Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Uniform heat load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

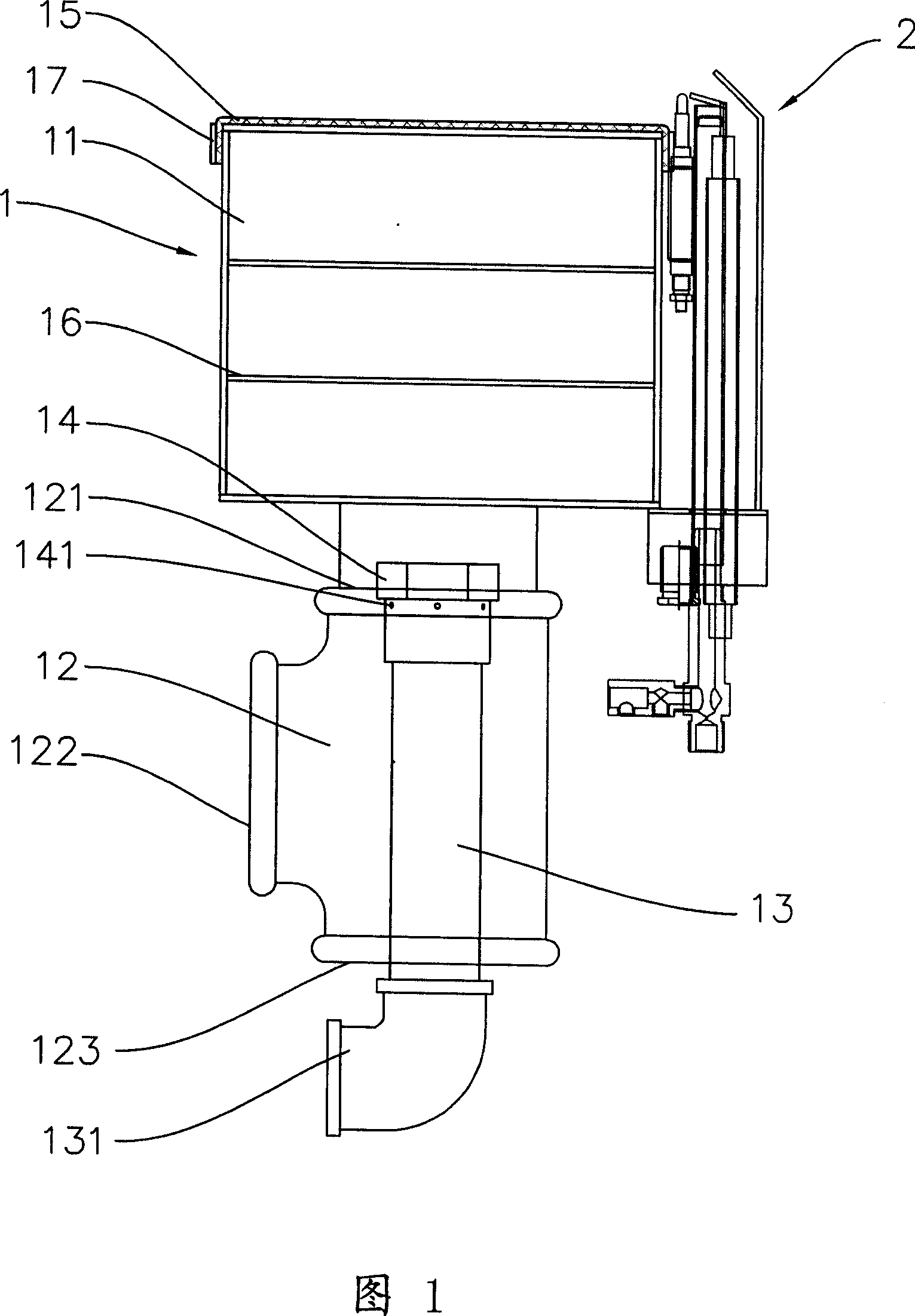

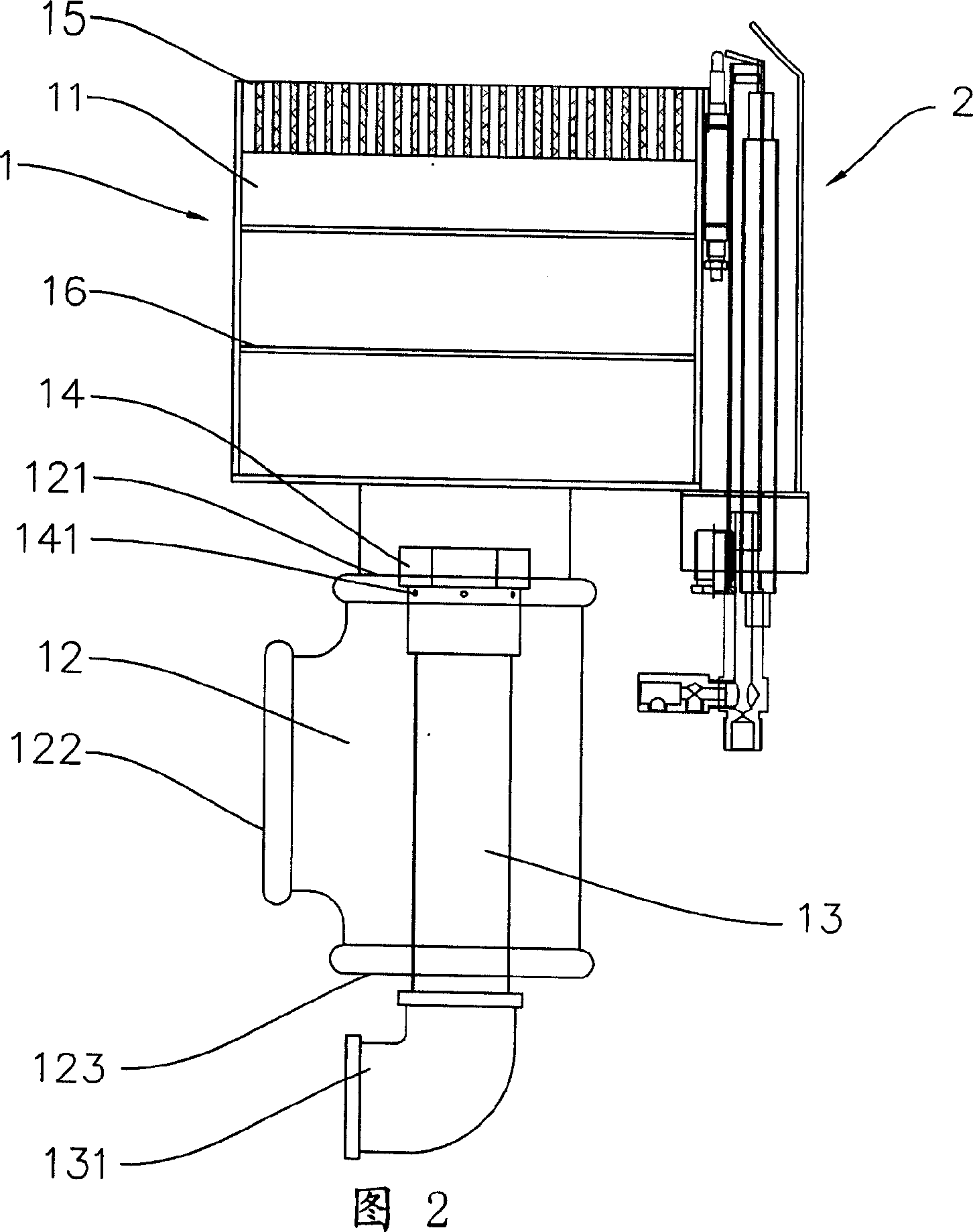

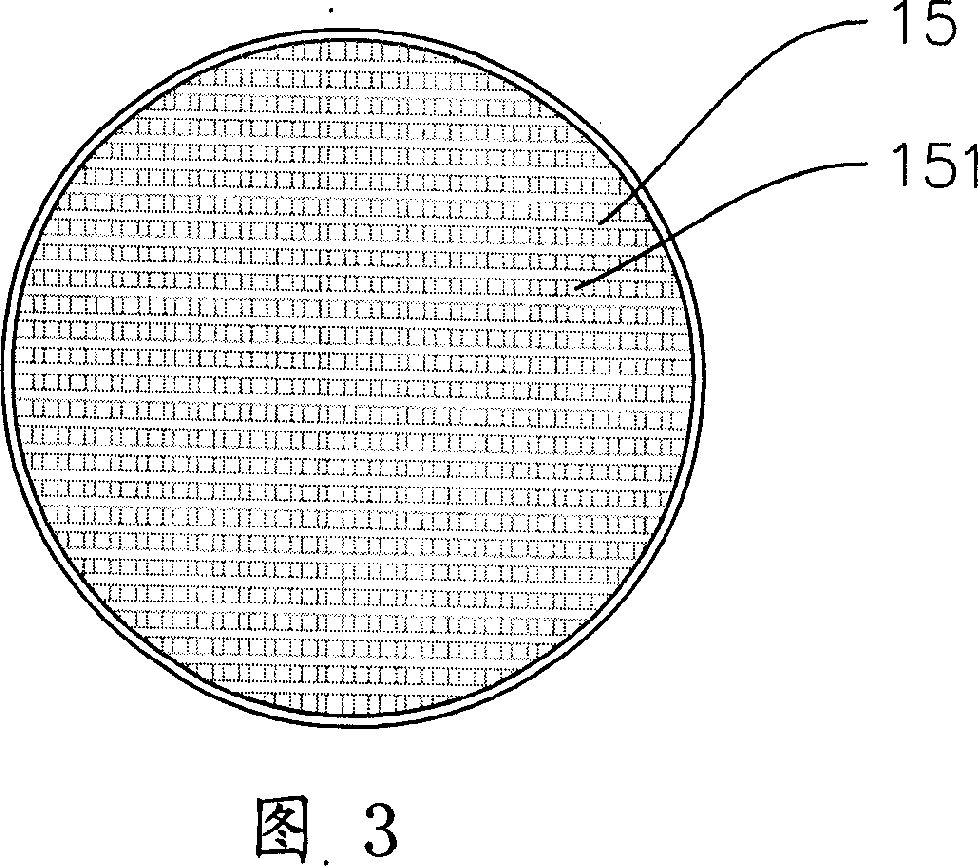

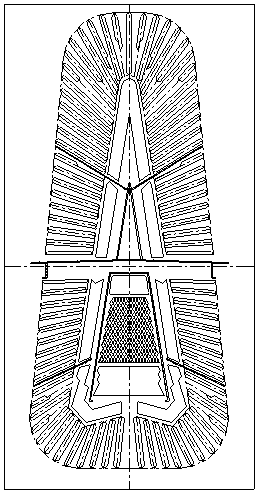

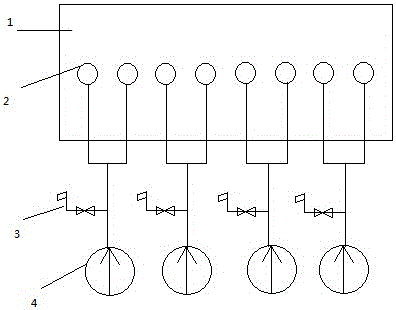

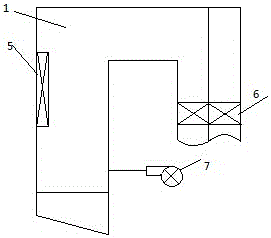

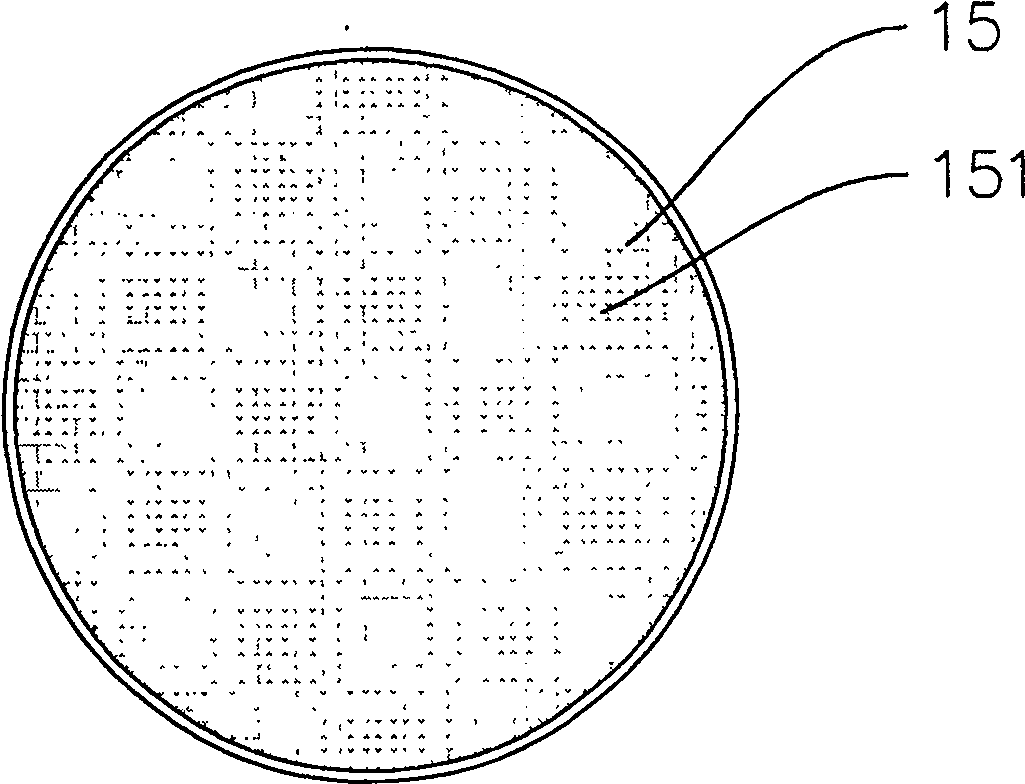

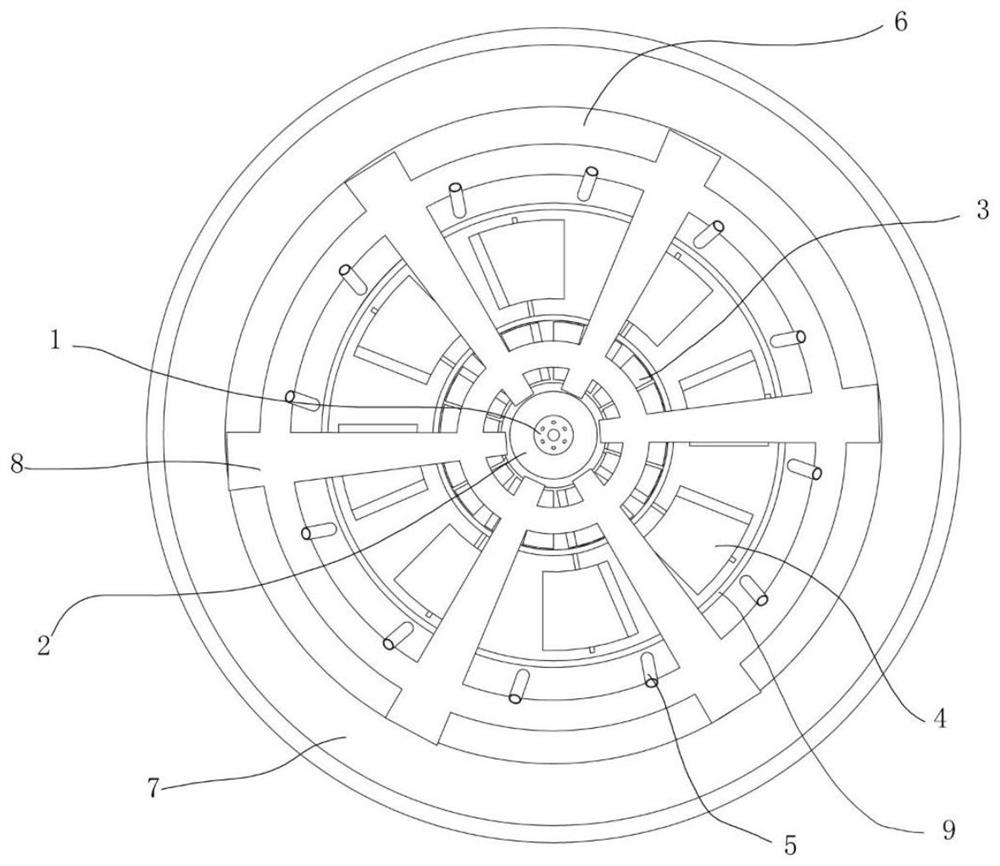

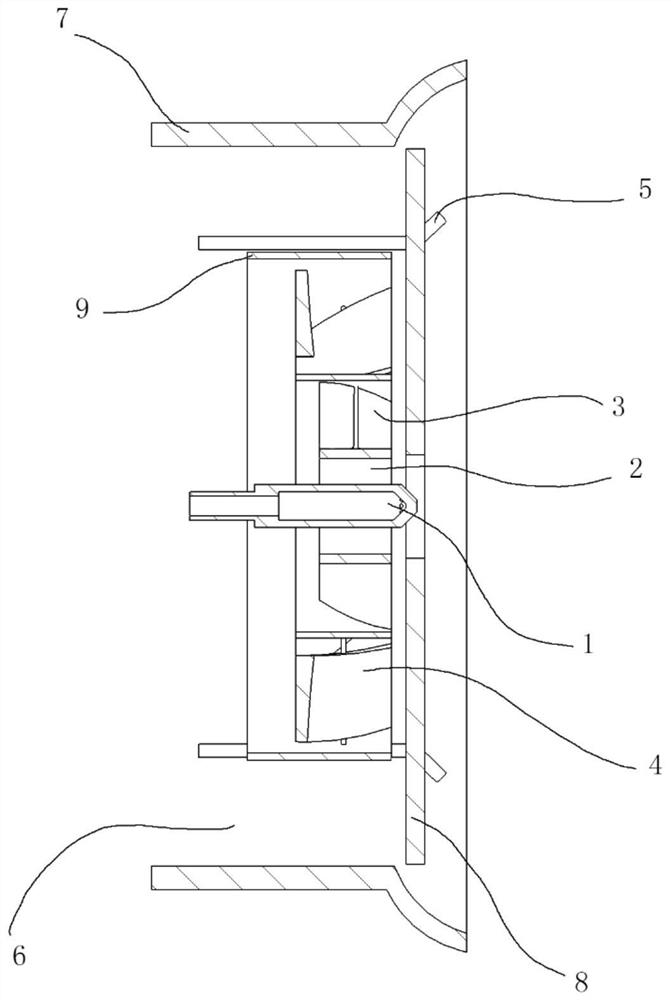

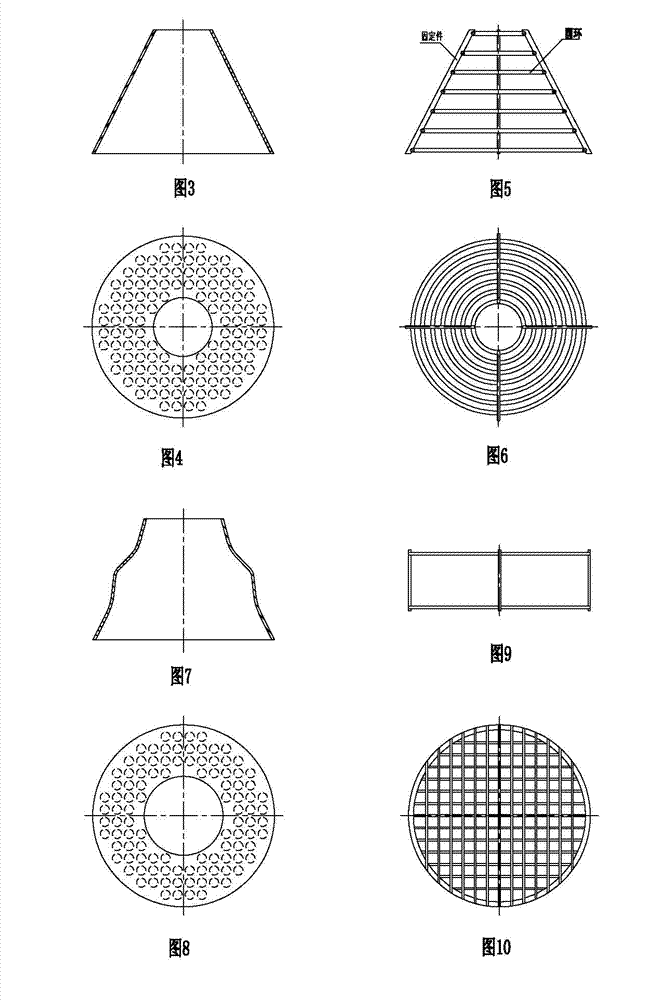

Pre-mixing burner

The pre-mixing burner includes one burning unit and one ignition unit, and features the burning unit including one gas mixing chamber with upper and lower openings, one air chamber connected to the lower end of the gas mixing chamber and with side opening, one gas inlet pipe stretched into the air chamber from the bottom, one main burning nozzle in the end of the gas inlet pipe, one perforated flame plate in the upper opening of the gas mixing chamber, and porous plates inside the gas mixing chamber to separate the gas mixing chamber into several cavities. The pre-mixing burner has well mixing between the fuel gas and air, complete combustion, high heat efficiency, stable flame and homogeneous heat load.

Owner:YUFUBAO KITCHENWARE EQUIP SHENZHEN CO LTD

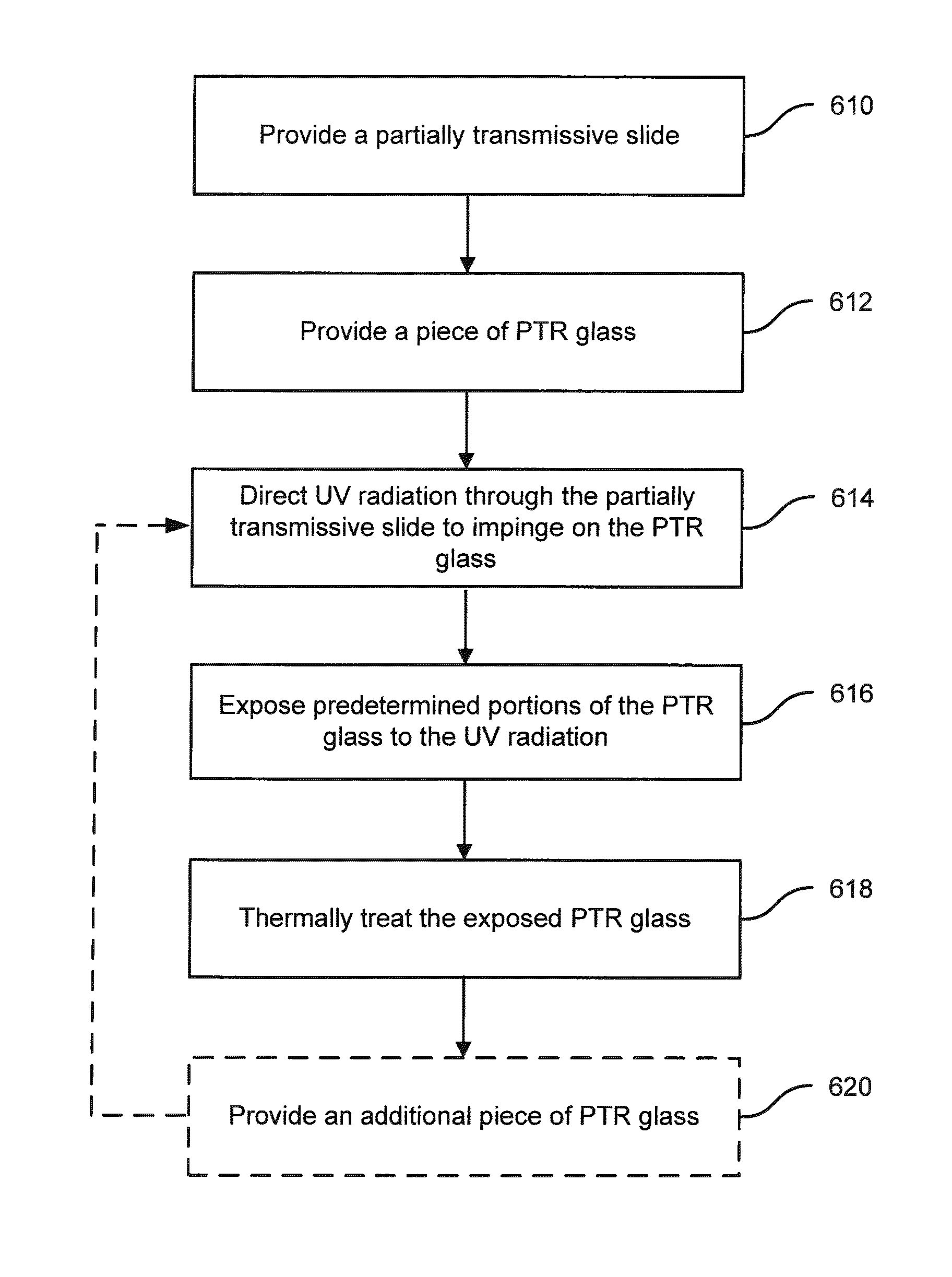

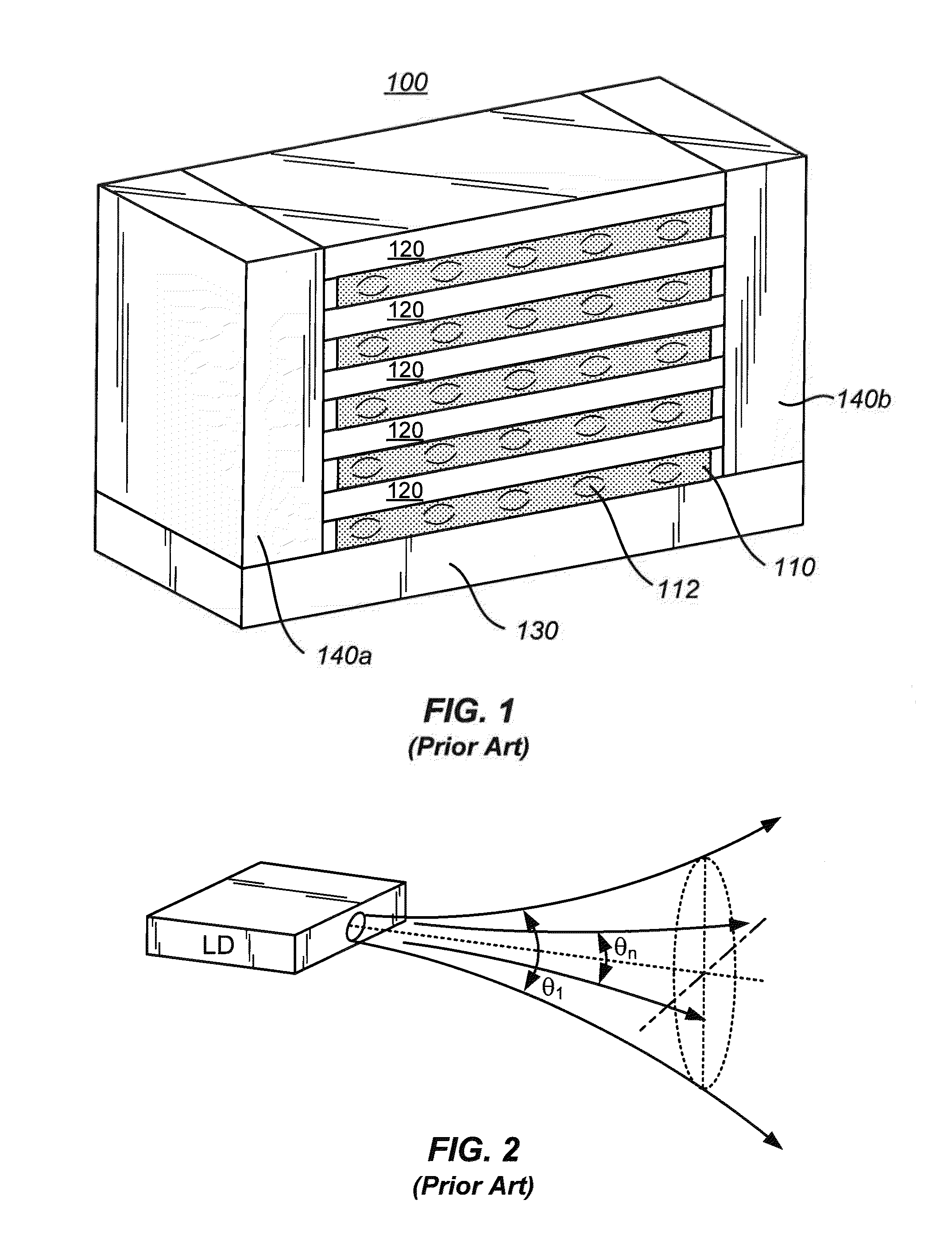

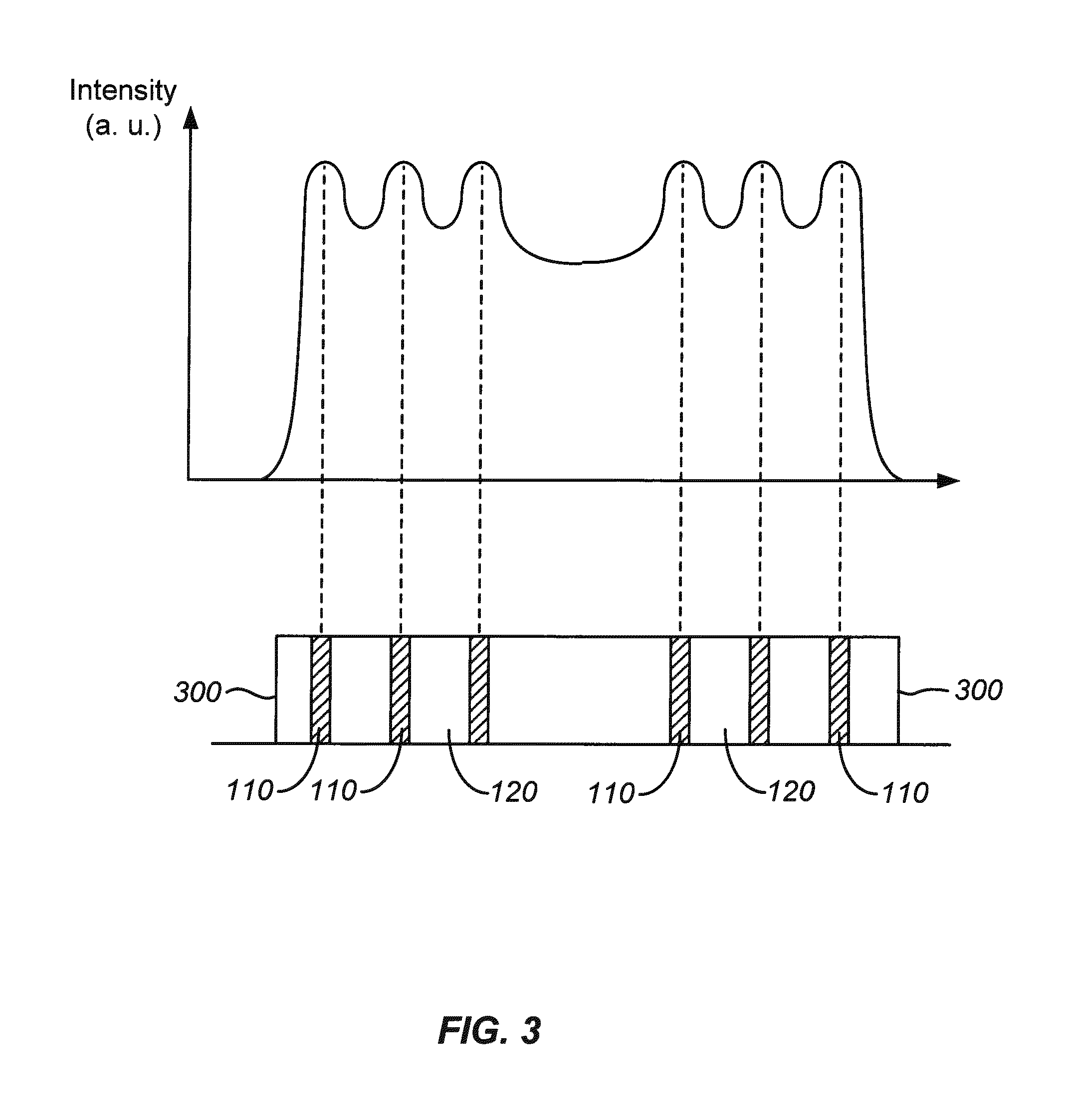

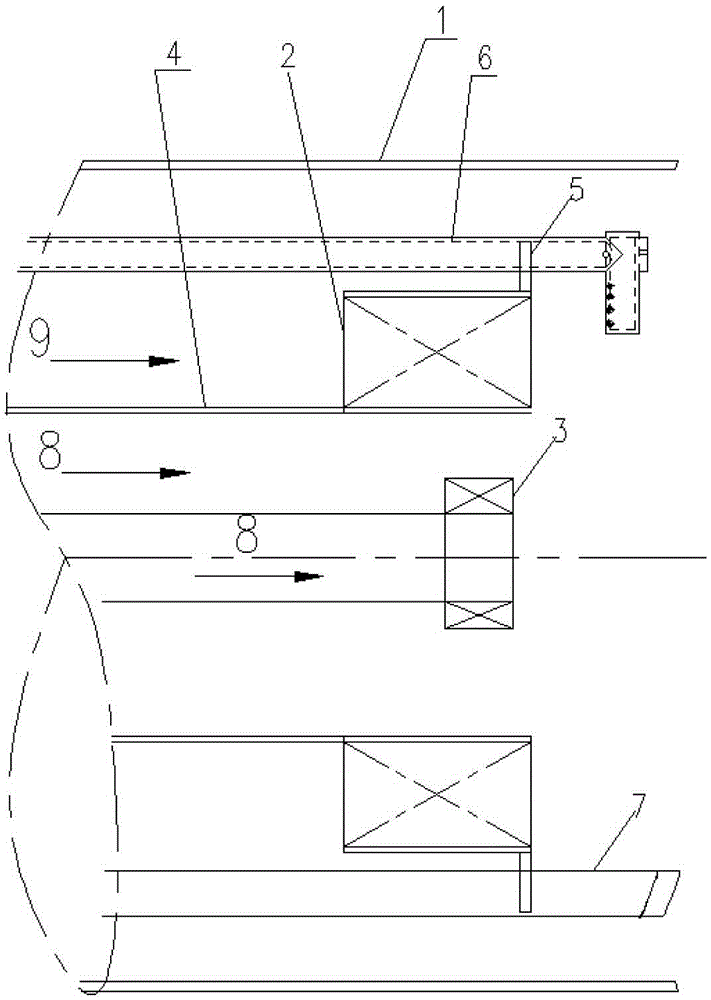

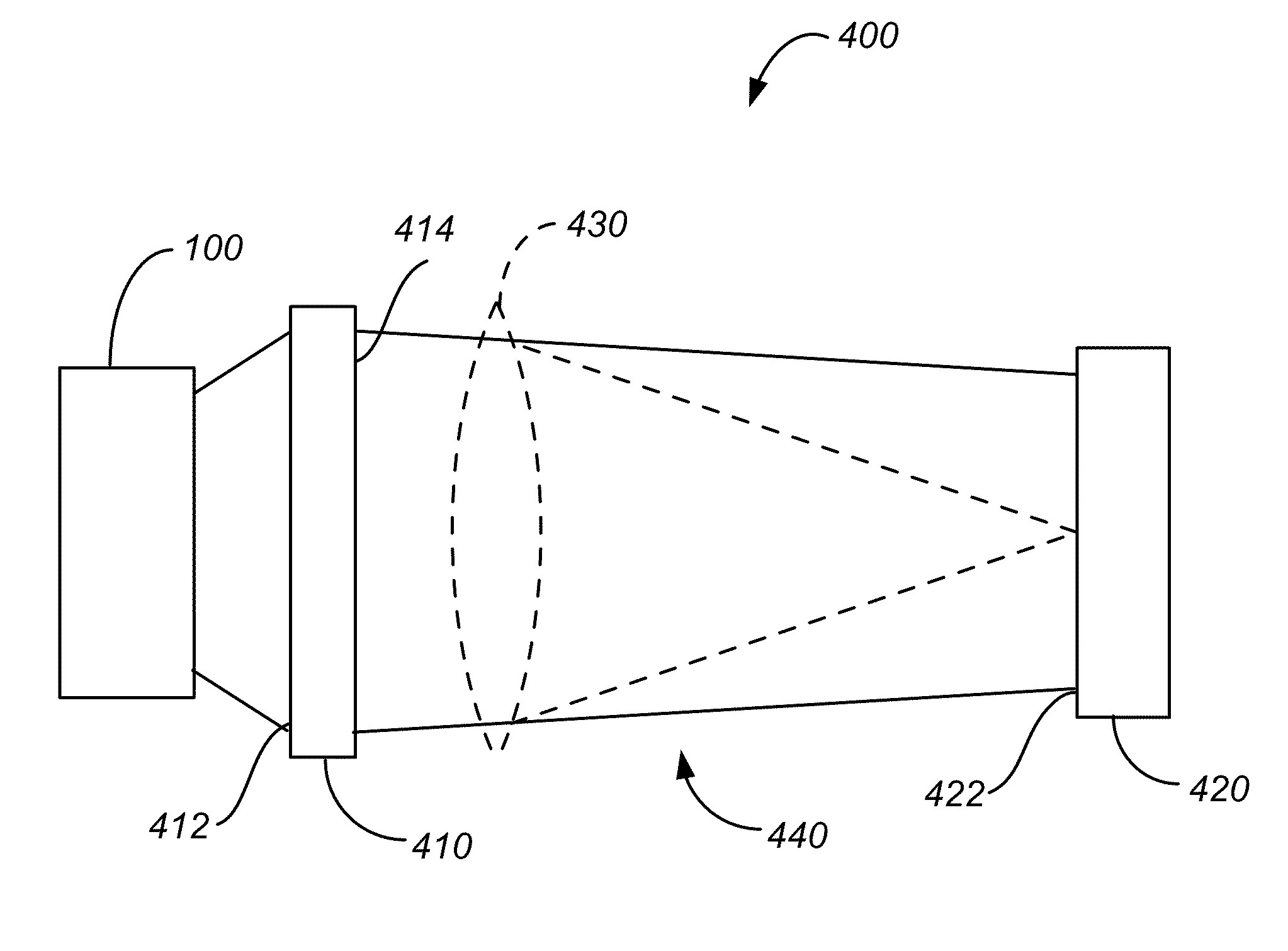

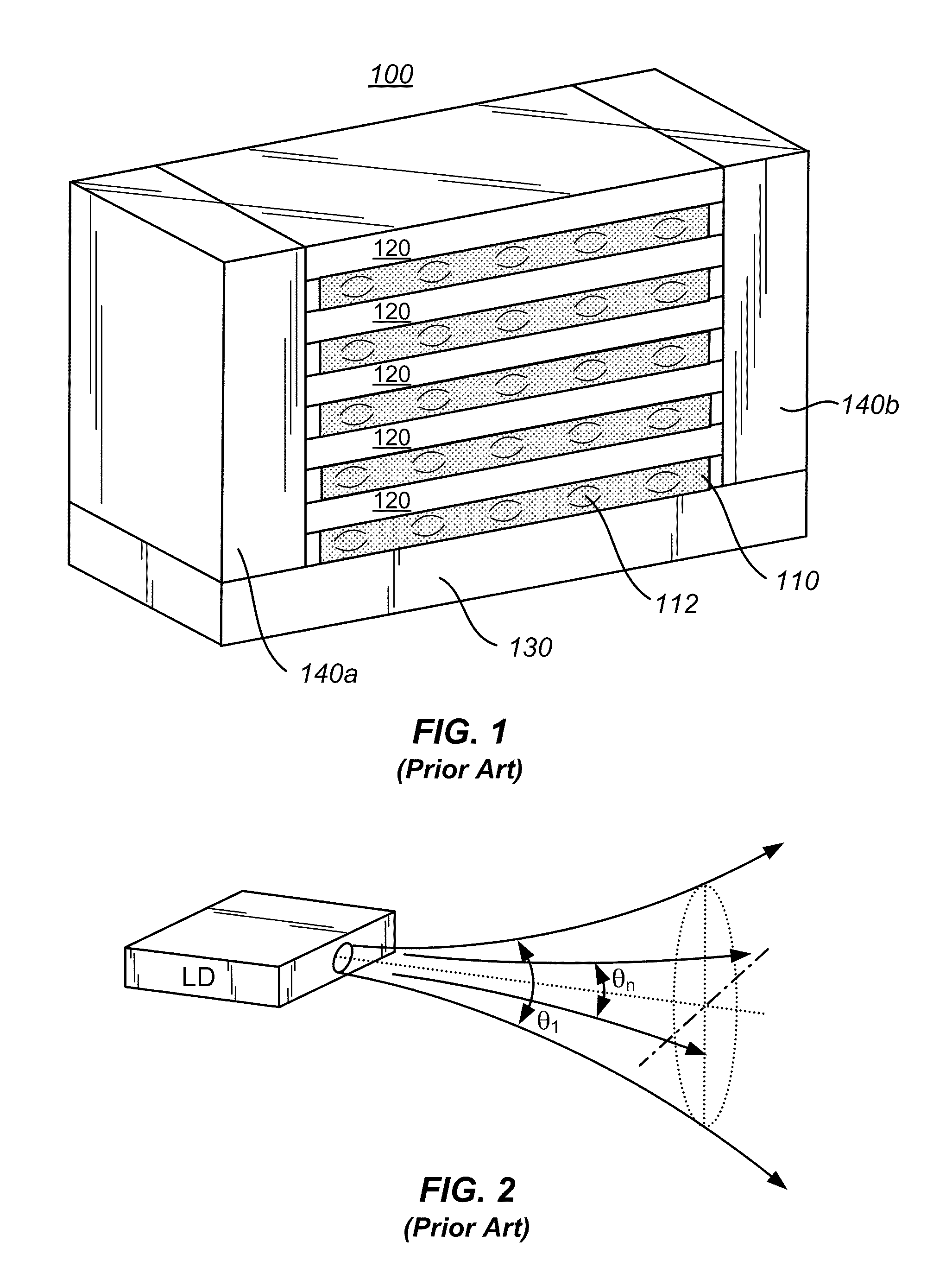

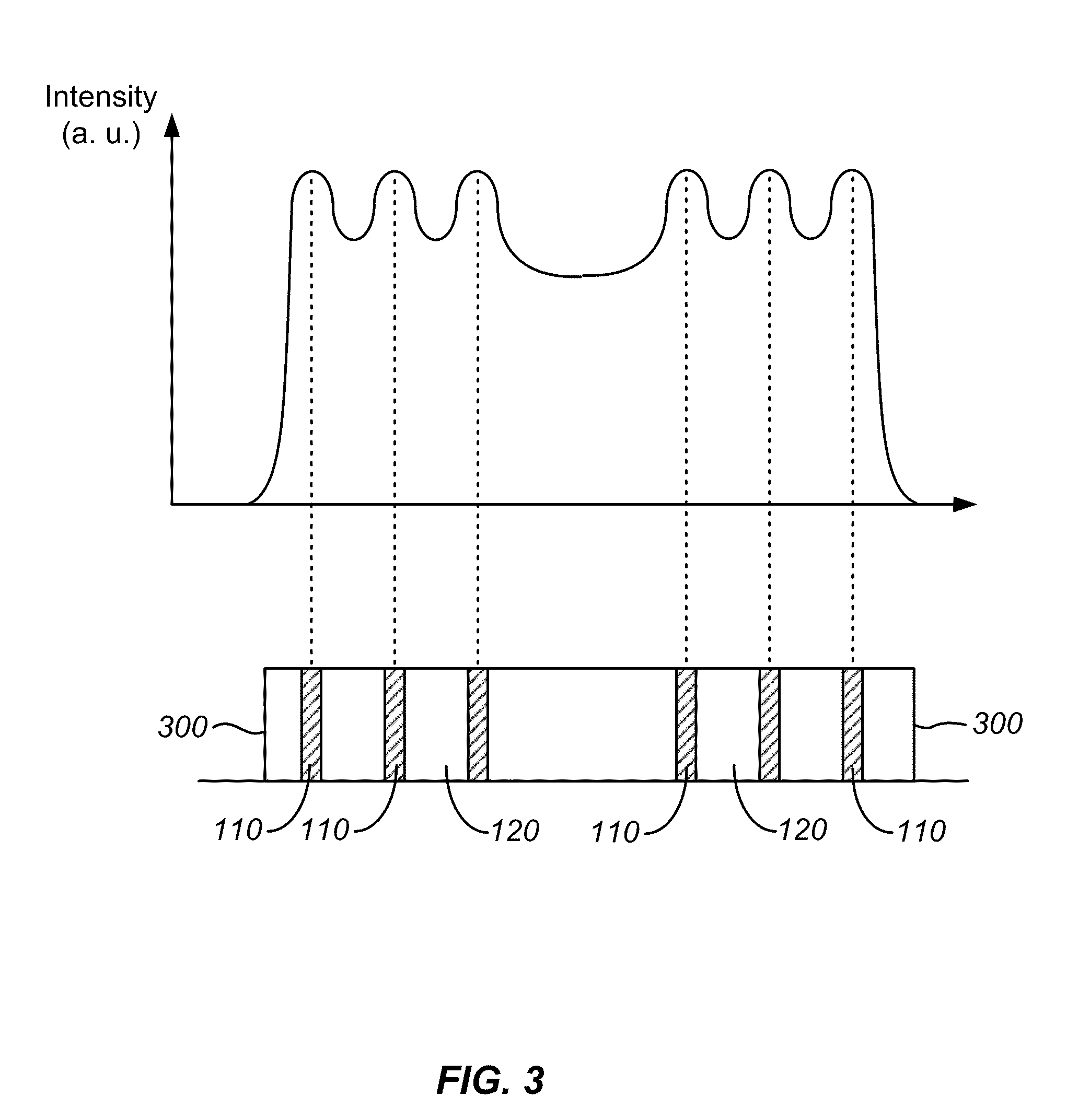

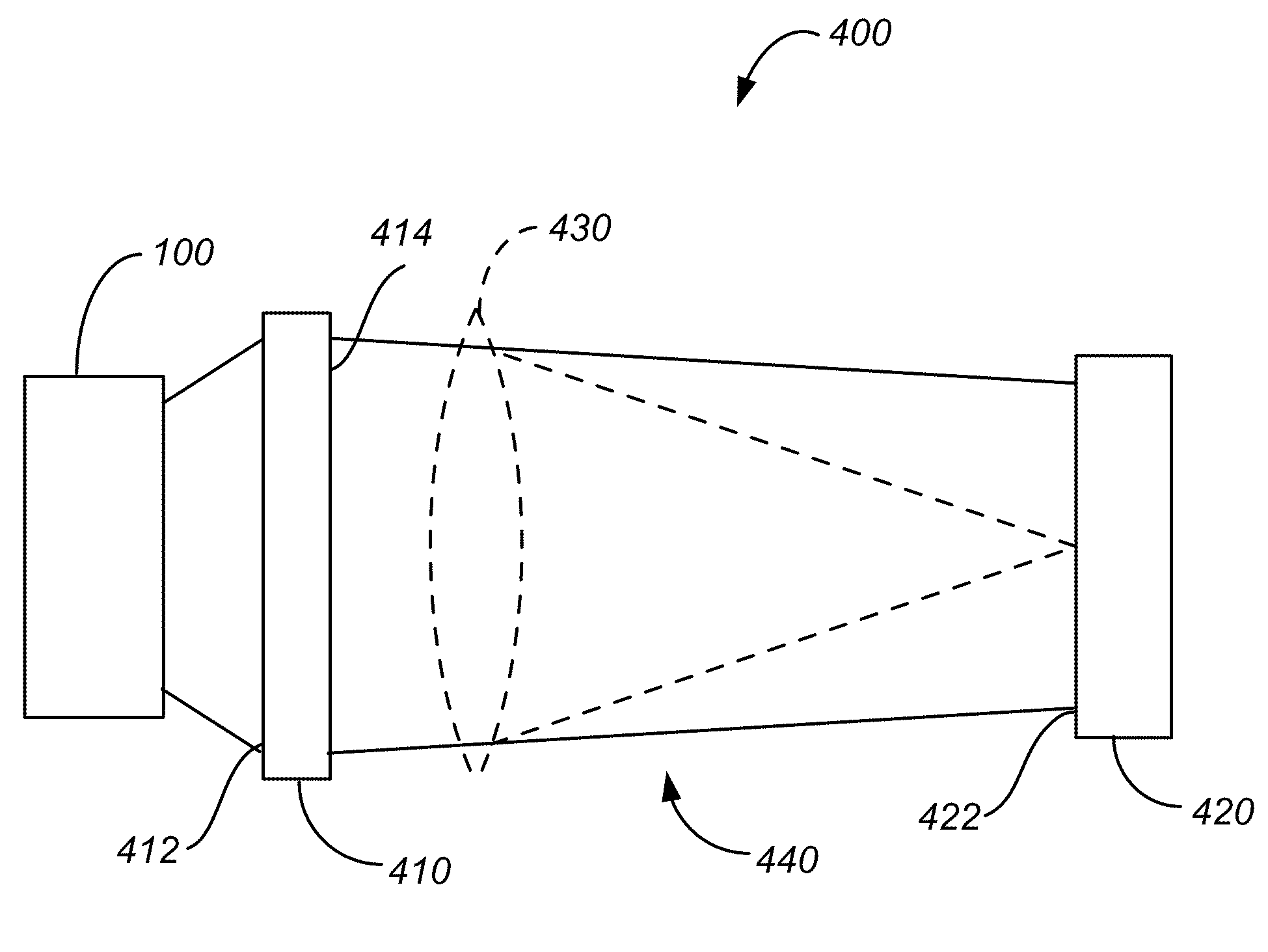

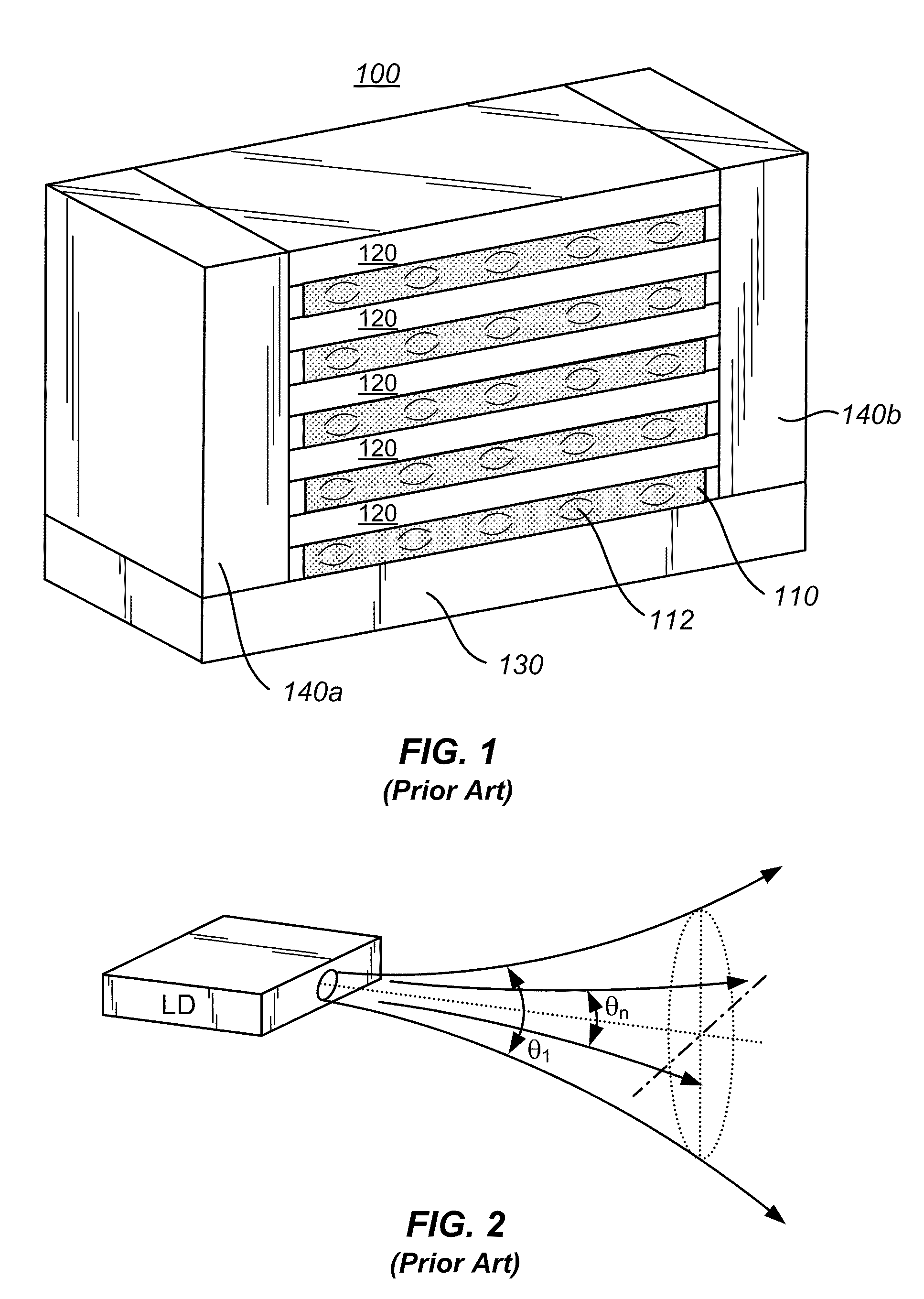

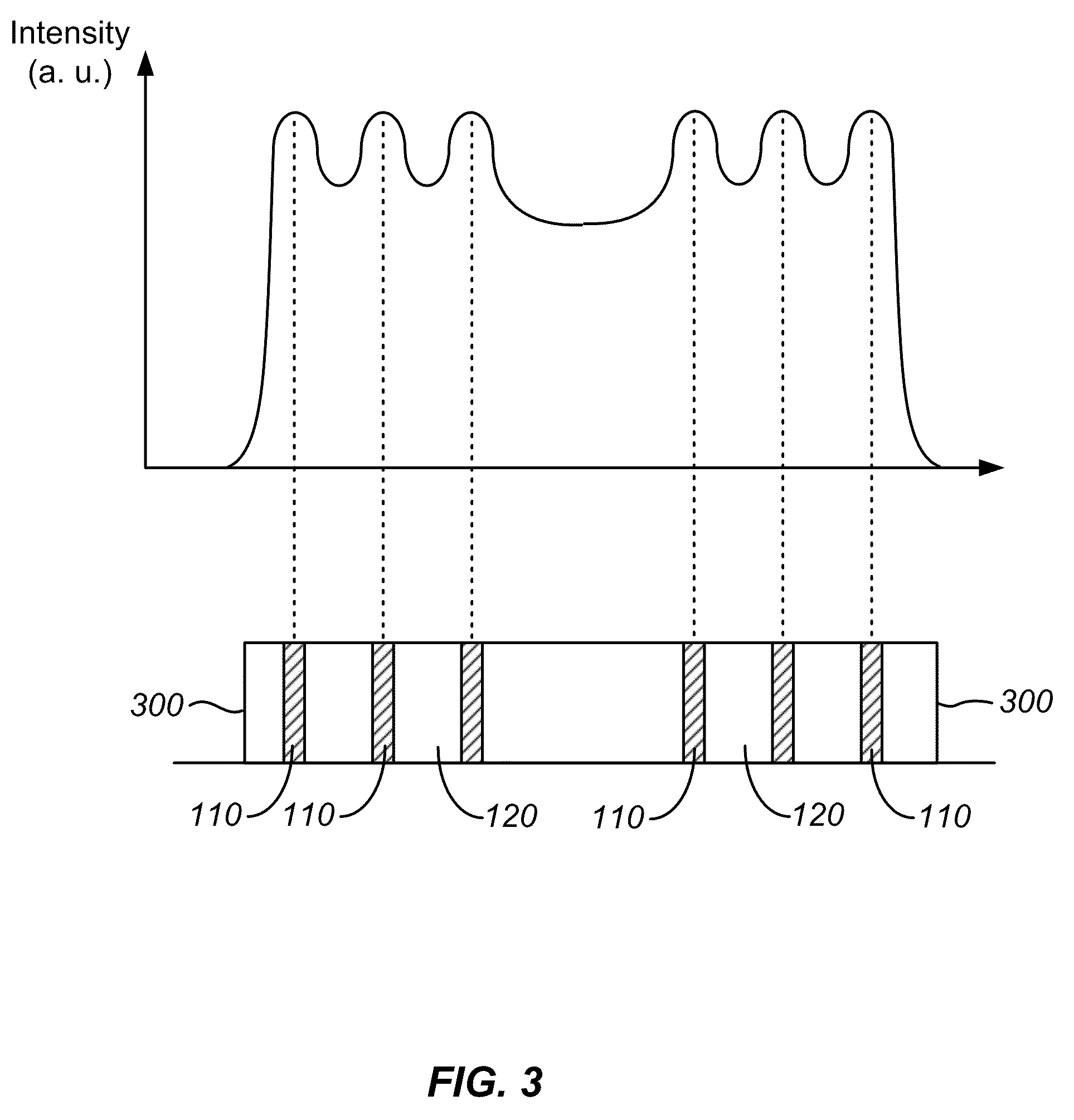

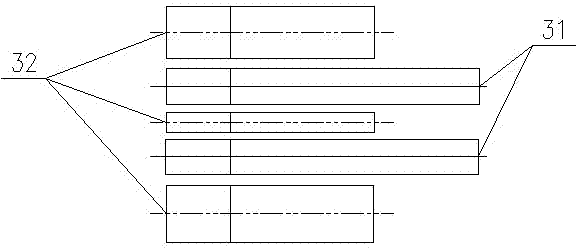

Method and system for homogenizing diode laser pump arrays

ActiveUS9331452B2Improve extraction efficiencyHigh beam qualitySemiconductor laser arrangementsLaser arrangementsAudio power amplifierUltimate tensile strength

An optical amplifier system includes a diode pump array including a plurality of semiconductor diode laser bars disposed in an array configuration and characterized by a periodic distance between adjacent semiconductor diode laser bars. The periodic distance is measured in a first direction perpendicular to each of the plurality of semiconductor diode laser bars. The diode pump array provides a pump output propagating along an optical path and characterized by a first intensity profile measured as a function of the first direction and having a variation greater than 10%. The optical amplifier system also includes a diffractive optic disposed along the optical path. The diffractive optic includes a photo-thermo-refractive glass member. The optical amplifier system further includes an amplifier slab having an input face and position along the optical path and separated from the diffractive optic by a predetermined distance. A second intensity profile measured at the input face of the amplifier slab as a function of the first direction has a variation less than 10%.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Low-emission gas combustion furnace and combustion air preparation method thereof

ActiveCN105351925AHomogeneous mixed combustionAvoid it happening againGaseous fuel burnerCycloneEngineering

The invention provides a low-emission gas combustion furnace and a combustion air preparation method thereof and relates to the technical field of combustion equipment. The technical purpose of NOx emission reduction is achieved. A first cyclone, a middle barrel and a second cyclone are sequentially and coaxially arranged in a throat of the gas combustion furnace in a sleeving manner from outside to inside. Multiple flame stabilizing boards are symmetrically arranged between the outer ring of the first cyclone and the inner wall of the throat. Multiple L-shaped gas guns and inclined-port gas guns which are arranged between the flame stabilizing boards are fixedly distributed around the axis of the throat at equal diameter. Forward spray holes, radial spray holes, return spray holes and multiple side spray holes are formed in the L-shaped gas guns. Multiple inclined spray holes are formed in the inclined-port gas guns. All the gas spray directions incline outwards in a scattered manner without mutual interference. Combustion air enters the throat through a center combustion air channel in the middle barrel and a second combustion air channel outside the middle barrel, and the combustion air entering the throat from the second combustion air channel accounts for 80% to 95% of the total amount of the combustion air. By the adoption of the gas combustion furnace, the NOx emission is low.

Owner:SHANGHAI WISEBOND TECH

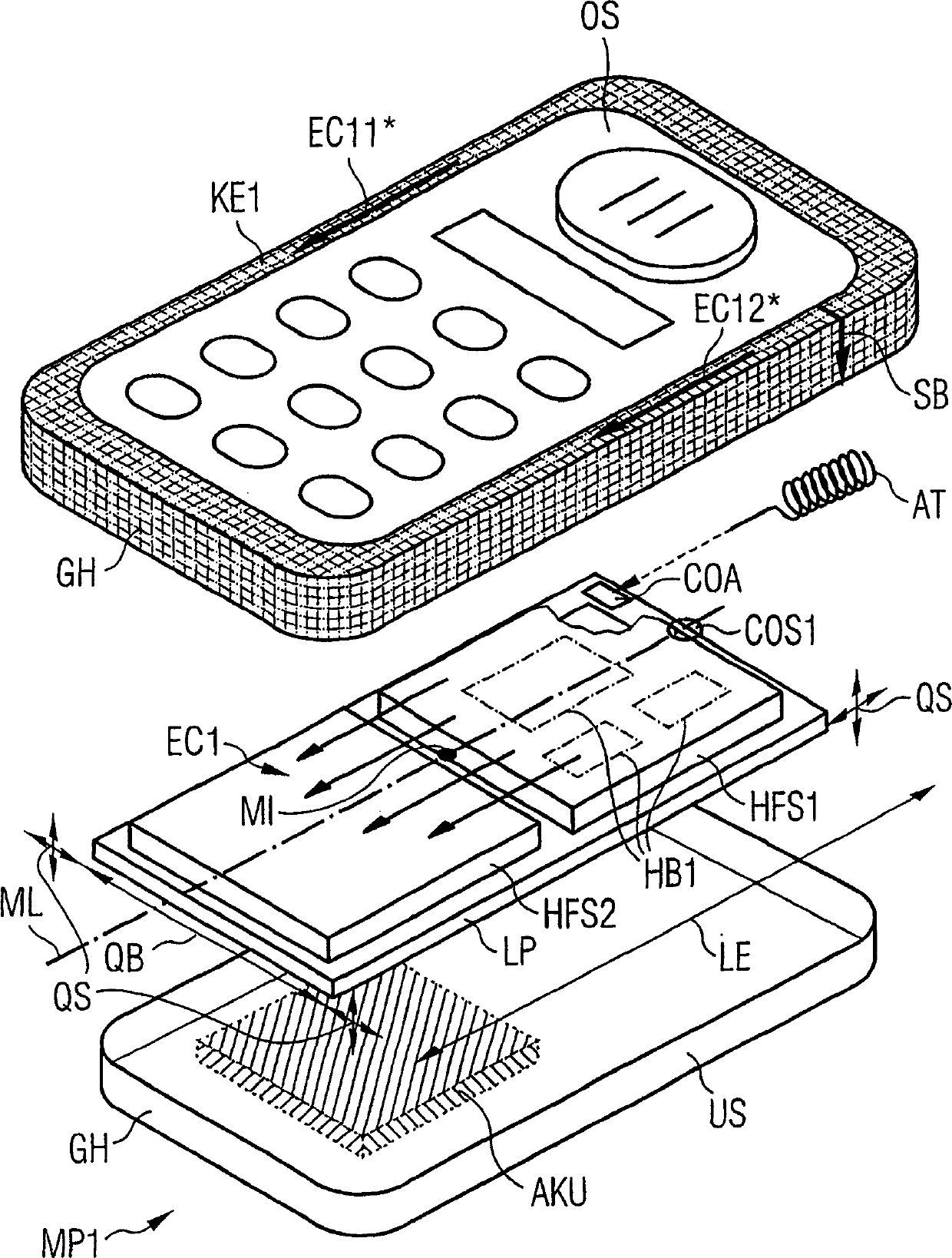

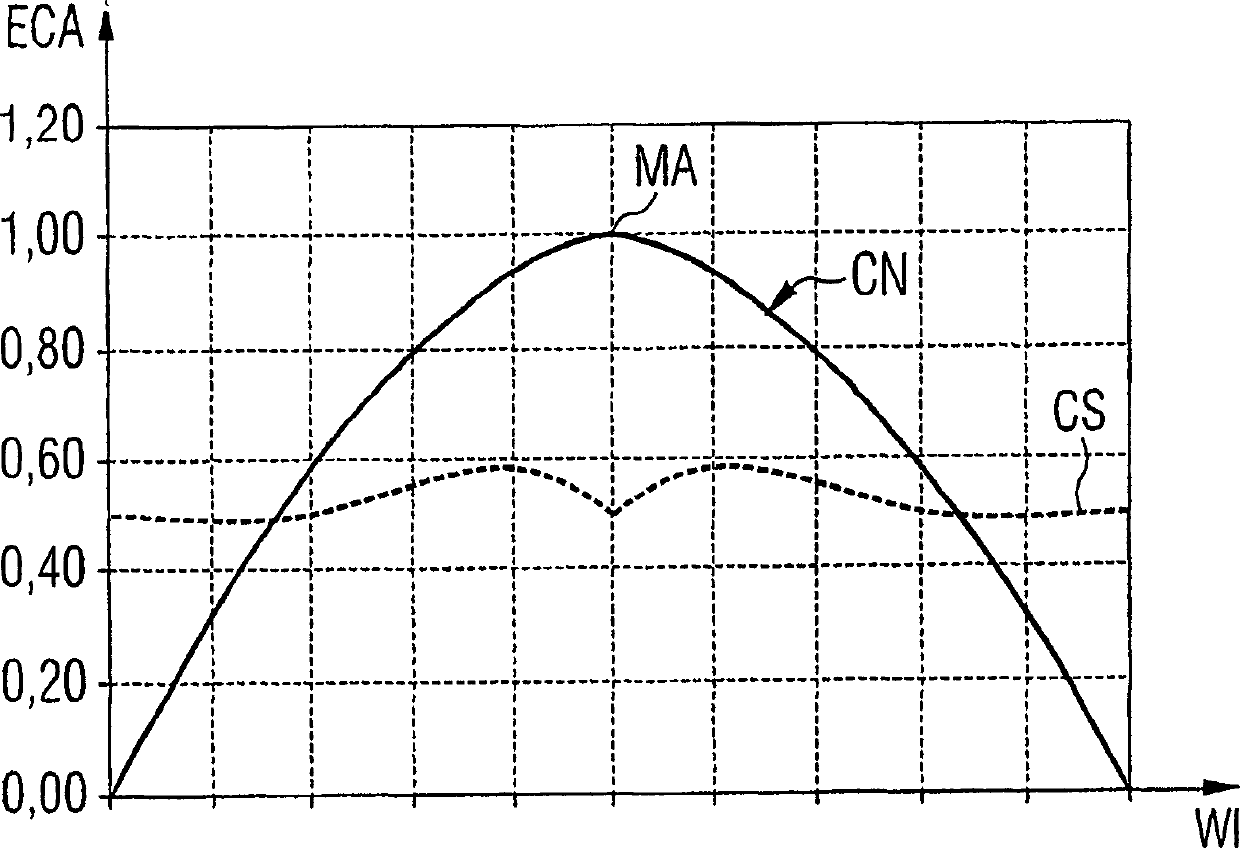

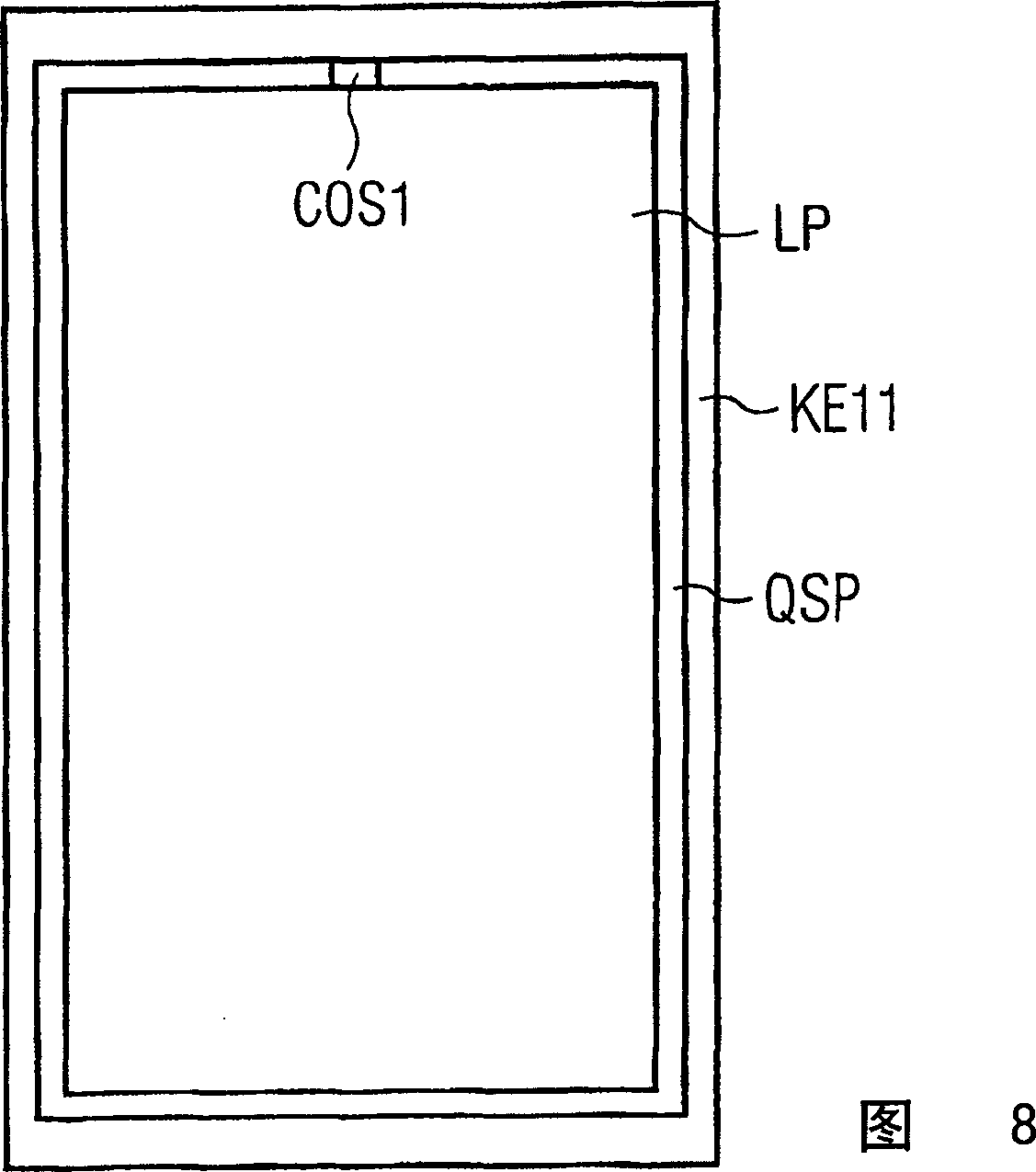

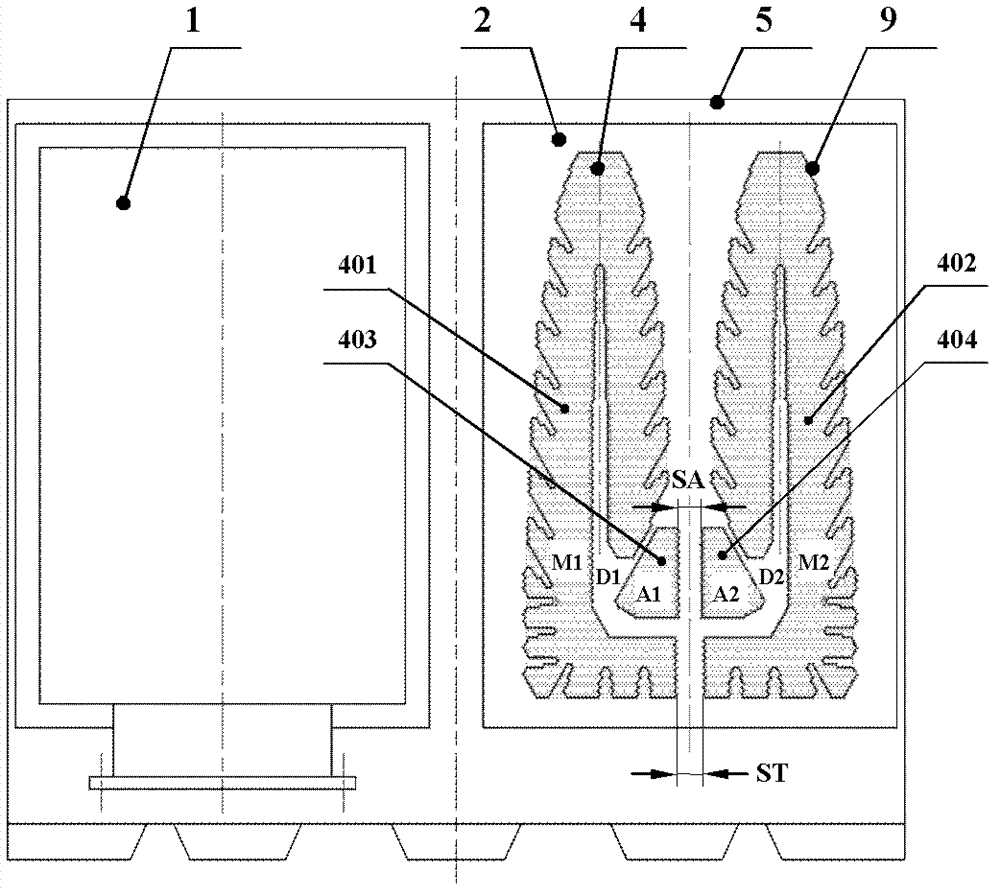

Ridio communications device comprising an SAR value-reducing correction element

InactiveCN1507674AAvoid local fluctuationsUniform heat loadAntenna supports/mountingsRadiating elements structural formsPeak valuePrinted circuit board

The invention relates to a radio communications device in which at least one additional SAR value-reducing correction element (KE1) is provided in and / or on the housing (GH) in such a manner that the distribution of any electric current (EC1) which might be flowing on the printed circuit board (LP) is effected from one or more local maxima (MA) thereof up to the correction element (KE1). When using the mobile radio device (MP1), a homogenization and / or a shift thus adjusts with regard to the local distribution of the overall resulting electric current (EC1*).

Owner:SIEMENS AG

Method and system for homogenizing diode laser pump arrays

ActiveUS20110043900A1Improve extraction efficiencyHigh beam qualityLaser detailsSemiconductor laser optical deviceAudio power amplifierDiffraction optics

An optical amplifier system includes a diode pump array including a plurality of semiconductor diode laser bars disposed in an array configuration and characterized by a periodic distance between adjacent semiconductor diode laser bars. The periodic distance is measured in a first direction perpendicular to each of the plurality of semiconductor diode laser bars. The diode pump array provides a pump output propagating along an optical path and characterized by a first intensity profile measured as a function of the first direction and having a variation greater than 10%. The optical amplifier system also includes a diffractive optic disposed along the optical path. The diffractive optic includes a photo-thermo-refractive glass member. The optical amplifier system further includes an amplifier slab having an input face and position along the optical path and separated from the diffractive optic by a predetermined distance. A second intensity profile measured at the input face of the amplifier slab as a function of the first direction has a variation less than 10%.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

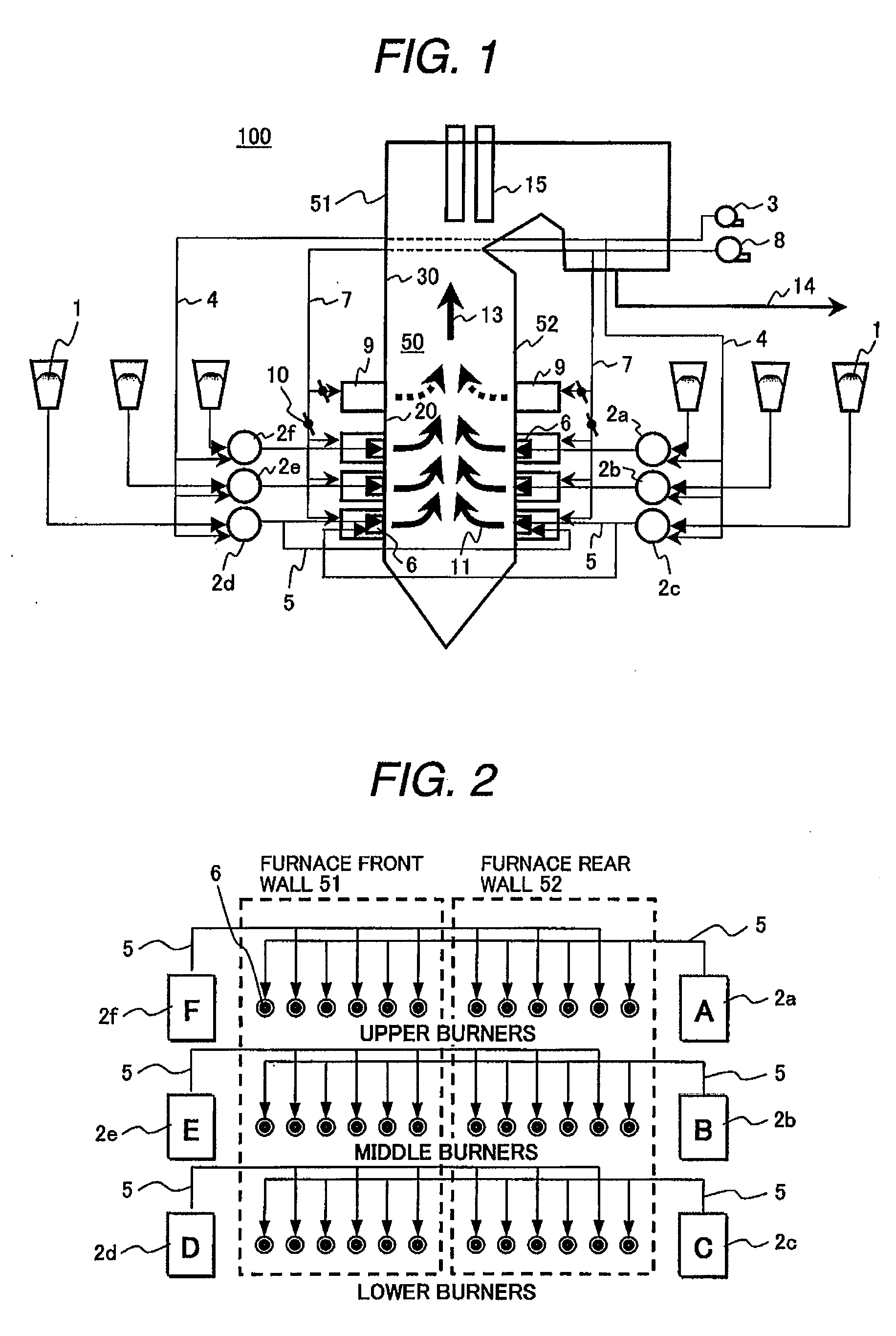

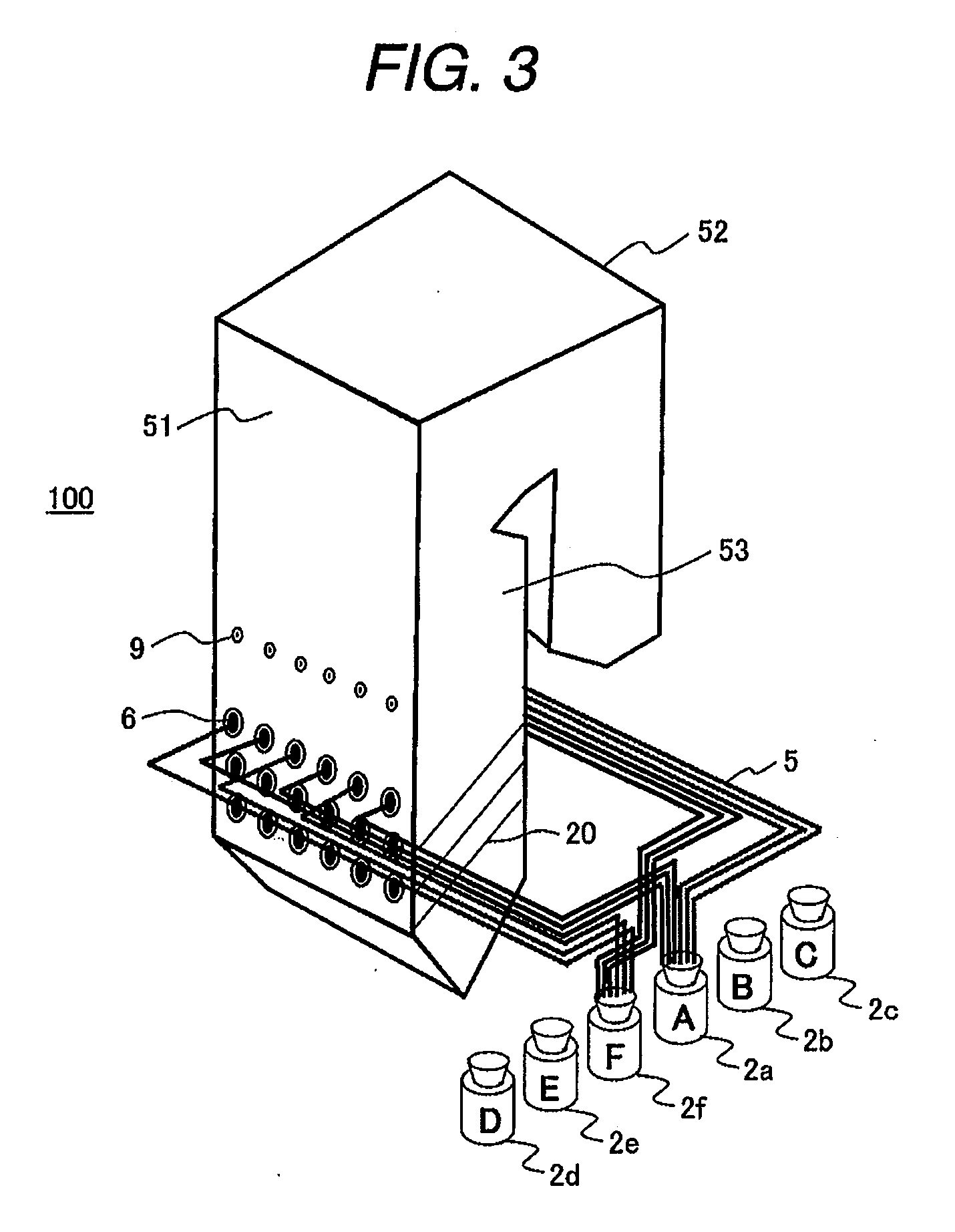

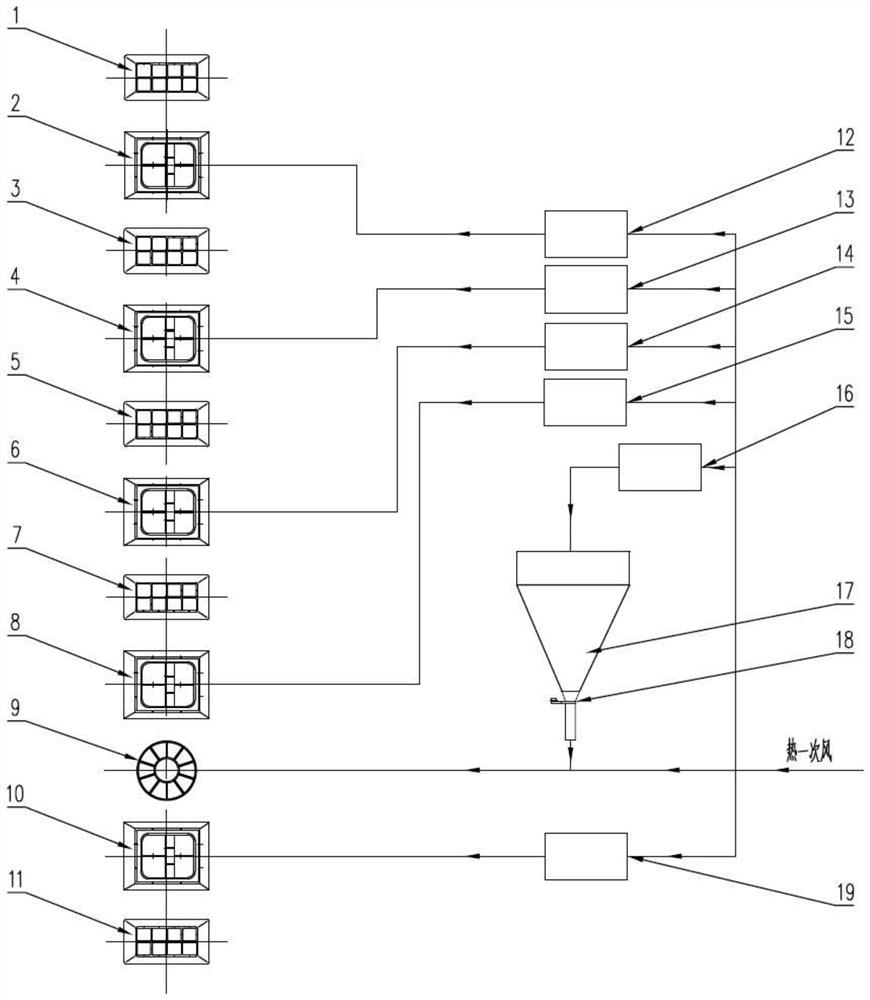

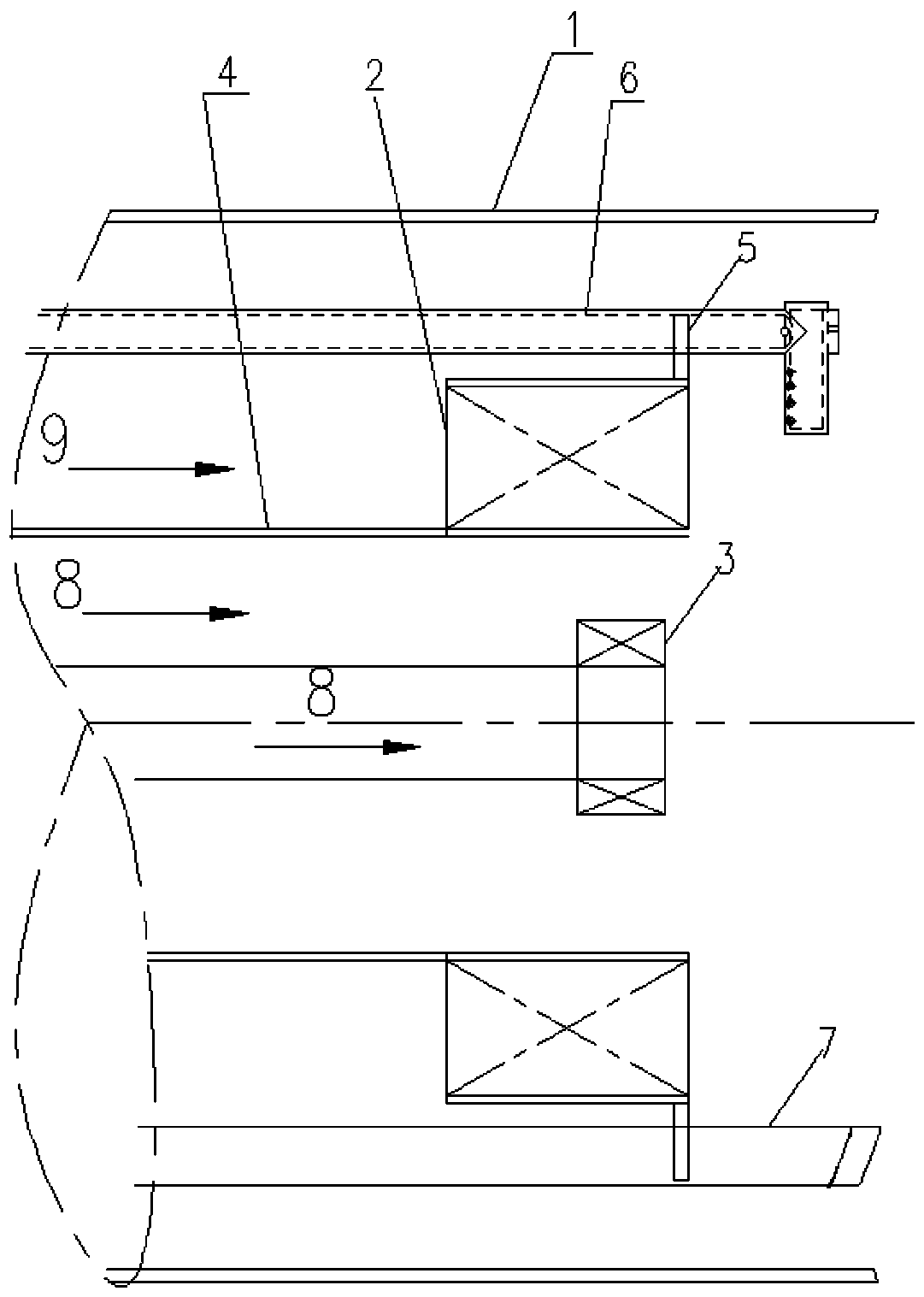

Pulverized coal combustion boiler

InactiveUS20080156236A1Ensure performanceRetention stabilityPulverulent fuel combustion burnersSolid fuel combustionCombustorEngineering

A pulverized coal combustion boiler 100 comprising: a furnace 50; a plurality of burners 6 for supplying and burning pulverized coal fuel in the furnace arranged at positions of a plurality of stages having different heights on a furnace front wall 51 and a furnace rear wall 52 of furnace wall surfaces forming the furnace 50, the furnace rear wall 52 arranged for facing the furnace front wall 51; a plurality of mills 2 arranged for supplying the pulverized coal fuel to the plurality of burners 6 arranged at each of the plurality of stages; and pulverized fuel pipes 5 arranged for distributing and supplying the pulverized coal to the plurality of burners 6 at each of the stages of the furnace front wall 51 and the furnace rear wall 52 from each of the plurality of mills 2.

Owner:HITACHI LTD

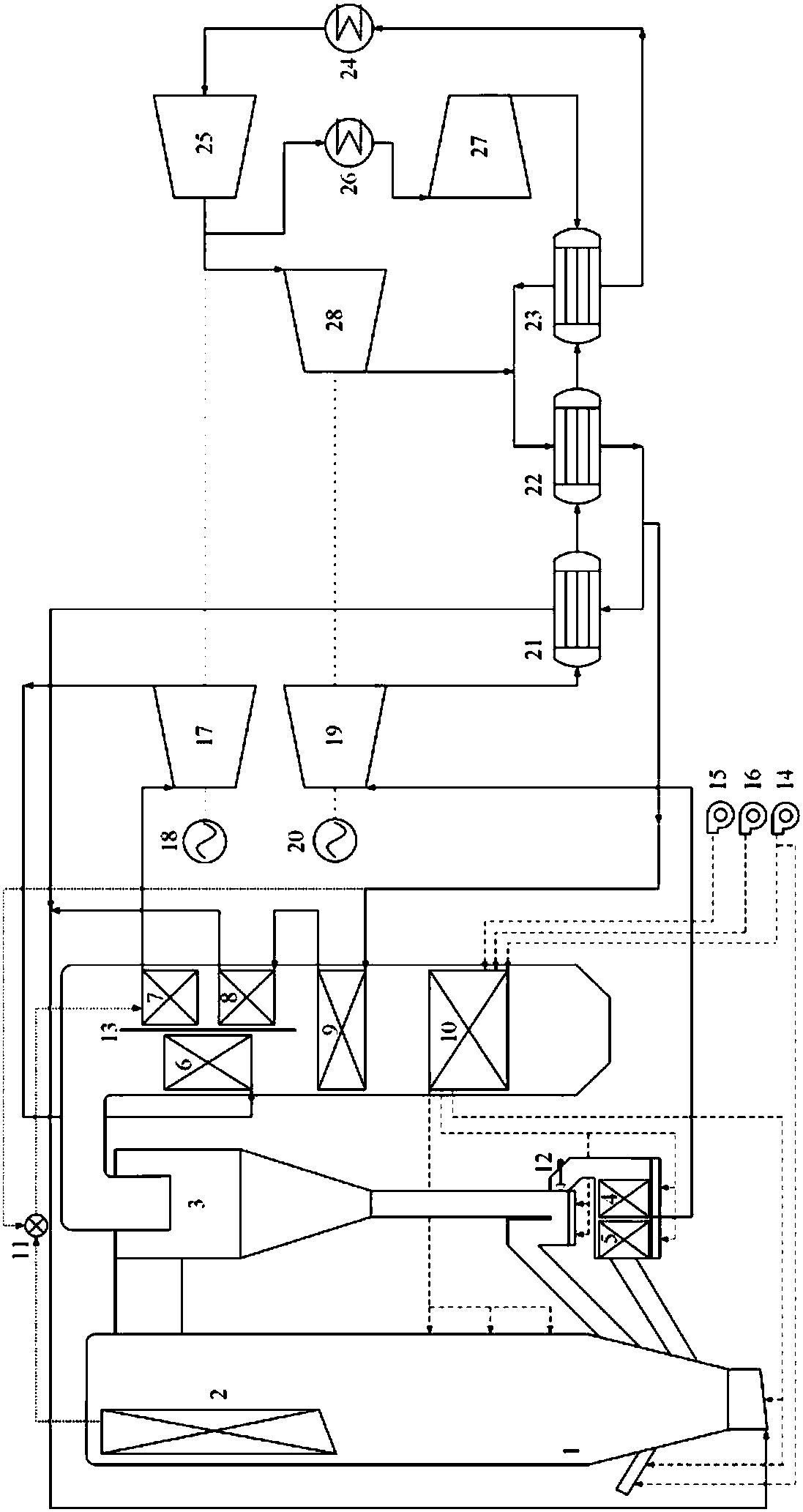

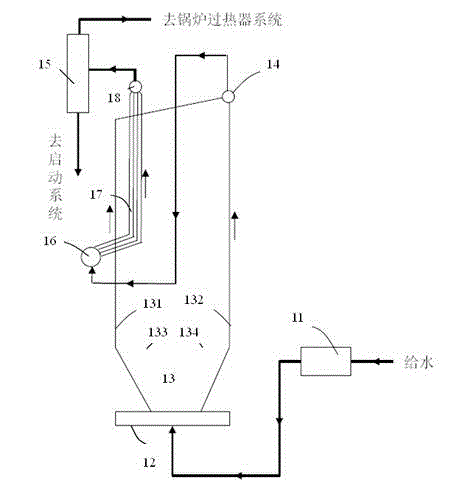

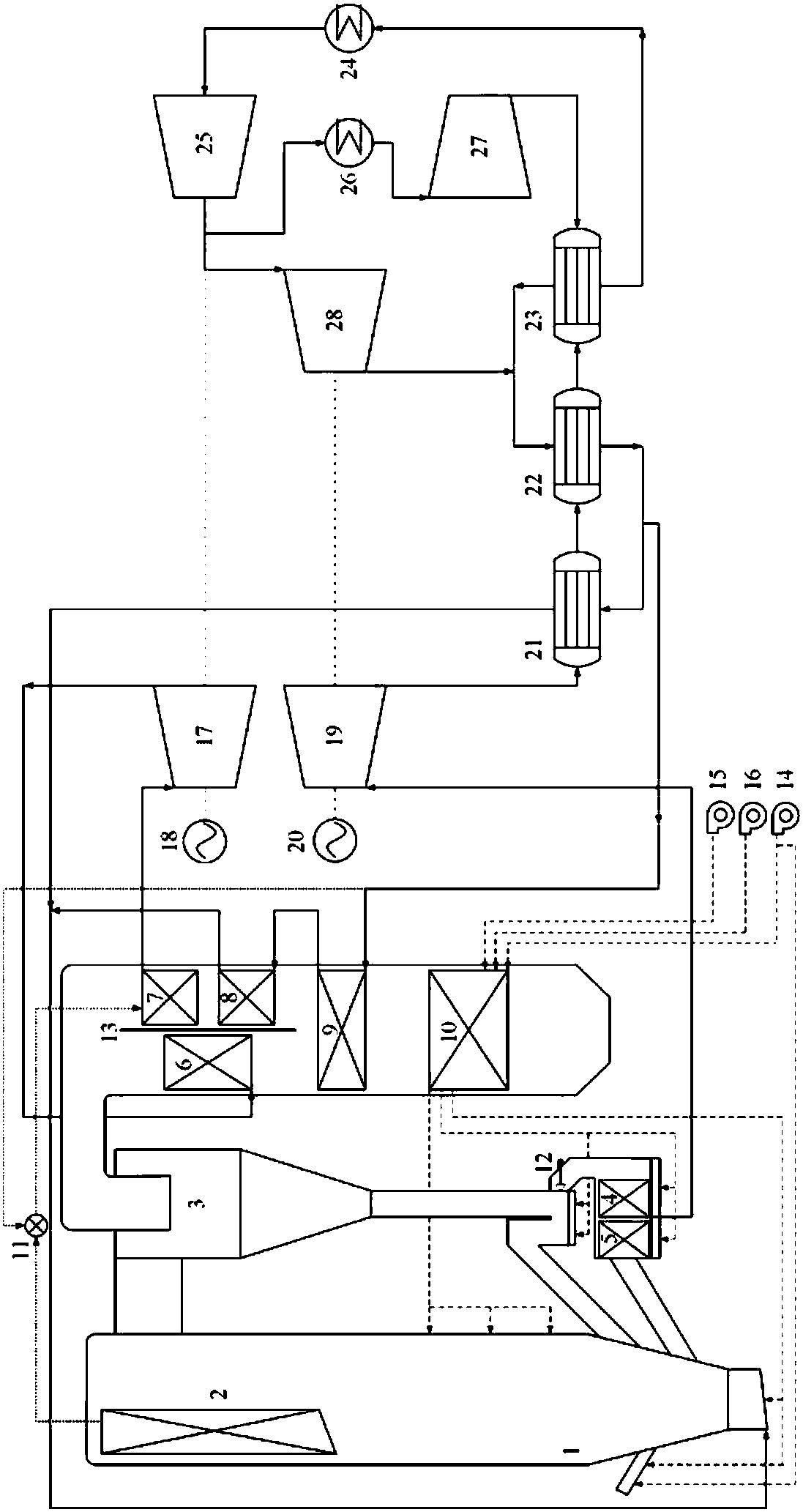

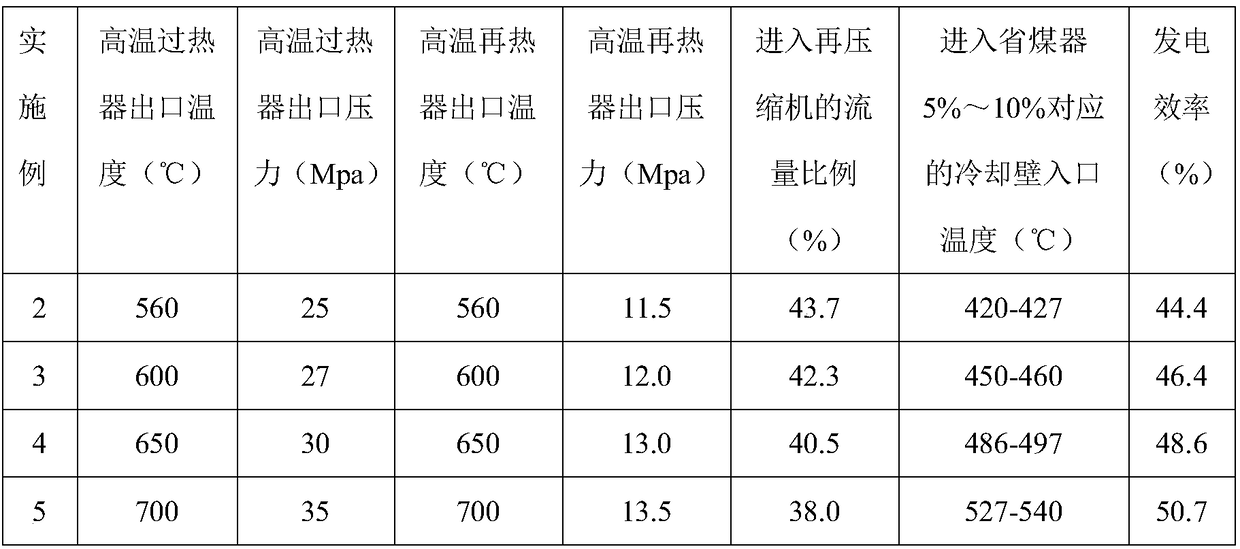

Supercritical carbon dioxide coal-fired circulating fluidized bed boiler, power generation system and power generation method

ActiveCN108180470AReduce thermal deviationGuaranteed uptimeFluidized bed combustionSteam engine plantsAir preheaterSuperheater

The invention discloses a supercritical carbon dioxide coal-fired circulating fluidized bed boiler, a power generation system and a power generation method. The supercritical carbon dioxide coal-firedcirculating fluidized bed boiler comprises a hearth, a separator, a tail flue and an externally-arranged type heat exchanger located in a material back section of the separator. A cooling wall and anintermediate-temperature overheater are arranged in the hearth. A high-temperature reheater and a low-temperature overheater are arranged in the externally-arranged type heat exchanger, wherein the low-temperature overheater communicates with the cooling wall and the intermediate-temperature overheater. A low-temperature reheater, a high-temperature overheater, an upper-level economizer, a lower-level economizer and an air preheater are arranged in the tail flue, wherein the high-temperature overheater communicates with the intermediate-temperature overheater, the low-temperature reheater communicates with the high-temperature reheater. The working medium of the boiler is supercritical carbon dioxide. By the adoption of the supercritical carbon dioxide coal-fired circulating fluidized bedboiler, the wall temperature of the cooing wall can be effectively controlled, it is guaranteed that the boiler safely and reliably operates, and the heat efficiency is high; a power generator set tends to be miniature, a higher load response speed is obtained, the deep peak load regulation adaptability is high, the advantages of coal resources are taken into full play, the energy utilization rate is improved, and energy safety is guaranteed.

Owner:SOUTHEAST UNIV

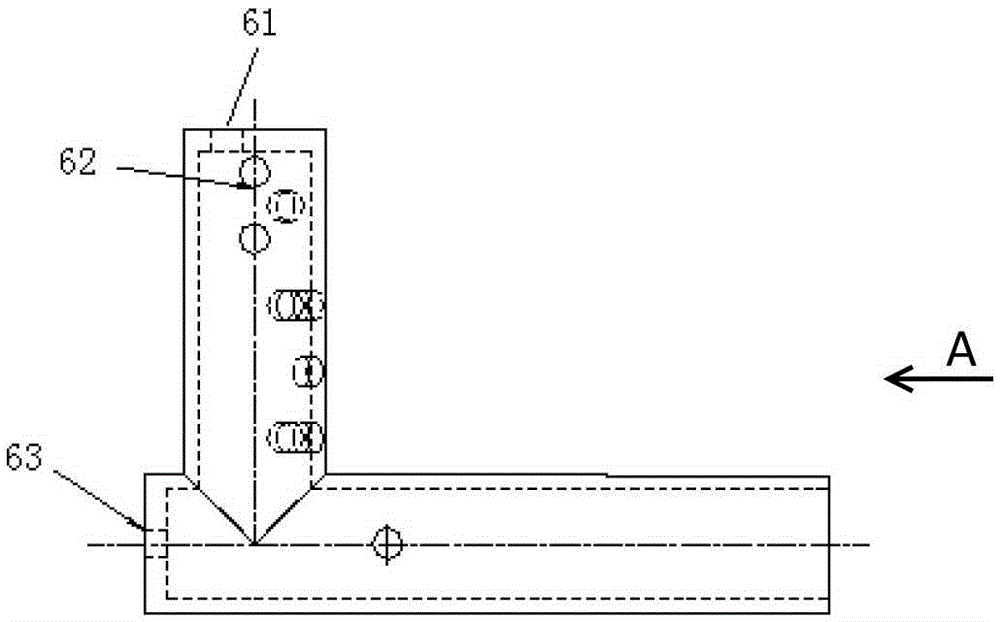

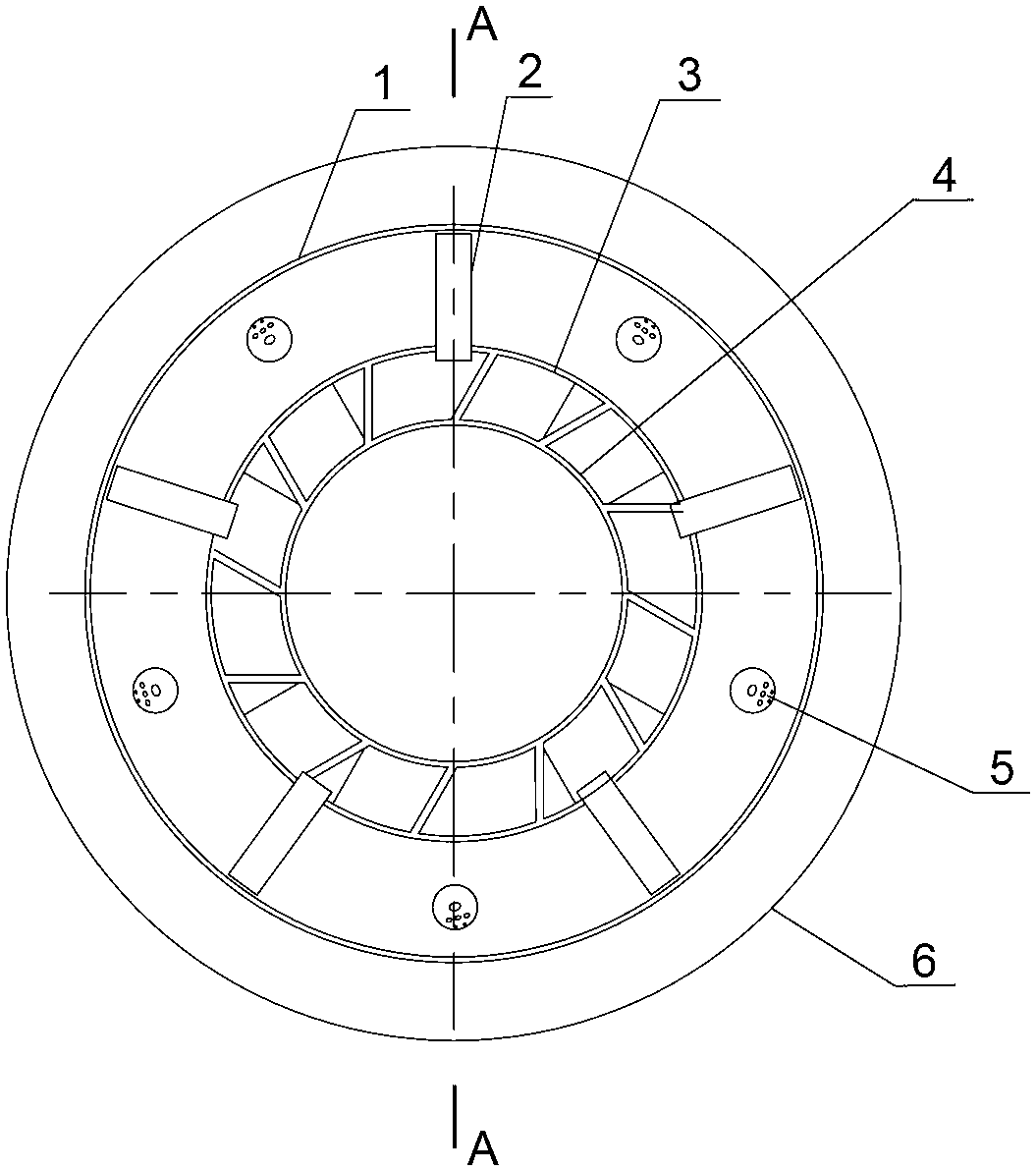

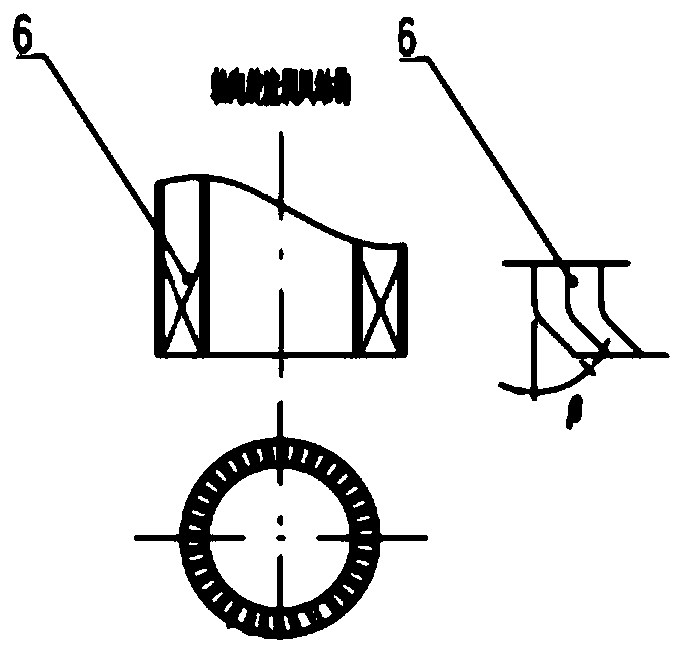

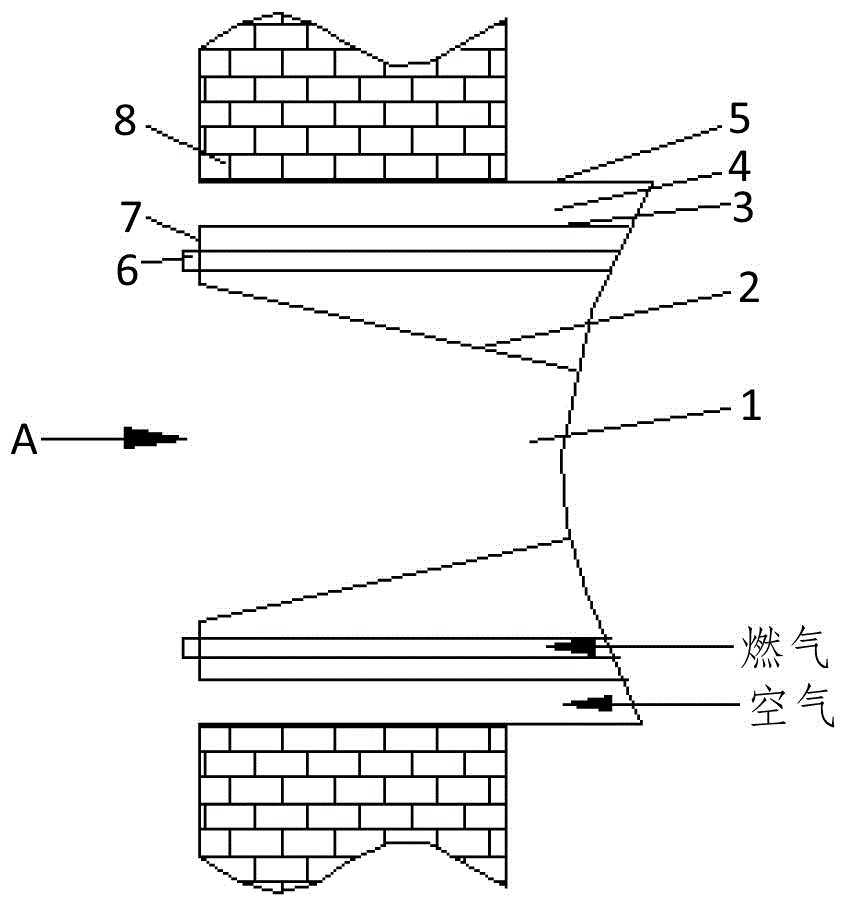

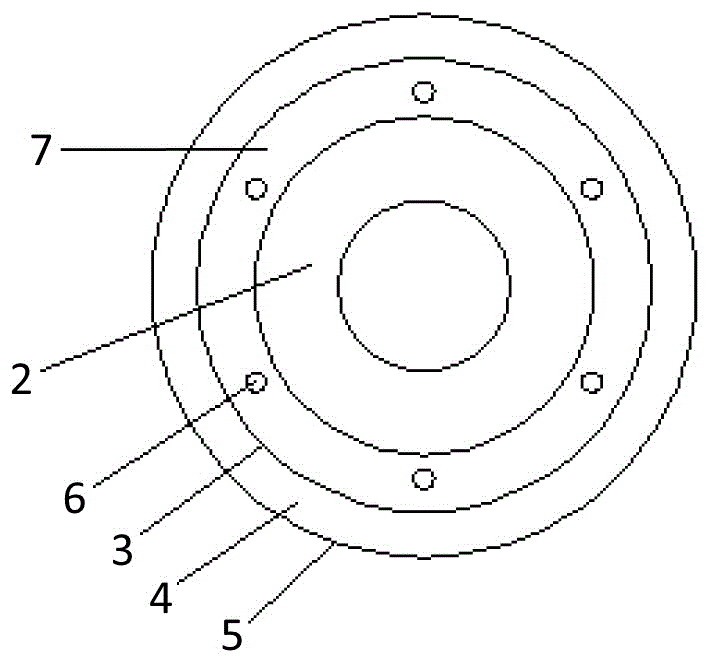

Fuel gas combustion device with ultra-low NOx emission amount and fuel gas distribution method

ActiveCN103267286AAvoid local high temperatureUniform heat loadGaseous fuel burnerPhysicsAutomotive engineering

The invention relates to a fuel gas combustion device with ultra-low NOx emission amount and a fuel gas distribution method, aims at enabling NOx emission amount to be smaller than 20ppm and meeting the low-emission requirement of a high-power combustor and belongs to the technical field of industrial boilers. The fuel gas combustion device with the ultra-low NOx emission amount is characterized in that a central barrel, a swirler, an inner throat and an outer throat are sequentially and coaxially arranged along the central axis of the combustion device outward, a first combustion air channel is arranged between the inner throat and the outer throat, a second combustion air channel is arranged between the inner side of the inner throat and the outer side of the central barrel, and a plurality of T-shaped fuel gas guns and a plurality of oblique-mouth fuel gas guns are arranged, staggered and evenly distributed in an equal-diameter mode. The fuel gas combustion device with the ultra-low NOx emission amount and the fuel gas distribution method have the advantages that fuel gas holes of the oblique-mouth fuel gas guns are outward, flame is formed in the first combustion air channel on the outer side of flame of the T-shaped fuel gas guns, accordingly a boiler furnace space is utilized to the most extent, the amount of produced NOx is little and is smaller than 20ppm, no CO is produced, and combustion is stable and reliable. The maximum power of one machine can reach to more than 70MW.

Owner:上海诺特飞博燃烧设备有限公司

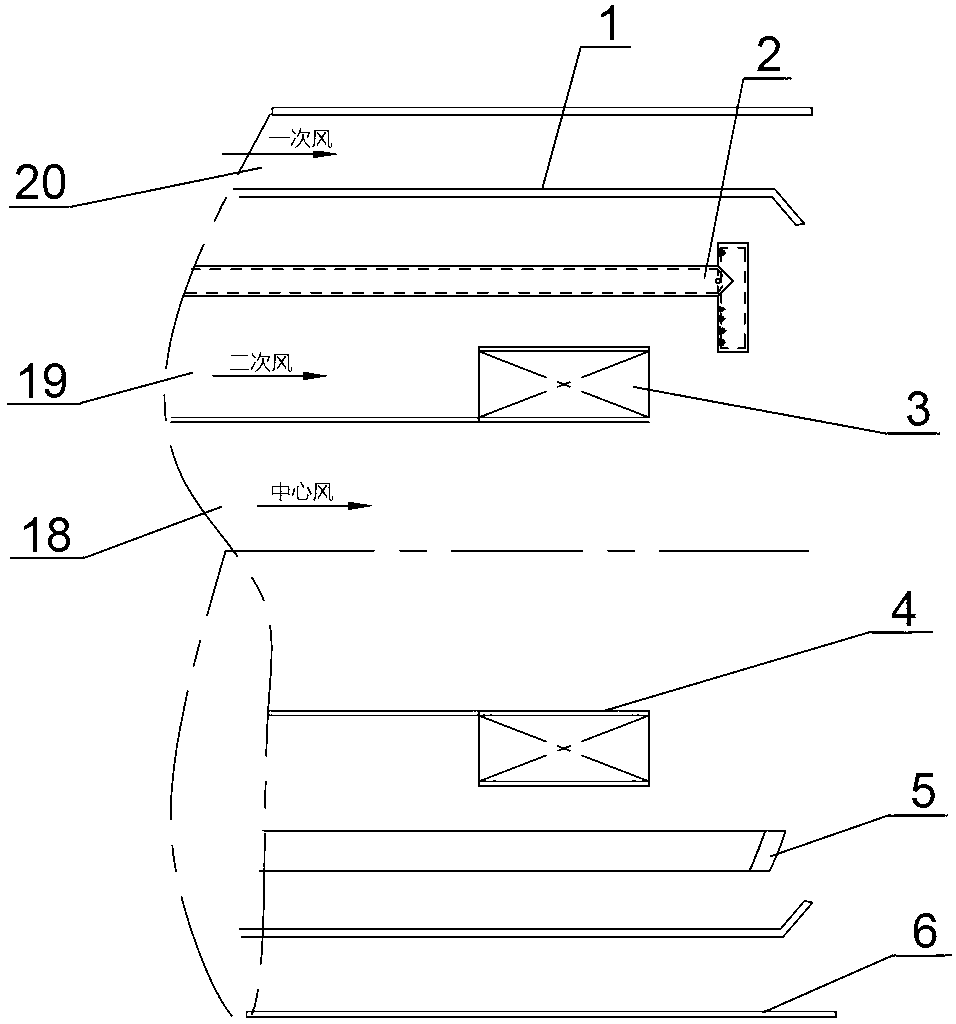

Supercritical CO2 circular and elliptical tangential boiler furnace body with uniform thermal loads

InactiveCN111550771AEnsure safe and economical operationAvoid overheatingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsBoiler furnace

The invention relates to a supercritical CO2 circular and elliptical tangential boiler furnace body with uniform thermal loads. A furnace hearth comprises a burner cavity. The cross section of an inner cavity of the burner cavity is circular or elliptical. At least one burner assembly is axially arranged in the burner cavity, and the burner assembly comprises a first deflection secondary air nozzle, a primary air nozzle, a second deflection secondary air nozzle and a direct current secondary air nozzle which are arranged in a spaced manner from bottom to top successively. A SOFA air nozzle isarranged on a cavity wall of the burner cavity. An air path system comprises a primary air fan, a secondary air fan, a coal mill and a secondary air distributor. An outlet of the primary air fan and apulverized coal outlet of the coal mill are connected to the primary air nozzle through a primary air pipe. An air outlet of the secondary air fan is connected to the first deflection secondary air nozzle, the second deflection secondary air nozzle, the direct current secondary air nozzle and the SOFA air nozzle separately. The supercritical CO2 circular and elliptical tangential boiler furnace body has the advantages that the thermal loads in the furnace hearth are uniformly distributed axially and radially, so that overtemperature of a heated surface of the boiler furnace is avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

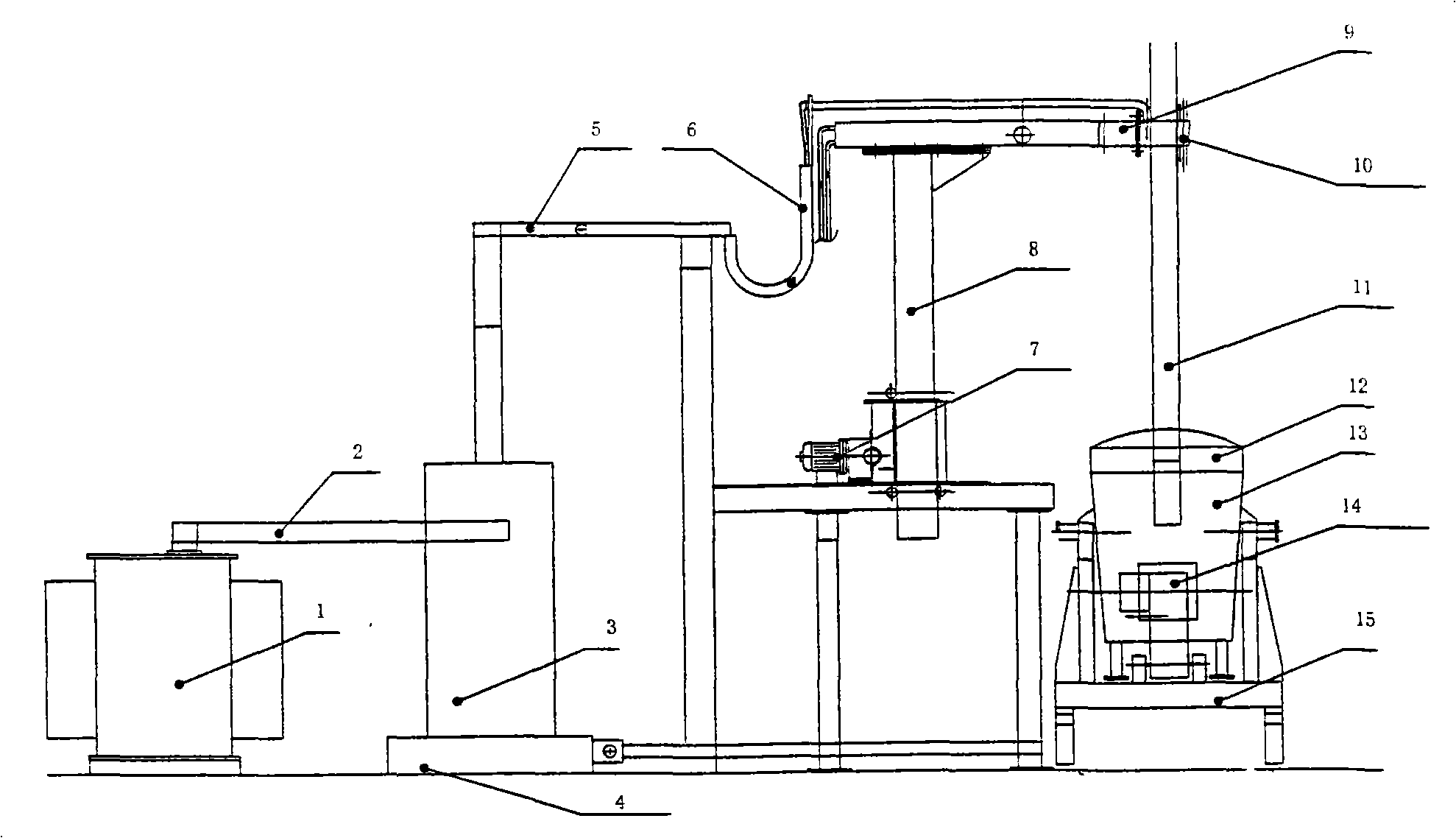

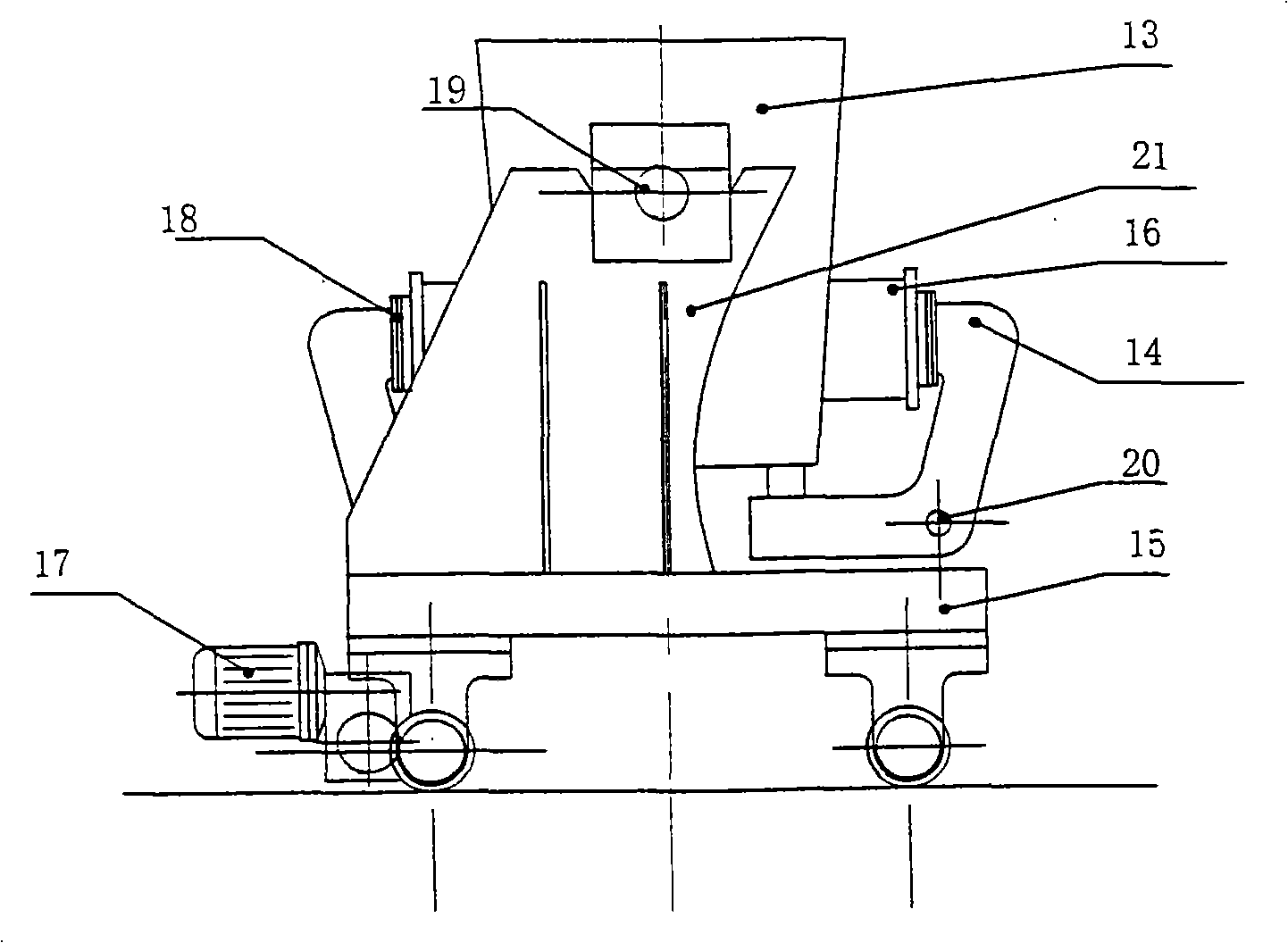

Bottom anode side conductive direct current ladle furnace

InactiveCN101323892AUniform compositionGuaranteed symmetric distributionLighting and heating apparatusLadle furnaceArc length

The invention discloses a ladle furnace which is conductive and direct-current at a bottom anode side. The ladle furnace of the invention comprises a buggy ladle part and a ladle part and is characterized in that a buggy ladle body is provided with a side bottom anode automatic clamping device which has two symmetrical clamping chunks, wherein, the clamping face of each clamping chunk is connected with a heavy-current water-cooling switch the outside of which is provided with a water cooling pipe; two side bottom anode conductive bumps, which have a compound structure of a metallic part and a non-metallic part respectively, are arranged at the side face of the bottom of a ladle body as bottom anodes and connected with the ladle detachably. By adopting the ladle furnace which is conductive and direct-current at the bottom anode side, the consumption by graphite electrodes is greatly reduced and the noise is relatively low, the arc length short, the submerged arc good, temperature rise fast and carburetion of the molten steel low. In addition, the ladle furnace of the invention is applicable to heat and refine low-carbon steel and ultra-low-carbon steel and less refractories are consumed by the ladle with high heating efficiency so as to save energy.

Owner:NORTHEASTERN UNIV

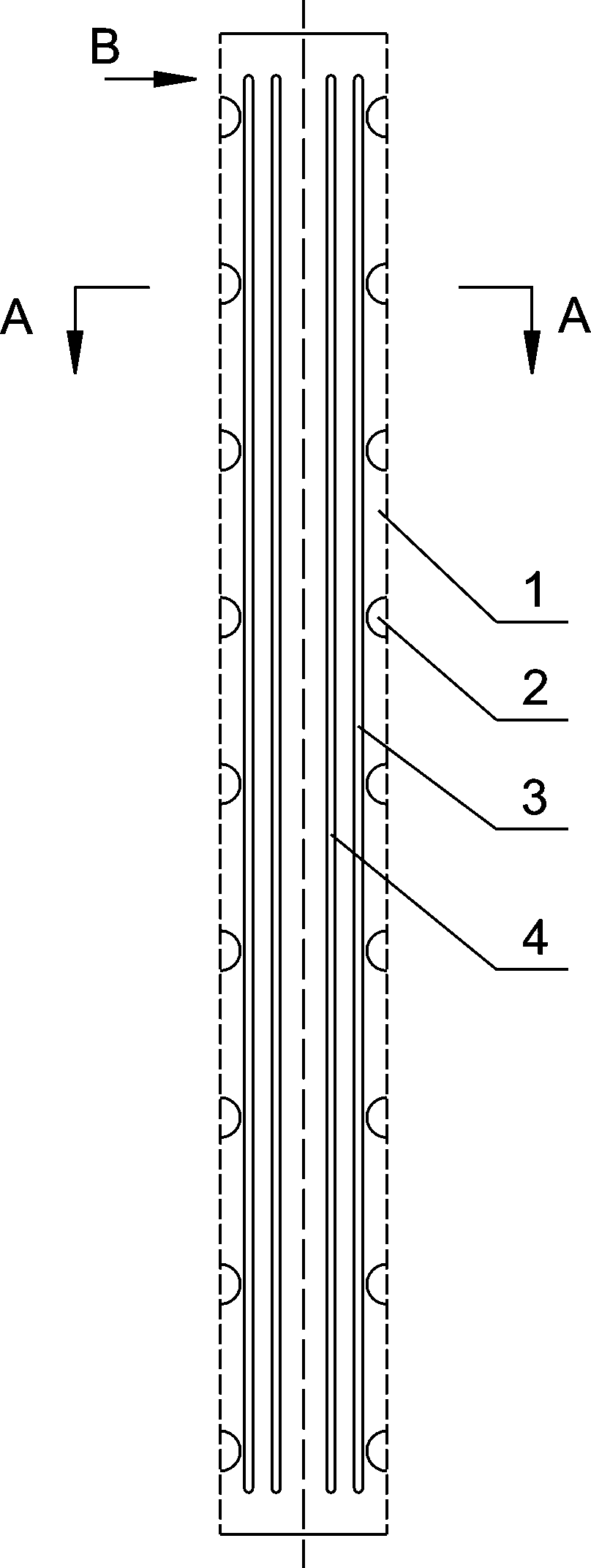

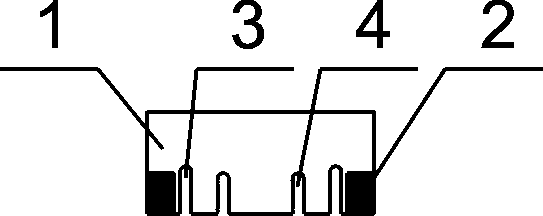

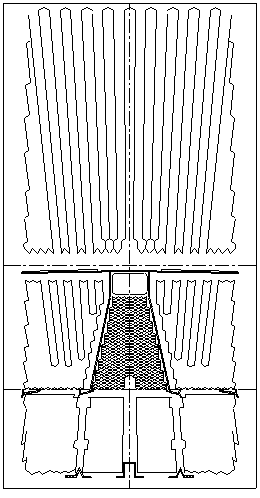

Wide-surface copper plate of crystallizer for high-efficiency slab caster

A wide-surface copper plate of a crystallizer for a high-efficiency slab caster relates to a continuous casting crystallizer. The wide-surface copper plate comprises a wide-surface copper plate main body, a plurality columns of screw holes arranged on the wide-surface copper plate main body, and cooling water tanks arranged on a cold surface of the wide-surface copper plate main body. The wide-surface copper plate is characterized in that the cooling water tanks includes deep water tanks and shallow water tanks which are different in depth, between the adjacent two columns of screw holes, two deep water tanks are symmetrically arranged close to the screw holes, and two shallow water tanks are symmetrically arranged close to the central line of the two columns of screw holes. According to the invention, on the basis of thermophysical parameters of the copper plate of the crystallizer and heat transfer between a high-temperature solidified blank shell and the copper plate of the crystallizer, by changing the depth and the distribution of the cooling water tanks, the copper plate of the crystallizer is high in cooling intensity and cooling uniformity. Therefore, basing on ensuring rapid heat exchange between the copper plate and a high-temperature casting blank, heat exchange uniformity is realized, and thermal load uniformity of the copper plate is ensured, so that the purposes of improving the casting blank quality, prolonging the service life of the copper plate and lowering the production cost can be achieved.

Owner:WISDRI ENG & RES INC LTD

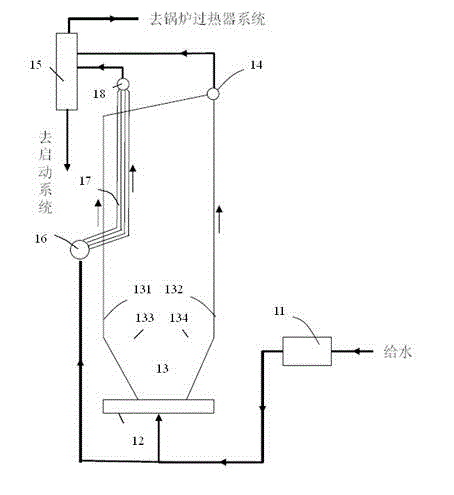

Supercritical circulating fluidized bed boiler with double-return evaporating heating surface

The invention relates to a supercritical circulating fluidized bed boiler with a double-return evaporating heating surface, which is characterized by comprising a descending section water-cooled screen inlet collection box connected with a hearth water-cooled wall outlet collection box, a descending section water-cooled screen connected with the descending section water-cooled screen inlet collection box, a water-cooled screen connecting collection box connected with the descending section water-cooled screen, an ascending section water-cooled screen connected with the water-cooled screen connecting collection box, and an ascending section water-cooled screen outlet collection box connected with the ascending section water-cooled screen, wherein the descending section water-cooled screen and the ascending section water-cooled screen adopt a double-return arrangement mode. The double-return arrangement mode is adopted, the hearth outlet collection box and the descending section water-cooled screen inlet collection box are arranged on the top of a hearth, the connecting length of pipelines is reduced, smaller hearth water-cooled wall heating area can be required, and the height of the hearth can be reduced.

Owner:SHANGHAI BOILER WORKS

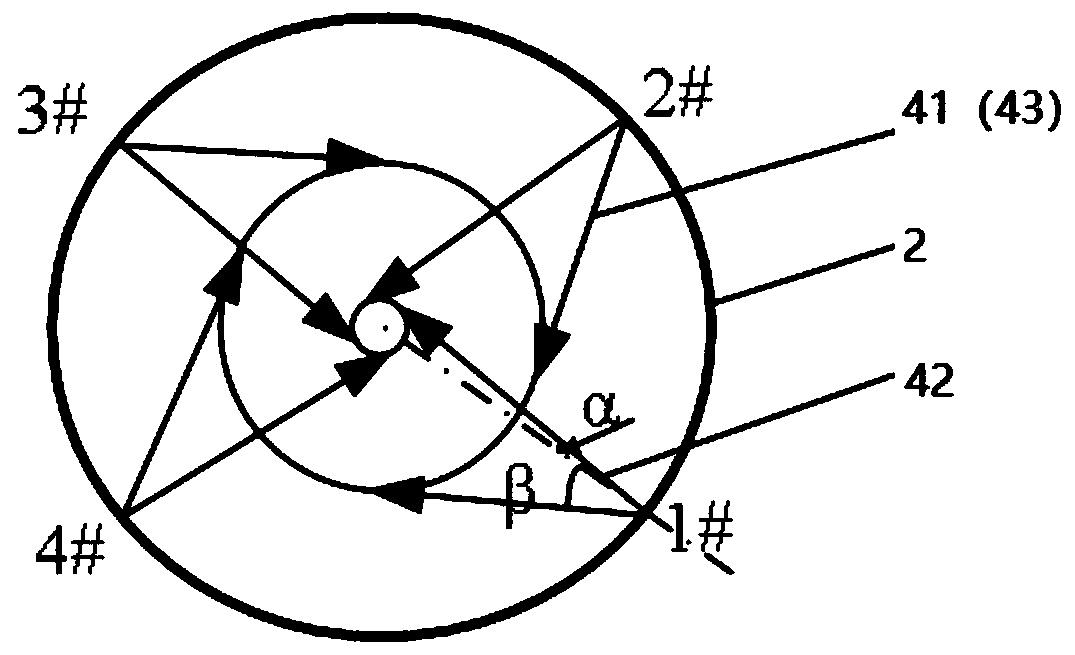

Combustion system suitable for flexible peak regulation of four-corner tangential boiler, and operation method thereof

PendingCN112032710AImprove low-load combustion stabilityUniform heat loadCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemNew energy

The invention discloses a combustion system suitable for flexible peak regulation of a four-corner tangential boiler, and an operation method thereof. According to the system, a layer of swirling pulverized coal burner is compactly arranged between two layers of direct-current pulverized coal burners, and air-powder mixtures of the swirling burner are from an independent air-powder conveying system; Coal for combustion of the swirling burner is high-quality coal with high volatile components and heat values, and primary air and secondary air of the swirling burner are both swirl flow; and theswirl strength can be adjusted by 0-100% through a pull rod. When the boiler needs to be subjected to deep peak regulation, the turbulent burner and the adjacent direct-current pulverized coal burnerare put into operation; When the boiler operates at medium and high loads, the swirling burner is stopped, and only secondary air is introduced to participate in boiler combustion; and the situation that the boiler nozzle is coked or burnt out at medium and high loads is avoided. According to the combustion system and the operating method thereof, the deep peak regulation capacity of the coal-fired boiler can be effectively improved, and the consumption capacity of a power grid for new energy power generation is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD +3

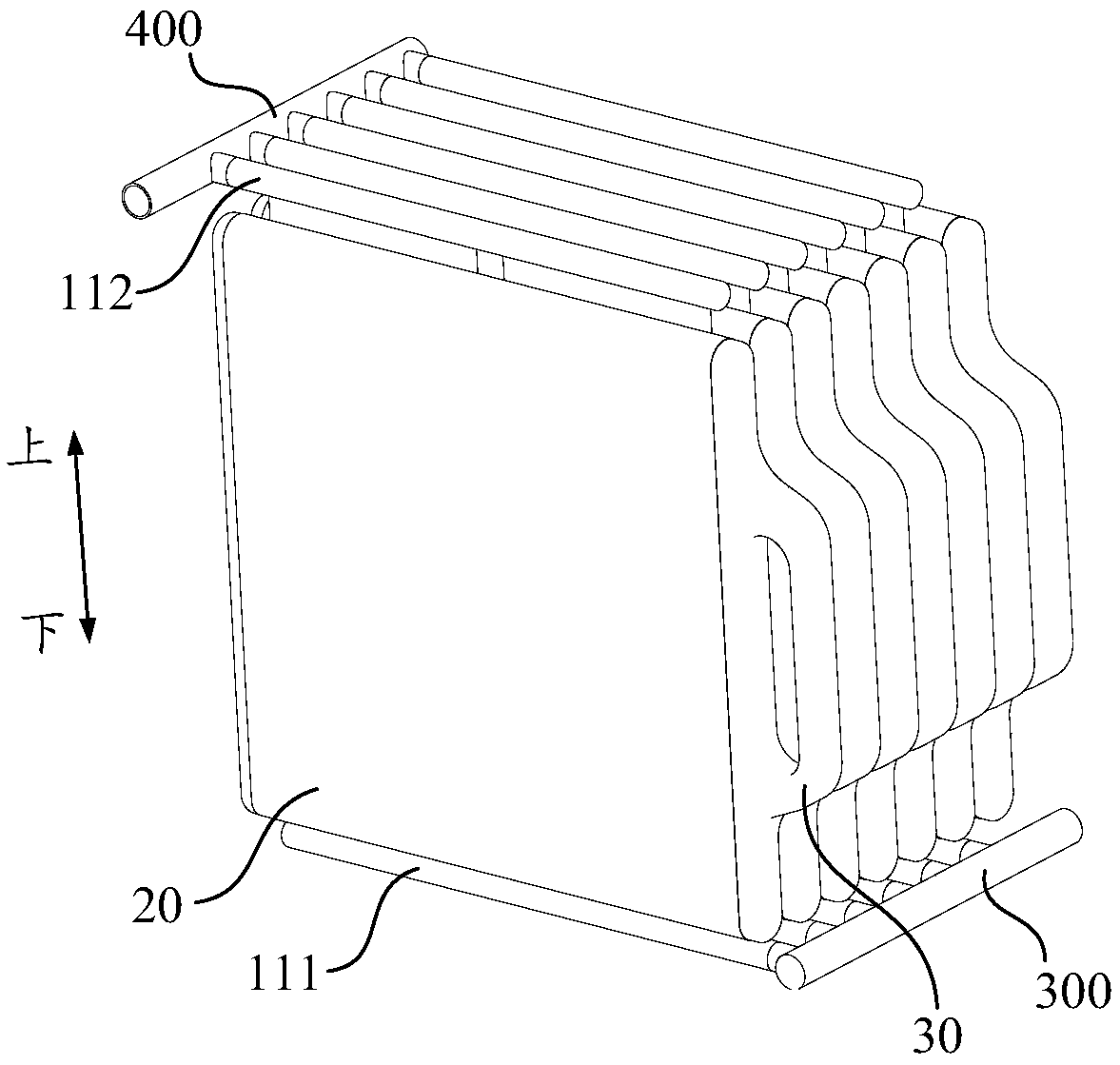

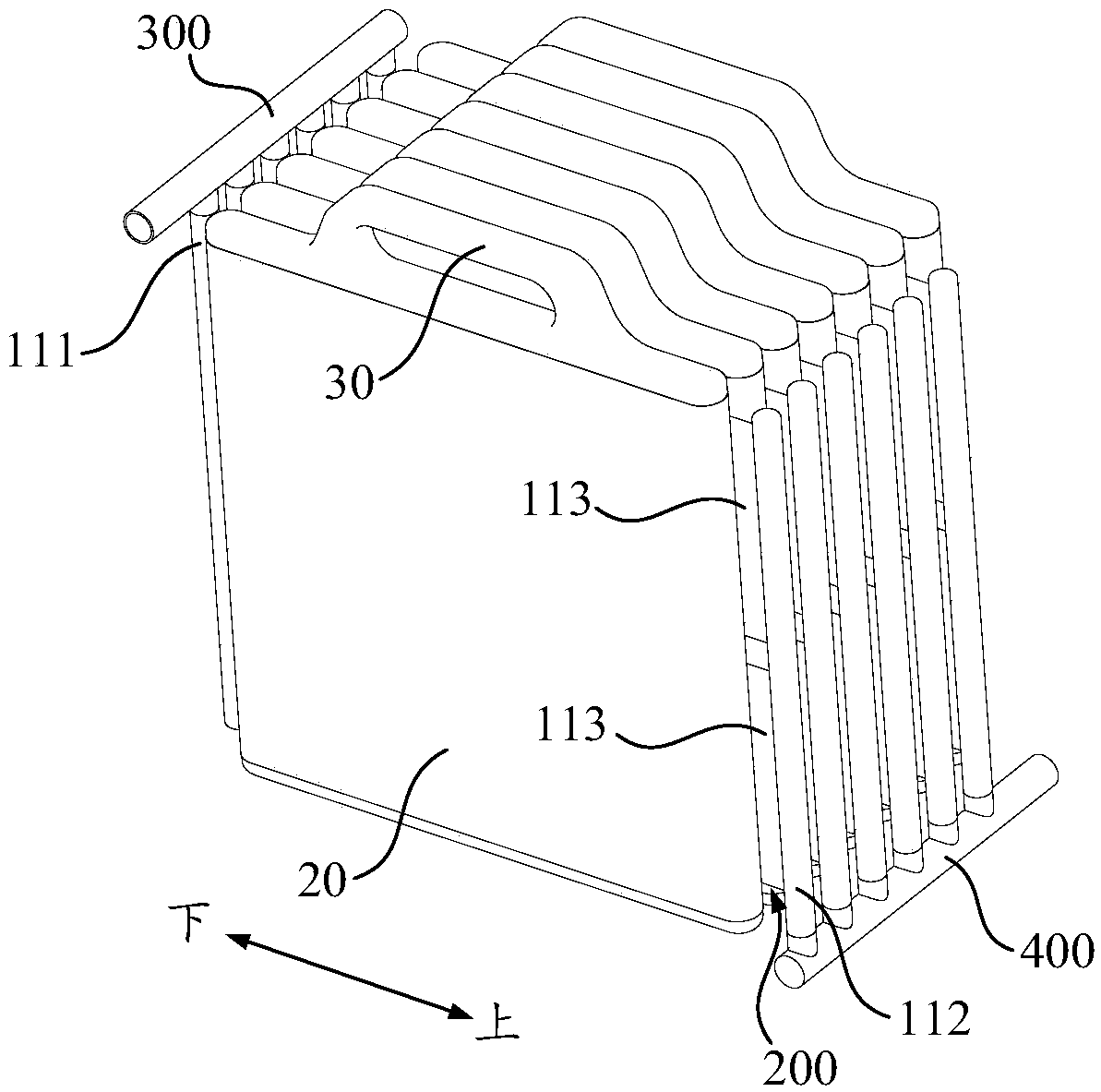

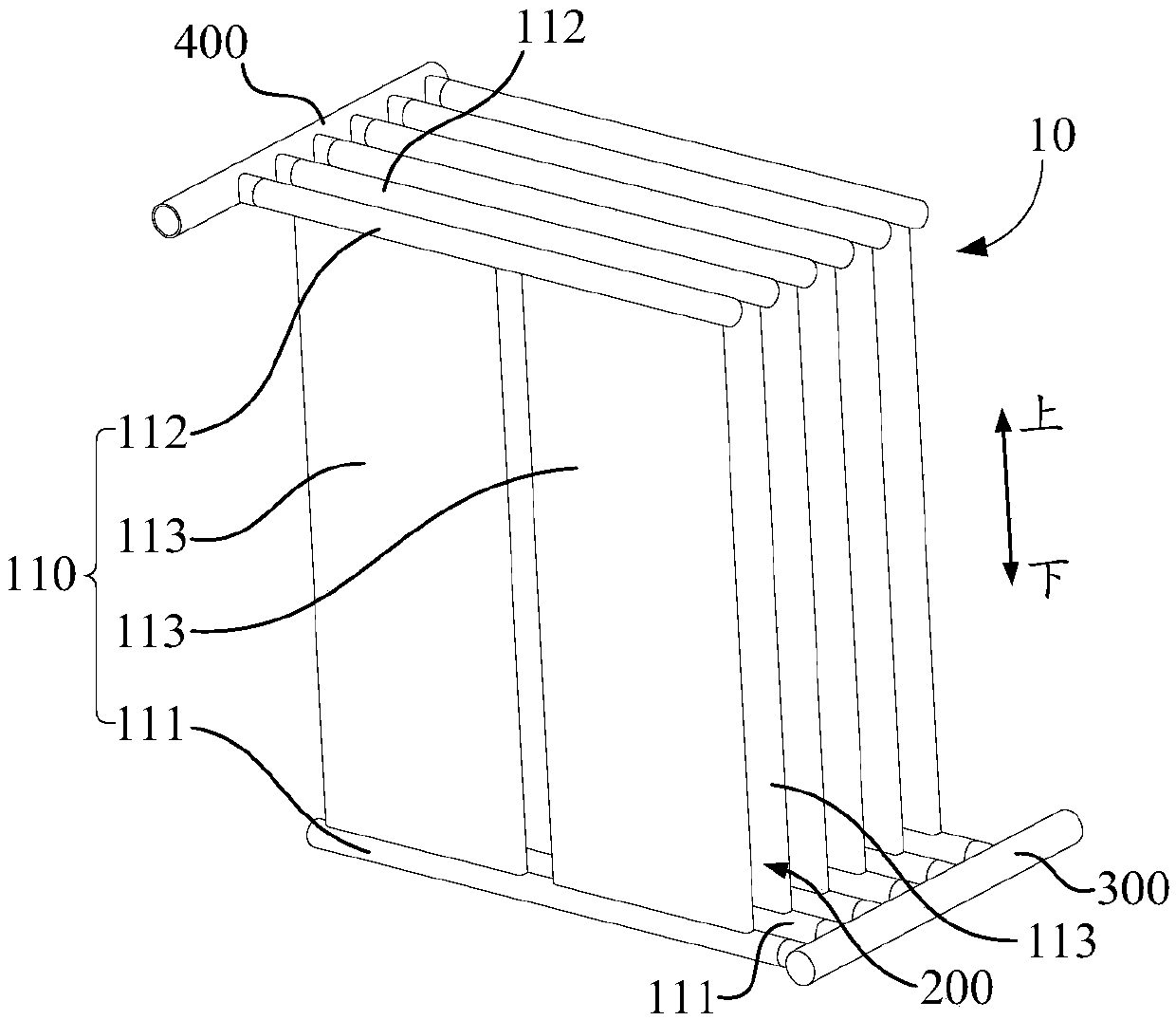

Energy storage heat exchange device and air conditioning equipment

InactiveCN110879015AEasy to assembleEasy to splitHeat storage plantsHeat exhanger sealing arrangementEngineeringProcess engineering

The invention provides an energy storage heat exchange device and air conditioning equipment. The energy storage heat exchange device comprises: a heat exchanger which comprises a plurality of heat exchanger units, wherein the heat exchanger units are distributed at intervals, and an inserting groove is formed between the adjacent heat exchanger units; and an energy storage piece which is internally provided with an energy storage material, wherein the energy storage piece can be inserted into the inserting groove and can be detached from the inserting groove, and the energy storage piece canmake contact with the heat exchanger units on the two sides of the inserting groove and exchange heat when inserted into the inserting groove. According to the energy storage heat exchange device provided by the scheme, the energy storage piece and the heat exchanger can be conveniently assembled and disassembled, intermittent refrigeration of the air conditioning equipment can be achieved throughcold storage regeneration-refrigeration cycle circulation, and continuous refrigeration can be achieved in a mode of replacing the energy storage piece in time.

Owner:GUANGDONG MIDEA WHITE HOME APPLIANCE TECH INNOVATION CENT CO LTD +1

Method and system for homogenizing diode laser pump arrays

ActiveUS8547632B2Improve extraction efficiencyHigh beam qualityLaser detailsPhotomechanical apparatusAudio power amplifierDiffraction optics

An optical amplifier system includes a diode pump array including a plurality of semiconductor diode laser bars disposed in an array configuration and characterized by a periodic distance between adjacent semiconductor diode laser bars. The periodic distance is measured in a first direction perpendicular to each of the plurality of semiconductor diode laser bars. The diode pump array provides a pump output propagating along an optical path and characterized by a first intensity profile measured as a function of the first direction and having a variation greater than 10%. The optical amplifier system also includes a diffractive optic disposed along the optical path. The diffractive optic includes a photo-thermo-refractive glass member. The optical amplifier system further includes an amplifier slab having an input face and position along the optical path and separated from the diffractive optic by a predetermined distance. A second intensity profile measured at the input face of the amplifier slab as a function of the first direction has a variation less than 10%.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

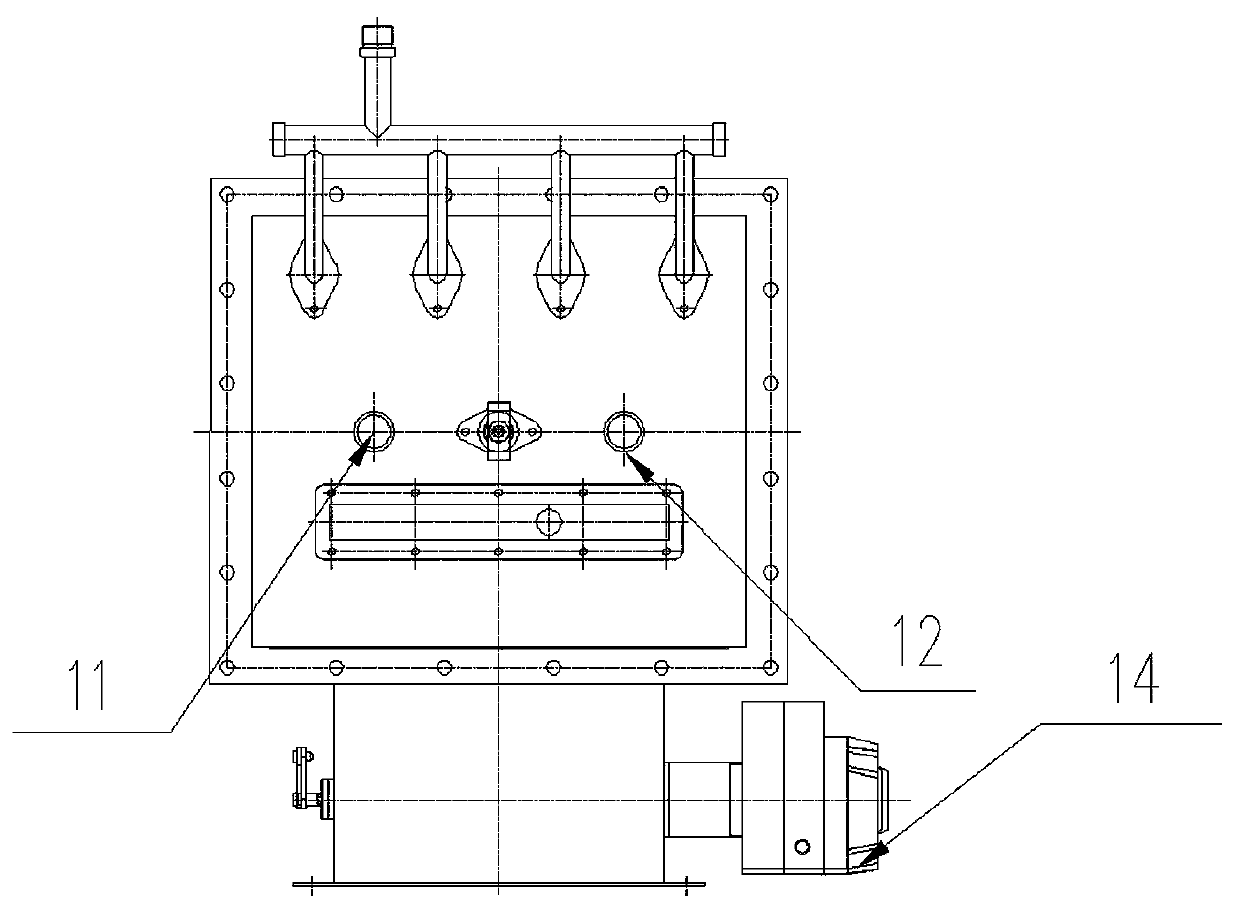

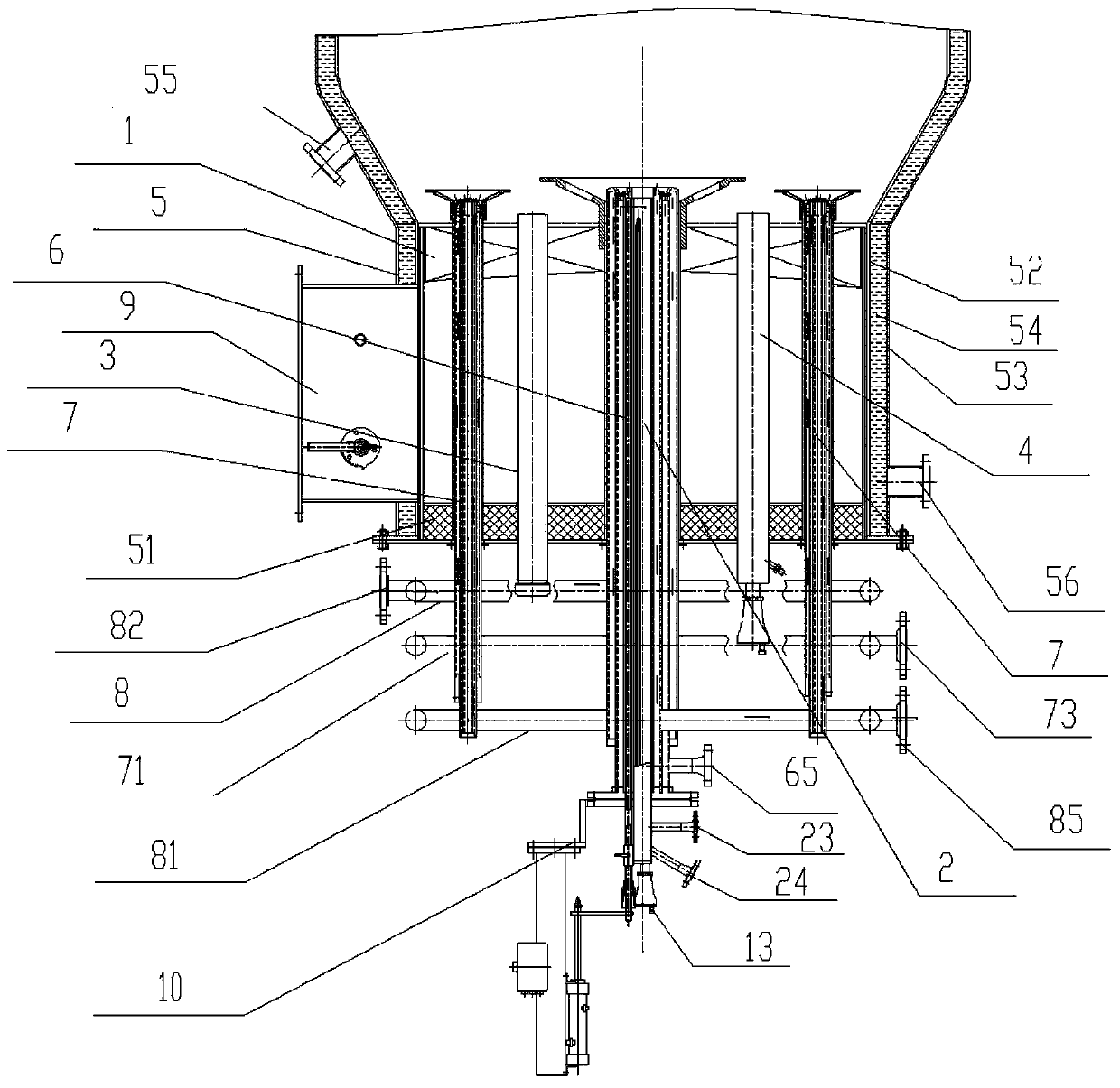

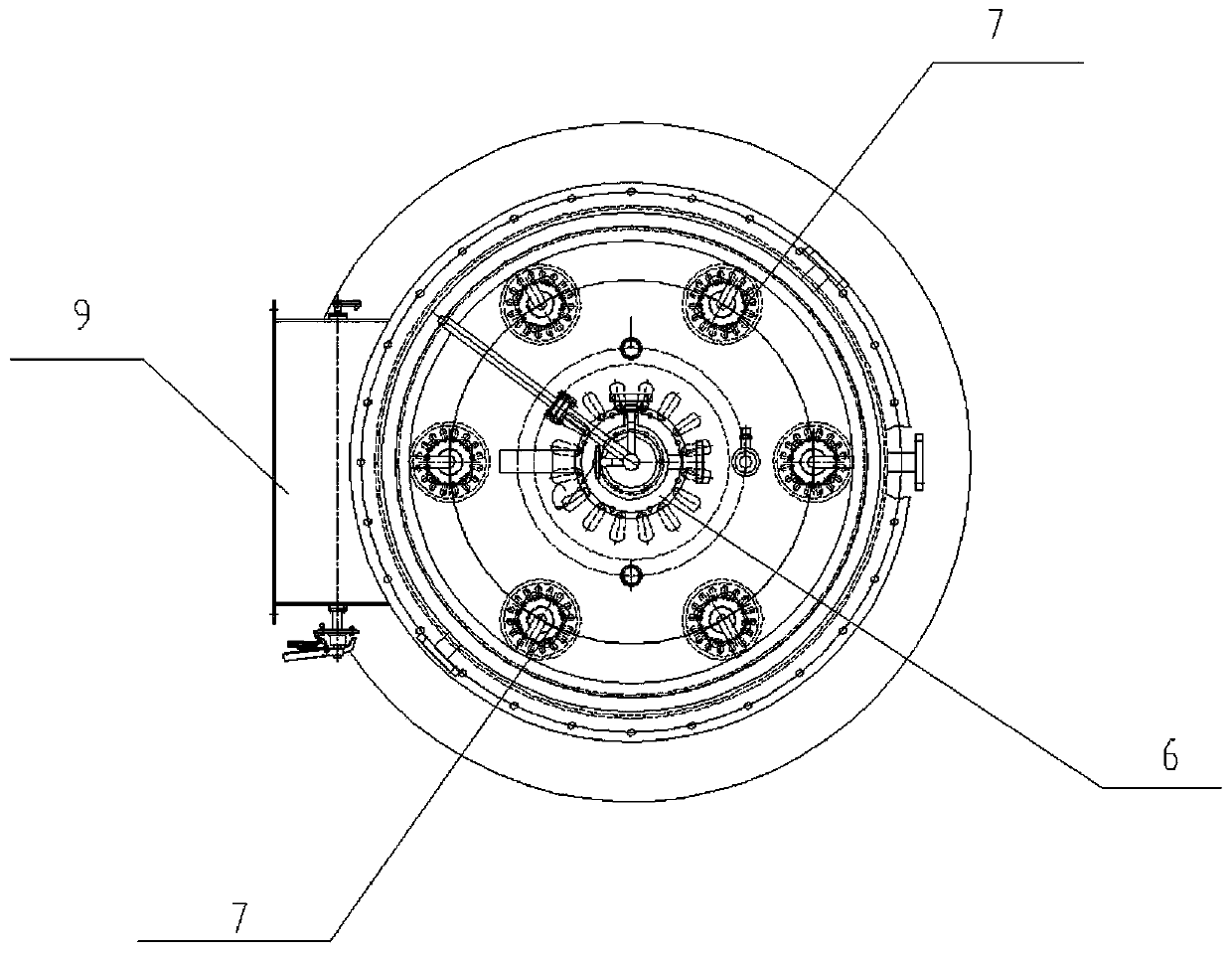

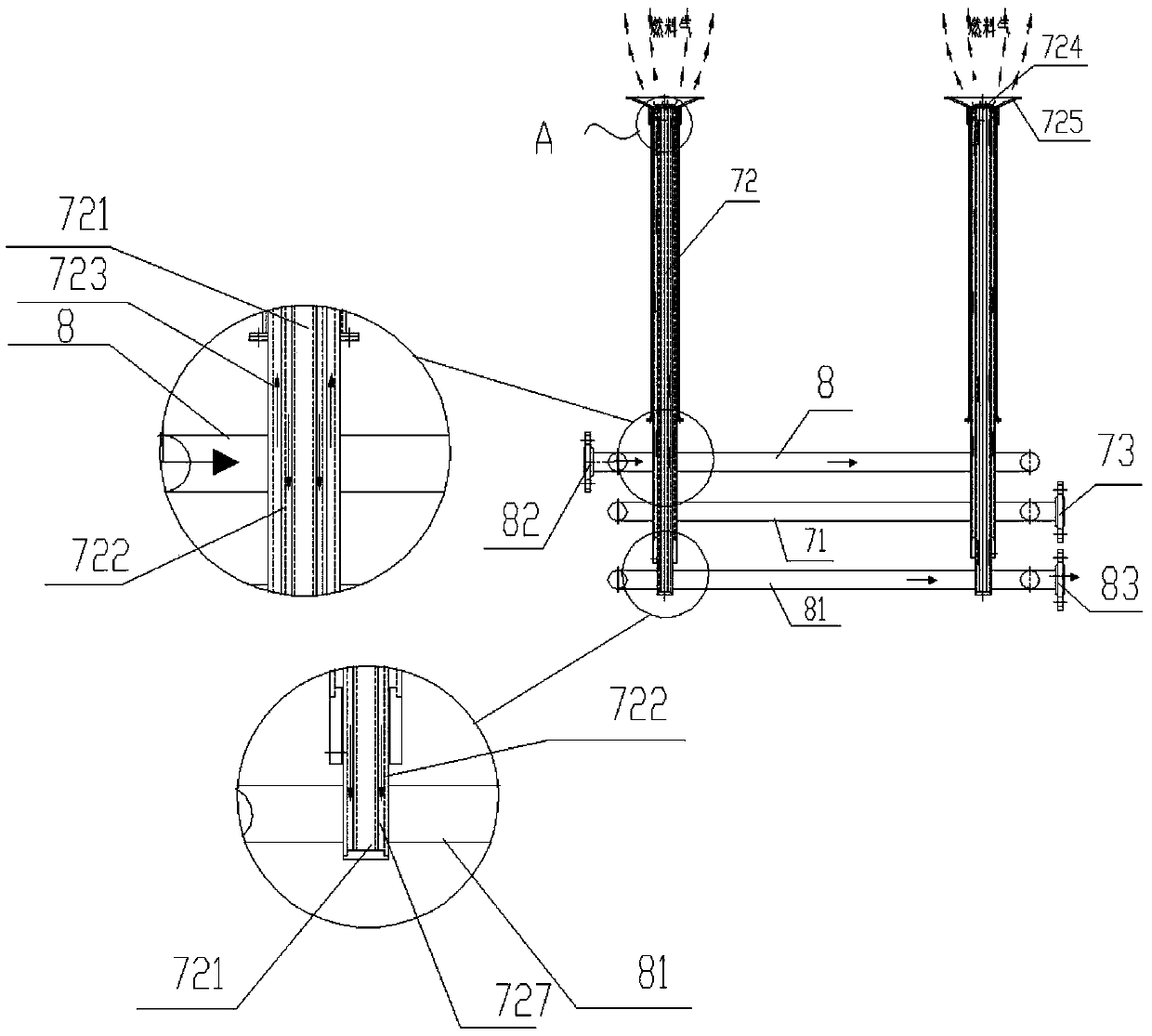

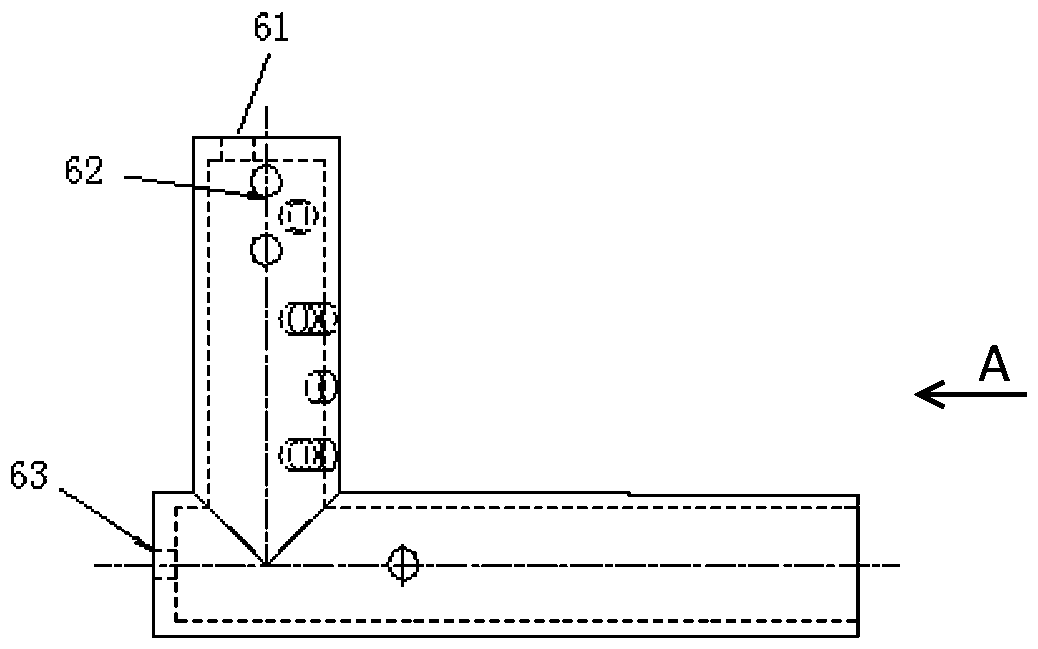

Gas burner for flat fan-shaped flame ultra-low NOx emission large-load cracking furnace

PendingCN109737408AStable Dispersed CombustionStable ignitionFuel supply regulationGaseous fuel burnerBrickWave shape

The invention discloses a gas burner for a flat fan-shaped flame ultra-low NOx emission large-load cracking furnace, comprising a brazier brick assembly, a cylinder body, a T-shaped gun assembly and 2-6 outer gun assemblies; the brazier brick assembly comprises an upper brazier brick and a lower brazier brick; the middle part of the lower brazier brick is provided with a lower air flow channel, which is a straight flow channel with constant cross-sectional area; the middle part of the upper brazier brick is provided with an upper air flow channel, the two sides of the upper air flow channel are inclined outwards, and the front surface and the back surface of the upper air flow channel are wave-shaped surfaces. The flame emitted by the T-shaped gun assembly and the flame emitted by the large holes of the outer gun assemblies form a flat fan-shaped flame, so that the furnace space is utilized to the maximum extent, the fuel gas can be combusted in the space as large as possible in a whole radiation chamber, the heat distribution in the furnace chamber is uniform, the furnace tube is heated uniformly, the average temperature and the peak temperature of the flame are simultaneously reduced, the emission of NOx is reduced, the generation of carbon monoxide is effectively avoided, and the combustion is stable and reliable.

Owner:YUEYANG ZHONGDING THERMAL ELECTROMAGNETIC TECH CO LTD

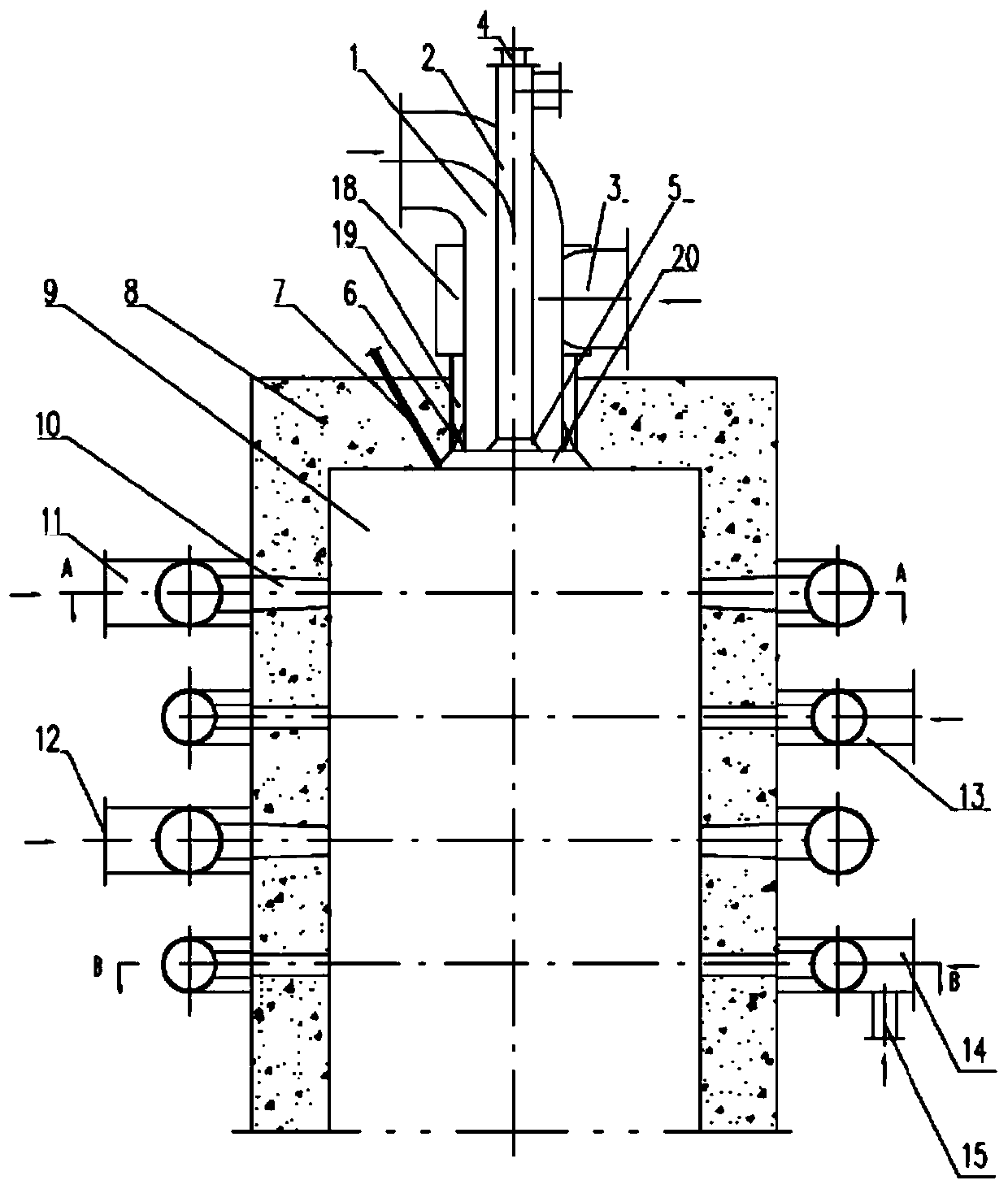

Low-nitrogen combustion process and device combining direct flow with rotational flow and supplying air at multiple stages in hearth

ActiveCN111536505ASolution volumeSolve for uniformityFuel supply regulationIndirect carbon-dioxide mitigationThermodynamicsCombustor

The invention belongs to the field of gas combustion, and particularly relates to a low-nitrogen combustion process and device combining direct flow with rotational flow and supplying air at multiplestages in a hearth. 30%-80% of fuel gas is fed from a basic load gas pipe into a rotational flow mixing area as the basic heat load, 20%-70% of combustion air enters a combustion air channel tangentially from a volute type air box as primary combustion air; and a rotational flow air regulator is arranged at an outlet of the combustion air channel, the combustion air rotationally flows out of the channel according to the angle of the air regulator and is rotationally injected into directly entering gas flow, and the combustion air and the directly entering gas flow are mixed in a rotational flow mixing area and ignited and combusted by an igniter. Other fuel gas and secondary combustion air enter a combustion area as corner tangential direct flow through 2-7 stages of pipelines penetratingthrough the side wall of the hearth, and are mixed and combusted. A flue gas recirculation pipeline penetrates through the side wall of the hearth in a staged mode and enters the combustion area, andthe combustion effect is improved. The integrated design of a burner and the hearth can be realized, a high-power combustion device is compact in structure, and the investment cost and the operation cost can be reduced.

Owner:SHANDONG XIANGHUAN ENVIRONMENTAL TECH CO LTD

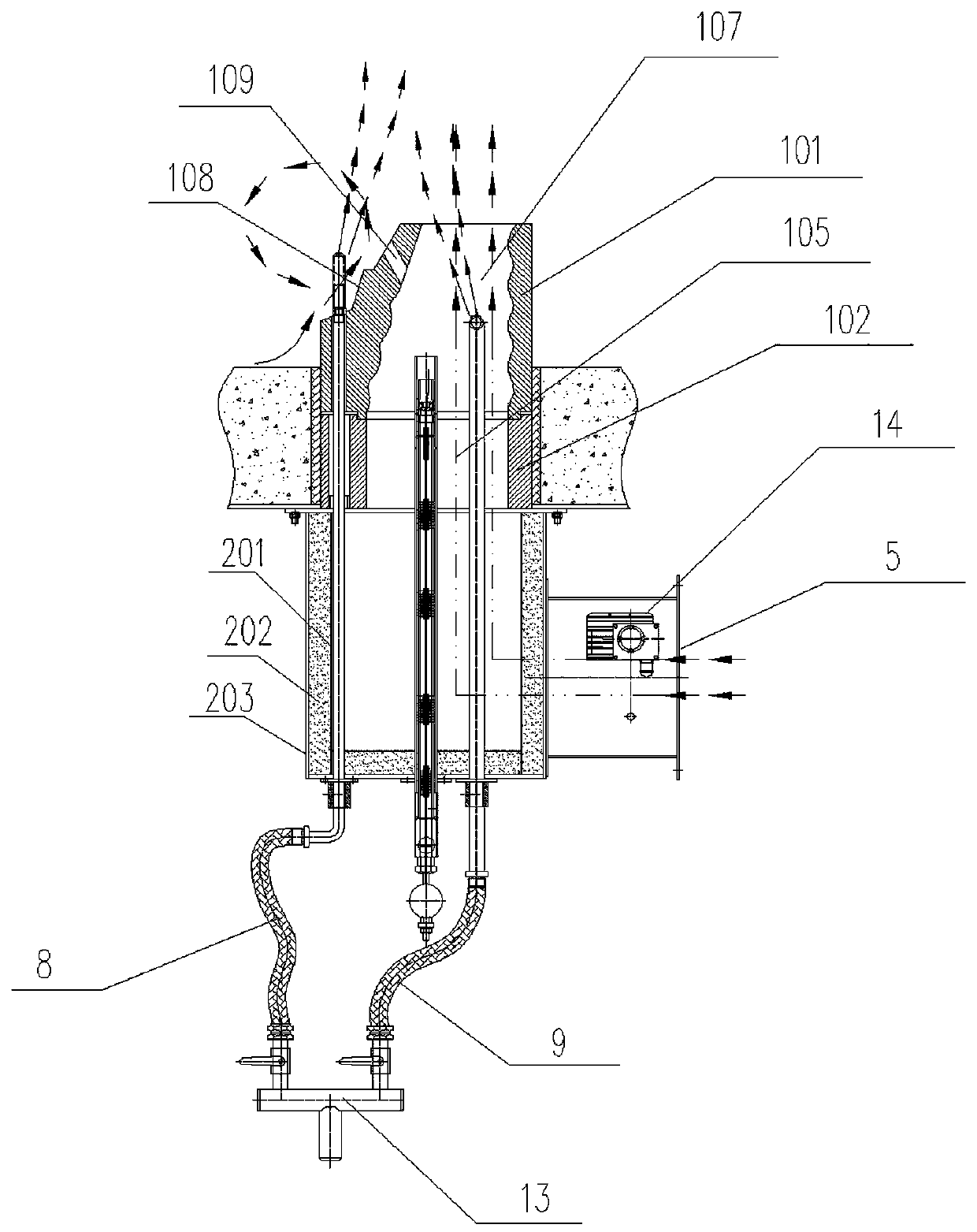

Ultra-large-load water-cooling low-NOx gas burner

The invention discloses an ultra-large-load water-cooling low-NOx gas burner. The ultra-large-load water-cooling low-NOx gas burner comprises a high-pressure cooling water circulating assembly, a swirl piece assembly, an incandescent light assembly, a burner barrel body assembly, a central fuel gas gun assembly and an annular fuel gas gun assembly, the central fuel gas gun assembly and the annularfuel gas gun assembly penetrate through the bottom of the burner barrel body assembly and extend into the burner barrel body assembly, the incandescent light assembly extends into the central fuel gas gun assembly from the bottom of the central fuel gas gun assembly and is fixed in the center of the central fuel gas gun assembly, and the swirl piece assembly is arranged in the burner barrel bodyassembly. The ultra-large-load water-cooling low-NOx type gas burner has the advantages that the temperature of an annular flue gas gun, the central fuel gas gun assembly, the burner barrel body assembly, a heating furnace barrel body, a flame center high-temperature region can be effectively reduced, and generation of the NOx can be inhibited.

Owner:YUEYANG ZHONGDING THERMAL ELECTROMAGNETIC TECH CO LTD

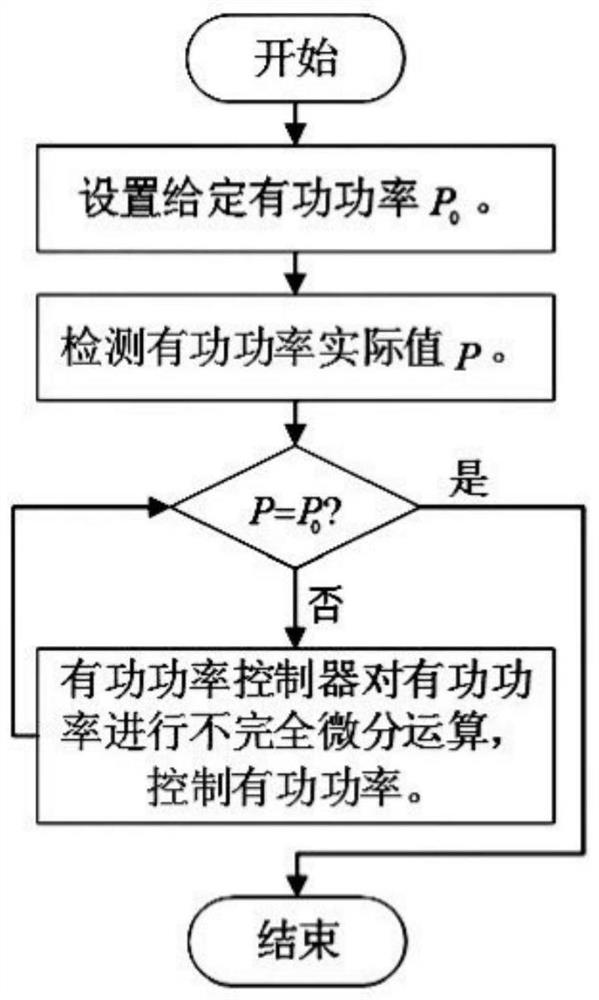

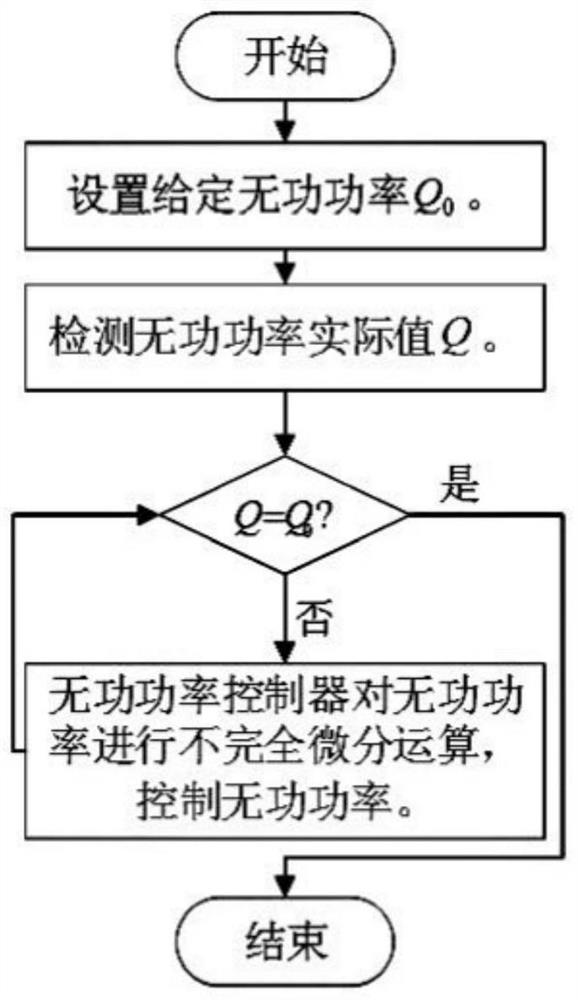

Power tracking excitation control method and system for dual-shaft excitation generators

ActiveCN112600470BGuaranteed uptimeUniform heat loadReactive power compensationGenerator control by field variationControl systemElectric machine

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Low emission gas combustion furnace and its combustion air configuration method

ActiveCN105351925BHomogeneous mixed combustionAvoid it happening againGaseous fuel burnerCycloneEngineering

Owner:SHANGHAI WISEBOND TECH

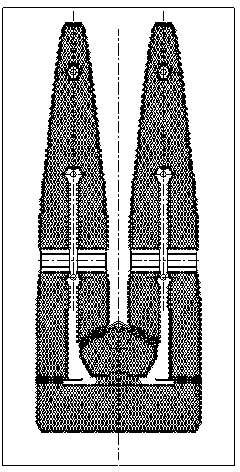

Steam turbine condenser exhaust pipe

ActiveCN102121797BShort pathImprove heat exchange capacitySteam/vapor condensersNuclear powerEngineering

The invention provides a tube tank of a turbine condenser. The tube tank comprises multiple cooling tubes with parallel axes, and a tube containing area with two mutually independent tube areas, namely an air cooling area and a main condensation area, wherein the main condensation area is arranged around the air cooling area; the projection of an envelope curve of the tube containing area on a plane vertical to the axes of the cooling tubes forms a 'torch'-shaped pattern; the air cooling area is arranged at the middle lower part of the 'torch'; the tube tank of the main condensation area forms multiple 'flames' which are bilaterally symmetrical relative to the centre line of the 'torch' and called as trunk tube bundles of the tube tank of the condenser; and a clearance exists between adjacent trunk tube bundles in the width direction of the 'torch', and forms a steam channel. Through the invention, the heat exchange performance of the condenser is enhanced so that the condenser technology is further improved; and the applicable range of the tube tank of the condenser is expanded, and the tube tanks can be used as the tube tanks of condensers configured in the turbine units of various power levels, particularly to the nuclear power condensers with unit power over the million-kilowatt level.

Owner:DONGFANG TURBINE CO LTD

Supercritical carbon dioxide coal-fired circulating fluidized bed boiler, power generation system and power generation method

ActiveCN108180470BGuaranteed uptimeHas emissionsFluidized bed combustionSteam engine plantsAir preheaterSuperheater

Owner:SOUTHEAST UNIV

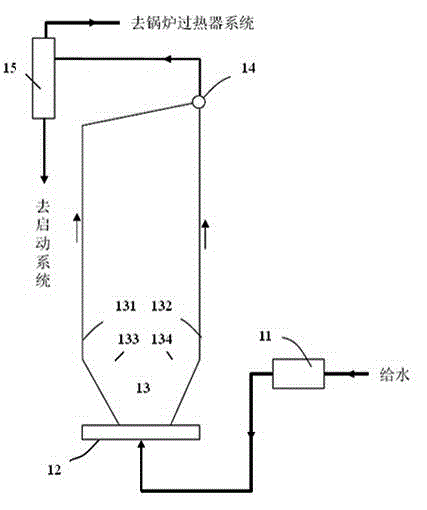

An anti-overheating device and control method for a CFB boiler after burning peat

ActiveCN104776425BGuaranteed fullnessAvoid overheatingSuperheating controlFluidized bed combustionPipeline.airExhaust valve

The invention discloses an over-temperature prevention device for a CFB (circulating fluid bed) boiler after addition and burning of peat and a control method of the over-temperature prevention device; the device comprises a secondary air fan (7), a low temperature overheater, a lower temperature reheater (6), pasty fluid pumps (4) and peat spouts (2); the pasty fluid pumps (4) and the peat spouts (2) are connected by peat feeding pipelines; a peat pipeline air exhaust valve (3) is installed on each of the peat feeding pipelines; the air of the peat pipeline air exhaust valve (3) is exhausted every 3h for 3-5min, so that the output of the secondary air fan (7) is reduced and the oxygen content in a hearth is kept between 1.5% and 2.0%. According to the device and the method disclosed by the invention, the problems of the prior art that when the peat is added and is combusted in the CFB boiler, the combustion conditions are easily deviated from a design standard greatly if the peat exceeds the standard, the heating surfaces inside the boiler and on the tail part of the boiler are over-temperature, the safety operation of the boiler is affected or the machine set is in non-planned outage in a severe case, and the like are solved.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

Pre-mixing burner

The present invention relates to a premixed burner, comprising a main fire device and an ignition device, characterized in that the main fire device includes an air mixing chamber with upper and lower openings, an air inlet opening connected to the lower end of the air mixing chamber and a side wall The air chamber, the air inlet pipe extending into the air chamber from the bottom, the main fire nozzle set at the end of the air inlet pipe located in the air chamber, the fire outlet plate covering the upper opening of the air mixing chamber, the mixing chamber The air chamber is provided with a porous plate which divides the air mixing chamber into multiple spaces, and the porous plate is provided with a plurality of air holes. The air mixing chamber is divided into multiple cavities by setting a perforated plate, so that the air entering from the air chamber and the gas injected by the main fire nozzle on the intake pipe are fully mixed in the multiple cavities separated by the perforated plate, and the combustion is complete and High thermal efficiency; by setting a fire orifice plate at the upper end of the gas mixing chamber, the flame is stable and the heat load is uniform during combustion.

Owner:YUFUBAO KITCHENWARE EQUIP SHENZHEN CO LTD

Fuel gas graded and segmented distribution combustion device and fuel gas graded and segmented distribution method thereof

The invention relates to a fuel gas graded and segmented distribution combustion device. The fuel gas graded and segmented distribution combustion device can be matched with various boiler furnaces, and the purpose of ultra-low NOx emission is realized. The fuel gas graded and segmented distribution combustion device belongs to the technical field of emission reduction of industrial boilers and is characterized in that an outer fuel gas gun fixing plate perpendicular to the central axis is arranged between the end of the outer edge of a throat and the end of an inner annular barrel; a gun head of an outer fuel gas gun penetrates through and is exposed out of the outer fuel gas gun fixing plate; a combustion air passage is arranged between the inner annular barrel and an outer annular barrel; and the outer wall of the outer annular barrel is attached to and connected with the inner wall of a refractory material layer. The fuel gas graded and segmented distribution combustion device has the positive effects that a novel gas and air graded and segmented distribution method is provided, and the outer fuel gas gun is arranged on the outer side of the throat, so that the space of the boiler furnace is used to the maximum extent, and the average temperature and peak temperature of flame are lowered; and the outer-layer combustion air passage is arranged, overall dense-lean combustion of a combustor area is formed, and the generation of NOx is further reduced, so that ultra-low NOx emission smaller than 30 mg / Nm<3> is realized, and no CO is generated.

Owner:SHANGHAI WISEBOND TECH +1

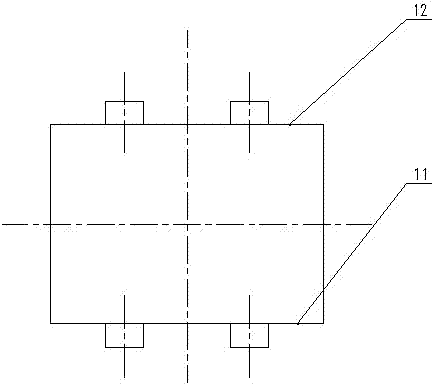

Wall type arrangement direct-current pulverized coal combustion technology used for industrial pulverized coal boiler

ActiveCN103712204APrevent slaggingLow shape requirementCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorSlag

The invention relates to a wall type arrangement direct-current pulverized coal combustion technology used for an industrial pulverized coal boiler, and belongs to the pulverized coal boiler filed. The problems of slag bonding and high temperature corrosion of present industrial pulverized coal boilers are solved in the invention. The boiler comprises a boiler body, the boiler body comprises a front wall, a rear wall and a hearth formed in the boiler body, each of the front wall and the rear wall is provided with at least one direct current combustor connected with the hearth, and the direct current combustor of the front wall is arranged facing to the direct current combustor of the rear wall. The wall type arrangement direct-current pulverized coal combustion technology can avoid the slag bonding caused by the phenomena comprising too large tangent circle and deflective wall attachment, and has low requirements on the shape of the cross section of the hearth because of the wall type arrangement combustion mode, so with the increase of capacity of a set, the width of the hearth needs to be increased, there is no need to increase the depth of the hearth, the capacity of the boiler is not restricted by the sectional area of the hearth, and it is convenient to carry out the arrangement of the heated surface of a tail portion.

Owner:芮城县丰蕴热力有限公司

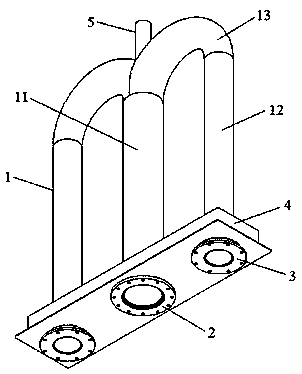

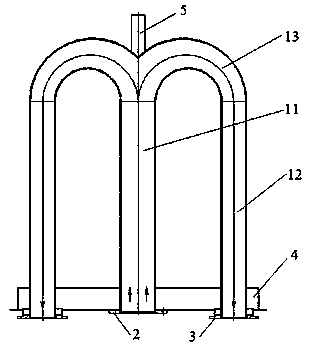

M-shaped flame radiant tube

The invention discloses an M-shaped flame radiant tube which comprises a radiant tube body, a combustion tube connecting flange, flue gas side connecting flanges and a mounting plate. The radiant tubebody which is M-shaped comprises a middle combustion tube, flue gas discharge tubes on two sides and bend pipes which connect the combustion tube to the flue gas discharge tubes on two sides. The combustion tube is mounted on the mounting plate through the combustion tube connecting flange, and the flue gas discharge tubes on two sides are mounted on the mounting plate through the flue gas side connecting flanges. In this way, the heat utilization ratio can be improved and the service life of the radiant tube is prolonged.

Owner:CHANGSHU BURNER FACTORY

Double-bionic tree-shaped pipe bundle type condenser of umbrella-shaped air cooling area

ActiveCN102261855BImprove heat transfer coefficientReduce subcoolingSteam/vapor condensersSuper coolingEngineering

The invention discloses a double-bionic tree-shaped pipe bundle type condenser of an umbrella-shaped air cooling area and belongs to the technical field of heat exchangers. The condenser consists of a plurality of heat exchange pipes, an end pipe plate, an intermediate pipe plate, an air cooling steam baffle component, an evacuation pipeline, a shell component, a water chamber and the like, wherein the heat exchange pipes on the end pipe plate of the condenser are in two separated bionic tree shapes to form a double-bionic tree-shaped pipe bundle; and the air cooling steam baffle component, two gradually-reduced air cooling pipe bundles, an air cooling communication hole or an air cooling communication pipe and the evacuation pipeline form an umbrella-shaped air cooling pipe bundle component. The condenser has the advantages of uniform and vortex-free steam flow field of the bundles of the condenser, low steam resistance, uniform heat load, low degree of super-cooling, reheat-free airevacuation, shorter evacuation pipe and higher heat transfer coefficient of the condenser. The heat transfer coefficient of the condenser can be higher than a calculation value according to a heat exchange institute (HEI) standard by over 10 percent. The condenser is obvious in energy-saving effect of a condenser set.

Owner:TSINGHUA UNIV

A kind of ammonia low nitrogen multi-stage swirl burner

ActiveCN112963833BWell mixedUniform heat loadAir supply regulationGaseous fuel burnerCombustorThermal radiation

Owner:XI AN JIAOTONG UNIV

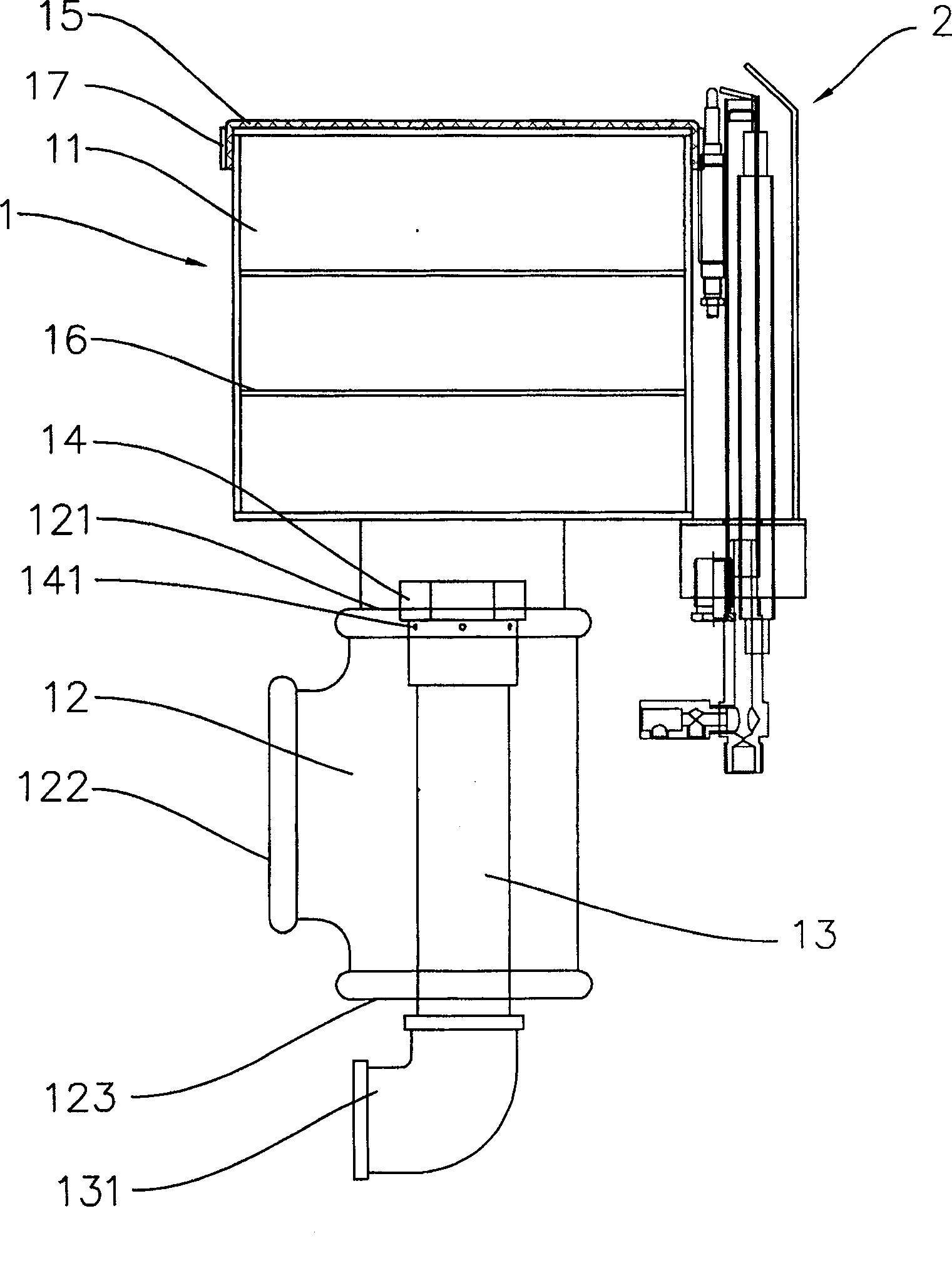

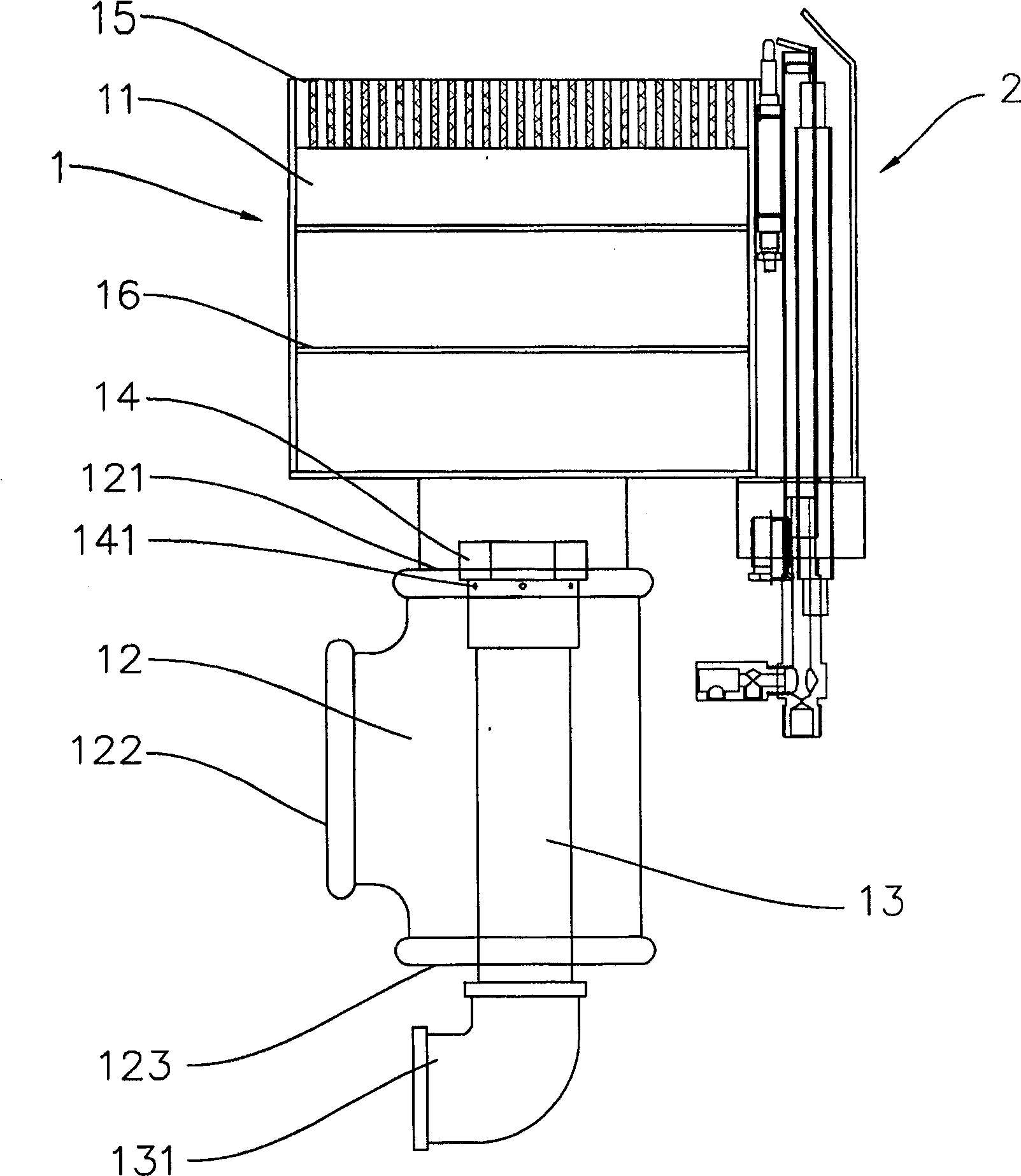

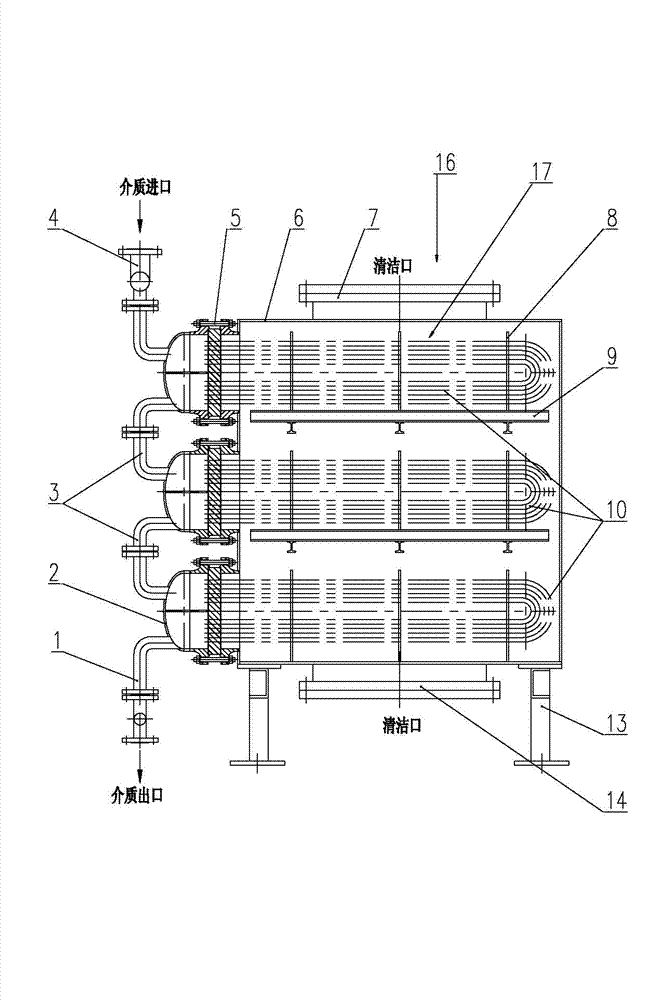

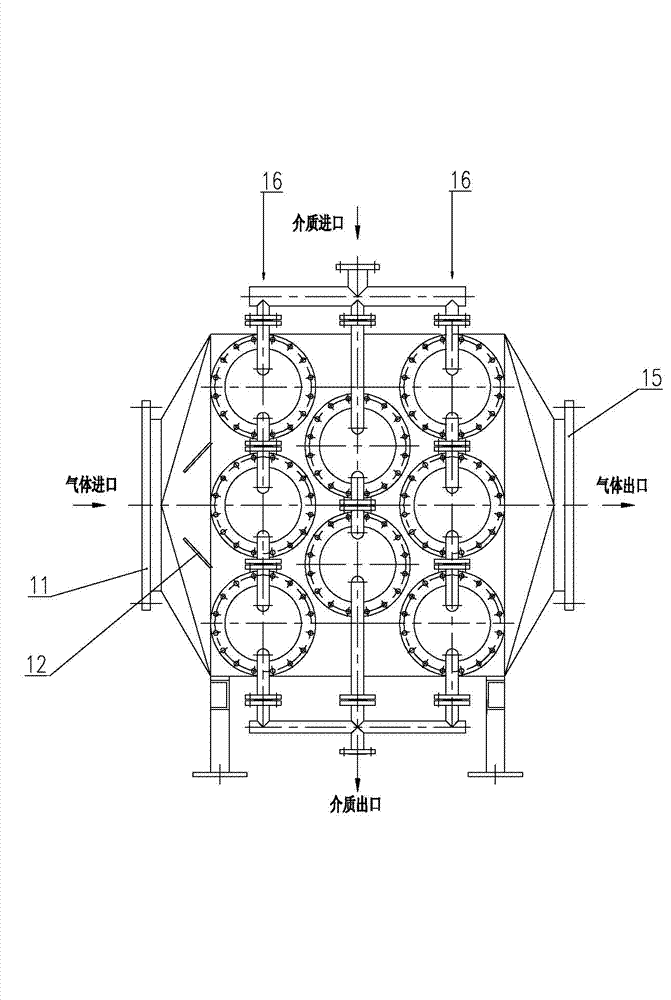

Detachable waste heat recovery high-efficiency heat exchanger

ActiveCN102384675BTo achieve the purpose of energy savingTo achieve the purpose of process requirementsStationary conduit assembliesHeat exchanger casingsEngineeringDistributor

Owner:江苏中圣压力容器装备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com