Method for preventing and controlling flue gas pollutant and domestic refuse incineration system

A domestic waste incineration, prevention and control technology, applied in the direction of combustion methods, emission prevention, incinerators, etc., can solve the problems of no incinerator, no collection and discarding anywhere, etc., to achieve elimination of regeneration, reduction of operating costs, and scientific system structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

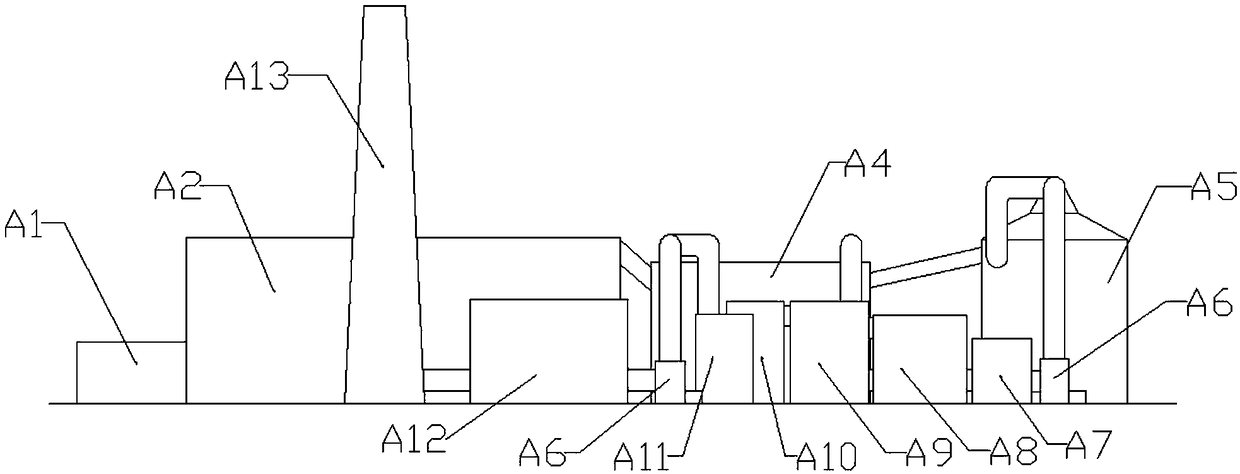

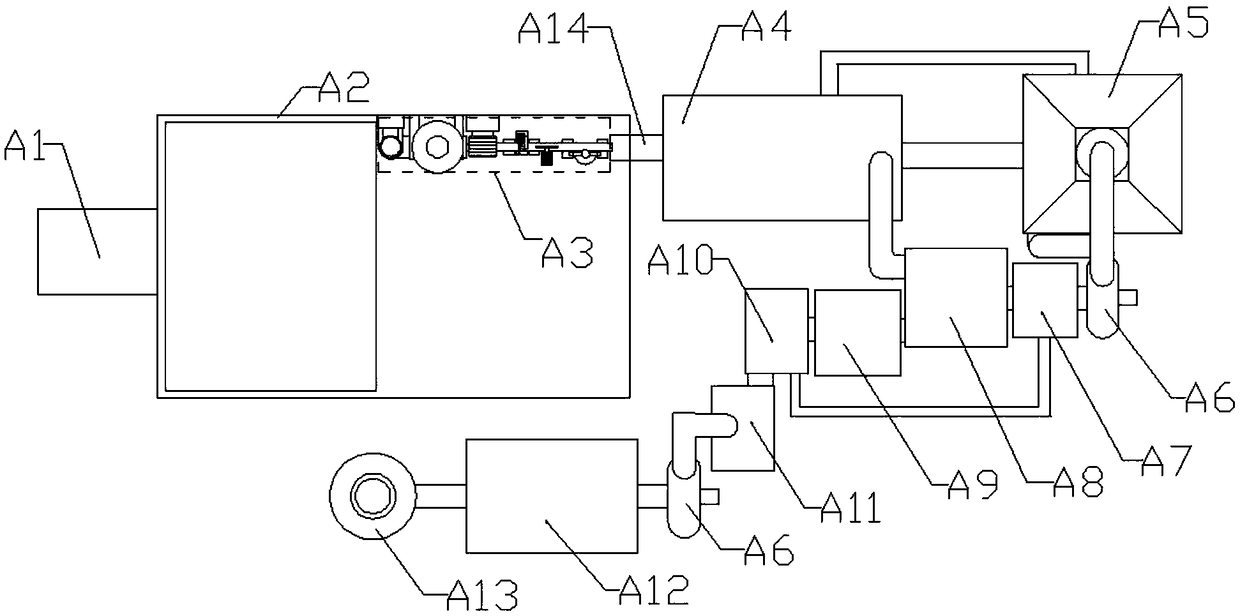

[0050] Such as Figure 1 to Figure 10 As shown, a domestic waste incineration system for preventing and controlling flue gas pollutants, including a solid matter treatment system, ash and dust treatment system and a gas treatment system;

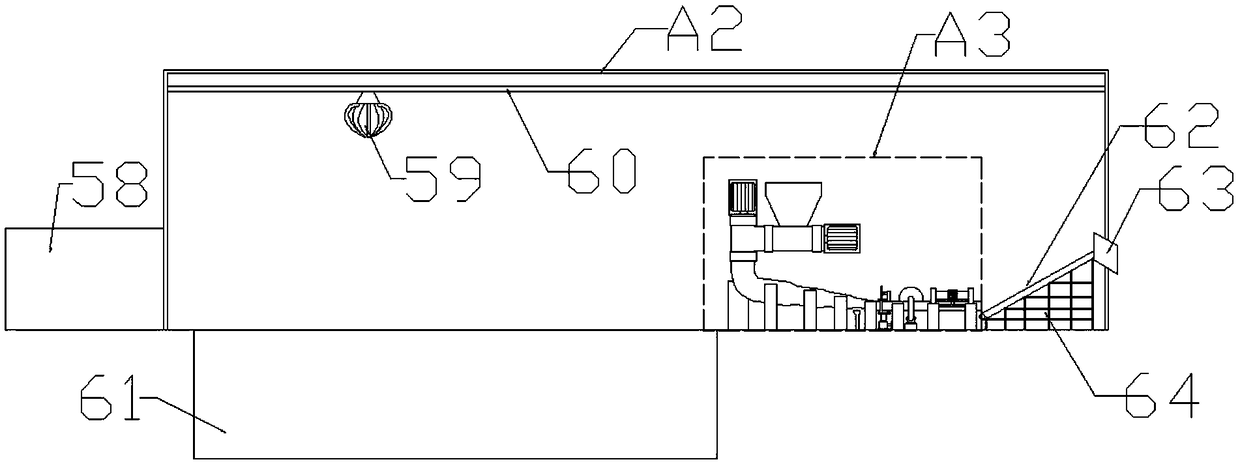

[0051] 1. The solid matter treatment system includes a garbage storage warehouse A2, a compression crushing system A3, a drying system A4, a conveying system and an integrated incinerator A5;

[0052] 1. Garbage crushing and drying:

[0053] The garbage enters the garbage storage warehouse A2 from the transport vehicle entrance 58 through the weighbridge room A1. A grab rail 60 is installed above the garbage storage warehouse A2. The grab bucket 59 is connected to the grab bucket rail 60. The compression crushing system A3 is located in the garbage storage warehouse A2. Among them, the grab hopper 59 grabs garbage from the garbage filling pit 61 and feeds it into the compression and crushing system A3. The compression and crushing system A3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com