Ultralow-nitrogen gas burner

A gas burner, ultra-low nitrogen technology, applied in the direction of gas fuel burner, burner, combustion method, etc., can solve the problems of poor nitrogen oxide effect, high investment, and large space occupied by external flue gas recirculation, etc. Achieve combustion balance, uniform temperature distribution, and achieve the effect of flame stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

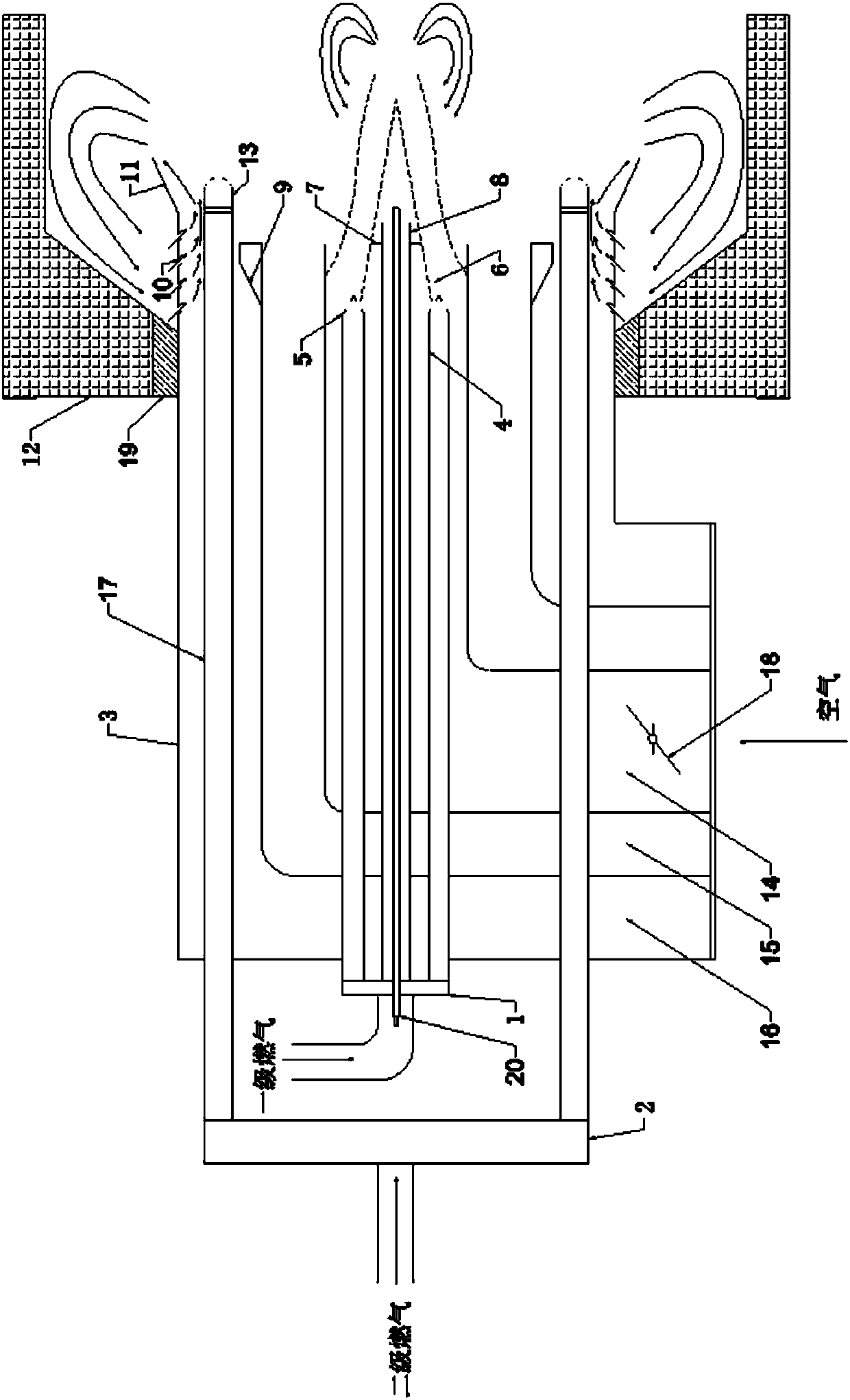

[0036] join Figure 1 to Figure 5 , the present invention comprises a primary gas header 1, a secondary gas collector ring 2, a body of furnace, an igniter 20 and an air duct 3 with openings at both ends, the outlet of the air duct 3 passes through the furnace wall 12 of the body of heater and enters the furnace; The channel 3 at least includes a central air channel 14, a primary air channel 15 and a secondary air channel 16 which are set sequentially from the inside to the outside. The primary gas header 1 and the secondary gas collecting ring 2 are connected to the gas main pipe.

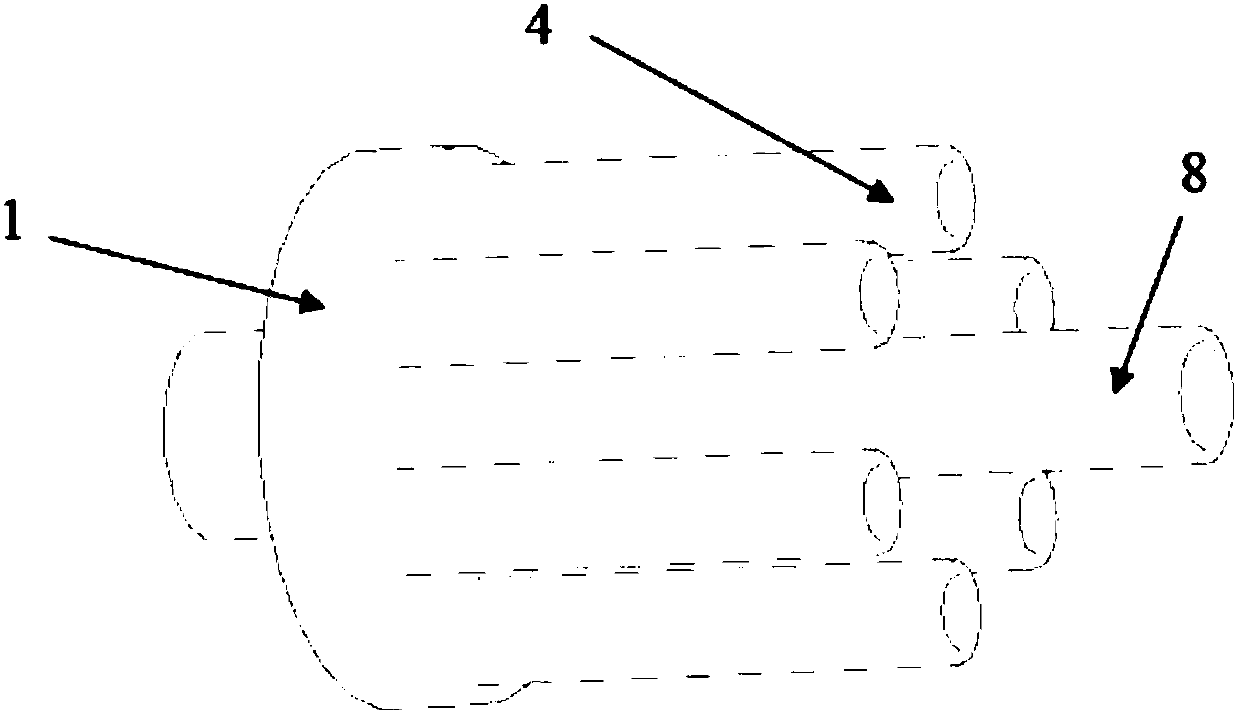

[0037] Among them, refer to figure 2 The primary gas header 1 connects the central spray gun 8 and several primary gas spray guns 4, the primary gas spray guns 4 are evenly distributed around the central spray gun 8, and the central spray gun 8 and the primary gas spray gun 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com