Supercritical CO2 circular and elliptical tangential boiler furnace body with uniform thermal loads

A heat load, supercritical technology, applied in the direction of combustion air/fuel supply, lighting and heating equipment, non-flammable liquid/gas transportation, etc. temperature and other issues, to ensure safe and economical operation, reasonable structural design, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

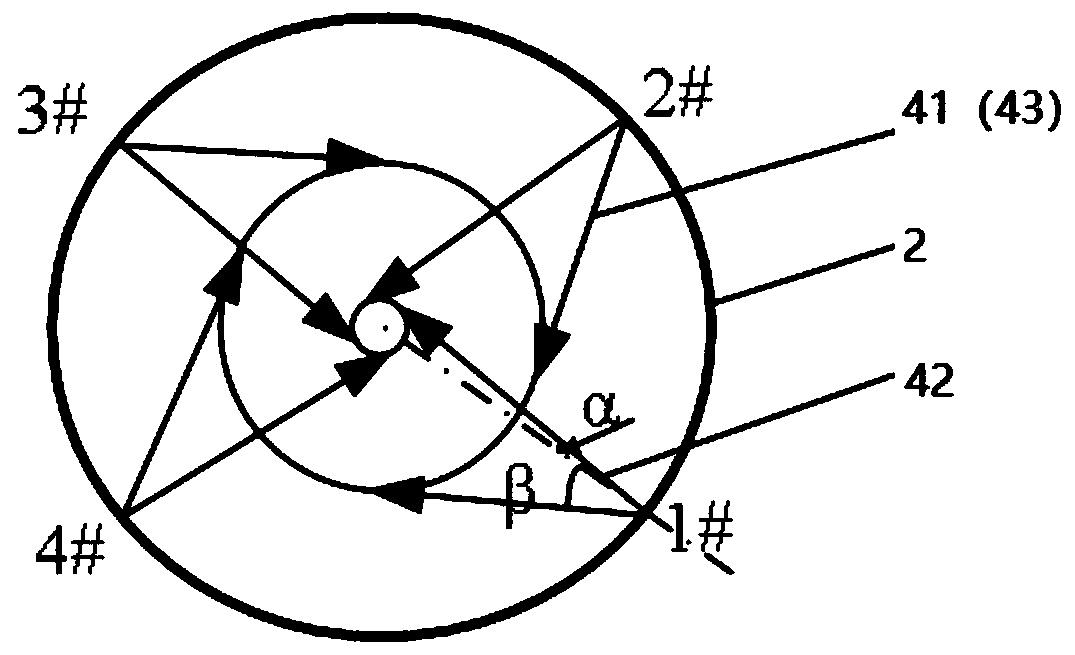

[0025] Example: such as figure 1 As shown, this embodiment provides a supercritical CO with uniform heat load 2 Circular and elliptical tangential boiler body, including boiler furnace and air duct system, wherein, the boiler furnace includes ash hopper 1, burner chamber 2 and upper furnace 3 connected sequentially from bottom to top, the burner chamber 2 The cavity cross section is circular or elliptical, and the inner cavities of the ash hopper 1 and the upper furnace 3 are cube-shaped or cuboid, and are tangent to the inner cavity of the burner cavity 2; At least one layer of burner assembly is provided, and the above-mentioned burner assembly includes the first deflected secondary air nozzle 41, the primary air nozzle 42, the second deflected secondary air nozzle and Air jet 43 and DC secondary air nozzle 44; SOFA air nozzle 6 is provided on the wall of the above-mentioned burner cavity 2 above the burner assembly; the above-mentioned air path system includes a primary ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com