Solid waste combustion system

A solid waste and furnace technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of high air pollution, high incineration costs, and inability to change, so as to improve resource utilization, incineration efficiency, and utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

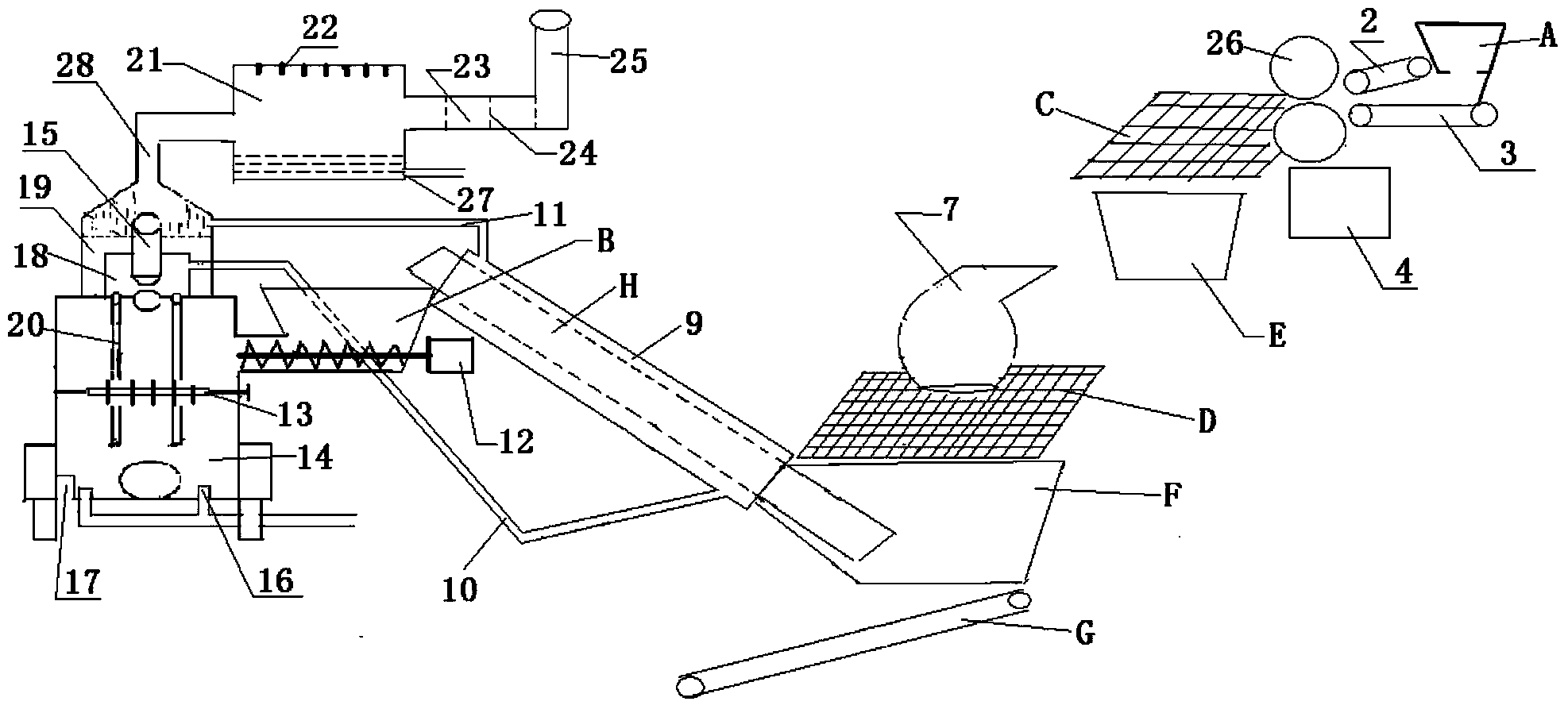

[0029] Such as figure 1 As shown, a solid waste incineration system includes in sequence according to the solid waste incineration treatment process:

[0030] Pressing and dewatering device, which includes a garbage hopper A, the feeding hopper A sends the garbage to the roller 26 through the upper pressure belt 2 and the lower pressure belt 3, and the roller 26 is provided with a collector. Sink 4 is used to receive the sewage produced by pressing the garbage;

[0031] A screening device, the screening device is composed of a shaking screen C and a collection box E located at the lower end of the shaking screen C, and the garbage treated by the pressing water removal device is placed on the shaking screen C for filter;

[0032] The crushing device includes a counter-knife crusher 7, and a shaking screen D positioned at the bottom of the counter-knife crusher 7, and the rubbish on the shaking screen D in the screening device is put into the counter-knife crusher 7 crushed, ...

Embodiment 2

[0037] Pour the garbage into the feed hopper A of the press water removal device, and the garbage is conveyed to the roller 26 through the upper pressure conveyor belt 2 and the lower pressure conveyor belt 3 at the bottom of the feed hopper A; the garbage squeezed by the roller 26 falls to the screening device On the vibrating screen C, the garbage is screened, and part of it falls into the collection box E located at the lower end of the screen. The garbage that does not fall into the collection box E enters the counter-knife crusher 7 through shaking and shaking. Crushing, the crushed garbage falls on the vibrating screen D located at the lower end of the counter knife crusher 7, part of the garbage falls into the collection box F at the lower end of the vibrating screen D, and the larger garbage vibrates and falls into the transmission belt On H, the transmission belt H is driven, and after being dried by the drying box 9, the transmission falls into the feed hopper B conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com