A kind of deep processing preparation and quality control method of propolis compound

A technology of propolis extract and propolis, which is applied in directions such as medical preparations without active ingredients, medical preparations containing active ingredients, and drug combinations, can solve problems such as poor properties of propolis powder, uniform mixing of auxiliary materials, and difficulty in drying. , to achieve the effect of good liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention discloses a preparation method of propolis powder and a product thereof. Those skilled in the art can refer to the content of this article and appropriately improve the process parameters to realize it. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and the relevant personnel can obviously make changes or appropriate changes and combinations to the method and application described herein without departing from the content, spirit and scope of the present invention to realize and Apply the technology of the present invention.

[0044] The preparation method of the propolis powder provided by the invention and the raw materials or auxiliary materials used in the product can be purchased from the market.

Embodiment 1

[0046] The preparation of embodiment 1 propolis powder

[0047] 1. Pretreatment

[0048] Freezing the raw material of Brazilian green propolis at -20°C for 3 hours to harden the propolis; then crushing it with a pulverizer to obtain the raw material of propolis powder;

[0049] 2. Extraction

[0050] Take the pulverized propolis raw material, put it in an extraction tank, add 85% ethanol in an amount 4 times the volume of the medicinal material, stir and extract at room temperature for 3 hours, filter, and store the filtrate separately; , take the filtrate, and combine the extracts.

[0051] 3. Concentration and grinding

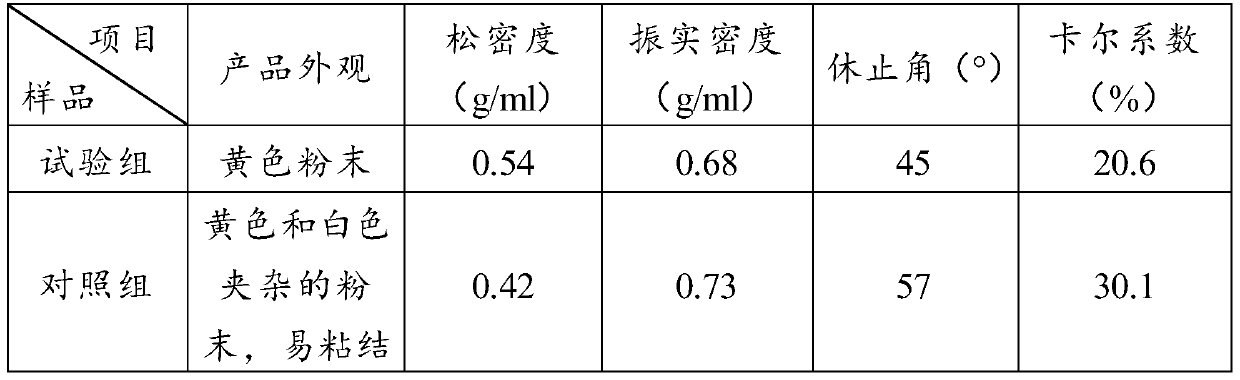

[0052]Test group: take the ethanol extract of propolis and concentrate it in a concentrator under reduced pressure. The vacuum degree is controlled at -0.01MPa and the temperature is 50°C. Centrifuge at a speed of 2000r / min for 5min, remove the suspended matter in the upper layer, take the centrifuge and continue to concentrate under reduced pressure unt...

Embodiment 2

[0062] The preparation of embodiment 2 propolis powder

[0063] 1. Pretreatment

[0064] Freezing the raw material of Brazilian green propolis at -20°C for 3 hours to harden the propolis; then crushing it with a pulverizer to obtain the raw material of propolis powder;

[0065] 2. Extraction

[0066] Take the pulverized propolis raw material, put it in an extraction tank, add 75% ethanol in an amount 10 times the volume of the medicinal material, stir and extract at room temperature for 2 hours, filter, and store the filtrate separately; , take the filtrate, and combine the extracts.

[0067] 3. Concentration and grinding

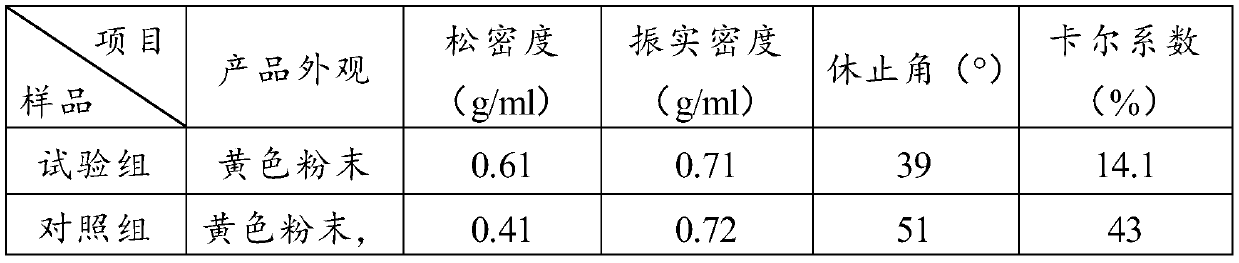

[0068] Test group: take the propolis ethanol extract and concentrate it in a concentrator under reduced pressure. The vacuum degree is controlled at -0.03MPa and the temperature is 60°C. Centrifuge at a speed of 1500r / min for 8min, remove the suspended matter in the upper layer, and then take the centrifuged liquid and continue to concentrate under redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com