Pre-mixing burner

A technology of premixed combustion and air mixing chamber, which is applied in the direction of burners, gas fuel burners, combustion methods, etc. It can solve the problems of high noise, insufficient heat load, and scattered firepower, so as to achieve sufficient combustion and uniform heat load , flame stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

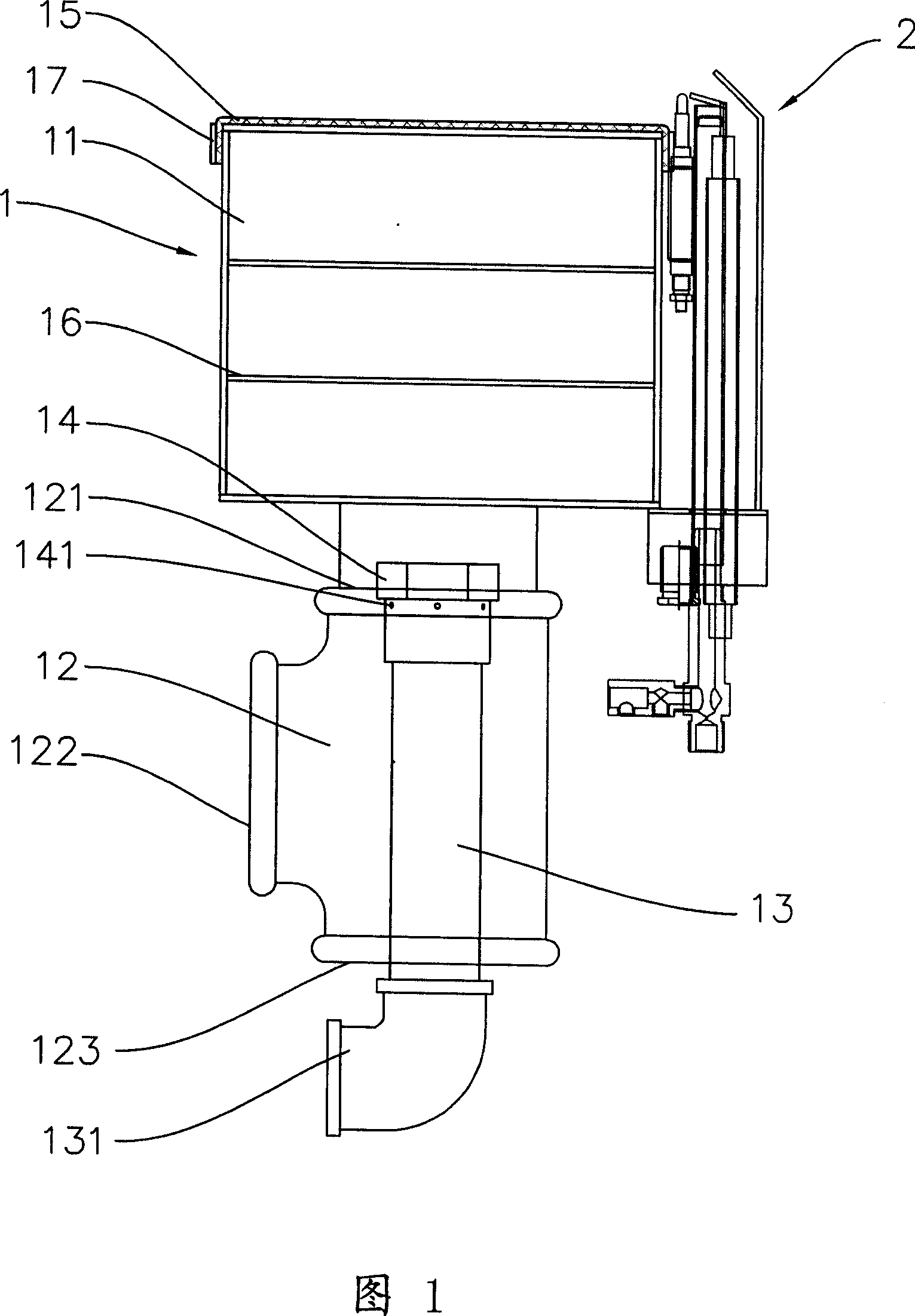

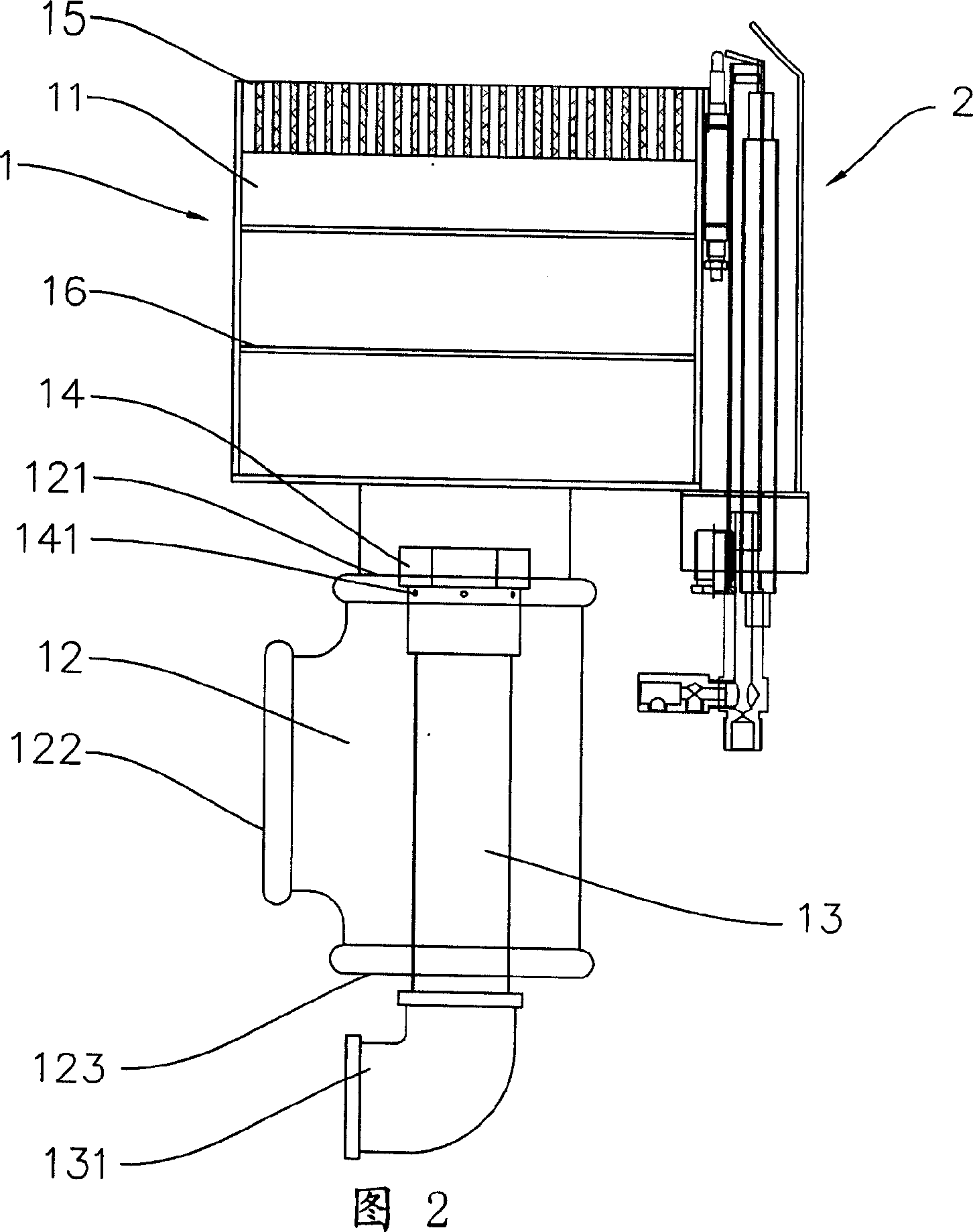

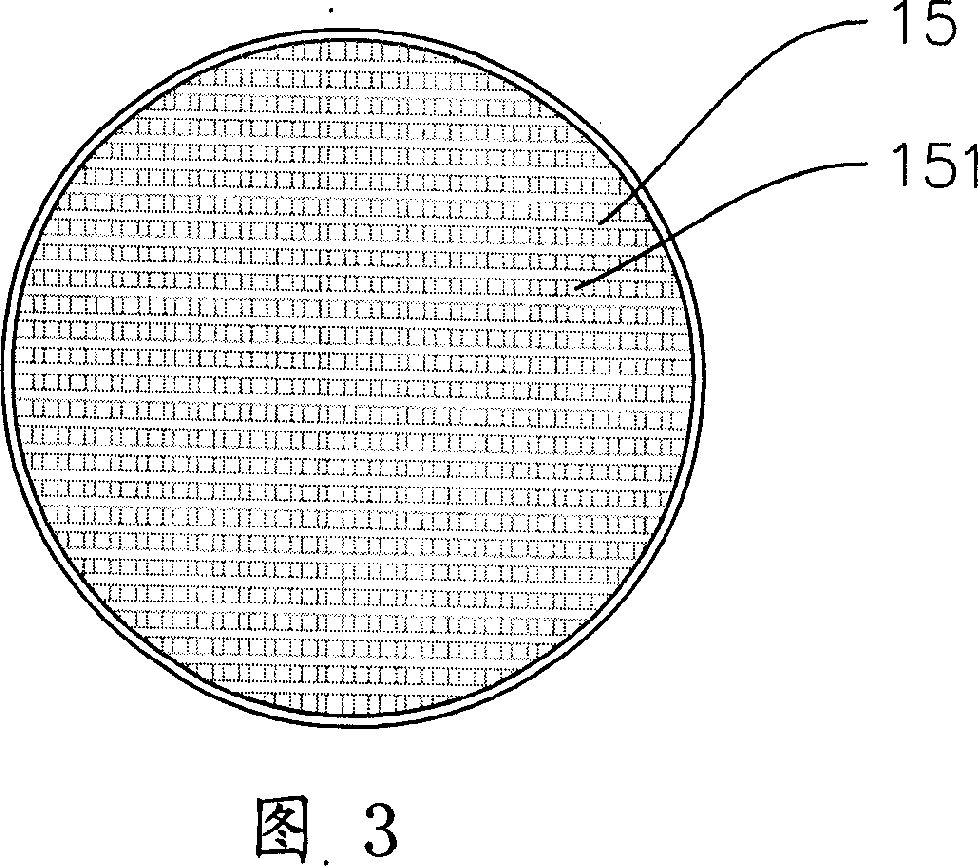

[0021] As shown in Figure 1, in a preferred embodiment of the premix burner of the present invention, it includes a main ignition device 1 and an ignition device 2 arranged next to the main ignition device 1, and the main ignition device 1 includes an air mixing chamber 11 , Air chamber 12, intake pipe 13, main fire nozzle 14, fire outlet plate 15. Wherein the gas mixing chamber 11 is a cylindrical or similar cylindrical shell with openings at its upper and lower ends. The air chamber 12 is a three-way pipe, and the upper end interface 121 of the three-way pipe is sealed and detachably connected to the lower opening of the air mixing chamber 11; the lateral interface of the three-way pipe is an air inlet 122, and the air inlet 122 communicates with the outlet of the blower through a pipe to introduce air into the air chamber; the lower end interface 123 of the three-way pipe is sealed and detachable connected with the middle part of the air inlet pipe 13 . One end of the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com