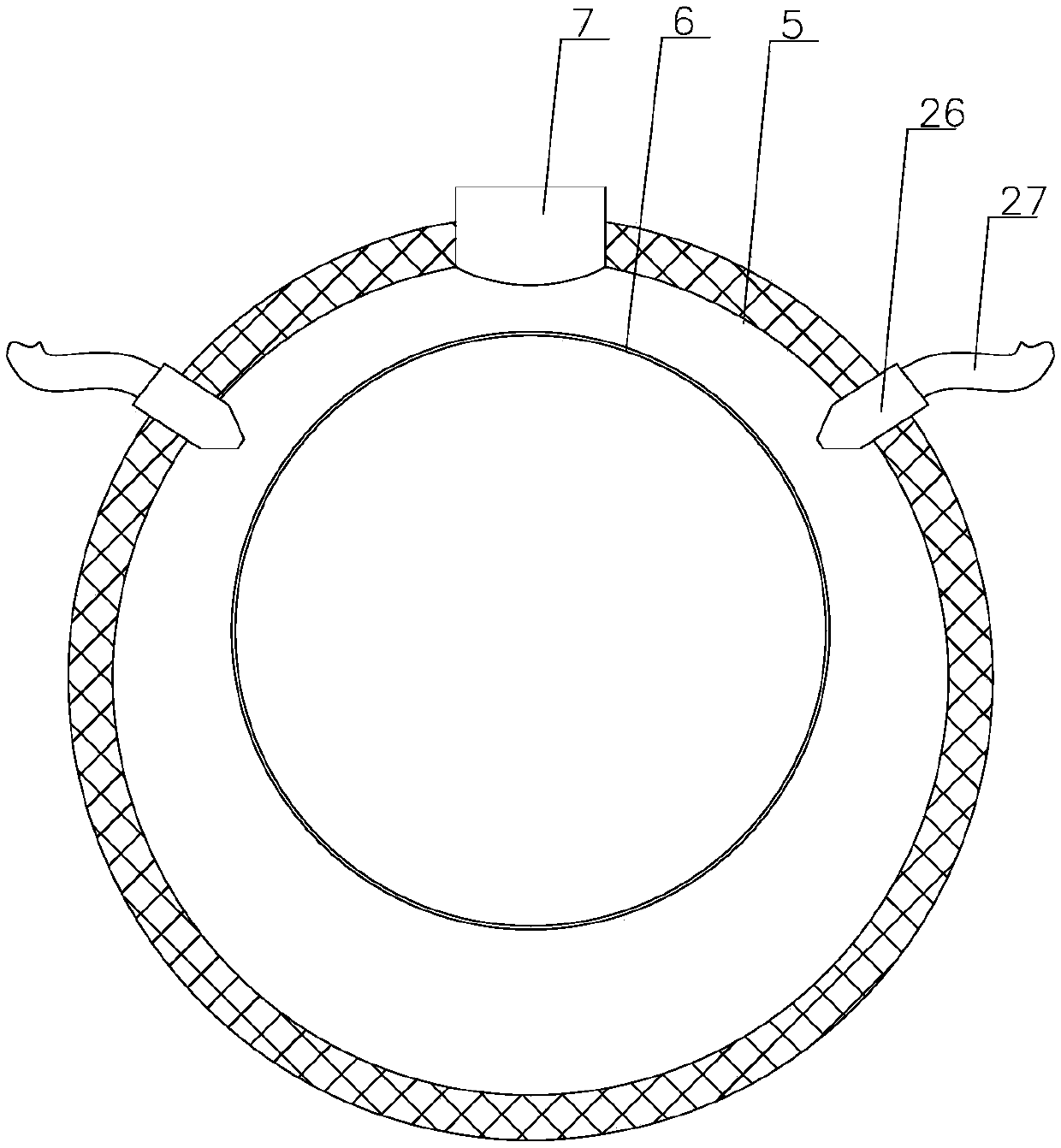

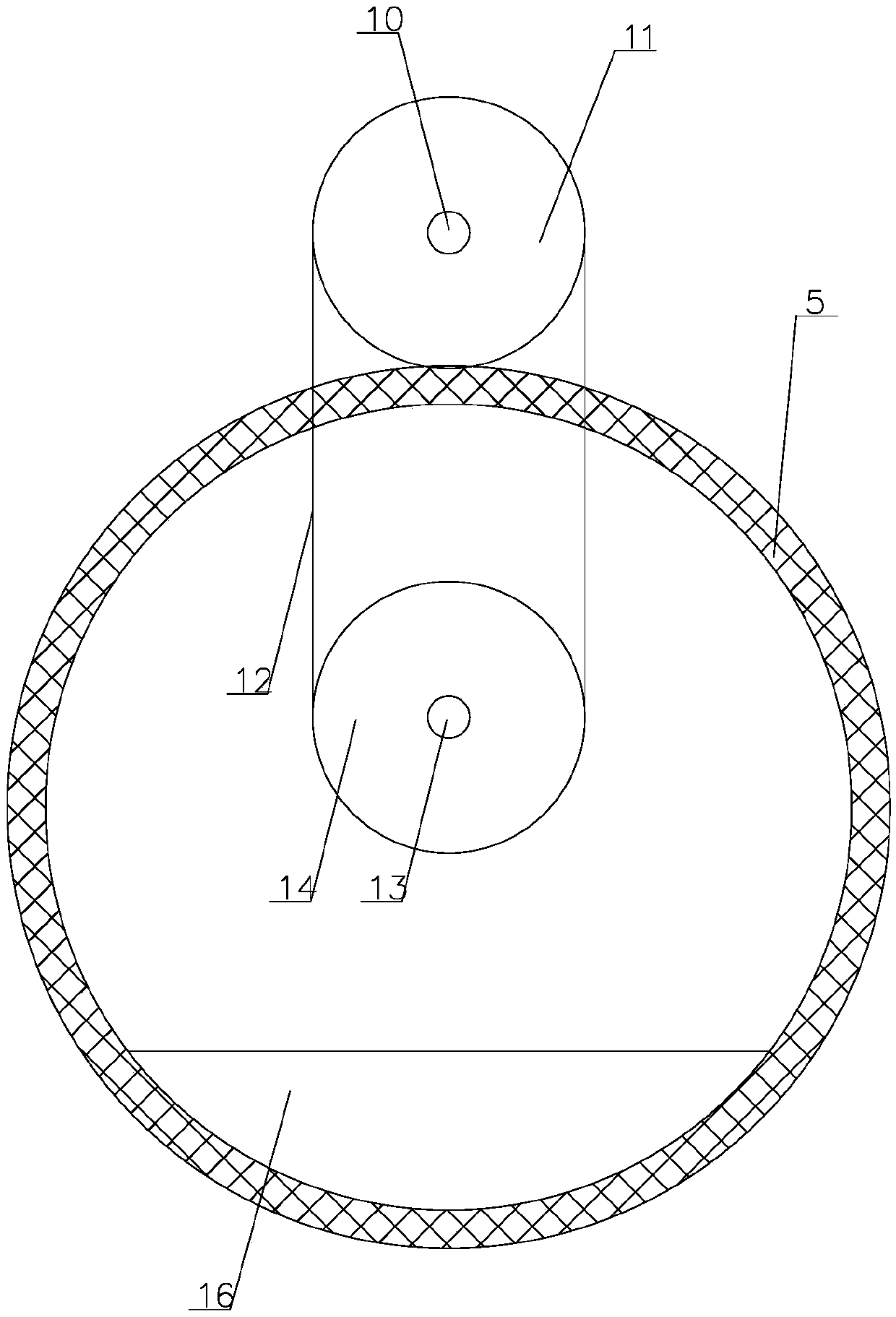

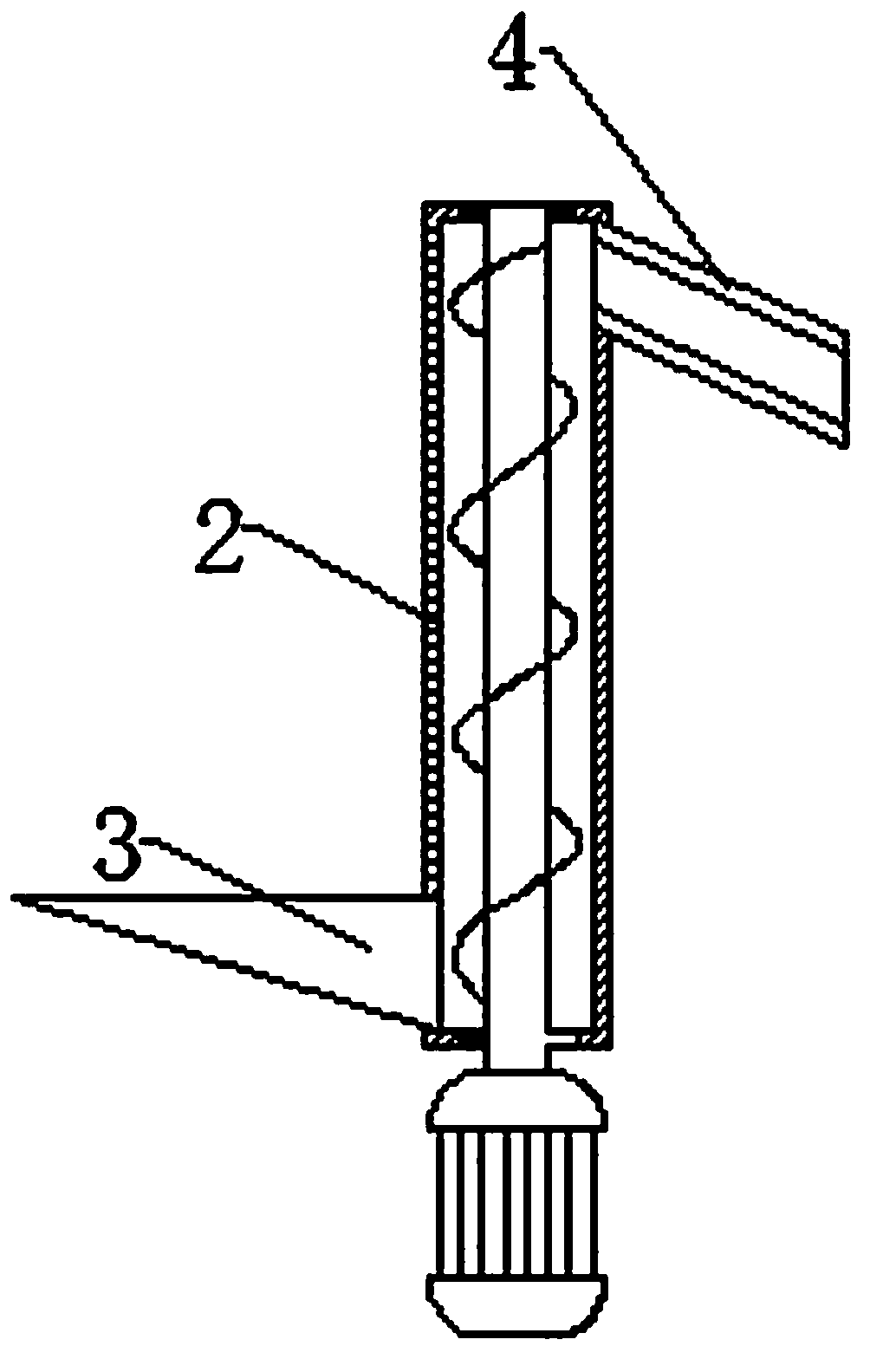

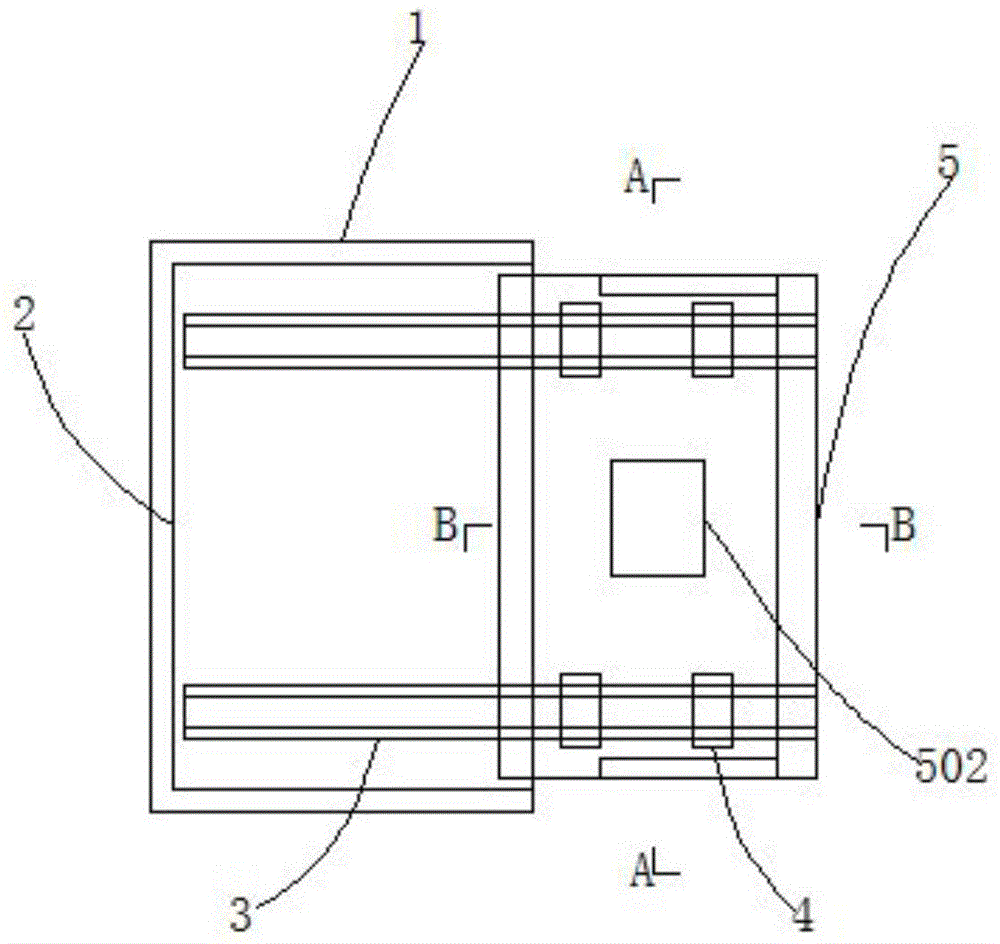

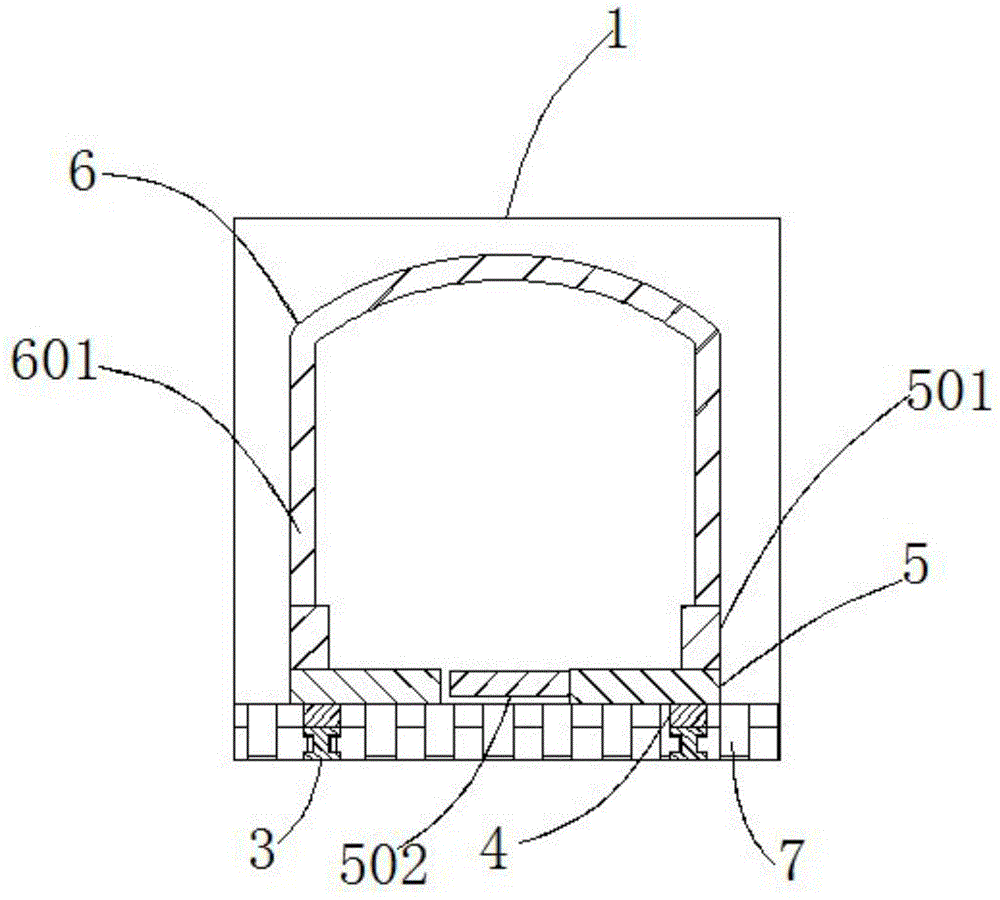

Rotary vertical garbage incinerator

InactiveCN104235856AEasy to manufactureSimplify the installation processIncinerator apparatusCombustion chamberFlue gas

The invention discloses a rotary vertical garbage incinerator, and relates to waste treatment equipment. The rotary vertical garbage incinerator comprises a shell, a combustion chamber positioned in the shell, and a feeding device, wherein the combustion chamber comprises a primary combustion chamber, an annular flue gas pyrolysis chamber, a secondary combustion chamber and a tertiary combustion chamber; space between the shell and each stage of combustion chamber is filled with a vermiculite refractory material; the feeding device comprises a hopper, a rotary drying and feeding drum and a transmission system; the rotary drying and feeding drum is arranged on a drying and feeding drum support mechanism, and is connected with the output end of the transmission system; a feeding spiral plate is arranged in the rotary drying and feeding drum; one end of the drum is connected with the hopper; the other end of the drum extends into the primary combustion chamber, and is provided with drying holes, which are communicated with the primary combustion chamber, on the part in the primary combustion chamber. The rotary vertical garbage incinerator does not need separate garbage pretreatment equipment, drying equipment or secondary combustion equipment, has the advantages of simple structure, low use and maintenance costs, high incineration efficiency and wide application range, and is ideal equipment for garbage incineration.

Owner:杨学勤

Environment-friendly agricultural straw machining equipment with good machining effect

InactiveCN107830526AImprove incineration efficiencyEasy to sprayCuttersIncinerator apparatusCombustion chamberAgricultural engineering

The invention discloses an environment-friendly agricultural straw processing equipment with good processing effect, which comprises a processing main box body. The inner chamber of the processing main box body is sequentially provided with a crushing chamber, a combustion chamber and a material storage chamber from top to bottom. The top of the processing main box is provided with a feed pipe, the middle of the crushing chamber is provided with a rotating shaft, and the outside of the rotating shaft is provided with a crushing blade, and the surface of the crushing blade is provided with crushing teeth. The left side of the shaft is connected with the driving motor, the bottom of the driving motor is provided with a driving motor fixing bracket, the right side of the driving motor fixing bracket is connected with the left side of the processing main box, and the bottom of the driving motor fixing bracket is provided with Reinforcing ribs, the bottom of the reinforcing ribs is connected with the processing main box, and both sides of the bottom of the crushing chamber are provided with baffles. The invention has the advantage of absorbing the nutrients taken away by the thick smoke, and solves the problem of reducing the effect of the straw on the soil.

Owner:江门市新会银洲湖纸业基地投资有限公司

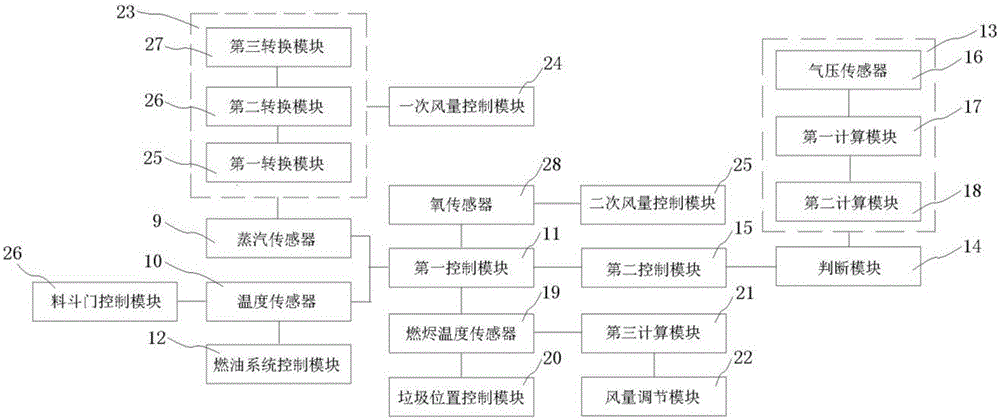

Garbage incinerator control system

InactiveCN108332213AImprove intelligenceImprove adaptabilityIncinerator apparatusAutomatic controlCombustion

The invention provides a garbage incinerator control system. The system comprises an incinerator and an automatic control module, wherein a data acquisition module is arranged on the incinerator and used for collecting combustion condition data related to control parameters of the incinerator, and the combustion condition data characterizes combustion conditions of the incinerator; the automatic control module performs collaborative optimization on at least two control parameters of the incinerator according to the combustion condition data to obtain optimized control parameters and automatically controls the incinerator according to the optimized control parameters. The garbage incinerator control system achieves the purposes of intelligence and adaptability of the incinerator and has theeffects of saving energy, increasing efficiency and improving operating economy.

Owner:光大环保能源(宁波)有限公司

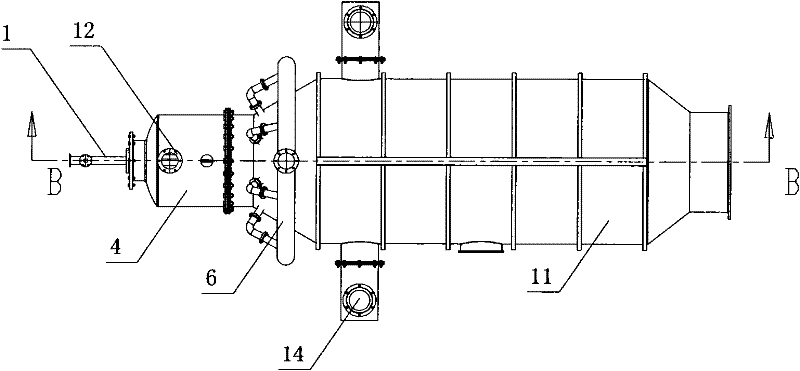

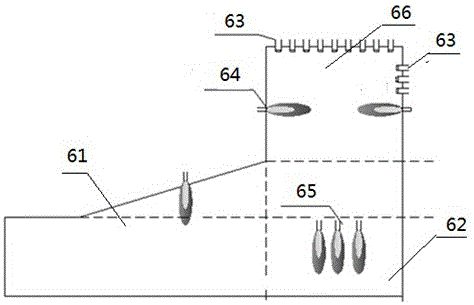

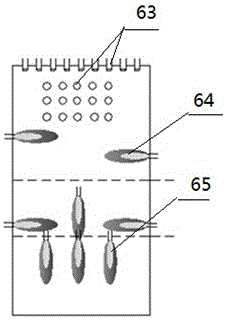

Compulsory mixed tail gas furnace

ActiveCN102192515AIncrease the degree of mixingImprove flame stabilityIncinerator apparatusCombustorCombustion chamber

The invention relates to a compulsory mixed tail gas furnace. An igniter is communicated with a burner inner pipe; a composite air distribution blade is positioned at the other end of a burner, and is communicated with a combustor; a primary air inlet is arranged on a shell of the combustor; a vortex guide vane is positioned in an air chamber between the primary air inlet and the composite air distribution blade; the combustor is sequentially communicated with an air cavity and a tail gas cavity; a secondary air inlet is arranged out of the shell of the combustor at the air cavity, and the air cavity is communicated with the combustor; a vortex mixing blade is installed at the connecting end of the combustion chamber and the tail gas cavity; and an inner shunting and accelerating mixing blade and an outer shunting and accelerating mixing blade are installed at a tapered end of the combustion chamber, and are fixed at the inner surface of a fire-proof lining of the combustion chamber. The structure has the characteristics that the fuel gas and air are mixed fully, the combustion is complete, the heat energy utilization is full, and the like; and the hydrogen sulfide content in the tail gas is reduced obviously, which plays an active role in pushing the integral performance and environment protection of a tail gas burning device.

Owner:PETROCHINA CO LTD

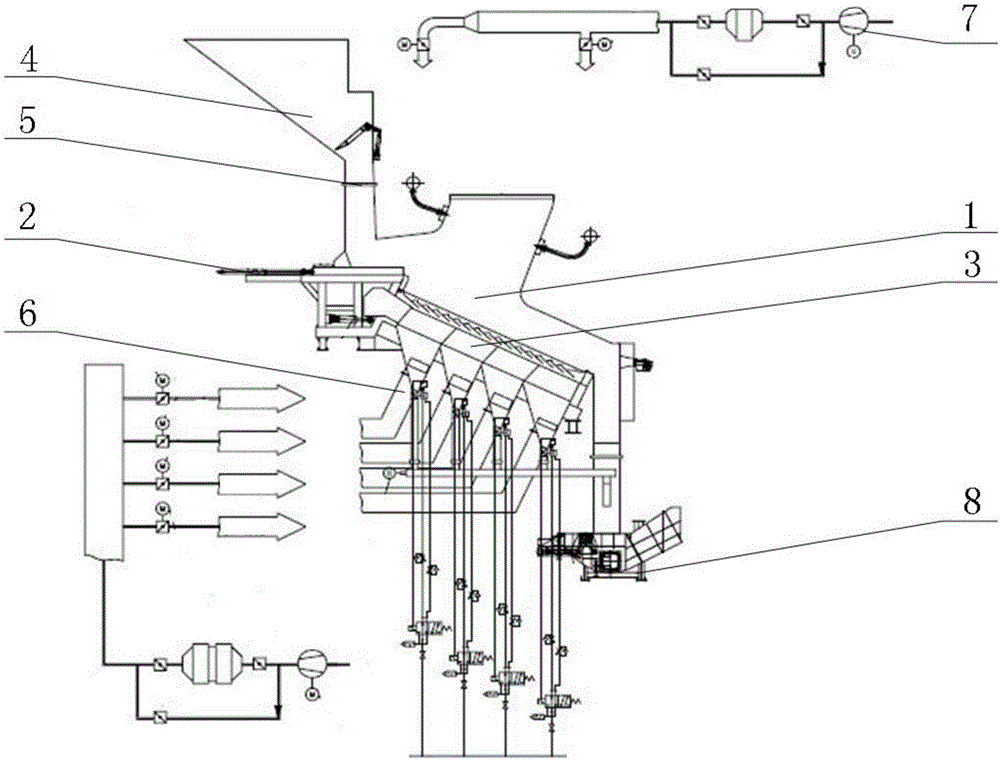

Control system of inclined and reciprocating inverse-pushing type garbage incinerator

InactiveCN106838931AImprove incineration efficiencyEfficient running stateIncinerator apparatusFurnace temperatureCombustion chamber

The invention discloses a control system of a tilting reciprocating reverse thrust type garbage incinerator, comprising a steam sensor arranged in the furnace for detecting the main steam flow, a temperature sensor for detecting the temperature of the furnace, and the steam sensor and the temperature sensor A first control module that is signaled to operate the feeder and each grate when the main steam flow and furnace temperature values are within preset ranges. The control system of the oblique reciprocating and reverse-push garbage incinerator disclosed in the present invention detects the main steam flow and furnace temperature in the furnace through the steam sensor and the temperature sensor, and then judges the current incineration in the incinerator according to the detected values of the two. According to the incineration environment, the first control module accurately controls the feeder and each grate to perform corresponding operations to ensure that the waste incineration is in an efficient operation state and improve the waste incineration efficiency of the incinerator.

Owner:HANGZHOU HOLLYSYS AUTOMATION +1

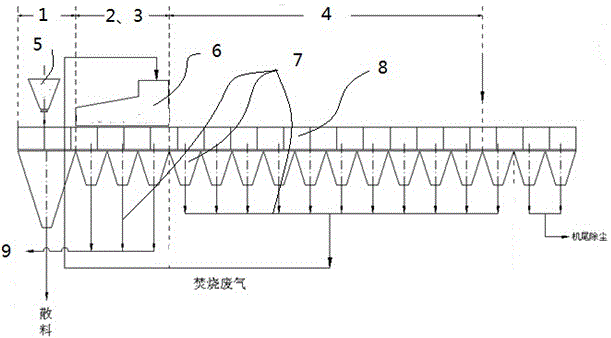

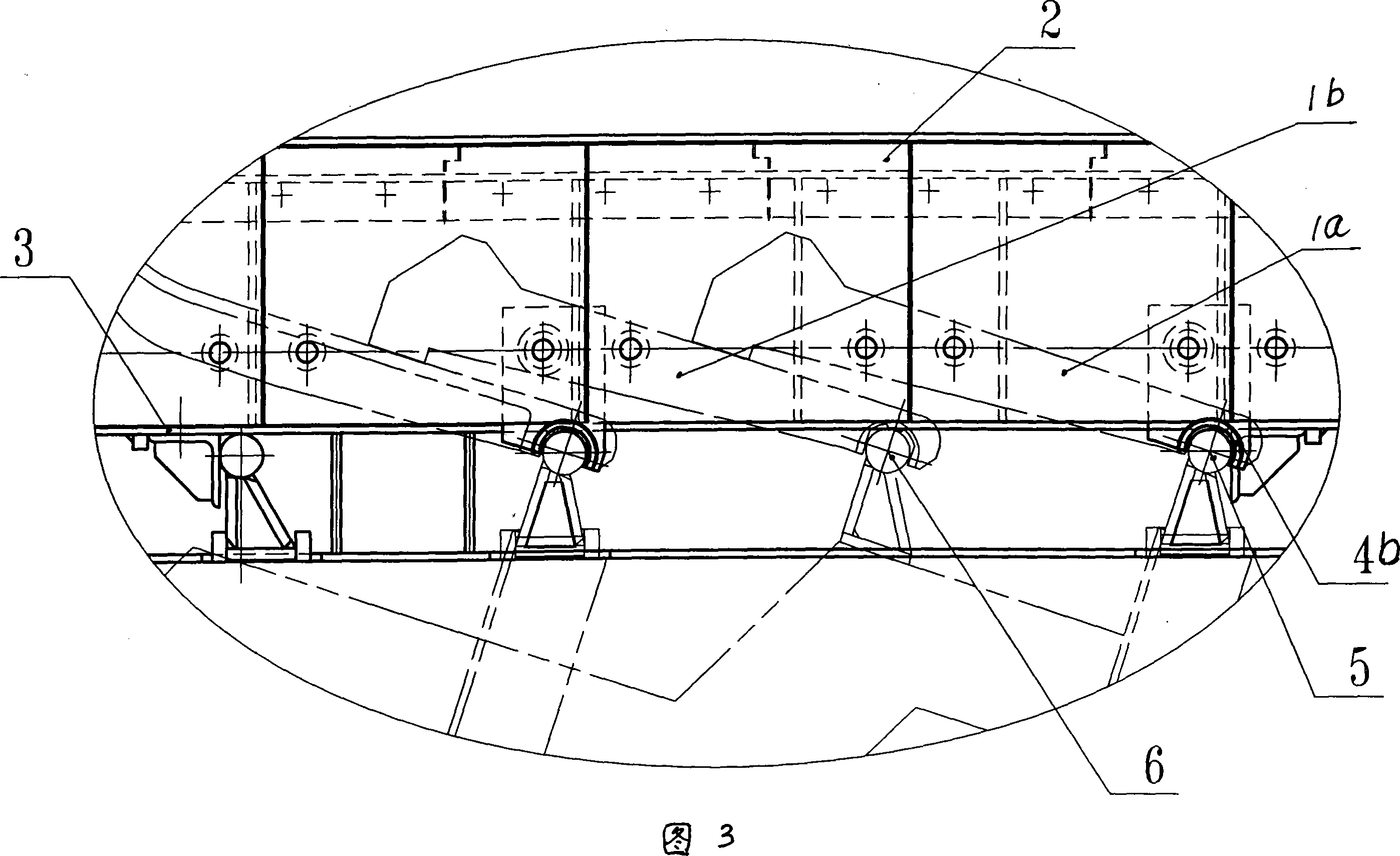

Reciprocating grate furnace with two-section-reverse-acting and one-section-forward-acting grate

InactiveCN102901108AStable combustion conditionsImprove incineration efficiencyIncinerator apparatusCombustionSlag

The invention provides a reciprocating grate furnace with a two-section-reverse-acting and one-section-forward-acting grate. The reciprocating grate furnace with the two-section-reverse-acting and one-section-forward-acting grate provided by the invention comprises a feeding system, a hydraulic device, a grate, an automatic grate control system, a slag discharge device, an air chamber and an ash-placing channel, wherein the grate is divided into a drying section, a combustion section and a burnout section in sequence from top to bottom; a height difference is reserved between every two sections; both the grate bodies of the drying section and the combustion section are in a reverse-acting type; and the grate body of the burnout section is in a forward-acting type. By the reciprocating grate furnace adopting a two-section-reverse-acting and one-section-forward-acting grate structure implemented by the invention, the problems that the conventional mechanical grate furnace is inadequate in drying and incomplete in stirring and scattering, and agglomerates are easily formed during drying and combusting can be solved; the waste incineration efficiency can be improved effectively; the incineration cost can be reduced; and the reciprocating grate furnace is applicable to incinerate the waste with high moisture content and a low calorific value.

Owner:福建省丰泉环保控股有限公司

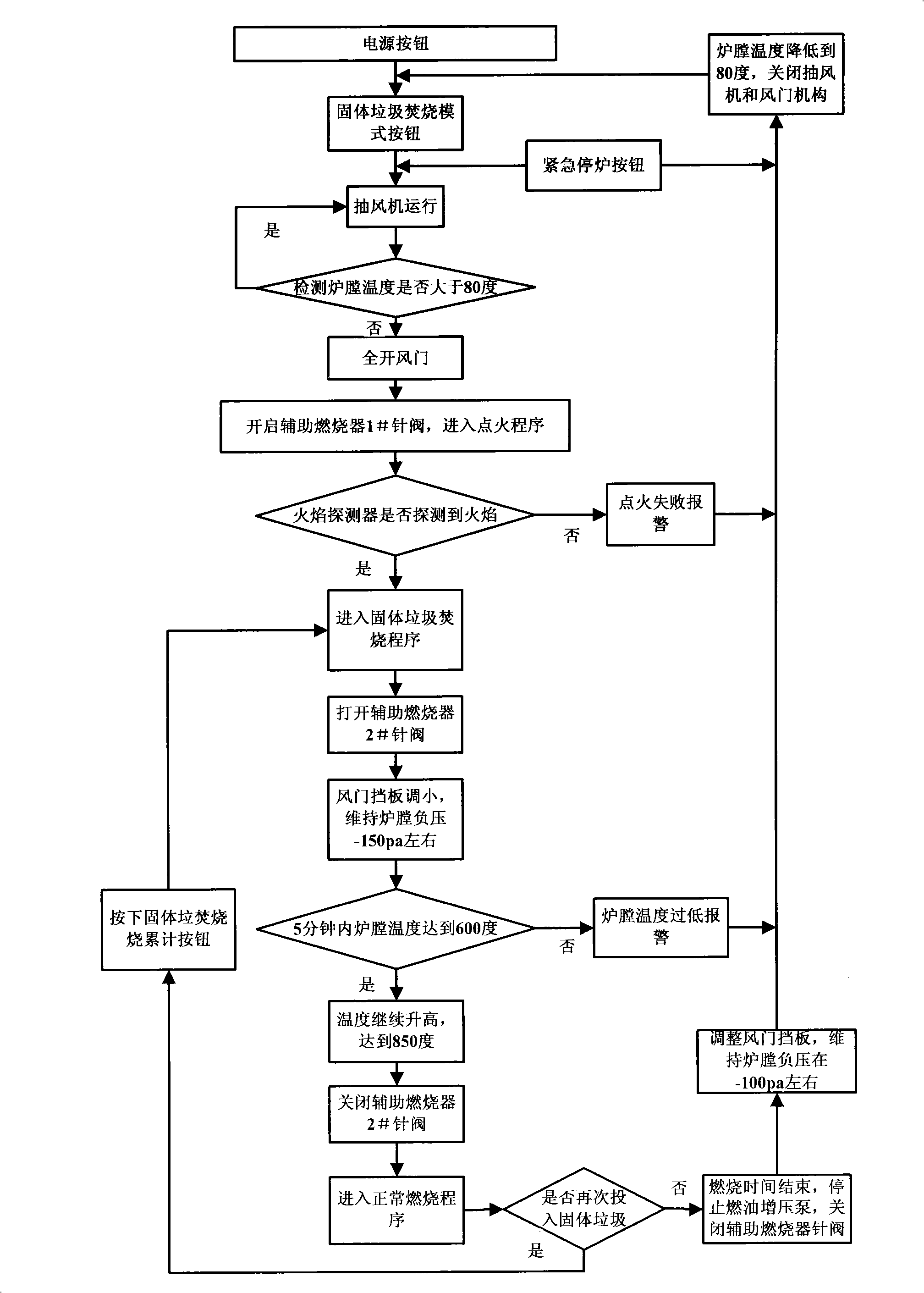

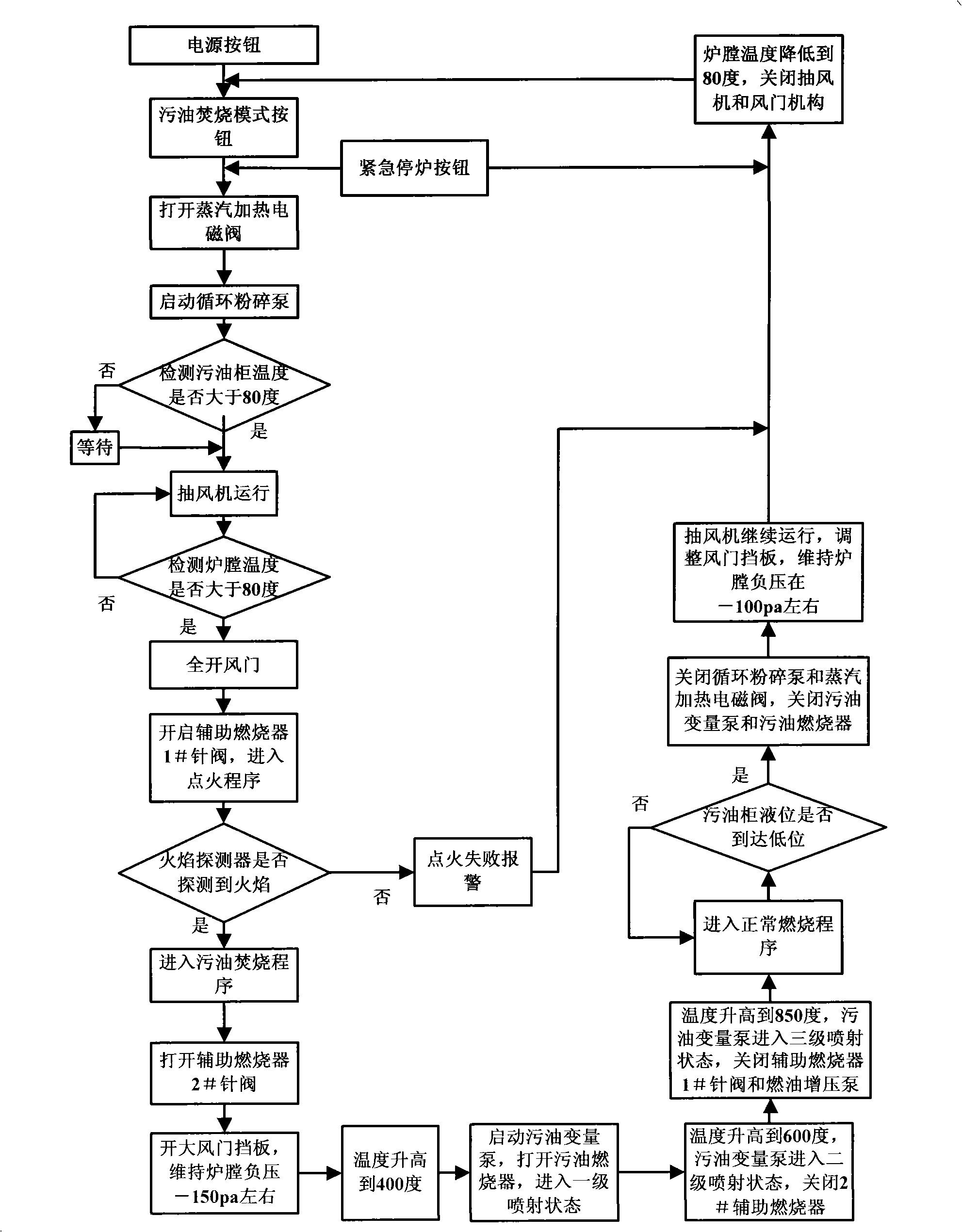

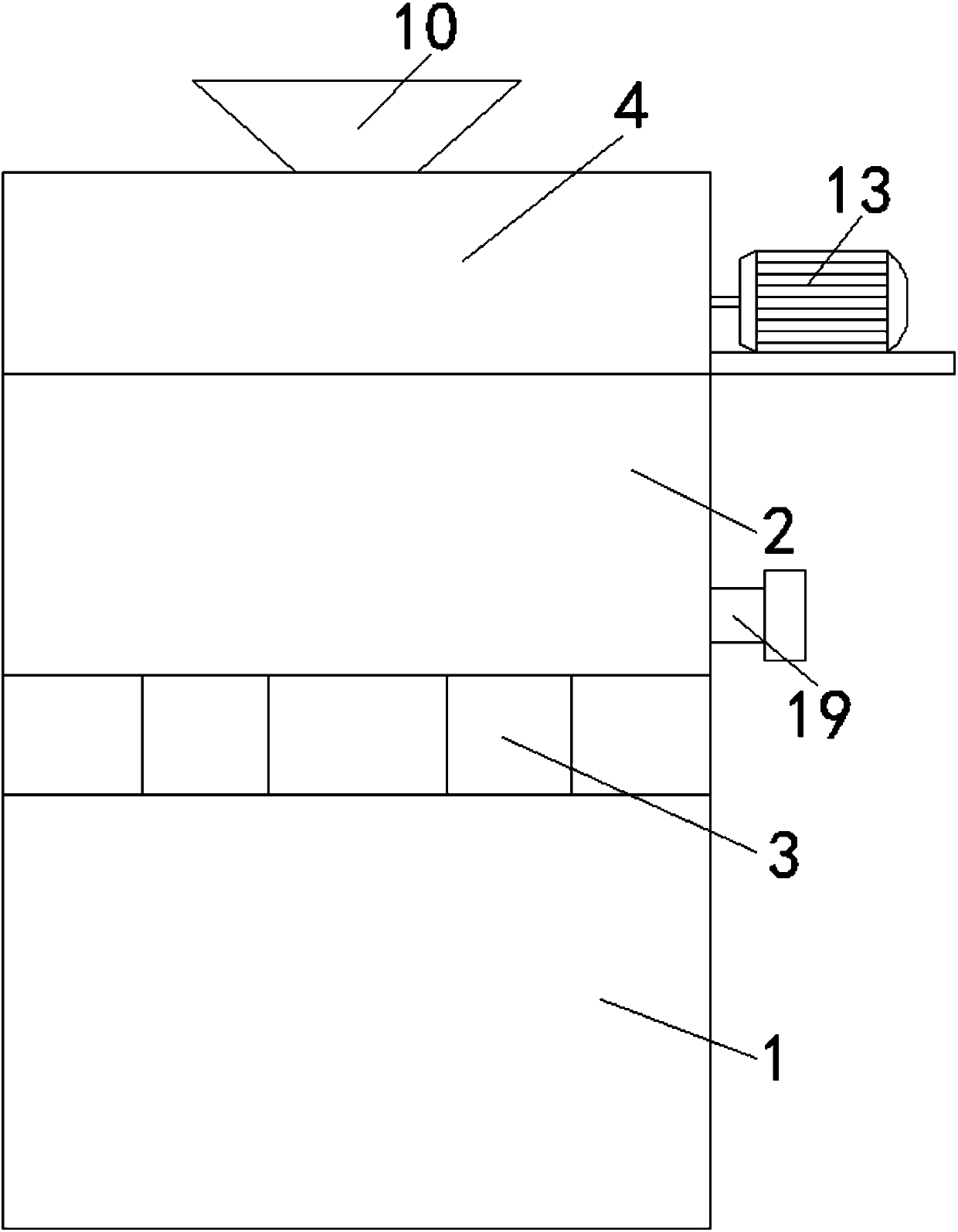

Control method of incineration furnace for vessel

InactiveCN101344253AFix stability issuesSolve uncontrollable problemsIncinerator apparatusFlue gasEngineering

The invention discloses a control method of a marine incinerator, which belongs to the field of combustion technology, shipboard automation technology and environment technology. The control method is applicable to three combustion modes, namely, solid waste combustion, sump oil combustion, and solid waste combustion and sump oil combustion, is simple and easy to be realized, and utilizes sensor technology and programmable control technology to control the whole working process of the incinerator. Considering the working parameter of the marine incinerator under various working condition completely, the automation, high efficiency, stabilization and reliable operation of the marine incinerator can be realized on the basis of accuracy control of the incinerator hearth temperature, hearth pressure and releasing temperature of flue gases. The invention completes the influence of continuous changing of various parameters to the whole combustion process during the spraying burning process, leads the waste and sump oil to be burnt fully, improves the burning efficiency, and reduces the dusty gas emission greatly.

Owner:SHANGHAI JIAO TONG UNIV

Energy-saving and environment-friendly garbage incineration device

InactiveCN108194930AAchieve purificationReduce pollutionIncinerator apparatusEngineeringIncineration

The invention discloses an energy-saving and environment-friendly garbage incineration device comprising an incineration box. The energy-saving and environment-friendly garbage incineration device ischaracterized in that an incineration grid is horizontally arranged in an incineration cavity of the incineration box; deslagging plates arranged in the mode of being low in left and high is right arearranged at the position, below the incineration grid, of the bottom of the incineration box; buffering filter plates are parallelly arranged in the position, above the incineration grid, of the incineration cavity; screening holes are evenly distributed on the buffering filter plates, and a water tank is arranged on the position, above the buffering filter plates, of the incineration cavity; thebottom face of the water tank is a big-end-down conical face; and a falling channel penetrates through the middle position of the water tank, the upper end of the falling channel communicates with apurifying box through a buffering box, a liquid spraying pipe is horizontally arranged in the purifying box, a plurality of spraying heads are arranged on the pipe wall of the lower side of the liquidspraying pipe at equal distances, and the left ends of the spraying heads stretch out of the left side of the purifying box. According to the energy-saving and environment-friendly garbage incineration device, the structure is simple and reasonable, the incineration efficiency of materials is greatly improved, pollution to the environment is reduced, and practicability is high.

Owner:KUNSHAN RUIHENGFENG TECH CONSULTING

Plasma melting cracking treating equipment

ActiveCN101737786BBurn completelyImprove incineration effectIncinerator apparatusIncinerationTest equipment

Owner:TAIZHOU WEIBO ENVIRONMENTAL PROTECTION EQUIP TECH

Fixed grate incinerator

InactiveCN104296148AAvoid subsequent continuous thermal expansion until it becomes soft and stuck.With self-cooling functionIncinerator apparatusCombustion chamberSlag

The invention belongs to the field of waste incineration equipment and particularly relates to a fixed grate incinerator comprising a main combustion chamber and a fixed fire grate. The fixed fire grate is arranged obliquely, the higher end is provide with a material input end, the lower end is provided a slag outlet for slags after material combustion, and the slag outlet is communicated with a slag discharging component; a hot air chamber is arranged below the main combustion chamber; a hot air supply path penetrates the fixed fire grate; the fixed grate incinerator further comprises an ejecting rod and a power portion; the maximum lift of the ejecting rod penetrates the material layer of the fixed fire grate; an ejecting rod component further comprises a shaft sleeve with the preset length, one end of the shaft sleeve penetrates and is fixedly connected to the fixed fire grate along the moving direction of the ejecting rod, a vent gap allowing the air to penetrate is formed between the shaft sleeve and the ejecting rod, and the other end of the shaft sleeve is communicated with the outside and / or an air cooling chamber. The fixed grate incinerator has the advantages that material burning efficiency is high, the component operation reliability is high, and the service life is prolonged effectively.

Owner:安徽盛燃焚烧炉科技有限公司

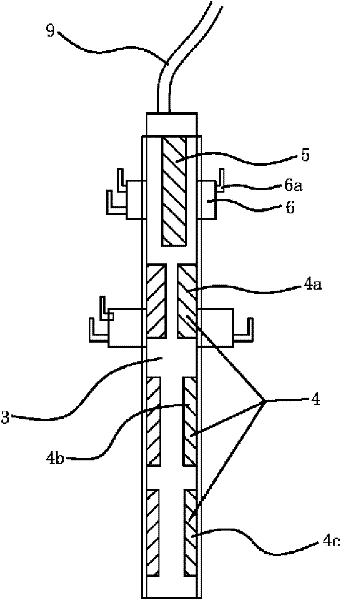

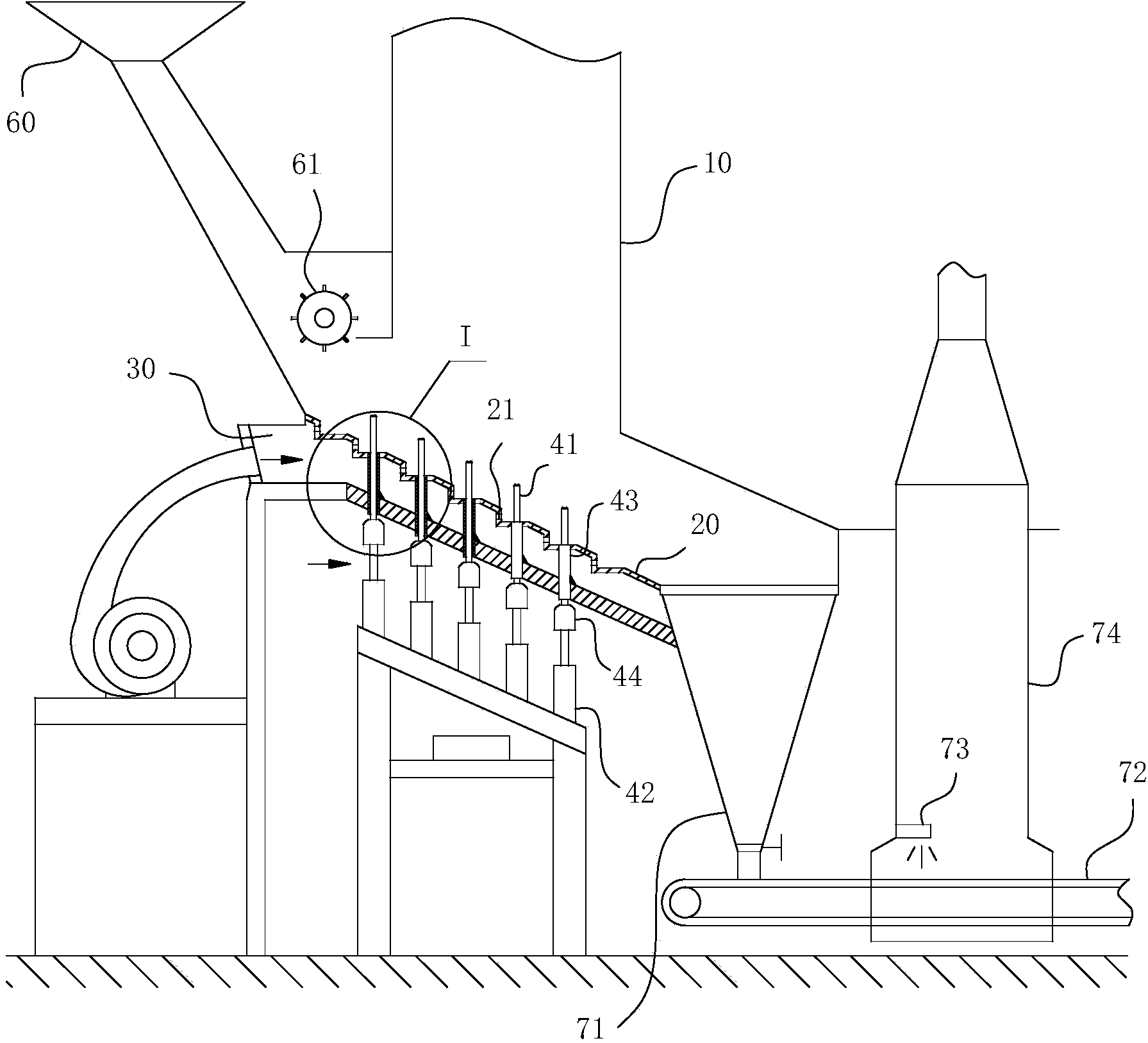

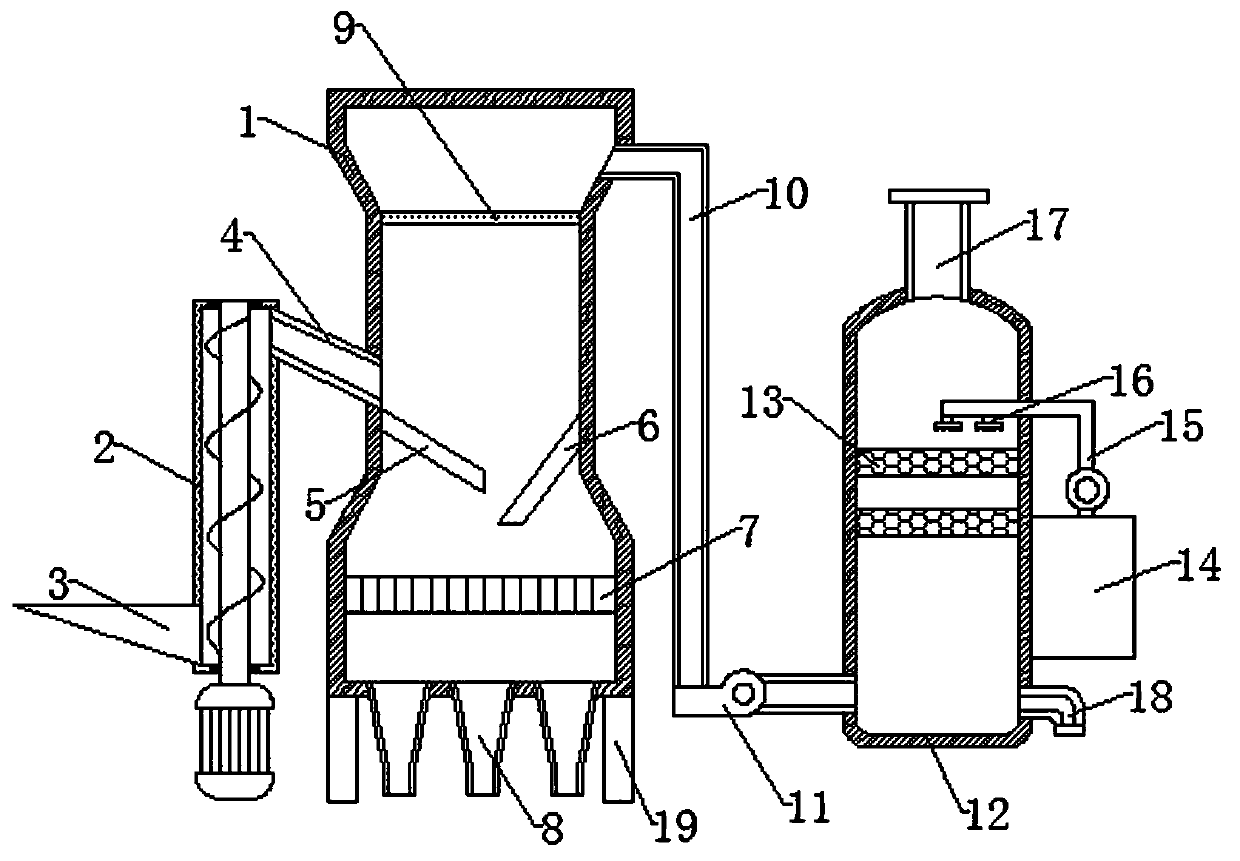

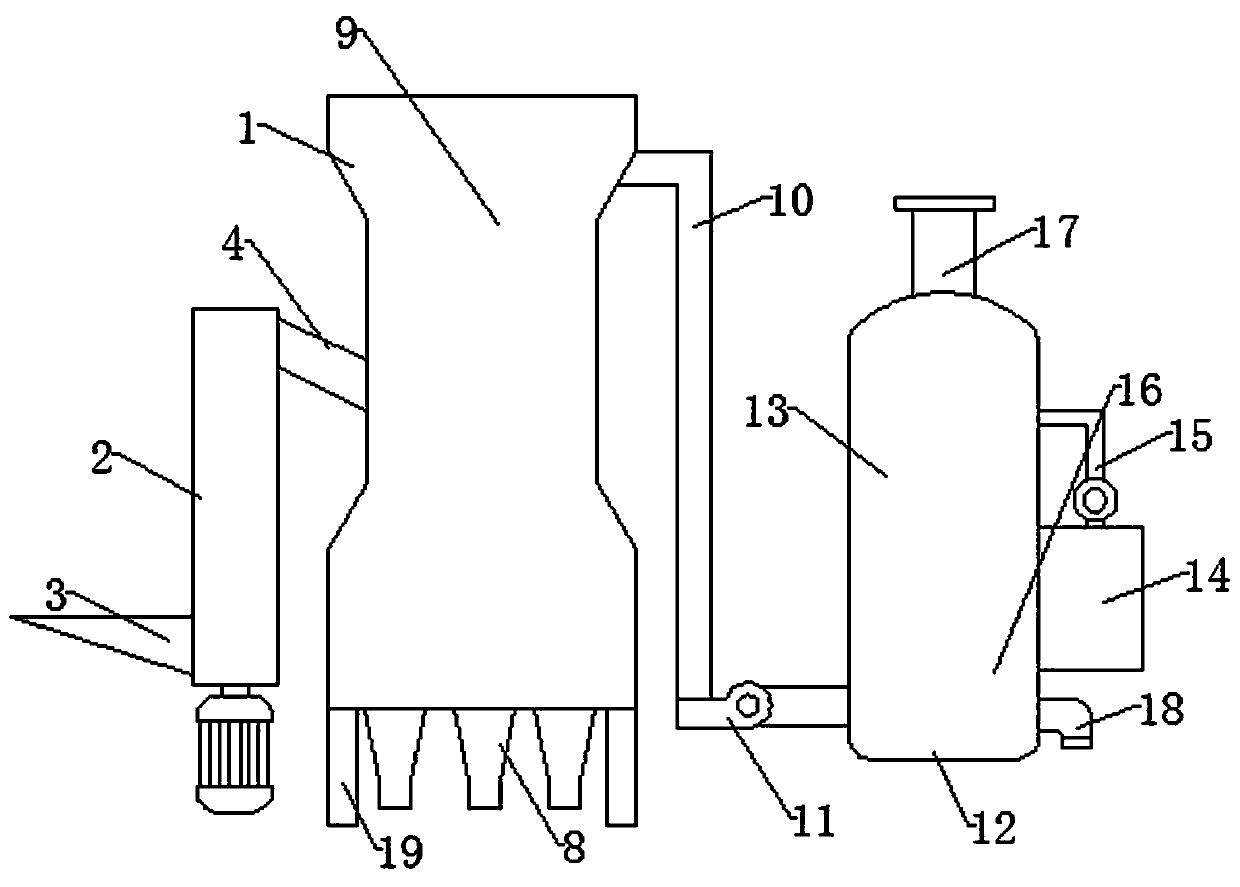

Solid waste incineration system with exhaust gas secondary combustion drying ignition device and treatment method thereof

ActiveCN105910111ALow investment costReduce operating expensesIncinerator apparatusCombustion chamberFlue gas

The invention discloses a solid waste incineration system with an exhaust gas secondary combustion drying ignition device and a treatment method thereof. The solid waste incineration system comprises an incineration device and an air extraction system, wherein the incineration device comprises a cloth section, a drying section, an ignition section and an incineration section; operation at the drying section and the ignition section is achieved through the exhaust gas secondary combustion drying ignition device; the exhaust gas secondary combustion drying ignition device is in a cover body form, covers sintering materials, and is divided into an exhaust gas secondary combustion drying part at the front section and an ignition part arranged at the tail end; the incineration exhaust gas returns to the ignition device and burns in the situation that gas fuel is externally added, and a secondary combustion chamber is formed; and combustible matters in the flue gas are completely combusted, and harmful substances such as CO, NOx and dioxin in the flue gas are decomposed and are effectively treated. According to the solid waste incineration system, a high temperature gas generated during combustion ignites the materials, and waste heat of the exhaust gas dries and preheats the materials before ignition.

Owner:CHONGQING ANGRUIYUE SCI & TECH

Efficient garbage incinerator capable of reducing garbage size and convenient to clean

The invention relates to the technical field of environmental protection equipment, and discloses an efficient garbage incinerator capable of reducing the garbage size and convenient to clean. The efficient garbage incinerator comprises a main body box, the top of the main body box is provided with a first feeding box, the left side and the right side of the first feeding box are fixedly connectedwith the top of the main body box through connecting rods, the top of the first feeding box extends to the outside of the main body box, and the interior of the first feeding box communicates with the interior of the main body box. According to the efficient garbage incinerator capable of reducing the garbage size and convenient to clean, a stirring block is driven by a second motor to rotate soas to stir incinerated garbage slag, then the size of the garbage slag is reduced, the garbage slag falls on a movable plate through through holes, the second motor drives a third rotating rod to rotate, then a rotating plate is driven to rotate, the movable plate is made to be continuously jacked up by the rotating plate, the garbage slag is accelerated to slide into a slag storage tank along thejolt of the movable plate, and the garbage slag can be conveniently collected through a box cover hinged to the right side of the slag storage tank.

Owner:重庆熵臻科技有限公司

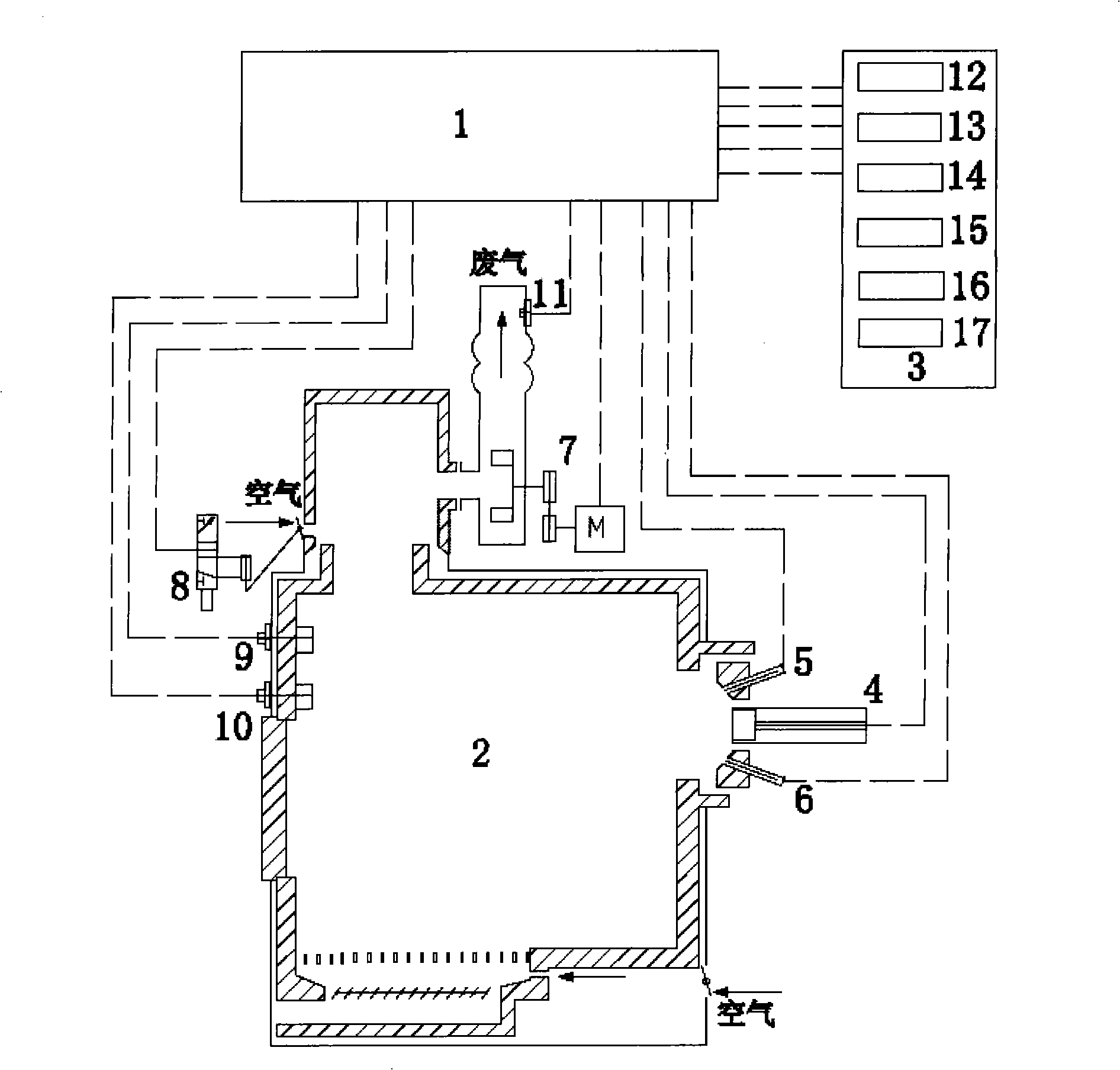

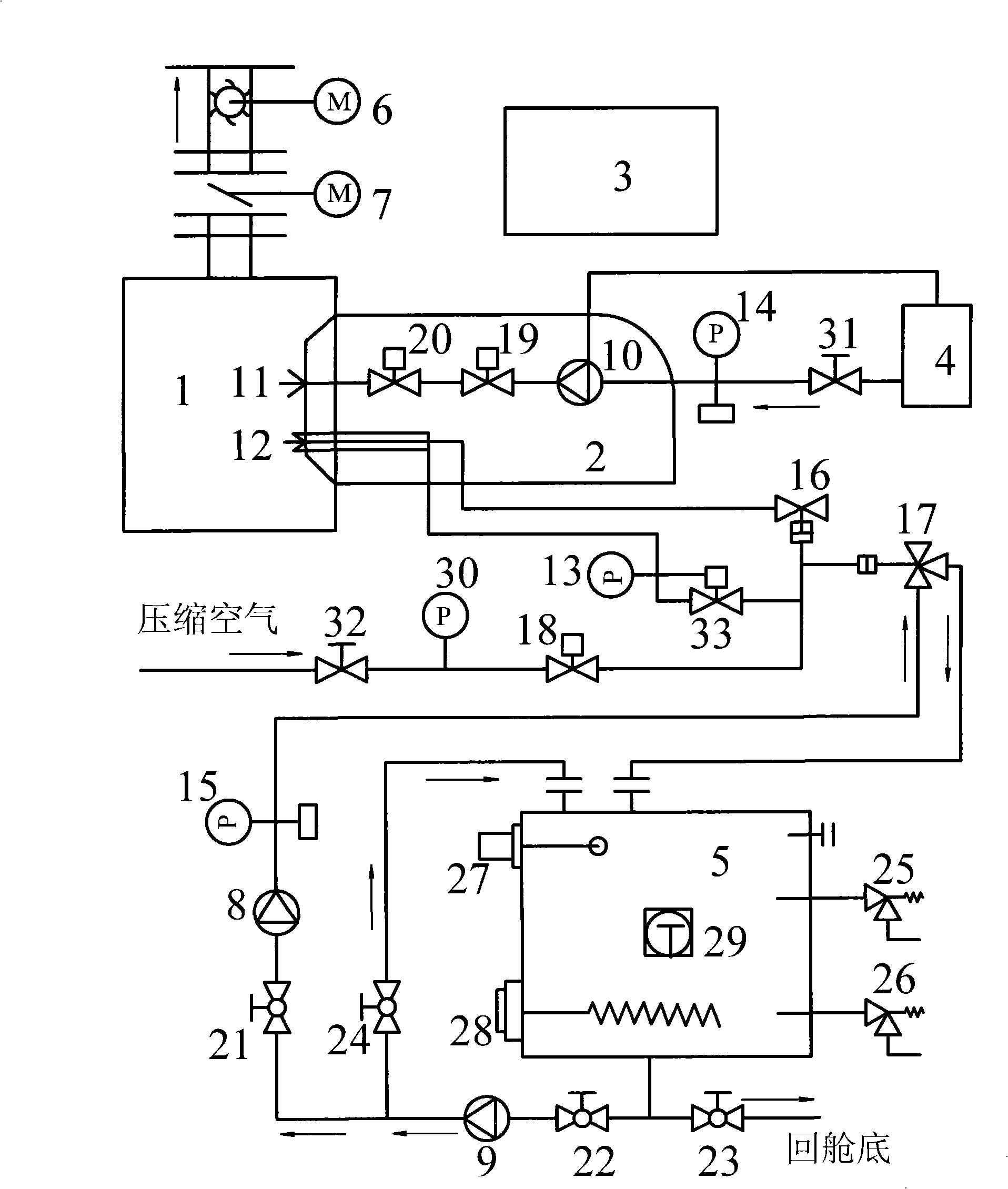

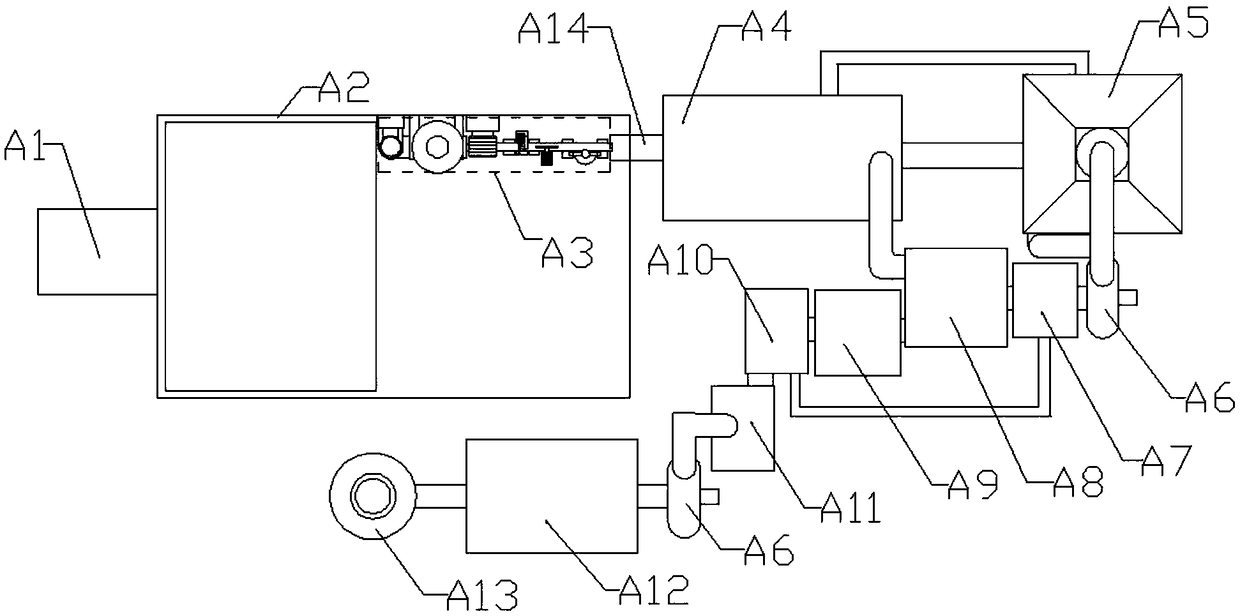

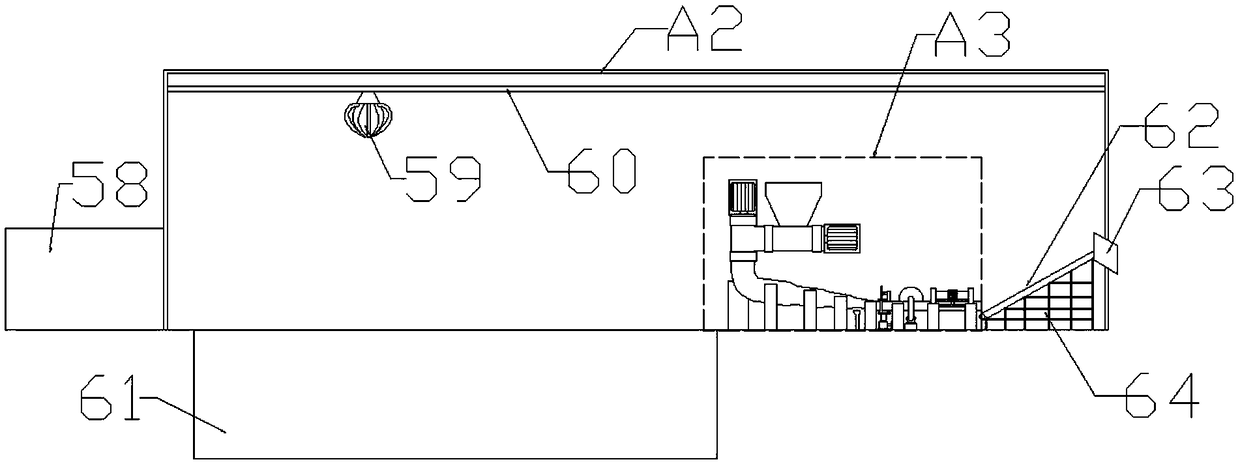

Marine incineration furnace control system

InactiveCN101338901AEnsure safetyRealize automatic stopIncinerator apparatusElectricityAutomatic control

The invention relates to a marine incinerator system, pertaining to the technical fields of incineration, marine automatic control and environment. The invention comprises an incinerator body, a burner, a control box, a fuel storage tank, a dirty oil storage tank, an exhaust fan, an air shutter, a dirty-oil variable delivery pump, a dirty oil circulating pump, a fuel-oil booster pump, a valve, a temperature and pressure sensor and an electric heater. The control system has a simple structure and the production cost is low; the effective incineration of both solid marine wastes and dirty marine oil and mud is ensured, and the solid marine wastes and dirty marine oil and mud can be processed effectively. The incinerator can realize automatic control during the process of operation, the operation is stable and reliable; the waste processing efficiency is high; little hazardous gas is produced during the process of incineration, the environmental pollution is reduced during the process of waste treatment; in addition, the invention can also well resolve the problems of waste stacking and dirty oil and mud placement on ocean-going vessels.

Owner:SHANGHAI JIAO TONG UNIV

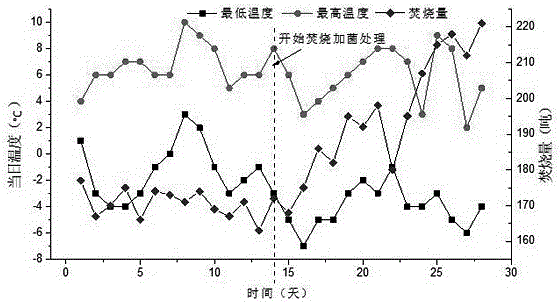

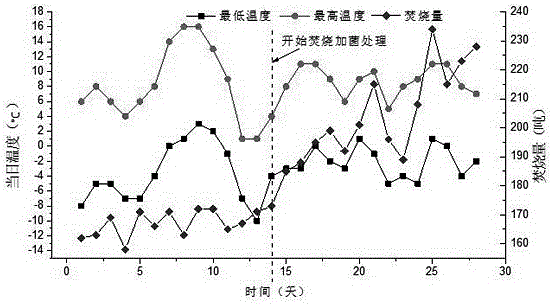

Microbial agent for garbage composting as well as preparation method and application thereof

ActiveCN105861369AEasy to produceImprove product qualityFungiBacteriaMicrobial agentLactobacillus acidophilus

The invention discloses a microbial agent for garbage composting as well as a preparation method and application thereof. The microbial agent comprises bacillus amyloliquefaciens, candida utilis, lactobacillus acidophilus and rhodopseudomonas palustris and is a liquid bacterial agent or solid bacterial agent. The microbial agent for garbage composting, disclosed by the invention, has the advantages of easiness in production, stable product quality, low cost and strong controllability in a garbage composting process; after the microbial agent is added into the garbage, the content of beneficial efficient microorganisms in the garbage can be increased, the microbial activity is improved, the garbage fermentation process is accelerated, the leaching of water and the increase of the lower calorific value of garbage are promoted, and the incineration efficiency of the garbage is improved; in a region with relatively low winter temperature, the microbial agent can reduce the influence caused by the low-temperature environment change so as to guarantee smooth operation of the garbage incineration according to the technology design; and by adopting the microbial agent, the generation of garbage smell can be reduced, and the working environment is improved.

Owner:QINGDAO GENYUAN BIOLOGICAL TECH GRP

Sludge drying and incinerating process

InactiveCN105371283AHigh specific heat capacityIncrease heatIncinerator apparatusThermal energySludge

The invention provides a sludge drying and incinerating process. According to the sludge drying and incinerating process, gas exhausted from a drying furnace is led into a hot air generating furnace and an incinerating furnace, so that the gas with a certain humidity is led into the hot air generating furnace and the incinerating furnace; the specific heat capacity of hot gas and high-temperature gas is improved, the thermal energy carried by the hot gas and the high-temperature gas is increased, and the thermal efficiency is improved. In addition, the gas exhausted from the drying furnace is burnt again in the hot air generating furnace and the incinerating furnace so that the thermal energy of retorting gas can be fully utilized, and smelly gas can be removed; the gas generated in the incinerating furnace can also enable the gas generated in the incinerating furnace to be led into the drying furnace to be burned when being led into the drying furnace, and the thermal energy carried by the gas exhausted from the incinerating furnace can be fully utilized. Through the mode, energy consumption in the whole drying and incinerating process is greatly lowered, and meanwhile the efficiency of drying and incinerating is improved.

Owner:江苏碧诺环保科技有限公司

Environment-friendly waste incineration device

InactiveCN109654510ARealize automatic feedingImprove incineration efficiencyIncinerator apparatusEngineeringReducer

The invention discloses an environment-friendly waste incineration device. The device comprises a furnace body, a support, an incineration cage, a rotating shaft, a plurality of supporting wheel frames, a wheel shaft, supporting wheels, a driving motor, a speed reducer, a main shaft, a first synchronous belt wheel, a second synchronous belt wheel, a synchronous belt, a feeding conveying mechanism,a feeding conveying belt, a discharging conveying mechanism, a discharging conveying belt, ash blowing nozzles, an air inlet pipe, an ash outlet, a smoke outlet, a plurality of air blowing nozzles and an electric control cabinet, wherein a control driving motor and a switching push button used for opening and closing the feeding conveying mechanism and the discharging conveying mechanism. The device has the advantages that the structure is simple; automatic feeding of garbage and automatic discharging of ash can be realized, the automation degree is high, and the labor intensity of workers isreduced; the waste incineration efficiency is further improved.

Owner:李利

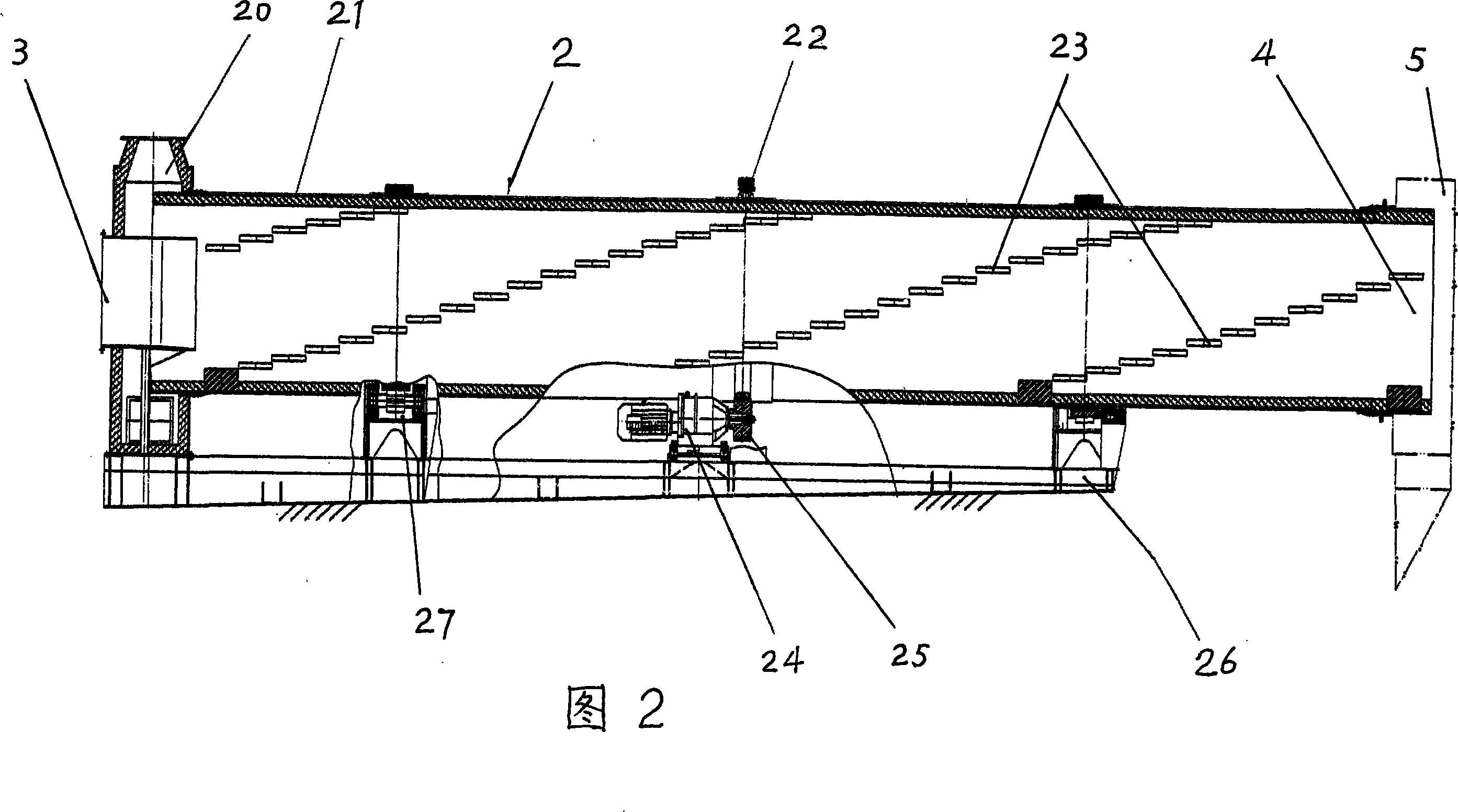

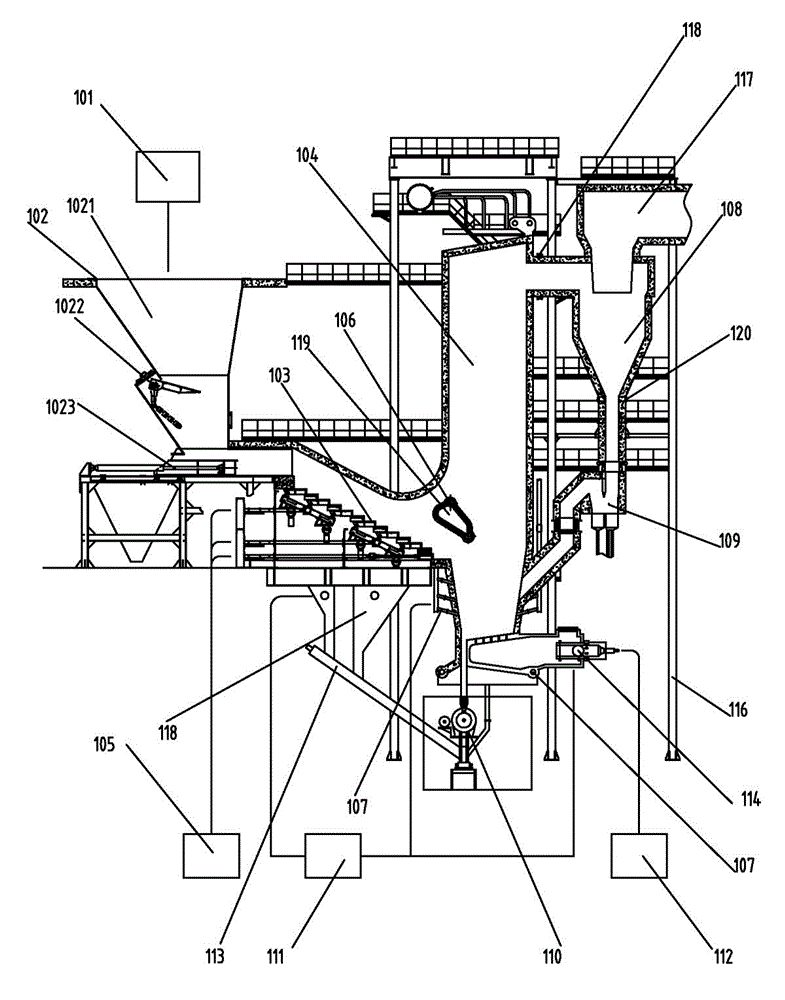

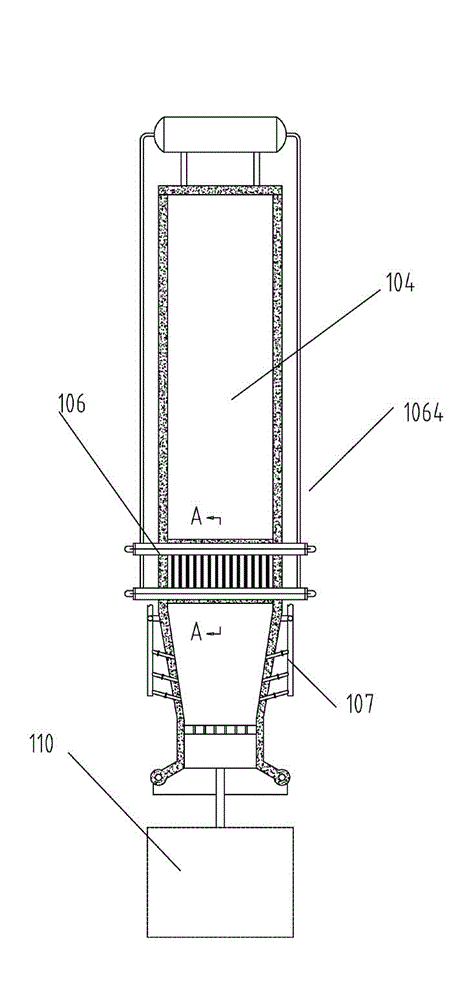

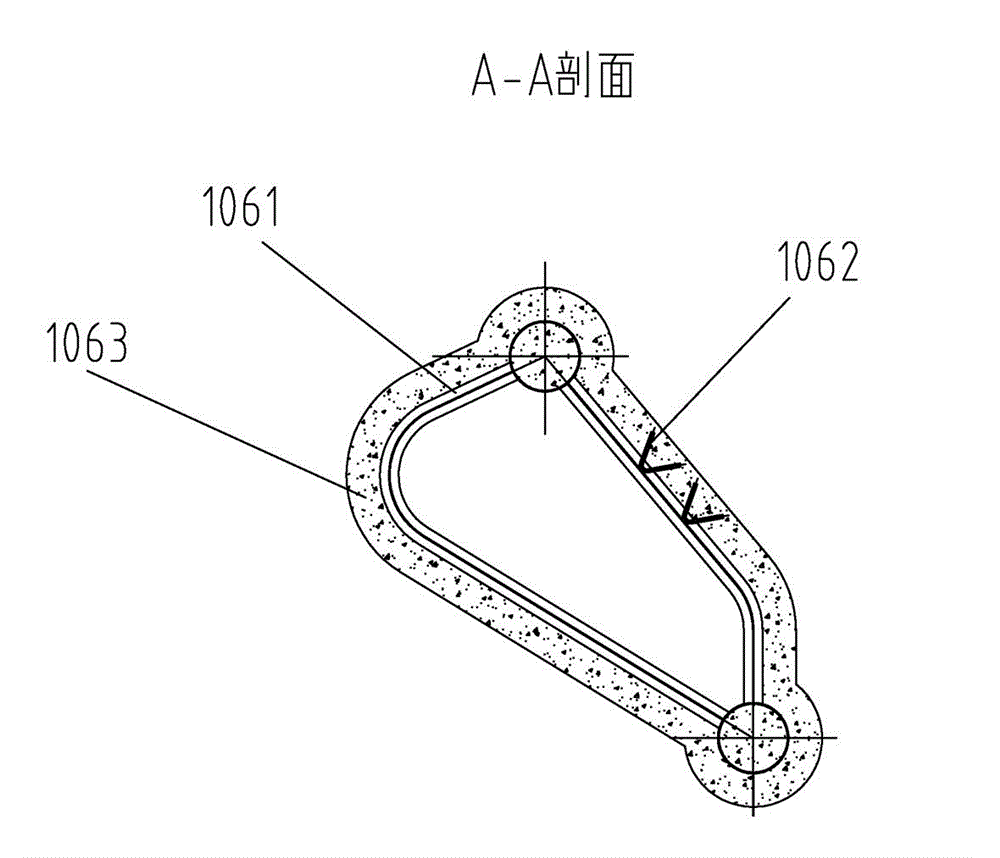

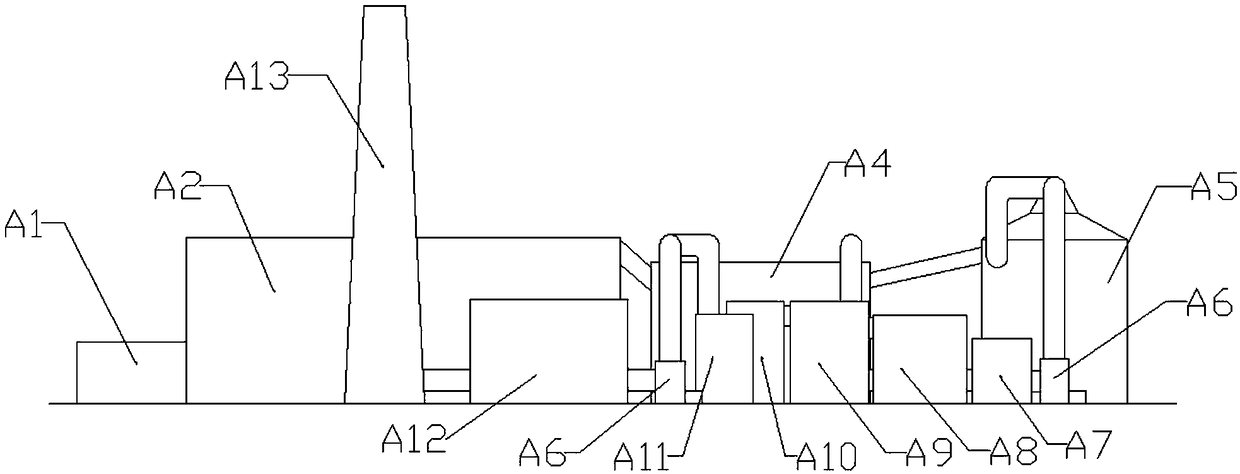

Moving grate drying bed-circulating fluidized bed boiler-compounded incineration equipment

InactiveCN102913916AKeep dryGood incineration efficiencyIncinerator apparatusFluidized bedProcess engineering

The invention provides moving grate drying bed-circulating fluidized bed boiler-compounded incineration equipment, which comprises a moving grate drying bed and a circulating fluidized bed boiler, wherein the moving grate drying bed comprises a feed system arranged on the moving grate drying bed; the circulating fluidized bed boiler comprises a dreg outlet formed in the bottom of a furnace of the circulating fluidized bed boiler; and the moving grate drying bed is connected with the circulating fluidized bed boiler in a dense phase zone of the moving grate drying bed. The moving grate drying bed-circulating fluidized bed boiler-compounded incineration equipment realized by the invention is reasonable and scientific in design, can be used for processing dregs with the characteristics of low heat value, high moisture content and poor air permeability, and can be further used for processing municipal solid wastes with the similar characteristics.

Owner:福建省丰泉环保控股有限公司

Method for preventing and controlling flue gas pollutant and domestic refuse incineration system

PendingCN108826303AAdsorption reductionReduction of passive governance measuresEmission preventionCombustion technology mitigationCombustion chamberGreenhouse

The invention discloses a domestic refuse incineration system for preventing and controlling flue gas pollutant. A material grabbing hopper of a refuse storage vault feeds materials into a compressionand crushing system, the compression and crushing system is connected with a drying system through a conveying system, a refuse discharging opening of the drying system is connected with a refuse feeding opening of an integrated incinerator, a hot bad smell outlet of the drying system is connected with an air inlet of the integrated incinerator, a combustible gas outlet and a flue gas discharge opening of the integrated incinerator and a hot air outlet of a second-stage heat exchanger are connected with a second combustion chamber, and the second combustion chamber, a first-stage heat exchanger, a quick cooling chamber, the second-stage heat exchanger and a flue gas desulfurization device are connected in sequence; and a hot air outlet of the first-stage heat exchanger is connected to anair inlet of the drying system. The domestic refuse incineration system is rigorous and reasonable in structure, the flue gas pollutant can be prevented and controlled in key processes including refuse drying, gasification burnout, flue gas burning purification and flue gas cooling, heat energy, combustible gas and combustion-supporting air needed by the system in all processes are provided, and the direct cost is almost zero.

Owner:庞礴 +2

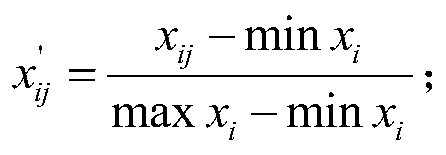

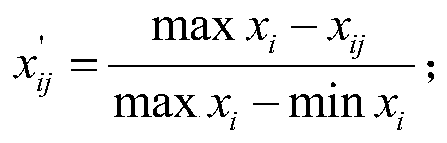

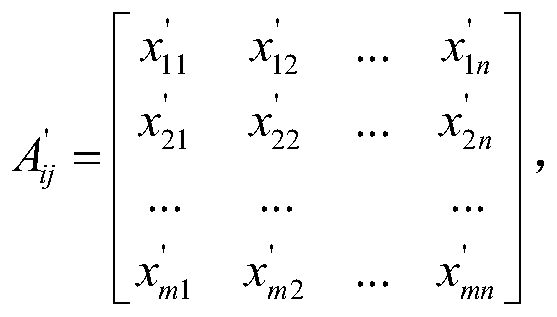

Incinerating and proportioning method for hazardous waste

InactiveCN109708114AGuaranteed stabilityImprove incineration efficiencyIncinerator apparatusCorrelation coefficientDegree of association

The invention relates to the field of hazardous waste treatment and discloses an incinerating and proportioning method for hazardous wastes for guaranteeing the stability of an incinerating process and improving the incinerating efficiency and quality. The incinerating and proportioning method comprises the following steps: S1, constructing an index matrix based on indexes affecting incineration of hazardous wastes, wherein the indexes affecting incineration of hazardous waste comprise unit volume hazardous waste heat value, moisture content, corrosivity and toxicity; S2, standardizing the index matrix; S3, determining a reference sequence according to the standardized matrix; S4, calculating correlation coefficients between the indexes and the reference sequence in various hazardous wastes; S5, calculating the degree of association of various hazardous wastes based on the correlation coefficient; S6, calculating proportioning weights of various hazardous wastes based on the correlation coefficient obtained in the step 5; and S7, incinerating and proportioning the hazardous wastes based on the proportioning weights of the hazardous wastes. The incinerating and proportioning methodfor hazardous wastes provided by the invention is suitable for incinerating and proportioning the hazardous wastes.

Owner:SICHUAN UNIV +1

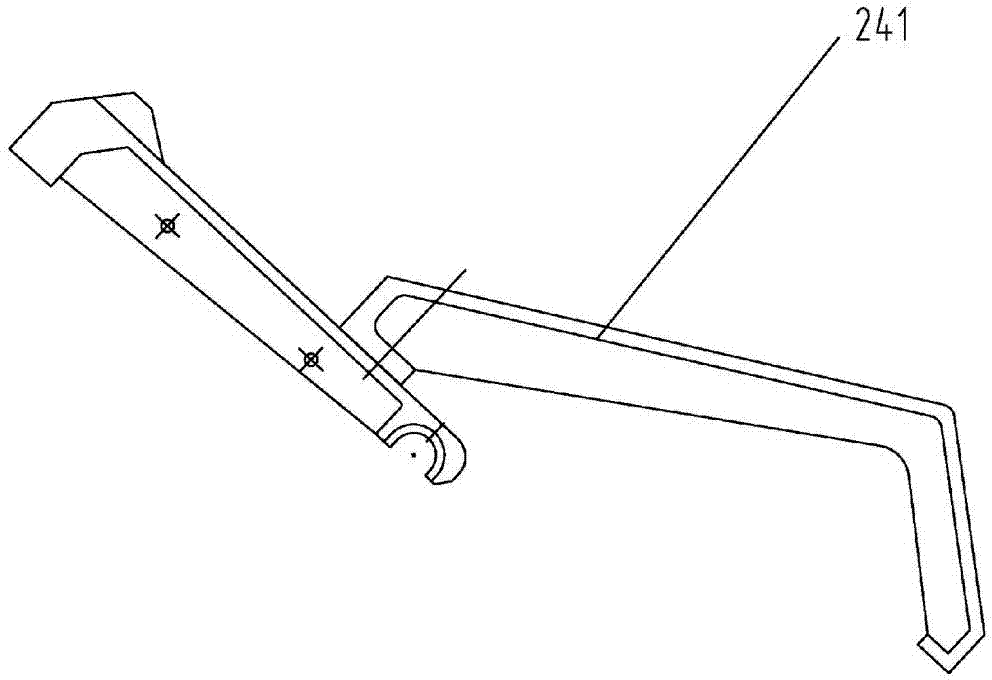

Mechanical compensating mechanism of incineration furnace grate

ActiveCN101178179AConstant ventilation areaEvenly ventilatedGratesIncinerator apparatusEngineeringForeign matter

The invention relates to a mechanical compensating device for a grate of an incinerator, in particular to a thermal expansion absorption device which avoids the ventilation gap change of the grate of the incinerator due to heat-expansion and cold-contraction. The invention comprises a fixed grate and a movable grate which are arranged crossly and one ends of which are fixed on the incinerator body. The invention is characterized in that the other end of each grate is provided with a sliding end which is used for sliding the grate when in expansion and extraction; and a supporting beam of the fixed grate positioned at the end is provided with a lateral compensating block, a connecting element and a sliding bracket in sequence, wherein, the connecting element comprises flat boards which are vertical to each other and a sliding block which takes the supporting beam of the grate as a guide rail and slides on the supporting beam; the sliding block is provided with a convex heave which can be circularly embedded inside a longitudinally inward groove of a grate sheet; and the sliding bracket is connected on the supporting beam of the fixed grate in a sliding way, thereby ensuring the grate gap of the incinerator to be constant and the wind feeding to be stable. Besides, as the grate sheet is always jointed with the lateral compensating block, the foreign objects are prevented from embedding into so as to avoid the short of burning and the local overheat of the grate, thereby reducing the ordinary maintenance amounts, increasing the burning efficiency and prolonging the service time of the incinerator.

Owner:HANGZHOU NEW CENTURY ENERGY ENVIRONMENTAL PROTECTION ENG CO LTD

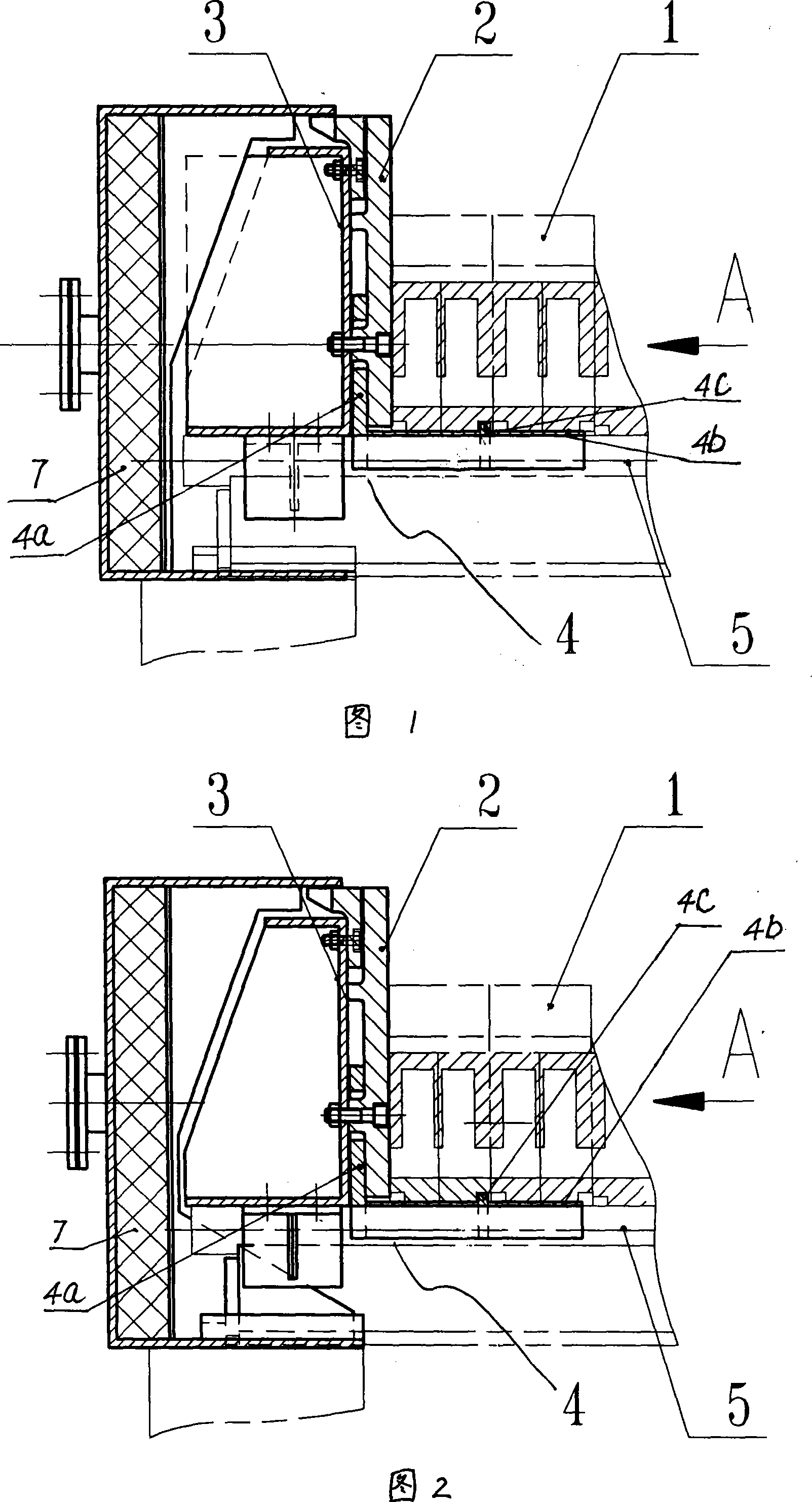

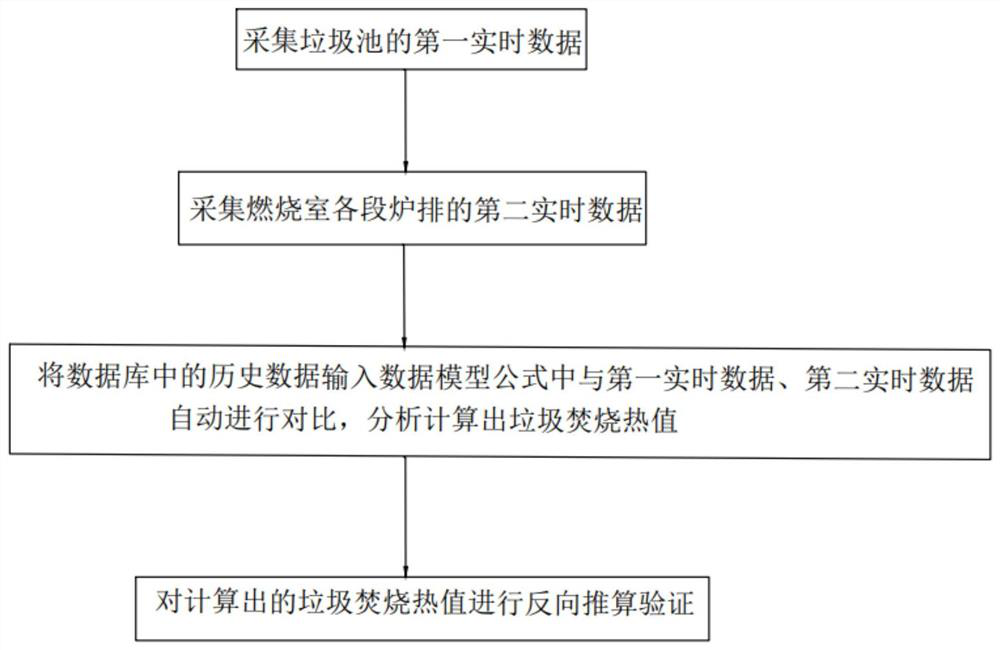

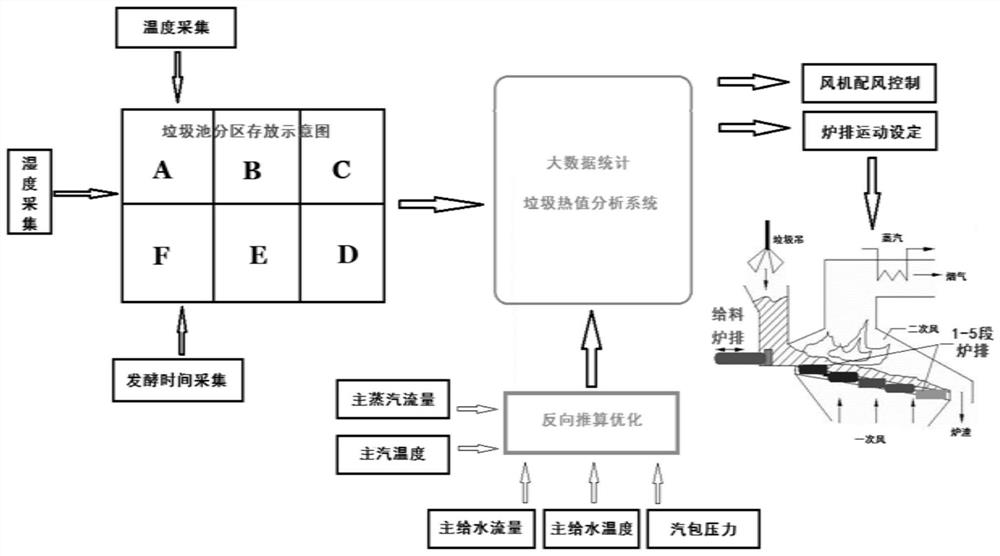

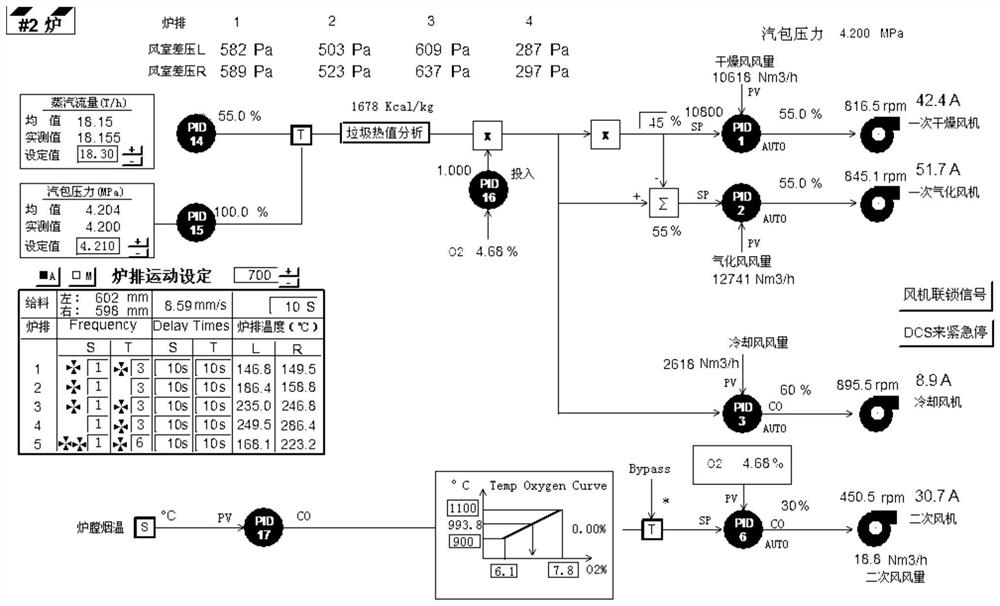

Method for quickly calculating heat value of waste incineration on line

PendingCN112818509AImprove incineration efficiencyGood combustion working conditionDesign optimisation/simulationIncinerator apparatusCombustion chamberEngineering

The invention discloses a waste incineration heat value online rapid calculation method. The method comprises the steps: collecting the real-time temperature and humidity data and waste fermentation time data of a waste pool, and collecting the real-time temperature data and air chamber pressure difference data of fire grates of all sections of a combustion chamber; inputting the historical data in a database into a data model formula to be automatically compared with the collected real-time data, rapidlly analyzing the garbage heat value of a certain area through big data statistics and the data model formula, and directly regulating and controlling the fire grate speed and the fan opening degree under the support of rapidly analyzing the garbage heat value, and achieving the best combustion working condition, so it is guaranteed that the waste incineration treatment effect and the pollutant emission index meet the national relevant standard requirements. After the heat value of the garbage is rapidly analyzed, the garbage enters the adjusting link of the garbage incinerator control system, the garbage incineration efficiency is improved, and the treatment requirements for harmlessness, reduction and recycling of the garbage solid waste are met.

Owner:SHENZHEN SHENZHEN ENERGY ENVIRONMENT EAST CO LTD +6

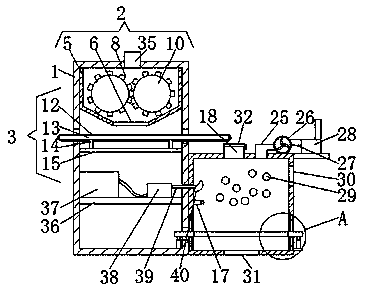

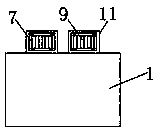

Waste power generation incinerator with purification function

InactiveCN109695880AImprove incineration efficiencyReduce generationIncinerator apparatusCombined useHigh intensity

The invention discloses a waste power generation incinerator with a purification function. The waste power generation incinerator comprises an incinerator body. A feed pipe communicates with one sideof the incinerator body. An auger lifting machine communicates with one end of the feed pipe. A waste feed hopper communicates with one side of the auger lifting machine. A first material guide platelocated at the bottom of the feed pipe is connected to one side of the inner wall of the incinerator body. A second material guide plate located below the first material guide plate is connected to the other side of the inner wall of the incinerator body. A fire grate located below the second material guide plate is connected to the inner wall of the incinerator body. Ash discharge hoppers at equal internals communicate with the bottom of the incinerator body. Through the waste feed hopper, the auger lifting machine and the feed pipe, waste can be conveyed into the incinerator for burning, labor intensity is greatly reduced, and waste burning efficiency is improved. Through cooperation of the first material guide plate and the second material guide plate, the waste is simply baked and preheated before burning so that the waste can be fully burned, and harmful gas is reduced.

Owner:申春月

Domestic garbage incineration equipment

InactiveCN107152687AImprove incineration effectImprove incineration efficiencyIncinerator apparatusLitterExhaust fumes

The invention discloses a domestic waste incineration equipment, which comprises a crushing box, an incineration box and an air purification box. The lower end of the crushing box is fixedly connected with a crossbeam through a support column, the left end of the crossbeam is connected with a driving roller through a rotating shaft, and the right end of the crossbeam passes through the The rotating shaft is connected with a driven kun, the driving kun and the driven kun are connected by a belt, and the right side of the driven kun is connected with a feed plate, which communicates with the inside of the incineration box. There are multiple ash holes on the top, and an air purification box is installed on the right side of the incineration box. The incineration box and the air purification box are connected through pipelines. The end is connected with a branch water pipe. The invention has a simple structure and a reasonable design, and can break large-volume garbage into small-volume garbage, improve incineration efficiency, and simultaneously process waste gas generated to reduce environmental pollution.

Owner:桐乡市大麻正扬家纺经营部

Environment-friendly garbage incineration device

InactiveCN109595560AImprove incineration efficiencyImprove practicalityIncinerator apparatusChamber safety arrangementEnvironmentally friendlyEngineering

The invention discloses an environment-friendly garbage incineration device. The environment-friendly garbage incineration device comprises a first box, a crushing structure is fixedly connected to the top of the interior of the first box, a conveying structure is fixedly connected to the interior of the first box, and an incineration structure is fixedly connected to the right side of the first box. According to the environment-friendly garbage incineration device, through arrangement of the first box, the crushing structure, the conveying structure and the incineration structure, the garbageincineration device has the advantages of being environmentally friendly and high in incineration efficiency, the practicability and the incineration efficiency of the garbage incineration device areimproved, the pollution degree of the garbage incineration device to the environment is reduced, the environment is protected, and meanwhile the problems that a traditional garbage incineration device is not environmentally friendly and low in incineration efficiency are solved; and through cooperative use of a second box, a circulating groove, a first motor, a first crushing roller, a second motor and a second crushing roller, garbage needing to be incinerated can be crushed, therefore, the garbage incineration contact area is increased, and incineration is faster and more comprehensive.

Owner:单卫光

Sliding feeding device

The invention discloses a sliding feeding device which comprises a furnace body, a combustion chamber, sliding rails, sliding wheels, a carrying plate and a furnace door. The sliding rails are located on the left side and the right side of the bottom of the combustion chamber and are in threaded connection with the combustion chamber. The cross sections of the sliding rails are in an I shape. The sliding wheels are located at the upper ends of the sliding rails and are connected with the sliding rails in a sliding manner. The carrying plate is located at the upper ends of the sliding wheels and connected with the sliding wheels in a welded manner, and the carrying plate is rectangular. The furnace door is located at the right end of the carrying plate and is connected with the carrying plate in a welded manner. According to the sliding feeding device, the bottom of the combustion chamber is changed to be movable from a fixed manner, the requirement for incineration of large-size incinerated objects can be met, mechanical casting can also be conveniently achieved, and the incineration efficiency is improved.

Owner:池州中宏运环保设备有限公司

Dry granular waste incinerator

ActiveCN109708118AEnhance the shake effectImprove incineration efficiencyIncinerator apparatusCombustion chamberElectromagnet

The invention belongs to the technical field of incinerators, and particularly discloses a dry granular waste incinerator. The dry granular waste incinerator comprises a shell, a combustion chamber isformed in the upper part of the shell, and a feed inlet is formed in the top of the shell. A discharge cavity is formed in the lower part of the shell, and a discharge hole is formed in the bottom ofthe shell. Two sliding grooves which are arranged symmetrically in a left-right mode are formed in the positions, at the discharge cavity, on the inner wall of the shell, and sliding blocks are arranged in the sliding grooves. Stroke switches are arranged at the bottoms of the sliding grooves, and sealing plates are correspondingly hinged to the end parts of the two sliding blocks. The end partsof the two sealing plates are in contact with each other and are attracted together by electromagnets arranged at the end parts of the sealing plates. Springs are arranged under the sealing plates, and the springs are used for supporting the sealing plates. According to the dry granular waste incinerator, the loss of heat in the incinerator can be effectively reduced, and meanwhile, the incinerator is enabled to be more automated.

Owner:苏州理合文科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com