Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

230results about How to "Improve flame stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

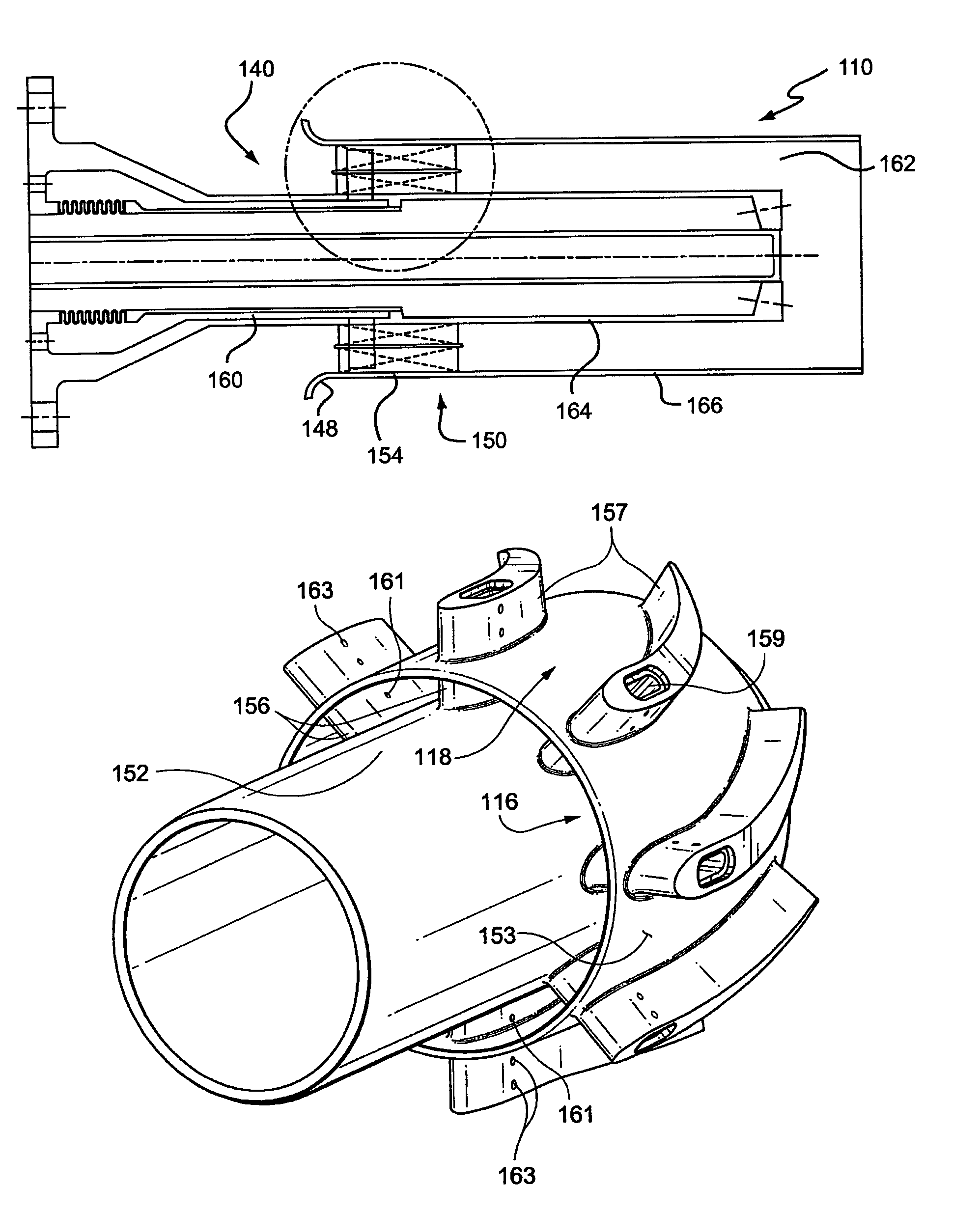

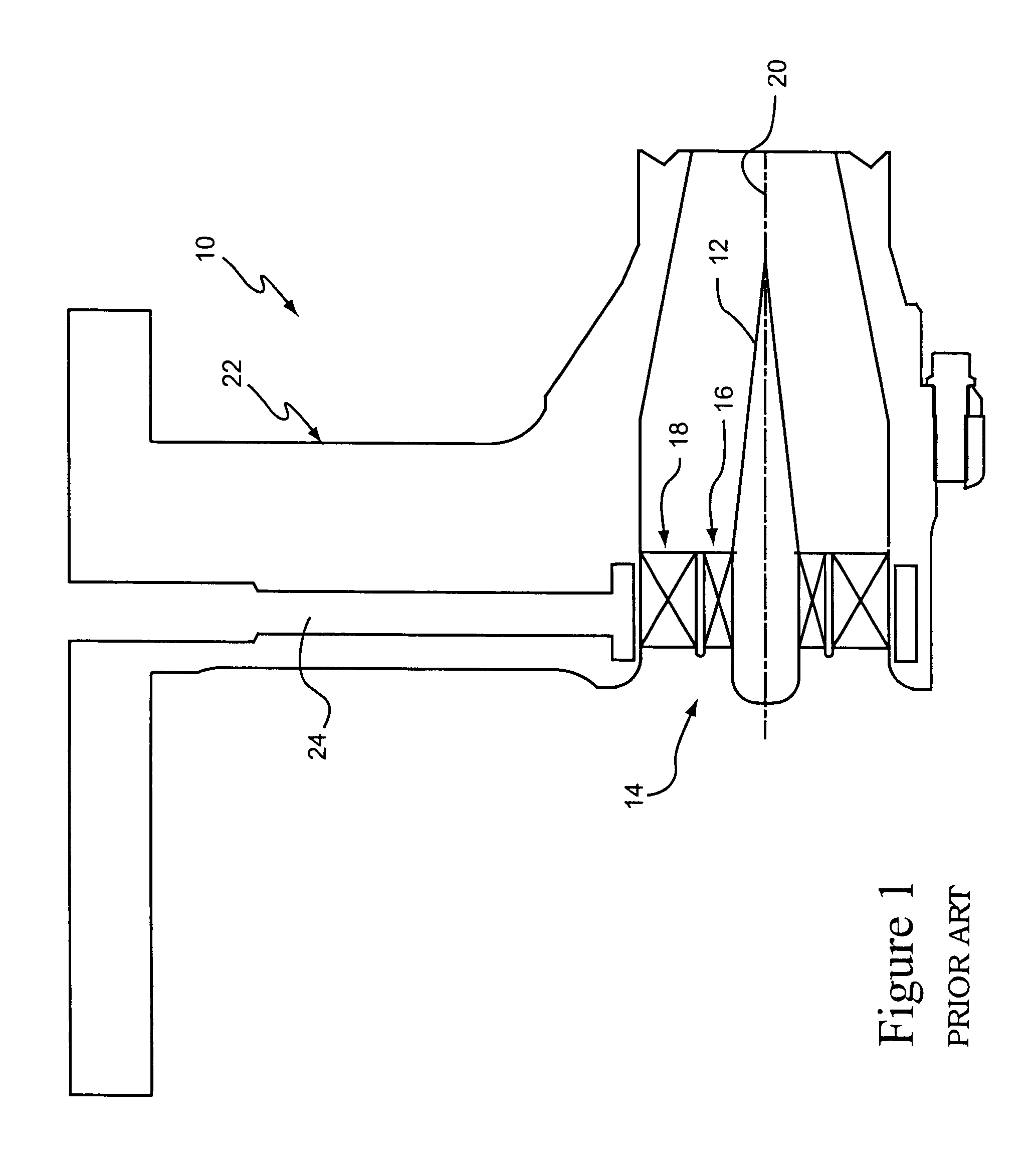

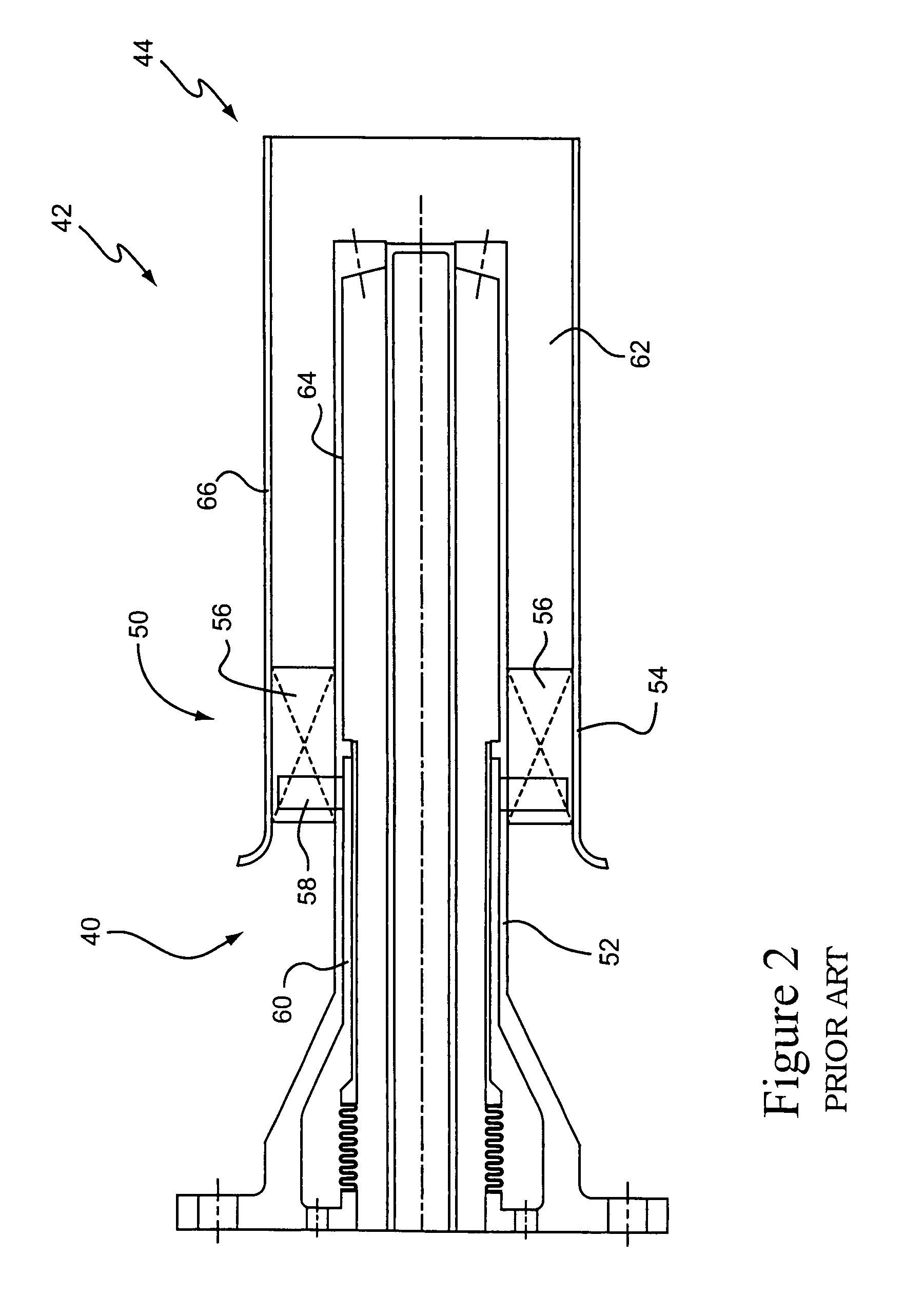

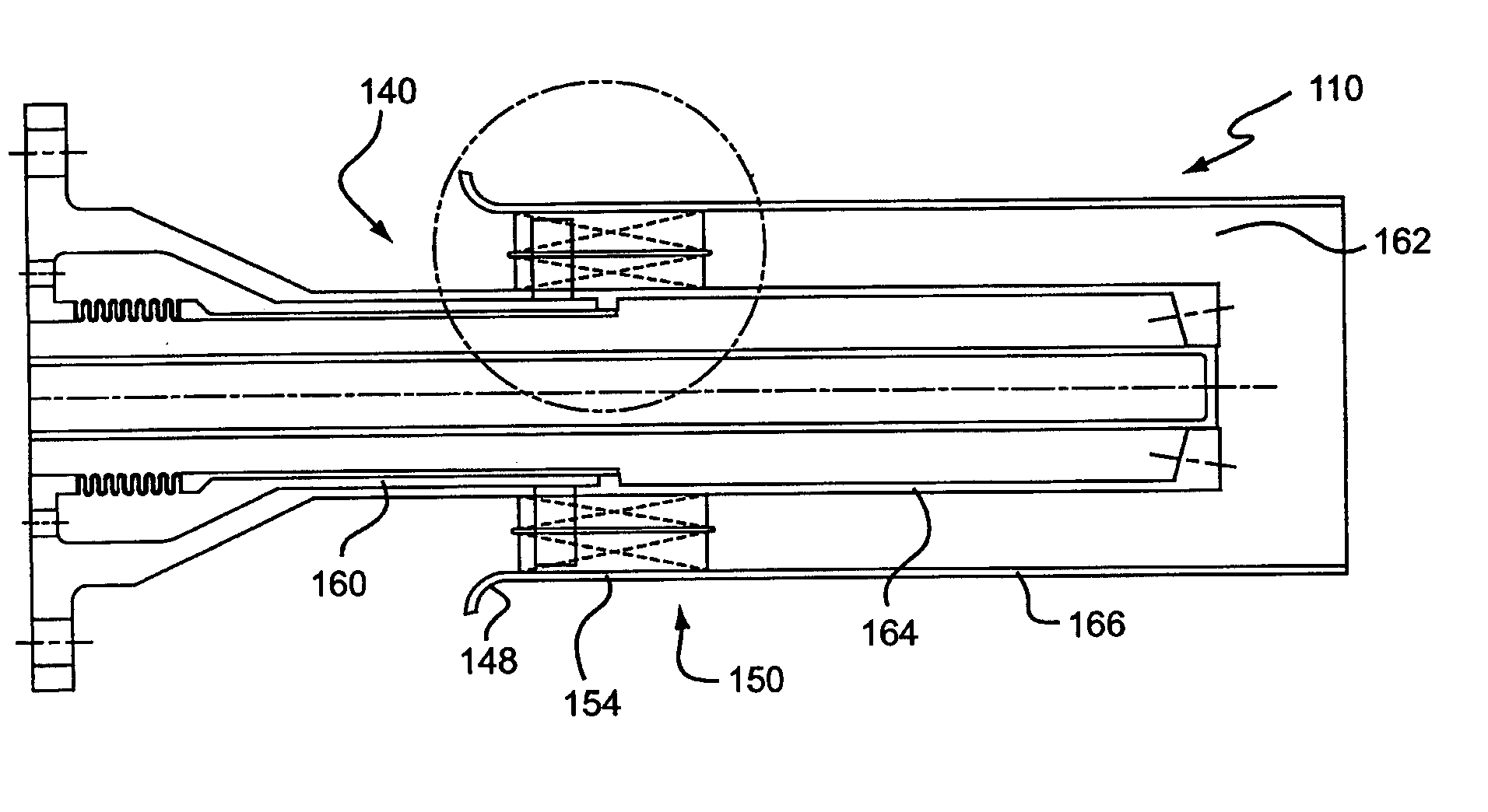

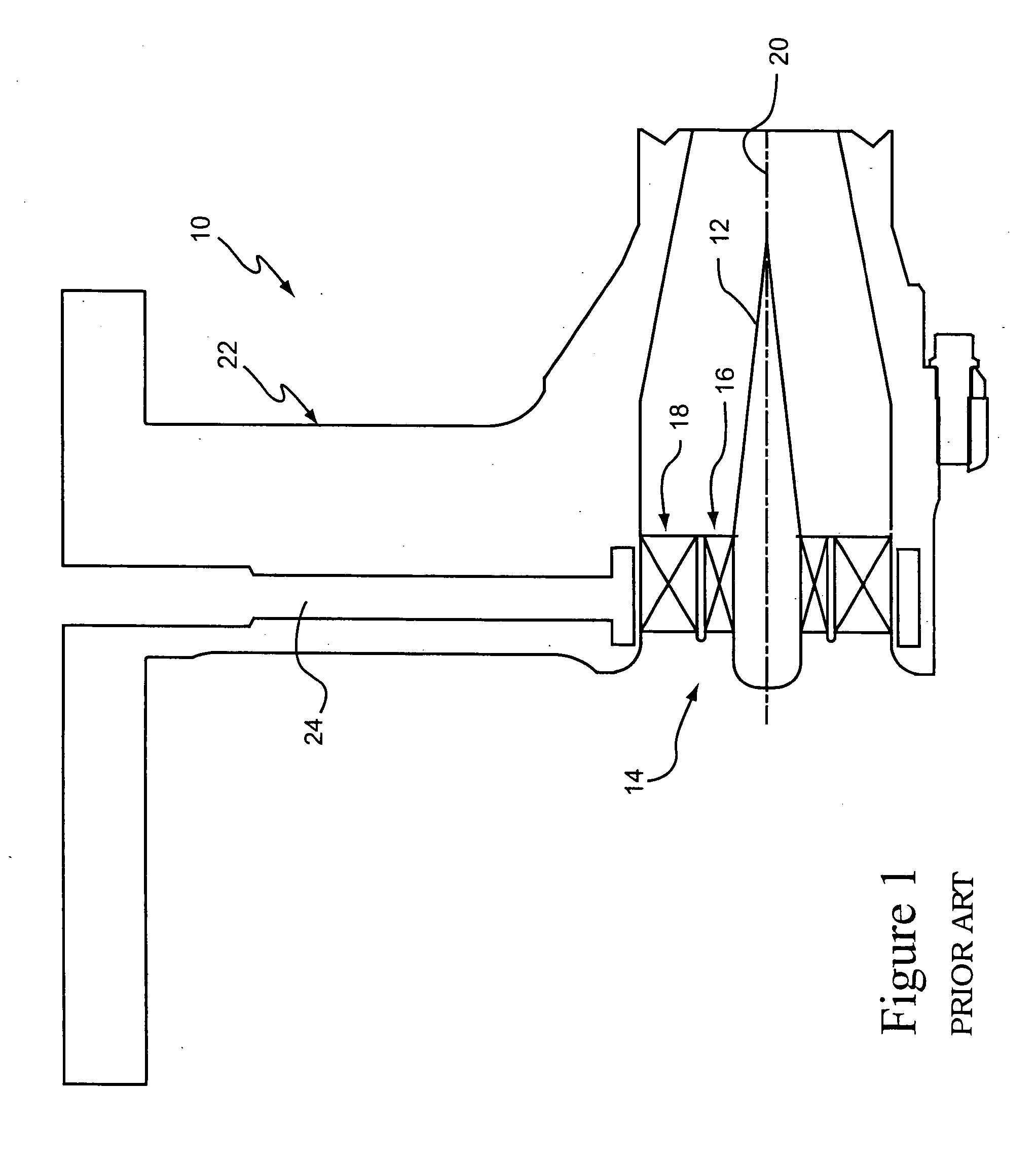

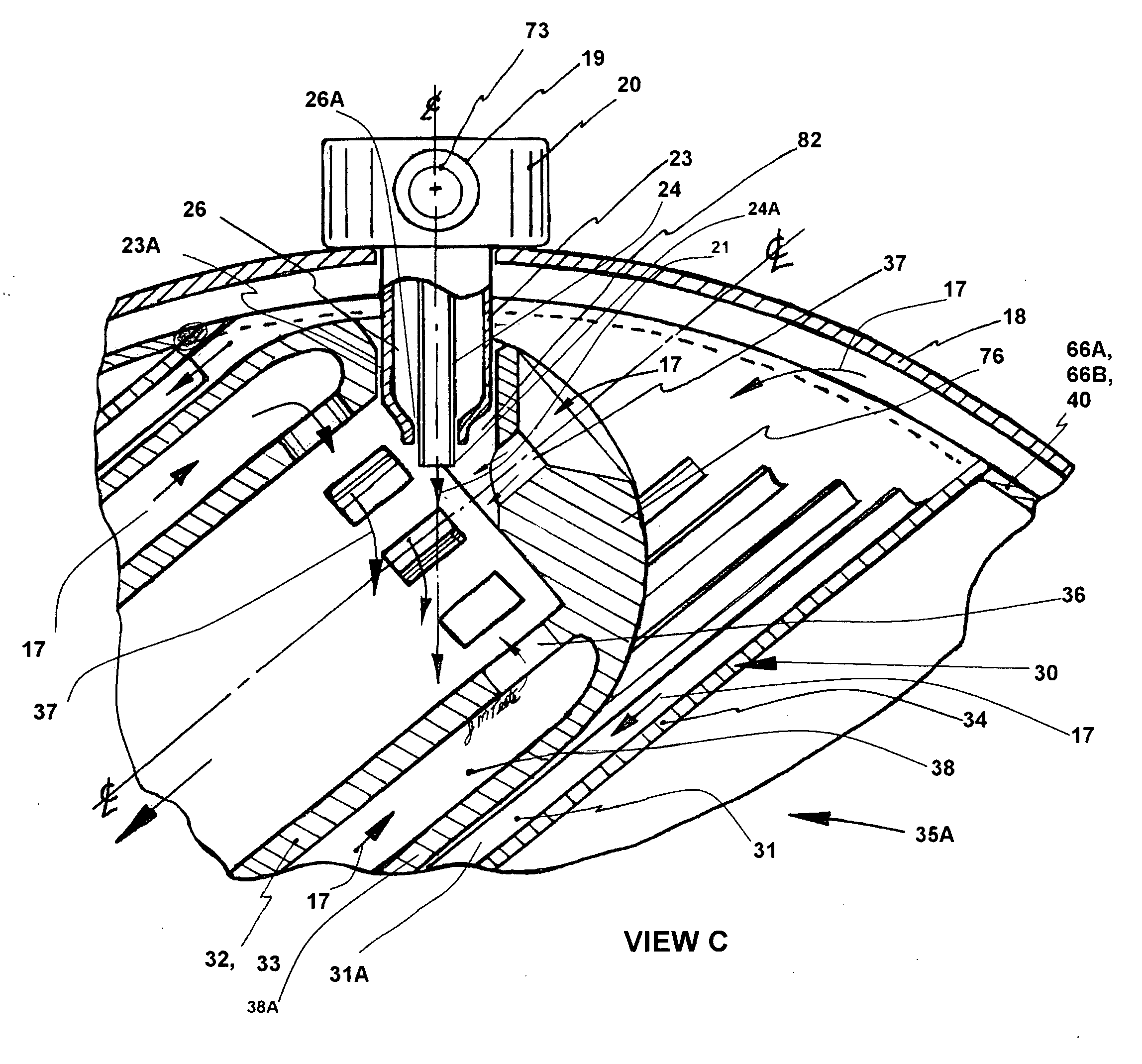

Burner tube and method for mixing air and gas in a gas turbine engine

InactiveUS6993916B2Good mixing propertiesImprove flame stabilityContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorGas turbines

Owner:GENERAL ELECTRIC CO

Burner tube and method for mixing air and gas in a gas turbine engine

InactiveUS20050268618A1Improve flame stabilityGood mixing propertiesTurbine/propulsion fuel supply systemsContinuous combustion chamberGas turbinesFuel gas

A hybrid structure that combines characteristics of the DACRS and Swozzle burners to provide the high mixing ability of an axial flowing counter rotating vane swirler with good dynamic flame stability characteristics of a bluff center body.

Owner:GENERAL ELECTRIC CO

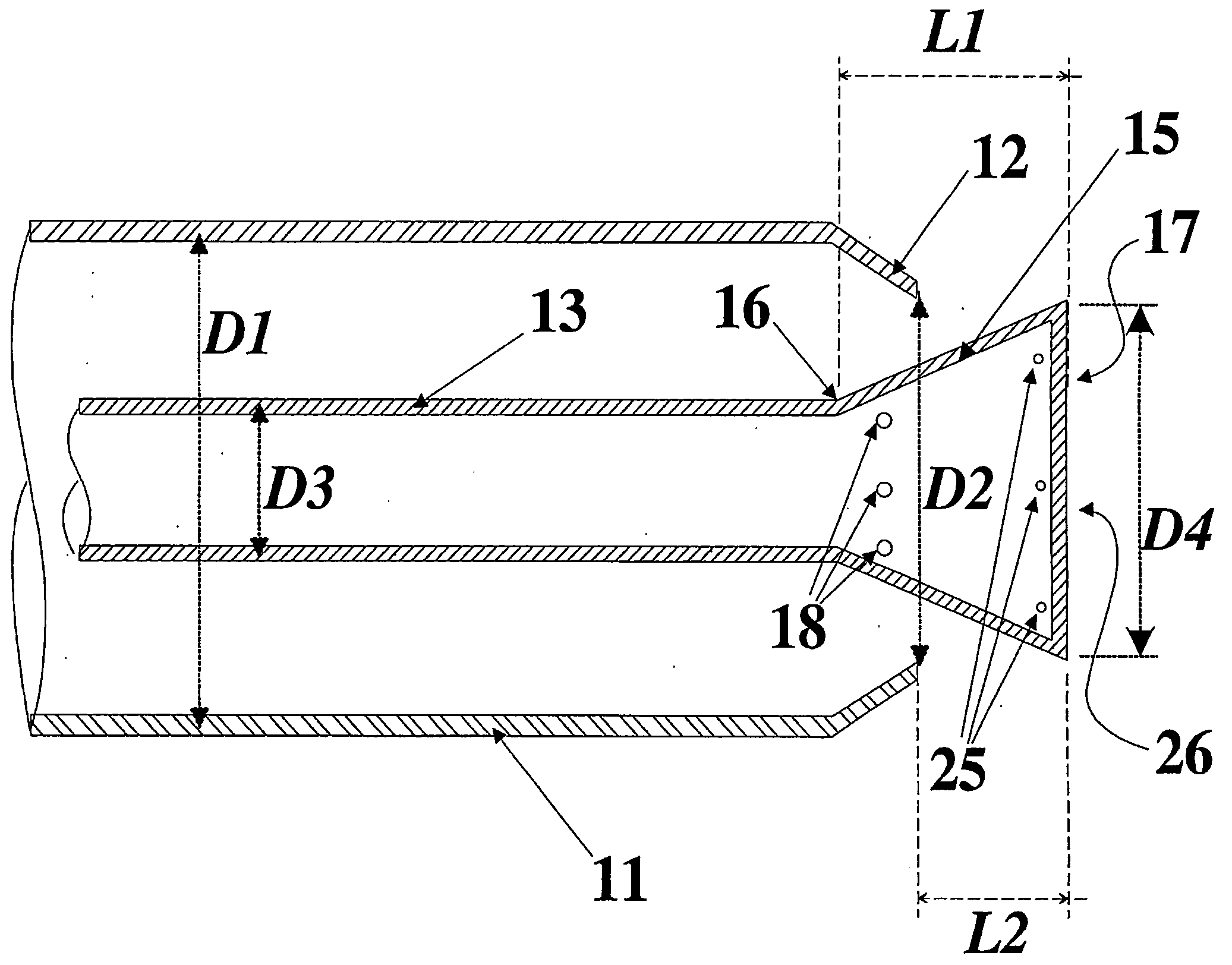

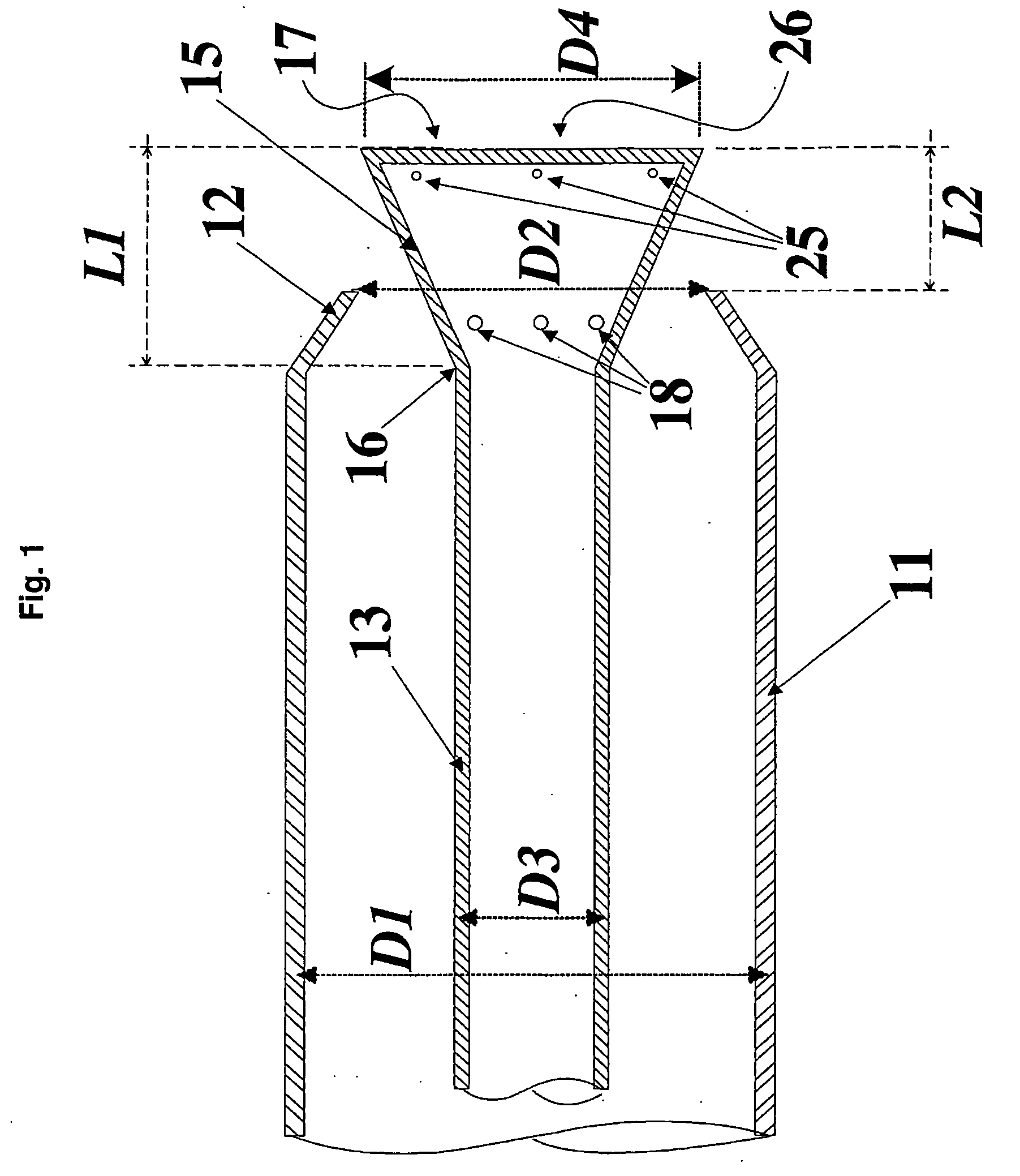

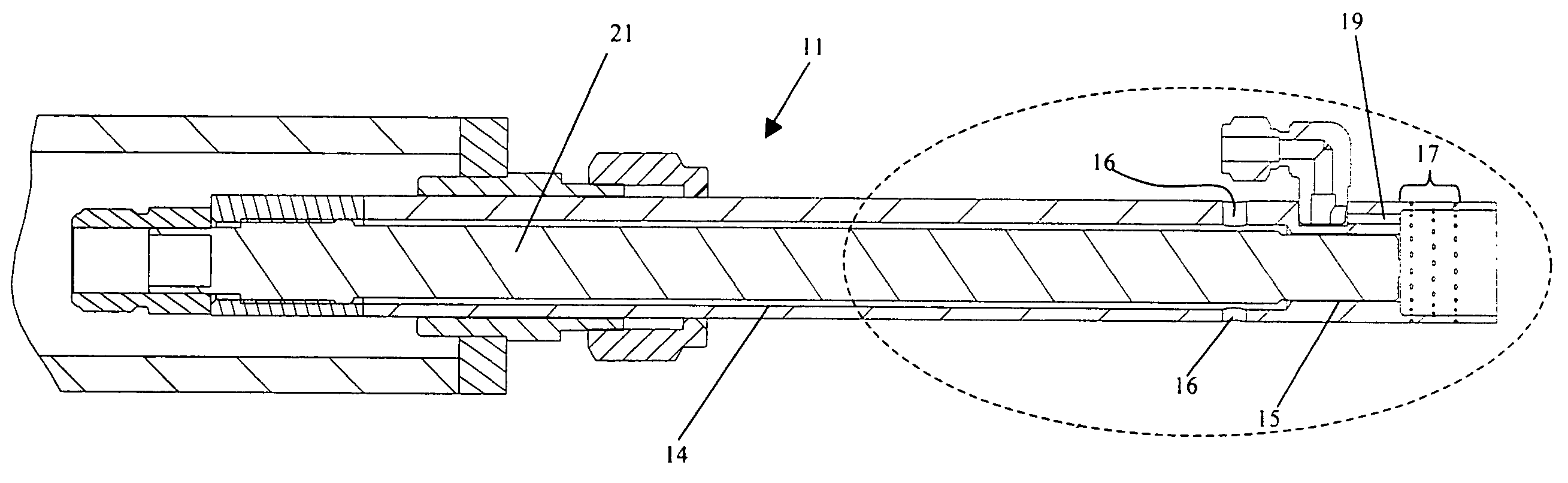

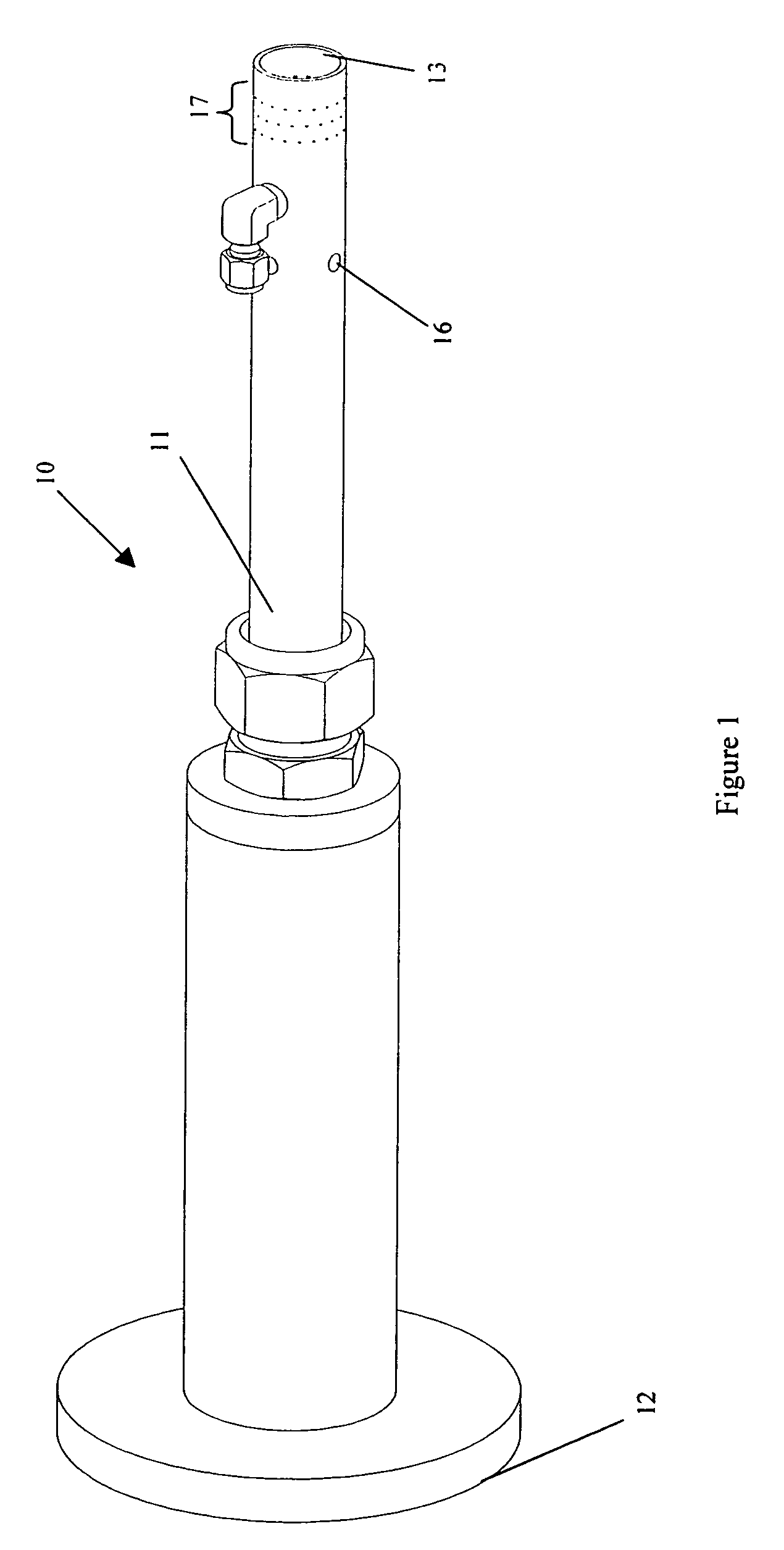

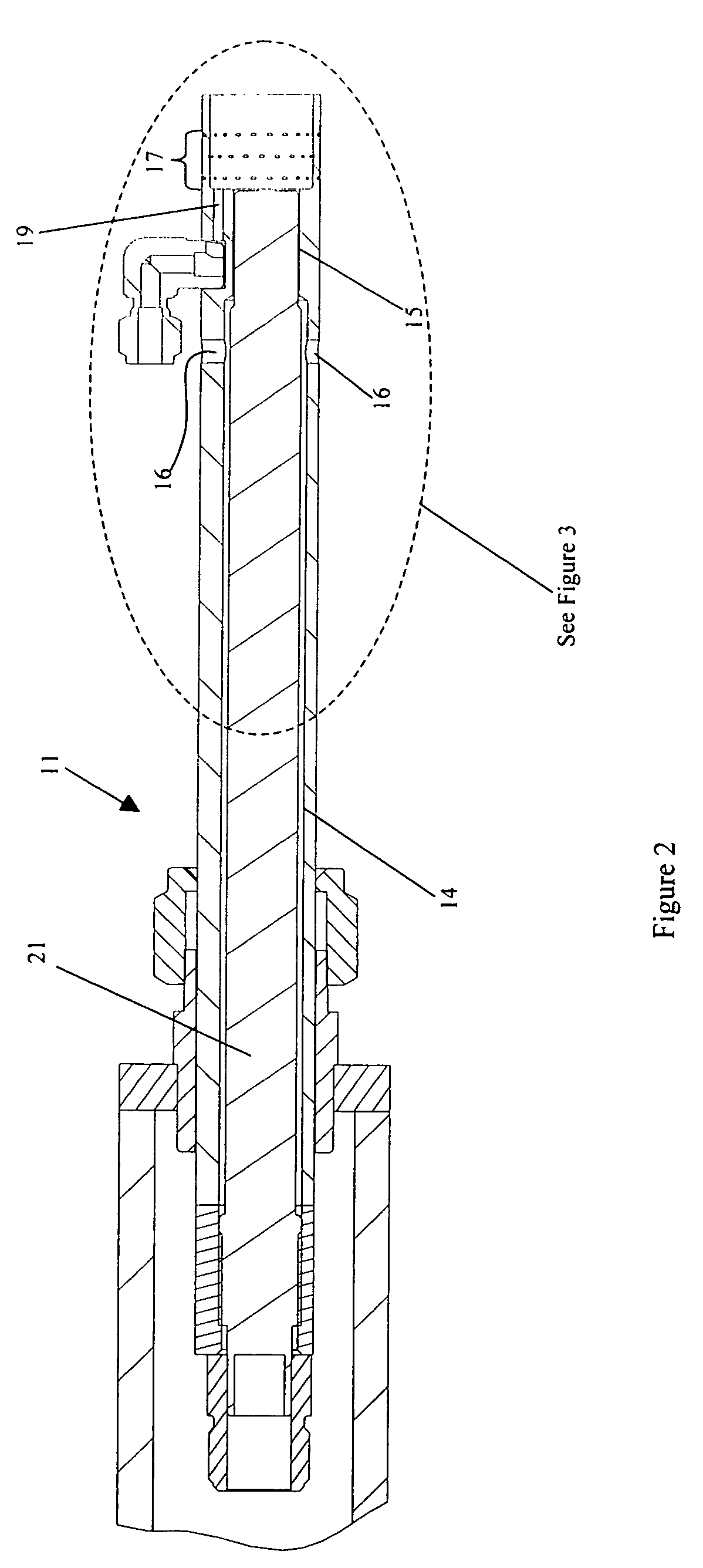

Method for Burning of Gaseous and Burner

ActiveUS20090220899A1Accelerate flowReduce cross sectionStaged combustionPilot flame ignitersAirflowProduct gas

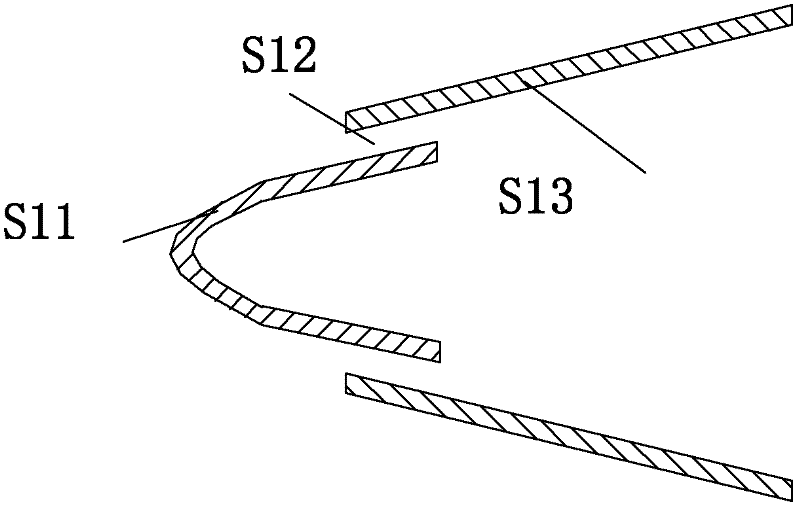

A method for burning gas in a burner, including leading the gas through an inner fuel tube (13) and introduction of combustion air through an annular space surrounding the inner fuel tube. This space forms of an outer tube (11) terminated by a conically converging section, wherein the end of the inner fuel tube forms a burner head (15). The major part of the primary gas is introduced into the upstream end of the burner head, to go into the combustion air that flows past the burner head, whereas a smaller part of a secondary gas is introduced into the free end of the burner head (15) and into the constricted part of the annular channel that surrounds the burner head. The gas flow is accelerated past the burner head due to the reducing cross section and is burned downstream in relation to the burning head, wherein the mixture has properties that reduces the formation of Nox at the same time as the combustion becomes complete. It is also described a burner for performing this method.

Owner:NORWEGIAN UNIVERSITY OF SCIENCE AND TECHNOLOGY (NTNU)

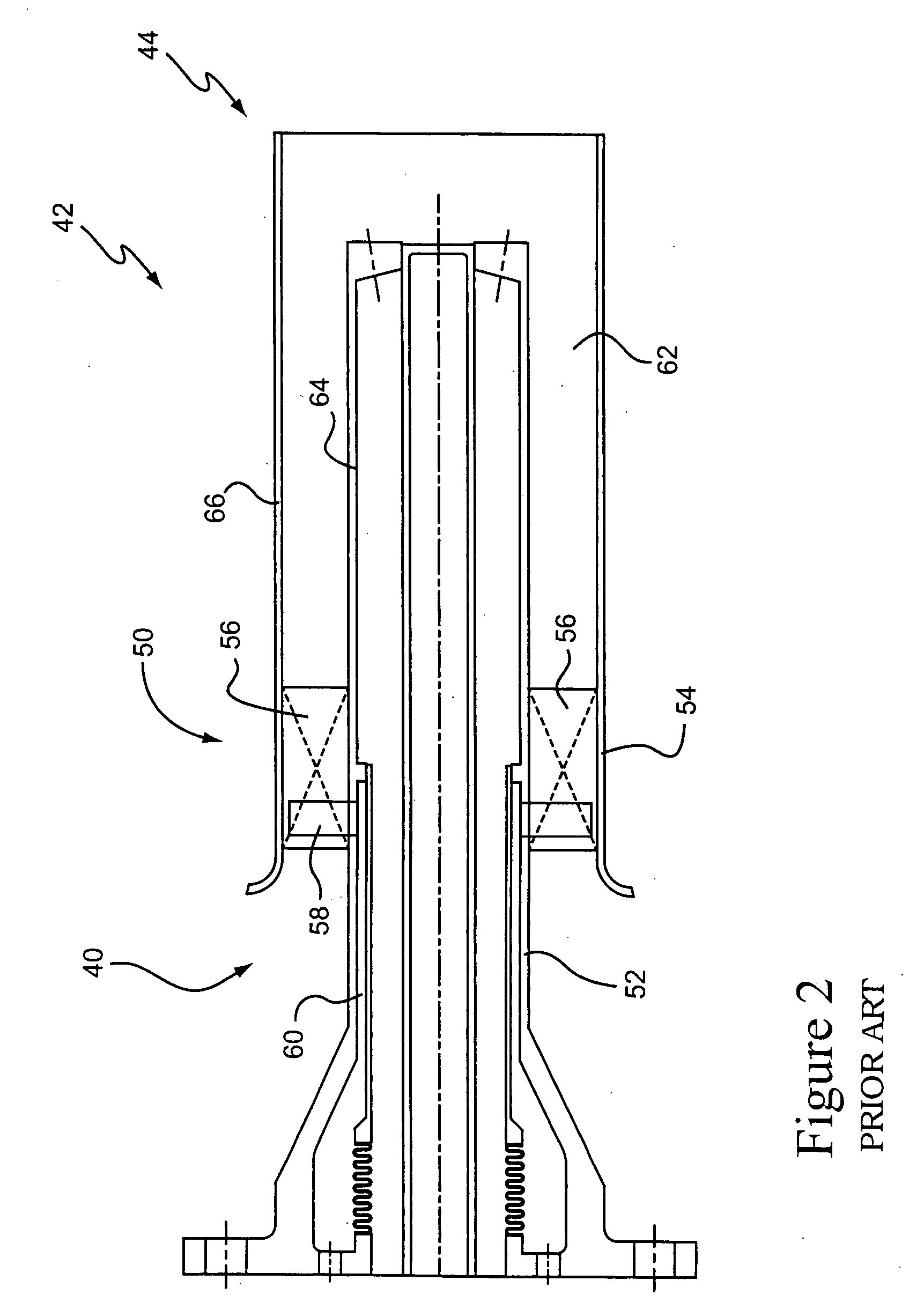

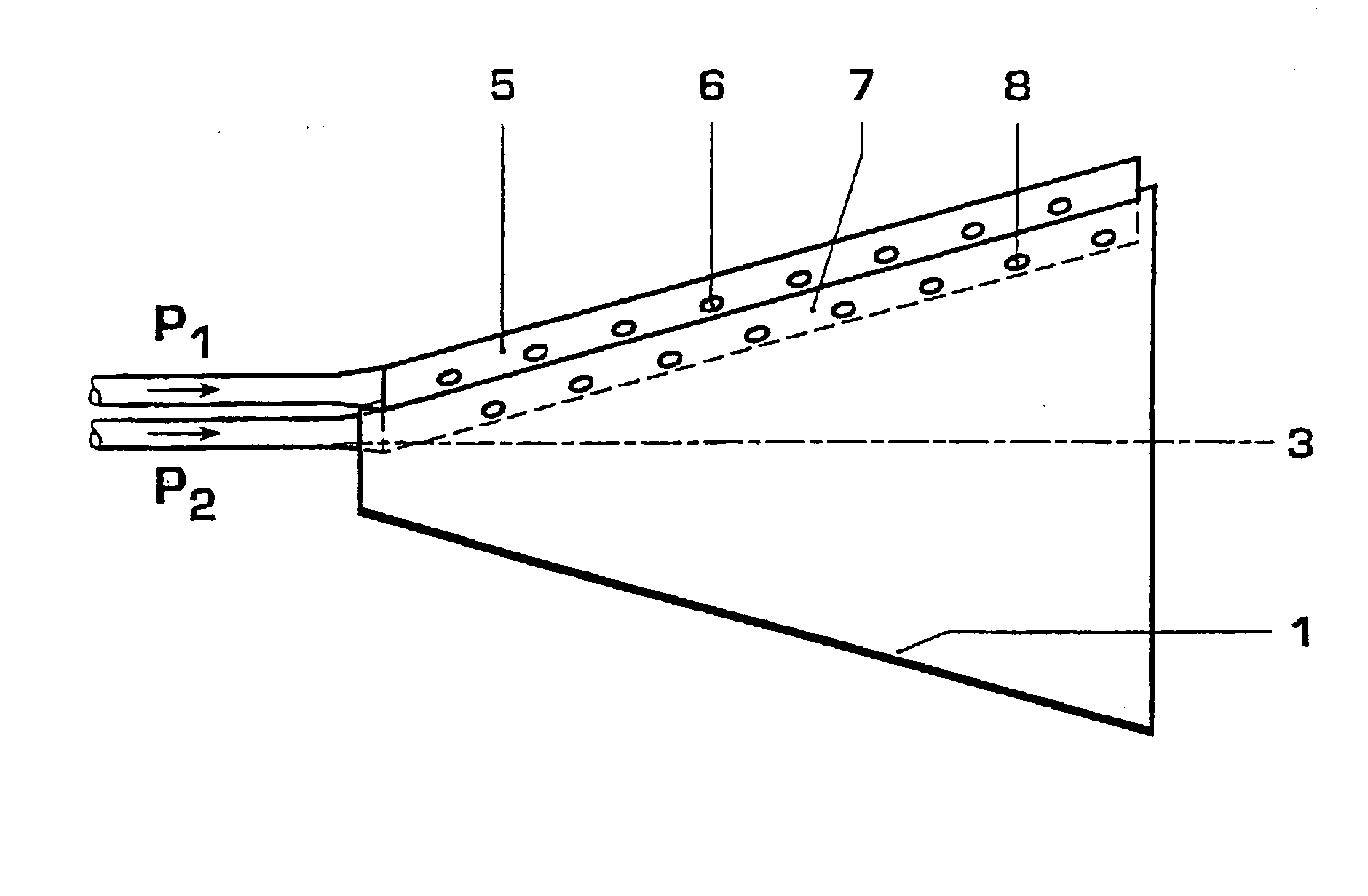

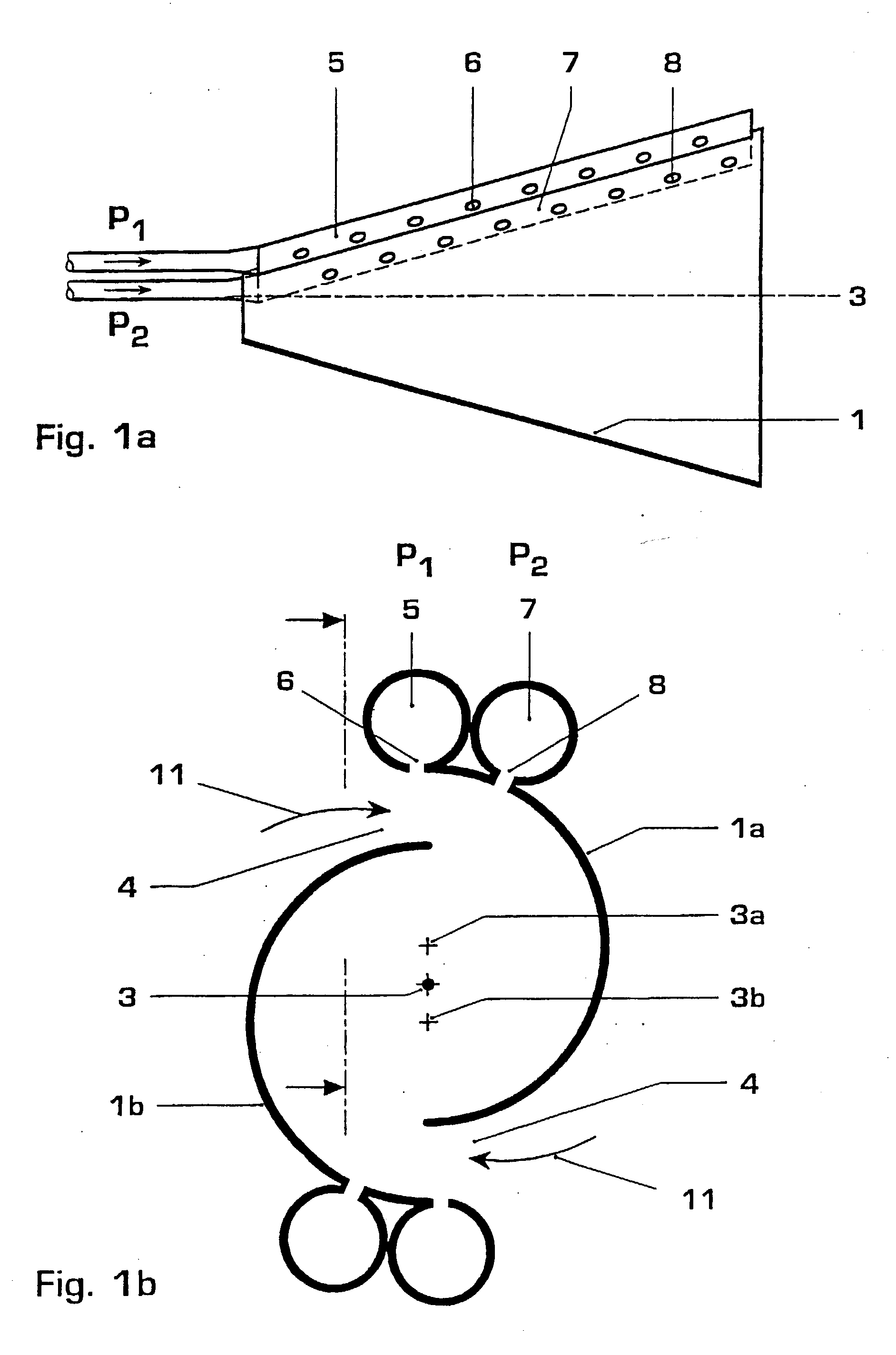

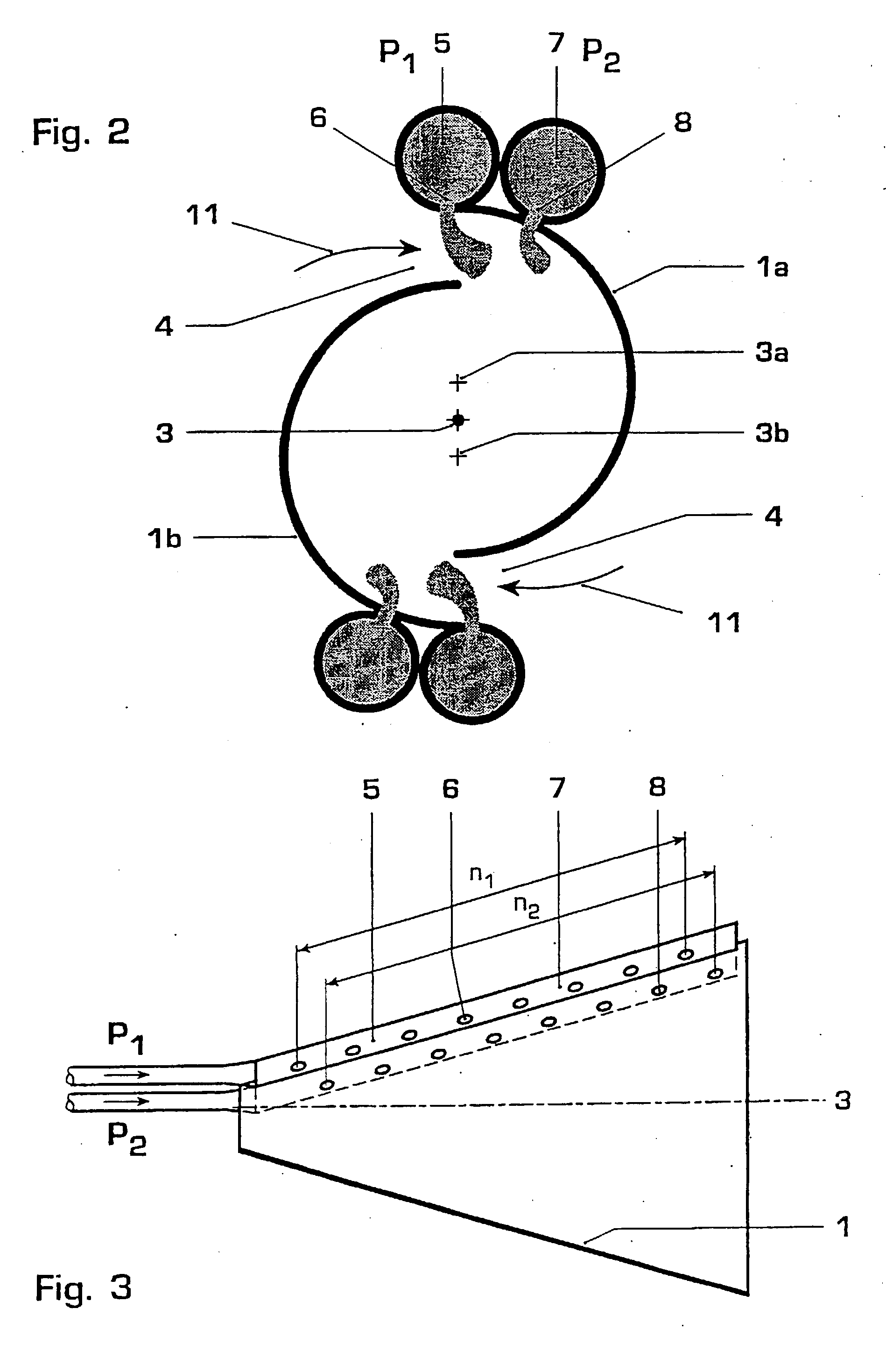

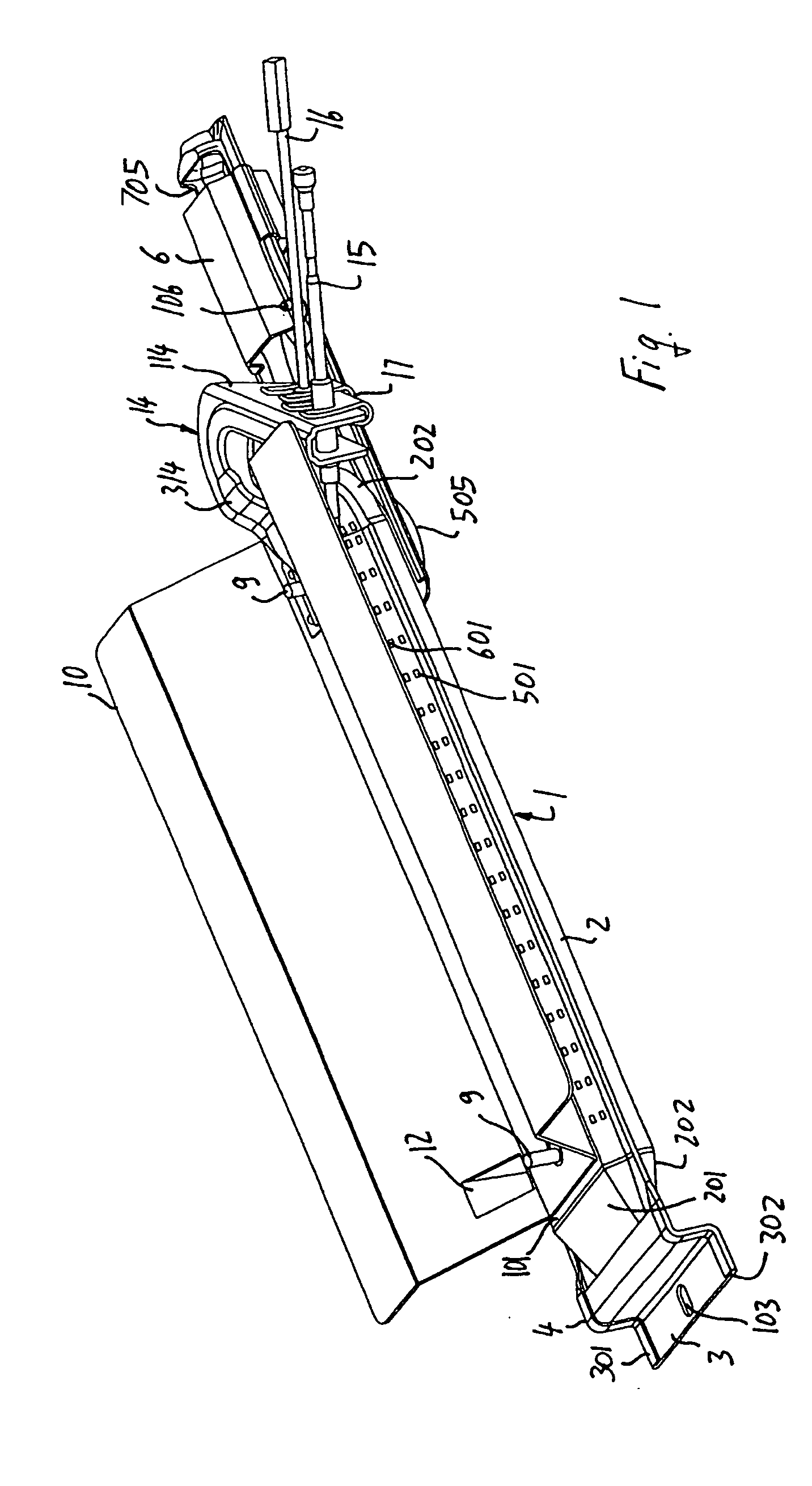

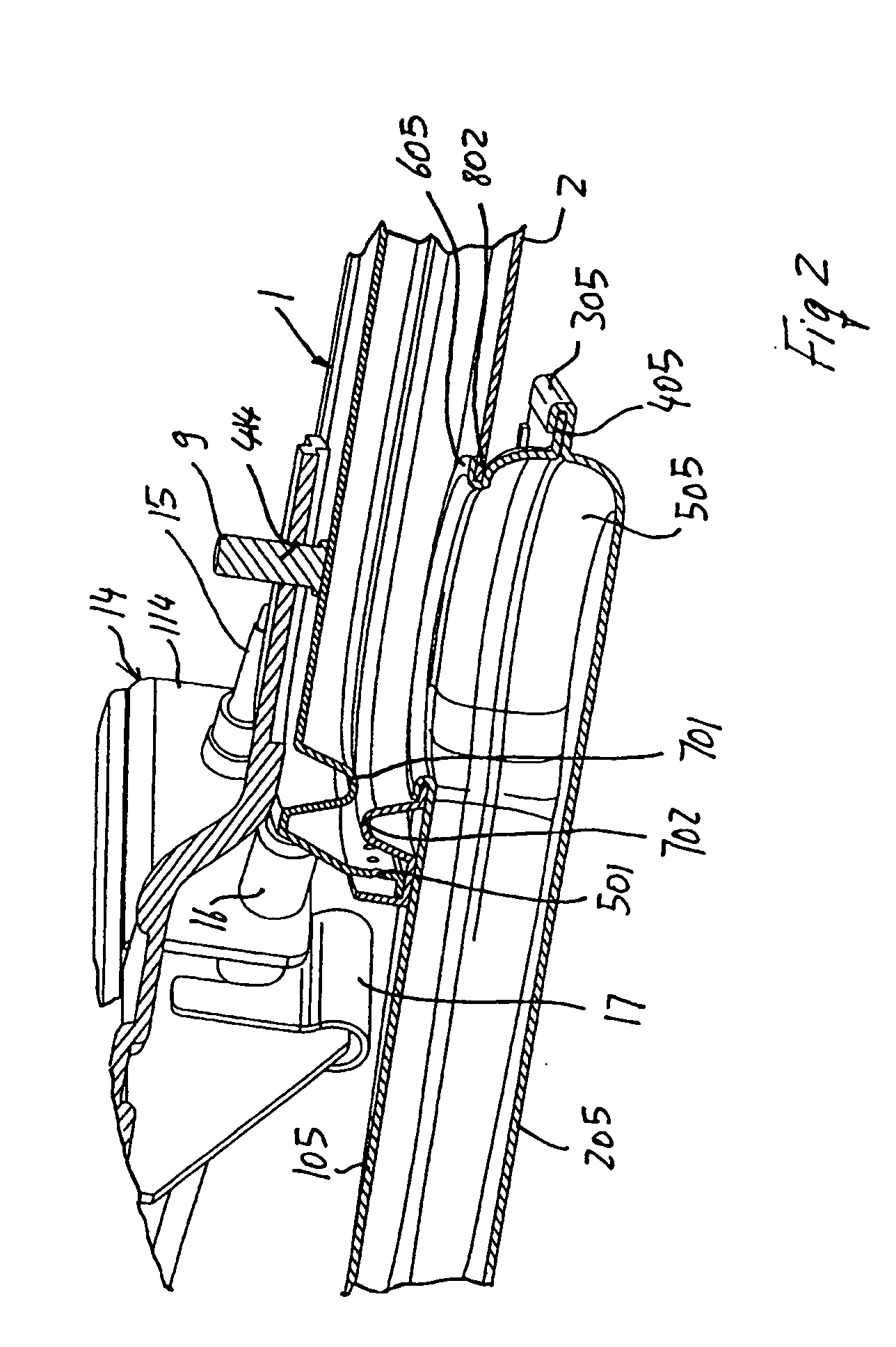

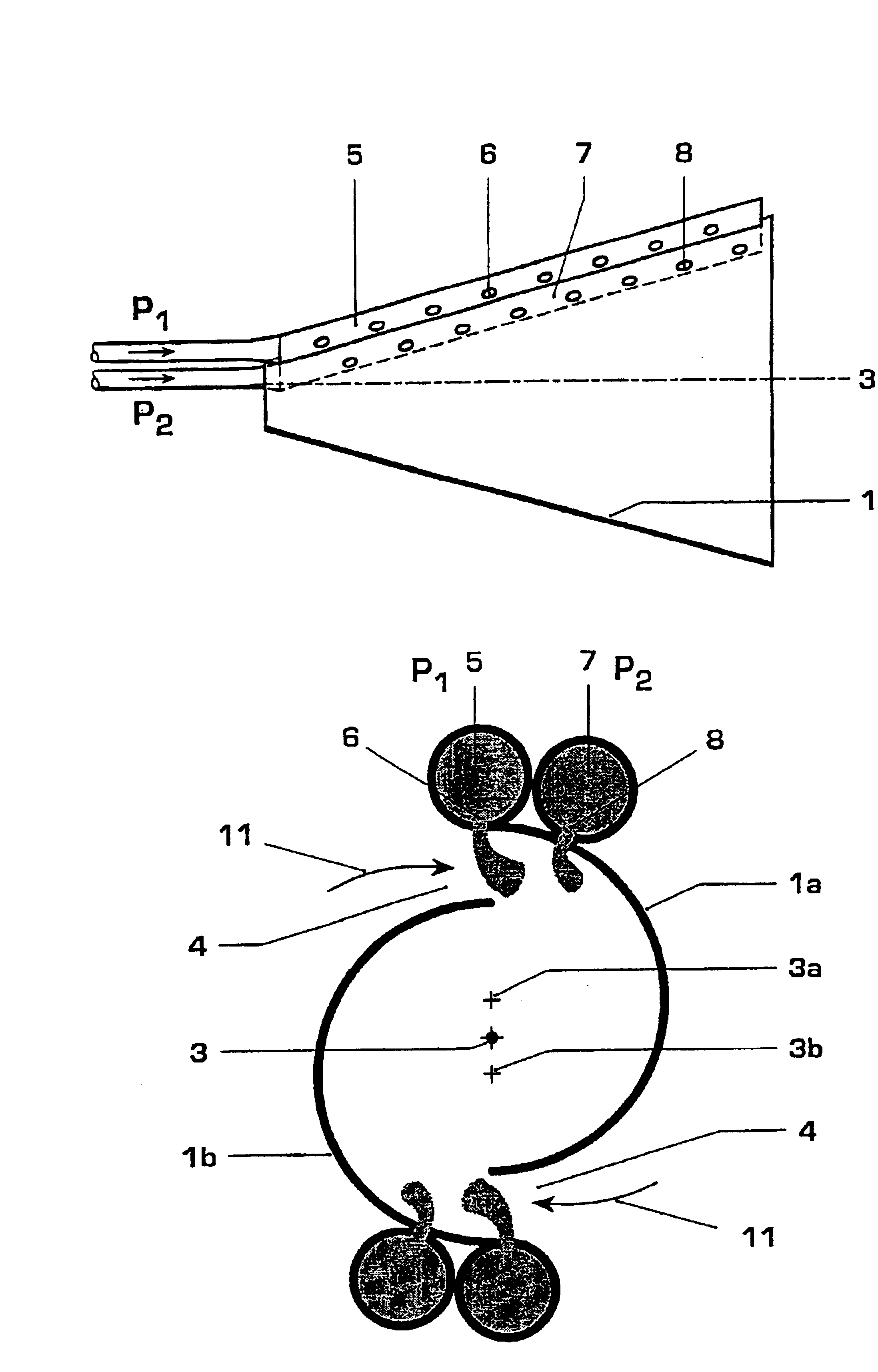

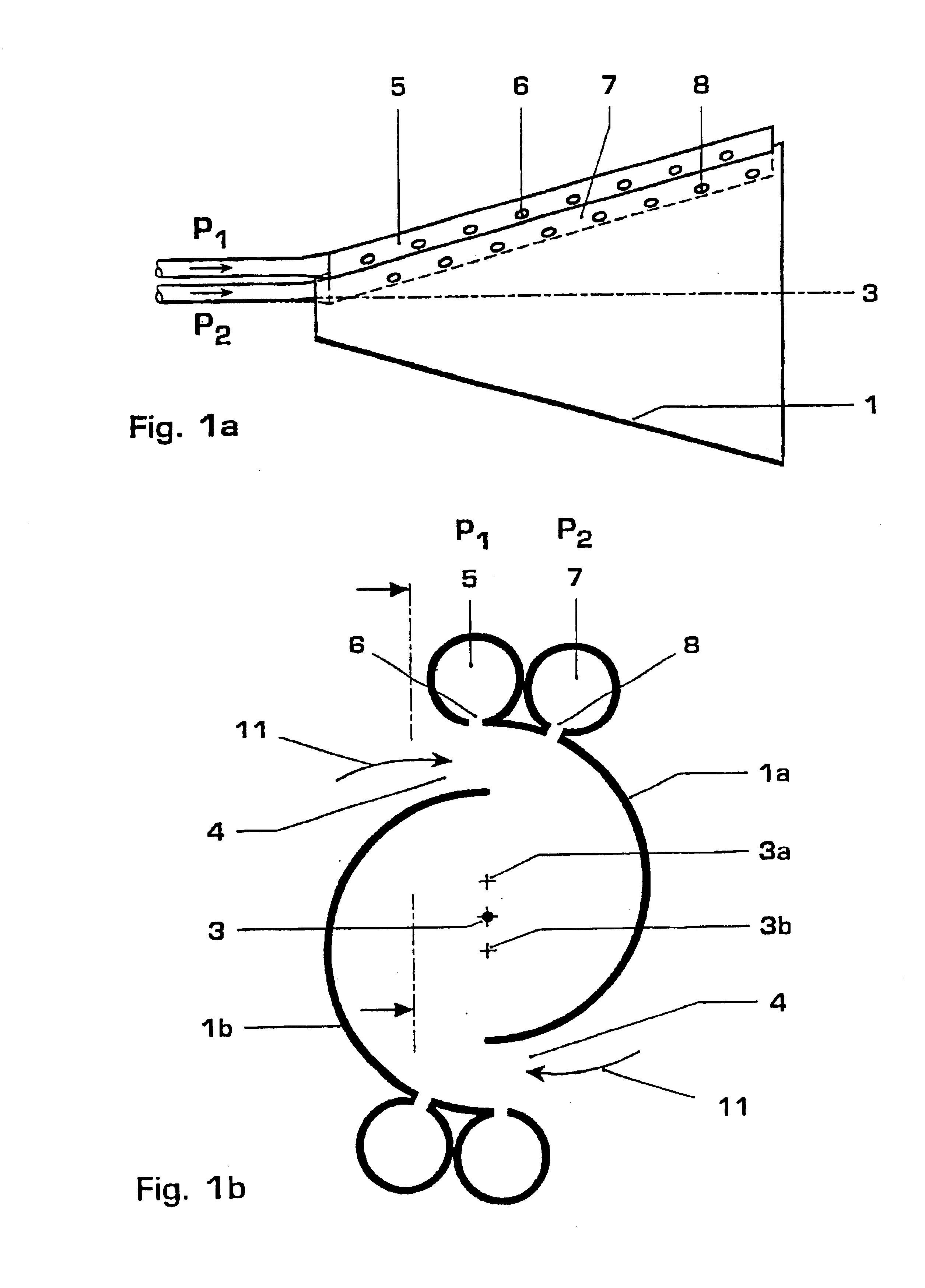

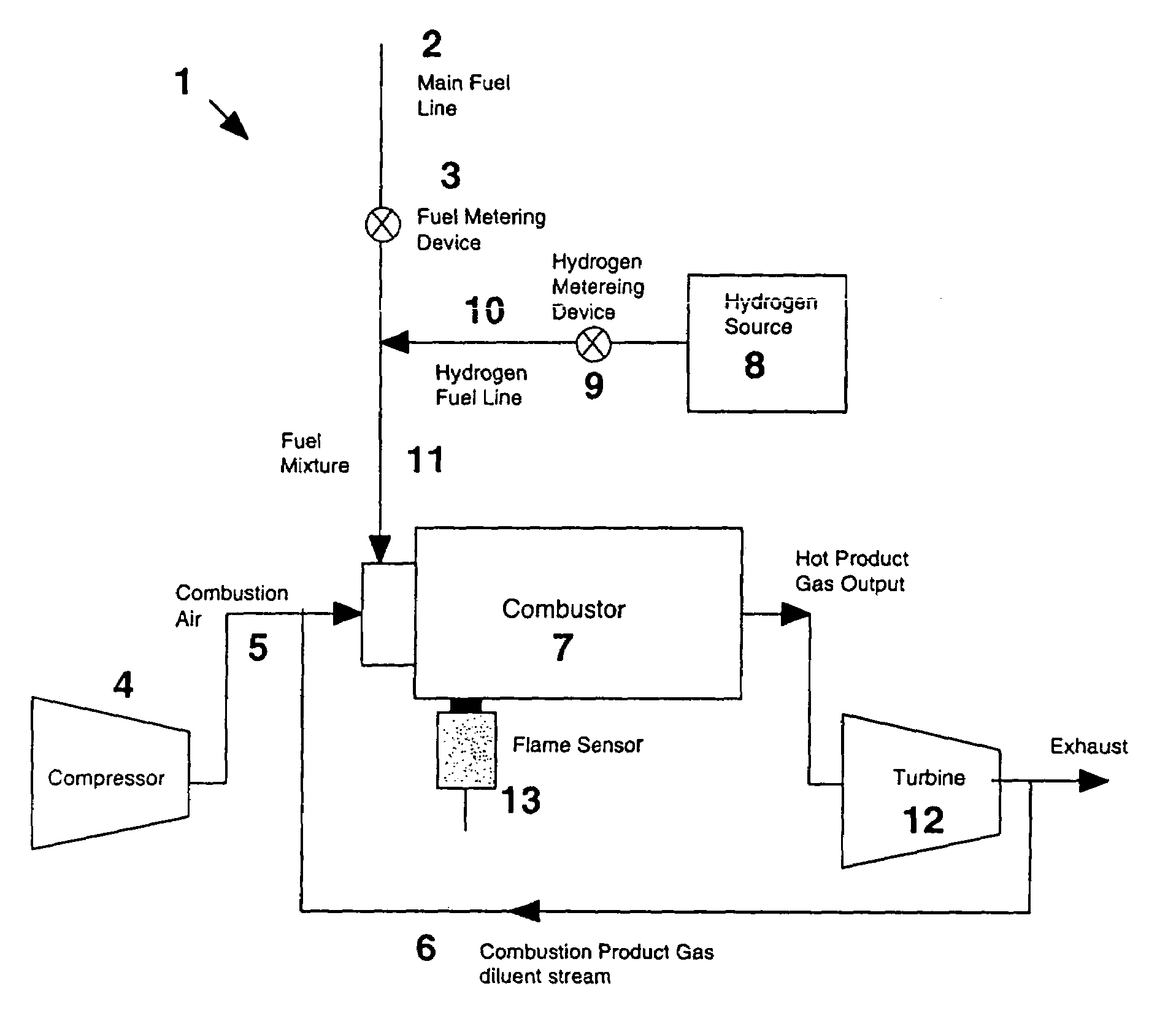

Method for operating a burner and burner with stepped premix gas injection

InactiveUS20030152880A1Improve flame stabilityEmission reductionGas turbine plantsTurbine/propulsion fuel controlFuel supplyProcess engineering

The present invention relates to a method of operating a burner, which comprises at least one first fuel supply conduit (5) with a first group of fuel outlet openings (6), essentially arranged in the direction of a burner longitudinal axis (3), for a first premix fuel quantity and one or a plurality of second-fuel supply conduits (7) with a second group of fuel outlet openings (8), essentially arranged in the direction of the burner longitudinal axis (3), for a second premix fuel quantity, it being possible to admit fuel to the second fuel supply conduits (7) independently of the first fuel supply conduit (5). In the method, both fuel supply conduits (5, 7) are operated with the same fuel. By means of the present method of operating a burner, optimum mixing conditions can be set even in the case of different loads, gas qualities or gas preheat temperatures.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Radiant Burner

InactiveUS20120164590A1Improve energy efficiencyIncreased Radiation PowerBurner material specificationsGaseous fuel burnerCombustorOxygen

The invention relates to a burner, in particular a radiant burner, for the combustion of a gas mixture of fuel gas and an oxygen carrier gas, with a burner plate with passage channels for the throughflow of the gas mixture from a mixing chamber side to a combustion side, wherein, on the combustion side, combustion channels with an enlarged cross-section compared with the passage channels connect to the passage channels, wherein flow obstacles for a contact with the combustion flame are arranged in the combustion channels and the flow obstacles are made of a material which has a higher thermal conductivity than the material of the burner plate.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

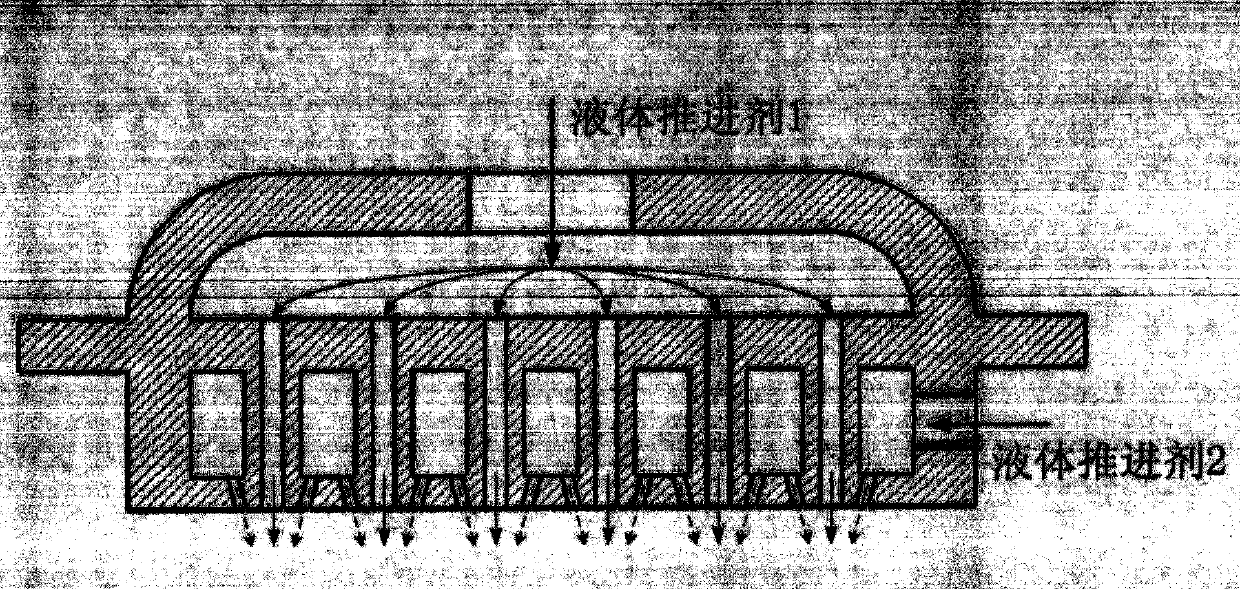

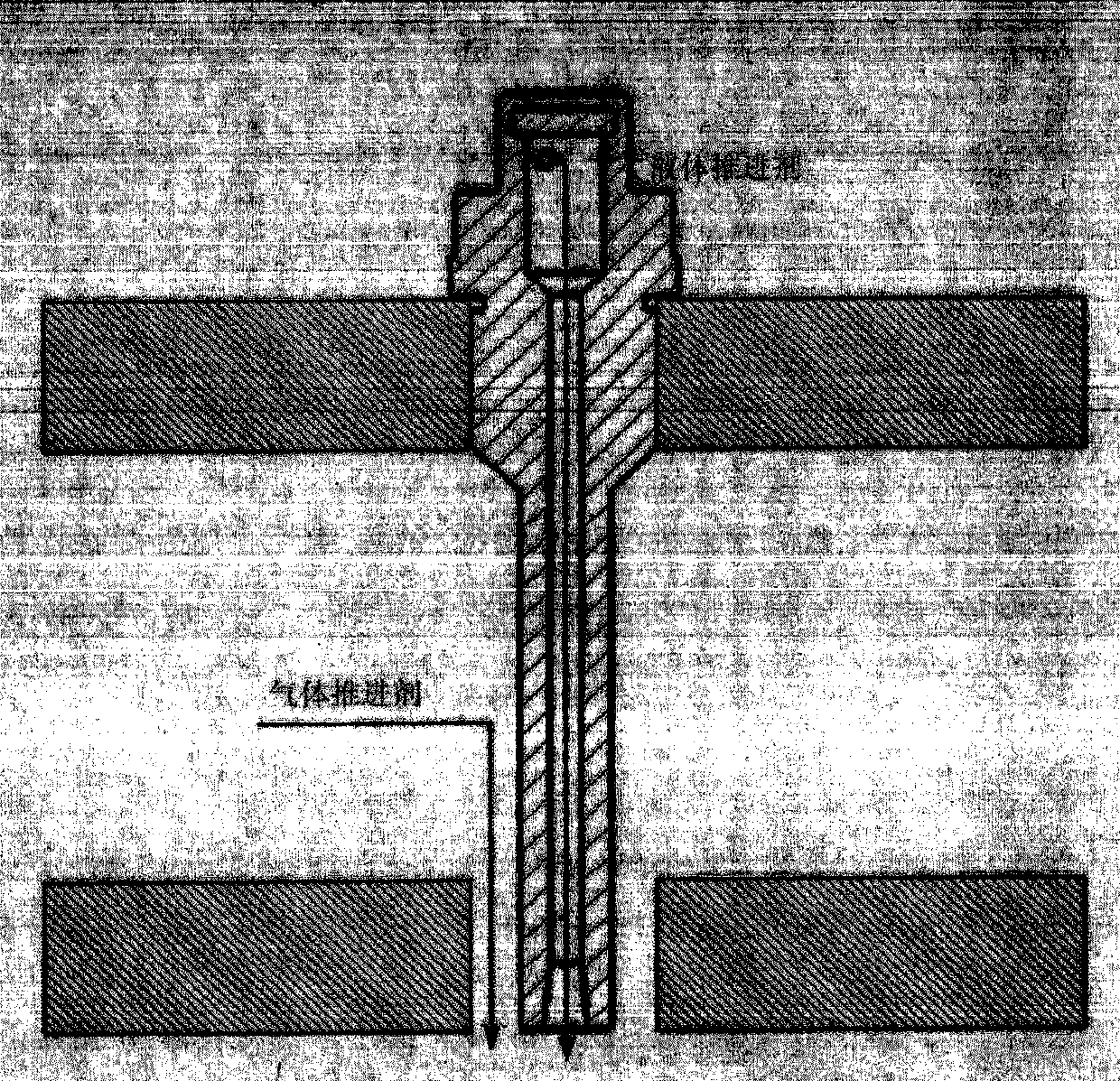

Dual-rotational-flow inspirator

ActiveCN103867340AStrong interactionGood atomization performanceRocket engine plantsHollow cylinderEngineering

The invention provides a dual-rotational-flow inspirator, which comprises a top cover, a nozzle, an upper bottom, a middle bottom, a gas whirlcone and an inspirator cavity, wherein the inspirator cavity is a barrel-shaped hollow cylinder; a fuel cavity is formed between the top cover and the upper bottom of the inspirator; a gas oxidizing agent cavity is formed between the upper bottom and the middle bottom of the inspirator; a water cavity is formed between the middle bottom of the inspirator and the base of the inspirator; an inner nozzle passes through mounting holes in the upper bottom, the middle bottom and the inspirator cavity and is fixedly arranged on the upper bottom via a thread; the gas whirlcone is installed on the nozzle by a thread; water nozzles are water holes evenly distributed on the circumstance on the base of the inspirator. The inspirator provided by the invention has the characteristics of simple structure, low cost, good atomization performance and stable flame.

Owner:NAT UNIV OF DEFENSE TECH

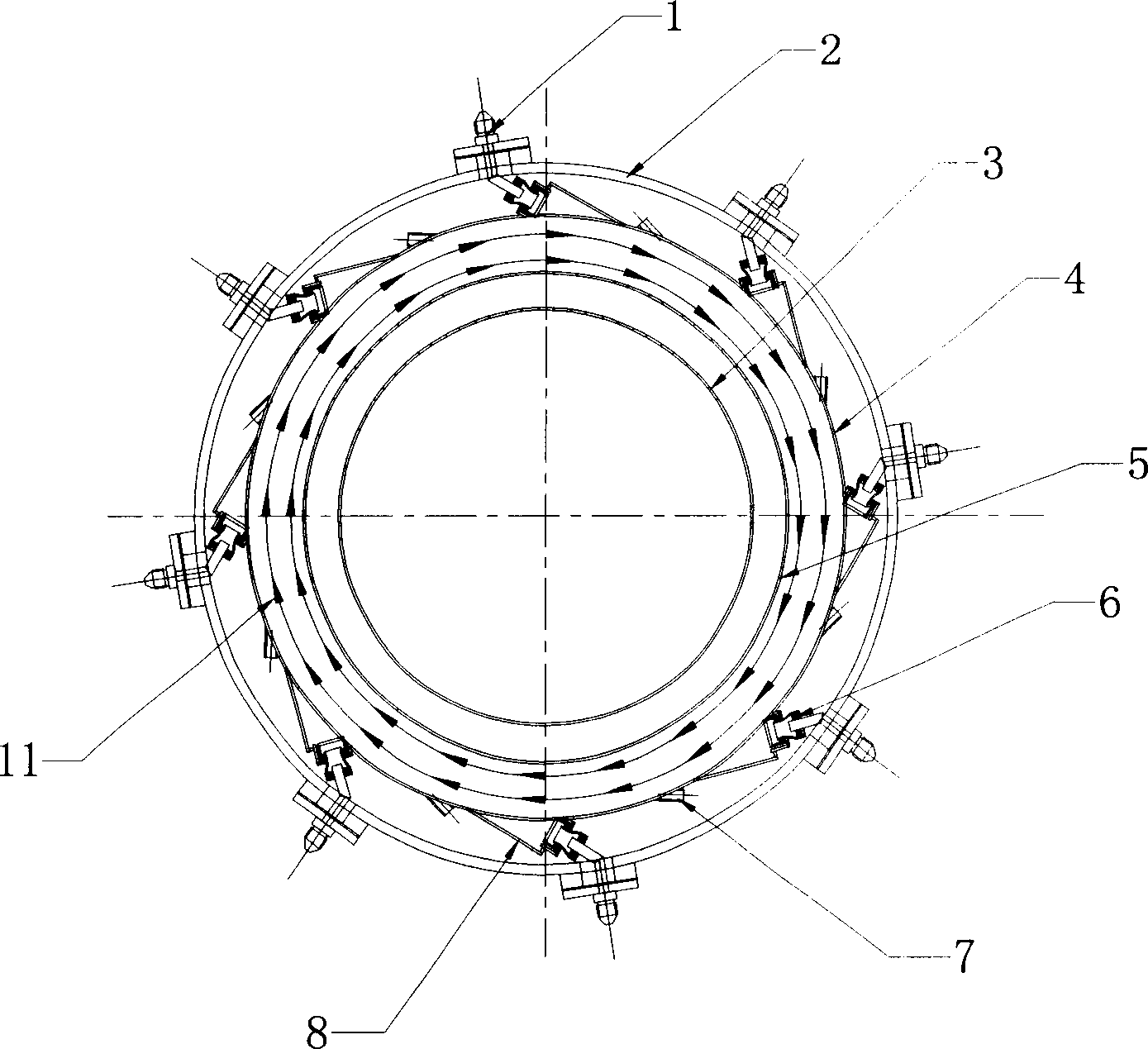

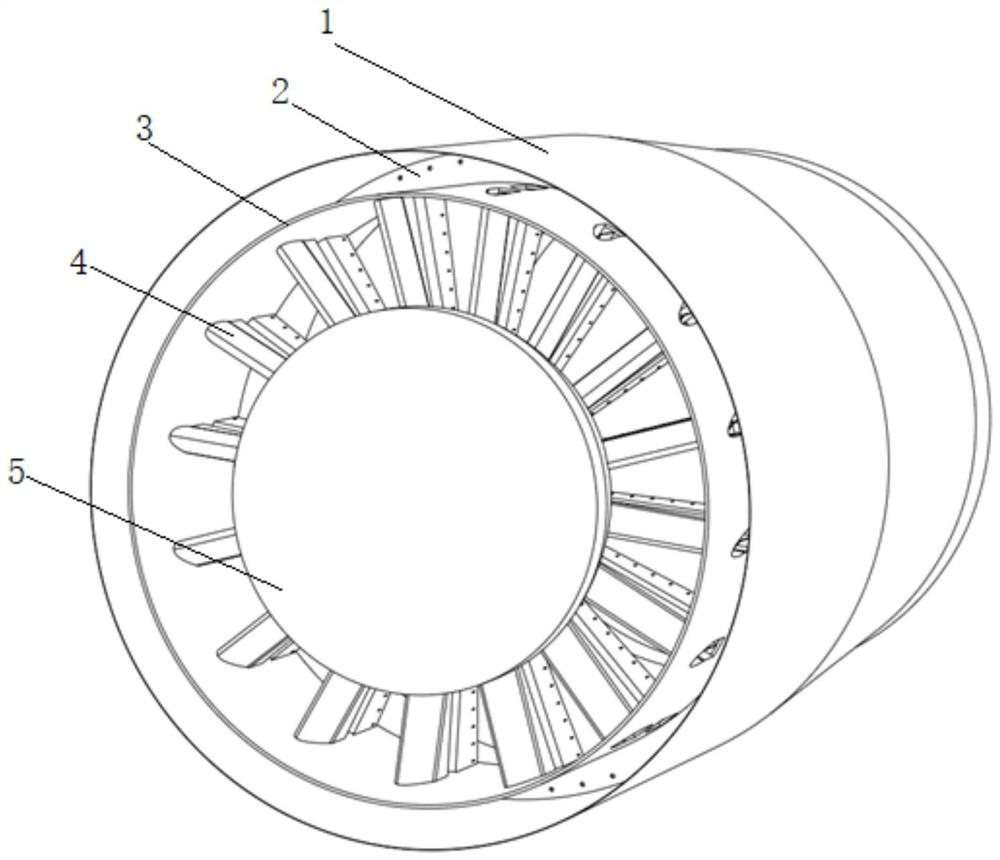

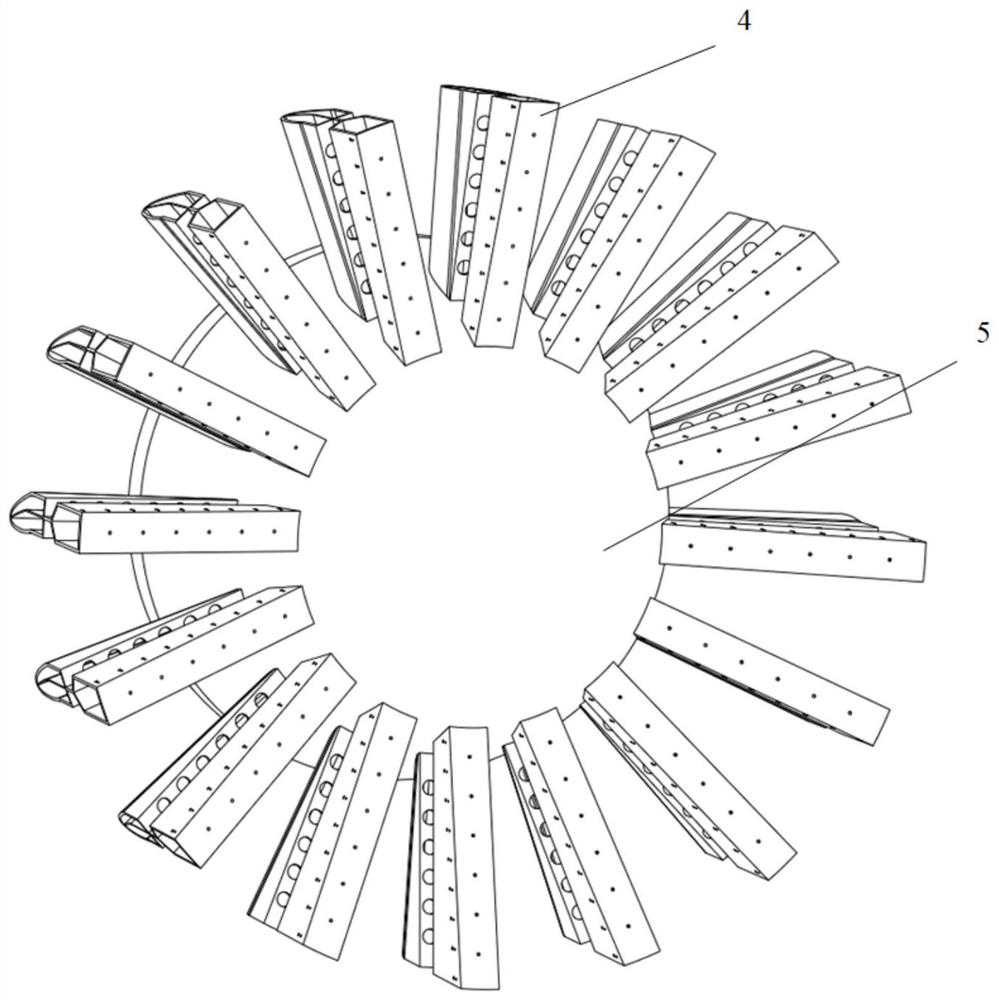

Tangential standing vortex burning chamber

InactiveCN1858498AReduce aerodynamic lossesReduce complexityContinuous combustion chamberCombustion chamberCombustor

The tangential standing vortex burning chamber in annular flame tube structure consists of inner and outer boxes and inner and outer flame tubes separately inside the inner and the outer boxes. The outer flame tube has one circumferential head including oil nozzle and flame stabilizing tube, and one main burning hole in the downstream of the head, and the central line of the head and the main burning hole is in some angle to the circumference tangent. The inner and outer flame tubes have inner and outer mixing holes separately in front of their combustors to ensure the excellent outlet temperature distribution, and inclined cooling holes in the walls and inclined to the main burning holes. The present invention has raised liquid atomizing combustion efficiency, reduced combustor outlet temperature distribution coefficient and expanded stable operation range of combustor.

Owner:BEIHANG UNIV

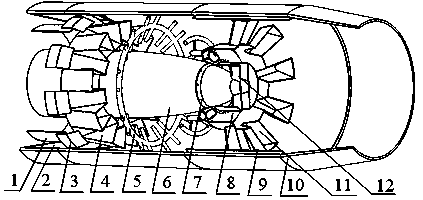

Turbine-based combined cycle engine super-combustion chamber

InactiveCN104019465ASatisfy Advancement RequirementsSolve key technical difficultiesContinuous combustion chamberRamjetGroove width

The invention discloses turbine-based combined cycle engine super-combustion chamber. Key parts of the super-combustion chamber comprise a shunt ring, a rear area-variable deflation valve, a flow guide tongue piece, a square lobe mixer, a first area fuel ejector, a center cone, a second area fuel injection ring, an evaporation tube flame stabilizer, a heat-isolating screen, a super-combustion chamber cylinder, an outer extending groove-width-variable radial flame stabilizer and an inner extending radial flame stabilizer. An internal flow field of the super-combustion chamber is reasonably distributed, the phenomenon of backflow from a punching duct to a turbofan duct can not occur, flow separation can not occur in the square lobe mixer, and the evaporation tube flame stabilizer can achieve soft ignition of the super-combustion chamber. The whole super-combustion chamber is high in mixing efficiency, little in cold flow resistance, high in combustion efficiency, reasonable in temperature distribution, and capable of meeting use requirements in a whole flight envelope of the super-combustion chamber in each work state and the requirement for boost of an turbofan ramjet.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

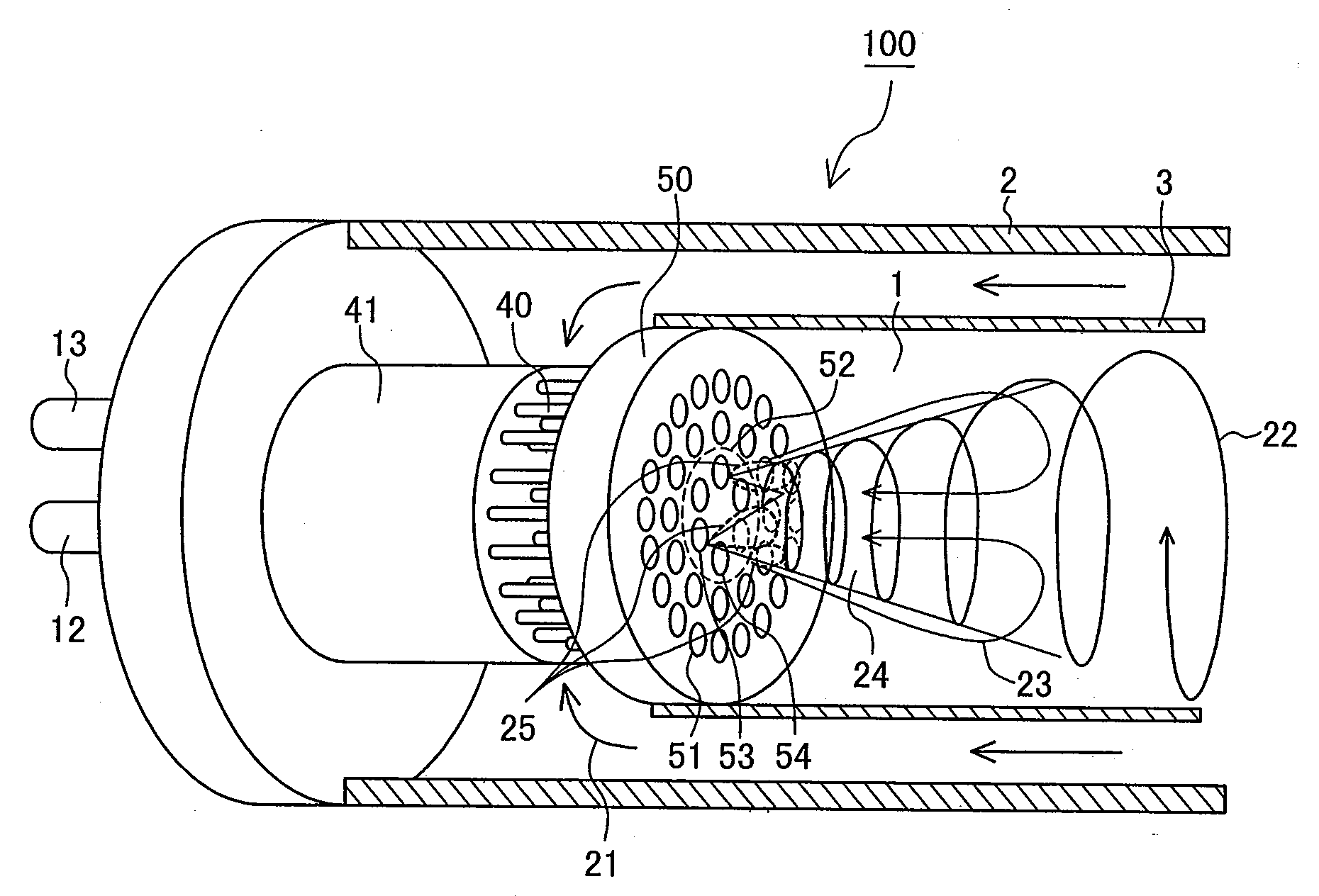

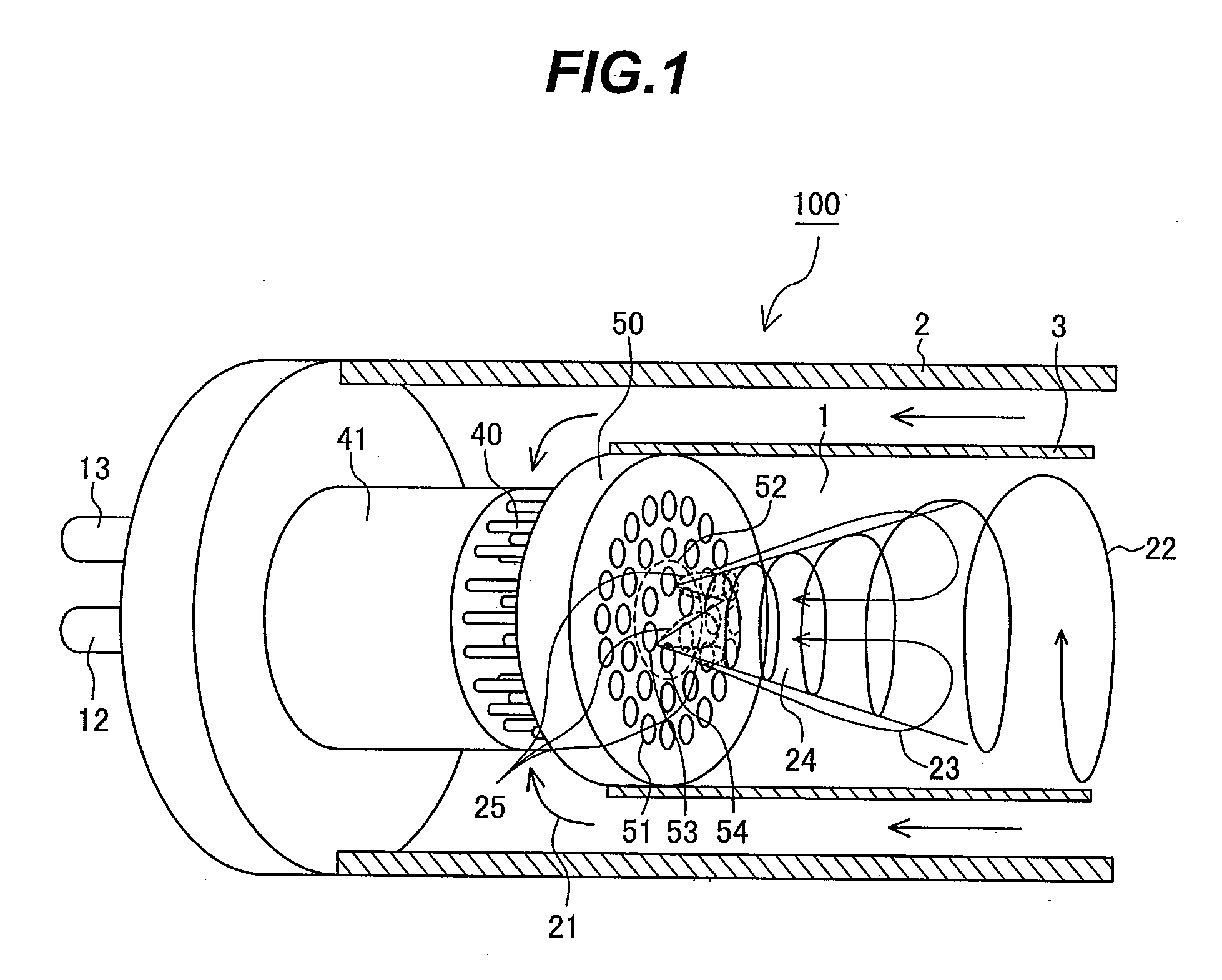

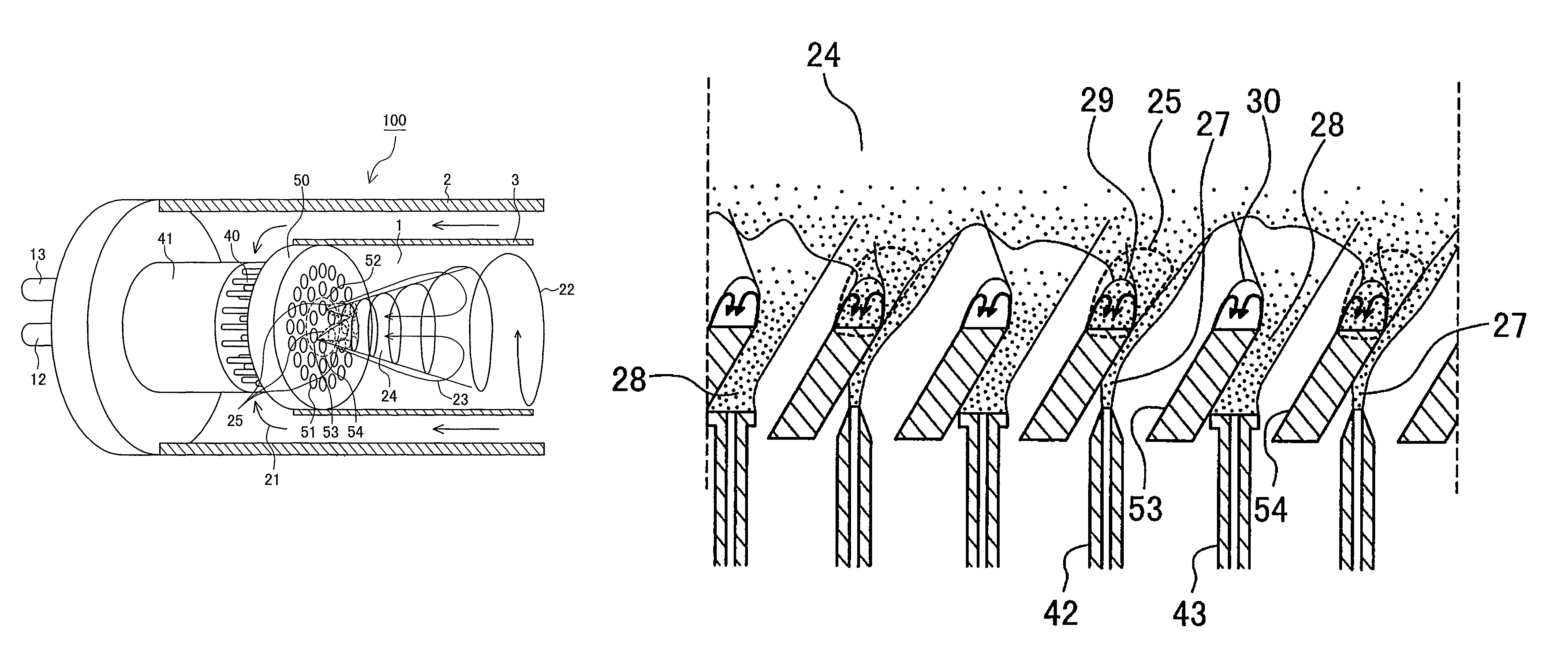

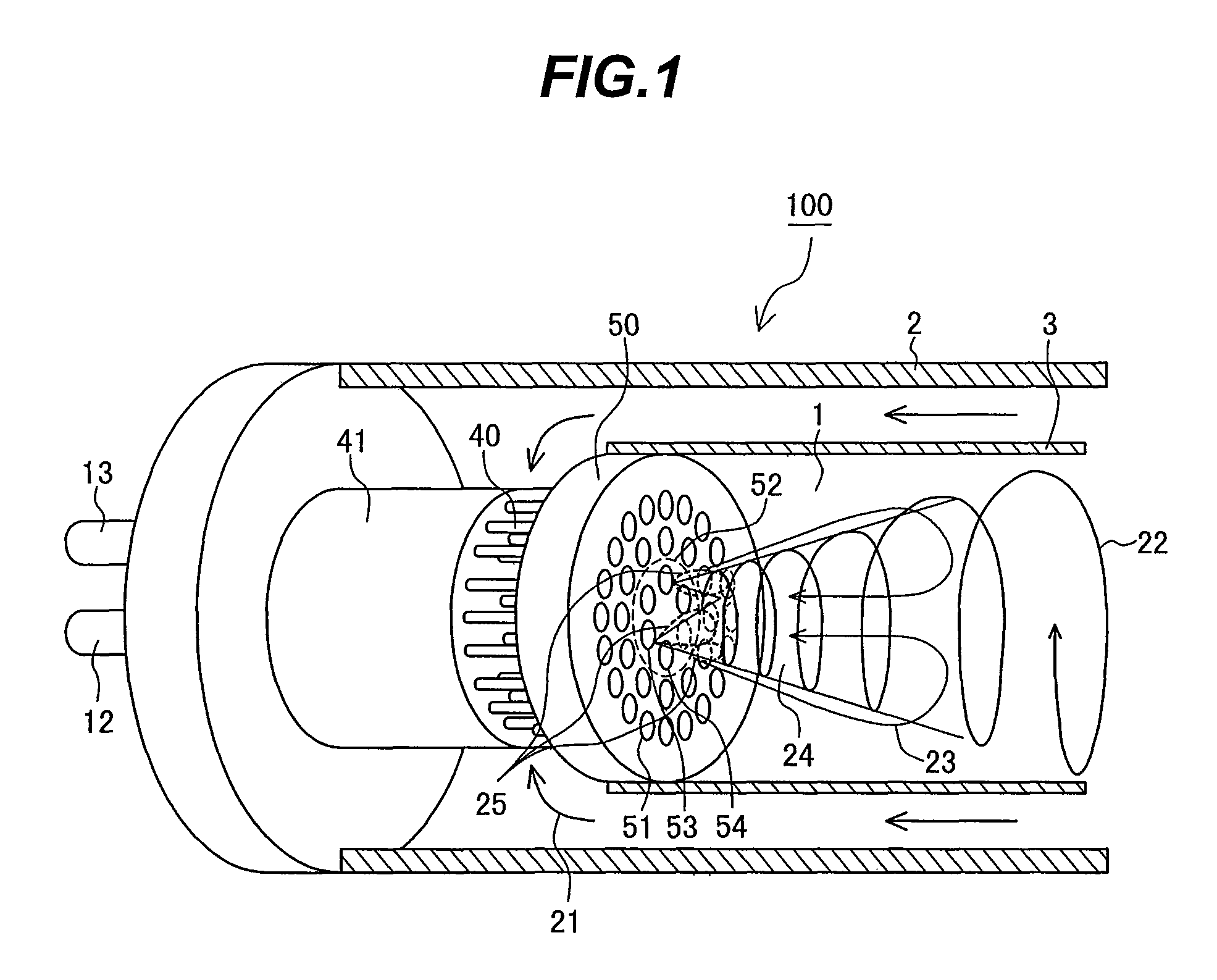

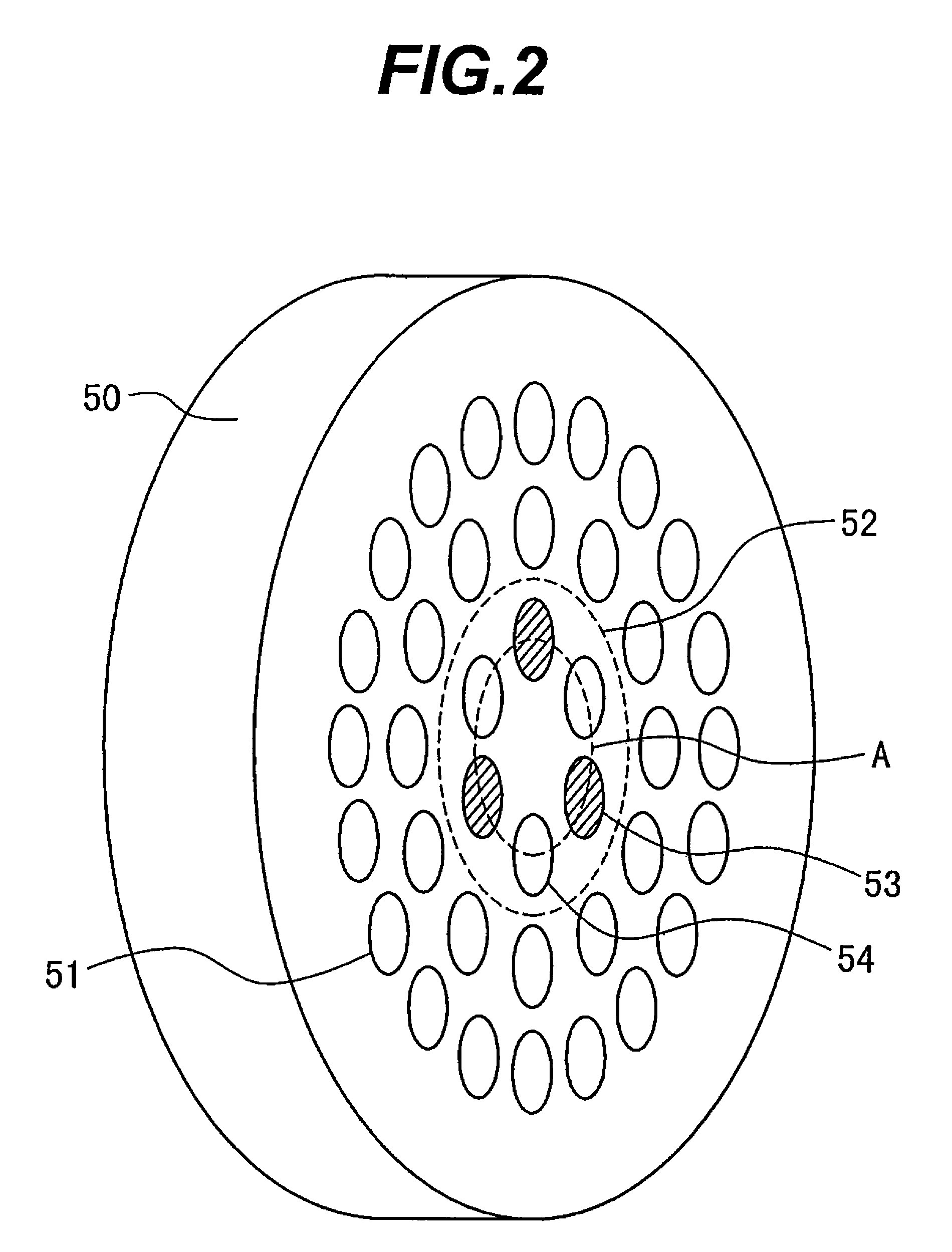

Combustor and a fuel supply method for the combustor

ActiveUS20090031728A1Improve flame stabilityMaintain stabilityContinuous combustion chamberGas turbine plantsCombustorEngineering

A combustor includes a chamber mixing and burning fuel and air and an air hole plate disposed on a wall surface of the chamber. The air hole plate includes a plurality of rows disposed concentrically of a plurality of air holes jetting coaxial jets of fuel and air into the chamber. A first fuel nozzle and a second fuel nozzle are disposed near a fuel hole for jetting fuel into an air hole row on an inner peripheral side. The first fuel nozzle is structured to suppress turbulence of surrounding air flow and the second fuel nozzle is structured to promote turbulence of a surrounding air flow.In accordance with the aspect of the present invention, good flame stability can be maintained while further reducing NOx in a combustor using coaxial jets.

Owner:MITSUBISHI POWER LTD

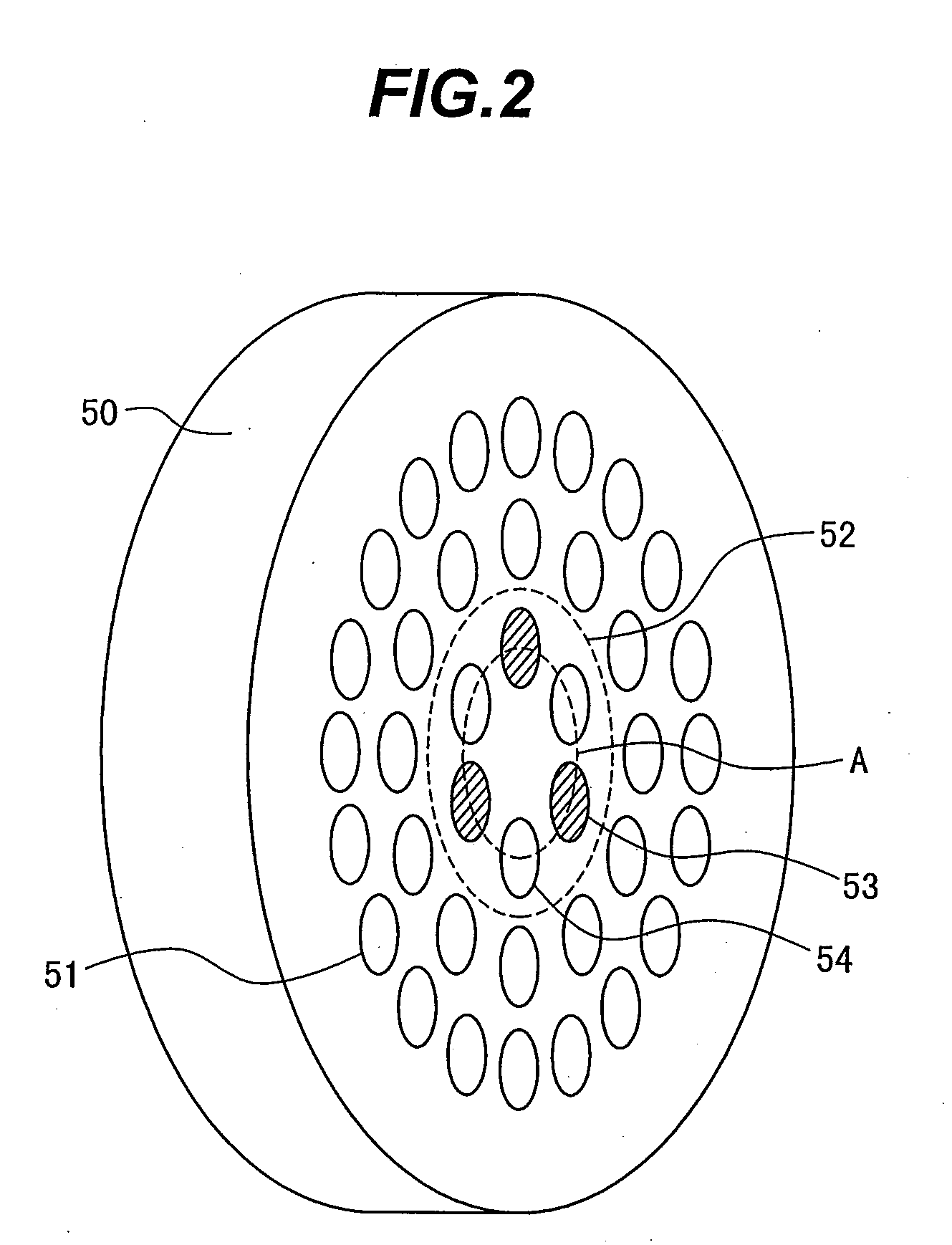

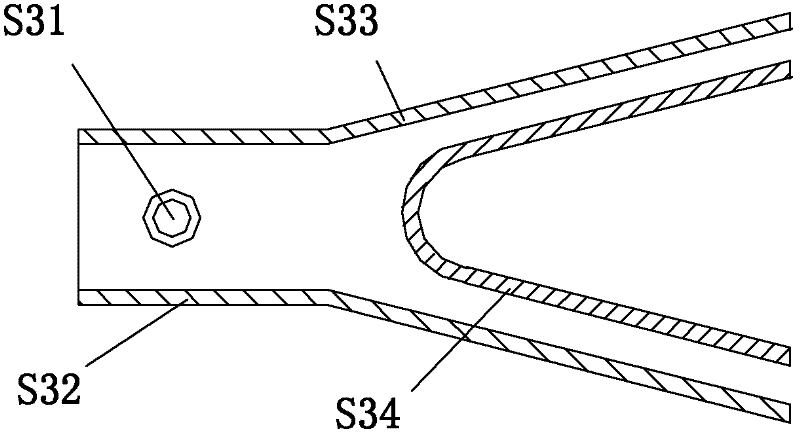

Oven or grill burner, venturi tube, mounting for a thermocouple and/or an igniter, and process for fabricating said burner

ActiveUS20050138789A1Function increaseStrong construction adaptabilityDomestic stoves or rangesBurner manufactureCombustorCoupling

The invention relates to a burner comprising two half shells, one of which is perforated, that are tightly joined together along at least a portion of their edges, so as to form a tubular body communicating with a venturi tube. At least two corresponding ends of the two half shells have a truncated profile, providing the tubular body has at least one truncated end. The invention also relates to a venturi tube for said burner that is composed of two half shells The invention further relates to a mounting for a thermocouple and for an igniter of said burner, the mounting having coupling means that cause mutual contact surfaces to be oriented in at least three non-parallel planes and that prevent mounting rotation, so that the position thereof is accurately defined. The invention also relates to a process for fabricating said burner.

Owner:CAST SPA

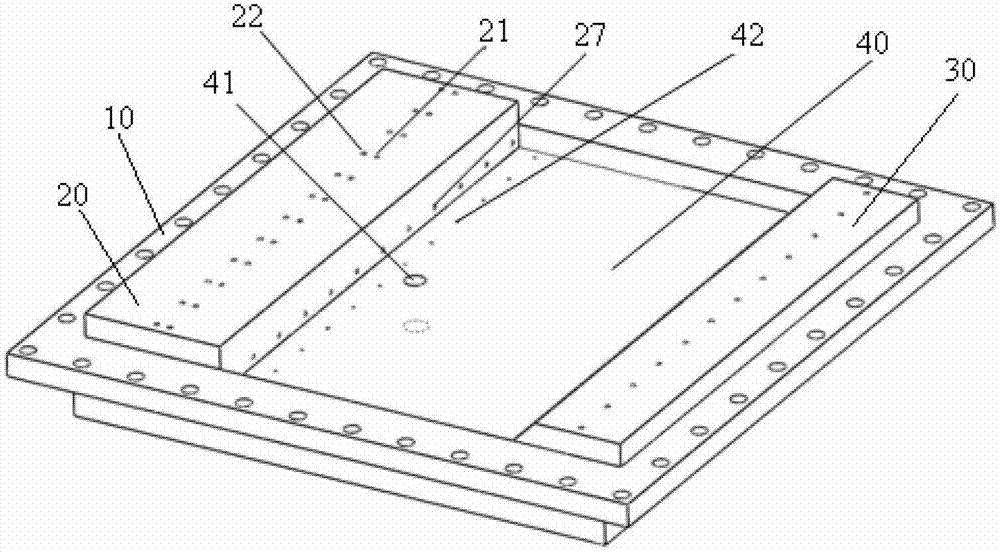

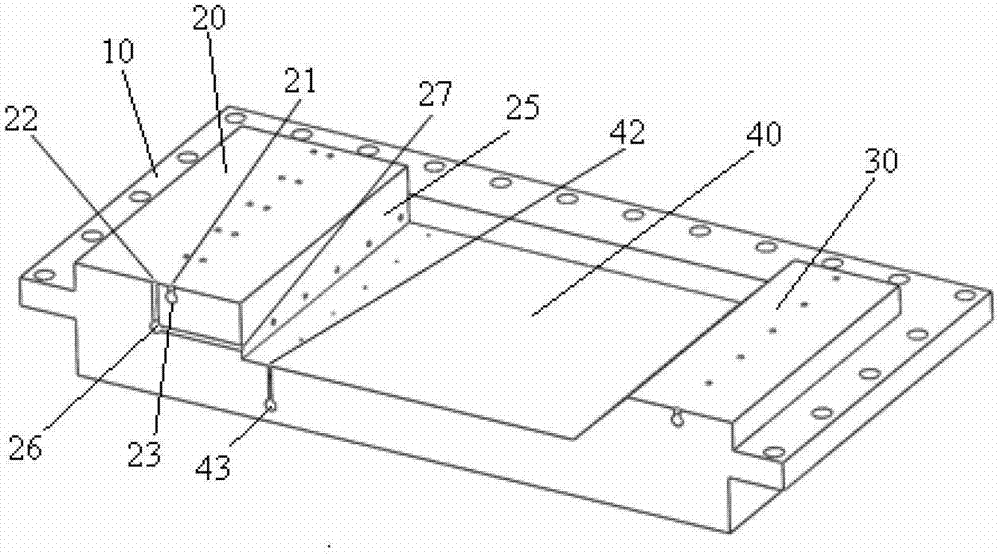

Supersonic combustor wall surface concave cavity structure and engine combustor comprising same

ActiveCN102966974AWarm upImprove combustion efficiencyContinuous combustion chamberEngineeringCombustor

The invention provides a supersonic combustor wall surface concave cavity structure and an engine combustor comprising the same. The supersonic combustor wall surface concave cavity structure comprises a mounting base (10), wherein a combustor wall surface concave cavity (40) is arranged in the mounting base (10); the upstream of the combustor wall surface concave cavity (40), positioned on the air inlet side, is equipped with a flow guiding hole (22); and correspondingly, the downstream of the flow guiding hole (22) is equipped with a concave cavity upstream fuel spray hole (21); the concave cavity upstream fuel spray hole (21) is nearer to the flow guiding hole (22); the downstream of the concave cavity upstream fuel spray hole (21) is equipped with a flow guiding hole outlet (27) which is communicated with the flow guiding hole (22); and the flow guiding hole outlet (27) is communicated with the concave cavity upstream fuel spray hole (21). The supersonic combustor wall surface concave cavity structure provided by the invention has a simple structure, can urge the ignition of fuels in the concave cavity before the ignition, and can reinforce the jet combustion of the fuels after the ignition.

Owner:NAT UNIV OF DEFENSE TECH

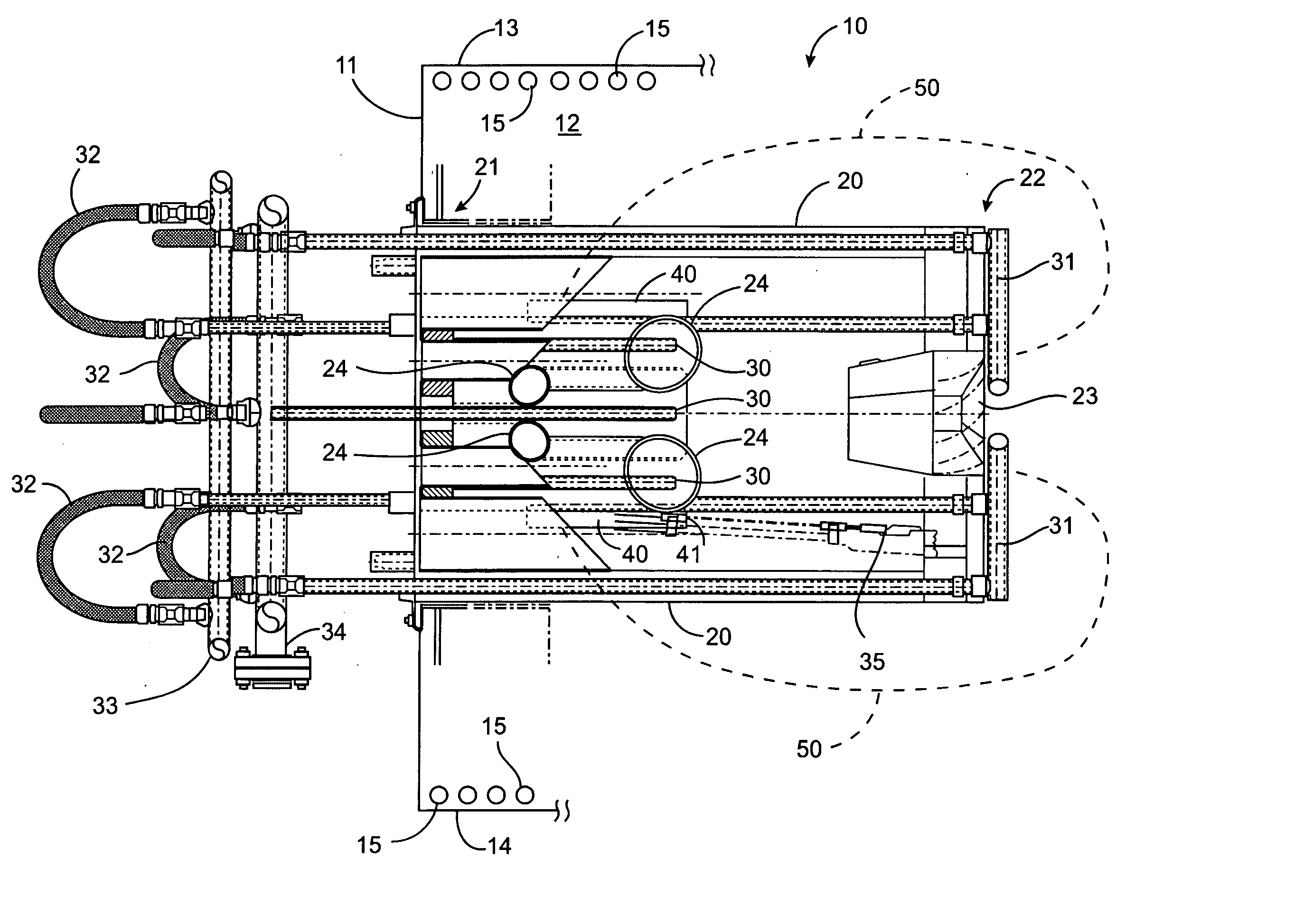

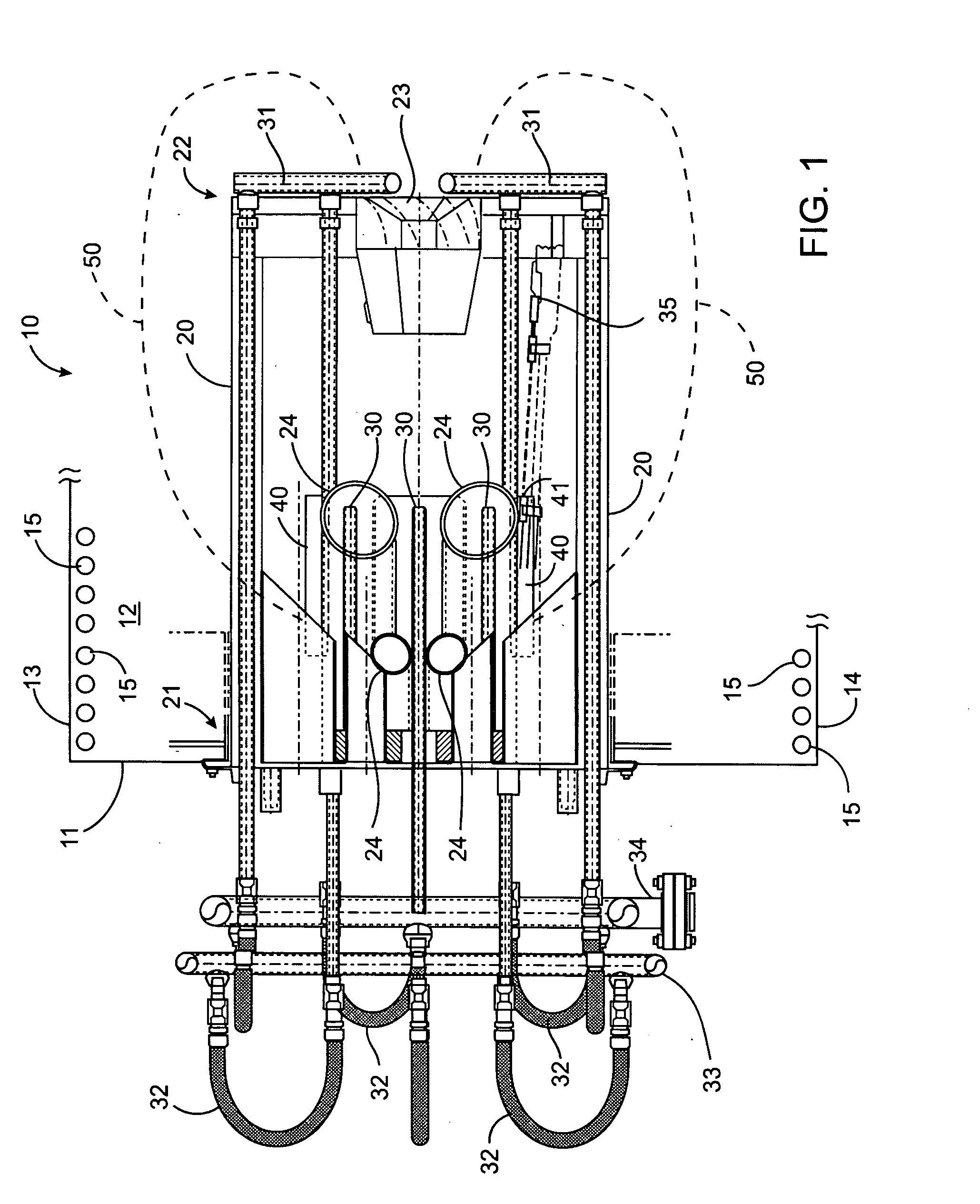

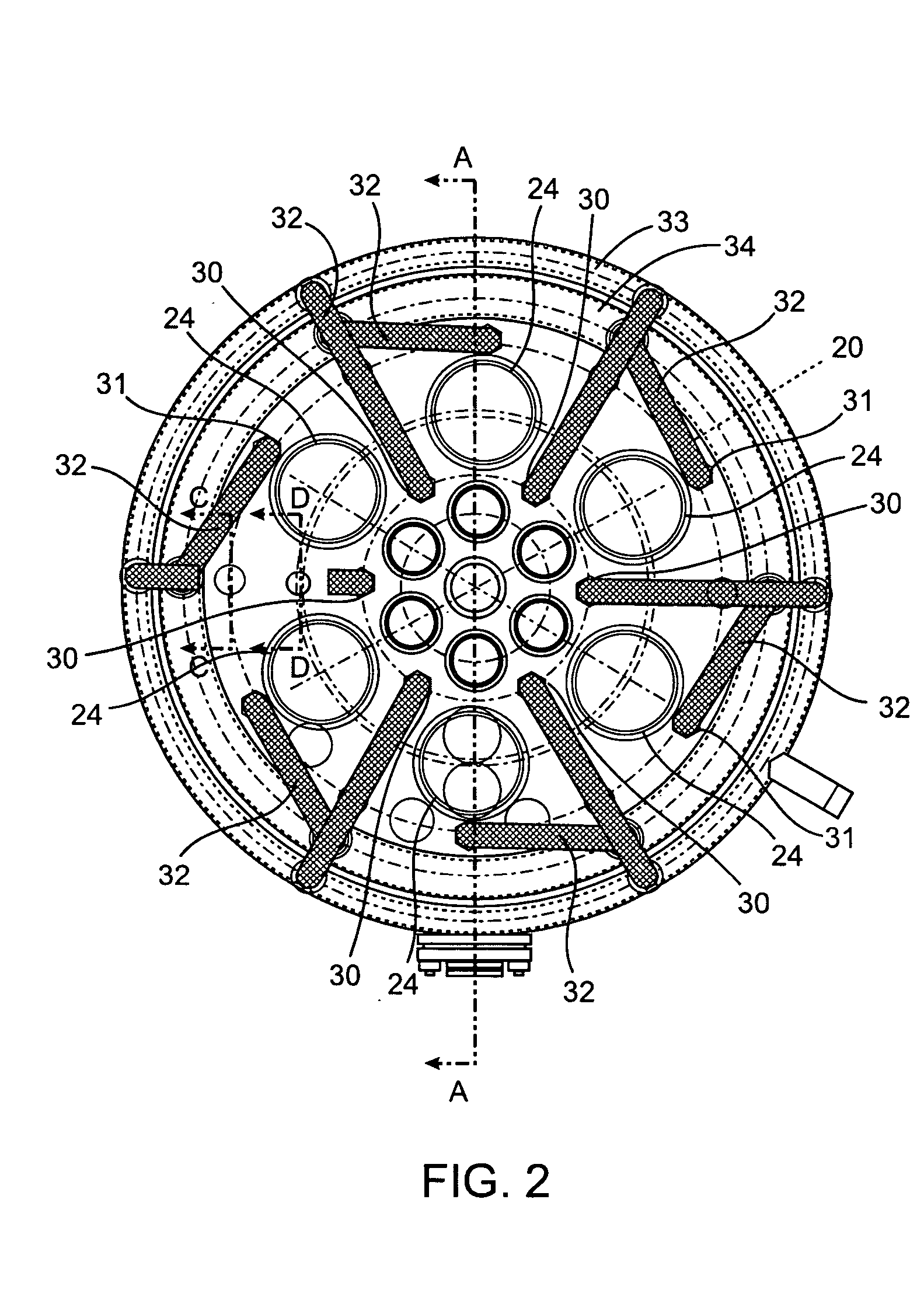

Method for operating a burner and burner with stepped premix gas injection

InactiveUS6769903B2Improve flame stabilityEmission reductionGas turbine plantsTurbine/propulsion fuel controlPresent methodCombustor

The present invention relates to a method of operating a burner, which comprises at least one first fuel supply conduit (5) with a first group of fuel outlet openings (6), essentially arranged in the direction of a burner longitudinal axis (3), for a first premix fuel quantity and one or a plurality of second fuel supply conduits (7) with a second group of fuel outlet openings (8), essentially arranged in the direction of the burner longitudinal axis (3), for a second premix fuel quantity, it being possible to admit fuel to the second fuel supply conduits (7) independently of the first fuel supply conduit (5). In the method, both fuel supply conduits (5, 7) are operated with the same fuel. By means of the present method of operating a burner, optimum mixing conditions can be set even in the case of different loads, gas qualities or gas preheat temperatures.

Owner:ANSALDO ENERGIA SWITZERLAND AG

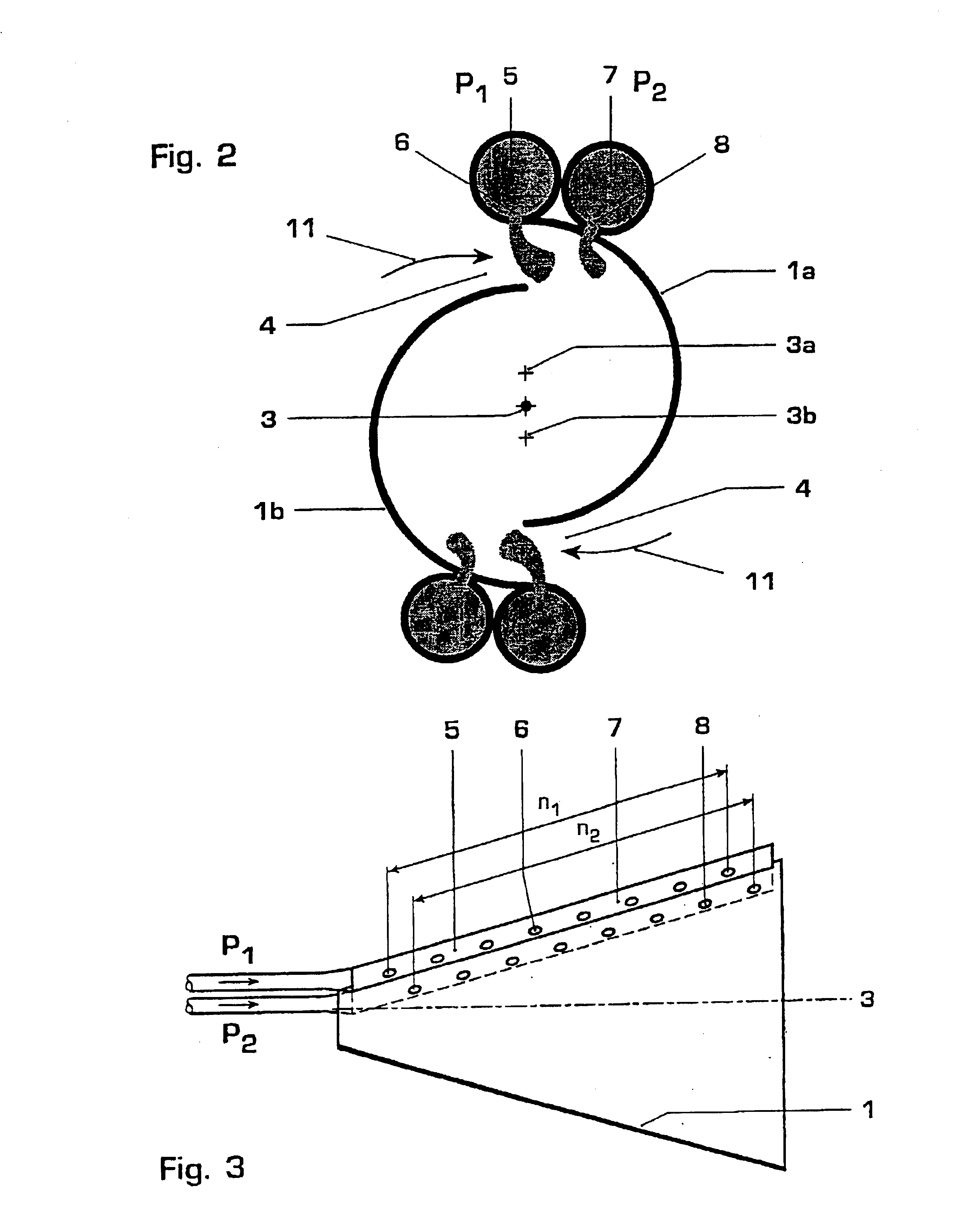

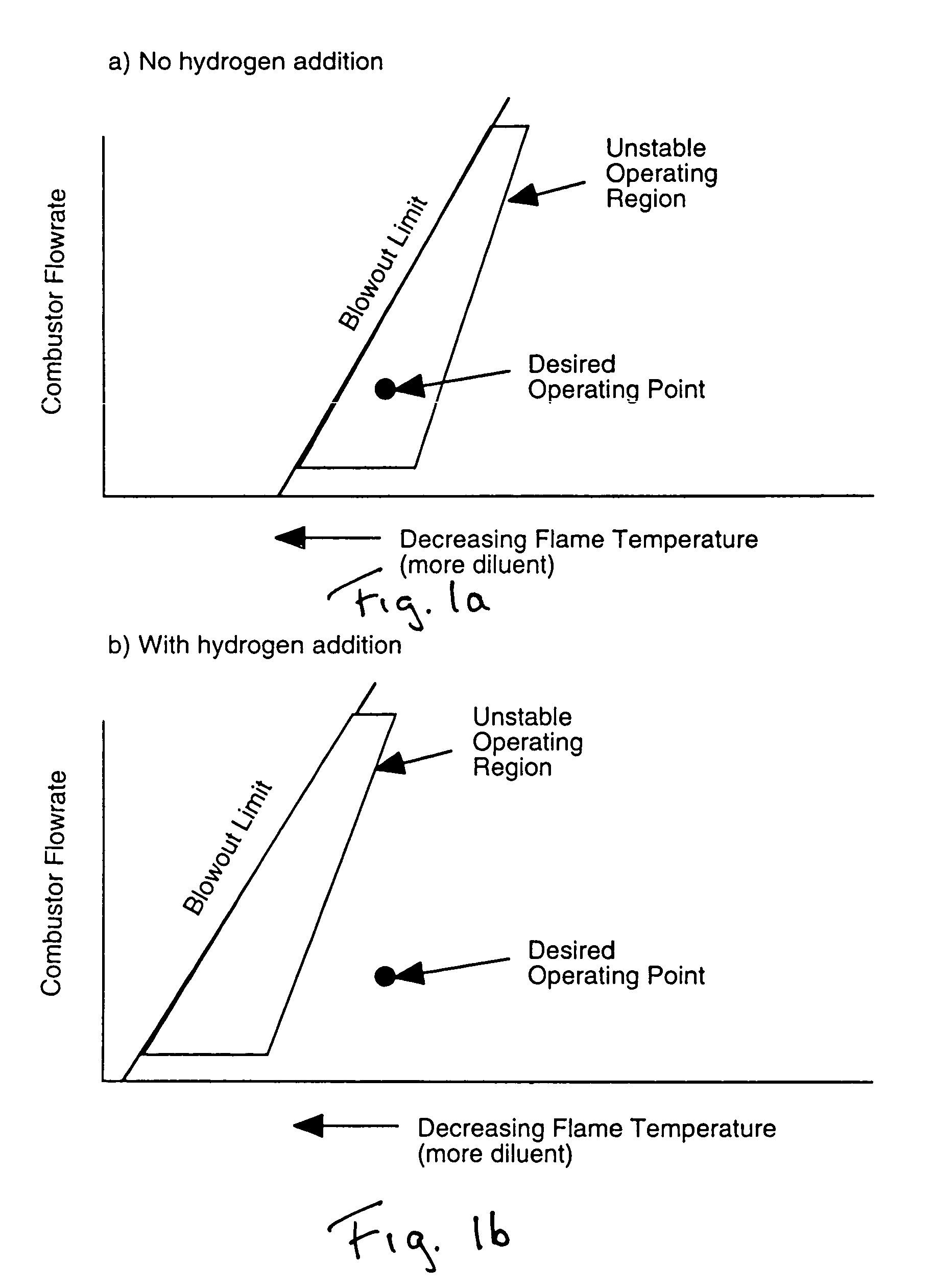

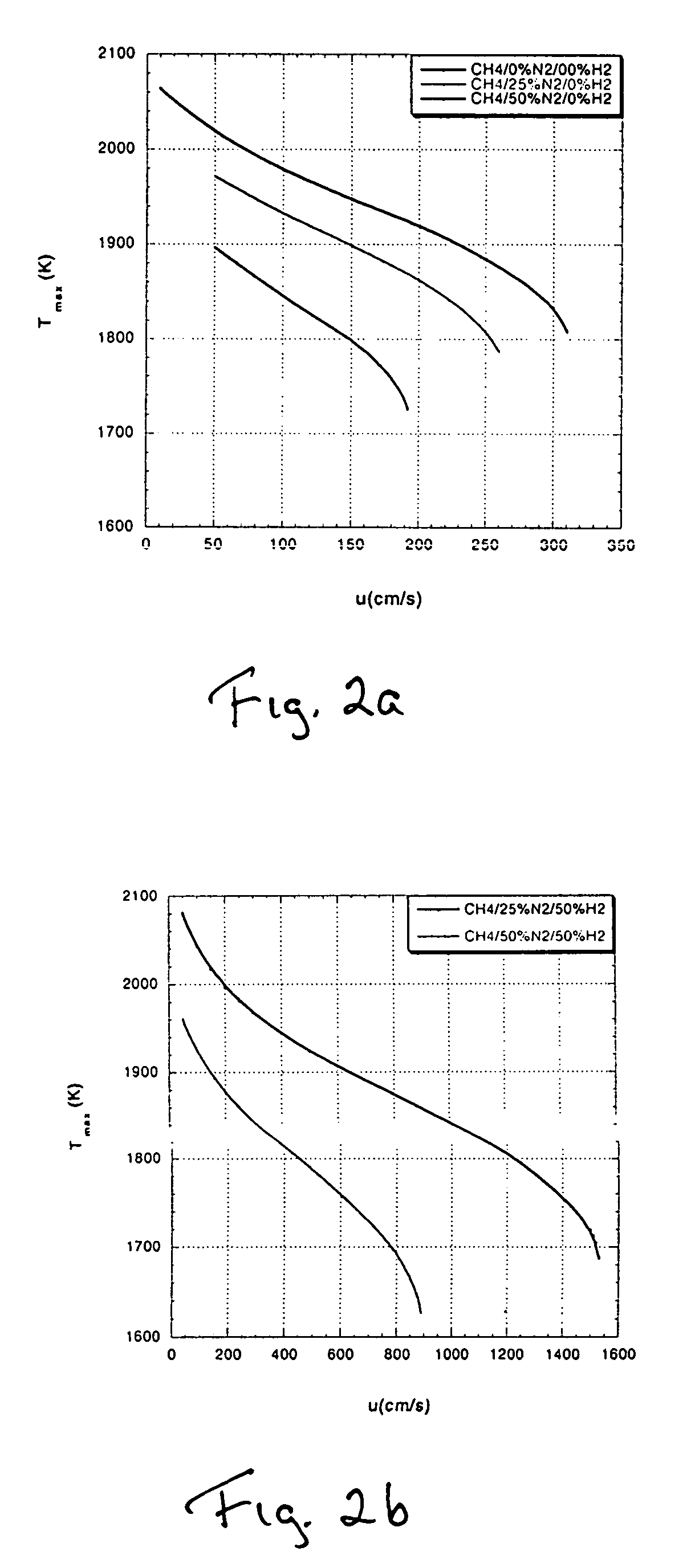

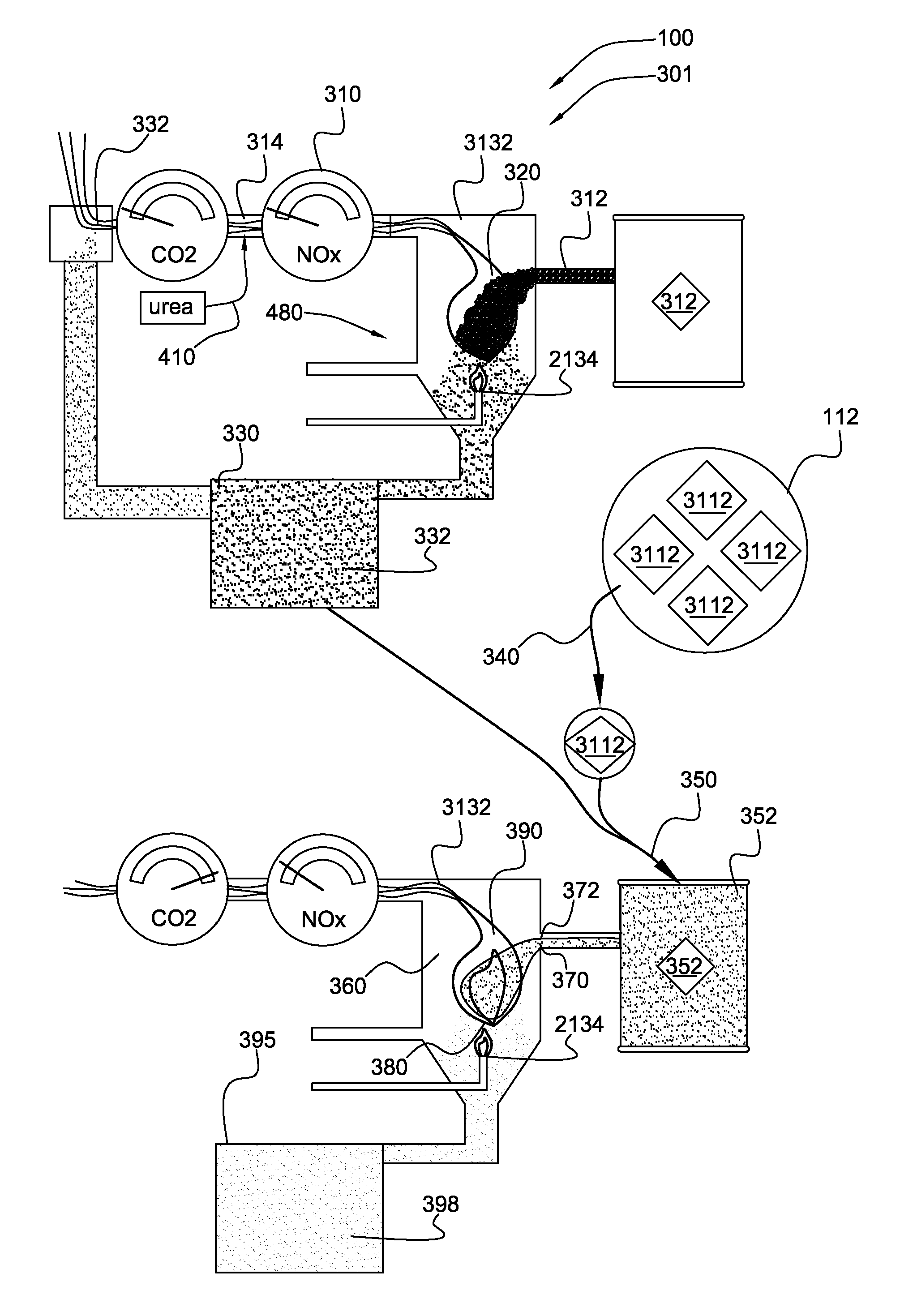

Method for control of NOx emission from combustors using fuel dilution

ActiveUS7162864B1Fast reaction timeLower temperatureInternal combustion piston enginesExhaust apparatusBiomassGas turbines

A method of controlling NOx emission from combustors. The method involves the controlled addition of a diluent such as nitrogen or water vapor, to a base fuel to reduce the flame temperature, thereby reducing NOx production. At the same time, a gas capable of enhancing flame stability and improving low temperature combustion characteristics, such as hydrogen, is added to the fuel mixture. The base fuel can be natural gas for use in industrial and power generation gas turbines and other burners. However, the method described herein is equally applicable to other common fuels such as coal gas, biomass-derived fuels and other common hydrocarbon fuels. The unique combustion characteristics associated with the use of hydrogen, particularly faster flame speed, higher reaction rates, and increased resistance to fluid-mechanical strain, alter the burner combustion characteristics sufficiently to allow operation at the desired lower temperature conditions resulting from diluent addition, without the onset of unstable combustion that can arise at lower combustor operating temperatures.

Owner:SANDIA NATIOANL LAB

On-duty flame stabilizer

The invention discloses an on-duty flame stabilizer, which comprises an atomization slot, an oil injection rod, an evaporation tube, a stabilizer side wall and air injection holes, wherein the atomization slot is a slot-shaped structural part with certain wall thickness and is arranged in the evaporation tube, a slot mouth points downstream, and the oil injection rod is at downstream position; the oil injection rod is provided with a plurality of oil injection holes and is arranged in the evaporation tube; the evaporation tube is a slot-shaped structural part with the air injection holes at both sides and certain wall thickness, and the outer side of the evaporation tube is provided with a stabilizer side wall; the stabilizer side wall is a two-side plat plate type structural part with certain wall thickness, and two flat plates have a certain flare angle downstream; a gap is left between the atomization slot and the evaporation tube, and the gap is flush at the head part of the stabilizer; a gap is left between the evaporation tube and the stabilizer side wall, and the gap is flush at the head part of the stabilizer; the air injection holes are positioned at both sides of the evaporation tube close to the bottom; and the on-duty flame stabilizer can be used in an aircraft engine and a stamping engine to improve the ignition performance, the flame stability and the combustion efficiency.

Owner:PEKING UNIV

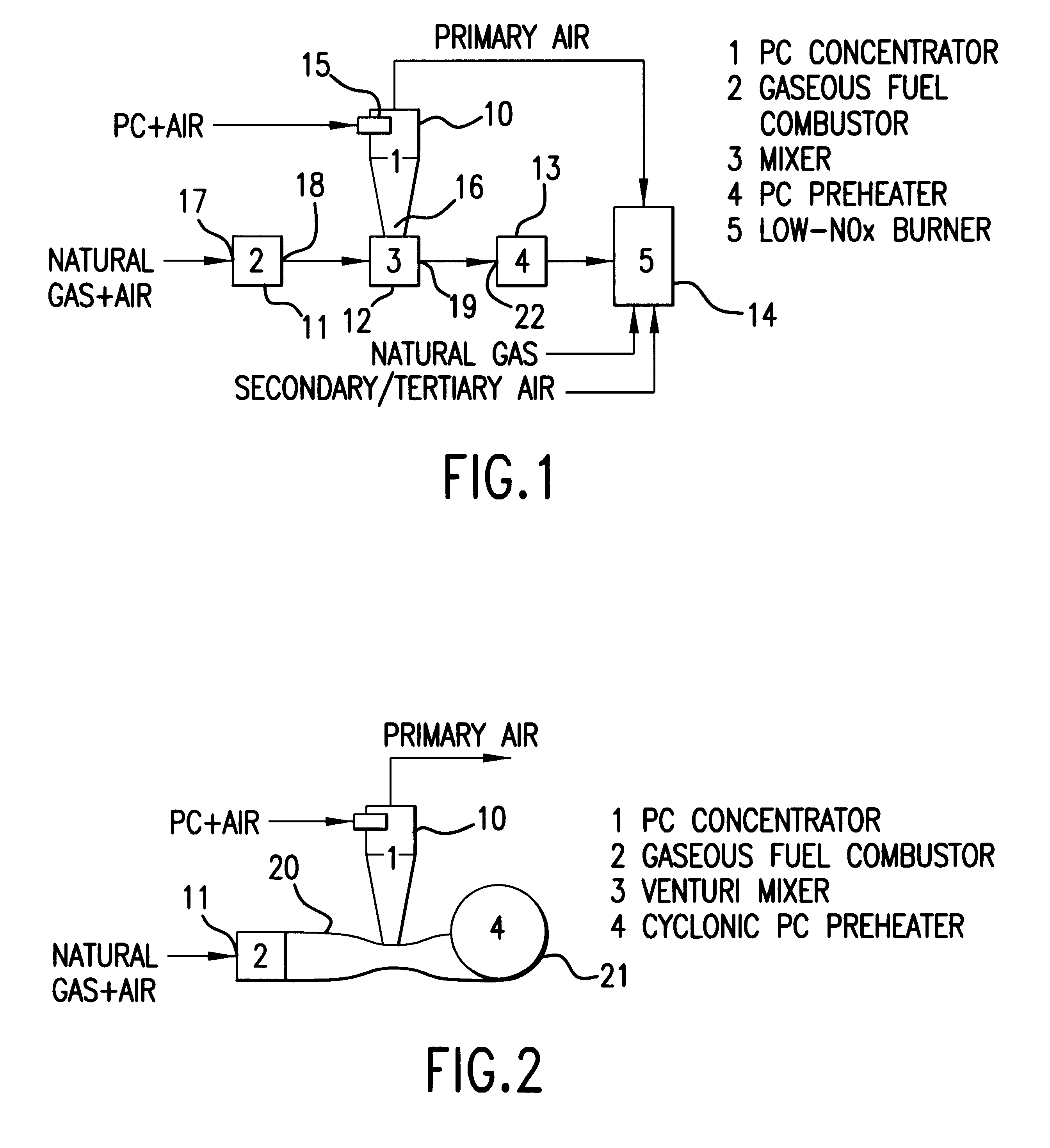

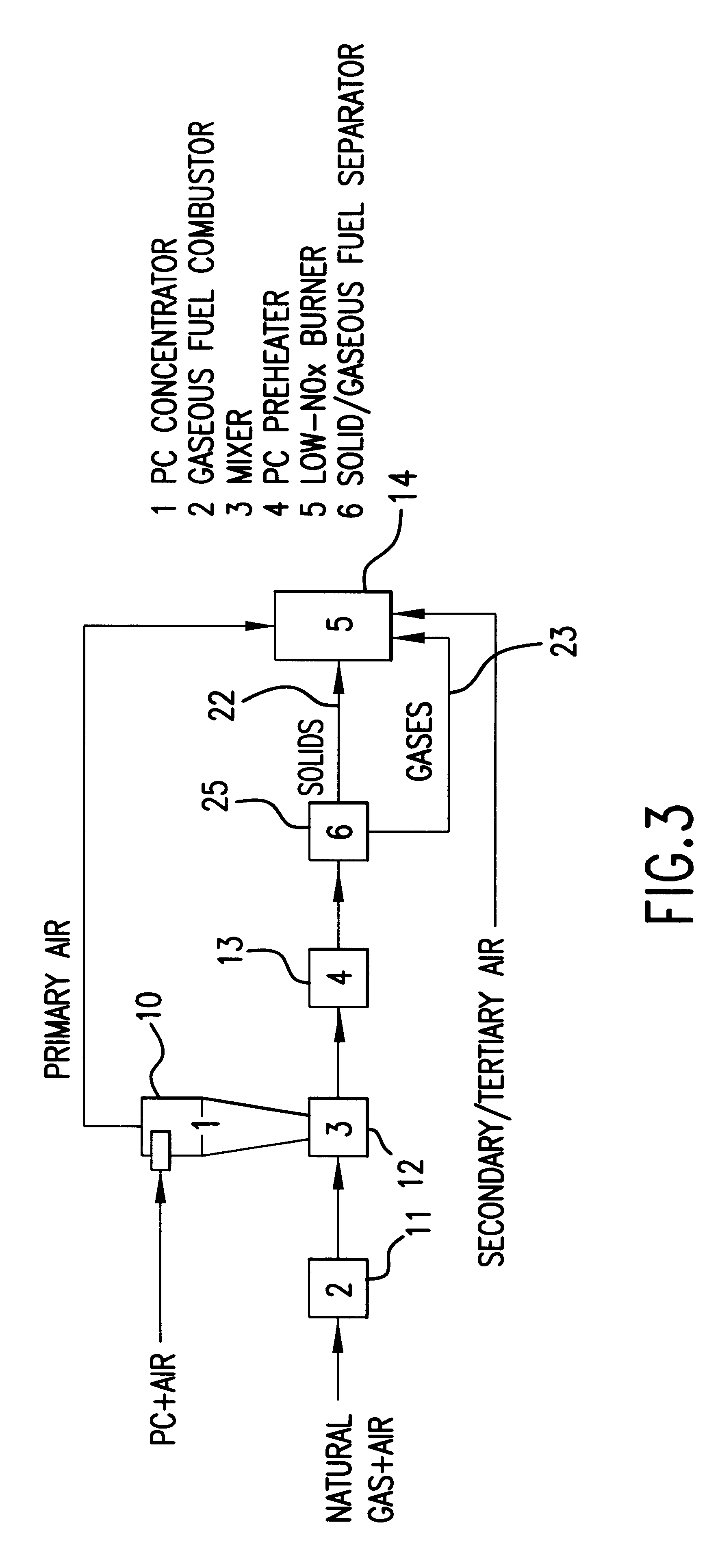

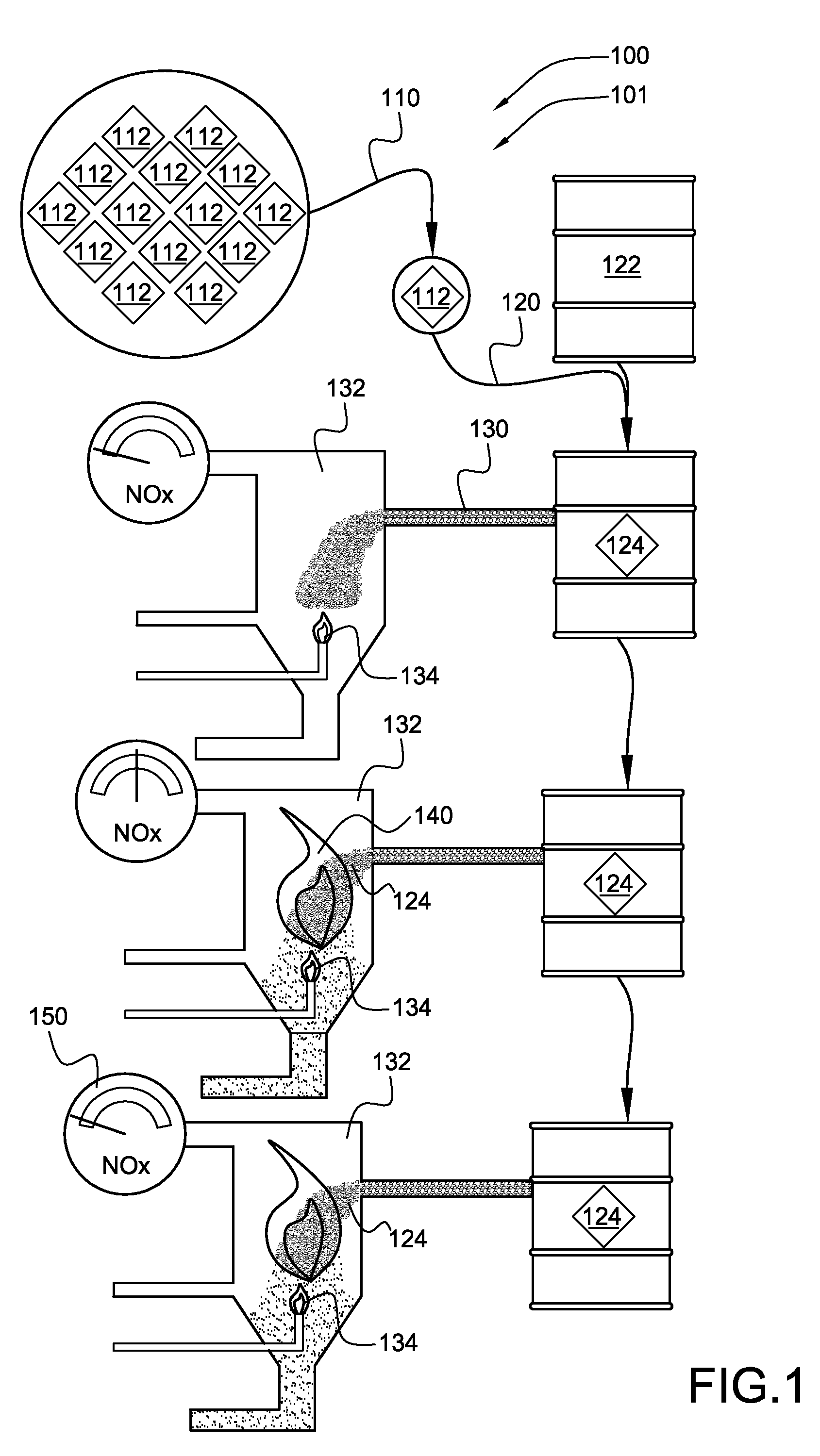

Low NOx pulverized solid fuel combustion process and apparatus

InactiveUS6244200B1Reduce the amount requiredImprove combustion effectCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberPartial oxidation

A method and apparatus for low-NOx combustion of a pulverized solid fuel in which combustion products from a partial oxidation combustor are mixed with a pulverized solid fuel, thereby preheating the pulverized solid fuel and resulting in devolatilization of at least a portion of the pulverized solid fuel. The preheated pulverized solid fuel and the devolatilization products are then burned in a burner firing directly into a combustion chamber.

Owner:INST OF GAS TECH

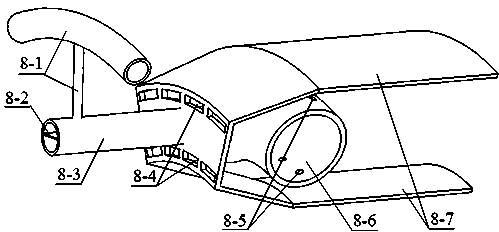

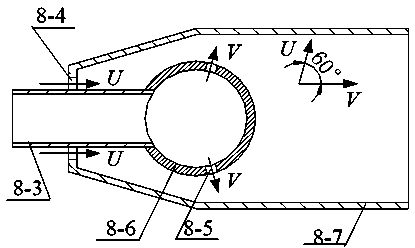

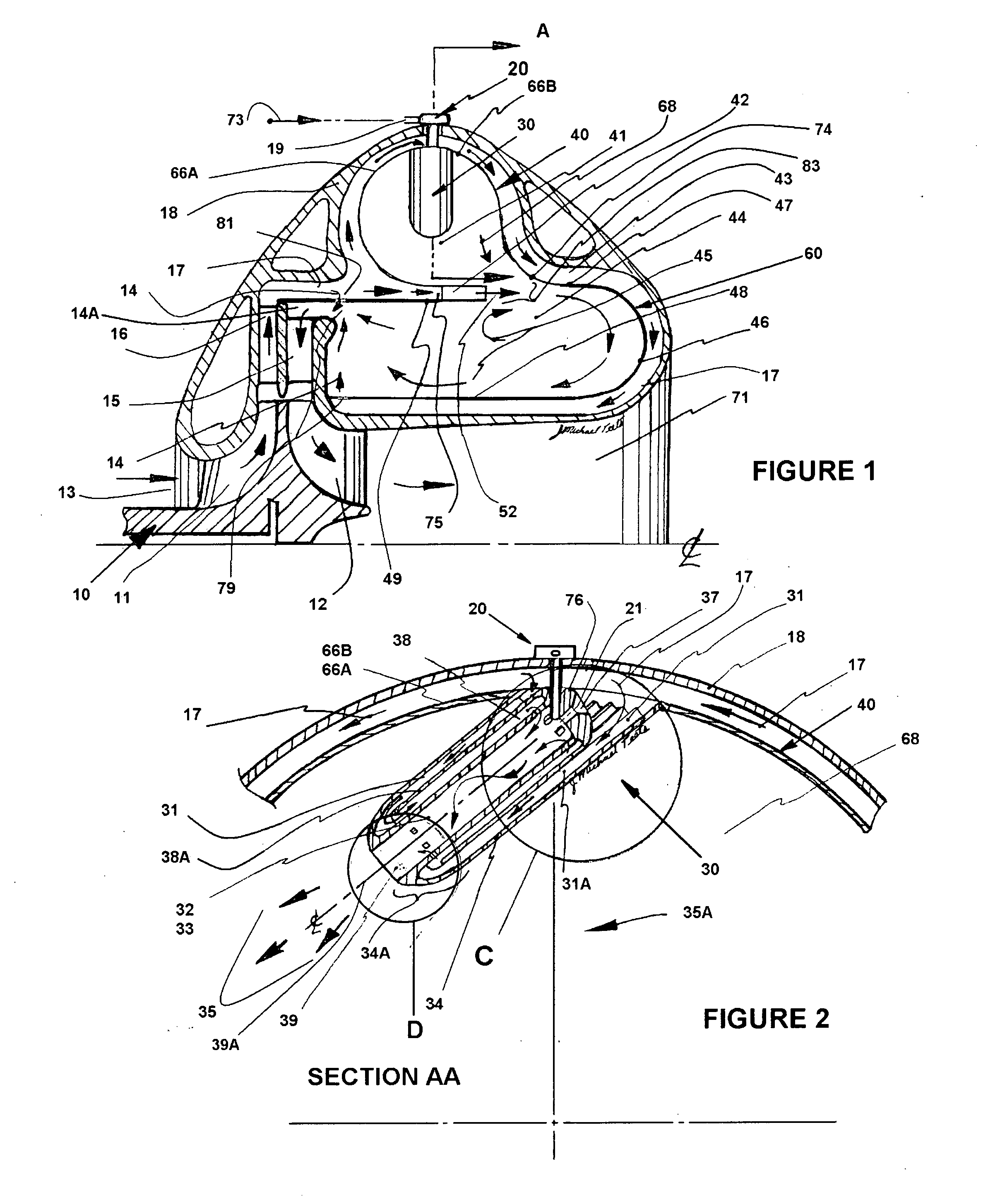

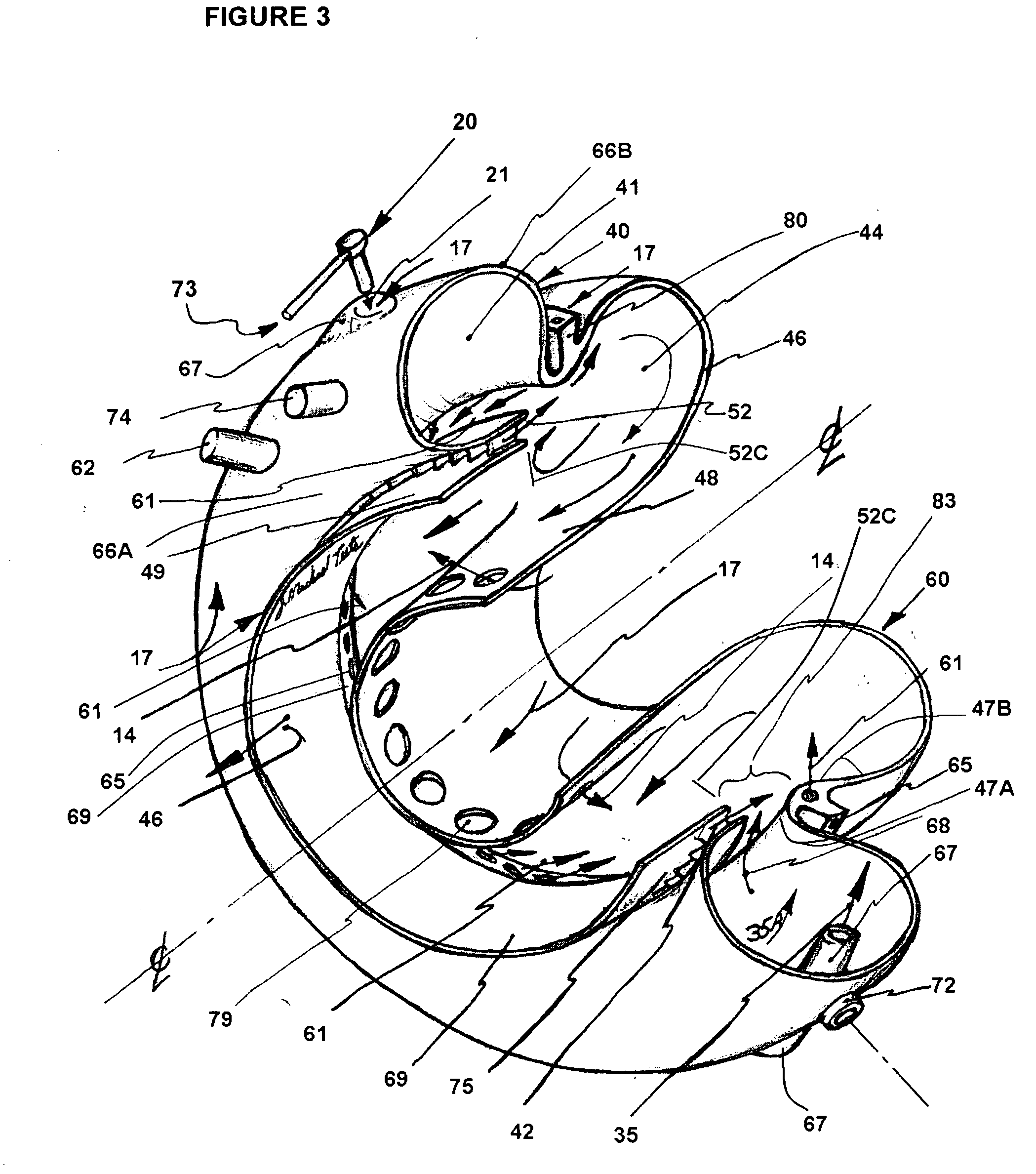

Fuel Air Premix Chamber For a Gas Turbine Engine

ActiveUS20140366542A1Low emissionCost reductionContinuous combustion chamberGas turbine plantsAirflowCombustion chamber

Fuel / air premixing chambers are applied to a gas turbine combustor RQL or LPP type integrated to the combustor with extension into the combustion zone. An integral heat exchange structure cools the premix chamber outer wall, preheating the compressor air supply as it passes into an inner central longitudinal premix tube preheating also the fuel and F / A mixture for improved mixedness, low emissions combustion and low differential combustor pressure.The F / A premix flow thru the central longitudinal tubes yields an exiting spouting velocity into the primary combustion zone for swirl / circumferential flow combustion yielding flame stability. Circumferentially close spaced premixing chambers about the combustor outer wall, are tangentially positioned for internal combustion hot gas flow, preheating the adjacent premix chamber and generates internal sweeping hot gas flow preventing combustion chamber carbon issues. Incorporates low pressure fuel injection into a central longitudinal tube for reduced cost and system simplicity.

Owner:TEETAB JOSEPH MICHAEL

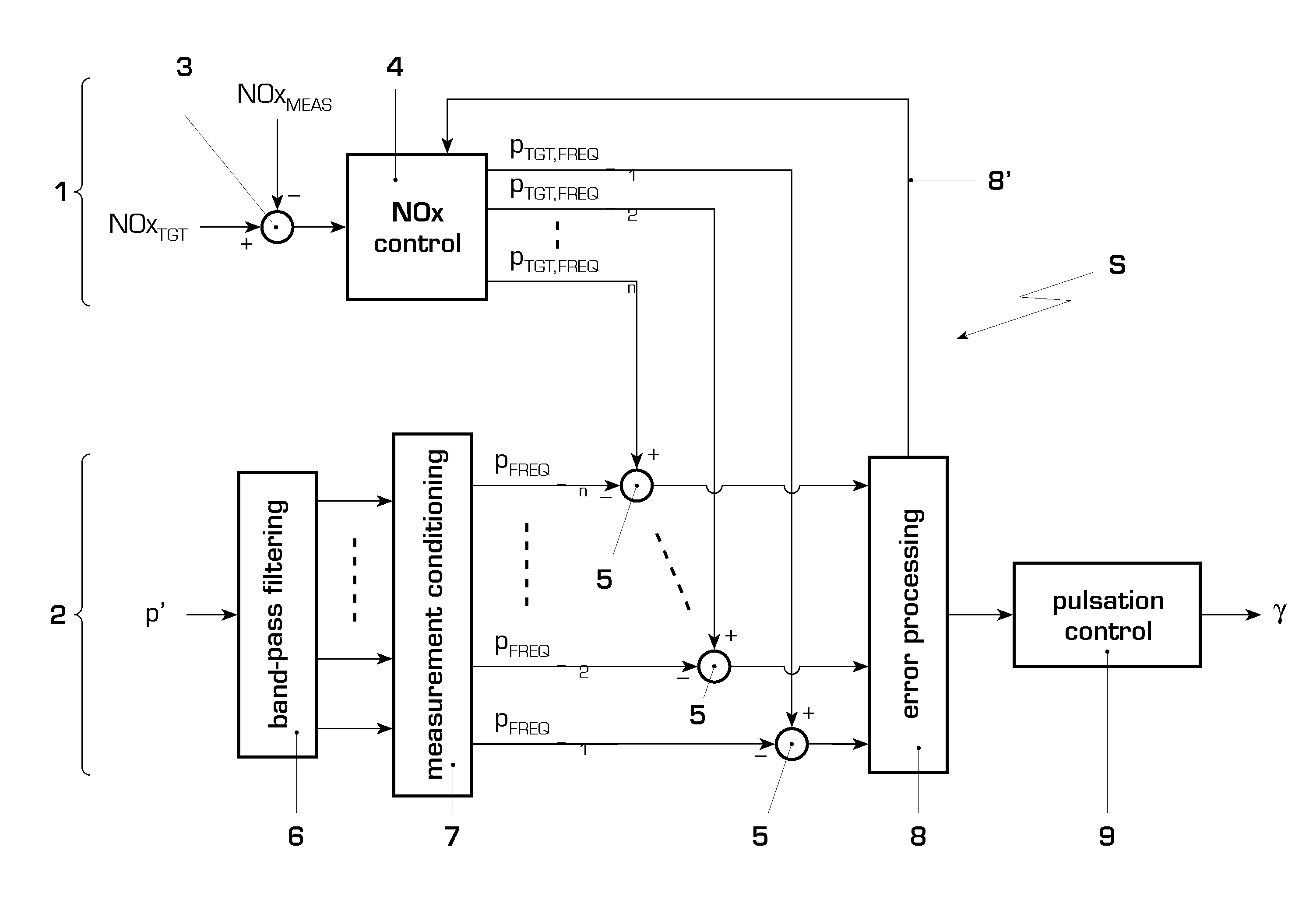

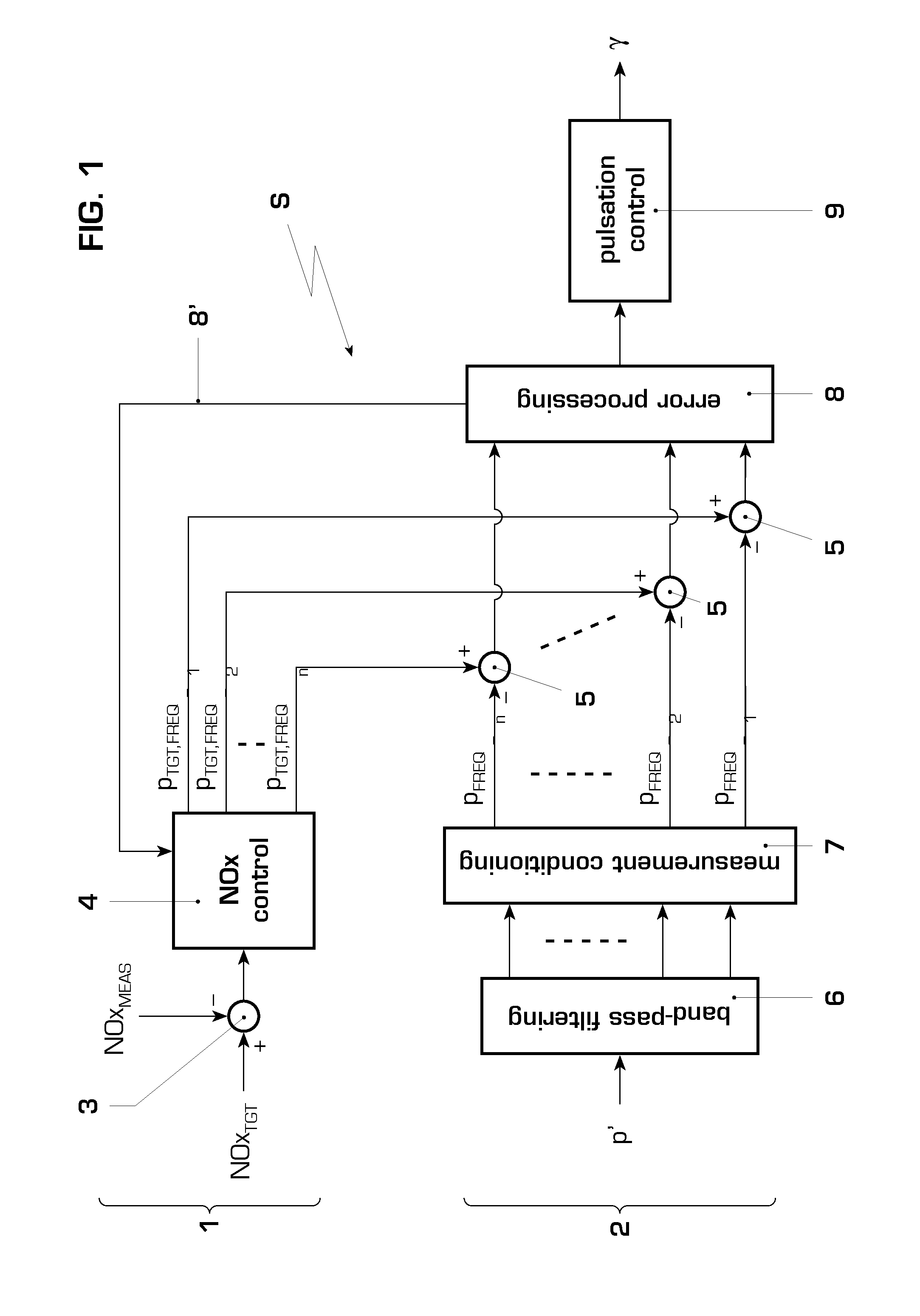

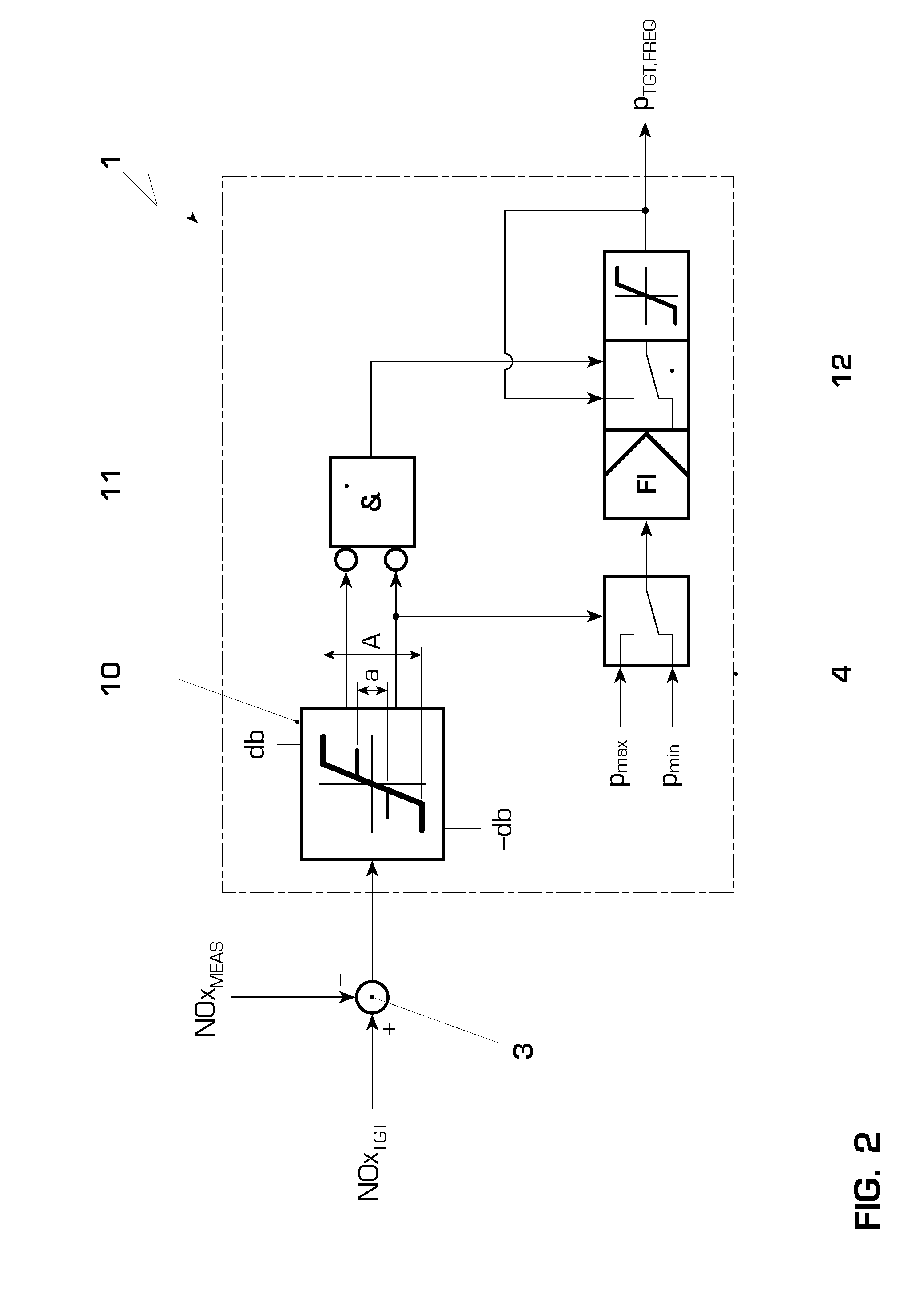

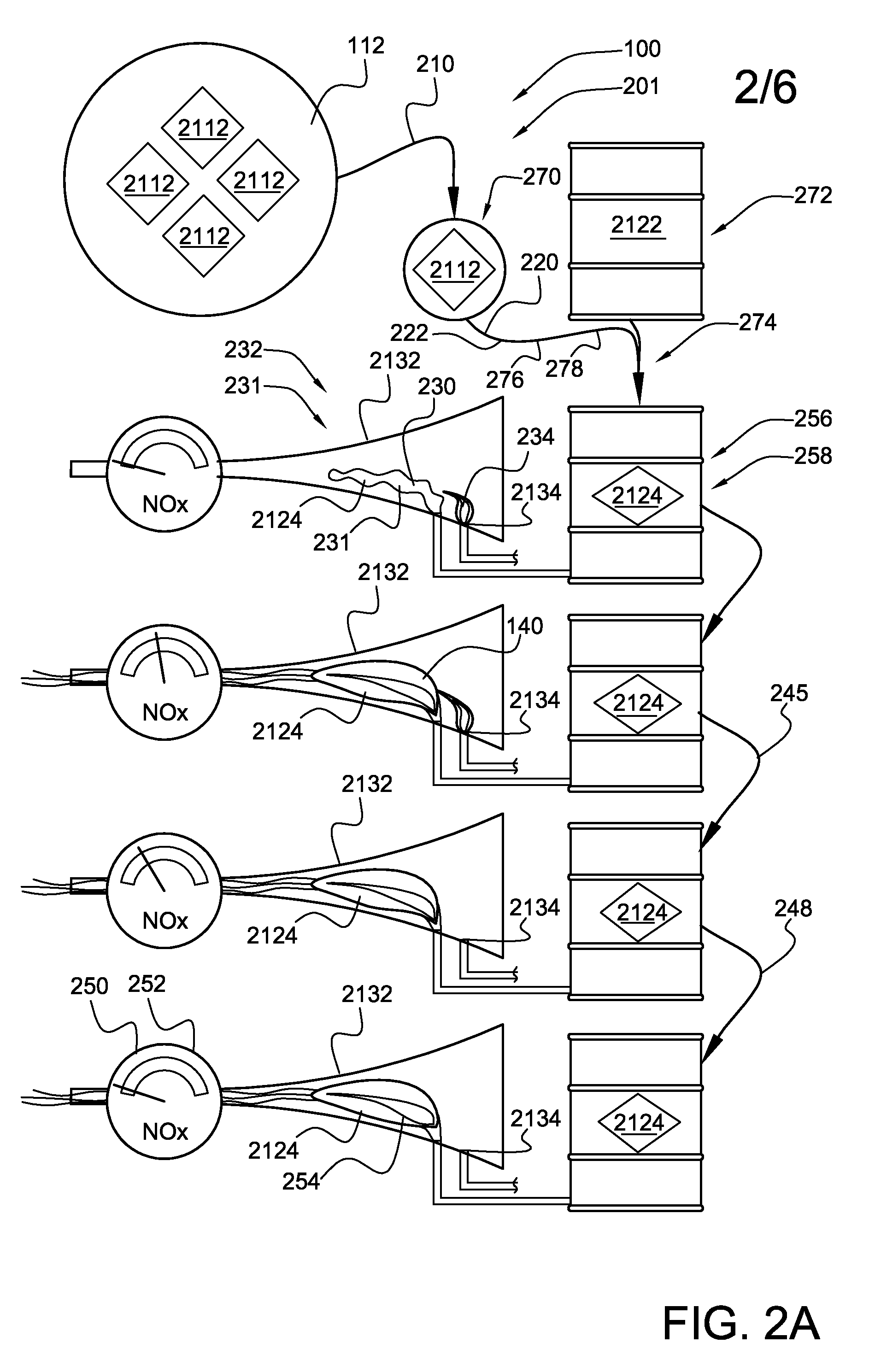

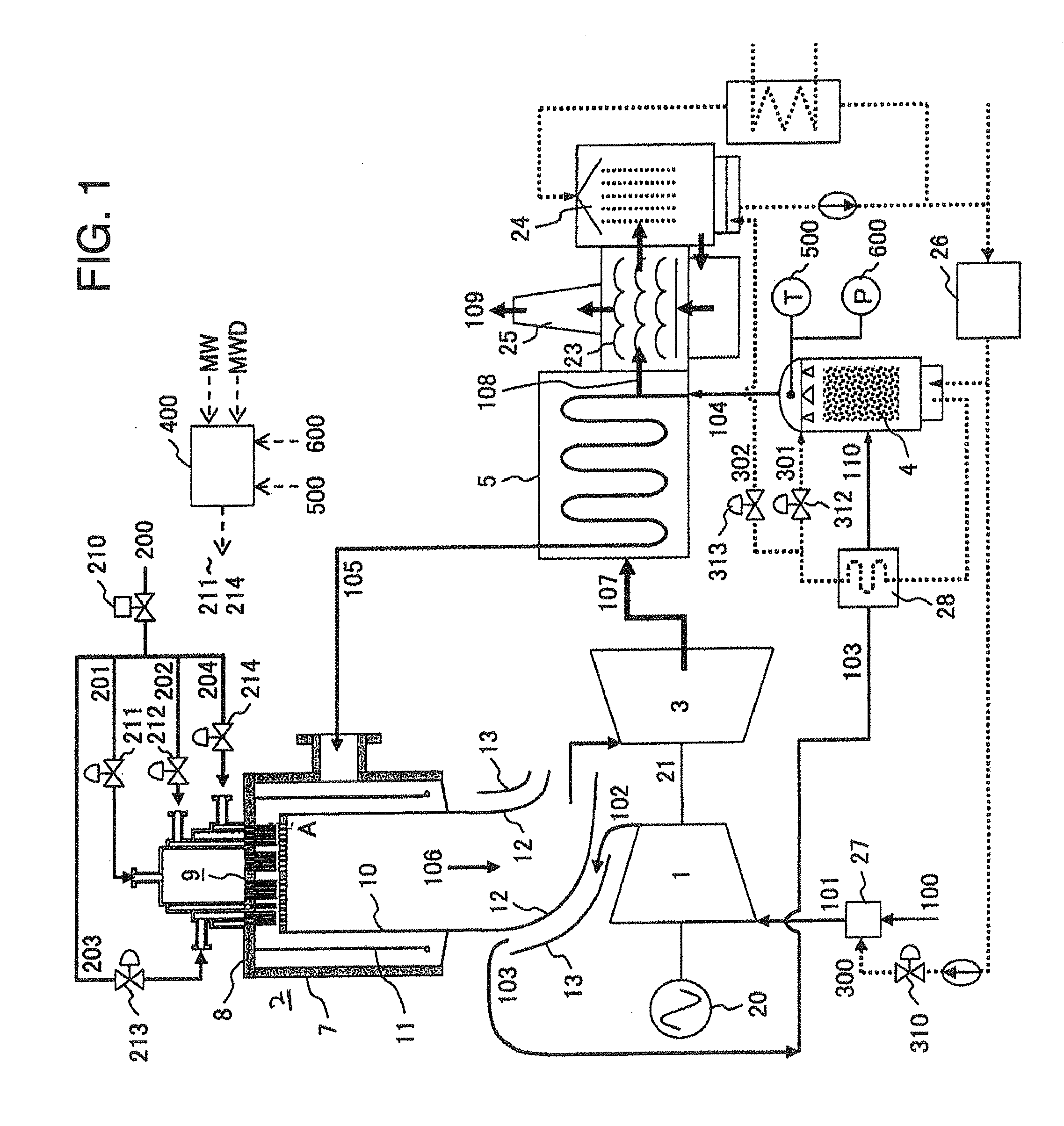

System for controlling a combustion process for a gas turbine

InactiveUS20090229238A1Improved and advantageous operationImprove abilitiesContinuous combustion chamberTurbine/propulsion engine ignitionCombustion systemCombustion chamber

A system (S) for controlling nitrogen oxide (NOx) emissions and combustion pulsation levels of a gas turbine having a gas turbine combustion system, having a single combustion chamber and multiple burners, includes a cascade structure having a first and second control level (1, 2), the first level (1) having a device to control NOx emissions and generate combustion pulsation target levels based on the difference between measured and target NOx emission levels, and the second level (2) having a device to control pulsation levels and generate a ratio (γ) of fuel flow to different types of burners or to different stages of each burner. The fuel flow ratio (γ) is based on the difference between the measured and generated target pulsation levels. The control system (S) enables the operation of a gas turbine to meet NOx emission requirements, while maintaining combustion pulsation levels within limits that ensure improved lifetime of the combustion system.

Owner:ANSALDO ENERGIA IP UK LTD

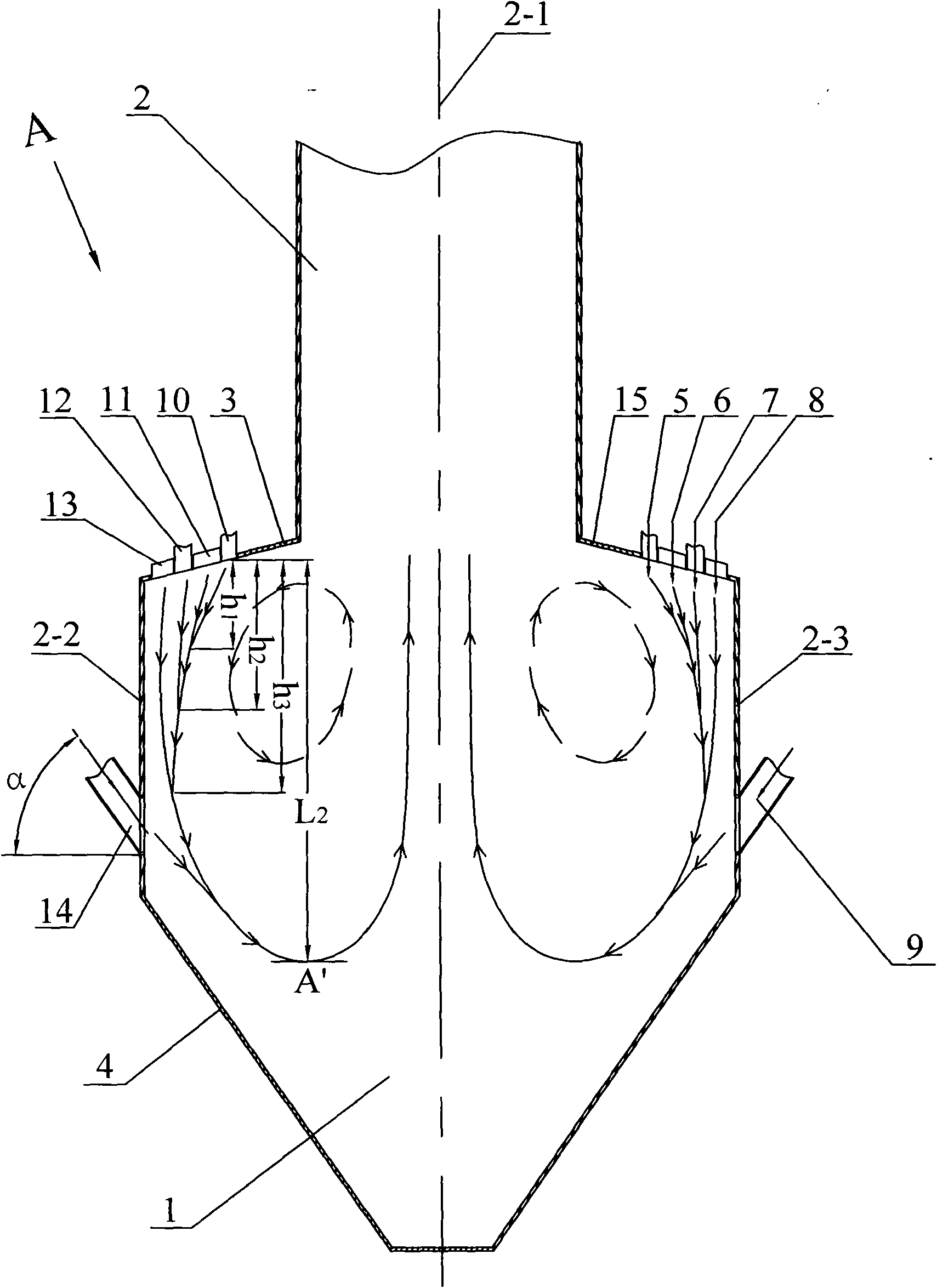

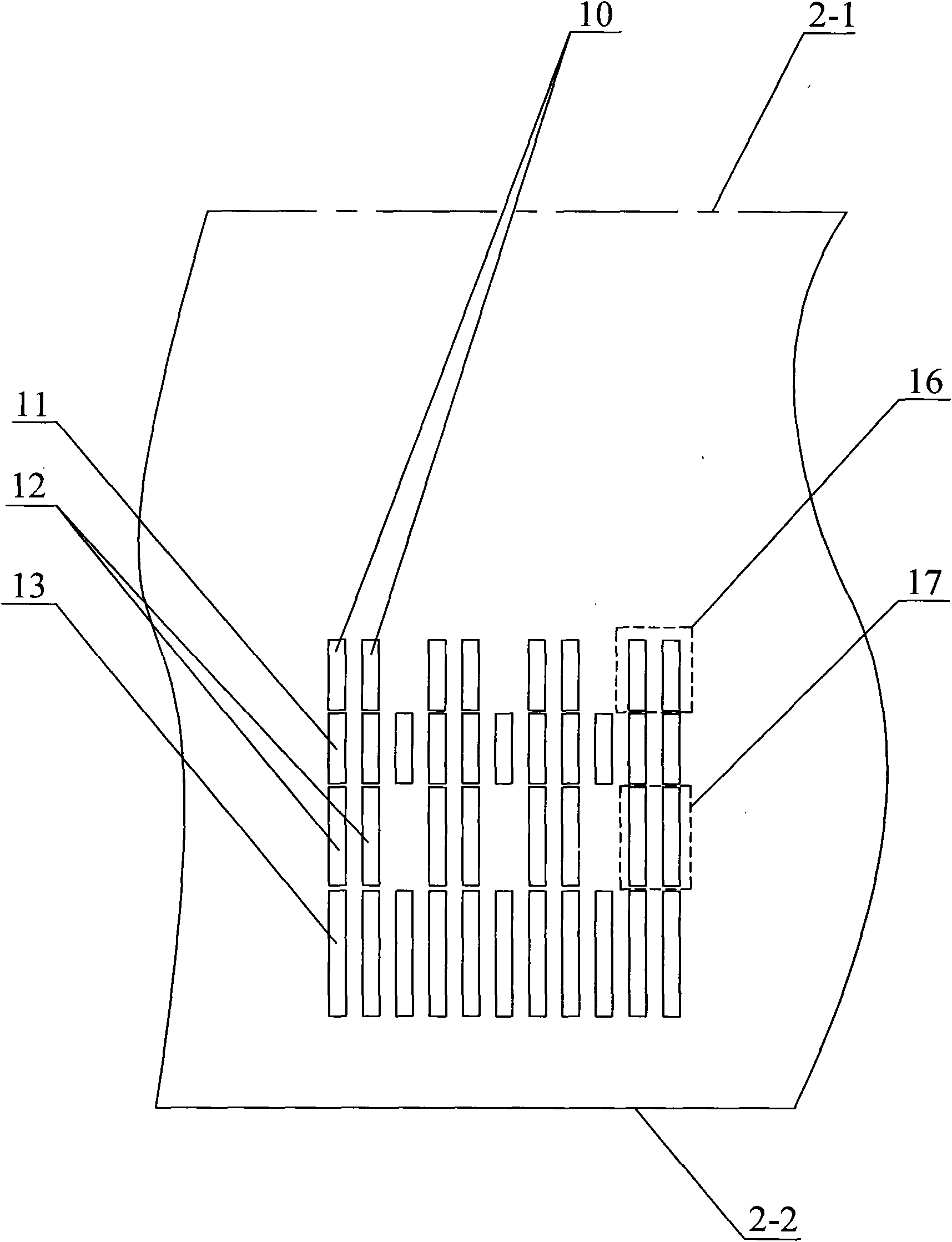

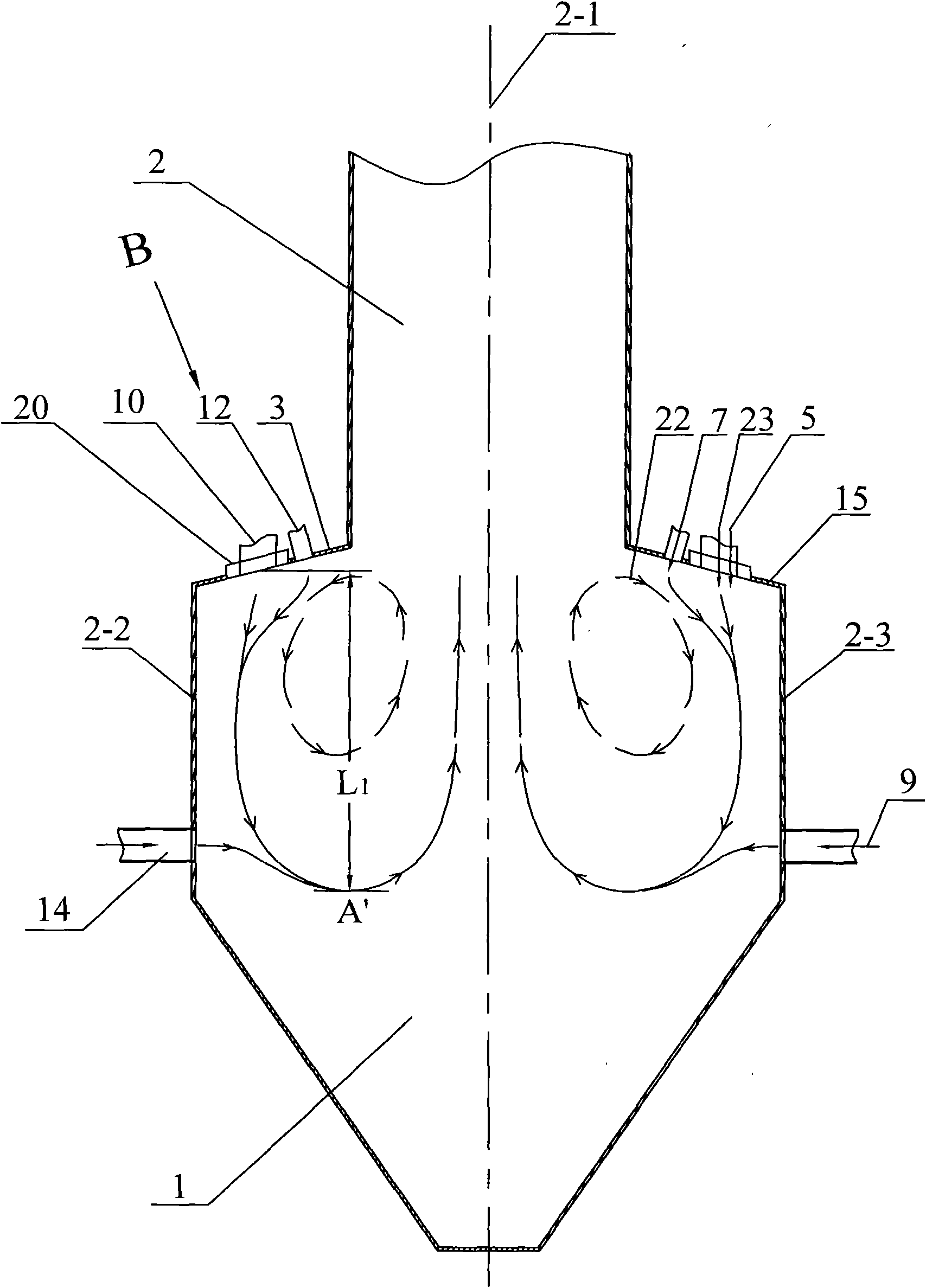

Multi-ejection grading combustion method and W flame boiler device for realizing same

ActiveCN101832549ALower the feverImprove flame stabilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir velocityCombustion

The invention discloses a W flame boiler device for realizing a multi-ejection grading combustion and a method thereof, and relates to a W flame boiler device of a grading combustion and a method, which aims at the problems of high NOx exhaust, high fly ash combustible material content, late fire of the pulverized coal airflow and bad flame stability in the W type flame boiler referred in the background technology.The method comprises the following steps of: ejecting internal and external secondary air at the air speed of 35-65m / s step by step and downwards ejecting by carrying a concentrated coal dust airflow at the air speed of 10-20m / s to realize first and second stage grading combustion; and injecting arch lower secondary air at the air speed of 35-65m / s into the lower heath by an arch lower secondary air nozzle to realize third stage grading combustion. A concentrated coal dust airflow nozzle, an internal secondary air nozzle, a light coal dust airflow nozzle and an external secondary air nozzle are sequentially distributed from the center side of the hearth to the water-cooling wall of the front and rear wall of the lower hearth on a boiler arch; and the front and rear wall of the lower hearth is provided with the arch lower secondary air nozzle along the width direction of the hearth. The invention can greatly reduce NOx exhaust and fly ash combustible material content when used for the W flame boiler.

Owner:HARBIN INST OF TECH

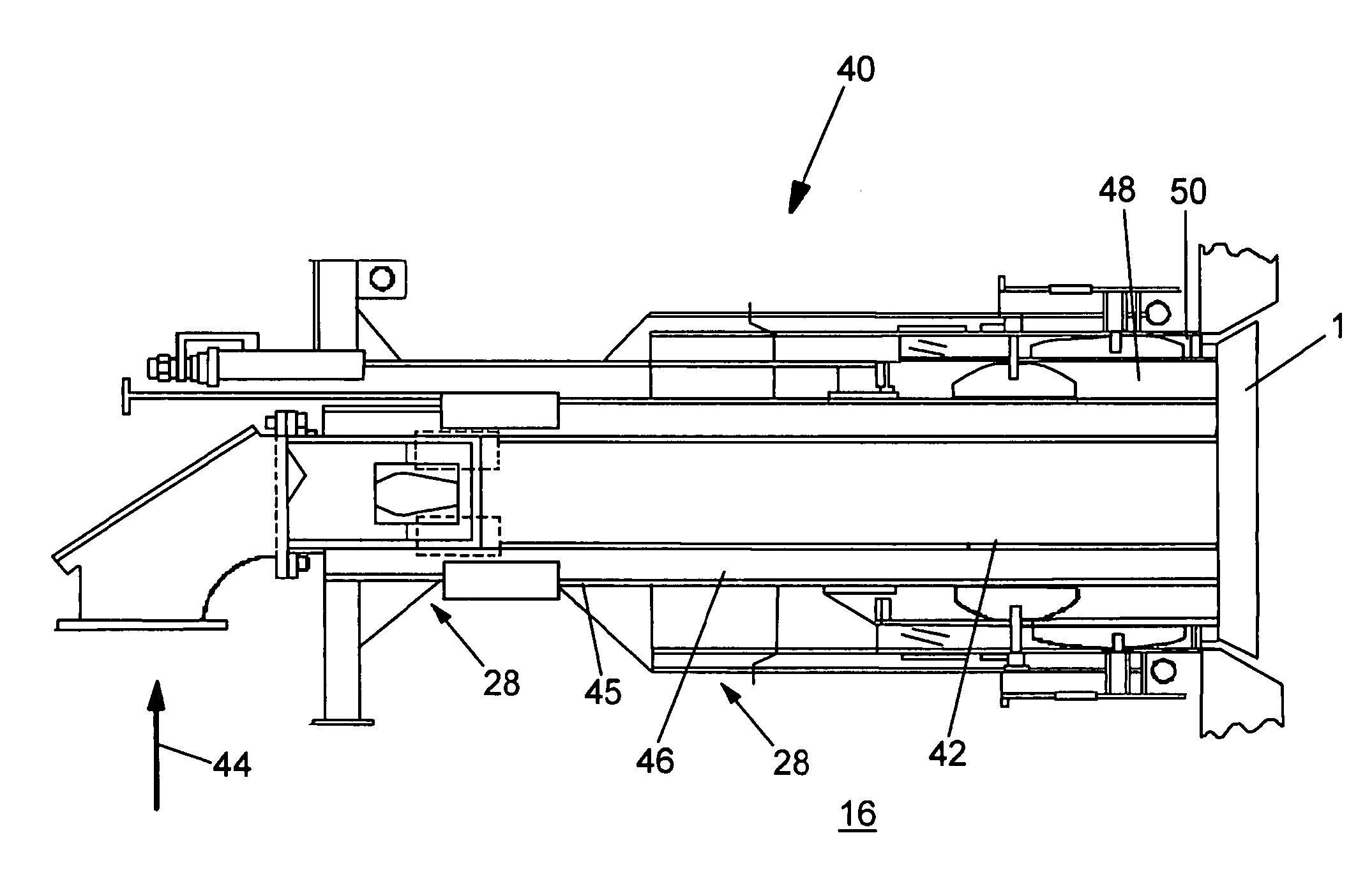

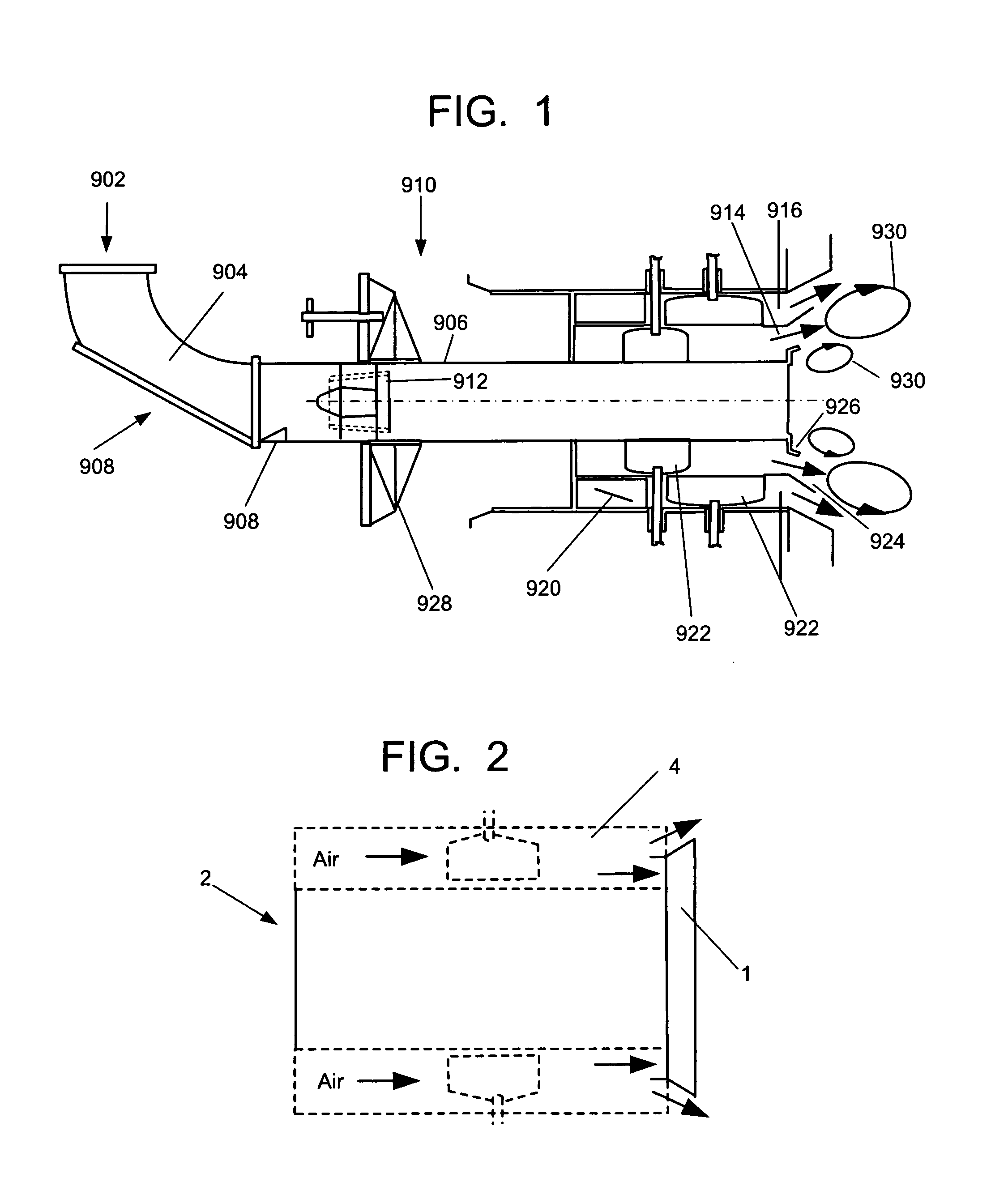

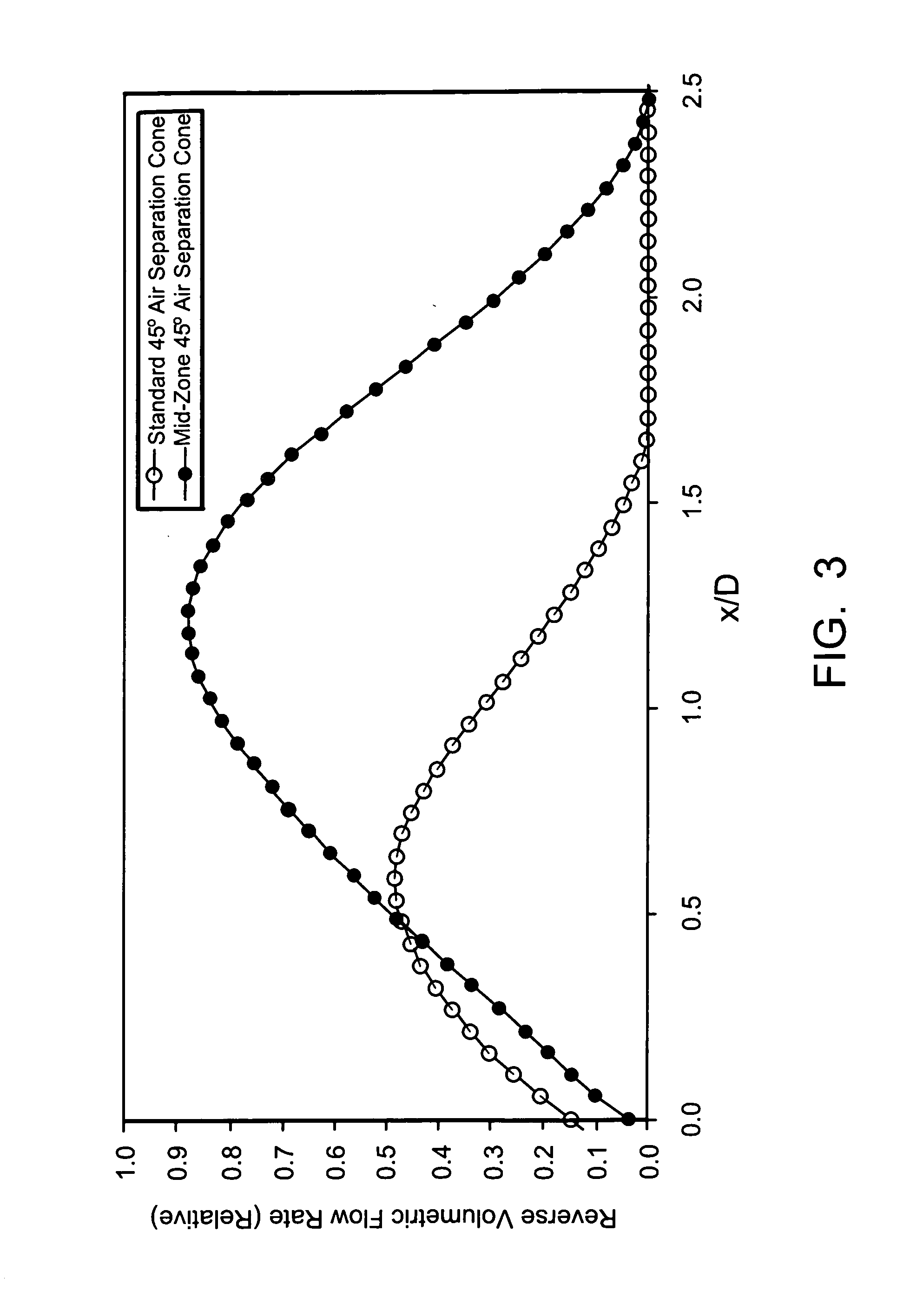

Large diameter mid-zone air separation cone for expanding IRZ

ActiveUS20070281265A1Safely and effectively increases sizeIncreased NOx emissionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLeading edgeCombustor

A large diameter mid-zone air separation cone is provided for decreasing NOx during burner operation by expanding the internal recirculation zone (IRZ) at the burner exit. The mid-zone air separation cone has a short cylindrical leading edge that fits in the outer air zone of a burner. The mid-zone air separation cone splits the outer air zone secondary air flow into two equal or unequal streams depending on the position of the air separation cone with respect to the outer air zone, and deflects a portion of the secondary air flow radially outward. Since the radial position of the air separation cone is farther from the burner centerline, the IRZ size is expanded and NOx emissions are minimized.

Owner:THE BABCOCK & WILCOX CO

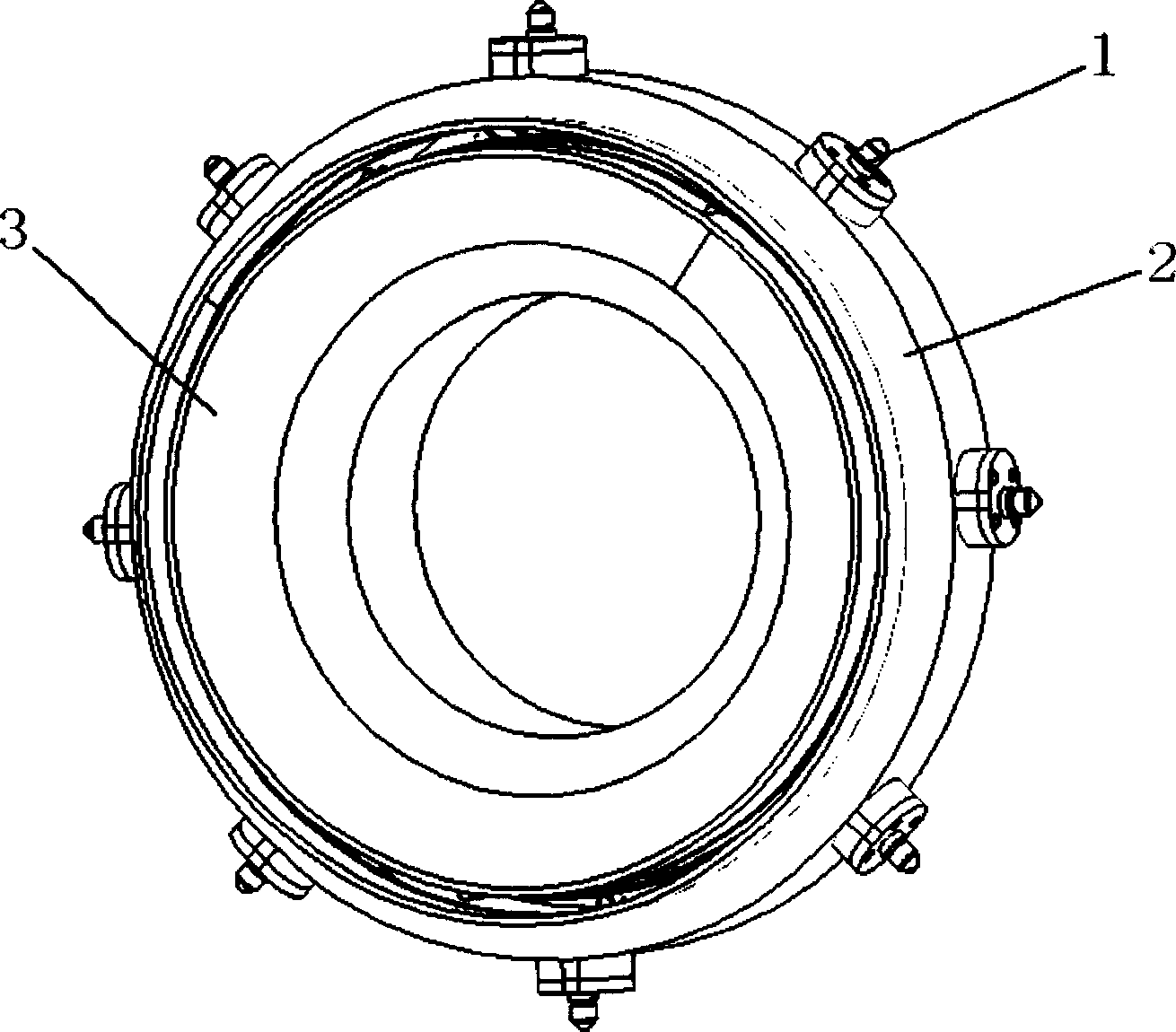

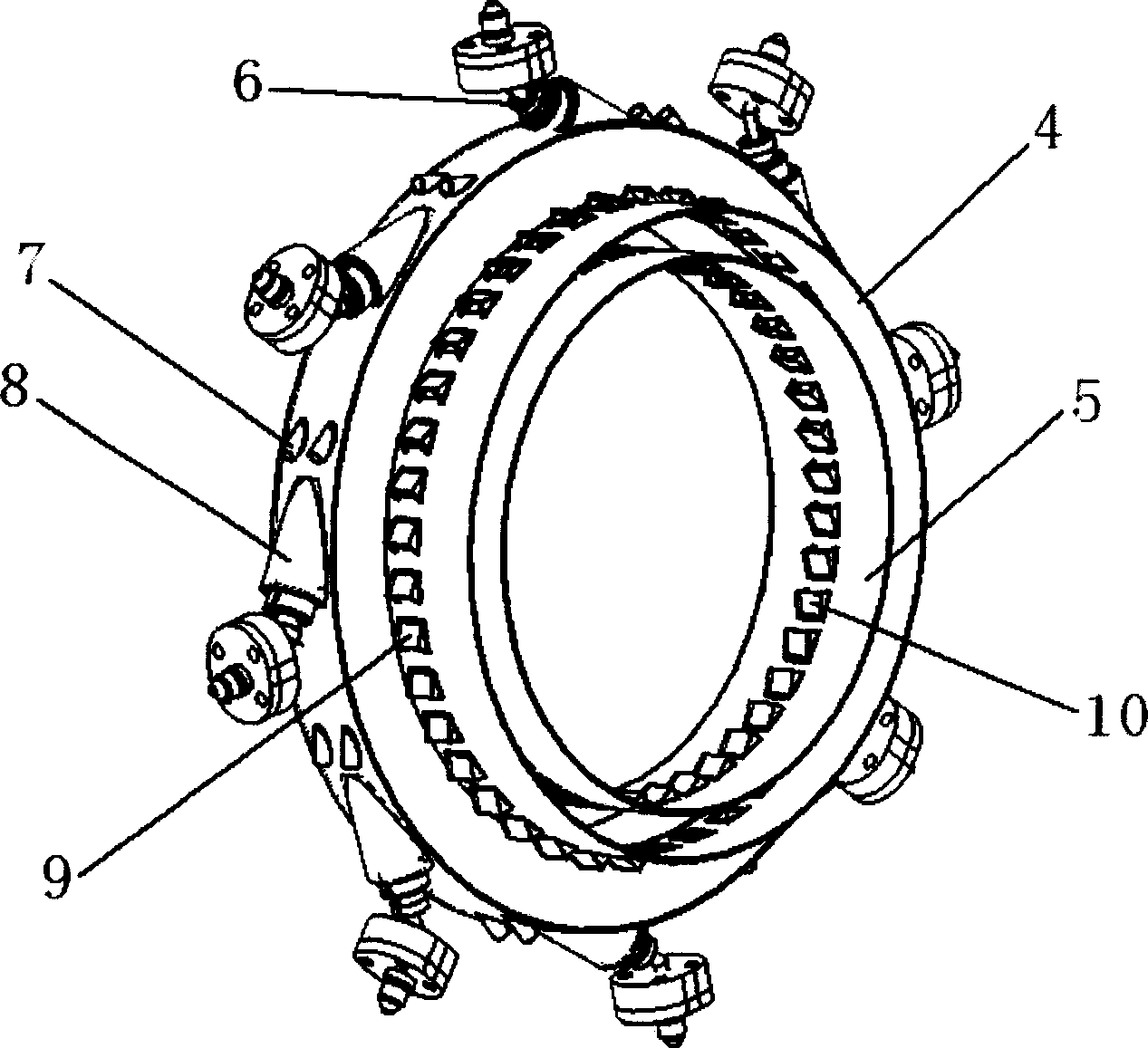

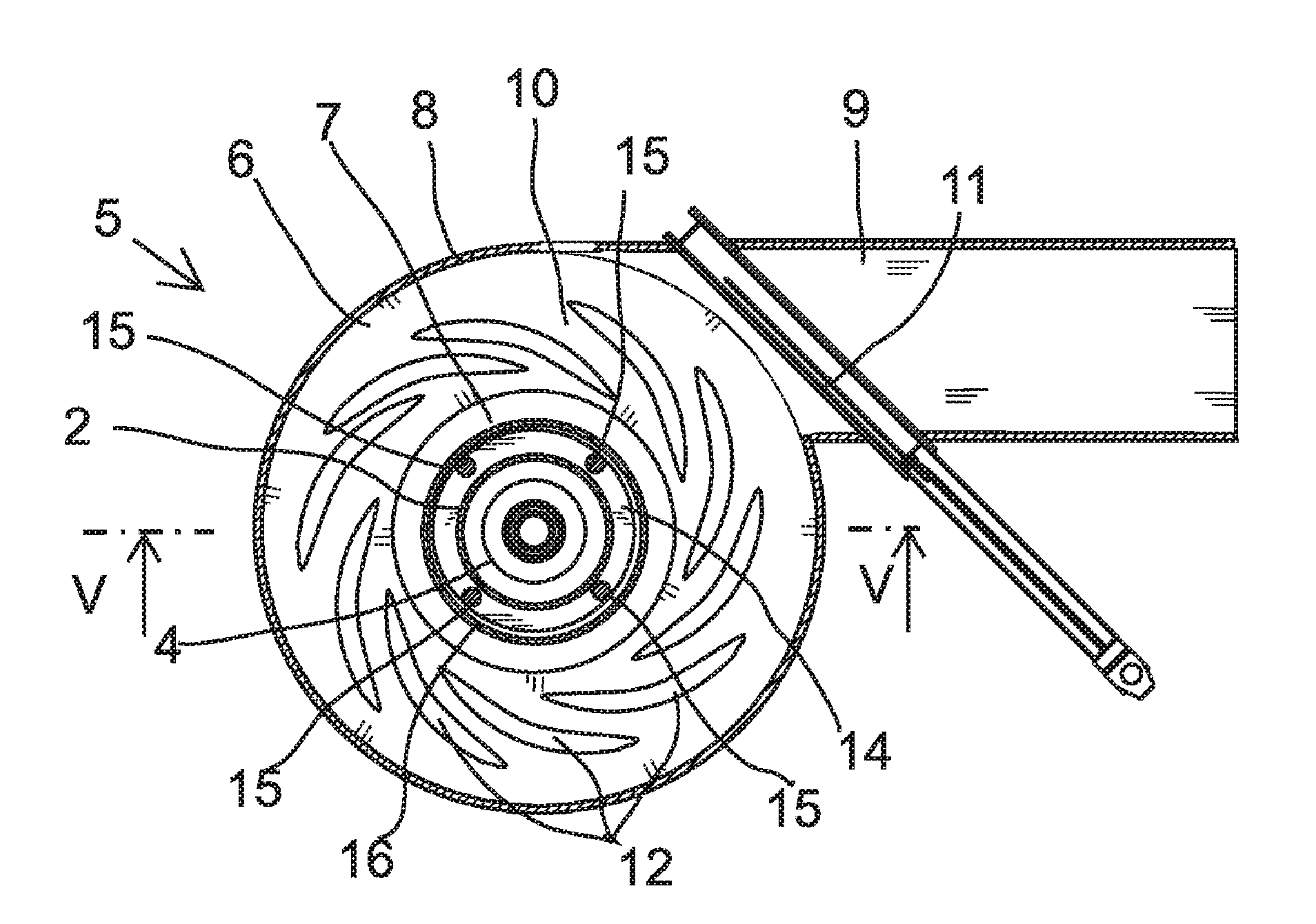

Concentrate burner

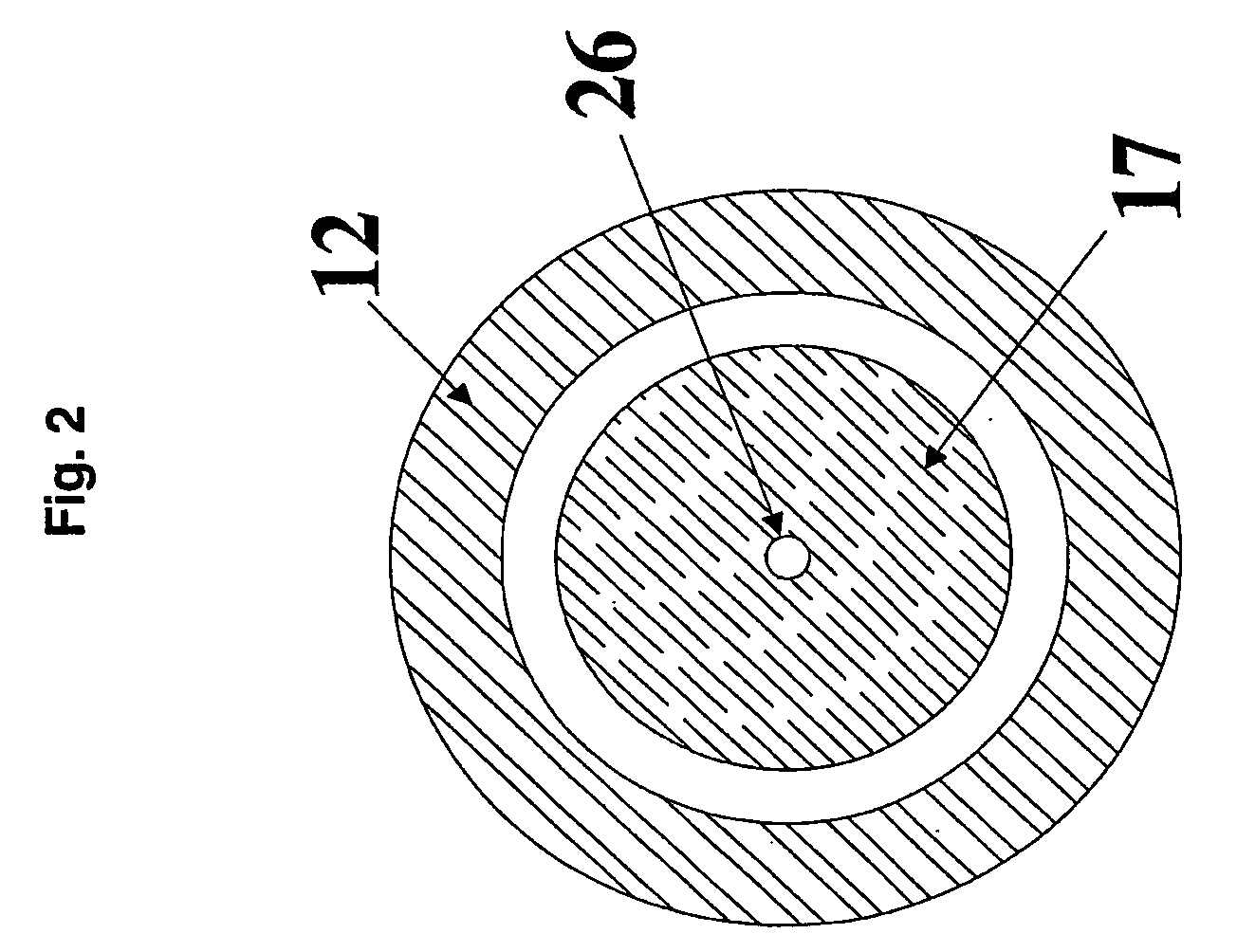

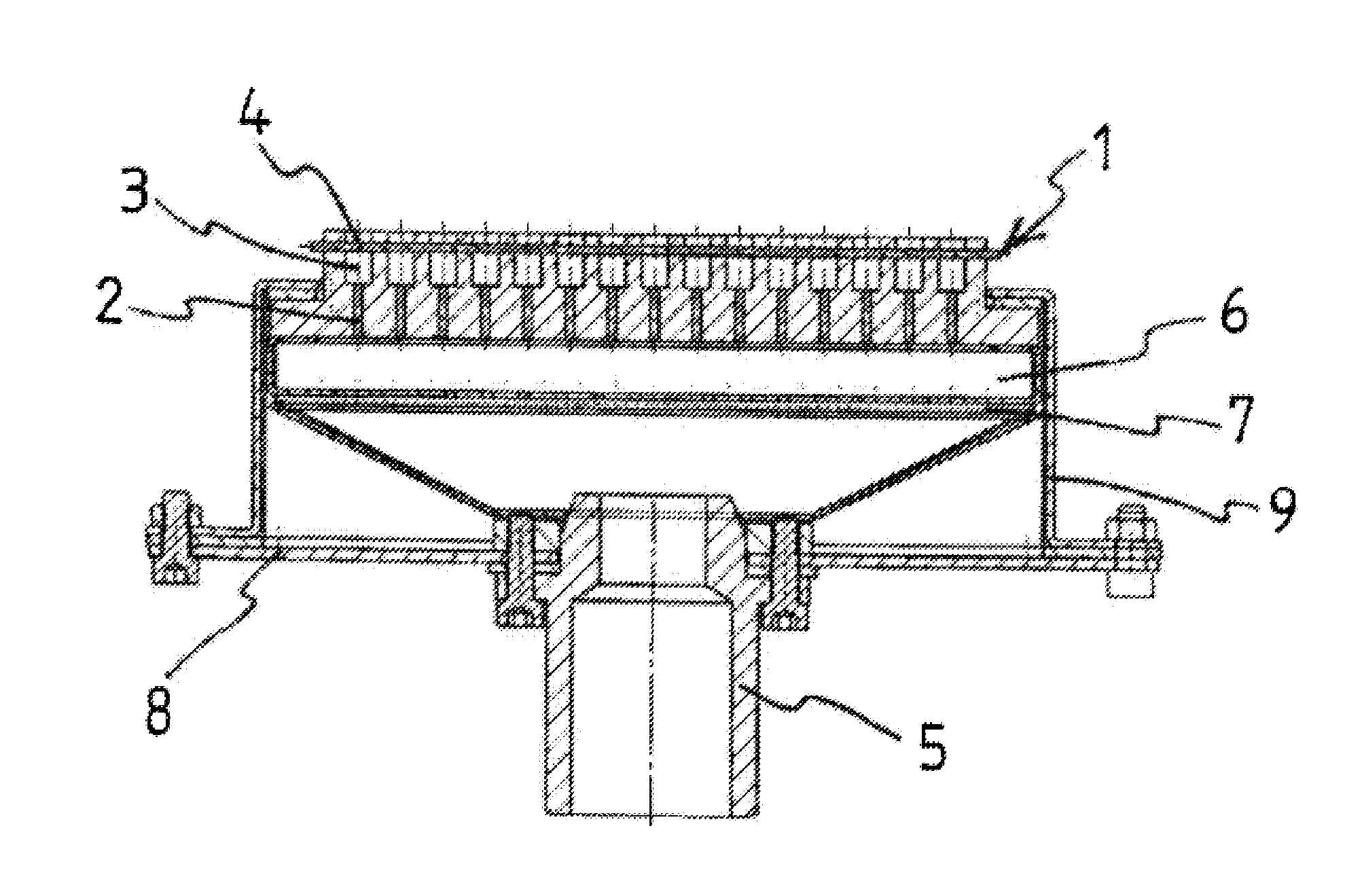

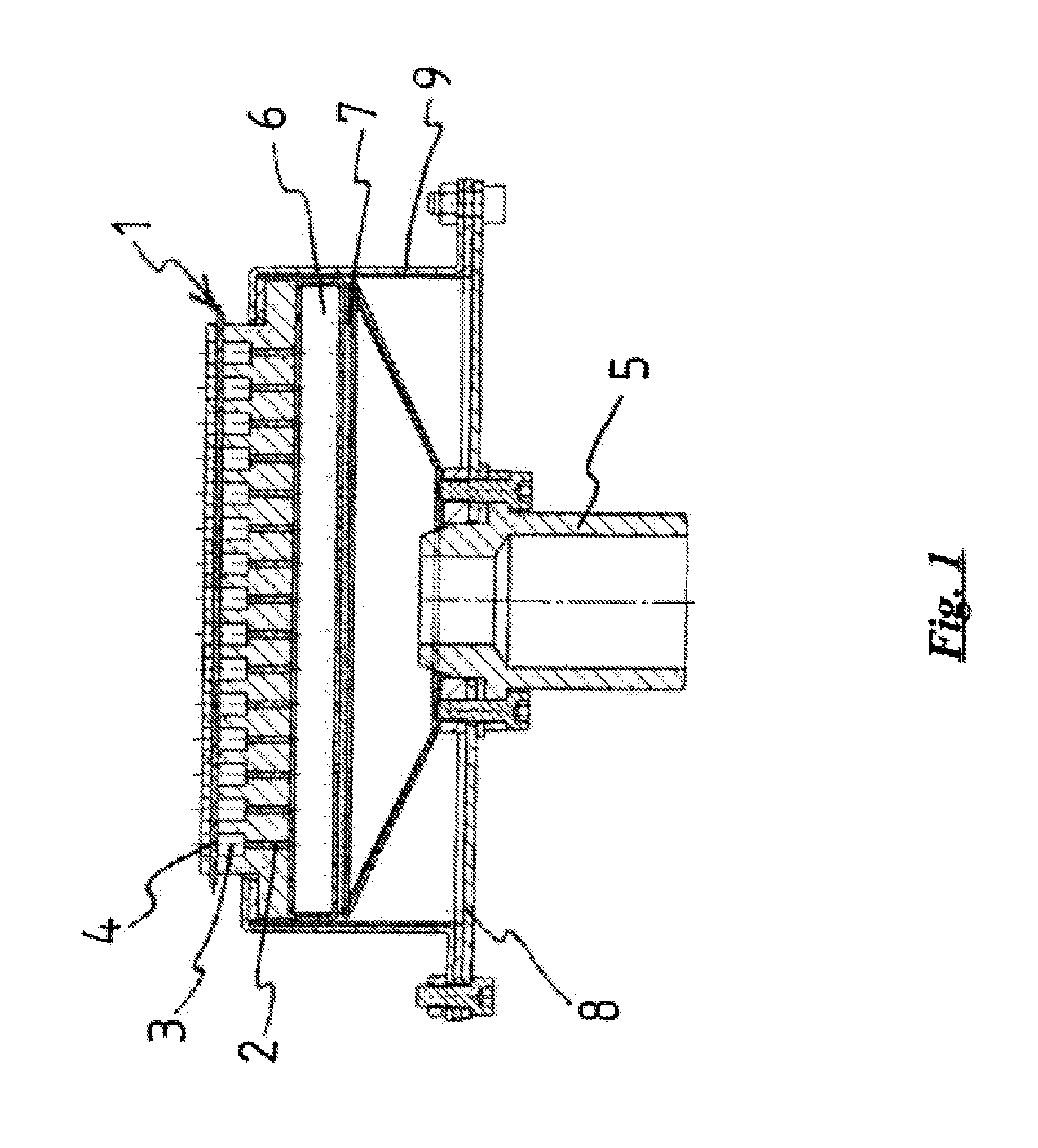

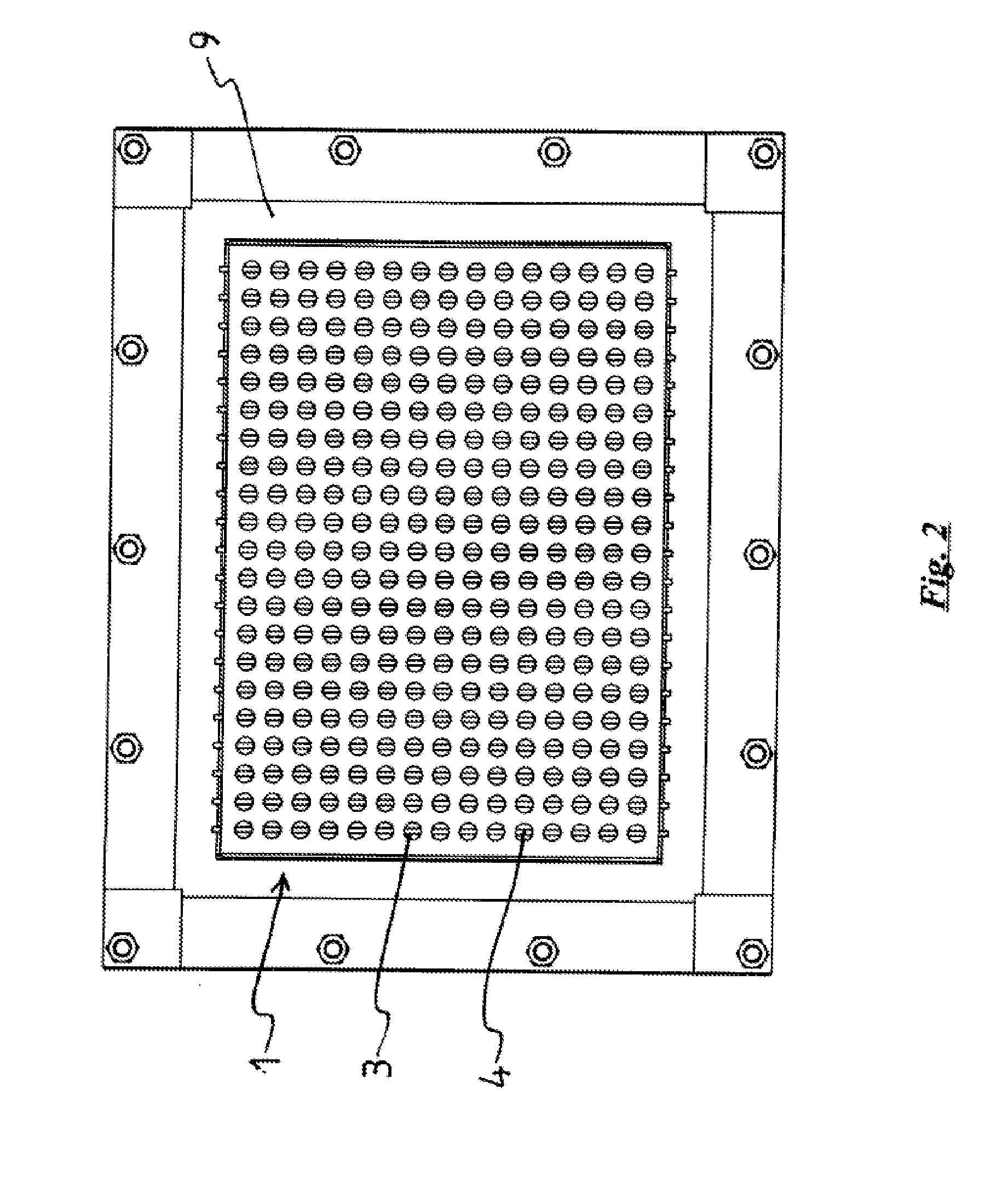

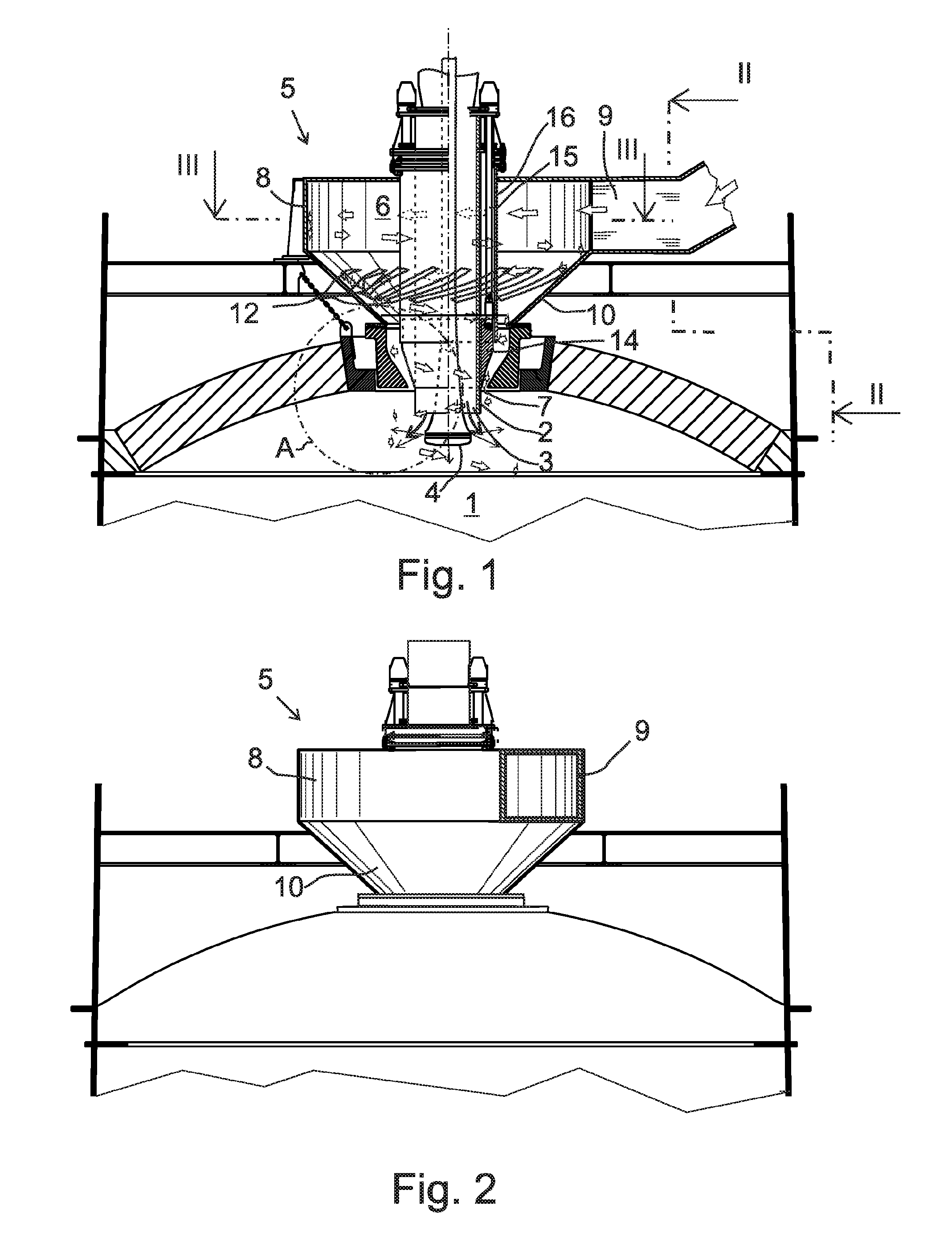

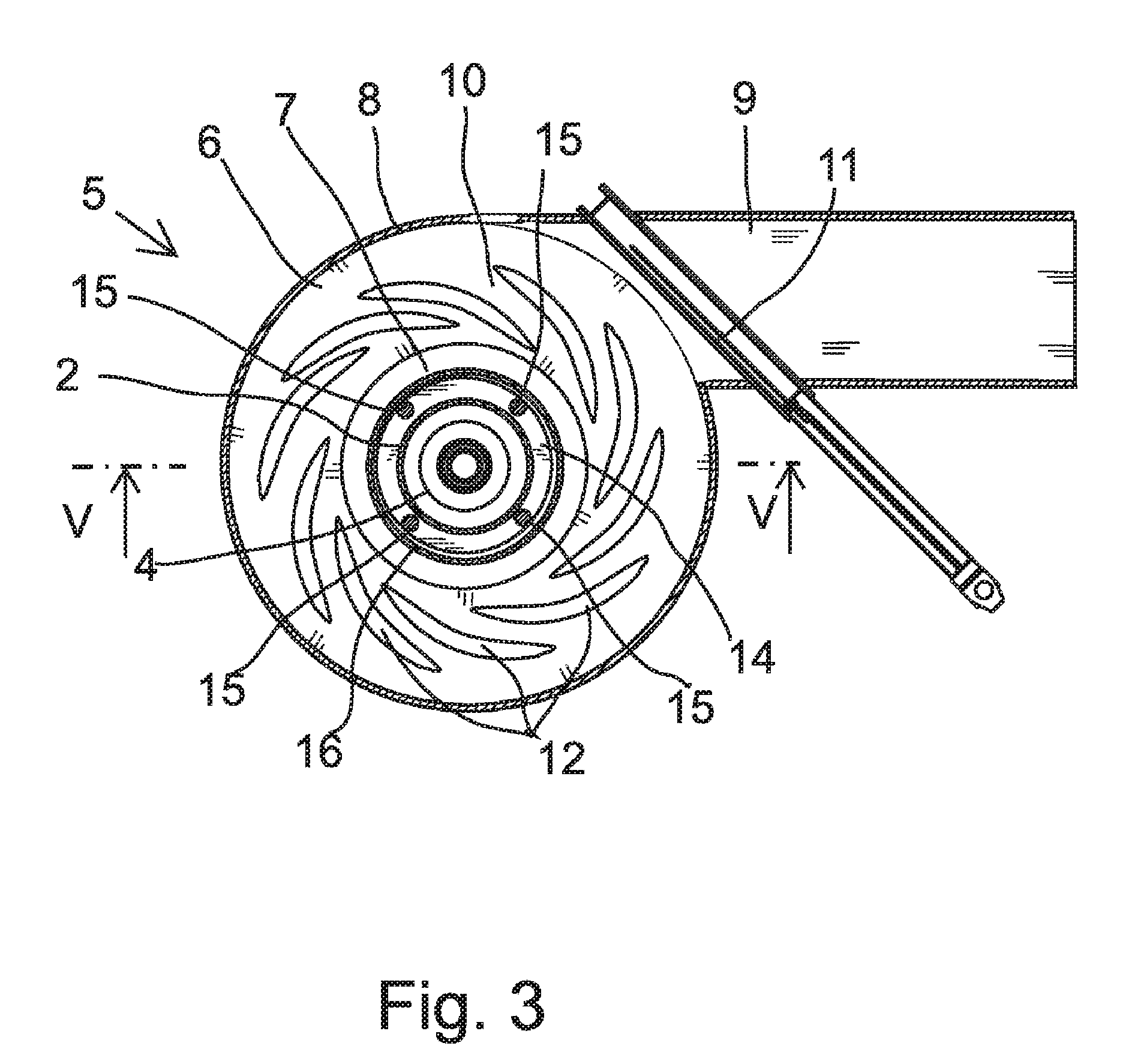

InactiveUS20100207307A1Easy to disassembleOptimal swirl angleTuyeresBell-and-hopper arrangementCombustorInlet channel

A concentrate burner for feeding a pulverous concentrate mixture and reaction gas into the reaction shaft (1) of a flash smelting furnace. The concentrate burner includes a feeder pipe (2) for feeding the concentrate mixture into the reaction shaft (1), the orifice (3) of the feeder pipe opening to the reaction shaft, a dispersing device (4), which is arranged concentrically inside the feeder pipe (2) and which extends to a distance from the orifice inside the reaction shaft (1) for directing dispersing gas to the concentrate mixture flowing around the dispersing device. For feeding the reaction gas into the reaction shaft (1), a gas supply device (5) includes a reaction gas chamber (6), which is located outside the reaction shaft and opens to the reaction shaft (1) through an annular discharge orifice (7) that surrounds the feeder pipe (2) concentrically for mixing the reaction gas discharging from the discharge orifice with the concentrate mixture discharging from the middle of the feeder pipe, the concentrate mixture being directed to the side by means of the dispersing gas. The reaction gas chamber (6) comprises a turbulent flow chamber, to which an inlet channel (9) opens tangentially for directing the reaction gas to the reaction gas chamber in a tangential direction. In the inlet channel (9), an adjusting member (11) is arranged for adjusting the cross-sectional area of the reaction gas flow.

Owner:OUTOTEC OYJ

Combustion stabilization systems

InactiveUS20070281253A1Improve flame stabilityMinimize NOx emissionBurnersLiquid carbonaceous fuelsCombustorEngineering

Systems for stabilizing combustion while minimizing NOx generation by using high-flame-speed additives to stabilize the flame front in combustors operating at relatively low temperatures and / or under oxygen constraints. The system is adapted for use in coal-fired boilers, oil-fired boilers, and gas turbine engines. The methods stabilize the flame front to permit stable combustion under an expanded range of part-load conditions. The system provides substantially complete combustion of coal in coal boilers resulting in ash saleable for use in concrete manufacturing.

Owner:TOQAN MAJED

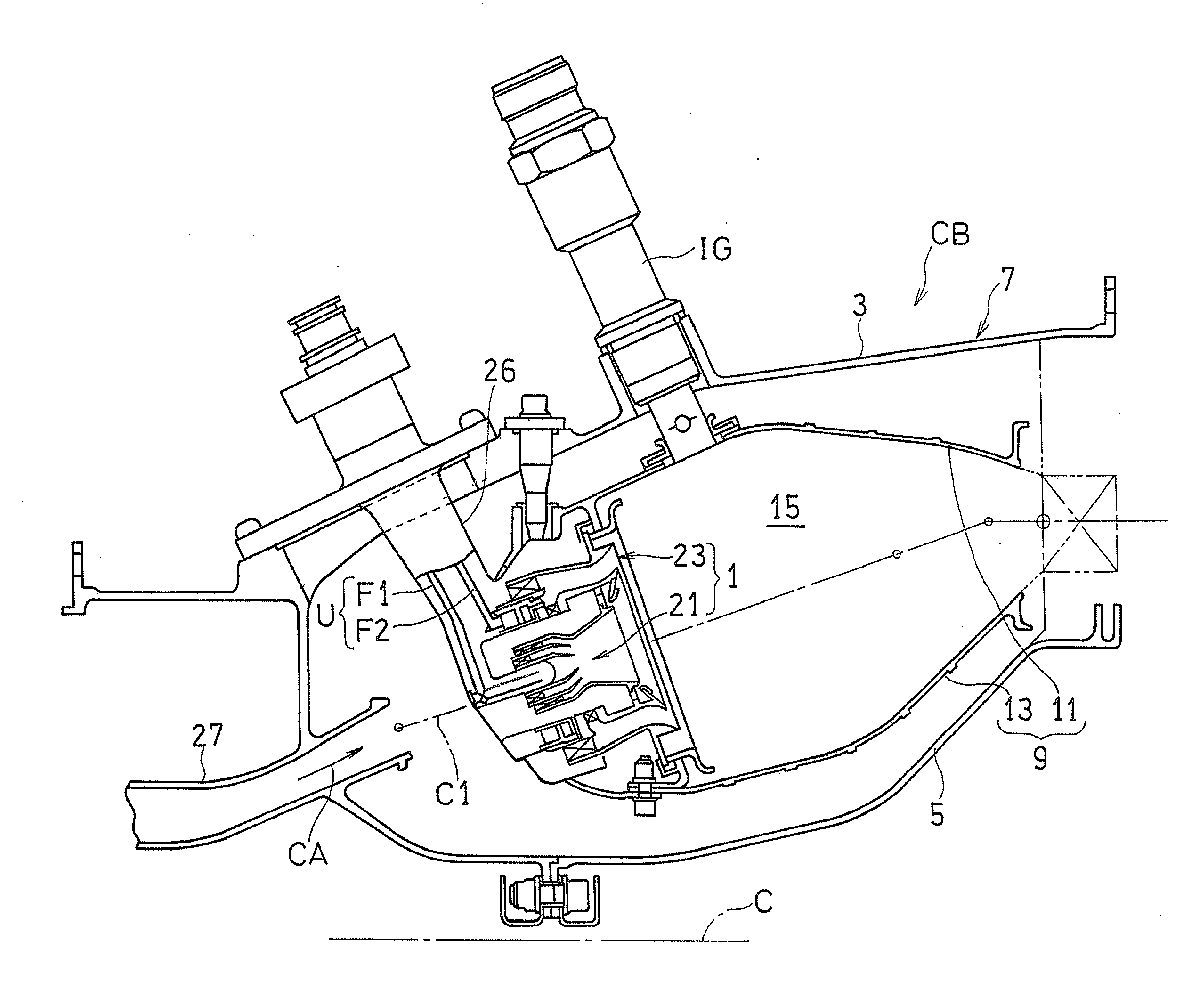

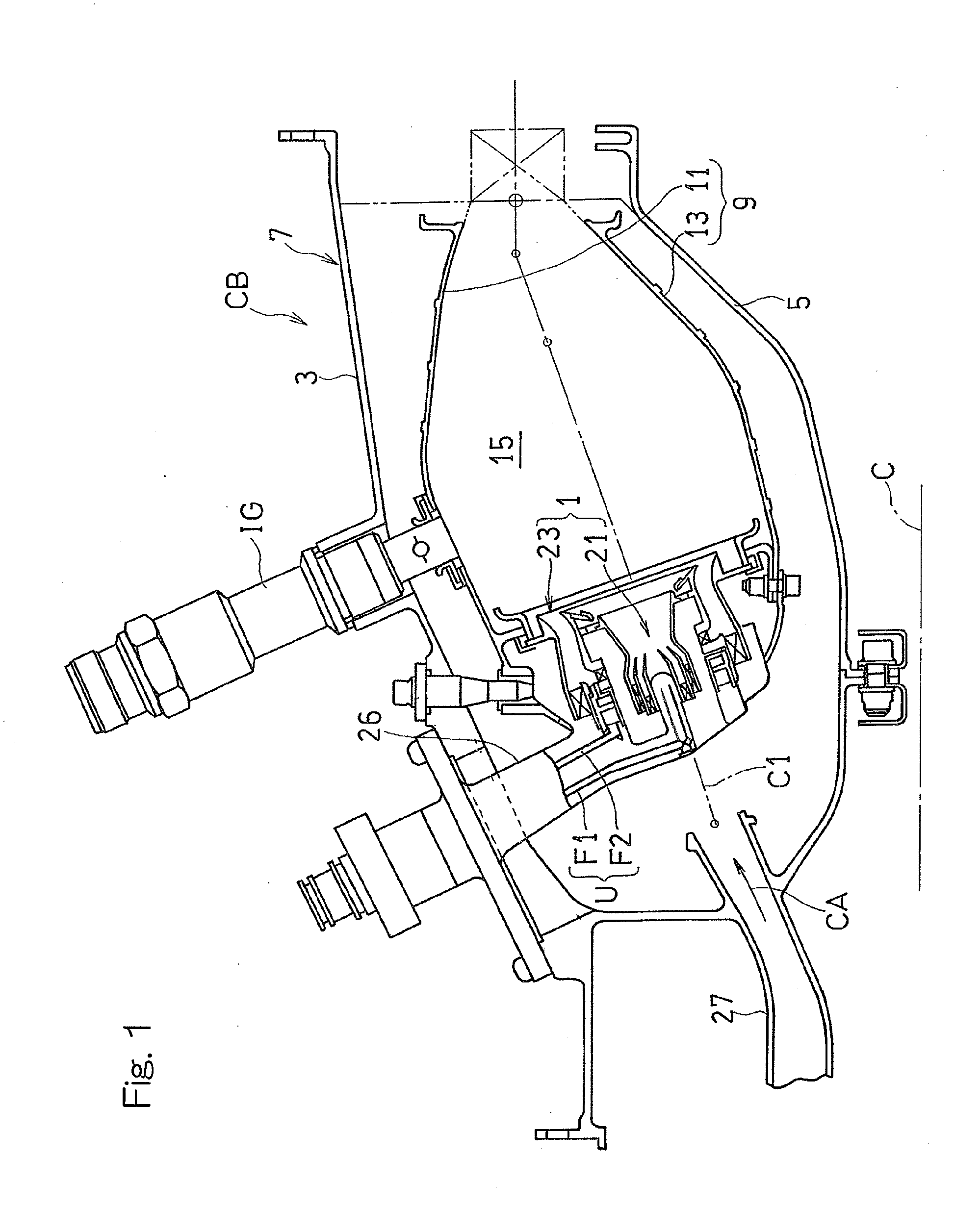

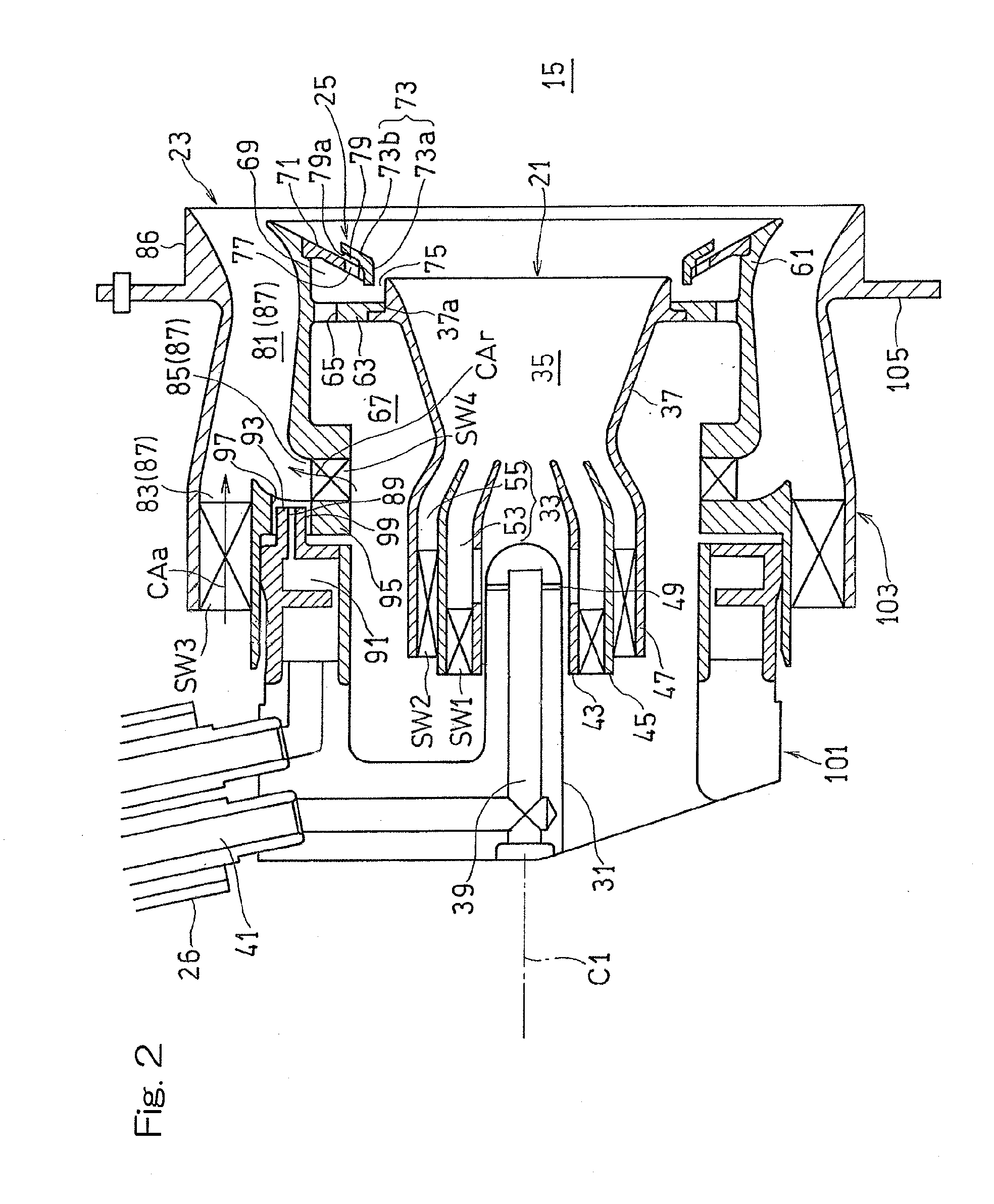

Fuel injection device

ActiveUS20150082797A1InhibitionImprove combustion efficiencyContinuous combustion chamberGas turbine plantsCombustion chamberInjection air

A fuel injection device for supplying a fuel to a compressed air includes: a pilot fuel injector; a main fuel injector located at an outer periphery of the pilot fuel injector; and an air injection unit located between an outlet end portion of the pilot fuel injector and the main fuel injector. The air injection unit includes: a partition wall plate separating the air injection unit from a combustion chamber; a flame stabilization plate provided at a downstream side of the partition wall plate; a first opening at a downstream side between the flame stabilization plate and the outlet end portion of the pilot fuel injector; and a second opening provided in the partition wall plate and through which the compressed air is supplied. The flame stabilization plate includes an inclined portion inclined in a radially outward and downstream direction with respect to an axis.

Owner:KAWASAKI HEAVY IND LTD +1

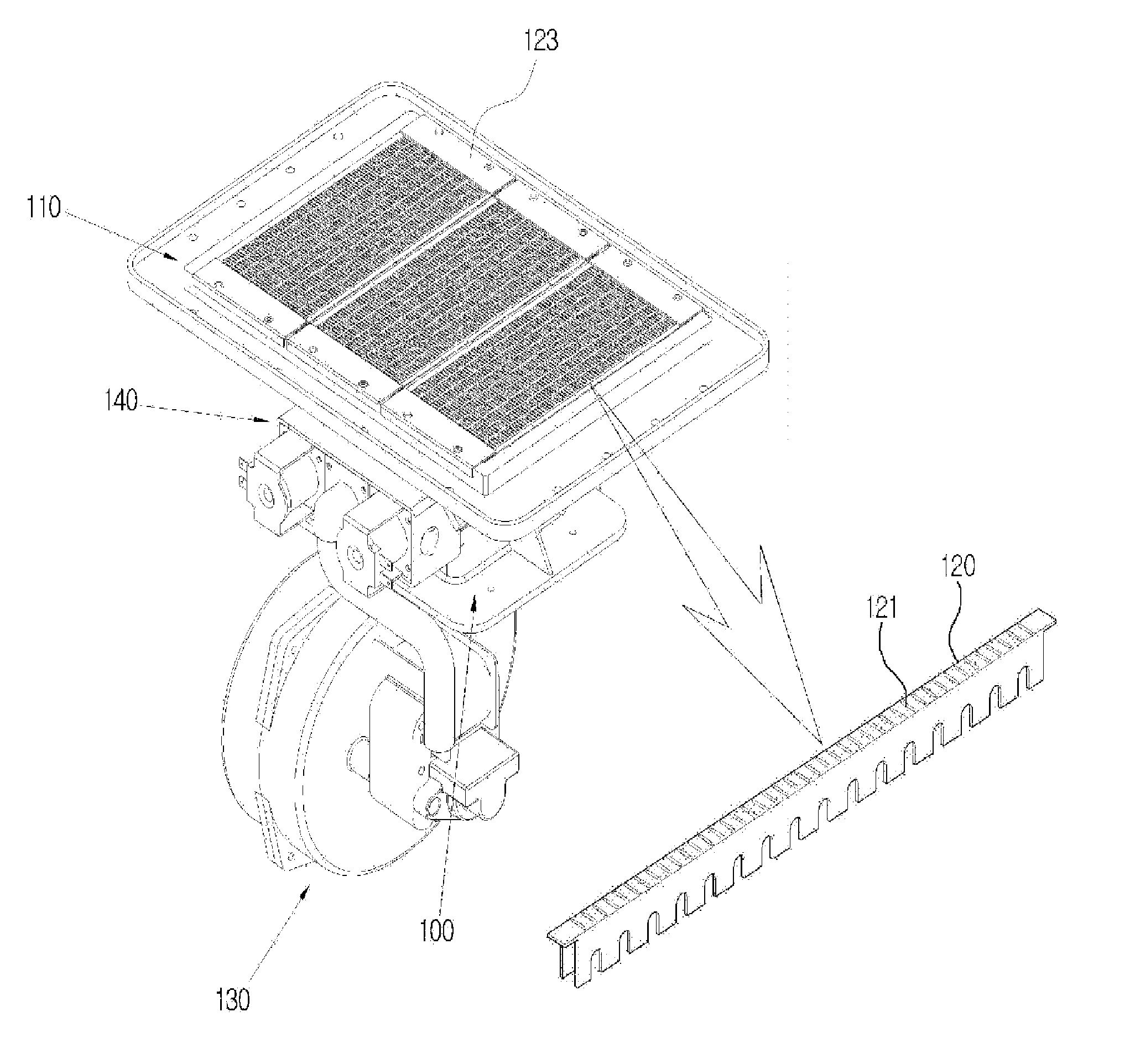

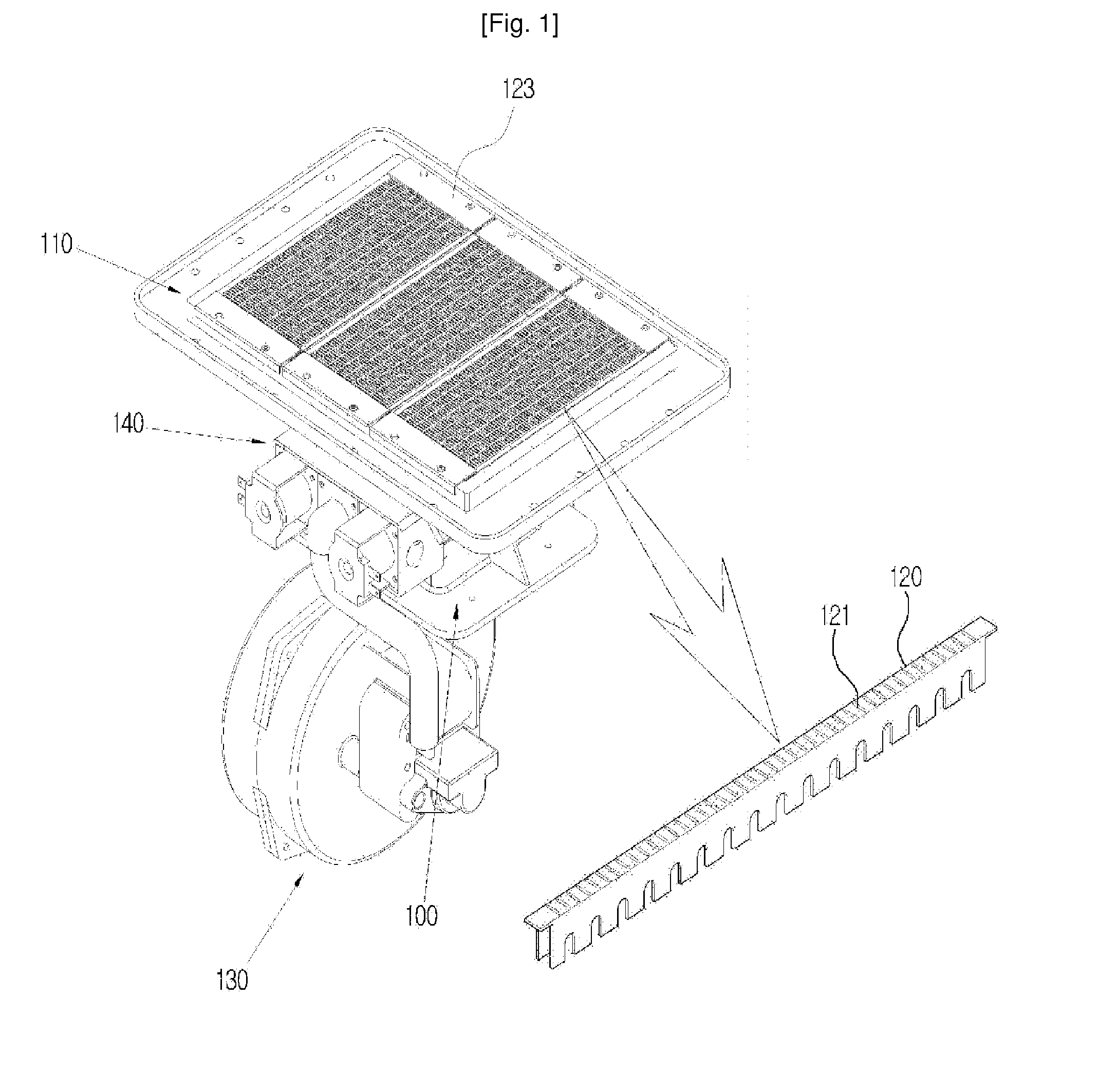

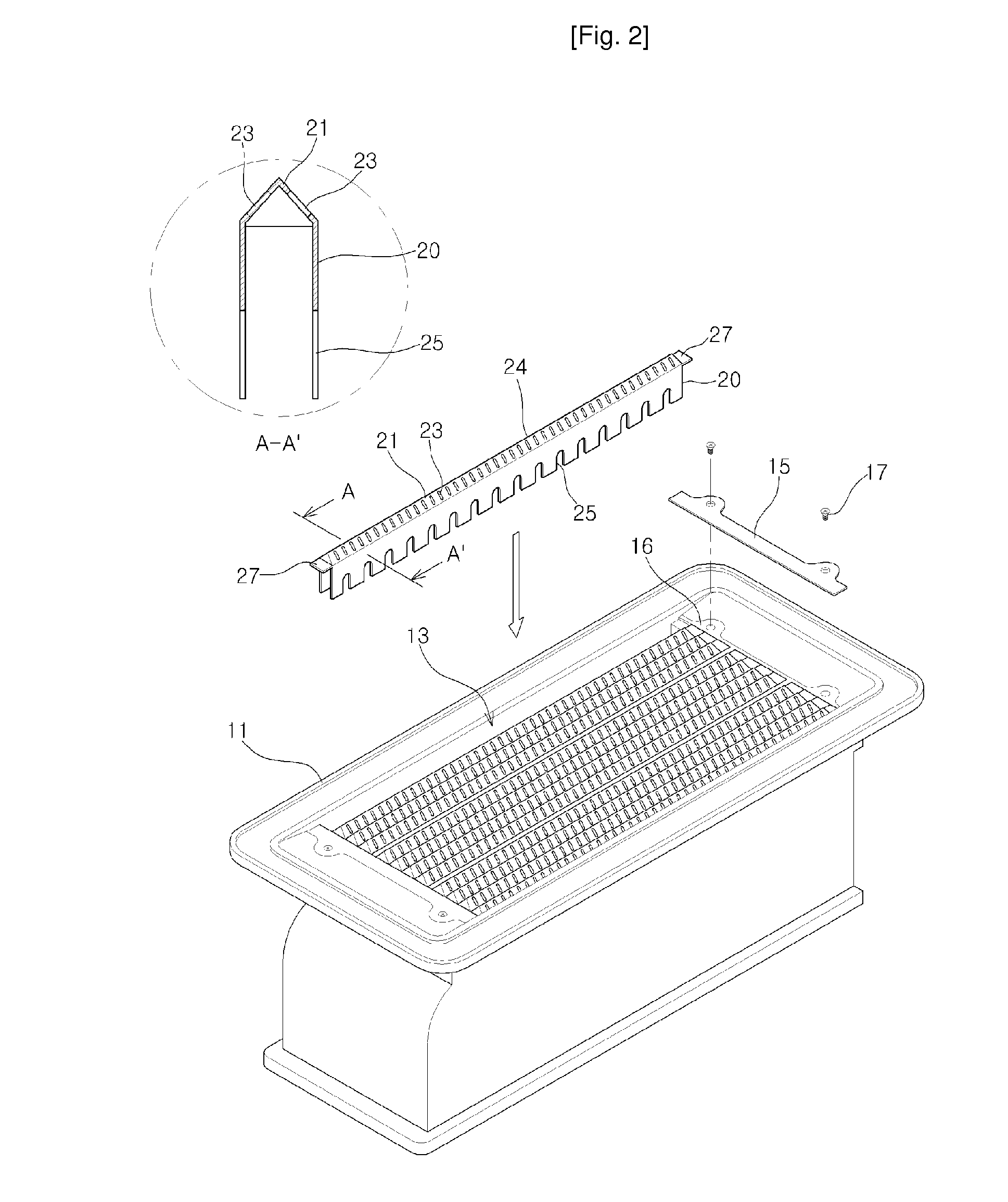

Flame structure of gas burner

InactiveUS20090291402A1Reduce in sizeCombustion load be increasePilot flame ignitersGaseous fuel burnerGas burnerFlame structure

A fire hole part structure of a gas burner, which is constructed to be manufactured at a low cost, can improve flame stability, and can prevent incomplete combustion due to the length of flame. The structure is provided to a premixing ignition burner, which is installed to apply heat to a heat exchanger of a boiler, and includes fire hole pieces which are installed parallel to one another in mounting openings of a burner body, and each of which is defined with fire holes at regular intervals. An upper wall of at least one of the fire hole pieces is bent or curved to extend in at least two directions, and the fire holes are defined through respective surface portions of the upper wall, which extend in different directions, to face different directions.

Owner:KYUNGDONG NAVIEN

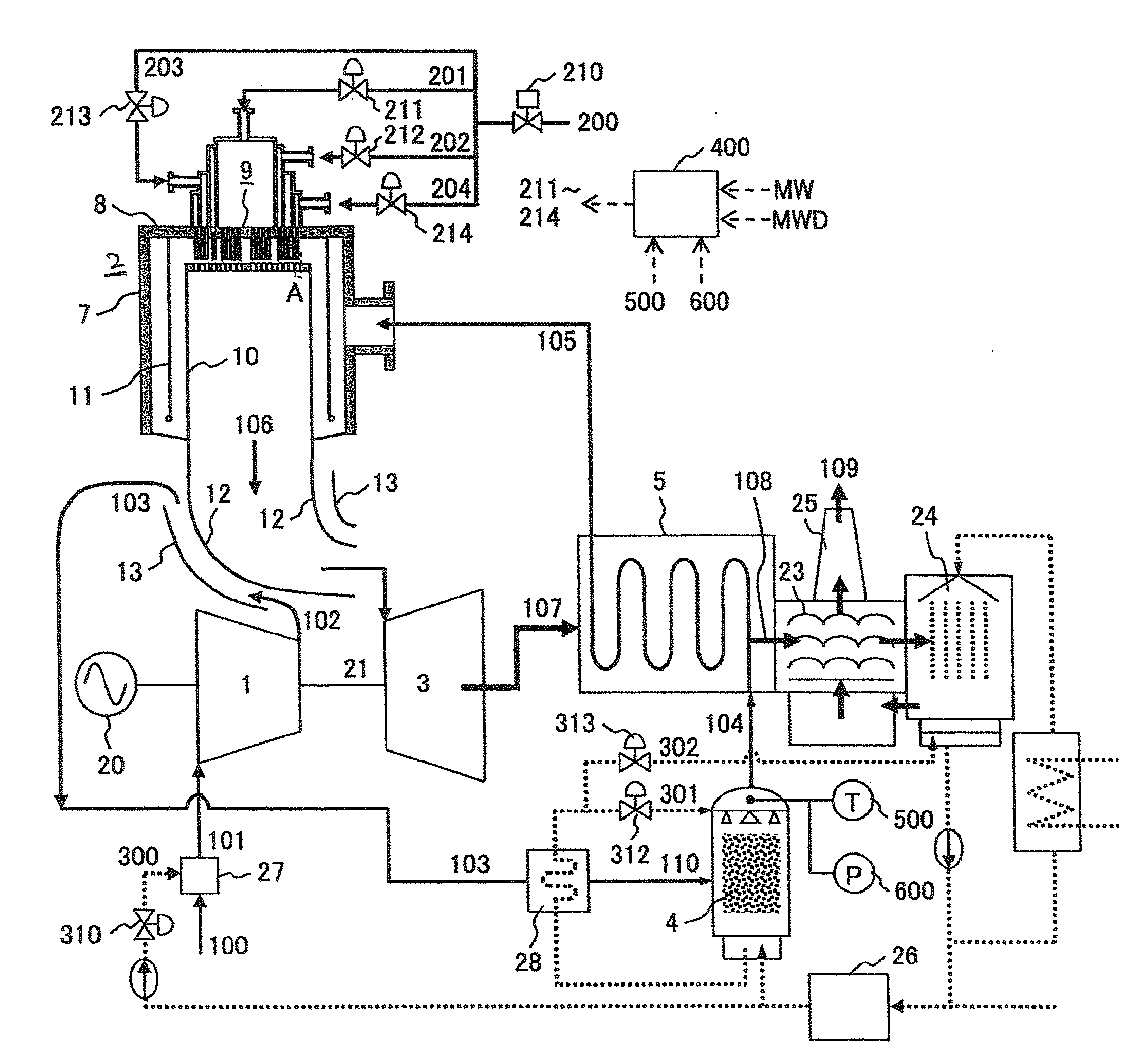

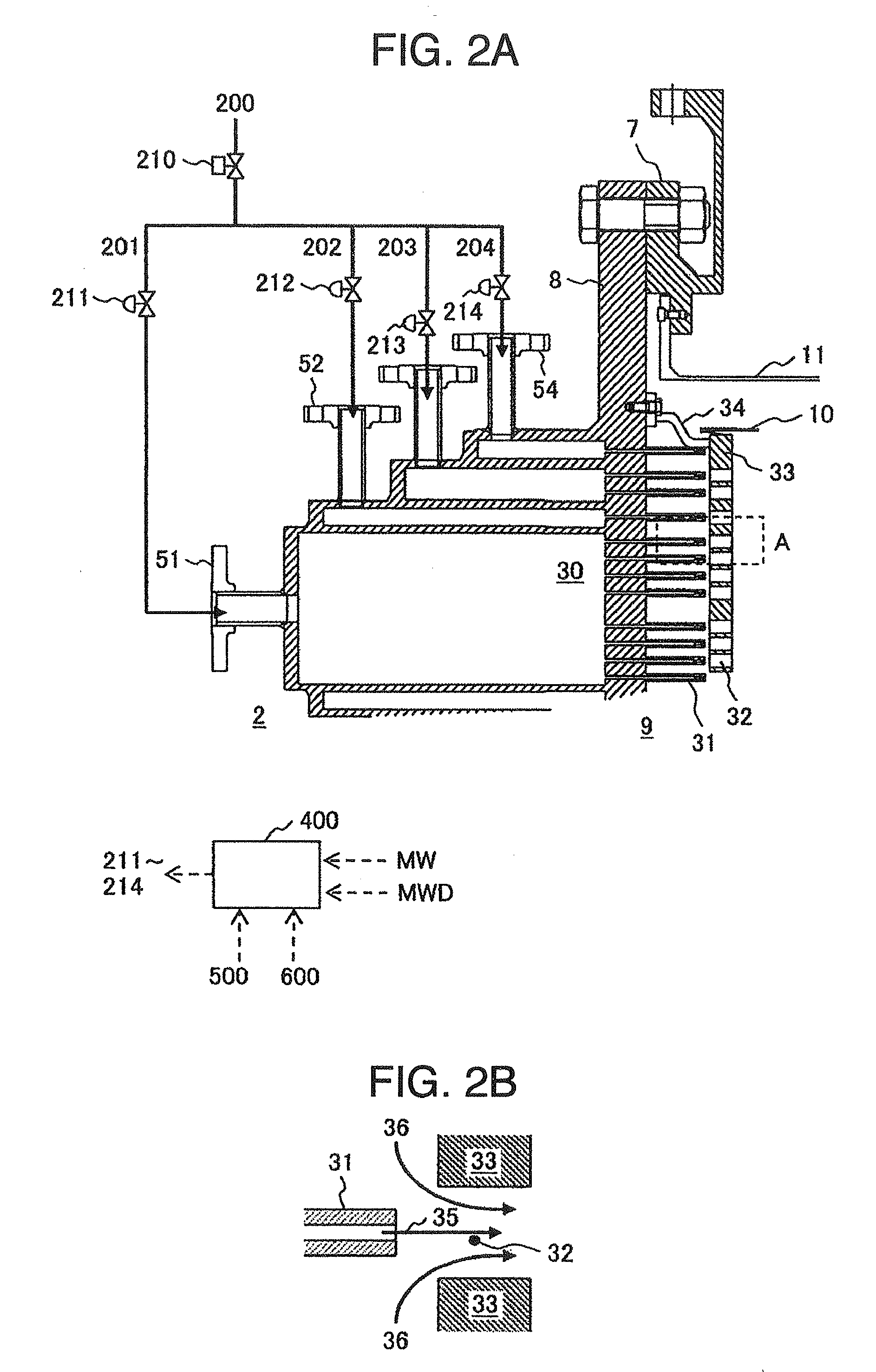

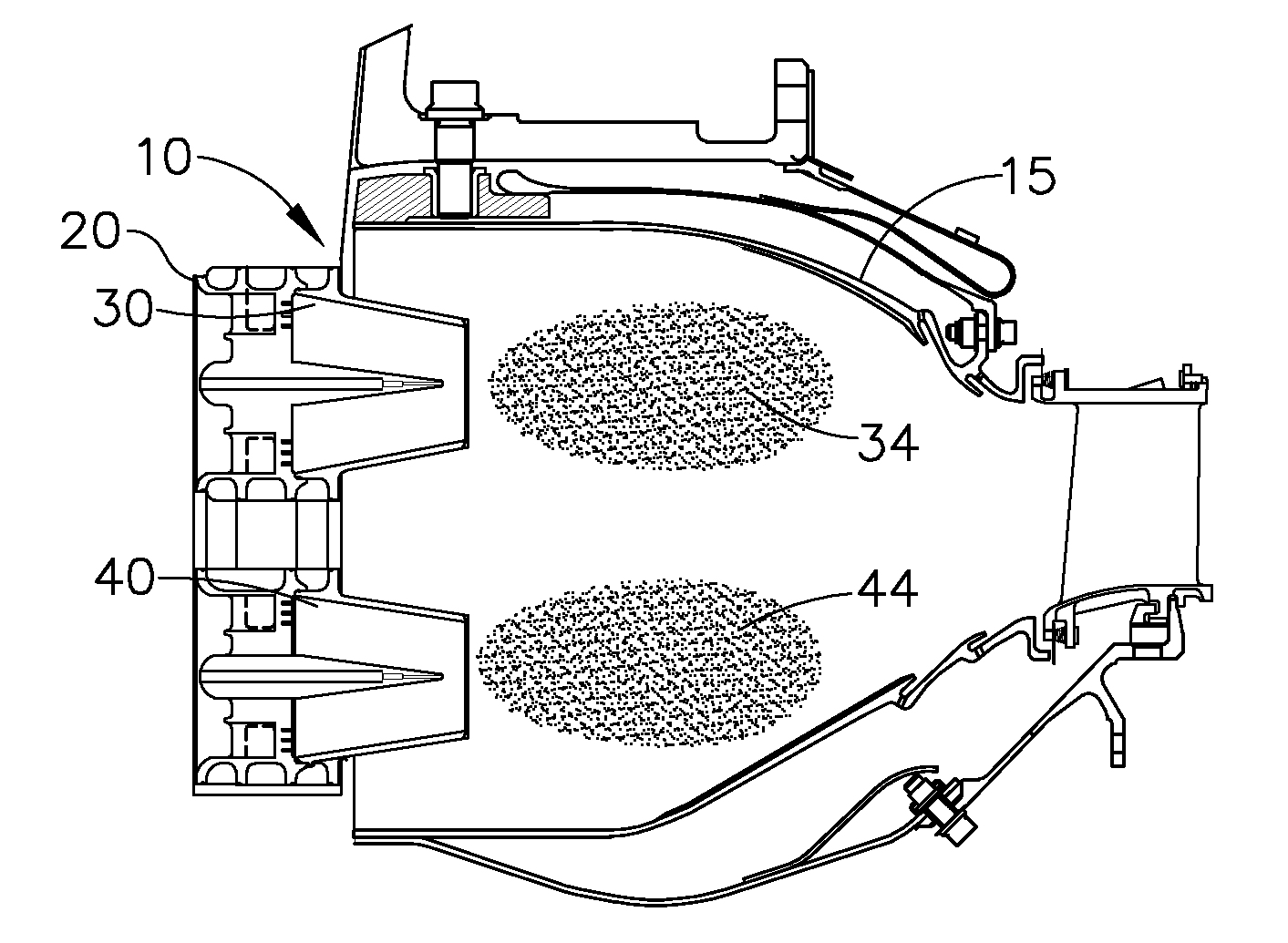

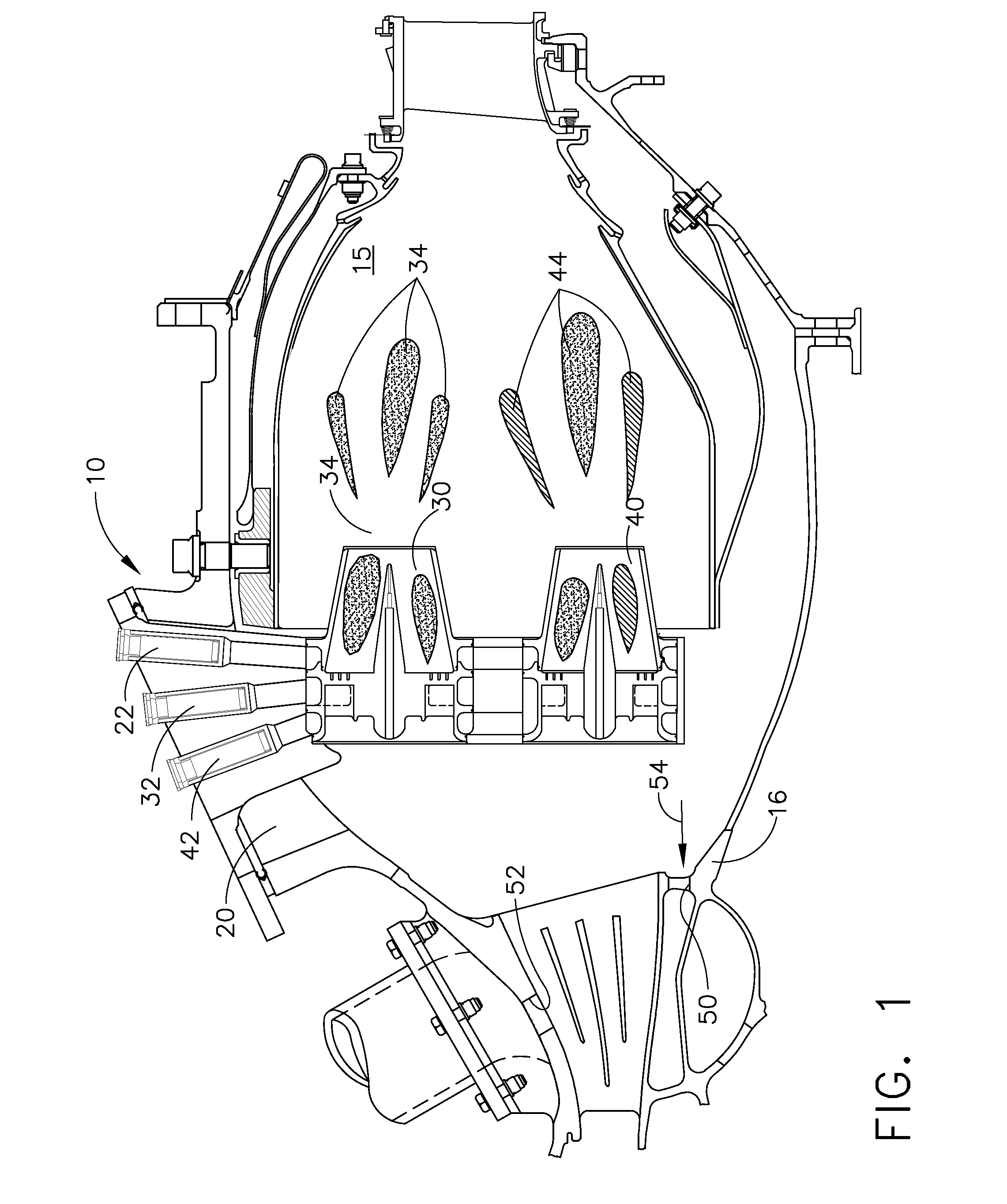

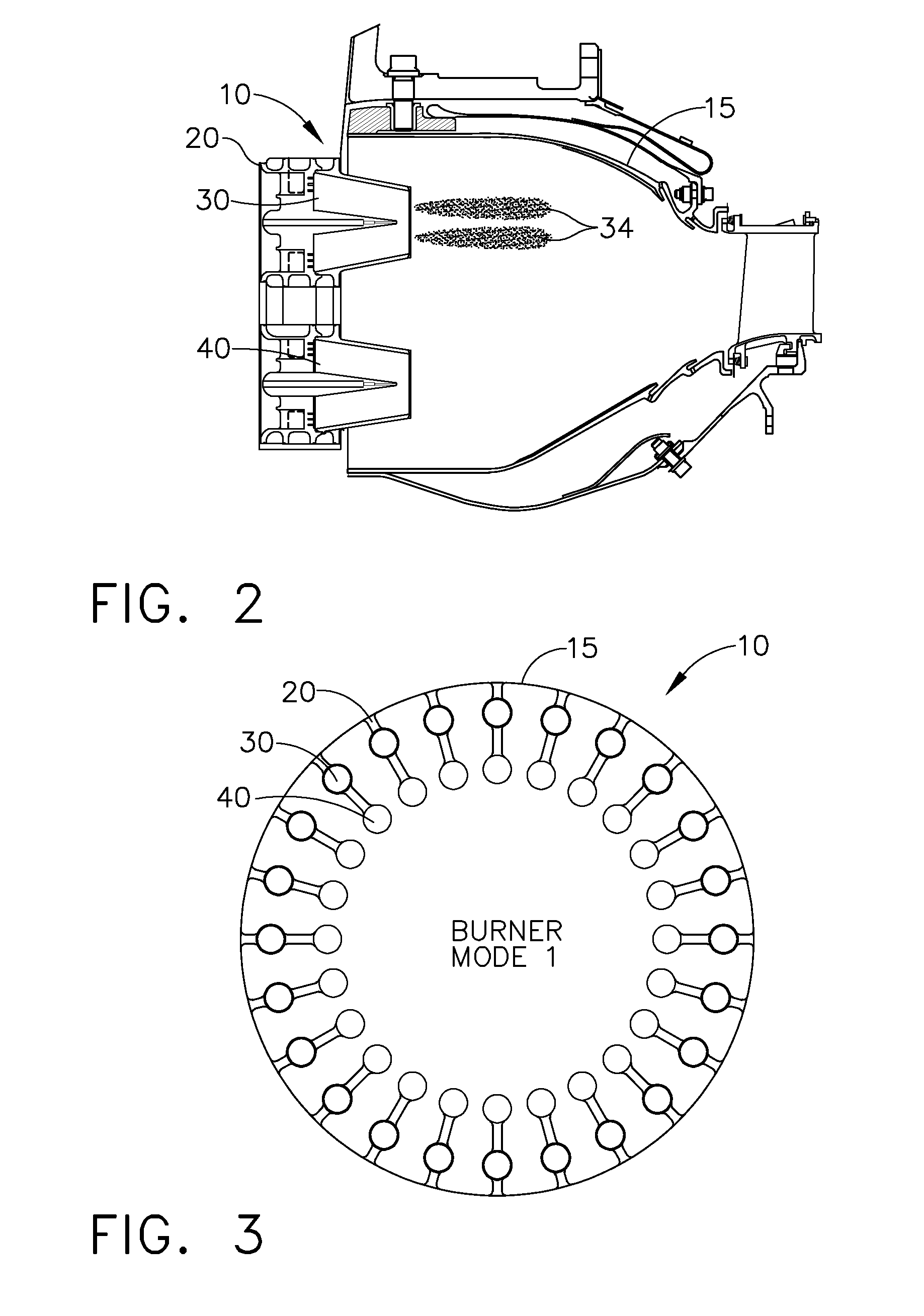

Combustor and the Method of Fuel Supply and Converting Fuel Nozzle for Advanced Humid Air Turbine

ActiveUS20120031103A1Low NOxImprove flame stabilityContinuous combustion chamberTurbine/propulsion engine ignitionInternal pressureCombustion chamber

A fuel control device and method of a gas turbine combustor, for advanced humid air turbines, in which plural combustion units comprising plural fuel nozzles for supplying fuel and plural air nozzles for supplying air for combustion are provided. A part of the plural combustion units are more excellent in flame stabilizing performance than the other combustion units. A fuel ratio, at which fuel is fed to the part of the combustion units is set on the basis of internal temperature of the humidification tower and internal pressure of the humidification tower to control a flow ratio of the fuel fed to the plural combustion units.

Owner:MITSUBISHI POWER LTD

Combustor and a fuel supply method for the combustor

ActiveUS8104284B2Maintain stabilityNOx is further reducedContinuous combustion chamberGas turbine plantsCombustorFuel supply

Owner:MITSUBISHI POWER LTD

System and method for flame stabilization

ActiveUS20130152597A1Increase rangeImprove flame stabilityBurnersContinuous combustion chamberPower settingMarine engineering

A system and method for flame stabilization is provided that forestalls incipient lean blow out by improving flame stabilization. A combustor profile is selected that maintains desired levels of power output while minimizing or eliminating overboard air bleed and minimizing emissions. The selected combustor profile maintains average shaft power in a range of from approximately 50% up to full power while eliminating overboard air bleed in maintaining such power settings. Embodiments allow for a combustor to operate with acceptable emissions at lower flame temperature. Because the combustor can operate at lower bulk flame temperatures during part power operation, the usage of inefficient overboard bleed can be reduced or even eliminated.

Owner:GENERAL ELECTRIC CO

Energy efficient low NOx burner and method of operating same

ActiveUS20050271990A1Low level of NOxImprove flame stabilityPilot flame ignitersFirebridgesCombustion chamberCombustor

A burner assembly that produces very low NOx emissions includes a plurality of furnace gas openings for receiving a portion of furnace gasses back into a combustion cylinder. The burner assembly includes the combustion cylinder, a plurality of combustion air inlet conduits that extend into the cylinder and a plurality of fuel gas discharge nozzles that also extend into the cylinder. The burner assembly is mounted within a combustion chamber of a furnace, wherein the walls of the combustion chamber are provided with or are made up of heat transfer pipes. Thus, in operation, furnace gasses exit the combustion cylinder and, due to combined aspirating action created by air jets as they exit the air conduits and fuel gas jets discharging from the fuel gas discharge nozzles inside the combustion cylinder and a pressure differential between the combustion cylinder and the combustion chamber, a portion of the furnace gasses flow from the outlet of the combustion cylinder and past the heat transfer pipes toward the proximal or upstream end of the combustion cylinder. Passage of the furnace gasses past the heat transfer pipes cools the furnace gasses and the furnace gasses then flow through the furnace gas openings and mix with the combustion air and fuel gas to provide a lower NOx emission in an energy-efficient manner.

Owner:JOHN ZINK CO LLC

Tornado torch igniter

ActiveUS7299620B2Improve cooling effectImprove flame stabilityTurbine/propulsion engine ignitionWorking fluid for enginesCombustorTorch

An ignition system having improved reliability for a gas turbine combustor is disclosed. The ignition system comprises an outer housing having at least one fuel passage and an electrode extending therethrough forming a generally annular passage for cooling air to pass to a mixing chamber. Fuel and air mix in the mixing chamber to form a combustible mixture that is ignited by the electrode. The outer housing further comprises a plurality of air swirl holes to effectively cool the walls of the mixing chamber as well as to provide improved flame stability.

Owner:H2 IP UK LTD

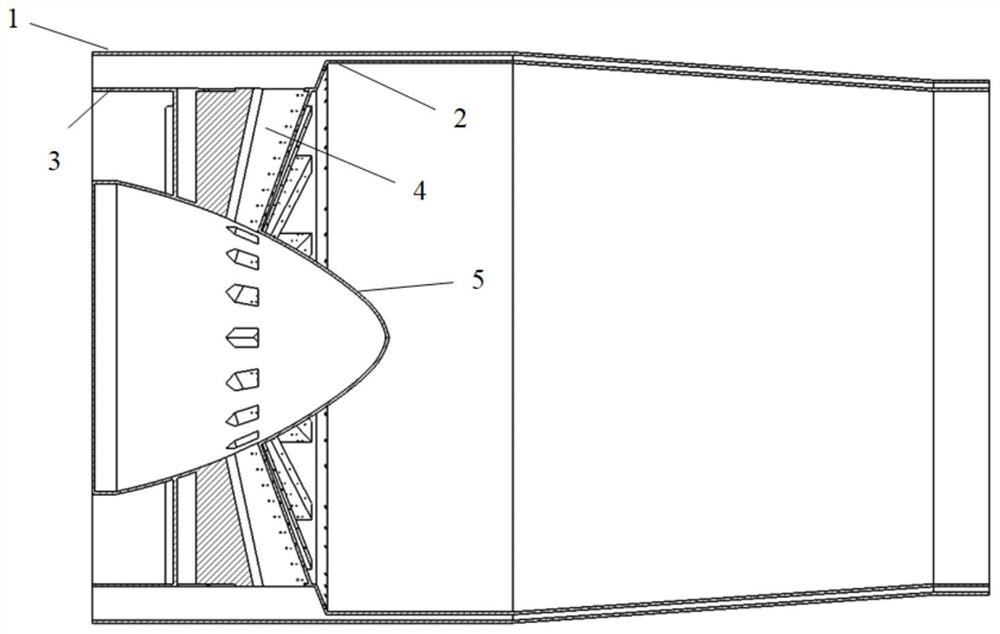

Support plate stabilizer with gas mixing function and integrated afterburner

ActiveCN114738795ASimple structureRealize integrated designContinuous combustion chamberEfficient propulsion technologiesCombustion chamberEngineering

In order to solve the problems that according to an existing afterburner integrated design scheme, a backflow area and a combustion area move forwards, consequently, combustion is insufficient, and the difficulty of ignition and flame stabilization is increased, the invention provides a supporting plate stabilizer with a gas mixing function and an integrated afterburner. The two symmetrical open type concave cavities are formed in the middle of the supporting plate stabilizer, the open type concave cavities have the gas mixing function and can replace a mixer in a traditional afterburner, and the structure of the afterburner is simplified; in addition, due to the fact that the oxygen content of the outer culvert air flow is higher than that of the inner culvert air flow, the oxygen content of the mixed air is increased after the outer culvert air flow and the inner culvert air flow are mixed, the outer culvert air flow and the inner culvert air flow are combusted while being mixed, and the combustion efficiency is improved. Therefore, combustion is more sufficient, and flame stability and combustion efficiency are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

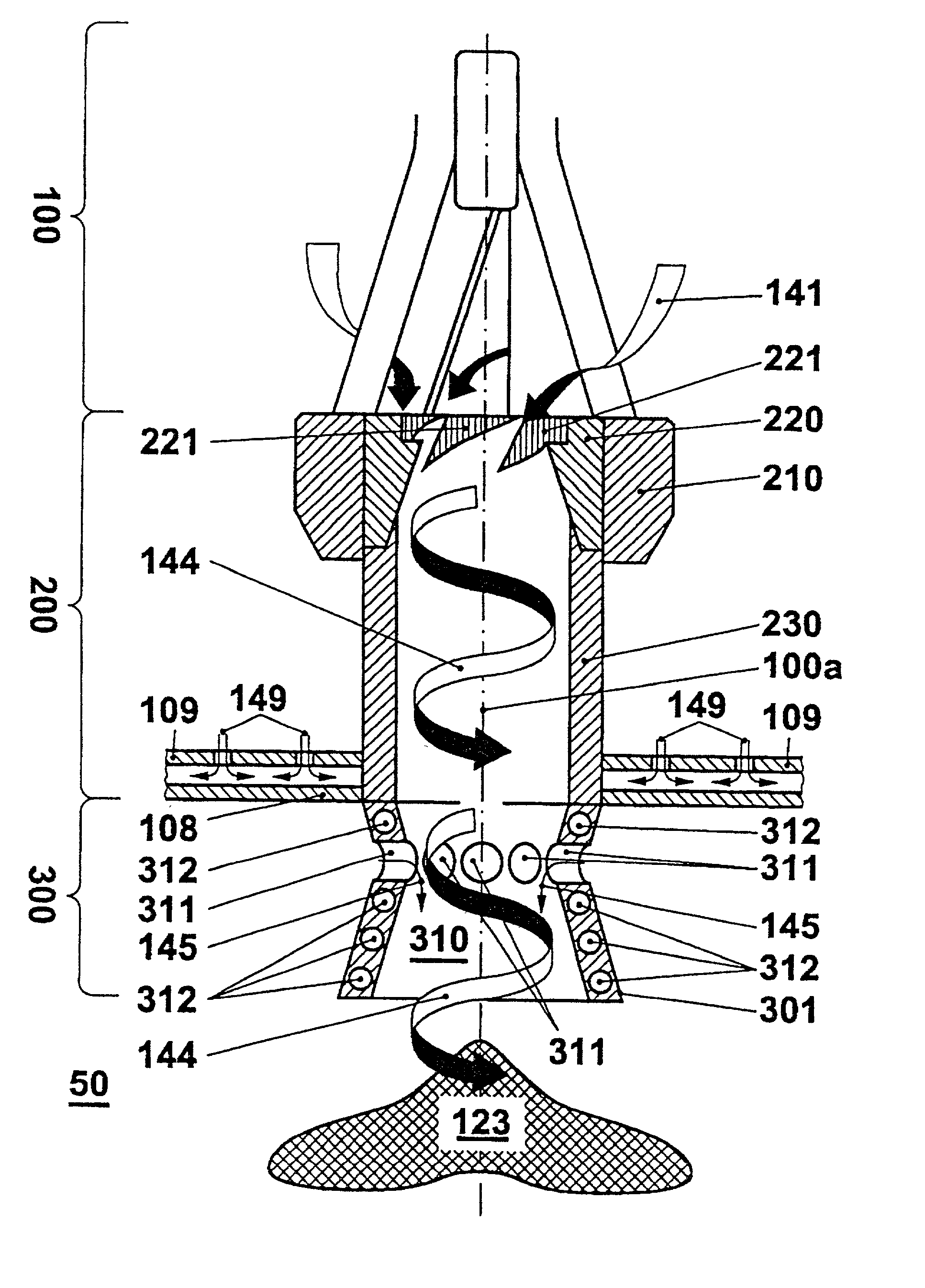

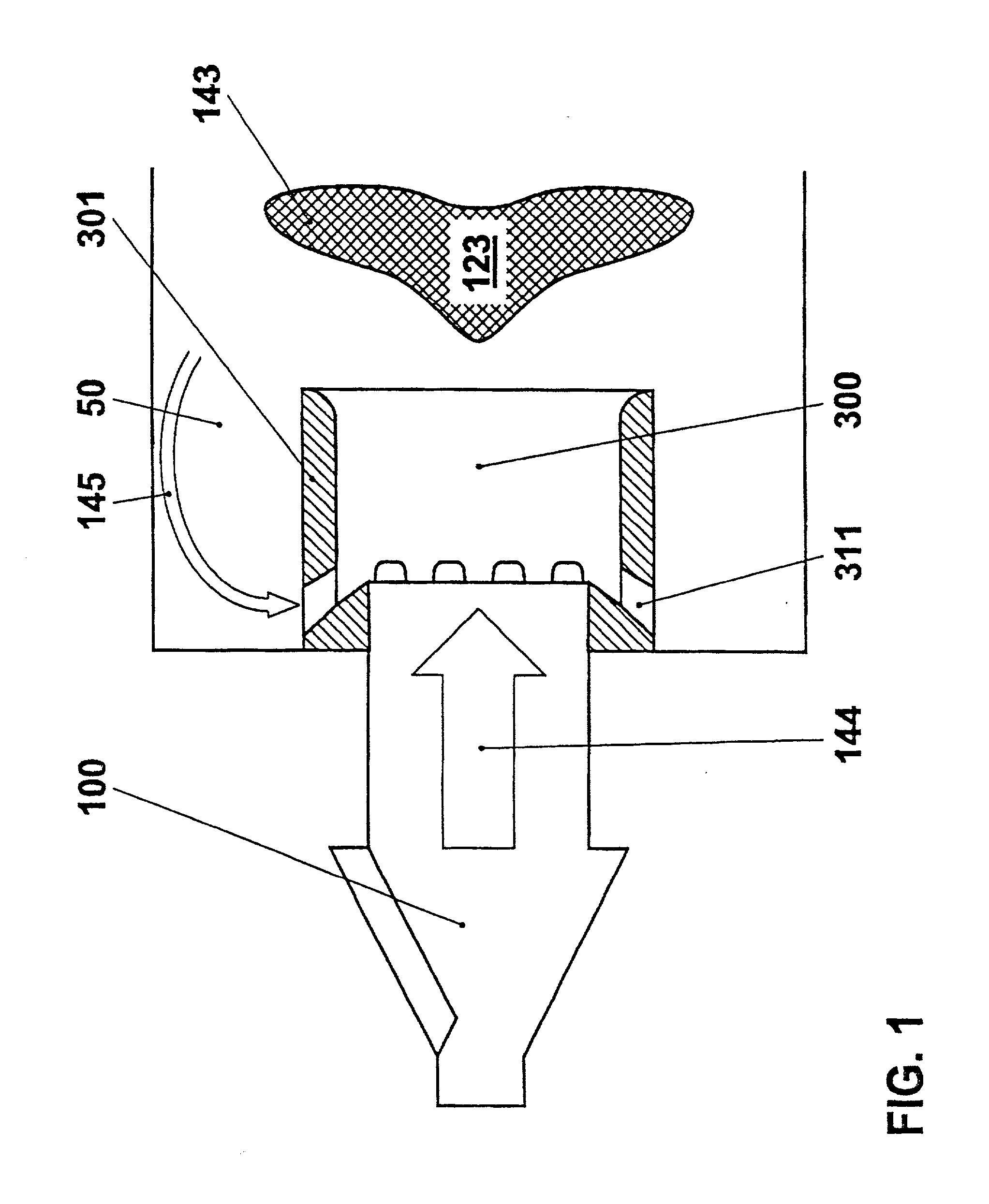

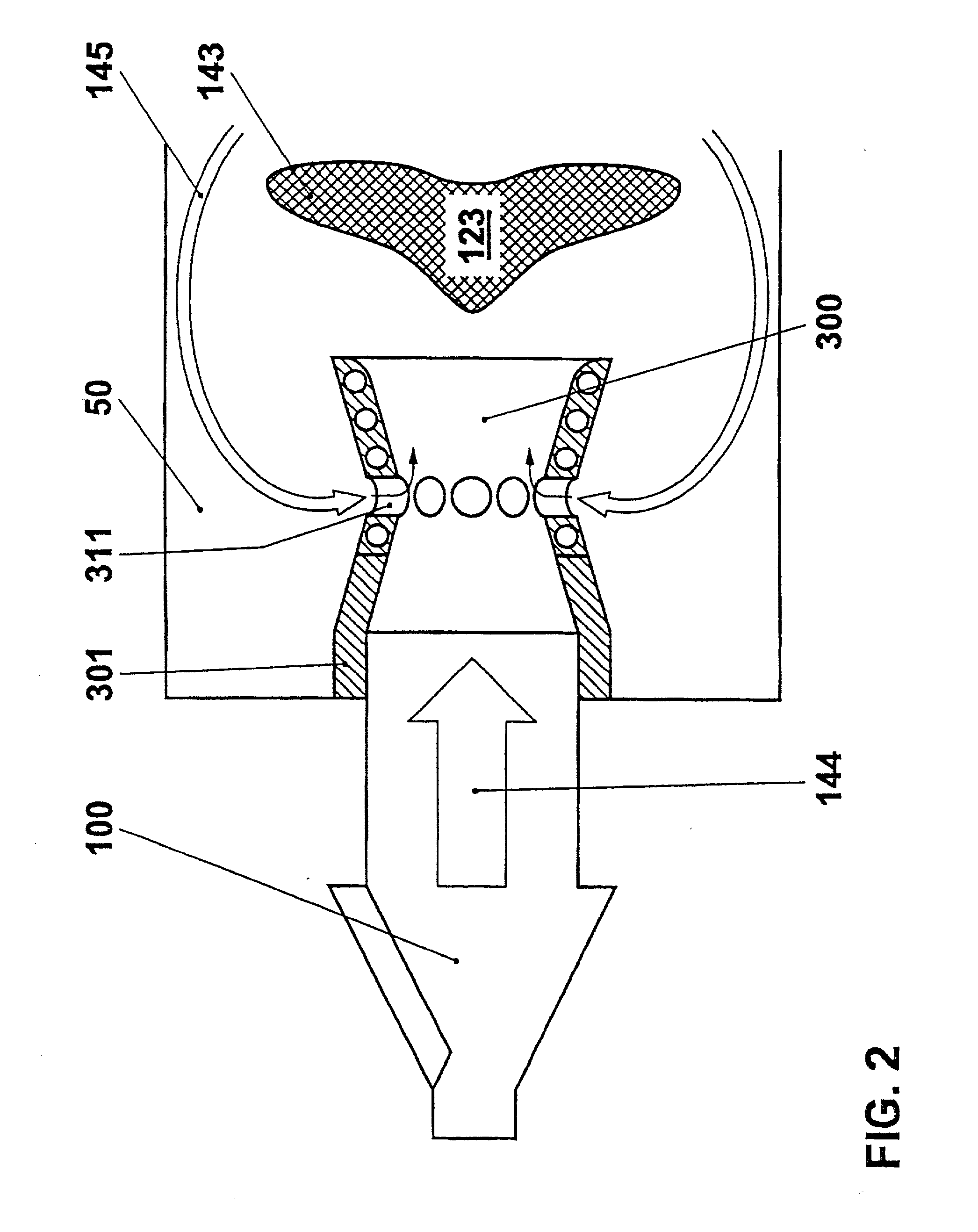

Burner with high flame stability

InactiveUS20020172905A1Improve flame stabilityReduce pressureGas turbine plantsBurner material specificationsCombustorCombustion chamber

The invention relates to a premix burner with high flame stability for use in a heat producer, preferably in the combustion chamber of a gas turbine. Modem lean operated premix burners make possible very low pollutant emissions, but sometimes operate very close to the extinction limit. To increase the stability of the lean premix combustion by increasing the distance between the flame temperature and the extinction limit temperature, it is proposed according to the invention to arrange a downstream combustion gas mixing section (300) for the burner, which mixing section (300) projects at least partially into the combustion chamber (50) and enables combustion gases from the combustion chamber (50) access to the fuel / air mixture (144) by means of combustion gas inlet openings (311). The added combustion gases (145) are mixed with the fuel / air mixture (144), and in this manner increase its temperature. This increase in temperature results in a significant increase in the flame speed, as a consequence of which the extent of the flame front (123) and the extinction limit temperature of the burner decrease.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com