Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

328results about How to "Flame stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

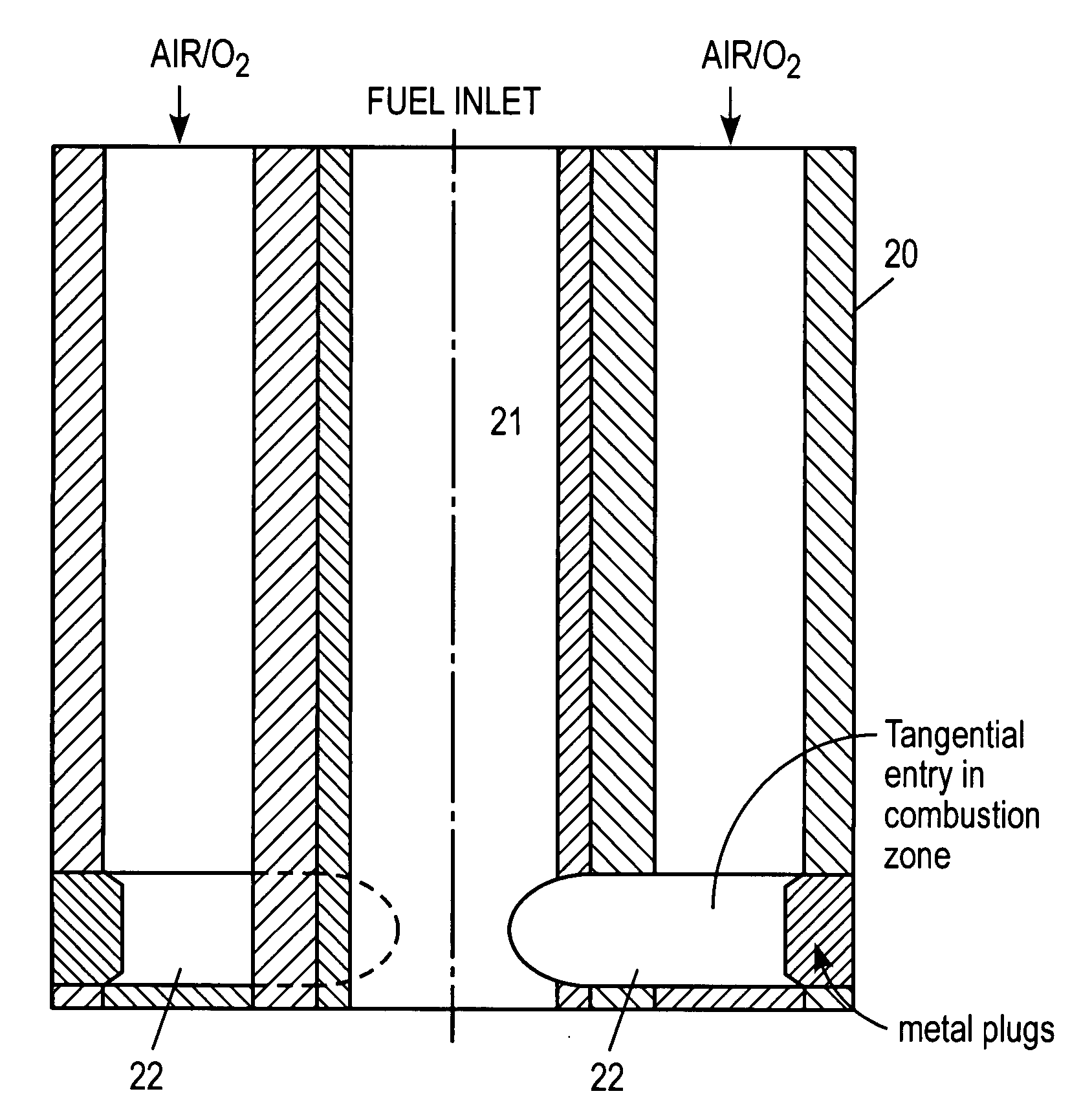

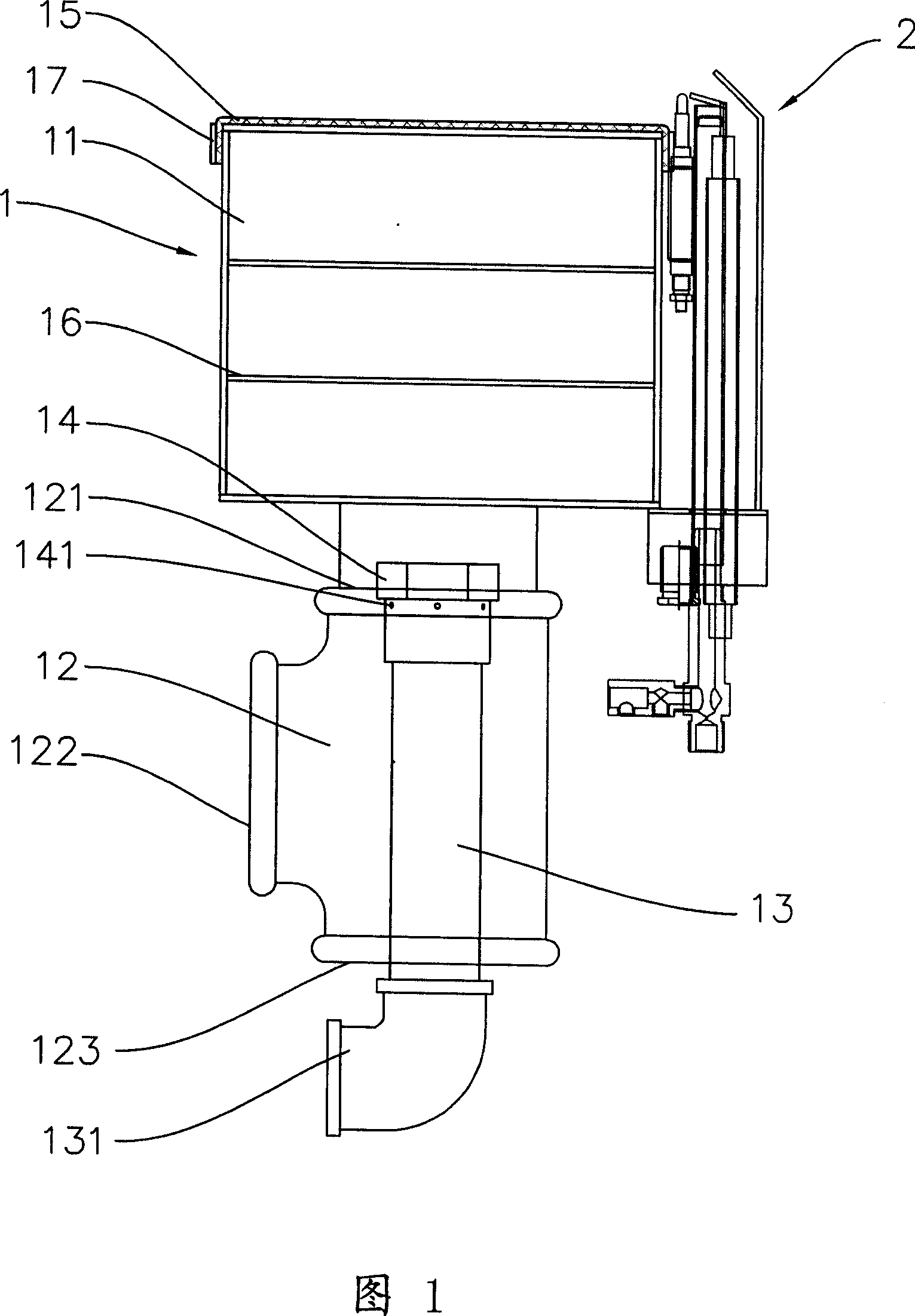

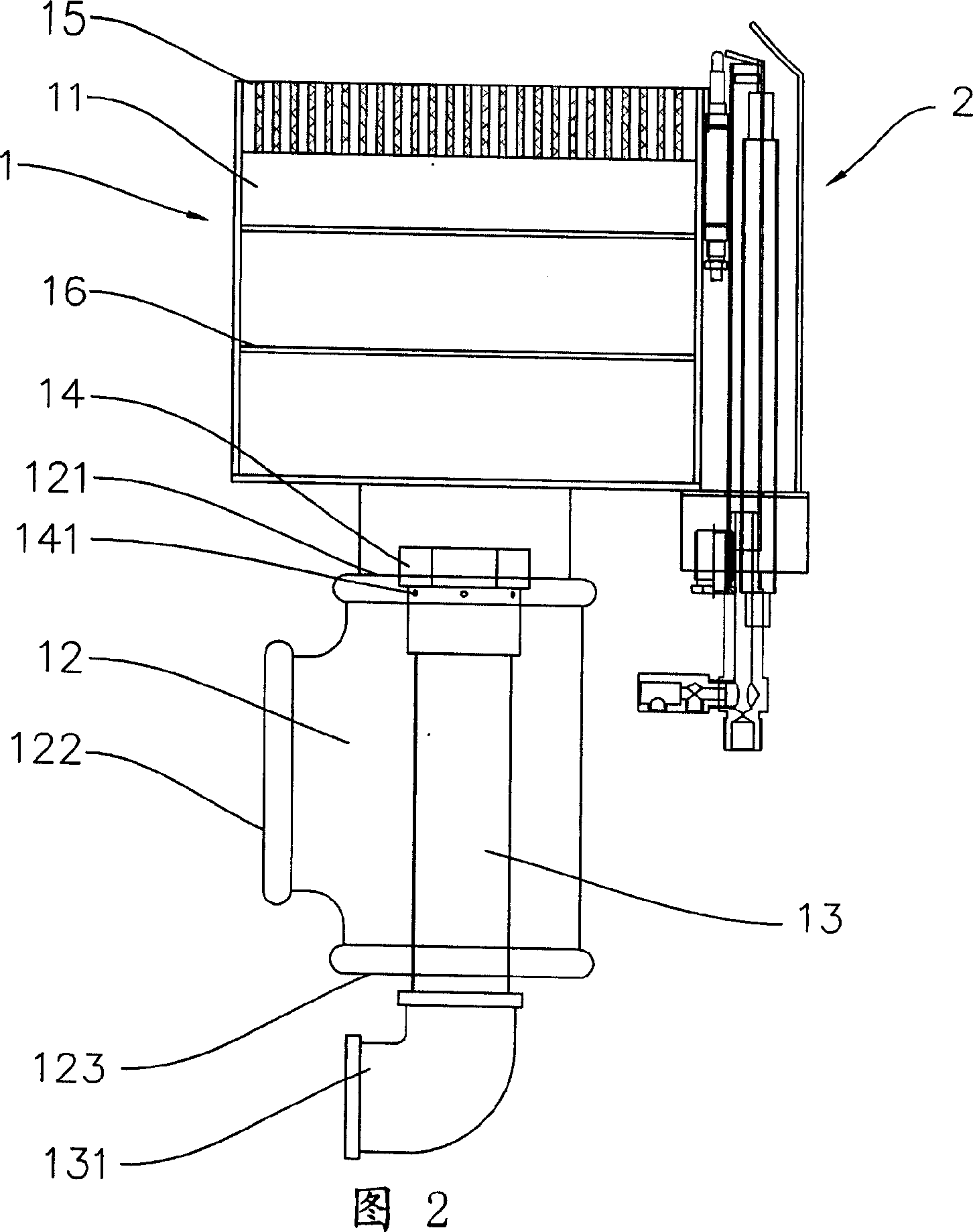

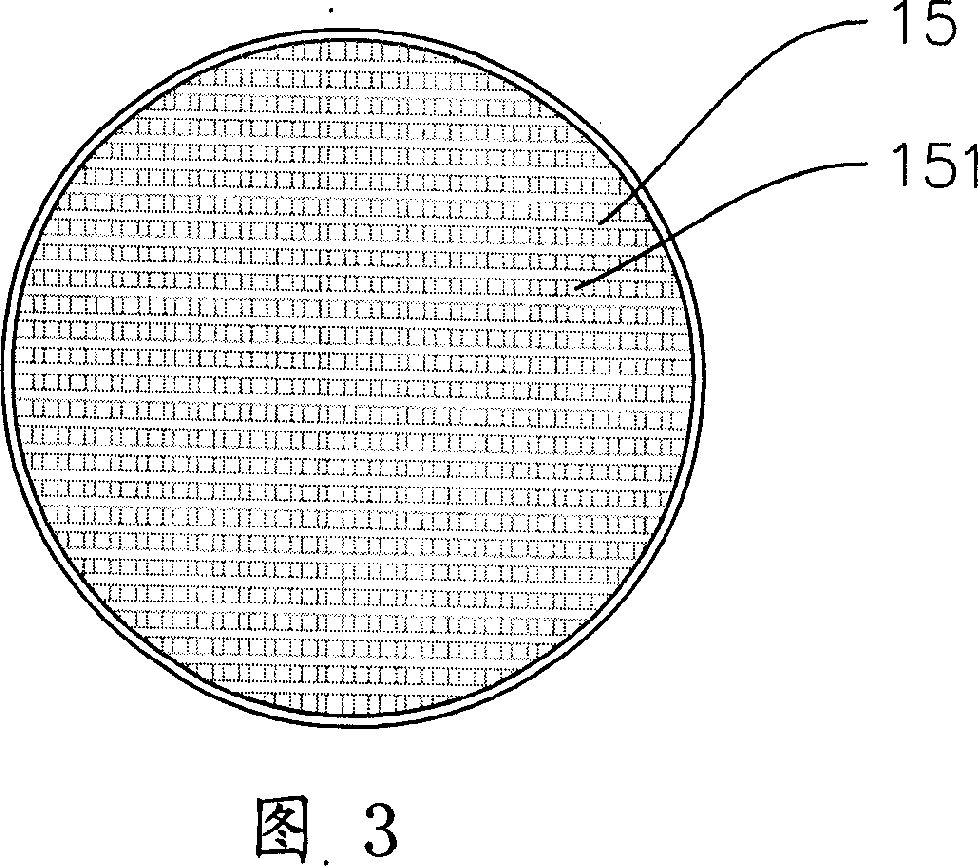

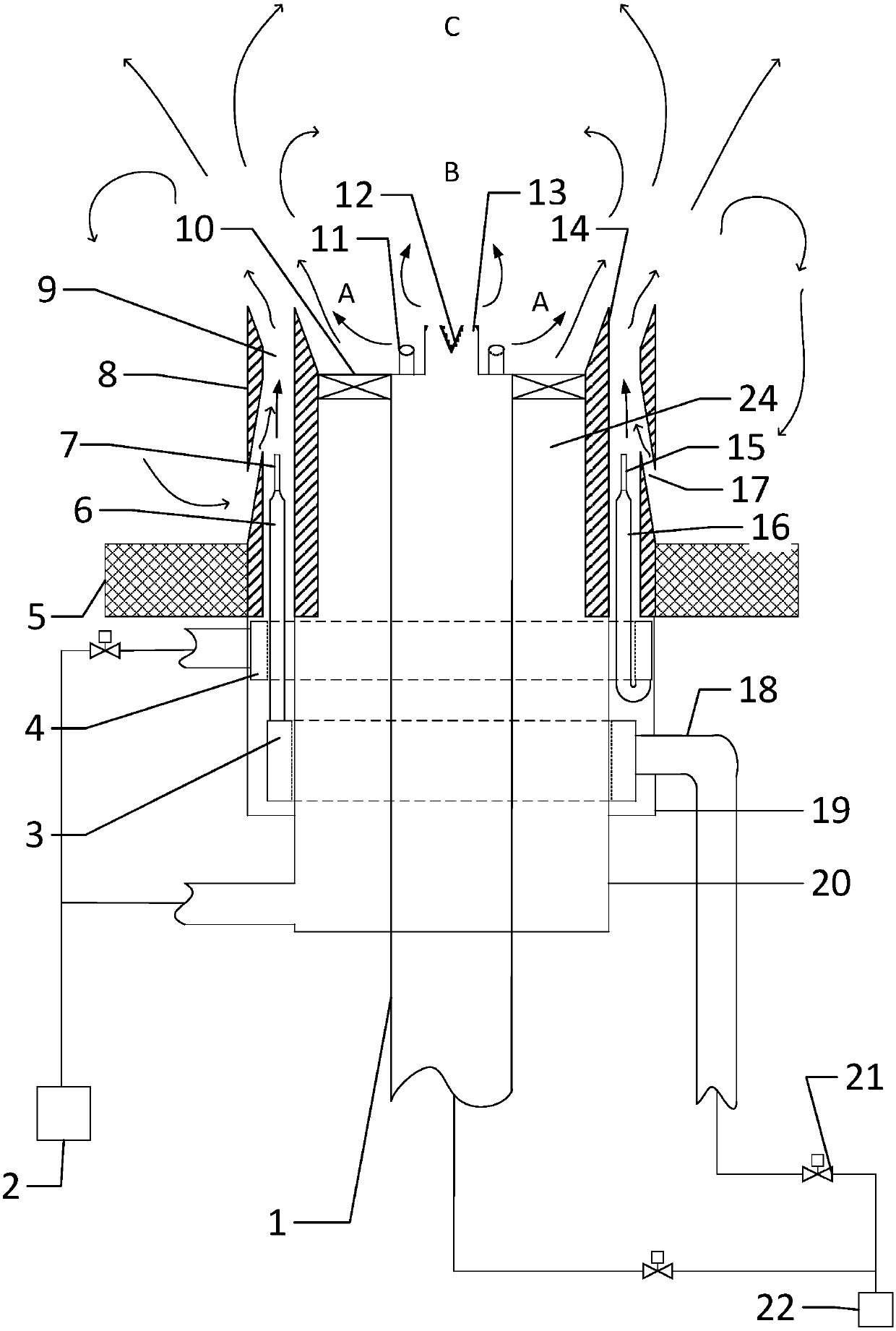

Direct combustion steam generator

ActiveUS20070202452A1Flame stabilizationHigh strengthGas turbine plantsFluid removalDirect combustionProcess engineering

A method and apparatus for generating steam by heating water with a flame is provided. The water is introduced into a vortex sustaining container and flows through the container in a spiraling manner creating a liquid vortex with an open axial core. The flame effects heat transfer and is the product of the ignition of fuel mixed with a tangentially swirling oxygen containing gas.

Owner:DIRECT COMBUSTION TECH

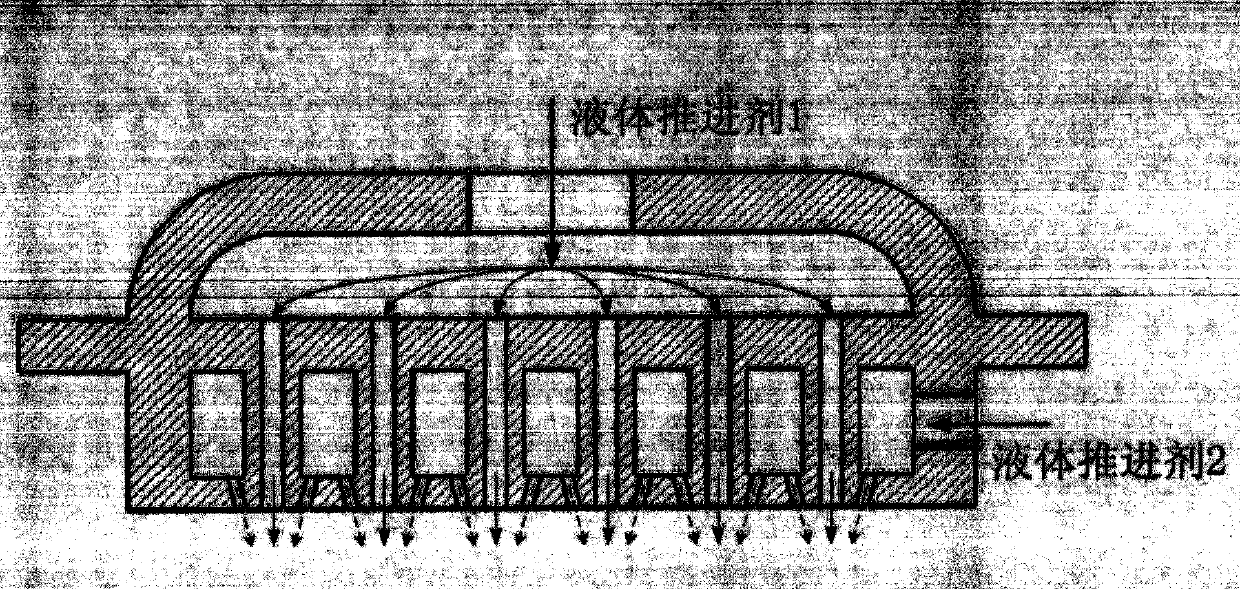

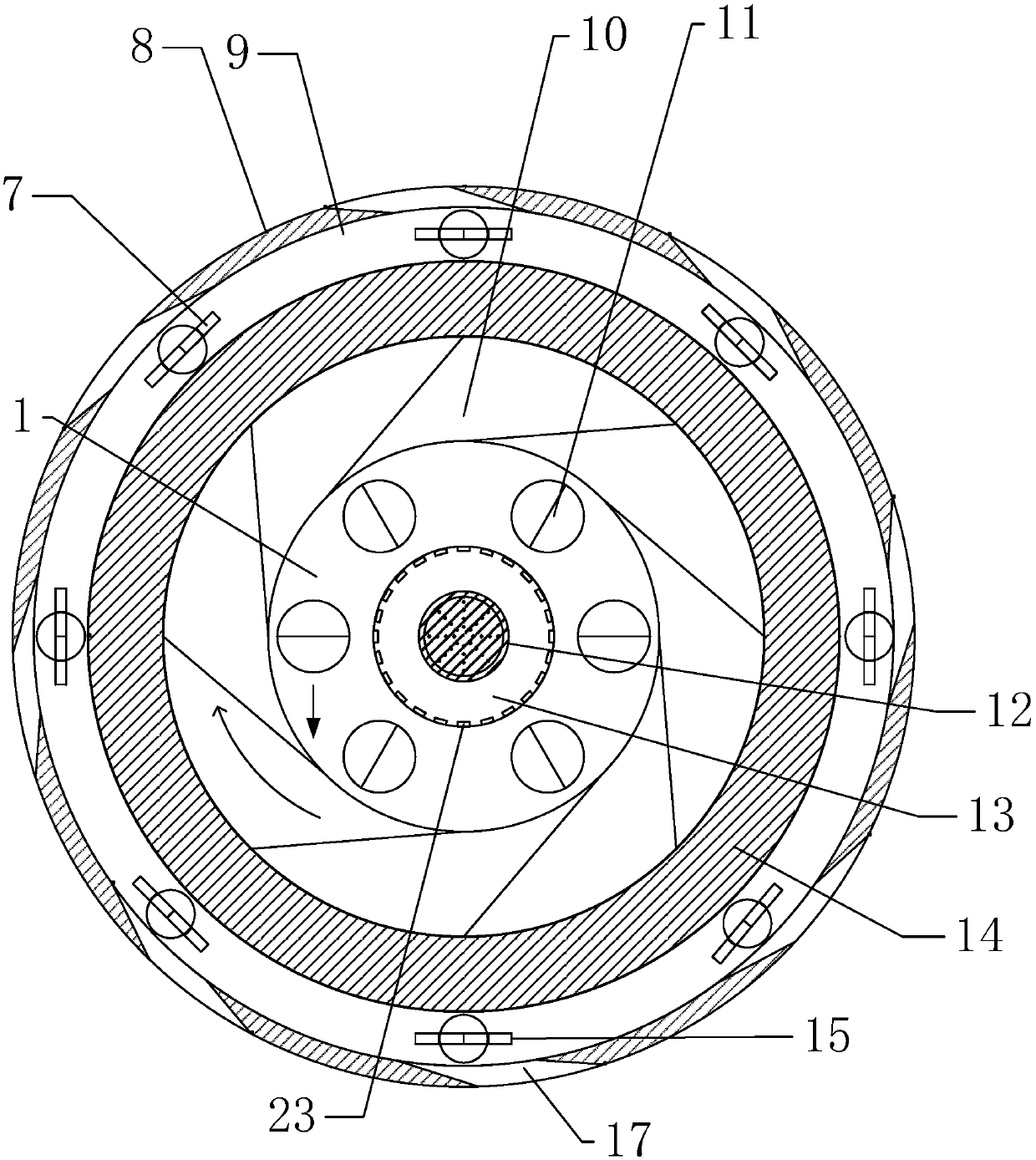

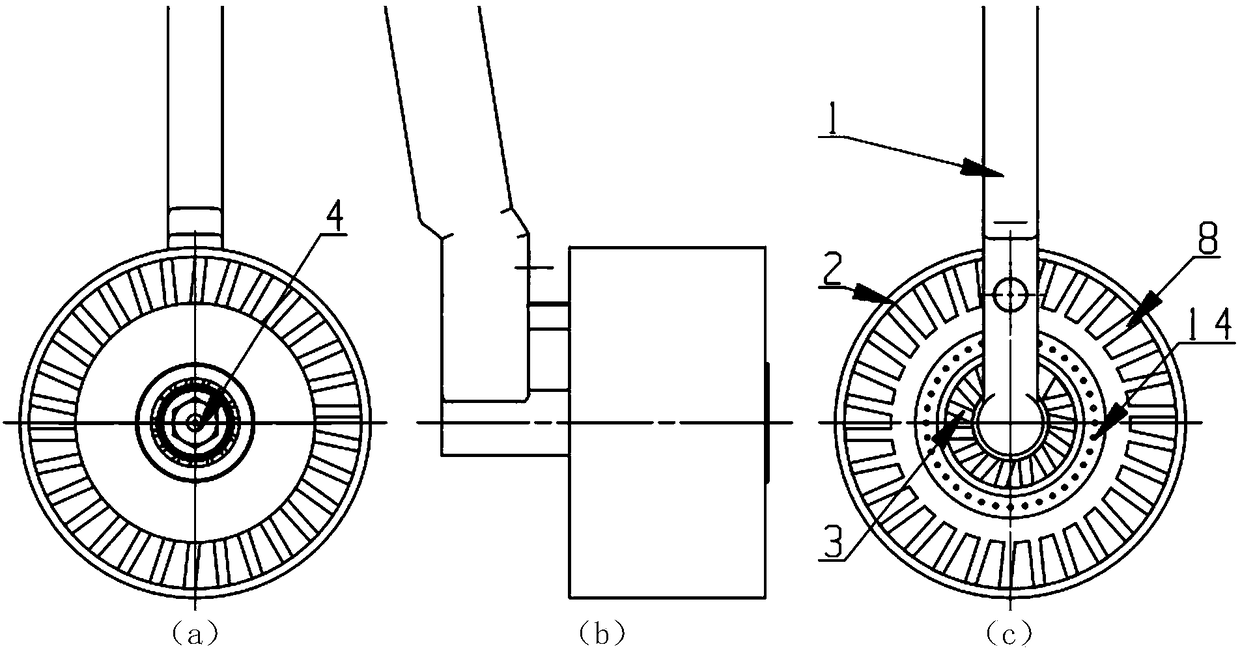

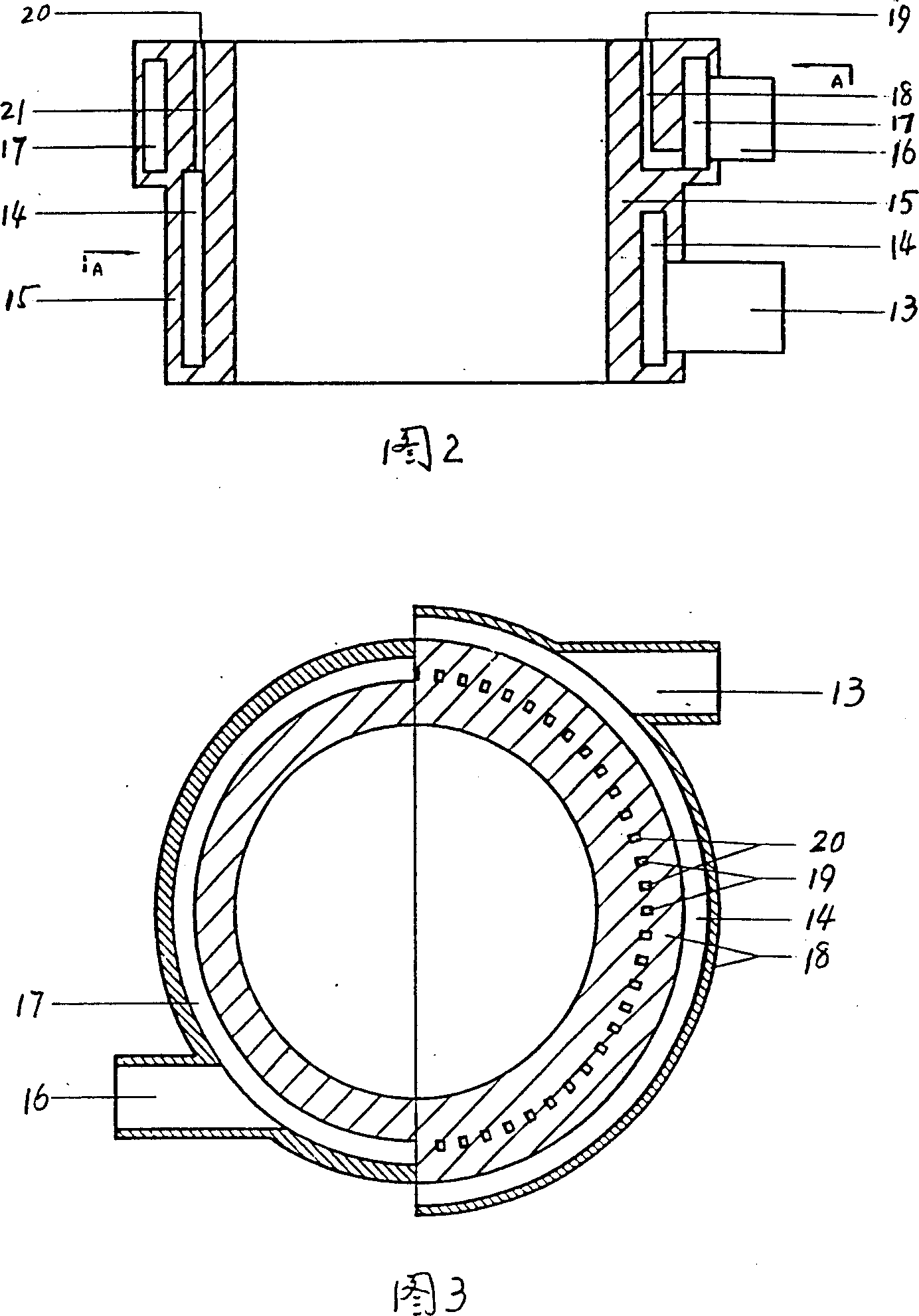

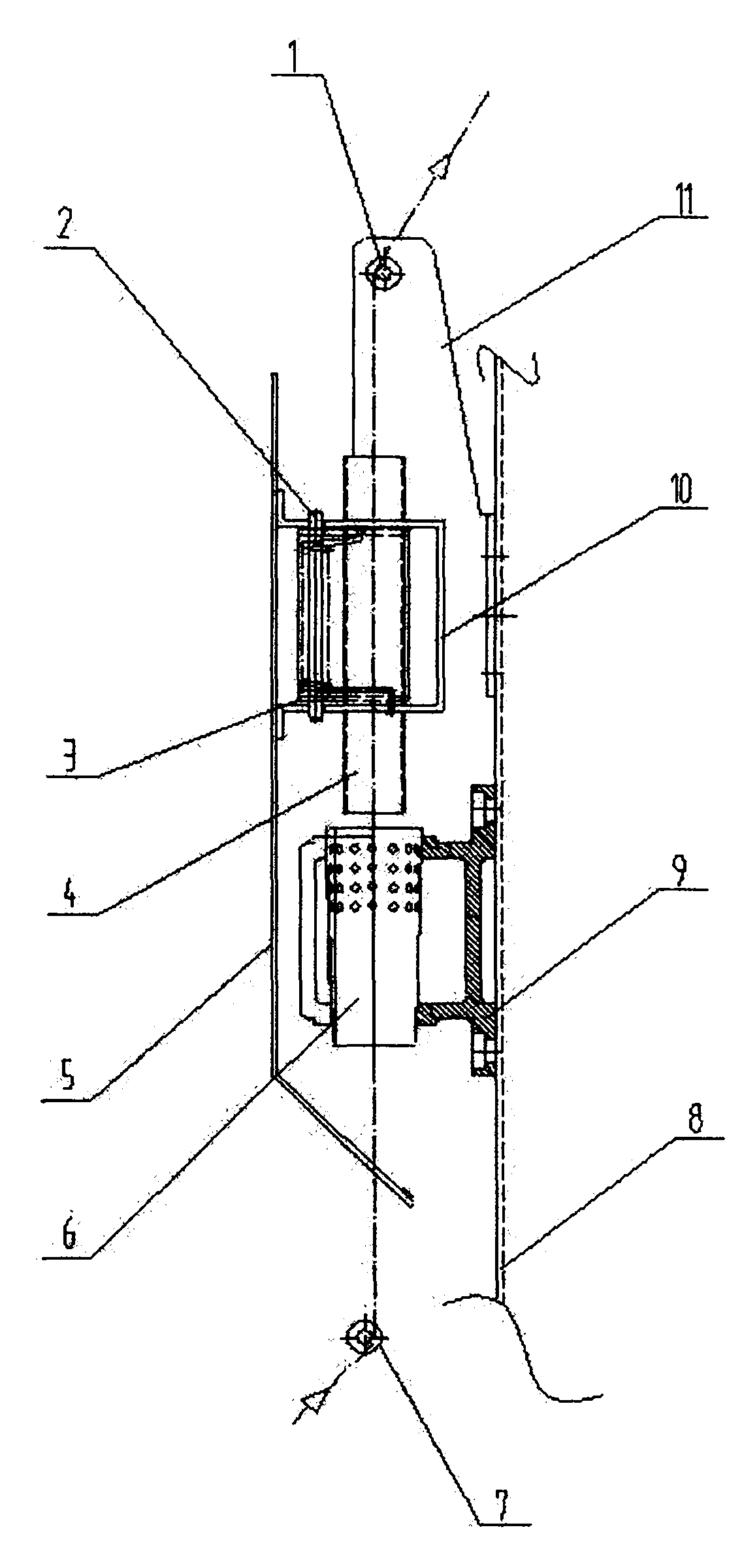

Dual-rotational-flow inspirator

ActiveCN103867340AStrong interactionGood atomization performanceRocket engine plantsHollow cylinderEngineering

The invention provides a dual-rotational-flow inspirator, which comprises a top cover, a nozzle, an upper bottom, a middle bottom, a gas whirlcone and an inspirator cavity, wherein the inspirator cavity is a barrel-shaped hollow cylinder; a fuel cavity is formed between the top cover and the upper bottom of the inspirator; a gas oxidizing agent cavity is formed between the upper bottom and the middle bottom of the inspirator; a water cavity is formed between the middle bottom of the inspirator and the base of the inspirator; an inner nozzle passes through mounting holes in the upper bottom, the middle bottom and the inspirator cavity and is fixedly arranged on the upper bottom via a thread; the gas whirlcone is installed on the nozzle by a thread; water nozzles are water holes evenly distributed on the circumstance on the base of the inspirator. The inspirator provided by the invention has the characteristics of simple structure, low cost, good atomization performance and stable flame.

Owner:NAT UNIV OF DEFENSE TECH

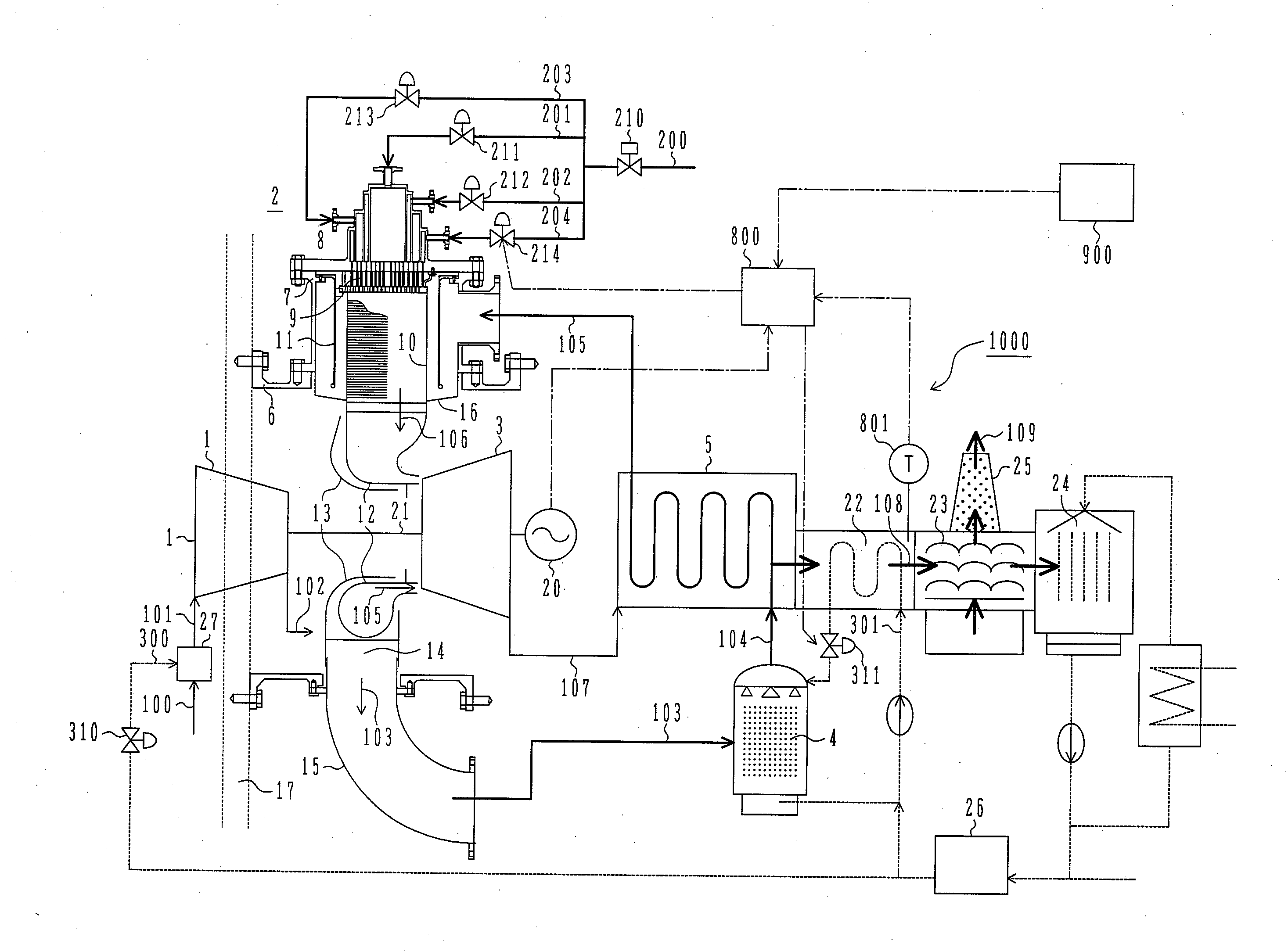

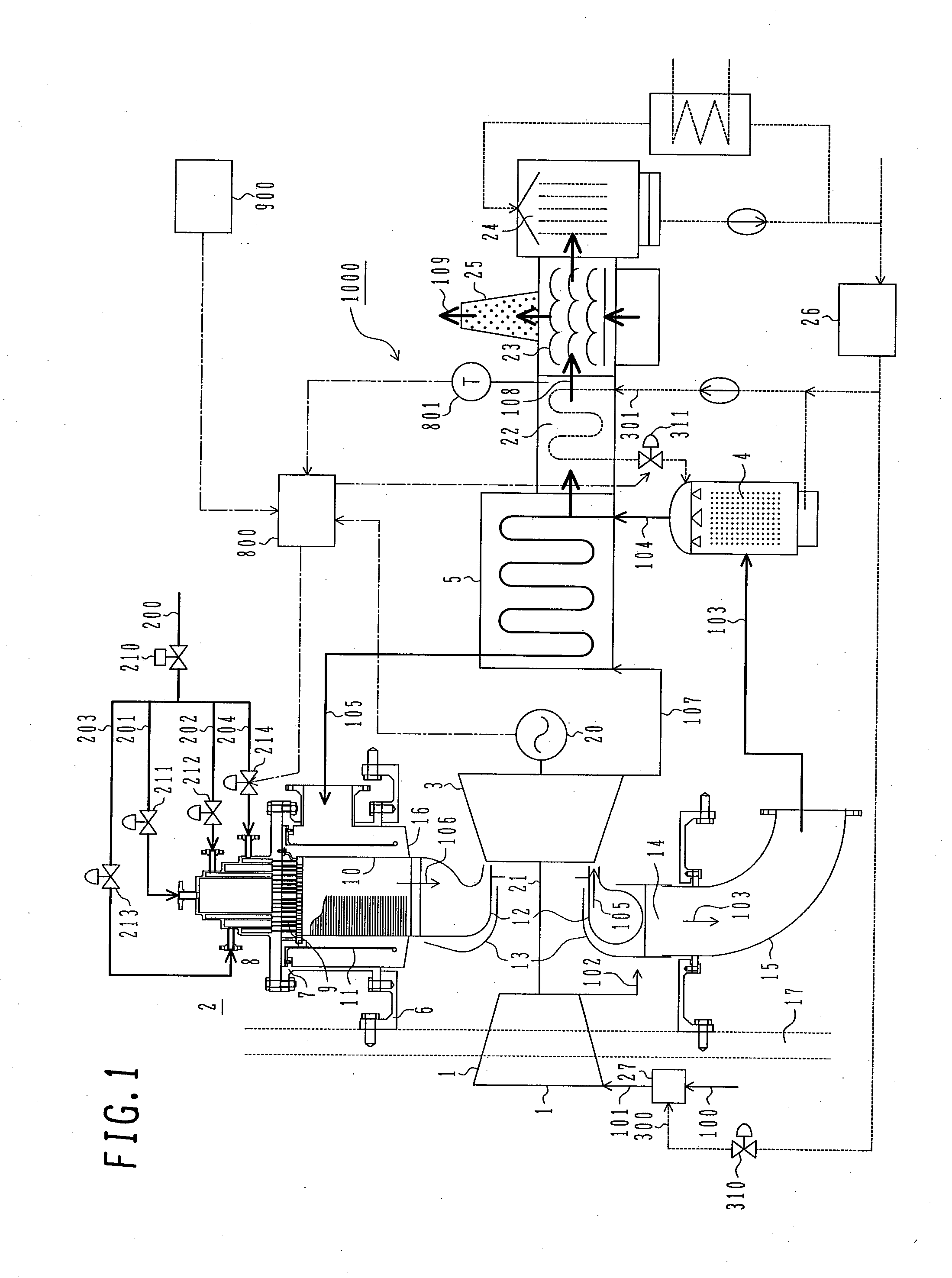

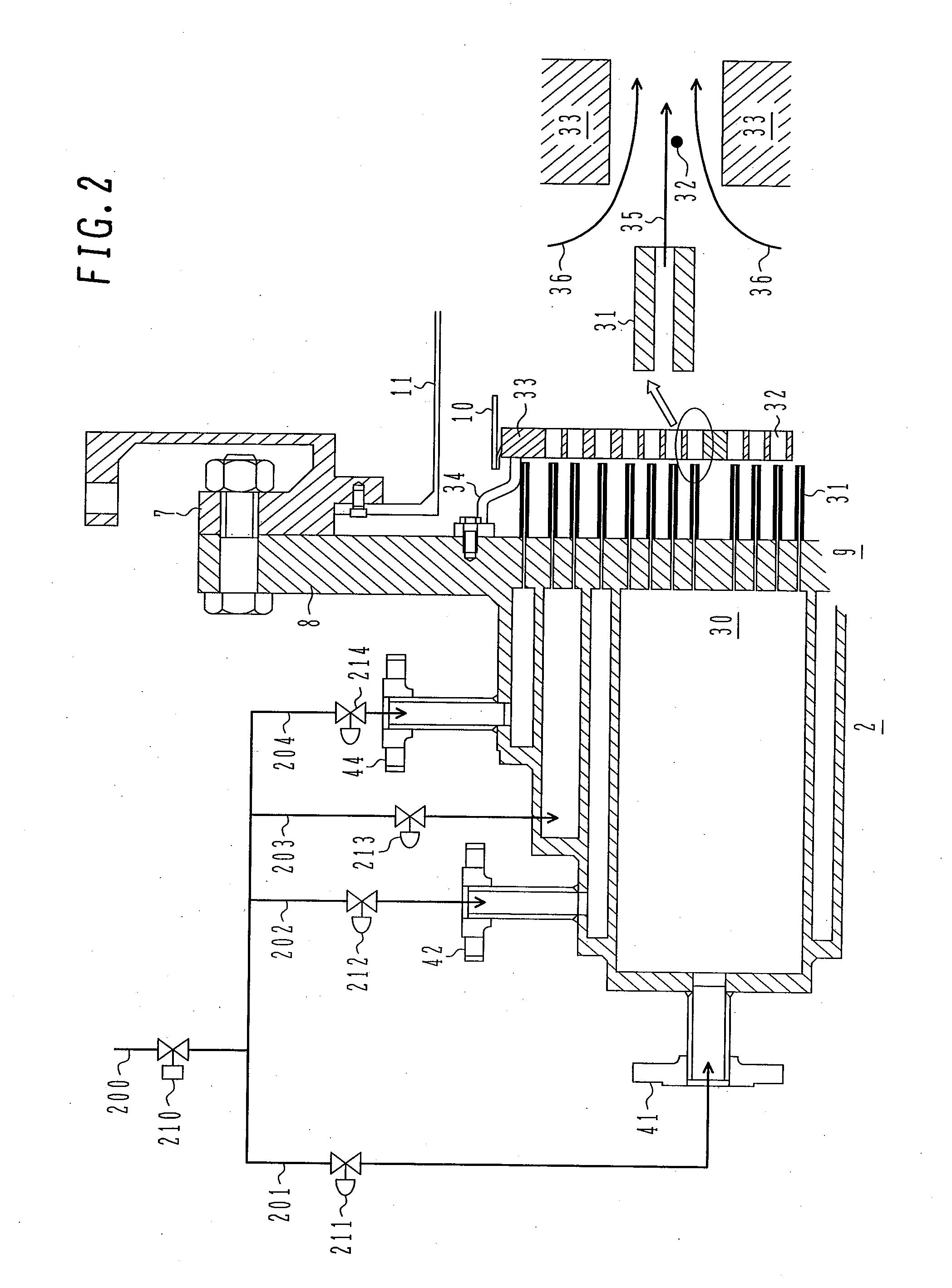

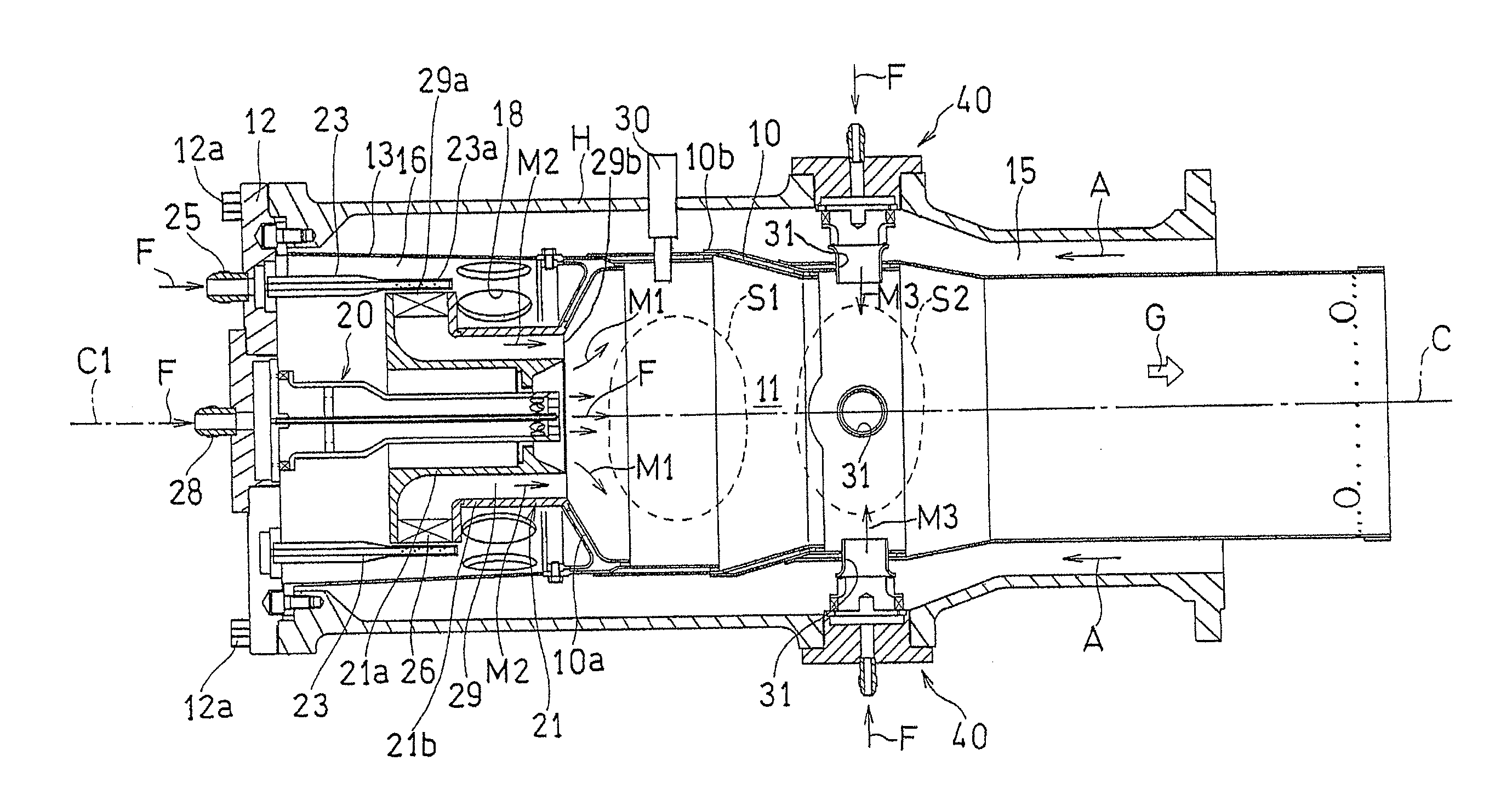

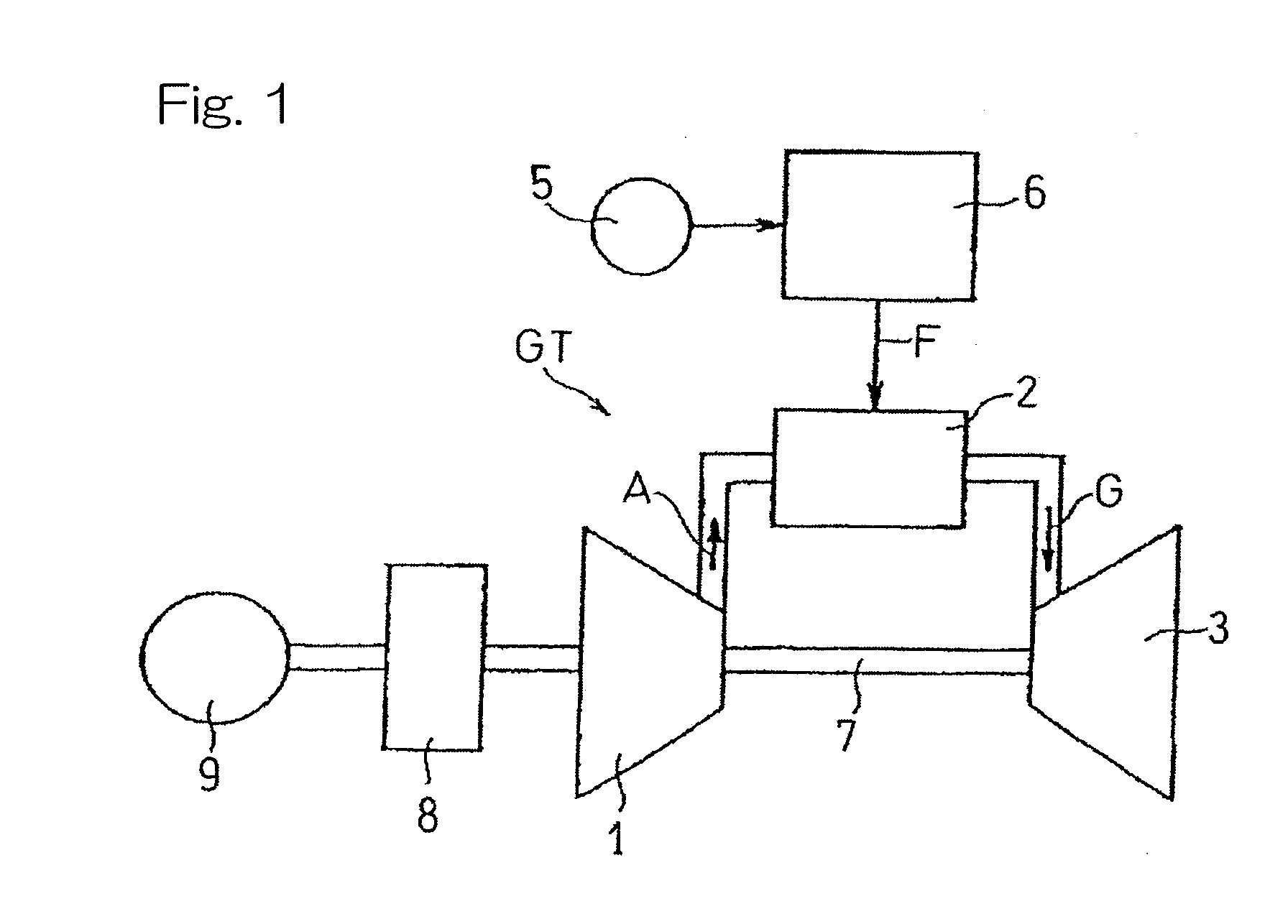

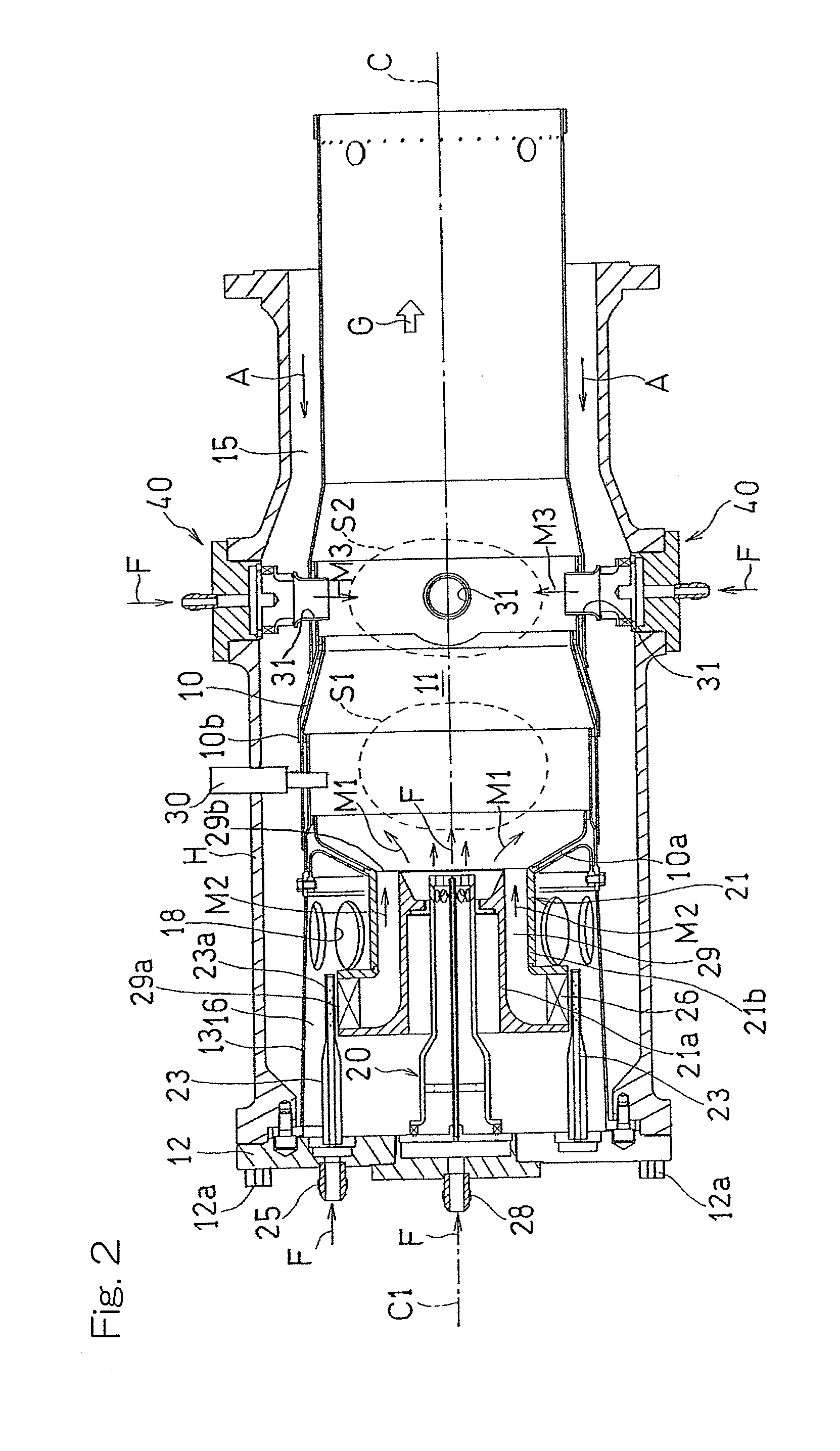

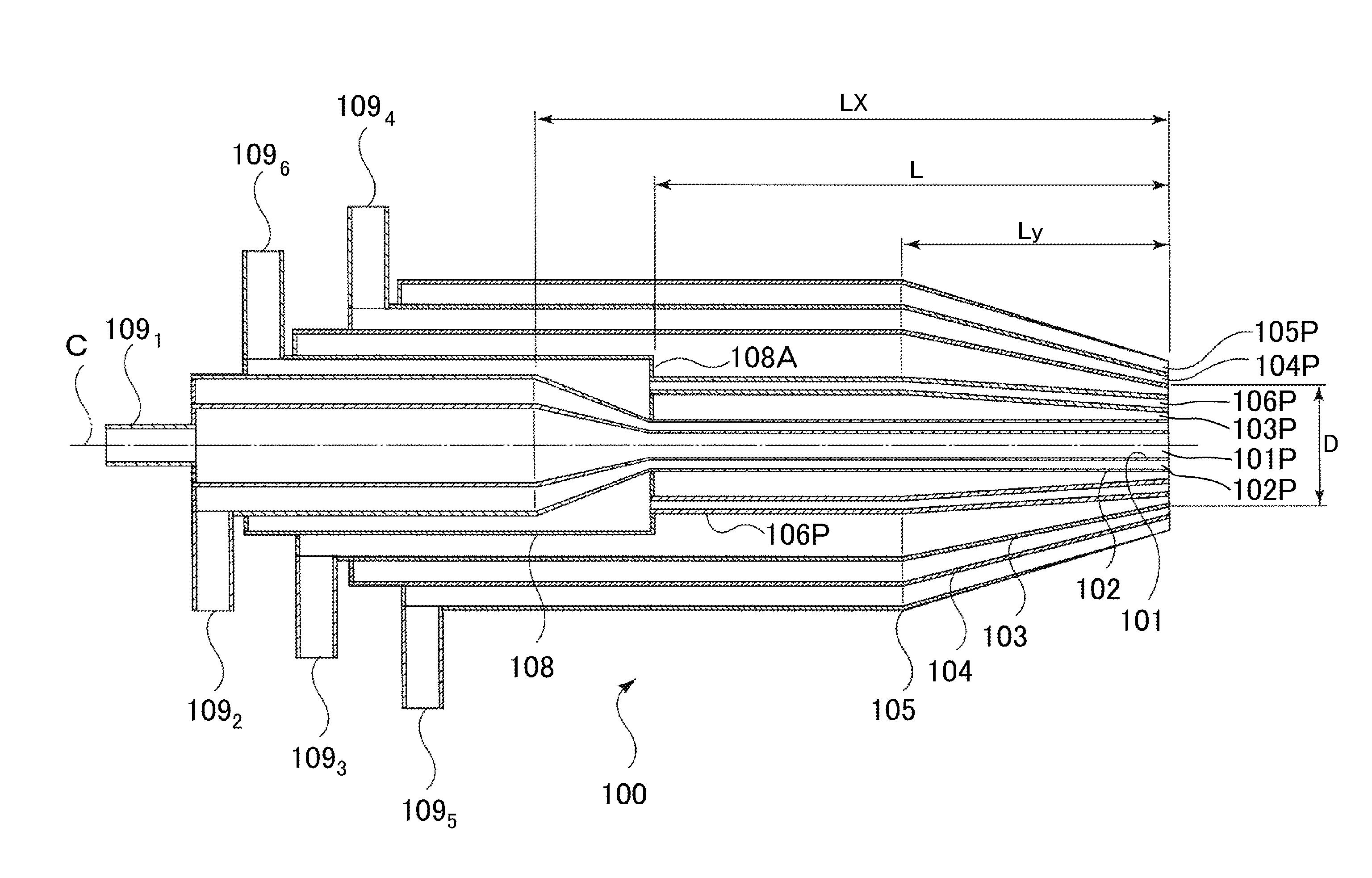

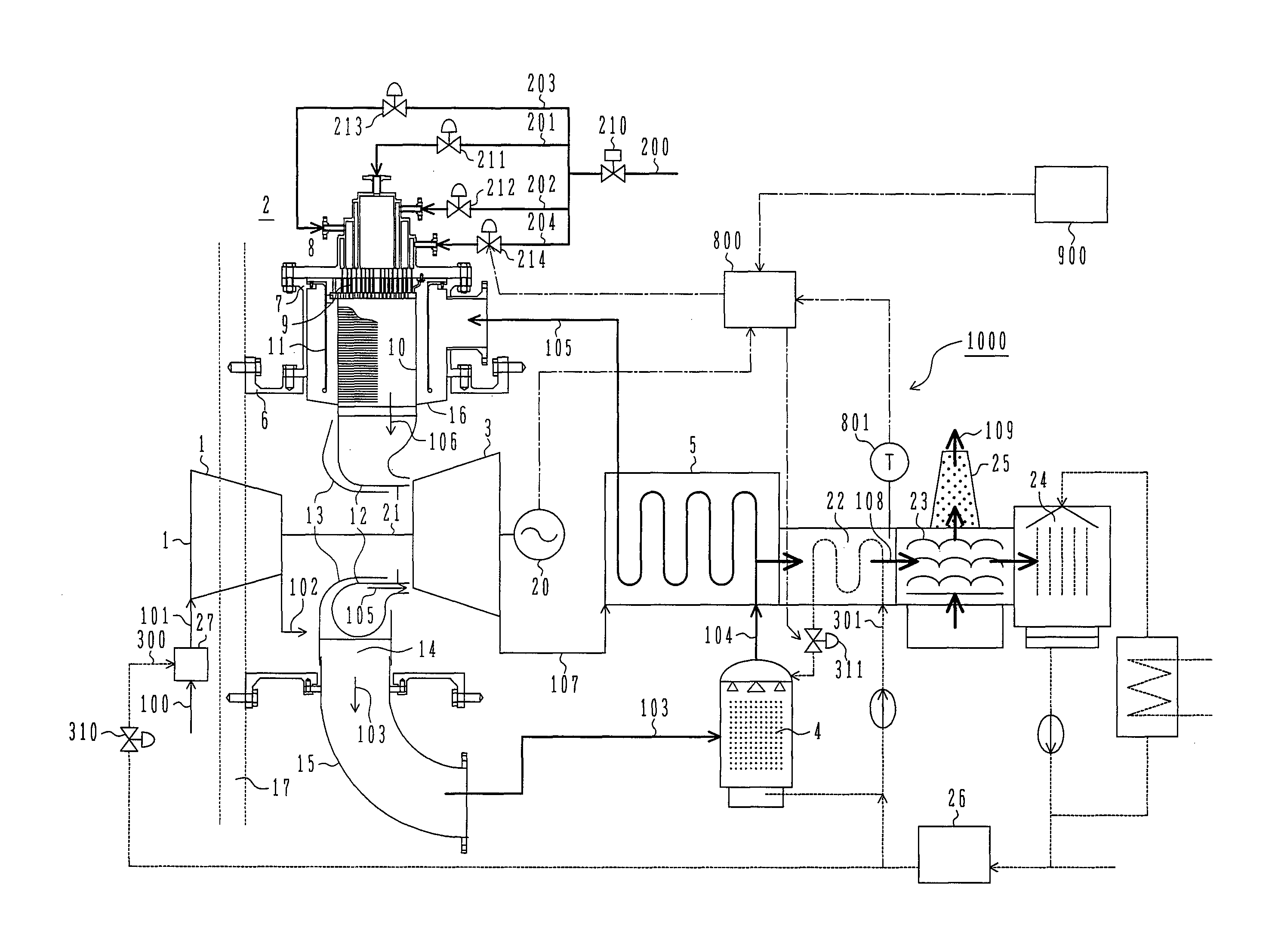

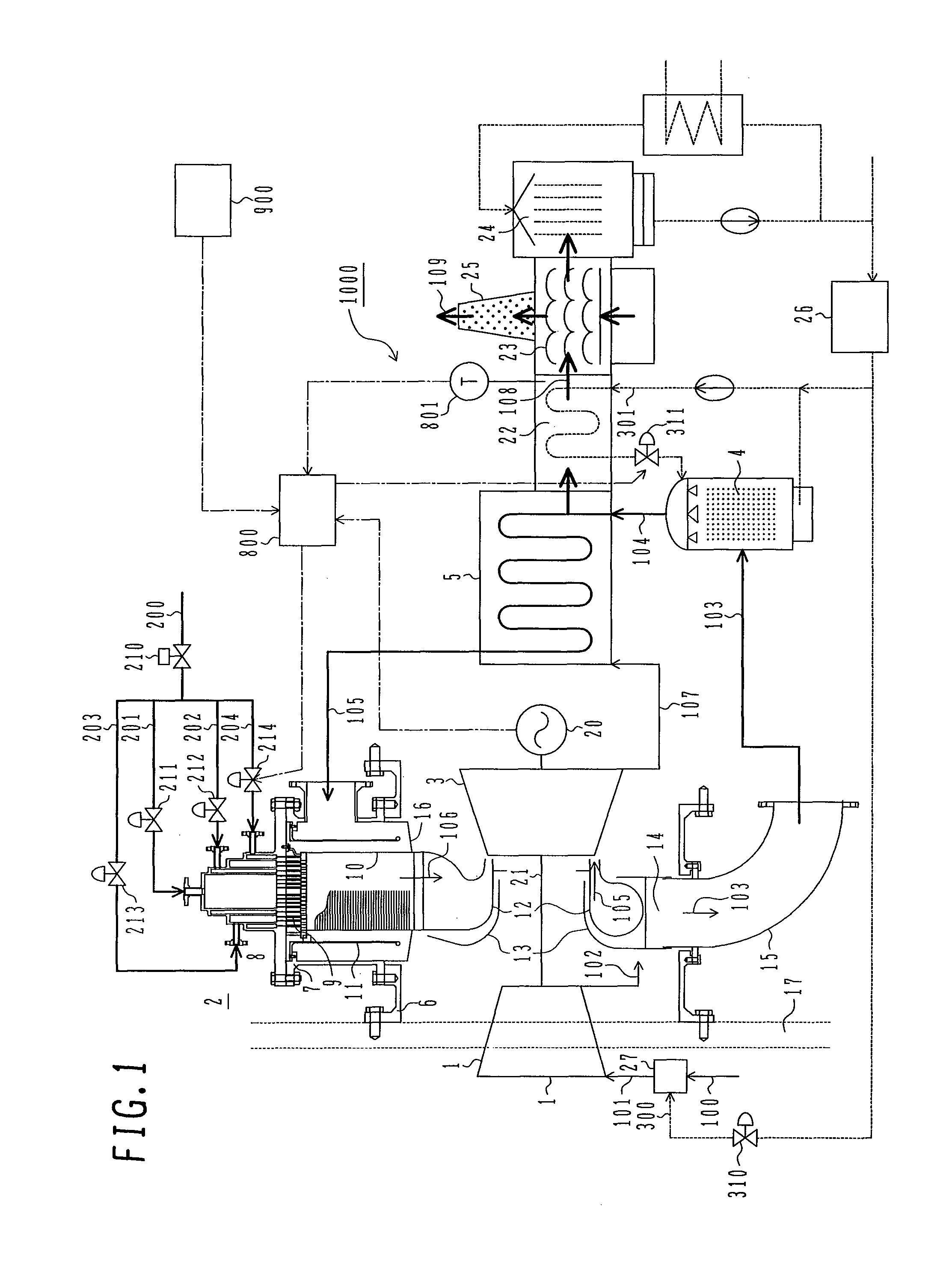

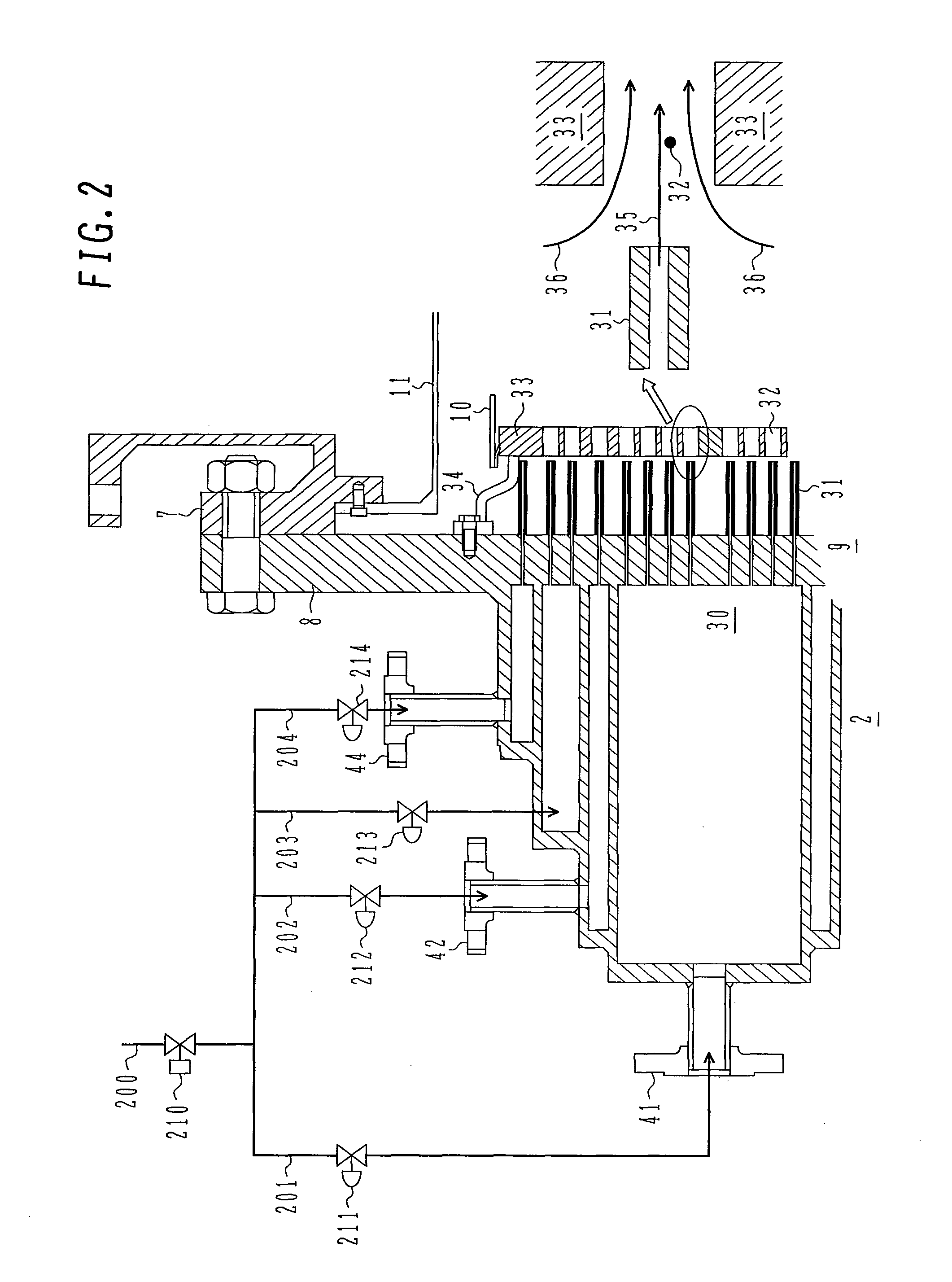

Humid air turbine, humid air turbine control system, and humid air turbine control method

ActiveUS20080229755A1Guaranteed flame stabilityReduce the amount of fuelTurbine/propulsion fuel supply systemsGas turbine plantsCombustorControl system

The present invention provides a humid air turbine having a compressor, a humidificator for generating humid air by adding moisture to compressed air supplied from the compressor, a combustor, a turbine, a recuperator for effecting heat exchange between exhaust from the turbine and the humid air, an economizer for effecting heat exchange between exhaust from the recuperator and water, and a system for supplying the water heated by the economizer to the humidificator. The humid air turbine includes a temperature measurement device for measuring the temperature of gas discharged from the economizer, and a control device for adjusting the amount of moisture to be supplied to the humidificator in accordance with a temperature signal from the temperature measurement device. The present invention assures low NOx of combustor and flame stability before and after water addition to the humid air turbine.

Owner:MITSUBISHI POWER LTD

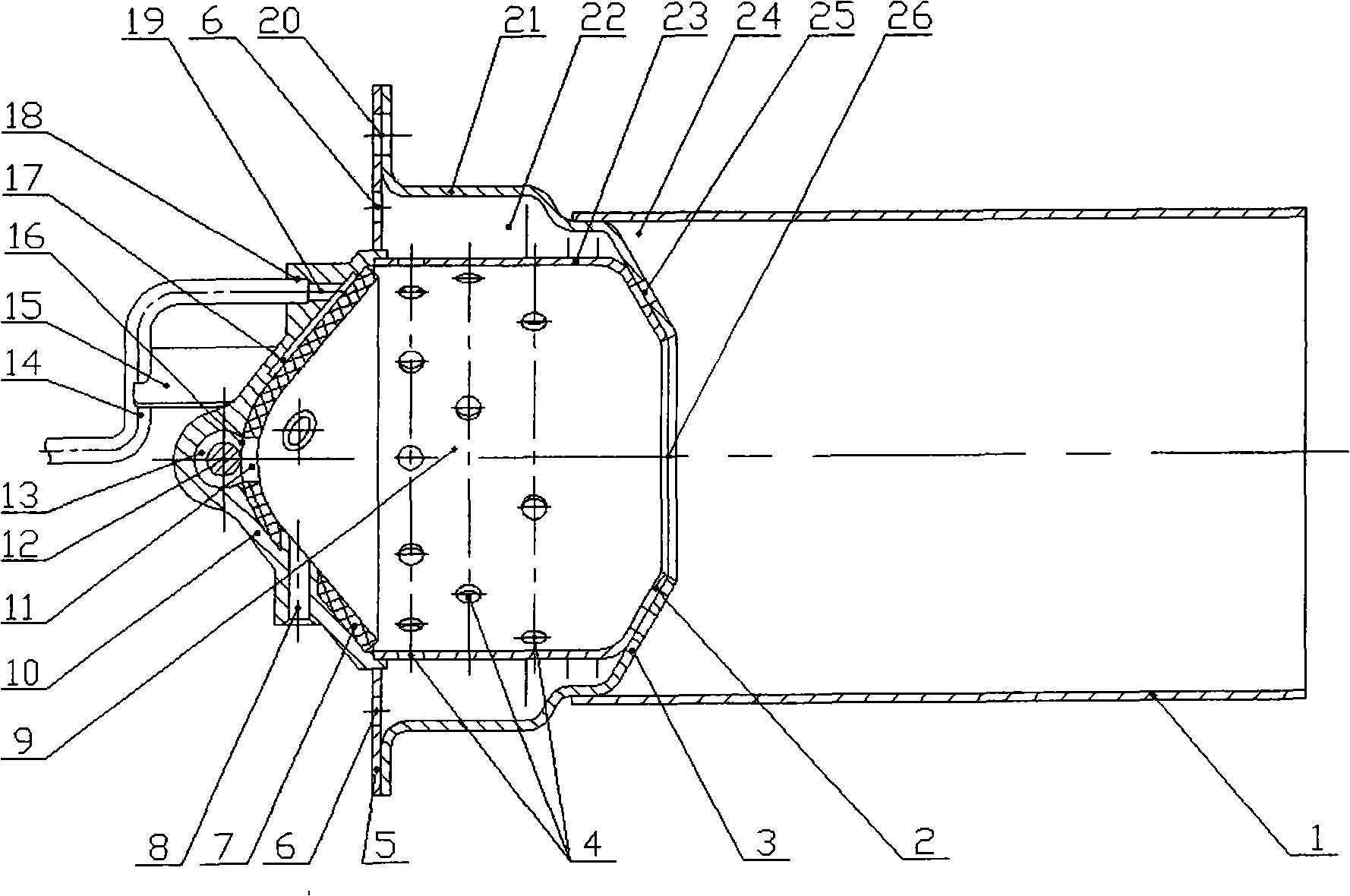

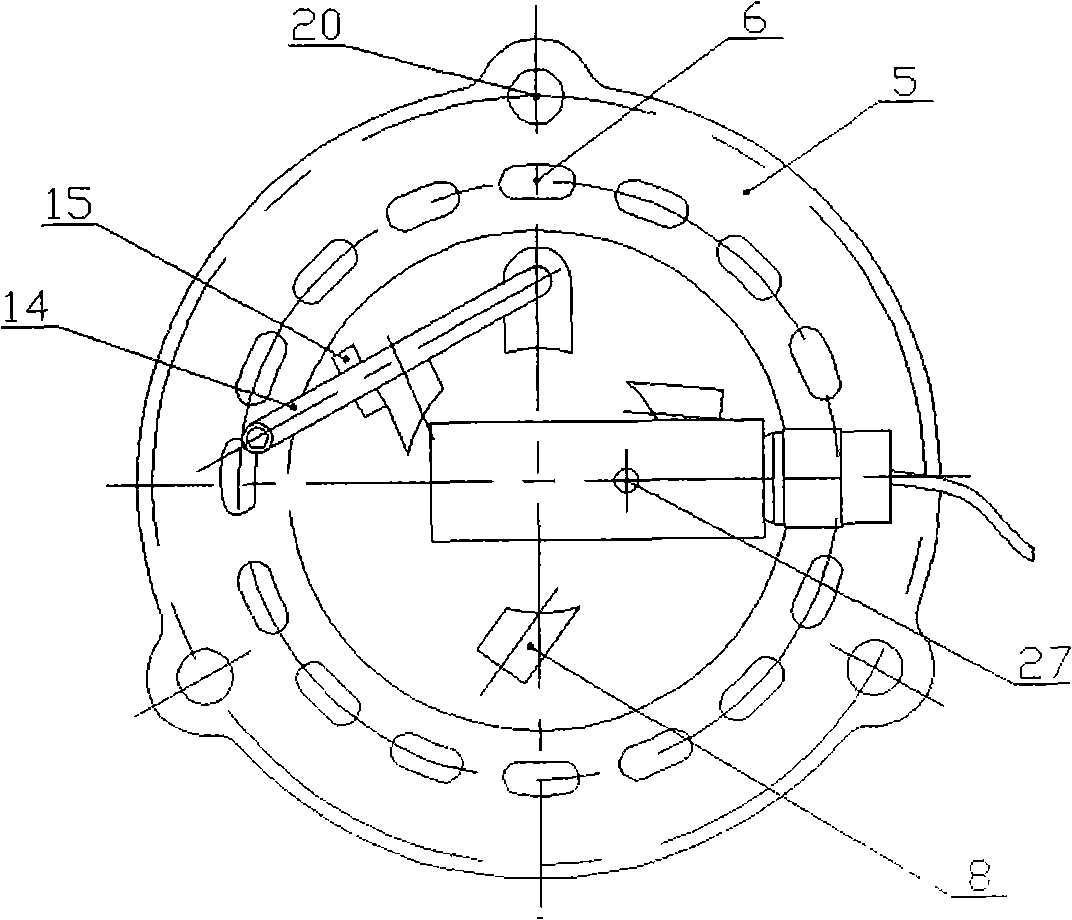

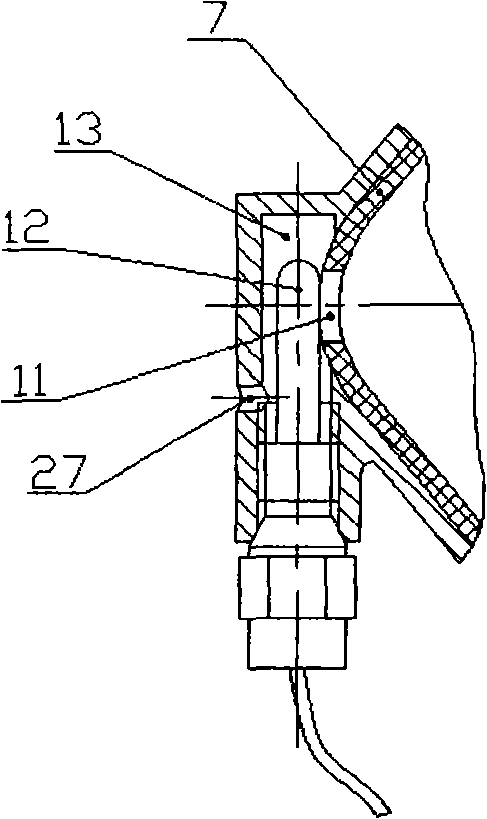

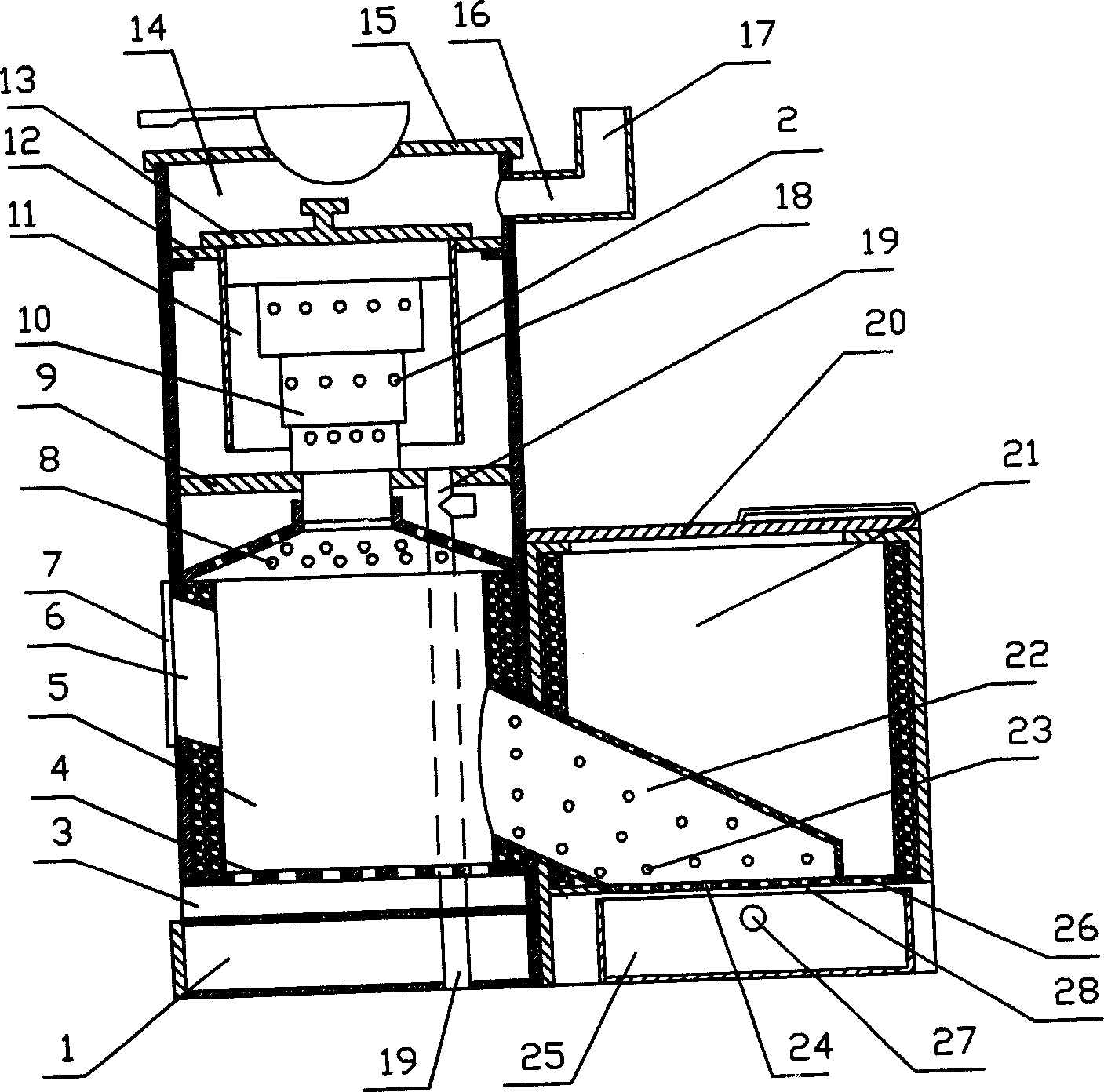

Wimble cap-shaped combusting device of oil heater

InactiveCN101280922AEasy to moveReduce flowLiquid fuel evaporation burnersCombustorCombustion chamber

The present invention provides a wimble cover shaped combustor of fuel heater comprising a combustion chamber cover, a oil suction wimble liner, a primary combustion barrel, a secondary combustion barrel, an air inlet guide barrel, an air inlet split stream slice, a fuel oil tube and a glow plug; the oil suction wimble liner is applied on the combustion chamber cover internal surface, an oil groove is arranged between the both; the primary combustion barrel is connected to the combustion chamber cover, and the air inlet guide barrel is arranged at outer portion of the primary combustion barrel, and air inlet holes are arranged circumferentially on the barrel wall of the primary combustion barrel; the primary combustion barrel is connected to the back end of the air inlet guide barrel to form a conical contraction hole; the front end of the air inlet guide barrel connects to the air inlet split stream slice which is provided with air split stream holes; the secondary combustion barrel connect is connected to the back end of the air inlet guide barrel; the combustion chamber cover has a conical shape, a fuel oil tube connected onto, a glow plug arranged on top, and tangential air holes are arranged circumferentially on the combustion chamber cover. The invention provides credible, rapid ignition start, uneasily generates carbon deposition, has high combustion efficiency and economical efficiency improved by more than 6%.

Owner:河北宏业永盛汽车加热器股份有限公司 +1

Gas turbine combustor

InactiveUS20140182294A1Minimized variation in concentrationWell mixedContinuous combustion chamberGas turbine plantsCombustorCombustion chamber

A gas turbine combustor includes a pilot burner, provided at a top portion of a combustion liner having a combustion chamber defined therein, and a main burner of a premixing type disposed adjacent an outer periphery thereof. The pilot burner is provided with an inflow passage, provided in an upstream end portion to allow the compressed air from a radially outer area into a radially inner area, a plurality of fuel supply holes for injecting the fuel into the inflow passage in a direction perpendicular to the flow of the compressed air, a premixing passage for guiding the air-fuel mixture from the inflow passage in an axially downstream direction while the compressed air and the fuel are mixed together, and a plurality of premixed air-fuel mixture injection holes for injecting the premixed air-fuel mixture from the premixing passage into the combustion chamber.

Owner:KAWASAKI HEAVY IND LTD

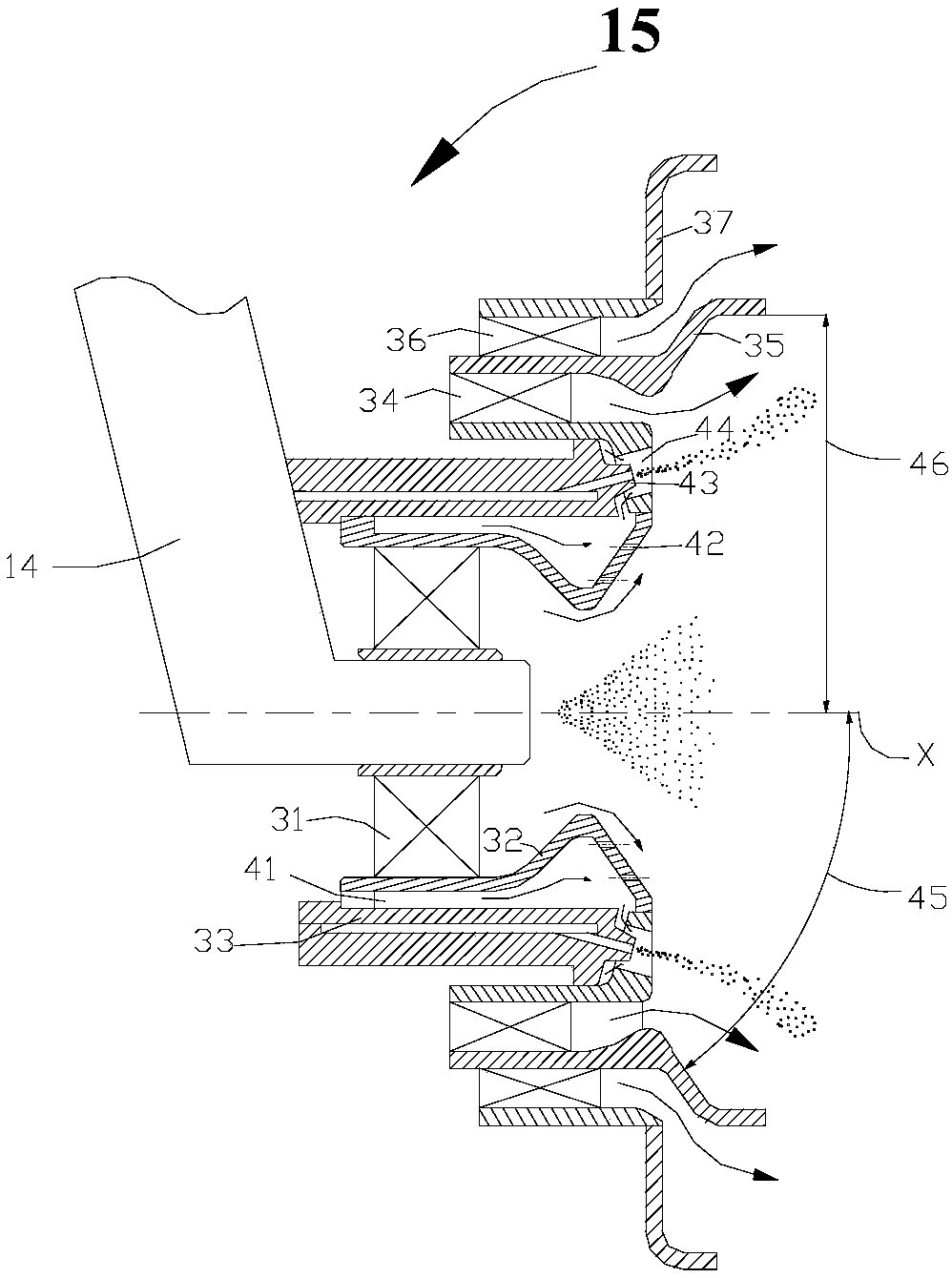

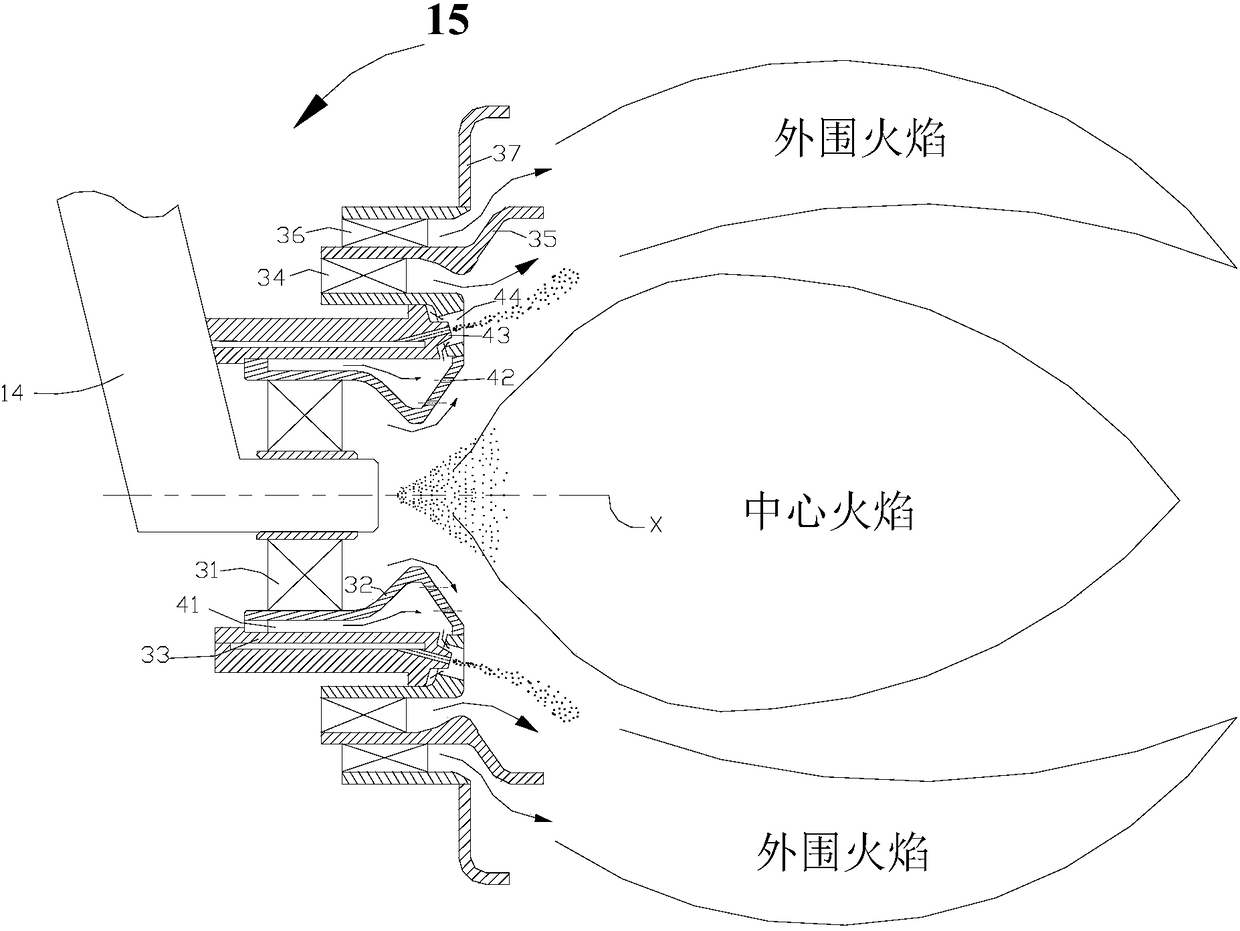

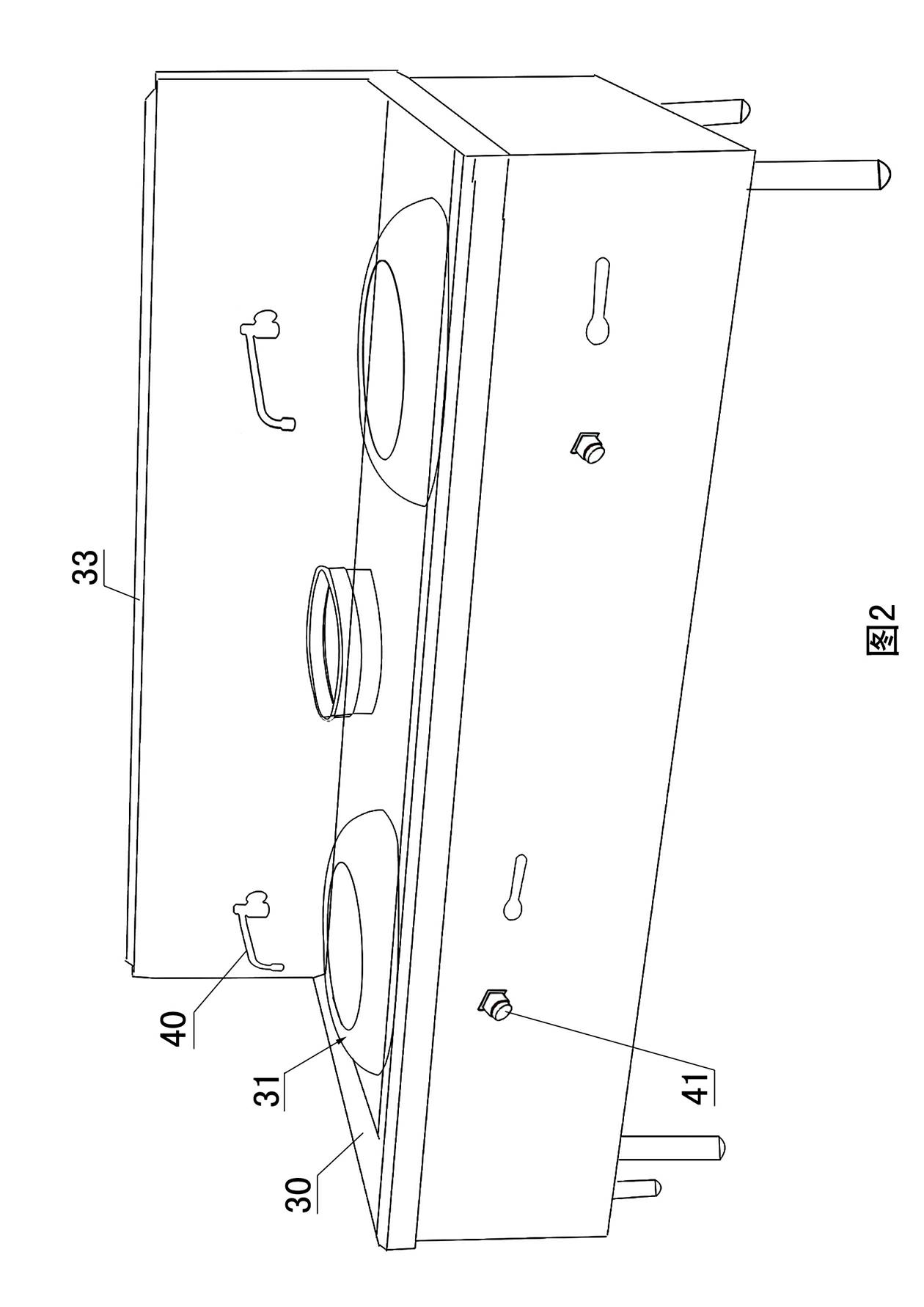

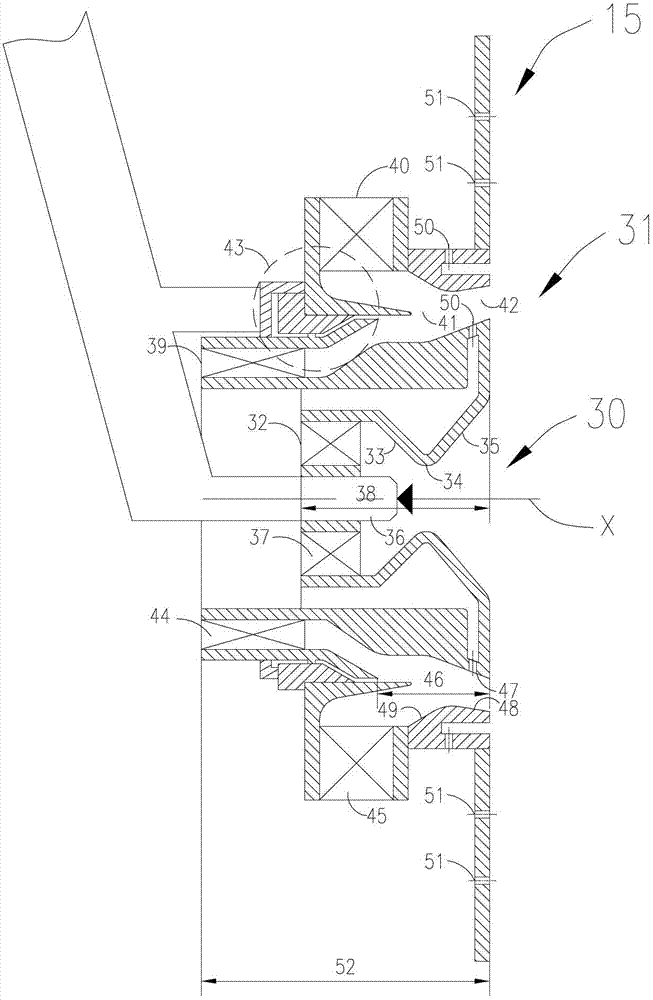

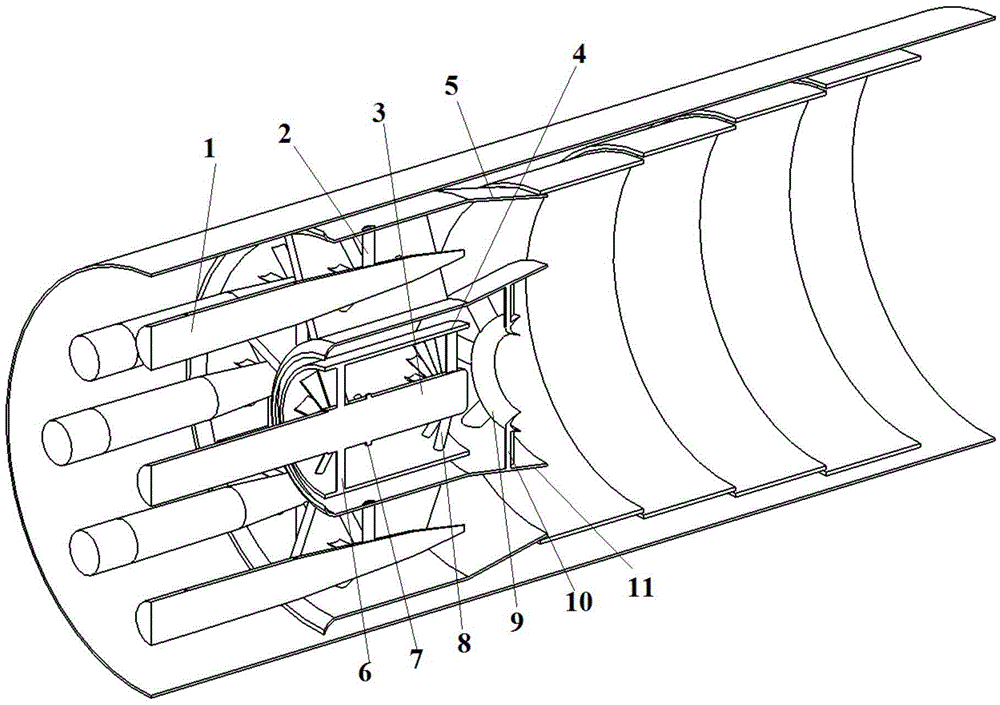

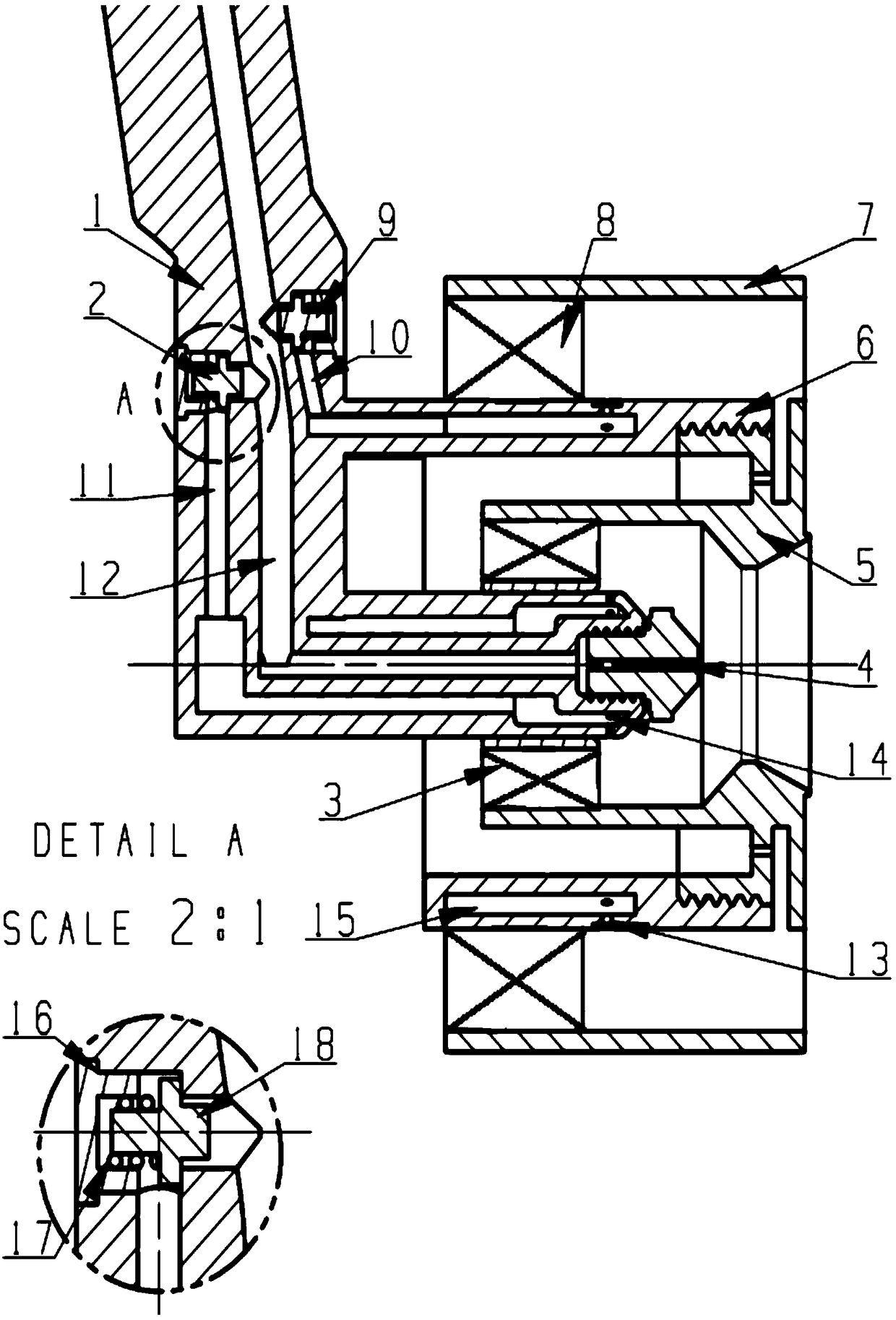

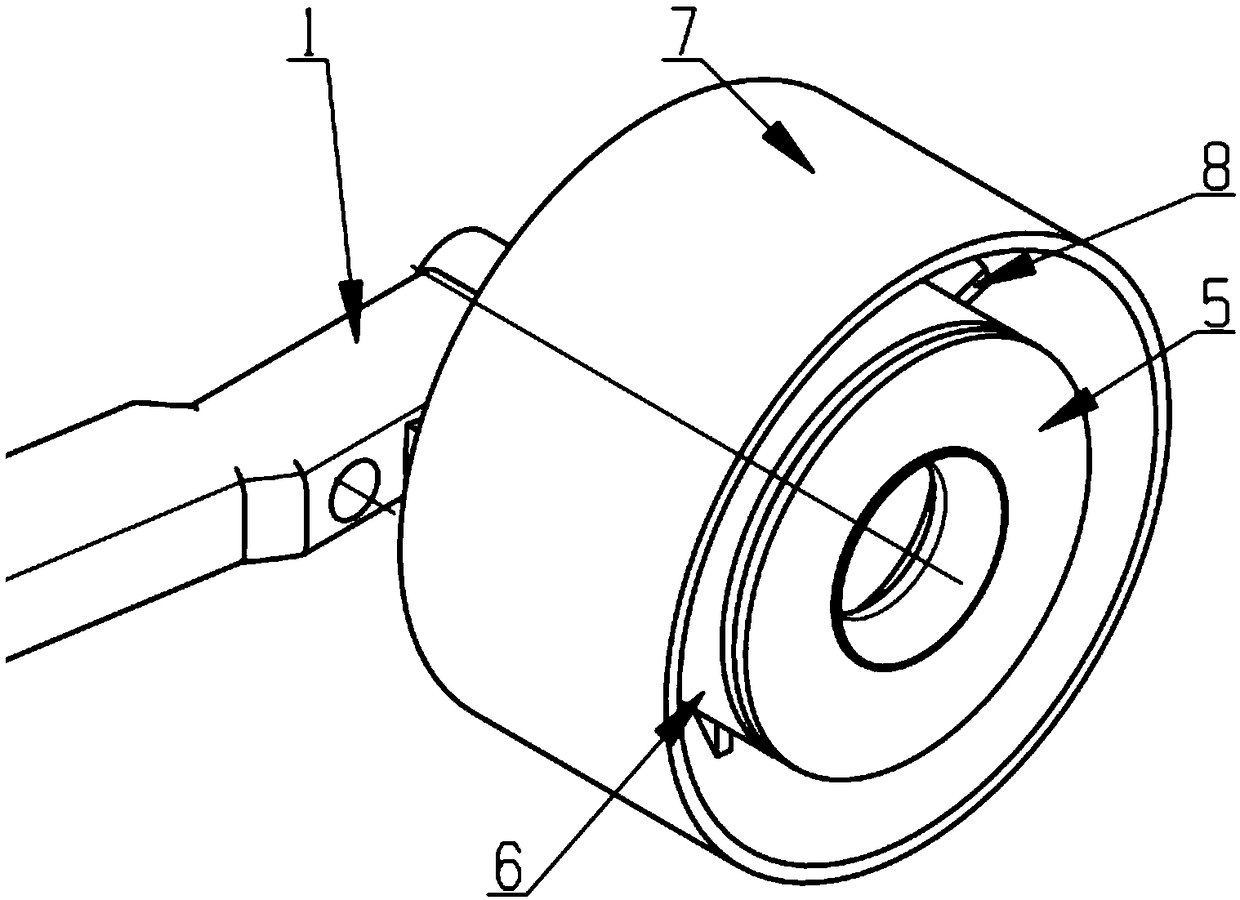

Coaxial partition high-temperature-rise combustor head

ActiveCN108561898AReliable ignitionStable jobContinuous combustion chamberCombustorCombustion chamber

The invention relates to a coaxial partition high-temperature-rise combustor head which comprises a first-stage axial hydrocyclone (31), a venturi (32), a main-stage fuel oil way (33), a second-stageaxial hydrocyclone (34), a baffling device (35), a three-stage axial hydrocyclone (36) and a splash pan (37). A middle cooling runner (41) is formed between the venturi (32) and the main-stage fuel oil way (33), an expansion section of the venturi (32) is provided with a plurality of rows of cooling small holes (42), part of air flowing into the middle cooling runner (41) flows out from the cooling small holes (42) in the expansion section of the venturi (32), the other part of air flows through the periphery of a main spraying opening (43) in the tail end of the main-stage fuel oil way (33) to flow out from a main-stage fuel oil atomization channel (44).

Owner:AECC SICHUAN GAS TURBINE RES INST

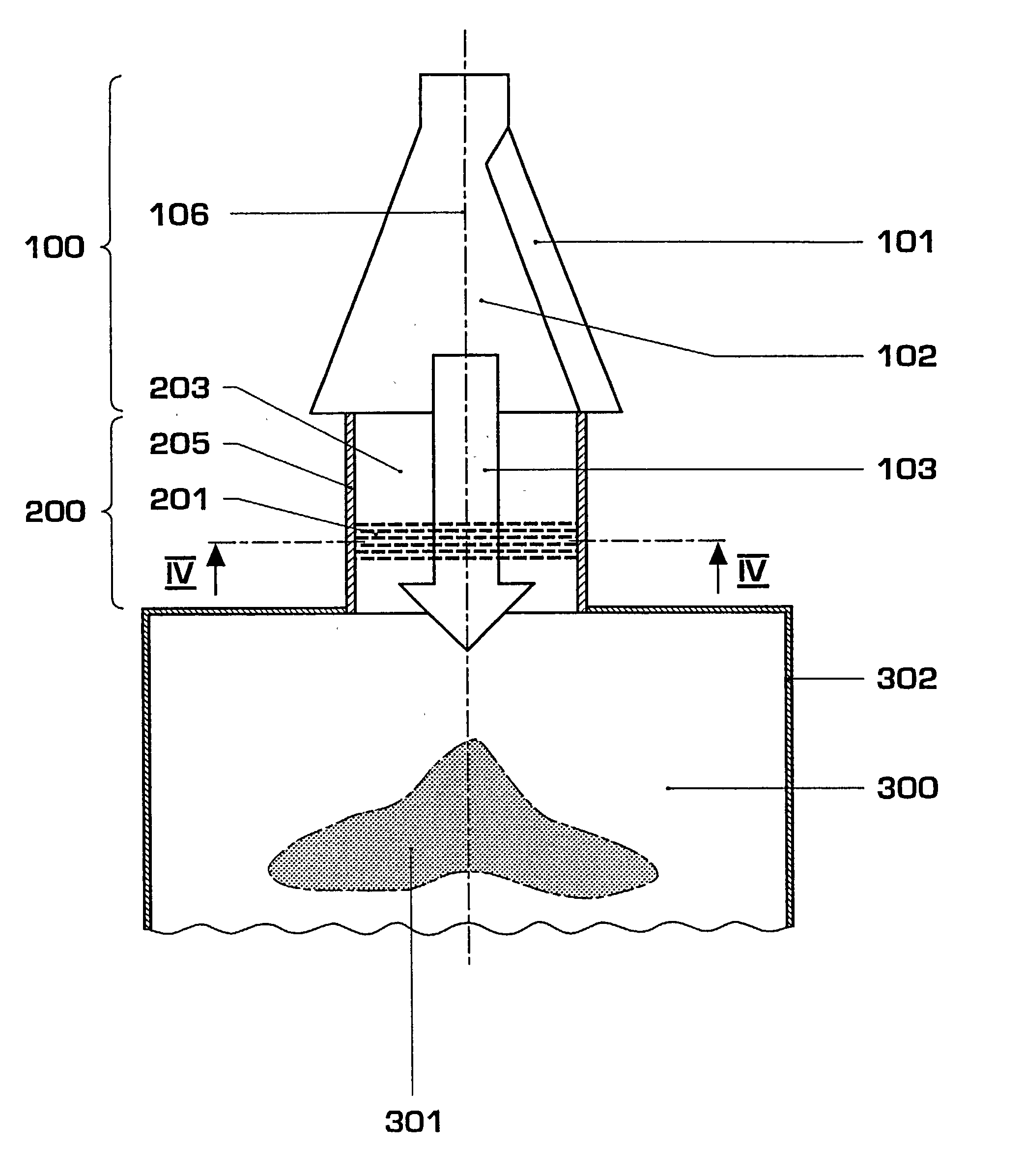

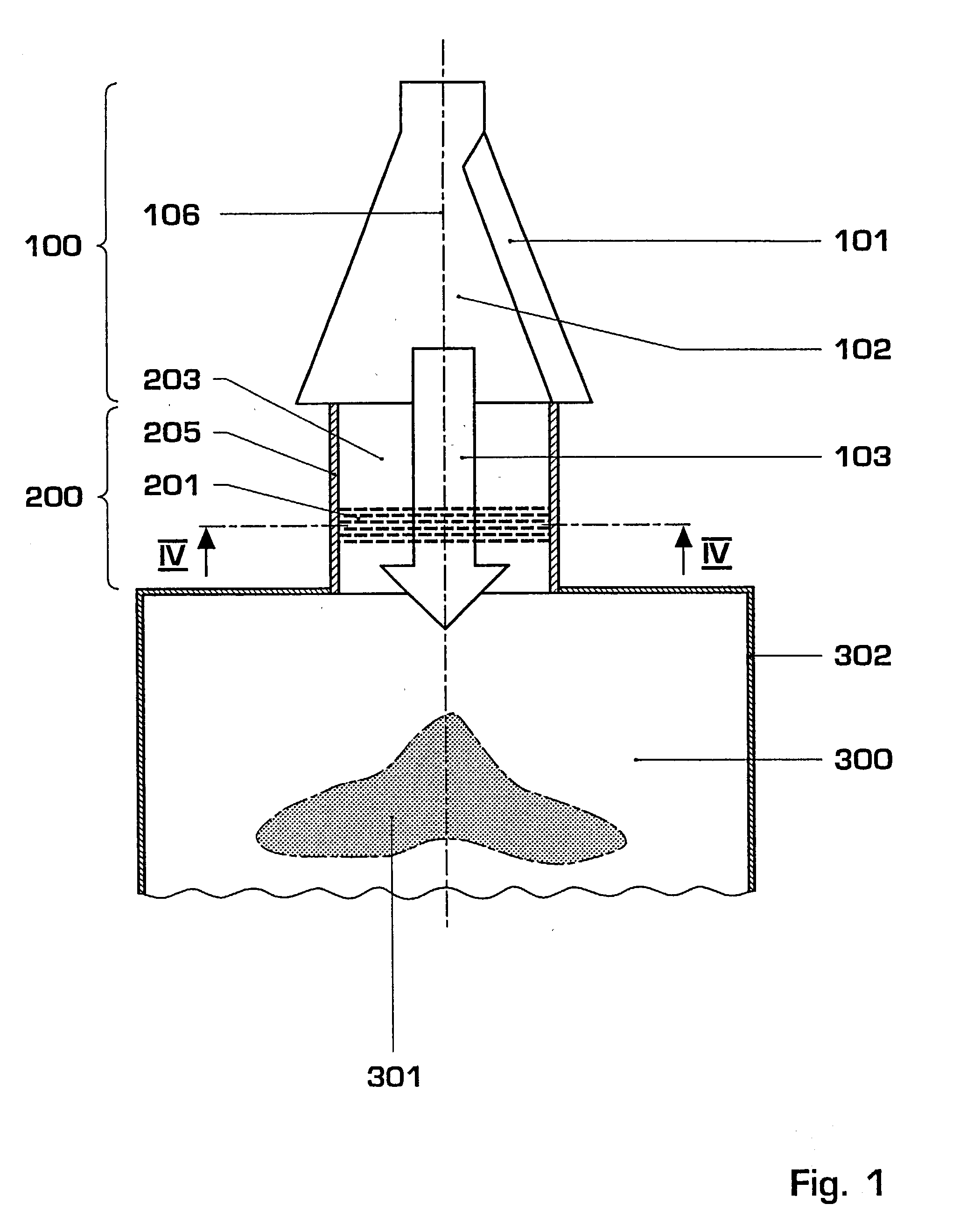

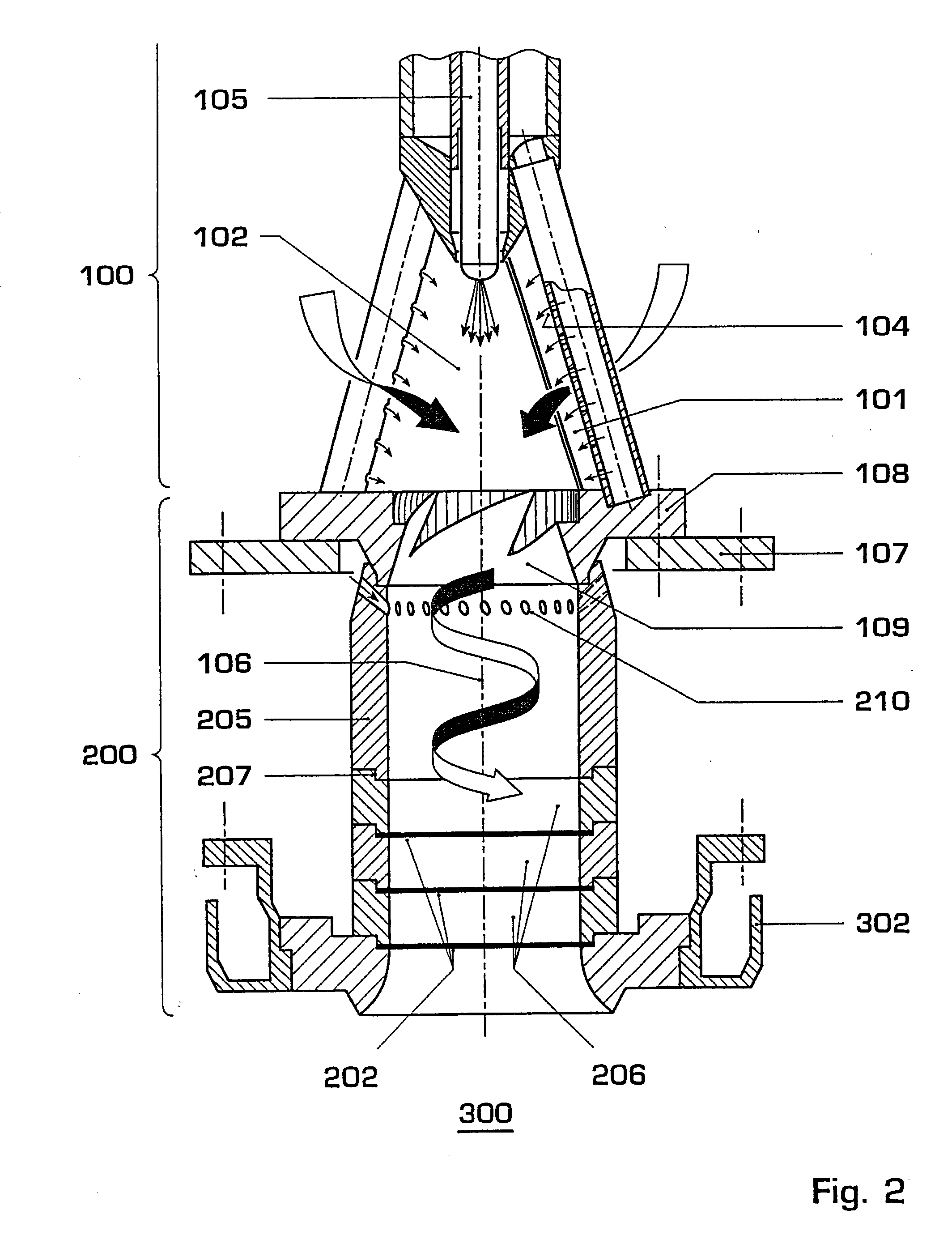

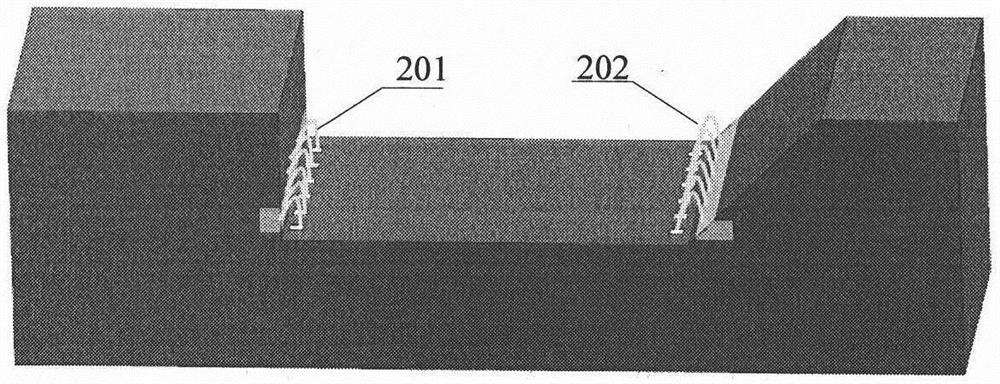

Premix burner with high flame stability

InactiveUS20030031972A1Reduce oscillationFlame stabilizationContinuous combustion chamberSpray nozzlesCombustorCombustion chamber

The invention relates to a premix burner with high flame stability for use in a heat generator, preferably in the combustion chamber of a gas turbine. Modern, lean-operated premix burners enable very low noxious emissions, but sometimes operate very close to the extinction limit. To increase the stability of the lean premix combustion by increasing the distance between flame temperature and extinction limit temperature the invention proposes to equip the burner in the mixing zone (200) with a net-like structure (201) for the premixing of combustion air and fuel. According to a preferred embodiment, the net-like structure (201) consists of a plurality of layers of individual wire mesh fabrics (202) arranged at a distance from each other. The wire mesh fabrics (202) are preferably equipped with an oxidation-promoting, catalytically active surface. It was found that the net structure (201) positively influences the thermoacoustic behavior of the burner and dampens and insulates pressure waves from the combustion chamber (300), and in this way reduces the excitation of pressure waves in the combustion chamber (300).

Owner:ALSTOM TECH LTD

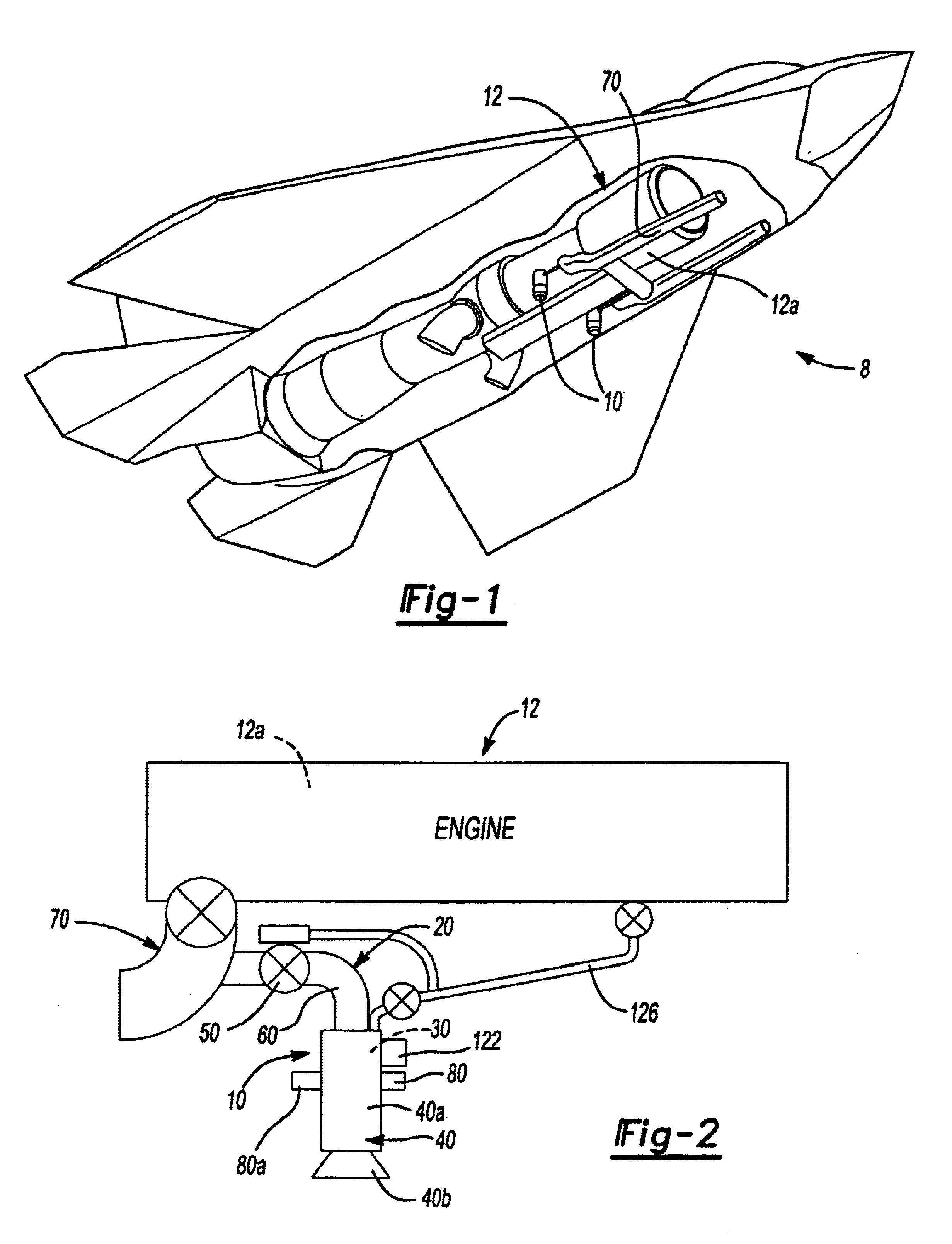

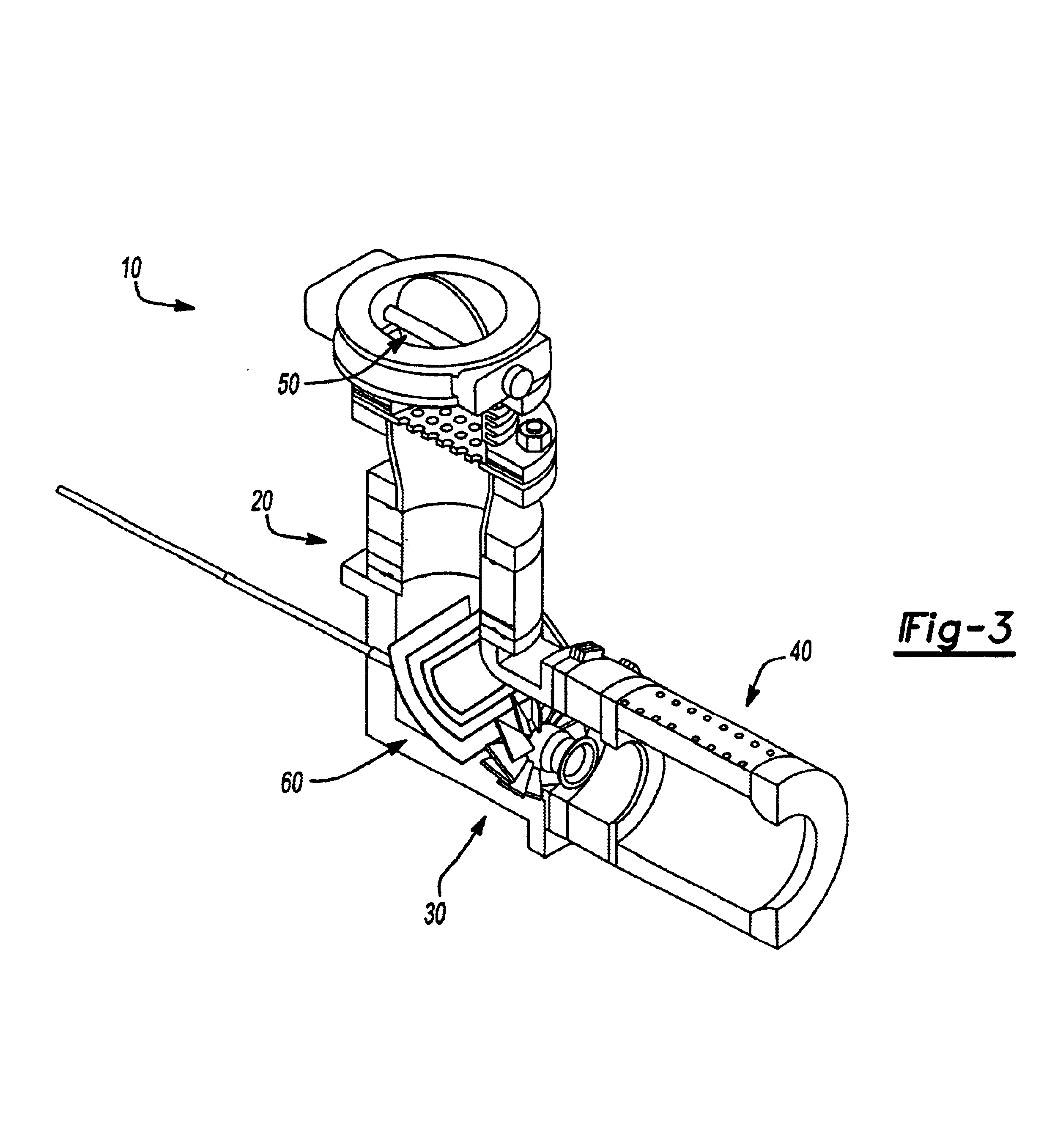

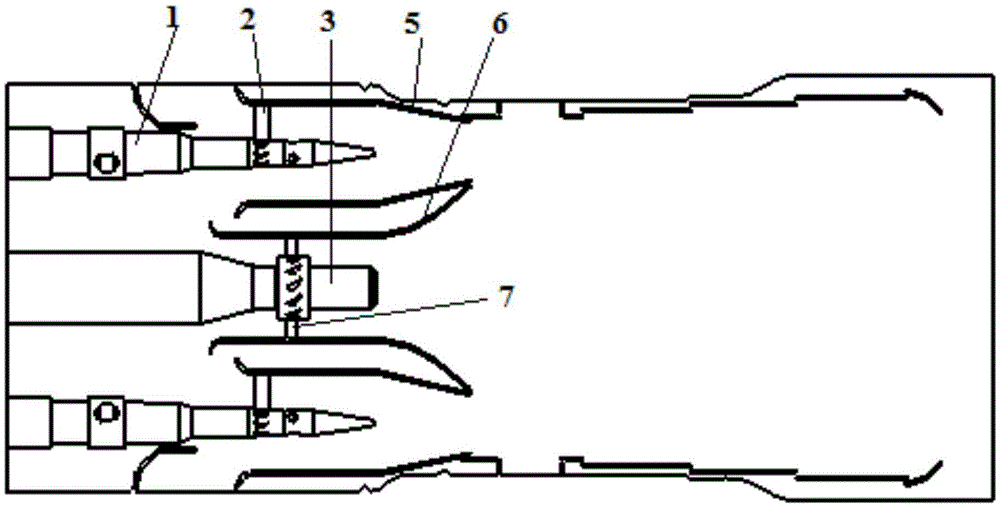

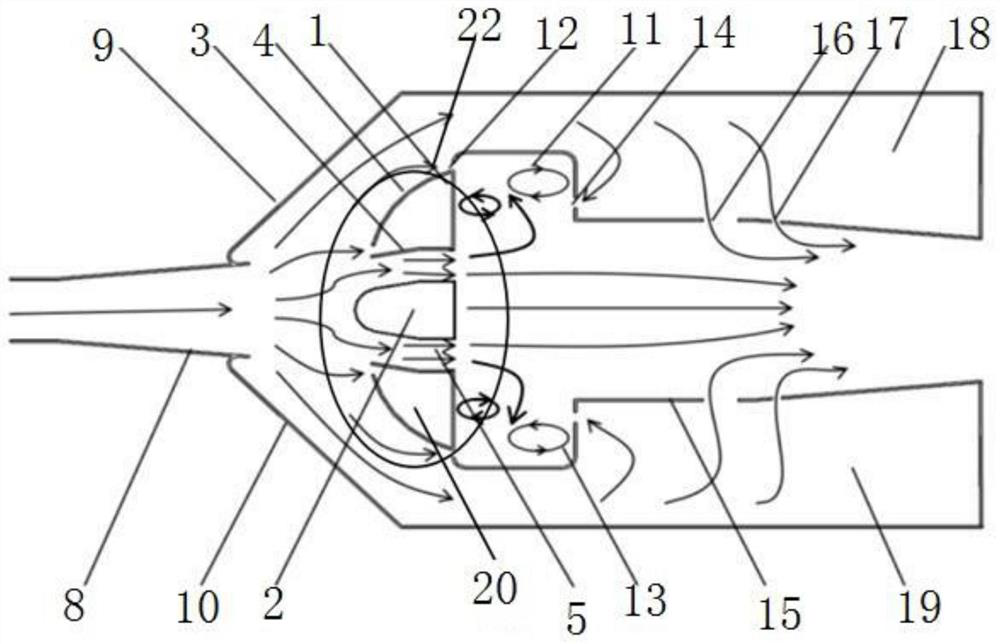

Compact lightweight ramjet engines incorporating swirl augmented combustion with improved performance

InactiveUS6968695B2Flame stabilizationEasy to operateContinuous combustion chamberEfficient propulsion technologiesRamjetFlame propagation

A ramjet powered device that utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel into an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and an inner central recirculation zone, both of which are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers and stabilizes flame propagation and accelerates combustion throughout the entire combustor. The swirl generator provides smooth combustion with no instabilities and minimum total pressure losses and enables significant reductions in the L / D ratio of the combustor. Other benefits include simplicity, reliability, wide flammability limits and high combustion efficiency and thrust performance.

Owner:THE BOEING CO

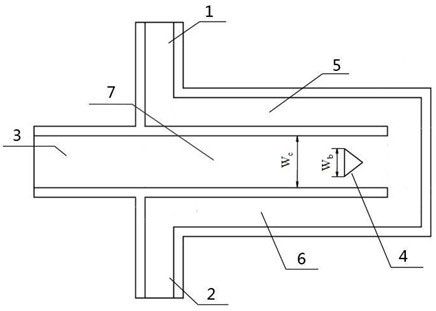

Micro-combustor

InactiveCN102183019AReduce heat lossSave energyIndirect carbon-dioxide mitigationGaseous fuel burnerAutomotive engineeringCombustion chamber

The invention discloses a micro-combustor, which comprises a bluff body, two preheating channels and a combustion chamber, wherein the preheating channels and the combustion chamber are all plate-shaped; the cross section of the bluff body is triangular or circular; the bluff body is arranged at an inlet of the combustion chamber; the ratio of the width of the bluff body to the width of the combustion chamber is 0.3-0.6; the two preheating channels are both L-shaped and are respectively arranged at upper and lower sides of the combustion chamber; and outlets of the preheating channels are both communicated with the inlet of the combustion chamber. By using the micro-combustor, the defect of the prior art is overcome. By preheating and catalyzing fuels and air (when a non-pre-mixing combustion mode is adopted) or the pre-mixture of the fuels and air (when a pre-mixing combustion mode is adopted), the energy used for igniting is lowered, the igniting delay time is shortened and the exhaust heat loss is reduced. Besides, a low-speed high-temperature recirculation region formed behind the bluff body is utilized to fully mix the fuels and air, prolong the gas retention time and stabilize the flame. The micro-combustor can be used for efficiently expanding the stable combustion limit and increasing the combustion efficiency and can be widely applied to various micro-power systems.

Owner:HUAZHONG UNIV OF SCI & TECH

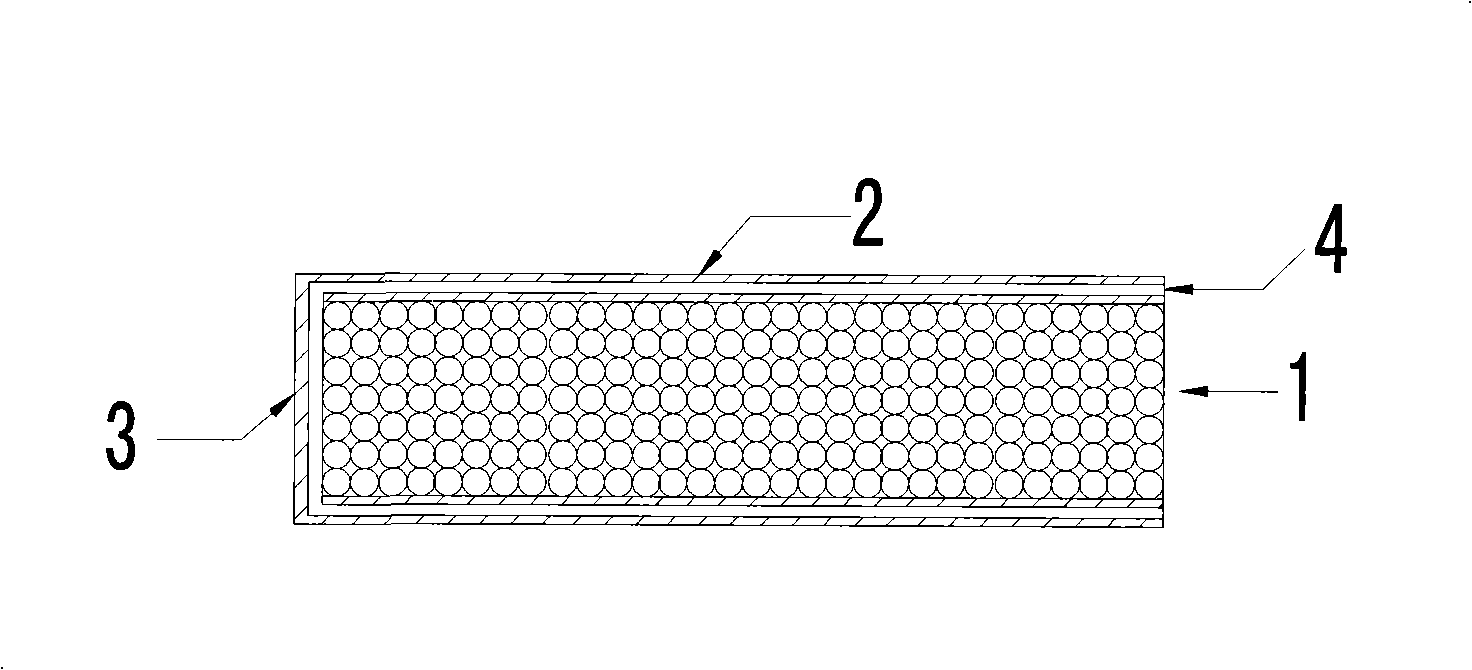

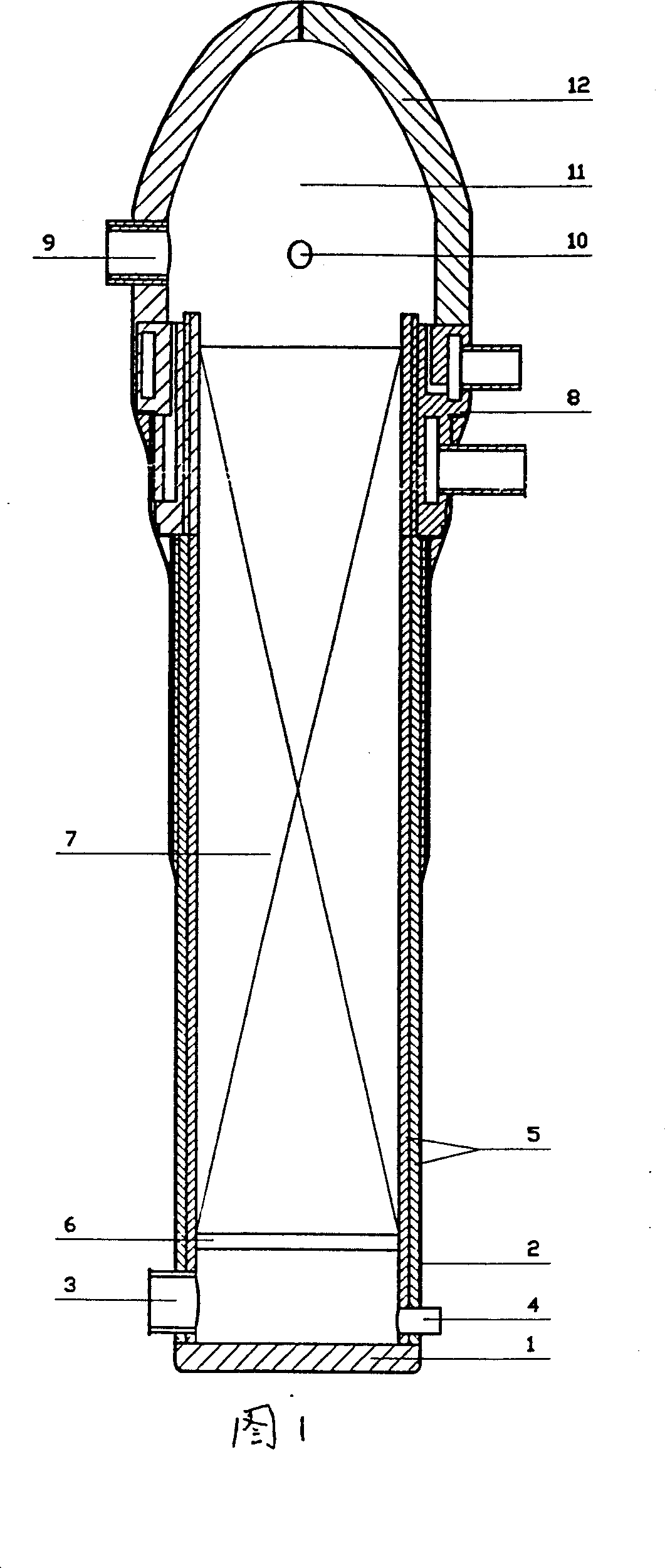

High-efficiency porous media combustor for minitype heat optoelectronic system

InactiveCN101354132AImprove temperature distributionStable and efficient workGaseous fuel burnerExhaust gasProduct gas

The invention provides a high-efficiency porous medium burner used in a micro thermo photovoltaic system, relating to the technical field of combined combustion of a two-phrase gas. SiC ceramic spherules with diameter of 0.3mm to 0.35mm are filled in a shell of the burner in the form of oblique parallelepiped and then sintered with the shell to form a porous medium structure with porosity epsilon equal to 26 percent to 27 percent and a tail gas discharging channel is arranged on the external wall of the burner. The shell of the burner is processed first and then a bottom cover (3) of the burner is processed and sintered with the shell, and finally, in the interior of which the screened SiC ceramic spherules with diameter of 0.34mm are filled, after sintering, the porous medium structure is formed and the tail gas discharging channel is arranged in the interior of the shell (2) of the burner. The porous medium burner reduces the heat loss brought by increase of surface to volume ratio due to microscale, greatly improves the temperature distribution on the external wall of the burner, promotes combustion efficiency and combustion stability, lowers gas discharging temperature and heightens the temperature of the external wall, thus greatly advancing the efficiency of the whole micro thermo photovoltaic system.

Owner:JIANGSU UNIV

Pre-mixing burner

The pre-mixing burner includes one burning unit and one ignition unit, and features the burning unit including one gas mixing chamber with upper and lower openings, one air chamber connected to the lower end of the gas mixing chamber and with side opening, one gas inlet pipe stretched into the air chamber from the bottom, one main burning nozzle in the end of the gas inlet pipe, one perforated flame plate in the upper opening of the gas mixing chamber, and porous plates inside the gas mixing chamber to separate the gas mixing chamber into several cavities. The pre-mixing burner has well mixing between the fuel gas and air, complete combustion, high heat efficiency, stable flame and homogeneous heat load.

Owner:YUFUBAO KITCHENWARE EQUIP SHENZHEN CO LTD

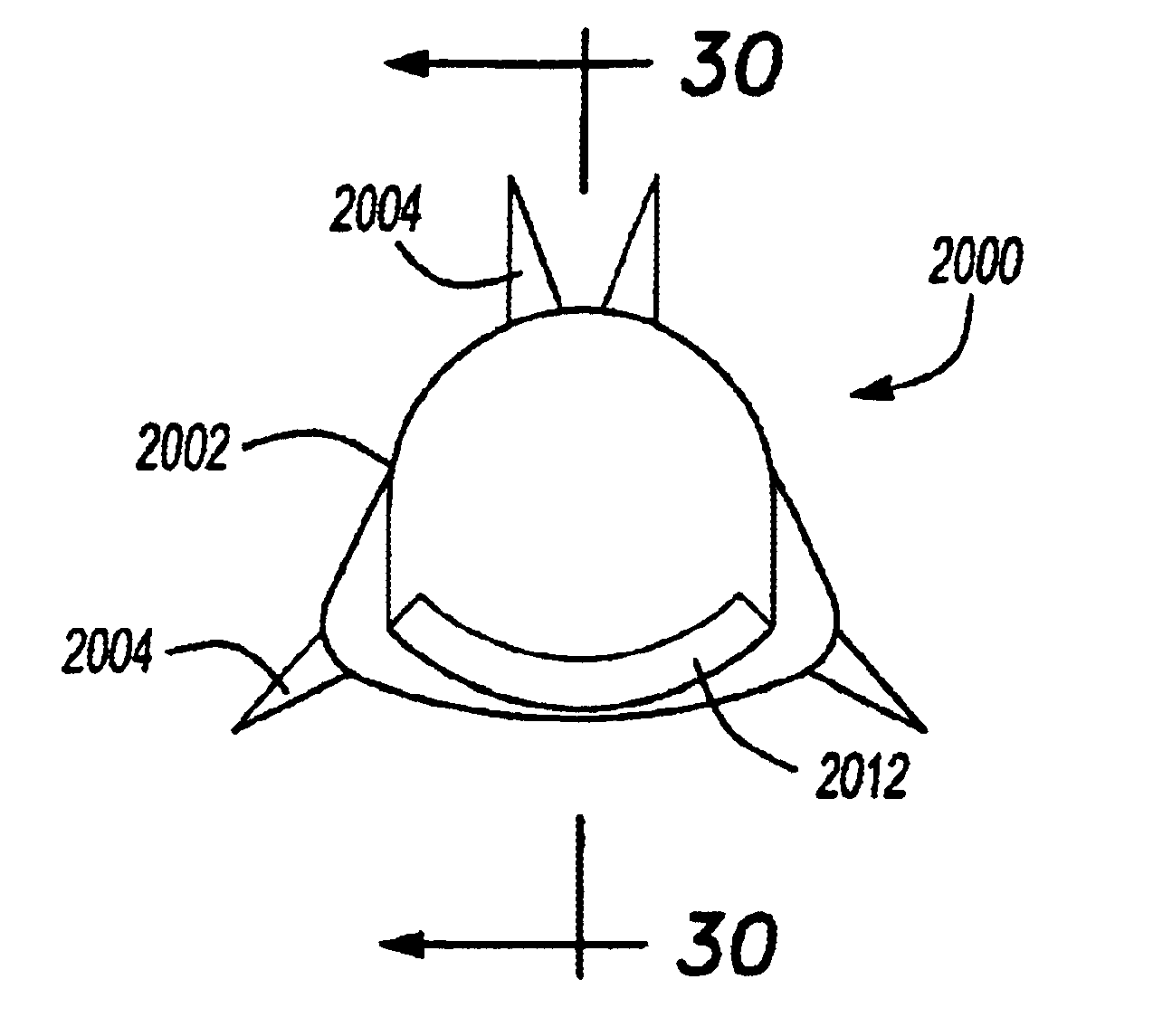

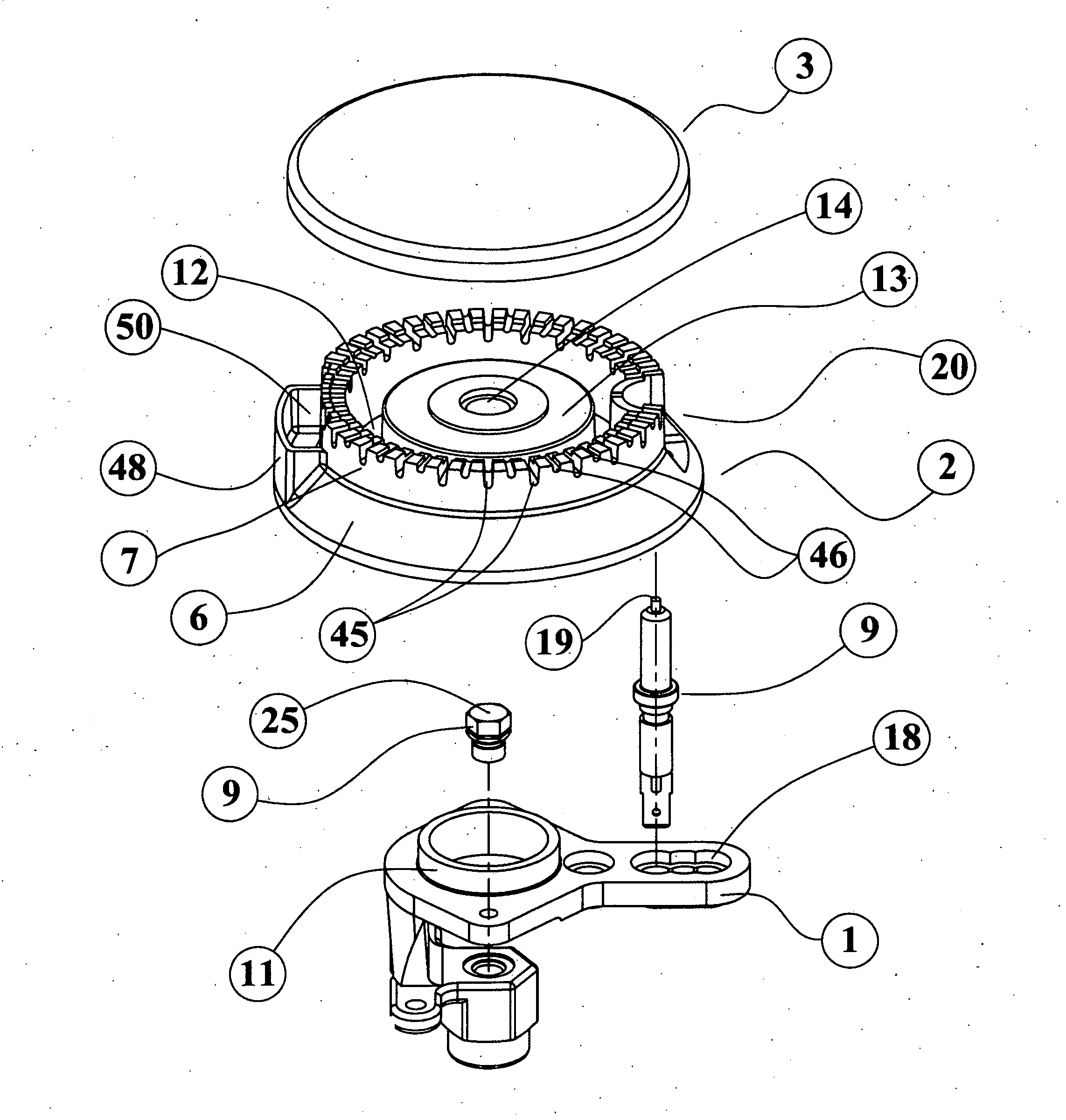

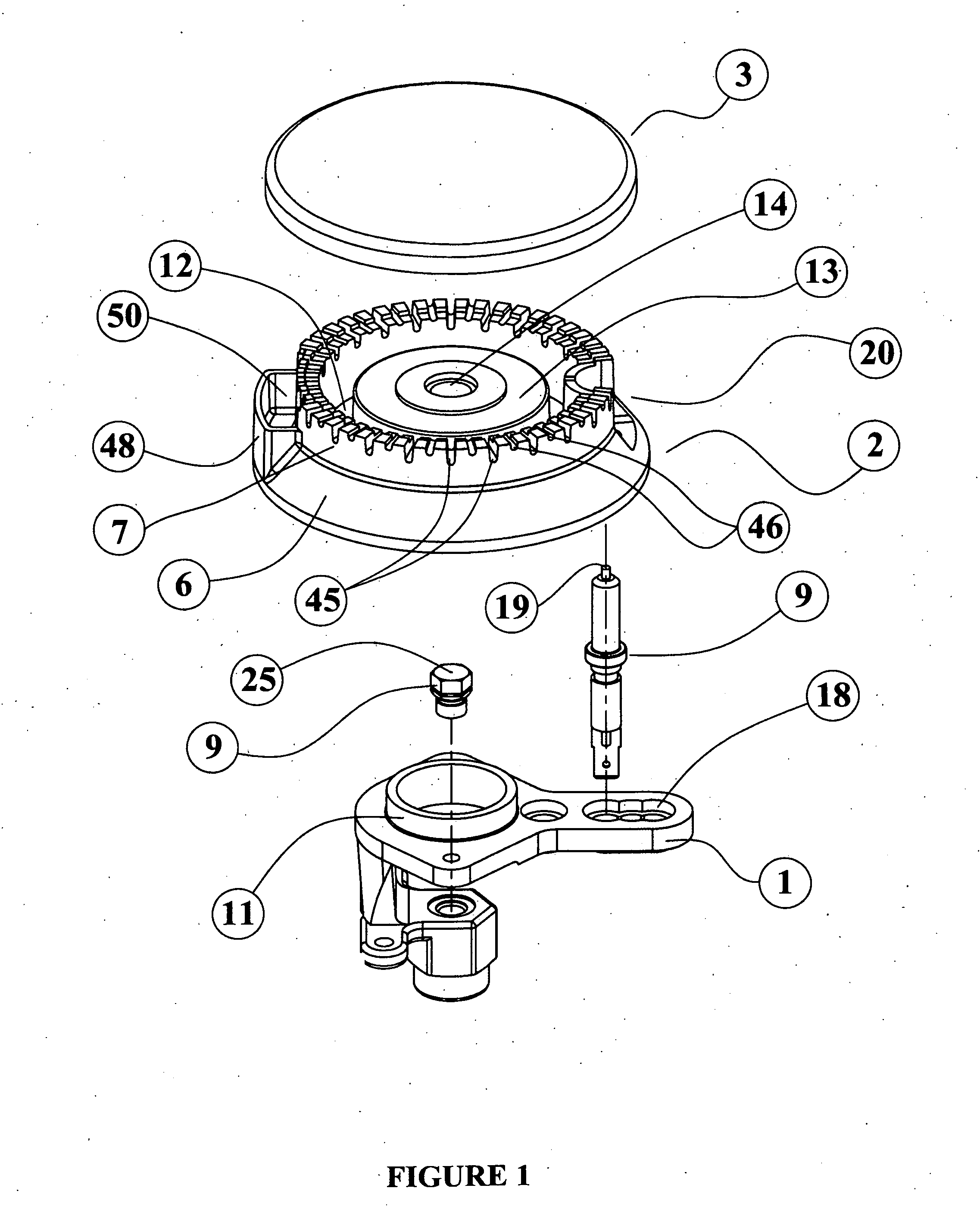

Burner with flame ring stabilization chamber

InactiveUS20110129783A1Preserve flame stabilizationFlame stabilizationDomestic stoves or rangesBurner ignition devicsCombustion chamberCombustible gas

Gas burners on modern kitchen cooking appliances are subject to fluctuations caused by drafts, breezes, etc. These burners will require flame stabilization chambers or another suitable engineering solution to overcome this problem. This invention describes a flame stabilization chamber that is constructed exterior to the main burner chamber and covered by the burner cap. The flame stabilization chamber acts to prevent extinguishing of the flame due to a random draft or breeze, by providing additional captured flammable gas / air so as to maintain the flame.

Owner:DESIGNGASPARTS

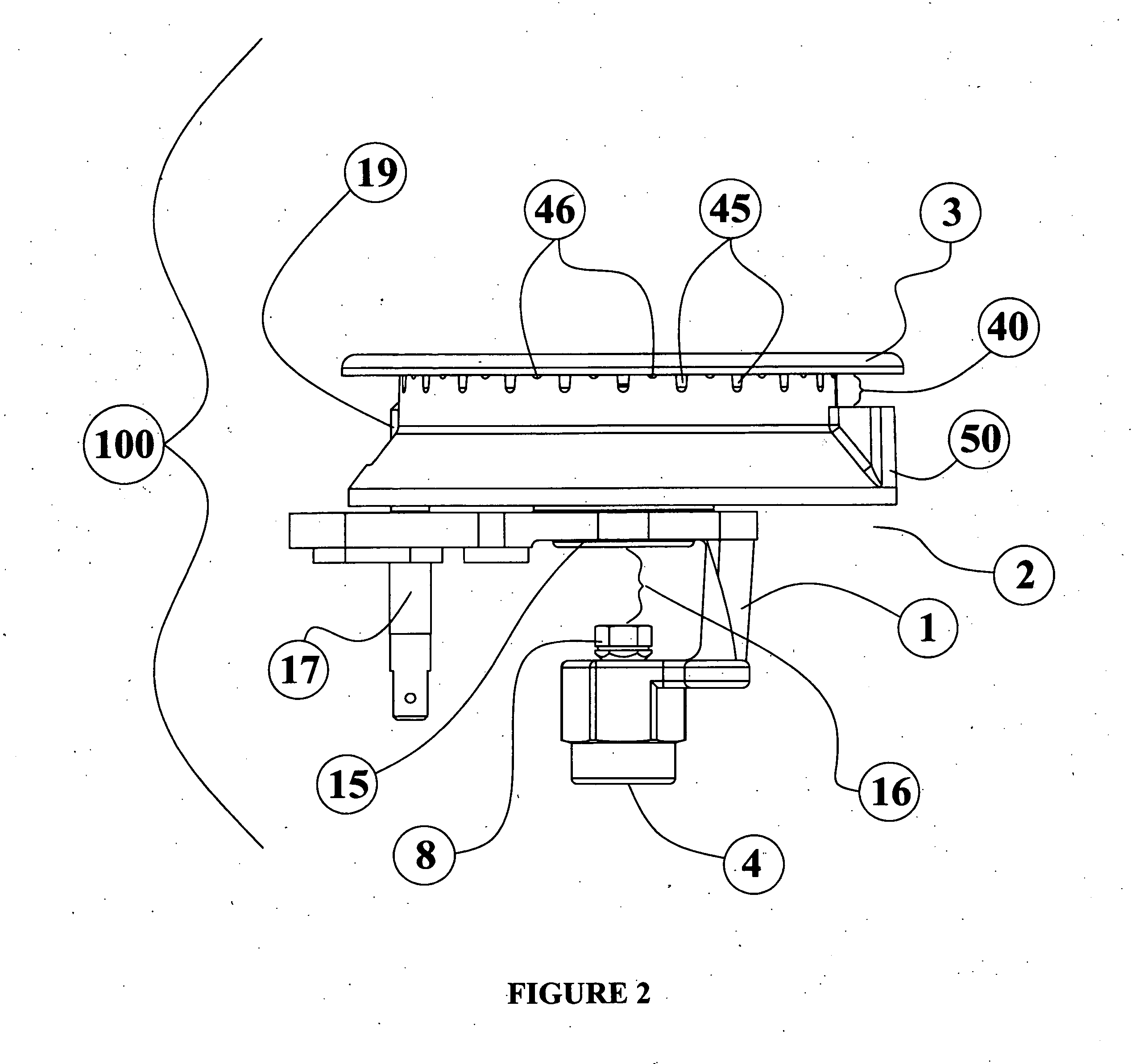

Collected heat type high efficient and energy-saving burning Chinese food frying-oven

InactiveCN102221228ATemperature does not dropSpeed will not decreaseWater heating stoves/rangesCooking fumes removalThermal energyCombustor

The invention relates to a collected heat type energy-saving burning Chinese food frying-oven which comprises a cooking stove and a burner assembly, a fan, a storage water tank, an electronic ignition device arranged on the cooking stove, wherein, the burner assembly comprises a burner and a hearth, the storage water tank is connected with a swing hot-water cock, the hearth comprises a side wall of the hearth and a waste heat collected jacket, the side wall of the hearth is of a hollow structure and comprises an inner side wall, an outer side wall and an air cavity clipped the inner side wall and the outer side wall, wherein, the upper part of the inner side wall is provided with a waste gas air hole which is communicated with the air cavity, the lower part of the outer side wall is provided with a waste gas air inlet which is communicated with the air cavity, the waste heat collected jacket is attached to the outer side surface tightly and is connected with the storage water tank to form a cycling water way through a water inlet and a return water pipe. The frying-oven has the advantages of energy-saving effect and high economic benefit, providing hot water to the kitchen, meanwhile, the frying-oven effective reduces the influence of the Chinese style frying-furnace on kitchen environment, and the capability of collecting the heat energy from hearth is greatly improved.

Owner:宫润涛

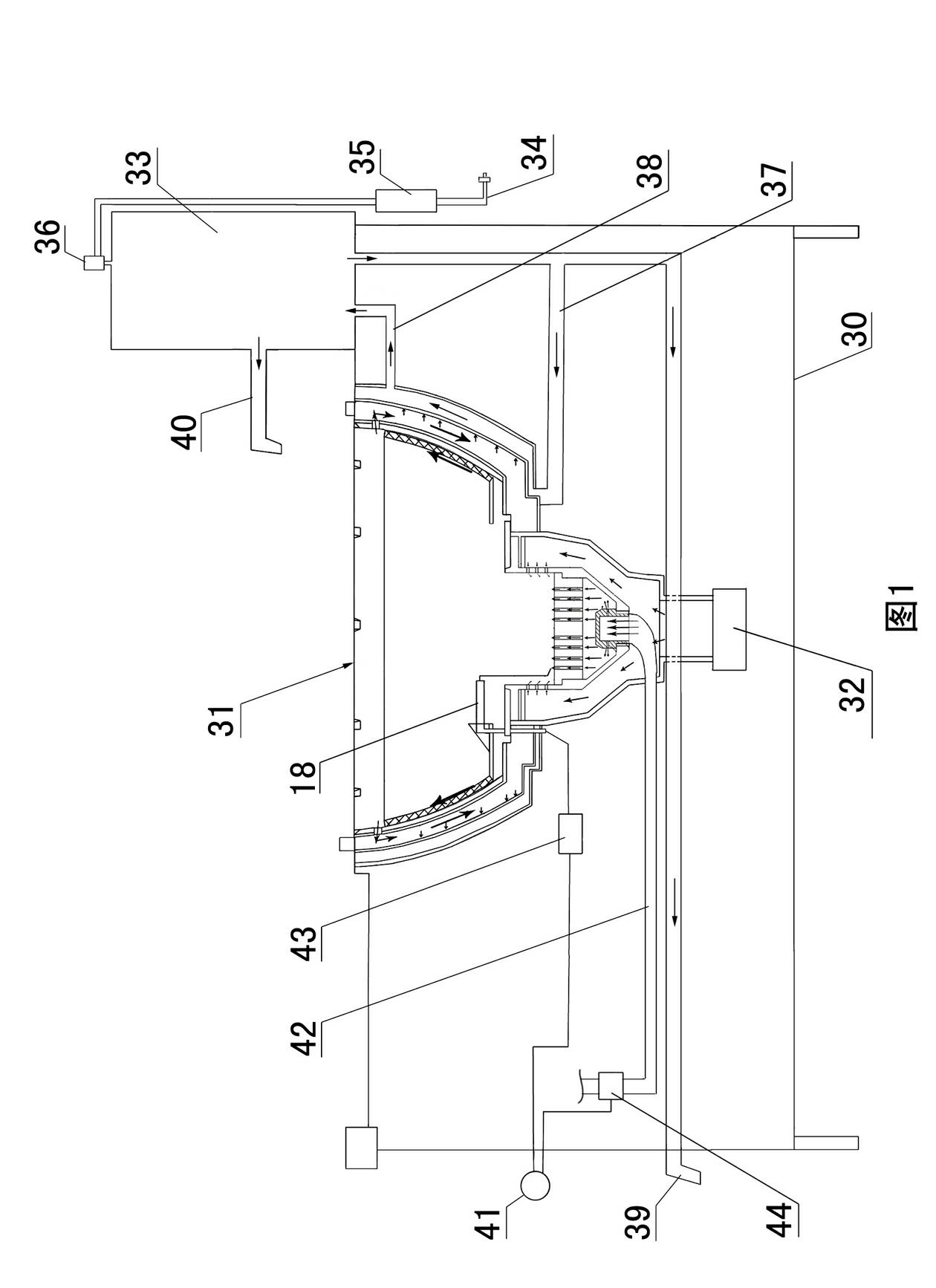

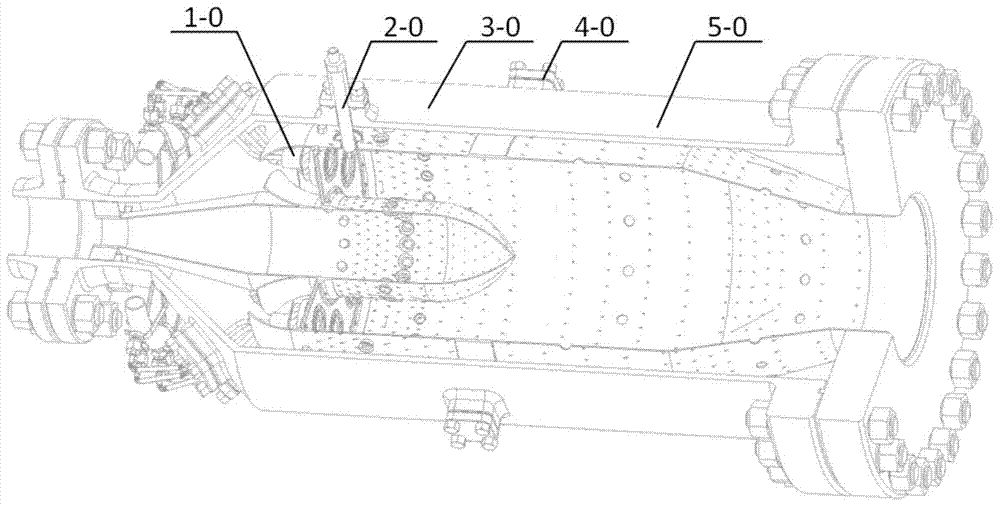

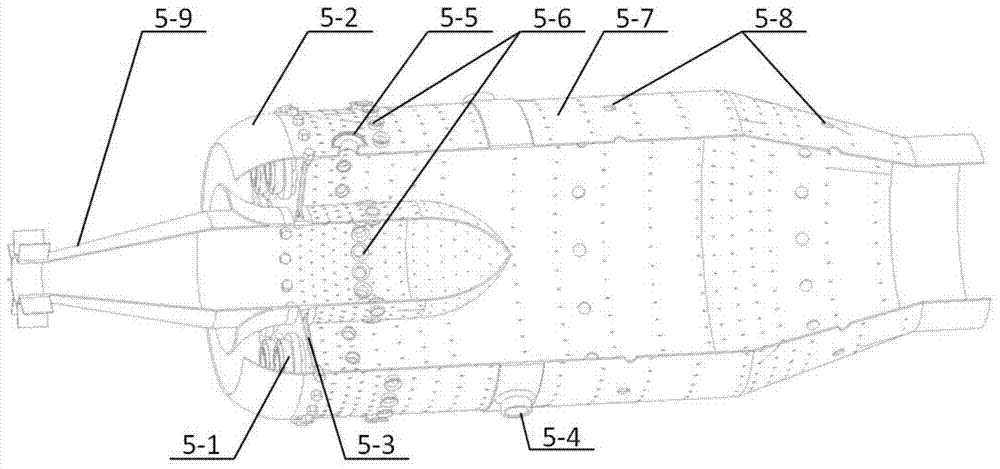

Annular combustion chamber fuel gas generator using alcohol as fuel

ActiveCN103697471AImprove atomization effectImprove ignition reliabilityBurnersAlcoholCombustion chamber

The invention belongs to the technical field of fuel gas generators, and particularly relates to an annular combustion chamber fuel gas generator. The annular combustion chamber fuel gas generator using alcohol as fuel comprises a plurality of dual-oil path centrifugal sprayers (1-0) distributed uniformly along the peripheral direction, a plasma ignition electric nozzle (2-0), a shell (3-0), a positioning pin (4-0) and a flame drum (5-0); the flame drum (5-0) is arranged in the shell (3-0) and is coaxial with the shell (3-0), and two cavity paths are formed between the flame drum and the shell; the dual-oil path centrifugal sprayers (1-0), the plasma igniter (2-0) and the positioning pin (4-0) are combined and assembled with the flame drum (5-0) by the shell (3-0). The fuel gas generator uses air as an oxidizing agent and the alcohol as the fuel, so the fuel gas has high enthalpy value. Air is very easy to obtain, and the alcohol is low in price, so the disadvantages of low enthalpy value and high operation cost of fuel gas of the existing fuel gas generator in the application field are solved.

Owner:AECC SICHUAN GAS TURBINE RES INST

Biomass combined type gasification furnace

InactiveCN101021336ASuitable for consumptionFierce firepowerDomestic stoves or rangesLighting and heating apparatusCombustorEngineering

The present invention relates to a biomass combined gasification furnace. It has gas-forming tank, furnace cavity and combustor. The gas-forming tank is positioned in the side portion of said furnace cavity, the combustor is mounted in the top portion of said furnace cavity, in the gas-forming tank an oxidation combustion pipe is set, one end of said oxidation combustion pipe is communicated with atmosphere outside of the furnace body, another end of said oxidation combustion pipe is communicated with furnace cavity, on the oxidation combustion pipe an air-guiding hole is set, the side portion of said furnace cavity is equipped with a feeding hole, the upper portion of said furnace cavity is equipped with can oxygen-supplying hole, the periphery of furnace cavity portion with oxygen-supplying hole is equipped with an oxygen-supplying chamber, said oxygen-supplying chamber is communicated with air inlet pipe communicated with atmosphere, in the combustor interior are set several layers of oxygen-supplying holes, said several layers of oxygen-supplying holes are communicated with atmosphere outside of said furnace body.

Owner:周松林

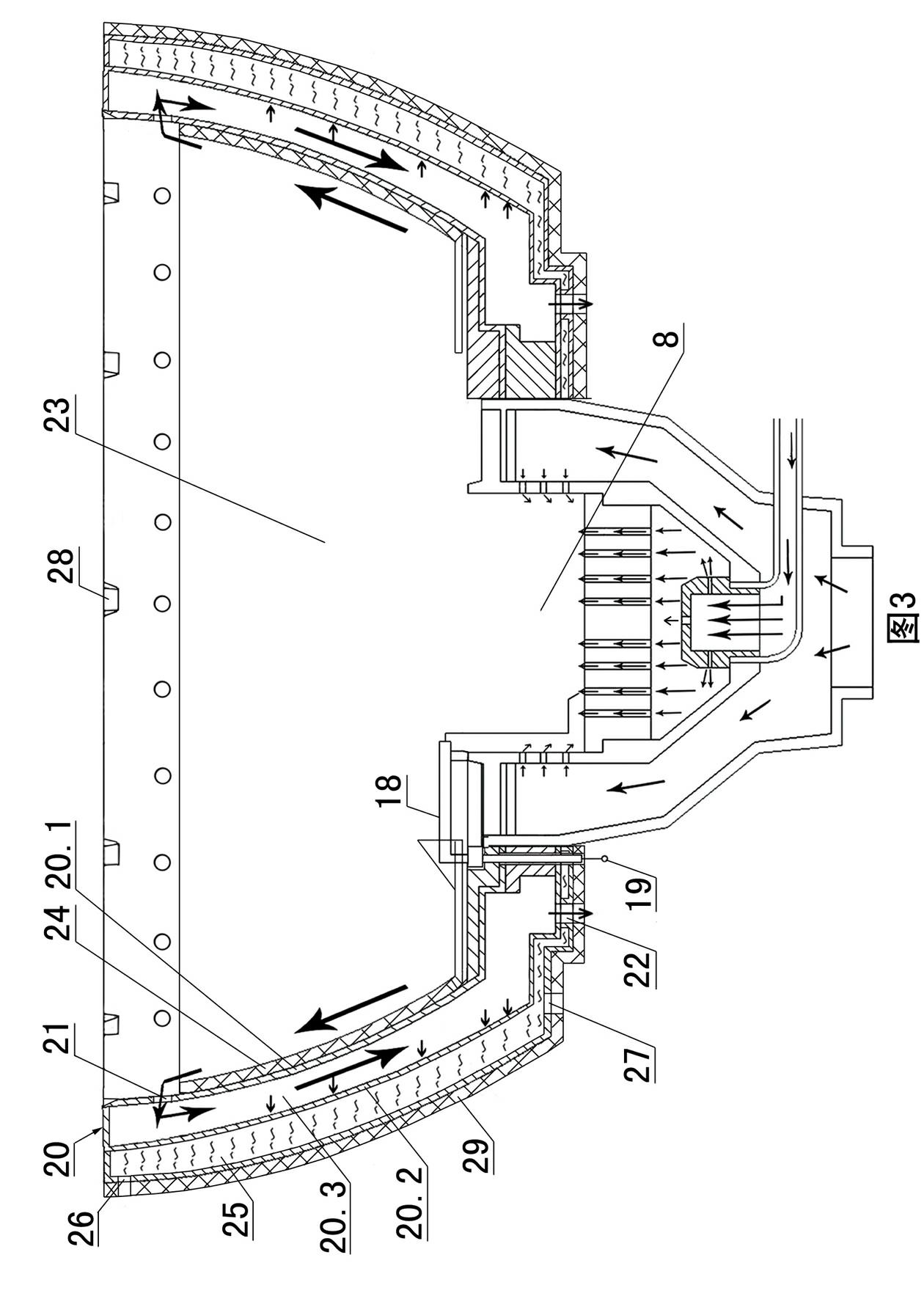

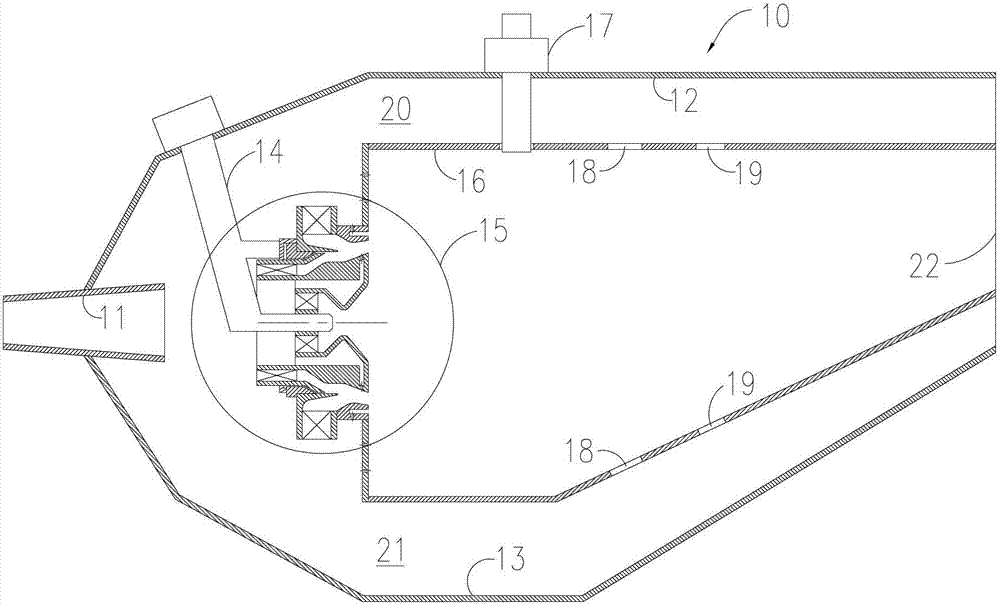

Partial pre-mixing and pre-evaporation burning chamber with prefilm type nozzle

InactiveCN103047682AStable jobStable emissionsContinuous combustion chamberCombustion chamberEvaporation

The invention belongs to the field of aeroengines and mainly relates to a partial pre-mixing and pre-evaporation burning chamber with a prefilm type nozzle. The head of the burning chamber consists of an auxiliary burning level and a main burning level, wherein the auxiliary burning level comprises a primary axial swirler, a contraction section, a throat, an expansion section and an auxiliary oilway nozzle; and the main burning level comprises a primary axial swirler, a primary radial swirler, a pre-mixing section, a contraction throat and the prefilm type nozzle. The burning chamber at the head in the above structure adopts a DIPME (direct injection pre-mixing and pre-evaporation) mixed burning mode with central classification, when in small fire state, the auxiliary burning level adopts a rich oil direct injection burning mode, and when in large fire state, the auxiliary burning level adopts a lean oil direct injection burning mode, and the main burning level adopts a lean oil partial pre-mixing and pre-evaporation burning mode. In order to guaranteeing fuel oil atomization, the main burning level adopts the prefilm type nozzle. The head of the burning chamber can guarantee performance of the burning chamber, and pollutant discharge is greatly reduced.

Owner:CHINA GAS TURBINE ESTAB

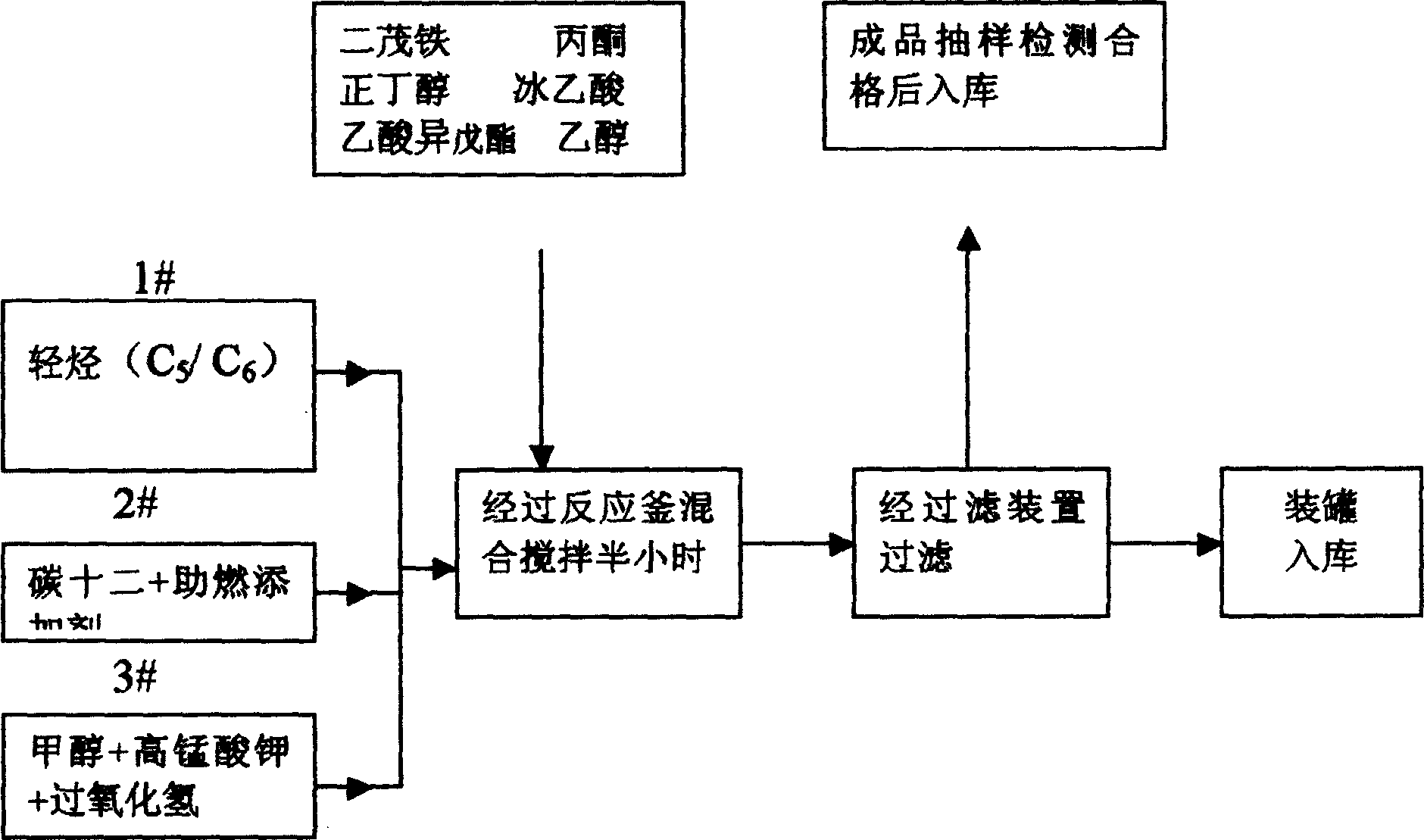

Liquid fuel and producing method thereof

InactiveCN1552824AHigh calorific valueFlame size can be adjusted at willLiquid carbonaceous fuelsLiquid fuelN-Butyl Alcohol

A clean and cheap liquid fuel and its production are disclosed. The fuel consists of (by weight) light hydrocarbon (C5 / C6) 50-65, methanol 0-15, alcohol 10-25, modified C12 20-25,, mineral chameleon 0-0.006, hydrogen peroxide 0-0.008, ferrocene 0.002-0.006, acetone 0.3-0.7, n-butyl alcohol 0.04-0.08, acetic acid matte 0-0.007, and isoamyl acetate 0-0.08. The fuel is prepared from byproducts of refineries, such as C5, C6 and C12 hydrocarbons, with high thermal value above 8000 kilocalorie / Kg and stable flame. Its advantages include simple production and use, no odd smell, easy and complete combustion, explosion-resistance, cheap, safety and stability, no environmental pollution and harmless to human beings.

Owner:宋志荣 +5

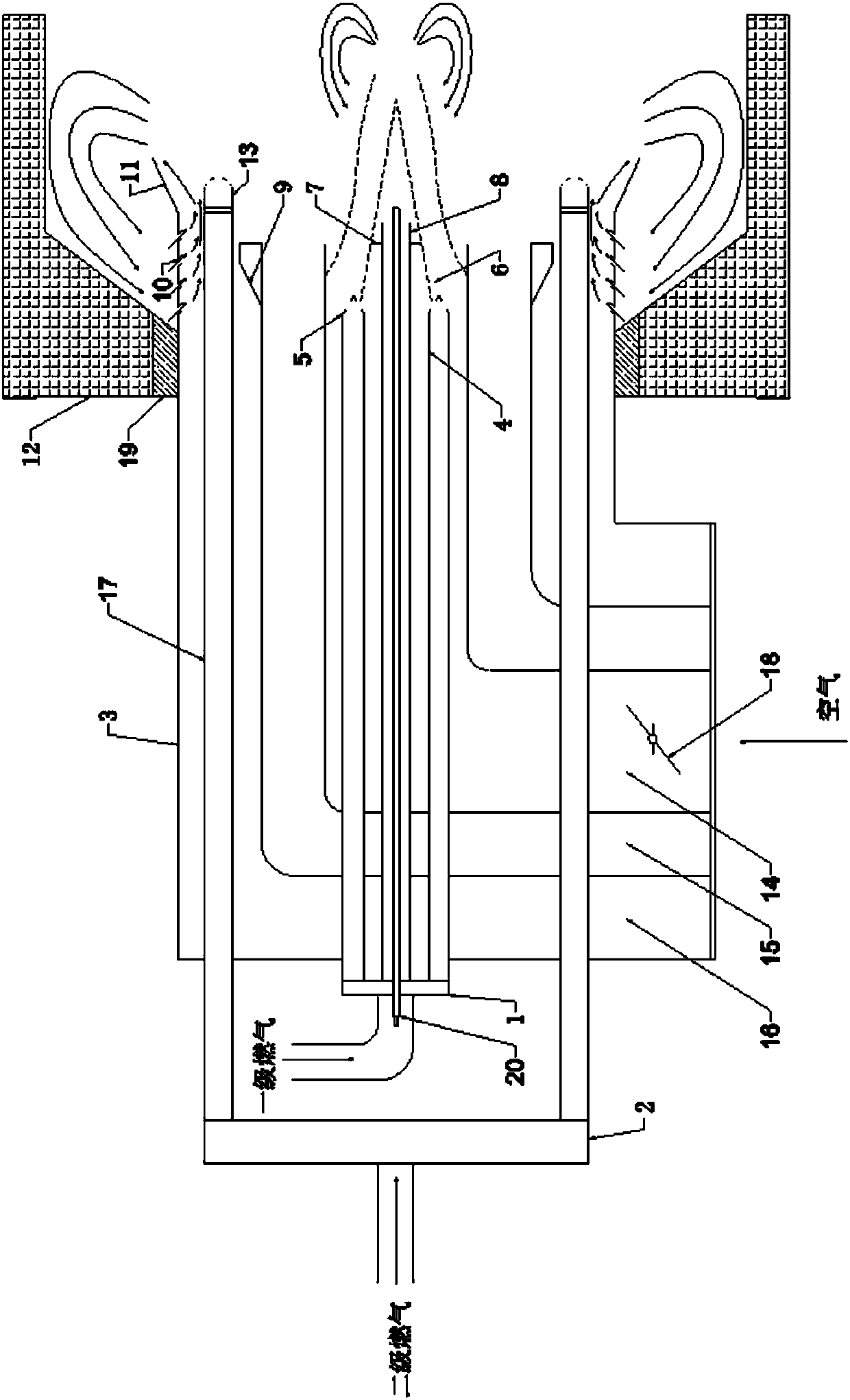

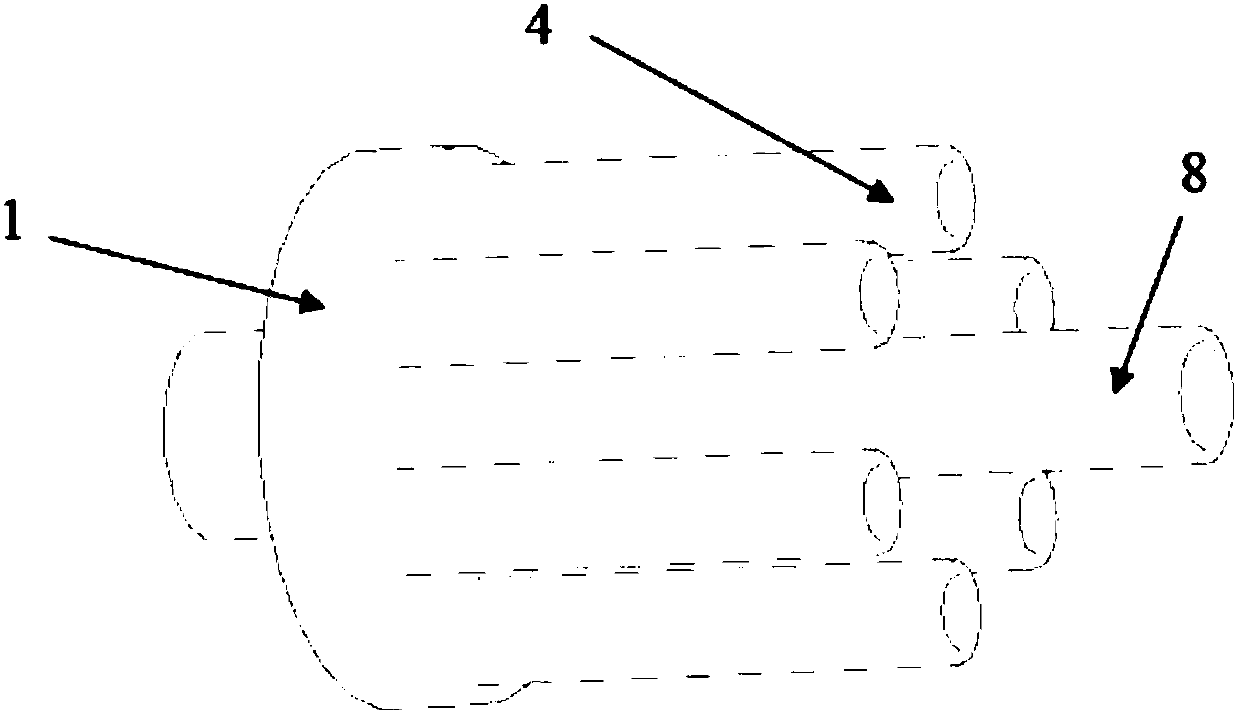

Low nitrogen cyclone gas burner with gas-air accurate classification function and internally provided with flue gas recirculation channels

The invention relates to a low nitrogen cyclone gas burner with the gas-air accurate classification function and internally provided with flue gas recirculation channels. The low nitrogen cyclone gasburner comprises a hearth, a furnace wall, a center fuel conveying pipeline, a primary air channel and a mixing channel, wherein the center fuel conveying pipeline, the primary air channel and the mixing channel are arranged sequentially from inside to outside in a sleeved mode; the front ends of the center fuel conveying pipeline, the primary air channel and the mixing channel penetrate through the furnace wall to extend into the hearth; the multiple sections of recirculation channels are arranged on the outer side wall of the mixing channel and located in the hearth; a center fuel sprayer and a plurality of secondary fuel sprayers are arranged at the front end of the center fuel conveying pipeline; a plurality of third-stage fuel guns and a plurality of secondary air spray guns are evenly arranged in the mixing channel at intervals, and the center fuel conveying pipeline and the third-stage fuel guns are connected with a fuel supply device; and the primary air channel and the secondary air spray guns are connected with an oxidizing agent supply device. By means of the low nitrogen cyclone gas burner, the burning conditions are effectively improved, the burning efficiency is high,and the concentration of nitric oxides is effectively reduced.

Owner:XI AN JIAOTONG UNIV

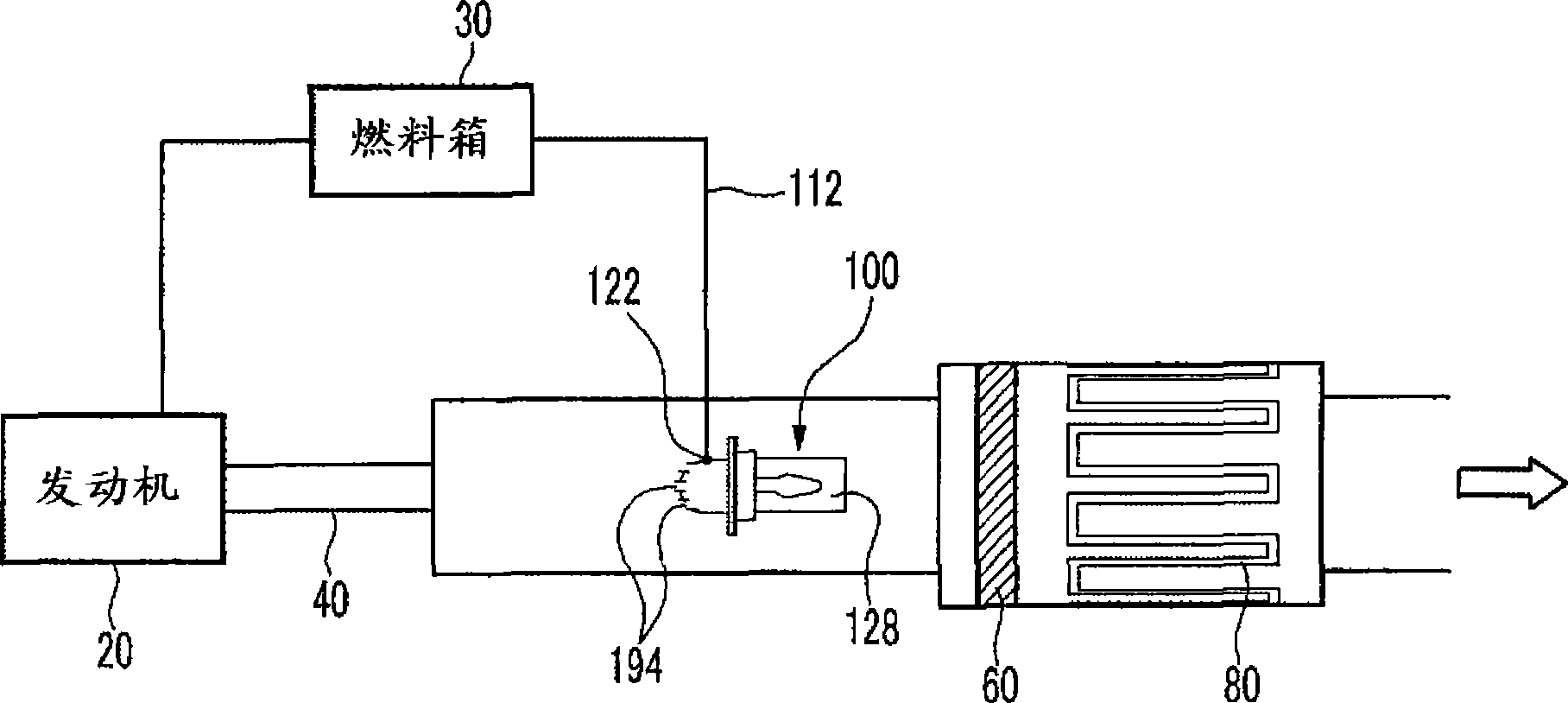

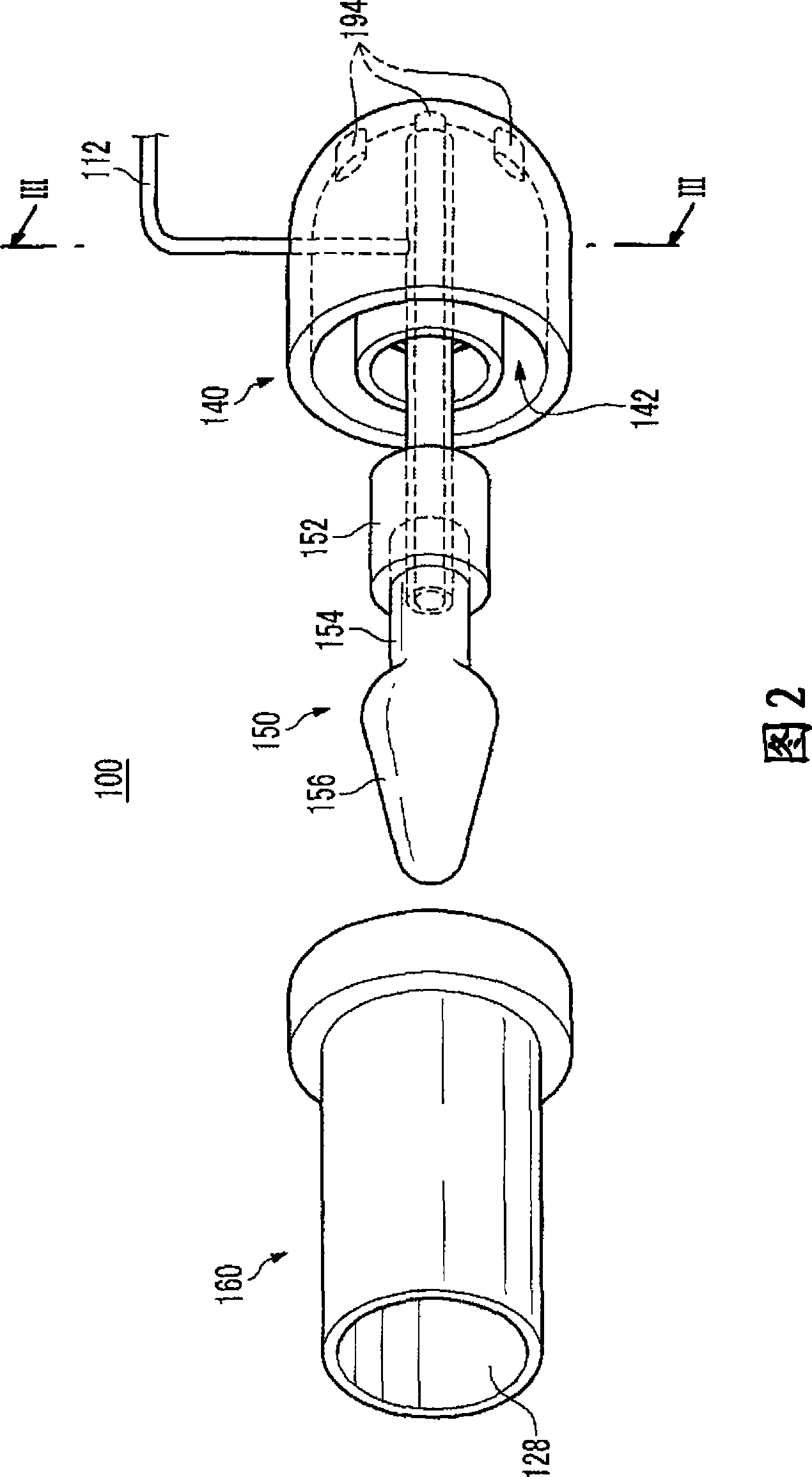

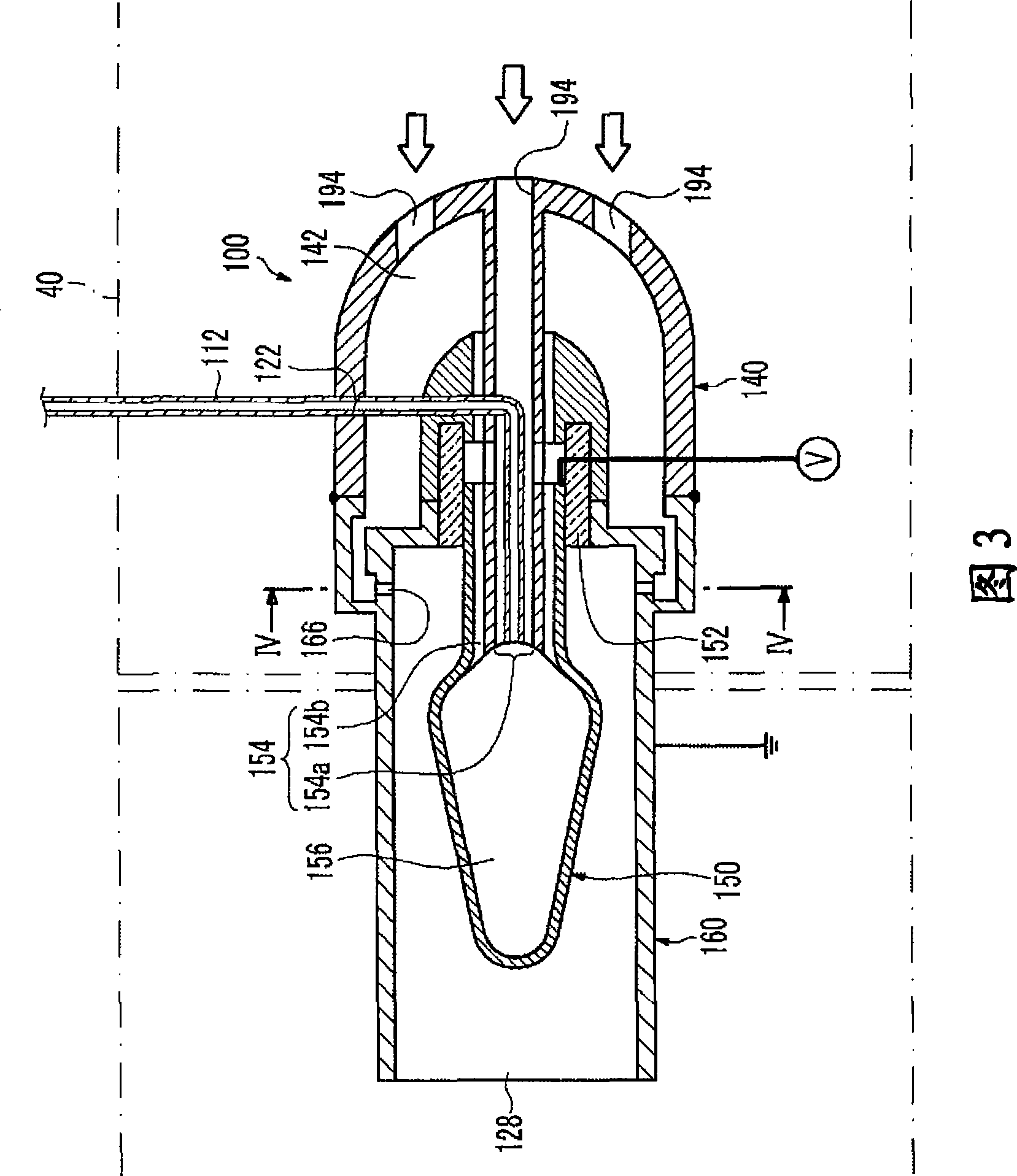

Plasma burner and diesel particulate filter trap

ActiveCN101372910AEffective oxidationEfficient removalExhaust apparatusDispersed particle separationExhaust fumesFuel tank

A plasma burner and a diesel particulate filter (DPF) trap that can effectively oxidize and remove a particulate material (PM) within an exhaust gas by preheating fuel and mixing the fuel with the exhaust gas are provided. The DPF includes: a filter that is connected to an exhaust conduit at a side opposite to that of an engine; the plasma burner that is provided within the exhaust conduit between the engine and the filter and includes a fuel inlet that supplies fuel and a flame vent that projects a flame by a plasma discharge; and a fuel inflow conduit that connects the fuel inlet and a fuel tank.

Owner:KOREA INST OF MASCH & MATERIALS

Ultralow-nitrogen gas burner

ActiveCN107559827AAchieving Circumferential GradingImprove the mixIndirect carbon-dioxide mitigationGaseous fuel burnerHearthProcess engineering

The invention relates to an ultralow-nitrogen gas burner. The ultralow-nitrogen gas burner comprises a first-stage gas header, a second-stage gas collecting ring, a furnace body, an igniter and an airflue with openings in the two ends, and the outlet of the air flue penetrates through a furnace wall of the furnace body to enter a hearth; the air flue at least comprises a central air flue, a primary air flue and a secondary air flue which are sequentially arranged from inside to outside in a sleeved mode, and the first-stage gas header and the second-stage gas collecting ring are connected with a fuel gas main pipe; the first-stage gas header is connected with a central spray gun and a plurality of first-stage gas spray guns, the first-stage gas spray guns are uniformly distributed on theperiphery of the central spray gun, and the central spray gun and the first-stage gas spray guns extend into the central air flue; the second-stage gas collecting ring is uniformly connected with a plurality of second-stage gas spray guns, and the second-stage gas spray guns extend into the secondary air flue; and the igniter is arranged in the central spray gun, and an ignition end of the igniterextends out of an outlet end of the central spray gun. According to the ultralow-nitrogen gas burner, a double-header and pipe group type supply mode is adopted, so that circumferential grading of the fuel is realized, air / gas mixing condition is improved, combustion balance is realized, and NOx generation is reduced.

Owner:XI AN JIAOTONG UNIV

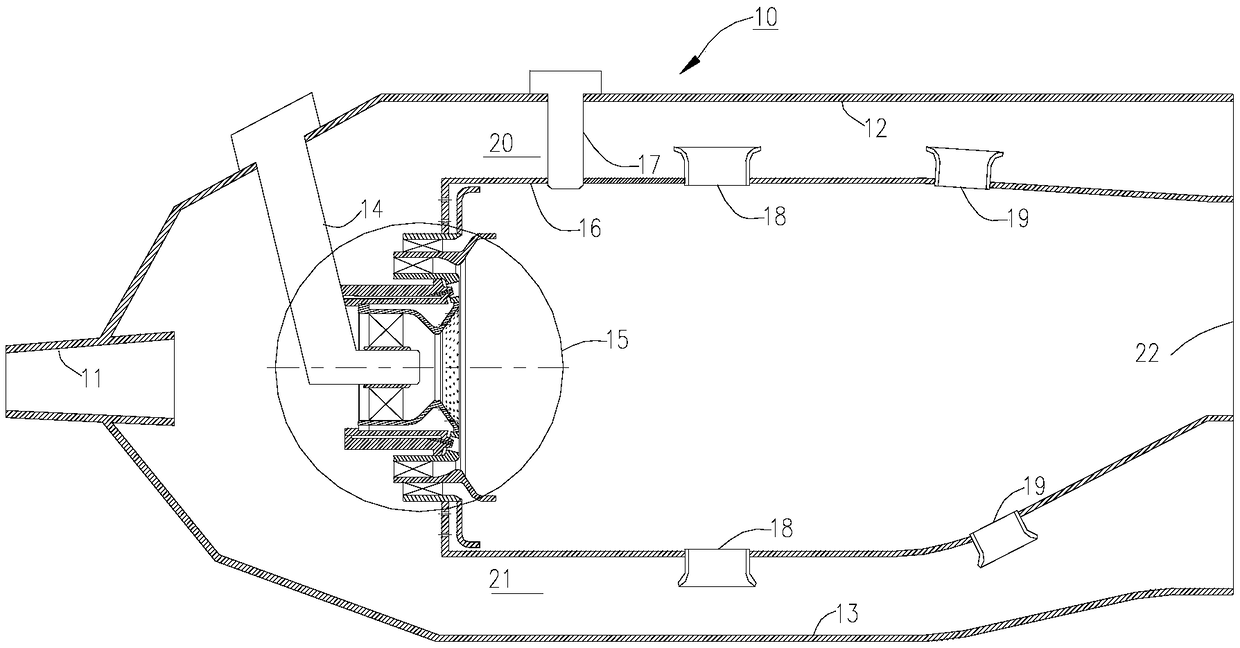

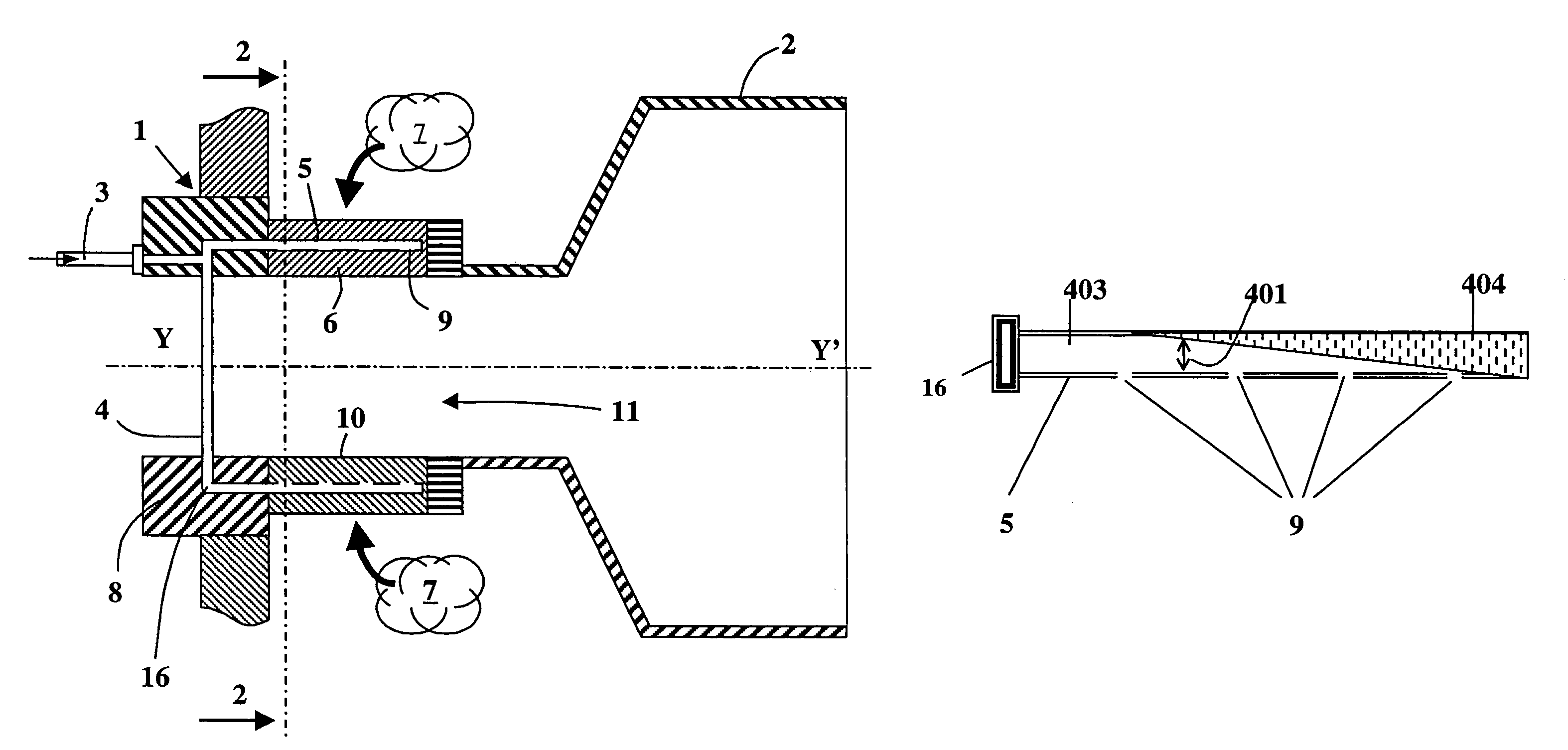

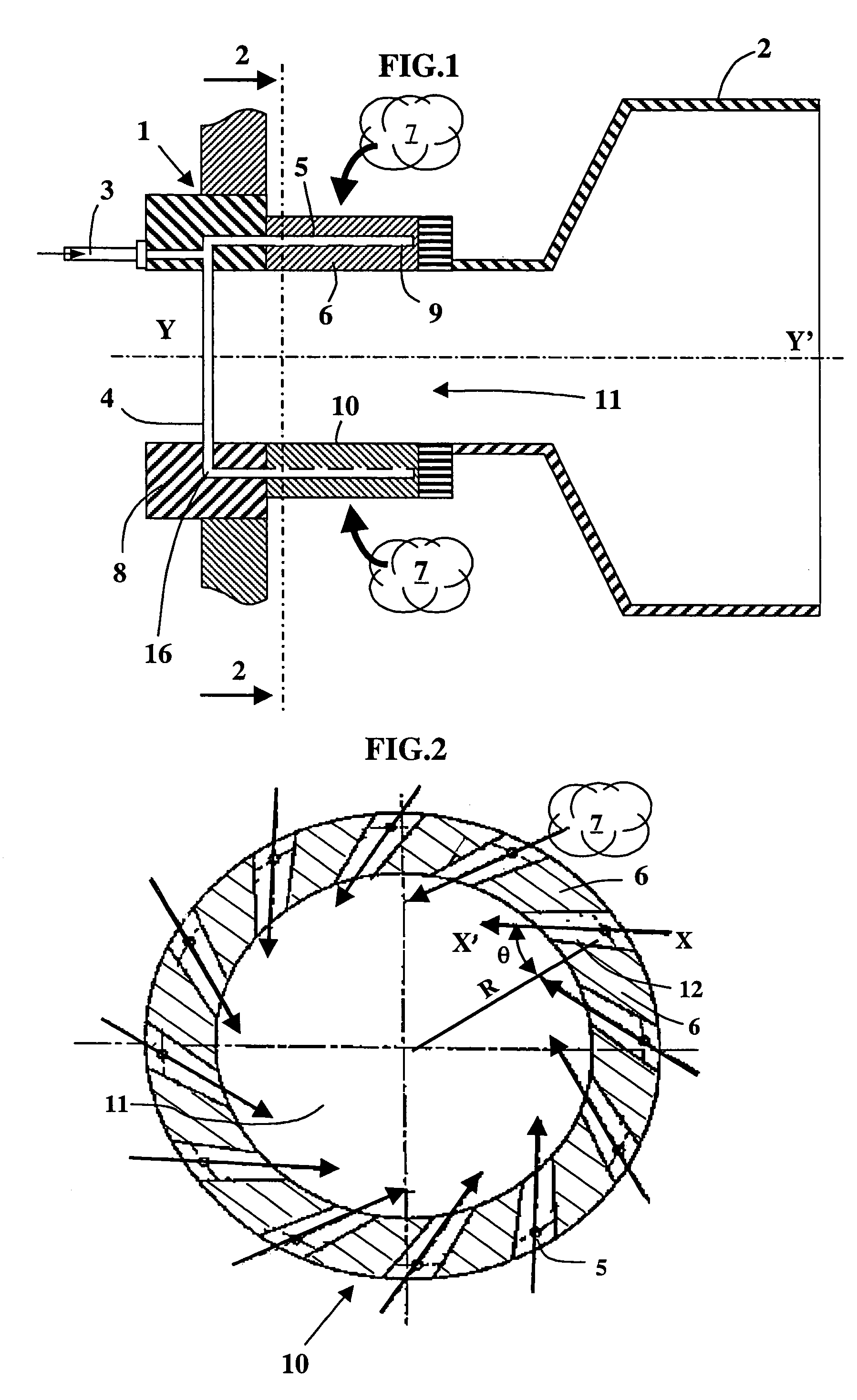

Device and method for injecting a liquid fuel into an air flow for a combustion chamber

InactiveUS7249721B2Minimized pressure dropFlame stabilizationBurnersTurbine/propulsion fuel supply systemsCombustion chamberLiquid fuel

The present invention relates to a device for injecting a liquid fuel into a pressurized air flow (7), in particular for a combustion chamber, comprising a hollow cylindrical body (10) of longitudinal axis (YY′) delimiting a substantially cylindrical central volume (11), fluid veins (12) substantially radial in relation to the longitudinal axis of body (10) and arranged on the periphery of said body to allow passage of said flow, and axial fuel injection pipes (5) arranged inside said fluid veins and connected to at least one fuel inlet (3) by at least one supply point (16). According to the invention, pipes (5) are pierced with openings (9) that open onto central volume (11) of said body (10) and which are oriented substantially in the direction of the flow in fluid veins (12).

Owner:SAFRAN HELICOPTER ENGINES

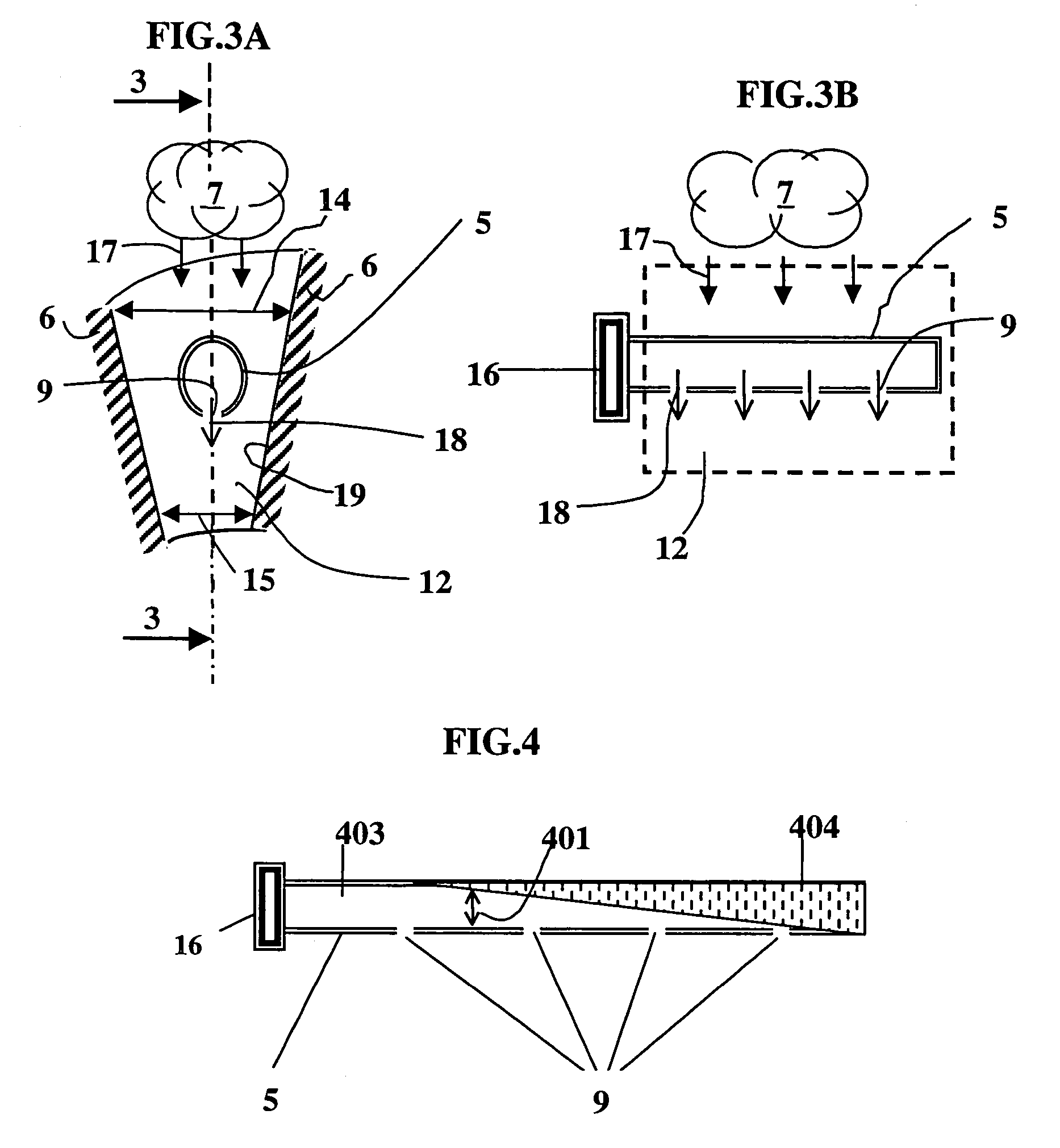

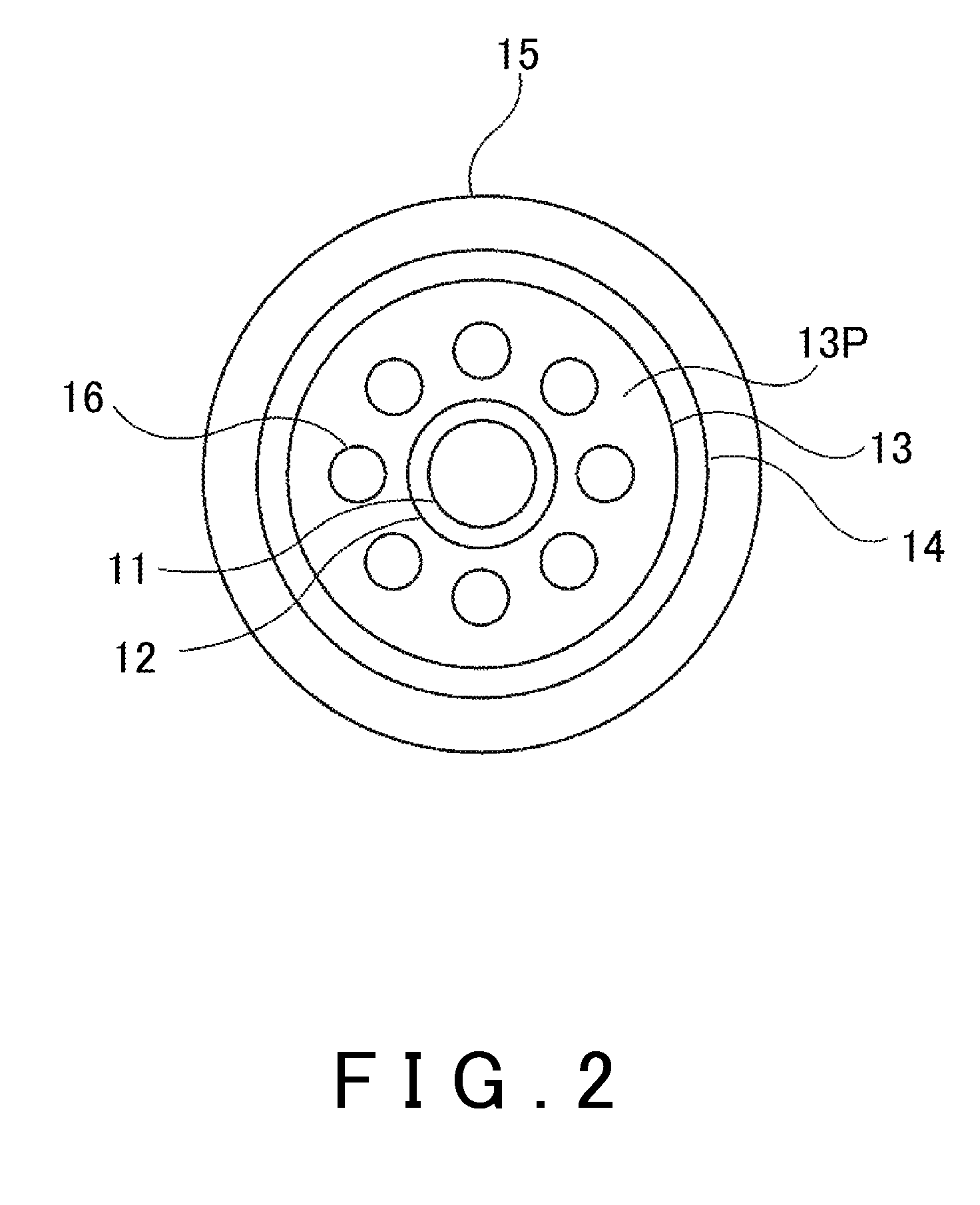

Burner for manufacturing porous glass base material

ActiveUS20100323311A1Flame stabilizationGuaranteed uniform velocityGlass shaping apparatusGlass deposition burnersPorous glassEngineering

The present invention provides a burner for manufacturing a porous glass base material that has small-diameter gas discharge ports and that achieves uniform linear velocity at the gas discharge ports, a uniform reaction, and a stable flame, and improved deposition efficiency. In the burner for manufacturing a porous glass base material, inner diameters of the pipes forming the gas discharge ports positioned farther inward in a radial direction than the gas discharge ports in which the small-diameter gas discharge port nozzles are arranged contract beginning from a position farther on a burner source side than the prescribed length L position, the contraction being greater closer to a burner tip side, and inner diameters of the pipes forming the gas discharge port in which the small-diameter gas discharge port nozzles are arranged and the gas discharge ports that are positioned farther outward in the radial direction than this gas discharge port contract beginning from a position farther on a burner tip side than the prescribed length L position, the contraction being greater closer to a burner tip side.

Owner:SHIN ETSU CHEM IND CO LTD

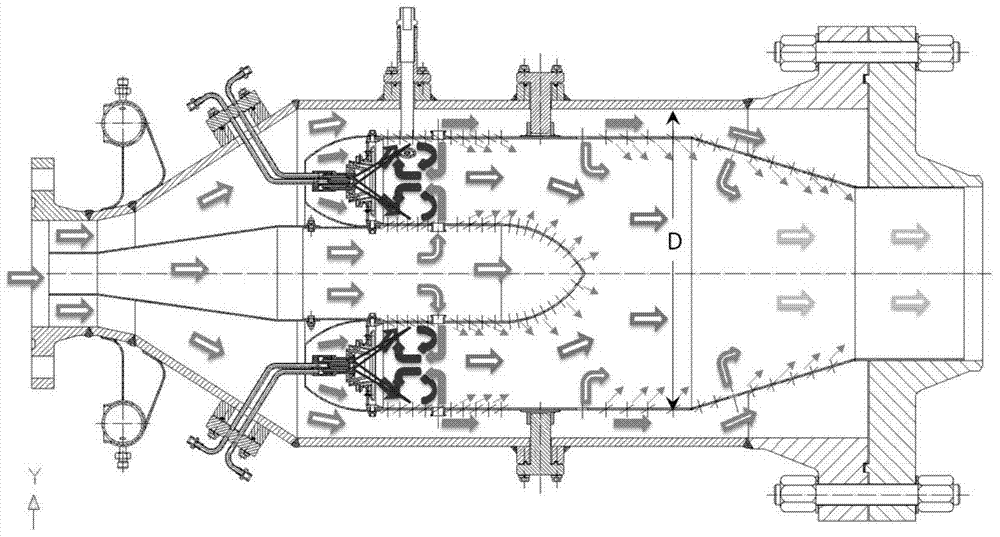

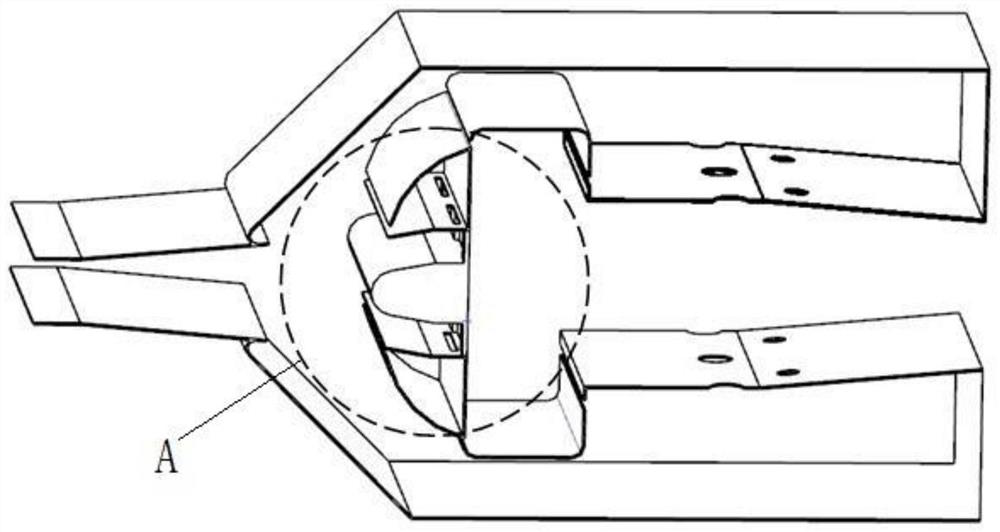

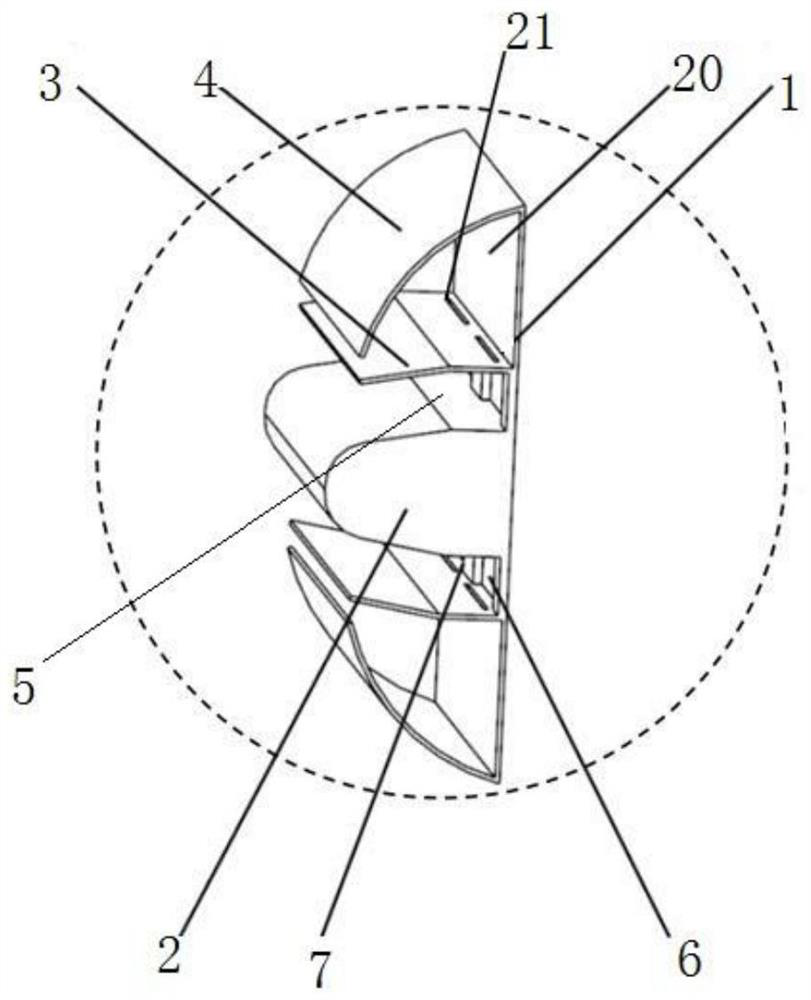

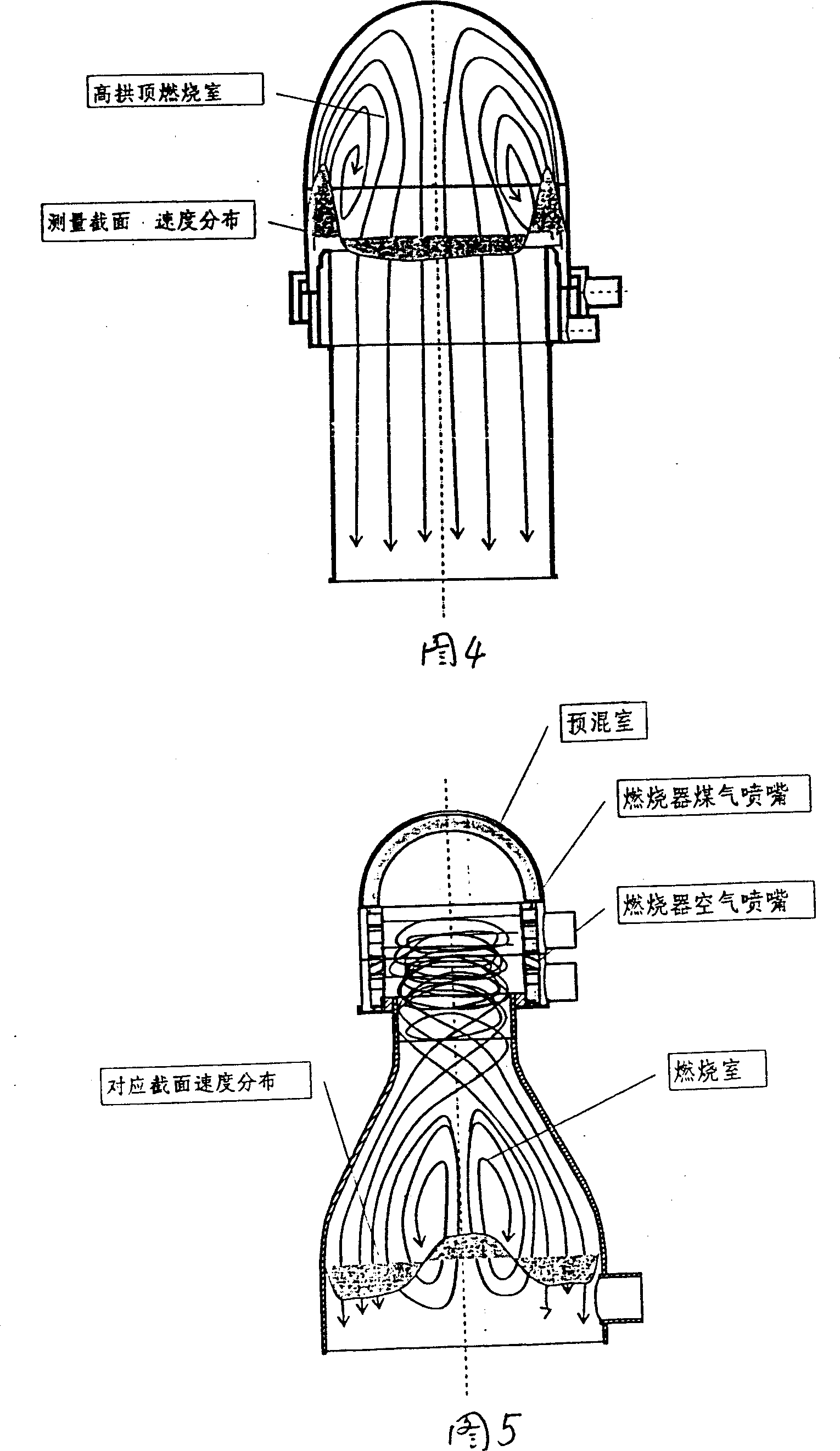

Head design of combustion chamber of twin-stage premixing ground-based gas turbine

InactiveCN105650680AImprove combustion efficiencyImprove ignitabilityContinuous combustion chamberCombustion chamberEngineering

The invention provides a head design of a combustion chamber of a twin-stage premixing ground-based gas turbine. The basic structure of the head comprises a central vortex tube, a crescent-shaped flame stabilizer and an outside annular vortex tube, wherein the central vortex tube is provided with double hydrocyclones; the crescent-shaped flame stabilizer is arranged at the down stream of the central vortex tube; and the outside annular vortex tube surrounds the central vortex tube. According to the design, a full-premixing combustion mode of the head is adopted mainly, so that the emission of NOx is reduced; air entering from a central value grade vortex tube of the head firstly passes through the first hydrocyclone, and then is mixed with ejected fuel; when a mixture flows out of the central vortex tube, the mixture is mixed and enhanced by the second hydrocyclone; at the same time, the hydrocyclone further prevents tempering; the central value grade premixed fuel forms a stable ignition source on the flame stabilizer; and the premixed fuel flowing out of the outside main burning stage is ignited, burning is carried out stably and mildly, and uniform combustion is achieved. The design can guarantee that the ground-based gas turbine can keep low emission of NOx and stable combustion on operating conditions of all loads.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

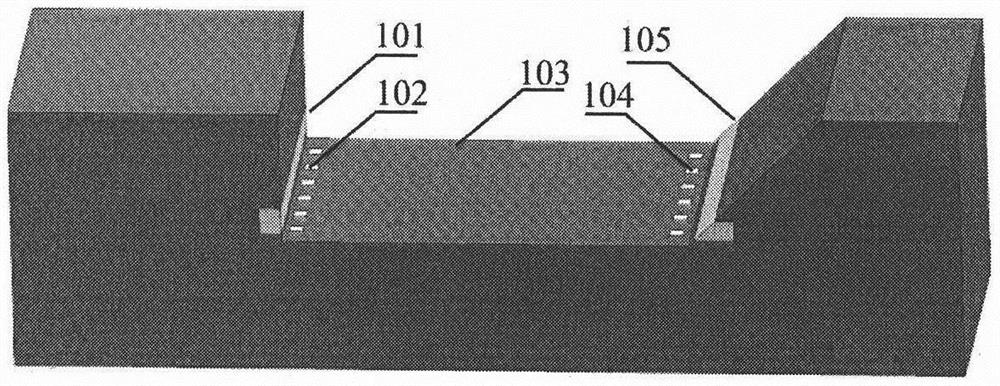

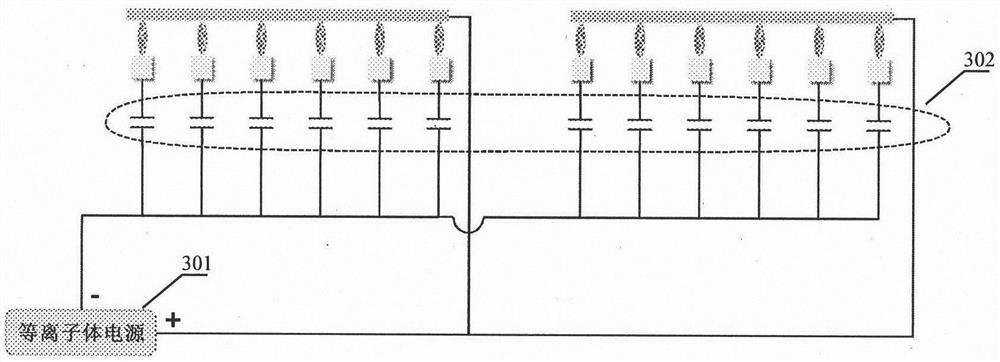

Sliding arc plasma stimulating type cavity flame holder

ActiveCN111706877AImprove low Mach number flameout boundaryReduced chance of flameoutContinuous combustion chamberPlasma techniqueCapacitanceHeating effect

The invention provides a sliding arc plasma stimulating type cavity flame holder. The flame holder is composed of an insulator (103), a first discharge electrode (101), a second discharge electrode (102), a third discharge electrode (104), and a fourth discharge electrode (105); the first discharge electrode (101) and the second discharge electrode (102) constitute a first set of plasma stimulator, and the third discharge electrode (104) and the fourth discharge electrode (105) constitute a second set of plasma stimulator; the first discharge electrode (101) and the fourth discharge electrode(105) are respectively connected with a positive electrode of a plasma power source (301); different rectangular electrodes of the second discharge electrode (102) and the third discharge electrode (104) are respectively in series connection with one of a plurality of coupling capacitors (302); and the other ends of the coupling capacitors (302) are connected with a negative electrode of the plasma power source (301). Compared with existing cavity flame holders, the sliding arc plasma stimulating type cavity flame holder utilizes oil and gas activation, decomposition and heating effects of anenhanced multi-passage sliding arc plasma, and can reduce the probability of flame extinction and widen the boundary of a flame on the basis that structure of an original cavity flame holder is unchanged.

Owner:AIR FORCE UNIV PLA

Low-emission combustion chamber head part with oil way automatic regulating valve structure

ActiveCN109237515ALarge adjustment rangeSimple structureContinuous combustion chamberCombustion chamberSpray nozzle

The invention discloses a low-emission combustion chamber head part with an oil way automatic regulating valve structure. Design of a main oil pipeline simultaneously and automatically supplying oil to three oil ways is adopted in the head part; the head part consists of a pre-combustion level and a main combustion level, and the pre-combustion stage is a double oil way spray nozzle. Under a working condition of low power, oil supply pressure is small, and the main oil pipeline separately supplies oil to a pre-combustion level auxiliary oil way so as to ensure atomization quality; under a working condition of middle power, oil supply pressure is increased, a spring valve of a pre-combustion level main oil way is opened and oil supply is started; under a working condition of large power, oil pressure is further increased, a spring valve of a main combustion level oil way is opened and oil supply is started; the design of automatic three oil way adjustment in the heat part can help ensure a simple structure of a combustion chamber, and a wide fuel oil flow adjustment scope can be realized; high flame stability, low emission and other properties of the combustion chamber can be ensured under different working conditions.

Owner:BEIHANG UNIV

Trapped vortex combustor head device for preventing main flow from being entrained towards cavity

ActiveCN112610982AReduce structural weightSuppressed forced entrainmentContinuous combustion chamberCombustorCollapsed cavity

The invention discloses a trapped vortex combustor head device for preventing main flow from being entrained towards a cavity. The front wall face of the cavity in the device, a central bluff body, a flow guide plate, a supporting plate and a cap form an integrated structure; the front wall face of the cavity, the flow guide plate and the cap form a cavity structure; an air inlet seam for making the cavity structure communicate with a main flow channel is formed in the flow guide plate; and air in the cavity structure is jetted by the air inlet seam into the main flow channel in the direction perpendicular to the main flow channel. By reasonably designing and arranging the air inlet seam of the flow guide plate, the entrainment, caused by the supporting plate, of partial air towards the cavity can be effectively prevented, the influence of entrainment air on the flow field in the cavity is further reduced, and the cavity can stabilize flame at a higher main flow rate. Meanwhile, the burden of the head device can be reduced, and therefore, the structural weight of the whole combustor is reduced.

Owner:JIANGSU UNIV OF SCI & TECH +1

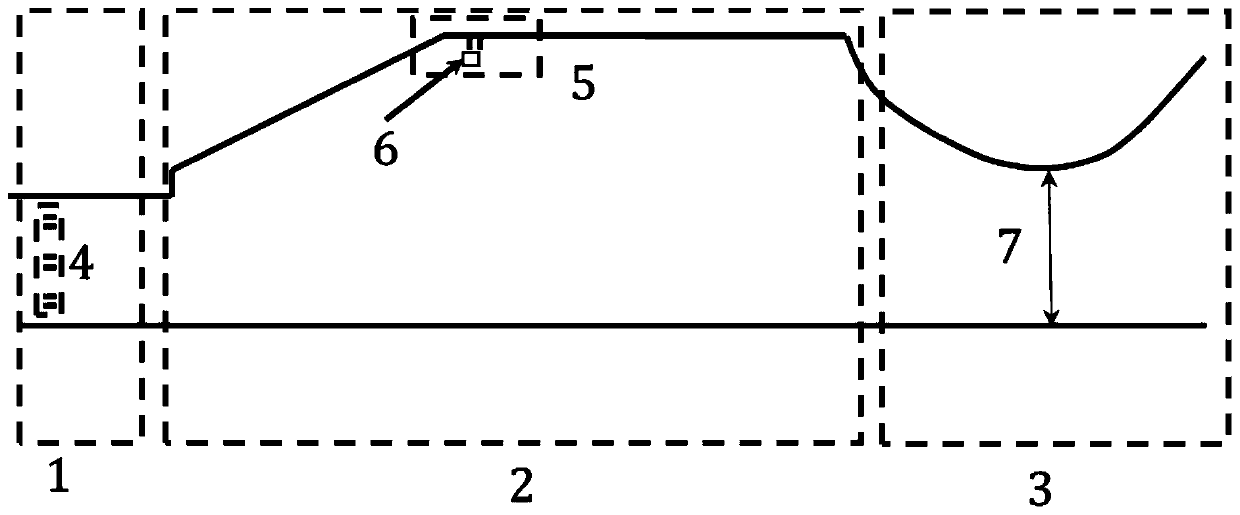

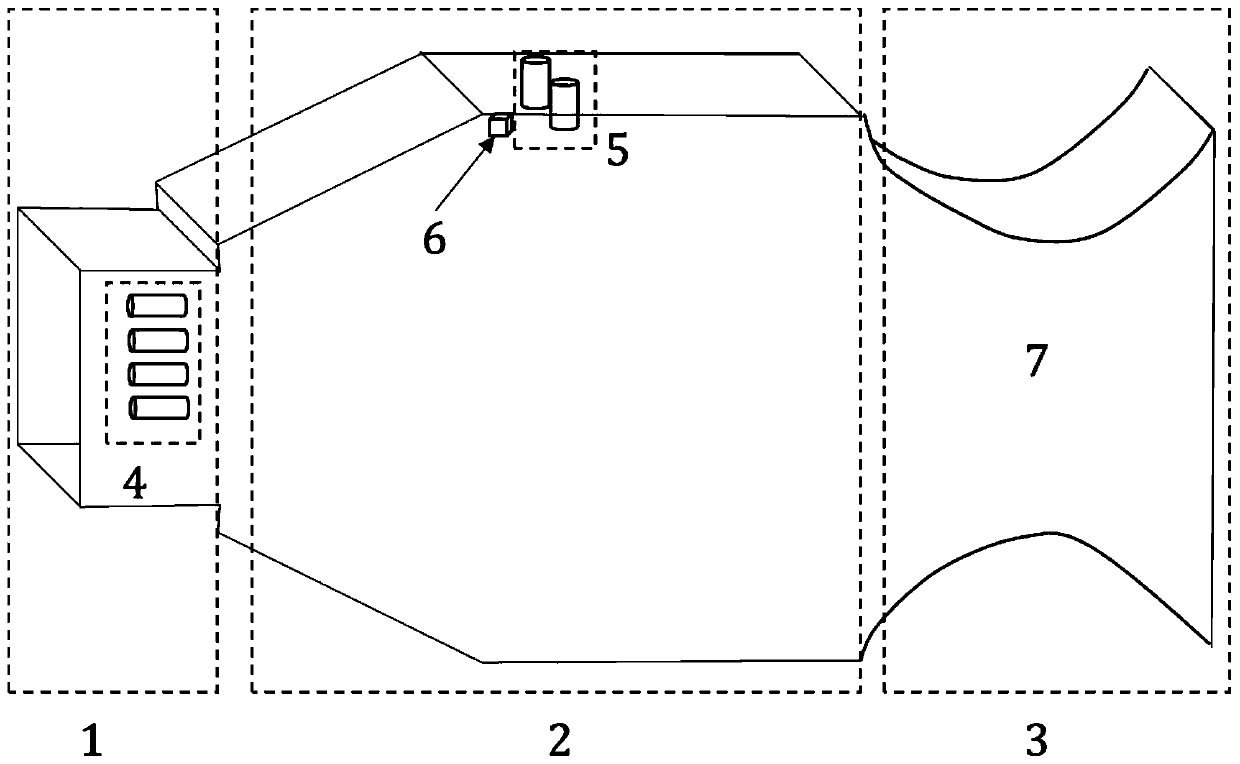

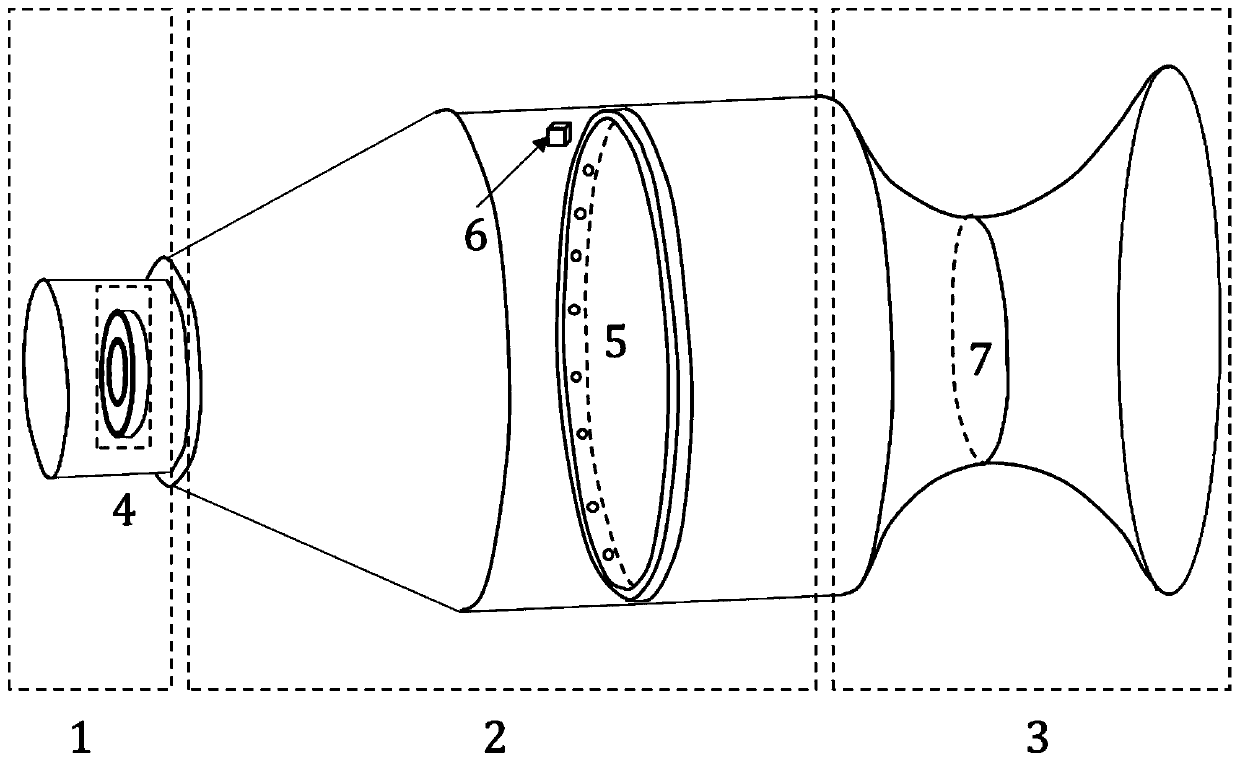

Combustion chamber of wide speed range ramjet engine and working method thereof

ActiveCN110541773AImprove reliabilityVersatilityTurbine/propulsion fuel supply systemsContinuous combustion chamberRamjetCombustion chamber

The invention provides a combustion chamber of a wide speed range ramjet engine and a working method thereof, wherein the combustion chamber comprises an air inlet connecting section (1), a forward-inclined concave combustion chamber (2) and a tail nozzle (3), wherein the air inlet connecting section (1), the forward-inclined concave combustion chamber (2) and the tail nozzle (3) are arranged successively; the air inlet connecting section (1) is a bridge component, through which a variable supersonic air inlet outlet is connected with the combustion chamber inlet, the area of the forward-inclined concave combustion chamber (2) is larger than that of the air inlet connecting section (1); the air inlet connecting section (1), the forward-inclined concave combustion chamber (2) and the tail nozzle (3) as well as the structure of the combination of the air inlet connecting section (1), the forward-inclined concave combustion chamber (2) and the tail nozzle (3) is symmetrical with a centralplane, or rotationally symmetrical with a central axis.

Owner:SHANGHAI JIAO TONG UNIV

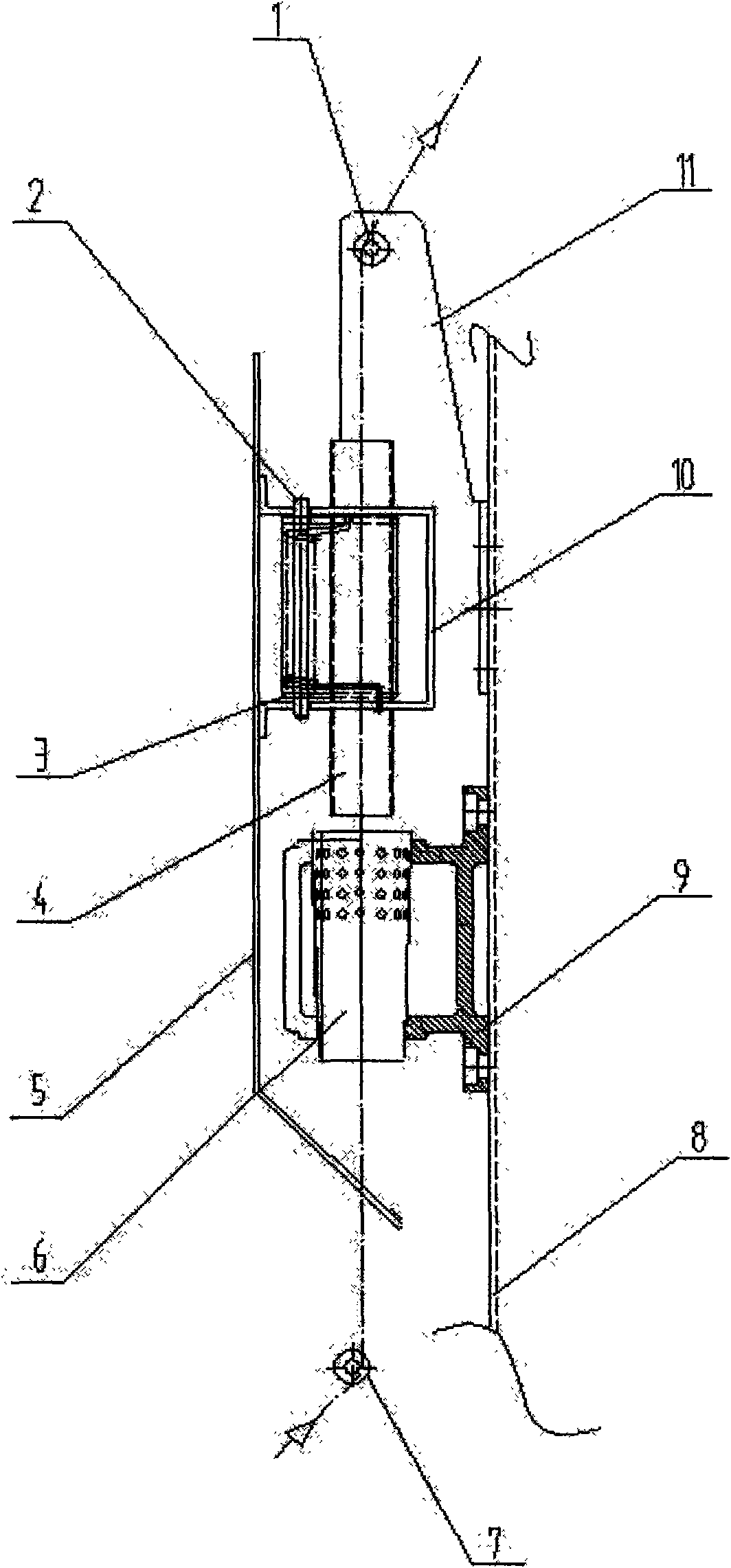

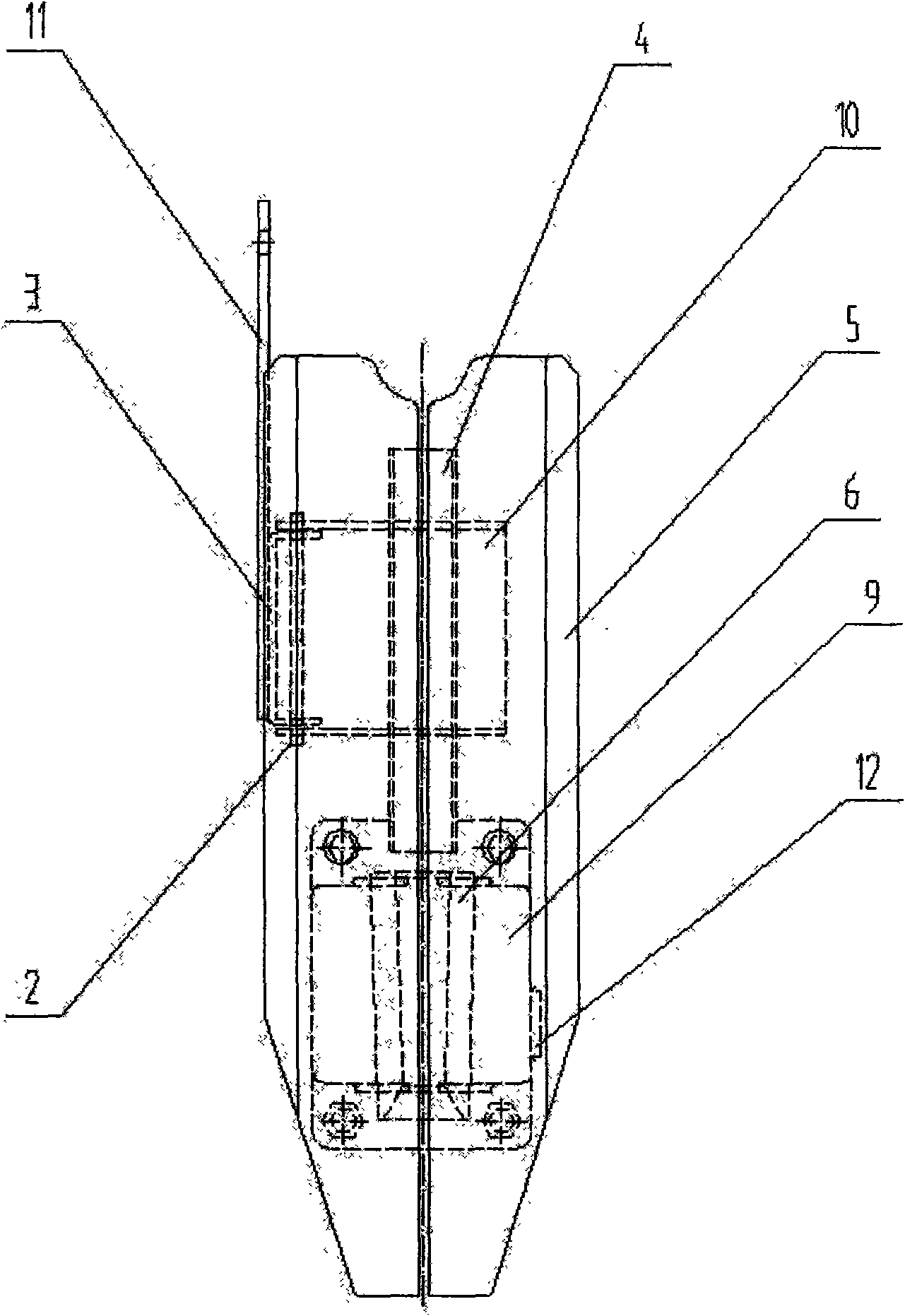

Ball-shape top-burning type hot-air furnace with annular-arranged vertical up-spray burner

InactiveCN101024859AExtended service lifeReduce the temperatureBlast furnace detailsIndirect carbon-dioxide mitigationCombustorEngineering

The invention relates to a spherical top combustion hot air furnace with annularly distributed and vertically upward-jetting burner, and its structure: the lower part of the furnace body is equipped with flue hole, furnace bottom and furnace grate, a heat storage room is in the furnace body, there is a burner between the upper part of the furnace body and the furnace top, the furnace top is made with hot air outlet, there is coal gas preheating loop in the wall body of the burner, there is combustion supporting air preheating loop in swelling body at the upper part of the coal gas preheating loop, there are coal gas outlet and top nozzle at the upper part of the coal gas preheating loop, the wall body of the burner is equipped with coal gas inlet connected with the coal gas preheating loop, the wall body of the burner at the upper part of the coal gas inlet is equipped with combustion supporting air preheating loop connected with combustion supporting air inlet and outlet, the upper part of the air outlet is equipped with air nozzle. And the invention has a special and novel structure, and skillfully solves the key problems in the gas-flow mixing, gas-flow distribution, fume preheating and other combustion courses and has huge economic and social benefits.

Owner:河南省豫兴热风炉工程技术有限公司

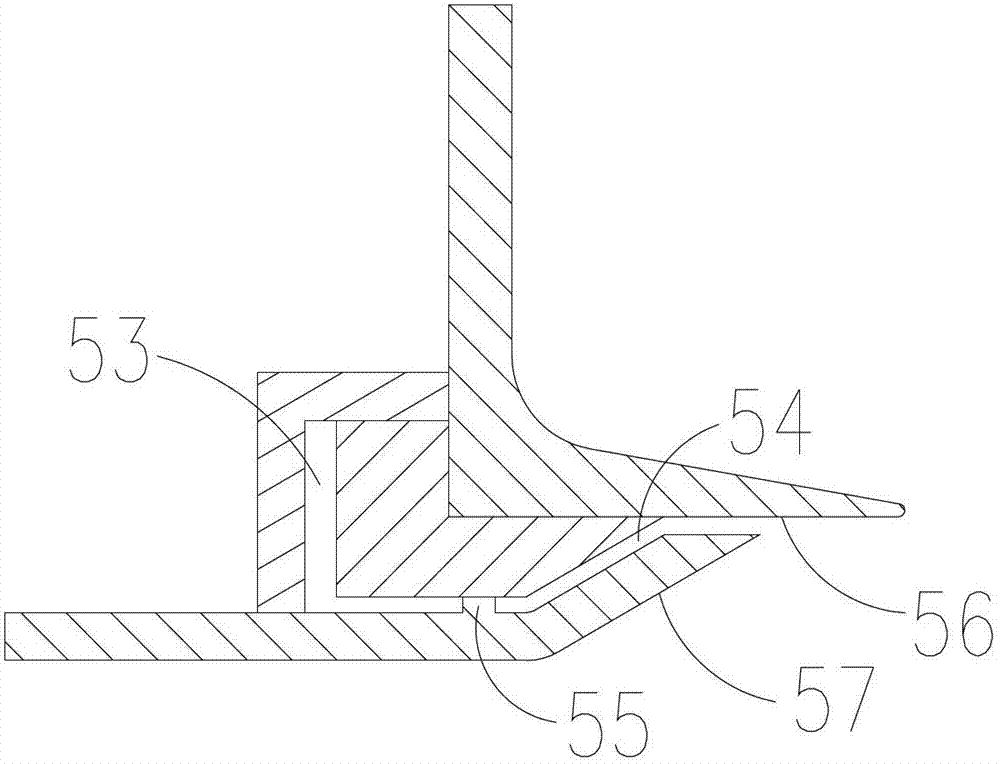

Jet combustion device for yarn singeing machine

The invention discloses a jet combustion device for a yarn singeing machine, and aims to solve the problems of insufficient combustion, a low flame temperature and short and instable flames of the conventional combustion device. The center of a fire distributor in the middle of an air supply support of the device is provided with a combustion channel for yarn singeing; the front surface of the air supply support and the circumferential wall of the fire distributor are provided with a vertically through yarn feeding and discharging channel; the circumferential wall of the fire distributor is provided with ventilation combustion holes which are formed radially and are communicated with a mixed gas inlet through the air supply support; the wall of a flame guiding pipe which is arranged over and adjacent to the fire distributor is provided with a vertically corresponding yarn feeding and discharging channel and a ventilation hole; the flame guiding pipe is fixed at the back of a protective mask; the middle of the protective mask is provided with a corresponding yarn feeding and discharging channel; the edge of the protective mask is provided with a hinge for resetting the protective mask; an upper yarn guiding ring and a lower yarn guiding pipe are arranged on the axis lines of the fire distributor and the flame guiding pipe; and the inside of the air supply support has a cavity structure, and the air supply support is in Morse taper fit with the fire distributor.

Owner:SHANDONG TONGJI ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com